Patents

Literature

41results about How to "Eliminate buildup" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

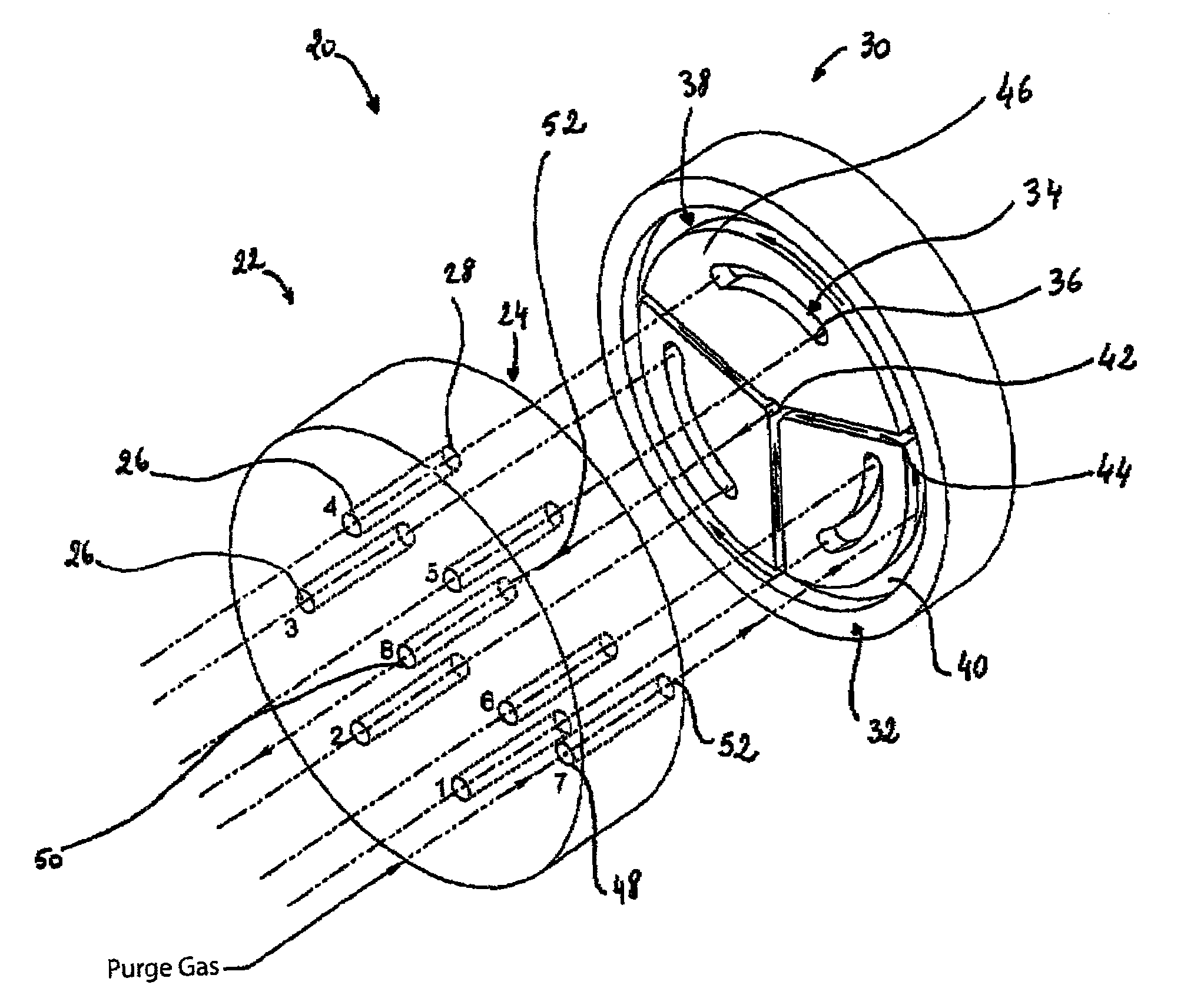

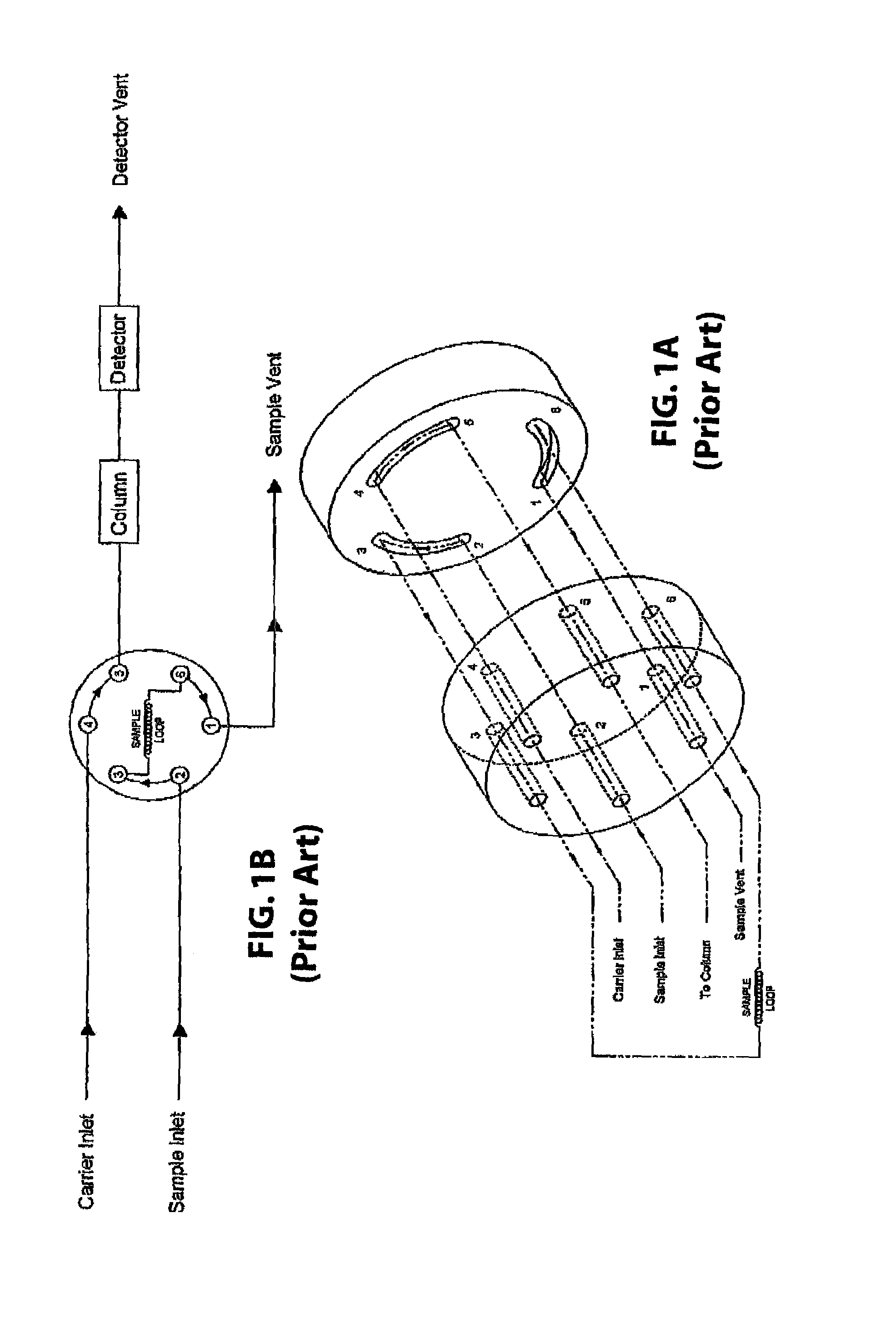

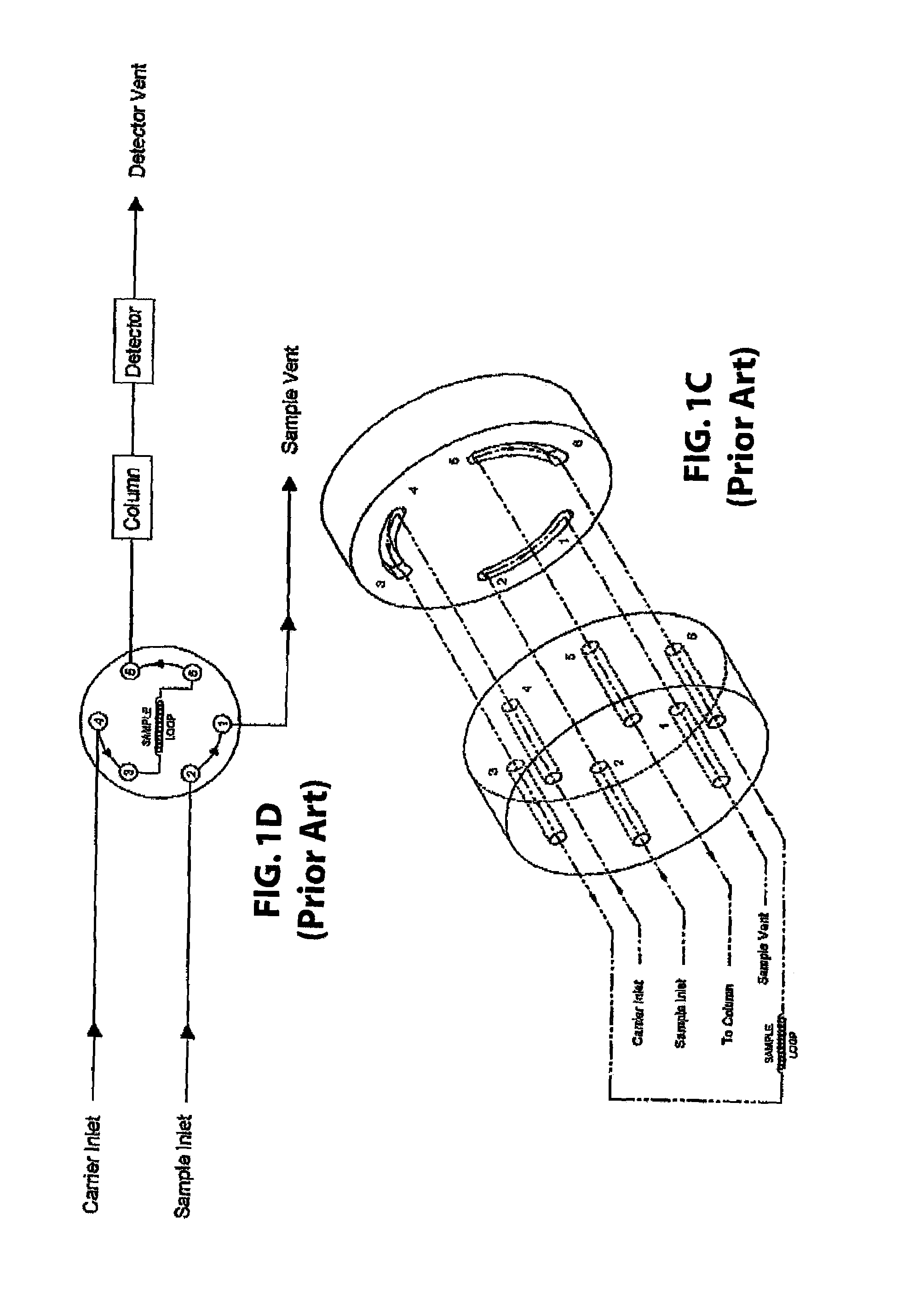

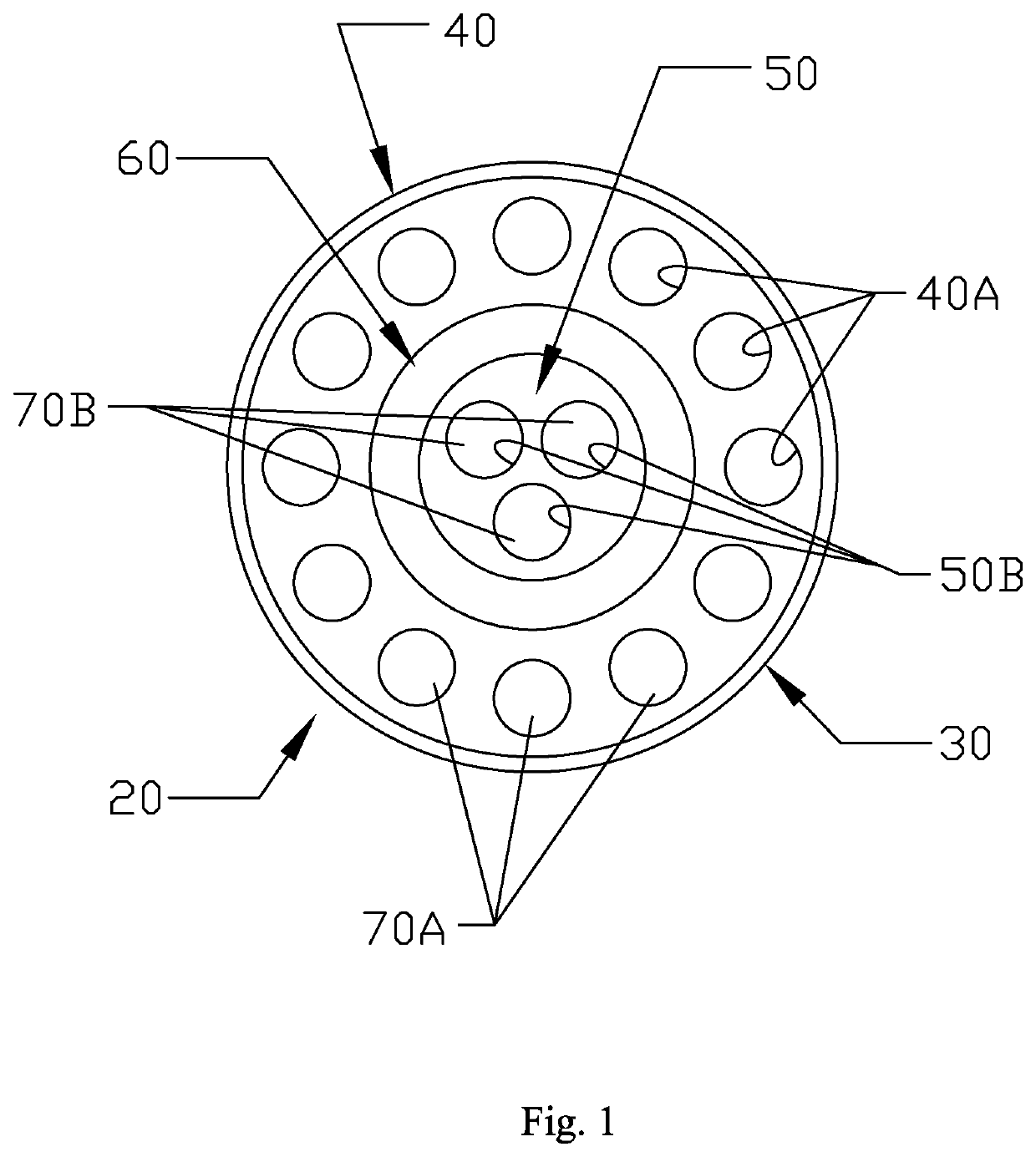

Rotary valve and analytical chromatographic system using the same

ActiveUS7503203B2Eliminate buildupReduce the possibilityComponent separationMultiple way valvesRotary valveEngineering

There is provided a rotary valve for fluid analytical systems. The present valve provides improved characteristics such as an extended lifetime. The valve can fulfil different fluid analytical functions and can be a multi-ports and / or multi-positions valve. The valve is provided with extra recesses in the rotor and extra ports in the stator. These recesses allow to cancel the effect of any possible leaks by evacuating them. Such a valve then prevents cross-port leaks and can advantageously be used in highly critical applications. Moreover, the present valve can be used in an analytical system which is advantageously self-diagnostic.

Owner:APN INC

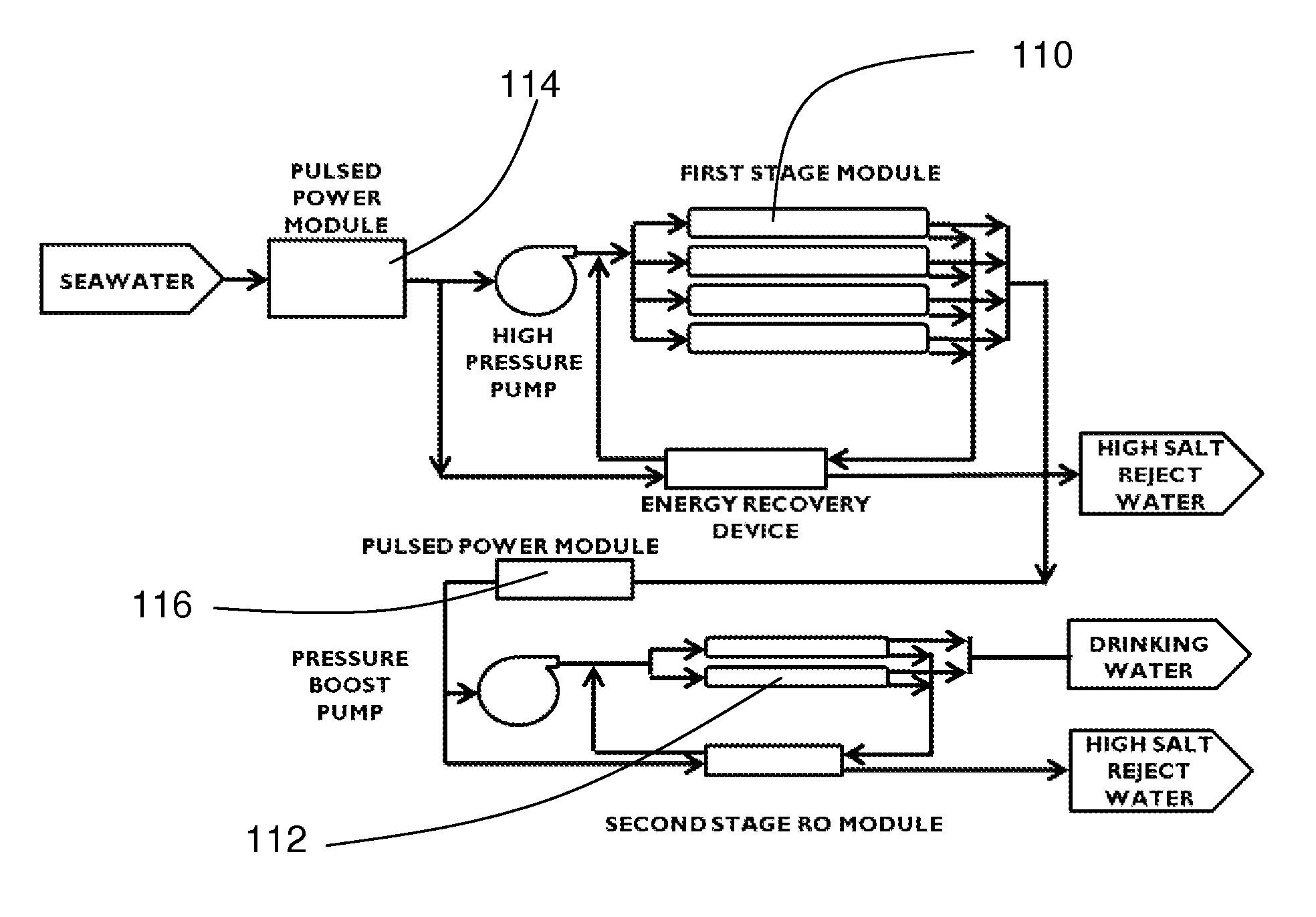

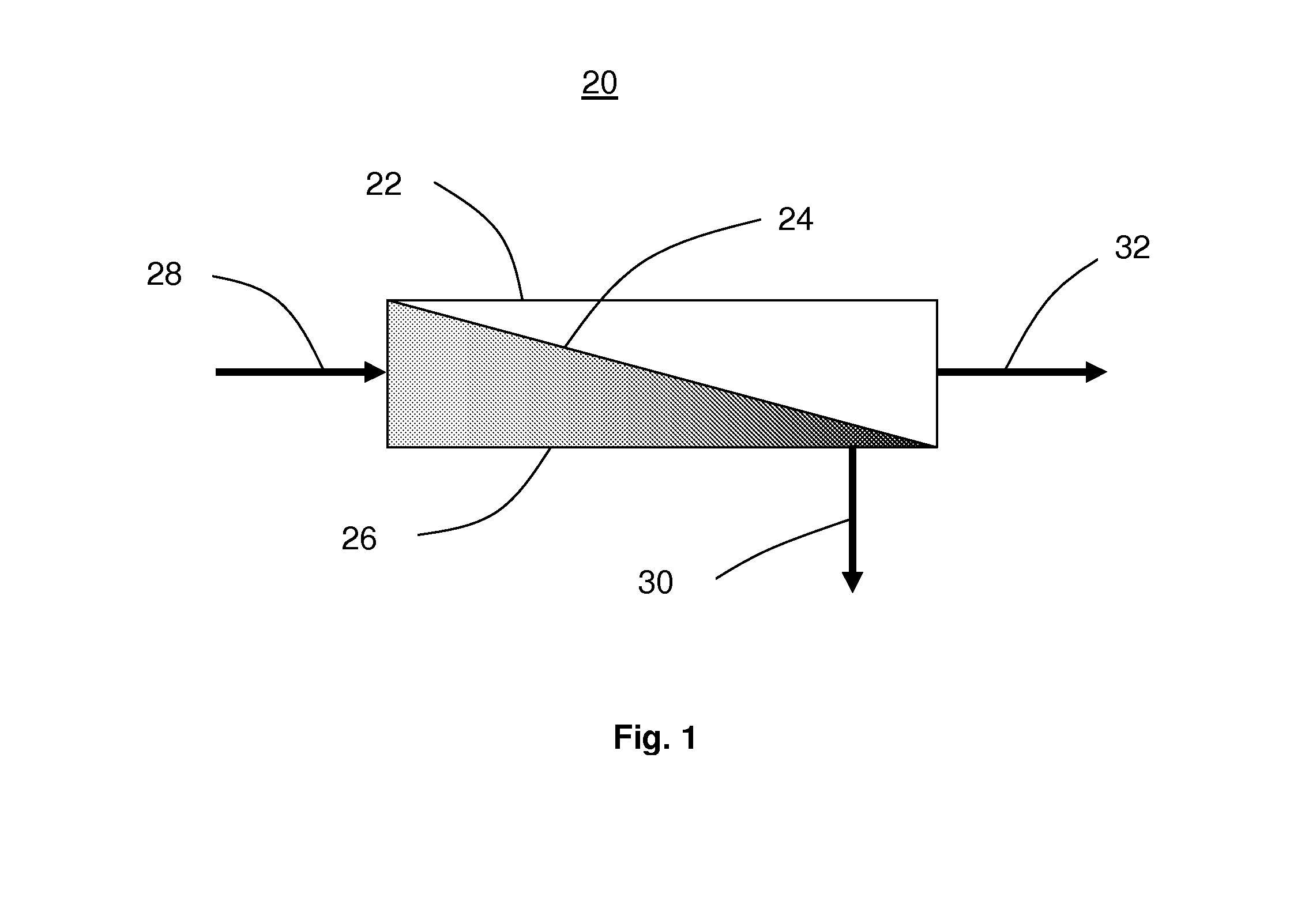

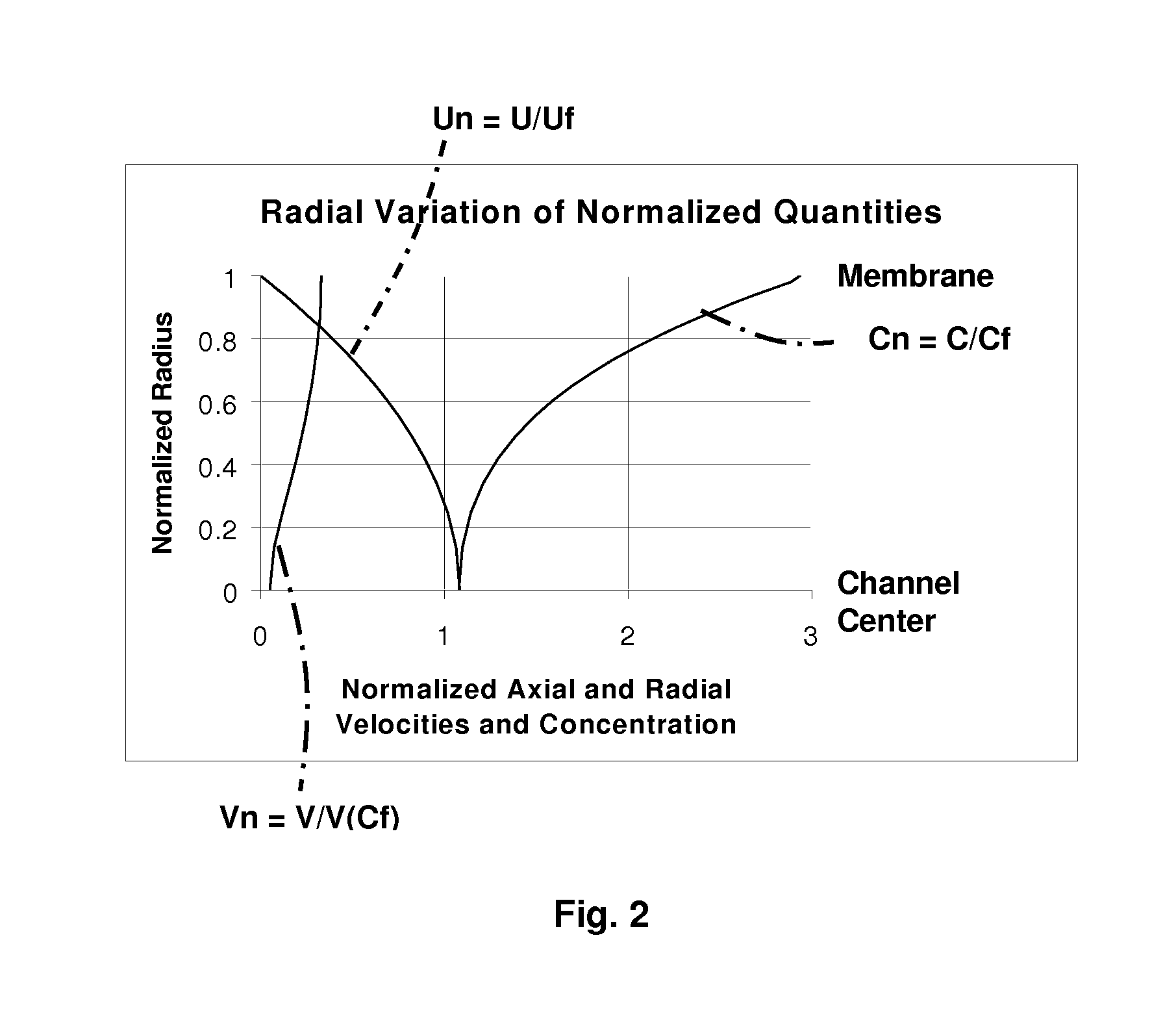

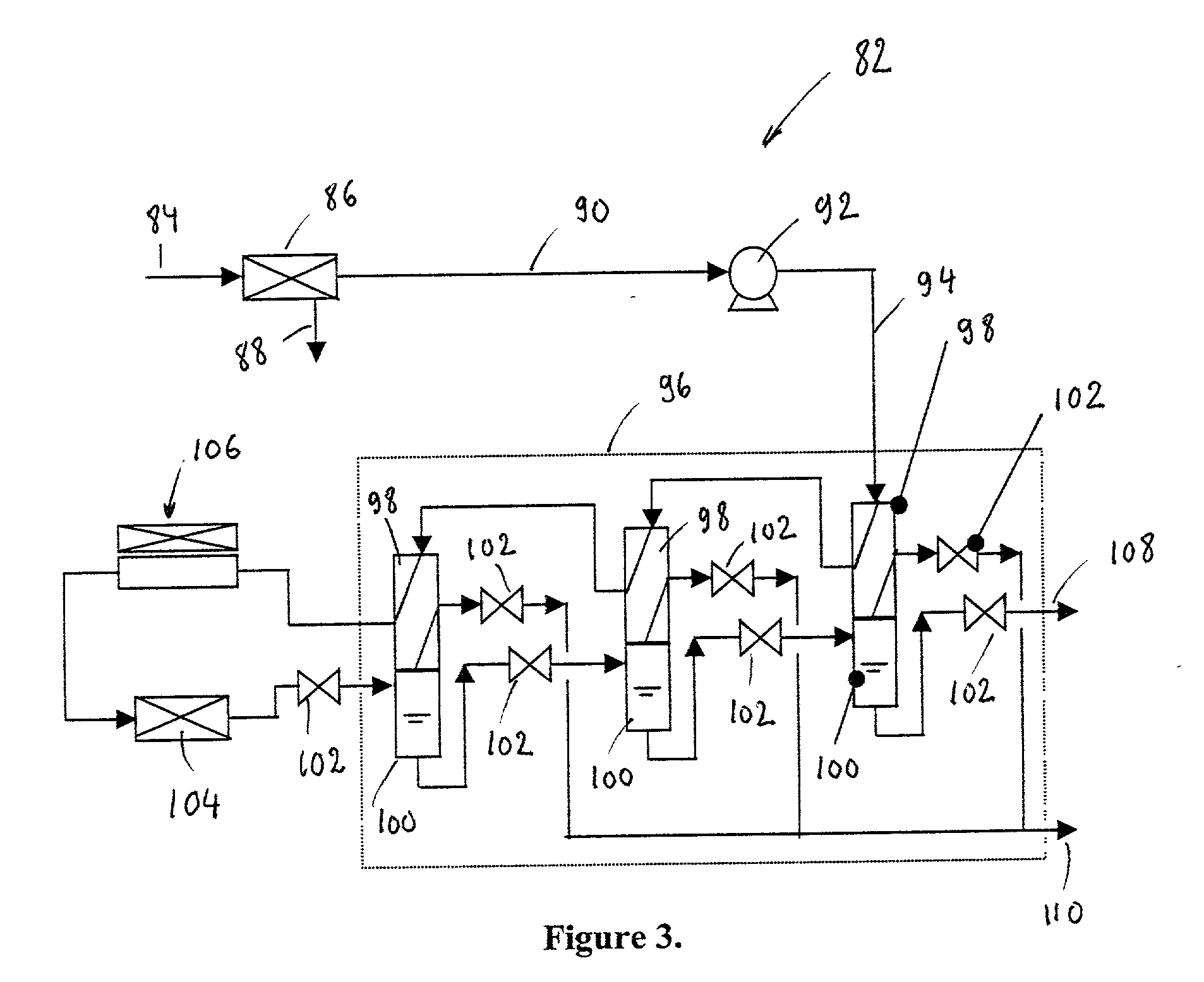

Systems and methods for filtration

InactiveUS20120298578A1Reduce foulingImprove water qualityMaterial nanotechnologyGeneral water supply conservationMicroorganismFiltration membrane

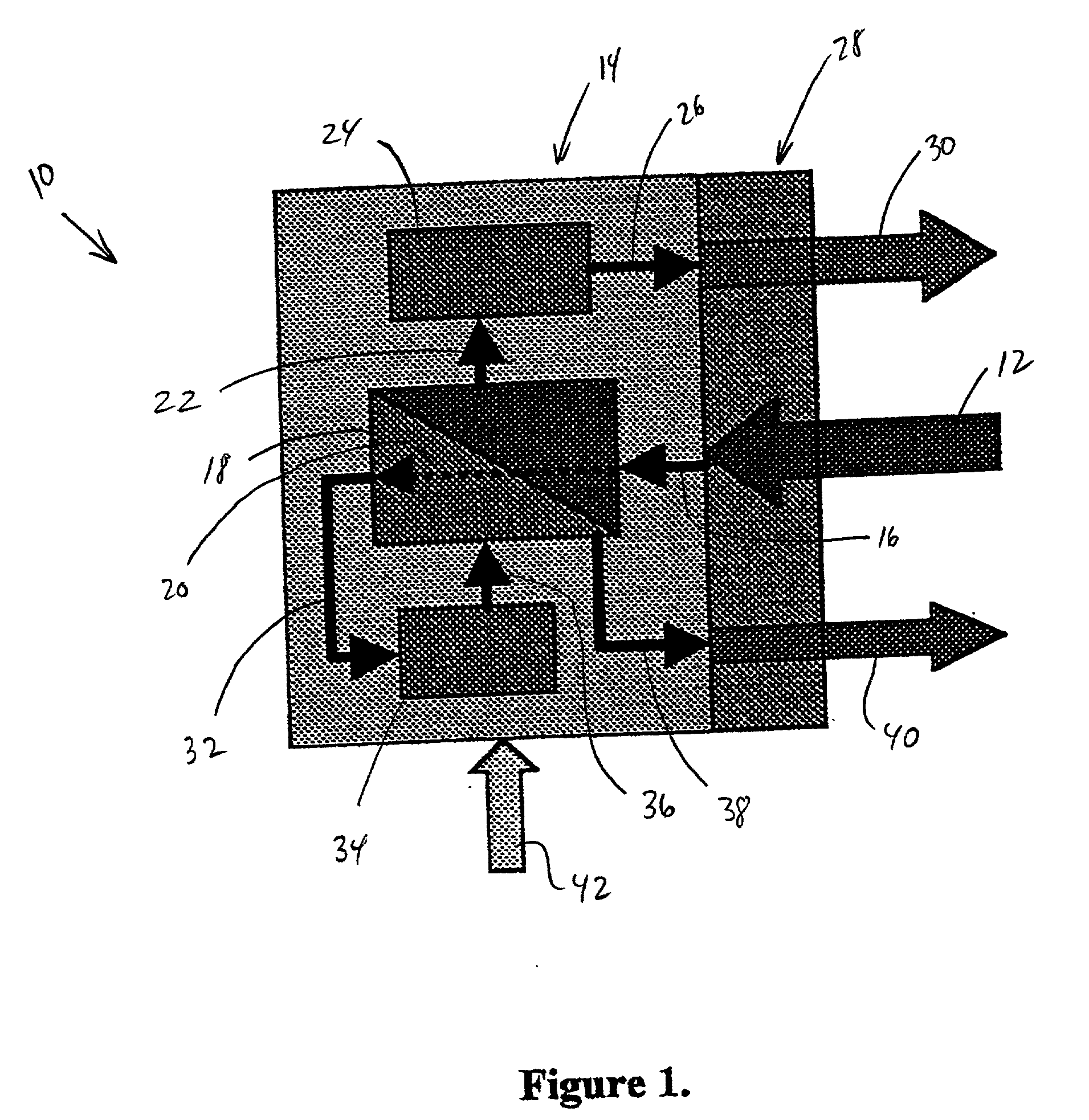

Filtration systems (40) utilize a pre-treatment method to cause scale formation to occur on particles (94) in the fluid stream (96) rather than on the filter surface and may also destroy microorganisms in the fluid stream. More specifically, but not limited to, a filtration device can be a filtration membrane, such as spiral wound filtration membrane (60), that utilizes an open feed spacer (80), such for example an embossed or printed pattern on the membrane, to create a thin feed spacer channel which replaces a conventional feed spacer mesh material. System (40) further utilizes a treatment device (54) to enable a pulsed power, magnetic, electro-magnetic, electro-static, or hydrodynamic fluid treatment scheme to condition particles in the fluid stream (96) such that scale forming elements precipitate (94) on to the particles in the fluid stream rather than on the filtration surfaces.

