Patents

Literature

47 results about "Specific consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

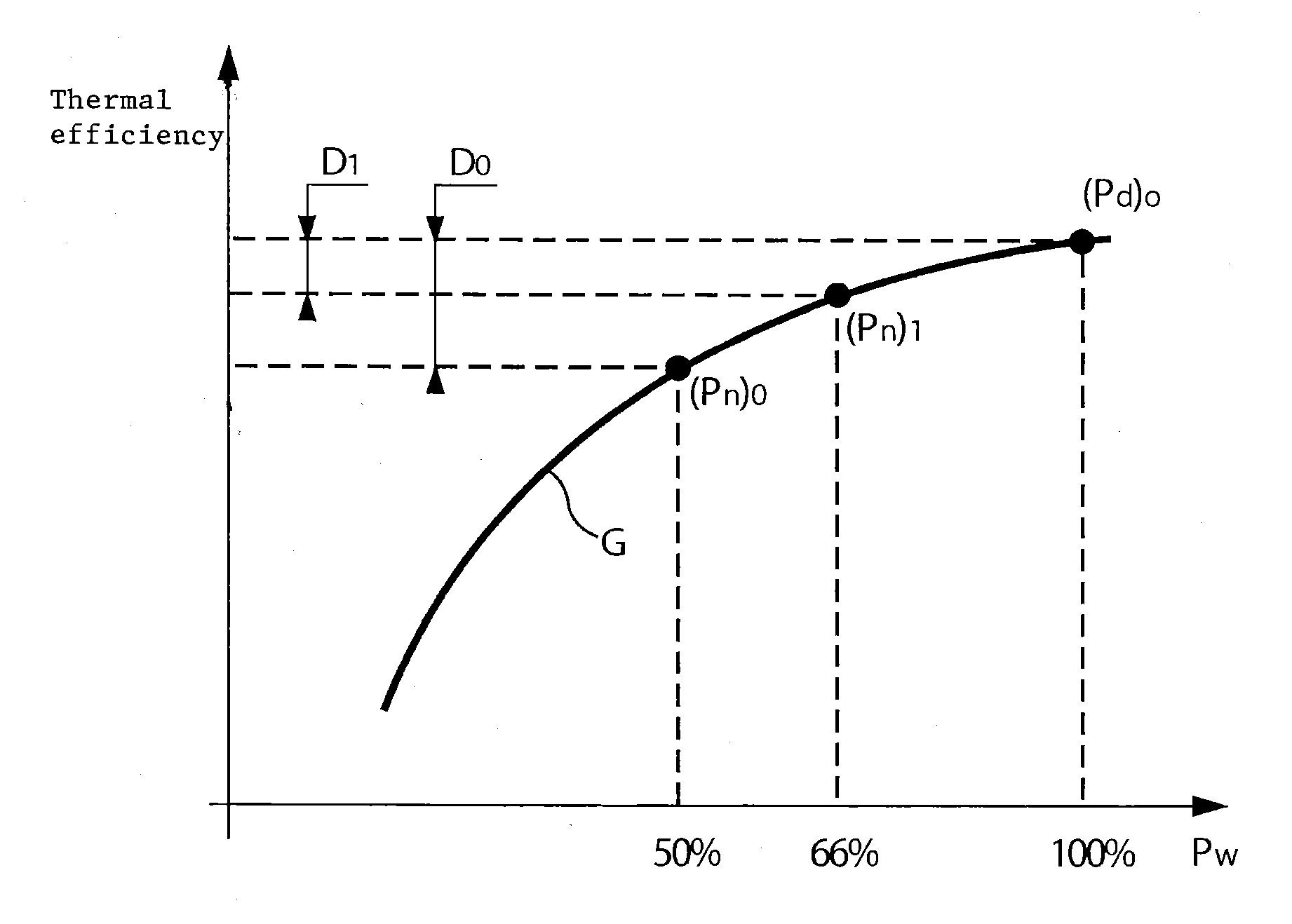

Specific fuel consumption is a more appropriate way of comparing engine of different size on its efficiency. According to the definition it is ratio of fuel consumption per unit time (in Kg/hr) to power produced by engine (in kWh). According to the power produce (Indicate power or brake power), it has two types indicate SFC and brake SFC.

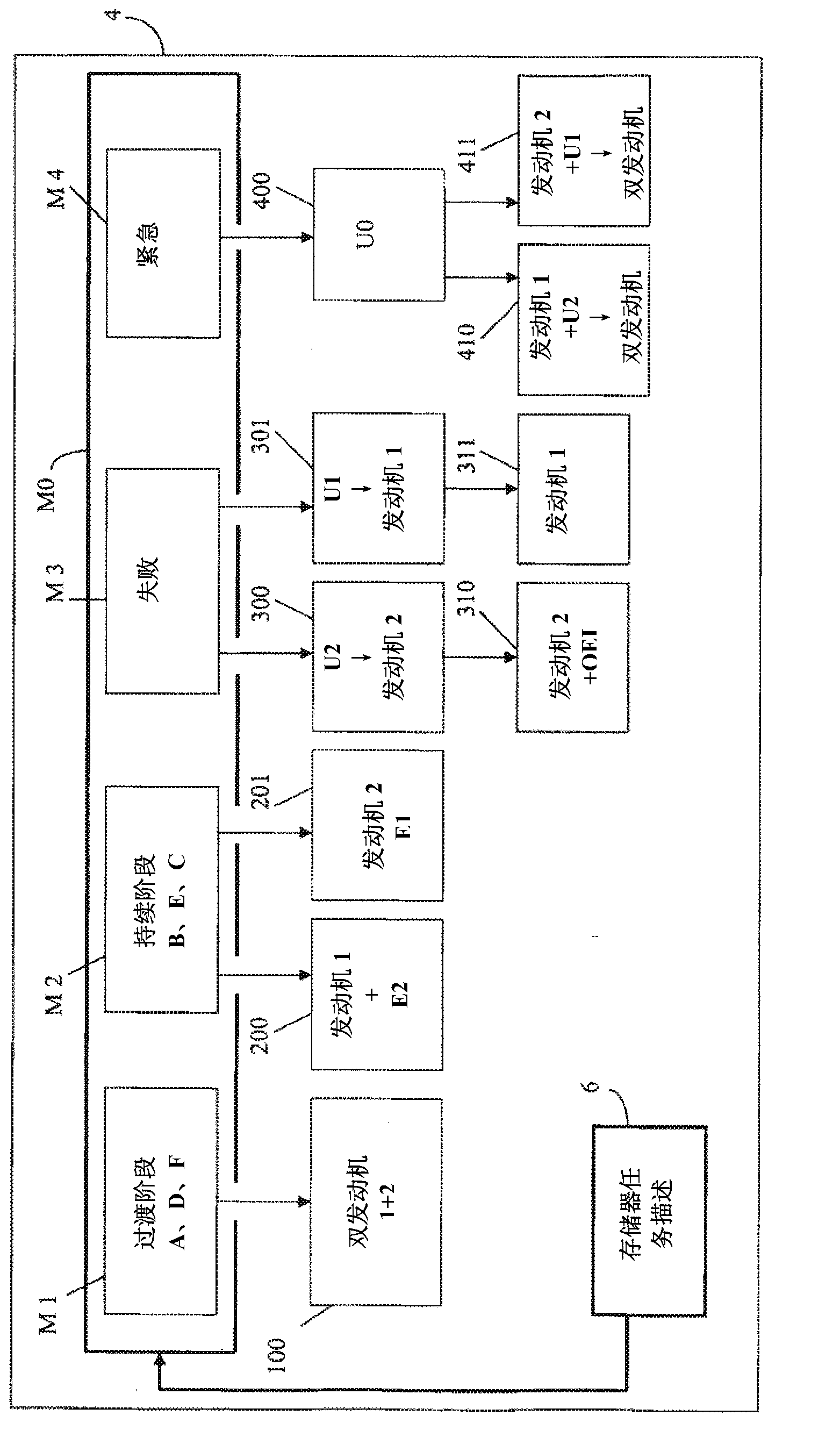

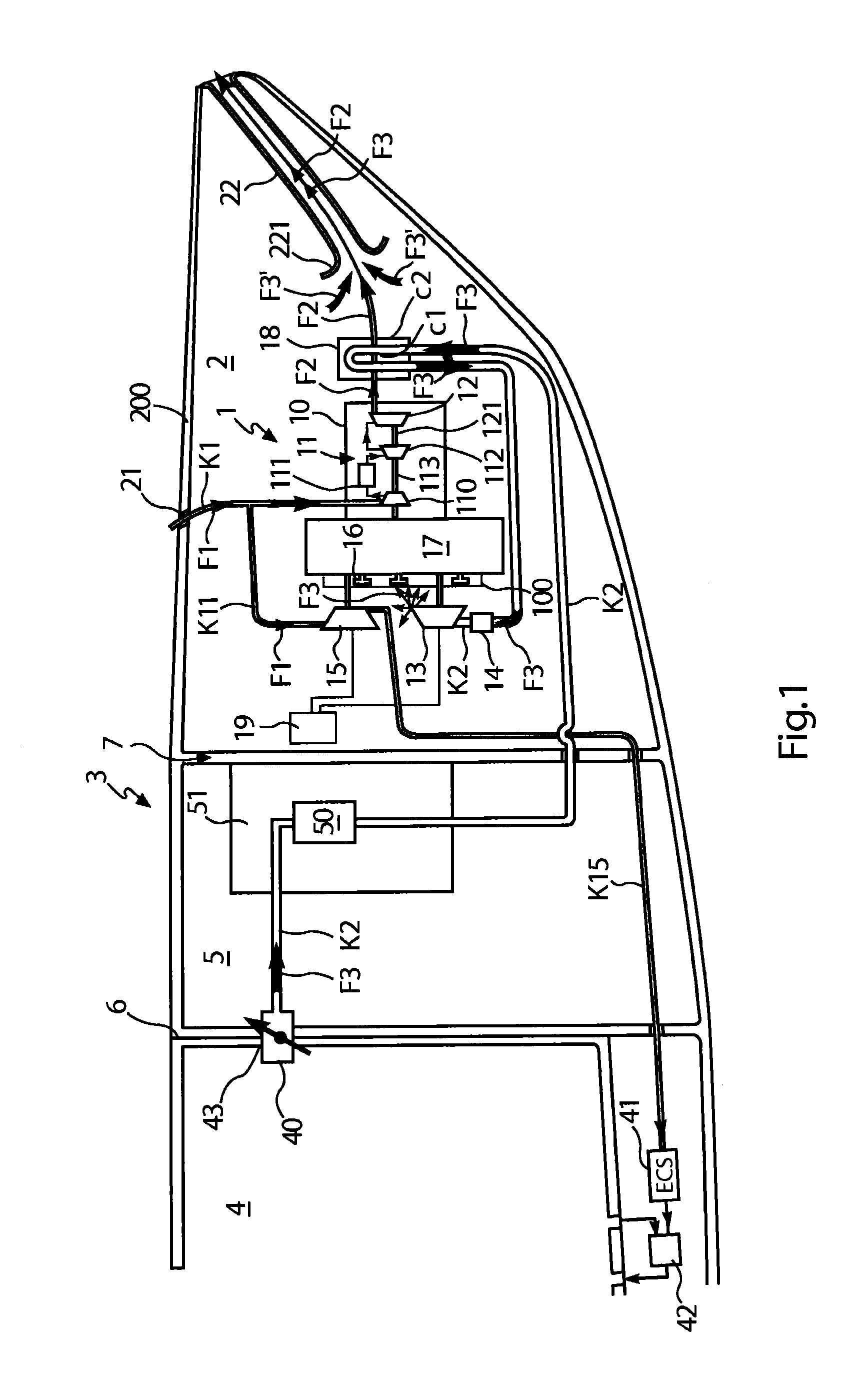

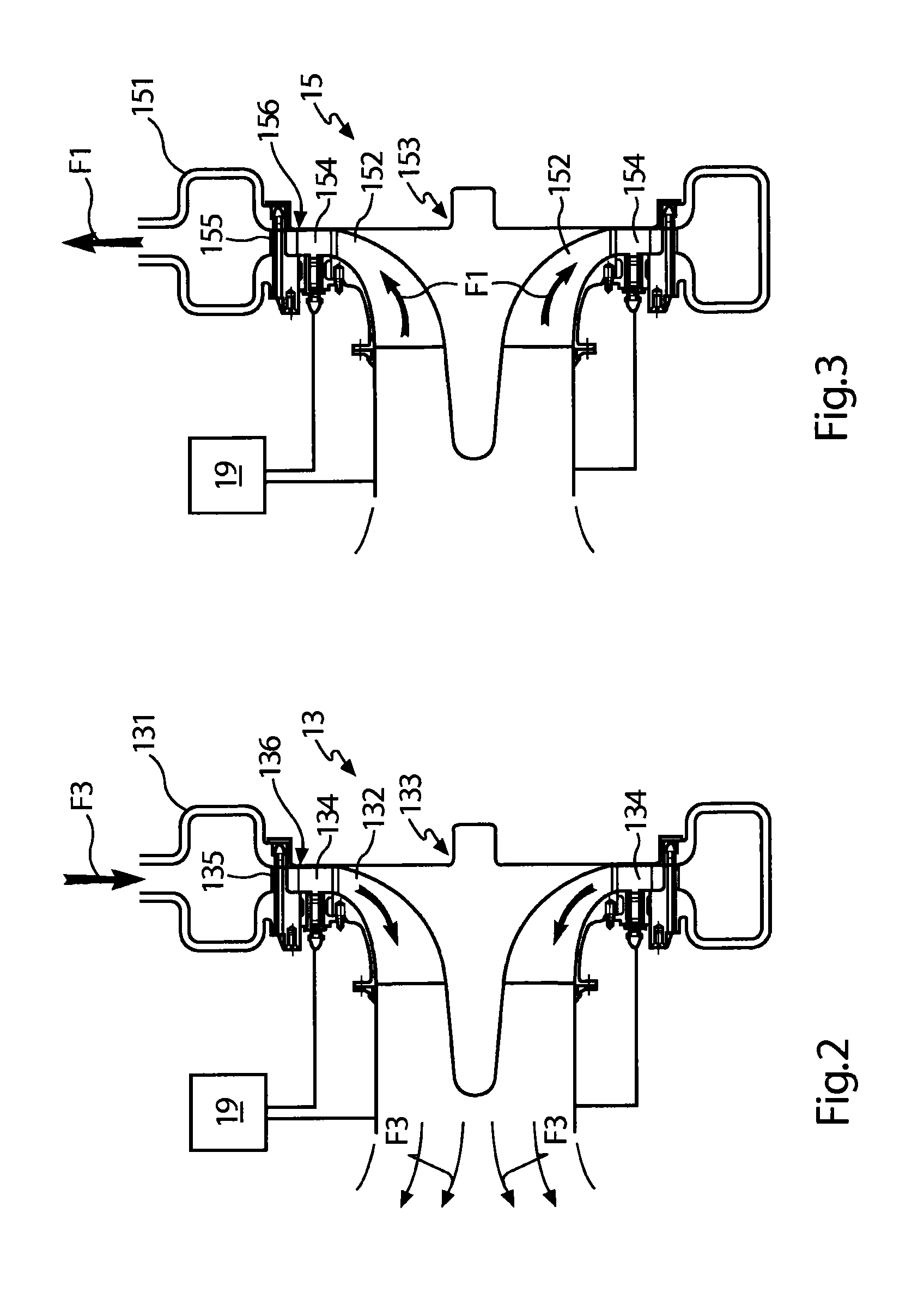

Method of optimizing the specific fuel consumption of a twin engine helicopter and twin engine architecture with control system for implementing it

InactiveUS20130219905A1Reduce decreaseCombustion enginesGas turbine plantsBrake specific fuel consumptionCombustion chamber

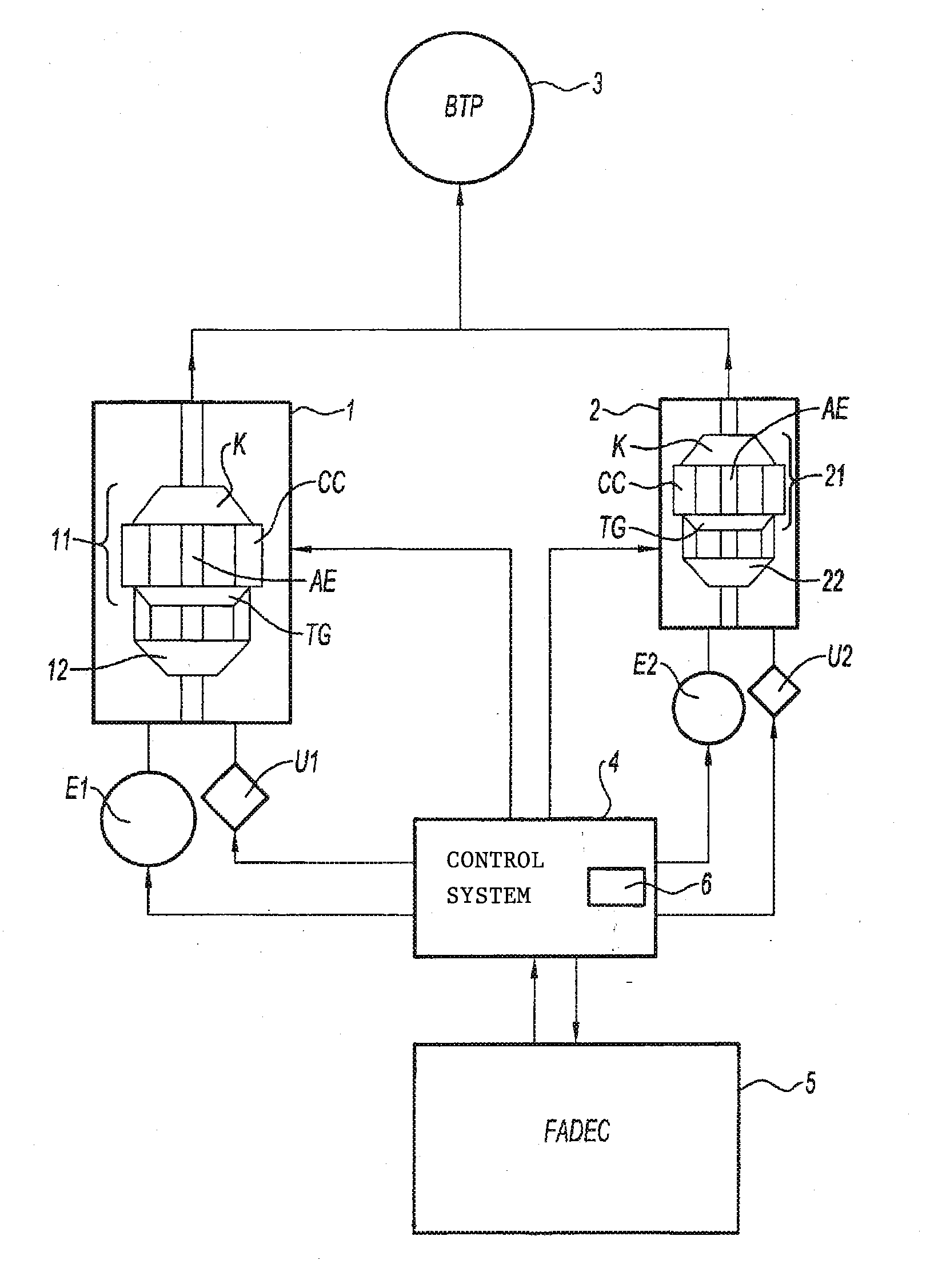

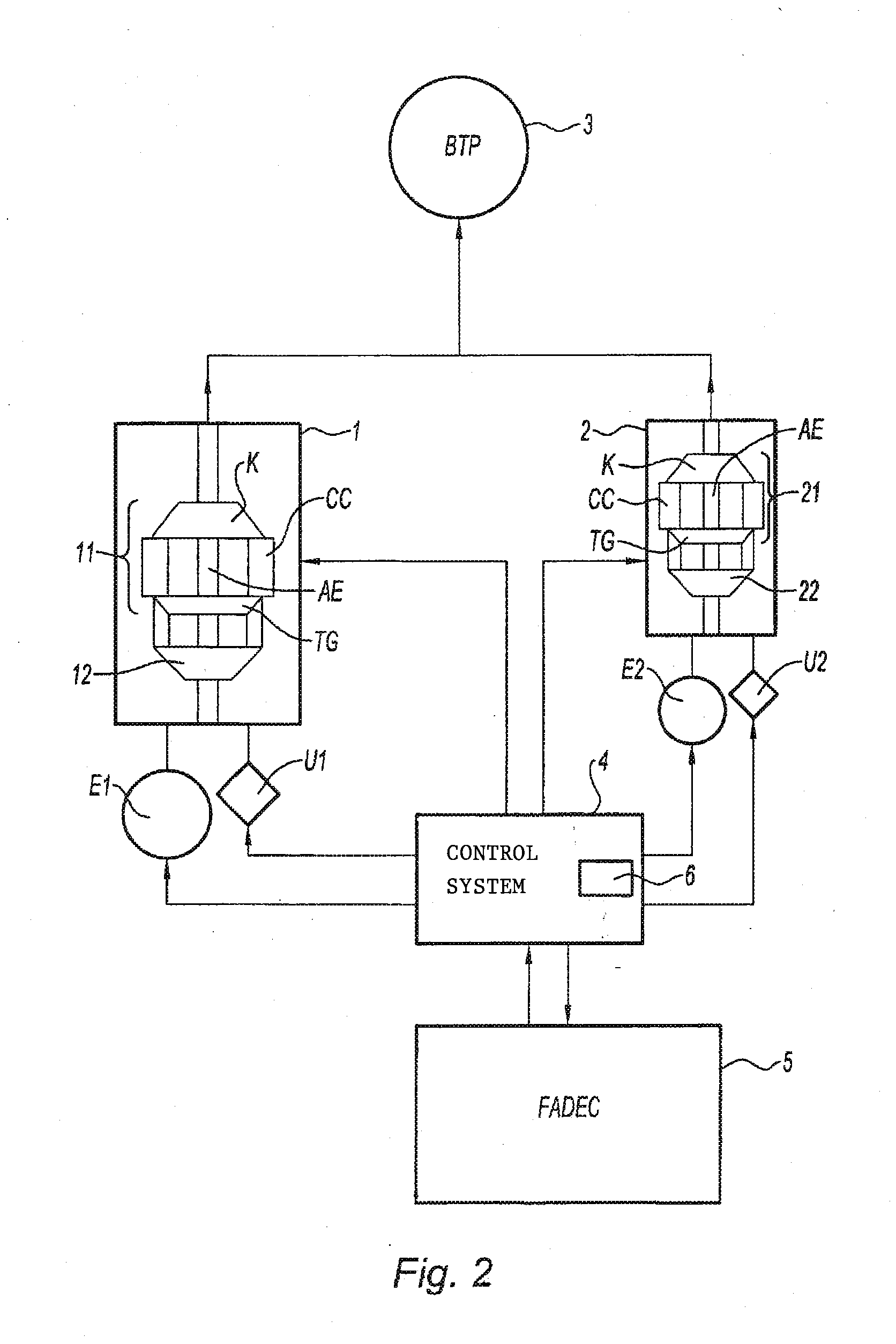

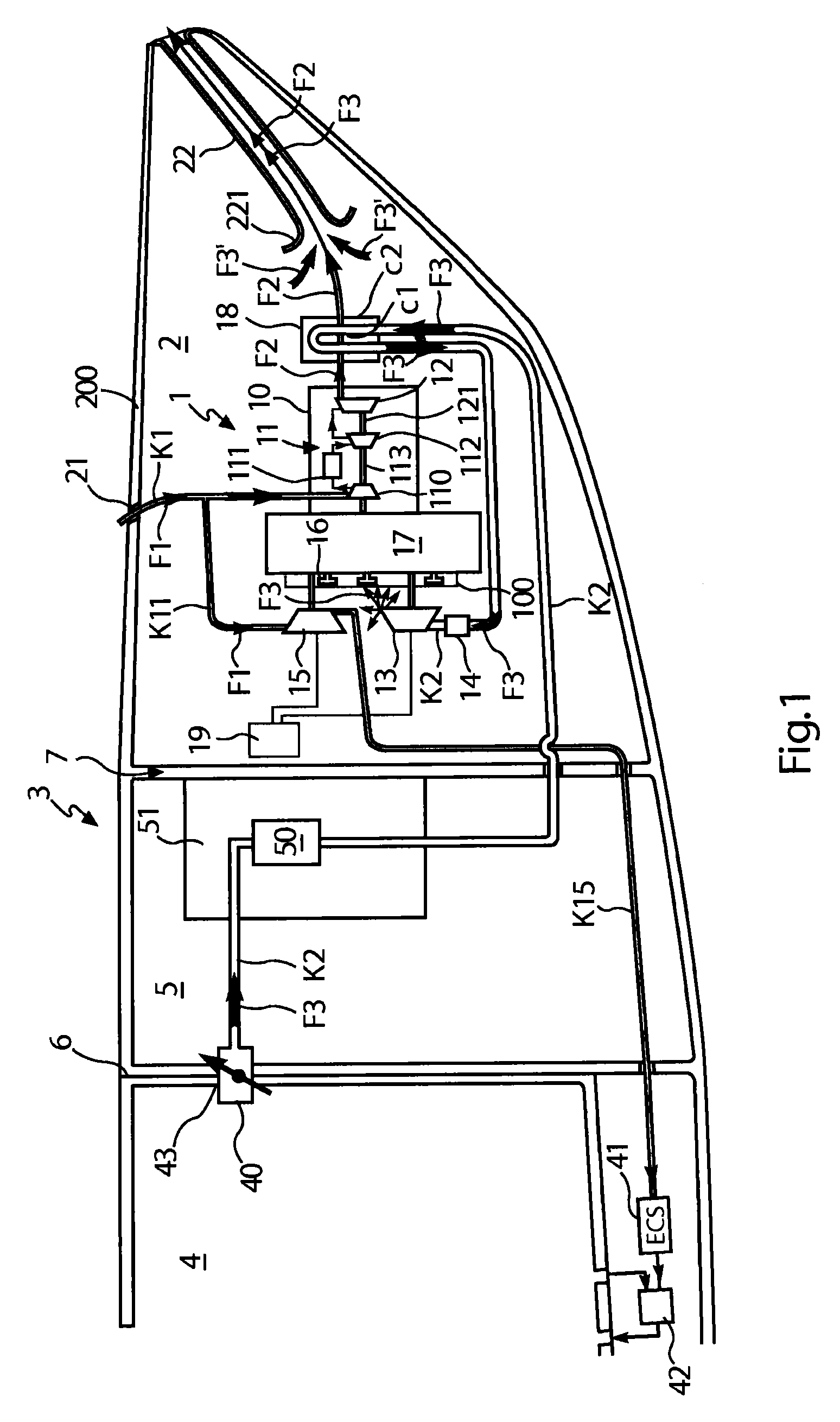

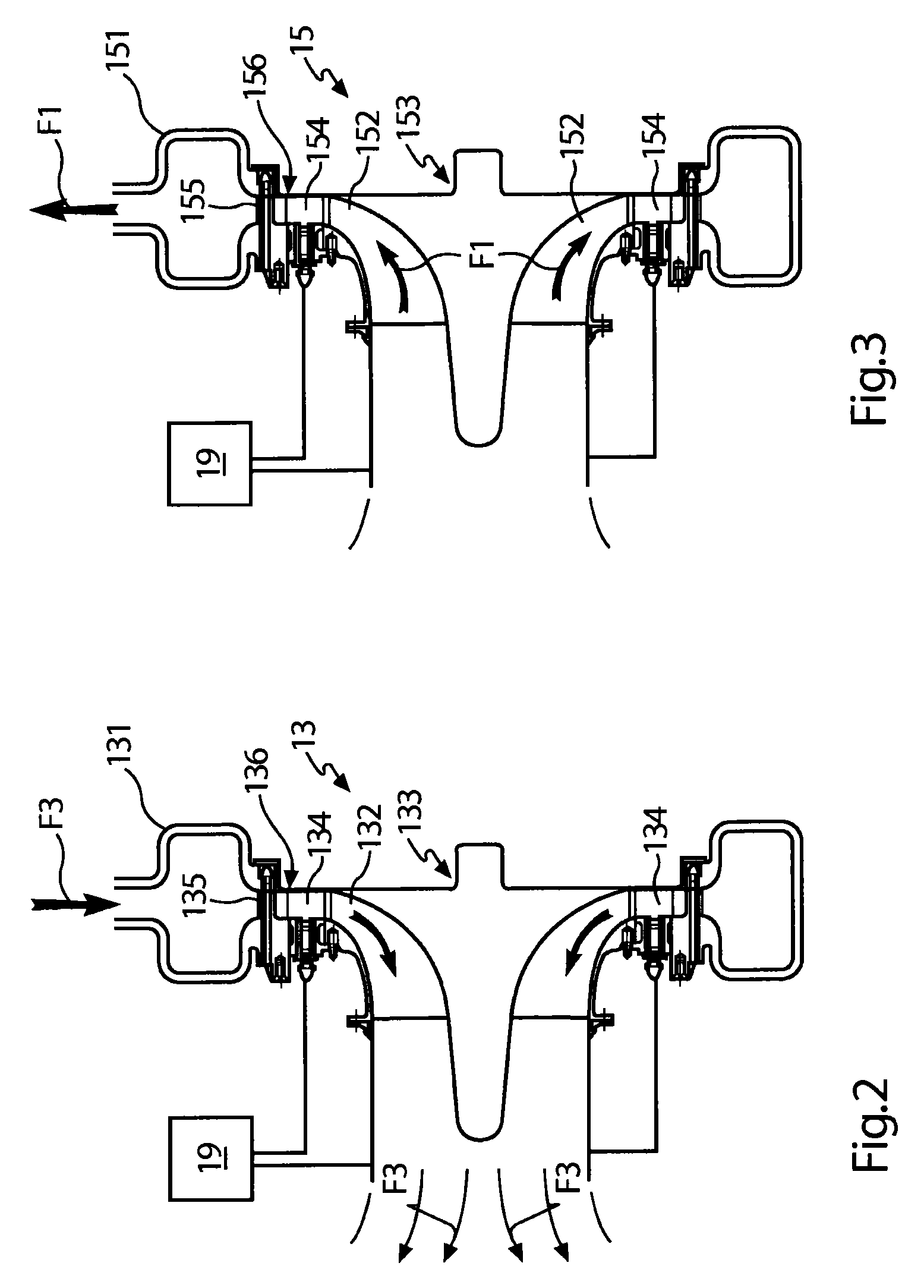

A method and architecture to reduce specific fuel consumption of a twin-engine helicopter without compromising safety conditions regarding minimum amount of power to be supplied, to provide reliable in-flight restarts. The architecture includes two turbine engines each including a gas generator and with a free turbine. Each gas generator includes an active drive mechanism keeping the gas generator rotating with a combustion chamber inactive, and an emergency assistance device including a near-instantaneous firing mechanism and mechanical mechanism for accelerating the gas generator. A control system controls the drive mechanism and emergency assistance devices for the gas generators according to the conditions and phases of flight of the helicopter following a mission profile logged beforehand in a memory of the system.

