Patents

Literature

46results about How to "Stay in place" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

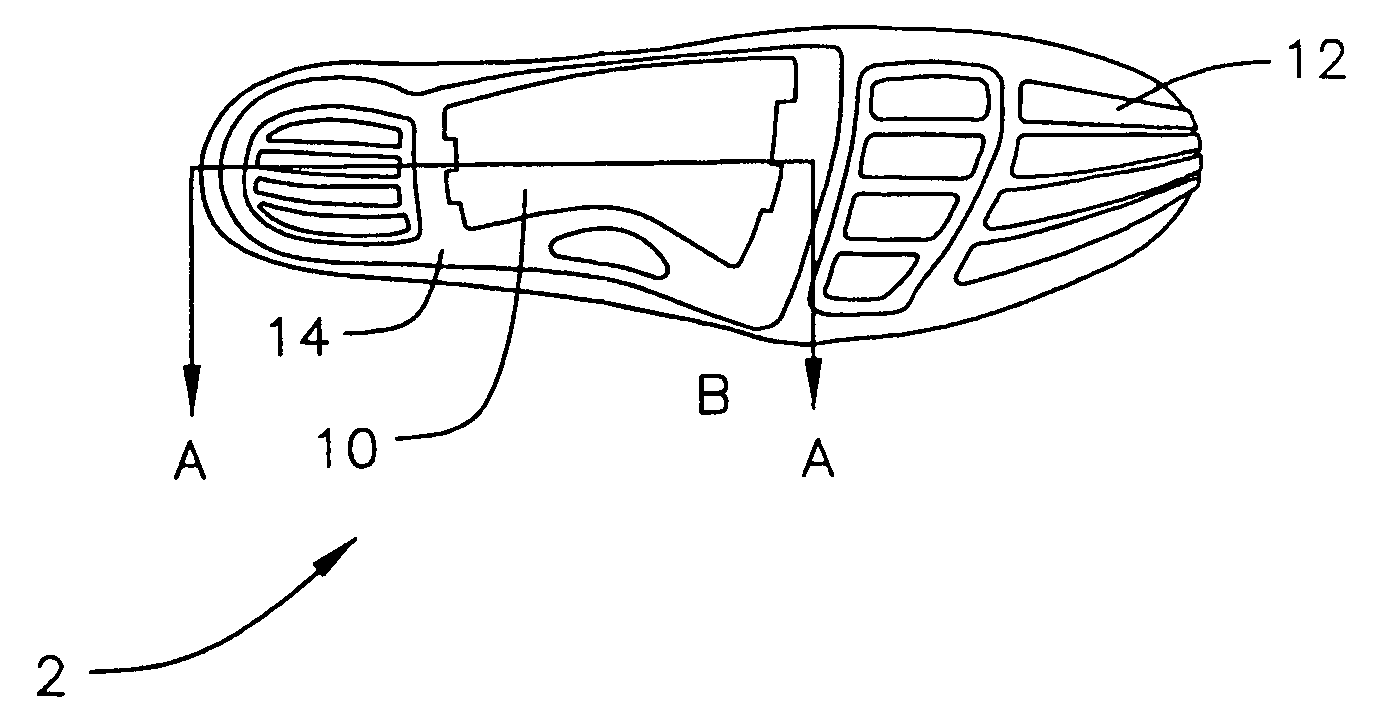

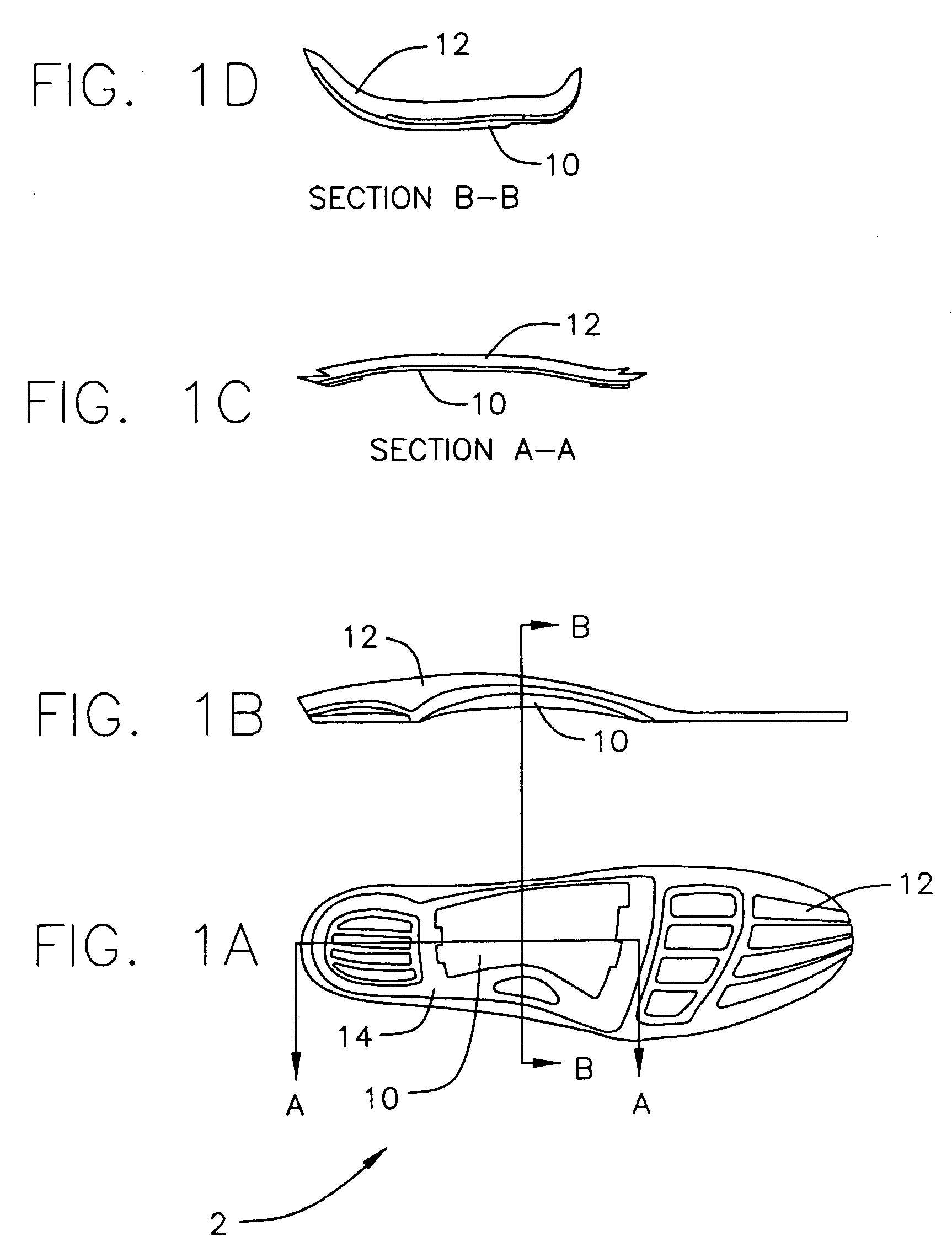

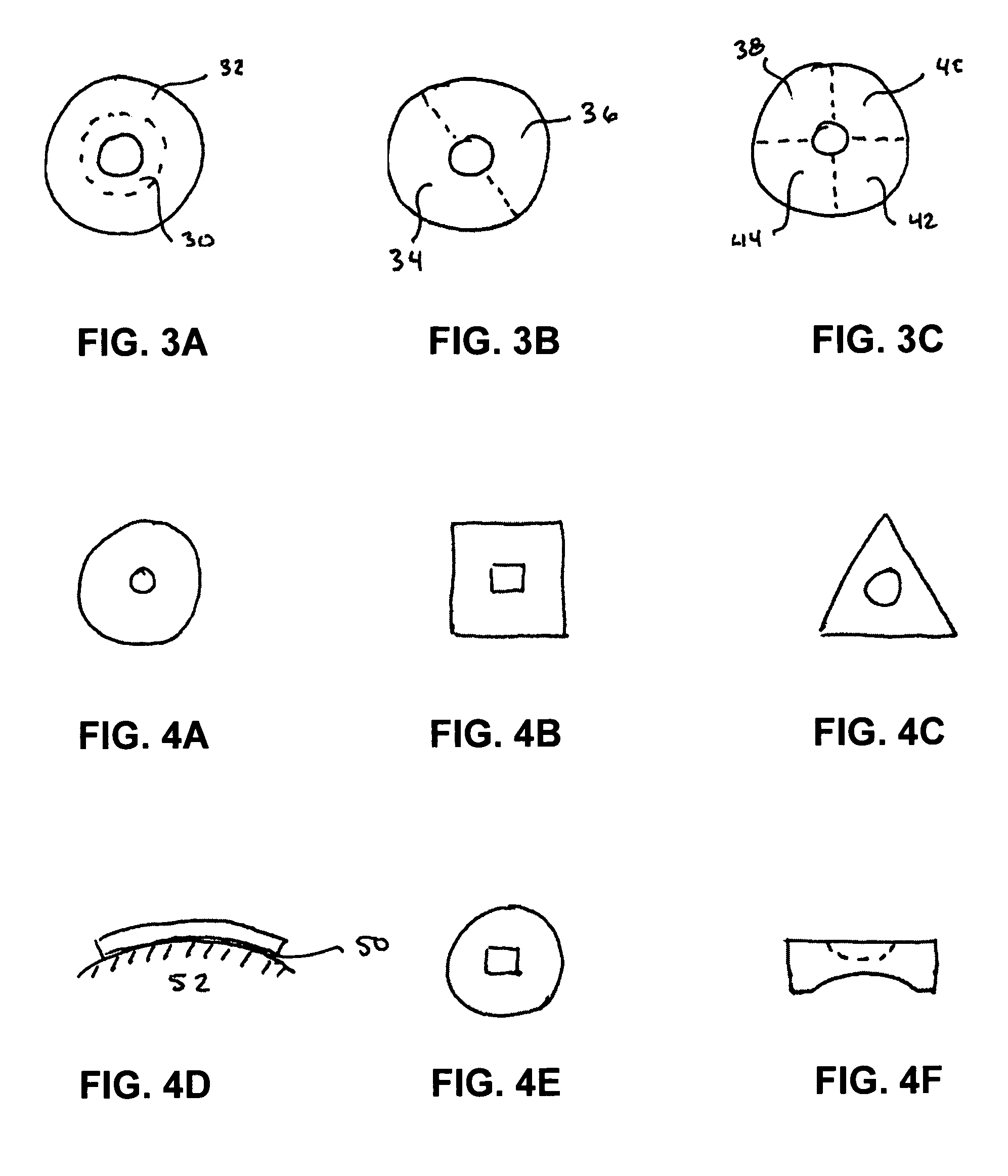

Customizable insole

InactiveUS20090165334A1Easy to customizeImprove personalizationSolesShoemaking devicesBiomedical engineering

