Molybdenum disulfide quantum dot/graphene/polymer-based super-wear-resistant self-lubricating composite material and preparation method and application thereof

A technology of graphene composite and molybdenum disulfide, which is applied in the field of advanced composite material science, can solve the problems of high cost, large demand, and low yield, and achieve the effects of increasing yield, shortening reaction time, and promoting usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a method for preparing a molybdenum disulfide quantum dot / graphene / polymer-based super wear-resistant self-lubricating composite material, which specifically includes the following steps:

[0032] Step 1: Molybdenum disulfide quantum dots (MoS 2 Preparation of QDs)

[0033] 1 to 5 copies of MoS 2 The powder is dispersed into a single organic solvent / mixed organic solvent, and after ultrasonic treatment at a certain power for a certain period of time, the reaction mixture solution is transferred to a high-temperature and high-pressure reactor for a certain period of time. After cooling to room temperature, the reaction product is centrifuged at a certain speed for a certain period of time, and the supernatant obtained by the centrifugation is the prepared solution containing molybdenum disulfide quantum dots.

[0034] Step 2: Molybdenum disulfide quantum dots / graphene (MoS 2 Preparation of QDs / G) composite particles

[0035] First, 1 part of gr...

Embodiment 1

[0053] Step 1: Share 1 MoS 2 The powder was dispersed into 50 parts of N,N-dimethylformamide and stirred evenly. After ultrasonic treatment at 200W for 2 hours, the reaction mixture was transferred to a high-temperature and high-pressure reactor at 150°C for 3 hours. After cooling to room temperature, the reaction product was centrifuged at 8000r / min for 20min, and the supernatant obtained from the centrifugation was the prepared MoS 2 QDs solution.

[0054] Step 2: First, combine 1 share of GO with 1 share of MoS 2 QDs were mixed and added to 500 parts of ethanol and water mixed solvent (volume ratio 5:4) and ultrasonically stirred for 0.5h. Next, after stirring at room temperature for 6 hours, 1 part of hydrazine hydrate was added, condensed and refluxed at 100°C for 6 hours, after it was cooled to room temperature, it was suction filtered and washed several times with deionized water. Finally, it is freeze-dried to obtain MoS 2 QDs / G composite particles.

[0055] Step ...

Embodiment 2

[0058] Step 1: Share 2 copies of MoS 2 The powder was dispersed into 250 parts of N-methyl-2-pyrrolidone and stirred evenly. After ultrasonic treatment for 2.5 hours at a power of 200W, the reaction mixture was transferred to a high-temperature and high-pressure reactor at 160°C for 3 hours. After cooling to room temperature, the reaction product was centrifuged at 10000r / min for 30min, and the supernatant obtained by filtration and centrifugation was the prepared MoS 2 QDs solution.

[0059] Step 2: First, combine 1 GO with 2 MoS 2 QDs were mixed and added to 500 parts of ethanol and water mixed solvent (volume ratio 5:4) and ultrasonically stirred for 1 h. Next, after stirring at room temperature for 12 hours, 1.5 parts of hydrazine hydrate was added, condensed and refluxed at 100°C for 6 hours, cooled to room temperature, suction filtered, and washed several times with deionized water. Finally, freeze-dry the product to obtain MoS 2 QDs / G composite particles.

[0060] ...

PUM

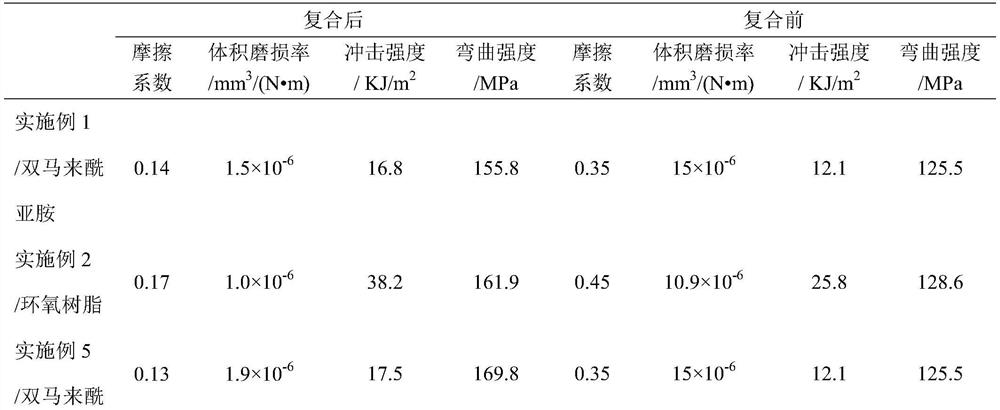

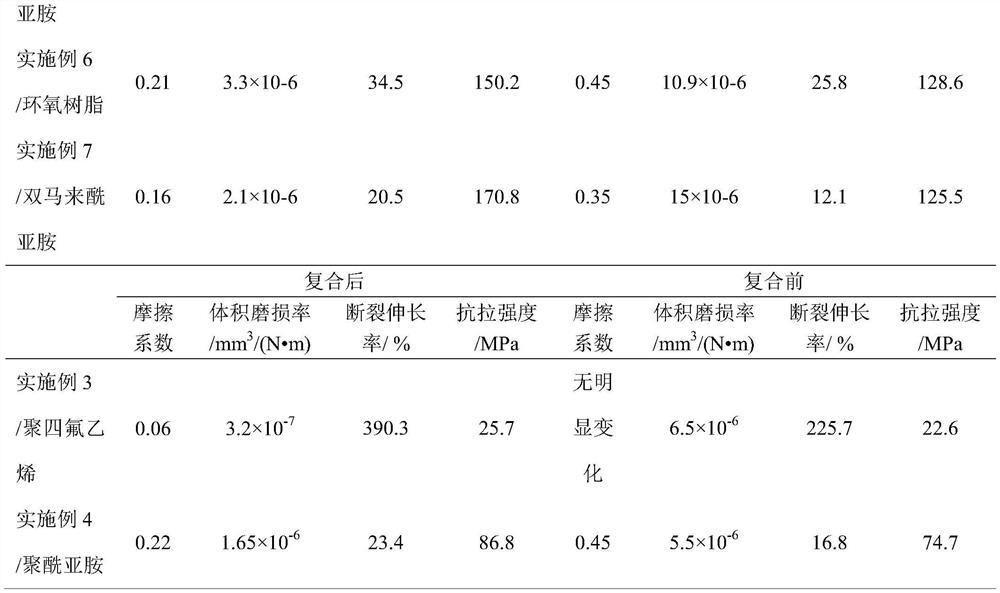

| Property | Measurement | Unit |

|---|---|---|

| Volume wear rate | aaaaa | aaaaa |

| Volume wear rate | aaaaa | aaaaa |

| Volume wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com