Patents

Literature

44 results about "Macrocrystalline" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geology, macrocrystalline rocks have crystals large enough to easily be identified by sight. Macrocrystalline or phaneritic texture is common in intrusive igneous rocks which cooled slowly enough for crystal growth. Pegmatites are noted for very large crystal size.

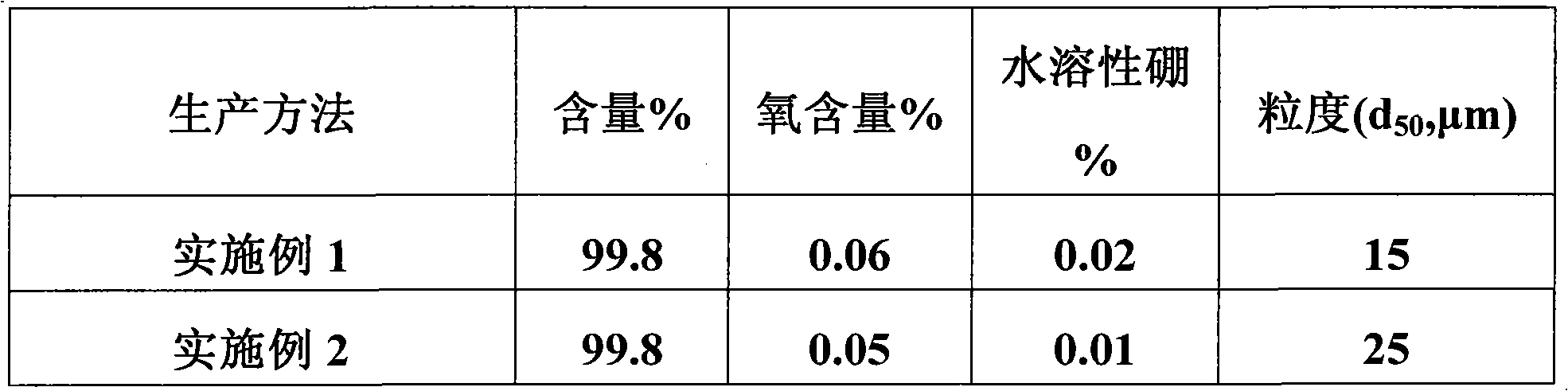

Production method of macrocrystalline hexagonal boron nitride

InactiveCN101891165AEnsure mixing uniformitySimple processNitrogen compoundsHexagonal boron nitrideMacrocrystalline

The invention relates to a production method of macrocrystalline hexagonal boron nitride, comprising the following steps of: reacting boric acid with melamine by using water as a medium, wherein the mole ratio of the melamine and the boric acid is 1:1.8-2.3; then filtering, drying, then placing a product into a crucible, and placing the crucible into a high temperature furnace to be heated to 800-2000 DEG C; preserving heat for 2-12 hours; carrying out acid cleaning on the obtained product by using dilute acid; and then filtering and drying to obtain a macrocrystalline hexagonal boron nitride product. The invention has simple and convenient process and low production cost, ensures the mixing uniformity of materials in a liquid-phase mixing material way and reduces the side reaction by fast carrying out high-temperature decomposition reaction; and in addition, the obtained product has crystalline granularity larger than 20 micrometers and high purity.