Owner:SAFRAN HELICOPTER ENGINES

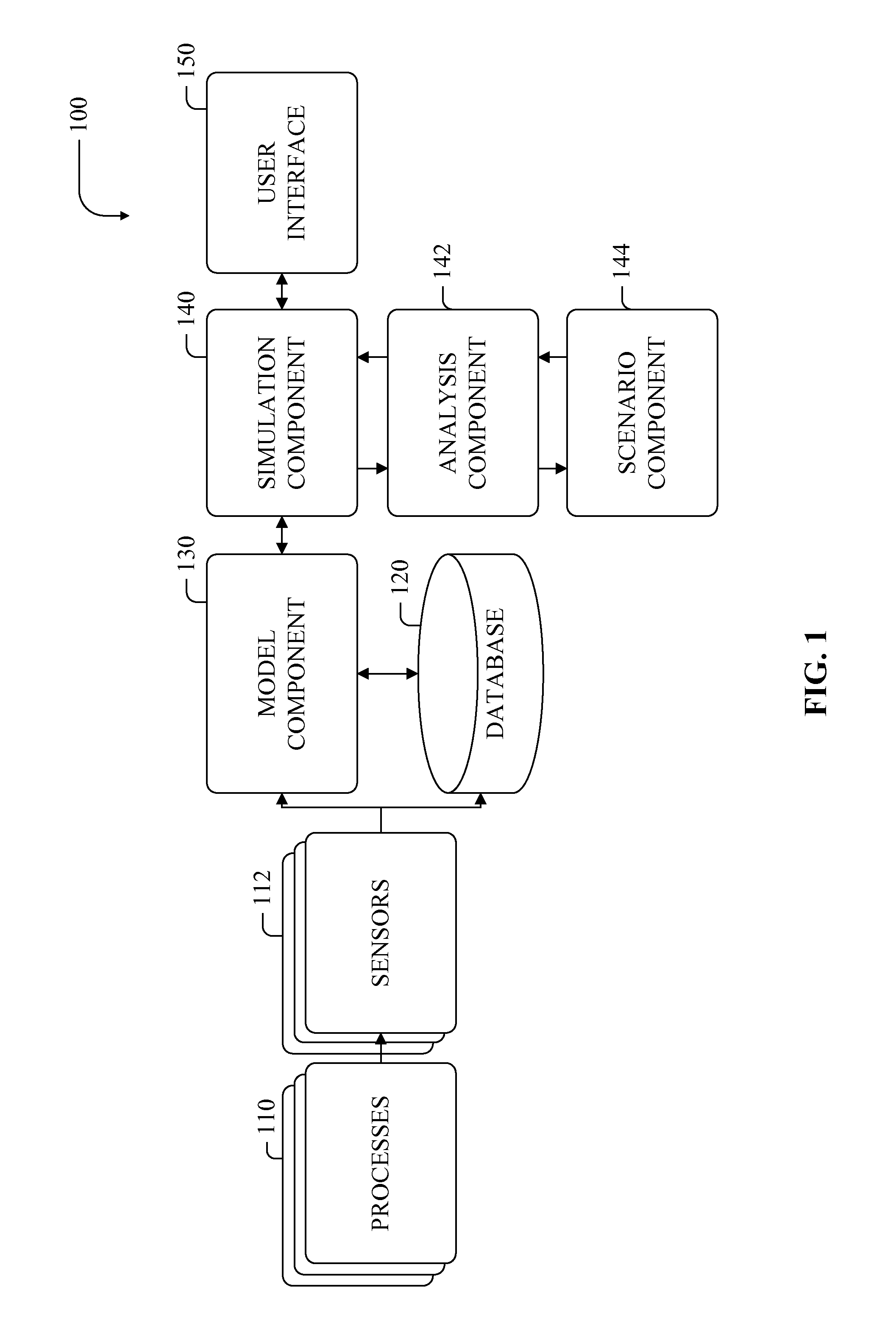

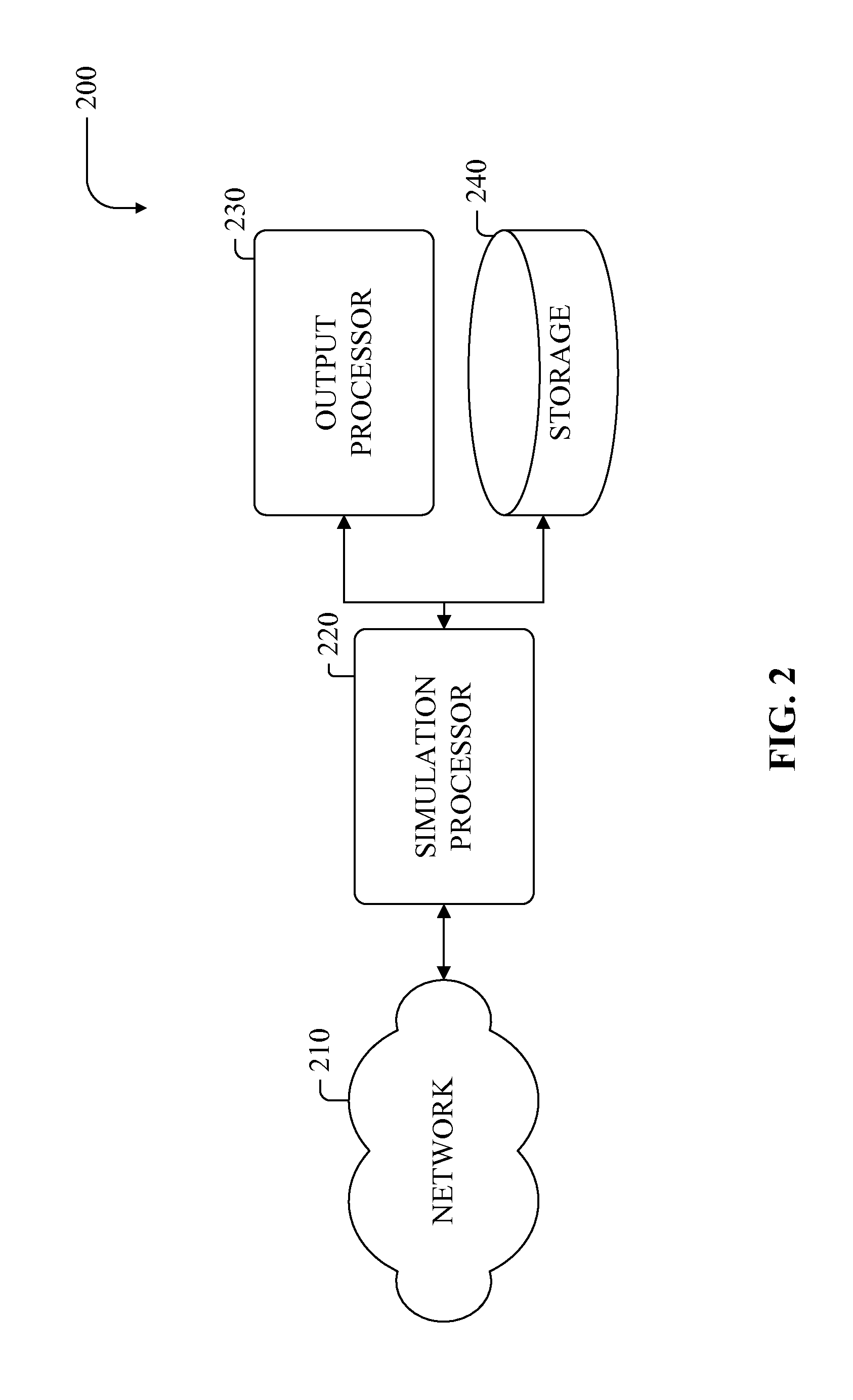

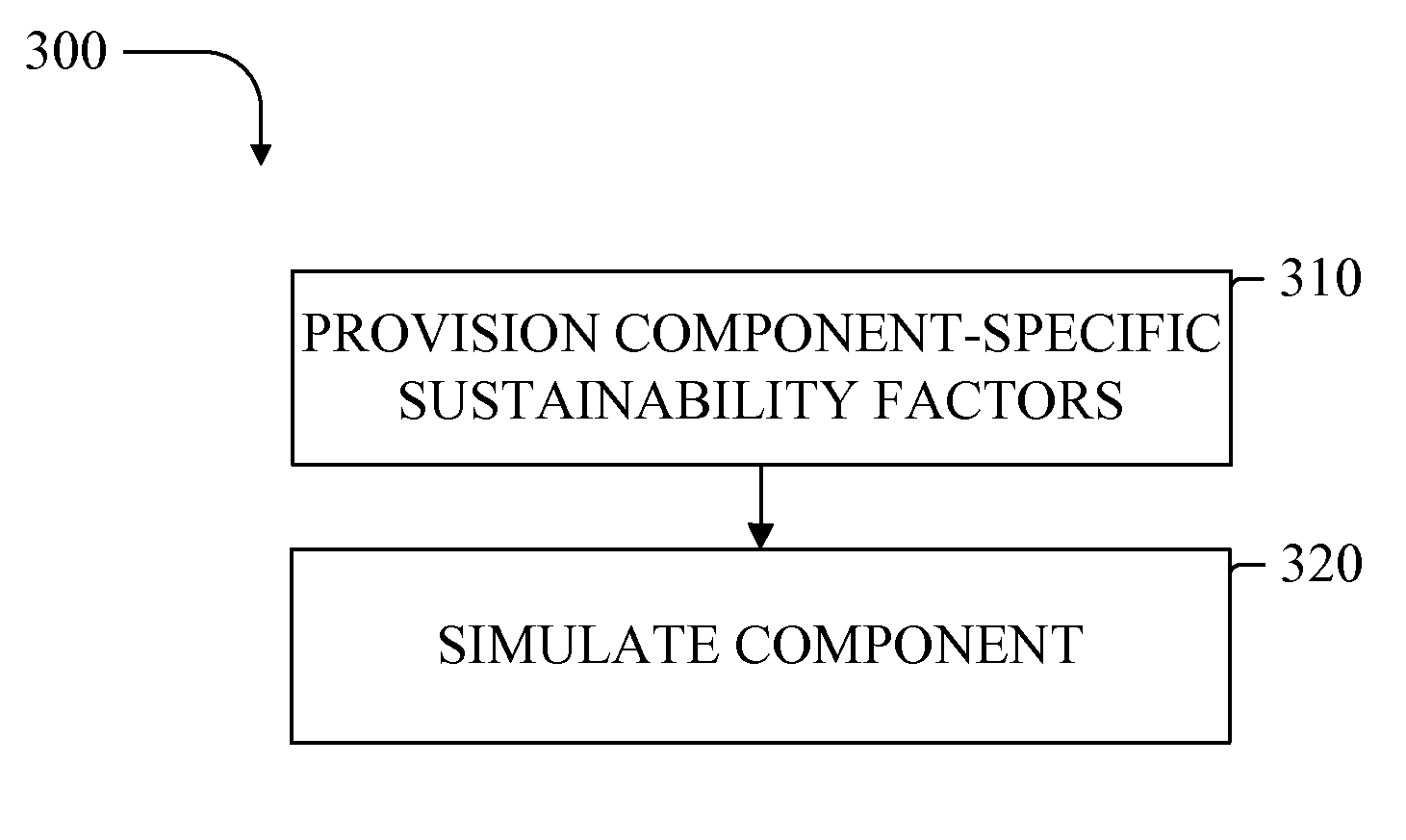

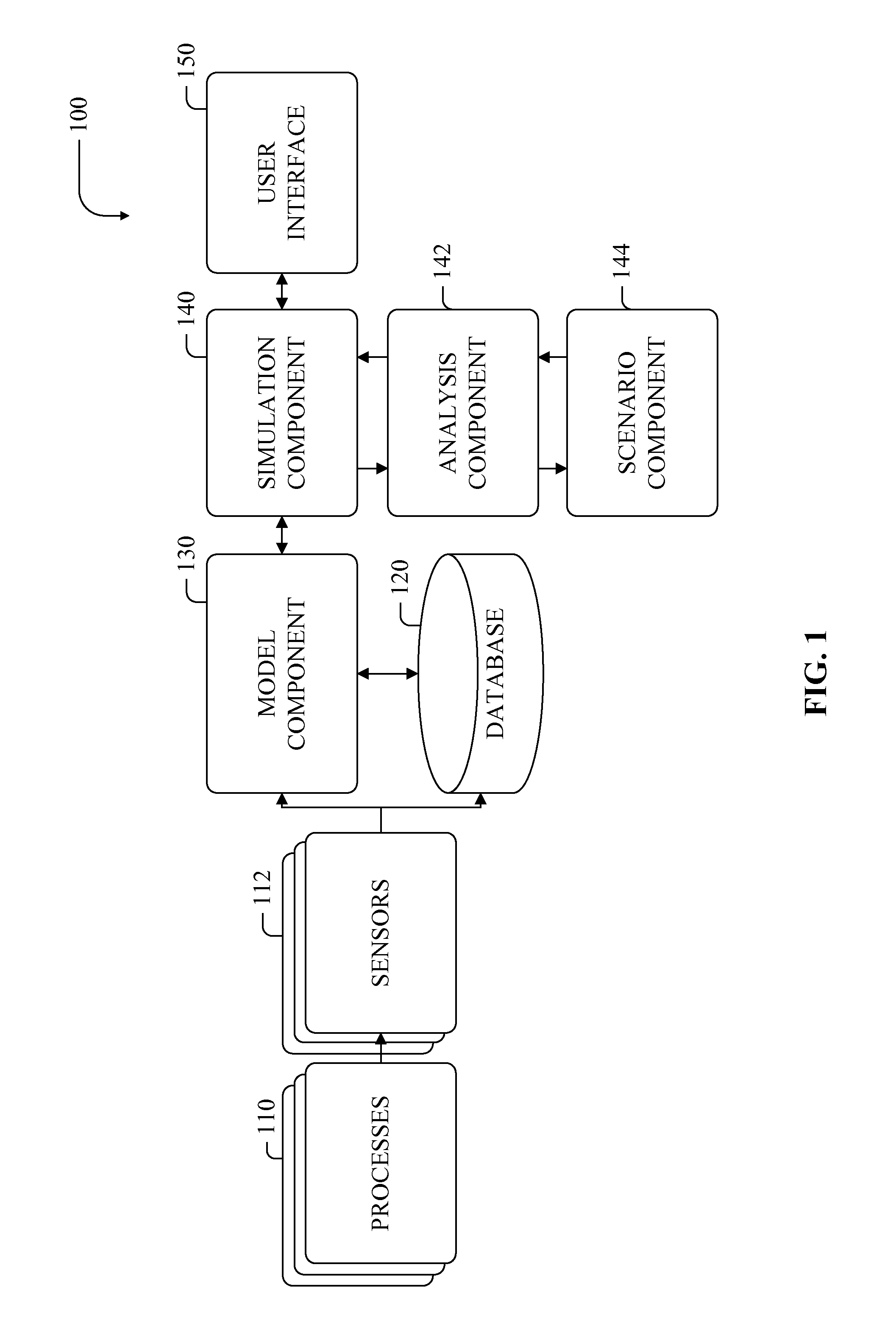

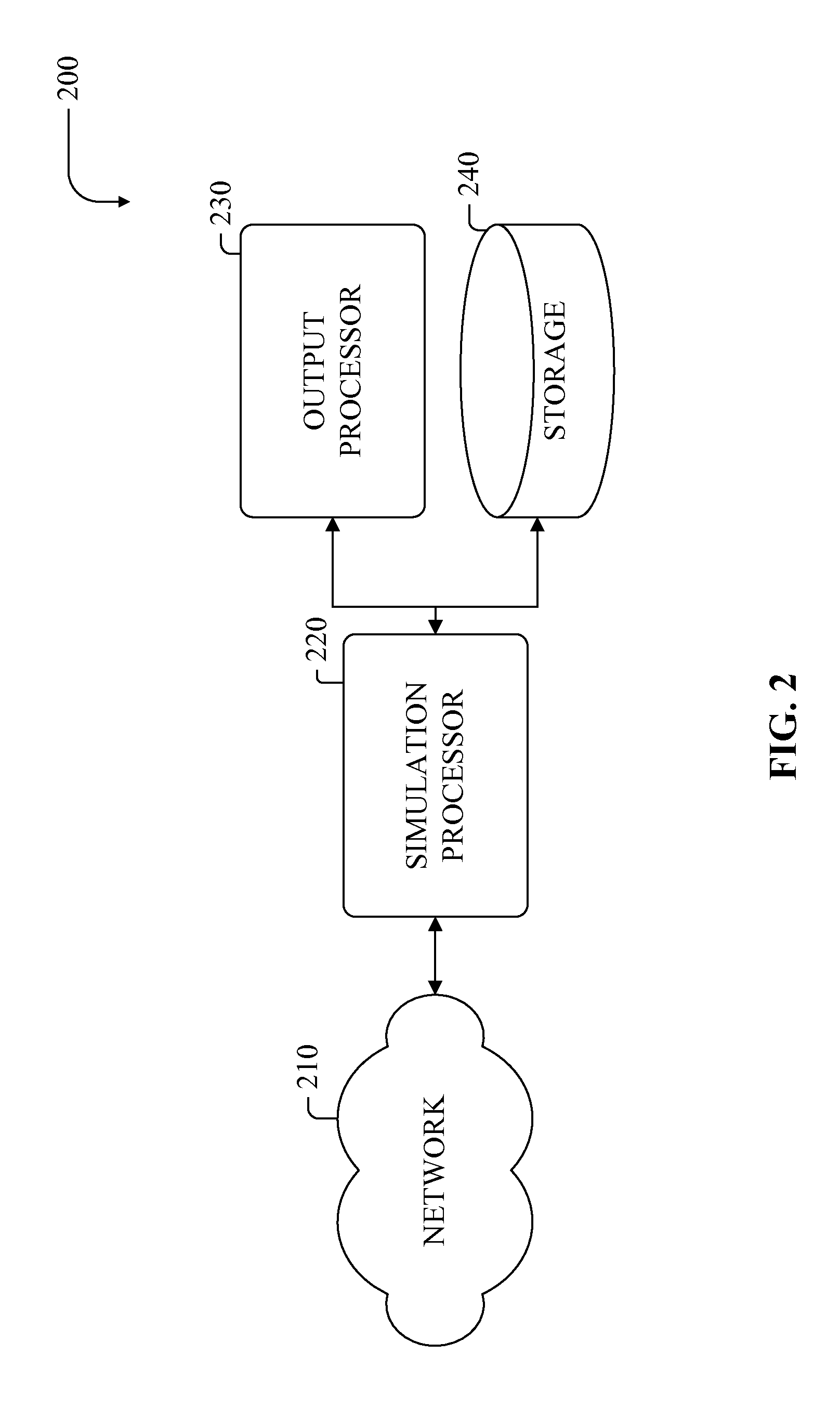

Process simulation utilizing component-specific consumption data

ActiveUS20100274367A1Low costStable supportLevel controlVolume/mass flow measurementGranularityParallel computing

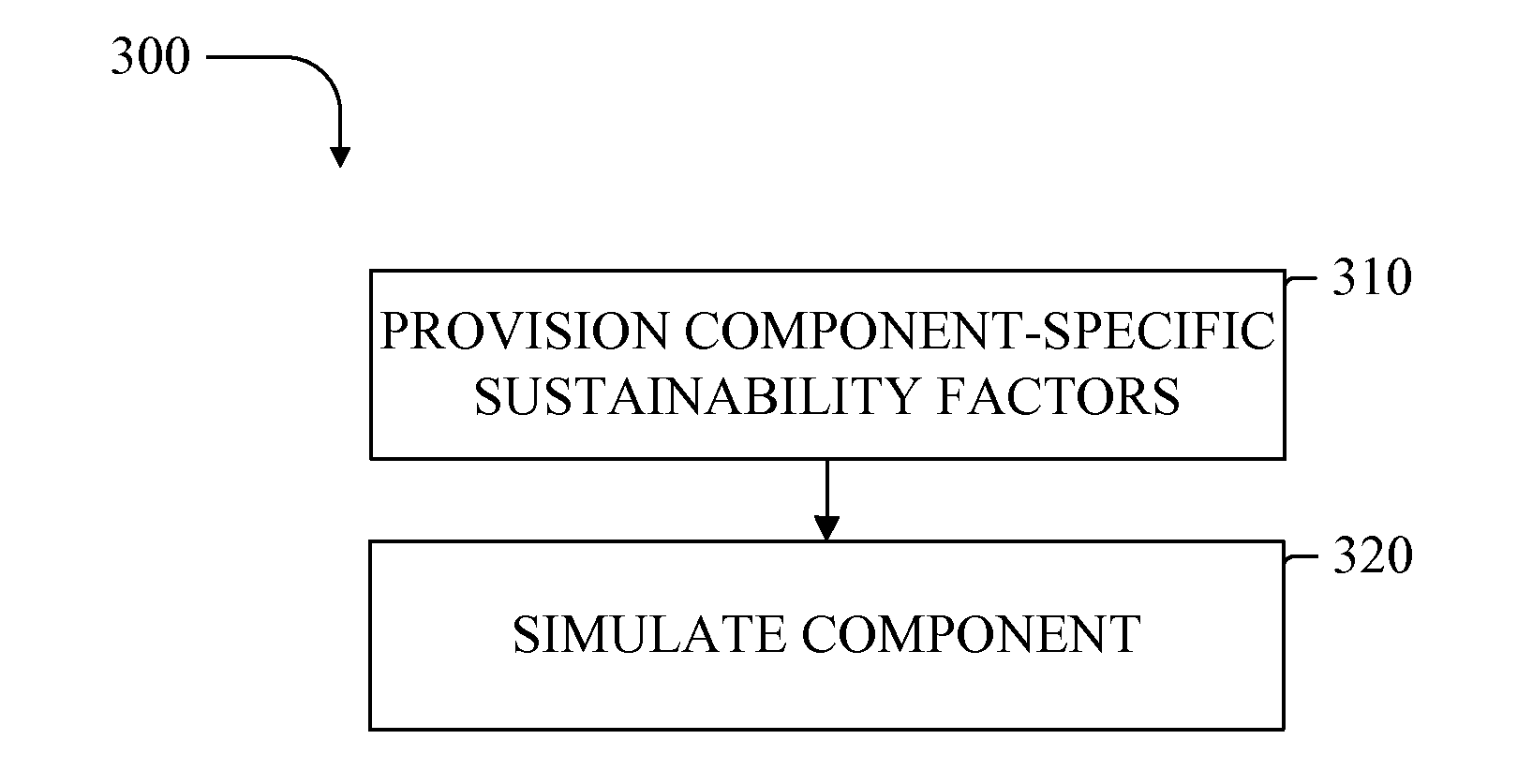

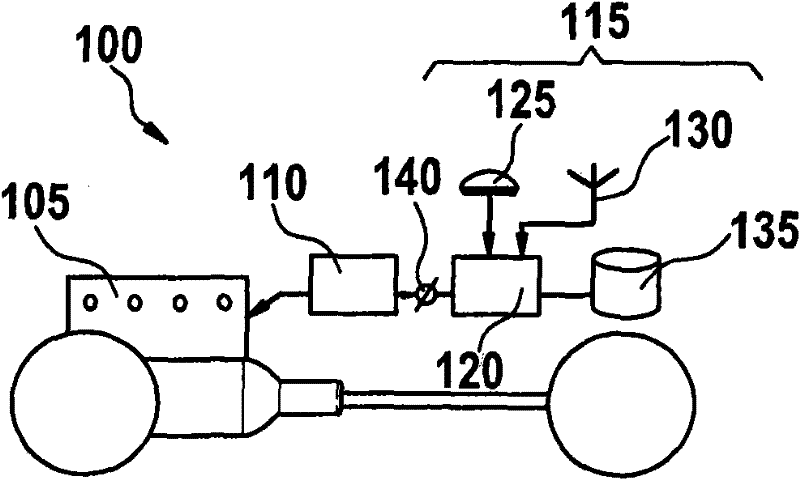

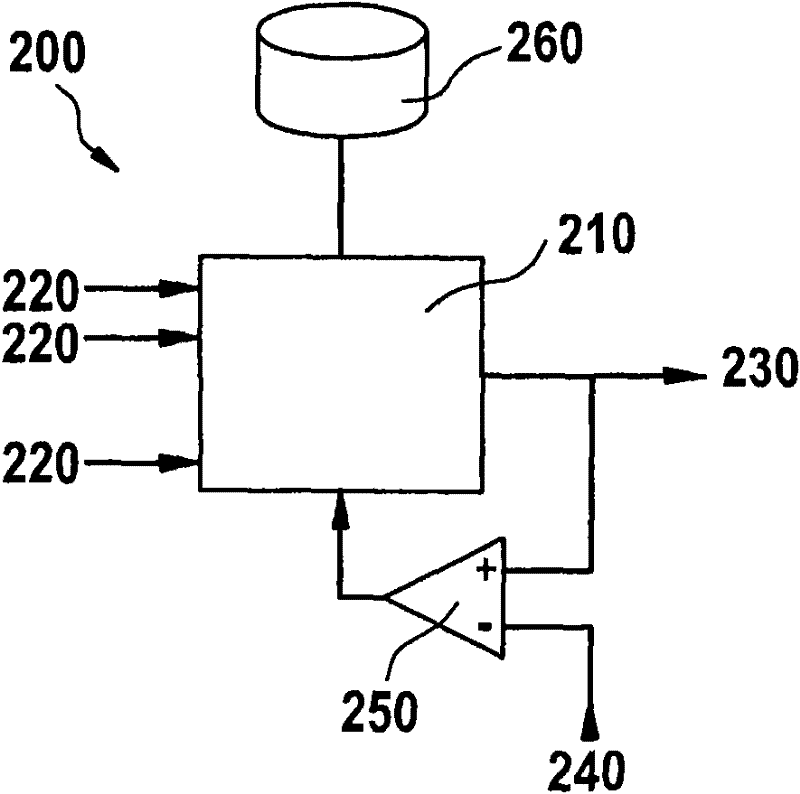

Methods and apparatuses are provided for simulating components and processes using discrete, variable-granularity, component-specific data relating to energy consumption or other sustainability factors. Simulations can be analyzed and optimized to facilitate forecasting of sustainability factors and determine advantageous modifications to the components or processes.

