Patents

Literature

749results about How to "Mildew proof" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Multifunctional inorganic diatom ooze coating and preparation method thereof

InactiveCN104387816AStir wellNot easy to reuniteAntifouling/underwater paintsAlkali metal silicate coatingsCelluloseEmulsion

The invention relates to a multifunctional inorganic diatom ooze coating, which is prepared from the following components in percentage by mass: 10%-25% of water, 0.4%-0.8% of cellulose, 10-30% of a mixture of potassium metasilicate and silica sol, 0.2%-0.4% of a stabilizer, 0.1%-0.3% of a dispersing agent, 0.1%-0.3% of a silicon additive, 0.3%-0.5% of a defoaming agent, 0.1%-0.3% of an antibacterial agent, 0-20% of titanium dioxide, 5%-15% of nanometer kieselguhr, 10%-30% of coarse whiting, 2%-4% of talcum powder, 1%-3% of medical stone, 0-1.5% of anion, 0-2% of a nano-photocatalyst, 1%-2% of inorganic gel powder, 0-9% of an order-removing emulsion and 0-1.5% of pigment, wherein the sum of the components is 100%. The invention also provides a preparation method of the coating. The coating disclosed by the invention has the functions of sterilizing, preventing mold, purifying air and the like; and the preparation method disclosed by the invention is simple and easy to operate.

Owner:佛山市南海万磊建筑涂料有限公司

Bamboo charcoal viscose fiber and manufacturing method thereof

InactiveCN1807711ASoft touchComfortable to wearMonocomponent cellulose artificial filamentEmulsionViscose fiber

The invention discloses a bamboo charcoal viscose and preparing method, wherein the bamboo charcoal viscose consists of bamboo charcoal micro powder and bamboo vinegar liquid. The method consists of preparing rubber process and spinning process, wherein it is characterized by the following: preparing viscose solution and bamboo charcoal powder emulsion; adding in disperser and bamboo charcoal powder emulsion in deionized water; mixing up to get bamboo charcoal micro powder emulsion; mixing up viscose solution and bamboo charcoal micro powder emulsion; sending to spinning machine to prepare fiber.

Owner:上海恒加纺织有限公司

High weather resistant water-thinned wall paint and its preparing method

InactiveCN1392210ASelf-cleaningMildew proofPolyurea/polyurethane coatingsEmulsion paintsWeather resistanceEngineering

The present invention relates to high weather resistant water-thinned wall paint, and especially relates to environment friendly high weather resistant water emulsion paint and its preparation process. The paint consists of water emulsion, netted skeleton material, nano functional material, hydrophilic and hydrophobic raedical containing material, solid stuffing and assistant. The preparation principle includes basing on emulsion with excellent performance, constructing netted structure, introduction nano material with UV resisting, photocatalytic and high shielding performance, introducing assistant with both hydrophilic and hydrophobic characteristic to form compact and high-adhesion coating with integrated high weater resistance.

Owner:SUN YAT SEN UNIV

Wood wax oil for protecting lumber and preparation technique thereof

InactiveCN101407068AStay flexibleKeep greenCoatingsWood impregnation detailsVegetable oilHazardous substance

The invention discloses wood wax oil for protecting wood and a method for preparing the same. The raw materials of the wood wax oil comprise vegetable oil and wax, and the wood wax oil is characterized in that the compositions of the raw materials of the wood wax oil comprise vegetable oil, animal or vegetable wax, ferric oxide and a catalyst. The wood wax oil and the preparing process can protect the wood completely, can keep the elasticity and environmental protection performance of wood, can prevent the wood from cracking effectively and enable the wood to have various comprehensive properties such as drying, as well as corrosion, insects, moisture, mildew, termite, anti-cracking, and fire-retardant resistance, and the like, and meet all requirements of environmental protection, and does not to release any harmful substance during long-term use. The preparing process of the wood wax oil is simple and no organic solvent is needed to be added, thereby avoiding the incorporation of harmful substances.

Owner:张海林

Stone papermaking method

InactiveCN101831835AControl the amount of inflationLight weightInorganic fibres/flakesSpecial paperFilm baseWhite powder