Owner:丹东市化工研究所有限责任公司

Thermoplastic polymer propellant compositions

Owner:CESARONI ANTHONY JOSEPH

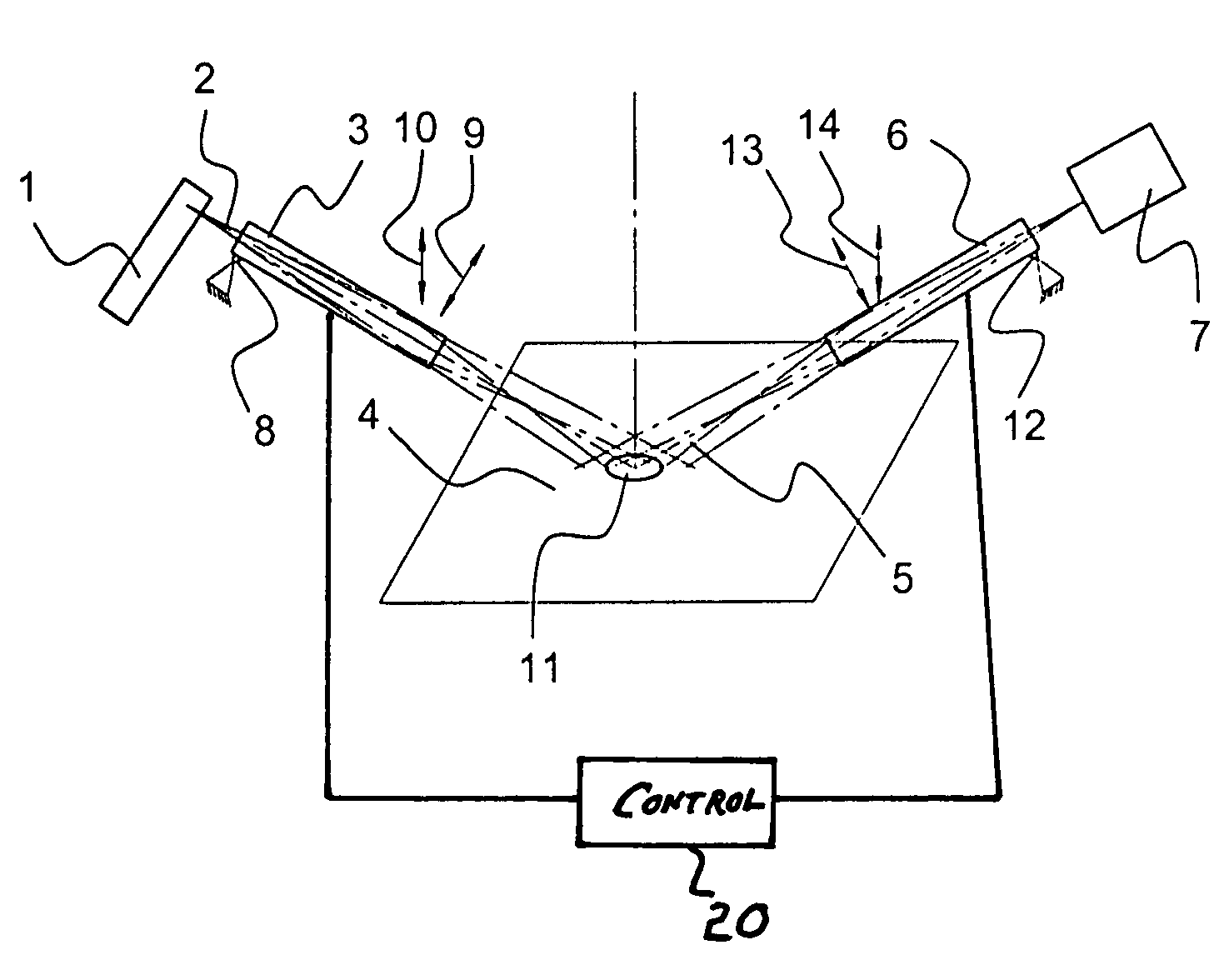

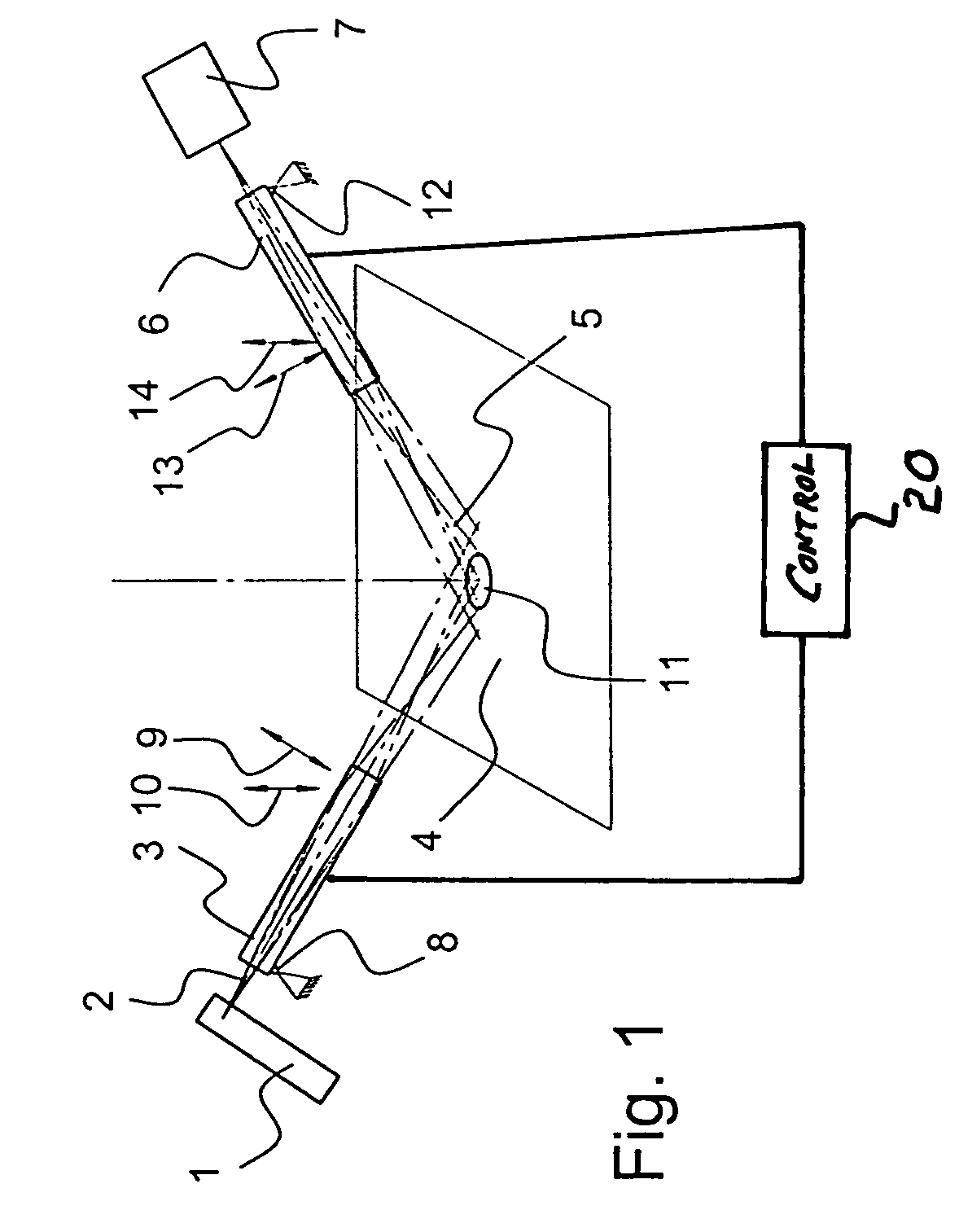

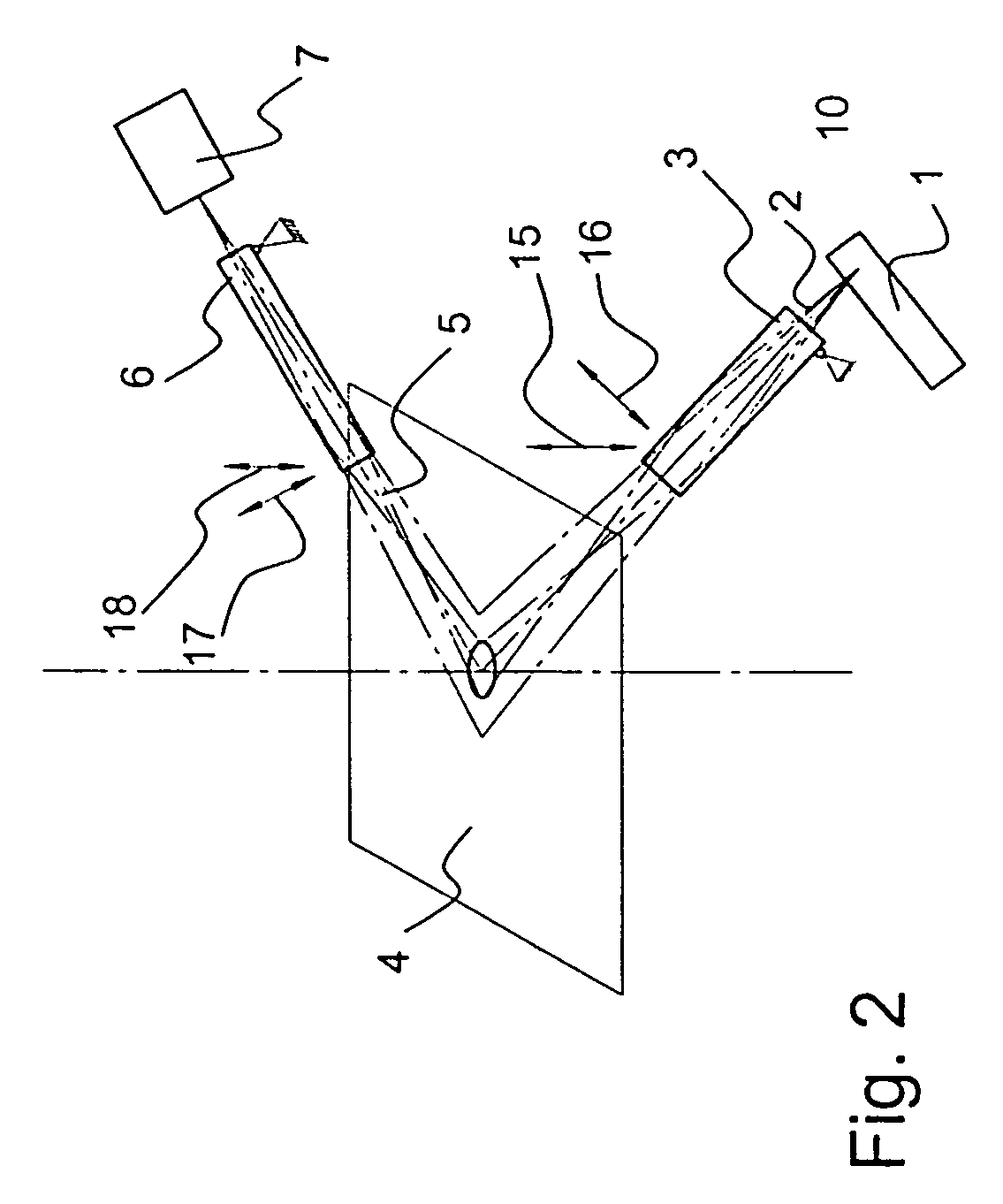

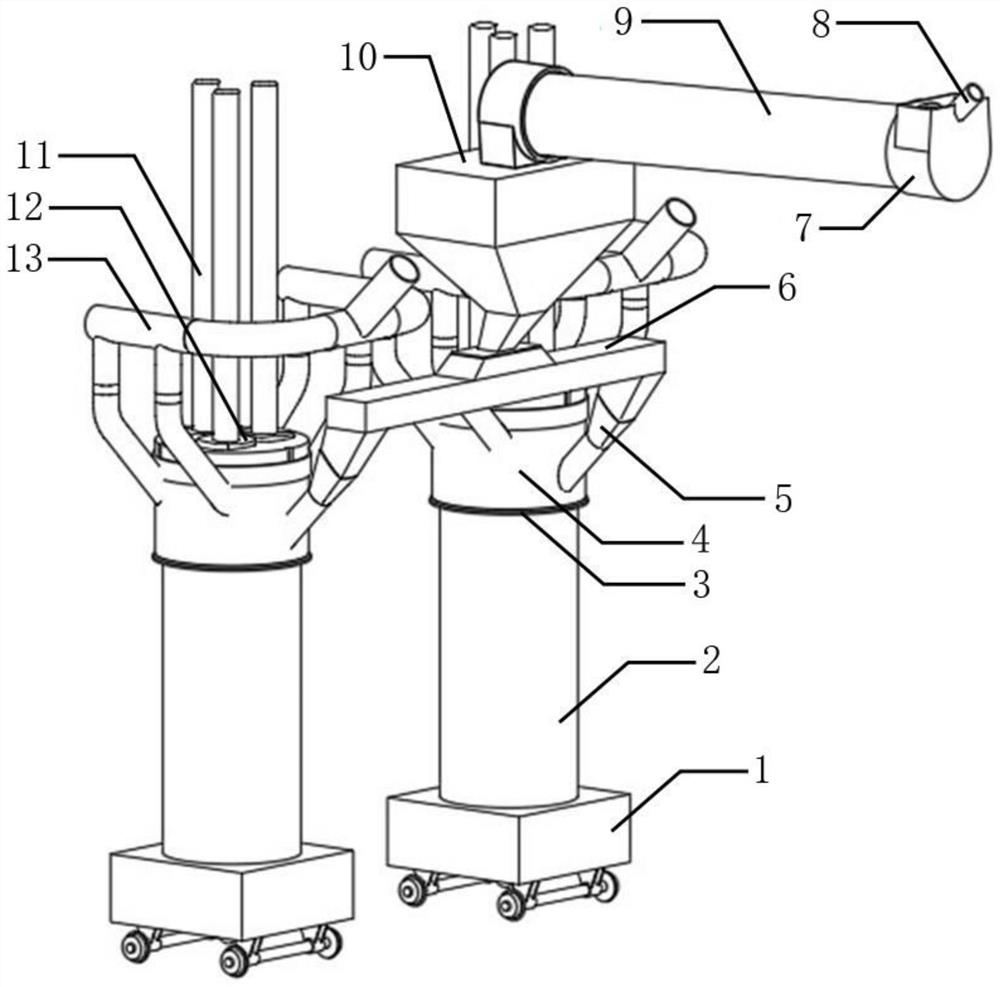

X-ray optical system with wobble device

ActiveUS6996208B2Little controlHandling using diaphragms/collimetersMaterial analysis using radiation diffractionMacrocrystallineMonochromator

An X-ray optical system comprising an X-ray source (1), from which X-ray radiation (2) is guided to a sample (4) under investigation, and an X-ray detector (7) for receiving radiation (5) diffracted or scattered from the sample (4), wherein a beam-guiding X-ray optical element (3, 6), such as e.g. a collimator, a mono- or polycapillary, an X-ray mirror or a monochromator, is disposed between the source (1) and the sample (4) and / or between the sample (4) and the detector (7), is characterized in that a wobble means is provided for moving the X-ray optical element (3, 6) in an oscillating fashion during the measurement. The inventive X-ray optical system obtains averaged X-ray analysis information from objects under investigation having large mass which consist of macrocrystalline material without destroying or accelerating the object under investigation.

Owner:BRUKER AXS

Extraction method of aucubin and application of aucubin

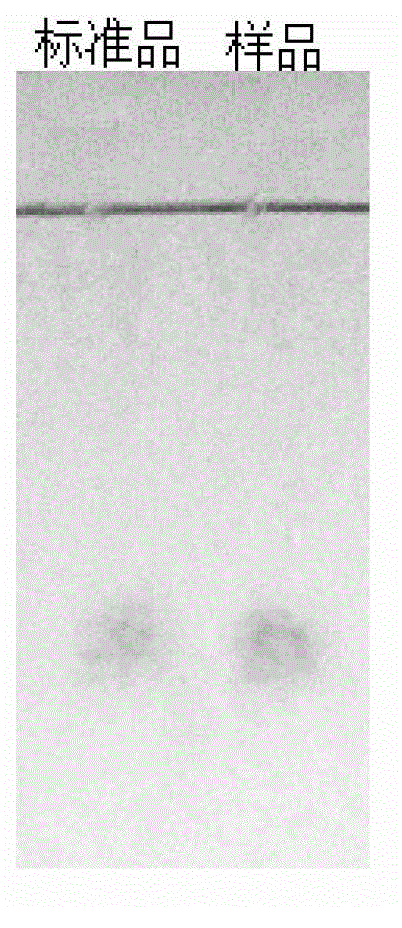

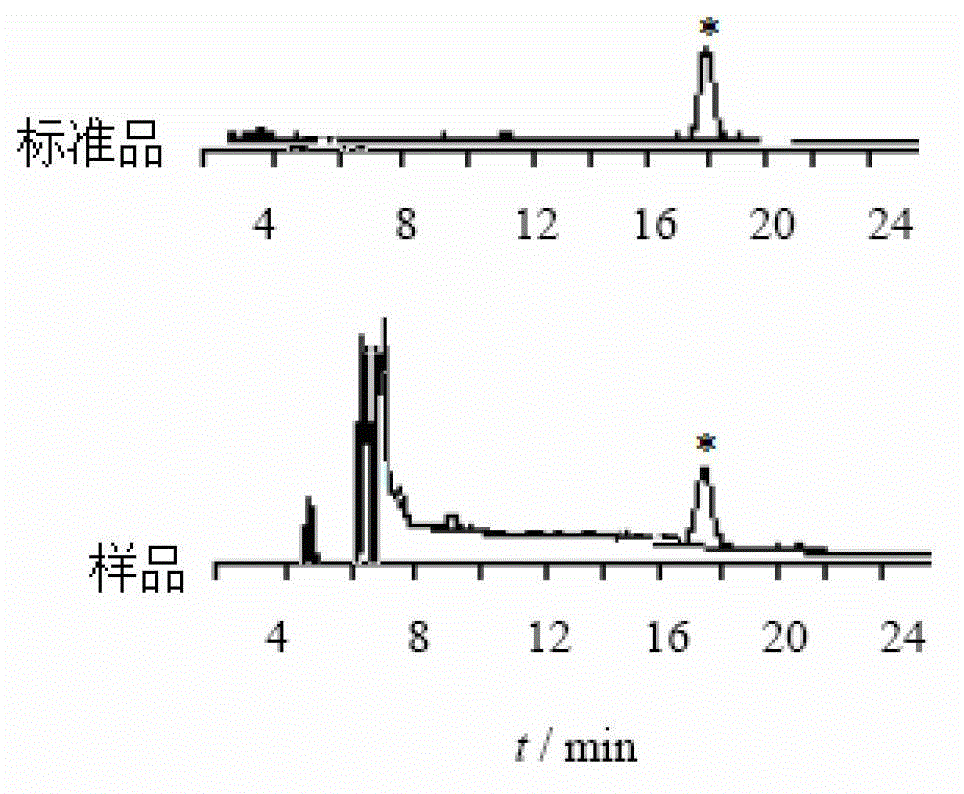

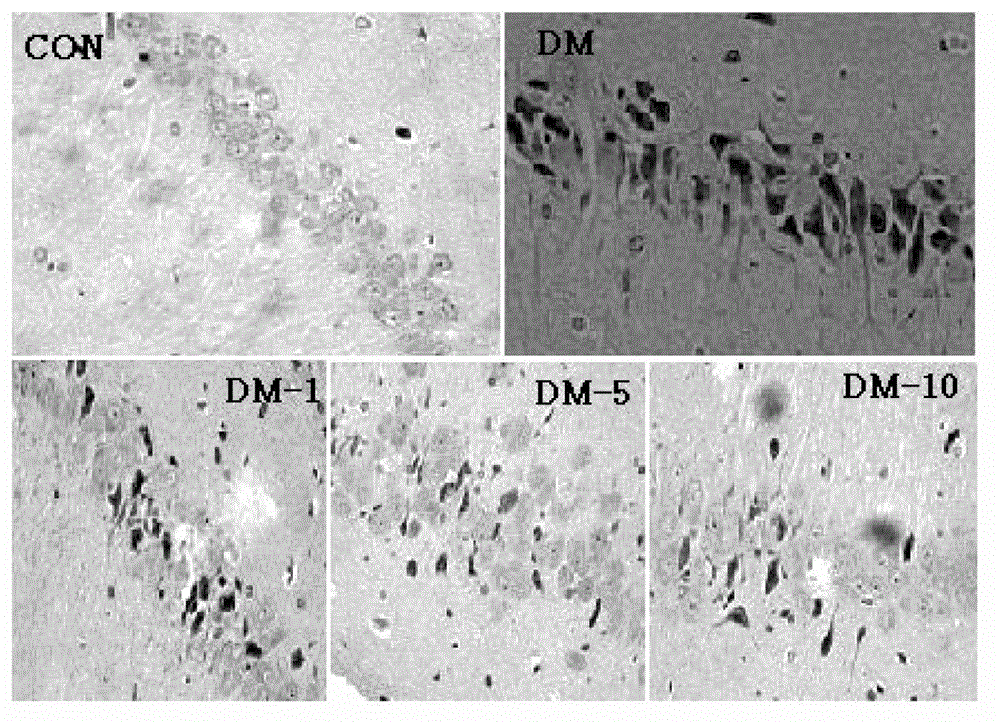

The invention relates to an extraction method of aucubin and an application of the aucubin. The method comprises the simple steps of crushing plantain, soaking in alcohol overnight, conducting ultrasonic extraction, merging, recovering, concentrating and centrifuging an extracting solution, obtaining supernate, adopting macroporous resin and eluting an alcohol solution, conducting thin-layer chromatography detection, collecting and concentrating fraction at a target point, conducting silicagel column chromatography on a concentrate, and then collecting and concentrating the fraction at the target point, repeating the silicagel column chromatography to obtain macrocrystalline, purifying a crude product through high performance liquid chromatography, collecting target components, freezing and drying, and finally obtaining white amorphous powder. The substance extracted from the plantain by the method is the aucubin. The aucubin can be used for treating and preventing diabetes mellitus and concurrent encephalopathy of the diabetes mellitus, the occurrence and development mechanisms of the diabetes mellitus and complications of the diabetes mellitus are further deeply studied, and new-generation drugs for resisting the diabetes mellitus and the complications of the diabetes mellitus can be developed.

