Patents

Literature

45 results about "Tangential displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tangential displacement is the distance that a given point travels around the circumference of a circle as a function of anangular displacement in radians. tangential speed is the speed at which a point travels around the circumference of a circle as a function of an angularvelocity in radians.

Method for determining a surface contact force

ActiveUS7127950B2Aerodynamic testingForce measurement by measuring optical property variationLuminophoreTangential displacement

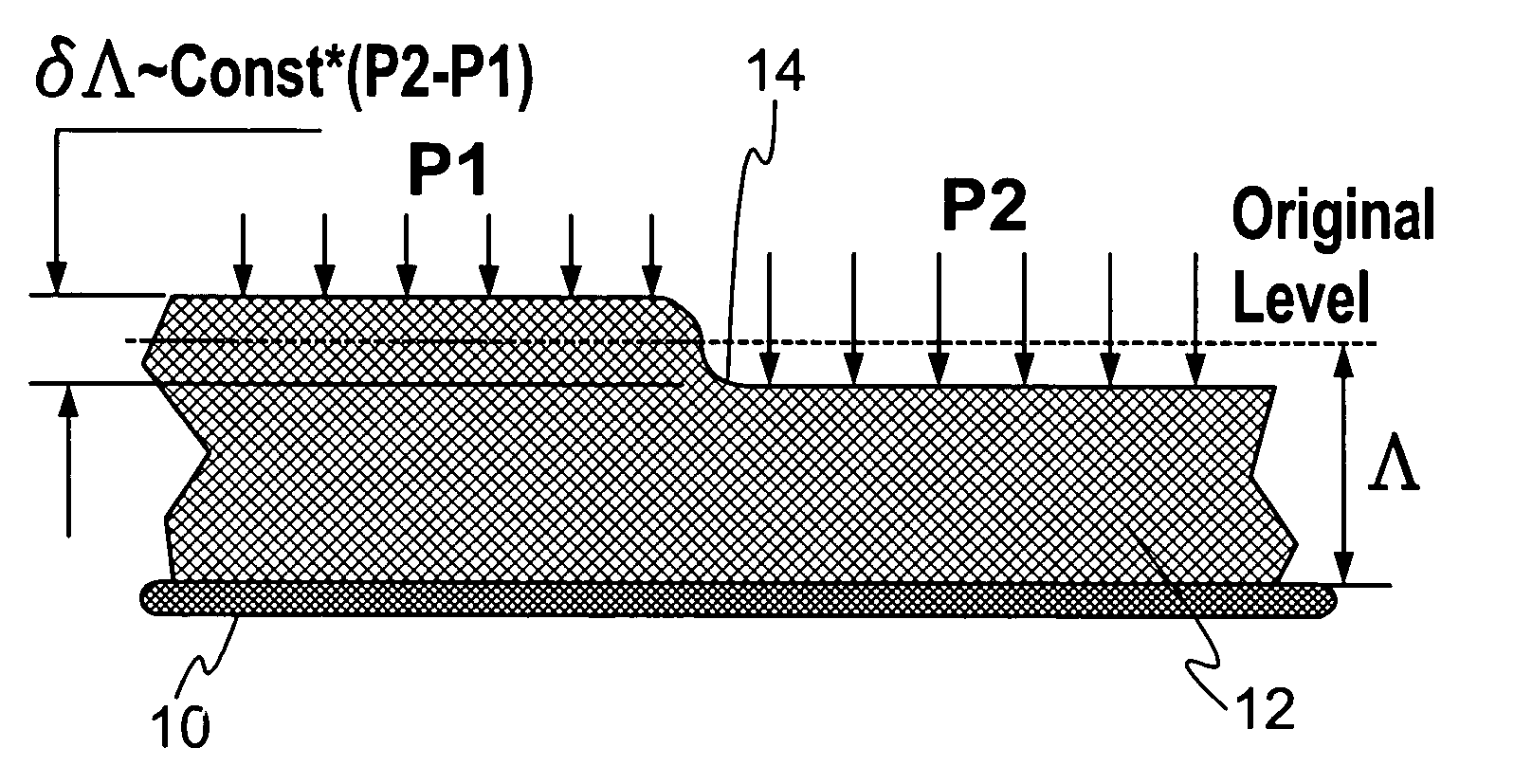

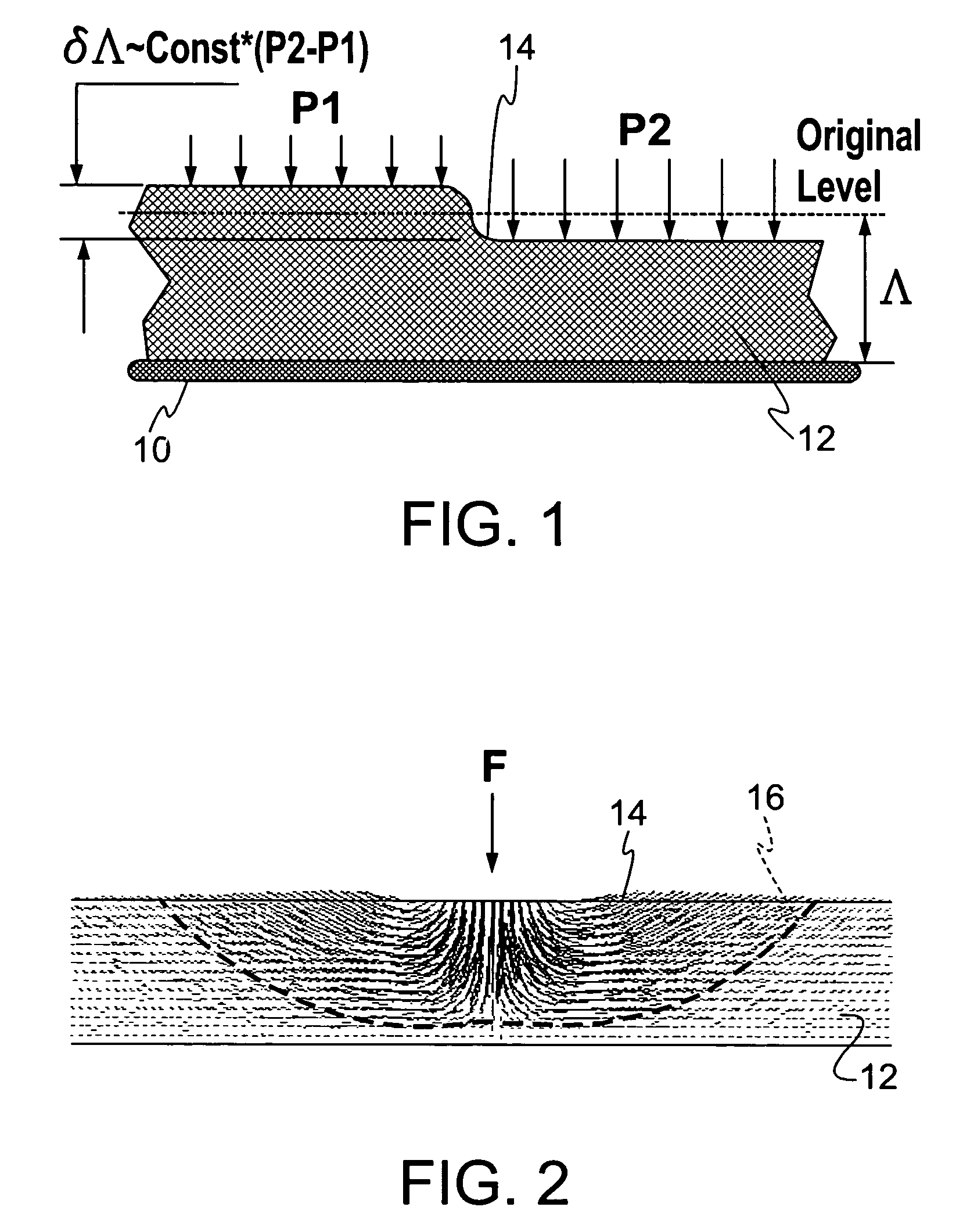

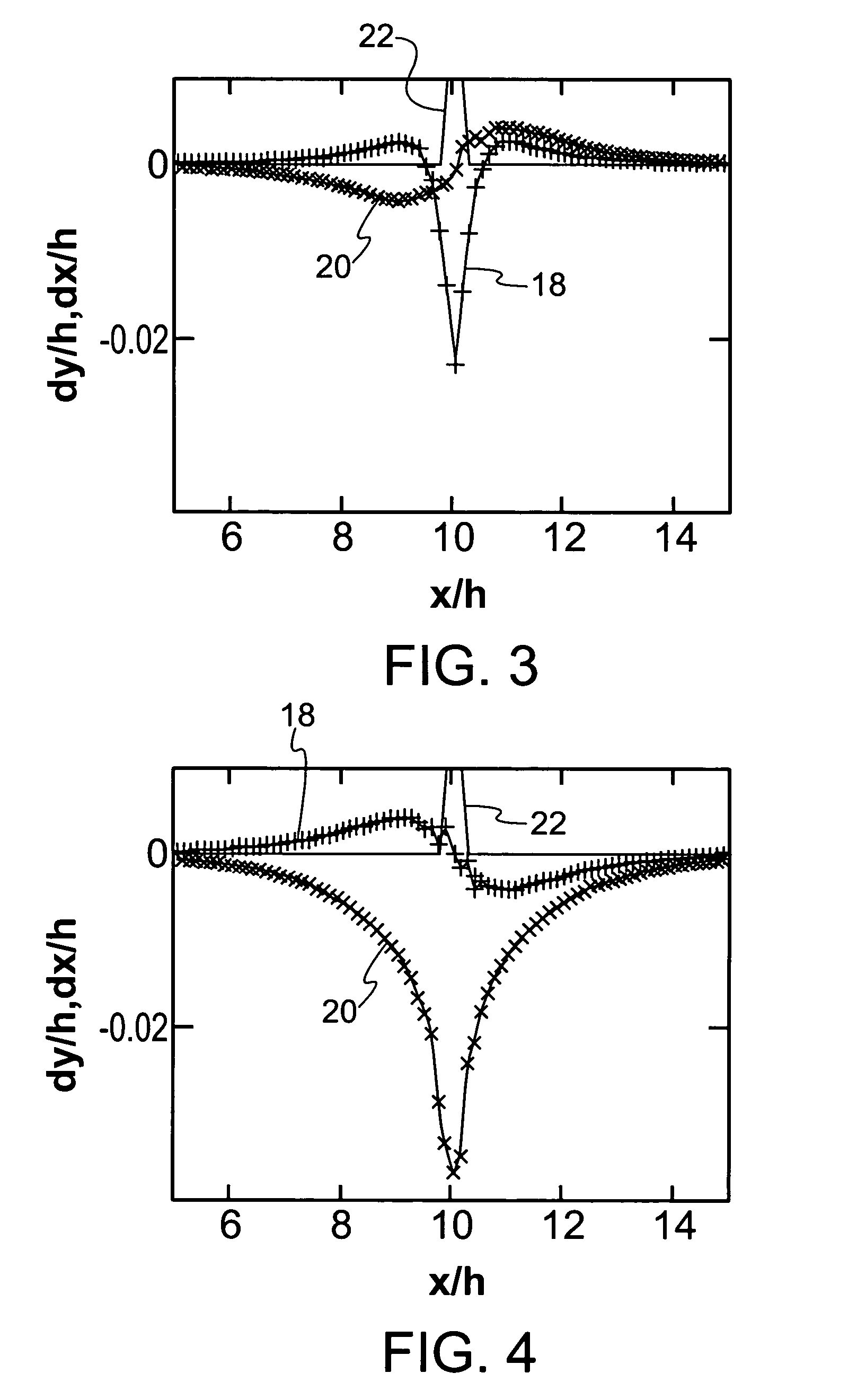

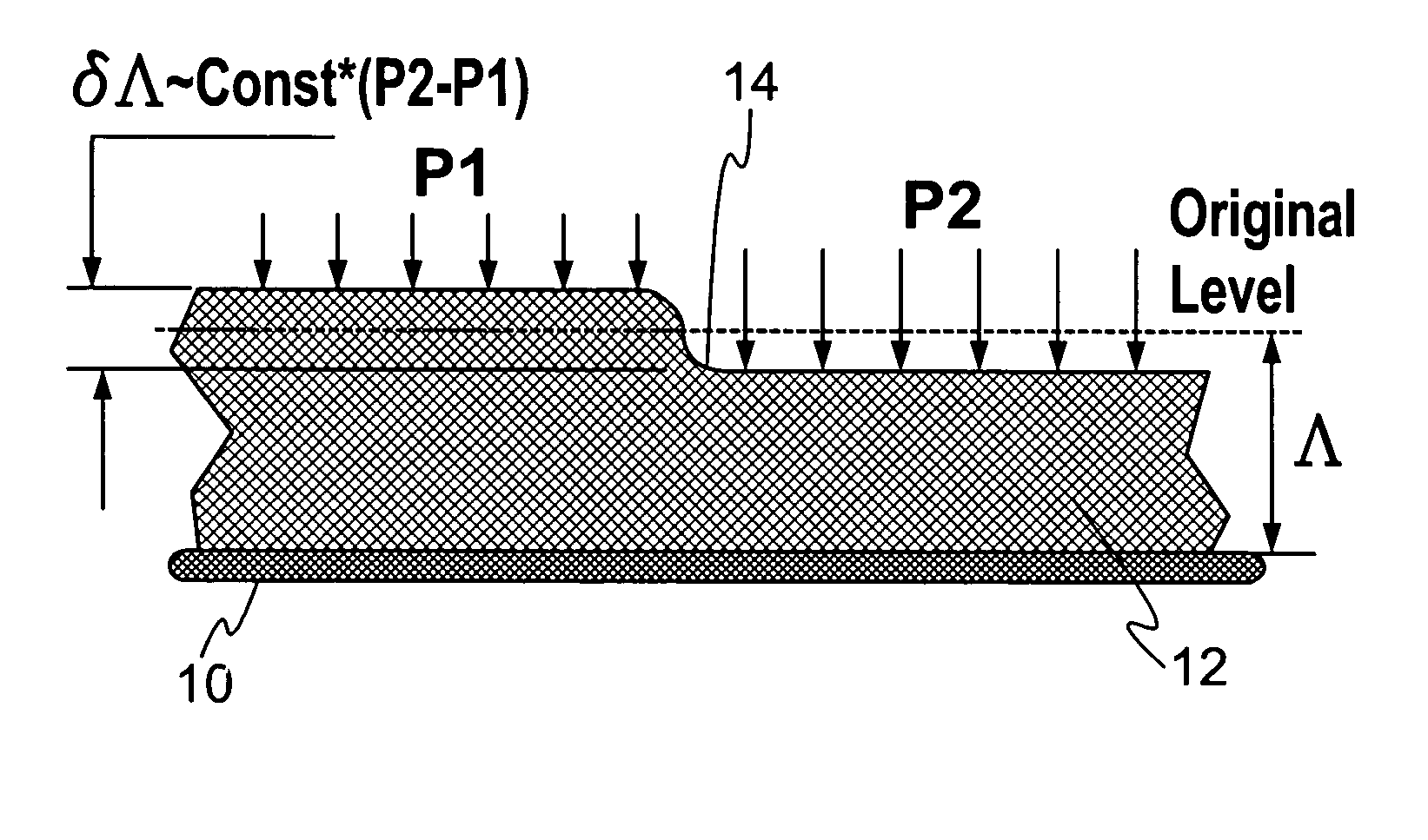

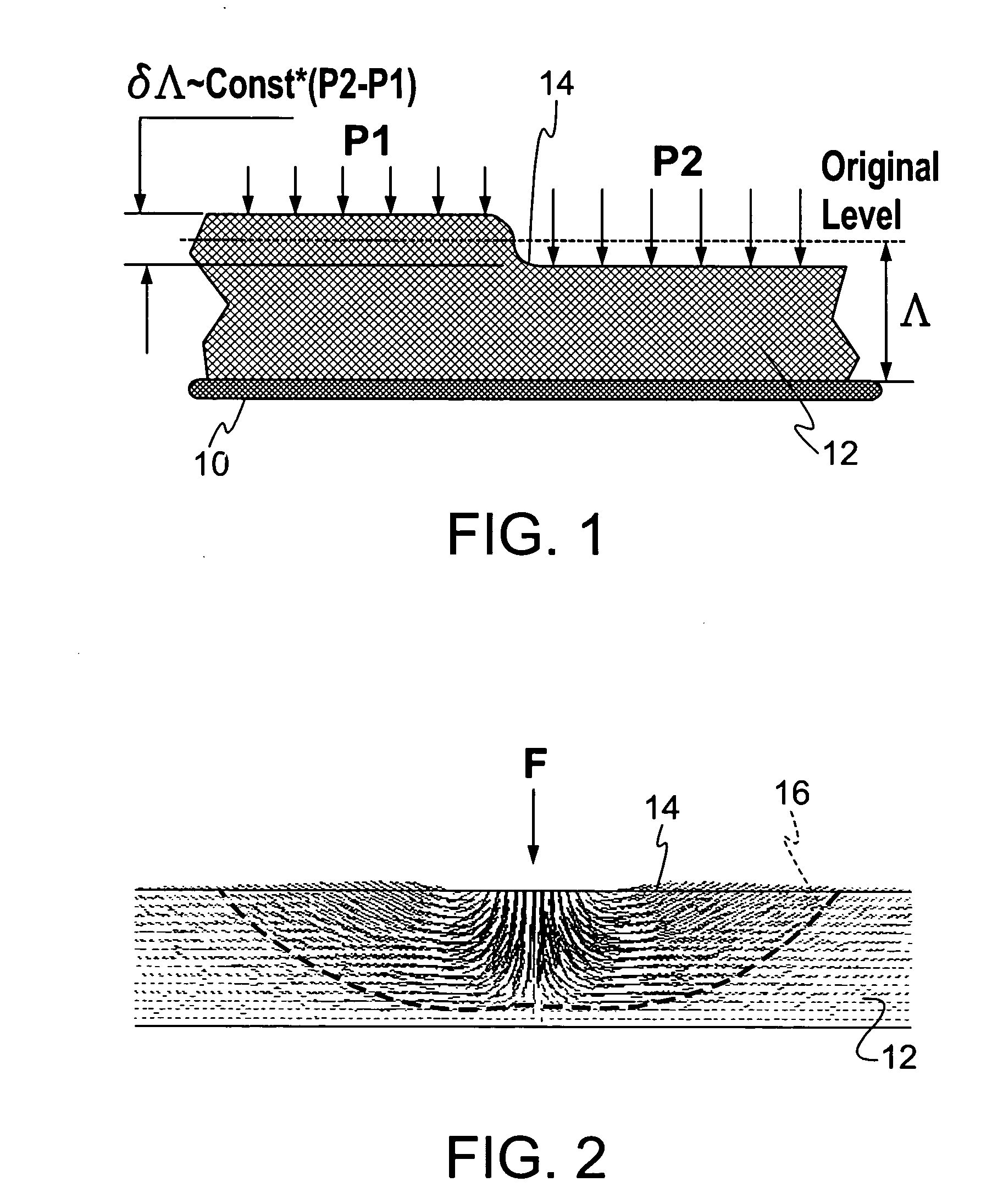

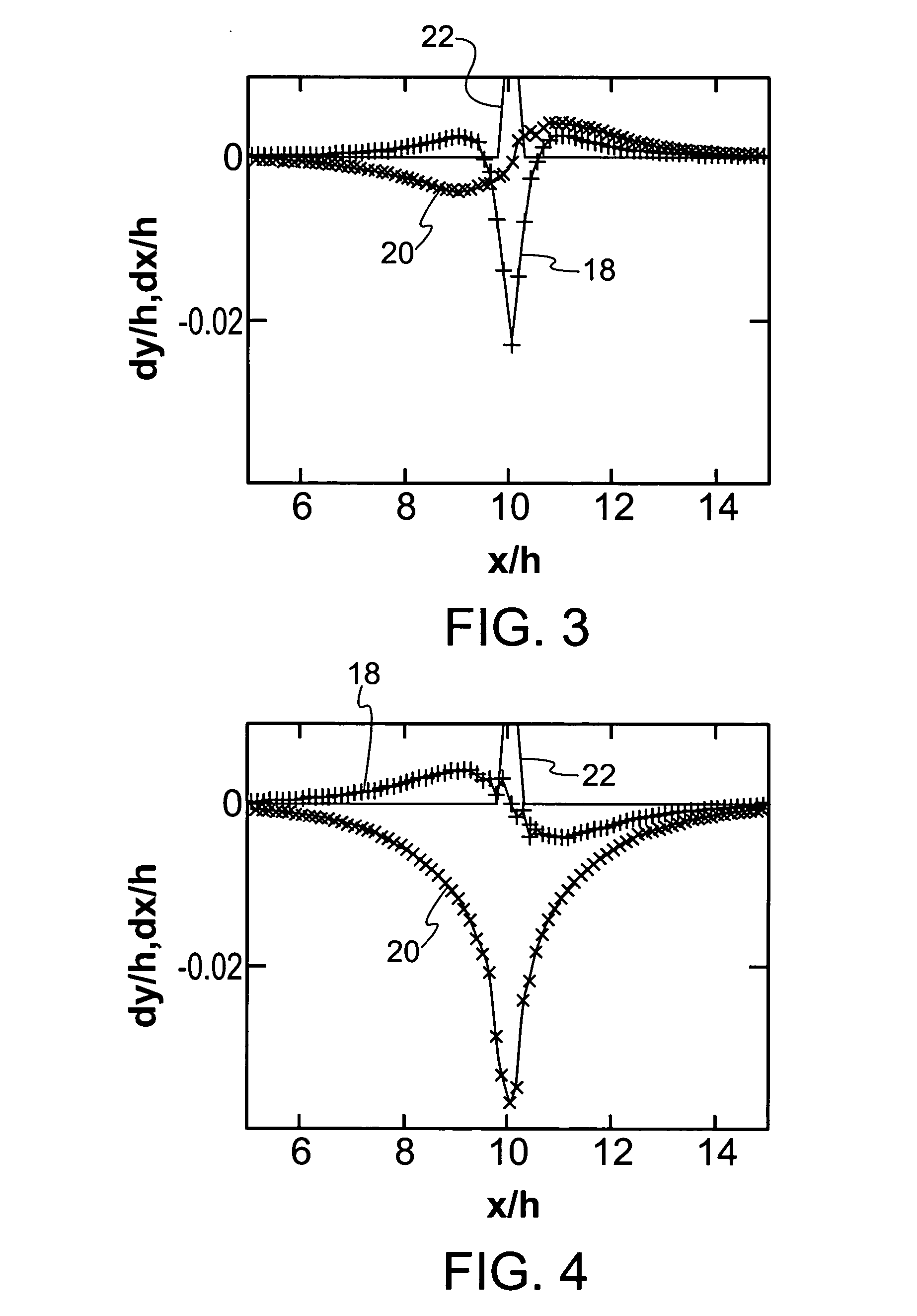

A method of measuring a load on a surface produced by a contact force. An elastic film or coating is located on a supporting surface to provide an indication of normal and tangential or shear forces applied to the surface. A thickness measurement, corresponding to a normal displacement, and a tangential displacement of the film, corresponding to a shear displacement, is obtained and input to a response function to reconstruct the normal and shear load components of the contact force on the surface. A differential thickness measurement of the film is detected by an optical method in which a luminescent output from a luminophore in the film is measured. A luminescent output from a reference luminophore located below the film is also measured to provide a measurement system independent of the illumination source used to produce the luminescent output.

Owner:INNOVATIVE SCI SOLUTIONS

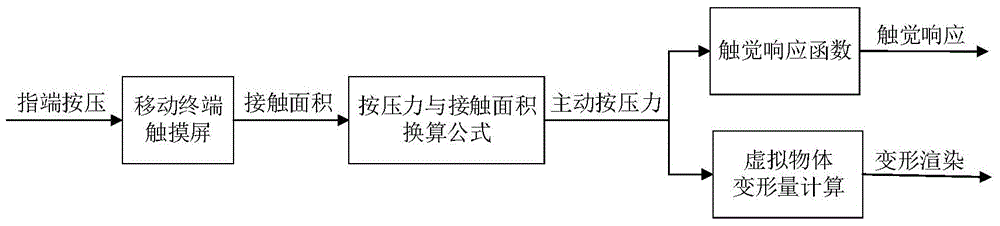

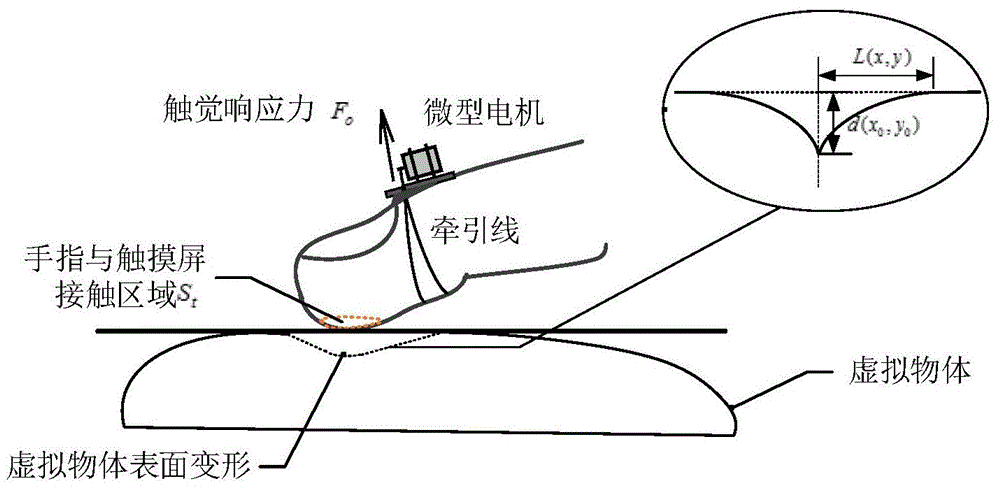

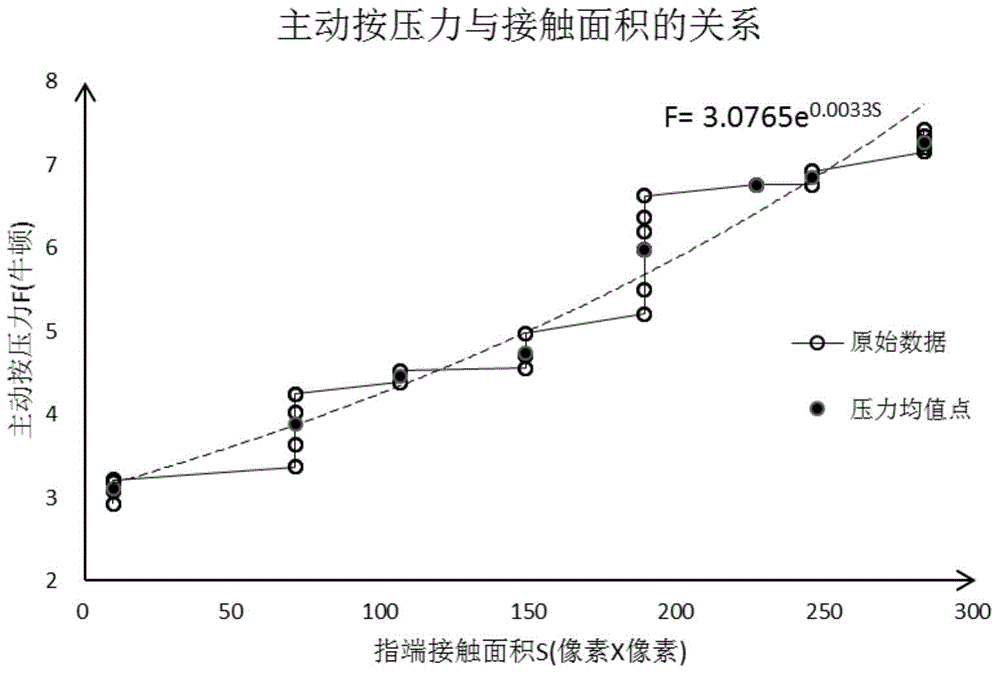

Flexible object tactile modeling and expressing method applied to mobile terminal

InactiveCN104834380AReal tactile experienceAccurate interactionInput/output for user-computer interactionGraph readingRelative displacementTouch Perception

The invention discloses a flexible object tactile modeling and expressing method applied to a mobile terminal. The method is characterized in that the change of a contact area between a human finger end and a touch screen is obtained in real time on the mobile terminal by utilizing a contact area detection function of the mobile terminal, then the magnitude of finger press force is calculated according to pre-marked relation between the press force and the contact area and is used for calculating tactile response and virtual flexible object deformation, then contact force is fed back to a user in virtue of a certain tactile reproduction device, and meanwhile a deformation effect is displayed on the mobile terminal. The method has the advantages that 1, the problem that traditionally, in case of touch screen-based tactile reproduction, only tangential displacement is detected, and normal direction relative displacement cannot be directly detected is solved; 2, based on a principle that acting force and counter-acting force are balanced, the accurate calculation of virtual contact force is realized; 3, by considering object hardness and the magnitude of the finger active press force, deformation rendering and touch interaction with sense of reality are realized.

