Patents

Literature

31results about How to "Achieving aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

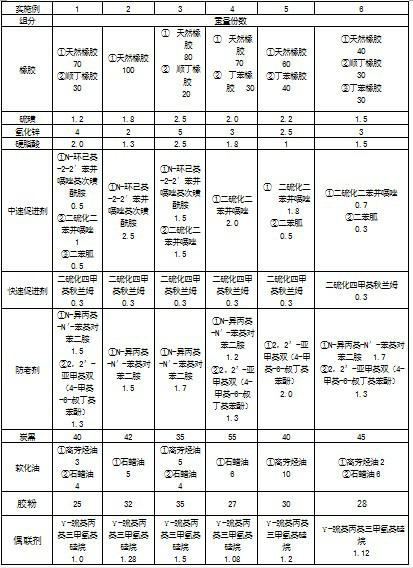

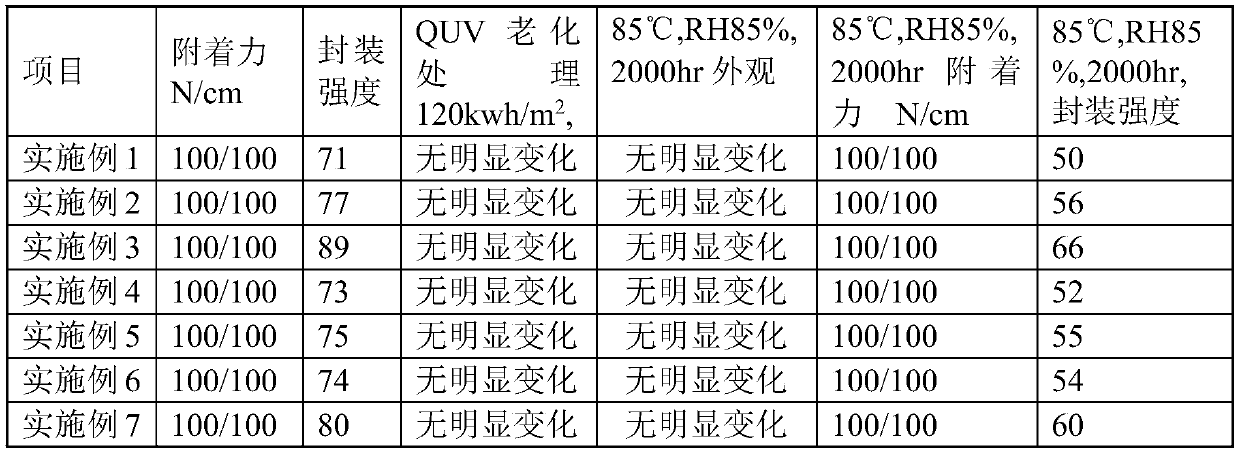

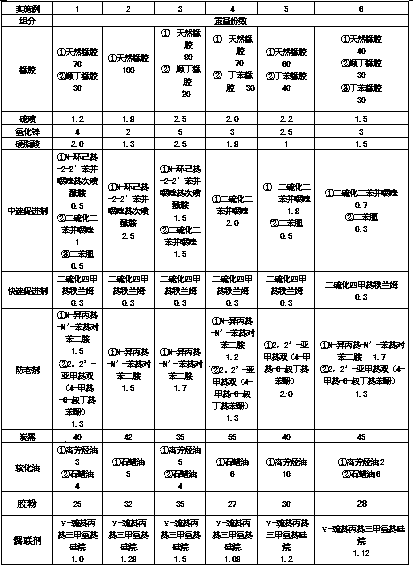

Sizing material for rubber shoe sole and preparation method thereof

The invention discloses a sizing material for a rubber shoe sole and a preparation method thereof. The sizing material comprises the following raw materials for preparing active ingredients in parts by weight: 100 parts of rubber, 1.2-2.5 parts of sulfur, 2-5 parts of zinc oxide, 1-2.5 parts of stearic acid, 1-3 parts of a medium-speed accelerant, 0.3 part of a high-speed accelerant, 1.5-3 parts of an anti-ageing agent, 35-55 parts of carbon black, 5-10 parts of softening oil, 25-35 parts of rubber powder and 1-1.5 parts of coupling agent. The preparation method comprises the following steps of: pretreating the rubber powder; plastifying rubber; compounding; milling, and the like. The rubber shoe sole produced by using a rubber powder formula and the preparation method thereof has the advantages of reduction in the tensile strength change rate by 3-5 percent, reduction in the tensile yield change rate by 5-8 percent, the same wear resistance and bending resistance as those of a rubber shoe sole produced without using rubber powder in the same type of products, smooth appearance handfeel, soft brightness and increase in grade. The sizing material is suitable for preparing rubber shoe soles of dress shoes and outdoor shoes.

Owner:JIHUA 3514 LEATHER & FOOTWARE

Nano composite top facing paint with hydrophobic foul resisting sticking-proof and preparation process thereof

InactiveCN1861714AAchieving aging resistanceAchieve scrub resistanceAntifouling/underwater paintsPaints with biocidesMaterials scienceWetting

The invention relates to a nanometer compound cover paint which has the hydrophobicity and is resistance to the pollution and the sticking. The paint contains the film forming material, the antifouling component, the filler and the diluting agent, necessary the wetting agent, dispersant and the thickener. So it can be used for the antifouling of the high-end building and the protection for the outlook of the public utility.

Owner:江西中江纳米科技有限公司

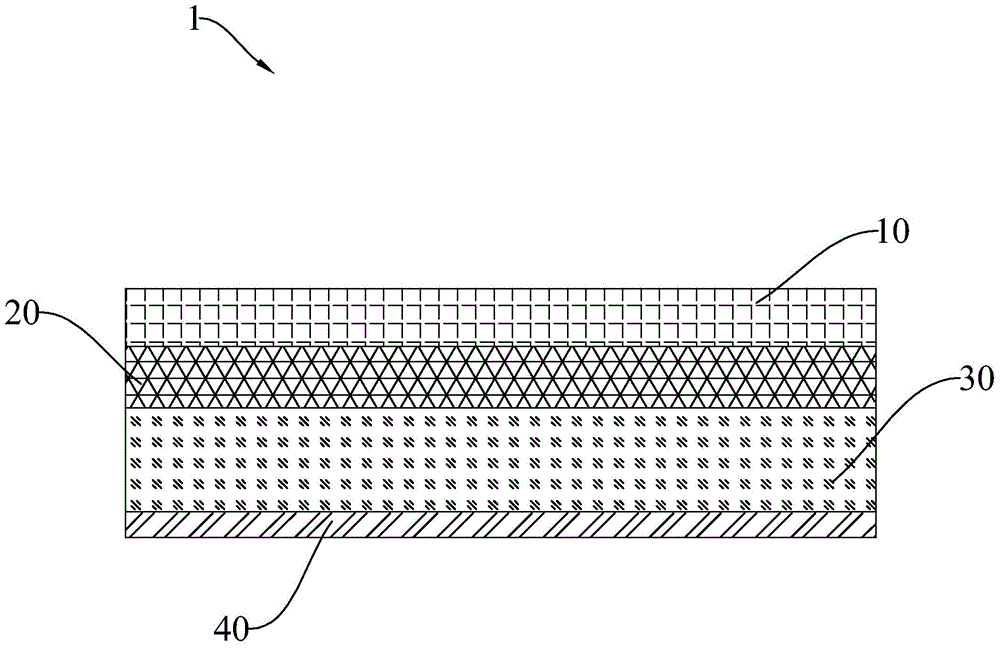

Brightening and anti-scraping protective film capable of being used for car paint or electronic product

PendingCN109233669AStrong adhesionImprove anti-agingFilm/foil adhesivesTectorial membraneAcrylic resin

The invention discloses a brightening and anti-scraping protective film capable of being used for car paint or an electronic product, and relates to the technical field of protective films. The brightening and anti-scraping protective film comprises a base material layer, wherein the upper surface of the base material layer is coated with a self-repair layer; a protective film layer is arranged onthe upper surface of the self-repair layer; the lower surface of the base material layer is coated with an acrylic acid glue layer; the lower surface of the acrylic acid glue layer is adhered with arelease film layer; the base material layer is selected from an aliphatic-series TPU material or a TPV material or a TPU and PVC composite material which is directly tape-cast by multiple layers in acomposite mode; and the self-repair layer is formed by acrylic resin, and is added with an ultraviolet-light absorber and a light stabilizer. The brightening and anti-scraping protective film integrates functions of scraping and ageing resistance, dirt resistance and brightening, good repair effect and the like, can realize the effects of enabling the car to be ageing-resistant, improving new carvalue-holding degree and the like while used on car paint, also can be used for car interior protection, can replace a relatively conventional paint protective film and a paint crystal-coating process, has service life of ten years or more, further can be used to the electronic product field, and achieves a good anti-scraping effect.

Owner:HENGSHAN JIACHENG NEW MATERIAL

High-wear-resistance super-hydrophobic composite coating, preparation method thereof and coating layer prepared from coating

ActiveCN108485522AAchieving aging resistanceReduce washoutAntifouling/underwater paintsPaints with biocidesFiberCarbon fibers

The invention discloses a high-wear-resistance super-hydrophobic composite coating. The high-wear-resistance super-hydrophobic composite coating consists of the following components in parts by mass:5 to 15 parts of organic silane, 1 to 10 parts of an inorganic wear-resistant agent, 2 to 9 parts of a catalyst, 1 to 3 parts of a hydrophobic agent, 0 to 3 parts of carbon fiber, 0 to 3 parts of glass flake powder, 2 to 8 parts of one or two of tetraethylenepentamine and tetraethylenetriamine and 60 to 90 parts of solvent. The invention also provides a preparation method of the high-wear-resistance super-hydrophobic composite coating as well as a preparation method of a coating layer. The invention has the following beneficial effects: the coating layer continuous phase has high hardness, high wear resistance, high smoothness and superhydrophobicity and also has high compactness and strong binding force with a matrix; and the coating can be used for coating and cured at normal temperature, realizes anti-scouring, anti-fouling, anti-corrosion and anti-ageing effects, is suitable for matrixes such as steel, glass and rubber, can be applied to high-voltage cables, outdoor high-voltage equipment, ships and automobile glass, and can maximally reduce scouring and shearing on the coating layer by seawater, silt and wind sand.

Owner:泰安乐邦环保科技有限公司

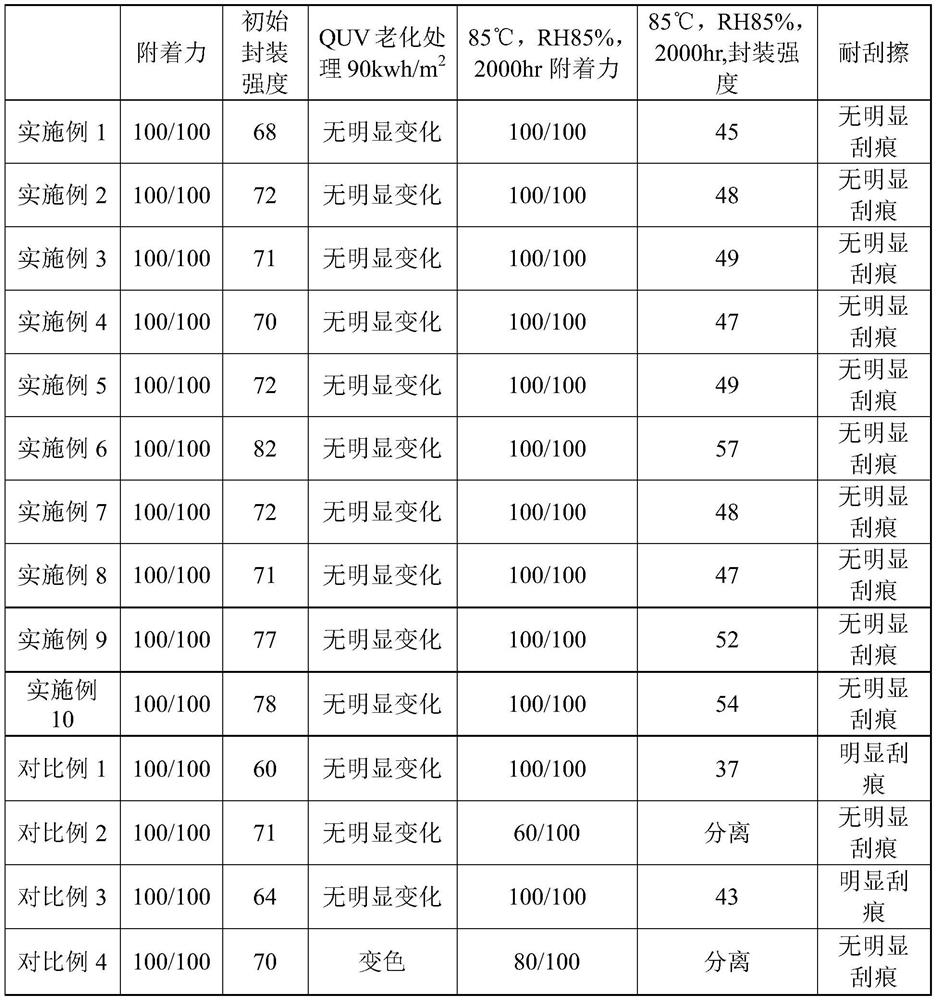

Fluorocarbon coating solution and solar backplane using fluorocarbon coating

InactiveCN110172282AGood weather resistanceExcellent UV aging resistanceCoatingsPhotovoltaic energy generationWeather resistanceAcrylate ester

The invention relates to the technical field of solar backplanes, in particular to a fluorocarbon coating solution and a solar backplane using the fluorocarbon coating. In order to improve the ultraviolet aging resistance and wet-heat aging resistance of an existing solar backplane, the fluorocarbon coating solution and the solar backplane using the fluorocarbon coating solution are provided. Theprovided fluorocarbon coating solution is prepared from, by weight, 40%-70% of fluorocarbon resin, 20%-50% of titanium dioxide, 1%-5% of matting powder, 0.2%-0.8% of polyacrylate and 3%-10% of isocyanate. The solid content is controlled to be 40-60%, all the components are limited to be within the above content ranges, the fluorocarbon resin can react at high temperature preliminarily and then iscured at 50 DEG C for 48 hours, a high-density fluorocarbon coating is formed on the surface of PET, UV light can be blocked, and it is found that there are no obvious performance degradation throughvarious weatherability tests.