Owner:KANTRO SCOTT +2

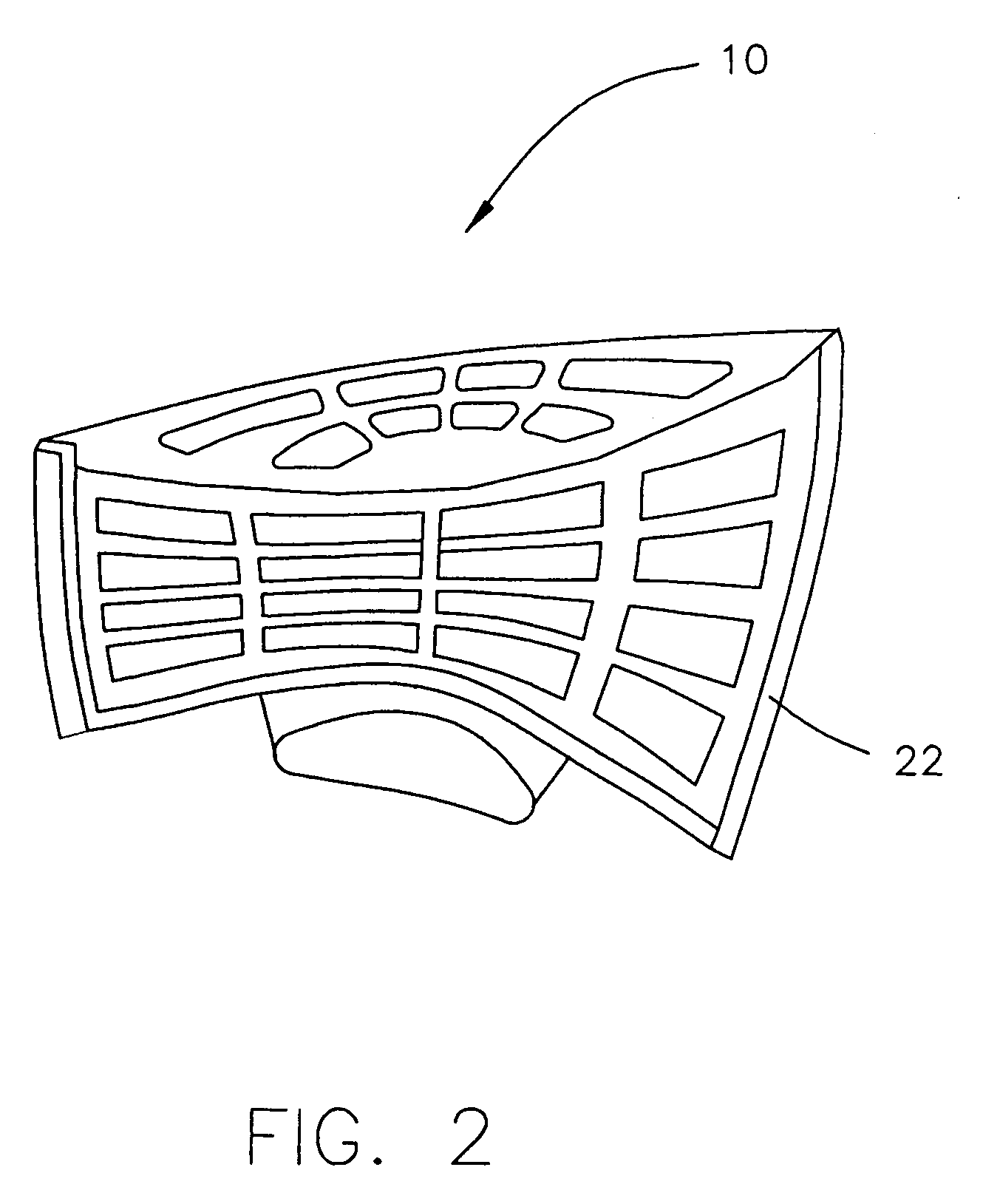

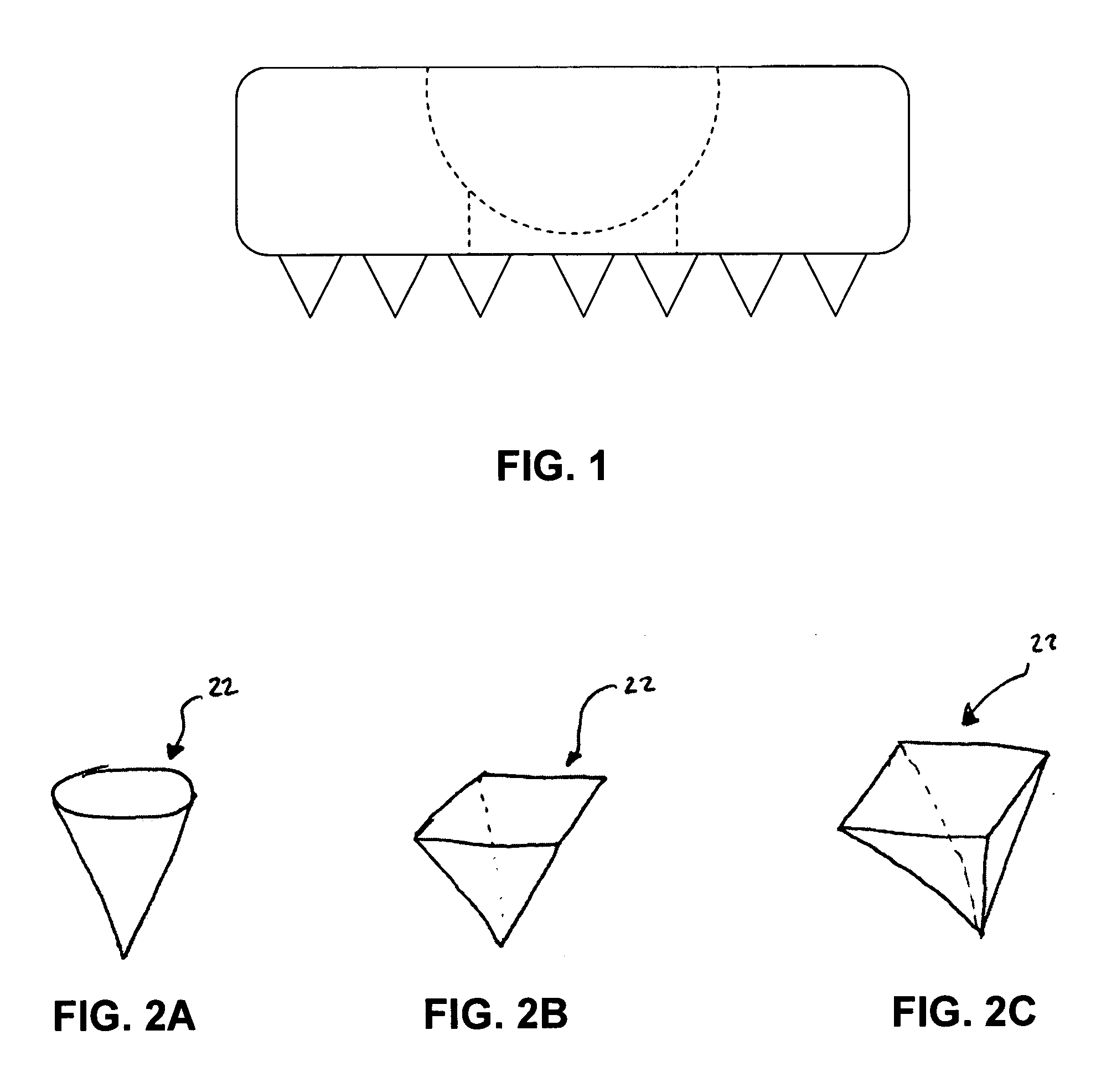

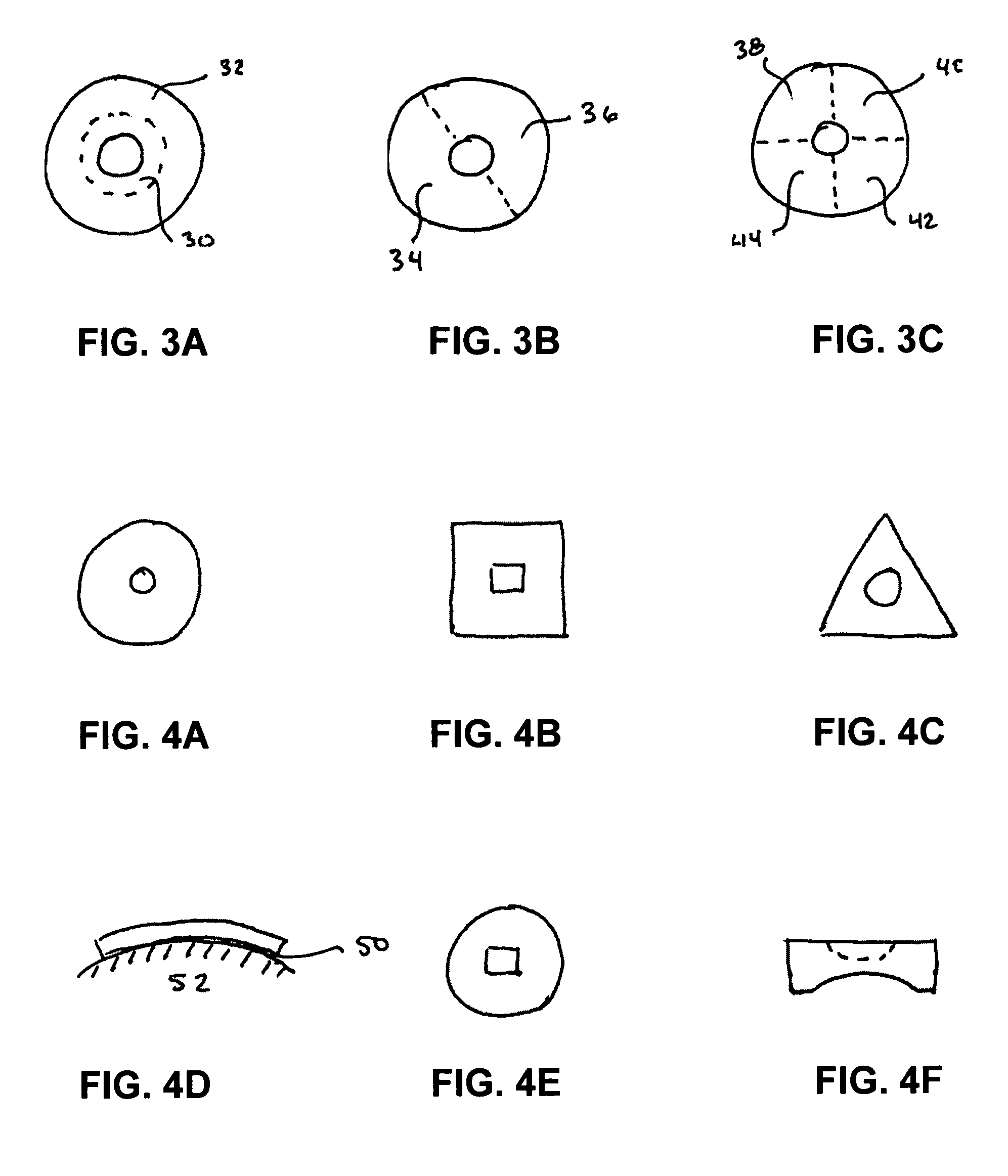

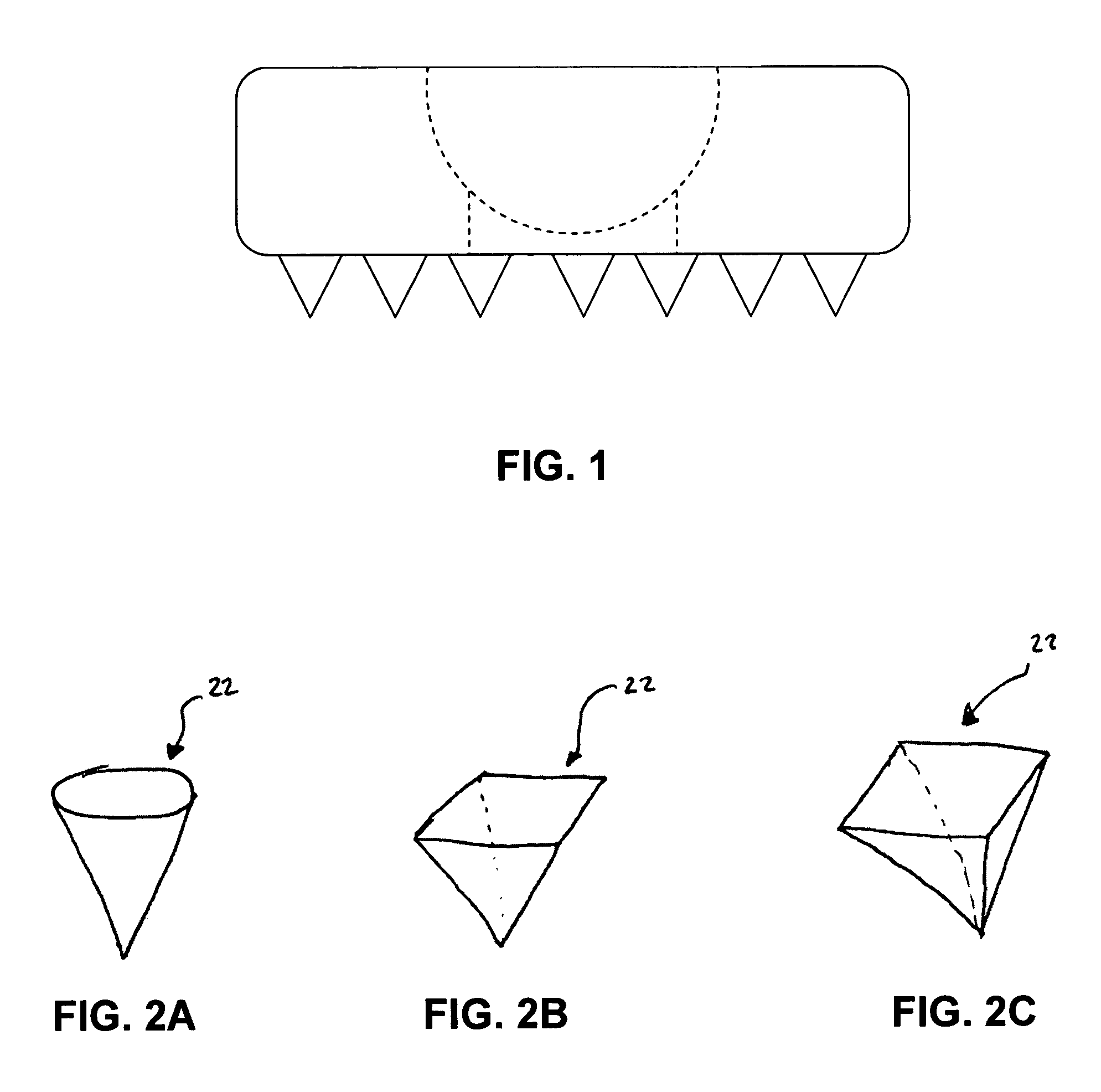

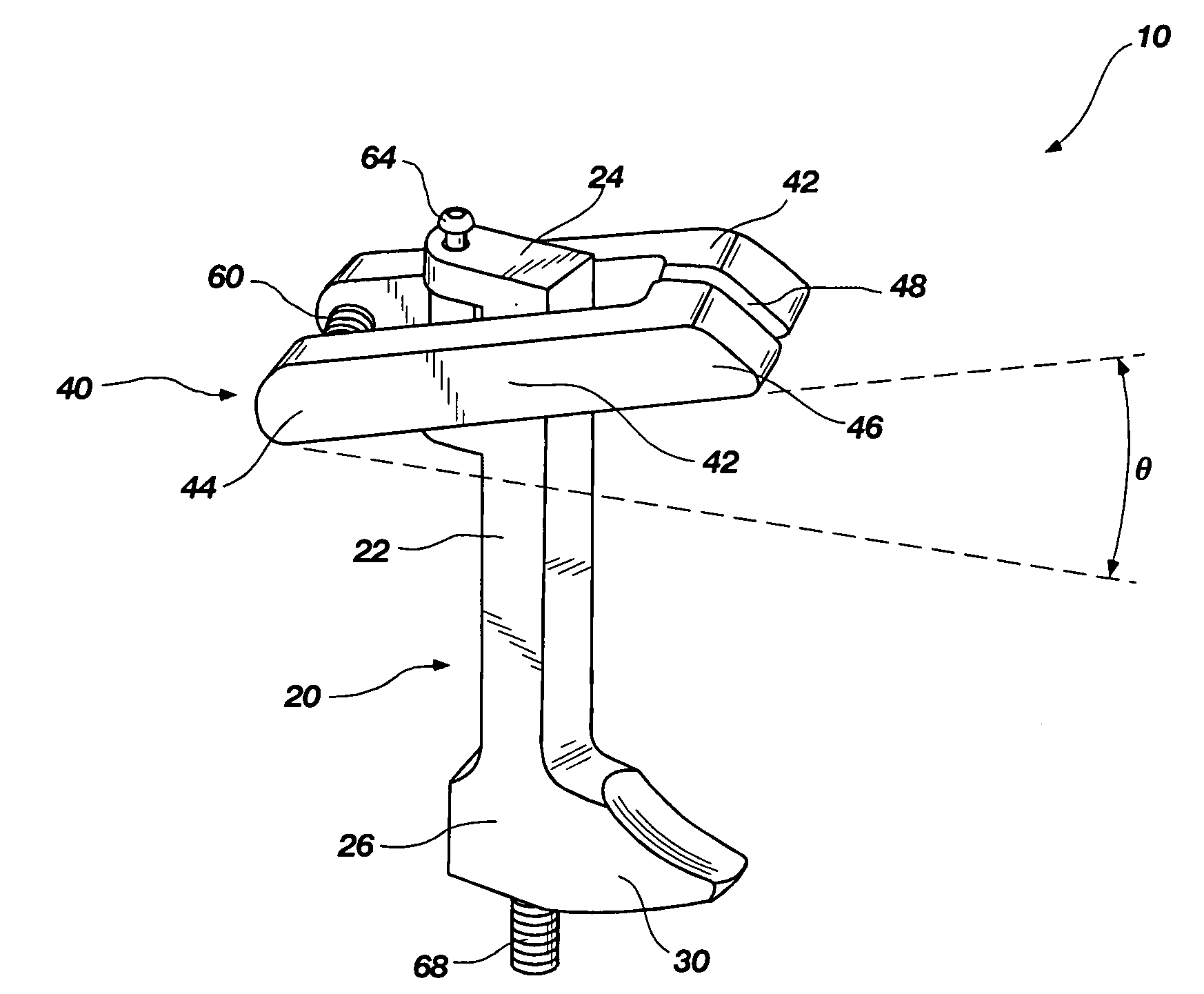

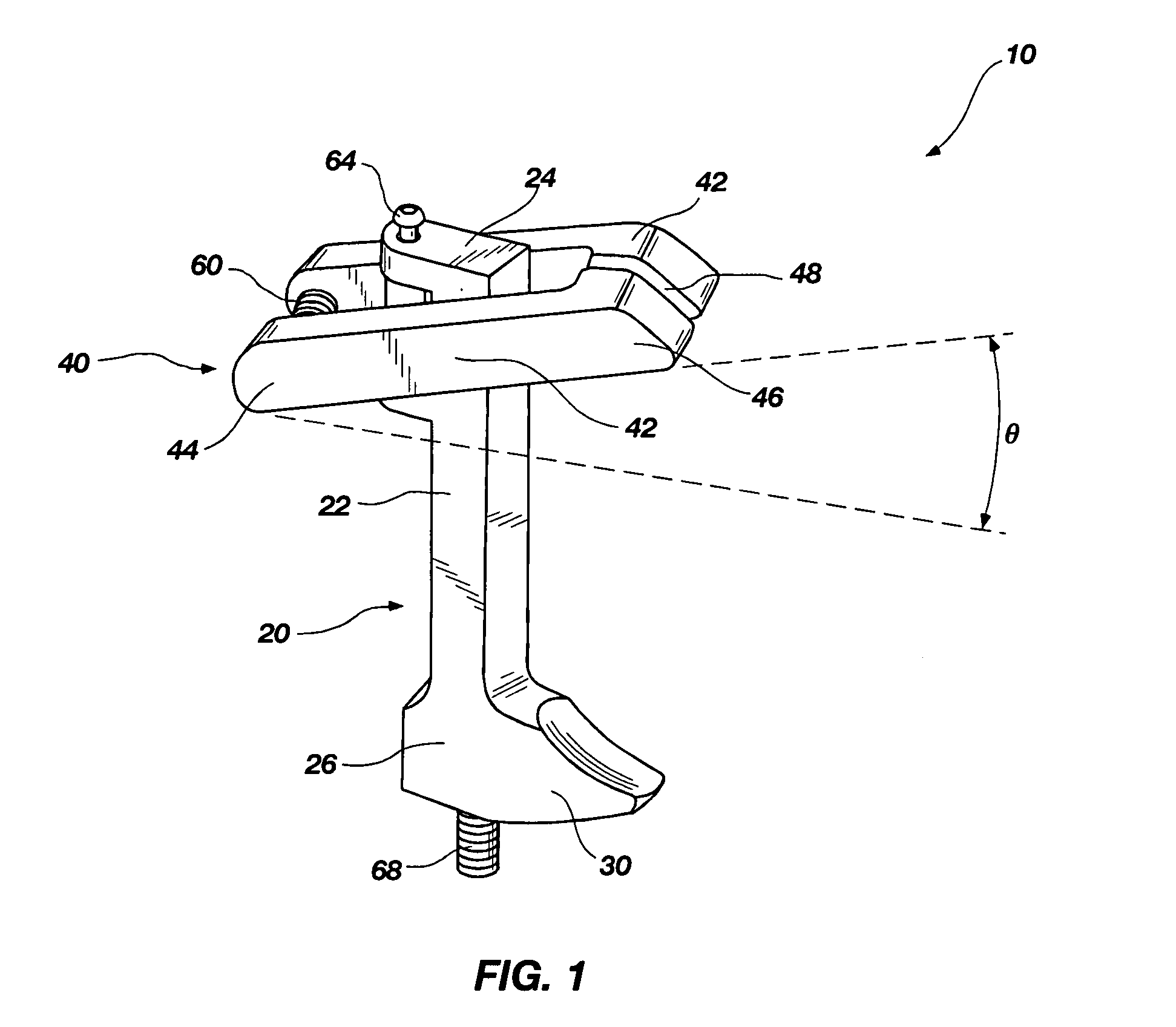

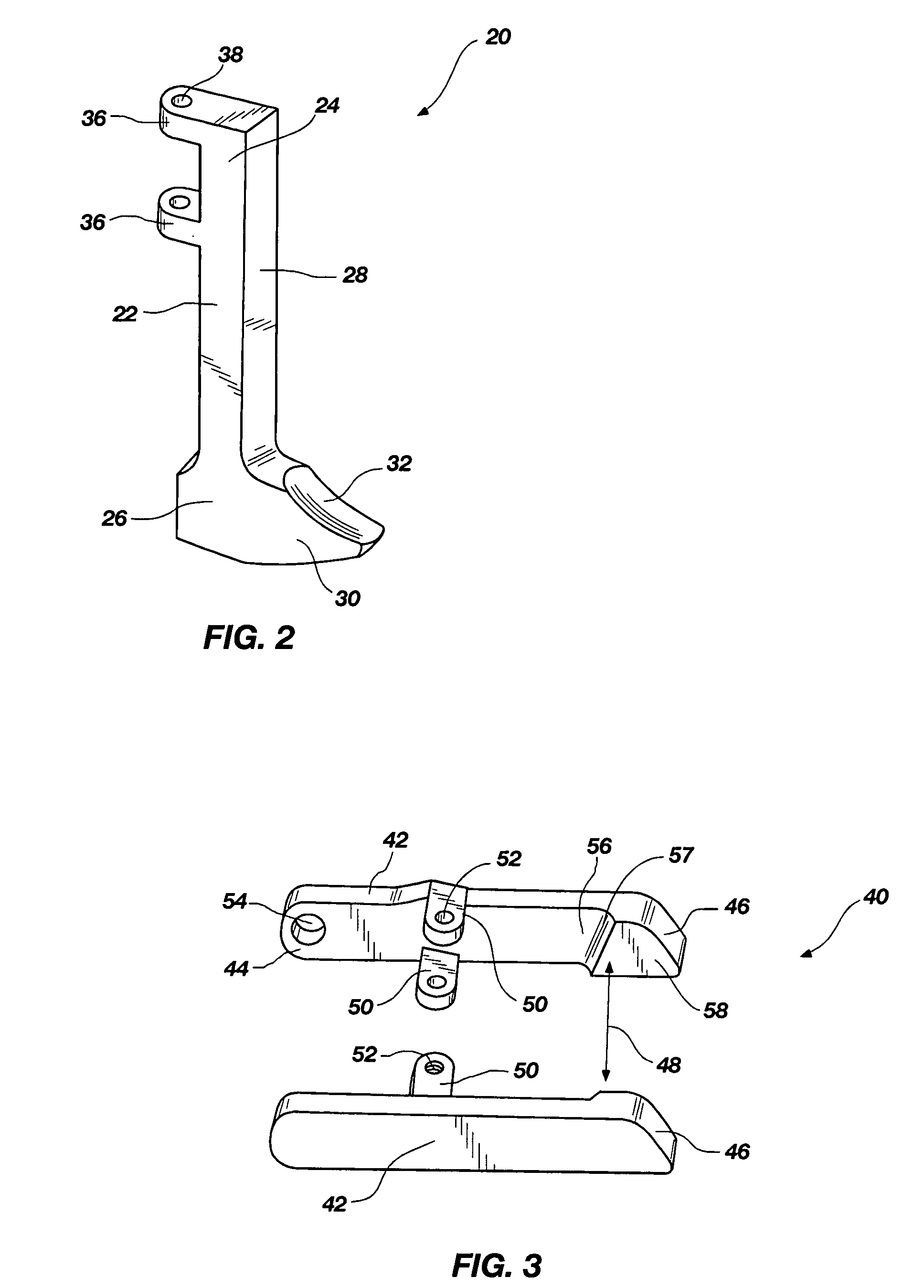

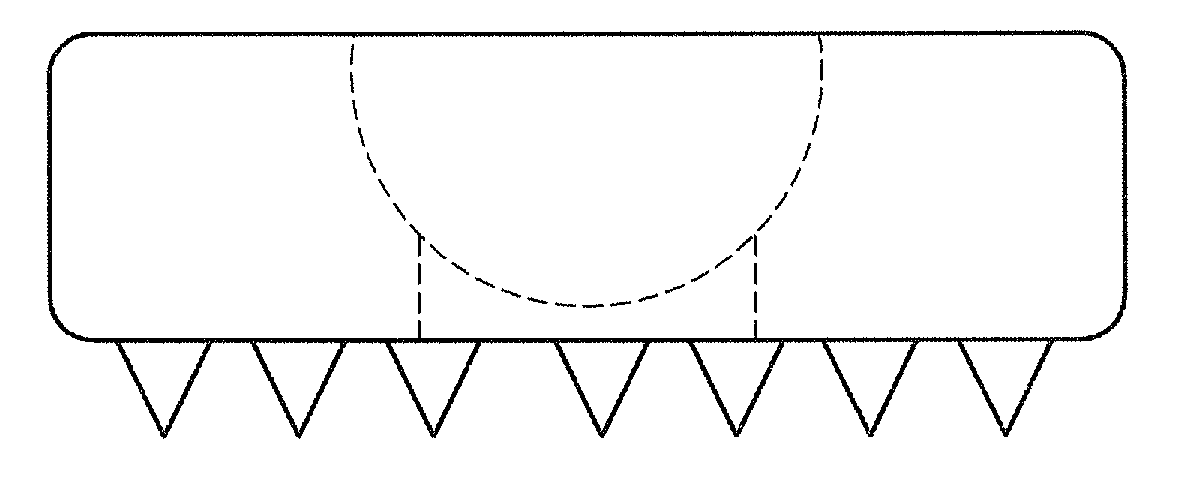

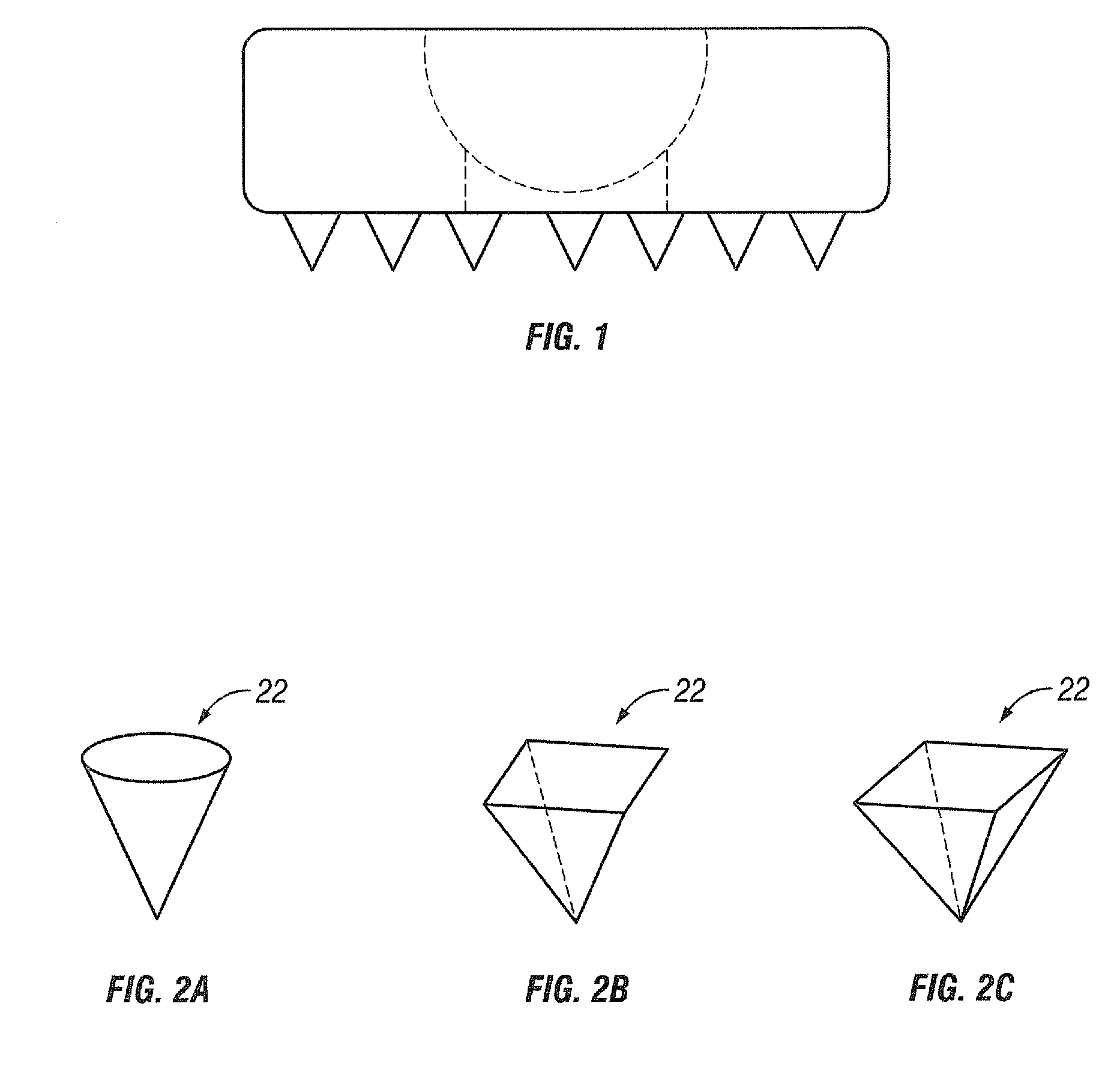

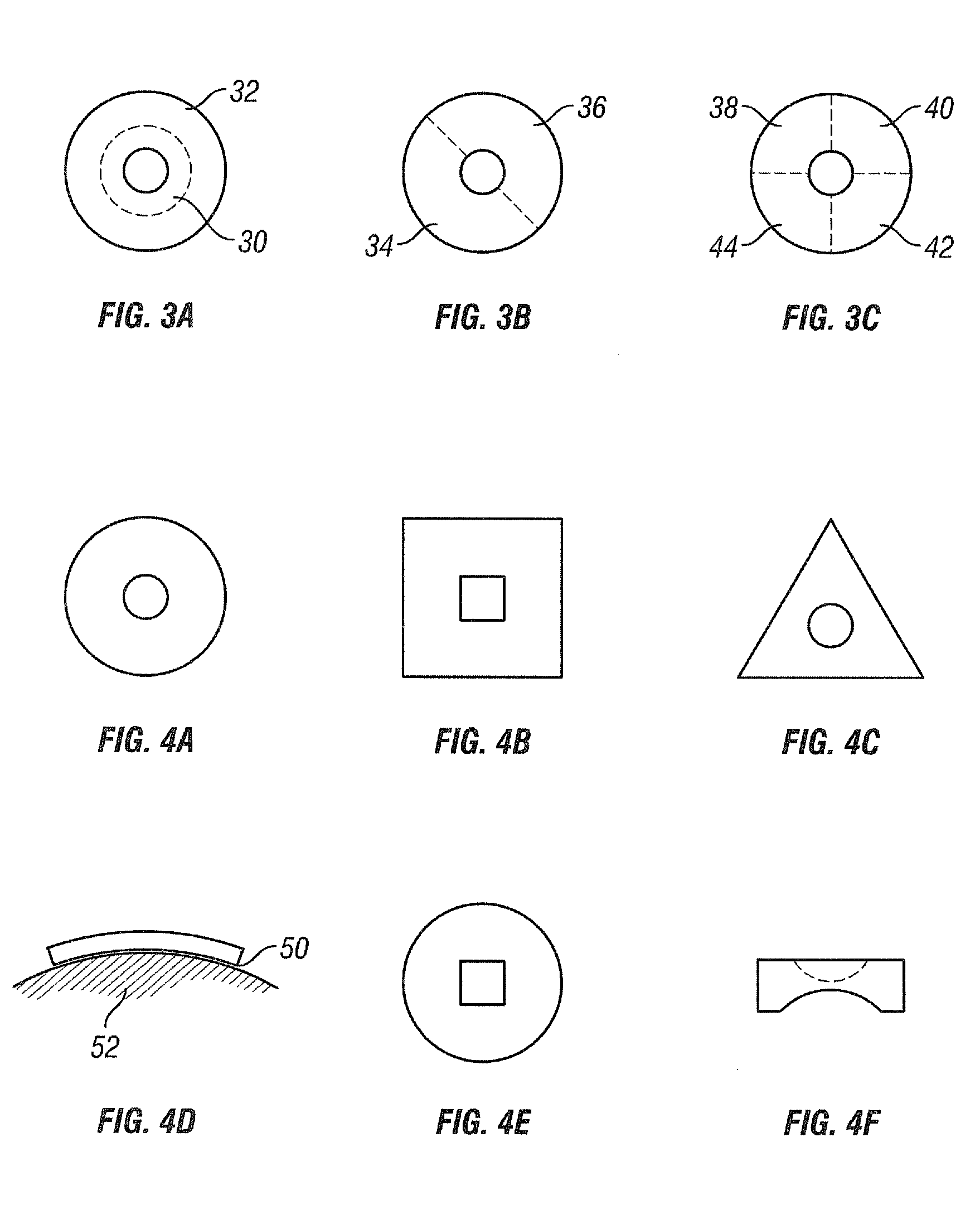

Load distribution crown

ActiveUS20050228387A1Reduce chanceEqually distributedSuture equipmentsInternal osteosythesisLoad distributionNon orthogonal

An apparatus for distributing the load caused by the insertion of a fastening device into bony tissue is disclosed. In one embodiment, the apparatus comprises a crown having a plurality of protrusions. The protrusions may have any desired physical properties, and function to obtain purchase in the bony tissue. Preferably, the crown includes an opening that is selectively engageable with a spherical head of the fastening device. The opening preferably comprises a spherical curvature that allows the surfaces of the spherical head and the opening to maintain flush contact, even when the fastening device is inserted into the bony tissue at a non-orthogonal angle. When the fastening device is inserted into the bony tissue, the crown distributes the load over a wider section of the bone, allowing the bone to maintain its structural integrity.

Owner:GLOBUS MEDICAL INC

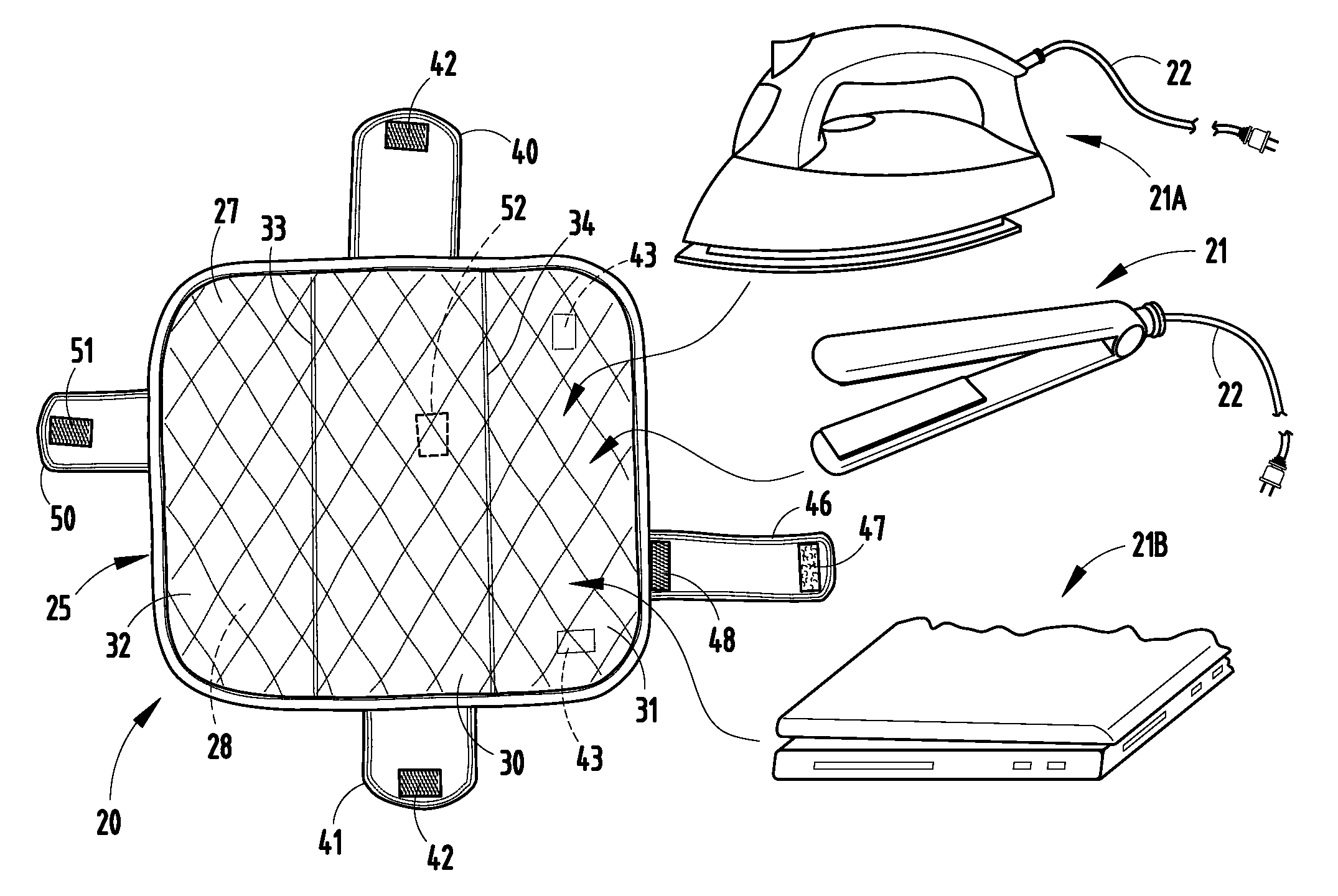

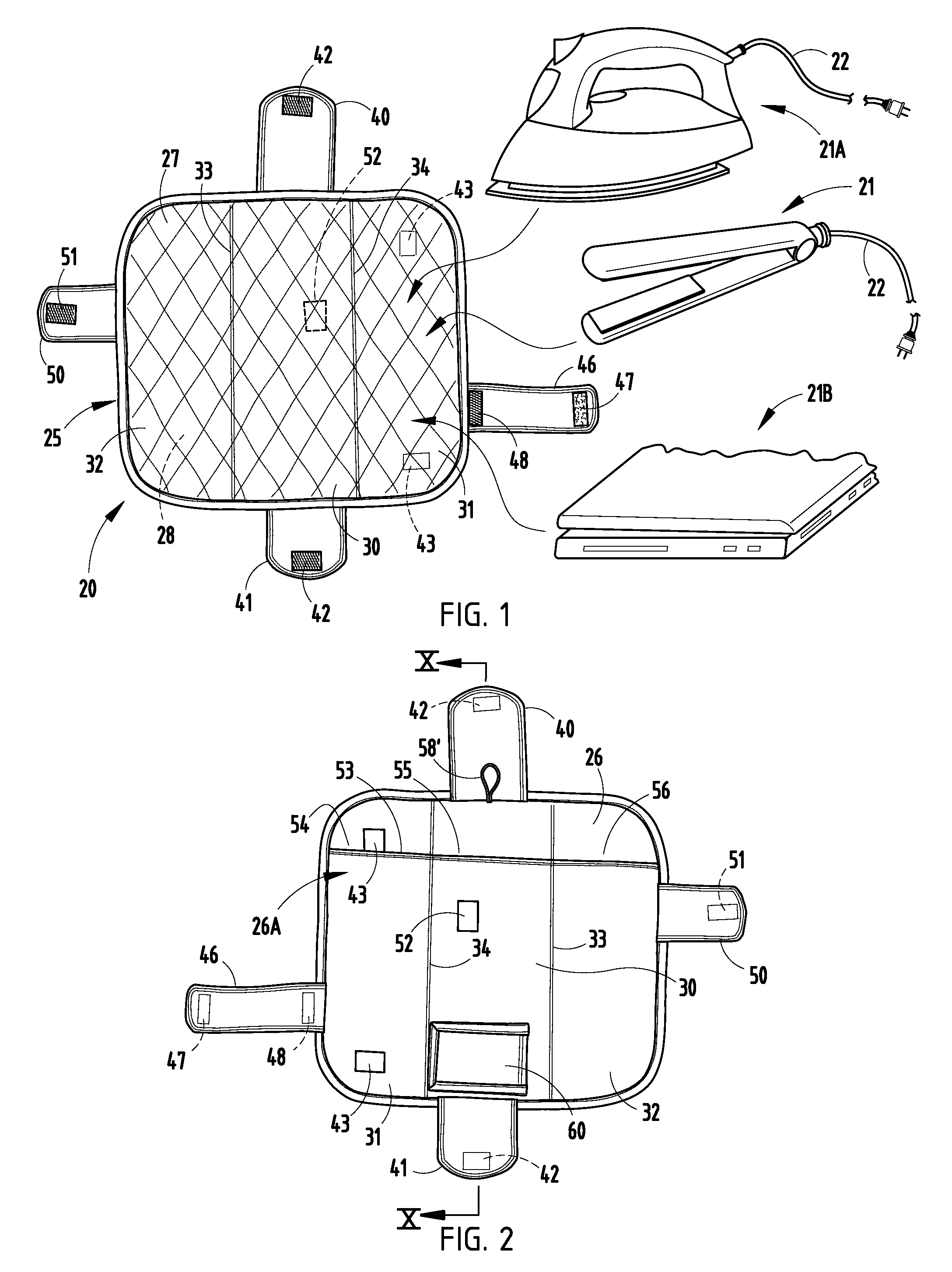

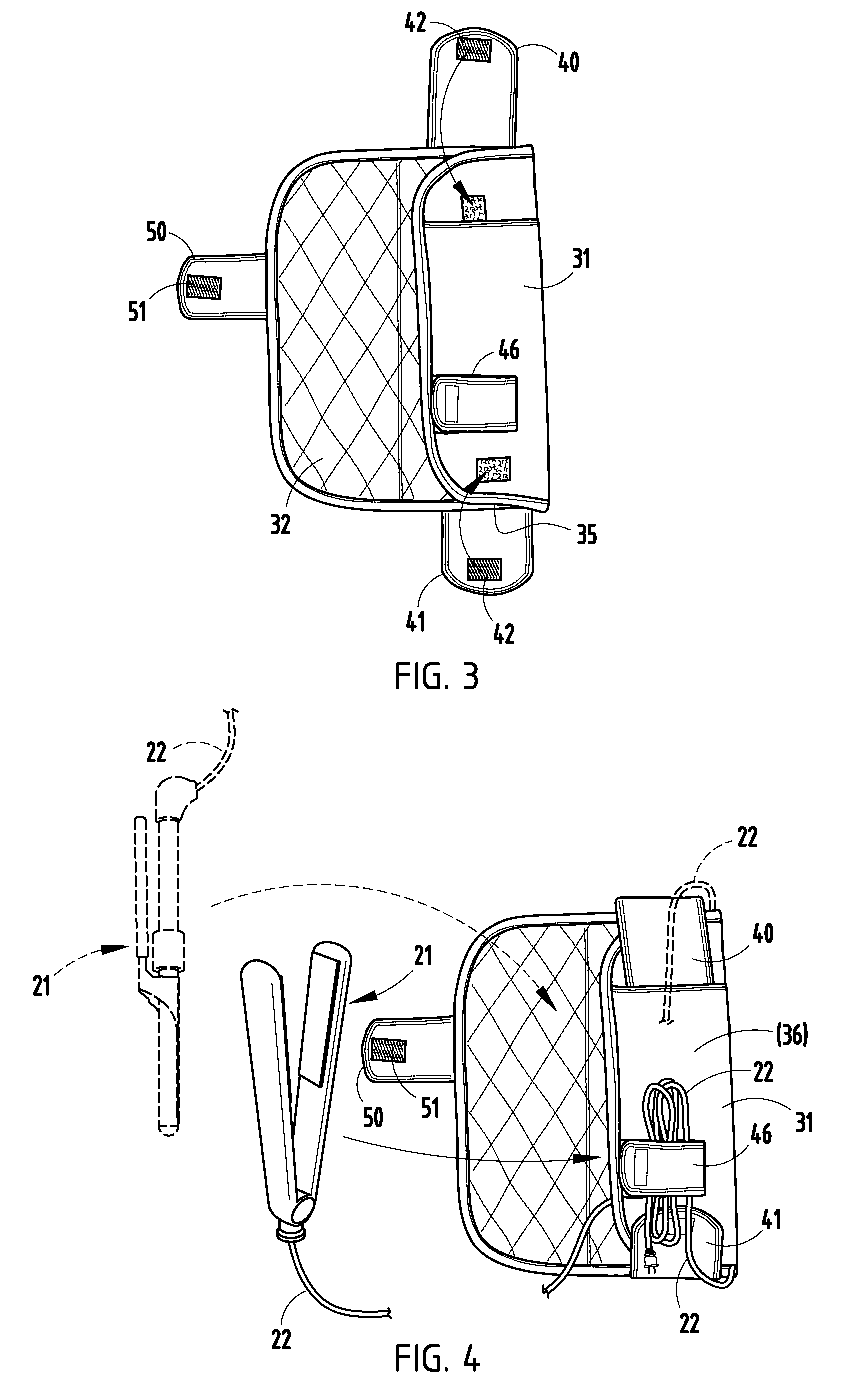

Multi-function holder and carrier for hot appliances

A carrier includes foldable sheets attached together and including an aesthetic outer surface and a heat-resistant insulating inner surface. The sheets include end flaps and first closures for closing the end flaps to form a three-sided pocket adapted to retain a hot appliance therein, and further the sheets include a side flap and second closure for closing the side flap to totally enclose the pocket to securely positively retain the hot appliance therein. The carrier includes a retainer for holding a power cord to the hot hair care device, regardless of an orientation of the device, in a location spaced from a hot portion of the hot appliance. Also, a scent is embedded in the sheets to provide a desired aroma when warmed by a heated appliance.

Owner:GENEVA RHONDA W

Load distribution crown

ActiveUS7615069B2Reduce chanceEqually distributedSuture equipmentsInternal osteosythesisLoad distributionNon orthogonal

An apparatus for distributing the load caused by the insertion of a fastening device into bony tissue is disclosed. In one embodiment, the apparatus comprises a crown having a plurality of protrusions. The protrusions may have any desired physical properties, and function to obtain purchase in the bony tissue. Preferably, the crown includes an opening that is selectively engageable with a spherical head of the fastening device. The opening preferably comprises a spherical curvature that allows the surfaces of the spherical head and the opening to maintain flush contact, even when the fastening device is inserted into the bony tissue at a non-orthogonal angle. When the fastening device is inserted into the bony tissue, the crown distributes the load over a wider section of the bone, allowing the bone to maintain its structural integrity.

Owner:GLOBUS MEDICAL INC

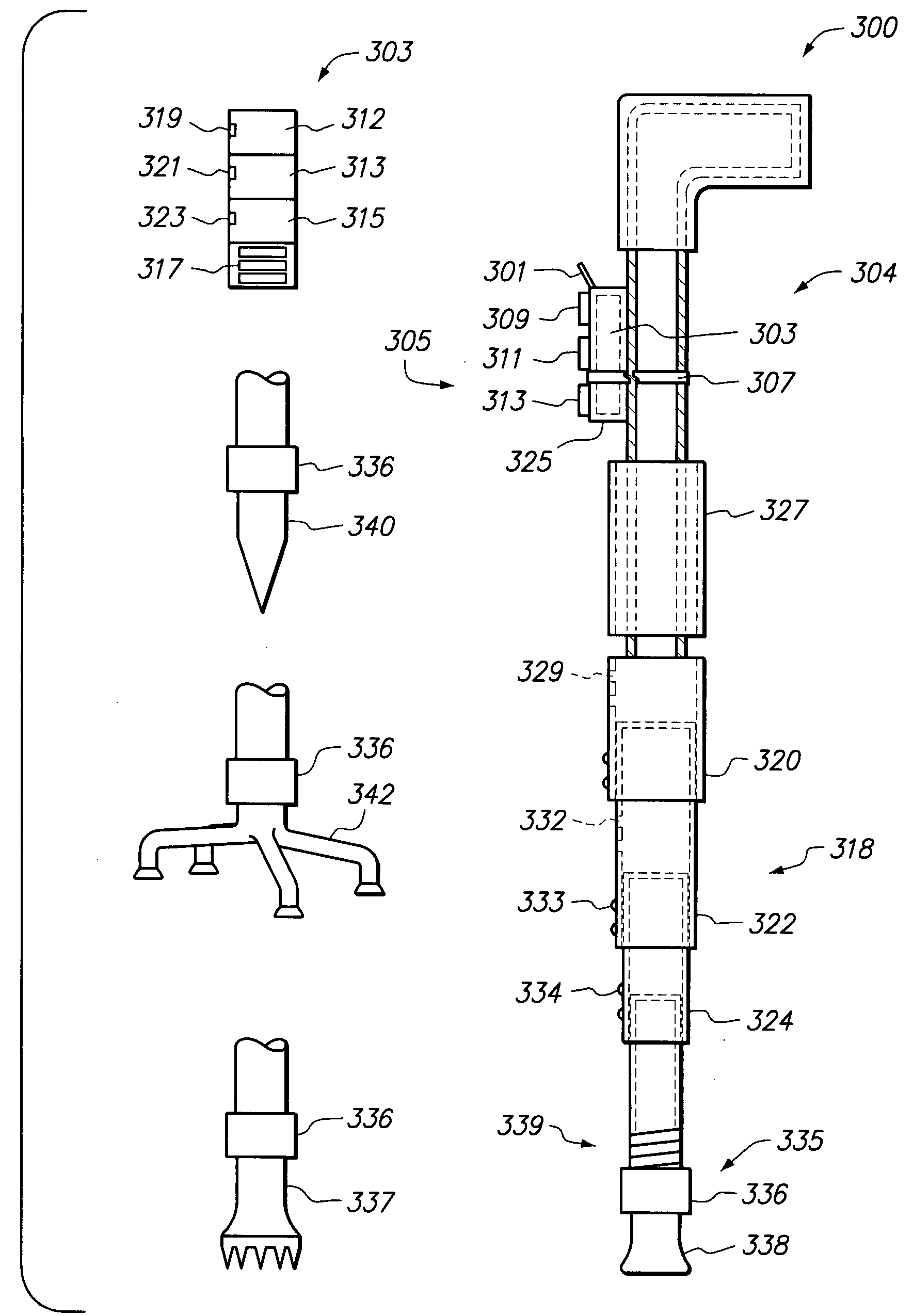

Multifunctional walking stick with dog deterrent and adaptable base

InactiveUS20090038663A1Easy accessJeopardizing their stabilityWalking sticksRepellant gas/chemical self-defence devicesEngineeringFlare

A multifunctional walking stick includes a telescopic stem having an adjustable handle and an interchangeable base. A modular safety device is detachably attached to the stem. The modular safety device includes a dog deterrent device, an audible alarm device and a location tracer device. The dog deterrent device can issue inaudible ultrasonic sound to deter barking dogs from a user. The interchangeable base can receive different selectable base bottoms for different activities i.e. walking, hiking, etc. The multifunctional walking stick also includes a compass, a flare compartment and a shock absorber for reducing vibrations caused by a walking surface.

Owner:JUSLIN SYLVIA +2

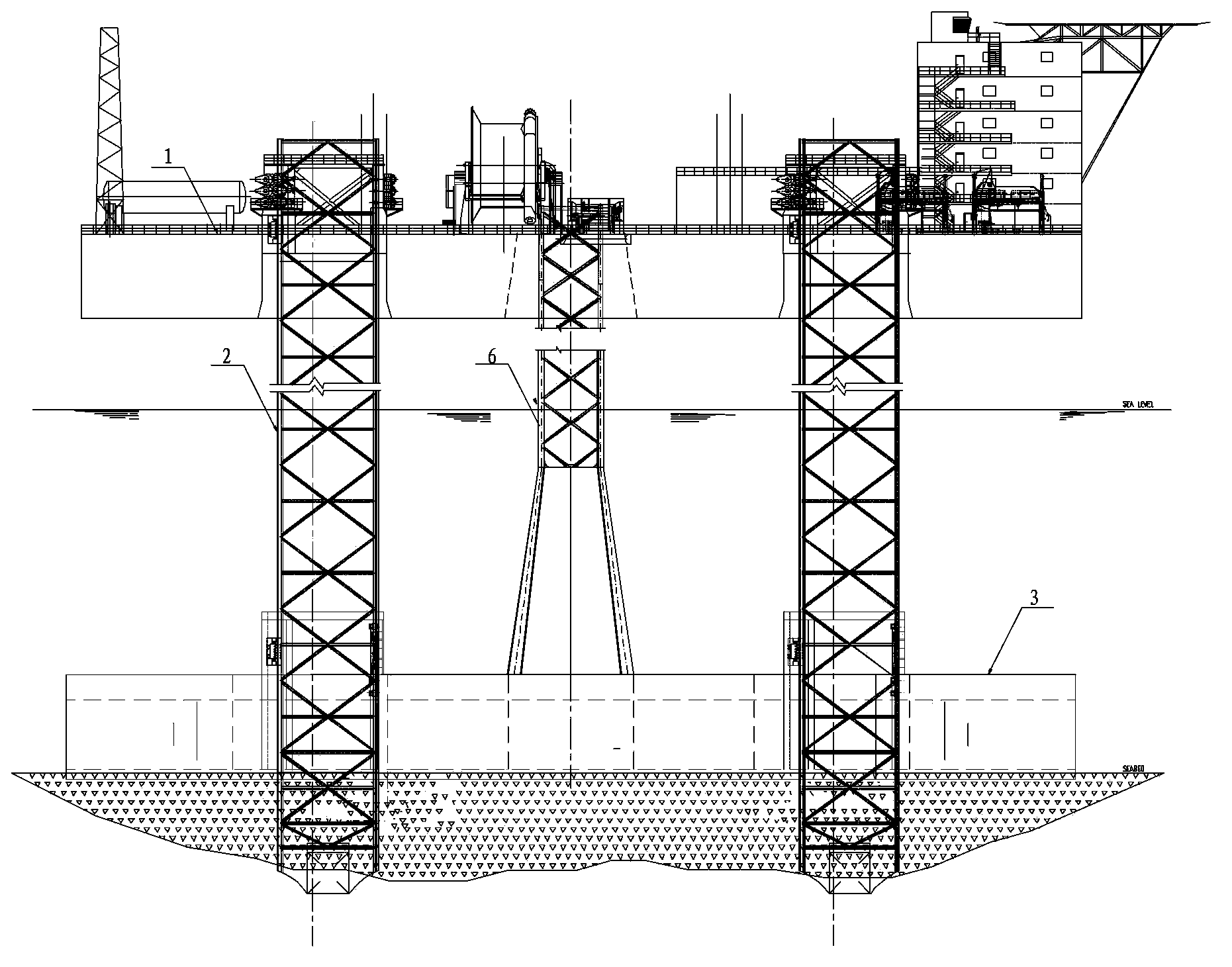

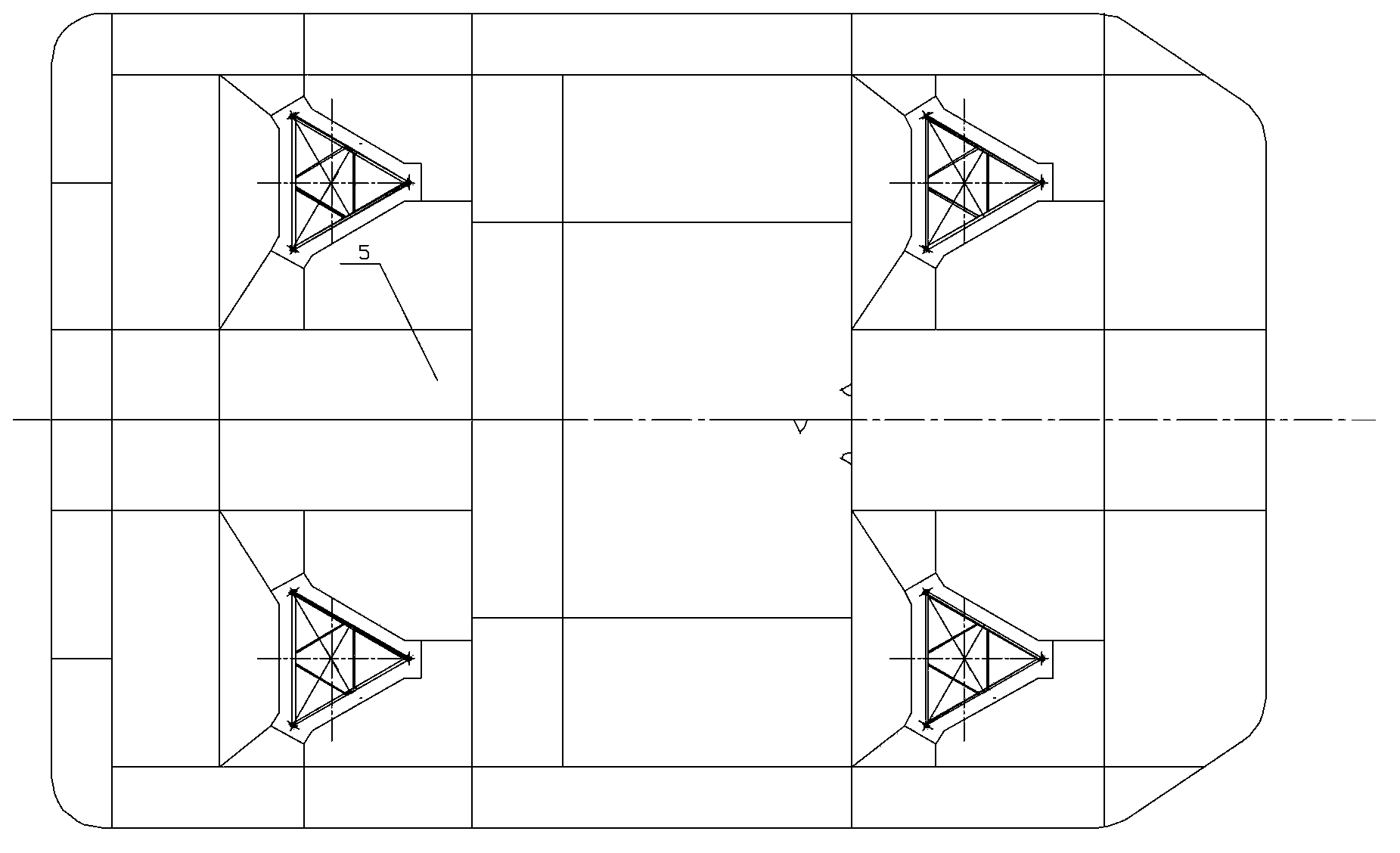

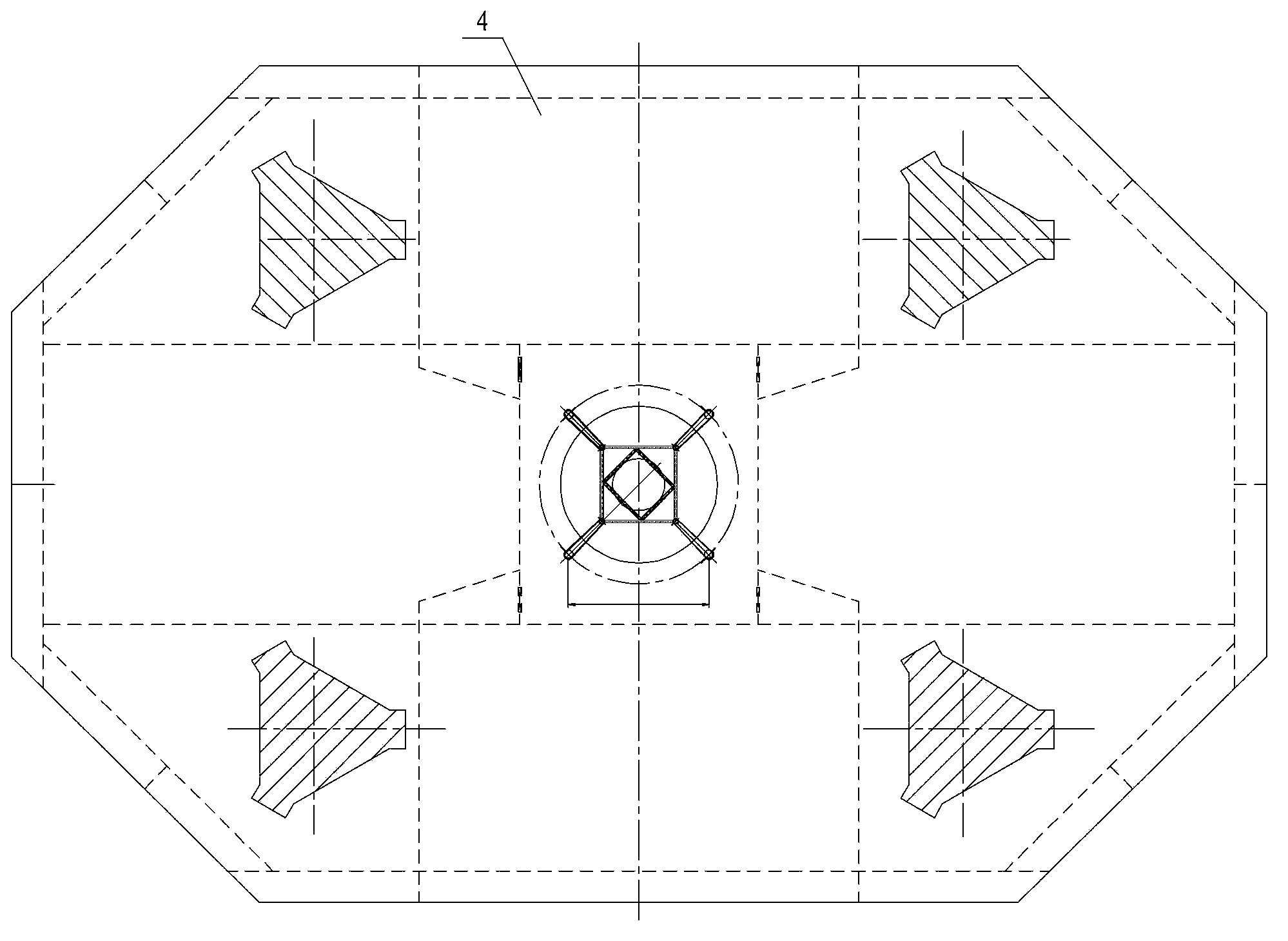

Mat-assisted driving movable platform

InactiveCN103452086ALighten structural loadsControl the amount of steel used in the structureArtificial islandsUnderwater structuresOcean bottomSeabed

The invention provides a mat-assisted driving movable platform comprising an upper platform, a plurality of pile legs and a bottom platform foundation. The upper portion of every pile leg is connected with the upper platform. The lower portion of every pile leg is inserted into the bottom platform foundation and extends out of the other end of the bottom platform foundation. The bottom platform foundation is a mat foundation with skirt plates. A body of the bottom platform foundation is provided with an oil store inside. The mat-assisted driving movable self-installed platform is a novel engineering facility for the development and research of offshore marginal oilfields, is applicable to movable reusable facilities different in water depth and seabed conditions and cost control in the development and offshore installation process of facilities, is available for the development of marginal oilfields, and is effective for controlling the risk in the development of marginal oilfields.