Owner:ROCKWELL AUTOMATION TECH

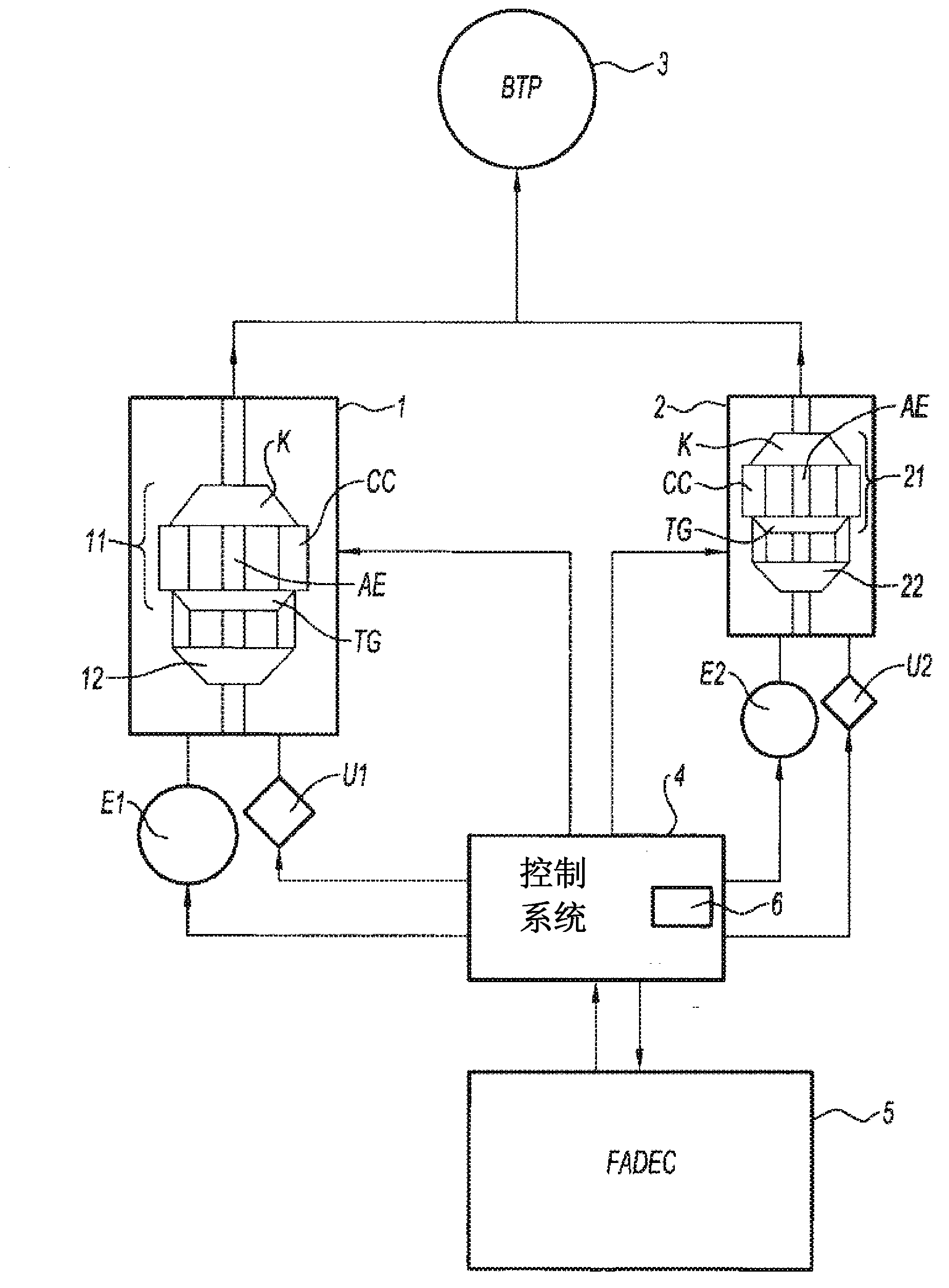

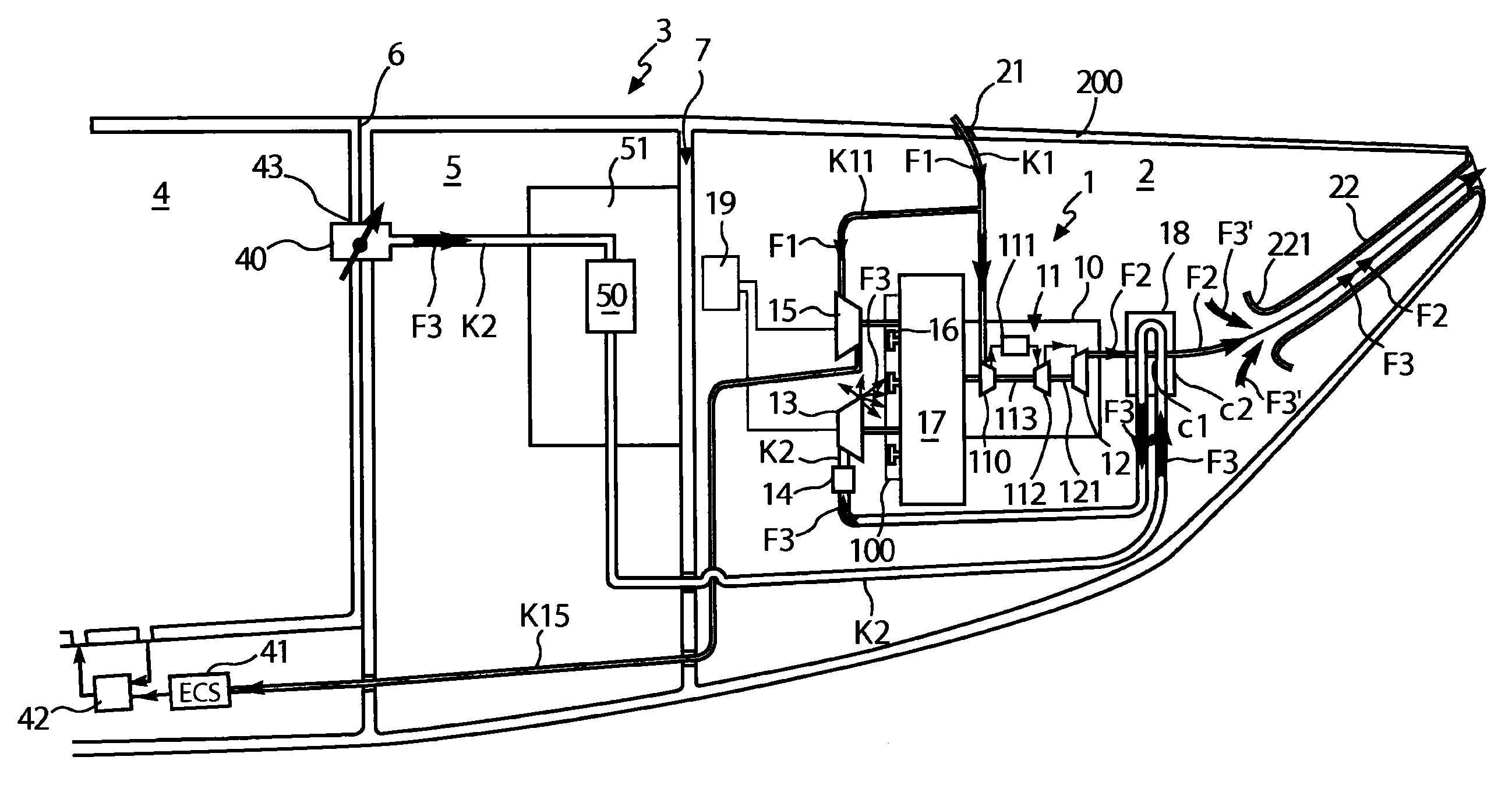

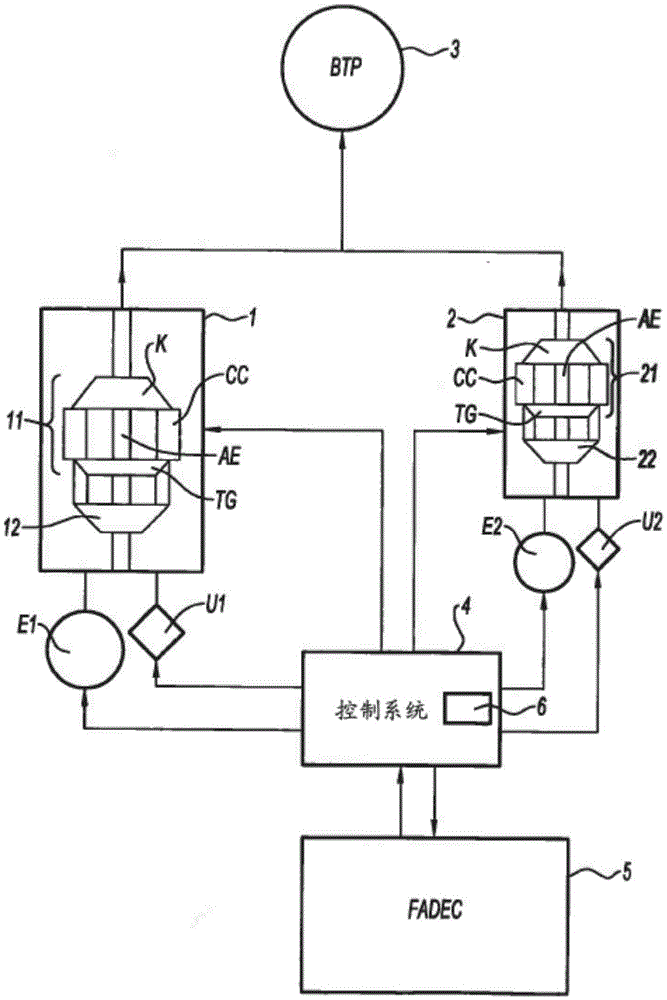

Method of optimizing the specific fuel consumption of a twin engine helicopter and twin engine architecture with control system for implementing it

ActiveCN103314198AGas turbine plantsEfficient propulsion technologiesBrake specific fuel consumptionCombustion chamber

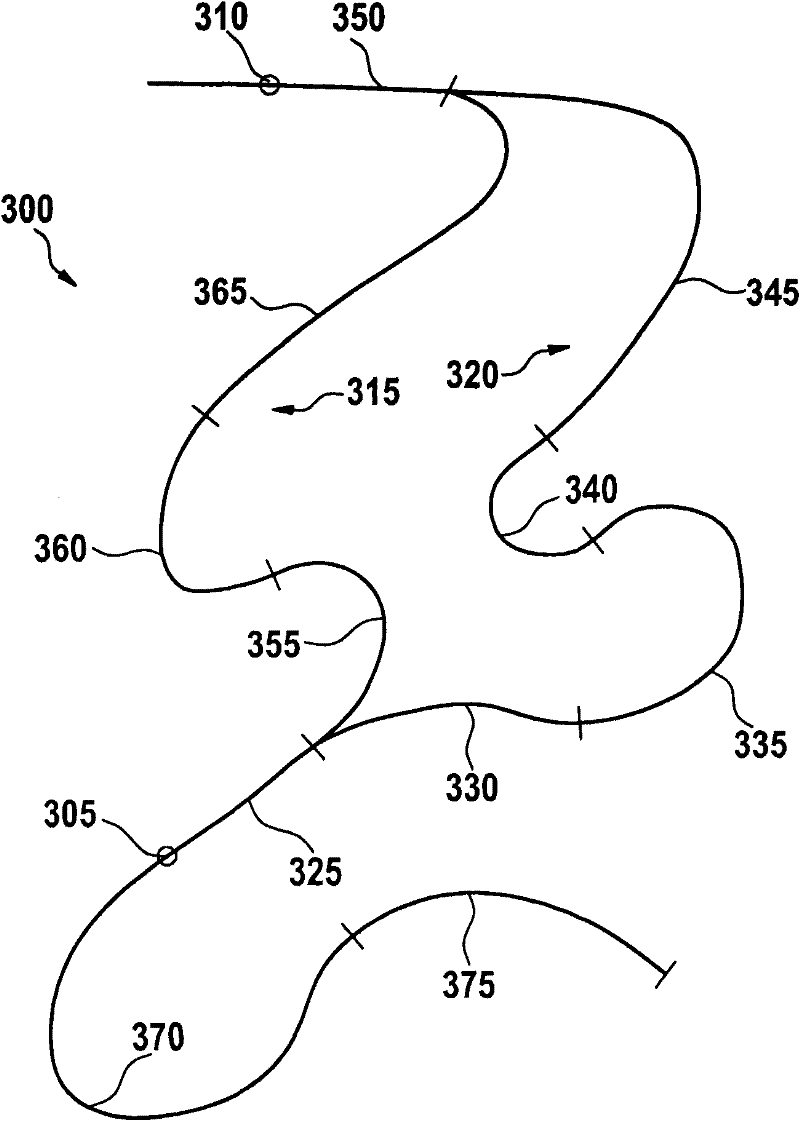

The invention seeks to reduce the specific fuel consumption Cs of a twin engine helicopter without compromising on the safety conditions regarding the minimum amount of power to be supplied for any kind of mission. To achieve this, the invention plans to make available special means capable of guaranteeing reliable in-flight restarts. One example of an architecture according to the invention involves two turbine engines (1, 2) each equipped with a gas generator (11, 21) and a with a free turbine (12, 22). Each gas generator (11, 21) is equipped with active drive means (E1, E2) capable of keeping the gas generator (1, 21) rotating with the combustion chamber inactive, and an emergency assistance device (U1, U2) comprising near-instantaneous firing means and mechanical means for accelerating the gas generator (11, 21).; The control system (4) controls the drive means (E1, E2) and the emergency assistance devices (U1, U2) for the gas generators (11, 21) according to the conditions and phases of flight of the helicopter following a mission profile logged beforehand in a memory (6) of this system (4).

Owner:TURBOMECA SA

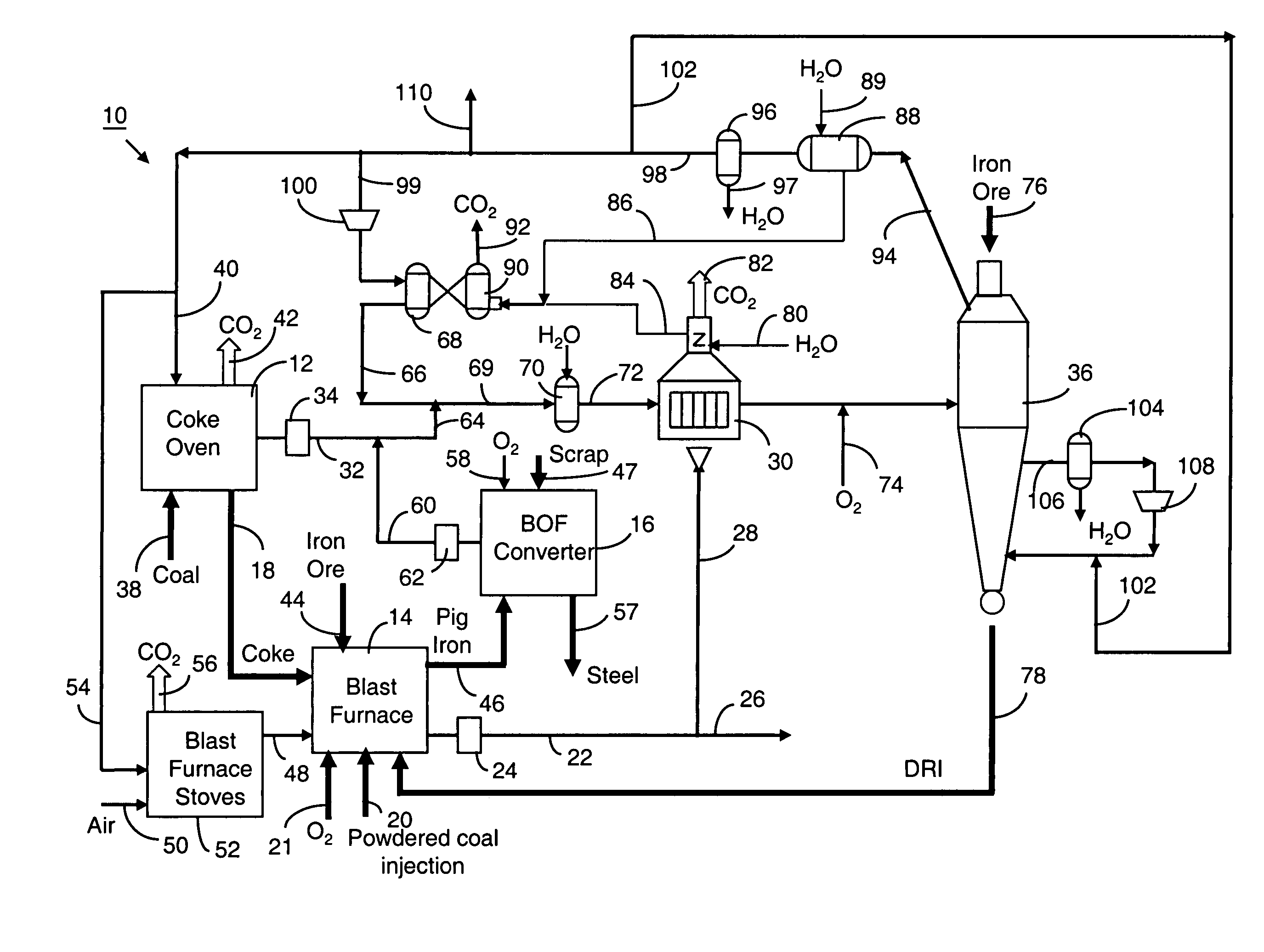

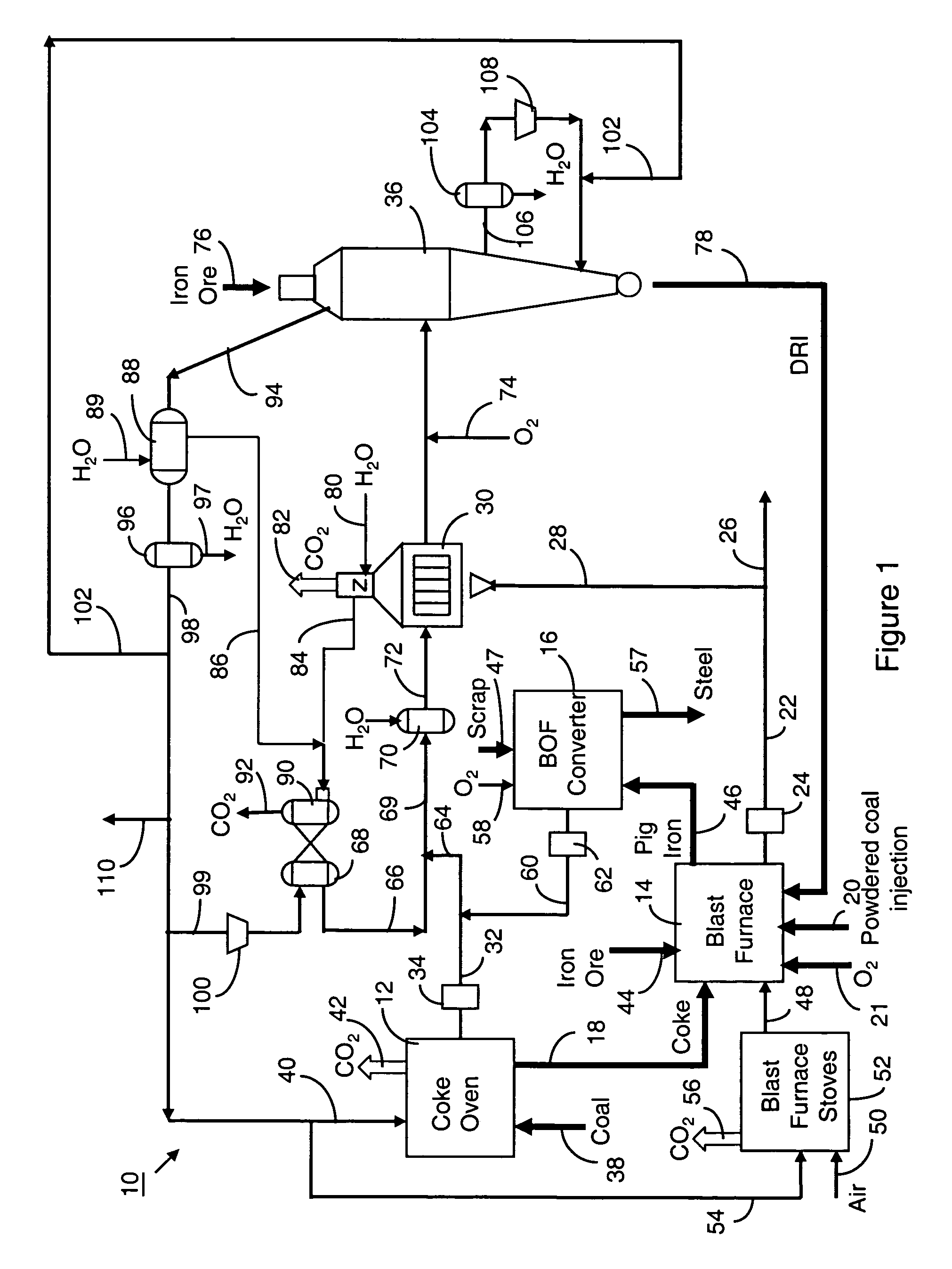

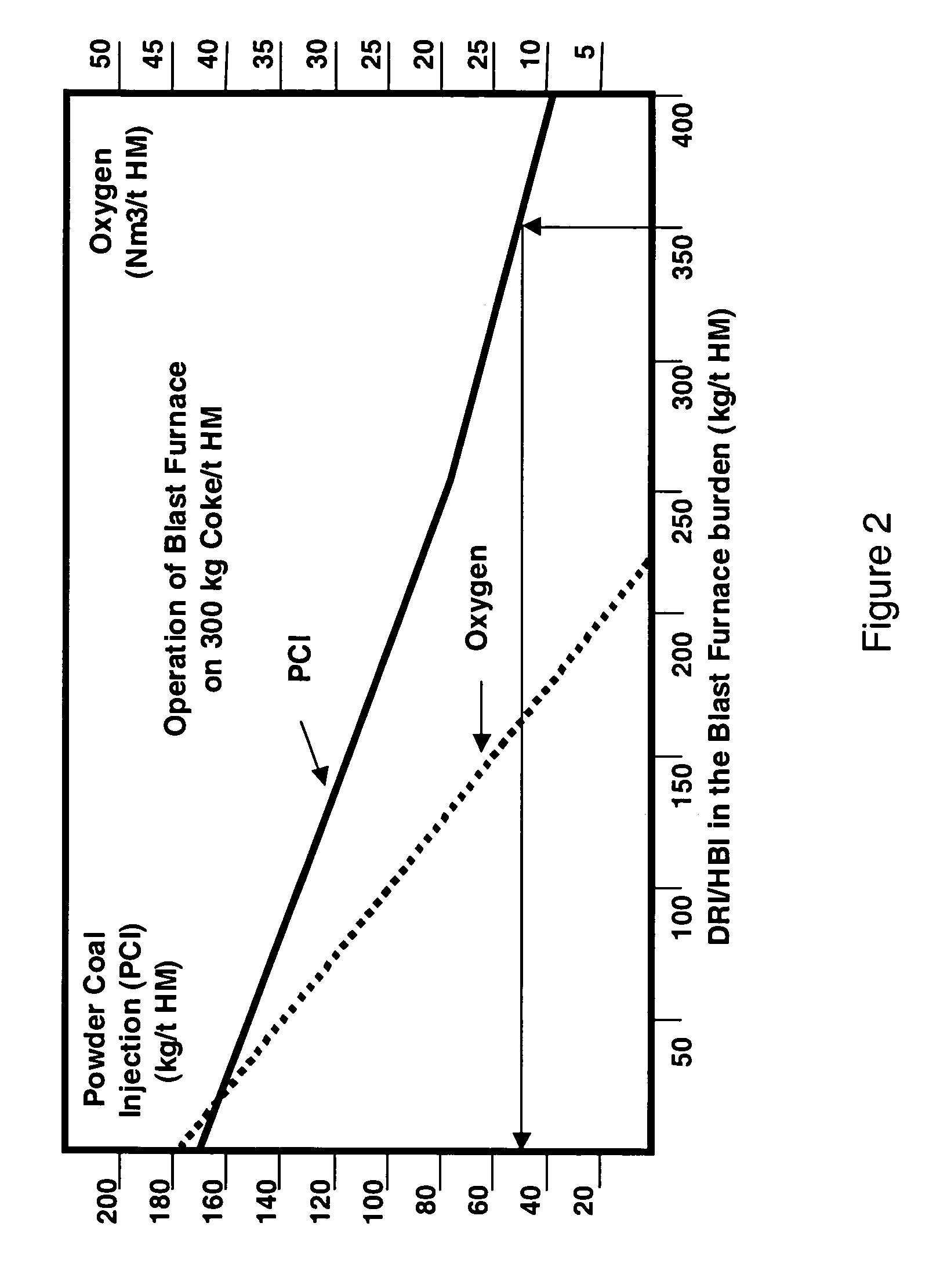

Method and apparatus for improved use of primary energy sources in integrated steel plants

ActiveUS6986800B2Increase productionReduction of fossil fuel specific consumptionBlast furnace detailsManufacturing convertersChemical agentFossil fuel

A method and an integrated steel plant wherein, instead of using coke oven gases, converter gases and blast furnace top gases available as fuel for power generation or other heating purposes, these gases are more efficiently utilized as chemical agents for direct reduction of iron ores producing DRI.DRI is charged to blast furnaces increasing production of crude steel without increasing the capacities of the coke oven plant and blast furnaces and without changes in the quality of the crude steel, or, if production rate is maintained, the fossil fuels specific consumption is significantly reduced.Utilisation of primary fossil energy according to the invention also reduces the specific CO2 emissions per ton of crude steel. The specific CO2 emission in conventional integrated mills is about 1.6 tons of CO2 per ton of crude steel.

