Super hydrophobic self-cleaning coating and preparation method thereof

A self-cleaning coating and super-hydrophobic technology, applied in the field of super-hydrophobic self-cleaning coating and its preparation, can solve the problems of high cost of raw materials and equipment, low practical use value, difficulty in large-scale industrialization, etc., to reduce surface Current conduction, good industrial application prospect, environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

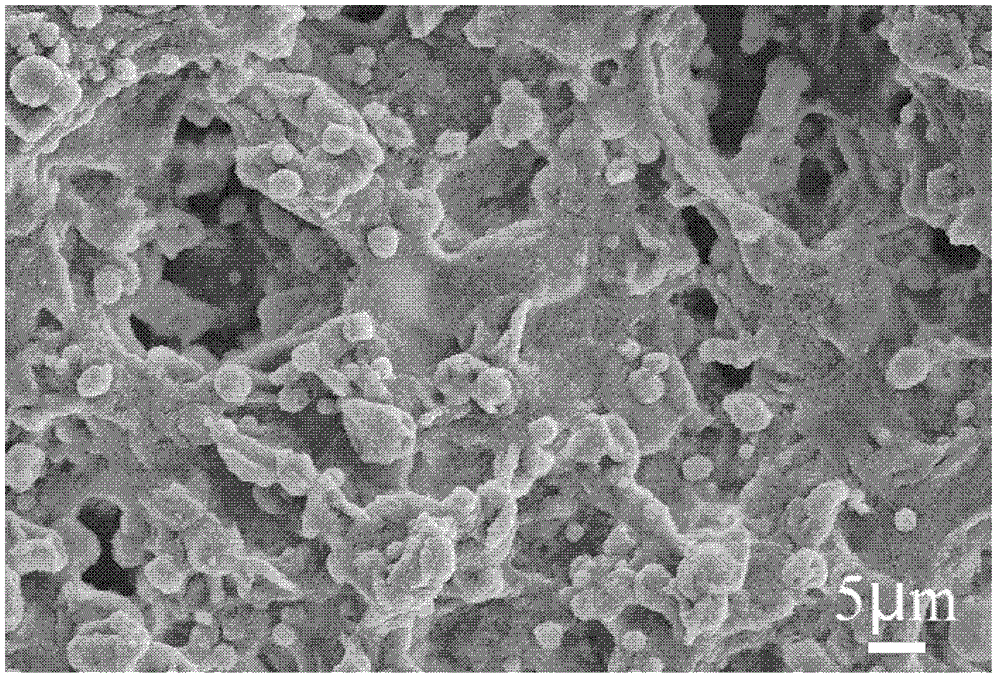

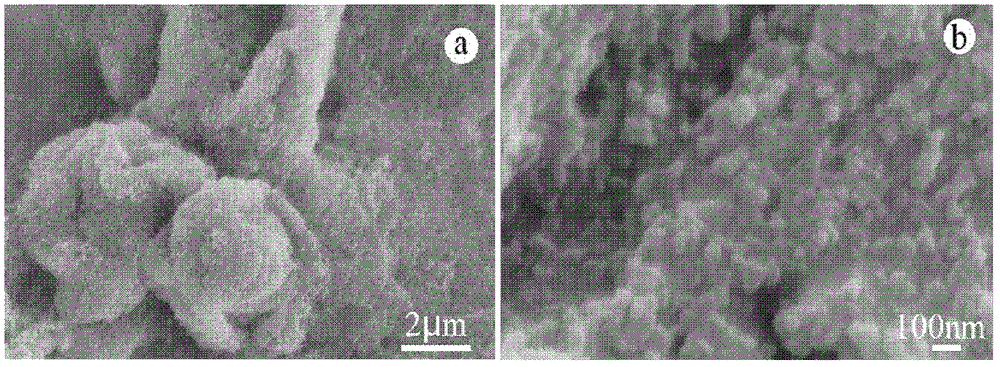

Embodiment 1

[0031] The chemical structural formula is (R 2 SiO) n 3.5g of hydrophobic silicone resin (wherein: R is methyl; n is 3~50, and this hydrophobic silicone resin is the product RHODORSIL-BP9400 of French Rhodia Company, is a kind of polymethylsiloxane oligomer) and SiO with a particle size of 15-25nm 2 1.5 g of the particles were dispersed in 46.5 g of cyclohexane, and magnetically stirred for 6 h to mix evenly to obtain a dispersion.

[0032] Carry out degreasing, decontamination, dewatering, oxygen plasma treatment (Chengdu Mingheng Technology Development Co., Ltd. PDC-M plasma cleaner) to the glass substrate, seal it for later use.

[0033] Add the above-prepared dispersion into the liquid-carrying barrel of the spray gun (Iwata small spray gun, the air compressor is Zhejiang Cixi Chaochao Air Compressor Parts Co., Ltd. BOX0506 type, the maximum pressure is 1.4MPa), and adjust the position of the spray gun so that it is in contact with the glass. The surface of the substrat...

Embodiment 2

[0037] The chemical structural formula is (R 2 SiO) n 3.5g of hydrophobic silicone resin (wherein: R is methyl; n is 3~50, and this hydrophobic silicone resin is the product RHODORSIL-BP9400 of French Rhodia Company, is a kind of polymethylsiloxane oligomer) and SiO with a particle size of 15-25nm 2 2.0 g of the particles were dispersed in 46.5 g of cyclohexane, and magnetically stirred for 10 h to mix evenly to obtain a dispersion.

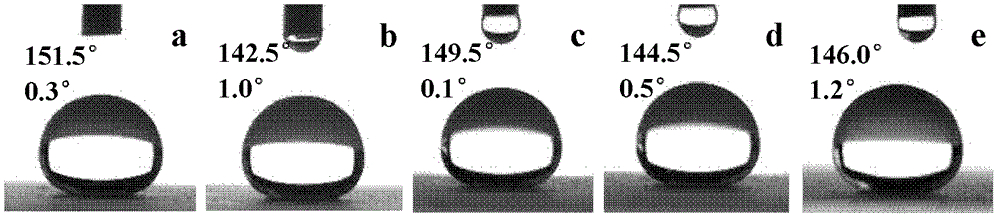

[0038] The glass substrates were then treated as described in Example 1. Spray the uniformly mixed raw materials on the treated glass substrate, and repeat the spraying 4 times to prepare the coating. After natural drying at room temperature and atmosphere for 5-10 minutes, drop 15 μL of deionized water on the superhydrophobic self-cleaning coating obtained above. Surface, the static contact angle of described superhydrophobic self-cleaning coating and water is measured to be 142.5 °, and the rolling angle of water droplet on described superhy...

Embodiment 3

[0041] The chemical structural formula is (R 2 SiO) n 2g of hydrophobic silicone resin (where: R is a methyl group; n is 3-50, the hydrophobic silicone resin is RHODORSIL-BP9400, a product of Rhodia, France, which is a polymethylsiloxane oligomer) and granules SiO with a diameter of 15-25nm 2 1.5 g of the particles were dispersed in 48 g of cyclohexane, and magnetically stirred for 8 h to mix evenly to obtain a dispersion. The glass substrates were then treated as described in Example 1. Spray the uniformly mixed raw materials on the treated glass substrate, repeat spraying 5 times to prepare the coating, and dry it naturally for 5-10 minutes at room temperature and atmosphere, then drop 15 μL of deionized water on the superhydrophobic self-cleaning coating obtained above The surface of the surface, the measured static contact angle with water is 149.5 °, and the rolling angle of water droplets on the surface of the super-hydrophobic self-cleaning coating is less than 0.1 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com