Patents

Literature

38results about How to "Super wear-resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Highly wearable vacuum coating ultraviolet curing coatings

ActiveCN101157808AImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsWear resistantLacquer

The invention relates to the electronic application-coating field, in particular to uv-curing coating with high wearing resistance and vacuum coating. The compositions and contents of the invention are: 10 wt percent to 30 wt percent of difunctional group polyurethane acrylate, 10 wt percent to 40 wt percent of high functional group polyurethane acrylate, 5 wt percent to 20 wt percent of high functional group acrylate monomer, 0 wt percent to 15 wt percent of monofunctional group acrylate monomer, 1 wt percent to 10 wt percent of acid adhesive promoter, 1 wt percent to 6 wt percent of photoinitiator, 0 wt percent to 5 wt percent of nano wearing resistance materials, 0.1 wt percent to 2 wt percent of additive and 10 wt percent to 50 wt percent of solvent. The invention is designed for providing surface protection for vacuum coating parts of electric products such as mobile phone, MP3, and digital camera, etc., and is characterized by good surface effect, good performances of ultrawear-resistance, high temperature and humidity resistance, anti-cold thermal cycling and anti-yellowing, etc., wherein, RCA wear can be up to more than 1500 times, which can effectively improve the service life of electric products. The invention effectively enhances the adhesion and wearing resistant performance of the uv-curing and vacuum coating dope, solves the matching problem of the bottom and surface lacquer of the uv-curing and vacuum coating dope, and has broad university.

Owner:HUNAN SOKAN NEW MATERIAL

Extra-black environment-friendly tempered glass ink and preparation method thereof

The invention discloses extra-black environment-friendly tempered glass ink and a preparation method thereof. The extra-black environment-friendly tempered glass ink comprises the following components in percentage by weight: 18-30% of a coloring agent, 50-60% of glass-base glaze, 18-30% of varnish and 0.1-1% of an additive, wherein the coloring agent mainly comprises copper-chromium oxide. The extra-black environment-friendly tempered glass ink disclosed by the invention is not only efficient and environmental friendly, but also has the excellent characteristics of high blackness, high hardness, super wearing resistance, high acid and alkali resistance and the like.

Owner:FOSHAN CITY GREEND CHEM

Preparation method of silicon carbon black / natural rubber composite material

ActiveCN107337815ASimple production processMeet the requirements of sustainable developmentSilicon dioxideBall mill

The invention discloses a preparation method of a silicon carbon black / natural rubber composite material, belongs to the technical field of composite materials, and solves the problems of high cost, non renewable resources, complex process, difficult processing and uneven dispersion of use of surface modified silica for filling natural rubber in the prior art. According to the method, first purified rice husks are added into a reaction device for pyrolysis to obtain pyrolysis gas and pyrolytic carbon, and after decoking, cooling and separation, tar-free pyrolysis gas and tar-free pyrolytic carbon are obtained; then tar-free pyrolytic carbon gas flow is pulverized, and ball-milled to the average particle size within 10 mu m to obtain silicon carbon black powder, and the silicon carbon black powder is further processed to obtain the modified silicon carbon black powder and silicon carbon black masterbatch; and finally the silicon carbon black / natural rubber composite material can be obtained by mixing and kneading technology. The preparation method has the advantages of low cost, saving energy, environmental-friendliness, full use of renewable resources, and broad application prospects in the rubber field.

Owner:JILIN UNIV

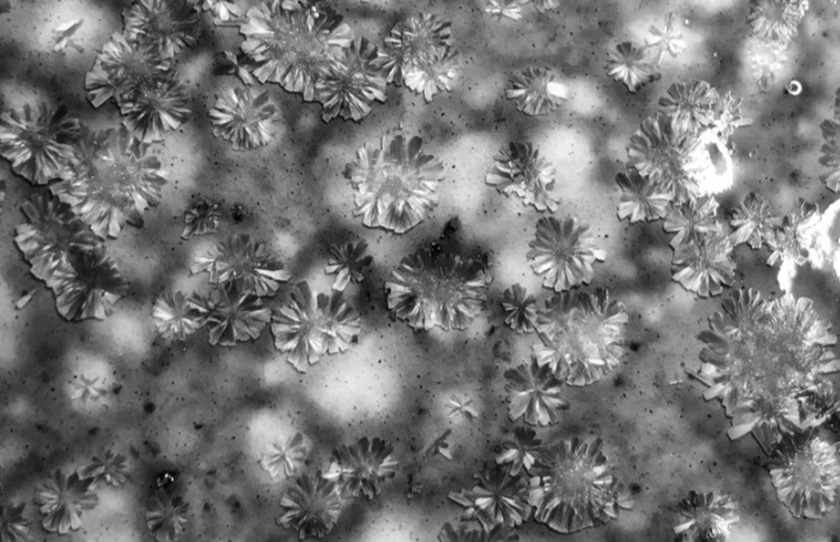

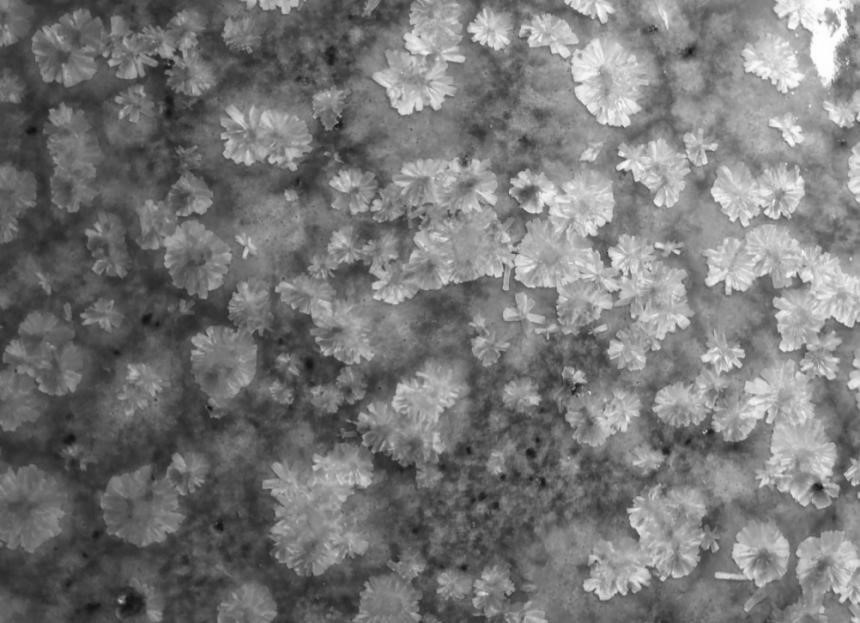

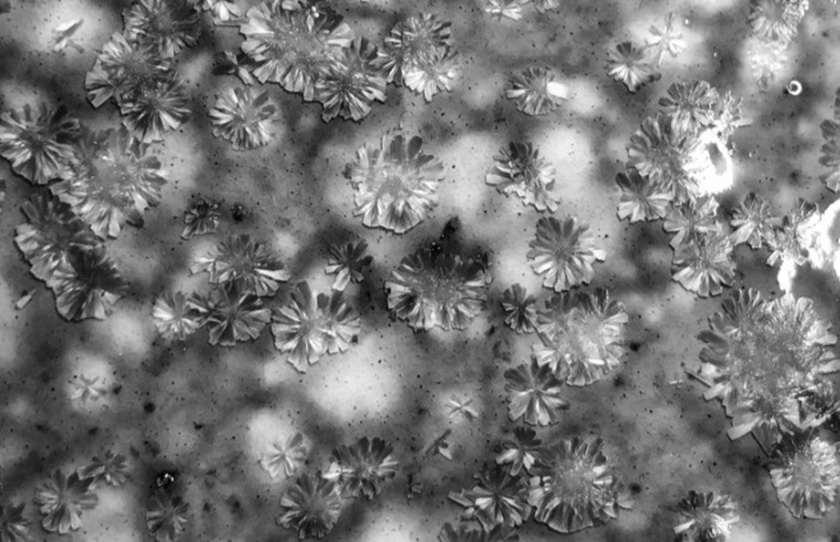

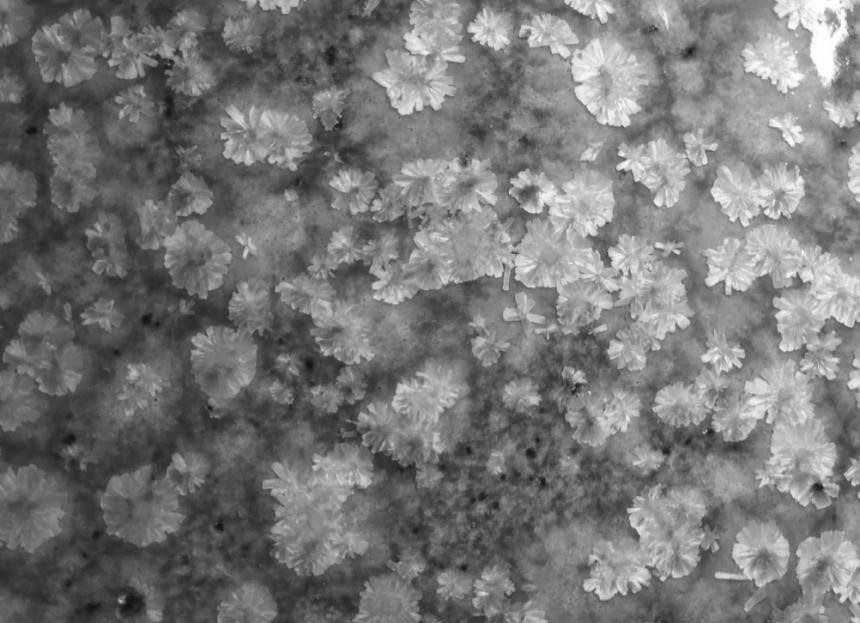

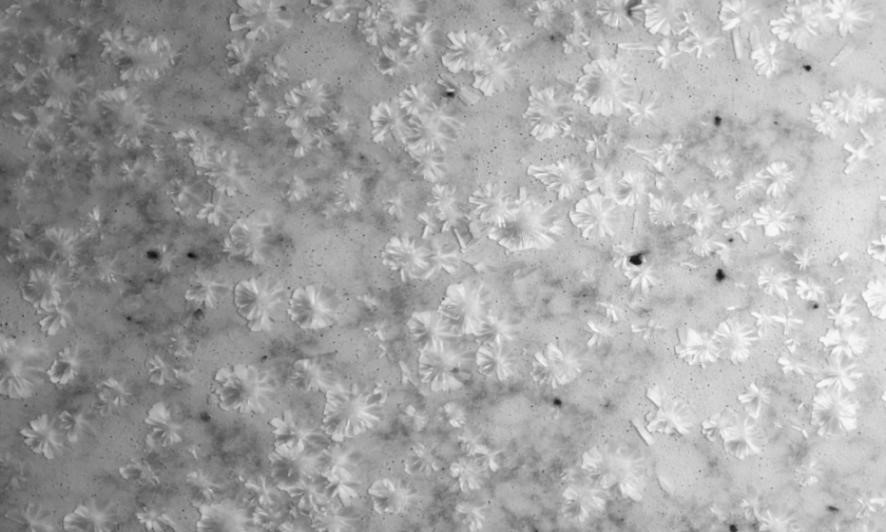

Macrocrystal particles capable of forming crystal flower, dry particle combination, particles for ceramic, ceramic and preparation method of ceramic

ActiveCN112456802ARich and varied colorsImprove the decorative effectMacrocrystallineTexture (crystalline)

The invention belongs to the technical field of ceramics, and discloses macrocrystalline particles capable of forming crystal flowers, a dry particle combination, particles for ceramic, the ceramic and a preparation method of the ceramic. The chemical mass composition of the macrocrystalline particles includes SiO2, Al2O3, K2O, Na2O, CaO, MgO, BaO, ZnO, F, Li2O, TiO2, and a metal oxide for coloring. The macrocrystalline particles can form macrocrystalline crystal flowers through low-temperature fast firing, the crystal flowers are petal-shaped, the colors of the crystal flowers can be changedand adjusted at any time according to designed colors and textures, the colors are rich and diverse, and the decorative effect is excellent. And the dry particles can be quickly sintered at low temperature and meet the energy-saving and environment-friendly requirements in the ceramic field. And the fired ceramic tile has the advantages of compact surface, high strength, super wear resistance andno hidden dirt. The surface of the product is crystal clear, a random crystal pattern effect is naturally formed, the color of the brick surface is richer and more diverse, and a very good effect canbe achieved through paving no matter on the ground or a wall.

