Patents

Literature

38 results about "Atkinson cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Atkinson-cycle engine is a type of internal combustion engine invented by James Atkinson in 1882. The Atkinson cycle is designed to provide efficiency at the expense of power density. A modern variation of this approach is used in some modern automobile engines. While originally seen exclusively in hybrid electric applications such as the earlier-generation Toyota Prius, later hybrids and some non-hybrid vehicles now feature engines with variable valve timing, which can run in the Atkinson cycle as a part-time operating regimen, giving good economy while running in Atkinson cycle, and conventional power density when running as a conventional, Otto cycle engine.

Atkinson cycle powertrain

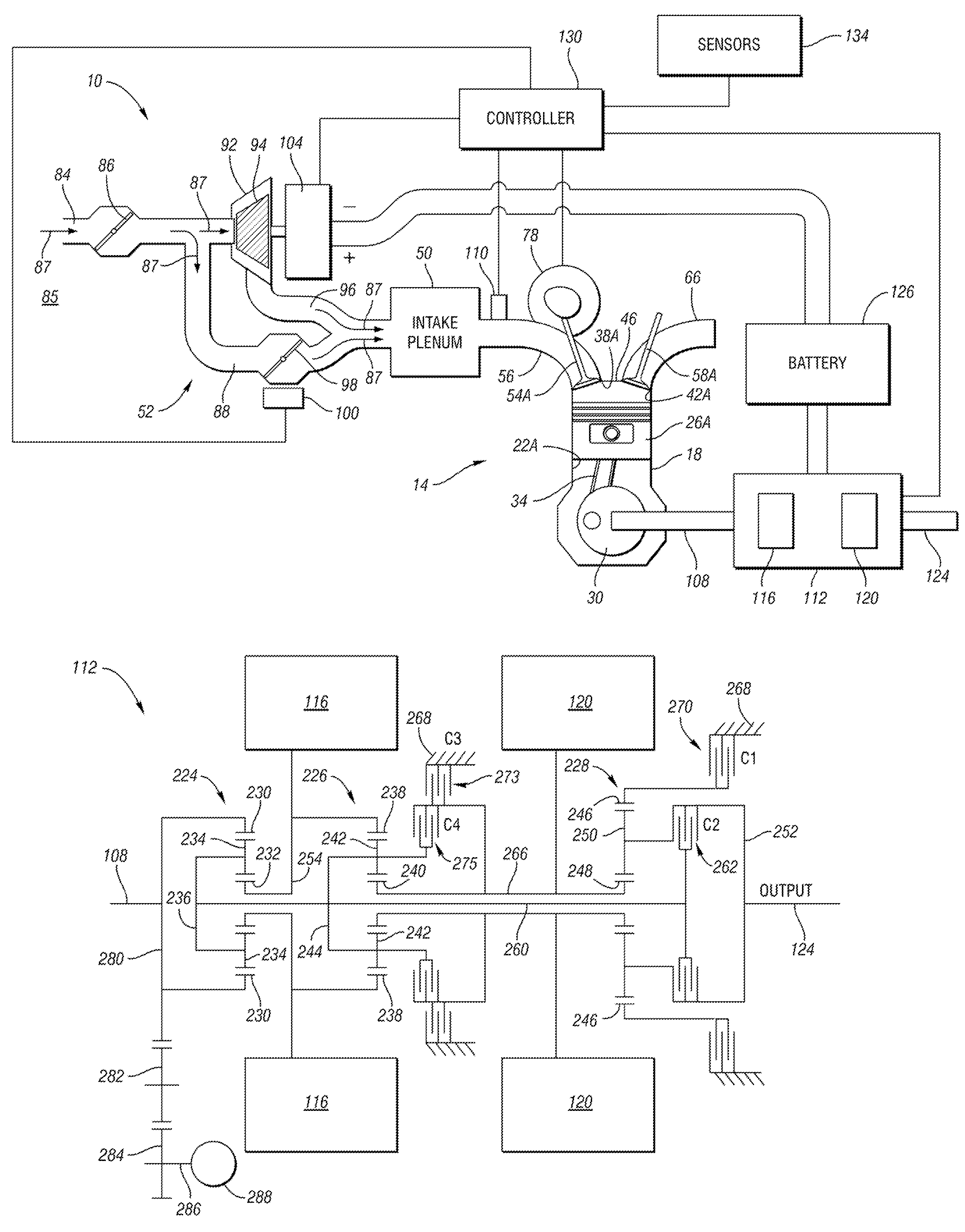

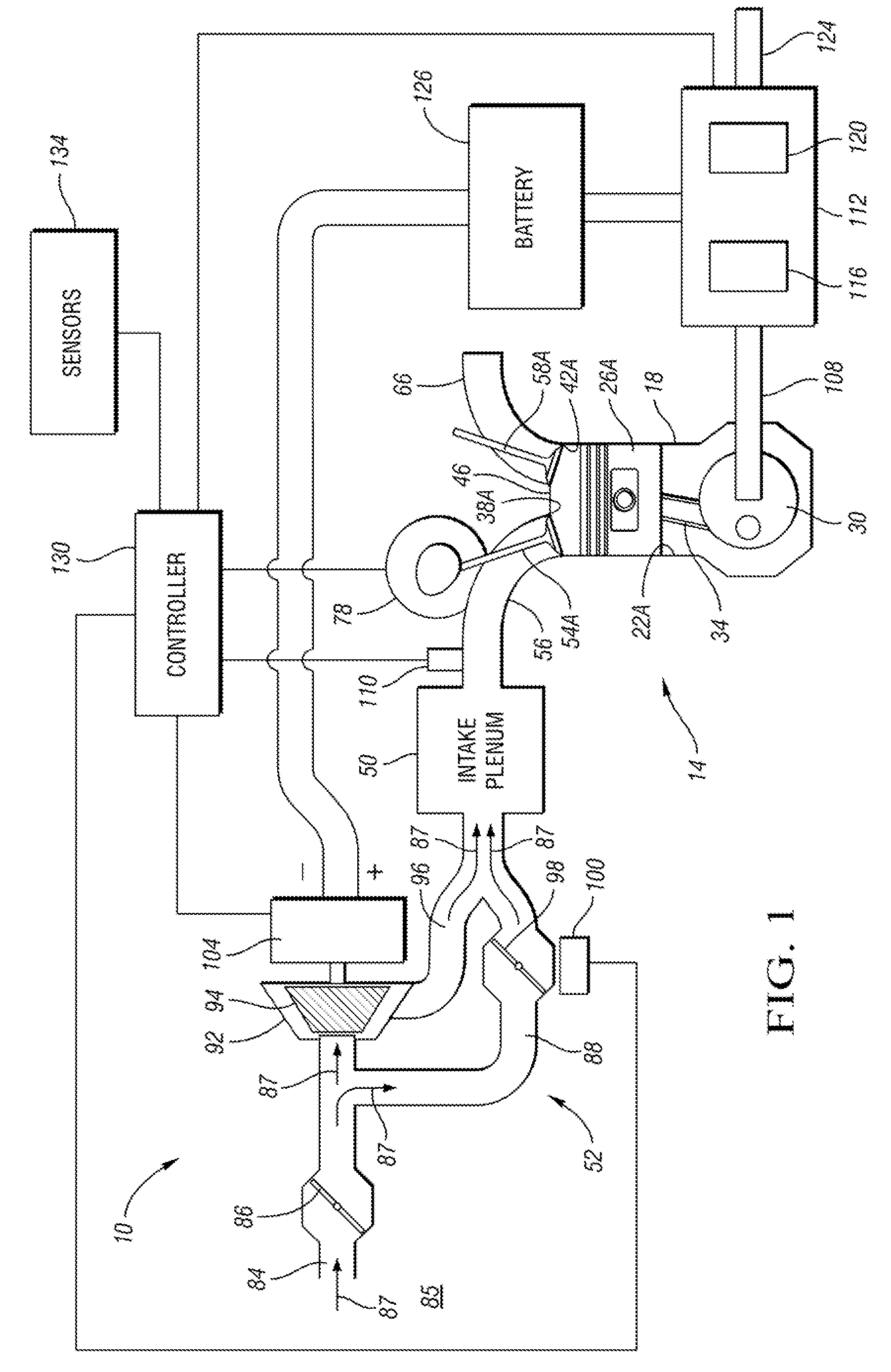

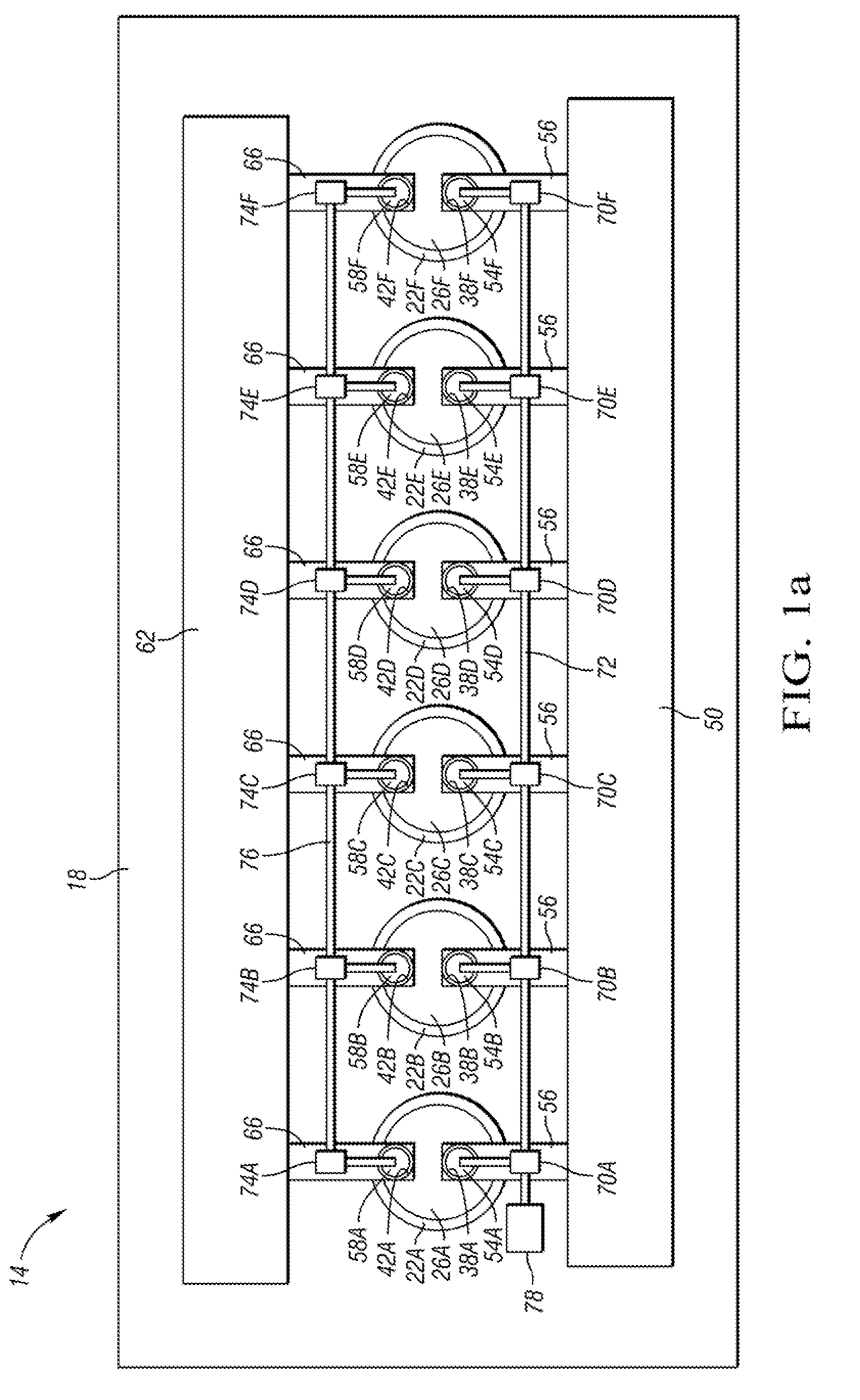

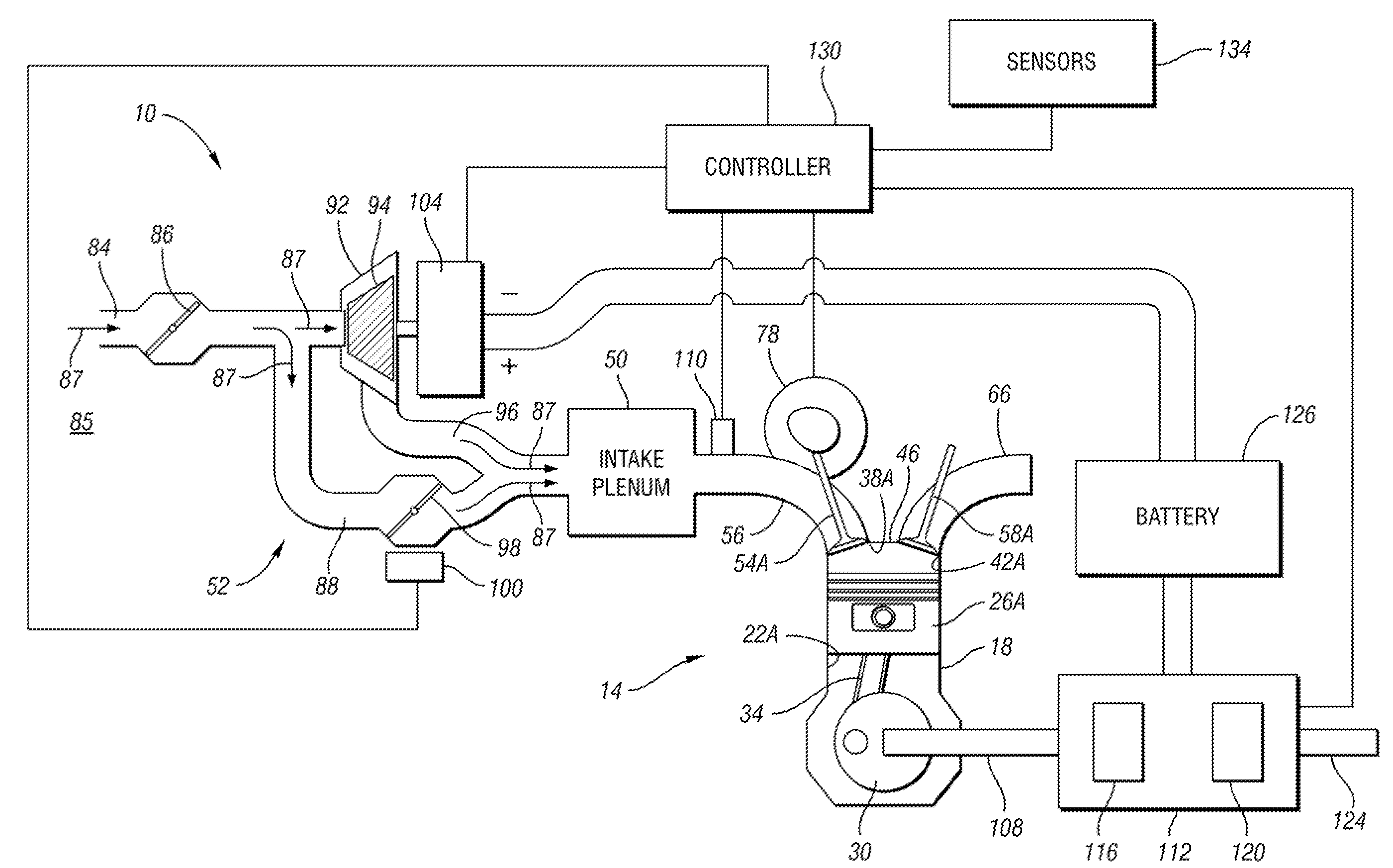

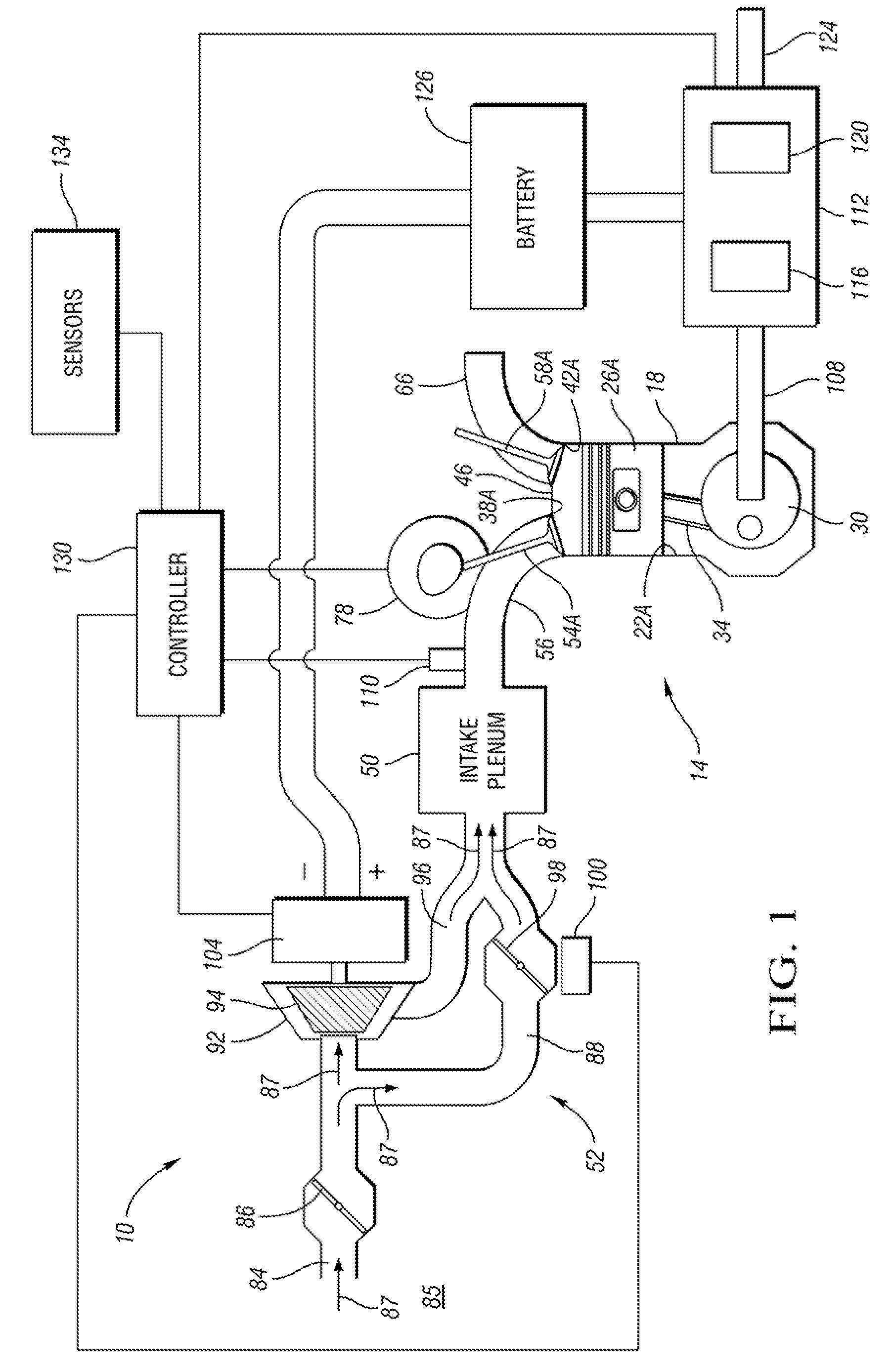

ActiveUS7765806B2Increased torque outputReduce power densityValve arrangementsInternal combustion piston enginesAtmospheric airAtkinson cycle

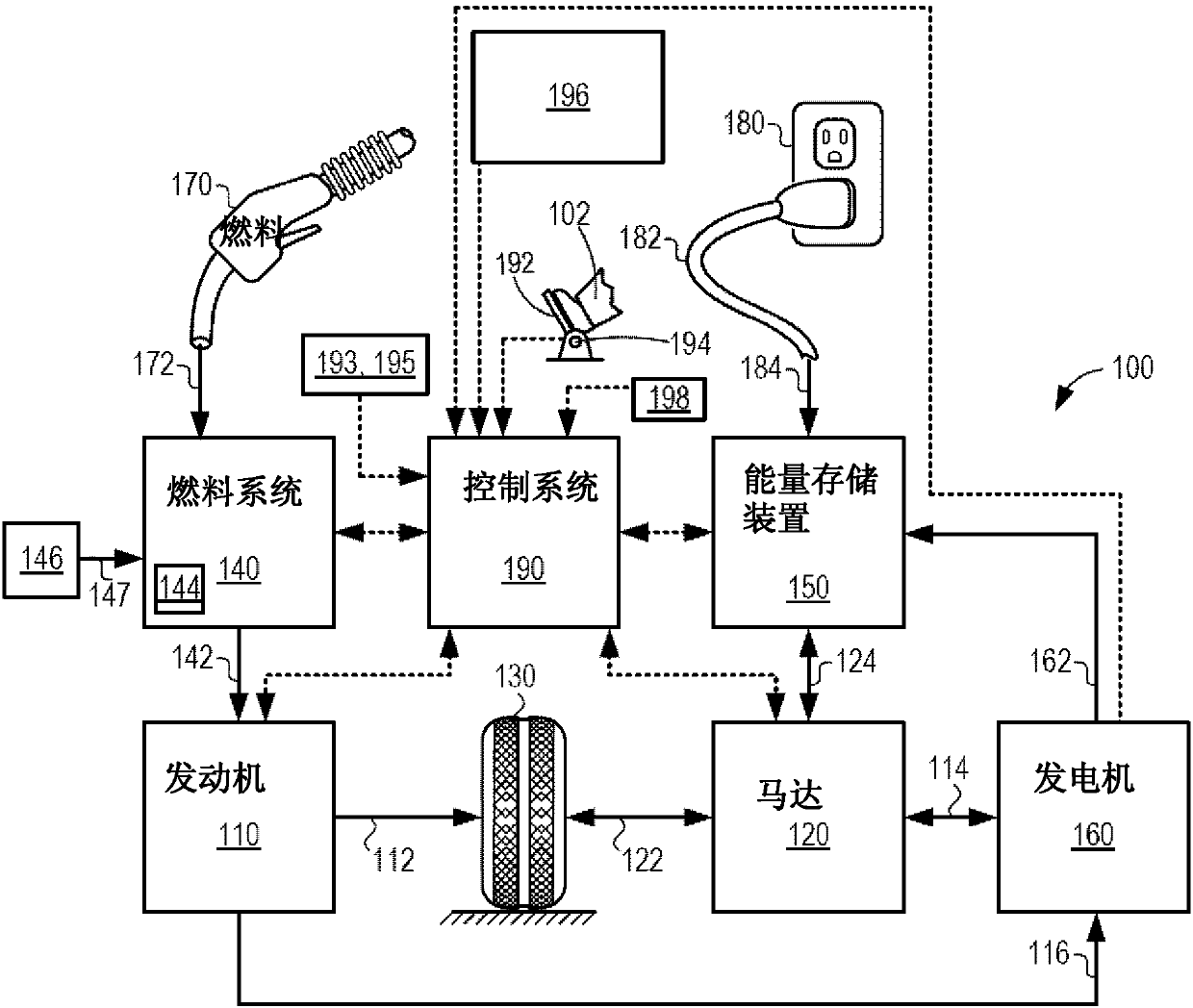

A powertrain includes an Atkinson cycle engine having at least one cylinder, a crankshaft, and an air intake system that provides selective fluid communication between the at least one cylinder and the atmosphere. A motor is in hybrid combination with the engine, and a compressor is configured to selectively pressurize air in the air intake system. The powertrain provides the fuel efficiency of an Atkinson cycle engine while compensating for the reduced torque output of an Atkinson cycle engine.

Owner:GM GLOBAL TECH OPERATIONS LLC

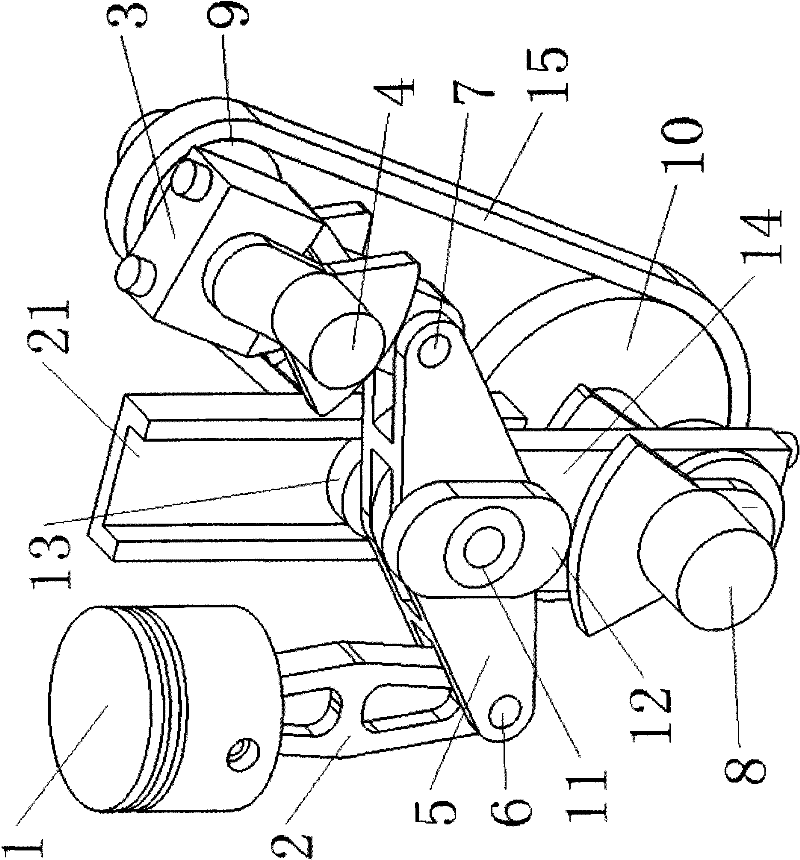

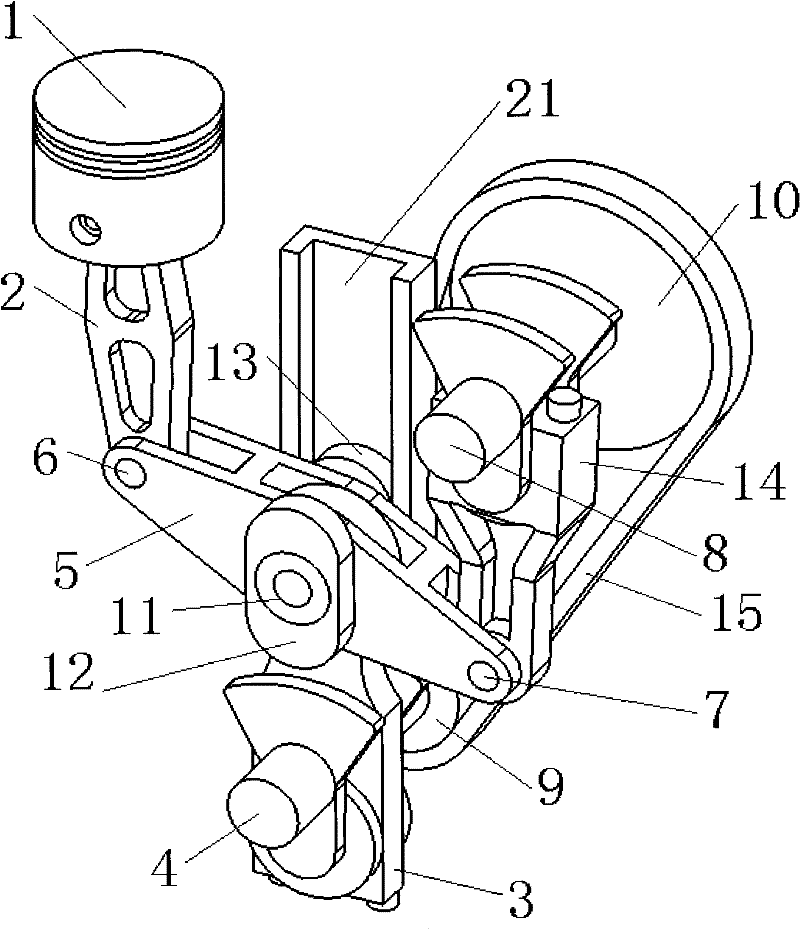

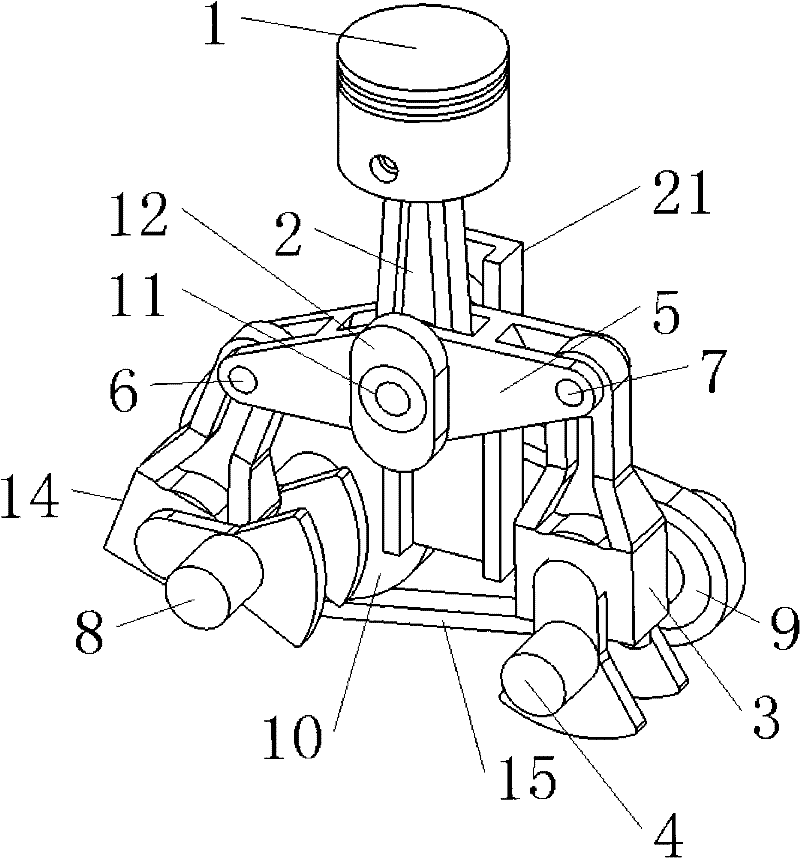

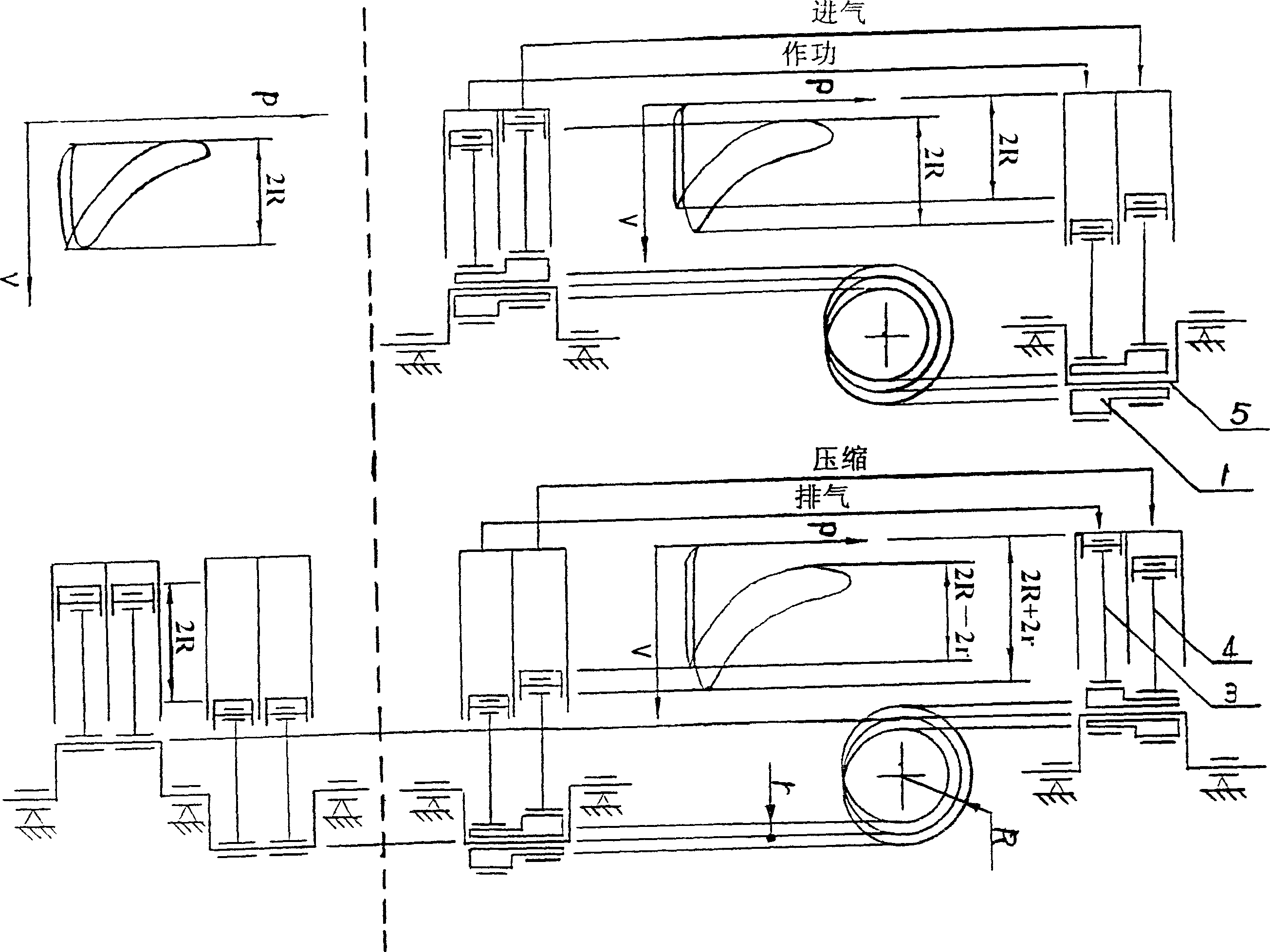

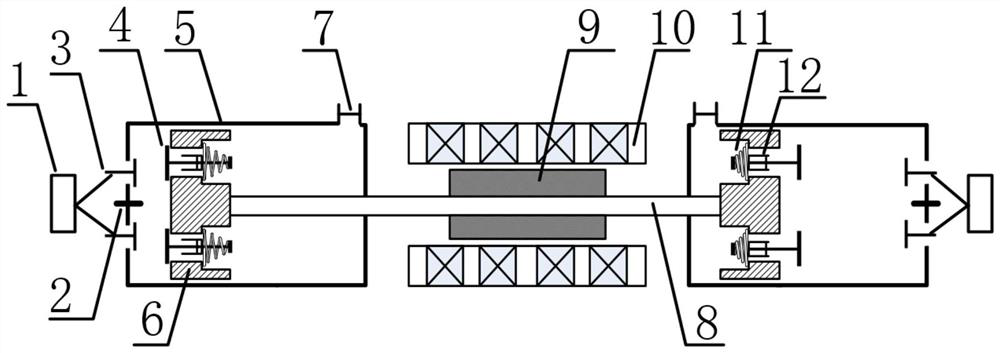

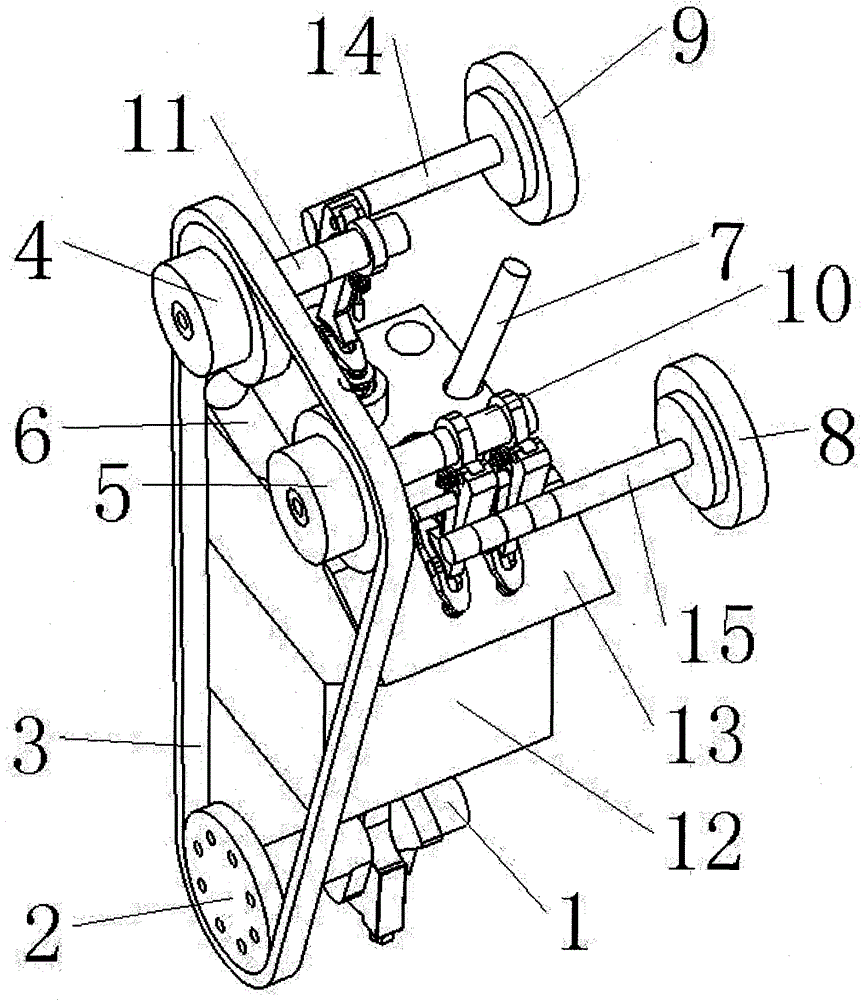

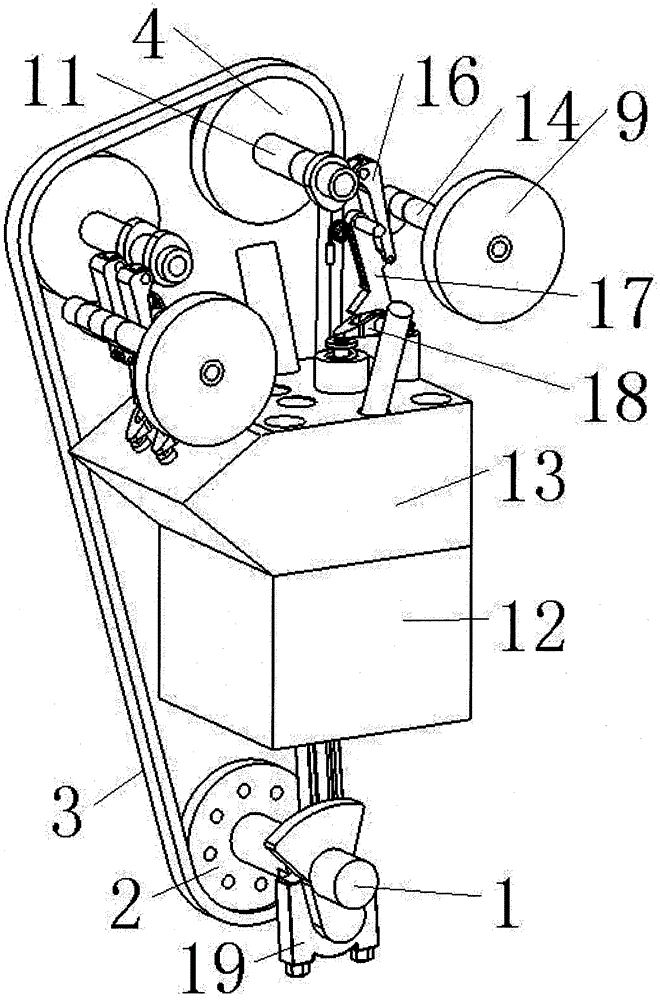

Double-crankshaft-contained variable-compression-ratio Atkinson-cycle internal-combustion engine mechanism

