Part-load control in a split-cycle engine

一种发动机、动力的技术,应用在燃烧发动机、机器/发动机、机械设备等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

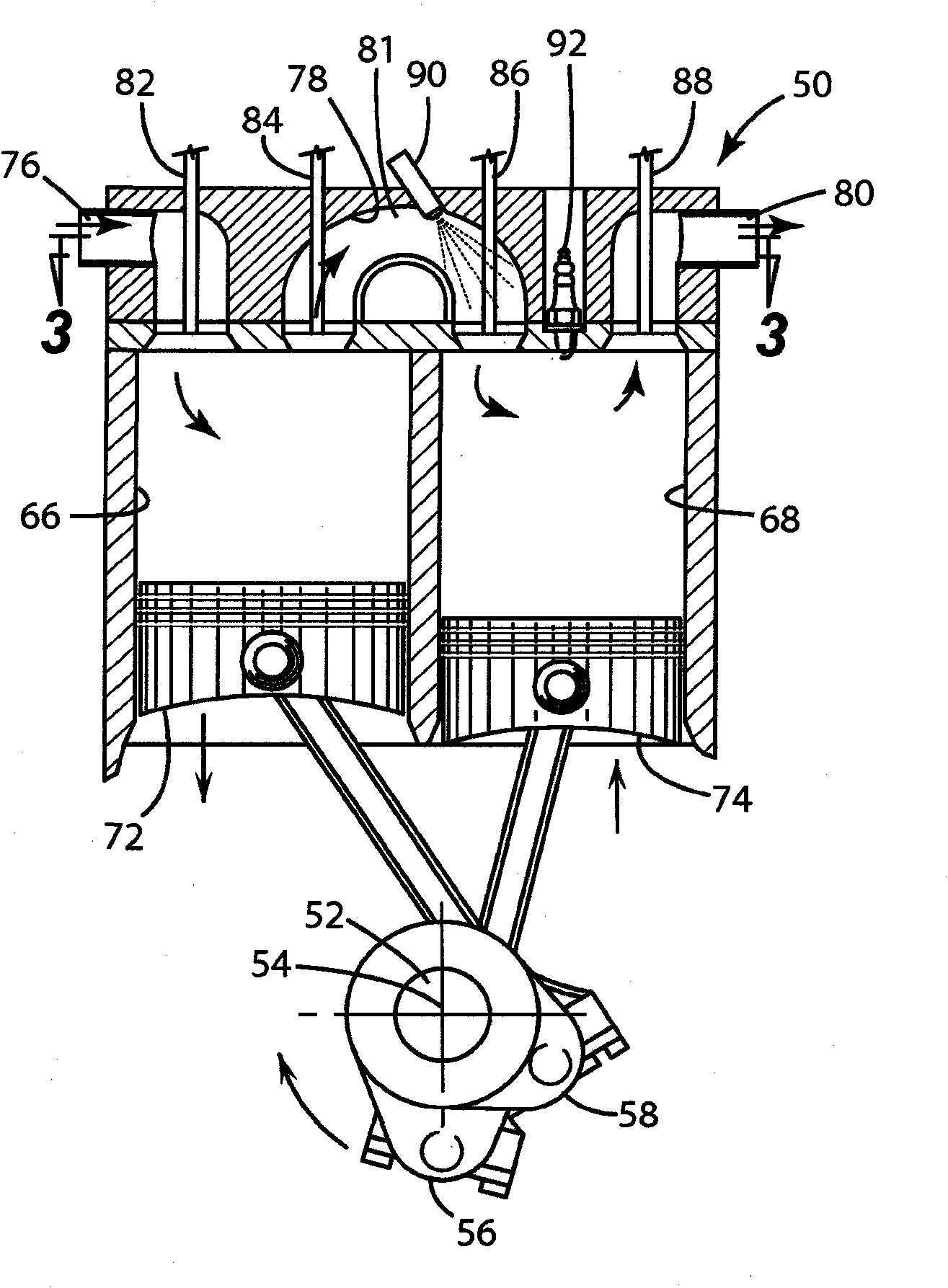

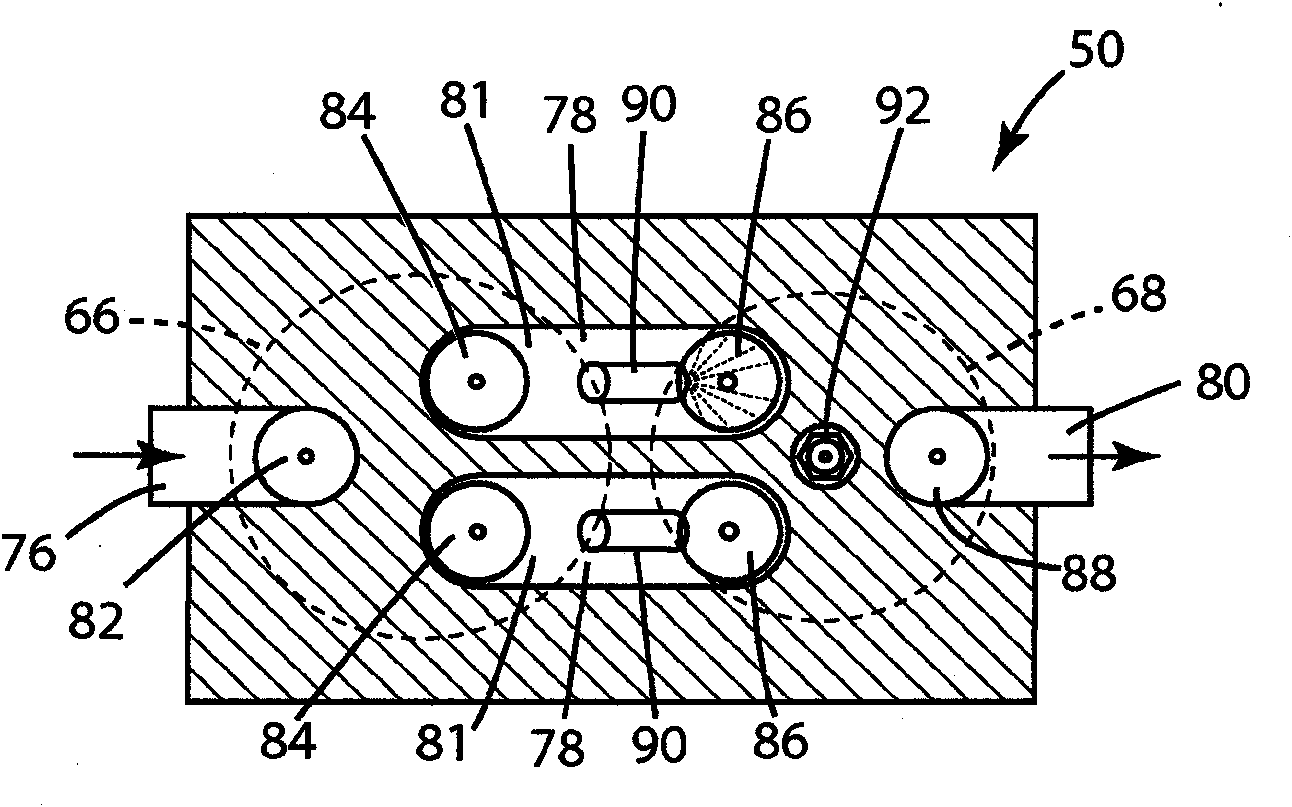

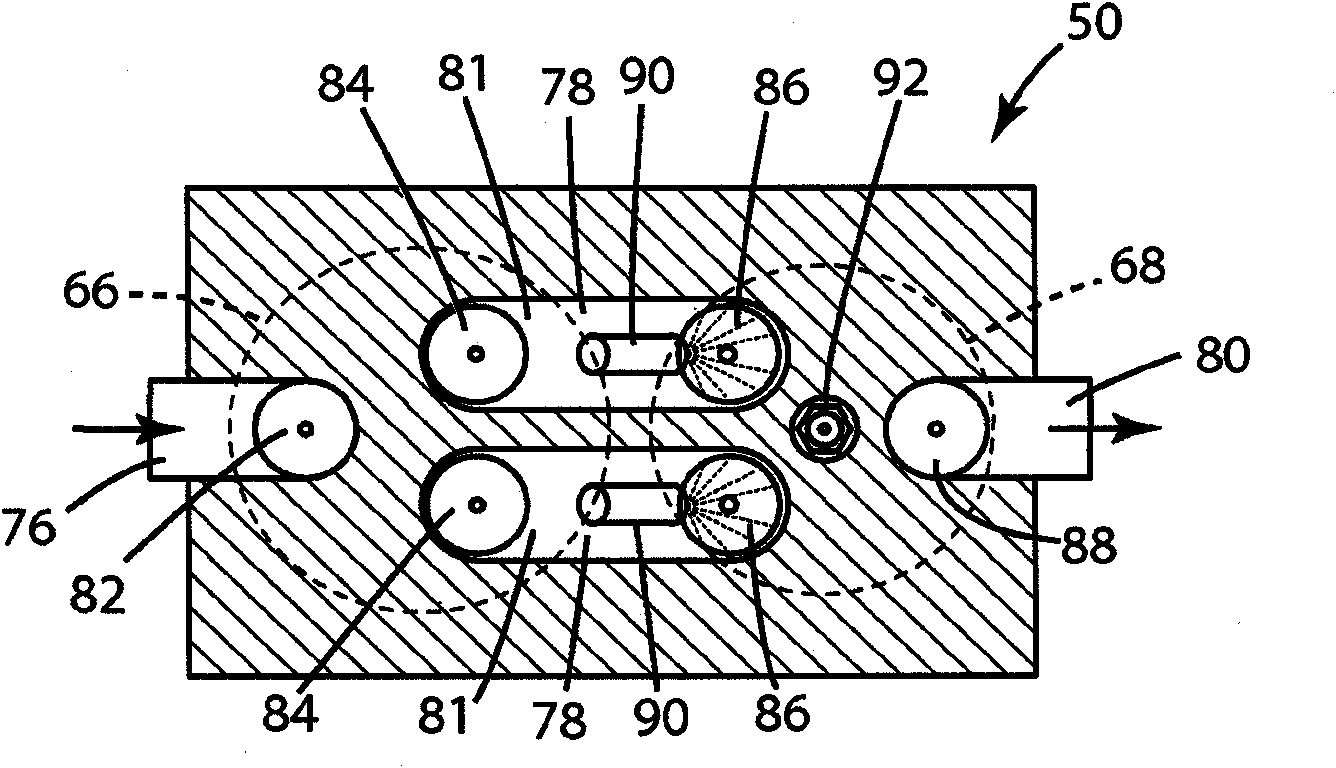

[0031] refer to figure 1 , numeral 50 generally denotes a split-cycle engine according to the invention. Split-cycle engine 50 includes a crankshaft 52 rotatable about a crankshaft axis 54 . Compression piston 72 is slidably received within compression cylinder 66 and is operatively connected to crankshaft 52 such that compression piston reciprocates through an intake stroke and a compression stroke during a single revolution of the crankshaft. Expansion (power) piston 74 is slidably received within expansion cylinder 68 and is operatively connected to crankshaft 52 such that the expansion piston reciprocates through the expansion stroke and the exhaust stroke during a single revolution of the crankshaft. At least two bridging passages 78 interconnect the expansion cylinder 66 and the compression cylinder 68 . Each crossover passage includes a crossover compression (XovrE) valve 84 and a crossover expansion (XovrE) valve 86 operable to define a pressure chamber 81 therebetwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com