Owner:FOSHAN DOWSTONG TECH

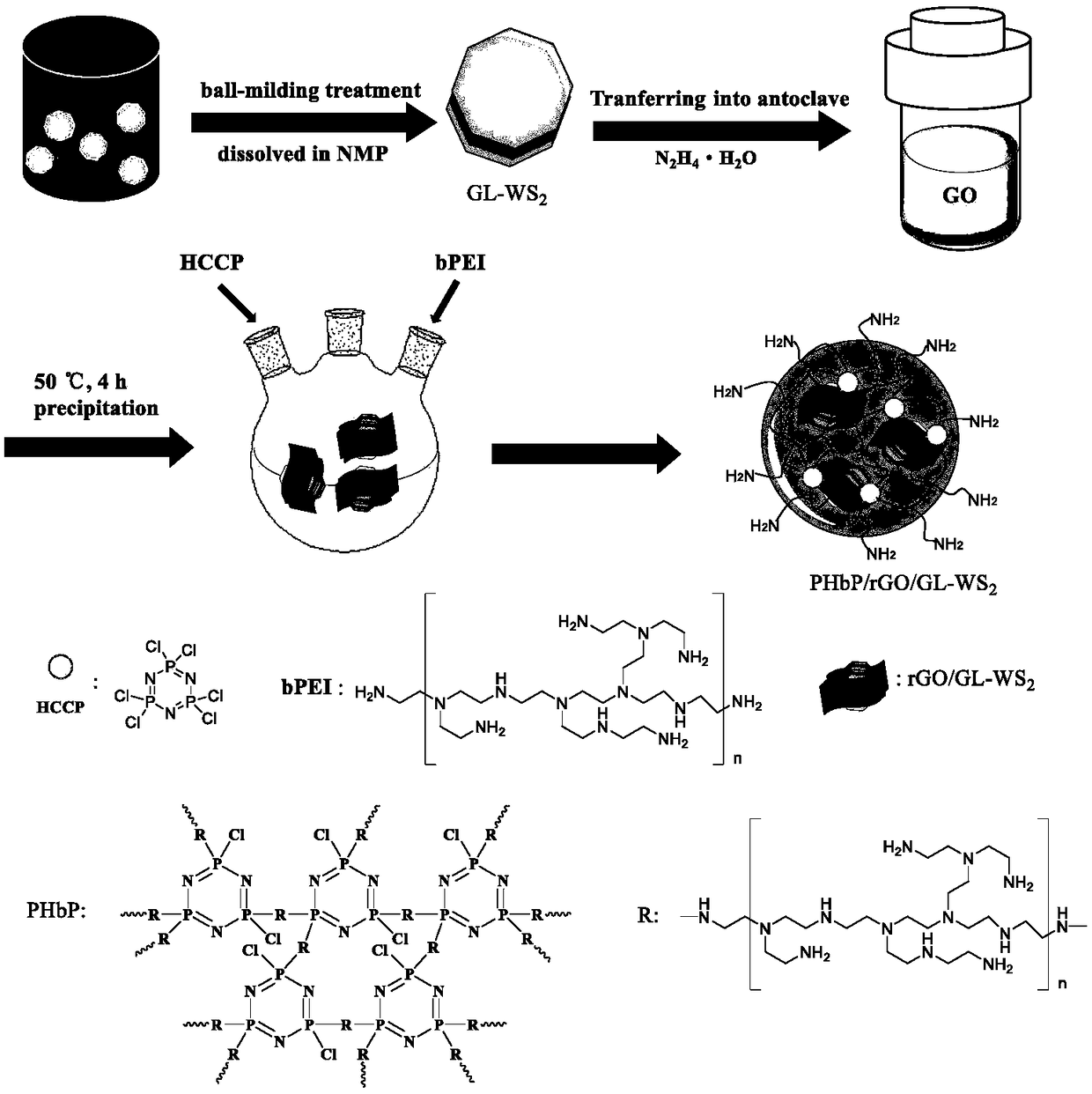

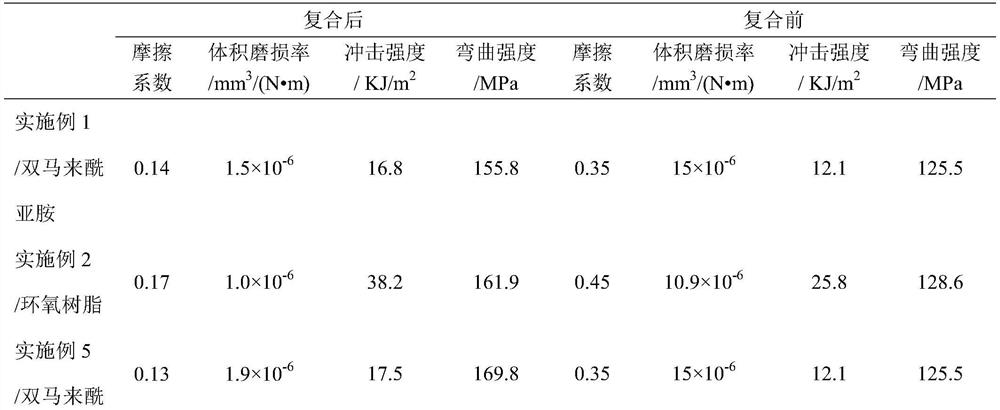

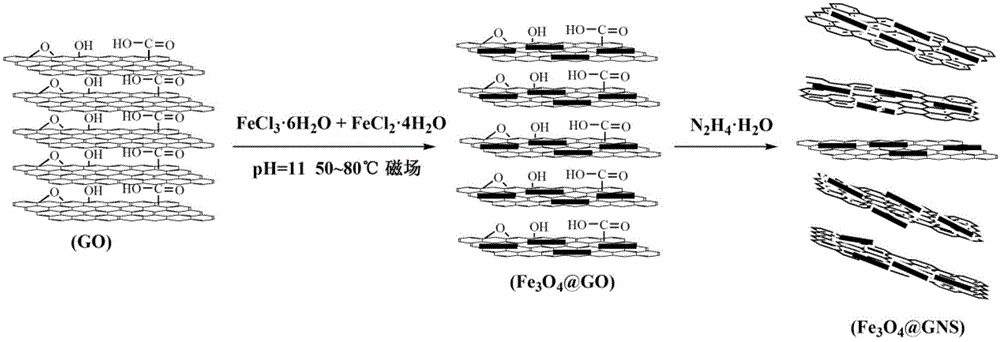

Graphene/graphene analogue WS2/bismaleimide composite material modified by cyclotriphosphazene polymer and preparation method thereof

InactiveCN108641356AGood dispersionImprove the bonding strength of the interfacePolymer scienceHigh pressure

The invention relates to a graphene / graphene analogue WS2 / bismaleimide composite material modified by cyclotriphosphazene polymer and a preparation method thereof. Firstly, WS2 is stripped into grapheme analogue WS2 by using methods of low-energy ball milling and ultrasonic, then, the grapheme analogue WS2 is added into a high-temperature high-pressure reaction kettle together with an oxidized graphite, a proper amount of hydrazine hydrate is added and a pot hydrothermal method is used to prepare the graphene / graphene analogue WS2. Then, the graphene / graphene analogue WS2, phosphonitrilic chloride trimer, and branched polyethyleneimine are used as a raw materials, triethylamine is used as an acid-binding agent, and the graphene / graphene WS2 modified by cyclotriphosphazene polymer is prepared by using an in-situ template method. Finally, the composite material is prepared by mixing the graphene / graphene WS2 modified by cyclotriphosphazene polymer, diphenylethane dimaleimide and diallylbisphenol A in a certain proportion. The prepared composite material has good interface bonding strength, and excellent mechanical property and tribology performance.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

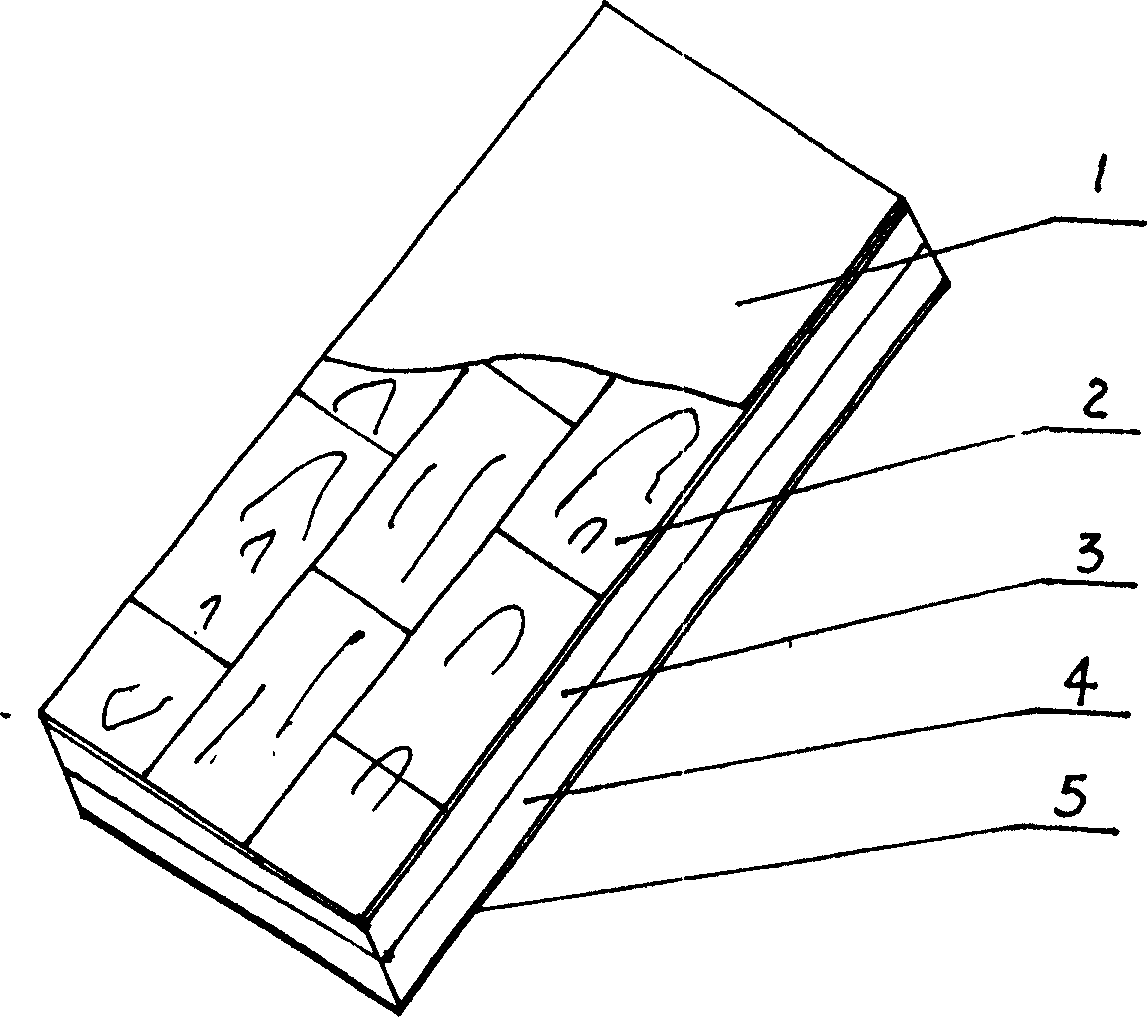

PVC wood-plastic foaming floor

The invention relates to a decorative material and provides a PVC wood-plastic foaming floor. The PVC wood-plastic foaming floor is provided with a PVC wood-plastic foaming base material layer and is characterized in that a PVC base plate balancing layer is bonded on the bottom face of the PVC wood-plastic foaming base material layer, a PVC wood-grain decorative plate layer is bonded on the upper surface of the PVC wood-plastic foaming base material layer, and an aluminum oxide abrasion-resisting layer is coated on the outer surface of the PVC wood-grain decorative plate layer. The base material layer of the PVC wood-plastic foaming floor is waterproof and fireproof and does not deform and crack. The abrasion-resisting layer is green and environment-friendly, can be recycled and is very good in abrasion-resisting performance, high in elasticity, very good in impact resistance, fireproof, flame-retardant, waterproof, damp-proof and is lifelike in grains, absorbs sound and prevents noise. The balancing layer is anti-slipping, anti-static and stable in balance, and the PVC wood-plastic foaming floor is widely used for indoor decoration of various house buildings.