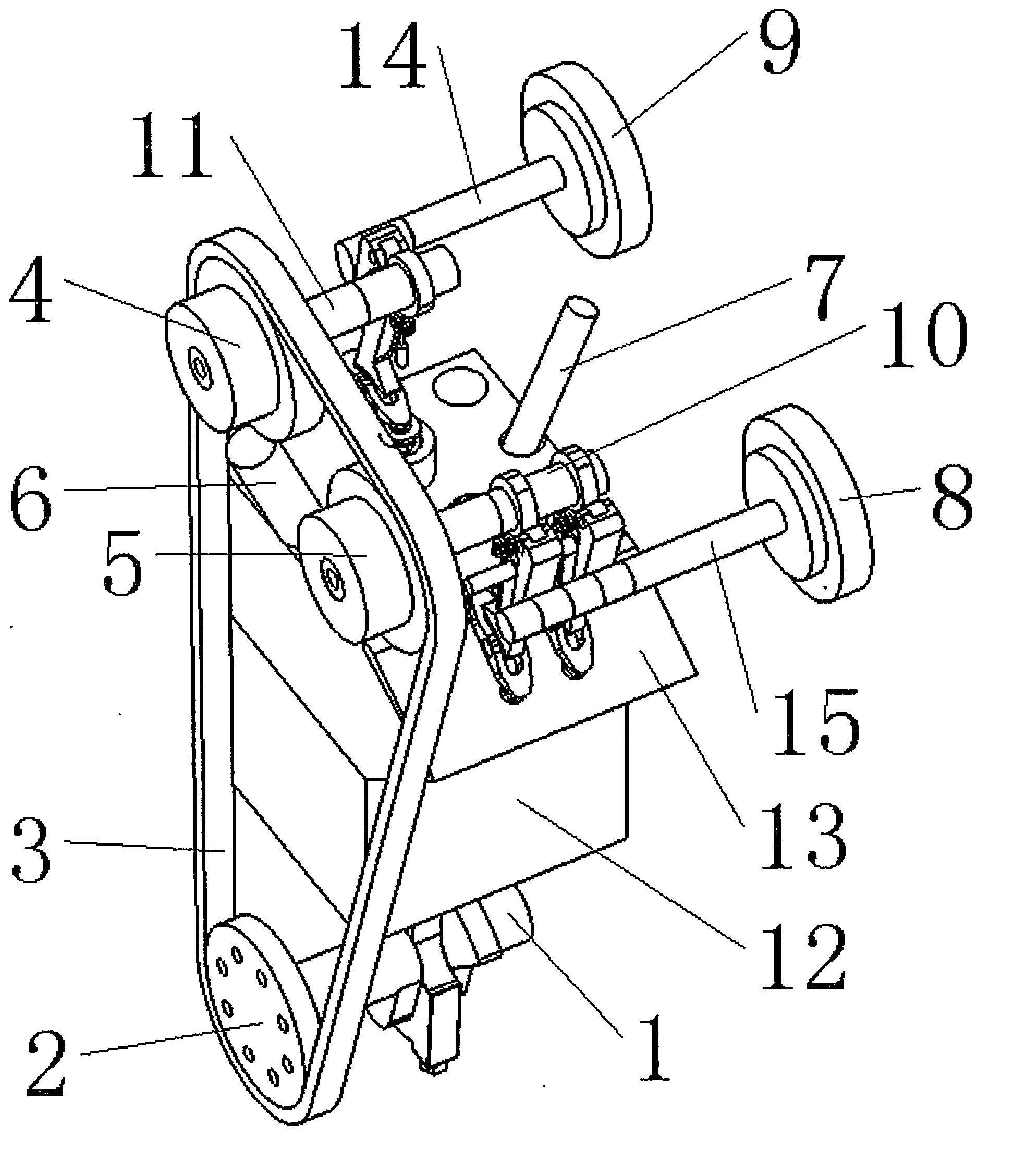

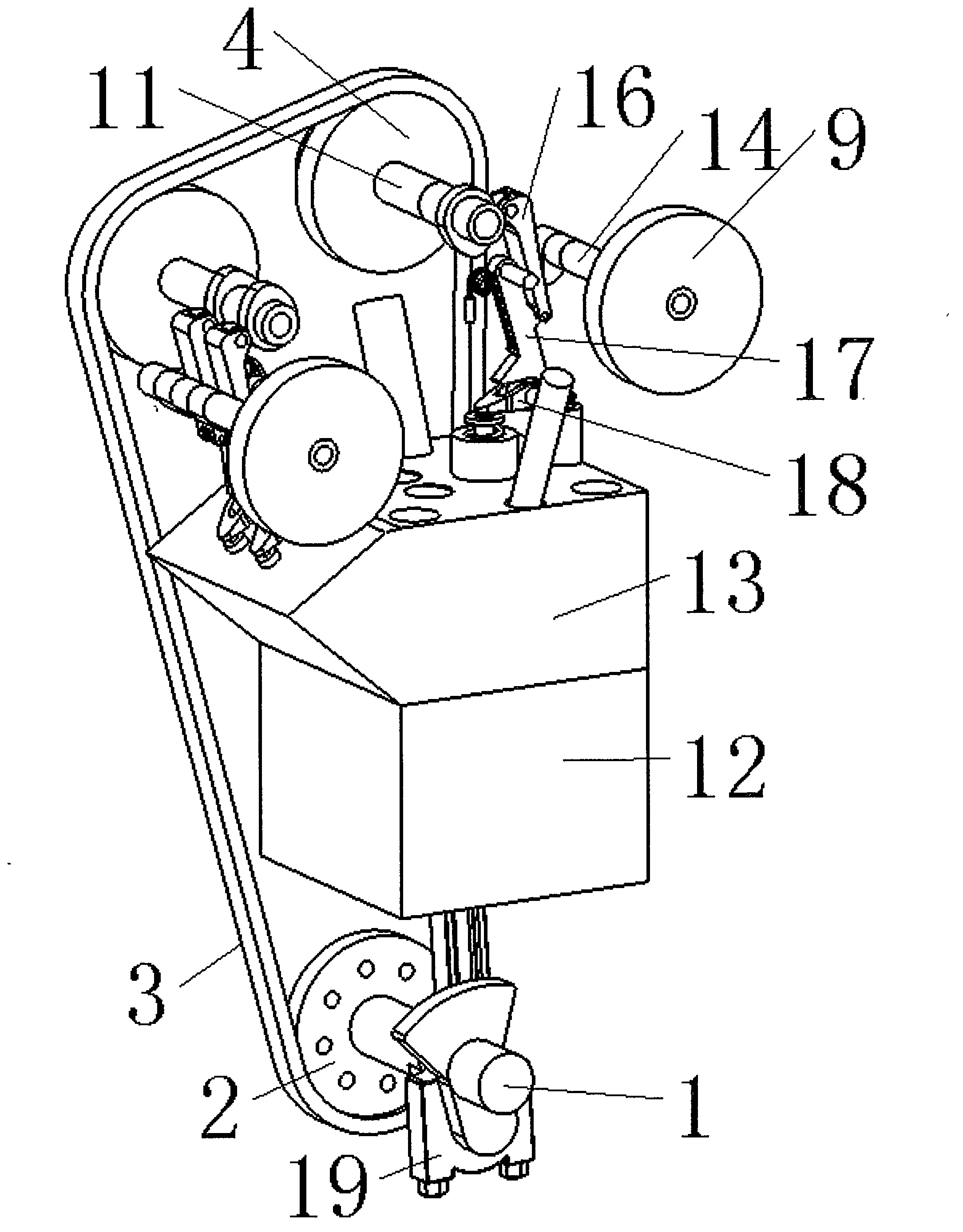

The invention discloses a double-crankshaft-contained variable-compression-ratio Atkinson-cycle internal-combustion engine mechanism, which is an internal-combustion engine technology and is used for improving the usability of an Atkinson-cycle internal-combustion engine and improving the thermal efficiency of the internal-combustion engine to enable the thermal efficiency to be approximate to the highest theoretical efficiency of a Carnot cycle. The mechanism comprises a rocking arm, a second crankshaft, a connecting rod of the second crankshaft, a driving chain, a phase regulator and a derived three-crankshaft Atkinson internal-combustion engine mechanism, wherein the rocking arm is used for connecting a piston connecting rod and a connecting rod of a first crankshaft; the second crankshaft and the connecting rod of the second crankshaft are used for driving the rocking arm to make periodic motion; the driving chain is used for connecting gears on the first crankshaft and the second crankshaft; the gear ratio of the gear for the first crankshaft to the gear for the second crankshaft is 1:2; and the phase regulator is used for regulating the rotary phase relation between the first crankshaft and the second crankshaft. Through the double-crankshaft-contained variable-compression-ratio Atkinson-cycle internal-combustion engine mechanism, the fuel efficiency of a naturally-aspirated internal-combustion engine can be effectively improved, and meanwhile, the double-crankshaft-contained variable-compression-ratio Atkinson-cycle internal-combustion engine mechanism has the actions of additionally regulating the compression ratio and changing the discharging quantity within a small range.

Owner:朱譞晟

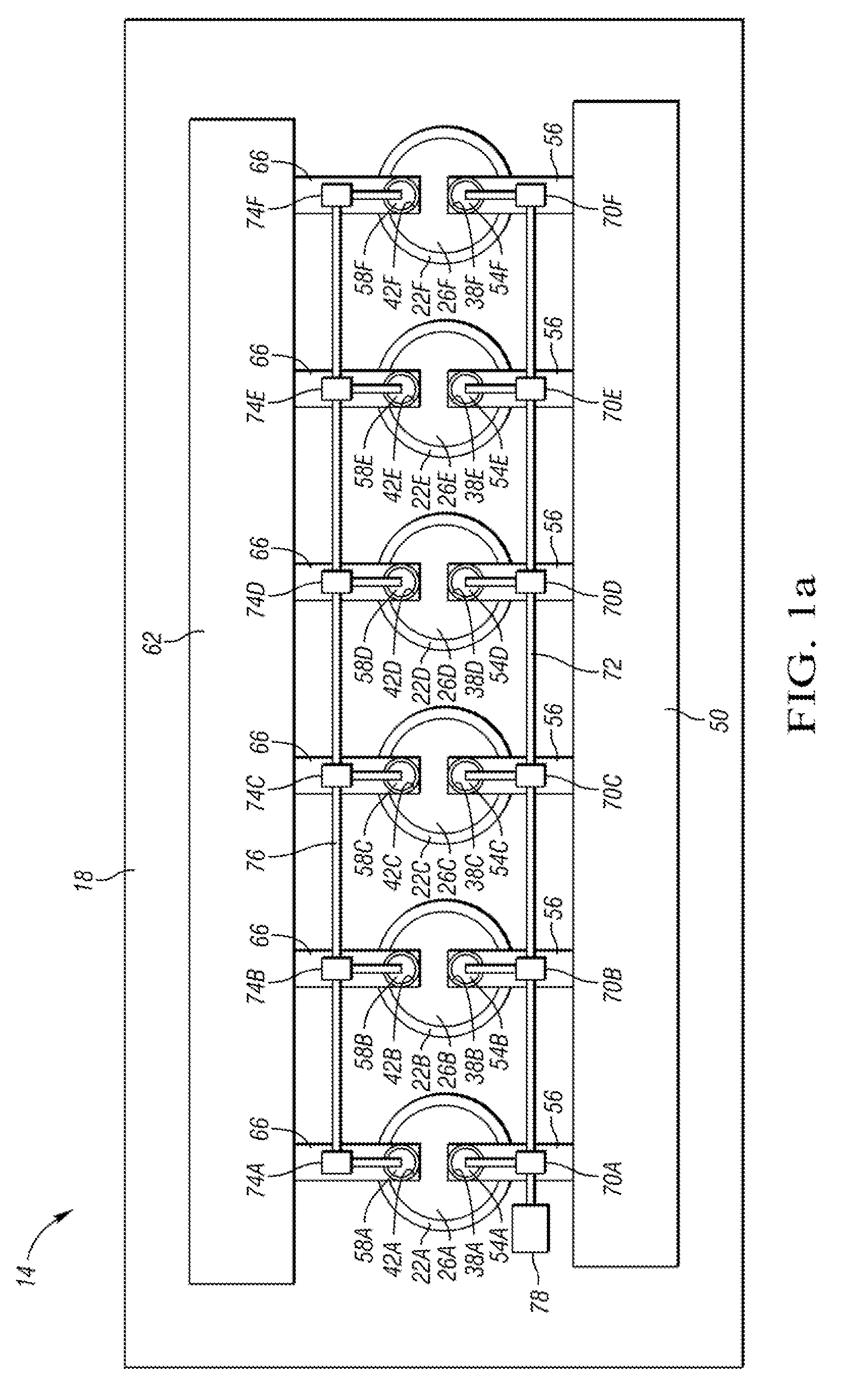

Atkinson Cycle Powertrain

ActiveUS20080041323A1Increased torque outputReduce power densityValve arrangementsInternal combustion piston enginesAtmospheric airFuel efficiency

A powertrain includes an Atkinson cycle engine having at least one cylinder, a crankshaft, and an air intake system that provides selective fluid communication between the at least one cylinder and the atmosphere. A motor is in hybrid combination with the engine, and a compressor is configured to selectively pressurize air in the air intake system. The powertrain provides the fuel efficiency of an Atkinson cycle engine while compensating for the reduced torque output of an Atkinson cycle engine.

Owner:GM GLOBAL TECH OPERATIONS LLC

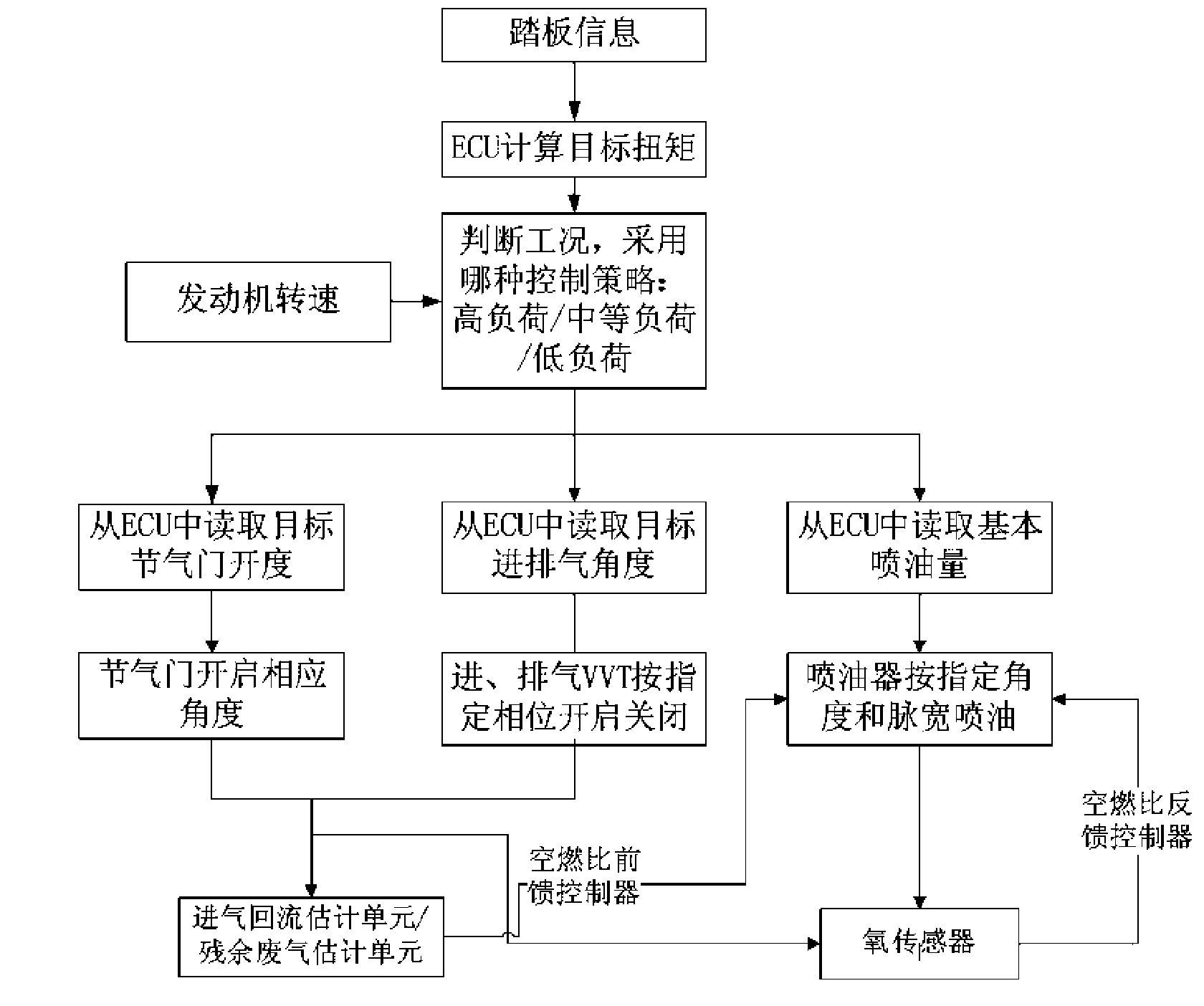

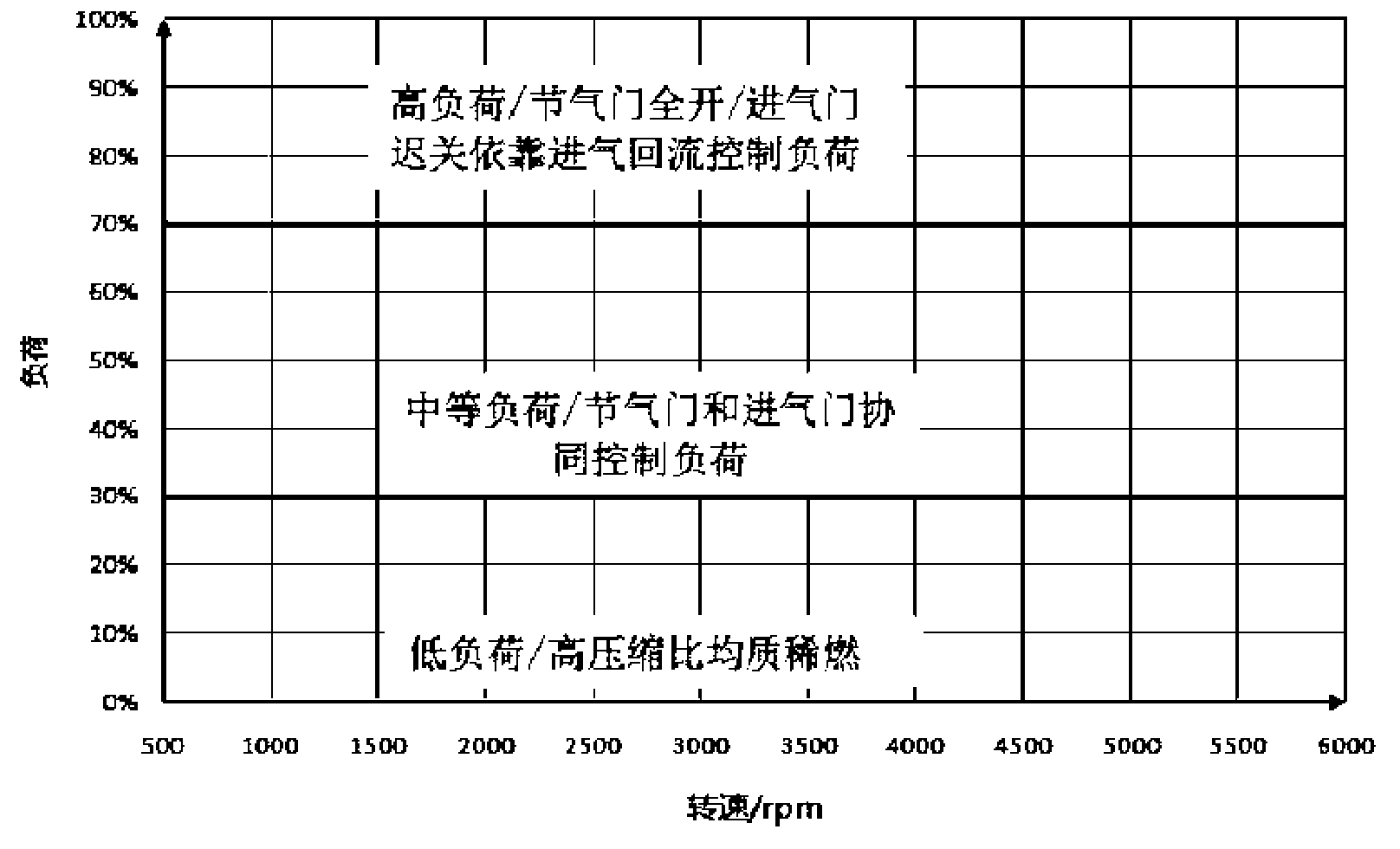

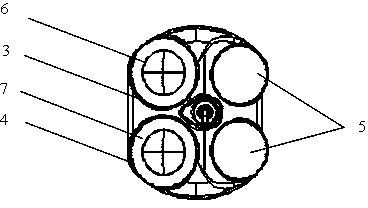

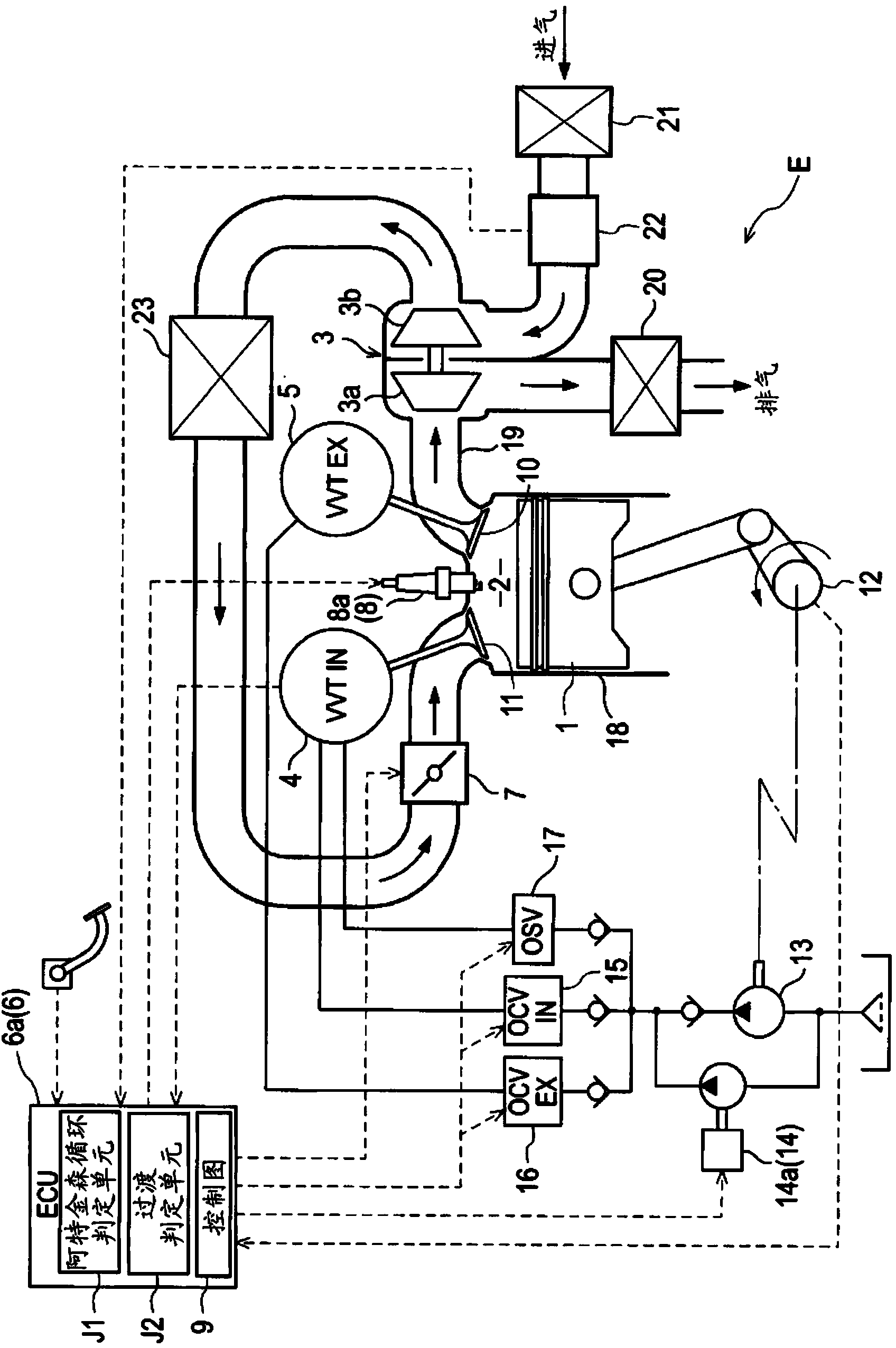

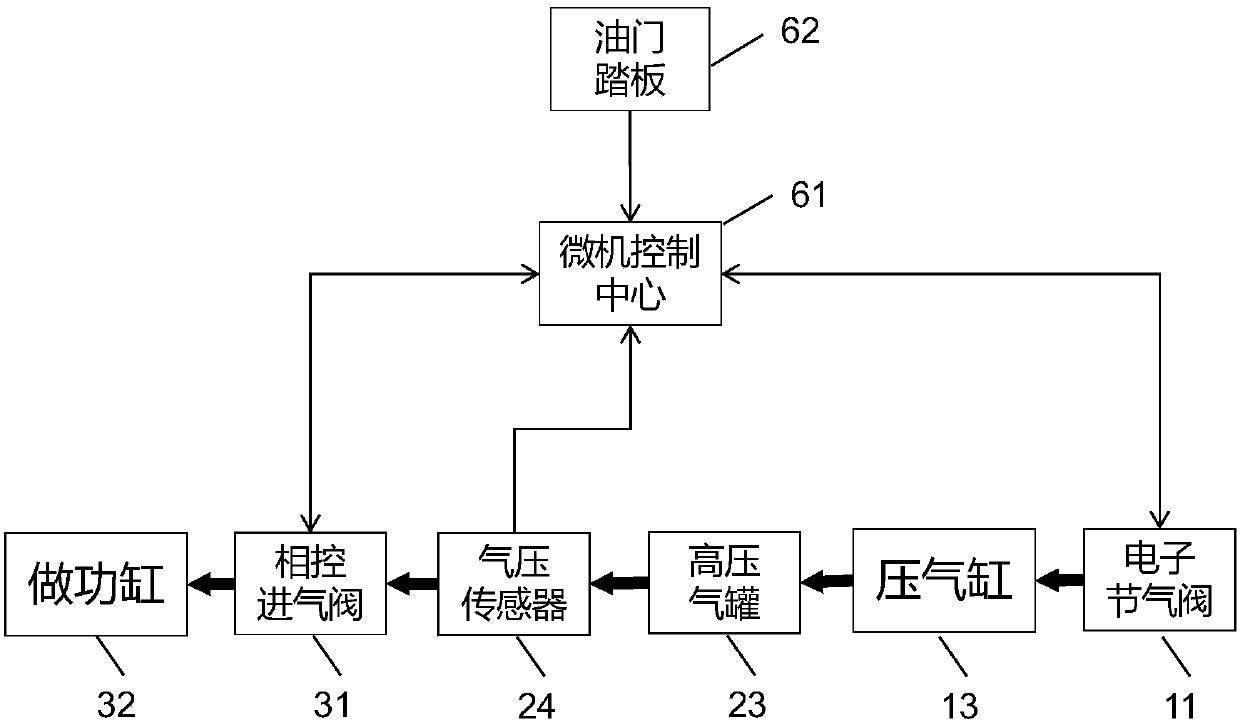

Atkinson cycle engine control system and control method thereof

InactiveCN101787933AReduce lossesReduce cycle variationElectrical controlInternal combustion piston enginesInlet valveAtkinson cycle

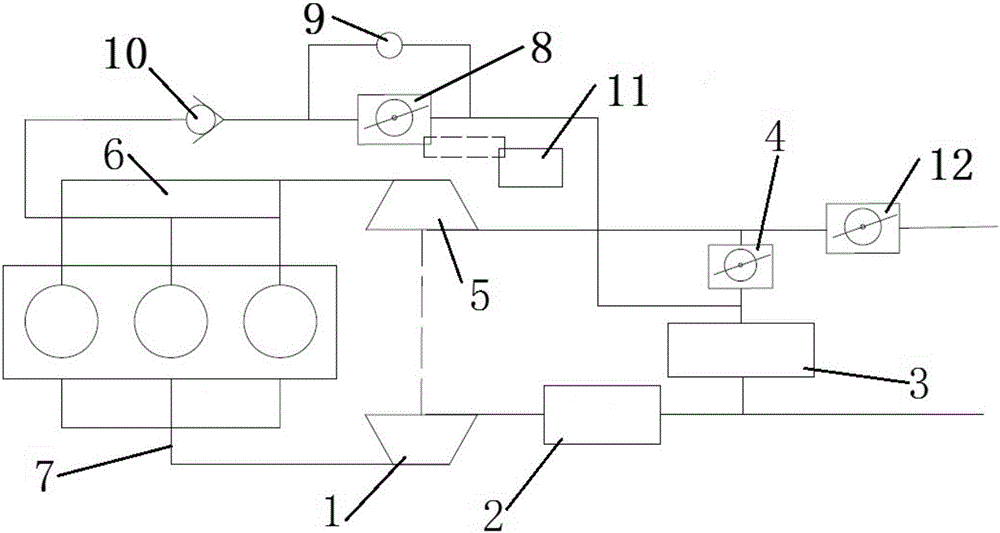

The invention relates to an Atkinson cycle engine control system belonging to the technical field of automobile engines and comprising a sensor system, a control executing mechanism and an engine control unit, wherein the sensor system is used for inputting the collected signals to the engine control unit, and the engine control unit is used for outputting a control instruction comprising a control throttle valve, an oil atomizer, a variable air inflow and exhaust correct timing device and a spark plug to the control executing mechanism. The invention can accurately control the air-fuel ratioof an Atkinson cycle engine and improve the economy and the exhaustion of the Atkinson cycle engine, adopts greatly higher geometrical compression ratio than that of the general gasoline engine so the opening of an intake valve is enlarged under low load, controls the oil atomizing amount and the ignition advance angle and controls the air-fuel ratio in the range of 16-19 so that thin combustion is formed, and therefore, the Atkinson cycle engine has improved combustion efficiency and more stable combustion.