Owner:NINGBO JIANGBEI EXCITON NEW MATERIAL TECH CO LTD

Medium for roof greening

InactiveCN103283525AHigh strengthRealize comprehensive utilizationReceptacle cultivationPorosityPolyester

The invention relates to a medium for roof greening. The medium comprises a medium body which comprises a matrix, the matrix is of a netted structure which is made of waste polyester wire meshes and has the porosity of 20-30%, a group of pits which is integrally formed with the matrix by means of heat sealing and stamping and protrudes towards the lower side of the matrix is formed in the middle of the matrix, each pit is of a structure with the internal diameter decreasing gradually from bottom to top, and reinforcing strips are arranged at the edges of the matrix. The advantages of high strength, large quantity and low cost of the waste polyester wire meshes are fully utilized by the medium, and the medium has functions of water retention, water drainage, pruning, heat preservation and heat insulation, is constructed at one time, has functions of traditional greening multilayered media, is higher in greening quality and simpler in construction steps, and has the advantages of lightness, simple structure, convenience in construction, low in construction and maintenance cost, low in requirements on construction techniques, wide in using range, convenience in construction and implementation and long service life.

Owner:HENAN JIAYI LANDSCAPE ENG

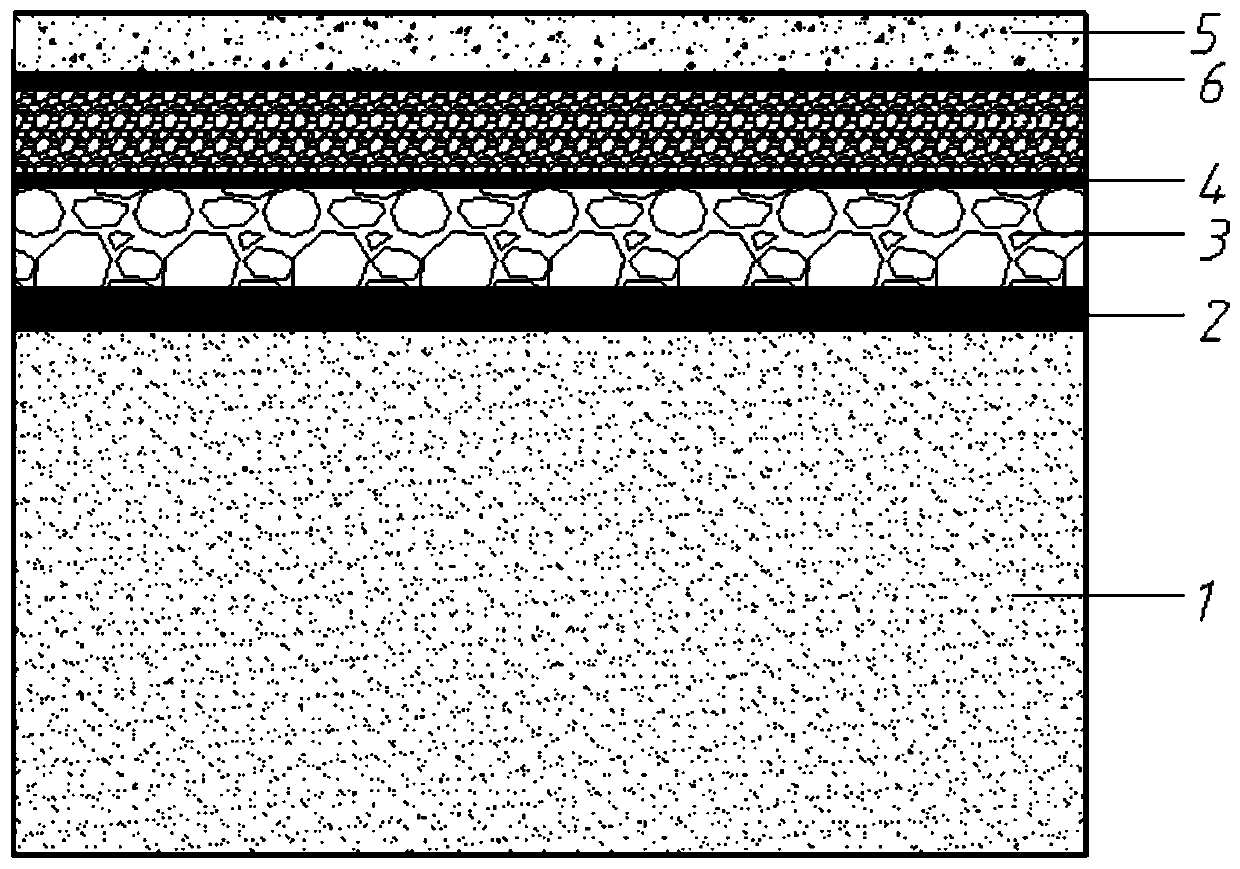

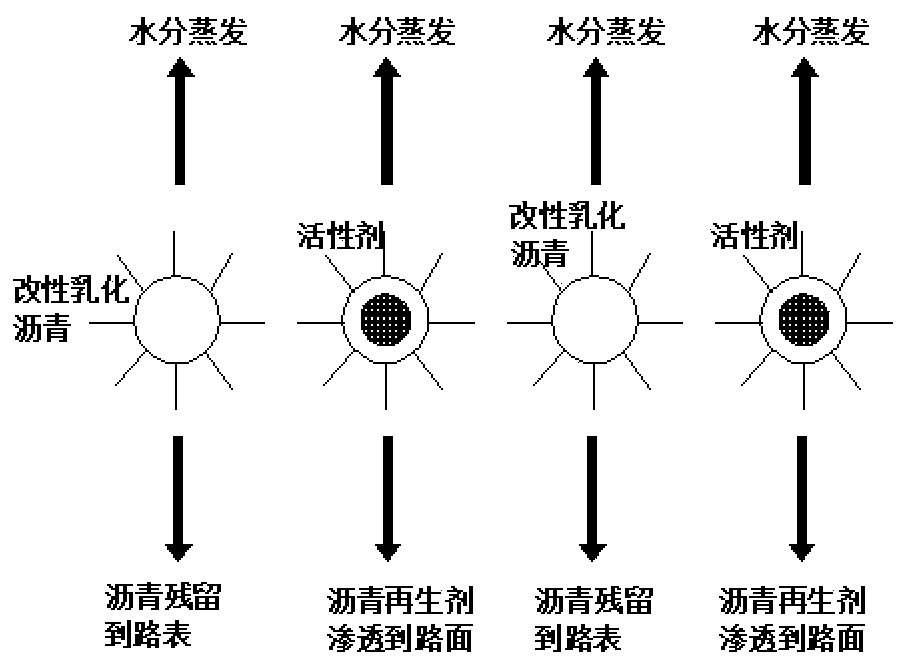

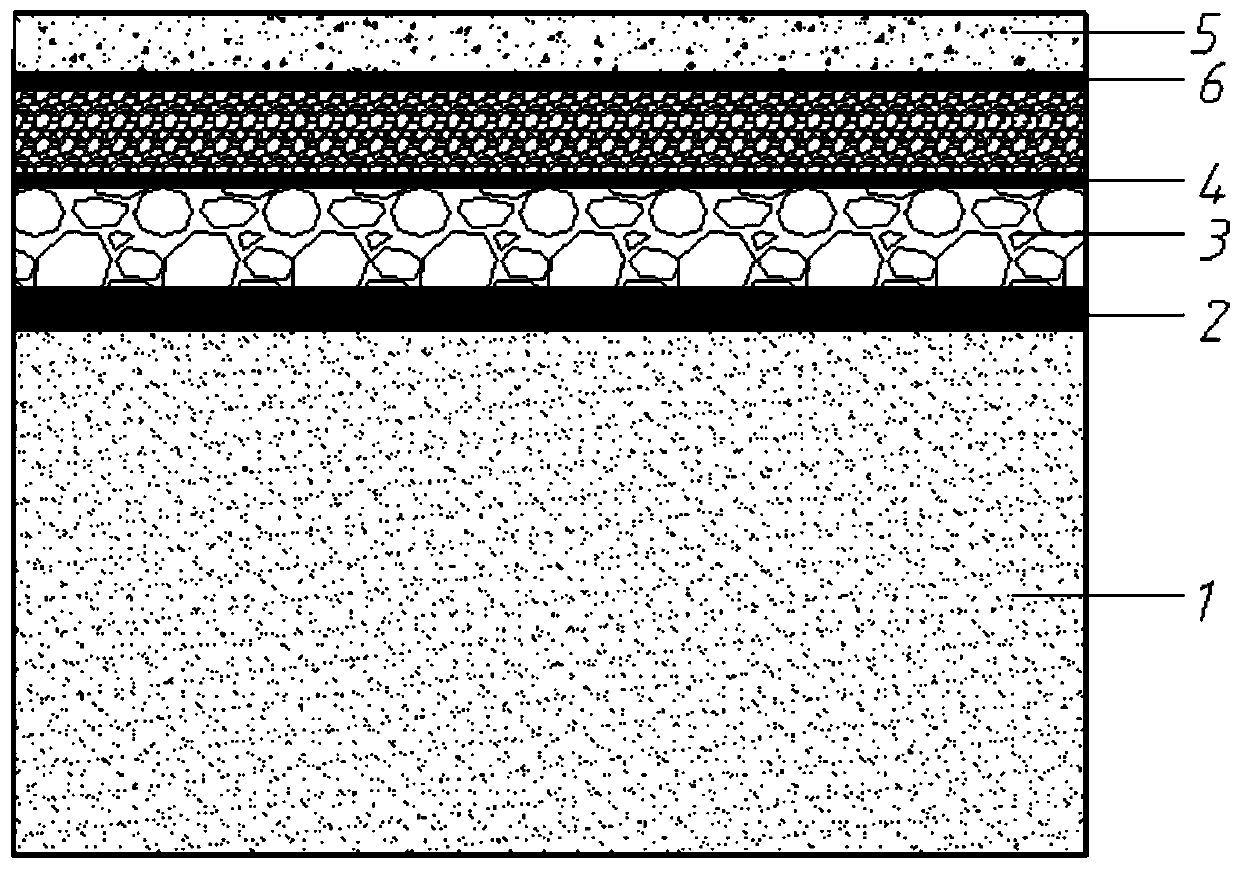

Multifunctional active composite seal coat pavement

PendingCN111172836AWith anti-crack functionAging resistantIn situ pavingsPaving detailsBitumen emulsionRoad surface

The invention discloses a multifunctional active composite seal coat pavement. The multifunctional active composite seal coat pavement comprises an asphalt pavement, a self-repairing sealing layer anda surface layer which are sequentially distributed from bottom to top, wherein the surface layer is a fog sealing layer or an anti-skid noise reduction micro-surfacing layer; the self-repairing sealing layer comprises an active emulsified asphalt layer, a plurality of gravel layers and an emulsified asphalt bonding layer which are sequentially distributed from bottom to top, a modified emulsifiedasphalt layer or a modified asphalt layer is arranged between every two adjacent gravel layers, and the pavement has the advantages of being high in skid resistance, good in abrasion resistance, lowin cost and short in service life and is simple in construction process.

Owner:CHANGAN UNIV +1

Scratch-resistant fluorocarbon layer coating liquid and solar back sheet using coating liquid

ActiveCN110358375AGood weather resistanceGood scratch resistance on the inner surfacePolyurea/polyurethane coatingsPhotovoltaic energy generationWeather resistanceThermoplastic polyurethane

The present invention relates to the technical field of solar back sheets, particularly to a fluorocarbon layer coating liquid and a solar back sheet using the coating liquid. In order to solve the problem that the existing fluorocarbon layer is easily scratched, the present invention provides a scratch-resistant fluorocarbon layer coating liquid and a solar back sheet using the coating liquid, wherein the fluorocarbon layer coating liquid comprises, by weight, 40-60% of a fluorocarbon resin, 20-30% of titanium dioxide, 1-5% of matting powder, 10-20% of a modified thermoplastic polyurethane resin, 0.2-0.8% of polyacrylate, and 5-10% of isocyanate. According to the present invention, the surface of the fluorocarbon layer formed by the fluorocarbon layer coating liquid has characteristics ofscratch resistance and good weather resistance; and the inner surface of the solar back sheet using the coating liquid is excellent in scratch resistance, and the weather resistance of the solar backsheet is good.

Owner:宁波激阳新材料有限公司

Wear-resistant rubber particle capable of being formed by injection molding, preparation method and application thereof