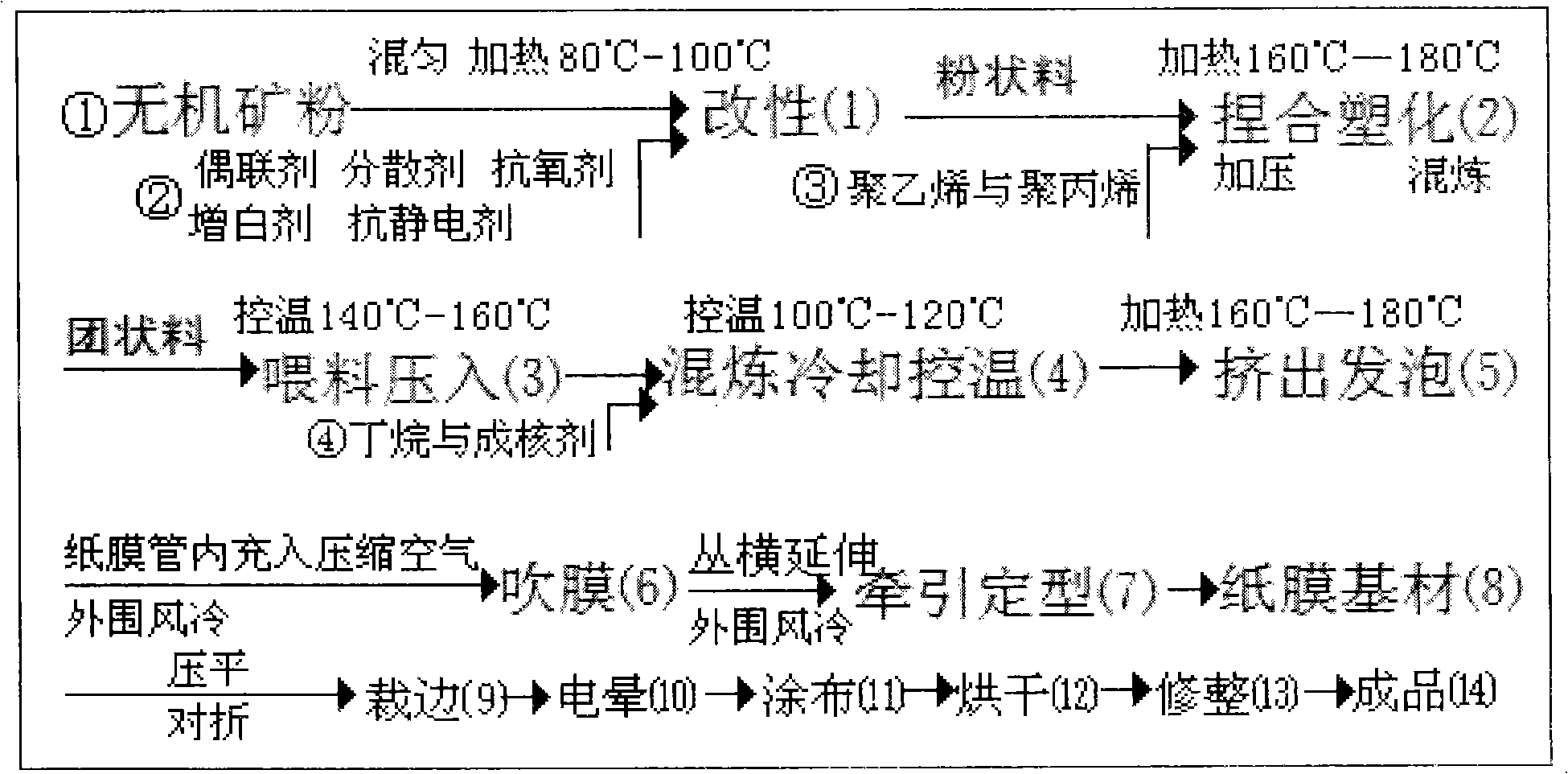

The invention discloses a stone papermaking method, which is characterized by comprising the following steps: adding 2 to 2.5 weight percent of auxiliary agent such as stearic acid and the like into 70 to 80 percent of natural inorganic ore powder such as heavy calcium, light calcium, talcpowder, titanium white powder and the like serving as main raw materials to modify the raw materials, adding 18 to 11.5 weight percent of polyethylene and 9 to 5 weight percent of polypropylene into the raw materials, and mixing, plasticizing and kneading the mixture to form a bulk material; and performing double-fold feed on the bulk material, pressing the bulk material into a paper film extruder, injecting 0.5 weight percent of butane and 0.5 weight percent of nucleating agent into the extruder, mixing and heating the mixture, extruding a paper film, then foaming, blowing, drawing, cooling and shaping the paper film to form a paper film base material, and forming a stone paper finished product through corona, coating, drying and finishing. The gram weight of stone paper is reduced by physical micro-foaming technology. The method has the advantages of simple manufacturing process, low cost, dry production, use of few water circulating cooling machines, no three-waste discharge and pollution avoidance.

Owner:山西典石晨晶科技有限公司

Reinforced composite bamboo board and its manufacturing method

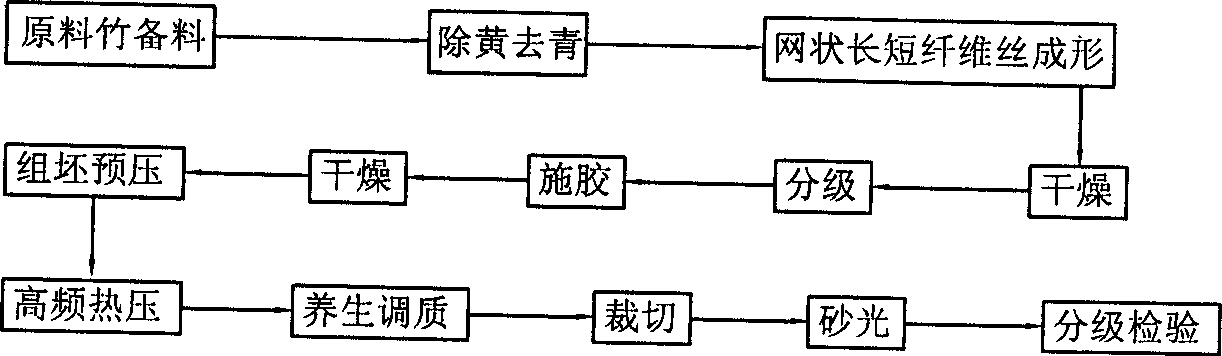

InactiveCN1769621ALight weightEnvironmentally friendlyWood working apparatusDomestic articlesSurface layerFiber bundle

The invention discloses a strengthening composite bamboo board and preparing method, which consists of net bamboo fiber bundle layer and surface layer, wherein the net bamboo fiber bundle layer is composed of parallel grain and cross grain. The invention is prior to wood fiber board, which prevents the common bamboo board (bar structure of multiple-layer parallel adhesion) from deforming and uneven strength.