Owner:SOUTHEAST UNIV

Space on-orbit capturing device based on bionic gecko dry adhesive material

The invention discloses a space on-orbit capturing device based on a bionic gecko dry adhesive material. The space on-orbit capturing device comprises an adhesion mechanism, a transmission mechanism, a drive mechanism and a bottom plate, wherein the adhesion mechanism comprises a loading tendon, a connecting tendon and the like as well as adhesion mechanism upper layers, flexible supporting parts and adhesion mechanism lower layers which are arranged in pairs; the adhesion mechanism upper layers are fixedly arranged on the lower bottom surface of the bottom plate; the flexible supporting parts are camped between the adhesion mechanism upper layers and the adhesion mechanism lower layers in a winding mode; adhesion materials are arranged on the lower surfaces of the adhesion mechanism lower layers; the two ends of the connecting tendon are fixedly arranged on the center positions of the adhesion mechanism lower layers separately; one end of the loading tendon is arranged on the middle position of the connecting tendon; the transmission mechanism comprises a plurality of fixed pulley assemblies, movable pulley assemblies and a return spring which are in series connected to form a closed loop through pulley lines; and the drive mechanism is started and the pulley lines are tightened to drive the movable pulley assemblies to move, the return spring is stressed to draw out, and the loading tendon and the connecting tendon are stressed to tighten, so that the adhesion mechanism lower layers generate tangential displacement, and the adhesion materials are in loading state to generate normal adhesion force.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