Owner:湖北舒嘉科技有限公司

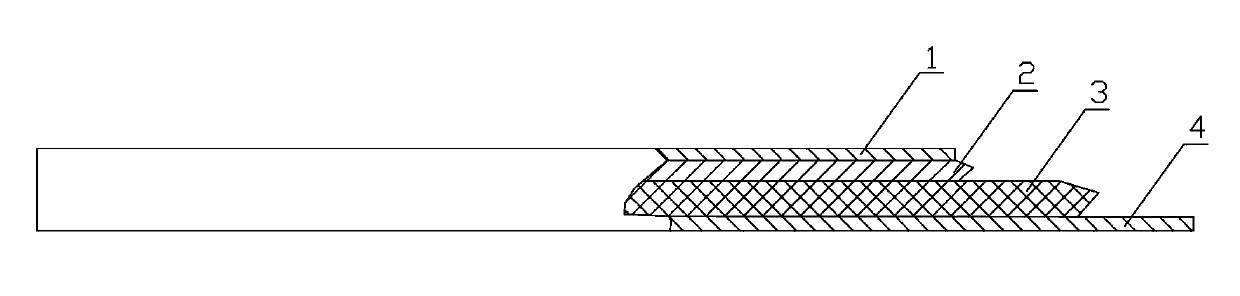

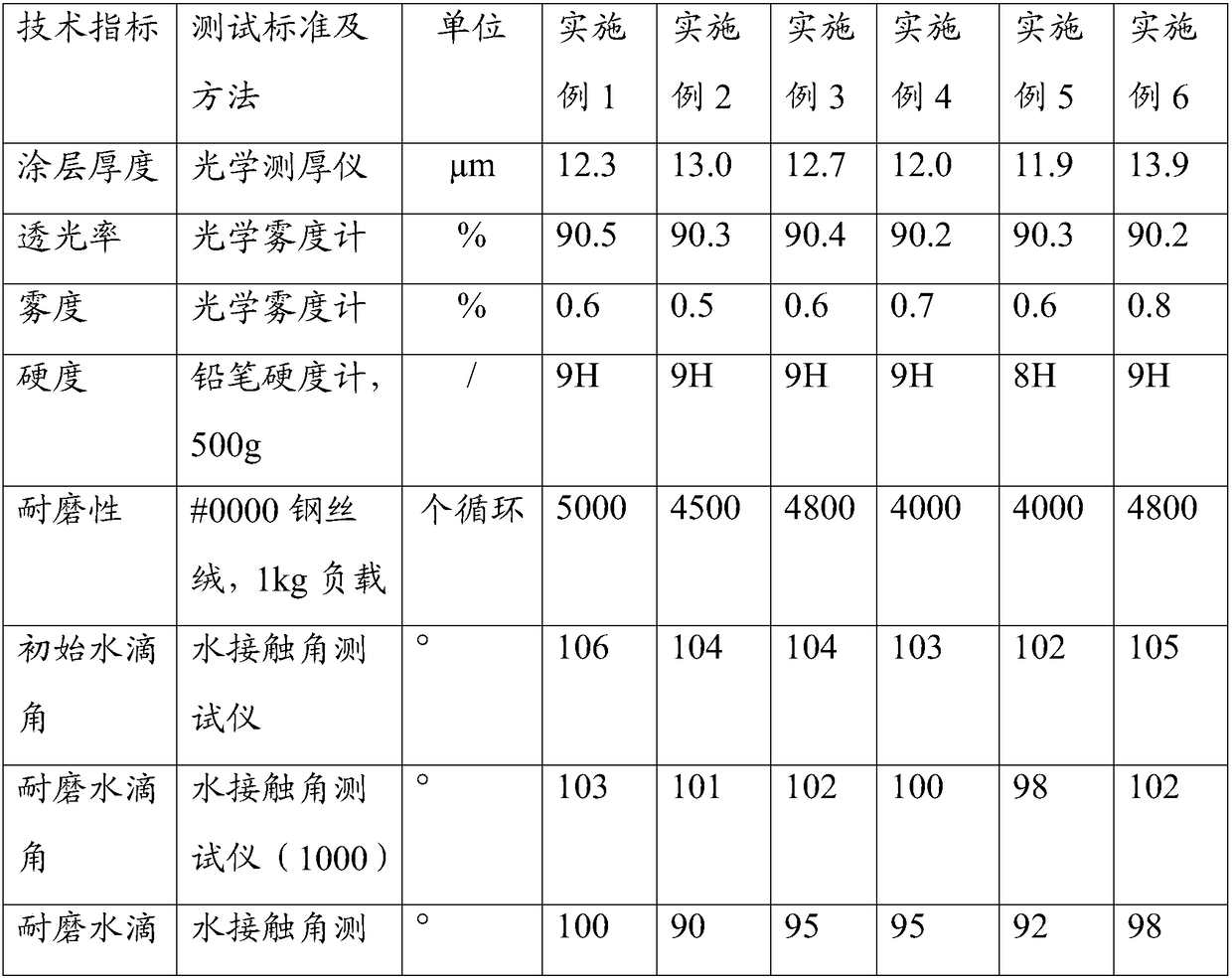

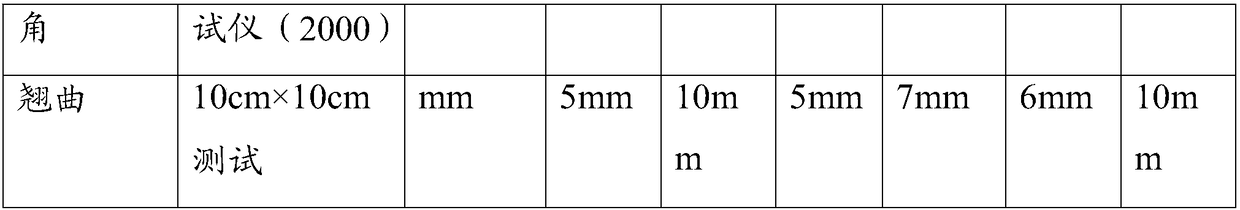

Photo-curing type hardening film with high hardness and preparation method of hardening film

InactiveCN109232942AHigh hardnessLow anti-fingerprintPolyurea/polyurethane coatingsPolyester coatingsOligomerHardness

The invention belongs to the field of optical film material application and particularly relates to a photo-curing type hardening film with high hardness and a preparation method of the hardening filmand provides the photo-curing type hardening film with high hardness and the preparation method of the hardening film to solve the technical problem of low hardness of thin coatings of hardening films. The photo-curing type hardening film with high hardness comprises a substrate layer and a photo-curing coating, wherein the photo-curing coating comprises high functional group acrylate compounds,perfluoro-modified oligomer, a photoinitiator, a dispersant, inorganic nanoparticles and a fluorine-containing aid, and raw materials of the photo-curing coating are prepared into a photo-curing coating firstly. The photo-curing type hardening film with high hardness has ultrahigh hardness, has the advantages of fingerprint prevention, super wear resistance and low warping and has very good comprehensive performance. The process of the preparation method is simple, roll-to-roll coating can be realized, and the production efficiency is high.

Owner:NINGBO HUGHSTAR ADVANCED MATERIAL TECH

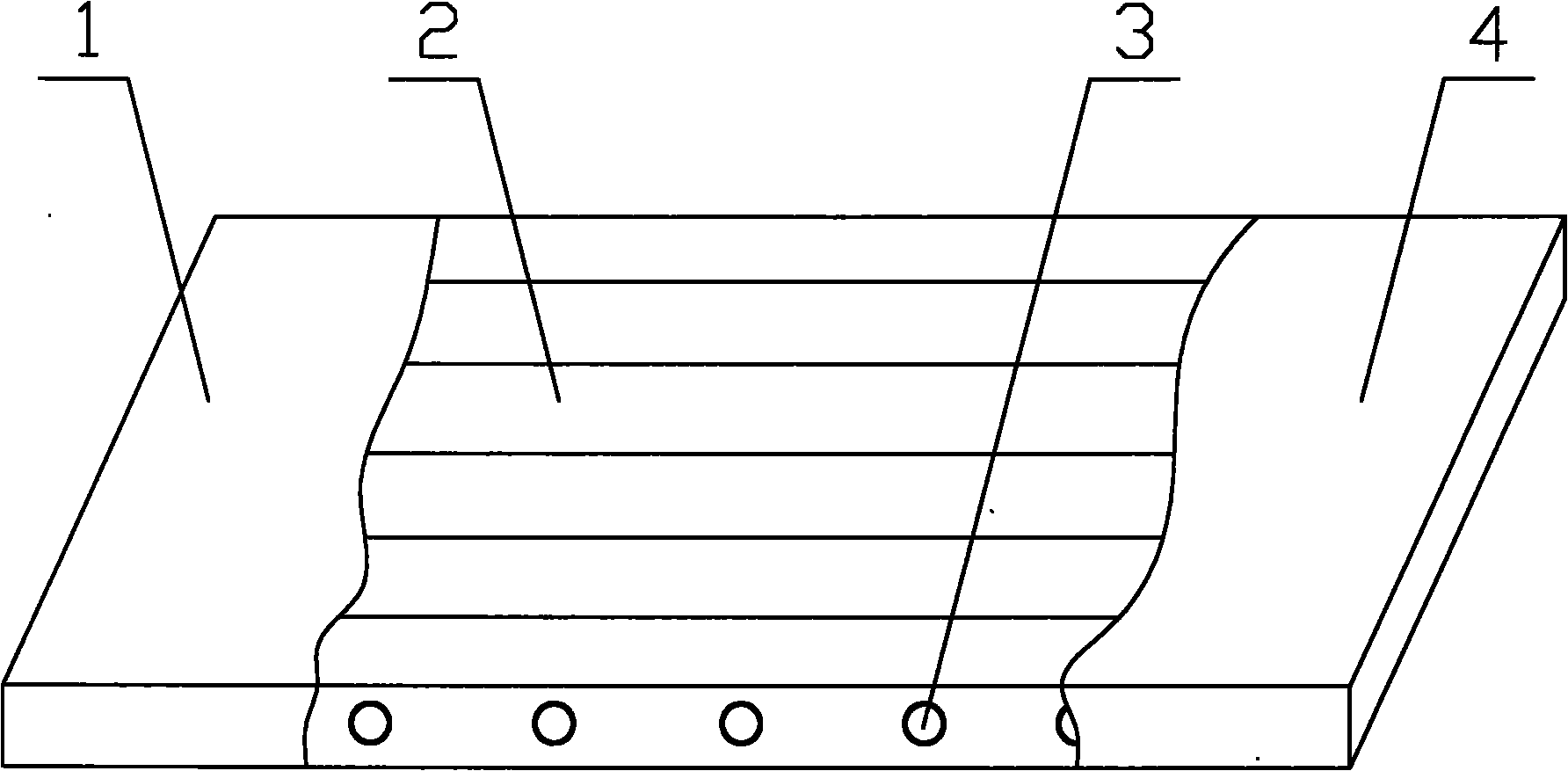

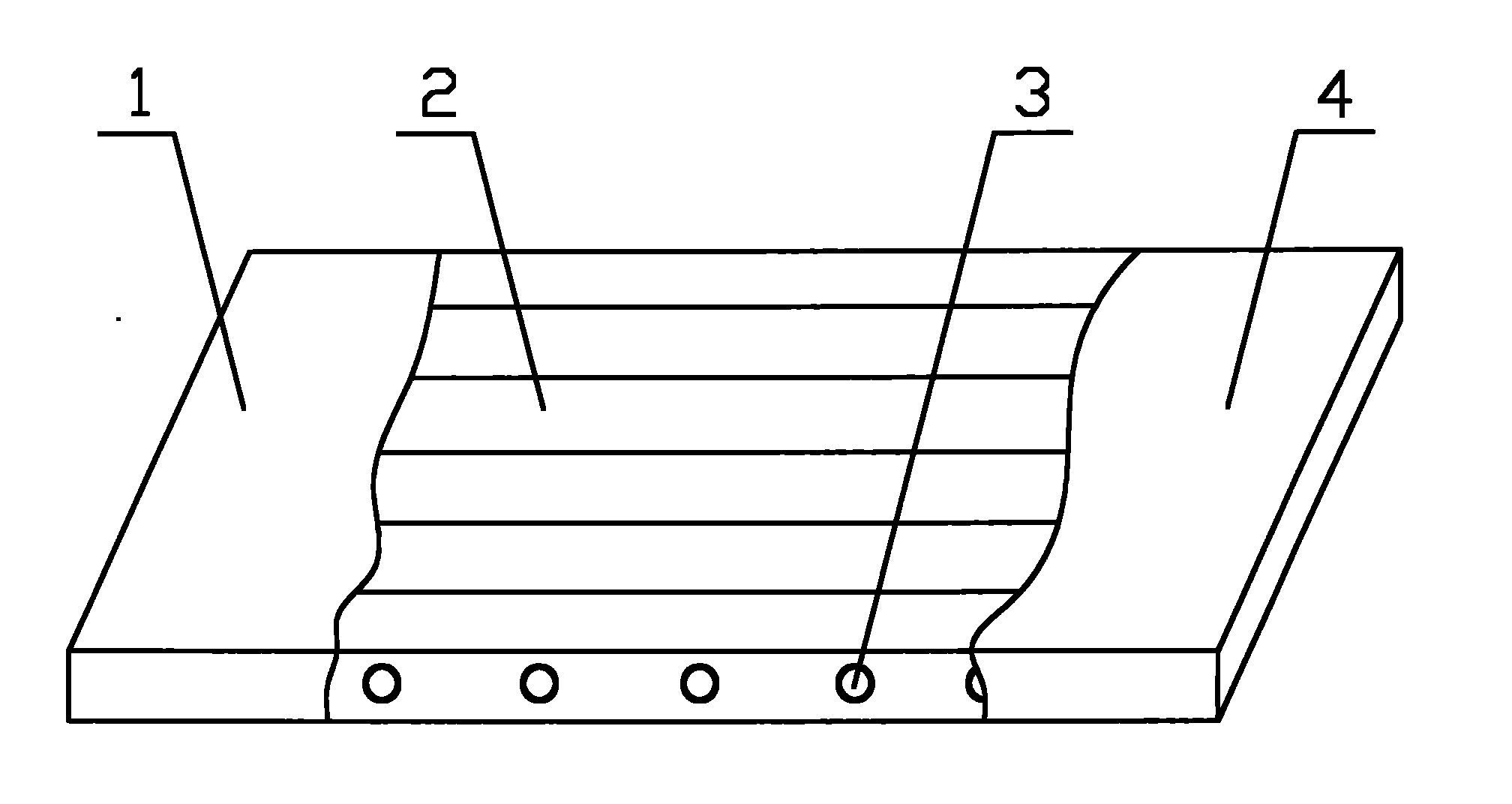

Light wear-resistant baking-free brick supporting plate and manufacturing method thereof

InactiveCN101774197AOutstanding FeaturesHighlight significant progressMouldsWood working apparatusBrickWear resistant

The invention provides a light wear-resistant baking-free brick supporting plate and a manufacturing method thereof. The supporting plate comprises a supporting plate body and wear-resistant plates arranged on two use surfaces of the supporting plate body, wherein the supporting plate body comprises M pieces of strip wood plates and N groups of screws and nuts which are matched with each other; N screw through holes are transversely formed along each strip wood plate; N pieces of screws are correspondingly inserted into the N bolt through holes of each piece of strip wood plate respectively; the nuts lock corresponding screws, wherein M and N are both natural numbers greater than 1. The manufacturing method comprises the following steps: manufacturing the supporting plate body of a steel and wooden structure; sanding the surface of the supporting plate body; coating an adhesive glue layer on the two use surfaces of the supporting plate body; and then pressing the high molecular composite wear-resistant plates on the two use surfaces of the supporting plate body so as to obtain the light wear-resistant baking-free brick supporting plate. The supporting plate has the advantages of light weight, super wear resistance, long life and capability of renewing. The method has the advantages of simple process, high practicability and low processing cost.

