Patents

Literature

37 results about "Split cycle engine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

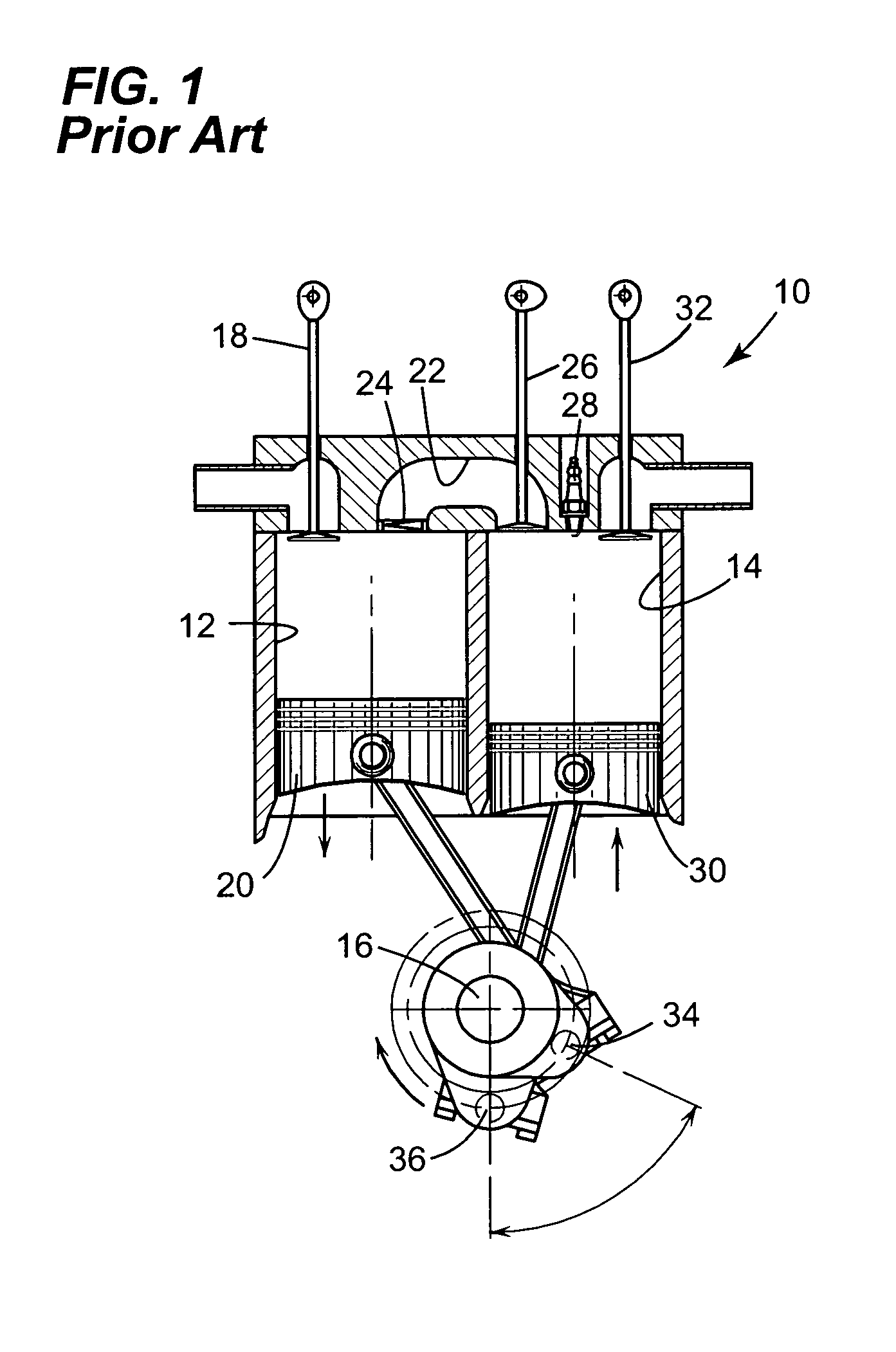

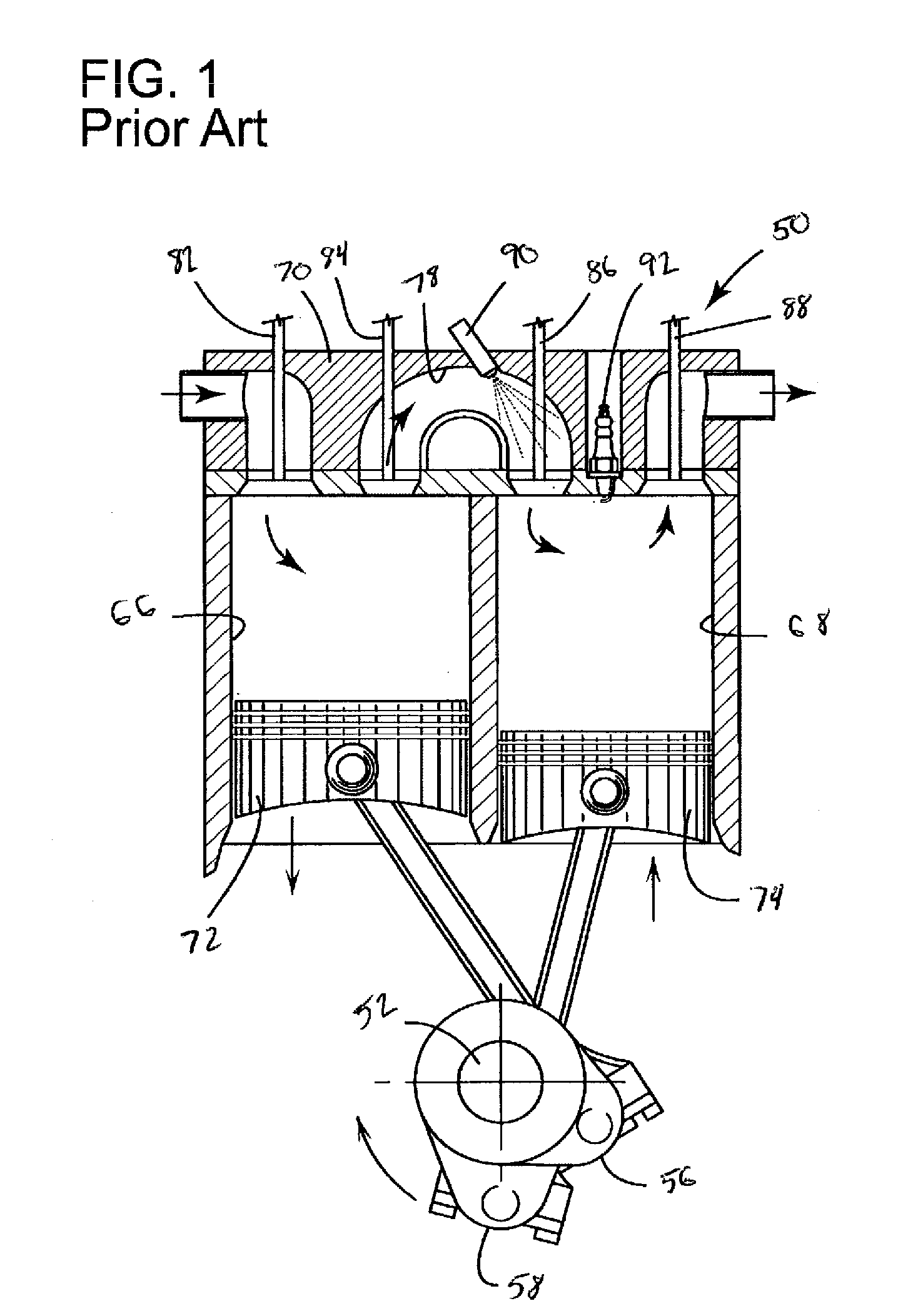

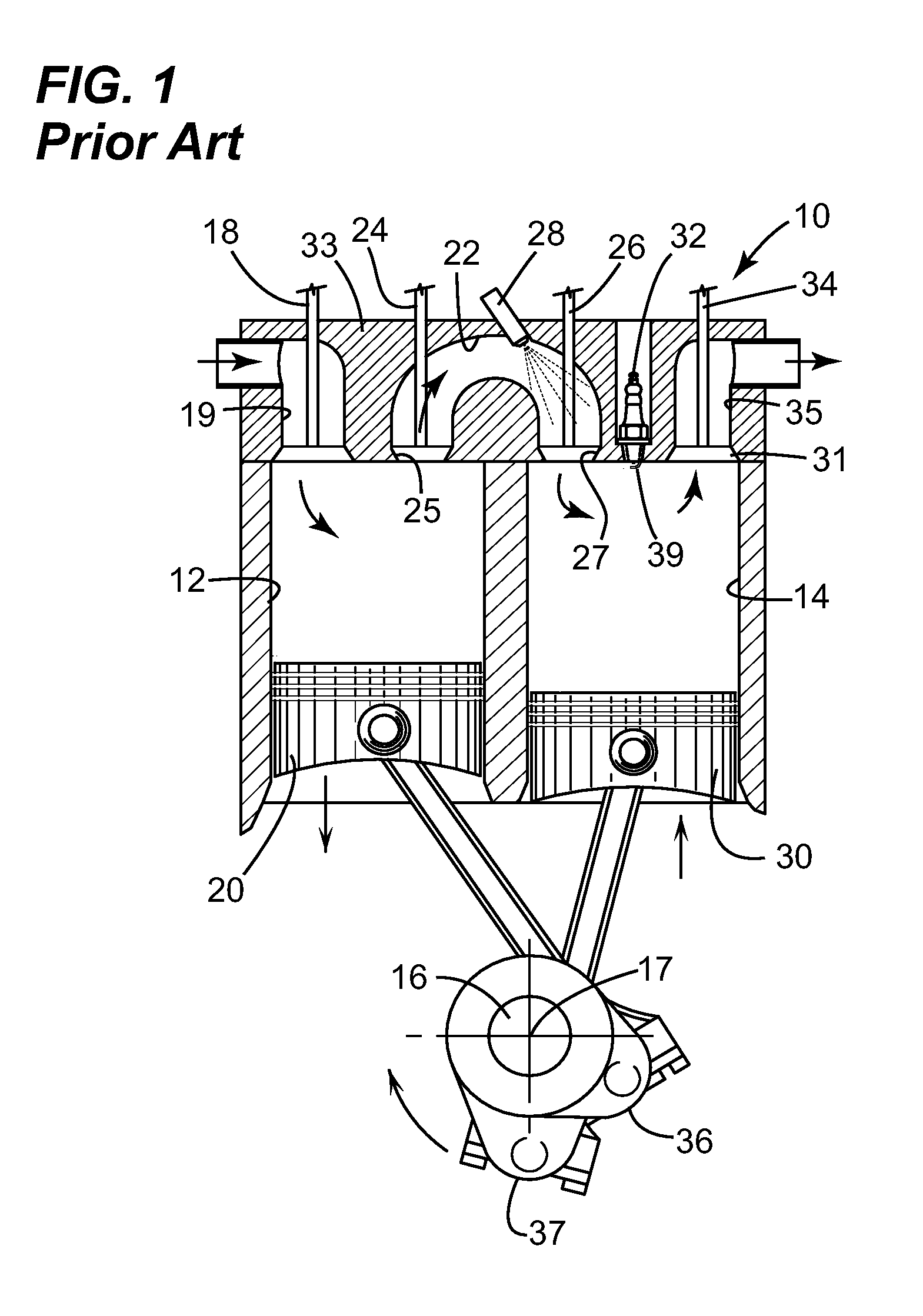

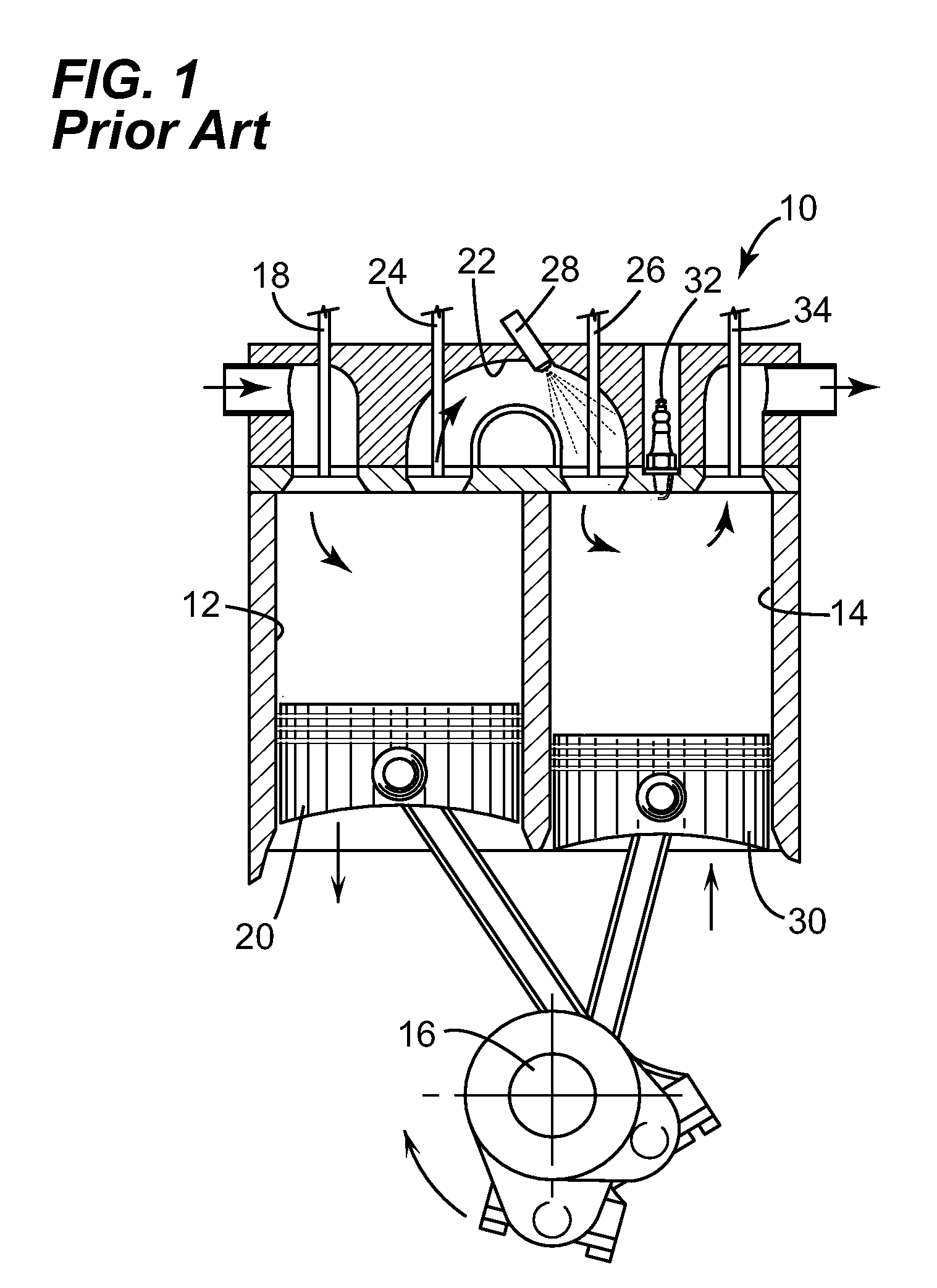

The split-cycle engine is a type of internal combustion engine.

Split-cycle air hybrid engine

InactiveUS7353786B2Internal combustion piston enginesEngine controllersTransmitted powerReciprocating motion

