Patents

Literature

83results about How to "Achieve anticorrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

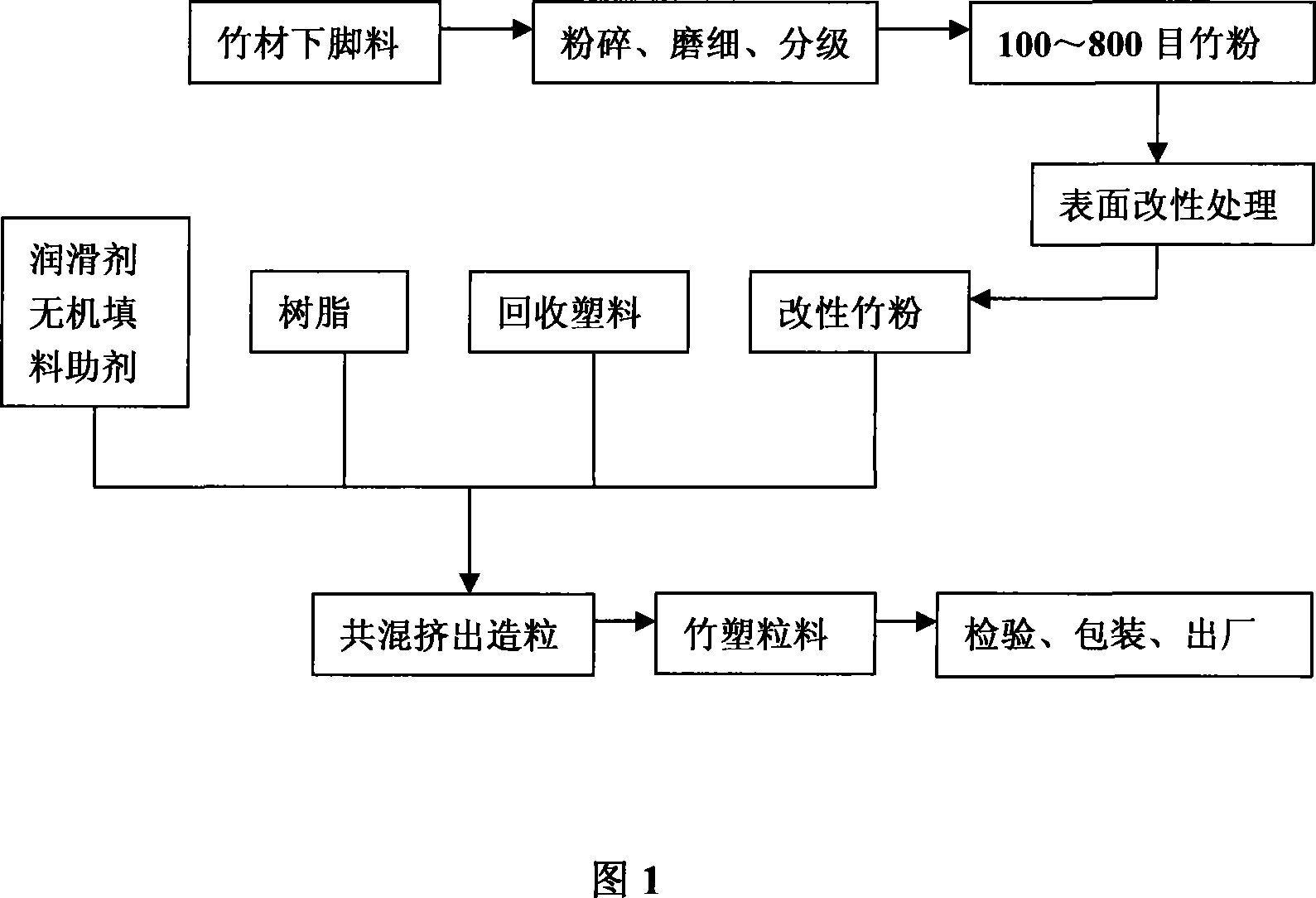

Bamboo-plastic composite material

The invention provides a bamboo-plastic composite material which is obtained by that raw materials such as plastic, recycled waste plastics, bamboo powder, modifier, chemical agent, lubricant, etc. are mixed in different proportions and extruded out to get series bamboo-plastic granule; the invention can be used for manufacturing different products such as bamboo-plastic boards, wood-plastic composite profiles and wood-plastic tubular products, etc. through extruding. The series bamboo-plastic granule can be produced in a continuous large volume and is characterized in that the production efficiency is high, the cost is low and the performance-price ratio is high, etc. The series bamboo-plastic granule can be used for replacing wood, and the cost thereof is lower than wood-plastic materials while the mechanical strength thereof is higher than wood-plastic materials, therefore the series bamboo-plastic granule can be widely popularized for use. The series bamboo-plastic granule is a novel cyclically reutilized material resource after wood-plastic material.

Owner:戴福寿 +1

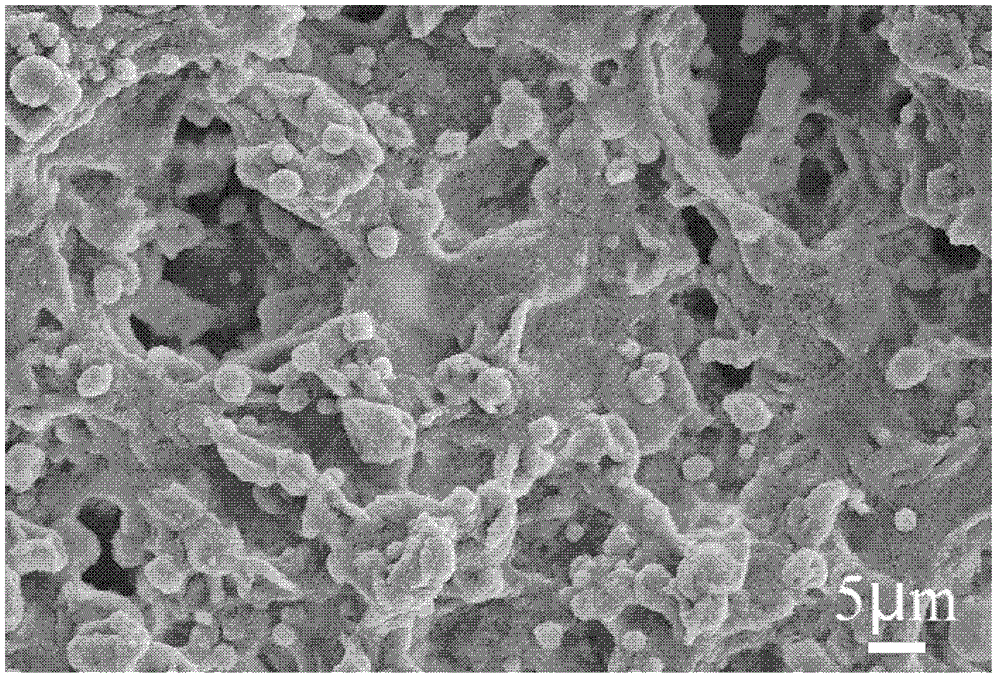

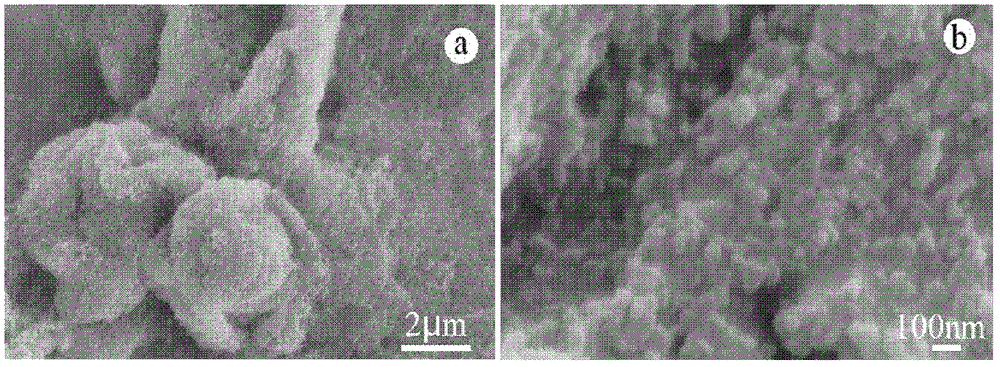

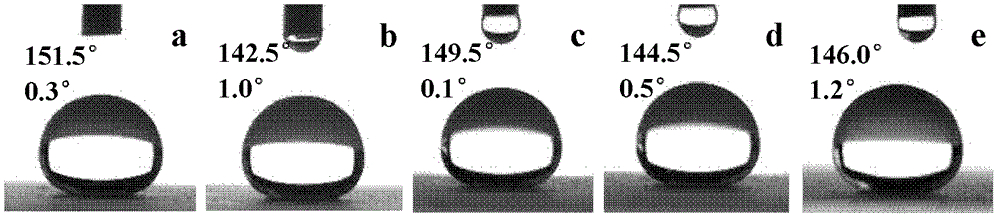

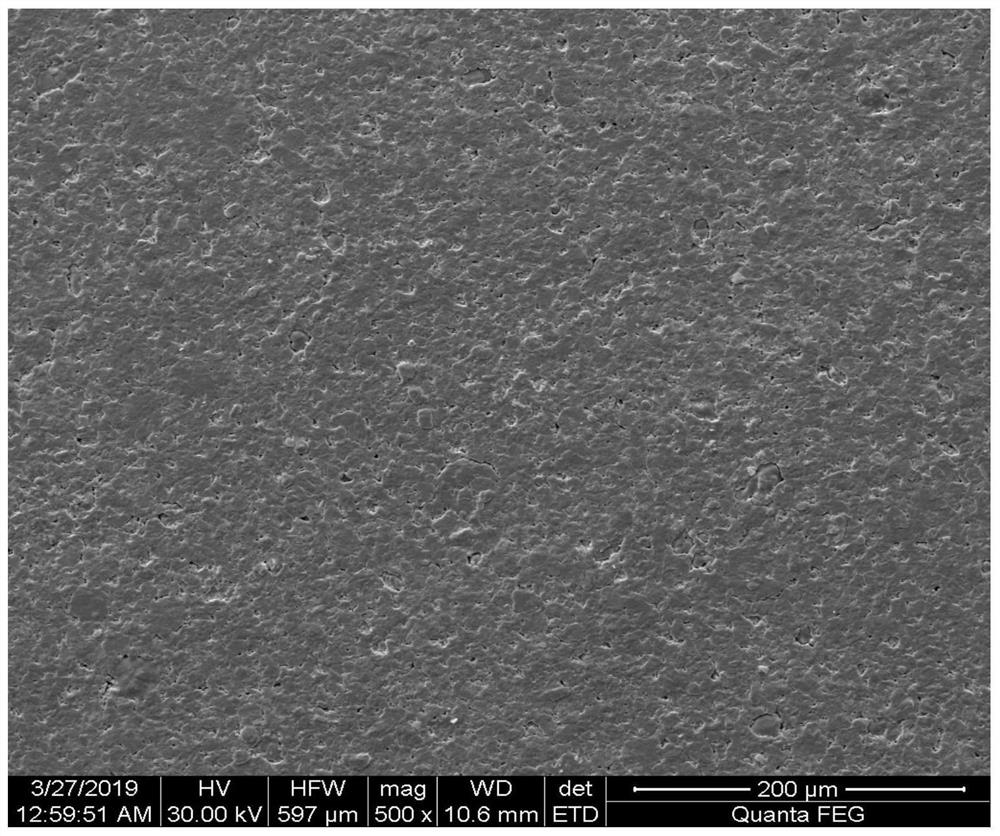

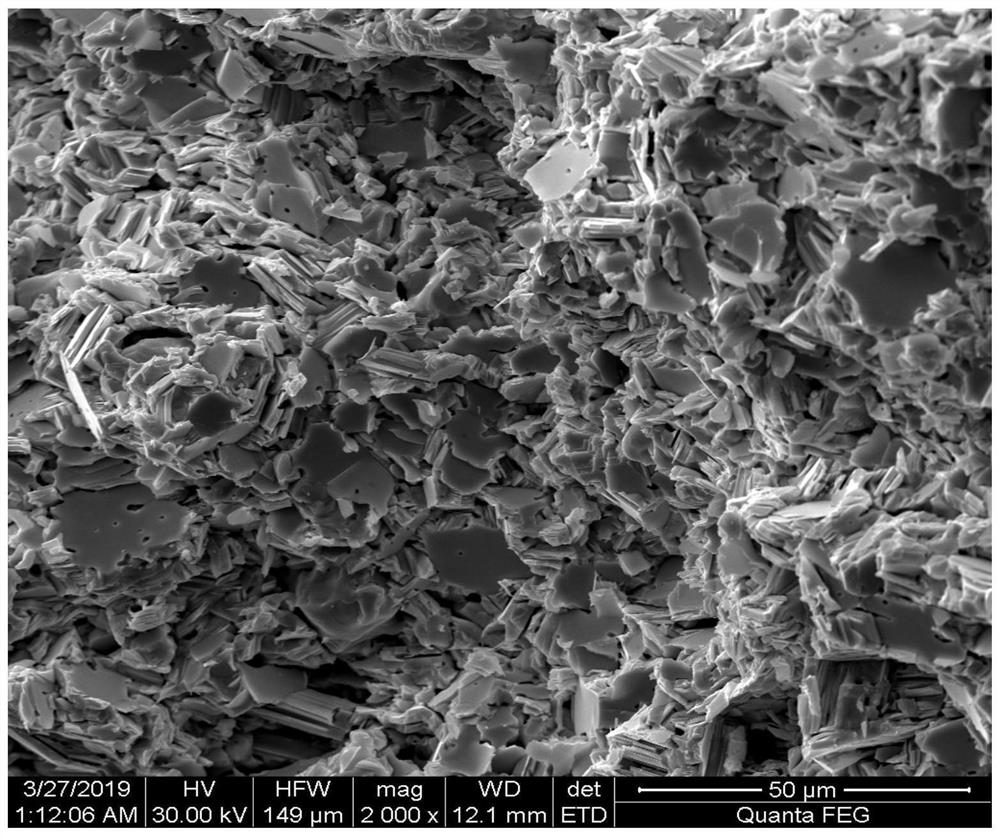

Super hydrophobic self-cleaning coating and preparation method thereof

The invention belongs to the technical field of preparation of nano materials, and in particular relates to a super hydrophobic self-cleaning coating and a preparation method thereof. The method comprises the following steps of: dispersing hydrophobic silicon resin and hydrophilic nano SiO2 particles into an organic solvent to obtain dispersion; and spraying the dispersion on a clean and dry glass sheet substrate, drying, and thus obtaining the super hydrophobic self-cleaning coating. The coating has a hierarchical structure compounded by using organic and inorganic components, namely the hydrophobic silicon resin and the hydrophilic nano SiO2 particles, and the structure has compound micro-nano surface topography; and the compound micro-nano hierarchical structure is constructed by spheroid-like protrusions with the diameters of 1 to 10 microns and agglomerate spheres with the diameters of 20 to 100 nanometers on the surface of the coating, wherein the spheroid-like protrusions are constructed by agglomerate spheres with the diameters of 20 to 100 nanometers. The contact angle between the coating and water is 140 to 155 degrees, and the rolling angles of water drops on the surface of the coating are less than 2 degrees.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

