Antistatic and flame-resistant casein-based graphene composite fabric and preparation method thereof

A graphene composite, flame-retardant technology, applied in the direction of carbon compounds, flame-retardant fibers, chemical instruments and methods, etc., to achieve good stability, excellent performance, and increase commercial value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

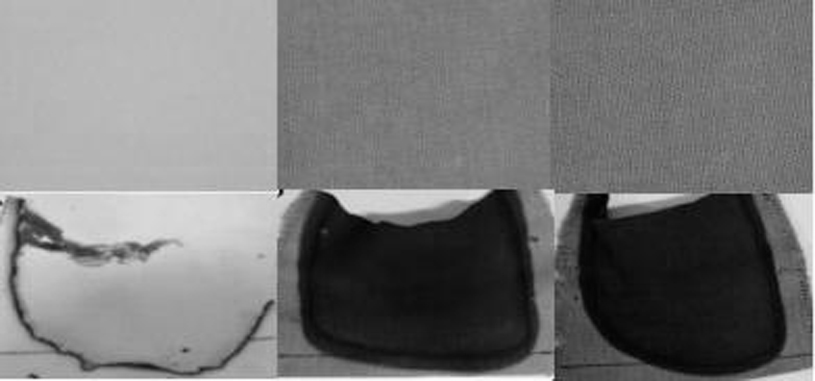

Image

Examples

preparation example Construction

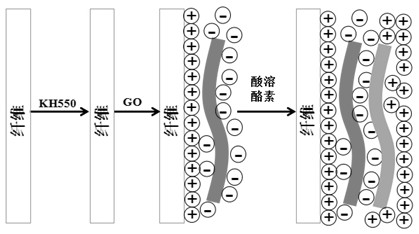

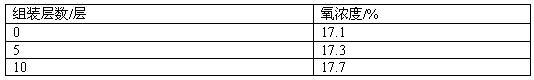

[0025] The preparation method of antistatic flame-resistant type casein-based graphene composite fabric comprises the following steps:

[0026] Step 1: Prepare graphene oxide (GO) by improving the Hummers method:

[0027] Take 7.5~7.8mL of concentrated sulfuric acid and add it into a three-necked flask, slowly add potassium persulfate and phosphorus pentoxide in a mass ratio of (1:1~1:3) into the concentrated sulfuric acid under vigorous stirring, and heat up the mixture to 70°C~90°C; then, add graphite into the mixed solution, stop heating after stirring for 8~12 hours, cool to room temperature, wash the obtained product after the reaction, let stand, and dry in the air;

[0028]Take 20~30ml of concentrated sulfuric acid and add it to a three-necked flask, then mix the pretreated graphite and sodium nitrate (the mass ratio of graphite and sodium nitrate is 1:1~1:3), and then slowly add it to the concentrated sulfuric acid. Keep it at 3°C~4°C; then, slowly add potassium perma...

Embodiment 1

[0041] Step 1: Prepare graphene oxide (GO) by improving the Hummers method

[0042] Take 7.5mL of concentrated sulfuric acid and add it to a 100mL three-necked flask, and slowly add potassium persulfate and phosphorus pentoxide to the concentrated sulfuric acid with a mass ratio of 1:1 under vigorous stirring. Heat the mixture to 70°C; then add graphite, wash the graphite on the bottle wall with 3~6ml concentrated sulfuric acid, stop heating after stirring for 8 hours, transfer to a 500mL beaker after cooling to room temperature, add 500mL distilled water to the beaker , stand still for 24 hours to wait for precipitation, discard the supernatant and suspension, then add 500mL distilled water, stir and stand still, repeat 4-5 times, filter with suction, wash with distilled water until neutral, place at room temperature for 1 hour, and dry in the air.

[0043] Take 18ml of concentrated sulfuric acid and add it to a three-necked flask, mix the pretreated graphite and sodium nitra...

Embodiment 2

[0050] Step 1: Prepare graphene oxide (GO) by improving the Hummers method

[0051] Take 7.6mL of concentrated sulfuric acid and add it to a three-necked flask, and slowly add potassium persulfate and phosphorus pentoxide into the concentrated sulfuric acid under strong stirring at a mass ratio of 1:2. Adding phosphorus pentoxide will cause exothermic phenomenon. Heat the mixture to 80°C, then add the graphite into the three-necked flask, wash the graphite stuck on the wall of the bottle with 3~6ml of concentrated sulfuric acid; after stirring for 10 hours, stop heating, cool to room temperature, transfer to a 500mL beaker, add 500mL of distilled water Stand still for 24 hours to wait for precipitation, pour out the supernatant and suspension; add 500mL of distilled water, stir and let stand, wash repeatedly 4-5 times, filter with suction, wash with distilled water until neutral, place at room temperature for 2 hours, and dry in the air.

[0052] Take 25ml of concentrated sulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com