Tangential final-motion frictional wear test equipment

A wear test and fretting friction technology, which is applied in the direction of testing wear resistance, etc., can solve the problems of low excitation force and displacement amplitude, difficulty in changing, poor precision, etc., and achieve precise displacement and frequency control, low production and test costs Low, manufacture and maintain accurate results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

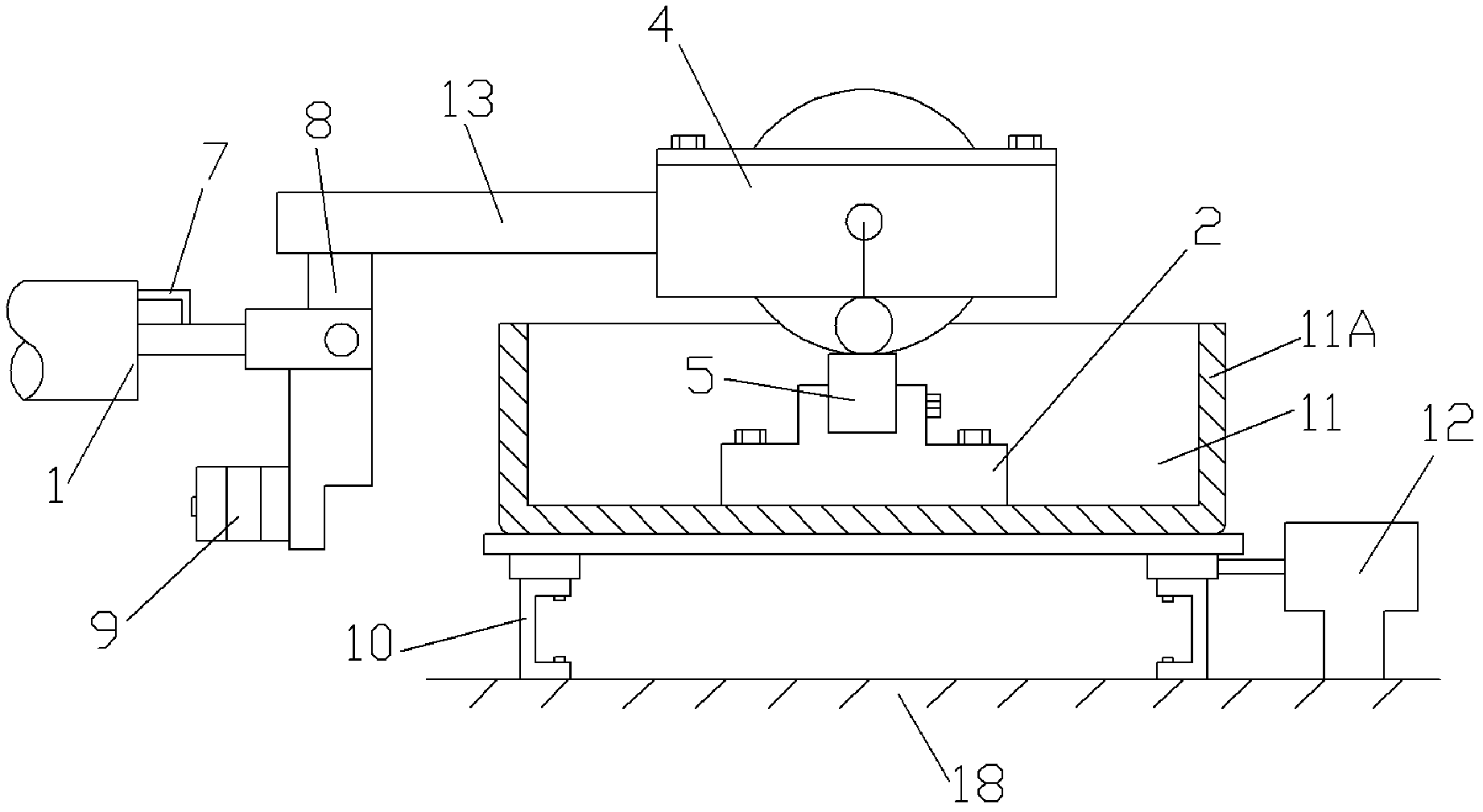

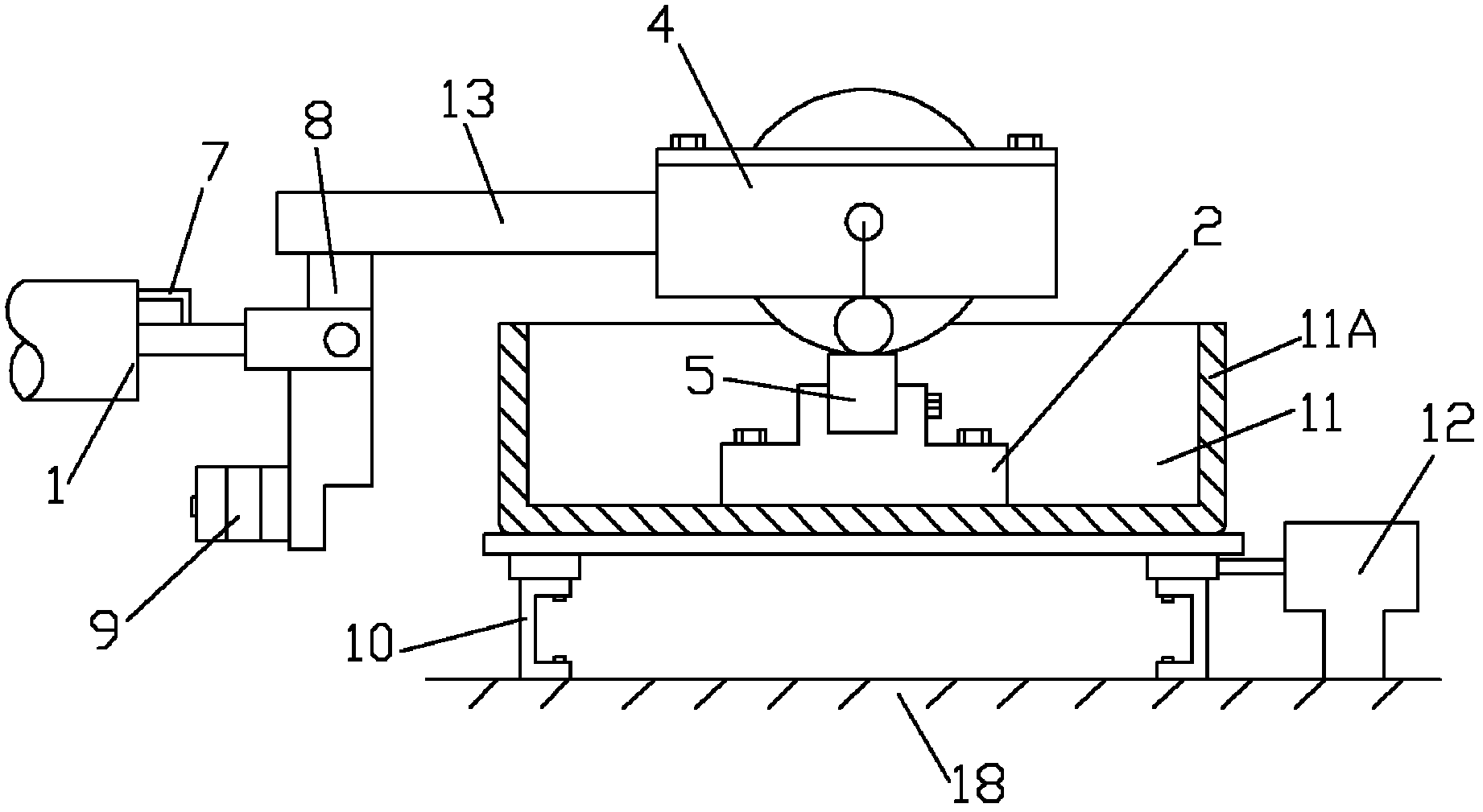

[0023] figure 1 Shown, a specific embodiment of the present invention is, a kind of tangential fretting friction and wear test equipment, its composition is:

[0024] The piston rod of the horizontal hydraulic piston 1 connected to the data acquisition and control system is connected to the hinge shaft in the upper part of the vertical connecting rod 8, and the upper end of the connecting rod 8 is connected to one side of the upper specimen chuck 4 through a cross bar 13; A tangential displacement sensor 7 is installed between the piston rod and the piston of the hydraulic piston 1; the upper specimen chuck 4 is a chuck for clamping a spherical specimen;

[0025] The lower specimen chuck 2 for clamping the plane specimen 5 is arranged directly below the upper specimen chuck 4, and the lower specimen chuck 2 is fixed on the bottom of the experimental medium chamber 11, and the bottom of the experimental medium chamber 11 is connected with two longitudinal The top of the suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com