Owner:SHANGHAI JIAO TONG UNIV

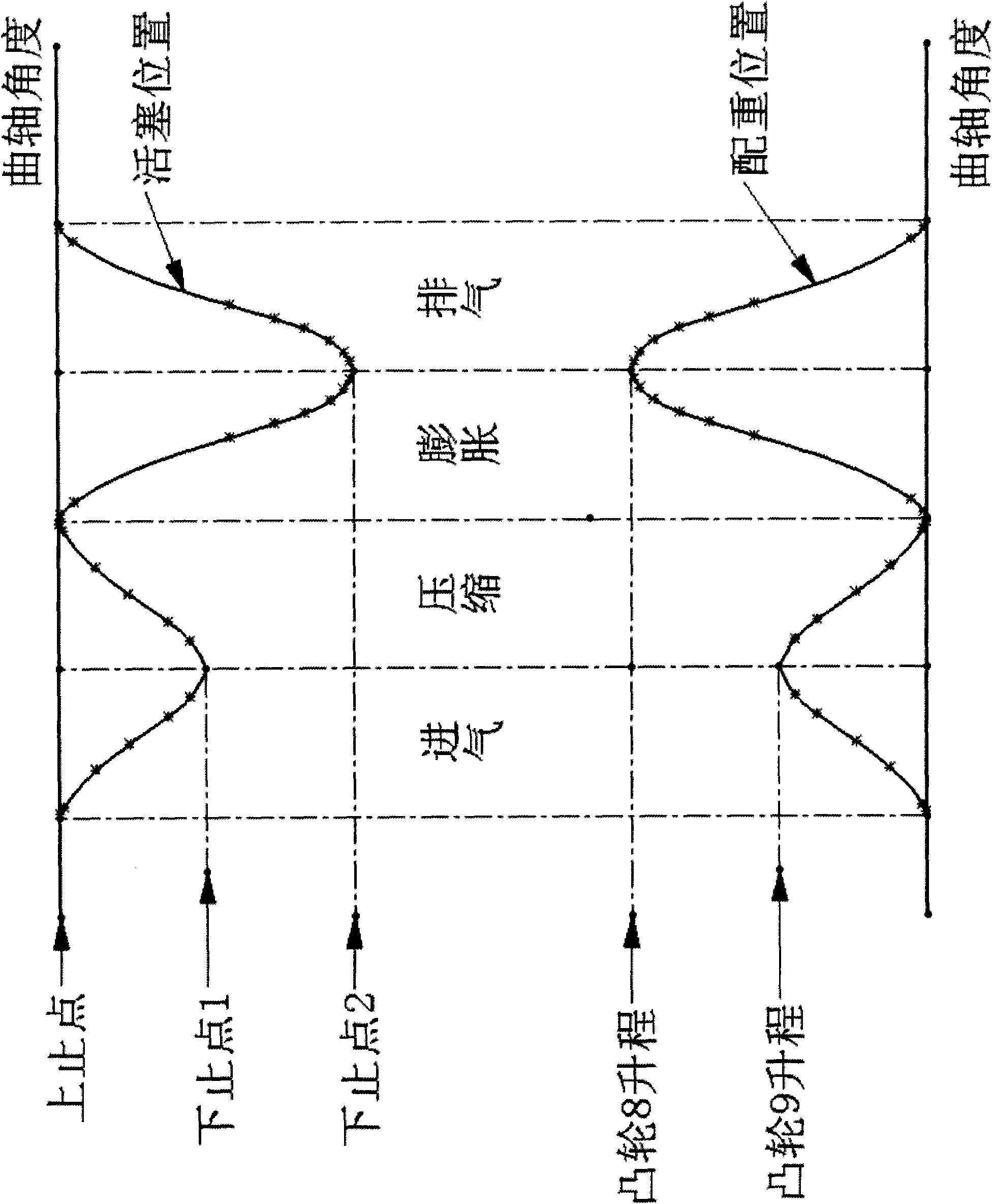

Multi-mode two-stroke atkinson cycle internal-combustion engine with fully overhead valve

InactiveCN103233789AValve arrangementsInternal combustion piston enginesExhaust valveVariable valve timing

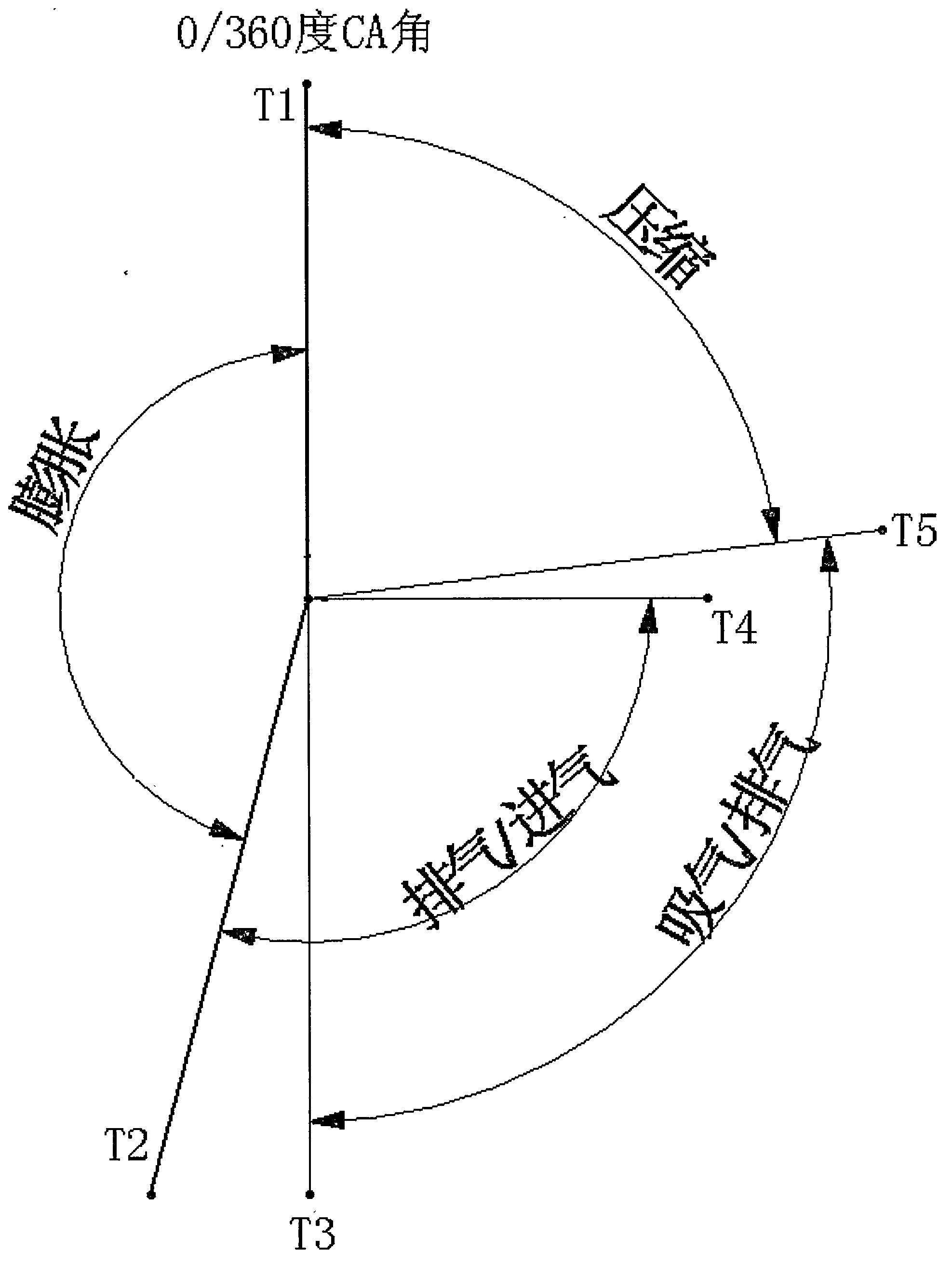

The invention discloses a multi-mode two-stroke atkinson cycle internal-combustion engine with a fully overhead valve. According to two-stroke atkinson cycle, a scavenging process is offset on the basis of the two-stroke cycle, the distance of a compression stroke is reduced, and the distance of an expansion stroke is prolonged, and therefore, the atkinson cycle is realized and the balance of the internal-combustion engine is kept. On the basis of a common two-stroke internal-combustion engine, the multi-mode two-stroke atkinson cycle internal-combustion engine adopts an overhead embedded inlet valve with large gradient degree and an air cylinder head structure of a common exhaust valve, when the inlet valve is opened, the inlet valve temporarily serves as a separation board, a guiding function of a bulge on a formed top piston is utilized, so that a high-efficiency scavenging structure is realized; a fully variable valve timing mechanism is used to adjust the angle relation of the valve and a crank shaft, the opening and closing time of the inlet and outlet valve can be adjusted, and therefore, the internal-combustion engine has the following working modes: two-stroke atkinson cycle, two-stroke cycle and adjustable discharge capacity and compression ratio; and the efficiency of the internal-combustion engine is greatly improved.

Owner:朱譞晟

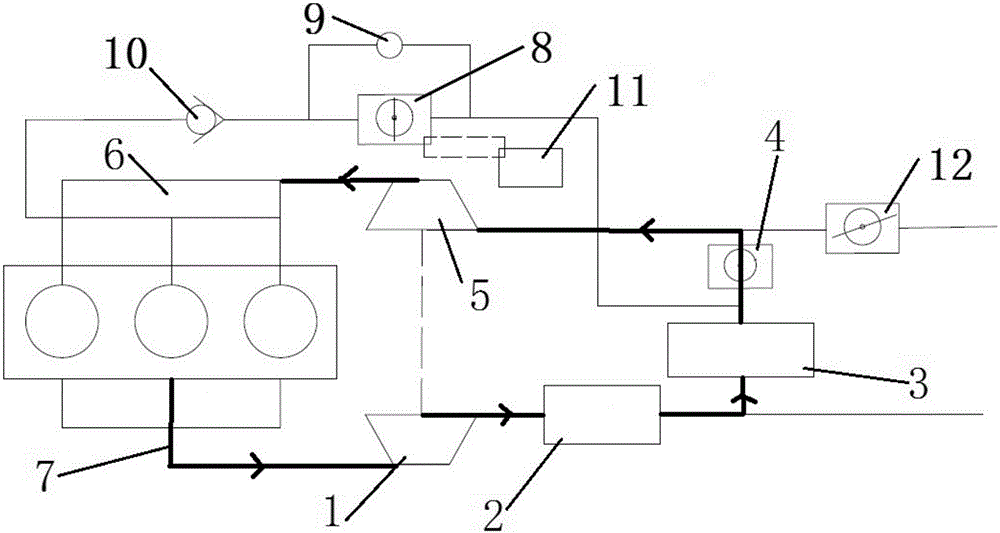

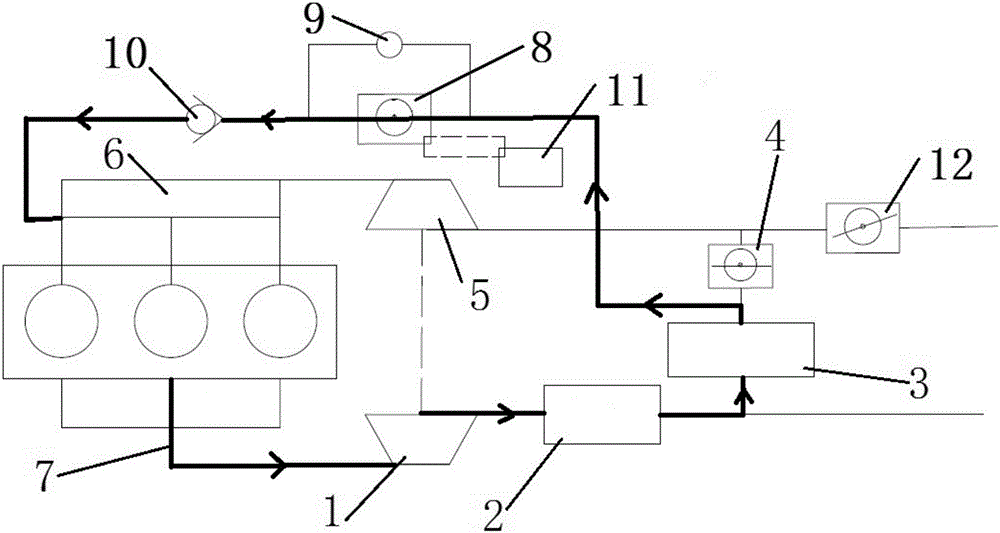

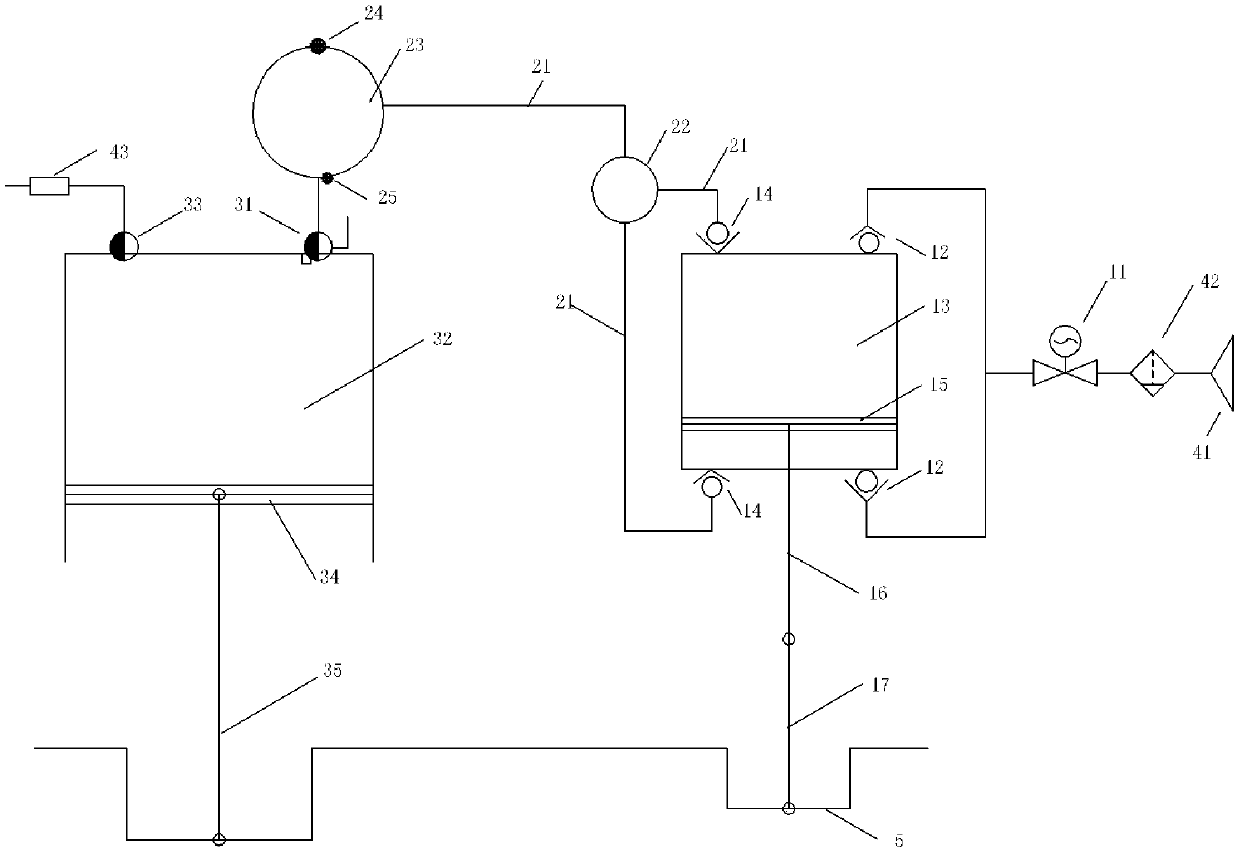

Low-pressure waste gas recirculating system based on supercharged engine

InactiveCN106762238AHigh recycling rateIncrease temperatureElectrical controlInternal combustion piston enginesProcess engineeringAtkinson cycle

The invention provides a low-pressure waste gas recirculating system based on a supercharged engine. The supercharged engine comprises a gas inlet side and a gas compressor arranged on the gas inlet side. The low-pressure waste gas recirculating system comprises a waste gas recirculating loop, an auxiliary waste gas recirculating loop and a controller; the waste gas recirculating loop is used for introducing part of waste gas exhausted out of a Miller and / or Atkinson circulating engine into the gas inlet side through the gas compressor for reburning; the auxiliary waste gas recirculating loop is used for introducing part of the waste gas exhausted out of the Miller and / or Atkinson circulating engine into the gas inlet side for reburning on the condition that the gas compressor is not used; the controller is used for controlling the waste gas to selectively flow through the waste gas recirculating loop and the auxiliary waste gas recirculating loop according to the vehicle driving speed. According to the low-pressure waste gas recirculating system based on the supercharged engine, part of the waste gas exhausted out of the engine can enter an air cylinder for reburning through the gas compressor or not through the gas compressor under the different conditions, therefore, the gas temperature in the air cylinder before stroke compressing and the gas temperature at the beginning of burning can be increased, then the engine efficiency is improved, and the waste gas recirculating rate is increased.

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD

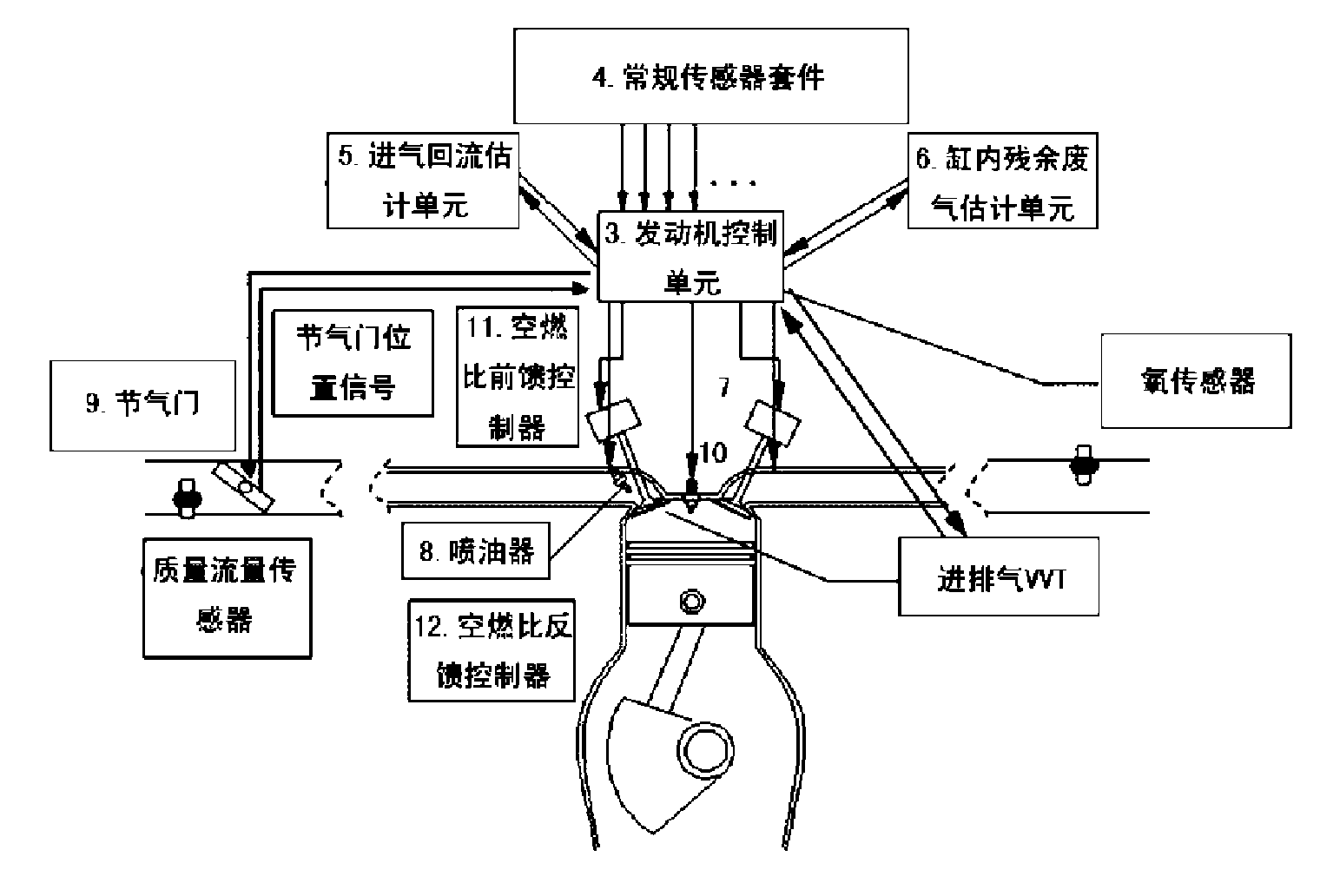

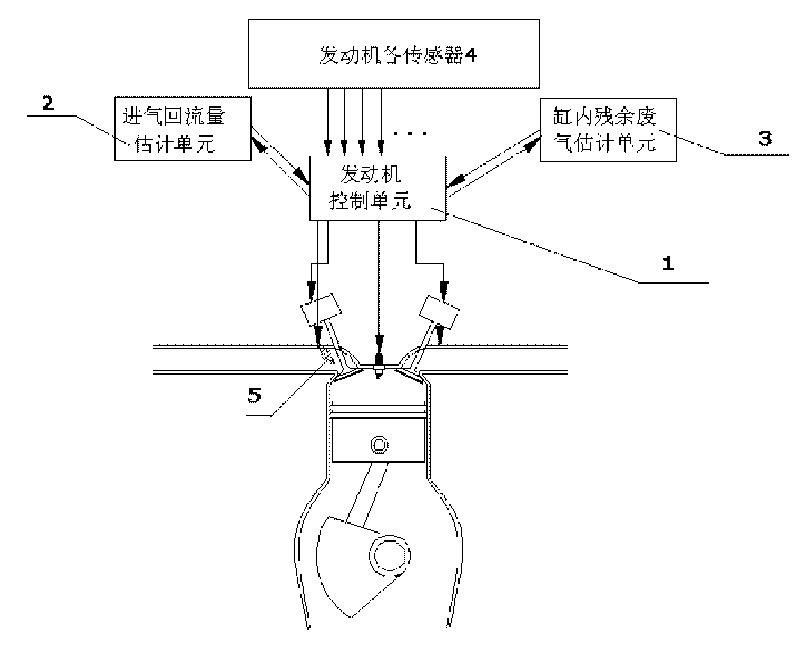

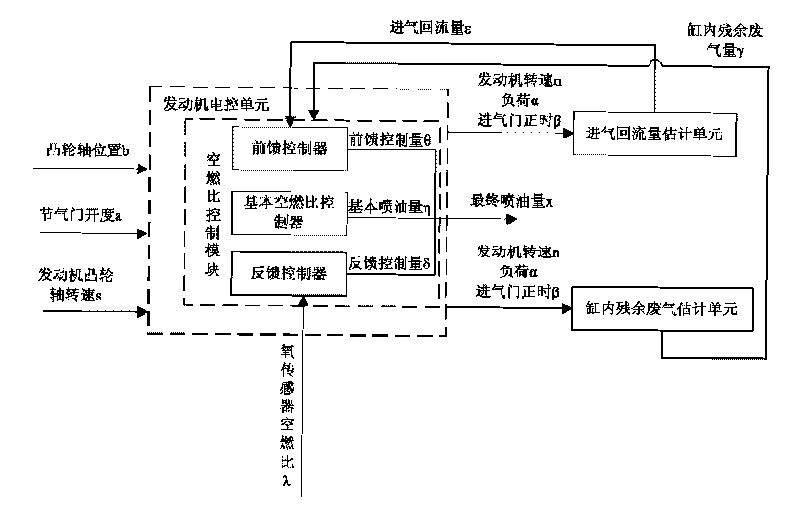

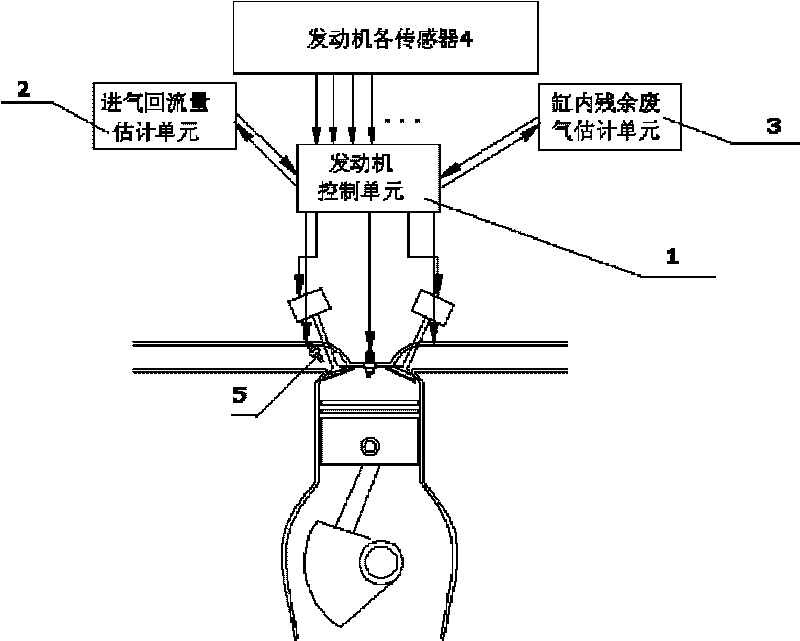

Atkinson cycle engine air-fuel ratio control system

InactiveCN101737187AAccurate estimateGuaranteed accuracyElectrical controlInternal combustion piston enginesArea networkElectric control

The invention relates to an Atkinson cycle engine air-fuel ratio control system in the technical field of automobile engines, which comprises an engine electric control unit, an inlet reflow estimation unit, a residual gas estimation unit, an engine rotating speed sensor, a throttle position sensor, a cam shaft position sensor, an oxygen sensor and a fuel sprayer, wherein the engine electric control unit, the inlet reflow estimation unit, the residual gas estimation unit and an engine air-fuel ratio feedforward controller are connected through a controller area network (CAN) bus; and the engine rotating speed sensor, the throttle position sensor and the cam shaft position sensor are connected with the engine electric control unit through a signal wire. The invention combines the air-fuel ratio feedforward control and the air-fuel ration feedback control, determines the fuel spraying amount in real time according to different inlet reflow amount and residual gas amount in a cylinder, improves the accuracy and the transient response characteristic of the air-fuel ratio control, and effectively improves the economy and the exhaust performance of the engine.

Owner:SHANGHAI JIAO TONG UNIV

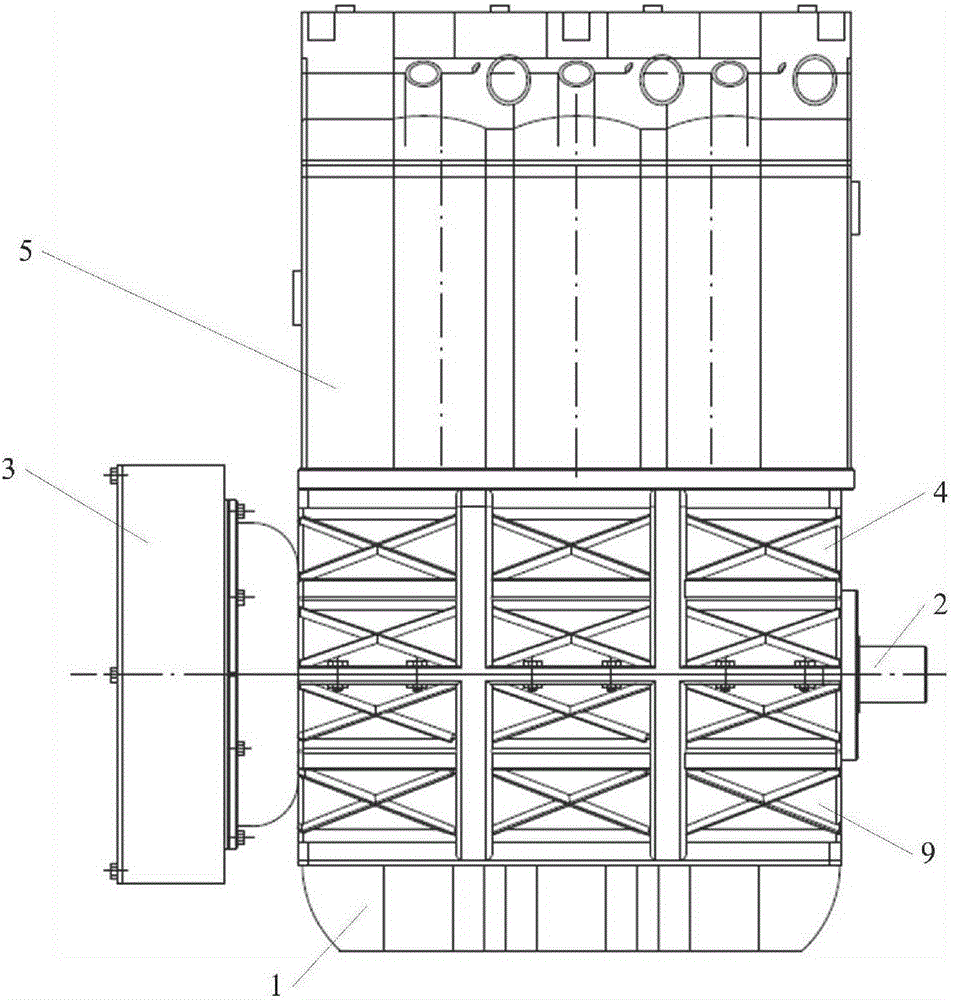

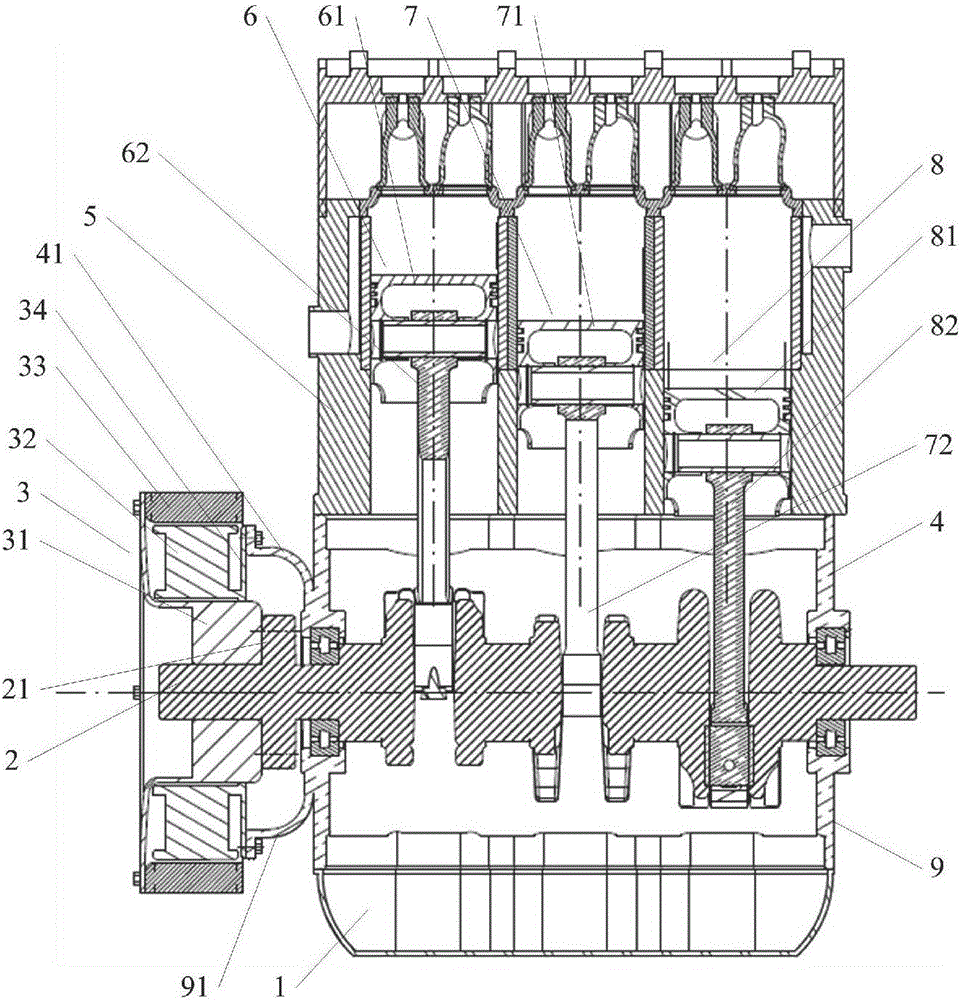

Power generation system of Atkinson cycle engine

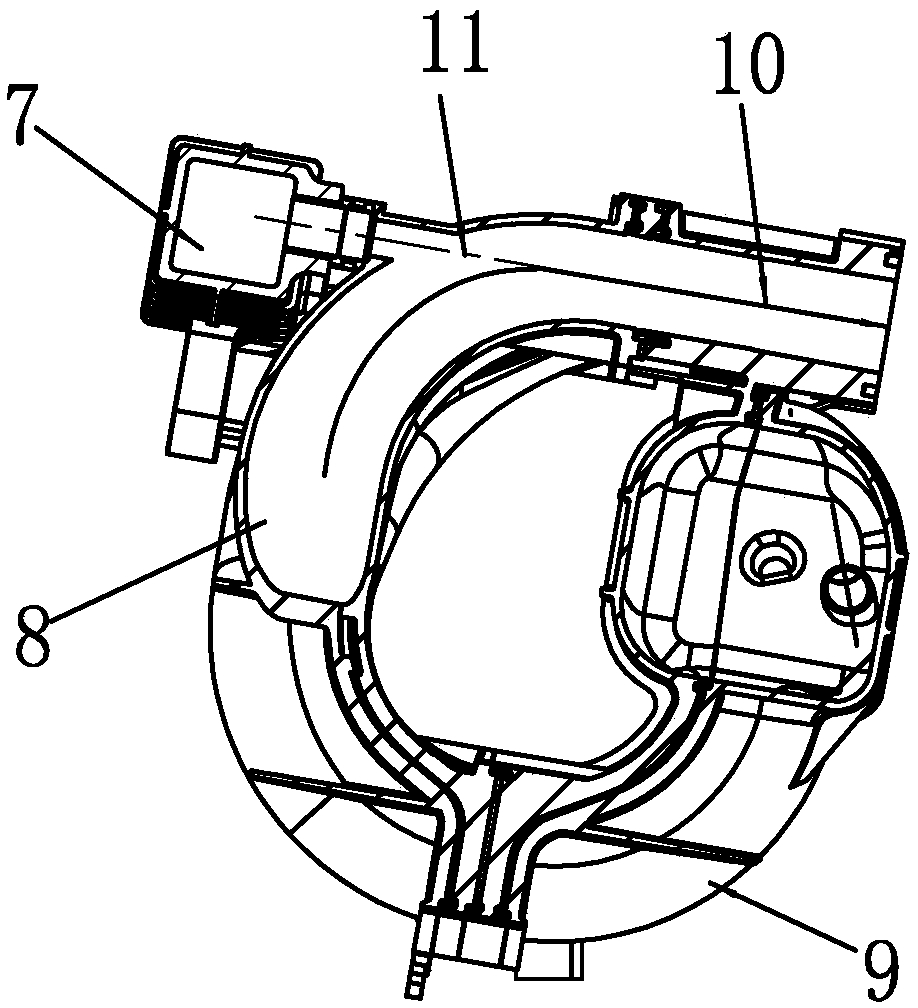

InactiveCN106787433AReduce weightReliable reboundMagnetic circuit rotating partsInternal combustion piston enginesAtkinson cycleEngineering

The invention provides a power generation system of an Atkinson cycle engine. The power generation system comprises the Atkinson cycle engine and an outer rotor generator, wherein the Atkinson cycle engine comprises an air cylinder body, an air cylinder cover connected with the air cylinder body, a piston connecting rod mechanism arranged in the air cylinder body and a crankshaft connected with the piston connecting rod mechanism; the outer rotor generator is directly connected with the crankshaft for power generation and comprises an inner stator, an outer rotor sleeving the inner stator and an outer rotor bracket for supporting the outer rotor; the inner stator is fixedly connected with the air cylinder body; the outer rotor is fixedly arranged on the circumference of the outer rotor bracket; and the center of the outer rotor bracket is directly connected with an output end of the crankshaft. The outer rotor of the outer rotor generator is directly connected with the crankshaft of the Atkinson cycle engine, so that heavy flywheels used by a traditional engine are omitted; the outer rotor in the whole system acts as the outer rotor of the generator, simultaneously acts as an energy storage component of the engine, has double effects and plays a role in reducing the weight of the power generation system; and meanwhile, the number of spare parts is also reduced.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