Owner:薛宏宇

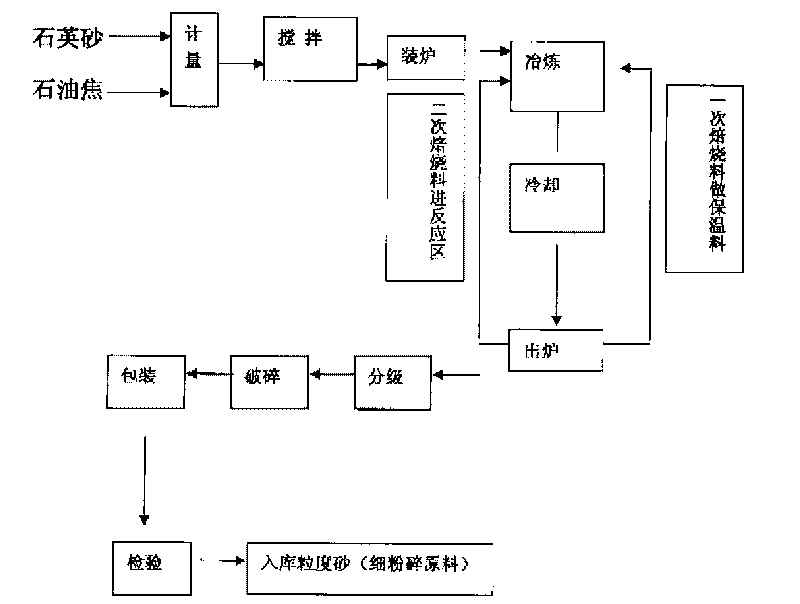

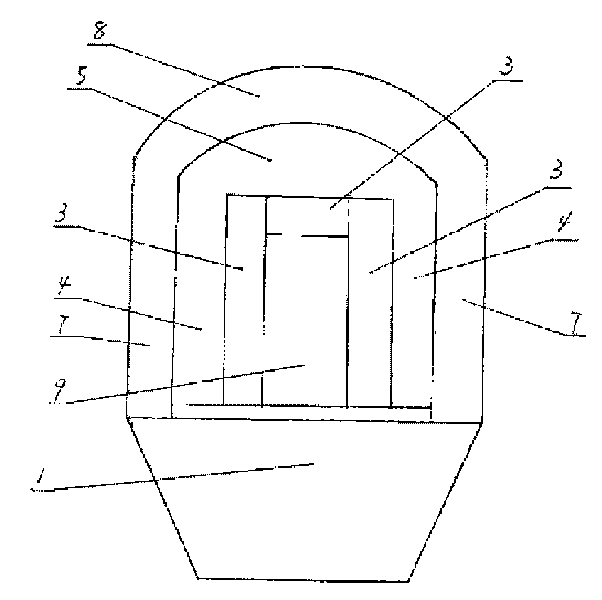

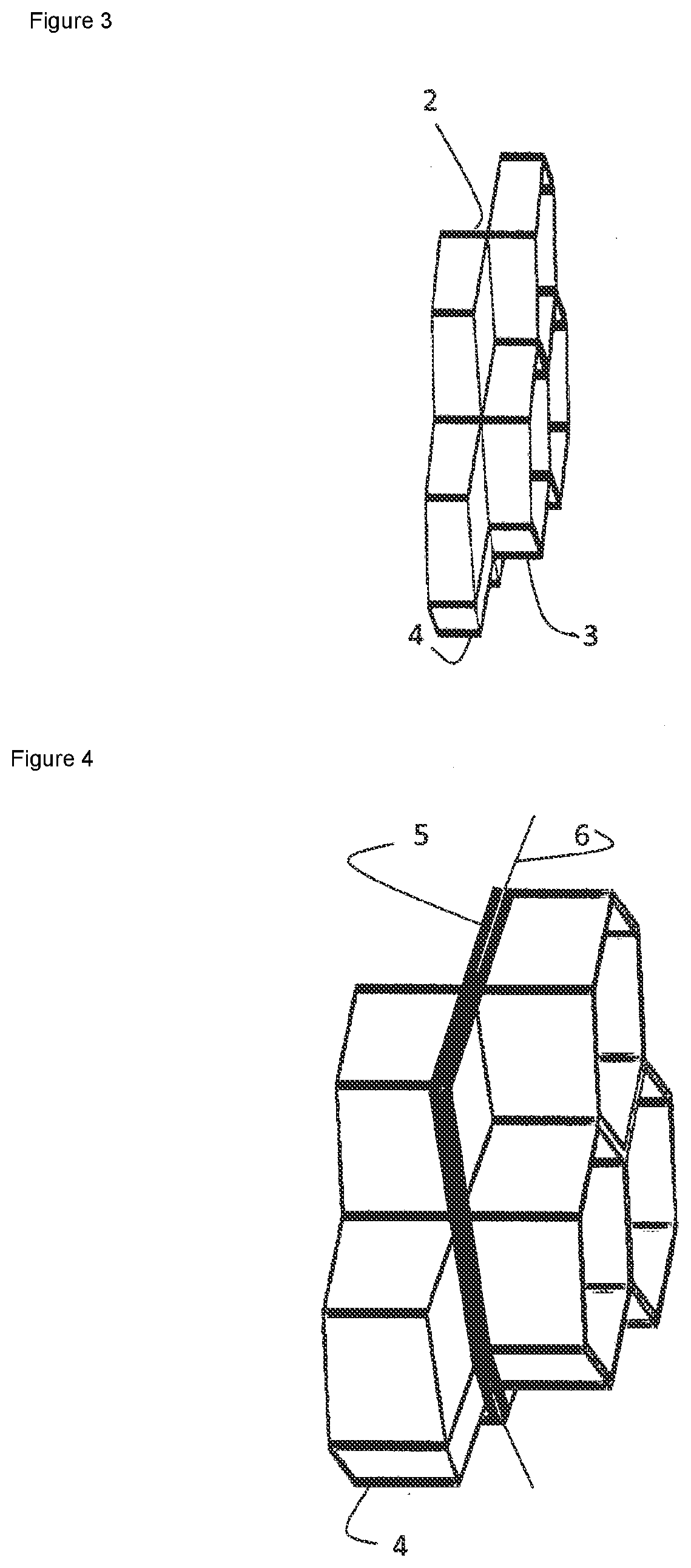

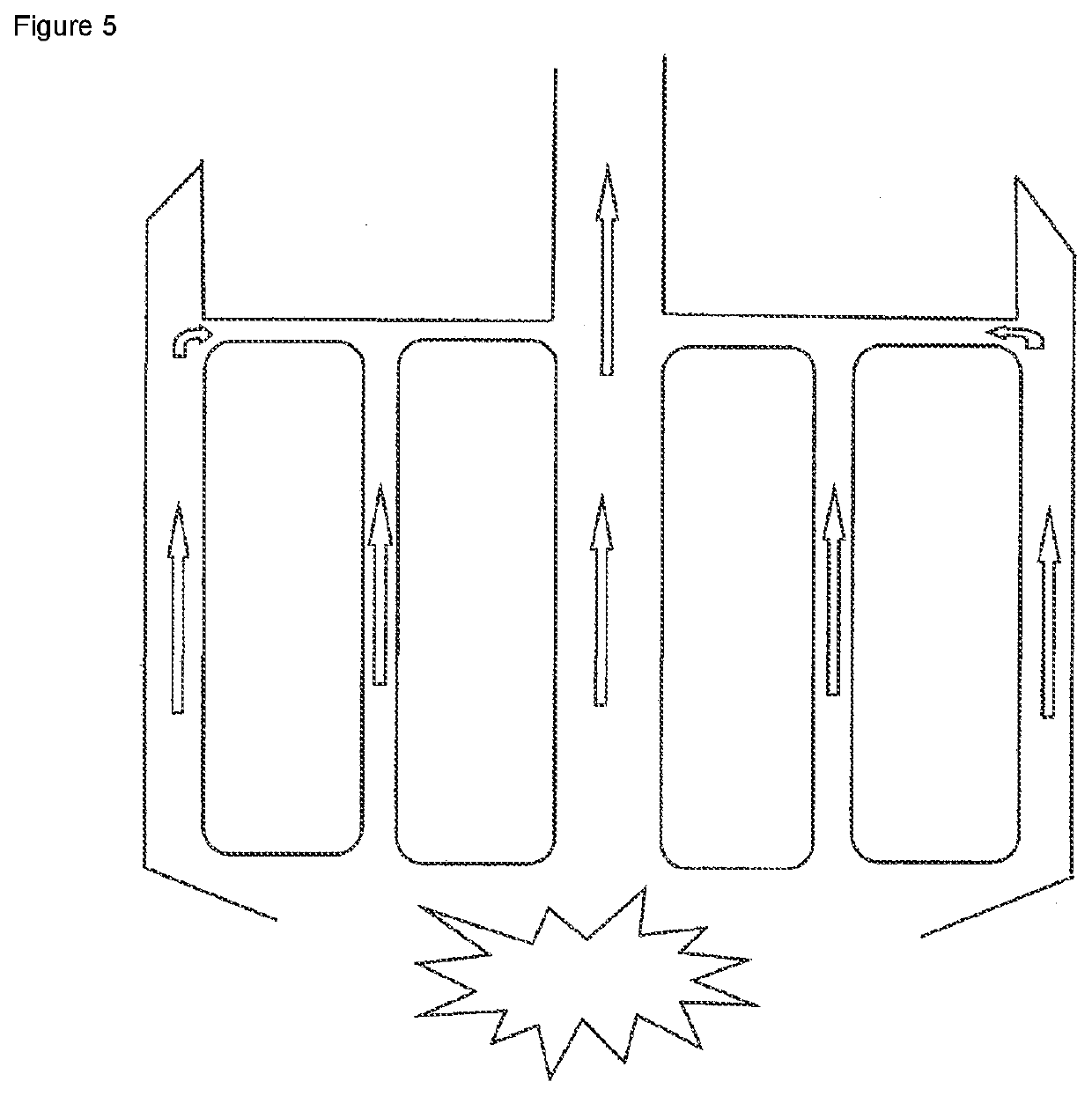

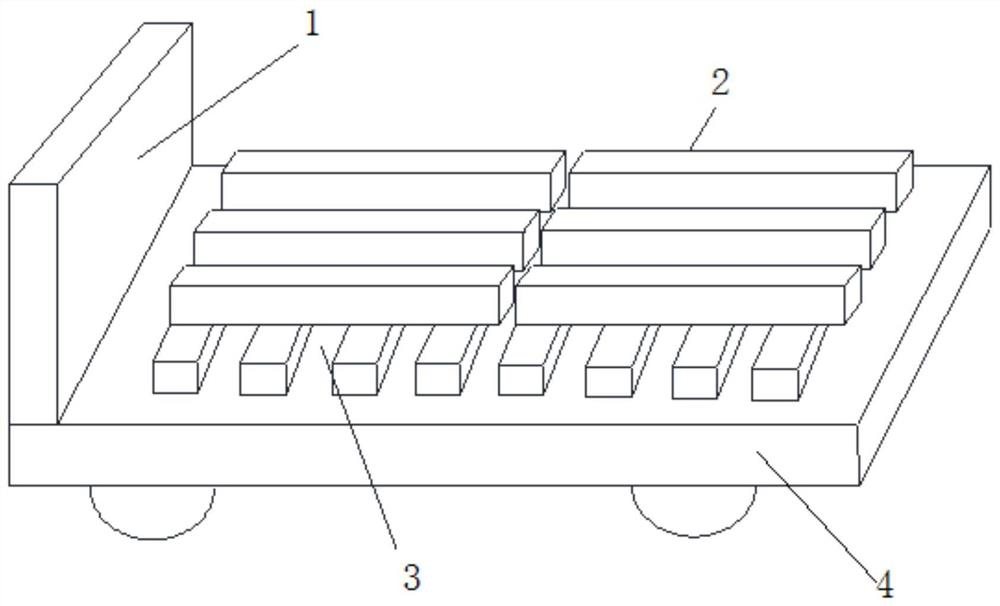

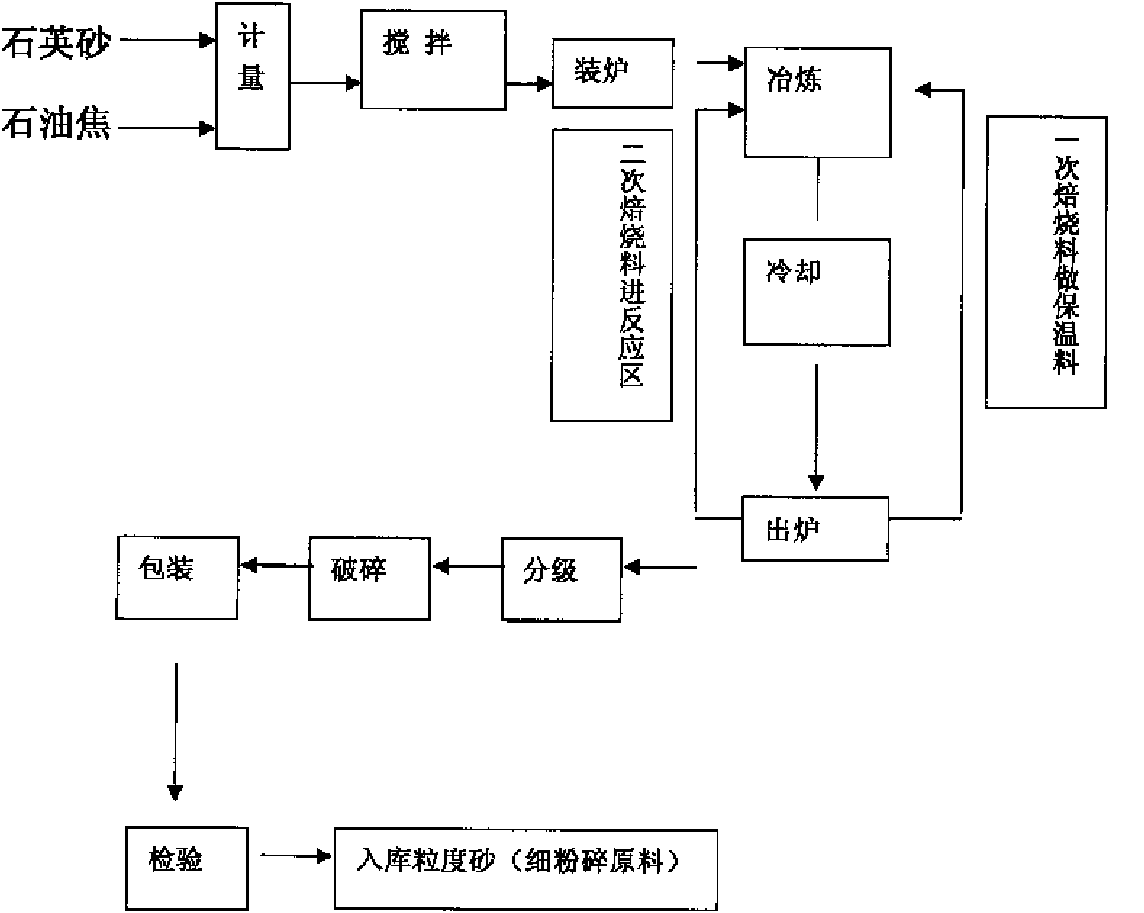

Process for smelting macrocrystalline green silicon carbide

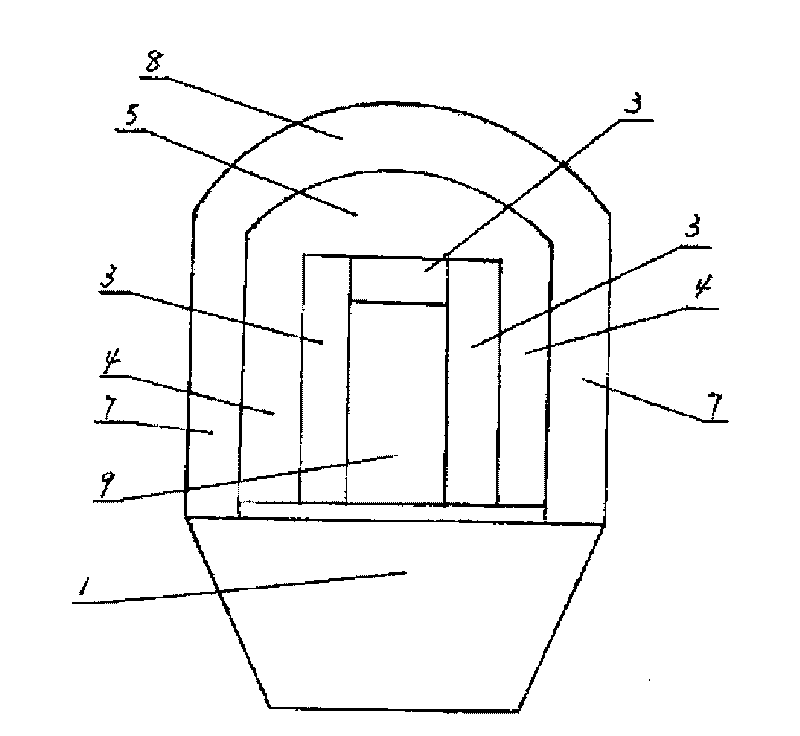

The invention relates to silicon carbide smelting, in particular to a process for smelting macrocrystalline green silicon carbide, which comprises the following: a, a step of preparing raw materials of quartz sand and petroleum coke in a ratio of 1.48 to 1.54; b, a step of material mixing; c, a step of furnace charge, in which homogenized raw materials are delivered to a material area (1) at the bottom of a furnace, a burden material subjected to secondary roasting is filled in reaction areas (3, 4 and 5) in the middle of the furnace, and a burden material subjected to primary roasting is filled in the external heat preservation areas (7 and 8); d, a step of smelting, in which the charged furnace is electrified for smelting for 32 to 36 hours, the power of a transmission transformer is 8,000 KVA, and after cooling for 72 hours, the materials are discharged and graded. By adopting a smelting process of roasting for two times, the process reduces the waste of primarily roasted material, the specific consumption of the petroleum coke, the quartz sand and power, and saves energy. Meanwhile, as a long-time lower power transmission is adopted, the reaction of grains is more uniform and complete and the structure of the grains is more compact and firm; and compared with products in the prior art, the product has higher hardness, larger grain size, higher content and more desirable powder grain form.

