Track connection cable

A track connection and cable technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problems of easy spontaneous combustion, easy wear and tear during use, and easy to be affected by moisture, so as to achieve the effect of increasing speed and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

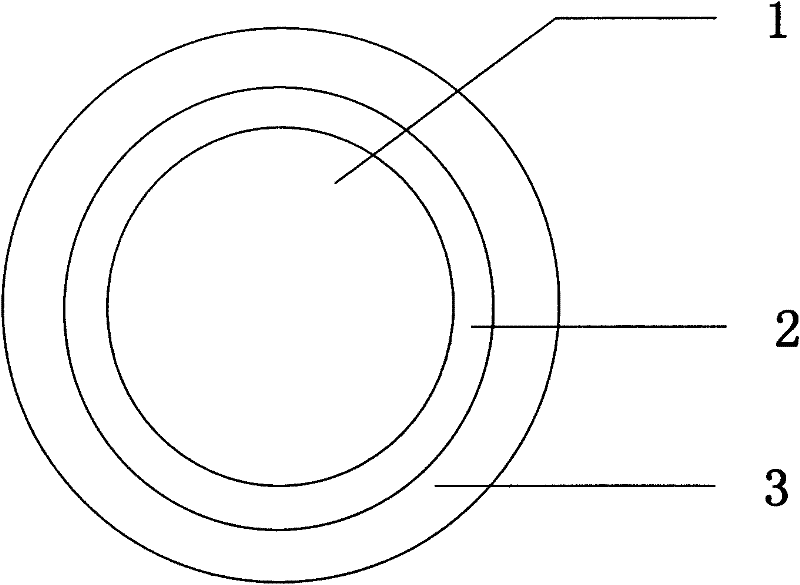

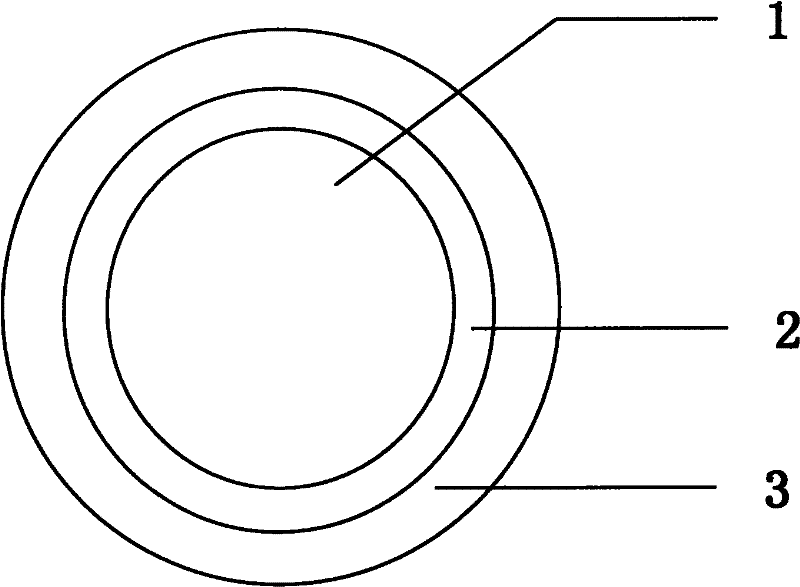

[0006] according to figure 1 As shown, the inner layer of the track connection cable of the present invention is a mixed metal conductor (1) formed by mixing and twisting two metal materials of copper and steel. The insulator (2) made of special thermoplastic material or thermosetting material is used for the outer wrapping, and the outer part of the insulator (2) is made of PVC elastomer sheath (3) or polyurethane sheath (3). Select the sheath (3) according to different conditions of use. The thickness of the insulator (2) and the sheath (3) combined with the structure of the conductor together ensure the performance of the track connection line; while ensuring electrical performance, it also has vibration resistance, weather resistance, and durability. Moisture, waterproof, wear-resistant, acid and alkali resistance, high temperature resistance, flame retardant and other properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com