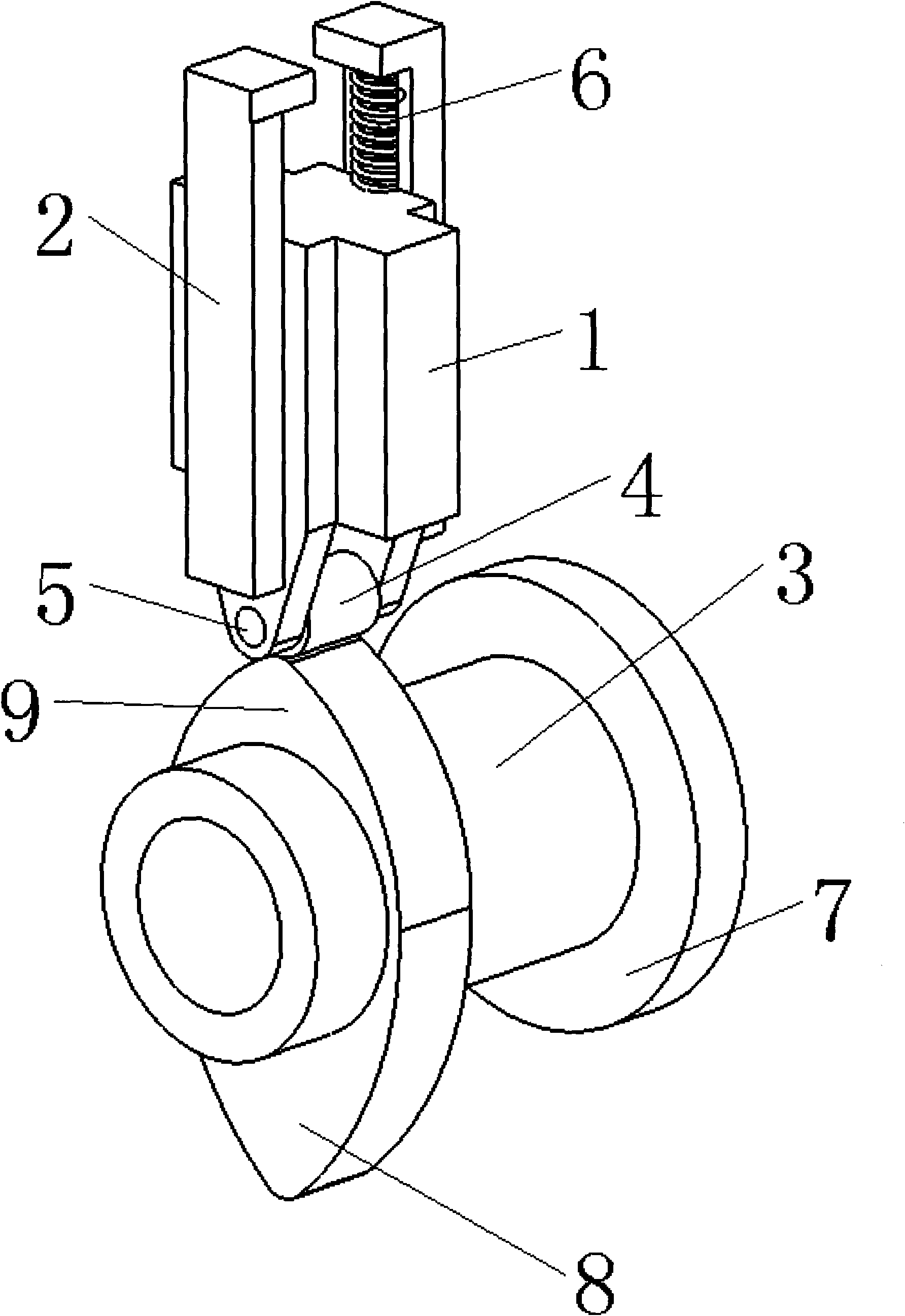

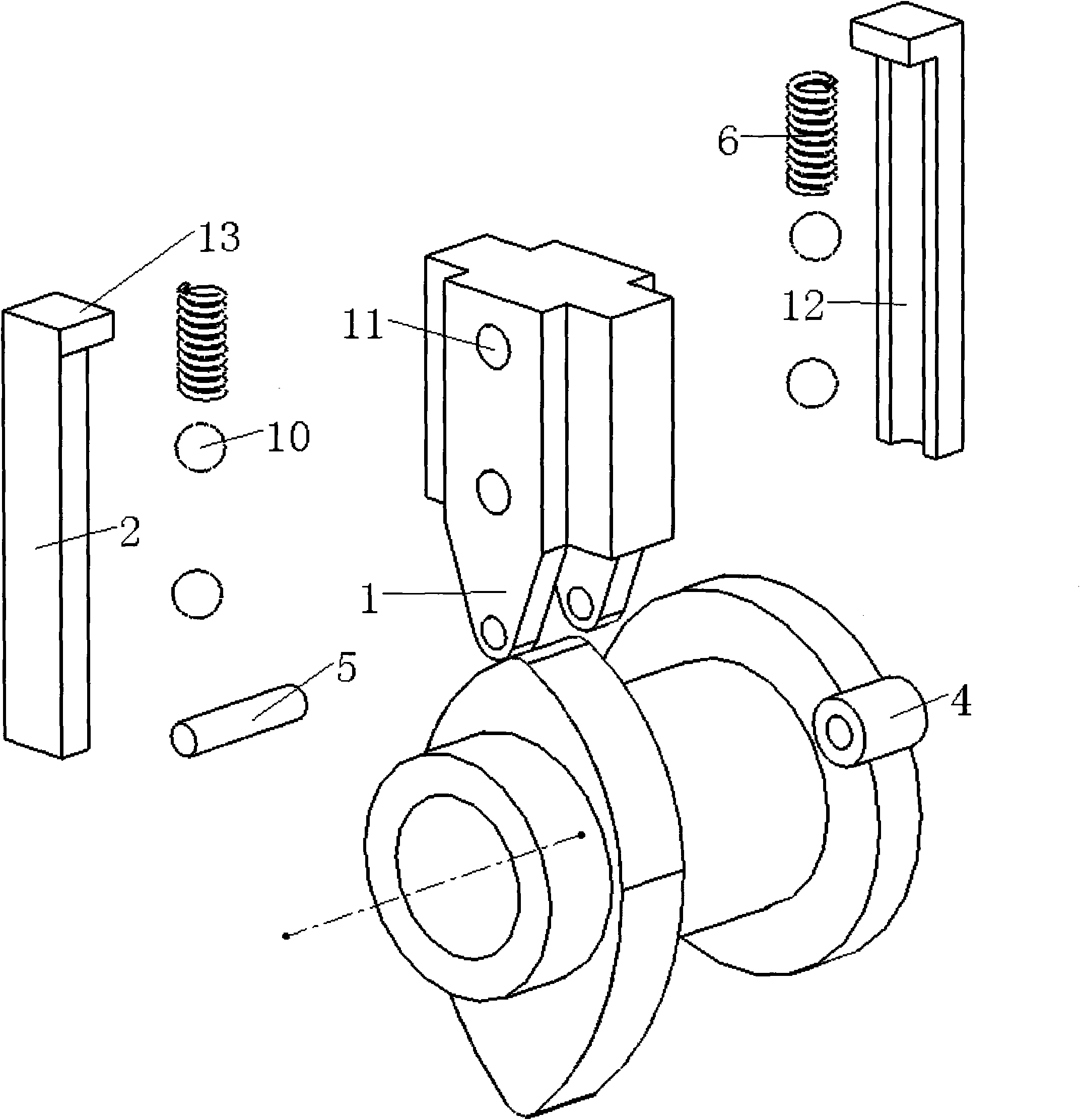

Balance device of internal combustion engine

InactiveCN102606675AVibration balanceInertia force compensationInternal combustion piston enginesVibration amplitudeDynamic balance

The invention discloses a balance device of an internal combustion engine, which relates to balance technology of a reciprocating piston internal combustion engine. The ride comfort of an existing internal combustion engine, particularly a line four-cylinder internal combustion engine, is much poorer than that of a V-type internal combustion engine due to the fact that a quadratic term portion of vibration of movement of a piston of the existing internal combustion engine cannot be balanced. The balance device is characterized in that a counterweight with a certain mass is driven by a reciprocating control device to reciprocate, accordingly, more complicated vibration can be balanced, each cylinder of the internal combustion engine can be independently and dynamically balanced, fuel economy is improved, and Atkinson cycle internal combustion engine which cannot realize dynamic balance easily can be widely applied. The balance device can also be used for balancing more other types of vibration including vibration with varying vibration strength, varying vibration amplitude and varying vibration frequency, damping vibration and self-excited vibration, and can also be widely applied to vibration elimination in the mechanical field.

Owner:朱譞晟

Improvement of Otto cycle, Diesel cycle and Atkinson cycle

InactiveCN1614213AReduce negative work of compressionImprove mechanical efficiencyInternal combustion piston enginesEngine controllersOtto cycleAtkinson cycle

A method for improving the Otto cycle, Diesel cycle and Atkinson cycle is disclosed, which can lower the specific consumption rate of fuel for the reciprocating 4-stroke IC engine and increase its power performance.

Owner:任军

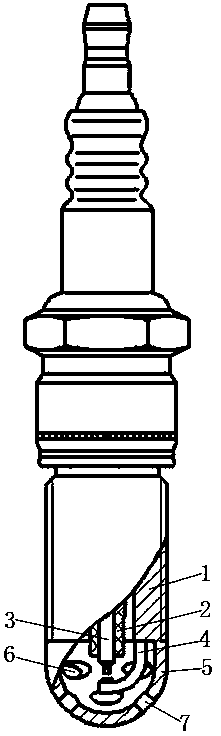

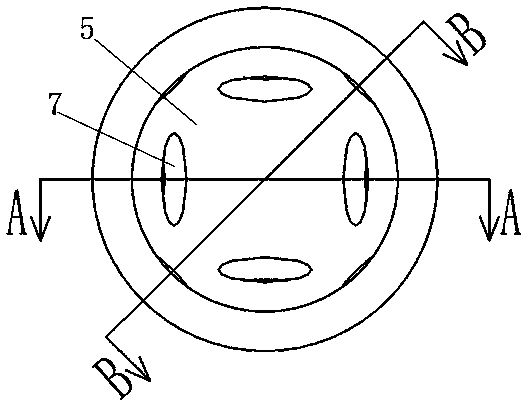

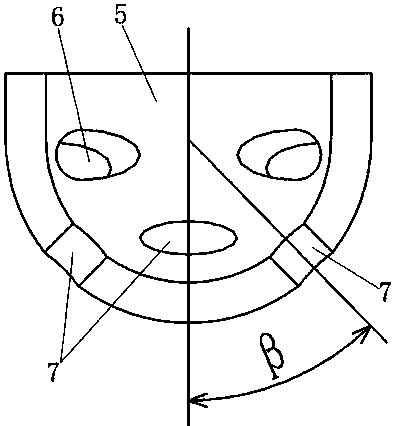

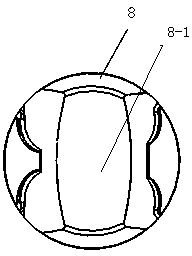

Spark plug with precombustion chamber structure

The invention relates to a spark plug with a precombustion chamber structure. The spark plug includes a tubular metal shell, an insulator fixed in the metal shell, a central hole arranged in the insulator, a central electrode mounted in the central hole and a side electrode connected to the metal shell. A spark plug gap is formed between the central electrode and the side electrode. A precombustion chamber shell is connected to the lower end of the metal shell. A precombustion chamber is defined by the lower ends of the precombustion chamber shell and the metal shell. The spark plug gap is located in the precombustion chamber. The precombustion chamber shell is provided with multiple upper spray holes and multiple lower spray holes. The multiple spray holes are located on the upper side ofthe multiple lower spray holes. The spark plug with the precombustion chamber structure can form up-down stratified jet flames with different spray cone angels during a combustion process of an engine, thereby accelerating the combustion of mixed gas, effectively solving the problem of decrease of burning rate when a gasoline engine adopts a Miller / Atkinson cycle, ensuring the ignition stability,and avoiding carbon deposition blockage.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Four-stroke reciprocating piston internal combustion engine

InactiveCN102852638AIncrease the itineraryIncrease powerInternal combustion piston enginesOtto cycleAtkinson cycle

The invention discloses a four-stroke reciprocating piston internal combustion engine which comprises a piston, a connecting rod and a bent shaft. The piston is connected onto a connecting rod shaft neck of the bent shaft, an eccentric shaft is sleeved on the connecting rod shaft neck, a connecting rod big end of the connecting rod is sleeved on the eccentric shaft, a driving mechanism capable of driving the eccentric shaft to self rotate is further arranged on the eccentric shaft, and the eccentric shaft rotates for one ring when the bent shaft rotates for two rings each time. Compared with the prior art, a piston stroke of the internal combustion engine in suction and exhaust strokes is larger than that in working and compression strokes, exhaust gas can be discharged out of the cylinder to the greatest extend, temperature in the cylinder can be reduced, more fresh low-temperature air can be sucked in a next suction stroke, burning is sufficient, and power of the internal combustion engine is promoted. Compared with the existing Atkinson circulation internal combustion engine, the internal combustion engine overcomes the shortcoming that a multiple-rod mechanism of the internal combustion engine is complex, high in failure rate and poor in low velocity torsion, and the internal combustion engine has power exceeding Otto cycle.

Owner:苏成胜

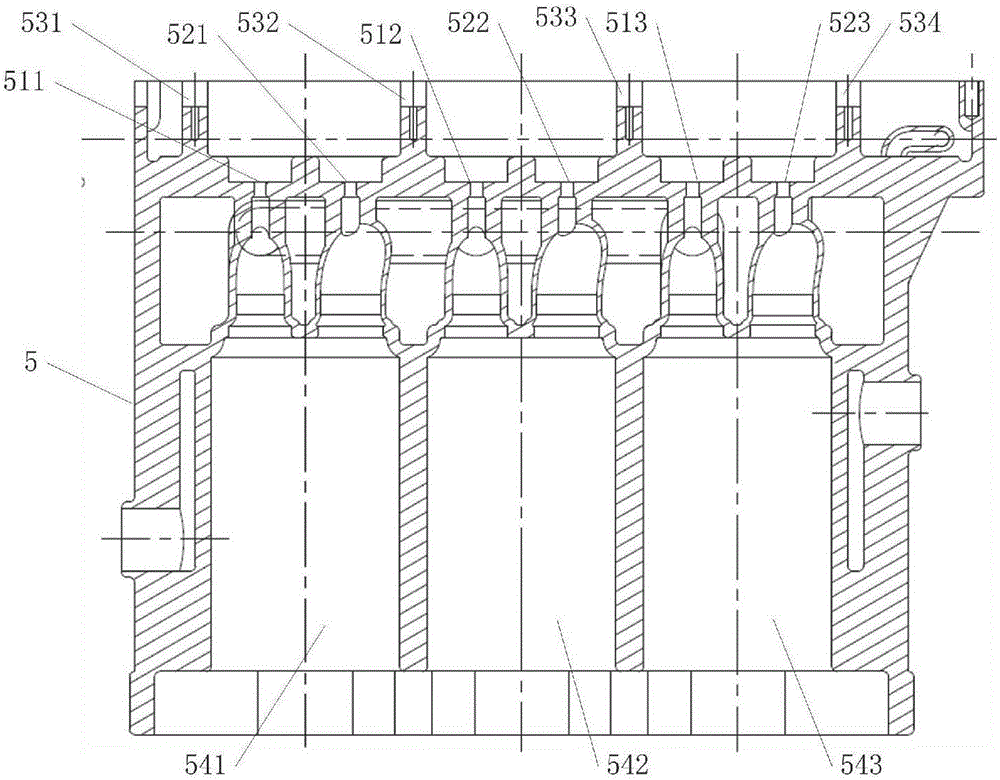

Atkinson cycle engine combustion system

ActiveCN103437897AStrong vortex motionImprove combustion efficiencyInternal combustion piston enginesCylinder headsCombustion systemCombustion chamber

The invention discloses an Atkinson cycle engine combustion system which comprises a cylinder cover and a piston. The design that the compression ratio of the piston is within the range from 4 to 12 is met, a top face of the piston is designed to be of a protruding structure, and the central area of the top face is designed to be in a concave spherical structure. Lift ranges of an exhaust valve, a first intake valve and a second intake valve are non-variable-valve lift ranges. The valve motion of the first intake valve and the valve motion of the second intake valve are driven by the same mechanism, the motion curves of the first intake valve and the second intake valve are not symmetrical and form an oblique axis vortex, the first intake valve and the second intake valve respectively comprises the lift range and a phase, vortex motion is formed in the air inside the cylinder due to the asymmetrical phase design, the asymmetrical design is combined with tumble and vortex and forms oblique axis vortex, and form much stronger turbulent motion at the ignition moment, and therefore the combustion efficiency is improved. According to the Atkinson cycle engine combustion system, on the premise that an original cylinder cover is not changed, due to the reasonable design of the valve motion and a combustion chamber, the combustion efficiency of the Atkinson cycle engine can be improved, therefore, a part of load oil consumption is reduced, and the low-speed torque is improved. The Atkinson cycle engine combustion system has the advantages of being simple in structure and easy to implement.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

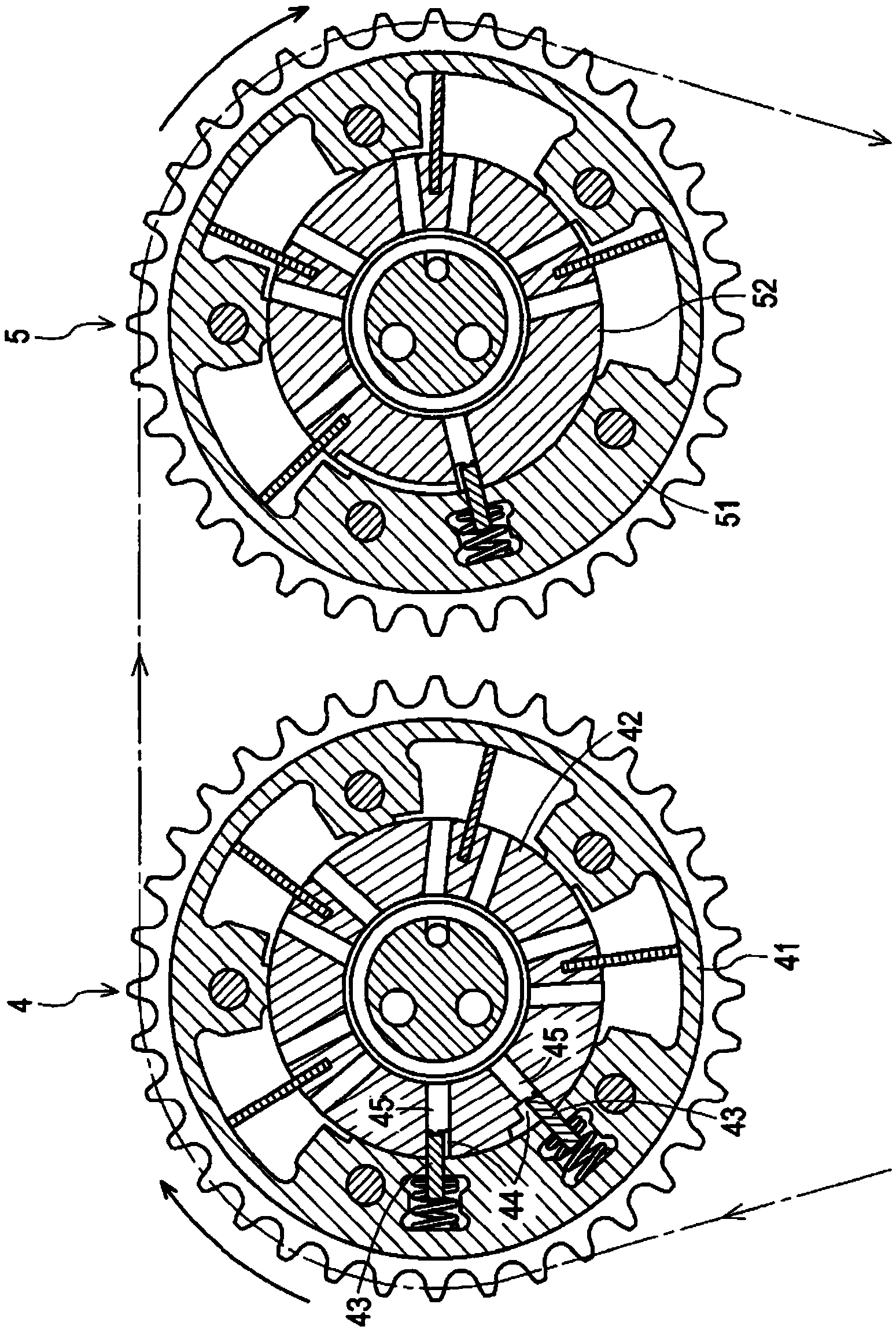

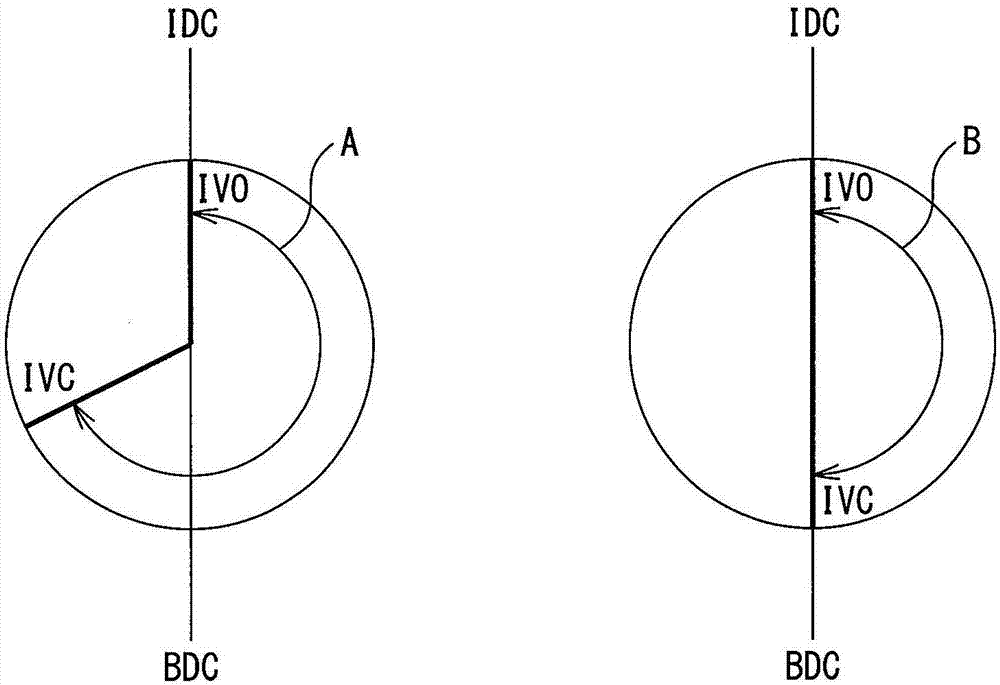

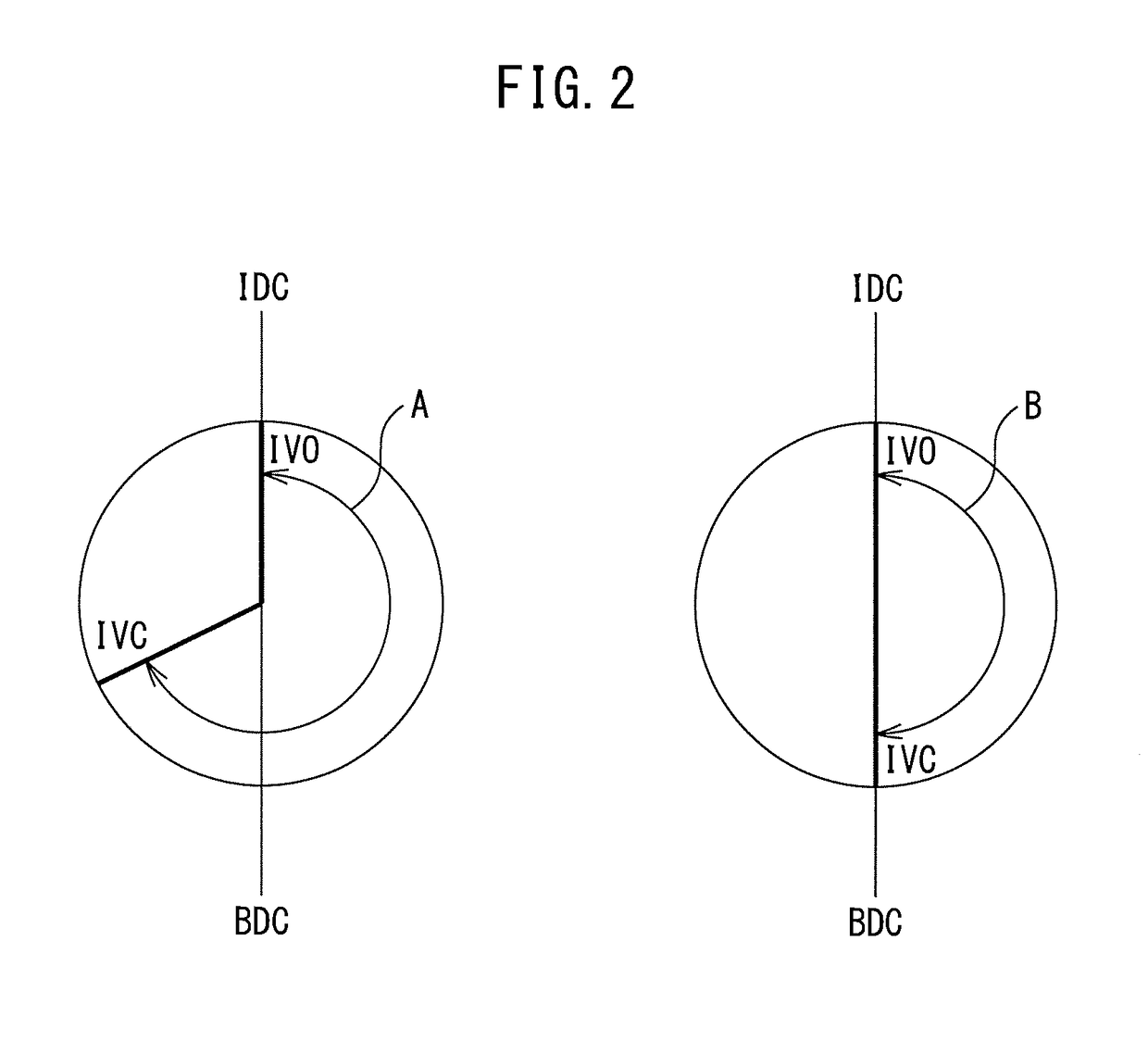

Engine control mechanism

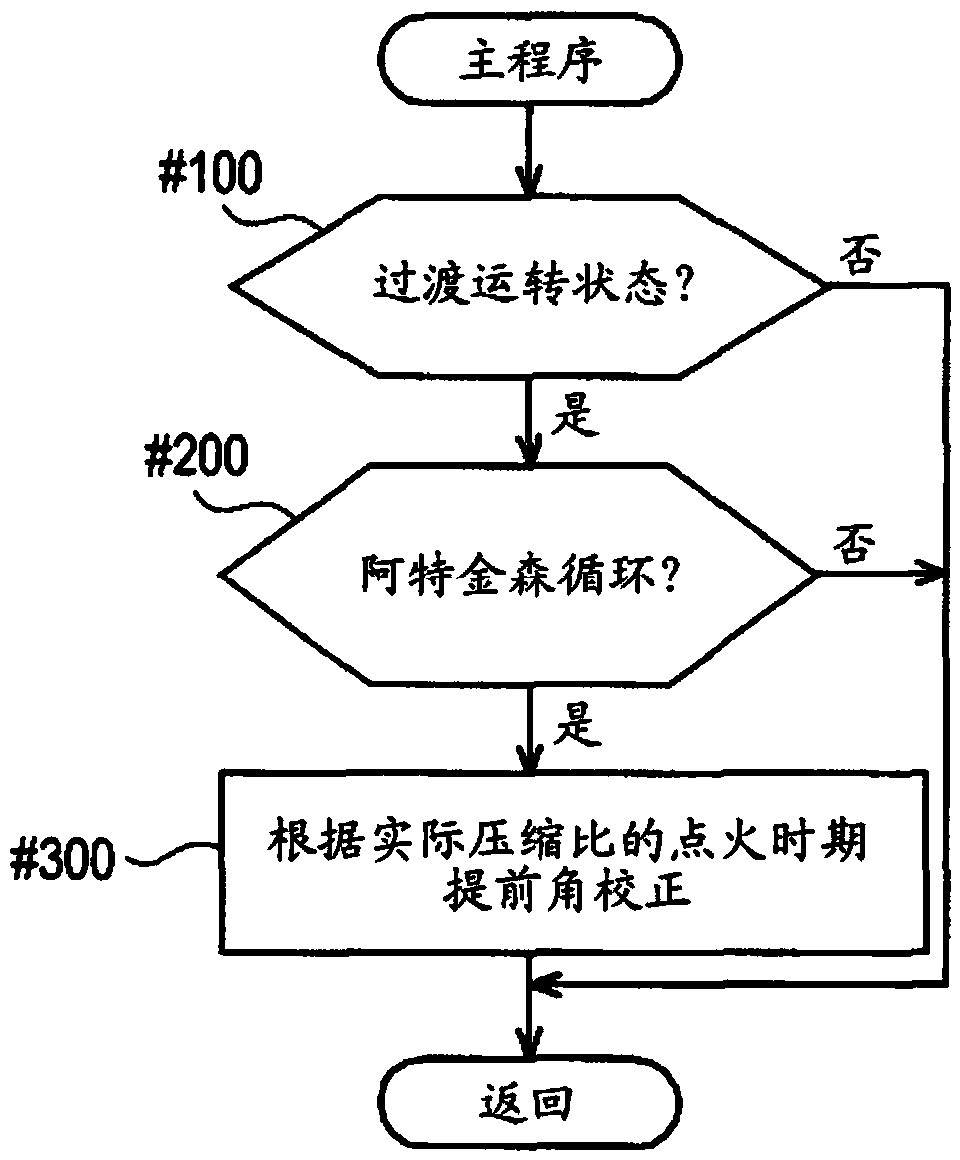

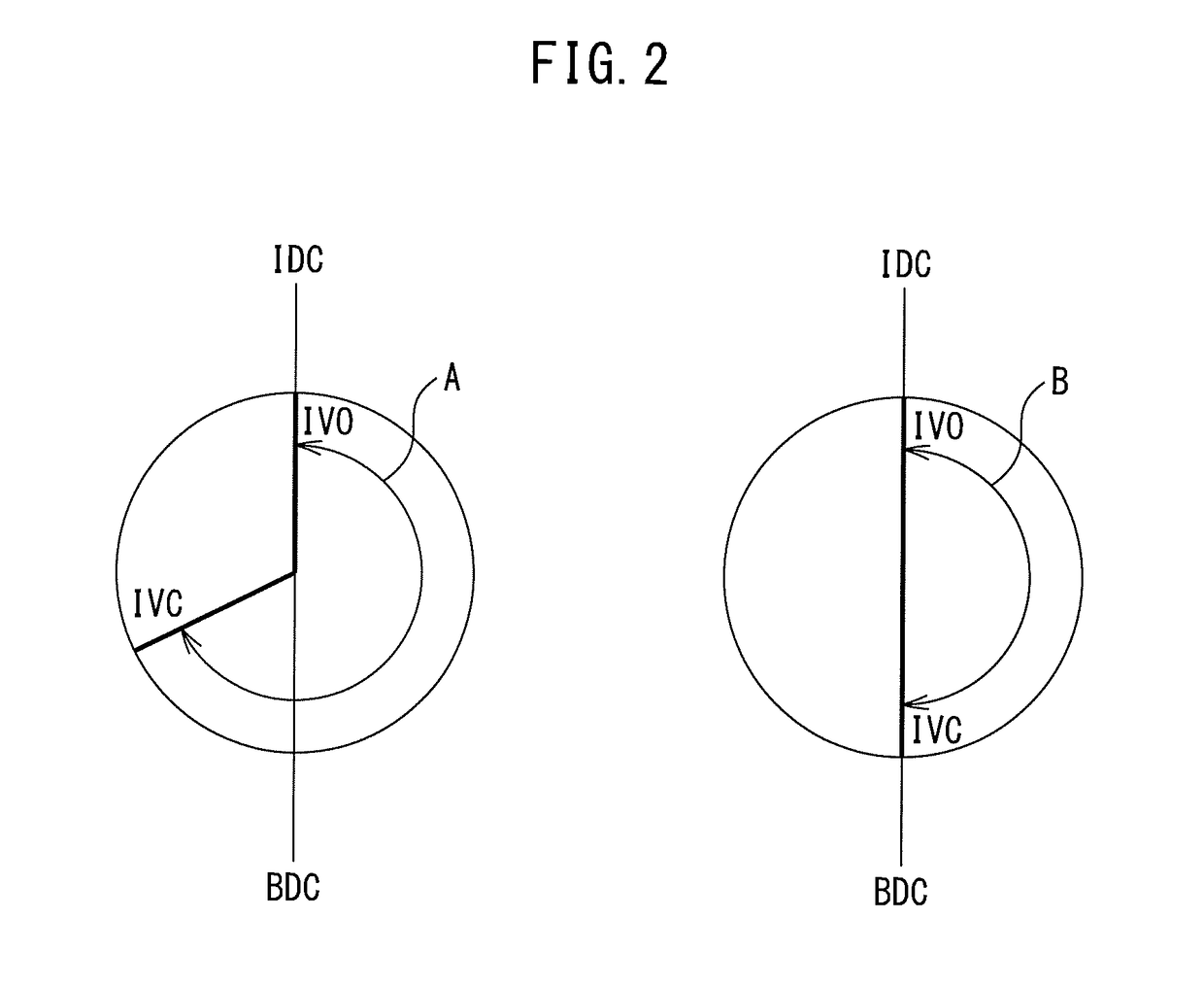

InactiveCN104343548AHigh outputAppropriate operating conditionValve arrangementsElectrical controlExhaust valveCombustion chamber

An engine control mechanism includes intake and exhaust valves that opens and closes a combustion chamber of an engine to be driven with gasoline. The engine control mechanism includes: an intake-side VVT including first driving-side and driven-side rotary bodies, and capable of setting a valve opening / closing timing of the intake valve such that a relative phase of the first driven-side rotary body is set to an intermediate lock phase at the time of starting of the engine, and the relative phase is set to a more retarded side than the intermediate lock phase after the starting; an exhaust-side VVT including second driving-side and driven-side rotary bodies, and setting a valve opening / closing timing of the exhaust valve such that a relative phase of the second driven-side rotary body is set to any phase between the most advanced phase and the most retarded phase; a control unit advance-controlling the ignition timing when an operational state has shifted from an Atkinson cycle state to a transient operational state; and an ignition timing changing mechanism in which the driving is controlled by the control unit.

