Patents

Literature

209 results about "Fretting wear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fretting wear is the repeated cyclical rubbing between two surfaces, which is known as fretting, over a period of time which will remove material from one or both surfaces in contact. It occurs typically in bearings, although most bearings have their surfaces hardened to resist the problem. Another problem occurs when cracks in either surface are created, known as fretting fatigue. It is the more serious of the two phenomena because it can lead to catastrophic failure of the bearing. An associated problem occurs when the small particles removed by wear are oxidised in air. The oxides are usually harder than the underlying metal, so wear accelerates as the harder particles abrade the metal surfaces further. Fretting corrosion acts in the same way, especially when water is present. Unprotected bearings on large structures like bridges can suffer serious degradation in behaviour, especially when salt is used during winter to deice the highways carried by the bridges. The problem of fretting corrosion was involved in the Silver Bridge tragedy and the Mianus River Bridge accident.

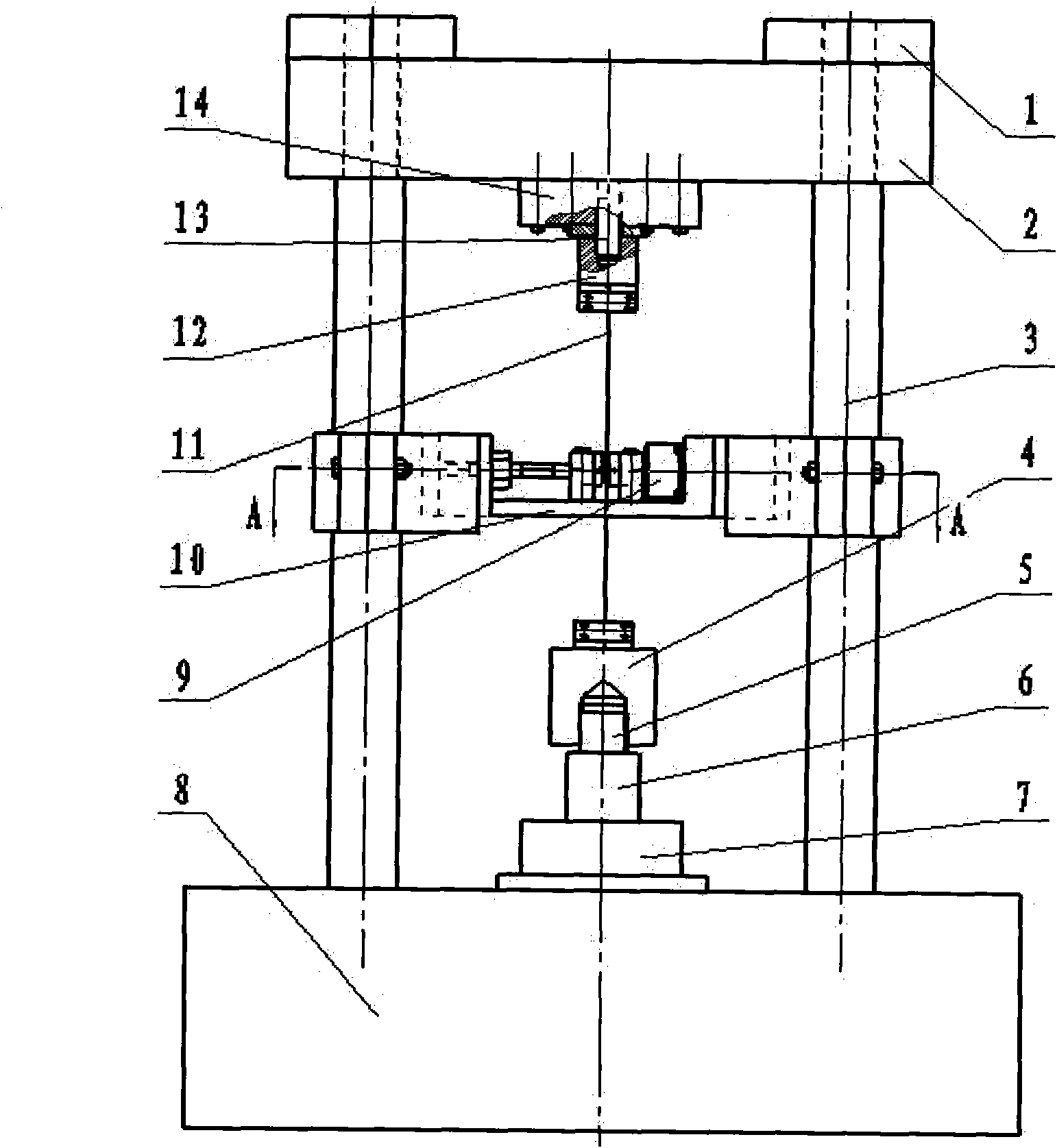

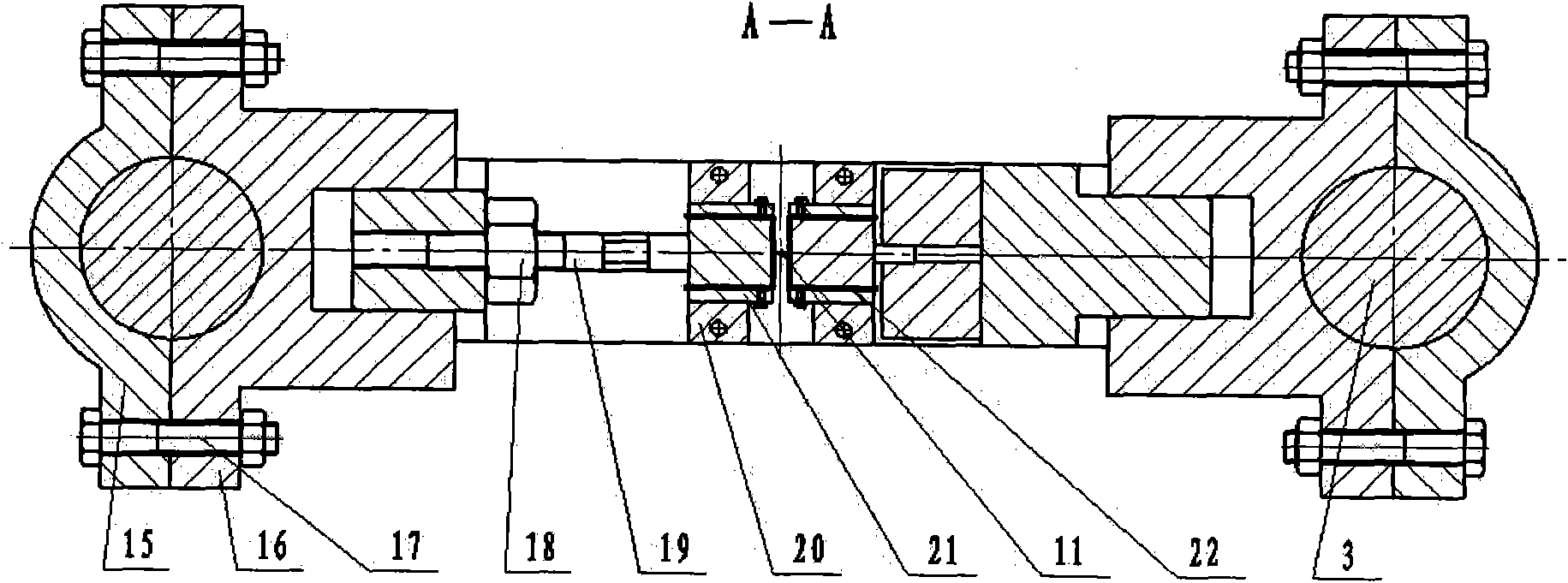

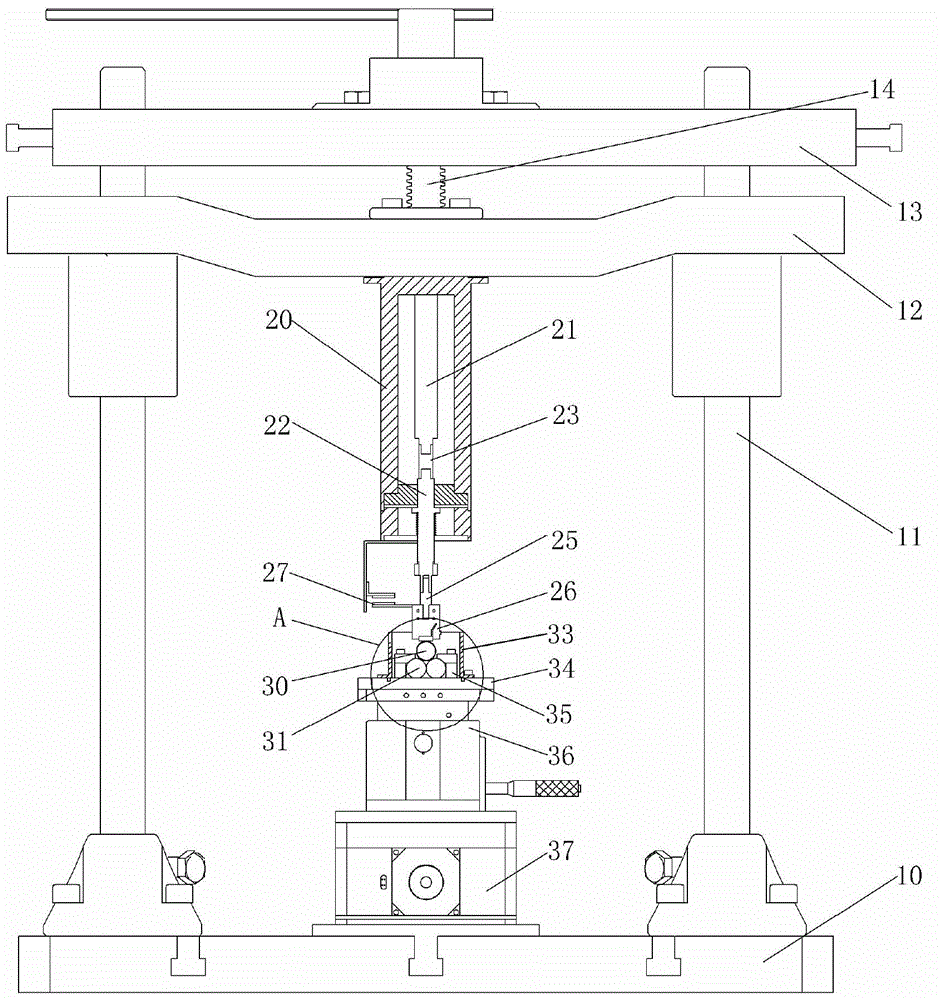

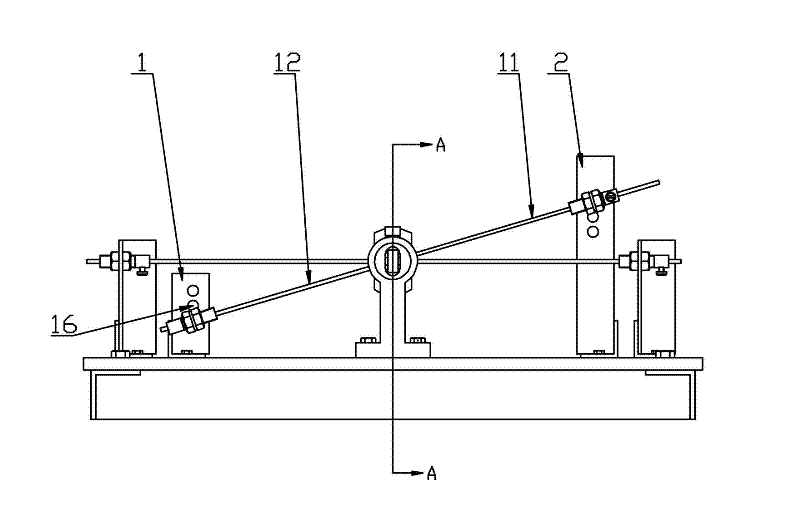

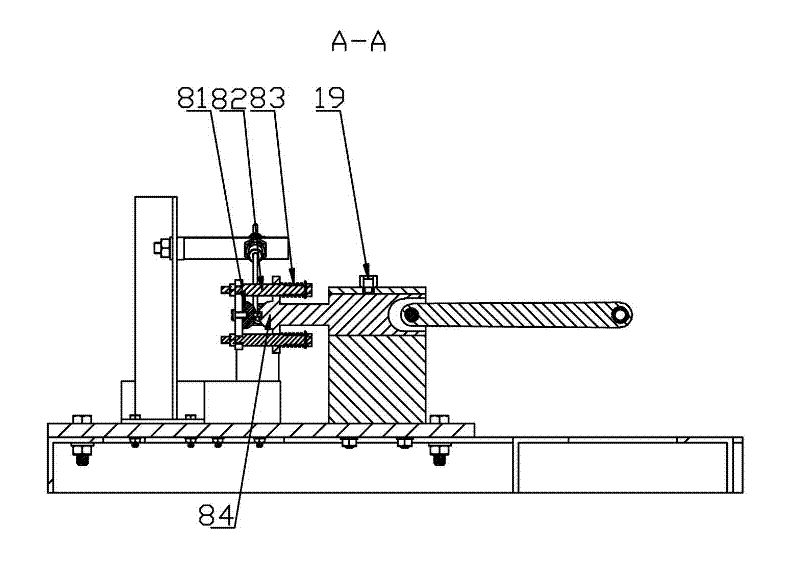

Steel wire fretting fatigue testing machine and method

InactiveCN101598647AEasy to controlEasy to measureMaterial strength using tensile/compressive forcesCompression deviceEngineering

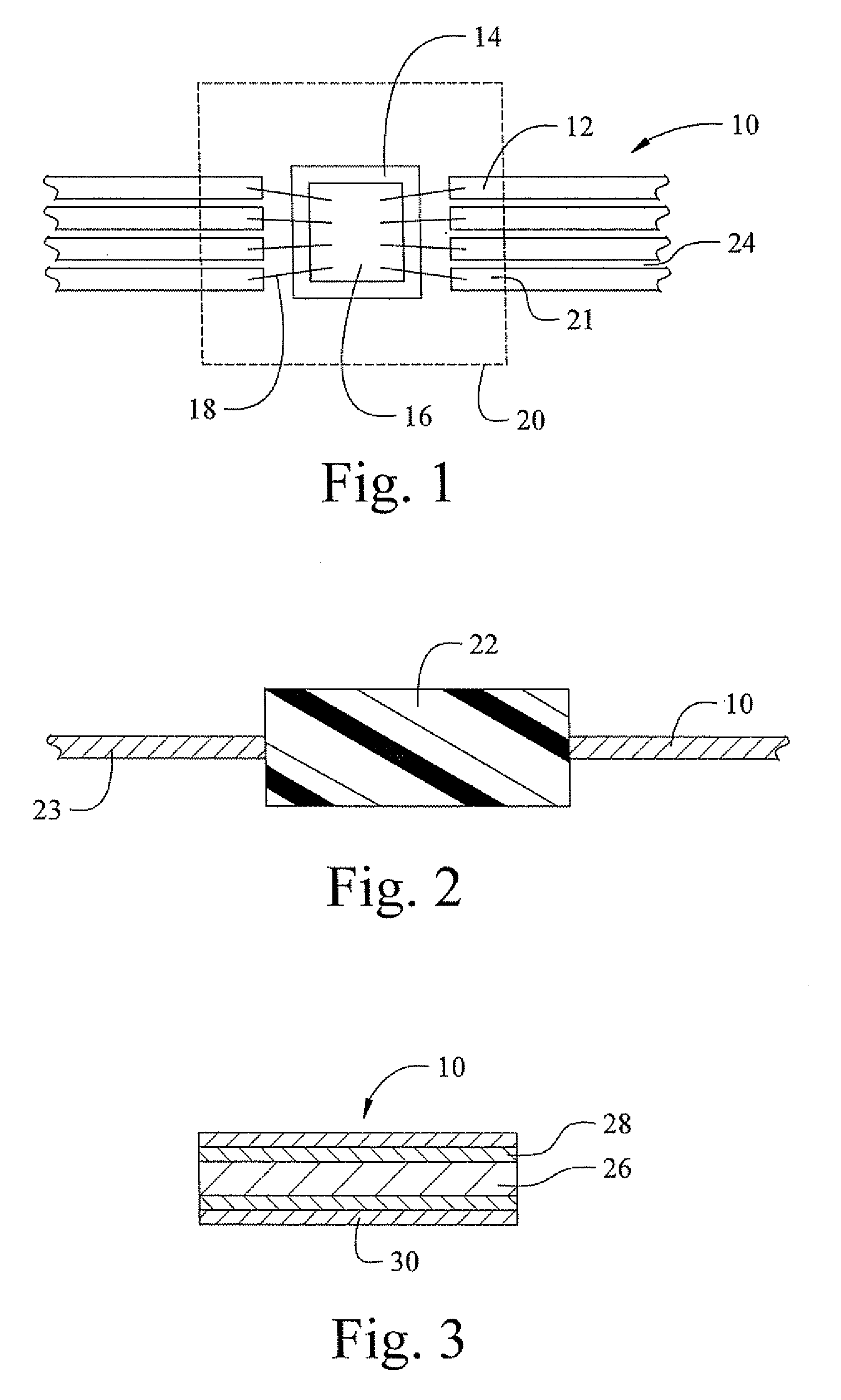

The invention relates to a steel wire fretting fatigue testing machine and a method. The testing machine mainly comprises a horizontal loading device, an axial clamping device and an axial tensile compression device, wherein the horizontal loading device consists of a concave horizontal support saddle, a guiding support saddle, a wedged slide block, a loading steel wire, a pressure sensor, a loading rod and a locking nut; the axial clamping device consists of a spoke-type tensile compression sensor, a threaded rod connected with the spoke-type tensile compression sensor and an upper holding block fixed on the threaded rod; and the axial tensile compression device consists of an oil cylinder, a threaded rod connected with the piston of the oil cylinder and a lower holding block fixed on the threaded rod. The steel wire fretting fatigue testing machine has the advantages that by exerting horizontal set load on an axial steel wire through the horizontal loading device and by acting axial fatigue stress on a steel wire sample through the axial clamping device and the axial tensile compression device, the testing machine realizes fretting fatigue test of the coaction of fretting wear and axial fatigue stress of the steel wire sample; dynamic adjustment of the concave horizontal support saddle ensures that an axial fatigue steel wire does not generate bending stress; moreover, fluctuation ranges of both amplitude and frequency are wide and easy to control and measure by utilizing computer program.

Owner:CHINA UNIV OF MINING & TECH

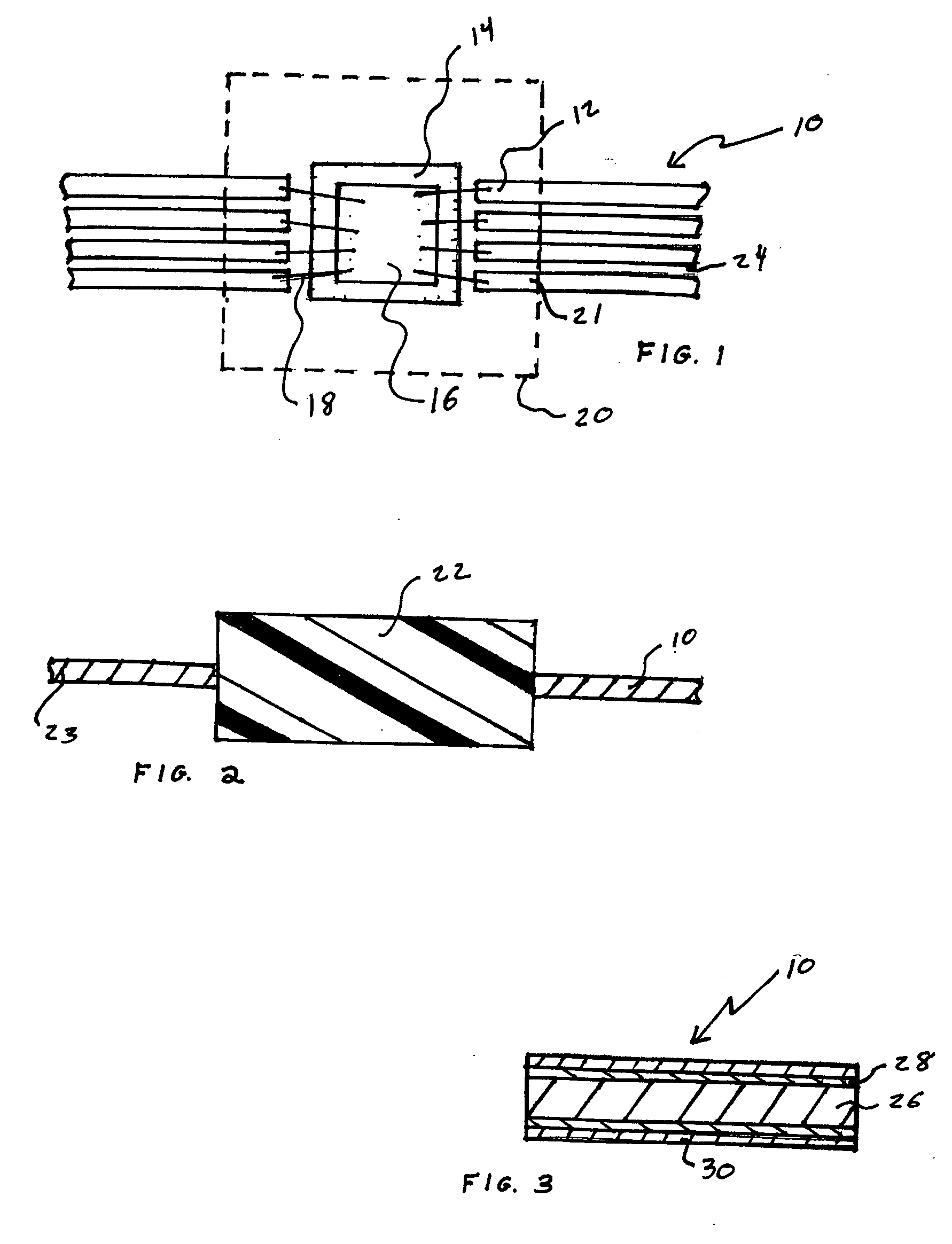

Fretting and whisker resistant coating system and method

ActiveUS20050106408A1Minimized increaseHigh resistivityAnodisationHot-dipping/immersion processesCoating systemFlexible circuits

A coated electrically conductive substrate has particular utility where there are multiple closely spaced leads and tin whiskers constitute a potential short circuit. Such substrates include leadframes, terminal pins and circuit traces such as on printed circuit boards and flexible circuits. This electrically conductive substrate has a plurality of leads separated by a distance capable of bridging by a tin whisker, a silver or silver-base alloy layer coating at least one surface of at least one of the plurality of leads, and a fine grain tin or tin-base alloy layer directly coating said silver layer. An alternative coated electrically conductive substrate has particular utility where debris from fretting wear may oxidize and increase electrical resistivity, such an in a connector assembly. This electrically conductive substrate has a barrier layer deposited on the substrate that is effective to inhibit diffusion of constituents the substrate into a plurality of subsequently deposited layers. The subsequently deposited layers include a sacrificial layer deposited on the barrier layer that is effective to form intermetallic compounds with tin, a low resistivity oxide metal layer deposited on said sacrificial layer, and an outermost layer of tin or a tin-base alloy directly deposited on the low resistivity oxide metal layer. In this alternative embodiment, the barrier layer is preferably nickel or a nickel-base alloy and the low resisitivity oxide metal layer is preferably silver or a silver-base alloy. When heated, the coated substrate of this second embodiment forms a unique structure having a copper or copper-base alloy substrate, an intervening layer formed from a mixture or metals including copper and tin, and an outermost layer which is a mixture of a copper-tin intermetallic containing phase and a silver-rich phase. It is believed that this silver-rich phase is particularly beneficial to reduce an increase in resistivity due to oxidation of fretting wear debris.

Owner:WIELAND ROLLED PROD NORTH AMERICA LLC

Fretting and whisker resistant coating system and method

ActiveUS7391116B2High resistivityInhibited DiffusionHot-dipping/immersion processesAnodisationCoating systemAlloy substrate

