Polycrystalline diamond drill bit matrix powder

A technology of polycrystalline diamond and matrix powder, which is applied in the direction of drill bits, earthwork drilling, drilling equipment, etc., can solve the problems of difficulty in meeting low-cost requirements, impact of drill bit permeability, and high manufacturing cost of drill bits, and achieve good wetting ability , reduce loose carcass defects, improve the effect of drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

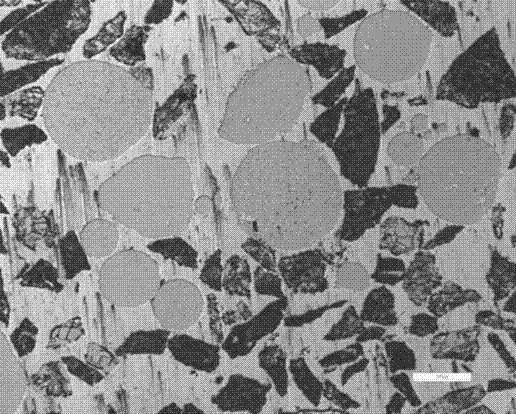

[0020] The carcass powder consists of 35% of spherical sintered WC particles with a particle size of 150-250 microns (the proportion of hollow spherical sintered WC particles is 25%), and 60% of macrocrystalline WC particles with a particle size of 50-150 microns. , nickel powder mixed with 5%. The mechanical properties of the sintered carcass were tested according to GB3851 and GB / T1817. The results showed that the strength ratio of the carcass containing spherical sintered WC particles and macrocrystalline WC particles ) Pure cast WC powder carcass strength increased by 30%, impact toughness increased by 35%.

Embodiment 2

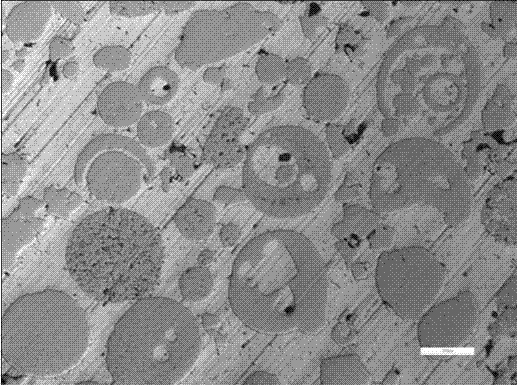

[0022] Carcass powder consists of 55% of spherical sintered WC particles with a particle size of 150-250 microns (the proportion of hollow spherical sintered WC particles is 25%), and 35% of macrocrystalline WC particles with a particle size of 50-150 microns. , 10% nickel powder mixed. The mechanical properties of the sintered carcass were tested according to GB3851 and GB / T1817. The results showed that the strength ratio of the carcass containing spherical sintered WC particles and macrocrystalline WC particles ) Pure cast WC powder carcass strength increased by 50%, impact toughness increased by 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com