Owner:TONGHUA HONGXIN ABRASIVE

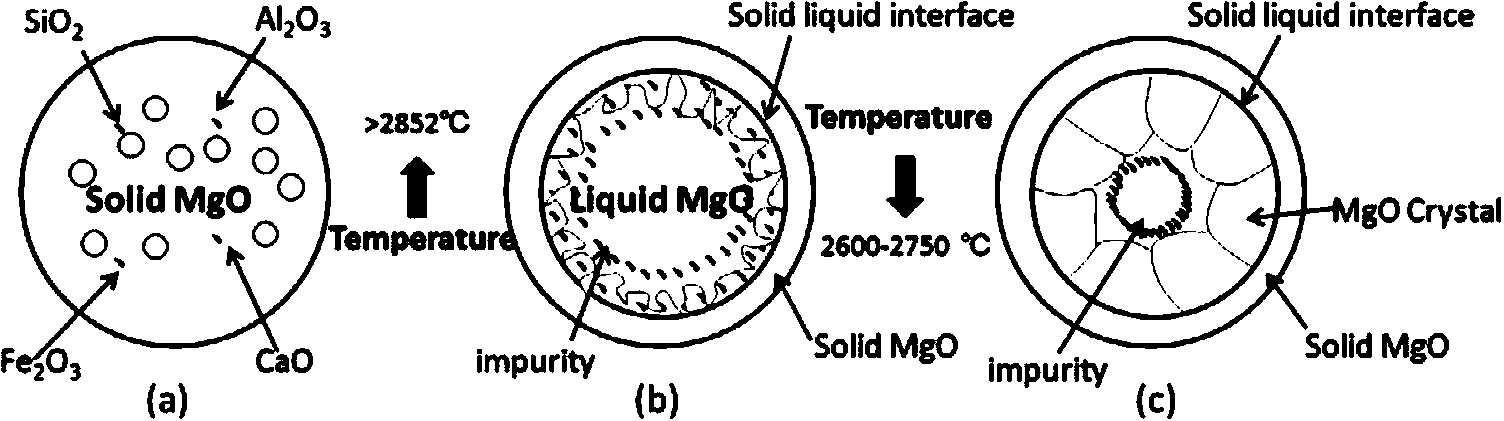

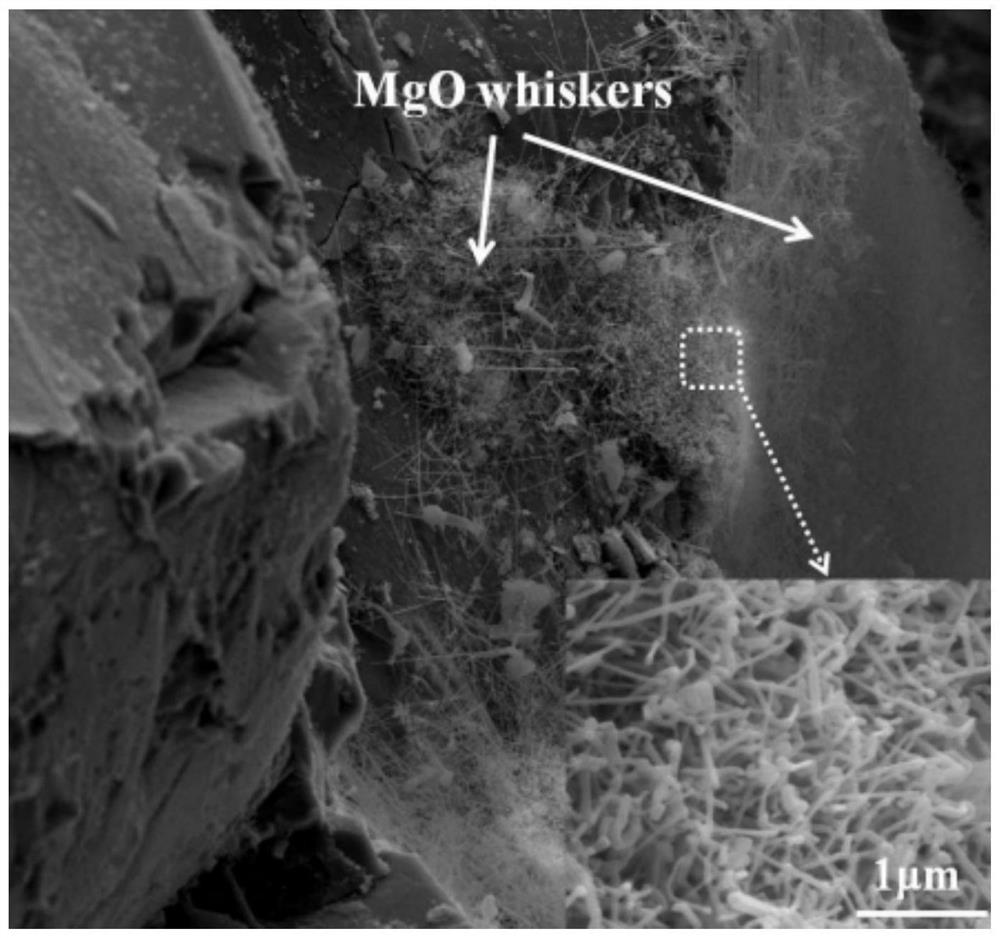

Additive for producing macrocrystalline fused magnesite

The invention relates to an additive for producing macrocrystalline fused magnesite. Main components of the additive are high purity graphite powder, rare earth oxide composition and zirconium oxide. The additive is characterized in that the addition mass of the high purity graphite powder accounts for 0.5-5% of the mass of magnesium oxide, the addition mass of the rare earth oxide accounts for 0.01-1.5% of the mass of magnesium oxide, and the addition mass of zirconium oxide accounts for 0.1-3% of the mass of magnesium oxide. The massive white transparent high purity fused magnesite is obtained by pointedly adding corresponding impurity removal materials according to the type and content of impurities in the magnesium oxide raw material in combination with an appropriate technological process; the technological process is simple; the dosage of the additive is small, but the additive has an obvious effect. Due to optimization of the additive and the technology, the melting power and time are reduced, the utilization rate of raw materials is increased, and the effects of energy conservation and emission reduction are achieved. The additive is easy to obtain, simple in process, low in cost and suitable for large-scale industrial production and application; requirements for required equipment are low.

Owner:EAST CHINA UNIV OF SCI & TECH

Polycrystalline diamond drill bit matrix powder

ActiveCN102773472AIncrease concentrationImprove bindingDrill bitsMacrocrystallinePolycrystalline diamond

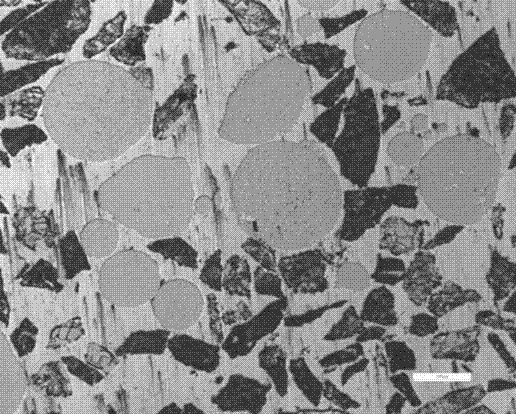

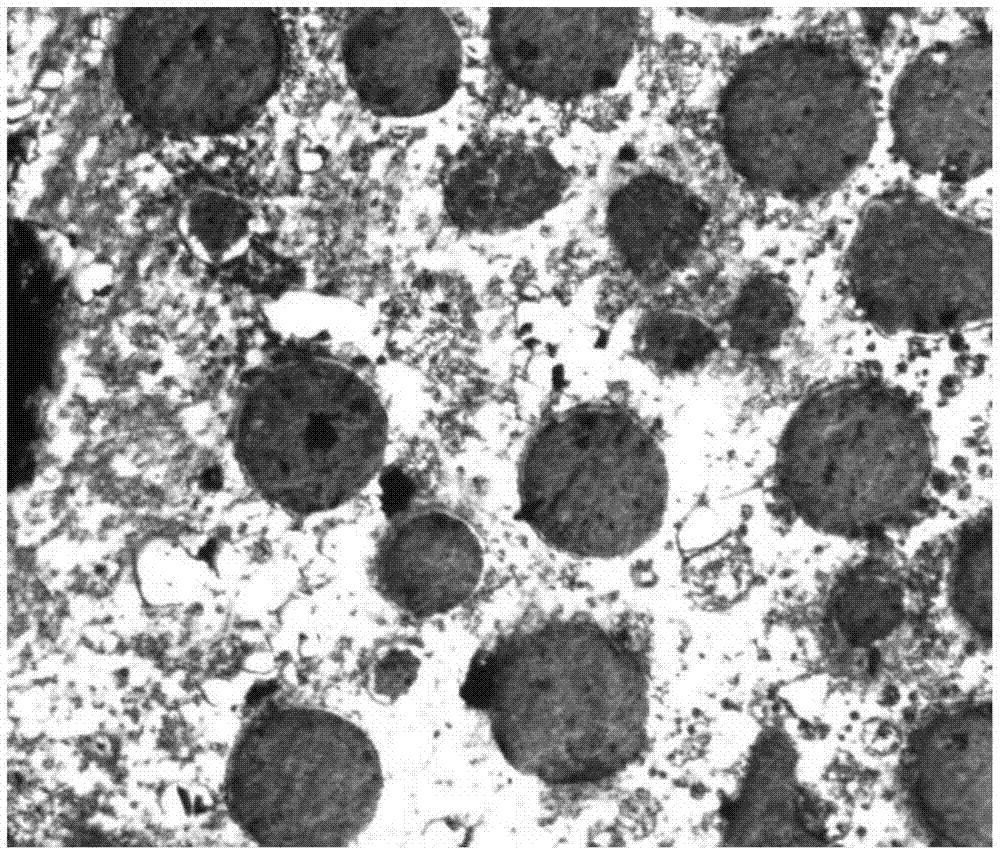

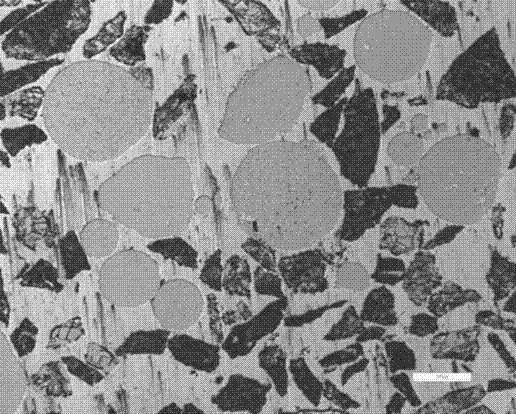

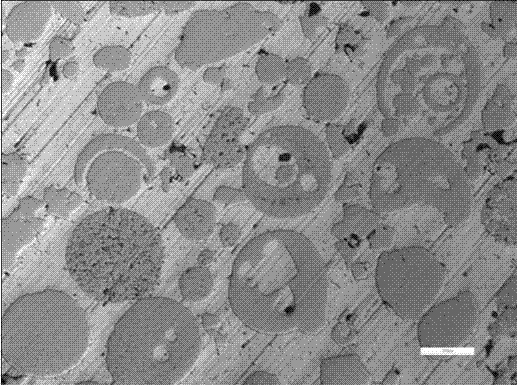

The invention relates to a powder metallurgy material for manufacturing a polycrystalline diamond drill bit matrix. The powder metallurgy material comprises the components by weight percent: 30-60% of spherical sintered WC particles with the particle size of 125-500 microns, 25-60% of fine macrocrystalline WC particles with the particle size of 50-200 microns, and 5-15% of nickel powder. According to the invention, bonding phase can penetrate into the hollow spherical sintered WC particles and can be used for filling the hollow spherical sintered WC particles, so that the bonding phase and hard phase in the matrix can be better combined with each other, and the matrix has higher strength and toughness; and gaps among coarse particles can be effectively filled by the fine macrocrystalline WC particles, so that the erosion resistance and the wear resistance of the matrix can be better improved. According to the invention, the matrix material cost of a drill bit is reduced; and as the performances of the matrix are improved, the polycrystalline diamond compact (PDC) drill bit with a thinner or longer scraping knife can be designed, and the drilling rate of the PDC drill bit can be greatly increased.