Owner:WIELAND ROLLED PROD NORTH AMERICA LLC

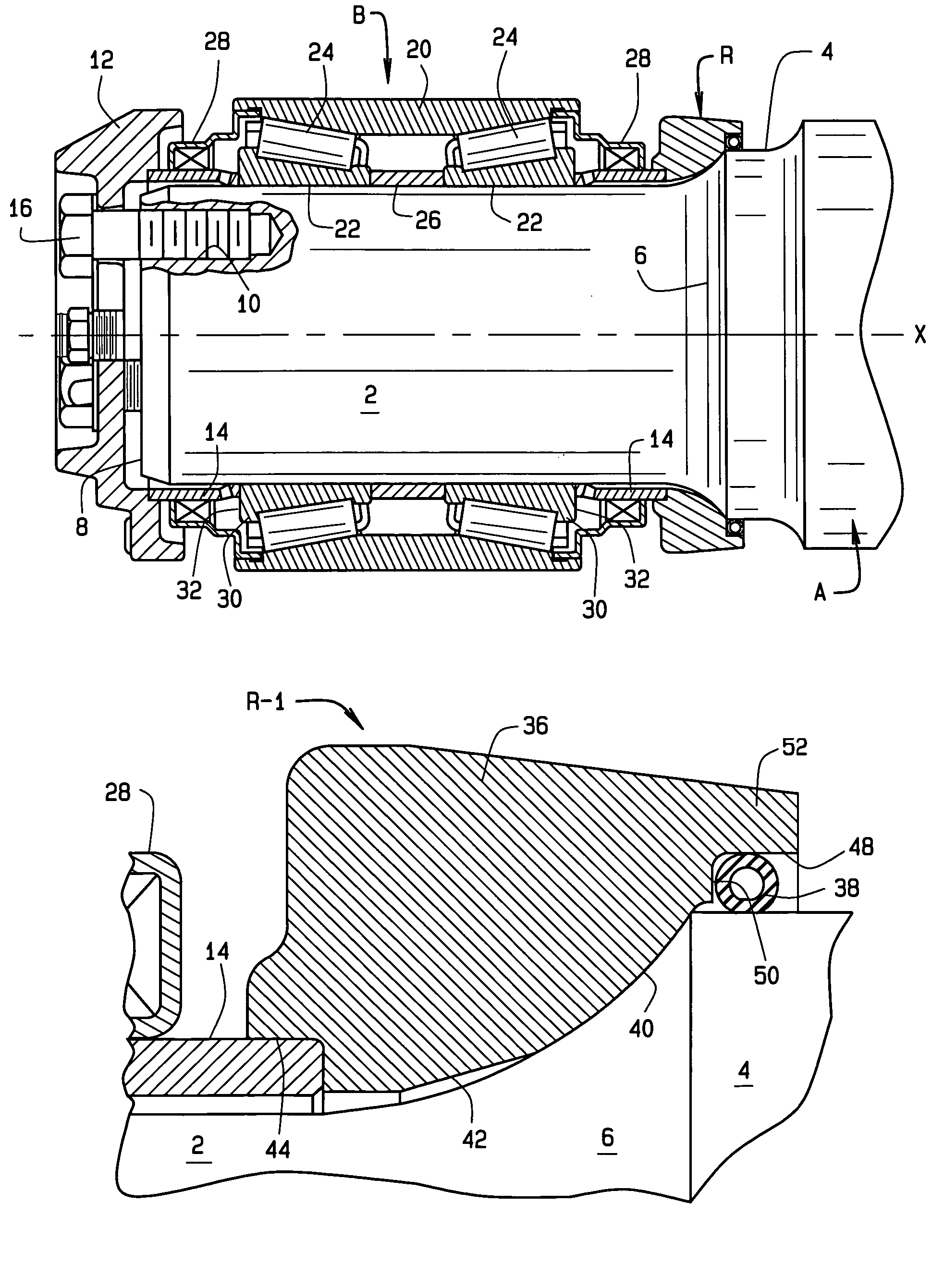

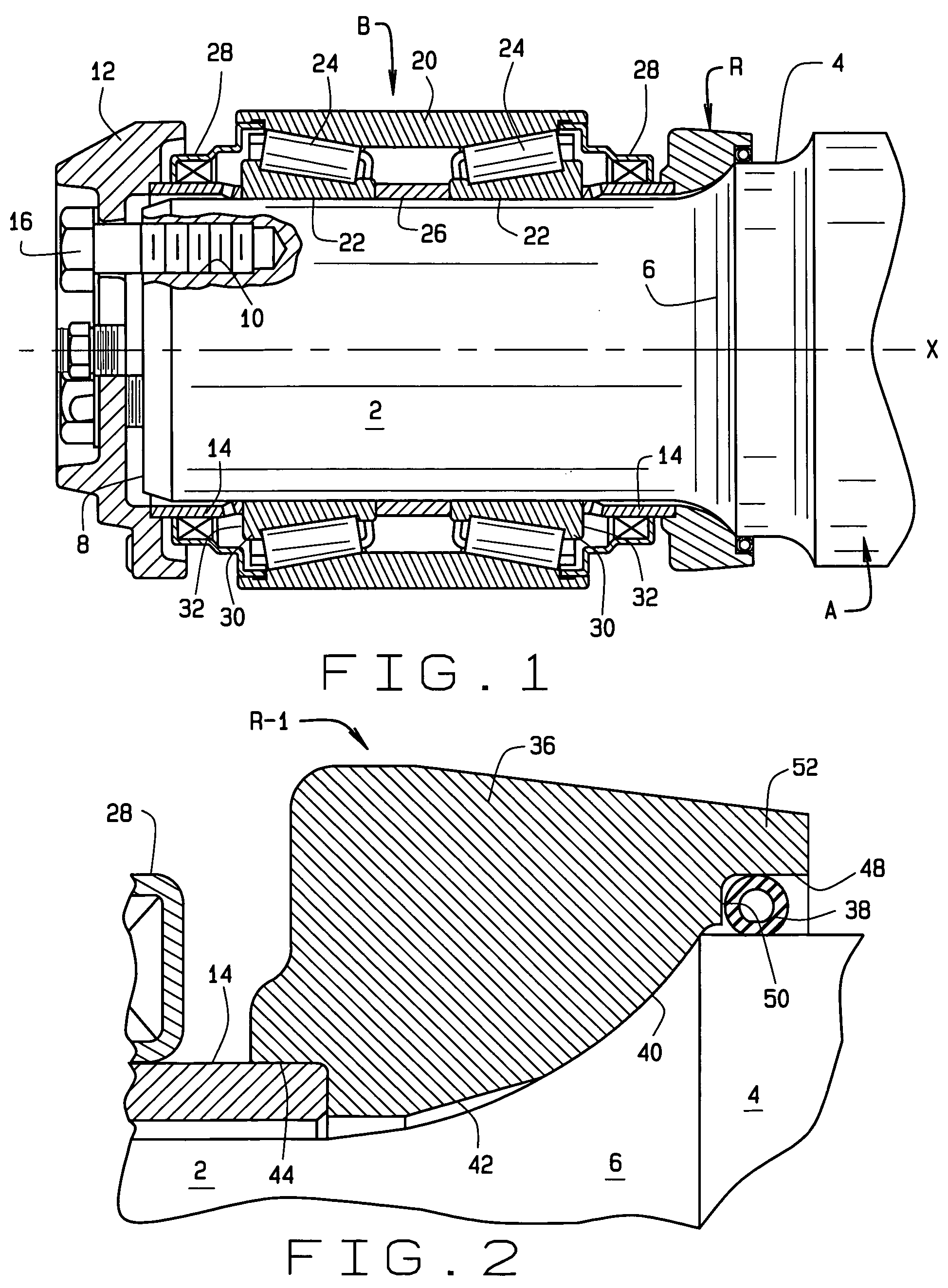

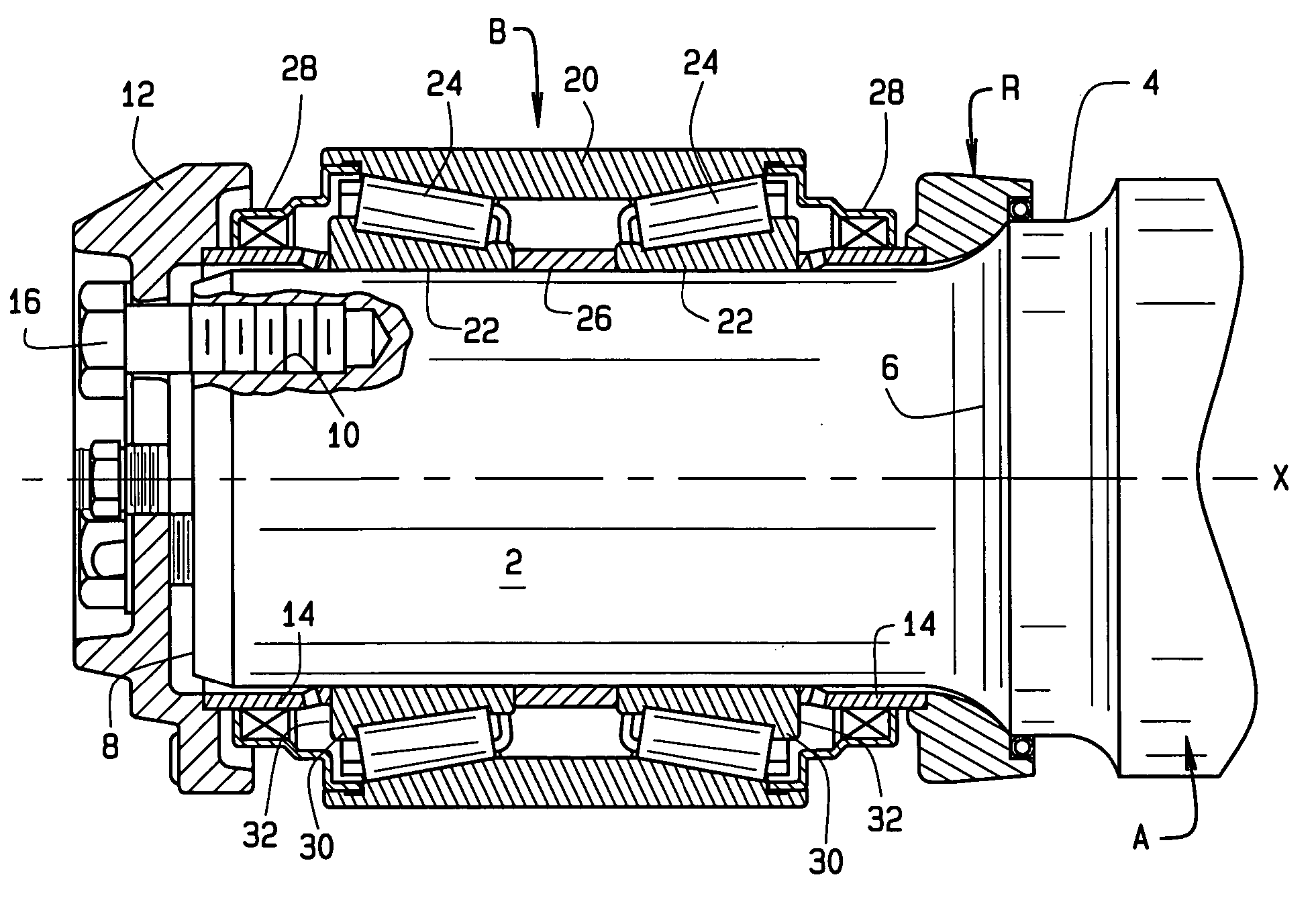

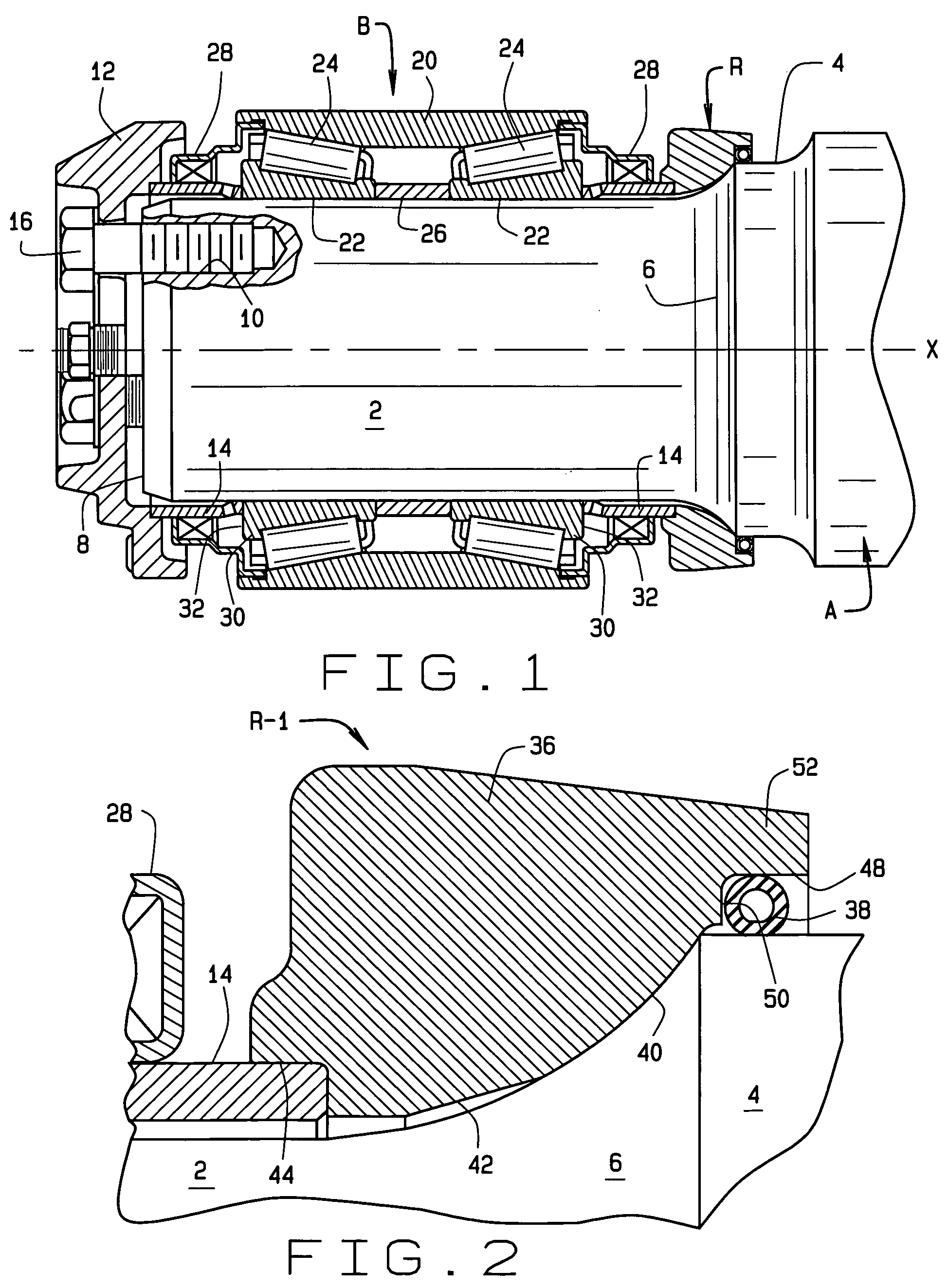

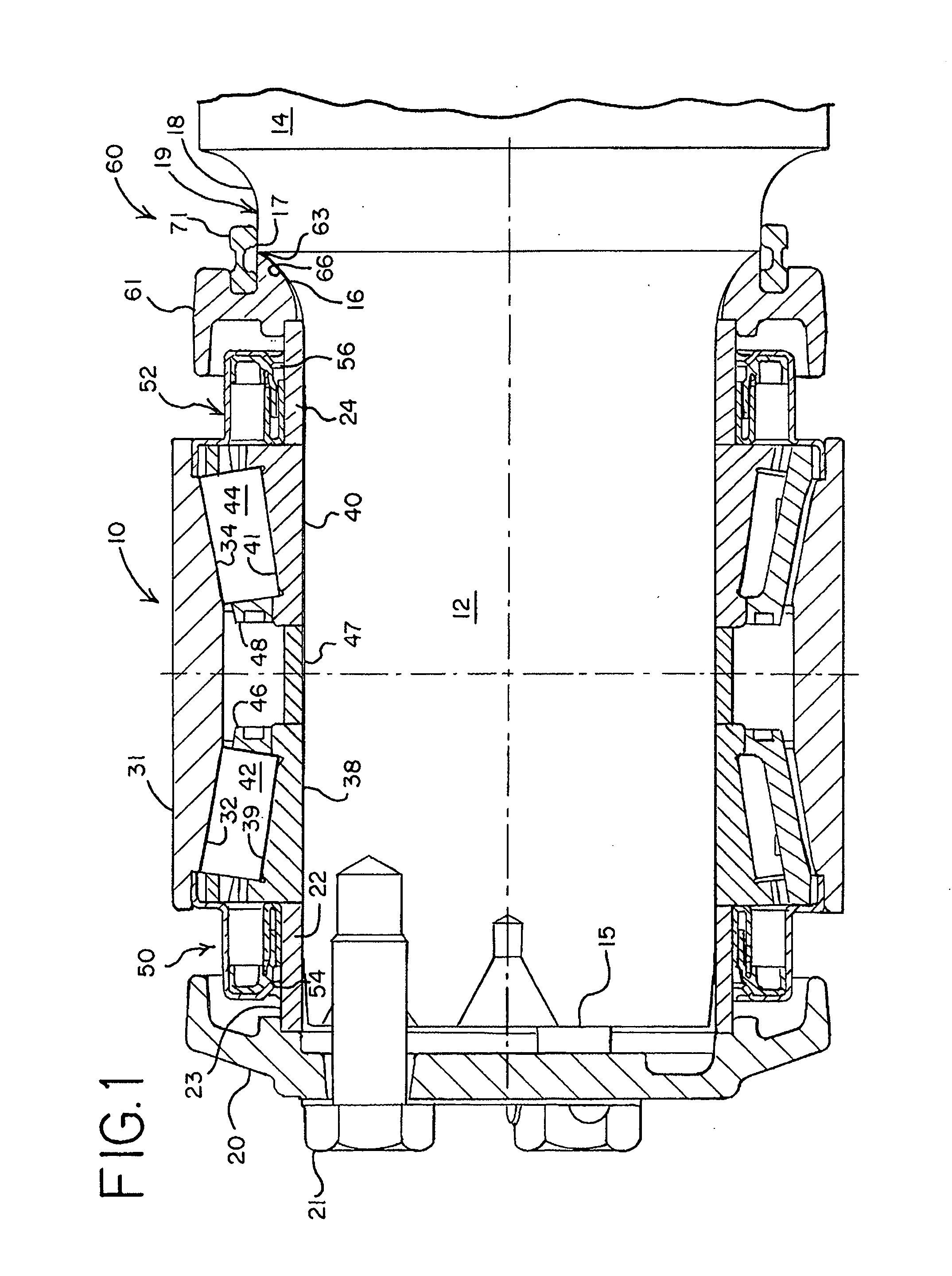

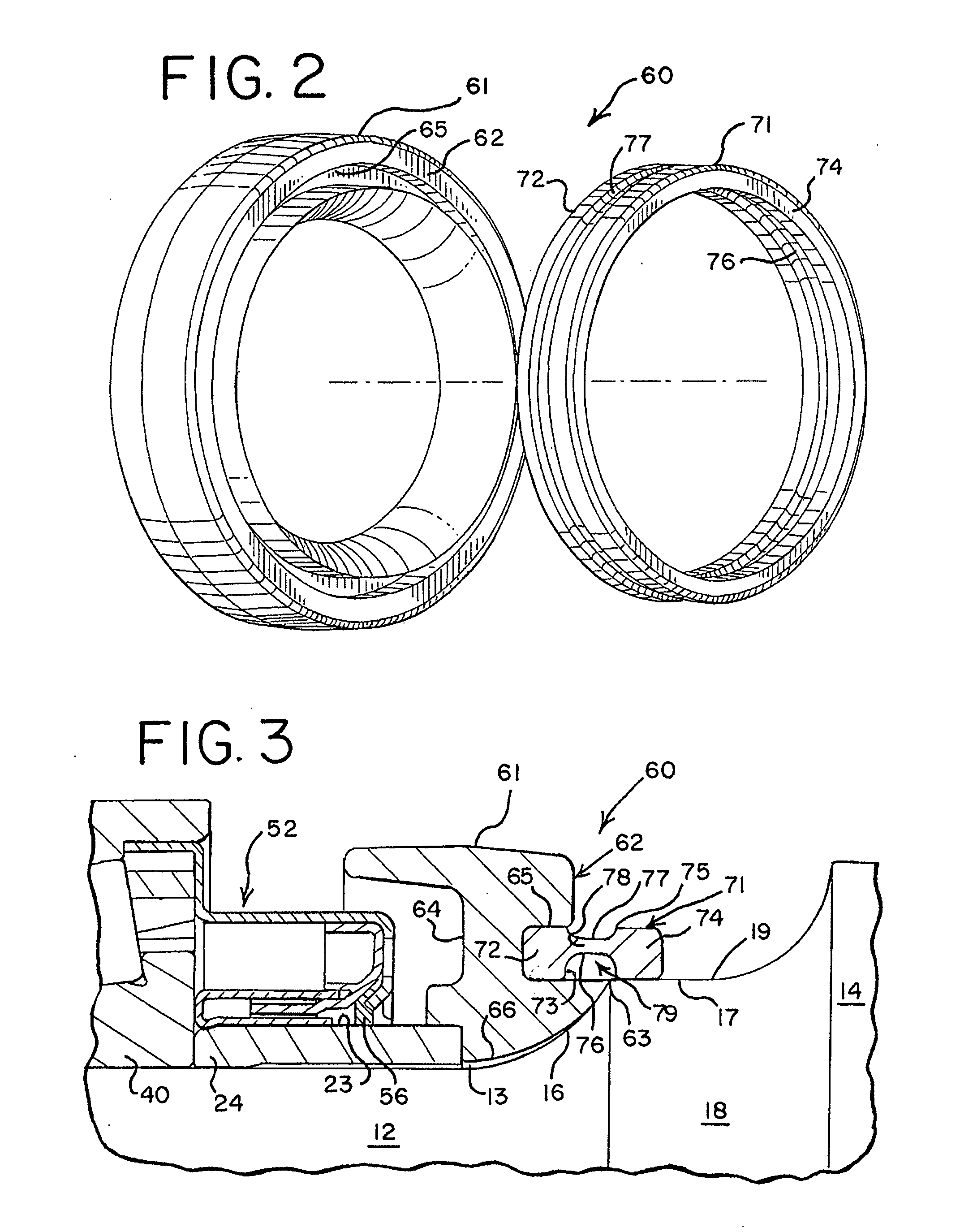

Backing ring for railcar axle

A backing ring that serves to back an antifriction bearing on the journal of a rail car axle includes an annular body that seats against a fillet that is located at the end of the journal and also a lip that projects over a larger dust guard diameter that is located on the axle immediately beyond the fillet. In addition, the backing ring includes a stabilizing element which cooperates with the lip and with the dust guard diameter to lessen the tendency of the annular body to work against the fillet and create a fretting wear when the journal undergoes cyclic flexures. The stabilizing element accommodates dust guard diameters of varying size. The stabilizing element may also establish a seal between the lip and the dust guard diameter.

Owner:THE TIMKEN CO

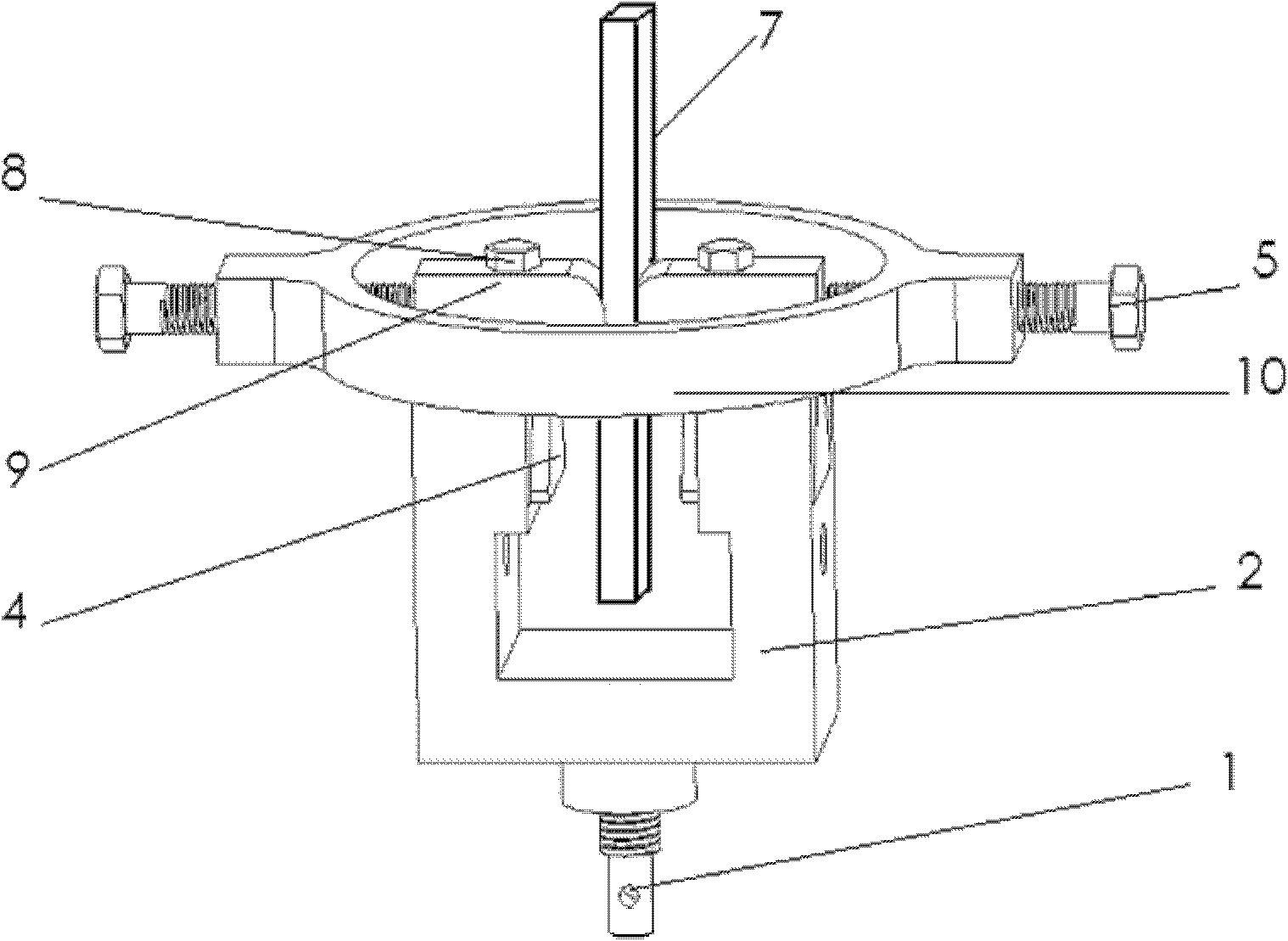

Tangential fretting test device and its test method

InactiveCN102279137AAct as a springEasy to operateMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceContact pressureEngineering

The invention discloses a tangential fretting test device and a test method thereof, and is characterized in that a load-controlled fretting fatigue test and a displacement-controlled fretting wear test can respectively be realized through different clamp combinations, thus generating a new detection method for material friction performance. Contact matching parts (contact pressure heads and testpiece) are in a line / plane type of contact, wherein, plane / plane contact and ball / plane contact can be realized respectively by replacing different contact pressure heads. The contact pressure heads are in connection with dovetail blocks in dovetail grooves and are slidable in the dovetail grooves, thus playing a positioning role. A pressure proving ring functions as a spring, so that detachment of the contact matching parts can be avoided and exertion of normal pressure can be guaranteed. And the pretension force and normal pressure are respectively obtained through a tension proving ring and the pressure proving ring, while the cyclic axial stress and cyclic displacement are set by a computer, thus finishing the fretting fatigue and the fretting wear tests respectively. The device and method of the invention are mainly used for tangential fretting tests.

Owner:XI AN JIAOTONG UNIV

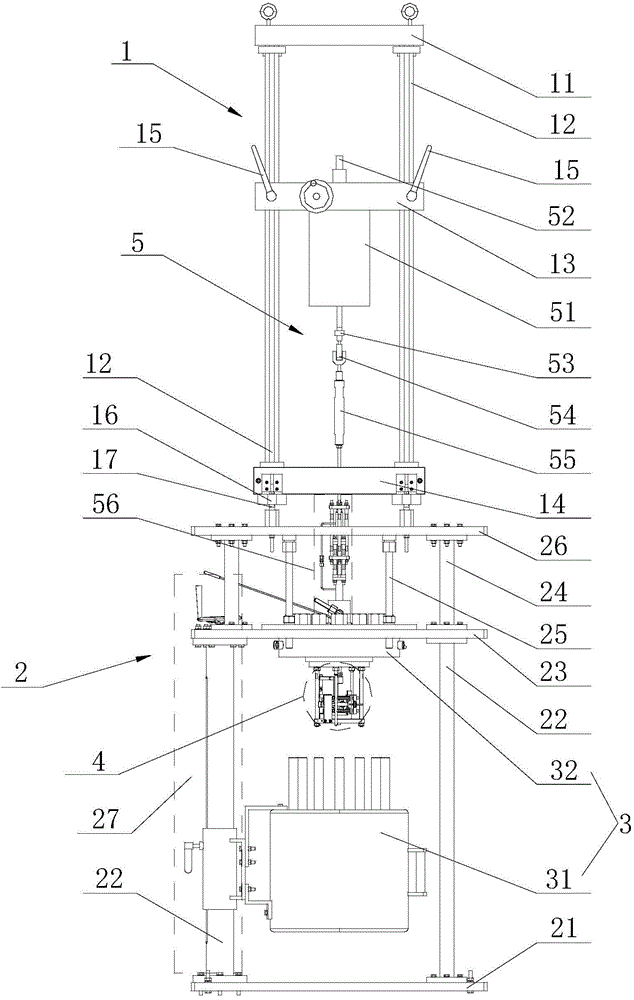

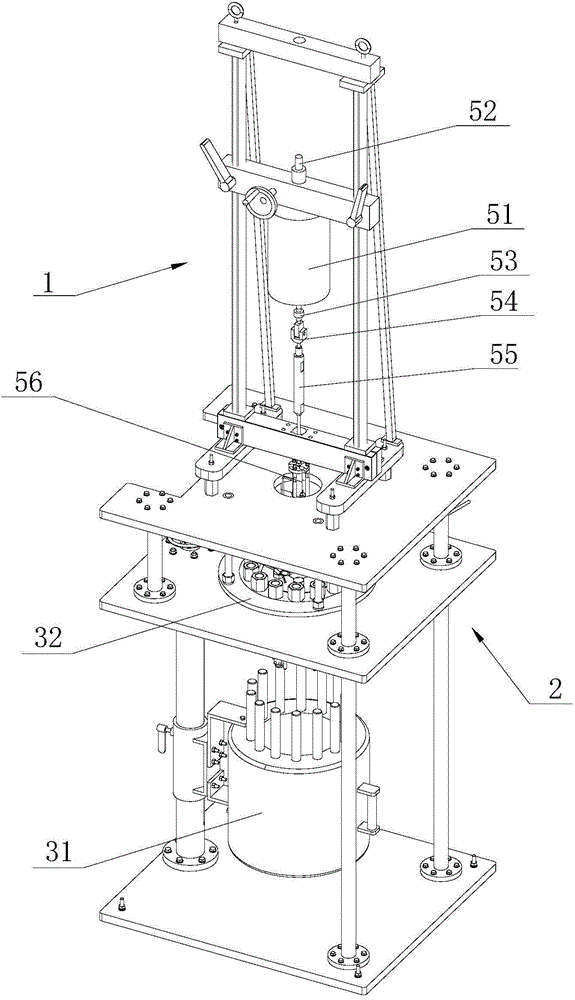

High temperature and high pressure in-situ fretting wear test device

ActiveCN104359778AHigh control precisionReal-time adjustment of micro-motion amplitudeInvestigating abrasion/wear resistanceEngineeringAuxiliary electrode

The invention relates to a fretting wear test device, in particular to a high temperature and high pressure in-situ fretting wear test device, and solves the problems that in-situ fretting wear is difficult to realize at a high temperature and a high pressure; fretting amplitude and frequency are difficult to control accurately; electrochemical signals are hard to measure during fretting wear. The fretting wear test device is provided with a vibration exciter, a thermocouple, a working electrode / auxiliary electrode seat, an autoclave cover, a hydraulic cylinder, an autoclave body, an upright, a positioning plate, a first sample holding and loading device, a moving shaft, an upper linear guideway, a working electrode, a moving shaft guide bracket, an auxiliary electrode, a connecting nut I, a reference electrode seat, a reference electrode, a lower linear guideway, an upper guide platform plate, an upper guide rod, a lower guide rod, a lower guide platform plate and a connecting nut II. The device is capable of performing in-situ fretting wear on the surface of a sample at a high temperature and a high pressure. The reference electrode, the working electrode and the auxiliary electrode mounted on an autoclave work with an electrochemical workstation to detect the electrochemical signals during fretting wear.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

