Patents

Literature

87results about How to "Anti-corrosion has" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Super hydrophobic self-cleaning coating and preparation method thereof

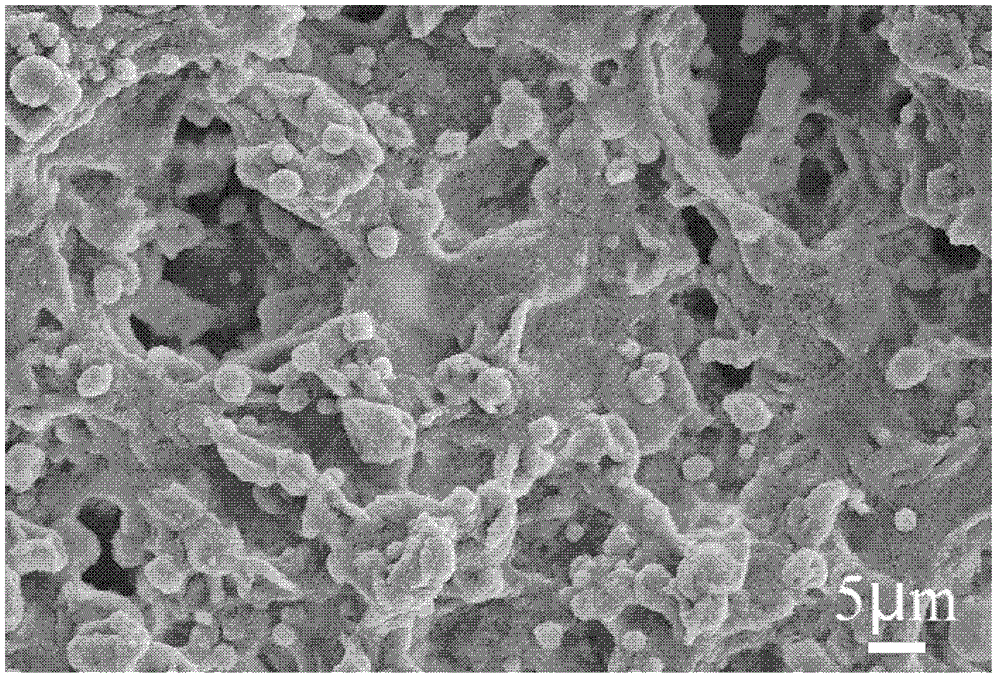

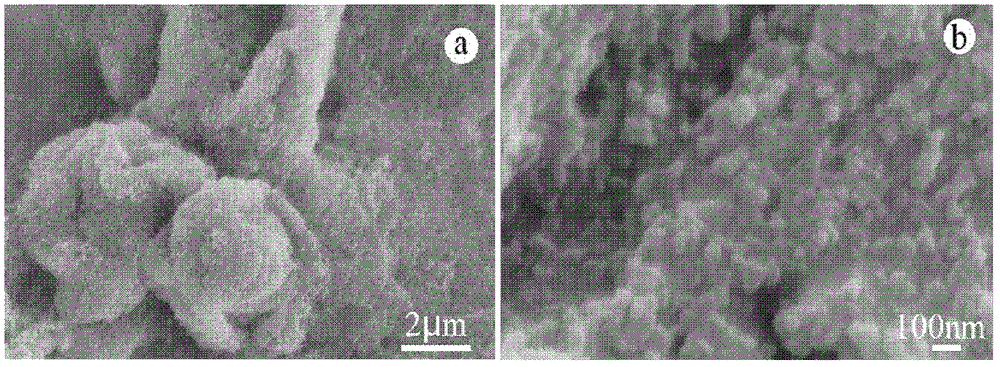

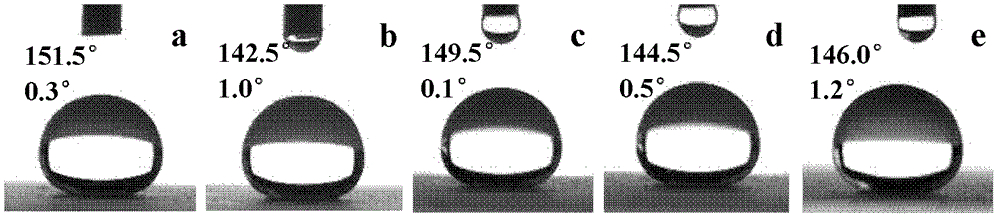

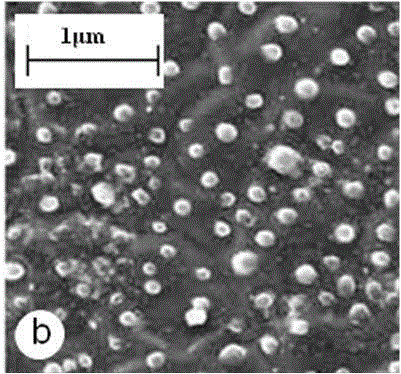

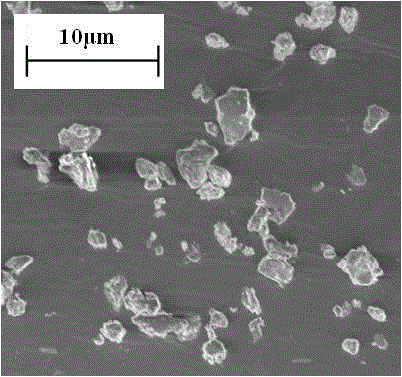

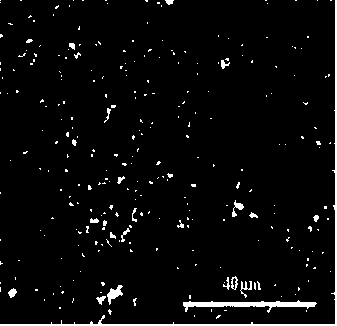

The invention belongs to the technical field of preparation of nano materials, and in particular relates to a super hydrophobic self-cleaning coating and a preparation method thereof. The method comprises the following steps of: dispersing hydrophobic silicon resin and hydrophilic nano SiO2 particles into an organic solvent to obtain dispersion; and spraying the dispersion on a clean and dry glass sheet substrate, drying, and thus obtaining the super hydrophobic self-cleaning coating. The coating has a hierarchical structure compounded by using organic and inorganic components, namely the hydrophobic silicon resin and the hydrophilic nano SiO2 particles, and the structure has compound micro-nano surface topography; and the compound micro-nano hierarchical structure is constructed by spheroid-like protrusions with the diameters of 1 to 10 microns and agglomerate spheres with the diameters of 20 to 100 nanometers on the surface of the coating, wherein the spheroid-like protrusions are constructed by agglomerate spheres with the diameters of 20 to 100 nanometers. The contact angle between the coating and water is 140 to 155 degrees, and the rolling angles of water drops on the surface of the coating are less than 2 degrees.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Self-cleaning nano protective liquid used for glass and preparation method

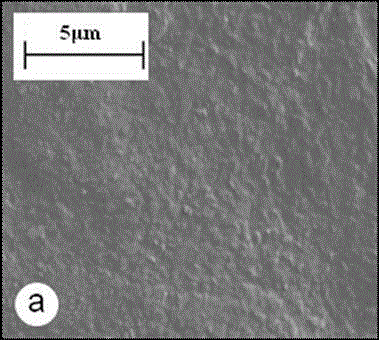

The present invention relates to a self-cleaning nano protective liquid used for glass and a preparation method. According to the self-cleaning nano protective liquid used for glass, a thin film coating formed by the nano protective liquid is provided with a similar structure of a lotus leaf surface in nature, wherein the structure is a nano-micro composite layer structure, and the coating is a colorless transparent thin film coating, with a thickness of 400-1000nm. The coating provided by the present invention has superior properties of water-proofing, oil-proofing, anti-fouling, anti-fogging, moisture-proofing, and the like. A contact angle of the coating and water is 140-155 DEG (a droplet volume is measured as 4 mu L), a roll angle of a water droplet on a coating surface is less than 5 DEG (a droplet volume is measured as 4 mu L). The water droplet existed on the the coating surface is freely rollably, meanwhile contaminations of dust and the like are removed, and thereby achieving the superior properties of anti-fogging, anti-fouling and the like.