Owner:KINGDREAM PLC CO +1

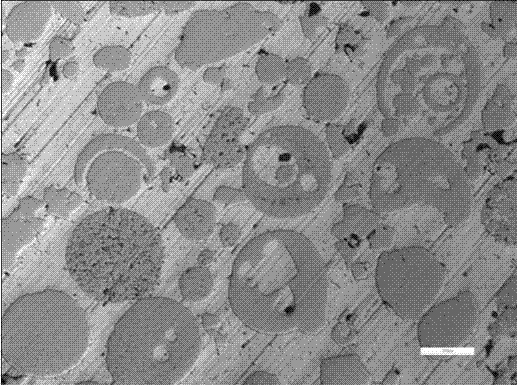

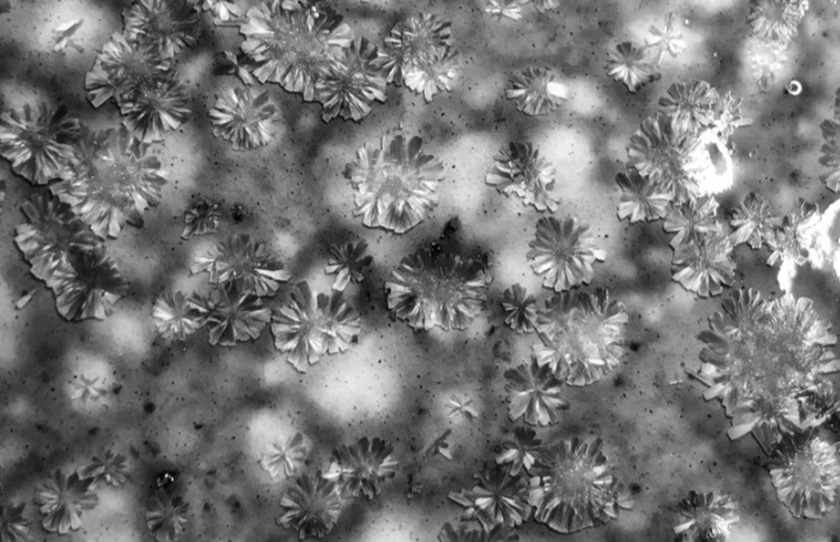

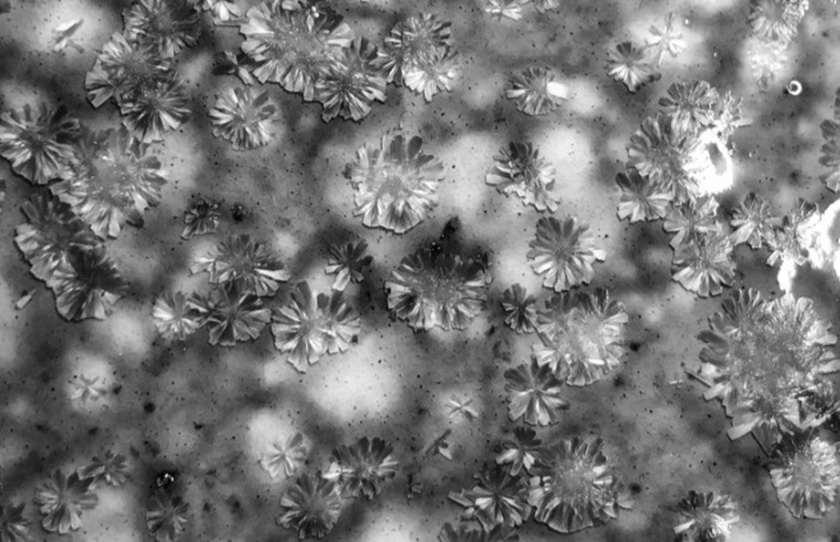

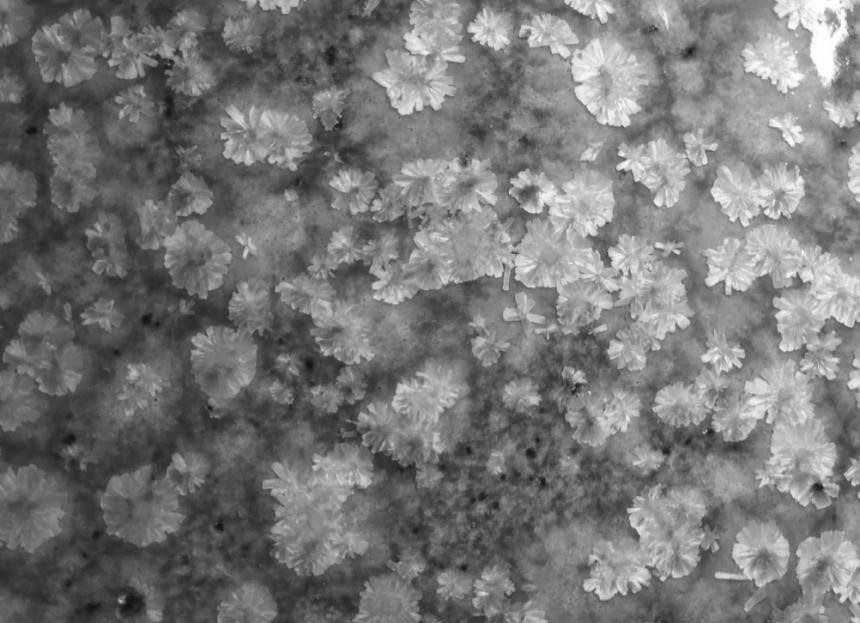

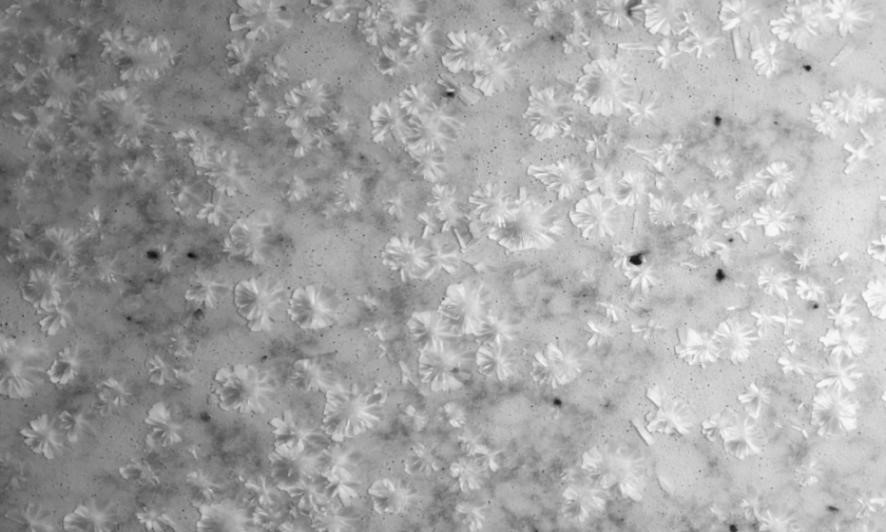

Macrocrystal particles capable of forming crystal flower, dry particle combination, particles for ceramic, ceramic and preparation method of ceramic

ActiveCN112456802ARich and varied colorsImprove the decorative effectMacrocrystallineTexture (crystalline)

The invention belongs to the technical field of ceramics, and discloses macrocrystalline particles capable of forming crystal flowers, a dry particle combination, particles for ceramic, the ceramic and a preparation method of the ceramic. The chemical mass composition of the macrocrystalline particles includes SiO2, Al2O3, K2O, Na2O, CaO, MgO, BaO, ZnO, F, Li2O, TiO2, and a metal oxide for coloring. The macrocrystalline particles can form macrocrystalline crystal flowers through low-temperature fast firing, the crystal flowers are petal-shaped, the colors of the crystal flowers can be changedand adjusted at any time according to designed colors and textures, the colors are rich and diverse, and the decorative effect is excellent. And the dry particles can be quickly sintered at low temperature and meet the energy-saving and environment-friendly requirements in the ceramic field. And the fired ceramic tile has the advantages of compact surface, high strength, super wear resistance andno hidden dirt. The surface of the product is crystal clear, a random crystal pattern effect is naturally formed, the color of the brick surface is richer and more diverse, and a very good effect canbe achieved through paving no matter on the ground or a wall.

Owner:FOSHAN DOWSTONG TECH

Macrocrystalline sintered plate-shaped corundum and preparation method thereof

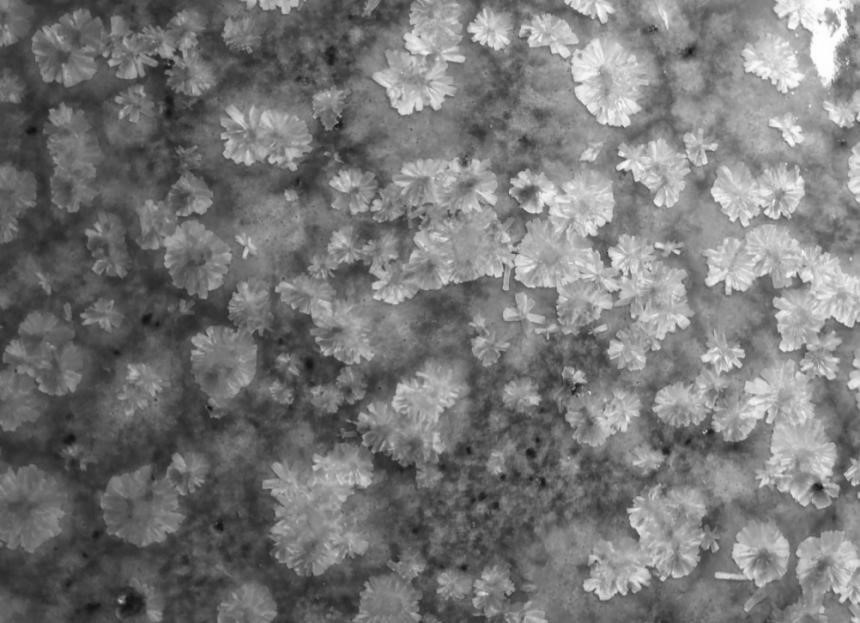

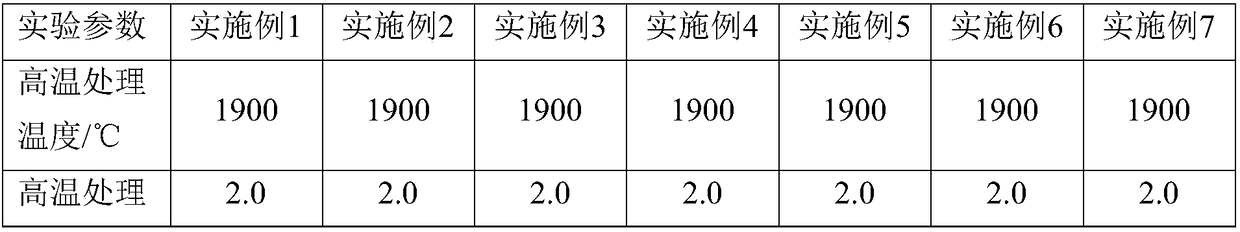

The invention discloses macrocrystalline sintered plate-shaped corundum and a preparation method thereof. The preparation method of the macrocrystalline sintered plate-shaped corundum comprises the following steps: treating industrial aluminum oxide powder at the temperature of 1100 to 1300 DEG C for 3 to 5h; grinding, pelleting, drying, sintering and cooling a product in sequence to obtain the macrocrystalline sintered plate-shaped corundum. 90 weight percent or more of ground powder can pass through a sieve with the size of 325 meshes. In a pelleting process, at least one of water, an ammonium chloride water solution, an ammonium fluoride water solution, a boric water solution and an aluminum fluoride water solution is used as a pelleting solution. By adopting the preparation method provided by the invention, the macrocrystalline sintered plate-shaped corundum with the grain diameter size of 300 to 500mu m can be prepared, the volume density reaches 3.70g / cm<3> or more and the apparent porosity is less than 3.0 percent; the wear resistance, the thermal shock resistance stability and the slag corrosion resistance of a fireproof product are improved.

Owner:浙江自立新材料股份有限公司

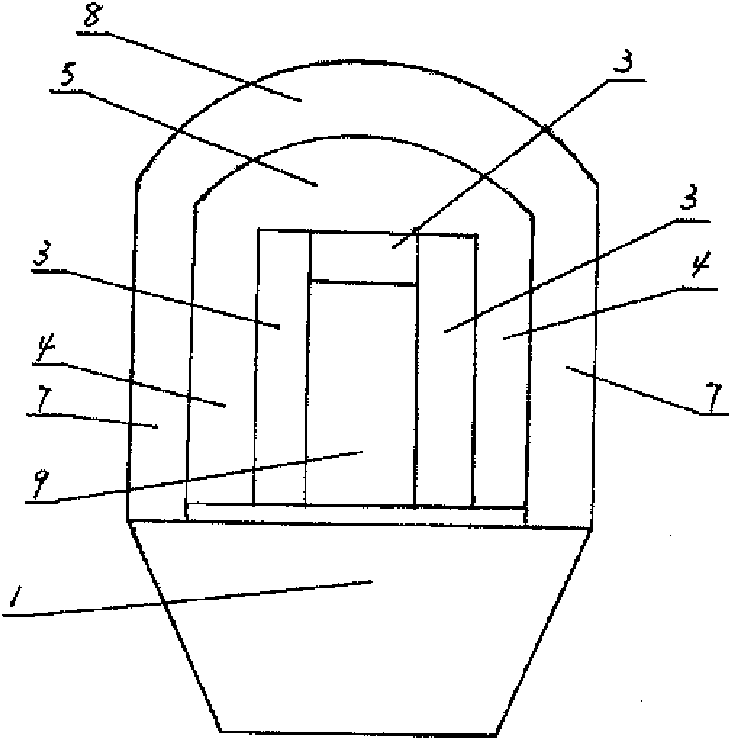

High-performance brick cup

InactiveCN105418093AImproved thermal shock stabilityImprove corrosion resistanceBrickMacrocrystalline

The invention relates to a high-performance brick cup. The high-performance brick cup comprises the following raw materials in percentage by weight: 50%-52% of fused magnesia with large crystal, 35%-38% of electric-fused chromium corundum sand, 5%-7% of high-purity flake graphite, 2% of a metal antioxidant, 1% of a special additive and 3% of high-strength phenolic resin, wherein the content of the fused magnesia with large crystal is 98% or above, and the particle size of the electric-fused macrocrystalline magnesium sand is 0-5mm; the particle size of the electric-fused macrocrystalline magnesium sand is 0-5mm; the raw materials are sequentially added, are mixed for a long time by virtue of a high-speed mixing machine and are pressed into the high-performance brick cup by virtue of high-tonnage friction pressure. The high-performance brick cup prepared by virtue of the scheme has the advantages of good erosion resistance, strong erosion resistance, high thermal shock resistance, convenience in construction, energy conservation, environmental friendliness, long service life and the like; the consumption of refractory materials is greatly reduced, and meanwhile, the discharge of refractory industrial solid waste is reduced; the high-performance brick cup has remarkable effects in the conservation of mineral resources and energy sources.

Owner:ZHEJIANG HUZHOU FUZILING REFRACTORY GRP CO LTD

Additives preventing caking and humectation of nitrogenous fertilizers

InactiveCN1525949AHigh anti-humidity effectMaterial granulationSpecial surfacesParaffin waxMacrocrystalline

The present invention relates to new additives for preventing caking and humectation of nitrogenous fertilizers having a material composition which is free of fatty amines or their salts and characterized in that it comprises: (i) between 50 and 90 parts by weight of a macrocrystalline paraffin having a viscosity at 100 DEG C between 2 and 5 cSt (ASTM D-455), with a paraffin oil content under 20% by weight (ASTM D-721); (ii) between 0 and 20 parts by weight of a paraffinic oil having a viscosity at 100 DEG C between 3 and 40 cSt (ASTM D-455); (iii) between 0 and 10 parts by weight of a microcrystalline paraffin having a viscosity at 100 DEG C between 10 and 25 cSt (ASTM D-455) with a paraffin oil content not greater than 15% by weight (ASTM D-721); (iv) between 10 and 50 parts by weight of phosphoric acid monoesters and / or diesters of C2-C22 alkyl or C2-C12 arylalkyl, optionally alkoxylated; so that the total paraffin oil content of the composition is greater than 1% by weight.

Owner:KAO CORP

Production method of macrocrystalline WC powder

InactiveCN101618873AAdvanced technologyReliable workmanshipTungsten/molybdenum carbideMacrocrystallineGranularity

The invention relates to a production method of macrocrystalline WC powder, which comprises the following steps: preparing seed crystal WC powder; then adopting Wo3 or Wo2.9 and C powder as raw materials, and processing by ball mill and mixing with Fe powder, oxides of Fe, Al-Ni alloy powder and the prepared seed crystal WC powder in a proportion; loading an obtained mixture into a boat for melting and carbonizing; and processing obtained alloy by ball milling, pulverizing, iron removing, acid washing for removing impurities, water washing, drying and sieving to obtain the macrocrystalline WC powder. Based on a background technology, the prepared seed crystal WC powder is added, and through a process of dissolving and separating, the method effectively changes the principle of generating WC mainly by C diffusion of the prior conventional process; thus the method breaks through a technical bottleneck of the conventional process, and the seed crystal granularity of the obtained WC powder is increased by more than one time compared with that of the background technology. The invention has the characteristics that the process is advanced and reliable; the produced WC powder has large seed crystal granularity and can be matched with cast WC, and the crystal granularity of a hard alloy product produced by using the macrocrystalline WC powder can be increased by 60-100 percent compared with the background technology; the physical and mechanical properties of the macrocrystalline WC powder are also obviously improved, and the like.

Owner:ZIGONG HUAGANG CEMENTED CARBIDE NEW MATERIAL

Preparation method for cynarin

InactiveCN102372634ALow costReduce energy consumptionOrganic compound preparationCarboxylic acid esters preparationReflux extractionAlcohol

The invention relates to a preparation method for cynarin. The preparation method includes the following process steps: artichoke leaves as material are ground, aqueous solution is added for reflux extraction, precipitator is added to extract for clarification, alkalescent anion resin is added for adsorption, 0.5 to 1 percent of acetic acid solution is used for elution, eluent is then added into macroporous resin for adsorption, 40 to 70 percent of alcohol solution is used for elution, eluent is concentrated and crystallized, macrocrystalline is then recrystallized by deionized water and alcohol, and after vacuumization pressure reduction and drying, the product is prepared. The process flow of the preparation method is easy to operate, the energy consumption of the production process is low, pollution is little, the cost of the prepared product is low, the quality of the product is good, and drugs or health-care products can be prepared according to the invention.