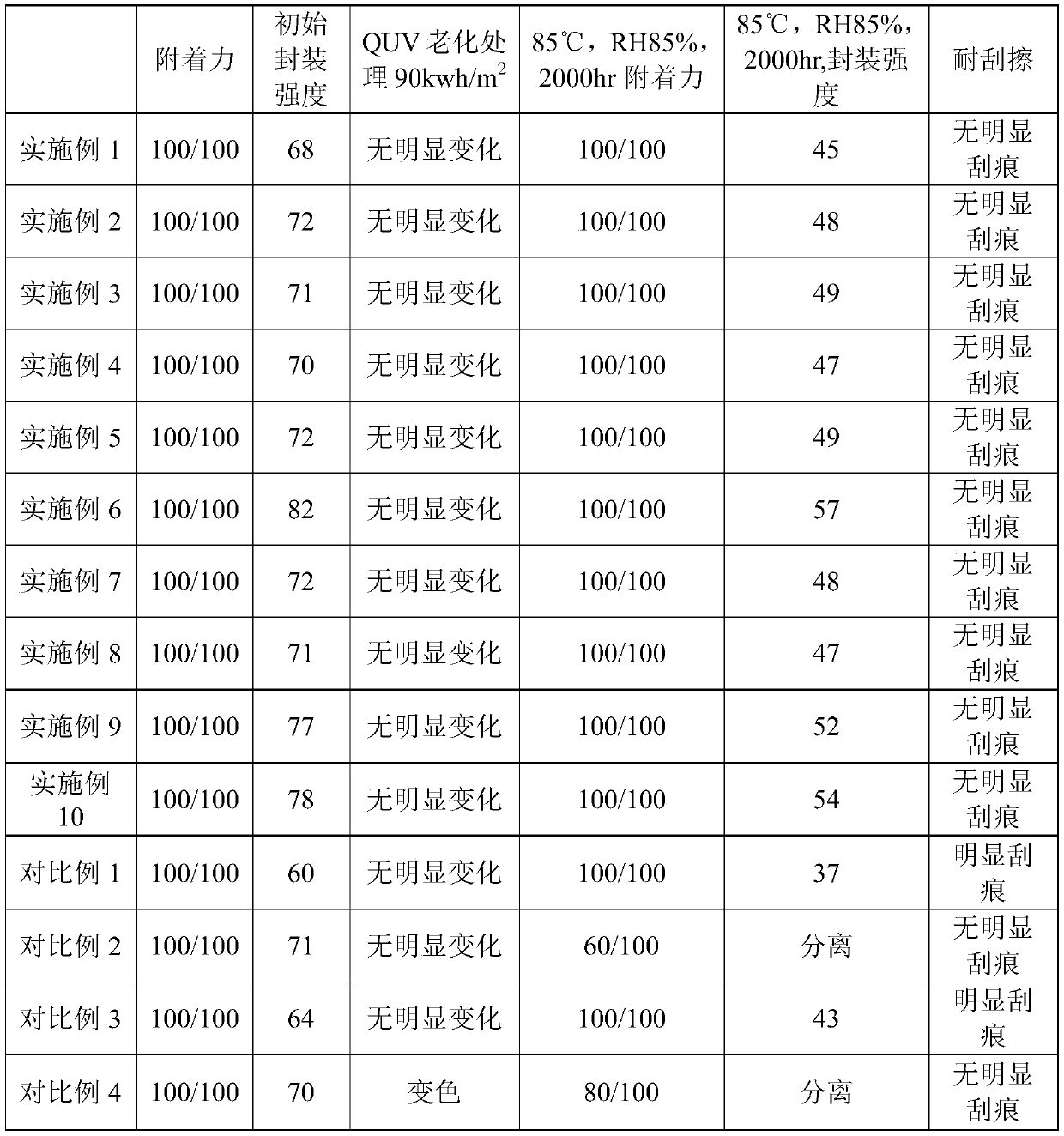

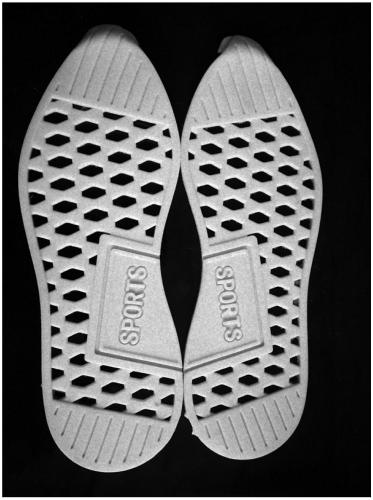

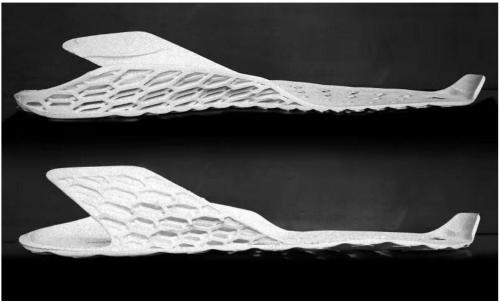

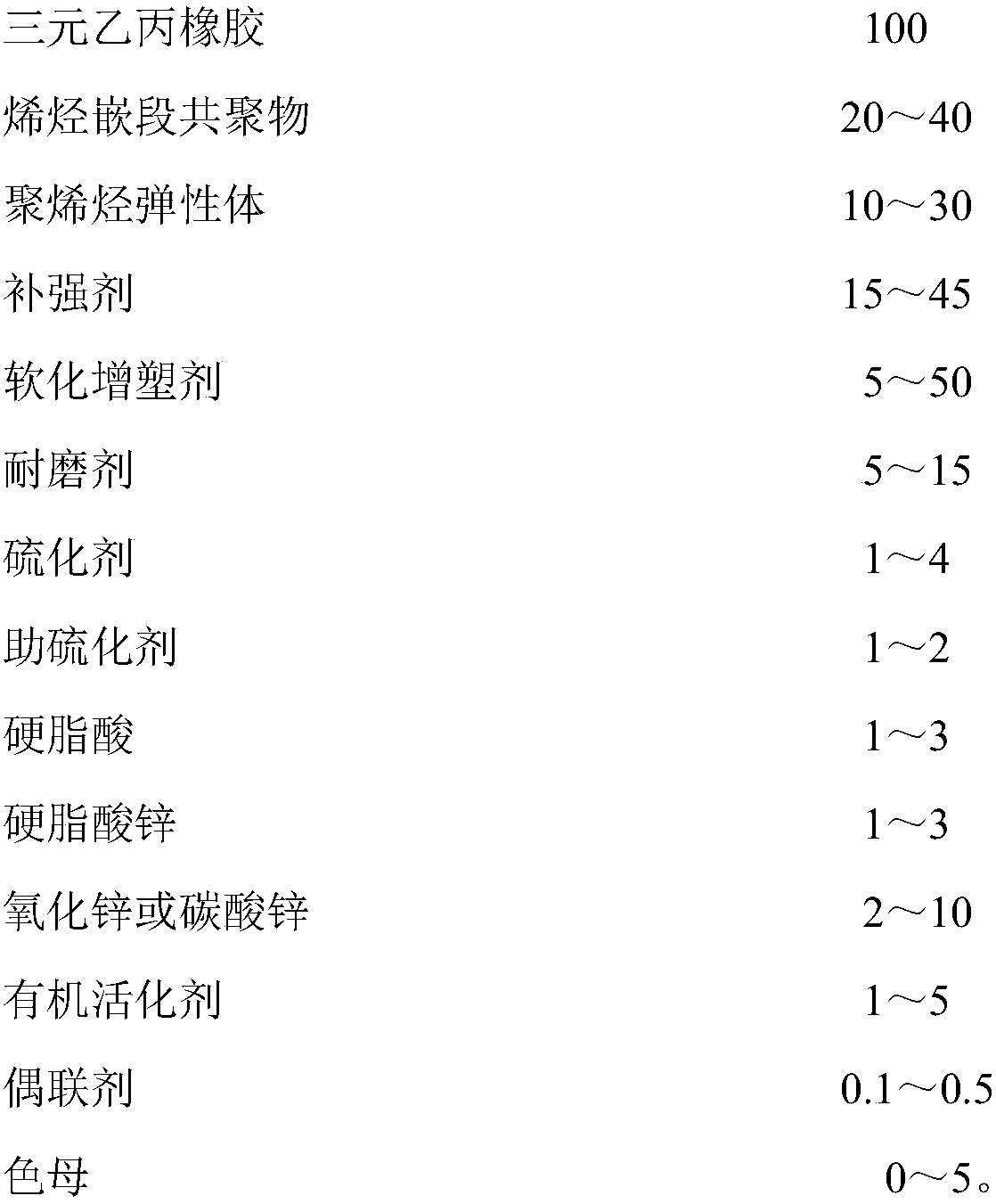

The invention discloses a wear-resistant rubber particle capable of being formed by injection molding, a preparation method and application thereof, wherein the rubber particle comprises, by mass, 100parts of ethylene propylene diene monomer, 20-40 parts of an olefin block copolymer, 10-30 parts of a polyolefin elastomer, 15-45 parts of a reinforcing agent, 5-50 parts of a softening plasticizer,5-15 parts of an anti-wear agent, 1-4 parts of a vulcanizing agent, 1-2 parts of an auxiliary vulcanizing agent, 1-3 parts of stearic acid, 1-3 parts of zinc stearate, 2-10 parts of zinc oxide or zinccarbonate, 1-5 parts of an organic activator, 0.1-0.5 part of a coupling agent and 0-5 parts of color master batch. According to the invention, injection molding can be realized; the wear-resistant rubber particle can be used for manufacturing outsoles of sneakers or casual shoes, and various properties of the manufactured outsoles are obviously superior to the requirements of high-quality standards of the sneakers; and the wear-resistant rubber particle has the advantages of super wear resistance, high skid resistance, high elasticity, yellowing resistance, aging resistance, high and low temperature resistance, light weight and the like, particularly can achieve outsole manufacturing of complex three-dimensional structures, is low in material loss and high in yield.

