Preparation method for small-crystal-grain Y molecular sieve with high specific surface area and high silicon-aluminium ratio

A technology with high silicon-aluminum ratio and high specific surface area is applied in the field of molecular sieves and achieves the effects of good industrial application prospect, simple preparation method, good hydrothermal stability and catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

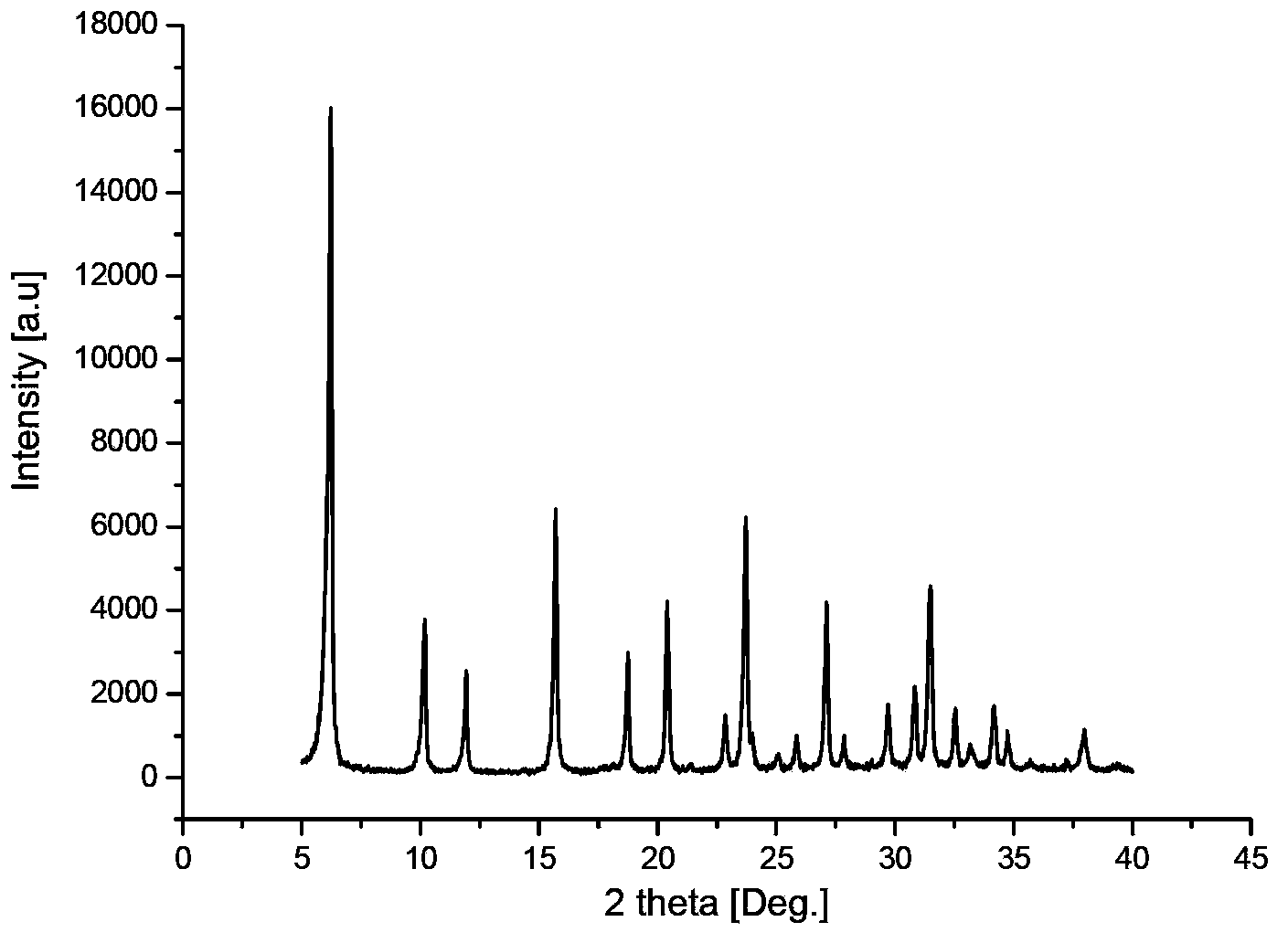

Image

Examples

Embodiment 1

[0025] Take water glass 47.20g (specific gravity 1.259, SiO 2 Content 250.5g / L, modulus 3.21) into a three-necked bottle, add sodium metaaluminate (Al 2 o 3 Content 2.9534mol / L,Na 2 (05.0000mol / L) 2.65ml, NaOH solid (produced by Tianjin Chemical Factory, purity 96%) 4.60g, water 10g, after mixing evenly, stir vigorously at room temperature (30°C) for 12h to obtain the desired transparent gel guide Agent, its molar ratio is Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=16:1:20:360.

[0026] NaY is synthesized according to Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=2.73:1:8.4:209 ratio synthesis: put 30.7448g of water glass in a three-neck flask, control the temperature in the flask to 60°C, add 7.0002g of sodium metaaluminate and aluminum sulfate (Al 2 (SO4) 3 Specific gravity 1.273Al 2 o 3 89.6g / L) 10.5565g and water 8.384g, directing agent 6g, stir evenly, aging for 6h, then add water glass 2.4107g, NaOH solution (3.4275mol / L) 0.15ml, make the feeding ratio become Na 2 O: Al 2 o 3 ...

Embodiment 2

[0028] Raw material and directing agent are identical with embodiment 1.

[0029] NaY is synthesized according to Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=2.73:1:8.4:209 Proportion Synthesis: Place 30.7448g of water glass in a three-neck flask, control the temperature in the flask to 80°C, add 7.0002g of sodium metaaluminate and aluminum sulfate (Al 2 (SO4) 3 Specific gravity 1.273Al 2 o 3 89.6g / L) 10.5565g and water 8.384g, directing agent 3.85g, stir evenly, aging for 4h, then add water glass 2.4107g, NaOH solution (3.4275mol / L) 0.15ml, make the feeding ratio become Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=2.93:1:9.0:217 Vigorously stir evenly, then raise the temperature to 120°C for dynamic crystallization for 10h, add raw material water glass 8.0356g, NaOH solution 1.8215ml and H 2 O3.2875g, make final gel proportioning be Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=3.73:1:11:258. Continue static crystallization at 120°C for 25h, then filter, wash, and dry to obtain NaY molecular sieve...

Embodiment 3

[0031] Take water glass 43.08g (specific gravity 1.259, SiO 2 Content 250.5g / L, modulus 3.21) into a three-necked bottle, add sodium metaaluminate (Al 2 o 3 Content 2.9534mol / L,Na 2 (05.0000mol / L) 4.79ml, NaOH solid (produced by Tianjin Chemical Factory, purity 96%) 9.770g, water 9.70g, after mixing evenly, stir vigorously at room temperature (30°C) for 12h to obtain the required transparent gel Directing agent, its molar ratio is Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=13:1:10:180.

[0032] NaY is synthesized according to Na 2 O: Al 2 o 3 :SiO2 2 :H 2 O=1:1:5:180 ratio synthesis: put 24.90g of water glass in a three-neck flask, control the temperature in the flask to 80°C, add 2.52ml of sodium metaaluminate, aluminum sulfate (Al 2 (SO4) 3 Specific gravity 1.273Al 2 o 3 89.6g / L) 14.00g and water 24g, guiding agent 6.0g, stir evenly, aging for 4h, then add water glass 11.10g, aluminum sulfate (Al 2 (SO4) 3 Specific gravity 1.273Al 2 o 3 89.6g / L) 5.00g. Change the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com