Owner:王金书

Preservative composition containing Chinese medicinal herbs and application thereof

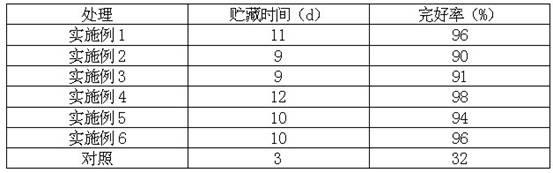

InactiveCN102028002AInhibitory activityReduce water evaporationBiocideFood preservationMedicinal herbsDistillation

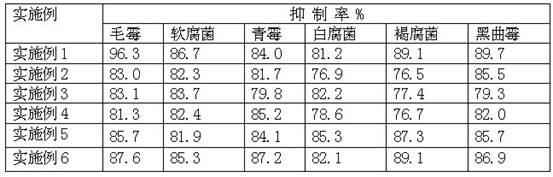

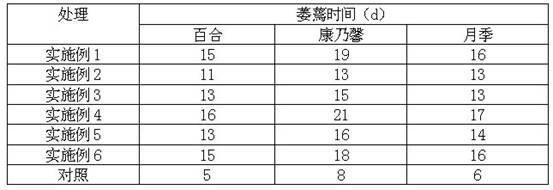

The invention relates to a preservative composition containing Chinese medicinal herbs and application thereof, belonging to the technical field of preservatives. The preservative composition is prepared by adopting the steps of: 1, weighting 0.1-0.78 percent of goldthread, 0-1 percent of the tuber of stemona, 0.1-0.84 percent of golden cypress, 0-0.58 percent of liquorice root, 0.1-1.5 percent of liquorice, 0-0.8 percent of poria cocos and 94.6-99.6 percent of water according to the weight proportion, uniformly stirring, soaking for 6-8h, heating to 110-130 DEG C, preserving the temperature for 30-50min, decocting, press-filtering, and collecting filtrate for later use; and 2, adding alcohol, which is 1.5-2.5 times the volume of the filtrate, in the filtrate, standing at a temperature of4 DEG C for 24-26h, filtering out sediment, decompressing and recycling the alcohol at a temperature of 75 DEG C, carrying out rotary distillation and condensation at a temperature of 85 DEG C until the volume is 8-15 percent of the original volume. The prepared preservative is natural and non-toxic, has no residual, good rot proofing effect on the foods, refreshing efficacy, low production cost and wide application range, and is safe in use.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Waterproof anti-corrosion flame retardant coating for airplane and preparation method thereof

InactiveCN101665657AExtended service lifePrevents delamination and even damageFireproof paintsAnti-corrosive paintsJet aeroplaneDecabromobiphenyl ether

The invention relates to a waterproof anti-corrosion flame retardant coating for an airplane and a preparation method thereof. The coating is prepared from tung oil, ethylene-vinyl acetatecopolymer emulsion, decabromodiphenyl oxide and magnesium hydroxide according to the weight ratio of 60-80:10-30:5-10:5-10. The waterproof anti-corrosion flame retardant coating for the airplane uses the tung oilhaving the characteristics of waterproof property, anticorrosion, high temperature resistance, and the like as the main material, matches the decabromodiphenyl oxide and magnesium hydroxide with theflame retardant function and uses the ethylene-vinyl acetatecopolymer emulsion as the adhesive. Therefore, when applied on the surface of a structural component of the airplane to form an adhesive film with the waterproof, anti-corrosion and flame retardant effects, the waterproof anti-corrosion flame retardant coating can prevent material lamination or even damage caused when the external moisture and corrosive substances enter the inside of the structural component and has flame retardant effect, thereby prolonging the service life of the structural component and ensuring good safety.

Owner:CIVIL AVIATION UNIV OF CHINA

Method for processing wood grain on aluminium section bar

InactiveCN101486289ASolve the technical problem that the surface cannot have wood grainExquisite appearanceDecorative surface effectsPretreated surfacesLacquerSpray coating

The invention relates to a method for processing wood grains on an aluminum section, which comprises a step of preprocessing, a step of spray coating and a step of wood grain transfer printing sequentially, wherein in the step of preprocessing, the aluminum section is mounted to perform chemical degreasing and roll scale removal, then the aluminum section is washed in water and chromized by chromate, and is washed in the water again and dried; in the step of spray coating: the aluminum section is hung up to perform dust blowing, wiping, spraying a fluorocarbon prime lacquer and a fluorocarbon top coat, drying and solidification; and in the step of wood grain transfer printing, a transfer printing water tank and a soaking water tank is added with water and heated up first, a wood grain membrane is tiled on the water surface of the transfer printing water tank, and the surface of the aluminum section is contacted with the wood grain membrane so as to transfer the paint on wood grains to the surface of the aluminum section; then the aluminum section is transferred to the soaking water tank; after that the aluminum section is cleaned and wiped clean and dried, and is baked and solidified. The method coats the wood grains on the surface of an aluminum veneer or the aluminum section by a transfer printing method, and solves the technical problem that in the prior art, and the surface of the aluminum veneer or the aluminum section cannot be provided with the wood grains.

Owner:SHANGHAI HUAHUI CURTAIN WALL MFG

Method for preparation of composite hollow tile for ornamenting

InactiveCN101117000AStrong three-dimensional surfaceUnique structureCeramic shaping apparatusBrickMixed materials

The invention comprises the following steps: (1) Stirring cement, stone dust, rock ballast and water to form base stock according to a certain weight proportion. (2) Putting the base stock in the lower mould frame of a mould, and prepressing the base stock in a hydraulic pressure moulding machine to form a base stock layer. (3) Stirring the solution mixed by cement, silver sand, colourful paint, water repellent and water according to a certain weight proportion to form a colourful material. (4) Filling the colourful material in the lower mould frame of the base stock layer, and pressing the colourful material with the hydraulic pressure moulding machine to form colourful decorated basso-relievo bricks. (5) Ejecting the basso-relievo bricks from the mould frame waiting to be used. (6) Stirring stone dust, rock ballast, cement and water separately according to a certain weight proportion to form a mixed material. (7) Pouring the mixed material in an air brick mould, shaking and pressing the mixed material to form a certain form. (8) Dipping the basso-relievo bricks in water and then taking out, putting the basso-relievo bricks on the air bricks, knocking and pressing the basso-relievo bricks, the grout flows in the flutes on the back of the basso-relievo bricks to make the basso-relievo bricks combine with the air bricks firmly. (9) Disassembling the mould, watering and maintaining the bricks after the bricks solidified.

Owner:谢永杰

Functional modified epoxy anticorrosive paint and preparation method

The invention relates to the technical field of paint, and in particular relates to functional modified epoxy anticorrosive paint and a preparation method thereof. The functional modified epoxy anticorrosive paint comprises constituents A, constituents B and constituents C, wherein constituents A comprise low molecular weight epoxy resin, anticorrosive pigment, titanium dioxide, environmental protection solvent, dispersant, defoamer, leveling agent and packing; constituents B comprise titanate, polyamide curing agent and environment-friendly solvent; and constituents C comprise polybasic divalent esters, S100# solvent and n-butanol. During use, the mass ratio of constituents A to B to C is 4:1:3. The functional modified epoxy anticorrosive paint has the advantages of alkali resistance, high and low temperature resistance, anticorrosion, strong adhesiveness to hot melting adhesive membranes and good paint film adhesiveness, is non-toxic, non-pollution, environment-friendly, safe to use and easy to operate; the paint film is fast to dry, can resist high temperature above 200 DEG C and low temperature above -30 DEG C; and the preparation method is simple, and is easy to realize mass production.

Owner:CHANGZHOU HUASHI CHEM

Oil-resisting, waterproof, anticorrosive and mildew resistant paint and production process thereof

InactiveCN102993839AAnti-oil hasWaterproofAntifouling/underwater paintsPaints with biocidesParaffin waxEpoxy

The invention discloses an oil-resisting, waterproof, anticorrosive and mildew resistant paint and a production process thereof. The paint comprises the following raw materials in parts by weight: 20 to 30 parts of polystyrene, 20 to 30 parts of acrylic emulsion, 5 to 10 parts of epoxy resin, 1 to 3 parts of preservative, 1 to 3 parts of mildew resistant antibacterial agent, 5 to 10 parts of pigment, 1 to 3 parts of dispersing agent, 5 to 8 parts of thickener, 1 to 3 parts of antioxidant, 5 to 8 parts of paraffin wax and 50 to 80 parts of water. The production process comprises the following steps of: at the temperature of between 50 and 80 DEG C, adding the raw materials in sequence, stirring at an intermediate speed, mixing uniformly, and adding an appropriate quantity of a pH regulator during stirring to ensure that the pH value is between 8.5 and 8.8. Therefore, the paint has the performance of oil resistance, anticorrosion, mildew resistance, waterproofness and the like.