Owner:AQUA MEMBRANES +1

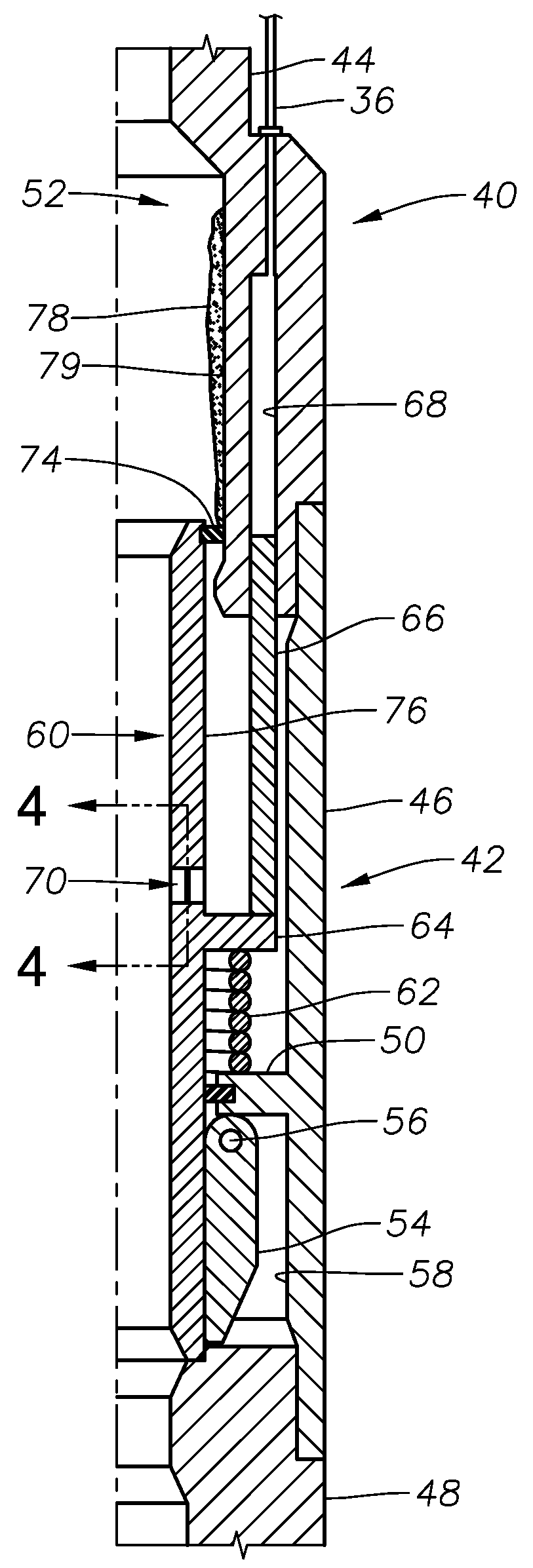

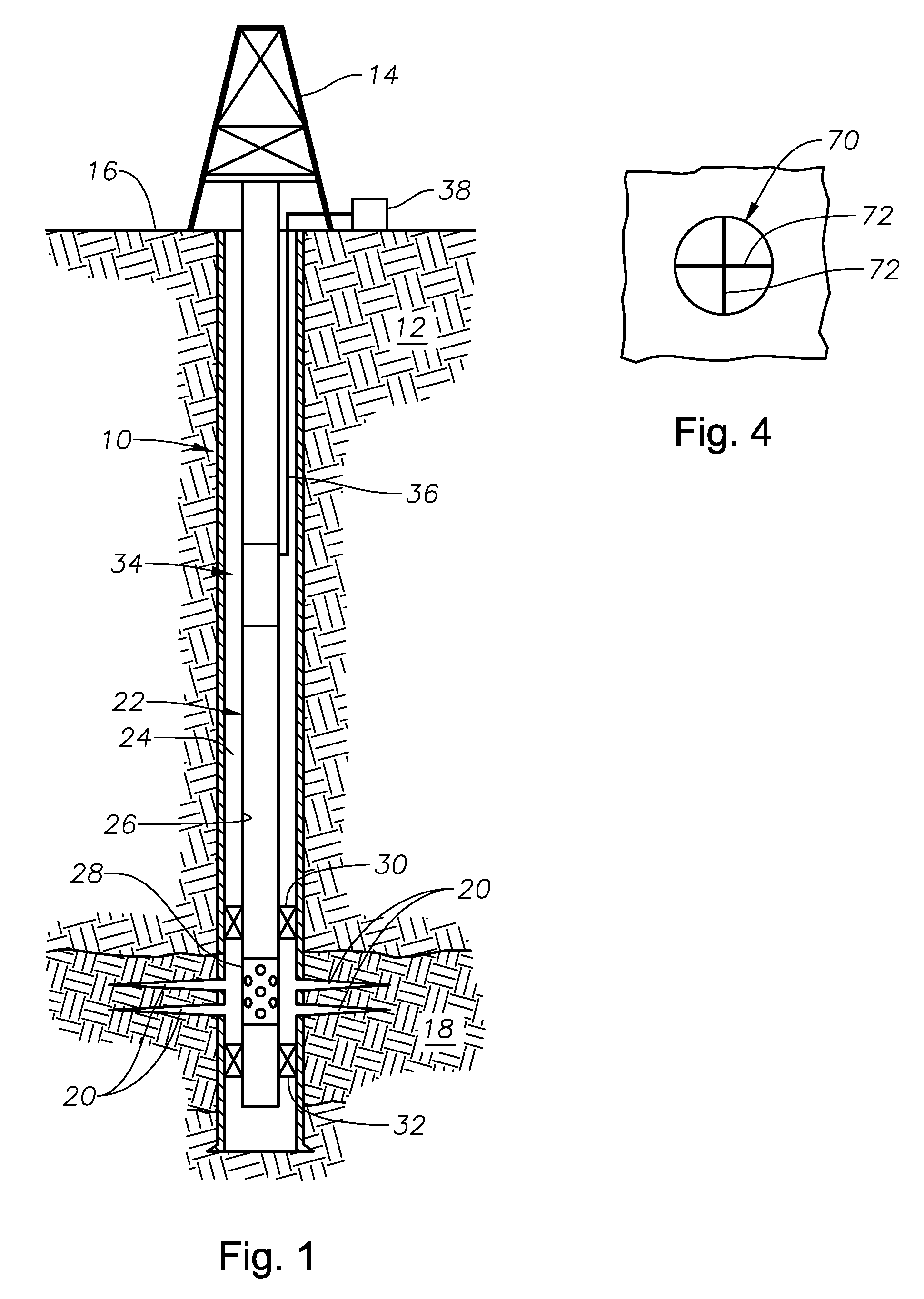

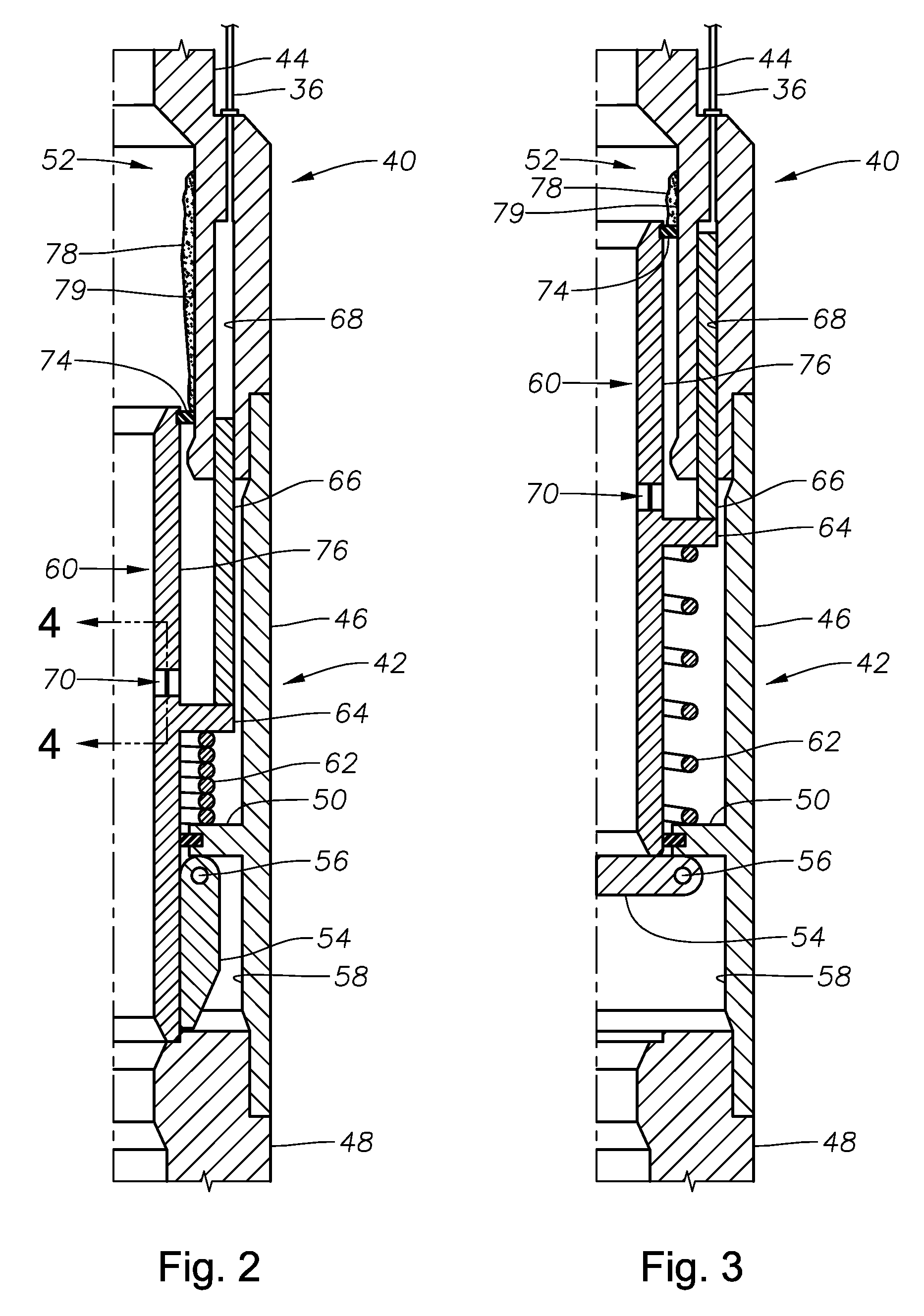

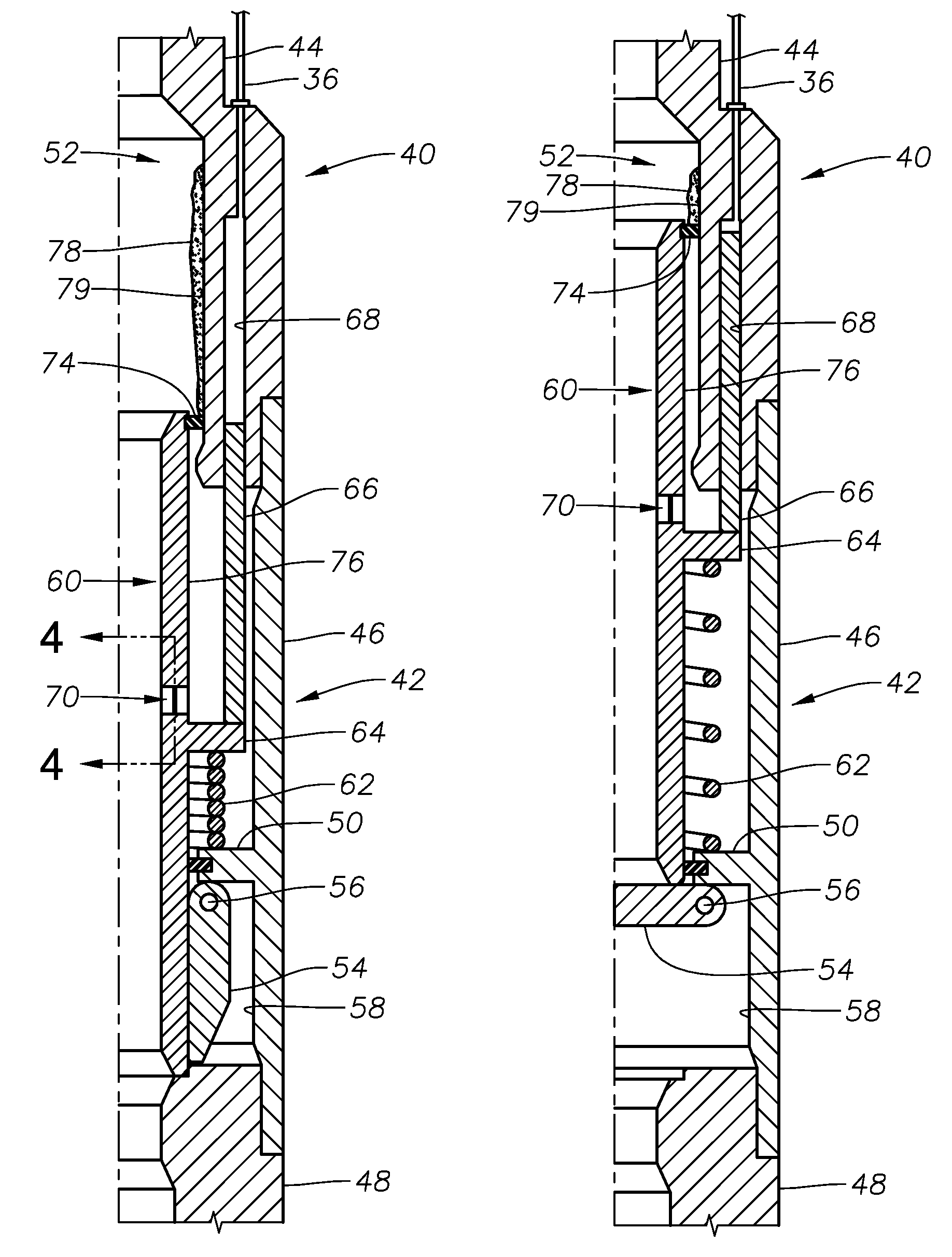

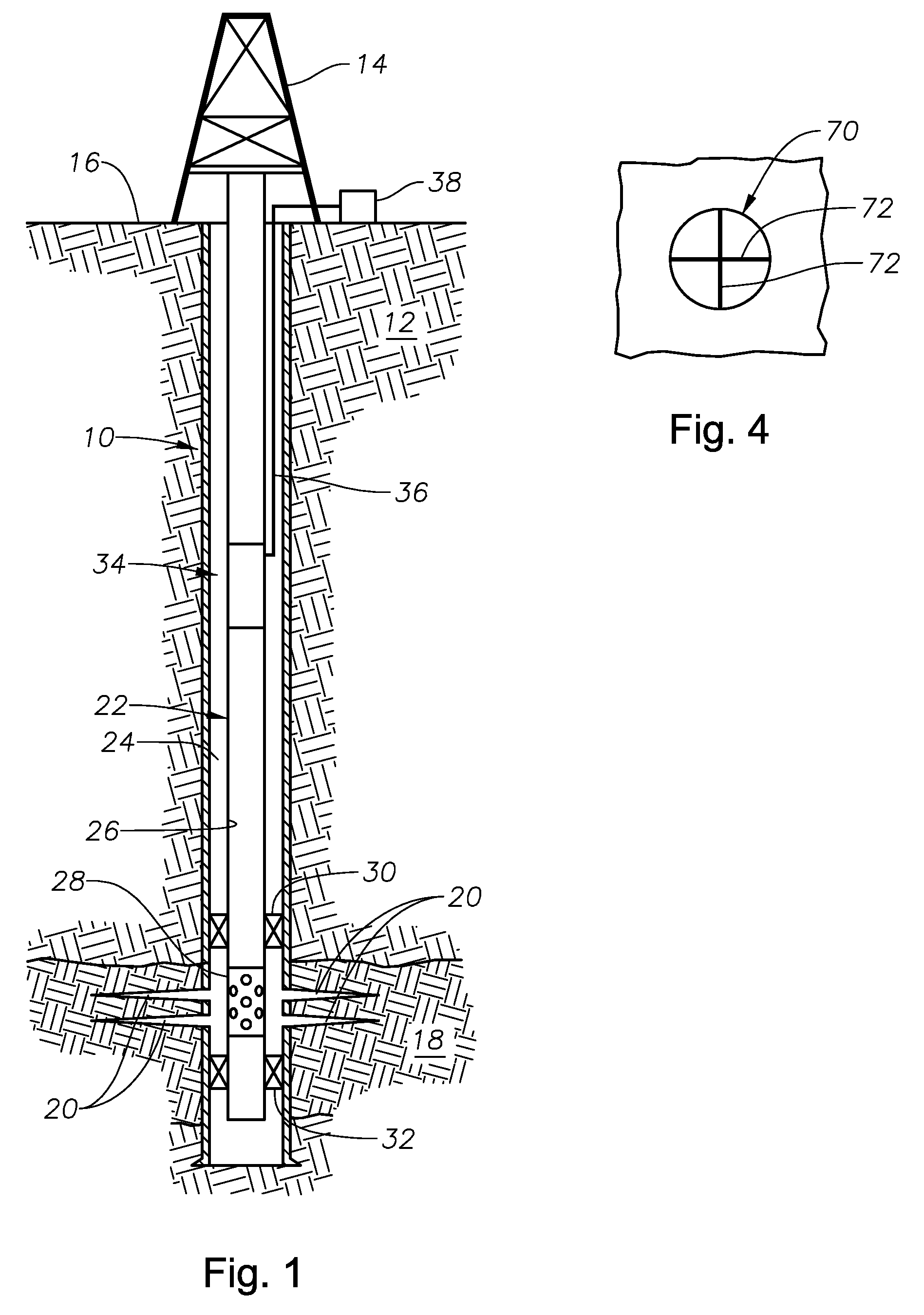

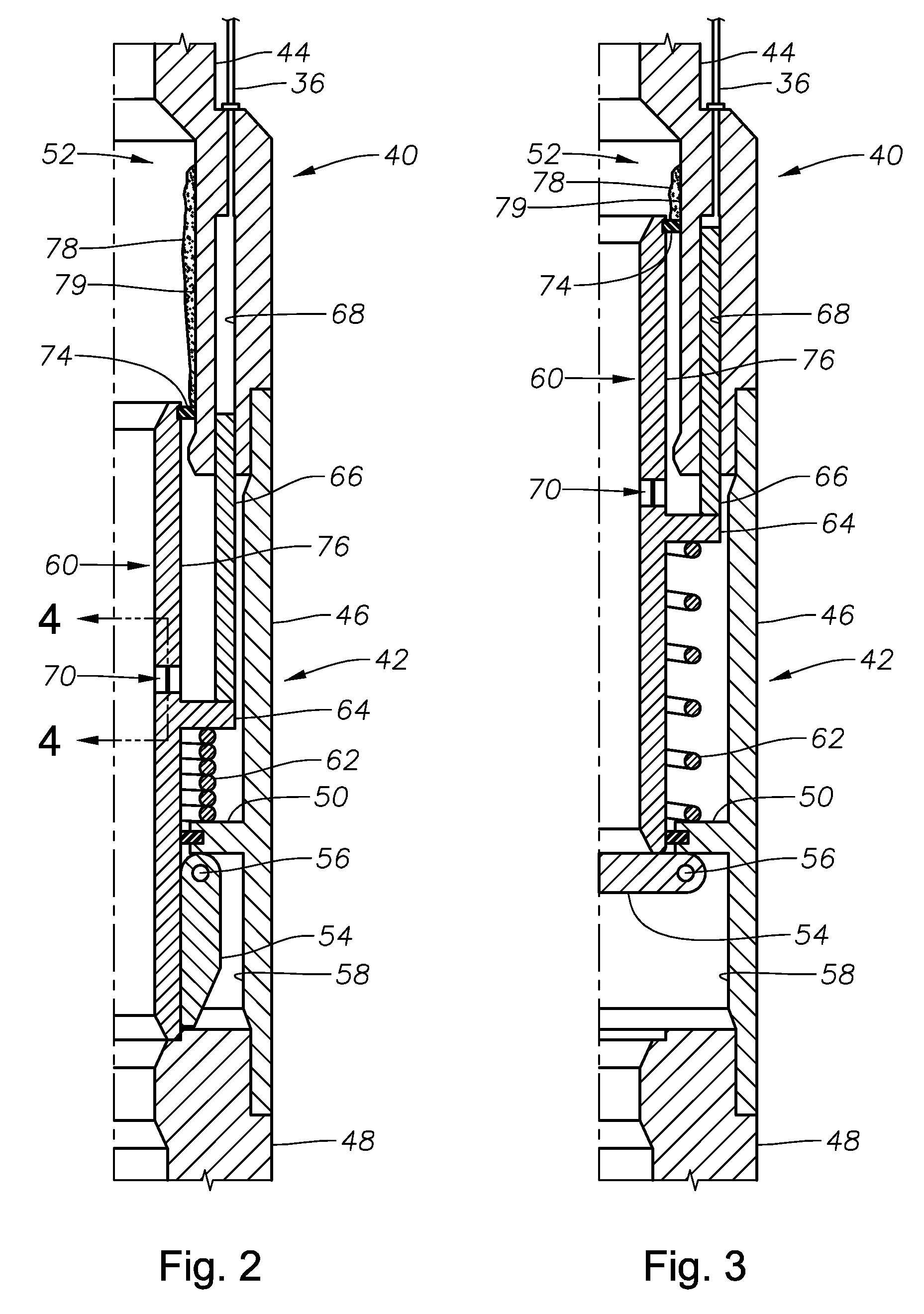

Methods for Preventing Mineral Scale Buildup in Subsurface Safety Valves

ActiveUS20100230109A1Prevent scalingRemove scale buildupConstructionsCleaning apparatusSleeve valveSafety valve

Methods and devices for negating scale buildups on interior surfaces of a sliding sleeve valve housing above the flow tube. In some aspects, a wiper member provides additional clearance between the flow tube and housing to compensate for scale buildup. In other aspects, the interior surface of the valve housing is provided with a sleeve that is disposed between the interior surface of the valve housing and the general flowbore passing through the valve housing to protect the interior surface against scale buildup.

Owner:BAKER HUGHES INC

Methods and apparatus for negating mineral scale buildup in flapper valves

ActiveUS7896082B2Prevent scalingEliminate buildupConstructionsCleaning apparatusSleeve valveEngineering

Methods and devices for negating scale buildups on interior surfaces of a sliding sleeve valve housing above the flow tube. In some aspects, a wiper member provides additional clearance between the flow tube and housing to compensate for scale buildup. In other aspects, the interior surface of the valve housing is provided with a sleeve that is disposed between the interior surface of the valve housing and the general flowbore passing through the valve housing to protect the interior surface against scale buildup.