Owner:上海帼帆化工新材料有限公司 +1

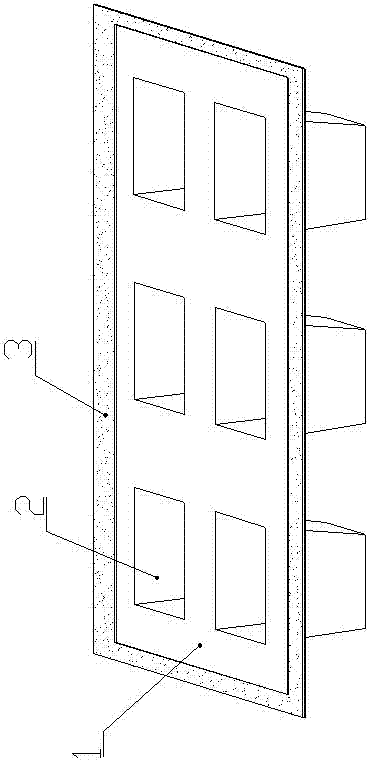

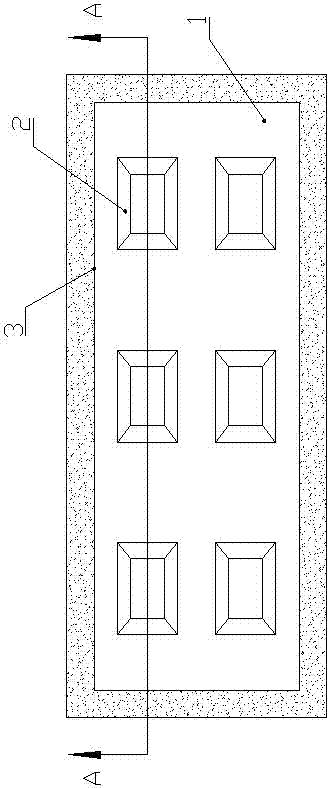

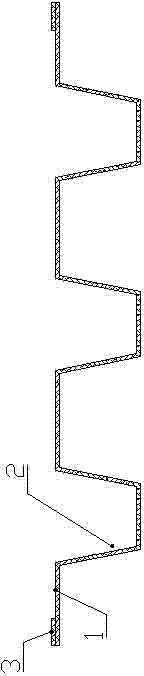

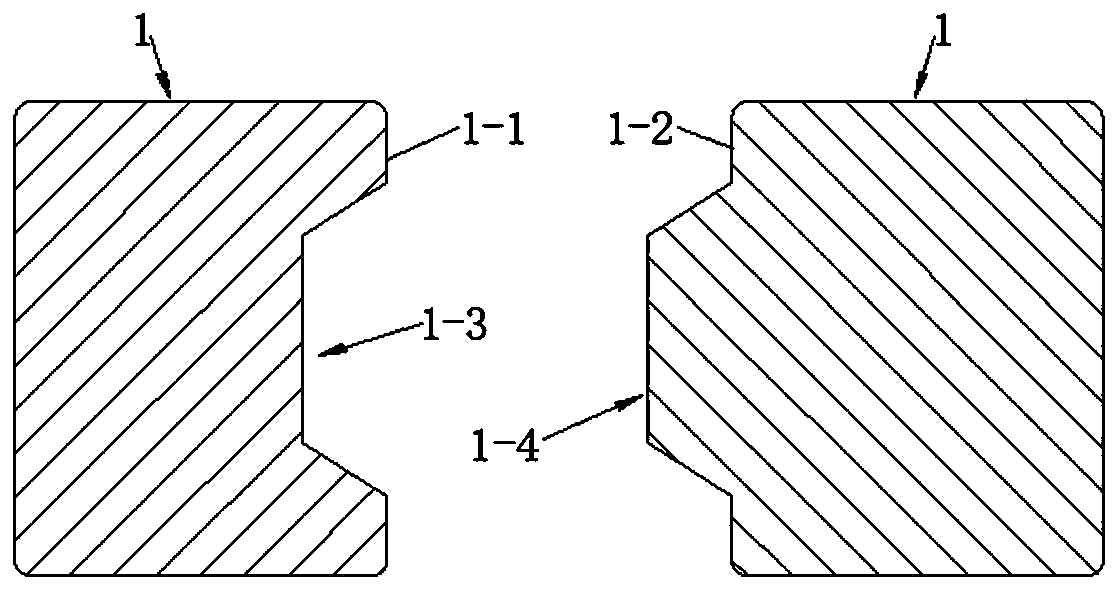

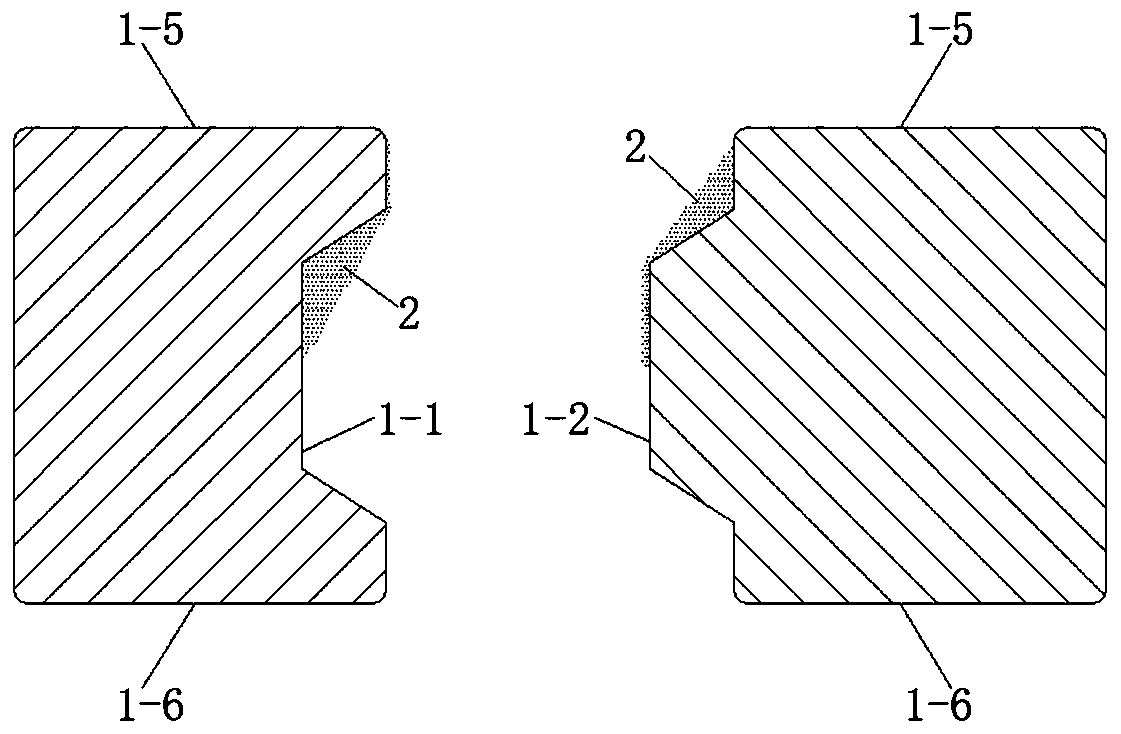

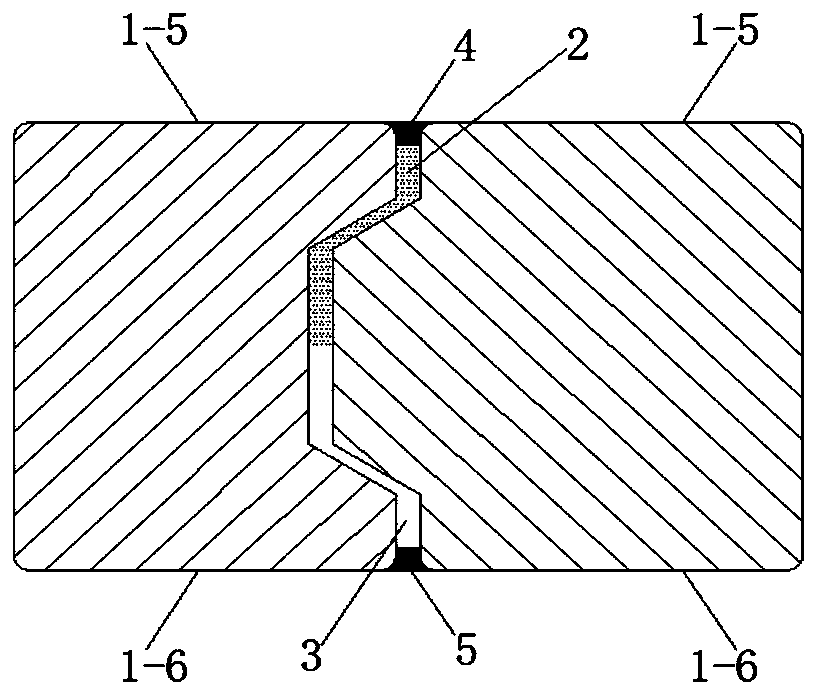

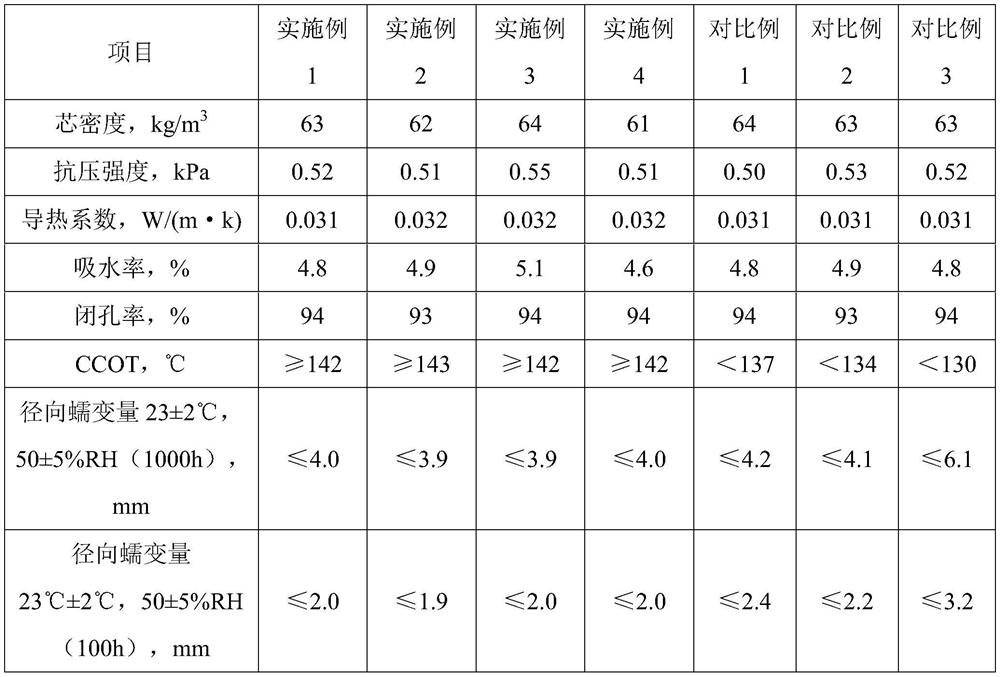

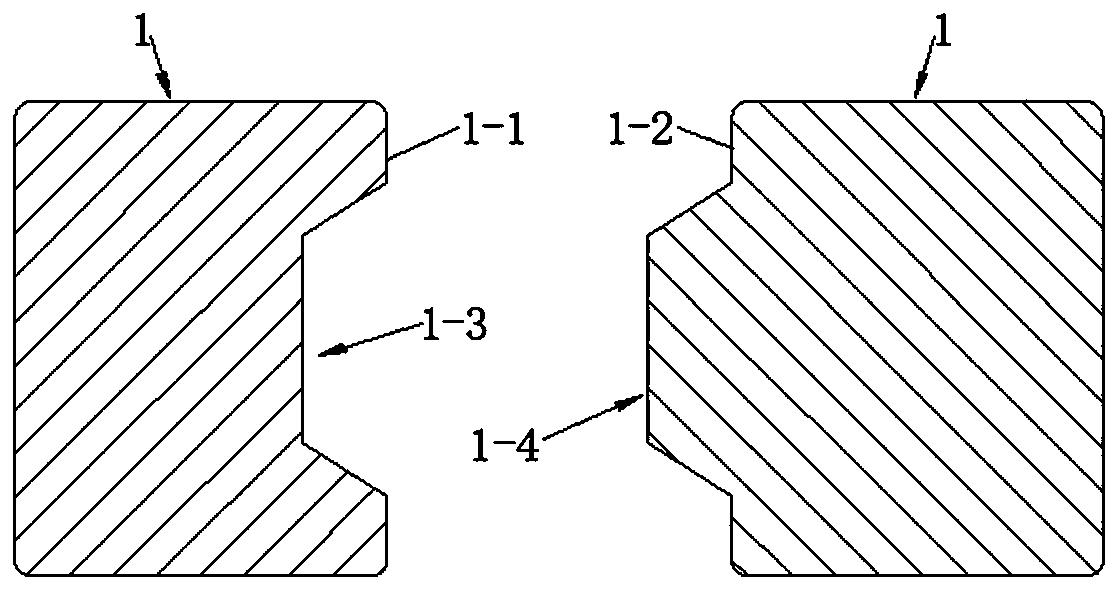

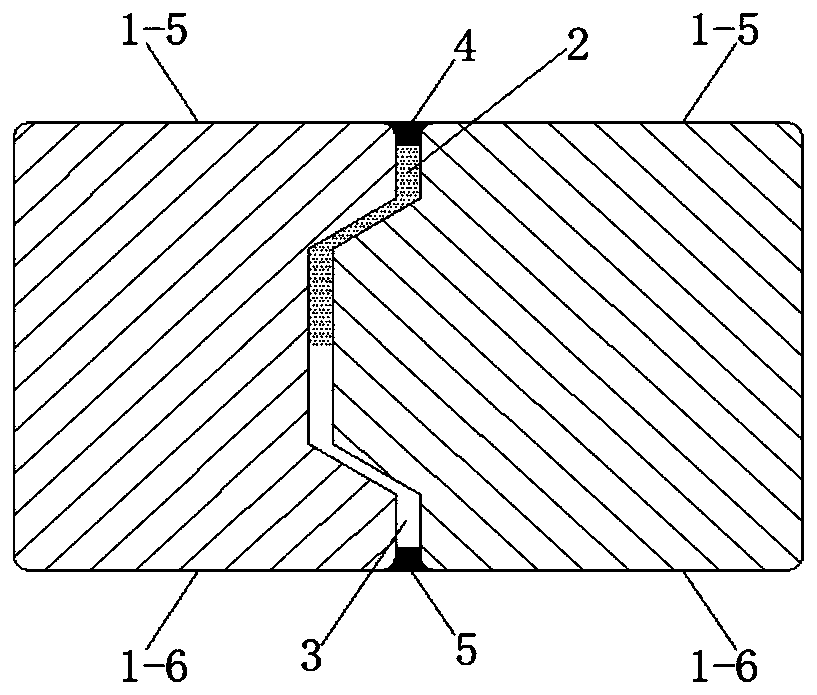

Treatment method of slab seam of autoclaved aerated concrete exterior wall slab

ActiveCN109853955BReduce dosageAvoid the problem of easy filling and not denseBuilding material handlingBuilding insulationsAdhesiveJoint (building)

The invention relates to the field of building materials, and provides a plate joint treatment method for autoclaved aerated concrete external wall plates. The plate joint treatment method comprises the following steps that S1, plate joint shoving materials are brushed at the first end of a first spliced face of one of the autoclaved aerated concrete external wall plates and / or the first end of asecond spliced face of the other autoclaved aerated concrete external wall plate; S2, the first spliced face and the second spliced face are moved oppositely until the space between the first end of the first spliced face and the first end of the second spliced face is filled with the plate joint shoving materials, and a gap is formed between the second end of the first spliced face and the secondend of the second spliced face; S3, a plate joint between the outer walls of the two autoclaved aerated concrete external wall plates is cleared; and S4, the plate joint between the outer walls of the two autoclaved aerated concrete external wall plates is filled with a sealing adhesive. According to the plate joint treatment method, the using amount of the sealing adhesive can be reduced, and the problem that the sealing adhesive is prone to uncompacted filling is avoided; and in addition, the gap between the second end of the first spliced face and the second end of the second spliced facecan further be utilized to further block transferring of moisture.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