Owner:CHINA NAT OFFSHORE OIL CORP +1

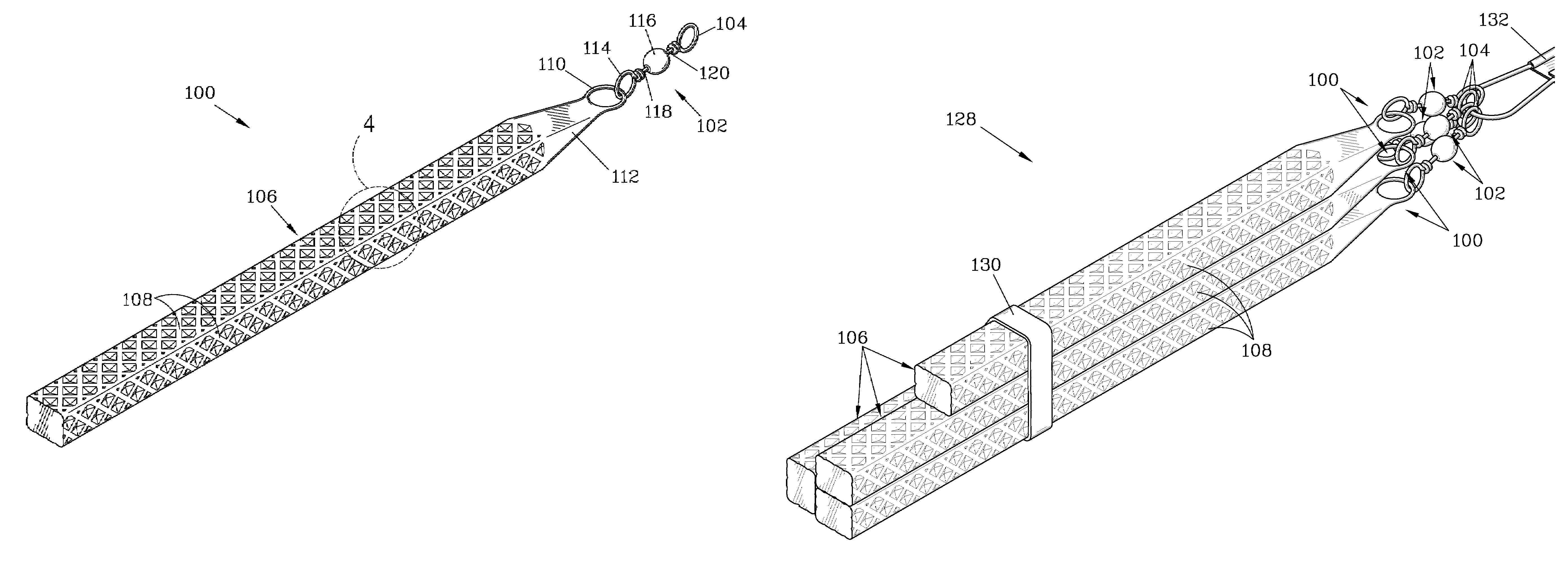

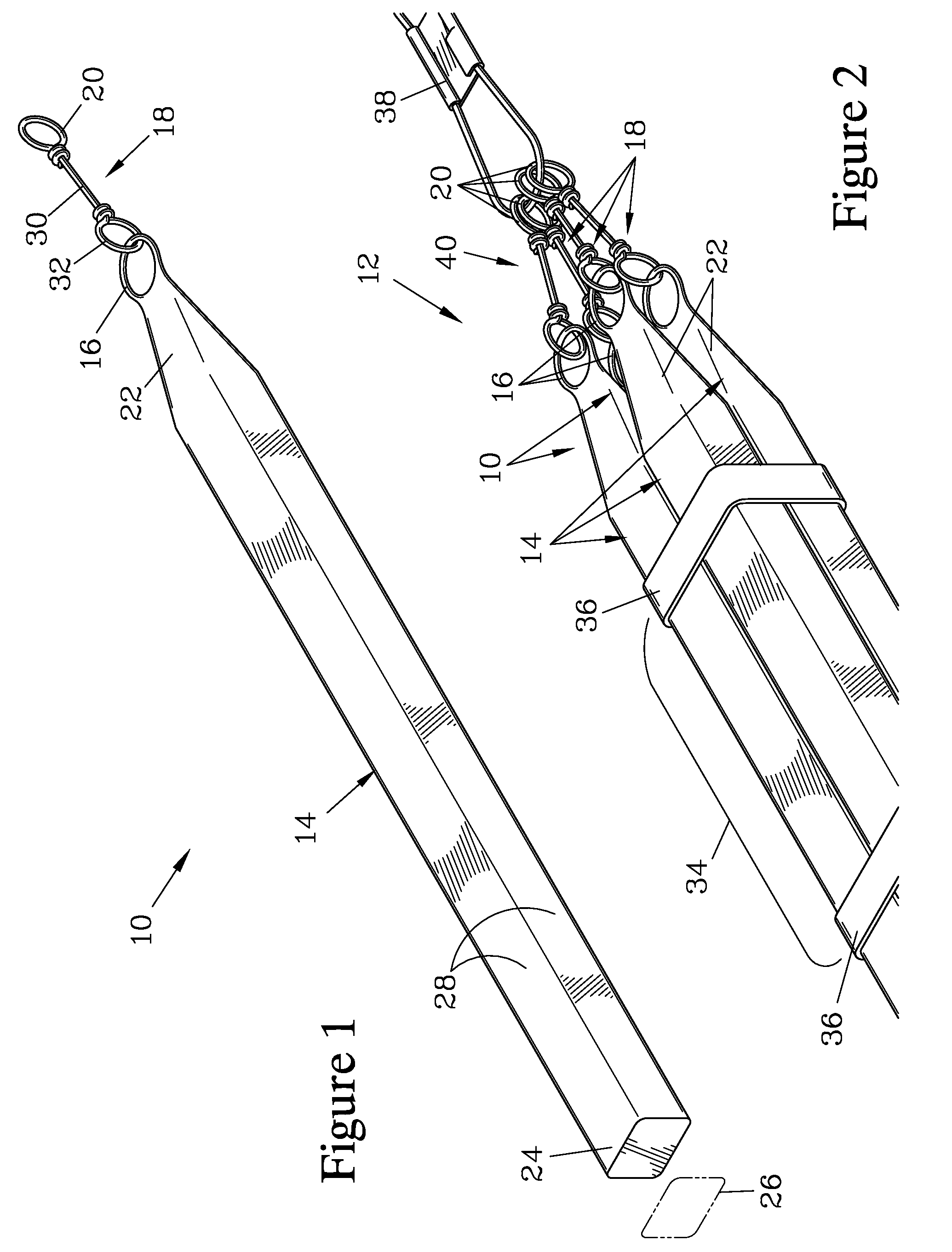

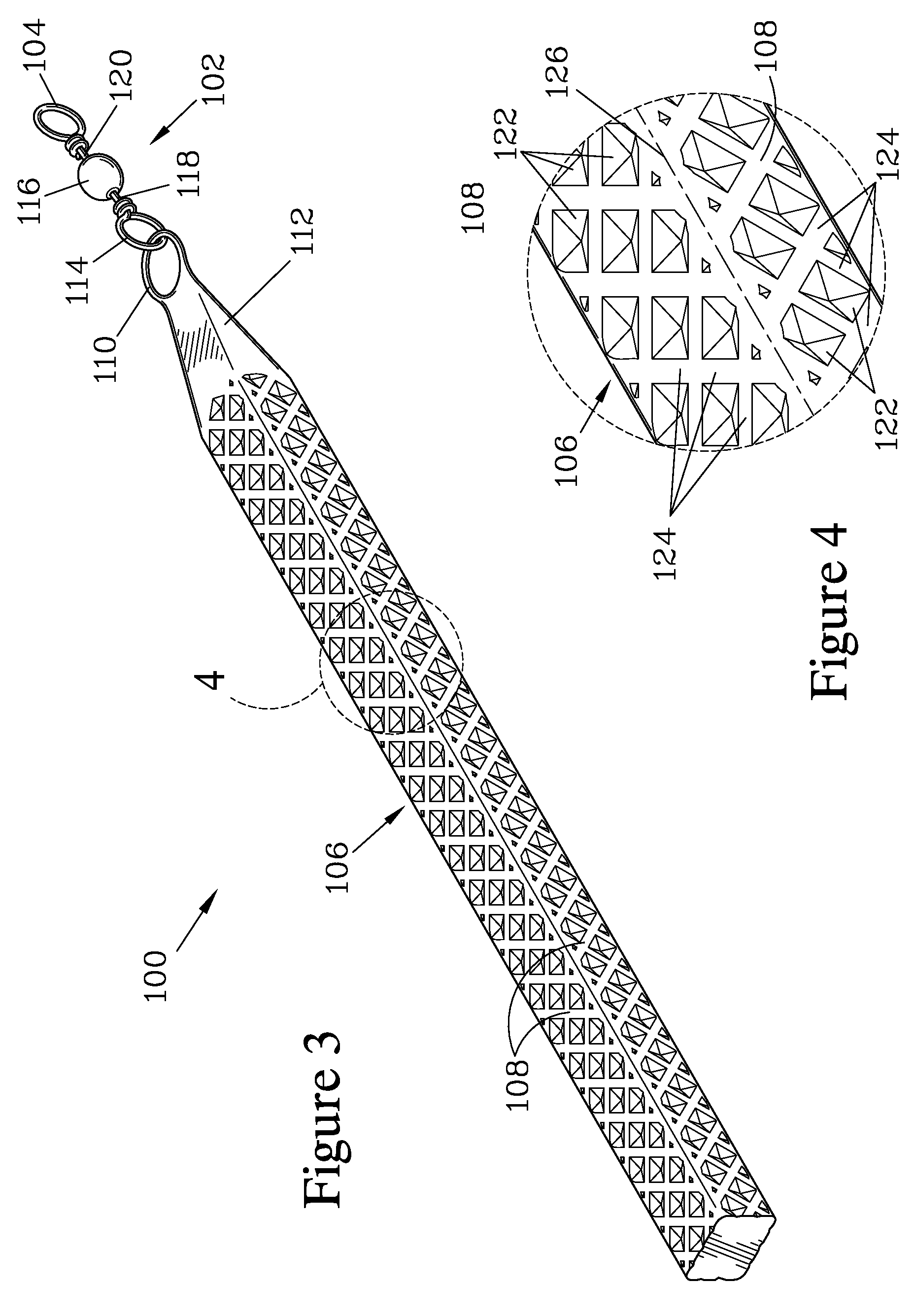

Stackable casting sinker

A number of stackable weights can be bundled together and secured with a lashing to form a modular sinker of a desired weight. Each stackable weight has an elongated bar bounded by four side surfaces and having a fixed eye. A link member is movably attached to the fixed eye and terminates in a coupling eye. The link member provides a degree of motion between the coupling eye and the fixed eye of the bar, allowing the coupling eyes of multiple stackable weights to be connected together to a single fastener while the bars are positioned together in a side-by-side relationship. When so connected, the link members form a pyramid-shaped coupling structure that will reduce the likelihood of snagging the resulting modular sinker. The bars preferably have textured side surfaces to frictionally engage each other to maintain the bars parallel and to retain an elastic band that provides the lashing.

Owner:BRASSEUR BERNARD P

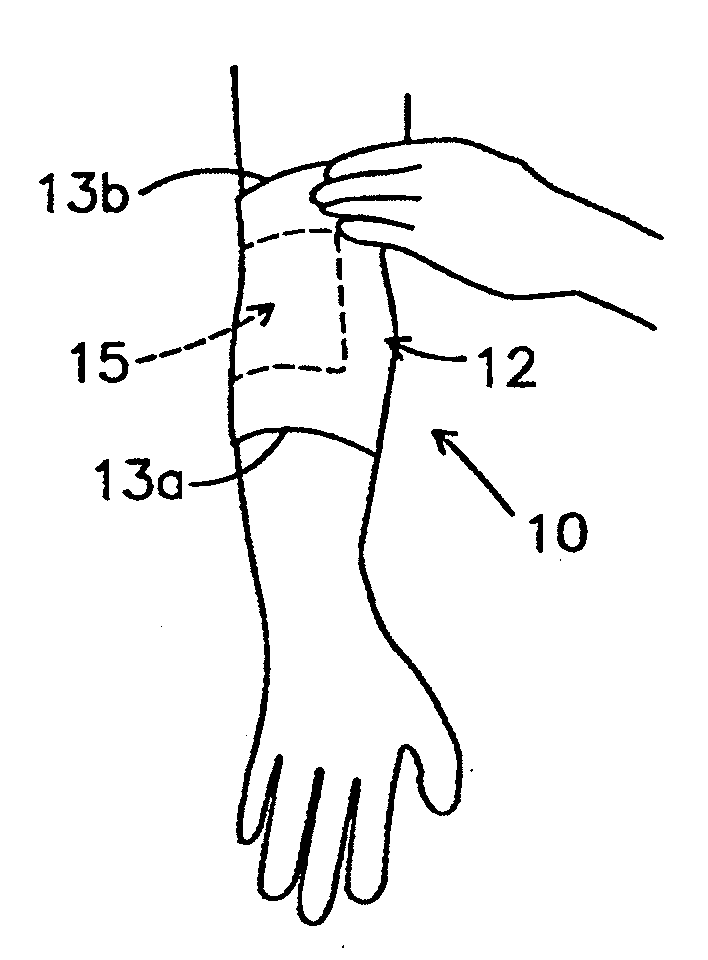

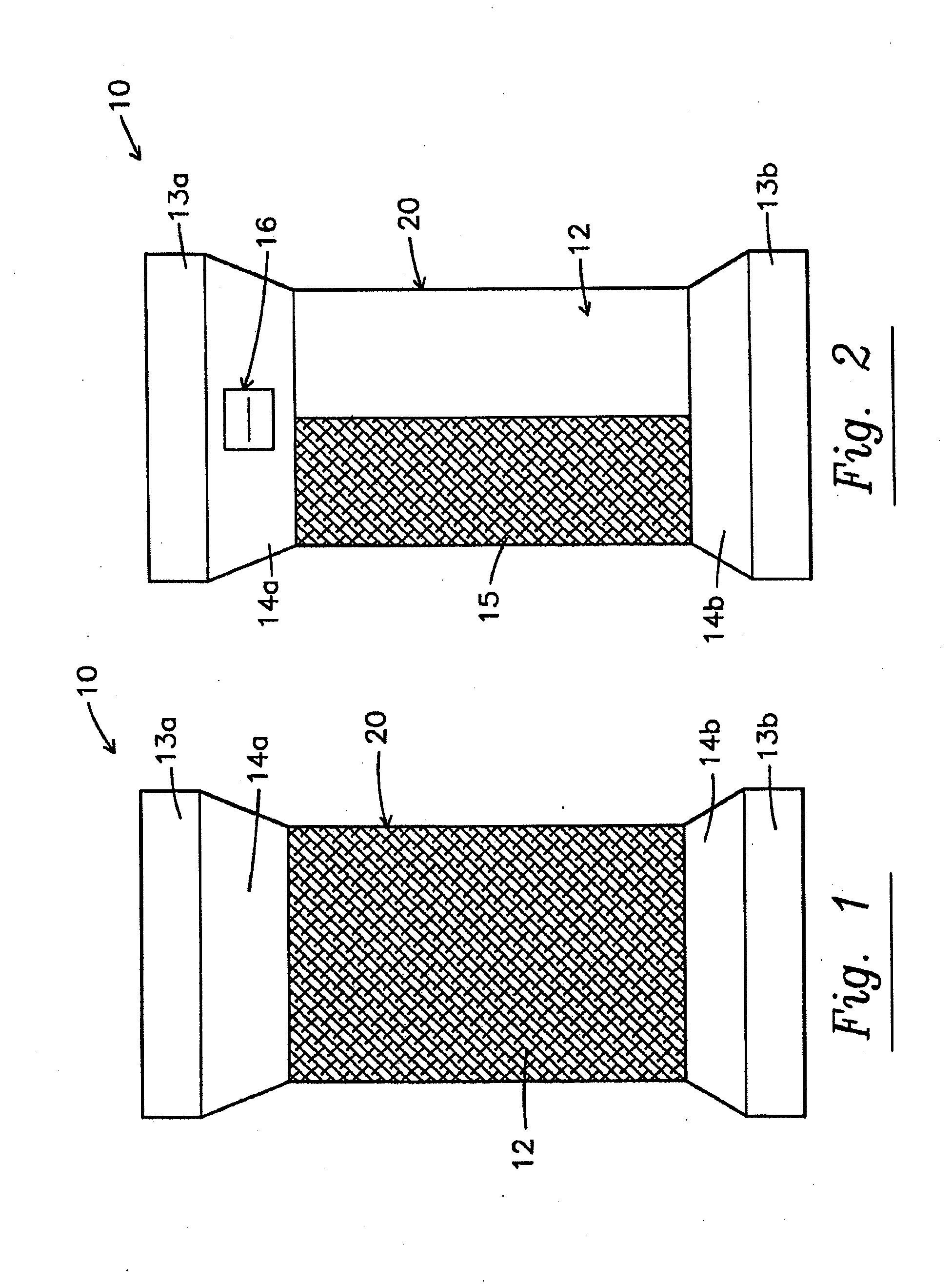

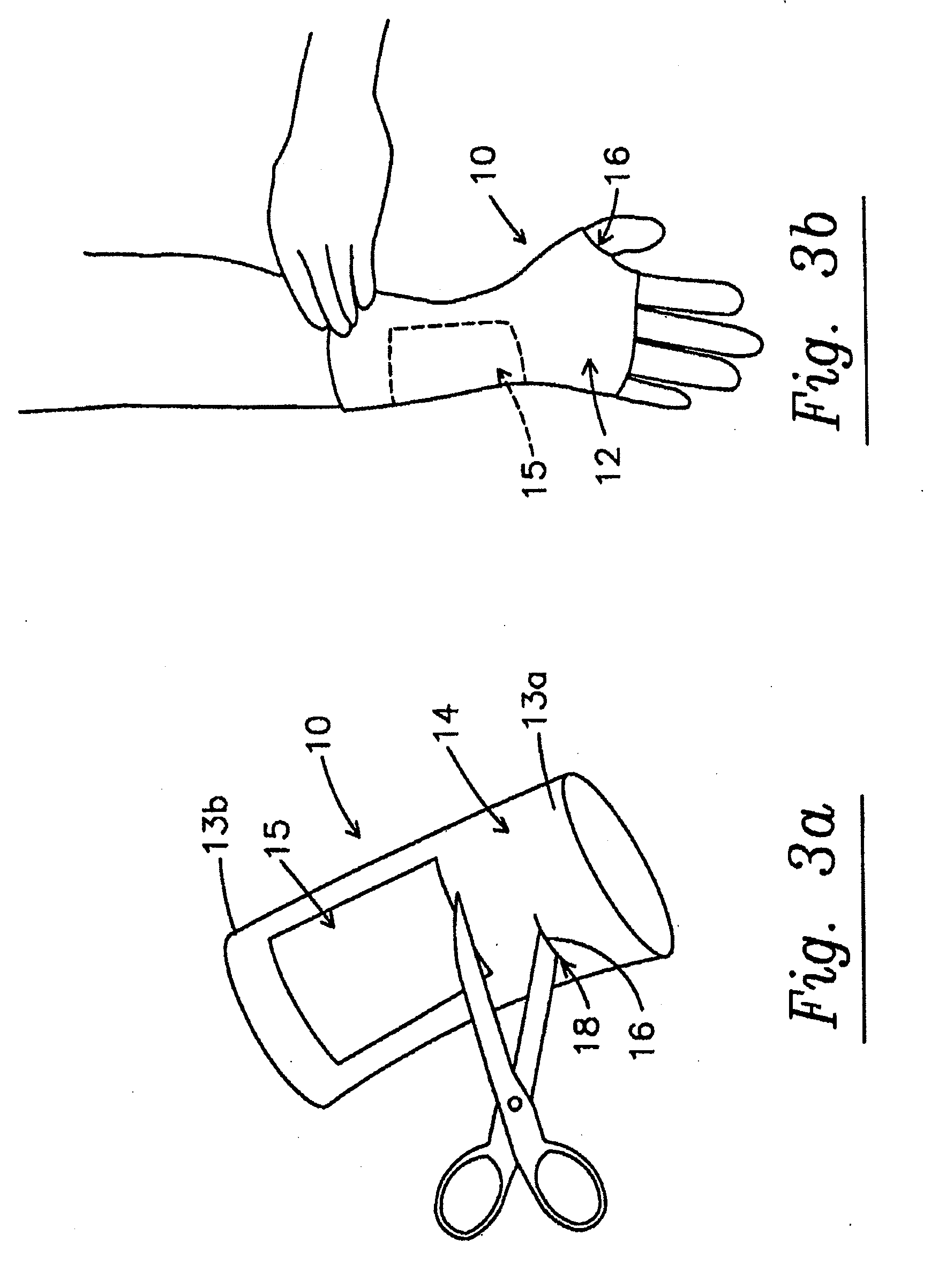

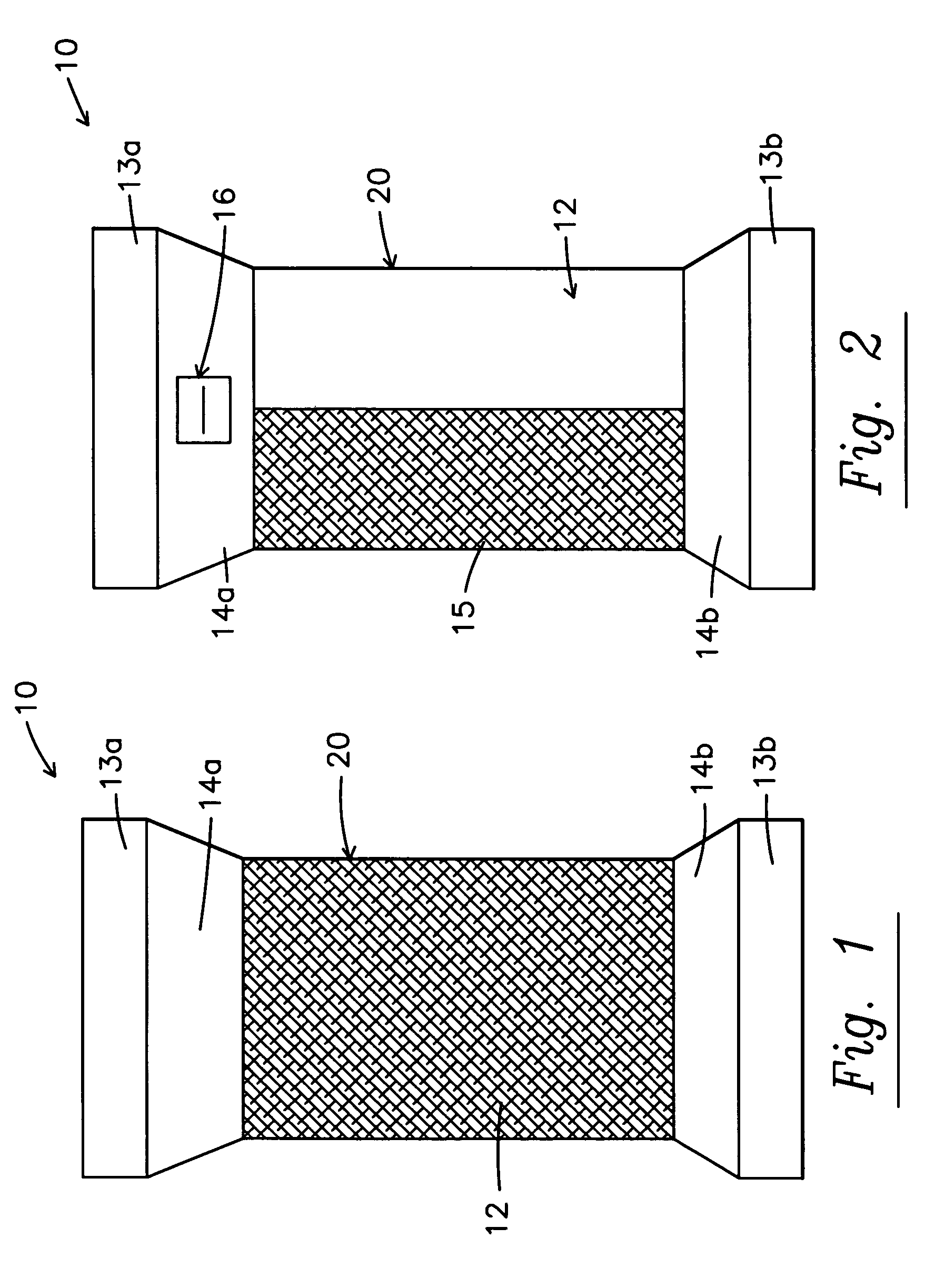

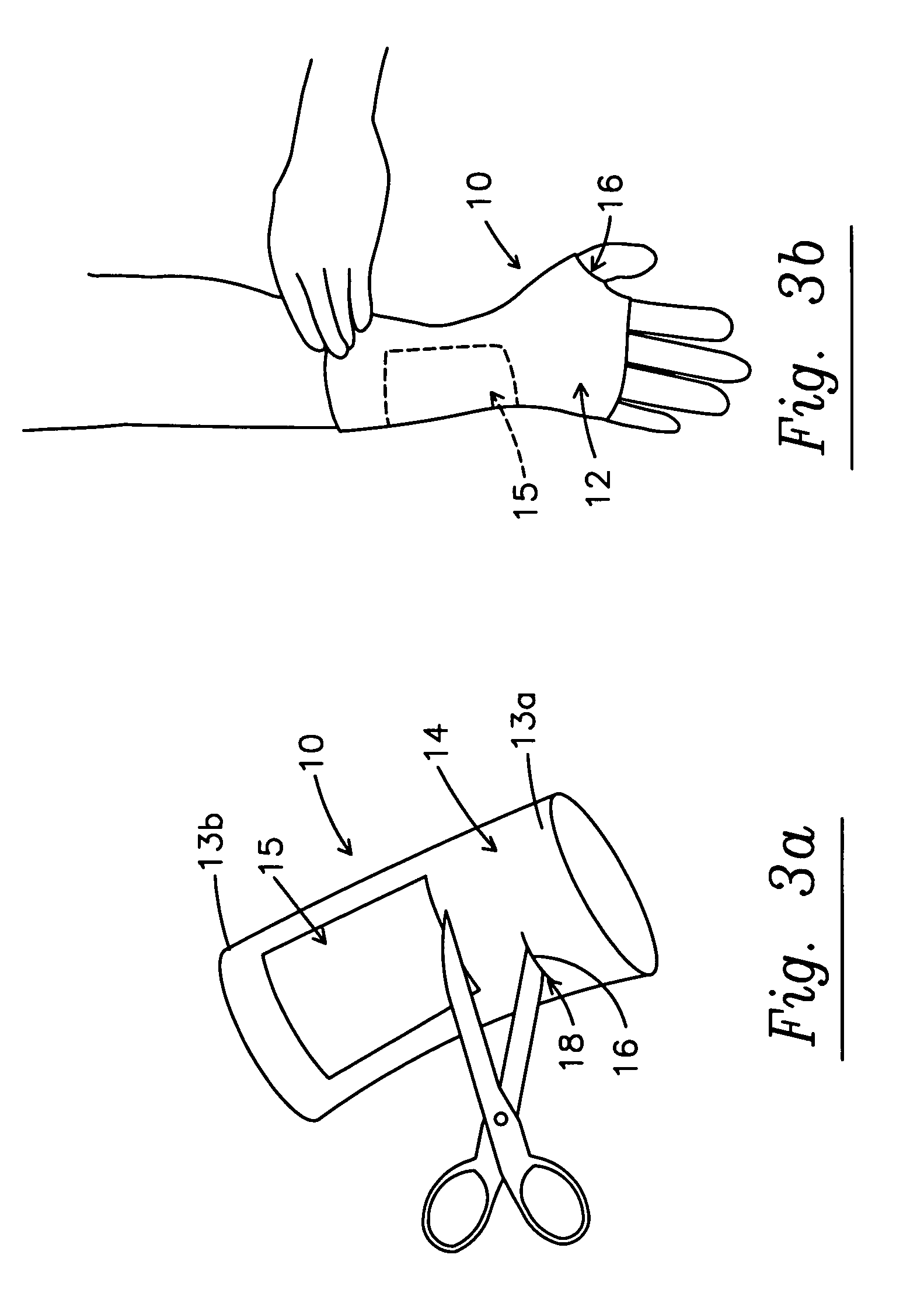

Preparation and Use of Sleeve and Micro-Encapsulated Topical Analgesic Patch For Treating Pain

ActiveUS20110004169A1Efficient use ofImprove joint functionOrganic active ingredientsAntipyreticSacroiliac jointPharmacology