Owner:BAKER HUGHES INC

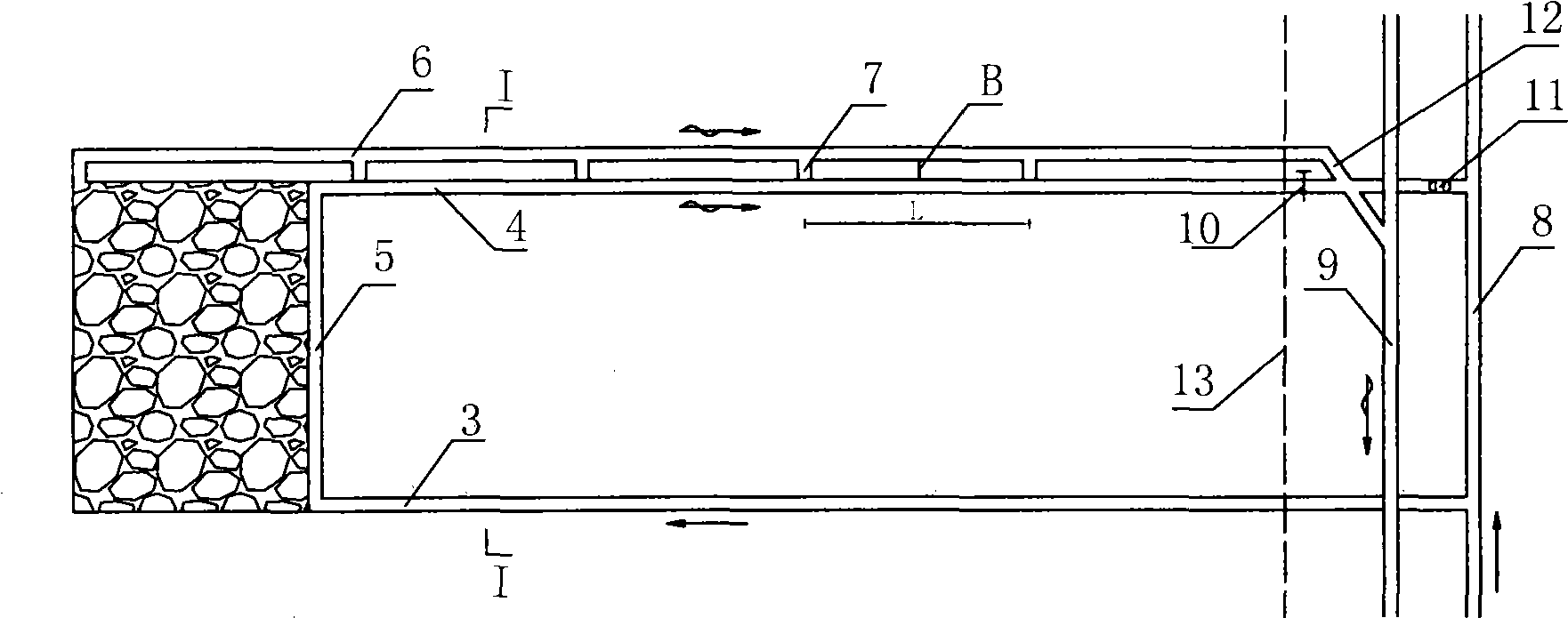

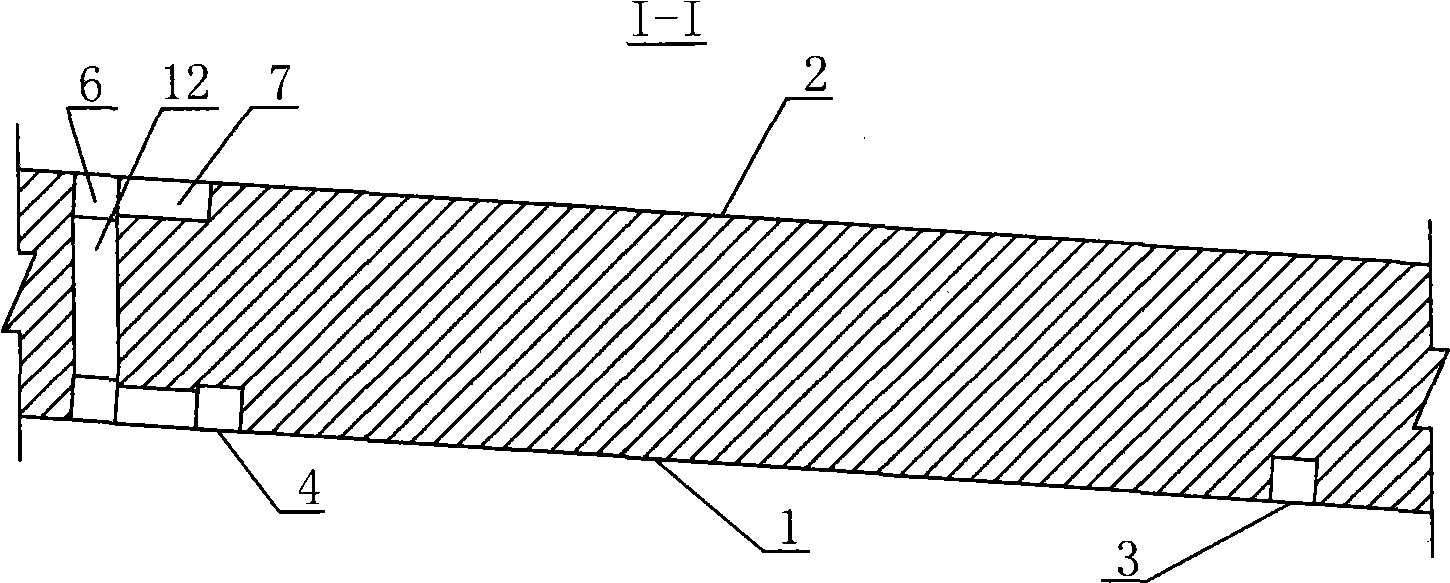

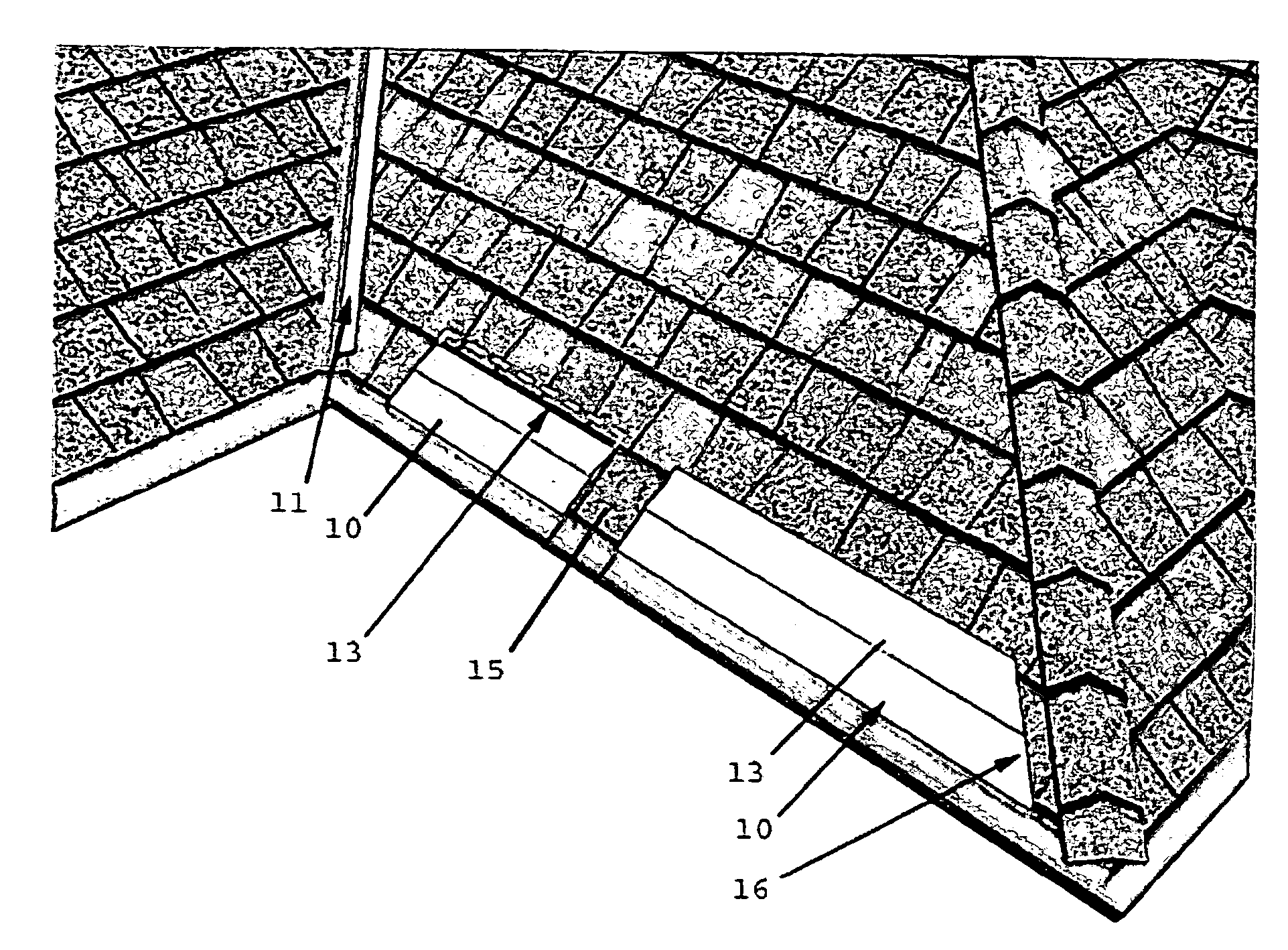

U+I type ventilating system for top-coal caving face

InactiveCN101498225AEfficient dischargeEliminate buildupUnderground miningSurface miningSpelunkingCoal dust

The invention provides a U+I type ventilation system for a work surface of top coal caving, which is an improvement of the arrangement of the U type, the U+L type and the E type or B type laneways and the ventilation systems in the prior art. An air intake way and an air return way of the work surface of top coal caving are arranged along a bottom board of a coal bed, and a regulation air door is arranged on the part of the air return way close to a big air return lane to control the reasonable ventilating parameter of the U+I type ventilating system. The invention is mainly characterized in that air exhausting lanes of top boards are arranged in parallel along the air return way with the parallel outward-staggered distance of 0 m to 5 m from the air return way to form the U+I type ventilating system of a one-intake and two-return mode. The invention fundamentally solves the problem of the accumulation of gas and coal dust on the upper section, the upper spatial angle and the gob area of the work surface of top coal caving, in particular the problem of the accumulation of the gas and the coal dust of the upper space of the upper gob area, provides a safe and high-effect ventilating system, and creates an excellent mechanical environment for realizing the exploitation of the top coal caving of small coal pillars and increasing the recovery rate of coal.

Owner:TAIYUAN UNIV OF TECH

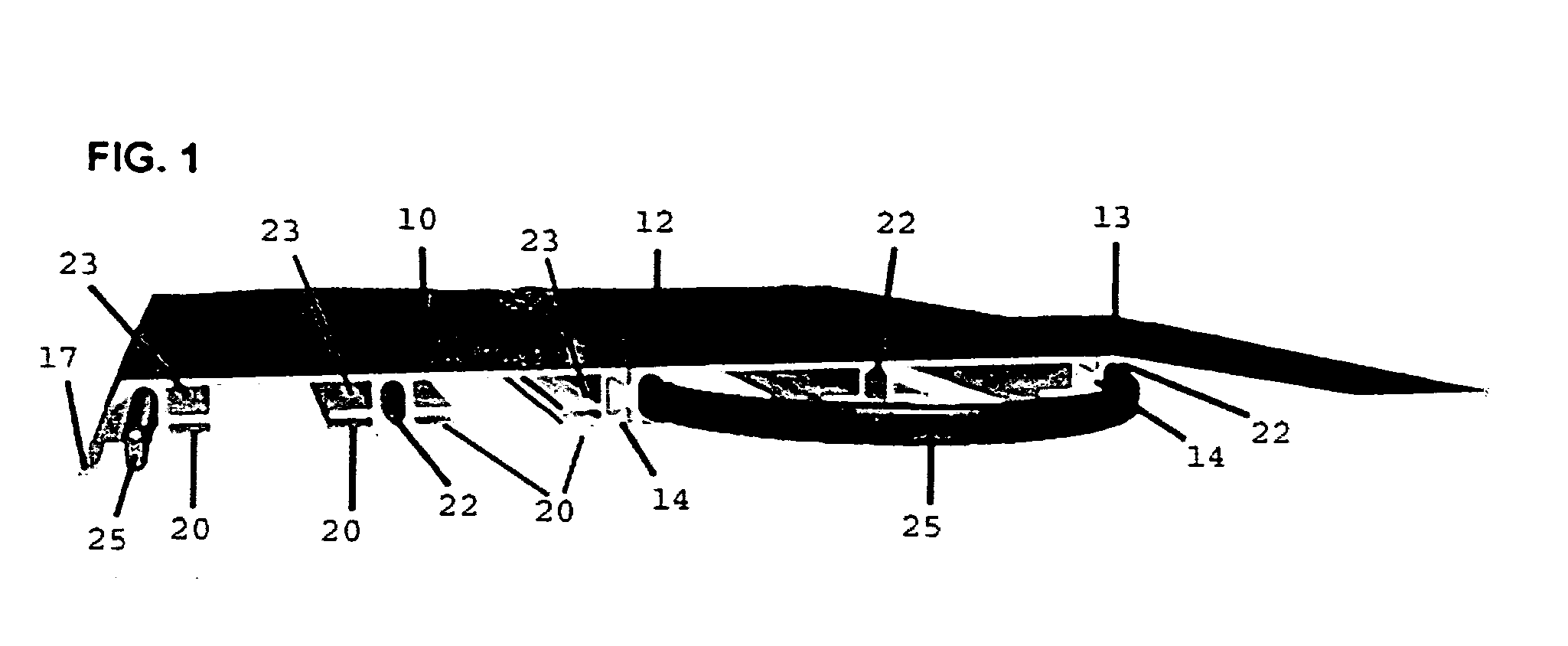

Roof ice and snow melt system

ActiveUS20060288652A1Eliminate buildupEliminates formationPhotovoltaic supportsBuilding roofsSnow meltingEngineering

A snow and ice melting device adapted to rest on a roof; having a flat plate with a series of channels therethrough containing a heating element to heat the flat plate and melt the ice and snow on the roof.

Owner:ENGINEERED ROOF DE ICING

Electrostatic spray coating apparatus and method

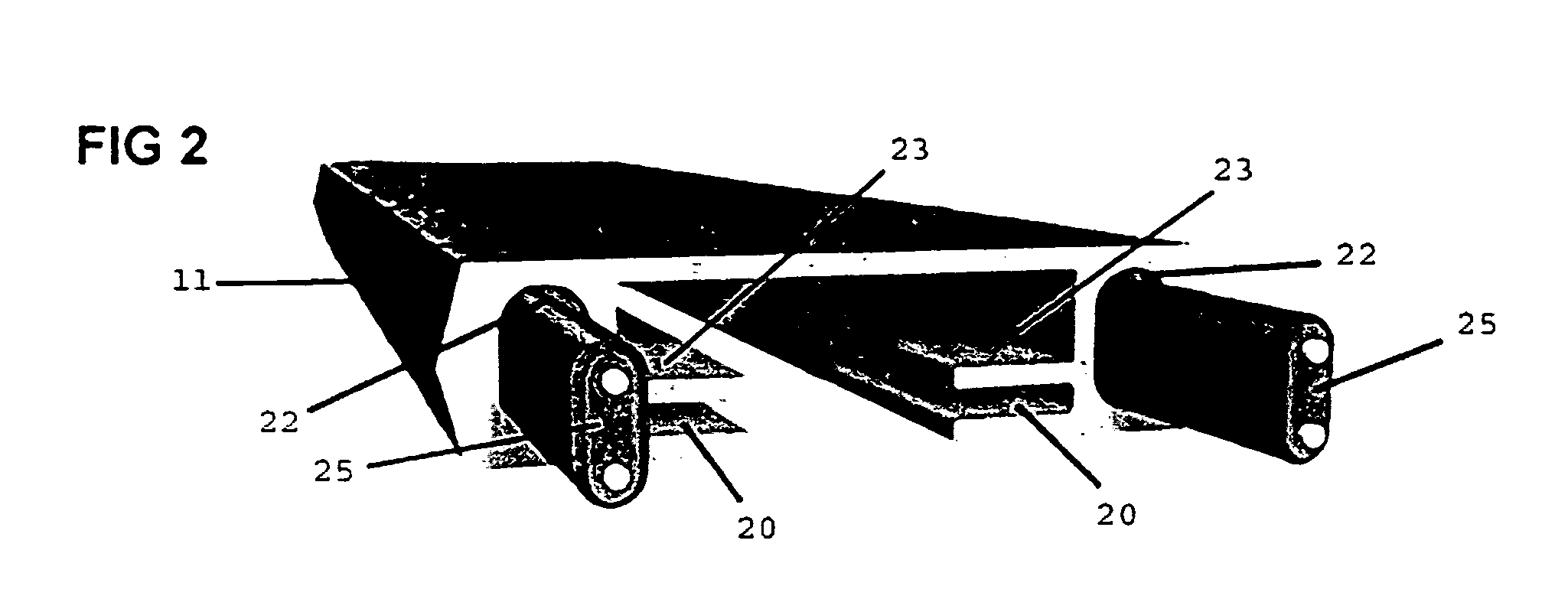

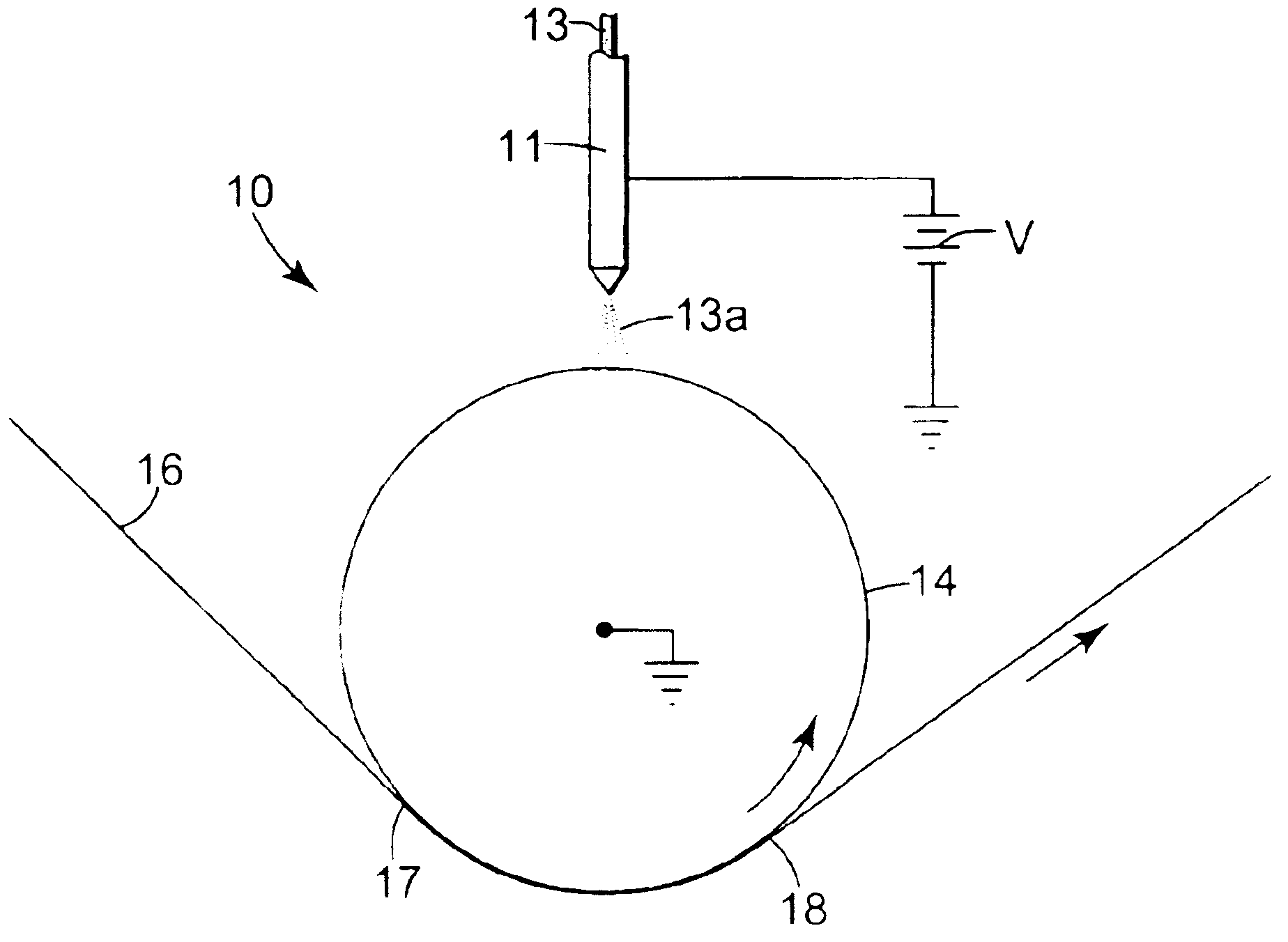

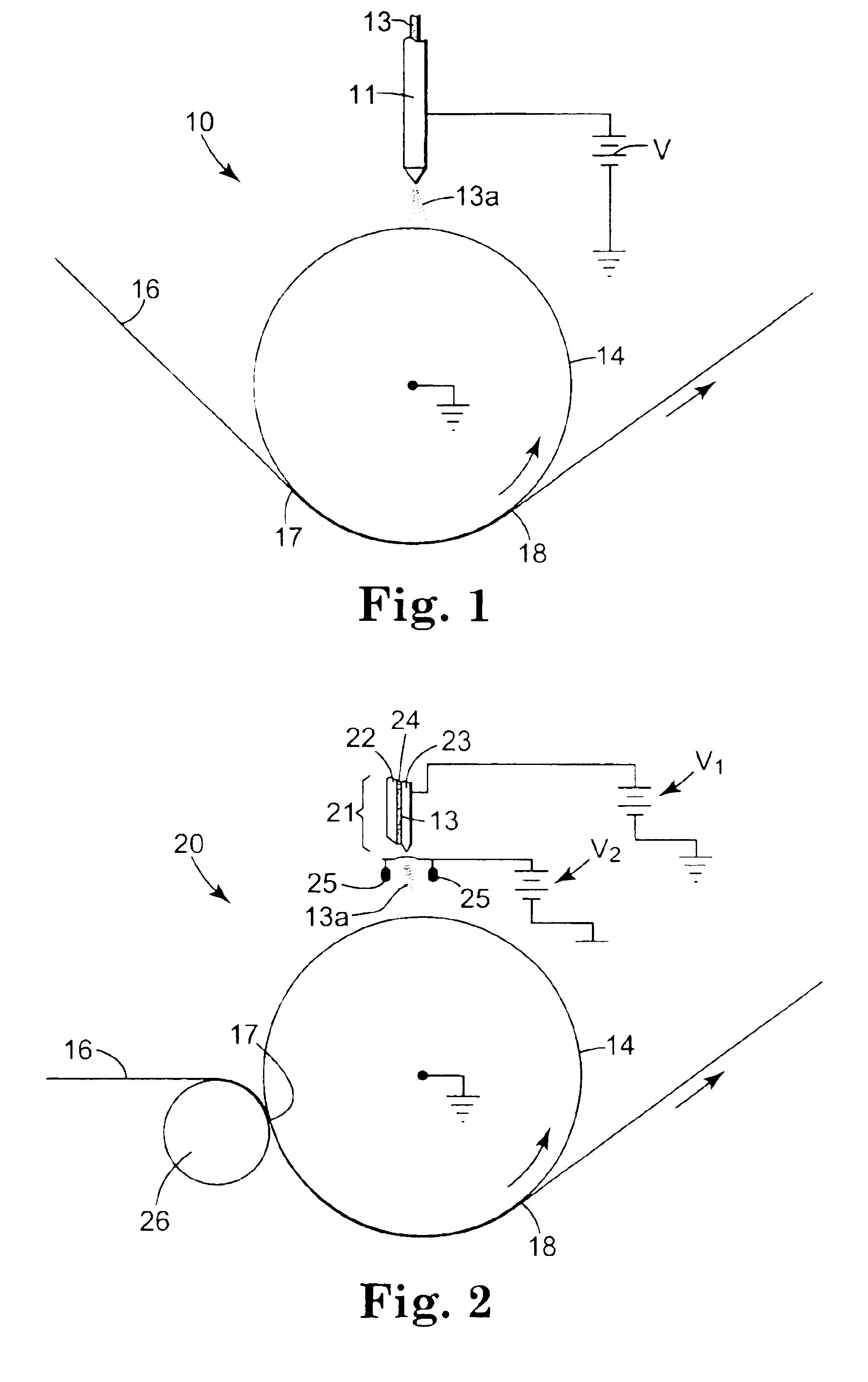

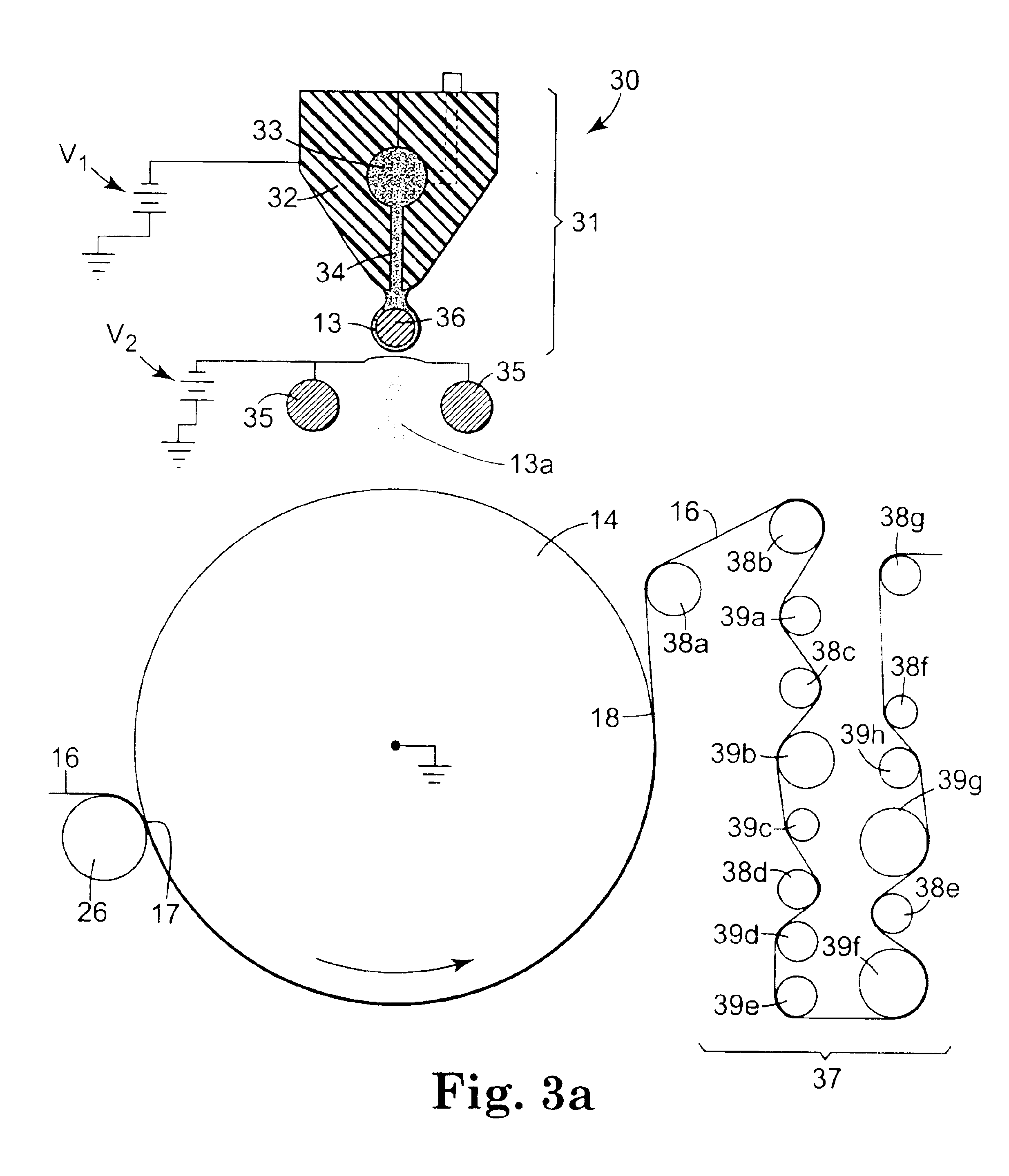

InactiveUS6969540B2Shorten the timeImprove coating uniformityLiquid spraying plantsLiquid surface applicatorsPorous substrateSpray coating

A liquid coating is formed on a substrate by electrostatically spraying drops of the liquid onto a liquid-wetted conductive transfer surface and transferring a portion of the thus-applied liquid from the transfer surface to the substrate. Optionally, one or more nip rolls force the substrate against the transfer surface, thereby decreasing the time required for the drops to spread and coalesce into the coating. Preferably, the coating is passed through an improvement station comprising two or more pick-and-place devices that improve the uniformity of the coating. The coating can be transferred from the conductive transfer surface to a second transfer surface and thence to the substrate. Insulative substrates such as plastic films can be coated without requiring substrate pre-charging or post-coating neutralization. Porous substrates such as woven and nonwoven webs can be coated without substantial penetration of the coating into or through the substrate pores.