Owner:苏州宝泽堂医药科技有限公司

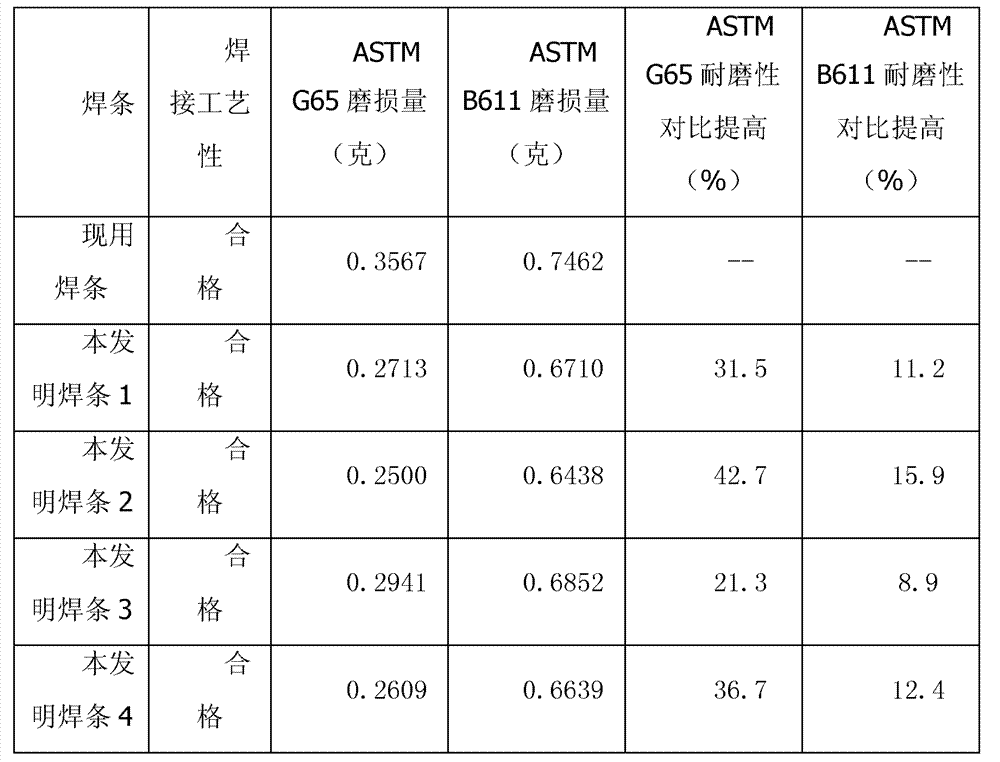

A pipe welding rod with low stress wear resistance

ActiveCN103228402BImprove welding processabilityAdvanced technologyDrill bitsWelding/cutting media/materialsMacrocrystallineAlloy

Owner:KINGDREAM PLC CO +1

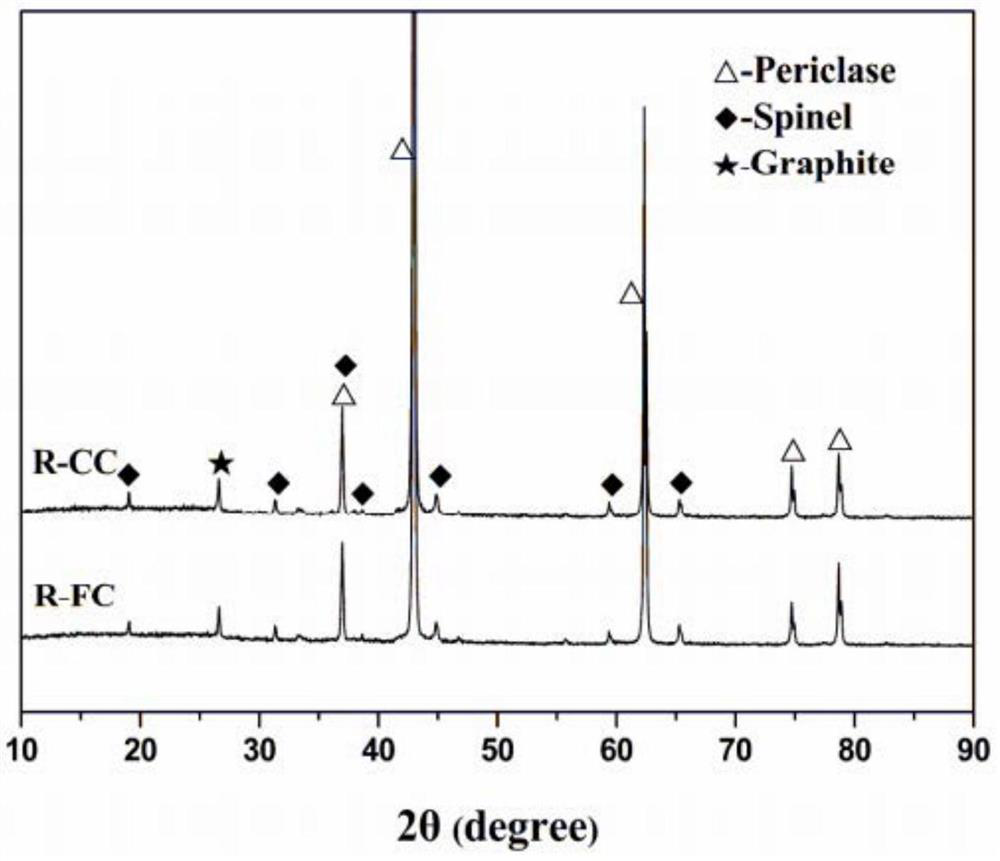

Preparation method of low-silicon high-calcium macrocrystalline fused magnesite

The invention discloses a preparation method of a low-silicon high-calcium macrocrystalline fused magnesite. The preparation method comprises the following steps: putting magnesite with the MgO content of over 45% into a light roasting furnace for continuous calcinations for 4 h, uniformly adding an Na2CO3 solution during calcinations, and smashing a product after calcinations to obtain a high-activity MgO powder; adding the high-purity graphite powder into the high-activity MgO powder, putting the mixture into a full-automatic electric smelting electric-arc furnace for smelting for 5 to 8 h,and carrying out classification crushing after the smelting is ended so as to obtain the low-silicon high-calcium macrocrystalline fused magnesite. According to the preparation method, a sodium carbonate solution is added, so that the melting point is effectively reduced, the calcination temperature is reduced, and the energy is saved; moreover, sodium silicate and carbon dioxide can be generatedthrough the reaction of sodium carbonate and impurity silicon dioxide, and the silicon dioxide impurity inside the magnesite can be effectively removed, so that the content of magnesium oxide is improved; the content of MgO inside the product reaches 99.90% or more than 99.90%, the calcium-silicate ratio reaches 2.30 or more, the fused magnesite has high high-temperature fire resistance and high-temperature scouring resistance, and the fused magnesite can be applied to the industries such as spaceflight, electrons, steel, metallurgy and the like as a high-quality advanced refractory material.

Owner:LIAONING XINFAZHAN REFRACTORY MATERIAL GRP

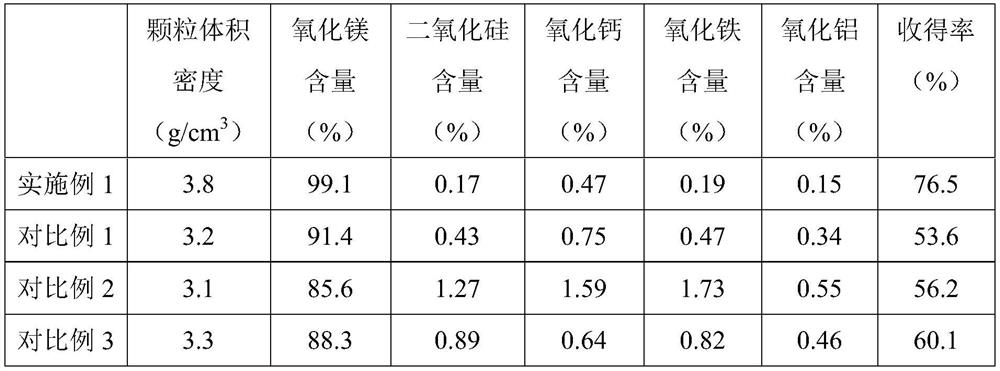

Preparation method of macrocrystalline magnesia with low silicon dioxide content

InactiveCN112094106AObvious performance advantageHigh in silicaFlotationElectric arc furnaceMacrocrystalline

The invention discloses a preparation method of macrocrystalline magnesia with low silicon dioxide content, and belongs to the technical field of mineral resource processing. The method comprises thefollowing steps: (1) fine selection: taking low-grade magnesite as a raw material, and finely selecting magnesite with the magnesium oxide content of 40%-45%; (2) cleaning: cleaning magnesite; (3) refining: refining the magnesite; (4) roasting: feeding the concentrate powder into a rotary kiln or a fluidized bed furnace for roasting, and cooling to room temperature to obtain light calcined magnesia; (5) dry pressing: feeding the light calcined magnesia into a ball press machine for dry pressing to obtain balls; and (6) electric melting: feeding the spheres prepared in the step (5) into an electric arc furnace for electric melting, and carrying out heat preservation, cooling and crystallization. The prepared macrocrystalline magnesia has good performance advantages, the test parameters suchas the particle volume density, the magnesium oxide content, the silicon dioxide content, the calcium oxide content, the iron oxide content, the aluminum oxide content and the yield show significantdifferences, and the macrocrystalline magnesia is high-quality macrocrystalline magnesia.