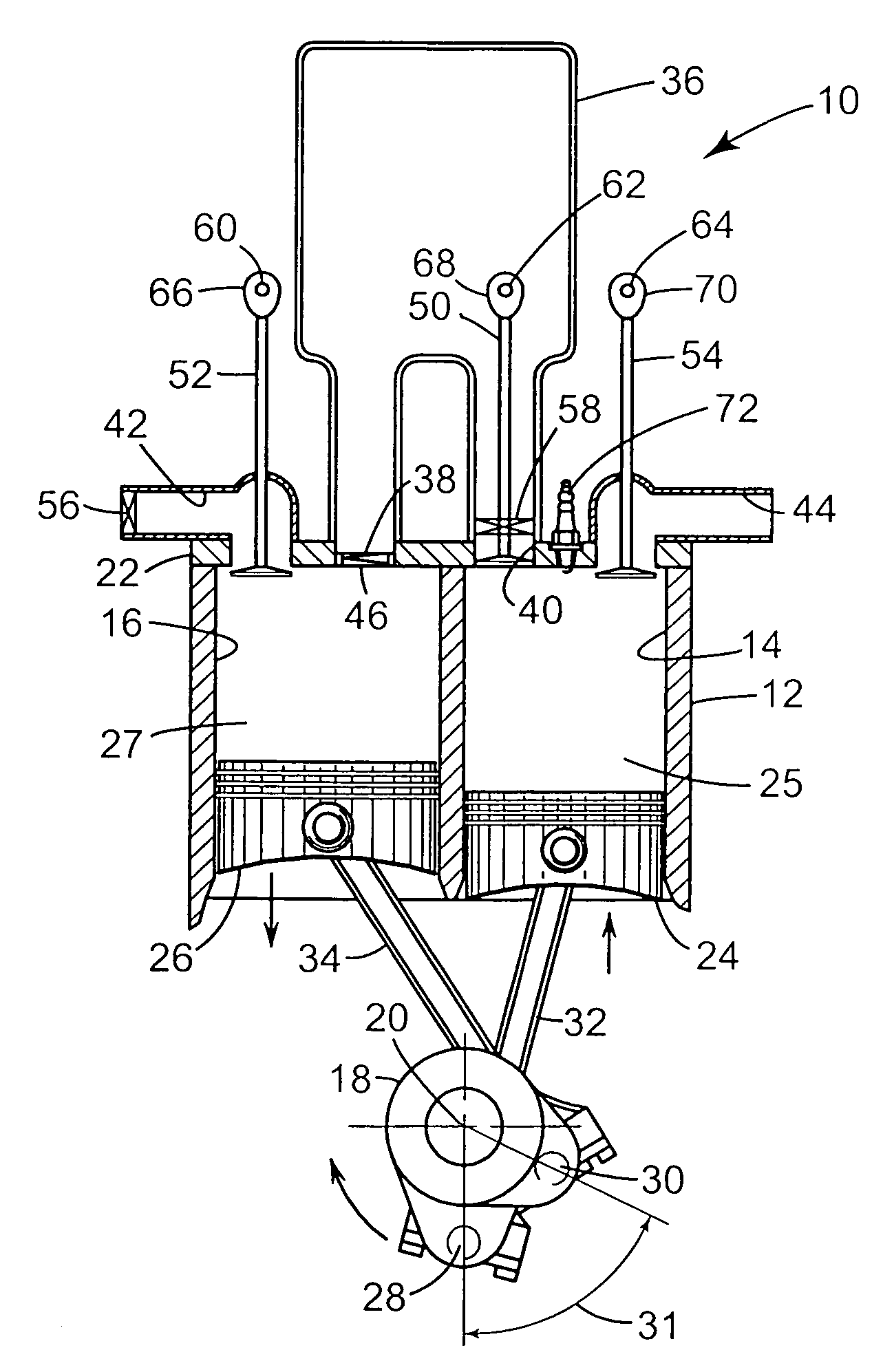

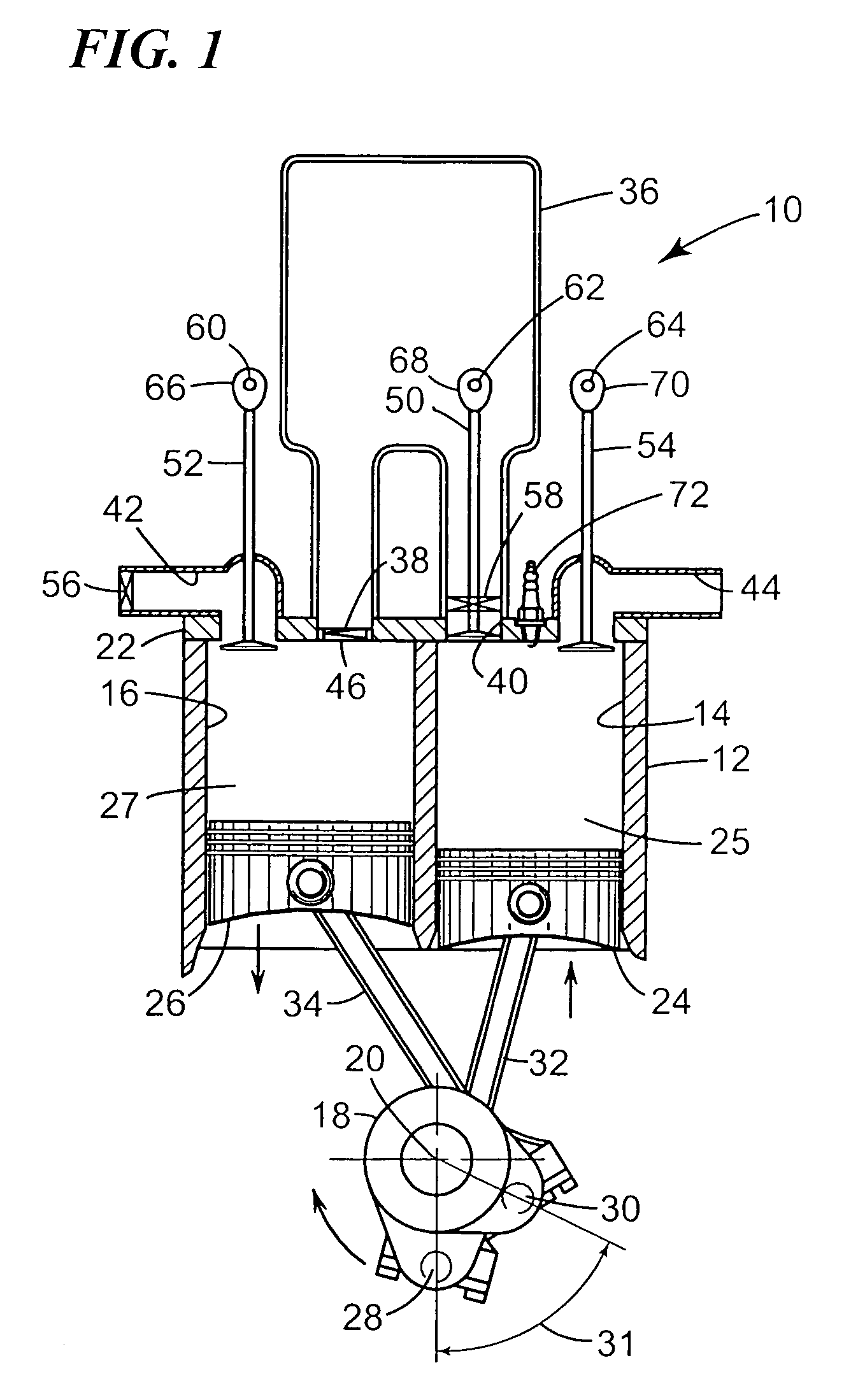

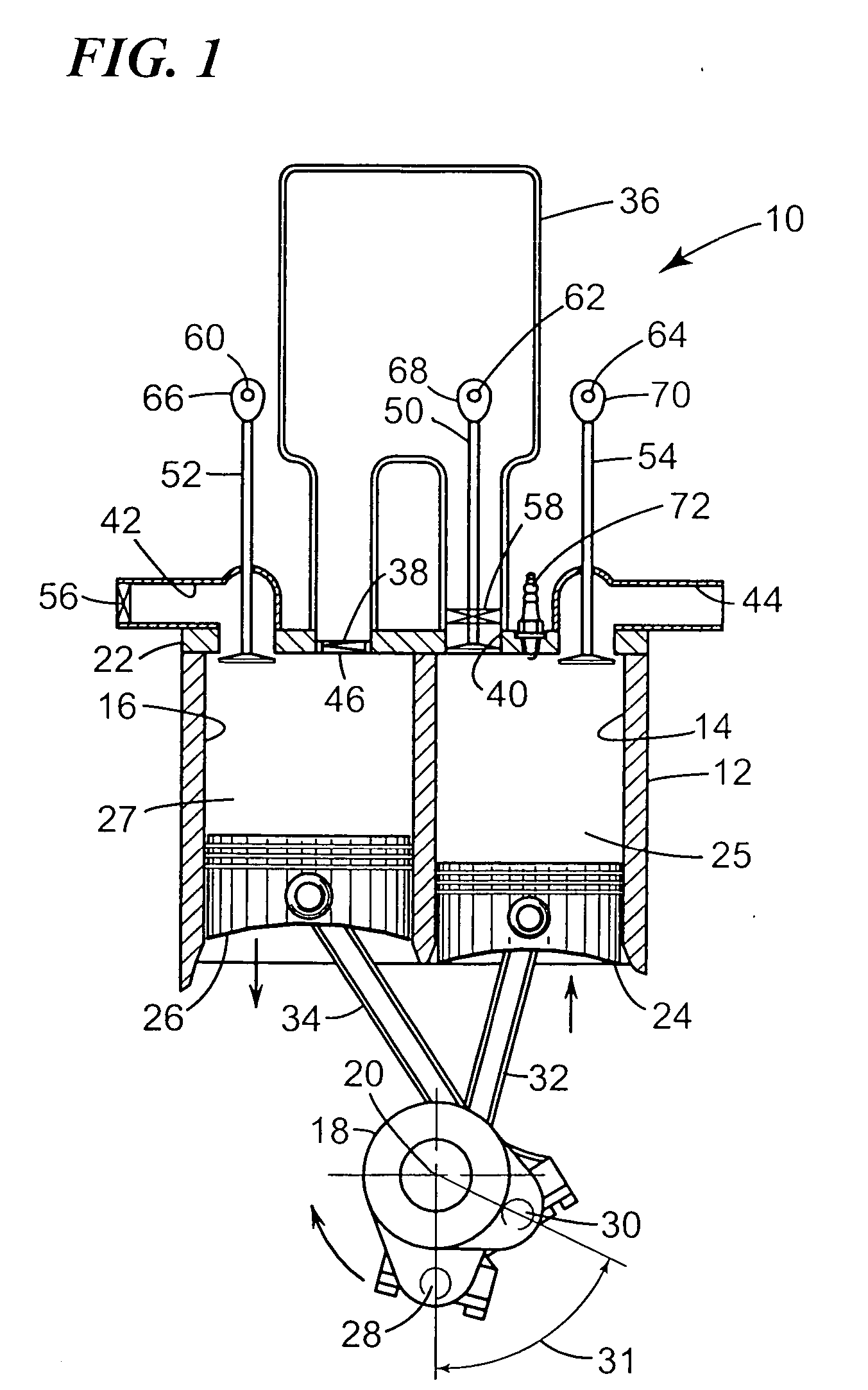

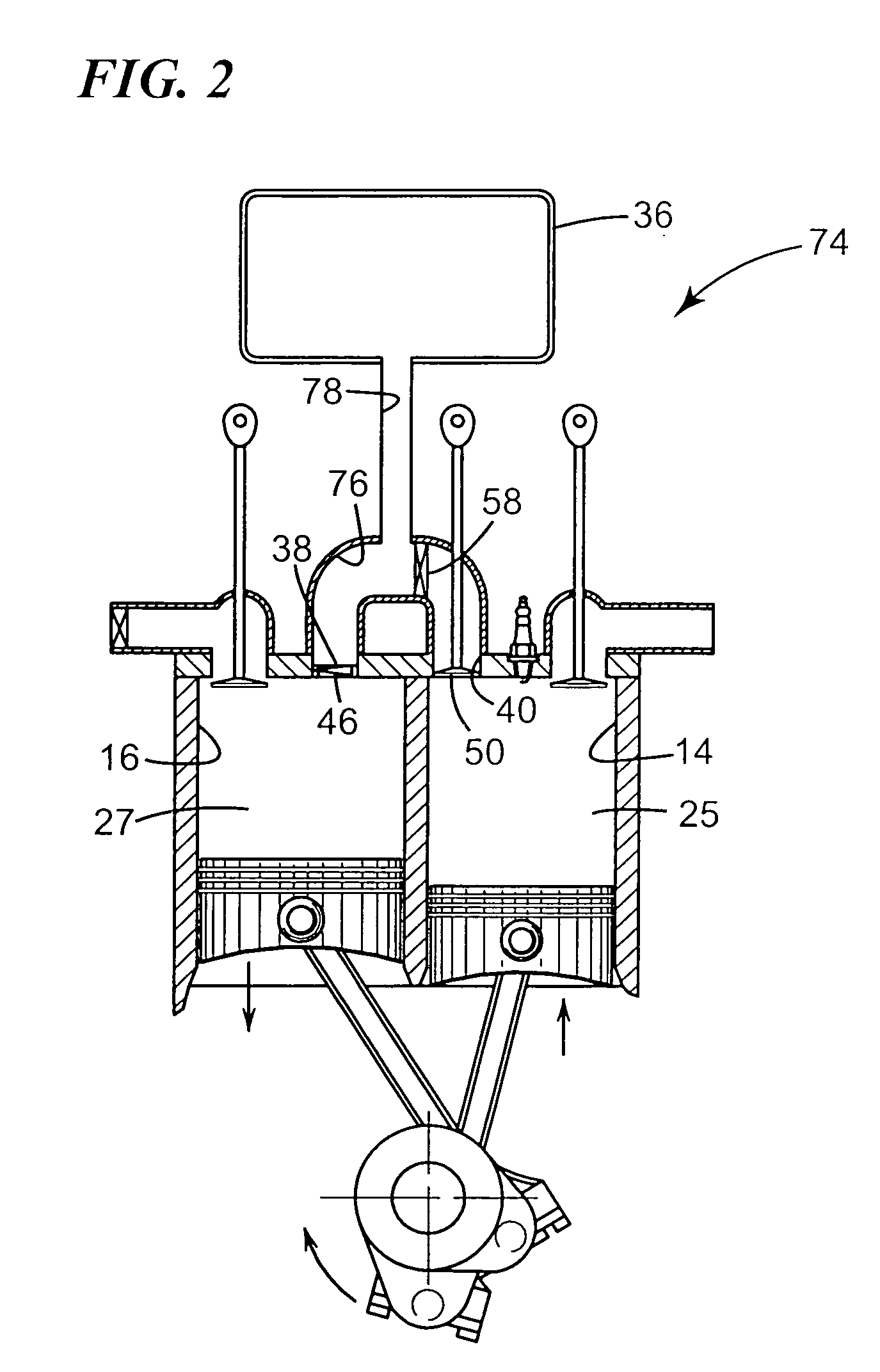

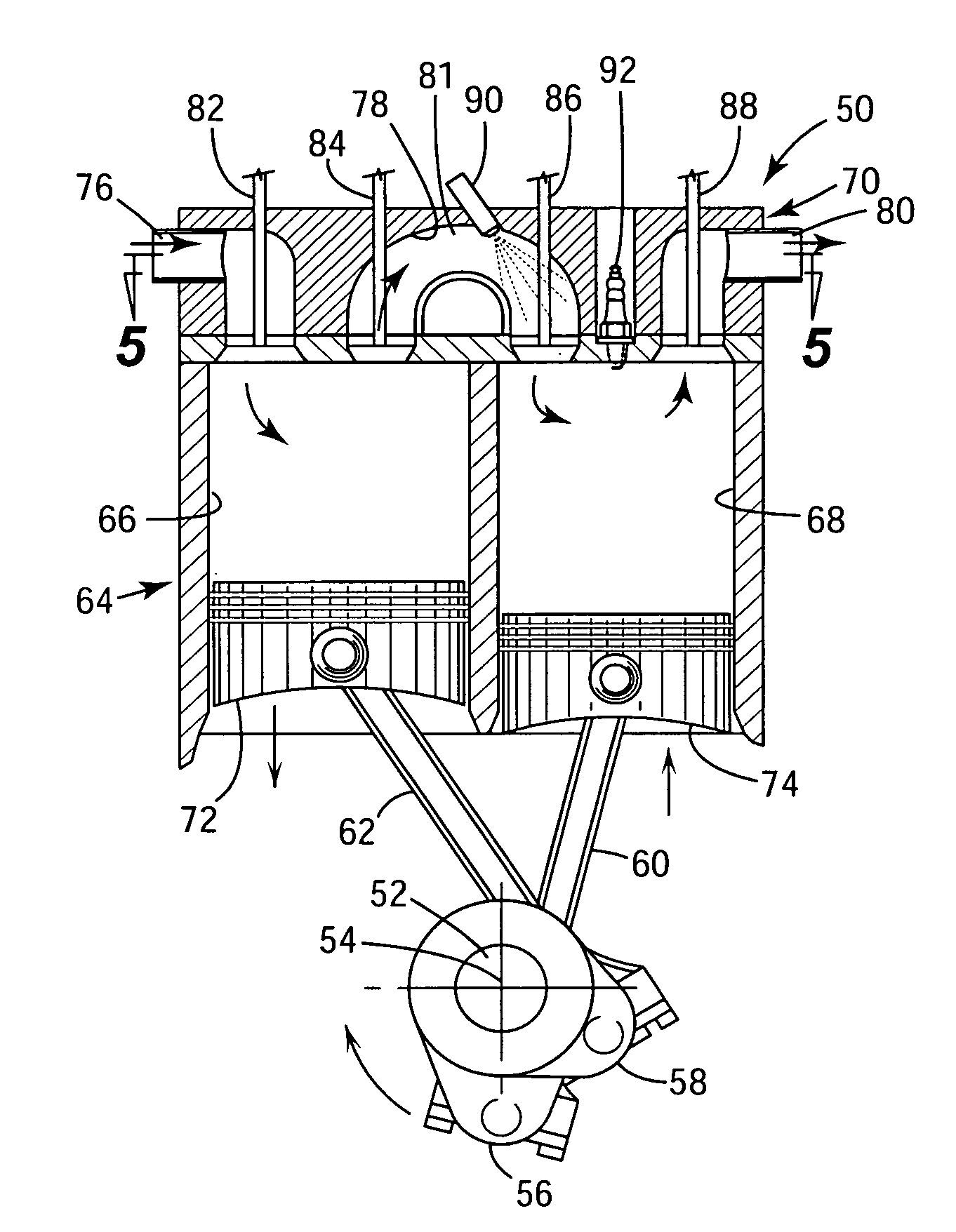

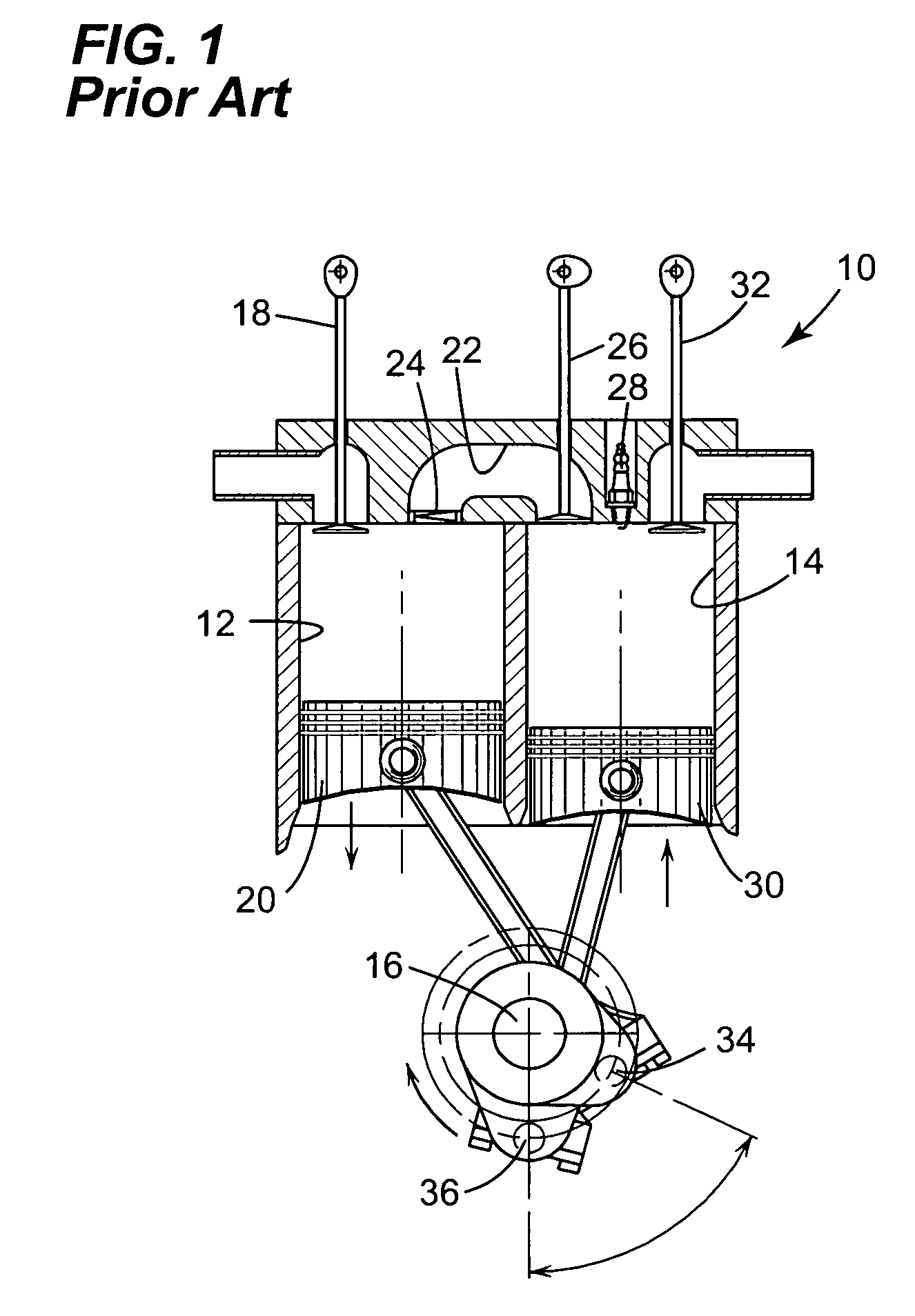

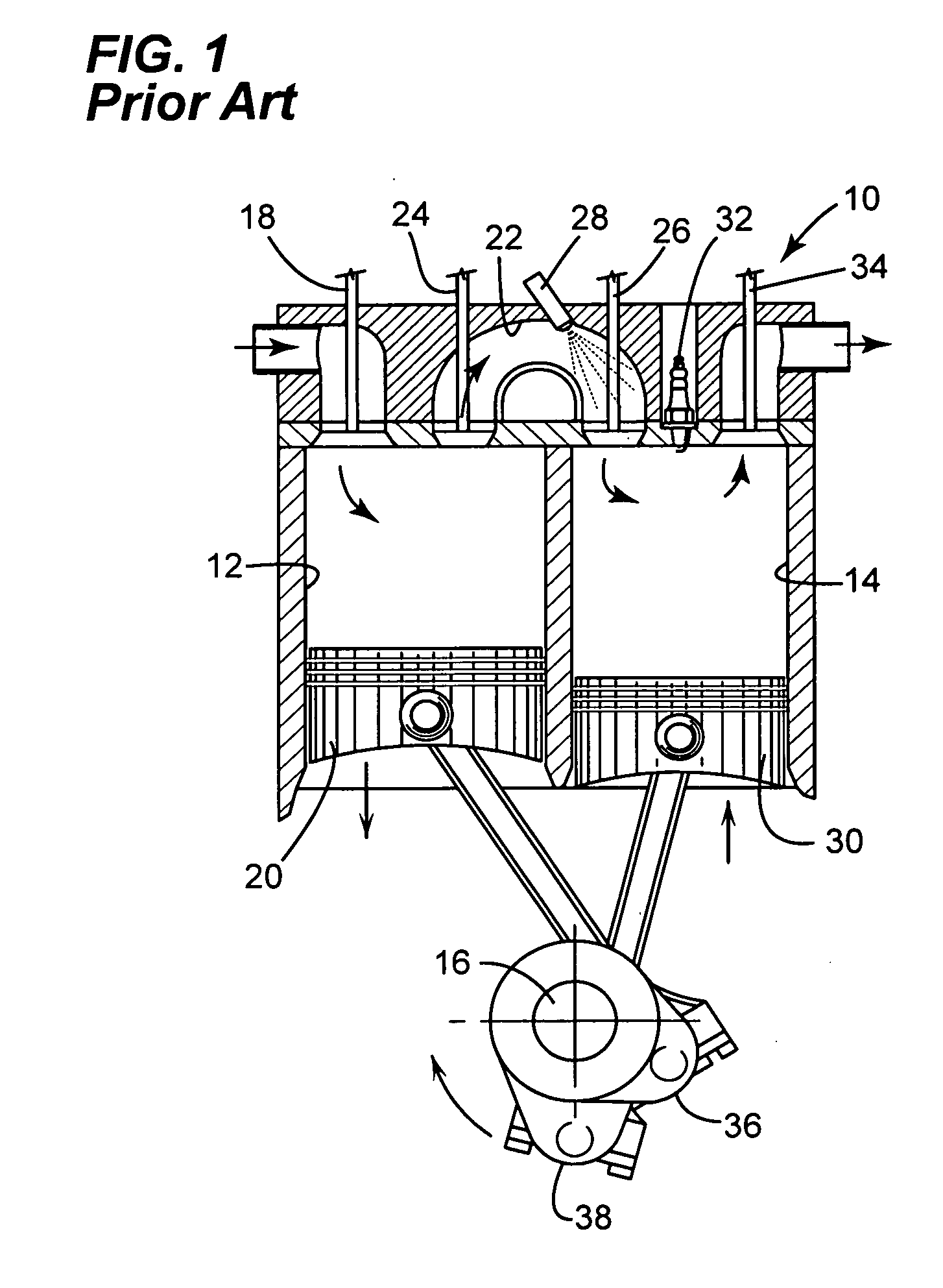

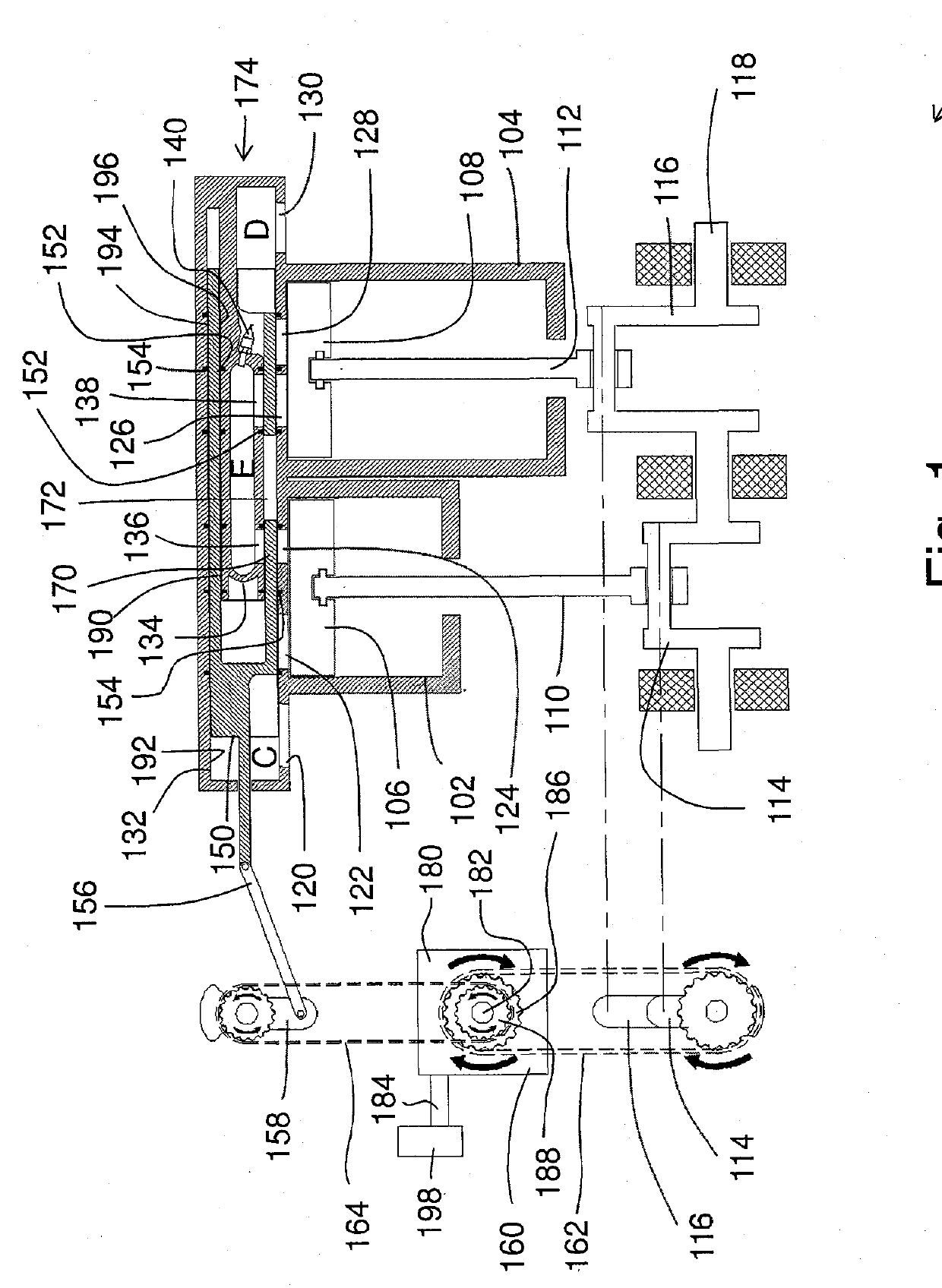

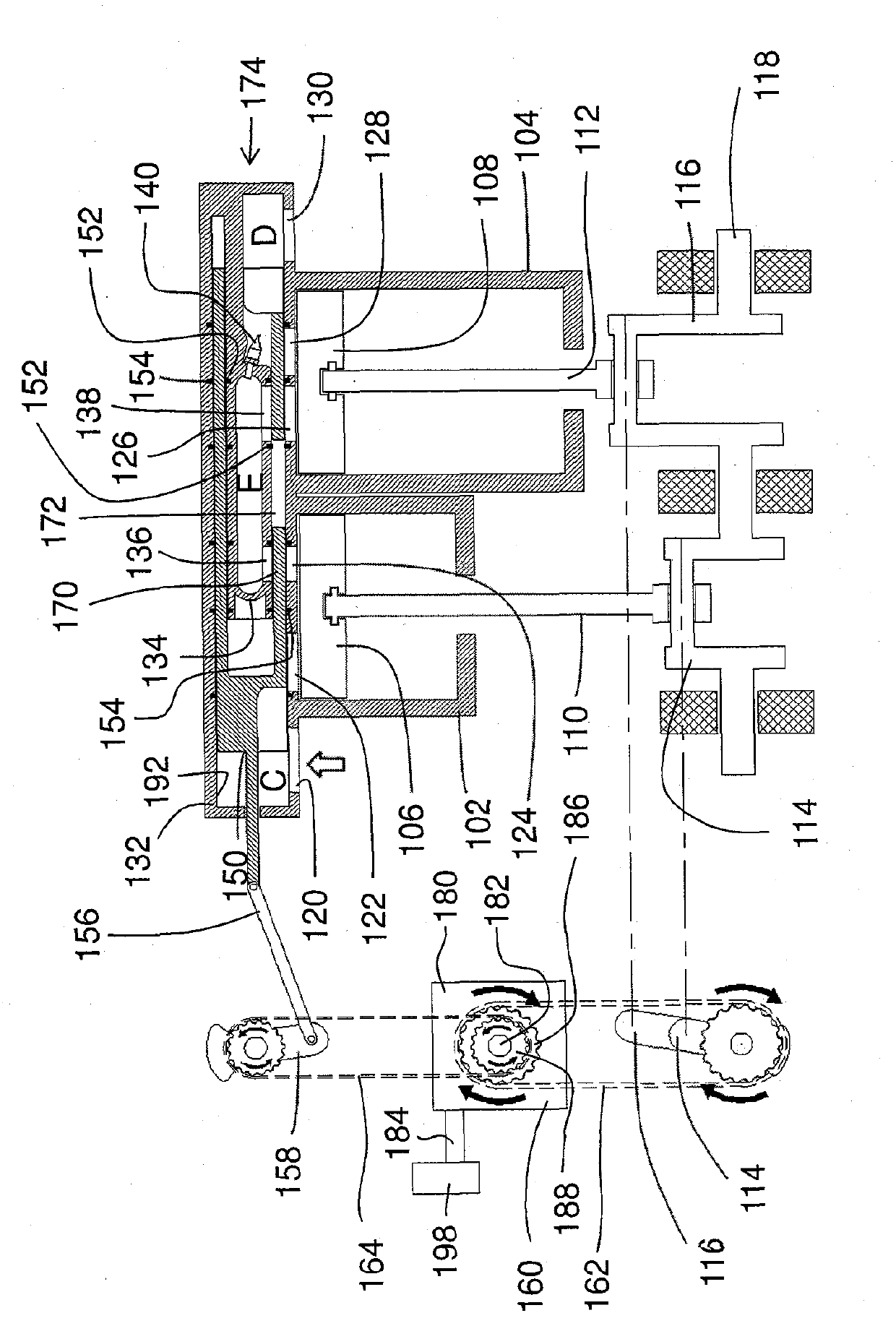

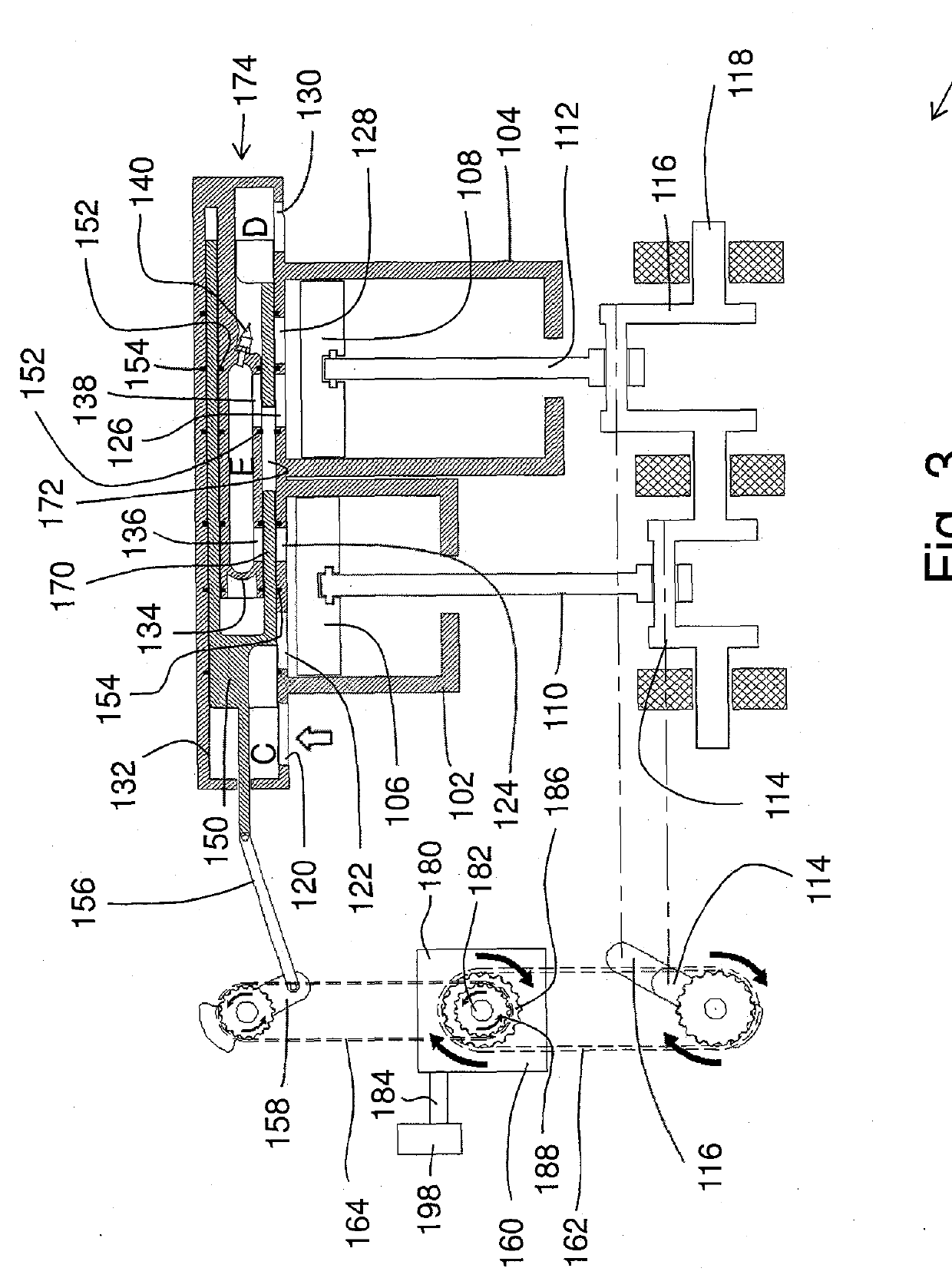

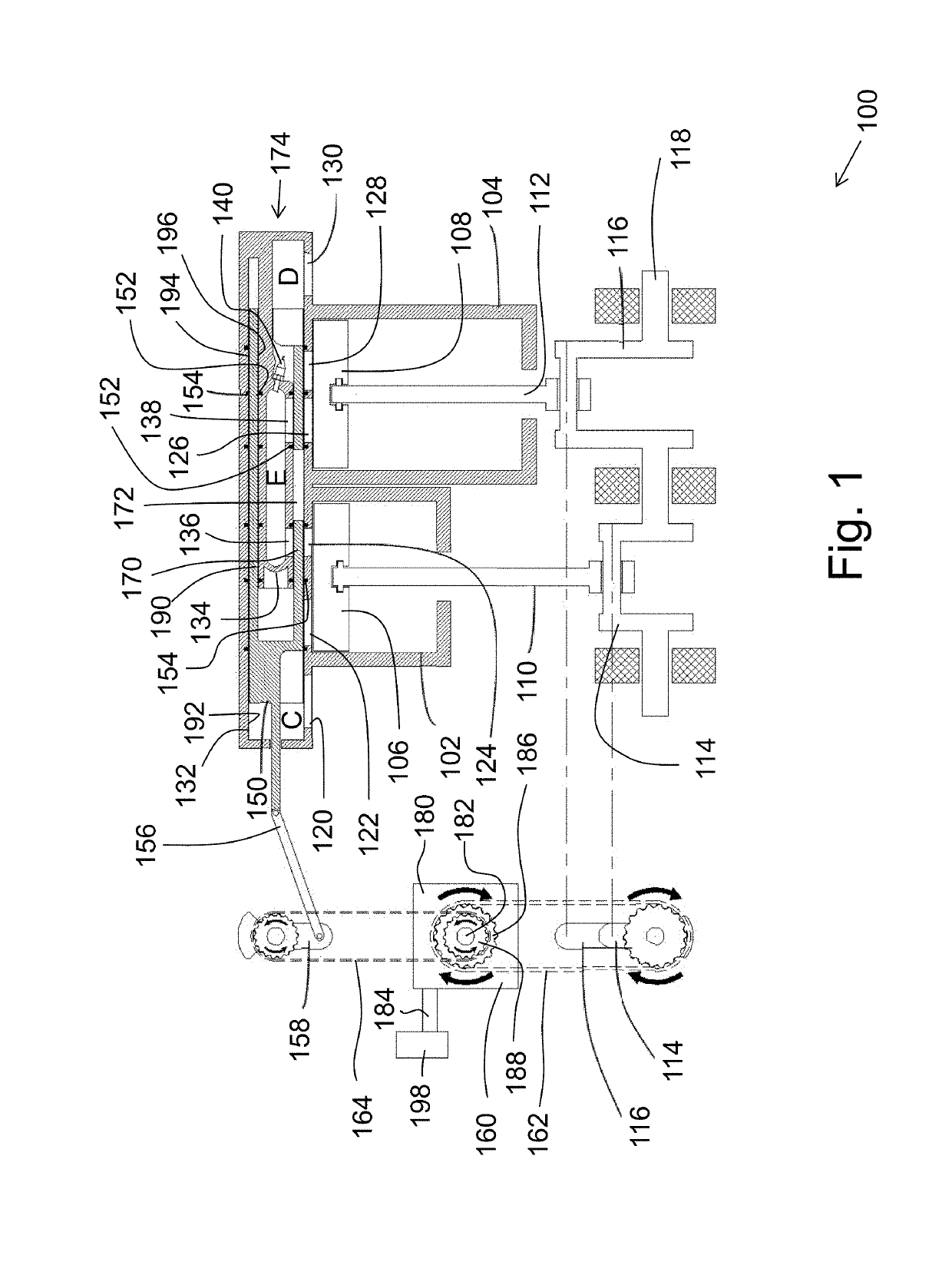

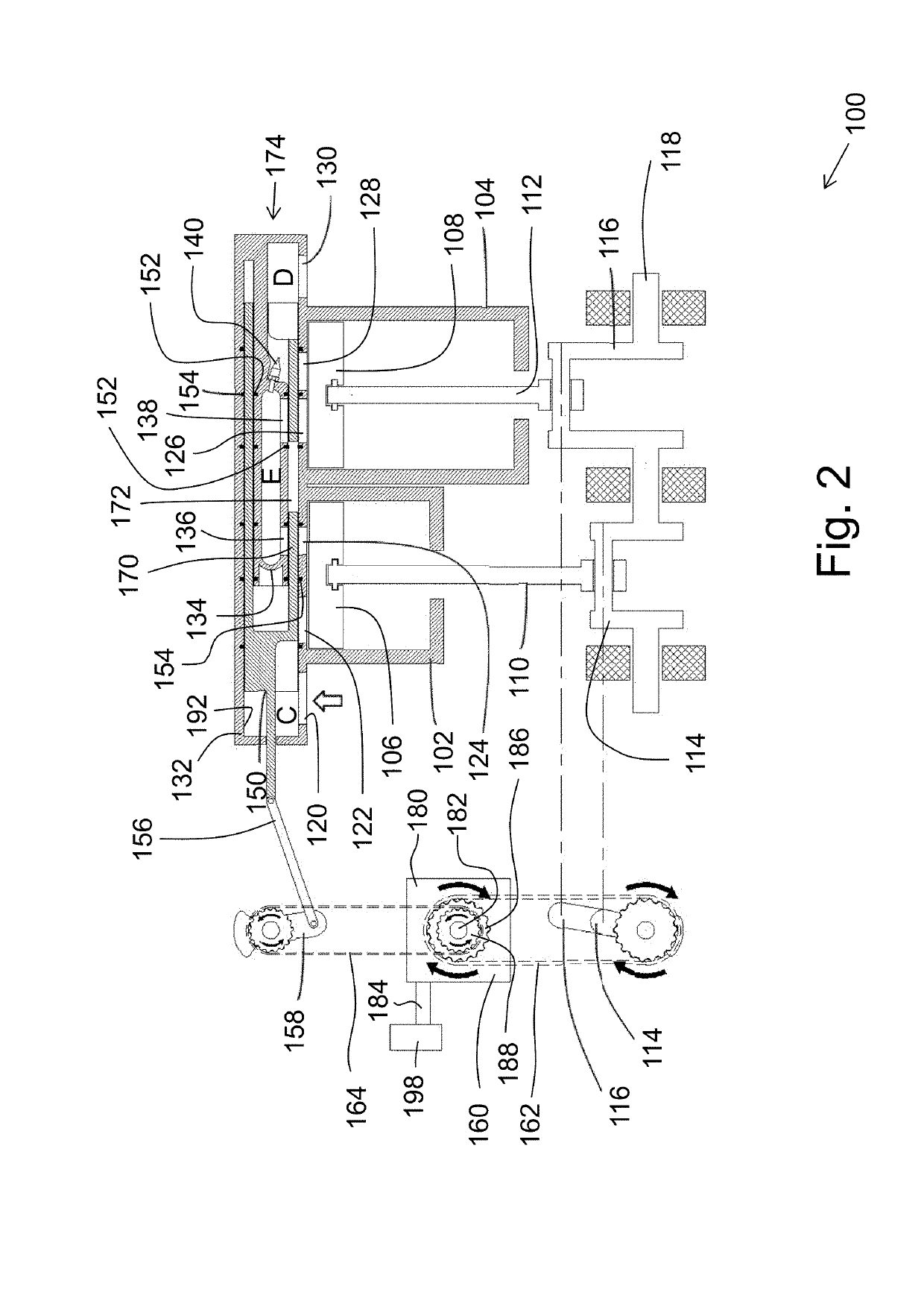

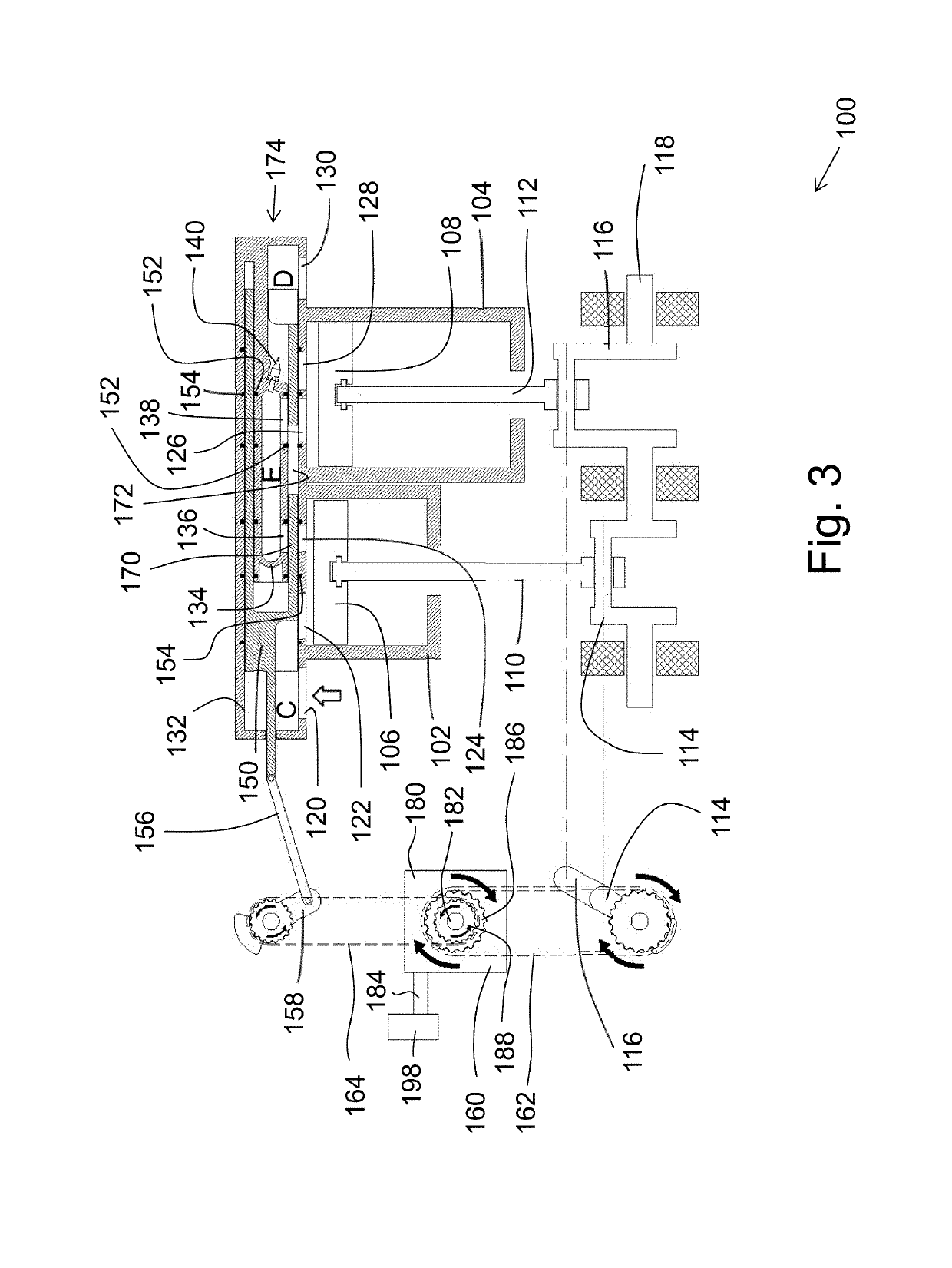

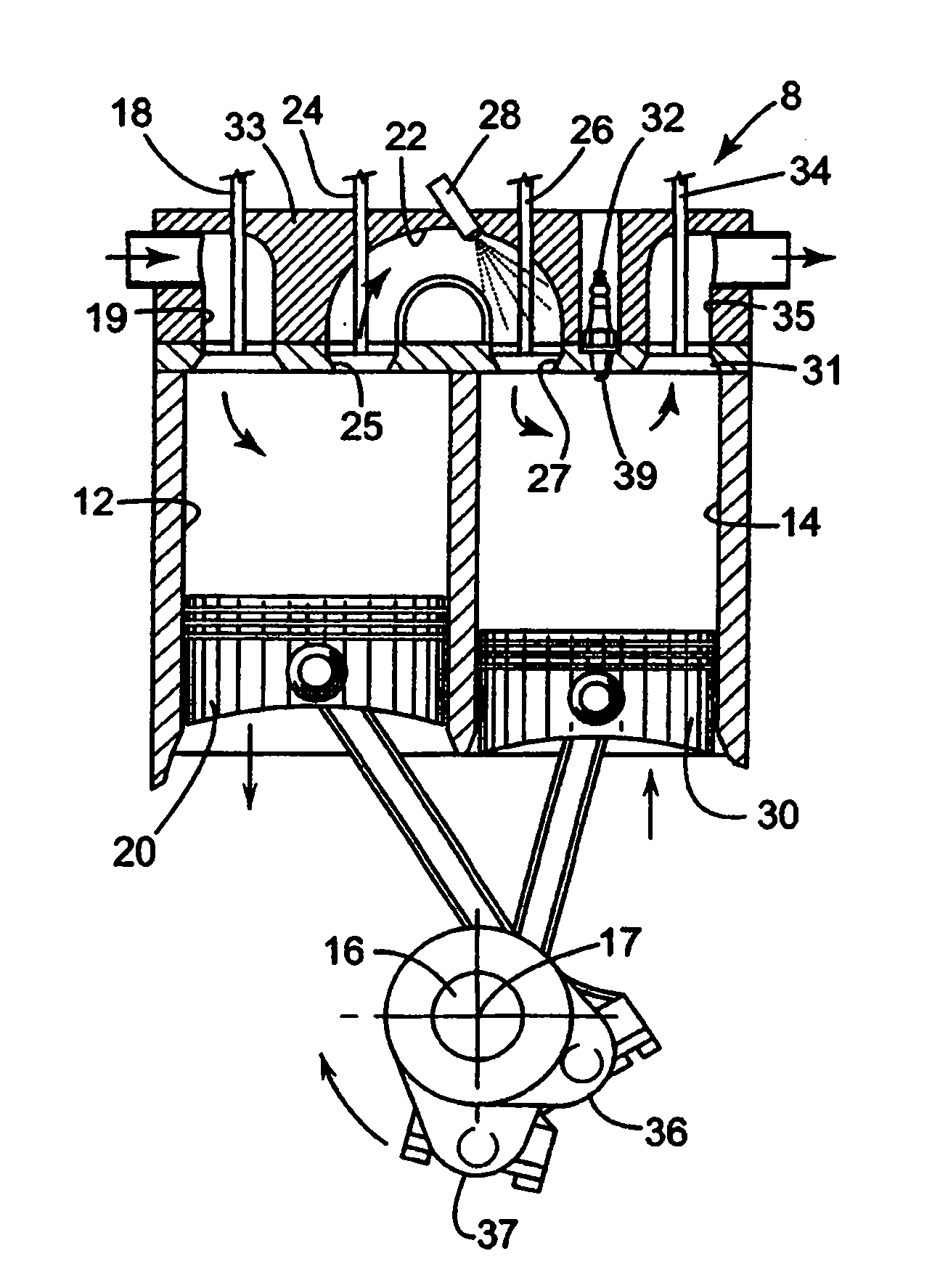

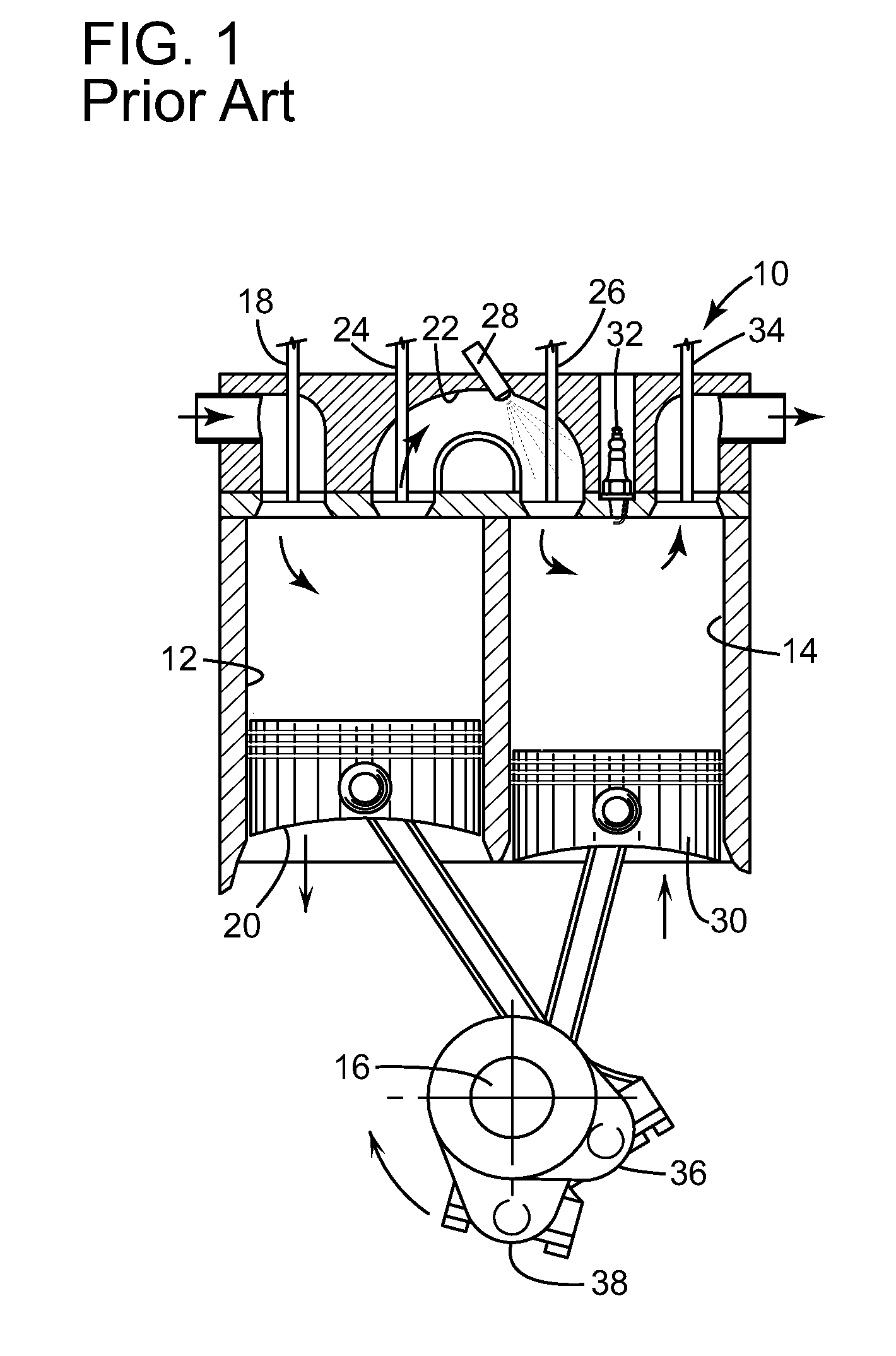

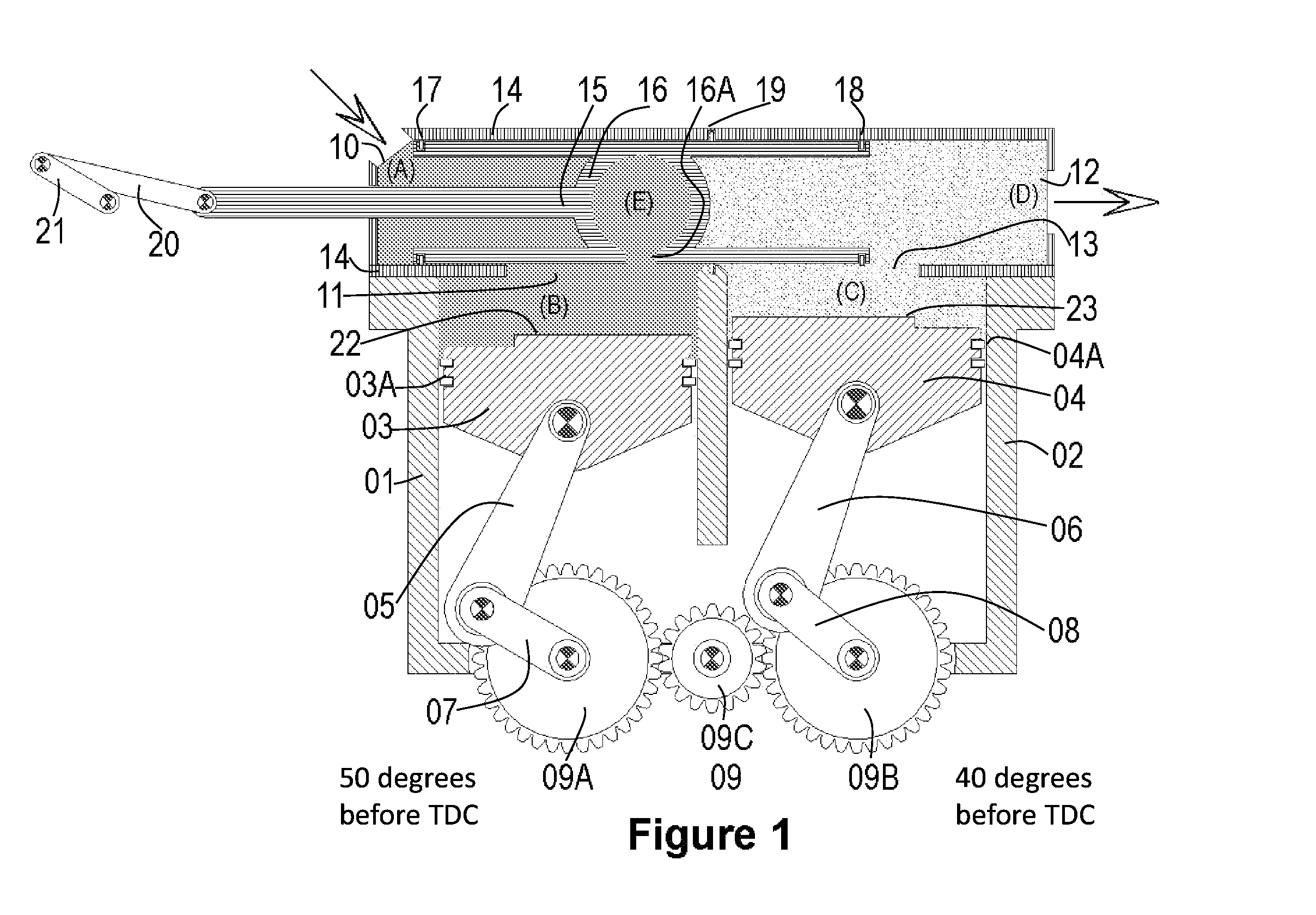

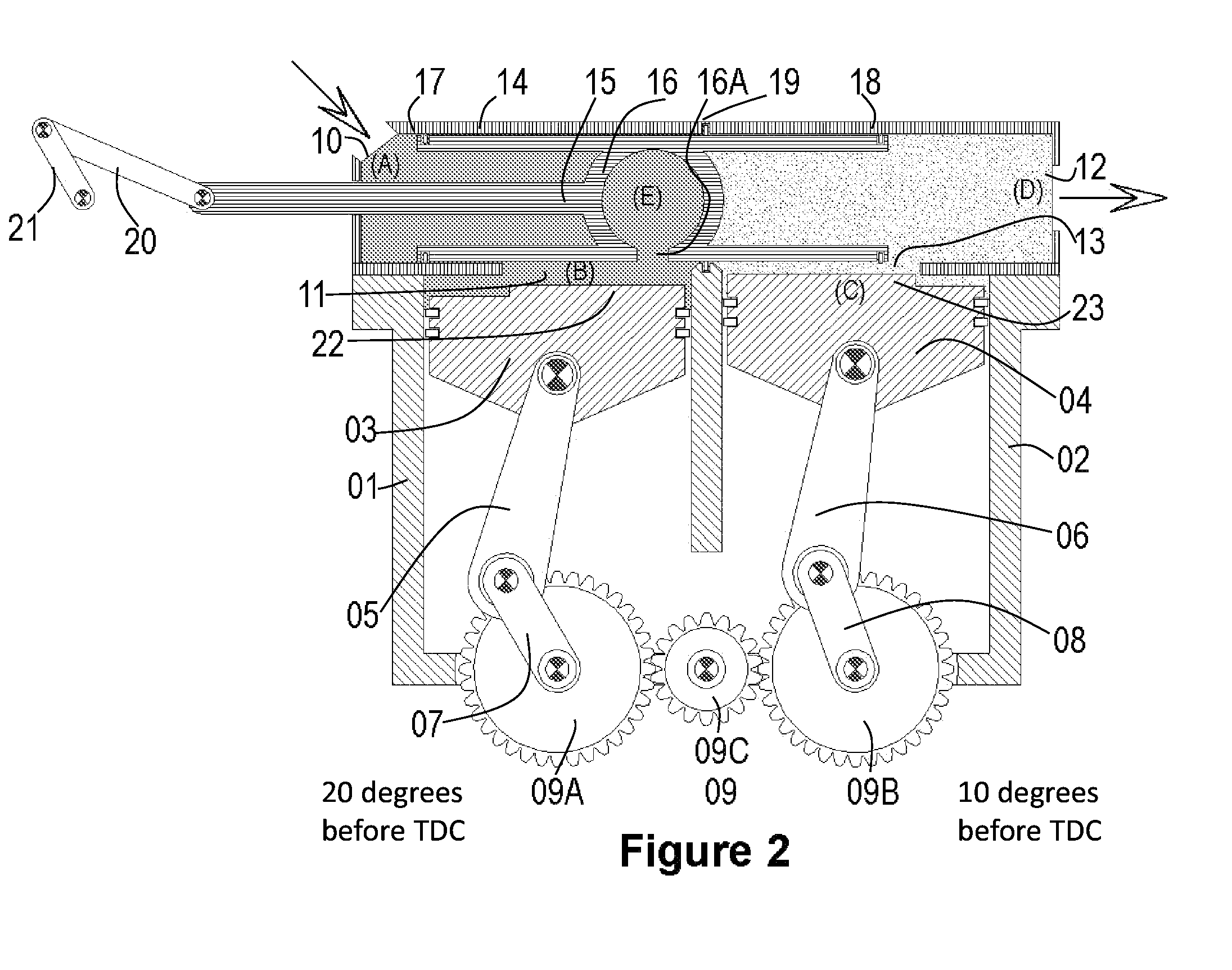

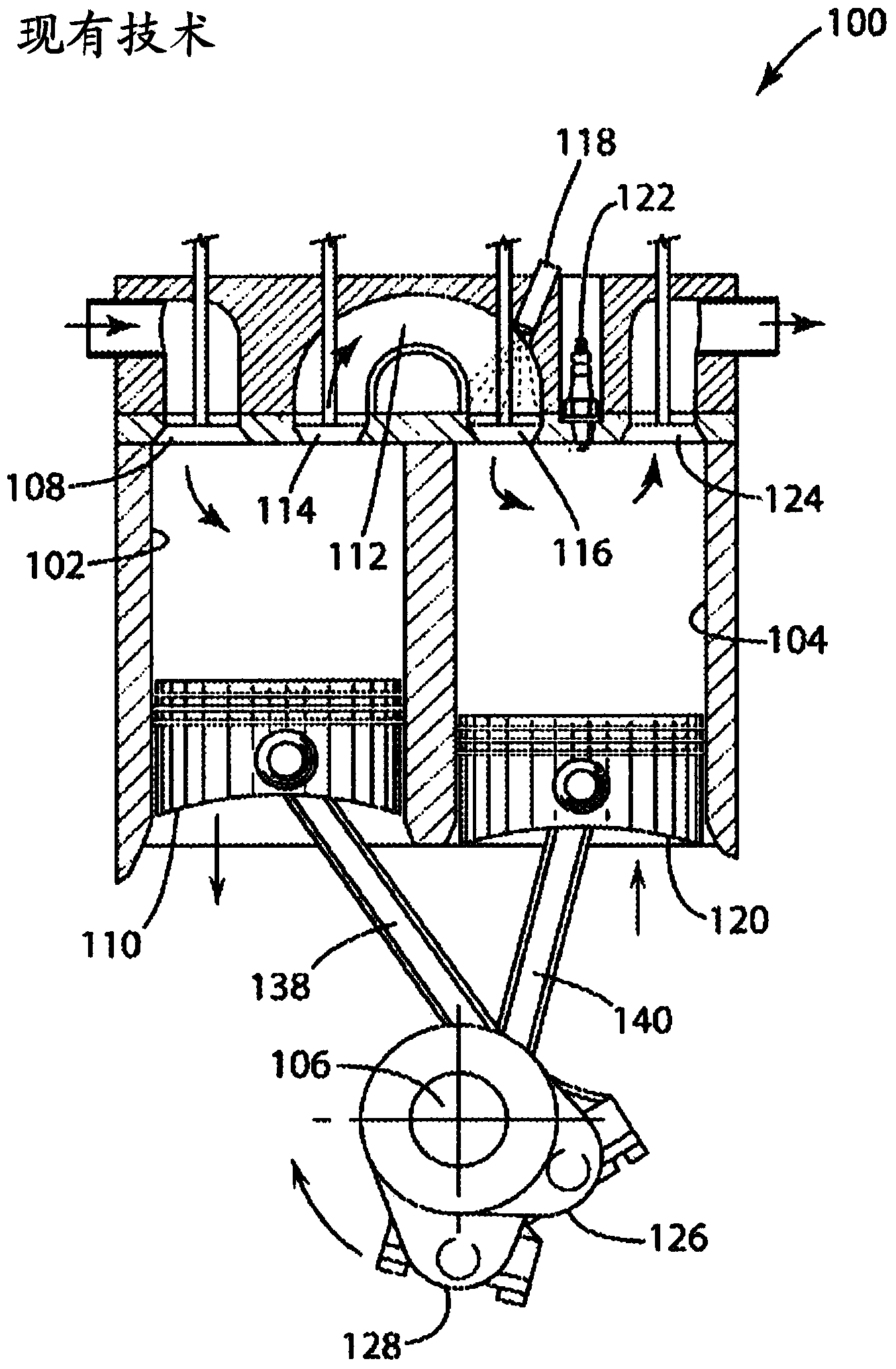

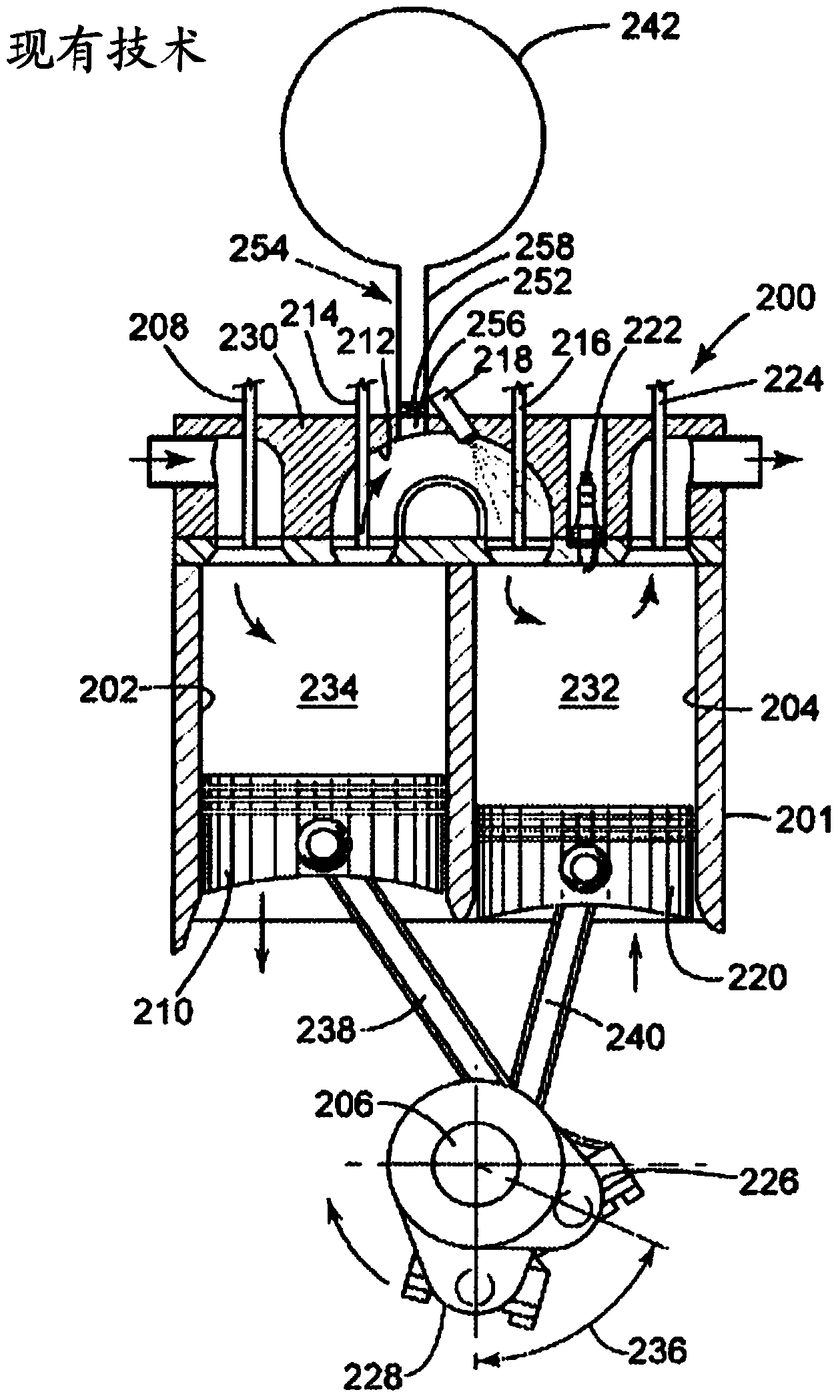

A split-cycle air hybrid engine operatively connects an air reservoir to a split cycle engine. A power piston is received within a power cylinder and operatively connected to a crankshaft such that the power piston reciprocates through an expansion stroke and an exhaust stroke during a single revolution of the crankshaft. A compression piston is received within a compression cylinder and operatively connected to the crankshaft such that the compression piston reciprocates through an intake stroke and a compression stroke in a single rotation of the crankshaft. The compression cylinder is selectively controllable to place the compression piston in a compression mode or an idle mode. An air reservoir is operatively connected between the compression cylinder and the power cylinder and selectively operable to receive compressed air from the compression cylinder and to deliver compressed air to the power cylinder for use in transmitting power to the crankshaft during engine operation.

Owner:SKADERI GRUP LLC

Split-cycle air hybrid engine

InactiveUS20070157894A1Internal combustion piston enginesEngine controllersReciprocating motionTransmitted power

A split-cycle air hybrid engine operatively connects an air reservoir to a split cycle engine. A power piston is received within a power cylinder and operatively connected to a crankshaft such that the power piston reciprocates through an expansion stroke and an exhaust stroke during a single revolution of the crankshaft. A compression piston is received within a compression cylinder and operatively connected to the crankshaft such that the compression piston reciprocates through an intake stroke and a compression stroke in a single rotation of the crankshaft. The compression cylinder is selectively controllable to place the compression piston in a compression mode or an idle mode. An air reservoir is operatively connected between the compression cylinder and the power cylinder and selectively operable to receive compressed air from the compression cylinder and to deliver compressed air to the power cylinder for use in transmitting power to the crankshaft during engine operation.