Owner:马建林

Preparation method of special anticorrosion high-temperature-resistant epoxy resin for oil exploitation sucker rod

The invention relates to a preparation method of a special anticorrosion high-temperature-resistant epoxy resin for an oil exploitation sucker rod. The preparation method comprises the following steps: preparation of an epoxy resin main agent, preparation of functionalized carbon nanotubes, preparation of a reinforcing and toughening liquid, preparation of a curing agent and preparation of epoxy resin. The special anticorrosion high-temperature-resistant epoxy resin for the oil exploitation sucker rod, prepared by the method, has the advantages of high temperature resistance, corrosion resistance and high bending strength; the Tg temperature reaches 180-200 DEG C, the Tg temperature is increased by 50% or above, the requirements for production and use of sucker rods of all oil fields including high-temperature oil wells and ultra-deep wells can be almost met, the average bending strength is equal to or larger than 150 MPa, and the bending strength is improved by 25%.

Owner:达森(天津)材料科技有限公司

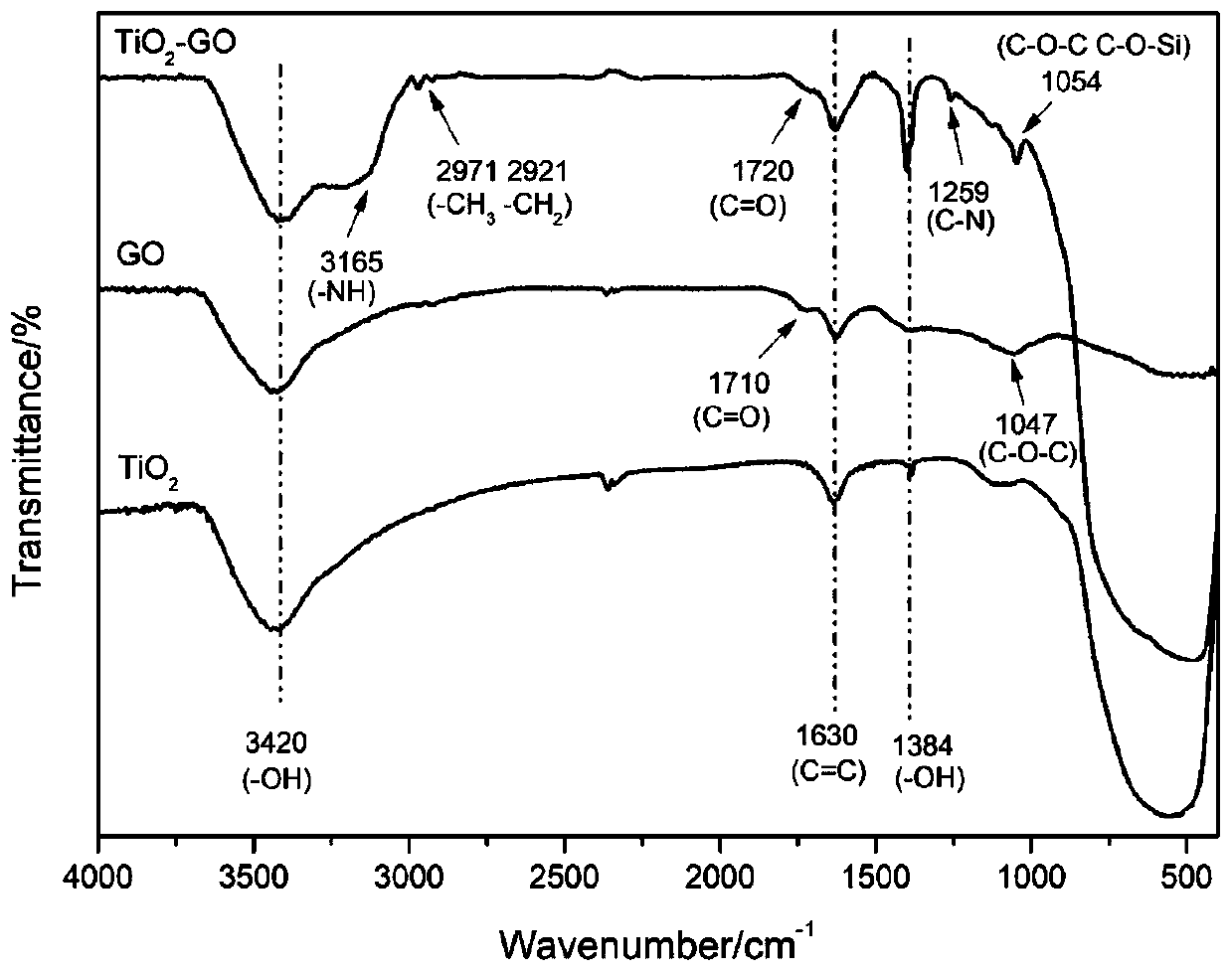

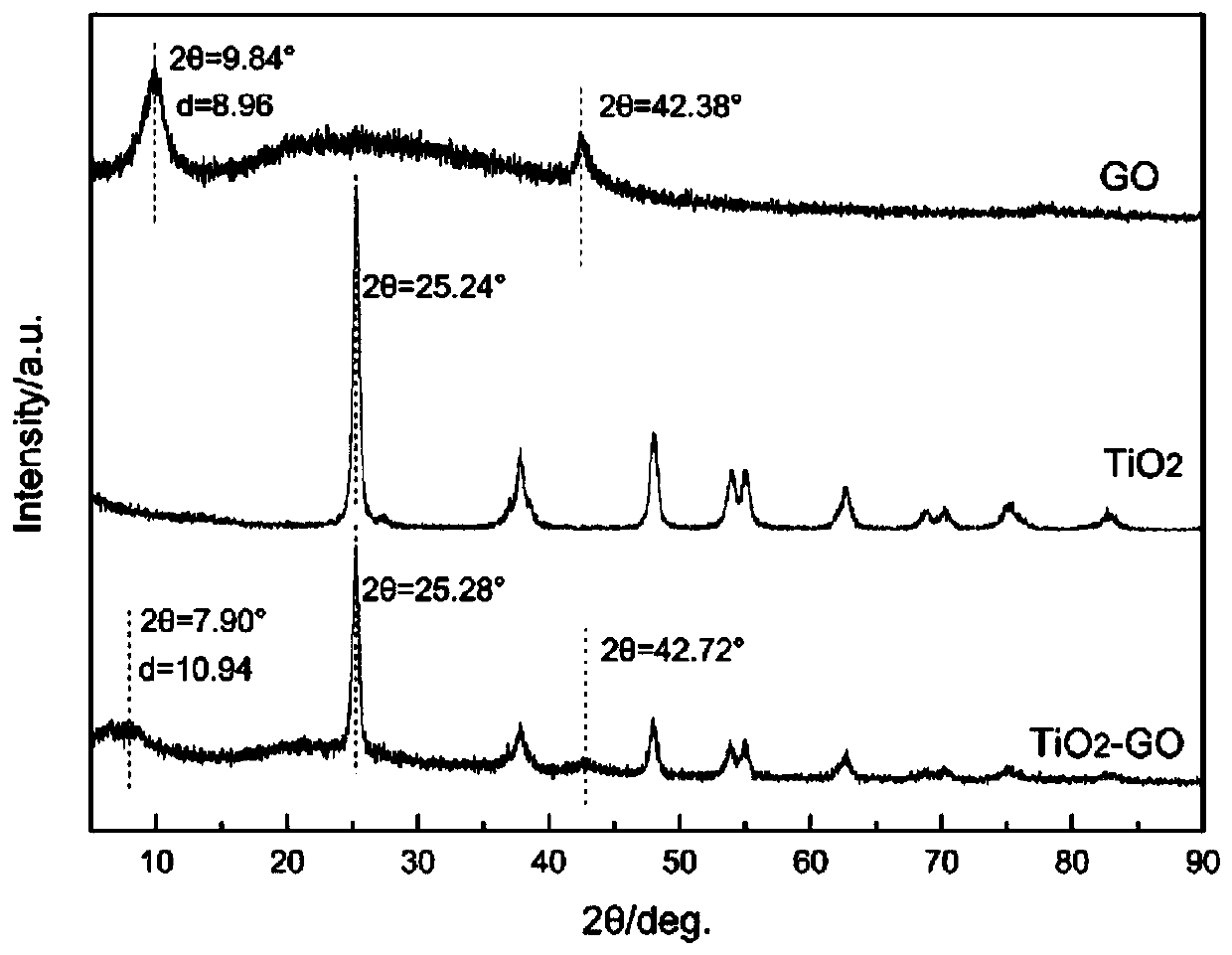

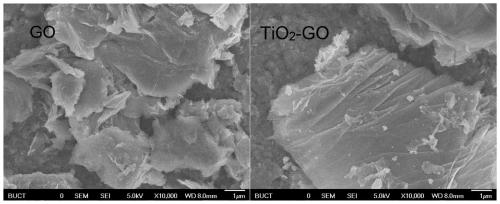

Amphiphilic graphene oxide and preparation method thereof and application in waterborne coating thereof