Owner:3M INNOVATIVE PROPERTIES CO

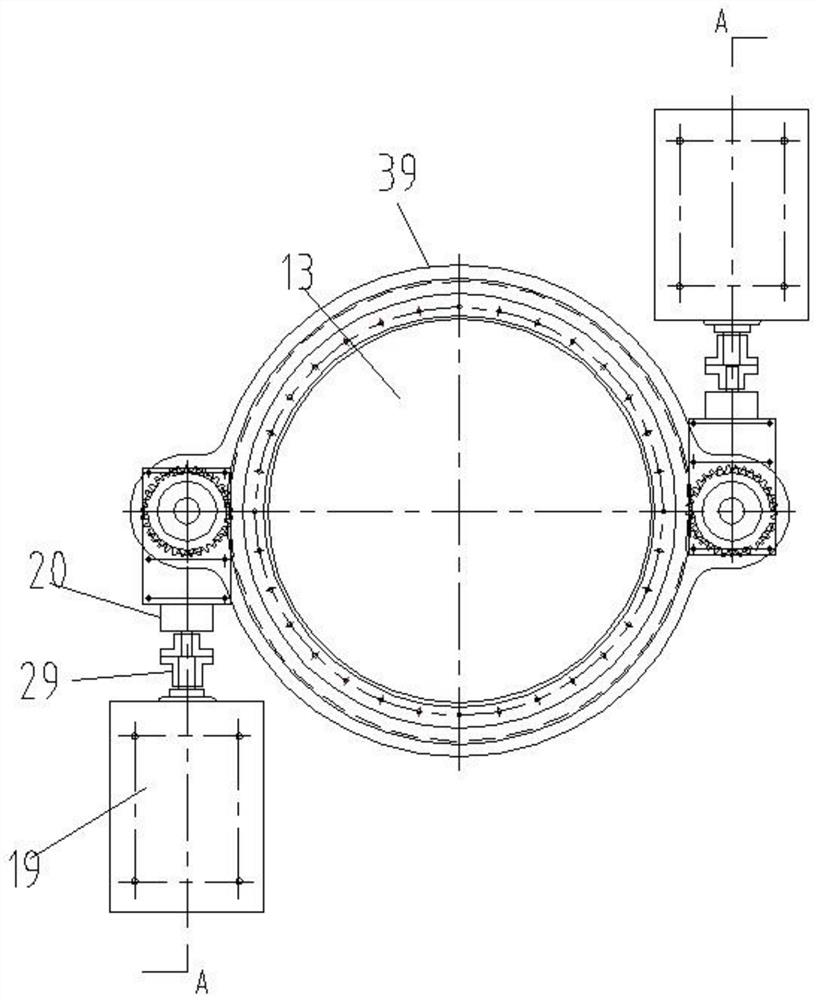

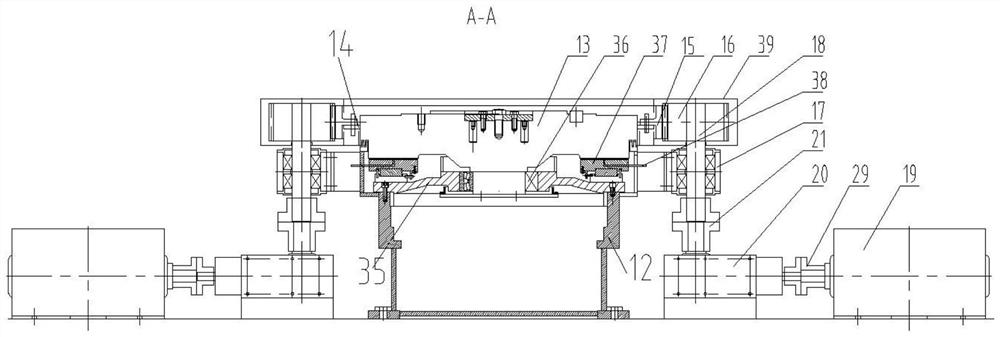

Floor mat and particulate laden material washing apparatus and method

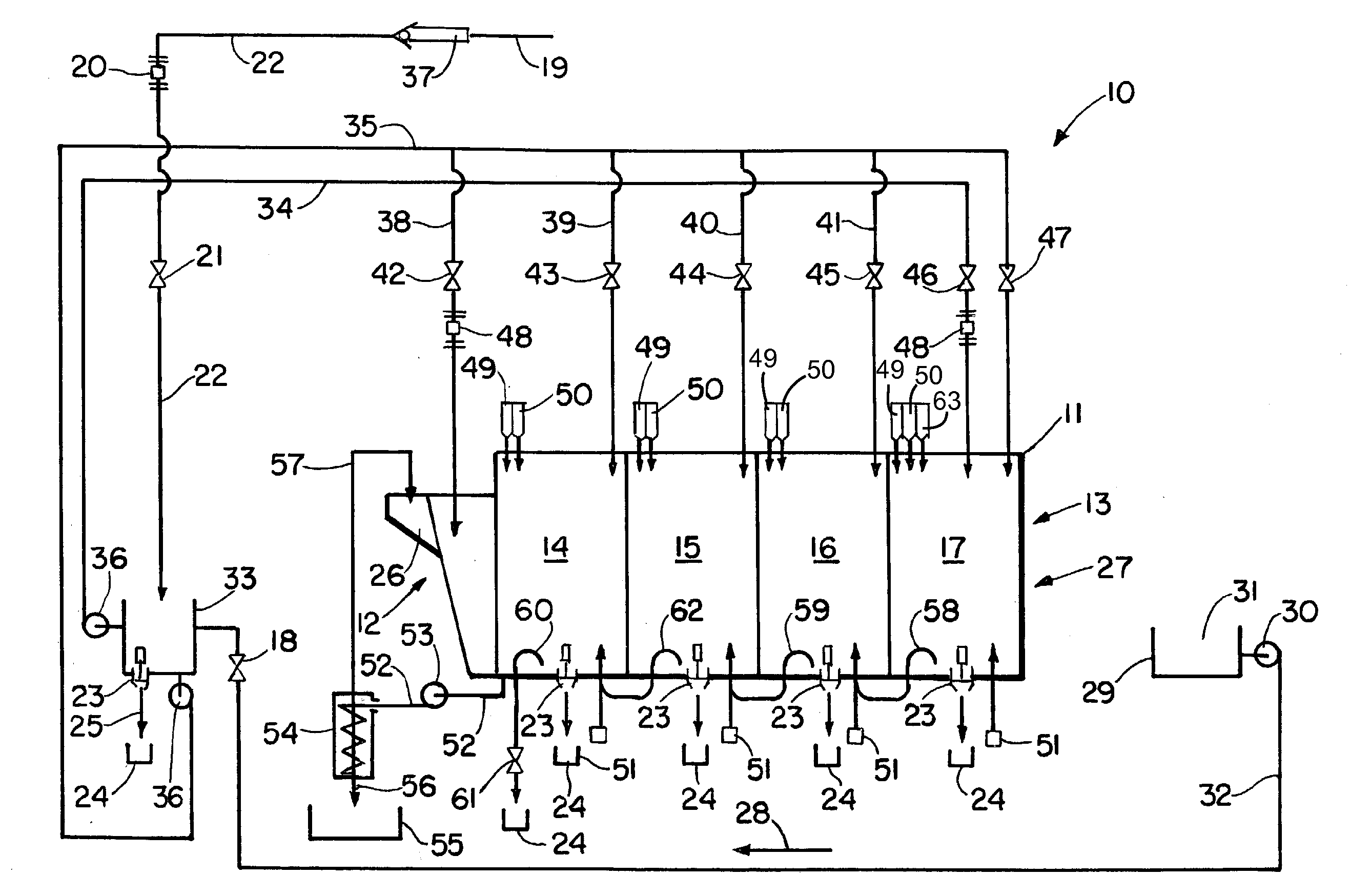

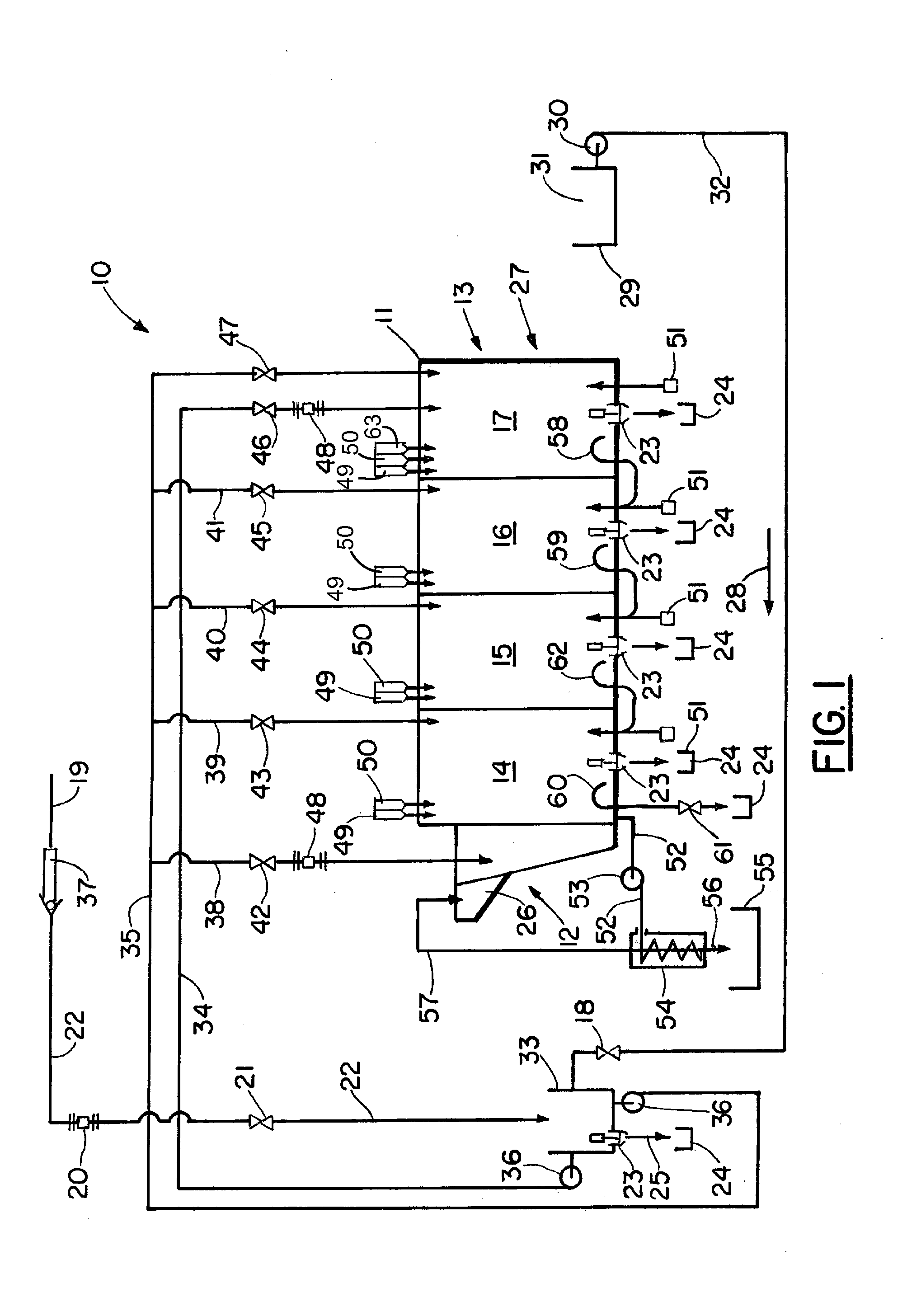

InactiveUS20150167221A1Improve performanceMaintains washing qualityOther washing machinesDetergent compounding agentsParticulatesCounter flow

A method of washing particulate laden material in a washer includes moving the particulate laden material from the intake of the washer to the discharge of the washer and through multiple modules or sectors. Liquid can be counter flowed in the washer interior along a flow path that is generally opposite the direction of travel of the particulate laden material. A specially configured recirculation / filtration arrangement removes a majority of particulate and organic matter from the washing fluid.

Owner:PELLERIN MILNOR

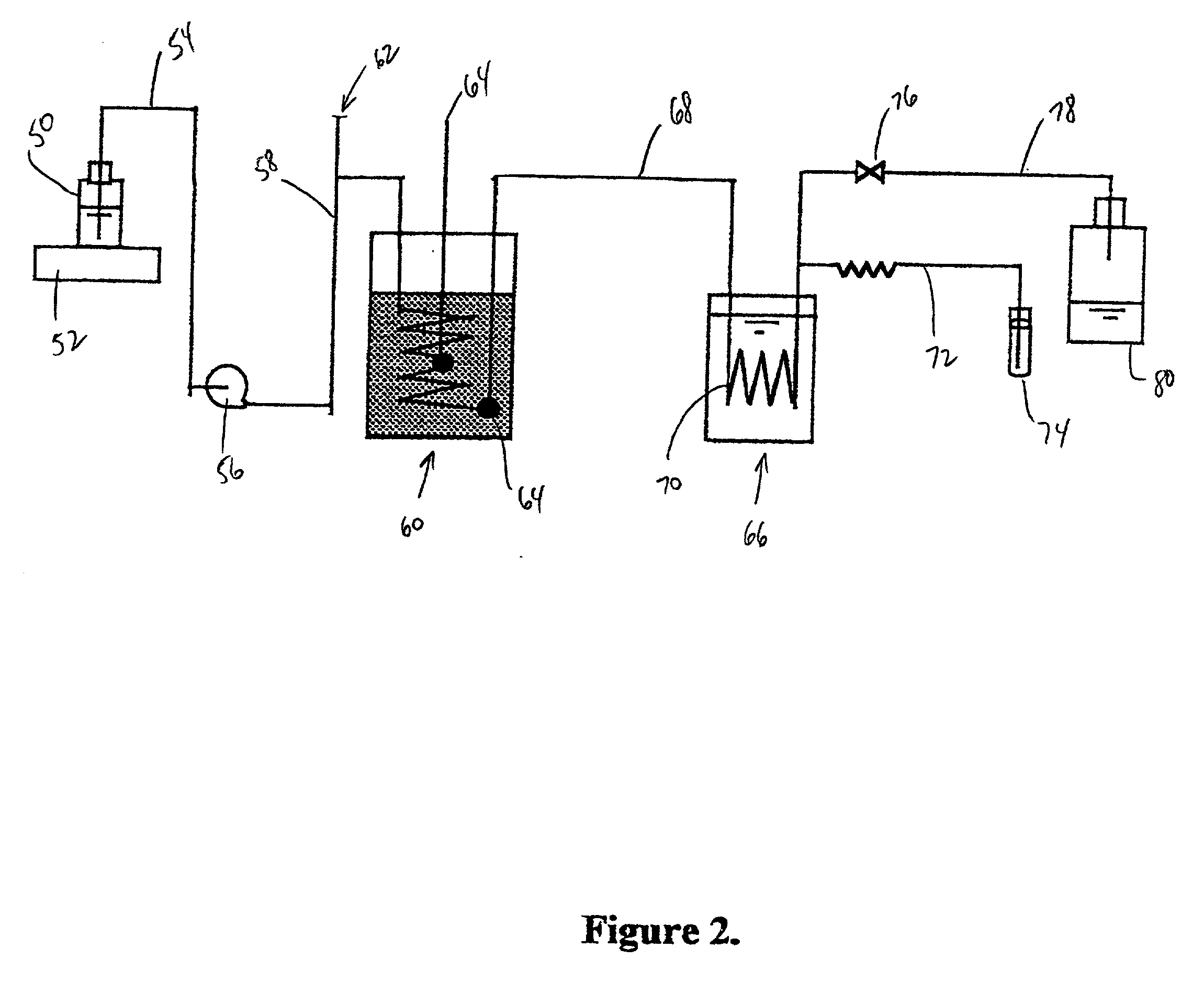

Process for producing sterile water for injection from potable water

InactiveUS20010050215A1Shorter treatment timeEasily deployableBiocideLiquid degasificationSubmarineProduct gas

By treating potable water at a temperature of at least 250.degree. C. (482.degree. F.) and at a pressure of at least 4 Mpa (570 psia), can produce pyrogen-free water using treatment times of 0.05 to 5 seconds or less. The addition of an oxidant, in the form of a gas, a liquid, or a solid, further decreases the required treatment time to less than 0.05 second. The reduction in equipment size achieved with this rapid treatment time allows the utilization of treatment units small enough to be easily transported to remote locations or installed in the restricted space environment existing in ships and submarines.

Owner:APPLIED RES ASSOCS INC

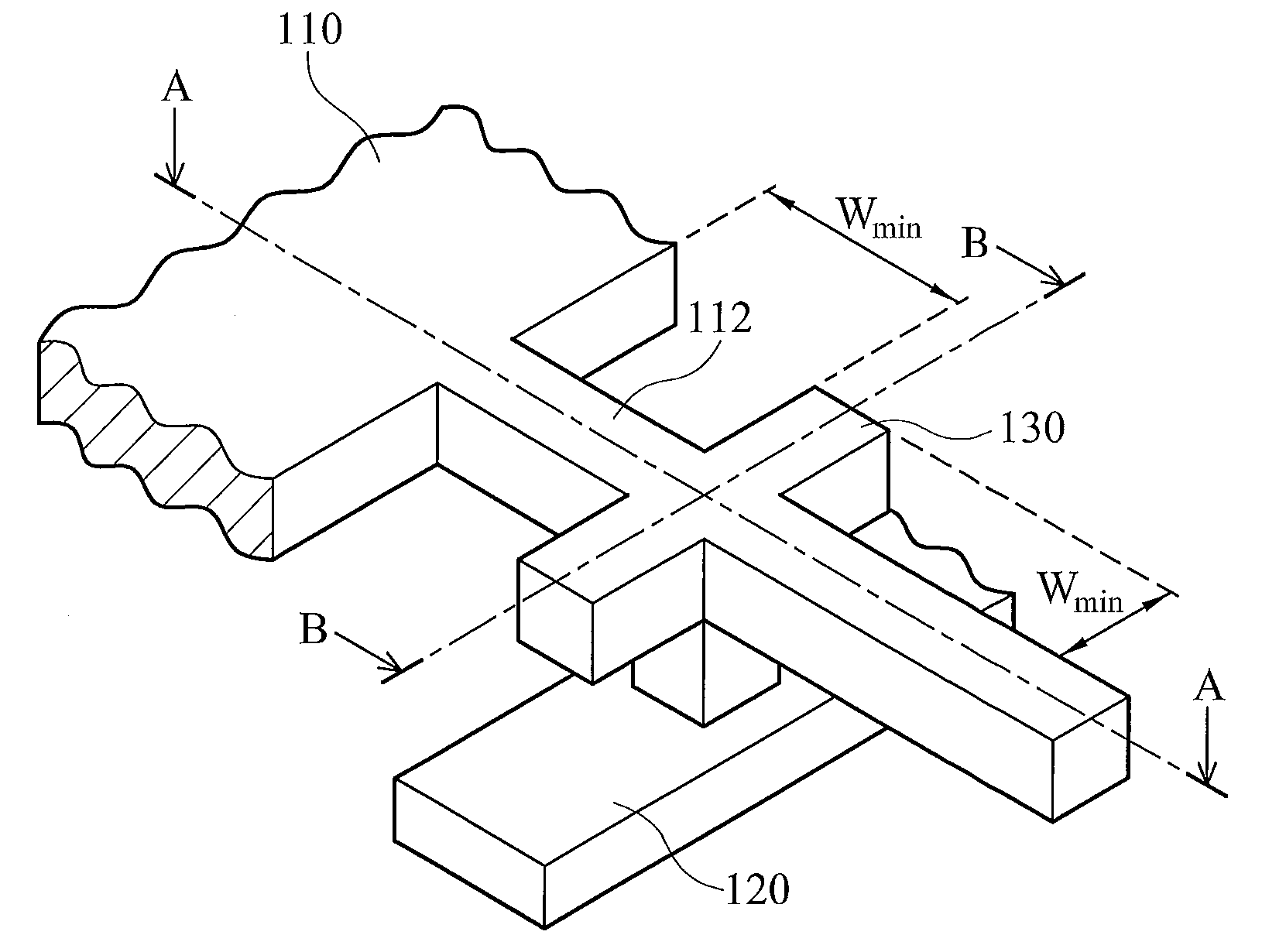

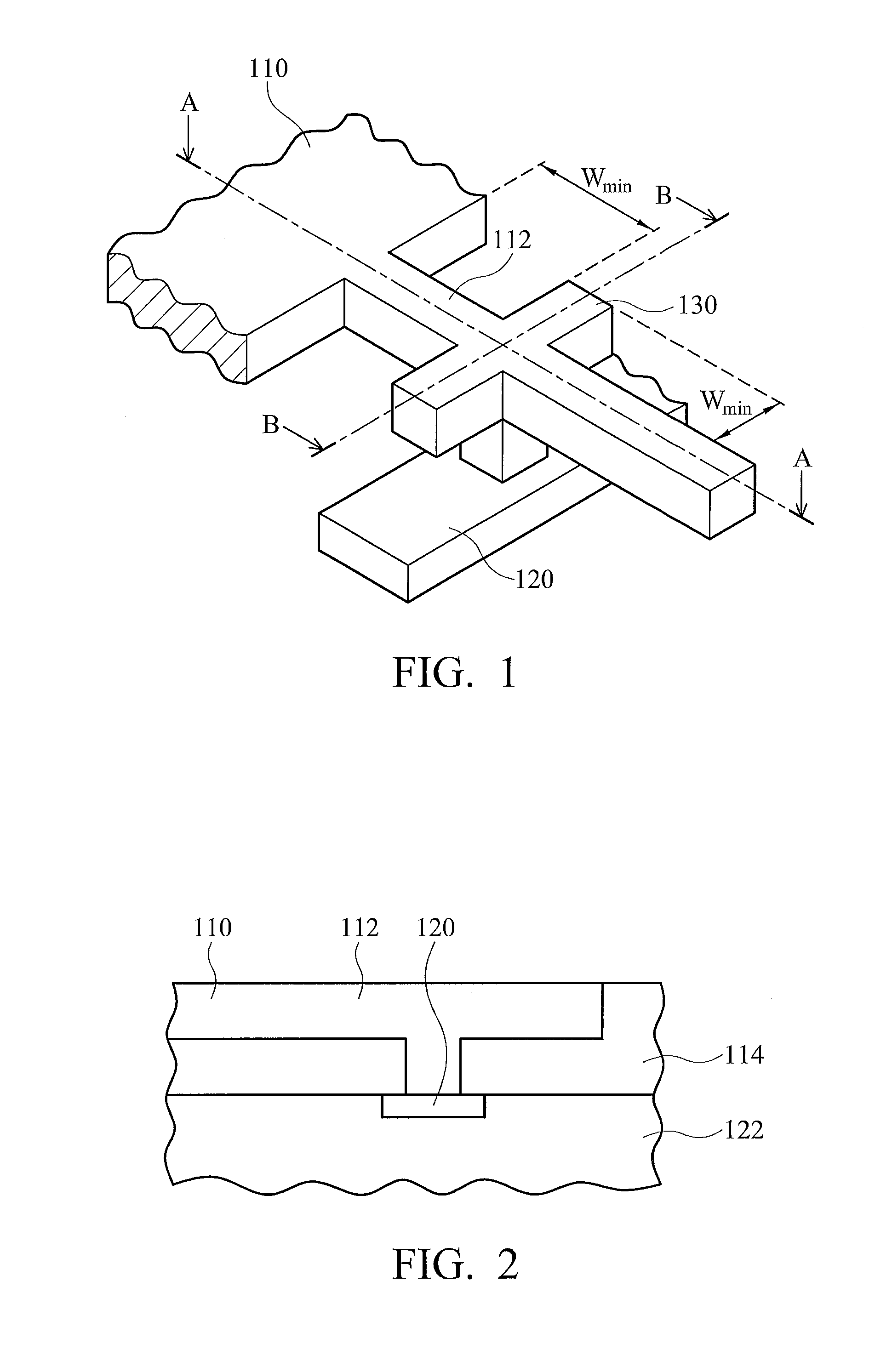

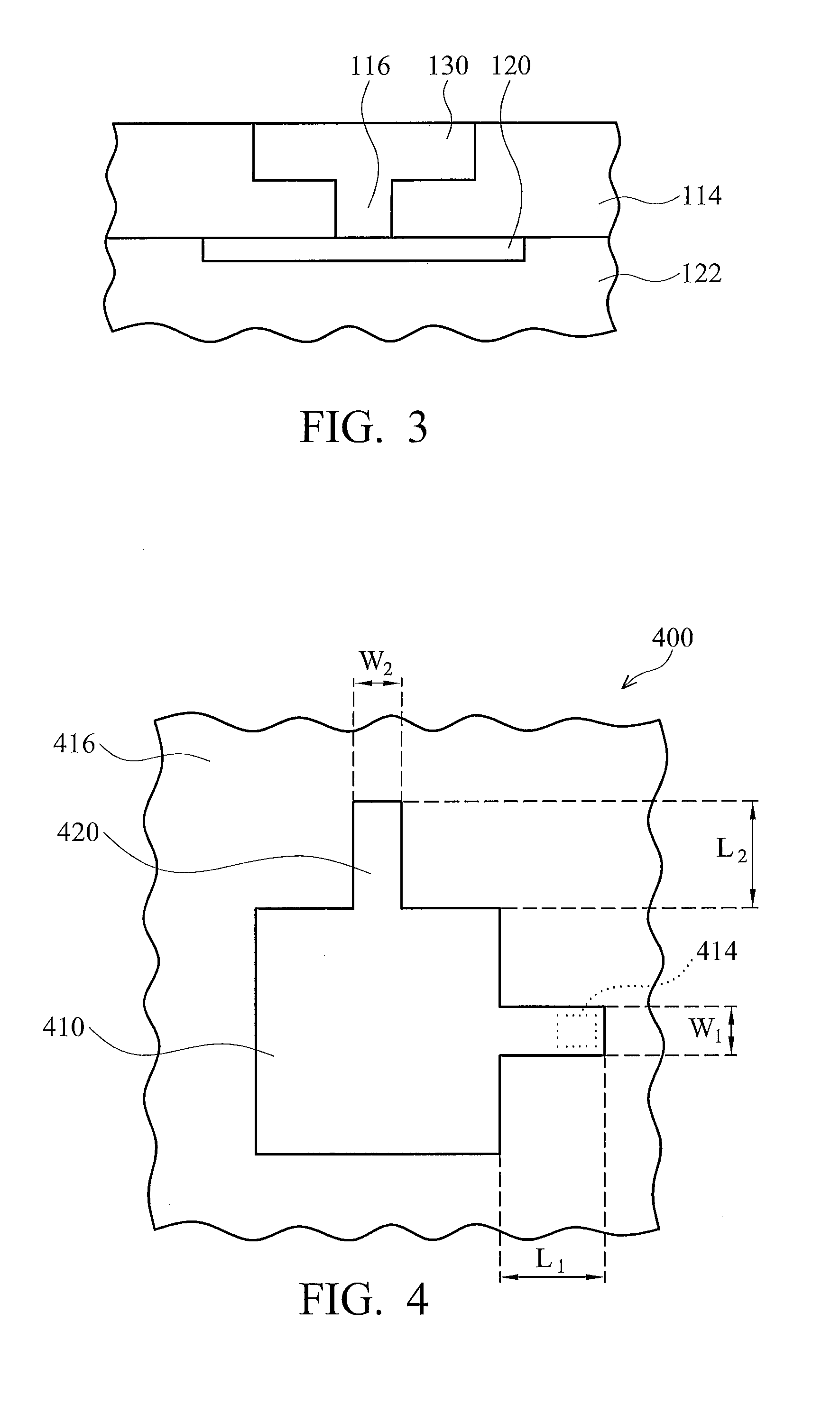

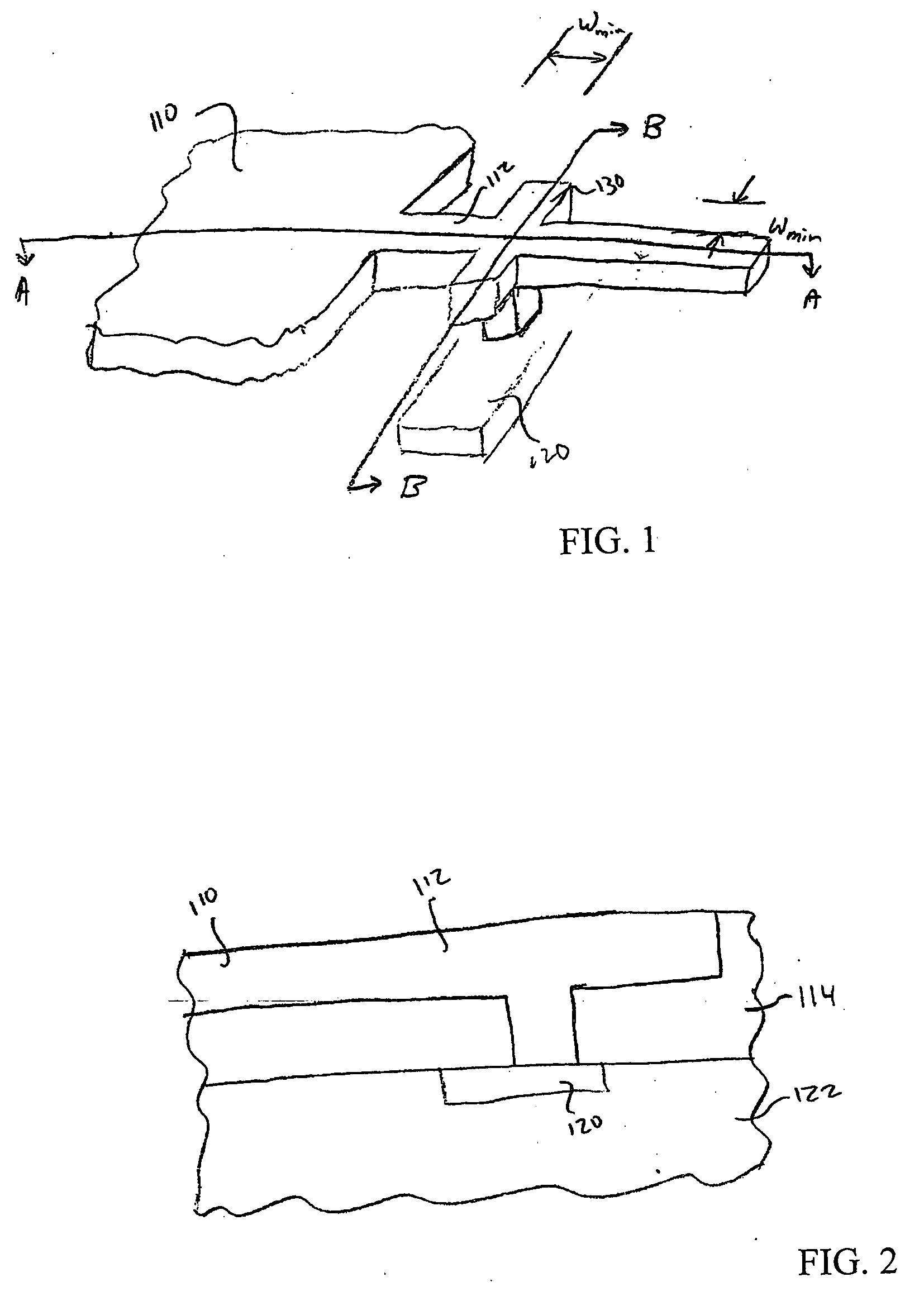

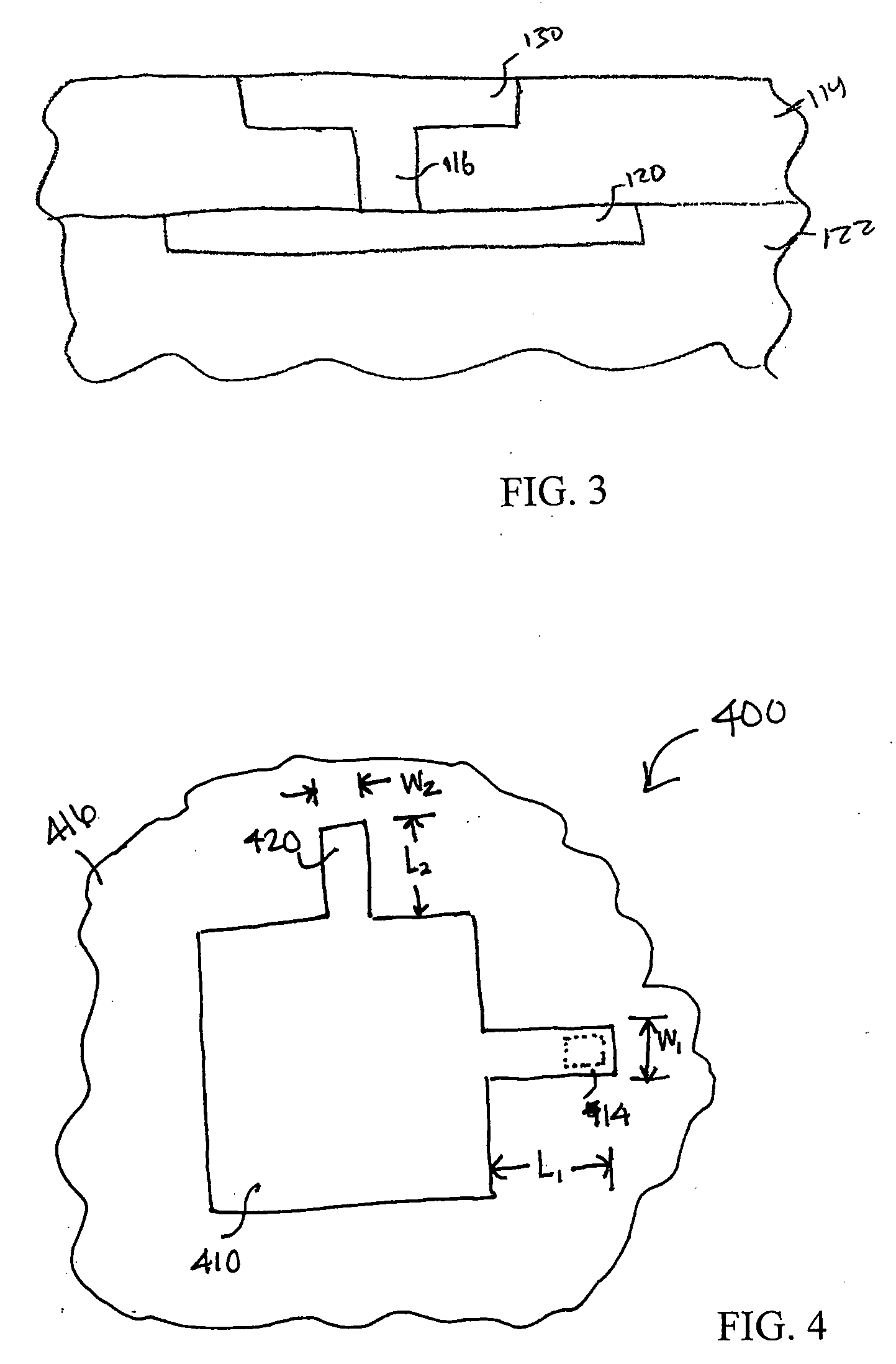

Interconnect structure to reduce stress induced voiding effect

InactiveUS7227266B2Reduce formationEliminate buildupSemiconductor/solid-state device detailsSolid-state devicesStress inducedContact pad

An interconnect structure that may reduce or eliminate stress induced voids is provided. In an embodiment, a via is formed below a conductive line to provide an electrical connection to an underlying conductive region. The conductive line includes a widened region above the via. The widened region serves to reduce or eliminate stress induced voids between the via and the underlying conductive region. In another embodiment, one or more redundant lines are formed extending from a conductive region, such as a contact pad, such that the redundant line does not electrically couple the conductive region to an underlying conductive region. In a preferred embodiment, the redundant lines extend from a conductive region on a side adjacent to a side having a conductive line coupled to a via.

Owner:TAIWAN SEMICON MFG CO LTD

Apparatus for preventing unintended or premature release of liquid in a beverage brewing device and method thereof

InactiveCN1957815APrevent or eliminate outflowPrevent or eliminate premature effluxBeverage vesselsMechanical engineeringBrewing

An apparatus useful for preventing the release of residual liquid in a beverage brewing device prior to and after the brewing process, and for preventing the premature release of liquid during the heating process is disclosed. The apparatus includes a flexible member, a closing member and a recess. The apparatus is fabricated such that the pressure of the liquid being delivered to the brewing chamber displaces or depresses the closing member sufficiently into the recess to form a first fluid passage. The pressure of the fluid also creates a channel or cavity on a surface of the flexible member. The first fluid passage and the channel or cavity form a second fluid passages which provide fluid communication between the fluid inlet and the brewing chamber. Preferably, the flexible member, closing member and recess is formed as an integral unit.