Owner:HYLSA SA DE CV

Method for optimizing the overall energy efficiency of an aircraft, and main power package for implementing same

InactiveUS20130151039A1Limiting specific consumptionEliminate the problemAircraft power plantsPower installationsNacelleElectric power

A method and system limiting specific consumption of an aircraft by matching sizing of a power supply to actual power needs of a cabin pressure control system. The method optimizes overall efficiency of energy supplied onboard an aircraft including, in an environment near the cabin, at least one main power-generating engine, sized to serve as a single pneumatic energy-generating source for the cabin and as an at most partial propulsive, hydraulic, and / or electric energy-generating source for the rest of the aircraft. The method minimizes power differential between a nominal point of the power sources when the sources are operating, and a sizing point of non-propulsive energy contributions of the sources when the main engine has failed, by equally dividing power contributions of the main engines and the main power generator under nominal operating conditions and in an event of failure of a main engine.

Owner:SAFRAN HELICOPTER ENGINES

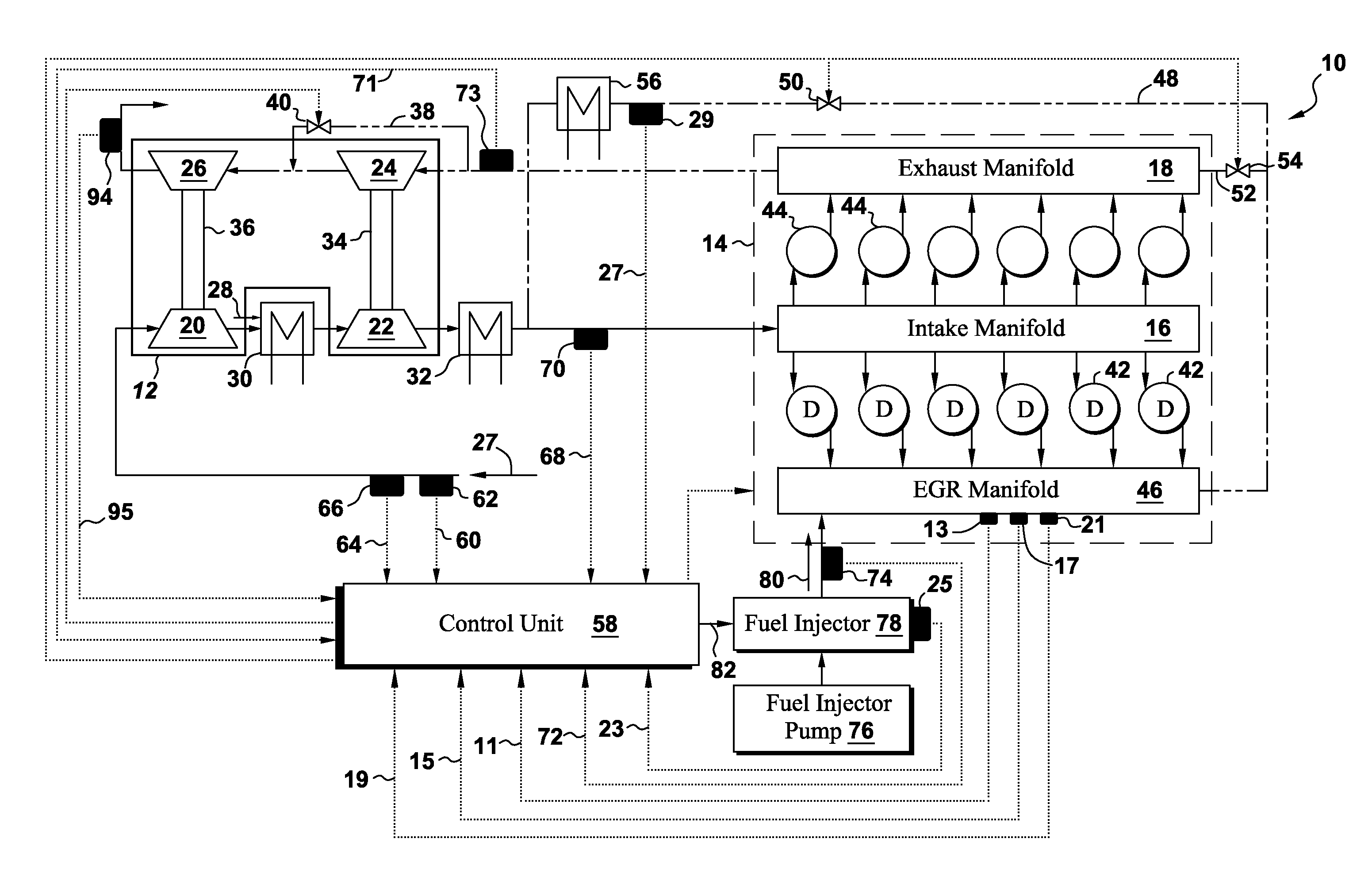

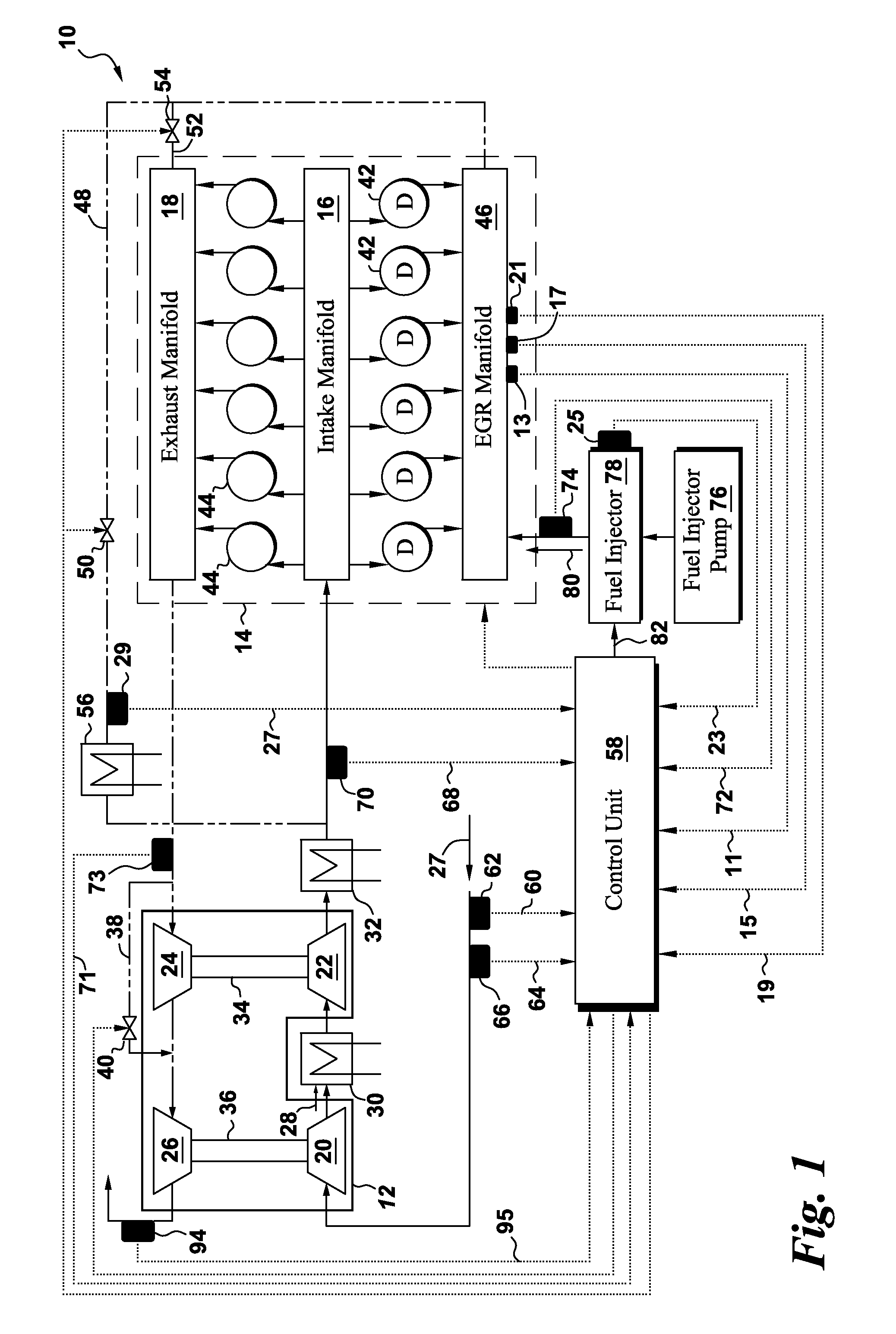

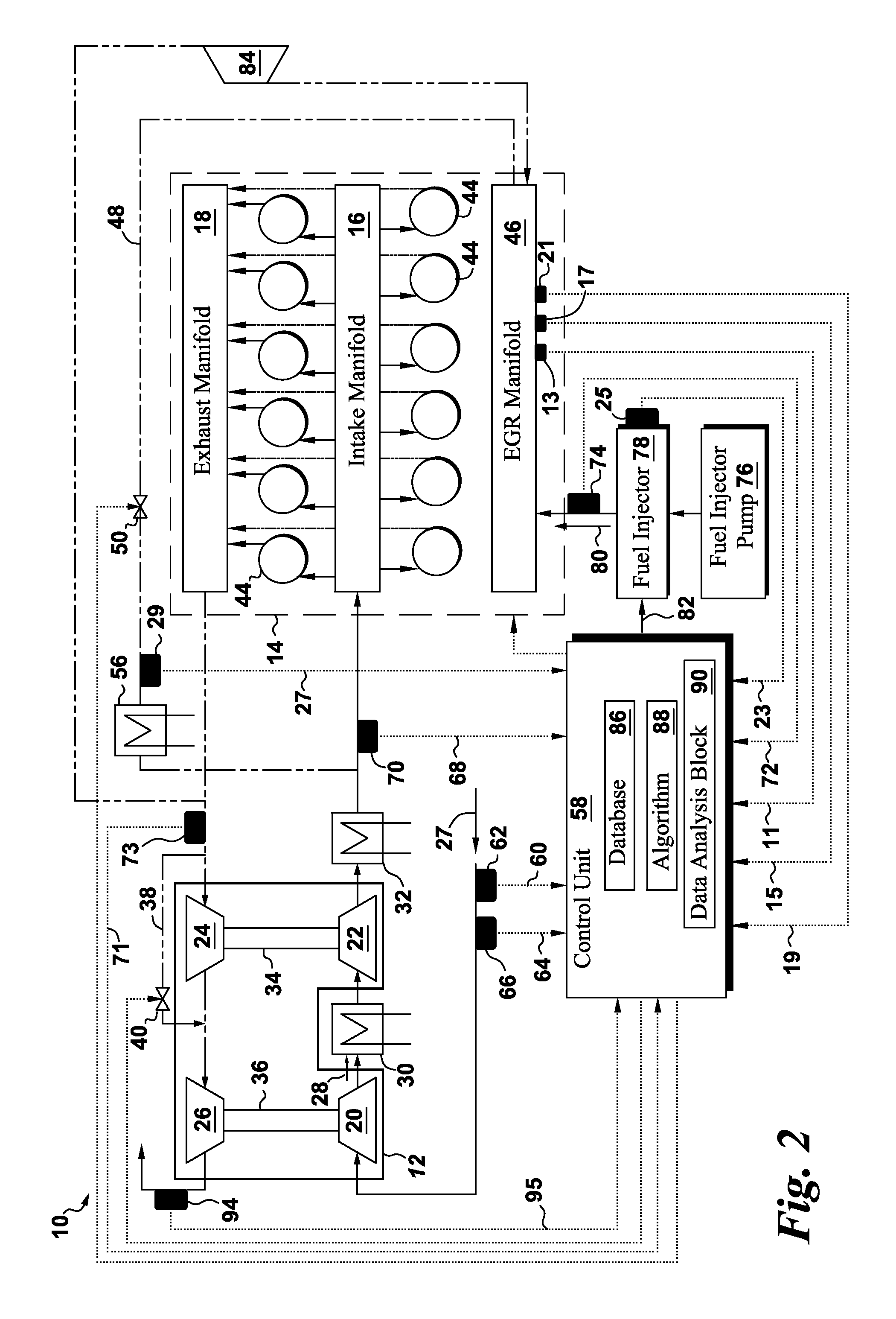

System and method for controlling exhaust emissions and specific fuel consumption of an engine

ActiveUS20160010576A1Fuel consumptionElectrical controlInternal combustion piston enginesBrake specific fuel consumptionEngineering

Owner:GE GLOBAL SOURCING LLC

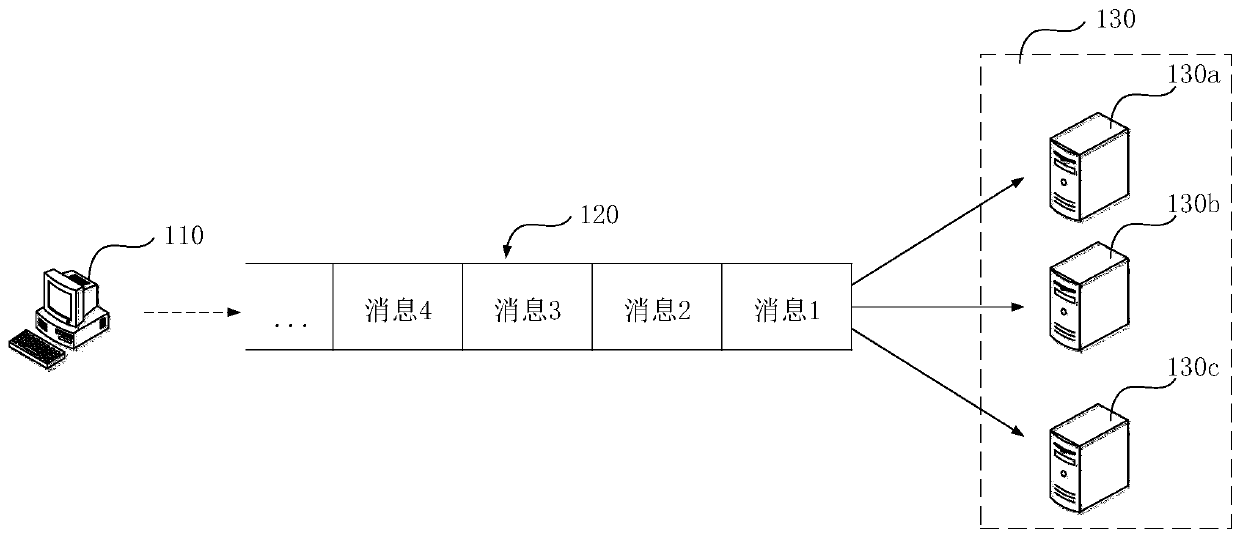

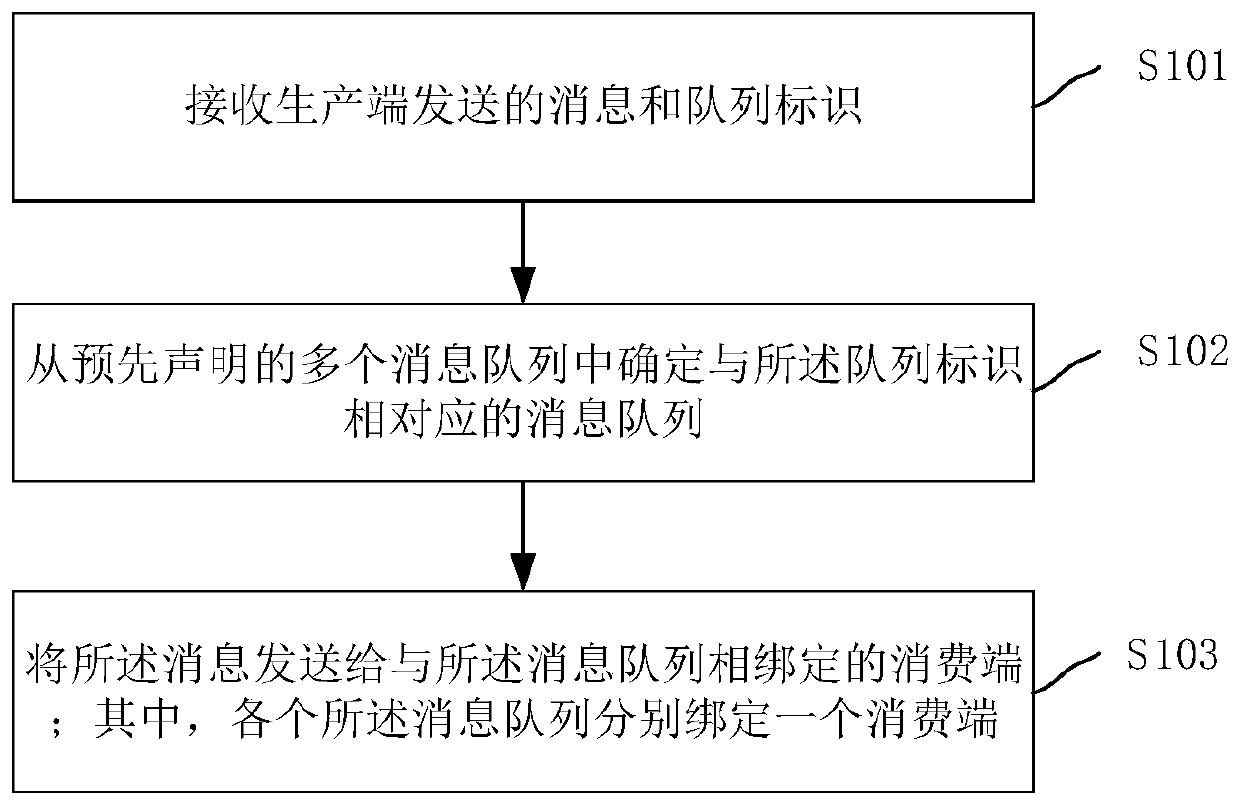

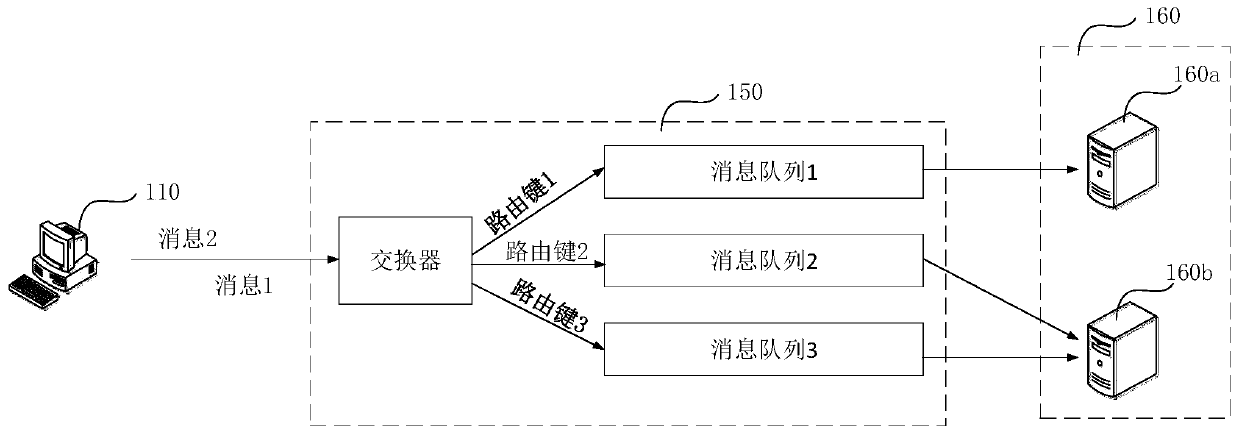

Message sending method and device, computer device and storage medium

ActiveCN109885410AIncrease flexibilitySolve concurrency issuesInterprogram communicationMessage queueSpecific consumption

The invention relates to a message sending method and device based on RabbitMQ, a computer device and a storage medium. The method comprises the following steps of receiving a message and a queue identifier sent by a production end, determining a message queue corresponding to the queue identifier from a plurality of message queues declared in advance; then, delivering the messages needing to be sent by the production end to the message queue; and sending the message to a consumer side bound with the message queue through the message queue, so that the consumer end can process the message sentby the production end, the production end can set the corresponding queue identifier according to the actual demand to send the message to the specific consumption end for processing; all operationsof the production end can hit the specified consumption end, thereby preventing the message of the production end from being polled and sent to a plurality of consumption ends for processing, improving the flexibility of message sending, being able to avoid the concurrency problem only by locking the message on one consumption end, and improving the concurrency performance.

Owner:GUANGZHOU SHIYUAN ELECTRONICS CO LTD +1

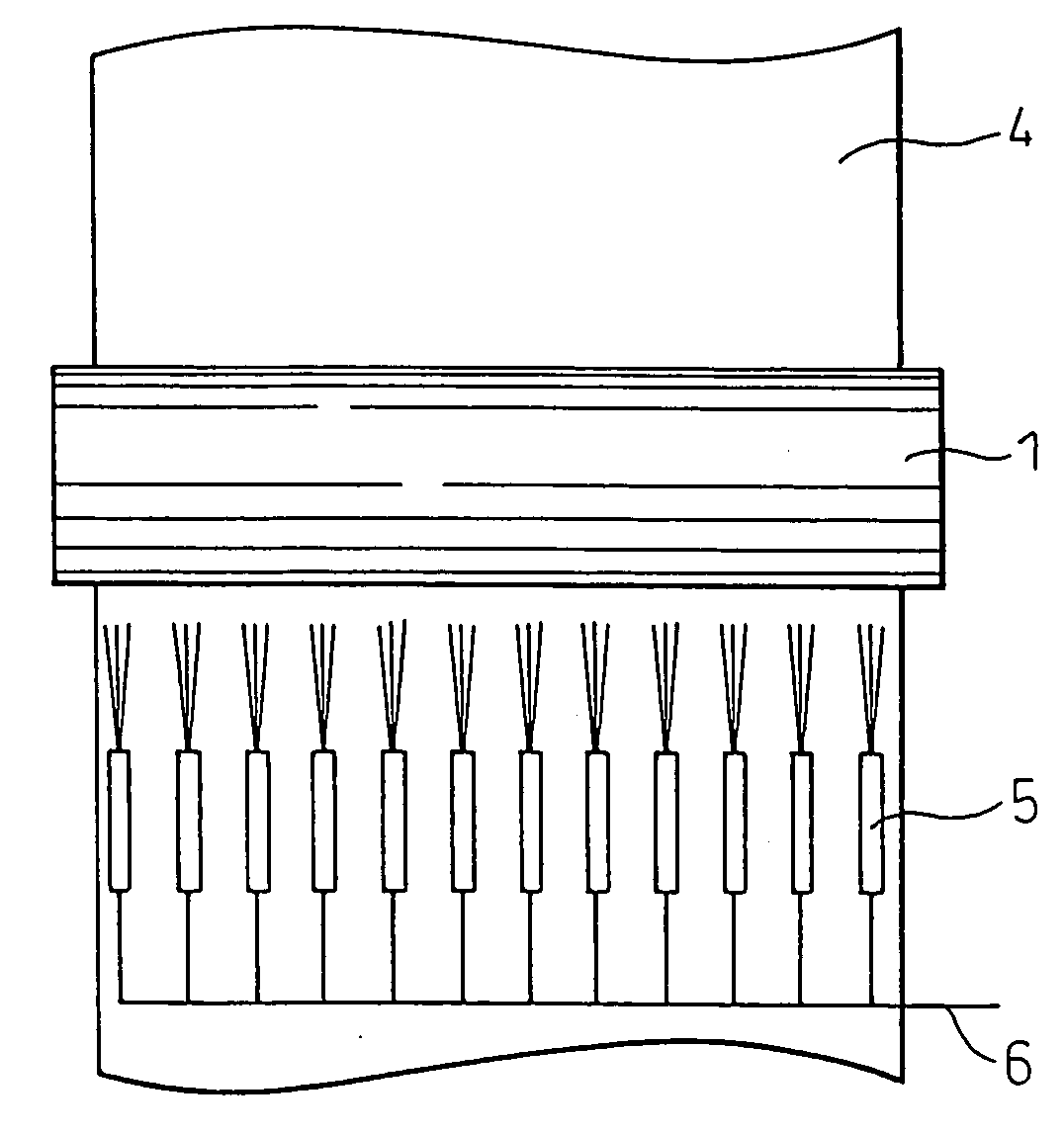

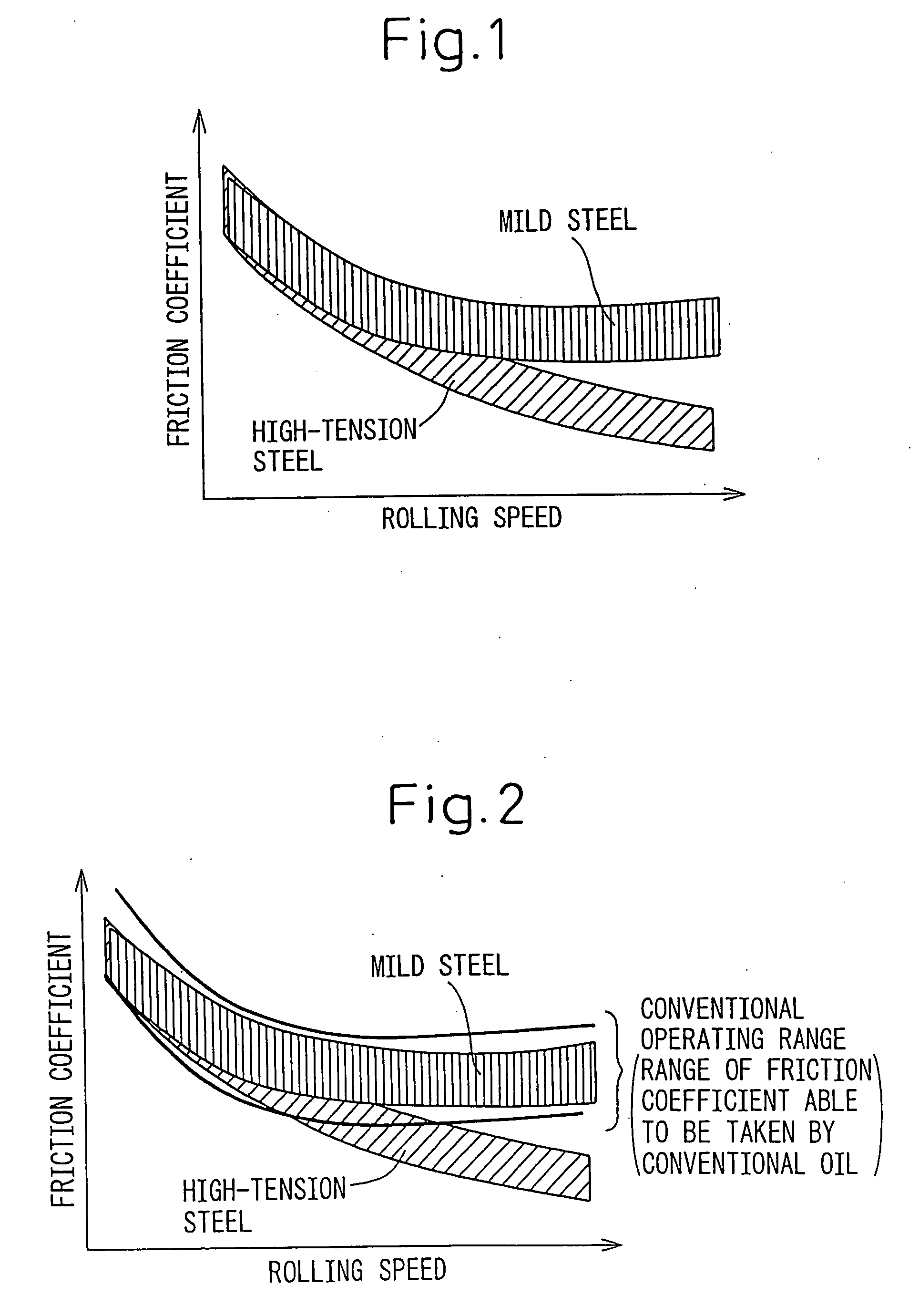

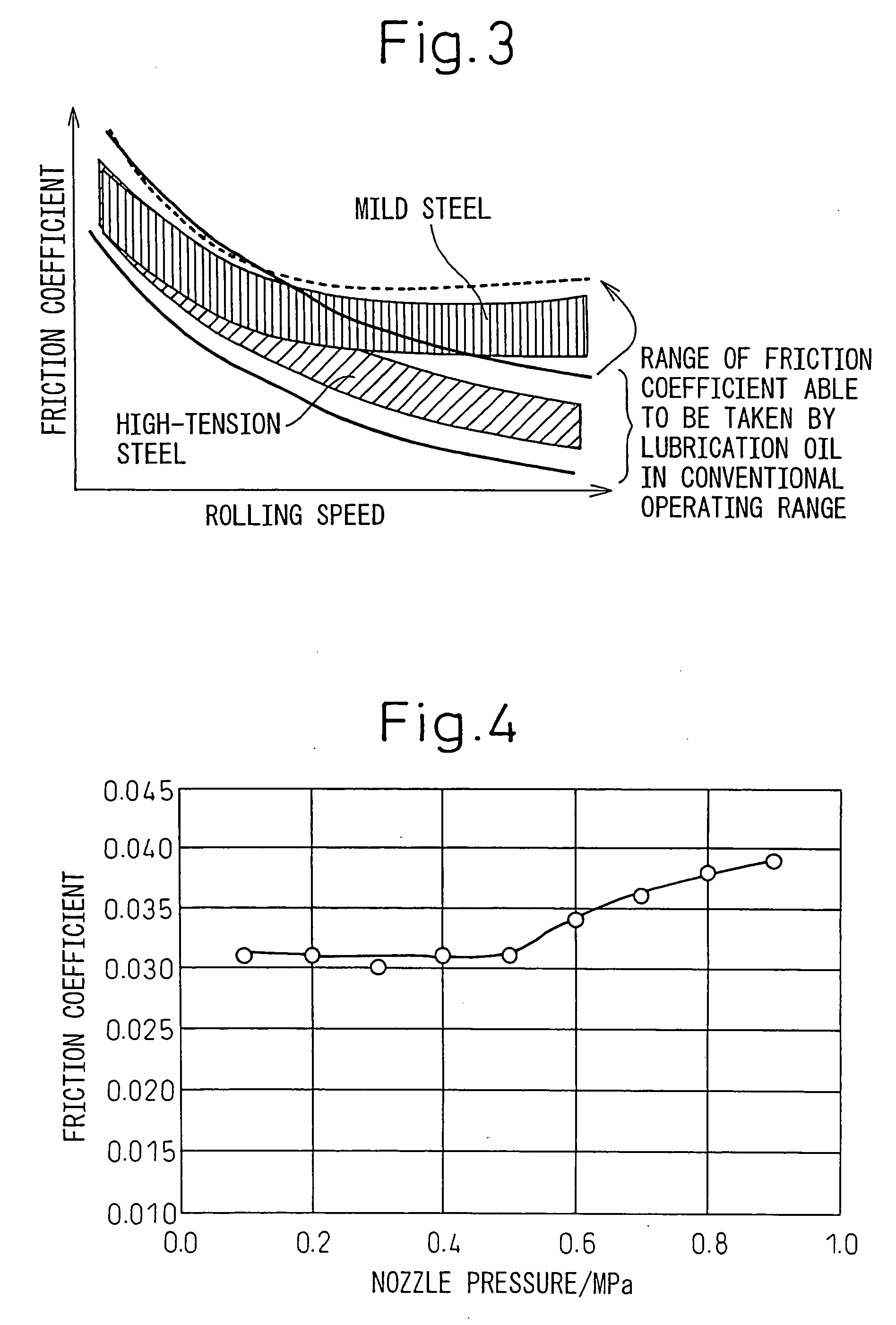

Method of Supplying Lubrication Oil in Cold Rolling

ActiveUS20080116011A1Improve productivityIncrease consumptionRolling equipment maintainenceRollsProduction rateEmulsion