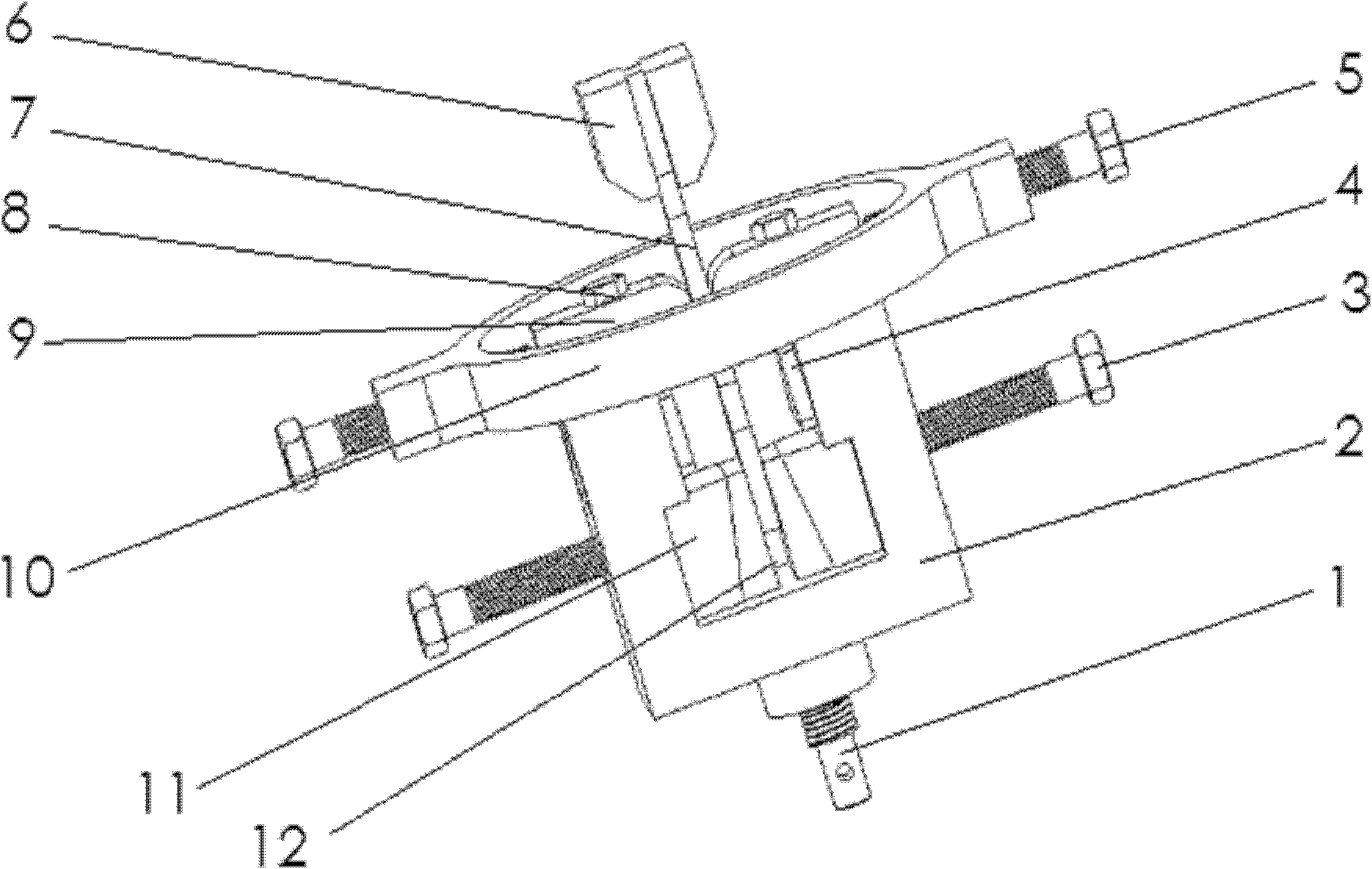

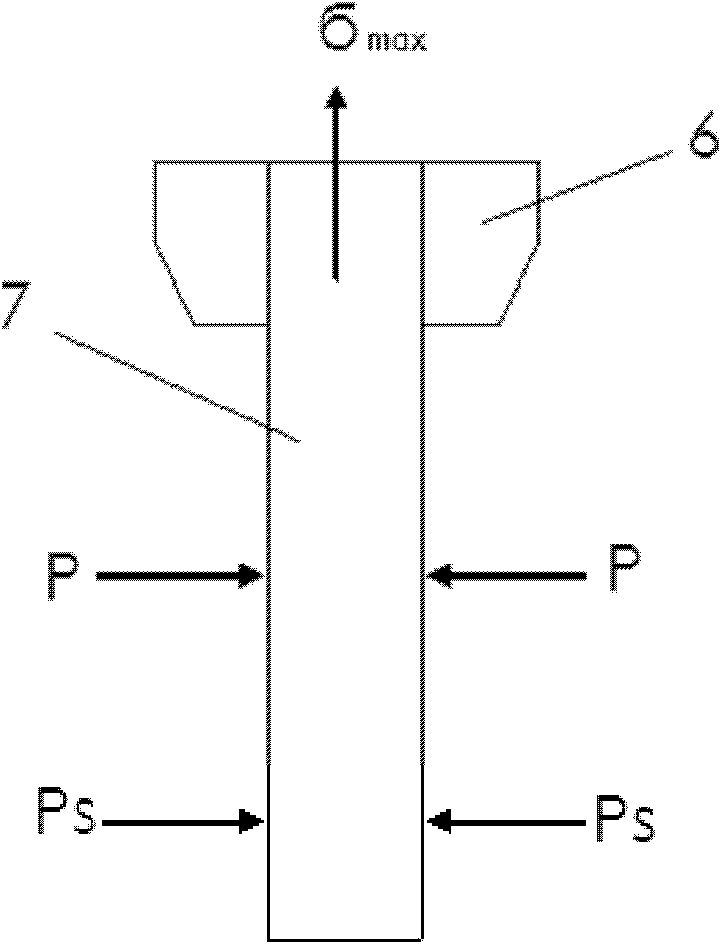

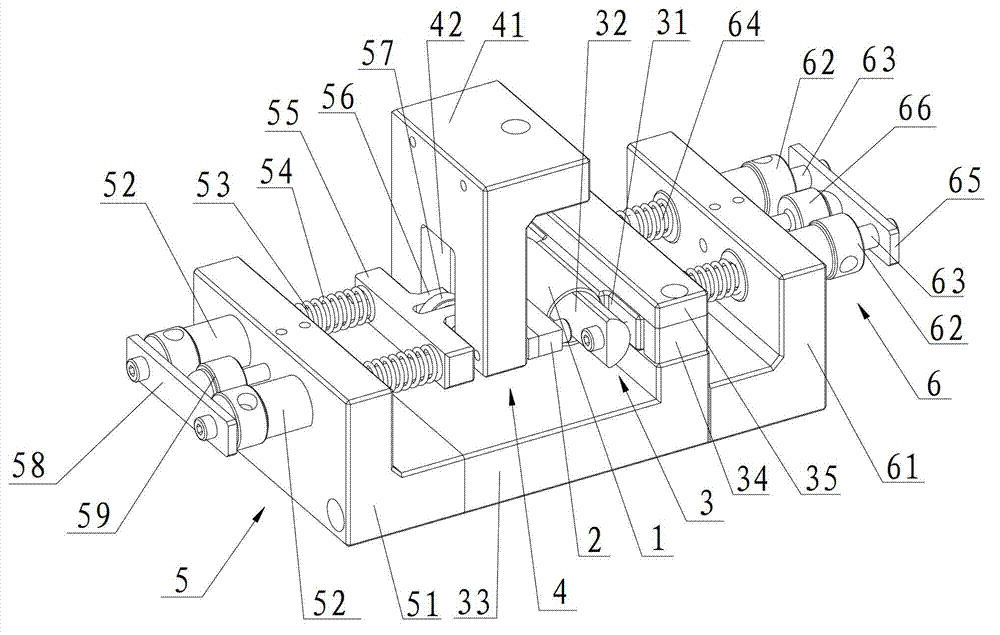

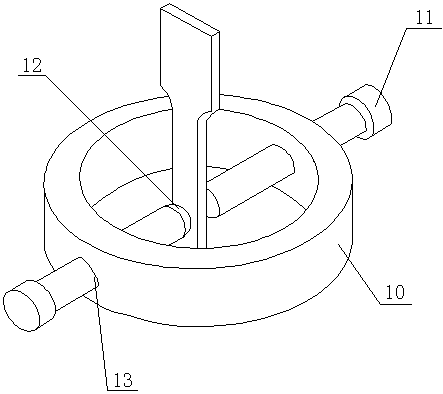

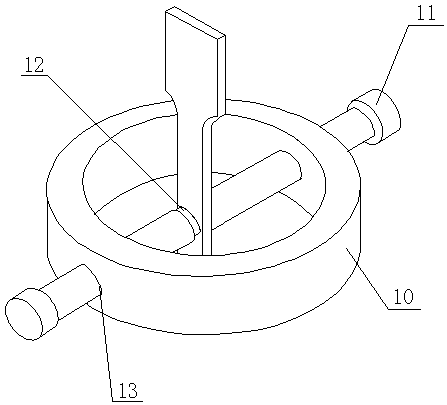

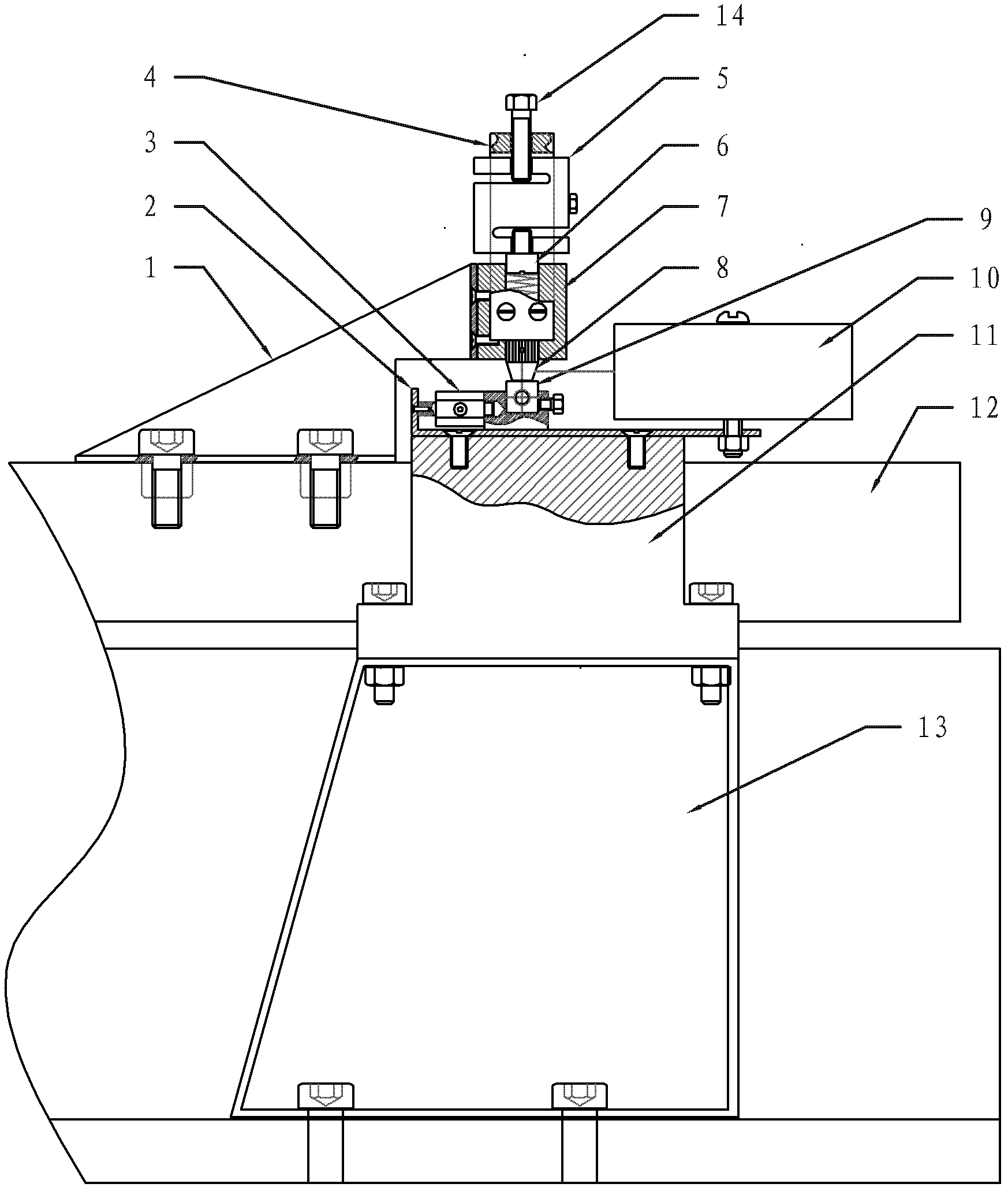

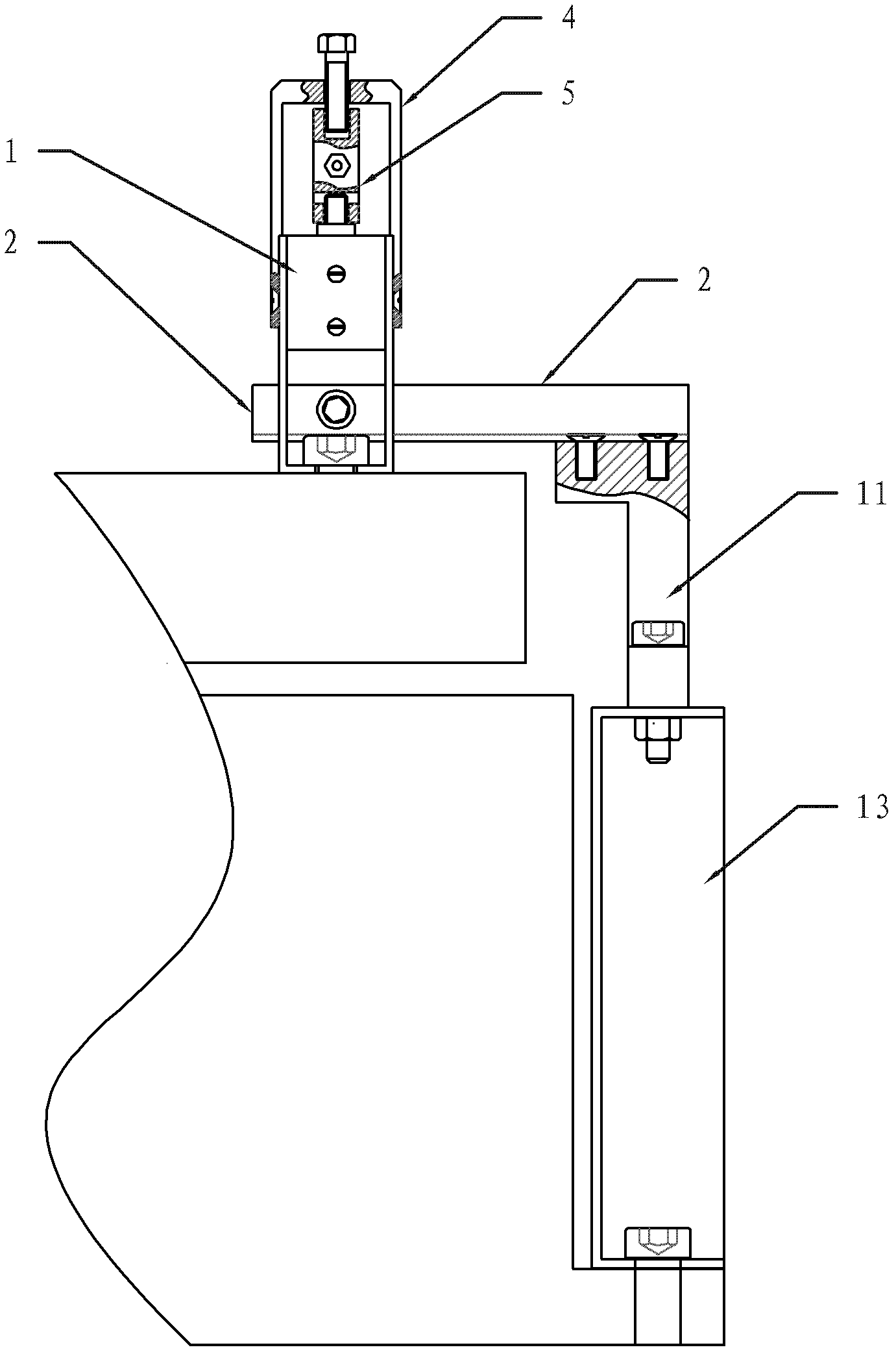

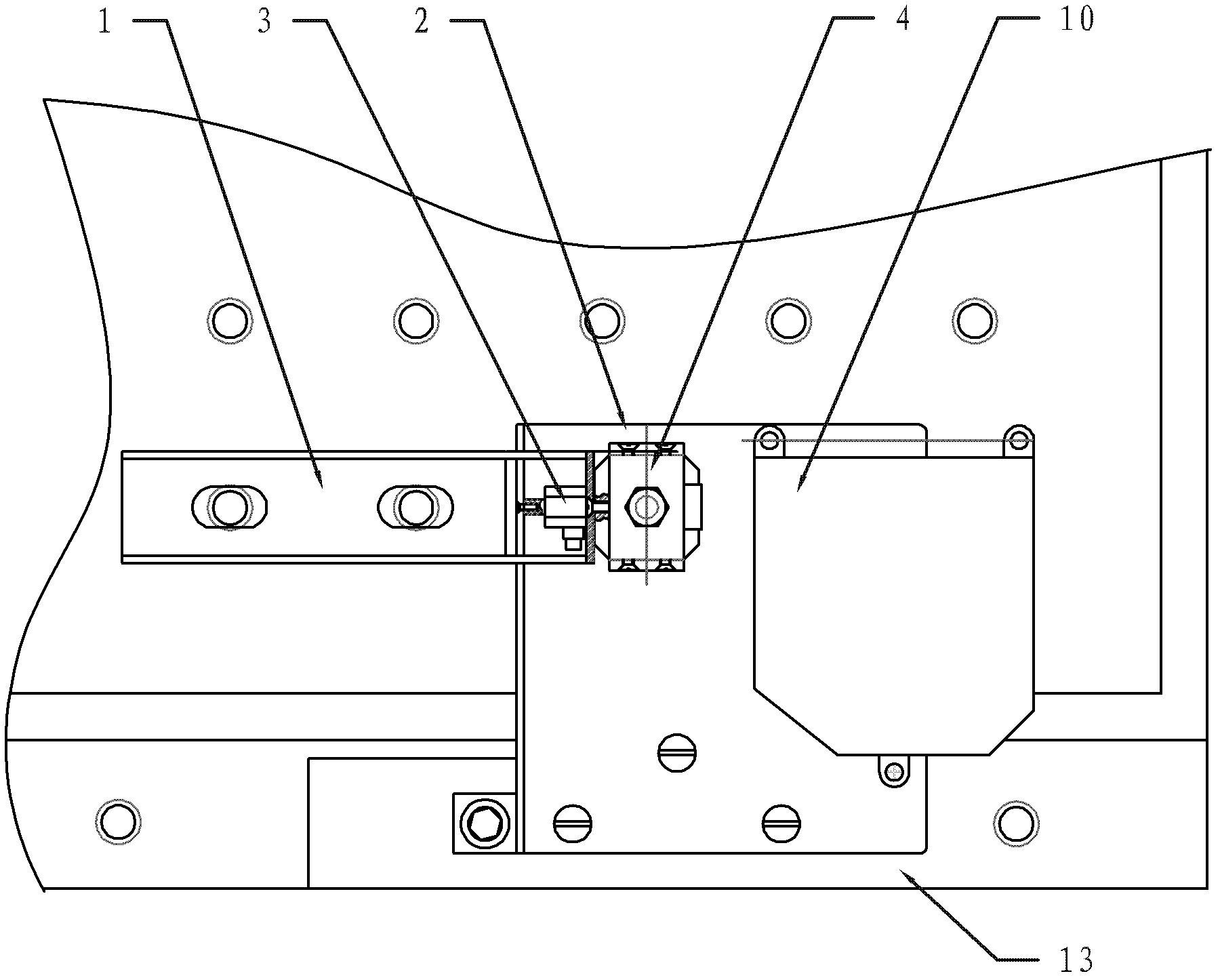

Clamping device for pipe-flat plate line contact fretting wear experiments

ActiveCN102866058ASimple structureEasy to operateStrength propertiesMechanical engineeringFatigue testing

The invention discloses a clamping device for pipe-flat plate line contact fretting wear experiments. In the clamping device, a cylindrical pipe clamping assembly and a flat plate clamping assembly are arranged to stably clamp experimental samples i.e., a cylindrical pipe and a flat plate respectively; a cylindrical pipe pressing assembly and a flat plate pressing assembly are arranged to respectively provide pressing forces along horizontal opposite directions for the cylindrical pipe and the flat plate, and therefore, the flat plate and the cylindrical pipe are in line contact and bear stable and uniform normal load and the pipe-flat plate line contact fretting wear experiments can be carried out in cooperation with a uniaxial fatigue testing machine. The clamping device is simple in structure, convenient for operation, capable of carrying out the experiments in cooperation with the conventional uniaxial fatigue testing machine, has no need for introducing a biaxial fretting wear testing machine, thereby reducing the experimental cost.

Owner:SUZHOU NUCLEAR POWER RES INST +1

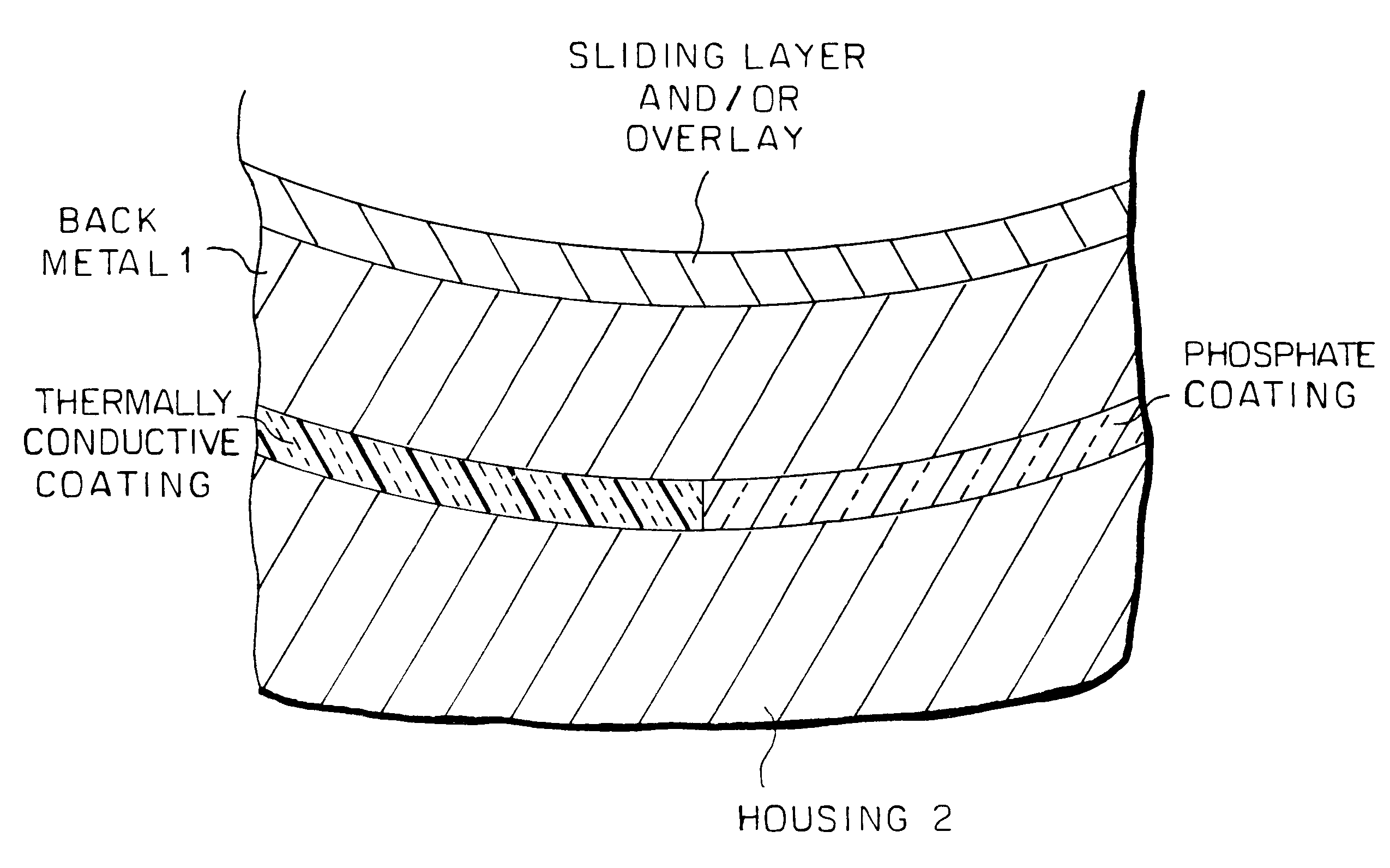

Sliding bearing and sliding bearing structure

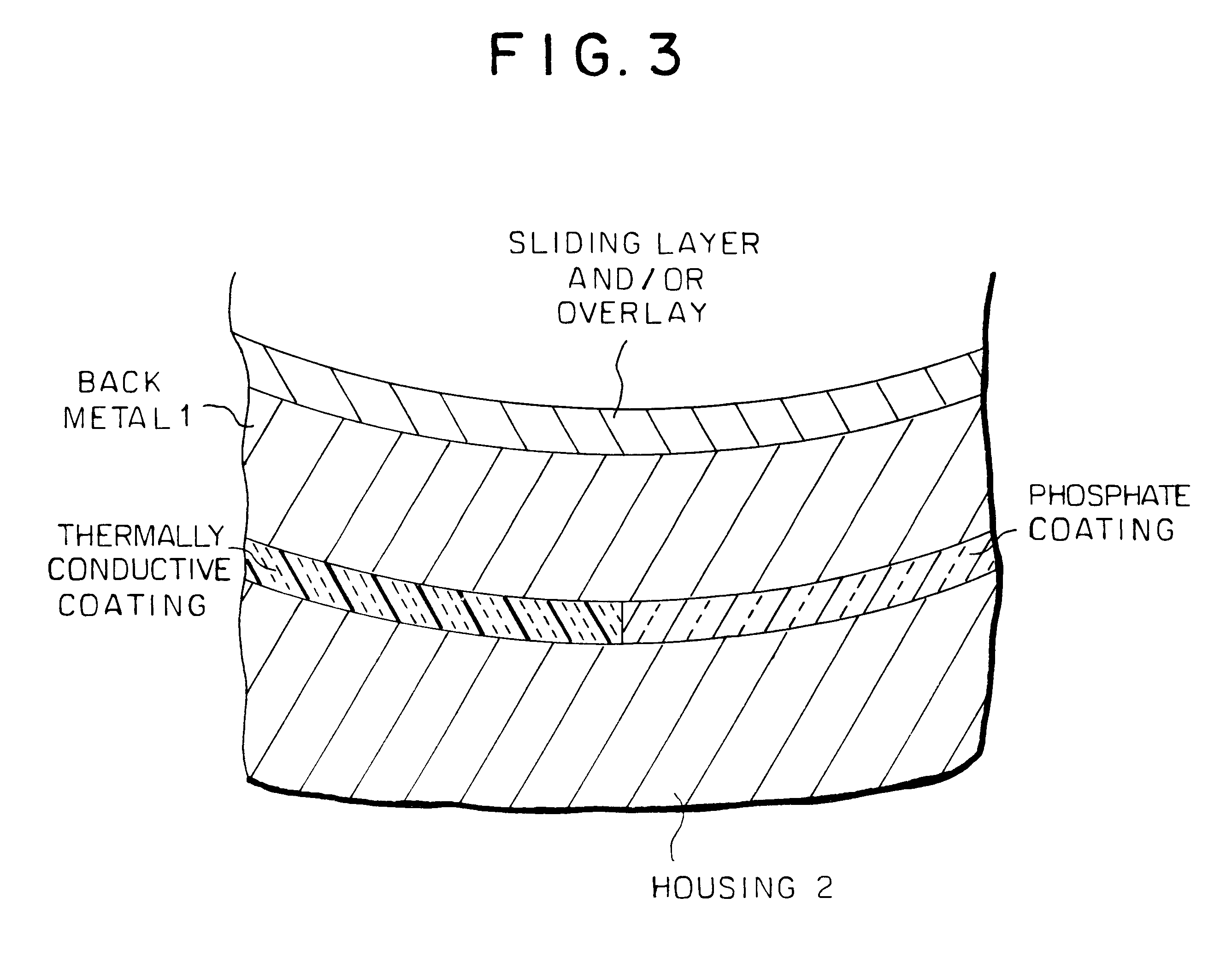

InactiveUS6357918B1Improve the immunityGood anti-occlusion performanceConnecting rod bearingsCrankshaft bearingsElectrical conductorFretting wear

There is disclosed a sliding bearing provided with a sliding bearing layer and a back metal layer bonded to the outer face of the sliding bearing layer, the back face of which back metal layer being coated with a phosphate coating at a portion where fretting wear is apt to occur while coated with a coating of a thermally good conductor at another portion where no phosphate coating is provided, whereby seizure resistance as well as fretting resistance is improved because the dispersing of heat can be improved by the coating of the thermally good conductor.

Owner:DAIDO METAL CO LTD

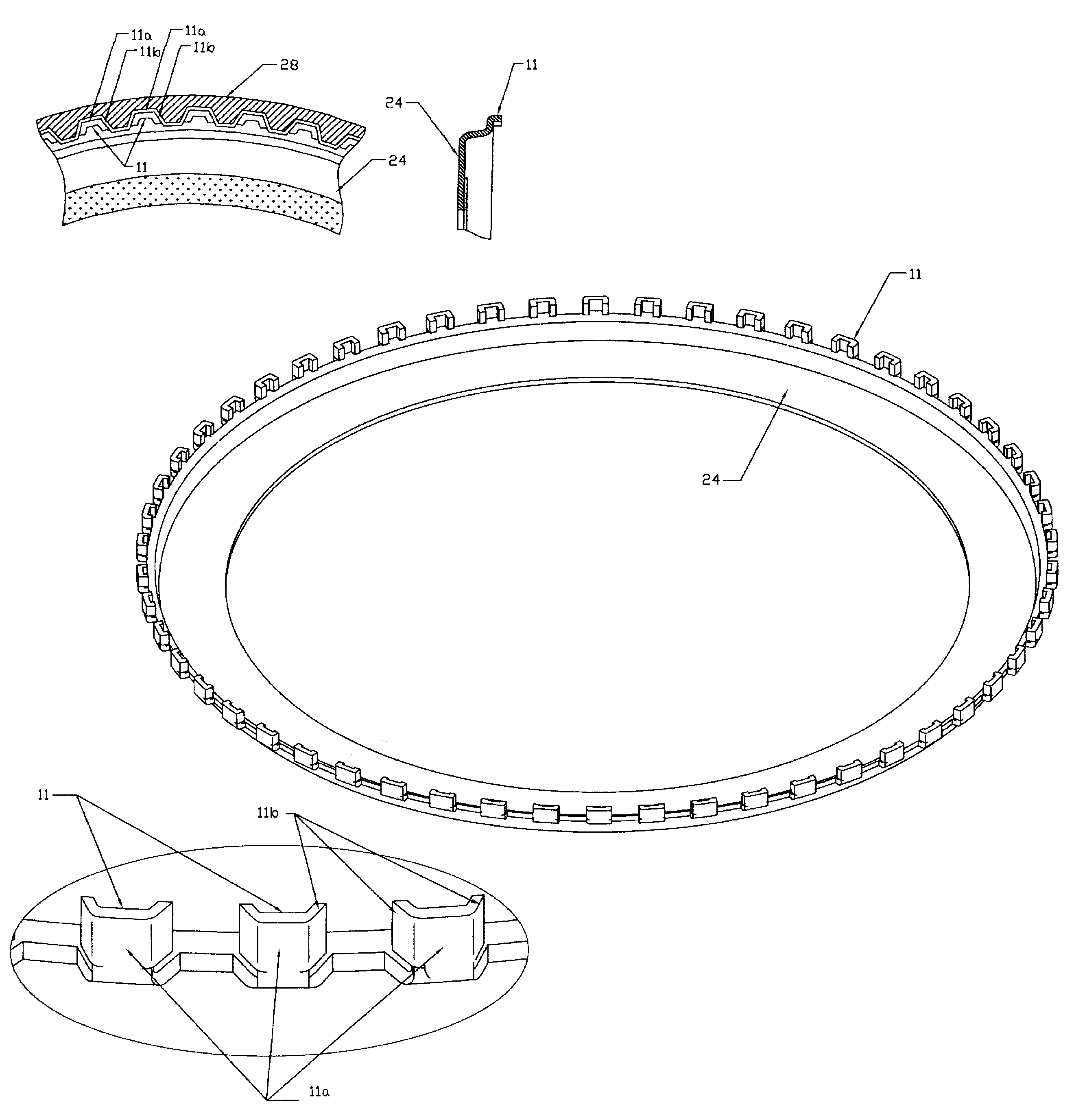

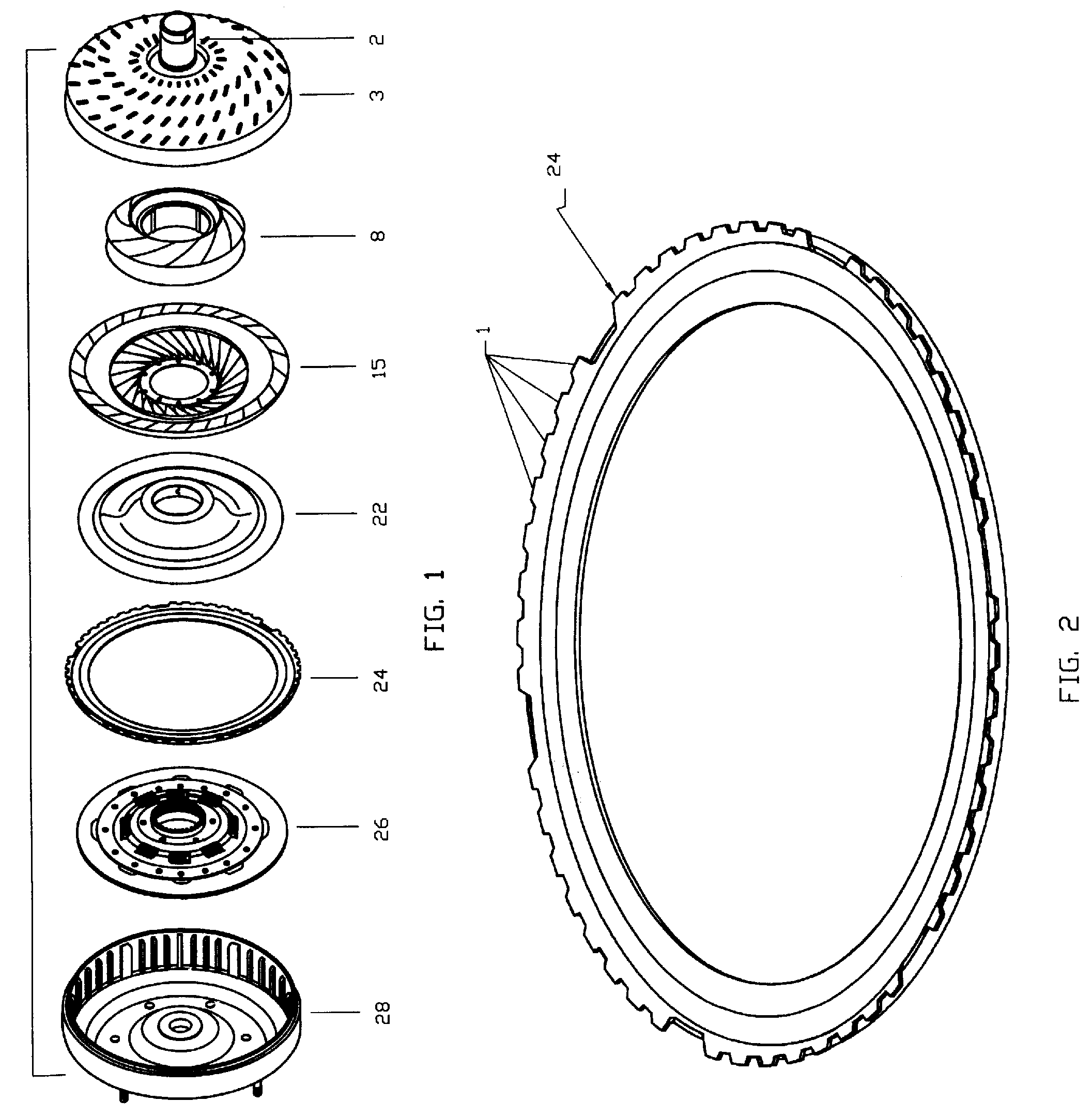

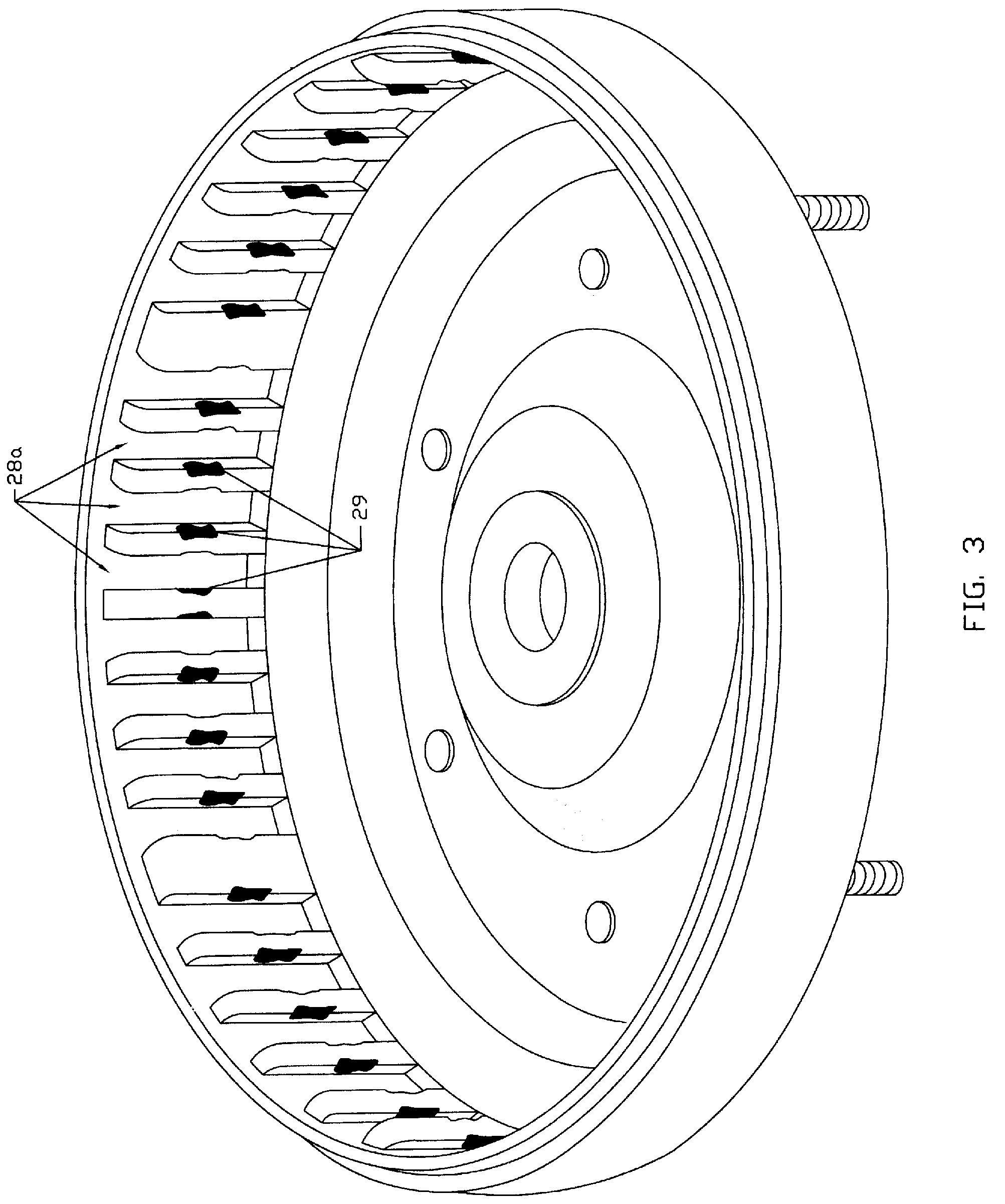

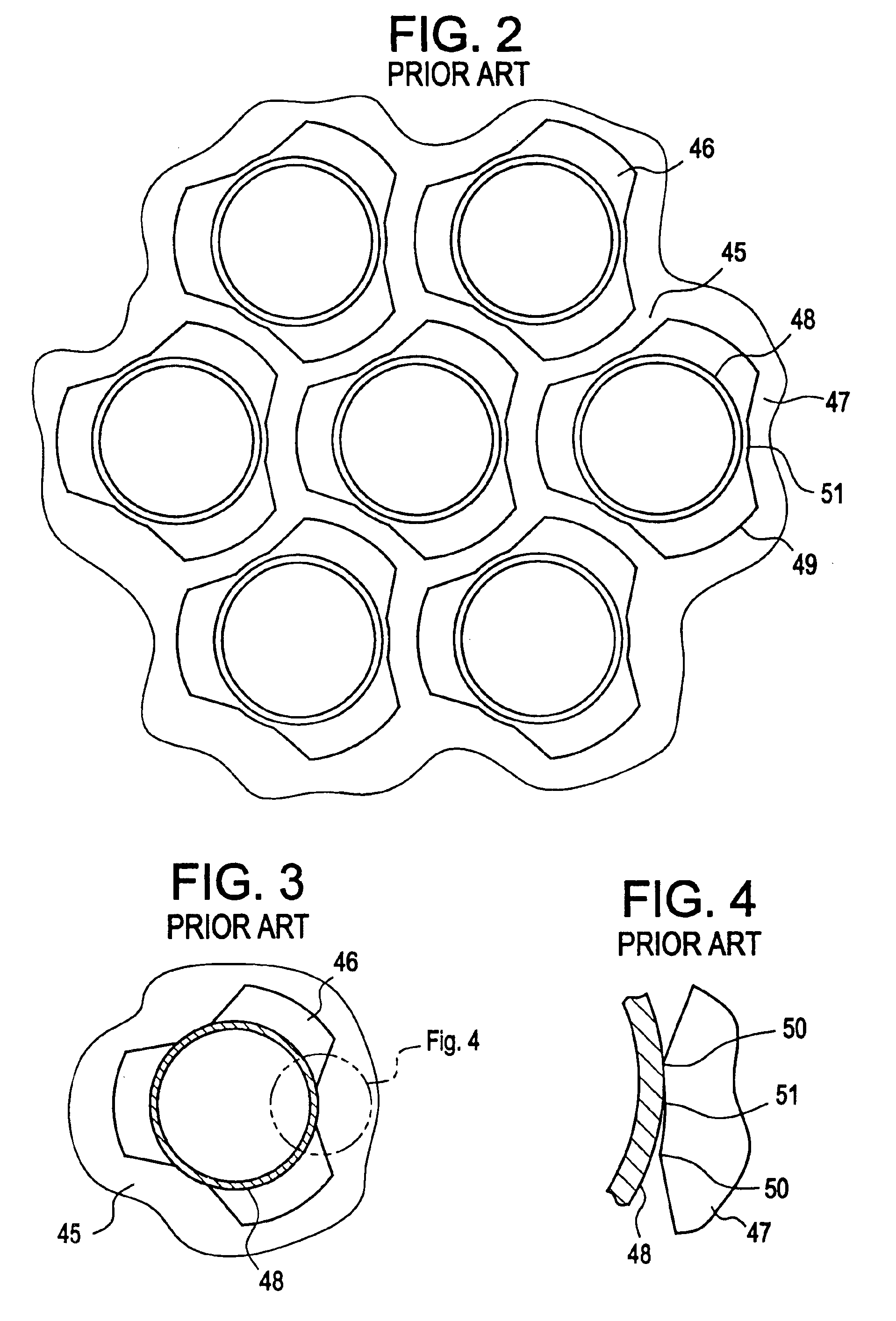

Wear resistant clutch plate

InactiveUS20110067971A1Reduce wearReduce in quantityFriction clutchesAutomatic transmissionWear resistant

A clutch member of a torque converter of an automatic transmission fitted slidingly with a splined connection between a number of extending teeth of the clutch member and channels of a torque converter housing configured to slidingly engage the teeth. At least two of the teeth are elongated for a distance beyond engagement with a base of the respective engaging channels and bent at right angles to the original tooth extension direction. The extent of parallel engagement of the bent tooth and base of the channel of the splined connection is significantly increased and fretting wear between the teeth and the channels of the housing is reduced or eliminated.