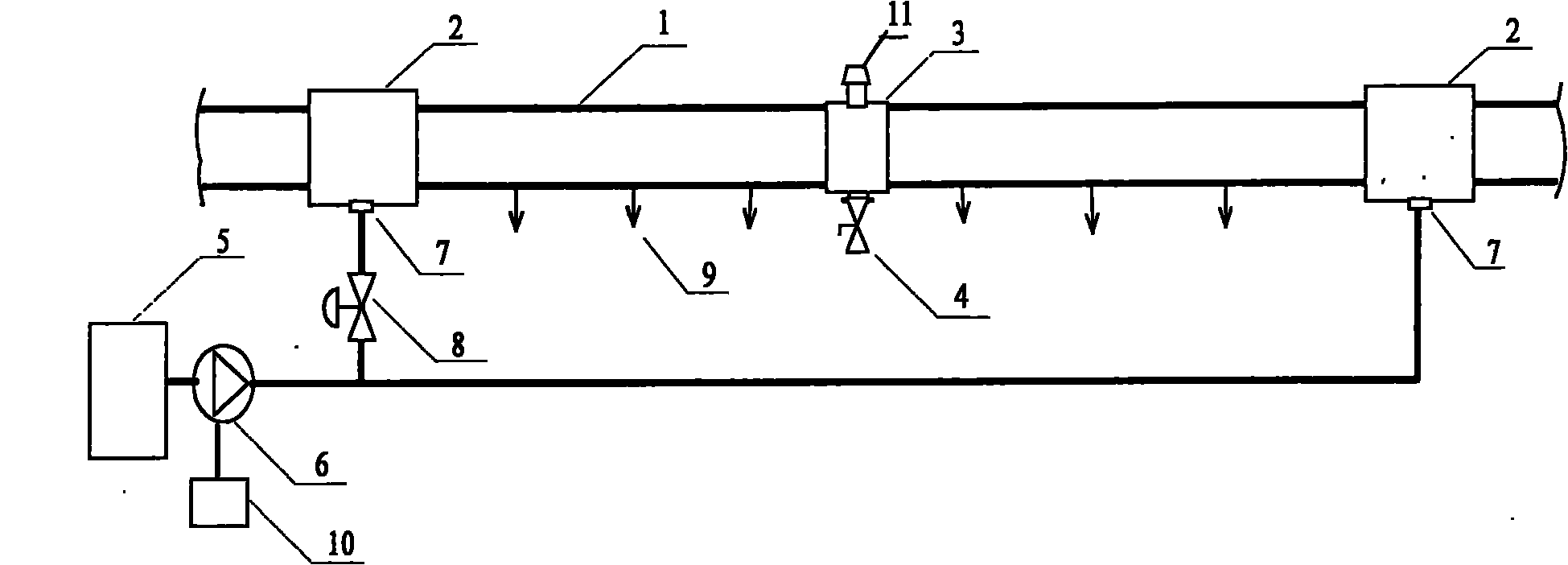

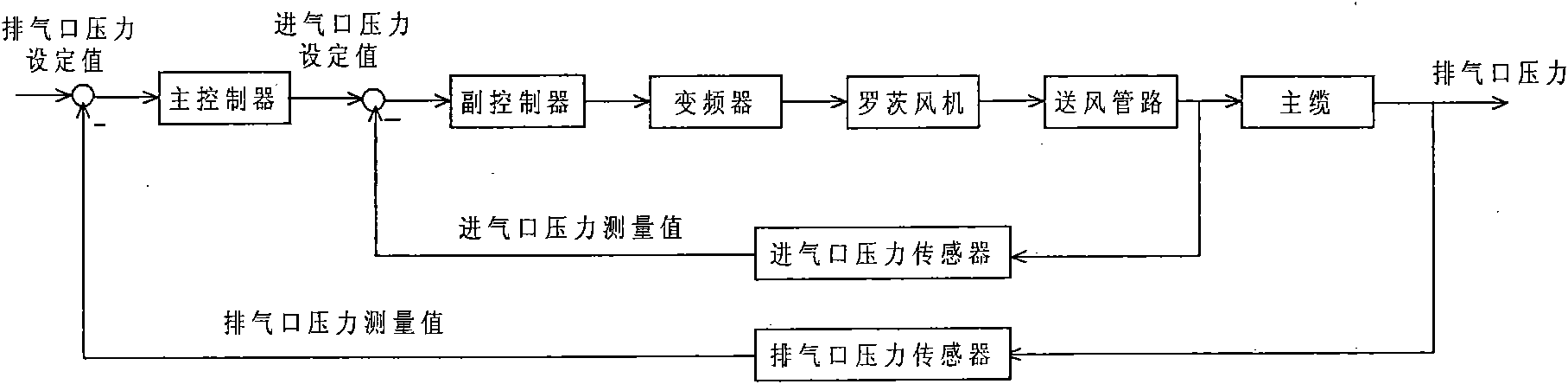

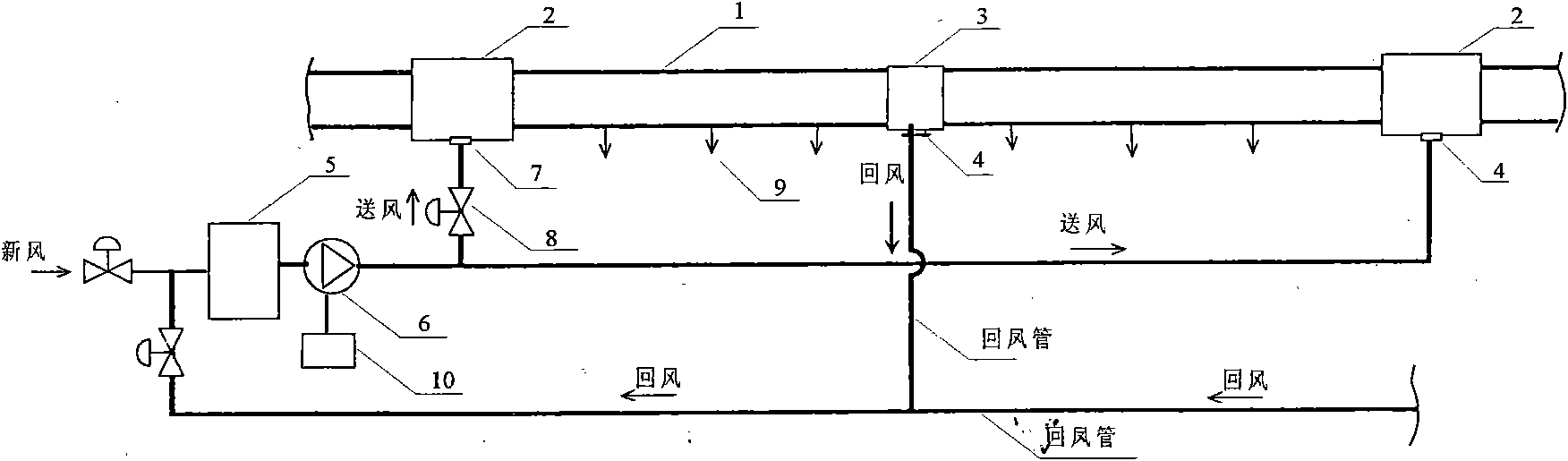

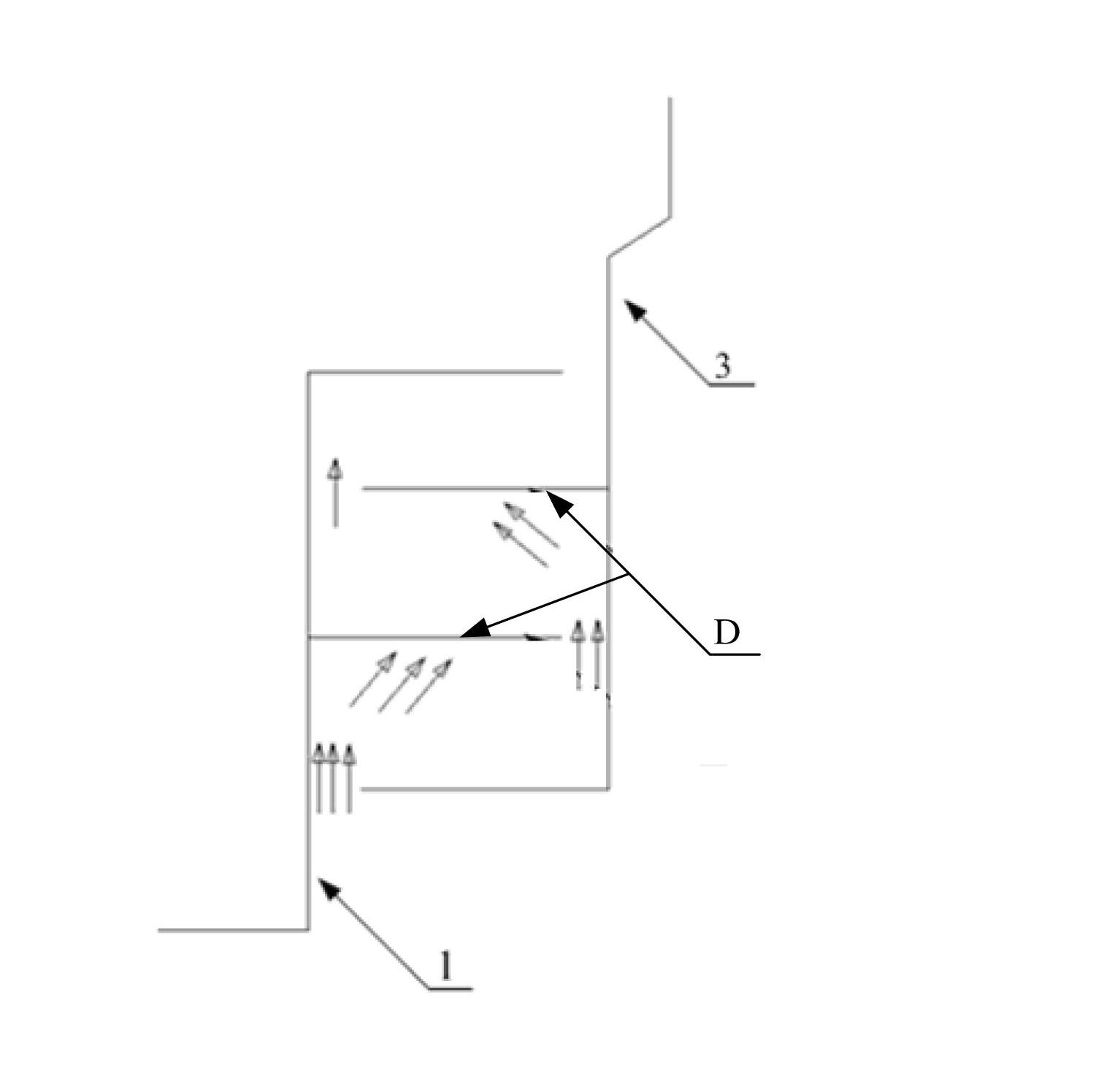

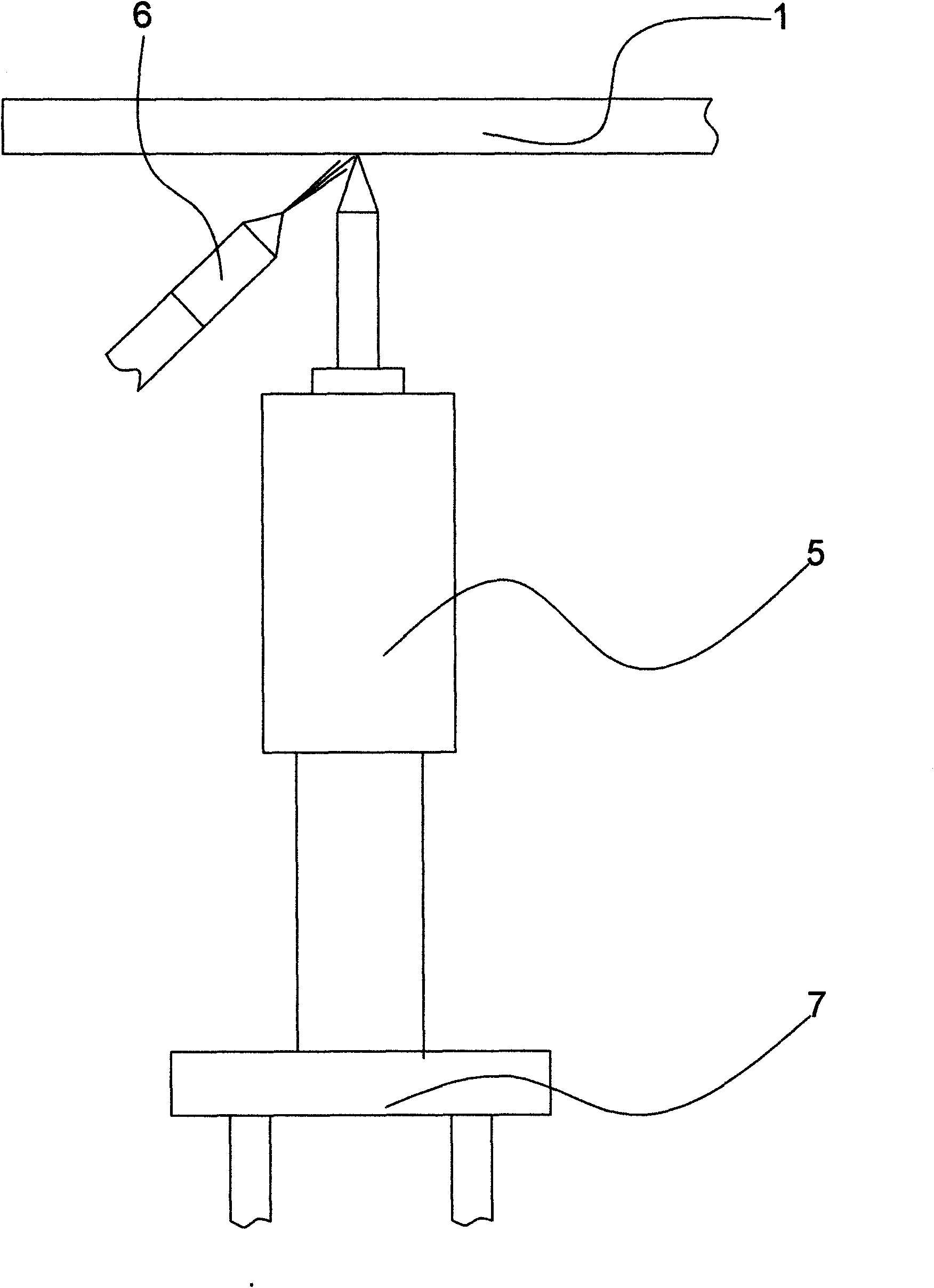

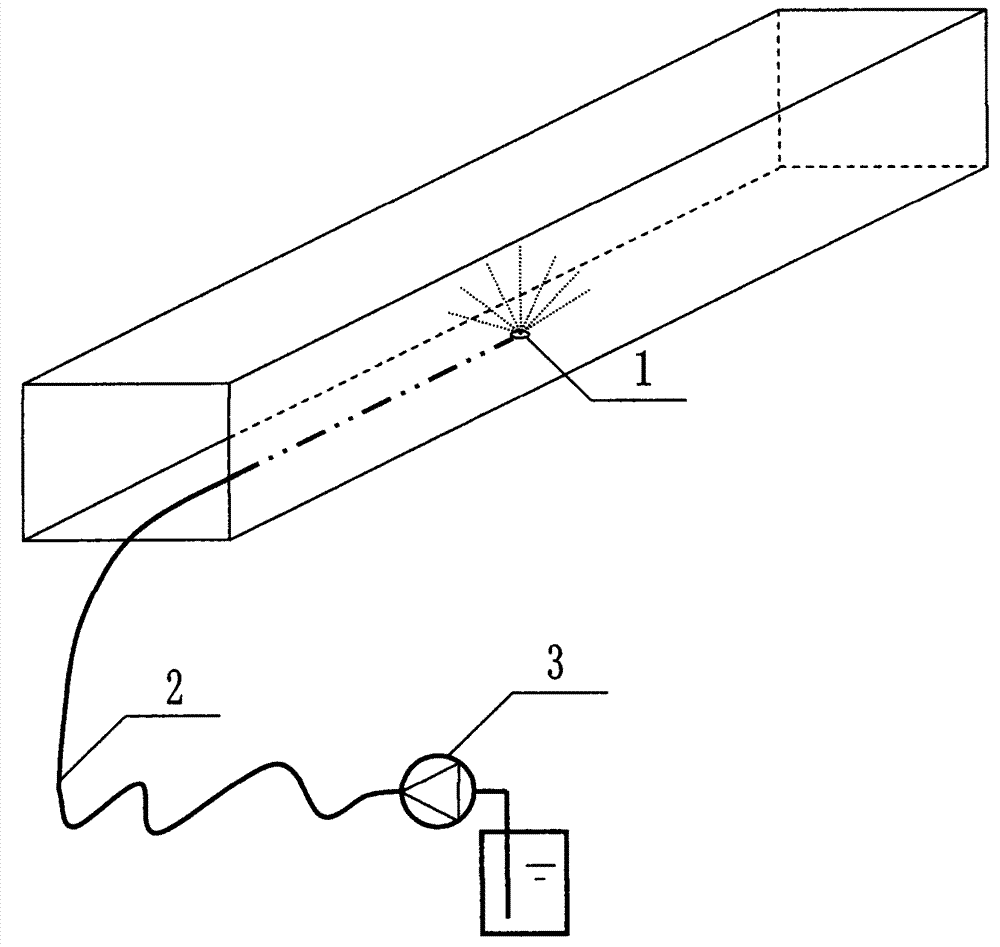

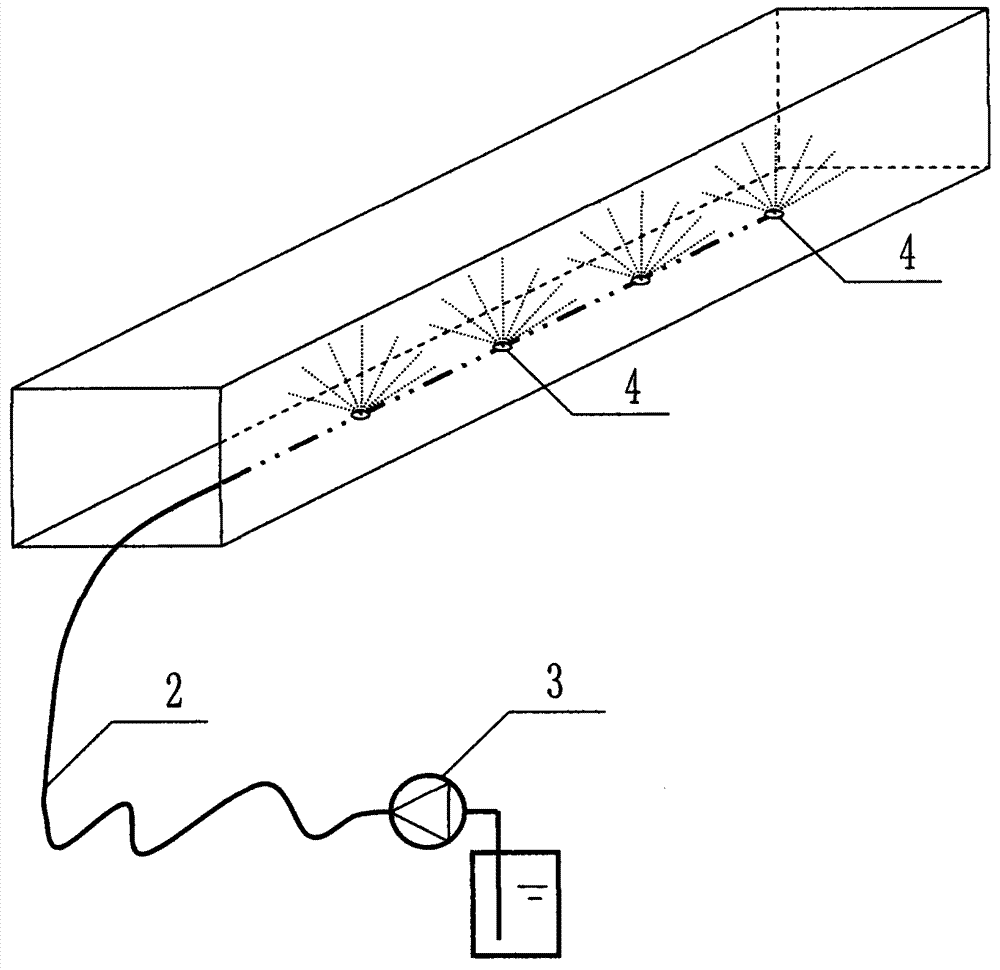

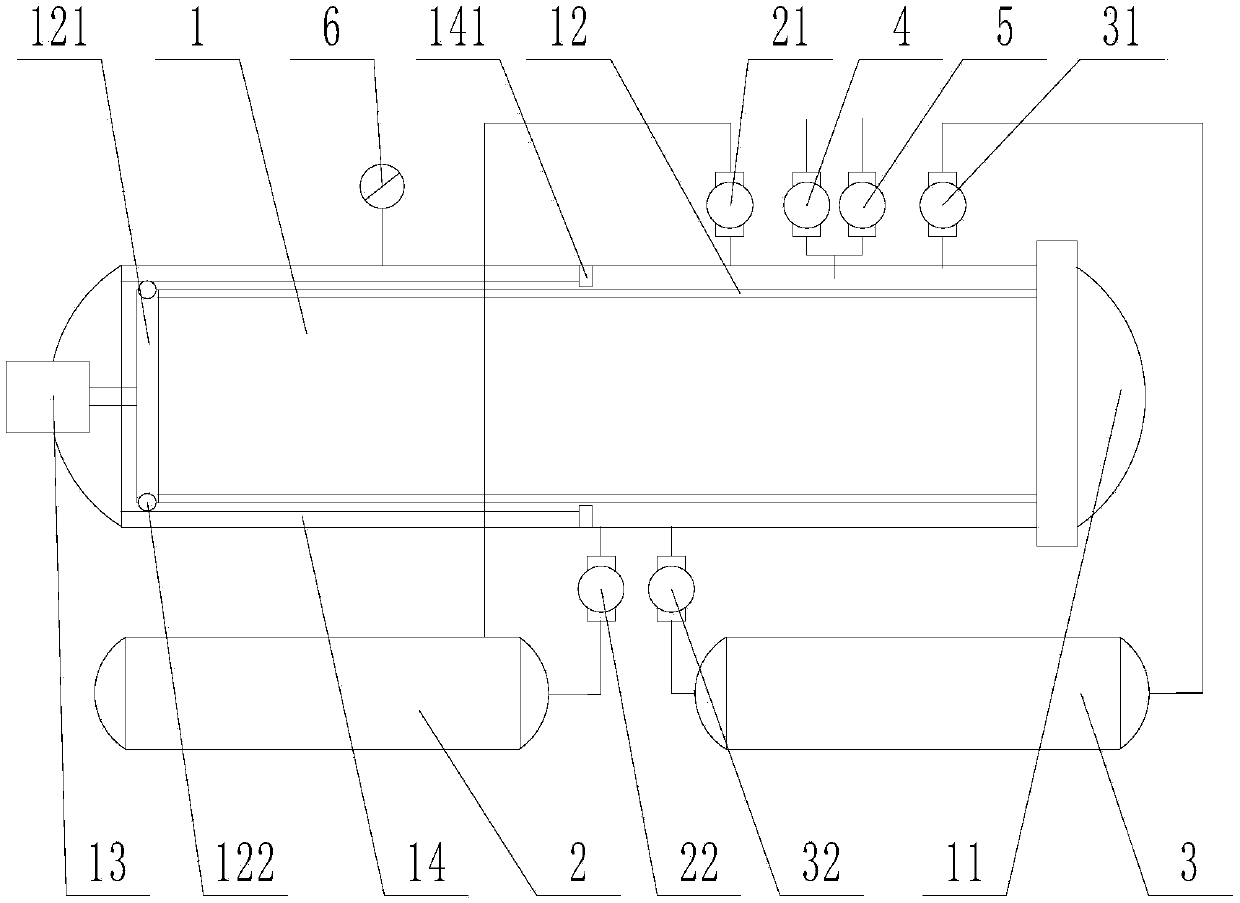

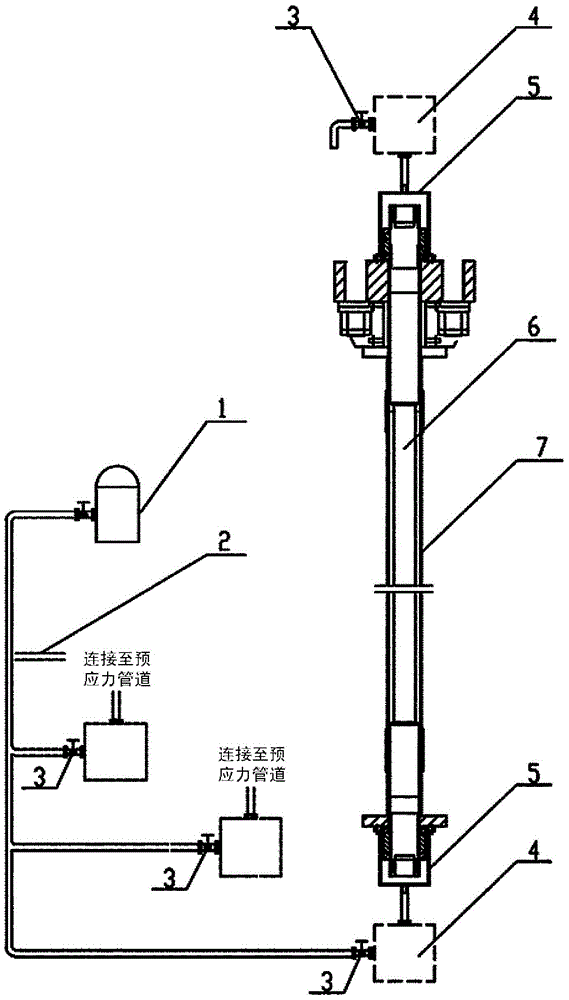

Drying and corrosion prevention method and system of main cable of suspension bridge

InactiveCN101831658AAchieve anticorrosionReduce operating energy consumptionBridge structural detailsExhaust valveMaintenance stage

The invention relates to a drying and corrosion prevention method of a main cable of a suspension bridge. The main cable of the suspension bridge is placed in a closed tubular jacket layer to ensure that the main cable of the suspension bridge is isolated with outside moist air. In an initial operation stage, a main cable dehumidification system is in a dehumidification stage; at the moment, vent valves on the lower part of a vent clamp of the main cable jacket layer of the suspension bridge are opened, and a larger flow of dry air is sent into the jacket layer from an air inlet clamp of the main cable jacket layer and then exhausted from a vent port of the vent clamp through gaps of main cable steel wires so that water in the main cable is drained as soon as possible; after the water in the main cable is exhausted, the main cable dehumidification system enters a maintenance stage; in the maintenance stage, all the vent valves on the vent clamp of the main cable jacket layer are closed to ensure that the main cable jacket layer forms a closed space; Through detecting the pressure of the vent clamp and controlling a dehumidification device and a blowing-in device, a small amount of dry air is sent to ensure that the pressure of the vent port of the main cable jacket layer of the suspension bridge is in a state of slightly exceeding the atmospheric pressure so as to maintain the main cable to be dry.