ActiveCN110240814AGood dispersionIncrease layer spacingAnti-corrosive paintsEpoxy resin coatingsEpoxyResin coating

The invention belongs to the technical field of waterborne coatings, and in particular relates to an amphiphilic graphene oxide and a preparation method thereof and an application in a waterborne coating thereof. The amphiphilic graphene oxide is composed of modified graphene oxide and titanium dioxide, the modified graphene oxide is composed of graphene oxide and 3-isocyanatopropyltrimethoxysilane, and titanium dioxide and graphene oxide are grafted together by 3-isocyanatopropyltrimethoxysilane. The application in a waterborne coating of the amphiphilic graphene oxide is as follows: adding the amphiphilic graphene oxide into a waterborne epoxy resin coating, and then adding a curing agent and auxiliary agents to obtain the waterborne coating. 3-isocyanatopropyltrimethoxysilane is used as a bridge to graft amphiphilic nano titanium dioxide on the surface of graphene oxide, graphene oxide is introduced into epoxy resin while dispersibility is improved, and thus anti-corrosion properties of the waterborne coating is improved.

Owner:SHANDONG UNIV

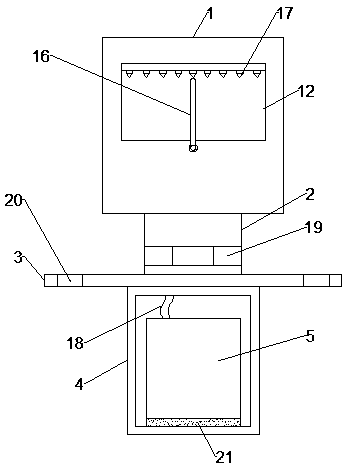

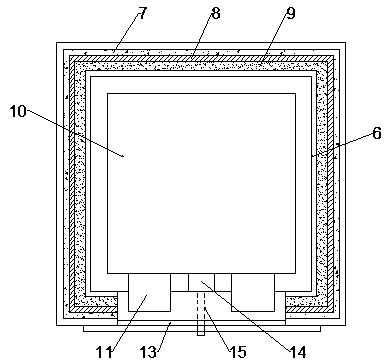

High-frequency radar level meter capable of sweeping dust

InactiveCN110553699AHigh strengthHigh measurement accuracyMachines/enginesCleaning using toolsRadarShock resistance

The invention discloses a high-frequency radar level meter capable of sweeping dust. The level meter comprises an outer shell; a connecting body is arranged at the bottom end of the outer shell; a flange plate is arranged at the bottom end of the connecting body; a box body is arranged at the bottom end of the flange plate; an air source is arranged in the box body; an inner shell is arranged in the outer shell; an anti-corrosion layer, a strength layer and an anti-seismic filling layer are arranged between the inner shell and the outer shell; a radar level meter body is arranged in the innershell; a plurality of detection heads are arranged at one end of the radar level meter body; a detection window is arranged on one side of the outer shell, a glass baffle is arranged in the detectionwindow, a motor is arranged at the bottom end of one side in the inner shell, a rotating shaft is arranged on an output shaft of the motor, a sweeping rod is arranged at the other end of the rotatingshaft, and an air nozzle is arranged on one side of the outer shell. The beneficial effects are that the detection window can be cleaned, the measurement precision is improved, and the level meter hasthe characteristics of corrosion resistance, shock resistance and high strength.

Owner:陕西诺盈自动化仪表有限公司

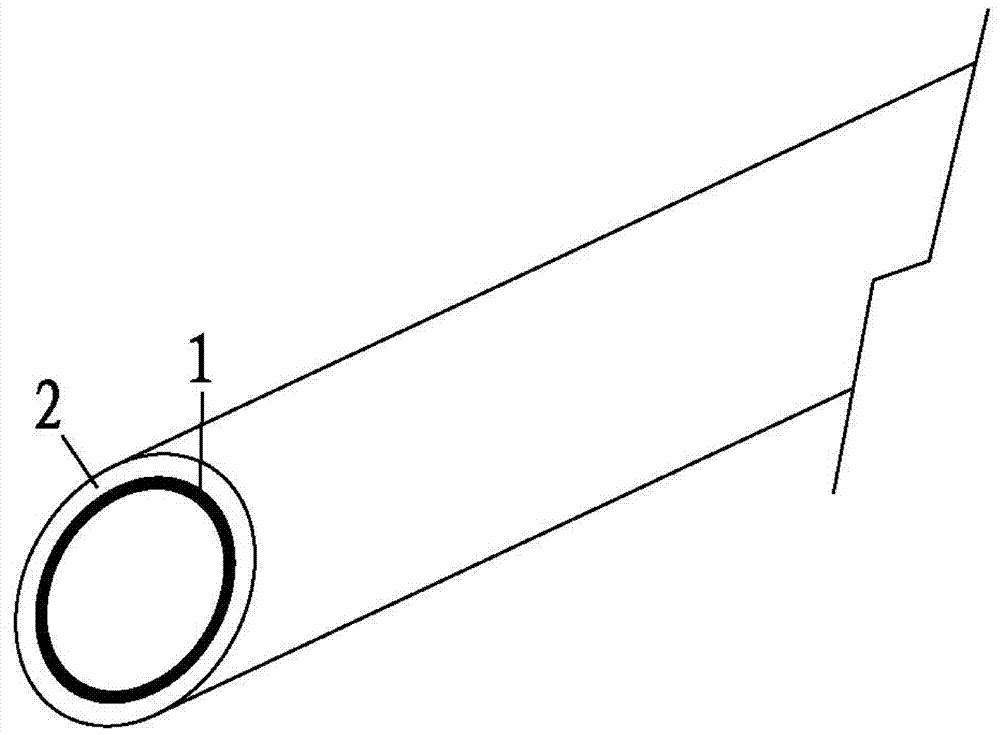

Wear-resistant and corrosion-resistant double-layer plastic pipeline and molding method thereof

InactiveCN106949319AWear-resistant and anti-corrosion hasAnti-corrosion hasCoatingsRigid pipesExplosion protectionWear resistant

The invention belongs to the technical field of plastic pipes, in particular to a wear-resistant and anti-corrosion double-layer plastic pipe, comprising an inner layer made of corrosion-resistant materials and an outer layer made of wear-resistant materials, the inner layer and the outer layer The inner layer is connected as a whole by injection molding, the inner layer is a nylon layer, polytetrafluoroethylene layer, polypropylene layer, polyether polyurethane layer or PVC layer, and the outer layer is a PU layer or a PE layer. Because the pipeline of the present invention has the above-mentioned structure, the pipeline of the present invention has the characteristics of explosion-proof, corrosion-resistant, wear-resistant, labor-saving, convenient to install, and easy to clean. In addition, the invention also discloses a forming method of a wear-resistant and anti-corrosion double-layer plastic pipe.