Owner:ELECTRICAL & ELECTRONICS LTD

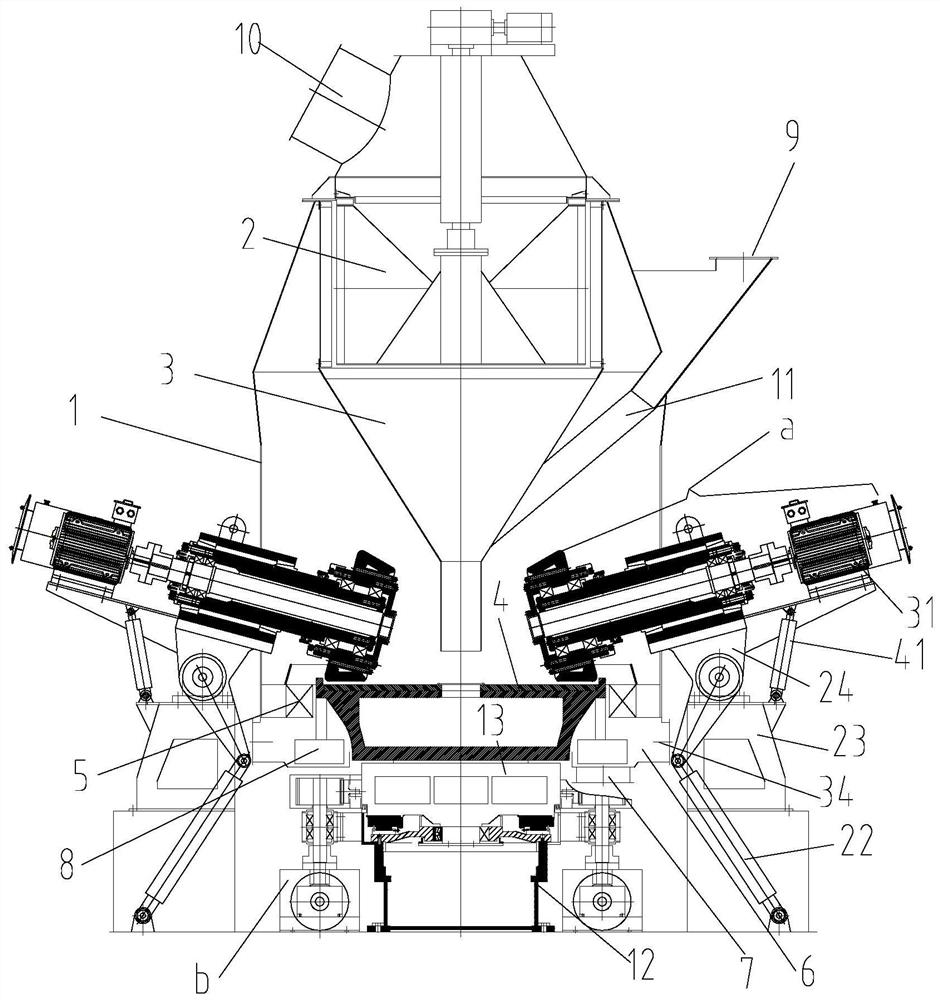

Double-driving roller type vertical mill

The invention provides a double-driving roller type vertical mill, which comprises a vertical mill barrel body, wherein a powder selection machine, an inner ash hopper and an abrasive disk are arranged in sequence from top to bottom in the inner cavity of the vertical mill barrel body; the bottom of the abrasive disk is installed and fixed on the output supporting connection disk of a weight carrying supporting barrel body; one end of each transmission grinding roller mechanism is positioned in the vertical mill barrel body and is evenly distributed above the circumference of the abrasive disk; the outer surface of the output supporting connection disk is provided with a connecting flange; a connecting flange is locked and connected with a large tooth ring through a plurality of bolts; thelarge tooth ring drives the output supporting connection disk to rotate through a plurality of vertical heavy load speed reduction device; each transmission grinding roller mechanism comprises a loading hydraulic oil cylinder, a supporting seat, a rocker arm and a grinding roller component; and the vertical mill barrel body is provided with an annular air duct hole which communicates with a material discharging annular channel. By use of the double-driving roller type vertical mill disclosed by the invention, materials enter a powder grinding gap in a uniform way, powder grinding efficiency is improved, and operation stability is high.

Owner:南京钜力粉体工程科技研究所有限公司 +1

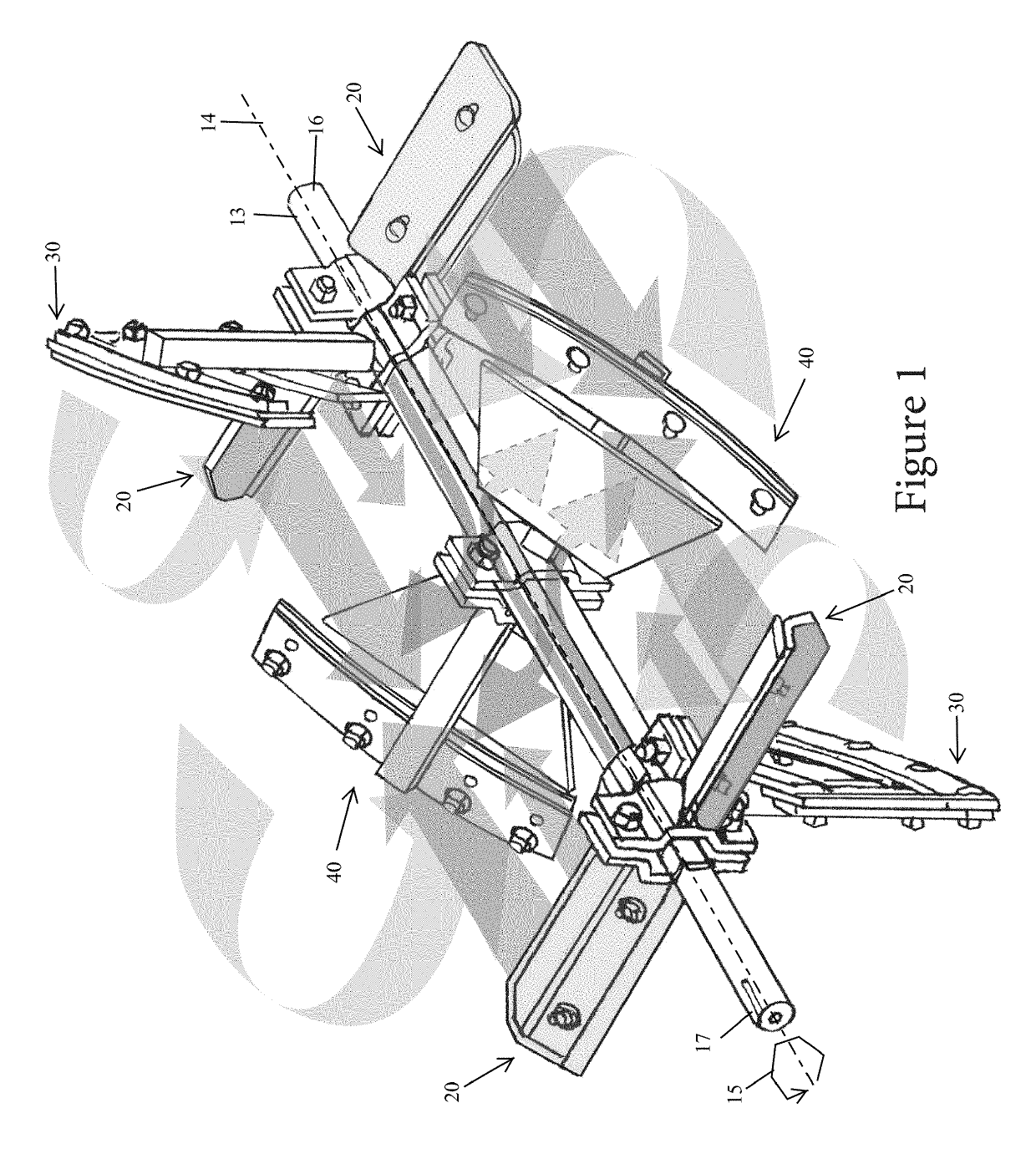

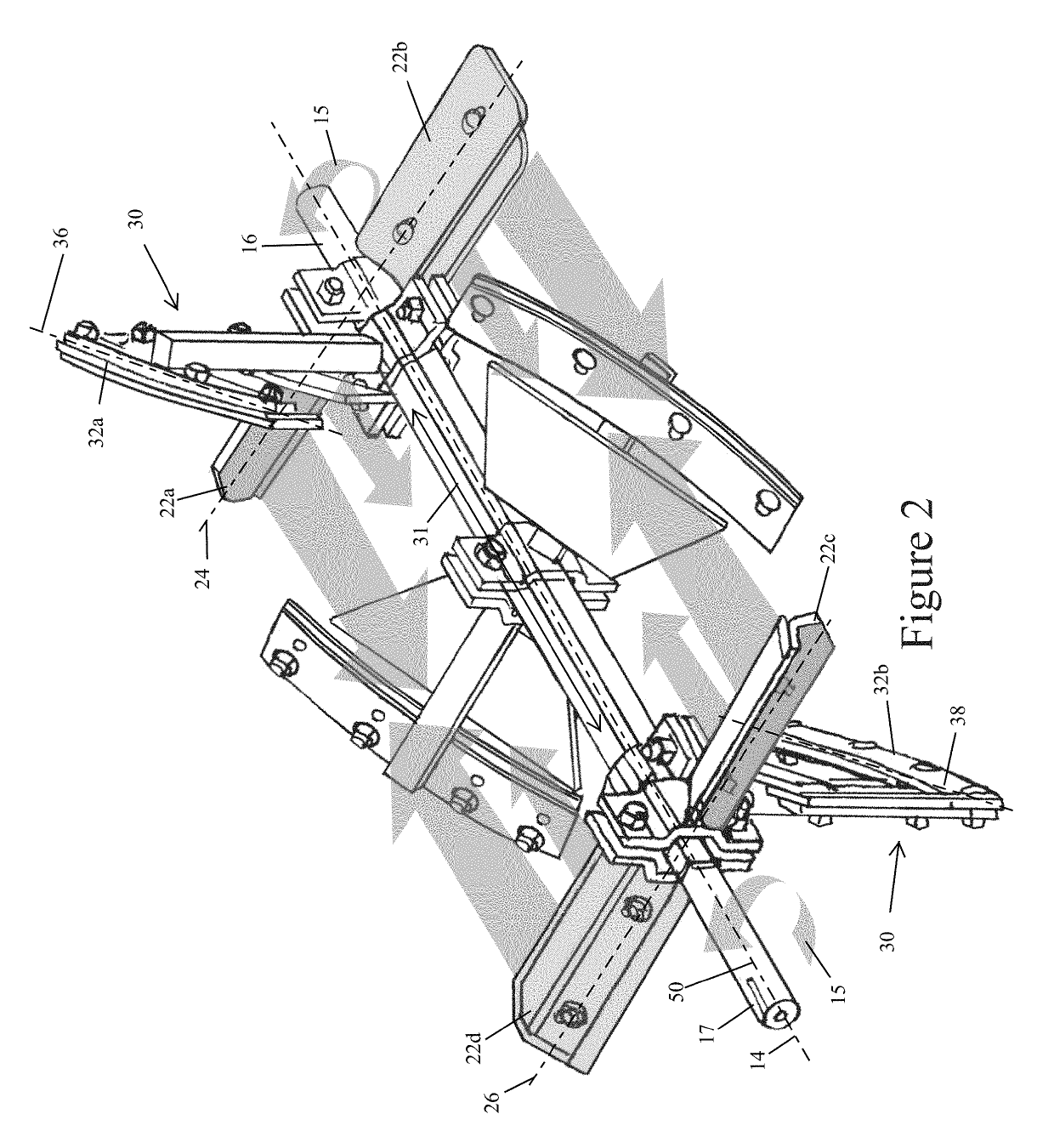

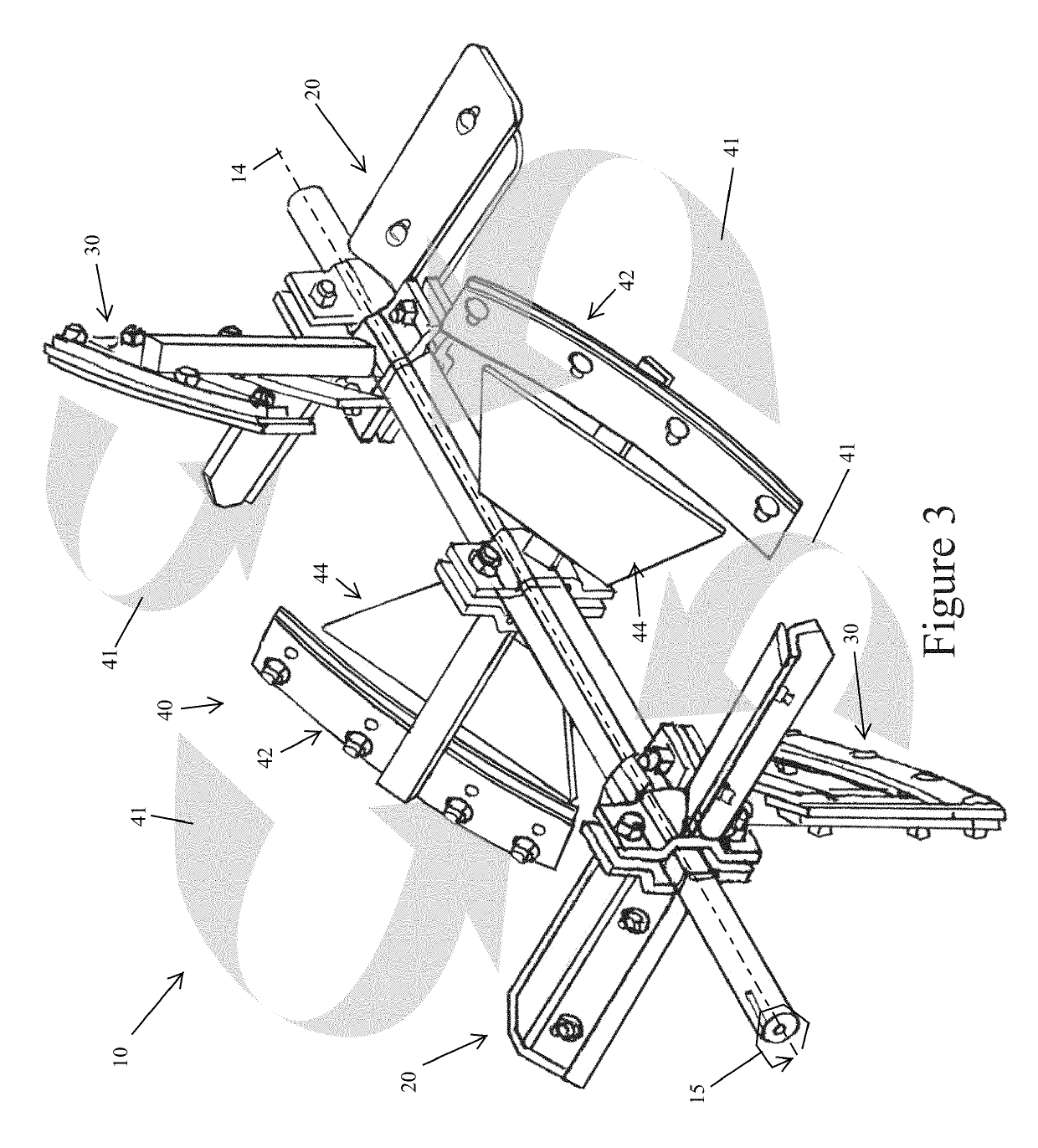

Mortar mixer paddle assembly for use with polyethylene drums and associated methods

ActiveUS10421215B1Eliminating mortar mixture slurry build-upEasy to cleanRotary stirring mixersTransportation and packagingReciprocating motionEngineering

The mortar mixer paddle assembly includes a rectilinear shaft having a centrally registered longitudinal axis, a tow-end and an engine-end axially opposed from the tow-end, and a plurality of rectilinear paddle arms radially extending outwardly from the centrally registered longitudinal axis. A mechanism for entraining air into the mortar mixture and along the rectilinear shaft inside the existing polyethylene drum is provided. A mechanism for horizontally reciprocating a mortar mixture slurry along a bi-directional linear travel path parallel to the centrally registered longitudinal axis of the rectilinear shaft is provided. A mechanism for radially redirecting slow-moving mortar mixture slurry, traveling along the rectilinear shaft, upwards into faster moving arcuate travel paths rotating about the rectilinear shaft thus eliminating mortar mixture slurry build-up on the rectilinear shaft and the rectilinear paddle arms is provided.