Owner:JIANGSU PROVINCIAL COMM PLANNING & DESIGN INST +2

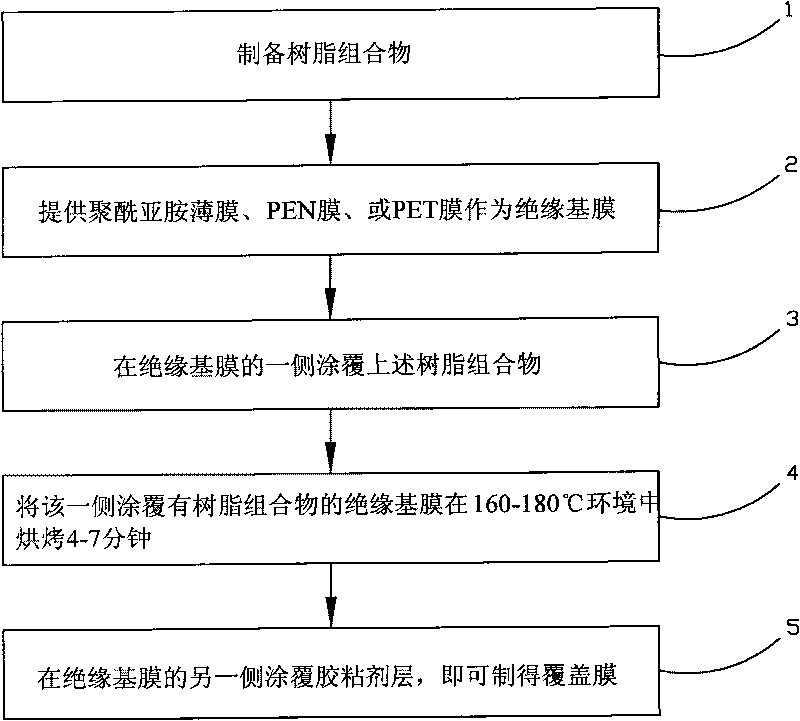

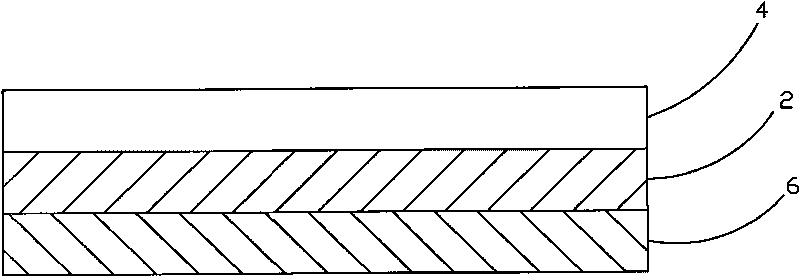

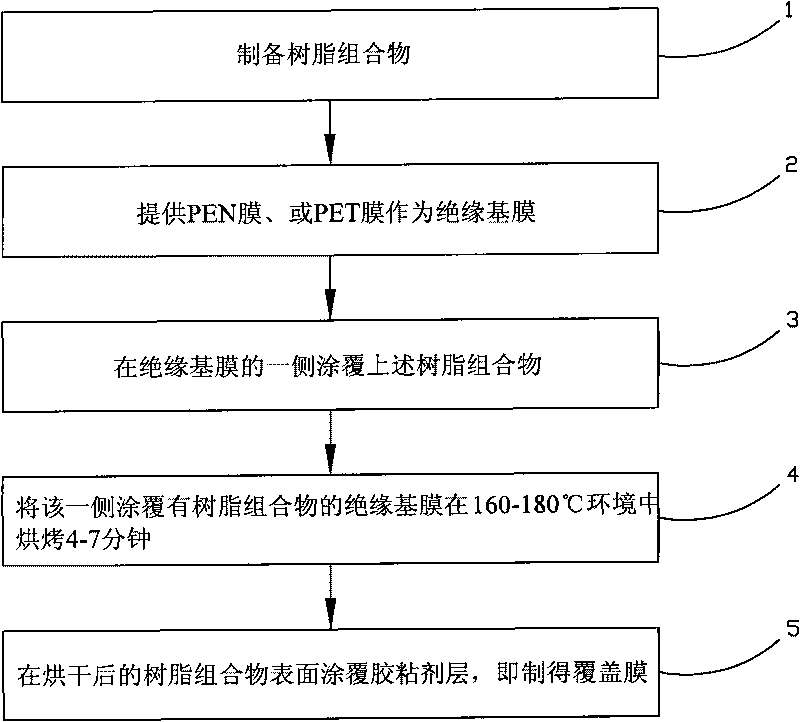

Resin composition and method for preparing FPC coverlay by using same

InactiveCN101735575AGood weather resistanceHigh hiding powerPrinted circuit detailsNon-metallic protective coating applicationPolyesterRope light

The invention relates to a resin composition and a method for preparing an FPC coverlay by using the same. The resin composition comprises the following components in part by weight: 50 to 70 parts of flexible saturated polyester, 30 to 50 parts of hard saturated polyester, 1 to 20 parts of enclosed isocyanate curing agent, 15 to 150 parts of pigment, 15 to 120 parts of inorganic filler, 0.5 to 2.5 parts of antifoaming agent, and 5 to 30 parts of organic solvent. The resin composition is applied to the FPC coverlay in a flexible printed circuit. The resin composition has the characteristics of excellent weather resistance, high covering power, high flexibility and adhesiveness, and the like. The method for preparing the FPC coverlay by using the same can realize the one-off coating of the FPC coverlay on the flexible printed circuit, has the advantages of simple manufacturing method, low cost and high yield, and can realize the continuous production and obviously improve the production efficiency. The FPC coverlay produced by the method can improve the contrast ratio of an LED rope light under the action of an insulating base film besides excellent dust prevention, corrosion resistance, weather resistance and other characteristics.

