Synthetic method of mesoporous-microporous molecular sieve by raising hydrothermal stability

A technology of microporous molecular sieve and synthesis method, which is applied in the direction of crystalline aluminosilicate zeolite, etc., can solve the problems of inappropriate ratio of polymer and silicone modifier, small molecules, etc., and achieve the effect of long-term order preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] Preparation of auxiliary templating agent 1:

[0067] 11 g of polypropyleneimine with a concentration of 50% and 1.0 g of vinyltrimethoxysilane were reacted at 50° C. for 12 hours to prepare auxiliary templating agent 1 .

[0068] Preparation of auxiliary templating agent 2:

[0069] 11 g of polyvinylamine with a concentration of 50% was reacted with 0.8 g of β-(3,4-epoxycyclohexyl)ethyltrimethoxysilane at 60° C. for 36 hours to prepare auxiliary templating agent 2 .

[0070] Preparation of auxiliary templating agent 3:

[0071] 20 g of polypropyleneimine with a concentration of 30% was reacted with 1.5 g of aminopropylaminoethyltrimethoxysilane at 100° C. for 12 hours to prepare auxiliary templating agent 3 .

[0072] Preparation of auxiliary templating agent 4:

[0073] 20 g of a 50% polyacrylamide solution was reacted with 1.5 g of 3-(2.3-glycidoxy)propyltrimethoxysilane at 50° C. for 36 hours to prepare auxiliary templating agent 4 .

[0074] Preparation of auxi...