Owner:AISIN SEIKI KK

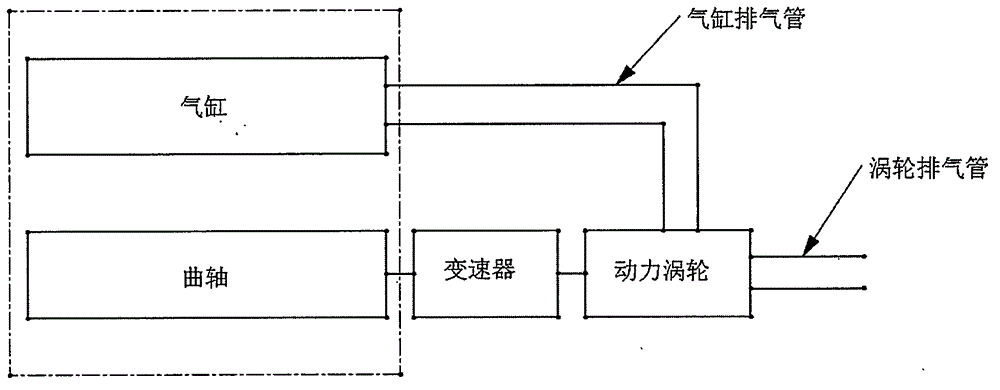

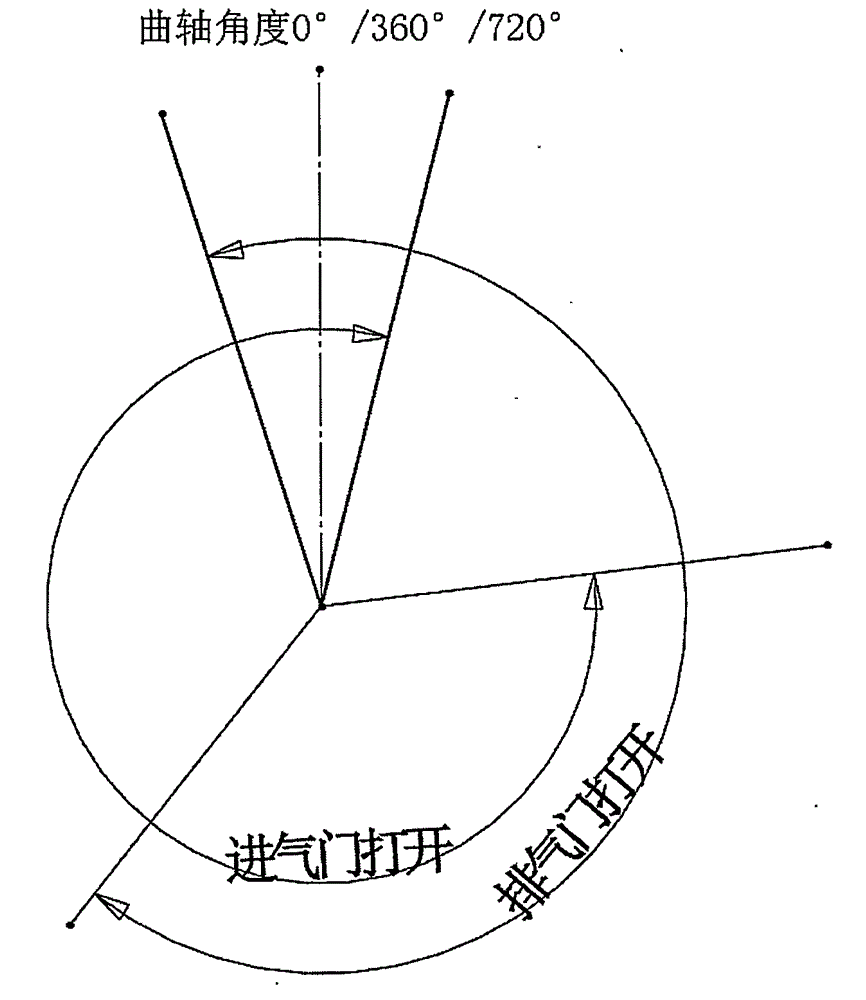

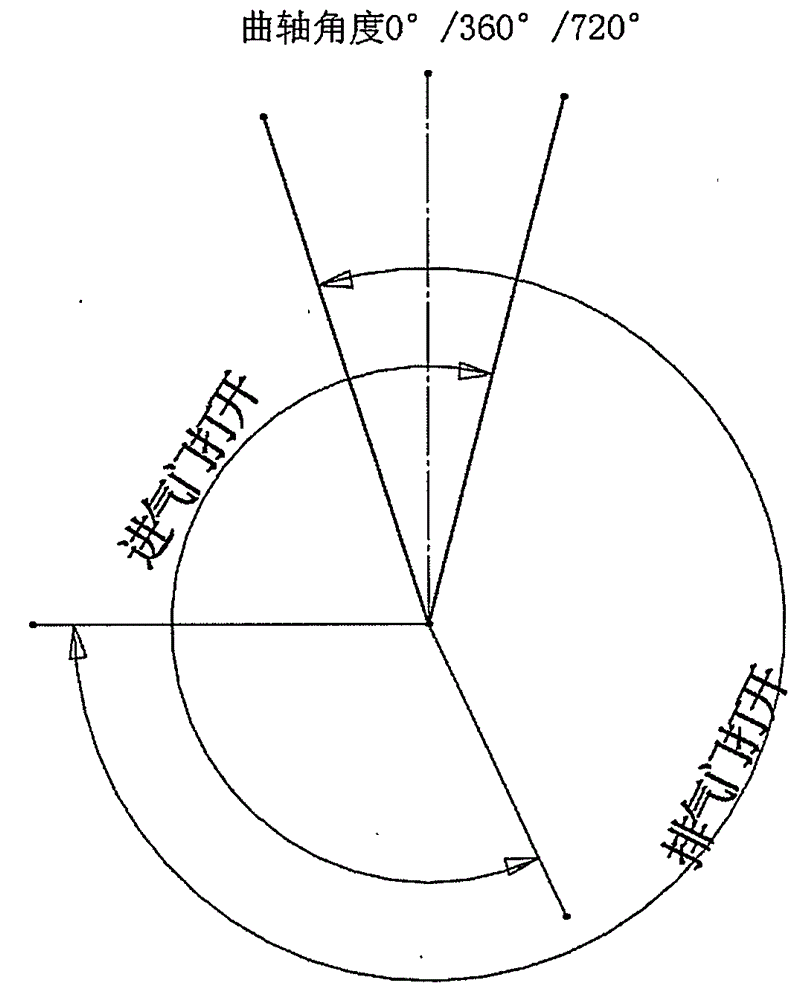

Double-Atkinson-cycle internal combustion engine

The invention discloses a double-Atkinson-cycle internal combustion engine. According to the internal combustion engine, a gas inlet door is adjusted and subjected to time correction according to the Atkinson cycle requirement, an exhaust door is opened earlier compared with a frequent situation, high-temperature fuel gas can be ejected out of a cylinder in advance, a turbine is propelled to do work, and when the gas pressure in the cylinder drops and approximates the gas pressure of a gas inlet pipe, a piston right reaches a lower dead center; the high-temperature and high-pressure fuel gas further expands through the turbine to do work, and more energy can be absorbed; the turbine is connected with a crankshaft of the internal combustion engine through a speed changer, absorbed mechanical work is transmitted to the crankshaft, the output power and the efficiency of the internal combustion engine are increased, an Atkinson cycle is also achieved, and in other words, the Atkinson cycle is achieved on both the gas inlet door and the exhaust door. The double-Atkinson-cycle internal combustion engine achieves balance and is high in power density and practical.

Owner:朱譞晟

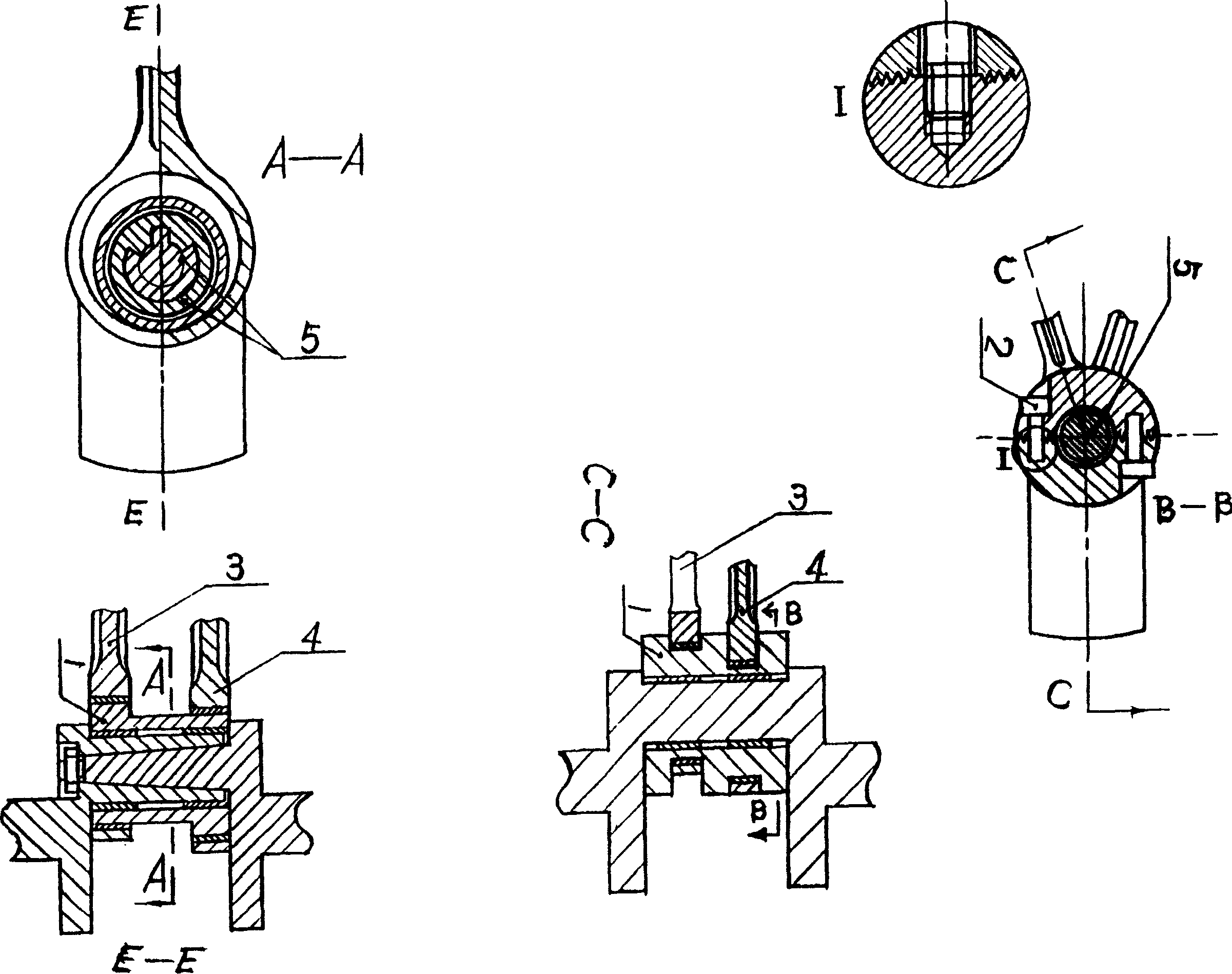

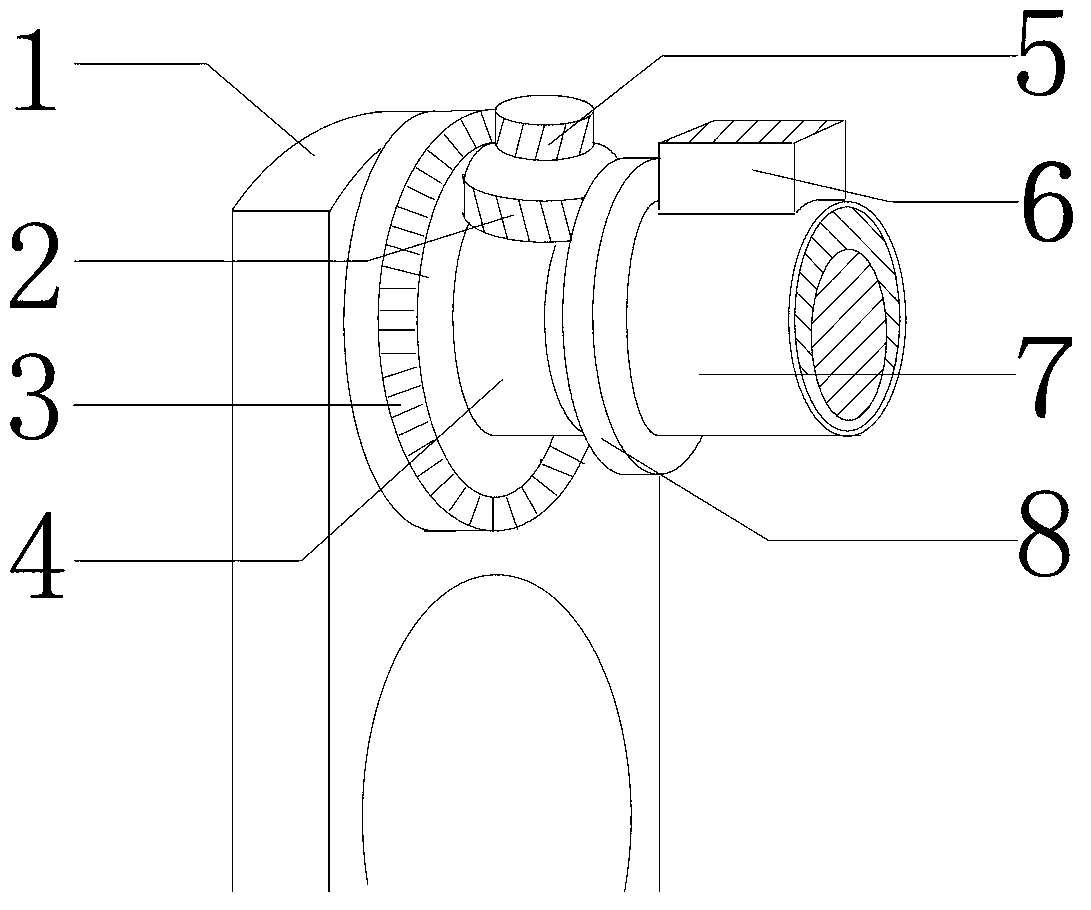

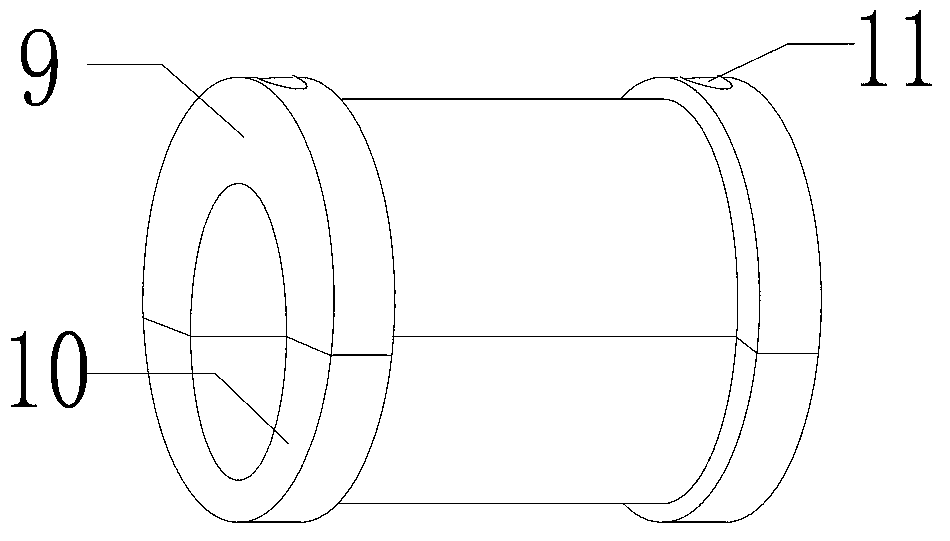

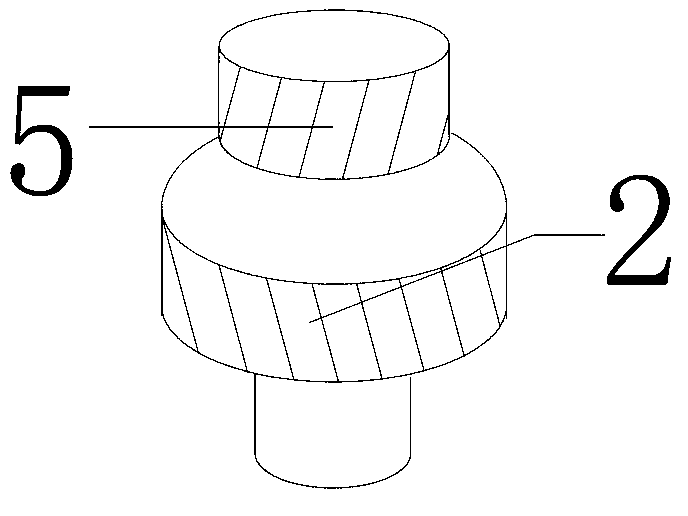

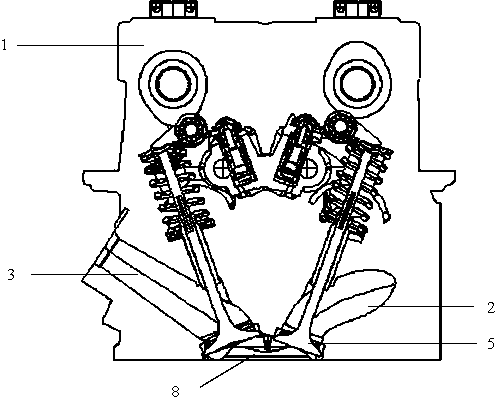

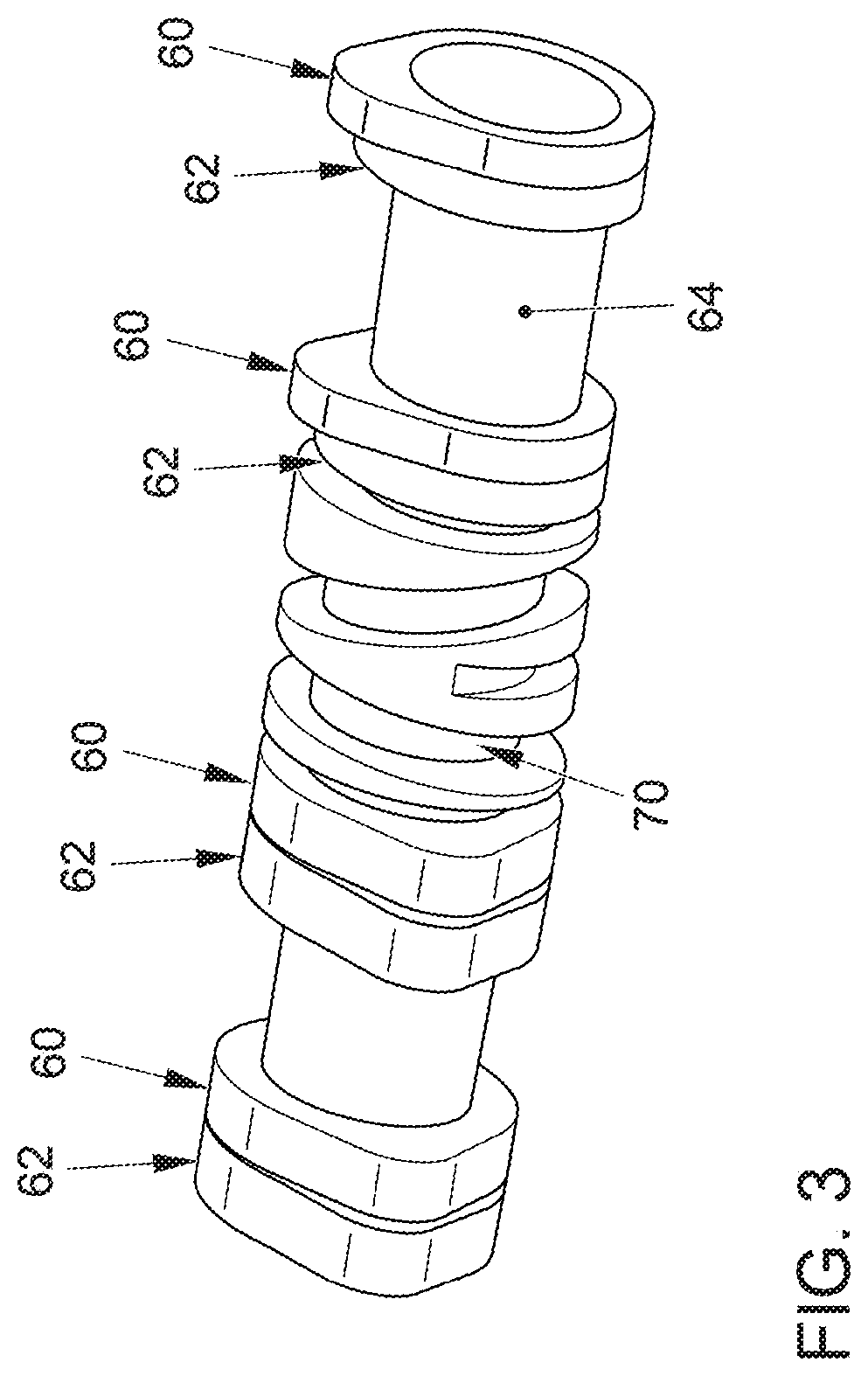

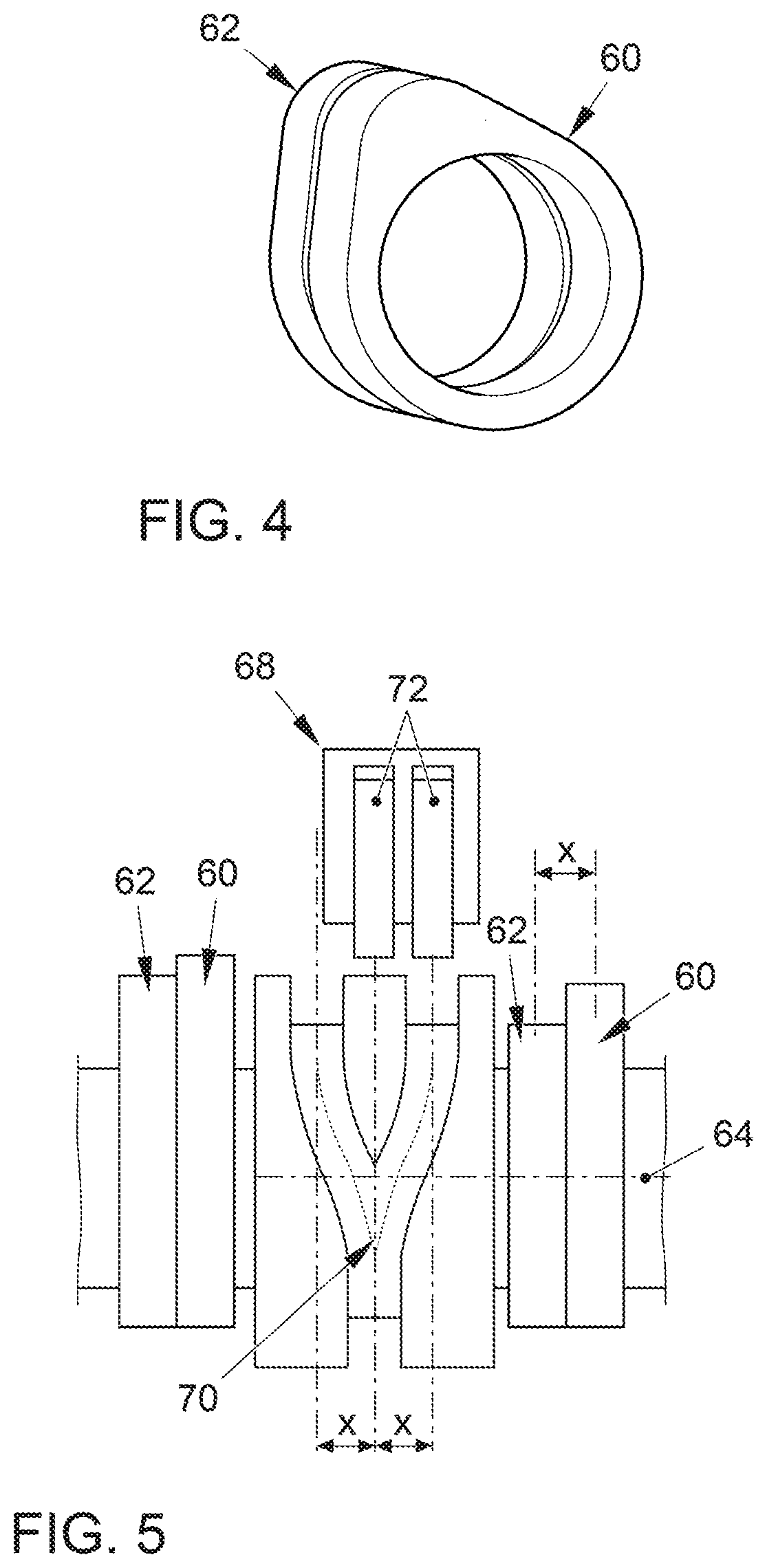

Axial piston internal combustion engine using an Atkinson cycle

InactiveUS9032920B2Internal combustion piston enginesReciprocating piston enginesCylinder headAtkinson cycle