Owner:TRI COMPONENT PROD

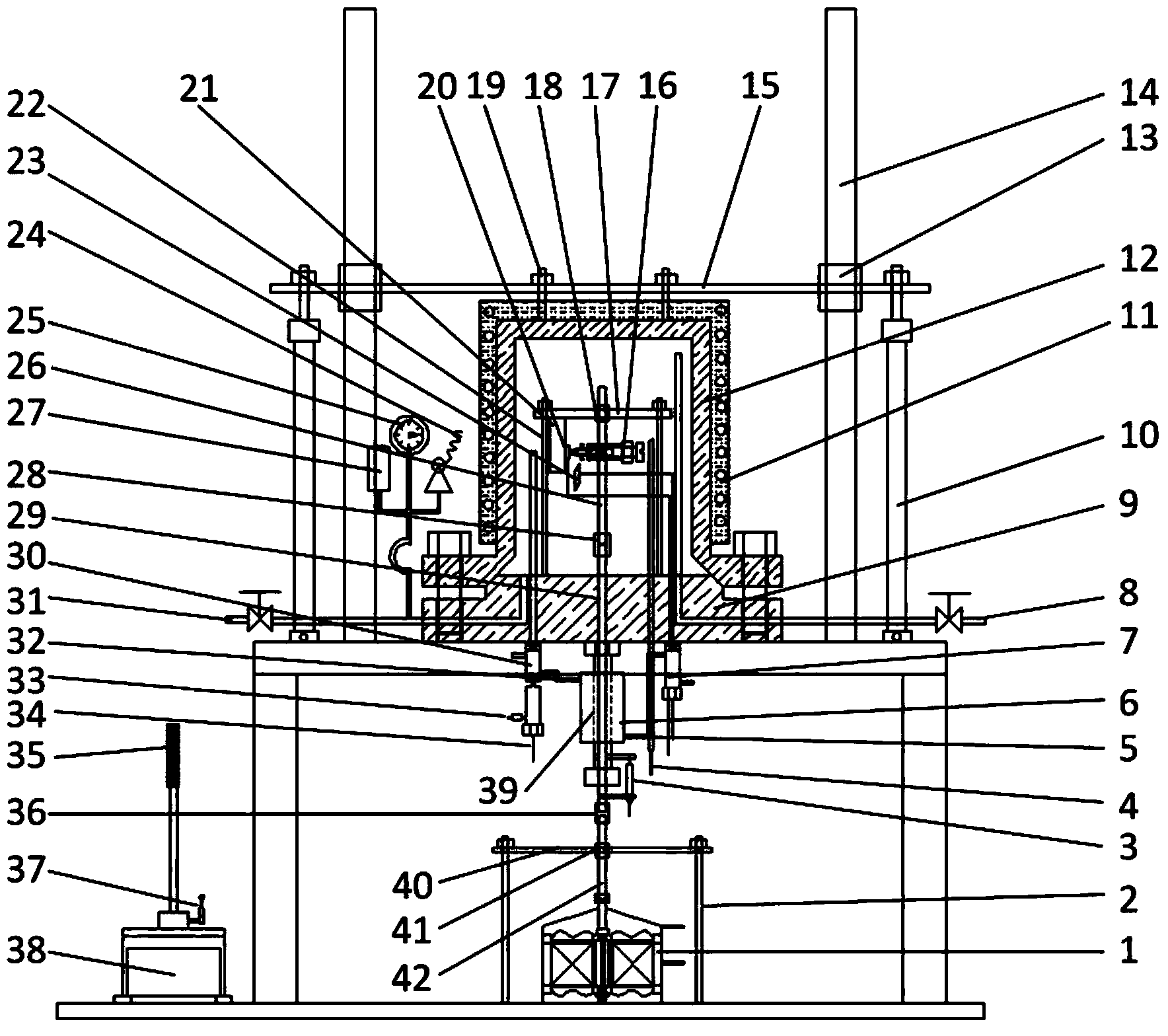

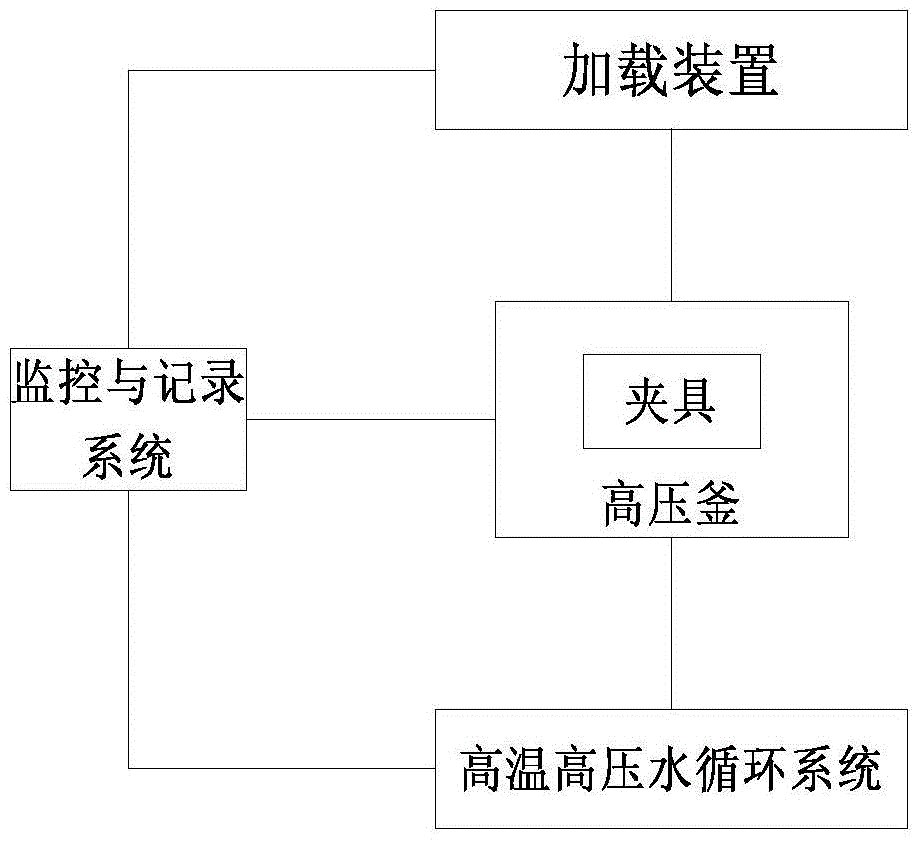

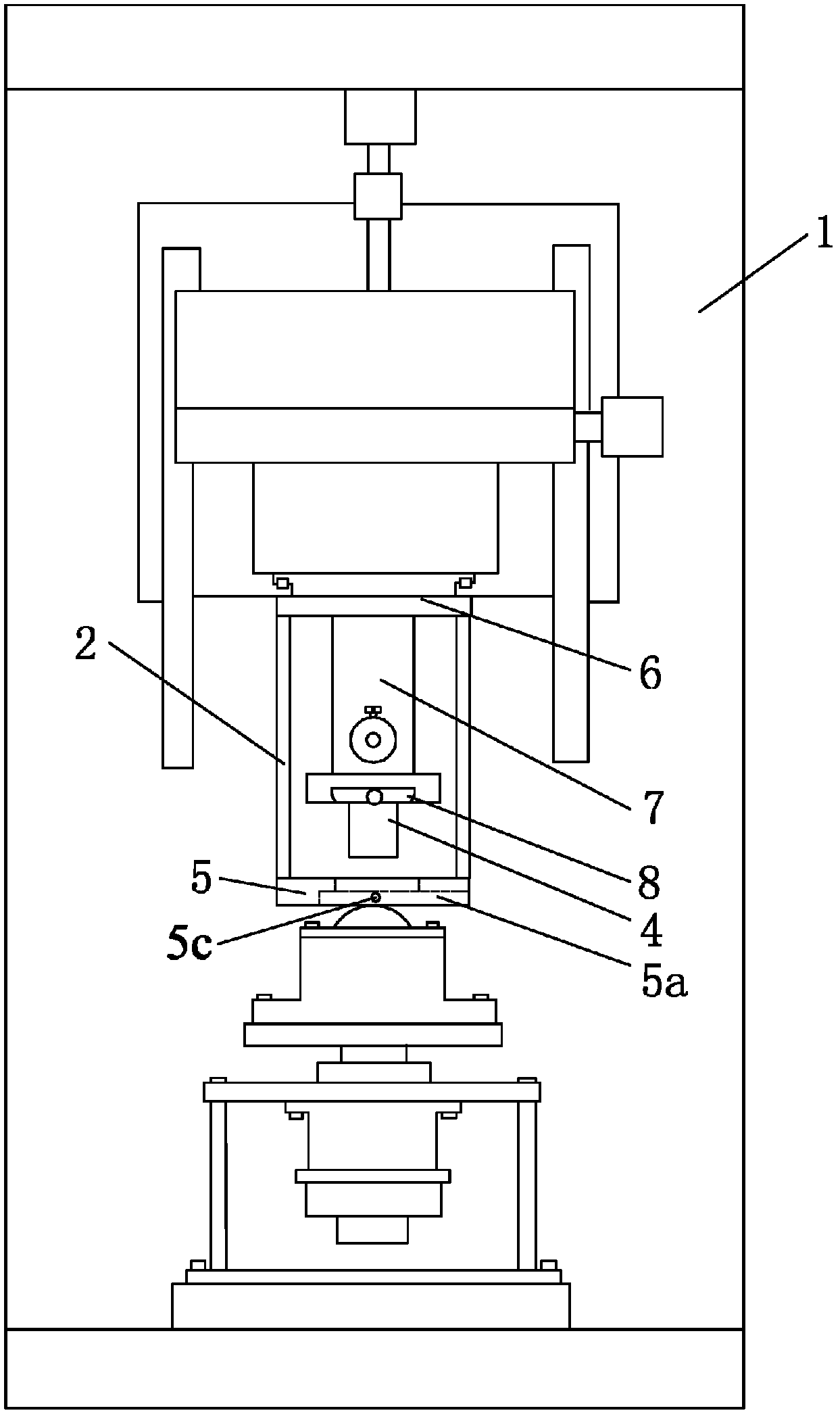

Fretting wear testing machine in high temperature and high pressure water or steam environment

ActiveCN104914042APayloadEffective displacement loadingUsing mechanical meansMaterial analysisFrictional coefficientEngineering

The invention discloses a fretting wear testing machine in a high temperature and high pressure water or steam environment, wherein two workpieces for testing are clamped by arranging fixtures and placed in an autoclave which is positioned in the high temperature and high pressure water or steam environment by a high temperature and high pressure water circulating system, vibration excitation effect is applied to the testing workpieces in the autoclave by a loading device, and thereby the fretting wear test in high temperature and high pressure water or steam environment can be performed. The testing machine can simulate infinitesimal displacement amplitude and high vibration frequency fretting wear test under the primary and secondary loop temperature, pressure and hydrochemistry condition of nuclear power plant; the testing machine can perform slip wear test or impact wear test, and the friction coefficient and the wear coefficient between the friction pair can be obtained by measurement; the components of the testing machine are reasonably distributed, thus ensuring that the load and displacement loading of the testing machine is effective and reliable; the load control and measurement accuracy is high, and the friction force between the friction pair can be quantificationally obtained.

Owner:SUZHOU NUCLEAR POWER RES INST +2

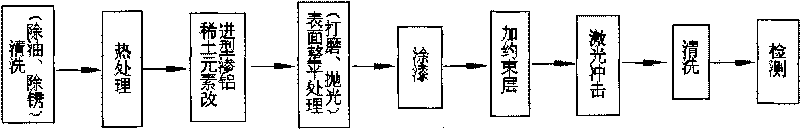

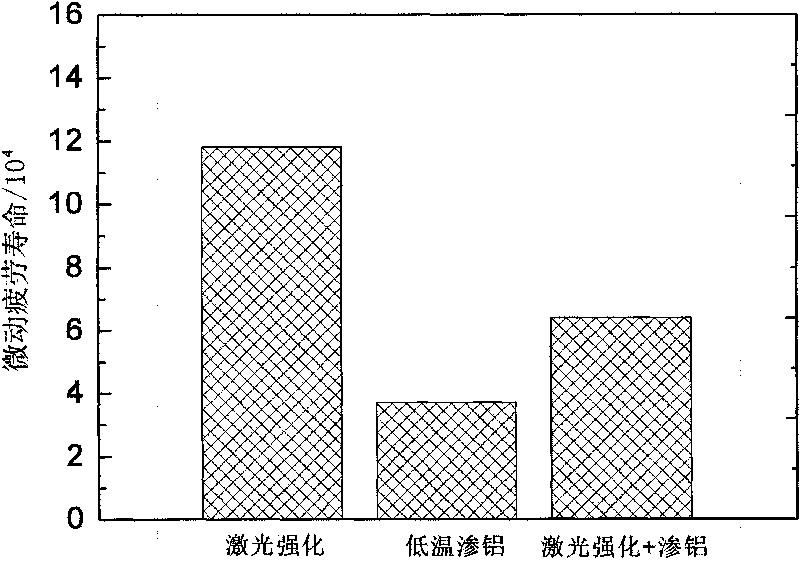

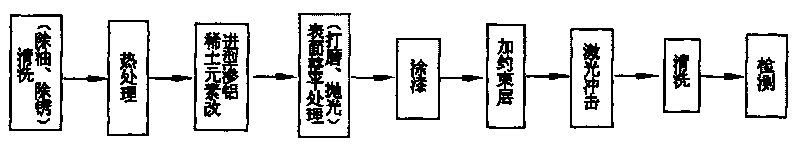

Reinforcement method for extending fretting fatigue life of material at high temperature

InactiveCN101698930AImprove thermal stabilityImprove antioxidant capacitySolid state diffusion coatingVolumetric Mass DensityHigh wear resistance

The invention discloses a reinforcement method for extending fretting fatigue life of a material under high temperature. The reinforcement method effectively combines a calorization technology and a laser impact reinforcement technology; and after a part is calorized, the surface of the part is processed in a laser impact reinforcement compounding way, so that high-amplitude residual compressive stress and high dislocation density are formed on the surface, thereby being beneficial to increasing the surface friction coefficient, improving the fretting wear performance and enhancing the fretting fatigue resistance. The part processed by the reinforcement method has the advantages of high wear resistance, corrosion resistance and high-temperature oxidation resistance, and the fretting fatigue life of the part under high temperature is greatly extended.

Owner:JIANGSU UNIV

Backing ring for railcar axle

A backing ring that serves to back an antifriction bearing on the journal of a rail car axle includes an annular body that seats against a fillet that is located at the end of the journal and also a lip that projects over a larger dust guard diameter that is located on the axle immediately beyond the fillet. In addition, the backing ring includes a stabilizing element which cooperates with the lip and with the dust guard diameter to lessen the tendency of the annular body to work against the fillet and create a fretting wear when the journal undergoes cyclic flexures. The stabilizing element accommodates dust guard diameters of varying size. The stabilizing element may also establish a seal between the lip and the dust guard diameter.

Owner:THE TIMKEN CO

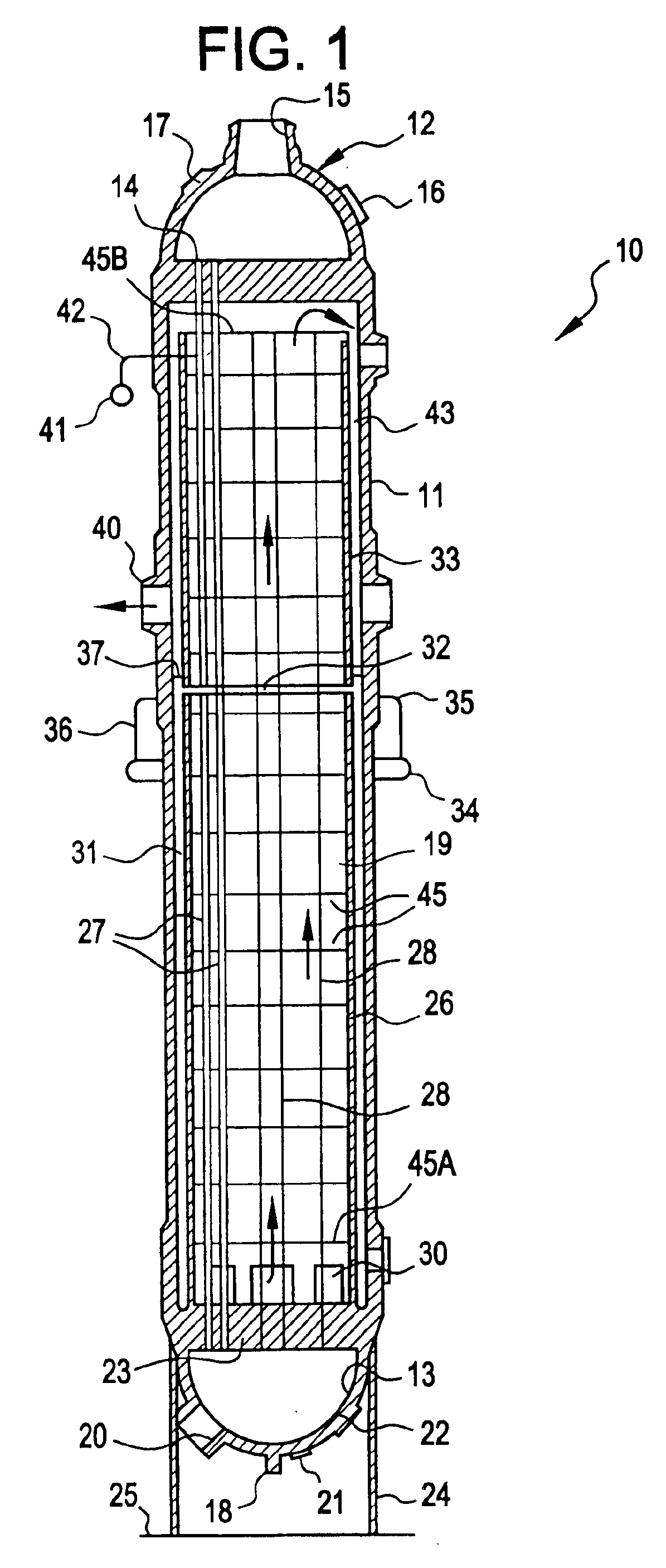

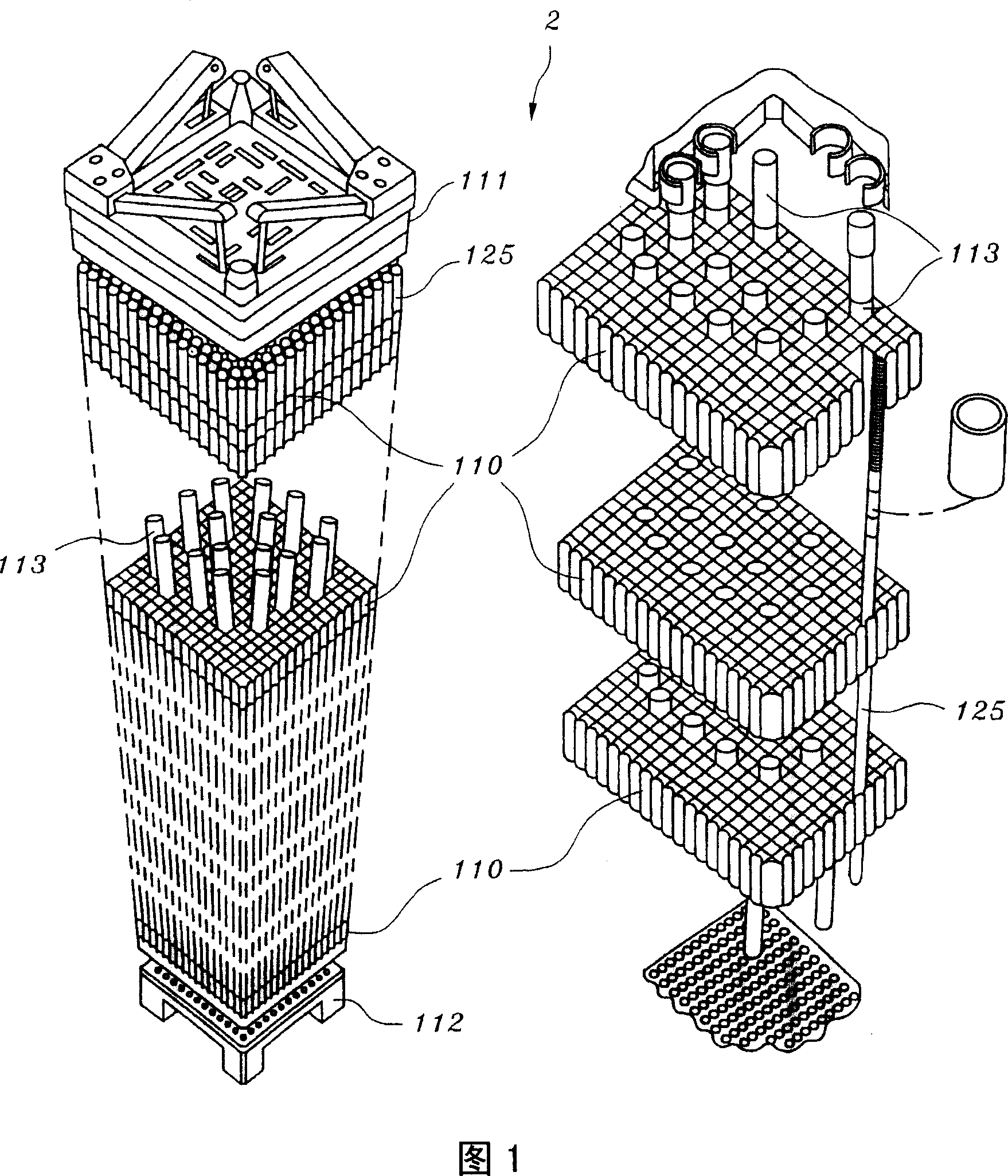

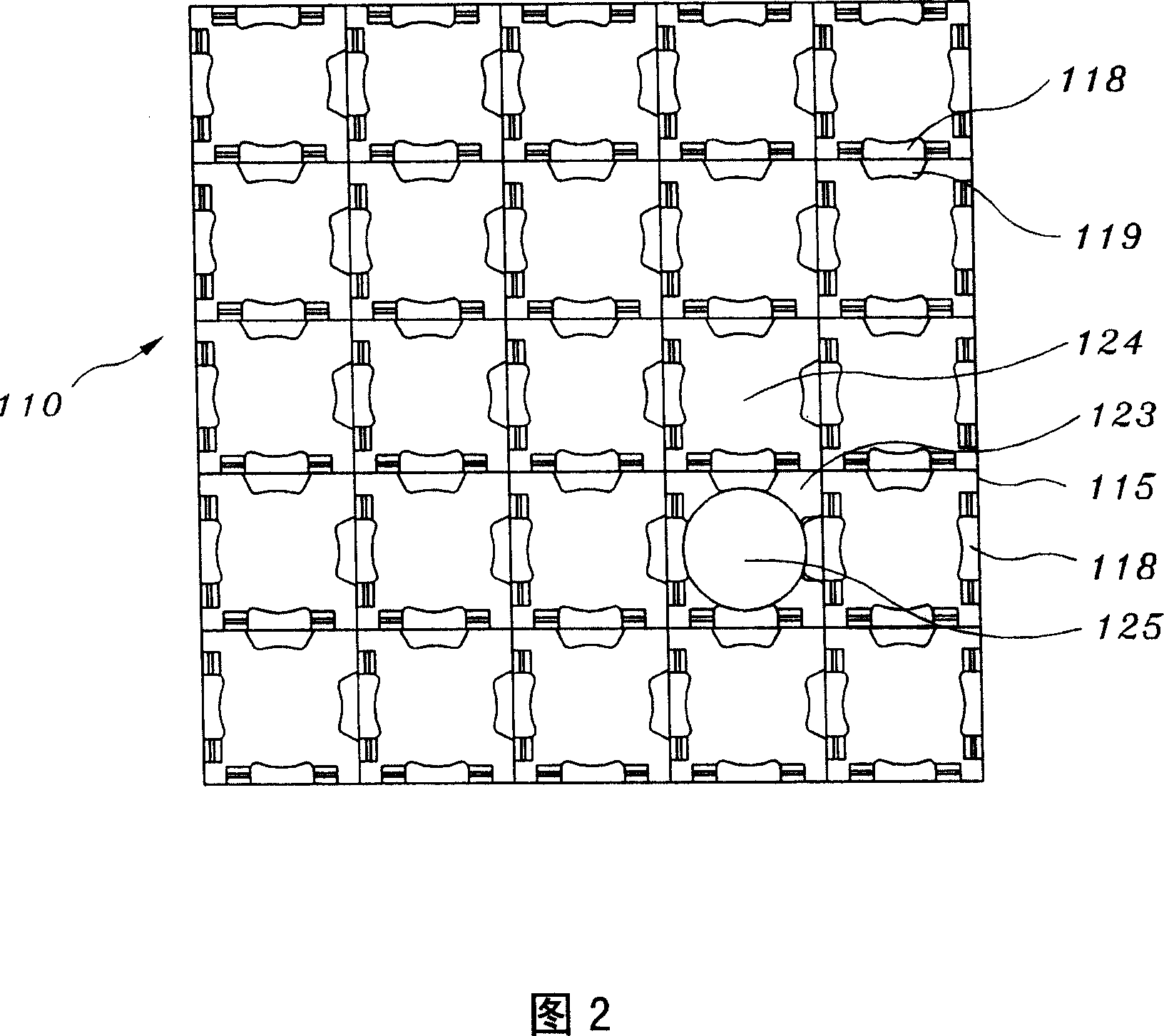

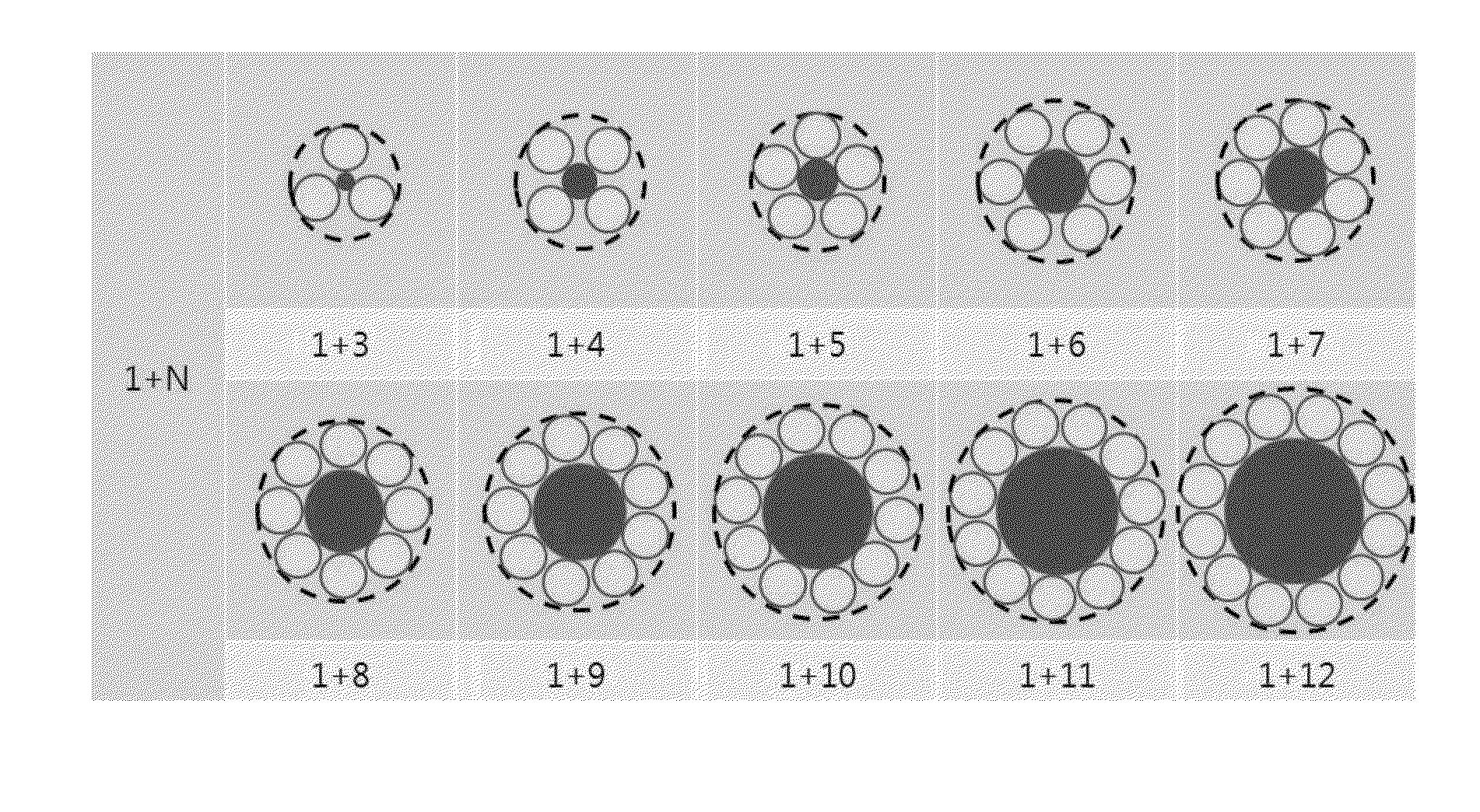

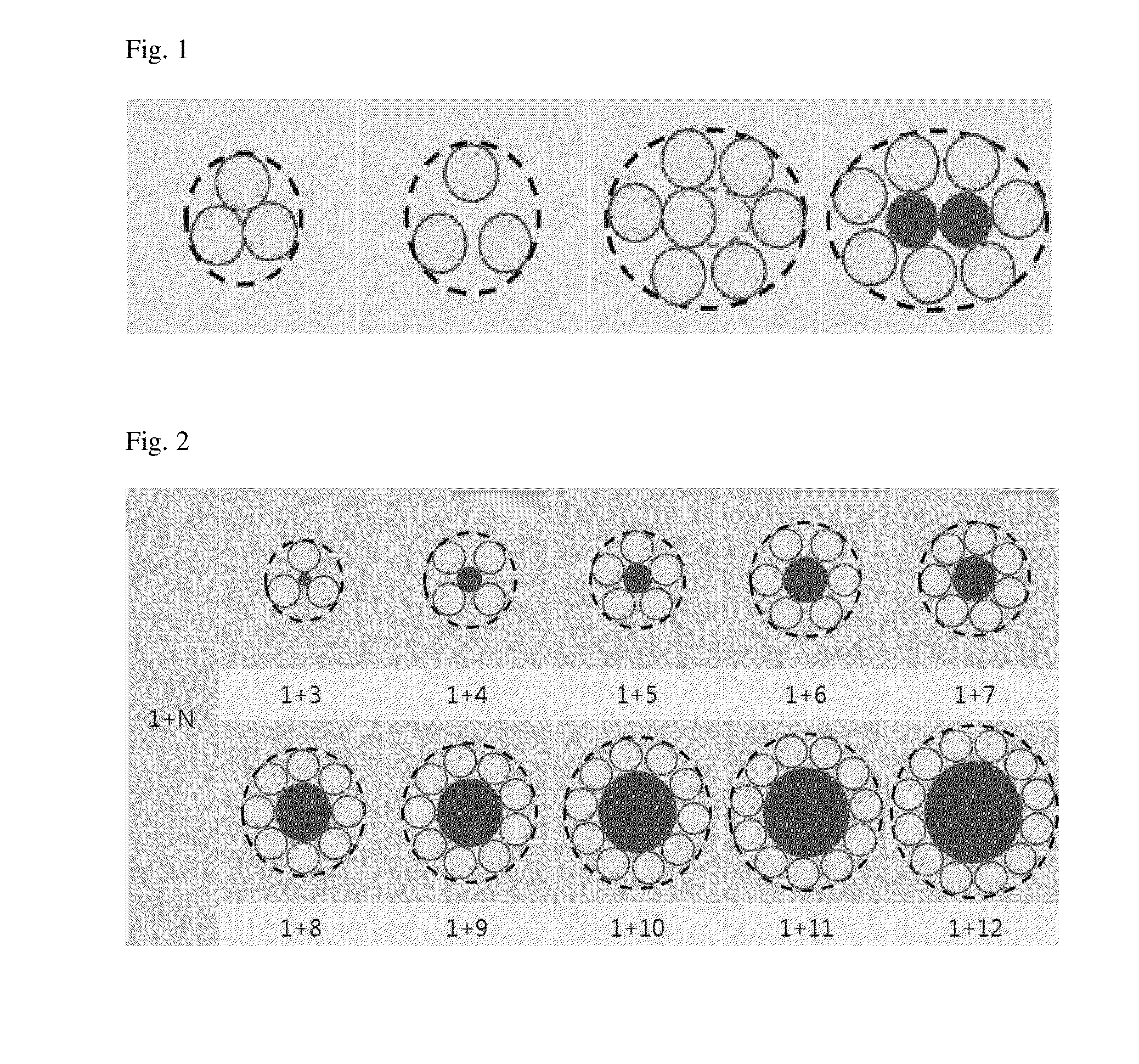

Heat exchanger tube support structure

InactiveUS6914955B2Minimized pressure dropReducing local turbulenceBoiler supporting/setting arrangementsFuel element assembliesParticulatesEngineering

A support plate for retaining tube array spacing within a heat exchanger tube and shell structure. The support plate having a plurality of individual tube receiving apertures formed therein. Each aperture has at least three inwardly protruding members and bights are formed therebetween when the tube associated therewith is lodged in place to establish secondary fluid flow through the support plate. The inwardly protruding members terminate in flat lands that restrain but do not all contact the outer surface of the respective tube. These flat lands minimize fretting wear and eliminate potential gouging of the outer wall of the tube. The plate wall forming each aperture has an hourglass configuration which, inter alia, reduces pressure drop, turbulence and local deposition of magnetite and other particulates on the support plates.