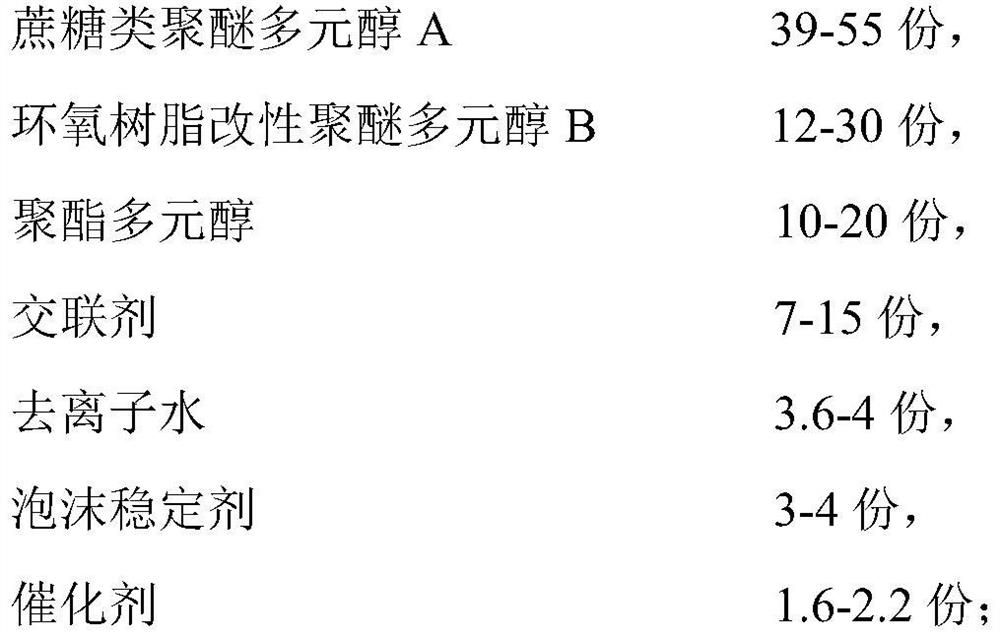

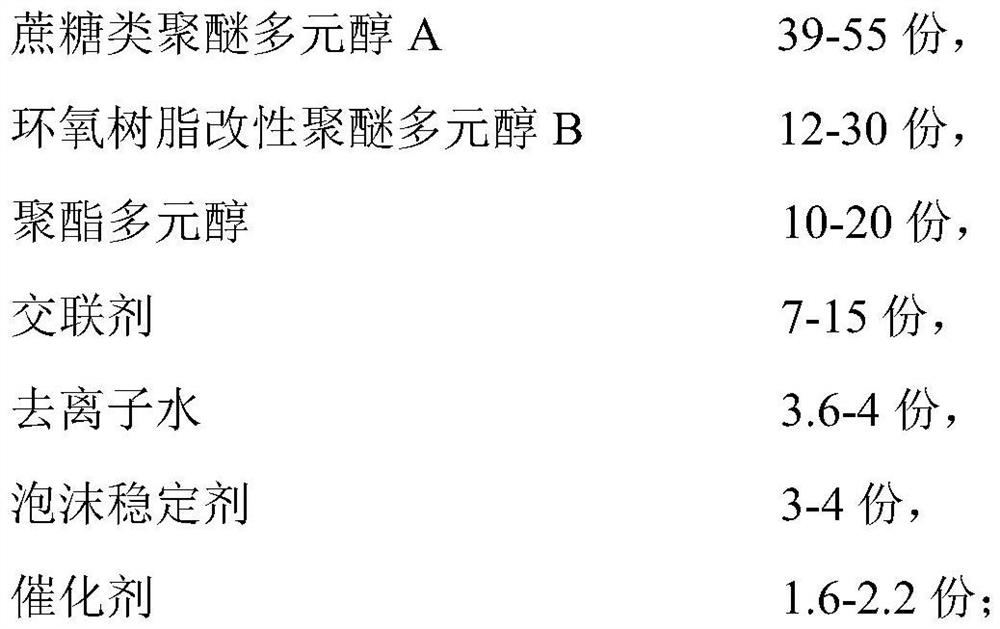

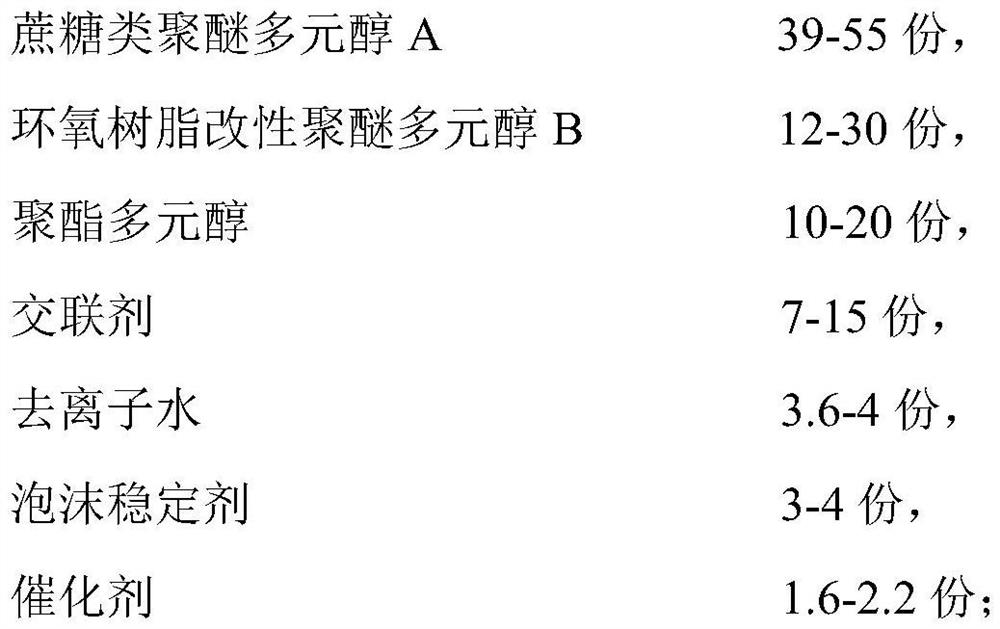

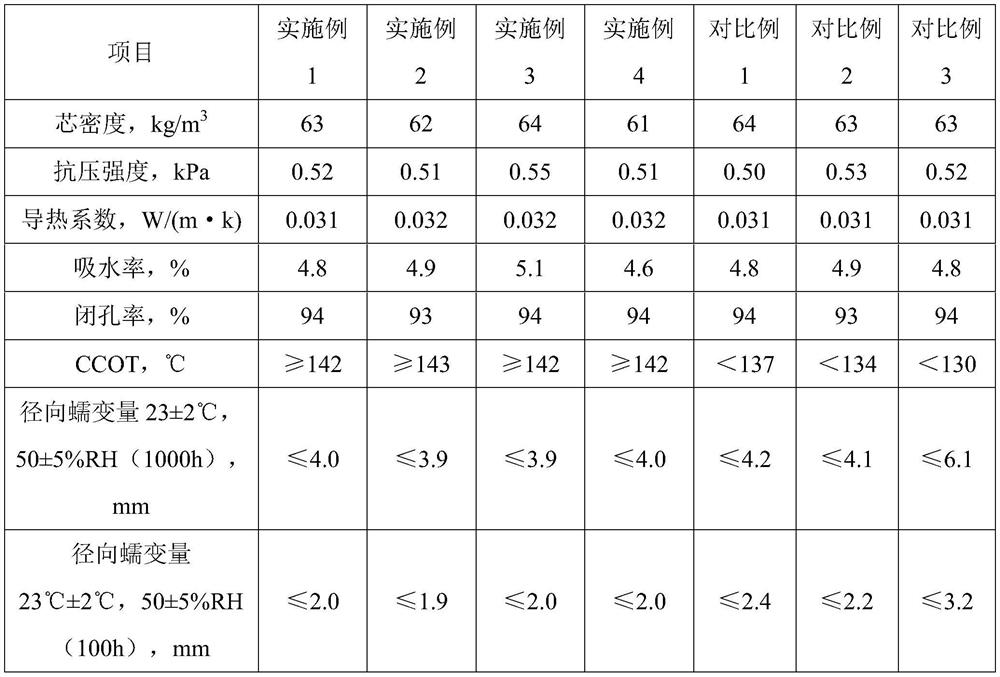

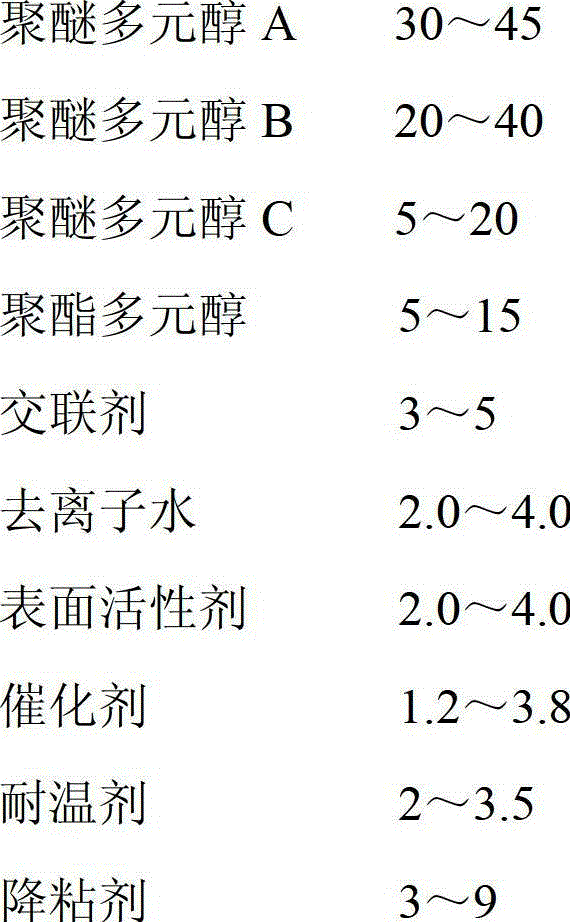

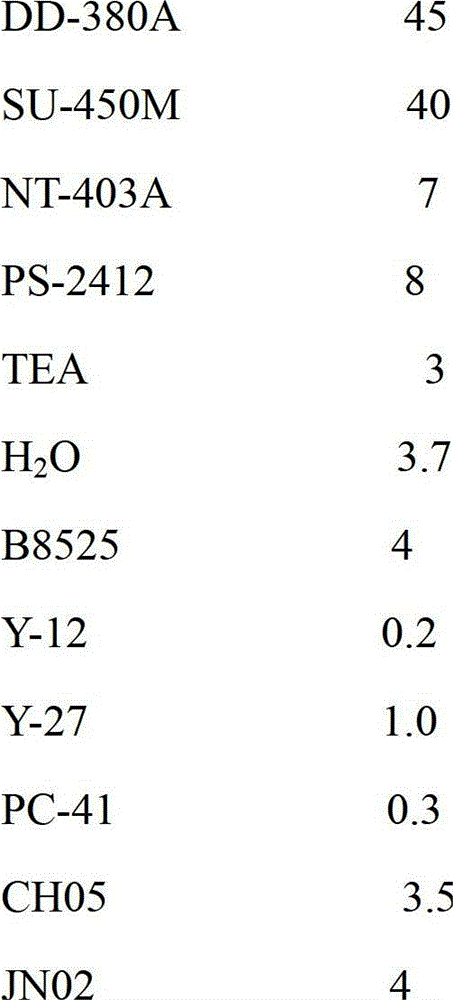

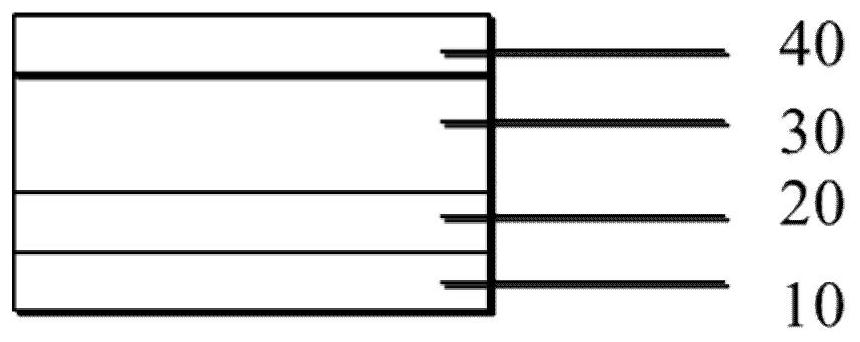

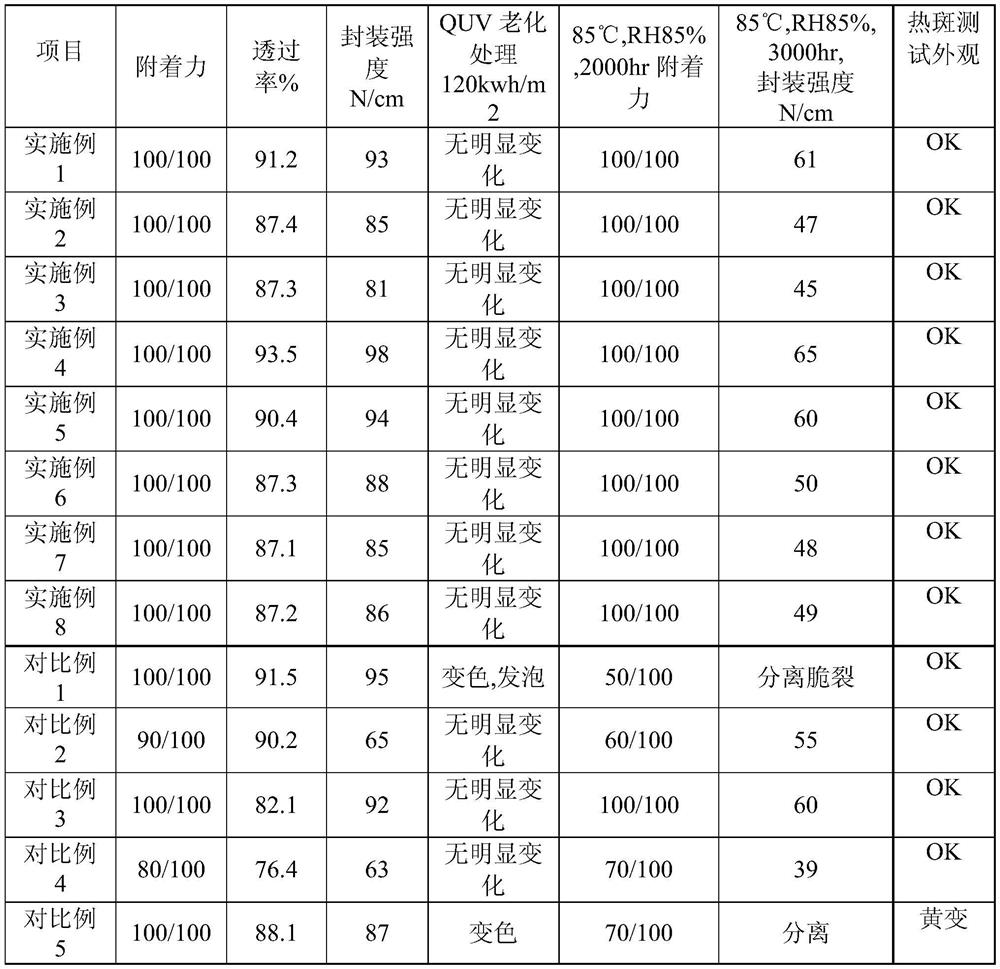

High-temperature-resistant creep-resistant pipeline thermal insulation material and preparation method thereof

ActiveCN112694596AImprove temperature resistanceIncrease the degree of cross-linkingThermal insulationPolyester

The invention relates to the technical field of polyurethane thermal insulation materials, and particularly relates to a high-temperature-resistant creep-resistant pipeline thermal insulation material and a preparation method thereof. The high-temperature-resistant creep-resistant pipeline thermal insulation material is formed by mixing a component A and a component B according to the mass ratio of 1:(1.4-1.6), and the component A is composed of sucrose polyether polyol A, epoxy resin modified polyether polyol B, polyester polyol, a cross-linking agent, deionized water, a foam stabilizer and a catalyst; and the modified isocyanate is prepared by modifying a mixture of polymethylene polyphenyl polyisocyanate and diphenylmethane diisocyanate by adopting one or two of hydroxyl-terminated fluorine-containing polyester polysiloxane and hydroxyl-terminated polysiloxane. The high-temperature-resistant creep-resistant pipeline thermal insulation material disclosed by the invention not only has excellent high-temperature dimensional stability, relatively low heat conductivity coefficient and good adhesive property, but also has good high-temperature resistance and creep resistance, and can meet the requirement of long-term high-temperature transportation. The invention also provides a preparation method of the high-temperature-resistant creep-resistant pipeline thermal insulation material.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Plate joint treatment method for autoclaved aerated concrete external wall plates

ActiveCN109853955AReduce dosageAvoid the problem of easy filling and not denseBuilding material handlingBuilding insulationsAdhesiveEngineering

The invention relates to the field of building materials, and provides a plate joint treatment method for autoclaved aerated concrete external wall plates. The plate joint treatment method comprises the following steps that S1, plate joint shoving materials are brushed at the first end of a first spliced face of one of the autoclaved aerated concrete external wall plates and / or the first end of asecond spliced face of the other autoclaved aerated concrete external wall plate; S2, the first spliced face and the second spliced face are moved oppositely until the space between the first end of the first spliced face and the first end of the second spliced face is filled with the plate joint shoving materials, and a gap is formed between the second end of the first spliced face and the secondend of the second spliced face; S3, a plate joint between the outer walls of the two autoclaved aerated concrete external wall plates is cleared; and S4, the plate joint between the outer walls of the two autoclaved aerated concrete external wall plates is filled with a sealing adhesive. According to the plate joint treatment method, the using amount of the sealing adhesive can be reduced, and the problem that the sealing adhesive is prone to uncompacted filling is avoided; and in addition, the gap between the second end of the first spliced face and the second end of the second spliced facecan further be utilized to further block transferring of moisture.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES

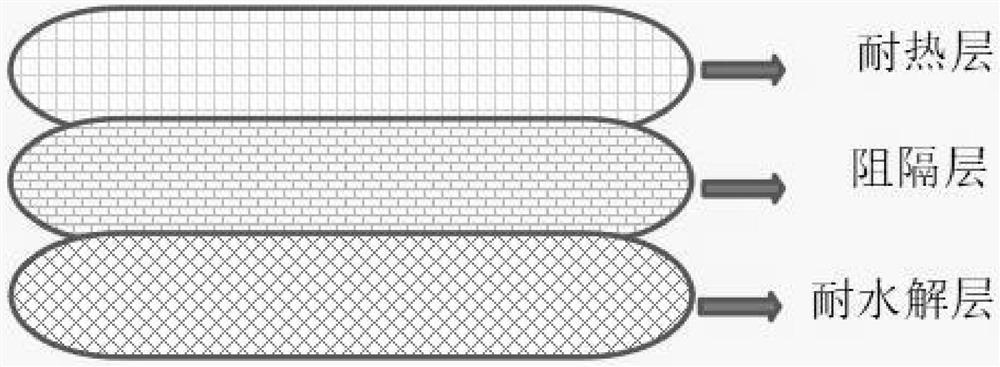

Full-biodegradable mulching film for peanut planting

PendingCN113841551AImprove water retentionImprove mechanical propertiesClimate change adaptationSynthetic resin layered productsPolymer sciencePlastic mulch

A full-biodegradable mulching film for peanut planting comprises a heat-resistant layer, a barrier layer and a hydrolysis-resistant layer, wherein the heat-resistant layer is prepared from the following raw material components: 70-90 parts of PBAT, 0-20 parts of PBS, 0-5 parts of PLA, 0-20 parts of an inorganic filler, 0.1-2 parts of a chain extender, 0.3-4 parts of a light stabilizer, 0.1-0.5 part of an antioxidant and 0.1-0.5 part of a slipping agent; the barrier layer is prepared from the following raw material components: 40-70 parts of PBAT, 0-30 parts of modified PPC, 3-10 parts of PLA, 5-30 parts of the inorganic filler, 0.3-2 parts of the chain extender, 0.2-3 parts of the light stabilizer, 0.1-0.5 part of the antioxidant, 0.1-2 parts of an anti-blocking agent and 0.2-3 parts of the slipping agent; and the hydrolysis-resistant layer is prepared from the following raw material components: 75-94 parts of PBAT, 0-10 parts of PLA, 0-5 parts of the inorganic filler, 0.5-3 parts of the chain extender, 0.1-0.8 part of the light stabilizer, 0.1-0.5 part of the antioxidant and 0.2-3 parts of a hydrolysis-resistant agent. The full-biodegradable mulching film is prepared by a three-layer co-extrusion method, so that the defect that the requirements of all layers cannot be simultaneously met in a single-layer film blowing production process is overcome.