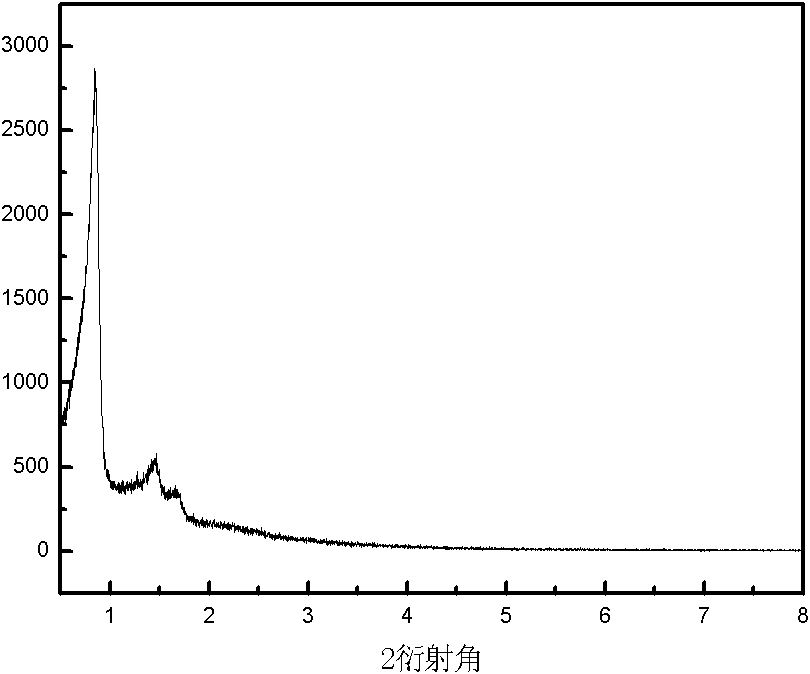

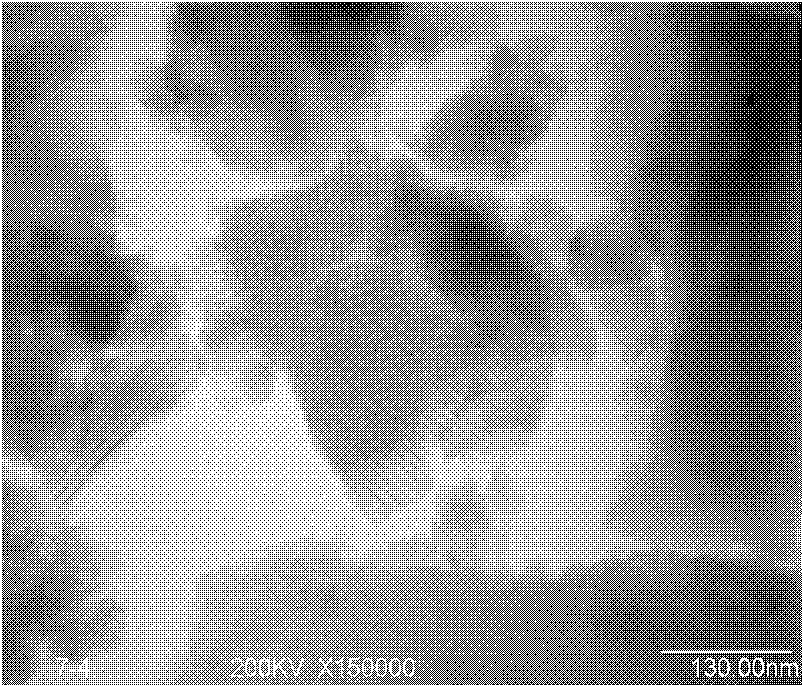

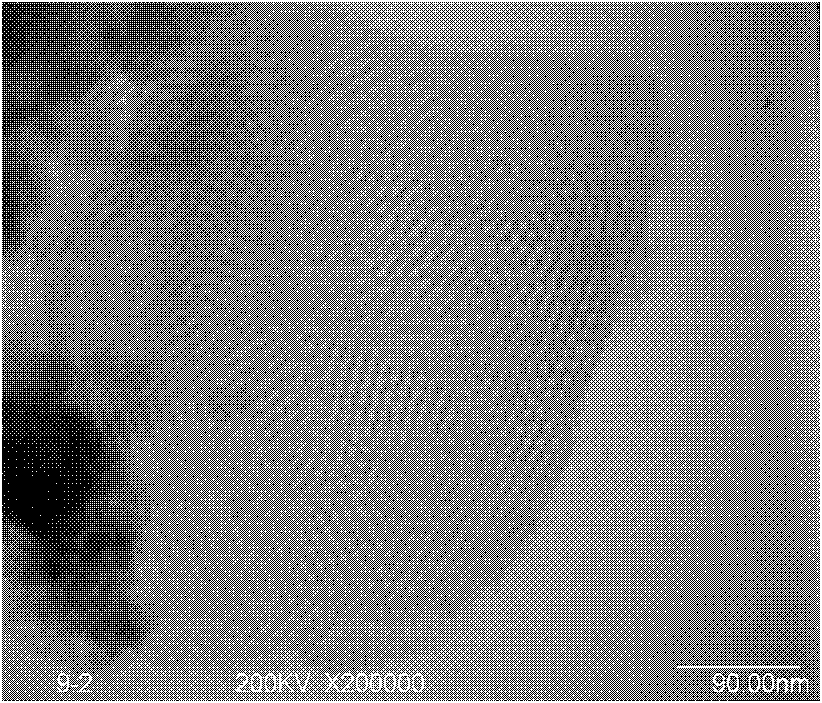

Embodiment 1

[0089] Get 50g microporous molecular sieve precursor 1 solution and add in the reactor and be placed in 25 ℃ of water baths, the concentration of 200g is 5% (EO) 100 (PO) 70 (EO) 100 (F127) solution was added dropwise into the above system for assembly, adjusted the pH value to about 1, stirred for 10 hours after the dropwise addition, added 5g of auxiliary templating agent 1, stirred for 0.5h, and aged at 30°C for 15h. Transfer the product from the previous step to a crystallization kettle, crystallize at 120°C for 24 hours, filter and wash the crystallized product, dry it at 60°C for 24 hours, then transfer it to a muffle furnace, and roast it at 500°C for 6 hours to remove the template agent to obtain ultra-high water Thermally stable meso-microporous molecular sieve M-1.

Embodiment 2

[0091] Get 50g microporous molecular sieve precursor 2 solution and add in the reactor and be placed in 25 ℃ water bath, the concentration of 250g is 3% (EO) 100 (PO) 70 (EO) 100 (F127) solution was added dropwise into the above system for assembly, adjusted the pH value to about 5, stirred for 24 hours after the dropwise addition, added 5g of template aid 2, stirred for 0.5h, and aged at 30°C for 15h. Transfer the product from the previous step to a crystallization kettle, crystallize at 120°C for 24 hours, filter and wash the crystallized product, dry it at 90°C for 9 hours, then transfer it to a muffle furnace, and roast it at 700°C for 3 hours to remove the template agent to obtain ultra-high water Thermally stable meso-microporous molecular sieve M-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com