Owner:BWXT CANADA

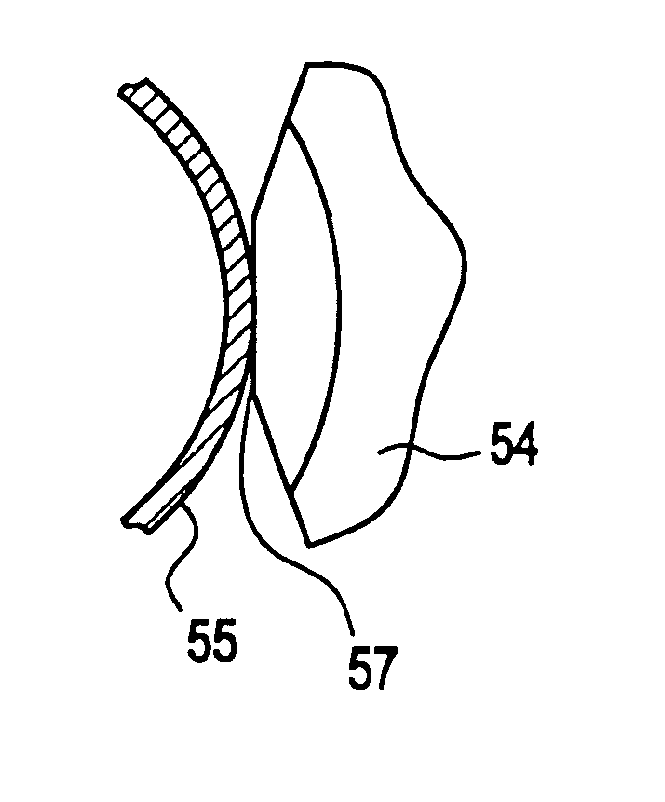

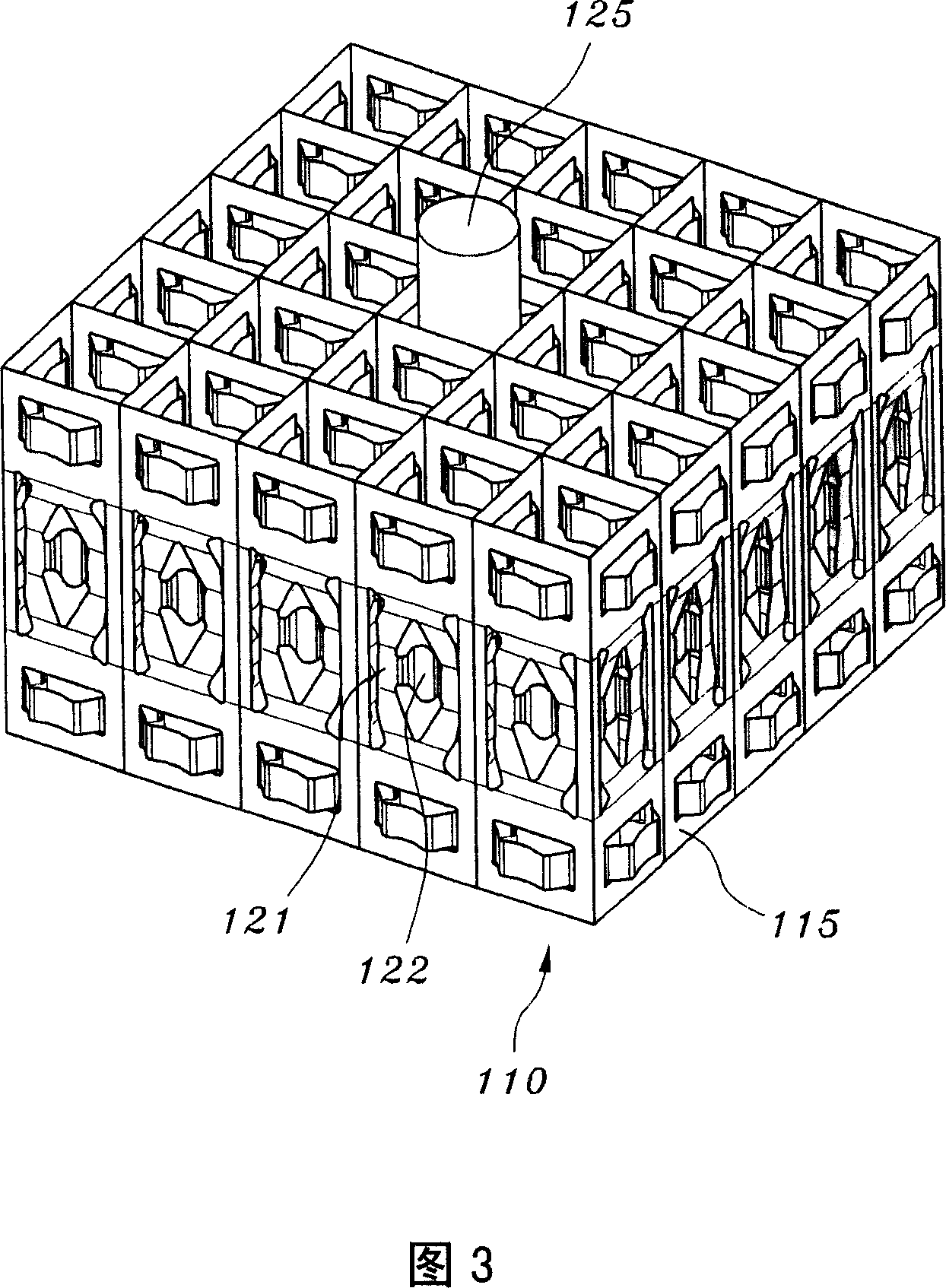

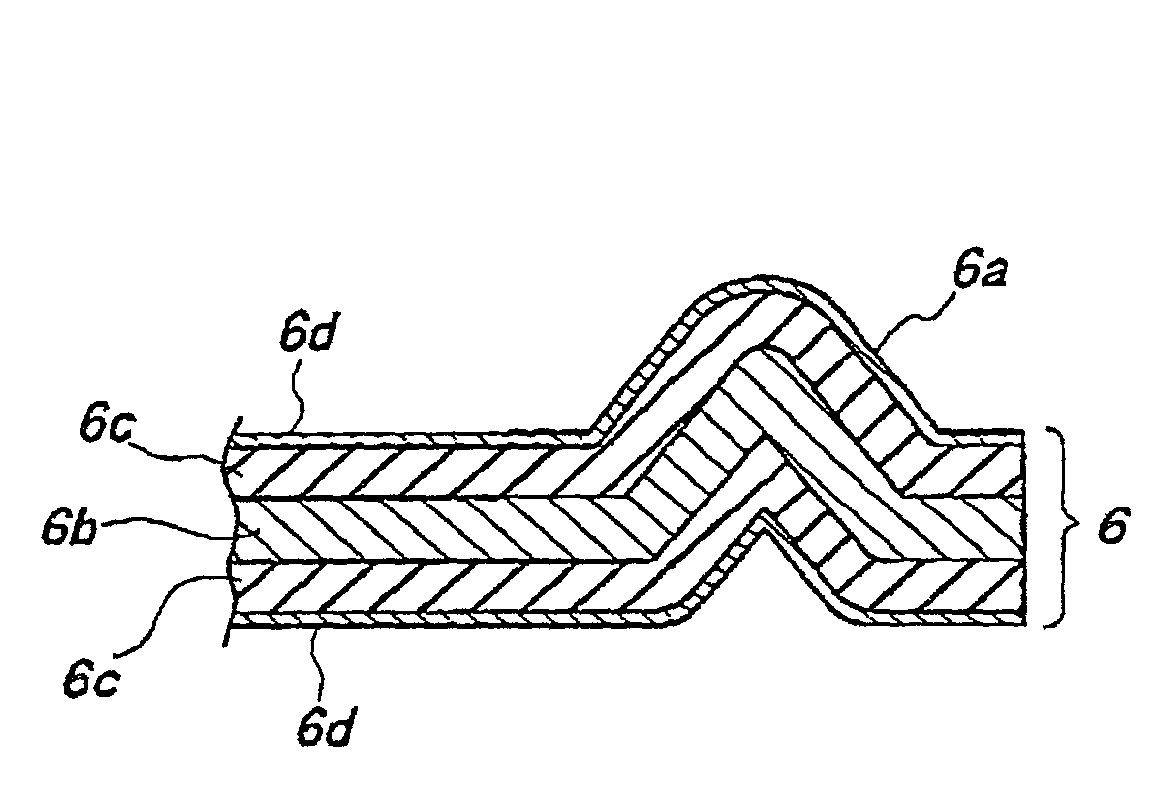

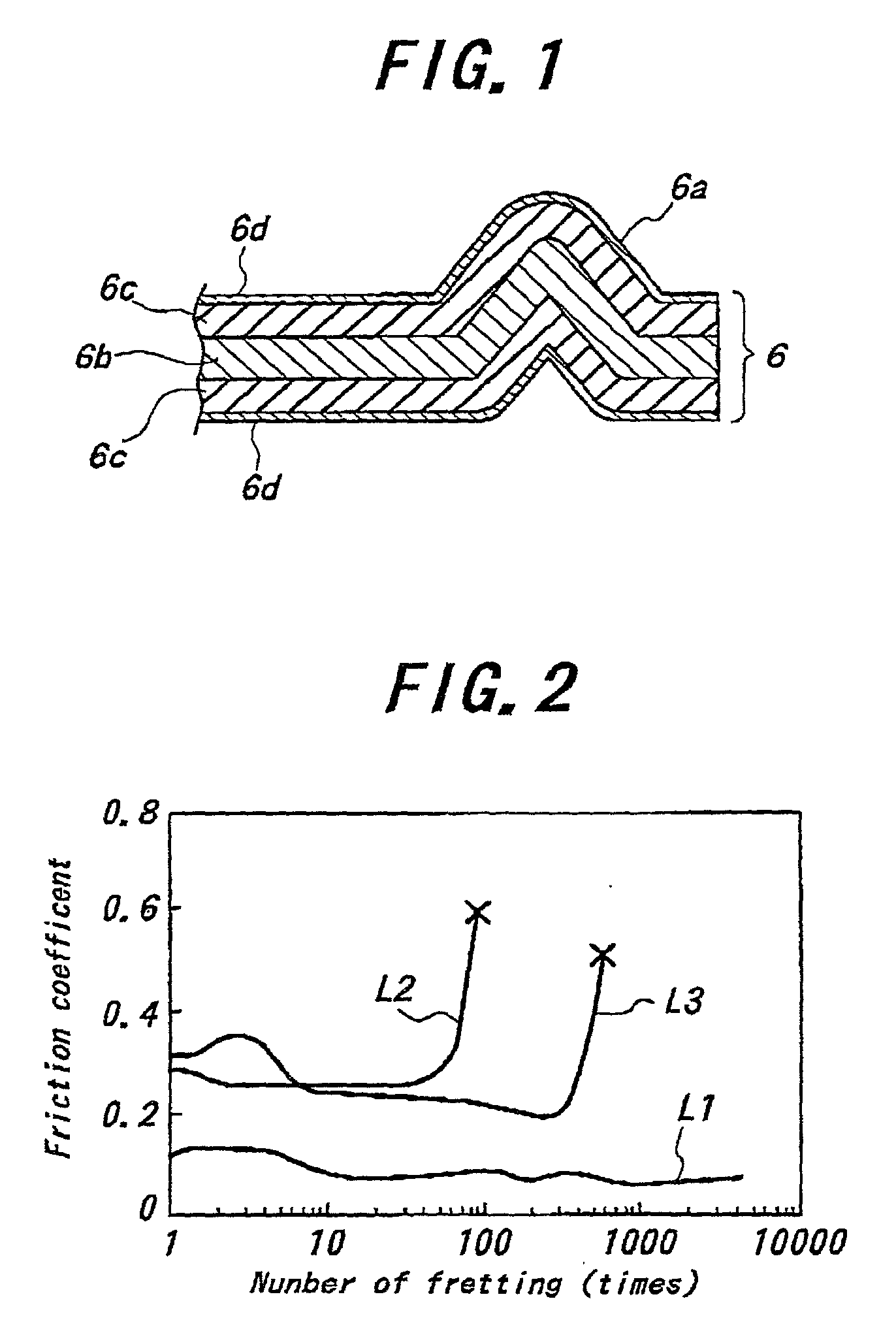

Spacer grid spring for increasing the conformal contact area with fuel rod

InactiveCN101055775ANuclear energy generationFuel element assembliesStress distributionContact pressure

A grid strap includes a spacer grid spring that increases the conformal contact area with a fuel rod of a nuclear fuel rod assembly. The shape of the spacer grid spring of the grid strap which is in contact with the fuel rod is optimized, thereby the elasticity of the spacer grid spring contacting the fuel rod is increased, the conformal contact area with a contact portion of the spacer grid spring contacting the fuel rod when the fuel rod is inserted into each cell of a spacer grid is expanded to obtain uniform stress distribution, and excessive plastic deformation of the spacer grid spring can be reduced. Further, magnitude and distribution of contact pressure between the fuel rod and the spacer grid spring are improved, thereby reducing the possibility of fretting wear caused by contact between the fuel rod and the spacer grid spring. The elastic behavior region of the spacer grid spring is expanded, so that the fuel rod can be reliably supported until the lifetime of the fuel rod expires despite changes in the supporting conditions of the fuel rod.

Owner:KOREA ATOMIC ENERGY RES INST +1

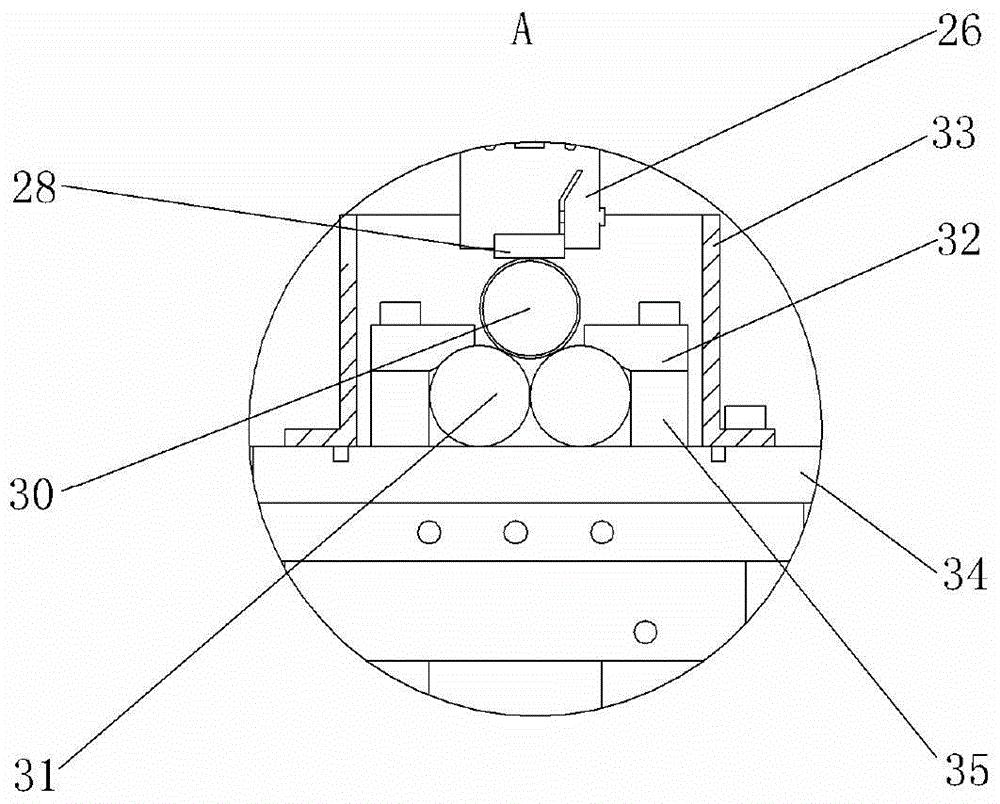

Multidirectional fretting wear device and testing method for heat transmission pipe of steam generator

ActiveCN103604713APrecise positioningSmall range of motionInvestigating abrasion/wear resistanceControl systemHeat transmission

The invention provides a multidirectional fretting wear device and a testing method for a heat transmission pipe of a steam generator. The device is composed of a rack, a driving device, a leveling hoisting system and a data acquisition control system, wherein the structure of the test piece driving device is as follows: the upper end of a piezoelectric ceramic acting device is fixedly connected with a middle beam and the lower end of the piezoelectric ceramic acting device is connected with an upper clamp for clamping a block-shaped test piece sequentially via a flexible connector, a connection rod and a force sensor; a displacement sensor is mounted between the upper clamp and the middle beam; the structure of the leveling hoisting system of the heat transmission pipe is as follows: an angular displacement platform is fixedly arranged on a base and a hoisting platform is fixedly arranged on the angular displacement platform; a test piece supporting plate is mounted on the hoisting platform; two cylindrical test pieces which are the same in diameter are placed on the supporting plate and are close to each other; the outer sides of the cylindrical test pieces are close to clamping plates and the clamping plates are in threaded connection with lower pressing plates; the lower pressing plates are in tight fit with the cylindrical test pieces; the heat transmission pipe is placed in the two cylindrical test pieces. The device is simple in structure and easy to operate, can carry out a multidirectional fretting wear test on the heat transmission pipe, and can provide accurate, reliable and high-precision experimental data.

Owner:SOUTHWEST JIAOTONG UNIV +1

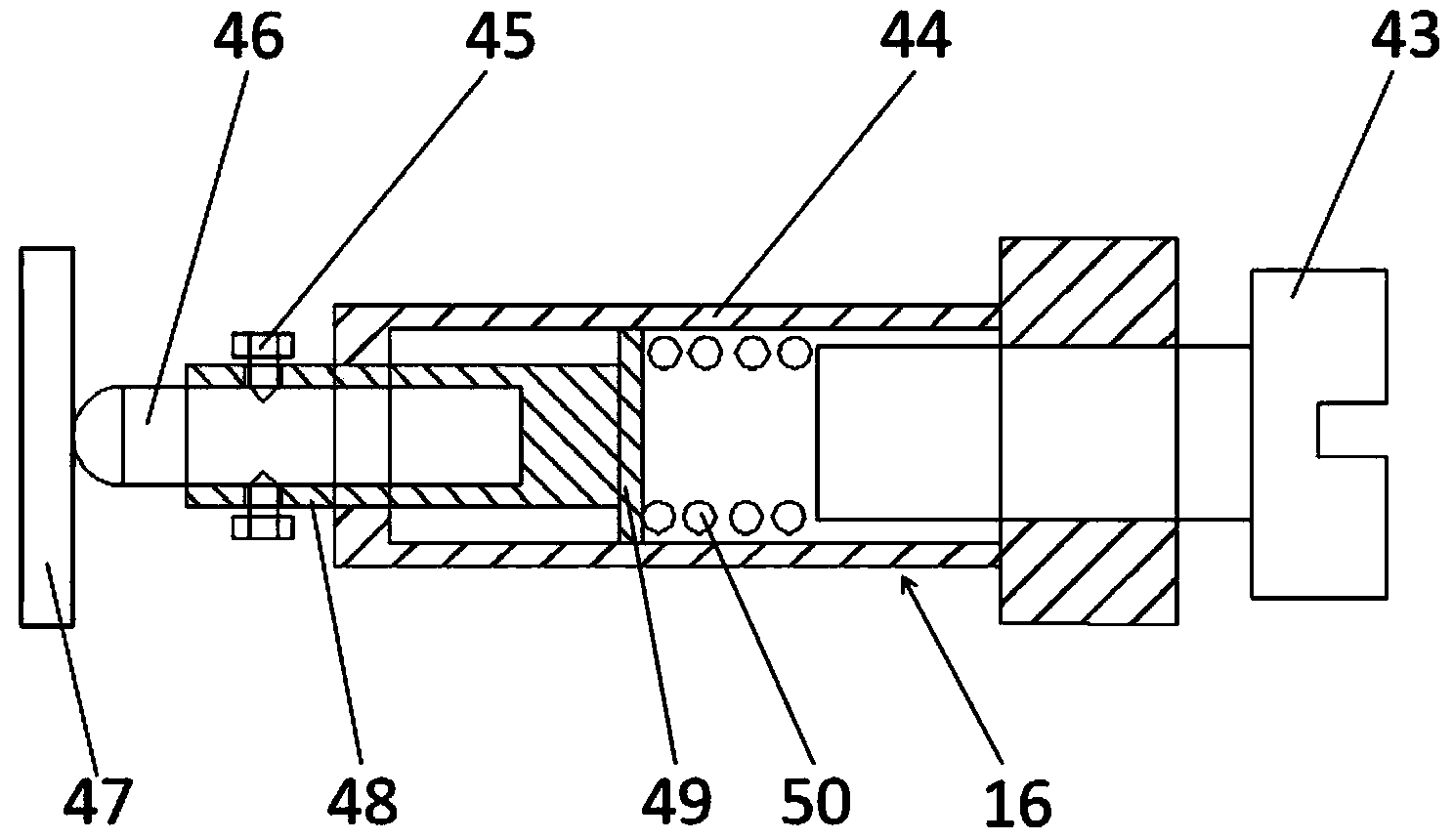

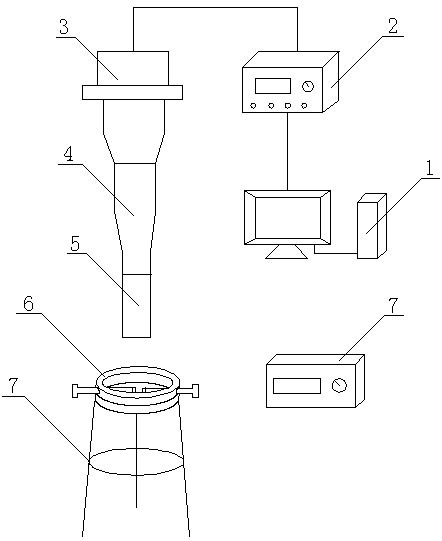

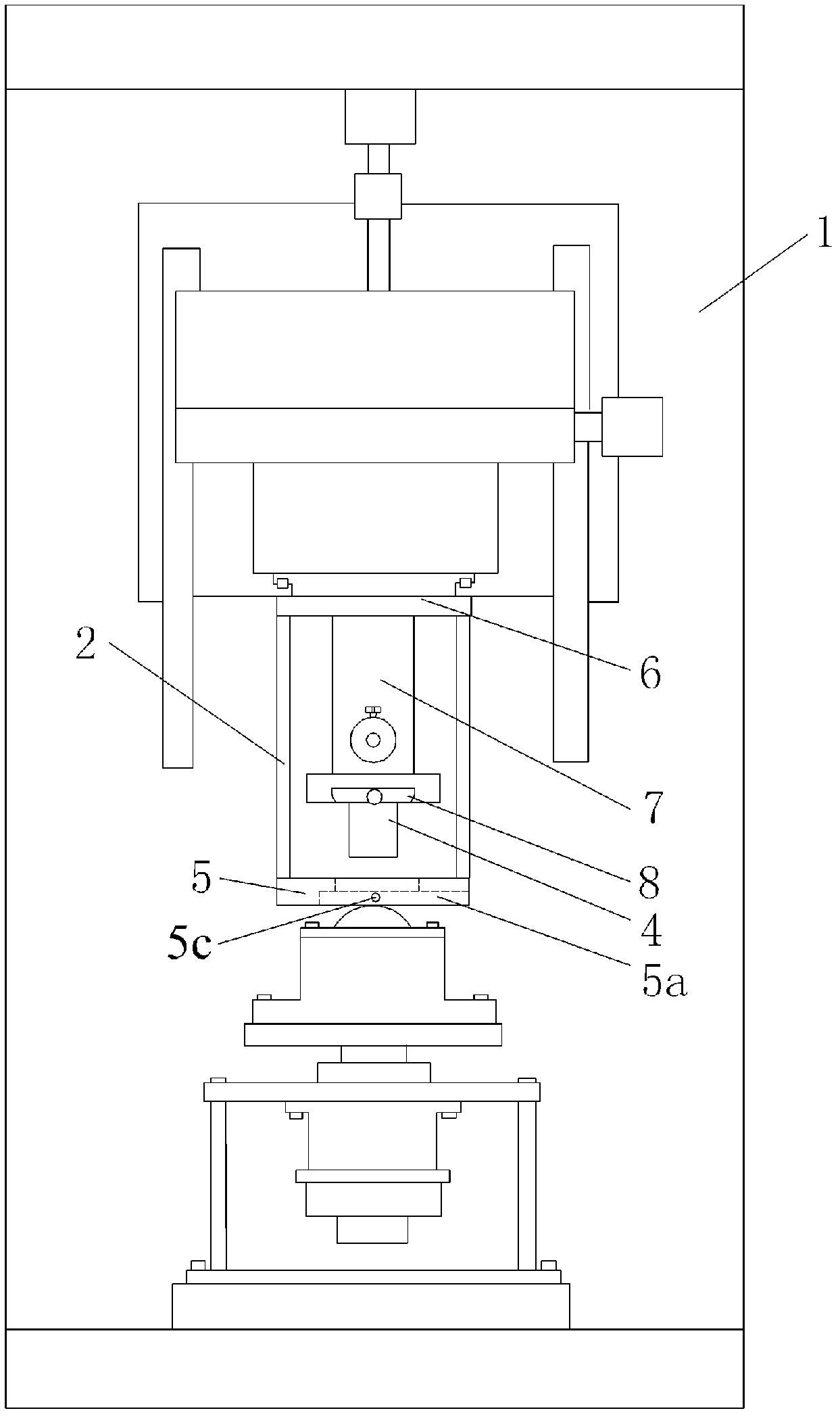

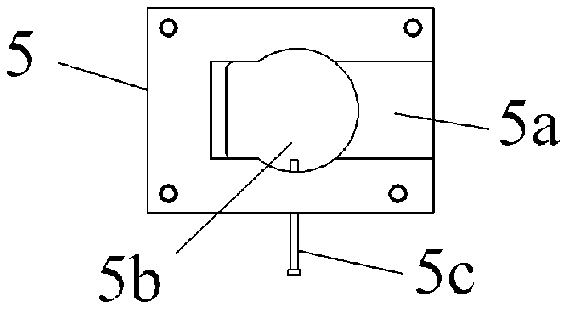

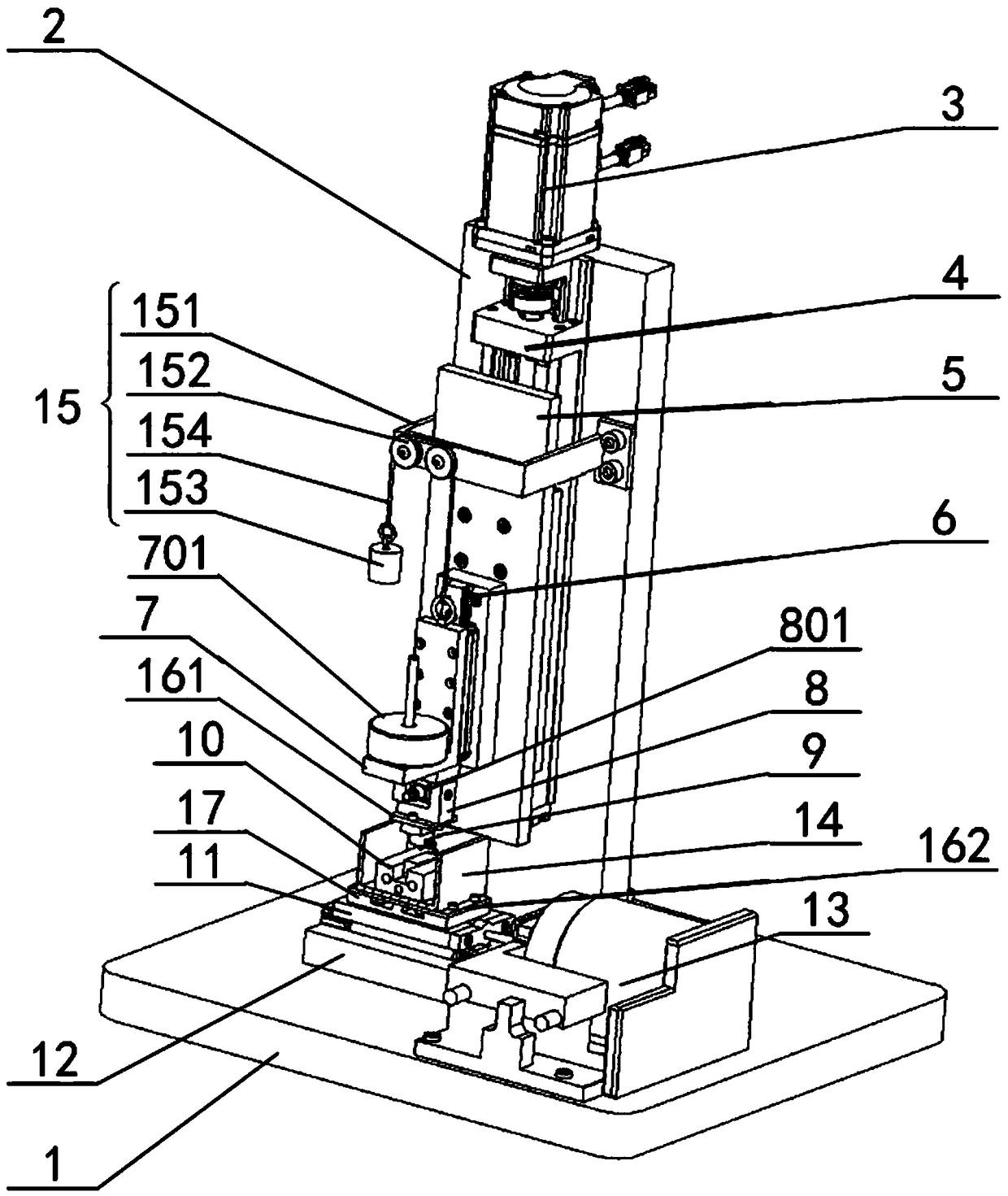

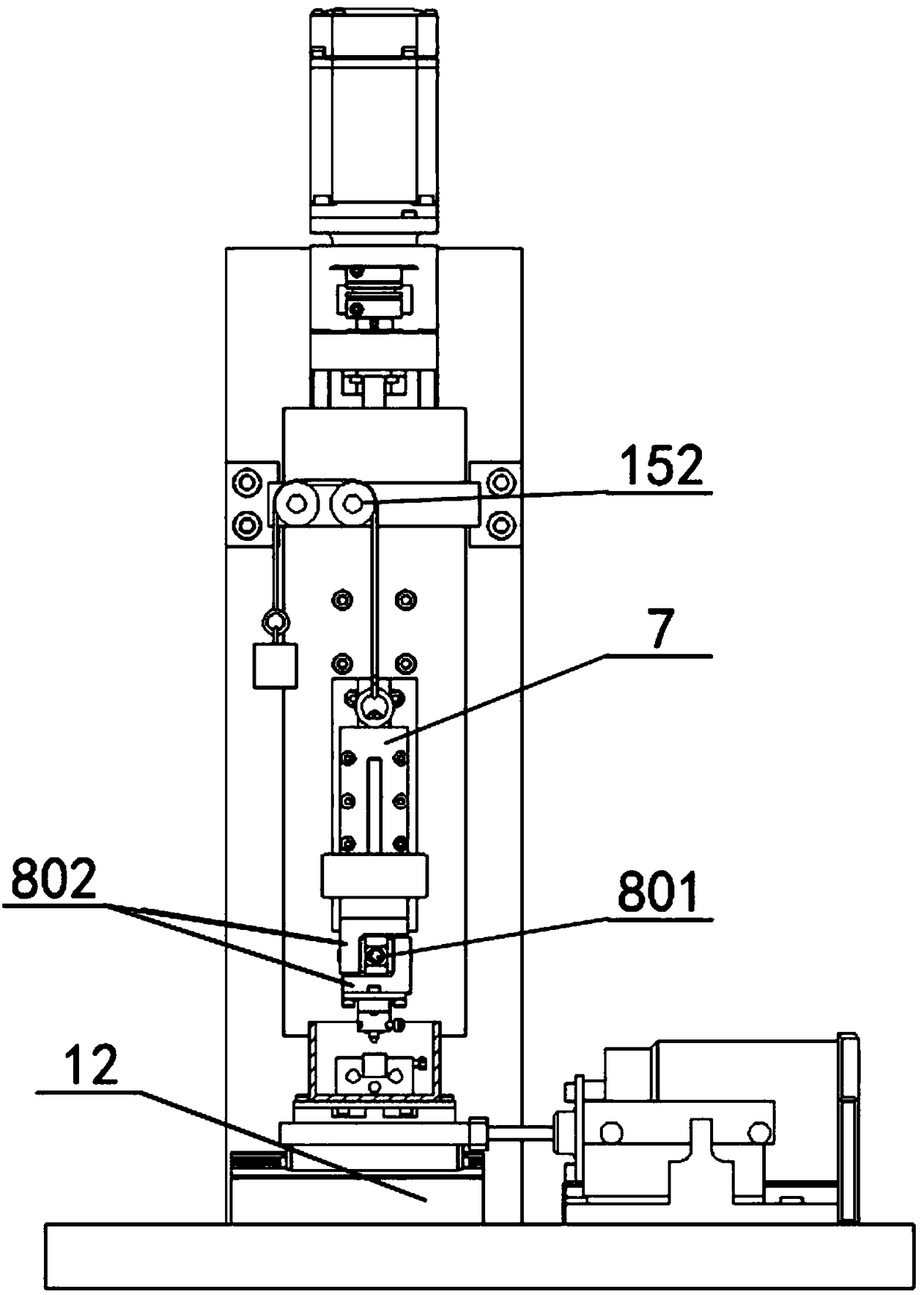

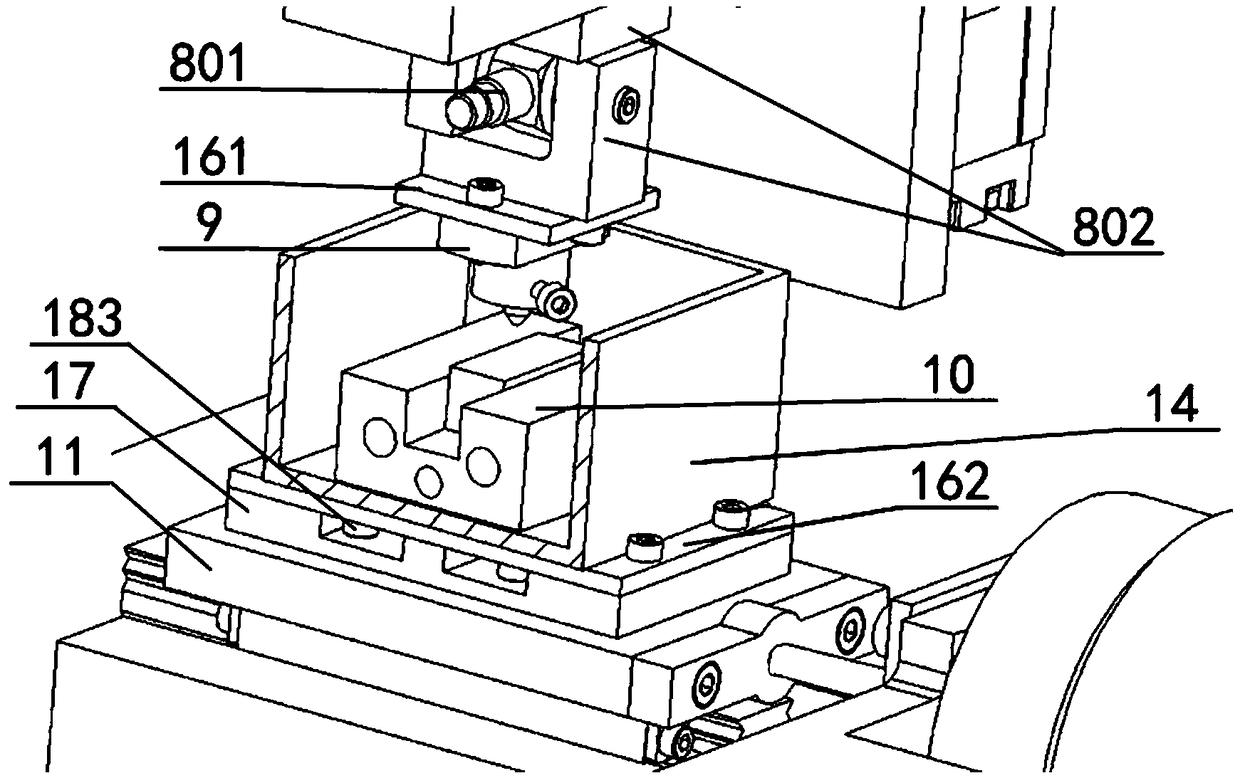

Fretting-wear ultrasonic-vibration ultralong-life fatigue test apparatus

ActiveCN102830029ASimple structureEasy to operateInvestigating abrasion/wear resistanceTransformerTransducer

The invention discloses a fretting-wear ultrasonic-vibration ultralong-life fatigue test apparatus. The apparatus comprises an ultrasonic fatigue test device, a fretting wear device (6) and a temperature test device, wherein the ultrasonic fatigue test device comprises a computer system (1), an ultrasonic generator (2) and a piezoelectric ceramic energy transducer (3) which are sequentially connected; the lower end of the piezoelectric ceramic energy transducer (3) is fixedly connected with a amplitude transformer (4); the output end of the amplitude transformer (4) is connected with a cylindrical extension rod (5) coaxial to the amplitude transformer (4); the size of the cross section of the output end of the amplitude transformer (4) is equal to the size of the cross section of the extension rod (5); and the temperature test device comprises a temperature test meter (8). By adopting the above structure, the apparatus has the advantages of experiment design difficulty reduction and high test precision.