Owner:SKADERI GRUP LLC

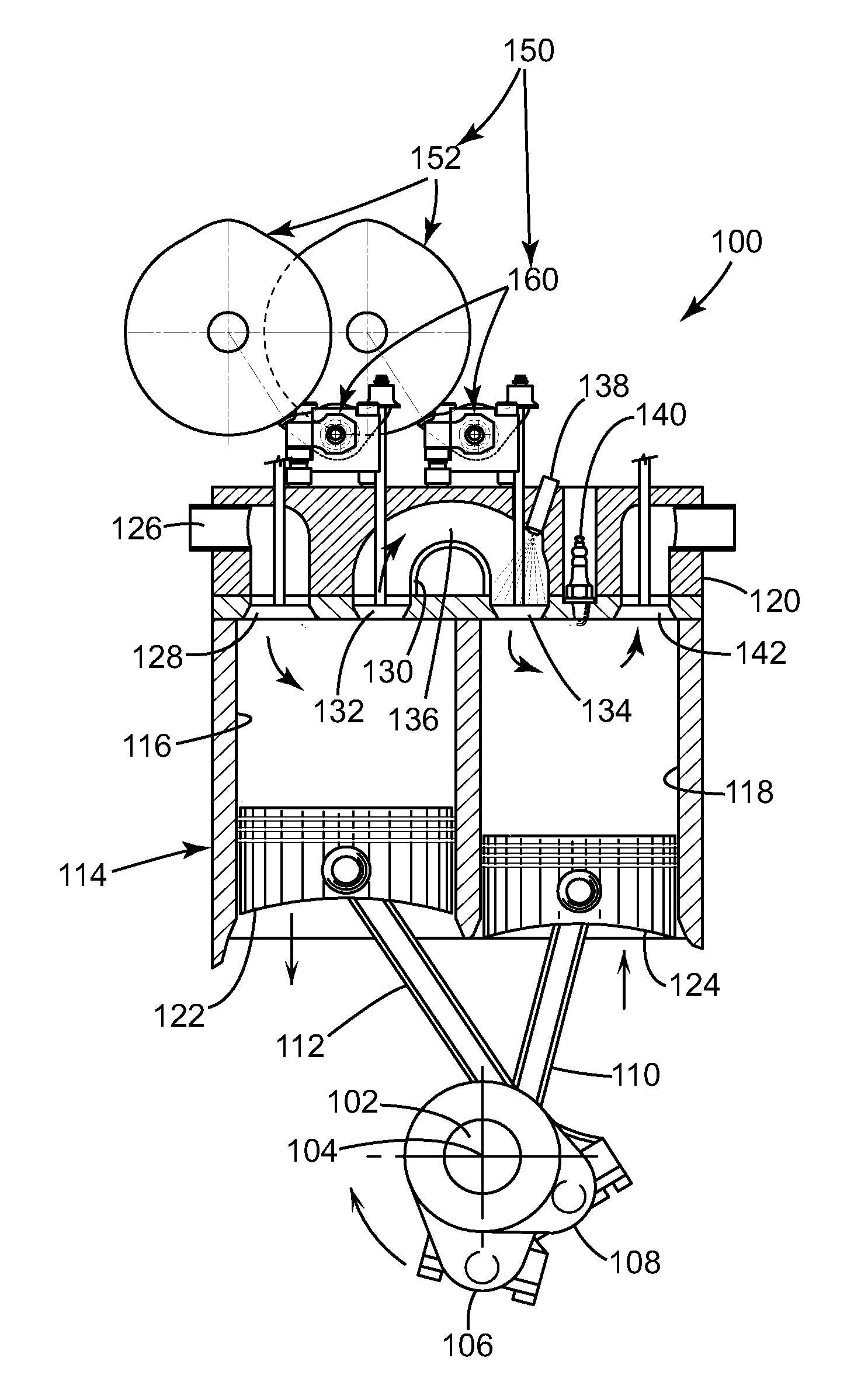

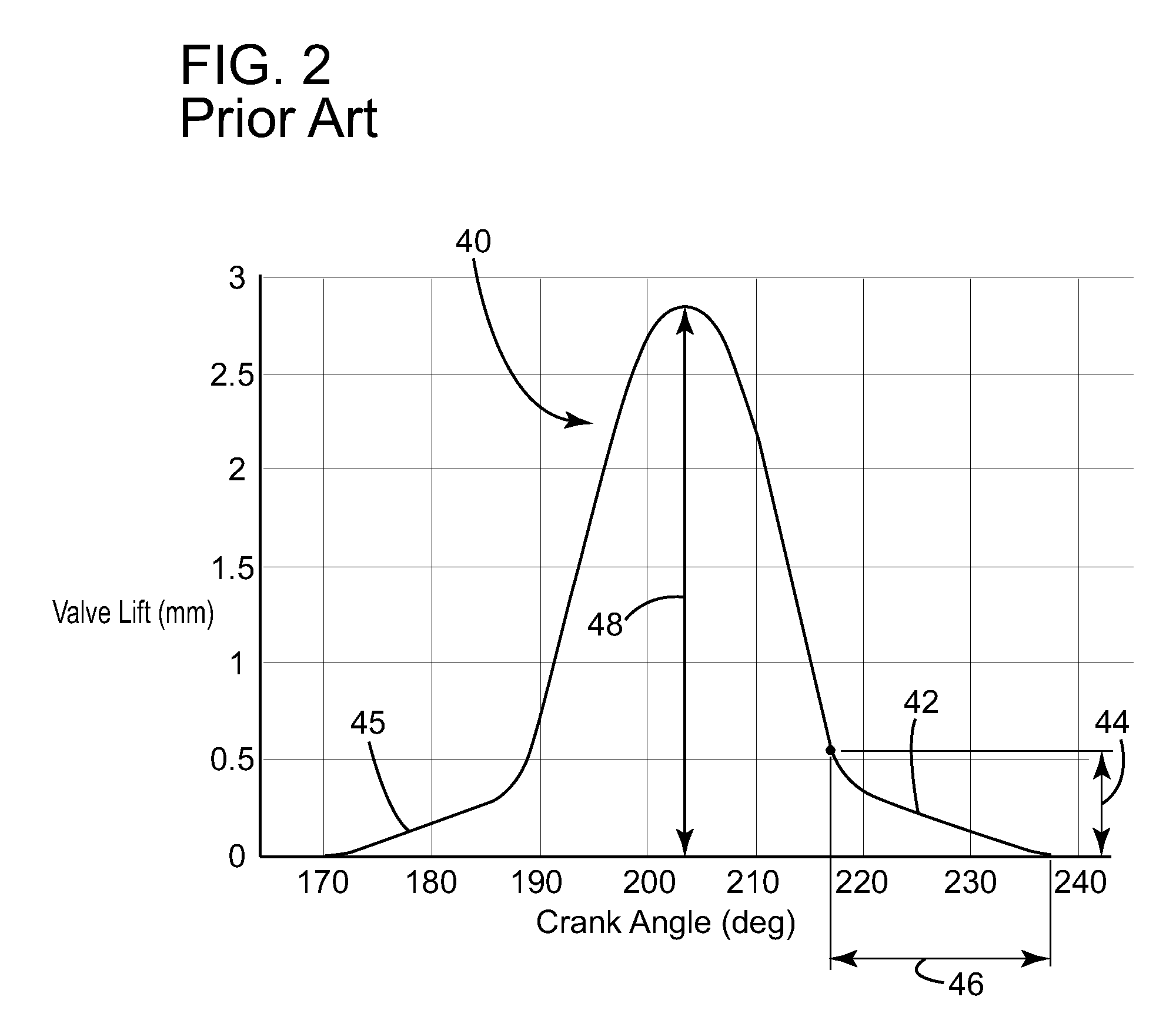

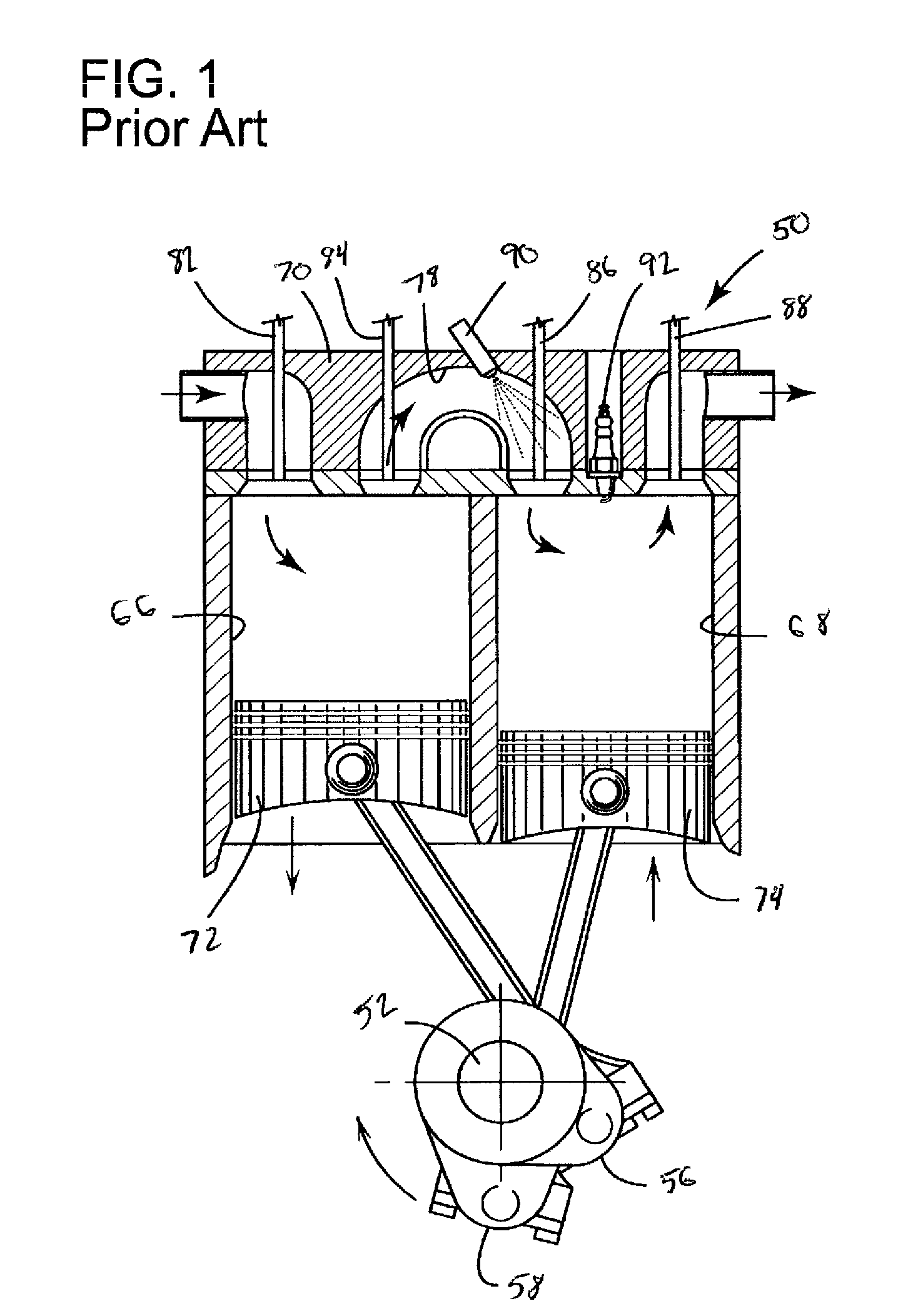

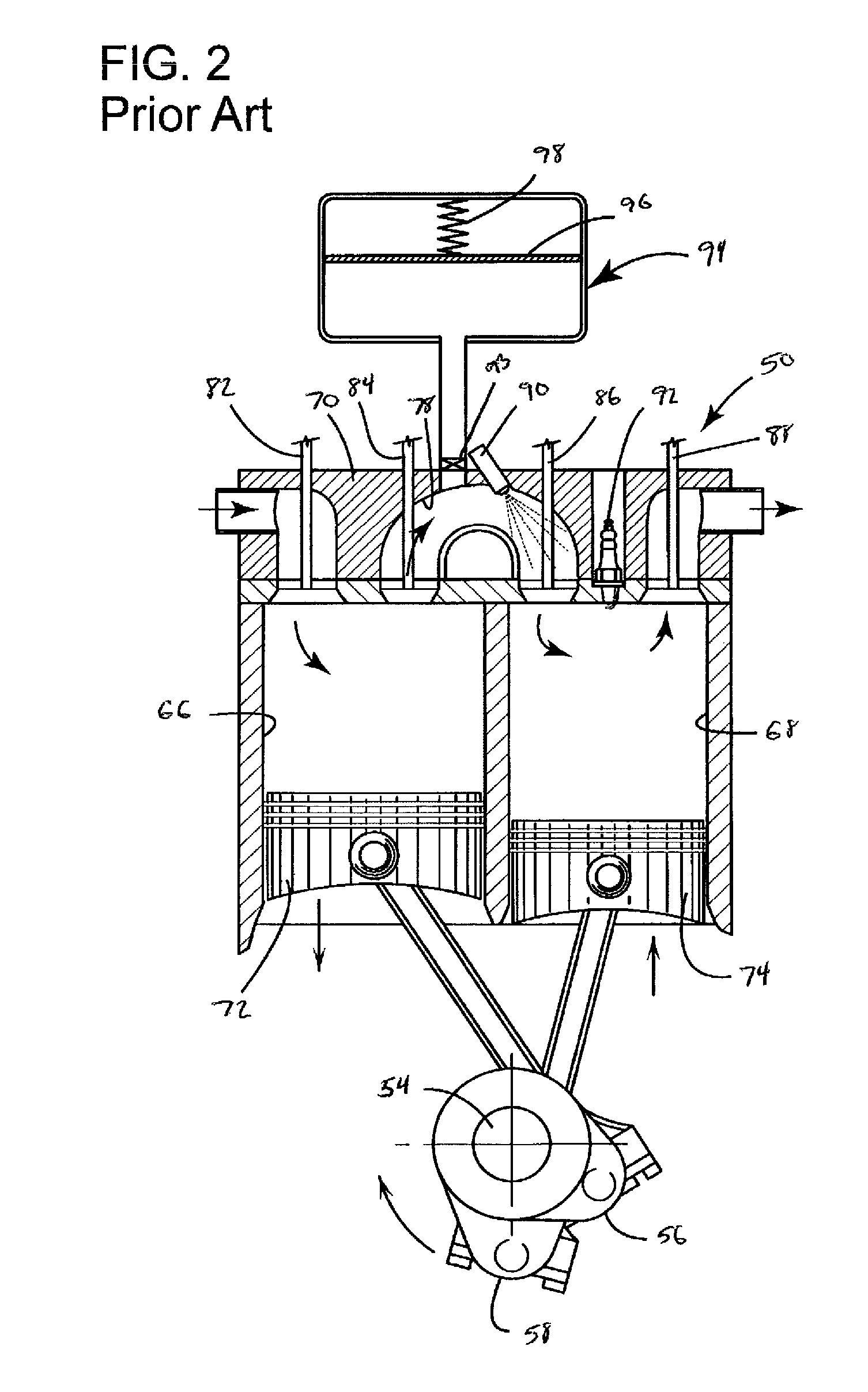

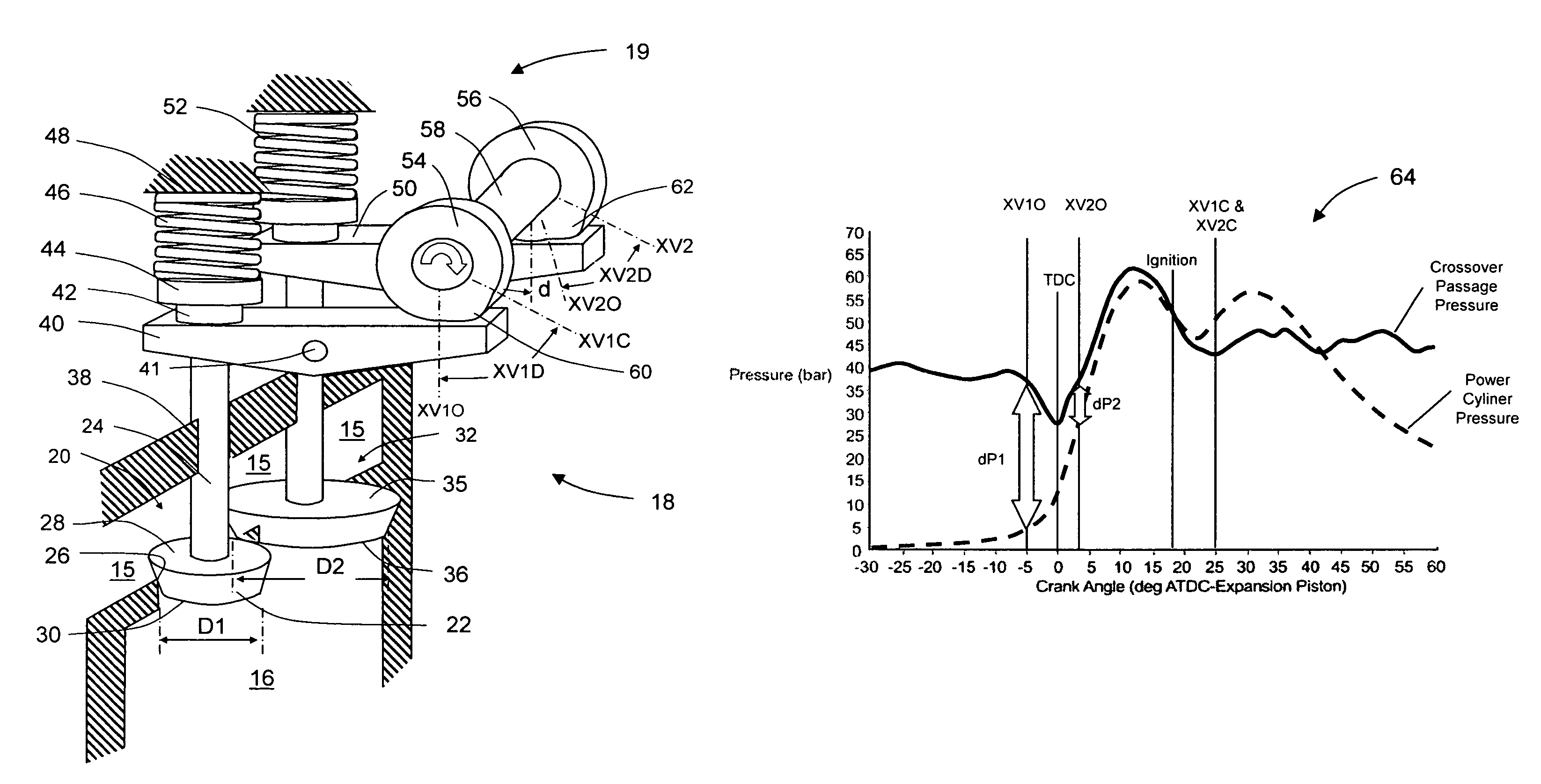

Knock resistant split-cycle engine and method

InactiveUS20090038597A1Internal combustion piston enginesLift valveReciprocating motionFuel injection

