High-hardness super wear-resistant and fouling-resistant diamond colorful UV coating

A paint, colorful technology, applied in multi-color effect paints, antifouling/underwater paints, polyurea/polyurethane paints, etc., can solve problems such as insufficient hardness and insufficient scratch resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

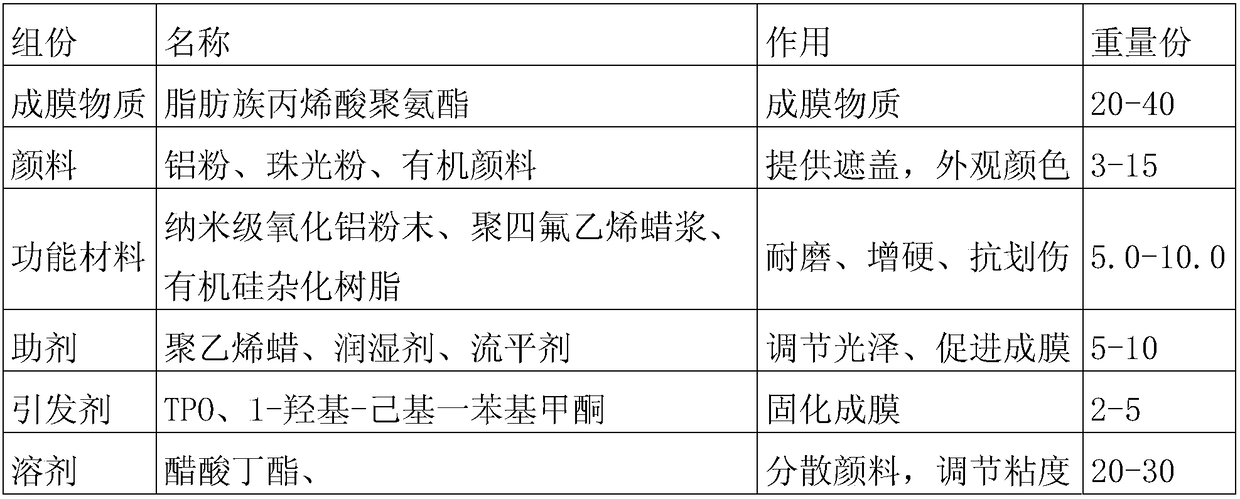

[0066] Diamond colorful UV coating of the present invention is made by above-mentioned composition, and preparation method comprises as follows:

[0067] Mix 20-40 parts by weight of film-forming substances, 3-15 parts by weight of pigments, 5-10 parts by weight of functional materials, and 5-15 parts by weight of coating additives, and disperse uniformly at high speed, and mix 2-5 parts by weight of initiator with solvent until dissolved , and then added to the mixture of film-forming substances and the like, stirred and dispersed uniformly to obtain the diamond multicolored UV coating.

[0068] Therefore, contain the component of following weight portion in the multicolored UV coating of diamond of the present invention:

[0069] 20-40 parts by weight of film-forming substances;

[0070] Pigment 3~15 parts by weight;

[0071] 5-10 parts by weight of functional materials;

[0072] 5-10 parts by weight of coating additives;

[0073] Initiator 2~5 parts by weight;

[0074]...

Embodiment 1

[0096] Preparation of Diamond Colorful UV Coatings

[0097] Prepare raw material according to the weight part in following table 2, adopt following steps to make coating:

[0098] First, put the UV resin and monomer into the dispersion tank, control the speed at 500 rpm, and disperse for 5 minutes until uniform; slowly add the functional material, wetting agent, and defoamer into the dispersion tank at 900 rpm, and disperse at a high speed 20 minutes; dissolve the initiator in part of the solvent first, disperse at 600 rpm until clear and transparent, and then add it to the dispersion tank; wet and soak the aluminum powder with solvent weight 1:1 for 1 hour, and stir at 400 rpm for 10 minutes Add it to the dispersion tank until it is uniform; add other toning pigments and disperse for 20 minutes; finally adjust the viscosity with a solvent for 15 seconds (NK-2# viscosity cup), and then the finished product is made.

[0099] Table 2 Example 1 formula

[0100]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com