Owner:潘家国

Method for preparing solid-wood composite strengthened plates

InactiveCN101607403ASuper wear-resistantHigh transparencyWood veneer joiningWood layered productsSanderAdhesive

The invention relates to a method for preparing solid-wood composite strengthened plates, which is characterized in that a solid-wood composite strengthened plate is prepared by the following steps: (1) a step of manufacturing a thin wood plate, which is to cut hard wood into dimension lumber, soak the dimension lumber in hot water at a temperature above 50 DEG C, perform bonding by use of water-resistant high-strength adhesive, perform solid-pressure molding through a cold press and a pressurizer and slice the obtained product into a thin wood plate; (2) a step of overlaying, which is to adopt an applicator to smear base glue on a density board, paste the thin wood plate onto the density board, send the obtained product into a hot press for pressing, perform polishing through a sander and prepare the obtained product into a base plate; and (3) a step of covering a wear-resistant layer, which is to cover the base plate with an aluminum sesquioxide wear-resistant layer, press through pressure at a temperature above 200 DEG C, perform hot-press treatment processing for 1 minute and prepare the obtained product into the solid-wood composite strengthened plate. The solid-wood composite strengthened plate has the characteristics of super wear resistance, strong paint-film smooth adhesive force, high transparency, acid-base resistance, strong flame-retardant moisture resistance, insusceptibility to cracking and bursting and low cost.

Owner:赵维东

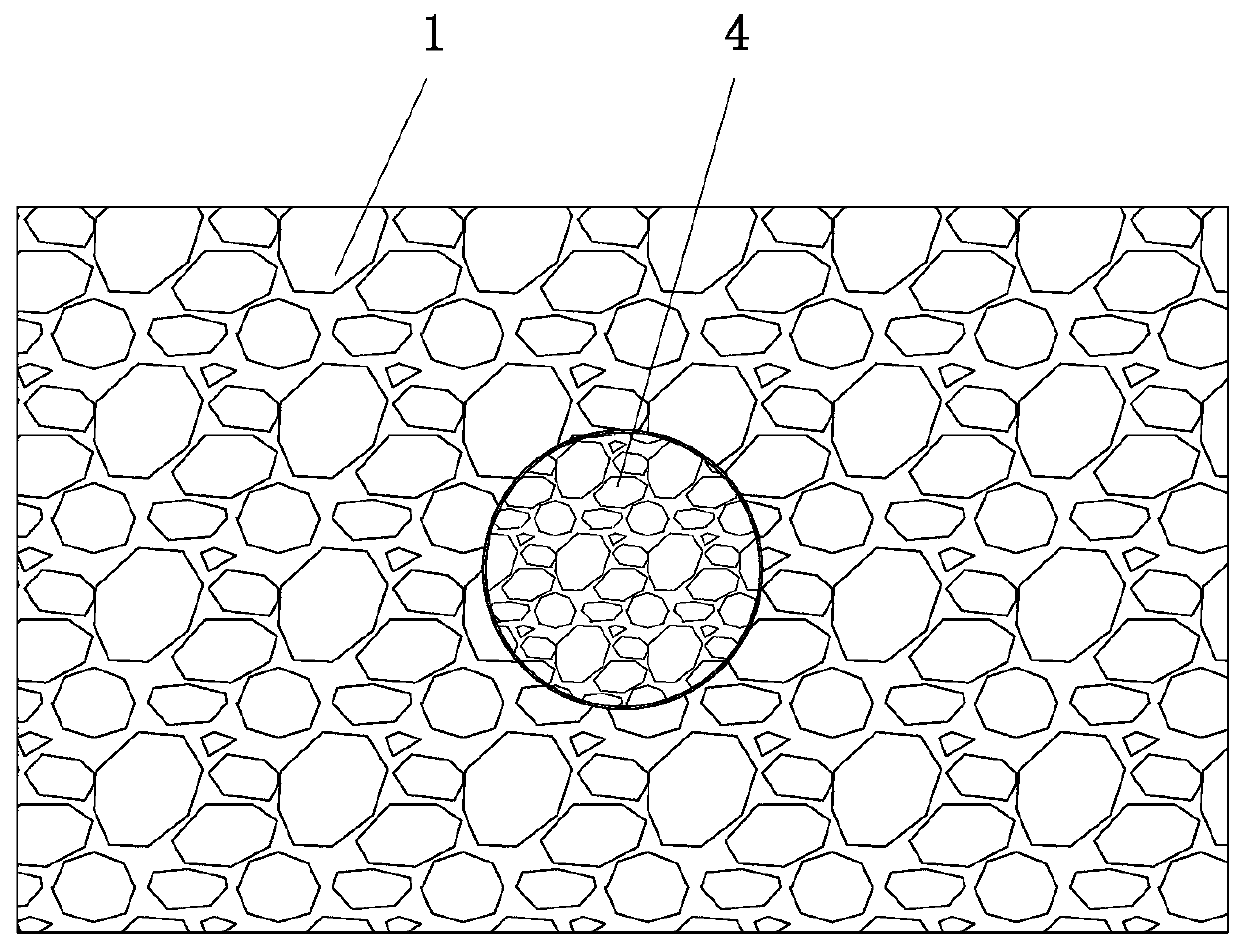

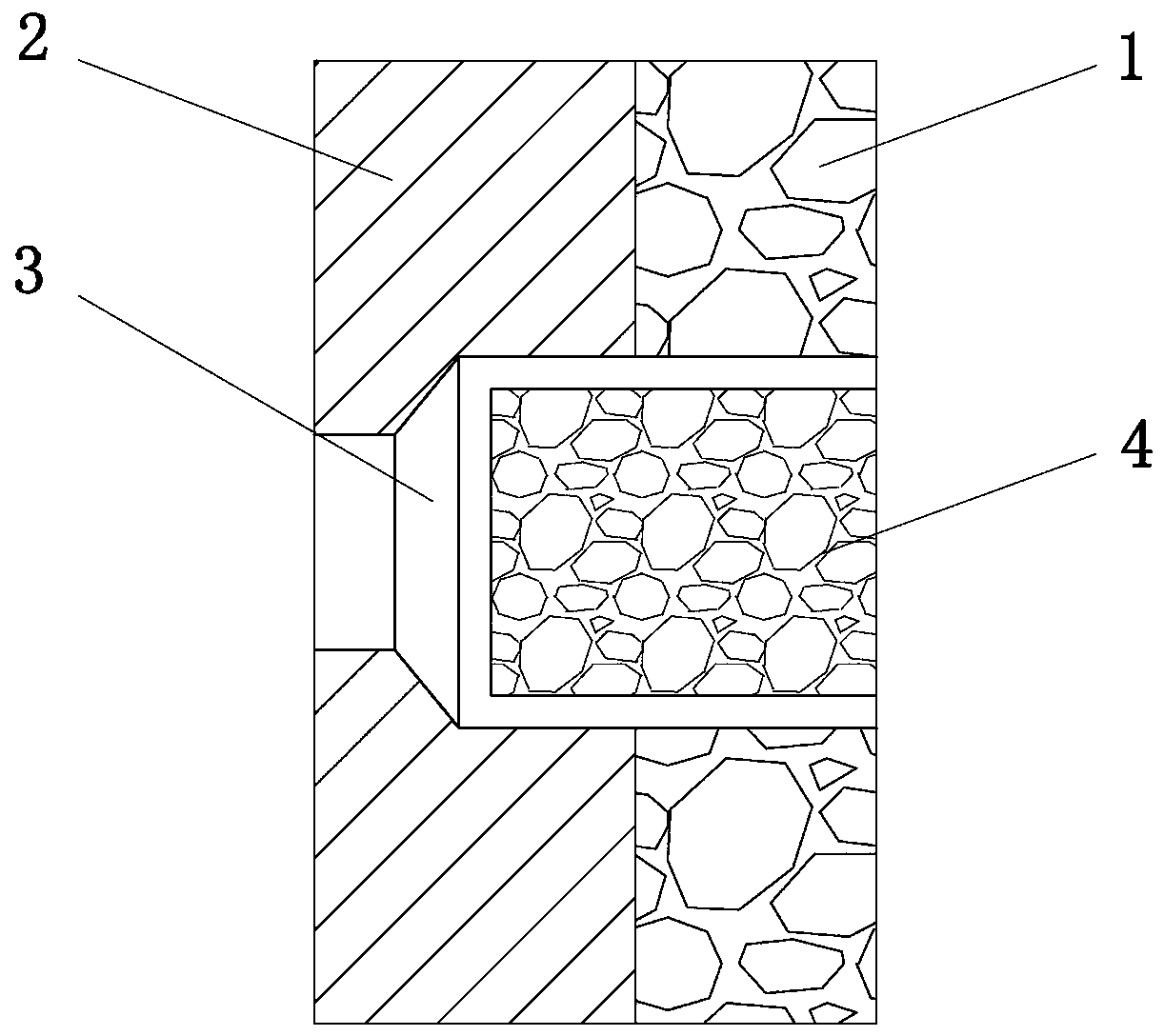

Super-wear-resistant steel-ceramic composite wear-resistant lining plate and molding method thereof

The invention relates to a super-wear-resistant steel-ceramic composite wear-resistant lining plate and a molding method thereof. The wear-resistant lining plate comprises a ZTA (zirconia toughened alumina) ceramic wear-resistant layer and a high-chromium cast iron layer, wherein the ZTA ceramic wear-resistant layer is positioned on the surface of the lining plate and is uniformly distributed; andthe high-chromium cast iron layer is positioned at the bottom of the lining plate and is integrally cast with the ZTA ceramic wear-resistant layer. The molding method of the wear-resistant lining plate comprises the following steps: 1) preparing ZTA ceramic granules; 2) preparing a honeycomb-shaped ceramic prefabricated body; 3) performing casting molding; and 4) performing thermal treatment. Thewear-resistant lining plate adopts a unique specific composite structure of steel and ceramic, respective advantages of the steel and the ceramic are provided by the anti-impact lining plate, and thewear-resistant lining plate has both high wear resistance of ceramic and toughness of the steel, and is capable of enduring impact of medium / high strength of materials. The lining plate provided by the invention has the advantages of being good in super wear resistance, high in performance cost ratio and simple and convenient to mount and is wide in applicability.

Owner:吴葵阳

Silicone rubber sealing gasket with high-pressure resistance and super wear resistance and preparation method thereof

The invention discloses a silicone rubber sealing gasket with high-pressure resistance and super wear resistance and a preparation method thereof. The silicone rubber sealing gasket is prepared from, by weight, 42-68 parts of methylvinyl silicone rubber, 34-56 parts of polyurethane rubber, 12-18 parts of polybutylene, 23-37 parts of polyamide thermoplastic elastomer, 25-35 parts of carbon black N220, 2-3 parts of zinc oxide, 3-4 parts of stearic acid, 5-7 parts of colloidal sulfur, 2-3 parts of gamma-thiopropyl triethoxy silane, 3-5 parts of 4,4'-methylenebis(2-chloroaniline), 16-22 parts of titanium diboride, 7-9 parts of pine tar, 10-15 parts of gum dammar, 2-3 parts of an accelerator PX, 1-2 parts of an accelerator OTOS, 1-2 parts of an antioxidant KY-405, 1-2 parts of an antioxidant 1076 and 14-18 parts of a modifier. The silicone rubber sealing gasket has the advantages of high strength, high elasticity, super wear resistance, tear resistance, aging resistance, ozone resistance, corrosion resistance and the like, and is long in service life and wide in application range.

Owner:HUAINAN CAOAN RUNLONG PLASTIC CO LTD

Coating capable of preventing wind and sand

InactiveCN104449299AWith super weather resistanceIncrease elasticityPolyurea/polyurethane coatingsPolyether coatingsAlcoholEmulsion

The invention discloses a coating capable of preventing wind and sand. The coating capable of preventing wind and sand comprises components with the following content proportions: 12-28 parts of organic silicon modified fluorocarbon resin, 22-34 parts of ethylene resin, 18-30 parts of polyimide, 44-52 parts of polyterephthalyl alcohol, 30-42 parts of waterborne polyurethane emulsion, 4-10 parts of glass steel particles, 3-6 parts of sodium silicate and 1-5 parts of titanium dioxide. By virtue of the mode, the invention provides the coating capable of preventing wind and sand, and the coating has the characteristics of super weather resistance, high elasticity, super wear resistance, wind and sand resistance, high and low temperature deformation resistance, and the like.

Owner:SUZHOU MINGXUAN FLOORING COATINGS

Insulated dust-proof coating

InactiveCN105255342AWith super weather resistanceIncrease elasticityPolyurea/polyurethane coatingsPolyether coatingsPolyesterEmulsion

The invention discloses an insulated dust-proof coating. The insulated dust-proof coating comprises the following components in parts by weight: 20-32 parts of a waterborne polyurethane emulsion, 12-14 parts of dimethyldichlorosilance, 34-42 parts of poly-terephthalyl alcohol, 12-18 parts of oxalic acid polyester, 8-14 parts of glass steel particles, 5-9 parts of titanium dioxide, 8-12 parts of hydroxyethyl cellulose, 3-5 parts of a dispersing agent and 100-110 parts of ionized water. The insulated dust-proof coating has the characteristics of super weather resistance, high elasticity, super wear resistance, wind-sand resistance, high-low temperature performance resistance and the like. The insulated dust-proof coating has insulativity and is capable of preventing high temperature influences caused by electric conduction.