Owner:GUANGDONG SHENGYI SCI TECH

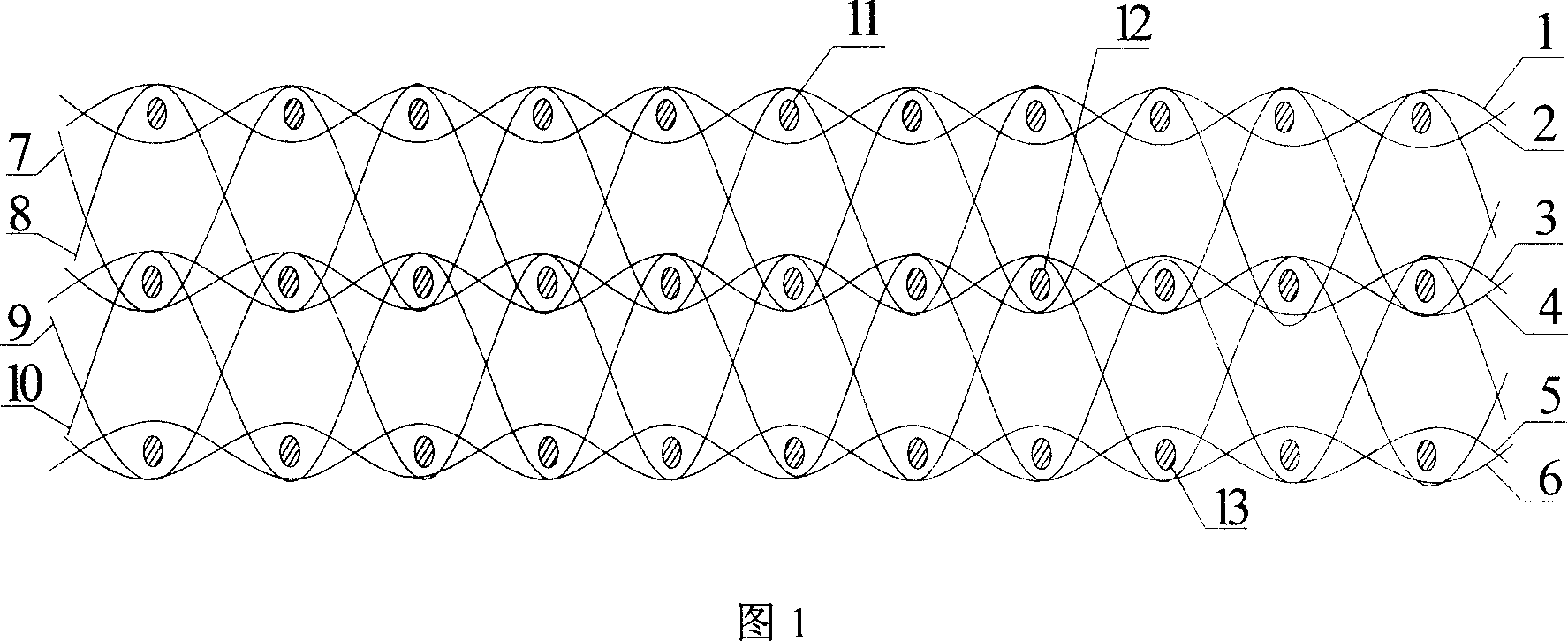

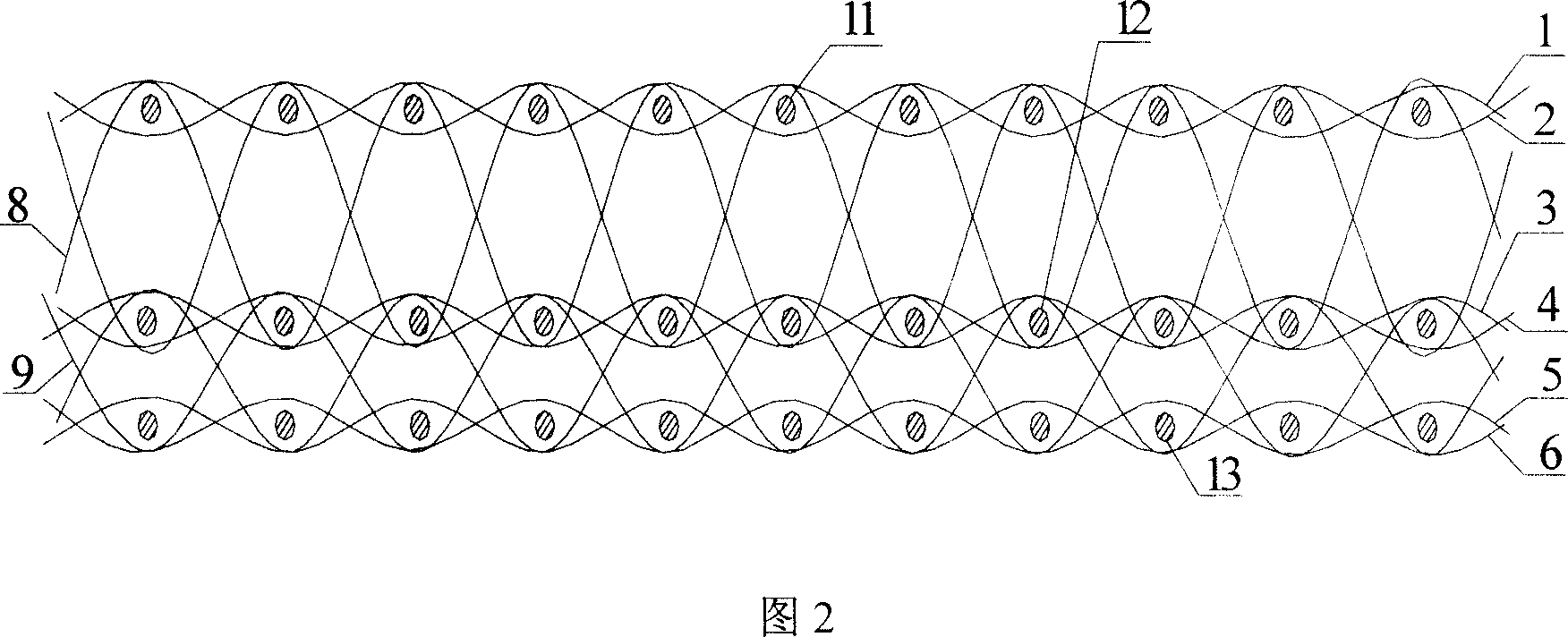

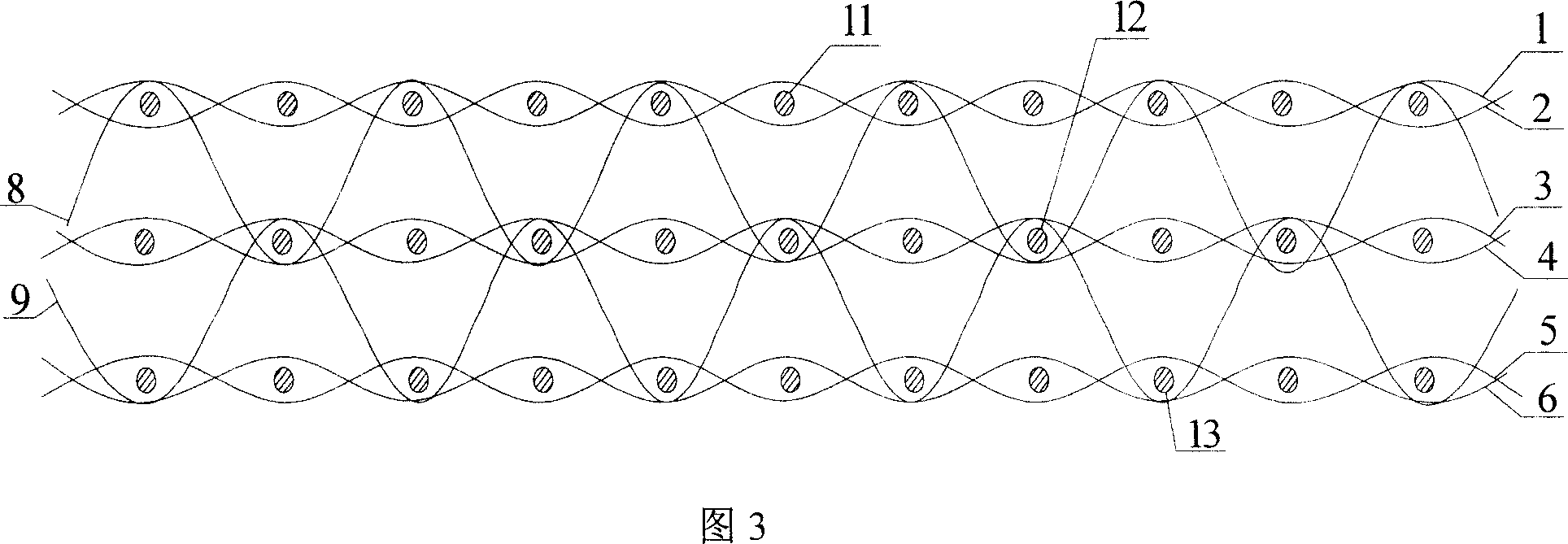

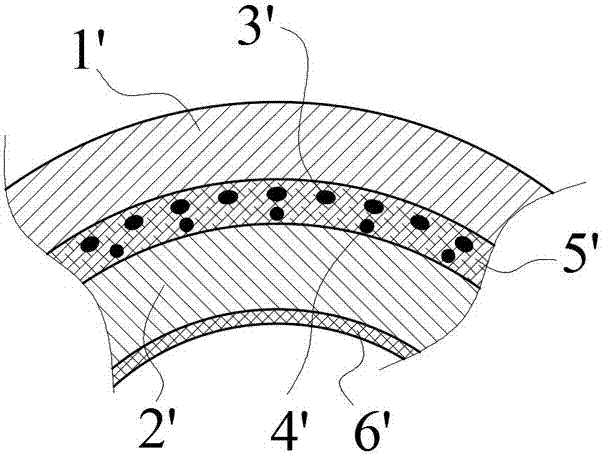

Three-dimensional hollow double sandwiched fabric

InactiveCN1974899ANot too high problem solvingImprove impact resistanceWoven fabricsEngineeringWeft yarn

The three-dimensional hollow double sandwiched fabric consists of one upper layer interwoven with two upper ground warp layers and one upper weft yarn layer, and one lower layer interwoven with two lower ground warp layers and one lower weft yarn layer, as well as one middle layer interwoven with two middle ground warp layers and one middle weft yarn layer. The weft yarn layers in the upper layer, the middle layer and the lower layer are also interwoven with the poil warps, so that the upper layer, the middle layer and the lower layer are connected integrally to form one hollow double sandwiched structure. The fabric of the present invention is uses as reinforcing body of composite material, and the composite material with the fabric is light, high in impact strength, high in antiwear performance, high in bending performance and high in rigidity. The double sandwiched structure may be also used in heat insulation, anticorrosion, real-time monitoring, etc.

Owner:SINOMA SCI & TECH

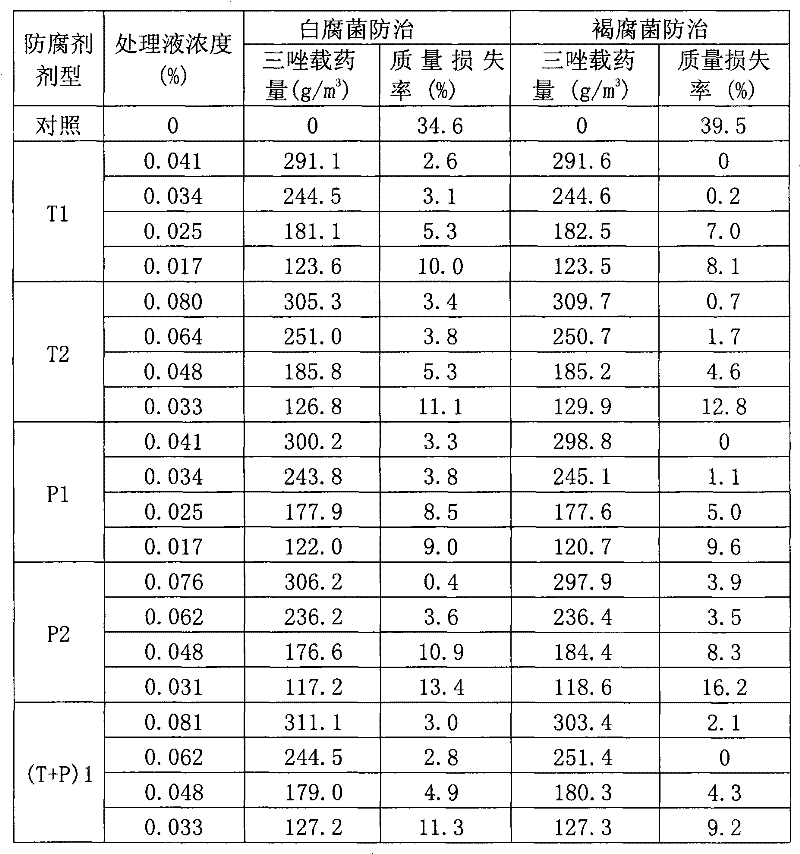

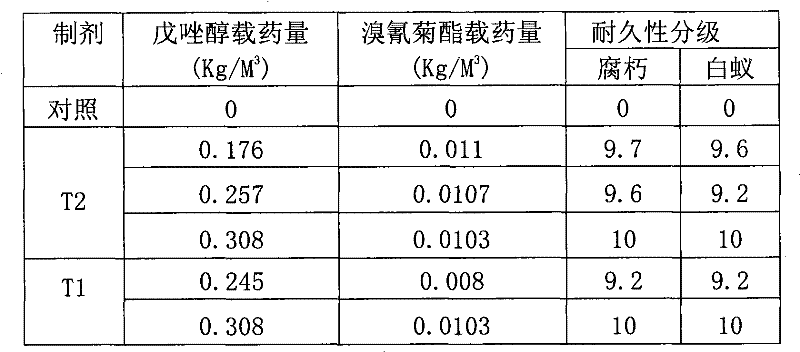

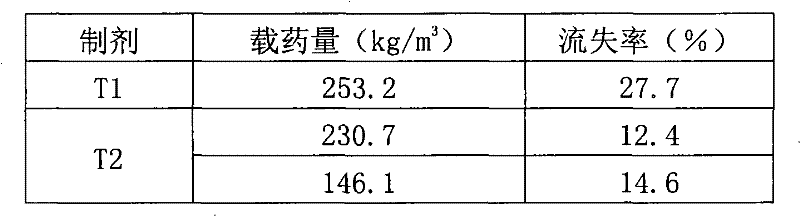

Water-soluble antiseptic anti-discoloration insect repellent composite for timber and bamboo wood as well as preparation method and application thereof

InactiveCN102232387AGood control effectAchieve anticorrosionBiocideFungicidesMethyl carbamateSolvent

The invention relates to a water-soluble triazole antiseptic anti-discoloration insect repellent composite for timber and bamboo wood as well as a preparation method and application thereof. Based on the total weight of the composite, the composite comprises the following components in percentage by weight: 3-8% of triazole compound, 24-48% of organic solvent, 24-40% of cosolvent, 3-10% of N-(2-benzimidazolyl)-methyl carbamate hydrochloride, 0-10% of prochloraz, 0.1-0.8% of esbiothrin insecticide and the balance of water, wherein the triazole compound is propiconazole, tebuconazole, cyproconazole or any combination of propiconazole, tebuconazole and cyproconazole. The composite can be used for processing timber and bamboo wood or timber and bamboo wood products indoor and outdoor. In the processing method, a vacuum pressurization or normal-pressure dipping method are used so that the processed timber and bamboo wood or timber and bamboo wood products have the antiseptic, anti-fungus discoloration and mothproof properties.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

Environment friendly energy-saving super strength combustion supporting efficient synthetic coal

The invention discloses environment-friendly energy-saving extra-strong combustion-supporting high-efficiency synthetic coal, which is characterized by comprising the following steps: adopting plant charcoal power and natural coal powder of powerful renewable resources to prepare into a main material through a scientific formula according to the variety and the quality of coal; adding a mixed material of coal gangue powder and fly ash powder of industrial waste to synthesize a filling auxiliary material, and reconstructing and changing structures, the performance and the characteristics of the coal to make the coal reach the highest efficiency; then adding a strong-oxygen combustion-supporting high-efficiency coal-saving synergistic fire-slowing agent which has quick firing, can prolong the combustion time of the coal, can make low-grade coal completely combusted, improve thermal efficiency, save the coal, has no pollution, and can achieve the aims of eliminating smoke, dedusting, supporting combustion and desulfurizing; and finally adding a certain amount of water , evenly stirring , and performing coal molding and manufacturing by special coal-making machinery . The coal is high-efficiency coal, has the use efficiency three to six times of that of the prior ordinary coal, is a novel energy-saving high-efficiency energy source, has the coal-saving rate reaching 80 percent or so, has extremely high coal-saving rate and convenient use, is safe, reliable and easy to store, and is called 'overground coal mine' and 'green coal'.