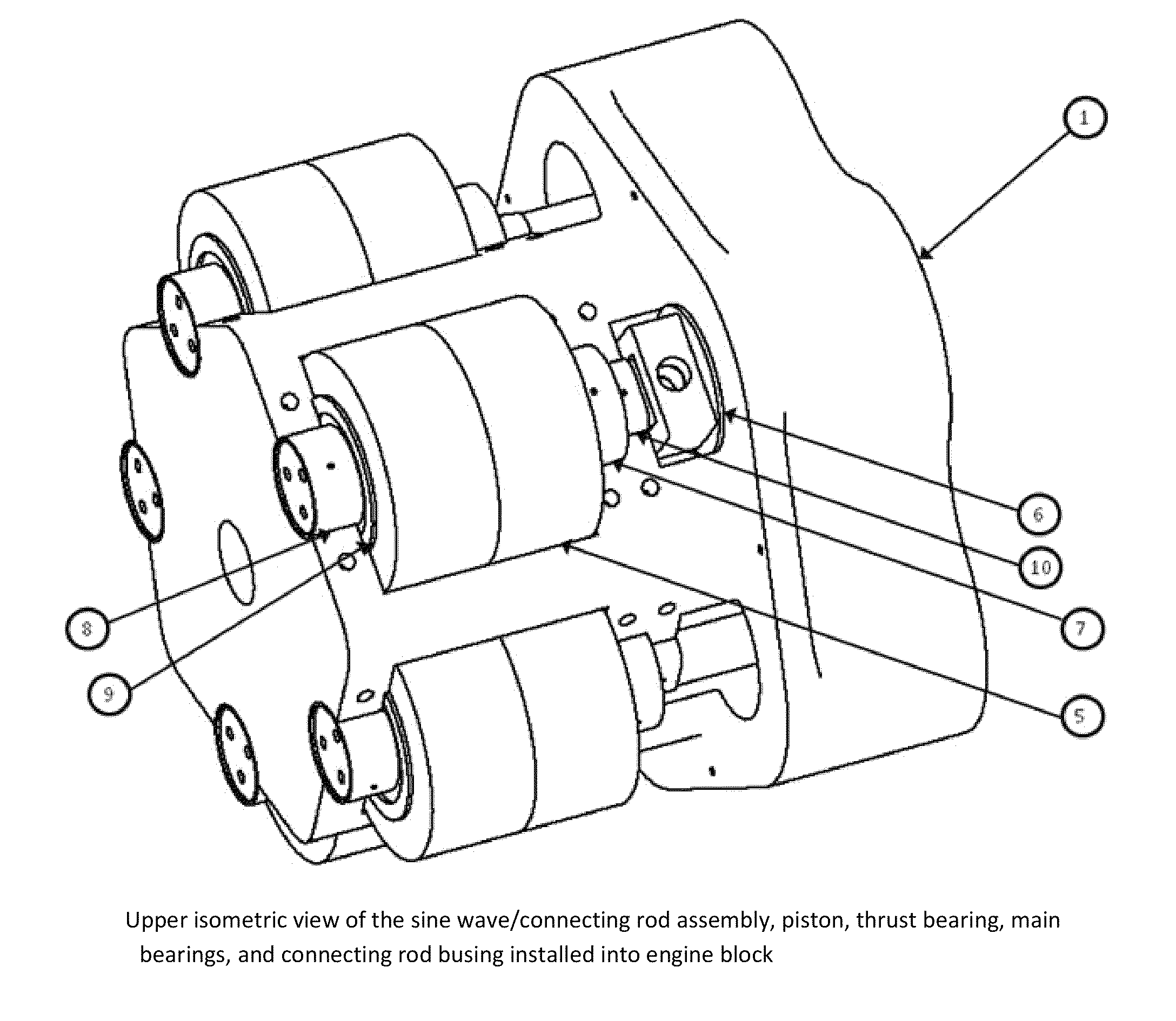

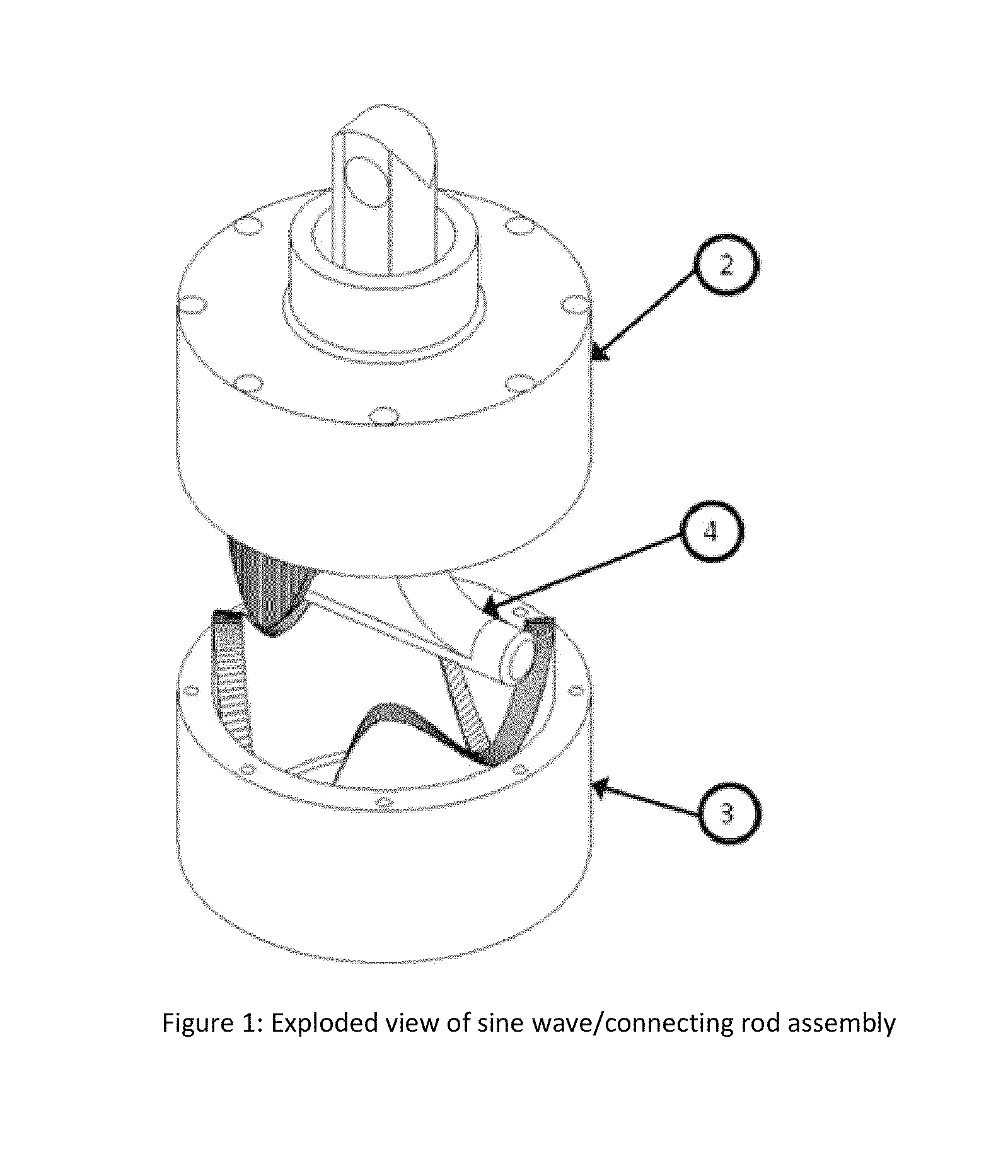

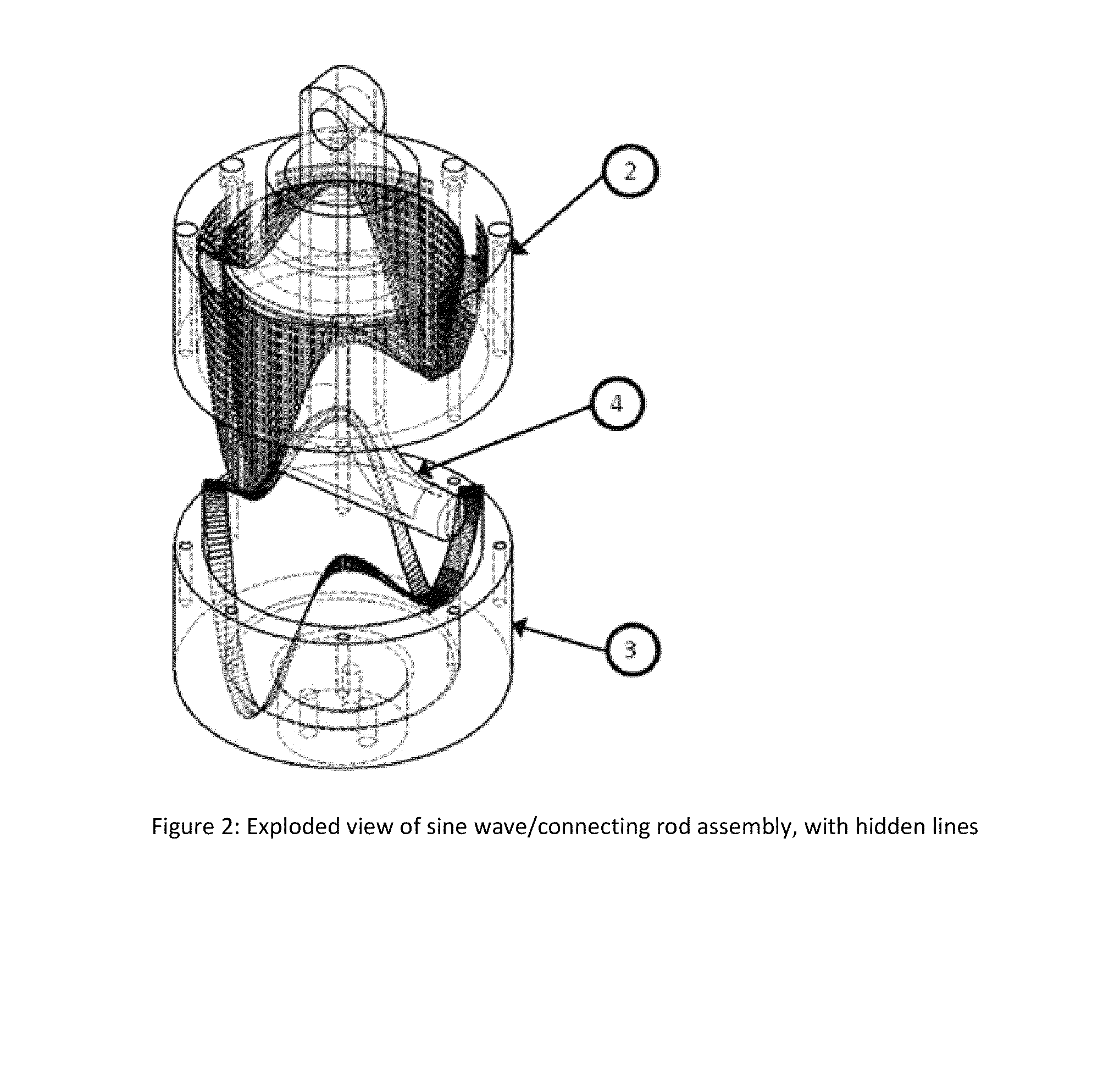

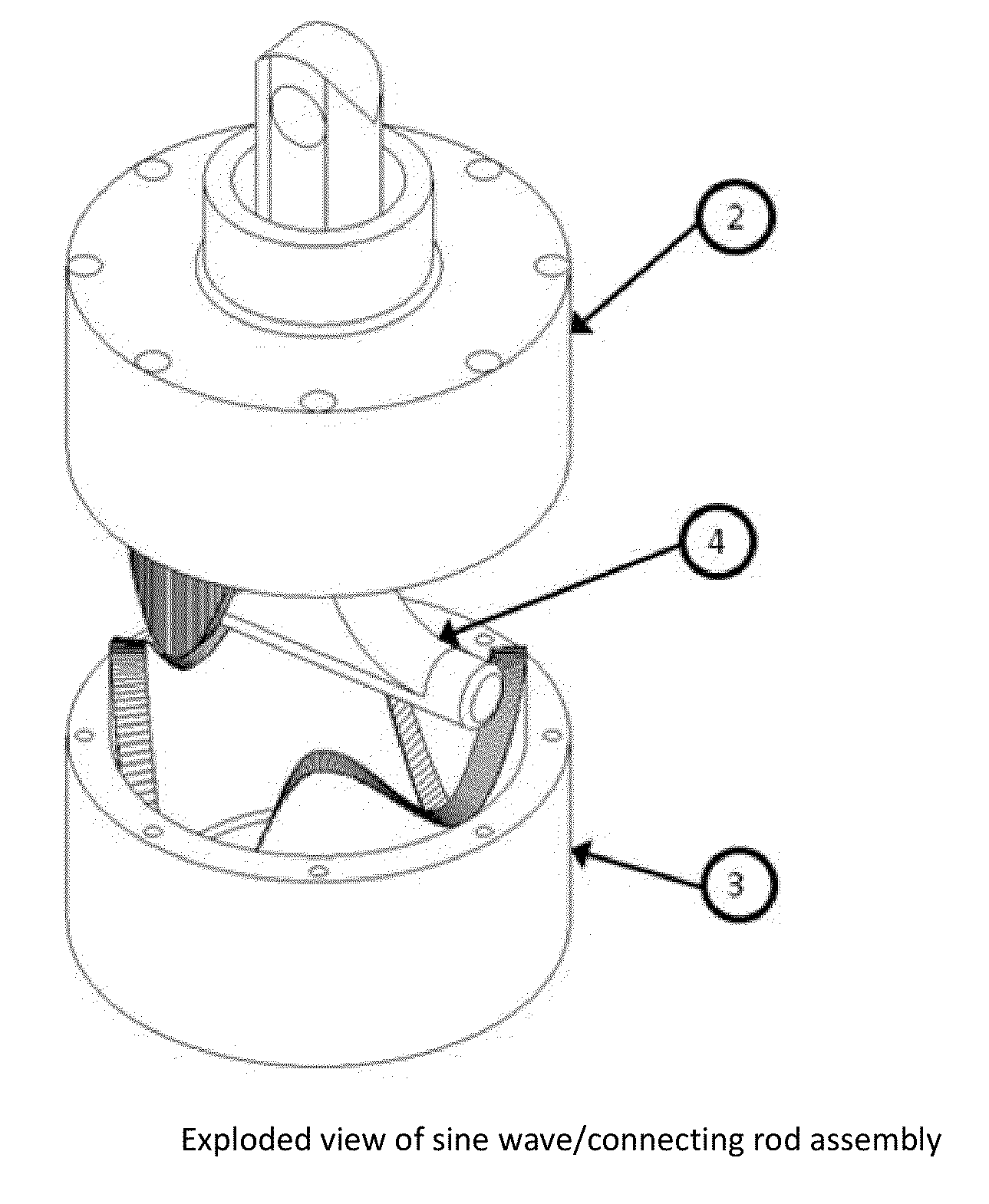

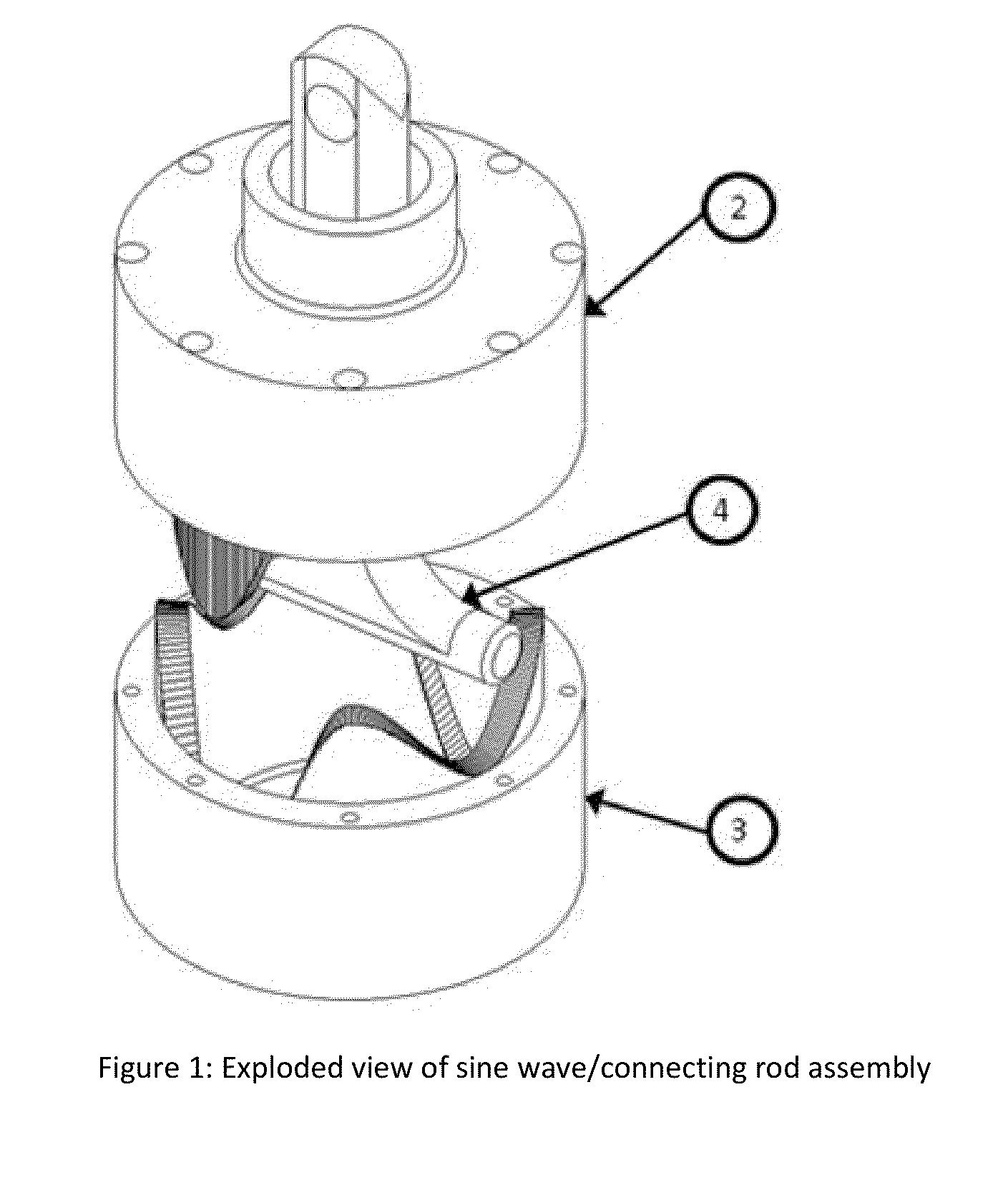

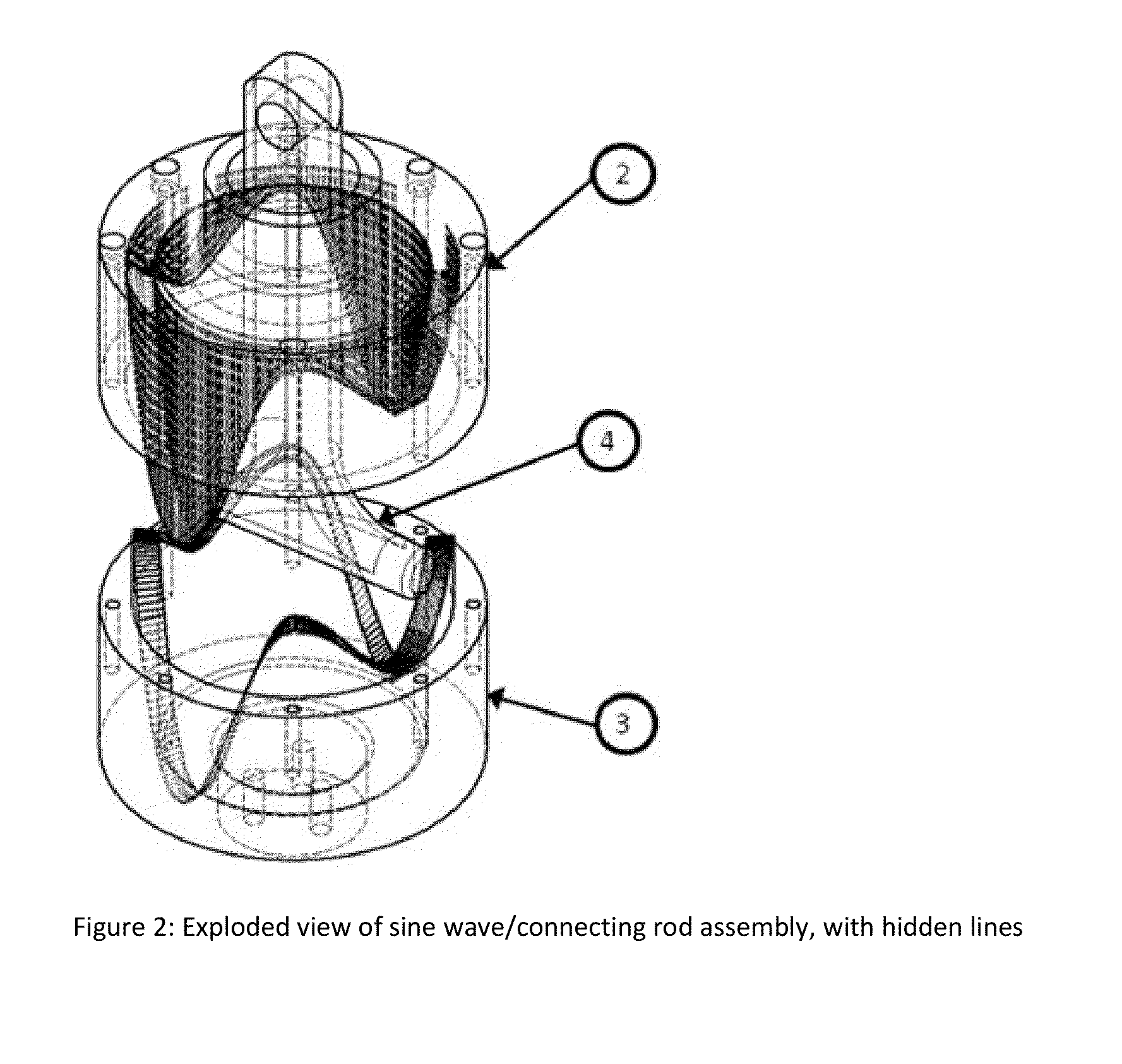

An axial piston internal combustion engine designed to improve the thermal efficiency of the engine by utilizing a sine wave / connecting rod assembly (5) to cause the piston (6) of the engine to travel vertically parallel to the engine's main shaft (13). The upper sine wave barrel (2) and lower sine wave barrel (3) have a channel in them that the cylindrical ends of the connecting rod (4) travel in, forcing the connecting rod (4) and piston (6) to travel vertically. The engine also utilizes slide valve (20) that has slots in it that when slid past the ports of the upper cylinder head (18) and lower cylinder head (19) controls the intake and exhaust timing events of the engine. The channel in the upper sine wave barrel (2) and lower sine wave barrel (3) is designed such that the vertical expansion / exhaust strokes of the engine are longer than the intake / compression strokes which allow the engine to make more efficient use of the energy produced by combusting the fuel, improving the thermal efficiency of the engine. The design also reduces the friction between the cylinder walls and piston (4) and the friction associated with typical engines valvetrain components, improving the overall efficiency of the engine. By reducing the frictional losses and improving the thermal efficiency the new engine should have decreased fuel consumption.

Owner:ROBARDS BRIAN

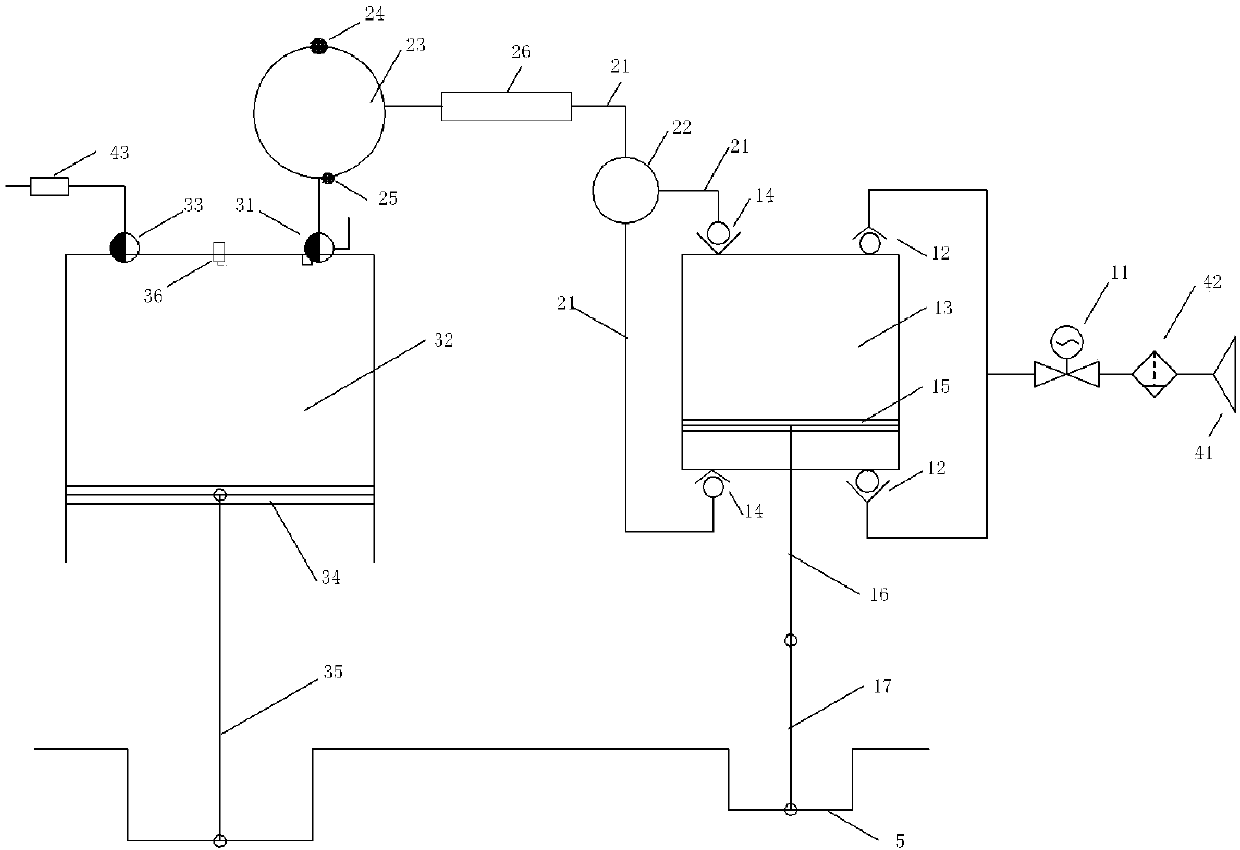

Split type superhigh-expansion-ratio engine and adjustment and control method

InactiveCN109519273AReduce fuel consumptionImprove fuel efficiencyInternal combustion piston enginesEngine componentsPressure stabilizationOtto cycle

The invention discloses a split type superhigh-expansion-ratio engine and an adjustment and control method and belongs to the field of engines. The split type superhigh-expansion-ratio engine comprises a gas compression device, an expansion acting device and a high-pressure pipe. A high-pressure gas tank is arranged between the gas compression device and the expansion acting device and is in gas circuit connection with the gas compression device and the expansion acting device through the high-pressure pipe. The air cylinder volume of the expansion acting device is greater than the air inlet natural volume. The split type engine is different from a common Otto-cycle internal combustion engine in that the gas compression stroke is moved into the gas compression device out of an acting cylinder and the engine is provided with the high-pressure gas tank for achieving buffering, pressure stabilization and temporary storage of compressed gas. By means of a certain technical scheme and the adjustment and control method, the engine can achieve the Atkinson cycle easily at the low cost in all working conditions; and in addition, the expansion ratio can be far greater than the compression ratio under the working condition of small acceleration, thus, oil consumption is remarkably lowered, and the effect is particularly obvious under the working condition of the small acceleration.

Owner:谢炳炎

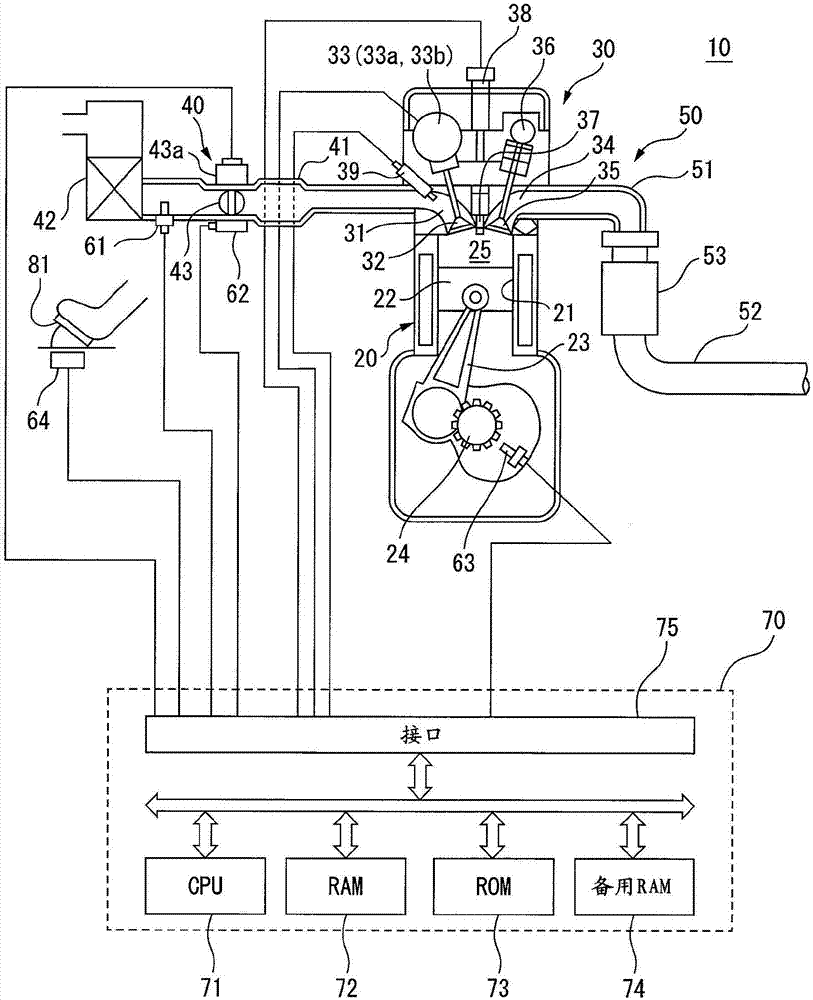

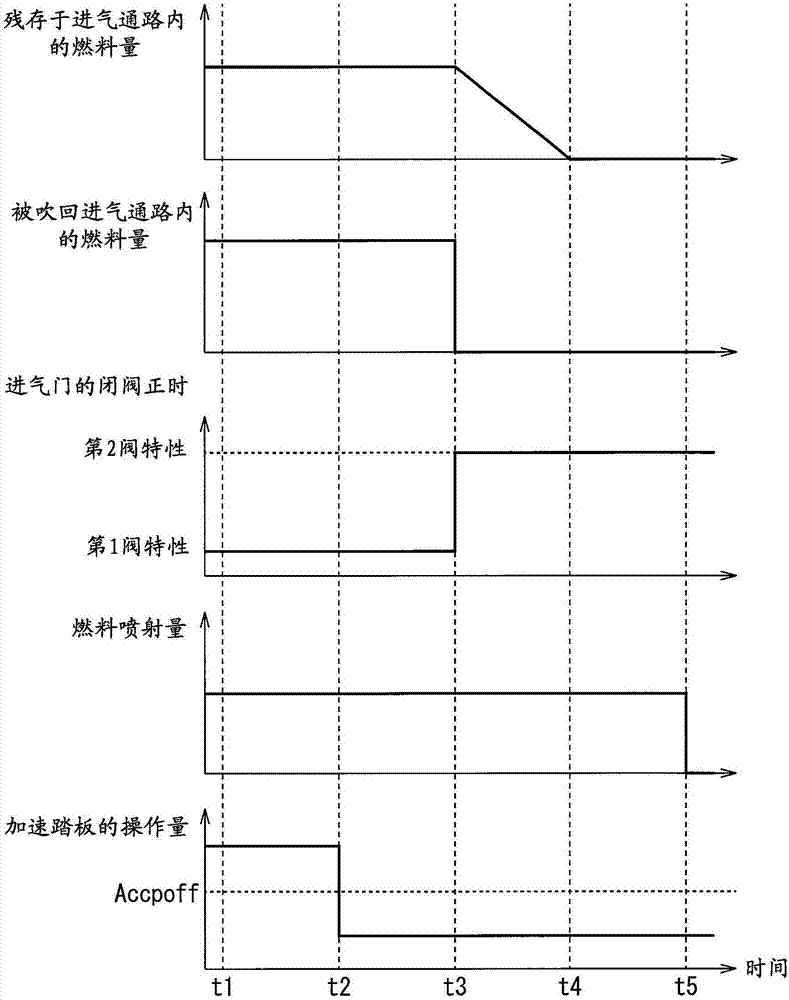

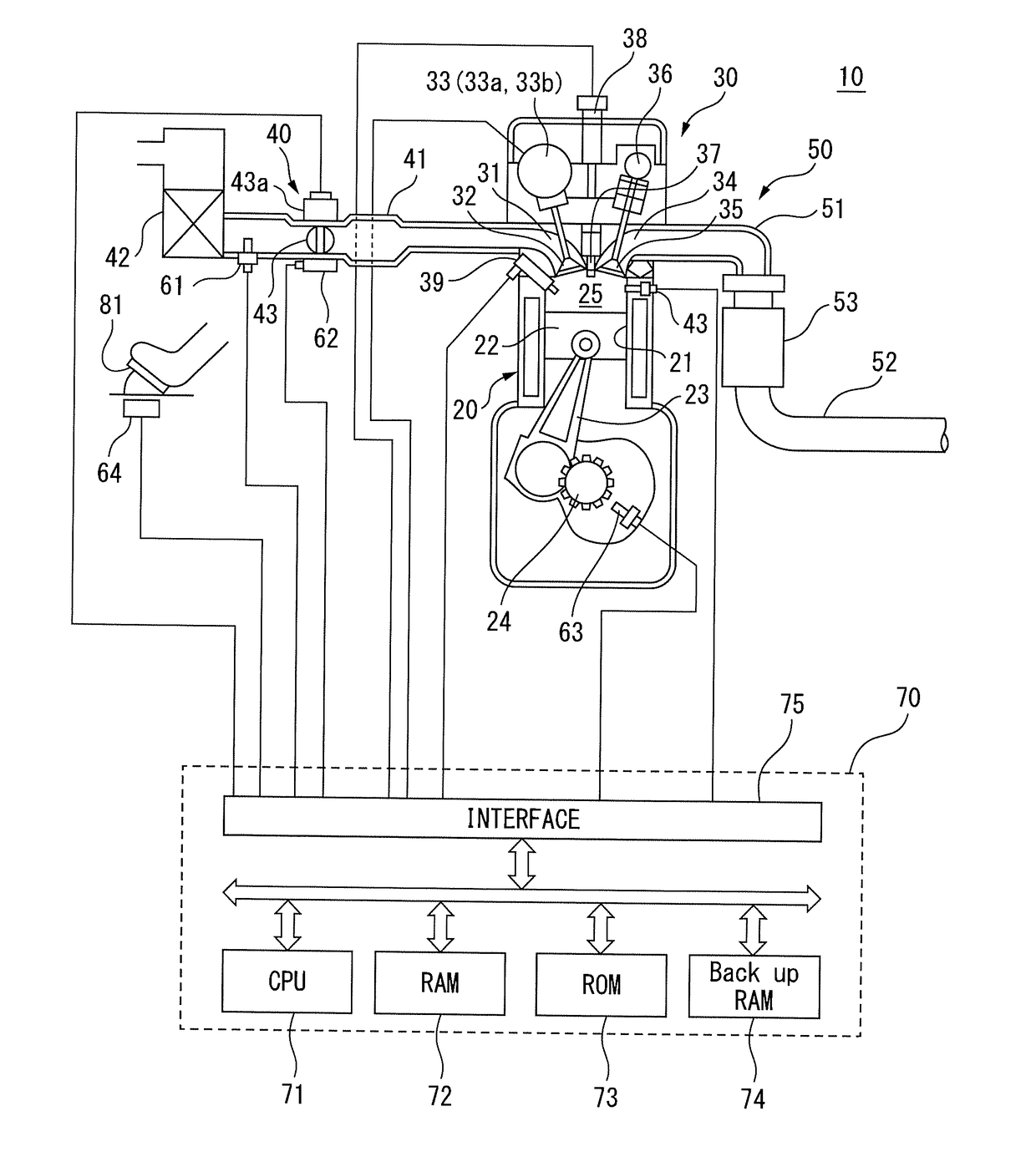

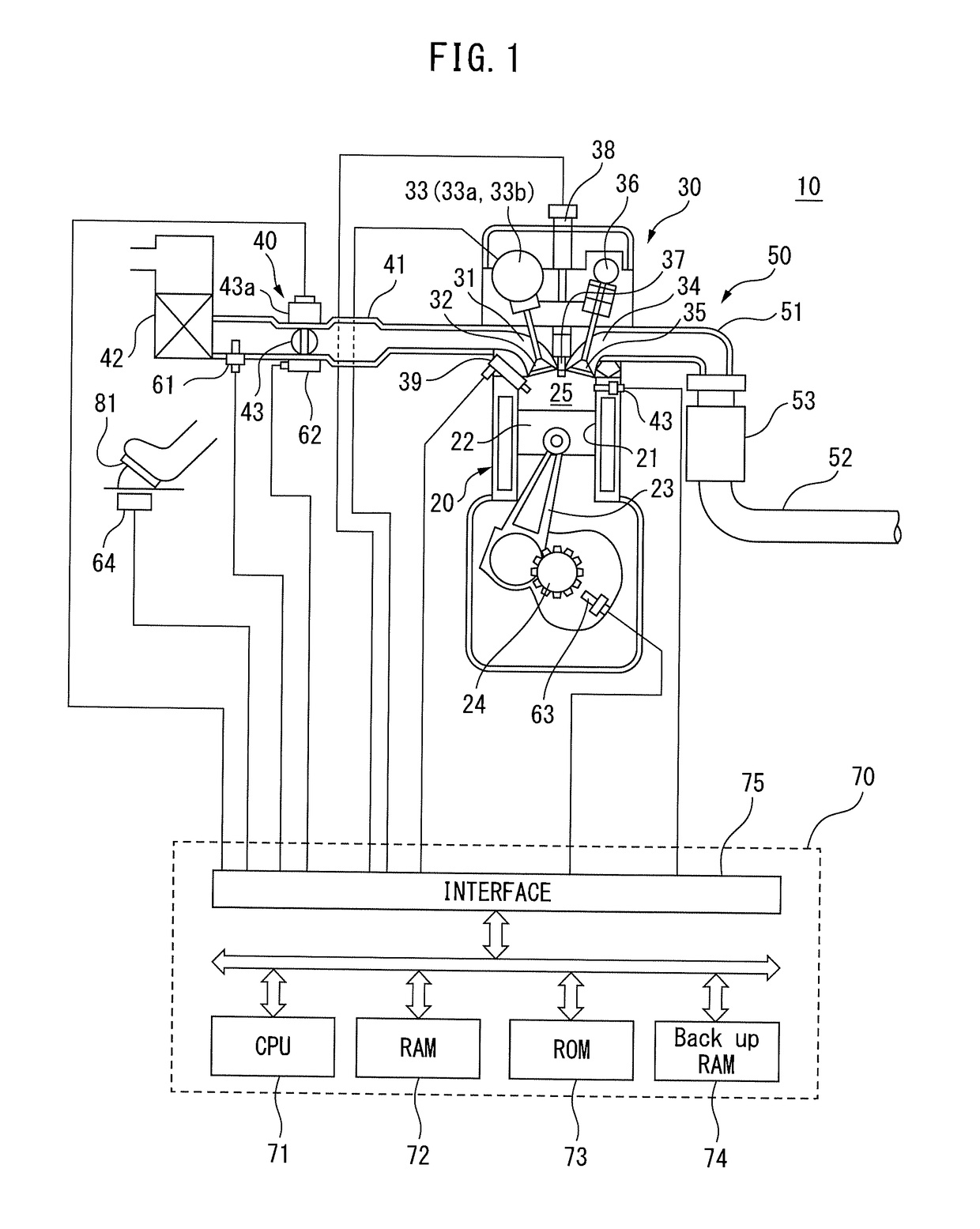

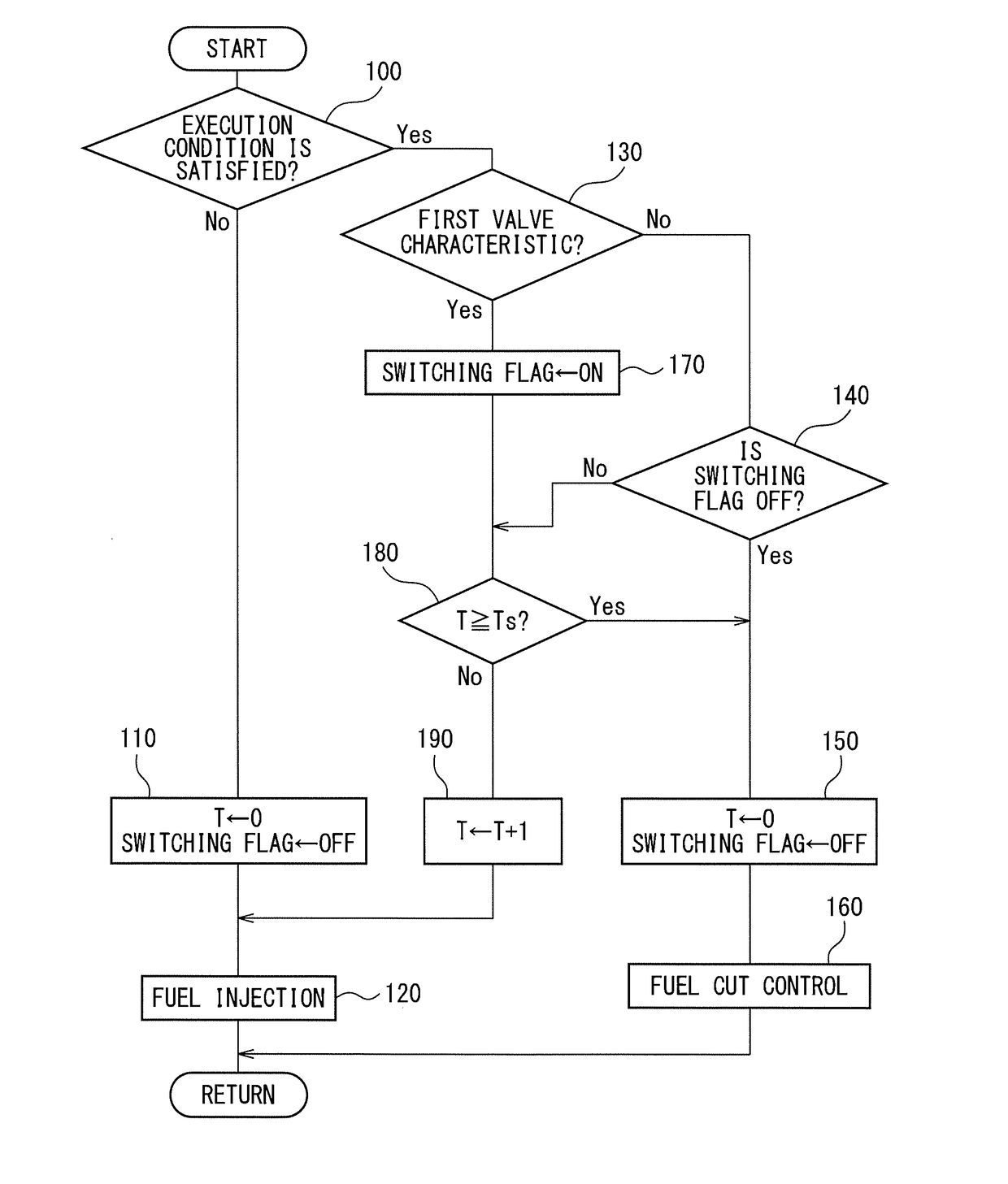

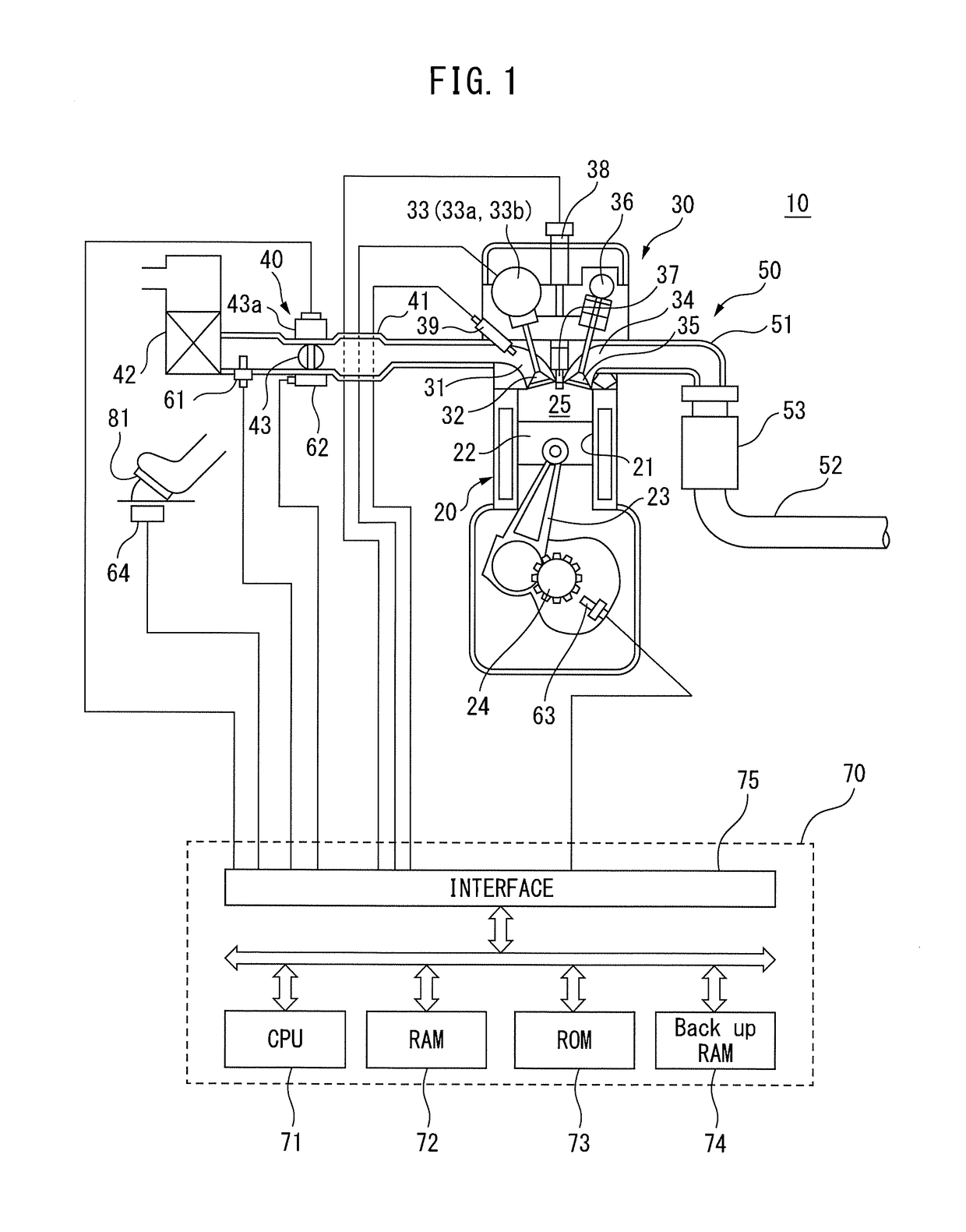

Control system of internal combustion engine

InactiveCN106907253AAchieve cycleSuppress blowoutElectrical controlInternal combustion piston enginesControl systemInlet valve

A control system according to one aspect of the present invention is applied to an internal combustion engine. The engine 10 comprises a port injector 39 and an intake valve driving device 33 capable of changing the closing timing of the intake valve 32. The engine10, if an execution condition for performing a fuel cut control is satisfied when performing an Atkinson cycle, executes the fuel cut control after advancing the closing timing of the intake valve. As a result, by reducing the amount of the fuel which is blown back to the inside of the intake passage in a period where the intake valve is open after intake bottom dead center, the amount of the fuel which flows into the exhaust passage as unburned gas when the fuel cut control is executed can be reduced.