Owner:CHATTEM

Safety and rescue carabiner holder

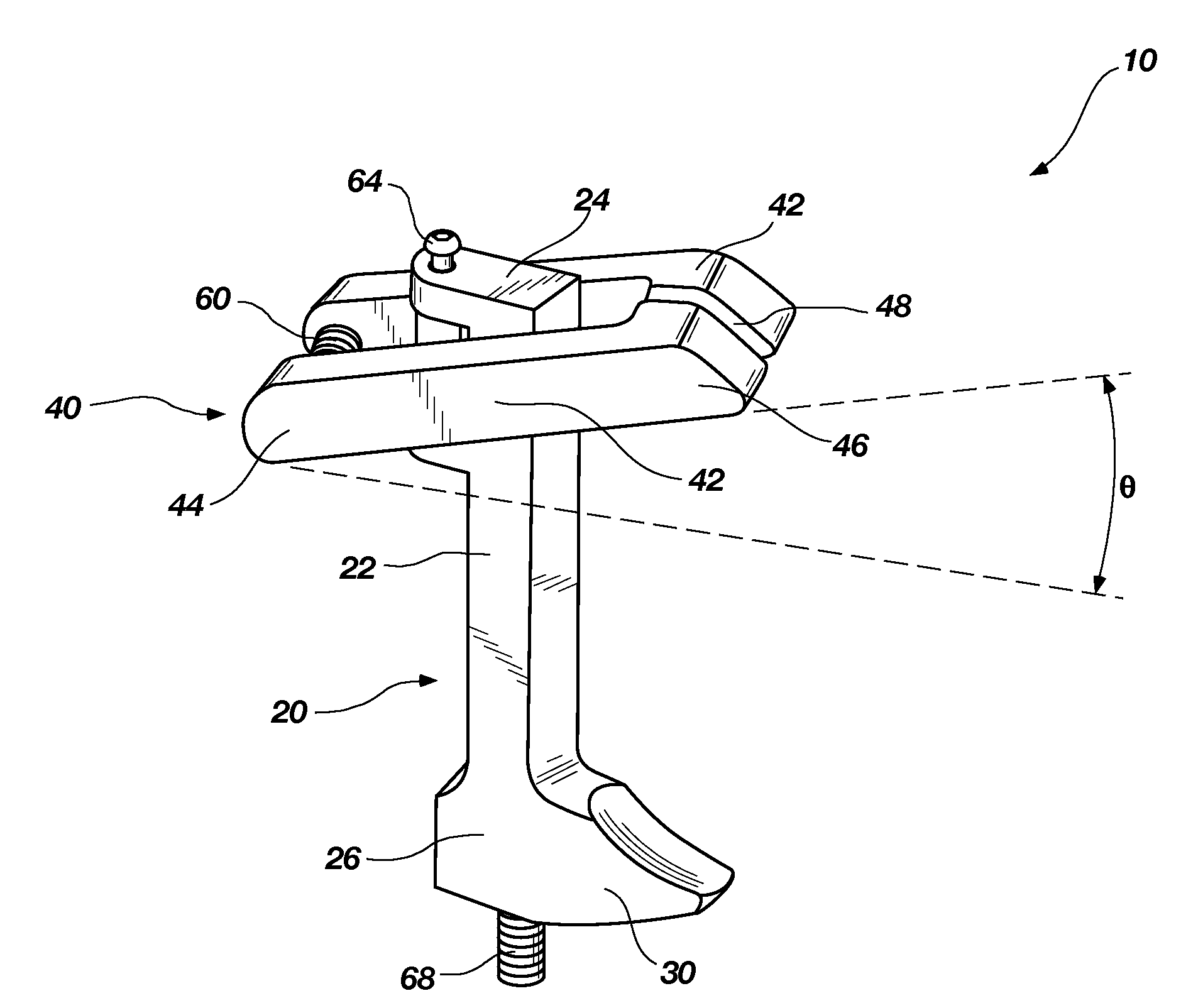

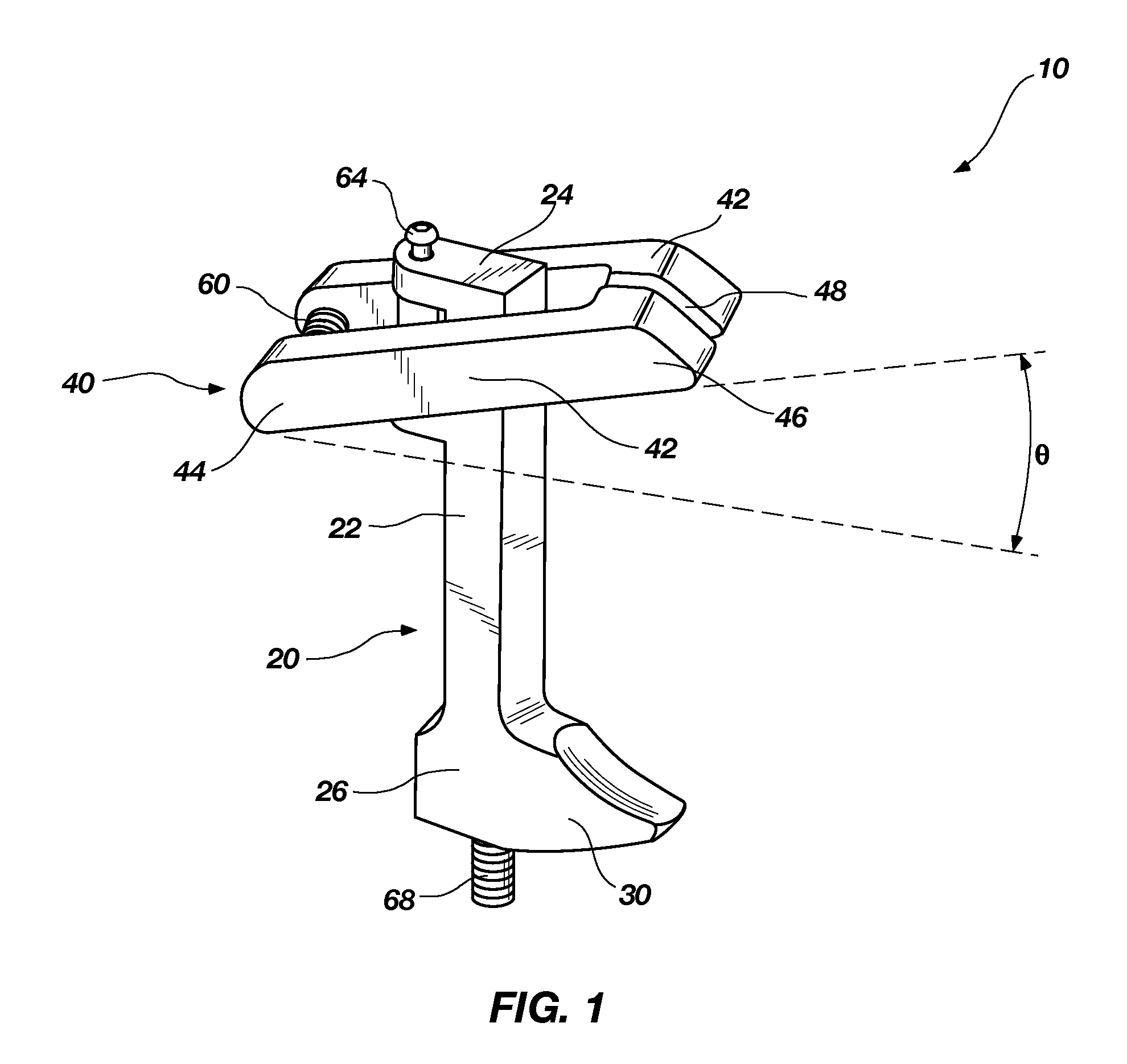

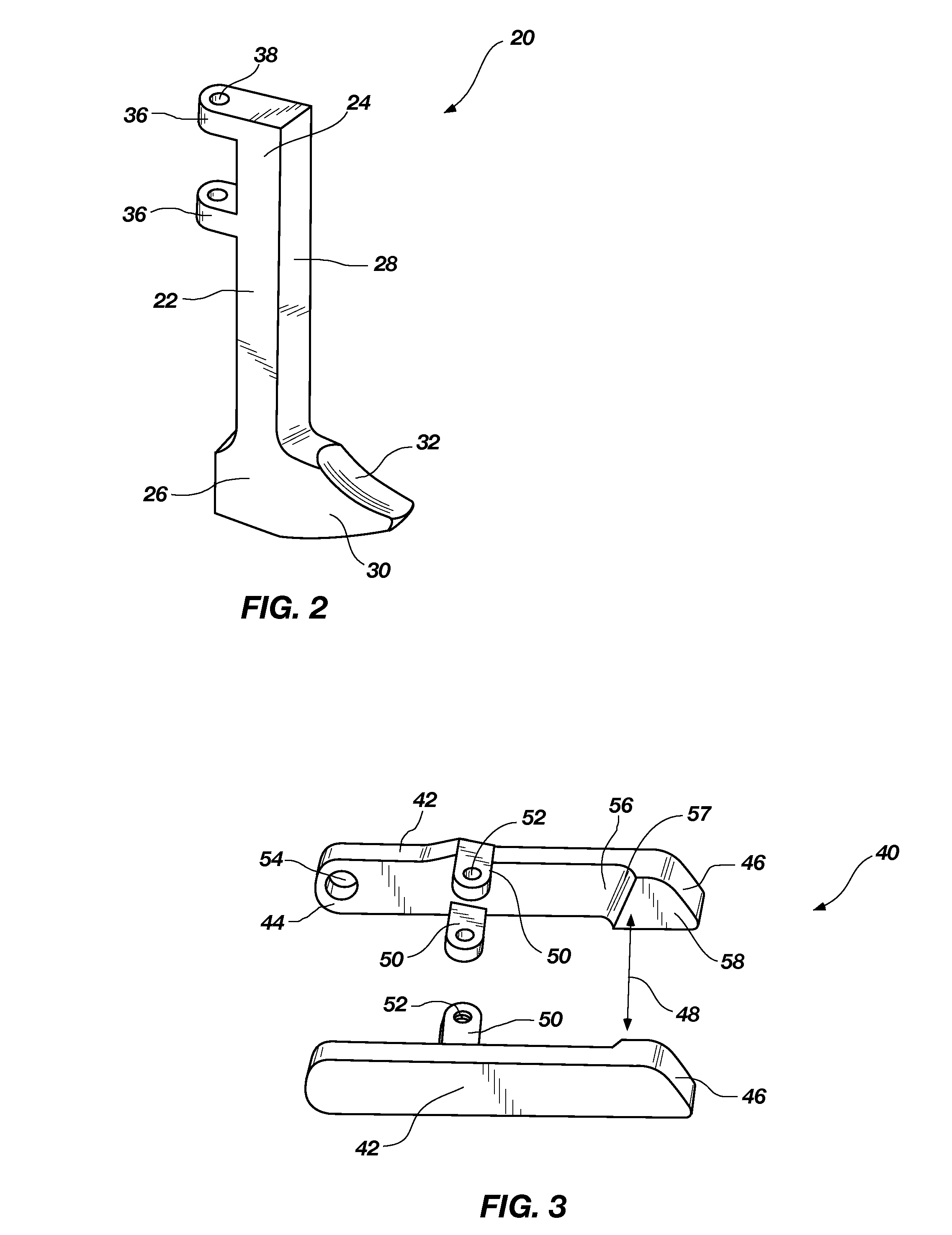

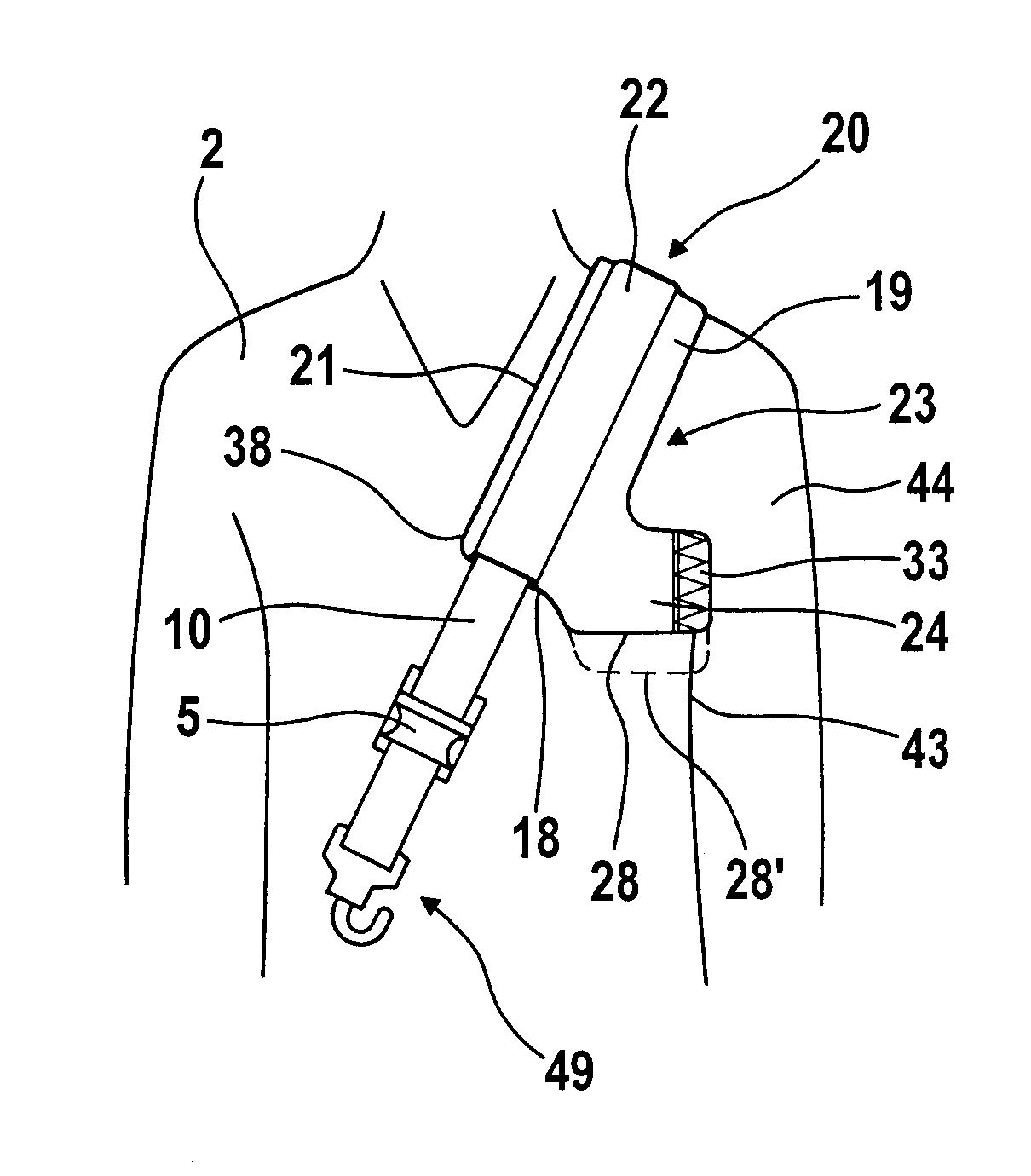

InactiveUS7571944B2Overcome deficienciesSecurely holdBreathing protectionMachine supportsEngineeringMechanical engineering

A safety and rescue carabiner holder for securing a carabiner with its gate in the open position while extending the user's reach several feet in any direction, which is also capable of supporting a long and heavy segment of attached safety rope. The carabiner holder is mounted to the end of an extension pole and includes a restraining structure that grips the bottom of the carabiner and a set of spring-loaded jaw arms that firmly clamp the spine and gate arm of the carabiner in a manner strong enough to withstand any inadvertent shaking and bouncing, ensuring that the carabiner will stay in place until hooked into a target ring and the user releases the carabiner by pulling backwards on the extension pole.

Owner:QUASAR SERVICES

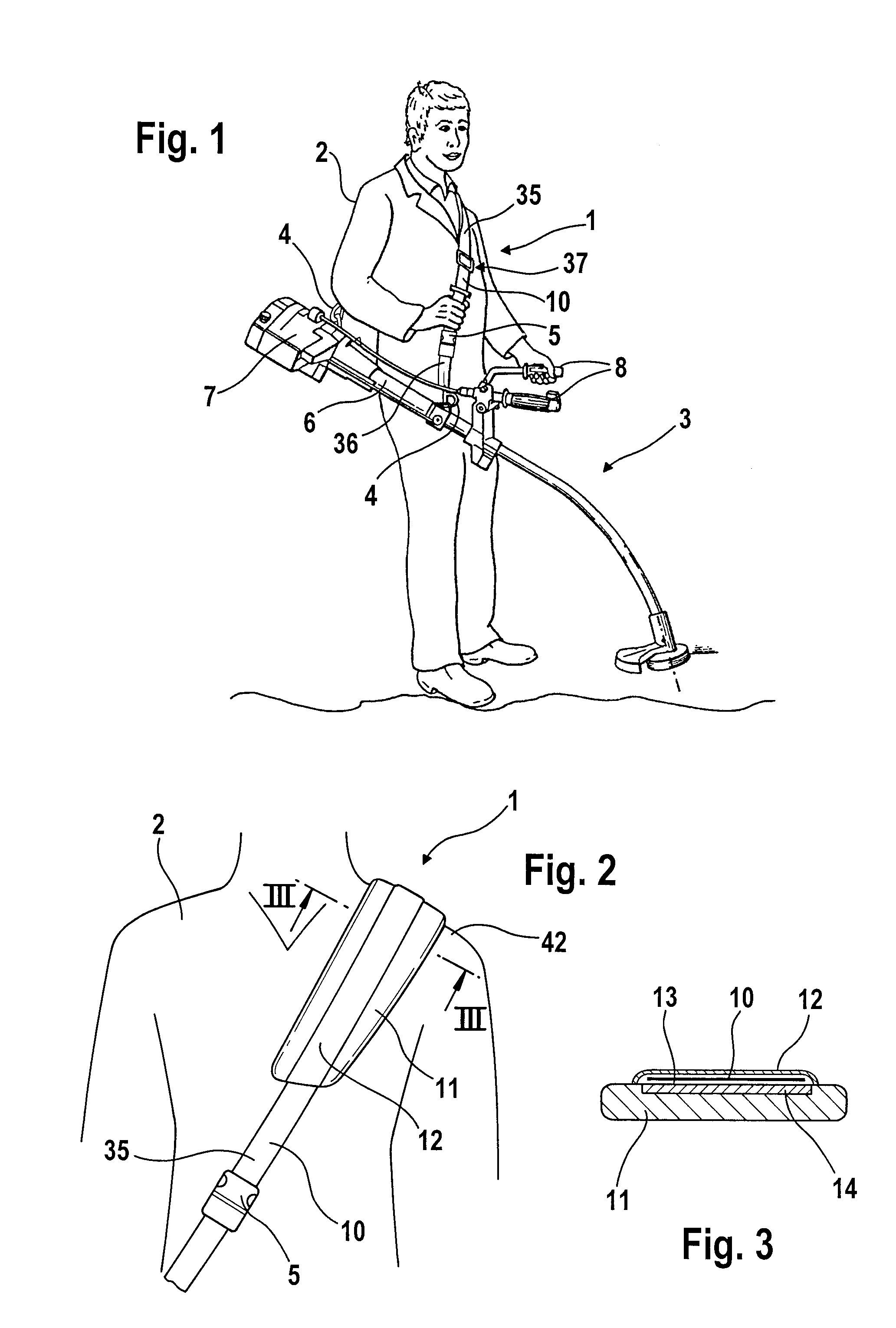

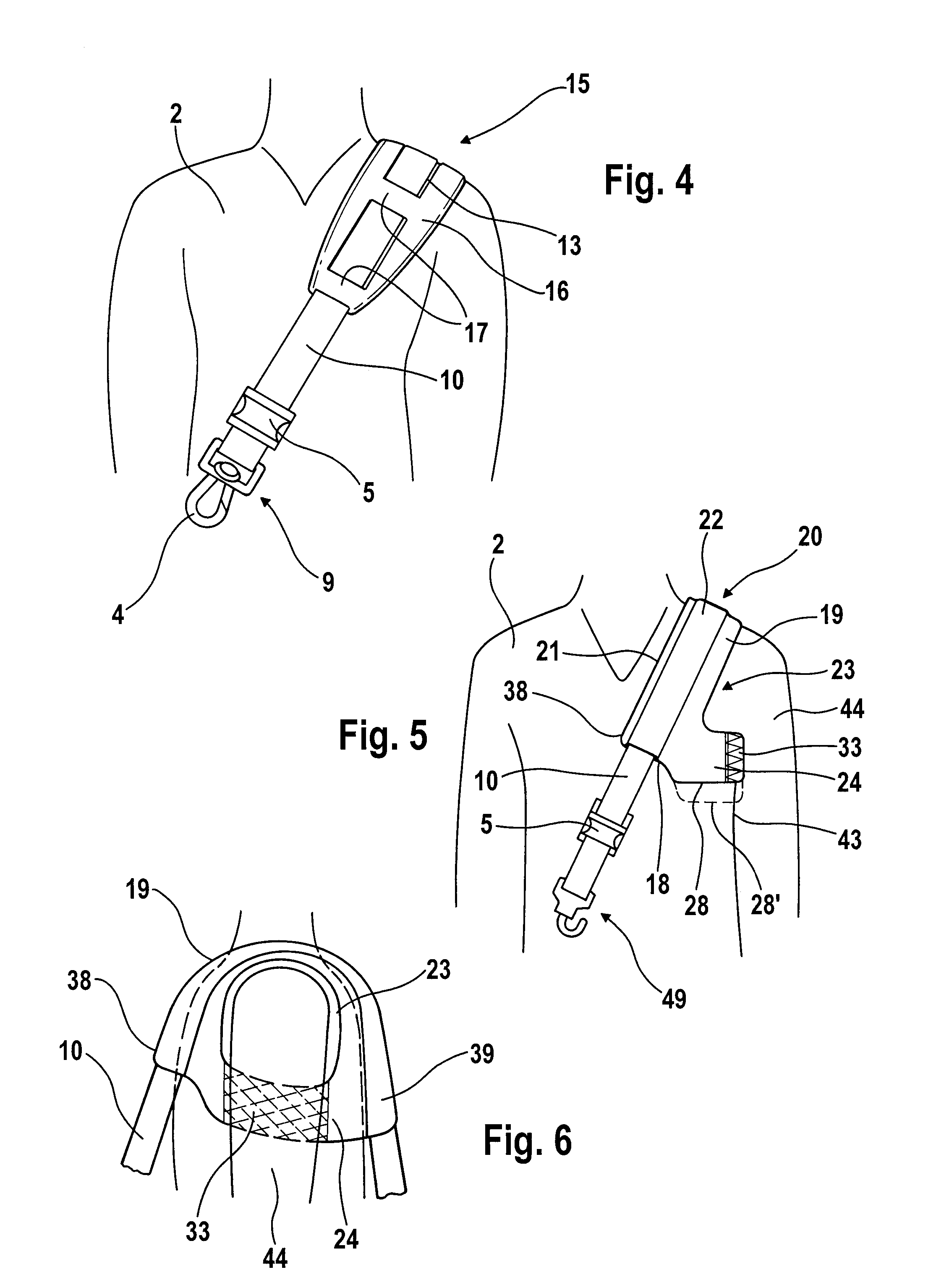

Carrying Arrangement

InactiveUS20070205237A1Impair operationReduce frictionTravelling sacksShoulder strapPower toolEngineering

A carrying arrangement for a hand-guided power tool has a carrying element to be guided across a shoulder of an operator and a shoulder support arranged slidably in a longitudinal direction on the carrying element. A friction-reducing element for reducing friction between the carrying element and the shoulder support is provided. The shoulder support has a shoulder section and a lateral support section connected to the shoulder section. The carrying element is arranged on the shoulder section and the lateral support section rests against a side of the operator. In this way, excellent force distribution during operation is ensured.

Owner:ANDREAS STIHL AG & CO KG

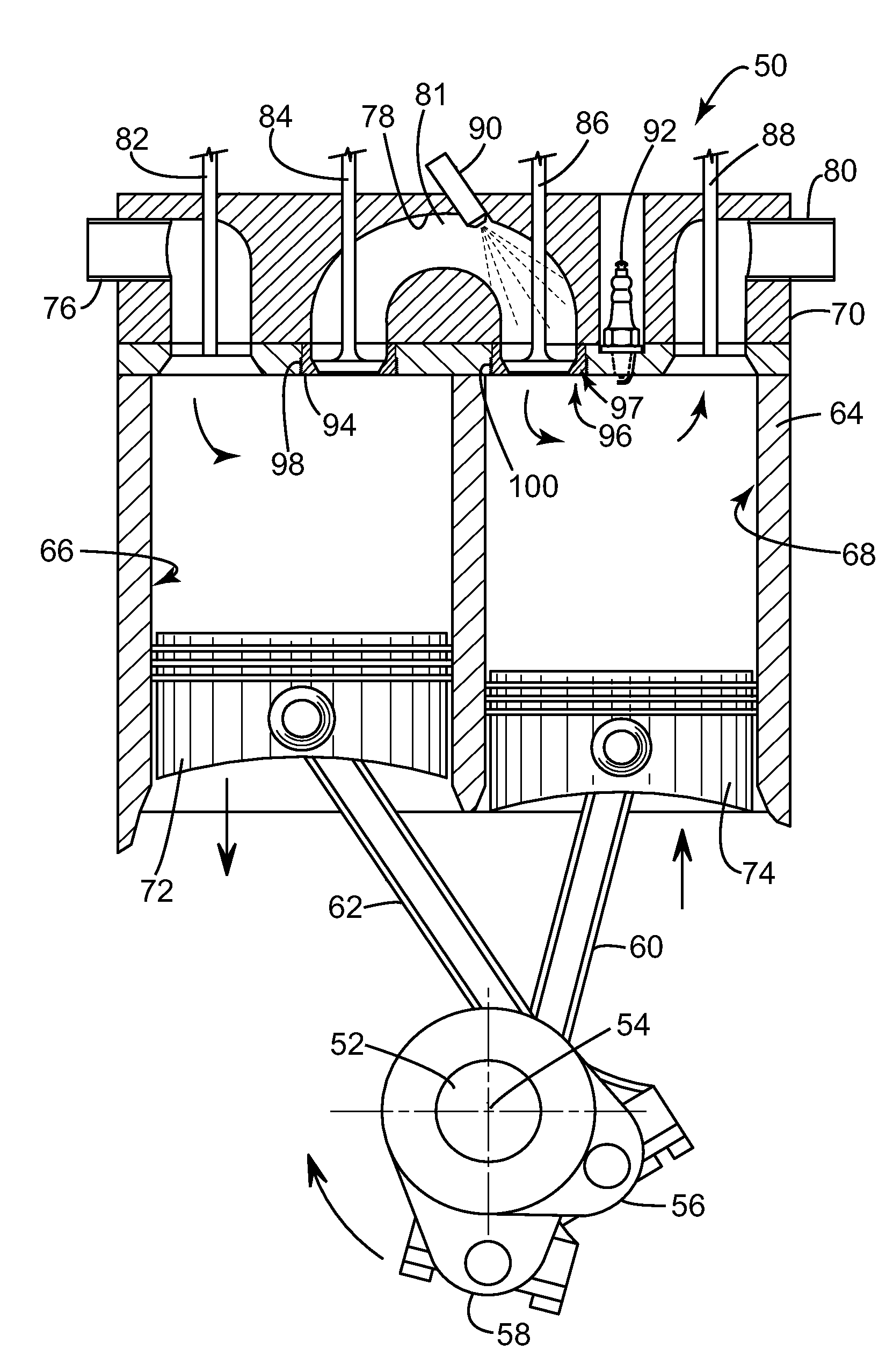

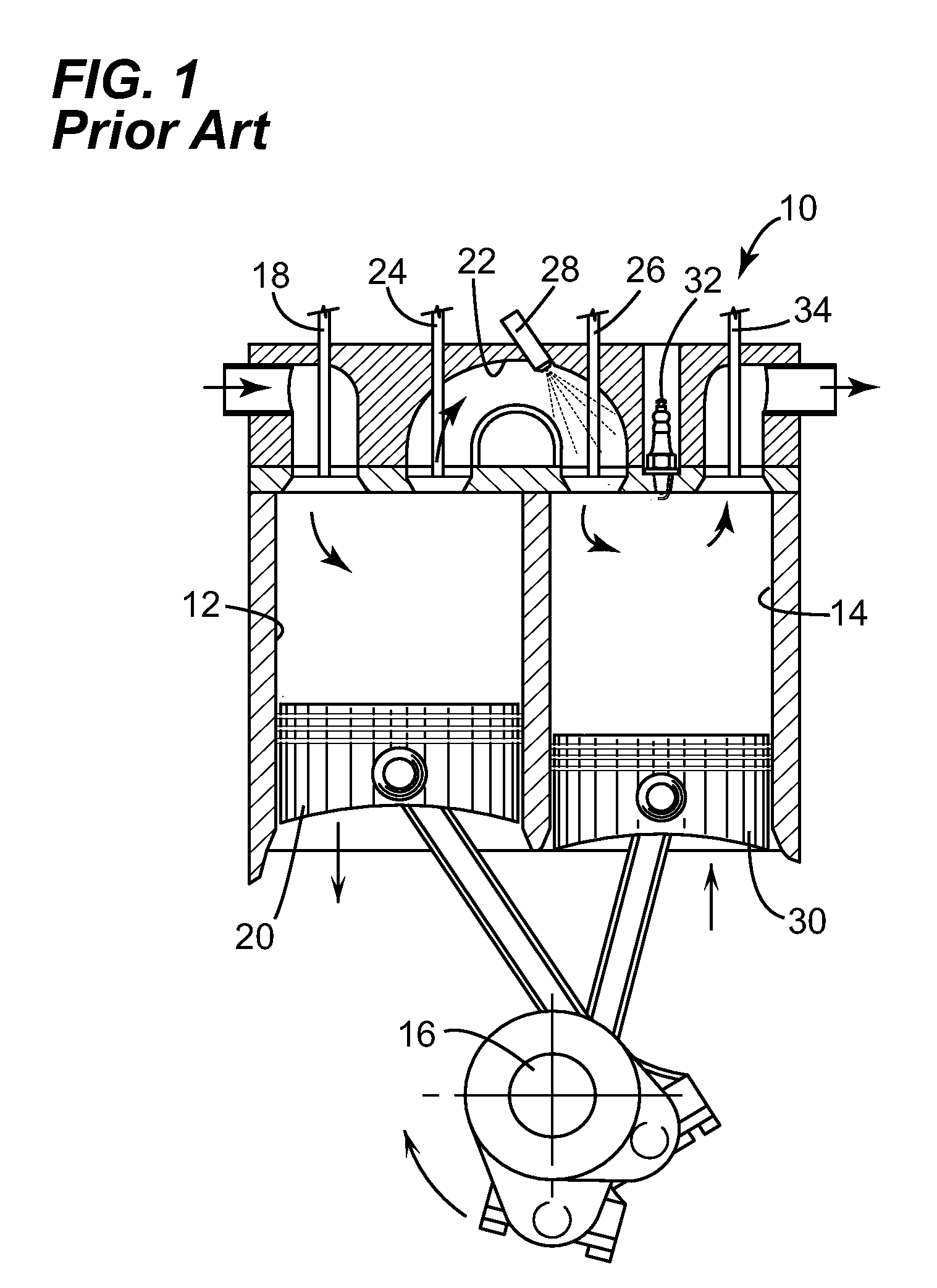

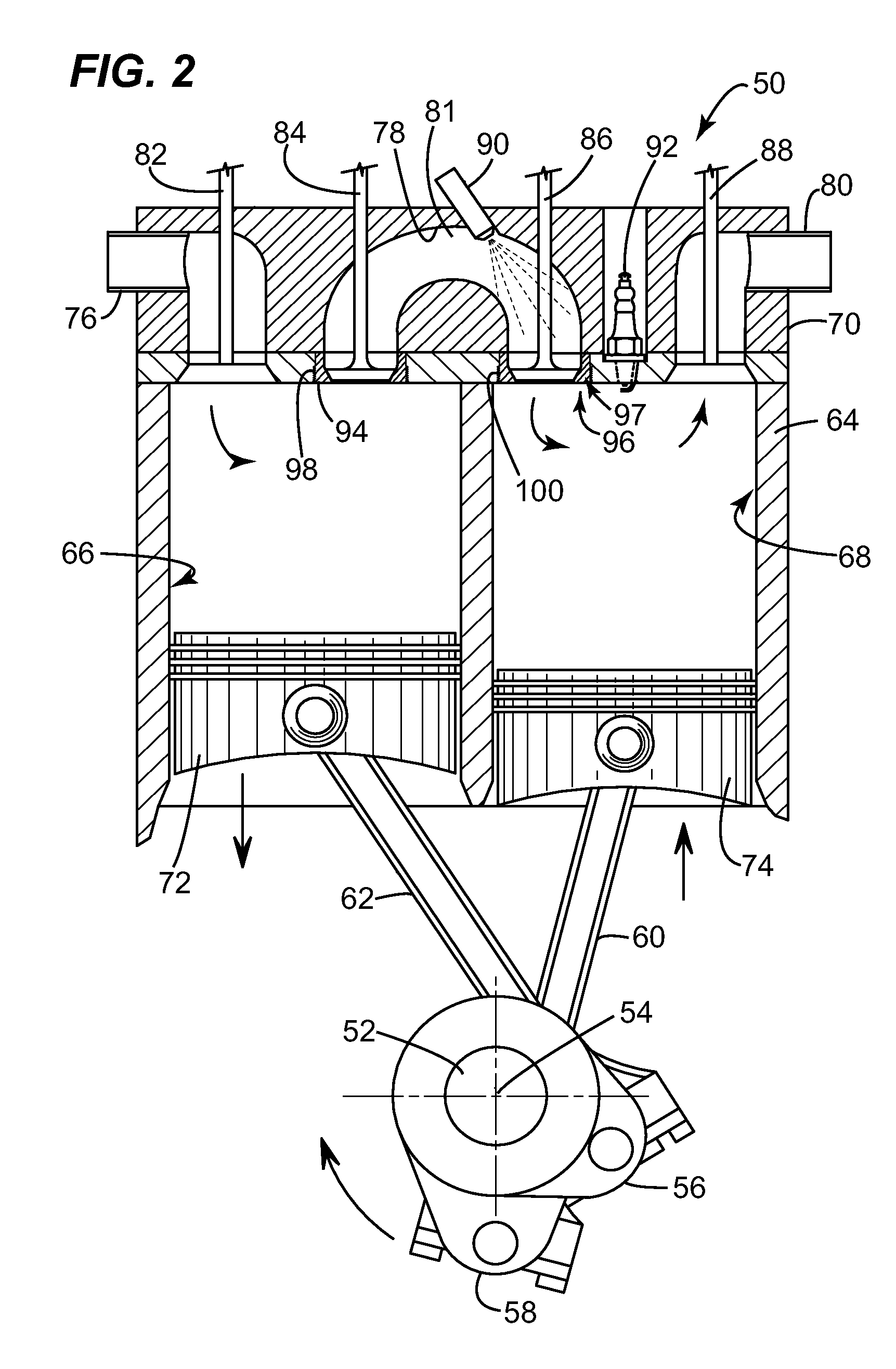

Valve Seat Insert for a Split-Cycle Engine

InactiveUS20100236533A1Stay in placeStart fastCombustion enginesLift valveInterference fitEngineering

The present invention provides an improved valve seat insert, particularly for split-cycle engines with outwardly opening crossover valves. The improved valve seat insert combines an interference fit section with a threaded section. The interference fit section aligns a valve seat and can prevent rotation of the valve seat insert. The threaded section prevents axial movement of the valve seat insert.

Owner:SKADERI GRUP LLC

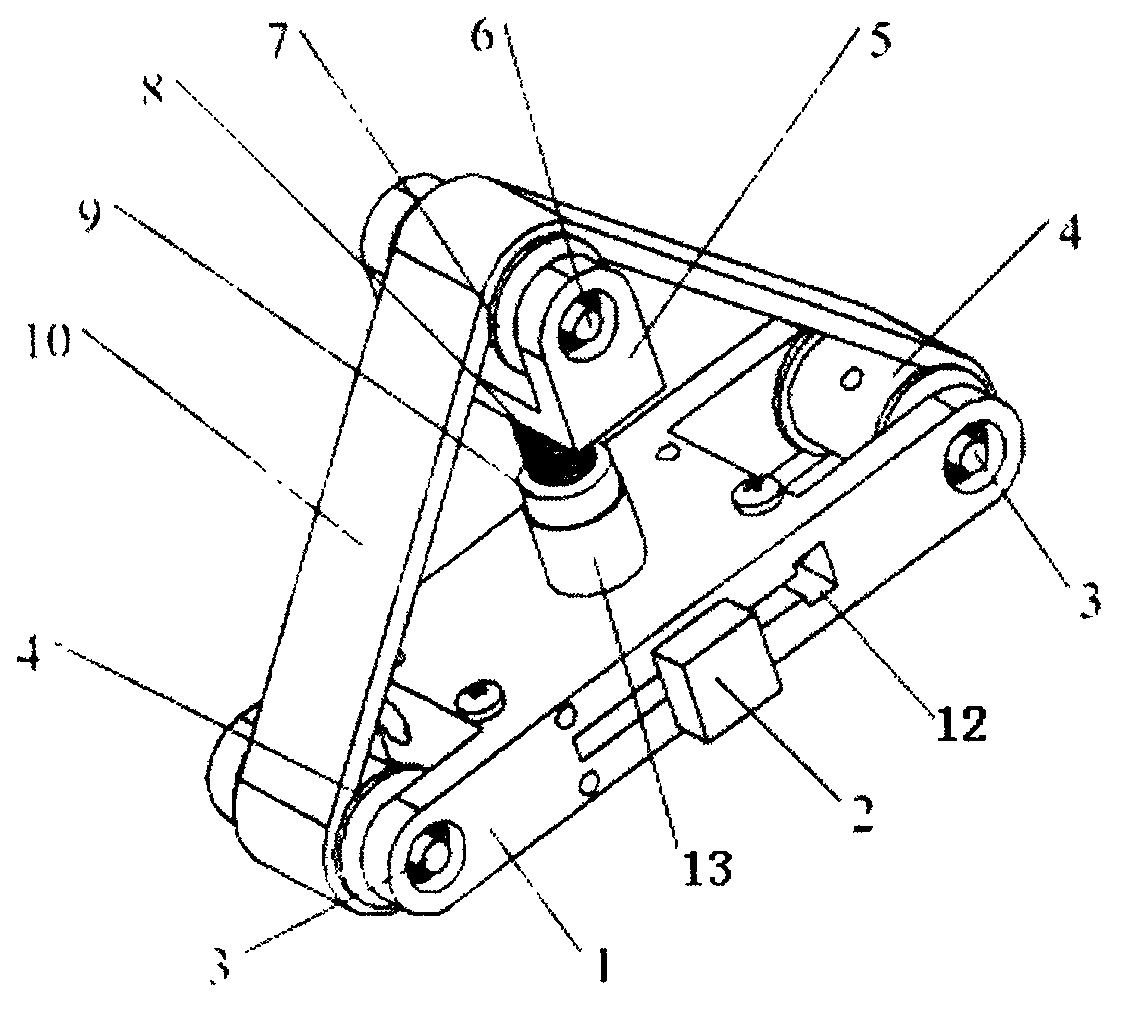

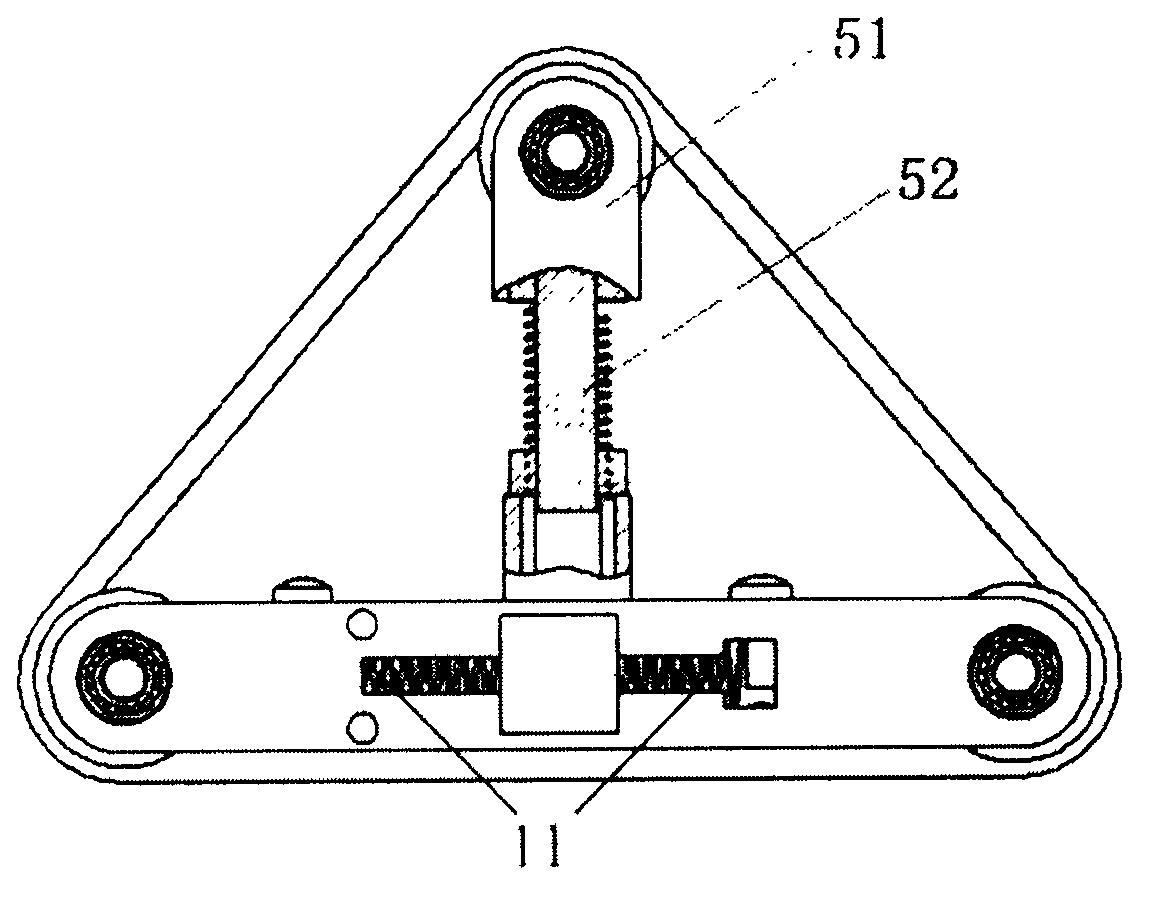

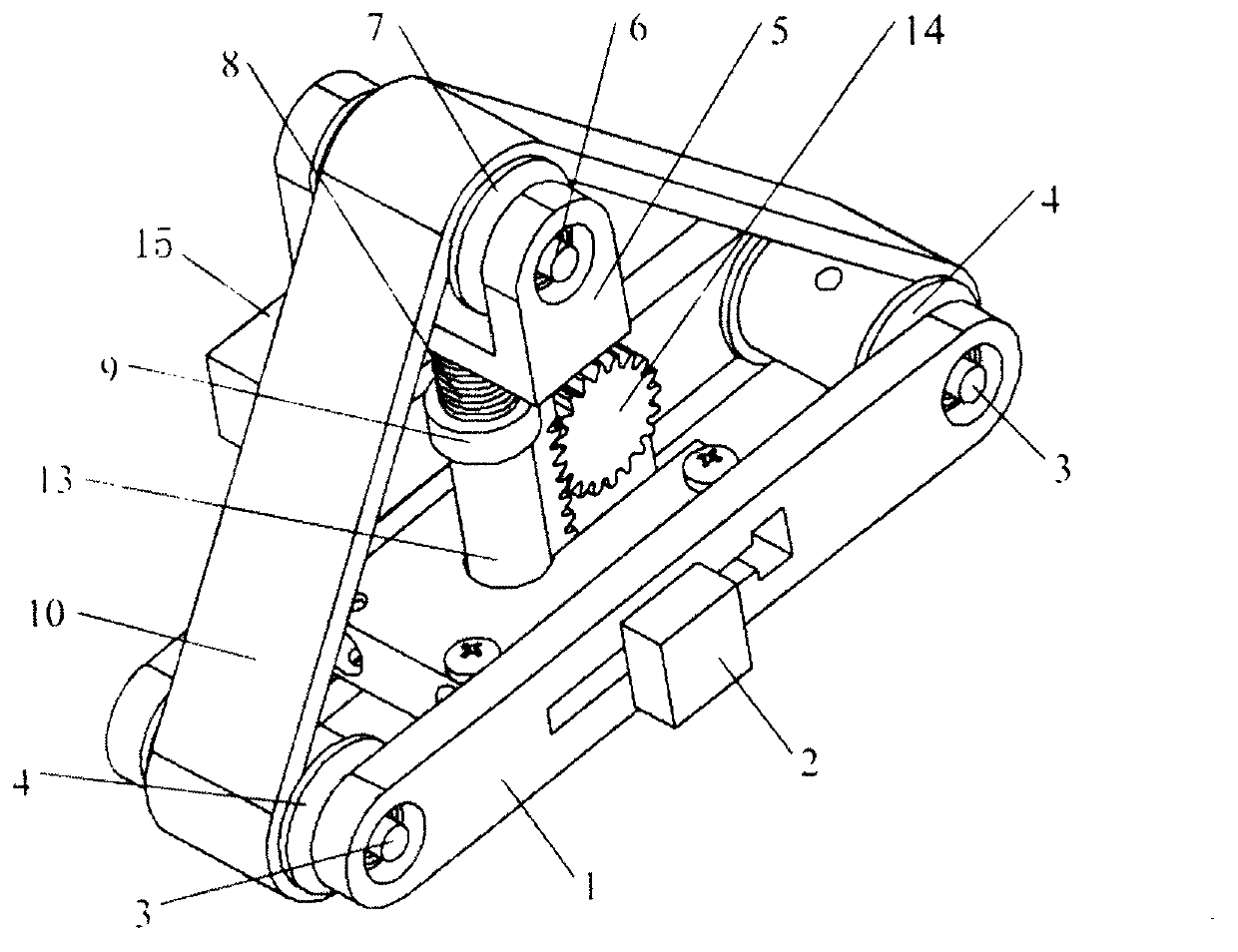

Sole structure of crawler-type bionic wall-climbing robot and motion method thereof

InactiveCN103847823AAchieve adhesionReal-time feedbackEndless track vehiclesBionicsTangential displacement

The invention discloses a sole structure of a crawler-type bionic wall-climbing robot. The sole structure comprises a body frame, rolling wheels, a tension mechanism, an adhesion crawler belt and a driving mechanism, wherein the rolling wheels are arranged at the two ends of the body frame through rolling wheel axles; the tension mechanism comprises a tension wheel frame, a tension spring, a micro force sensor, a tension wheel and a sleeve; the sleeve is arranged on the upper surface of the body frame; the micro force sensor is arranged on the upper surface of the sleeve; the tension wheel frame comprises a shaft extension and a mounting end; the lower end of the shaft extension passes through the micro force sensor and the sleeve; the shaft extension is sleeved with the tension spring; the tension spring is arranged between the micro force sensor and the mounting end; the tension wheel is arranged at the mounting end through a tension wheel axle; the tension wheel is connected with the rolling wheels through the adhesion crawler belt; the driving mechanism is arranged on the body frame. Certain tangential displacement and posture angles are output by a robot body, so that adhesion, detachment and pressing of the sole are realized, and the robot is helped to walk and stop on a wall face.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