Owner:万金林

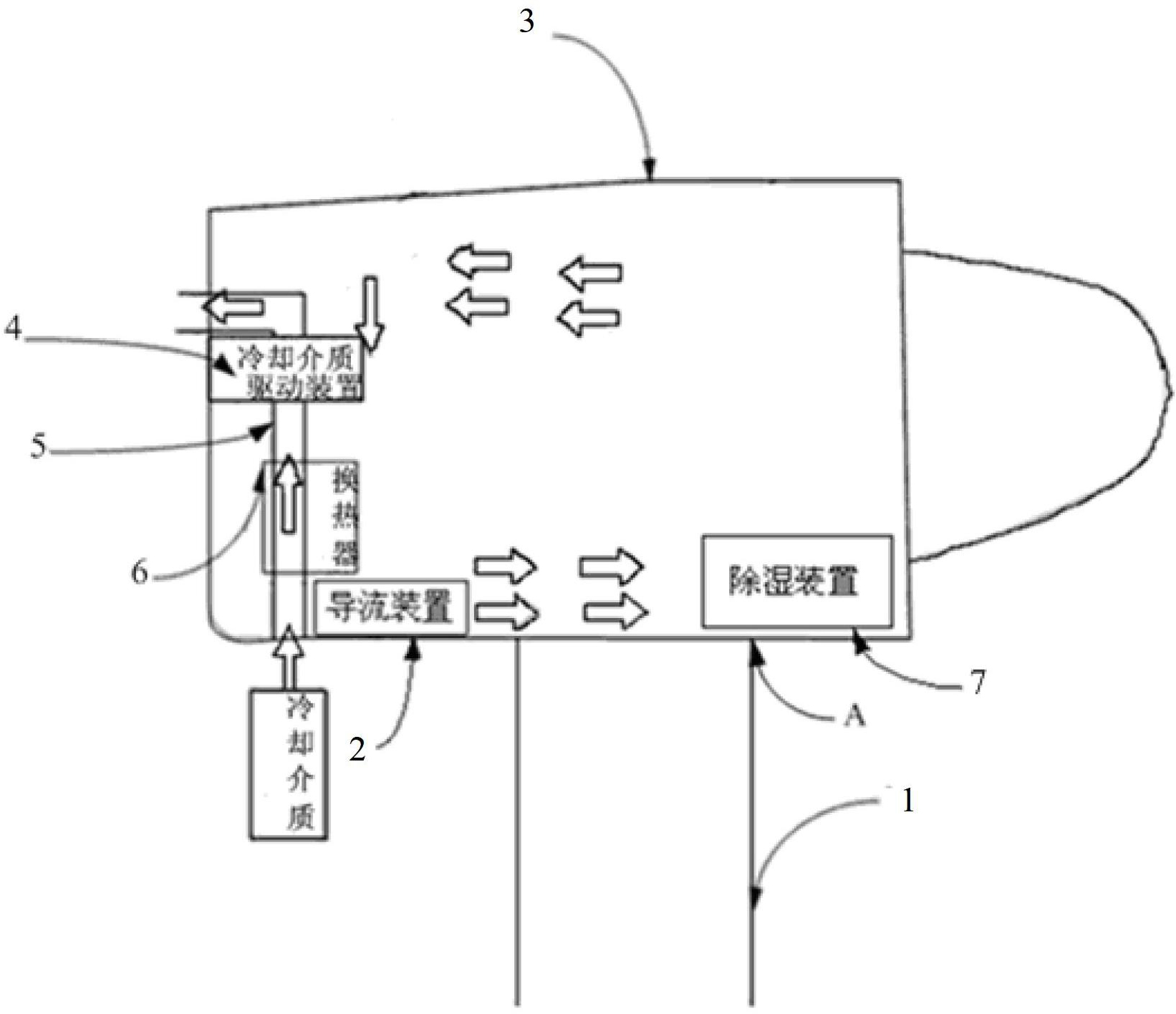

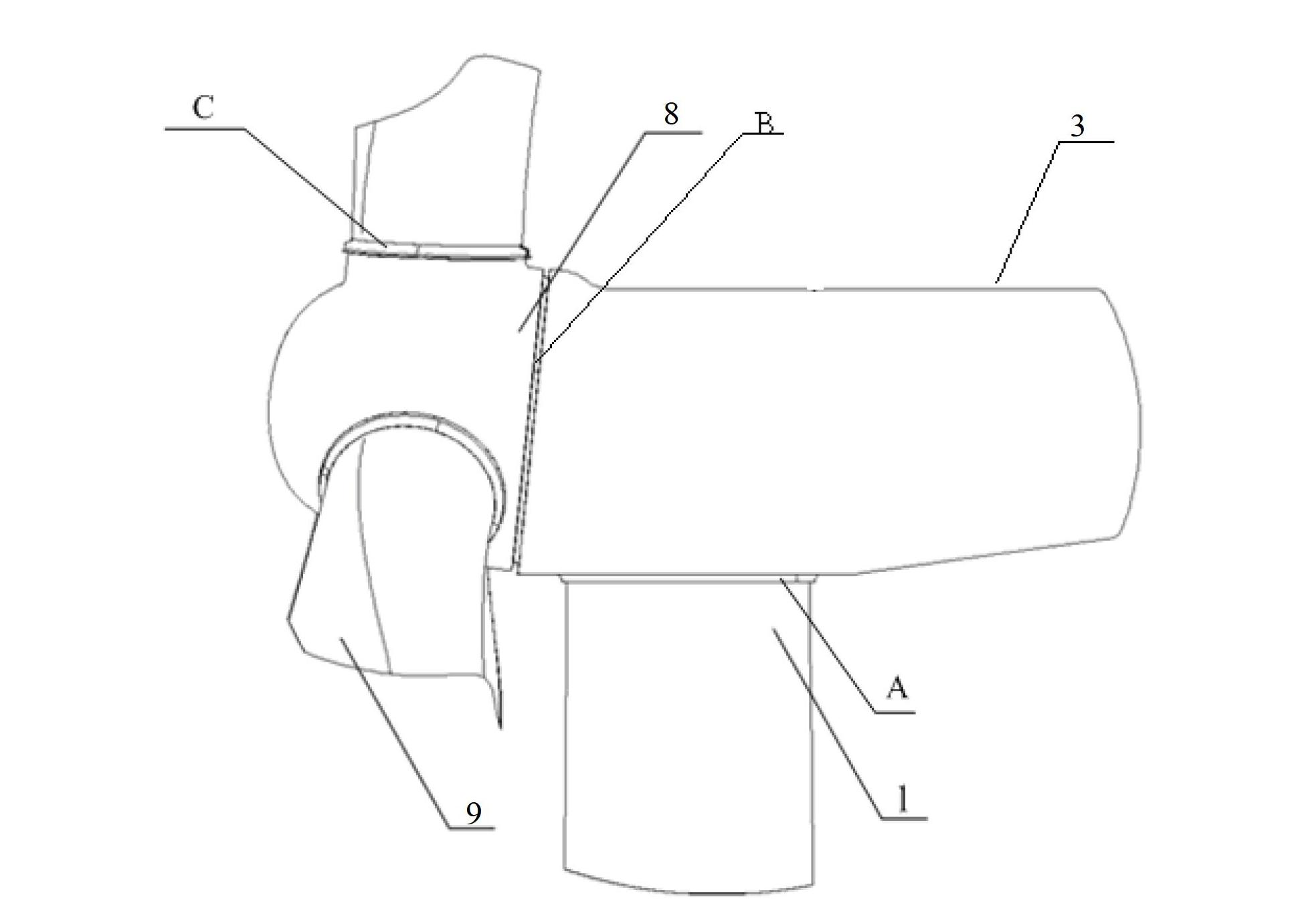

Corrosion-resistant cooling structure for offshore wind turbine

ActiveCN102661251AAchieve anticorrosionAnti-corrosion cooling achievedMachines/enginesWind energy generationAir cooling systemTower

The invention discloses a corrosion-resistant cooling structure for an offshore wind turbine. The wind turbine comprises a tower, an engine room arranged on the tower in a rotatable mode, and a spindle arranged inside the engine room in a rotatable mode. A running fit part of the tower and the engine room and a running fit part of the spindle and the engine room are sealed in a labyrinth seal mode, and an air cooling system is arranged inside the sealed engine room. Because the rotating parts are subjected to labyrinth seal, parts inside the engine room are isolated from outside air, so that harm of corrosive substances contained in the outside air to the inside parts is reduced; and therefore, the anti-corrosion grade of the inside parts can be properly reduced, so that the cost of the parts inside the engine room is reduced; and meanwhile, an aim of cooling the interior of the engine room through the air cooling system at low operating cost is fulfilled.

Owner:CSIC CHONGQING HAIZHUANG WINDPOWER EQUIP

Making method of grilled prawns

The invention discloses a making method of grilled prawns. The making method is characterized by comprising the steps that shelled fresh prawns or frozen prawns are cleaned; prawn raw materials are mixed with hot water according to the mass ratio being 1:6-8 and then cooked for 45-60 s at the temperature of 95+ / -5 DEG C; the cooked prawns are evenly mixed with seasoning fluid according to the mass ratio being 1:1 and then placed in a low-temperature room with the temperature of 4-10 DEG C for taste penetration, wherein the penetration balance time is 20-24 h; the seasoned prawns are dried through hot air for 25-35 min at the temperature of 40-60 DEG C, and then dried at the temperature of 95+ / -5 DEG C by combining hot air with infrared drying or microwave drying till the water content is 40-45% and the water activity is 0.85-0.88; packaging and sterilization are performed, and finally the grilled prawns are obtained. The grilled prawns have the advantages of being convenient to carry and eat, high in nutritive value, good in elasticity and taste, high in water content, long in shelf life and capable of well keeping original flavor of the prawns.

Owner:NINGBO UNIV

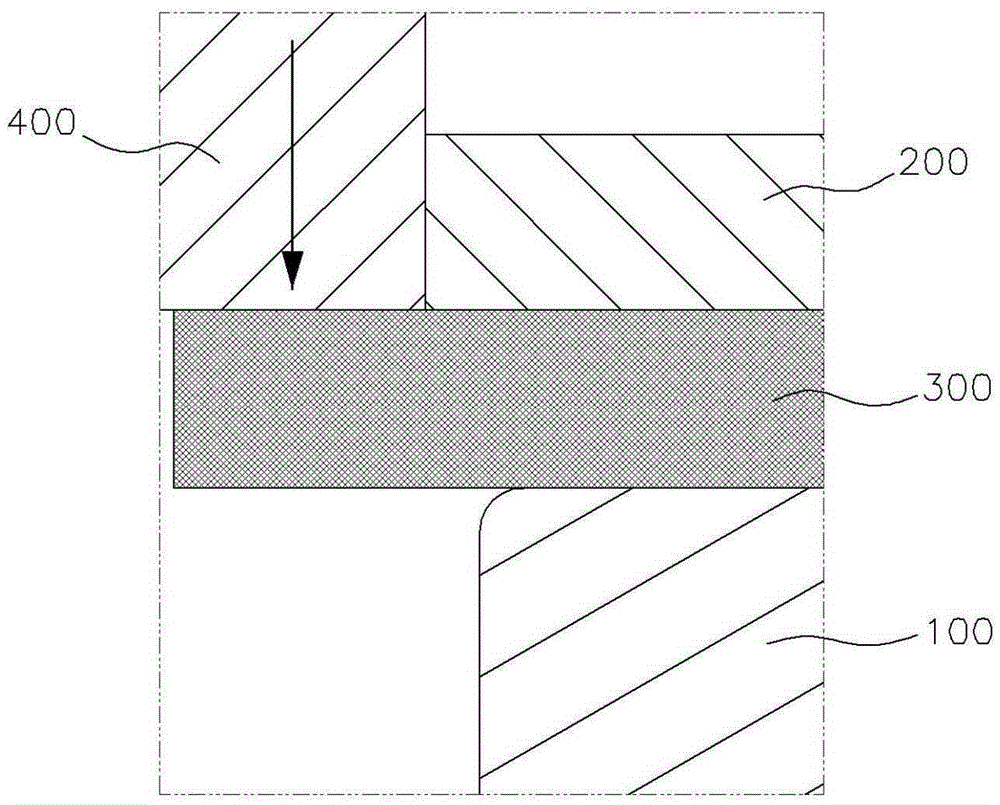

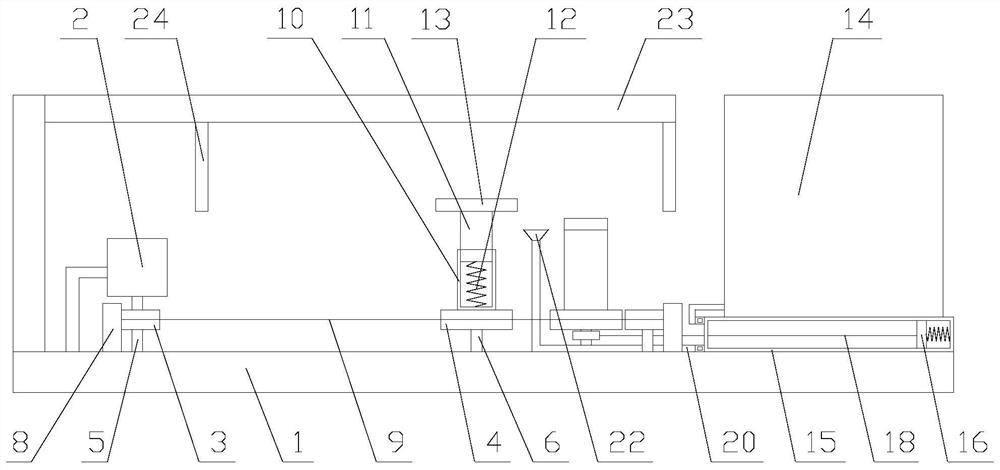

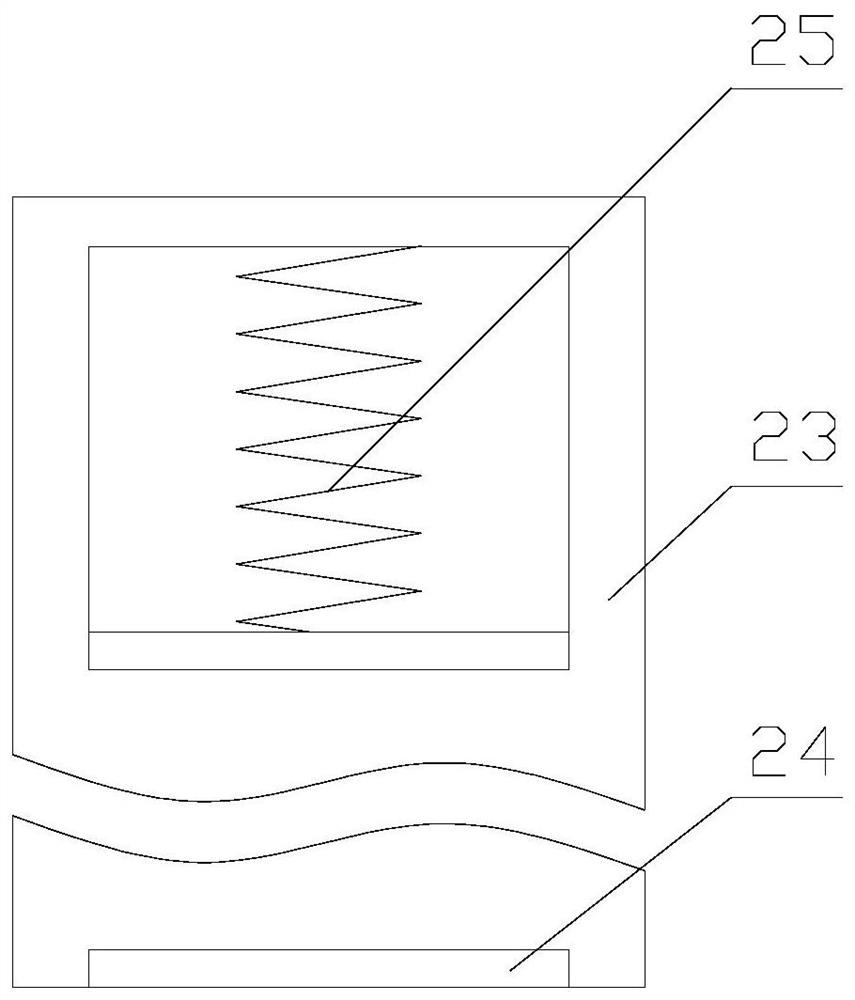

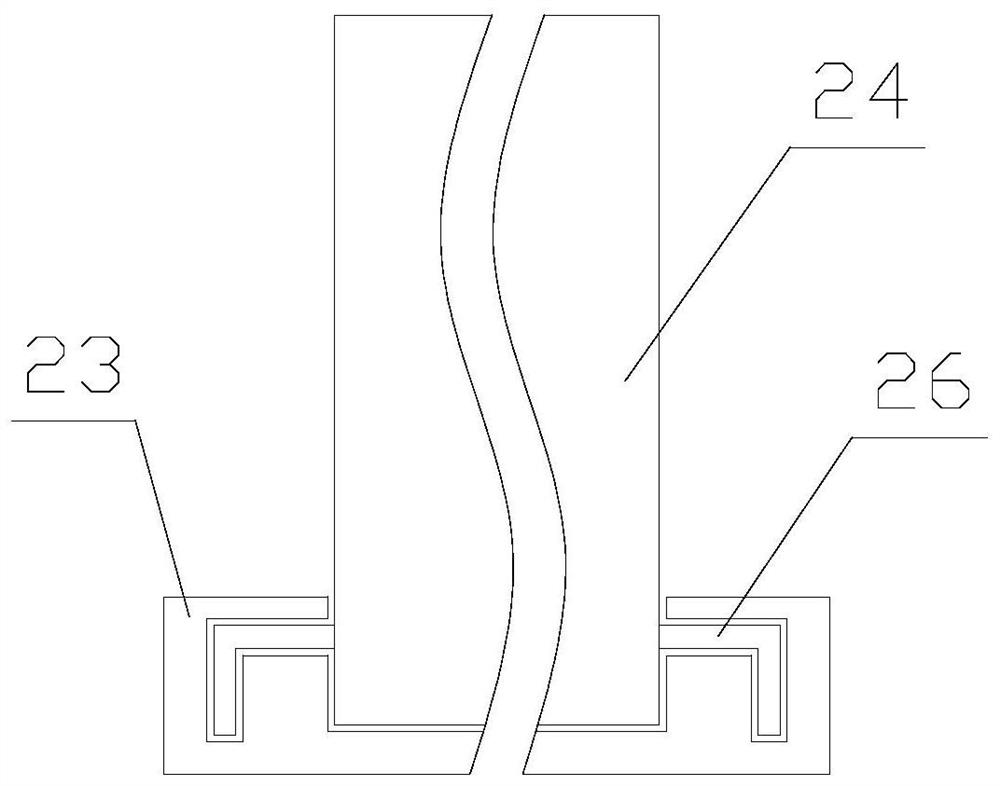

Apparatus and method of shearing for quality improvement for steel plate shearing edge

