Split type superhigh-expansion-ratio engine and adjustment and control method

An engine, split technology, applied in engine components, combustion engines, machines/engines, etc., can solve problems such as low fuel efficiency, reduced compression ratio, and unstable compression ratio, and achieve improved fuel efficiency, reduced fuel consumption, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

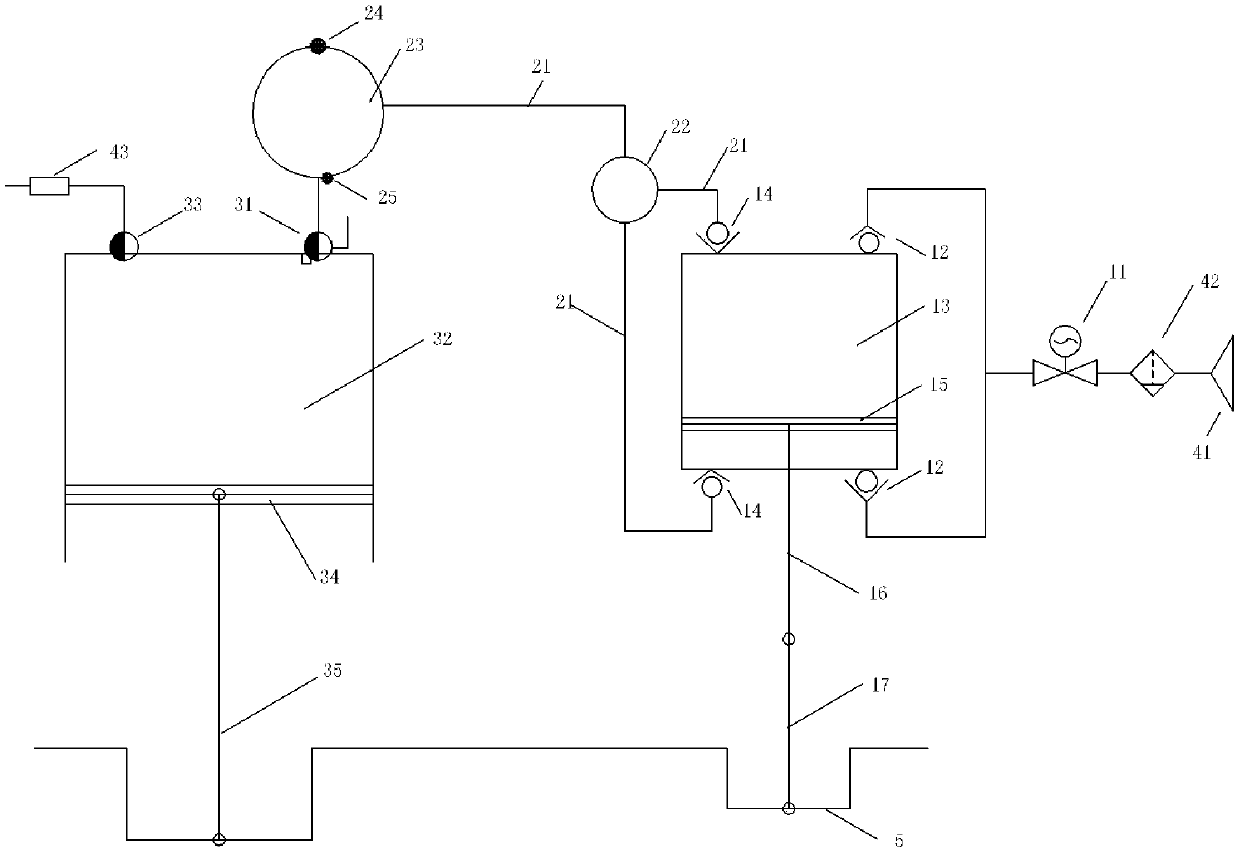

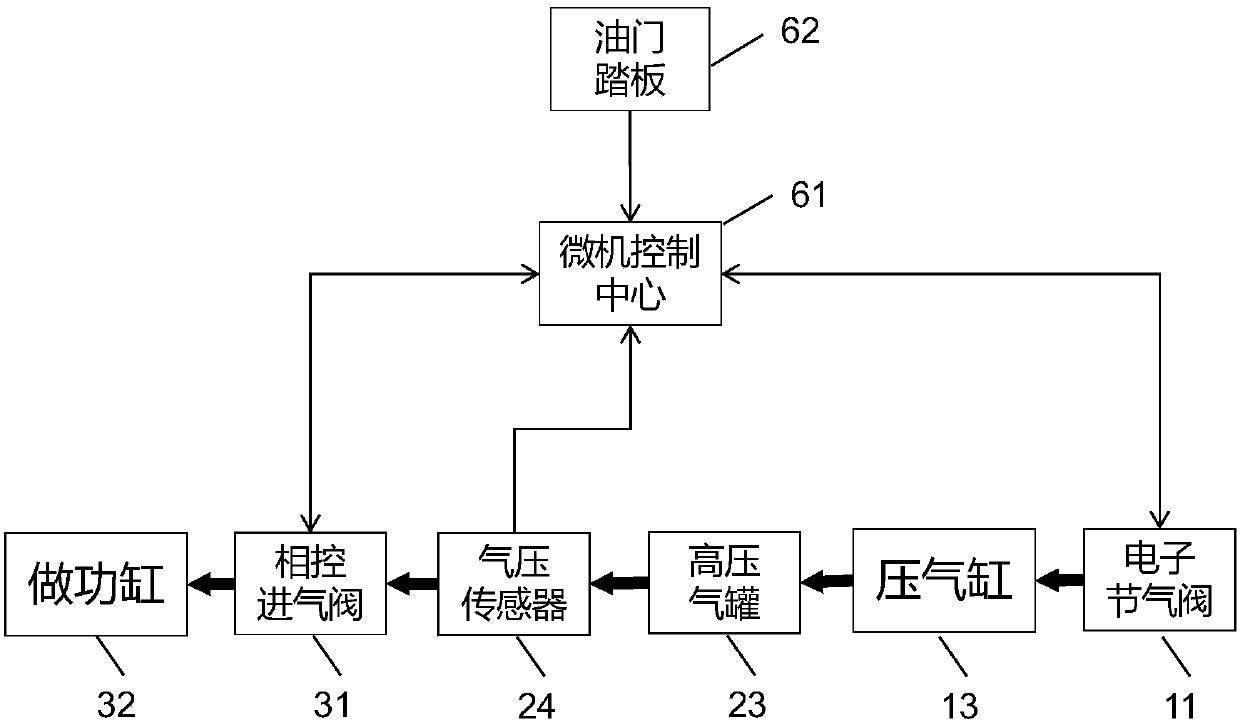

[0066] Such as figure 1 figure 2 As shown, the technical solution of a split-type ultra-large expansion ratio engine provided in this embodiment is mainly applicable to diesel compression ignition engines, and the specific implementation method includes the following steps:

[0067] Compression and storage of air

[0068] The crankshaft 5 rotates, and the fixed connecting rod 16 and the connecting rod 17 drive the piston 15 in the cylinder 13 to reciprocate up and down. The piston 15 divides the cylinder 13 into two halves.

[0069] Under the check action of the one-way valves 12 and 14, the compressed air first enters the buffer gas tank 22 for buffering through the high-pressure pipeline 21, and then is guided into the high-pressure gas tank 23 for temporary storage, and at the same time, the outside air is smoothly sucked through the air supply pipeline. Inlet air cylinder 13. The function of the buffer gas tank 22 is to buffer, slow down the air flow pulsation and redu...