Owner:SICHUAN UNIV

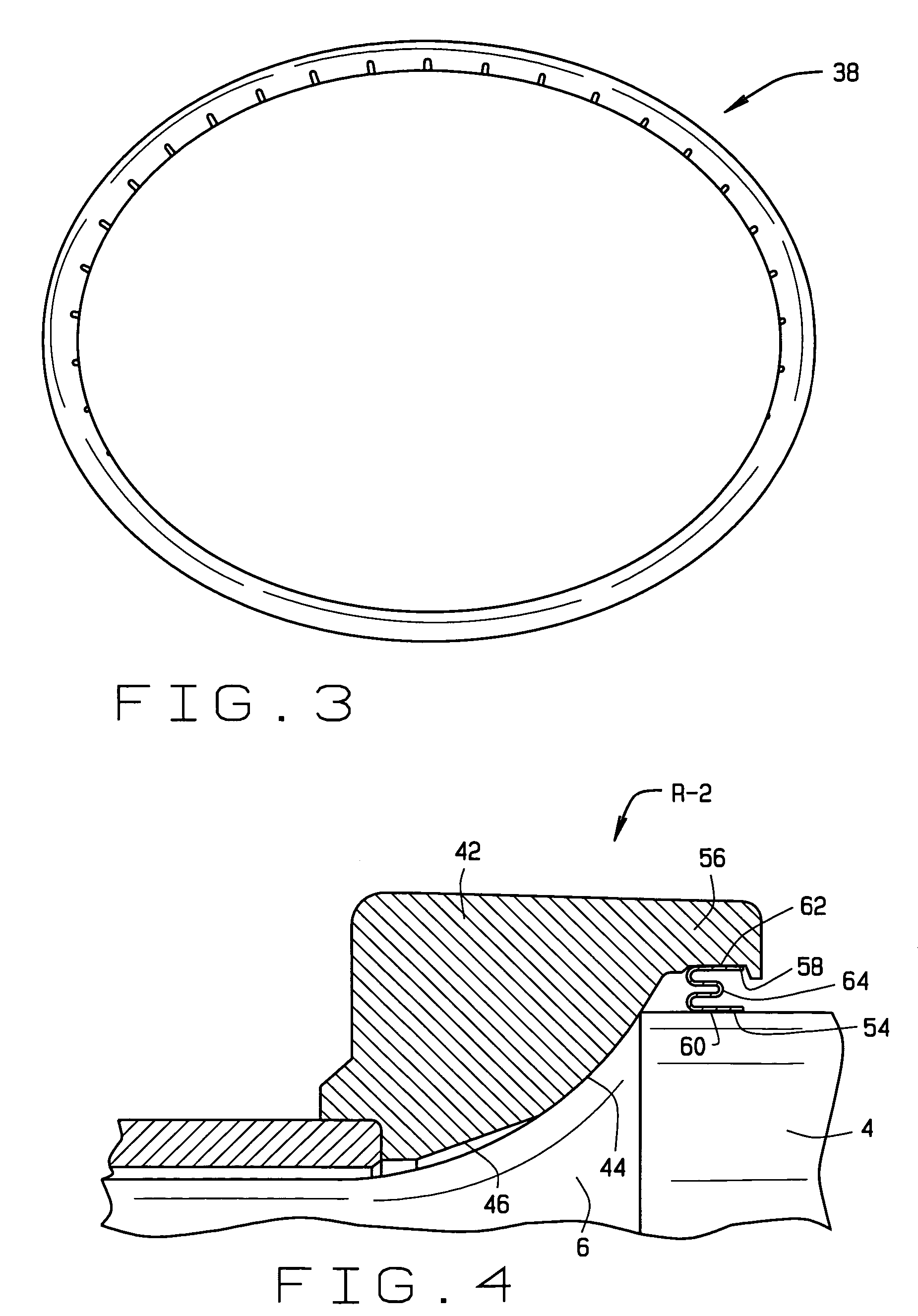

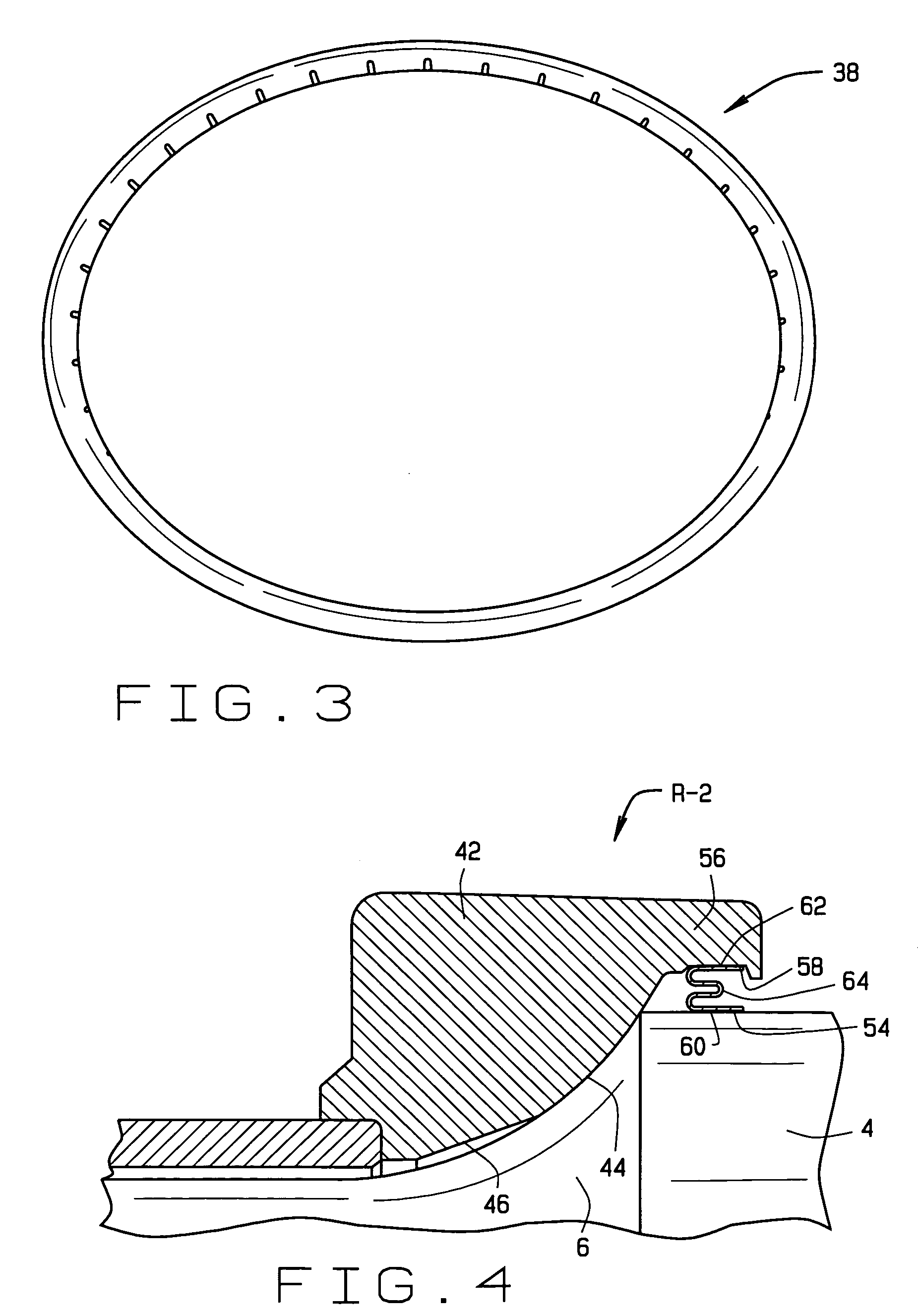

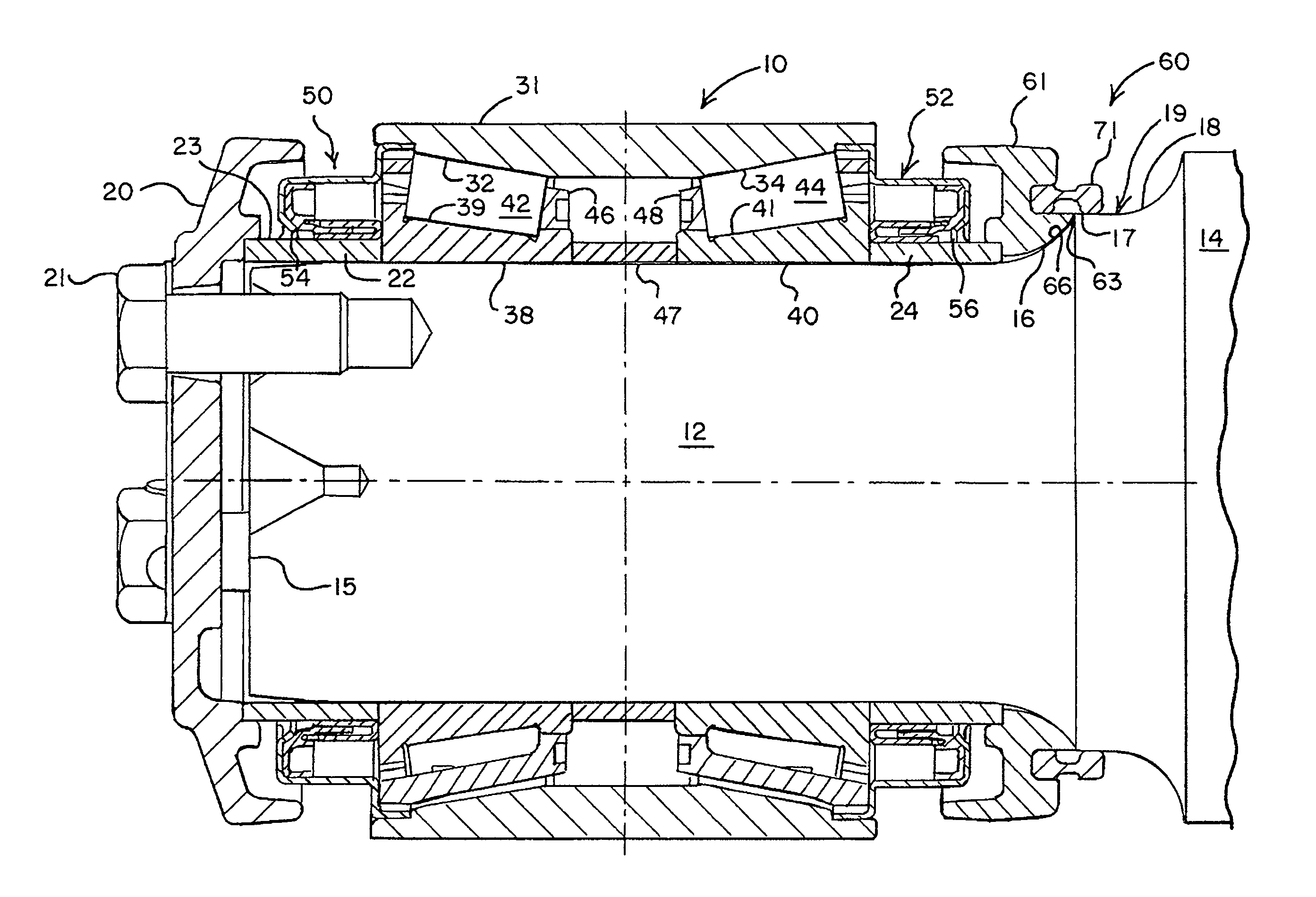

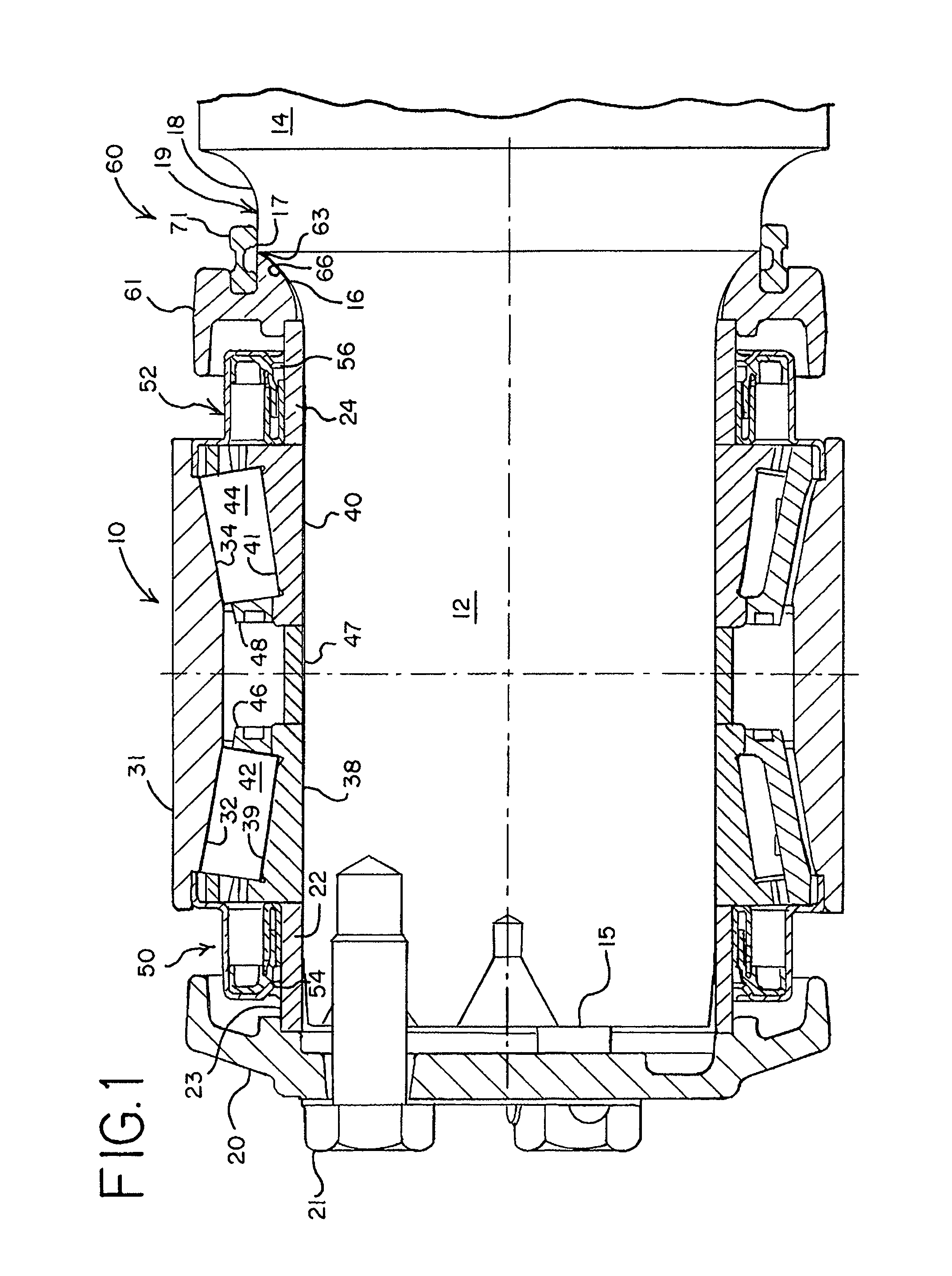

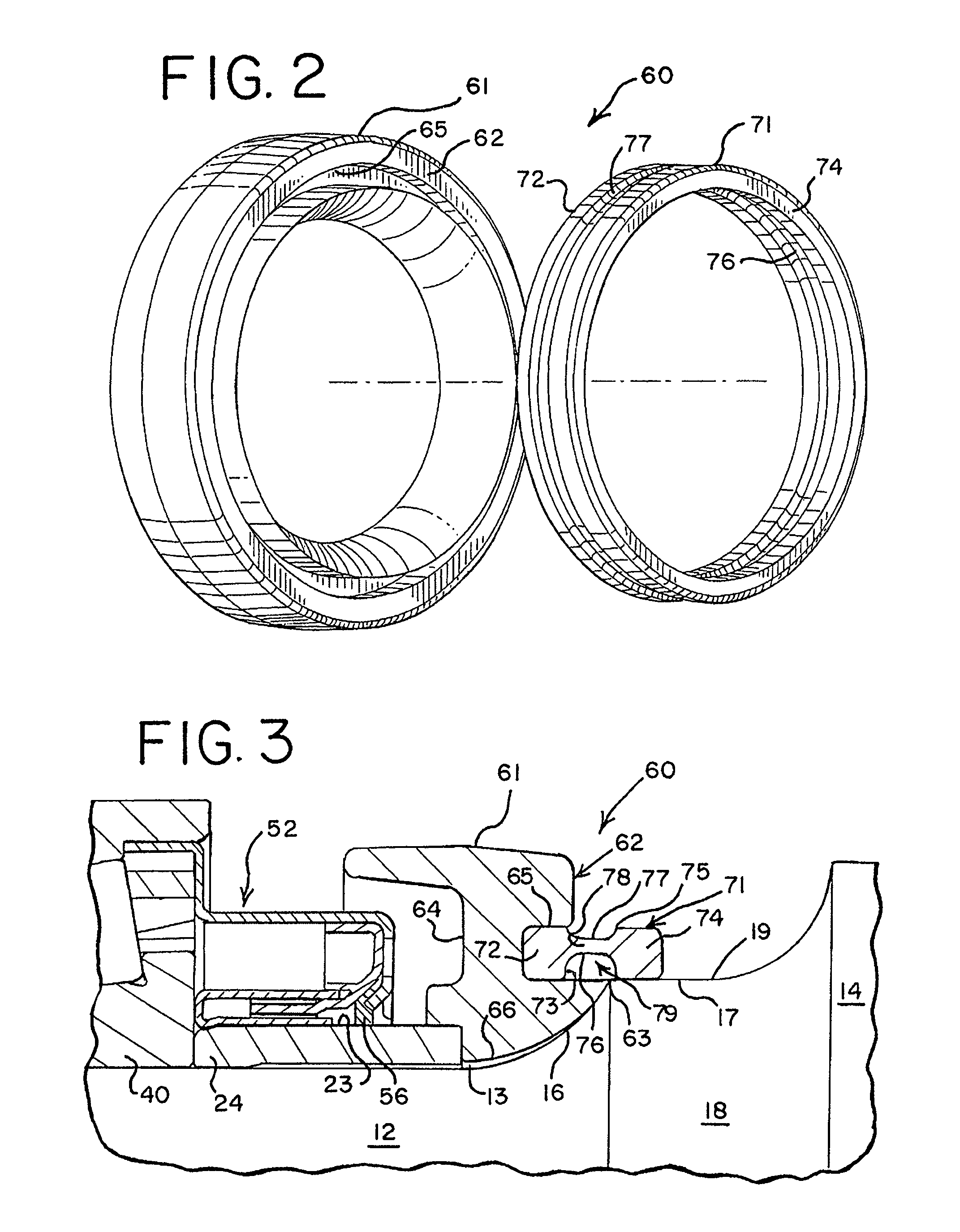

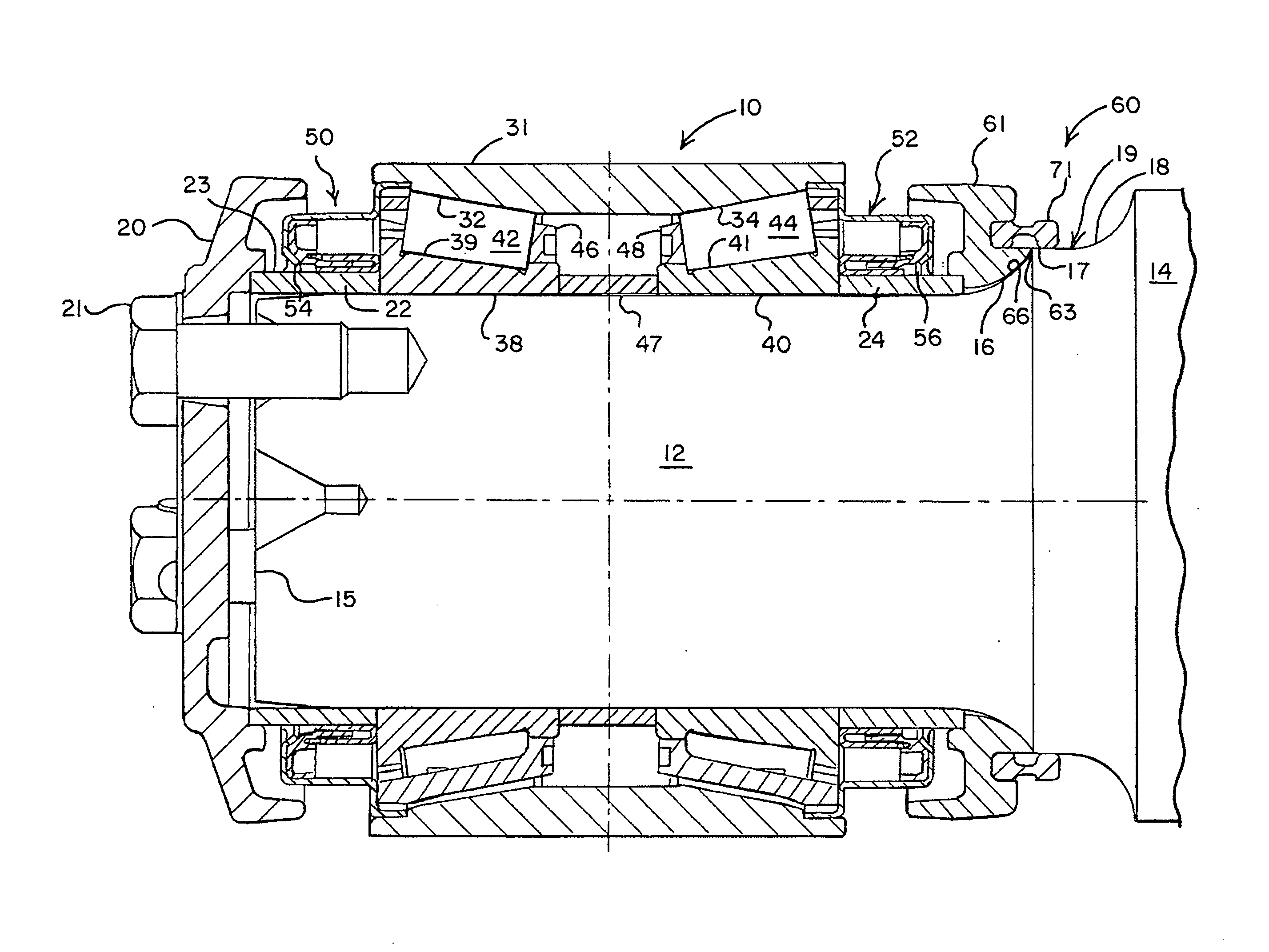

Roller bearing backing ring

ActiveUS8226299B2Reduce axial movementReduced fretting wearRolling contact bearingsRailway vehiclesMechanical engineeringFretting wear

A novel two-piece backing ring assembly for a railcar axle is presented. The backing ring assembly has an annular body affixed to the fillet of the journal and a locking ring for further affixing the annular body into position on the journal. The locking ring has an inboard end affixed to the dust guard of the shaft and an outboard end for engaging a slot in the annular body. The locking ring assembly may be retrofitted to older generation railcar axles to increase the structural rigidity of the bearing assembly and minimize fretting wear caused by railcar axle deflection.

Owner:AMSTED RAIL CO INC

Roller bearing backing ring

ActiveUS20110064347A1Reduced fretting wearReduce axial movementRolling contact bearingsRailway vehiclesEngineeringOrbit

A novel two-piece backing ring assembly for a railcar axle is presented. The backing ring assembly has an annular body affixed to the fillet of the journal and a locking ring for further affixing the annular body into position on the journal. The locking ring has an inboard end affixed to the dust guard of the shaft and an outboard end for engaging a slot in the annular body. The locking ring assembly may be retrofitted to older generation railcar axles to increase the structural rigidity of the bearing assembly and minimize fretting wear caused by railcar axle deflection.

Owner:AMSTED RAIL CO INC

Apparatus for real time observation and recording of fretting wear

InactiveCN102435516AAccurate test basisAnalyze the mechanism of wearInvestigating abrasion/wear resistanceElectricityMagnifying glass

The invention provides an apparatus for real time observation and recording of fretting wear. According to the invention, a screw thread in a top board of a frame of the apparatus is fixed in a thread connection hole in a plane sample clamp of a fretting testing stand; the upper end of a lens cone in the frame is in fixed connection with the top board, the lower end of the lens cone is connected with a magnifier, and the inner cavity of the lens cone is provided with a light source which emits light rays downwardly and is further provided with a camera which is electrically connected with a computer through a connecting wire; the bottom of a base plate of the frame is provided with a clamping slot used for clamping a plane sample, and the part of the base plate under the magnifier is provided with a through hole communicating with the clamping slot. The apparatus is applicable to any fretting operation mode and can be used for real time observation and recording of dynamic morphological characteristics of a transparent sample, and then accurate dynamic relationship between occurrence of damage and cycle numbers can be obtained through further analysis, thereby providing a more accurate test basis for designing, utilization and maintenance of a machine.

Owner:SOUTHWEST JIAOTONG UNIV

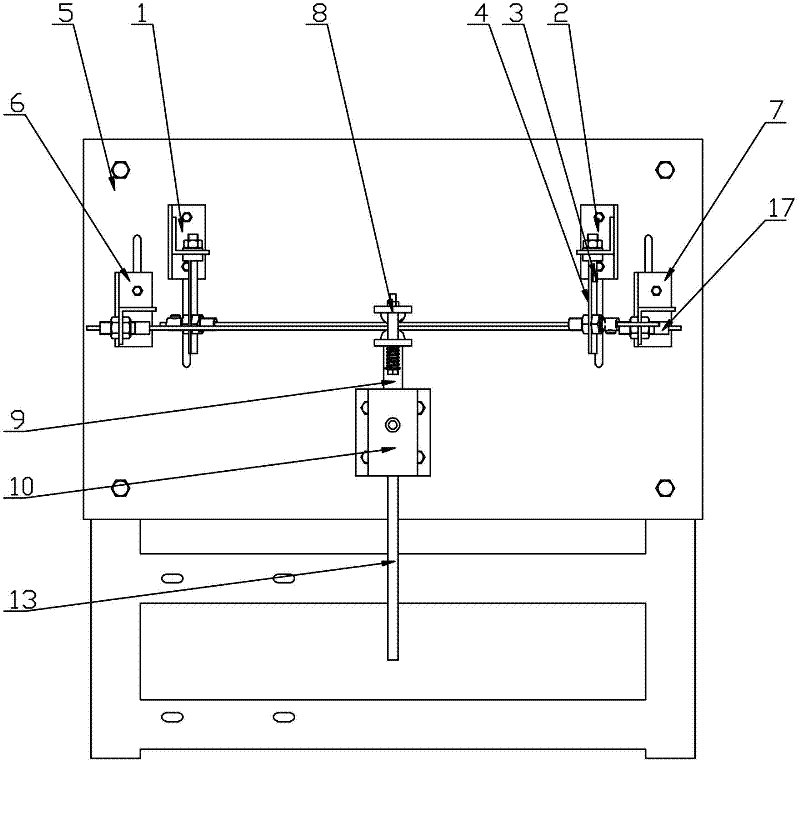

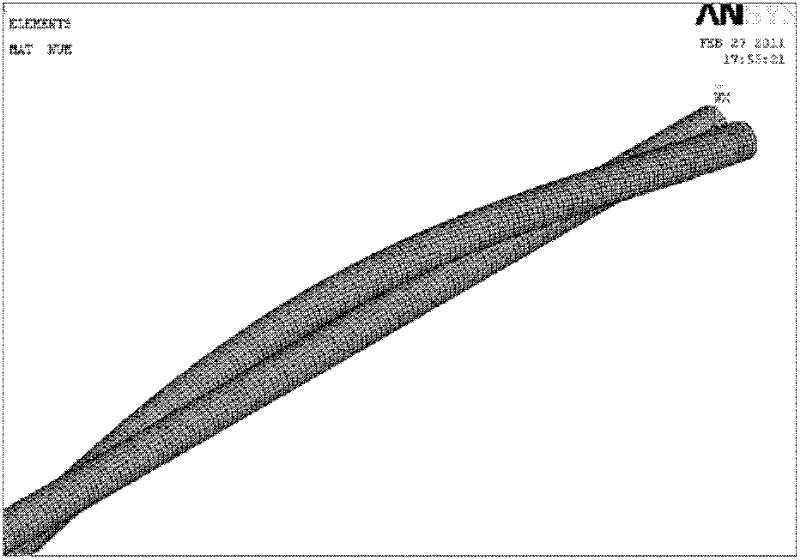

Test bench for fretting abrasion of double-strand aluminum lead

InactiveCN102175542AReduce the impactReduce the effects of frictionMaterial strength using repeated/pulsating forcesInvestigating abrasion/wear resistanceEngineeringLead frame

The invention relates to a test bench for fretting abrasion of a double-strand aluminum lead, and the test bench comprises a base plate, wherein a first lead frame and a second lead frame are arranged on the base plate in pair; a third lead frame and a fourth lead frame are arranged on the base plate in pair; a sliding slot is arranged at one sides of the third and fourth lead frames; one end of a sliding block in the sliding slot is connected to a holding device while the other end is connected to a connecting rod; and the connecting rod is connected to an eccentric block. The test bench canbe used for truly simulating the fretting abrasion between external aluminum leads of an overhead transmission line under various working conditions (such as fretting amplitude, frequency, load, leadincluded angle, wrap angle, and the like), thereby analyzing the fretting characteristics of the lead under the conditions, supplying a method for improving the fretting abrasion, reducing the abrasion between the leads and prolonging the service life of the overhead transmission line. The test bench provided by the invention plays an important role in researching the fretting abrasion between the leads.

Owner:CHINA THREE GORGES UNIV

High-frequency fretting wear tester

InactiveCN102435518AReal-time detection of electrical signalsInvestigating abrasion/wear resistanceSignal conditioningTest sample

The invention which relates to the technical field of test and concretely relates to the technical field of wear test provides a high-frequency fretting wear tester. According to the tester, an electric vibration table is adopted to provide the fretting needed by the fretting wear test, the vibration table surface of the electric vibration table is fixedly connected with a fretting clamping mechanism for clamping a first test sample to realize the fretting, a precompaction structure is adopted to provide precompaction force for the first test sample, and a pressure sensor is adopted to measure the precompaction force; a wear mechanism is fixedly connected with the table body of the electric vibration table to provide a wear structure which can generate friction with test samples, the upper end surface of a second test sample on the wear mechanism tightly contact the lower end surface of the first test sample, and a frictional force sensor is adopted to measure the frictional force born by the second test sample; a laser displacement sensor is adopted to measure the displacement of the first test sample; and a signal conditioning and acquiring circuit acquires pressure signals and frictional force signals and measures output signals of four electrodes of above two test samples.