The present invention provides a method of supplying lubrication oil in cold rolling for stable rolling without heat scratches or slip and realizing high productivity and improvement of the specific consumption of lubrication oil, that is, a method of supplying lubrication oil in cold rolling for lubricating rolling in cold tandem rolling of metal sheet by supplying a predetermined kind of emulsion lubrication oil comprised of a mixture of rolling oil and water at the rolling stand inlet side from nozzles, the method of supplying lubrication oil in cold rolling characterized by measuring or estimating the pressure in the lubrication nozzle pipe (lubrication nozzle pressure), controlling the lubrication nozzle pressure of any rolling stand where lubrication is liable to become excessive with the predetermined emulsion lubrication oil to 0.5 MPa or more, and, while doing so, supplying the lubrication oil to the roll bite inlet of the stand by direct injection.

Owner:NIPPON STEEL CORP +1

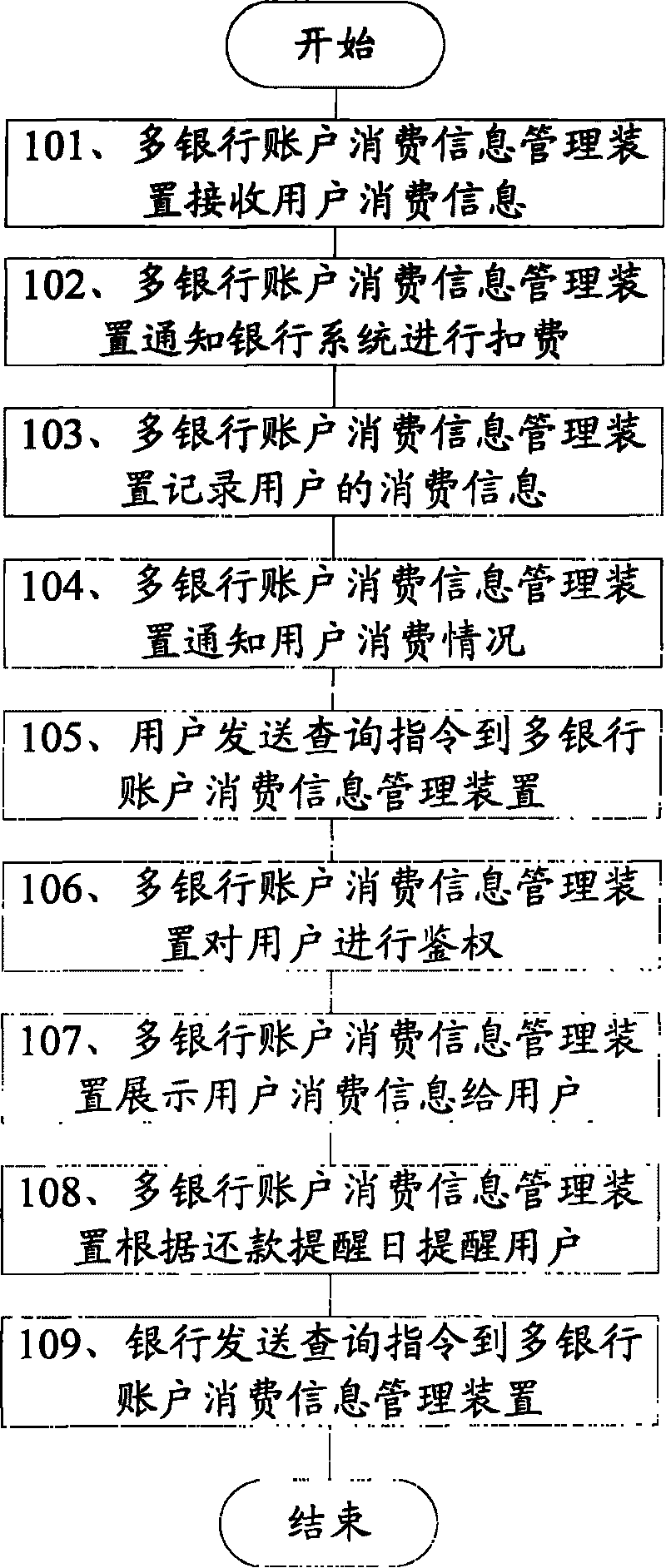

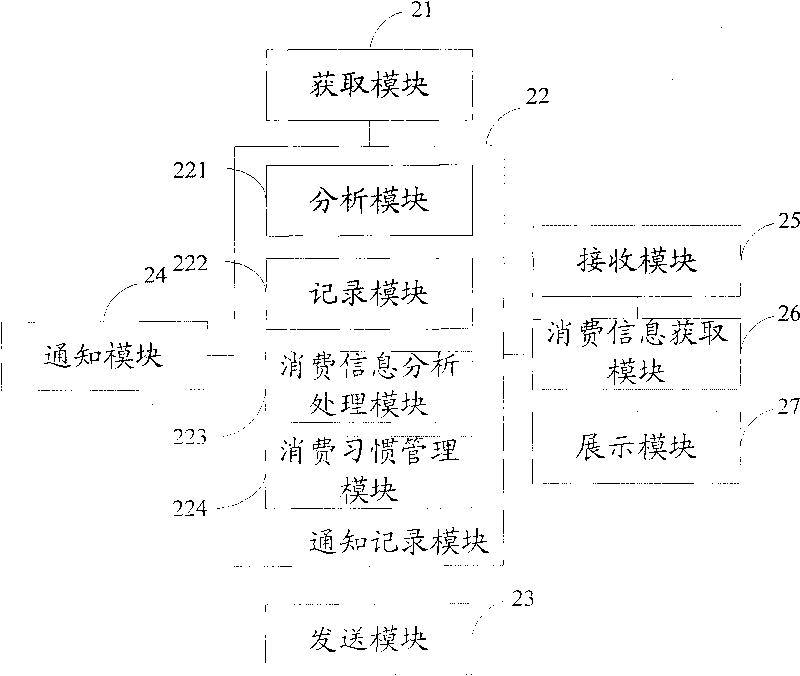

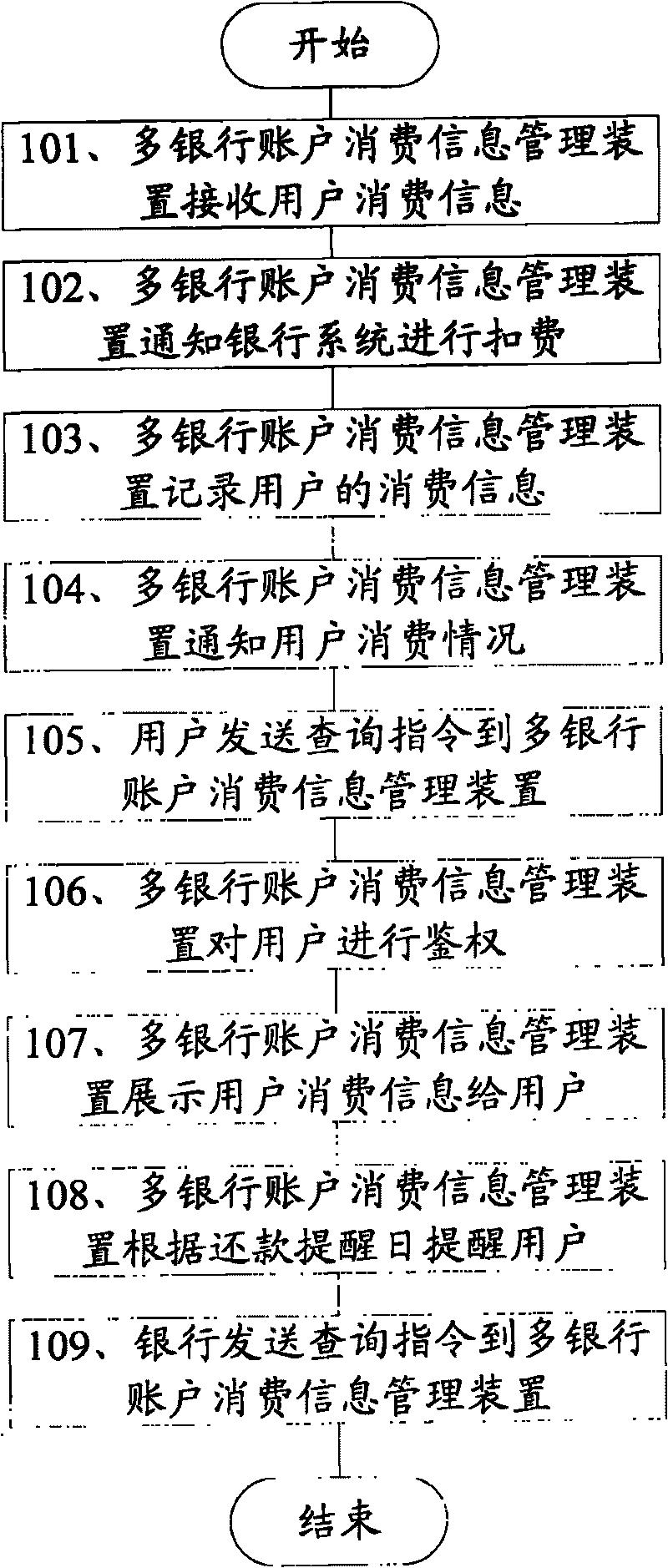

Multiple bank account consumption information management method and device

The invention discloses a multiple bank account consumption information management method. The method comprises the following steps: a consumption information recording device receives all the bank card consumption information of one user; the consumption information recording device informs the bank system to charge and records the consumption information. The method of the invention can obtain the specific consumption information of various bank cards of the user according to the consumption information by obtaining the consumption information of various bank cards of one user and performing statistical record, when the user or the bank conducts inquiries.

Owner:ZTE CORP

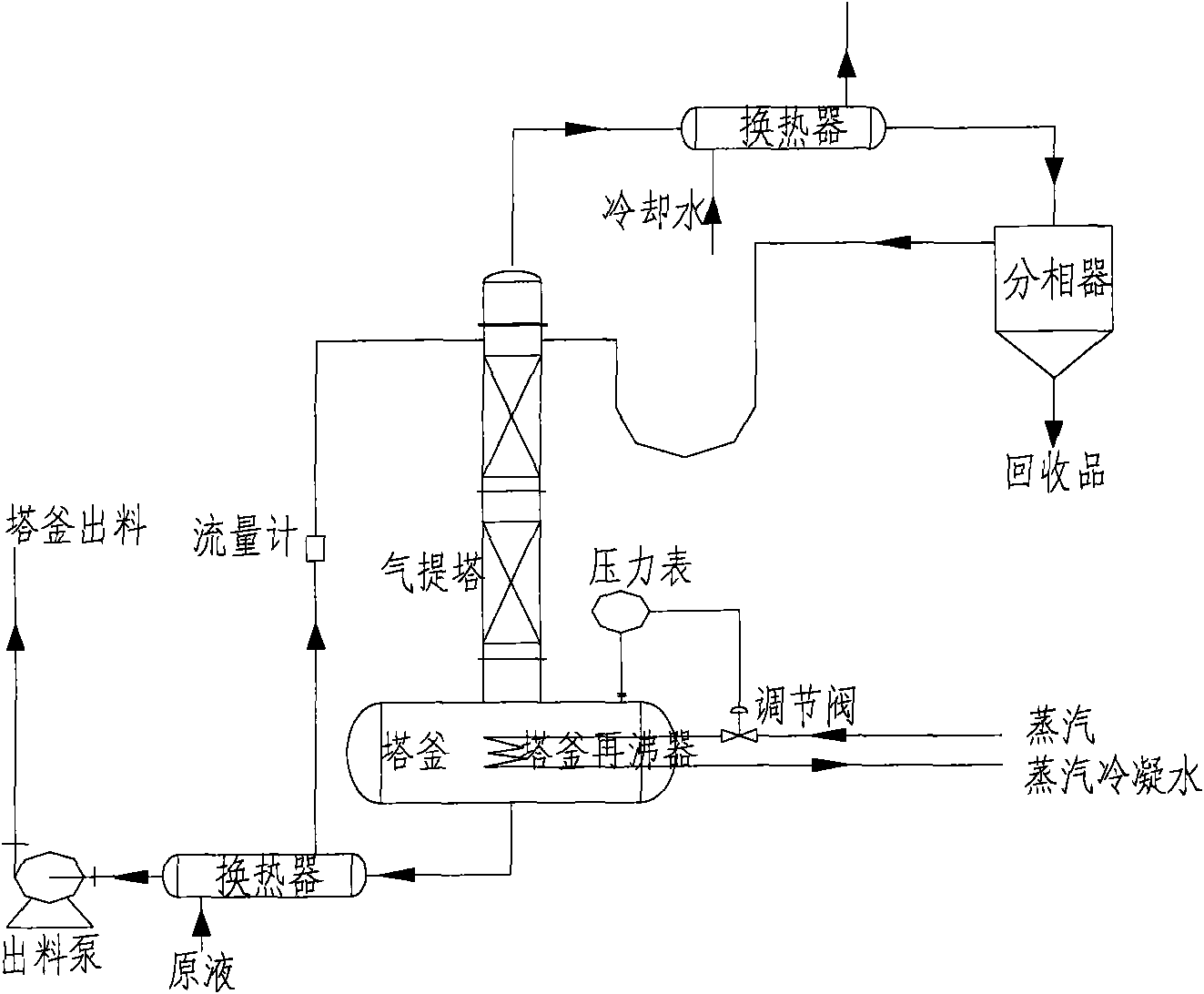

Method for recovering epoxy chloropropane from wastewater containing epoxy chloropropane

InactiveCN101665474AEasy to handleHigh recovery rateOrganic chemistryWater/sewage treatment by heatingEpoxyWater vapor

The invention relates to a method for recovering epoxy chloropropane from wastewater containing epoxy chloropropane, which comprises the following steps: preheating wastewater to 60-90 DEG C and thenspraying from the top of a tower body of an air stripping tower; charging water vapor from a reboiler of a tower kettle; introducing rising steam in the tow kettle to carry out heat exchange with thewastewater containing epoxy chloropropane; condensing the steam at the top of the tower body and then entering a phase splitter to precipitate and delaminate; and acquiring the epoxy chloropropane atthe lower layer, wherein the air stripping tower comprises the tower body positioned at the upper part and the tower kettle positioned at the lower part, and the reboiler of the tower kettle is arranged in the tower kettle. The method can recover the epoxy chloropropane with the content being larger than and equal to 99 percent from the wastewater containing 2-5 percent of epoxy chloropropane, andthe epoxy chloropropane can be directly used as a raw material for producing epoxy resin; and the invention has large processing ability, high recovery rate, investment saving and low running cost, greatly reduces the specific consumption for producing the epoxy resin and reduces the difficulty and the cost for directly carrying out biochemical treatment on the wastewater containing the epoxy chloropropane.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

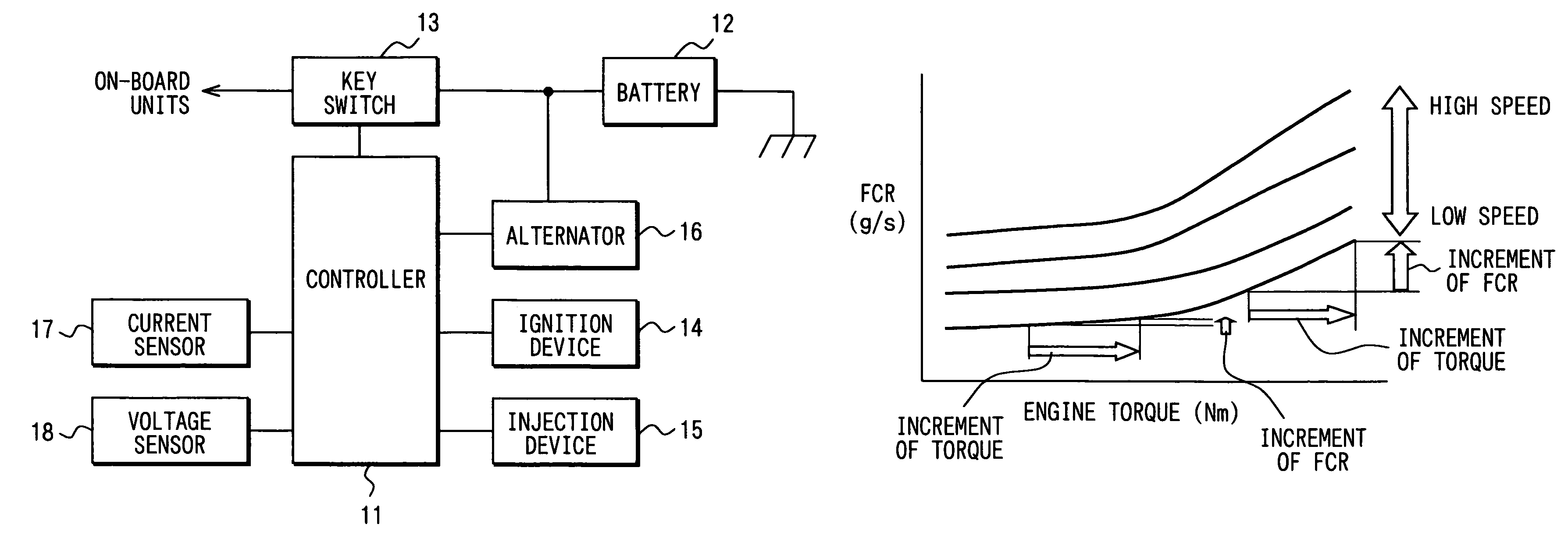

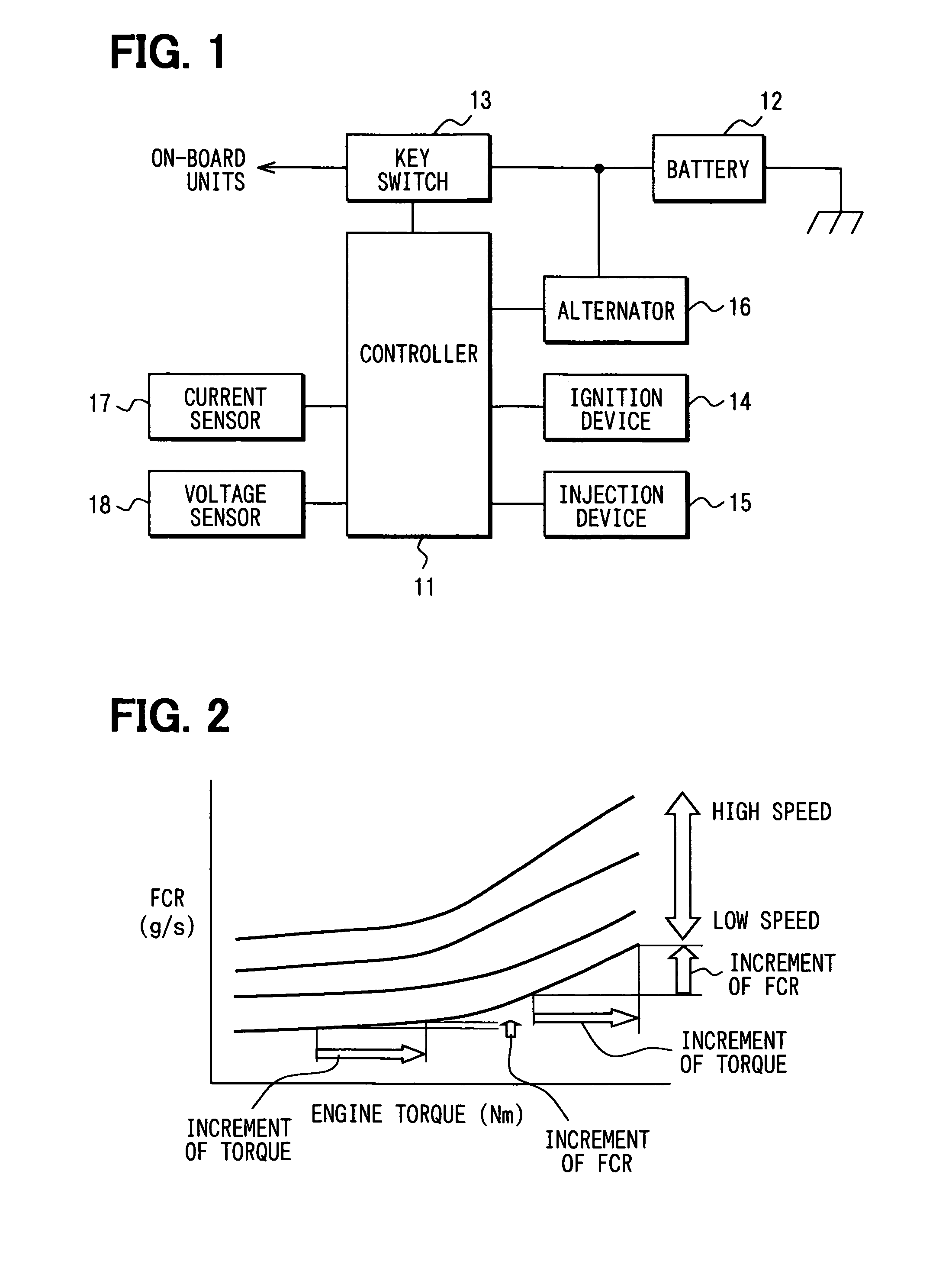

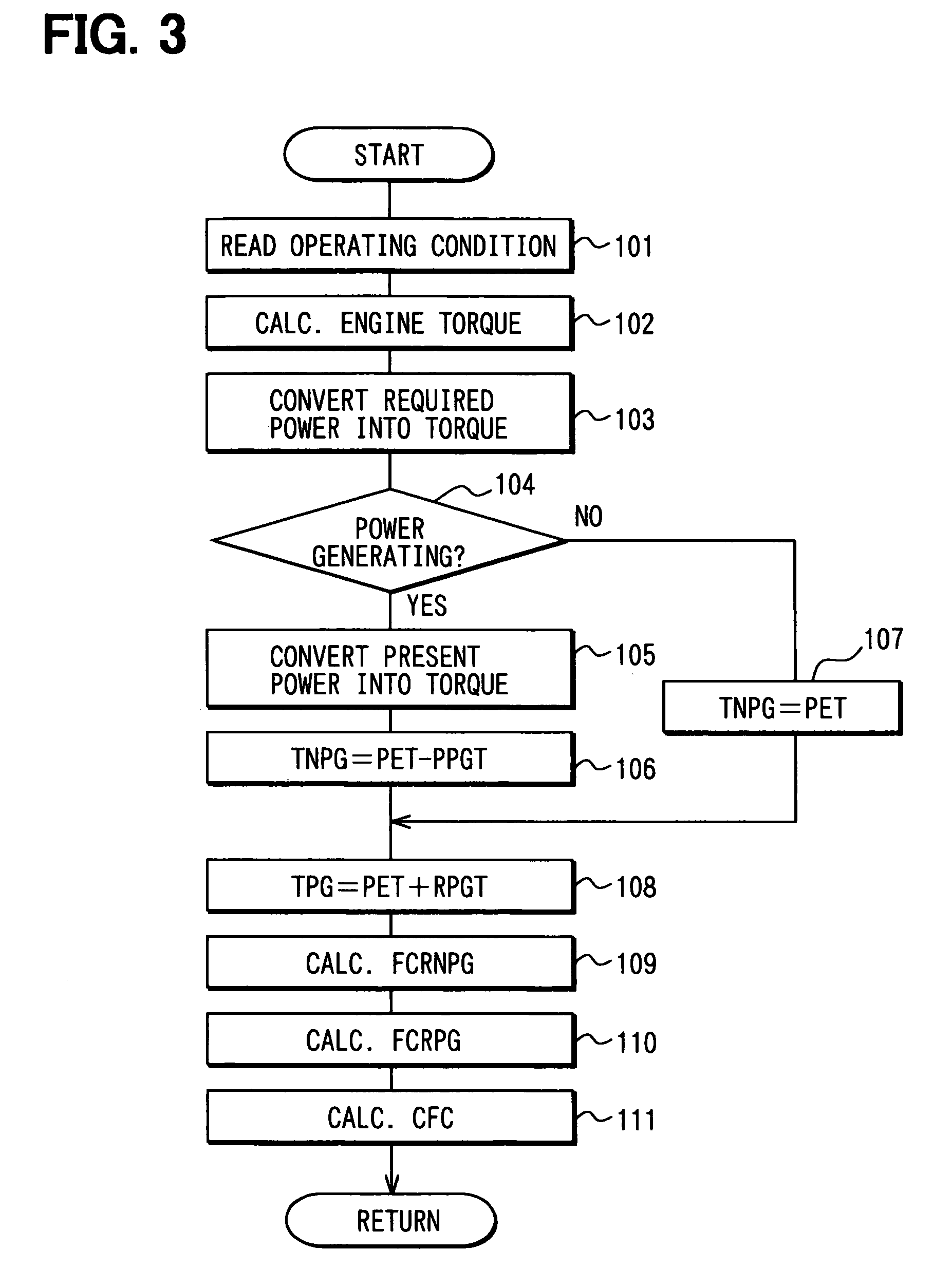

Power generation control apparatus for internal combustion engine

InactiveUS7355292B2Reduce incrementSaving effectBatteries circuit arrangementsLevel controlAlternatorElectric consumption

An increment of a fuel consumption rate caused by power generation is determined from a difference in fuel consumption rate between a case of performing power generation of an alternator and a case of stopping the power generation. The increment of the fuel consumption rate is divided by a power generation amount of the alternator to determine an increment of a fuel consumption per unit power generation amount. A use-frequency of the electric consumption is determined and also a possible power generation amount and average consumption power are calculated. A target electric consumption is set based upon the use-frequency, the possible power generation amount and the average consumption power so that the charge and discharge balance of the battery becomes zero. The present electric consumption is compared with the target electric consumption to determine whether or not to perform the power generation of the alternator.