Owner:TOYOTA JIDOSHA KK

Two-stroke Atkinson cycle free piston internal combustion engine generator

InactiveCN111852649AImprove ventilation efficiencyRealize straight-line ventilationInternal combustion piston enginesPistonsFree-piston engineInlet valve

The invention relates to a two-stroke Atkinson cycle free piston internal combustion engine generator, and belongs to the field of energy power. The generator mainly comprises a free piston engine, alinear generator and a connecting rod. A piston is provided with a plurality of air inlet channels. Each air inlet channel is provided with an air inlet valve. An air inlet valve spring and an air inlet valve damper are installed between the air inlet valve and the piston. By adjusting the elasticity and the air inlet valve spring and the damping coefficient of the air inlet damper, the opening and closing moments of the air inlet valve can be optimized, Atkinson cycle is achieved on the two-stroke free piston engine, and the heat efficiency is improved.

Owner:SHANDONG JIAOTONG UNIV

Control system of internal combustion engine

InactiveUS20170107922A1Avoid flowInhibitionElectrical controlInternal combustion piston enginesControl systemAtkinson cycle

A control system according to one aspect of the present invention is applied to an engine. The engine comprises a cylinder injector and an intake valve driving device capable of changing the closing timing of an intake valve. If the execution condition is satisfied when the injection timing of fuel of the cylinder injector is before intake bottom dead center and an Atkinson cycle is carried out, the engine delays the injection timing of the fuel of the cylinder injector to a time after intake bottom dead center, injects the fuel, then executes fuel cut control.

Owner:TOYOTA JIDOSHA KK

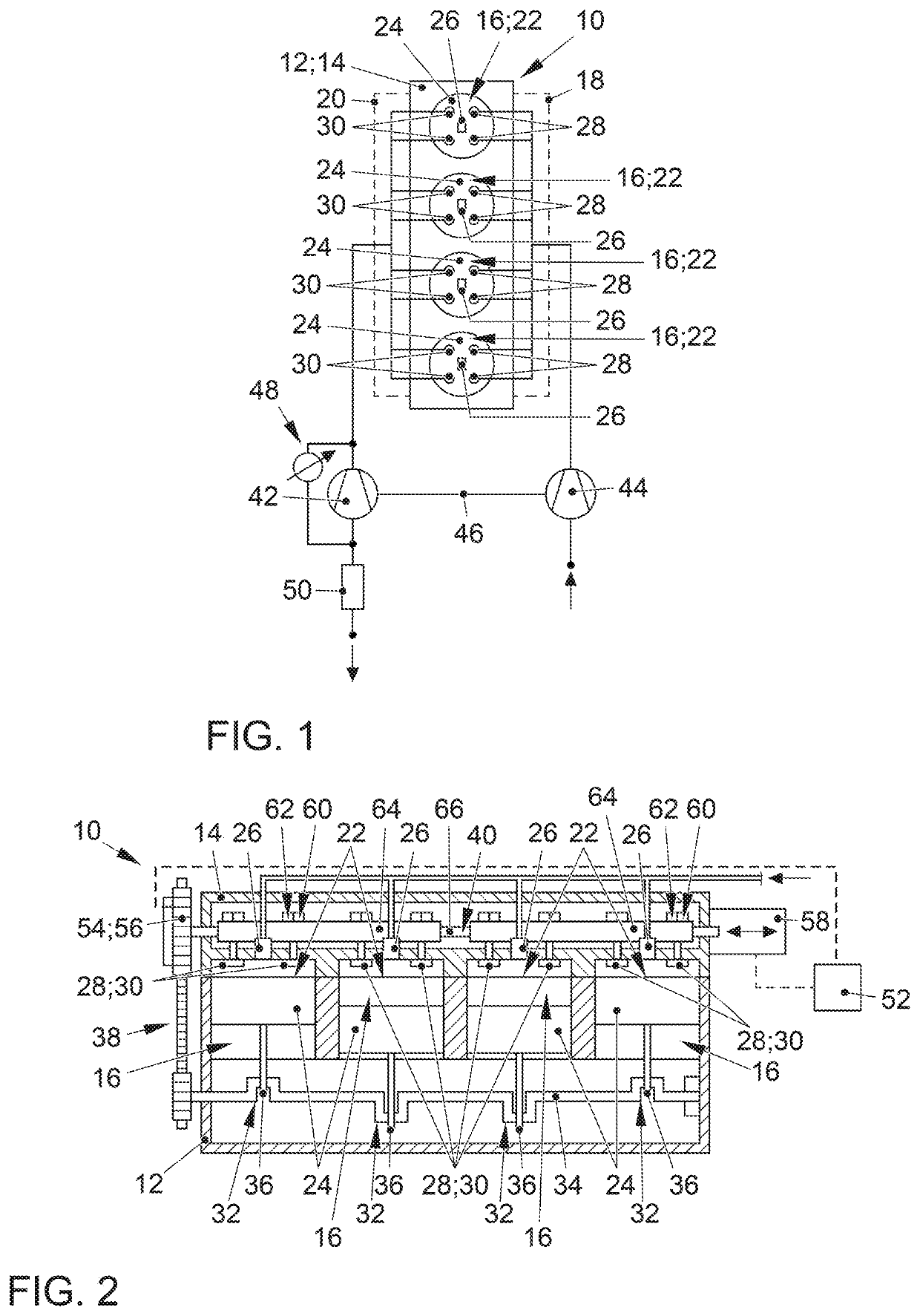

Method for operating an internal combustion engine, and internal combustion engine

ActiveUS20200040828A1Easy to adjustDrive torqueElectrical controlInternal combustion piston enginesCombustion chamberAtkinson cycle

A method for a combustion motor that is initially used in a full Miller cycle or full Atkinson cycle that is advantageous with regard to efficiency. In full operation, a switchover to a partial operation takes place, wherein the intake valves associated with the combustion chambers that are to continue to be operated are switched over to actuation in accordance with a second valve lifting curve in order to achieve a switchover that is as torque-neutral as possible and is optimal with regard to efficiency. The closing time of the intake valve brought about by this second valve lifting curve is designed with respect to maximum volumetric efficiency.

Owner:VOLKSWAGEN AG

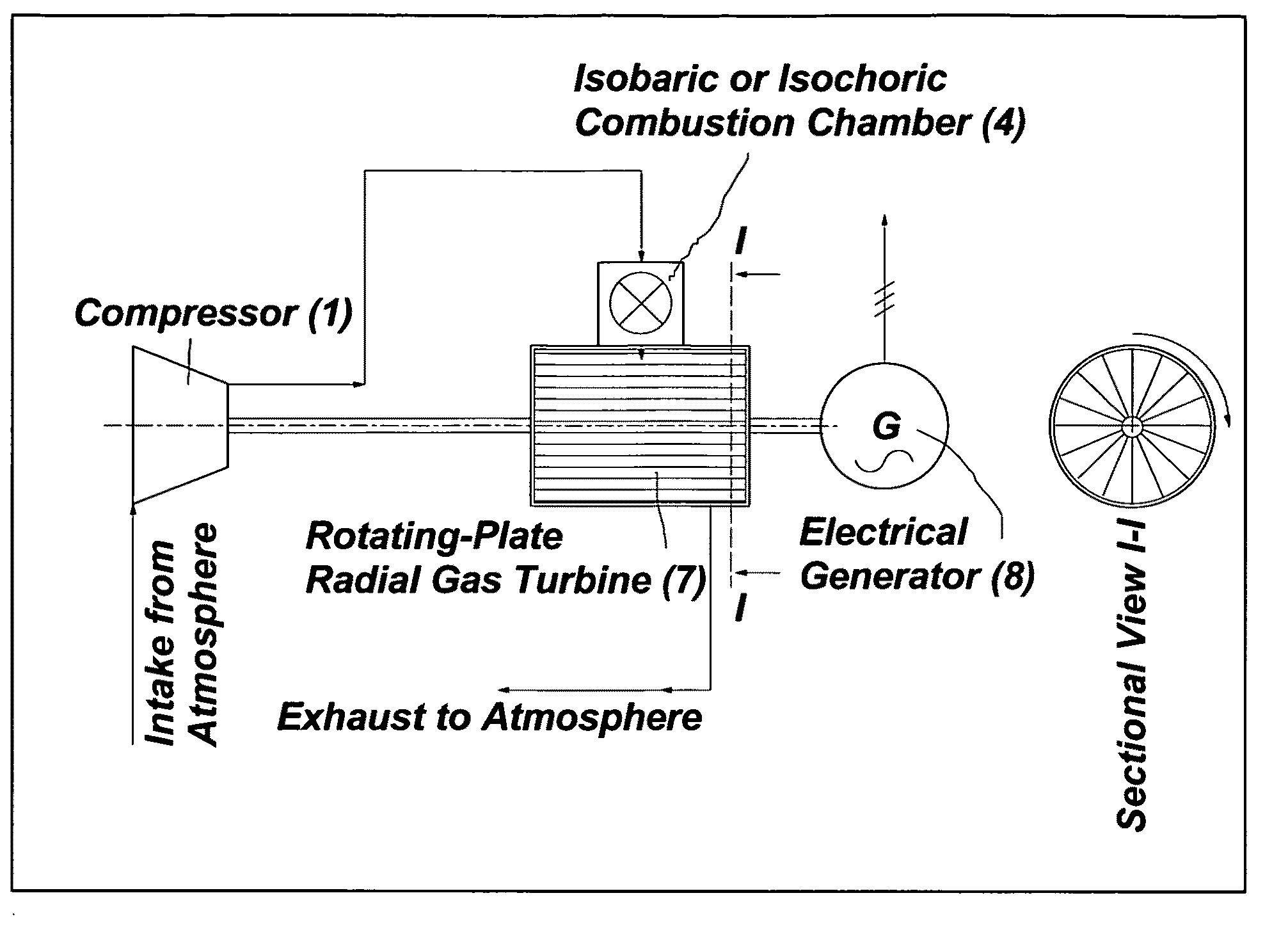

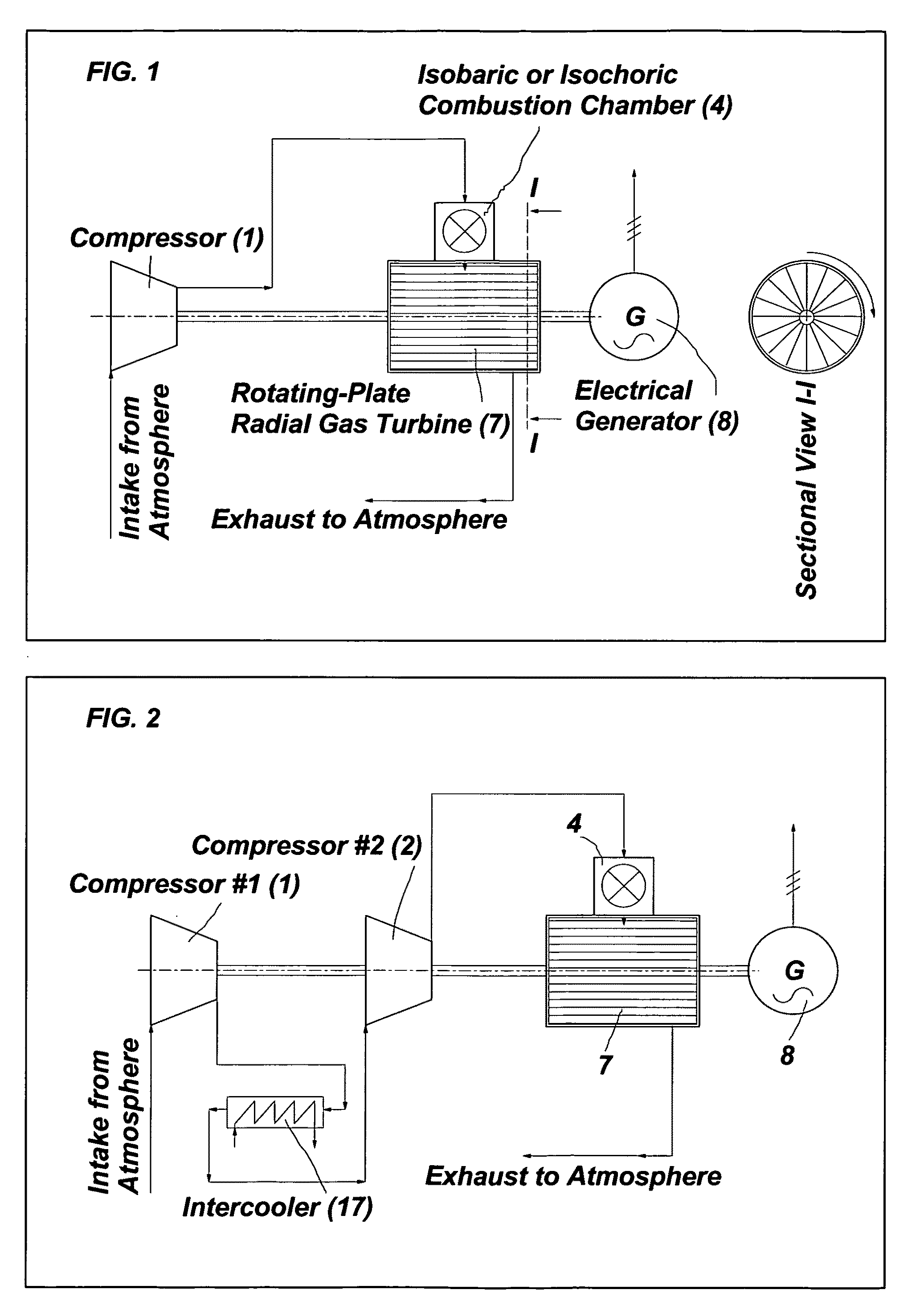

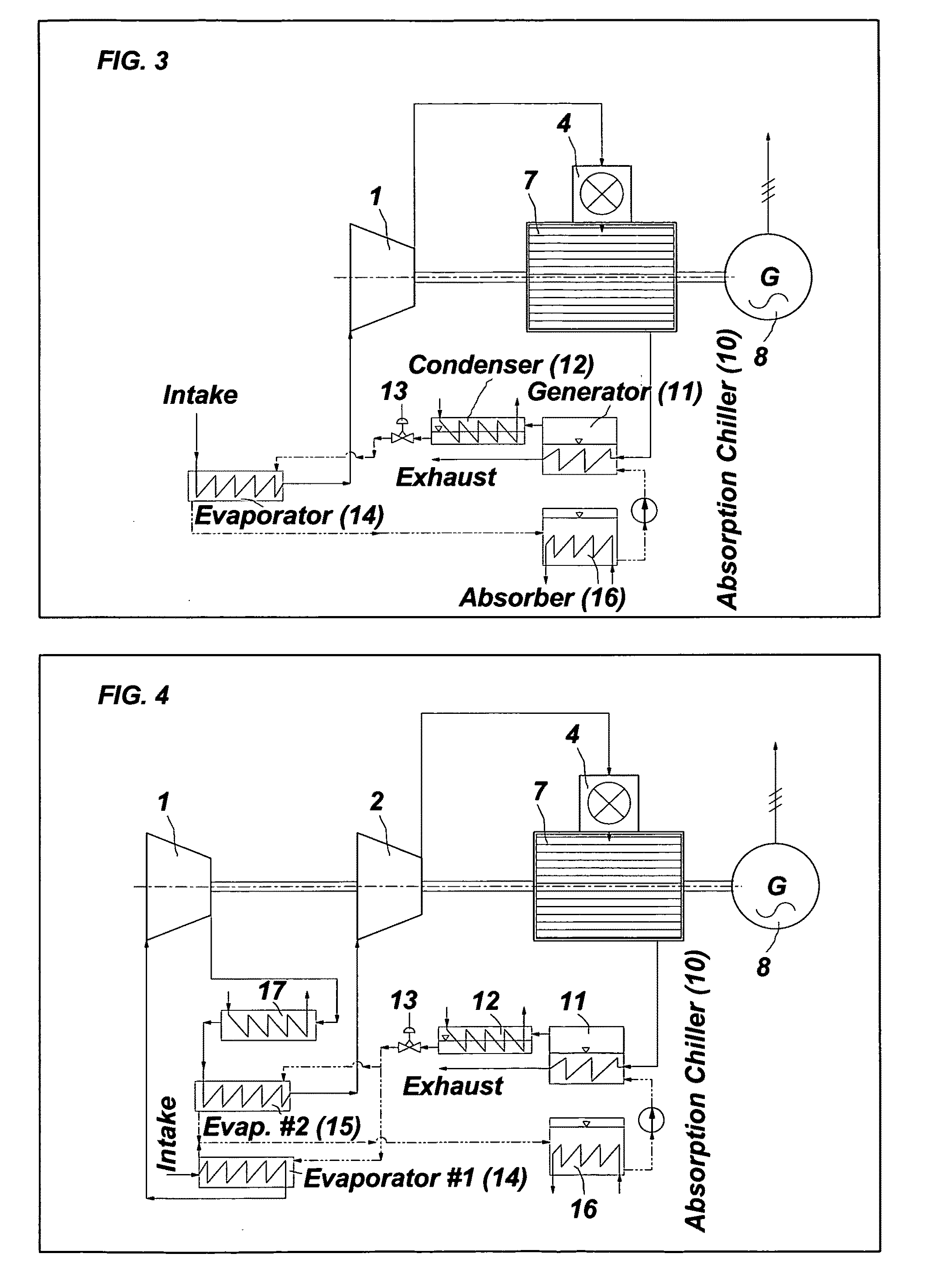

Rotating-Plate Radial Turbine in Gas-Turbine-Cycle Configurations

InactiveUS20100150713A1Huge cycle thermal efficiency improvementReducing greenhouse gas emissionPump componentsBlade accessoriesTurbine bladeAtkinson cycle

A novel power-producing concept is disclosed, employing a rotating-plate radial gas turbine in various gas-turbine cycle configurations. The “rotating-plate radial gas turbine” is a rotating barrel with robust rectangular plates fitted into the turbine rotor, performing the function and the role of turbine blades, contained within a motionless rigid horizontal cylinder (casing). Combustion can take place in the spaces confined between adjacent rotating plates and the static cylinder, thus enabling a practical achievement of the Atkinson cycle (constant-volume heat addition) with improved cycle thermal efficiency. Alternatively, two or more compressor stages can be combined to feed a single rotating-plate radial gas turbine in cascades, thus gradually increasing pressure of working gas within a volume bordered by adjacent un-cooled rotating plates of the radial gas turbine and the casing. Alternatively, a single compressor may be combined with one or more stages of an axial turbine for cascade feeding of a single rotating-plate radial gas turbine. This “isochoric stuffing” effect enables achievement of significantly and even drastically improved gas-turbine-cycle thermal efficiencies. Cycle heat addition may be either isobaric or isochoric in either an open-cycle or a closed-cycle configuration. Using a sufficiently efficient radial gas turbine, it is theoretically possible to obtain 100% cycle thermal efficiency in a simple radial-gas-turbine configuration with appropriately chosen compressor-stages compression pressure ratios.

Owner:STANKOVIC BRANKO

Control system of internal combustion engine

InactiveUS20170107916A1Reduce the amount requiredControl is carry-outElectrical controlInternal combustion piston enginesControl systemAtkinson cycle

A control system according to one aspect of the present invention is applied to an engine. The engine comprises a port injector and an intake valve driving device capable of changing the closing timing of the intake valve. The engine, if an execution condition for performing a fuel cut control is satisfied when performing an Atkinson cycle, executes the fuel cut control after advancing the closing timing of the intake valve. As a result, by reducing the amount of the fuel which is blown back to the inside of the intake passage in a period where the intake valve is open after intake bottom dead center, the amount of the fuel which flows into the exhaust passage as unburned gas when the fuel cut control is executed can be reduced.

Owner:TOYOTA JIDOSHA KK

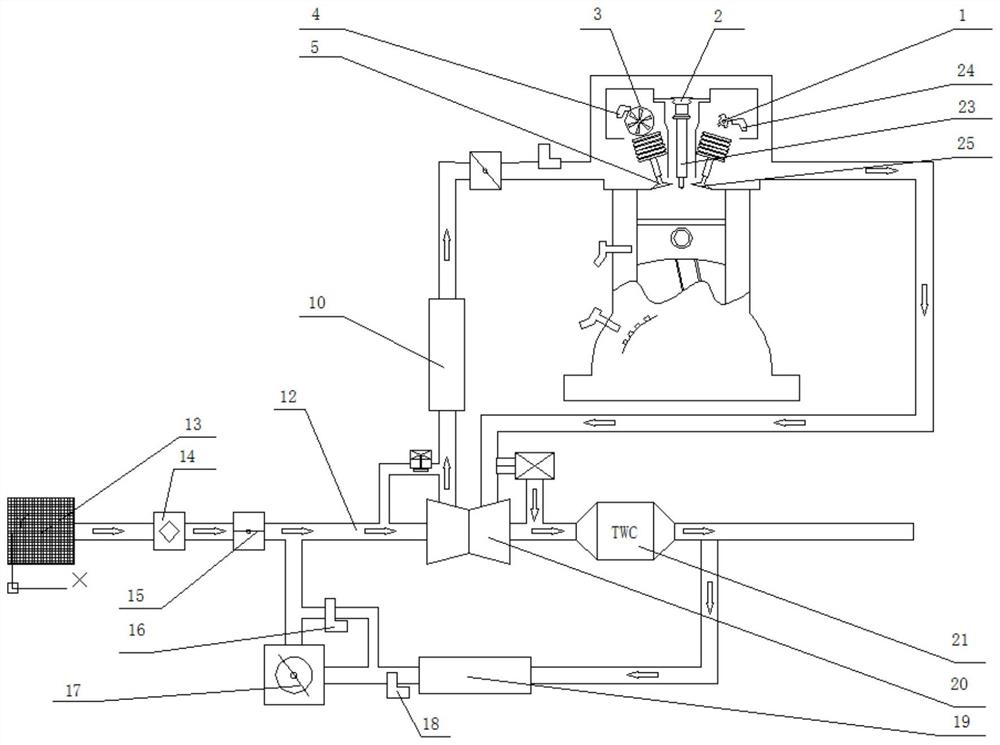

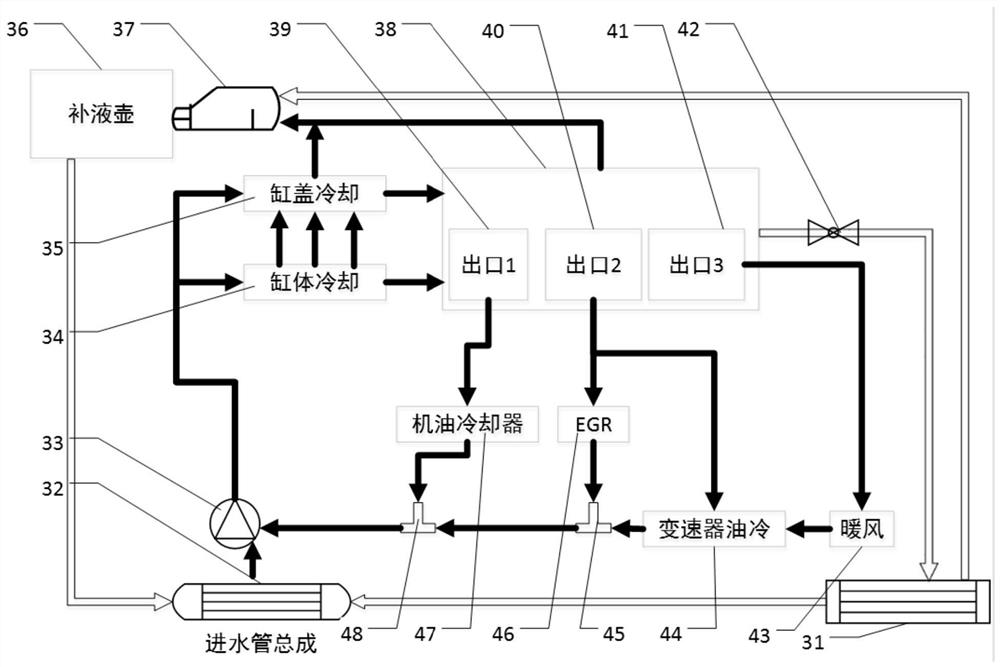

Atkinson cycle engine assembly with cooled EGR

ActiveCN114458434AIncreased power and torqueIncrease torqueLiquid coolingCoolant flow controlCrankAtkinson cycle

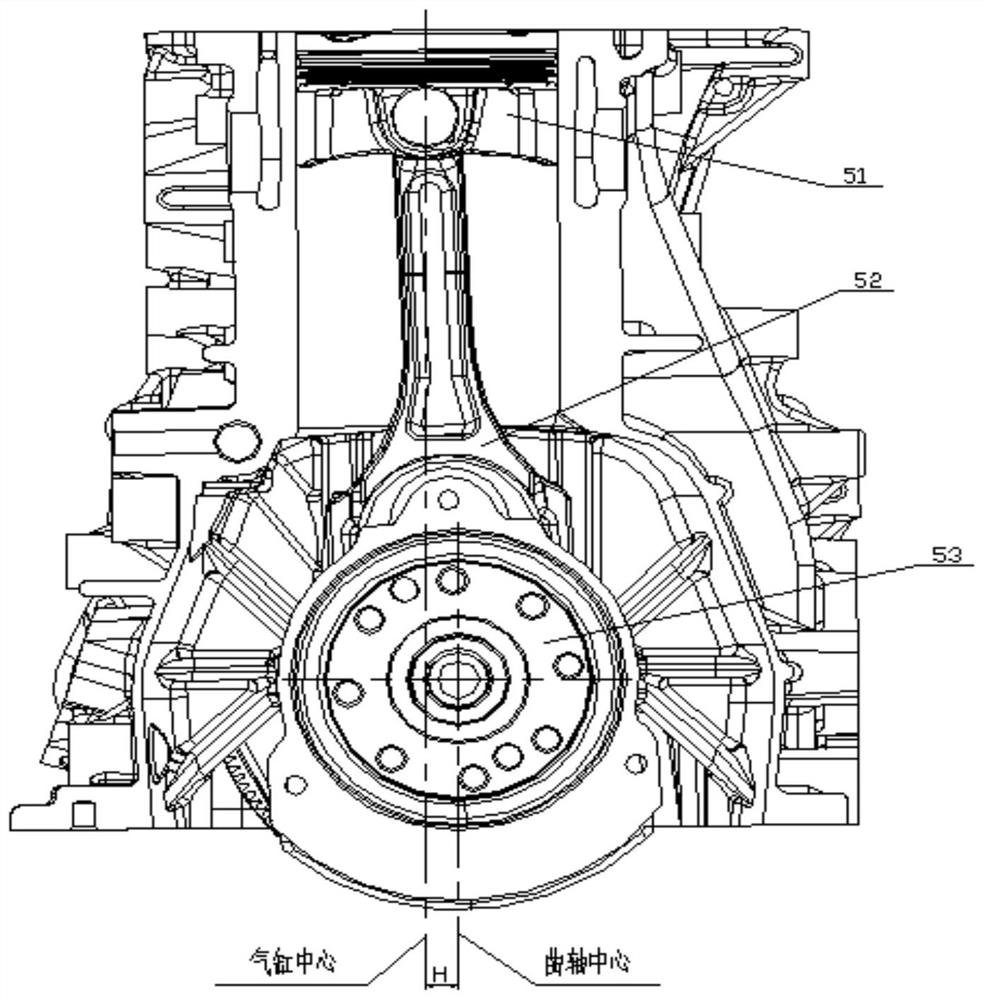

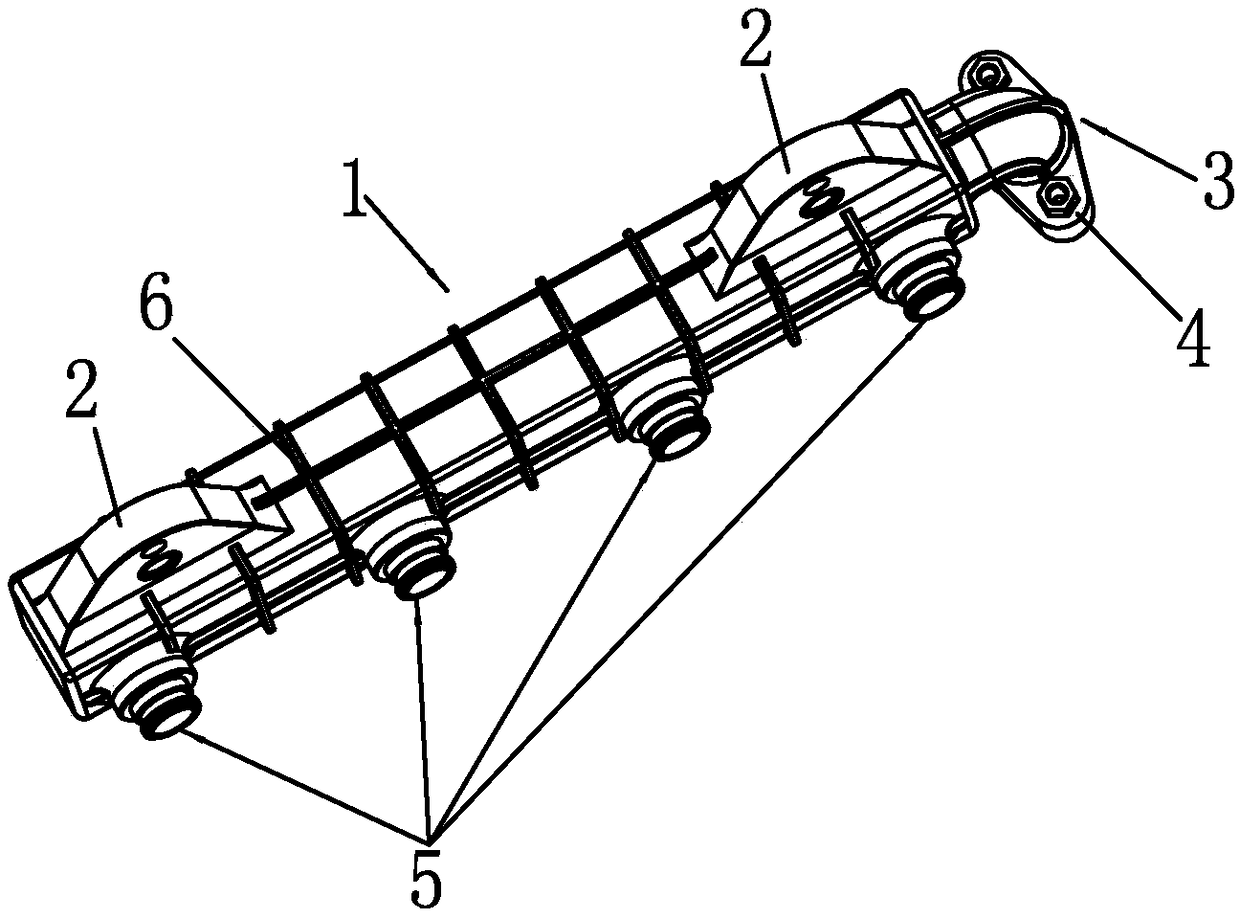

The invention discloses an Atkinson cycle engine assembly with a cooling EGR (Exhaust Gas Recirculation) function, and belongs to the technical field of ignition type engines with distribution mechanisms. A crank connecting rod mechanism, an ignition system, a gas distribution system, a gas inlet system and a gas exhaust system are mounted in each engine cylinder; the air distribution system adopts the Atkinson cycle technology, and the eccentric distance H between the piston axis of the crank connecting rod mechanism and the crankshaft axis is approximately equal to 9-11 mm. The low fuel consumption rate and the high engine power torque are achieved in the mode that cooling EGR and Atkinson circulation are combined, and the engine torque can be increased by 30% to the maximum. The waste gas temperature is reduced through the cooler, the waste gas amount and the EGR rate can be effectively increased, and when low-temperature waste gas participates in in-cylinder combustion, the contribution to oil consumption reduction and emission is larger. The crankshaft bias technology is adopted, the Atkinson ratio is increased under the condition that the gas distribution phase is not changed, and the low fuel consumption rate is achieved as well.

