Graphene/graphene analogue WS2/bismaleimide composite material modified by cyclotriphosphazene polymer and preparation method thereof

A technology of bismaleimide and cyclotriphosphazene, which is applied in the field of graphene/graphene-like WS2/bismaleimide composite materials and its preparation, can solve the problem of uneven dispersion of graphene composite materials, bimaleimide Solve problems such as poor compatibility of imide resin, achieve the effect of preventing agglomeration, improving interfacial bonding strength, and improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

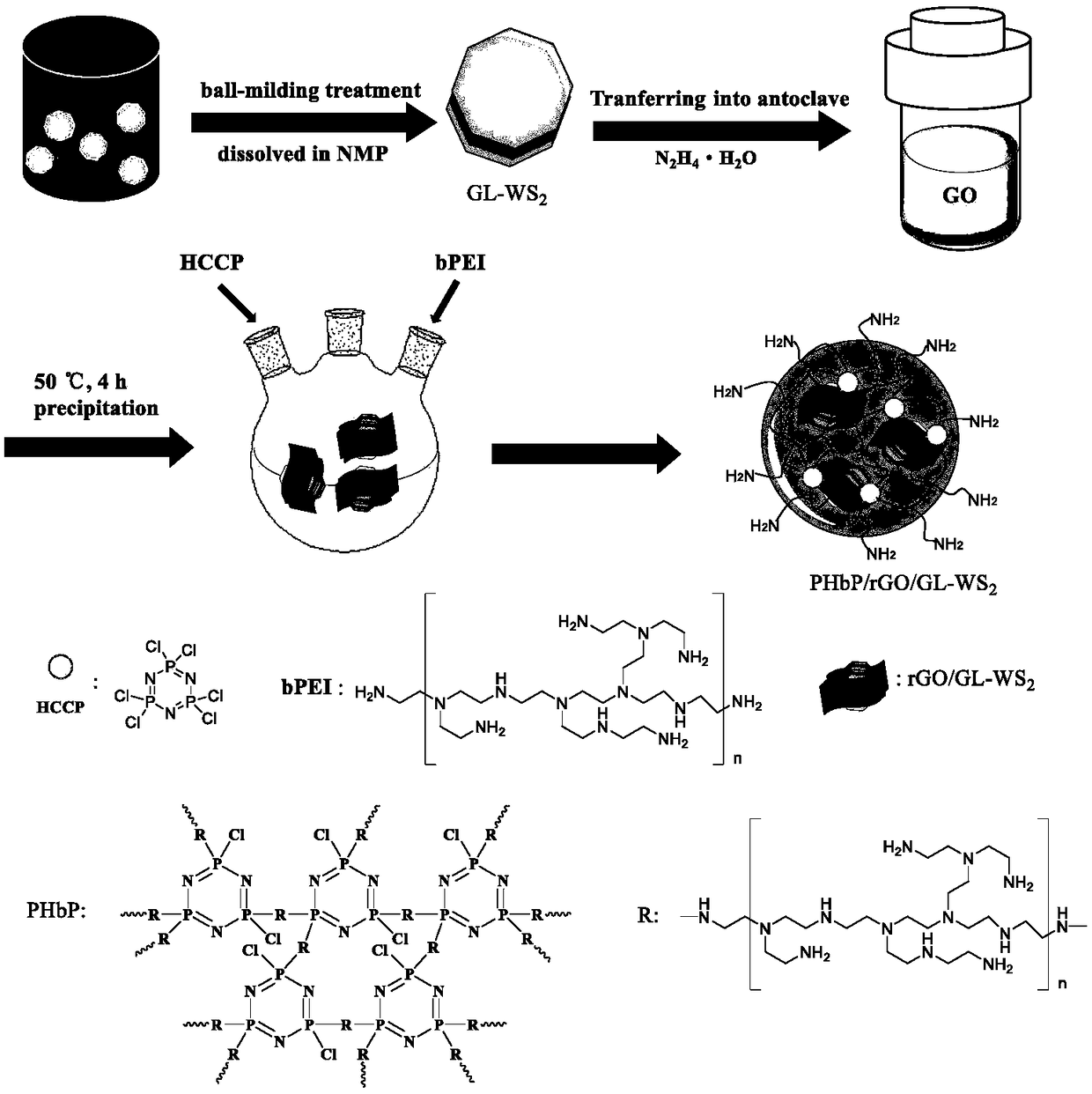

[0028] The preparation method comprises the following steps:

[0029] The first step is to prepare graphite-like WS by low-energy ball milling and ultrasonic method 2 (GL-WS 2 ); Prepare graphene oxide (GO) by modified Hummer's method.

[0030] In the second step, the GO and graphene-like WS prepared in the previous step 2 Dissolve in deionized water, ultrasonically disperse and stir for 30min. Then it was transferred to a high-temperature and high-pressure reactor, and an appropriate amount of hydrazine hydrate was added to react at high temperature and high pressure for 24 hours. Finally, wait for it to cool to room temperature, filter it with suction and wash it several times with deionized water, and dry it to obtain graphene / graphene-like WS 2 Nanocomposite particles (rGO / GL-WS 2 ).

[0031] In the third step, the graphene / graphene-like WS 2 Nanocomposite particles were dissolved in tetrahydrofuran and ultrasonically dispersed for half an hour. Under stirring, hexa...

Embodiment 1

[0039] Step 1: Put the WS 2 And NaCl dry mix with the ratio of 1:10 in the ball mill agate grinding bowl mechanochemical treatment 2h (reaction mixture: ball weight ratio is 1:7), the product that obtains the nanostructure is washed thoroughly with water, and is carried out drying at 100 ℃, Then ultrasonic 30min to prepare graphene-like WS 2 .

[0040] Step 2: Combine graphene oxide and graphene-like WS 2 Mixed and added to 100mL ethanol at a mass ratio of 1:0.5, ultrasonicated at 180W for 30min, transferred to a high-temperature and high-pressure hydrothermal reactor, and added with 5mL hydrazine hydrate, sealed and reacted at 220°C for 24h. After cooling to room temperature, it was filtered with suction and washed several times with deionized water and ethanol, and the product was vacuum-dried at 60°C overnight to obtain graphene / graphene-like WS 2 Nanocomposite particles (rGO / GL-WS 2 ).

[0041] Step 3: The prepared rGO / GL-WS 2 , hexachlorocyclotriphosphazene, and bra...

Embodiment 2

[0044] Step 1: Put the WS 2 And NaCl dry mix with the ratio of 1:10 in the ball mill agate grinding bowl mechanochemical treatment 2h (reaction mixture: ball weight ratio is 1:7), the product that obtains the nanostructure is washed thoroughly with water, and is carried out drying at 100 ℃, Then ultrasonic 30min to prepare graphene-like WS 2 .

[0045] Step 2: Combine graphene oxide and graphene-like WS 2 Mixed and added to 200mL ethanol at a mass ratio of 1:1, ultrasonicated at 180W for 30min, transferred to a high-temperature and high-pressure hydrothermal reactor, and added with 3mL hydrazine hydrate, sealed and reacted at 220°C for 24h. After cooling to room temperature, it was filtered with suction and washed several times with deionized water and ethanol, and the product was vacuum-dried at 60°C overnight to obtain graphene / graphene-like WS 2 Nanocomposite particles (rGO / GL-WS 2 ).

[0046] Step 3: The prepared rGO / GL-WS 2 , hexachlorocyclotriphosphazene, and branc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com