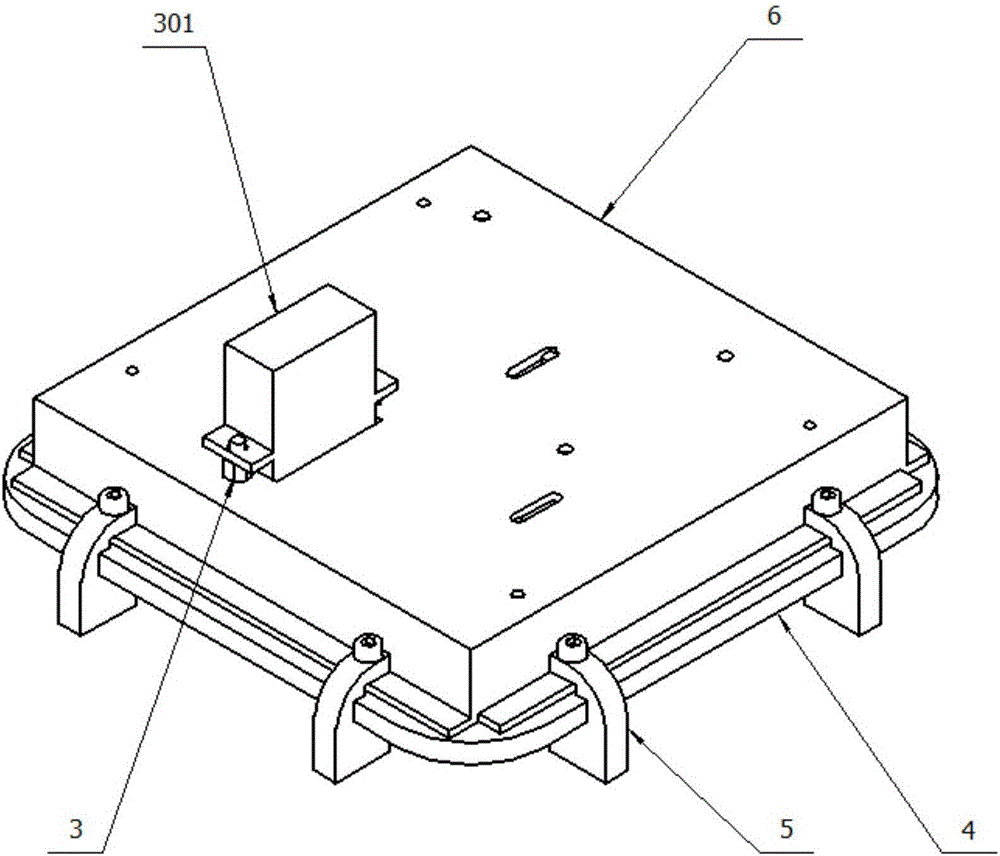

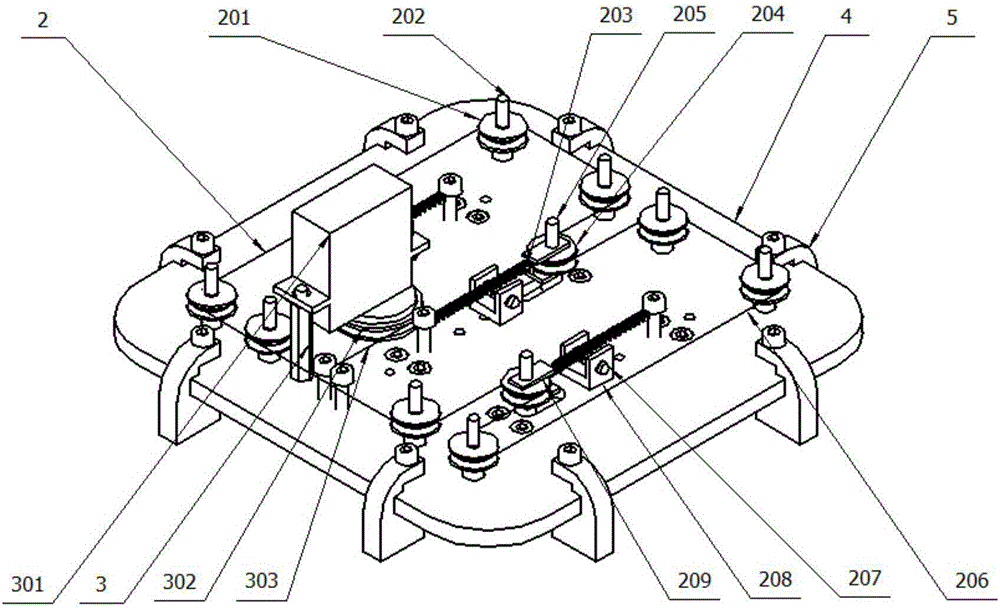

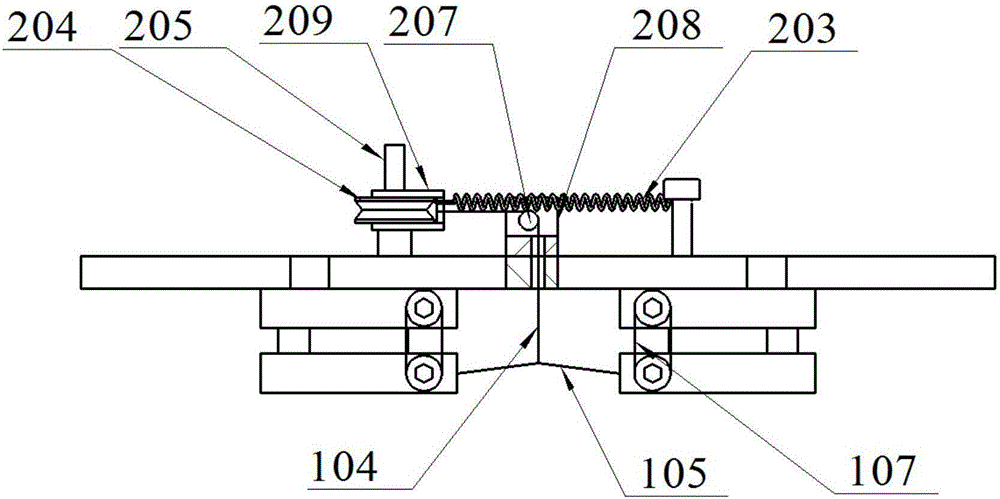

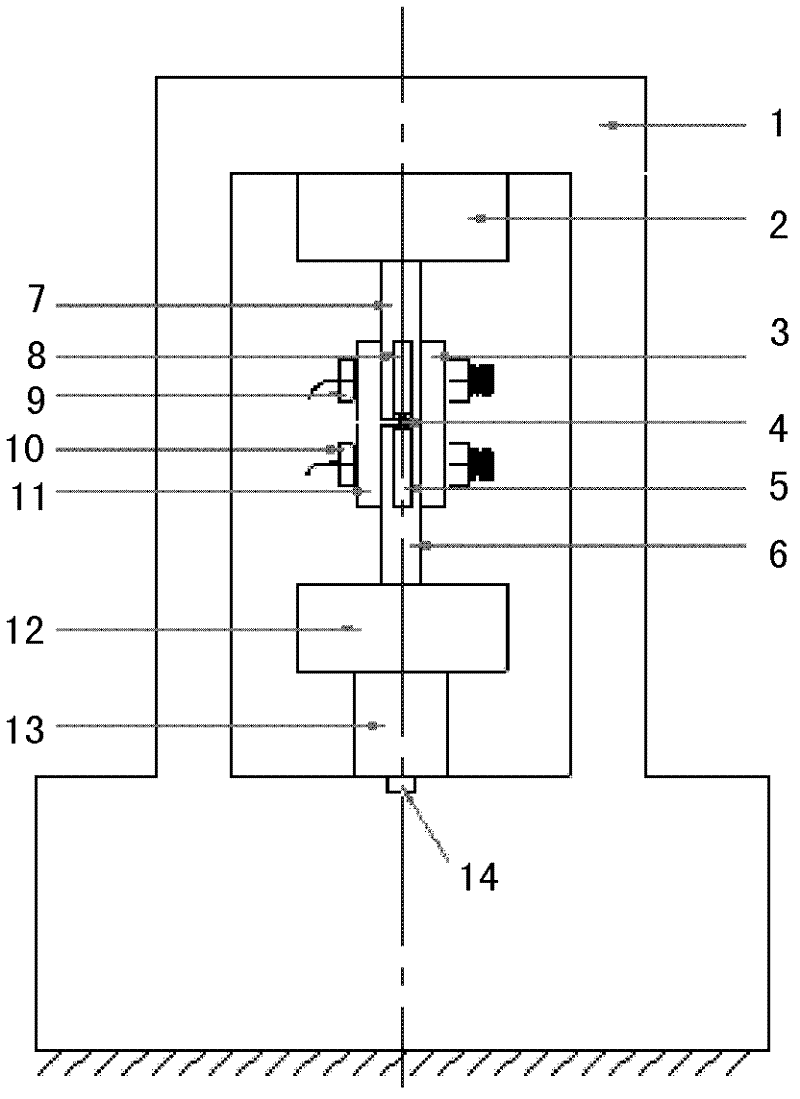

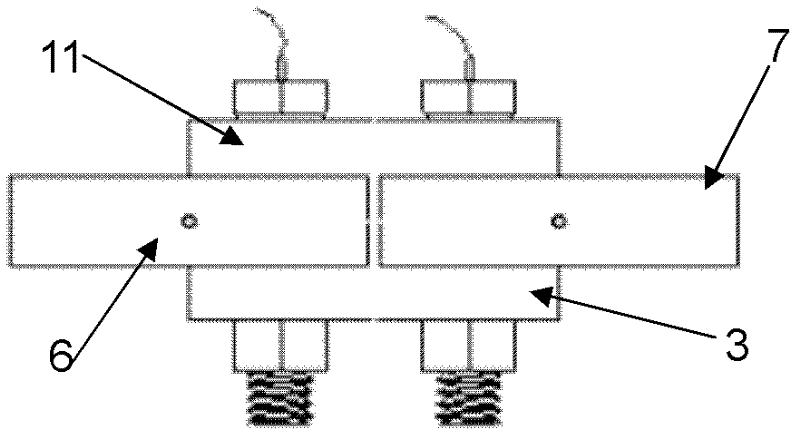

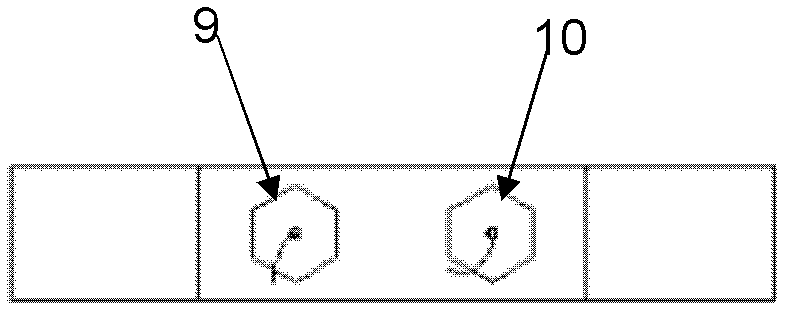

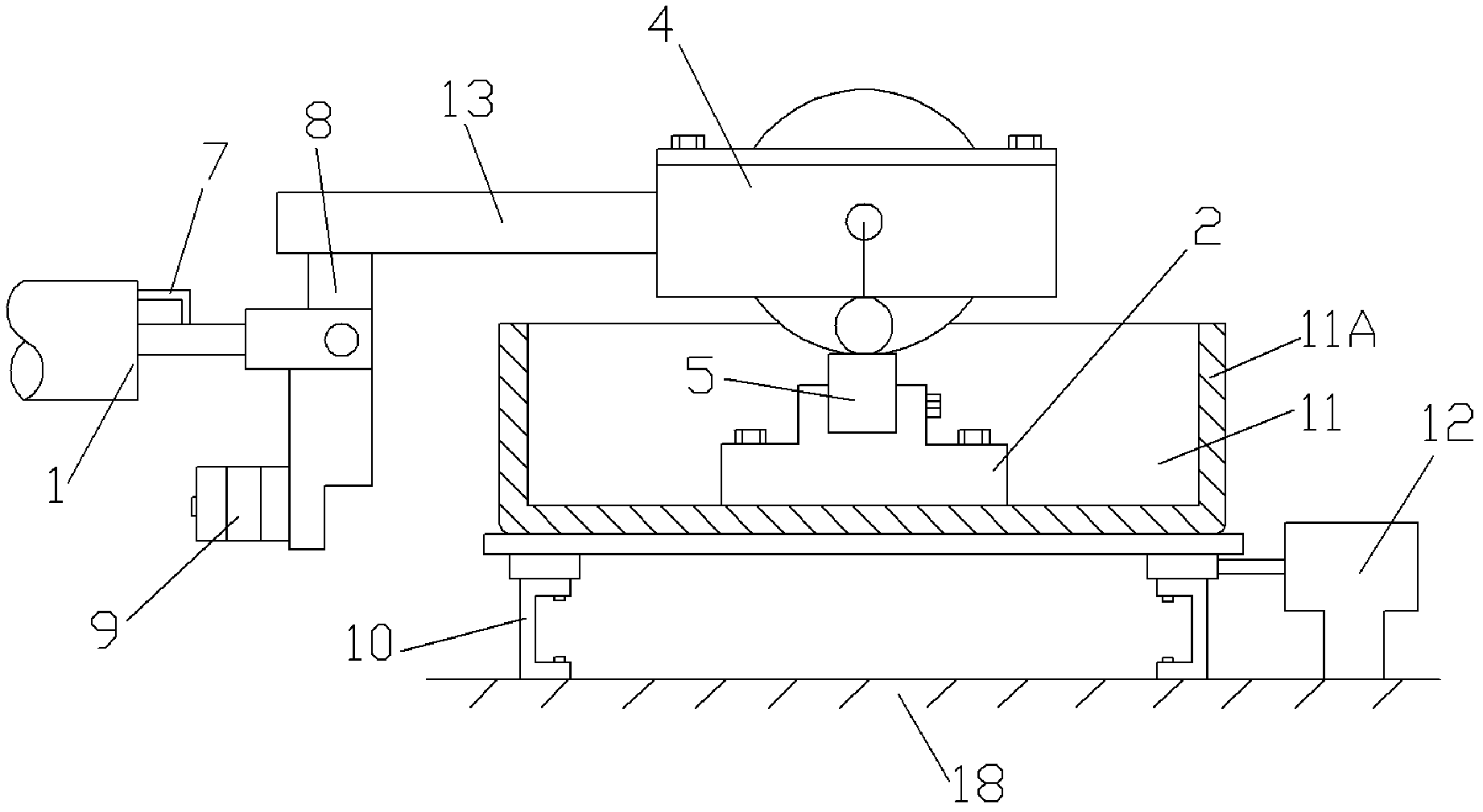

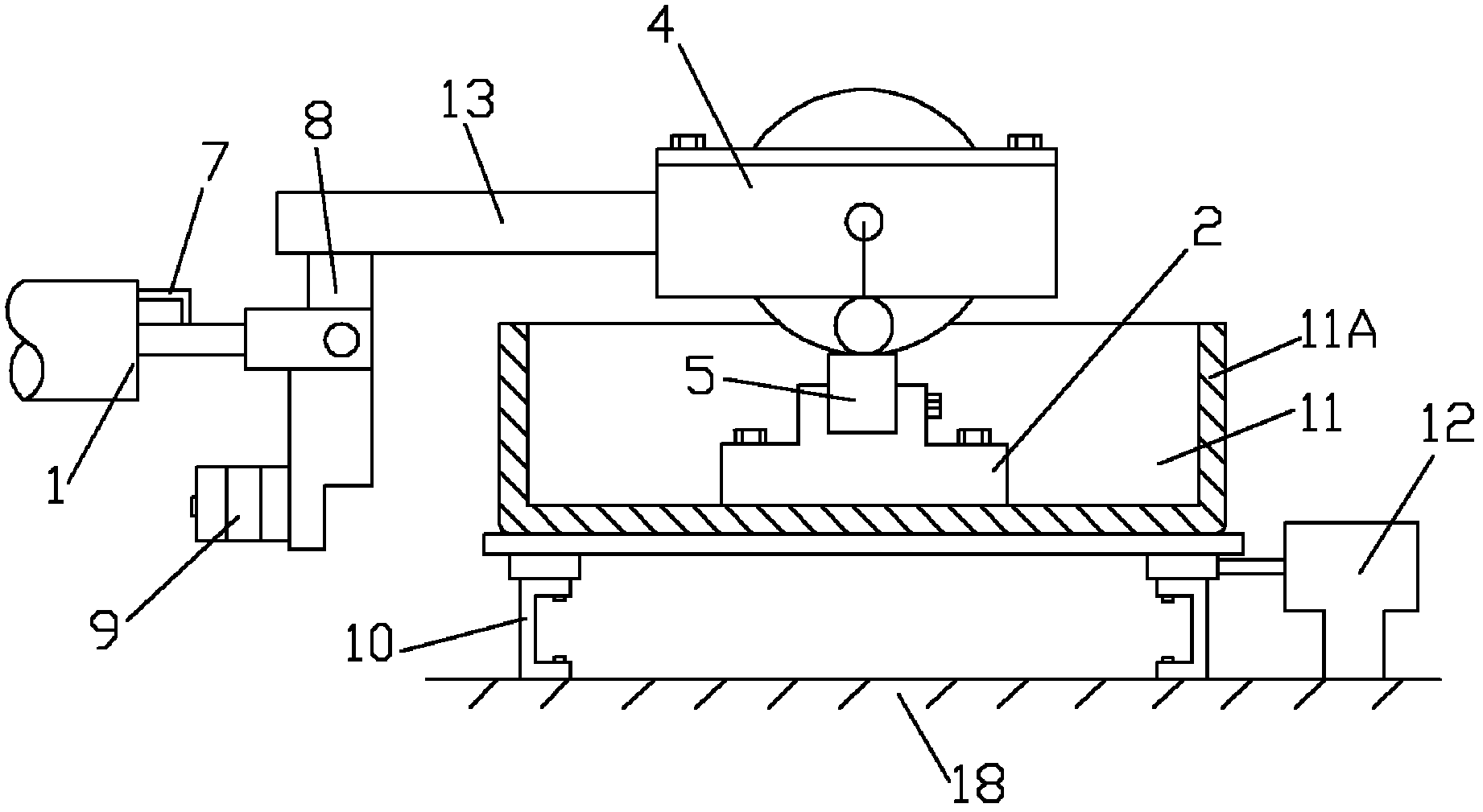

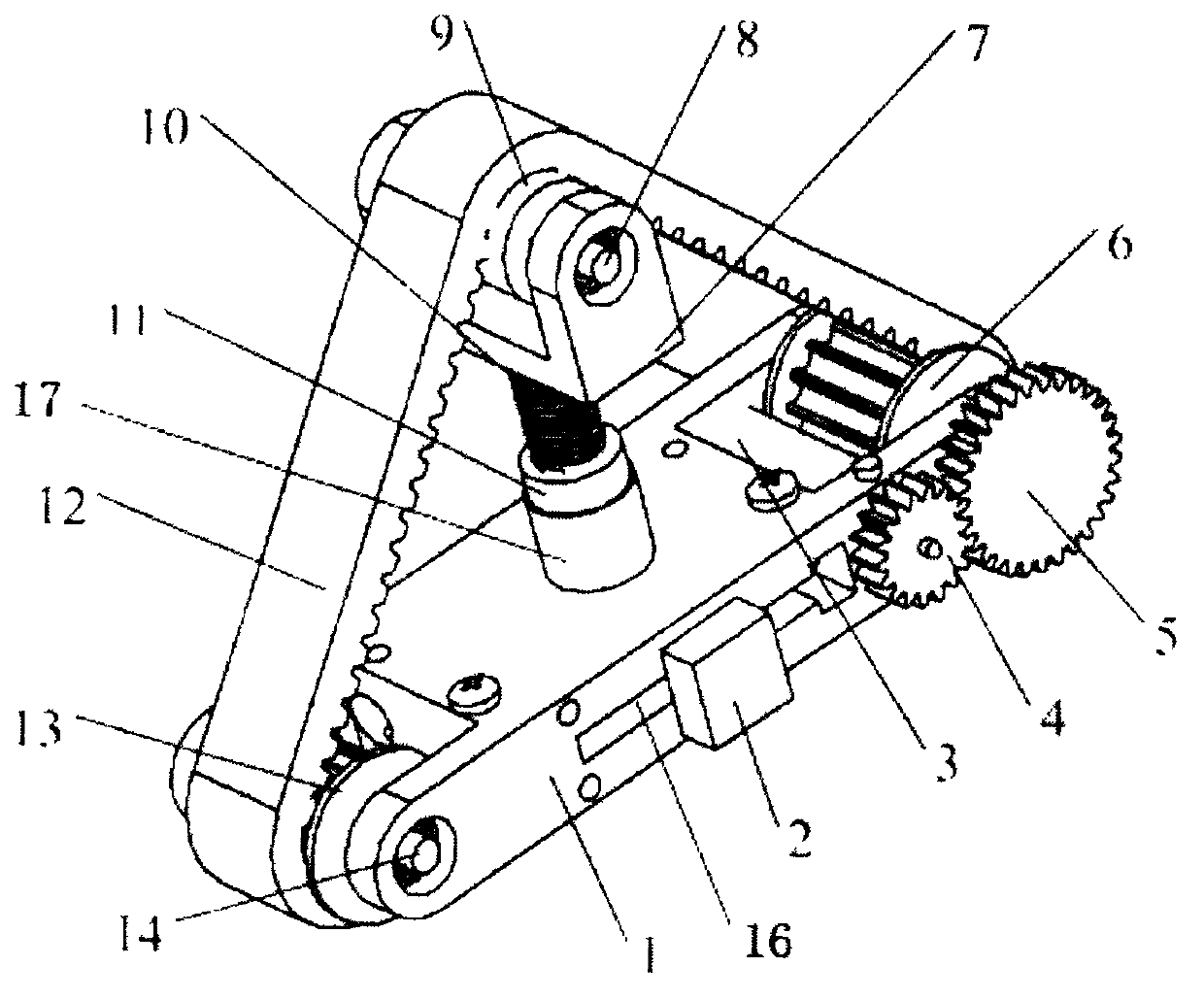

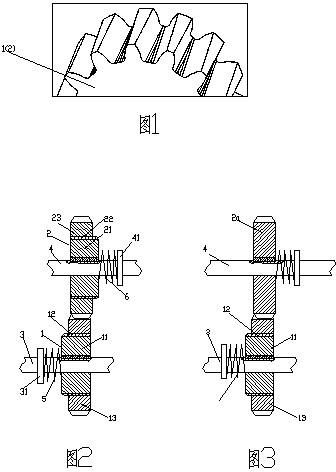

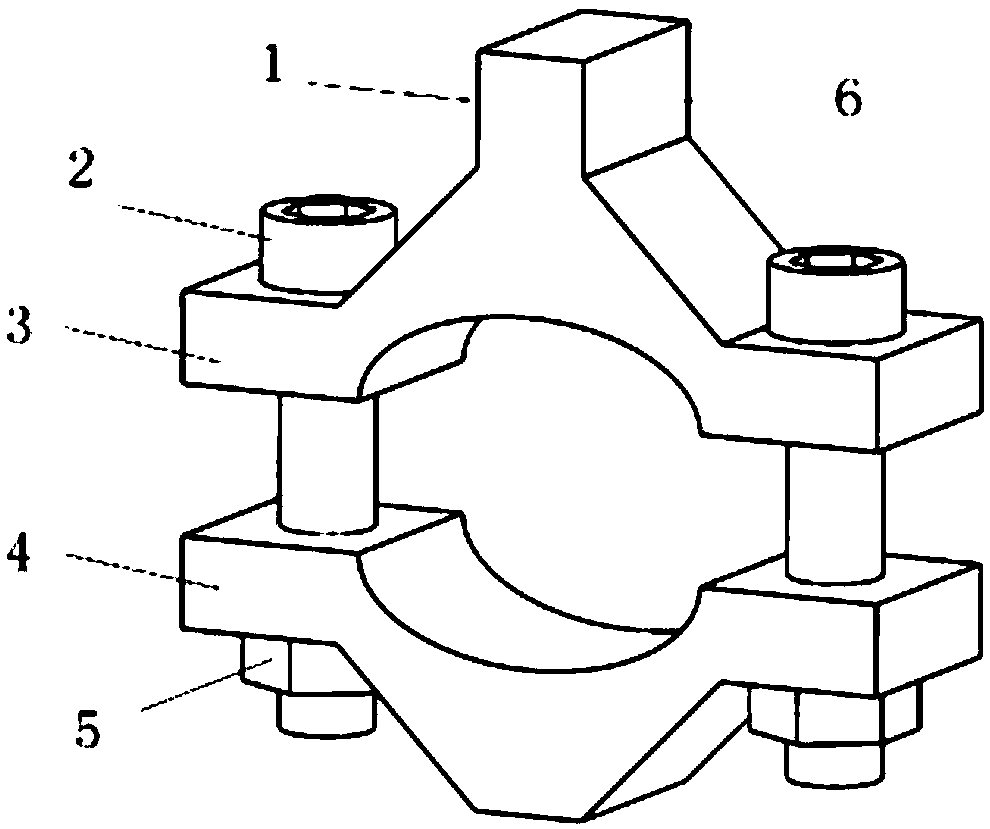

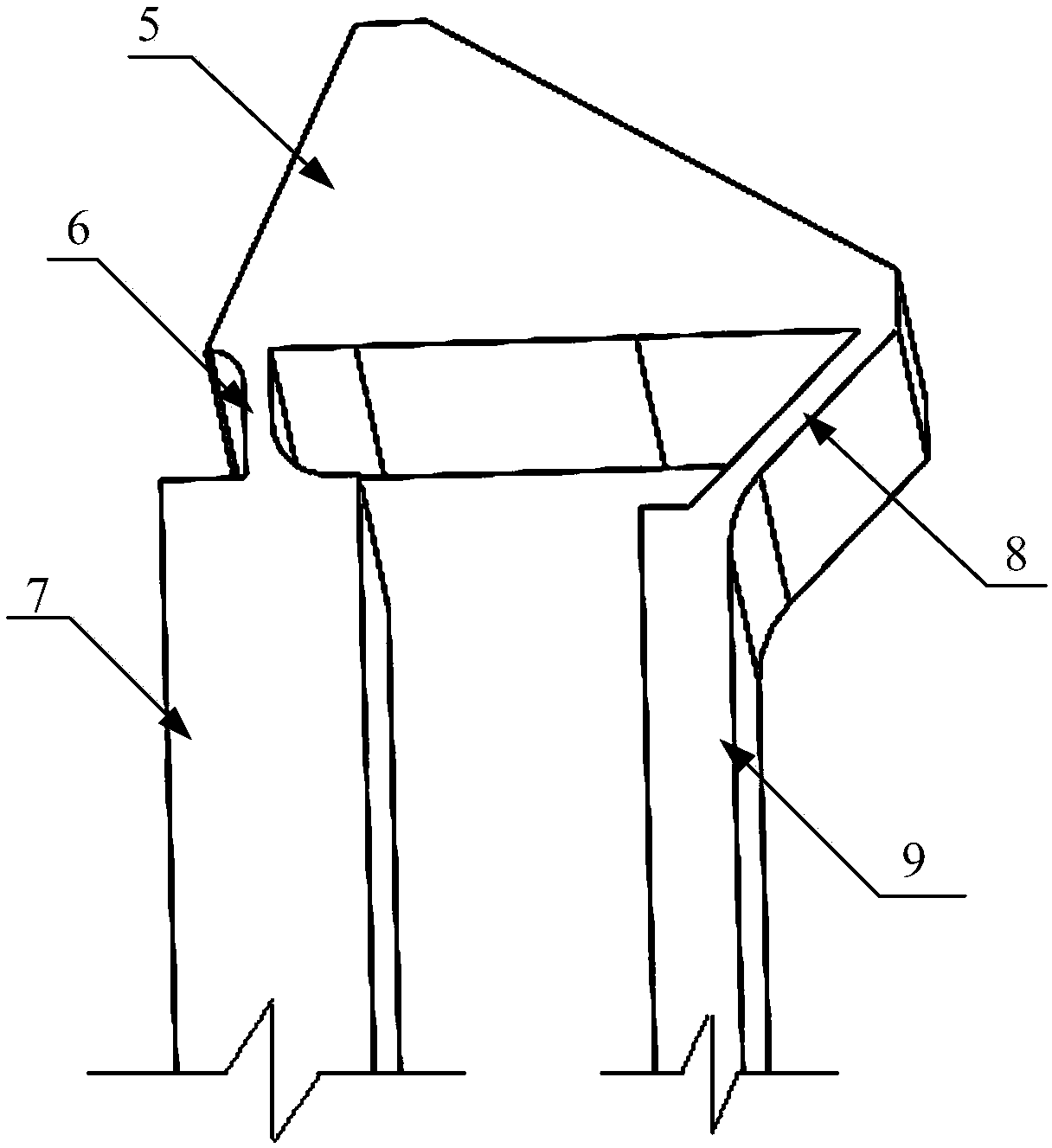

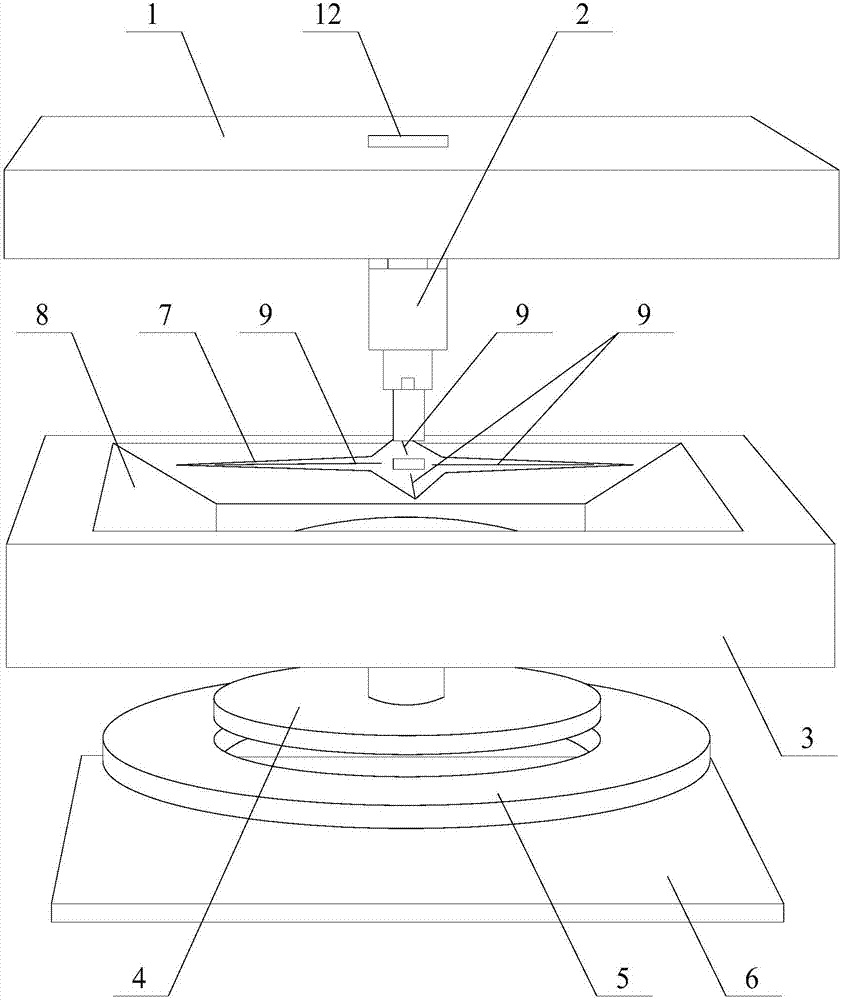

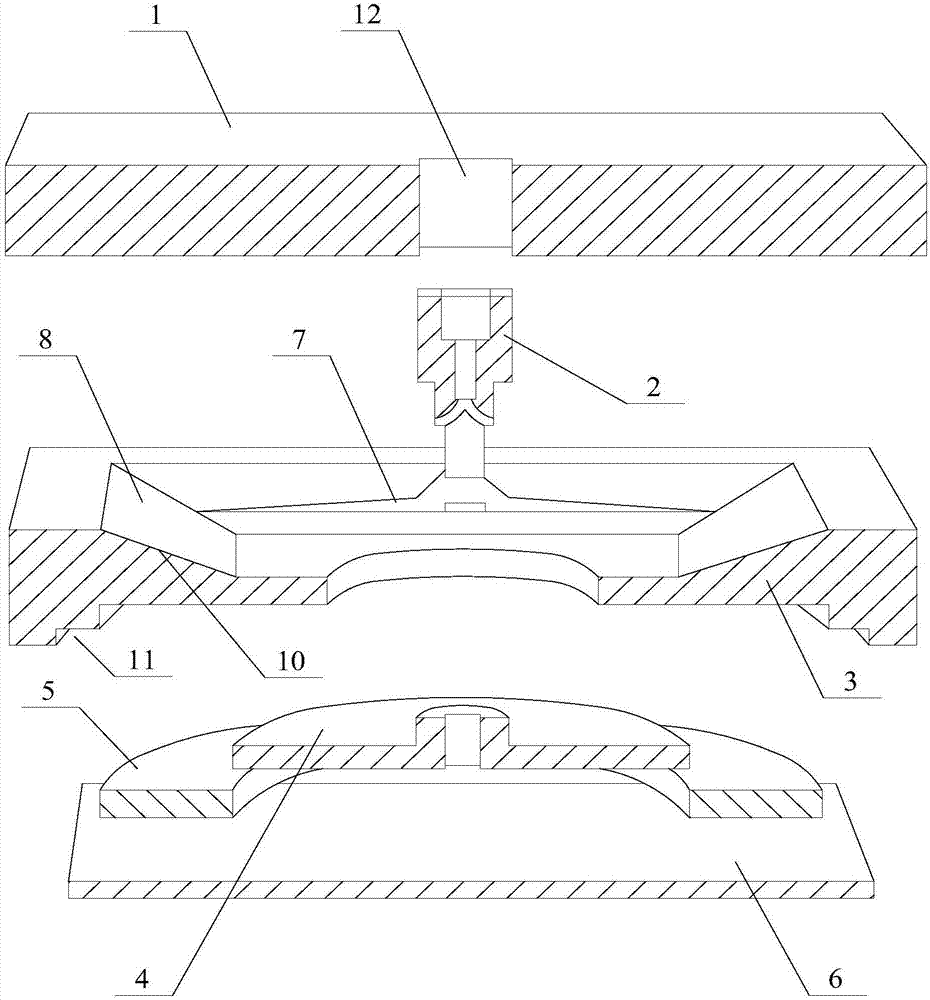

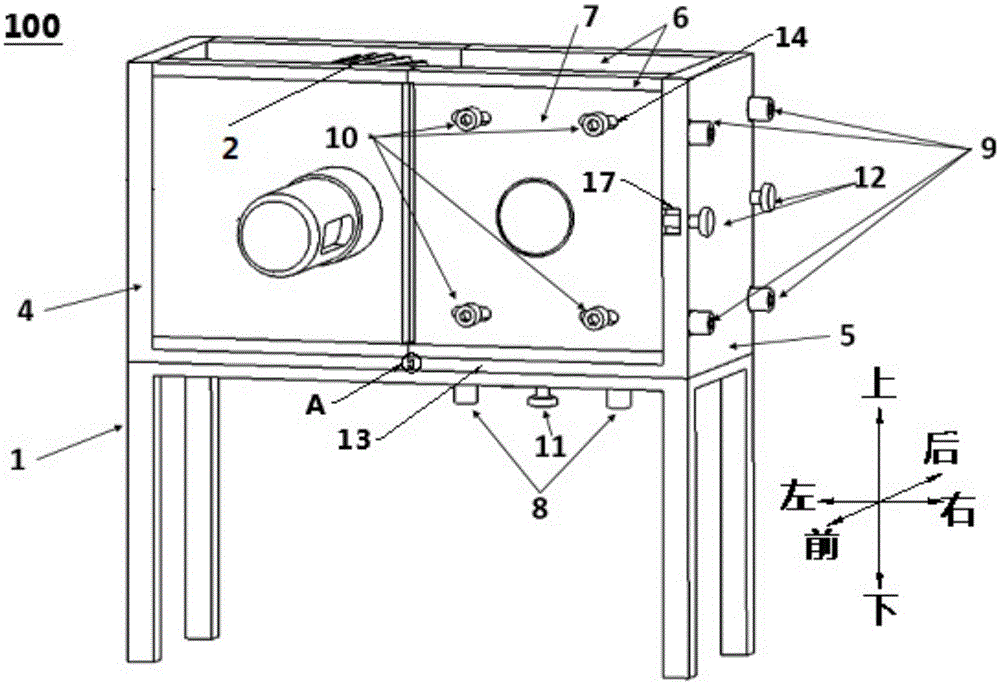

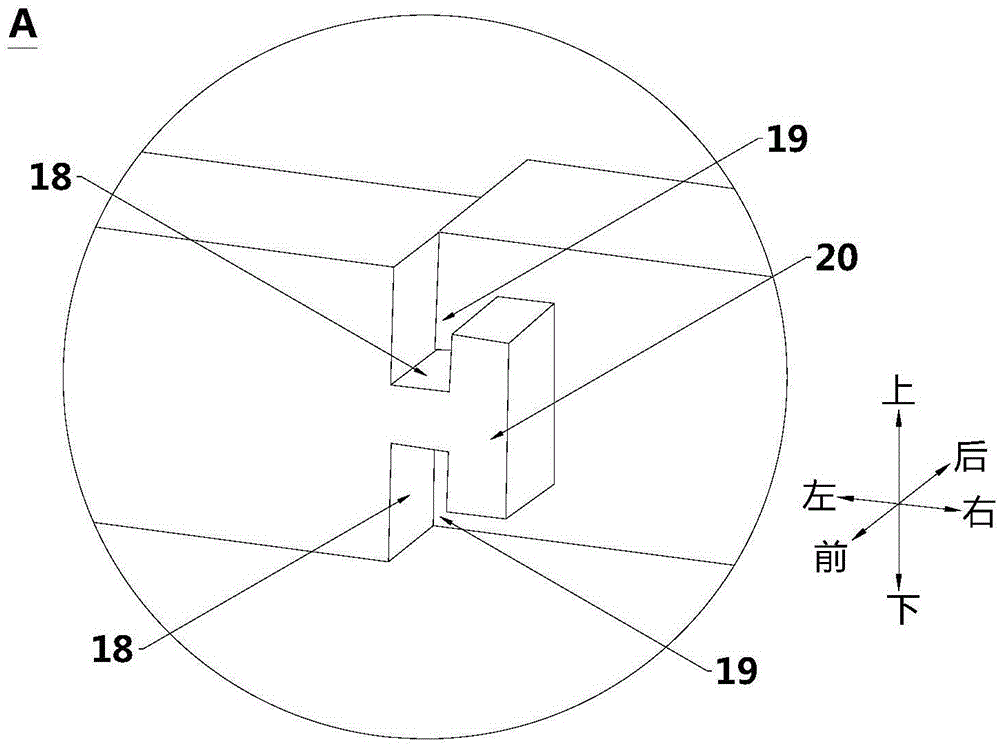

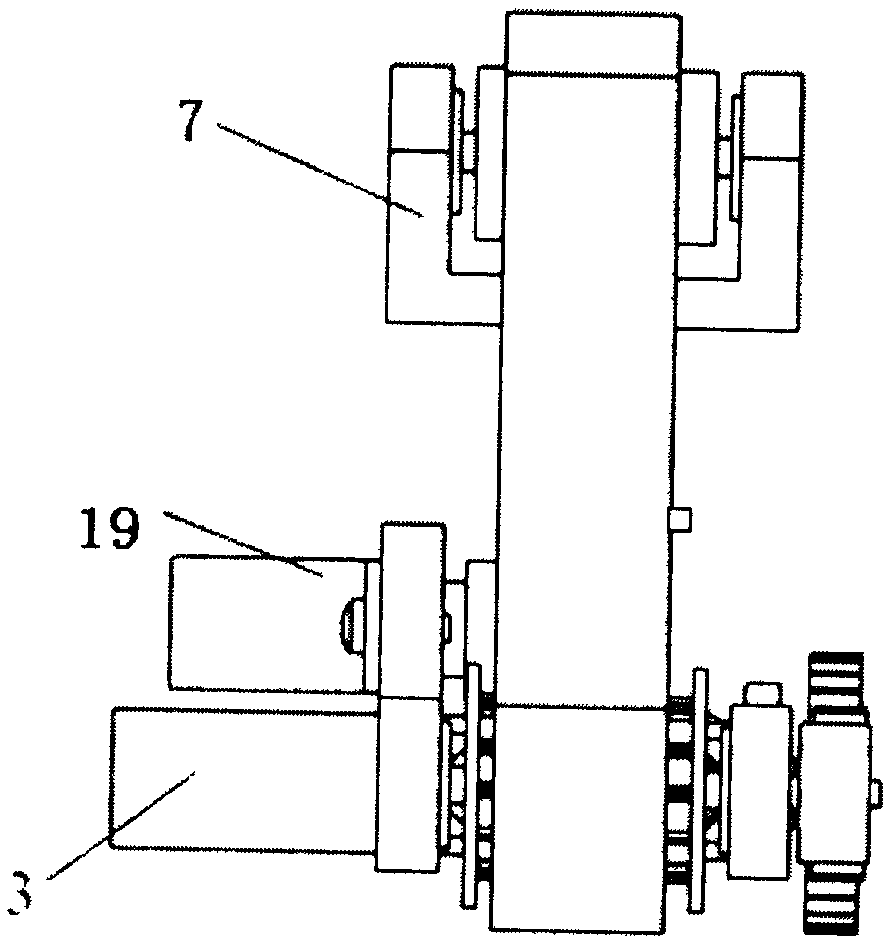

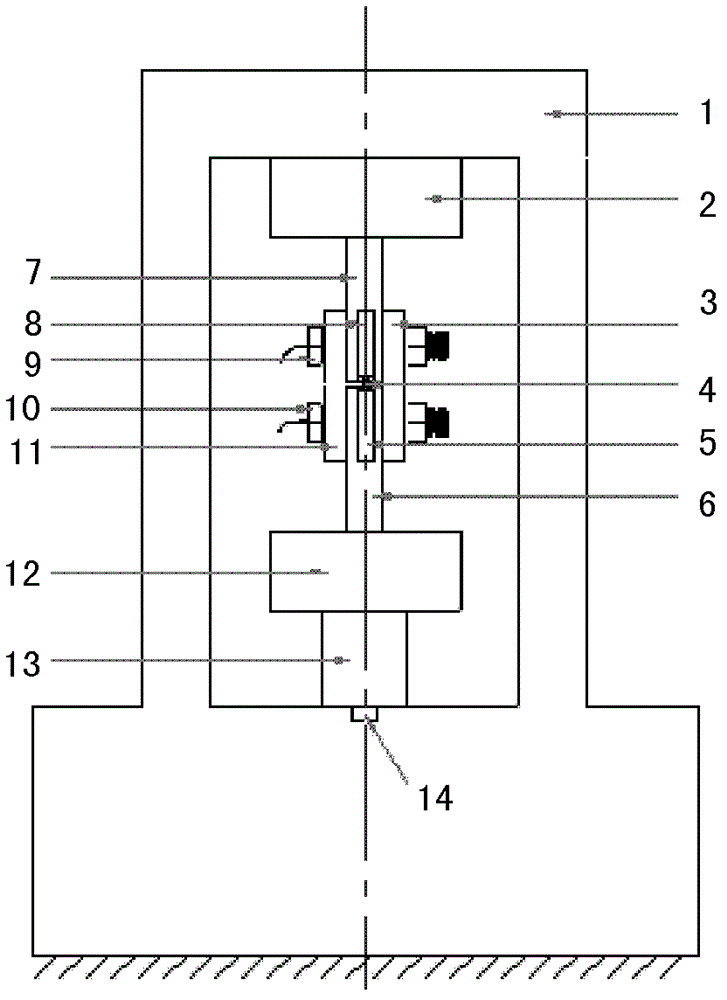

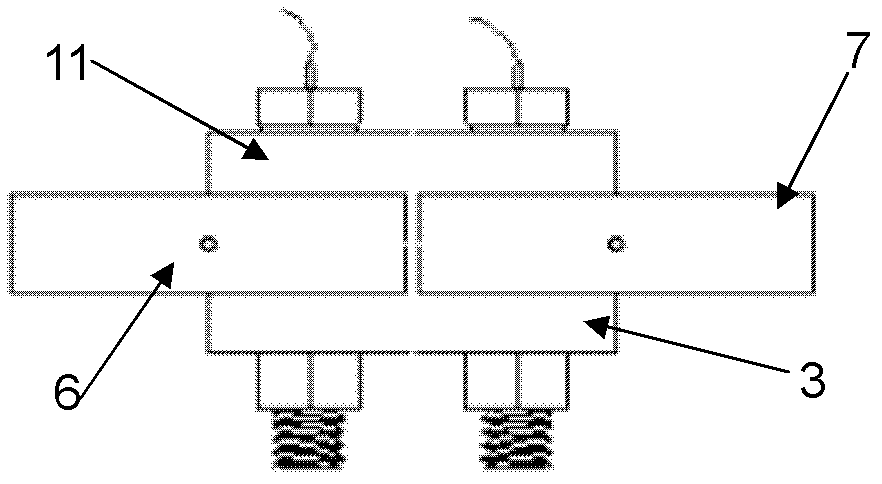

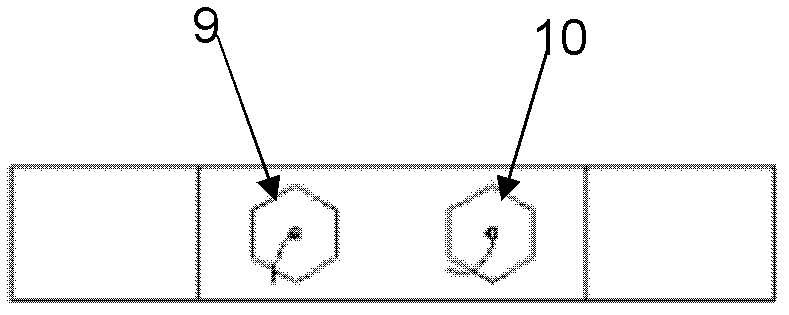

Device for testing tangential stiffness property of joint surface

InactiveCN102393330AEasy to processEasy to installMaterial strength using tensile/compressive forcesTangential displacementHigh intensity

The invention discloses a device for testing a tangential stiffness property of a joint surface, and belongs to the fields of mechanical design and manufacture. The device consists of a test loading device (1) and a tangential test assembly. An upper test piece (7) is butted with a lower test piece (6), and a gap is reserved at the joint; a pressing plate (3) and a pressing plate (11) are arranged on two surfaces vertical to the test piece butting surface, and are fixedly connected through two high-strength bolts (9) and (11) to form the tangential test assembly; the high-strength bolts (9) and (11) are symmetrical about the gap of the joint of the upper and lower test pieces; brackets (8) and (5) are arranged on two sides of the gap of the joint for accommodating an eddy current displacement sensor (4); and a force sensor (14) for measuring loading force signals and the eddy current displacement sensor (4) for measuring the tangential displacement variation of the joint surface are connected to a signal acquisition system. The device has the advantages of simple machining, convenience for clamping, high universality, high controllability of the parameters and the like.