Owner:SICHUAN SHENGDA FOREST PROD IND GRP CO LTD

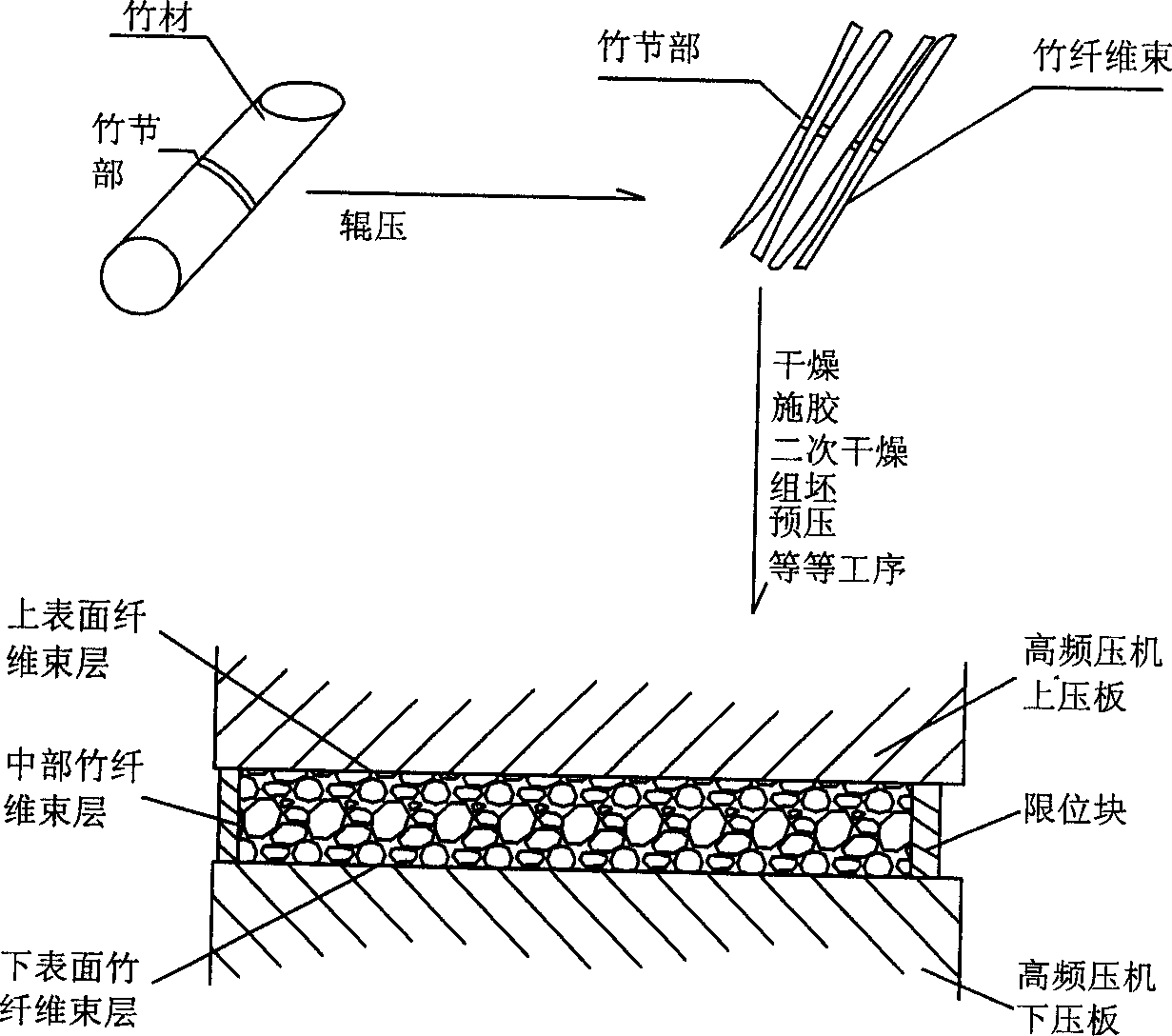

Super hydrophobic self-cleaning coating and preparation method thereof

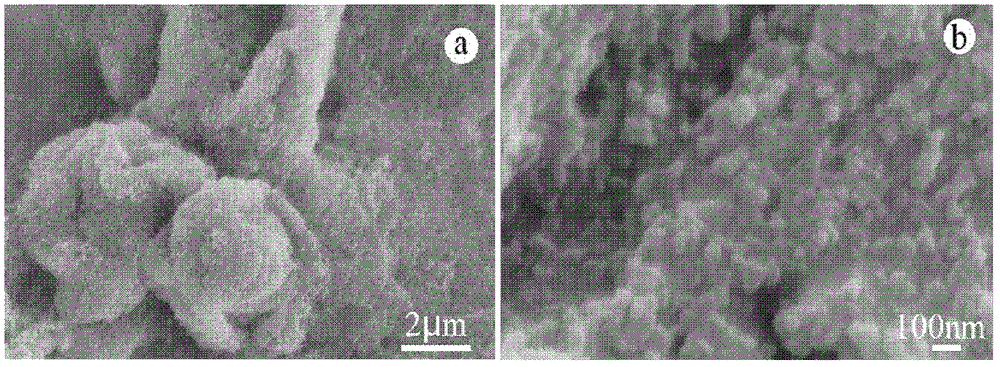

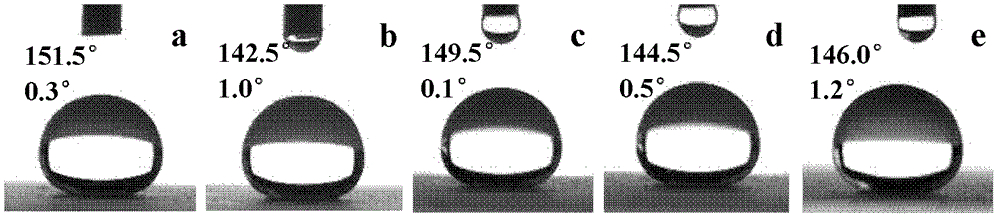

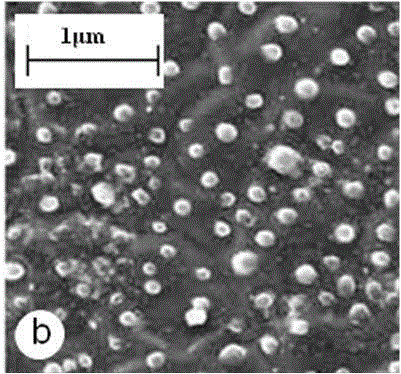

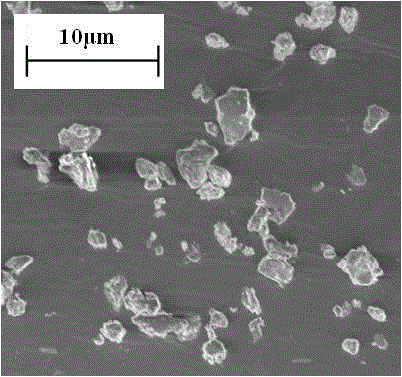

The invention belongs to the technical field of preparation of nano materials, and in particular relates to a super hydrophobic self-cleaning coating and a preparation method thereof. The method comprises the following steps of: dispersing hydrophobic silicon resin and hydrophilic nano SiO2 particles into an organic solvent to obtain dispersion; and spraying the dispersion on a clean and dry glass sheet substrate, drying, and thus obtaining the super hydrophobic self-cleaning coating. The coating has a hierarchical structure compounded by using organic and inorganic components, namely the hydrophobic silicon resin and the hydrophilic nano SiO2 particles, and the structure has compound micro-nano surface topography; and the compound micro-nano hierarchical structure is constructed by spheroid-like protrusions with the diameters of 1 to 10 microns and agglomerate spheres with the diameters of 20 to 100 nanometers on the surface of the coating, wherein the spheroid-like protrusions are constructed by agglomerate spheres with the diameters of 20 to 100 nanometers. The contact angle between the coating and water is 140 to 155 degrees, and the rolling angles of water drops on the surface of the coating are less than 2 degrees.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Antibacterial viscose rayon and production thereof

InactiveCN1779004AEvenly dispersedHigh antibacterial rateMonocomponent cellulose artificial filamentCelluloseAntiseptic Agent

The invention provides an antiseptic viscose fiber. It is spinned by the silver antiseptic agent and the cellulose sulphonic acid ester. The silver antiseptic agent is 0.5-5% weight of the cellulose. The product has the good antisepsis and the detergent resistance.

Owner:XINXIANG CHEM FIBER

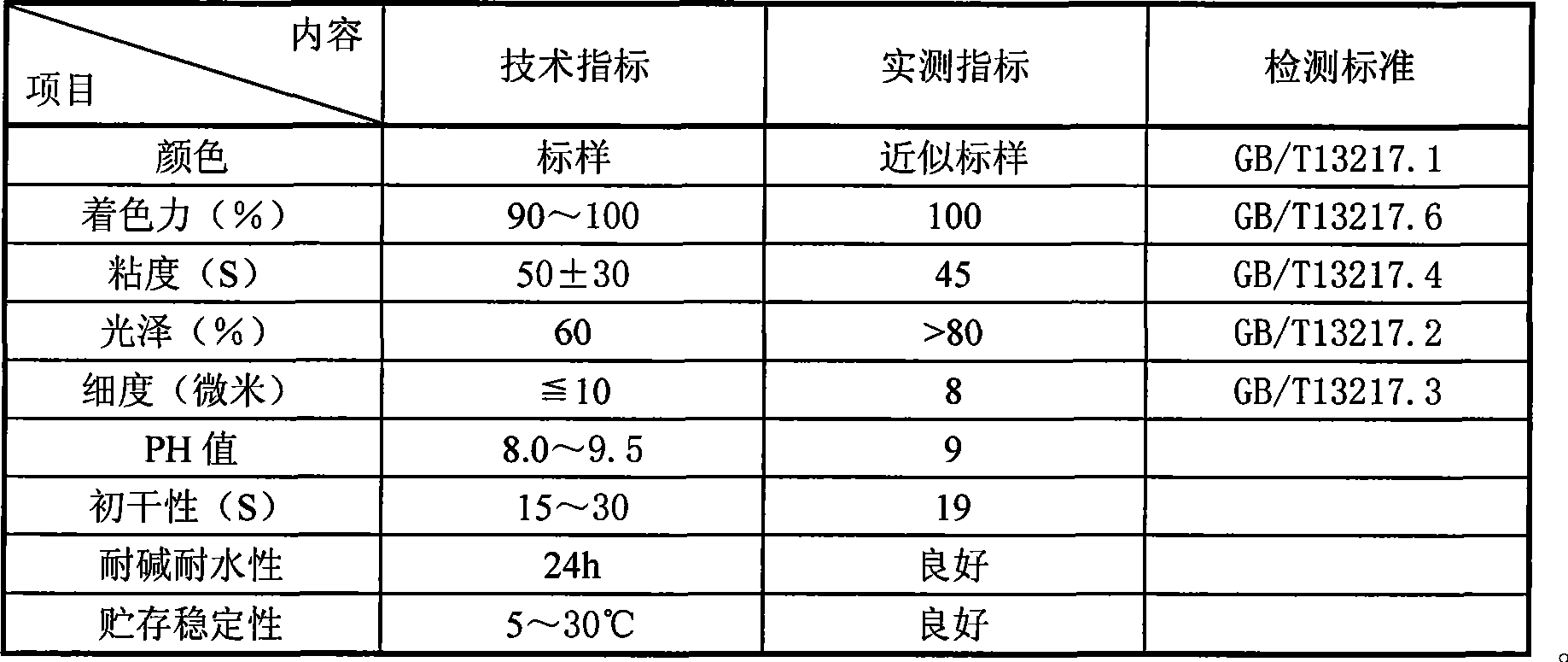

Method for multifunctional water-based ink

The invention provides a multifunctional water-based ink, which comprises the following components by weight percent: 25 to 35 percent of water-soluble acrylic resin, 10 to 20 percent of paint, 3 to 10 percent of silicon oxide, 15 to 25 percent of water, 5 to 15 percent of complex solubilizer, 5 to 10 percent of neutralizing agent, 1 to 3 percent of emulsifier, 0.2 to 1 percent of antifoaming agent, 5 to 9 percent of dispersant, 0.2 to 1 percent of antistatic agent, and 0.1 to 1 percent of anti mildew agent. The multifunctional water-based ink is a novel printing water-based ink which is nontoxic, odorless and low in comprehensive price, and has watertight, anti-mildew and antistatic functions and other functions.