Owner:DENSO CORP

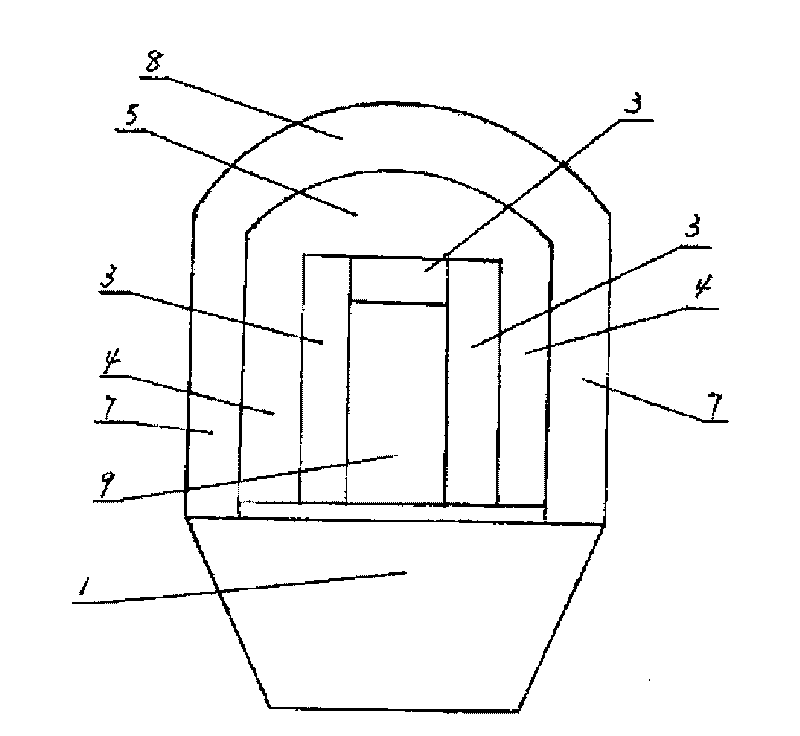

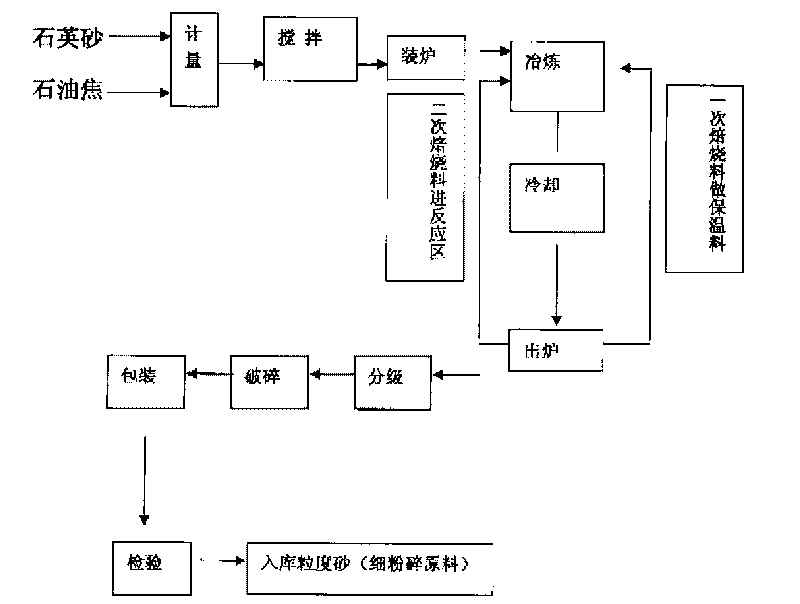

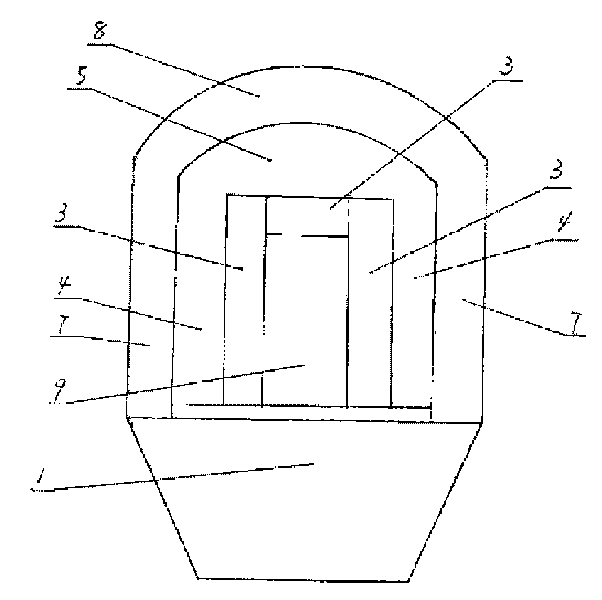

Process for smelting macrocrystalline green silicon carbide

The invention relates to silicon carbide smelting, in particular to a process for smelting macrocrystalline green silicon carbide, which comprises the following: a, a step of preparing raw materials of quartz sand and petroleum coke in a ratio of 1.48 to 1.54; b, a step of material mixing; c, a step of furnace charge, in which homogenized raw materials are delivered to a material area (1) at the bottom of a furnace, a burden material subjected to secondary roasting is filled in reaction areas (3, 4 and 5) in the middle of the furnace, and a burden material subjected to primary roasting is filled in the external heat preservation areas (7 and 8); d, a step of smelting, in which the charged furnace is electrified for smelting for 32 to 36 hours, the power of a transmission transformer is 8,000 KVA, and after cooling for 72 hours, the materials are discharged and graded. By adopting a smelting process of roasting for two times, the process reduces the waste of primarily roasted material, the specific consumption of the petroleum coke, the quartz sand and power, and saves energy. Meanwhile, as a long-time lower power transmission is adopted, the reaction of grains is more uniform and complete and the structure of the grains is more compact and firm; and compared with products in the prior art, the product has higher hardness, larger grain size, higher content and more desirable powder grain form.

Owner:TONGHUA HONGXIN ABRASIVE

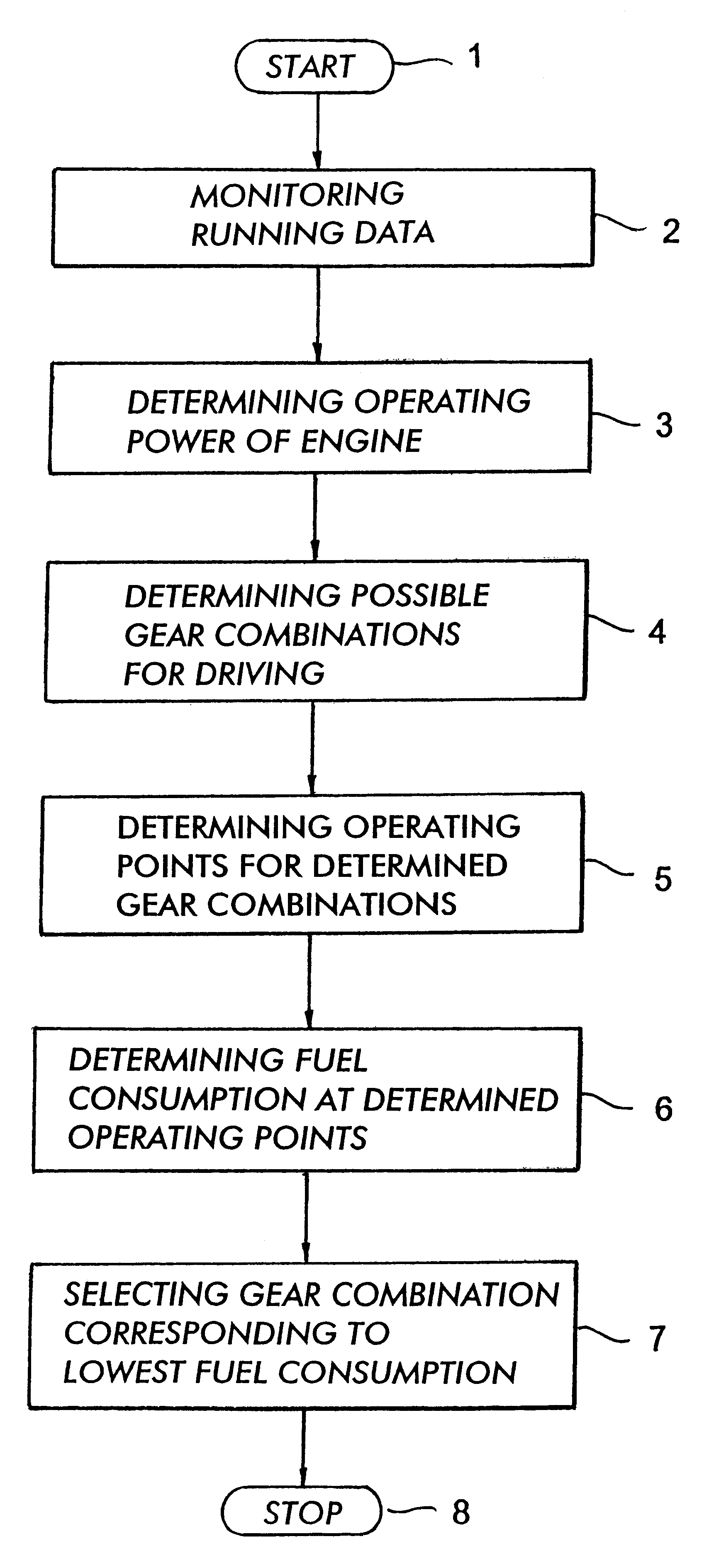

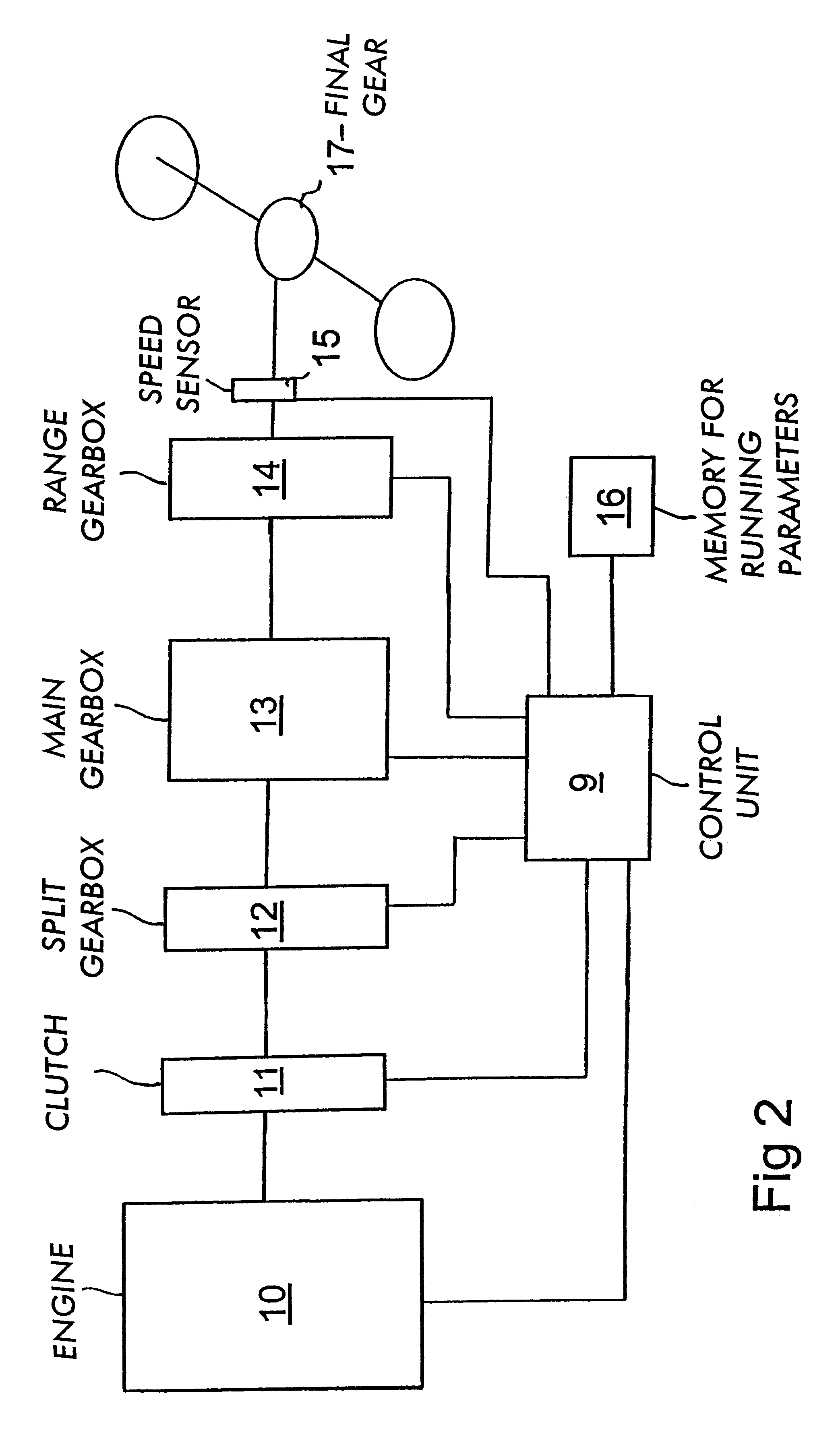

Method and apparatus for controlling an automatic gearbox

A process and an arrangement for the control of an automated gearbox. Control is conducted by determining possible gear combinations for driving, determining the operating points for the gear combinations, determining the specific fuel consumption at the operating points, selecting the gear combination with the lowest specific fuel consumption and emitting a command signal for changing to the selected gear combination.

Owner:SCANIA CV AB

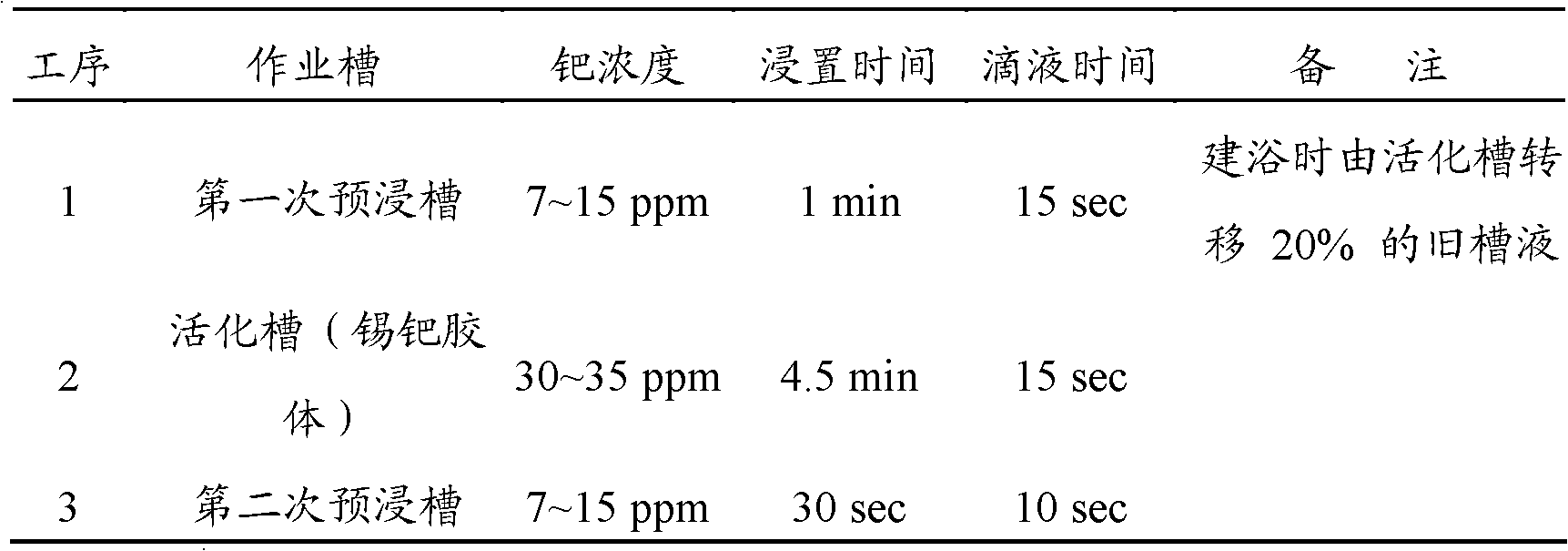

Surface activation method for nonmetal material

InactiveCN102321878AGuaranteed activation effectReduce wasteLiquid/solution decomposition chemical coatingHigh concentrationActivation method

The present invention discloses a surface activation method for a nonmetal material. The method comprises the following steps: adding tin palladium colloid to a pre-immersion solution to obtain a mixed solution; immersing a nonmetal substrate in the mixed solution; immersing the processed nonmetal substrate in a first activation solution, and then immersing the nonmetal substrate in the mixed solution. According to the present invention, the nonmetal substrate processed by the first activation solution is immersed in the mixed solution, such that the first activation solution absorbed on the surface of the nonmetal substrate, in the inner holes of the nonmetal substrate, and in the skeleton gaps of the nonmetal substrate are taken out and can be completely released in the mixed solution so as to reduce the waste of the noble metal palladium; the nonmetal substrate is respectively subjected to the low concentration activation treatment, the high concentration activation treatment and the low concentration activation treatment so as to provide the three activation functions at different concentrations for the nonmetal substrate, to enable adsorption of the activator, and the completeness and the compactness of the plating coat, to reduce specific consumption of the noble metal palladium, and to ensure the activation effect of the nonmetal material.

Owner:SHENZHEN FARCIEN APPLIED MATERIALS

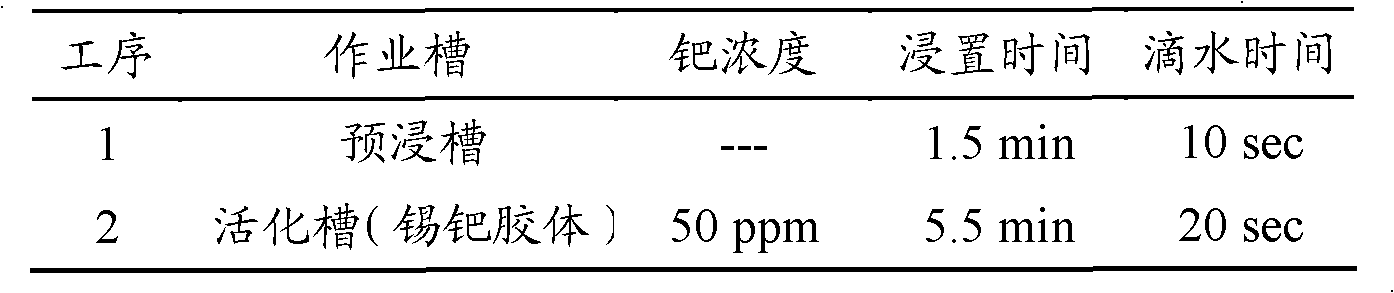

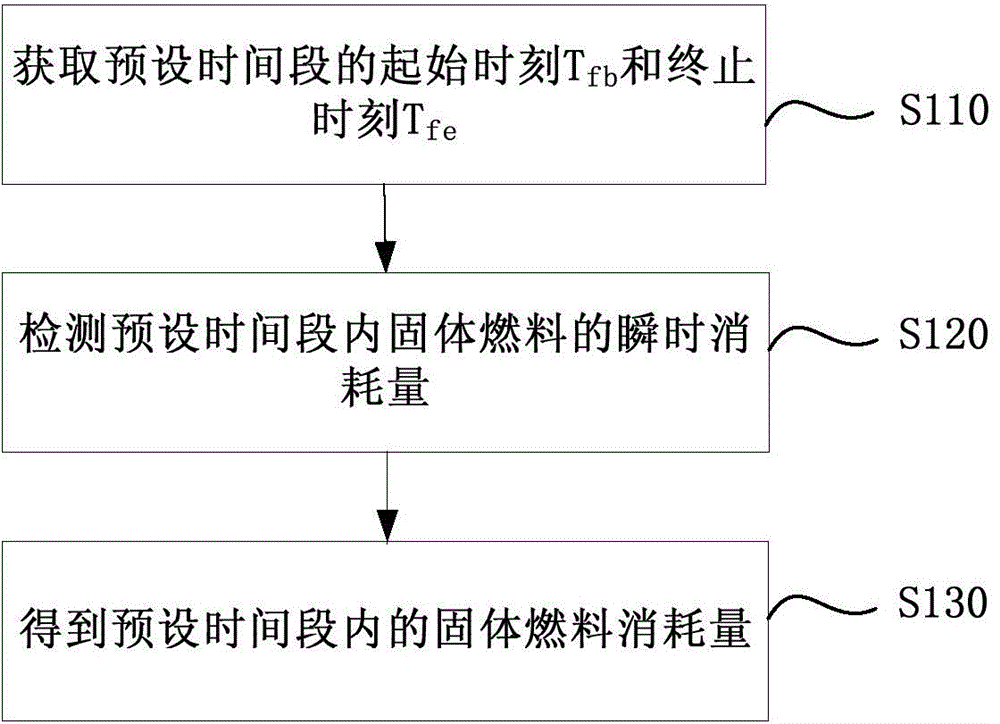

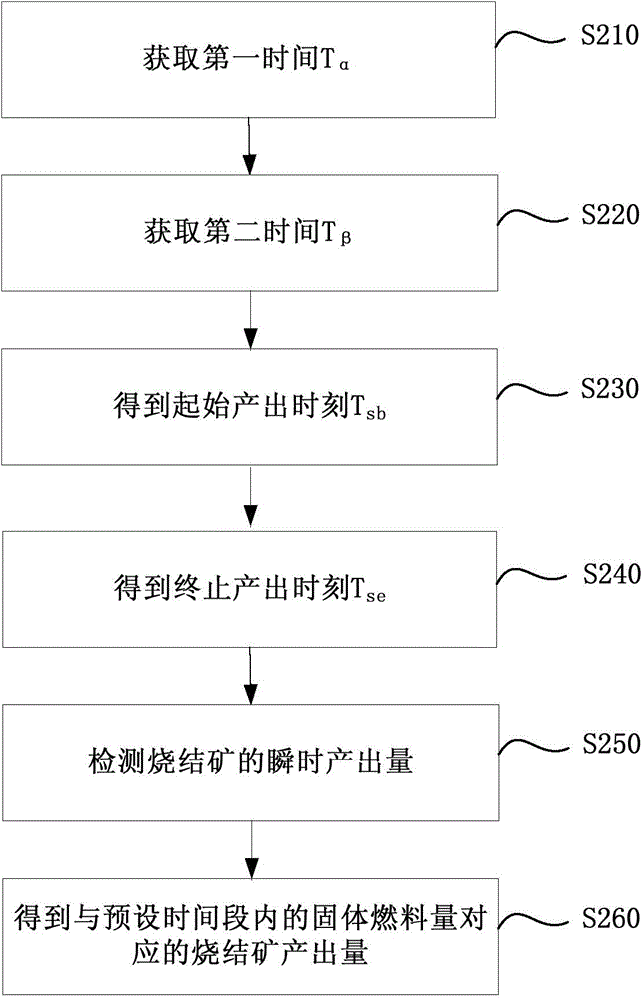

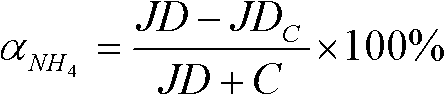

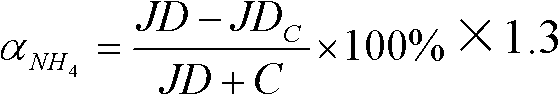

Method and device for measuring specific consumption of sintering ore solid fuel

ActiveCN104313306AAccurate measurementReduce consumptionSpecial data processing applicationsSolid fuelProduction unit

The embodiment of the invention discloses a method and device for measuring the specific consumption of a sintering ore solid fuel. The method and device are used for measuring the amount of a solid fuel consumed to produce a unit of sintering ore in a sintering process in real time, and the specific consumption of the solid fuel, namely the amount of the solid fuel consumed to produce each unit of the sintering ore is calculated by using the consumption of the solid fuel in a preset time period and the output of the sintering ore corresponding to the consumption of the solid fuel in the preset time period. The measuring method and device, disclosed by the embodiment of the invention, not only can be used for measuring the specific consumption of the solid fuel in any time period in real time, but also can be used for directing optimized production of the sintering ore and reducing the consumption of the solid fuel by grasping the specific consumption of the solid fuel in the sintering process.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Process simulation utilizing component-specific consumption data

ActiveUS8321187B2Stable supportLow costMechanical power/torque controlLevel controlGranularityParallel computing

Methods and apparatuses are provided for simulating components and processes using discrete, variable-granularity, component-specific data relating to energy consumption or other sustainability factors. Simulations can be analyzed and optimized to facilitate forecasting of sustainability factors and determine advantageous modifications to the components or processes.