Owner:HARBIN INST OF TECH

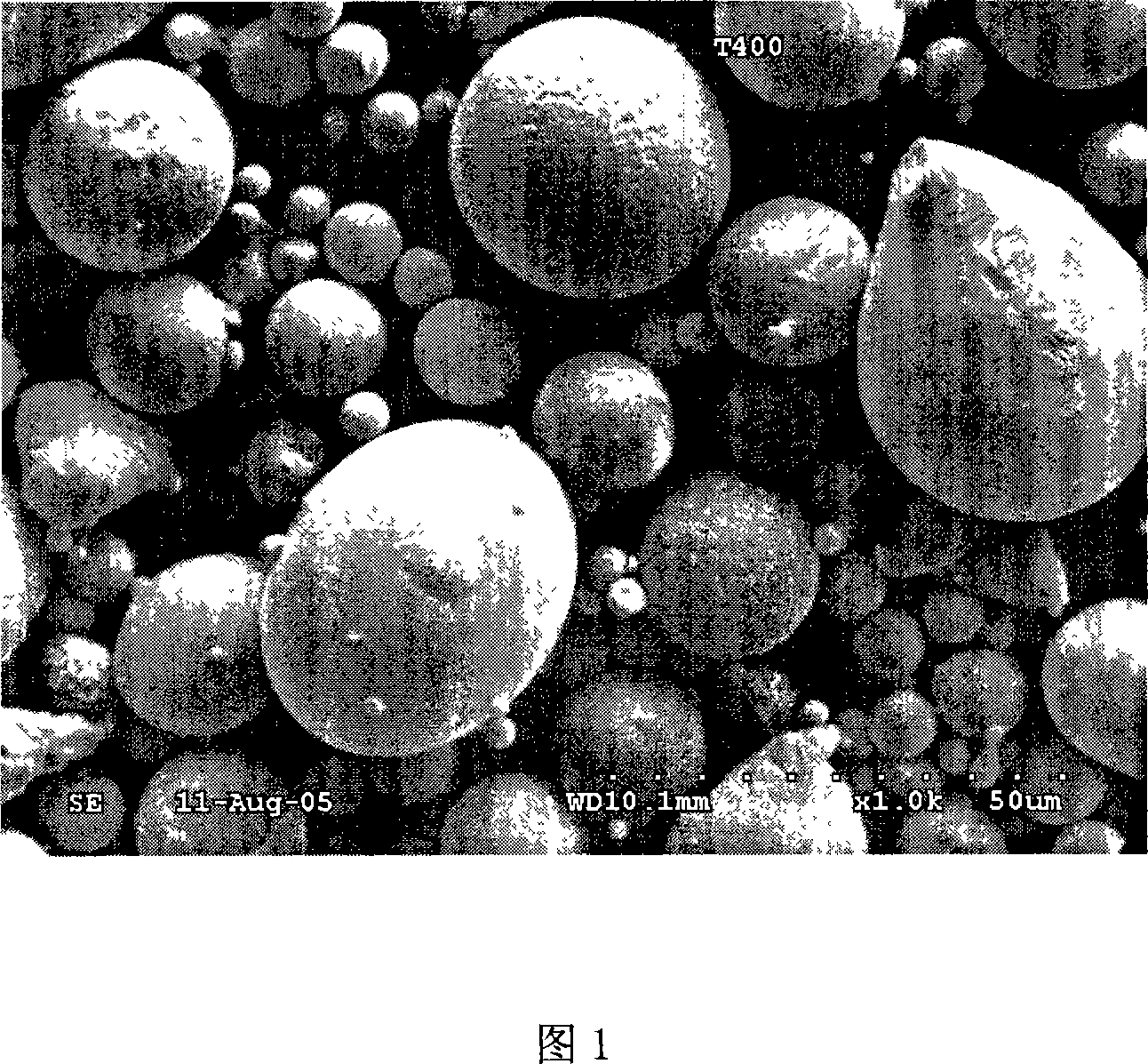

Method for preparing hot-spraying T400 coating material and coating layer

InactiveCN101158014AImprove performanceReduce manufacturing costMolten spray coatingThermal sprayingPower flow

The invention discloses a coating material of T400 for heat spraying and a preparation method, wherein the heat spraying coating material of T400 is chrome molybdenum silicon cobalt alloy powder, which comprises chrome 7-12% (weight percentage), molybdenum 20-30% (weight percentage), silicon 2-5 (weight percentage), the rest being Co. The particle size of the chrome molybdenum silicon cobalt alloy powder is:-100+500 mesh; the main body is within -120+400 mesh. The preparation method for the T400 heat spraying coating is that air plasma or flame heat spraying technique is adopted, the technical parameter for the preparation for T400 heat spraying coating is: arc current is less than or equal to 600A; arc voltage is less than or equal to 90V; argon pressure 0.6-0.9MPa; argon flux 30-70L / min; powder feeding speed 30-60g / min; spraying distance 150mm-250mm. The invention is an anti-oxidation wear resistant coating material. The oxygen content of the powder is low, the coating technique process is easy to control, the coating is with multiple good performances such as anti-oxidation, wear resistant, anti-fretting wear, and the preparation cost is relatively low, the application range is wide. The invention has provided a novel material for the protection and repairing of some of the parts of aviation and metallurgy industries of China.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

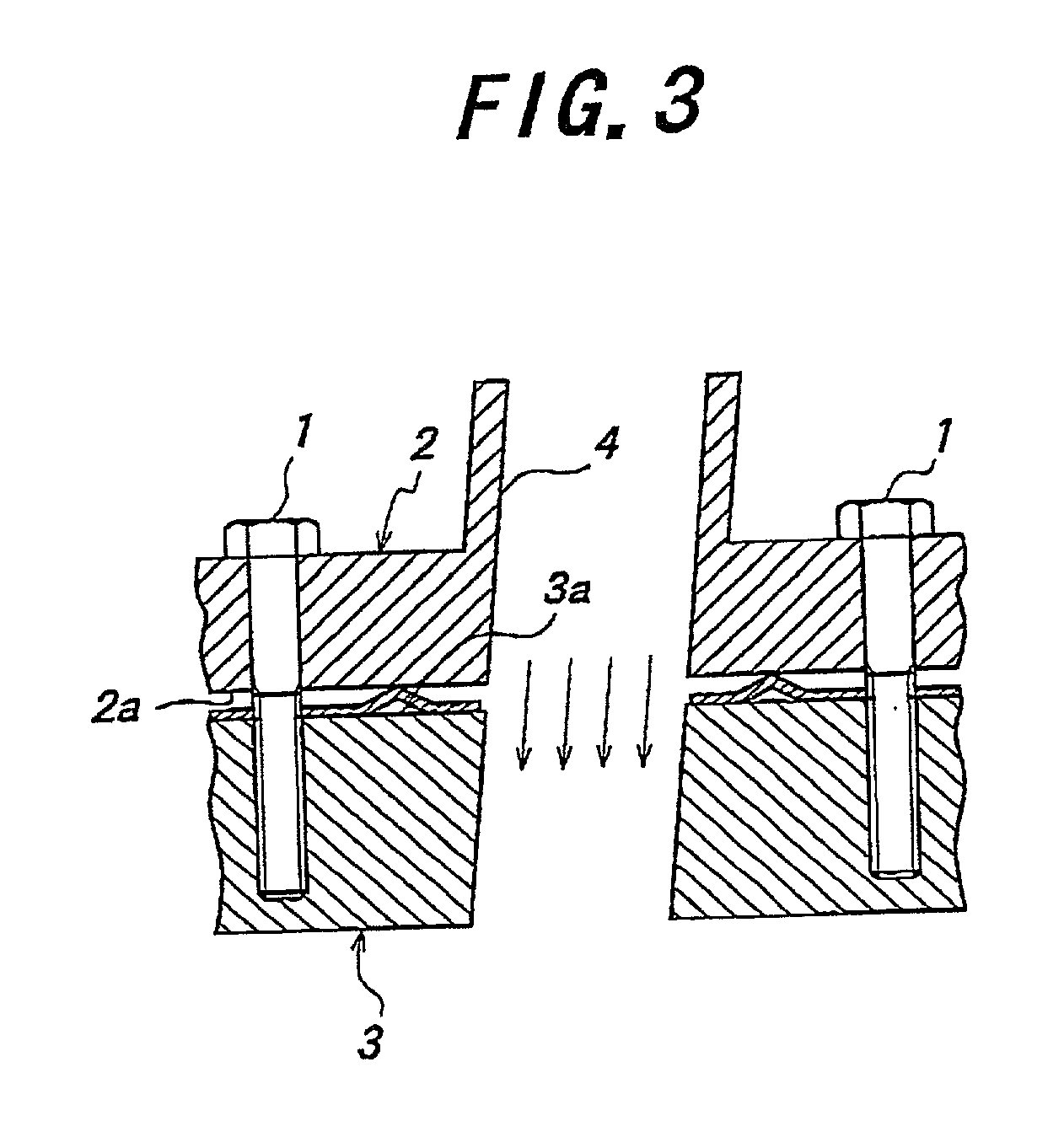

Composite material for metal gasket

InactiveUS20020127411A1Reduce coefficient of frictionImprove heat resistanceEngine sealsSynthetic resin layered productsFretting wearLubricant

A composite material for a metal gasket is disclosed, including: a metal plate; a rubber layer fixed on the surface of the metal plate; and a solid lubricant layer fixed on the rubber layer. The solid lubricant layer contains polytetrafluoroethylene and a resin as main components, and has a friction coefficient equal to 0.15 or lower. Thus, the seal durability of the metal gasket is improved by effectively preventing fretting wear

Owner:HONDA MOTOR CO LTD +1

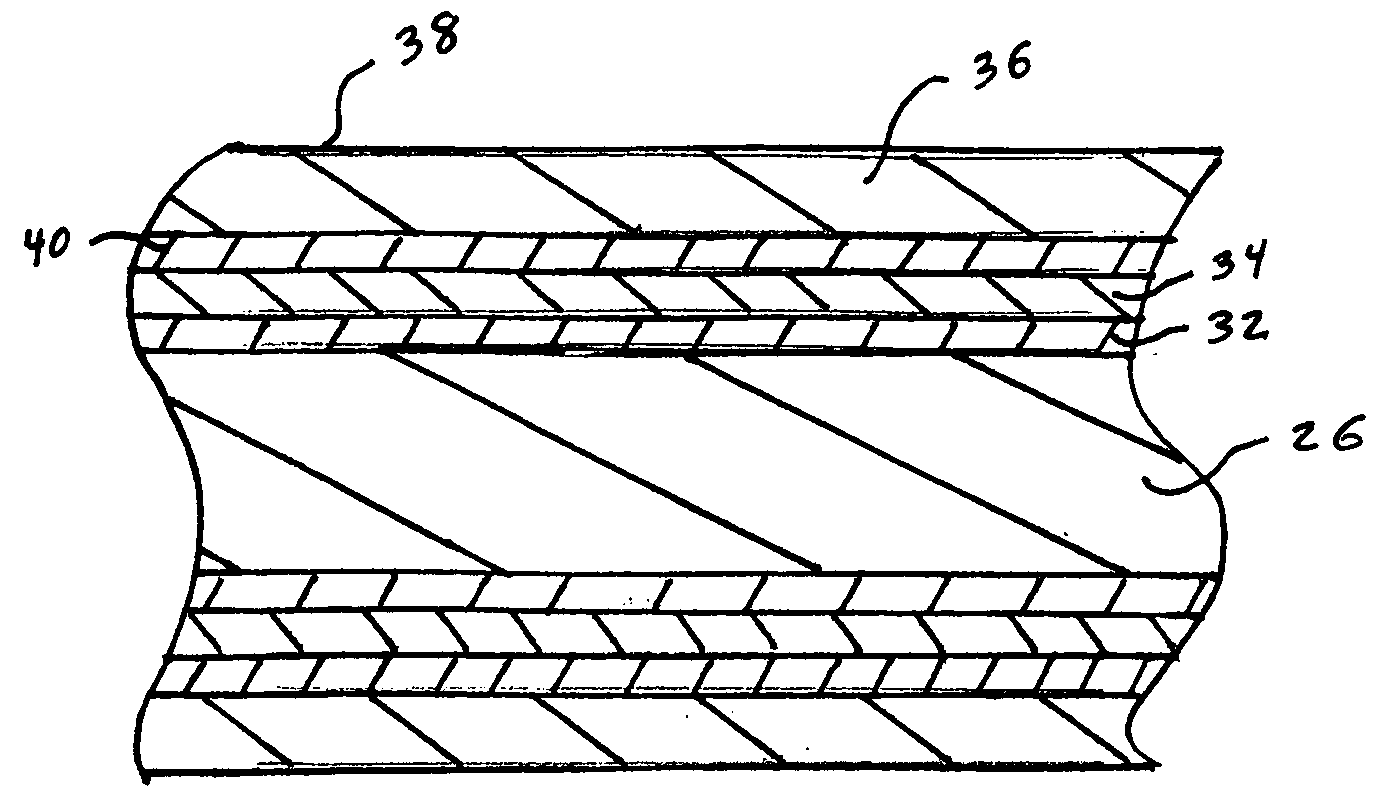

Fretting and whisker resistant coating system and method

ActiveUS20090017327A1High resistivityInhibited DiffusionAnodisationHot-dipping/immersion processesCoating systemFlexible circuits

A coated electrically conductive substrate has particular utility where there are multiple closely spaced leads and tin whiskers constitute a potential short circuit. Such substrates include leadframes, terminal pins and circuit traces such as on printed circuit boards and flexible circuits. This electrically conductive substrate has a plurality of leads separated by a distance capable of bridging by a tin whisker, a silver or silver-base alloy layer coating at least one surface of at least one of the plurality of leads, and a fine grain tin or tin-base alloy layer directly coating said silver layer.An alternative coated electrically conductive substrate has particular utility where debris from fretting wear may oxidize and increase electrical resistivity, such an in a connector assembly. This electrically conductive substrate has a barrier layer deposited on the substrate that is effective to inhibit diffusion of constituents the substrate into a plurality of subsequently deposited layers. The subsequently deposited layers include a sacrificial layer deposited on the barrier layer that is effective to form intermetallic compounds with tin, a low resistivity oxide metal layer deposited on said sacrificial layer, and an outermost layer of tin or a tin-base alloy directly deposited on the low resistivity oxide metal layer.In this alternative embodiment, the barrier layer is preferably nickel or a nickel-base alloy and the low resisitivity oxide metal layer is preferably silver or a silver-base alloy.When heated, the coated substrate of this second embodiment forms a unique structure having a copper or copper-base alloy substrate, an intervening layer formed from a mixture or metals including copper and tin, and an outermost layer which is a mixture of a copper-tin intermetallic containing phase and a silver-rich phase. It is believed that this silver-rich phase is particularly beneficial to reduce an increase in resistivity due to oxidation of fretting wear debris.

Owner:WIELAND ROLLED PROD NORTH AMERICA LLC

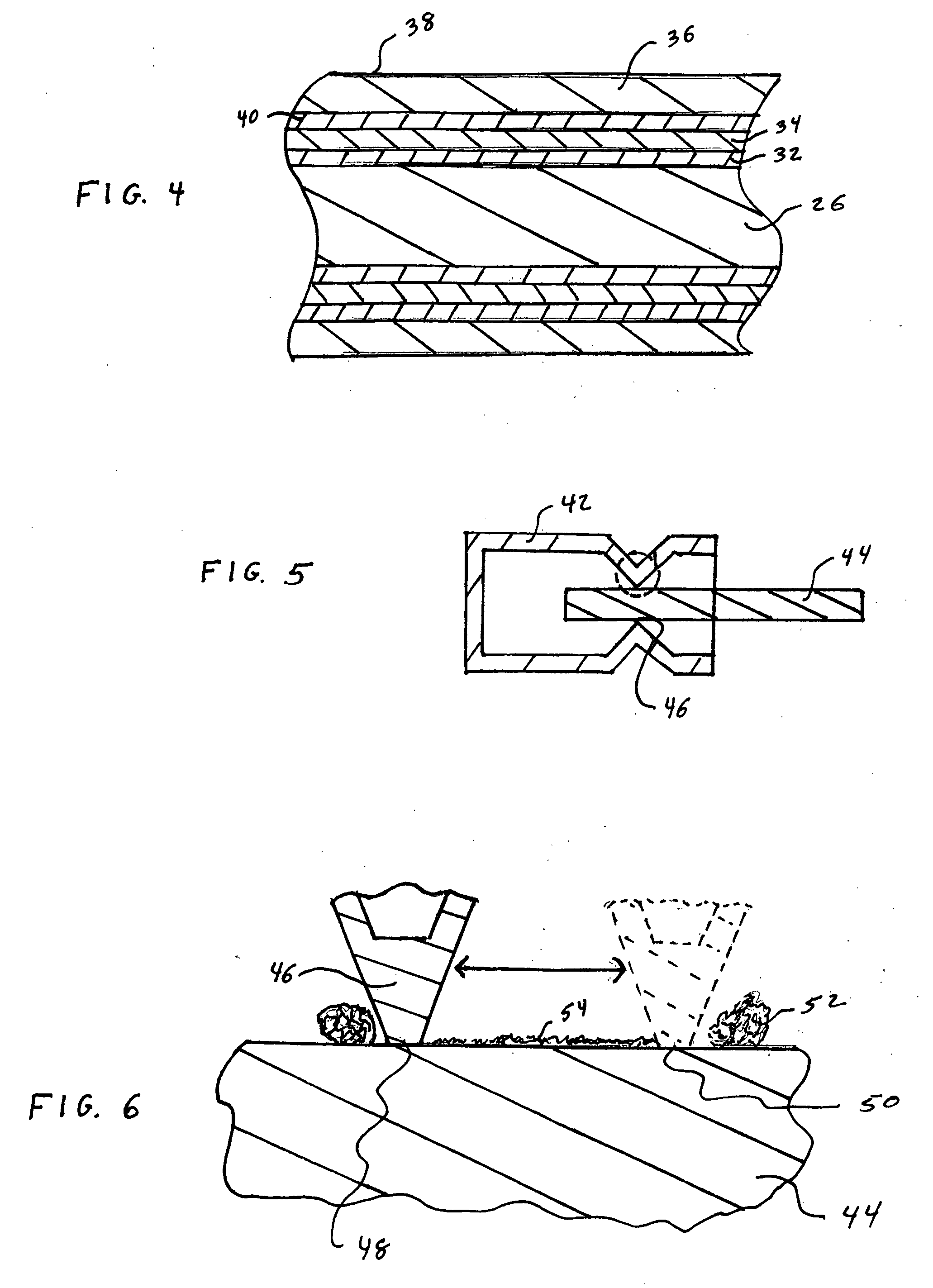

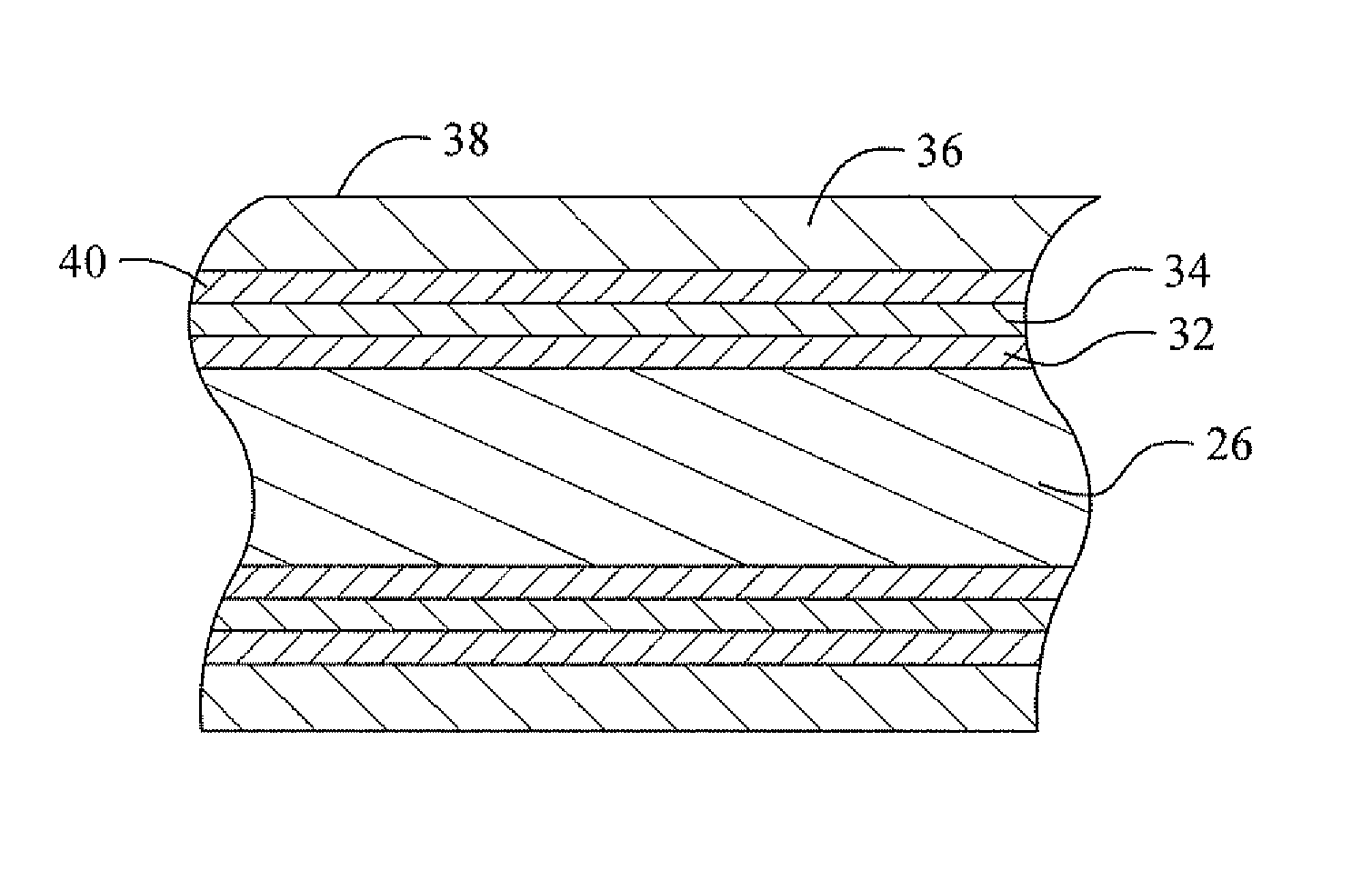

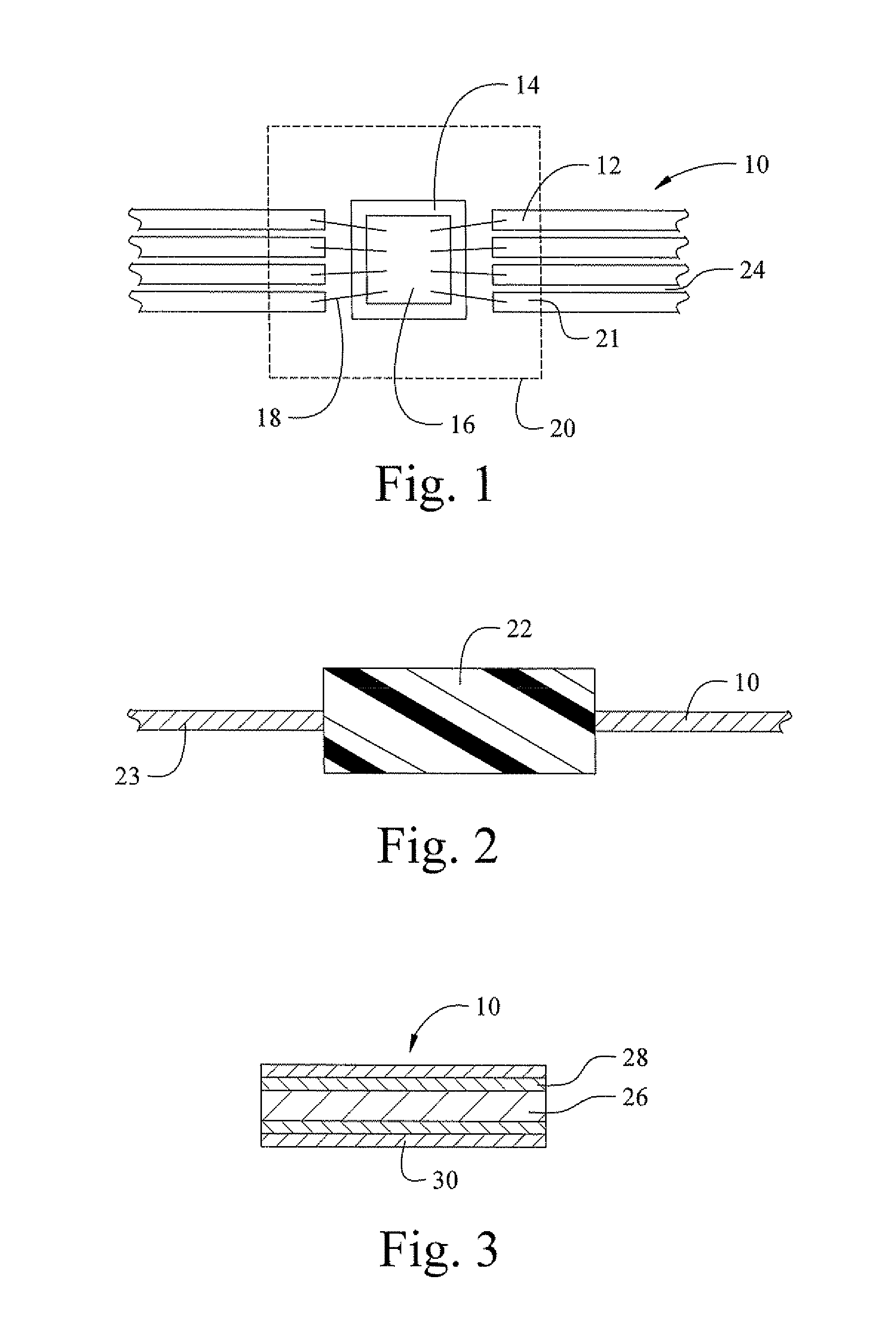

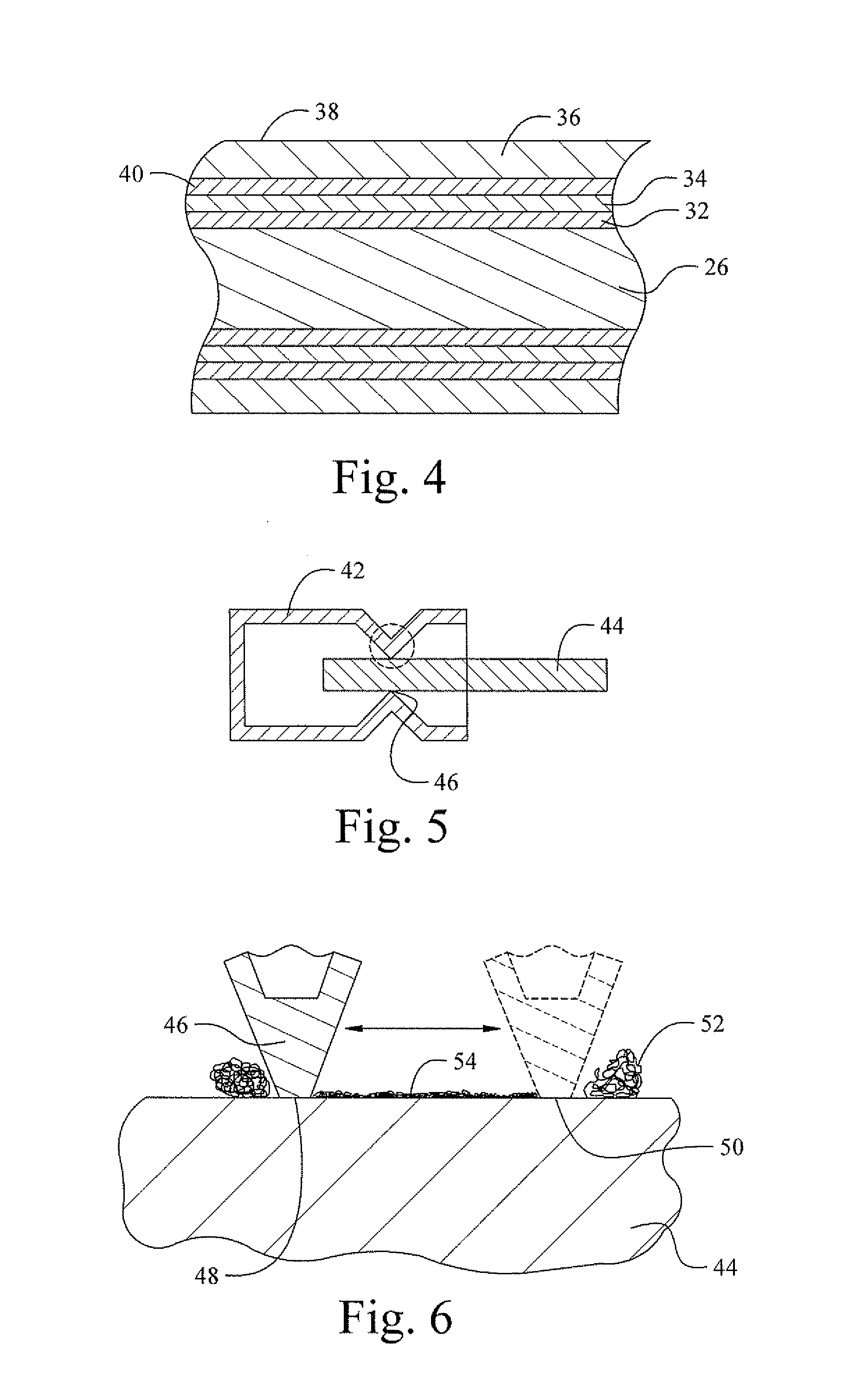

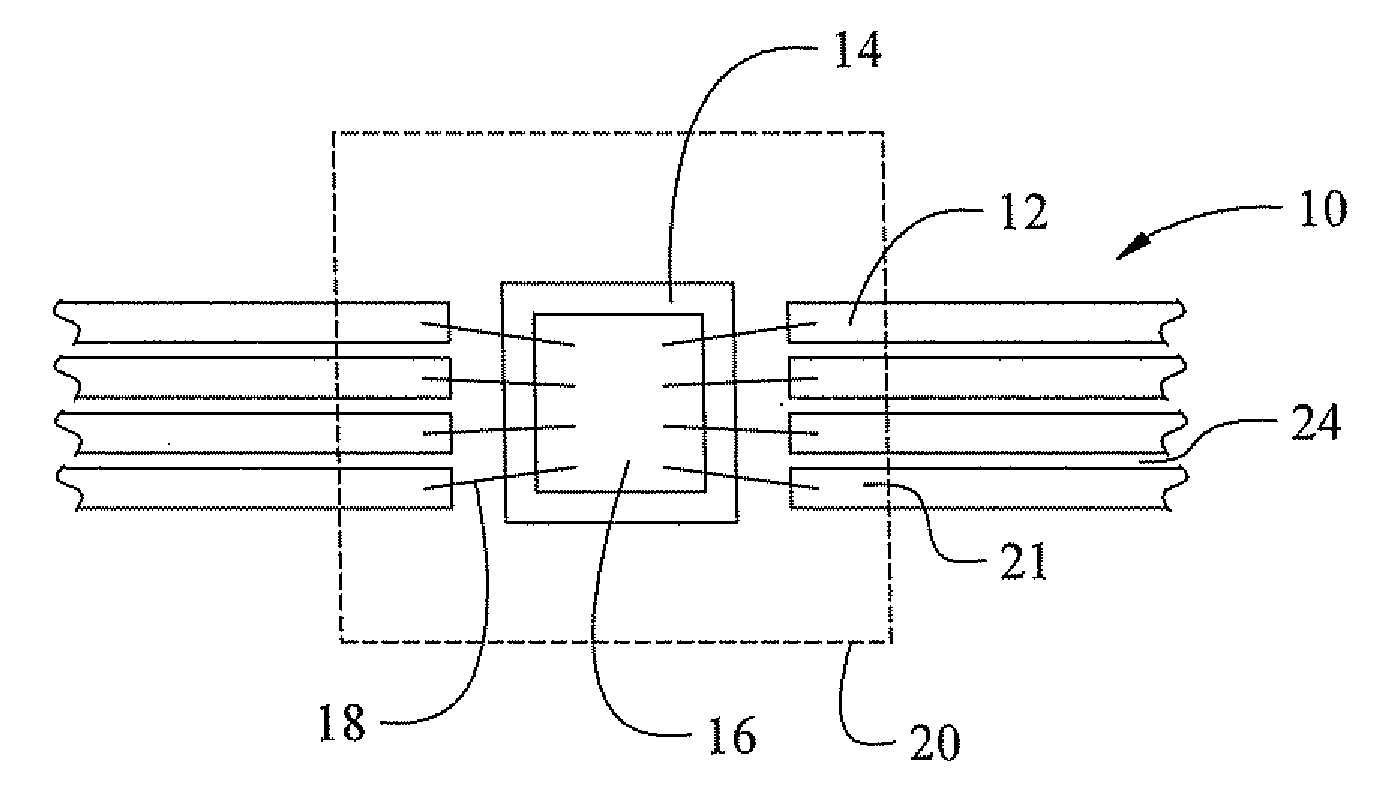

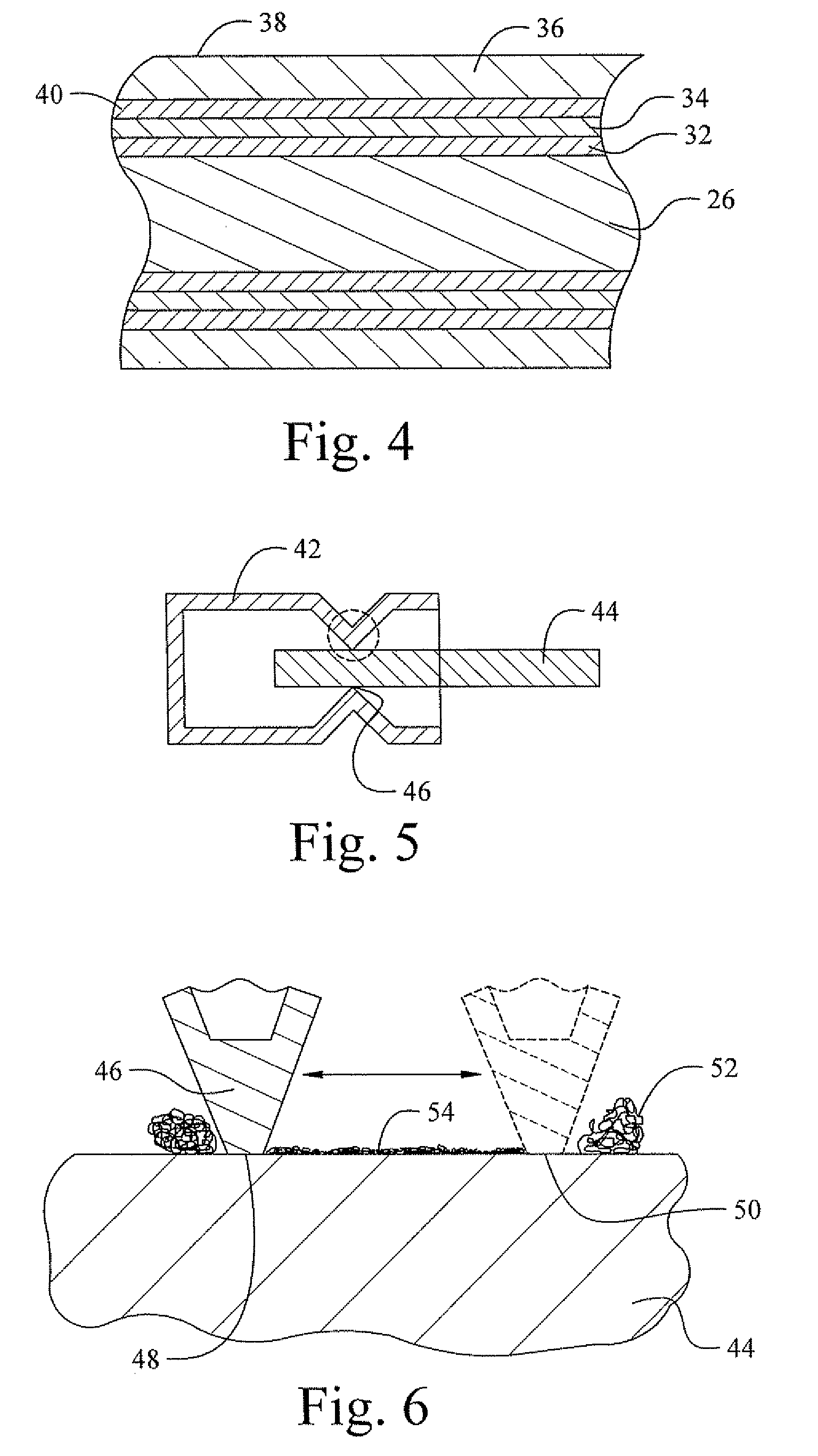

Hybrid Cord for Tire

InactiveUS20150233027A1Avoid absorptionImprove permeabilityPneumatic tyre reinforcementsYarnFiberMoisture

Disclosed is a hybrid cord in which fiber is used for a core wire so as to facilitate rubber permeation into a steel cord, and thus fretting wear of the steel cord due to a repeated collision between the steel cords may be prevented, and moisture movement may be prevented even when the moisture permeates.