Owner:HUNAN DIMENSION INTELLIGENT TECH CO LTD

Self-cleaning nano protective liquid used for glass and preparation method

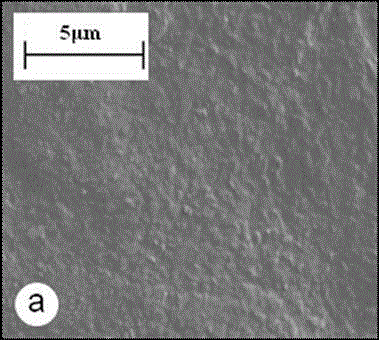

The present invention relates to a self-cleaning nano protective liquid used for glass and a preparation method. According to the self-cleaning nano protective liquid used for glass, a thin film coating formed by the nano protective liquid is provided with a similar structure of a lotus leaf surface in nature, wherein the structure is a nano-micro composite layer structure, and the coating is a colorless transparent thin film coating, with a thickness of 400-1000nm. The coating provided by the present invention has superior properties of water-proofing, oil-proofing, anti-fouling, anti-fogging, moisture-proofing, and the like. A contact angle of the coating and water is 140-155 DEG (a droplet volume is measured as 4 mu L), a roll angle of a water droplet on a coating surface is less than 5 DEG (a droplet volume is measured as 4 mu L). The water droplet existed on the the coating surface is freely rollably, meanwhile contaminations of dust and the like are removed, and thereby achieving the superior properties of anti-fogging, anti-fouling and the like.

Owner:王金书

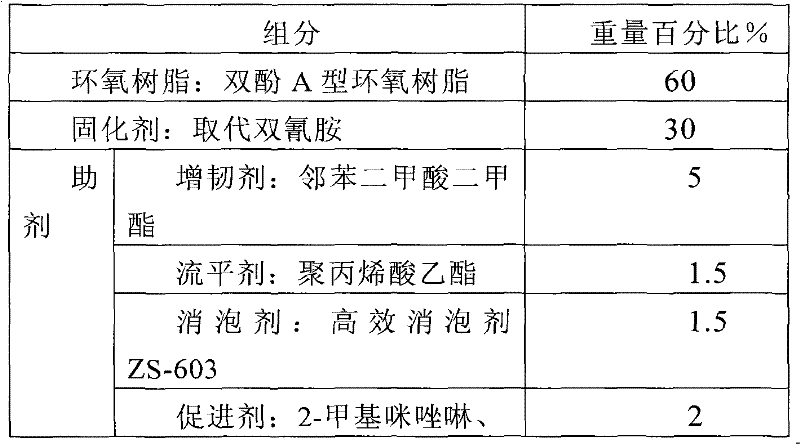

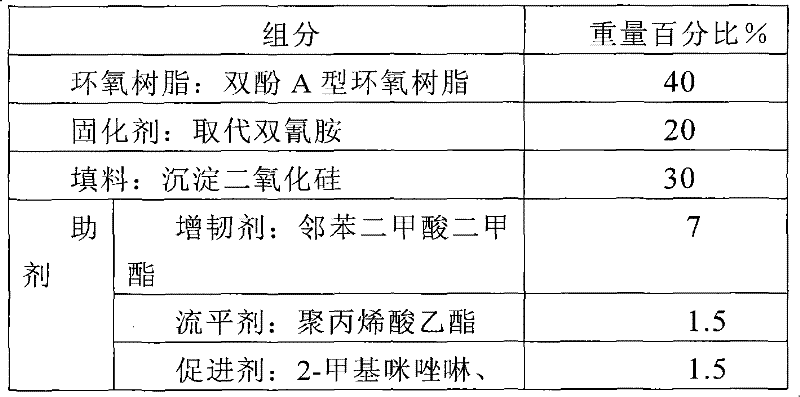

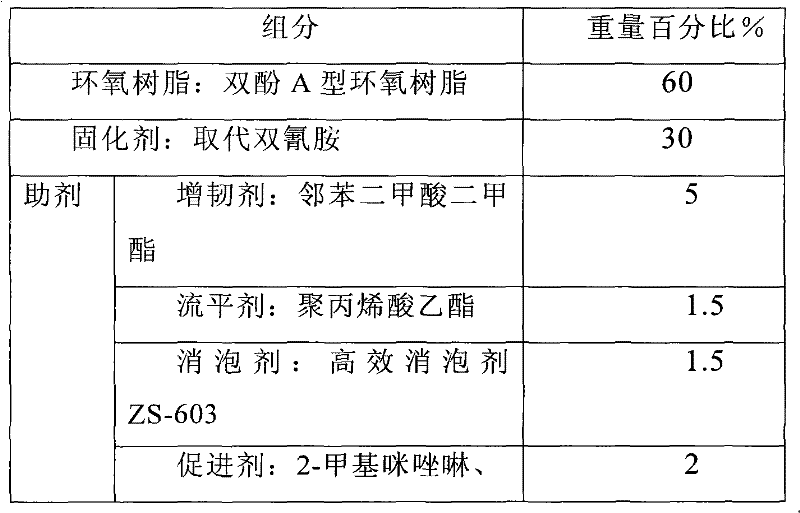

A kind of epoxy powder insulation anticorrosion coating

InactiveCN102294869AStrong adhesionImprove insulation performanceSynthetic resin layered productsAnti-corrosive paintsEpoxyMelt extrusion

The invention belongs to thermosetting epoxy powder insulation anticorrosion paint. It consists of a primer and a top coat, which together form an electrically insulating and anti-corrosion coating. The primer is composed of epoxy resin, curing agent and auxiliary agent; the surface coating is composed of epoxy resin, curing agent, filler and other auxiliary agents; both the primer and the surface coating are made by melt extrusion mixing method Powdered product. The primer coating does not contain or contains less filler, so the adhesion of the formed primer coating is not affected; the surface coating bears the main functions of electrical insulation and anti-corrosion, so the coating of the present invention has strong adhesion, excellent electrical insulation performance, and has Anti-corrosion, anti-rust, anti-mildew, heat-resistant, wear-resistant and other functions, and has the characteristics of low cost.

Owner:NINGBO KEXIN CORROSION CONTROL ENG

Fiberboard with formaldehyde self-absorbing function and manufacturing method thereof

InactiveCN101585204AAnti-corrosionMoisture-proofWood working apparatusFlat articlesActivated carbonFiber

The present invention provides a fiberboard with formaldehyde self-absorbing function and a manufacturing method thereof. The fiberboard of the invention adopts the wood fiber, aldehyde adhesive and active carbon as main raw materials. The dosage of the adhesive is 9%-12% of that of the wood fiber mass, and the dosage of the active carbon is 2%-30% of that of the wood fiber mass. The invention provides the novel fiberboard which is added with a certain amount of active carbon component with the absorbing function in the manufacturing process of the board so that the fiberboard has the function of free formaldehyde (harmful gas) self-absorbing function in the board for a long time. The releasing of the formaldehyde in the board can be reduced for reducing the formaldehyde pollution to the environment. Simultaneously the fiberboard has the functions of corrosion resistance, moisture resistance, deodorization and fungus resistance. Furthermore the fiberboard has the advantages of high absorbing efficiency, excellent absorbing effect, low cost, no toxicity, no side effect, etc.