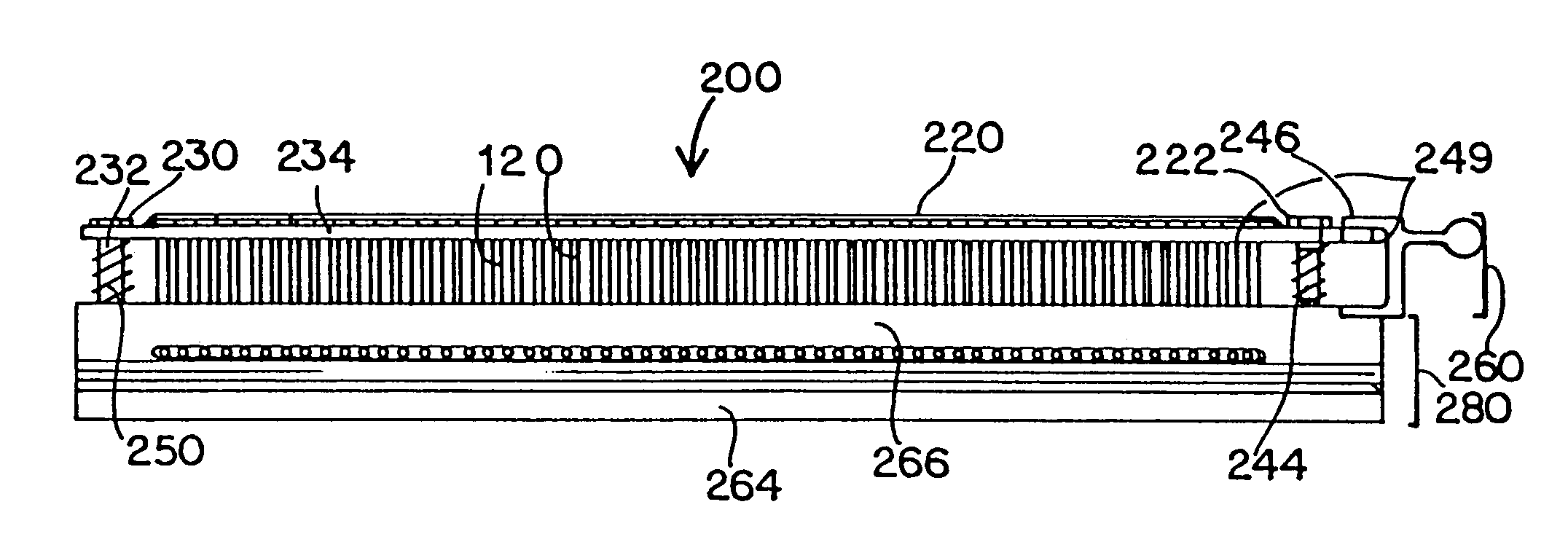

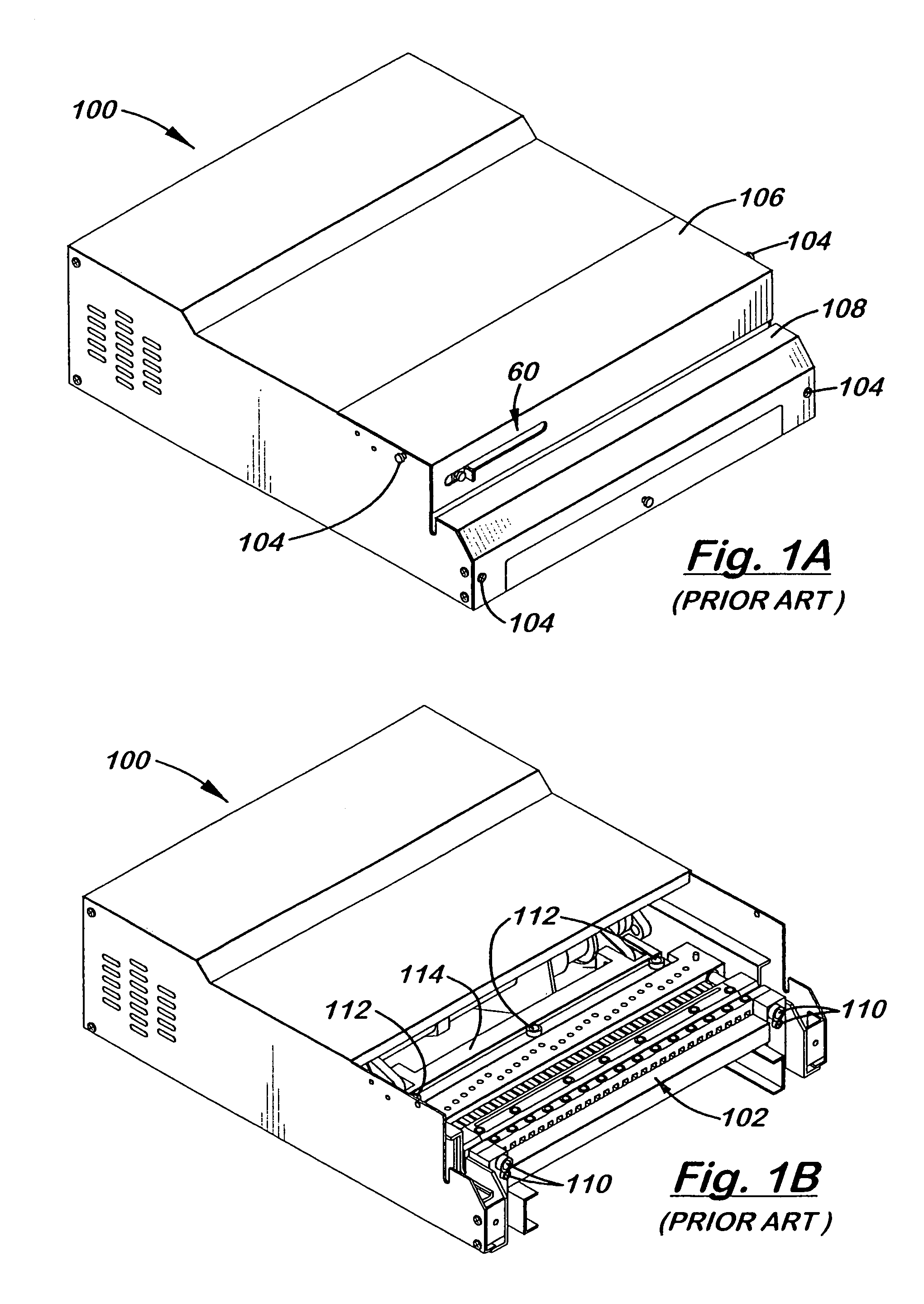

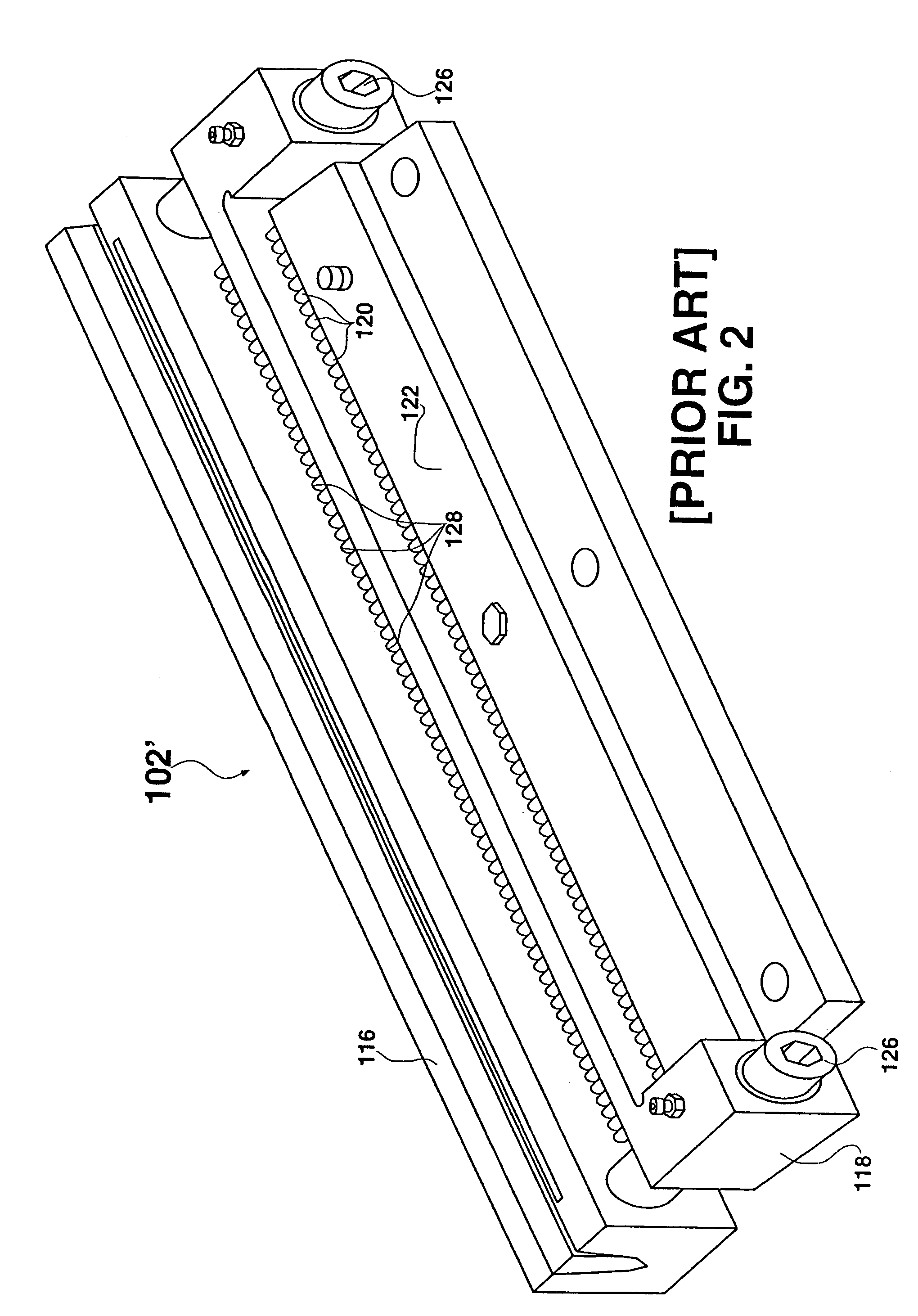

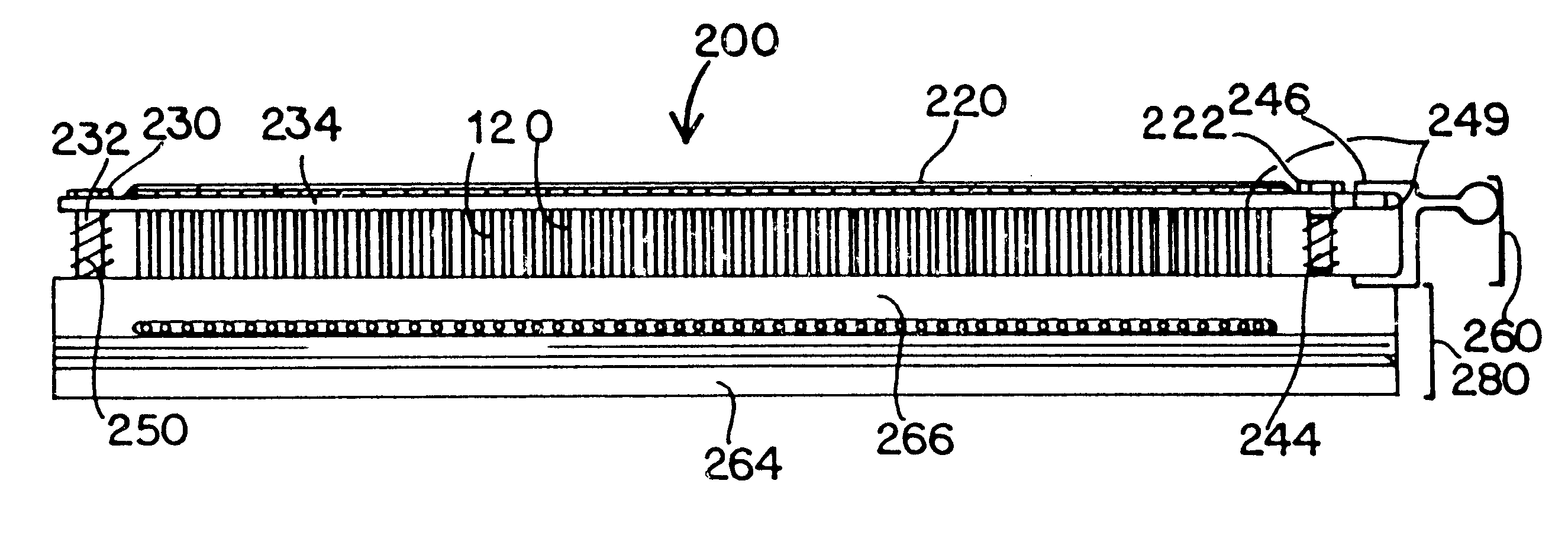

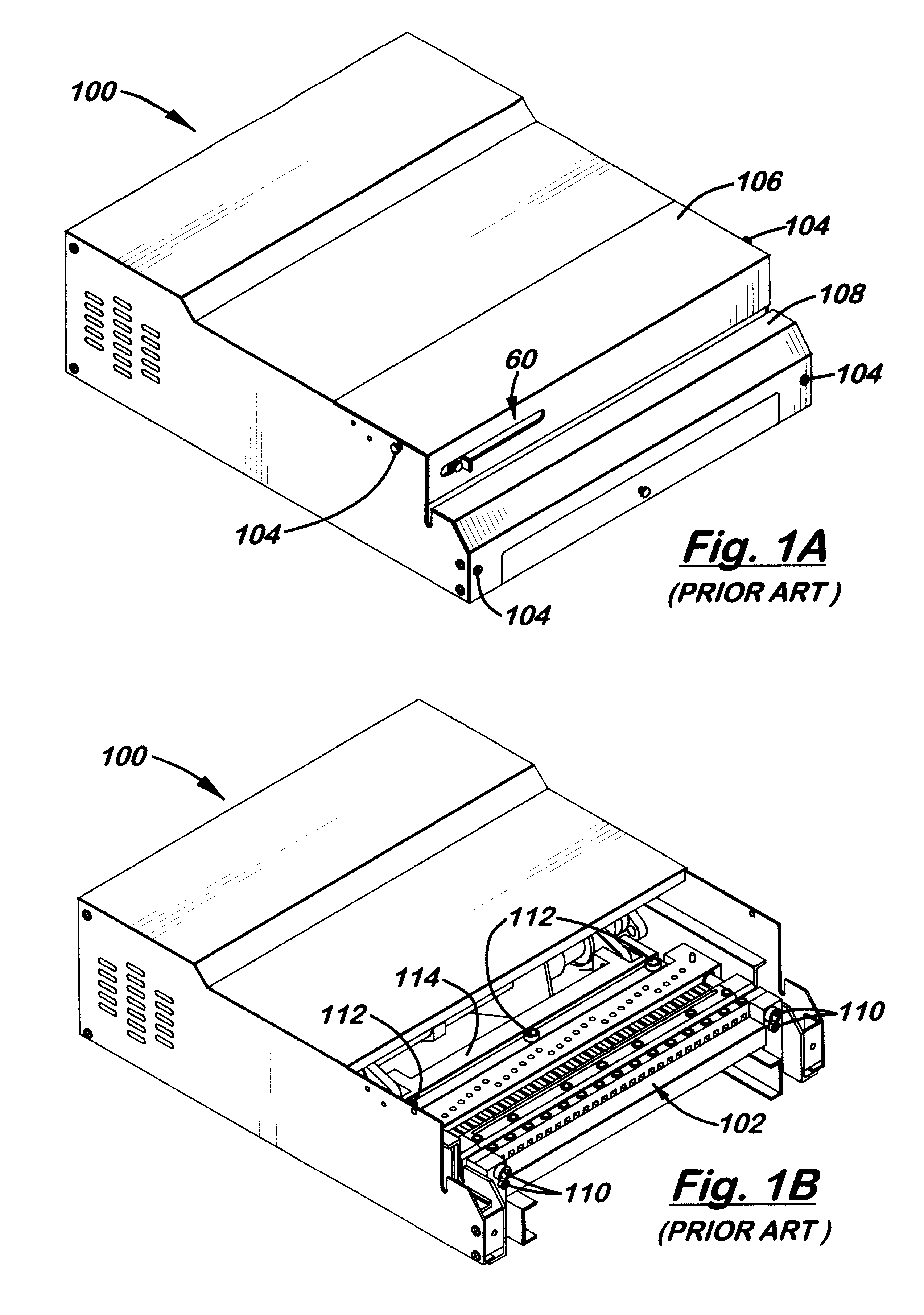

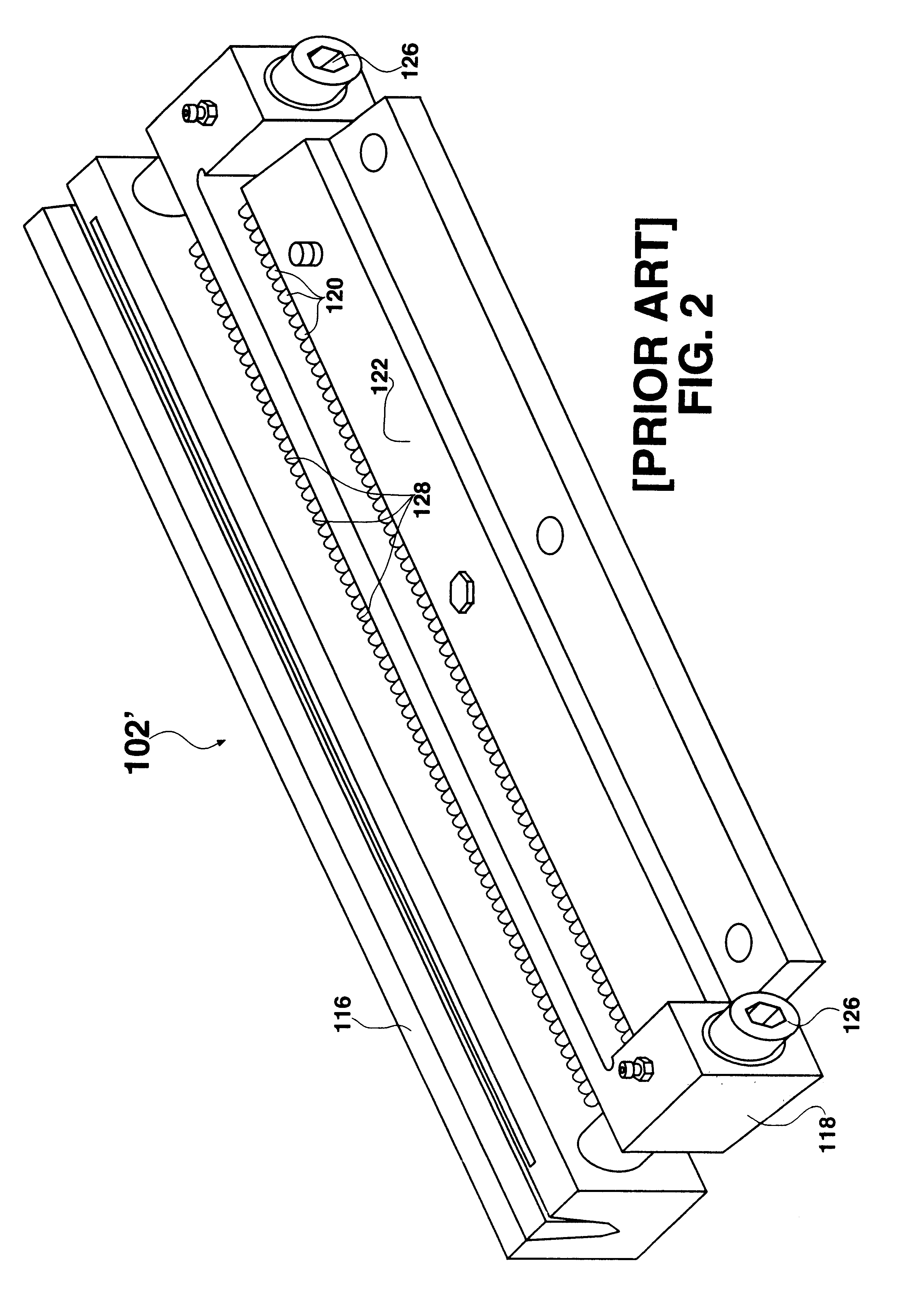

Hole punch quick-change die assembly with pin strap and positioning system

InactiveUS7036416B2Easily be reinsertedStay in placePerforating toolsMetal working apparatusPunch pressEngineering

Embodiments of an punch machine and a quick-change die assembly are shown and described. The die assembly may be quickly installed and removed from the punch machine, without bolting or unbolting of either machine housing or the die assembly itself. The die assembly is slid into the machine through a hole in the machine housing and into a position which mates part of the die assembly with the push-bar. A clamp, with a handle outside the machine, is then pivoted against the die assembly. The push-bar is adapted to be self-supporting without being bolted to the die assembly, keeping the push-bar in place without manual adjustment and alignment. The die assembly preferably includes a die, pin retainer, and punch pins, and preferably includes a flexible, pivotal, or hinged pin strap to secure the pins to the retainer. The preferred die assembly includes a positioning system that biases the pin retainer with its pin heads out from the die a proper distance for easy and unobstructed sliding into the machine housing and into a channel of the bar that drives the die assembly. The die assembly preferably includes a system for consistent referencing between various die assemblies, for reducing the instances in which the paper stop must be adjusted when a die assembly is changed.

Owner:PERFORMANCE DESIGN LLC

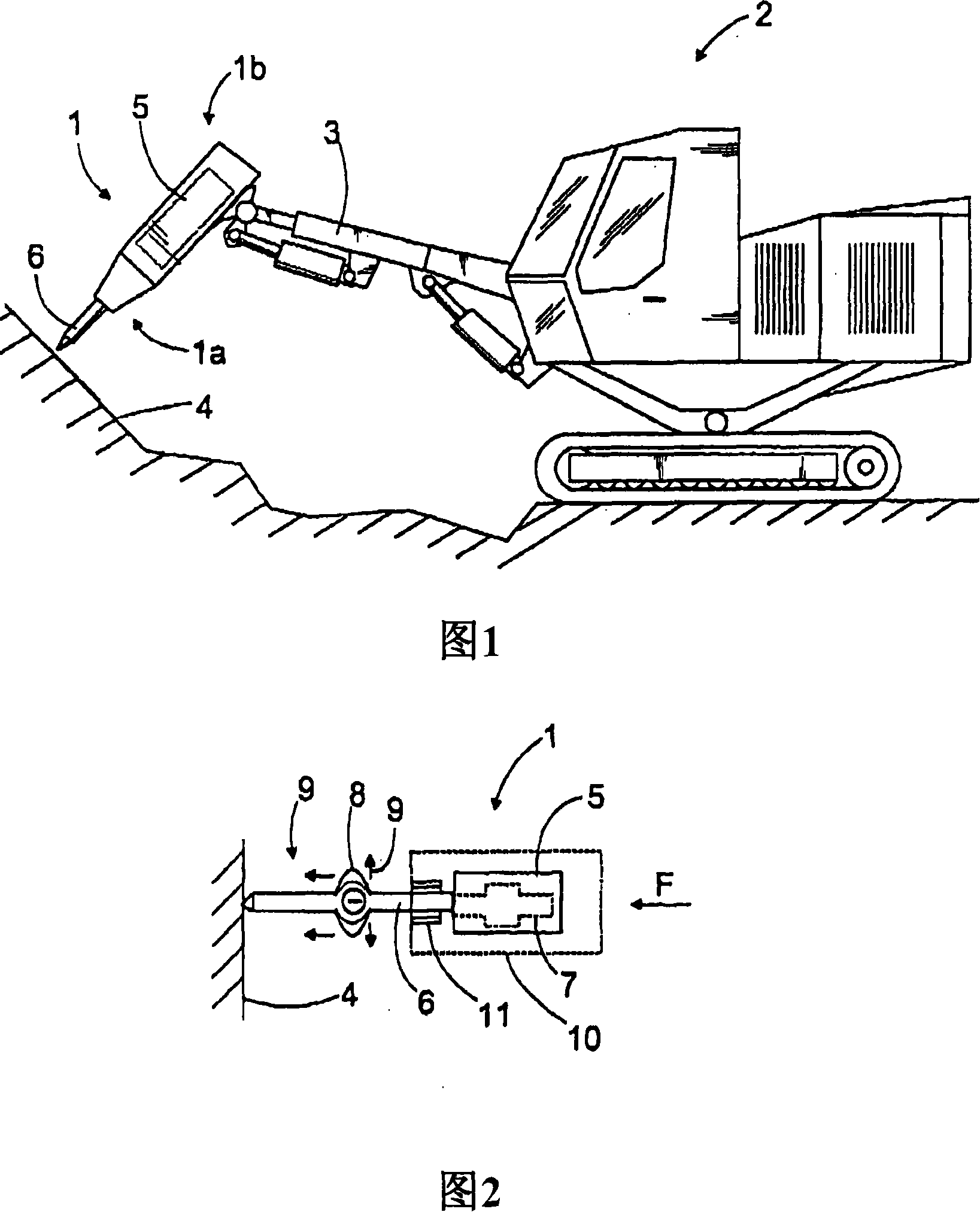

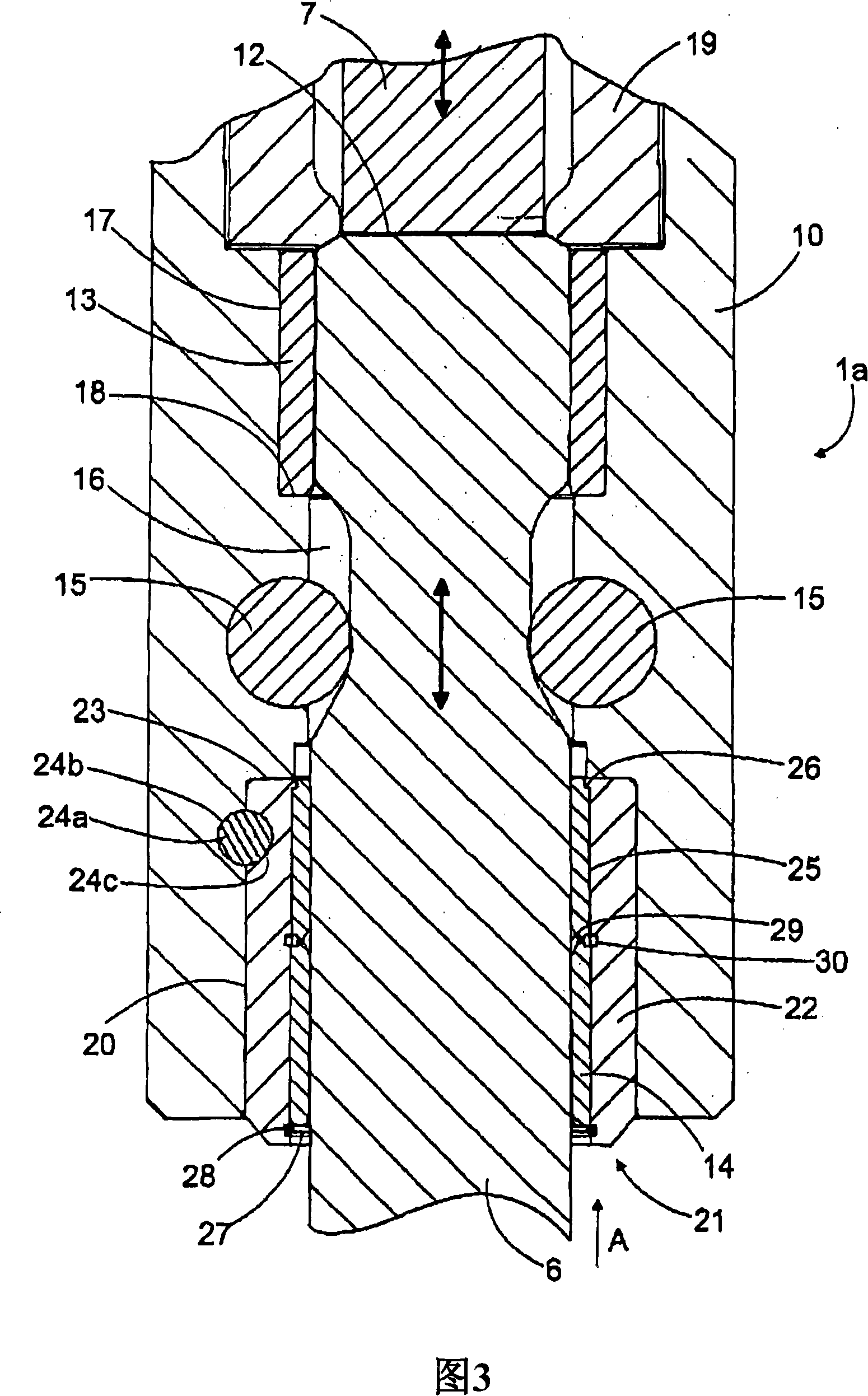

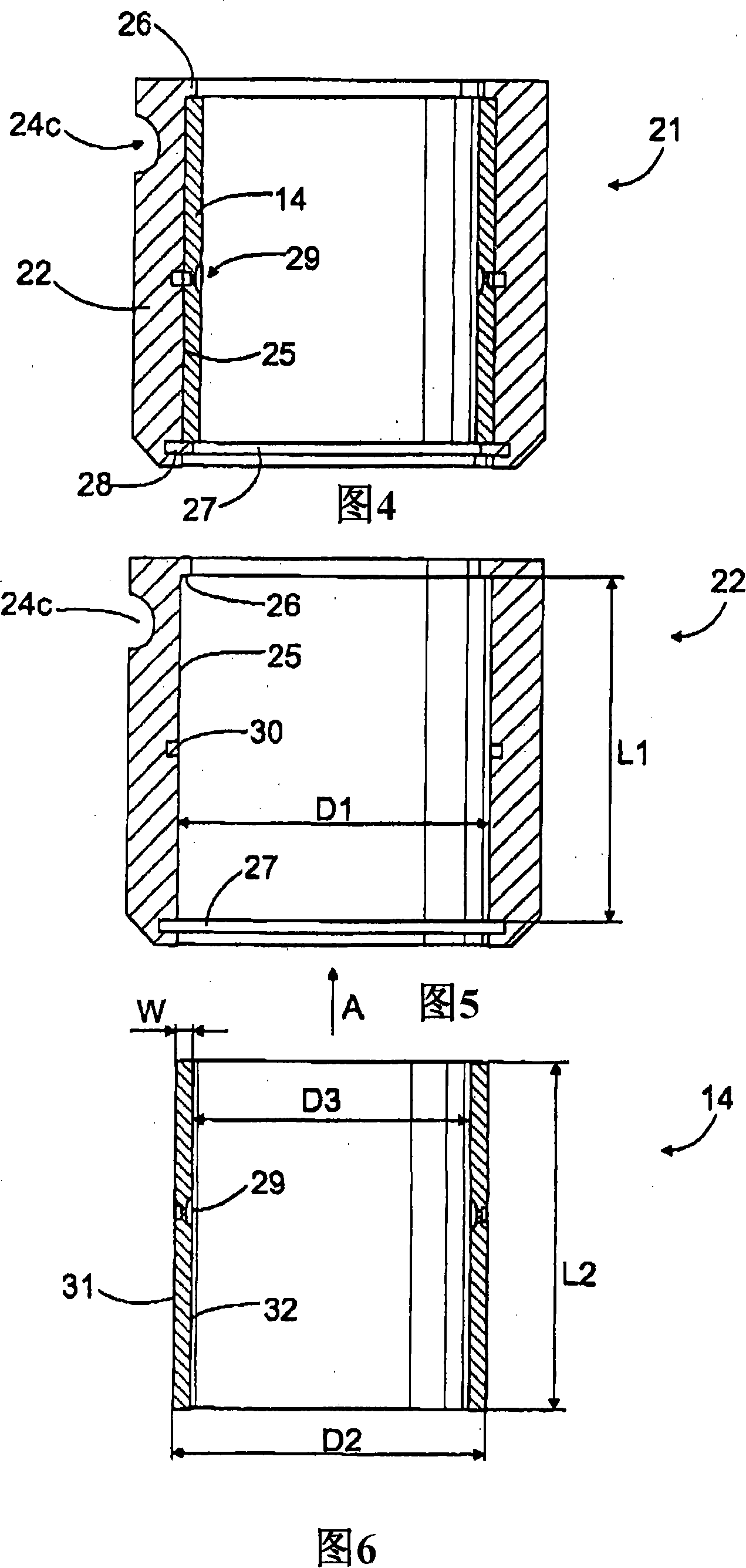

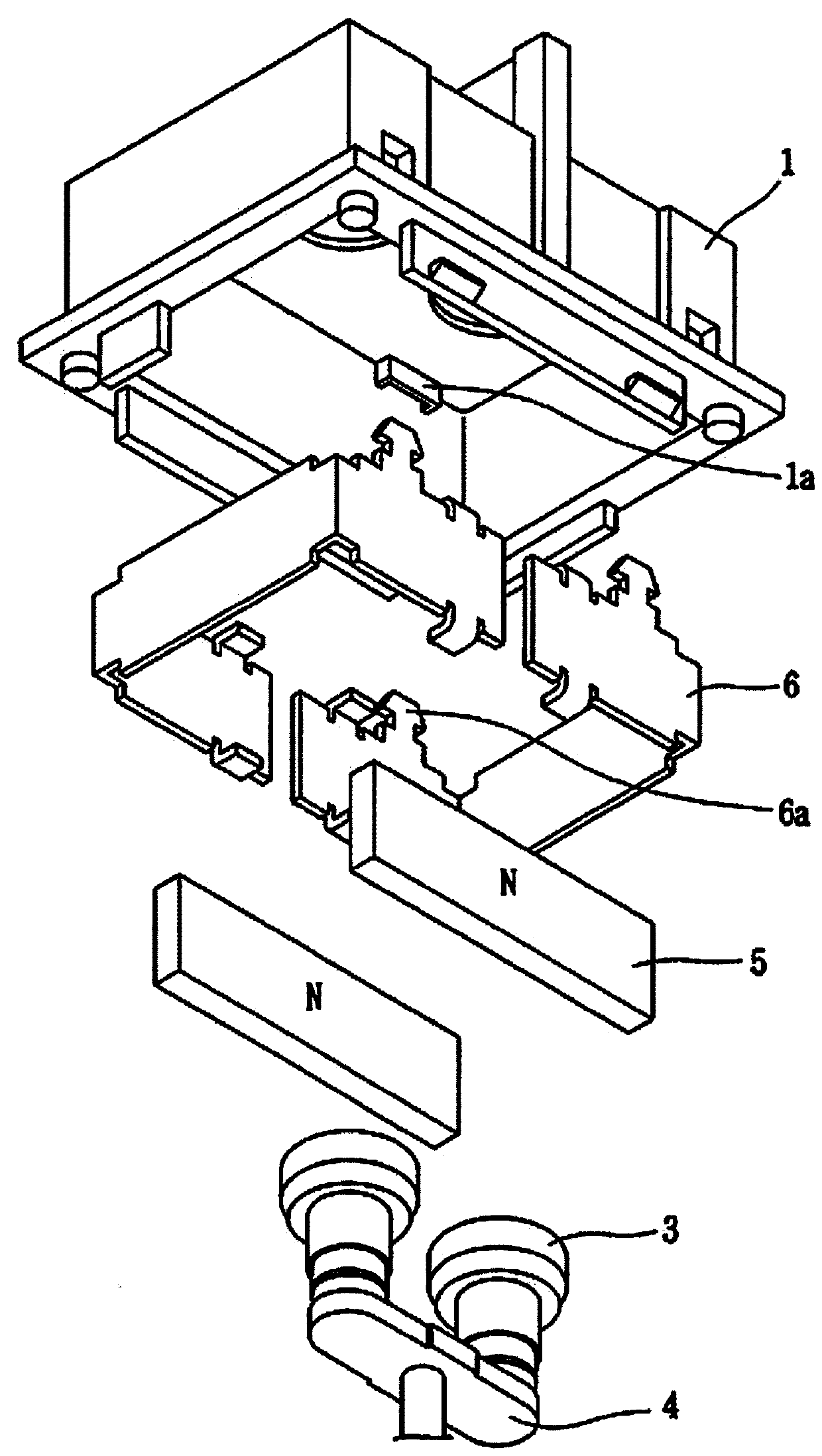

Bearing of a breaking device tool

InactiveCN101195215AEasy to installEasy to insertMechanical machines/dredgersPortable percussive toolsMotion transferStress wave

The invention relates to a method for assembling a breaker tool with a bearing, a breaker and a tool bushing. The tool (6) of the crushing device (1, 40) is equipped with a bearing, wherein at least one bearing bush (14) is made of bearing material and is arranged in the bearing space (25). There is a clearance fit between the bearing bush and the bearing space, whereby the bearing bush can be inserted manually into the bearing space. During use, the tool is supplied with a compressive stress pulse by means of the percussion device (5), whereby a stress wave (9) is transmitted in the tool, which stress wave generates motion on the tool surface in a direction perpendicular to the tool surface. This movement is transmitted to the bearing bush and deforms the bearing bush in the radial direction so that the bearing bush is pressed against the bearing space.