Owner:QINGDAO RICH PLASTIC NEW MATERIAL +1

Preparation process of steel belt reinforced spiral corrugated pipe

InactiveCN110760034AImprove antistatic properties and anti-oxidation propertiesAchieving aging resistanceOrganic chemistryCoatingsPolymer scienceNetwork structure

The invention discloses a preparation process of a steel belt reinforced spiral corrugated pipe. The preparation process comprises the following specific preparation steps: an electroconductive anti-oxidation polymer is added into an extruder for melt extrusion, a steel belt is spirally input from one side, and extruded polyethylene wraps the steel belt from the inner side and outer side of a spiral corrugated pipe to obtain the steel belt reinforced spiral corrugated pipe. According to the process, the two ends of an unsaturated antioxidant and bisallyl benzoate added in the preparation process of the corrugated pipe contain olefin groups, so that the unsaturated antioxidant and the bisallyl benzoate both can be subjected to a polymerization reaction with two adjacent high-density polyethylene, the two adjacent high-density polyethylene can be cross-linked together through the unsaturated antioxidant and the bisallyl benzoate, after multiple high-density polyethylene is cross-linked,a network structure is formed, a large amount of the unsaturated antioxidant and the bisallyl benzoate are uniformly dispersed at the connection points of the network structure, so that the antistaticperformance and aging resistance are uniform, and the antistatic performance and oxidation resistance of the corrugated pipe are effectively improved.

Owner:安徽瑞琦塑胶科技有限公司

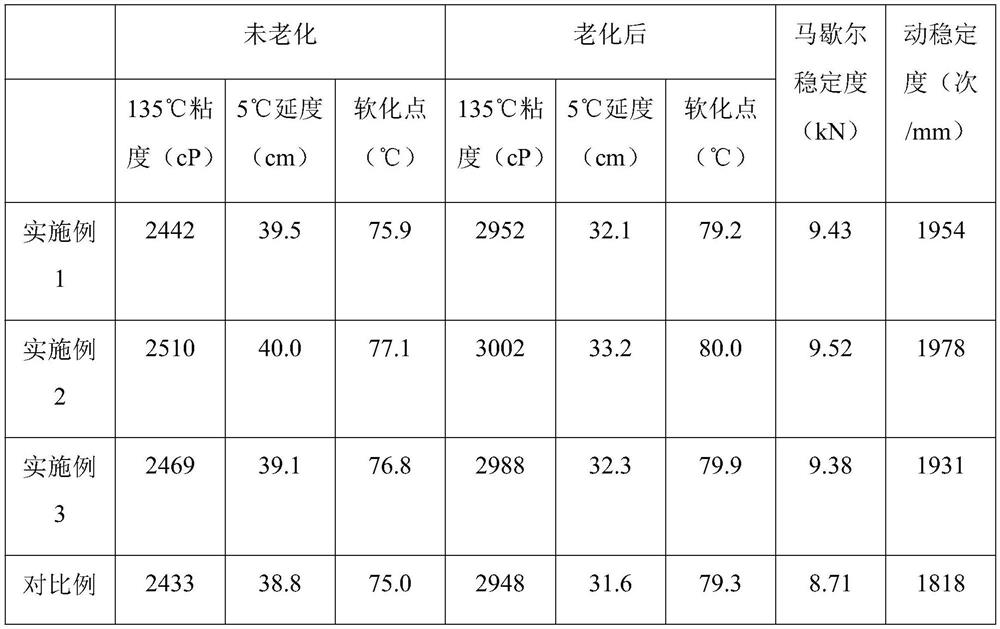

Anti-aging asphalt for muck truck road and preparation method of anti-aging asphalt

PendingCN114854222AAchieving aging resistanceAnti-ultraviolet agingClimate change adaptationBuilding insulationsVinyl esterPhenols

The invention discloses anti-aging asphalt for a muck truck road and a preparation method of the anti-aging asphalt, and relates to the technical field of asphalt. The foamed asphalt is firstly subjected to microwave heating treatment, and internal fine lines are expanded and communicated by utilizing magnetic nanoparticles to form a stable three-dimensional structure, so that the mechanical property of the asphalt is improved; after oxidation treatment, the foamed asphalt is modified by utilizing 1, 2, 3-tribromopropane, polyether glycol, dimethyl diphenyl diisocyanate and furanamide, so that the rut resistance of the asphalt is improved; then, the titanium dioxide nanosheets, 3-(4-bromophenyl)-2-propylene-1-alcohol, 2-(tert-butyl)-4-chloro-5-nitrophenol, 2-amino-4-chlorodiphenylamine, succinic anhydride, 2-chlorobenzoic acid vinyl ester and N-phenylbutylene diimide are used for preparing a self-made filler, and the anti-aging effect of the asphalt is improved. The asphalt prepared by the invention has anti-rutting and anti-aging effects.

Owner:刘敏泉

Plastic film with high stretching resistance and preparation process thereof

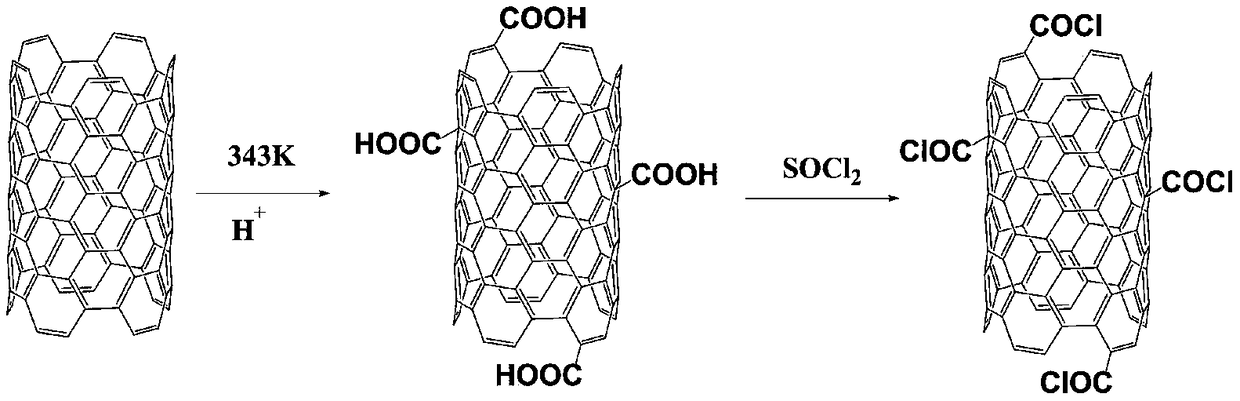

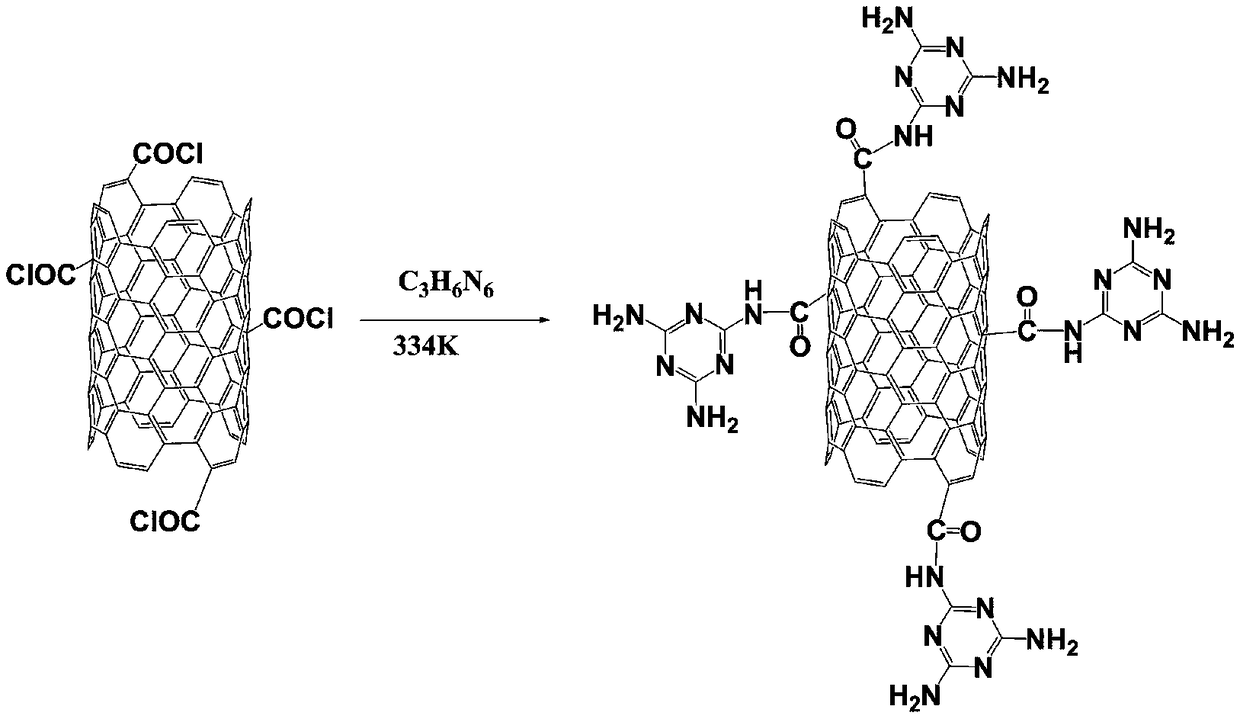

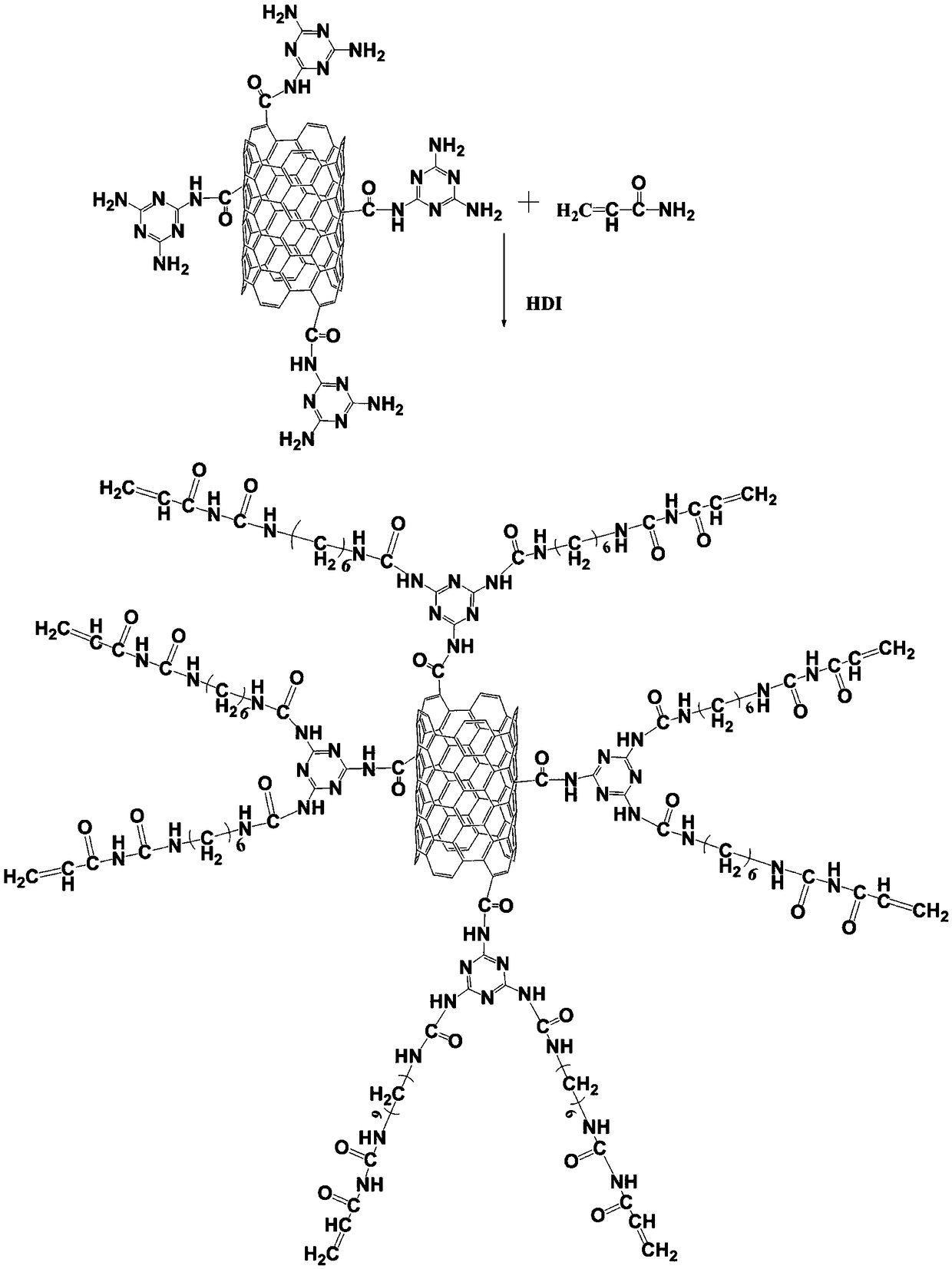

The invention discloses a plastic film with high stretching resistance. The plastic film is prepared from the following components in parts by weight: 43-52 parts of grafted carbon nanotubes, 14-16 parts of trifluoroacetic anhydride, 27-33 parts of vinyl trimethoxy silane, 75-82 parts of diethyl ether, 31-34 parts of azodiisobutyronitrile, 3-5 parts of polyoxyethylene glycol bisstearate, 2-4 partsof a plasticizer and 100 parts of water. The prepared resin takes carbon nanotubes as a neutral supporting body, and the surfaces of the carbon nanotubes are grafted with a plurality of branch chains, a plurality of fluorine elements are contained by each branch chain, so that resin aging resistance can be realized; one end of each branch chain is super-branched through polymerization reaction, so that the polymer branch chains are polymerized on the branch chains; the super-branching can improve strength and toughness of the resin; the polymer is polymerized from vinyl trimethoxy silane, sothat a plurality of alkoxy groups are uniformly distributed on the prepared resin super-branched chains, and thus the resin has relatively high strength and water resistance; and the resin has certainflame resistance in the presence of the alkoxy groups.