Owner:SWISHER JAMES A

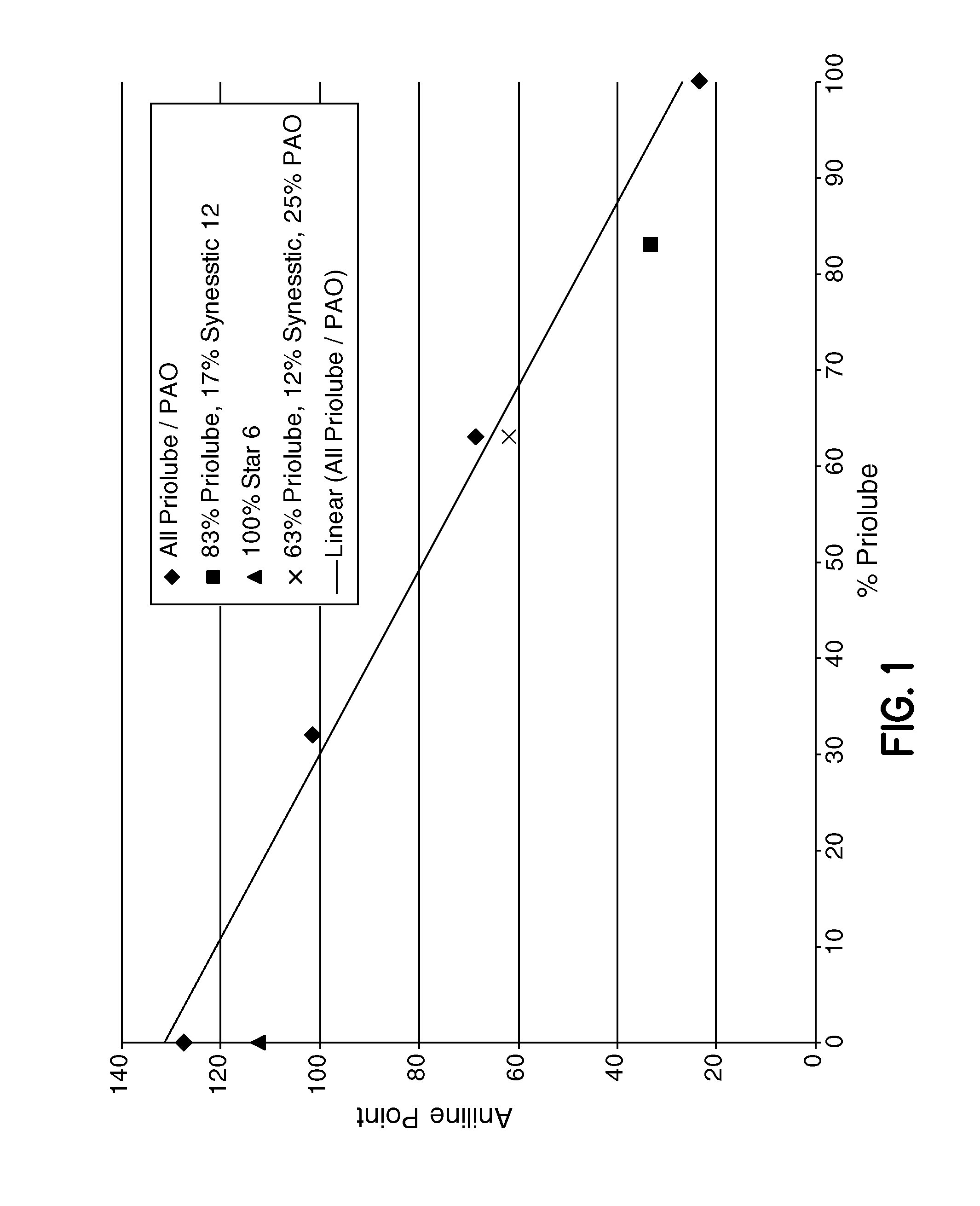

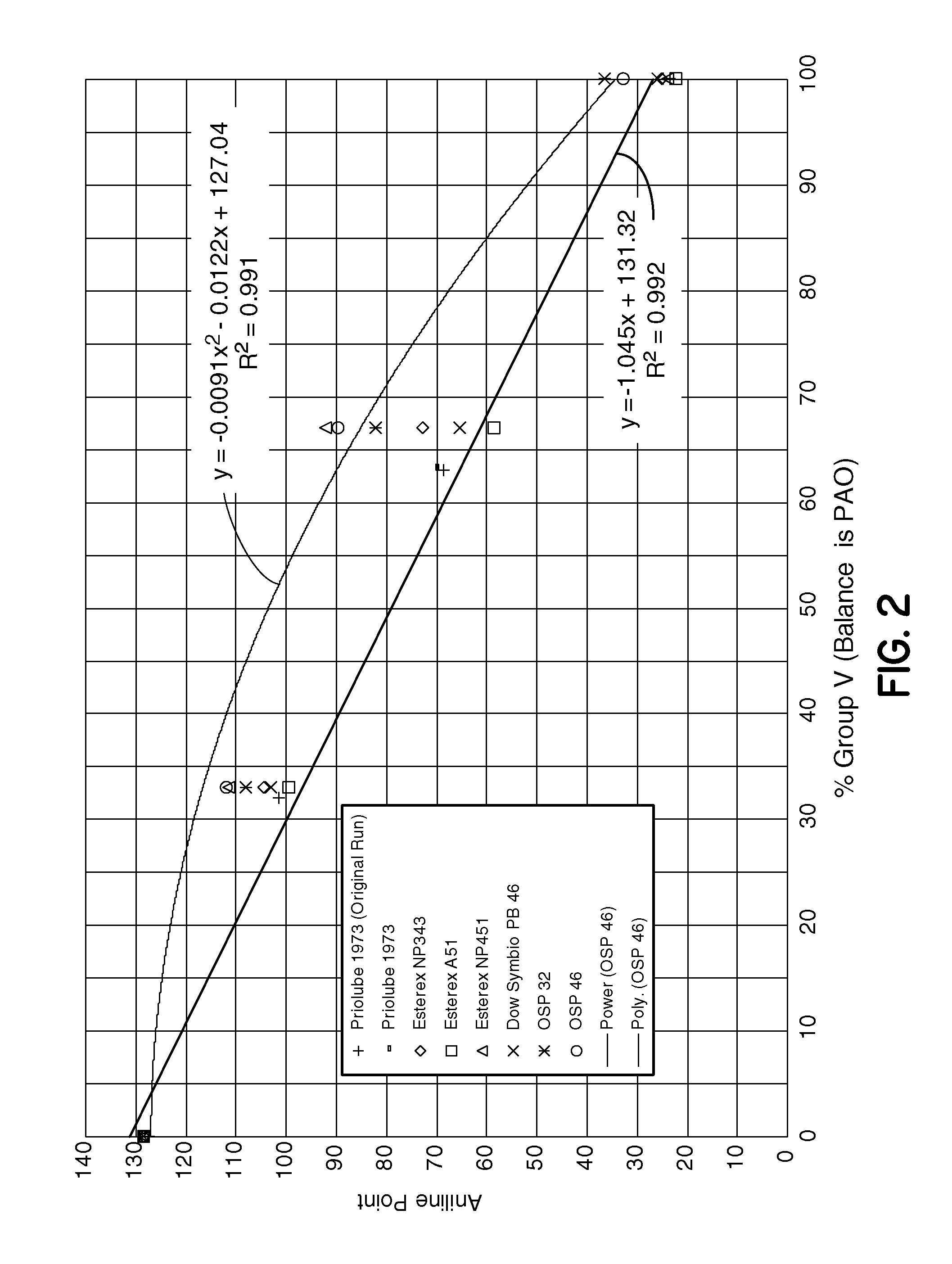

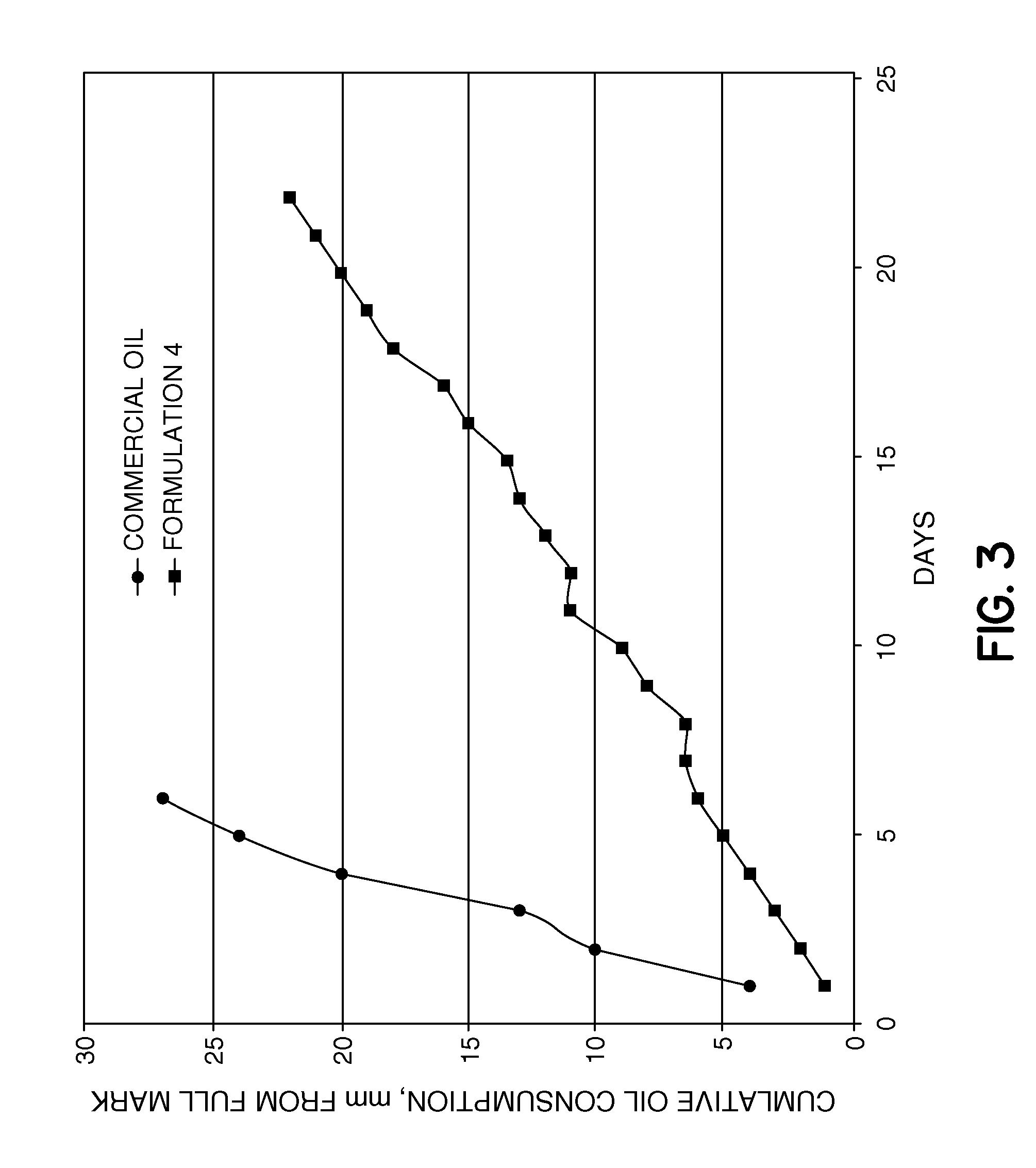

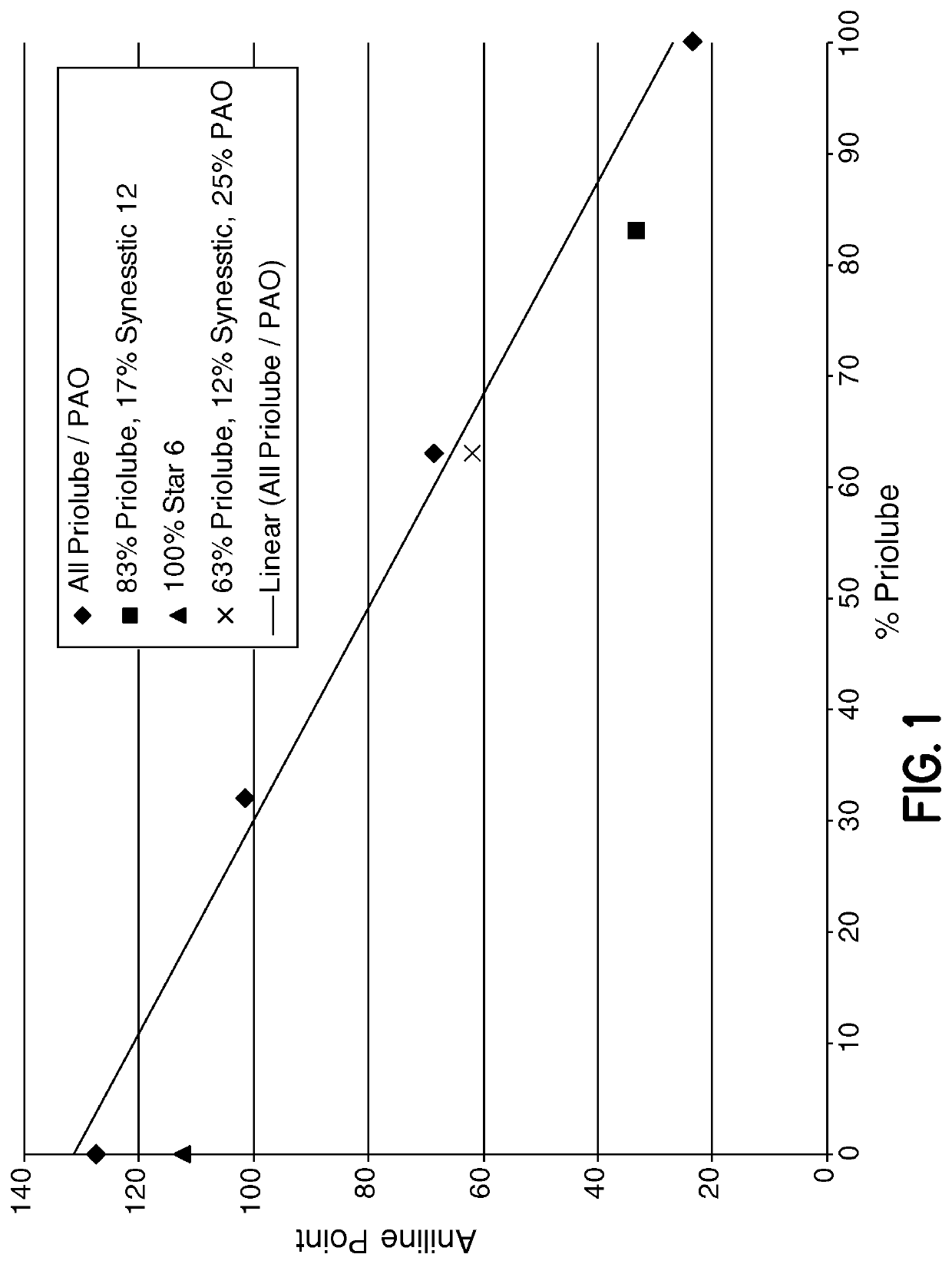

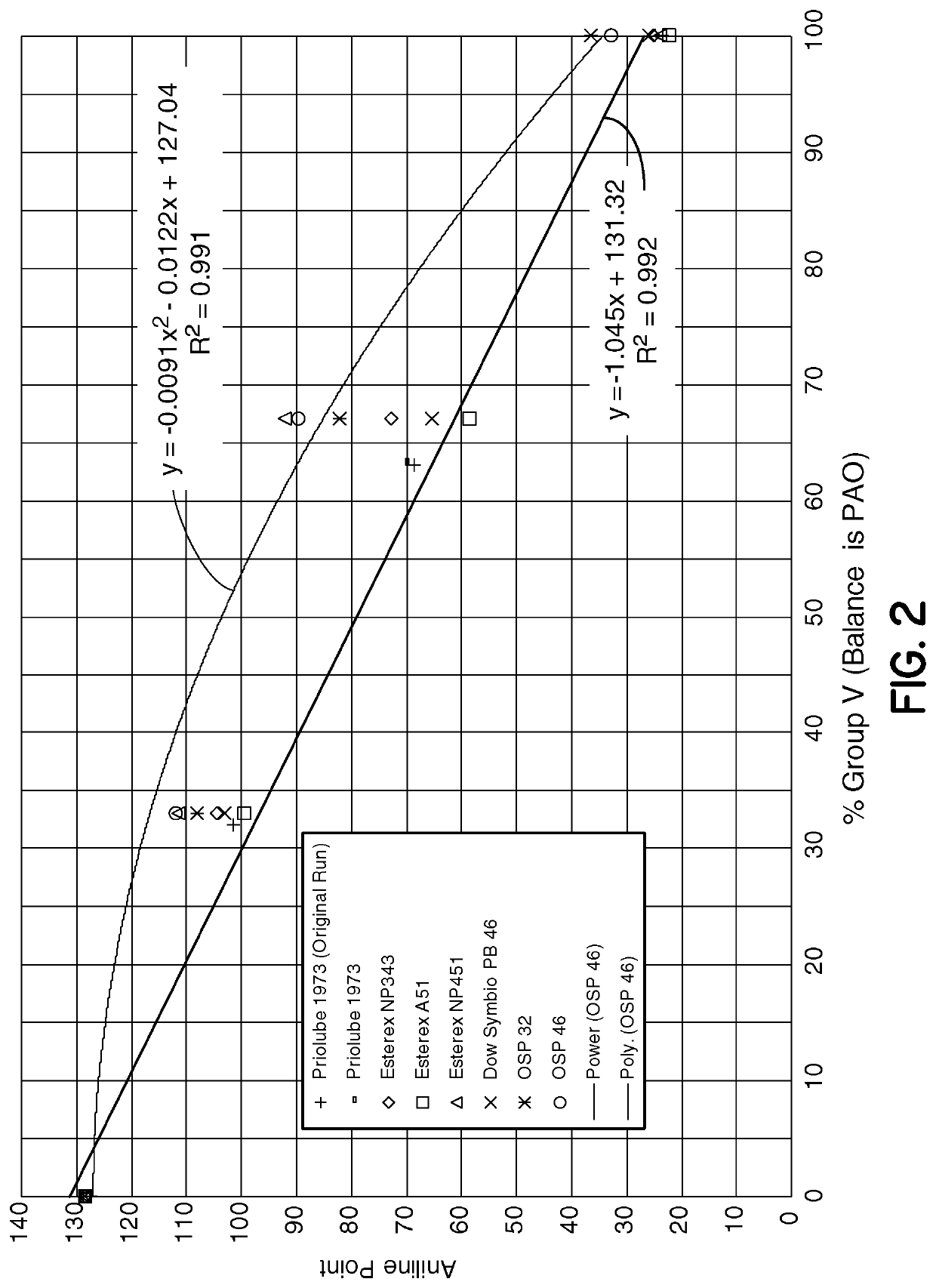

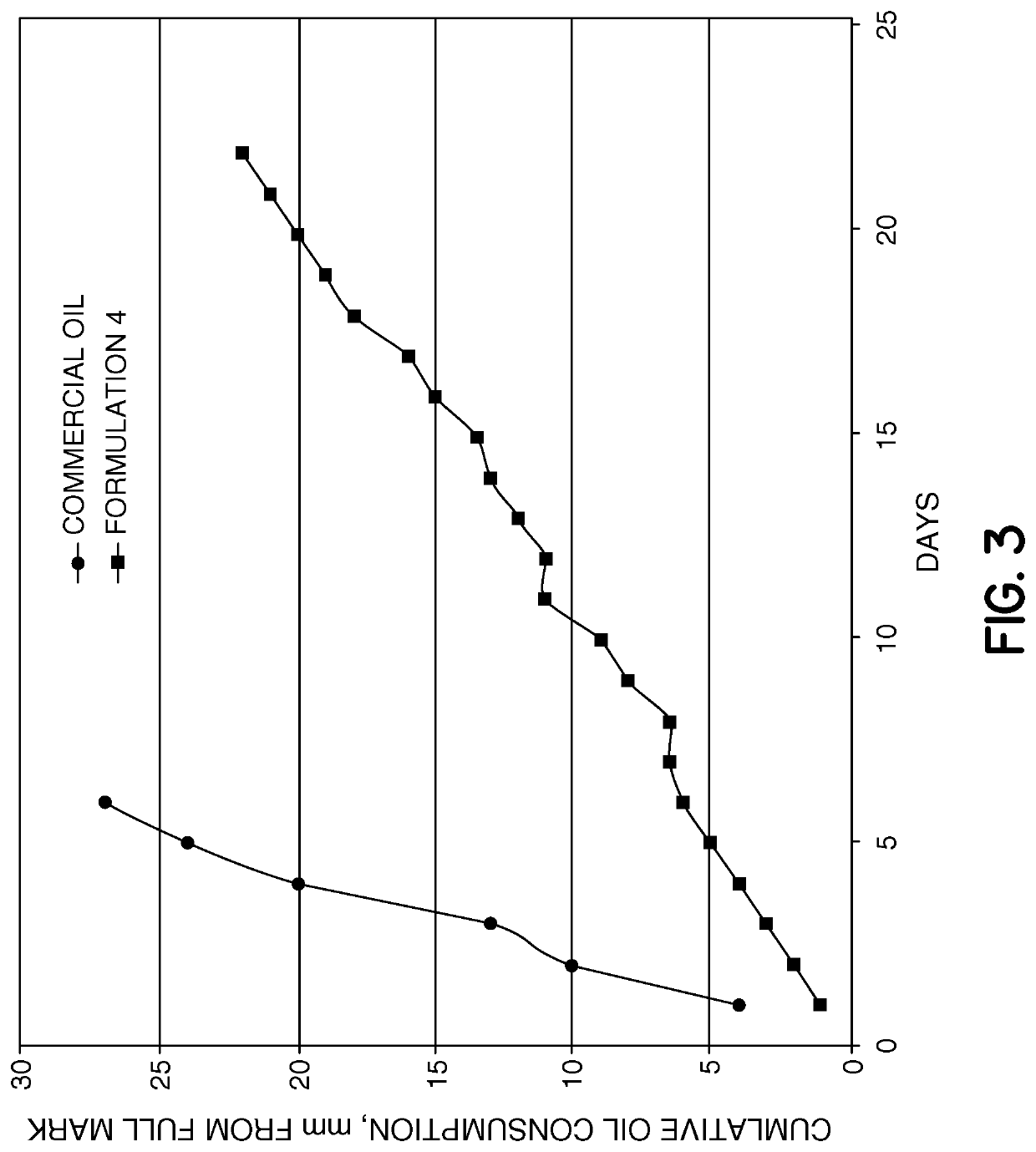

Lubricant for preventing and removing carbon deposits in internal combustion engines

ActiveUS20170029734A1Prevent and remove carbon buildupPreventing buildup of carbonBase-materialsAniline pointExternal combustion engine

A lubricant formulation which is effective to remove or prevent carbon deposits in internal combustion engines has a solvency as defined by aniline point from about 20 to about 115, a volatility (as measured by NOACK) of less than 15%, an oxidative stability (as measured by PDSC) of above 40 minutes and a base oil viscosity of above 2 and below 10 cSt. The lubricant formulation can be formed from a blend of Group III, IV and V lubricants, in particularly polyalphaolefins, alkylated naphthalenes and polar Group V base stocks such as polyol esters. The carbon deposits can be removed from the engine piston by simply running the engine with the lubricant for one required cycle, or can be used continuously in the engine to prevent buildup.

Owner:VGP IPCO LLC

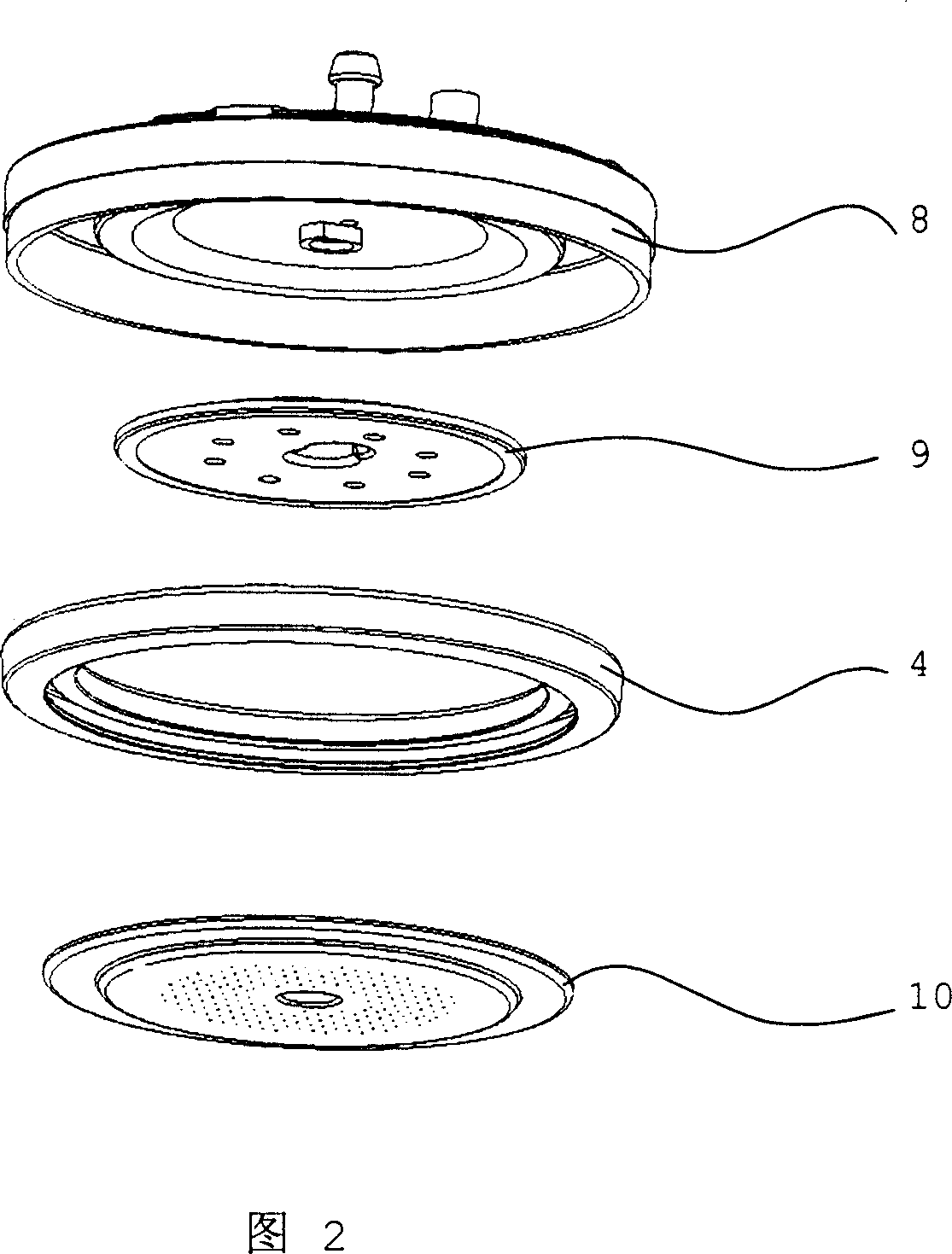

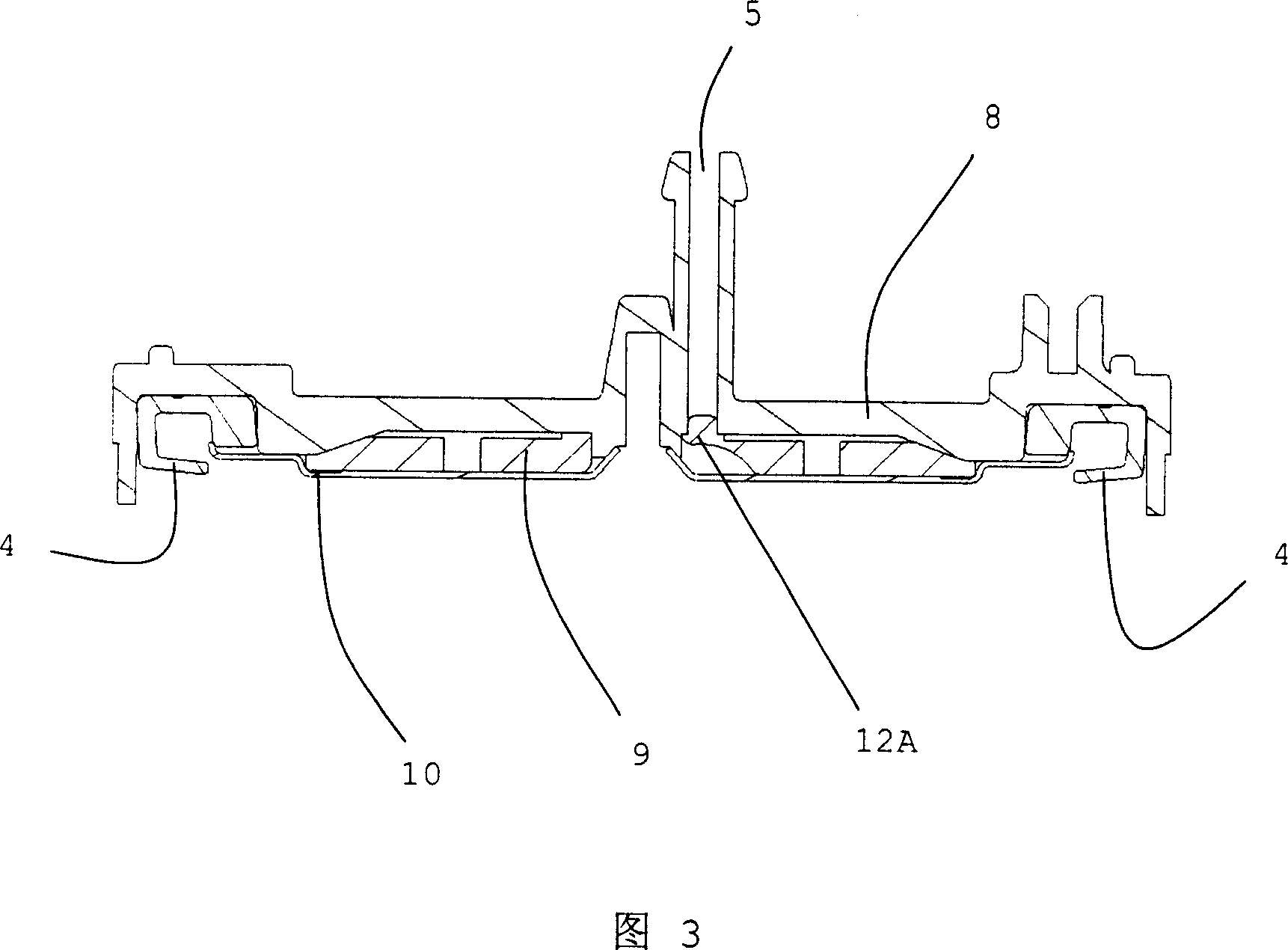

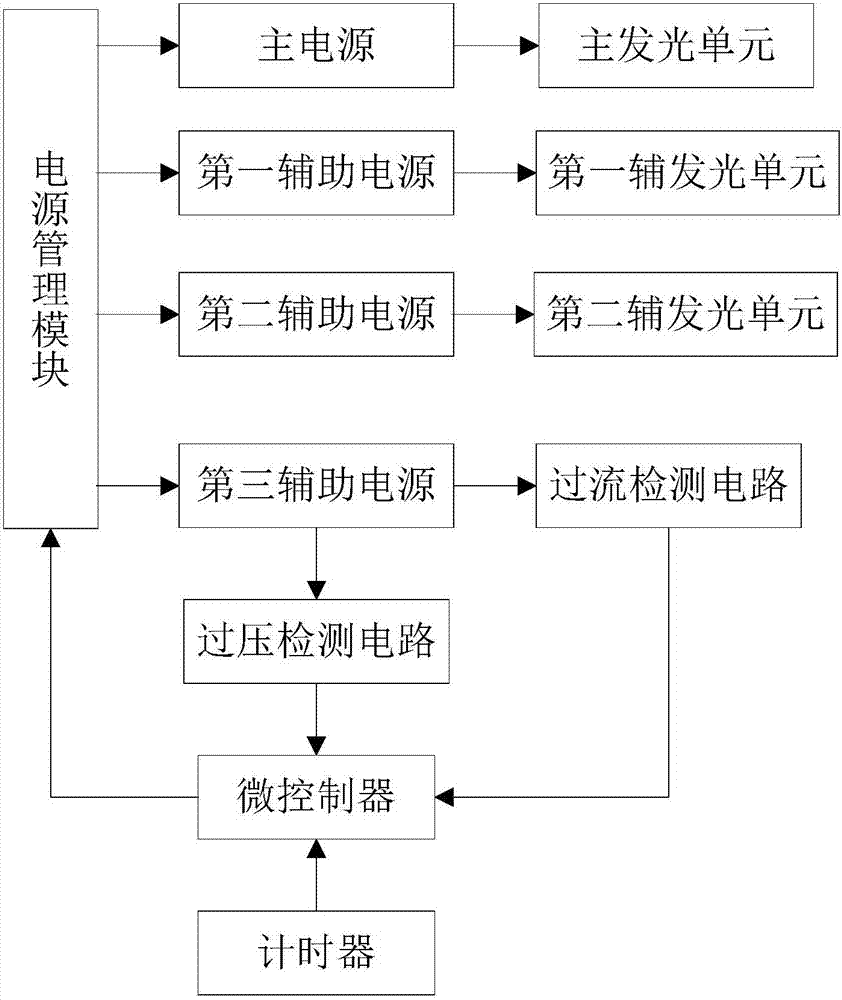

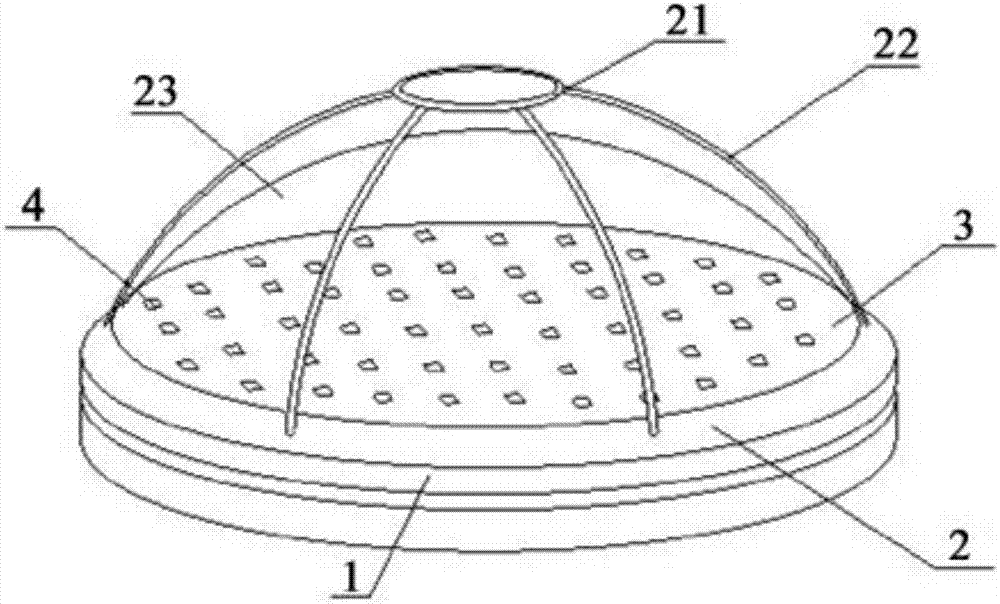

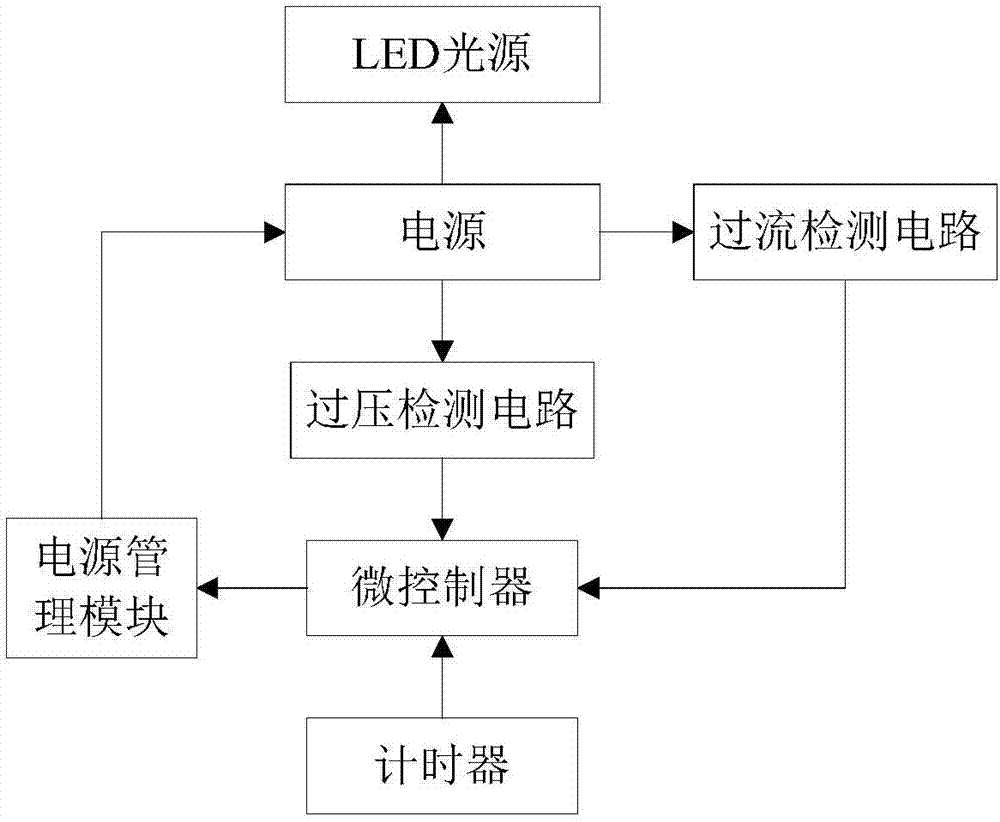

Multifunctional LED lamp

InactiveCN107339850AIncrease or decrease light intensityReduce light intensityElectrical apparatusElectric circuit arrangementsGlass coverLight guide

The invention discloses a multifunctional LED lamp. The multifunctional LED lamp comprises a lamp body, a metal cover and a lamp plate; the metal cover is composed of a top end metal ring and metal supporting pieces evenly connected between the top end metal ring and the lamp body, and a glass cover is arranged between the metal supporting pieces; the lamp plate is sequentially provided with a main light emitting unit, a first auxiliary light emitting unit and a second auxiliary light emitting unit from inside to outside; the main light emitting unit, the first auxiliary light emitting unit and the second auxiliary light emitting unit are each provided with a plurality of LED light sources; the positions, matched with the LED light sources, of the back side of the lamp plate are provided with cooling columns; a light guiding plate and a light diffusion plate are sequentially arranged on the light outgoing side of the LED light sources; and the lamp plate, the light guiding plate and the light diffusion plate are sequentially installed in the lamp body. According to the multifunctional LED lamp, the light intensity of an LED refrigeration house lamp can be increased or decreased by controlling the number of the light emitting units, the light guiding plate and the light diffusion plate are arranged on the light outgoing side of the LED light sources, dazzle light is effectively eliminated, and the temperature accumulation phenomenon on a center point of the lamp plate is eliminated through the cooling columns.

Owner:成都青岗科技有限公司

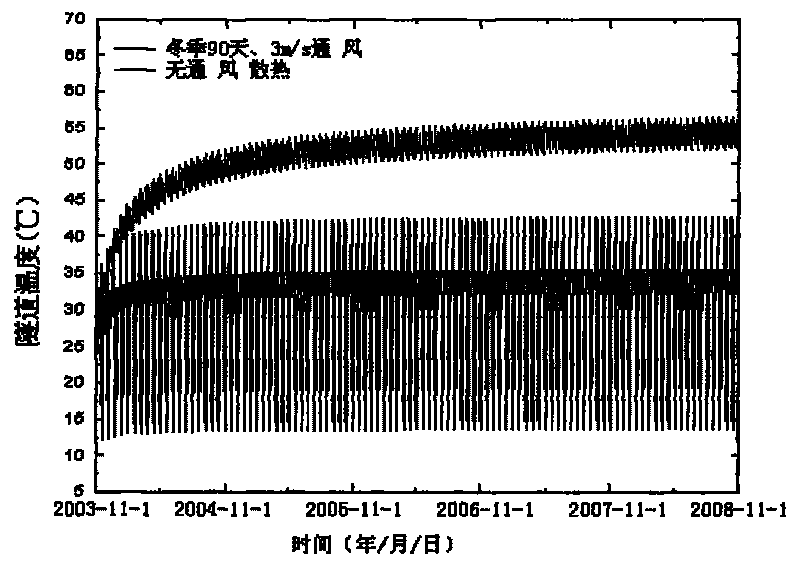

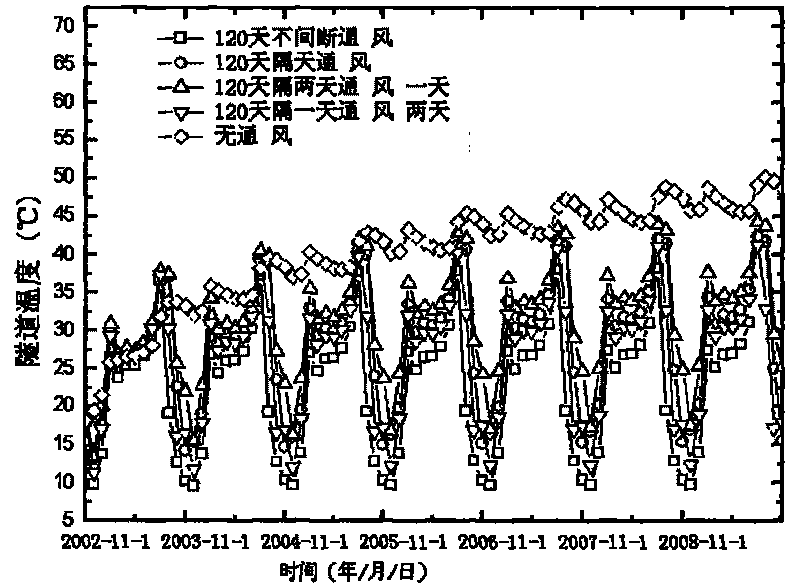

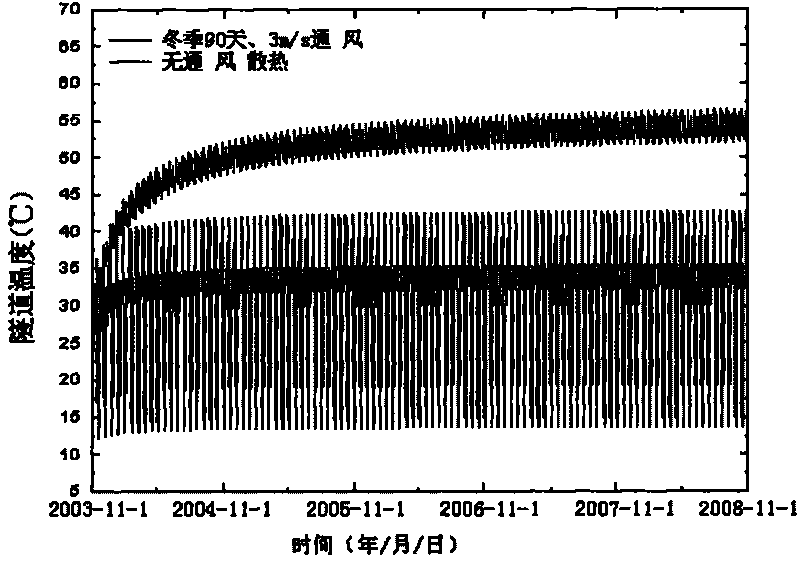

Method for reducing temperature of cable tunnel

InactiveCN101694933AReduce the temperatureReduce cooling costsCable installations in tunnelsTunnel/mines ventillationControl systemTemperature difference

The invention discloses a method for reducing the temperature of a cable tunnel. The method comprises at least the following steps: step 1: a ventilation system is arranged in the cable tunnel and the ventilation system at least comprises a blast blower, an exhauster and a control system; step two: the control system obtains and computes the temperature difference inside and outside the cable tunnel; and step 3: when the internal and external temperature difference in the step 2 is greater than the first set value, the control system starts the blast blower and the exhauster so as to exhaust the heat in the cable tunnel. In the invention, the ventilation system arranged in the cable tunnel is utilized to set different ventilation time intervals and different ventilation strategies, the safety of the cable tunnel is ensured and the temperature of the cable tunnel is reduced at low cost.

Owner:SHANGHAI ELECTRIC POWER DESIGN INST +1

Method for deeply removing phosphorus in water by using calcined limonite

ActiveCN105152267AEfficient and specific adsorptionImprove acid resistanceWater contaminantsWater/sewage treatment by ion-exchangeParticulatesNanostructure

The invention discloses a method for deeply removing phosphorus in water by using calcined limonite. The method is characterized by comprising the steps of calcining limonite particulates with the particle sizes of 0.5-3mm at the temperature of 250-500 DEG C to obtain nanometer structured calcined limonite particulates with hematite as a main physical phase, filling a water treatment tank for deeply removing phosphorus with the nanometer structured calcined limonite particulates, and then, treating sewage through enabling the sewage to flow through the water treatment tank for deeply removing phosphorus in a filtering way of keeping hydraulic retention time within 0.5-2 hours, wherein the concentration of phosphorus in the treated effluent is smaller than 0.1mg / L; and enabling the adsorbed and saturated limonite particulates to sequentially pass through a NaOH water solution and a hydrochloric acid solution to soak and regenerate. The calcined limonite particulates provided in the method have an efficient specific adsorption effect on a trace of phosphorus in water, the concentration of phosphorus in the effluent can reach the standard of a second-class ground water body, and the effective period of adsorption operation can exceed four years.