Owner:DONGGUAN CNISOO PAINTING ACCESSORIES

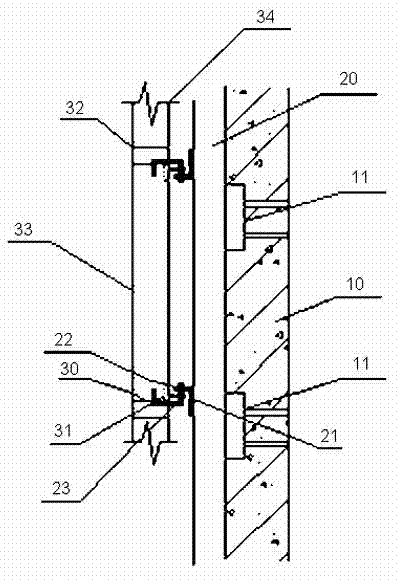

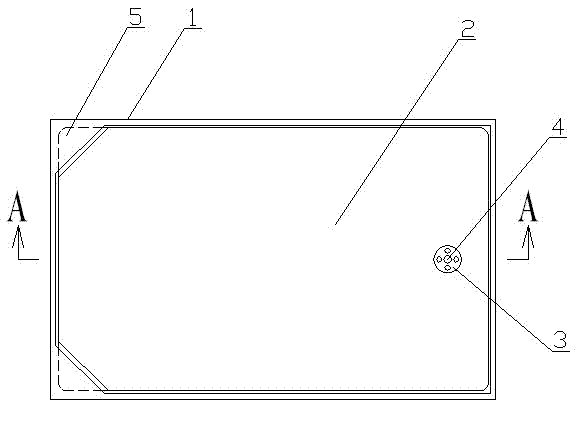

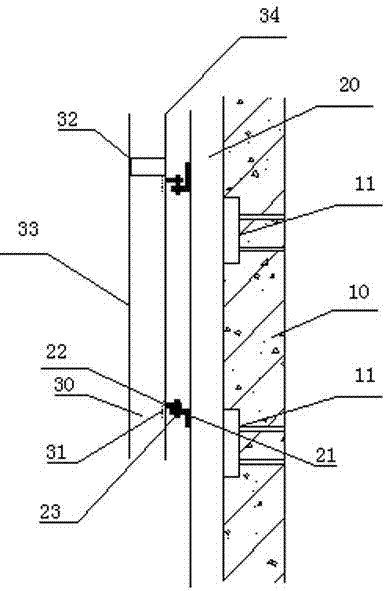

Construction-used art curtain wall insulation board made of thermoset nonmetallic composite and construction-used art curtain wall insulation board preparation method

ActiveCN103243824AHigh degree of mechanical automationImprove yieldSynthetic resin layered productsHeat proofingFiberCarbon product

The invention discloses a construction-used art curtain wall insulation board made of thermoset nonmetallic composite and a construction-used art curtain wall insulation board preparation method. The curtain wall insulation board comprises a shell made of the thermoset nonmetallic composite and an A-level anti-flaming cellular insulant main body in the shell. The shell comprises a decorating surface and a connecting surface, and the decorating surface is a flat surface with different shapes or a flat plate with space patterns or signs or a concave-convex plate. The shell composite materials contain, by weight proportion, 18%-30% of vinylite, 20%-30% inorfil, 45%-60% of aluminum hydroxide, 1%-2% of initiator, 1%-4% of curing agent and 0%-2% of mill base. The surface of the curtain wall board can be processed into yogon, highlighting, dull polishing and variable space pattern effects and has strong overall artistic attraction. The curtain wall board can resist high temperature, erosion, aging and ignition, good in sealability and water resistance and light in weight, can greatly reduce loads of buildings, is a green low-carbon product capable of reusing, is low in production cost, energy-saving and heat-preserving, good in overall effect and has epoch-making significance.

Owner:SHANGHAI HUDA INVESTMENT & DEV CO LTD +1

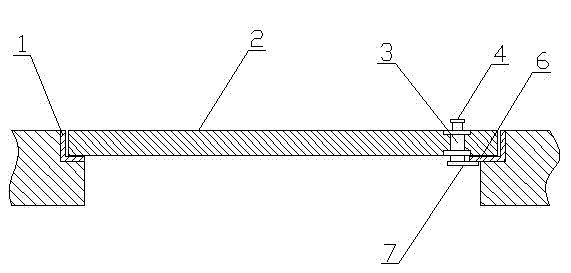

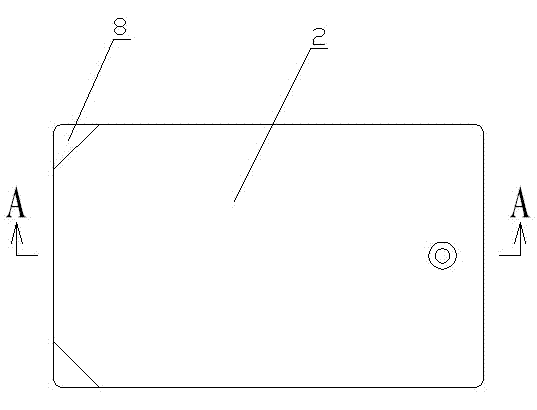

Anti-theft well cover with wooden core coated with compound material

InactiveCN102808424AImprove corrosion resistanceAnti-corrosion hasArtificial islandsUnderwater structuresSolid woodAging resistance

The invention discloses an anti-theft well cover with a wooden core coated with a compound material. The anti-theft well cover comprises a well cover body and a frame, wherein the well cover body comprises a wooden core and a compound material layer covering the outer surface of the wooden core, wherein a built-in locking device capable of locking the well cover body onto the frame is arranged on the well cover body. A crossly-laminated solid wood plate is adopted as the wooden core, and the compound material with a certain thickness covers the outer surface of the wooden core, so that the anti-theft well cover is endowed with good corrosion resistance, aging resistance and slip resistance; and the anti-theft well cover comprises the frame with an insert hole and a built-in locking hole as well as a well cover with a built-in lock part and a special lock remover, so that compared with the conventional cement product and cast iron material, the anti-theft well cover has the advantages of high strength, light weight, corrosion resistance, long service life and the like, and the problem that the well cover is lost is also radically solved.

Owner:江门市德山复合材料科技有限公司

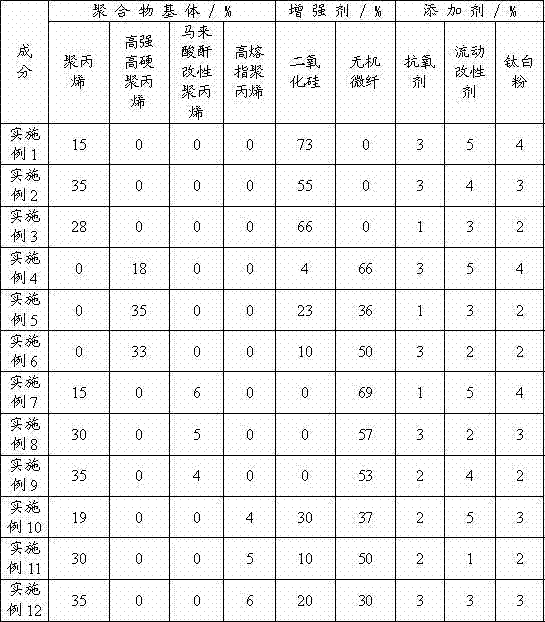

Thermoplastic non-metal composite material curtain wall board for architectural decoration and preparation method thereof

InactiveCN102733538AHigh degree of mechanical automationImprove yieldCovering/liningsWallsAntioxidantPolypropylene

The invention discloses a thermoplastic non-metal composite material curtain wall board for architectural decoration and a preparation method of the thermoplastic non-metal composite material curtain wall board. The curtain wall board comprises a shell made from a thermoplastic non-metal composite material through injection molding and integral formation and a flame retardant foam material main body pressure injected in the shell. The composite material comprises the following raw materials in percentage by weight: 53-73% of reinforcing agent, 15-35% of polypropylene, 1-5% of flowing modifying agent, 2-4% of titanium pigment and 1-3% of antioxidant. The reinforcing agent is silicon dioxide or inorganic microfiber or a mixture of the two ingredients. The outline of the curtain wall board provided by the invention can be prepared to be level and smooth or to have such decoration effects with three-dimensional sense organ as simulative natural stone material, wood grain and metal board, and the like, the curtain wall board has high strength, high hardness, small weight, corrosion resistance and aging resistance, and the curtain wall board has the properties of heat preservation and flame retardant and is simple and convenient in installation, so that the curtain wall board has an obvious energy saving effect if being applied on outer walls of building materials.