Owner:LIAONING DONGHE NEW MATERIAL CO LTD

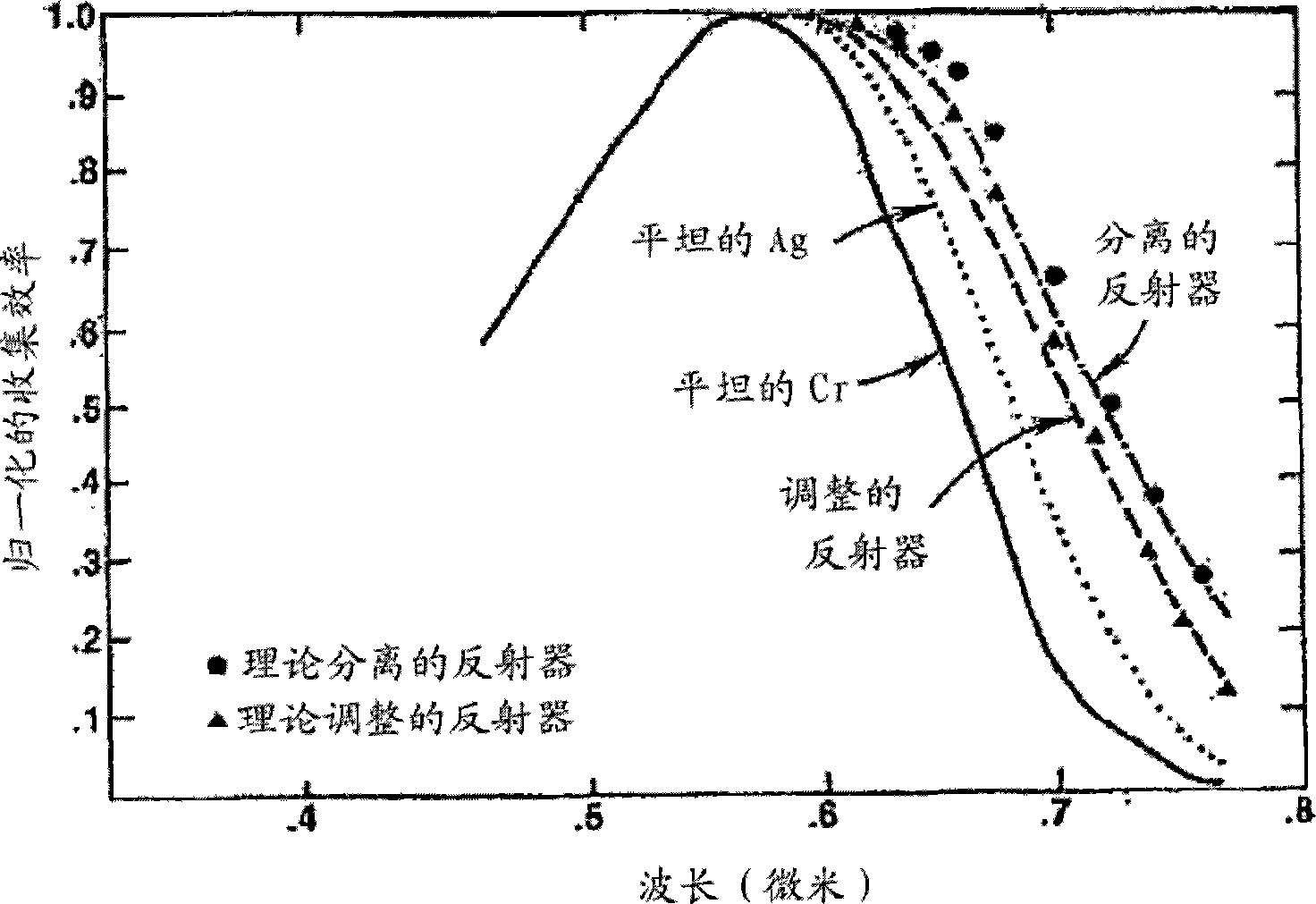

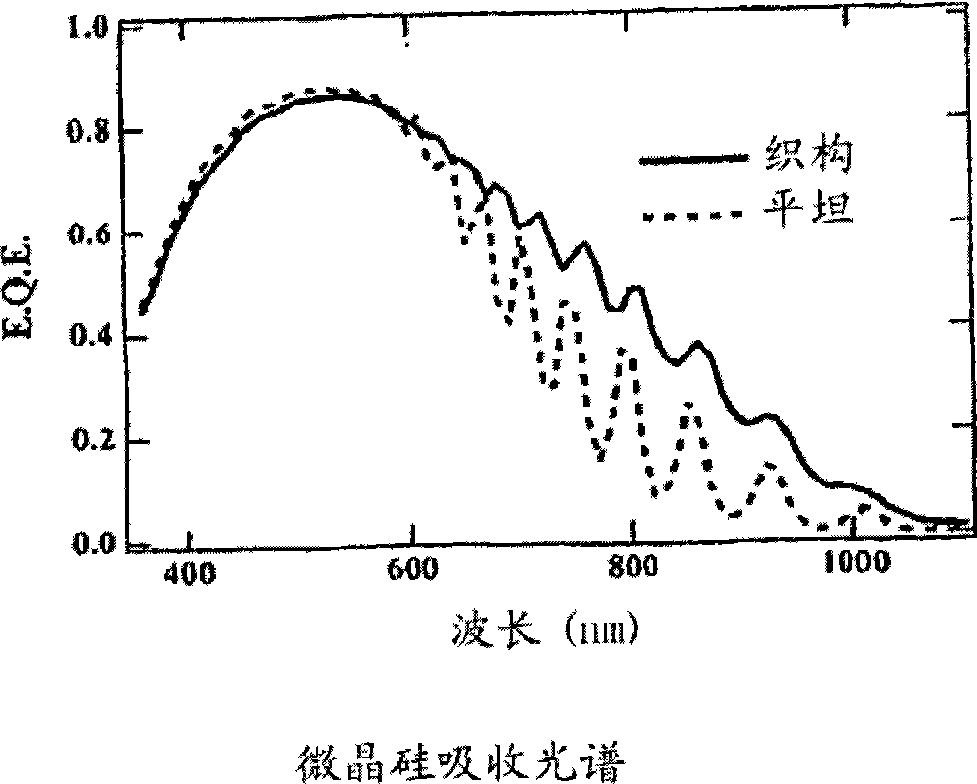

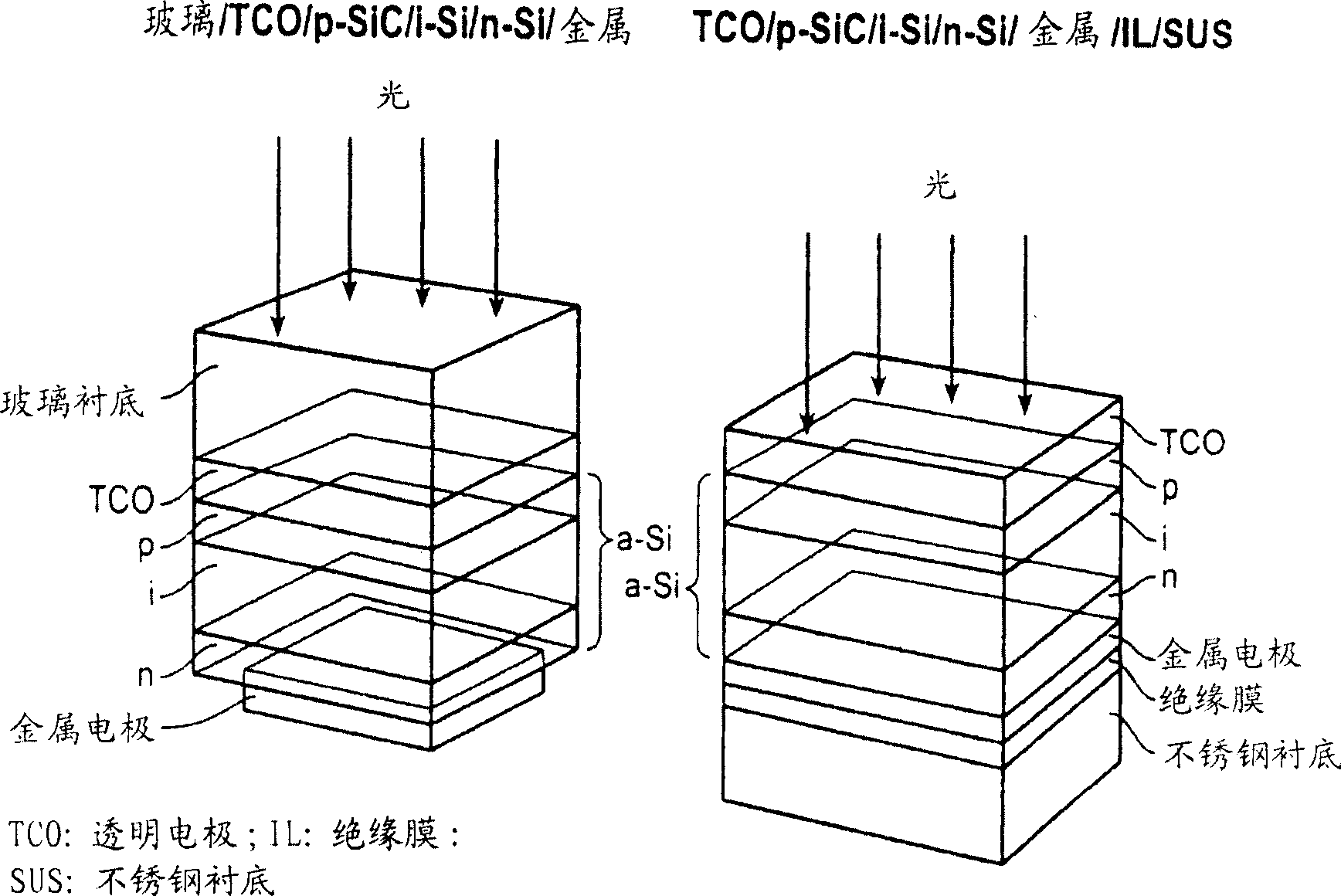

Photovoltaic device with nanostructured layers

Photovoltaic devices or solar cells are provided. More particularly, the present invention provides photovoltaic devices having IR and / or UV absorbing nanostructured layers that increase efficiency of solar cells. In some embodiments the nanostructured materials are integrated with one or more of: crystalline silicon (single crystal or polycrystalline) solar cells and thin film (amorphous silicon, macrocrystalline silicon, CdTe, CIGS and III-V materials) solar cells whose absorption is primarily in the visible region. In some embodiments the nanoparticle materials are comprised of quantum dots, rods or multipods of various sizes.

Owner:SOLEXANT CORP (US)

Low-carbon converter tapping hole bushing brick

InactiveCN113045321AImprove thermal shock resistanceLow apparent porosityManufacturing convertersSteelmakingAl powder

The invention discloses a low-carbon converter tapping hole bushing brick, which comprises the following components: fused macrocrystalline magnesia, fused magnesium aluminate spinel, graphite, alumina micro powder, metal aluminum powder, silicon powder, boron carbide, CarboresP carbon-containing resin powder, a binding agent and rare earth. The bushing brick provided by the invention has the advantages of high thermal shock resistance, high molten steel and slag scouring erosion resistance, high temperature resistance, lower apparent porosity and excellent oxidation resistance, greatly prolongs the service life of the steel tapping hole bushing brick, can meet the fast-paced production of a steel mill, guarantees the stable follow-up steelmaking rhythm, and improves the production efficiency.

Owner:云南濮耐昆钢高温材料有限公司

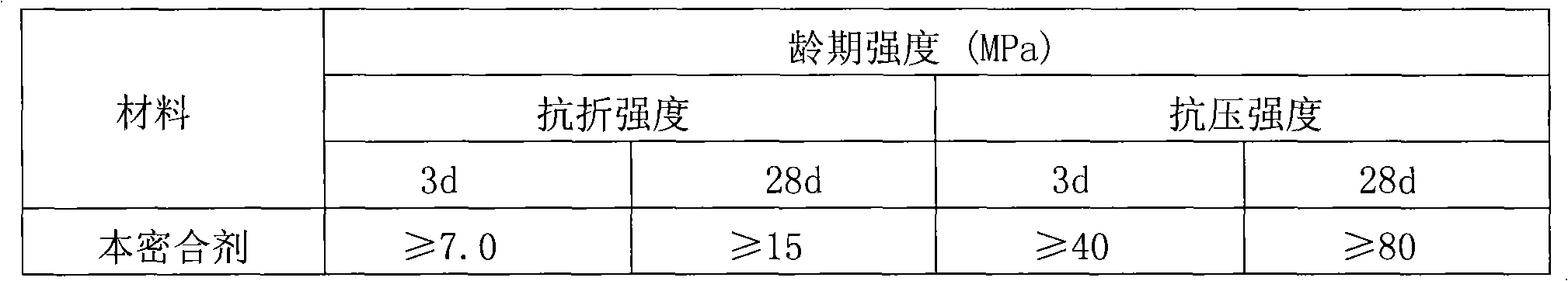

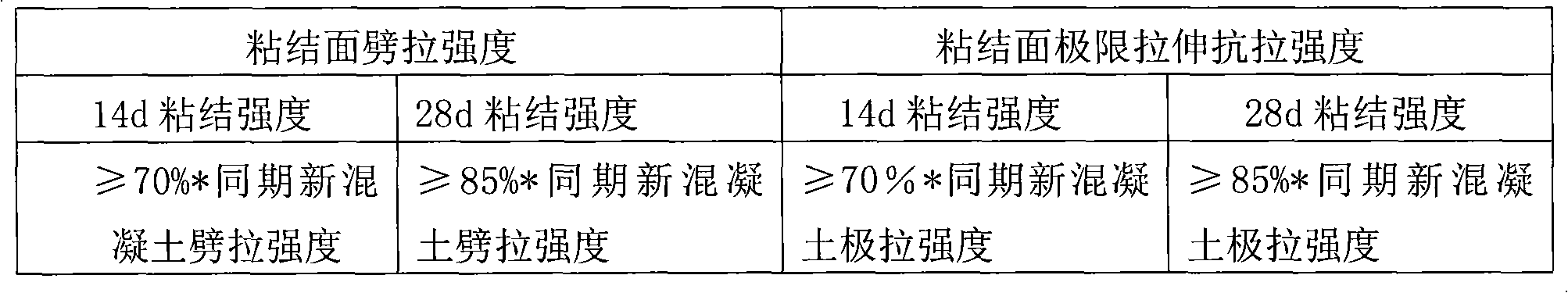

Sealing agent for combined interface of new and old concrete

An interface sealing agent for combining new and old concrete applies to bond combining interface of new and old concrete, which comprises silicate mineral powder, pozzolana powder, active powder for reducing contraction, inert particles for reducing contraction, surfactant and retarder. The silicate mineral powder provides bonding strength; the pozzolana powder raises flowability and viscosity of slurry and reduces numbers of calcium hydrate macrocrystalline, and enhances continuously late strength; the active powder for reducing contraction is expansion component; the inert particles can reduce slurry contraction; the surfactant can reduce ratio of water and glue and regulates coagulation time, the technique improves bonding property and sealing property of bond combining interface of new and old concrete, comparing with conventional material and present interface material improved greatly, capable of bonding combining interface of new and old concrete firmly without crack; productshave little toxicity and environment pollution.

Owner:HUBEI GEZHOUBA TESTING

Androstenedione purification method

The invention relates to an androstenedione purification method comprising the steps of crystal washing and recrystallizaiton, wherein a composite solvent composed of normal hexane and ethyl acetate in the proportion of 1:1 is adopted in the step of crystal washing, and methyl alcohol is used as a solvent in the step of recrystallization. The androstenedione purification method comprises the concrete steps of: (1) primary crystal washing: adding a macrocrystalline and a composite solvent according to the proportion of 1:2.5, stirring the macrocrystalline and the composite solvent for 2h, and then, carrying out centrifugal separation to obtain crystal powder A; (2) secondary crystal washing: adding the crystal powder A and the composite solvent according to the proportion of 1:2, stirring the crystal powder A and the composite solvent for 2h, and then, carrying out centrifugal separation to obtain crystal powder B; (3) recrystallization: drying the crystal powder B, and then recrystallizing by using the methyl alcohol to obtain a finished product with the purity of over 99%, wherein the dosage ratio of the methyl alcohol to the crystal powder B is 1:16; and (4) solvent recovery: inspissating the washing solutions obtained in the primary and secondary crystal washing processes through a membrane lifting concentrator to recover the composite solvent. By using the androstenedione purification method, impurities can be effectively removed, the operation can be simplified, a great number of solvents can be saved, the energy consumption during solvent recovery is also reduced, and finally, the finished product with the purity of over 99% is obtained.

Owner:ZHEJIANG QIANJIANG BIOCHEMICAL CO LTD

Method for extracting purified tracheloside from safflower seeds

ActiveCN107602642ALow costNon-absorptiveSugar derivativesSugar derivatives preparationMacrocrystallineDissolution

The invention provides a method for extracting purified tracheloside from safflower seeds, and mainly solves the problems of low yield, unsuitability for industrial production and complicated processin the prior art. The method mainly comprises the following steps that firstly, raw materials of safflower seeds are subjected to oil expression; then, obtained safflower seed meal is smashed; ethyl alcohol is used for extraction; next, extracting liquid is concentrated, decolored and filtered; filter liquid is purified by anion resin; effluent liquid is collected and adsorbed; then, the pH is regulated to be 3 to 5 by hydrochloric acid; filtering is performed; an organic solution is added into the filter liquid for extraction and concentration; placing crystallization, filtering and drying are performed to obtain macrocrystallines; finally, the macrocrystallines are smashed; the ethyl alcohol is used for stirring and dissolution; filtering is performed; precipitates are collected; dryingis performed to obtain the tracheloside. The method has the advantages that the residual meal obtained after the oil expression of the safflower seeds is effectively utilized; the tracheloside is obtained through separation and purification from the residual meal; the goal of changing waste into valuable is realized, so that the resources are comprehensively utilized; the raw material cost is reduced; the whole process is simple; the operation is easy; the yield is high; the quality is stable.

Owner:陕西嘉禾药业有限公司

Diamond drill bit matrix and manufacturing method thereof

InactiveCN109022995AReduce coefficient of frictionExtended service lifeTransportation and packagingMetal-working apparatusMacrocrystallineTin bronze

The invention discloses a diamond drill bit matrix. Manufacturing raw materials of the diamond drill bit matrix include cast tungsten carbide powder, nickel powder, spherical tungsten carbide powder,macrocrystalline tungsten carbide powder, tin bronze powder and a solid lubricant. The diamond drill bit matrix comprises, by weight, 15-25 parts of the cast tungsten carbide powder, 20-35 parts of the nickel powder, 20-25 parts of the spherical tungsten carbide powder, 5-15 parts of the macrocrystalline tungsten carbide powder, 10-15 parts of the tin bronze powder and a proper quantity of the solid lubricant. According to the diamond drill bit matrix, the solid lubricant is added into the manufacturing materials, the friction coefficient between cutting teeth and processed materials in the running process of the cutting teeth can be reduced through the solid lubricant, the service life of the cutting teeth is prolonged and processing efficiency is improved. Meanwhile, diamond particles can be distributed in the cutting teeth more uniformly through a pelletizing technology, and the added manufacturing raw materials can be obtained easily. Moreover, the service life of a diamond drill bit can be prolonged to a certain extent by changing the coefficient of production, and mass production can be conducted.

Owner:铜陵长江金刚石工具股份有限公司

Composition, method of preparation and use thereof, based on a harmless natural organic mixture free of contamination having chemical and physical aspects similar or equal to original beeswax

PendingUS20220312745A1Return them their strengthHealthy environmentCosmetic preparationsToilet preparationsMicrocrystalline waxMacrocrystalline

The invention comprises a beeswax analogue composition which enables the efficient replacement thereof, for beekeeping and any industries that normally use it in their production processes and products, based on a harmless natural organic mixture free of contamination having chemical and physical aspects similar or equal to said wax, which comprises: Fine crystal wax, known as microcrystalline wax, with a high percentage of hydrocarbon, branched, isoparaffinic and naphthenic hydrocarbons. Macrocrystalline wax made of non-branched alkanes of non-fine crystals. Organic resin. Organic pigment to determine the colour, distinguishing region, place and factory batch. (Published in a timely manner, to prevent falsifications). The method of preparation comprises the following steps, tools and actions: Proportional weighing of components. Verification of asepsis of machines and tools. Pouring of components into a steam-jacketed shell boiler in order for hot gases to simultaneously transfer heat to the entire mixture coming from an industrial burner with cross-over to medium or high-pressure liquefied gas. Upon verifying the total liquefaction of the components, it can be observed that from that moment the mixture reaches a temperature equal to or greater than 140° C. After waiting for 1 to 10 minutes, the energy (burner) is turned off and the mixture emptied into moulds for cooling. Once the equipment is hot after the first batch has been produced, it takes 25 to 35 minutes to obtain a liquefied product from the raw material for the second and subsequent batches, followed by 1 to 10 minutes at 140° to obtain a balanced product. Its use replaces beeswax in beekeeping and also for storing honey and pollen.