Owner:ROCKWELL AUTOMATION TECH

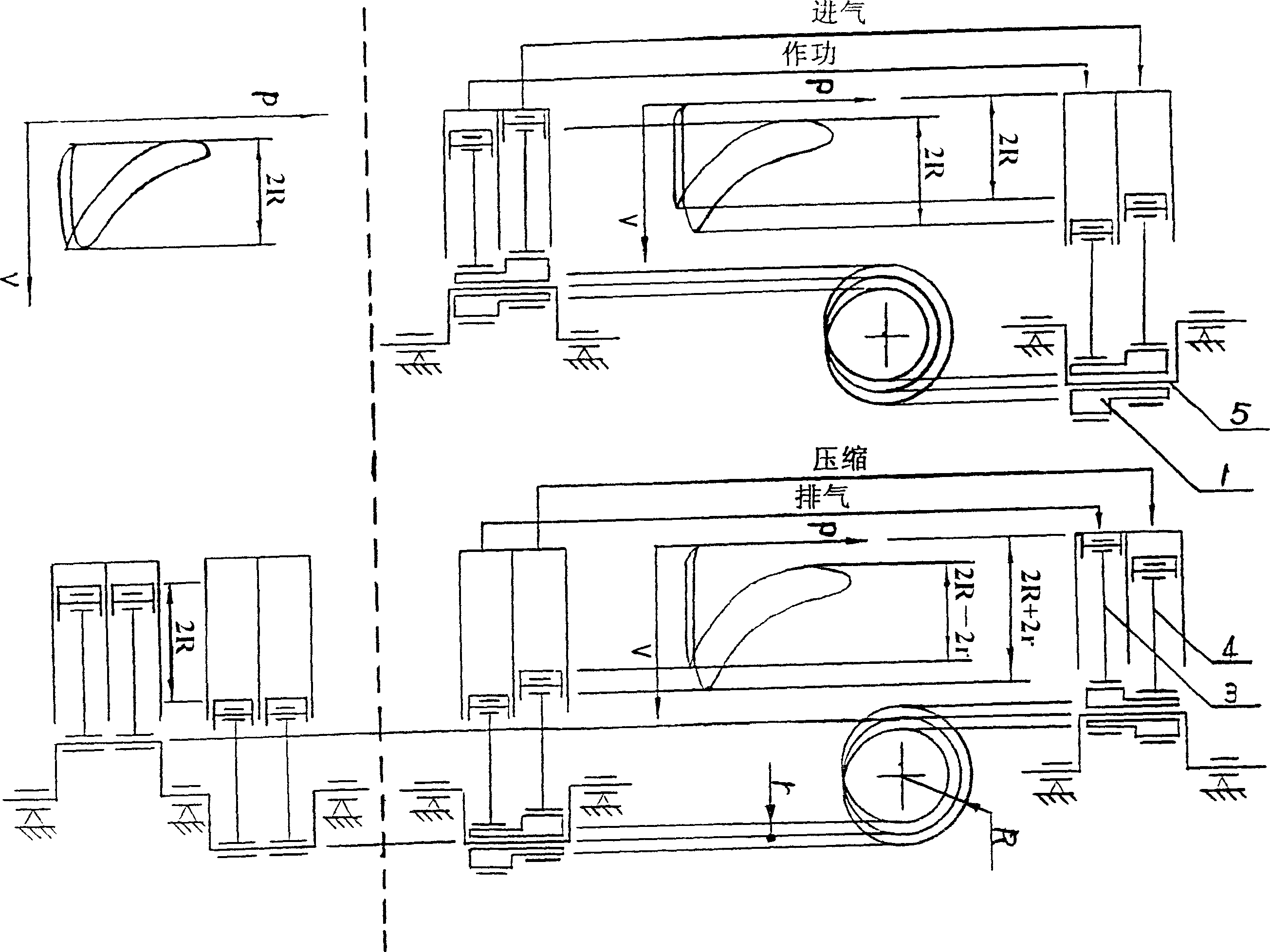

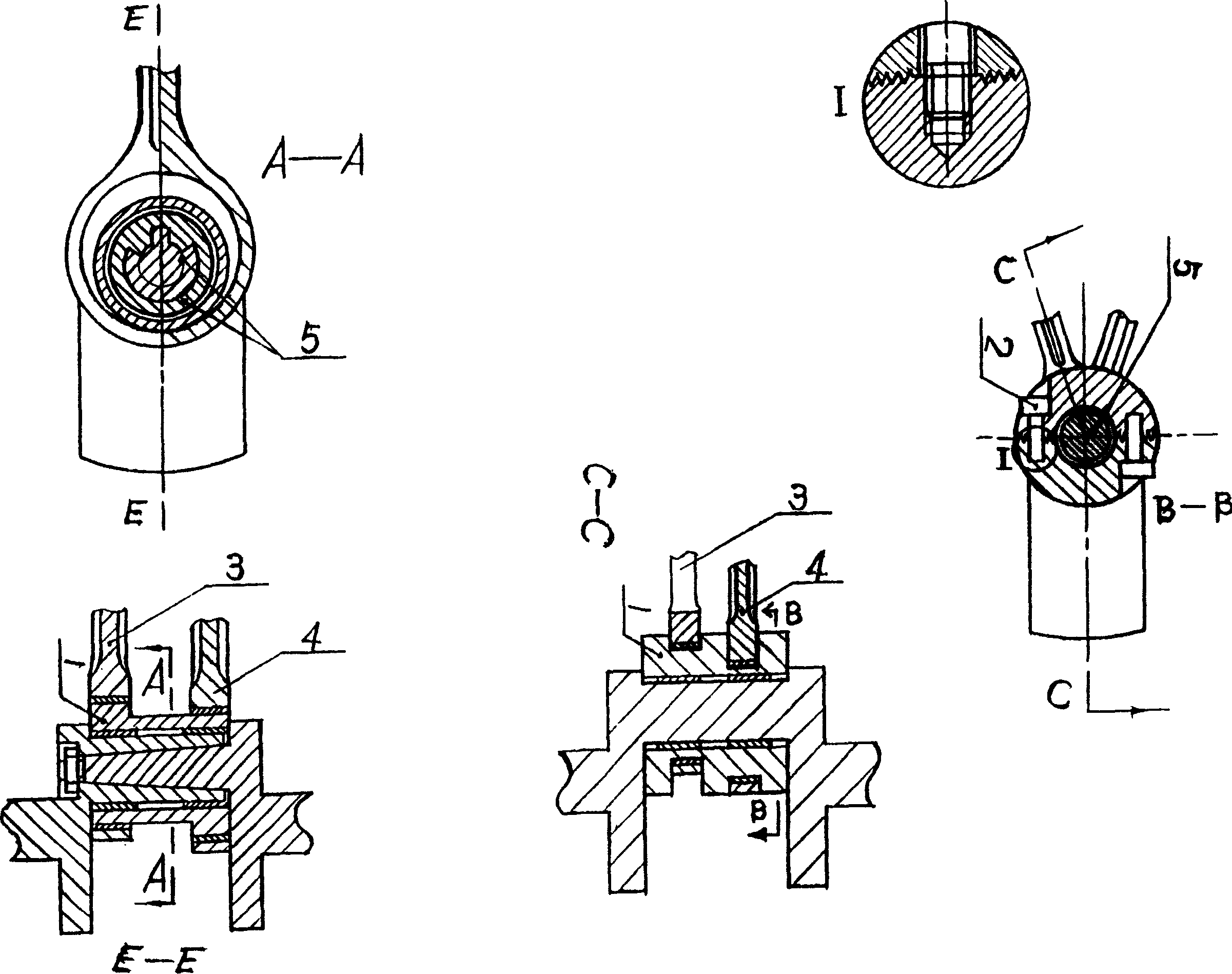

Improvement of Otto cycle, Diesel cycle and Atkinson cycle

InactiveCN1614213AReduce negative work of compressionImprove mechanical efficiencyInternal combustion piston enginesEngine controllersOtto cycleAtkinson cycle

A method for improving the Otto cycle, Diesel cycle and Atkinson cycle is disclosed, which can lower the specific consumption rate of fuel for the reciprocating 4-stroke IC engine and increase its power performance.

Owner:任军

Method for optimizing the overall energy efficiency of an aircraft, and main power package for implementing same

InactiveUS8868262B2Energy balanceRecover energyAircraft power plantsPower installationsNacelleSizing

A method and system limiting specific consumption of an aircraft by matching sizing of a power supply to actual power needs of a cabin pressure control system. The method optimizes overall efficiency of energy supplied onboard an aircraft including, in an environment near the cabin, at least one main power-generating engine, sized to serve as a single pneumatic energy-generating source for the cabin and as an at most partial propulsive, hydraulic, and / or electric energy-generating source for the rest of the aircraft. The method minimizes power differential between a nominal point of the power sources when the sources are operating, and a sizing point of non-propulsive energy contributions of the sources when the main engine has failed, by equally dividing power contributions of the main engines and the main power generator under nominal operating conditions and in an event of failure of a main engine.

Owner:SAFRAN HELICOPTER ENGINES

Fuel-efficient route determination

InactiveCN102213598ADetermination of consumption valueReduce overheadInstruments for road network navigationForecastingPath networkRoad networks

A navigation method for determining a fuel-efficient route of a motor vehicle between a start point and a destination point comprises on a predetermined path network steps of determining the consumption value of the vehicle on a section of the road network on the basis of another on a section of the road network collected consumption value of the vehicle and determining the fuel-efficient route based on the specific consumption value.

Owner:ROBERT BOSCH GMBH

Production method for polysilicic acid

ActiveCN103043671AReduce processing costsImprove utilizationSilicon compoundsCollocationSilicic acid

The invention provides a production method for polysilicic acid. The method comprises the following steps: using excessive water glass to improve the resin exchange efficiency through the cation exchange; reducing the regenerant specific consumption and improving the finished product purity through collocation of weak acid type cation exchange resin and strong acid type cation exchange resin; backwards flowing the water glass to guarantee the flow smoothness through the weak acid type cation exchange resin; using exchanged flushing liquid to dilute concentrated water glass in order to improve the utilization rate of the water glass and reduce the waste water emission; and using collected acid residual liquid and generated flushing liquid for the next cycle of resin regeneration in order to further reduce the consumption of acid for regeneration and reduce the waste water neutralization cost. The method has the advantages of low regenerant specific consumption, high finished product purity, low consumption of de-ionized water and low waste water treatment cost, and has very remarkable commercial value.

Owner:SHANGHAI XINANNA ELECTRONICS TECH +1

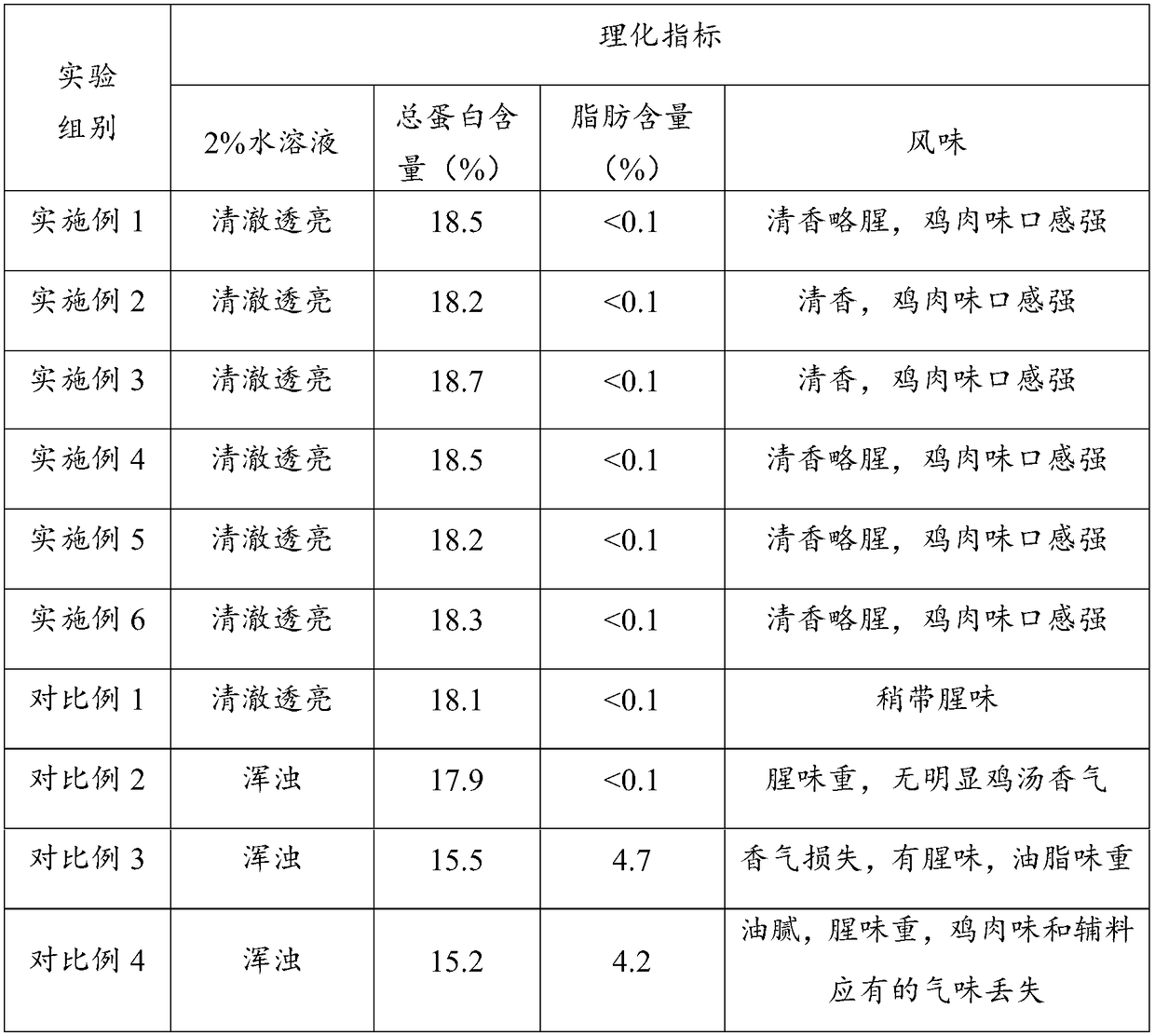

Low-fat chicken broth and making method

The invention provides low-fat chicken broth and a making method, and relates to the technical field of foods. According to the low-fat chicken broth disclosed by the invention, chicken skeletons andchicken breast are selected as main materials, raw materials of table salt, auxiliary materials and the like are used for cooperation, and through joint cooperation of the main materials and the auxiliary materials in specific consumption, the made low-fat chicken broth is good in flavor, low in fat content, high in nutrient components and easy to absorb. The invention further provides a making method of the low-fat chicken broth. The making method comprises the following steps of firstly performing pressure cooking on the raw materials so as to increase dissolving out of nutrient substances in the raw materials, and then performing fat separation on cooking mixed liquor obtained through pressure cooking by a membrane separation technique. Through the cooperation of the steps, nutrient components in the chicken broth can be effectively increased, the fat content in the chicken broth can be reduced, the protein molecular weight in the made chicken broth is low, absorption by human bodies is facilitated, fragrance is reserved to the maximum extent, and the mouth feel and the flavor of the low-fat chicken broth are improved.

Owner:HEBI PULETAI BIOLOGY TECH

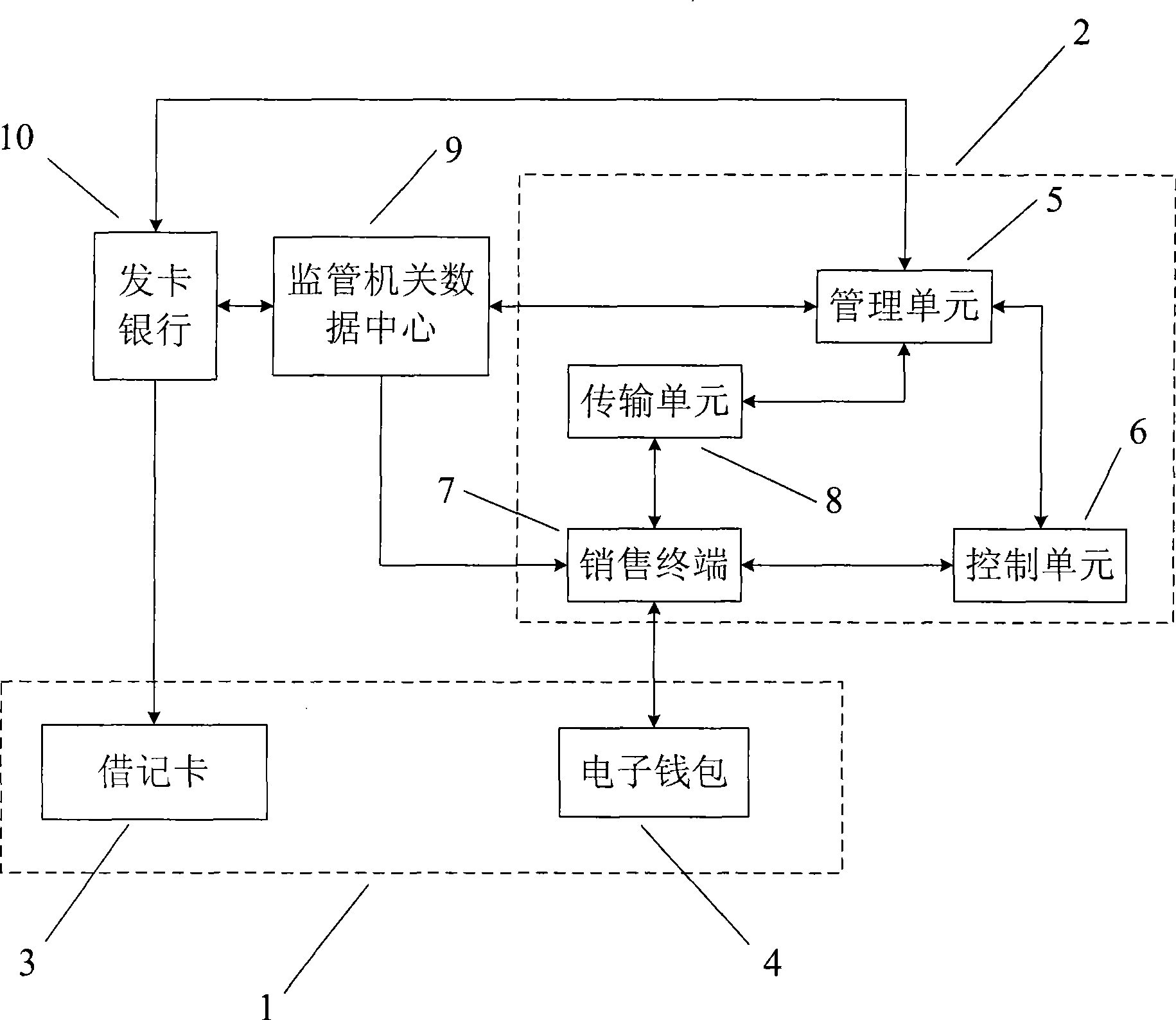

Monitoring management type bank card system and its use method

InactiveCN101470918AProtection of rights and interestsRealize monitoring and managementComplete banking machinesCoded identity card or credit card actuationData centerComputer terminal

The invention relates to a monitoring management type bank card system and a using method, which are used by specific consumption groups whose payment and cash realization are restricted. The system comprises a bank card and a bank card computer network, wherein the bank card computer network also comprises a control unit, a managing unit, a transmitting unit and a consumption network, the bank card comprises a debit card and a purpose-made electronic purse corresponding to the debit card, wherein the purpose-made electronic purse only can be used in appointed selling terminals. The using method comprises: opening the debit card, manufacturing the electronic purse corresponding to the debit card for users by supervision institutions, transmitting balance information of the debit card to the control unit through the managing unit, inputting into the electronic purse by the selling terminals, sending transfer consumption fund information to a supervision institution data center according to consumption records of the electronic purse, and sending to the selling terminals. The system and the method realize monitoring management to restricted consumption, which is beneficial for improving the managing quality and effect of the supervision institutions and for building good monitoring environment.

Owner:LIAONING TAIDE COMP NETWORK ENG

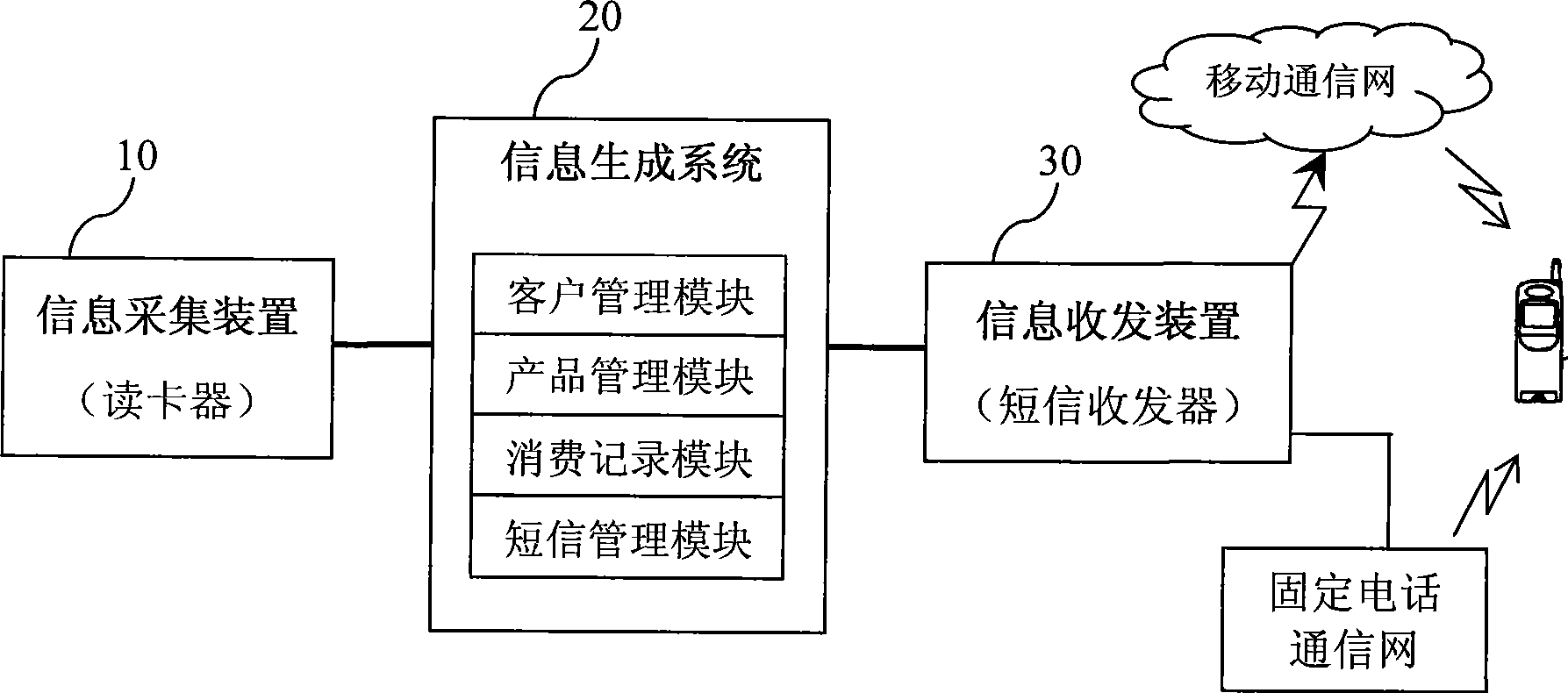

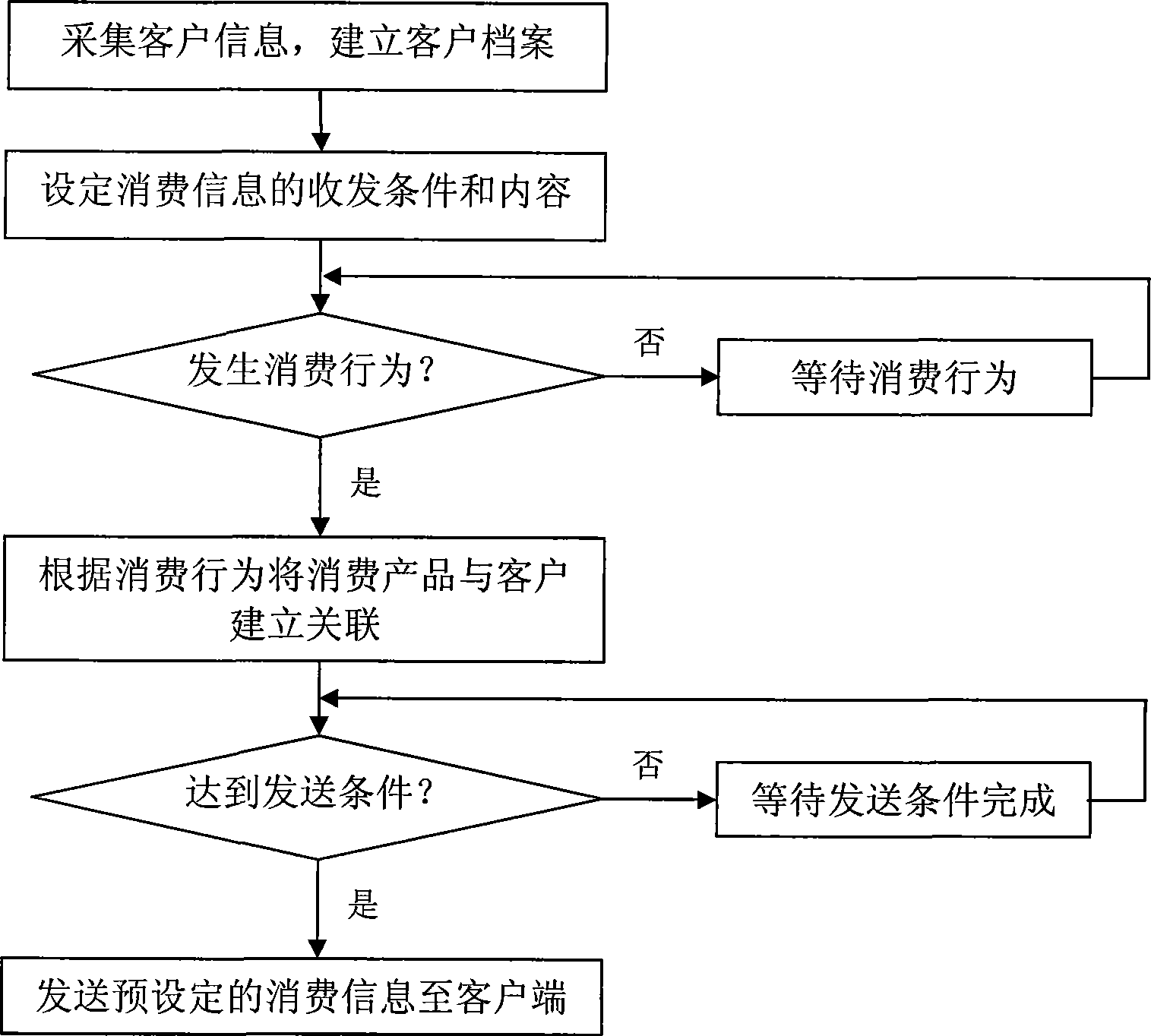

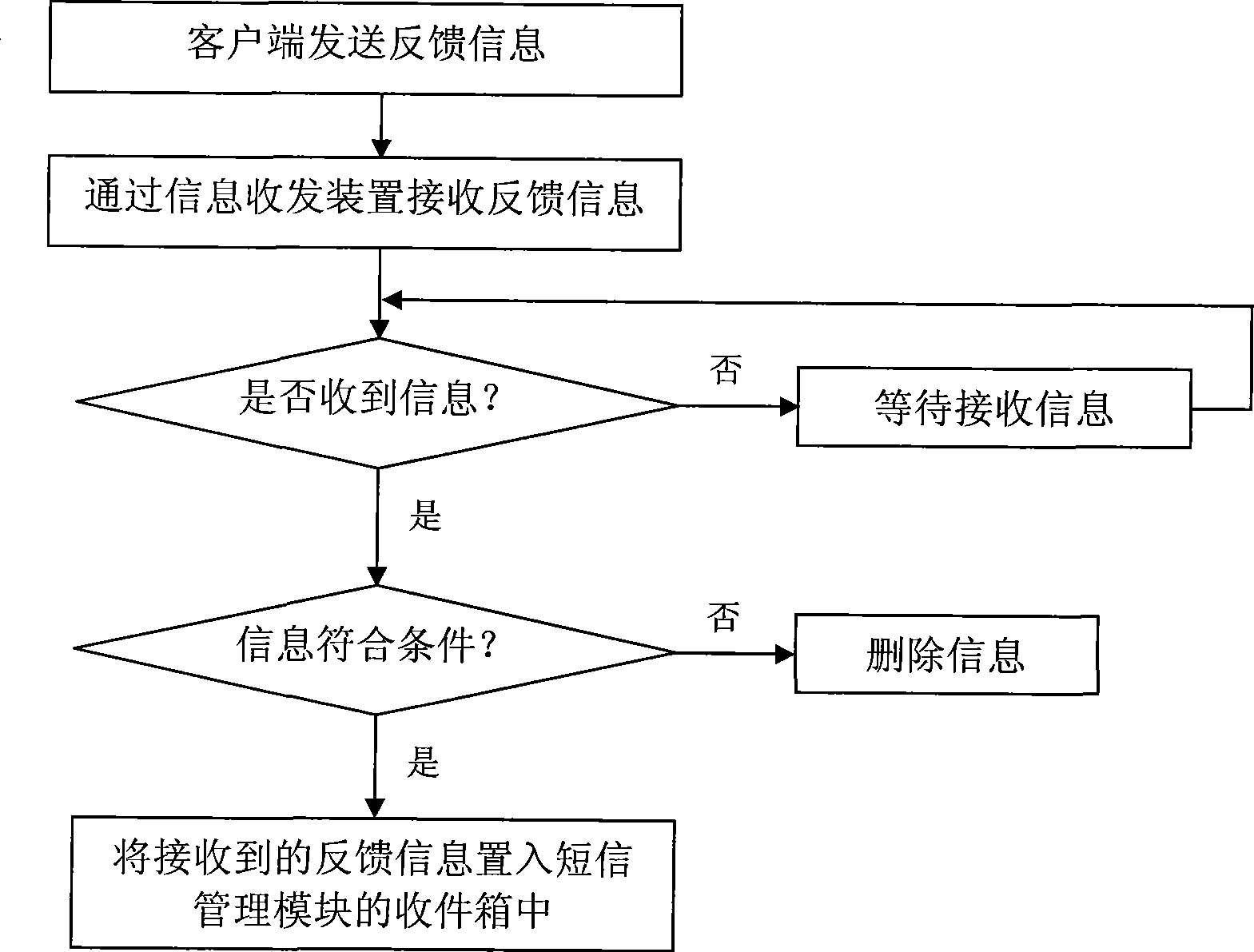

Consumer information transmitting and receiving system and method based on short message platform

InactiveCN101370184AImprove sending efficiencyAvoid differencesRadio/inductive link selection arrangementsData switching networksClient dataService efficiency

The invention discloses a consumption information receiving-transmitting system based on a short message platform and a method. The receiving-transmitting system comprises an information collecting device for collecting customer data, an information receiving-transmitting device for transmitting the consumption information to the client or receiving the feedback information from the client, and an information generating system. The input end of the information generating system is connected with the information collecting device, and the output end thereof is connected with the information receiving-transmitting device for transmitting the preset consumption information to the client or receiving the feedback information from the client. The receiving-transmitting method is to establish correlation between the customers and the consumption products; through setting the receiving-transmitting conditions and contents of the consumption information, when specific consumption behavior happens, the consumption information is automatically generated by the information generating system and transmitted to the customers. The receiving-transmitting processes of the consumption information are automatically performed by a computer completely without human operations, so the invention is favorable for improving the information service efficiency and quality of enterprises and reducing service costs.