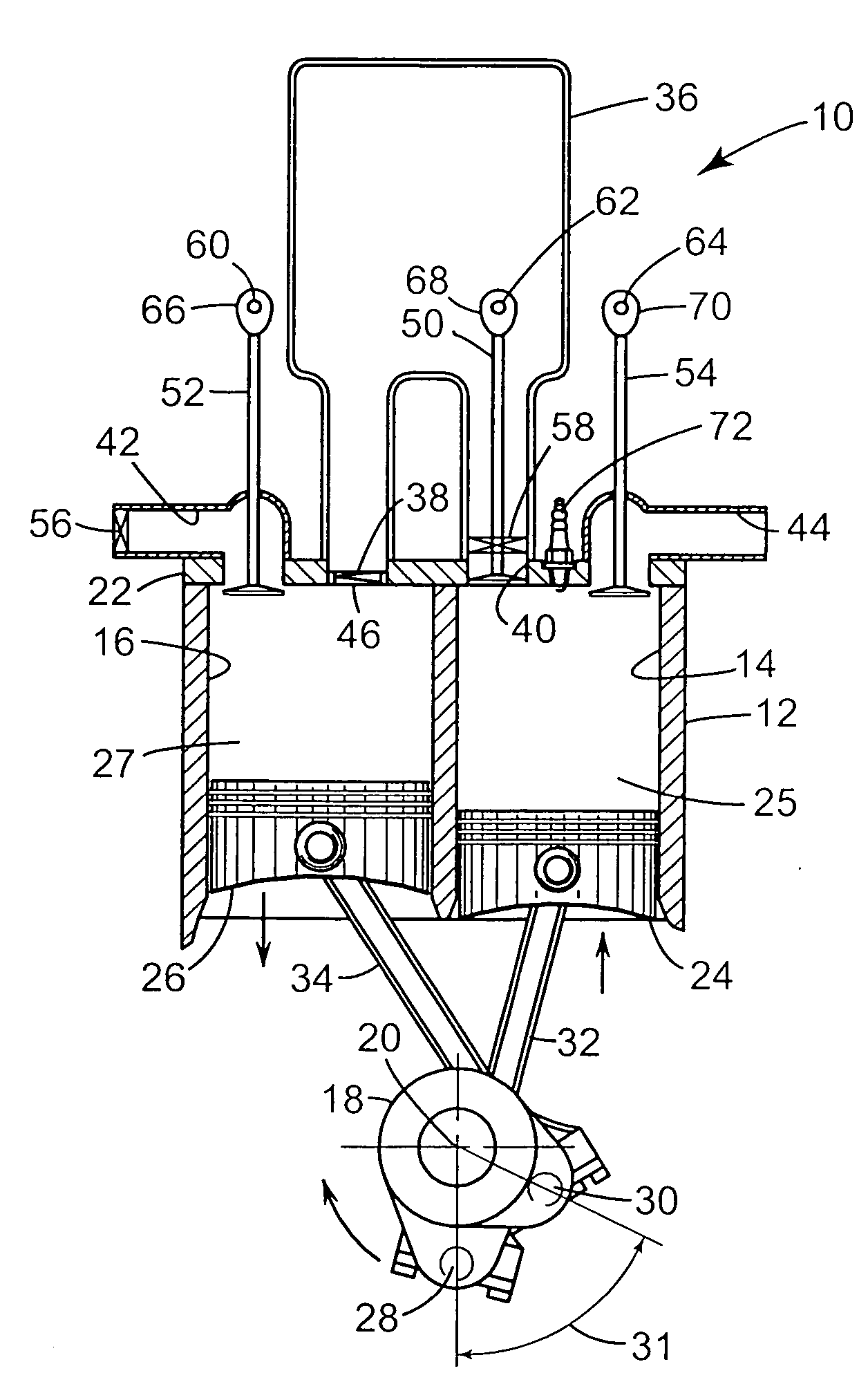

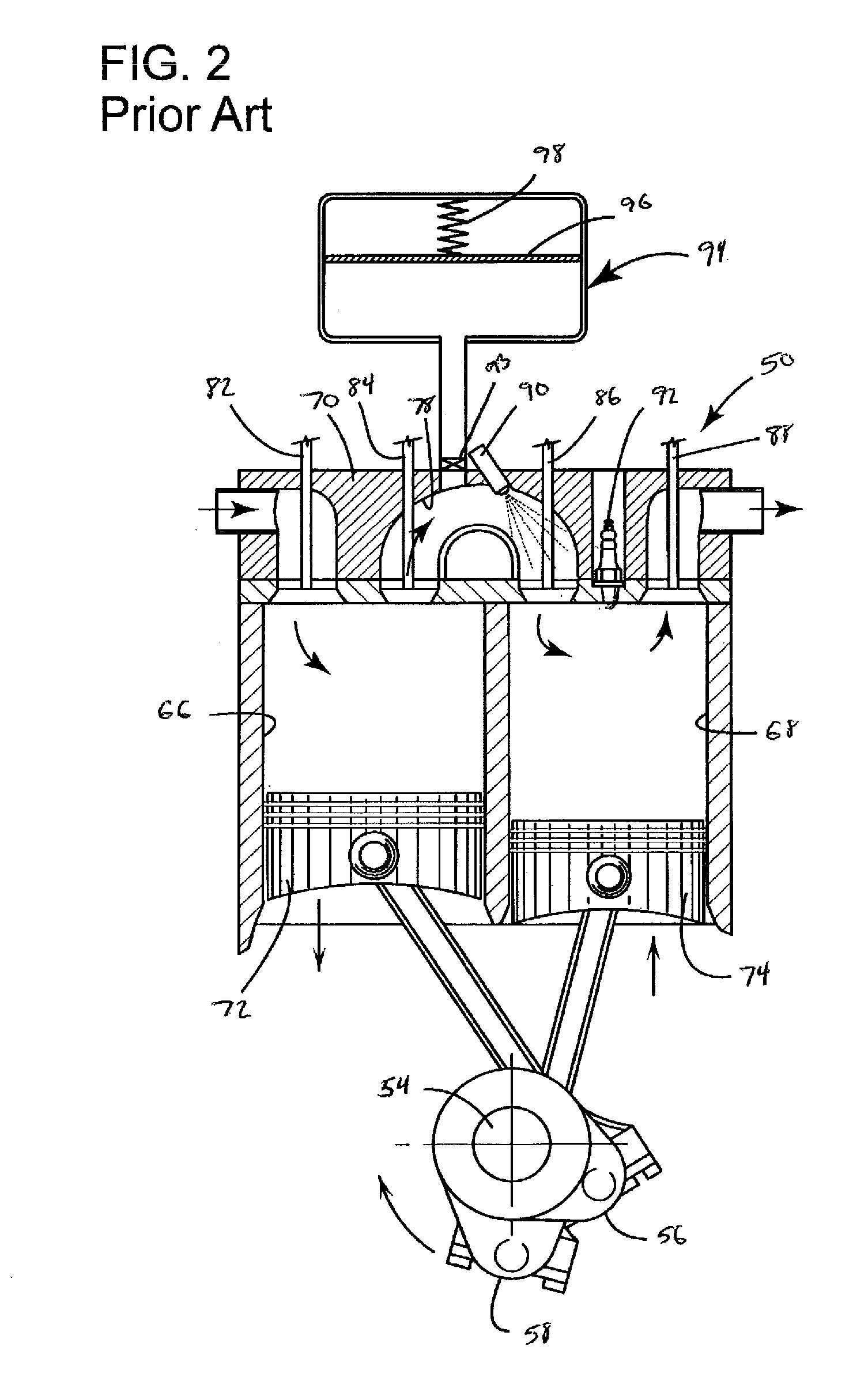

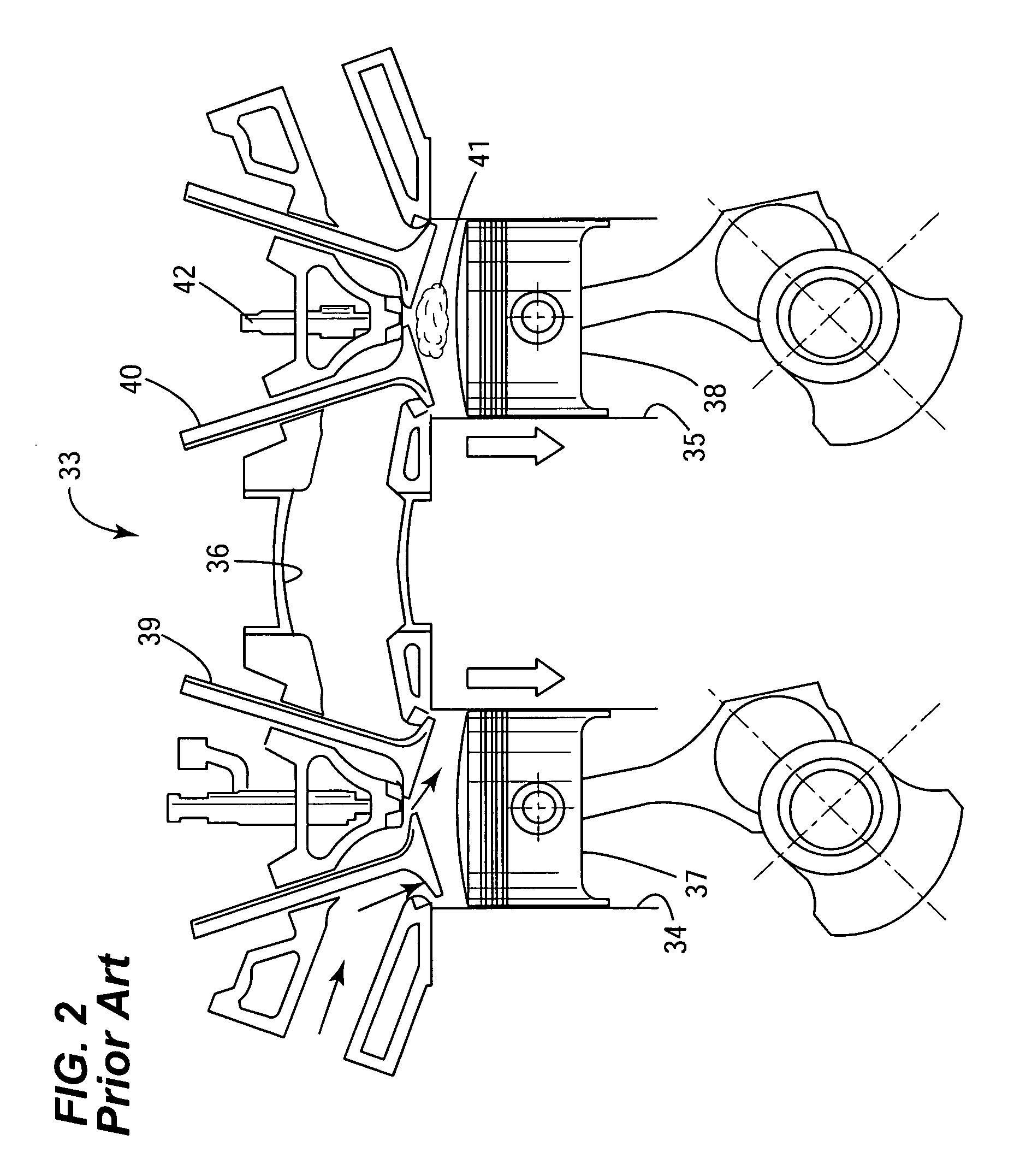

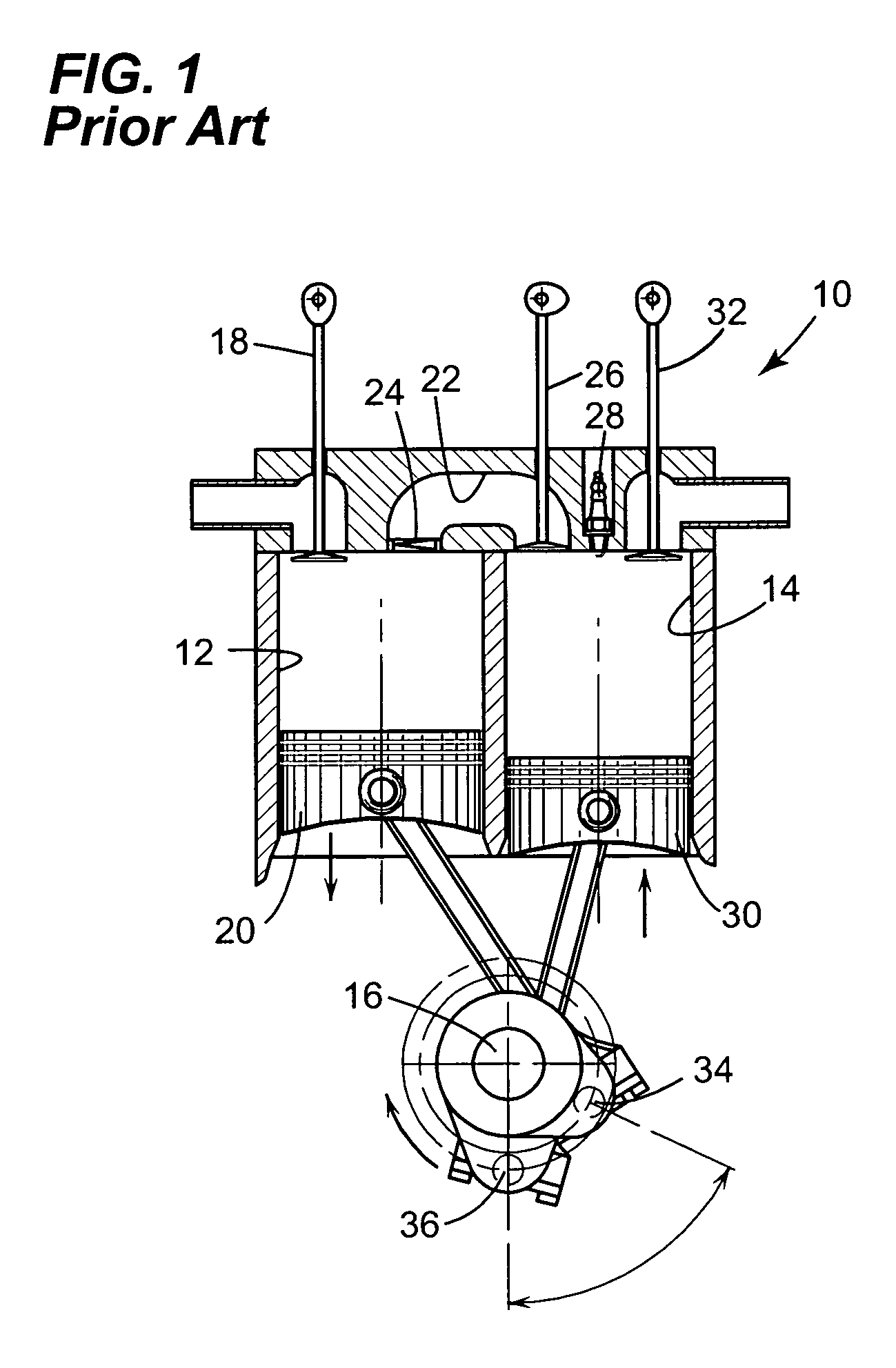

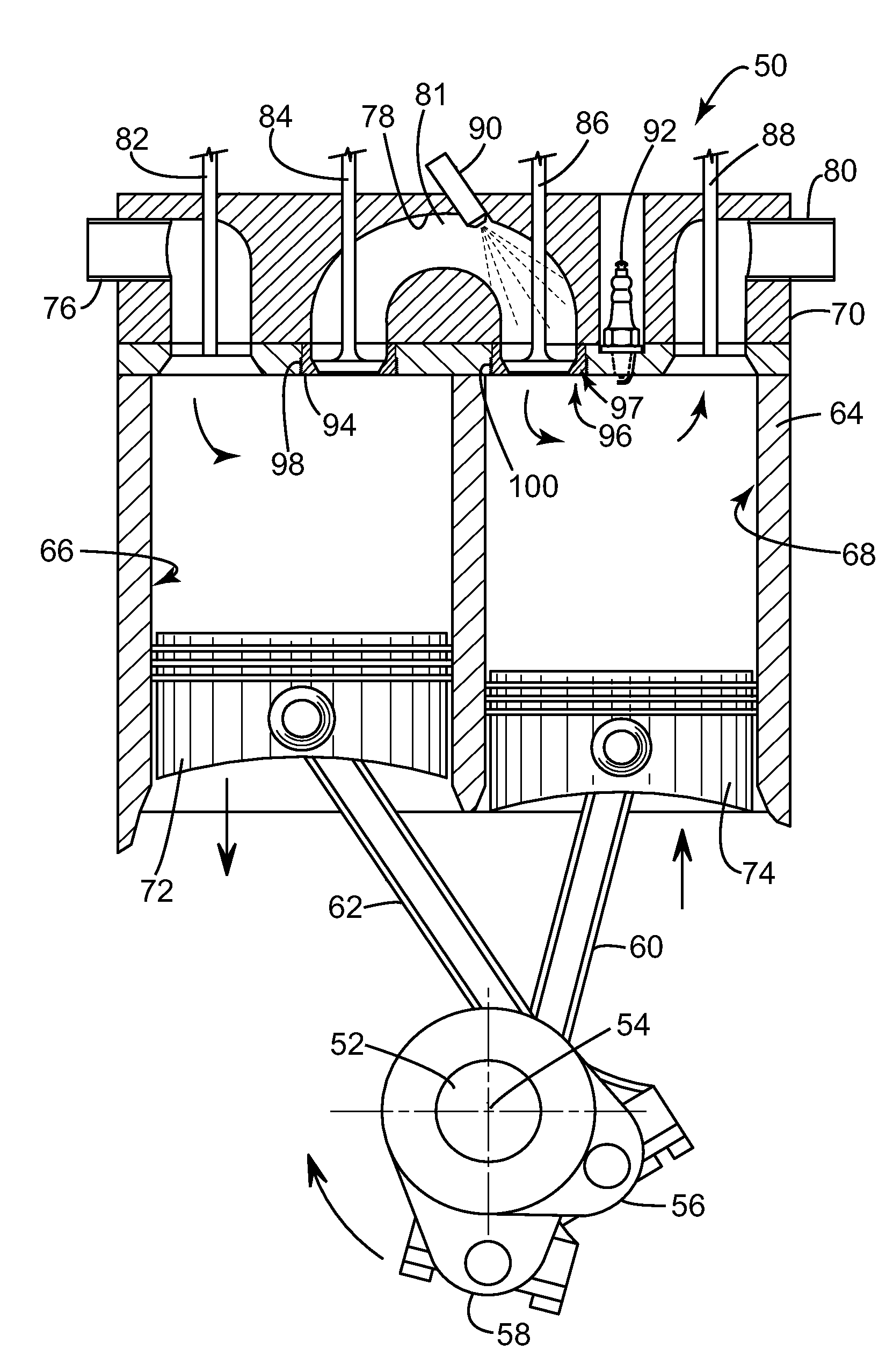

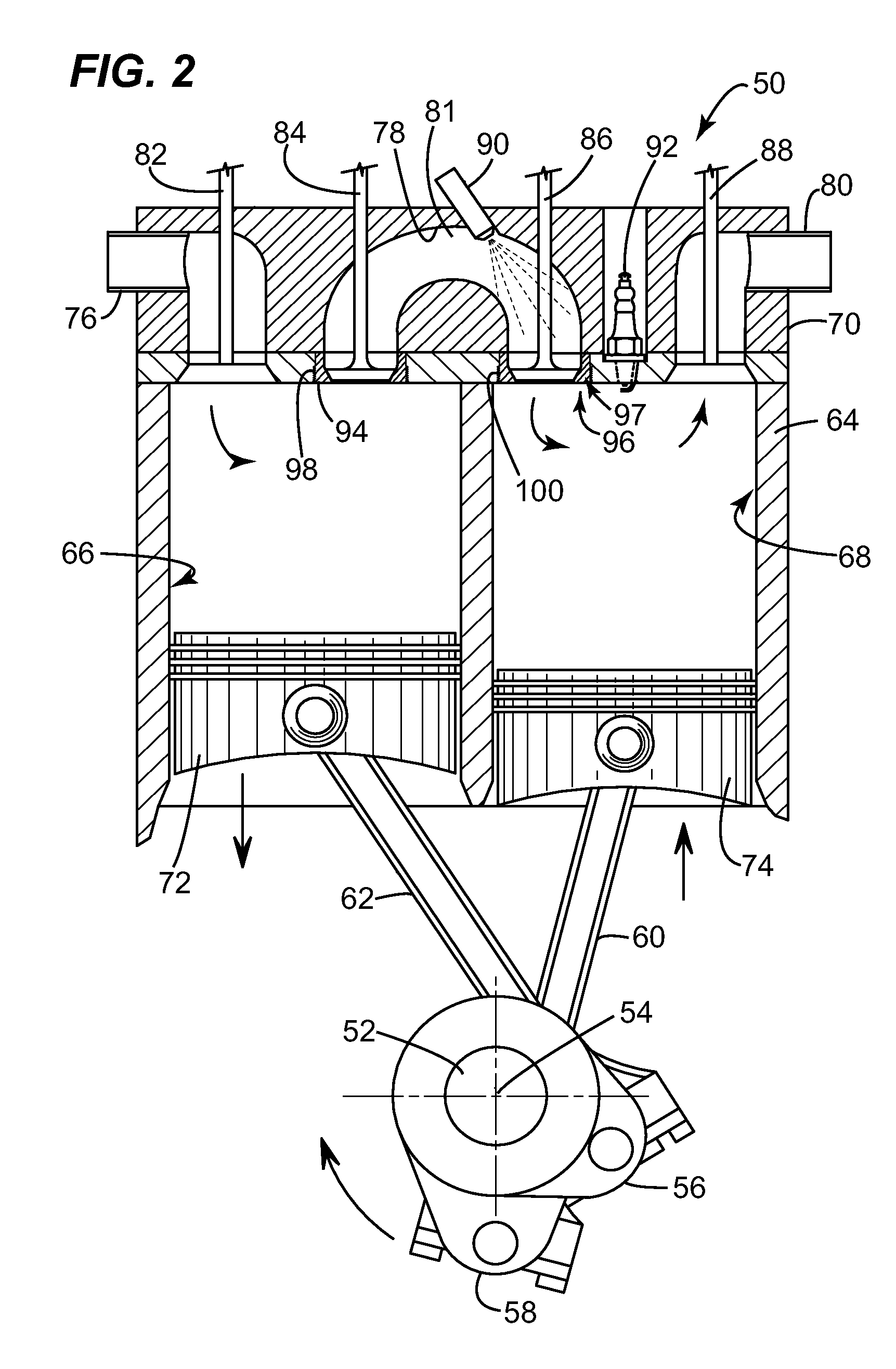

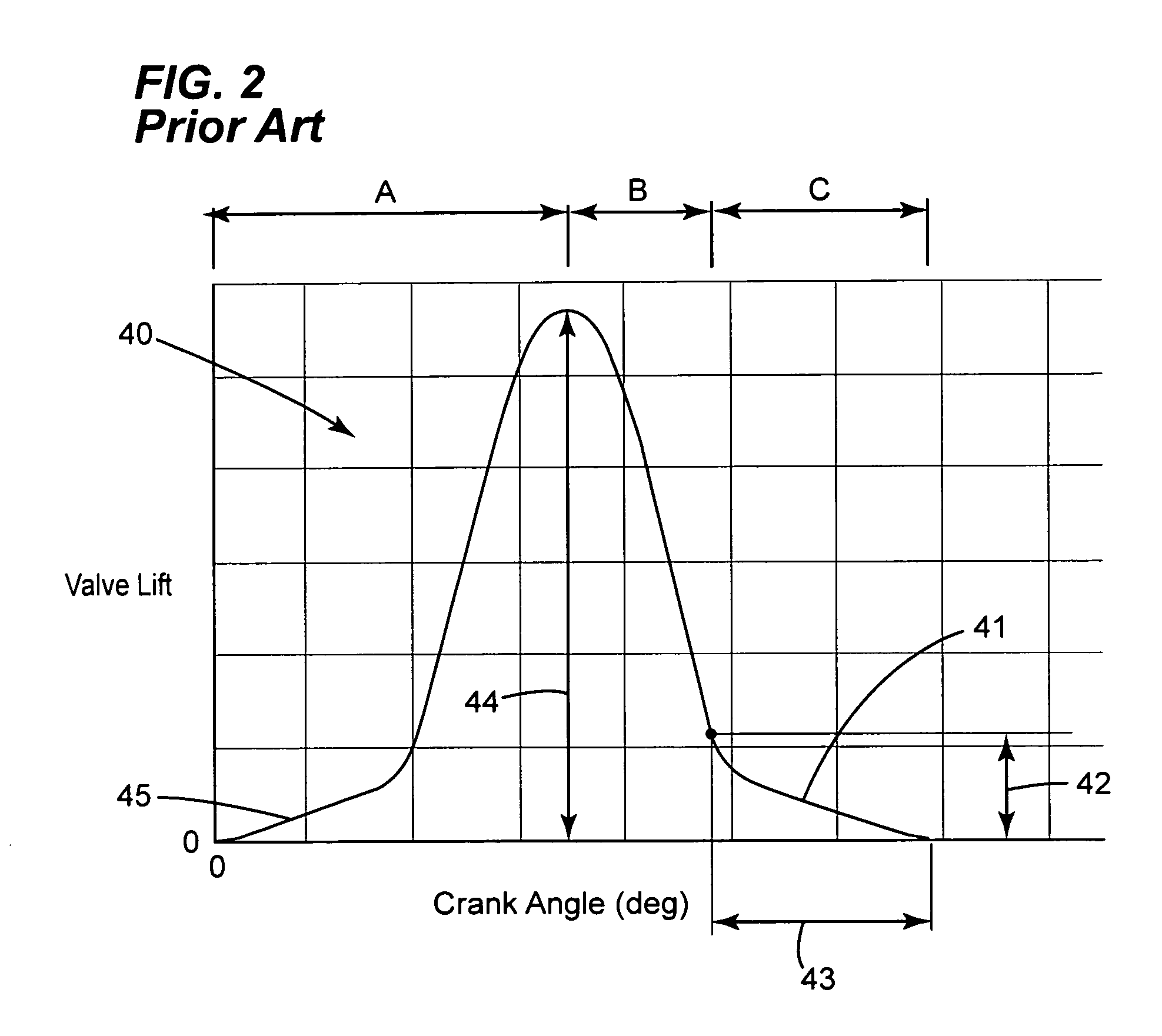

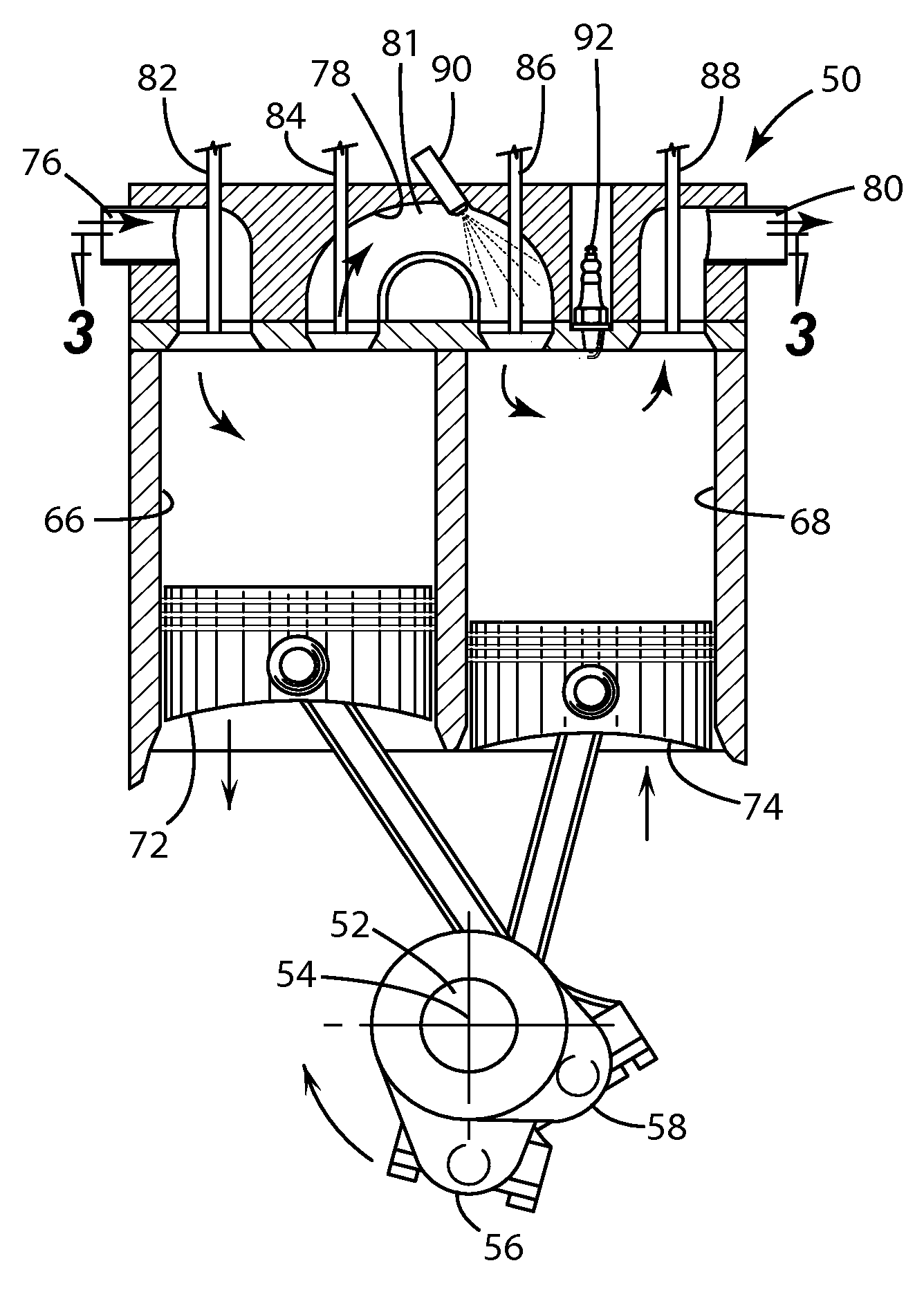

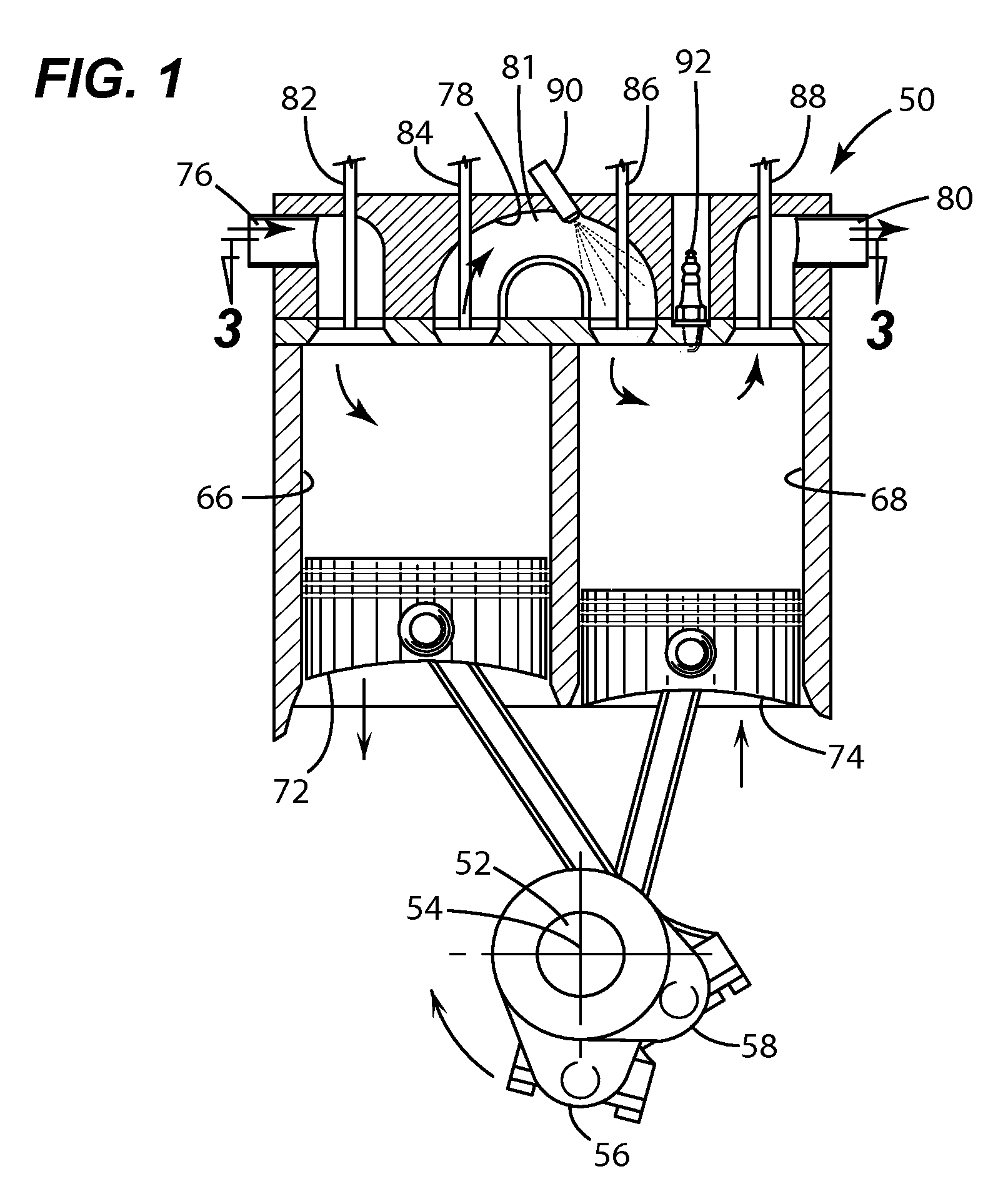

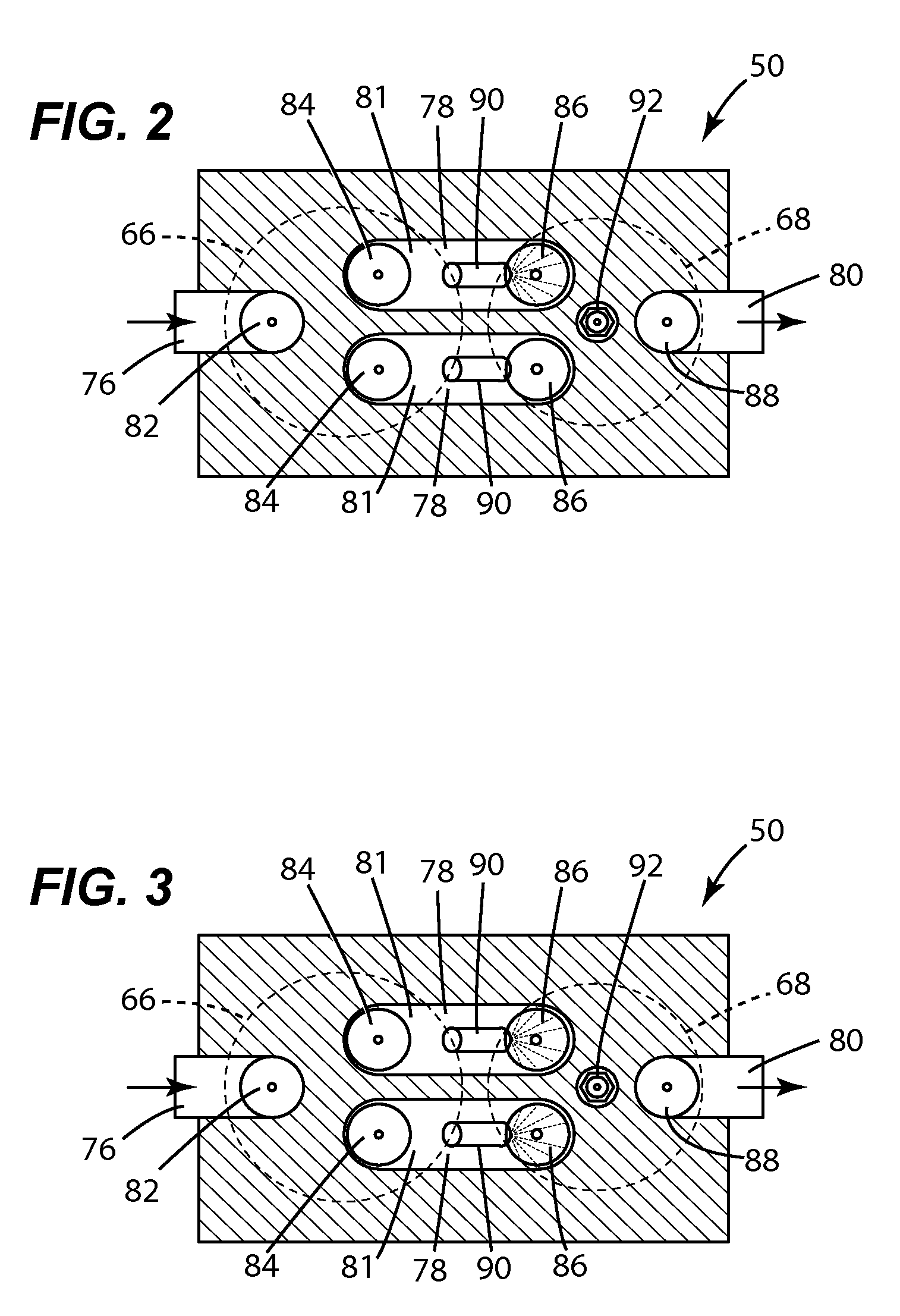

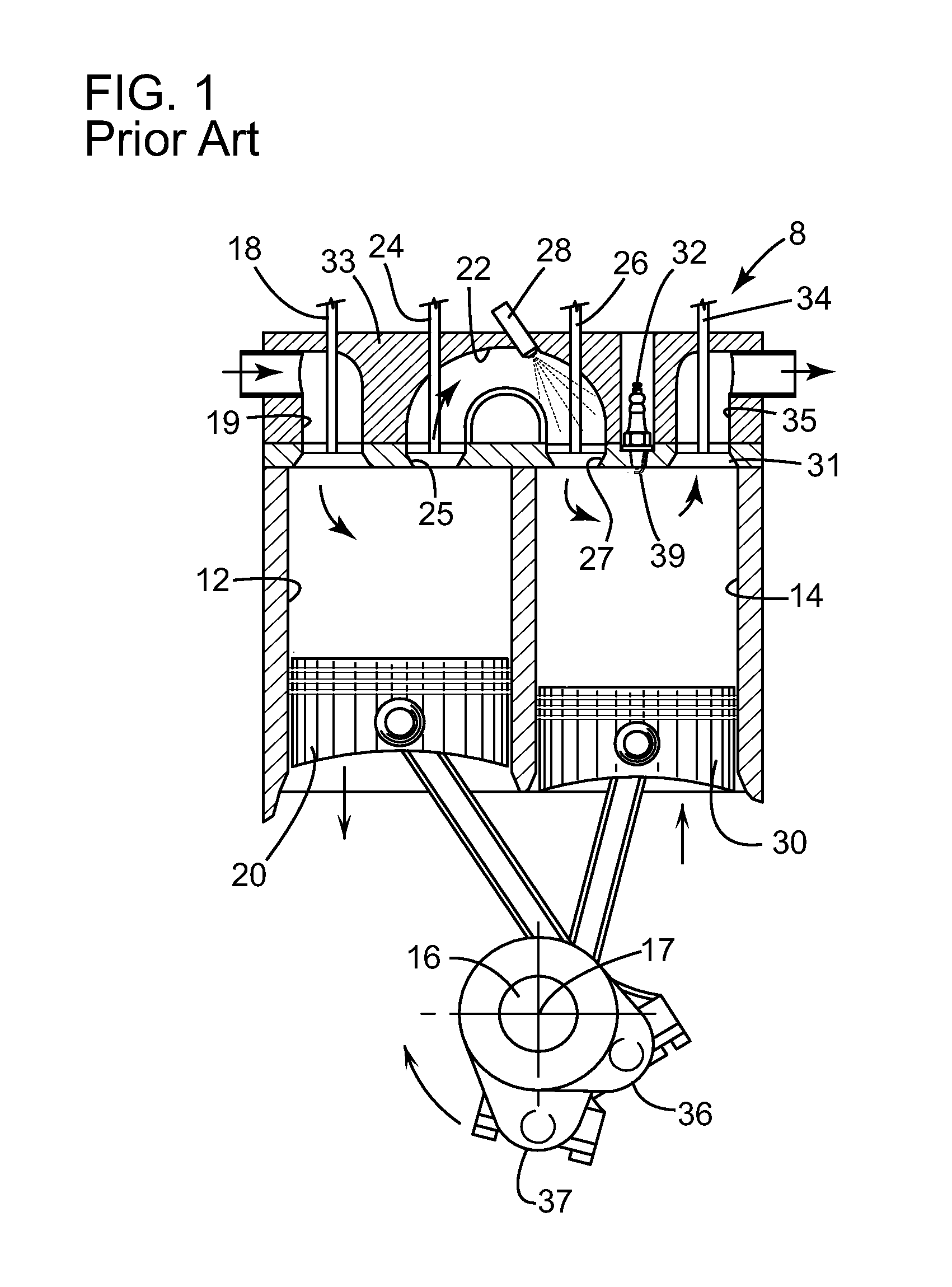

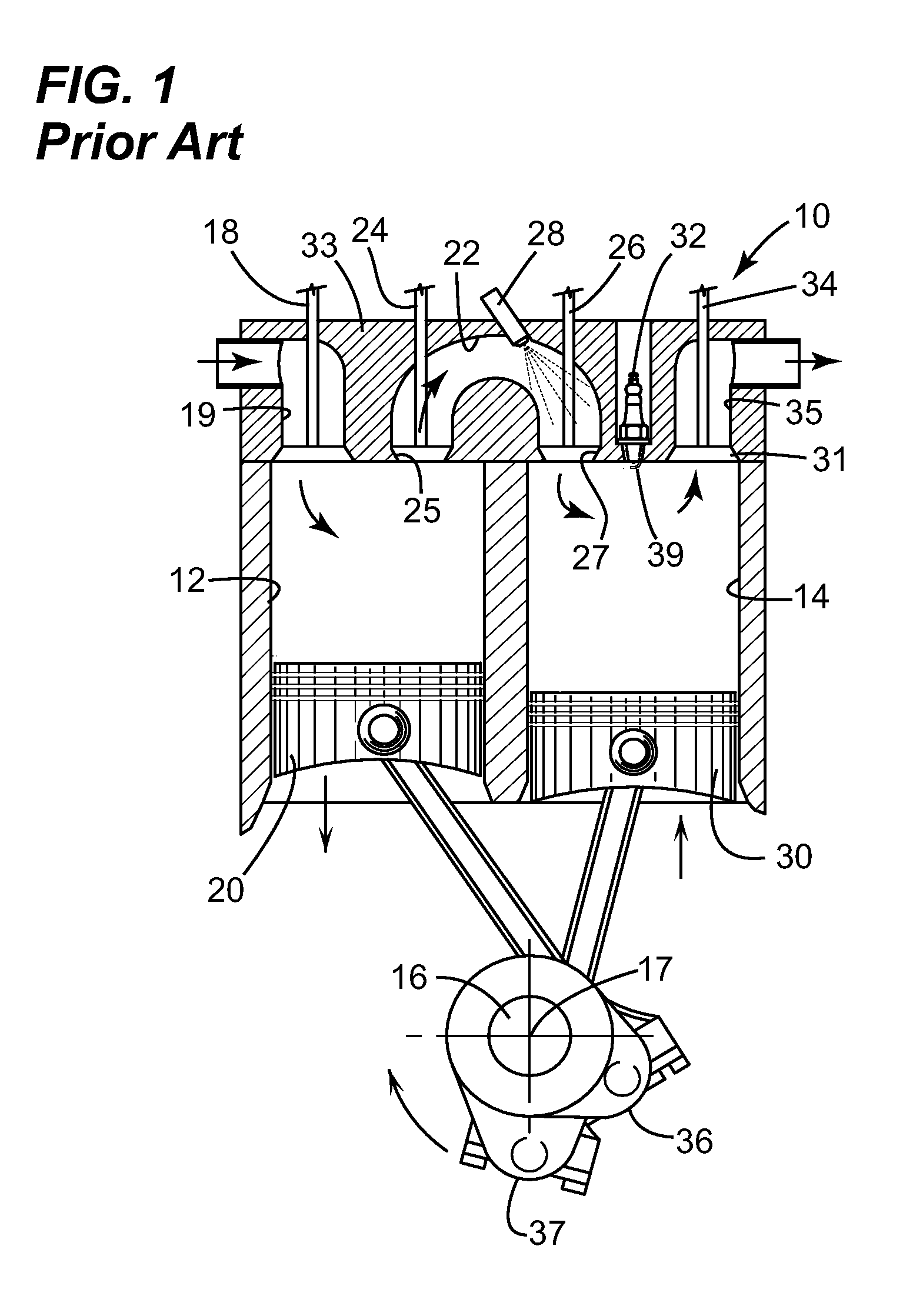

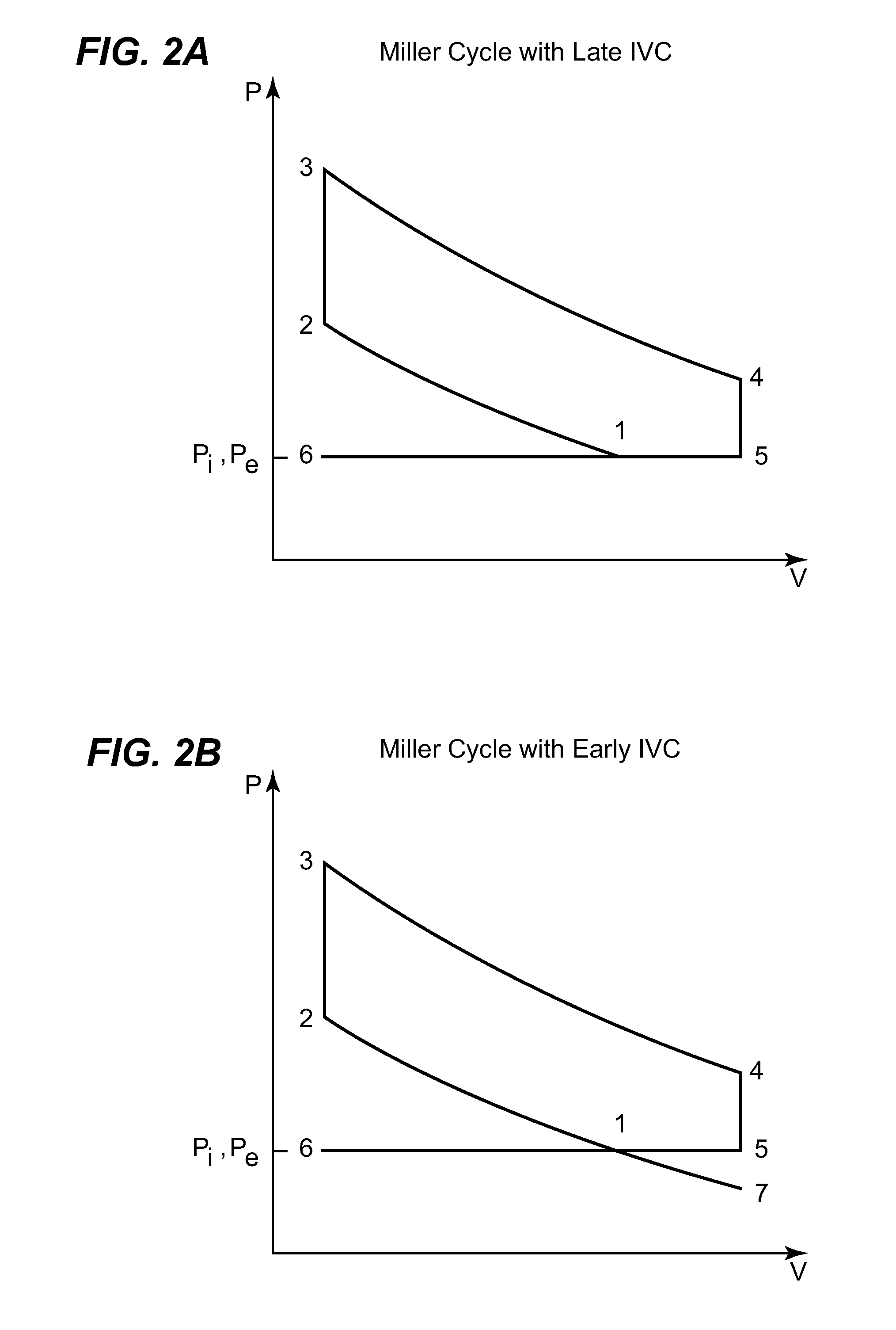

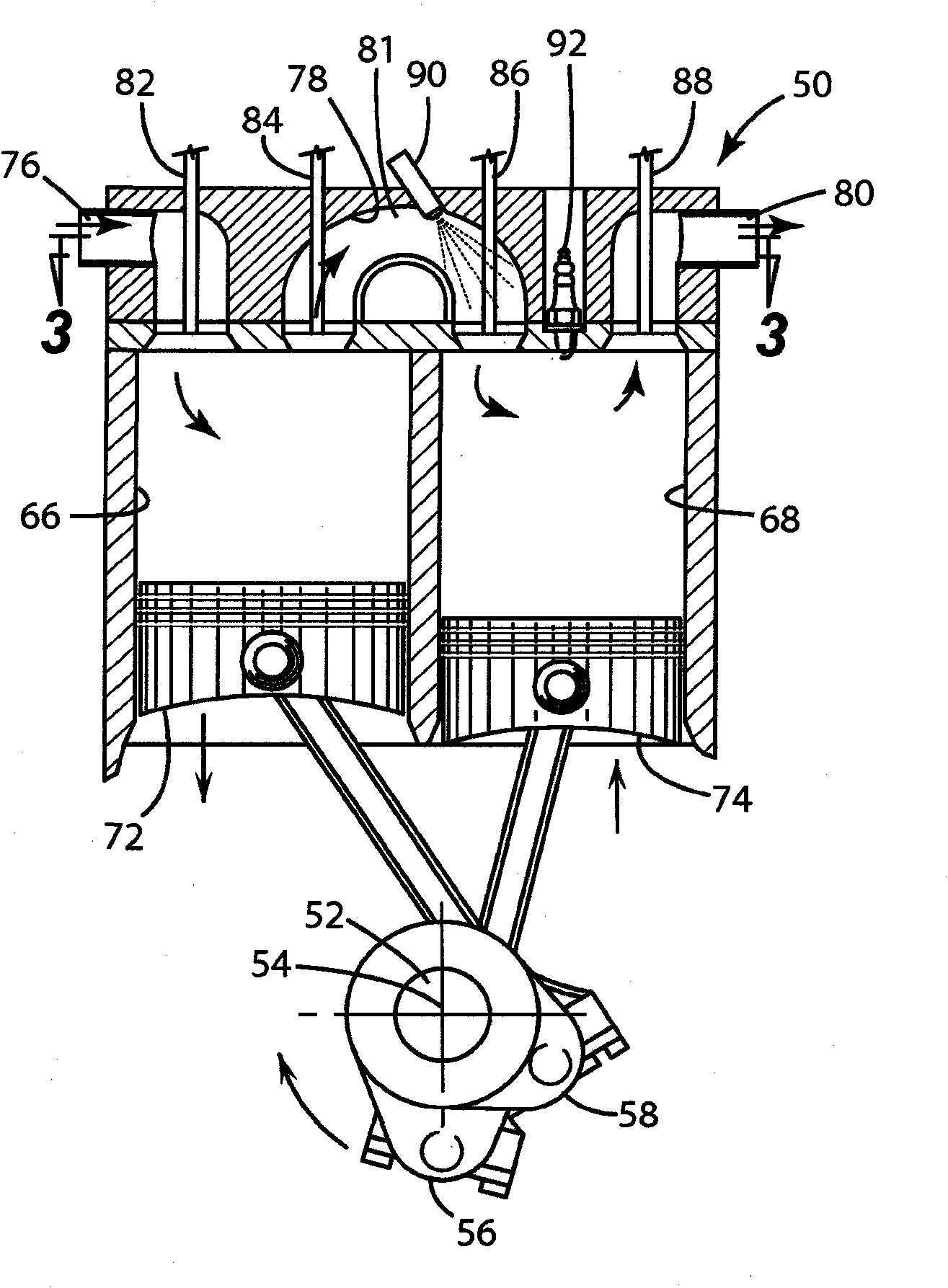

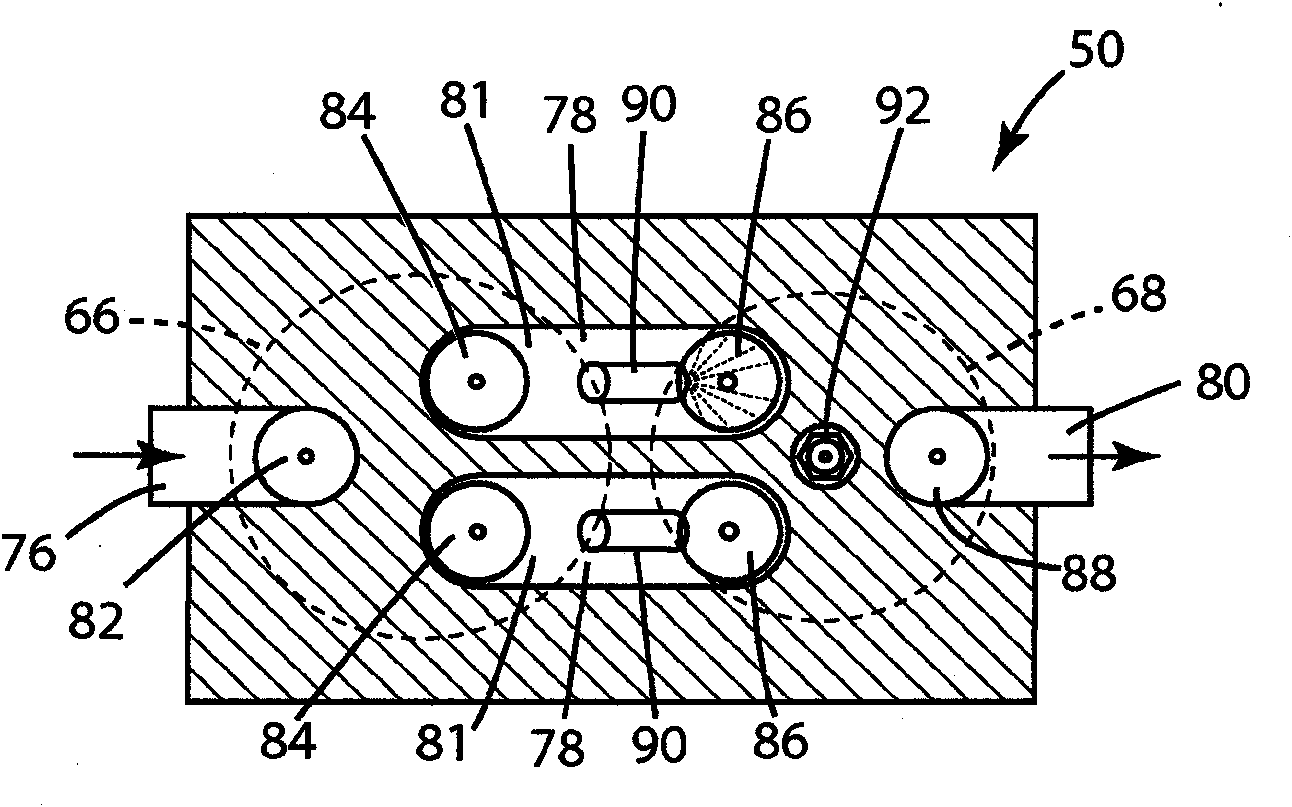

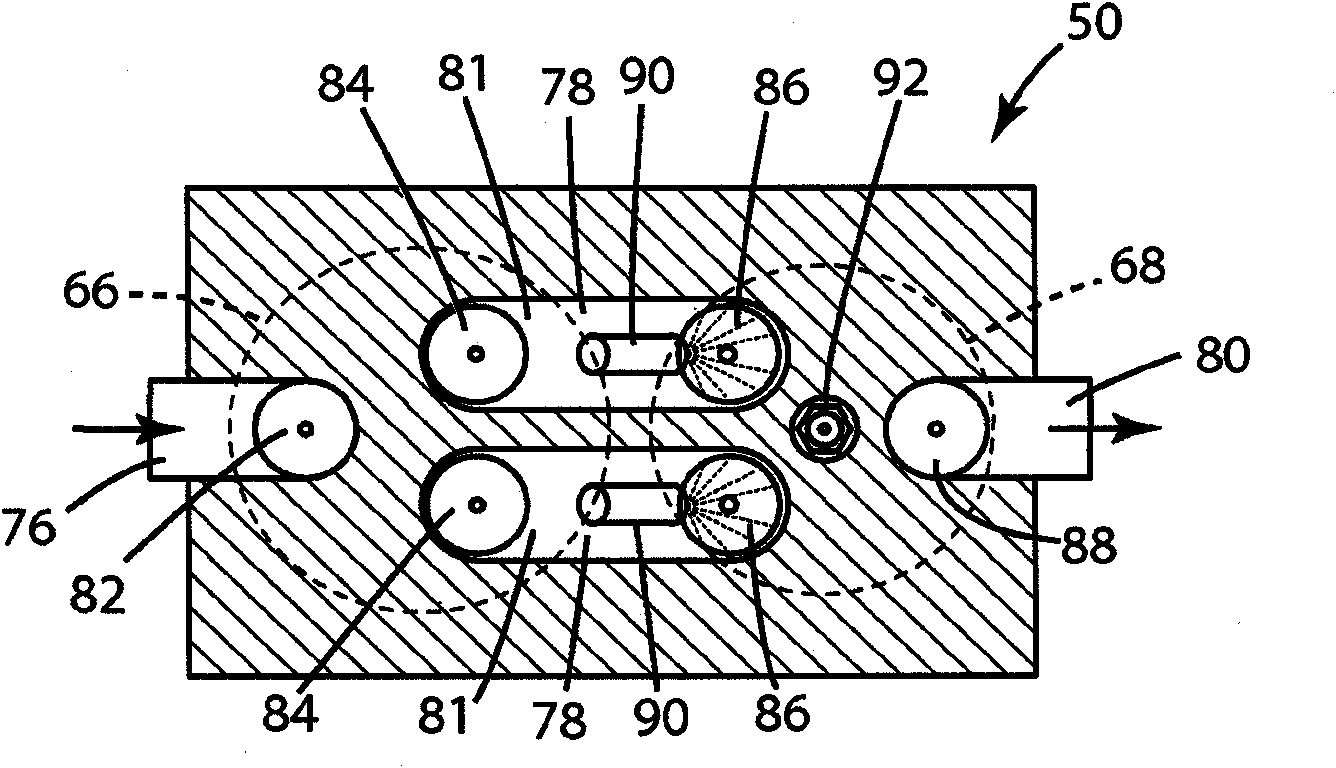

An engine has a rotatable crankshaft. A compression piston is received within a compression cylinder and operatively connected to the crankshaft such that the compression piston reciprocates through an intake stroke and a compression stroke during a single rotation of the crankshaft. An expansion piston is received within an expansion cylinder and operatively connected to the crankshaft such that the expansion piston reciprocates through an expansion stroke and an exhaust stroke during a single rotation of the crankshaft. A crossover passage interconnects the compression and expansion cylinders. The crossover passage includes a crossover compression valve and a crossover expansion valve defining a pressure chamber therebetween. A fuel injector is disposed in the pressure chamber of the crossover passage. Fuel injection from the fuel injector into the crossover passage is timed to occur entirely during the compression stroke of the compression piston.