Owner:HARBIN DONGAN AUTOMOTIVE ENGINE MFG CO LTD

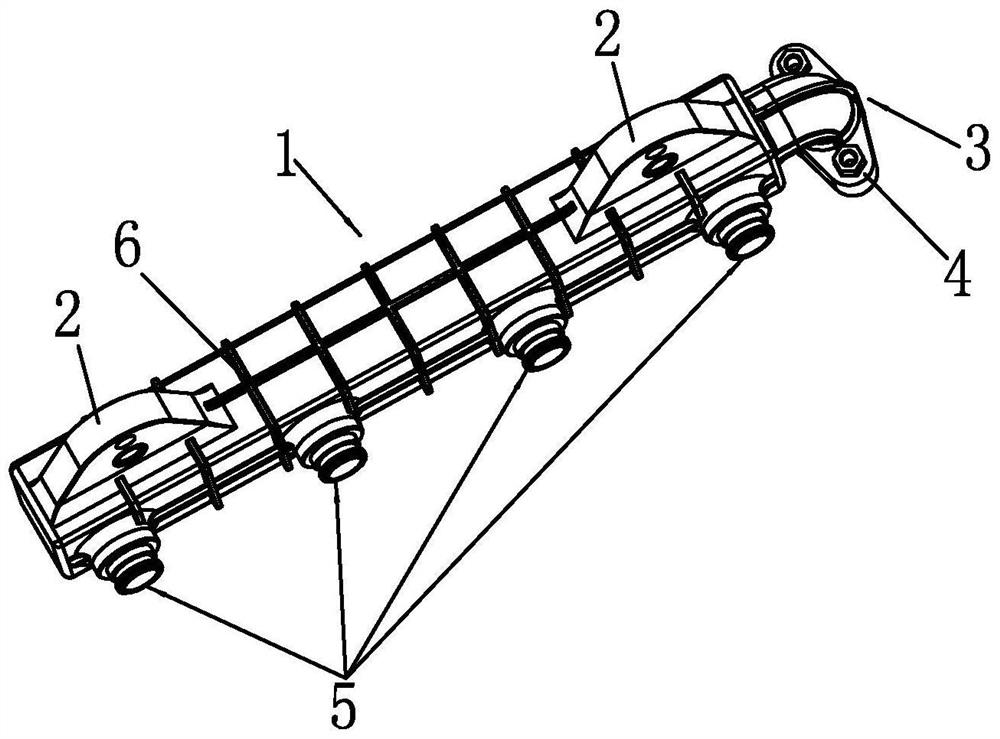

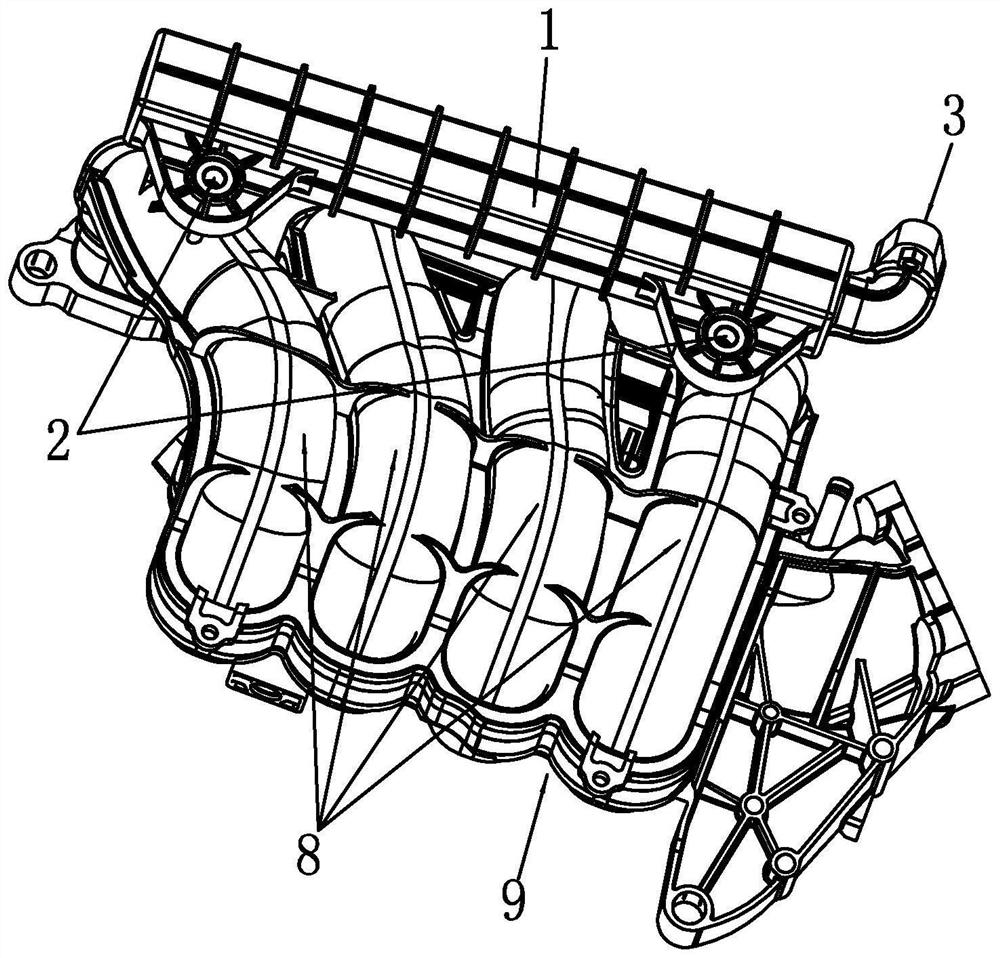

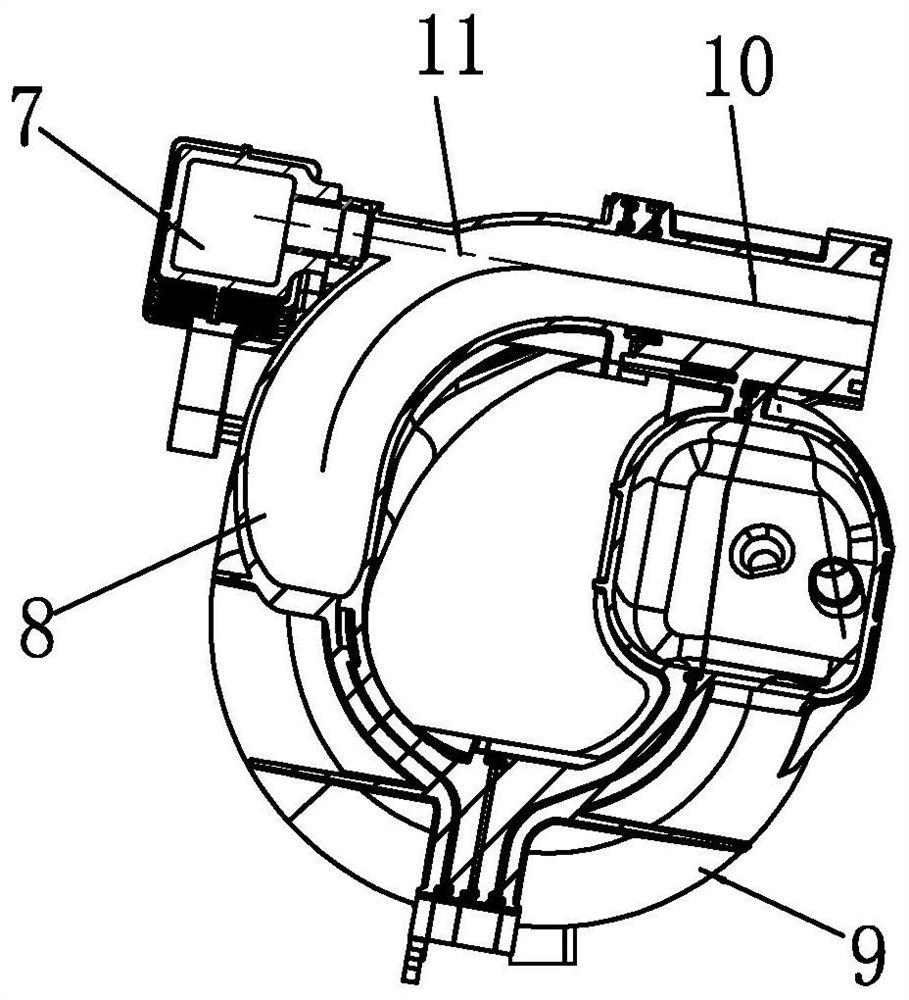

Atkinson cycle implement method for natural air suction gasoline engine

ActiveCN108915914AReduce low load misfire rateSuppression of high load knockingValve arrangementsInternal combustion piston enginesIgnition coilHigh energy

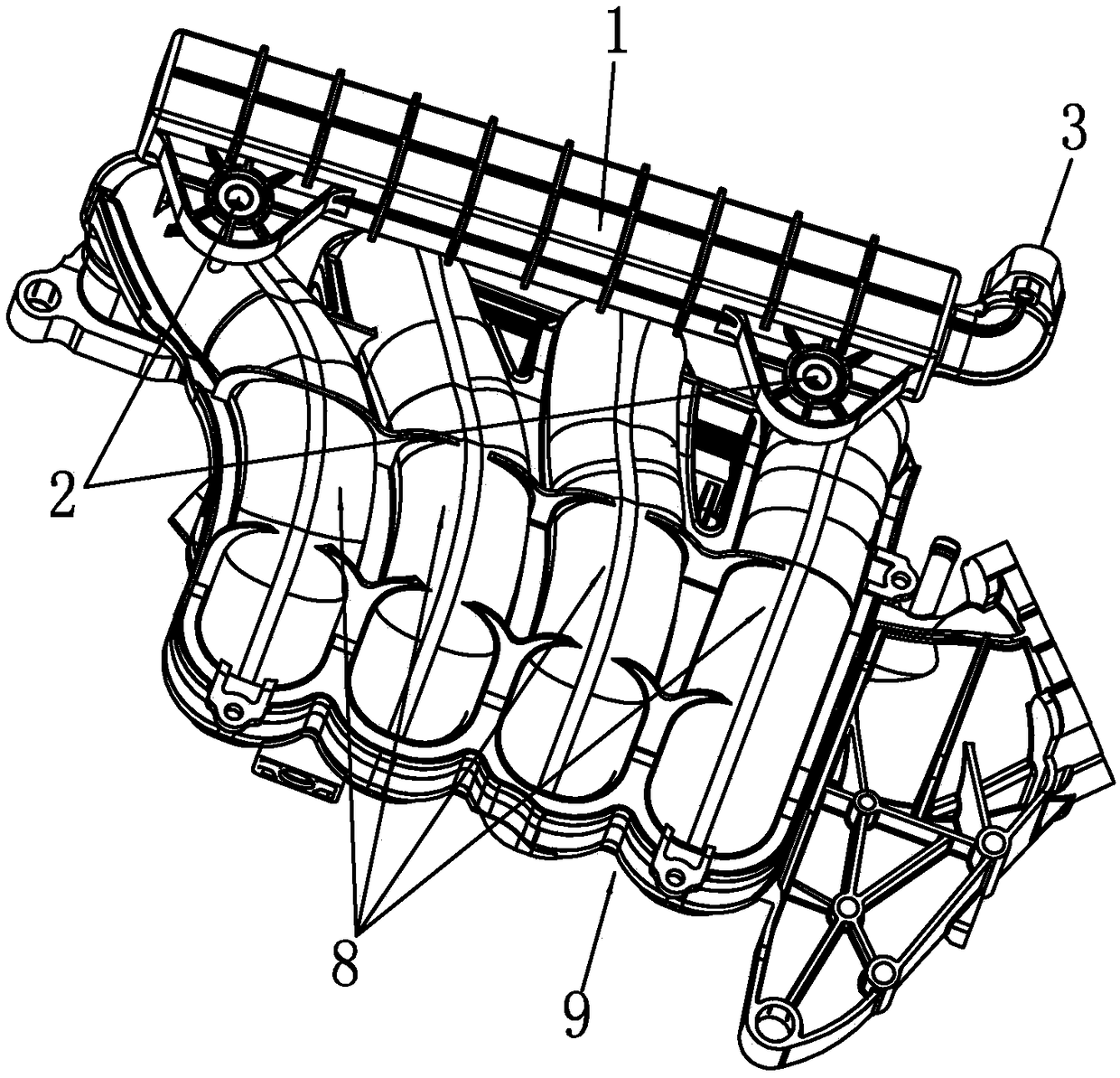

An Atkinson cycle implement method for a natural air suction gasoline engine comprises the following steps: (1) a high-energy ignition coil is used, and the ignition energy of the ignition coil is atleast 80 mJ; (2) an EGR pressure stabilizing cavity is integrated on an air inlet manifold, the EGR system takes exhaust gas from the outlet of an exhaust manifold, and the exhaust gas enters the EGRpressure stabilizing cavity after passing through the EGR system, and the exhaust gas is gathered in the EGR pressure stabilizing cavity and evenly distributed to each branch pipe of the inlet manifold; (3) a high-rolling-flow air inlet channel is used for matching a piston with a shallow pit on the top surface; (4) the intake camshaft is of a variable valve phase system, the phase adjustment angle of the intake valve is 58 DEG crankshaft angle, the delay closing of the intake valve is achieved, the maximum delay closing angle of the intake camshaft is maximum above 100 DEG crankshaft angle after the bottom dead center, and the effective compression ratio of the engine is adjusted. According to the method, the low-load misfire rate can be effectively reduced, high-load knocking can be restrained, the intermediate load heat efficiency is improved, and the combustion stability of the whole working condition is improved.

Owner:LIUZHOU WULING LIUJI POWER

Axial Piston Internal Combustion Engine Using an Atkinson Cycle

InactiveUS20140182526A1Internal combustion piston enginesReciprocating piston enginesFriction reductionSpool valve

An axial piston internal combustion engine designed to improve the thermal efficiency of the engine by utilizing a sine wave / connecting rod assembly (5) to cause the piston (6) of the engine to travel vertically parallel to the engine's main shaft (13). The upper sine wave barrel (2) and lower sine wave barrel (3) have a channel in them that the cylindrical ends of the connecting rod (4) travel in, forcing the connecting rod (4) and piston (6) to travel vertically. The engine also utilizes slide valve (20) that has slots in it that when slid past the ports of the upper cylinder head (18) and lower cylinder head (19) controls the intake and exhaust timing events of the engine. The channel in the upper sine wave barrel (2) and lower sine wave barrel (3) is designed such that the vertical expansion / exhaust strokes of the engine are longer than the intake / compression strokes which allow the engine to make more efficient use of the energy produced by combusting the fuel, improving the thermal efficiency of the engine. The design also reduces the friction between the cylinder walls and piston (4) and the friction associated with typical engines valvetrain components, improving the overall efficiency of the engine. By reducing the frictional losses and improving the thermal efficiency the new engine should have decreased fuel consumption.

Owner:ROBARDS BRIAN

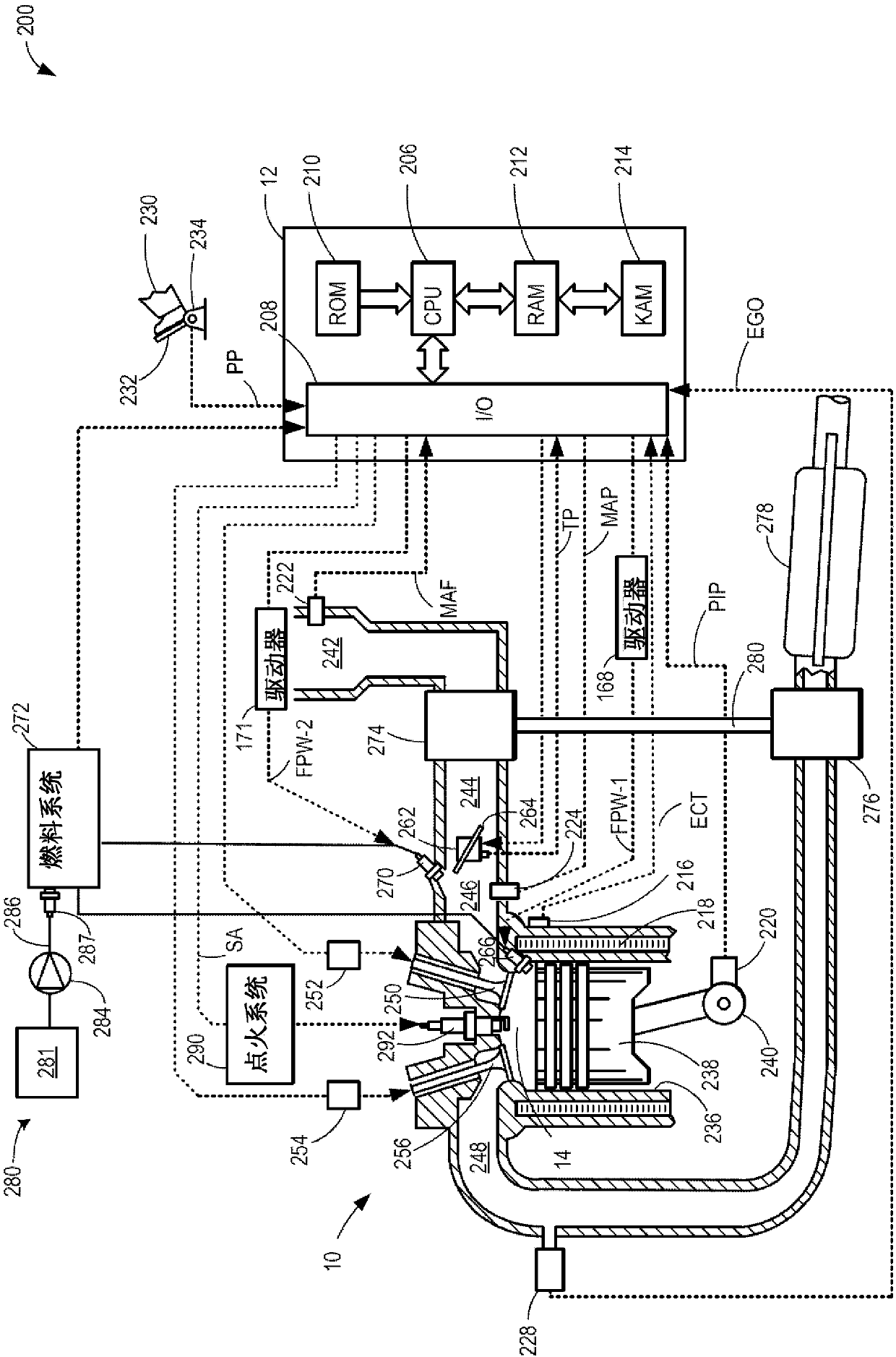

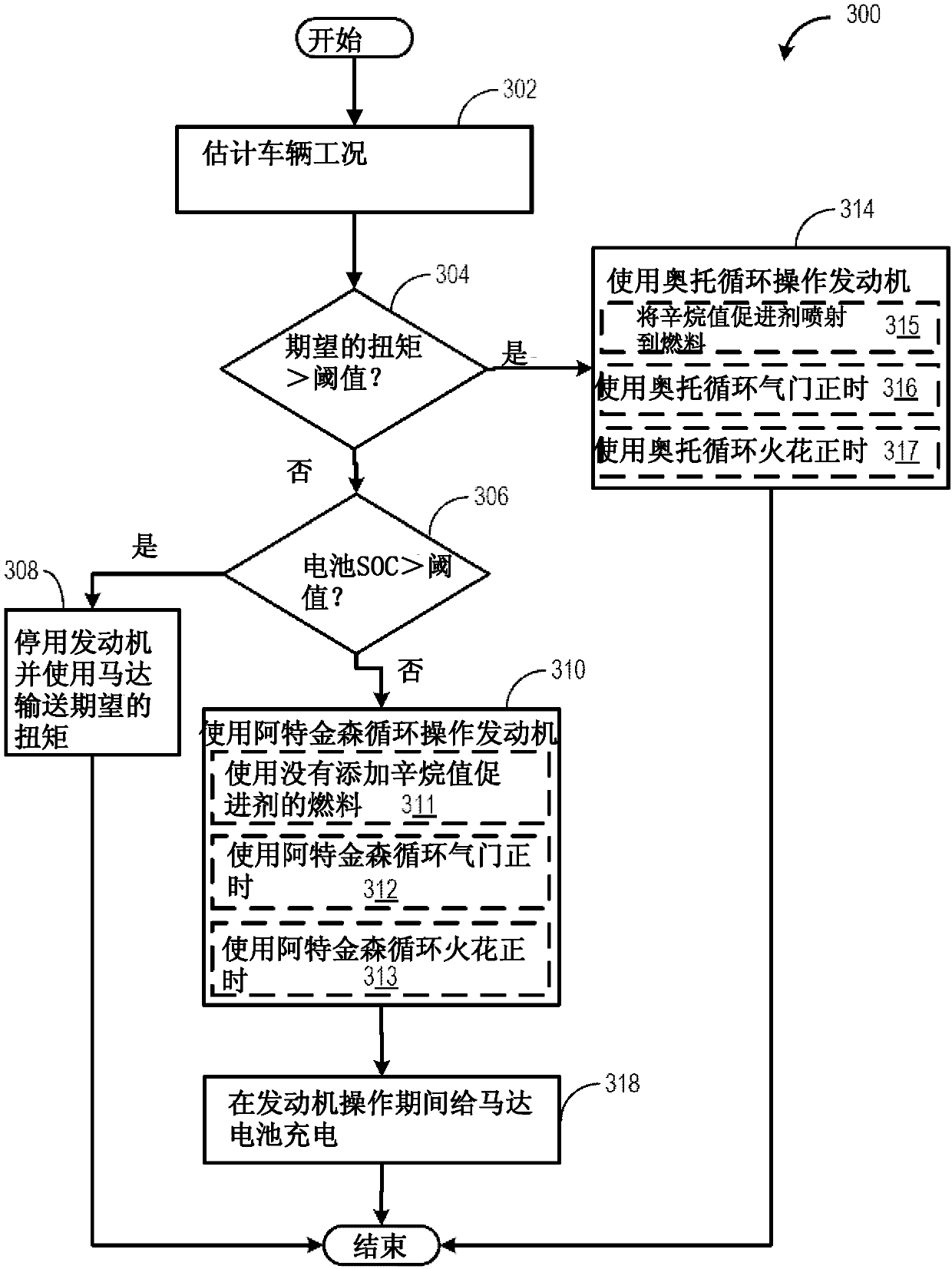

Methods and systems for hybrid vehicle power delivery

ethods and systems are provided for adjusting engine operation of a hybrid vehicle to increase power output, and fuel efficiency. In one example, a method may include operating the engine using an Atkinson cycle during a lower than threshold engine torque demand, and a lower than threshold battery state of charge, and operating the engine using an Otto cycle during a higher than threshold torque demand. During operating in the Otto cycle, an octane booster may be injected to the fuel line to increase the octane level in the fuel.

Owner:FORD GLOBAL TECH LLC

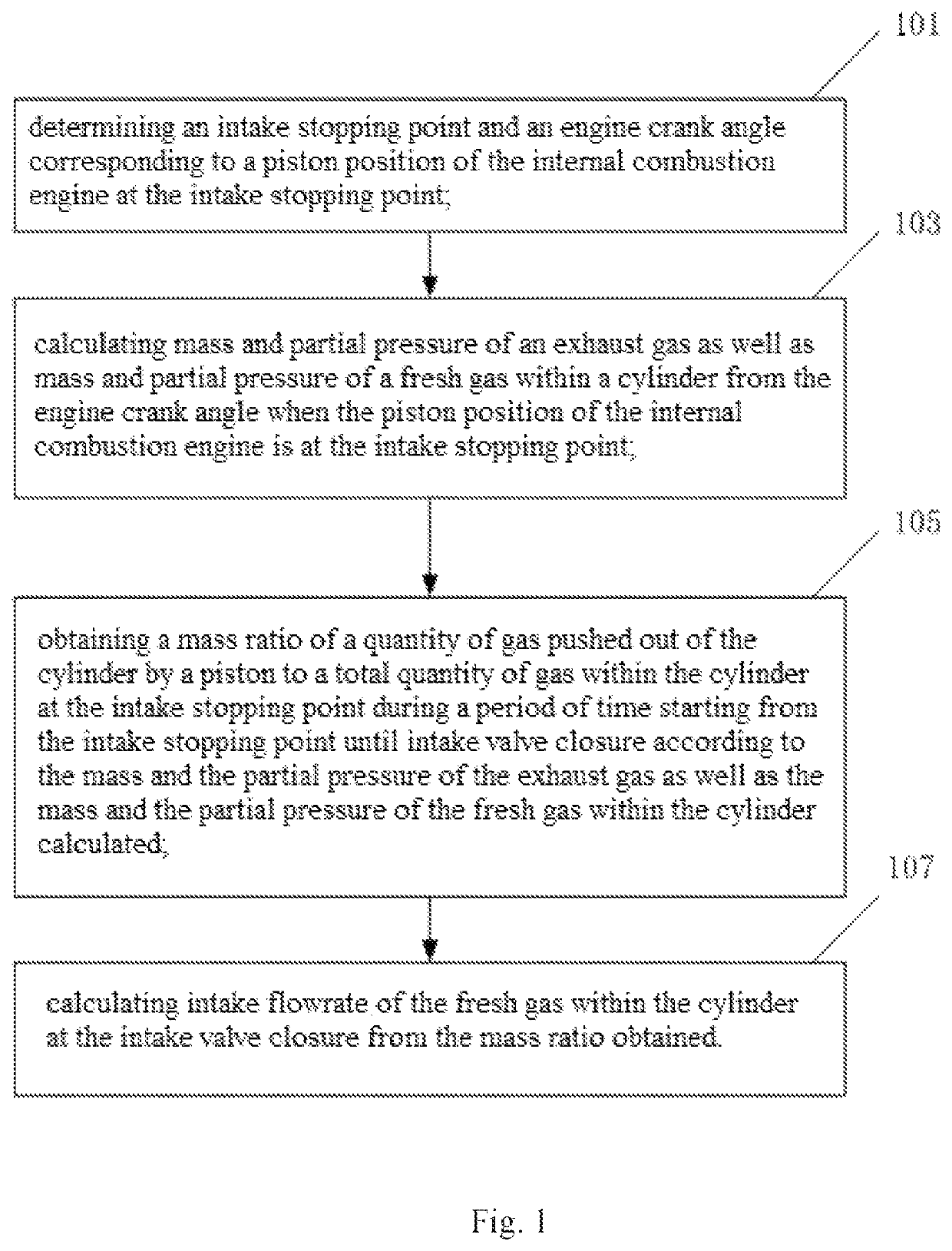

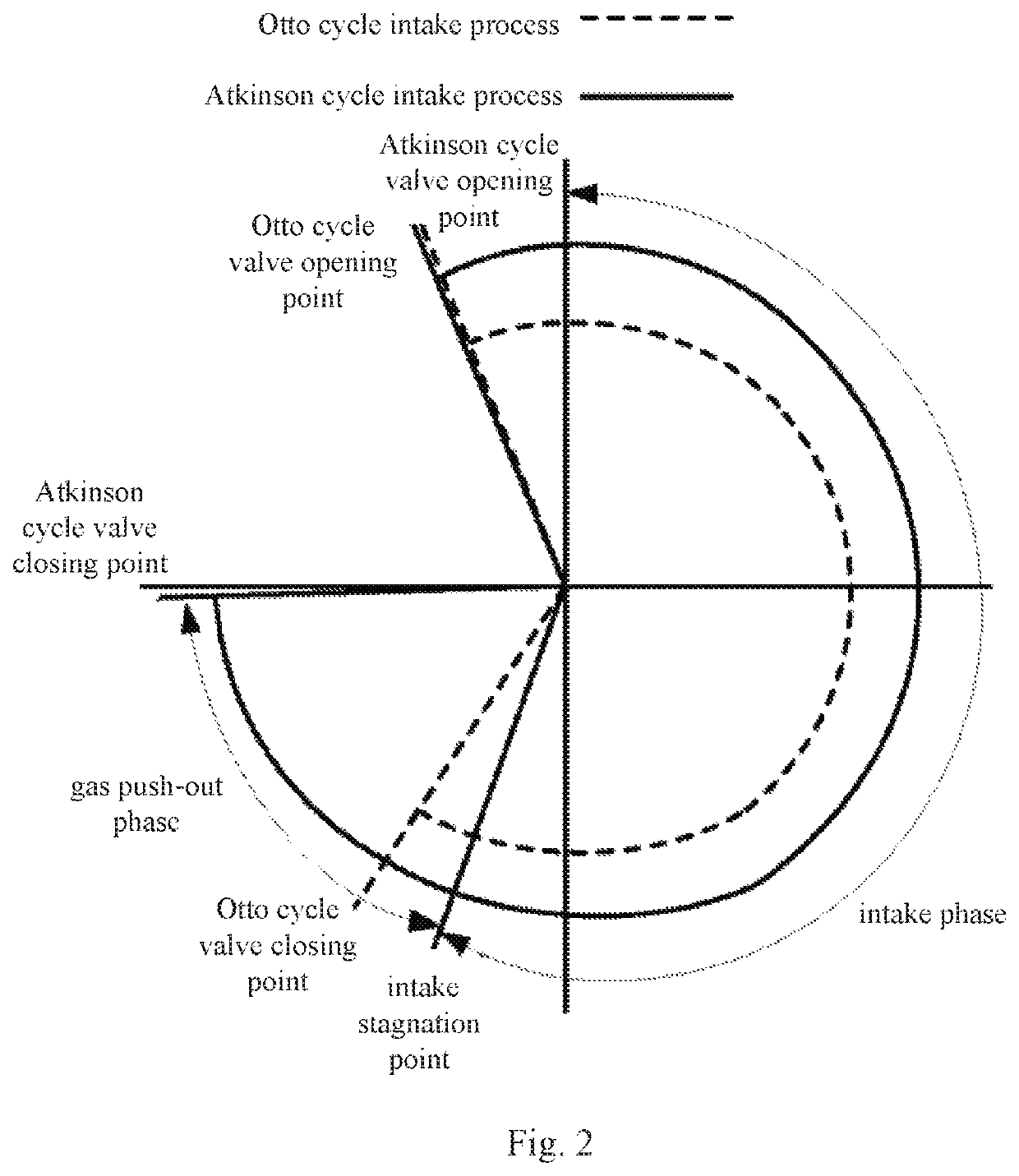

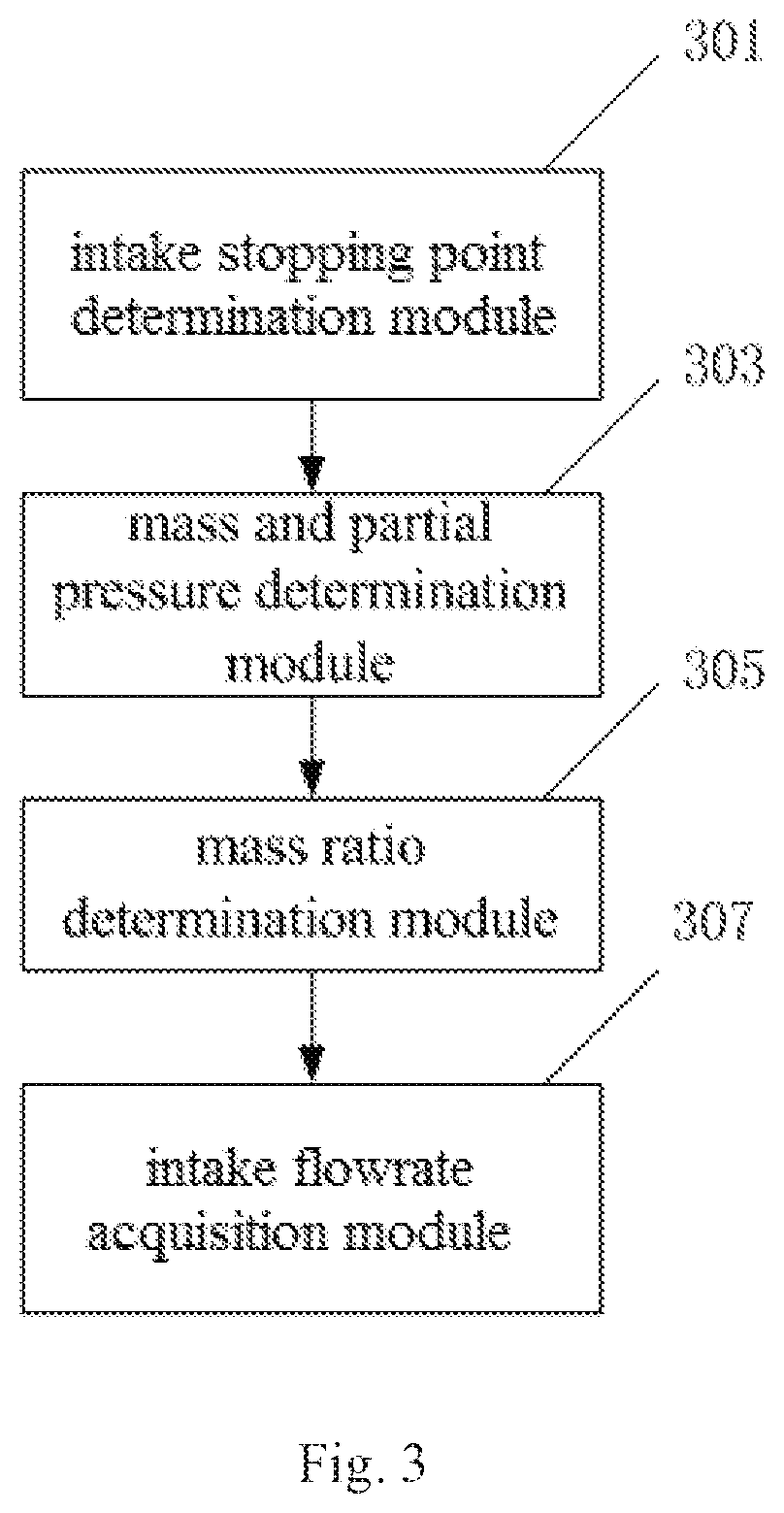

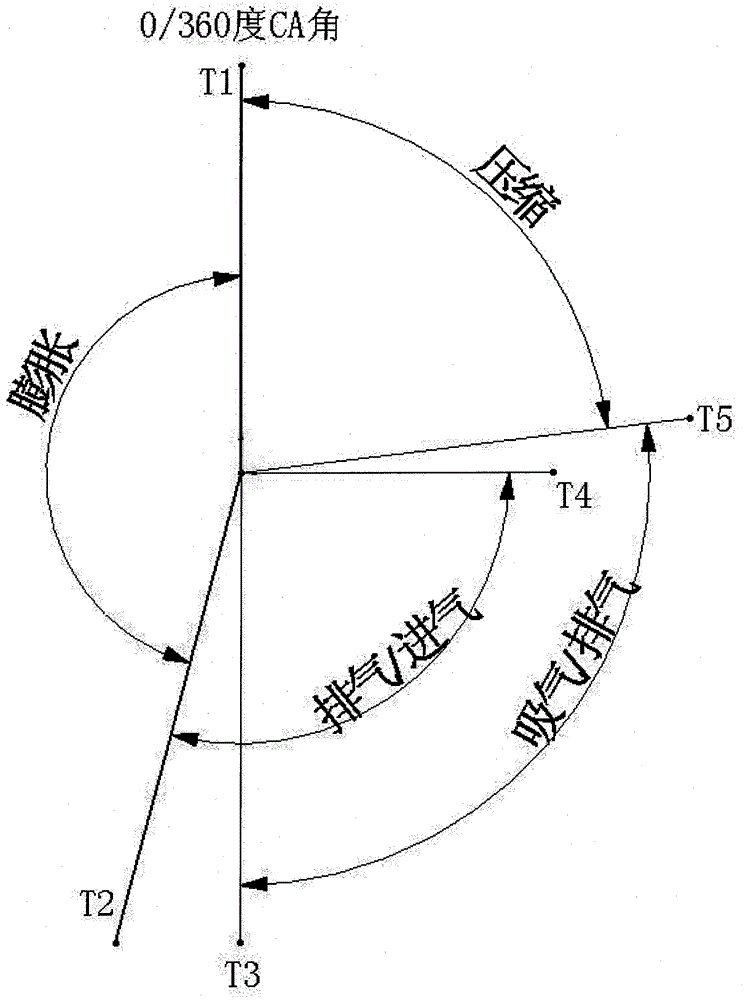

Method and system for calculating Atkinson cycle intake flowrate of internal combustion engine

ActiveUS10648418B2Wide applicationAccurate calculationHybrid vehiclesElectrical controlAtkinson cycleInlet valve

A method for calculating Atkinson cycle intake flowrate of an internal combustion engine includes determining an intake stopping point and an engine crank angle corresponding to a piston position of the internal combustion engine at the intake stopping point; calculating mass and partial pressure of an exhaust gas and a fresh gas within a cylinder from the engine crank angle; obtaining a mass ratio of a quantity of gas pushed out of the cylinder by a piston to a total quantity of gas within the cylinder at the intake stopping point during a period of time starting from the intake stopping point until intake valve closure; and calculating intake flowrate of the fresh gas within the cylinder at the intake valve closure from the mass ratio obtained. Also disclosed is a system for calculating Atkinson cycle intake flowrate of an internal combustion engine.

Owner:GUANGZHOU AUTOMOBILE GROUP CO LTD

Multimode full overhead valve two-stroke internal combustion engine using two-stroke Atkinson cycle

InactiveCN103233789BValve arrangementsInternal combustion piston enginesExhaust valveVariable valve timing

The invention discloses a multi-mode two-stroke atkinson cycle internal-combustion engine with a fully overhead valve. According to two-stroke atkinson cycle, a scavenging process is offset on the basis of the two-stroke cycle, the distance of a compression stroke is reduced, and the distance of an expansion stroke is prolonged, and therefore, the atkinson cycle is realized and the balance of the internal-combustion engine is kept. On the basis of a common two-stroke internal-combustion engine, the multi-mode two-stroke atkinson cycle internal-combustion engine adopts an overhead embedded inlet valve with large gradient degree and an air cylinder head structure of a common exhaust valve, when the inlet valve is opened, the inlet valve temporarily serves as a separation board, a guiding function of a bulge on a formed top piston is utilized, so that a high-efficiency scavenging structure is realized; a fully variable valve timing mechanism is used to adjust the angle relation of the valve and a crank shaft, the opening and closing time of the inlet and outlet valve can be adjusted, and therefore, the internal-combustion engine has the following working modes: two-stroke atkinson cycle, two-stroke cycle and adjustable discharge capacity and compression ratio; and the efficiency of the internal-combustion engine is greatly improved.

Owner:朱譞晟

A Method for Realizing the Atkinson Cycle of a Naturally Aspirated Gasoline Engine

ActiveCN108915914BReduce low load misfire rateSuppression of high load knockingValve arrangementsInternal combustion piston enginesIgnition coilHigh energy

The invention provides a method for realizing the Atkinson cycle of a naturally aspirated gasoline engine, the method comprising: (1) adopting a high-energy ignition coil, the ignition energy of which is at least 80mJ; (2) integrating EGR on the intake manifold to stabilize the voltage The EGR system takes the exhaust gas from the outlet of the exhaust manifold, and enters the EGR pressure stabilizing cavity after passing through the EGR system. The exhaust gas is collected in the EGR stabilizing cavity and evenly distributed to each branch of the intake manifold; The air intake port matches the piston with a shallow pit on the top surface; (4) The intake camshaft adopts the variable valve phase system, and the intake valve phase adjustment angle is 58 ° crankshaft angle to realize the delayed closing of the intake valve, and the intake cam The maximum delayed closing angle of the shaft is more than 100 ° crankshaft angle after the bottom dead center to adjust the effective compression ratio of the engine. The method of the invention can effectively reduce low-load misfire rate, suppress high-load detonation, improve intermediate-load thermal efficiency, and improve combustion stability in all working conditions.

Owner:LIUZHOU WULING LIUJI POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com