Owner:SHANGHAI HUDA INVESTMENT & DEV CO LTD +1

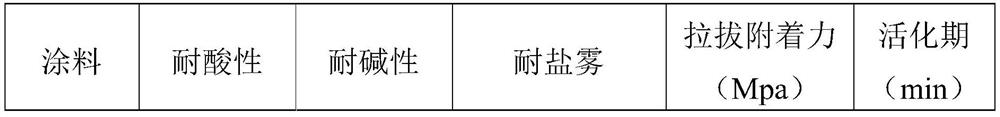

Modified polyaspartic acid ester DTM anticorrosive paint and preparation method thereof

InactiveCN113652155AEnvironmentally friendlyLong activation periodAnti-corrosive paintsPolyurea/polyurethane coatingsPolyaspartic acidManufactured material

The invention relates to a modified polyaspartic acid ester DTM anticorrosive paint. The paint comprises a component A and a component B. The component A comprises the following components in parts by weight: 40-60 parts of polyaspartic acid ester, 30-40 parts of an antirust base material, 4-8 parts of an auxiliary agent A and 5-15 parts of a solvent A. The component B is hydrophilic modified polyisocyanate and comprises 80 to 110 parts of HDI tripolymer, 1 to 3 parts of an auxiliary agent B and 1 to 5 parts of a solvent B. The invention also relates to a preparation method of the modified polyaspartic acid ester DTM anticorrosive paint. The paint is simple in preparation process, and has the advantages of environmental protection, easy construction, corrosion resistance, curing at normal temperature and the like; the solid content of the paint is 100%, and zero emission of VOC is achieved; raw materials do not need to be subjected to dehumidification, environmental humidity does not need to be controlled in a construction process, the activation period of the paint is long, and a construction window is wide; and the paint has large adhesive force to a metal surface, has good waterproof and anti-corrosion performance, can directly coats the metal surface, and does not need to be matched with primer.

Owner:苏州佩琦材料科技有限公司

Novel anti-corrosion plastic coating floor

The invention belongs to the PVC floor, especially relates to a novel anti-corrosion plastic coating floor. The novel anti-corrosion plastic coating floor is characterized in that: the formula of the novel anti-corrosion plastic coating floor comprises, by weight, 100-120 parts of polyvinyl chloride resin, 50-100 parts of nano-scale quartz sand, 8-10 parts of a rare earth stabilizer R108A and 25-30 parts of dipentaerythritol. According to the present invention, the novel anti-corrosion plastic coating floor is provided, and the floor has advantages of anti-corrosion, wear resistance and the like.

Owner:SUZHOU FUTONG NEW MATERIALS & HIGH TECH

Making method for wicker bowls

InactiveCN107553681APromote absorptionQuality assuranceWood treatment detailsCane mechanical workingToughnessChemistry

The invention discloses a making method for wicker bowls, and relates to the technical field of handiwork processing and making. The making method for wicker bowls is characterized by comprising the following steps of selecting materials, soaking wicker, baking the wicker, soaking the wicker again, carrying out baking again, making the wicker into bowls, cleaning the bowls, soaking the bowls and taking out the bowls for use. The making method for wicker bowls is reasonable, convenient to operate, good in toughness and resistant to moths.

Owner:FUNAN NATURE ARTS & CRAFTS

Fabrication technology for PVC plastic floor

InactiveCN106368414AMake up for deficienciesAnti-corrosion hasSynthetic resin layered productsLaminationAntioxidantVacuum level

The invention provides a fabrication technology for a PVC plastic floor. The fabrication technology comprises the steps that raw materials are weighed, the raw materials comprise, by weight, 50-100 parts of resin powder, 10-30 parts of light calcium carbonate, 1-2 parts of stearic acid, 2-6 parts of GB-101 titanium dioxide, 0.8-1.2 parts of polyethylene wax, 1-3 parts of barium stearate, 2-6 parts of antioxidants, 5-10 parts of epoxidized soybean oil, 2-6 parts of rare earth, 3-6 parts of modified heat stabilizers, 2-4 parts of filling matrix and 0.4-0.8 part of foaming agents, and the weighed raw materials are mixed in a high speed mixer at 160 DEG C; the mixed raw materials are subjected to one-time extrusion molding in a high pressure double-screw extruder with the temperature controlled at 210 DEG C; extrusion-molded materials are leveled in a vacuum environment; vacuum-leveled materials are forcedly cooled to obtain a floor substrate; the forcedly-cooled products are subjected to multicolor printing; multicolor-printed floor substrate is obtained; a 3D printed solid-wood-imitating stripe layer is installed on the multicolor-printed floor substrate; and UV high-abrasion-resistance paint is painted on the floor substrate with the installed solid-wood-imitating stripe layer to obtain the PVC plastic floor. According to the fabrication technology for the PVC plastic floor, the shortages and defects of laminate floors and vitrified floors are overcome.

Owner:云南祥盛予建筑装饰材料有限公司

Fresh-keeping deodorizing corrosion-preventing device

InactiveCN101558903ASimple processLow costDead plant preservationFood preservationGARLIC POWDERAllium sativum

The invention discloses a fresh-keeping deodorizing corrosion-preventing device which comprises the steps of: washing selected garlic, green Chinese onion, and ginger clearly and later crushing for preparing garlic powder, green Chinese onion powder, and ginger powder; taking hydrated lime for being mixed with water at room temperature, drying and crushing the hydrated lime into powder; mixing the garlic powder, the green Chinese onion powder and the ginger powder with the hydrated lime evenly according to the mixture ratio and then packing the mixture in small bags made of non-woven cloth; and later placing the package into a container with a hole and finally obtaining a finished product. The fresh-keeping deodorizing corrosion-preventing device provided by the invention has the advantages of simple process, low cost and long preservation life, can effectively prevent the occurrence of harmful substance residues in the using process by adopting plants as the main raw material, and is characterized by keeping fresh, deodorizing and preventing corrosion, etc.

Owner:李隆基

Expandable graphite nanometer fire-proof coating, preparation and use thereof

InactiveCN1296447CImprove fire performanceGood weather resistanceFireproof paintsGlass fiberPentaerythritol

The invention opened a process to product the inflatable graphite nano fire resisting paint. The composition is : acrylic resin20-25; amine resin 3-4; pentanol1-4; inflatable graphite 18-22; organic siliconresin2-4; melocol ammonia polyphosphate12-16; nano-compound fire retardant 2-6; intensify spun glass4-6; rutile titanium white3-5; elasticizer2-4; smoke abatementer2-4; antifoam agent0.3-0.6; flow promoter0.3-0.6; mixing solvent15-20. The product has the good mechanical character, weather resisting property and rotproofness.

Owner:中科纳米涂料技术(苏州)有限公司

A flexible polyurea heavy-duty anti-corrosion coating

ActiveCN106854428BHigh solid contentFast curingAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyHeavy duty

The invention discloses a flexible heavy-duty anticorrosive polyurea coating, belonging to the technical field of surface protection. According to the invention, hydrogenated epoxy resin modified polyaspartic acid ester resin and an aliphatic HDI trimer curing agent are used as main film-forming substances; a flaky preservative composite system is employed; so a film formed by the coating has improved compactness and enhanced resistance to mediums and corrosion. The flexible heavy-duty anticorrosive polyurea coating provided by the invention is a two-component system and has a NCO index of 1.05 to 1.1. The coating at least comprises, by mass, 100 parts of polyaspartic acid ester resin, 6 to 18 parts of hydrogenated epoxy resin, 56 to 85 parts of a flaky preservative additive, 20 to 35 parts of pigment, 20 to 35 parts of a filling material and 10 to 20 parts of an auxiliary agent. The coating integrates primer and finishing coat into one, and has fast curing speed, high tensile strength, certain hardness and flexibility and good adhesion on a substrate; and the coating has the advantages of weatherability, water resistance, corrosion resistance, wear resistance, impact resistance and the like, so the coating is applicable to long-acting anticorrosion protection of hydraulic steel structures like steel gates and trash screens and outdoor steel structures like steel bridges, iron towers and wind-power towers.

Owner:SHANDONG NON METALLIC MATERIAL RES INST

Preparation methods of high temperature resistant anticorrosion potassium silicate coating and corresponding coat

ActiveCN102558924BHigh temperature resistance hasHigh temperature resistance and corrosion resistance haveAlkali metal silicate coatingsAnti-corrosive paintsPotassium silicateSolvent

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Chemical fiber cloth production method

InactiveCN109295772APromote absorptionAnti-corrosion hasDyeing processChemical fiber clothPulp and paper industry

The invention relates to a chemical fiber cloth production method. The method comprises the following steps: yarn selection and weaving, bleaching and dipping, dyeing liquid burdening, fabric dyeing,hot setting, and cleaning and removal of impurities. By using acrylic fiber as the warp yarn and cotton yarn as weft yarn, and the warp and weft yarns are knitted into the fabric through a knitting machine, the water absorption performance at the later stage is improved, sweat can be better absorbed, In the production process, the chemical fiber fabric produced by the production process has the advantage of preventing corrosion by adding an anticorrosive agent. The preparation method of the invention is used to produce the chemical fiber fabric by steps of yarn selection and weaving, bleachingand dipping, dyeing liquid burdening, fabric dyeing, hot setting, and cleaning and removal of impurities, and the surface of the chemical fiber cloth is free from excess wool and impurities, and thequality of the chemical fiber cloth can be improved.