Owner:NORTHEAST FORESTRY UNIVERSITY +3

Flame retardant polystyrene foamed hard wood-imitating material and preparation method thereof

The invention discloses a flame retardant polystyrene foamed hard wood-imitating material and a preparation method thereof. The hard wood-imitating material comprises, by weight, 50-70 parts of recovered polystyrene, 55-75 parts of high impact polystyrene, 35-45 parts of flame retardant masterbatch for a core layer, 30-40 parts of special flame retardant masterbatch for a surface layer, 0.5-0.9 parts of a foaming agent, 1-4 parts of a flexibilizer, 0.1-0.5 parts of a plasticizer, and 0.5-0.9 parts of a coloring agent. The flame retardant polystyrene foamed hard wood-imitating material of the present invention has high intensity flame retardation, is a hard foamed wood-imitating material with certain toughness and low density, and simultaneously has the advantages of fireproofing, waterproofing, oil resistance, insect prevention, mildew resistance, weatherproofing, light weight and the like.

Owner:SHANGHAI INTCO INDUSTRIES CO LTD +1

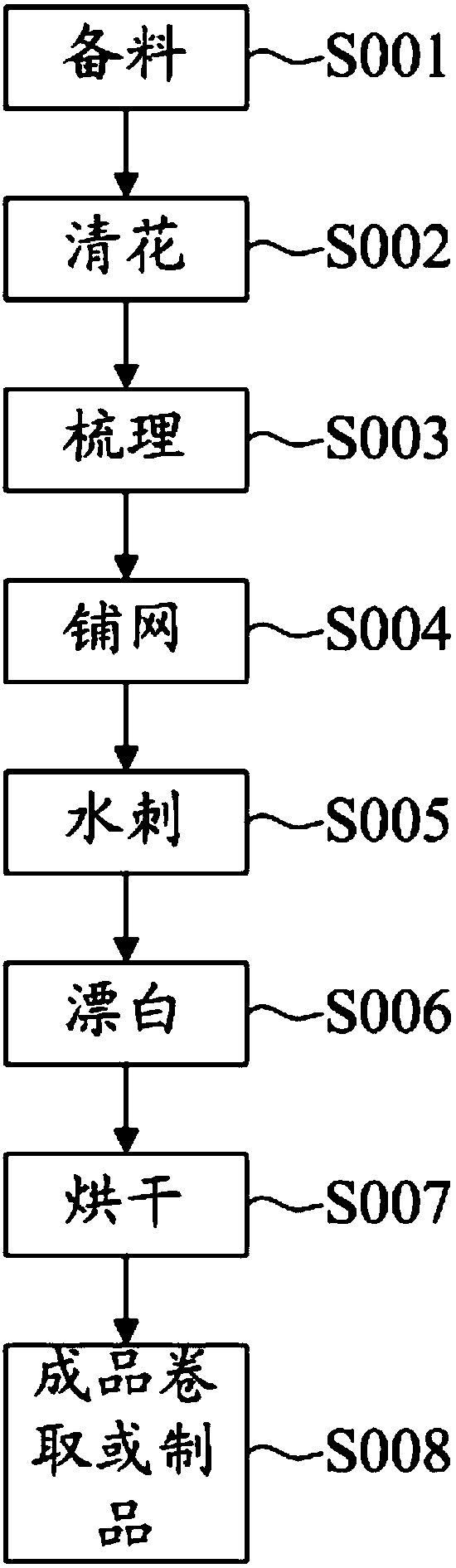

Production method of kapok fiber spunlaced nonwoven fabric

InactiveCN103205862AKeep natural propertiesMaintain propertiesNon-woven fabricsVegetal fibresKapok fiberPulp and paper industry

The invention belongs to the technical field of weaving, in particular to a production method of kapok fiber spunlaced nonwoven fabric. The method includes: pretreating kapok fiber to improve spinnability; using a weighing curtain feeder to feed kapok fiber into a blowing-carding device for opening, blending and purification; using an induced fan to collect web in a blowing-carding machine to feed into a tiny dust removing device for further dust removing and opening; connecting the tiny dust removing device with a spunlaced line carding machine, carding the fiber into web on the spunlaced line carding machine, cross lapping, spunlacing to form fabric, coiling, degreasing and bleaching, drying and slitting to obtain the finished product. The method is safe, environment-friendly, energy-saving, efficient, high in automation level, and advanced in spunlaced kapok nonwoven fabric weaving, and various characteristics of fiber raw materials are protected effectively.

Owner:蒋海彦

Nano shell powder ecological functional flatly painted coating

The invention relates to environmental protection paint, in particular to nano shell powder ecological functional flatly painted coating. The coating is prepared from shell powder (calcined), ash-calcium, kaolin, heavy calcium carbonate, hydrated magnesium silicate, titanium dioxide, vinyl acetate, hydroxyethyl cellulose, polyving akohol, polydimethylsiloxane, a water reducer and a defoamer. The coating solves the problem that indoor ornament or decoration paint is not environment-friendly. The coating has the characteristics that the coating is antifungal, purifies the air, prevents mildew, adopts a spiral pore structure, is 3.0mm in press coating thickness and high in glossiness, does not has obvious color aberration, is resistant to shock, abrasion, water, high and low temperature weather and aging, and ensures that the service life of a product reaches more than 20 years.

Owner:通化市星赛尔生物科技有限公司

Plant fiber reinforced inorganic light composite and preparation method thereof

InactiveCN106747031APrevent shrinkageFast condensationSolid waste managementCeramicwareMagnesium chloride hexahydrateFlexural strength

The invention discloses a plant fiber reinforced inorganic light composite which is mainly prepared from magnesium chloride hexahydrate, magnesium sulfate heptahydrate, light calcined magnesia, water, a water reducer, a reinforcing agent, reinforcing fibers, a foaming agent, an exciting agent, a stabilizer and adjusting admixture. The preparation method comprises steps as follows: magnesium chloride hexahydrate, magnesium sulfate heptahydrate and water are mixed to be made into a saline solution; light calcined magnesia, the water reducer and the reinforcing agent are added to the saline solution, the mixture is stirred at a constant speed, and an inorganic sizing material is obtained; the reinforcing fibers are added to the inorganic sizing material and stirred at a constant speed, the adjusting admixture, the stabilizer and the exciting agent are dropwise added slowly, finally, the foaming agent is added quickly, the mixture is stirred at a high speed, and a foamed inorganic sizing material is obtained; the foamed inorganic sizing material is poured into a die, left to stand for foaming, removed from the die and maintained, and the plant fiber reinforced inorganic light composite is obtained. The composite has the advantages of high pressure resistance, high bending resistance, low density, no formaldehyde, aging resistance, mildew resistance, termite resistance, moisture-proof performance, no deformation, sound and heat insulation, good heat preservation and the like.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Kapok spunlace non-woven fabric, preparation method thereof and product of kapok spunlace non-woven fabric

InactiveCN107916499ABreathableWarm and antibacterialNon-woven fabricsMaterials preparationForeign matter

The invention discloses a kapok spunlace non-woven fabric, a preparation method thereof and a product of the kapok spunlace non-woven fabric. The preparation method of the kapok spunlace non-woven fabric comprises the following steps: material preparation: independently preparing kapok fibers, or uniformly mixing the kapok fibers with one or more of other natural fibers and chemical fibers to obtain mixed fibers; blowing: removing impurities from the prepared kapok fibers or mixed fibers, and sieving out foreign matters; carding: opening the blown kapok fibers or mixed fibers into single fibers at first, and then smoothly combing the single fibers; carrying out lapping; carrying out spunlace; carrying out bleaching; carrying out drying; and rolling a finished product or obtaining a product. Because the kapok fibers have characteristics of lightness and softness, breathability, high wet permeability, high degree of hollowness, anti-bacterial property, mothproof property and mildew proofproperty. The kapok spunlace non-woven fabric is prepared by the spunlace non-woven process, chemical auxiliaries are not added in a whole fabric forming process, and therefore, the prepared kapok spunlace non-woven fabric has the advantages of warming and bacteria inhibition, lightness, softness and comfort, dryness and breathability and the like.