Owner:BEIJING UNIV OF TECH

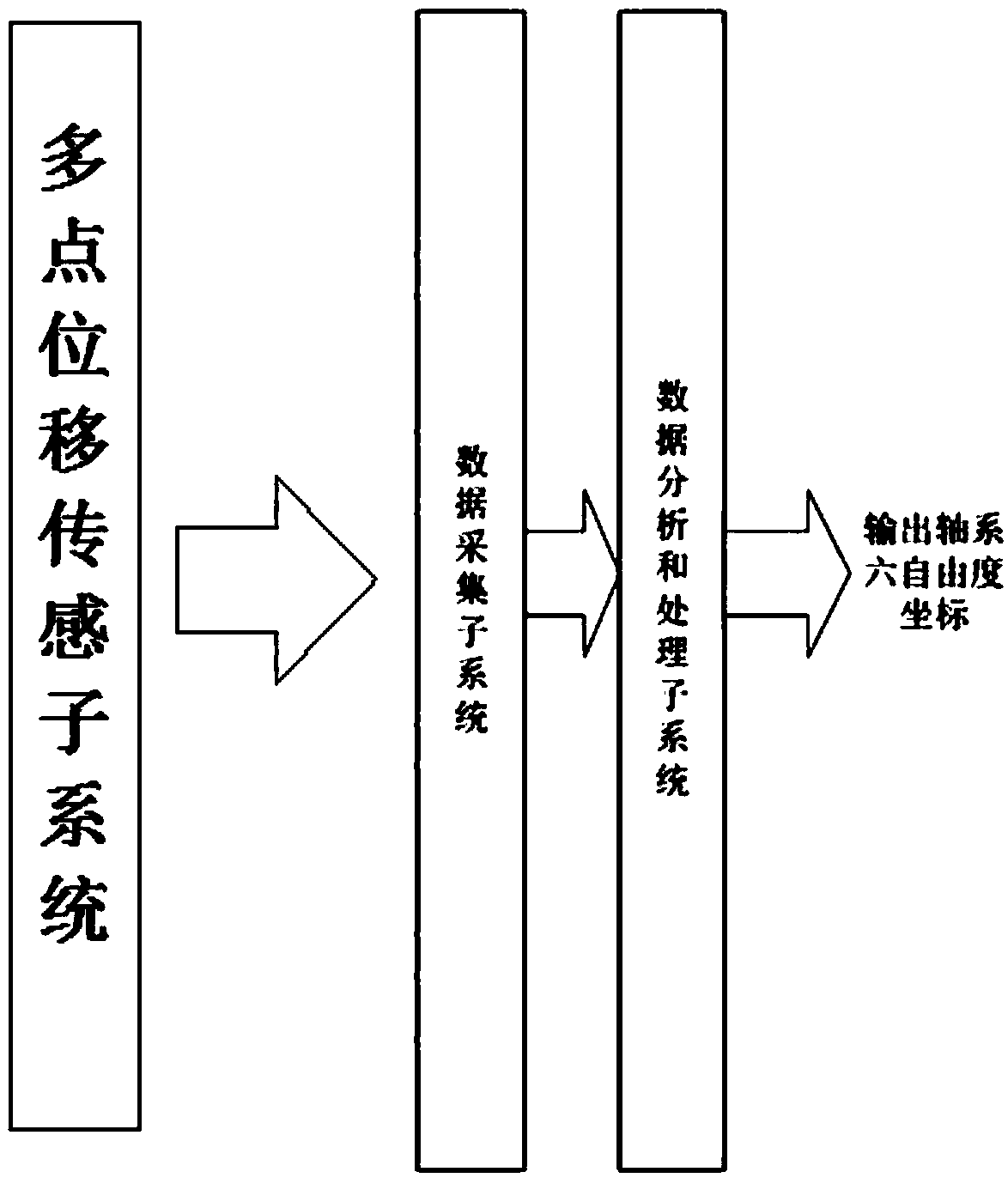

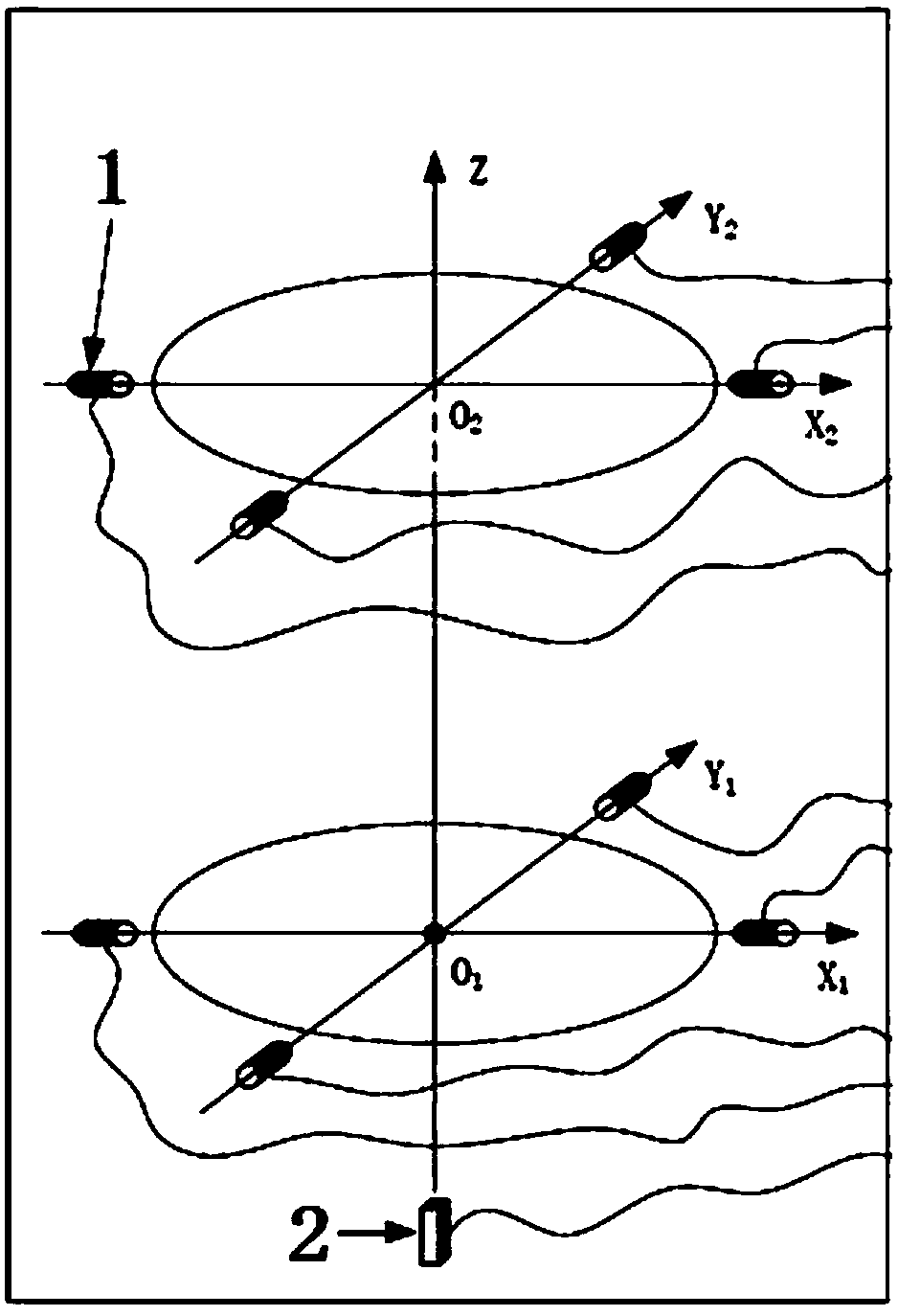

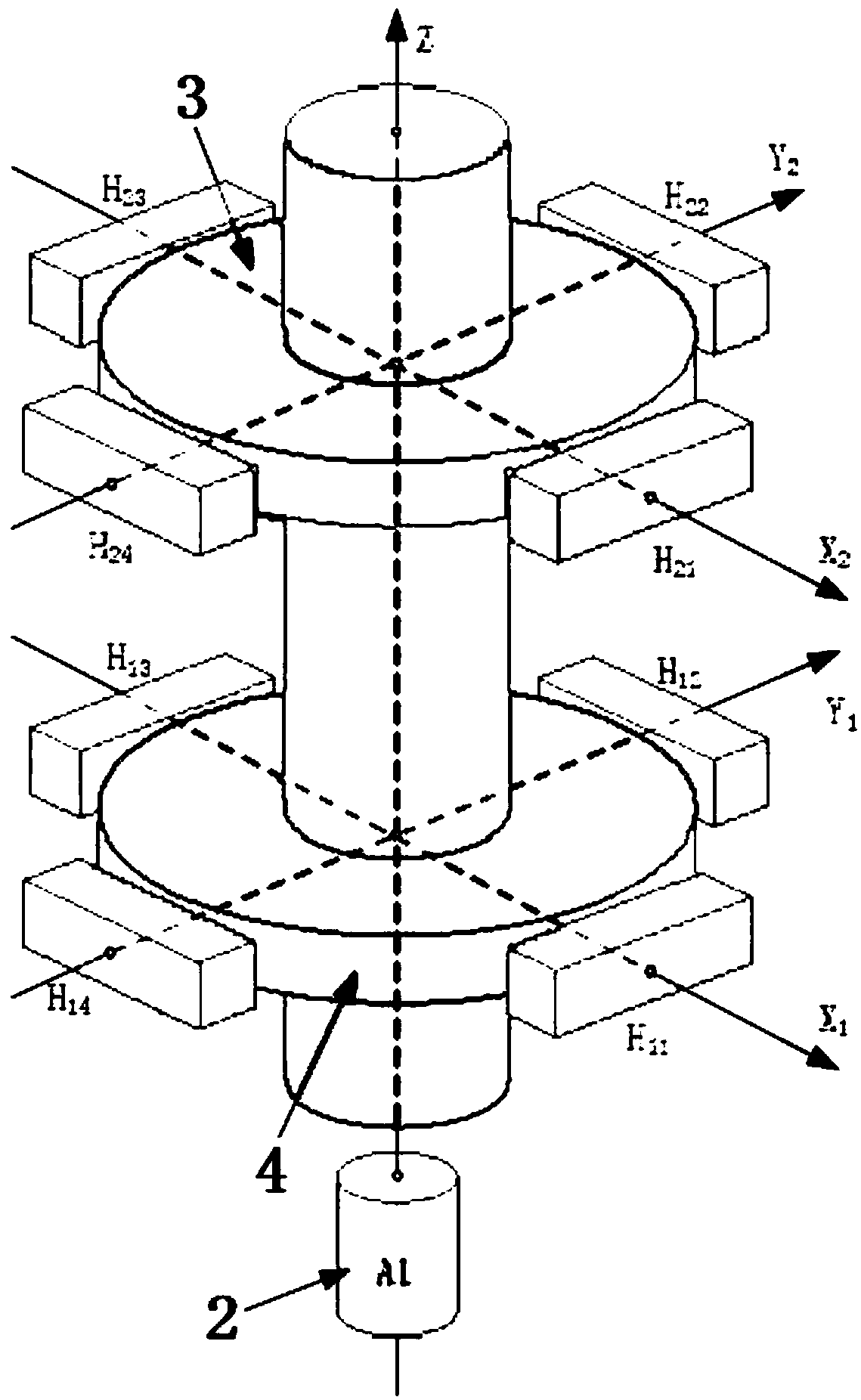

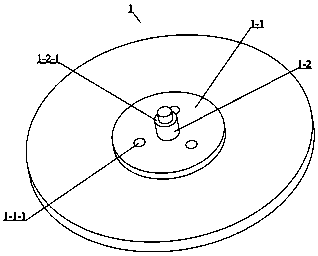

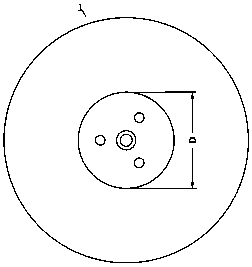

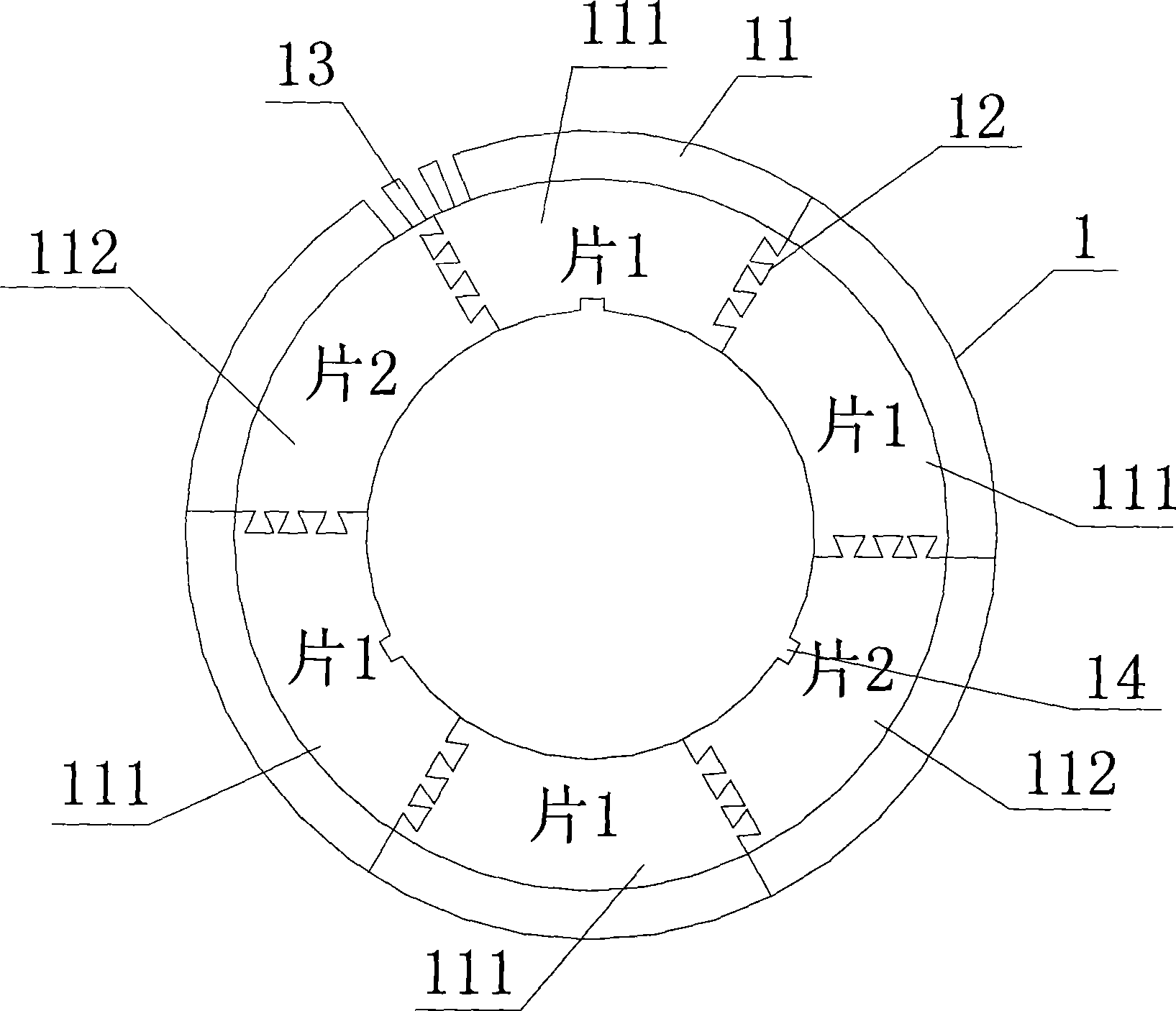

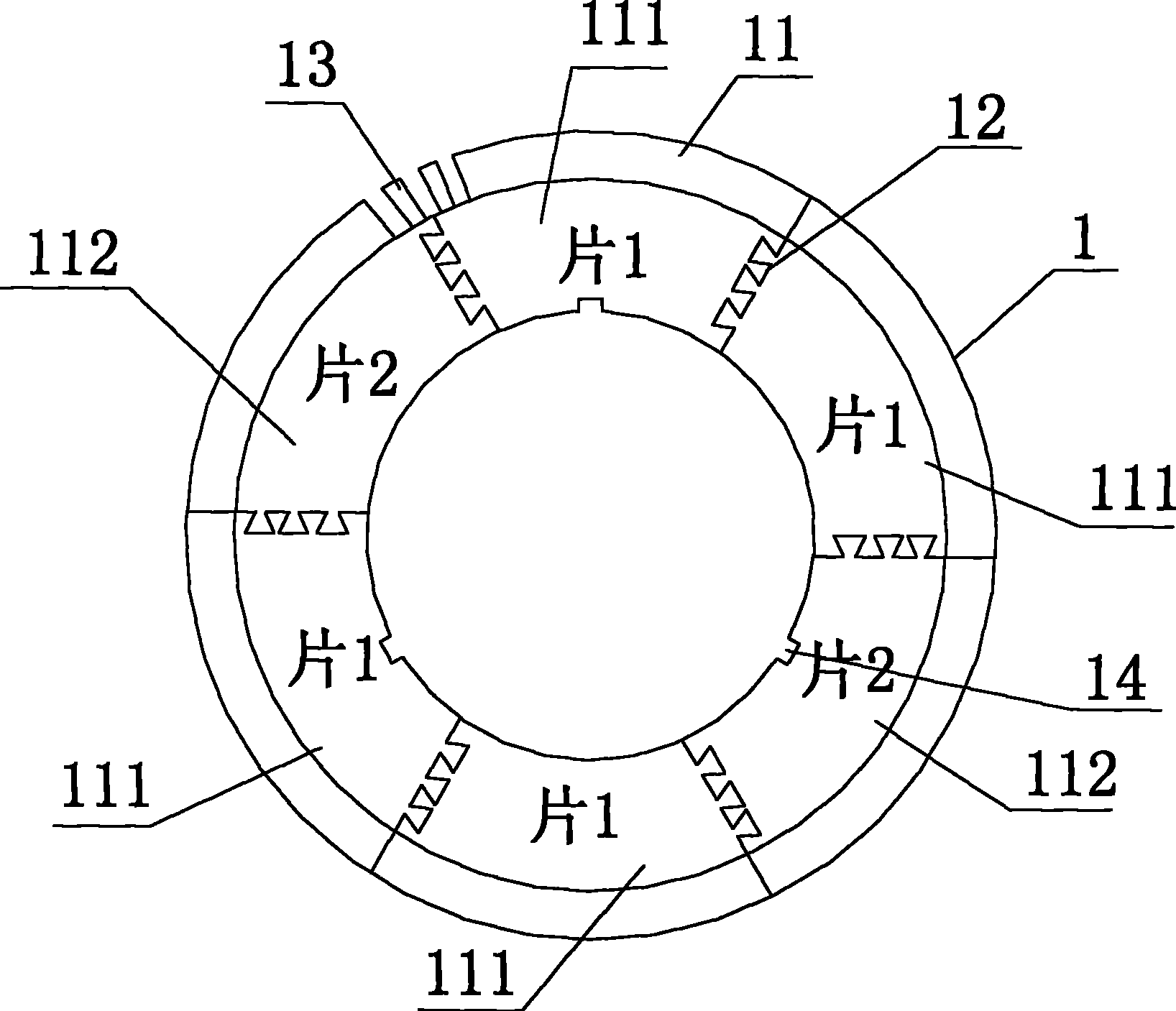

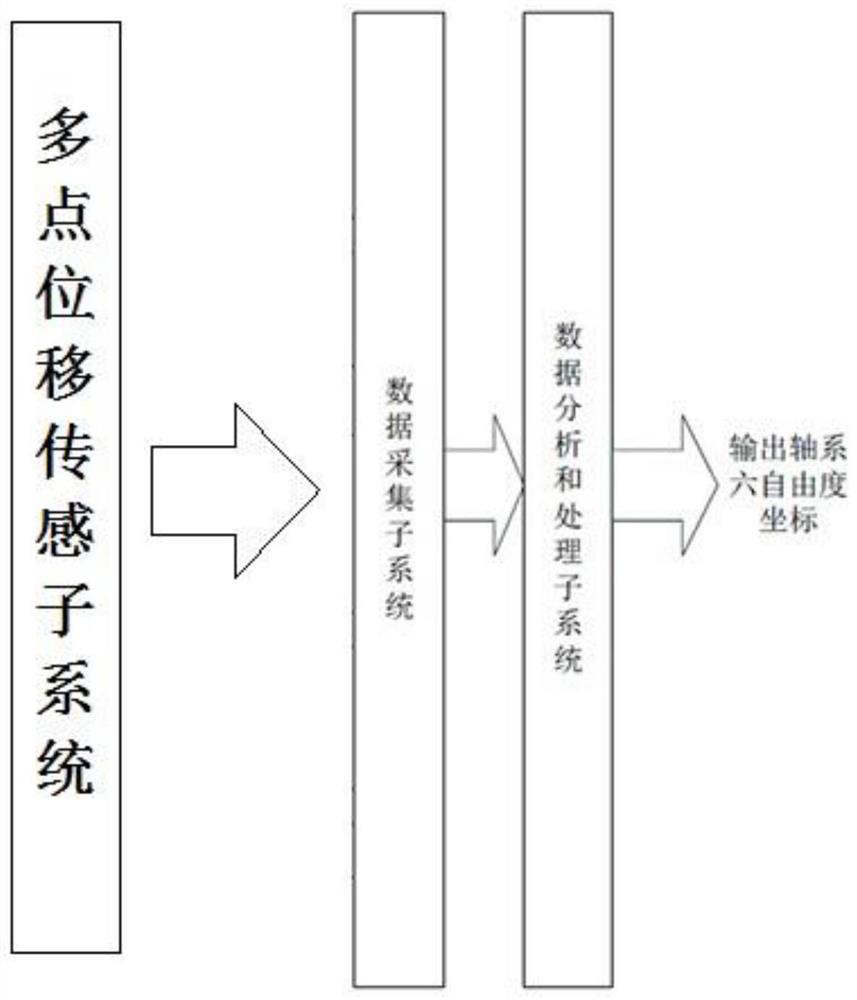

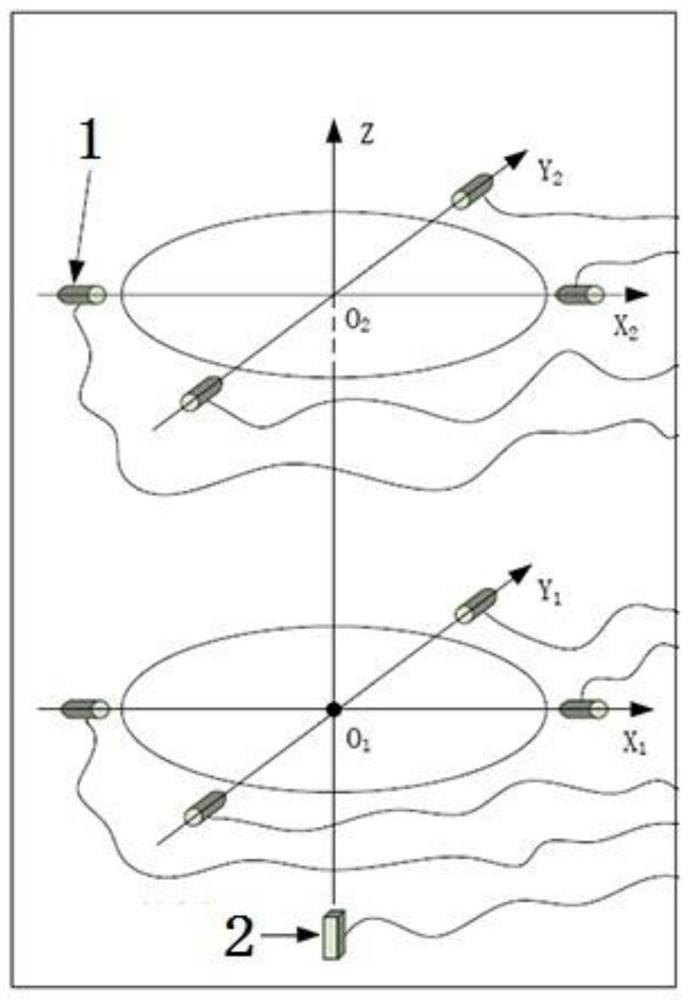

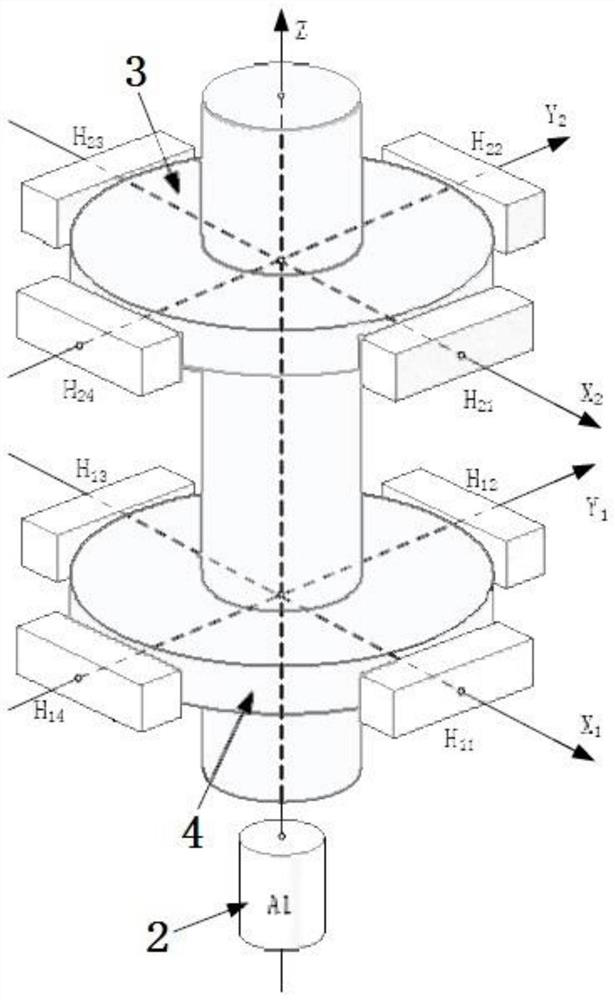

Circular grating-based shaft system five-degree-of-freedom error measurement method, six-degree-of-freedom error measurement method and measurement system

The invention relates to a circular grating-based shaft system five-degree-of-freedom error measurement method, a circular grating-based shaft system six-degree-of-freedom error measurement method anda measurement system. According to the measurement methods and measurement system, two or more measuring planes are arranged at intervals on the axial position of the measured shaft of a shaft system; circular gratings are disposed at positions on the measured shaft which are corresponding to each of the measuring planes respectively; each measuring plane is provided with a reading head corresponding to the corresponding circular grating; if the axis of the measured shaft moves, the tangential displacement of the measured shaft changes when the measured shaft rotates in the measuring planes,and therefore, the plane displacement of the measured shaft on the detecting planes can be generated; and since the displacement is a relative variable relative to the initial position of the measuredshaft, the displacement is not affected by the roundness of the measured shaft itself.

Owner:HENAN UNIV OF SCI & TECH

Tangential final-motion frictional wear test equipment

InactiveCN102590002AAchieve decouplingRealize the application of vertical loadInvestigating abrasion/wear resistanceControl systemData acquisition

The invention discloses tangential final-motion frictional wear test equipment. The equipment is characterized in that a lateral hydraulic piston connected with a data acquisition and control system is connected with a hinged shaft at the middle upper part of a vertical connecting rod; the upper end of the connecting rod is connected with one side of an upper test piece chuck through a cross bar; the other side of the upper test piece chuck is connected with a tangential displacement sensor fixed on the side wall of an experiment medium cavity; the upper test piece chuck is used for clamping a spherical test piece; a lower test piece chuck for clamping a plane test piece is arranged right below the upper test piece chuck; the lower test piece chuck is fixed at the bottom of the experiment medium cavity; the bottom of the experiment medium cavity is arrange on two longitudinal supporting rods; and a deformation sensor is arranged between the top of the longitudinal supporting rods and the bottom of the experiment medium cavity. The tangential final-motion frictional wear test equipment can effectively simulate the tangential final-motion friction and has the advantages of simple structure and high test precision, is convenient to maintain, can carry out a final-motion frictional test under the medium conditions, such as controllable high temperature, lubrication and liquid, and can provide more accurate and reliable test bases for designing, manufacturing and maintaining relevant parts.