InactiveCN105798106AReduced post-processingQuality improvementShaping toolsShearing machinesSheet steelArea ratio

The present disclosure provides a shearing method for improving the quality of a steel plate shearing edge, and a shearing apparatus to improve the quality of the steel plate shearing edge. The apparatus includes: a die; a stripper for fixing a steel plate positioned on the top of the die; a trim punch for shearing the steel plate fixed between the die and the stripper, and a finishing die for reducing an area ratio of a fracture surface of a shearing edge formed by shearing the steel plate and removing a burr. By using the apparatus, components can be prevented from being damaged and a life-span can be increased through removing a burr generated at the shearing edge of the steel plate and reducing a fracture surface ratio.

Owner:HYUNDAI MOTOR CO LTD

Modified wood and its production process

InactiveCN1935475ADifferent functionsNo deformationWood treatment detailsWood impregnation detailsFiberHoneycomb structure

The present invention relates to a modified wood and its production process. It is characterized by that said invention adopts a vacuum equipment, and makes a modification sol be filled into the honeycomb structure of unsawn timber base material, solidified and combined together with unsawn timber base material fibre so as to obtain the invented modified wood.

Owner:周志邦

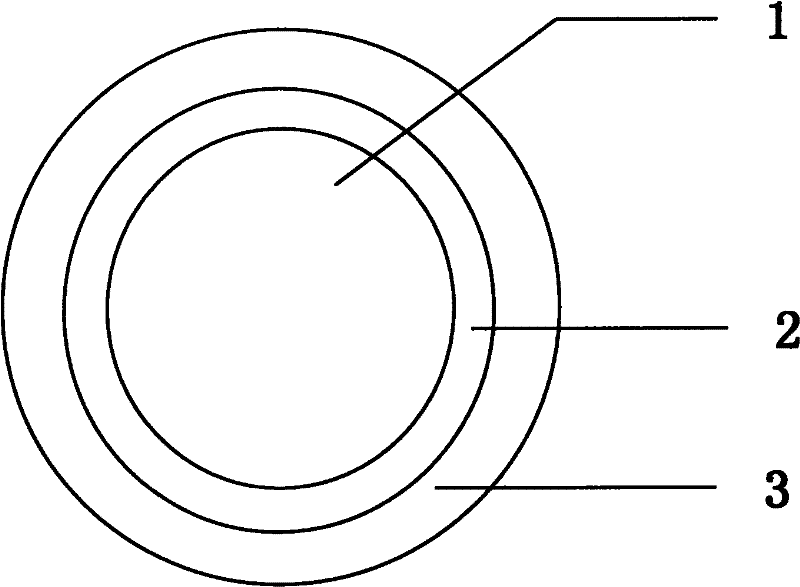

Anti-corrosion flame-retardant wind power cable sheath, insulating material and preparation method of sheath and insulating material

InactiveCN106280024AGuarantee the safety of useExtended service lifeRubber insulatorsInsulated cablesPolyvinyl chlorideEngineering

The invention belongs to the field of power cables and particularly relates to an anti-corrosion flame-retardant wind power cable sheath, an insulating material and a preparation method of the sheath and the insulating material. The inner layer insulating material is prepared from, by weight, 40-60 parts of EPDM, 10-25 parts of polyvinyl chloride, 5-10 parts of paraffin oil, 5-15 parts of calcium carbonate, 30-60 parts of kaoline, 1-3 parts of anti-ageing agent, 1-3 parts of assistant crosslinker, 0.5-2 parts of vulcanizing agent and 1.5-3.5 parts of flame-retardant agent. The outer layer sheath material is prepared from, by weight, 40-60 parts of ethylene propylene terpolymer A, 35-60 parts of ethylene propylene terpolymer B, 3-8 parts of activating agent, 2-4 parts of stabilizer, 2-4 parts of antioxidant, 2-4 parts of cold-resistant plasticizer, 1-3 parts of silane coupling agent, 5-10 parts of compound vulcanizing agent, 3-8 parts of flame-retardant agent and 30-50 parts of filling agent. Process improvement is conducted on the inner layer insulting material and the outer layer sheath material of a wind power cable, the cable can be used in the environment of -40-100 DEG C for a long time, the cable has good softness, oil resistance, cold resistance, abrasion resistance, acid and alkali resistance, flame retardancy and the like, and the requirement that a draught fan safely and normally runs in the changeable and severe weather environment is met.

Owner:JIANGSU LONG E CABLE

Metallic material surface treating method

InactiveCN101367079AAnti-corrosionWith decorationPretreated surfacesCoatingsMetal oxide nanoparticlesMetallic materials

The invention discloses a surface treatment method for a metal material, which comprises the following steps: metal to be treated is dipped into 20 percent sodium hydroxide solution, and the soaking time is between 1 and 5 minutes; the metal is dipped into water, and the soaking time is between 2 and 10 minutes; the metal is dipped into 10 to 30 percent sulphuric acid solution, and the soaking time is between 1 and 5 minutes; the metal is dipped into the water, and the soaking time is between 2 and 10 minutes; the metal washed and treated by the water is then dipped into a metal oxide nanoparticle dispersion liquid with a mass concentration of between 10 and 30 percent, and the soaking time is between 5 and 10 minutes; the treated metal is dried at a temperature of between 80 and 200 DEG C, the surface of the metal is covered with a layer of dispersion liquid wet film which forms an oxide dry-film through the drying and high-temperature treatment, and the dry-film has functions of antisepsis, decoration, protection, heat dissipation promotion, fouling resistance and so on.

Owner:SOUTH CHINA UNIV OF TECH

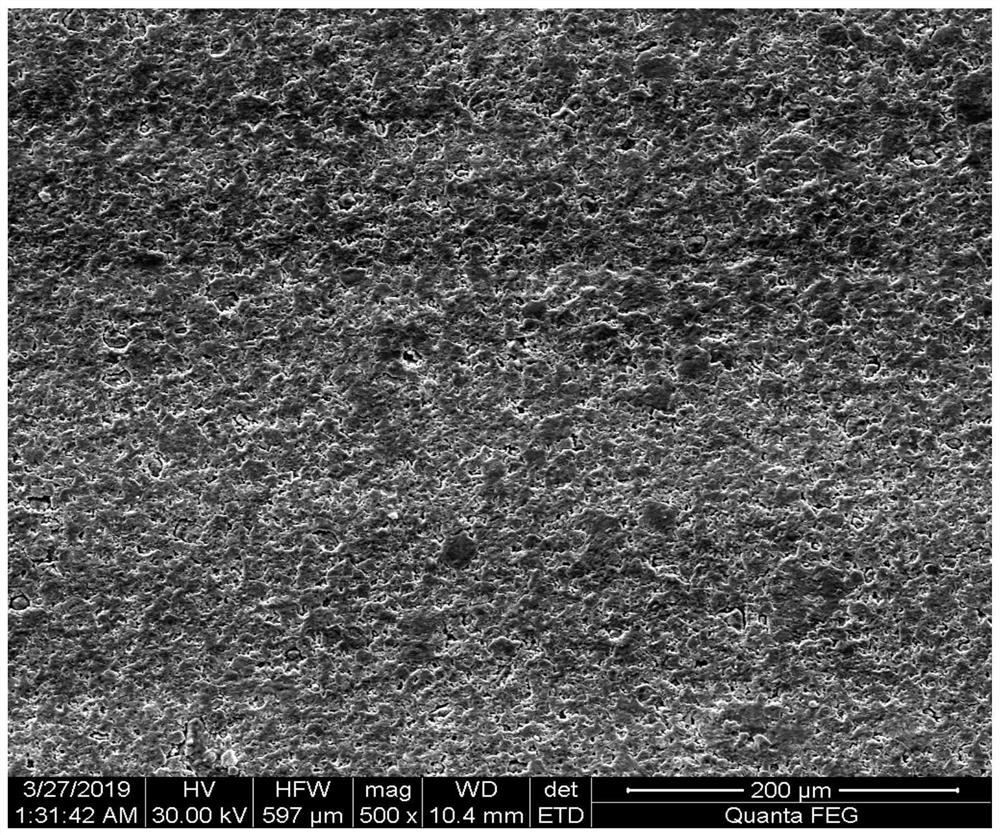

High-wear-resistance super-hydrophobic composite coating, preparation method thereof and coating layer prepared from coating

ActiveCN108485522AAchieving aging resistanceReduce washoutAntifouling/underwater paintsPaints with biocidesFiberCarbon fibers

The invention discloses a high-wear-resistance super-hydrophobic composite coating. The high-wear-resistance super-hydrophobic composite coating consists of the following components in parts by mass:5 to 15 parts of organic silane, 1 to 10 parts of an inorganic wear-resistant agent, 2 to 9 parts of a catalyst, 1 to 3 parts of a hydrophobic agent, 0 to 3 parts of carbon fiber, 0 to 3 parts of glass flake powder, 2 to 8 parts of one or two of tetraethylenepentamine and tetraethylenetriamine and 60 to 90 parts of solvent. The invention also provides a preparation method of the high-wear-resistance super-hydrophobic composite coating as well as a preparation method of a coating layer. The invention has the following beneficial effects: the coating layer continuous phase has high hardness, high wear resistance, high smoothness and superhydrophobicity and also has high compactness and strong binding force with a matrix; and the coating can be used for coating and cured at normal temperature, realizes anti-scouring, anti-fouling, anti-corrosion and anti-ageing effects, is suitable for matrixes such as steel, glass and rubber, can be applied to high-voltage cables, outdoor high-voltage equipment, ships and automobile glass, and can maximally reduce scouring and shearing on the coating layer by seawater, silt and wind sand.

Owner:泰安乐邦环保科技有限公司

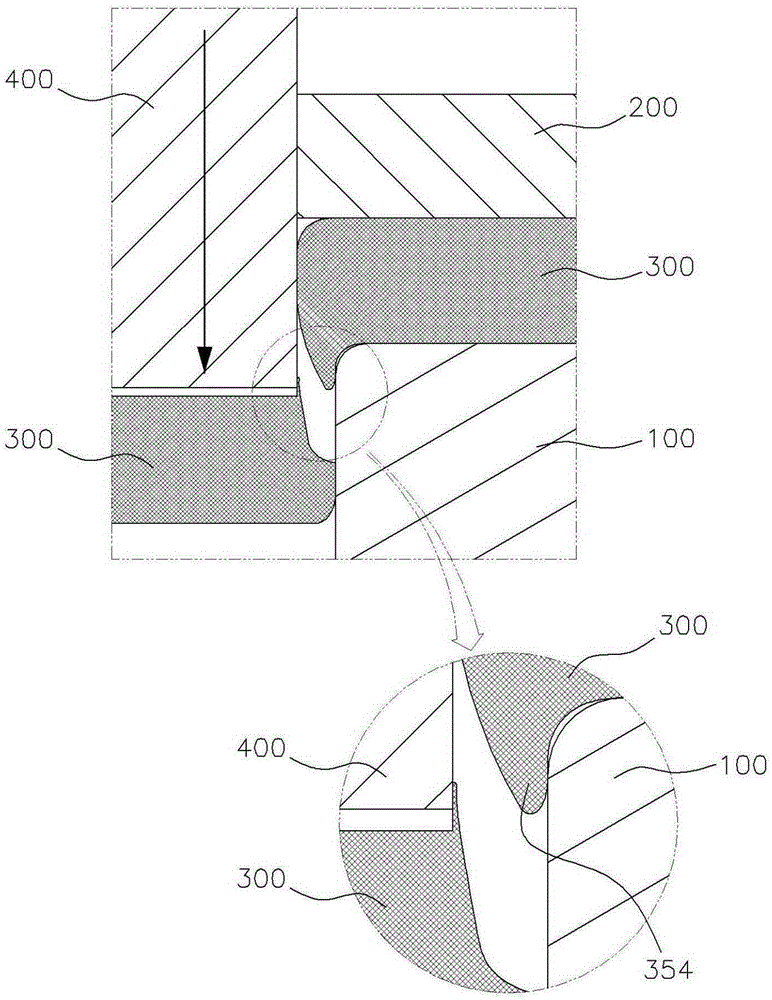

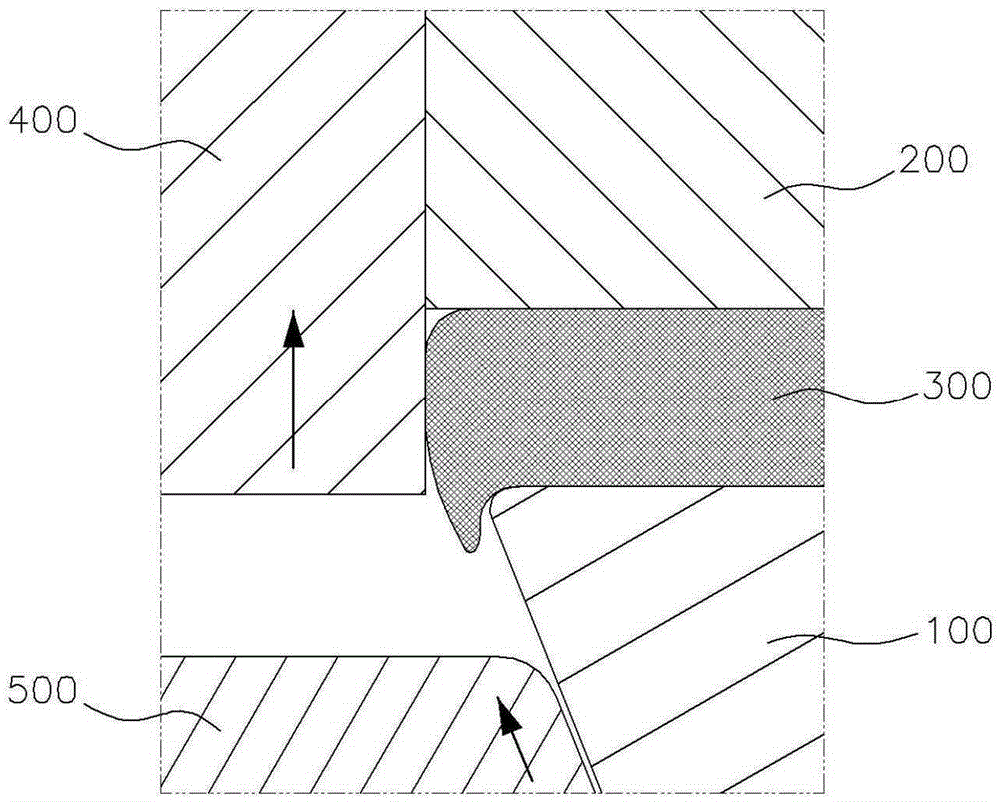

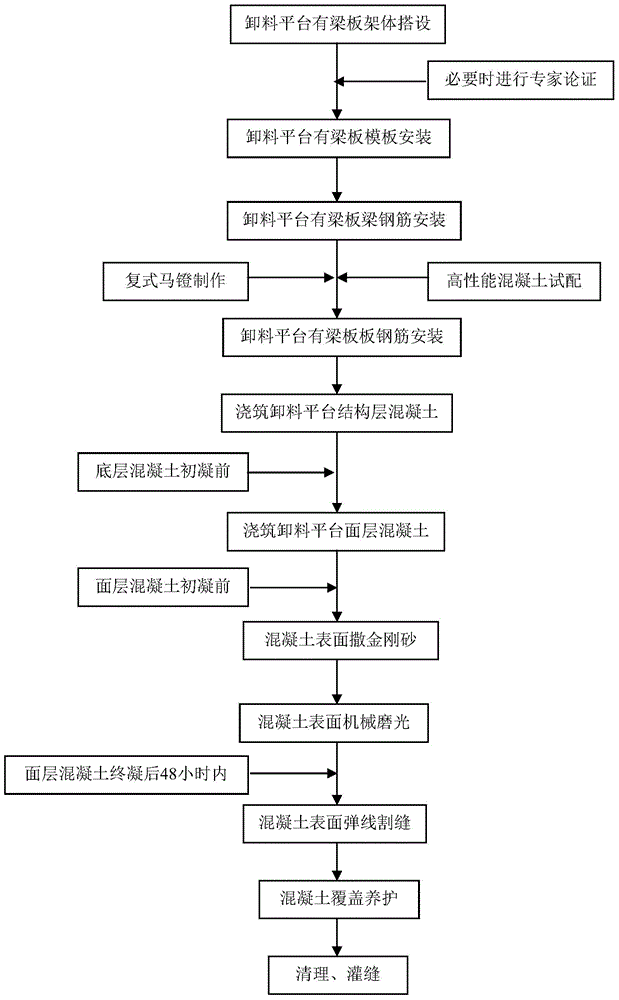

Composite surface construction technology for garbage discharging platform of garbage incineration power plant

