Heat exchanger tube support structure

a technology of heat exchanger tube and support structure, which is applied in the direction of indirect heat exchangers, nuclear elements, lighting and heating apparatus, etc., can solve the problems of high cost of corrective actions such as power derating, chemical cleaning or water slap, and increase the secondary water level in the downcomer. , to achieve the effect of reducing local turbulence and reducing pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

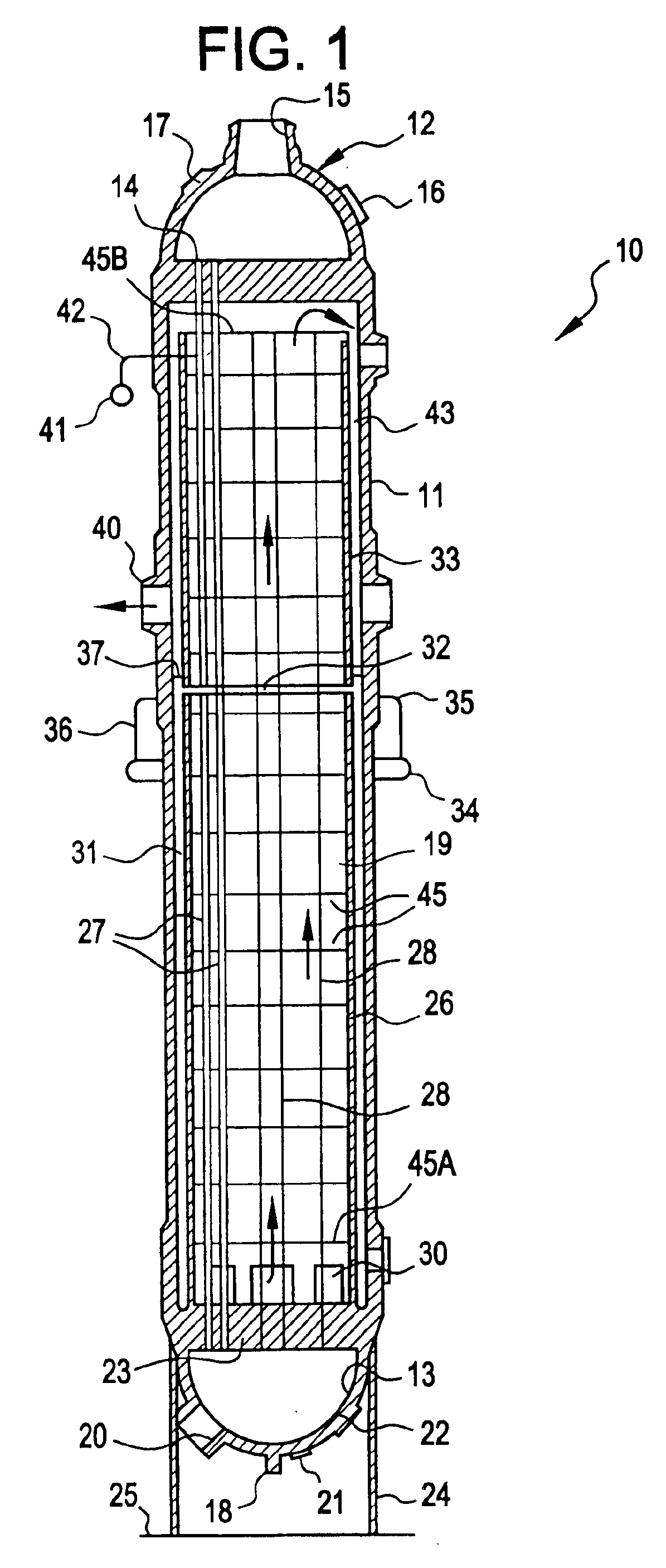

[0022]The present invention is described in connection with a once-through steam generator for a nuclear power plant, although these principles are generally applicable to shell and tube heat exchangers in any number of diverse fields of activities. Thus, as shown in FIG. 1 for the purpose of illustration, a once-through steam generator unit 10 comprising a vertically elongated cylindrical pressure vessel or shell 11 closed at its opposite ends by an upper head member 12 and a lower head member 13.

[0023]The upper head includes an upper tube sheet 14, a primary coolant inlet 15, a manway 16 and a handhole 17. The manway 16 and the handhole 17 are used for inspection and repair during times when the vapor generator unit 10 is not in operation. The lower head 13 includes drain 18, a coolant outlet 20, a handhole 21, a manway 22 and a lower tube sheet 23.

[0024]The vapor generator 10 is supported on a conical or cylindrical skirt 24 which engages the outer surface of the lower head 13 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com