Owner:WINNER MEDICAL CO LTD +1

Preparation method of water hyacinth rattan

InactiveCN103264423ADoes not affect flexibilityIncrease productivityReed/straw treatmentDrying timeWater Hyacinths

The invention relates to a preparation method of water hyacinth rattan. The preparation method comprises the following steps of: collecting stalk of water hyacinth, drying the stalk of the water hyacinth for 48-72 hours in air by using a natural air drying method, and subsequently drying the stalk by using a heating and drying method till the water content of the stalk is 10-15%, wherein the temperature of the heating and drying environment is 75-85 DEG C and the humidity is 30-50% in the heating and drying method. With the combination of the natural air drying method and the heating and drying method, the drying time is shortened on the premise that the flexibility of the water hyacinth rattan is not affected, so that the production efficiency of the water hyacinth rattan is greatly improved.

Owner:GUANGDONG DOER SCI & TECH

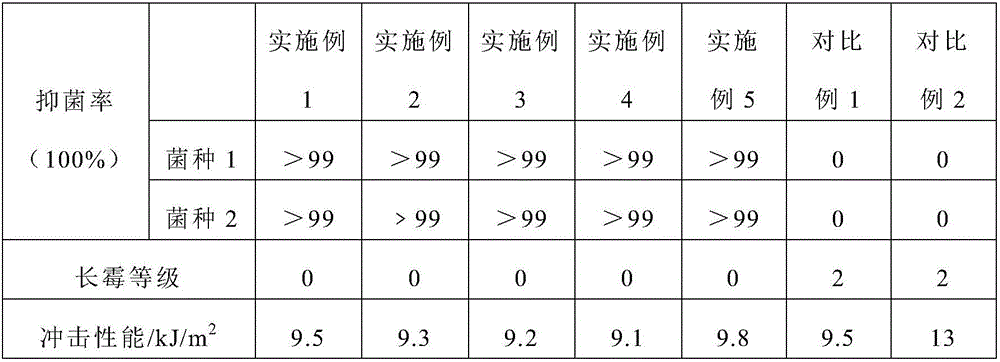

Transparent plastic with antibacterial and mouldproof capacity and preparing method thereof

The invention discloses transparent plastic with antibacterial and mouldproof capacity and a preparing method thereof and belongs to the field of functional polymer materials and inorganic-organic nanocomposite. The transparent plastic is prepared from, by mass, 85-97% of transparent resin, 1-10% of antibacterial agent, 1-10% of mouldproof agent, 0.1-1.0% of complex antioxidant and 0.1-1.0% of dispersing agent. The preparing method comprises the steps of 1, conducting physical mixing according to mass percentage; 2, adding evenly mixed raw materials into a twin-screw extruder for melting granulation. According to the transparent plastic, light transmittance is larger than 85%, escherichia coli inhibition rate is larger than 99%, staphylococcus aureus inhibition rate is larger than 99%, and fungi-growth grade is 0. Furthermore, the preparing method is simple, implementation is convenient, and production cost is low.

Owner:武汉威雷博科技有限公司

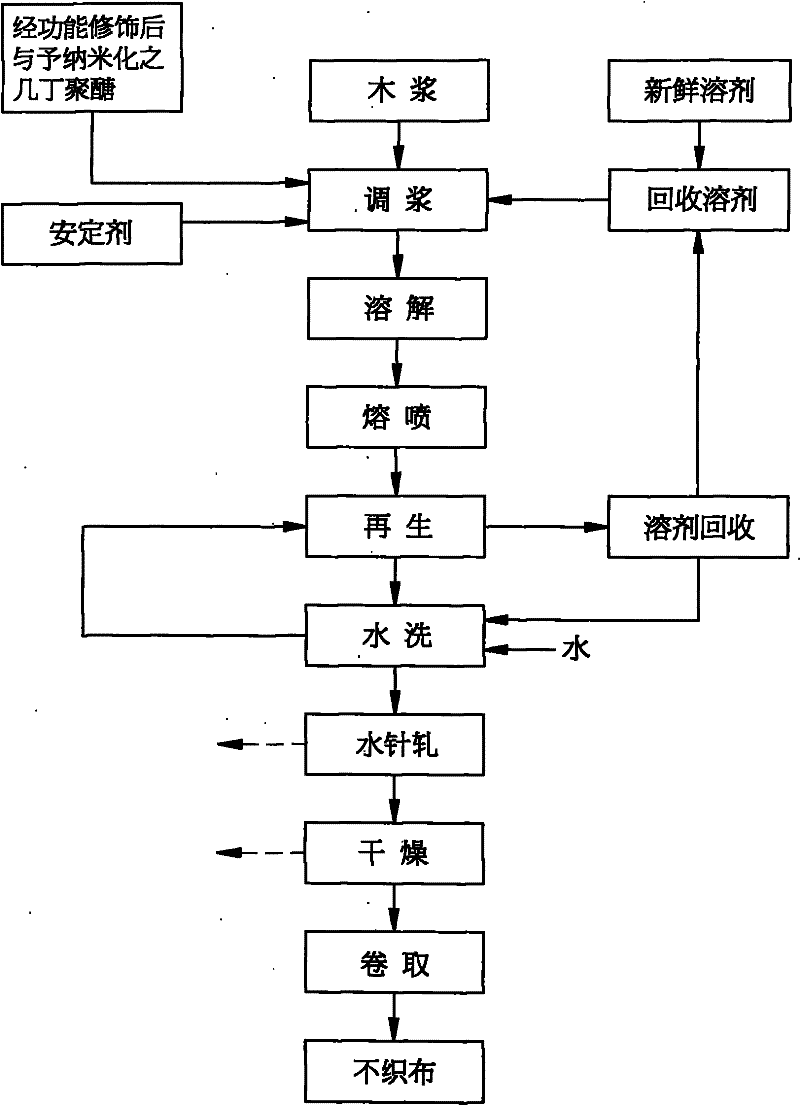

Production method of cellulose non-woven fabric with functions of mildew proofing, antibiosis and deodorization through wet-type meltbrown

ActiveCN102127841AChance of infectionReduce the chance of being infected by microorganismsMonocomponent cellulose artificial filamentWet spinning methodsSlurryNatural fiber