Owner:SKADERI GRUP LLC

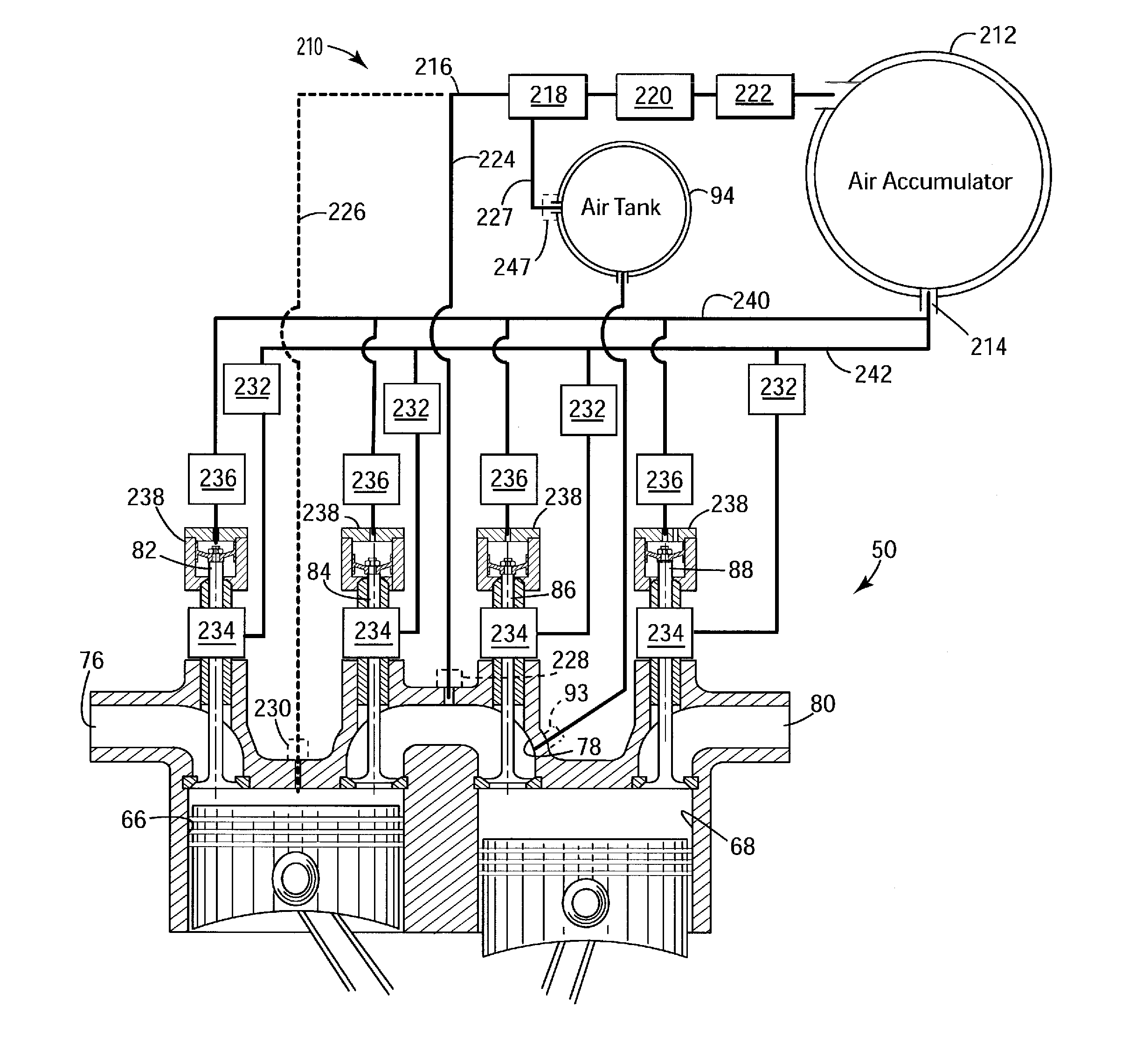

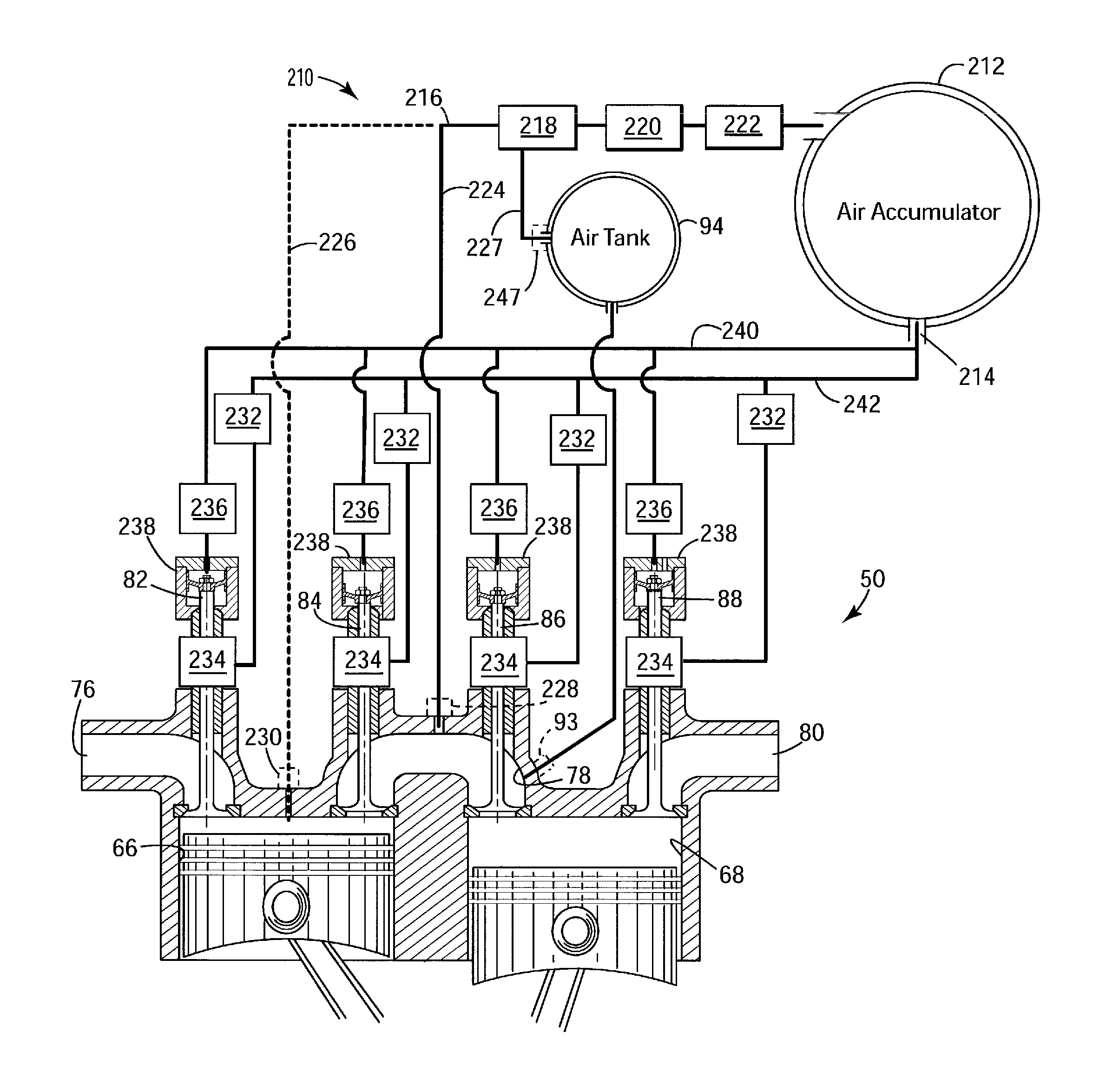

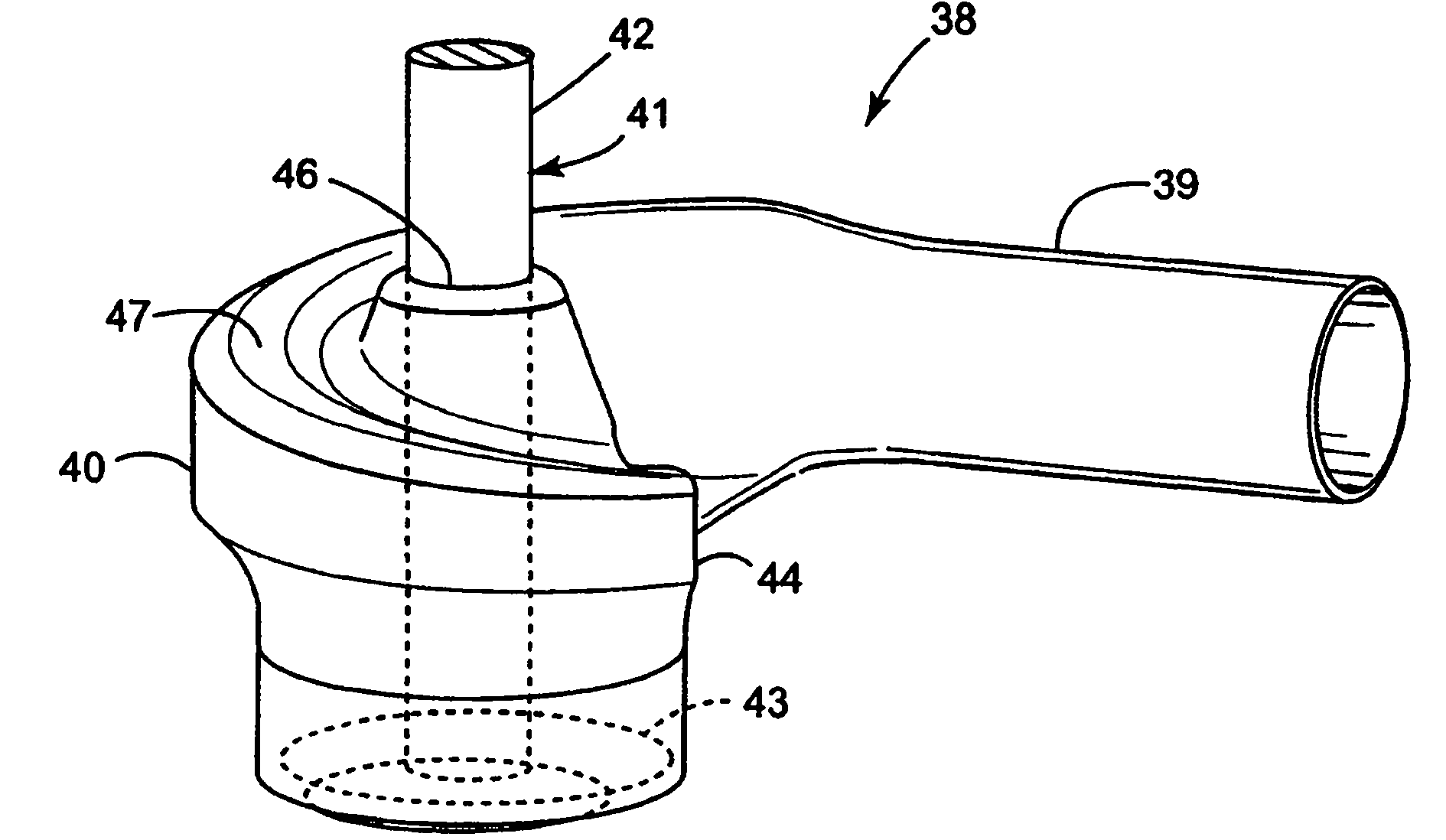

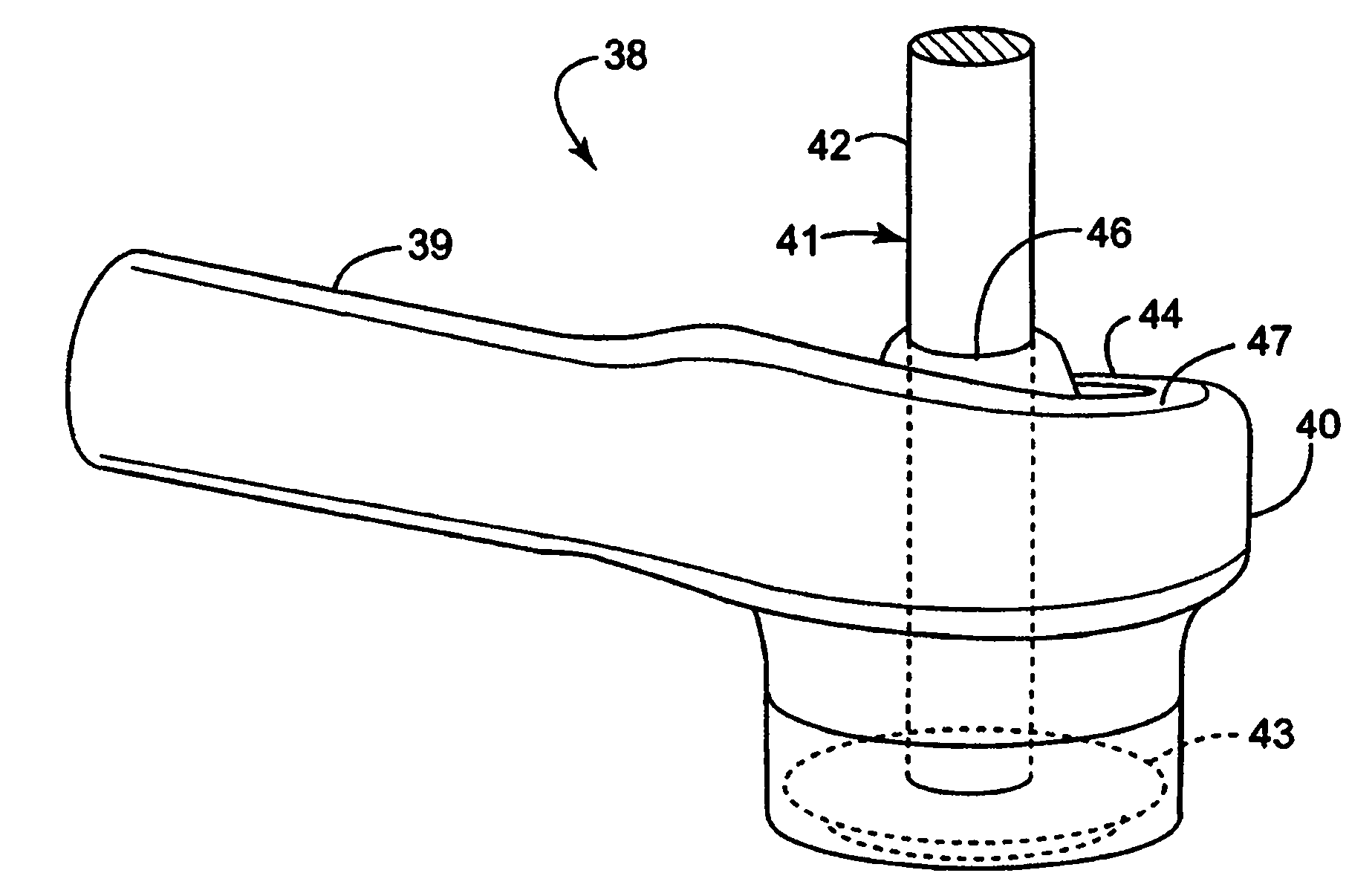

Air Supply for Components of a Split-Cycle Engine

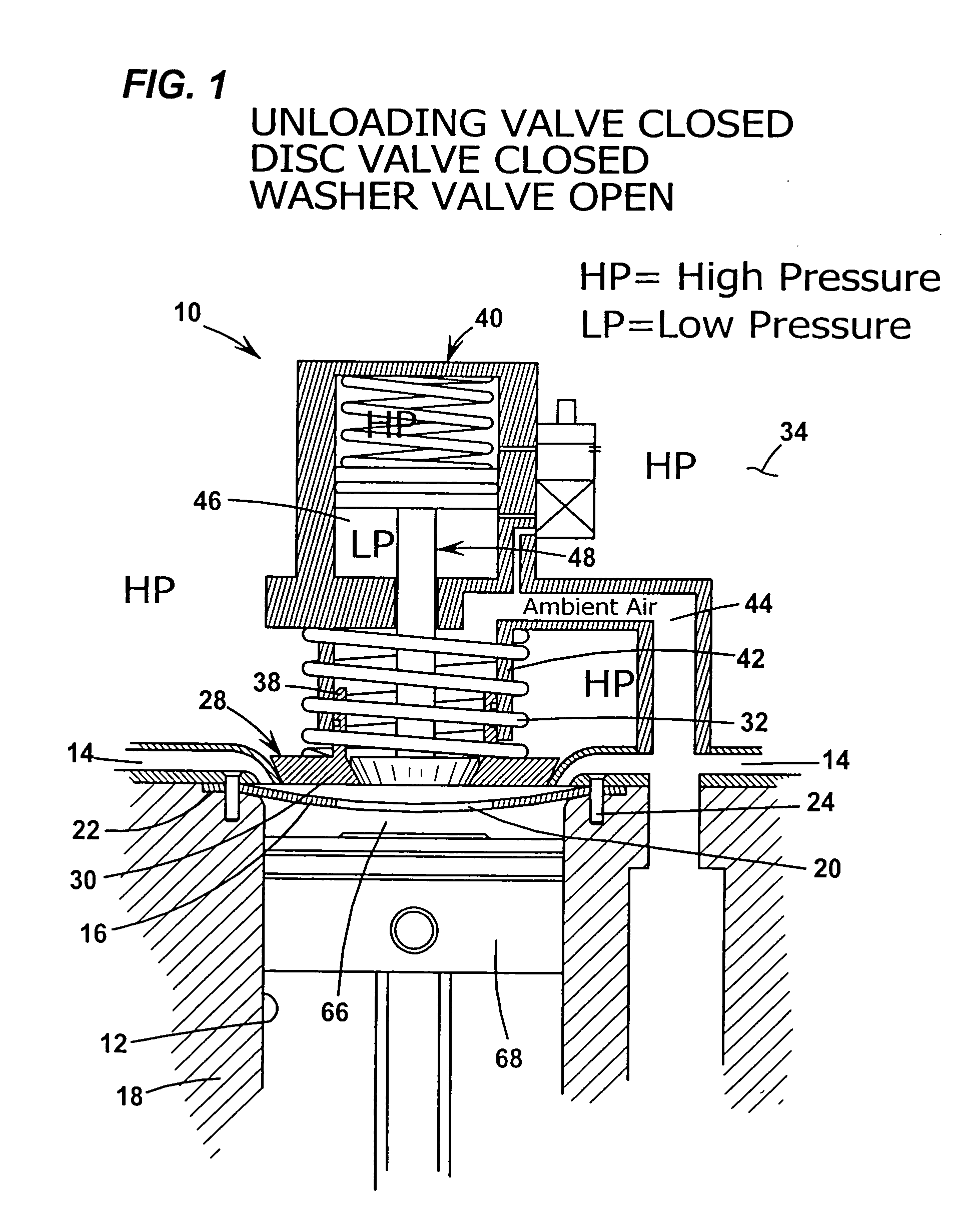

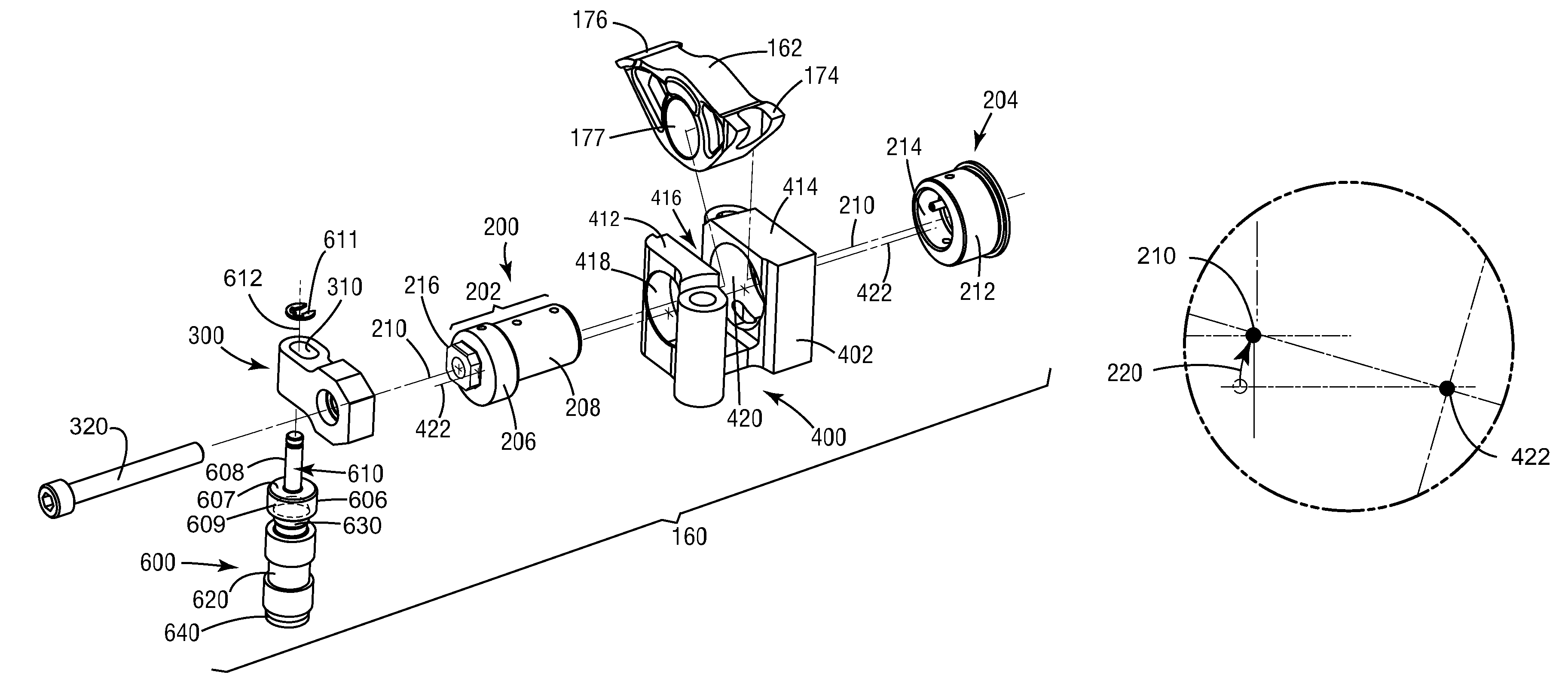

InactiveUS20100282225A1Operating means/releasing devices for valvesNon-fuel substance addition to fuelAir springPower component

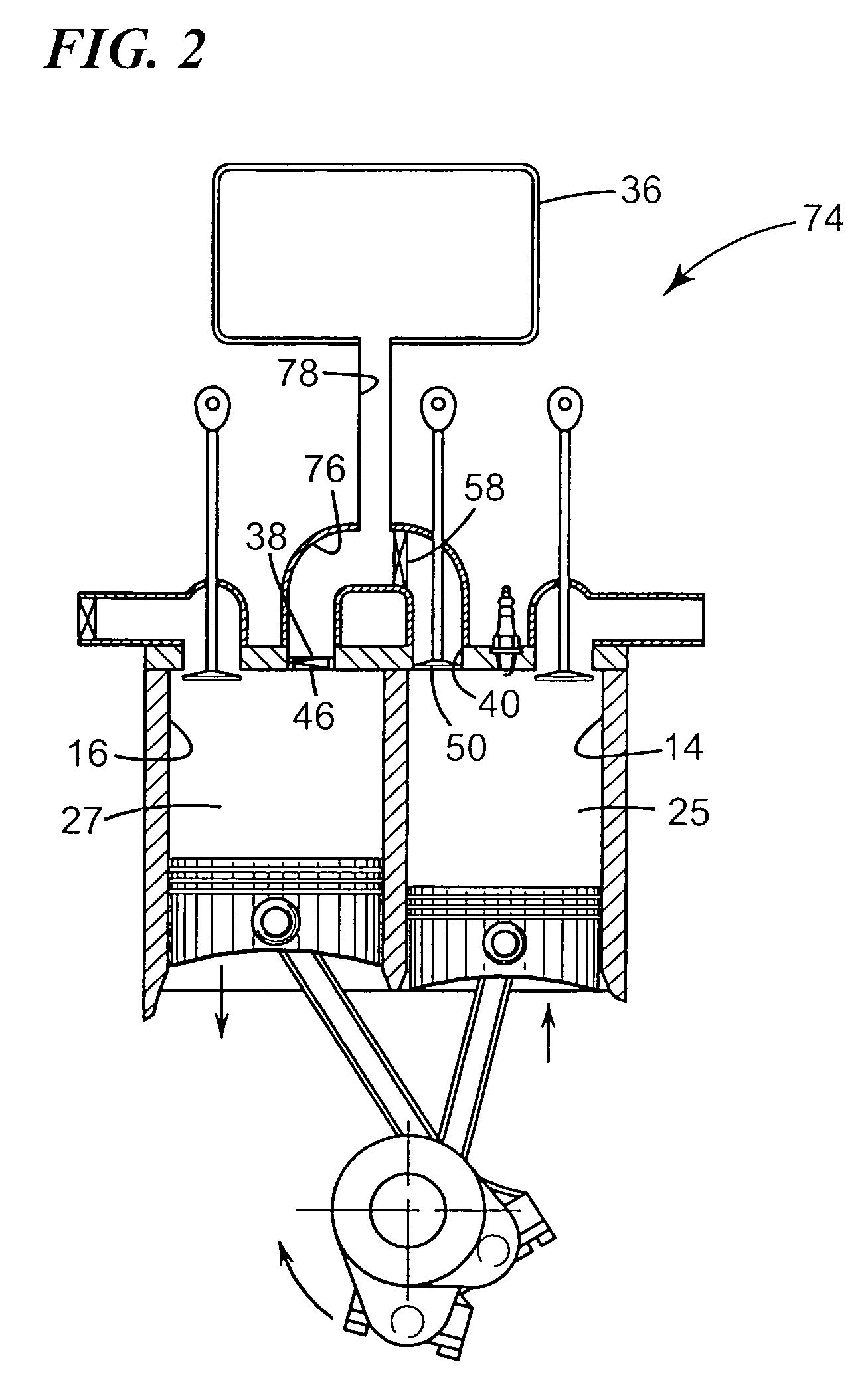

The present invention generally relates to providing an air supply for components associated with an engine. More particularly, the present invention relates to a system and method for using compressed air generated by a split-cycle engine to power components such as valves or air springs associated with the split-cycle engine.

Owner:SKADERI GRUP LLC

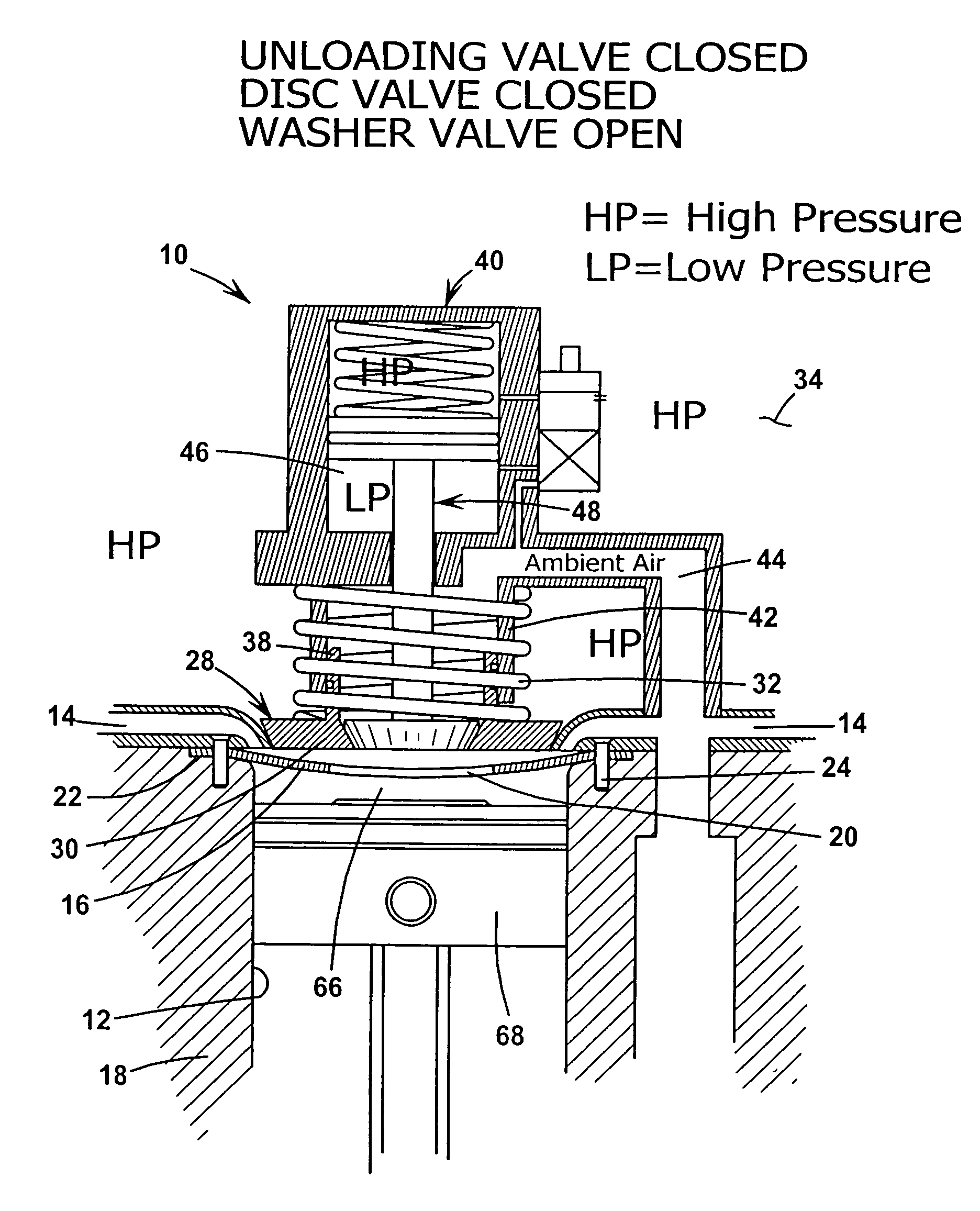

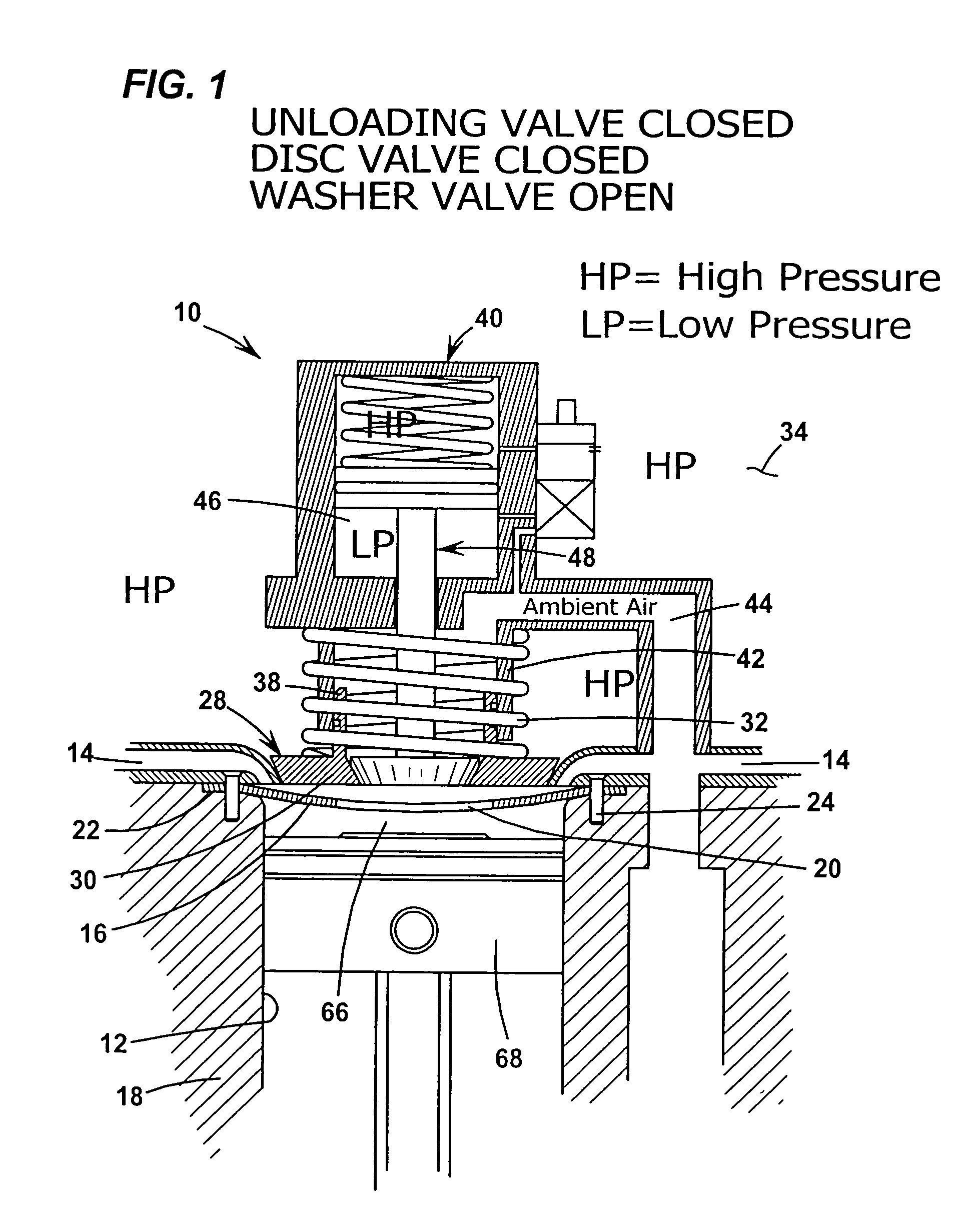

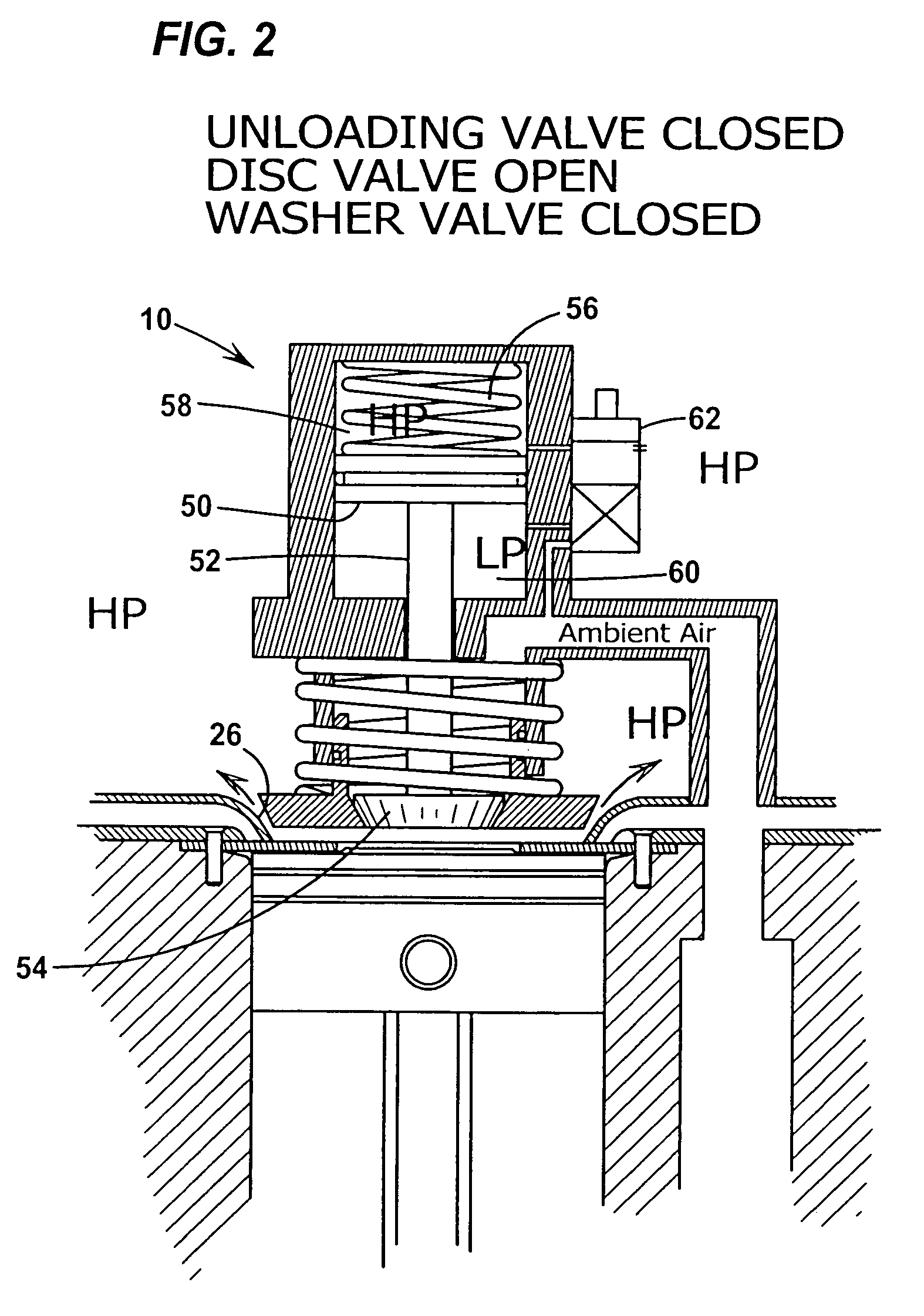

Split-cycle engine with disc valve

InactiveUS7481190B2Lower the volumeImprove efficiencyCombustion enginesRotary slide valveEngineeringValve seat

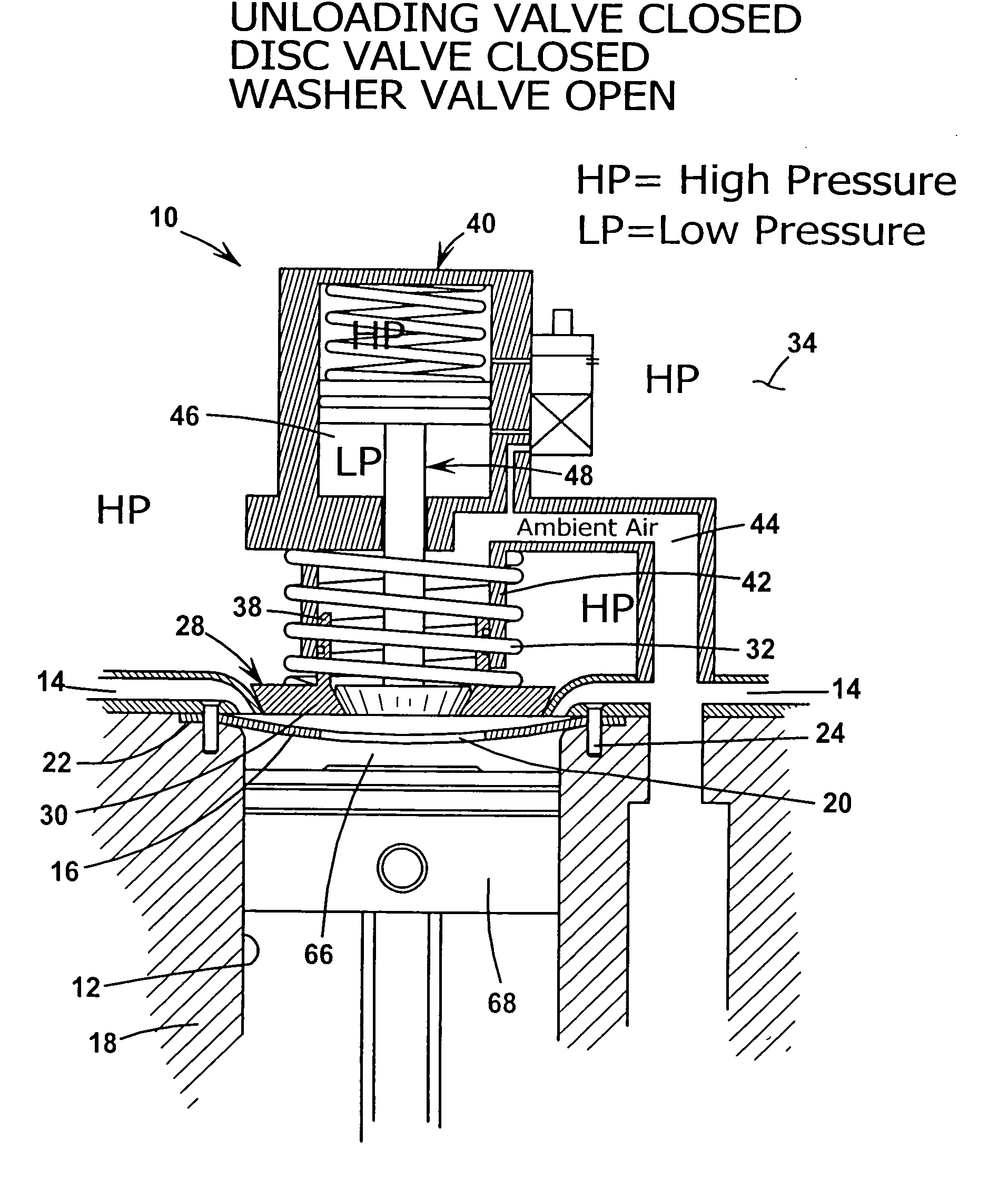

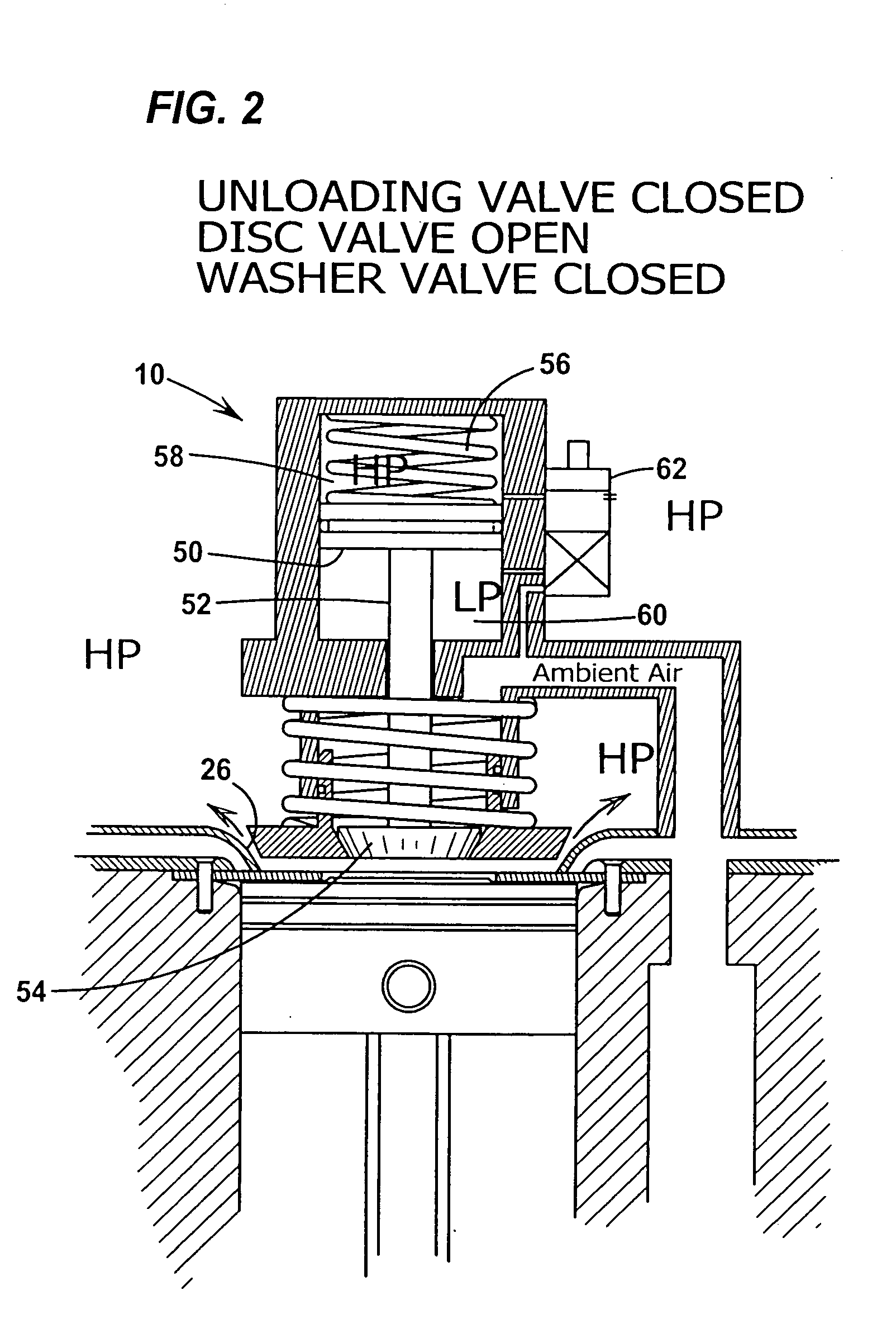

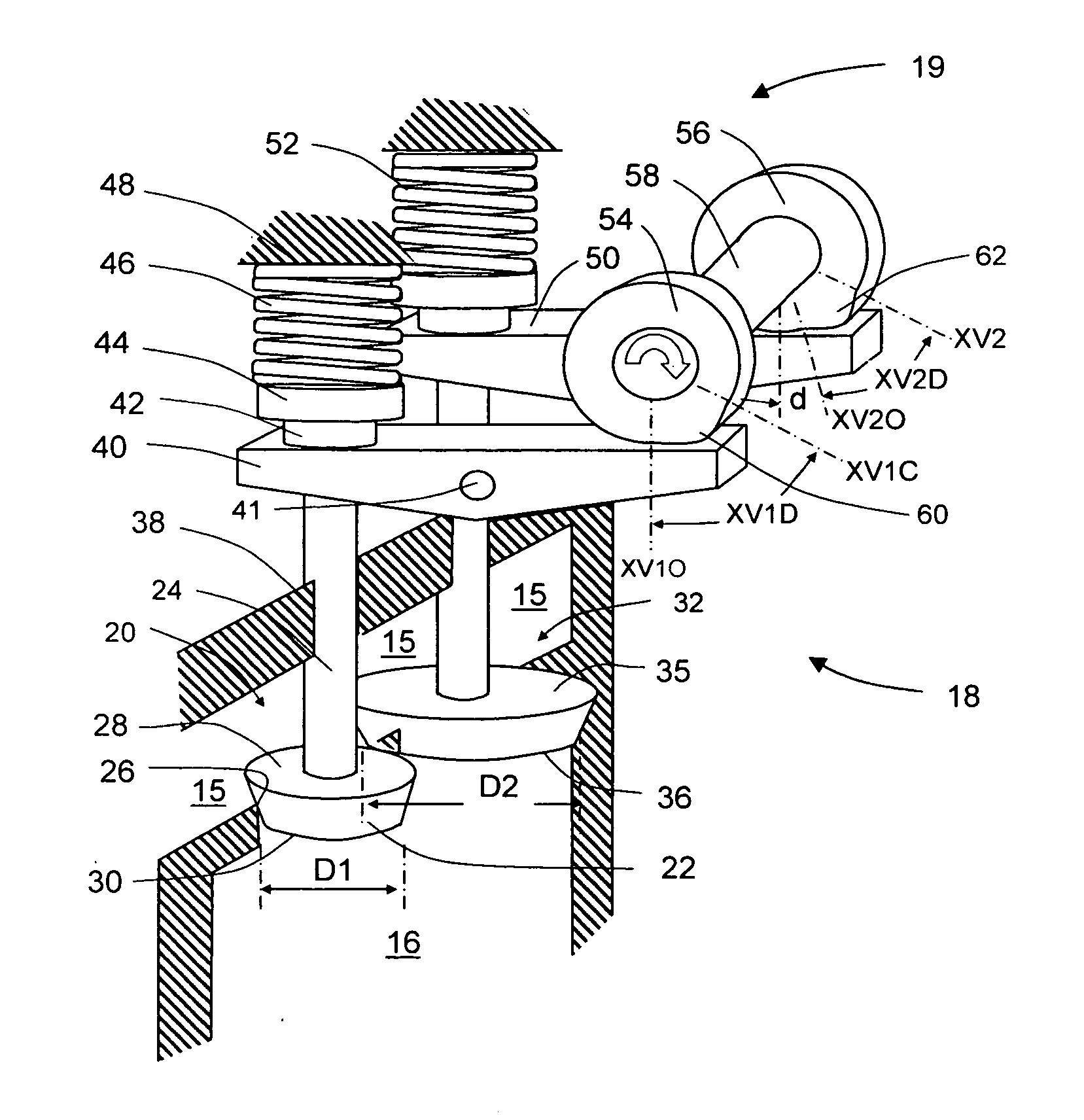

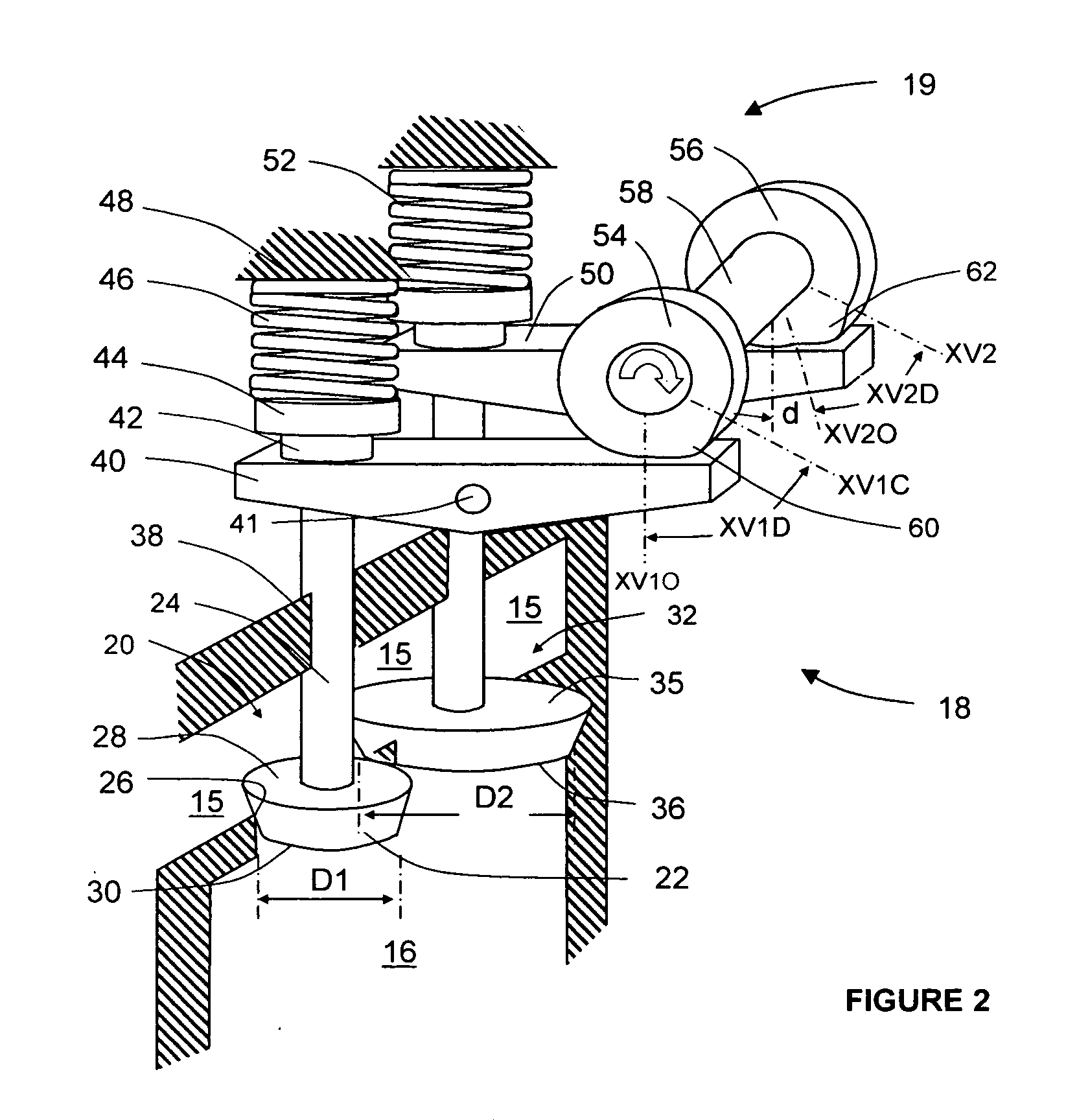

A split-cycle engine with disc valve includes a crankshaft, a power cylinder and a compression cylinder. A gas crossover passage interconnects the compression cylinder and the power cylinder. An air intake port circumscribes a periphery of the compression cylinder and defines an outer valve seat. An annular ring having a generally central opening is disposed between the compression cylinder and the air intake port and forms a washer valve for opening and closing the air intake port. A disc valve member is concentrically mounted over the central opening of the annular ring. The disc valve member includes a piston portion having a sidewall biased into engagement with the outer valve seat for controlling flow between the compression cylinder and the gas crossover passage.

