Stone papermaking method

A technology of stone and talc powder, which is applied in papermaking, textiles and papermaking, paper and other directions, can solve the problems of complex process and high energy consumption, and achieve the effect of simple production process, less electricity consumption and lower gram weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

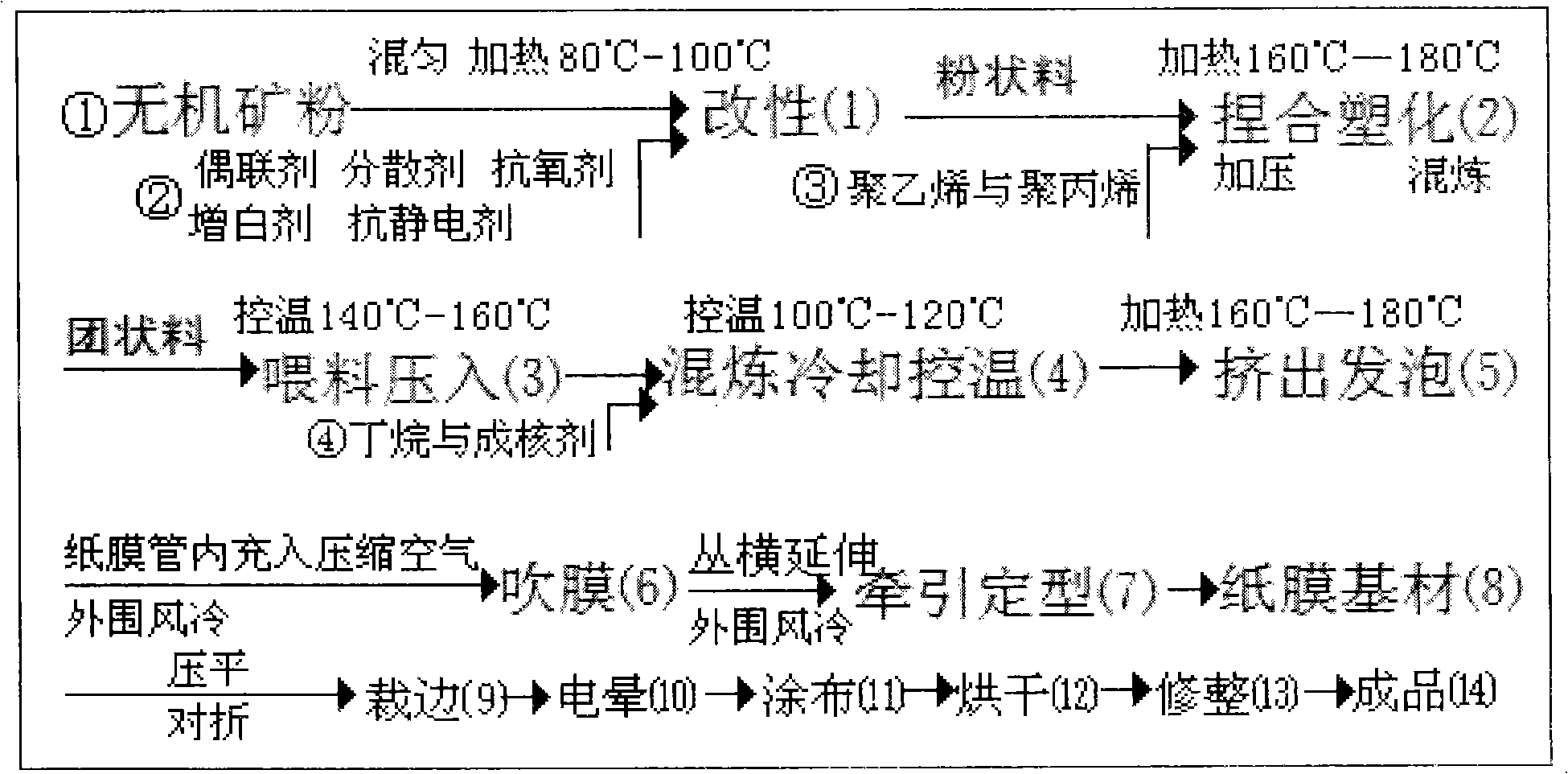

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the manufacture of environment-friendly paper

[0027] With 70% weight of natural inorganic mineral powder (wherein heavy calcium accounts for 67% weight, titanium dioxide accounts for 3% weight); 2% weight auxiliary agent (wherein coupling agent accounts for 1% of weight, dispersant accounts for weight 0.5%, antioxidant accounts for 0.285% by weight, whitening agent accounts for 0.015% by weight, antistatic agent accounts for 0.2% by weight,), 18% polyethylene by weight (wherein high density polyethylene accounts for 12% by weight, 6% by weight linear low density polyethylene; 9% by weight polypropylene; 0.5% by weight butane and 0.5% by weight nucleating agent. The total weight of the above material ingredients is 100%. After powder modification, mixing, plasticization and kneading, it is made into a lump material, which is extruded by a paper film making machine to form a micro-foaming closed-cell structure of 100 microns to 200 microns and has a bidire...

Embodiment 2

[0028] Embodiment 2: the manufacture of stone paper

[0029] With the natural mineral powder of 80% weight (wherein heavy calcium accounts for 78% weight, titanium dioxide accounts for 2% weight); 2.5% weight auxiliary agent (wherein coupling agent accounts for 1.3% by weight, and 0.7%, antioxidant accounts for 0.29% by weight, whitening agent accounts for 0.01% by weight, antistatic agent accounts for 0.2% by weight); 11.5% by weight of polyethylene (wherein high density polyethylene accounts for 7.5% by weight, linear 4% by weight of low density polyethylene); 5% by weight of polypropylene; 0.5% by weight of butane and 0.5% by weight of nucleating agent.

[0030] 100% of the total weight of the above material ingredients is modified by powder, kneaded, mixed, plasticized, and made into a dough material, which is extruded by a paper film manufacturing machine to form a micro-foaming closed-cell structure of 200 microns to 300 microns and The paper film substrate with bidirec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com