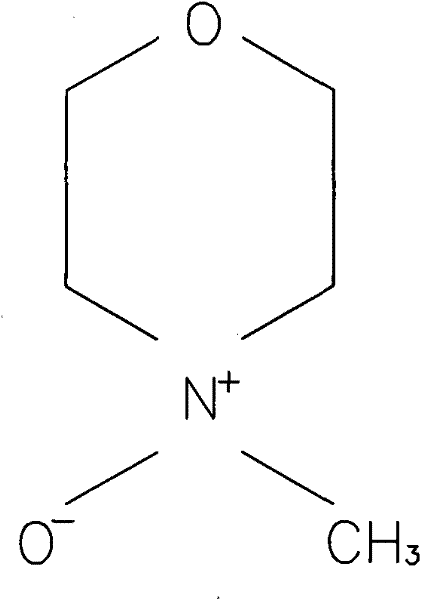

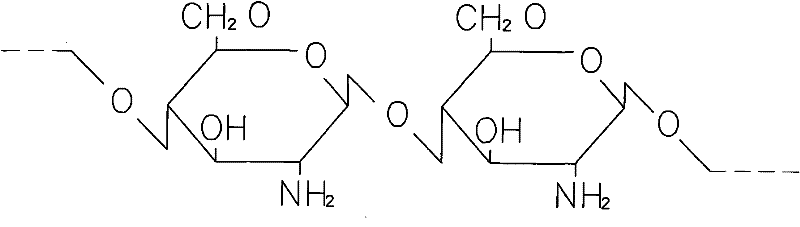

The invention provides a production method of a cellulose non-woven fabric with functions of mildew proofing, antibiosis and deodorization through wet-type meltbrown, comprising the following steps of: adding natural chitosan macromolecules subjected to functionalized modification and nanocrystallization into a size prepared from pulp and N-methylmorpholine N-oxide (short for NMMO) to be mixed and dissolved to form a dope; then spraying the dope from a spinning nozzle in a meltbrown way to form a non-woven fabric silk net, and carrying out water mist solidification and regeneration; and finally, washing with water, rolling with a squirt cut, drying, rolling and carrying out other procedures to obtain a natural cellulose non-woven fabric with functions of mildew proofing, antibiosis and deodorization and a continuous filament form. The cellulose non-woven fabric with functions of mildew proofing, antibiosis and deodorization can be applied to wiping textiles, medical consumables, filtering materials, biotechnical materials, photoelectric wafers and the like with functions of mildew proofing, antibiosis and deodorization.

Owner:张文波

Environment-friendly latex paint for external wall

Disclosed is an environment-friendly latex paint for external wall which comprises water, thinning agent methyl glycol, dispersing agent P-998, multifunctional adjuvant AMP-95, wetting agent PE-100, water solution of thickening agent HEC, defoaming agent 220, titanium dioxide R215, porcelain clay, ultra-fine grammite, ultra-fine aluminum silicate, talcum powder, antiseptic 981, polyurethane thickening agent SN636, thickening agent 2020, levelling agent DSX 2000, defoaming agent 202 and thixotropic agent AT.

Owner:OCEAN UNIV OF CHINA

Heat-insulation and heat-preservation water-based coating material with air purifying function

InactiveCN103450761ALow thermal conductivityQuality improvementFireproof paintsLignin material coatingsWater basedHazardous substance

The invention provides a heat-insulation and heat-preservation water-based coating material with an air purifying function. The water-based coating material is prepared through compounding raw materials, such as diatomite, hollow glass beads, lignocellulose, zirconium phosphate loaded sliver powder, nano zinc oxide, tourmaline powder, aluminum oxide, hydroxypropyl methylcellulose, a pure acrylic emulsion, a dispersing agent 5040, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, 1,2-propanediol, Kathon, a silicone defoamer, deionized water and the like. The water-based coating material provided by the invention further has the functions of improving air quality, regulating air humidity, preventing mildew and the like through adsorbing harmful substances in air and releasing negative ions, besides an excellent heat insulation function.

Owner:深圳市宜丽环保科技有限公司

Ink-absorbing quick-drying painting canvas

ActiveCN103741481AImprove antioxidant capacityNot easy to fadeFibre treatmentChemistryEconomic shortage

The invention discloses an ink-absorbing quick-drying painting canvas. The preparation method of the canvas comprises the following steps: (1) painting gel resin on the surface of fabric, drying in an oven with a temperature of 100 to 120 DEG C so as to obtain a gel resin layer; (2) painting prime paint on the gel resin layer, drying in an oven with a temperature of 90 to 100 DEG C so as to obtain a prime paint layer; (3) painting surface paint on the prime paint layer, drying in an oven with a temperature of 70 to 85 DEG C so as to obtain a surface paint layer, wherein during this process, the fabrics go through the oven in a speed of 6 meters per minute to 7 meters per minute; (4) painting ink-absorbing quick-drying paint on the surface paint layer, drying in an oven with a temperature of 70 to 85 DEG C, wherein in this process, the fabrics go through the oven in a speed of 6 meters per minute to 7 meters per minute. The ink-absorbing quick-drying painting canvas preserves the unique wash-painting effect of raw Xuan paper, overcomes the inherent shortages of raw Xuan paper, thus enlarges the application range and increases the collection value of wash paintings.

Owner:沭阳凤凰画材有限公司

High-strength magnesian coal ash clinker-free cement

The invention relates to high-strength magnesian coal ash clinker-free cement, which comprises the following raw materials in part by weight: 100 parts of coal ash, 30 to 40 parts of light roasting magnesium oxide, 10 to 15 parts of magnesium sulfate heptahydrate, 2 to 4 parts of calcium sulfate, ferrous sulfate or aluminum sulfate, 0.5 to 1.0 part of phosphoric acid and 50 to 100 parts of water. The high-strength magnesian coal ash clinker-free cement has the advantages that a large amount of coal ash is utilized, and produced wastes are used as production raw materials and are put into use, so that environmental pollution is reduced; and the product is long in service life and high in board strength, and is widely applied to wallboards, suspended ceilings, decorative materials and furniture.

Owner:湖北兆驰新材料有限公司

Process for producing nano-modified health-care bamboo charcoal

InactiveCN1690130AHas the ability to decomposeEliminate hidden dangers of infringementBiocideOther chemical processesNanometreNano titania

A nano modified healthy bamboo charcoal, which taking powdery bamboo charcoal of 20-400 order as main material, produced with slight nano titania and nano titania antibacterial agent. Because of porous structure and high adsorbability of bamboo charcoal, in addition to disassembling adsorbed toxic and harmful substance to carbon dioxide and water that is nontoxic and harmfulless, which is bactericide and disinfection, so the invention can clean effectively indoor air, diminish effluvium, nullifying the harm to people, which is useful in indoor mattress, velvet toy, insole and in-car cushion and backing mattress.

Owner:周娟

Optic catalyst anti-bacterial mildw-proof negative ion polypropylene monofilament and its preparing method and use

ActiveCN1944722AAntibacterialMildew proofMonocomponent polypropylene artificial filamentMelt spinning methodsPolymer scienceAir filter

The photocatalytic antibacterial moldproof negative ion polypropylene monofilament contains photocatalyst powder, antibacterial powder, moldproof agent powder and negative ion powder in the weight ratio of 35-45 to 15-25 to 4-8 to 25-35 and in the total amount of 3-8 wt% of the polypropylene monofilament, coupler in the amount of 0.5-1.5 wt% of the foregoing four additives, solvent for diluting the coupler in the same amount as the coupler, and dispersant in the amount of 1-3 wt% of the foregoing four additive. The present invention also provides the preparation process and use of the polypropylene monofilament. The polypropylene monofilament is used in weaving air strainer for air filter, and has the functions of resisting bacteria, preventing mildew, deodorizing, self-cleaning, emitting negative ion, etc.

Owner:ZHEJIANG GOLDENSEA ENVIRONMENT TECH

Water-based paint and its preparation technique

InactiveCN101240139AReduce labor intensityProtect your healthEmulsion paintsBuilding materialEmulsion

The invention relates to a waterproof paint for architecture and building materials, especially to a water-base paint which is widely applied to brushing objects such as boarded floor, toy for children, corrugated paper, inner wall, outer wall, woodwork, damp proofing, cement, leak stopping, metal product, etc. The prescription of water-base paint totally differs from the traditional one, comprising: adding raw materials such as glycerin, xylitol, etc., except crylic acid emulsion, which are food-grade raw materials substantially, nontoxic and environmental-friendly absolutely. The water-base paint can be constructed directly, bring handsome looking and relieving labor strength of constructors. Furthermore, the water-base paint does not damage health of constructors, with multiple advantages of current waterproof paints.