Owner:巢湖信泰纺织有限公司

Anti-corrosive paint

InactiveCN106433376AGood ductilityHigh elongation at breakFireproof paintsAnti-corrosive paintsDuctilitySulfone

The invention discloses anti-corrosive paint and belongs to the field of fine chemical engineering. The paint is prepared from raw materials in parts by weight as follows: 1.2-2.4 parts of feldspar powder, 0.8-1.6 parts of tribenzyl phenol polyoxyethylene ether, 1.4-2.9 parts of zinc phosphate, 2.6-4.7 parts of polysiloxane, 6-12 parts of epoxy grafted aacrylic resin, 1.8-3.9 parts of polyether sulfone, 1.6-3.2 parts of sodium thiocyanate and 1.2-2.9 parts of sodium diisopropyl naphthalene sulphonate. Compared with existing anti-corrosive paint, the paint has the advantages of corrosion resistance, aging resistance, high / low-temperature resistance, good ductility and high elongation at break, is suitable to be applied to surfaces of multiple base materials, has good friction resistance and has excellent storage stability.

Owner:SICHUAN LIJIU INTPROP SERVICE CO LTD

Durable anti-corrosion printing ink

The invention discloses durable anti-corrosion printing ink which comprises a binder, a filler, an anti-corrosion agent, an anti-oxidant, a slipping agent, a pigment and a solvent, wherein the binder is nitrile butadiene rubber; the binder is pentaerythritol polymerized rosin resin; the filler is aluminum hydroxide powder; the anti-corrosion agent is chlorophenol; the anti-oxidant is 2,6-di-tert-butyl-4-methylphenol; the slipping agent is high density polyethylene polyethylene wax; the pigment is phthalocyanine blue; the solvent is isopropyl alcohol. As the printing ink comprises the binder, the filler, the anti-corrosion agent, the anti-oxidant, the slipping agent, the pigment and the solvent, the printing ink is resistant to oxidation, abrasion and corrosion, low in cost, long in service life, and good in using effect.

Owner:SUZHOU YONGJIN COLOR PRINTING PACKAGING

Photocuring skin wound adhesive

InactiveCN113521375APrevent respawnIncrease motivationSurgical adhesivesBandagesGas phasePolymethyl methacrylate

The invention aims to provide a photocuring skin wound adhesive. The photocuring skin wound adhesive is prepared from the following raw materials: n-butyl alpha-cyanoacrylate, fumed silica, polymethyl methacrylate, a stabilizer, a photoinitiator and an accelerant. Compared with the prior art, the skin can be tightly attached to the product, wound infection can be effectively prevented, wound healing is accelerated, and the wound can be immediately soaked in water, bathed, subjected to field work and the like after being glued and cured, so that the wound can be effectively protected.

Owner:东莞市瞬力新材料科技有限公司

Colorful tension rope made of waste galvanic aluminum and method of preparation thereof

A colorful tension rope made of waste galvanic aluminum and method of preparation thereof, wherein the base material of the galvanic aluminum thin film is PET macromolecular plastic, a pellumina is obtained with a spraying surface layer having a different color, and possessing the advantages of strong tension force, acid resistance and corrosion resistance, the multi-ply colored tension force rope is manufactured through collecting, selecting, cleaning, airing, cutting, second rope-strand machine forming, checking and packing. The rope can be used to substitute nylon cord and twine.

Owner:徐兆平

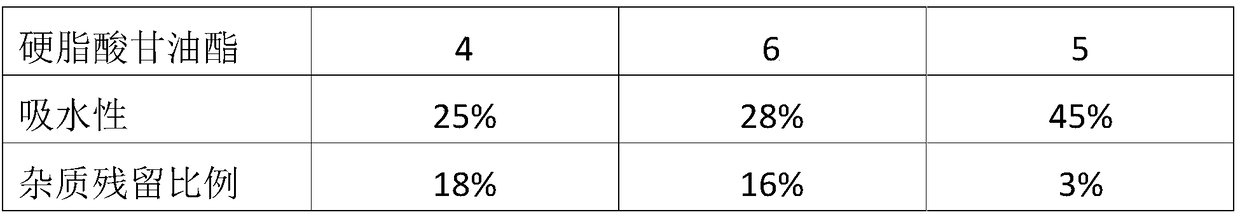

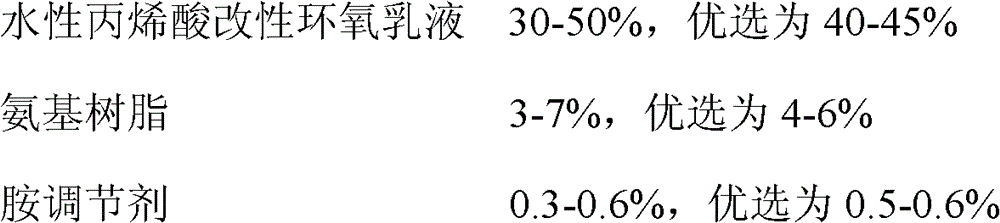

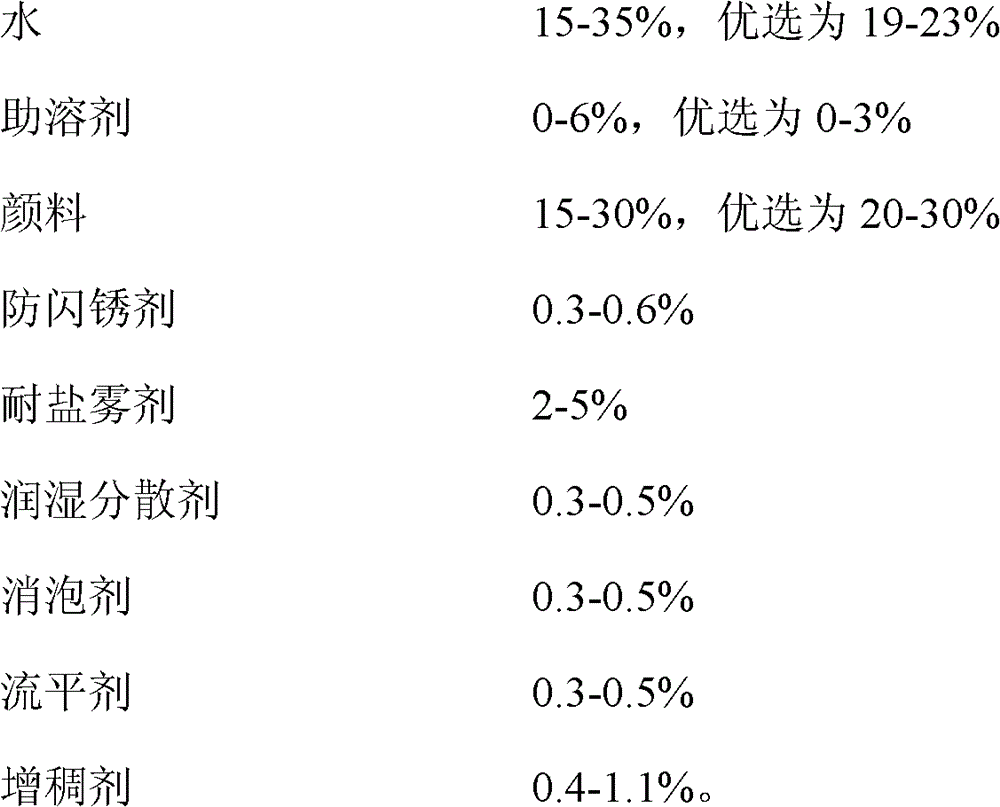

Nano-reinforced water-based acrylic modified epoxy bottom surface integrated anti-corrosion baking paint coating and preparation method thereof

InactiveCN102627902BNo pollution in the processImprove adhesionAnti-corrosive paintsEpoxy resin coatingsCooking & bakingEpoxy

The invention provides an acrylic acid modified epoxy primer-topcoat anticorrosion paint coating and a preparation method thereof. The coating comprises, by weight, 30-50% of an aqueous acrylic acid modified epoxy emulsion, 3-7% of an amino resin, 0.3-0.6% of an amine regulator, 15-35% of water, 0-6% of a cosolvent, 15-30% of a pigment, 0.3-0.6% of a flash rust prevention agent, 2-5% of a salt spray resisting agent, 0.3-0.5% of a wetting dispersant, 0.3-0.5% of an antifoaming agent, 0.3-0.5% of a leveling agent, and 0.4-1.1% of a thickener. The coating of the invention, which is simple and fast to operate and can be directly diluted with water, can be sprayed, and also can be dip-coated. The baking time is fast to 30s (the baking temperature is maintained at 220DEG C), and the resulting film can be completely solidified and there is no yellow stain under the baking conditions. The coating of the invention can satisfy rapid automated coating production line requirements.