Owner:SOUTHWEST JIAOTONG UNIV

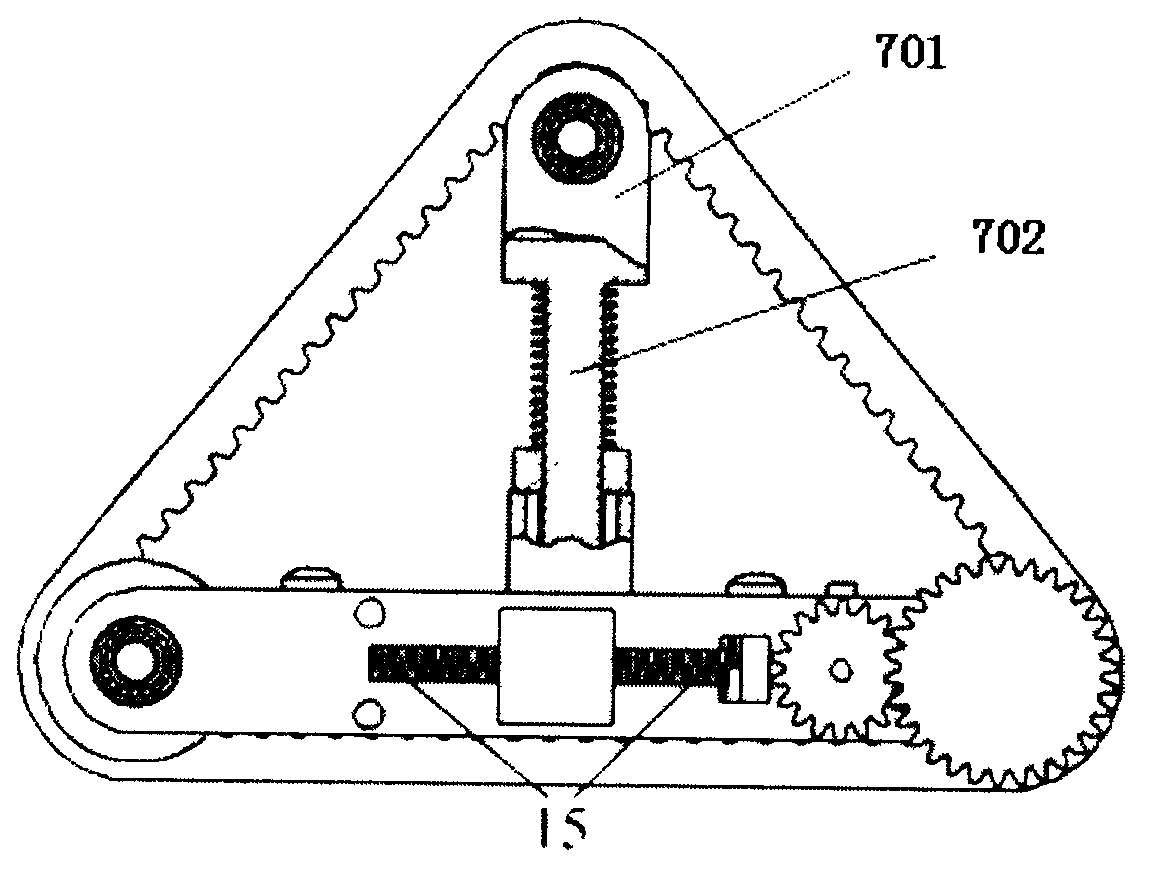

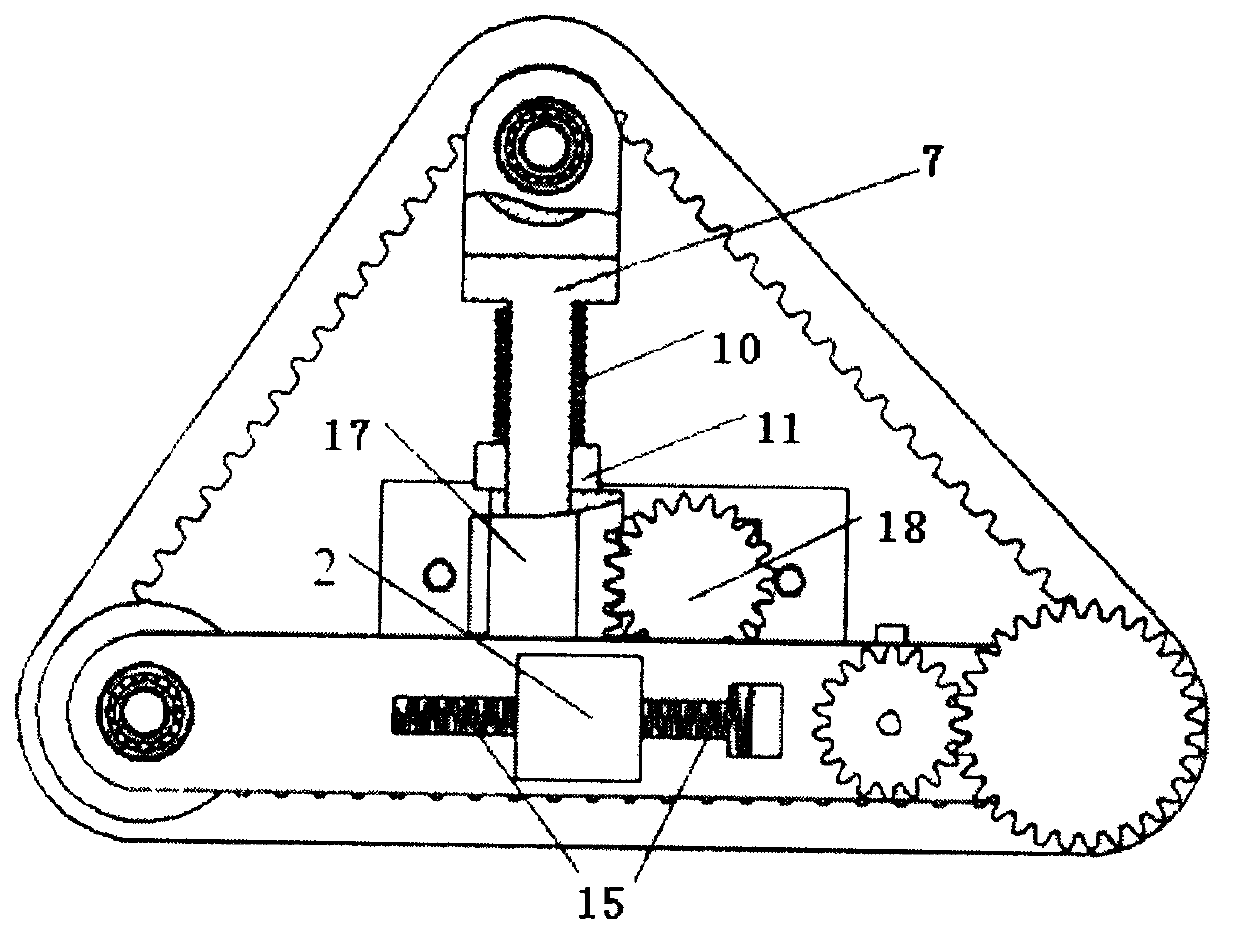

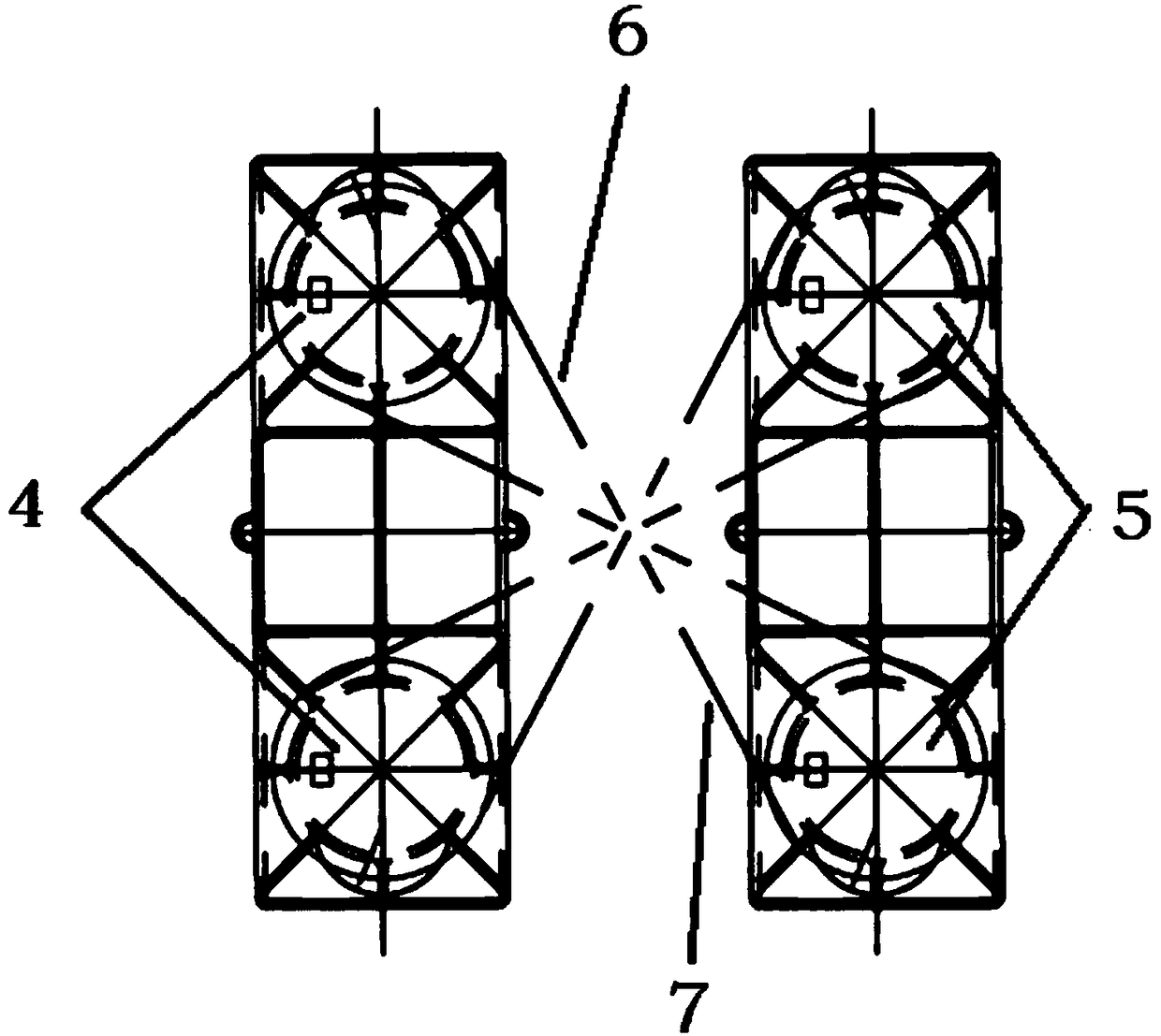

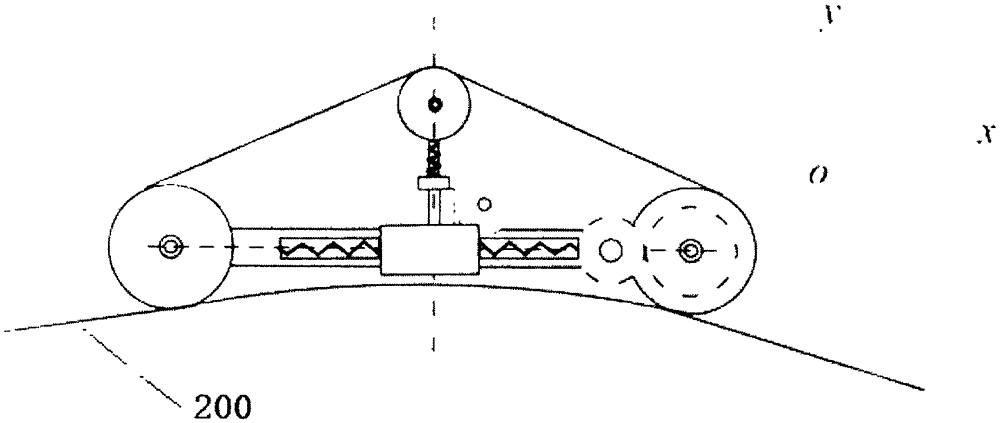

Sole structure of crawler-type bionic wall-climbing robot and motion method thereof

InactiveCN103847823AAchieve adhesionReal-time feedbackEndless track vehiclesBionicsTangential displacement

The invention discloses a sole structure of a crawler-type bionic wall-climbing robot. The sole structure comprises a body frame, rolling wheels, a tension mechanism, an adhesion crawler belt and a driving mechanism, wherein the rolling wheels are arranged at the two ends of the body frame through rolling wheel axles; the tension mechanism comprises a tension wheel frame, a tension spring, a micro force sensor, a tension wheel and a sleeve; the sleeve is arranged on the upper surface of the body frame; the micro force sensor is arranged on the upper surface of the sleeve; the tension wheel frame comprises a shaft extension and a mounting end; the lower end of the shaft extension passes through the micro force sensor and the sleeve; the shaft extension is sleeved with the tension spring; the tension spring is arranged between the micro force sensor and the mounting end; the tension wheel is arranged at the mounting end through a tension wheel axle; the tension wheel is connected with the rolling wheels through the adhesion crawler belt; the driving mechanism is arranged on the body frame. Certain tangential displacement and posture angles are output by a robot body, so that adhesion, detachment and pressing of the sole are realized, and the robot is helped to walk and stop on a wall face.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Method for determining a surface contact force

ActiveUS20050115331A1Aerodynamic testingForce measurement by measuring optical property variationLuminophoreTangential displacement

A method of measuring a load on a surface produced by a contact force. An elastic film or coating is located on a supporting surface to provide an indication of normal and tangential or shear forces applied to the surface. A thickness measurement, corresponding to a normal displacement, and a tangential displacement of the film, corresponding to a shear displacement, is obtained and input to a response function to reconstruct the normal and shear load components of the contact force on the surface. A differential thickness measurement of the film is detected by an optical method in which a luminescent output from a luminophore in the film is measured. A luminescent output from a reference luminophore located below the film is also measured to provide a measurement system independent of the illumination source used to produce the luminescent output.

Owner:INNOVATIVE SCI SOLUTIONS

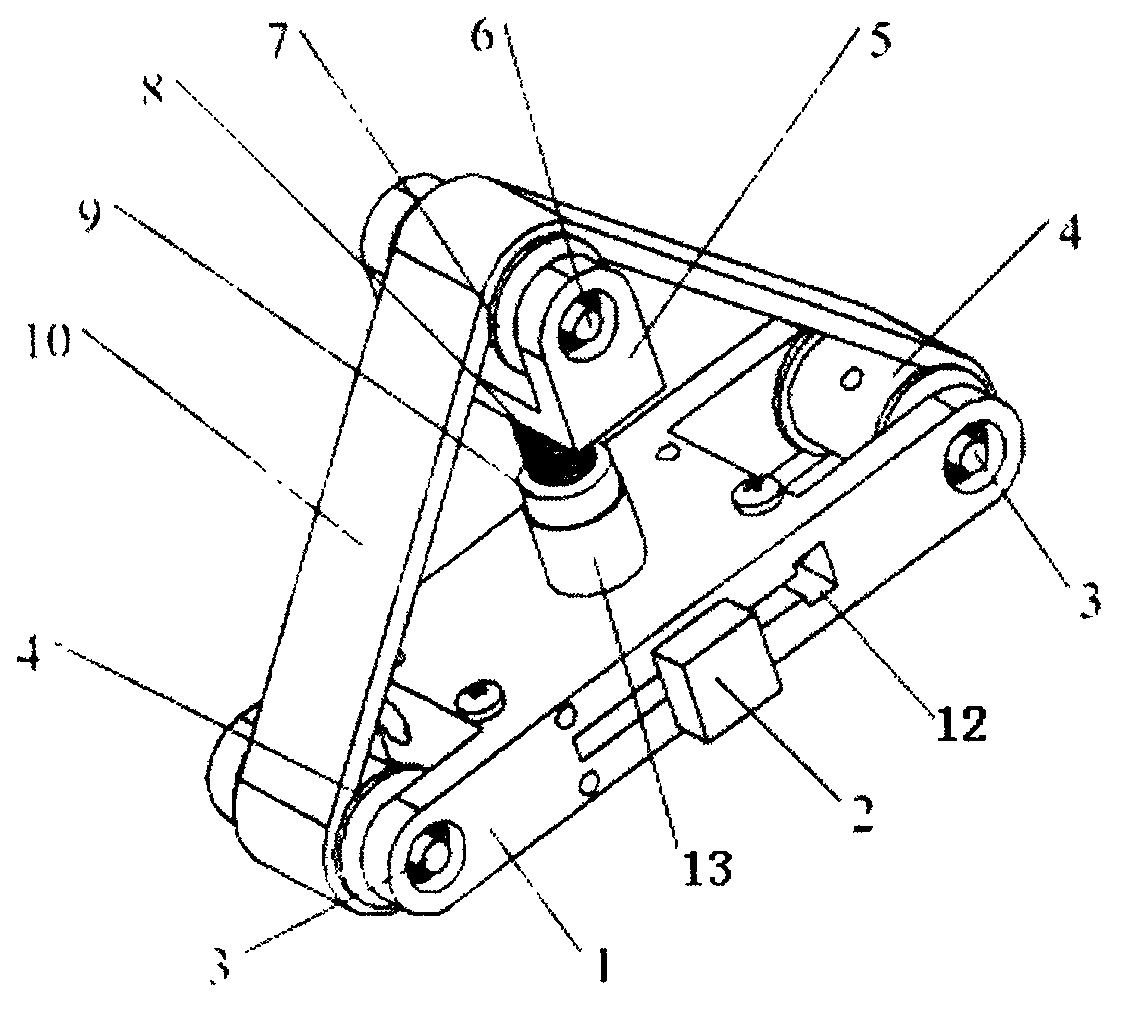

Bionic crawler-type adhesion walking mechanism and moving method thereof

The invention discloses a bionic crawler-type adhesion walking mechanism and a moving method thereof. The bionic crawler-type adhesion walking mechanism comprises a machine frame, a tensioning mechanism, a driving mechanism and an adhesion belt, wherein the driving mechanism comprises a driving motor, a driving motor gear, a driving wheel and a driven wheel; the driving wheel is connected with one end of the machine frame through a gear shaft; the driven wheel is connected with the other end of the machine frame through a driven wheel shaft; the driving motor gear is driven by the driving motor; the driving motor gear is meshed with the gear shaft; the tensioning mechanism comprises a tensioning wheel frame, a tensioning spring, a miniature force sensor, a tensioning wheel and a sleeve; the tensioning wheel, the driving wheel and the driven wheel are connected through the adhesion belt; the tensioning mechanism further comprises a mechanism connecting device arranged on the machine frame. A certain tangential displacement and a posture angle are outputted by a robot body, so that the adhesion, detachment and pressing of soles are realized and the walking and halting of a robot on a wall are assisted.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

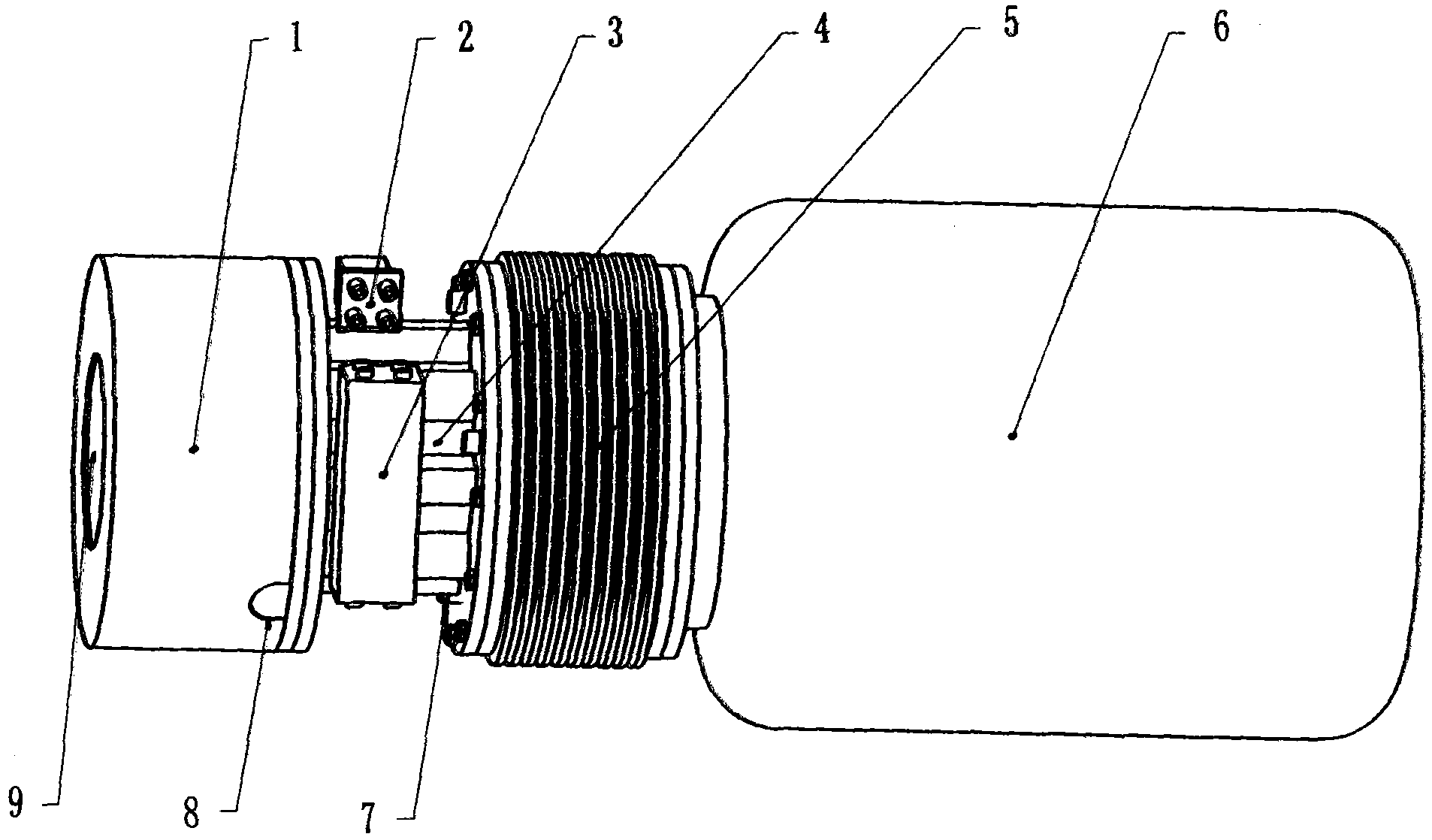

Solar sterling generator

InactiveCN102146900ACompact structureReduce volumeFrom solar energyMachines/enginesBlocked ConnectionTangential displacement

The invention provides a solar sterling generator. A plurality of symmetrically-distributed rotor support frame mounting grooves are arranged on the inner wall of a generator body of the solar sterling generator, two rotor support frames are arranged in the generator body respectively from two ends of the generator body along the mounting grooves and fixed together by a plurality of groups of fastening screws, and the generator body, the rotor support frames and rotors are fixed together. Central lines of pin holes at two ends of a connecting rod of a piston group are perpendicular to each other, assembly clearances are arranged at a piston connection part and a guide block connection part, and the piston group has the functions of automatically compensating radial and tangential displacements of an air cylinder, therefore, the assembly difficulty in the production process is reduced, and the reliable degree in the operation process is improved. By comprehensively adopting latest technologies of a countercurrent heat exchanging type regenerator, an annular heat exchanger, and the like, the whole generator has a compact structure and small size. By adopting an air cooling manner for heat dissipation, the solar sterling generator can be widely applied to water-deficient areas.

Owner:郯城瑞康食品有限公司

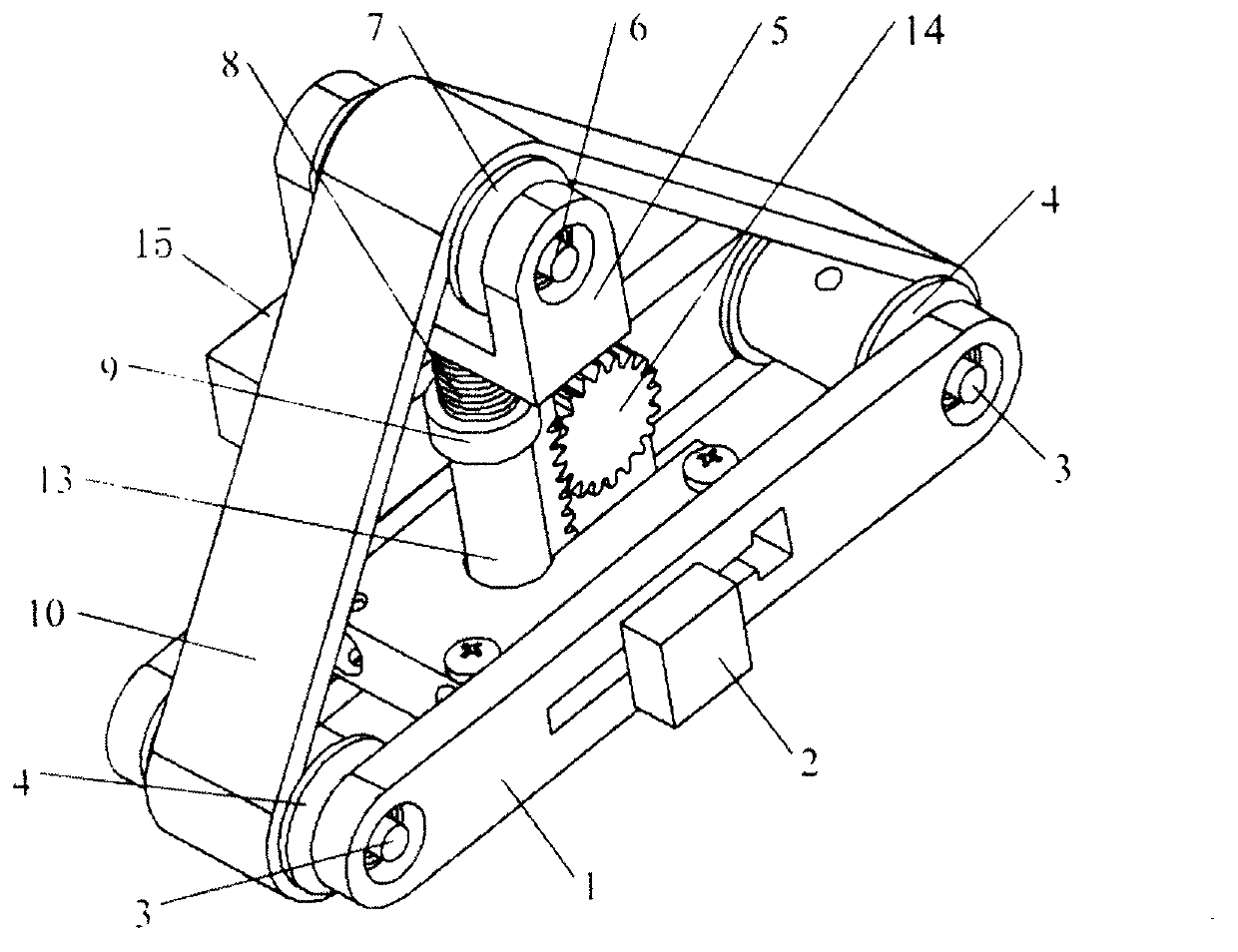

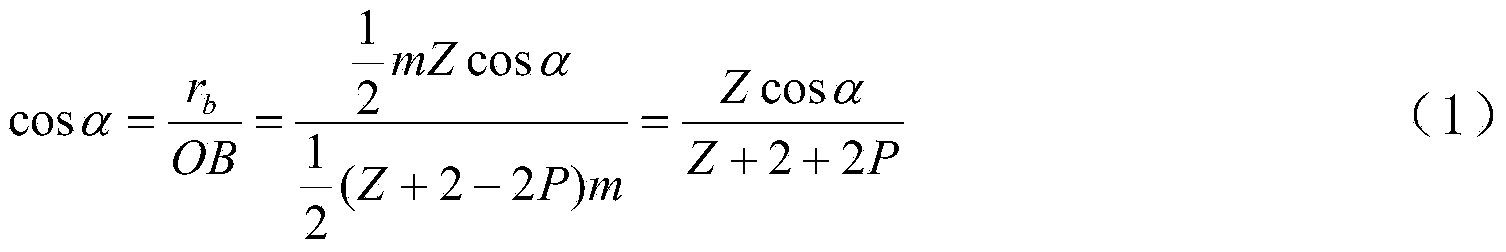

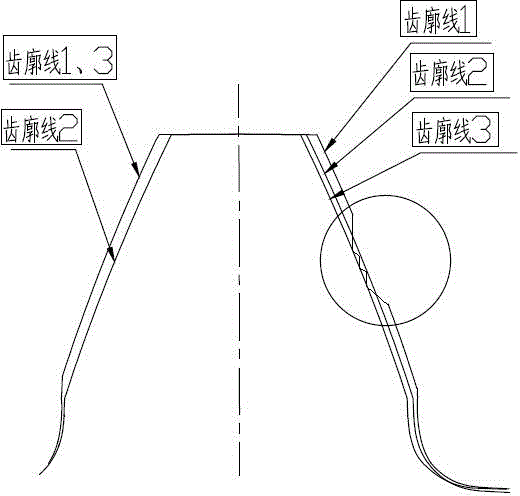

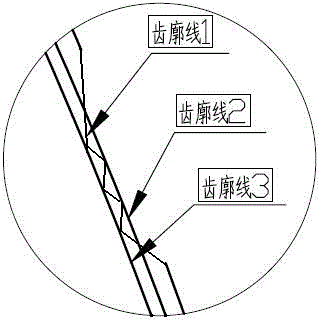

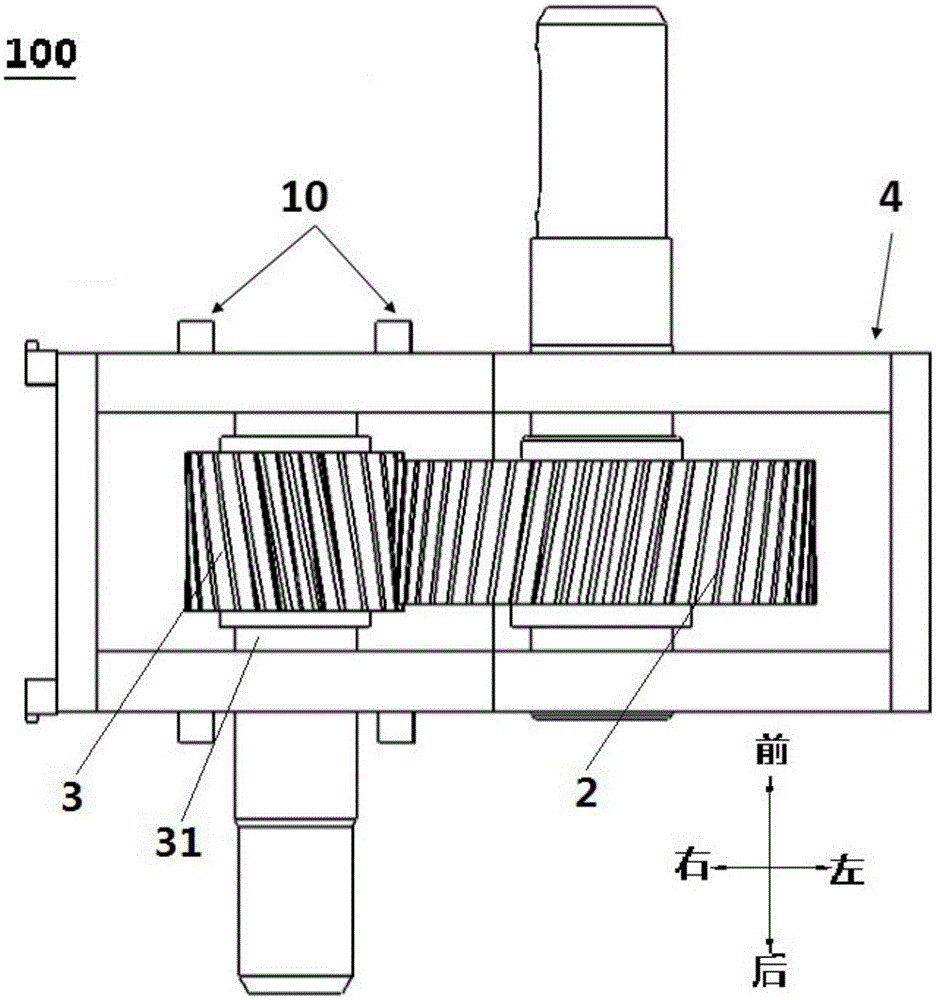

Backlash-free gear transmission pair

InactiveCN103775611AGuaranteed StrengthReduce volumePortable liftingGearing elementsTangential displacementAxial force

The invention discloses a backlash-free gear transmission pair. A gear adopts gradually-varied tangential displacement, tangential displacement coefficients change in the gear disc axial direction according to a definite law from small to large to enable two tooth faces of gear teeth to form a certain included angle, a driving gear and a driven gear are respectively provided with axial pre-tightening force identical to the gear teeth in the front-thick-to-thin direction, and meshing backlashes can be adjusted by adjusting the axial relative positions of the meshed gears. The driving gear or the driven gear is prevented from retreating by utilizing the axial pre-tightening force, so that reverse axial force is exerted to eliminate return difference in the transmission process and enable the process to be tender, pause is avoided, and the backlash-free gear transmission pair has the advantages of being simple in structure, small in size and the like. The tangential displacement influence on tooth thickness can be avoided by utilizing a radial displacement mode, the gear tooth strength is ensured, increase of the meshing contact ratio is facilitated, the bearing capacity is high, and the backlash-free gear transmission pair is suitable for high-speed input during precise transmission.