Owner:SKADERI GRUP LLC

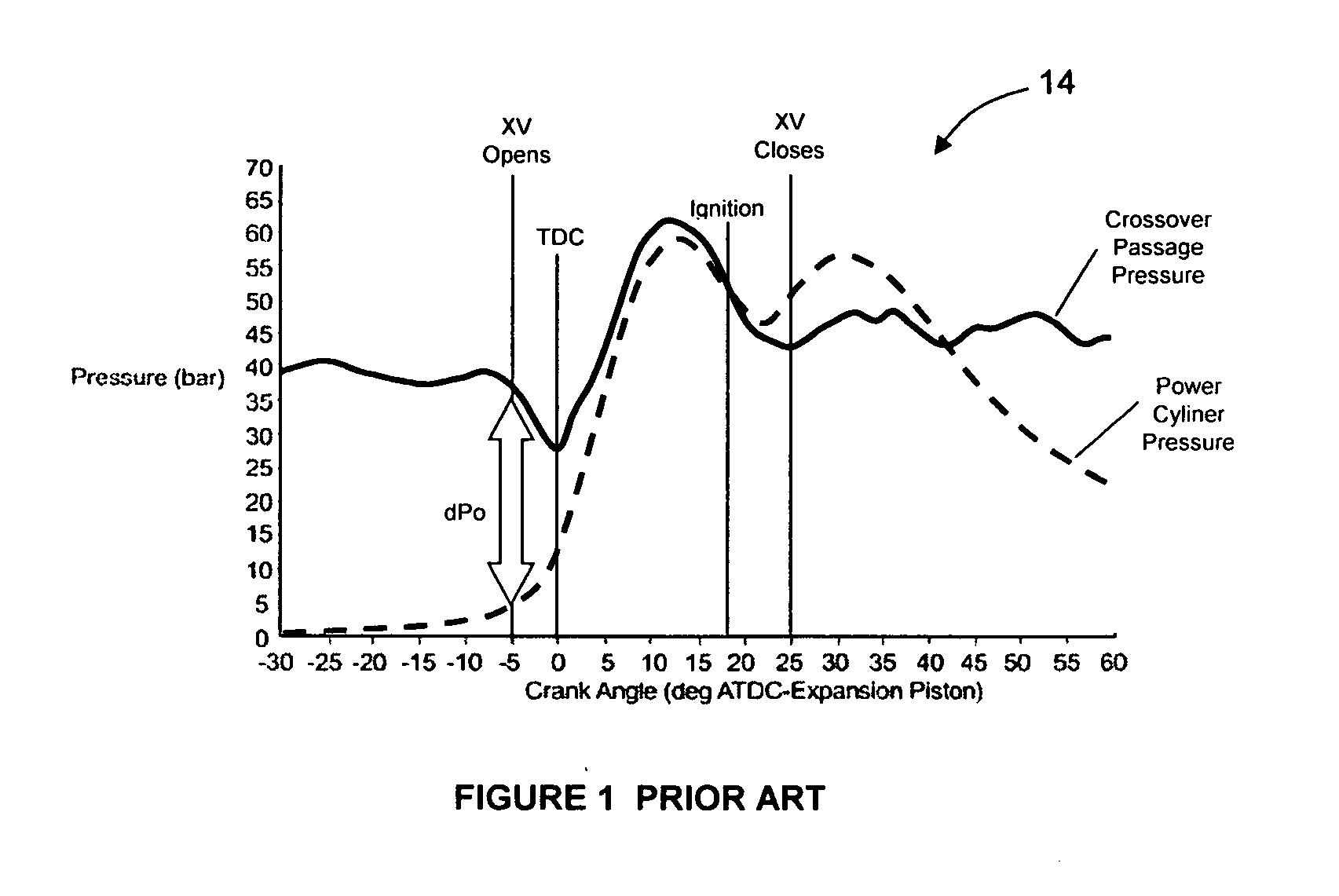

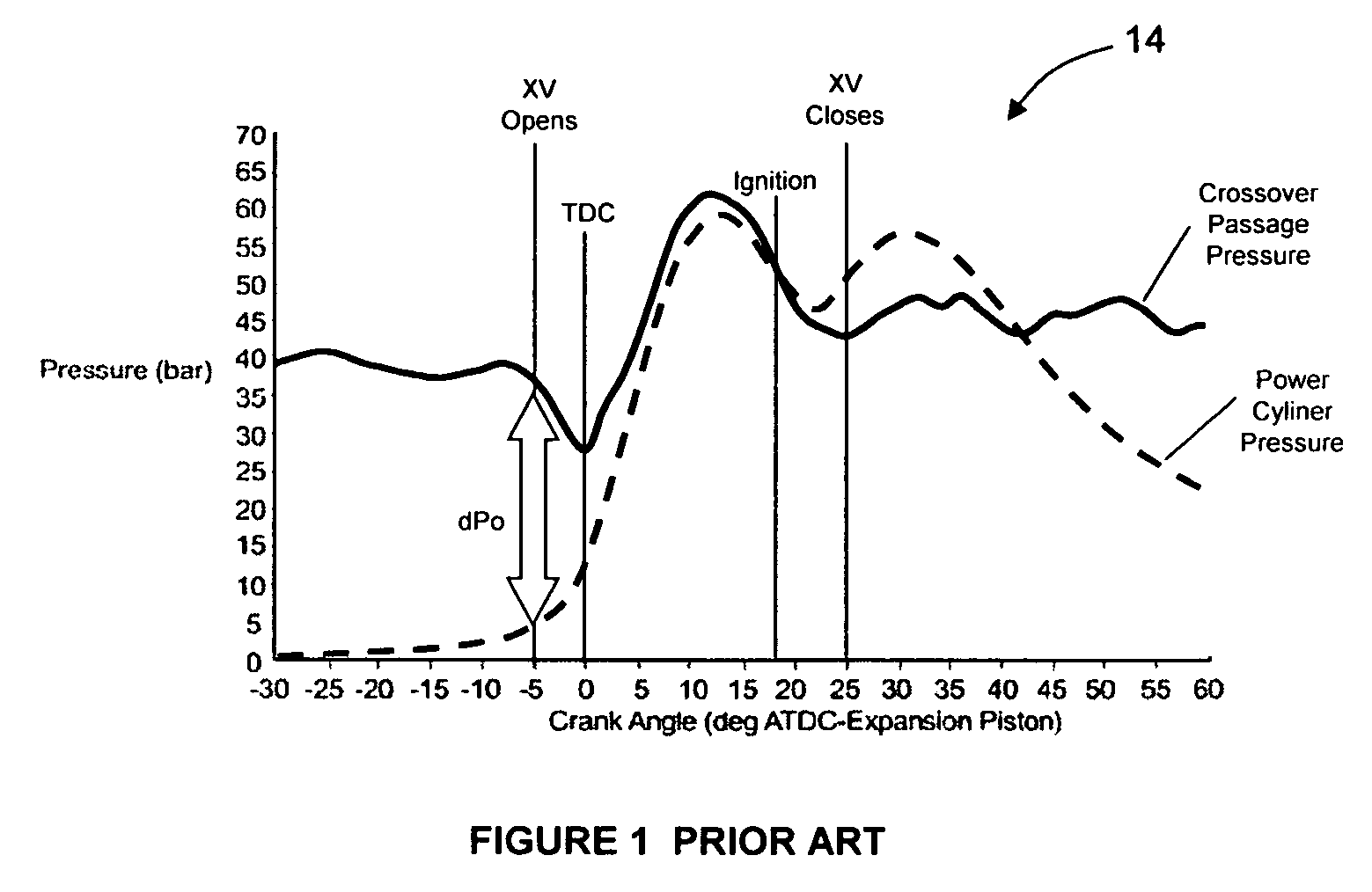

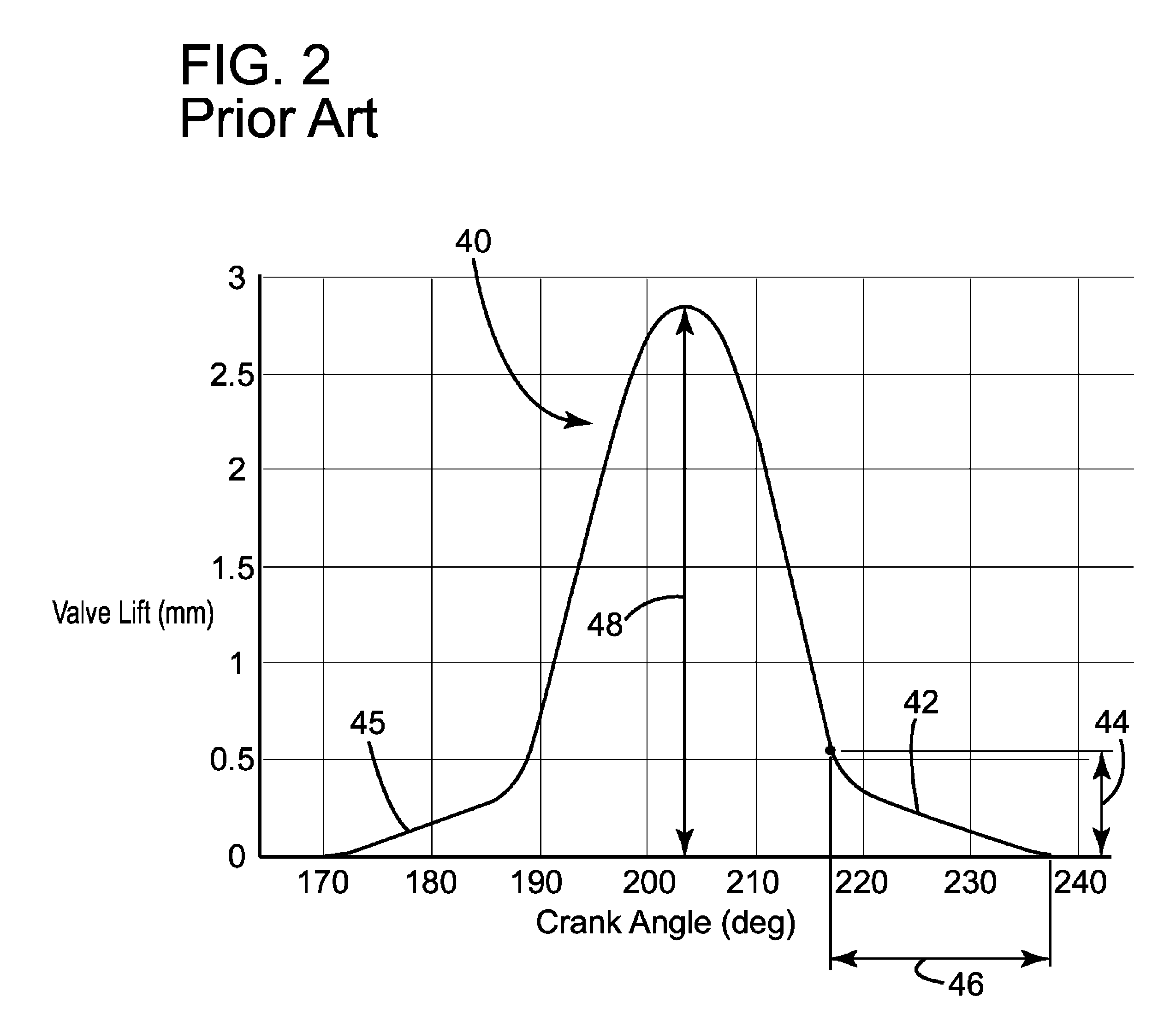

Split-cycle engine with early crossover compression valve opening

InactiveUS20090038598A1Internal combustion piston enginesLift valveReciprocating motionValve opening

A split-cycle engine includes a crankshaft. A compression piston is received within a compression cylinder and operatively connected to the crankshaft such that the compression piston reciprocates through an intake stroke and a compression stroke during a single rotation of the crankshaft. An expansion piston is received within an expansion cylinder and operatively connected to the crankshaft such that the expansion piston reciprocates through an expansion stroke and an exhaust stroke during a single rotation of the crankshaft. A crossover passage interconnects the compression and expansion cylinders. The crossover passage includes a crossover compression (XovrC) valve and a crossover expansion (XovrE) valve defining a pressure chamber therebetween. The crossover compression valve is timed to open when the pressure in the compression cylinder is less than the upstream pressure in the crossover passage at the crossover compression valve.

Owner:SKADERI GRUP LLC

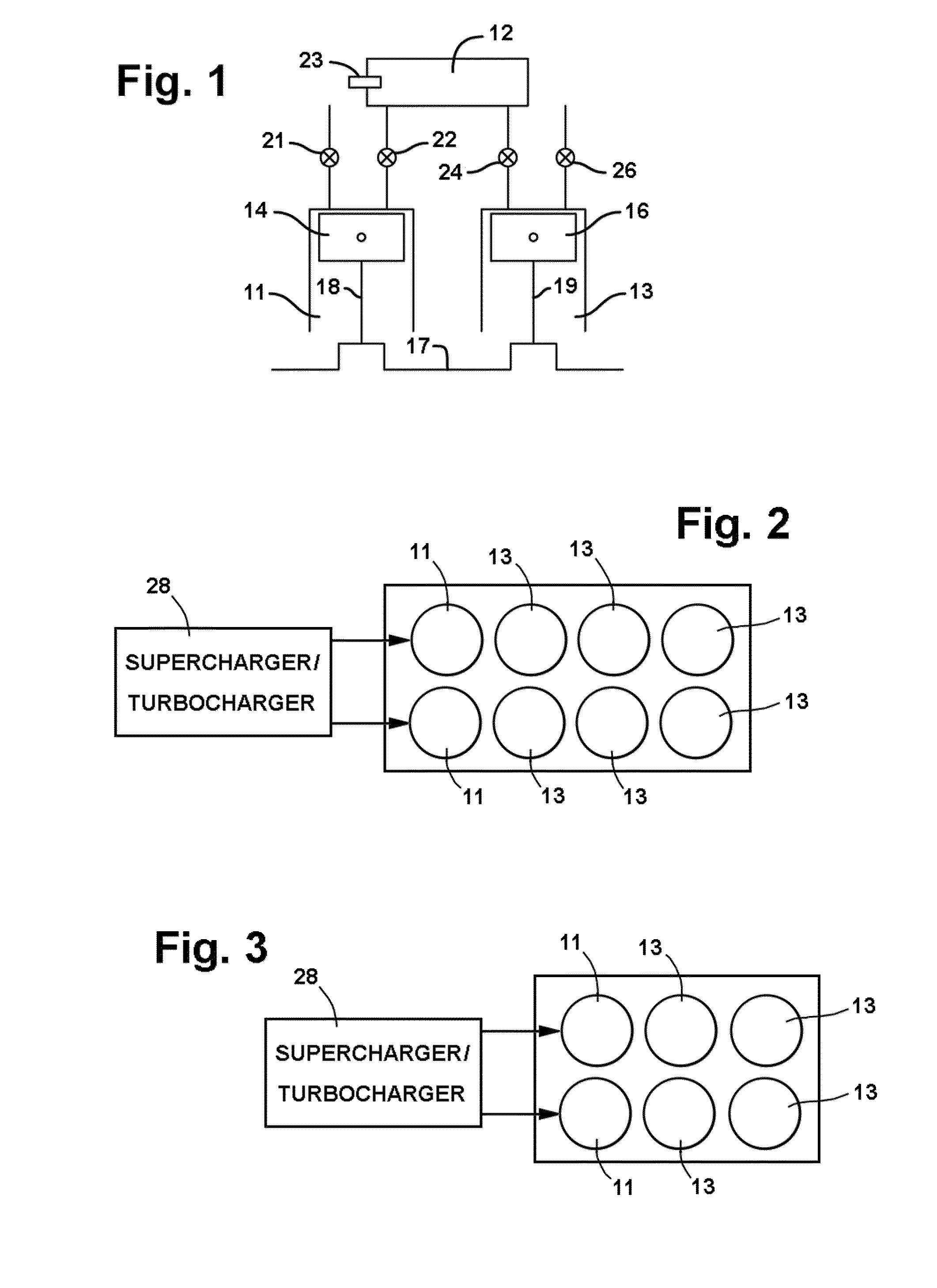

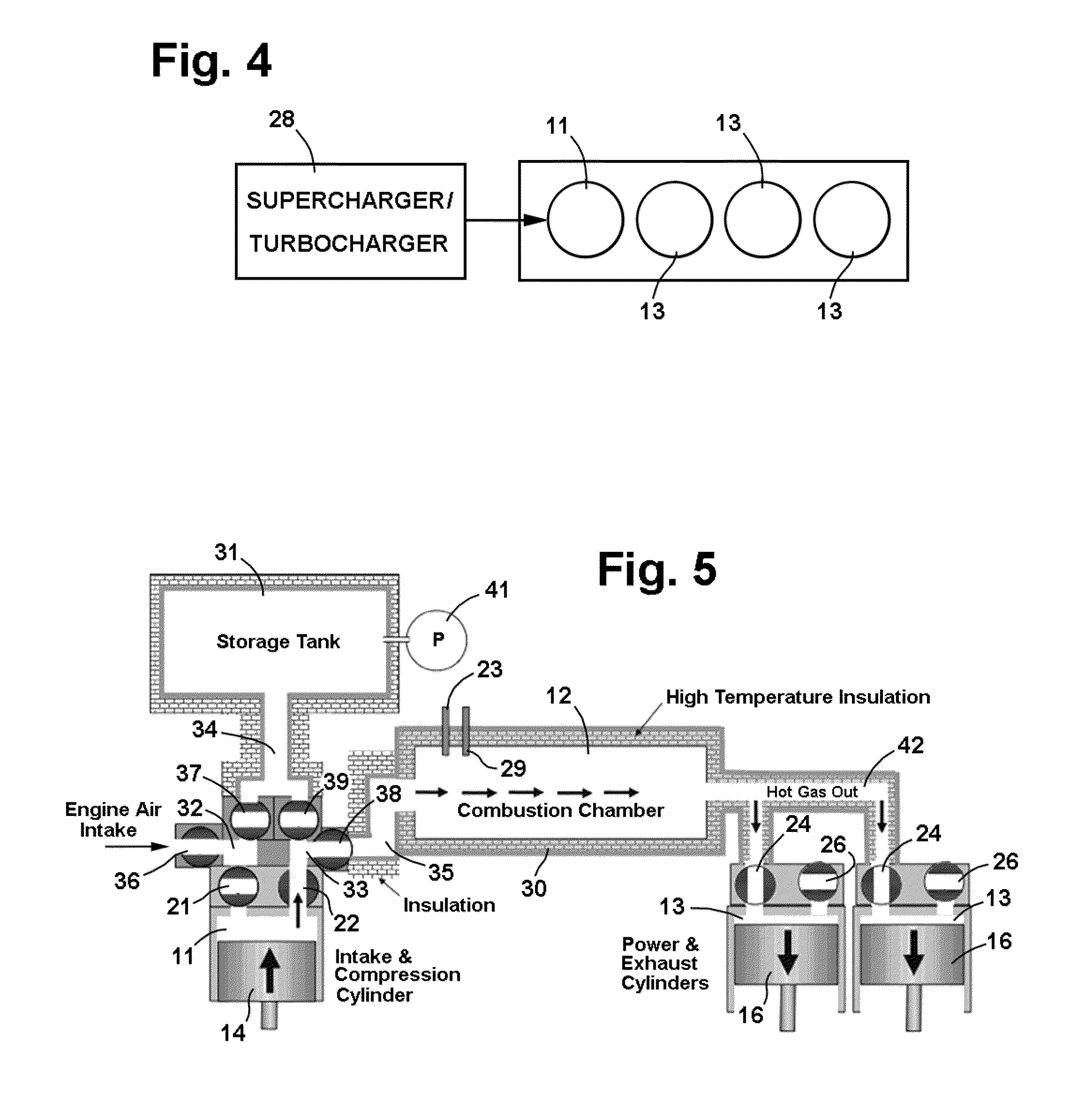

Split Cycle Engine and Method with Increased Power Density

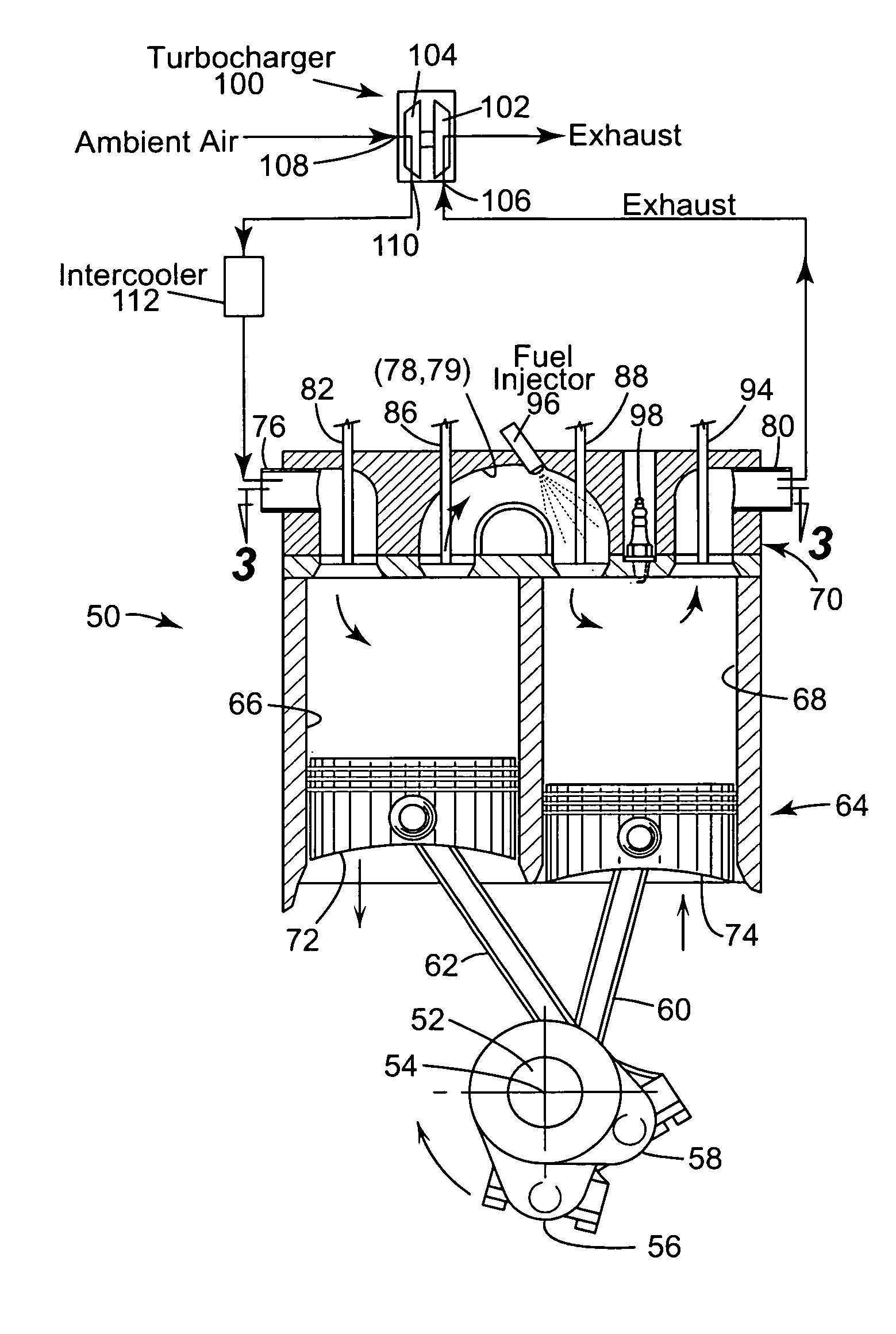

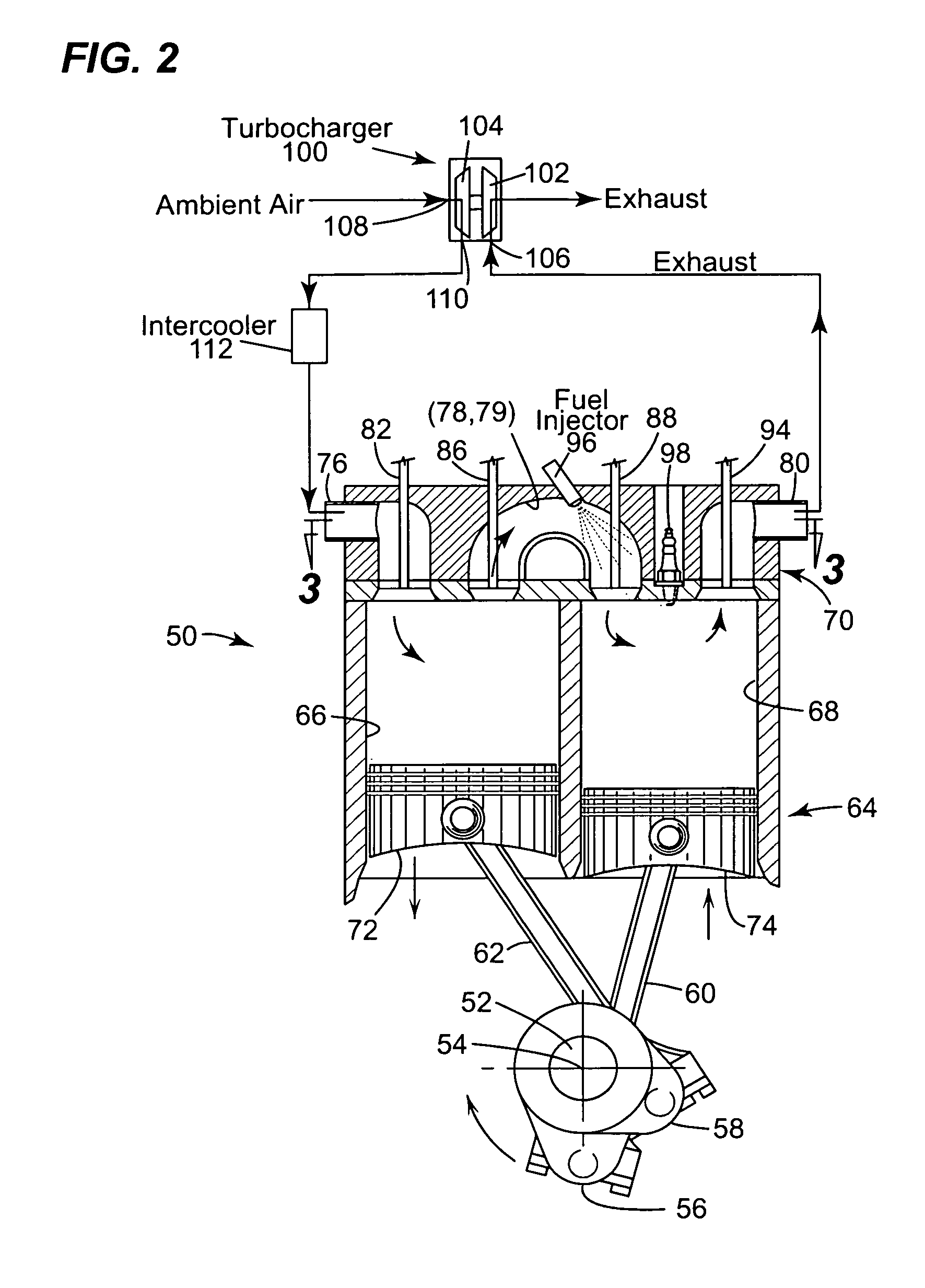

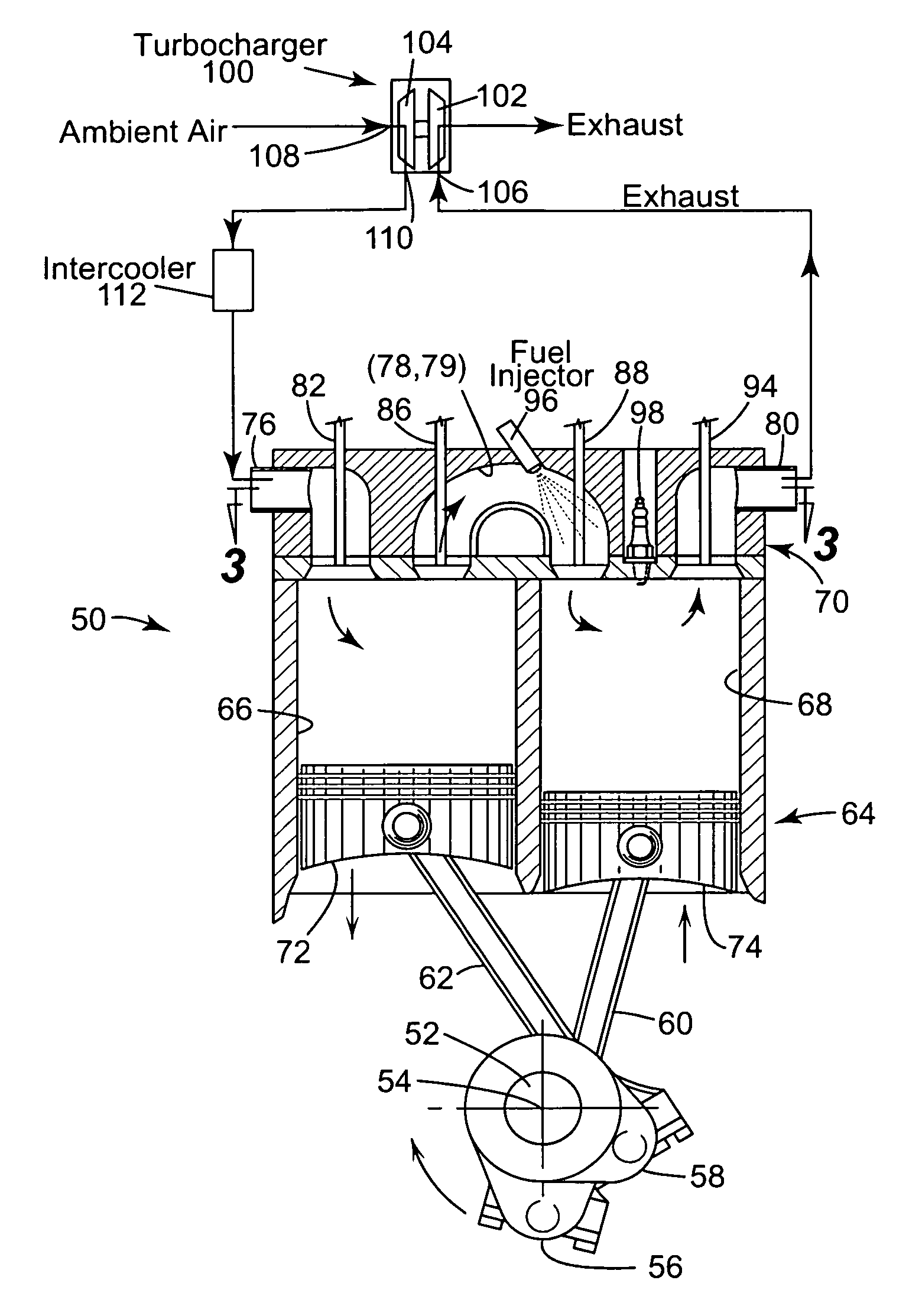

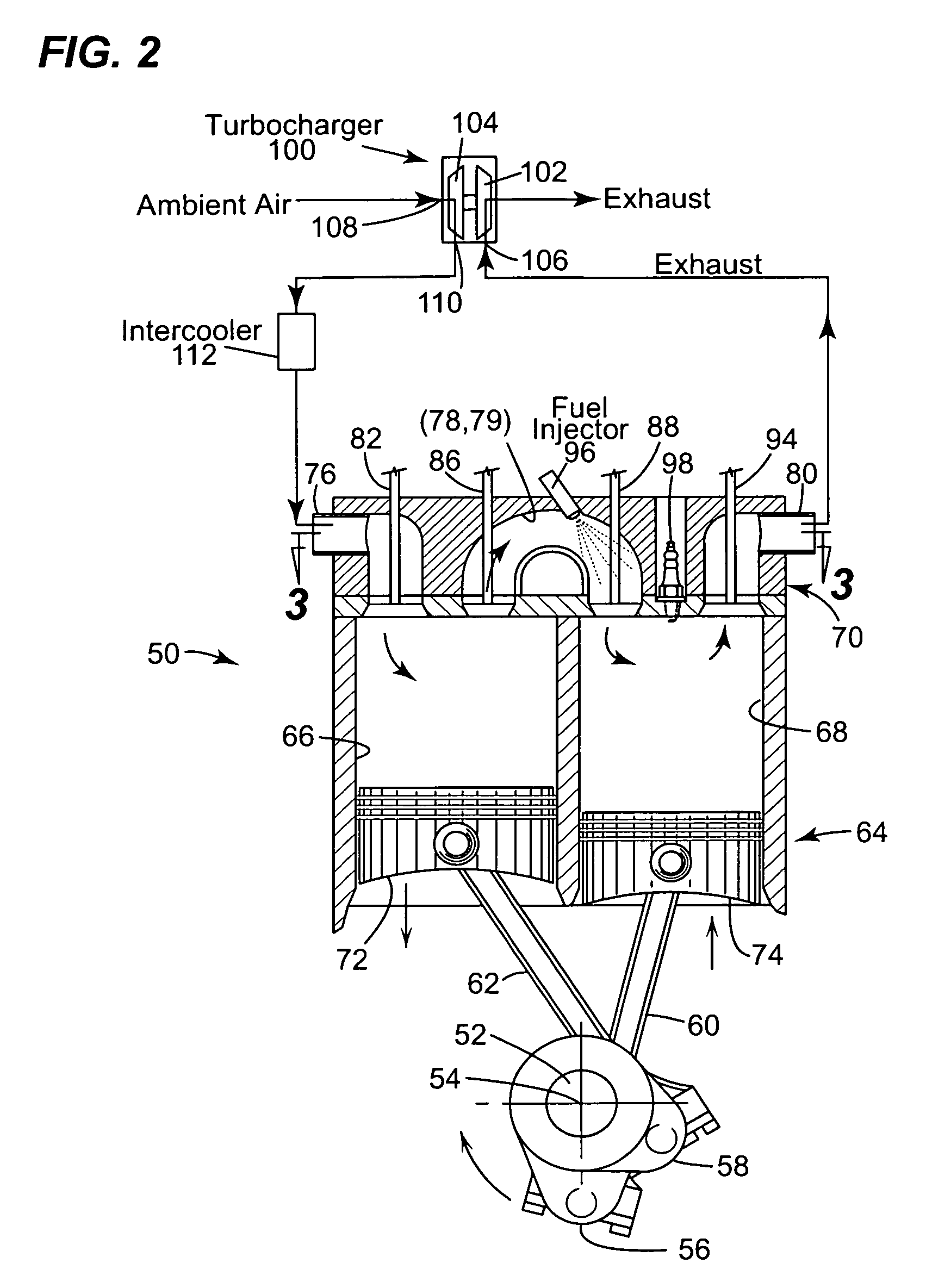

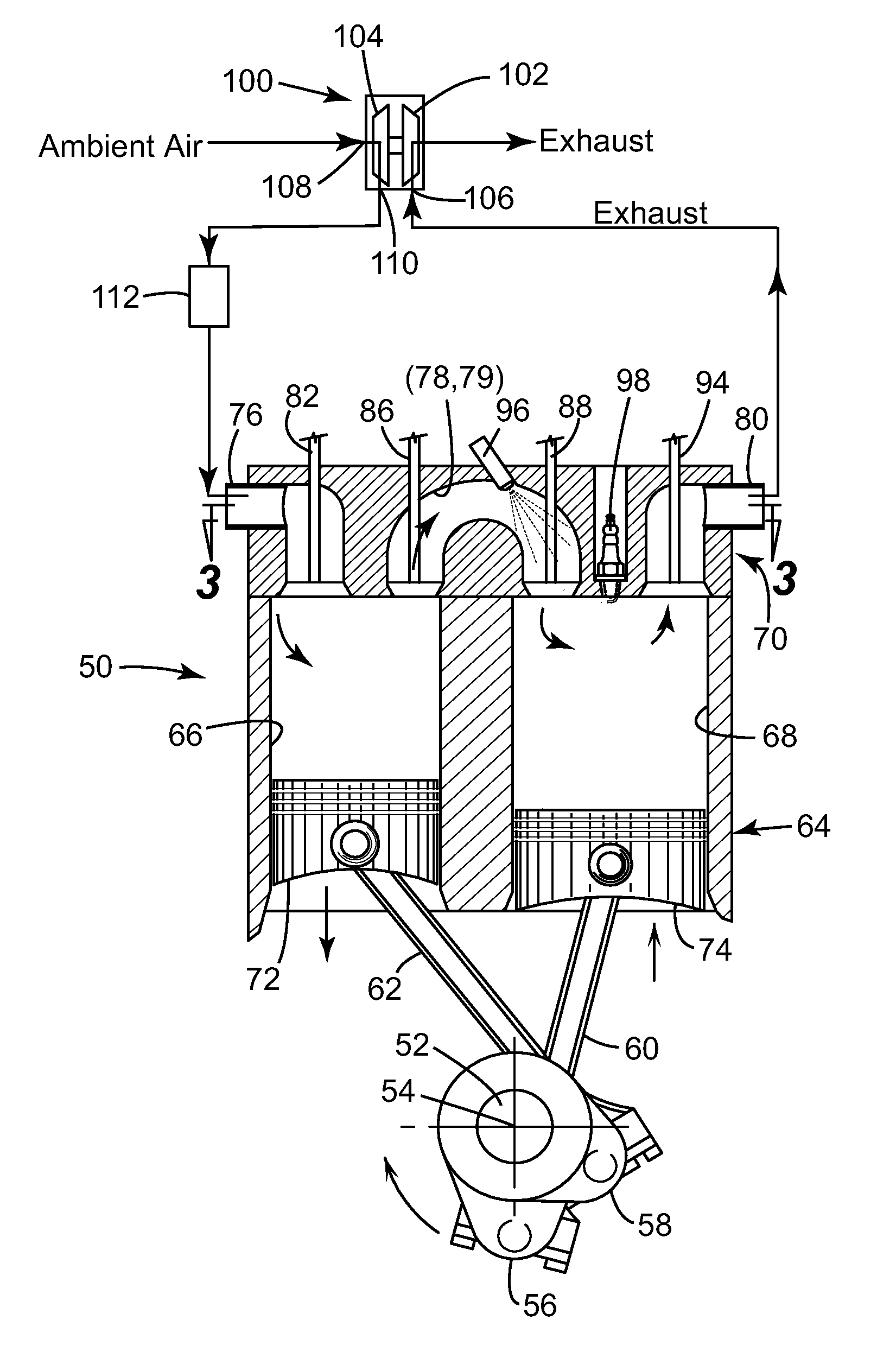

InactiveUS20110303185A1Increase in cost of efficiencyIncrease in loss of efficiencyInternal combustion piston enginesTurbochargerPower density

Split cycle engine and method in which output power and power density are increased in some embodiments with a turbocharger or supercharger which increases the pressure in the compression cylinder and also increases the power output of the engine without a corresponding decrease in the efficiency of the engine (work done per unit fuel). In other embodiments, the engine is used for braking, and the energy produced by braking is stored pneumatically and then used in driving the compressor.

Owner:ZAJAC OPTIMUM OUTPUT MOTORS

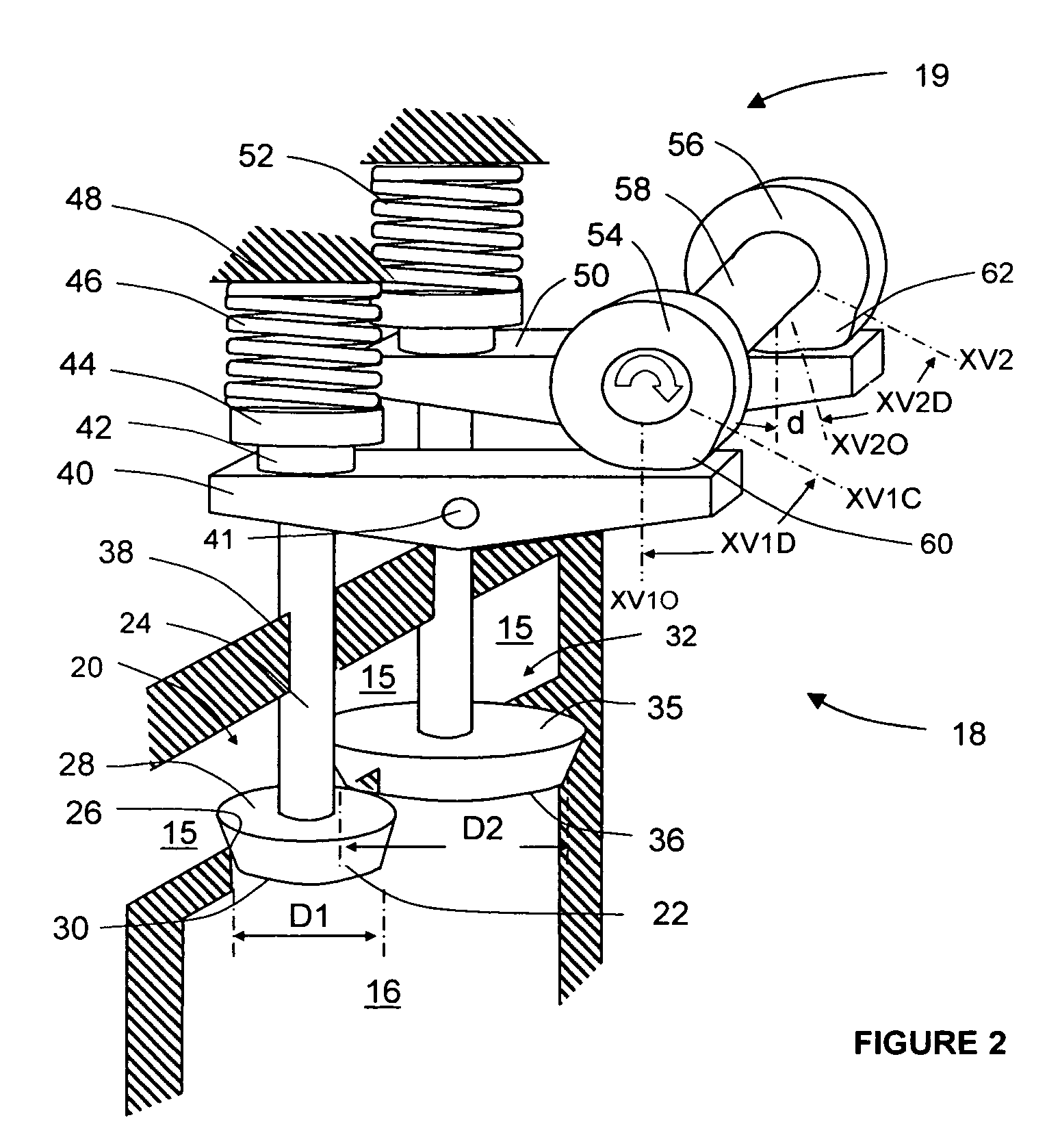

Valve lash adjustment system for a split-cycle engine

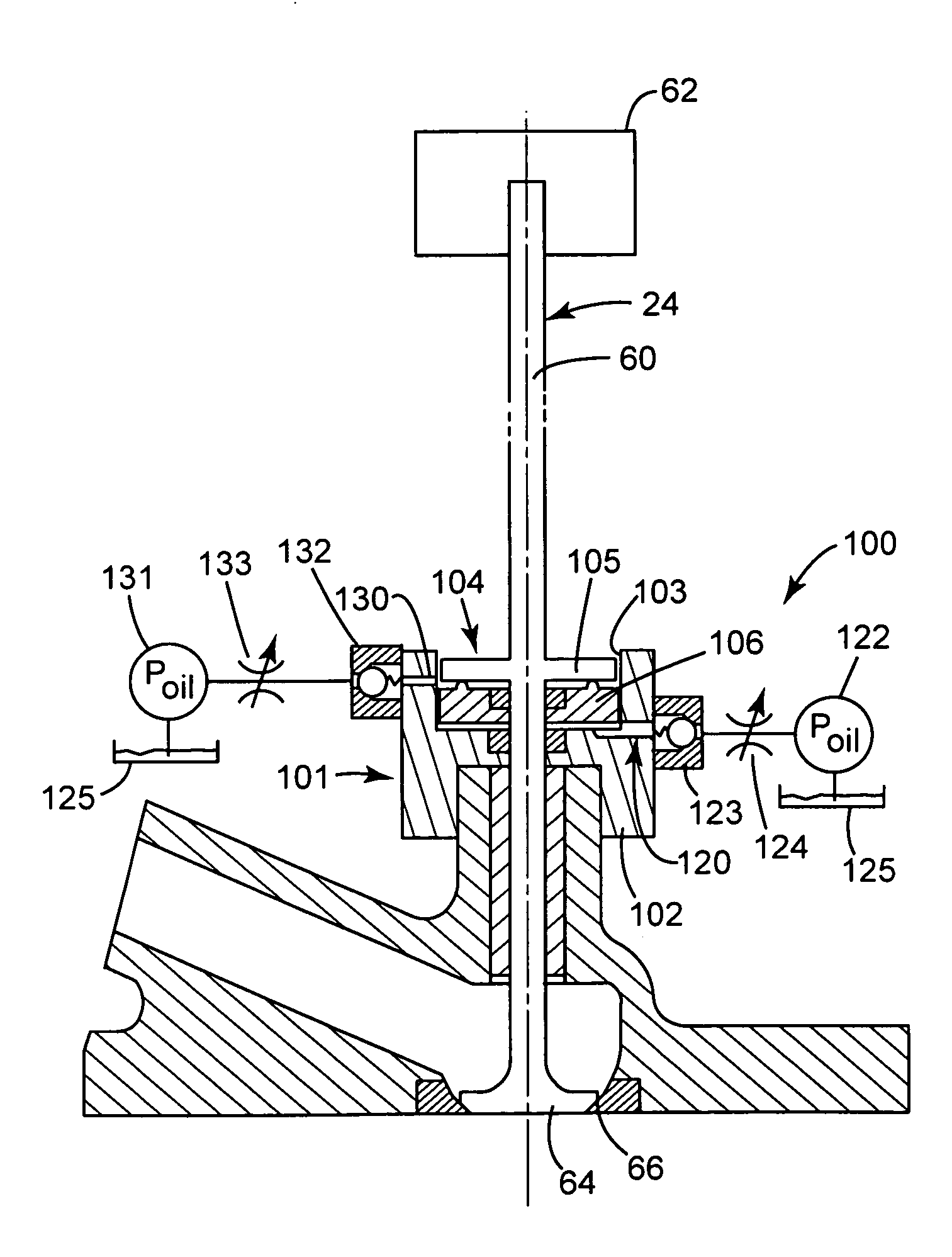

The present invention provides a valve actuation system comprising a valve train for actuating a valve, the valve train including actuating elements and a valve lash, and a valve lash adjustment system for adjusting the valve lash, wherein the valve train and the valve lash adjustment system do not share any common actuating elements.