ActiveCN104929365ASolve the performance of compression resistance and bending resistanceImprove wear resistanceBuilding material handlingPower stationArchitectural engineering

The invention particularly relates to a composite surface construction technology for a garbage discharging platform of a garbage incineration power plant. The composite surface construction technology for the garbage discharging platform of the garbage incineration power plant is characterized by comprising the steps that 1, concrete is prepared; 2, a formwork support and steel bars are erected; 3, composite horse stools are prepared and welded; 4, double-deck double-way steel bars are arranged; 5, inspection is conducted before the concrete is poured; 6, concrete pouring is conducted; 7, carborundum is sprinkled when strengthened surfaces are poured; 8, concrete surface elevation is controlled, and screeding and leveling are conducted; 9, concrete curing is conducted. Compared with a construction technology of the prior art, the composite surface construction technology for the garbage discharging platform of the garbage incineration power plant has the advantages that the construction technology is detailed, the innovativeness is strong, the scientificity is strong and the operability is strong; integrality construction is achieved, the construction technology is not compressing and stacking of the construction steps, the function of a whole structure layer is changed, and the comprehensive effects of being resistant to pressure, abrasion, corrosion, seepage, fracture and the like are achieved; construction is simultaneously conducted on the structure layer and the surface effectively, and the construction period is shortened; 4, the safety and the reliability are achieved, and the economic benefits are significant.

Owner:SHANDONG ZIJIAN GRP

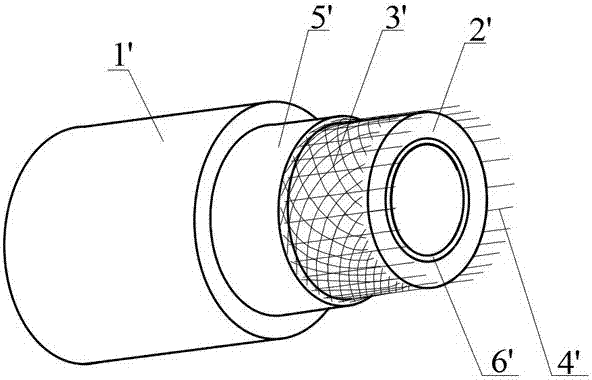

Steel mesh plastic composite pipe machining process

PendingCN108000831AIncreased strength and rigidityNot easy to bend and deformCoatingsRigid pipesMachining processUltimate tensile strength

The invention relates to a plastic pipe machining process, in particular to a novel steel mesh plastic composite pipe machining process. The novel steel mesh plastic composite pipe machining process comprises the steps of dividing wires, coating rubber, extruding an inner-layer plastic layer, extruding a hot-melt adhesive, winding a steel wire mesh layer, extruding a hot melt adhesive layer, extruding an outer-layer plastic layer and the like. According to the novel steel mesh plastic composite pipe machining process, axial steel wires and annular steel wire mesh structure are adopted at the same time, so that rigidity strength of a pipe is improved, and the pipe is not easy to bend and deform and is more suitable for the use working condition of overhead installation.

Owner:杨明昆

Method for treating wood/bamboo

InactiveCN102198680AAchieve anticorrosionAchieve mildew resistanceWood working apparatusVegetable oilWork in process

The invention mainly aims to provide a method for treating wood / bamboo. By the method, anticorrosive, mildew-proof, anti-cracking and mothproof treatment can be well performed on the raw wood / bamboo material. In order to fulfill the purposes, the invention adopts the technical scheme that the method comprises the following steps of: a, soaking the raw wood / bamboo material into water; b, dehydrating the raw wood / bamboo material soaked into the water; c, drying the dehydrated wood / bamboo; and d, finally soaking the dried wood / bamboo into edible vegetable oil. According to the treatment method, after the raw wood / bamboo material is soaked into the water, dehydrated, dried and soaked into the edible vegetable oil, the purposes of dehydrating, degreasing and avoiding deformation of the wood / bamboo are fulfilled; and meanwhile, all pores in the semi-finished product are closed by the edible vegetable oil, so that the semi-finished product forms a whole, and the purposes of resisting corrosion, mildew, cracking and moths are fulfilled.

Owner:蒋雨金

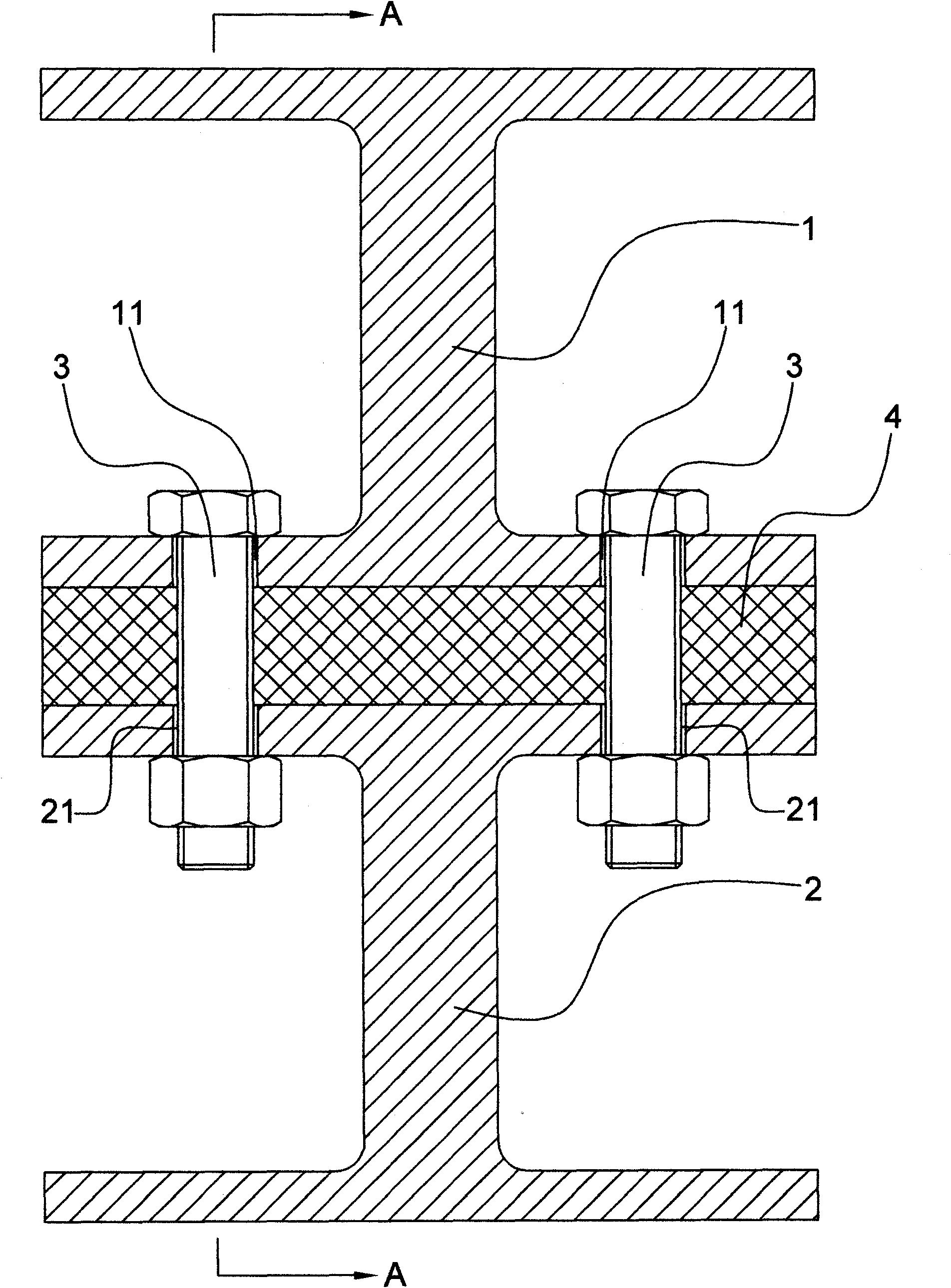

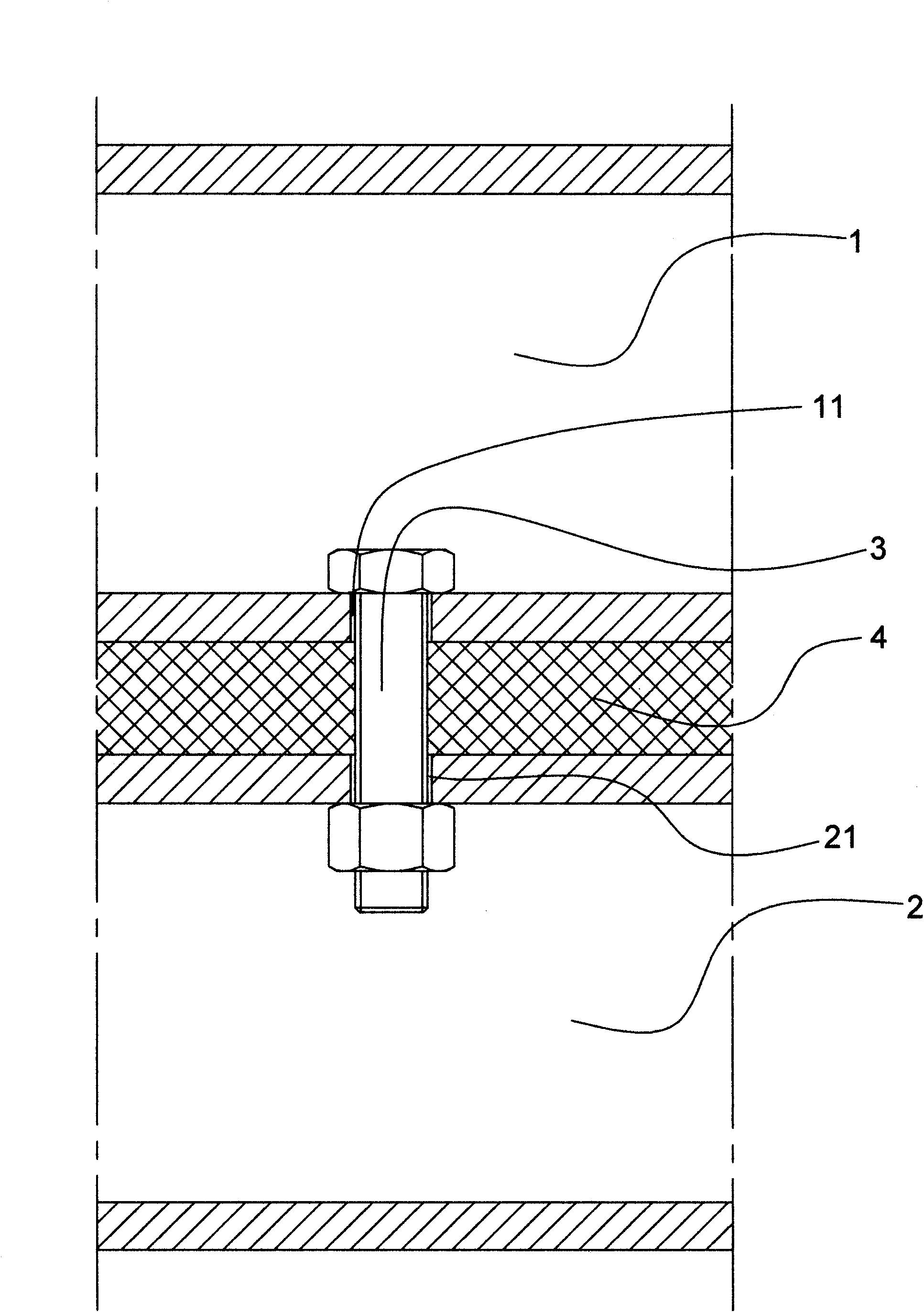

Steel construction reinforced structure and reinforcing method thereof

InactiveCN101644107AImprove shear resistanceTo meet the requirements of anti-slipBuilding repairsSheet steelAdhesive

The invention discloses a steel construction reinforced structure, comprising original constructional steel, reinforcing steel and a reinforcing bolt, and a structure gluing connecting layer is arranged between the raw construction steel and the reinforcing steel plate. Construction method of the steel construction reinforced structure includes the following steps: a) a hole is bored; b) structureadhesive is placed and coated between the reinforcing steel plate processed with a through hole and raw steel member, so as to form the structure gluing connecting layer; c) the reinforcing bolt is used for connecting the raw constructional steel and the reinforcing steel tightly and firmly. The invention makes the best of connectivity of high strength bolt and utilizes structural adhesive to improve anti-shearing performance of the steel member, the bonding force of the structural adhesive causes no relative movement to be existed between steel plates, and anti-slippage requirement of designing institute on high strength bolt can be achieved. As the structural adhesive is filled between the steel members, anticorrosion of steel member can be realized, and simplification in construction period and construction technology is effectively improved. Reverse boring construction method is adopted, thus having the characteristics of strong construction operability and fast speed.

Owner:天地金草田(北京)科技有限公司

Air conditioner vent pipe cleaning method

The invention relates to an air conditioner vent pipe cleaning method. At least one layer of paint is sprayed on the inner surface of an air conditioner vent pipe, a paint covering layer is formed on the inner surface of the air conditioner vent pipe, paint forms a coating film after a solvent of the paint is dried naturally, and original dust and dirt on the inner surface of the air conditioner vent pipe are fixed in the coating film and prevented from entering an air conditioner vent system again; or the coating film and the dust and dirt covered by the coating the film are peeled off from the inner surface of the air conditioner vent pipe and moved out from the air conditioner vent pipe, and the cleaning of the inner surface of the vent pipe is achieved. The method has the advantages of being thorough in cleaning, free of dead angles and secondary pollution, simple in device, convenient to operate and the like. Meanwhile, air resistance of the air conditioner vent pipe can be reduced. The paint is sprayed on the inner surface of the air conditioner vent pipe by using a fixed sprayer or a movable sprayer. Various auxiliaries are added into the paint, and effects of sterilizing, corrosion prevention, fire prevention, mould prevention and the like are further achieved.