Owner:SANDVIK MINING & CONSTR OY

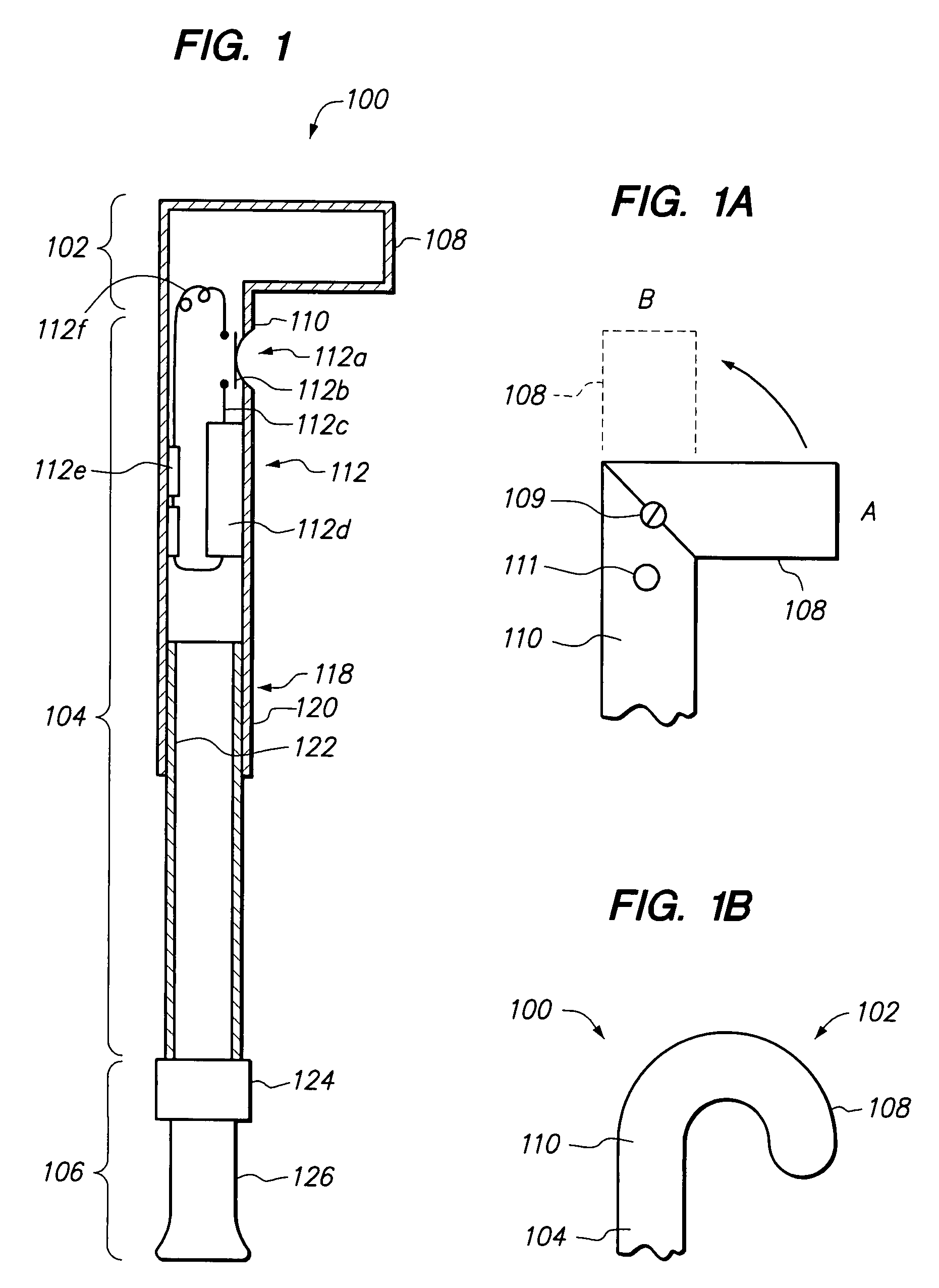

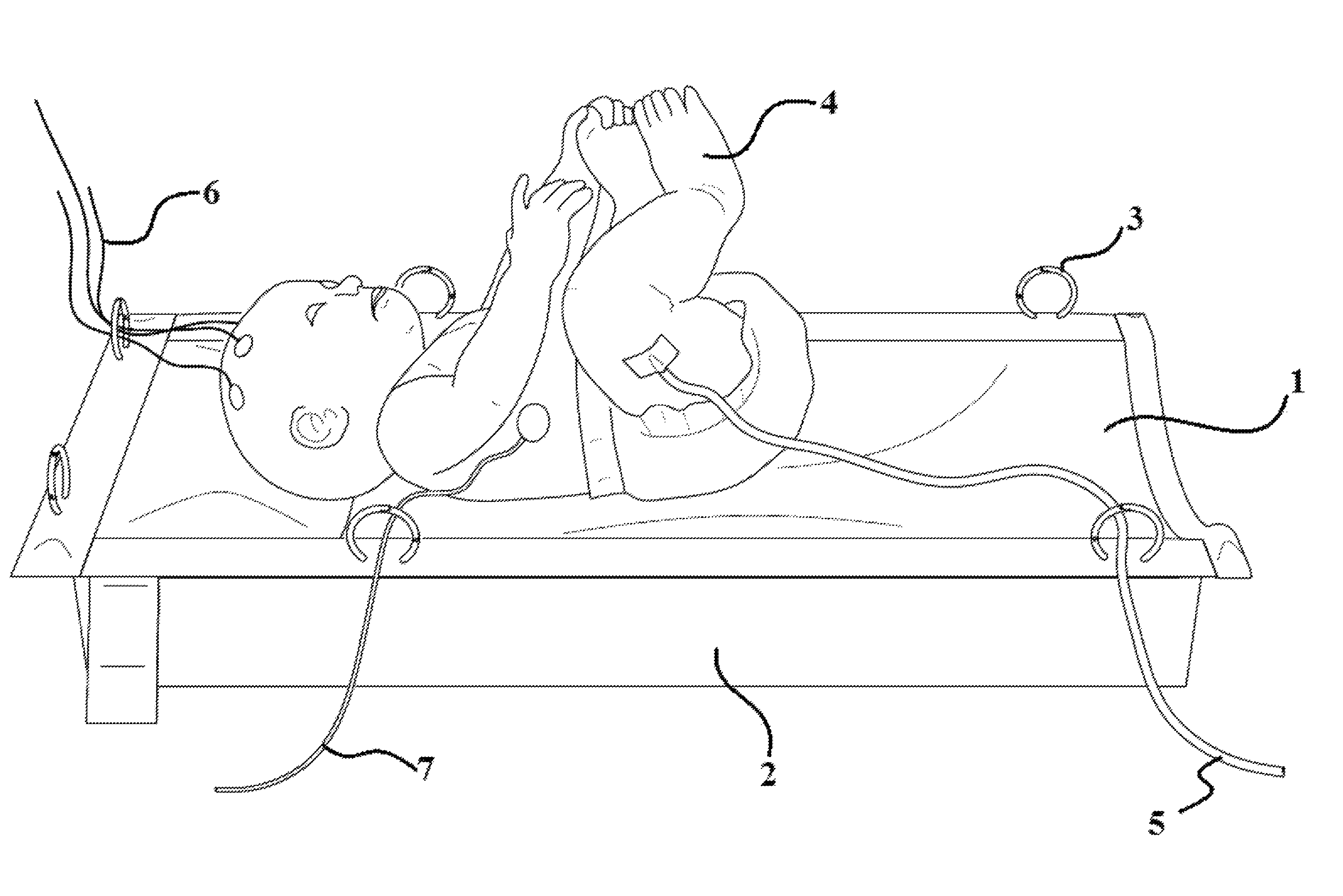

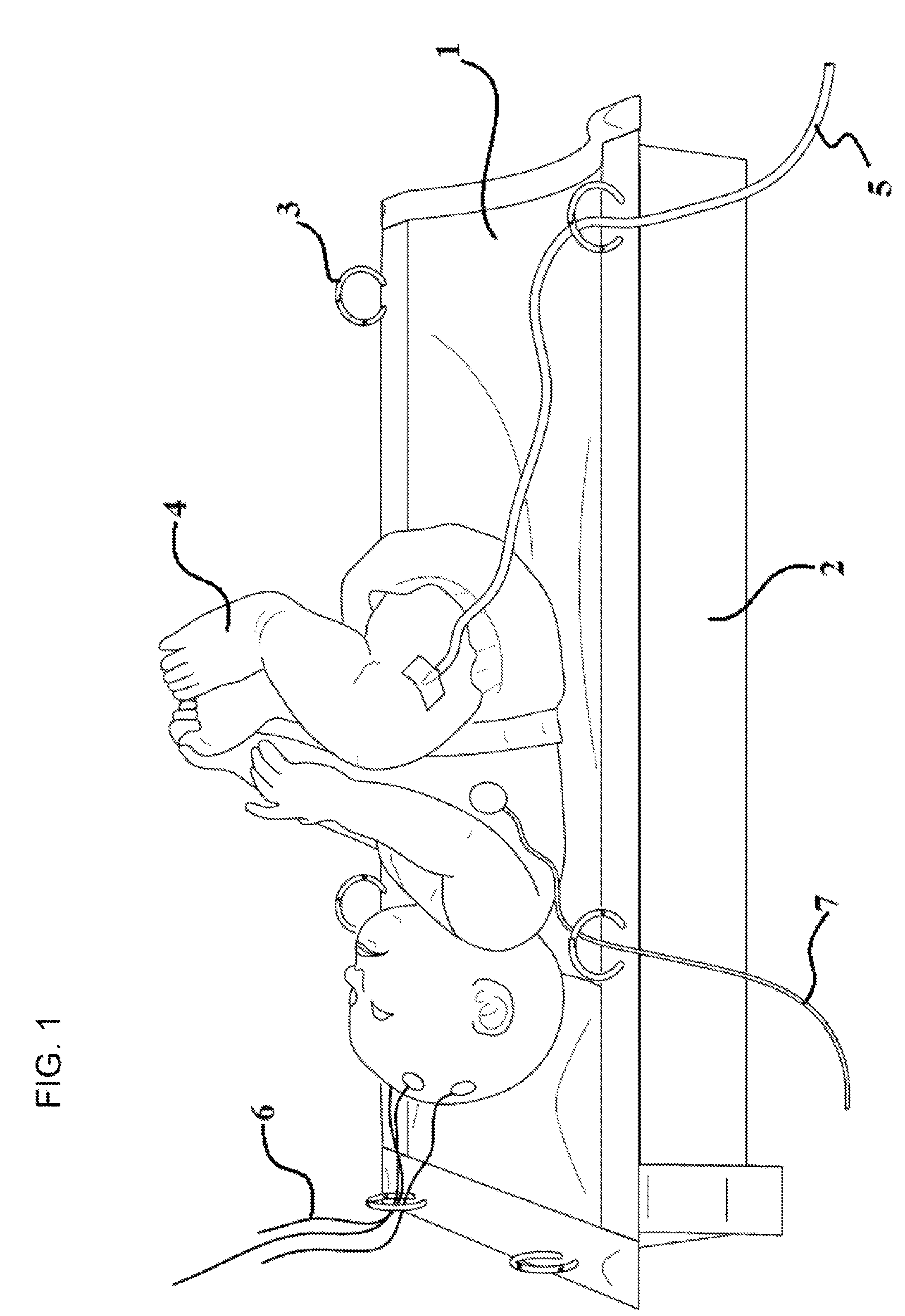

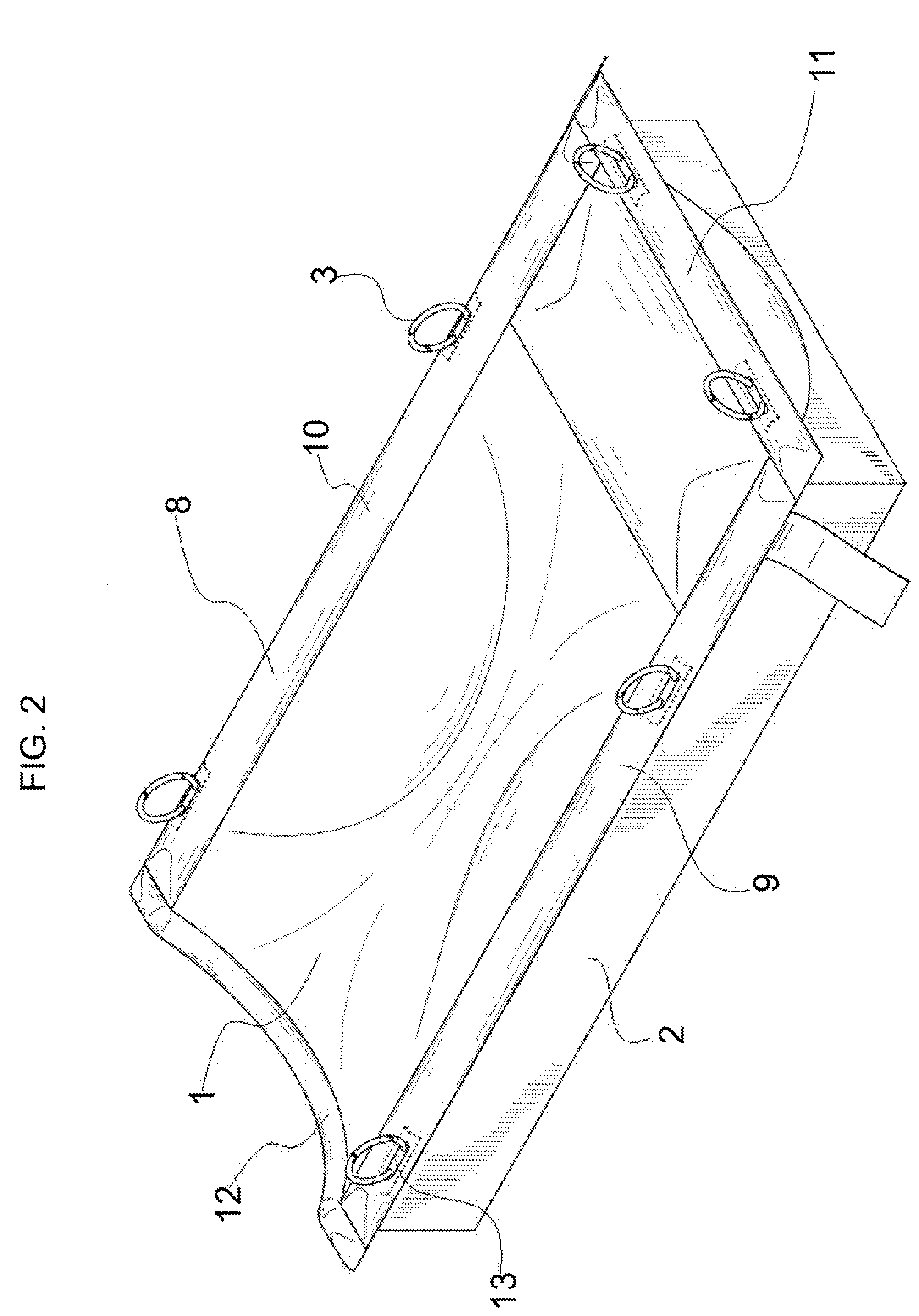

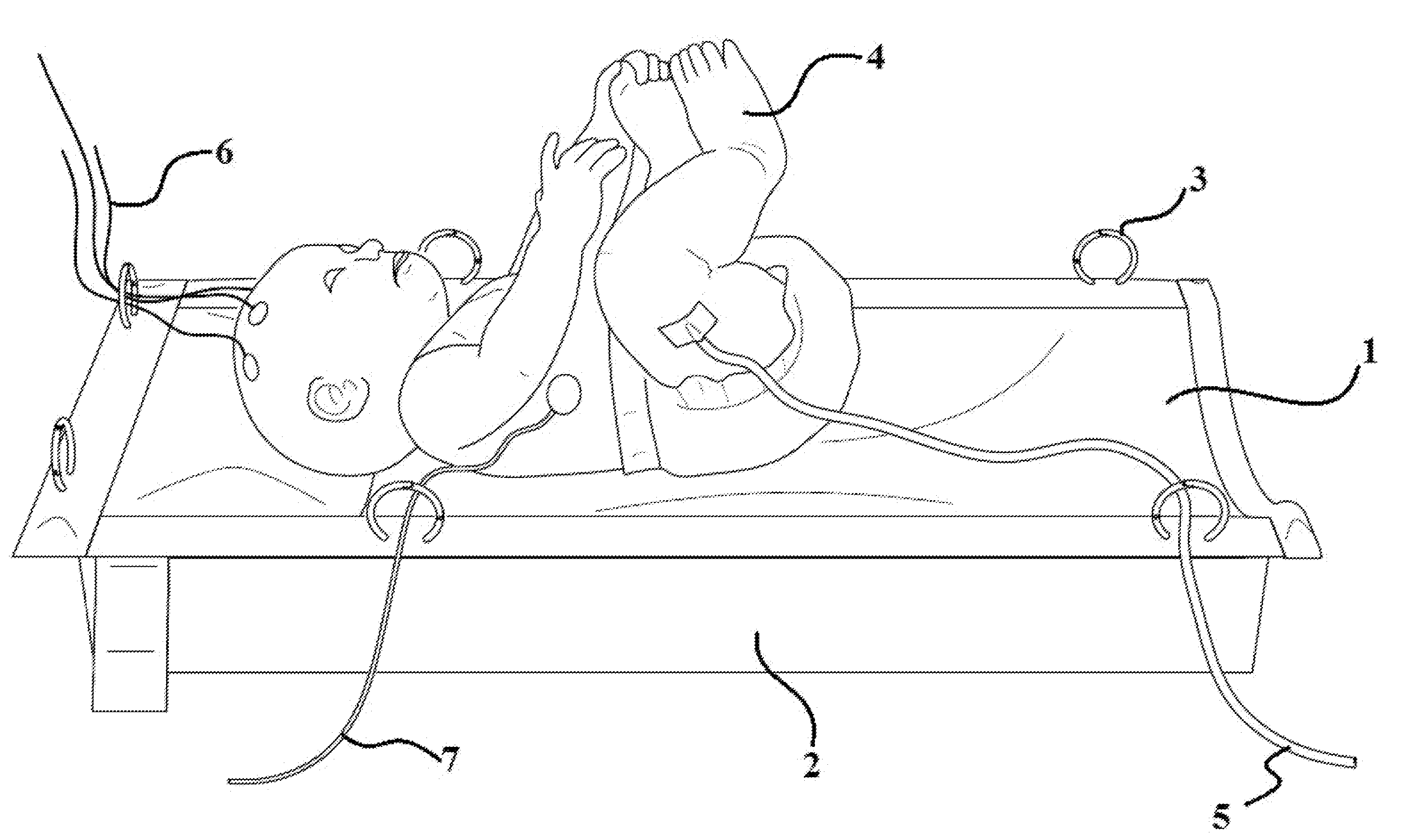

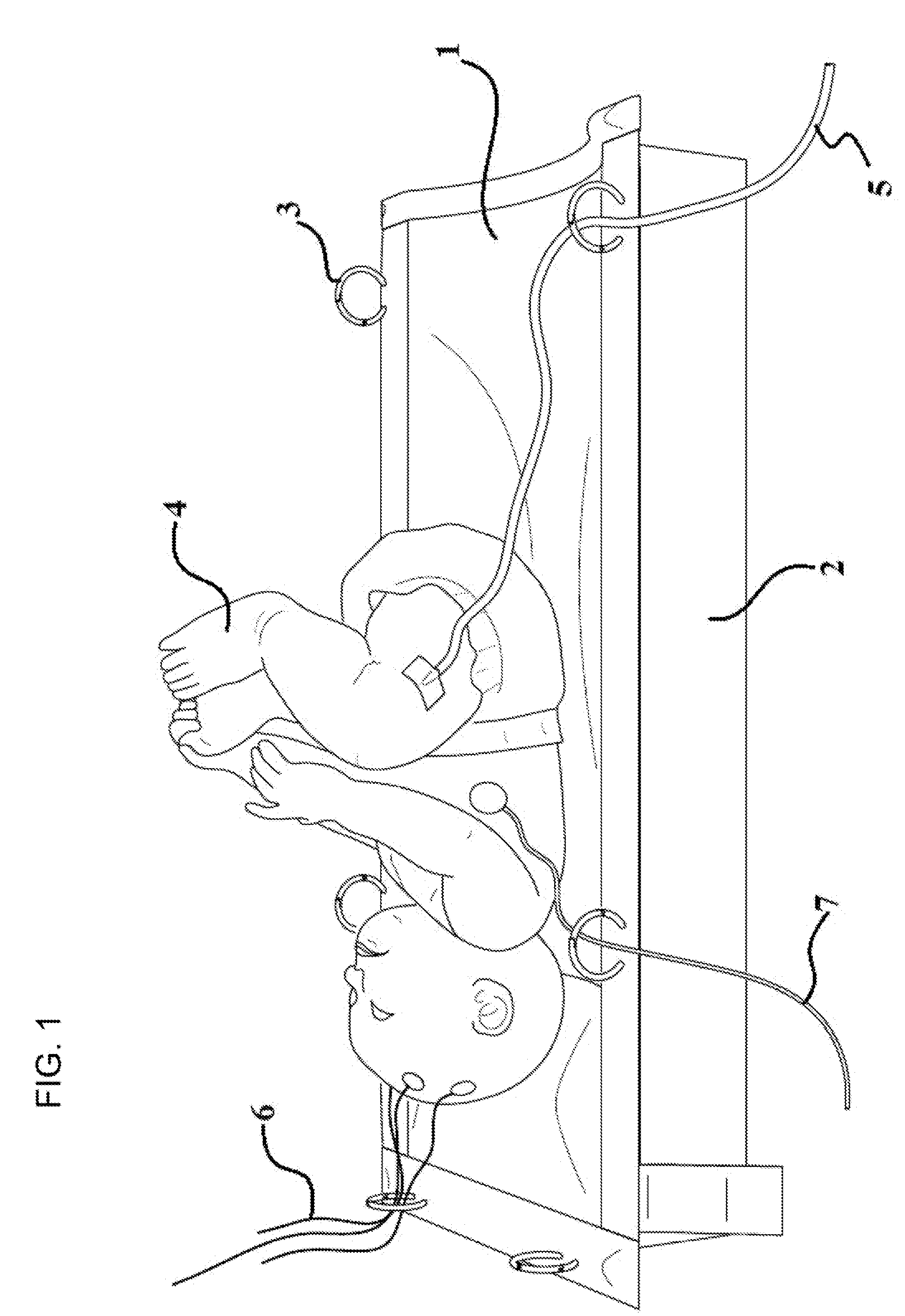

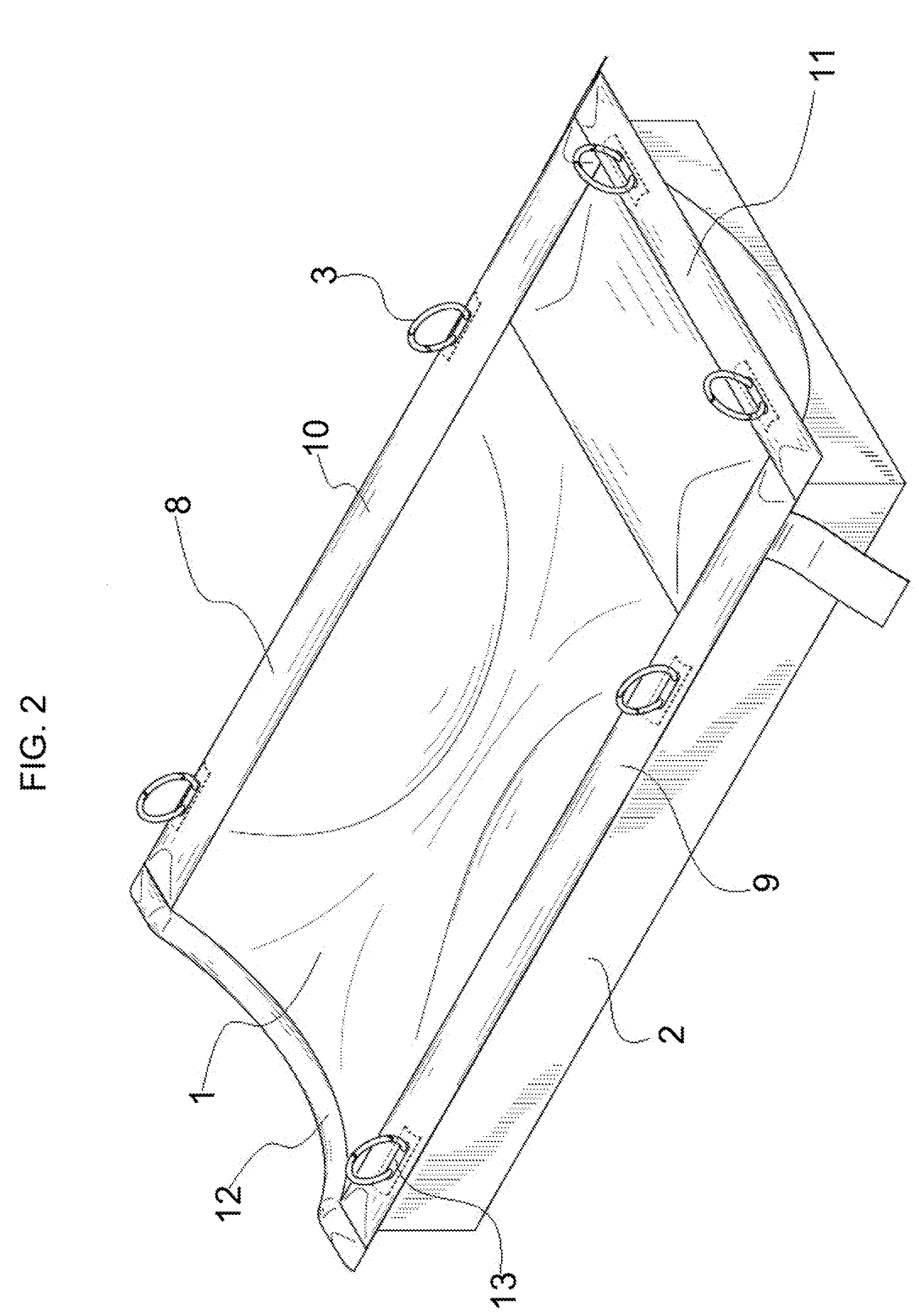

Hospital bed

InactiveUS8887336B2Easy to liftEasy to repositionBaby-incubatorsBlanketLine tubingBiomedical engineering

The present inventors disclose a bed comprising a bed insert and a base. An insert comprises one or more openable loops which can receive medical tubing or other types of medical lines. In some configurations, the one or more openable loops can be reversibly attached to the insert. An insert can be attached to the base by a reversible attachment such as Velcro. A patient, along with an insert, can be lifted from the base. A patient who has medical lines which extend through the loops can be lifted with the insert from the base without disrupting connections between the medical lines and the patient.

Owner:PEZZANI JOAN +1

Hospital bed

InactiveUS20120124750A1Easy to liftEasy to repositionBaby-incubatorsOperating tablesBiomedical engineeringMedical treatment

The present inventors disclose a bed comprising a bed insert and a base. An insert comprises one or more openable loops which can receive medical tubing or other types of medical lines. In some configurations, the one or more openable loops can be reversibly attached to the insert. An insert can be attached to the base by a reversible attachment such as Velcro. A patient, along with an insert, can be lifted from the base. A patient who has medical lines which extend through the loops can be lifted with the insert from the base without disrupting connections between the medical lines and the patient.

Owner:PEZZANI JOAN +1

Hole punch quick-change die assembly with positioning system

InactiveUS6748839B2Easily be reinsertedStay in placePerforating toolsMetal working apparatusPunch pressBolt connection

Embodiments of an punch machine and a quick-change die assembly are shown and described. The die assembly may be quickly installed and removed from the punch machine, without bolting or unbolting of either machine housing or the die assembly itself. The die assembly is slid into the machine through a hole in the machine housing and into a position which mates part of the die assembly with the push-bar. A clamp, with a handle outside the machine, is then pivoted against the die assembly. The push-bar is adapted to be self-supporting without being bolted to the die assembly, keeping the push-bar in place without manual adjustment and alignment. The die assembly preferably includes a die, pin retainer, and punch pins, and preferably includes a flexible, pivotal, or hinged pin strap to secure the pins to the retainer. The preferred die assembly includes a positioning system that biases the pin retainer with its pin heads out from the die a proper distance for easy and unobstructed sliding into the machine housing and into a channel of the bar that drives the die assembly. The die assembly preferably includes a system for consistent referencing between various die assemblies, for reducing the instances in which the paper stop must be adjusted when a die assembly is changed.

Owner:PERFORMANCE DESIGN LLC

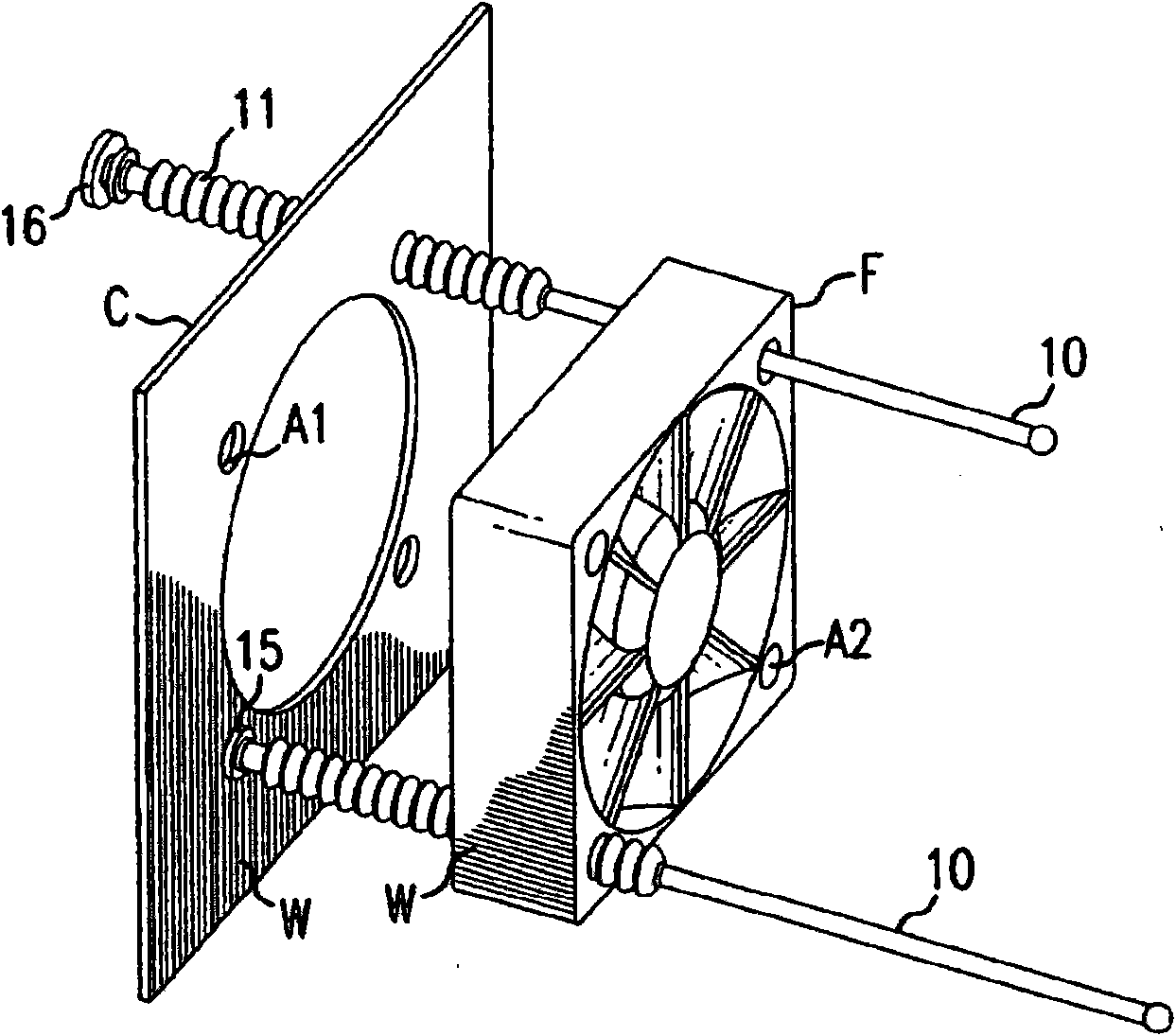

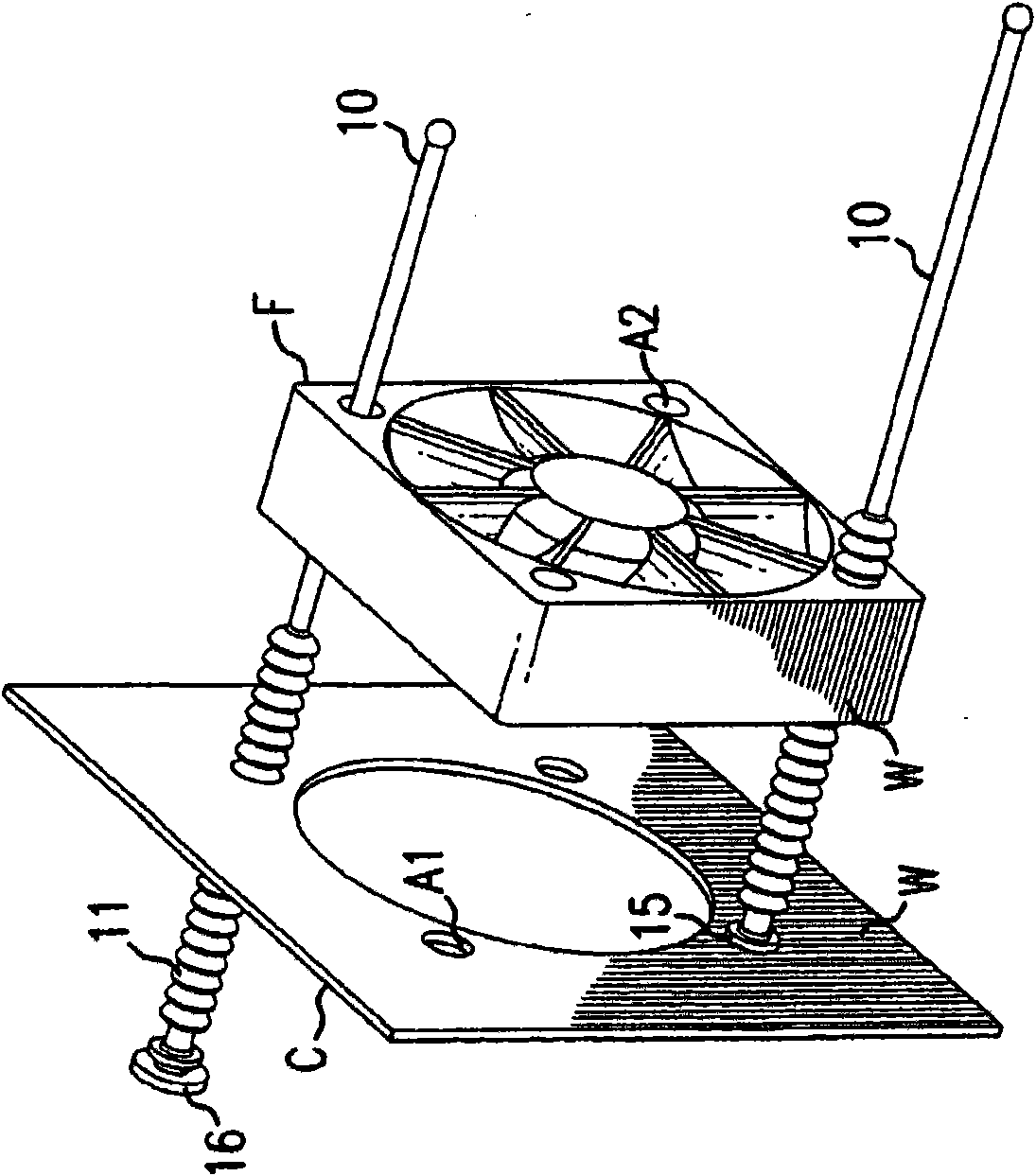

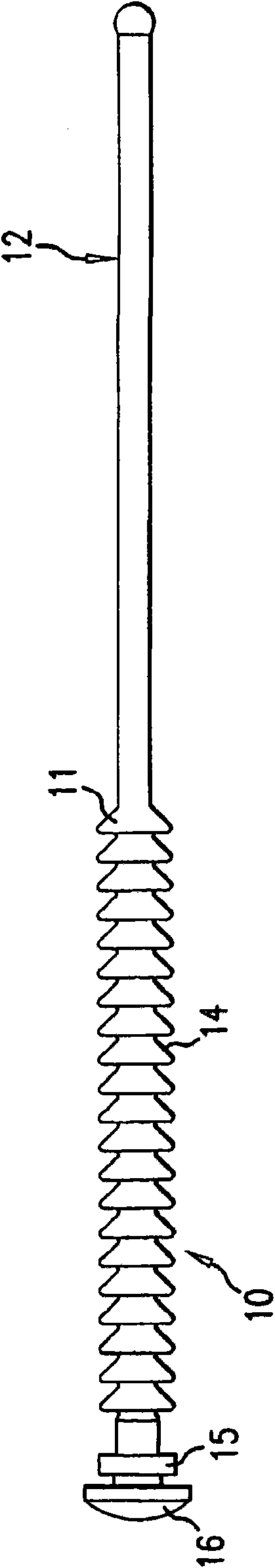

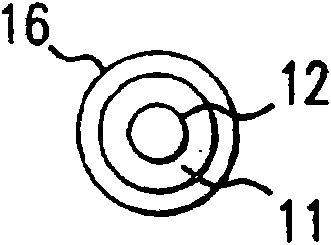

Flexible mount for a fan and like devices

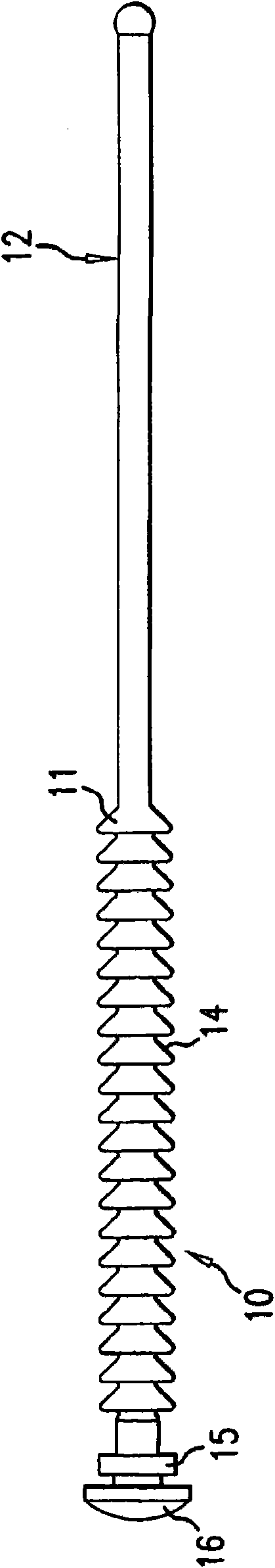

InactiveCN101784817AStay in placeQuick installationPump componentsNon-rotating vibration suppressionChassis

A flexible and stretchable mounting device for a fan or the like which has a shaft, a series of enlarged undulations axially arranged at one end of the shaft, and a head at one end of the shaft, the mounting device being adapted when stretched for insertion into aligned apertures on a chassis and a frame and relaxed to permit a selected undulation to hold the frame in spaced relation to the chassis. The device also includes a break away grip secured to the head for guiding the device into the apertures when stretched and which can be severed from the head when the device is arranged mounted on the chassis and frame.