Owner:SKADERI GRUP LLC

Knock resistant split-cycle engine

Owner:SKADERI GRUP LLC

Turbocharged downsized compression cylinder for a split-cycle engine

InactiveUS20120073551A1Reduced pumping workImprove volumetric efficiencyInternal combustion piston enginesInlet valveEngineering

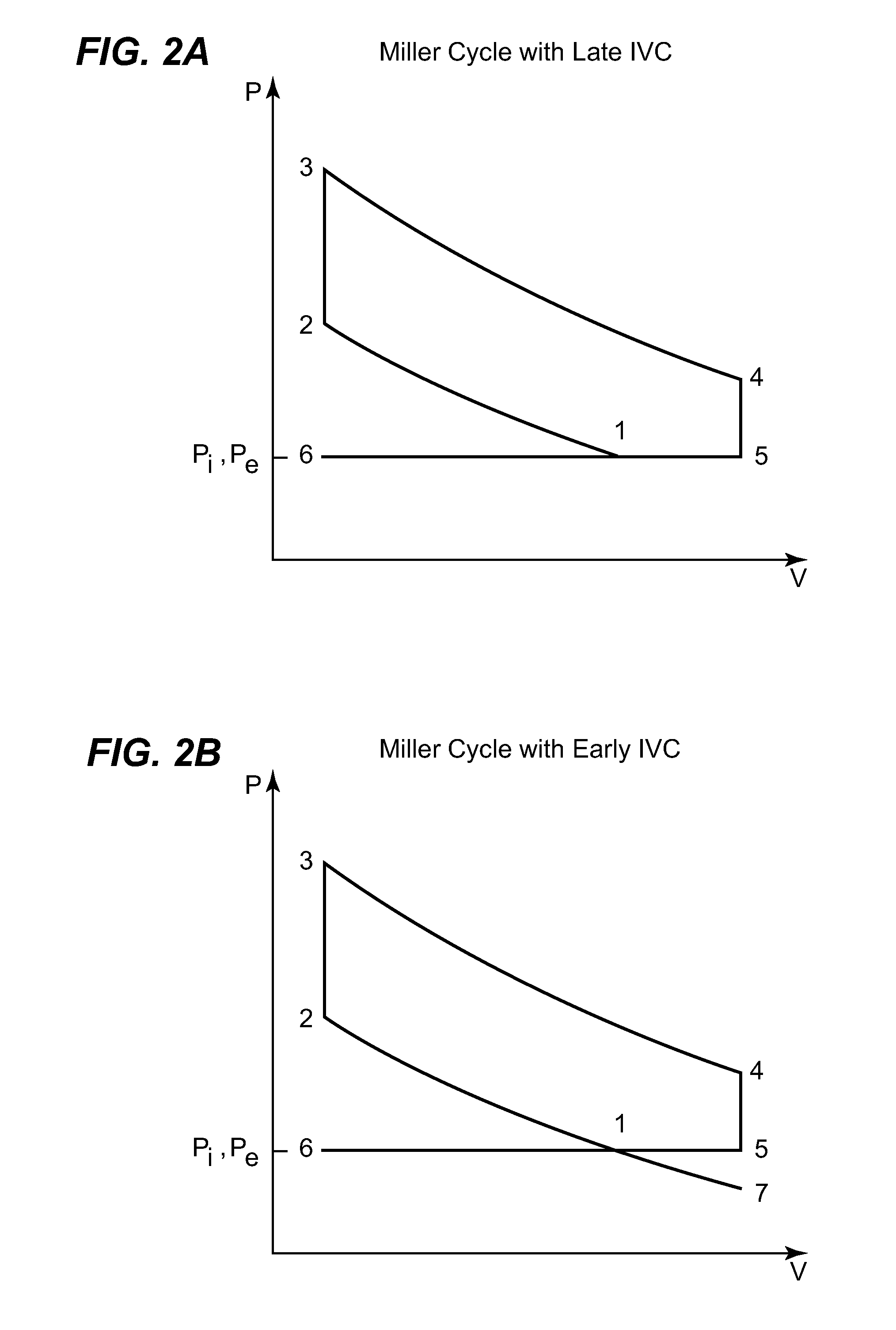

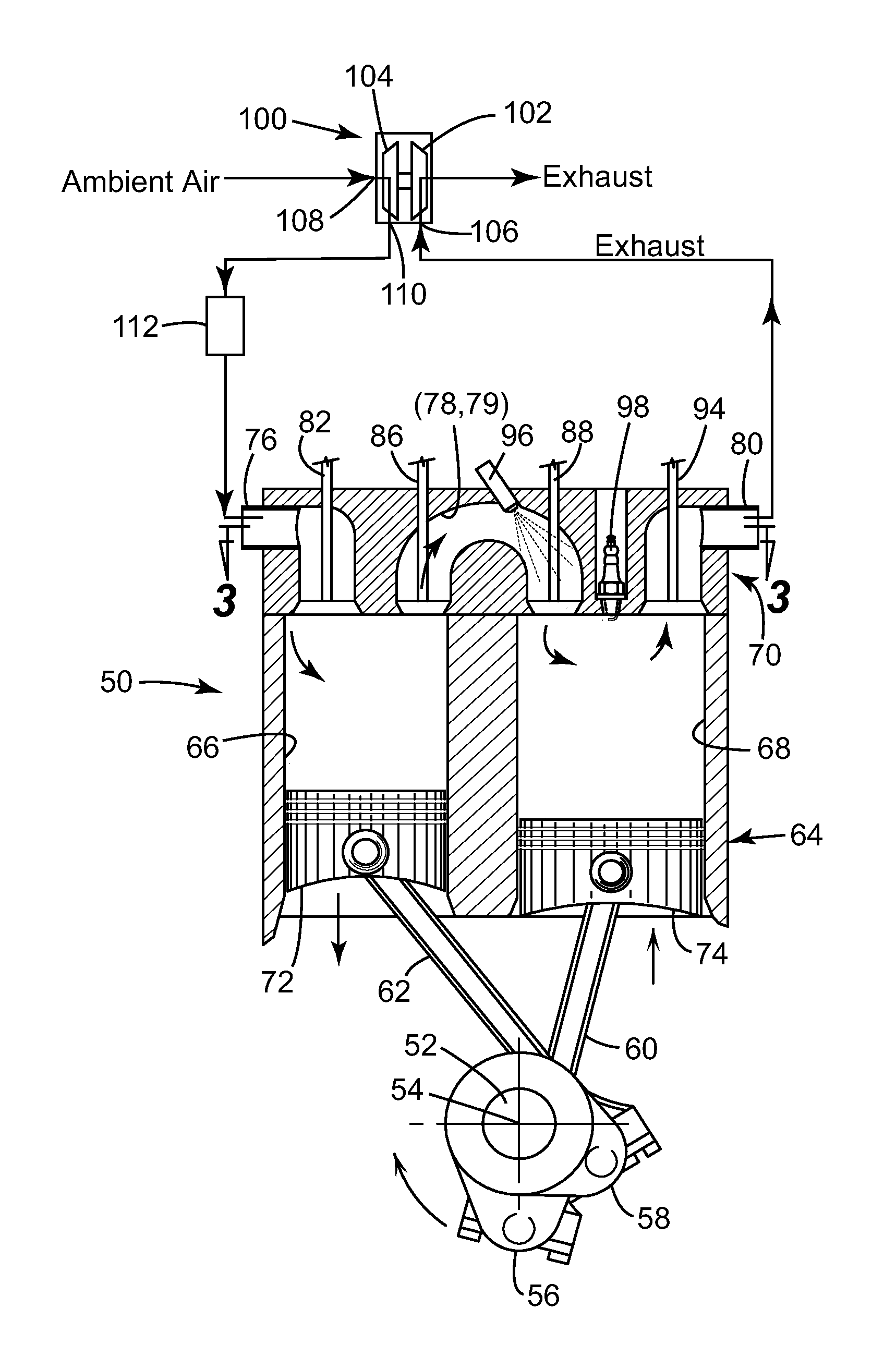

A split-cycle engine includes an expander, the expander including an expansion piston received within an expansion cylinder. A compressor includes a compression piston received within a compression cylinder. A crossover passage interconnects the compression and expansion cylinders. An intake manifold is connected to the compression cylinder. A boosting device providing a 1.7 bar absolute or greater boost pressure level is connected to the intake manifold. An intake valve is disposed between the intake manifold and the compression cylinder. The intake valve closing is timed to provide a compressor volumetric efficiency of 0.75 or greater. A compressor displacement volume is sized relative to an expander displacement volume such that the combination of compressor displacement volume and boost pressure level provides an expander volumetric efficiency relative to ambient conditions that is 0.90 or greater.

Owner:SKADERI GRUP LLC

Valve Seat Insert for a Split-Cycle Engine

InactiveUS20100236533A1Stay in placeStart fastCombustion enginesLift valveInterference fitEngineering

The present invention provides an improved valve seat insert, particularly for split-cycle engines with outwardly opening crossover valves. The improved valve seat insert combines an interference fit section with a threaded section. The interference fit section aligns a valve seat and can prevent rotation of the valve seat insert. The threaded section prevents axial movement of the valve seat insert.

Owner:SKADERI GRUP LLC

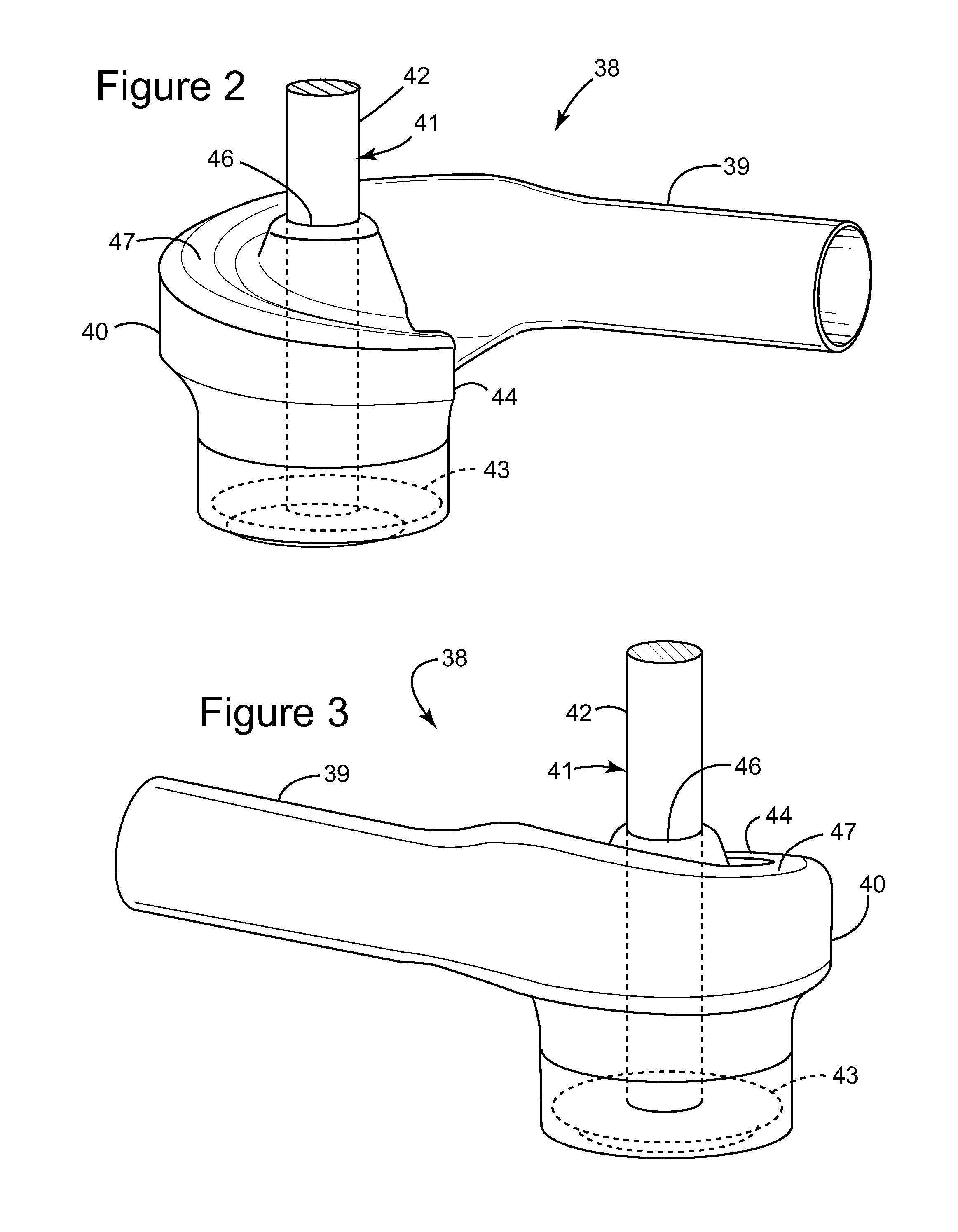

Seating control device for a valve for a split-cycle engine

A seating control device for a valve, comprising:a vessel for containing a fluid;an upper snubber element translatably receivable in the vessel for controlling the seating velocity of a valve associated therewith; anda lower snubber element translatably receivable in the vessel, adjacent the upper snubber element, presenting a surface to the upper snubber element, for controlling the seating of the valve.

Owner:SKADERI GRUP LLC

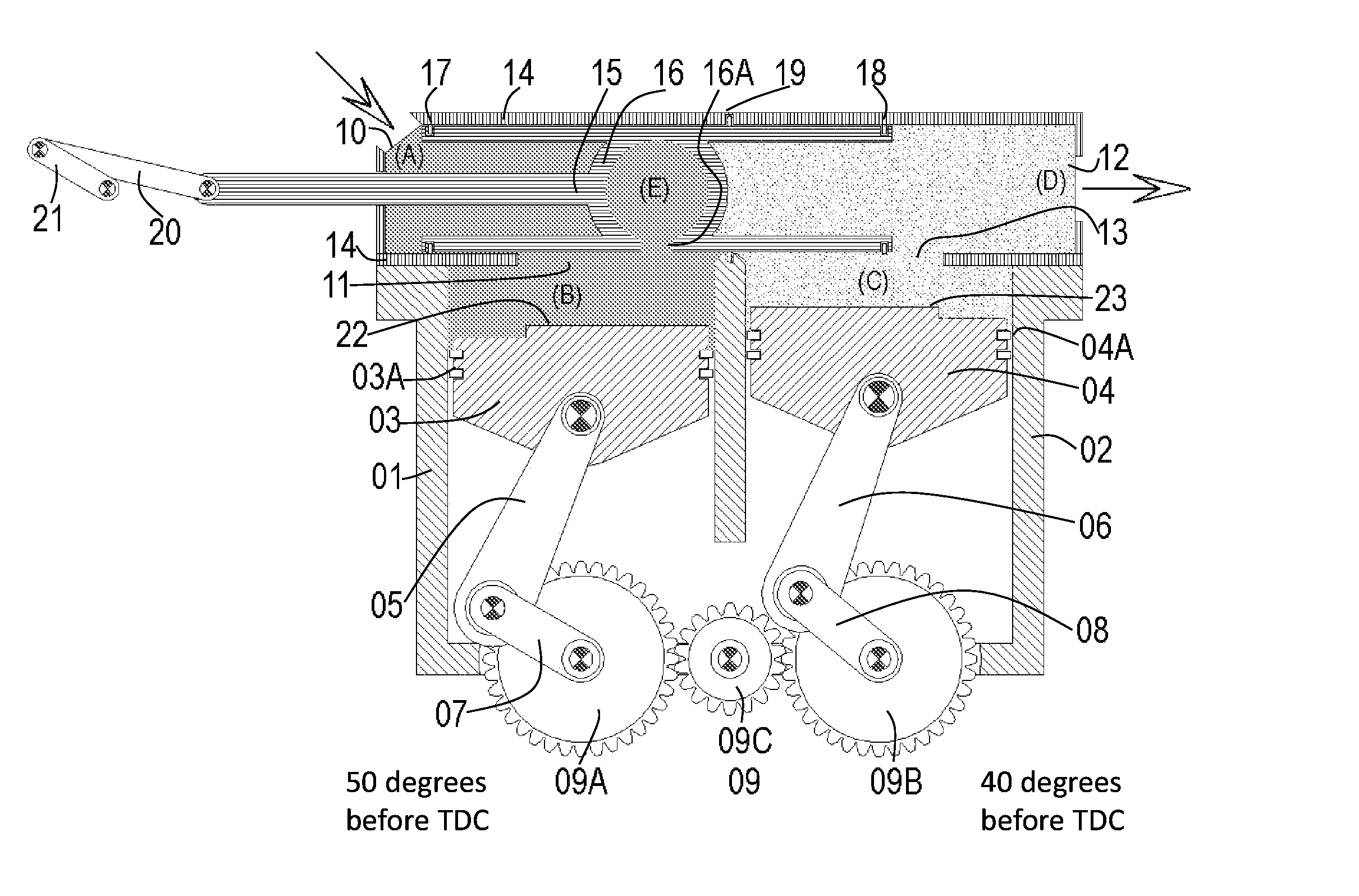

Split cycle engine with crossover shuttle valve

ActiveUS20180266308A1Acceleration and decelerationImprove sealingCombustion enginesSlide valvePhase shiftedExternal combustion engine

A split-cycle internal combustion engine (ICE) is provided, comprising a compression cylinder, an expansion cylinder and a crossover valve having a valve cylinder housing inside a shuttle and a combustion chamber structure defining a combustion chamber. The shuttle is configured to perform reciprocating motion inside the valve cylinder synchronously with a compression piston and an expansion piston, thereby alternatingly fluidly coupling and decoupling the combustion chamber with the compression cylinder and with the expansion cylinder, selectively. Sealing rings positioned between the valve cylinder and the shuttle prevent gas leaks between them during the reciprocating motion. In some embodiments, a phase shift between the pistons may be set or varied by a piston phase transmission gear. A bi-directional fluid flow split-cycle internal combustion engine (ICE) is also provided having a first cylinder, a second cylinder, a combustion chamber and a single crossover valve fluidly communicating them. A three-cylinders split-cycle internal combustion engine (ICE) is also provided, having a compression cylinder and a combustion chamber, wherein a single crossover valve alternatingly fluidly couples the combustion chamber to two or more expansion cylinders.

Owner:TOUR ENGINE INC

Part-load control in a split-cycle engine

An engine includes a crankshaft rotatable about a crankshaft axis. A compression piston is slidably received within a compression cylinder and operatively connected to the crankshaft such that the compression piston is operable to reciprocate through an intake stroke and a compression stroke during a single rotation of the crankshaft. An expansion (power) piston is slidably received within an expansion cylinder and operatively connected to the crankshaft such that the expansion piston is operable to reciprocate through an expansion stroke and an exhaust stroke during a single rotation of the crankshaft. At least two crossover passages interconnect the compression and expansion cylinders. Each of the at least two crossover passages includes a crossover compression (XovrC) valve and a crossover expansion (XovrE) valve operable to define a pressure chamber therebetween. The engine controls and maximizes engine efficiency at part-load by utilizing only selected crossover passages.

Owner:SKADERI GRUP LLC

Split-cycle engine with disc valve

InactiveUS20070204814A1Lower the volumeIncrease the compression ratioCombustion enginesRotary slide valveValve seatSplit cycle engine

A split-cycle engine with disc valve includes a crankshaft, a power cylinder and a compression cylinder. A gas crossover passage interconnects the compression cylinder and the power cylinder. An air intake port circumscribes a periphery of the compression cylinder and defines an outer valve seat. An annular ring having a generally central opening is disposed between the compression cylinder and the air intake port and forms a washer valve for opening and closing the air intake port. A disc valve member is concentrically mounted over the central opening of the annular ring. The disc valve member includes a piston portion having a sidewall biased into engagement with the outer valve seat for controlling flow between the compression cylinder and the gas crossover passage.

Owner:SKADERI GRUP LLC

Crossover valve systems

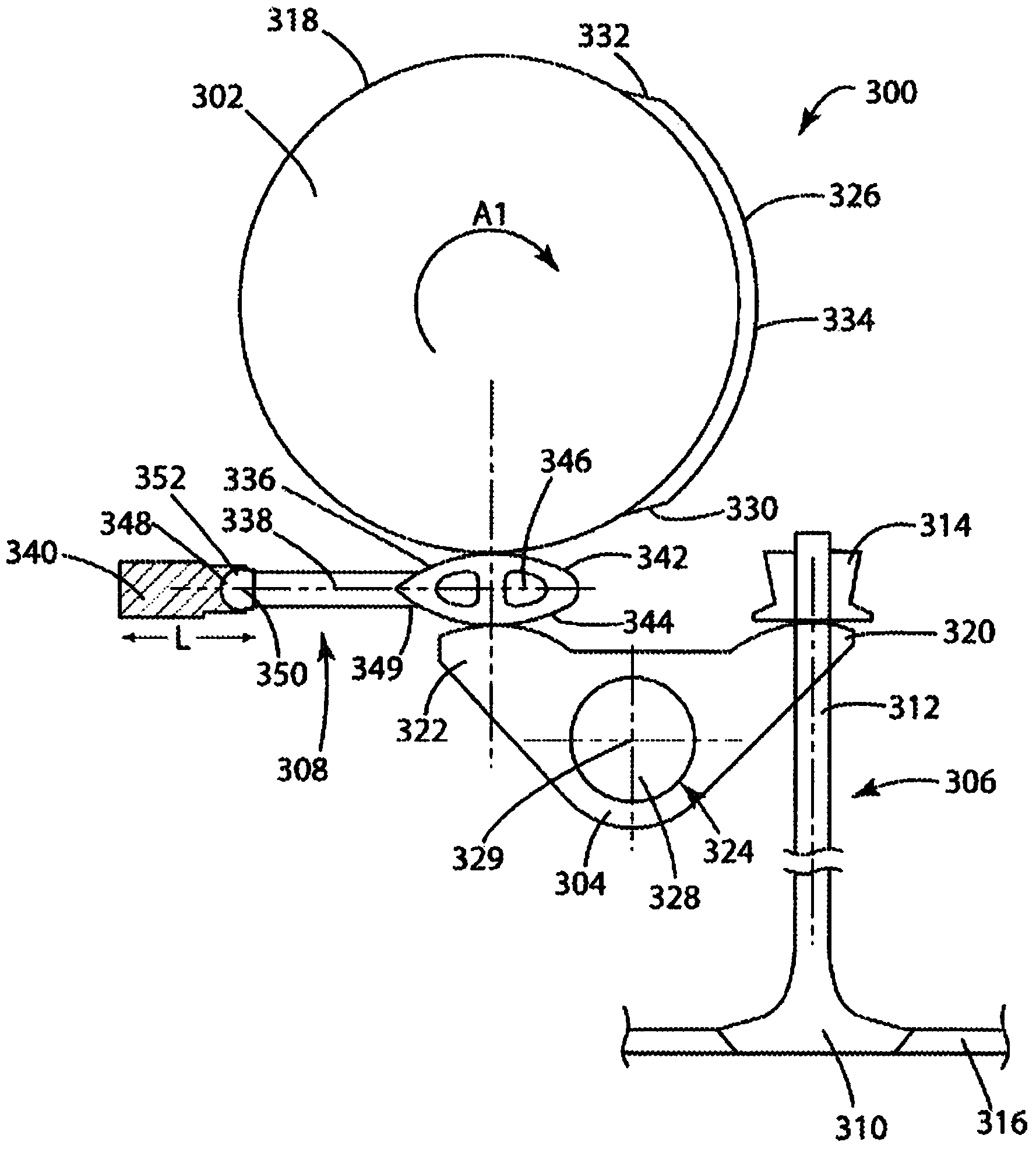

InactiveUS20110017181A1Large initial opening forceReduction in flow areaOperating means/releasing devices for valvesCombustion enginesDifferential pressureValve opening

Crossover valve systems and corresponding methods offer an effective means to overcome large opening pressure force, or provide reasonable gas flow area, or both. In an exemplary embodiment, a crossover valve system for a split-cycle engine having a power cylinder and a crossover passage comprises first and second crossover valves, each valve opening outwardly away from the power cylinder and providing fluid communication between the power cylinder and the crossover passage, with the diameter of the second crossover valve being larger than the diameter of the first crossover valve; and an actuation mechanism operative to open the first crossover valve, then the second crossover valve after a predetermined delay to allow a certain rise in the pressure inside the power cylinder, resulting in much smaller differential pressure forces across the crossover valves, larger flow areas, or both.

Owner:LGD TECH LLC

Split cycle engine with crossover shuttle valve

ActiveUS10378431B2Improve sealingEffective preventionCombustion enginesSlide valveCombustion chamberPhase shifted

Owner:TOUR ENGINE INC

Split-cycle engine

ActiveUS20120167566A1Reduce dust emissionsEmission reductionInternal combustion piston enginesLow pressure fuel injectionExhaust valvePhase shifted

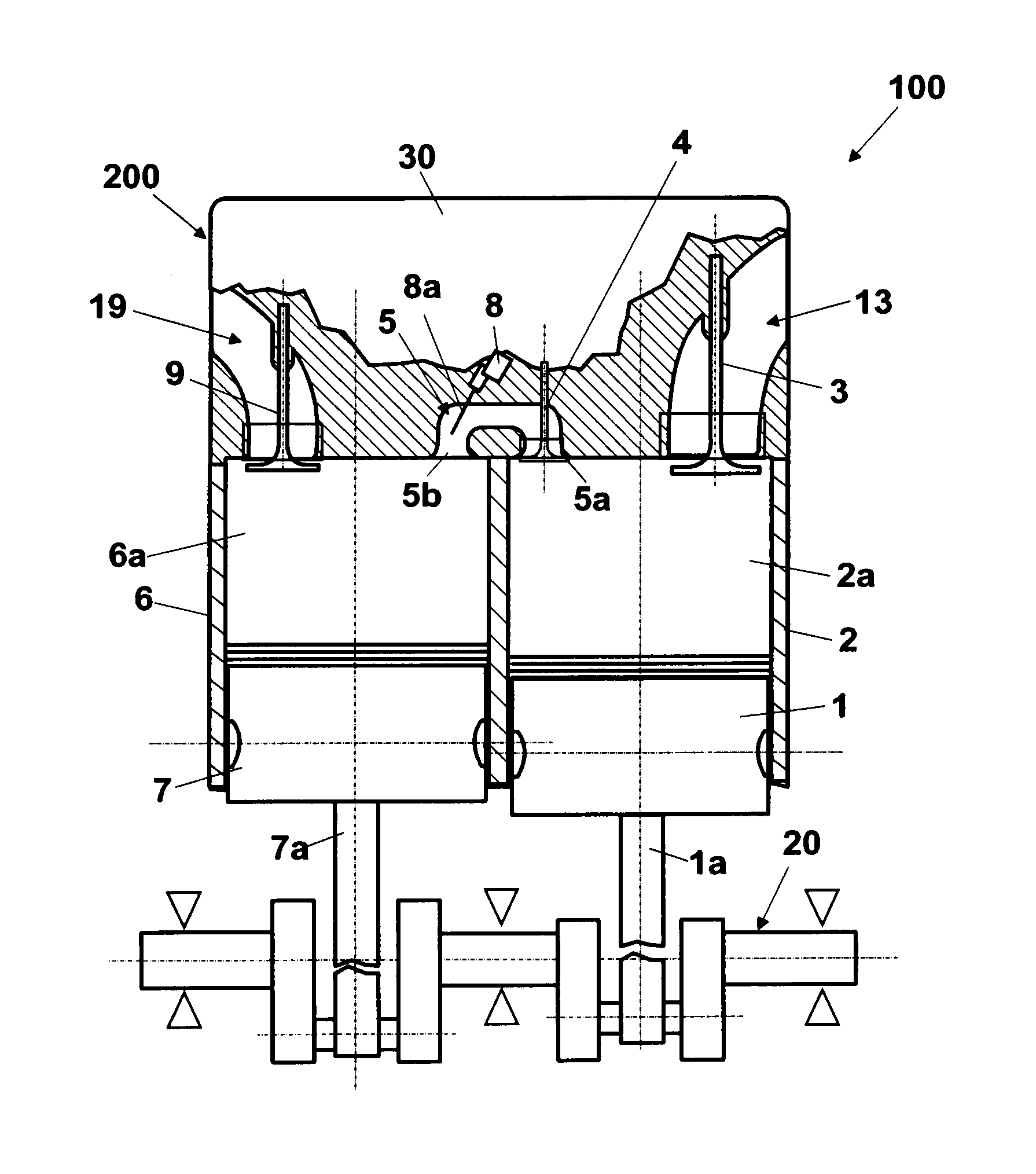

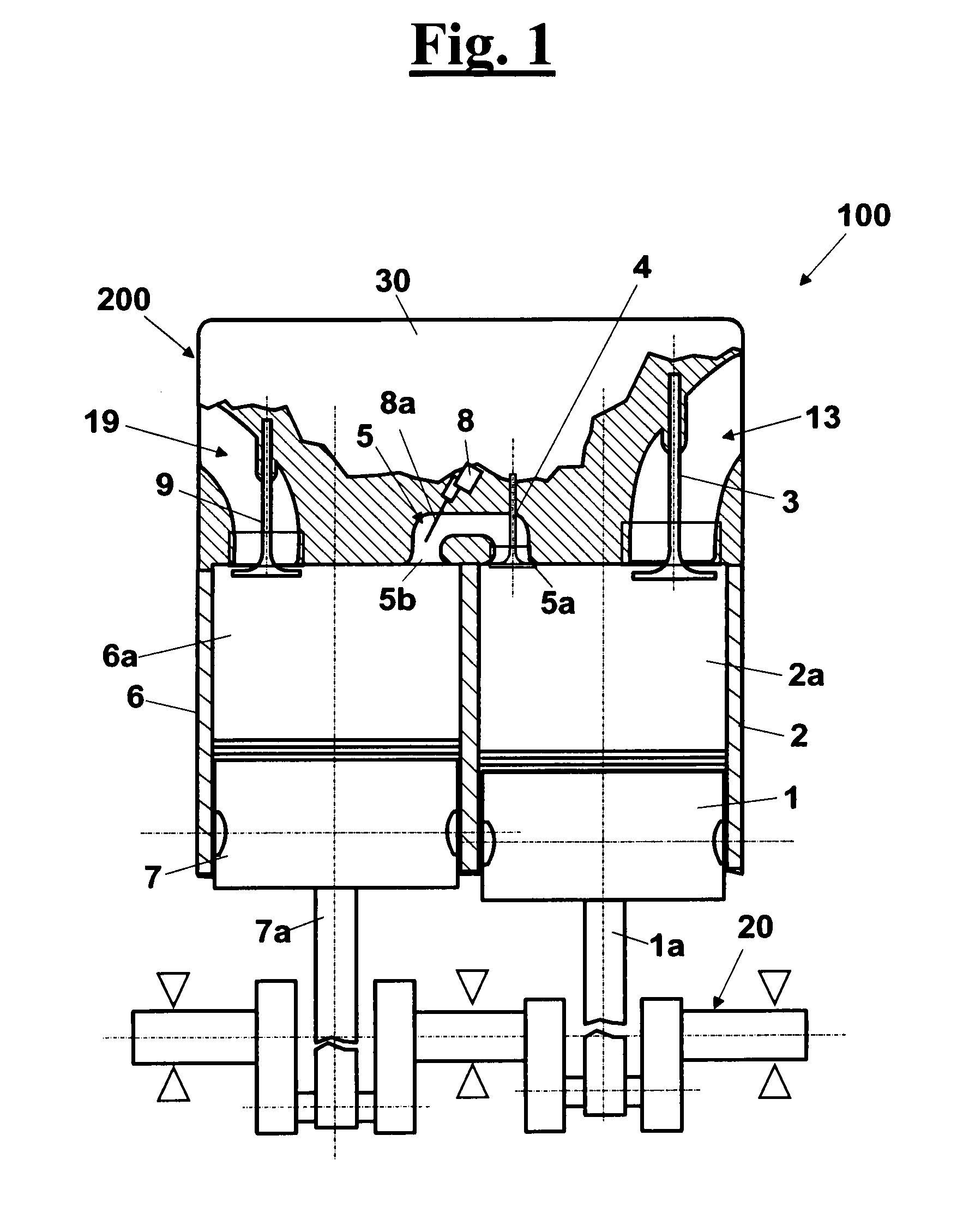

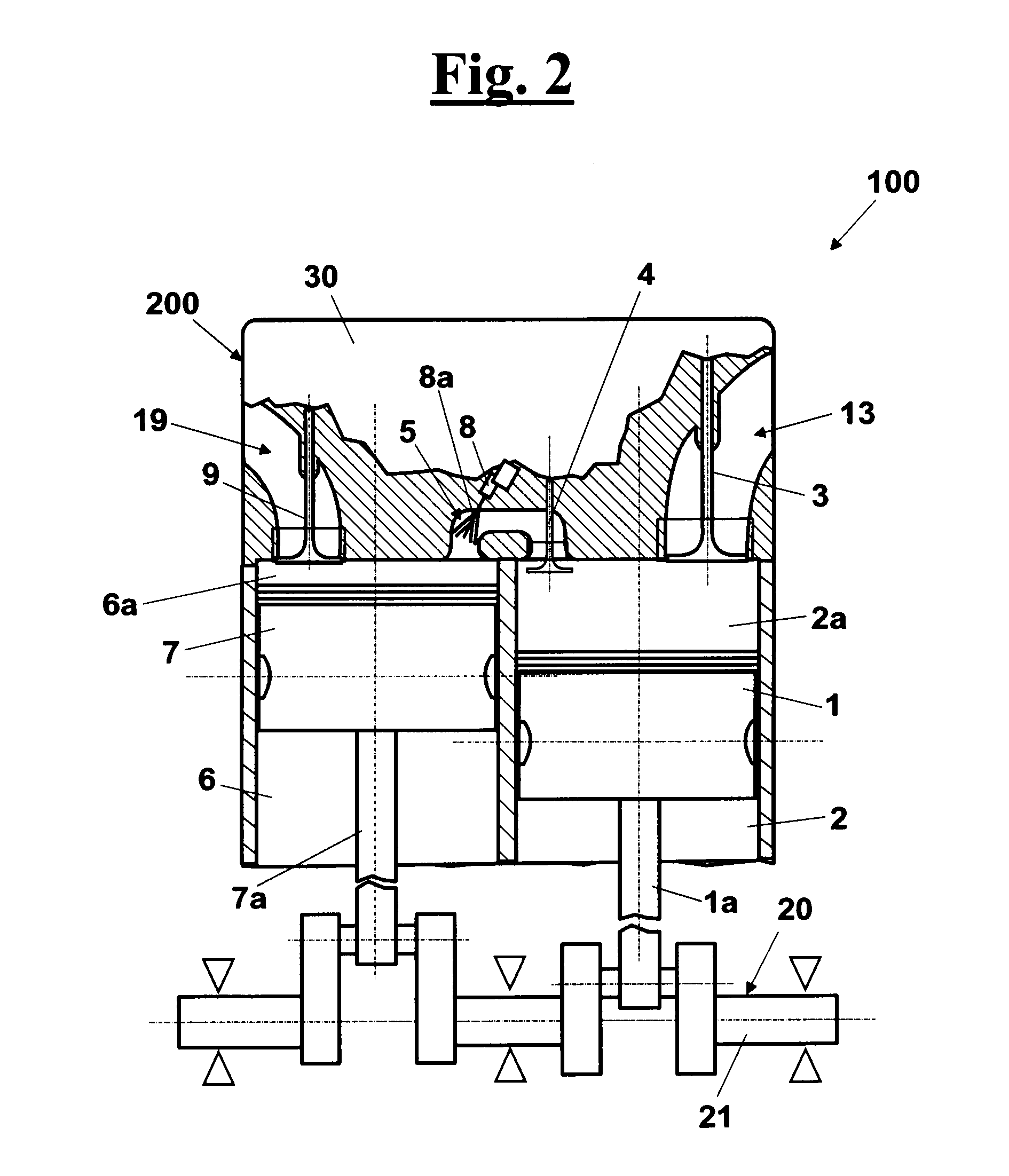

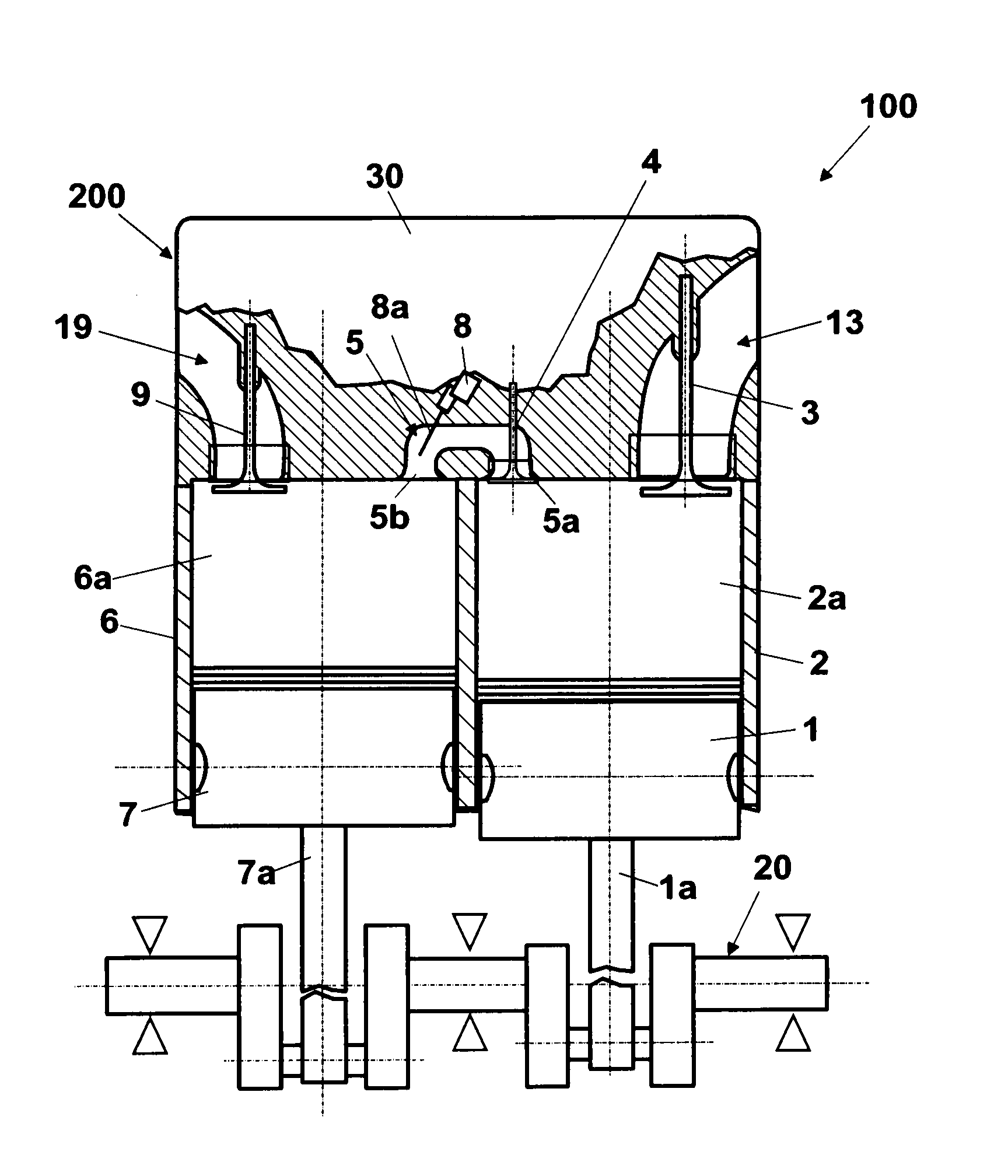

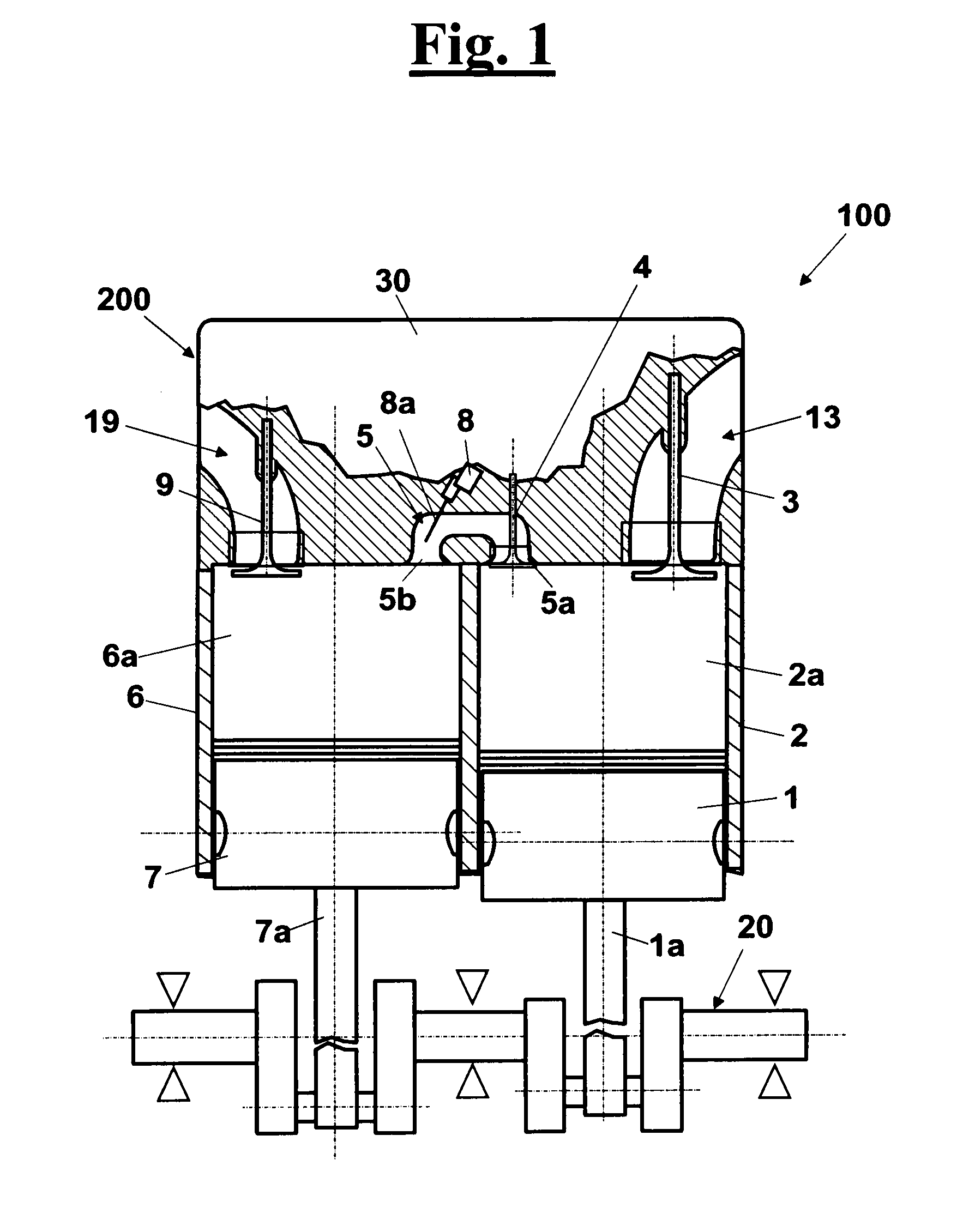

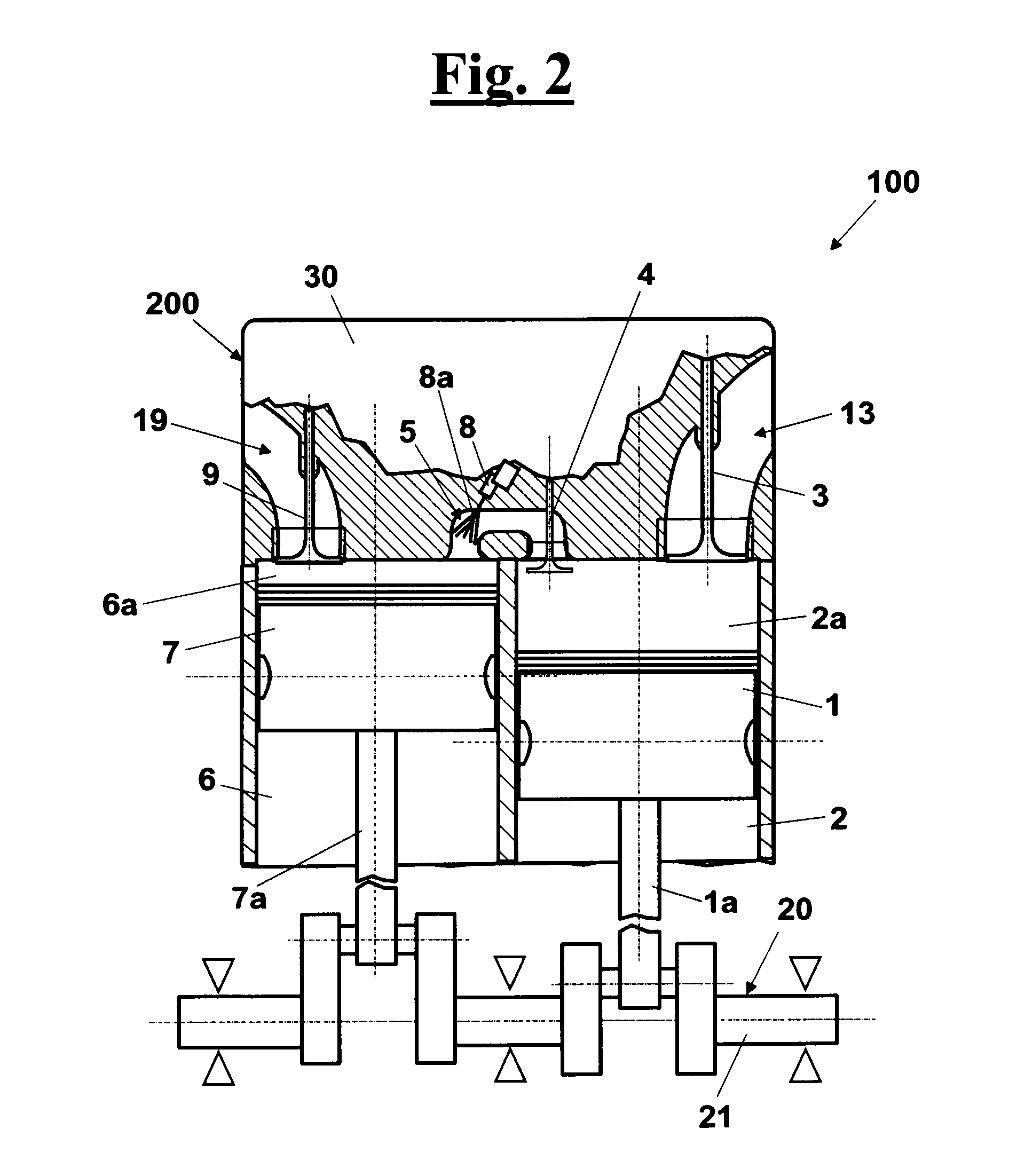

A compression-ignition “split-cycle” engine (100) comprises: a cylinder block (200) with an expansion cylinder (6) having an expansion piston (7) that is adapted to move alternatively between a top dead center (ETDC) and a bottom dead center (EBDC) by a crankshaft mechanism (20) that causes a predetermined position of the expansion piston (7) to correspond to a predetermined crankshaft angle; a compression cylinder (2) having a compression piston (1) that is adapted to move alternatively between a CTDC and a CBDC according to a predetermined angular phase shift in delay to the expansion piston (7); a cylinder head (30) that closes the cylinders and comprises a crossover passageway (5) with an opening (5a) in constant communication towards compression cylinder (2) and an opening (5b) having a transfer valve (4) towards expansion cylinder (6), an intake valve (3) and a exhaust valve (9); a means for opening / closing the transfer valve (4); a means for opening / closing exhaust valve (9) at predetermined moments of the alternative cycle of the pistons, and a fuel injector (8) in the crossover passageway (5). The opening movement of the transfer valve (4) is carried out in advance 20° or more of crankshaft angle with respect to the crankshaft angle of the ETDC, such that from the opening instant up to reaching the ETDC there is a substantial equalization of pressure between the cylinders, such that between the ETDC and the CTDC a transfer occurs of the comburent fluid between the two cylinders, and such that injector (8) injects the fuel (8a) starting from the achievement of the ETDC.