Owner:上海暄洋化工材料科技有限公司

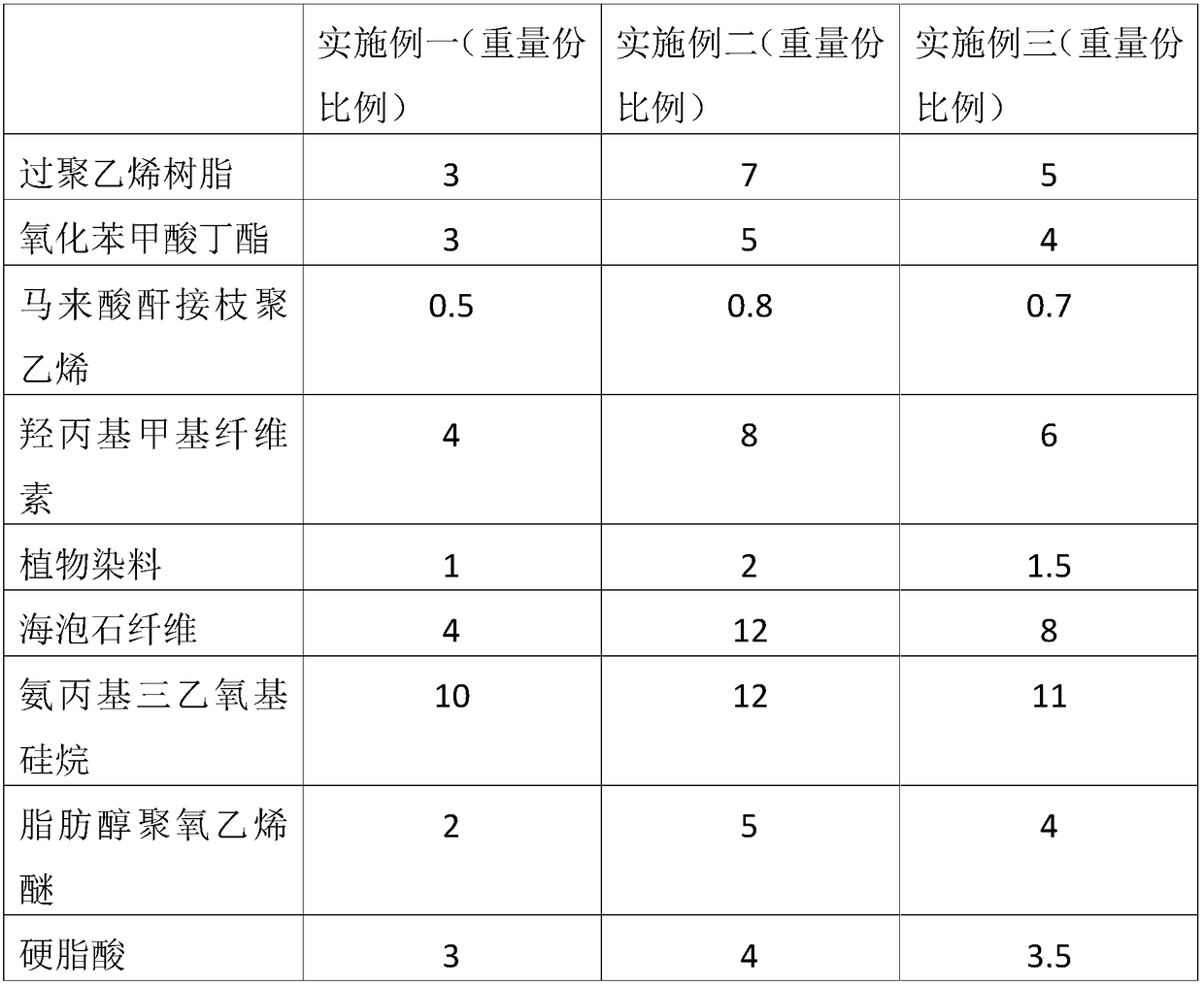

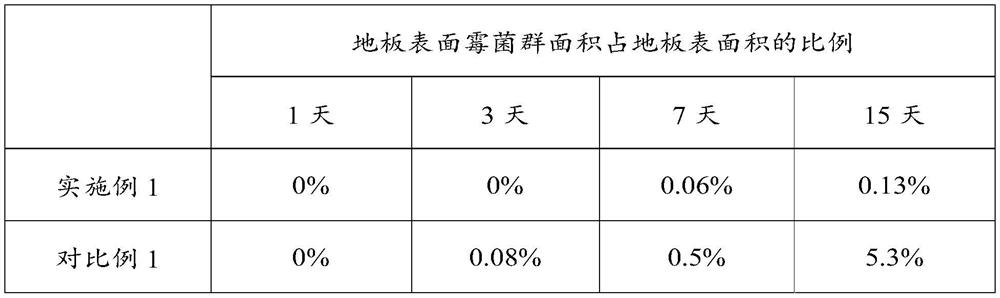

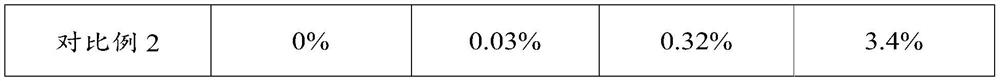

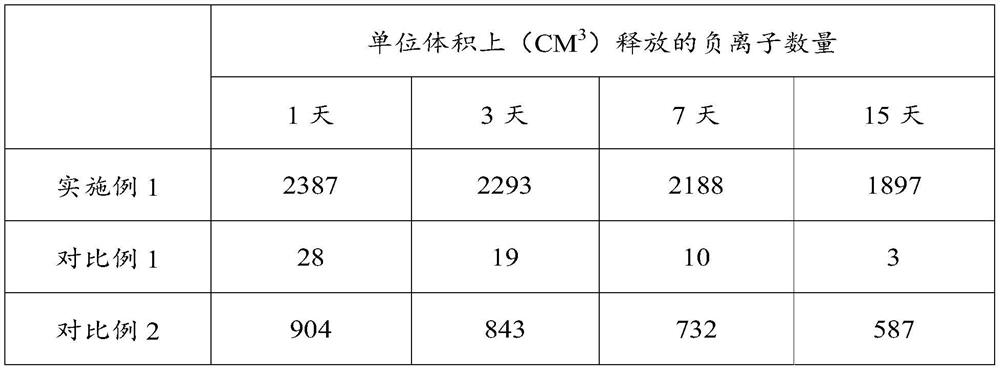

Multifunctional formaldehyde-free floor and preparation method thereof

ActiveCN113021536AAnti-corrosion hasMildew-resistantLaminationLamination apparatusCompression moldingFiber

The invention discloses a multifunctional formaldehyde-free floor and a preparation method thereof, and relates to the technical field of floors. The preparation method of the multifunctional formaldehyde-free floor comprises the steps that impregnated wear-resistant paper, impregnated decorative paper, a fiber base plate and impregnated balance paper which are arranged in sequence are subjected to compression molding, wherein the impregnated balance paper, the impregnated decorative paper and the impregnated wear-resistant paper are obtained after balance paper, decorative paper and wear-resistant paper are impregnated with glue; one or more of a preservative, a mildew preventive and negative oxygen ion powder are added into the glue for impregnating the wear-resistant paper. The floor is endowed with corrosion resistance and mildew resistance through the preservative and the mildew preventive, negative oxygen ions are released through the negative oxygen ion powder, the air quality of the environment is improved, and the floor with one or more effects of the corrosion resistance, the mildew resistance or peculiar smell removal can be prepared.

Owner:CHANGZHOU BEMATE HOME TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com