Owner:RICHCO

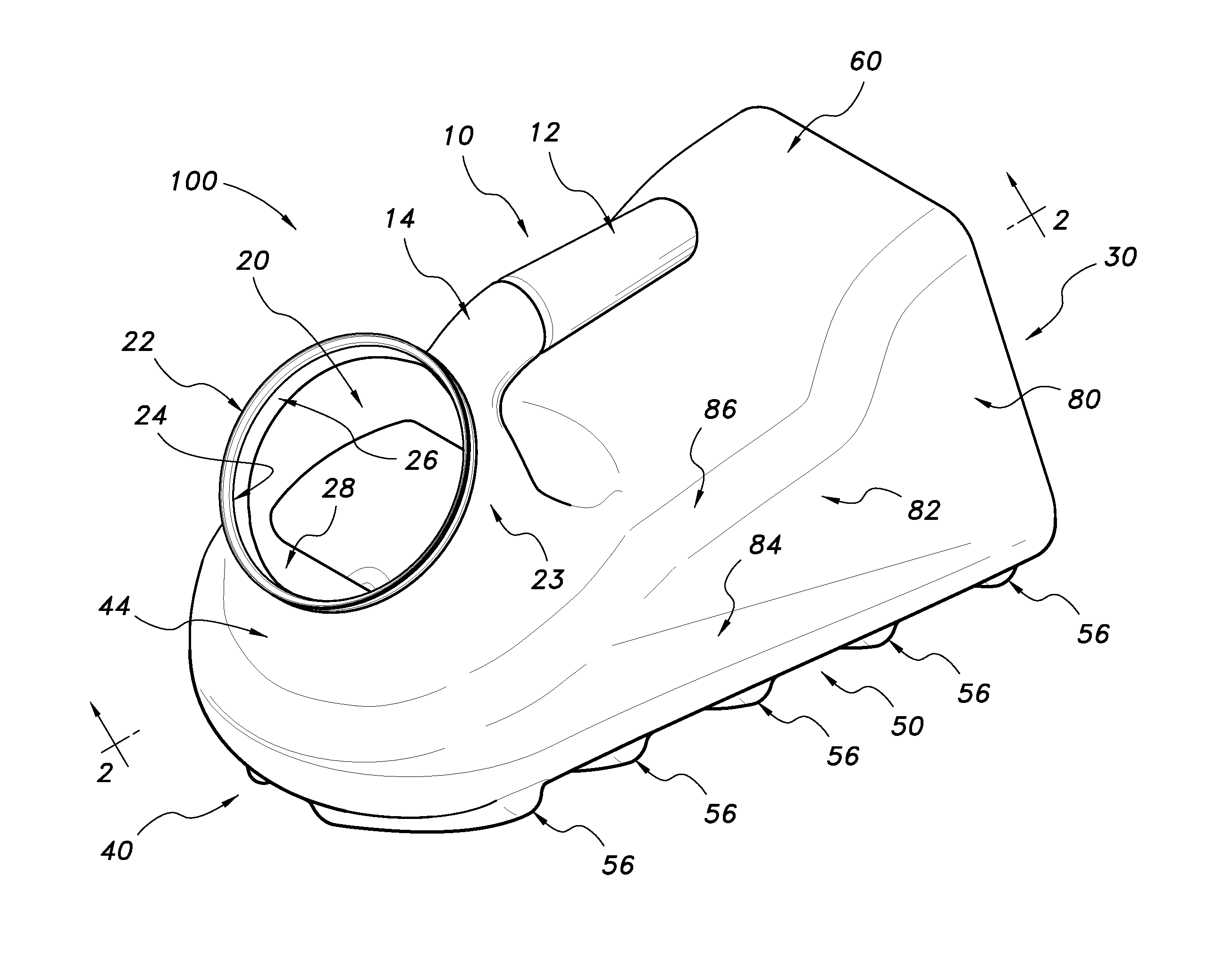

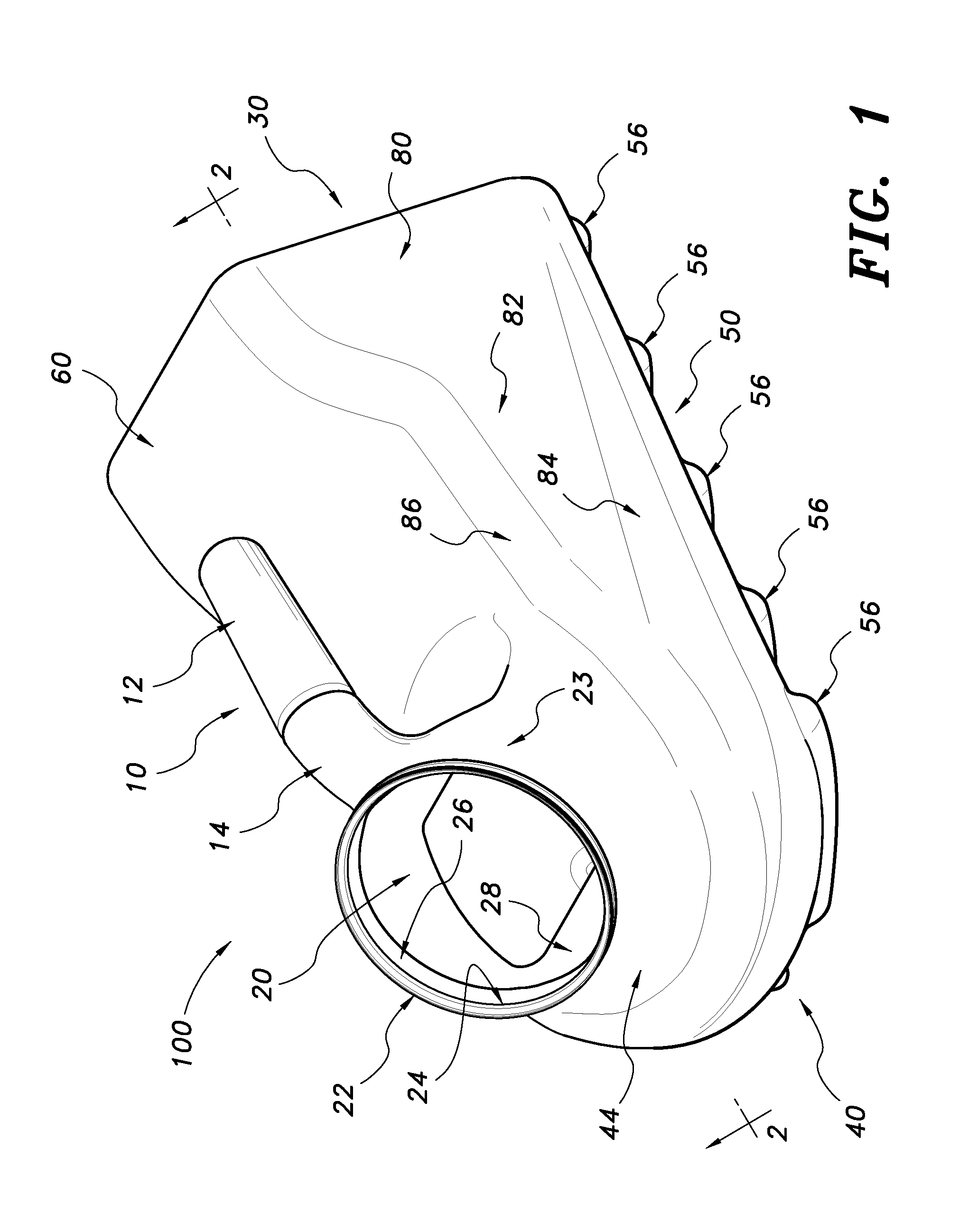

Ergo-male urinal

ActiveUS20150320628A1Resistant to spillageComfortable to useNursing urinalsBathroom accessoriesThighEngineering

A urinal includes a body that has a front wall, a rear wall, opposed side walls, a bottom wall and a top wall. The body has a front portion having an opening and has a rear portion. The body has an opening in the front wall portion adapted for entry of a male body portion. The front wall portion has an S-shaped portion forming a ridge extending below said opening. A ledge is formed by part of the S-shaped portion to form a support for the male body portion entered into the opening. The rear portion is higher than the front portion such that the body is tapered in a directon from back to front. The body also tapers in width from back to front, so that it is adapted to fit comfortably between the thighs of a user.

Owner:SANDS PATRICIA CAROL

Safety and rescue carabiner holder

InactiveUS20080012367A1Precise positioningStay in placeBreathing protectionMachine supportsMechanical engineering

A safety and rescue carabiner holder for securing a carabiner with its gate in the open position while extending the user's reach several feet in any direction, which is also capable of supporting a long and heavy segment of attached safety rope. The carabiner holder is mounted to the end of an extension pole and includes a restraining structure that grips the bottom of the carabiner and a set of spring-loaded jaw arms that firmly clamp the spine and gate arm of the carabiner in a manner strong enough to withstand any inadvertent shaking and bouncing, ensuring that the carabiner will stay in place until hooked into a target ring and the user releases the carabiner by pulling backwards on the extension pole.

Owner:QUASAR SERVICES

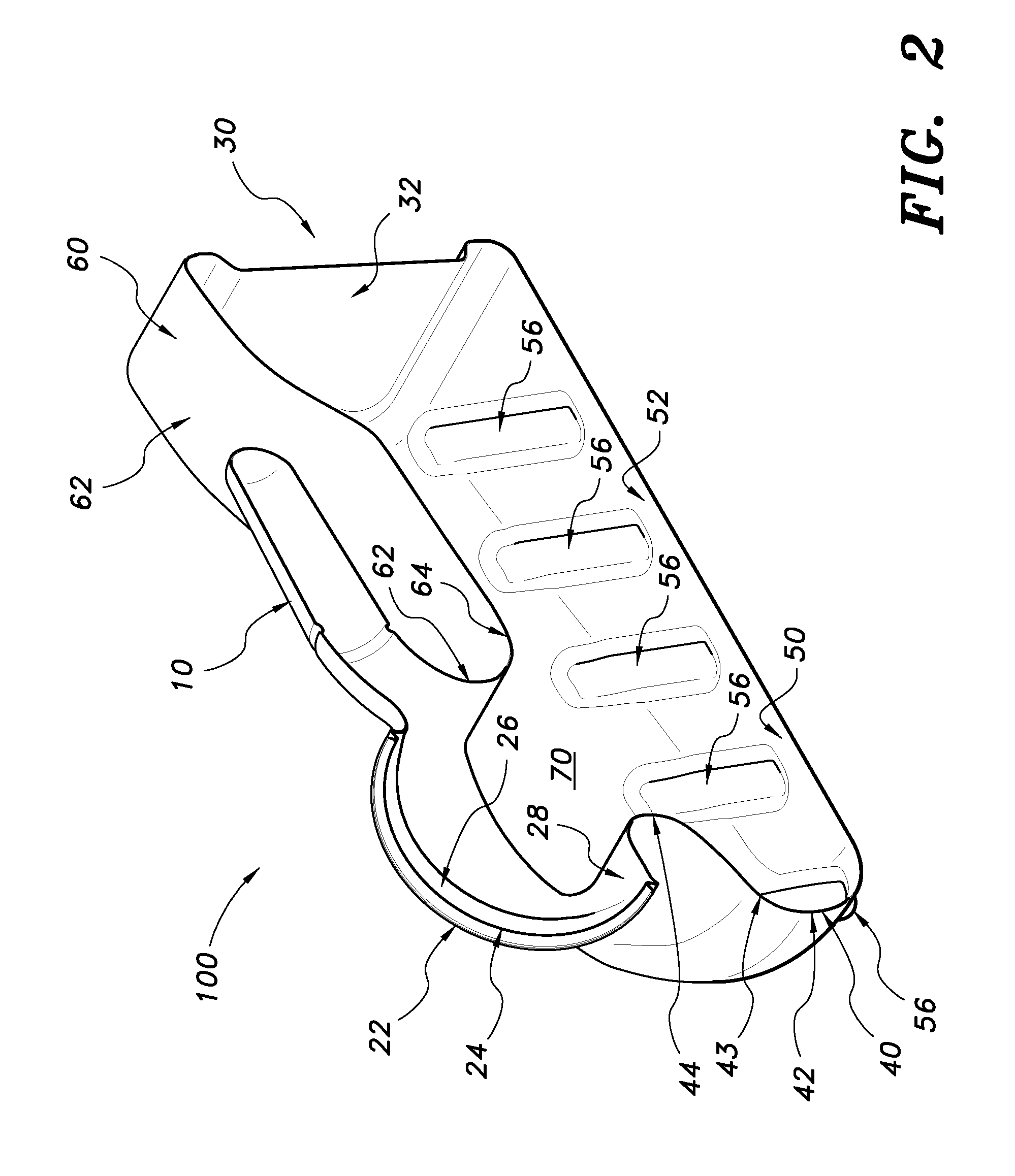

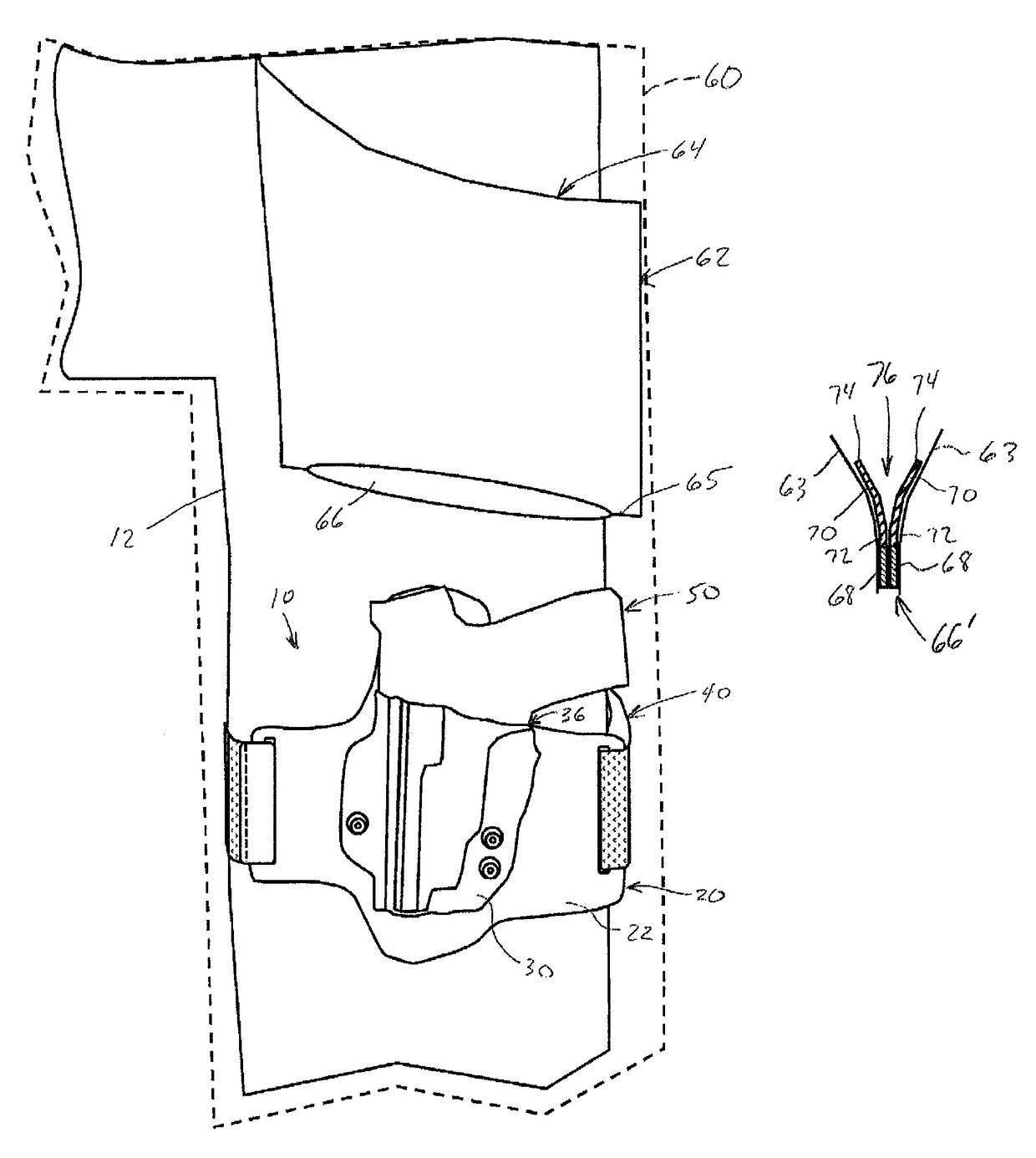

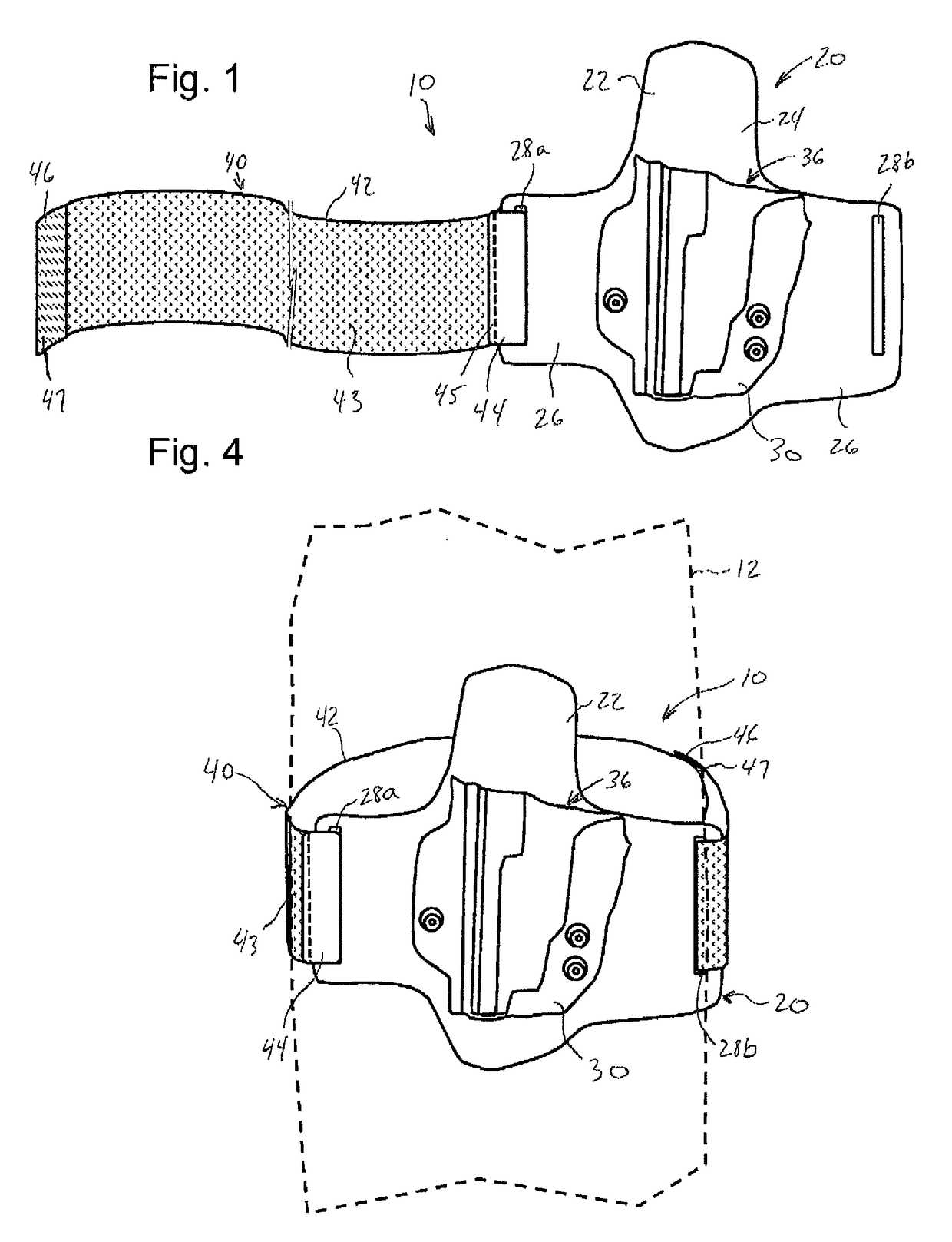

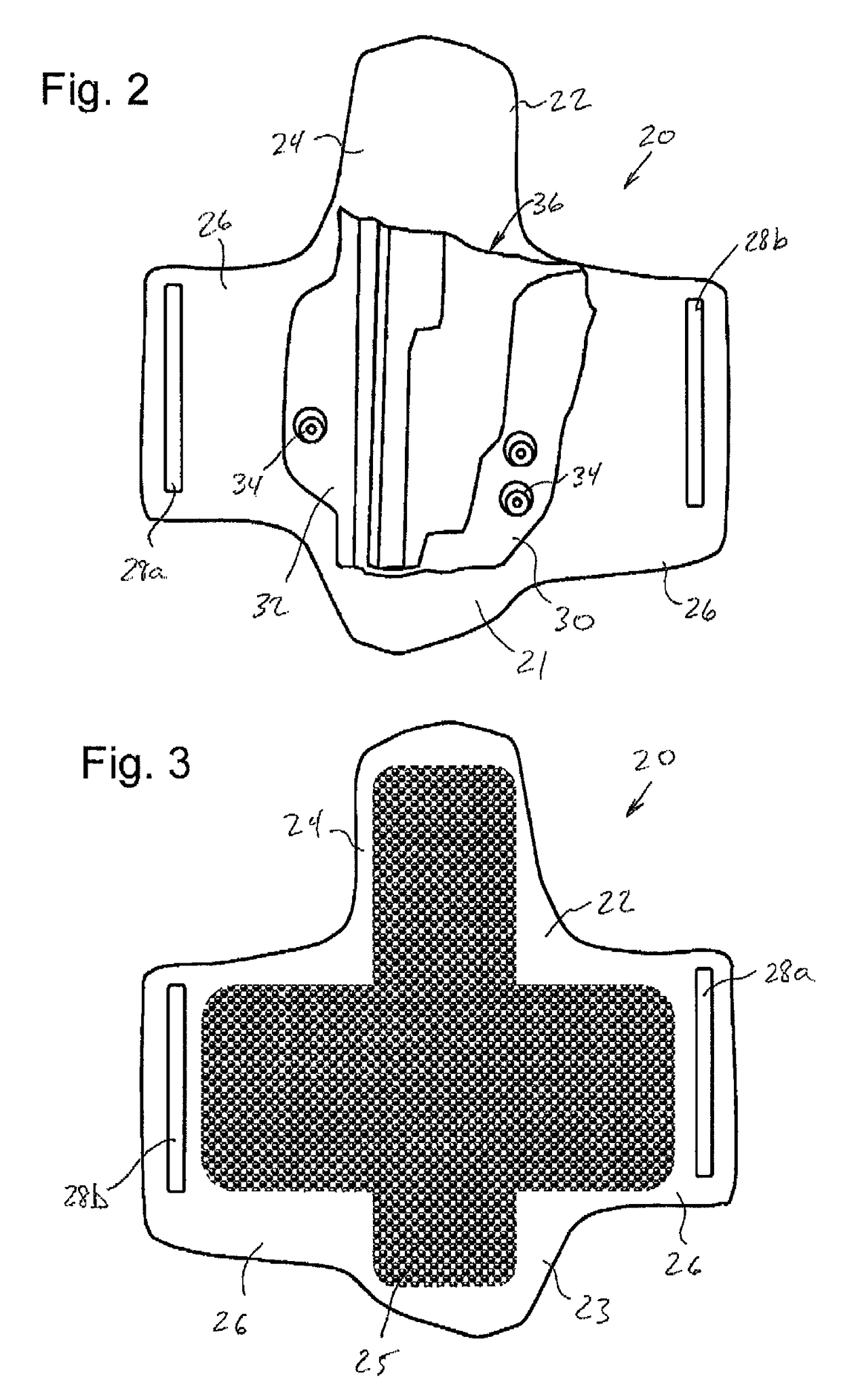

Concealed holster assembly

A holster assembly including a holster defining a receiving cavity and a strap extending between first and second ends. The first end of the strap is connected to the holster and the second end of the strap is adjustably connectable relative to the holster. The strap is manufactured from an elastic material.

Owner:BOWMAN JEFFREY R

Load Distribution Crown

ActiveUS20100106201A1Reduce chanceEqually distributedSuture equipmentsInternal osteosythesisLoad distributionNon orthogonal

An apparatus for distributing the load caused by the insertion of a fastening device into bony tissue is disclosed. In one embodiment, the apparatus comprises a crown having a plurality of protrusions. The protrusions may have any desired physical properties, and function to obtain purchase in the bony tissue. Preferably, the crown includes an opening that is selectively engageable with a spherical head of the fastening device. The opening preferably comprises a spherical curvature that allows the surfaces of the spherical head and the opening to maintain flush contact, even when the fastening device is inserted into the bony tissue at a non-orthogonal angle. When the fastening device is inserted into the bony tissue, the crown distributes the load over a wider section of the bone, allowing the bone to maintain its structural integrity.

Owner:GLOBUS MEDICAL INC

Sleeve and micro-encapsulated topical analgesic for pain relief

ActiveUS8282607B2Efficient use ofImprove joint functionPowder deliveryOrganic active ingredientsMedicineTopical analgesic

Owner:CHATTEM

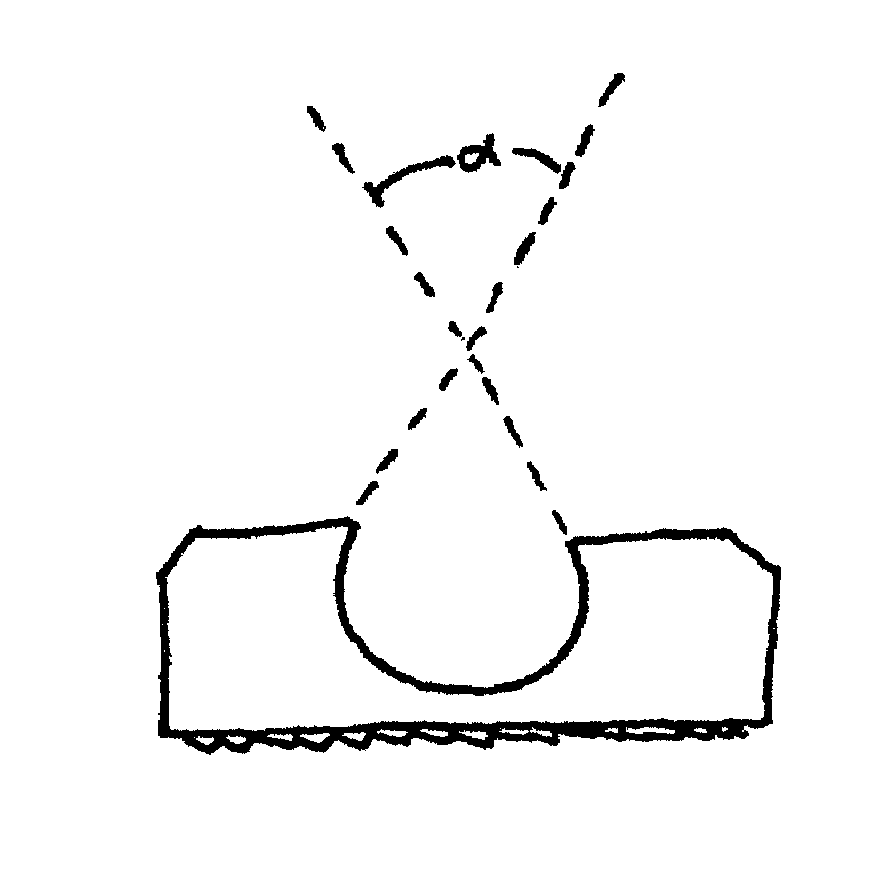

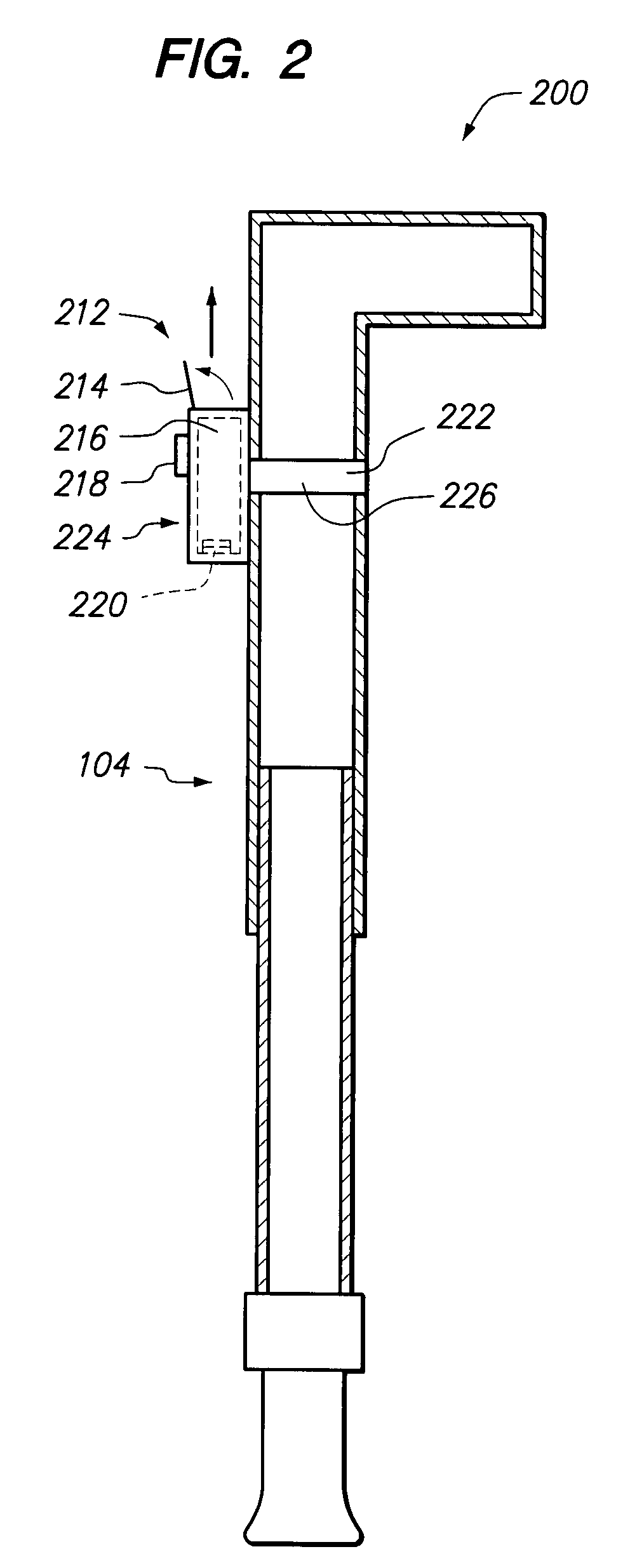

Positioning marker

InactiveUS20190167379A1Expensive to manufactureStay in placeSurgeryDiagnostic markersHollow coreAcute angle