Owner:SUZHOU MINGXUAN FLOORING COATINGS

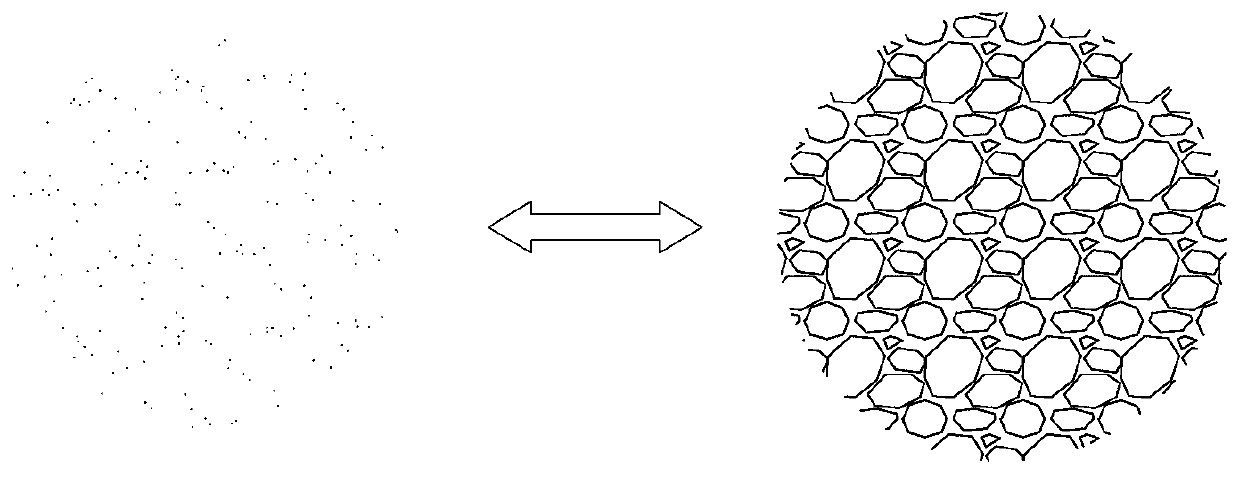

Molybdenum disulfide quantum dot/graphene/polymer-based super-wear-resistant self-lubricating composite material and preparation method and application thereof

The invention discloses a molybdenum disulfide quantum dot / graphene / polymer-based super-wear-resistant self-lubricating composite material and a preparation method and application thereof, and belongsto the technical field of advanced composite material science. The preparation method comprises the following steps: firstly, preparing molybdenum disulfide quantum dots by combining ultrasound and solvothermal; loading the molybdenum disulfide quantum dots on the surface of graphene through a physical adsorption effect to prepare molybdenum disulfide quantum dot / graphene composite particles, then introducing the molybdenum sulfide quantum dot / graphene composite particles into a polymer material, and preparing the polymer-based composite material with super wear resistance and excellent self-lubricating performance. The preparation method is simple in operation process and convenient for large-scale production, and has universality; compared with a pure polymer material, the molybdenum disulfide quantum dot / graphene / polymer-based super-wear-resistant self-lubricating composite material prepared by the method has the advantages that the friction coefficient can be reduced by 51-63%, the volume wear rate can be reduced by 70-95%, the molybdenum disulfide quantum dot / graphene / polymer-based super-wear-resistant self-lubricating composite material can be applied to super-wear-resistantmechanical parts, and the application of the polymer material is widened.

Owner:SHAANXI UNIV OF SCI & TECH

Novel glass super-hydrophobic transparent high-efficiency heat-insulating coating

PendingCN112322116AImprove insulation performanceImprove energy savingAntifouling/underwater paintsPaints with biocidesPROPYLENE GLYCOL BUTYL ETHERSlurry

The invention provides a novel glass super-hydrophobic transparent efficient heat-insulating coating and a preparation method thereof, and relates to the field of building materials, in particular tothe novel glass super-hydrophobic transparent efficient heat-insulating coating. The novel glass super-hydrophobic transparent high-efficiency heat-insulating coating comprises the following raw materials by weight: 2400 to 2600 kg of aqueous fluorocarbon resin (with solid content of 45 to 50%), 1200 to 1300 kg of slurry, 1100 to 1300 kg of deionized water, 130 to 160 kg of a 1053 dispersant, 50 to 70 kg of a DP082 antifoaming agent, 30 to 50 kg of a WT102 thickener, 80 to 100 kg of texanol, 90 to 110 kg of leveling agent and 4 to 6 kg of dipropylene glycol. The method comprises: uniformly mixing the water-based fluorocarbon resin with the slurry in proportion, then adding deionized water, a dispersing agent, an antifoaming agent, a thickener, texanol, leveling agent, dipropylene glycol monomethyl ether and dipropylene glycol butyl ether, adjusting the pH value to 7, and dispersing in a dispersion machine at a high speed of 1500 rpm for 30 min to obtain the glass super-hydrophobic transparent efficient heat-insulating coating.

Owner:成都享誉新材料科技有限公司

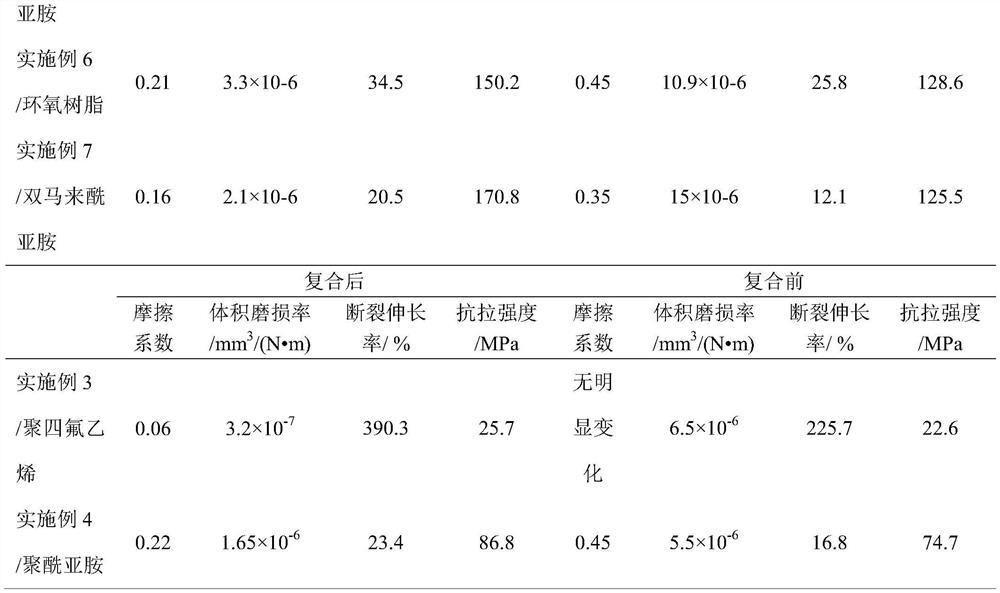

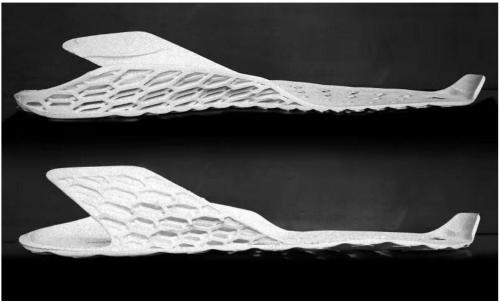

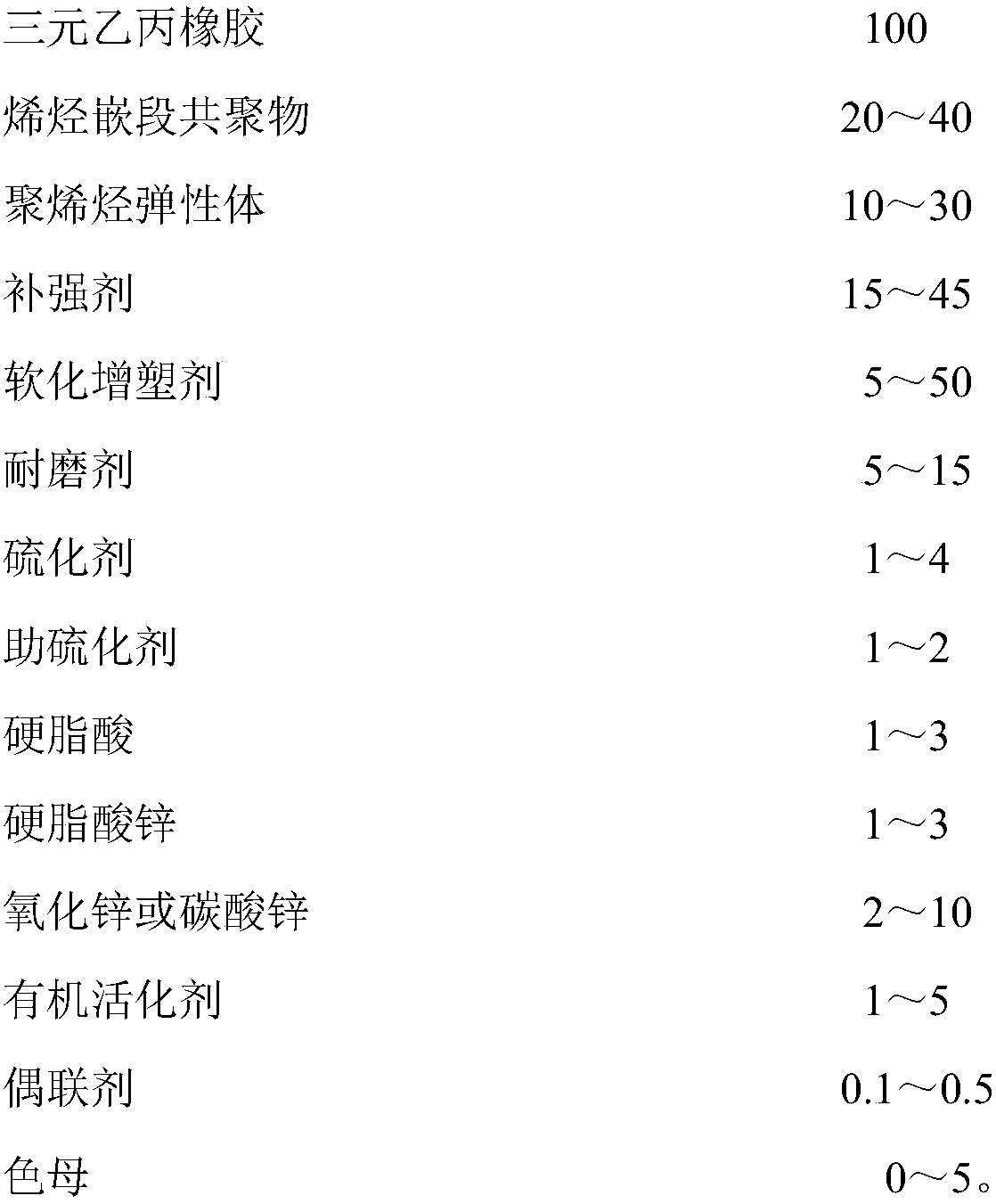

Wear-resistant rubber particle capable of being formed by injection molding, preparation method and application thereof

The invention discloses a wear-resistant rubber particle capable of being formed by injection molding, a preparation method and application thereof, wherein the rubber particle comprises, by mass, 100parts of ethylene propylene diene monomer, 20-40 parts of an olefin block copolymer, 10-30 parts of a polyolefin elastomer, 15-45 parts of a reinforcing agent, 5-50 parts of a softening plasticizer,5-15 parts of an anti-wear agent, 1-4 parts of a vulcanizing agent, 1-2 parts of an auxiliary vulcanizing agent, 1-3 parts of stearic acid, 1-3 parts of zinc stearate, 2-10 parts of zinc oxide or zinccarbonate, 1-5 parts of an organic activator, 0.1-0.5 part of a coupling agent and 0-5 parts of color master batch. According to the invention, injection molding can be realized; the wear-resistant rubber particle can be used for manufacturing outsoles of sneakers or casual shoes, and various properties of the manufactured outsoles are obviously superior to the requirements of high-quality standards of the sneakers; and the wear-resistant rubber particle has the advantages of super wear resistance, high skid resistance, high elasticity, yellowing resistance, aging resistance, high and low temperature resistance, light weight and the like, particularly can achieve outsole manufacturing of complex three-dimensional structures, is low in material loss and high in yield.

Owner:上海帼帆化工新材料有限公司 +1

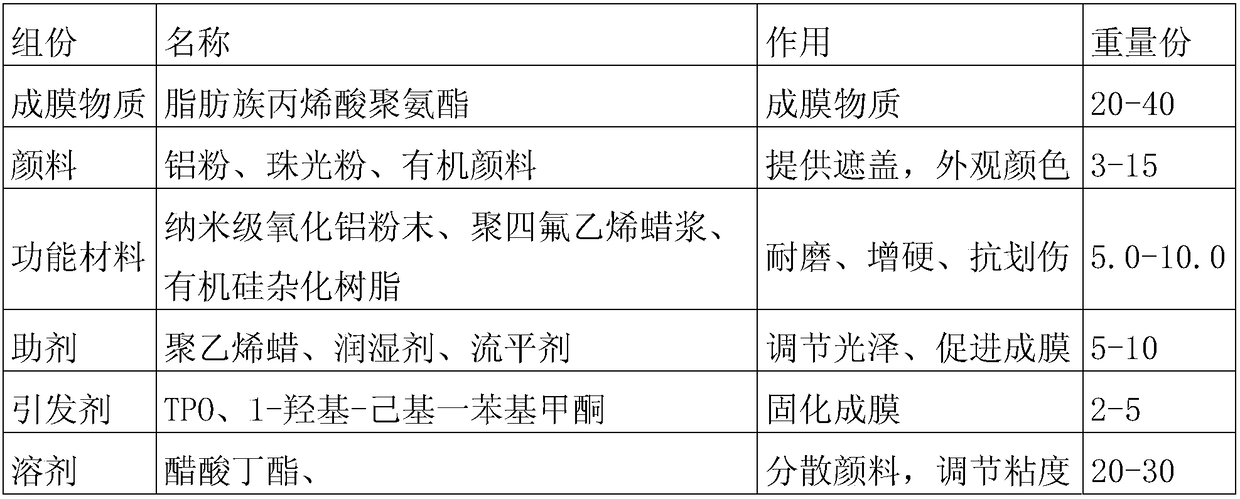

High-hardness super wear-resistant and fouling-resistant diamond colorful UV coating

PendingCN108285666AHigh hardnessSuper wear-resistantAntifouling/underwater paintsPaints with biocidesPolymer scienceWear resistant

The invention relates to a high-hardness super wear-resistant and fouling-resistant diamond colorful UV coating. Specifically, the coating disclosed by the invention is prepared from 20 to 40 weight parts of a film forming substance, 3 to 15 weight parts of a pigment, 5 to 10 weight parts of a functional material, 5 to 15 weight parts of a coating additive, 2 to 5 weight parts of an initiator anda diluent, wherein the film forming substance is 6-15-polyfunctional group aliphatic acrylic polyurethane and 4-6 functional group aliphatic monomer, and the functional material is a nano-scale hardening wear-resistant material. The UV coating prepared from the composition of the invention has 8-9 H pencil hardness, 100 times of tests on the coating with a tungsten resisting needle show that the coating is non-discoloring, and the high-hardness super wear-resistant and fouling-resistant diamond colorful UV coating is resistant to fouling and fingerprints, can be made into various colors and appearances, can be sprayed at one time, and can be widely applied to 3C products and medical equipment.