Owner:TIANJIN QIXING PRECISION MACHINERY

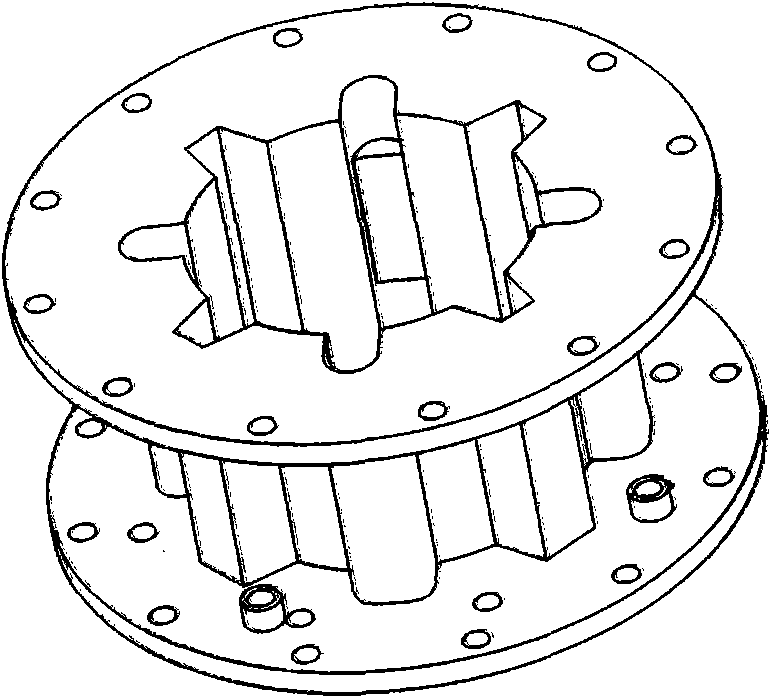

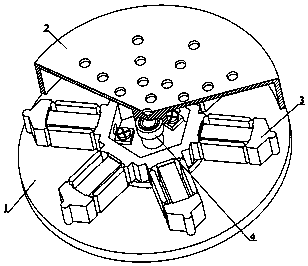

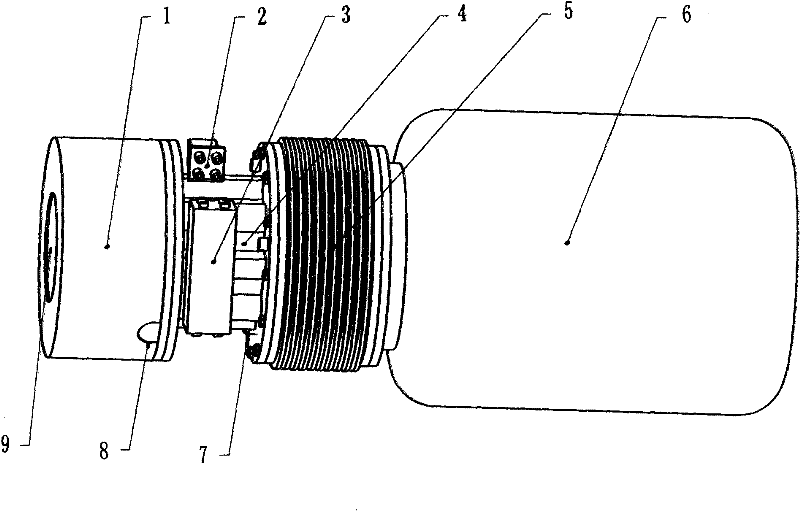

Piezoelectrically-driven precision rotation driving device using specially-shaped hinge transmission mechanism

PendingCN108233764AHigh frequency responseReduce volumePiezoelectric/electrostriction/magnetostriction machinesInterference fitEngineering

The invention relates to a piezoelectrically-driven precision rotation driving device using a specially-shaped hinge transmission mechanism, and belongs to the technical field of precision engineering. The piezoelectrically-driven precision rotation driving device using the specially-shaped hinge transmission mechanism comprises a base, a rotating table surface, a stator assembly, a bearing and other units, wherein the base and the rotating table surface are connected through the bearing; the base and the stator assembly are connected through bolts; the rotating table surface and the stator assembly are in contact fit through front ends of driving feet; the base and the rotating table surface are in interference fit with the bearing. When an excitation electric signal acts on a piezoelectric stack, the piezoelectric stack generates axial elongation based on an inverse piezoelectric effect, the driving feet generate tangential displacement to drive the rotating table surface to generateprecise rotating motion, and by changing the direction and the time sequence of driving voltage, the rotating table surface can be controlled to generate positive and reverse rotating motions and positioning can be achieved. The piezoelectrically-driven precision rotation driving device using the specially-shaped hinge transmission mechanism has many technical advantages such as simple structure, high positioning precision and high response speed, and has a wide application prospect in the technical field of precision engineering.

Owner:JILIN UNIV

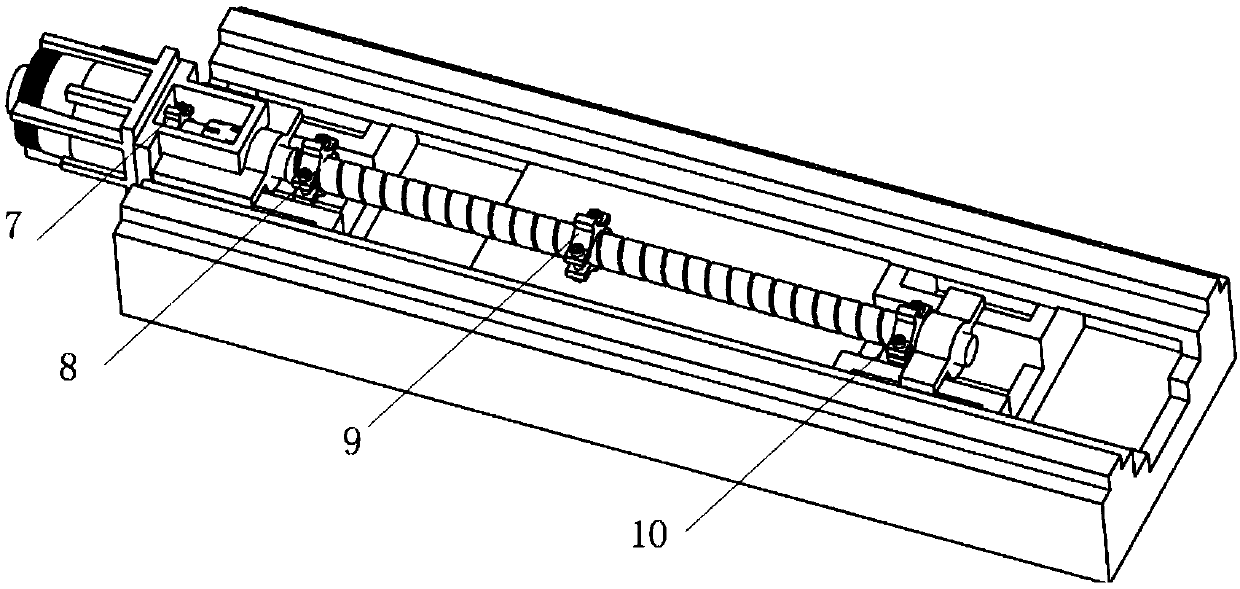

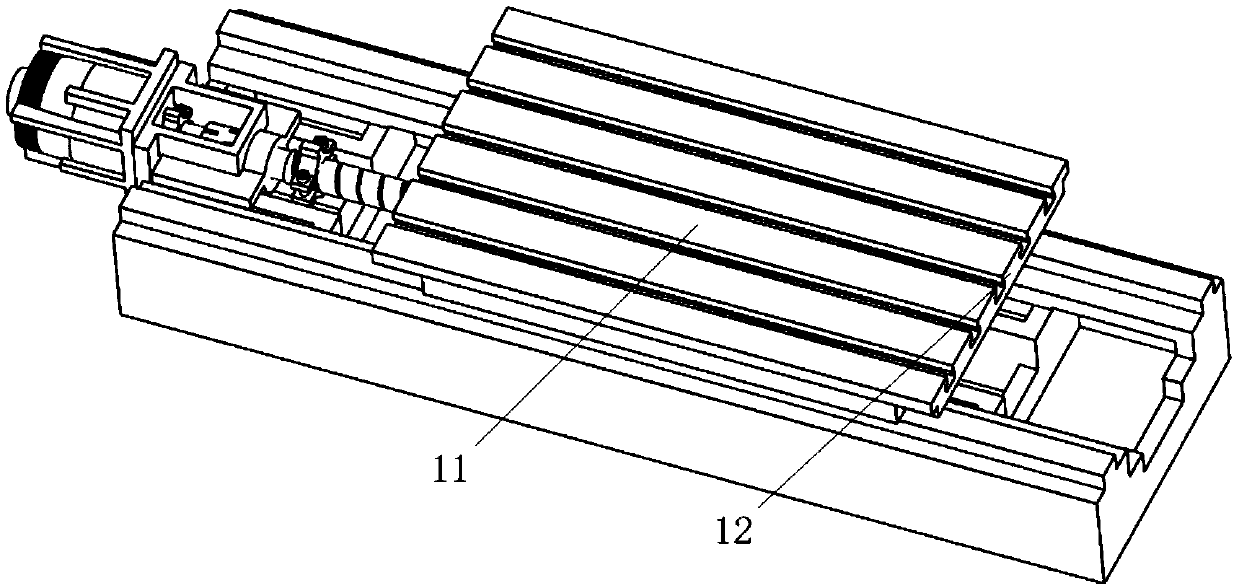

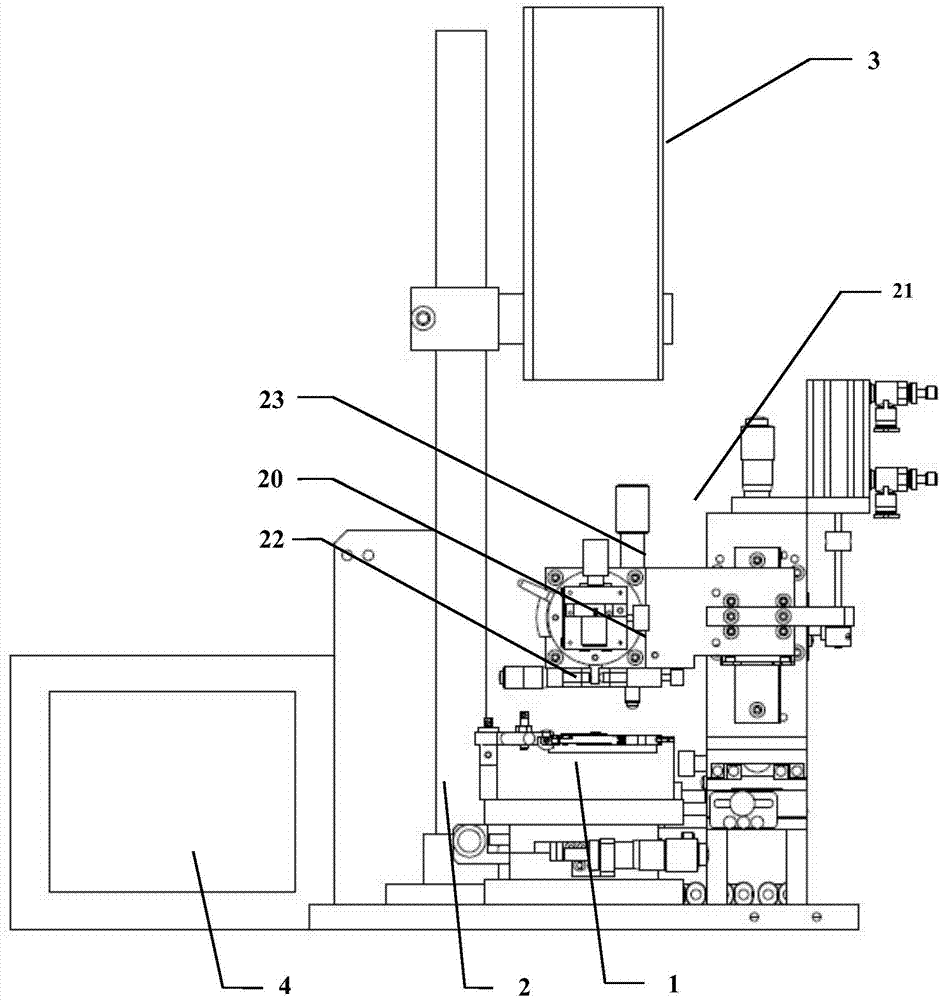

Modal test and parameter identification method for single-shaft ball screw feeding mechanical system

InactiveCN109596342AEliminate the effects ofImprove positionMachine gearing/transmission testingShock testingDirect testBall screw

The invention discloses a modal test and parameter identification method for a single-shaft ball screw feeding mechanical system. Firstly, an auxiliary clamping device is mounted on a rotary motion part in the ball screw feeding mechanical system, an acceleration sensor is arranged, a force hammer is used for carrying out excitation, an excitation signal and an acceleration signal are collected, and an experimental frequency response curve containing the rotary motion part is obtained; then, the experimental frequency response curve is converted, an excitation force is converted into an excitation torque, a tangential displacement is converted into a torsion angle, experimental modal parameter identification is carried out by means of a modal analysis theory, and structural physical parameters of the feeding system are reversely calculated by means of experimental modal parameters; and finally, the influence of the mass and the rotational inertia of the auxiliary clamping device on thestructural physical parameters and the experimental modal parameters of the feeding system is eliminated, and actual physical parameters and modal parameters of the feeding system are obtained. Direct testing of original point and cross point frequency responses of any parts of the mechanical structure of the ball screw feeding system is realized.

Owner:XI AN JIAOTONG UNIV

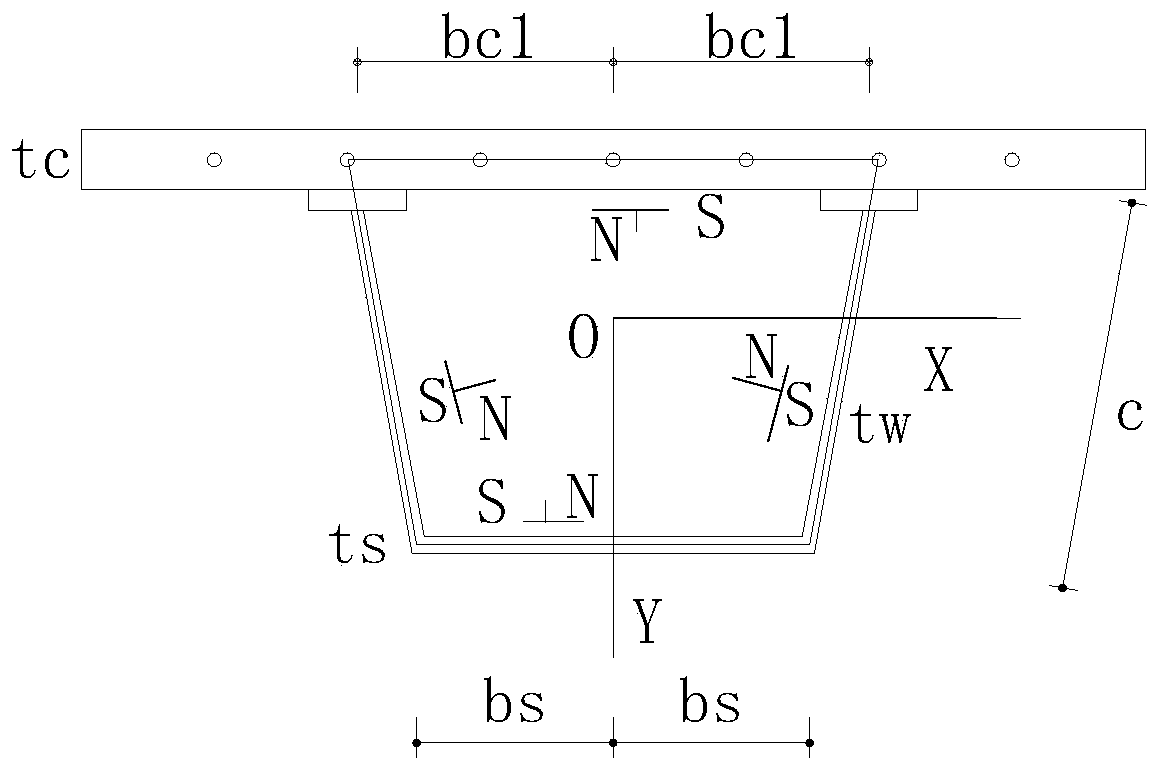

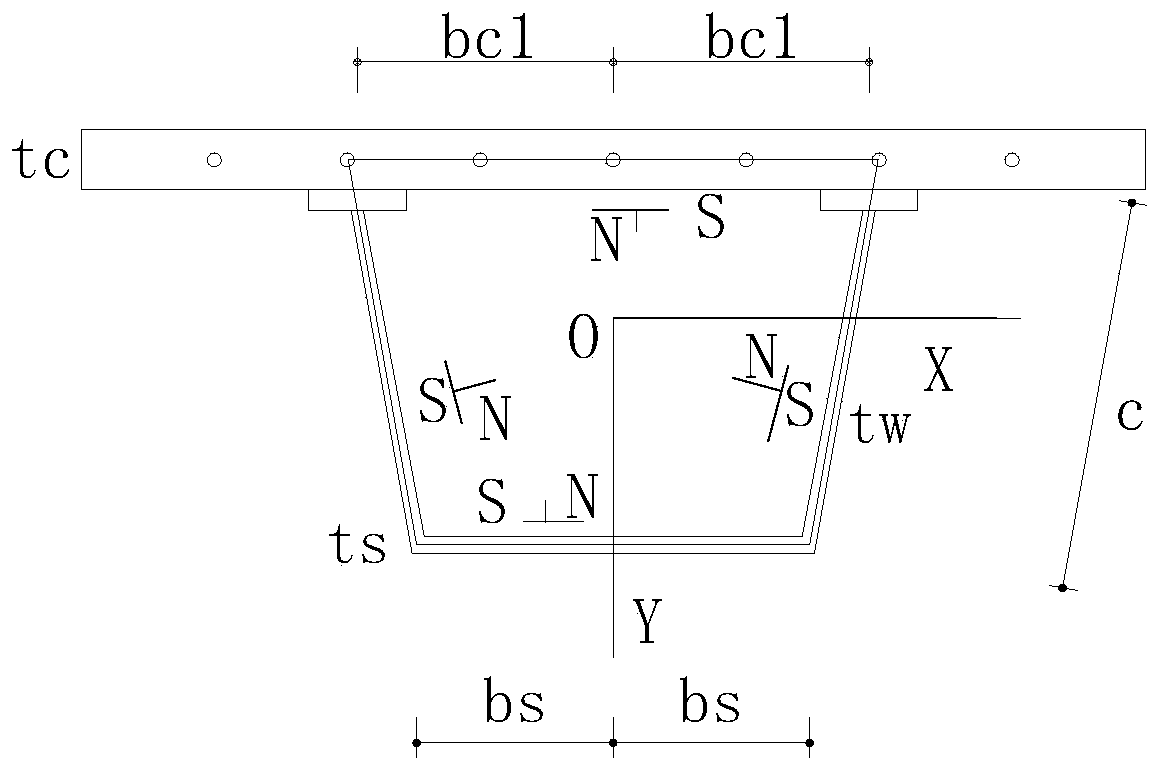

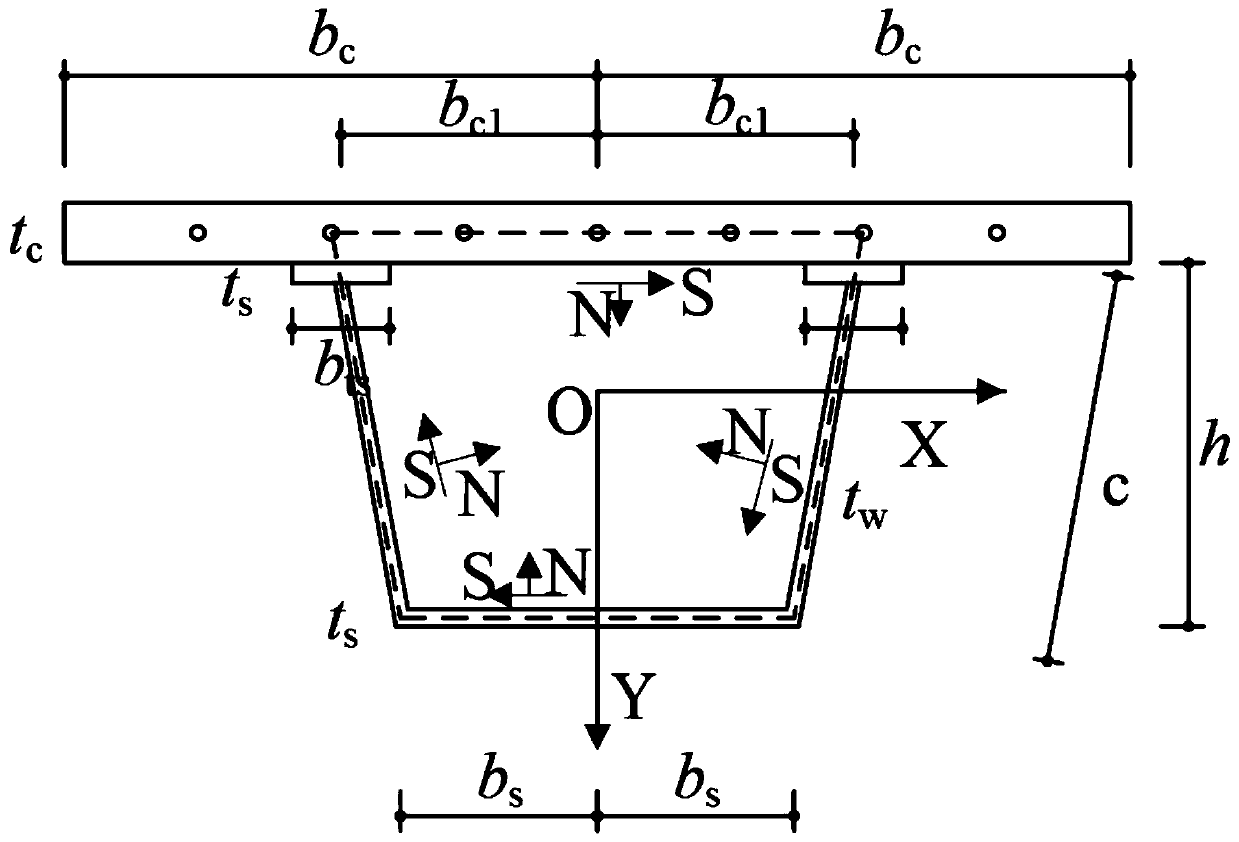

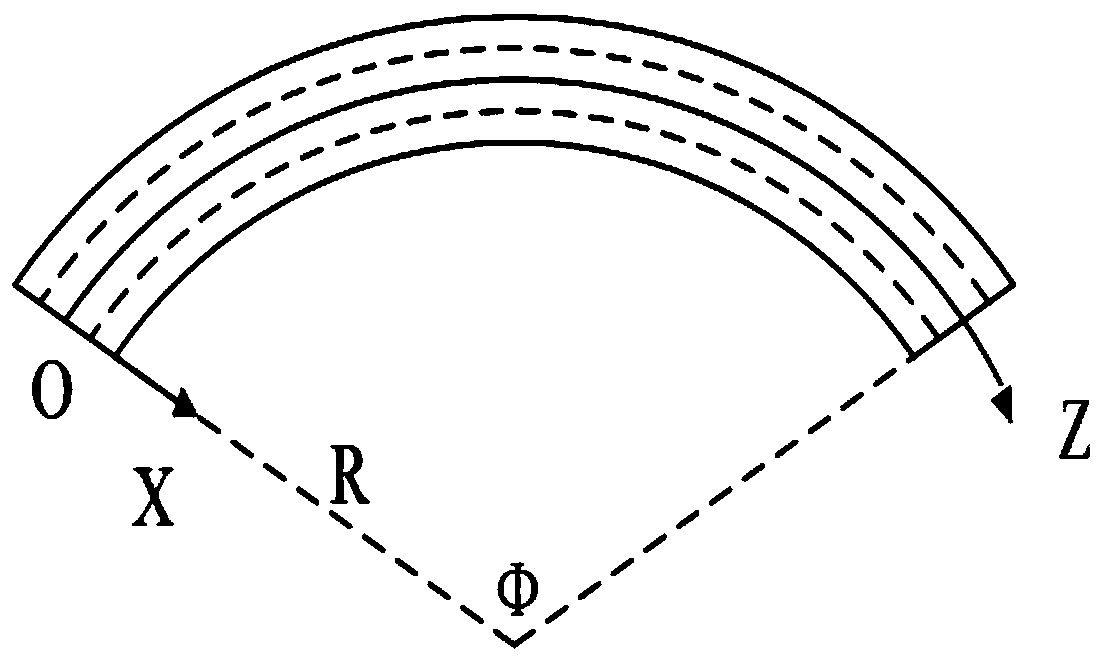

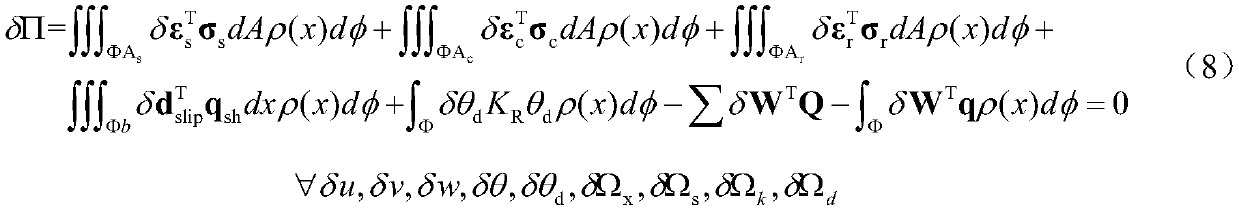

Construction method of one-dimensional finite element model of curved steel-concrete combined box girder

ActiveCN110020498AThe calculation result is accurateGeometric CADDesign optimisation/simulationElement modelTangential displacement

The invention relates to a construction method of one-dimensional finite element model of a curved steel-concrete combined box girder. The invention provides a theoretical model considering warping, distortion and slippage of a curved steel-concrete combined box girder. Each unit divided by the finite element in the model comprises 22 degrees of freedom, including radial displacement, vertical displacement, tangential displacement, torsion angle and distortion angle of the curved beam, relative sliding of the interface of the steel beam and the concrete slab and the like. A balanced equation of the curved steel-concrete combined box girder is constructed through the virtual work principle, and a rigidity matrix and an equivalent load matrix of the curved steel-concrete combined box girderis given.