Embodiment 2

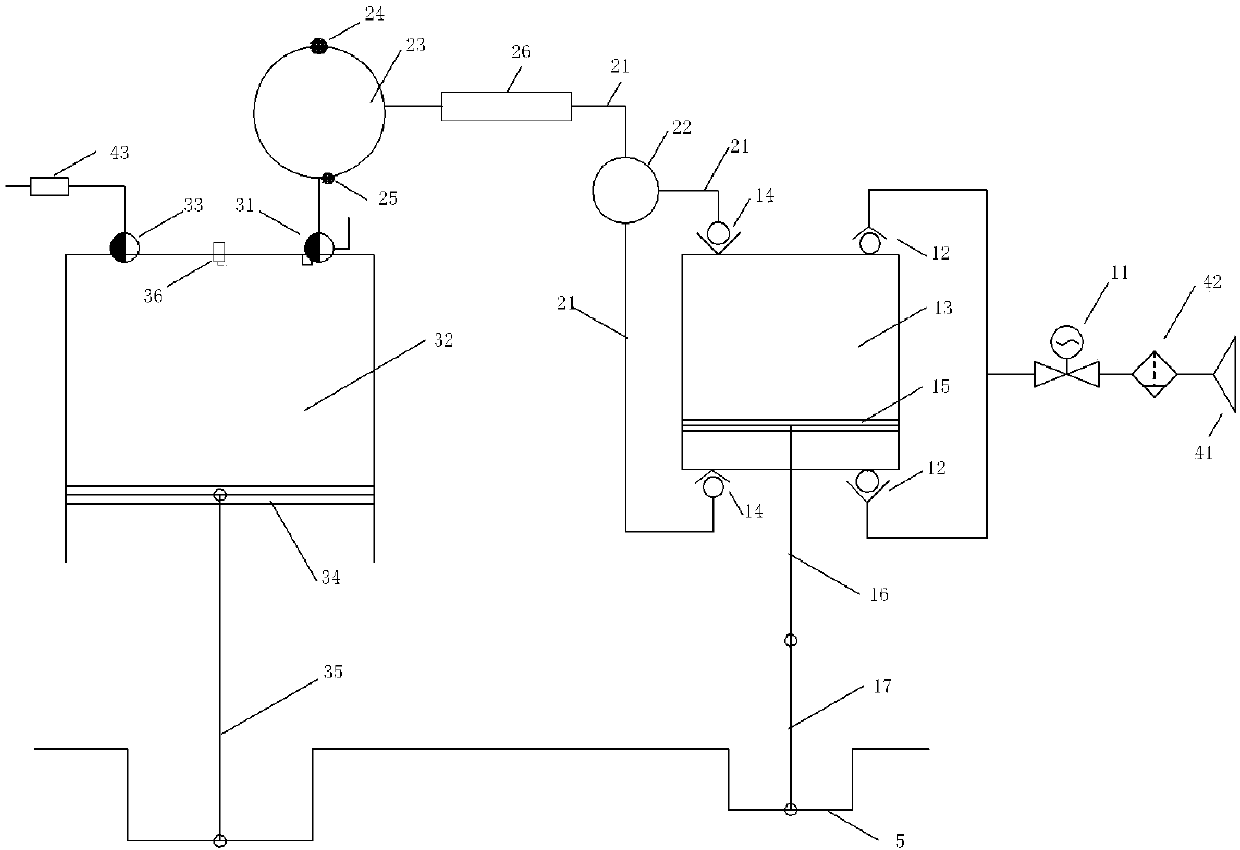

[0091] The engine technical solution provided in this embodiment is mainly applicable to gasoline non-compression ignition engines or gasoline-diesel dual-mode engines.

[0092] Such as image 3 As shown, this embodiment is basically the same as Embodiment 1, the difference mainly lies in: a heat dissipation and temperature control unit 26 is connected in series on the high-pressure pipeline 21, and a temperature sensor 25 is added in the high-pressure gas tank 23 near the gas outlet to perform work. Spark plug 36 is housed additional in the cylinder.

[0093] The difference also lies in the control of the compressed air temperature: the high-pressure gas tank 32 is also provided with a temperature sensor 25 near the air outlet to detect the temperature of the gas flowing into the working cylinder 32, and feeds back to the microcomputer control center 61, and the microcomputer control center 61 will feedback After the value is compared with the preset value, control the heat ...

Embodiment 3

[0096] The solution provided in this embodiment is mainly used to improve the pumping loss of the engine described in the first and second embodiments. The specific solution is to use a late-closing check valve to replace the one-way air intake of the medium-pressure cylinder in the first and second embodiments Valve 12, the corresponding electronic throttle valve 11 is cancelled.

[0097] Under the working condition of small throttle, the opening degree of the electronic throttle valve 11 is small, and the air resistance is large, so the pump air loss is large. If this part of energy loss is to be reduced, the one-way intake valve 12 of the pressure cylinder is replaced by a late closing check valve of the intake valve, and the corresponding electronic throttle valve 11 is canceled. The working principle of the late-closing check valve of the intake valve is: by controlling the late-closing check valve to delay the closing of a certain phase angle, a certain amount of air is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com