Owner:上海长润化工有限公司

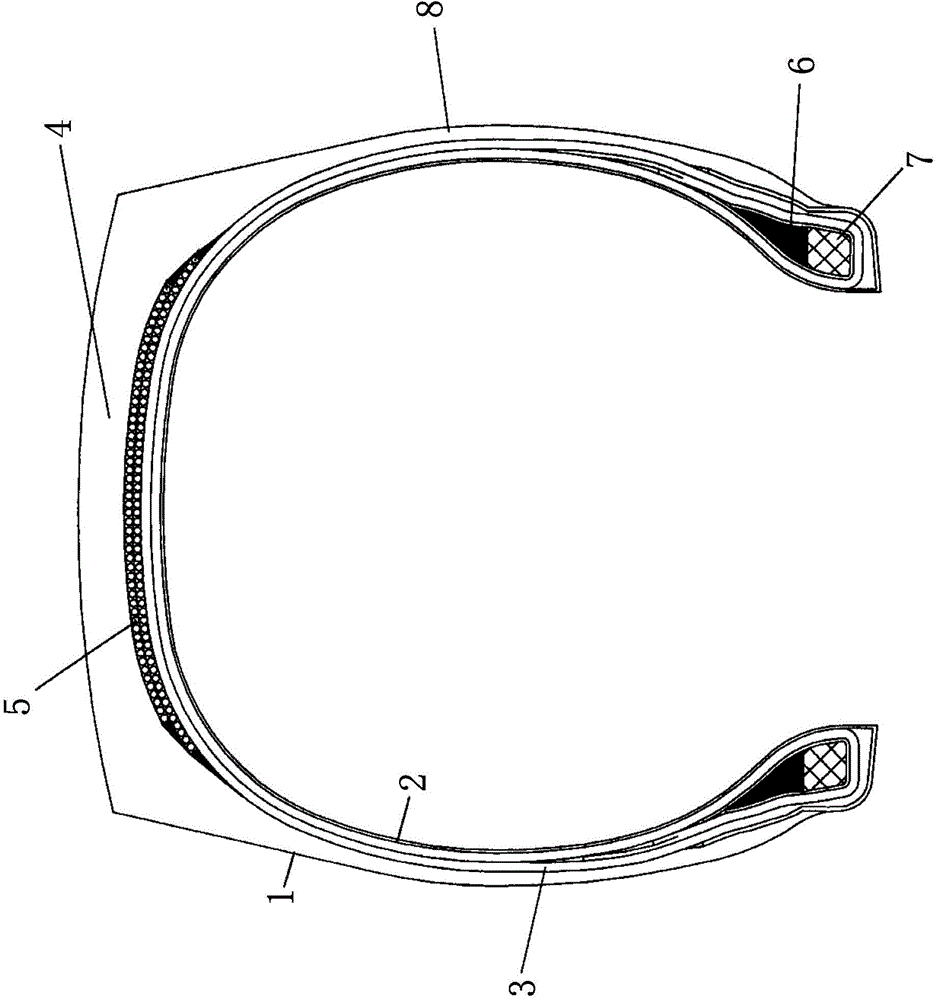

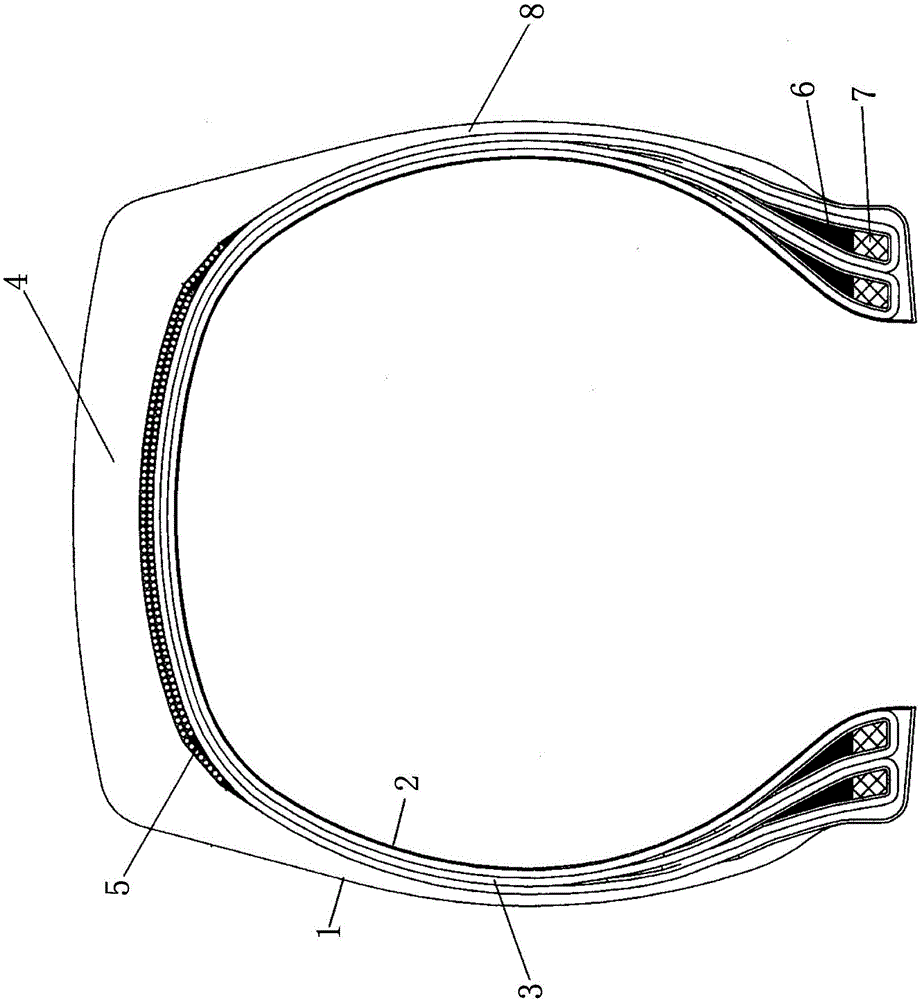

Steel wire belt ply oblique crossing type engineering tyre

InactiveCN104589926AHigh strengthReduce distortionPneumatic tyre reinforcementsPuncture resistanceEngineering

The invention discloses a steel wire belt ply oblique crossing type engineering tyre. The steel wire belt ply oblique crossing type engineering tyre is characterized in that a chinlon curtain cloth tyre body layer is arranged between a tyre outer wall and a tyre inner wall; a steel wire belt ply is arranged between a tyre crown body and the chinlon curtain cloth tyre body layer; and rubber strips with triangular sections, and steel wire rings are arranged at the inner edge of tyre side rubber. With the adoption of the structure, the steel wire belt ply oblique crossing type engineering tyre is applicable to arrangement of mechanical vehicles including forklifts, lift trucks and the like under ground complicated and bad working conditions, and has the good properties of strong tyre body strength, small deformation, ultra-strong wear resistance, puncture resistance and the like.

Owner:山东三工橡胶有限公司

Highly wearable vacuum coating ultraviolet curing coatings

ActiveCN100567413CImprove adhesionImproved RCA wear performancePolyurea/polyurethane coatingsHigh humidityWear resistant

The invention relates to the field of electronic application coatings, in particular to high wear-resistant vacuum coating ultraviolet light curing coatings. The composition and content of the high wear-resistant vacuum coating UV-curable coating are: 10-30wt% of difunctional urethane acrylate, 10-40wt% of high-functional urethane acrylate, 5-20wt% of high-functional acrylate monomer, single Functional acrylate monomer 0-15wt%, acid adhesion promotion 1-10wt%, photoinitiator 1-6wt%, nano wear-resistant material 0-5wt%, additive 0.1-2wt%, solvent 10-50wt%. The invention is aimed at protecting the surface of vacuum coating workpieces of electronic products such as mobile phones, MP3s, and digital cameras, and has the characteristics of good surface effect, super wear resistance, high temperature and high humidity resistance, cold and heat cycle resistance, and excellent yellowing resistance, among which RCA has the highest wear resistance It can reach more than 1500 times, effectively improving the service life of electronic products. The invention effectively solves the adhesive force and wear resistance of the UV-cured vacuum coating paint, solves the matching problem of the primer and top paint of the UV-cured vacuum coating paint, and has wide versatility.

Owner:HUNAN SOKAN NEW MATERIAL

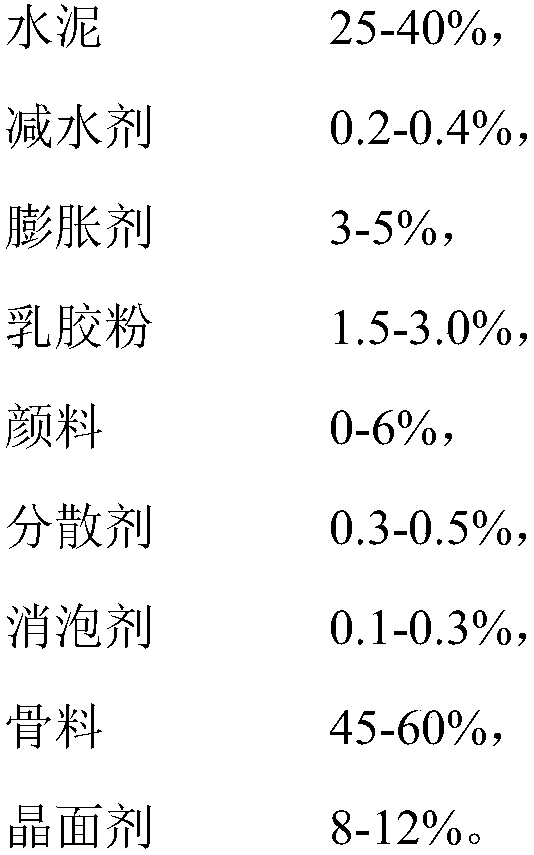

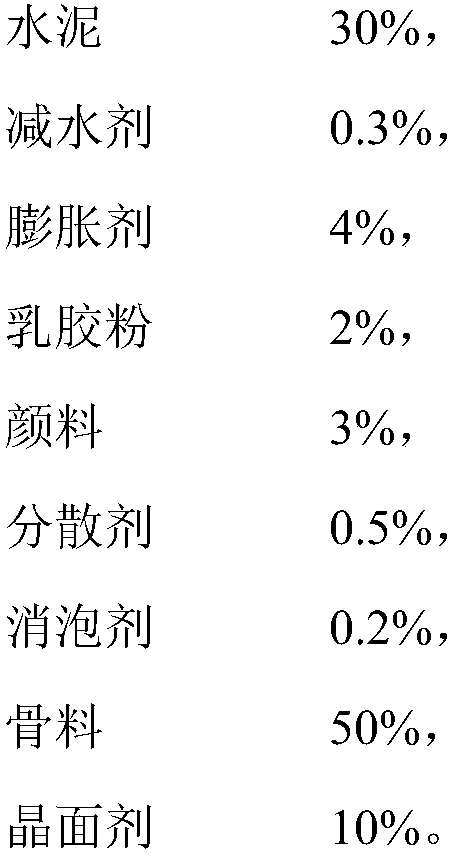

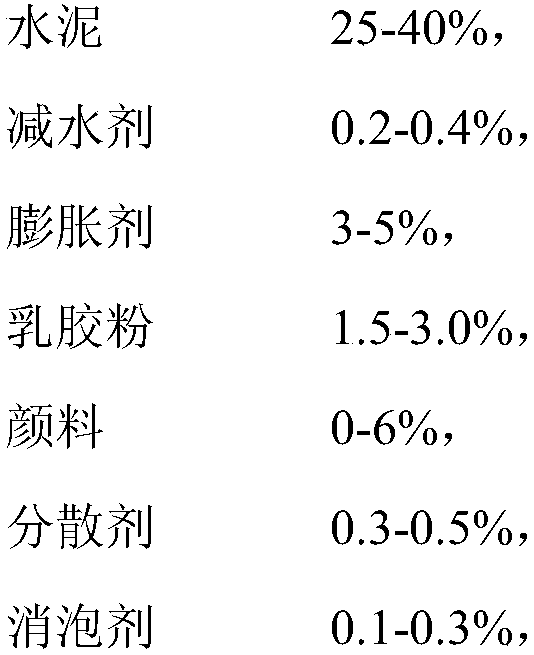

Integral material for laying ground

InactiveCN108033733AExcellent overall performanceSave resourcesVolatile organic compoundCrystal plane

The invention relates to an integral material for laying a ground. The integral material comprises cement, water reducing agents, expanding agents, latex powder, pigments, dispersing agents, defoamingagents, aggregates, crystal plane agents and the like. The integral material takes the cement, the aggregates and the crystal plane agents as main raw materials and takes the water reducing agents, the expanding agents, the latex powder, the pigments, the dispersing agents, the defoaming agents and the like as auxiliary materials, and the produced integral material is good in comprehensive performance, has super-abrasion resistance, decorativeness and corrosion resistance and does not release a VOC (volatile organic compound). According to the integral material, the aggregates are provided with renewable components, waste resources can be reused, resources can be saved, and energy conservation and emission reduction are achieved. Compared with a traditional terrazzo, the integral materialhas longer service life, and the service life of the integral material can reach 20 years.