Owner:ANHUI MEIZIRAN ENVIRONMENTAL TECH

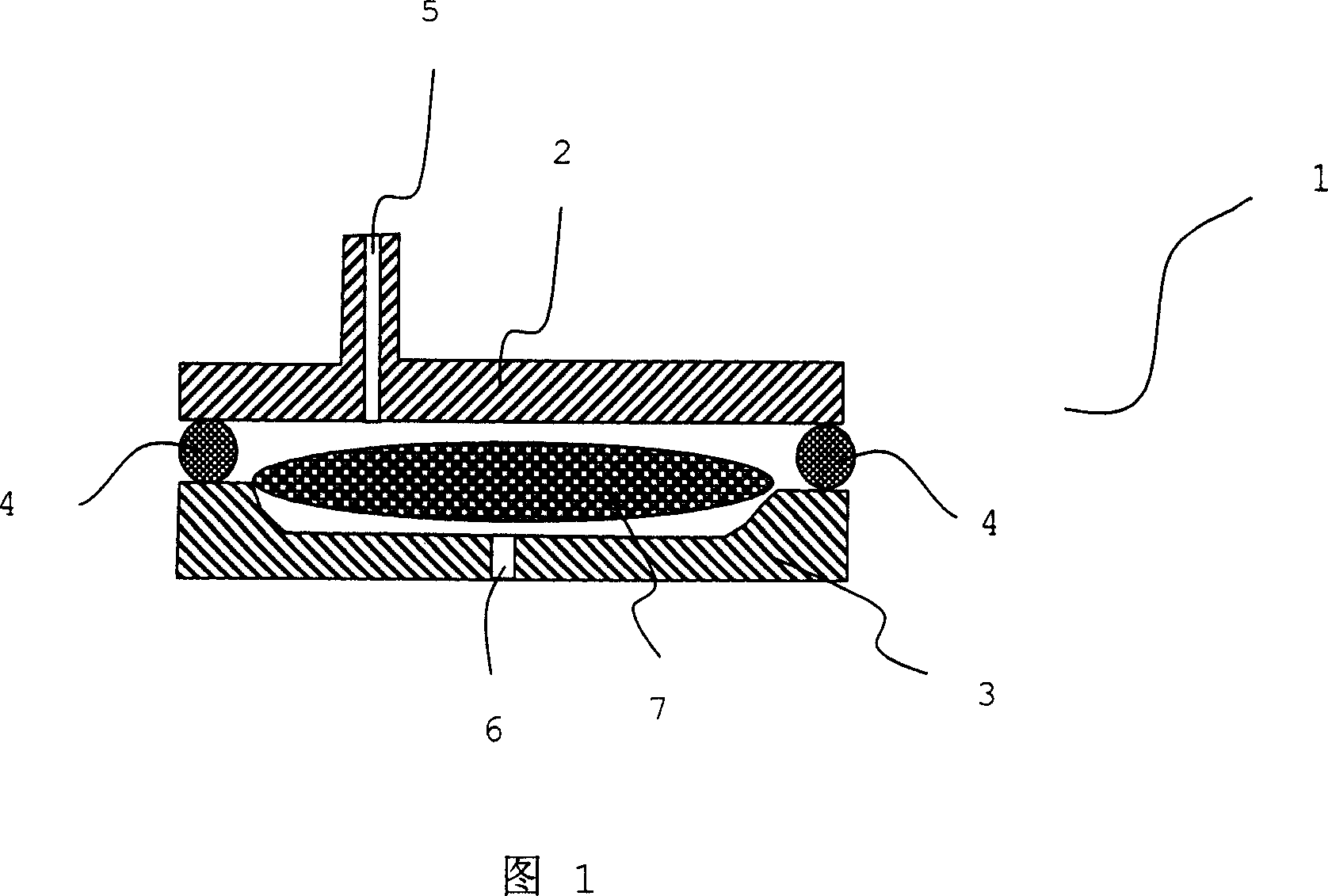

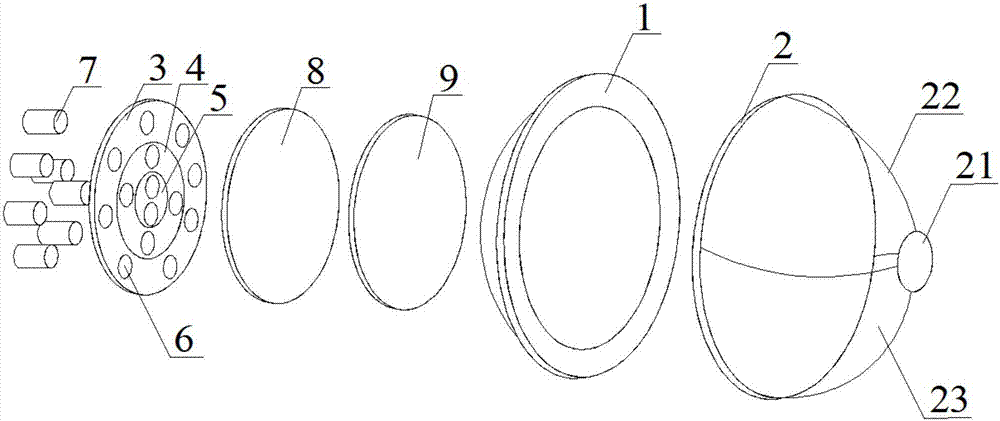

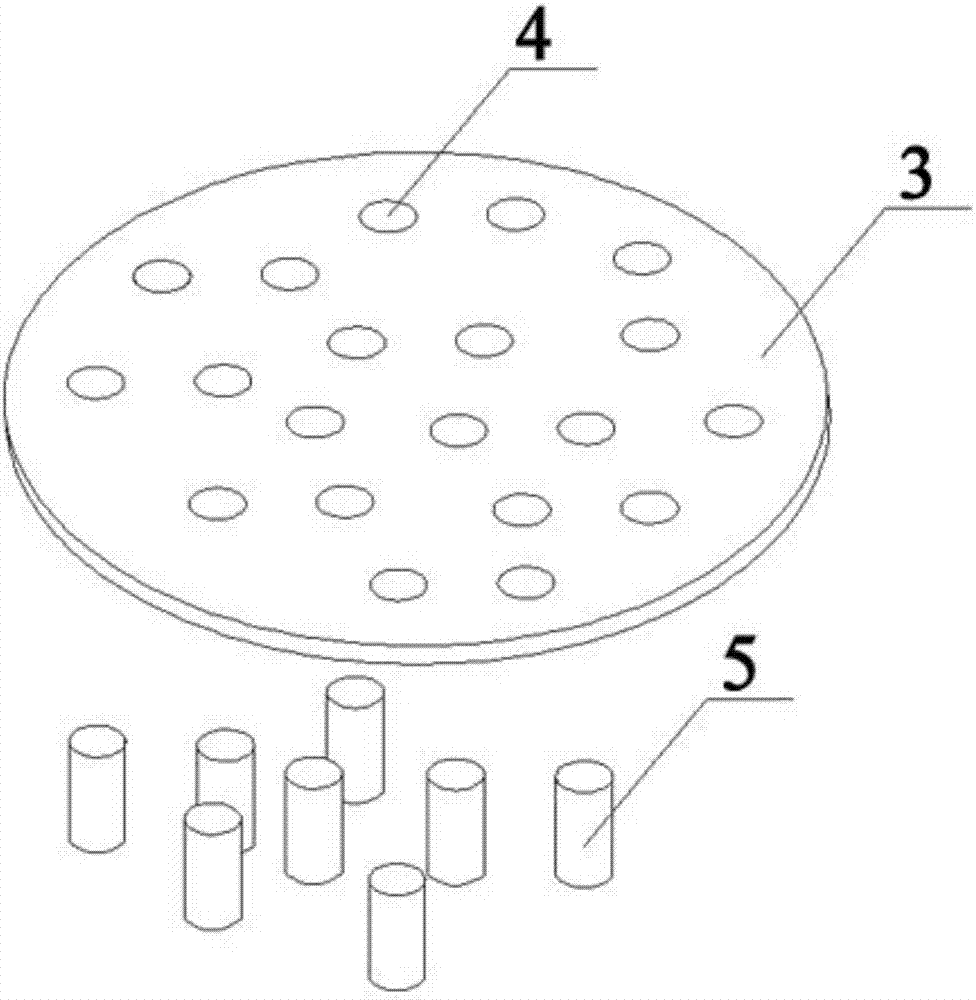

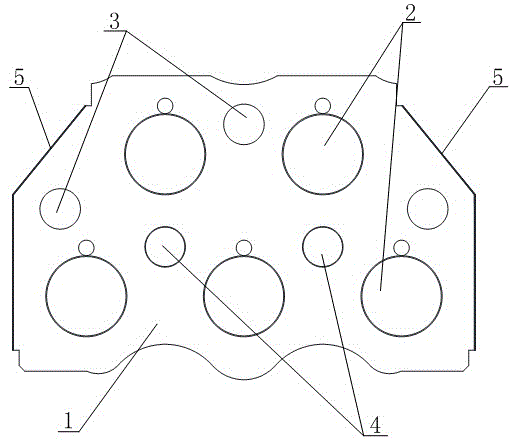

Large-area illumination LED refrigeration house lamp with good heat dissipation property

InactiveCN107328162ASolution to short lifeGuaranteed independenceElectrical apparatusLighting heating/cooling arrangementsGlass coverEngineering

The invention discloses a large-area illumination LED refrigeration house lamp with the good heat dissipation property. The large-area illumination LED refrigeration house lamp comprises a lamp body (1), a metal cover (2) and a lamp panel (3). The metal cover (2) is composed of a top metal ring (21) and metal supporting parts (22) uniformly connected between the top metal ring (21) and the lamp body (1). A glass cover (23) is arranged between every two adjacent metal supporting parts (22). The lamp panel (3) is arranged in a space defined by the glass covers (23) and the lamp body (1). The lamp panel (3) is detachably mounted on the lamp body (1). A plurality of LED light sources (4) are arranged on the lamp panel (3). Heat dissipation columns (5) are arranged in the positions, matched with the LED light sources (4), of the reverse surface of the lamp panel (3). According to the large-area illumination LED refrigeration house lamp, the environment-friendly and energy-saving LED lamps are adopted; the heat dissipation columns are arranged in the positions, matched with the LED lamps, of the reverse surface of the lamp panel; independence of heat dissipation of the LED light sources is guaranteed; the phenomenon of temperature accumulation at the center point of the lamp panel is effectively eliminated; and the service life of the LED lamps is prolonged.

Owner:成都青岗科技有限公司

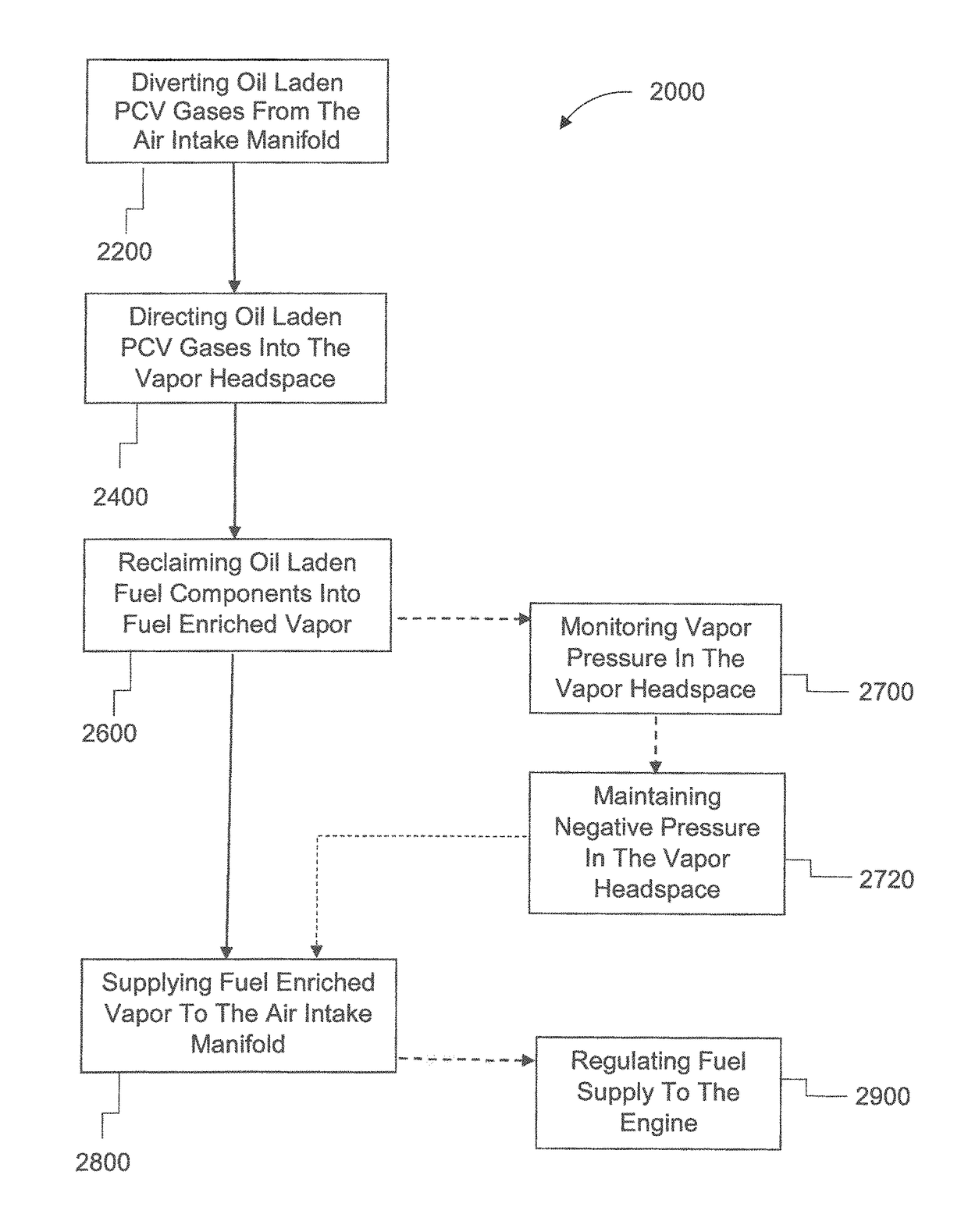

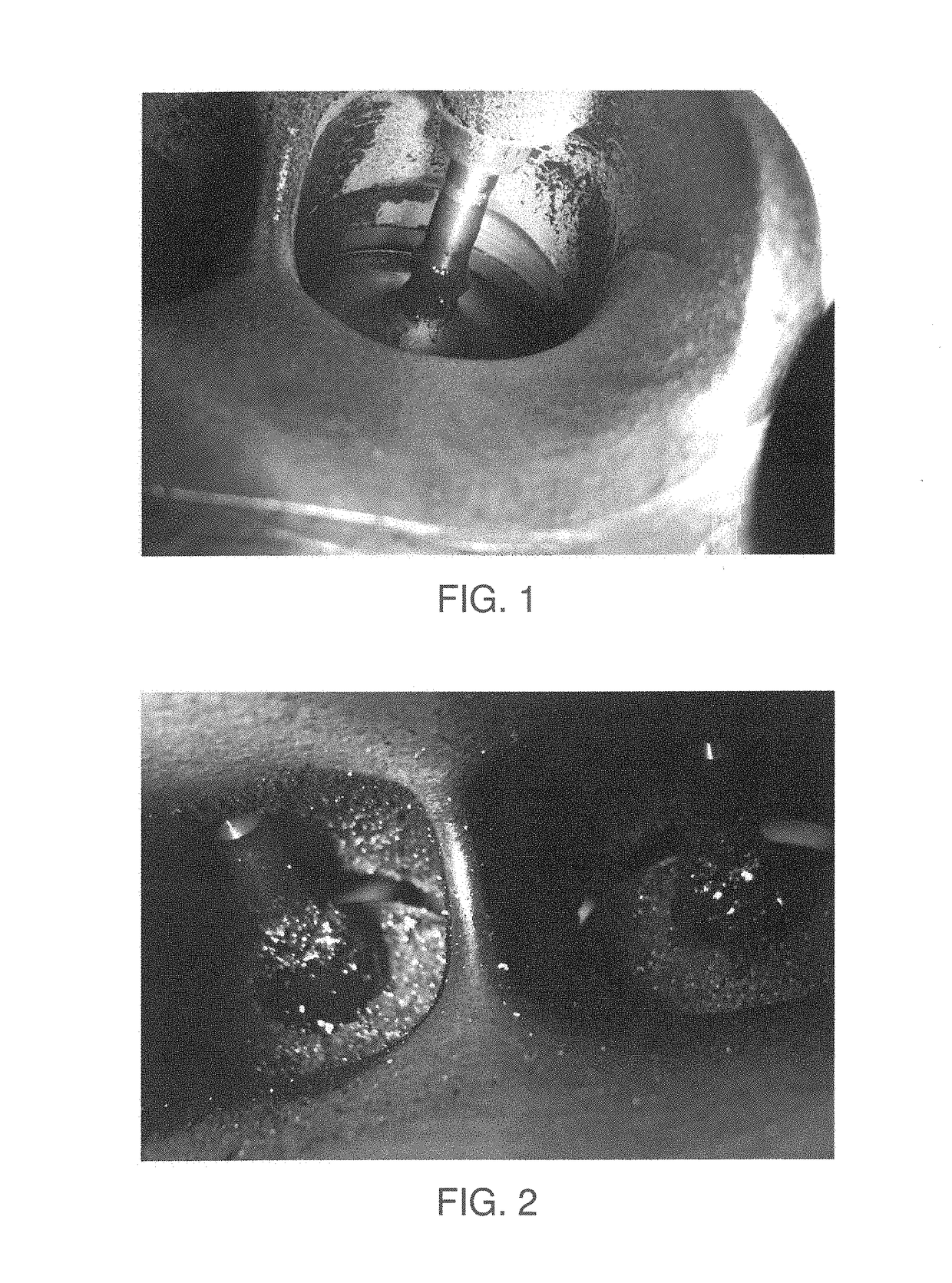

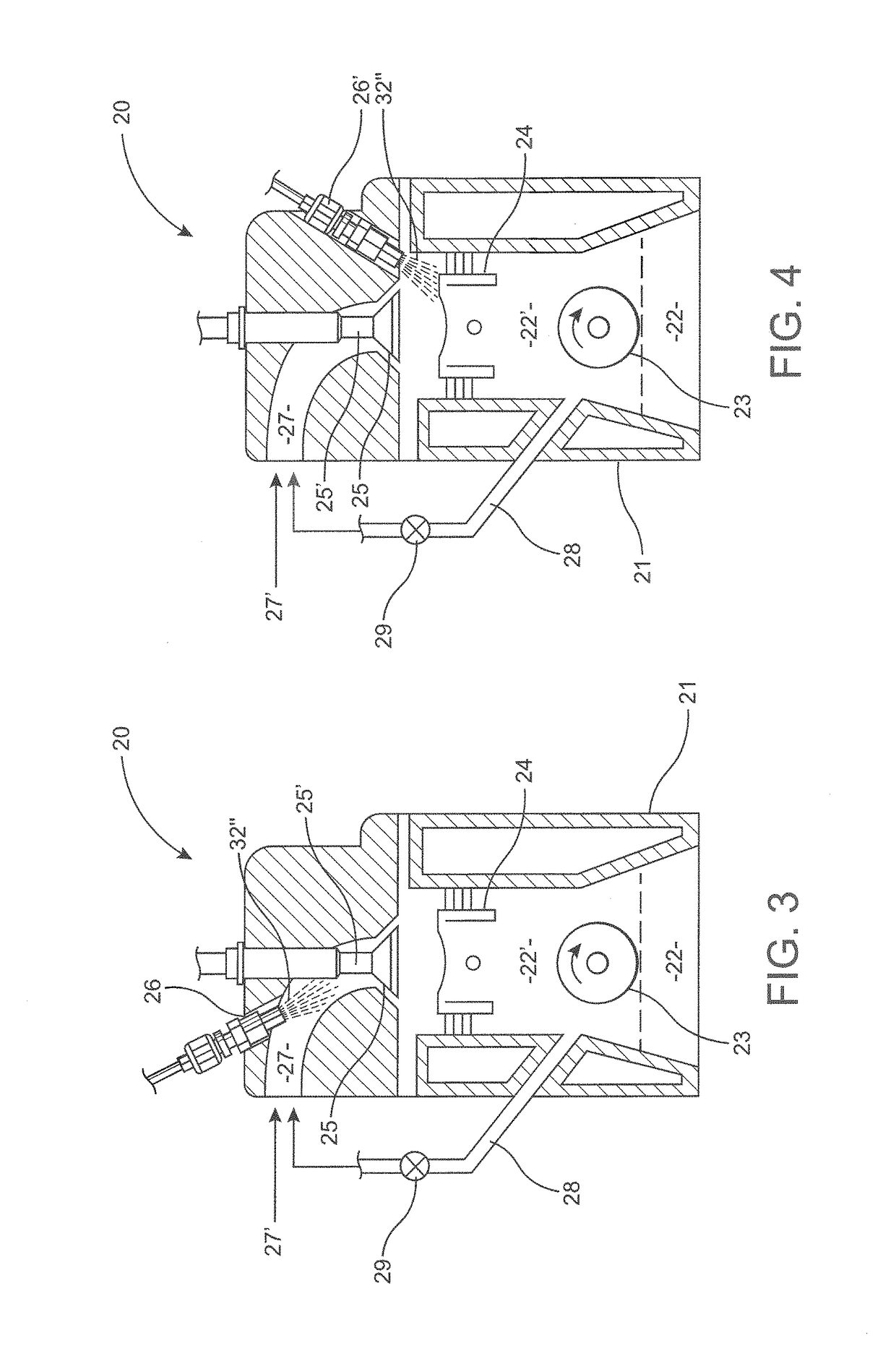

Positive crankcase ventilation gas diversion and reclamation system

InactiveUS10012119B1Eliminate buildupReduce gas emissionsElectrical controlNon-fuel substance addition to fuelFuel tankCrankcase

A positive crankcase ventilation gas diversion and reclamation system comprises a positive crankcase ventilation gas diversion line to divert oil laden positive crankcase ventilation gases from the air intake manifold of an internal combustion engine. A positive crankcase ventilation gas diversion line directs oil laden positive crankcase ventilation gases into a vapor headspace of a fuel tank. A pressure sensor measures a vapor pressure in a vapor headspace of a fuel tank, and a fuel tank vent valve is operative with a fuel tank vent line. A controller actuates the fuel tank vent valve into an open position and discharges fuel enriched vapor to the air intake manifold of the internal combustion engine. A method permits diverting positive crankcase ventilation gasses from the air intake manifold of an engine, and reclaiming oil laden fuel components and / or particulates from positive crankcase ventilation gasses.

Owner:MESA GILBERTO

Dynamic orthotic device

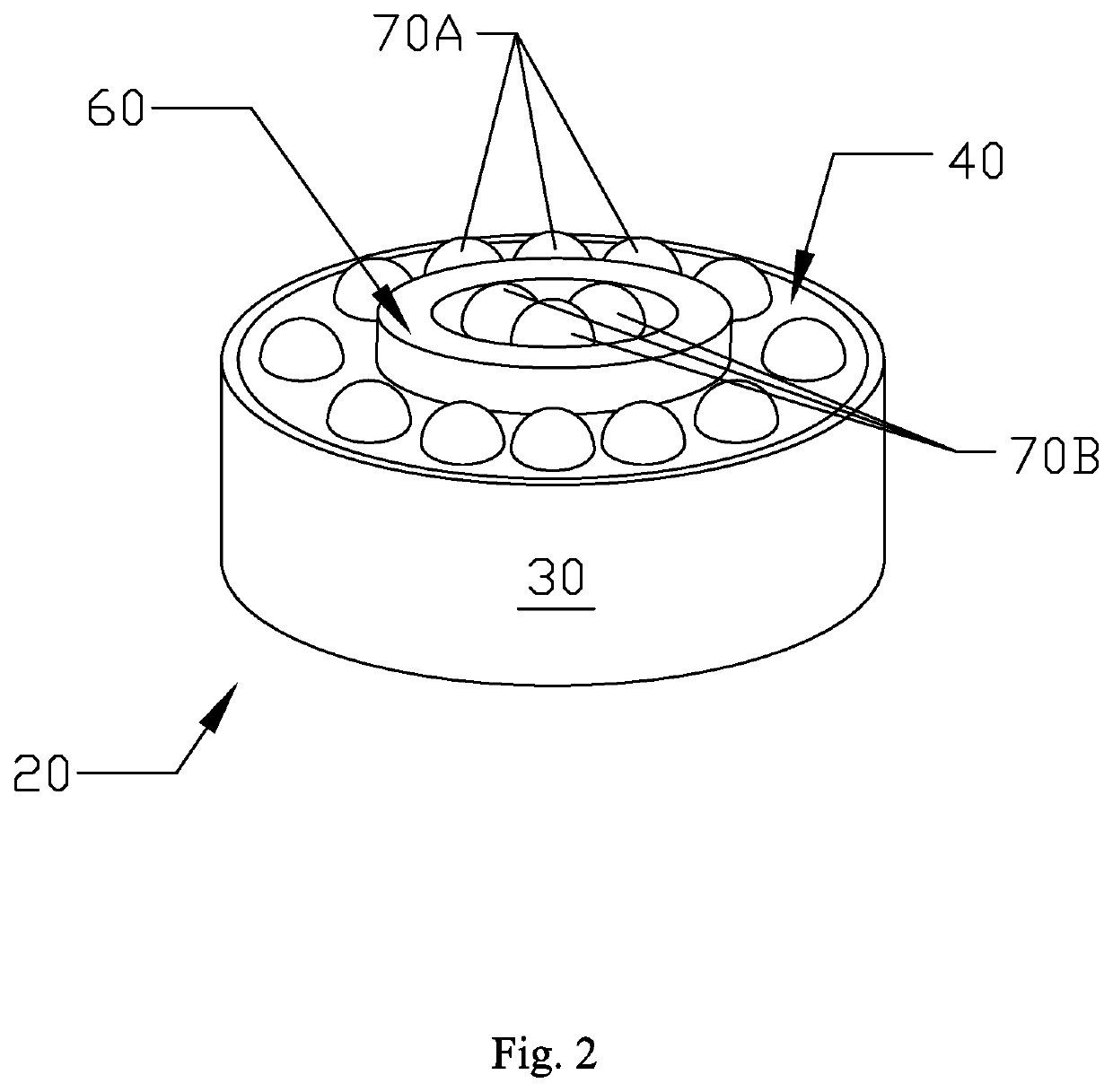

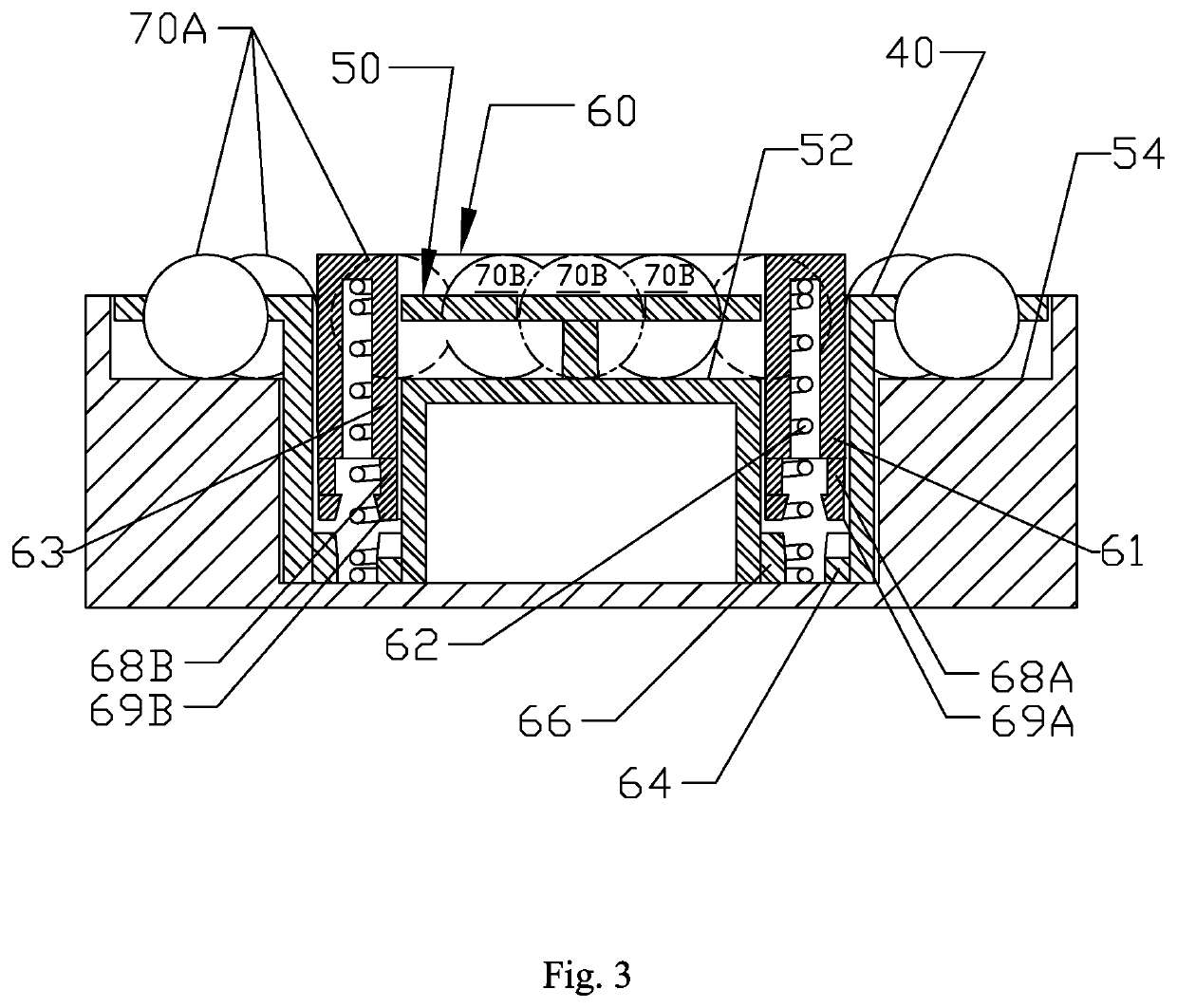

ActiveUS11452330B1Eliminating pressure buildupEliminate buildupDevices for pressing relfex pointsRoller massageCircular discOrthopedic devices

A dynamic orthotic device has a pair of rotating disks which are received in a base. Each disk houses a plurality of spherical foot-massaging balls. Each of the pair of disks is activated by a spring-biased pushbutton with arms mounted to a bottom edge of the pushbutton, each arm having a tine which engages a gear-toothed member affixed to the respective rotating disk and rotates them in opposite rotational directions. The massaging balls engage the soles of the wearer's feet in different locations with each respective step eliminating pressure buildup on the heels of the wearer.

Owner:NASIBYAN TIGRAN +1

Sulfur-based autotrophic microorganism denitrification material as well as preparation and application methods thereof

ActiveCN114620832AImprove accessibilityImprove efficiencyWater contaminantsTreatment with anaerobic digestion processesSodium acetateNitration

The invention discloses a sulfur-based autotrophic microorganism nitrogen removal material as well as a preparation method and an application method thereof. The autotrophic nitrogen removal material is a particulate matter obtained by mixing a sulfur-containing raw material with lime powder and then carrying out melting, forming and surface carbonation. The autotrophic nitrogen removal material disclosed by the invention is used as a filler of an anaerobic biological filter to construct a deep anaerobic biological filter bed, the nitrogen content of 25mg / L nitrate and nitrite can be reduced to be less than 5mg / L under the conditions that the hydraulic retention time is 40-60min at a proper temperature, the material disclosed by the invention is used for replacing an organic matter carbon source such as sodium acetate for nitrogen removal by denitrification, and the nitrogen removal cost is saved by more than 50%.