Owner:黄敏文

Sterilization processing method of rattan plaited article materials

InactiveCN104476639ASimple processing methodInsect-resistantBiocideWood treatment detailsMildewSoftening

The invention provides a sterilization processing method of rattan plaited article materials, and belongs to the technical field of rattan plaited article production. The sterilization processing method comprises following steps: rattan is harvested, and each 10 to 20 strips are bonded with a consistent direction so as to obtain one bouquet of rattan; the bonded rattan bouquets are immersed in a processing solution with the end tip of rattan upward, and are exposed to sunlight for 3 to 6 h; leaves of the rattan bouquets are removed, the rattan bouquets are dried with hot air, wherein at a first stage, the rattan bouquets are dried to medium dry, and are subjected to moisture retention for 30 to 50 min for a first time with softening steam, at a second stage, the rattan bouquets are dried to be sixty percent dry, and are subjected to moisture retention for 1 to 3 h for a second time with softening steam, and at a third stage, the rattan bouquets are dried to be eighty percent dry; and the processed rattan bouquets are stored at shade places for natural air drying. According to the sterilization processing method, the fresh rattan is processed firstly; the sterilization processing method is simple, is capable of realizing sterilization, insect prevention, moth prevention, and mildew and rot prevention, and prolonging service life of rattan plaited articles; the obtained steam used for softening is capable of realizing rattan softening, and volatile substances contained by the steam is capable of realizing sterilization and fragrance improvement of rattan.

Owner:ANHUI HONGFU CRAFTS

Inorganic-organic hybrid super-hydrophilic self-cleaning coating and production method thereof

ActiveCN104629617AImprove self-cleaning functionImprove adhesionCoatingsWeather resistanceDisplay device

The invention discloses an inorganic-organic hybrid super-hydrophilic self-cleaning coating and a production method thereof. The inorganic-organic hybrid super-hydrophilic self-cleaning coating is prepared from the following raw materials in percentage by weight: 60-90% of a solvent, 5-20% of a compound binder, 3-10% of a curing agent and 1-10% of a functional material. By adopting an inorganic-organic hybrid process, the inorganic-organic hybrid super-hydrophilic self-cleaning coating which is excellent in various performances such as hydrophilicity, dust resistance, pollution prevention, mildew resistance, weather resistance and durability is prepared. The coating is coated on the surface of a base material to form a concave-convex film of a micro-nano structure, so that the surface of the base material obtains the functions of hydrophilicity, dust resistance, pollution prevention, self-cleaning property and the like. The coating disclosed by the invention is suitable for large-area construction, has the advantages of high film forming hardness, high self-cleaning property, good wear resistance and good durability, and can be applied to surfaces of building external walls, glass, tiles, marbles, artificial stones, plastic, aluminum sheets, displays, walls and the like.

Owner:NANJING MISURFACE NEW MATERIAL TECH

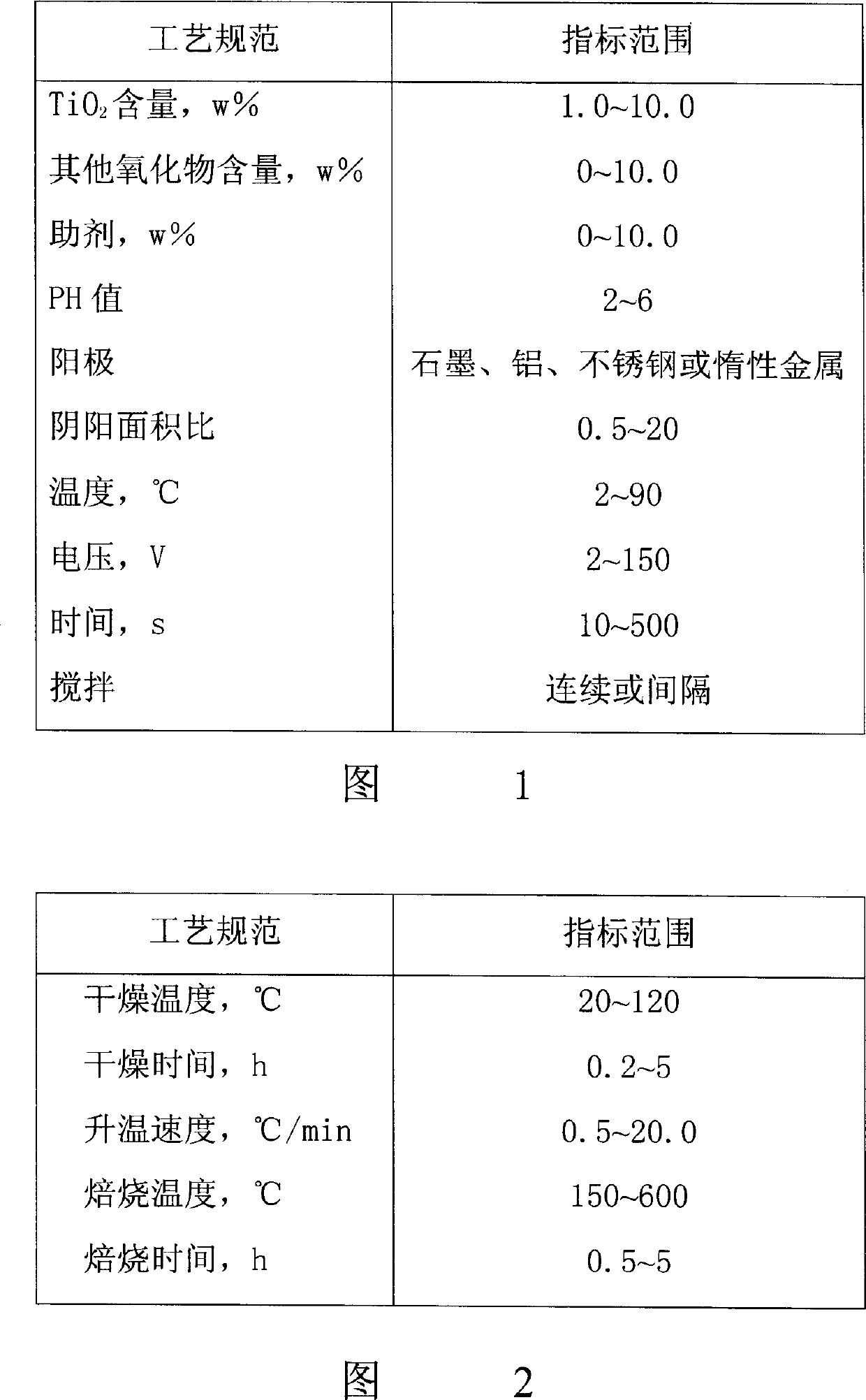

Electrophoresis preparation method for surface optical catalytic film of metal substrate

InactiveCN1438069AImprove adhesion strengthThickness is easy to controlWater/sewage treatment by irradiationCatalyst activation/preparationMetallic materialsMetallic substrate

The present invention discloses a preparation method of titanium dioxide photocatalytic membrane loaged on metal surface, its main technological process includes: in the electrophoretic solution containing a certain content of titanium dioxide sol or containing binary or multi-component compounded oxide sol of titanium dioxide using the pretreated metal base body as cathode, using graphite, aluminium, stainless steel and inert metal as anode, utilizing electrophoretic mode to form a layer of titanium dioxide membrane on the metal surface under the condition of a certain voltage, drying and calcining to make the titanium dioxide membrane be fixed on the metal surface. Said membrane is high in adhesive strength, and has high photocatalytic activity.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com