Owner:江门市卡斯乐建材有限公司

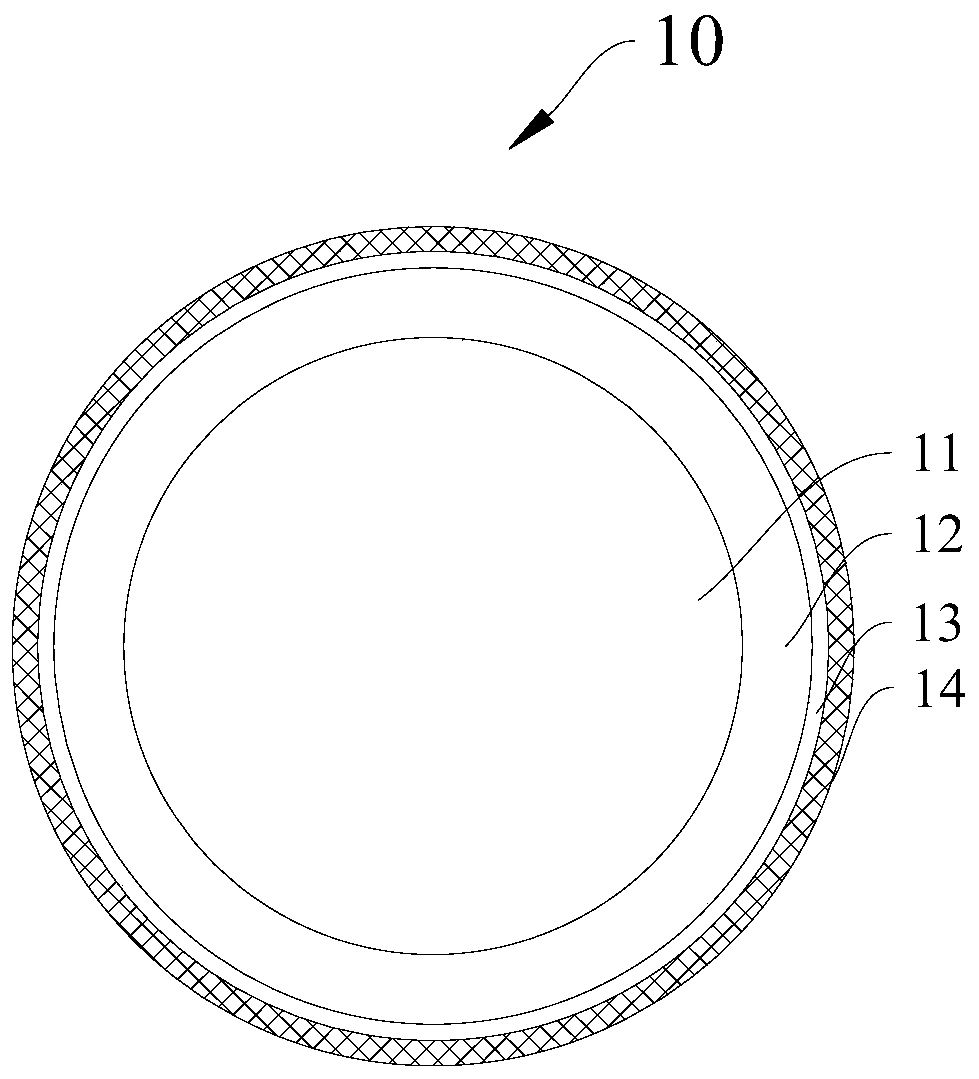

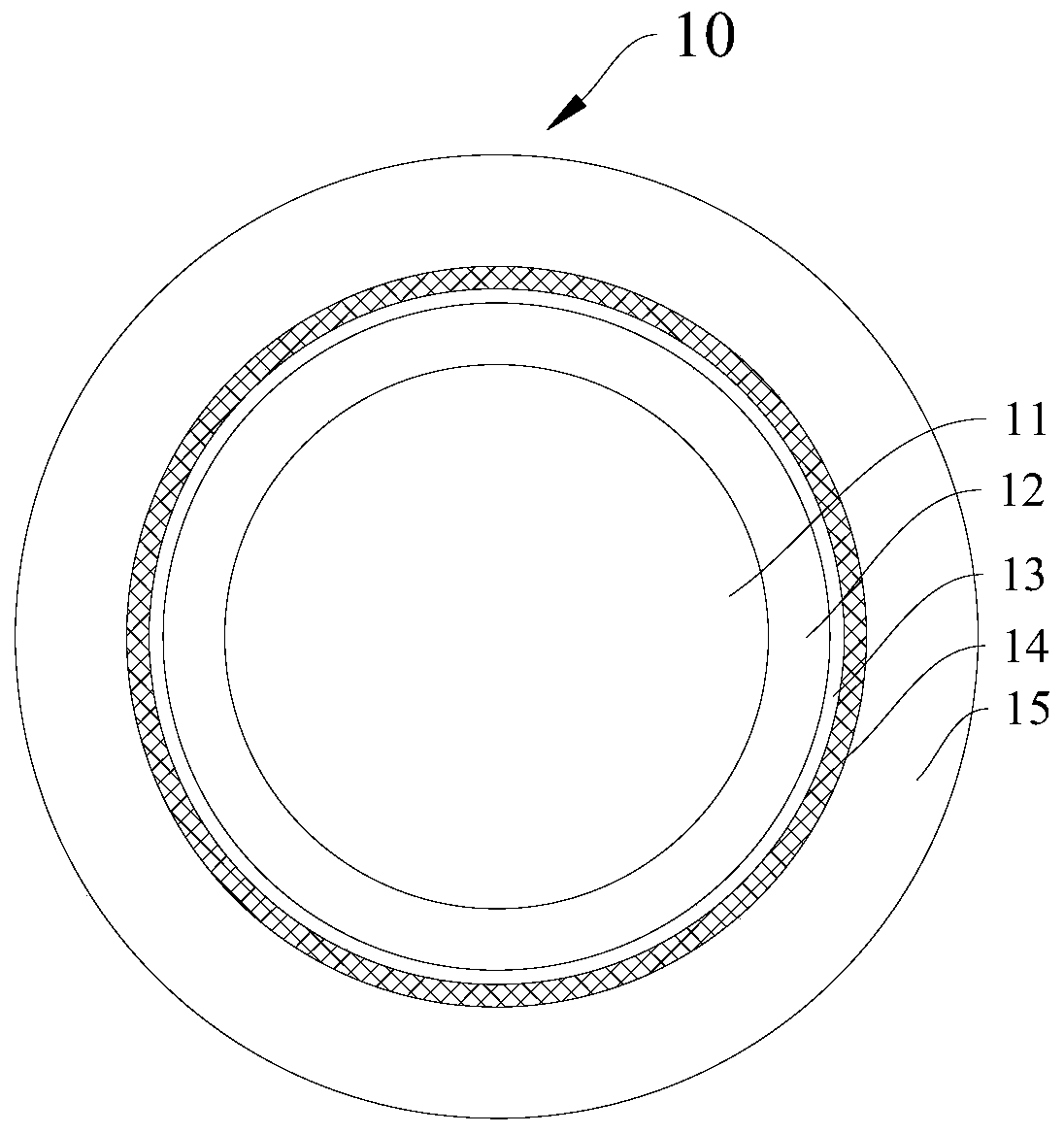

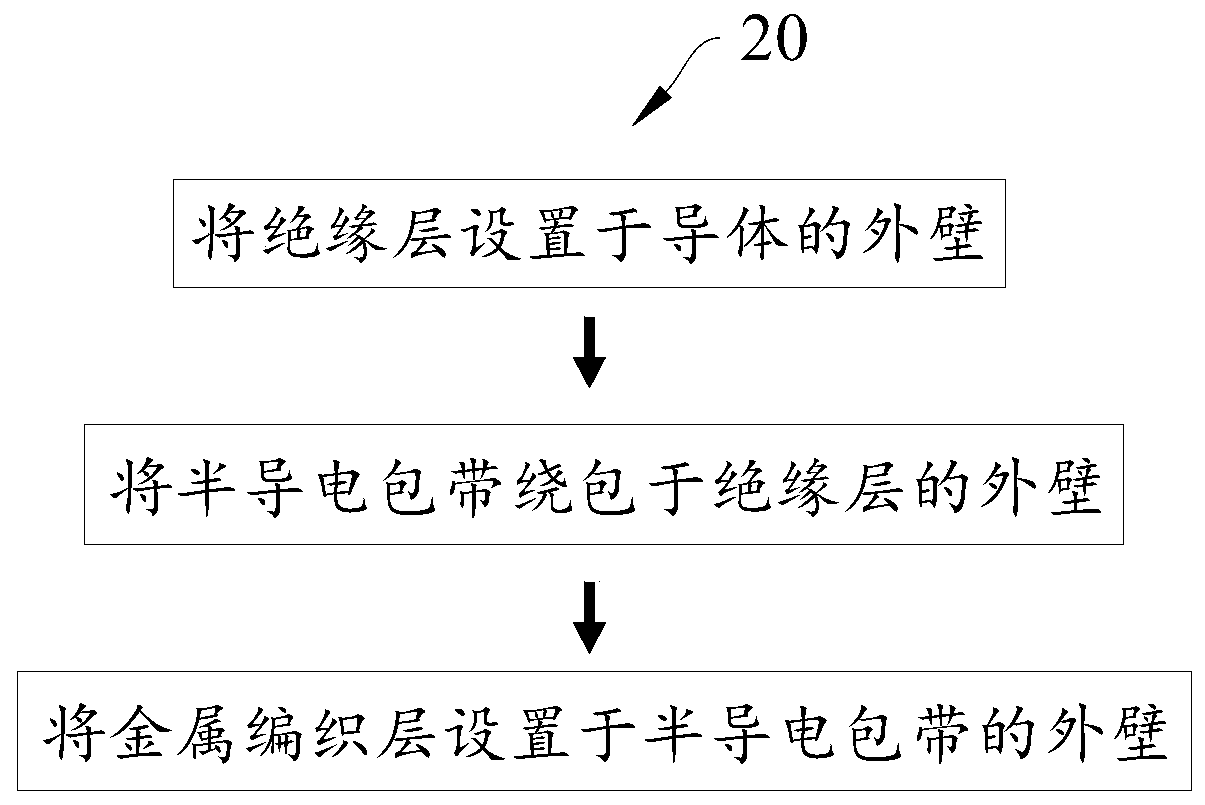

High-reliability flexible torsion-resistant low-voltage cable and manufacturing method thereof

InactiveCN110021453AImprove torsional and tensile propertiesGuaranteed safety and reliabilityFlexible cablesFlexible conductorsElectrical conductorLow voltage

The present application discloses a high-reliability flexible torsion-resistant low-voltage cable and a manufacturing method thereof. The high-reliability flexible torsion-resistant low-voltage cablecomprises a conductor, an insulating layer, a semi-conductive tape and a metal braided layer. The insulating layer is arranged on the outer wall of the conductor. The semi-conductive tape is wrapped around the outer wall of the insulating layer. The metal braided layer is arranged on the outer wall of the semi-conductive tape. The cable provided by the application and the cable manufactured by themanufacturing method can be efficiently subjected to electric leakage detection.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH +1

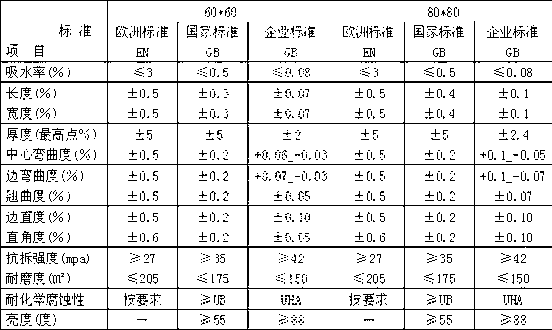

Platinum polished tile and production process for same

The invention relates to a platinum polished tile and a production process for the same. The platinum polished tile is characterized by being composed of a basic surface material and a crystalline grain material, wherein the basic surface material is composed of potassium feldspar sand A, potassium feldspar sand B, soda feldspar A, soda feldspar B, soda feldspar C, potassium-soda feldspar A, pyrophyllite, talcum, flint clay, pigment and clay; and the crystalline grain material is composed of potassium feldspar sand 1, soda feldspar 1, soda feldspar 2, pyrophyllite, talcum and clay. The production method for the platinum polished tile comprises the working procedures of raw material selection, powder preparation, material distribution, press-forming, drying, roller kiln once-firing, edging, polishing and the like. According to the production process, multiple fabrics, a super-transparent jadeite granulation technology and a natural grain reduction technology are applied, and time-delay crystallization and firing at 1300 DEG C are performed, so that the polished tile is greatly improved in physical performance and three-dimensional performance; and the polished tile is high in strength, strong in wear resistance, and excellent in anti-slide performance.

Owner:LIAONING JINDIYANG CERAMIC

A method of heat -solving power generation and comprehensive utilization of rice shells

ActiveCN110423635BReduce usageReduce consumptionMaterial nanotechnologySilicaSteam reformingSilicon dioxide

The invention relates to a rice husk pyrolysis electric power generating and comprehensive utilization method, and belongs to the field of biomass energy chemistry. The method comprises following steps: 1, biomass pyrolysis generation of pyrolysis gas and pyrolytic carbon; 2, synchronous oxygen removing, tar reduction, and phenol enrichment; 3, pyrolysis gas heat exchange cooling heat recycling, and separation of phenol containing waste water; 4, electrostatic tar capturing pyrolysis gas purifying, and tar enrichment; 5, pyrolytic carbon is adopted for dispersion of tar, synchronous water gasreaction, and steam reforming production of hydrogen-enriched gas; 6, reaction waste residue is taken as a biomass nanometer silica preparation raw material; and 7, preparation of phenolic resin adhesive from the phenol containing waste water. According to the method, hydrogen in water is adopted to solving problems of using of biomass as an energy that hydrogen content is low and oxygen content is high; pyrolysis and steam reforming two step method is adopted to prepare hydrogen-enriched high-energy combustion gas, electric power generation and heat supply are realized; at the same time, thephenol containing waste water is enriched to produce biomass phenol base adhesive, so that environment pollution caused by chemical phenol is reduced, cost is reduced, waste is changed into valuables;by-product natural nanometer silica is obtained, and an ultra wear resistance material is provided for green aviation tyres.