Owner:BEIJING JIAOTONG UNIV

Establishment method of one-dimensional beam unit model of curved steel-concrete combined box beam

ActiveCN110309605AImprove accuracyGeometric CADDesign optimisation/simulationTangential displacementVirtual work

The invention discloses an establishment method of a one-dimensional beam unit model of a curved steel-concrete combined box beam. The method comprises the following steps: S1, selecting a coordinatesystem oxyz of a box beam; S2, based on the coordinate system, according to a torsion warping displacement function, calculating the displacement mode and the strain component of the combined box girder, wherein the displacement mode comprises longitudinal displacement, tangential displacement and normal phase displacement; S3, calculating to obtain a balance equation of the composite beam througha virtual work principle; and S4, establishing a finite element equation of the curve composite beam through the balance equation. The model is established by adopting the method, so that the subsequent calculation accuracy is higher, and the defect that the complex mechanical effects such as constraint torsion, distortion and interface bidirectional slippage of the curve composite beam are generally difficult to comprehensively consider in the existing research is overcome.

Owner:BEIJING JIAOTONG UNIV

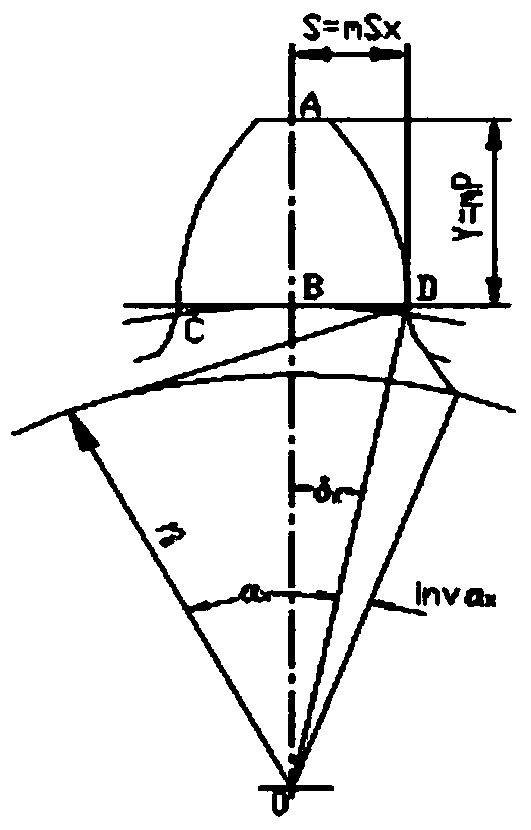

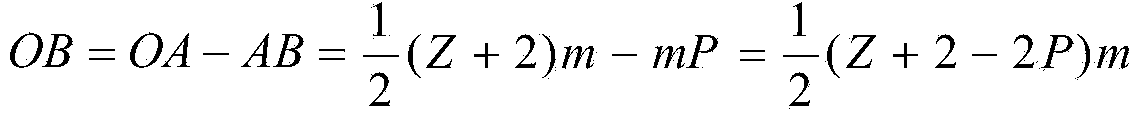

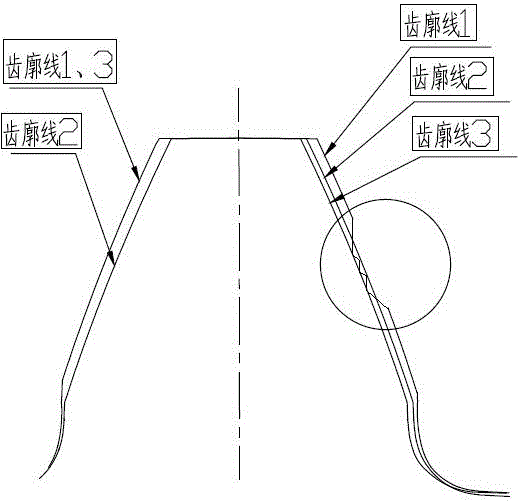

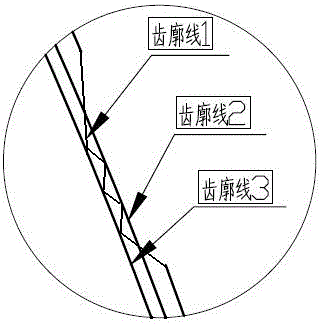

Method for checking gear involute tooth profile error

The invention relates to the field of transmission gears, in particular to a method for checking a gear involute tooth profile error. The method comprises the following steps: 1, measuring and calculating tooth profile coordinate points of a measured gear; 2, on the basis of calculating involute tooth profile coordinate points of an original straight toothed spur gear and a straight toothed bevel gear, deducing theoretical involute tooth profile coordinates of a height displacement bevel gear and a tangential displacement bevel gear; 3, regarding the distance between a tooth profile coordinate original point of the measured gear in the step 1 and theoretical involute tooth profile addendum circle coordinates deduced in the step 2 as the tooth profile error. According to the method, a theoretical coordinate value can be conveniently and quickly obtained according to the constant chord tooth thickness of the height displacement gear and the tangential displacement gear; each measured actual tooth profile point coordinate value is compared with the theoretical coordinate value, so that an operator can conveniently and quickly check the error.

Owner:XIAN NORTH ELECTRO OPTIC TECH DEFENSE

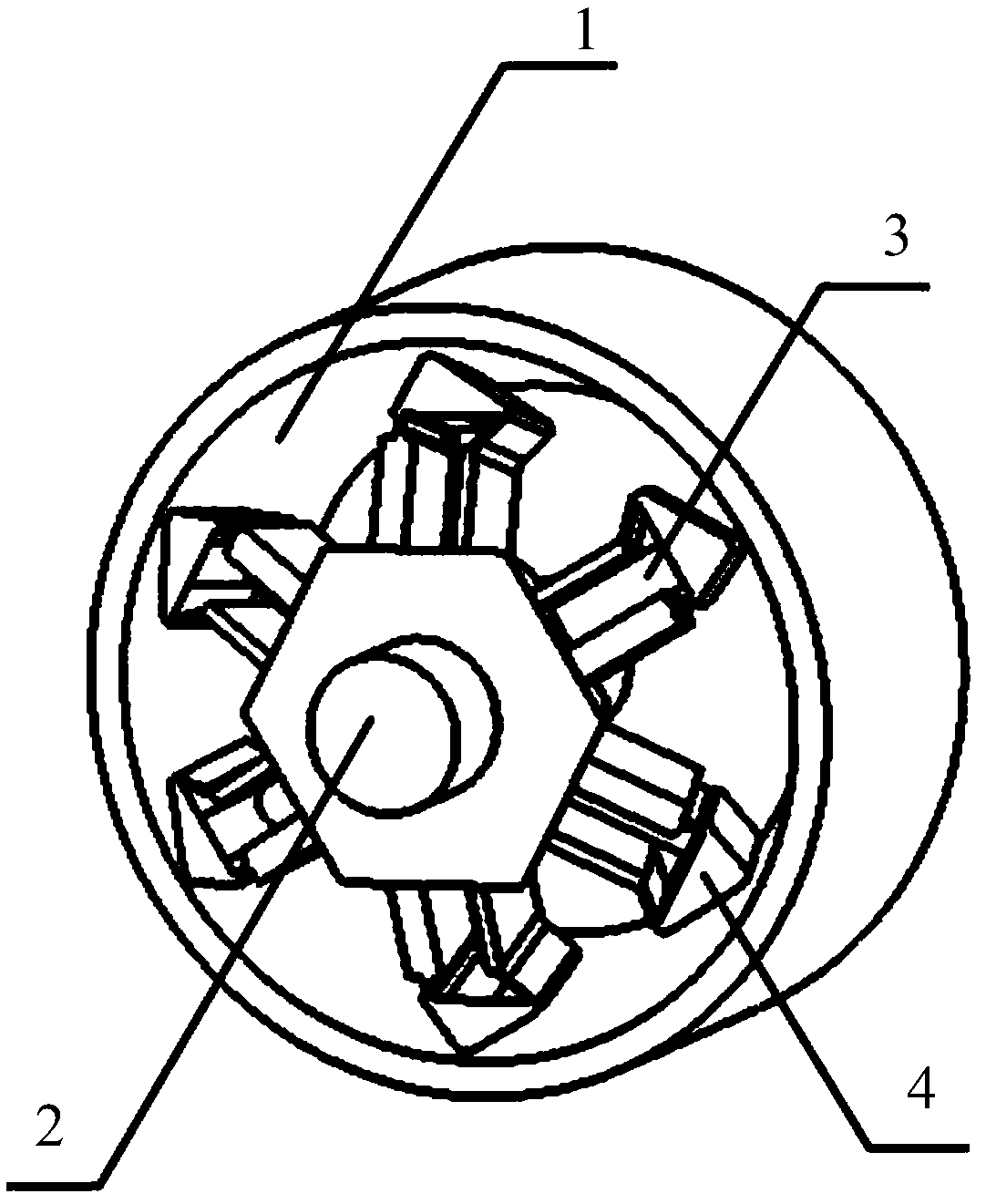

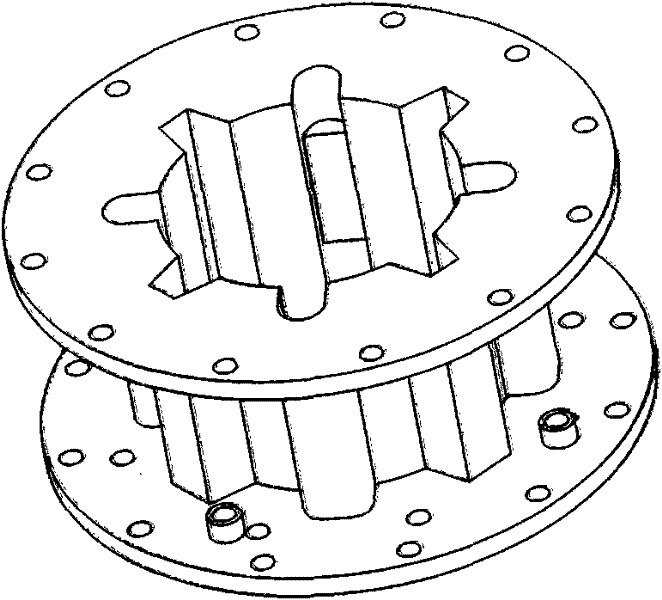

Piezoelectric driving motor

PendingCN109256982AThe output step increasesReducing the requirements of the piezo itselfPiezoelectric/electrostriction/magnetostriction machinesElectricityComputer module

The invention discloses a piezoelectric driving motor, comprising a central shaft and an output wheel, wherein a piezoelectric output module is radially connected between the output wheel and the central shaft; the piezoelectric output module comprises a piezoelectric ceramic block capable of electrifying and outputting radial displacement; and a flexible hinge assembly capable of converting the output radial displacement to a tangential displacement by limiting the position of the piezoelectric ceramic block. the integral structure of wheel-axle type is adopted, the piezoelectric output pairis arranged between the wheel and the axle to rotate and drive the output wheel to achieve continuous output, which is equivalent to increasing the output step distance; The piezoelectric ceramic block is elongated radially in the electrified state, the displacement conversion action of the flexure hinge assembly converts the output radial displacement into the tangential displacement, The precision of displacement output is maintained by the displacement amplification of the flexure hinge under the condition of increasing the magnitude of the output displacement. The precision of the flexurehinge is guaranteed by the design of the flexure hinge to reduce the requirement of the piezoelectric itself. The structure of the flexure hinge is simpler than that of the more mature inchworm-type transmission, and has the advantage of long-step continuity.

Owner:GUANGDONG UNIV OF TECH

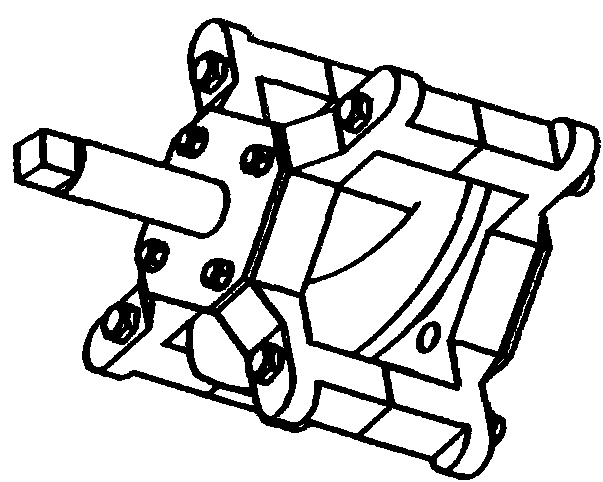

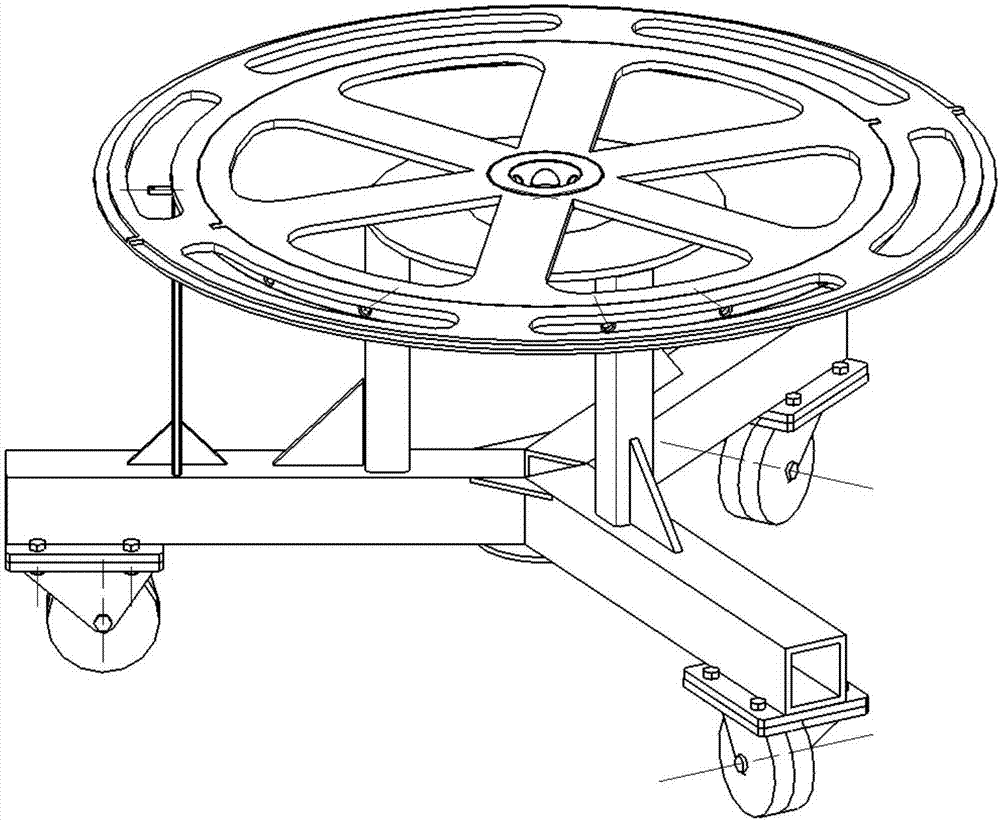

Device allowing engine component to rotate to be assembled

InactiveCN107984217AReduce labor intensityImprove work efficiencyAssembly machinesWork benchesAviationRotation function

The invention belongs to the technical field of aviation engine assembly, and particularly relates to a device allowing an engine component to rotate to be assembled. The device comprises an anti-thrust bearing 2, a braking pin 3, a rotating disc 4, a compression device 5, a platform main body 6 and trundles 7. The rotating disc 4 is connected with the anti-thrust bearing 2 through the compressiondevice 5, and the rotating function of the rotating disc 4 is achieved. When the rotating disc 4 rotates to a certain angle and needs to stay reliably, the braking pin 3 is inserted into a pin hole in the edge of the rotating disc 4, and thus it is ensured that the rotating disc 4 does not rotate any longer. The platform main body 6 bears the gravity of a workpiece. An extending ring 1 is used for meeting the assembly requirements of workpieces of different diameter sizes, and rotates with the rotating disc 4 together in the working process. The trundles 7 are used for achieving the moving function of a platform, have a braking function by itself and are used for ensuring reliable braking of the platform. Unnecessary workloads of tangential displacement generated between operation personnel and assemblies are omitted, the labor intensity is relieved, and the working efficiency is improved.

Owner:AECC SICHUAN GAS TURBINE RES INST

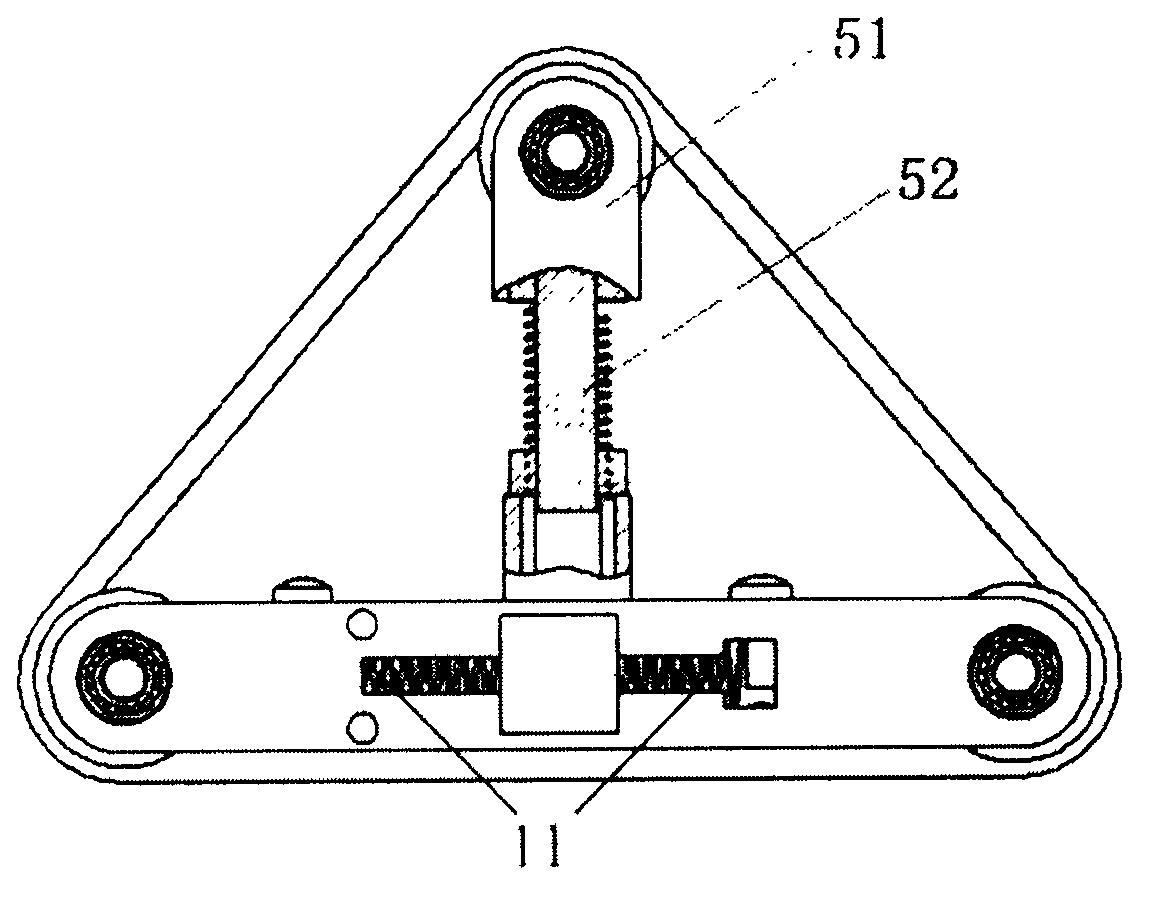

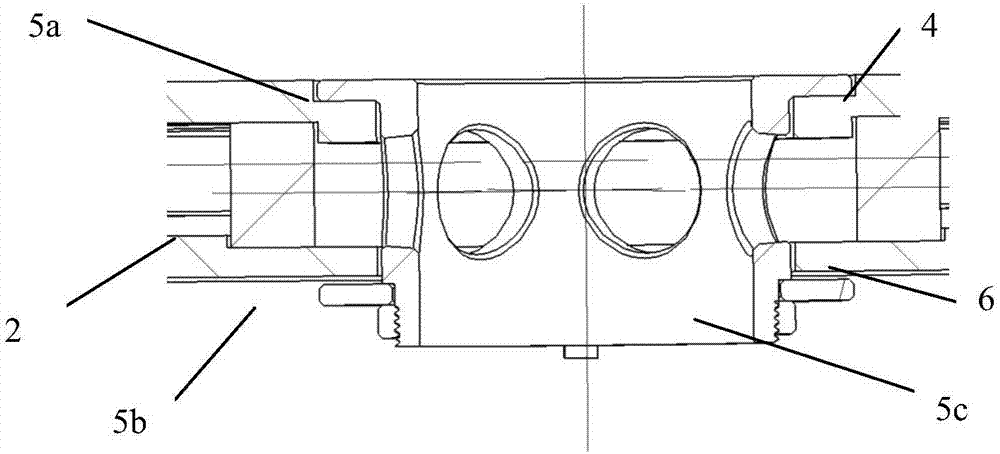

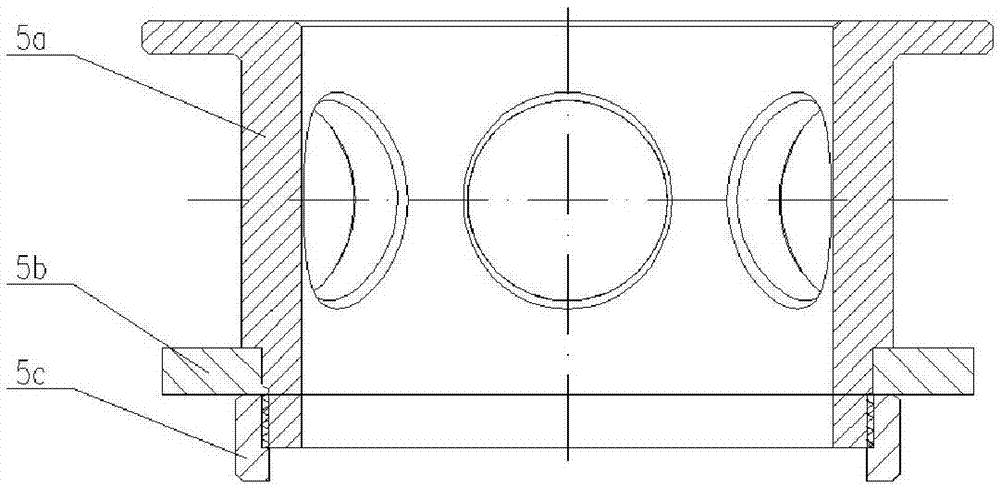

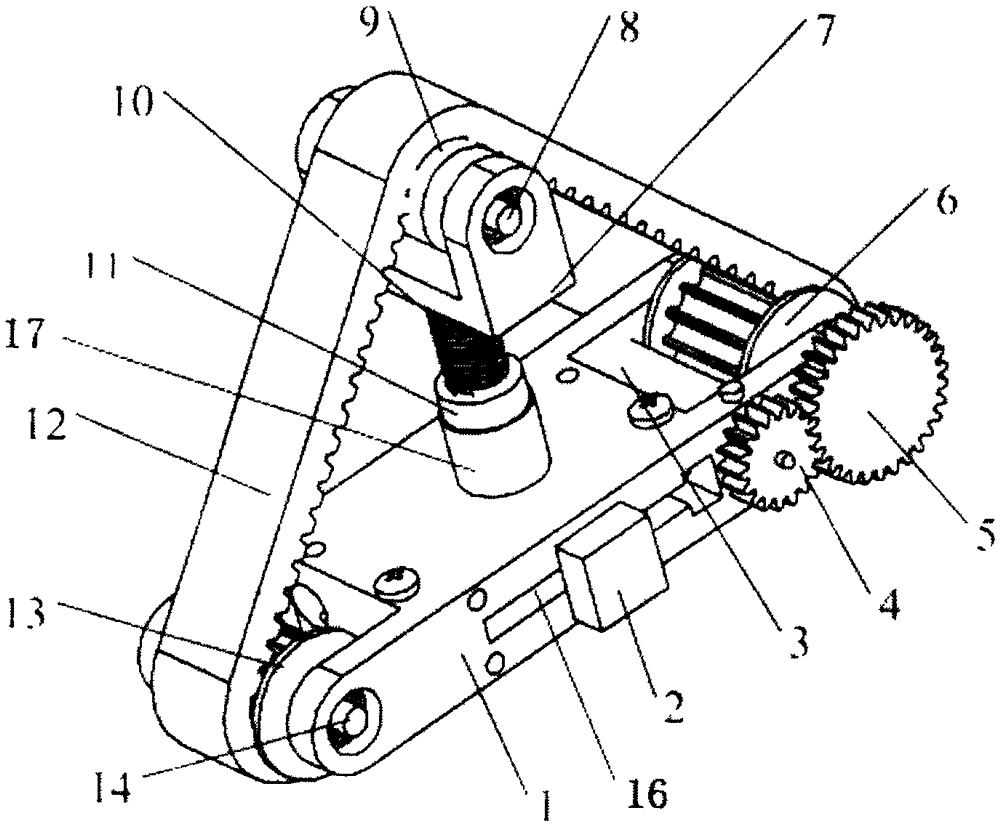

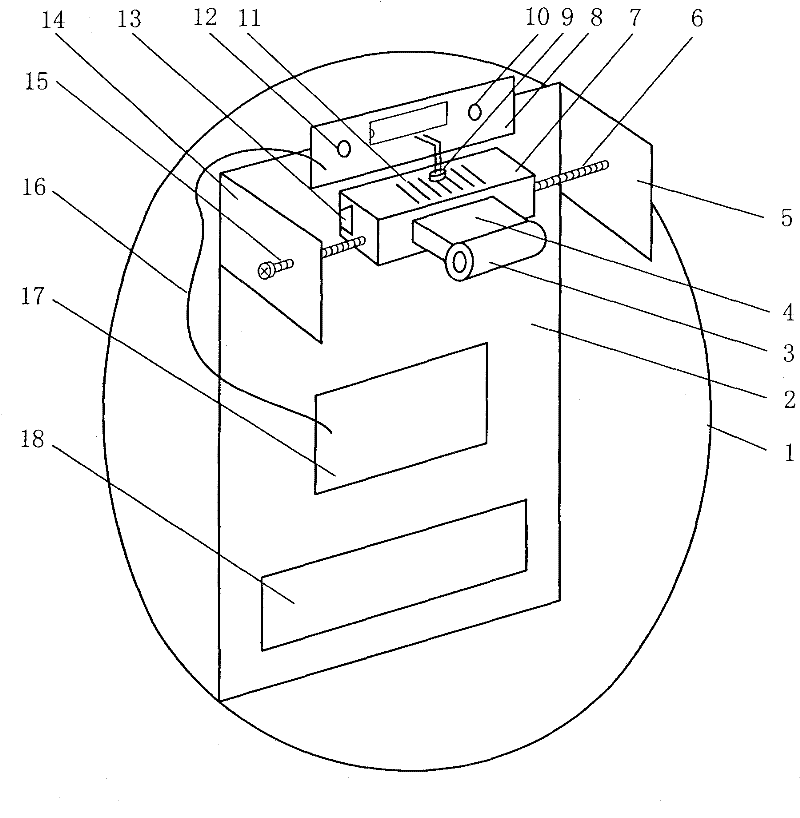

Method and device for adjusting position of objective lens in optical pick-up head

InactiveCN104282319AEasy to adjustImprove the efficiency of position adjustmentRecord information storageOptical beam guiding meansRadial positionTangential displacement

The embodiment of the invention provides a method and device for adjusting the position of an objective lens in an optical pick-up head. The device mainly comprises a tangential adjusting device, a radial adjusting device and an objective lens guide frame, wherein the tangential adjusting device is used for adjusting the tangential displacement of the objective lens guide frame in the tangential direction of the objective lens, the radial adjusting device is used for adjusting the radial displacement of the objective lens guide frame in the radial direction of the objective lens, the objective lens guide frame is used for making contact with the objective lens when the objective lens in the optical pick-up head moves towards an optical disc, the radial position of the objective lens can be adjusted through displacement of the objective lens guide frame in the radial direction of the objective lens, and the tangential position of the objective lens can be adjusted through displacement of the objective lens guide frame in the tangential direction of the objective lens. According to the method and device for adjusting the position of the objective lens in the optical pick-up head, the objective lens can be fast adjusted to the needed optimal position so that the position adjustment efficiency of the objective lens can be improved, and compared with the scheme of knob screw adjustment in the prior art, the accuracy and the stability of the position adjustment of the objective lens can be guaranteed.