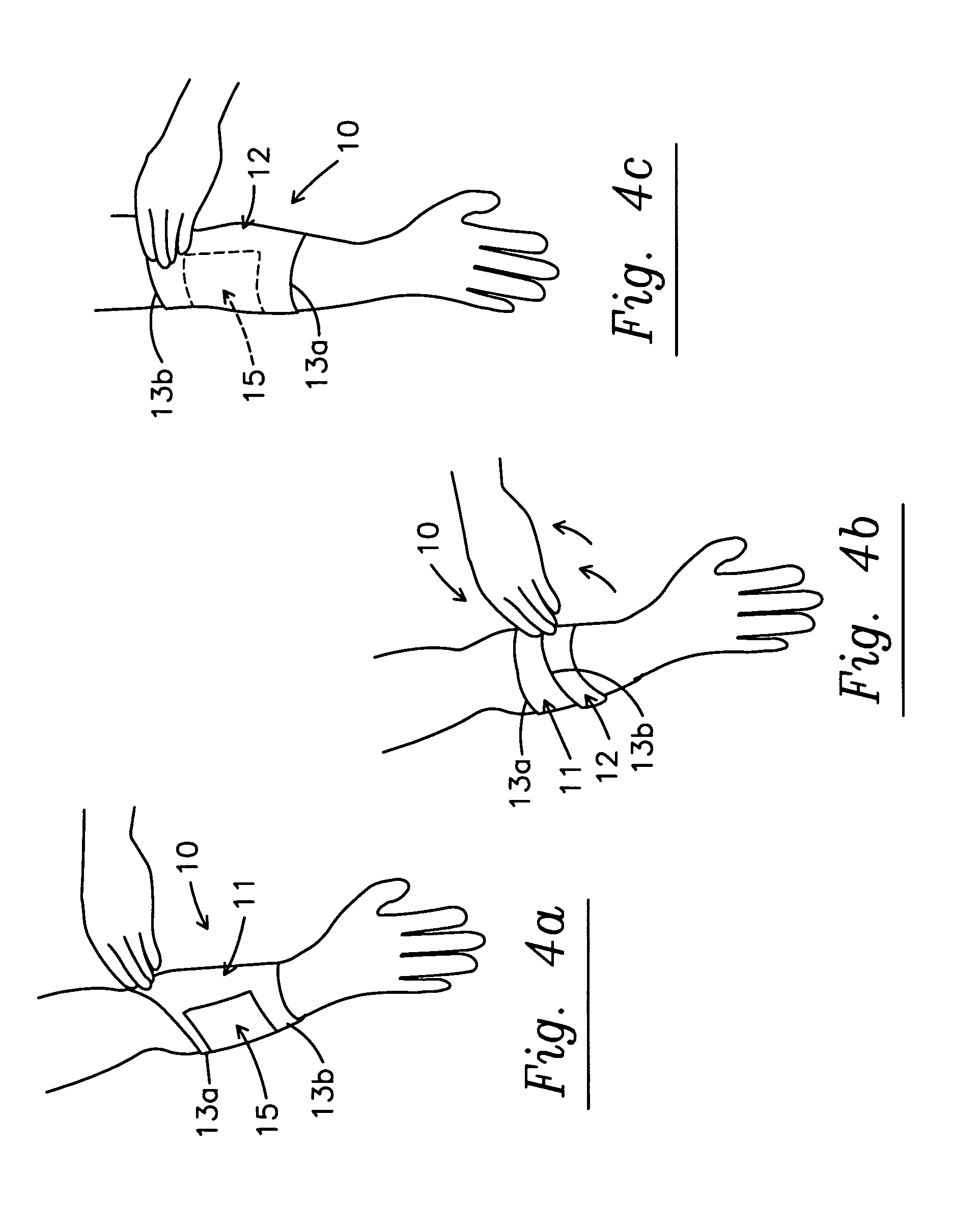

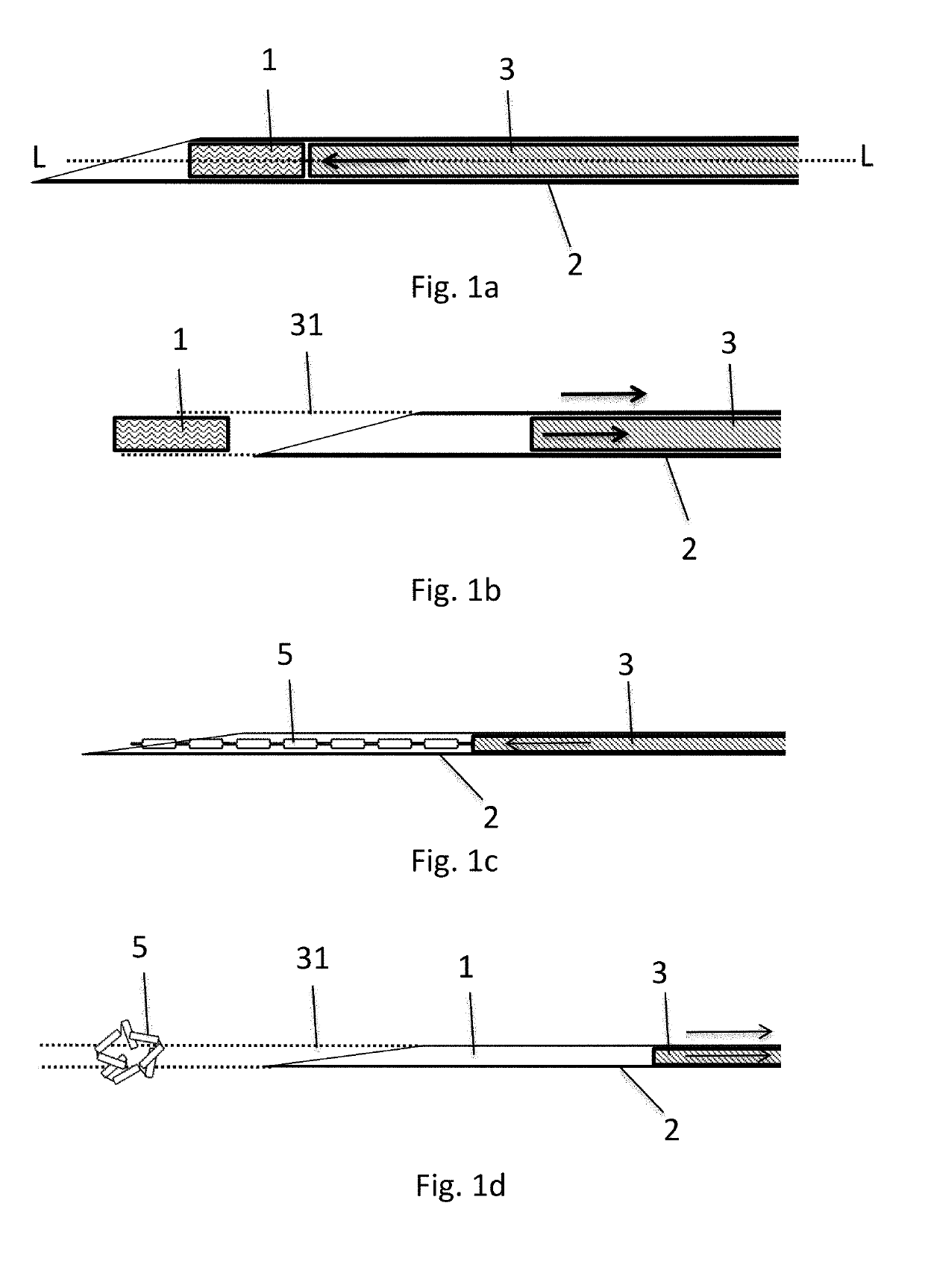

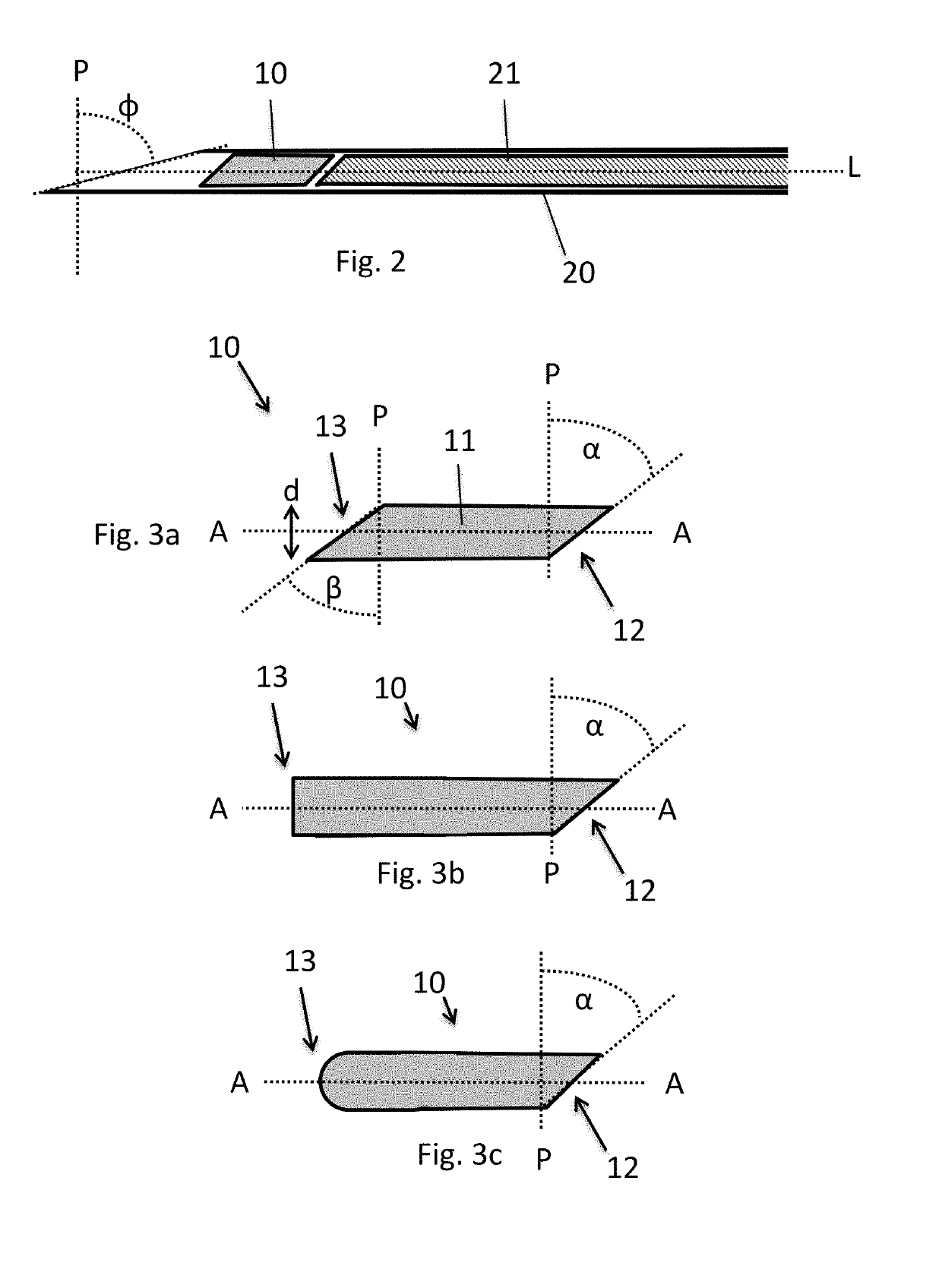

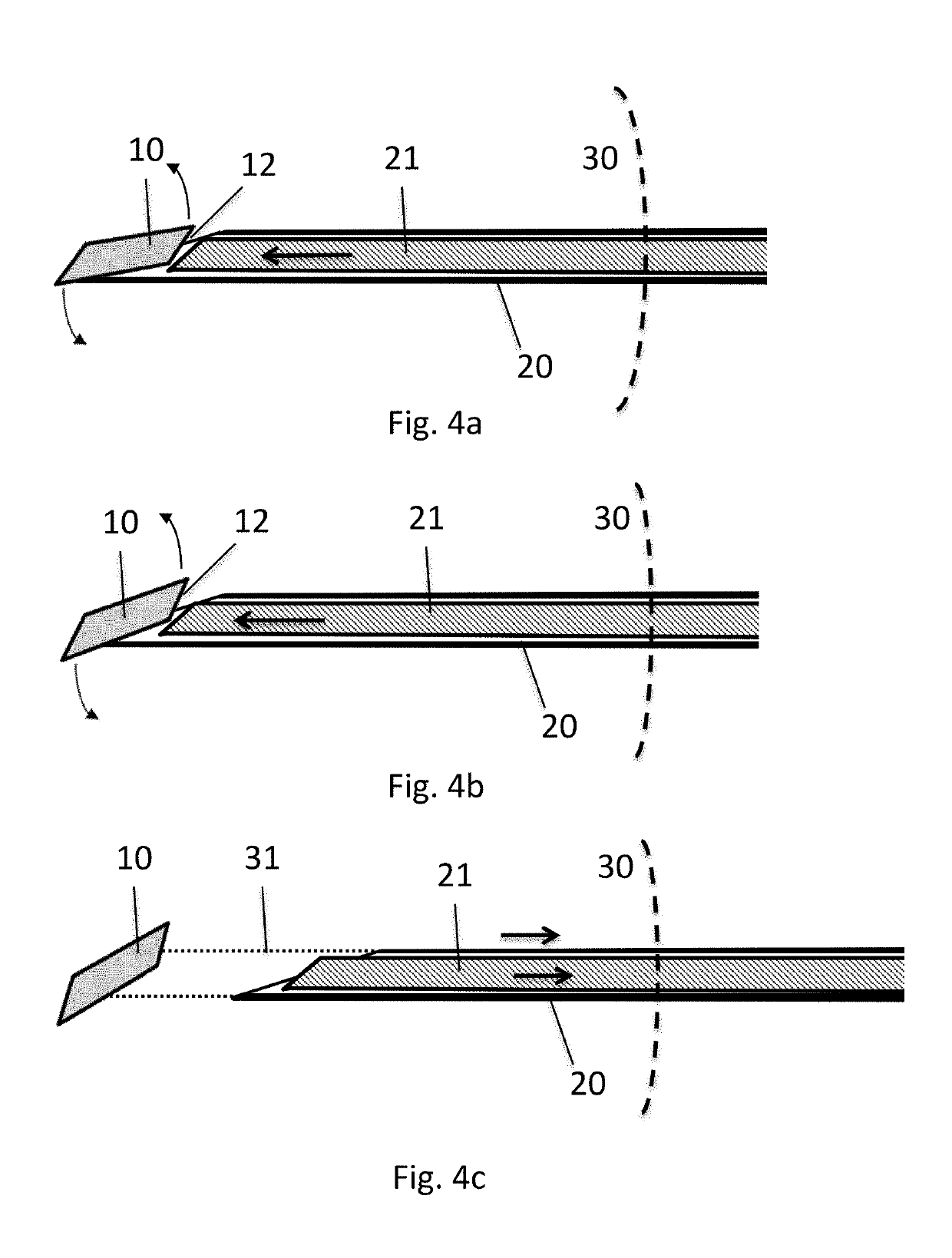

The present invention relates to an implantation assembly comprising a hollow needle (20) with a longitudinal axis (L) and an opening slanted at an first acute angle in relation to a plane perpendicular to said longitudinal axis (L), a mandrel (21) adapted to slide within the inside the needle along the longitudinal axis (L), and a plurality of positioning markers (10), wherein each of the plurality of markers (10) comprises an elongated marker body (11) with a proximal end (12) and a distal end (13), wherein said proximal end (12) and said distal end (13) of said marker body (11) is slanted essentially at a same second acute angle (α) in relation to the plane, wherein said plurality of positioning markers (10) are mounted distally of said mandrel (21) within said needle (20) and proximally of the distal end of said needle (20) before implantation, and said plurality of positioning markers (10) being adapted to be implanted using said hollow needle (20) and said mandrel (21), wherein the marker body (11) of each of the said plurality of positioning markers (10) is adapted to tilt and rotate in reference to the longitudinal axis (L) of the needle after exiting the slanted opening of the needle (20).

Owner:NASLUND INGEMAR

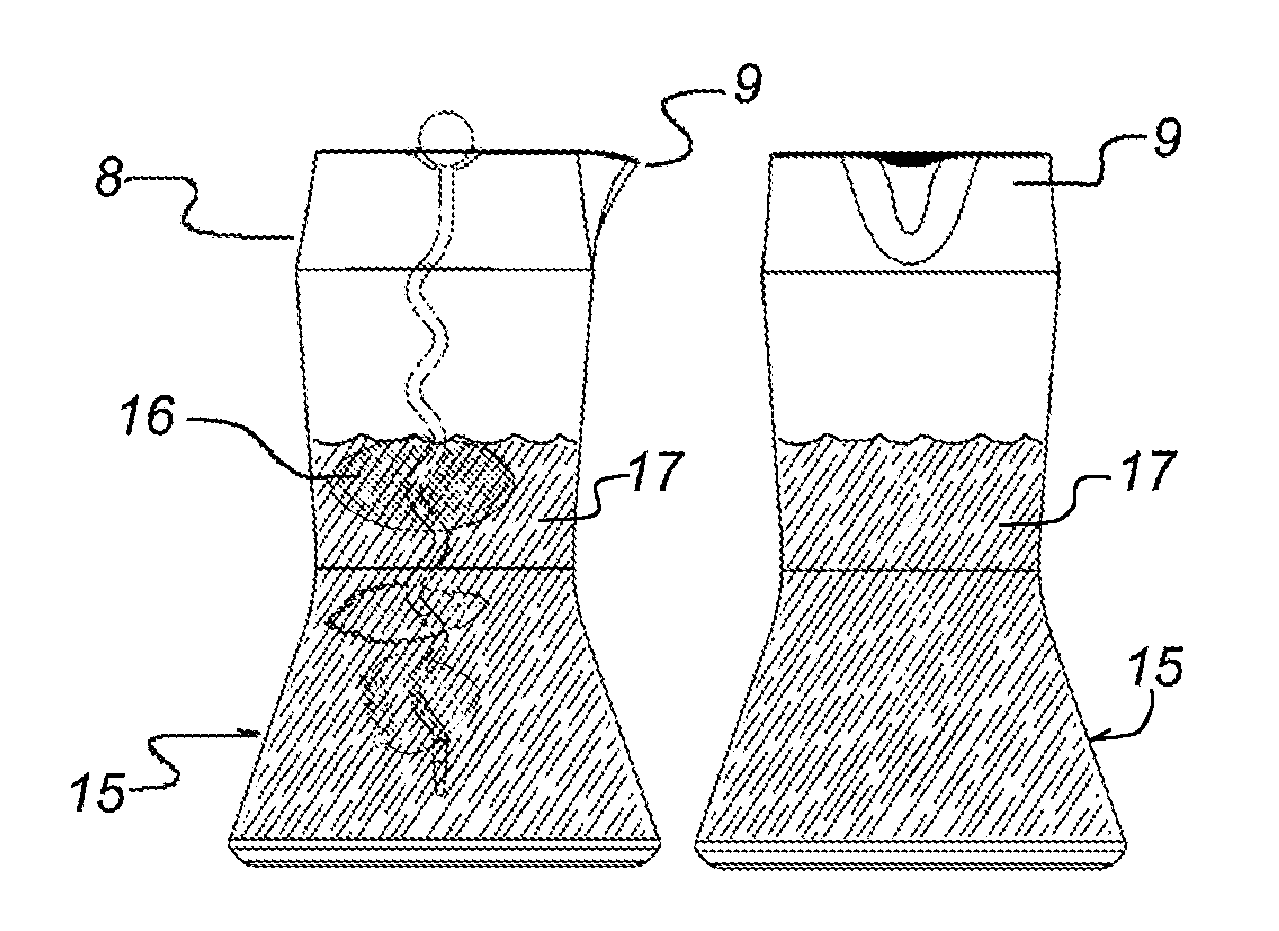

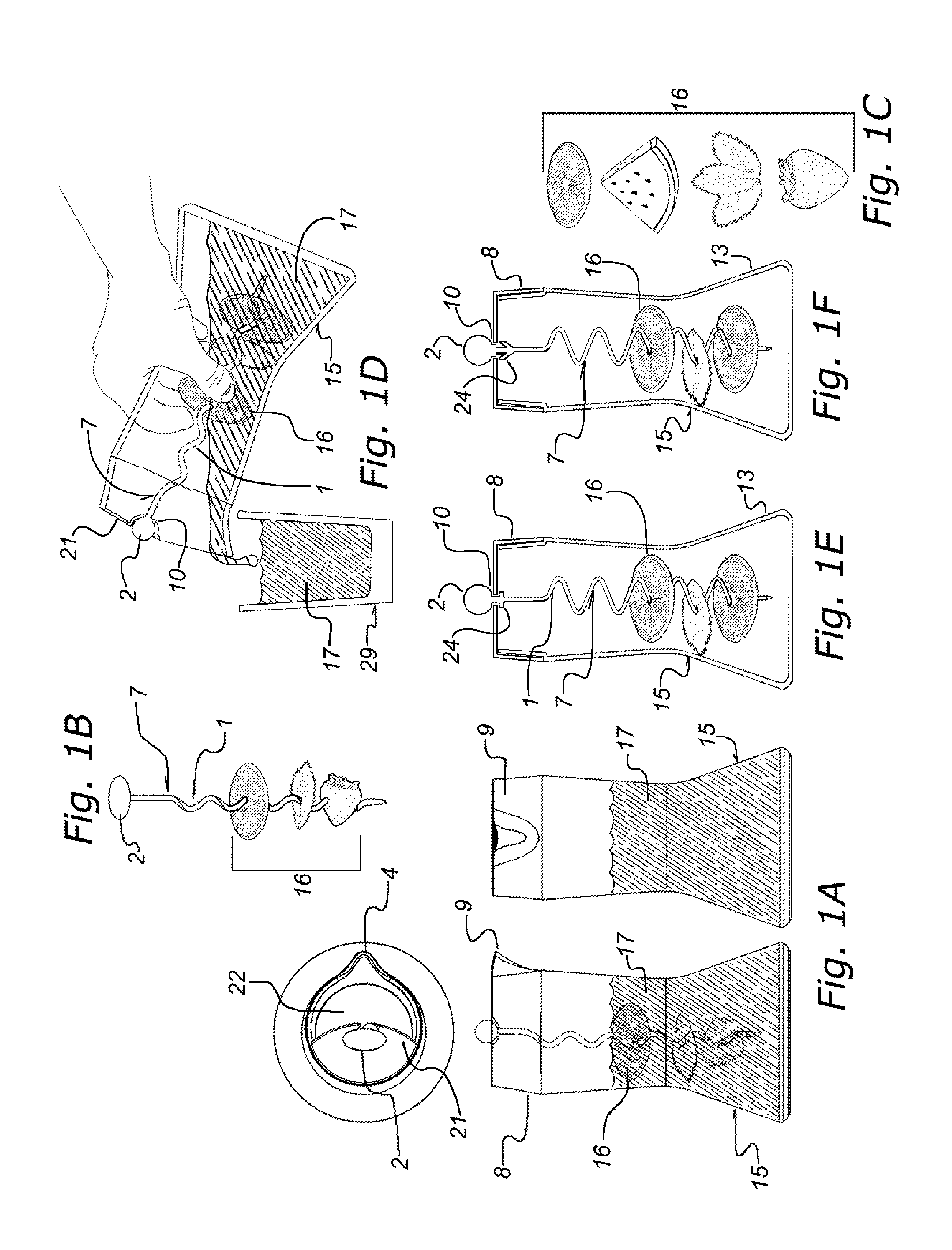

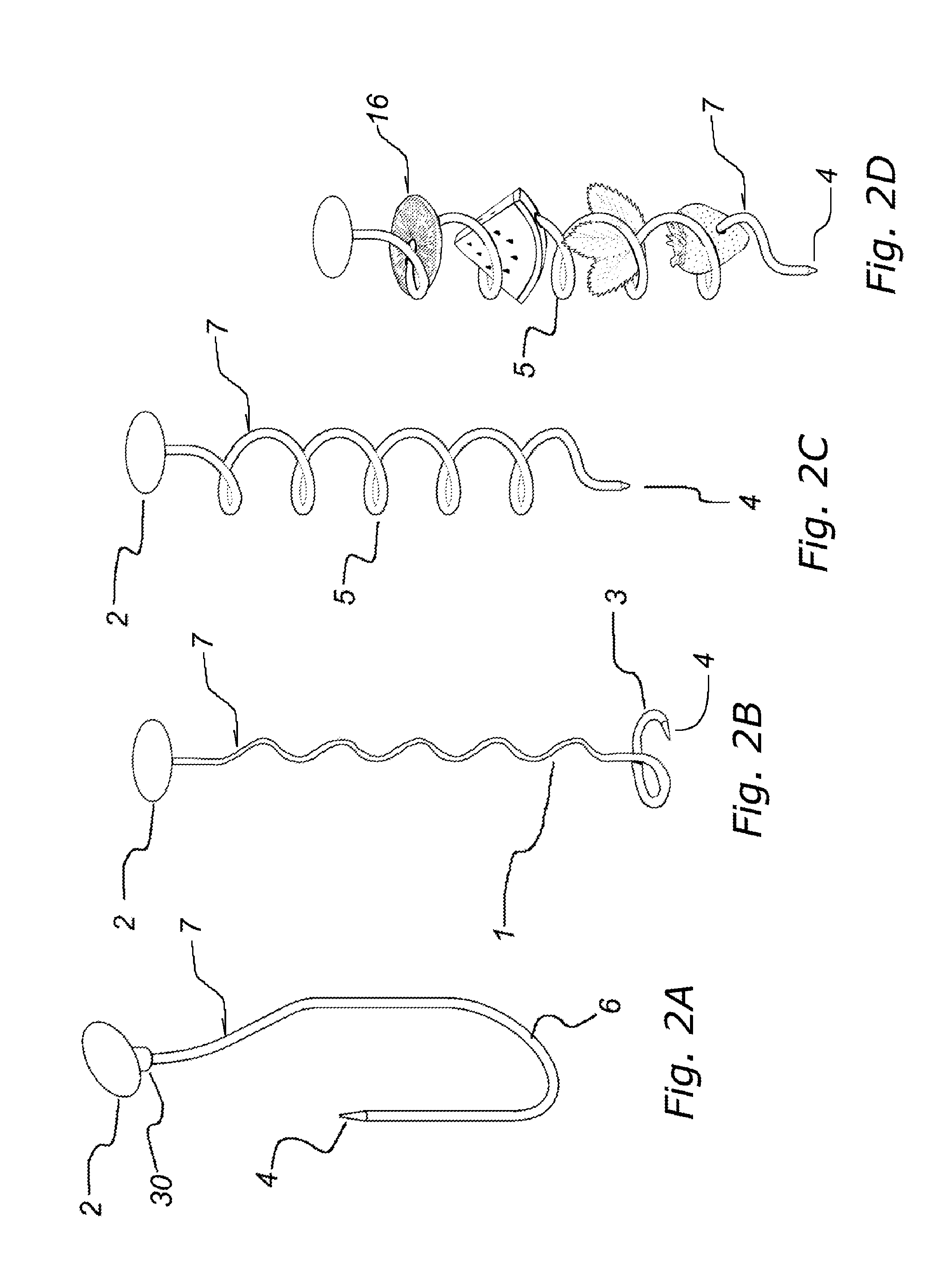

Flavor Infusion Pitcher

InactiveUS20140026758A1Bolstering visual appealAdd flavorBeverage vesselsFlavorUltimate tensile strength

A means of suspending flavor medium(s) within a pitcher or vessel containing a consumable liquid. The flavor medium(s) is retained by a removable, substantially central stem(s) which locates to and extends into the vessel. The stem(s) can be made of Stainless Steel, wood, or plastic and be flexible or rigid. The stem can be configurable to be “U” shaped, helical shaped, zigzag shaped, or other shape that aids in retaining fruit, herbs, or other desirable flavor medium(s). The stem functions to hold flavor medium(s) in place while submerging them and while pouring from the vessel. The flavor medium(s) are to be pierced or held under tension while submerged, and function to transfer flavor enhancement to the vessel's beverage with proportional strength to the length of time they are allowed to meld. The insertion of the stem and flavor medium(s) inside the vessel also functions to create an aesthetically pleasing presentation.

Owner:SANTARSIERO PAUL

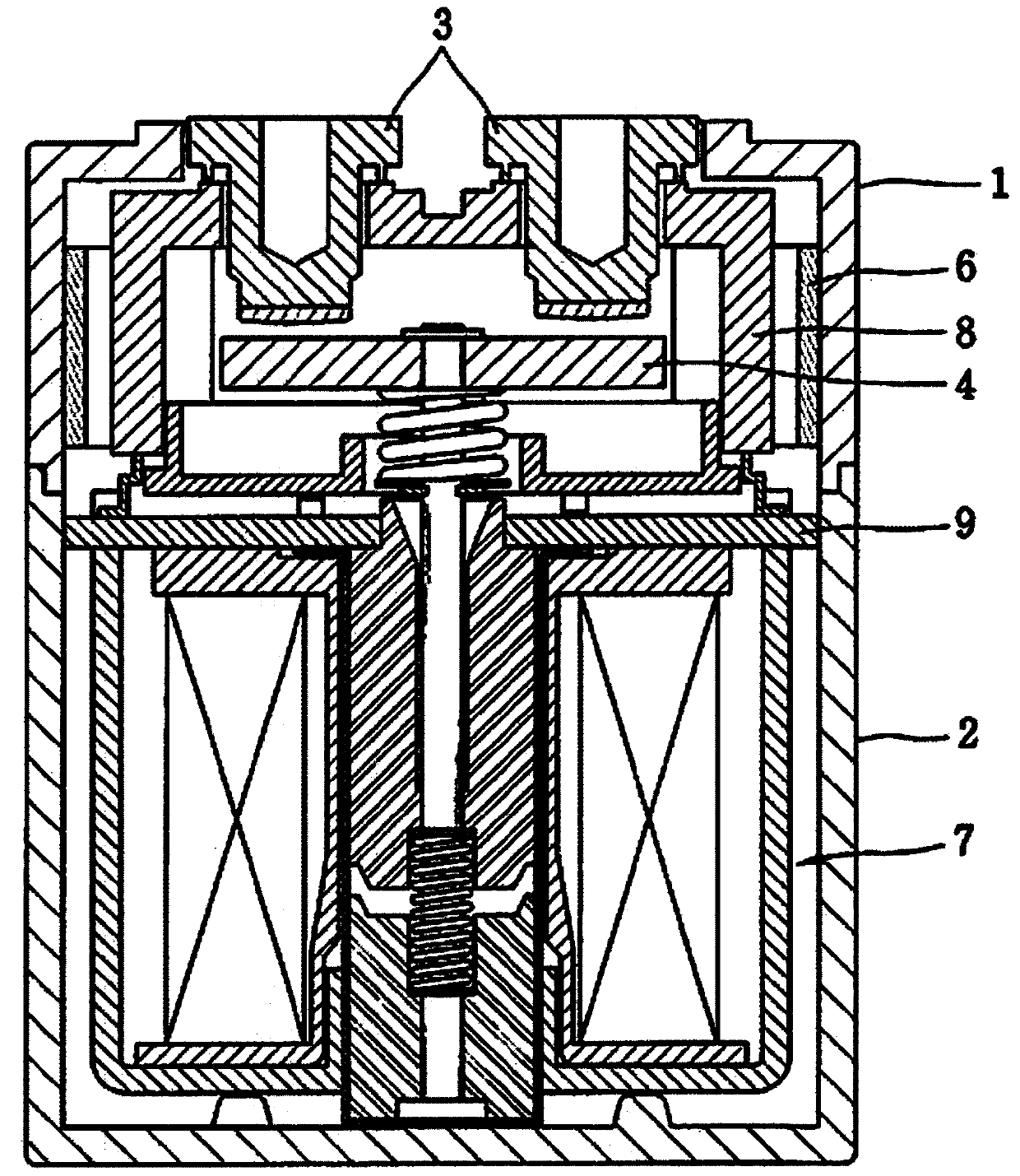

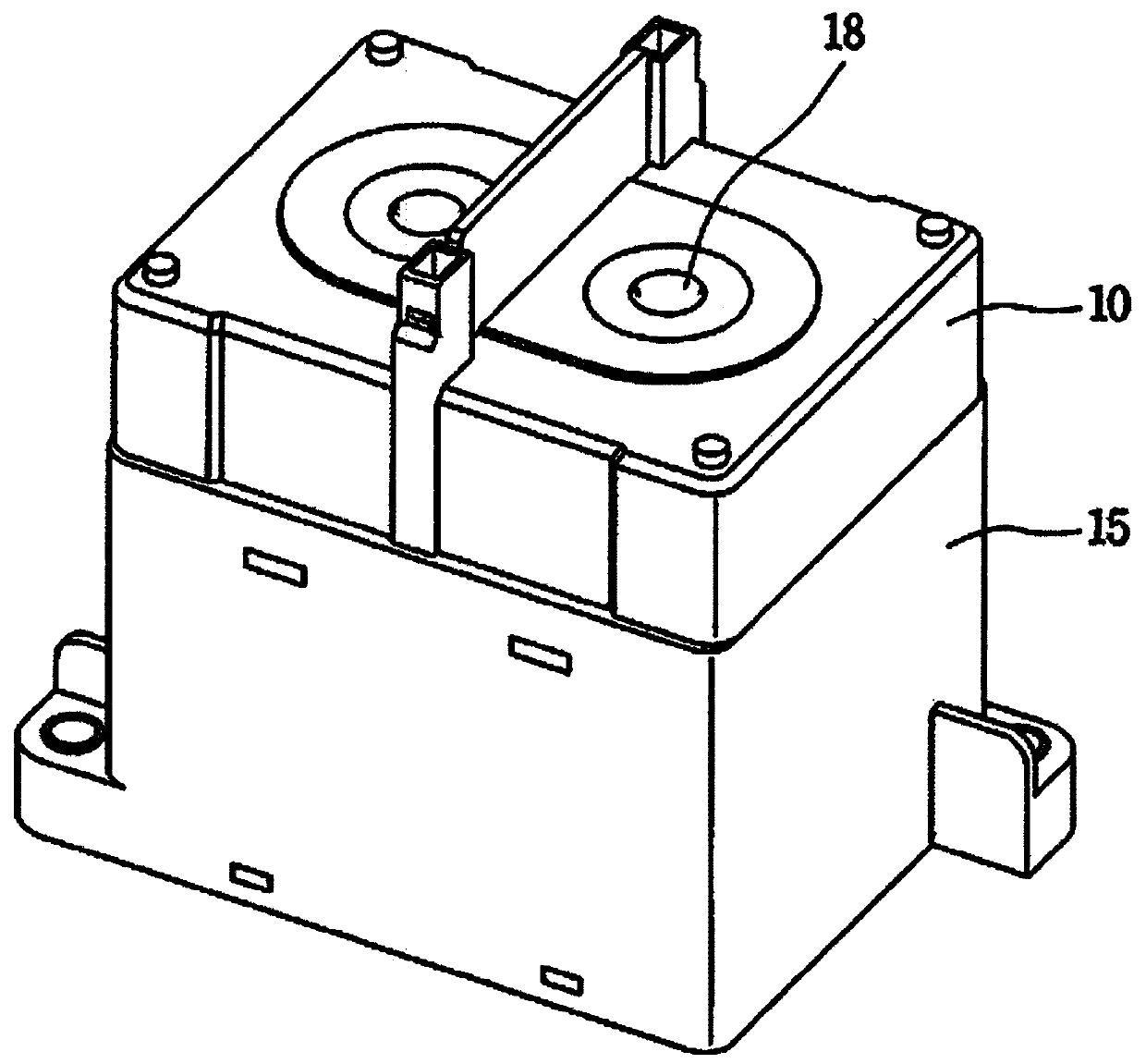

Direct current relay having permanent magnet housing

ActiveCN111512409AIncrease contact areaFixed state stableElectromagnetic relay detailsMechanical engineeringDirect current

The present invention relates to a direct current relay and, more specifically, to a direct current relay having a permanent magnet housing. A direct current relay having a permanent magnet housing according to one embodiment of the present invention comprises: an upper frame having an open lower surface, and a lower frame having an open upper surface and coupled to the lower portion of the upperframe; a permanent magnet housing formed in a box shape having an open lower surface, disposed inside the upper frame or lower frame, and having a permanent magnet insertion portions provided on eachof the front surface and the rear surface thereof; a permanent magnet arranged in the permanent magnet insertion portion; and a permanent magnet holder coupled to the permanent magnet housing and supporting the permanent magnet.

Owner:LS ELECTRIC CO LTD

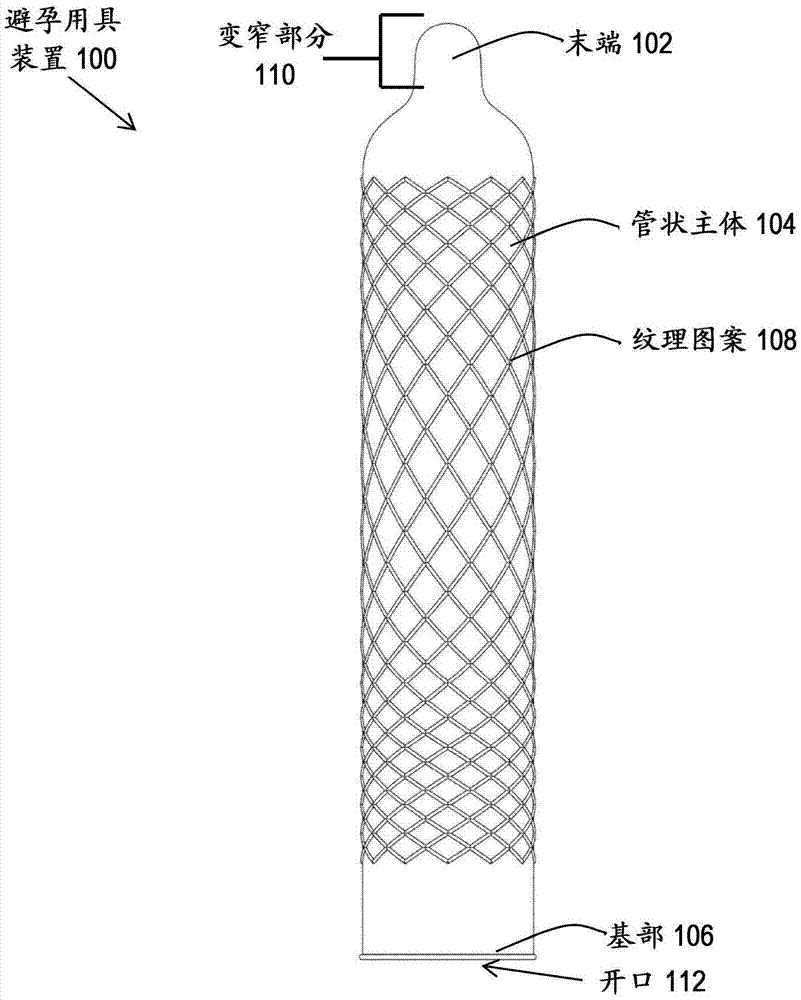

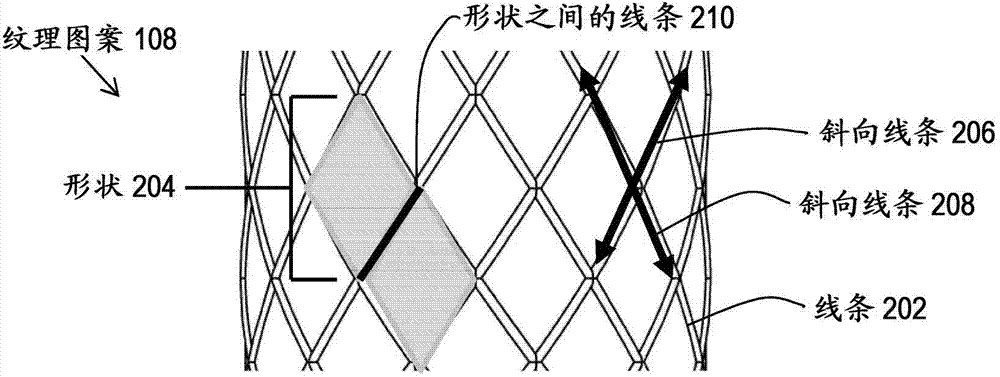

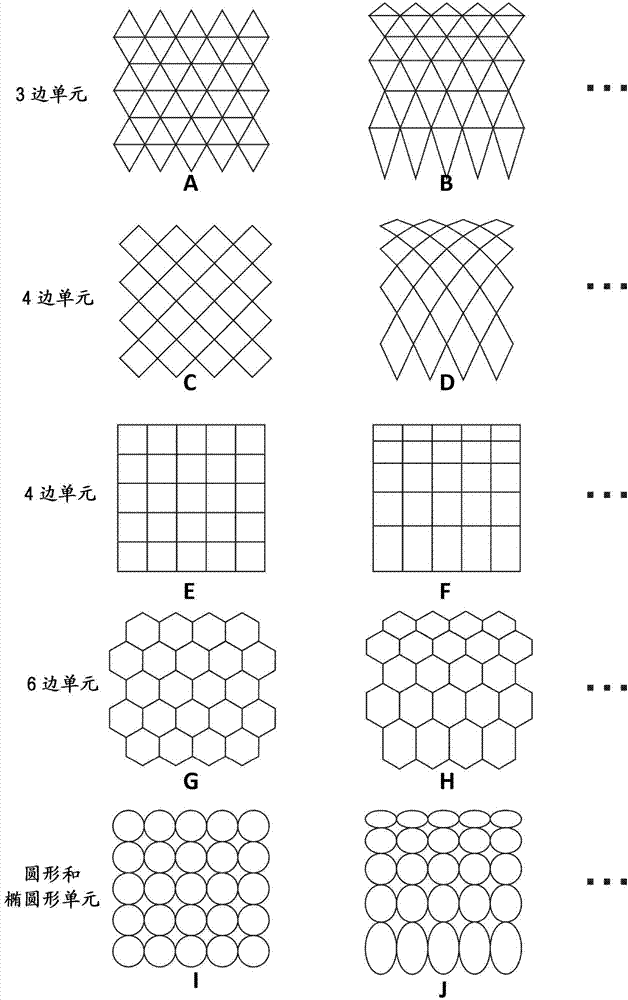

Prophylactic having a textured pattern

ActiveCN103800115AHigh strengthIncrease elasticityMale contraceptivesGenitals massageEngineeringBody fluid

Owner:莱珞公司

Flexible mount for a fan and like devices

InactiveCN101784817BStay in placeQuick installationPump componentsNon-rotating vibration suppressionEngineeringMechanical engineering

A flexible and stretchable mounting device for a fan or the like which has a shaft, a series of enlarged undulations axially arranged at one end of the shaft, and a head at one end of the shaft, the mounting device being adapted when stretched for insertion into aligned apertures on a chassis and a frame and relaxed to permit a selected undulation to hold the frame in spaced relation to the chassis. The device also includes a break away grip secured to the head for guiding the device into the apertures when stretched and which can be severed from the head when the device is arranged mounted on the chassis and frame.

Owner:RICHCO

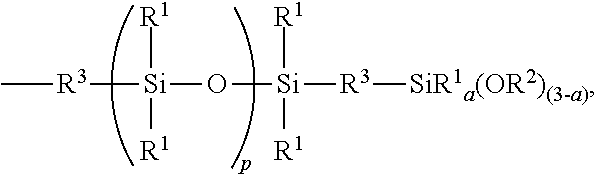

Thermal gap filler and its application for battery management system

PendingUS20210269643A1Improve heat transfer performanceLow modulusCell temperature controlPolymer sciencePtru catalyst

A thermally conductive silicone composition is provided. The composition comprises: (A) an alkenyl group-containing organopolysiloxane; (B) an organohydrogenpolysiloxane having an average of two to four silicon-bonded hydrogen atoms in a molecule, wherein an amount of the silicon-bonded hydrogen atoms in component (B) is 0.2 to 5 moles per mole of the alkenyl groups in component (A), and at least two of the silicon-bonded hydrogen atoms are located on the side chains of the molecule; (C) a hydrosilylation reaction catalyst; (D) a thermally conductive filler; (E) an alkoxysilane having an alkyl group containing 6 or more carbon atoms in a molecule; and (F) glass beads. A thermally conductive member is produced from the thermally conductive silicone composition. An electronic device has the thermally conductive member and a manufacturing method of the electronic device includes using the thermally conductive silicone composition.

Owner:DOW SILICONES CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com