Owner:JILIN UNIV

Super wear-resistant, fire-resistant and flame-retardant mineral floor coating and preparation method thereof

ActiveCN107739189BFire retardantSuper wear-resistantAlkali metal silicate coatingsCelluloseAluminium hydroxide

The invention belongs to the technical field of coatings, in particular to a novel inorganic super abrasion-resistant, fireproof and flame-retardant mineral floor coating. The novel inorganic super abrasion-resistant, fireproof and flame-retardant mineral floor coating is prepared from the following raw materials in percentage by mass: 1 to 10% of dispersant, 0 to 5% of cellulose, 0 to 5% of bentonite, 0 to 3% of defoaming agent, 0 to 5% of flatting agent, 0 to 4% of wetting agent, 1 to 15% of titanium dioxide powder, 0 to 15% of aluminum hydroxide, 0 to 10% of wollastonite powder, 15 to 30% of silicon dioxide, 0 to 5% of fused silicon dioxide, 0 to 40% of nanometer silicate, 0 to 5% of thickener, and the balance of water. The novel inorganic super abrasion-resistant, fireproof and flame-retardant mineral floor coating has the advantage that the mineral (silicate) is used as a filming matter, so that the characteristics of the traditional floor coating are realized, and the super abrasion-resistant, fireproof and flame-retardant characteristics are also realized.

Owner:河南华彩无机涂料有限公司

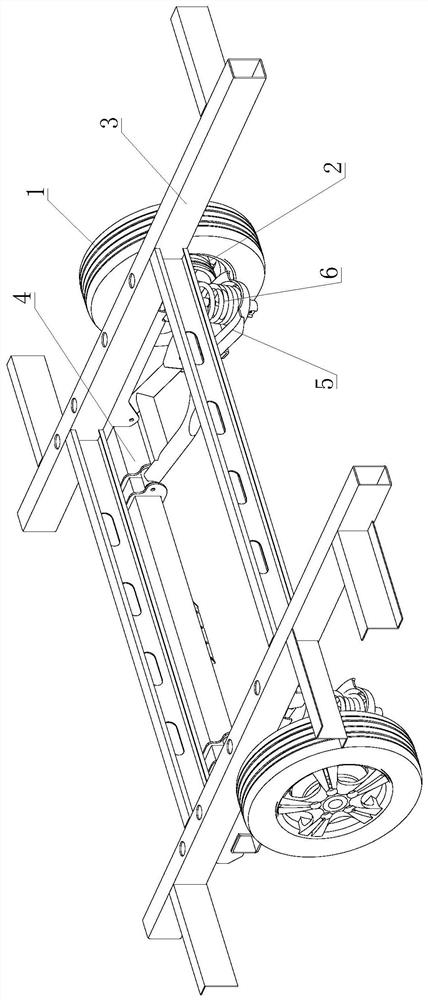

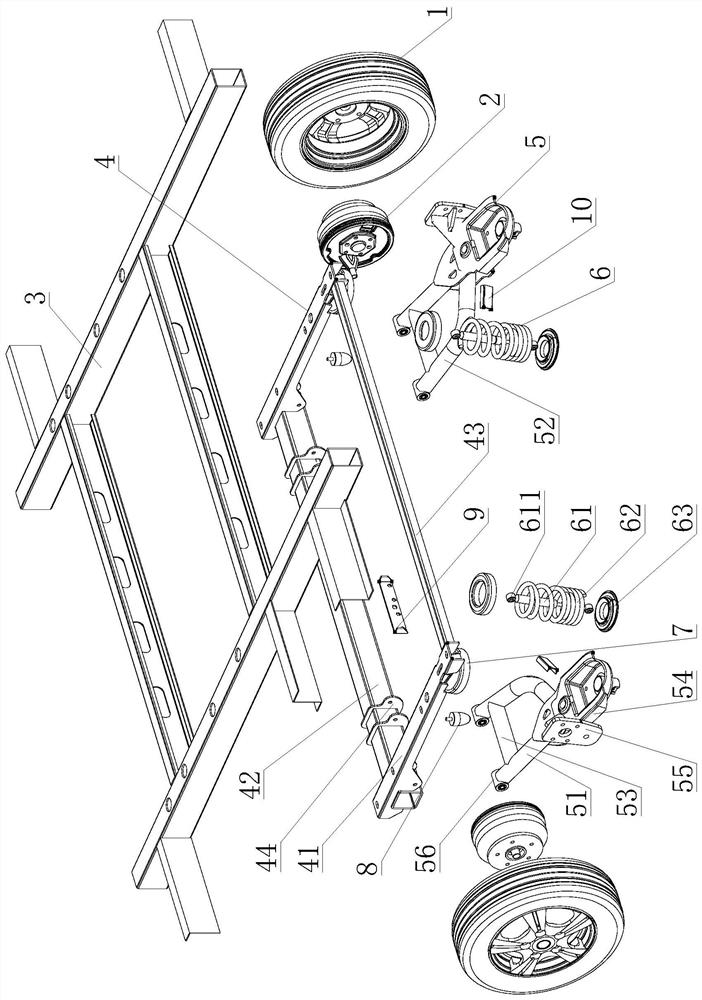

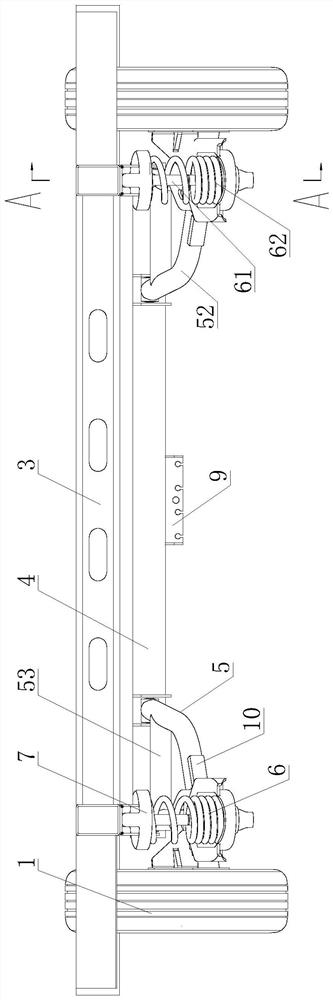

Independent suspension system of trailer

PendingCN114801617AGuaranteed stability and reliabilityReduce frame vibrationBraking componentsResilient suspensionsVehicle frameCantilever

The invention relates to the technical field of trailer suspensions, in particular to a trailer independent suspension system which comprises two wheel assemblies, two brake assemblies and a chassis bearing frame and further comprises a suspension connector, a cantilever connector and two damping assemblies. The brake assembly is installed at the axis position of the wheel assembly and fixedly connected with the cantilever combination piece, one side of the cantilever combination piece is movably connected with a front cross beam of the suspension combination piece, the other side of the cantilever combination piece is movably connected with a longitudinal beam of the suspension combination piece through the damping assembly, and the suspension combination piece is fixedly connected with the chassis bearing frame. The independent suspension system of the trailer is simple in structure and convenient to assemble, the impact force of the ground on wheels and a frame can be attenuated, vibration of the frame is reduced, the overall braking performance of the trailer is improved, the smooth stability of the trailer in the running process and the safety of goods are guaranteed, and the service life of parts of the trailer is prolonged; the occupied trailer chassis space is small, and the economic cost is saved.

Owner:常州市丹华机械有限公司

Giant crystal grains capable of forming crystal flowers, dry grain combination, grains for ceramics, ceramics and preparation method of ceramics

ActiveCN112456802BRich and varied colorsImprove the decorative effectMacrocrystallineTexture (crystalline)

The invention belongs to the technical field of ceramics, and discloses giant crystal particles capable of forming crystal flowers, a combination of dry particles, particles for ceramics, ceramics and a preparation method for ceramics. The chemical quality composition of macrocrystalline grains includes SiO 2 、Al 2 o 3 、K 2 O, Na 2 O, CaO, MgO, BaO, ZnO, F, Li 2 O, TiO 2 , and metal oxides for coloring. Giant crystal particles can be quickly fired at low temperature to form large crystal crystal flowers. The crystal flowers are in the shape of petals. The color of the crystal flowers can be adjusted at any time according to the design color and texture. The colors are rich and diverse, and the decorative effect is excellent. Dry granules can be burned quickly at low temperature, which meets the requirements of energy saving and environmental protection in the ceramic field. The fired ceramic tiles have dense surface, high strength, super wear resistance and no dirt. The surface of the product is crystal clear and has a natural random crystal flower effect. The color of the brick surface is richer and more diverse. Whether it is on the ground or on the wall, it can be paved to produce a good effect.

Owner:FOSHAN DOWSTONG TECH

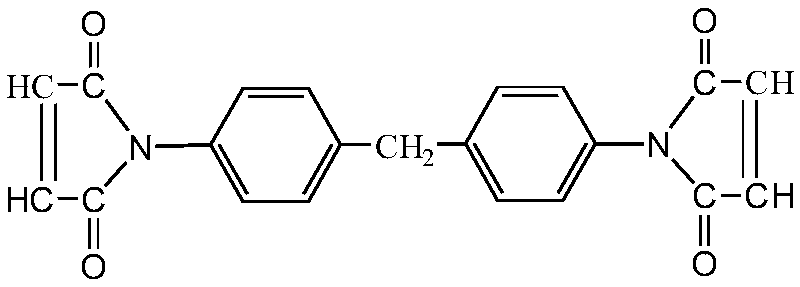

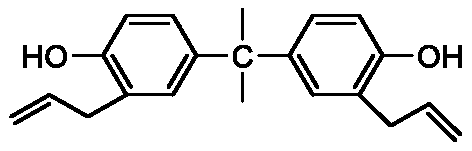

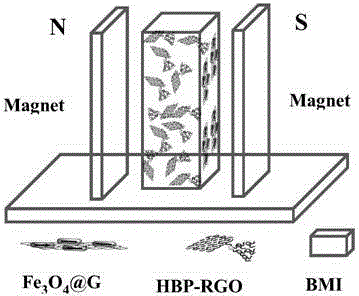

Oriented graphene/bismaleimide multilevel composite material and preparation method thereof

InactiveCN104558609ADefects that Inhibit AgglomerationImprove toughnessCvd grapheneMagnetic response

The invention relates to an oriented graphene / bismaleimide multilevel composite material and a preparation method thereof. The composite material is characterized by comprising the following components in parts by mass: 0.1-50 parts of GNS@Fe3O4, 0.1-50 parts of hyperbranched polysiloxane-modified graphene, 100 parts of diphenyl methane type bismaleimide and 10-100 parts of diallyl bisphenol A. By the composite material, the defect of agglomeration of graphene due to pi-pi stacking can be inhibited and magnetic response can be endowed to graphene, the distribution pattern of graphene in the resin is adjusted and the synergic effect of graphene and Fe3O4 in anti-wear and friction-reducing properties can be given to a full play so that the prepared composite material has the characteristics of high toughness, high strength, super anti-wear property, self-lubricating property and the like.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Production technology of real-wood handicraft composite reinforced board

InactiveCN1199766CSimple processing methodStrong smooth adhesionWood working apparatusSolid woodSander

The invention belongs to interior building decoration materials, and relates to a production process of a solid wood composite reinforced board, which is characterized in that precious and famous woods such as black walnut, sapele, Thai pomelo, rosewood, and sandalwood are selected to make 15-25mm thick thin For wood, the slicing process is effectively reflected on the composite reinforced board of solid wood technology, and the thin wood is pasted on the density board or wooden multi-layer board, put into a hot press for pressing, and sanding machine to make a substrate, covered with trioxide The two-aluminum film wear-resistant layer is processed by hot pressing with a pressure of 200kg, a temperature of 190-200°C, and a time of 45-60 seconds to make a composite reinforced board of solid wood technology. The solid wood process composite strengthened board of the present invention is produced by hot pressing one-time forming technology. The process method is simple and can be widely used in indoor architectural decoration. It has super wear resistance, smooth paint film, strong adhesion, high transparency, acid and alkali resistance, It is flame-retardant, moisture-proof, strong, not easy to crack, not easy to violent, and low in cost.

Owner:宁伯义

Low-cost high-performance floor tile polishing glaze and preparation method thereof

The invention discloses a low-cost high-performance floor tile polishing glaze which comprises the following components in percentage by mass: 0.2-1.5% of K2O, 0.1-0,8% of Na2O, 13.0% to 15.0% of CaO;3.5% to 5.0% of MgO; 10.0% to 11.5% of Al2O3; 53.5% to 55.5% of SiO2; 0.5% to 2.0% of B2O3; 2.5% to 5.0% of ZnO; 7.5% to 10.0% of BaO and SrO; PbO<0.1%; 0.0% to 1.5% of ZrO2; 0.1% to 0.4% of Fe2O3; 0.01% to 0.5% of TiO2; and Li2O<0.01%. The raw materials are uniformly mixed and stirred and packaged by woven bags to obtain a finished product. According to the low-cost high-performance floor tile polishing glaze and the preparation method thereof, the obtained product has the advantages of super wear resistance, high hardness, acid and alkali resistance, super clearness, good color developmentand the like, and the production cost of the product is relatively low.

Owner:张祥

A special wear-resistant ball for phosphate rock and its preparation method

Owner:ANHUI RUITAI NEW MATERIALS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com