Owner:陈建平

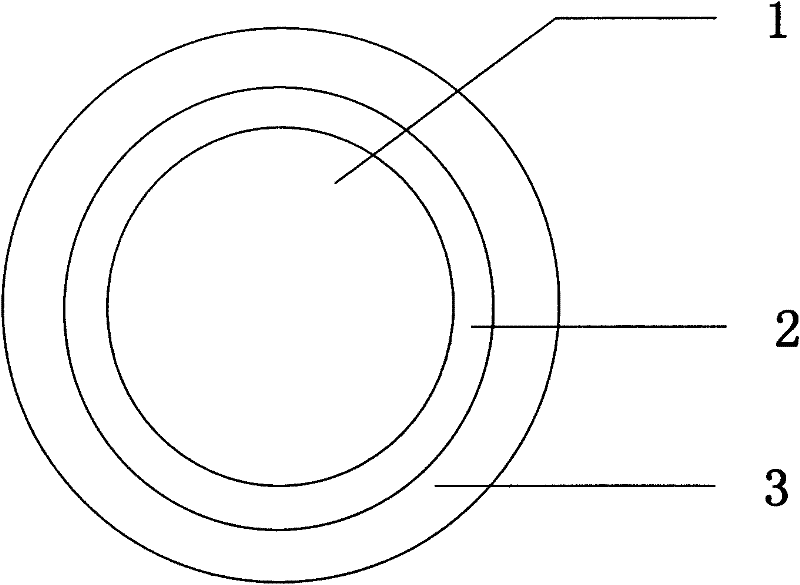

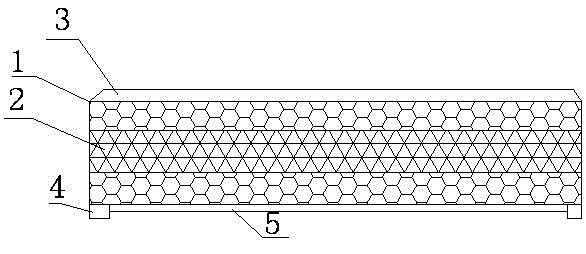

Track connection cable

InactiveCN102254598ARealize signal transmissionRealize simulation monitoringNon-insulated conductorsInsulated cablesElectric power transmissionElastomer

The invention provides a track connection cable. The track connection cable consists of a mixed metal conductor (1), an insulator (2) and a protection sleeve (3), wherein the protection sleeve (3) and the insulator (2) cover the mixed metal conductor (1), so that the mixed metal conductor (1) realizes the signal transmission and power transmission of a regional automatic blocking system; the mixed metal conductor (1) is manufactured by stranding copper and steel materials; the protection sleeve (3) is a polyvinyl chloride (PVC) elastomer protection sleeve (3) or a polyurethane protection sleeve (3) and the like; the protection sleeve (3) is selected according to use conditions; and the structure of combining the insulator (2) and the protection sleeve (3) with the conductor ensures the performance of the track connection cable. The track connection cable of a high-speed line regional automatic blocking system can realize the simulation monitoring of the automatic blocking system when the speed of high-speed railway trains is 350km / h; the novel track connection cable has moisture resistance, corrosion prevention, low-temperature resistance, high-temperature resistance, wear resistance, fire resistance and the like; and the service life of the track connection cable is prolonged.

Owner:天津市万博线缆有限公司

Synthetic method of phosphoric acid-type polyaniline for preparing anti-corrosion coating

The invention discloses a synthetic method of phosphoric acid-type polyaniline for preparing an anti-corrosion coating. The synthetic method includes the following steps: 1) adding an aniline monomer, an oxidant and a water solution containing a phosphorus-containing medium acid into a reactor at -20 - 50 DEG C; 2) performing a reaction under the condition of pH <= 3 for 0.5-30 h; and 3) washing, neutralizing and drying a reaction product to prepare a polyaniline finish product. The polyaniline finish product can be added to a solvent according to certain ratio to prepare the phosphoric acid-type polyaniline anti-corrosion coating. The polyaniline anti-corrosion coating can form a compact oxidation film on surface of metal, so that pitting corrosion caused by excessive oxidization due to excessive direct contact between the polyaniline and the surface of metal can be avoided, thereby achieving corrosion resistance on metal.

Owner:CHINA PETROLEUM & CHEM CORP +1

Device and method for preventing mildew and corrosion of plate

InactiveCN109693284AFast heatingReduce heat lossRadiation/waves wood treatmentWood treatment detailsCorrosion preventionEngineering

Owner:福建省格绿木业有限公司

Ecological environment-friendly foaming lightweight wallboard and preparation method thereof

InactiveCN107501687ALow costSave resourcesConstruction materialAntifouling/underwater paintsGlass fiberEcological environment

The invention provides an ecological environment-friendly foaming lightweight wallboard. The ecological environment-friendly foaming lightweight wallboard comprises a foaming matrix and a sealing layer outside the foaming matrix, and the raw materials comprise wood powder, polyethylene particles, an environment-friendly coating and other additives. The invention also provides a preparation method of the ecological environment-friendly foaming lightweight wallboard. The preparation method of the ecological environment-friendly foaming lightweight wallboard comprises the following steps: 1, pretreating the wood powder, the polyethylene particles and glass fiber; 2, mixing the glass fiber and the polyethylene particles to obtain glass fiber modified polyethylene; 3, adding the additives into the glass fiber modified polyethylene and stirring uniformly to obtain a molten mixture, dividing and dispersing the molten mixture into a powder material groove in a pelletizer material distributing device to adhere to the wood powder, and cooling and performing consolidation forming; 4, performing melt extrusion on the mixed materials and then performing forming, layer sealing and cutting processes to obtain the ecological environment-friendly foaming lightweight wallboard. The foaming wall body has the advantages of corrosion resistance, insect prevention, dampproof property, flame retardance and the like, has stripy wood texture, and has relatively good market promotion value.

Owner:HENAN INST OF ENG

Polyvinyl butyral solution bonded lead oxide ceramic for solid oxygen control and preparation method of polyvinyl butyral solution bonded lead oxide ceramic

ActiveCN112897988AUniform and sufficient grain growthStrong bonding force between grainsNuclear energy generationFast-neutron reactorCermet

The invention discloses polyvinyl butyral solution bonded lead oxide ceramic for solid oxygen control and a preparation method of the polyvinyl butyral solution bonded lead oxide ceramic, and belongs to the technical field of metal ceramics. The polyvinyl butyral solution bonded lead oxide ceramic comprises PbO and a polyvinyl butyral solution, based on PbO, more than 0 wt% and less than or equal to 6 wt% of a polyvinyl butyral solution is added; the preparation method comprises the following steps: fully mixing the polyvinyl butyral solution and PbO, and uniformly grinding to obtain a mixture; pre-pressing the obtained mixture to obtain a green body, re-crushing, uniformly grinding and sieving to obtain mixed powder, placing the mixed powder in a metal mold, and pressurizing, maintaining and releasing the pressure to obtain a ceramic pressed blank; subjecting the ceramic pressed blank to glue discharging; and finally sintering and cooling to obtain the lead oxide ceramic. The lead oxide ceramic has high hardness, three-point bending strength and density and good micromorphology, can keep shape integrity under the working condition of high-temperature flow scouring of a fourth-generation lead-based fast neutron reactor, and meets the requirement of solid oxygen control.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Water-based environment-friendly paint and preparation method thereof

InactiveCN110885628ASimple manufacturing methodReduce manufacturing costFireproof paintsAnti-corrosive paintsMicrosphereAcrylonitrile

The invention discloses a water-based environment-friendly paint. The water-based environment-friendly paint is characterized by being prepared from the following raw materials by weight: 40-50 partsof hyperbranched urethane acrylate, 4-8 parts of acrylonitrile-based cross-linked polymer hollow microspheres, 3-5 parts of allyl chloro(difluoro)acetate ionized N, N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid, 1-3 parts of 2, 2-dimethylethenylboronic acid pinacol ester, 1-3 parts of N, N'-(1, 2-dihydroxyethylene)diacrylamide, 0.3-0.6 part of a photoinitiator, 10-15 parts of filler, 1-3 partsof a dispersing agent, 0.5-1.5 parts of a defoaming agent and 25-35 parts of water. The invention also discloses a preparation method of the water-based environment-friendly paint. The water-based environment-friendly paint disclosed by the invention has the characteristics of good comprehensive performance, large adhesive force to a base material, excellent storage and transportation stability, excellent corrosion resistance, flame retardance and high temperature resistance, fast drying and curing speed, convenient construction, large coating hardness, good toughness and weather resistance, and long in service life.

Owner:郭涛

Graphene self-lubricating wear-resistant corrosion-resistant scale-inhibiting wax coating agent and preparation method thereof

ActiveCN110358377AImprove the level ofReduce surface tensionAnti-corrosive paintsWear resistantChemical stability

The invention provides a graphene self-lubricating wear-resistant corrosion-resistant scale-inhibiting wax coating agent and a preparation method thereof. The preparation method comprises the following steps: weighing the raw materials in parts by weight: 5-8 parts of graphene, 15-35 parts of a fluorine-containing polymers, 5-8 parts of tungsten disulfide, 12-15 parts of a bronze powder, 35-40 parts of a solvent, 1-5 parts of a solubilizer, 1-3 parts of a dispersing auxiliary agent and 5-10 parts of a rheological auxiliary agent; uniformly mixing the fluorine-containing polymer, tungsten disulfide, a bronze power and a solubilizer and dispersing auxiliary agent uniformly; then grinding the mixture by a sand mill to obtain a first mixture; uniformly mixing the rheological auxiliary agent with the residual solvent and leaving the mixture to stand to obtain a second mixture; and uniformly mixing the first mixture, the second mixture and graphene, mixing the mixture, cooling and crushing the mixture, filtering, discharging and packaging the mixture. The graphene self-lubricating wear-resistant corrosion-resistant scale-inhibiting wax coating agent has excellent characteristics of high-low temperature resistance, chemical stability, non viscidity, low friction coefficient and the like, and the economical benefit of an enterprise is increased greatly.

Owner:大庆市盛日石油技术开发有限公司

Enhancement magnesium board

InactiveCN103334508AHigh strengthImprove toughnessLayered productsFire proofingThermal insulationCohesive strength

The invention relates to an enhancement magnesium board, which comprises a magnesium core board, wherein a plurality of irregularly arrayed bubbles are formed in the magnesium core board, and a reinforcing rib layer is arranged in the magnesium core board, so that the strength of the magnesium core board is improved, and the service life of a magnesium oxide board is prolonged; a fire barrier made of fireproof materials is arranged around the bottom layer of the magnesium core board; a reinforcing clapboard made of fireproof materials is connected to the middle part of the bottom layer of the magnesium core board; and a decoration layer is arranged on an upper surface of the magnesium core board. According to the enhancement magnesium board, due to the reinforcing rib layer and the reinforcing clapboard, the strength, the toughness, the cohesive strength and higher fireproof performance of the magnesium board are greatly improved; the bubbles are arranged in the magnesium board, so that the effects of thermal insulation and sound insulation are achieved; and a layer of fluorocarbon coating is sprayed on a surface, so that not only is the surface smooth and attractive, but also the magnesium board can be used for exterior wall decoration, and the enhancement magnesium board has the effects of fire prevention, water tightness, moisture protection, corrosion prevention and moth proofing.

Owner:ZHANGJIAGANG EVERNICE BUILDING MATERIALS

Suspension bridge unbonded prestressed anchorage corrosion resistant method and structure

InactiveCN104818674AAchieve anticorrosionAvoid corrosionMeasurement devicesBridge structural detailsPre stressEngineering

A suspension bridge unbonded prestressed anchorage corrosion resistant structure comprises an air source and a plurality of prestressed pipelines, wherein the air source is clean dry air or inert gas and is connected with a plurality of pipeline networks; one end of each prestressed pipeline is provided with an air inlet, and the other end of each prestressed pipeline is provided with an air outlet; a seal cover is arranged at each air inlet and each air outlet; an air hole is formed in each seal cover and connected with a sealed monitoring component; each monitoring component is connected with the corresponding pipeline network; a valve is arranged at each monitoring component. The invention also discloses a suspension bridge unbonded prestressed anchorage corrosion resistant method. The suspension bridge unbonded prestressed anchorage corrosion resistant method and the suspension bridge unbonded prestressed anchorage corrosion resistant structure have the advantages that the unbonded prestressed anchorage corrosion resistant ability is improved, the life is prolonged, detection is convenient, and maintenance costs are lowered.

Owner:CCCC HIGHWAY CONSULTANTS

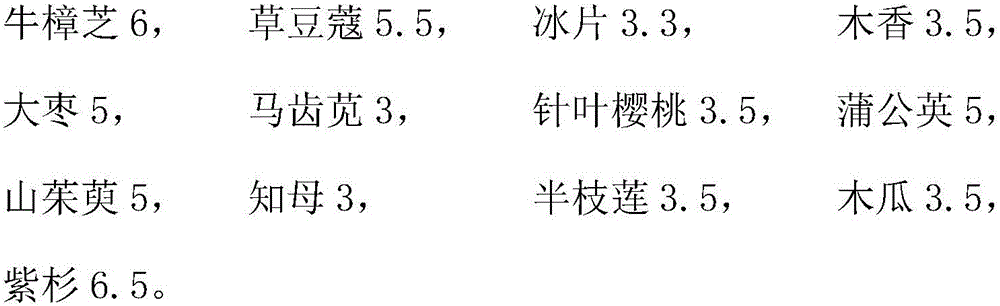

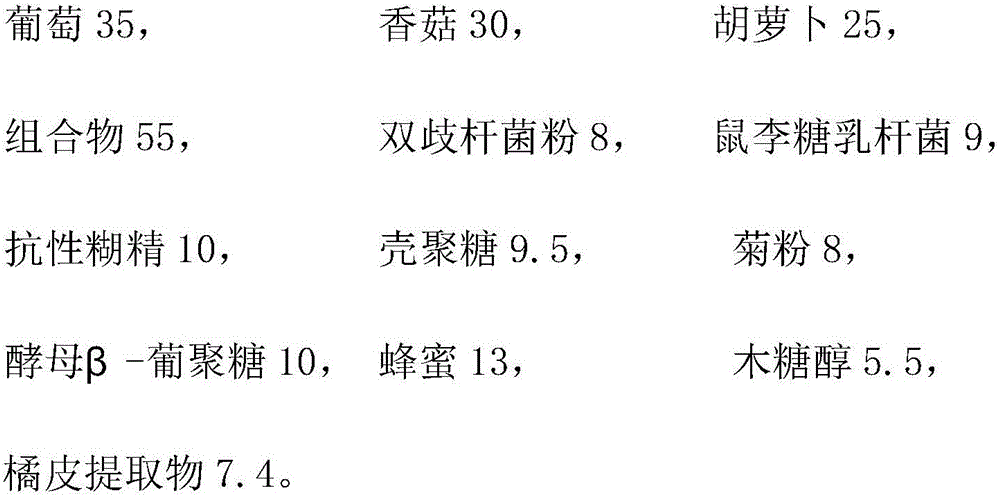

Composition preventing and regulating symptoms of cancer patients and prepared health-care food thereof

InactiveCN106072603AImprove the bitter taste of traditional Chinese medicineImprove the quality of lifeFood ingredient functionsMedicineDrug product

The present invention relates to a composition preventing and regulating symptoms of cancer patients and prepared health-care food thereof. The composition is mainly prepared by processing the following raw material medicines in parts by weight: antrodia camphorate, semen alpiniae katsumadai, borneol, radix aucklandiae, red dates, herba portulacae, acerola cherries, dandelions, fructus corni, and rhizoma anemarrhenae. The composition is prepared into health-care food. The preserved fruits are prepared according to a principle of medicinal and edible homology, so that eaters have very high adherences to the ''medicine''.

Owner:FOSHAN LANGDA INFORMATION TECH

Alloy plate grinding device with anti-corrosion function

InactiveCN112059776AEasy to moveAchieve grindingEdge grinding machinesLiquid spraying apparatusAlloyCorrosion prevention

The invention relates to an alloy plate grinding device with an anti-corrosion function. The alloy plate grinding device comprises a base, a moving mechanism, a grinding mechanism and an anti-corrosion mechanism, the moving mechanism is arranged on a fixed plate, and the grinding mechanism and the anti-corrosion mechanism are both arranged on the moving mechanism. According to the alloy plate grinding device with the anti-corrosion function, workpieces are ground through the grinding mechanism, the workpieces are prevented from being corroded through the anti-corrosion mechanism, the grindingmechanism and the anti-corrosion mechanism are moved through the moving mechanism, and the workpieces are integrally ground and prevented from being corroded; compared with an existing grinding device, workpiece grinding and online corrosion prevention of the workpieces are both achieved, procedures are saved, and the working efficiency is improved; and compared with an existing moving mechanism,the mechanism achieves grinding and corrosion prevention of the workpieces through one output end, energy is saved, pure mechanical linkage is adopted, the service life of the device is prolonged, andthe stability of the device is improved.

Owner:SHENZHEN BEIYOUTONG NEW ENERGY TECH DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com