Owner:DONGGUAN HUAQIANG INFORMATION TECH CO LTD

Road-use optical fiber grating interlayer relative horizontal displacement sensor

ActiveCN107014299AMeet the needs of interstory displacement monitoringEliminate wavelength driftUsing optical meansGratingGlass cover

The present invention provides a road-use optical fiber grating interlayer relative horizontal displacement sensor. According to the technical scheme of the invention, the test on the relative horizontal displacement between layers inside a pavement structure is realized. A top cover is embedded into the bottom of an upper-layer structure. A center column is connected with a top cover and a uniform strength beam, so that the top cover and the uniform strength beam move together. A bottom plate is embedded into the top of a lower-layer structure, and monitors the mutual displacement condition of the above two layers. A fixed ring is used for fixing the top cover and the bottom plate. Under the fixation of the fixed ring, only a tangential displacement is generated between the top cover and the bottom plate, so that the top cover and the bottom plate are not mutually separated. A silica gel pad is placed between the fixed ring and the bottom plate to limit the rotation of the bottom plate and the top cover, so that the top cover and the bottom plate are rebounded after the displacement. A fixed plate is used for fixing the silica gel pad of and other structures, so that the silica gel pad of and other structures are located inside the bottom plate. The uniform strength beam converts the horizontal sliding generated by the sensor into the vertical displacement. A sliding groove is arranged in the bottom plate and a glass cover plate is covered onto the sliding groove to increase the scratch resistance thereof. An optical fiber grating is stuck onto the uniform strength beam by a special structural adhesive, and the deformation of the uniform strength beam is converted into the wavelength change of the optical fiber grating.

Owner:HARBIN INST OF TECH

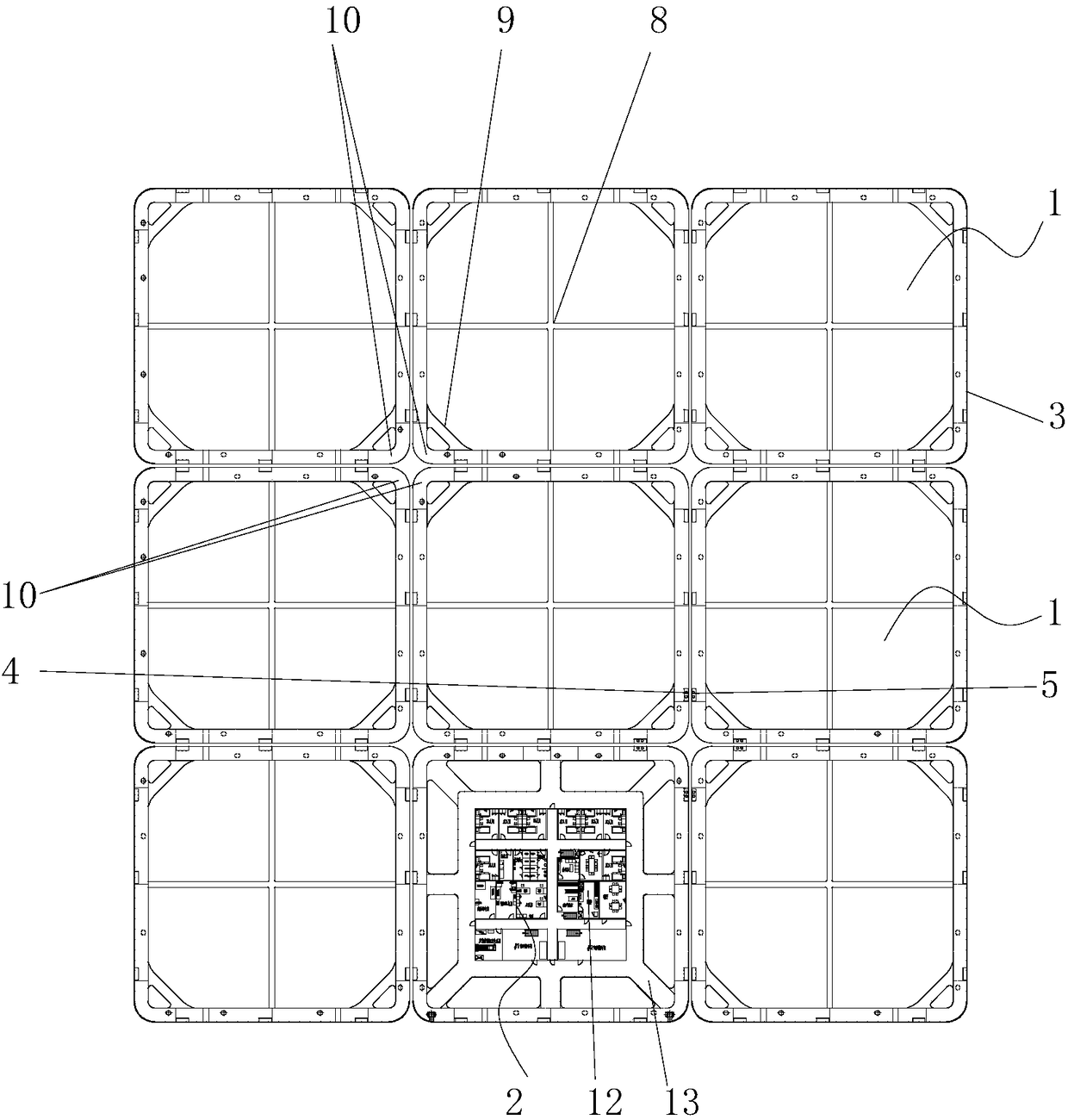

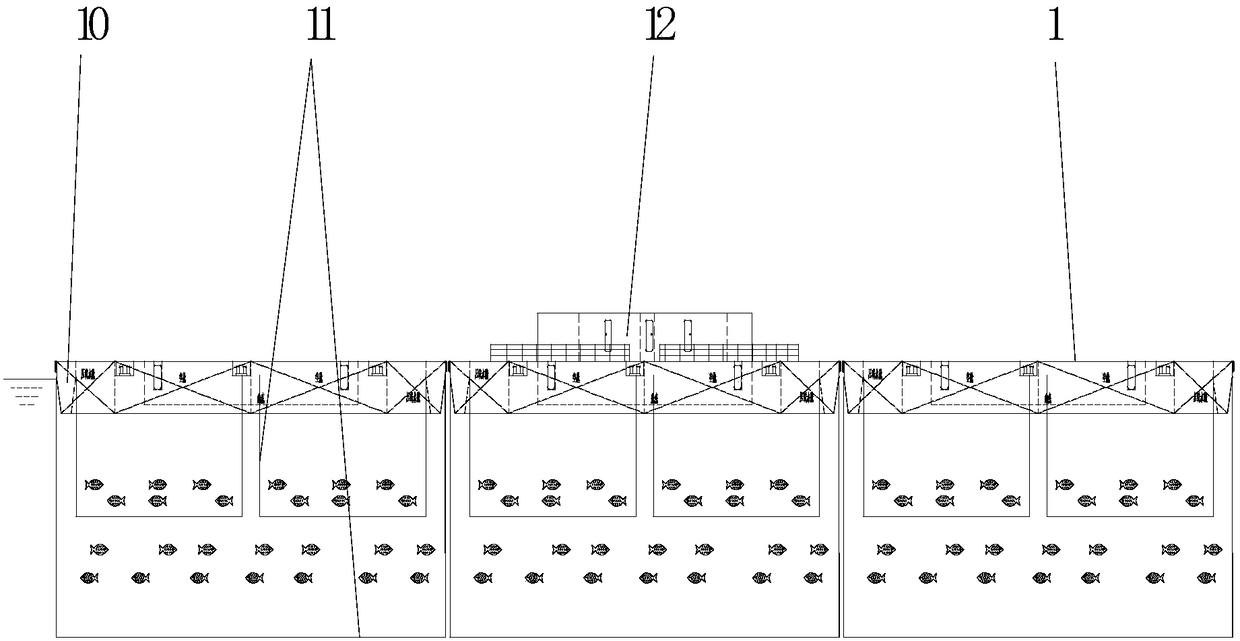

Deep and distant sea fishery ecological platform

PendingCN108338109ASubstitutableImprove connection stabilityClimate change adaptationPisciculture and aquariaTangential displacementEngineering

The invention discloses a deep and distant sea fishery ecological platform. The platform comprises floating modules, a ballast system used for controlling a draught depth of the floating modules and amooring system used for mooring the floating modules, a plurality of floating modules separately comprises a supporting module and a plurality of breeding modules, and the ecological platform can beformed by the plurality of the floating modules in a manner of free combination splicing. According to the platform provided by the invention, the plurality of breeding modules are mutually spliced toform the ecological platform, assembly is flexible, a platform shape can be flexibly changed or the number of the breeding modules can be increased or decreased according to actual conditions, and the modules have high replaceability; and each first cable belt and one corresponding second cable belt are arranged between each first cable pile group and one corresponding second cable pile group ina sleeving and staggered manner, so that edge tangential displacement among the modules can be effectively limited, the modules are guaranteed to have good stability after being connected, connectionstability among the deep and distant sea breeding modules is effectively improved through the staggered cable belts, windstorm resistant ability is improved, and the platform has a simple structure, and is convenient for operation.

Owner:重庆川东船舶重工有限责任公司

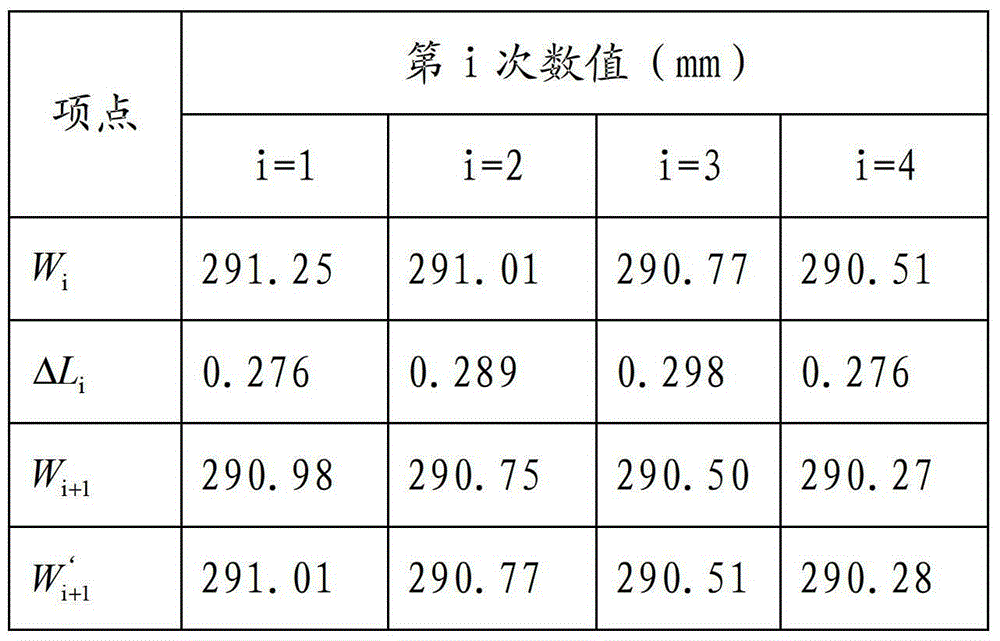

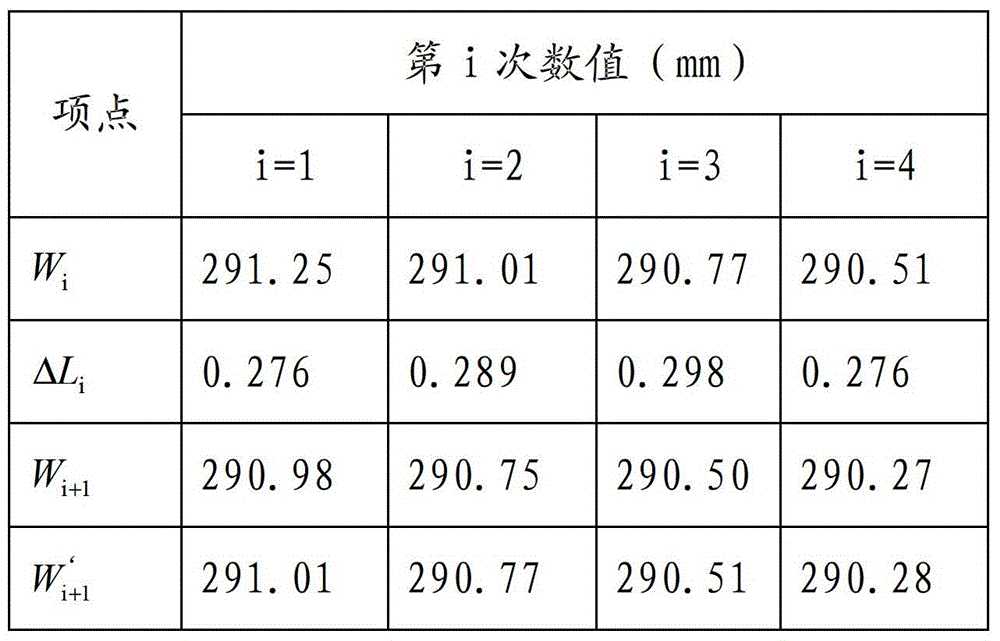

Tangential feeding hobbing method for hobbing machine

ActiveCN104368880AControl Tangential DisplacementMeet the design requirementsGear teethHobbingTangential displacement

The invention provides a tangential feeding hobbing method for a hobbing machine. The tangential feeding hobbing method has the advantages that the tangential feeding hobbing method is designed for solving the problem of defects of tooth surfaces due to faults of machine tools or hobs and the like and overcoming shortcomings of existing equipment, tangential displacement of hob frames can be effectively controlled in manual modes under the condition that special tangential frames for the existing equipment are omitted, accordingly, defects of tooth surfaces can be ingeniously removed, gear design requirements can be met, gear meshing and the service lives of gears can be guaranteed, and production loss can be recovered; the tangential frames do not need to be specially ordered owing to the tangential feeding hobbing method, accordingly, the cost can be reduced, the production effectiveness can be improved, and the tangential feeding hobbing method is economical and practical.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Gear eccentric simulation experiment device

InactiveCN105118374AHigh precisionImprove efficiencyEducational modelsAxial displacementVertical plane

The invention discloses a gear eccentric simulation experiment device comprising a first gear, a second gear meshed with the first gear, and a movable plate connected with the second gear. The movable plate is used for driving the second gear to move in order to simulate the first eccentric state, the second eccentric state, or at least two of the first to third eccentric states of the second gear. The first eccentric state comprises tangential displacement eccentricity and horizontal plane intersection angle eccentricity. The second eccentric state comprises radial displacement eccentricity and vertical plane intersection angle eccentricity. The third eccentric state comprises axial displacement eccentricity. The gear eccentric simulation experiment device simulates different eccentric states of the second gear by driving the second gear to move with the movable plate connected with the second gear, thereby researching an influence of different eccentric modes of a gear on the dynamic characteristic and the service life of the gear, and improving accuracy and efficiency of a gear eccentric simulation experiment.

Owner:TSINGHUA UNIV

Bionic crawler-type adhesive walking mechanism and its motion method

The invention discloses a bionic crawler-type adhesion walking mechanism and a moving method thereof. The bionic crawler-type adhesion walking mechanism comprises a machine frame, a tensioning mechanism, a driving mechanism and an adhesion belt, wherein the driving mechanism comprises a driving motor, a driving motor gear, a driving wheel and a driven wheel; the driving wheel is connected with one end of the machine frame through a gear shaft; the driven wheel is connected with the other end of the machine frame through a driven wheel shaft; the driving motor gear is driven by the driving motor; the driving motor gear is meshed with the gear shaft; the tensioning mechanism comprises a tensioning wheel frame, a tensioning spring, a miniature force sensor, a tensioning wheel and a sleeve; the tensioning wheel, the driving wheel and the driven wheel are connected through the adhesion belt; the tensioning mechanism further comprises a mechanism connecting device arranged on the machine frame. A certain tangential displacement and a posture angle are outputted by a robot body, so that the adhesion, detachment and pressing of soles are realized and the walking and halting of a robot on a wall are assisted.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

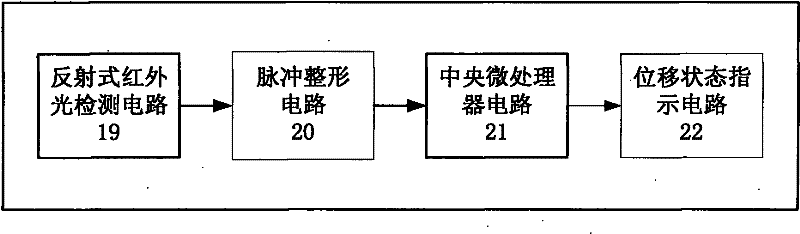

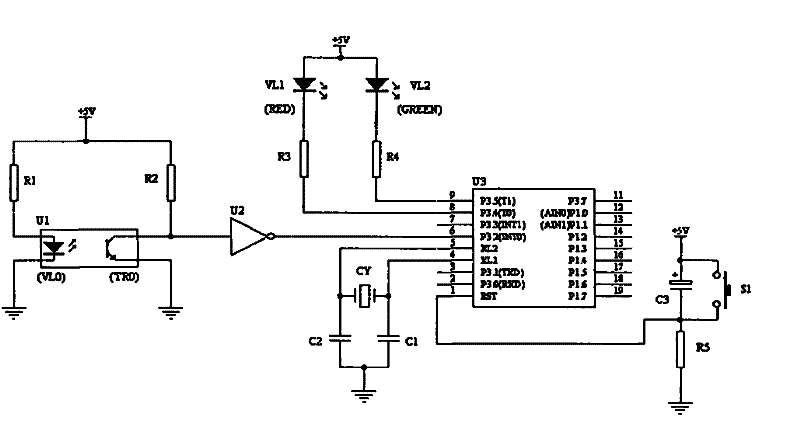

Device for measuring rotor centrifugal force resistant tangential displacement in tire electromechanical transduction

InactiveCN101799272BFill technology gapsEasy to operateUsing optical meansTangential displacementEngineering

The invention discloses a device for measuring rotor centrifugal force resistant tangential displacement in tire electromechanical transduction, which comprises a tire and a rotating mechanism, a general bearing plate and a circuit control panel. The tire is arranged on the rotating mechanism; a sliding mechanism is arranged on the general bearing plate fixedly connected with the tire, and is connected with a hollow simulated rotor; and the circuit control panel is fixedly connected with the general bearing plate. The invention provides a platform for measuring the rotor centrifugal force resistant tangential displacement in the tire electromechanical transduction, which can intuitively measure actual tangential displacement of the rotor in the centrifugal force state at different tire rotating speeds. The relationship data of the measured tangential displacement of the rotor and the tire rotating speed can provide a design basis for the efficiency of automotive electromechanical transduction.

Owner:SOUTH CHINA UNIV OF TECH

Device for testing tangential stiffness property of joint surface

InactiveCN102393330BEasy to processEasy to installMaterial strength using tensile/compressive forcesTangential displacementEngineering

The invention discloses a device for testing a tangential stiffness property of a joint surface, and belongs to the fields of mechanical design and manufacture. The device consists of a test loading device (1) and a tangential test assembly. An upper test piece (7) is butted with a lower test piece (6), and a gap is reserved at the joint; a pressing plate (3) and a pressing plate (11) are arranged on two surfaces vertical to the test piece butting surface, and are fixedly connected through two high-strength bolts (9) and (11) to form the tangential test assembly; the high-strength bolts (9) and (11) are symmetrical about the gap of the joint of the upper and lower test pieces; brackets (8) and (5) are arranged on two sides of the gap of the joint for accommodating an eddy current displacement sensor (4); and a force sensor (14) for measuring loading force signals and the eddy current displacement sensor (4) for measuring the tangential displacement variation of the joint surface are connected to a signal acquisition system. The device has the advantages of simple machining, convenience for clamping, high universality, high controllability of the parameters and the like.

Owner:BEIJING UNIV OF TECH

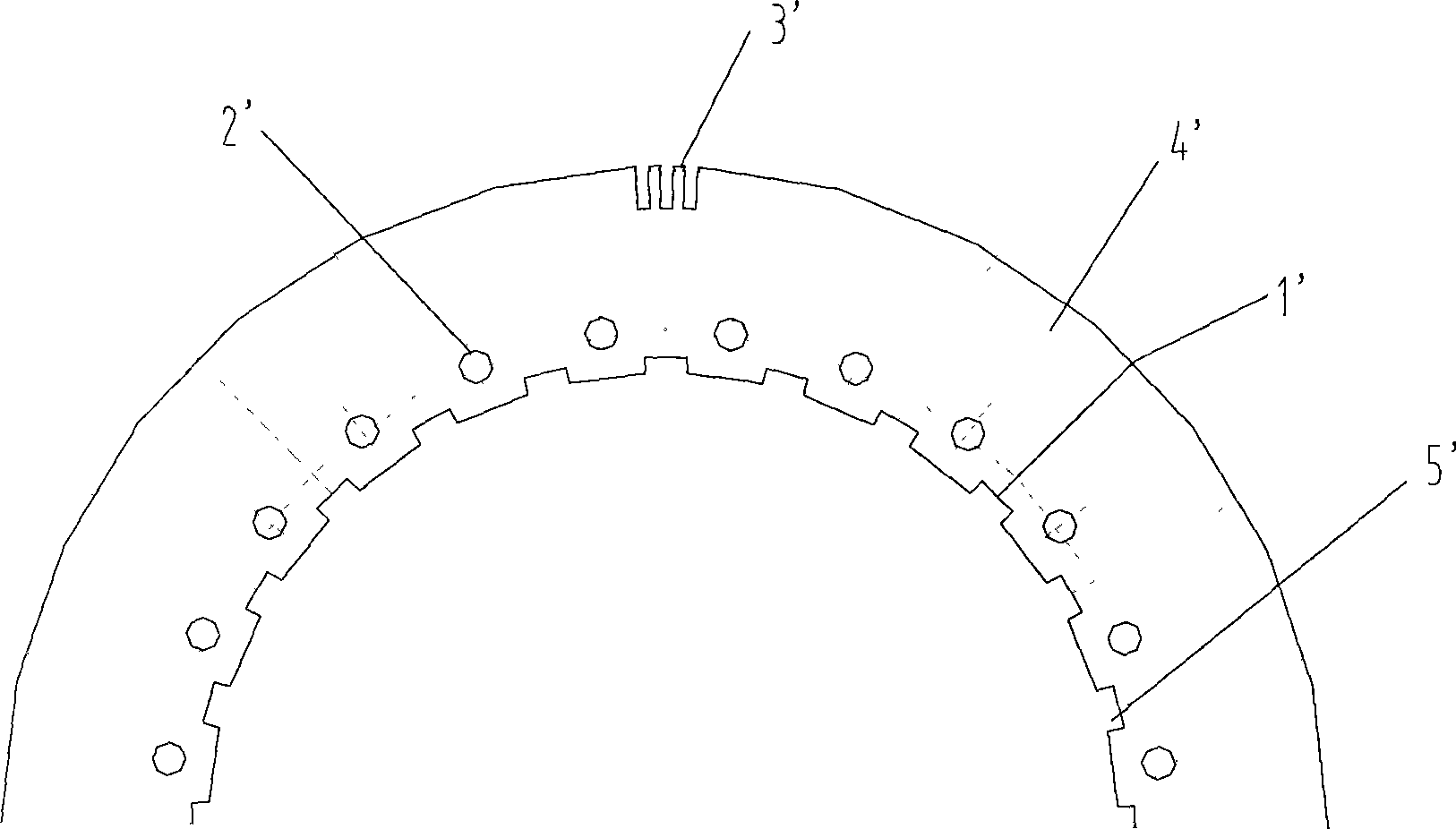

Chaining fanning strip for large-medium type motor and manufacturing method thereof

InactiveCN101282048BReduce targeting requirementsReduce die costManufacturing stator/rotor bodiesMagnetic circuit shape/form/constructionPunchingElectric machine

Owner:SHANGHAI NANYANG ELECTRICAL MACHINERY

Measuring method and system for five- and six-degree-of-freedom errors of shafting based on circular gratings

The invention relates to a circular grating-based shaft system five-degree-of-freedom error measurement method, a circular grating-based shaft system six-degree-of-freedom error measurement method anda measurement system. According to the measurement methods and measurement system, two or more measuring planes are arranged at intervals on the axial position of the measured shaft of a shaft system; circular gratings are disposed at positions on the measured shaft which are corresponding to each of the measuring planes respectively; each measuring plane is provided with a reading head corresponding to the corresponding circular grating; if the axis of the measured shaft moves, the tangential displacement of the measured shaft changes when the measured shaft rotates in the measuring planes,and therefore, the plane displacement of the measured shaft on the detecting planes can be generated; and since the displacement is a relative variable relative to the initial position of the measuredshaft, the displacement is not affected by the roundness of the measured shaft itself.

Owner:HENAN UNIV OF SCI & TECH

Solar sterling generator

InactiveCN102146900BCompact structureReduce volumeFrom solar energyMachines/enginesBlocked ConnectionTangential displacement

The invention provides a solar sterling generator. A plurality of symmetrically-distributed rotor support frame mounting grooves are arranged on the inner wall of a generator body of the solar sterling generator, two rotor support frames are arranged in the generator body respectively from two ends of the generator body along the mounting grooves and fixed together by a plurality of groups of fastening screws, and the generator body, the rotor support frames and rotors are fixed together. Central lines of pin holes at two ends of a connecting rod of a piston group are perpendicular to each other, assembly clearances are arranged at a piston connection part and a guide block connection part, and the piston group has the functions of automatically compensating radial and tangential displacements of an air cylinder, therefore, the assembly difficulty in the production process is reduced, and the reliable degree in the operation process is improved. By comprehensively adopting latest technologies of a countercurrent heat exchanging type regenerator, an annular heat exchanger, and the like, the whole generator has a compact structure and small size. By adopting an air cooling manner for heat dissipation, the solar sterling generator can be widely applied to water-deficient areas.

Owner:郯城瑞康食品有限公司

A tangential feed hobbing method for gear hobbing machines

ActiveCN104368880BControl Tangential DisplacementMeet the design requirementsGear teethHobbingTangential displacement

The invention provides a tangential feeding hobbing method for a hobbing machine. The tangential feeding hobbing method has the advantages that the tangential feeding hobbing method is designed for solving the problem of defects of tooth surfaces due to faults of machine tools or hobs and the like and overcoming shortcomings of existing equipment, tangential displacement of hob frames can be effectively controlled in manual modes under the condition that special tangential frames for the existing equipment are omitted, accordingly, defects of tooth surfaces can be ingeniously removed, gear design requirements can be met, gear meshing and the service lives of gears can be guaranteed, and production loss can be recovered; the tangential frames do not need to be specially ordered owing to the tangential feeding hobbing method, accordingly, the cost can be reduced, the production effectiveness can be improved, and the tangential feeding hobbing method is economical and practical.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com