Owner:GREEN ENGINE CONSULTING

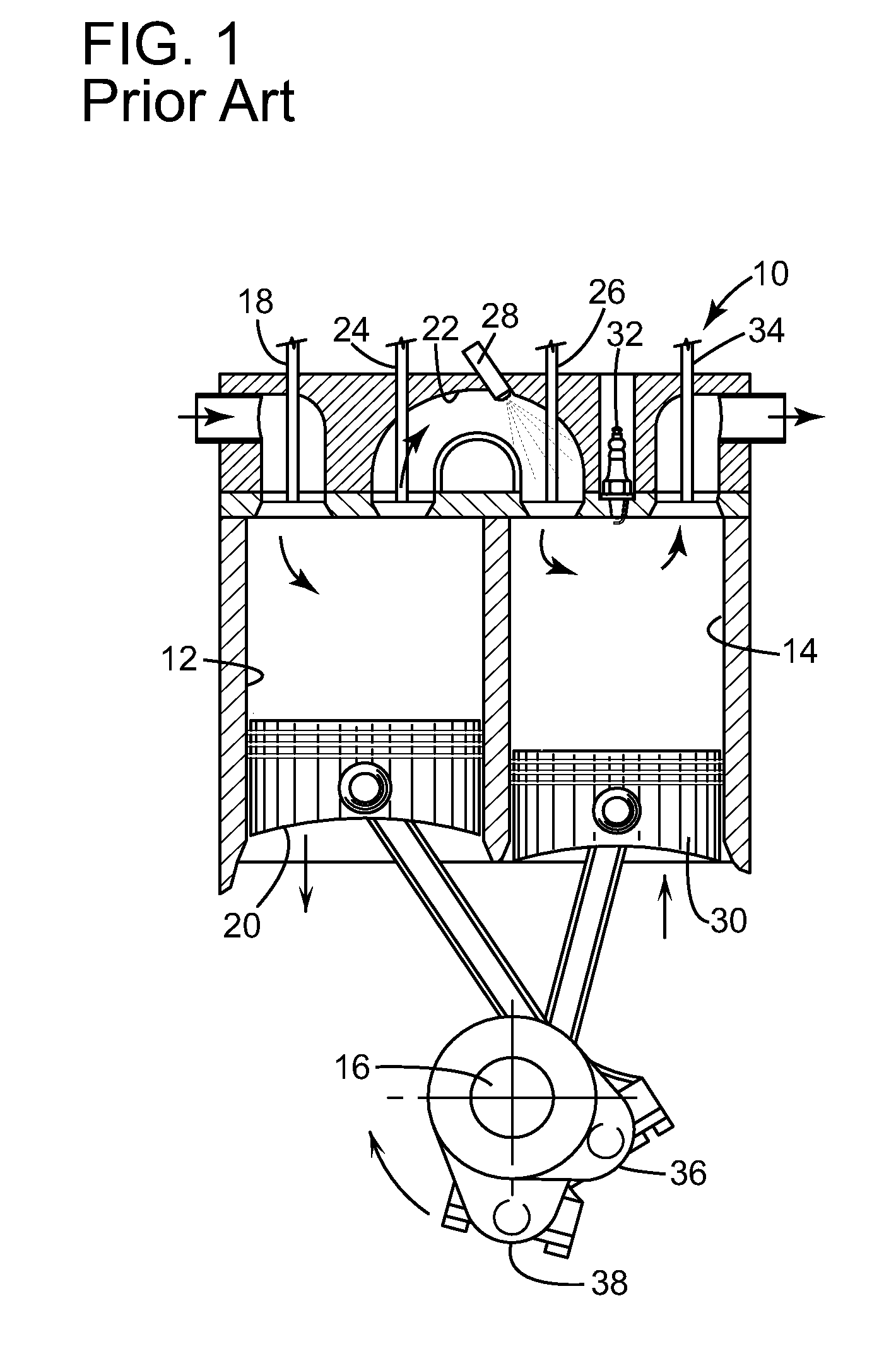

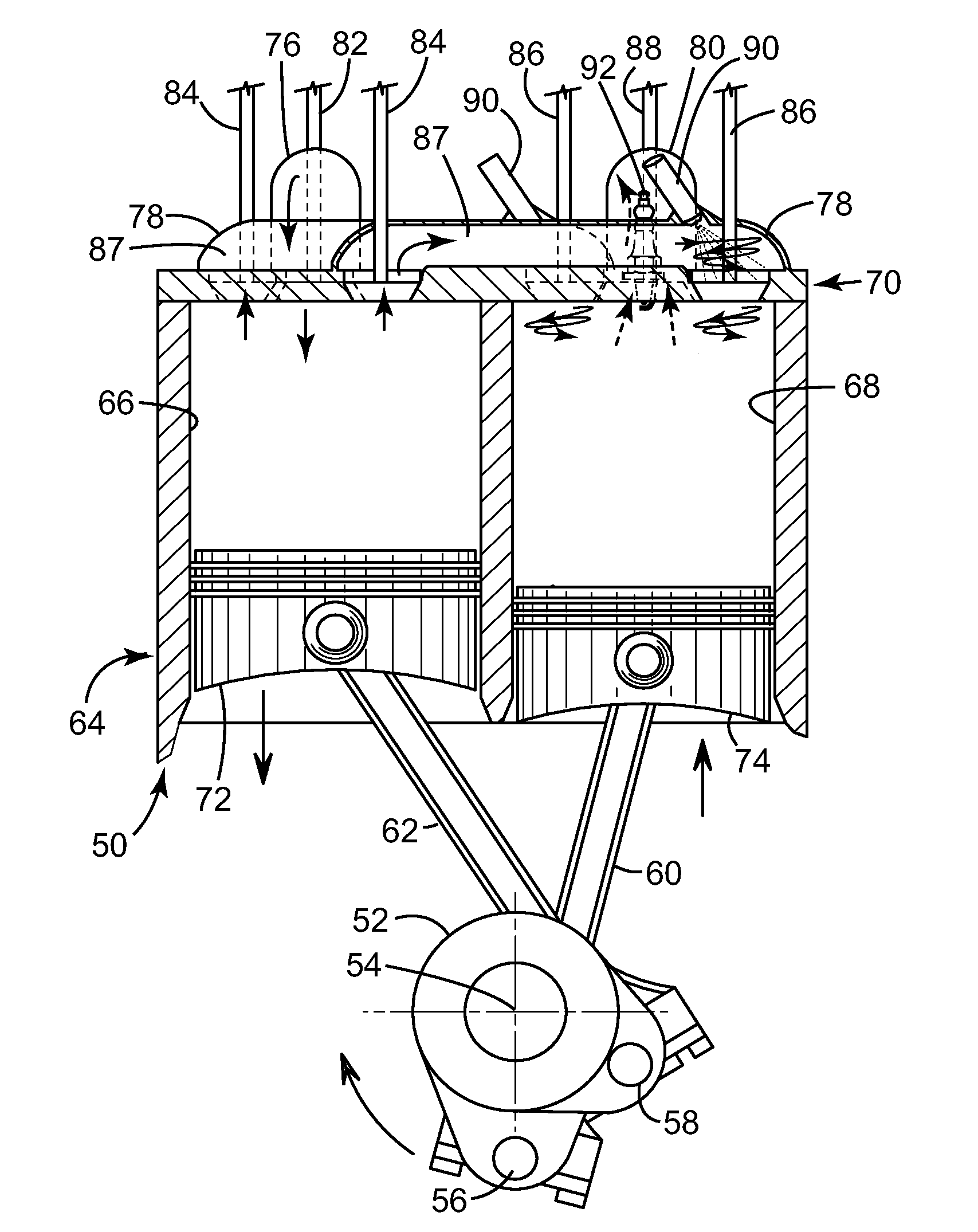

Split-cycle engine with dual spray targeting fuel injection

InactiveUS20100275878A1Improve engine performanceInternal combustion piston enginesCylinder headsHigh pressureValve stem

An engine includes a rotatable crankshaft and an expansion piston slidably received within an expansion cylinder and operatively connected to the crankshaft. A crossover passage including walls connects a source of high pressure gas to the expansion cylinder. A crossover expansion (XovrE) valve is operable to control fluid communication between the crossover passage and the expansion cylinder. The XovrE valve includes a valve head and a valve stem extending from the valve head. A fuel injector operable to inject fuel into the crossover passage includes a plurality of spray holes disposed in a nozzle end and aimed at an at least one target at which fuel emitting from the spray holes is directed to form at least one spray pattern. The at least one target is located above a seated position of the XovrE valve head and between the walls of the crossover passage and the XovrE valve stem.

Owner:SKADERI GRUP LLC

Air supply for components of a split-cycle engine

InactiveUS8763571B2Operating means/releasing devices for valvesCombustion enginesAir springPower component

The present invention generally relates to providing an air supply for components associated with an engine. More particularly, the present invention relates to a system and method for using compressed air generated by a split-cycle engine to power components such as valves or air springs associated with the split-cycle engine.

Owner:SKADERI GRUP LLC

Turbocharged downsized compression cylinder for a split-cycle engine

InactiveUS8807099B2Improve efficiencyReduce fuel consumptionInternal combustion piston enginesInlet valveEngineering

A split-cycle engine includes an expander, the expander including an expansion piston received within an expansion cylinder. A compressor includes a compression piston received within a compression cylinder. A crossover passage interconnects the compression and expansion cylinders. An intake manifold is connected to the compression cylinder. A boosting device providing a 1.7 bar absolute or greater boost pressure level is connected to the intake manifold. An intake valve is disposed between the intake manifold and the compression cylinder. The intake valve closing is timed to provide a compressor volumetric efficiency of 0.75 or greater. A compressor displacement volume is sized relative to an expander displacement volume such that the combination of compressor displacement volume and boost pressure level provides an expander volumetric efficiency relative to ambient conditions that is 0.90 or greater.

Owner:SKADERI GRUP LLC

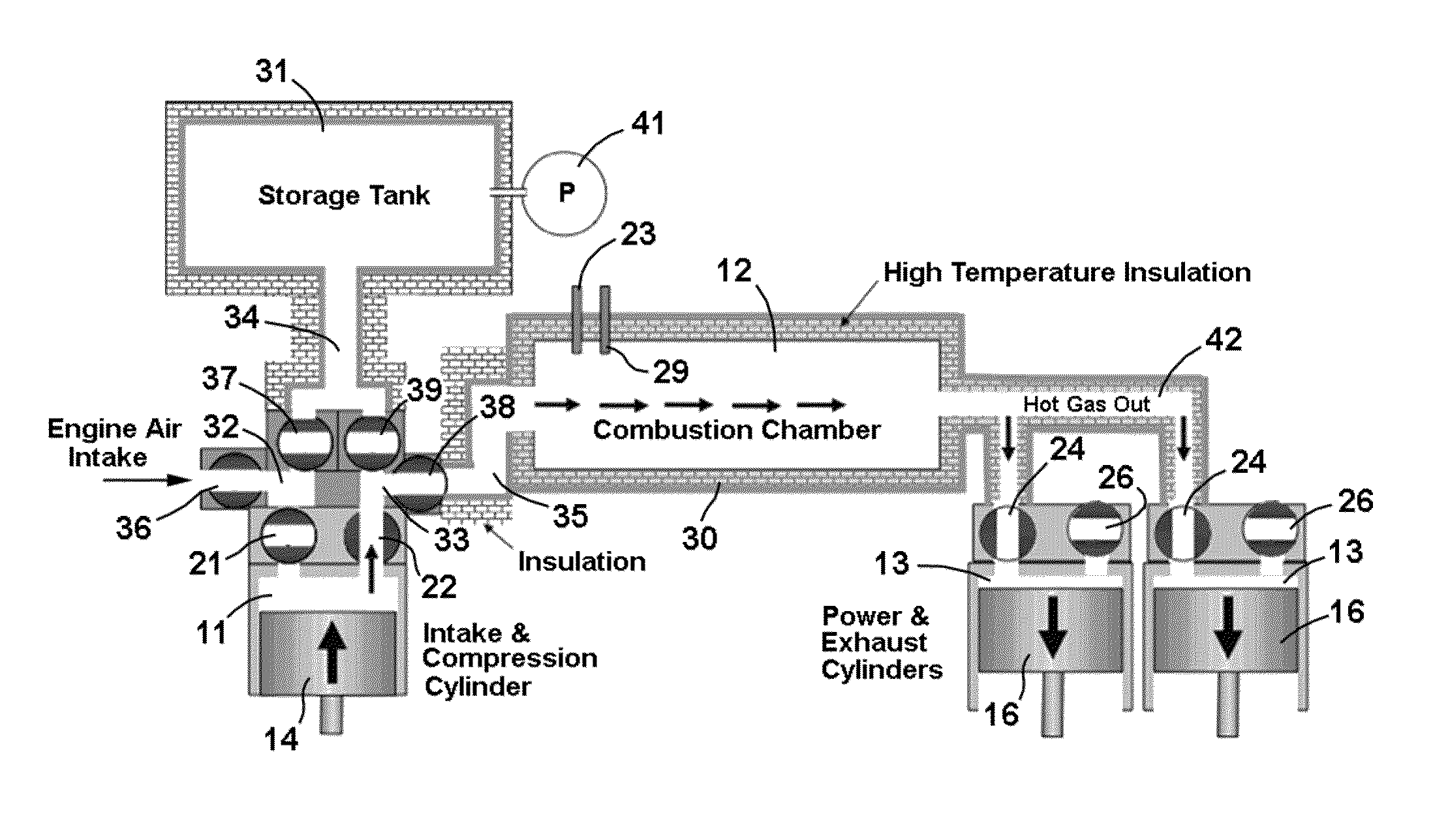

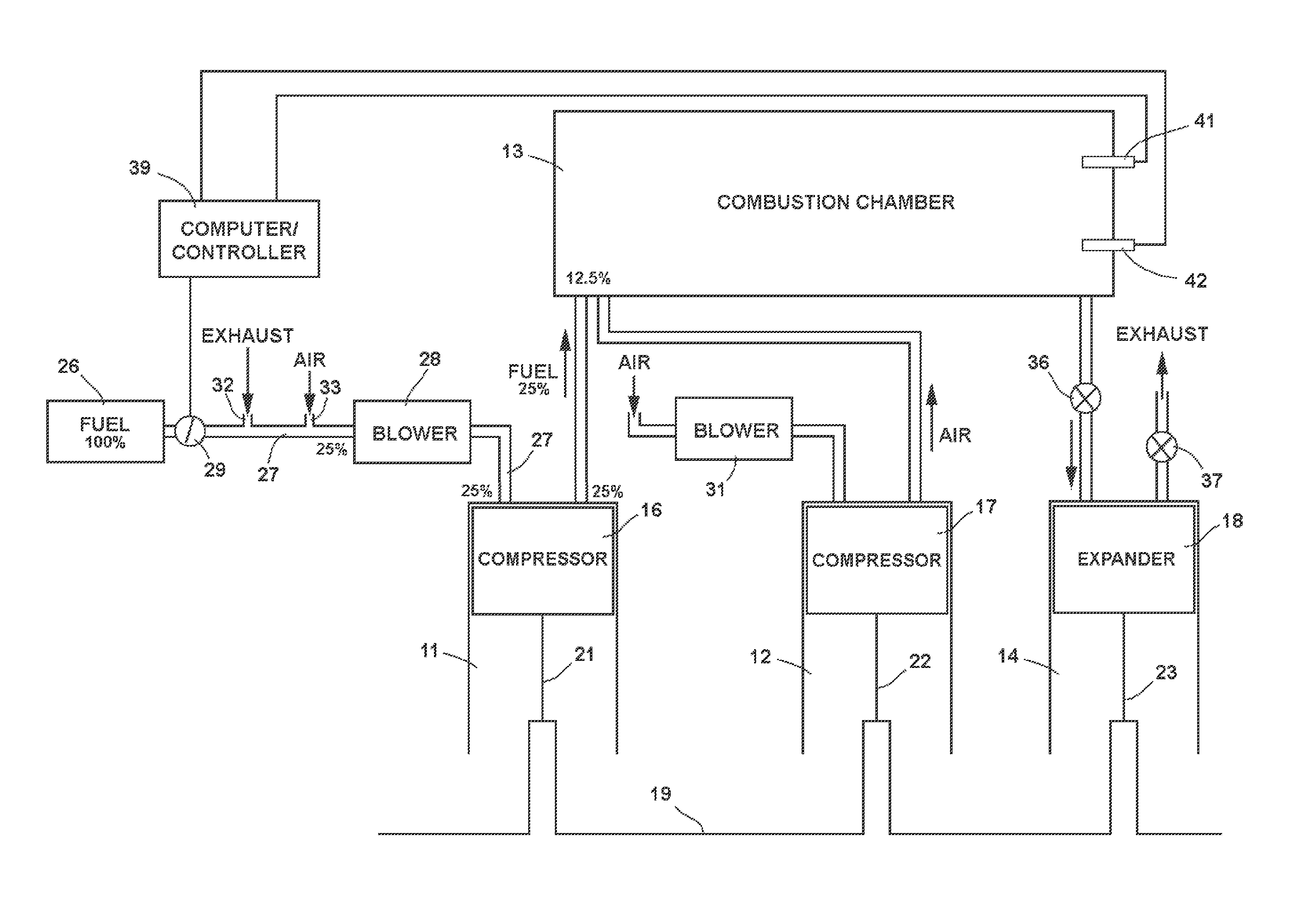

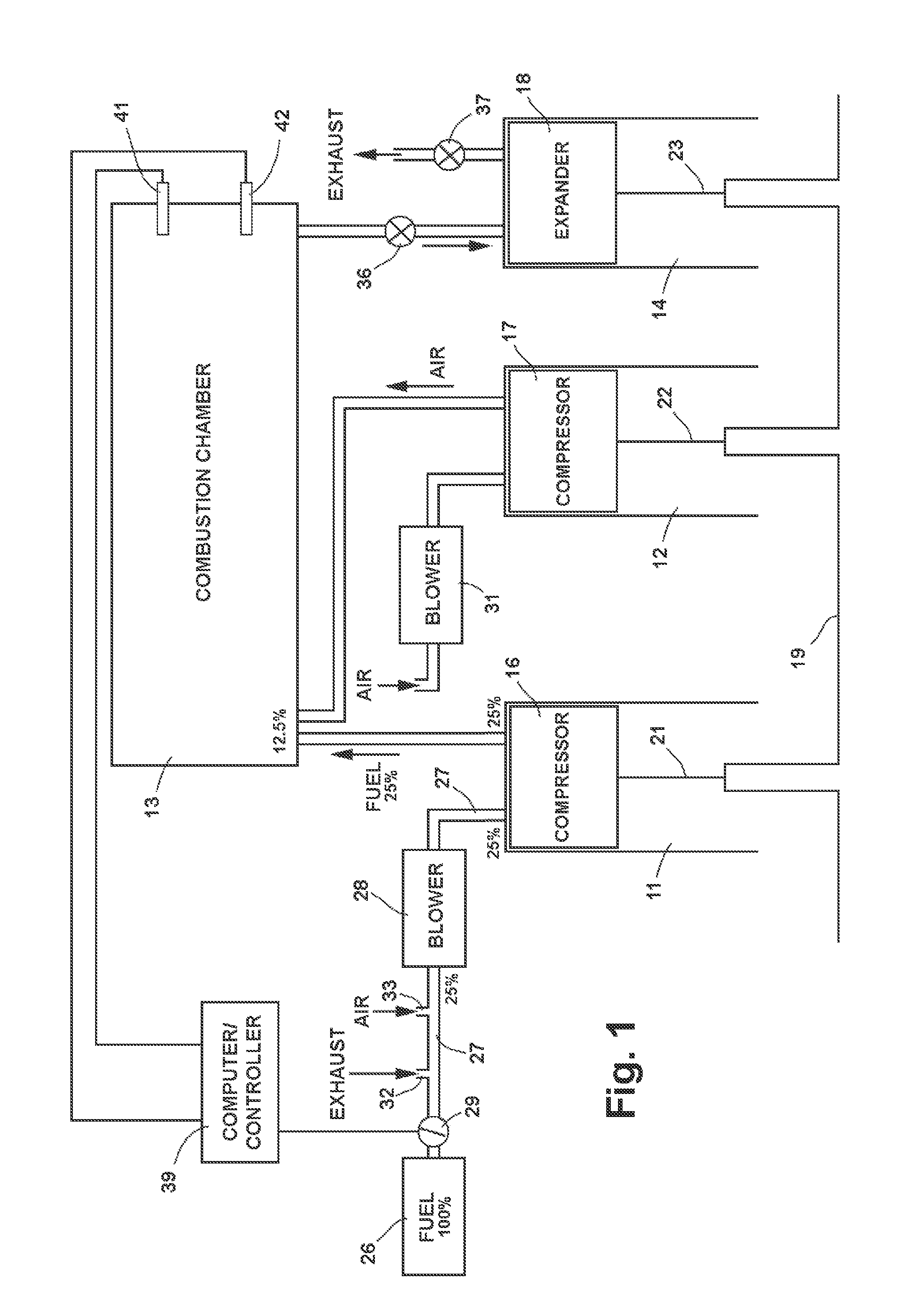

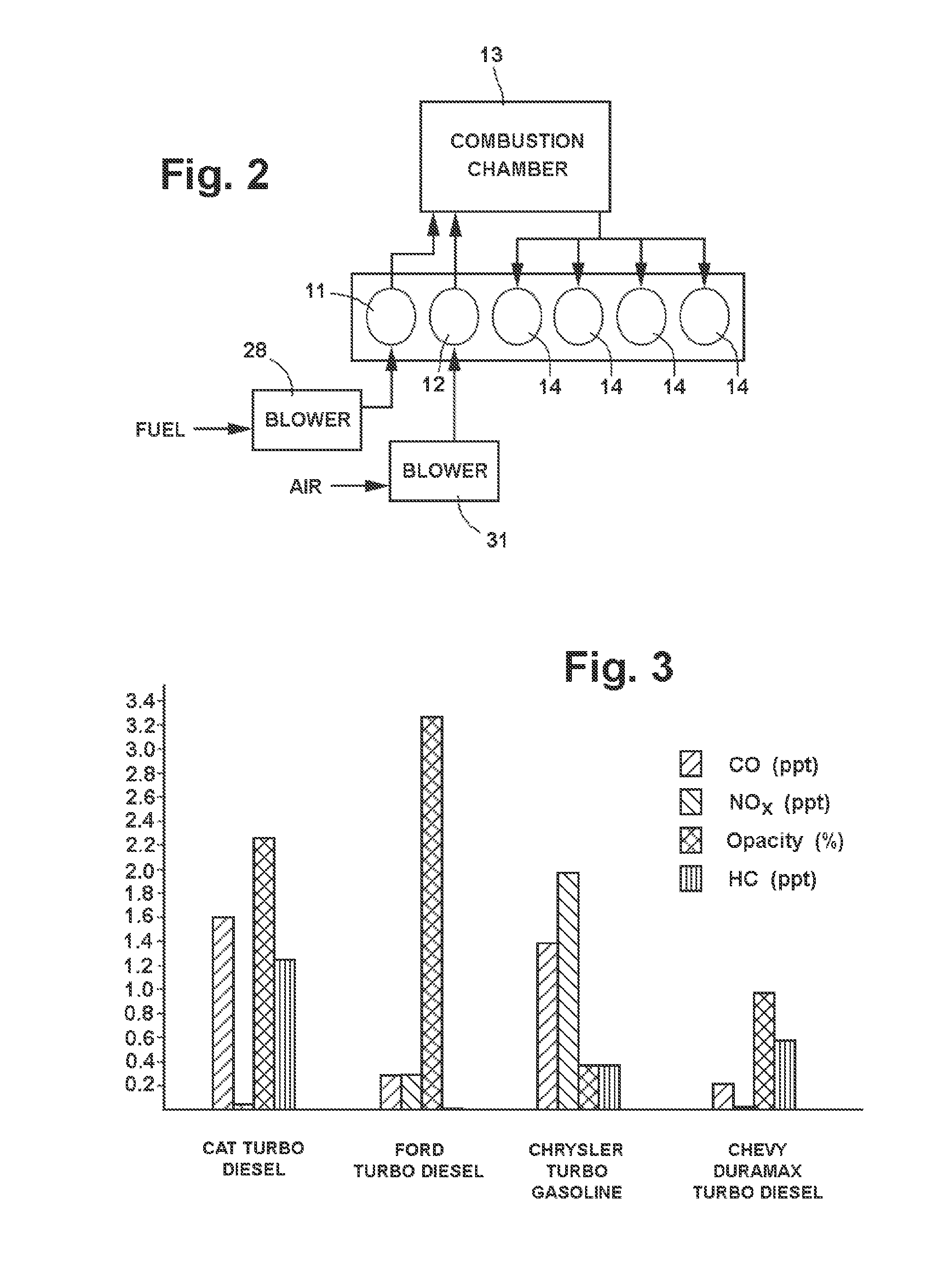

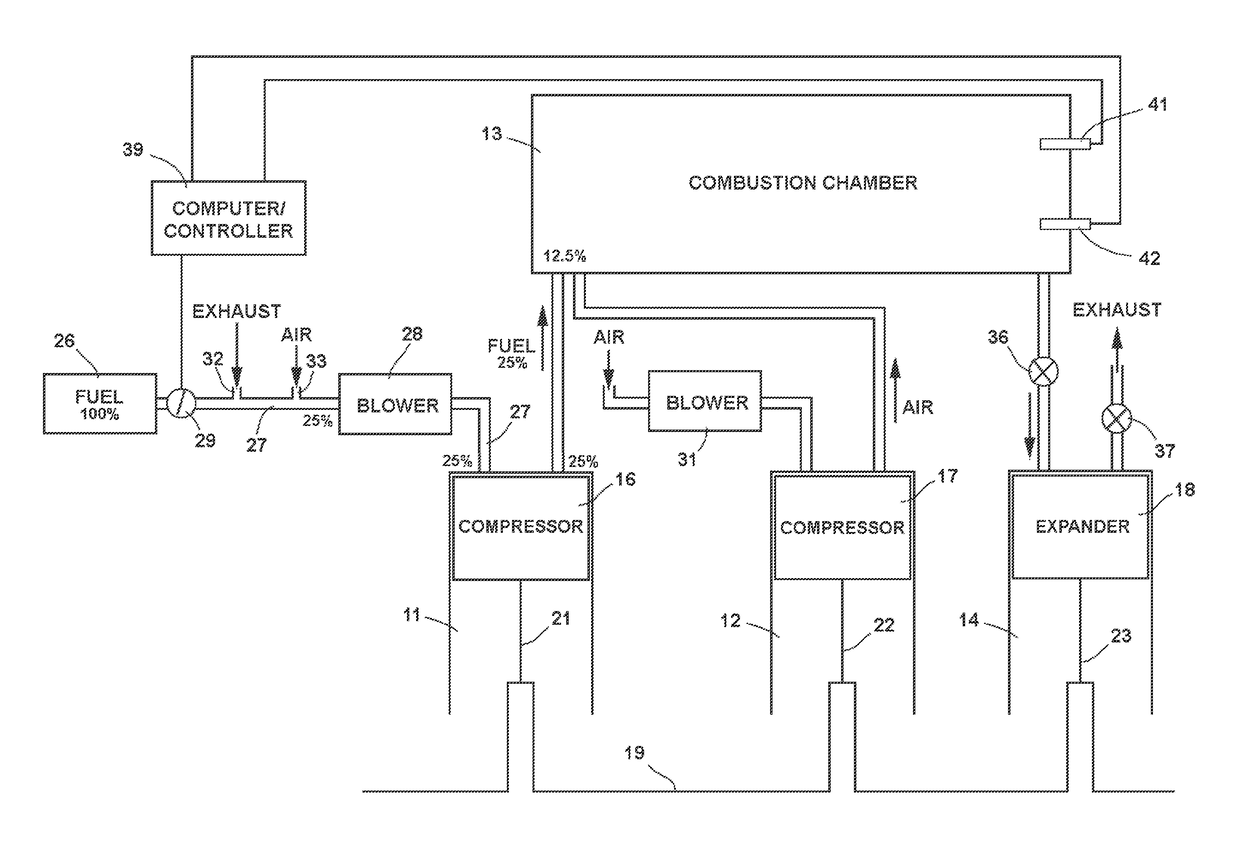

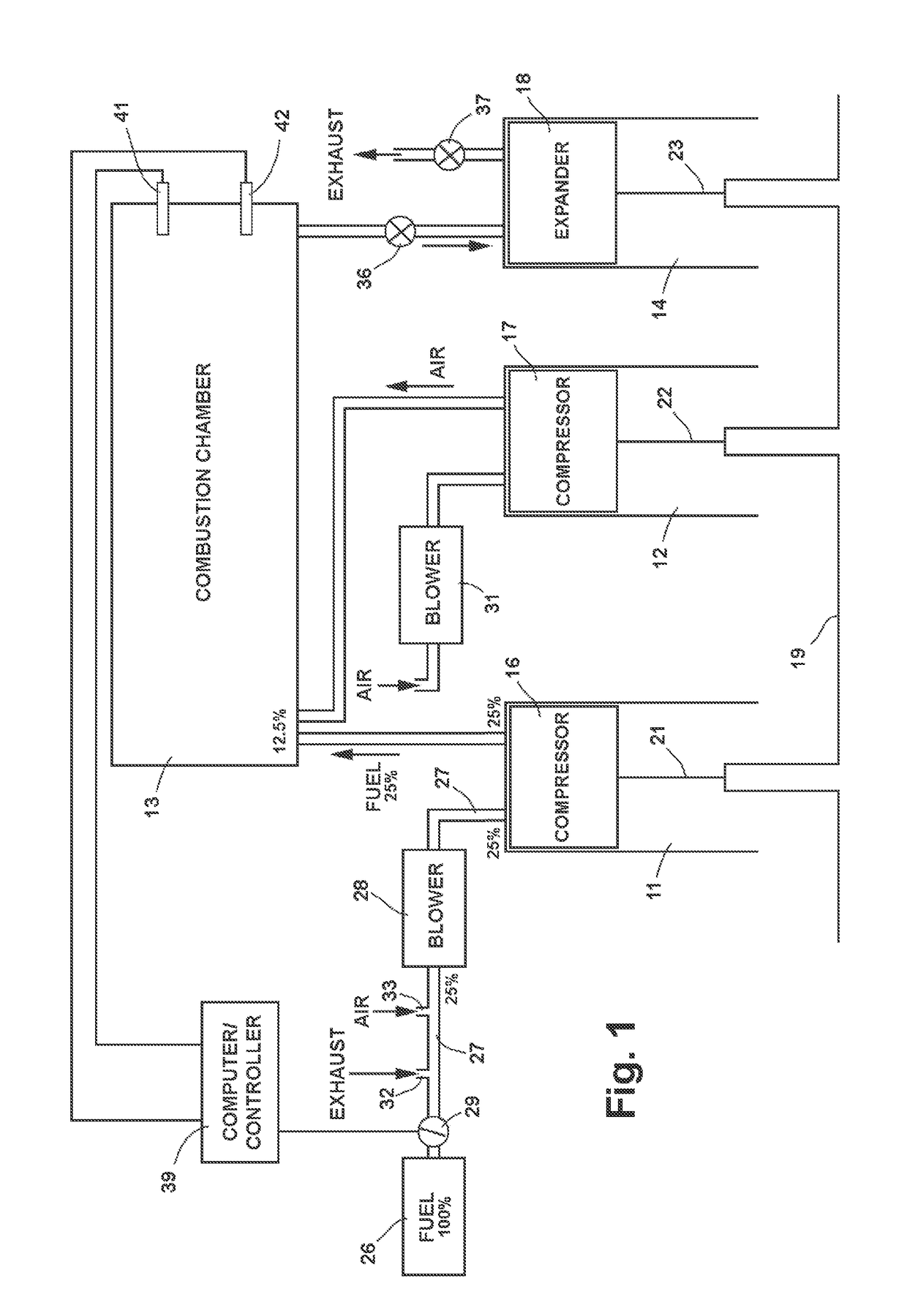

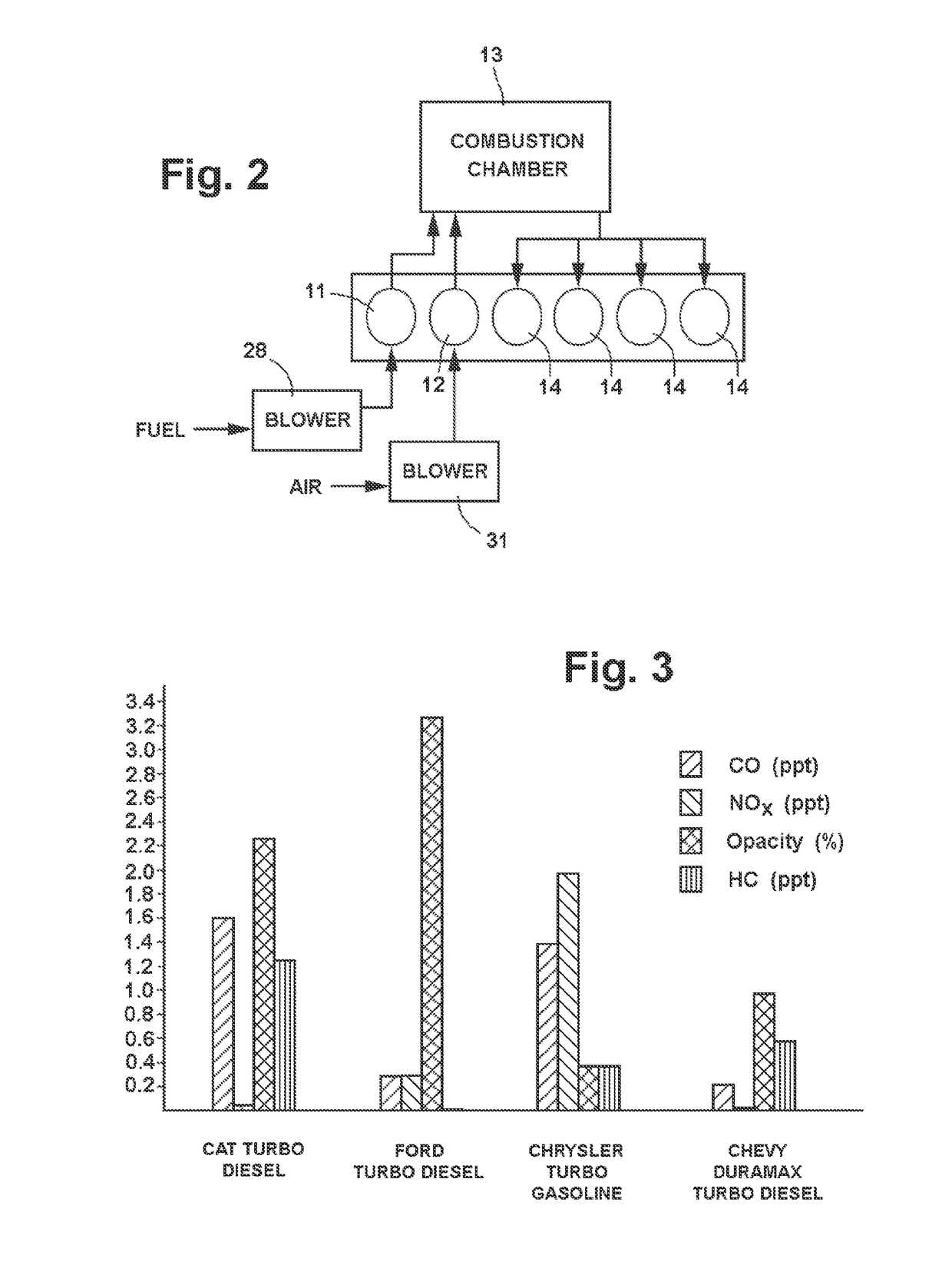

Split Cycle Engine and Method of Operation

InactiveUS20160040592A1Concentration of fuel will decreaseReduce concentrationInternal combustion piston enginesEngine controllersSyngasCombustion chamber

Split cycle engine that runs on gaseous fuels such as natural gas and synthesis gas (syngas) and to a method of operating the same. The engine includes a first compression chamber for compressing the gaseous fuel, means for supplying the gaseous fuel to the first compression chamber at a level of concentration that prevents predetonation of the fuel during compression, a second compression chamber for compressing air, a combustion chamber in which the compressed fuel and air are combined to reduce the concentration of the fuel to a level that allows the fuel to burn and expand in the combustion chamber, and an expansion chamber having an output member which is driven by expanding gas from the combustion chamber. Turbochargers or blowers pressurize and increase the volume of the fuel and air delivered to the respective compression chambers, and the concentration of the fuel is progressively reduced by the injection of air at spaced intervals as the fuel travels toward the compression chamber.

Owner:ZAJAC JOHN

Crossover valve systems

InactiveUS8272357B2Reduction in overall flow area and capacityIncrease the cross-sectional areaCombustion enginesLift valveDifferential pressureValve opening

Crossover valve systems and corresponding methods offer an effective means to overcome large opening pressure force, or provide reasonable gas flow area, or both. In an exemplary embodiment, a crossover valve system for a split-cycle engine having a power cylinder and a crossover passage comprises first and second crossover valves, each valve opening outwardly away from the power cylinder and providing fluid communication between the power cylinder and the crossover passage, with the diameter of the second crossover valve being larger than the diameter of the first crossover valve; and an actuation mechanism operative to open the first crossover valve, then the second crossover valve after a predetermined delay to allow a certain rise in the pressure inside the power cylinder, resulting in much smaller differential pressure forces across the crossover valves, larger flow areas, or both.

Owner:LGD TECH LLC

Split-cycle engine with dual spray targeting fuel injection

An engine includes a rotatable crankshaft and an expansion piston slidably received within an expansion cylinder and operatively connected to the crankshaft. A crossover passage including walls connects a source of high pressure gas to the expansion cylinder. A crossover expansion (XovrE) valve is operable to control fluid communication between the crossover passage and the expansion cylinder. The XovrE valve includes a valve head and a valve stem extending from the valve head. A fuel injector operable to inject fuel into the crossover passage includes a plurality of spray holes disposed in a nozzle end and aimed at an at least one target at which fuel emitting from the spray holes is directed to form at least one spray pattern. The at least one target is located above a seated position of the XovrE valve head and between the walls of the crossover passage and the XovrE valve stem.

Owner:SKADERI GRUP LLC

Valve lash adjustment system for a split-cycle engine

Owner:SKADERI GRUP LLC

Spool shuttle crossover valve in split-cycle engine

ActiveUS9435233B2Space minimizationReduce leakageLiquid coolingCoolant flow controlEngineeringMechanical engineering

Owner:TOUR ENGINE INC

Split-cycle engine

ActiveUS8720396B2Reduce dust emissionsEmission reductionInternal combustion piston enginesLow pressure fuel injectionExhaust valvePhase shifted

Owner:GREEN ENGINE CONSULTING

Lost-motion variable valve actuation system with cam phaser

Devices and related methods are disclosed that generally involve variable actuation of engine valves. In one embodiment, a valve train for a split-cycle internal combustion engine or an air hybrid split-cycle engine is provided that includes a cam phaser, a dwell cam, an adjustable mechanical element for performing a variable valve actuation function, and / or a valve seating control device. The devices and methods disclosed herein also have application in conventional internal combustion engines and can actuate inwardly-opening and / or outwardly-opening valves.

Owner:SKADERI GRUP LLC

Part-load control in a split-cycle engine

An engine includes a crankshaft rotatable about a crankshaft axis. A compression piston is slidably received within a compression cylinder and operatively connected to the crankshaft such that the compression piston is operable to reciprocate through an intake stroke and a compression stroke during a single rotation of the crankshaft. An expansion (power) piston is slidably received within an expansion cylinder and operatively connected to the crankshaft such that the expansion piston is operable to reciprocate through an expansion stroke and an exhaust stroke during a single rotation of the crankshaft. At least two crossover passages interconnect the compression and expansion cylinders. Each of the at least two crossover passages includes a crossover compression (XovrC) valve and a crossover expansion (XovrE) valve operable to define a pressure chamber therebetween. The engine controls and maximizes engine efficiency at part-load by utilizing only selected crossover passages.

Owner:SKADERI GRUP LLC

Split cycle engine and method of operation

InactiveUS9869241B2Reduce concentrationInternal combustion piston enginesFuel supply apparatusSyngasCombustion chamber

Split cycle engine that runs on gaseous fuels such as natural gas and synthesis gas (syngas) and to a method of operating the same. The engine includes a first compression chamber for compressing the gaseous fuel, means for supplying the gaseous fuel to the first compression chamber at a level of concentration that prevents predetonation of the fuel during compression, a second compression chamber for compressing air, a combustion chamber in which the compressed fuel and air are combined to reduce the concentration of the fuel to a level that allows the fuel to burn and expand in the combustion chamber, and an expansion chamber having an output member which is driven by expanding gas from the combustion chamber.Turbochargers or blowers pressurize and increase the volume of the fuel and air delivered to the respective compression chambers, and the concentration of the fuel is progressively reduced by the injection of air at spaced intervals as the fuel travels toward the compression chamber.

Owner:ZAJAC JOHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com