Owner:HIDALGO GONZALEZ DAVID ISAAC ALEJANDRO

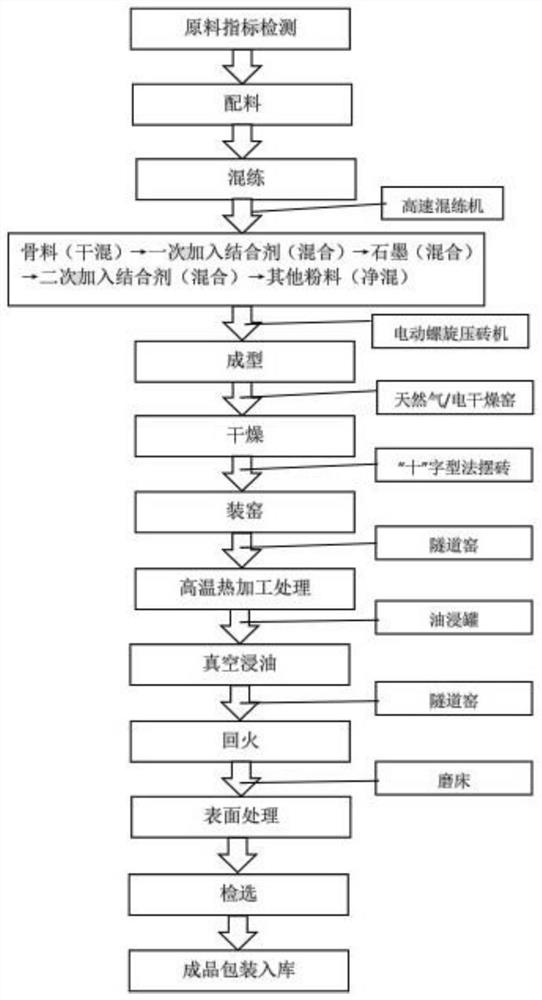

High-temperature treated magnesia carbon brick for RH dip pipe and circulating pipe and preparation method thereof

ActiveCN112897992AImprove densification performanceAvoid pollutionProcess efficiency improvementPorosityBrick

The invention discloses a high-temperature treated magnesia carbon brick for an RH dip pipe and a circulating pipe and a preparation method thereof. The magnesia carbon brick is prepared from the following raw materials in parts by weight: 20-30 parts of magnesia with a particle size of 3-5mm, 10-30 parts of magnesia with a particle size of 1-3mm, 20-30 parts of magnesia with a particle size of less than or equal to 1mm, 10-30 parts of magnesia with a particle size of less than or equal to 0.075 mm, 3-10 parts of crystalline flake graphite, 0.2-2 parts of ultrafine graphite with a particle size of 10-15 [mu]m, 0.2-2 parts of resin powder, 0.2-2 parts of carbon black, 0.1-3 parts of aluminum-silicon alloy powder, 0.1-2 parts of lanthanum oxide, 0.5-3 parts of macrocrystalline magnesia micro powder with a particle size of 10-15 [mu]m, 0.1-1 part of chromium metal and 2.2-3.5 parts of thermosetting phenolic resin. The high-temperature heat-treated magnesia carbon bricks are used as the RH dip pipe and circulating pipe lining refractory material to replace magnesia spinel bricks and magnesia-chrome bricks, the porosity of the RH dip pipe and circulating pipe refractory material is optimized, the high-temperature performance is improved, and the service life is prolonged.

Owner:鞍山市和丰耐火材料有限公司

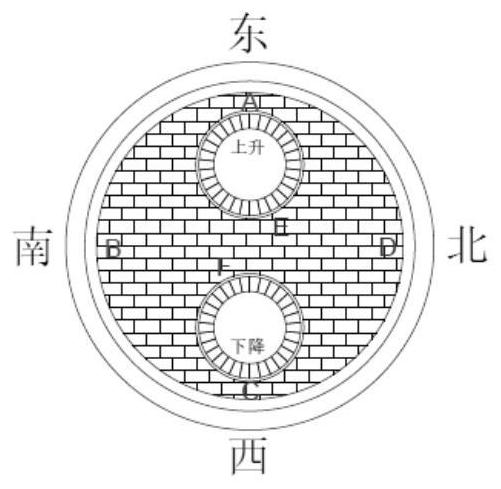

Closed device for producing macrocrystalline fused magnesite

The invention provides a closed device for producing macrocrystalline fused magnesite, which comprises a light calcined magnesia kiln and submerged arc furnaces, the light calcined magnesia kiln is connected with the submerged arc furnaces through a middle bin and a chain grate type feeder, the light calcined magnesia kiln is matched and butted with a plurality of sets of submerged arc furnaces, and the chain grate type feeder feeds materials to the submerged arc furnaces through magnesite powder articulated chutes. A heat preservation cover is arranged outside the chain grate type feeder, and the inner wall of the middle bin and the inner walls of the magnesite powder articulated chutes are each provided with a heat insulation abrasion-resistant refractory material. Light calcined magnesia powder is thermally conveyed in a closed channel, so that the heat loss is reduced, and the energy is saved; the smoke waste heat can be utilized to preheat raw materials through smoke recovery of the macrocrystalline fused magnesite submerged arc furnaces; and automatic feeding of the submerged arc furnaces is achieved through smoke temperature monitoring, heat preservation is conducted on furnace barrels of the submerged arc furnaces after smelting is completed, and the furnace barrels can be independently covered with covers or placed in a heat preservation chamber in a centralized mode.

Owner:岫岩满族自治县恒锐镁制品有限公司

Slag-stopping wall brick for slag-free tapping of quantum electric arc furnace and preparation method of slag-stopping wall brick

InactiveCN113979731AExtended service lifeSolve the problem of excessive melting lossFurnace componentsElectric arc furnaceMetallic aluminum

The invention relates to the technical field of refractory materials, in particular to a slag-stopping wall brick for slag-free tapping of a quantum electric arc furnace. The slag-stopping wall brick is prepared from the following raw materials in percentage by weight: 68-80% of macrocrystalline magnesia, 10-18% of crystalline flake graphite, 1-3% of metal aluminum powder, 1-5% of an additive, 2-8% of thermosetting phenolic resin and 2-3% of silica powder. By designing the slag-stopping wall brick for slag-free tapping of the quantum electric arc furnace, the problem that an existing slag-stopping wall brick is too fast in melting loss due to slag erosion and molten steel scouring is effectively solved, so that the melting loss rate of the slag-stopping wall brick of the quantum electric furnace built by the slag-stopping wall brick is low, the consumption of refractory materials per ton of steel of the slag-stopping wall brick can be obviously reduced, and then the overall service life of the quantum electric furnace is longer.

Owner:SHANGHAI LIER REFRACTORY MATERIAL +1

Process for smelting macrocrystalline green silicon carbide

The invention relates to silicon carbide smelting, in particular to a process for smelting macrocrystalline green silicon carbide, which comprises the following: a, a step of preparing raw materials of quartz sand and petroleum coke in a ratio of 1.48 to 1.54; b, a step of material mixing; c, a step of furnace charge, in which homogenized raw materials are delivered to a material area (1) at the bottom of a furnace, a burden material subjected to secondary roasting is filled in reaction areas (3, 4 and 5) in the middle of the furnace, and a burden material subjected to primary roasting is filled in the external heat preservation areas (7 and 8); d, a step of smelting, in which the charged furnace is electrified for smelting for 32 to 36 hours, the power of a transmission transformer is 8,000 KVA, and after cooling for 72 hours, the materials are discharged and graded. By adopting a smelting process of roasting for two times, the process reduces the waste of primarily roasted material, the specific consumption of the petroleum coke, the quartz sand and power, and saves energy. Meanwhile, as a long-time lower power transmission is adopted, the reaction of grains is more uniform and complete and the structure of the grains is more compact and firm; and compared with products in the prior art, the product has higher hardness, larger grain size, higher content and more desirable powder grain form.

Owner:TONGHUA HONGXIN ABRASIVE

Polycrystalline diamond drill bit matrix powder

ActiveCN102773472BIncrease concentrationImprove bindingDrill bitsMacrocrystallinePolycrystalline diamond

The invention relates to a powder metallurgy material for manufacturing a polycrystalline diamond drill bit matrix. The powder metallurgy material comprises the components by weight percent: 30-60% of spherical sintered WC particles with the particle size of 125-500 microns, 25-60% of fine macrocrystalline WC particles with the particle size of 50-200 microns, and 5-15% of nickel powder. According to the invention, bonding phase can penetrate into the hollow spherical sintered WC particles and can be used for filling the hollow spherical sintered WC particles, so that the bonding phase and hard phase in the matrix can be better combined with each other, and the matrix has higher strength and toughness; and gaps among coarse particles can be effectively filled by the fine macrocrystalline WC particles, so that the erosion resistance and the wear resistance of the matrix can be better improved. According to the invention, the matrix material cost of a drill bit is reduced; and as the performances of the matrix are improved, the polycrystalline diamond compact (PDC) drill bit with a thinner or longer scraping knife can be designed, and the drilling rate of the PDC drill bit can be greatly increased.

Owner:KINGDREAM PLC CO +1

Giant crystal grains capable of forming crystal flowers, dry grain combination, grains for ceramics, ceramics and preparation method of ceramics

ActiveCN112456802BRich and varied colorsImprove the decorative effectMacrocrystallineTexture (crystalline)

The invention belongs to the technical field of ceramics, and discloses giant crystal particles capable of forming crystal flowers, a combination of dry particles, particles for ceramics, ceramics and a preparation method for ceramics. The chemical quality composition of macrocrystalline grains includes SiO 2 、Al 2 o 3 、K 2 O, Na 2 O, CaO, MgO, BaO, ZnO, F, Li 2 O, TiO 2 , and metal oxides for coloring. Giant crystal particles can be quickly fired at low temperature to form large crystal crystal flowers. The crystal flowers are in the shape of petals. The color of the crystal flowers can be adjusted at any time according to the design color and texture. The colors are rich and diverse, and the decorative effect is excellent. Dry granules can be burned quickly at low temperature, which meets the requirements of energy saving and environmental protection in the ceramic field. The fired ceramic tiles have dense surface, high strength, super wear resistance and no dirt. The surface of the product is crystal clear and has a natural random crystal flower effect. The color of the brick surface is richer and more diverse. Whether it is on the ground or on the wall, it can be paved to produce a good effect.

Owner:FOSHAN DOWSTONG TECH

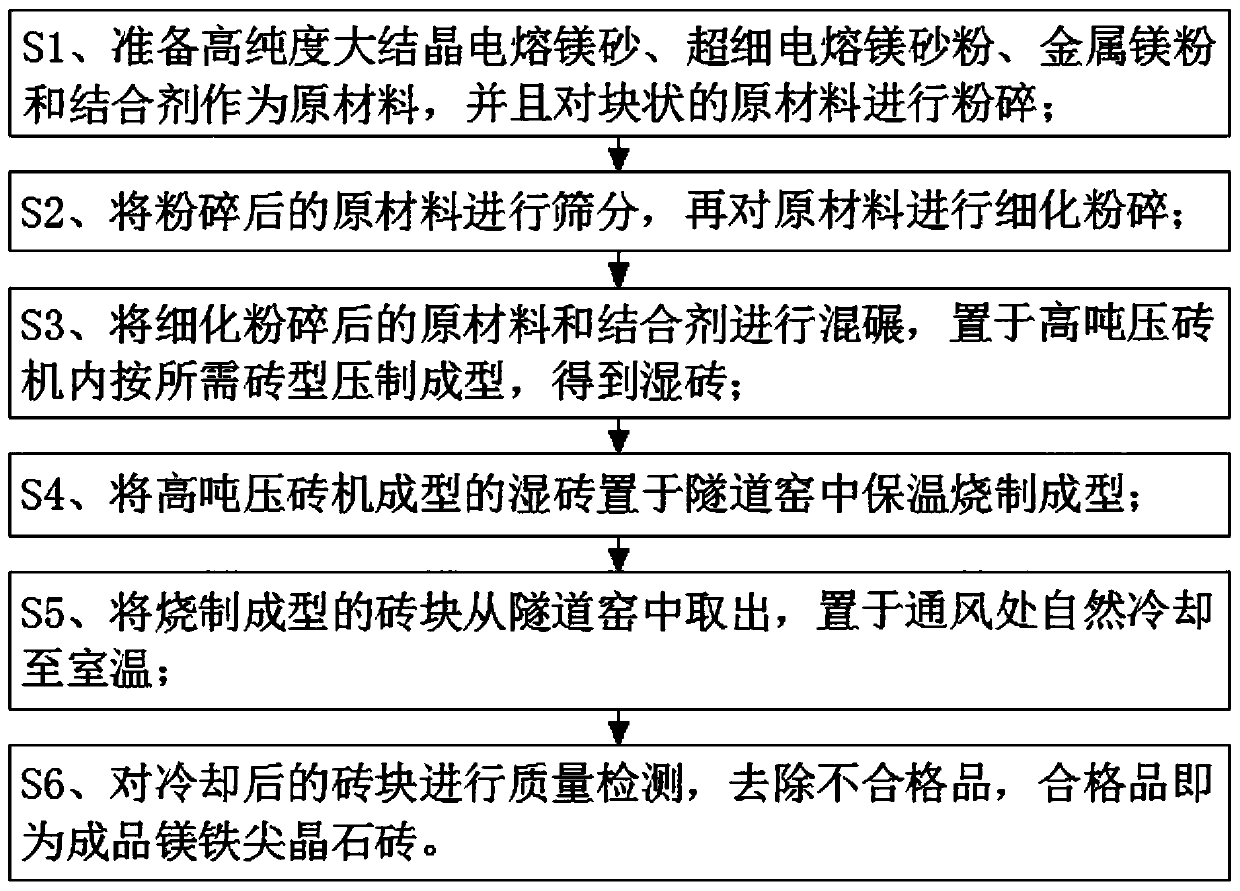

Preparation method of high-corrosion-resistance pleonaste brick

InactiveCN110483020AHigh temperature corrosion resistanceHigh thermal spalling resistancePorosityTunnel kiln

The invention discloses a preparation method of a high-corrosion-resistance pleonaste brick, and relates to the technical field of environmental protection. Raw materials comprise the following components: 85-90 parts of high-purity macrocrystalline fused magnesite, 15-25 parts of ultrafine fused magnesite powder, 10-25 parts of magnesium metal powder and 2-5 parts of a binding agent. According tothe brick, the high-purity macrocrystalline fused magnesite is adopted as a main raw material; the superfine fused magnesite powder and the metal magnesium powder material are added; a high-ton brickpress is adopted for molding; high-temperature firing in a tunnel kiln is performed; because of the addition of the high-purity fused magnesite, the high-temperature erosion resistance of the productis greatly improved; the added superfine fused magnesite sand enables the product to have good kiln coating hanging performance, the added metal magnesium powder enables the product to have high-temperature toughness, the thermal-state anti-stripping performance and the thermal shock resistance are improved, the product has high volume density and low porosity because of high-pressure forming, and the product has good high-temperature volume stability because high-temperature forming.

Owner:郑州瑞泰耐火科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com