Owner:嵊州市仲明新材料科技有限公司

Sizing material for rubber shoe sole and preparation method thereof

ActiveCN102504362BAchieving aging resistanceImprove aging resistanceSolesPolymer scienceStearic acid

The invention discloses a sizing material for a rubber shoe sole and a preparation method thereof. The sizing material comprises the following raw materials for preparing active ingredients in parts by weight: 100 parts of rubber, 1.2-2.5 parts of sulfur, 2-5 parts of zinc oxide, 1-2.5 parts of stearic acid, 1-3 parts of a medium-speed accelerant, 0.3 part of a high-speed accelerant, 1.5-3 parts of an anti-ageing agent, 35-55 parts of carbon black, 5-10 parts of softening oil, 25-35 parts of rubber powder and 1-1.5 parts of coupling agent. The preparation method comprises the following steps of: pretreating the rubber powder; plastifying rubber; compounding; milling, and the like. The rubber shoe sole produced by using a rubber powder formula and the preparation method thereof has the advantages of reduction in the tensile strength change rate by 3-5 percent, reduction in the tensile yield change rate by 5-8 percent, the same wear resistance and bending resistance as those of a rubber shoe sole produced without using rubber powder in the same type of products, smooth appearance handfeel, soft brightness and increase in grade. The sizing material is suitable for preparing rubber shoe soles of dress shoes and outdoor shoes.

Owner:JIHUA 3514 LEATHER & FOOTWARE

High temperature resistant creep resistant pipeline thermal insulation material and preparation method thereof

The invention relates to the technical field of polyurethane thermal insulation materials, in particular to a high temperature-resistant creep-resistant pipeline thermal insulation material and a preparation method thereof. The high temperature resistant and creep resistant pipeline insulation material is composed of A component and B component mixed in a mass ratio of 1:1.4-1.6, and A component is composed of sucrose polyether polyol A, epoxy resin modified polyether Polyol B, polyester polyol, cross-linking agent, deionized water, foam stabilizer, catalyst; modified isocyanate is one of hydroxyl-terminated fluorine-containing polyester polysiloxane and hydroxyl-terminated polysiloxane. It is prepared by modifying one or two mixtures of polymethylene polyphenyl polyisocyanate and diphenylmethane diisocyanate. The high-temperature-resistant and creep-resistant pipeline insulation material of the present invention not only has excellent high-temperature dimensional stability, low thermal conductivity, and good bonding performance, but also has good high-temperature resistance and creep resistance, and can meet the requirements of long-term high-temperature transportation. requirements; the present invention also provides its preparation method.

Owner:SHANDONG INOV NEW MATERIALS CO LTD

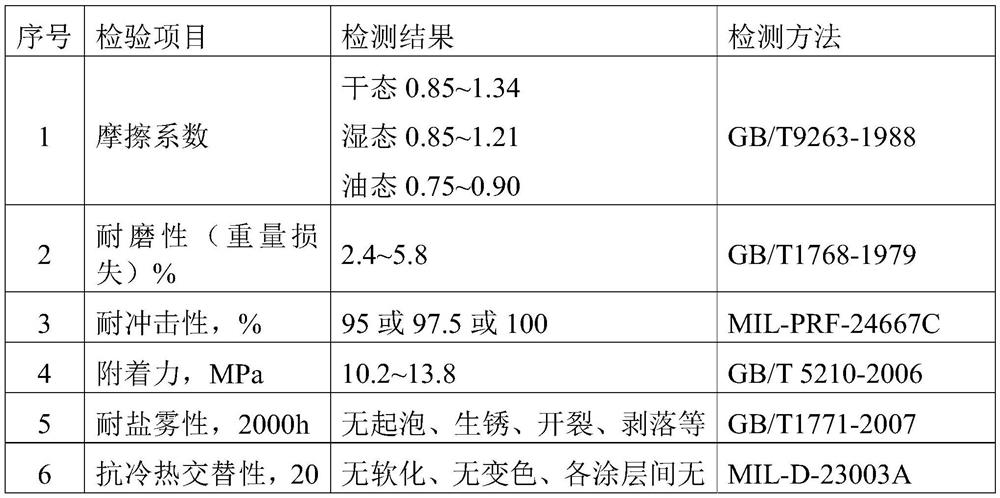

Composite anti-skid coating for heavy-load track and preparation method of composite anti-skid coating

ActiveCN114316729ALow viscosityQuick responseAnti-corrosive paintsPolyurea/polyurethane coatingsPolyaspartic acidSolid content

The invention relates to an anti-skid coating for a heavy-load track and a preparation method thereof, and the composite anti-skid coating for the heavy-load track comprises an anti-corrosion primer, a first anti-skid finishing coat and a second anti-skid finishing coat, wherein the anti-corrosion primer is epoxy anti-corrosion primer; the first anti-skid finish paint is epoxy anti-skid finish paint; and the second anti-skid finish paint comprises a polyaspartic acid ester finish paint and anti-skid particles. The selected resin has the characteristics of high solid content, low viscosity, high reaction speed and the like, and the special composition of the first anti-skid finishing coat and the second anti-skid finishing coat is adopted, so that the excellent adhesive force with the anti-corrosion primer is ensured, and the properties of quick drying, aging resistance, wear resistance and the like of the coating are realized.

Owner:MARINE CHEM RES INST

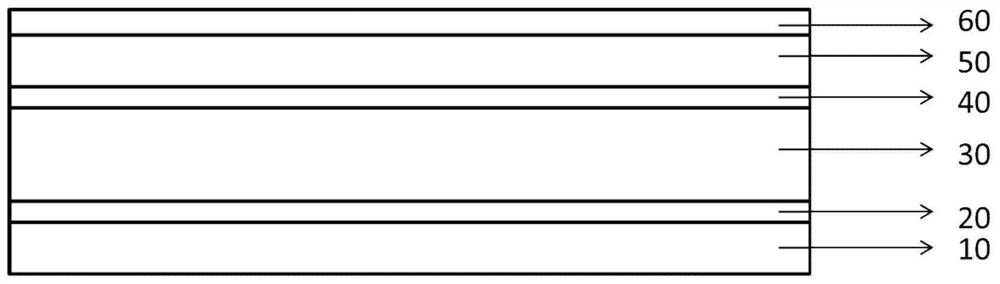

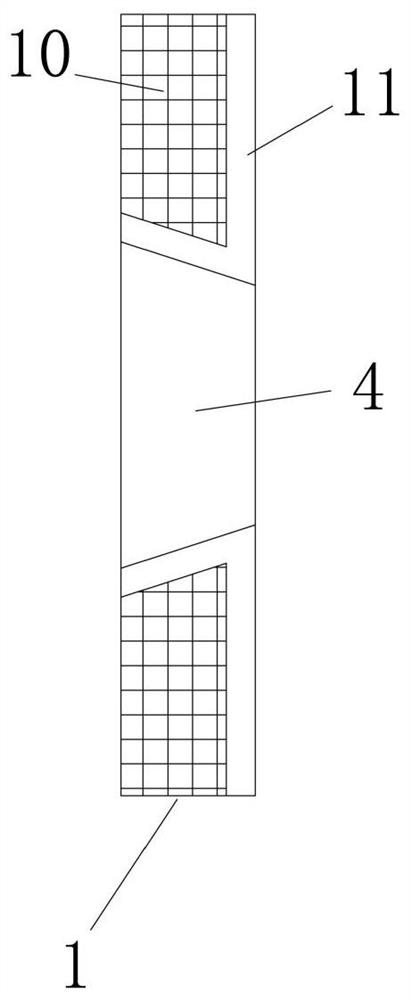

Fluorocarbon coating, fluorocarbon coating liquid and transparent solar backboard

ActiveCN114656844AAchieving aging resistanceRealize weather resistance testingReflecting/signal paintsSemiconductor devicesCarbon coatingWater vapor permeability

The invention relates to the technical field of solar back panels, in particular to a fluorocarbon coating, fluorocarbon coating liquid and a transparent solar back panel. In order to solve the problem that an existing transparent solar backboard is high in water vapor permeability, the invention provides the transparent solar backboard. The fluorocarbon coating comprises the following components in percentage by weight: 20%-40% of fluorocarbon resin, 20%-40% of titanium dioxide, 2%-5% of matting powder, 0.3%-0.6% of an additive, 30%-50% of an adhesion promoter and 5%-8% of isocyanate. The transparent solar backboard sequentially comprises a white grid fluorocarbon coating, a transparent PO film, a first adhesive layer, a base material, a second adhesive layer and a fluorine film layer from top to bottom. According to the transparent solar backboard provided by the invention, the water permeability index of the whole backboard can be effectively reduced.

Owner:NINGBO EXCITON NEW ENERGY CO LTD +1

External thermal-insulation environment-friendly composite polyether for delivering high-temperature media and preparation method thereof

ActiveCN102942671BModerate viscosityImprove high temperature oxidation resistancePolyesterFoaming agent

Owner:SHANDONG INOV NEW MATERIALS CO LTD

Super-hydrophobic paint and preparation method thereof

ActiveCN111393992AAchieving aging resistanceReduce washoutAntifouling/underwater paintsPaints with biocidesPolymer sciencePtru catalyst

The invention discloses a super-hydrophobic paint, which is composed of the following components by mass: 5-15 parts of organosilane, 1-10 parts of an inorganic wear-resistant agent, 2-9 parts of a catalyst, 1-3 parts of a hydrophobic agent, 2-8 parts of one or two of tetraethylenepentamine and tetraethylenetriamine and 60-90 parts of a solvent. The beneficial effects of the invention are that: acoating continuous phase of the paint provided by the invention has high hardness, high wear resistance, high smoothness and super-hydrophobicity, at the same time the coating has high compactness andstrong combing power to a matrix. The paint provided by the invention can be coated and cured at room temperature, realizes scouring resistance, fouling resistance, corrosion resistance, aging resistance and other effects, is suitable for steel, glass, rubber and other matrixes, can be used for high-voltage cables, outdoor high-voltage equipment, ships, automobile glass and the like, and reducesthe scouring and shearing of seawater, silt and sandstorm to the coating to the maximum extent.

Owner:TAIAN LEBANG ENVIRONMENTAL PROTECTION TECH CO LTD

A kind of high abrasion-resistant superhydrophobic composite coating, preparation method and coating made of it

ActiveCN108485522BAchieving aging resistanceReduce washoutAntifouling/underwater paintsPaints with biocidesFiberCarbon fibers

The invention discloses a high wear-resistant super-hydrophobic composite coating, which consists of the following components in parts by mass: 5-15 parts of organosilane, 1-10 parts of inorganic anti-wear agent, 2-9 parts of catalyst, and 1-3 parts of hydrophobic agent 0-3 parts of carbon fiber, 0-3 parts of glass flake powder, 2-8 parts of one or both of tetraethylenepentamine and tetraethylenetriamine, 60-90 parts of solvent; the present invention also provides a A preparation method of a high wear-resistant super-hydrophobic composite coating and a preparation method of the coating. The beneficial effects of the present invention are: the coating continuous phase of the present invention has high hardness, high wear resistance, high smoothness and superhydrophobicity, and has high compactness and strong bonding force with the substrate at the same time. The coating of the present invention can Coating and curing at room temperature to achieve anti-scouring, anti-fouling, anti-corrosion, anti-aging and other effects, suitable for steel, glass, rubber and other substrates, can be used for high-voltage cables, outdoor high-voltage equipment, ships, automotive glass, etc., to minimize seawater, The erosion and shearing of the coating by sediment and wind and sand.

Owner:泰安乐邦环保科技有限公司

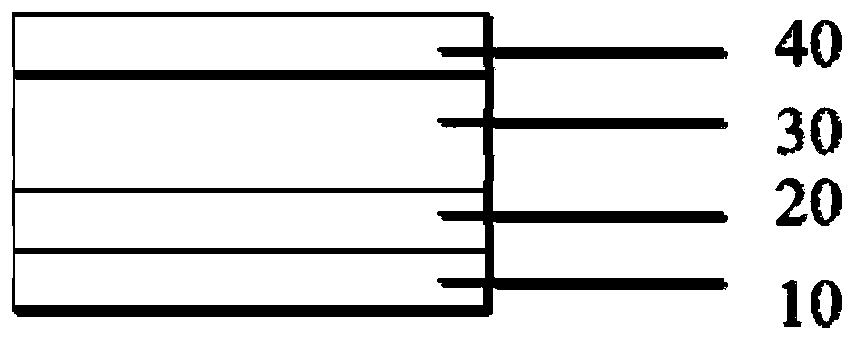

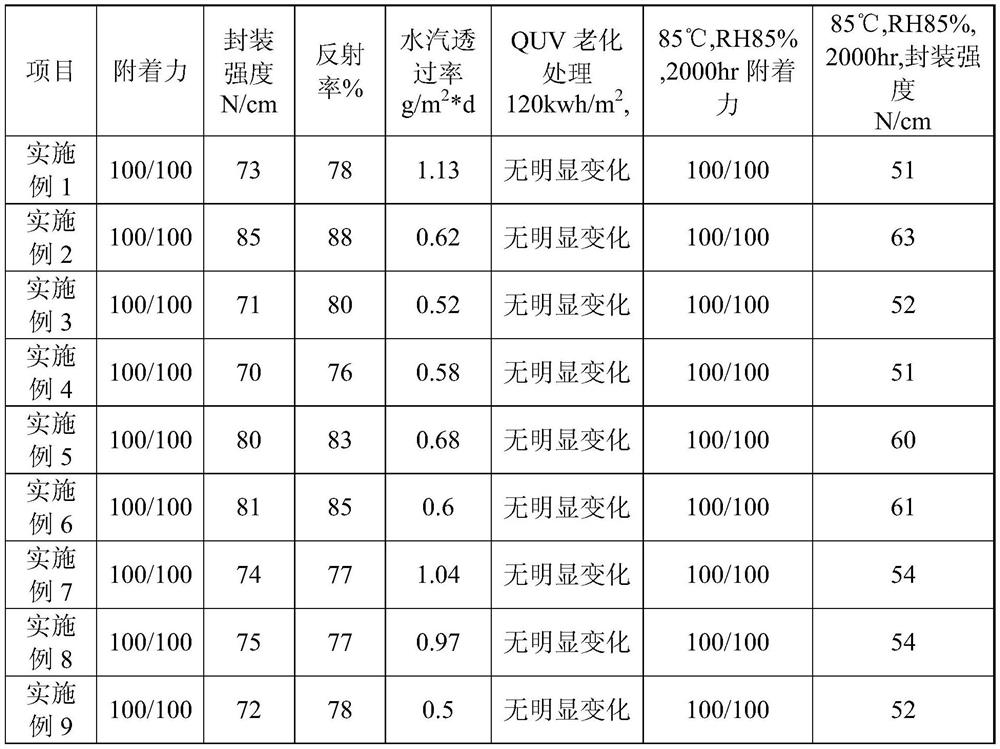

Fluorocarbon coating liquid, fluorocarbon coating and solar backboard

PendingCN114686055AMeet package strengthGood stabilityCoatingsSemiconductor devicesPhysicsFluorocarbon Resins

The invention relates to the technical field of solar back plates, in particular to fluorocarbon coating liquid, a fluorocarbon coating and a solar back plate. In order to solve the problem of poor heat resistance of a transparent fluorocarbon coating, the invention provides the fluorocarbon coating liquid, the fluorocarbon coating and the solar backboard. The fluorocarbon coating liquid comprises the following components in percentage by weight: 50%-80% of fluorocarbon resin, 3%-10% of an inorganic nano cerium dioxide UV absorbent, 1%-5% of extinction powder, 10%-20% of an adhesion promoter, 0.3%-0.8% of an additive and 5%-20% of isocyanate. A coating formed by the fluorocarbon coating liquid is good in heat resistance at the hot spot temperature (such as 170 DEG C), small molecule precipitation and macromolecule degradation are not prone to occurring, and yellowing of the coating cannot occur in the high-temperature hot spot testing process after heat sealing of an assembly.