Owner:HYOSUNG CORP

Gravity loading type fretting wear testing equipment capable of simulating high-temperature environment

InactiveCN108871991AAccurate measurementPositive pressure adjustmentInvestigating abrasion/wear resistanceTransverse forcePositive pressure

The invention relates to the field of fretting wear testing equipment and discloses gravity loading type fretting wear testing equipment capable of simulating a high-temperature environment. Through the invention, novel testing equipment capable of performing fretting wear tests in the high-temperature liquid environment or the high-temperature gas environment under the condition with constant positive pressure can be provided, namely, on one hand, as being not changed along with change of wear quantity, the positive pressure can keep constant in the whole process; and on the other hand, the high-temperature gas environment can be provided through an electrical bar heating manner, or the high-temperature liquid environment can be provided through a manner of injecting high-temperature liquid, so that the purpose of performing fretting wear tests in the high-temperature environment is realized, and the transverse force and the transverse fretting displacement amount can be accurately measured.

Owner:SOUTHWEST JIAOTONG UNIV

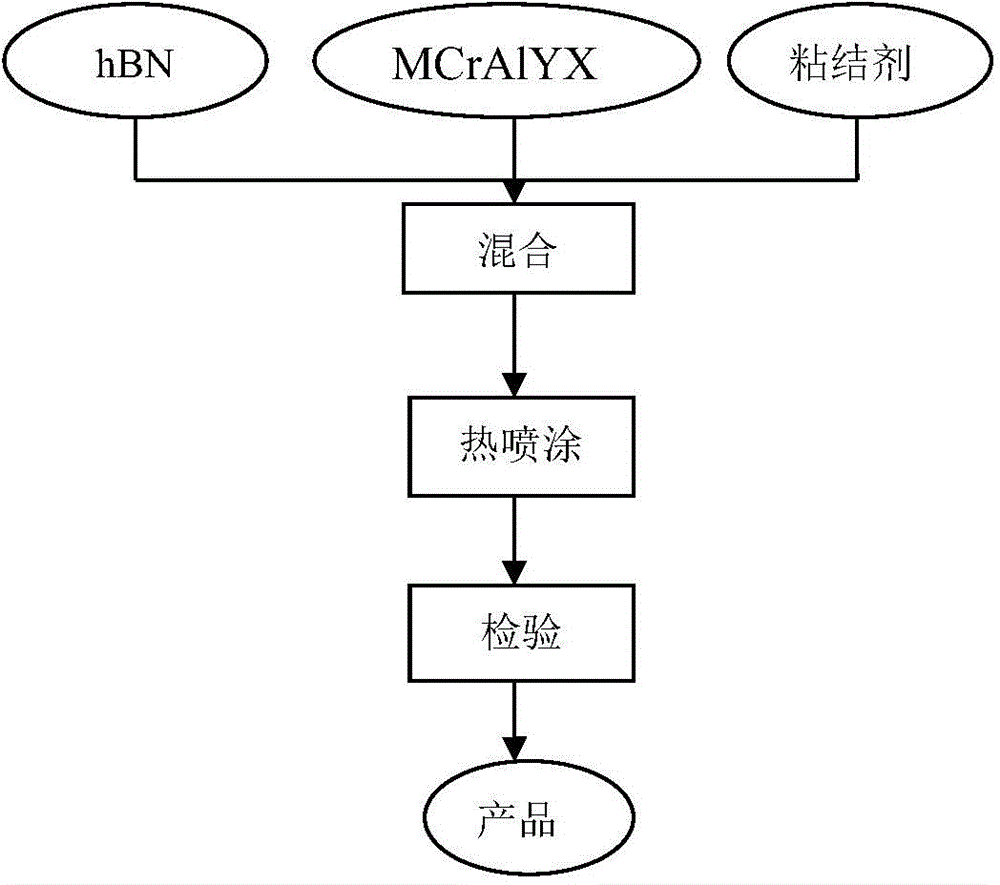

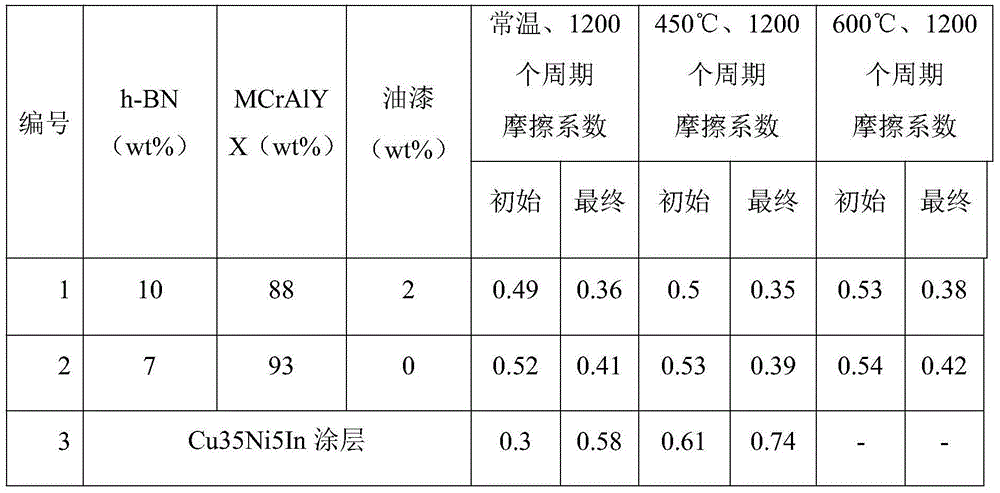

Titanium alloy high-emperature oxidation-resistant fretting-wear-resistant coating material, coating and preparation method of coating

ActiveCN104357792ASolve temperature problemsSolve the problem of poor anti-fretting wear performanceMolten spray coatingHexagonal boron nitrideMetallurgy

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY +1

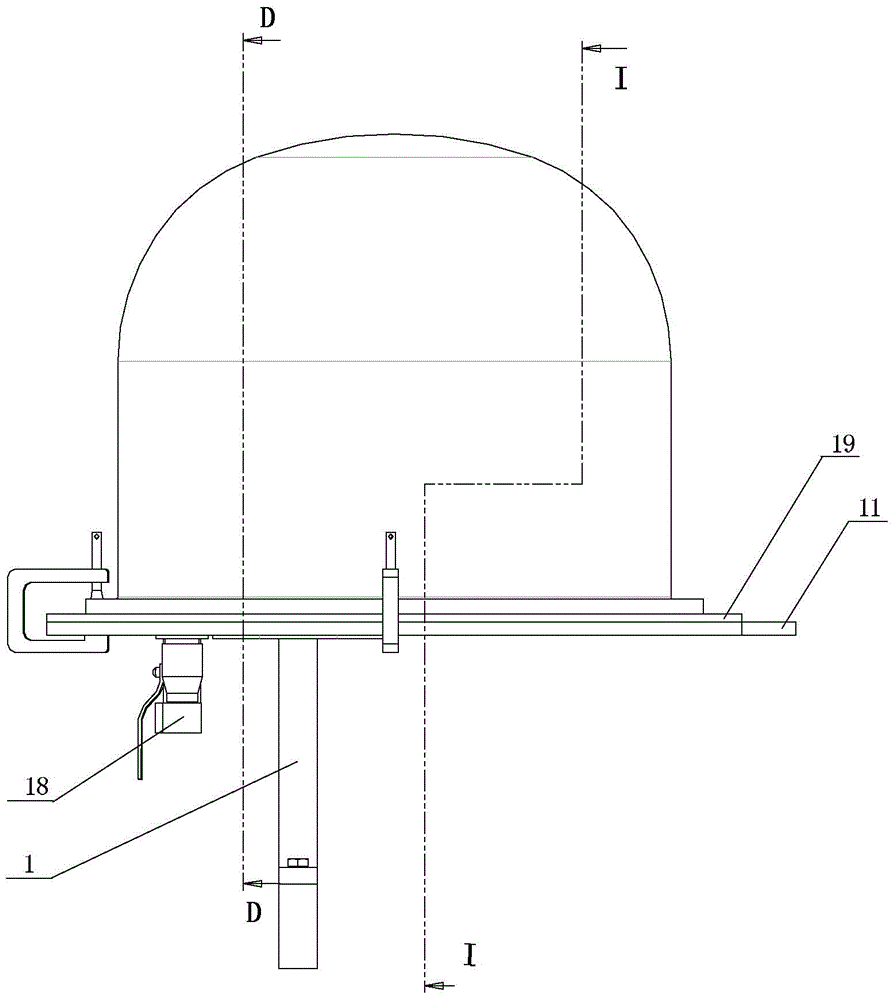

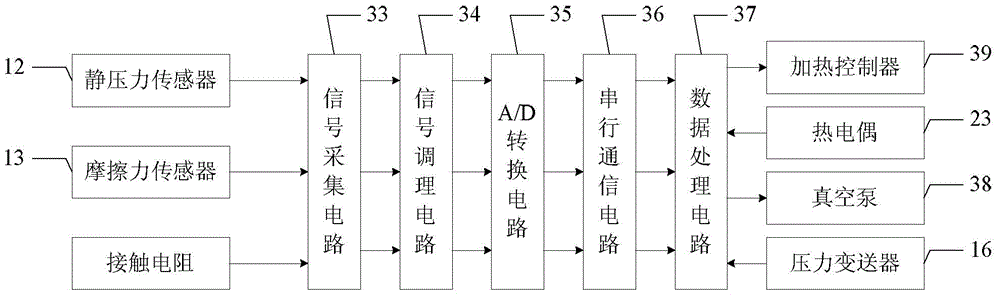

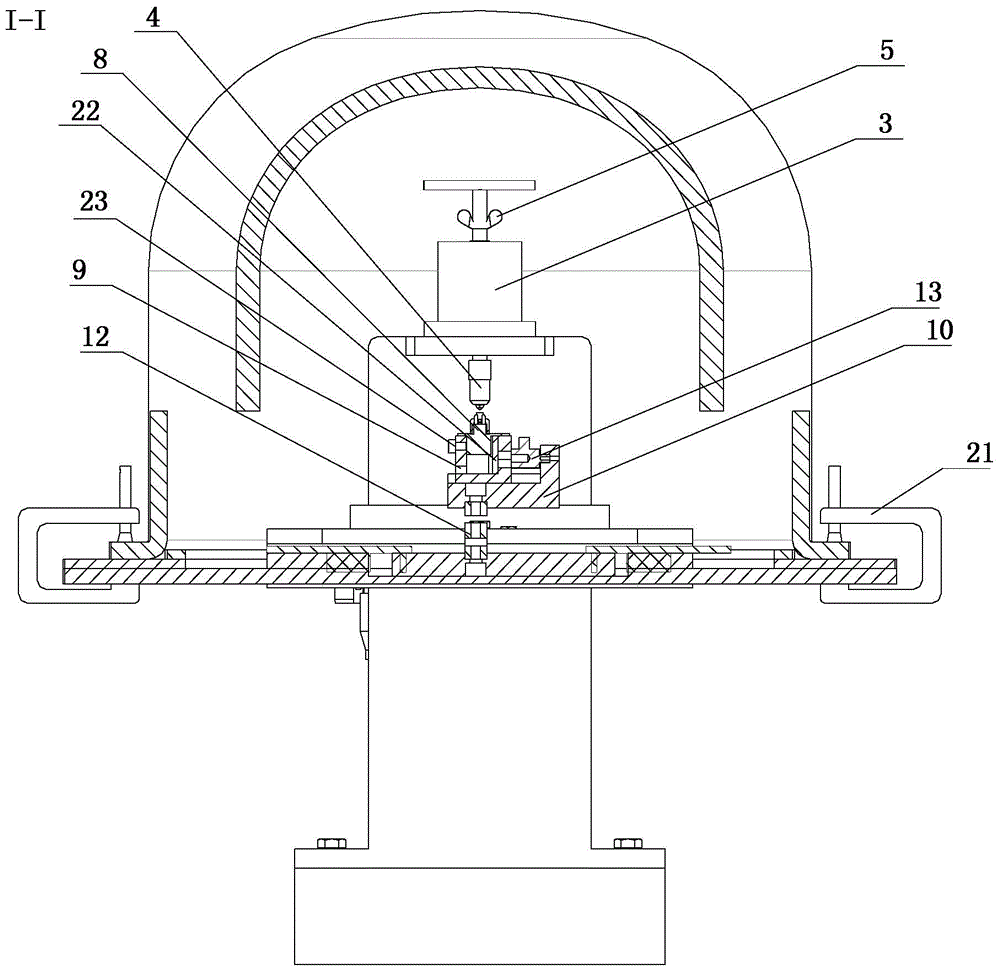

Compound stress environment testing system of contact point material

InactiveCN103604715AReal-time detectionThe detection work is stableInvestigating abrasion/wear resistanceElectricityEngineering

The invention discloses a compound stress environment testing system of a contact point material, relating to the technical field of abrasion testing, and solving the problems that an electric connector fails and further the detection of fretting wear performance can not be completed because the electric connector needs to bear long-term high-frequency vibration and repeated impaction of a compound stress in an existing process of detecting the fretting wear performance. The compound stress environment testing system comprises a vacuum chamber, a jogging clamping mechanism, a fixed clamping mechanism and a control circuit, wherein the jogging clamping mechanism is arranged in the vacuum chamber, a friction is formed between the jogging clamping mechanism and the fixed clamping mechanism through high-frequency vibration, and a control circuit respectively detects a friction force between samples, a static pressure, a temperature and a gas pressure in the vacuum chamber. The compound stress environment testing system is suitable for detecting the fretting wear performance.

Owner:HARBIN INST OF TECH

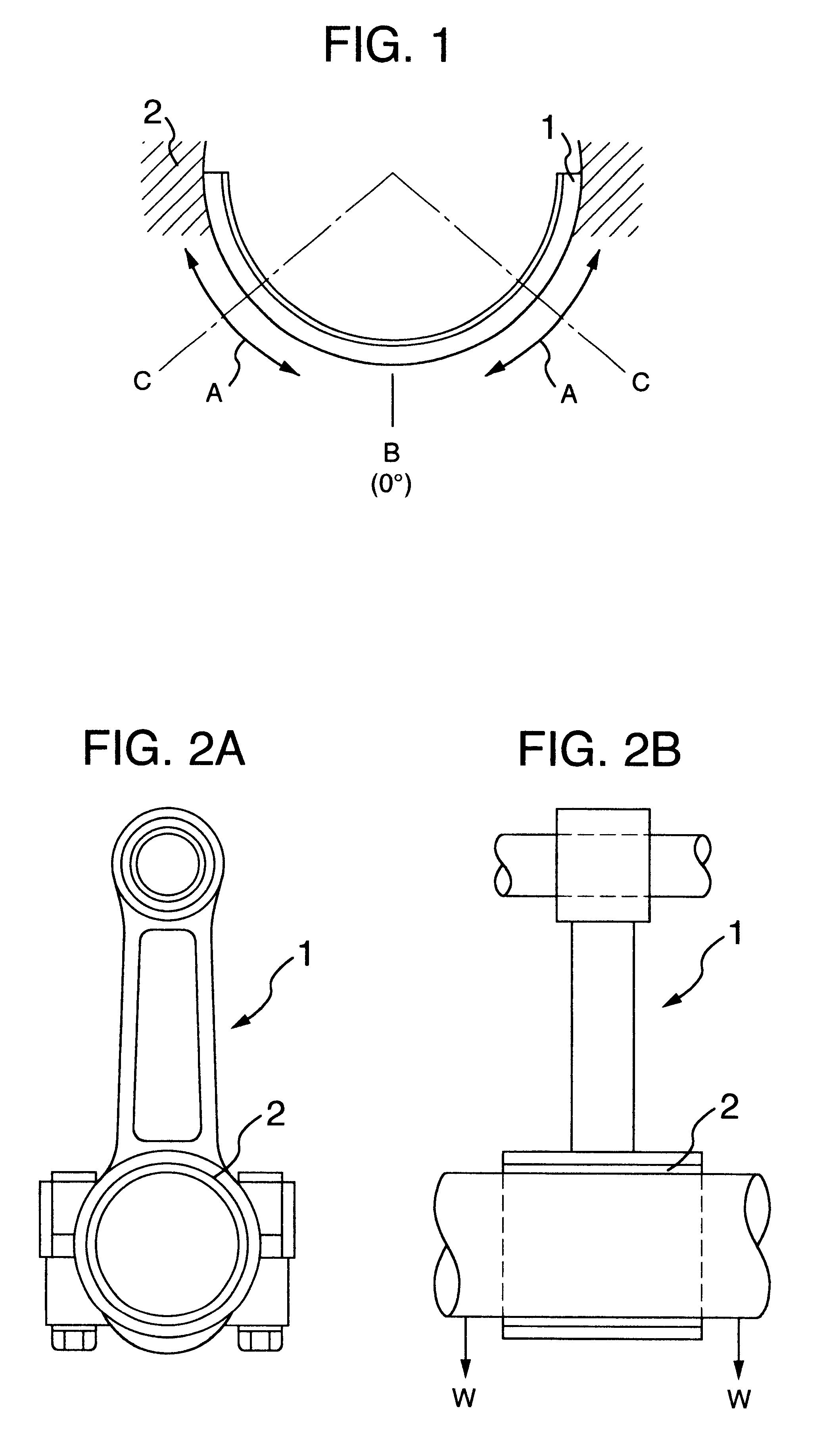

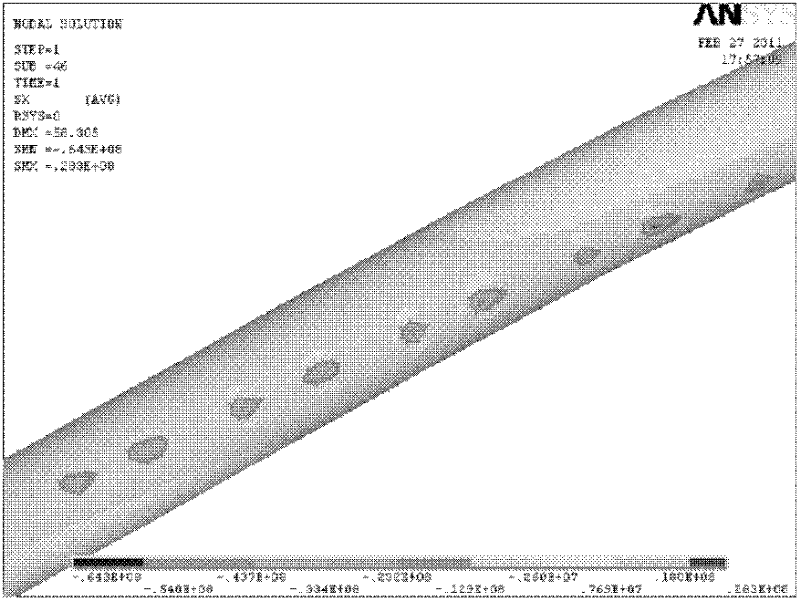

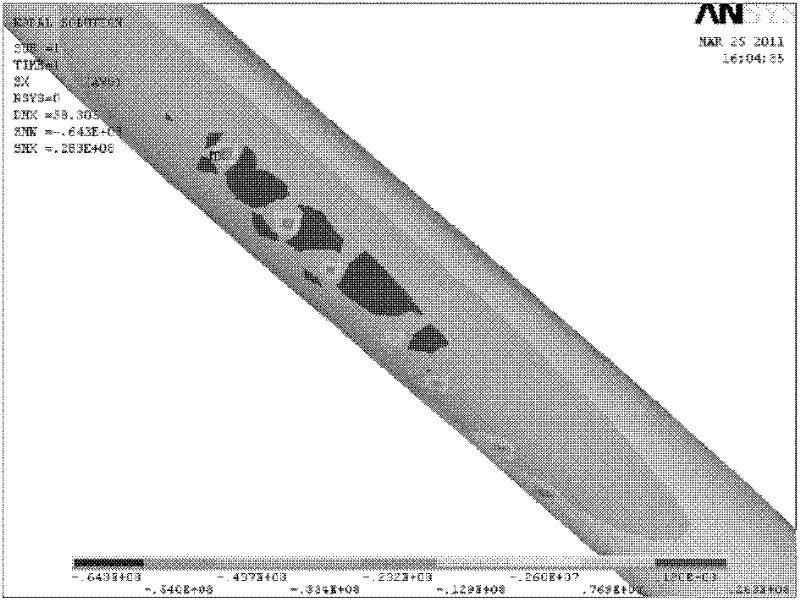

Method for evaluating resistance deterioration of stay cable of steel strand of cable-stayed bridge taking fretting fatigue

ActiveCN102375925AComprehensive assessmentAccurate assessmentSpecial data processing applicationsArchitectural engineeringEngineering

The invention provides a method for evaluating the resistance deterioration of a stay cable of a steel strand of a cable-stayed bridge taking fretting fatigue. The method comprises the following steps of: sampling practical parameters of steel wires of the stay cable of the cable-stayed bridge on site; obtaining a fretting fatigue depth fitting formula among steel wires of the stay cable of the steel strand of the cable-stayed bridge; dividing resistance deterioration phases of the stay cable; and substituting the actual fretting fatigue depth among the steel wires into the deterioration process of the stay cable of the steel strand of the cable-stayed bridge according to division of different phases to obtain a resistance deterioration equation of the stay cable of the steel strand of the cable-stayed bridge taking the fretting fatigue, and evaluating the situation of the resistance deterioration of the stay cable. The method describes the deterioration process of the stay cable of the steel strand more comprehensively and more accurately, and the evaluation process is simple and practical.

Owner:WUHAN UNIV OF TECH

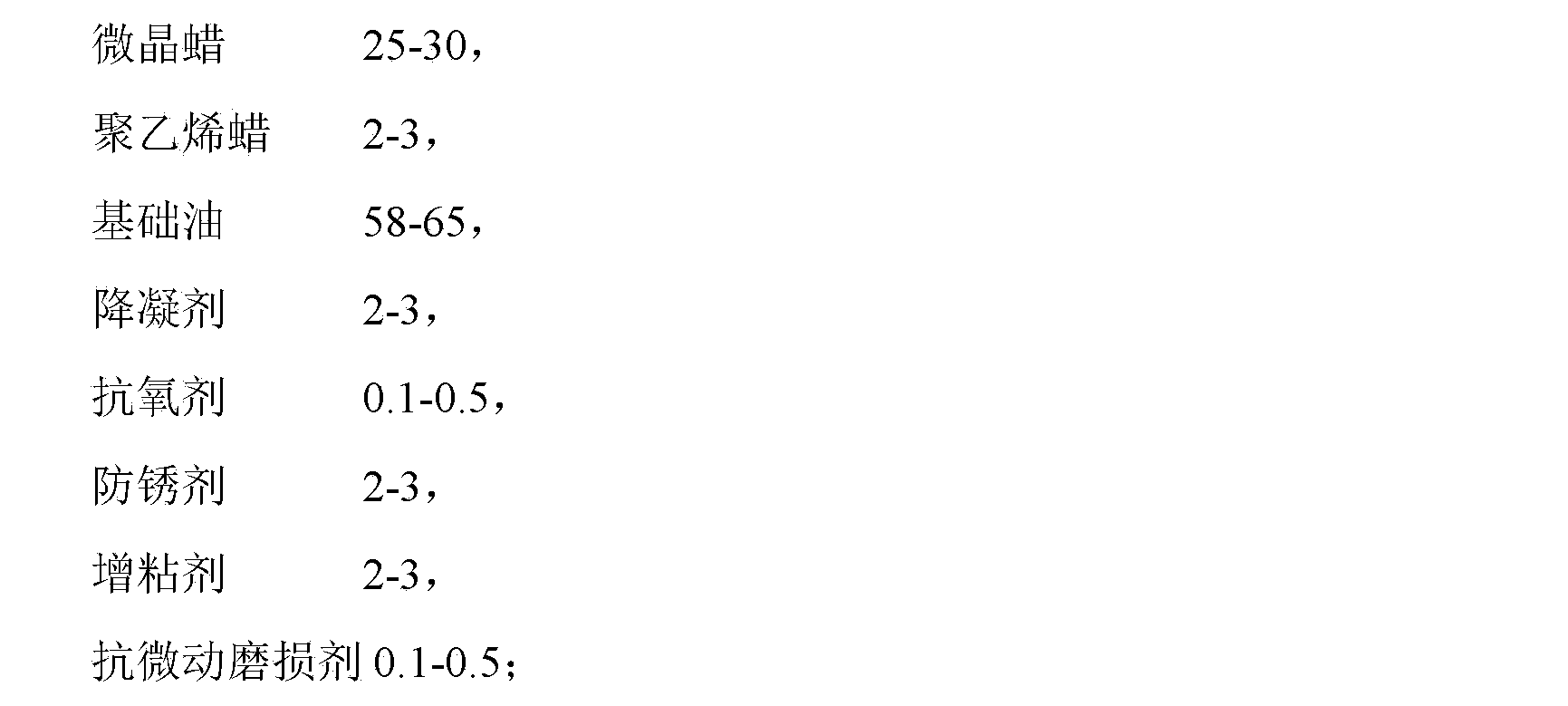

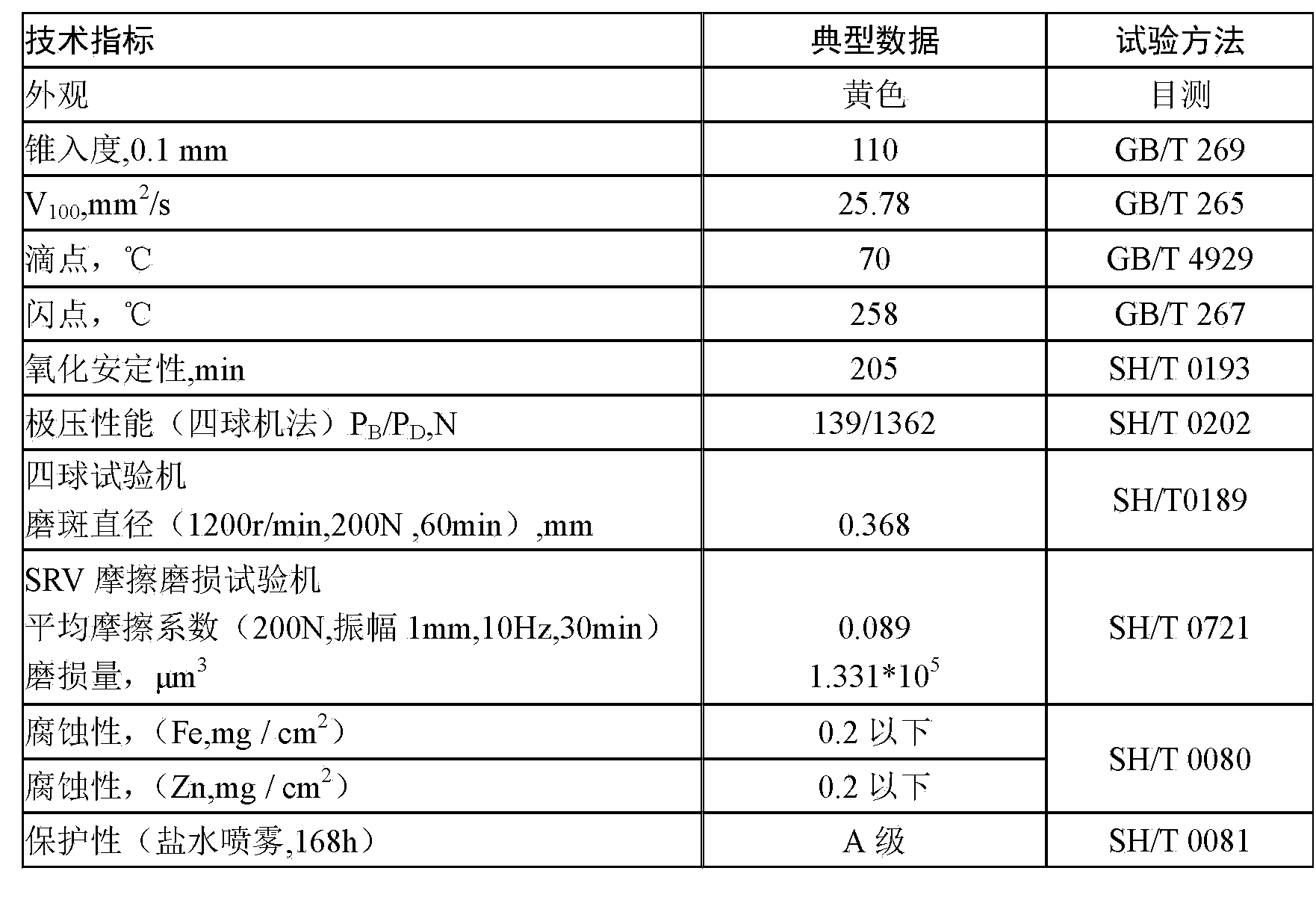

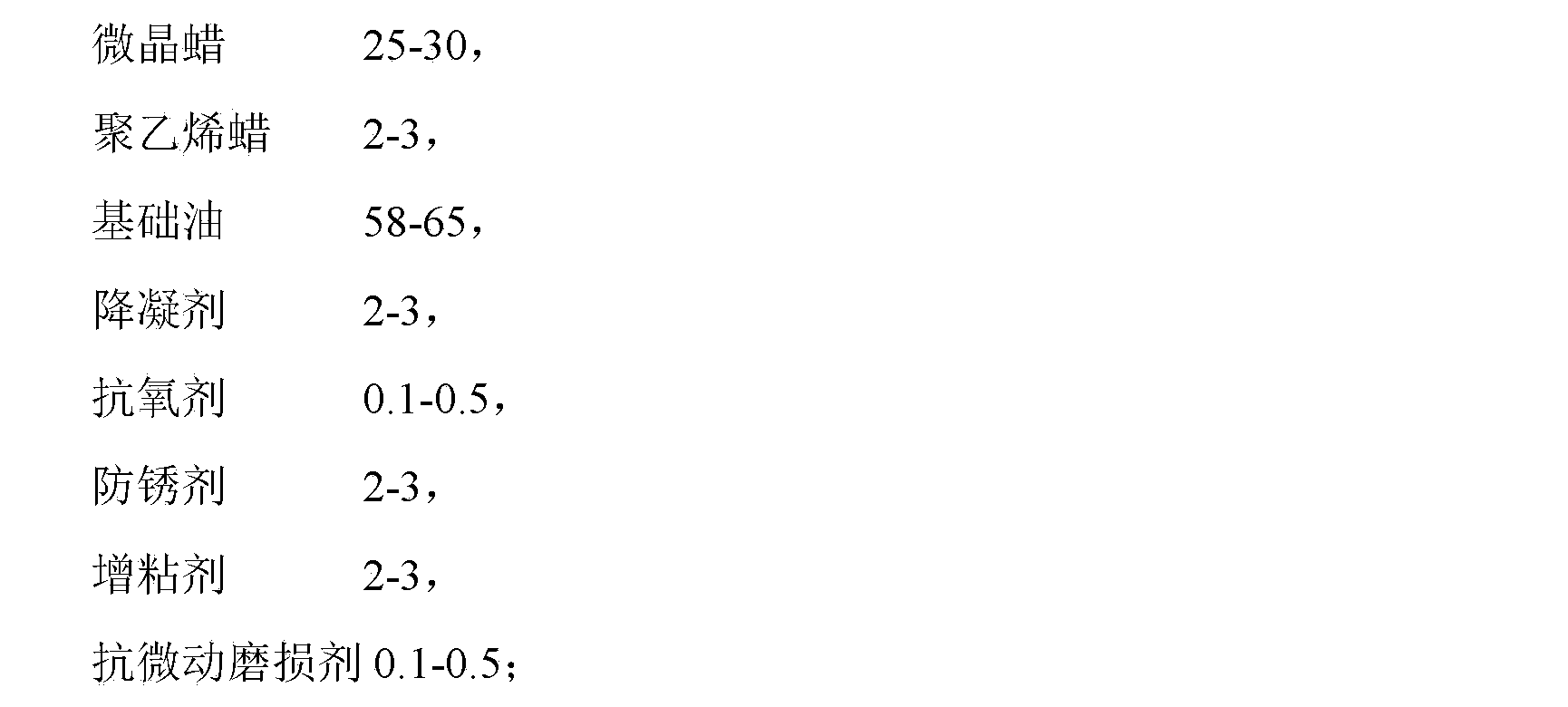

Elevator steel wire rope lubricating grease and preparation method thereof

ActiveCN103436329AExtended service lifeReduce coefficient of frictionLubricant compositionMicrocrystalline waxButylated hydroxytoluene

The invention relates to elevator steel wire rope lubricating grease and a preparation method thereof. The lubricating grease comprises the following components in parts by weight: 25-30 parts of microcrystalline wax, 2-3 parts of polyethylene wax, 58-65 parts of base oil, 2-3 parts of pour point depressant, namely poly-alpha olefin, 0.1-0.5 parts of antioxygen, namely butylated hydroxytoluene, 2-3 parts of antirust agent, namely barium sulfonate, 2-3 parts of tackifier, namely polyisobutylene, and 0.1-0.5 parts of fretting wear resistant agent, namely sulfur-phosphorous type ashless antiwear agent. The lubricating grease has the advantages that a using temperature range is wider; the carrying capacity is higher; and the oxidation stability, the rust resistance, the fretting wear resistance and the like are good.

Owner:辽宁海华科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com