Owner:林阳生

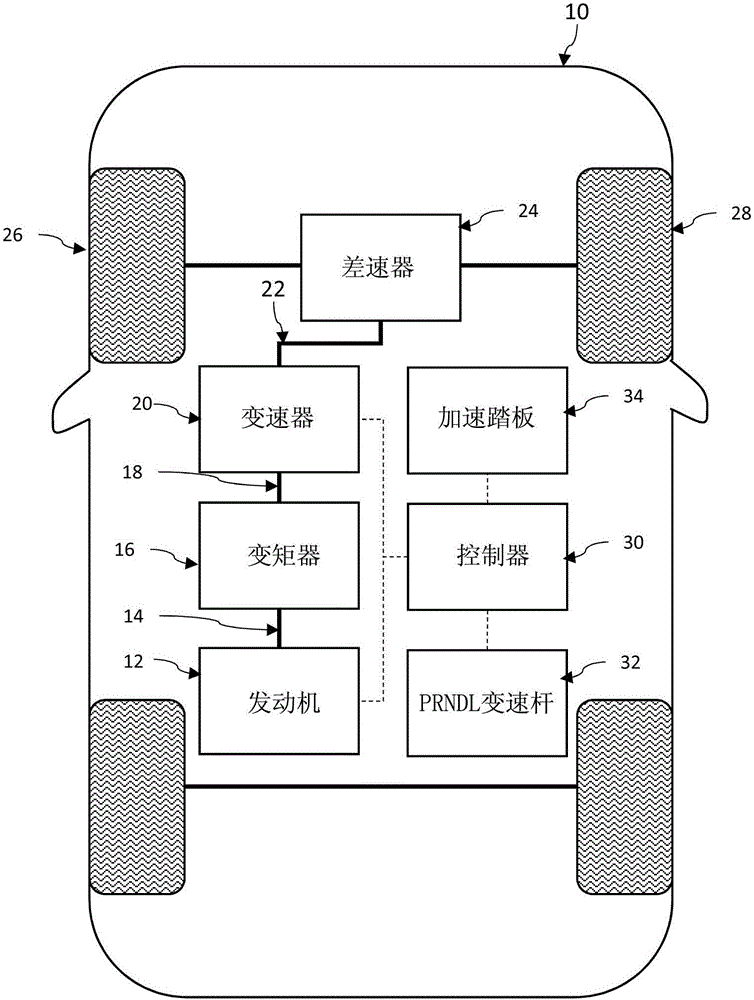

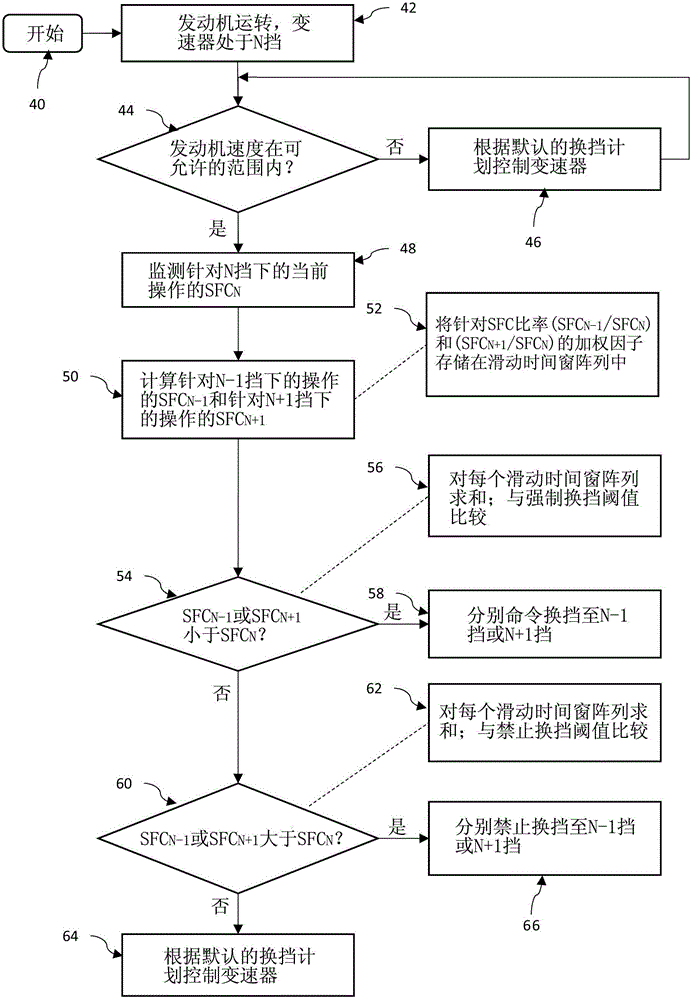

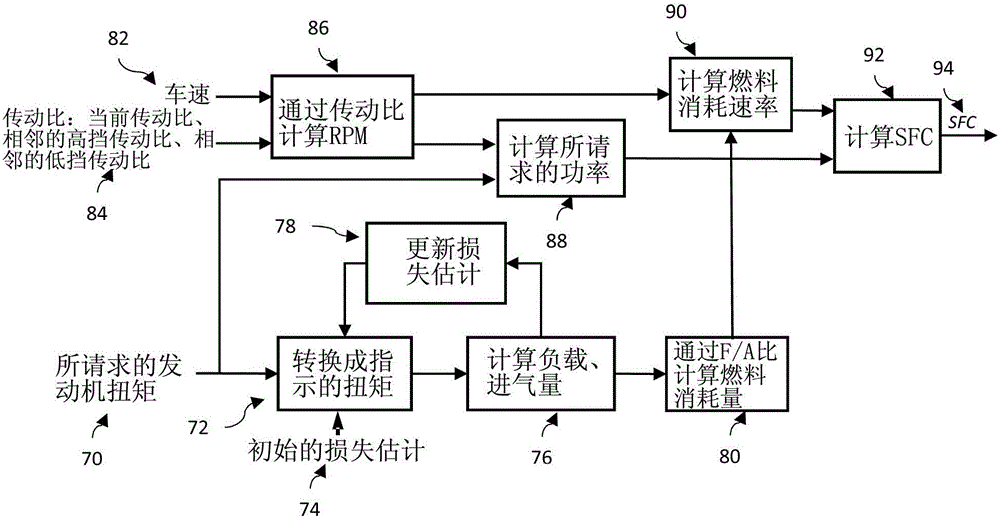

Transmission shift schedule optimization based on calculated specific fuel consumption

Owner:FORD GLOBAL TECH LLC

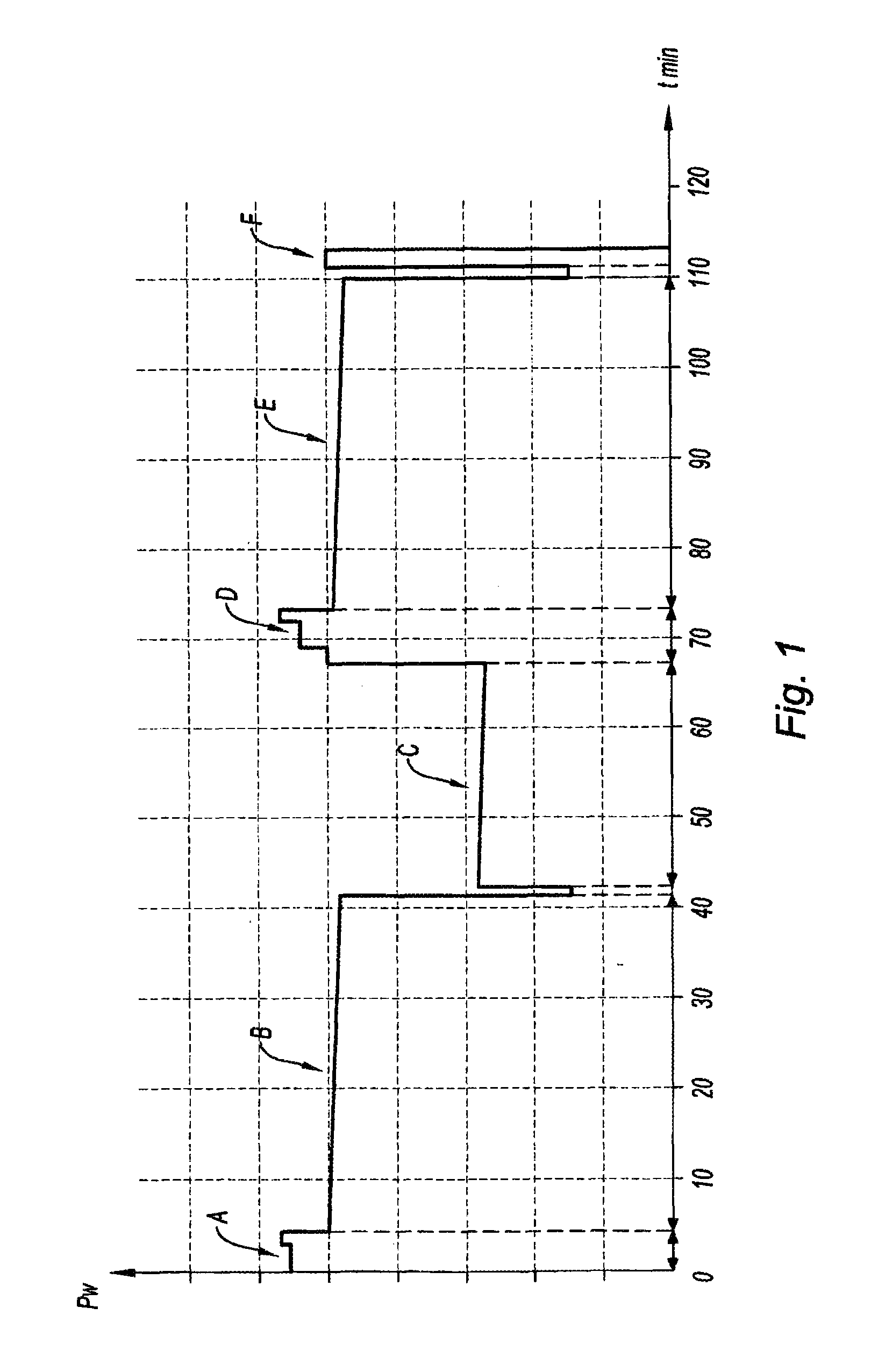

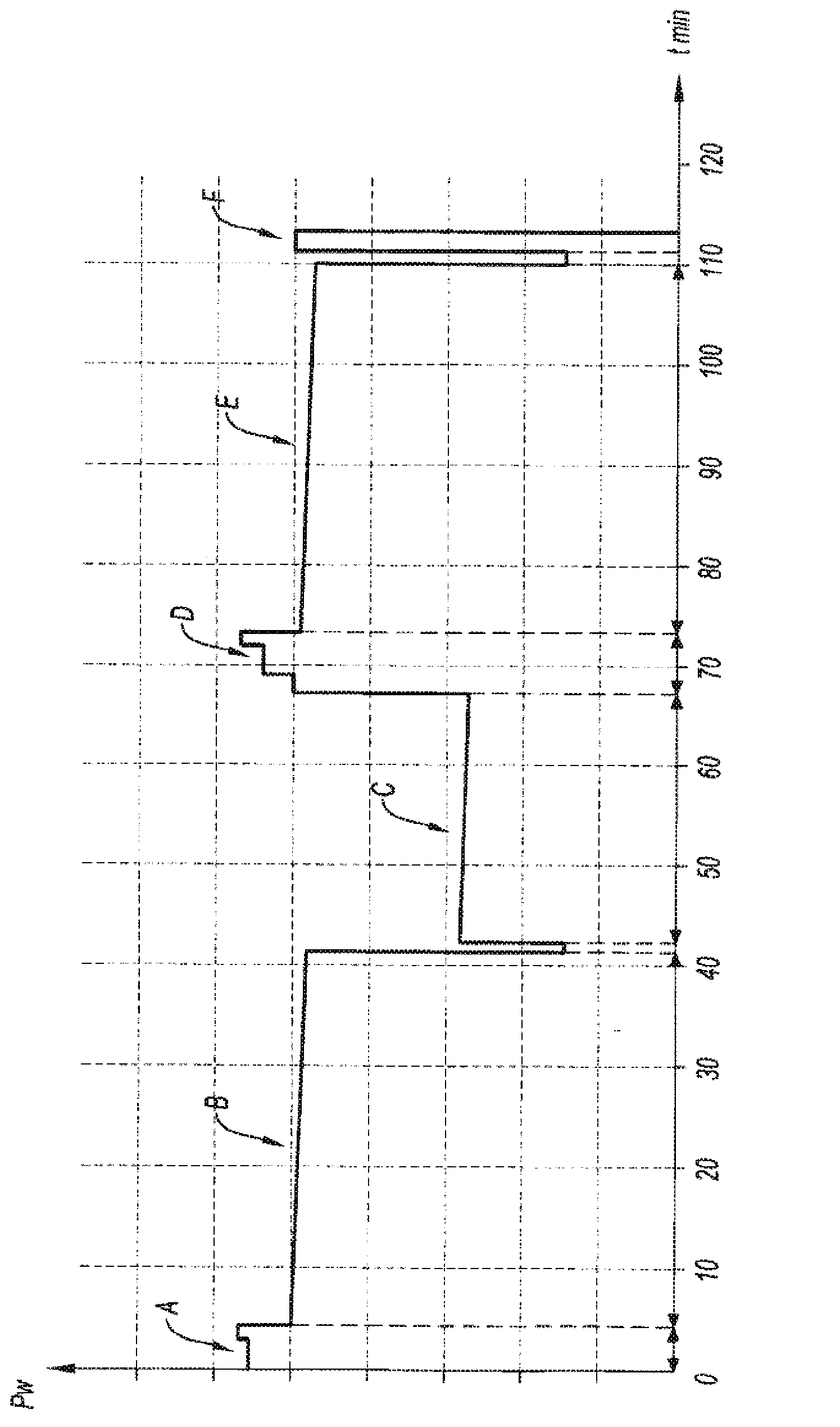

Method for optimising the specific consumption of a twin helicopter

ActiveCN105593493AGas turbine type power plantsEfficient propulsion technologiesCombustion chamberOperating temperature

The invention relates to a method for optimising the specific consumption of a helicopter provided with two turboshafts (1, 2), each one comprising a gas generator (11, 21) provided with a combustion chamber (CC), each of said turboshafts (1, 2) being able to operate alone in the continuous flight mode, the other turboshaft (2, 1) being then in a so-called super-slow mode with zero power and with the combustion chamber lit, said super-slow mode being assisted by a mechanical rotation of the shaft (AE) of the gas generator in this mode, in such a way as to reduce the operating temperature and the fuel consumption of said gas generator.

Owner:TURBOMECA SA

Preparation method of powder for sintering large-magnetic-core product

The invention provides a preparation method of a powder for sintering a large-magnetic-core product. The powder is composed of the following components in parts by weight: 70-71 parts of Fe2O3, 21-22 parts of MnO, 7-9 parts of ZnO, 0.5-0.7 part of V2O5, 0.02-0.05 part of H2SiO3, 0.2-0.4 part of CaCO3 and 0.1-0.3 part of Nb2O5. The preparation method comprises the following steps: presintering, sanding, spraying and cooling. By the formula improvement specific consumption composition of all the components, the powder has the characteristic of lower loose density, and is suitable for die design of large products with low density and high shrinkage; the powder has lower water content and lower alcohol content, is suitable for alcohol-water volatilization in the sintering process, and thus, can be pressed into a blank with the weight of 500g above without lowering the heating speed in the sintering process; and the product cracking rate can be controlled at 3% below within the rated output range of the sintering unit. The preparation method is simple and suitable for the demands of large-scale industrial production.

Owner:TIANJIN HAOGAO MAGNETS

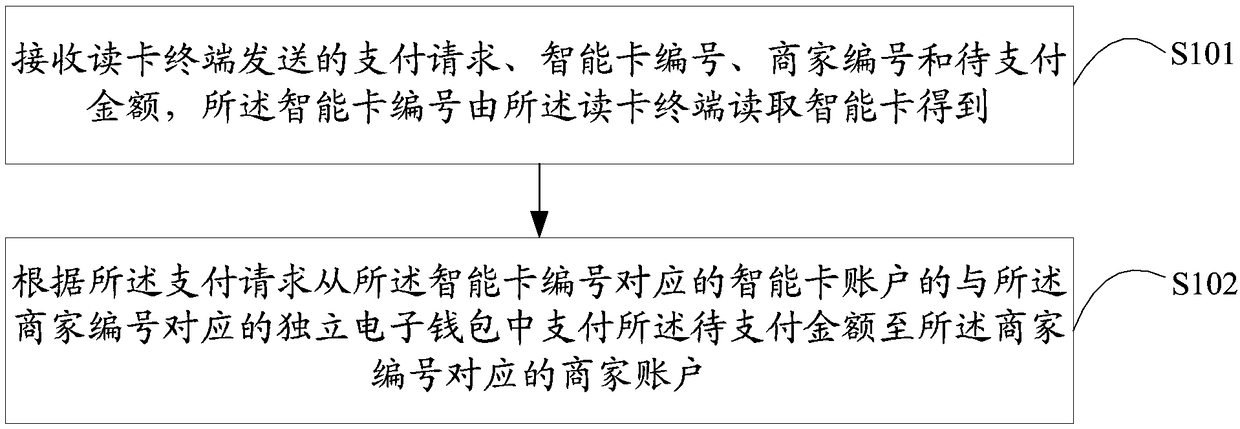

Smart card management method and device and terminal device

ActiveCN109359970AUnlimited number of extensionsConvenient consumption accountingPayment architecturePaymentMerchant account

The invention is applicable to the technical field of software application, and provides a smart card management method and device and a terminal device. The method comprises the following steps: receiving a payment request sent by a card reading terminal, a smart card number, a merchant number and an amount to be paid, wherein the smart card number is obtained by reading the smart card by the card reading terminal; according to the payment request, paying the amount to be paid from the independent electronic wallet corresponding to the merchant number of the smart card account corresponding to the smart card number to the merchant account corresponding to the merchant number. The application can solve the problems that it is difficult to expand the independent wallet in the existing one-card service, and the balance is queried when querying the information of the smart card, the specific consumption place and consumption amount cannot be obtained, and the consumption accounting process is tedious and complex.

Owner:厦门熵基科技有限公司 +1

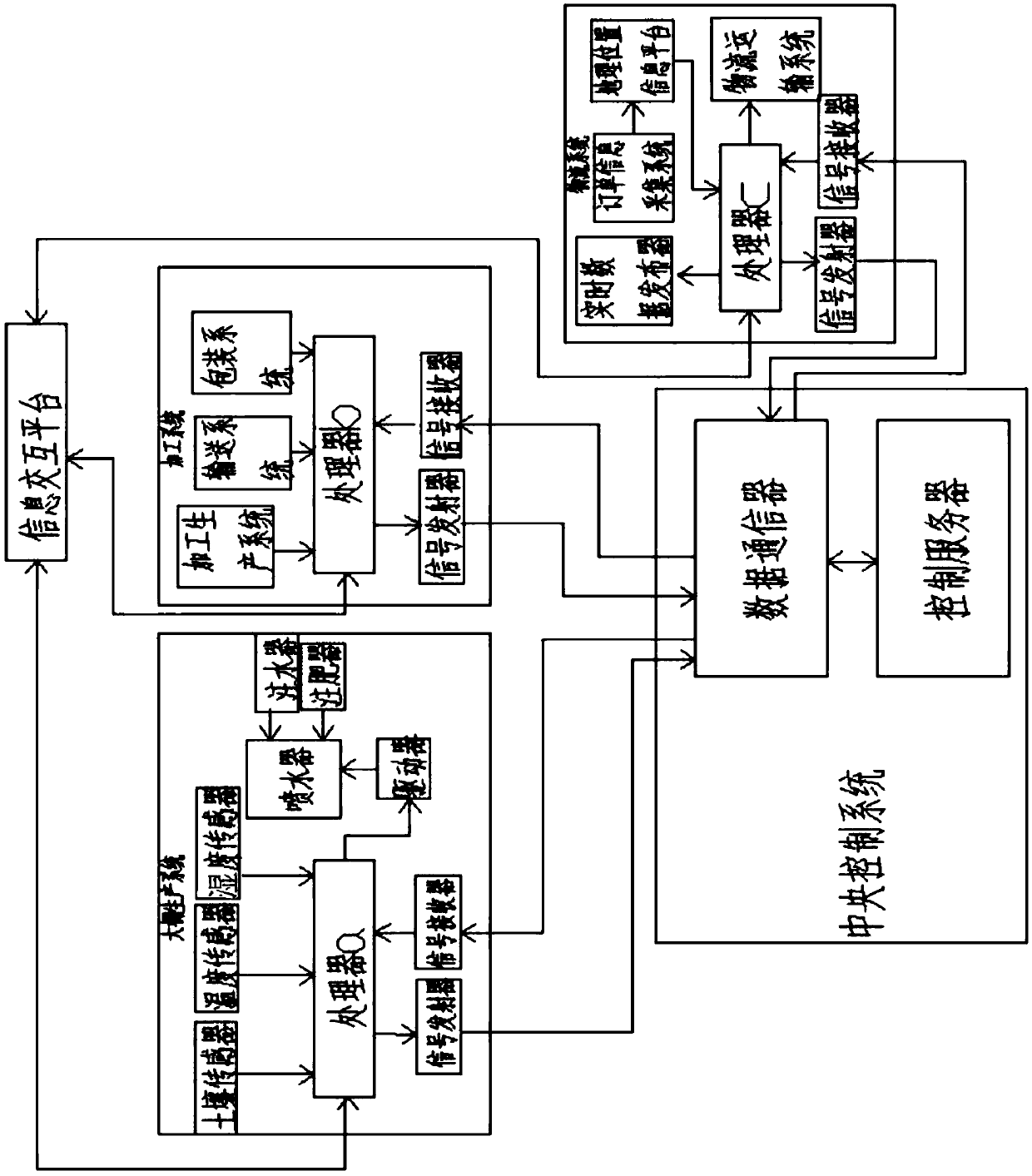

IoT-based farming comprehensive service system

InactiveCN107562032AExpand application development spacePromote production and incomeProgramme total factory controlInformatizationGreenhouse production

The invention belongs to the technical field of agricultural IoT and specifically relates to an IoT-based farming comprehensive service system. The system includes a greenhouse production system, a processing system, a logistics system and a central control system. Multiple fields including modern agricultural production and supervision, agricultural product processing, logistics transportation, agricultural product consumption and the like are combined together through application of IoT technology. The establishment of an IoT-based agricultural IoT networking construction project agricultural product quality safety assurance system, technical support is provided for agricultural product communication and transaction informatization. Information share is achieved through an information interaction platform. Specific consumption information of agricultural products is collected through logistics transportation and is centralized to the information interaction platform for sorting, so that different demands for agricultural products of the market in current season can be concluded clearly and feedback can be sent to the greenhouse production system and the processing system. Therefore, combination of the market and production is tightened and a condition that production divorces from market is avoided.

Owner:来安县威光绿园生态农业专业合作社

A sodium ion softening water treatment regeneration agent

ActiveCN102259987AReduce specific consumptionAvoid pollutionTreatment using complexing/solubilising chemicalsDecompositionSoftened water

The invention provides an improved regenerant for sodium ion softening water treatment. The regenerant has the advantage that: a certain amount of strong acid radical ammonium salt is added to a single sodium salt regenerant and an acid generated during ammonium salt decomposition can neutralize a base generated during sodium salt decomposition, thereby reducing the alkalinity of boiler water, preventing alkaline corrosion and caustic embrittlement and reducing excessive pollution discharge caused by excessive alkalinity; and NH3 generated during ammonium decomposition is carried in steam to neutralize CO2 in the steam, thus preventing the metal corrosion of steam equipment and a condensing water system and improving the recovery rate of condensing water. In the invention, a formula is provided to accurately calculate the proportions of the ammonium salts in the regenerants aiming at different water qualities, thereby optimizing the effects of the regenerant and reducing other adverseside effects. The regenerant provided by the invention can also contain a certain amount of complexing agent, thereby preventing the pollution of heavy metals on resin during the regeneration, improving the resin regeneration rate and reducing the specific consumption of the regenerant. The regenerant provided by the invention is simple to prepare, and is energy-saving, environmentally friendly, economical and practical.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Air filter paper and preparation method thereof

ActiveCN108978351AImprove high temperature resistanceReduce wind resistanceNatural cellulose pulp/paperPaper/cardboardParticulatesCellulose

The invention provides air filter paper, which is prepared from the following ingredients of 100 weight parts of body glass fiber, 10 to 20 weight parts of molecular sieve activation powder, 0.3 to 0.6 weight part of dispersing agents, 5 to 15 weight parts of wood pulp cellulose, and 5 to 15 weight parts of binding agents, wherein the body glass fiber consists of short cut continuous glass fiber and glass fiber cotton according to the mass ratio of (1 to 4):1. Compared with the prior art, the air filter paper provided by the invention uses the ingredients with the specific consumption; good mutual actions are achieved between all ingredients; the prepared air filter paper has good high-temperature-resistant performance, low wind resistance and high mechanical intensity; harmful particles can be effectively blocked; meanwhile, the whole filtering efficiency is high; in addition, acid gas such as hydrogen sulfide and carbon dioxide in the air can be efficiently filtered.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com