Owner:NINGBO EXCITON NEW ENERGY CO LTD +1

A scratch-resistant fluorocarbon layer coating solution and a solar backboard using the coating solution

ActiveCN110358375BAchieving aging resistanceAchieve scratch resistancePolyurea/polyurethane coatingsPhotovoltaic energy generationWeather resistancePhysical chemistry

The invention relates to the technical field of solar back panels, in particular to a fluorocarbon layer coating solution and a solar back panel using the coating solution. In order to solve the problem that the existing fluorocarbon layer is easily scratched, the invention provides a scratch-resistant fluorocarbon layer coating solution and a solar back panel using the coating solution. The fluorocarbon layer coating liquid contains 40%-60% fluorocarbon resin, 20%-30% titanium dioxide, 1%-5% matting powder, 10-20% modified thermoplastic polyurethane resin, 0.2%-0.8 % of polyacrylate, 5% to 10% of isocyanate, and the stated percentages are all percentages by weight. The surface of the fluorocarbon layer formed by the fluorocarbon layer coating solution provided by the invention is scratch-resistant and has good weather resistance. The inner surface of the solar backboard using the coating liquid has good scratch resistance, and the solar backboard has good weather resistance.

Owner:宁波激阳新材料有限公司

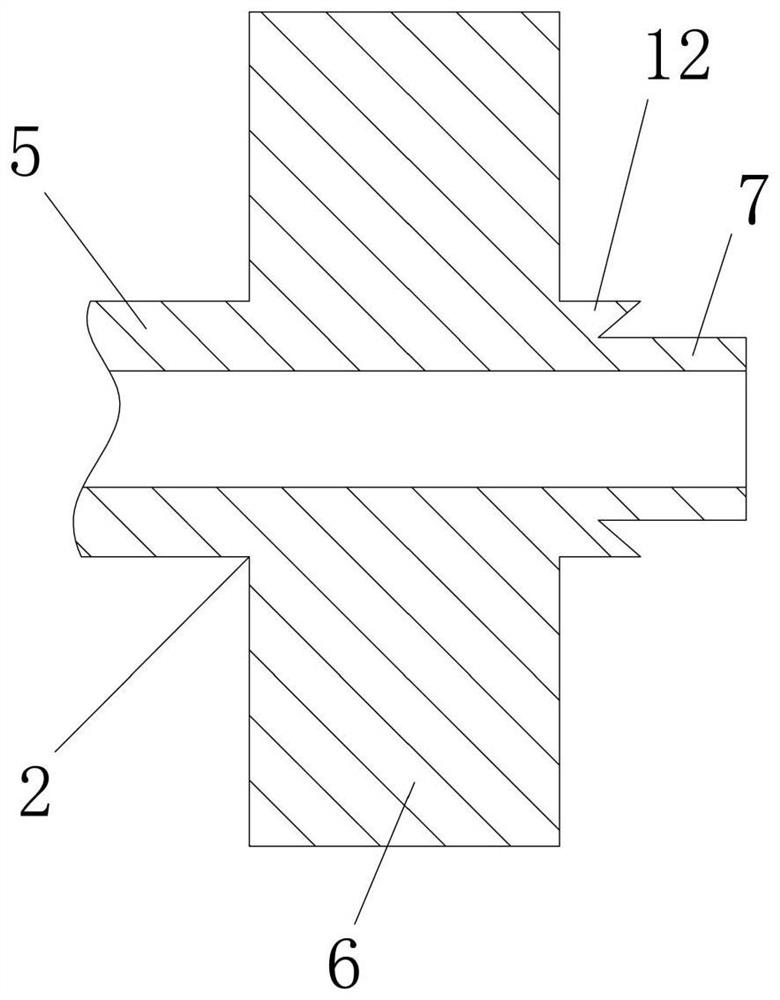

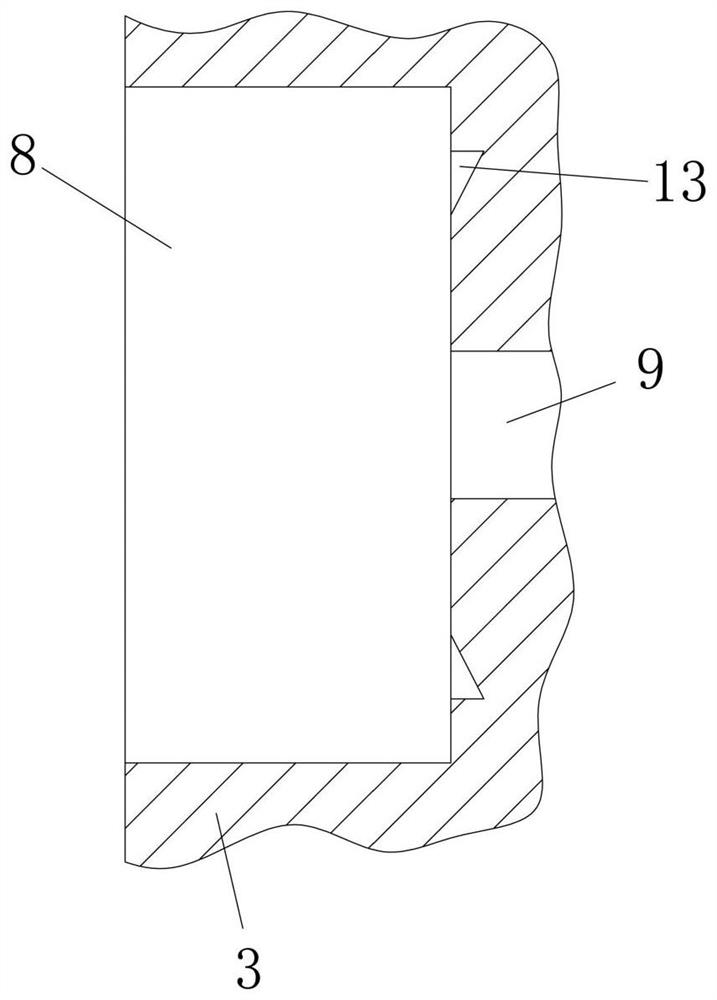

Structure of hard sealing gasket

PendingCN111750105AIncrease elasticityAchieve normal workSleeve/socket jointsEngine sealsPolymer chemistryMetal

The invention relates to a structure of a hard sealing gasket and belongs to the technical field of sealing of high pressure gas in operation. The sealing gasket is composed of a rubber layer and a metal layer. A combination structure of the rubber layer and the metal layer can be suitable for extremely wide temperature ranges according to the hard sealing state of a metal. On the other hand, theapplication temperature range of the rubber layer is within 50 DEG C below zero to 200 DEG C by means of volume incompressibility of rubber and excellent elasticity recovery performance of the rubberin a very wide temperature range, so that the structure has the effects of working normally and being oil-resistant and ageing-resistant.

Owner:浙江隆盛智控科技有限公司

Nano composite top facing paint with hydrophobic foul resisting sticking-proof and preparation process thereof

InactiveCN100500781CAchieving aging resistanceAchieve scrub resistanceAntifouling/underwater paintsPaints with biocidesMaterials scienceWetting

The invention relates to a nanometer compound cover paint which has the hydrophobicity and is resistance to the pollution and the sticking. The paint contains the film forming material, the antifouling component, the filler and the diluting agent, necessary the wetting agent, dispersant and the thickener. So it can be used for the antifouling of the high-end building and the protection for the outlook of the public utility.

Owner:江西中江纳米科技有限公司

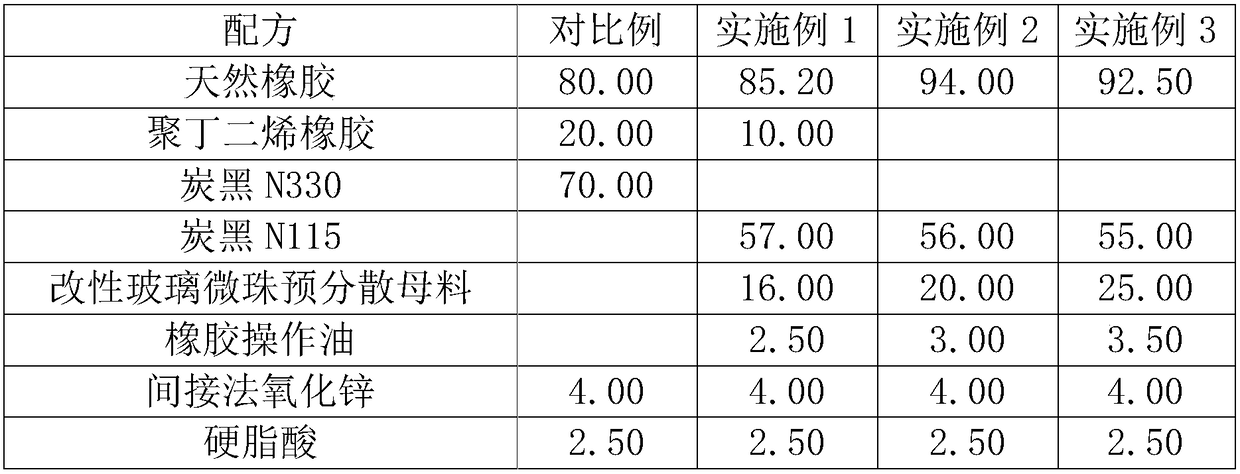

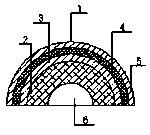

A kind of lightweight elastic inner support body formula and its preparation process

The invention relates to the technical field of military automobiles and particularly relates to a formula and preparation process of a lightweight elastic inner support body. The formula contains the following components in parts by weight: 80-100 parts of natural rubber, 0-20 parts of polybutadiene rubber, 50-70 parts of carbon black, 10-40 parts of a modified glass bead pre-dispersion master batch, 4.5-7.5 parts of an active agent, 3-8 parts of rubber operation oil, 1.5-6.5 parts of an anti-aging agent, 1.0-2.5 parts of protecting wax, 0.5-2.5 parts of an accelerant and 0.8-1.8 parts of sulfur. The important physical properties of a rubber material of the elastic inner support body are improved, meanwhile, the formula density of the lightweight elastic inner support body can be reduced, the volume weight can be reduced, and the light weight of a military bulletproof safety tread is realized; the elastic inner support body has the characteristics of high strength, low themogenesis, ageing resistance and light weight.

Owner:SAILUN GRP CO LTD

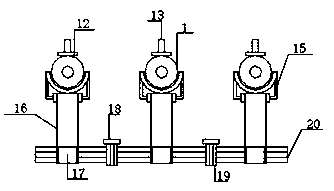

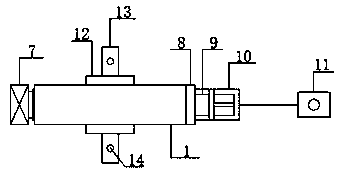

Universal heat dissipation floor heating pipe

InactiveCN109855148AImprove cooling effectAchieving aging resistanceLighting and heating apparatusSpace heating and ventilation detailsEngineeringThermal expansion

The invention belongs to the technical field of floor heating pipes, and particularly relates to a universal heat dissipation floor heating pipe. The universal heat dissipation floor heating pipe is provided with a pipe body, an inner heat-resistant layer, an insulating layer, a heat preservation layer, a flame-retardant plate, a cavity, a connecting valve, a heat conduction pipe, a heat transferpipe, a heating pipe, a controller, a mounting ring, a fixing plate, a mounting hole, a pipe holder, a supporting rod, a connecting hole, a fixing screw, a threaded hole and a pre-buried plate, wherein the pipe body is of a stainless steel hollow structure, the inner wall of the cavity is provided with internal hand threads, the flowing direction and the flowing speed of hot water are changed by the internal hand thread wall, so that the heat dissipation effect is further enhanced, scale does not generate on the inner wall of the floor heating pipe body, procedures for removing water scale every year are omitted, the use cost is reduced, blockage is not prone to happen, an outer corrugated wall is used for increasing the contact area between the exterior of the floor heating pipe body andair, the heat dissipation effect is enhanced, the outer corrugated wall can be used for effectively copying with thermal expansion so as to enhance stability performance of the floor heating pipe body, and the universal heat dissipation floor heating pipe is more humanized and suitable for popularization and application.

Owner:天长市雷克斯新能源科技有限公司

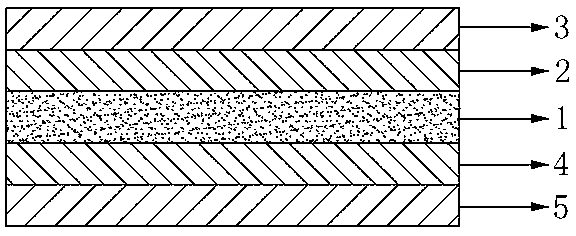

A kind of anti-aging high barrier solar panel back film and preparation method thereof

ActiveCN105355692BAchieving aging resistanceAchieve weather resistancePhotovoltaic energy generationSemiconductor devicesPolytetramethylene terephthalateHigh resistance

The invention relates to an anti-aging high resistance solar cell panel back film and a preparation method thereof. The back film comprises a weather-resistant layer arranged at an outer side of the back film, an ultraviolet resistance layer bonded at an inner surface of the weather-resistant layer, a matrix layer which is a polyethylene glycol terephthalate layer bonded at an inner surface of the ultraviolet resistance layer, and a bonding layer which is bonded at an inner surface of the matrix layer and faces the solar cell panel, wherein the bonding layer comprises polyurethane resin, diphenyl dimethoxy silane, organic peroxide, polybutylene telephthalate, octadecyl acrylate, isocyanate curing agent and ethanol solvent. Through the multi-functional film layer, the solar cell panel back film has properties of anti-aging, weatherability, heat resistance and ultraviolet resistance, and service life and durable performance of the solar cell panel are improved.

Owner:GUANGDONG GUOLI SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com