Owner:HEFEI UNIV OF TECH +1

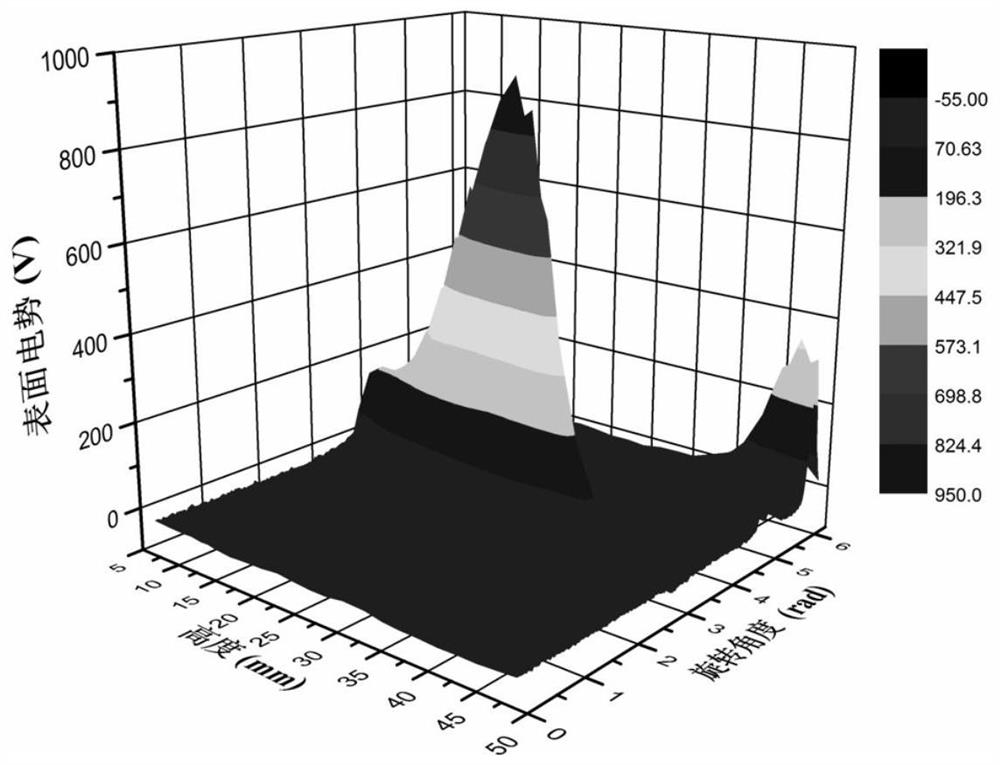

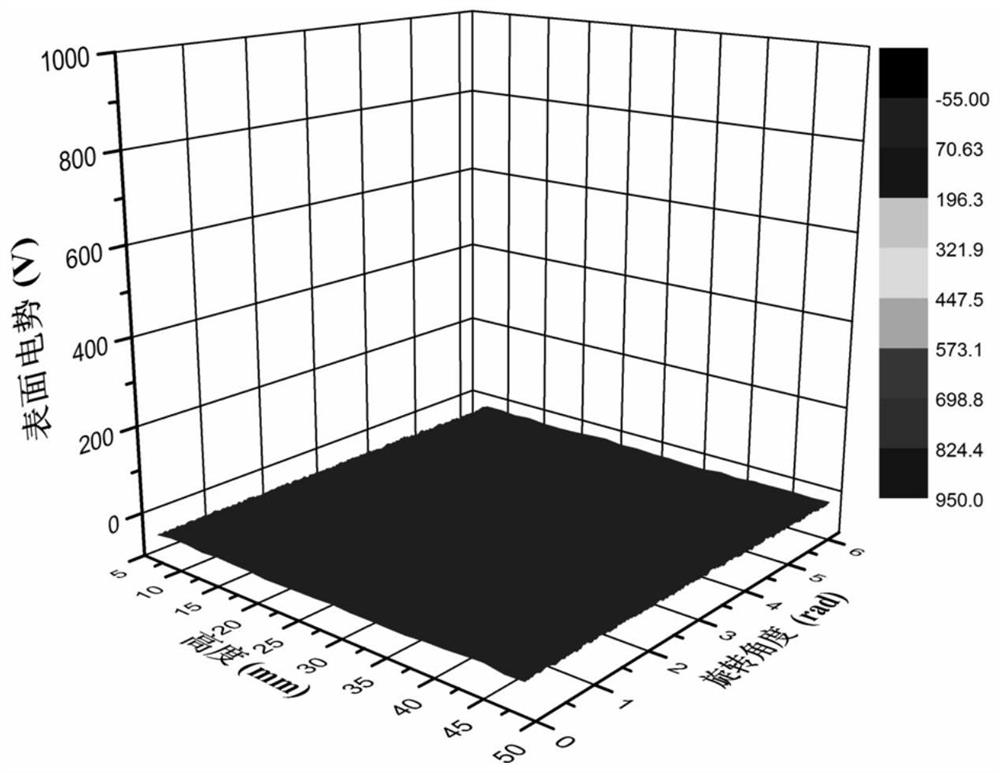

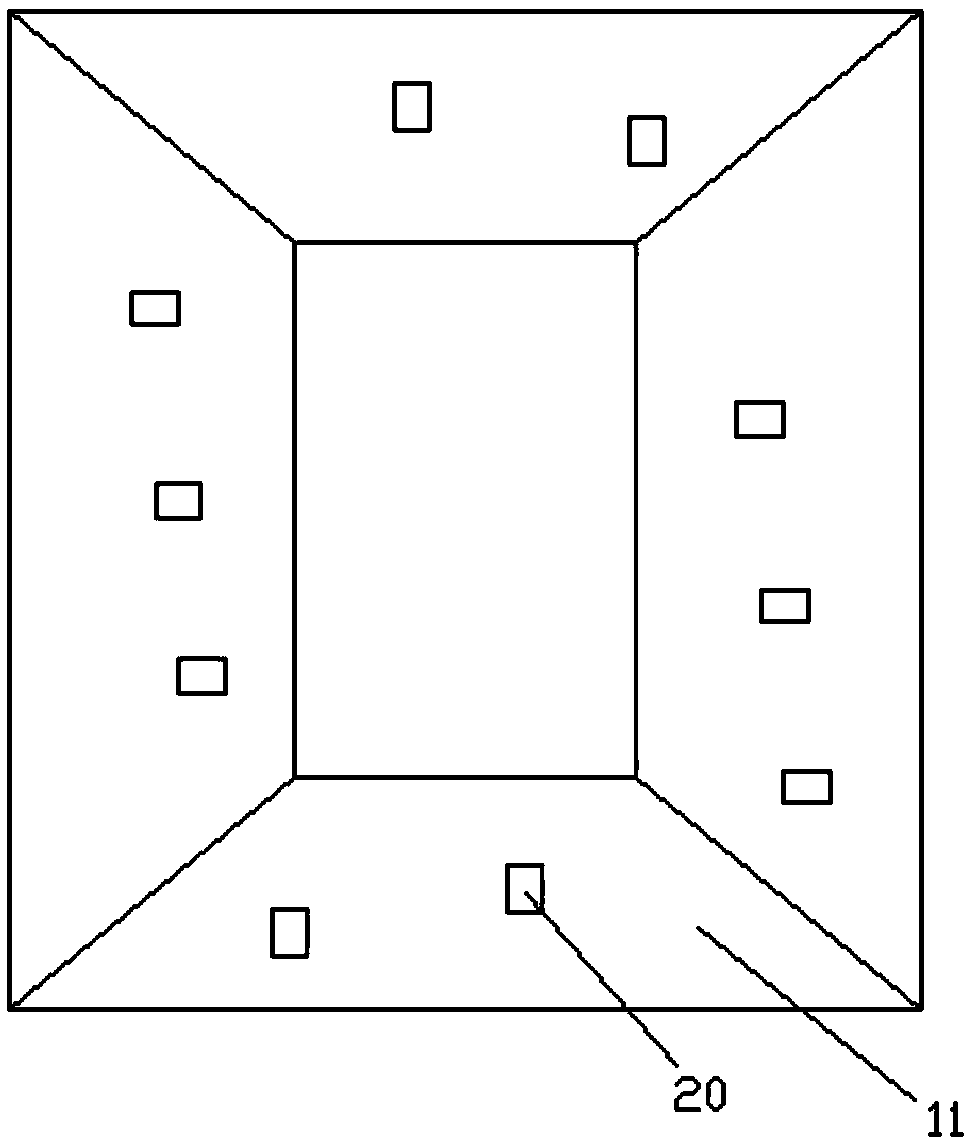

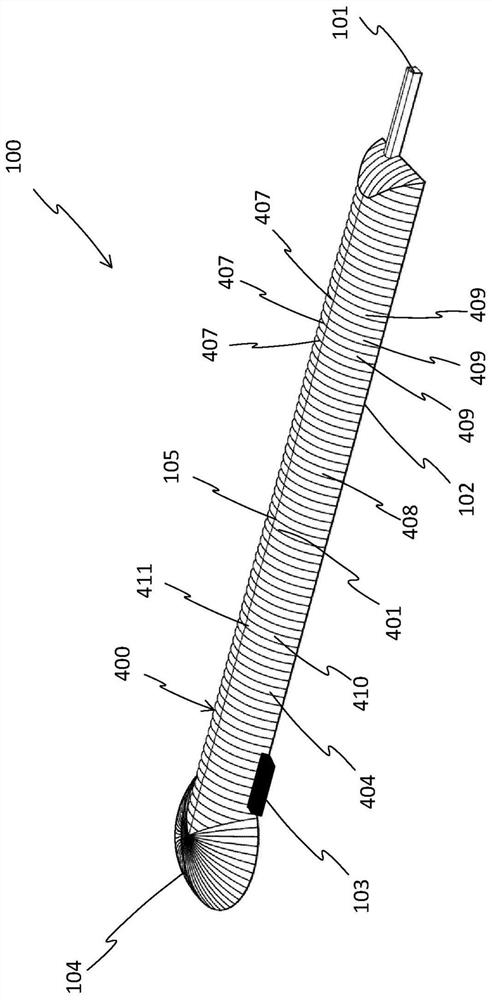

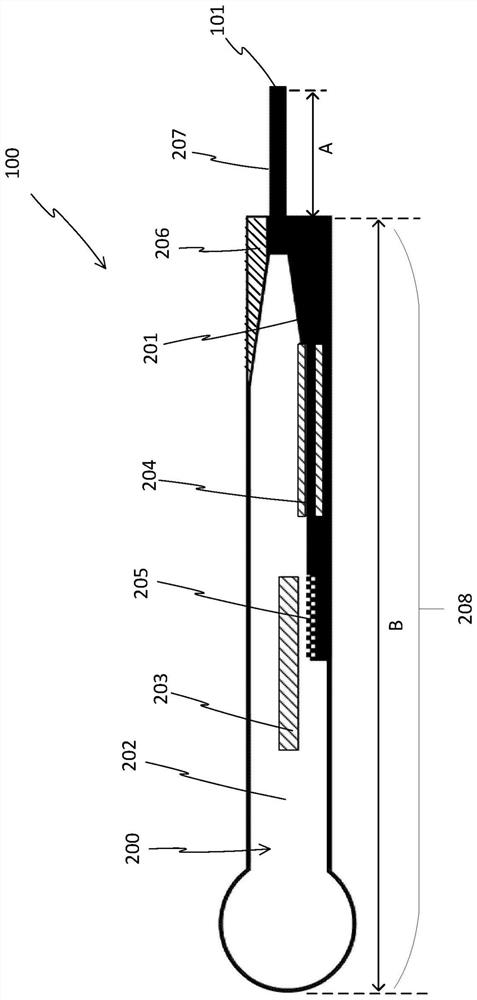

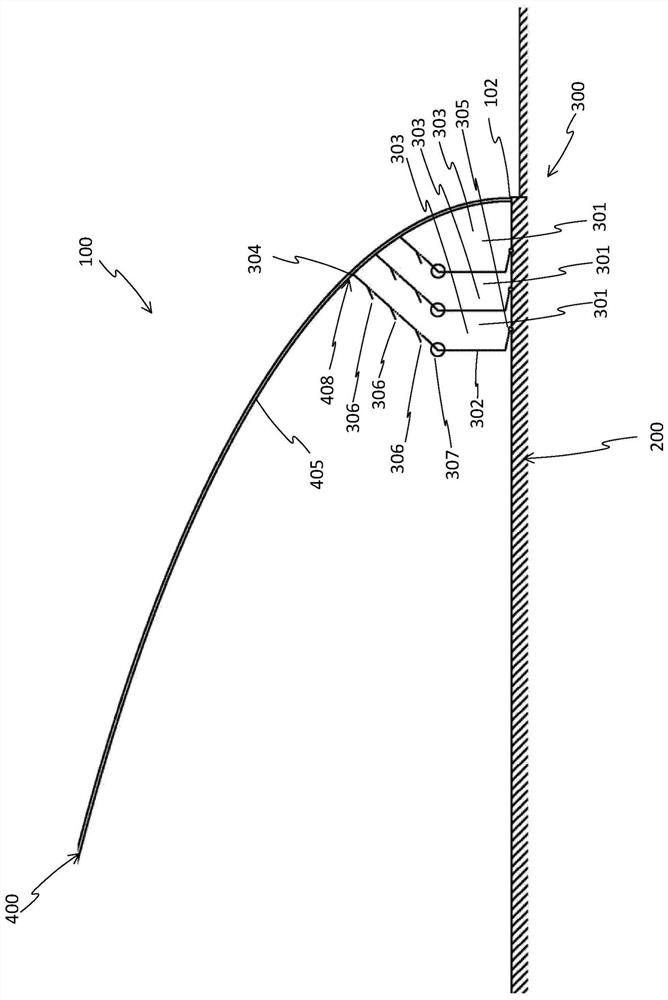

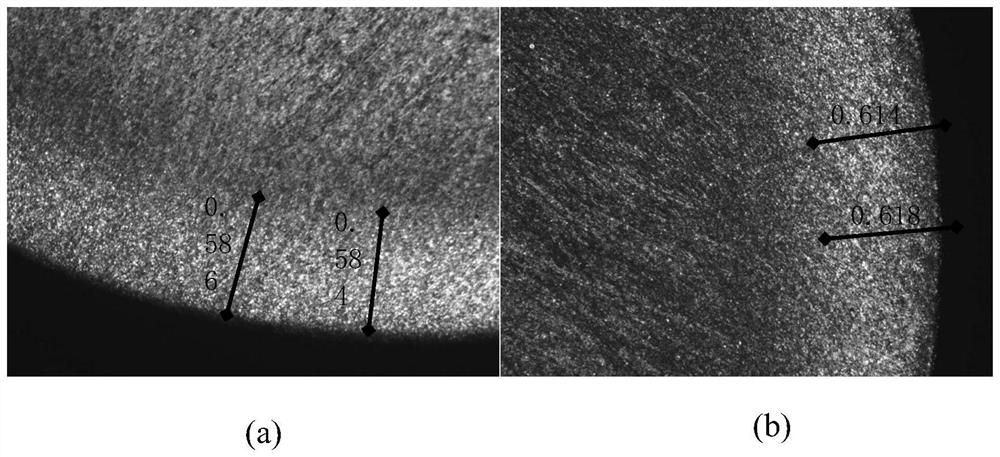

Insulator surface charge rapid dissipation method and device based on X-rays

ActiveCN111786309AIntegrity guaranteedEliminate buildupCable installation apparatusRadianceEngineering

The invention discloses an insulator surface charge rapid dissipation device and method based on X-rays. The method comprises the following steps 1, pre-installing an X-ray source around an insulatorof a gas insulated transmission line; and 2, periodically irradiating the surface of the insulator by adopting X-rays according to operation experience so as to eliminate accumulated charges. According to the invention, the device is flexible in design, and can adjust the radiation quantity, radiance, radiation time and other parameters of X-rays according to the operation voltage of GIL, the sizeof the insulator, the gas type and the surface charge accumulation condition, so that the accumulated surface charge can be reduced as much as possible; the operation is simple, wherein during working, only an X-ray source pre-mounted at the periphery of the GIL needs to be turned on to irradiate the surface of the insulator with accumulated charges for a certain period of time, so that the accumulated surface charges can be reduced; and the cost is low, wherein the existing GIL structure can effectively shield the influence of X-rays on the surrounding environment, so that an additional radiation protection problem is not introduced.

Owner:HUNAN UNIV

Heat-absorbing piece for five-tube gas water heater

InactiveCN103954042AHigh thermal efficiencyBurn out preventionFluid heatersEngineeringThermal efficiency

The invention discloses a heat-absorbing piece for a five-tube gas water heater to solve the problems of lower heat efficiency and shorter service life of the conventional heat-absorbing piece. The heat-absorbing piece comprises a heat-absorbing plate; the heat-absorbing plate is provided with five mounting holes for five heat-absorbing tubes to penetrate; the heat-absorbing plate is also provided with three convex bags protruding relative to the heat-absorbing plate and provided with two perforated overturned bags used for preventing heat from being gathered; two ends of the heat-absorbing plate are respectively provided with an edgefold which is used for turning hot air back to the heat-absorbing plate; the center distance of adjacent mounting holes is 32 millimeters. By applying the heat-absorbing piece, the flow track of the hot air can be fully changed, and the time for heat exchange between the hot air and the heat-absorbing plate is controlled, so that the heat efficiency is effectively improved, the damage of the heat-absorbing piece caused when heat is gathered at a certain local position is avoided, and the service life of the heat-absorbing piece is prolonged.

Owner:成都双流积利热能科技股份有限公司

Method for Preparing a Precoated Sheet and Associated Installation

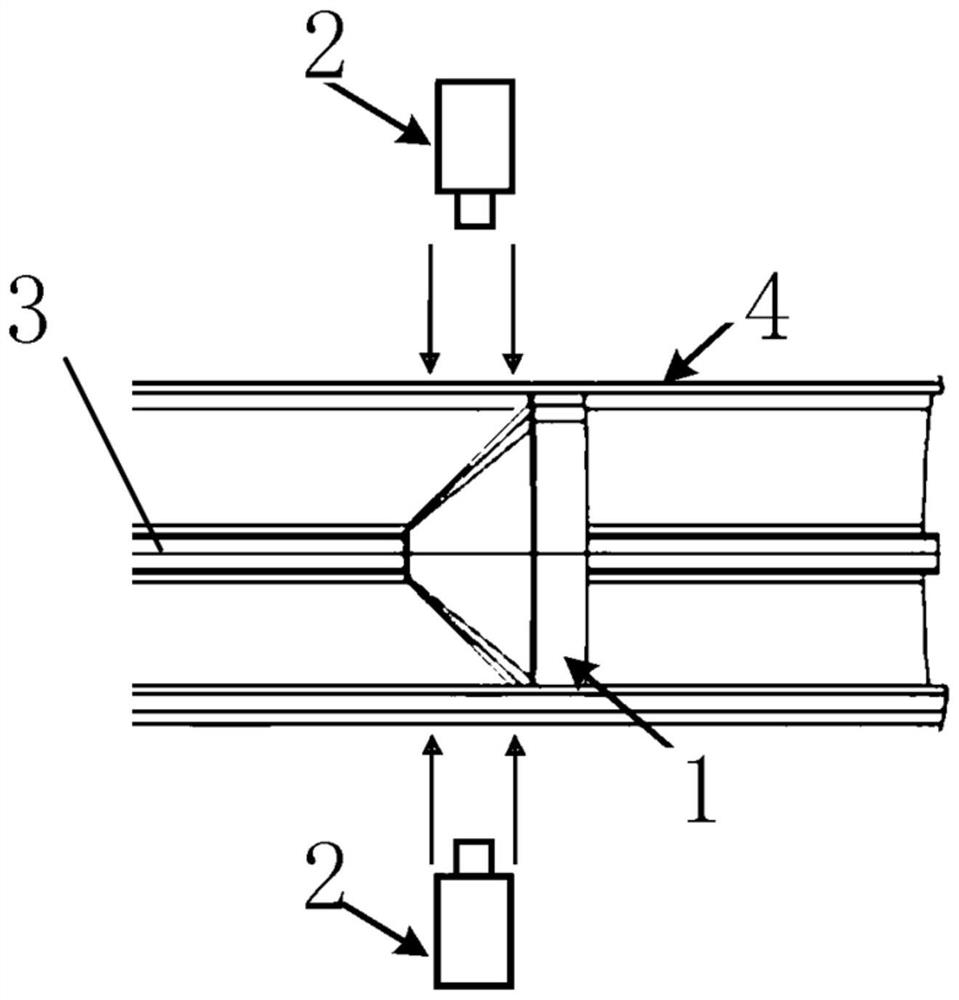

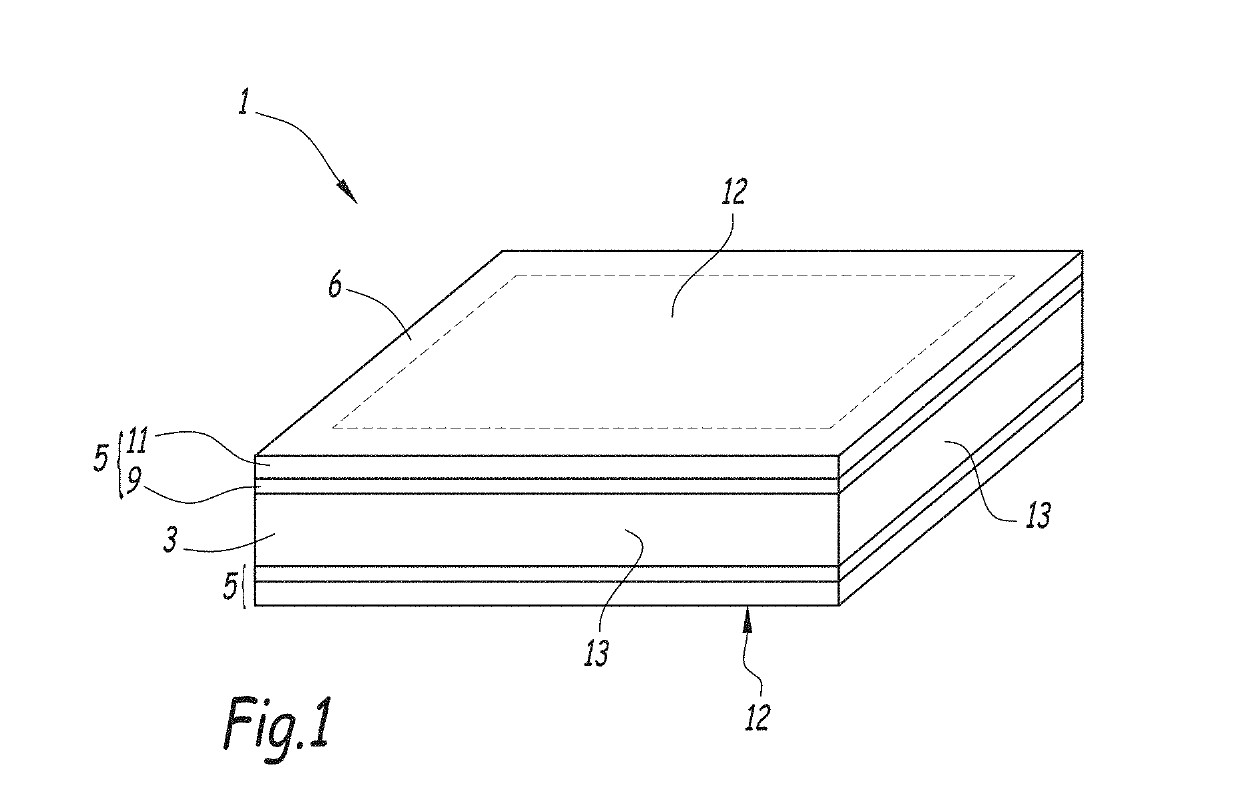

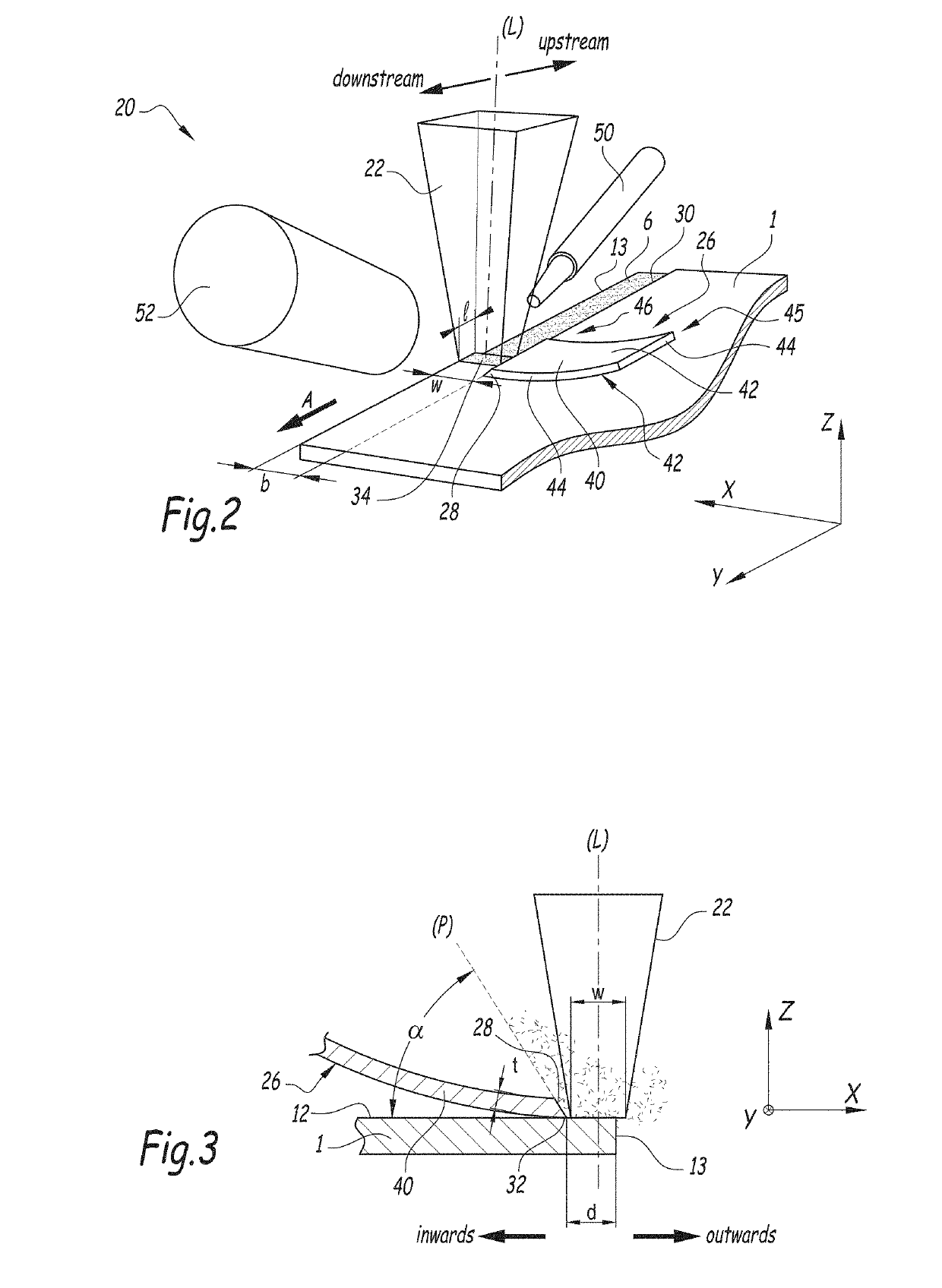

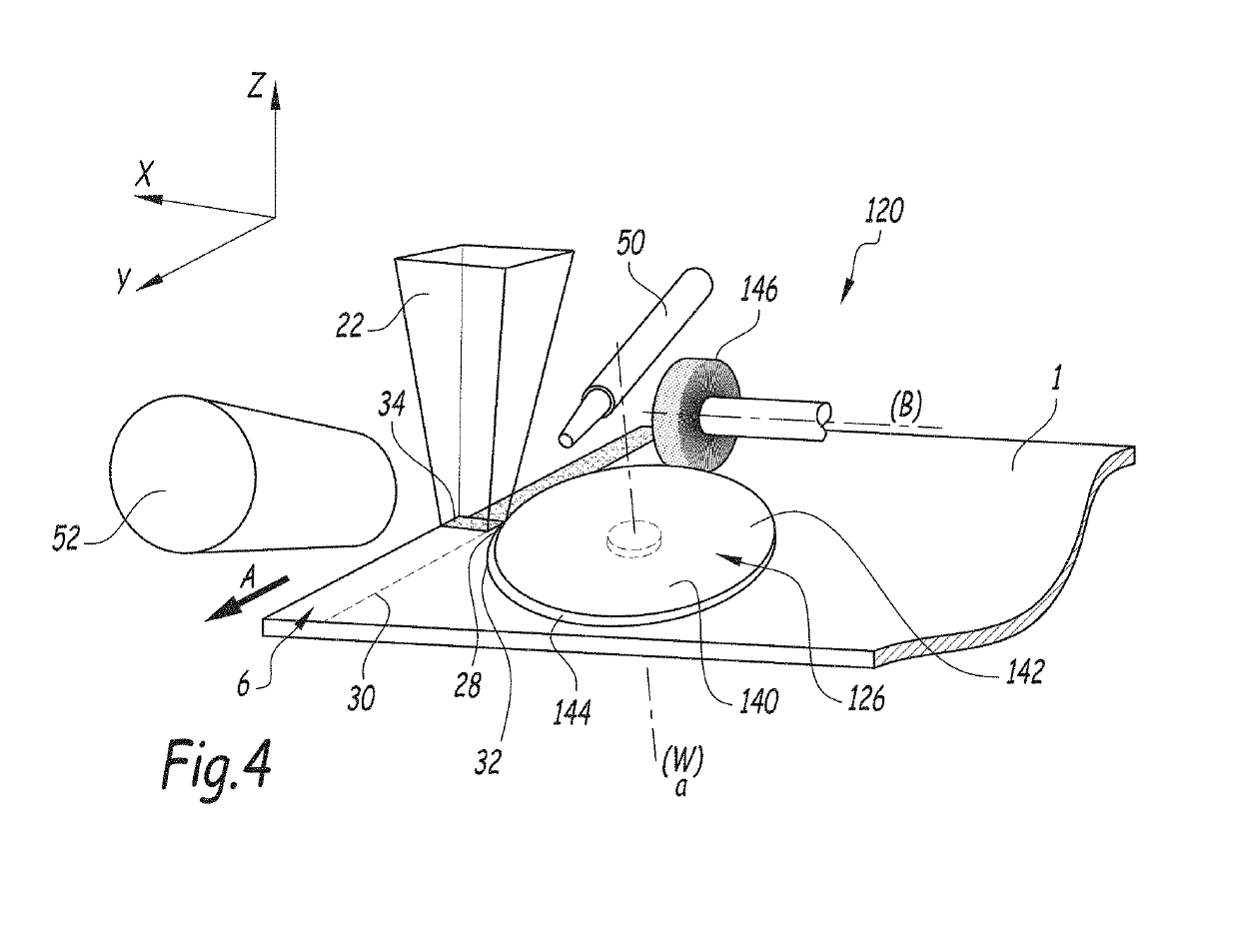

PendingUS20190193209A1Quality improvementEliminate buildupArc welding apparatusWelding/soldering/cutting articlesDihedral angleLaser beams

A method for preparing a precoated sheet is provided. The method includes providing a precoated sheet having a metallic substrate with a precoating on at least one of its faces and removing through laser ablation at least a portion of the precoating on the at least one face of the precoated sheet in a removal zone. The ablation step is carried out in an installation. The installation includes at least one protective element having a protective surface. During the ablation step, the protective surface contacts the precoated sheet in a contact area in register with the laser beam as the laser beam removes the portion of the precoating. A plane tangent to the protective surface at the contact area forms a dihedral angle with the plane of the face of the precoated sheet. This angle is strictly smaller than 90°.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

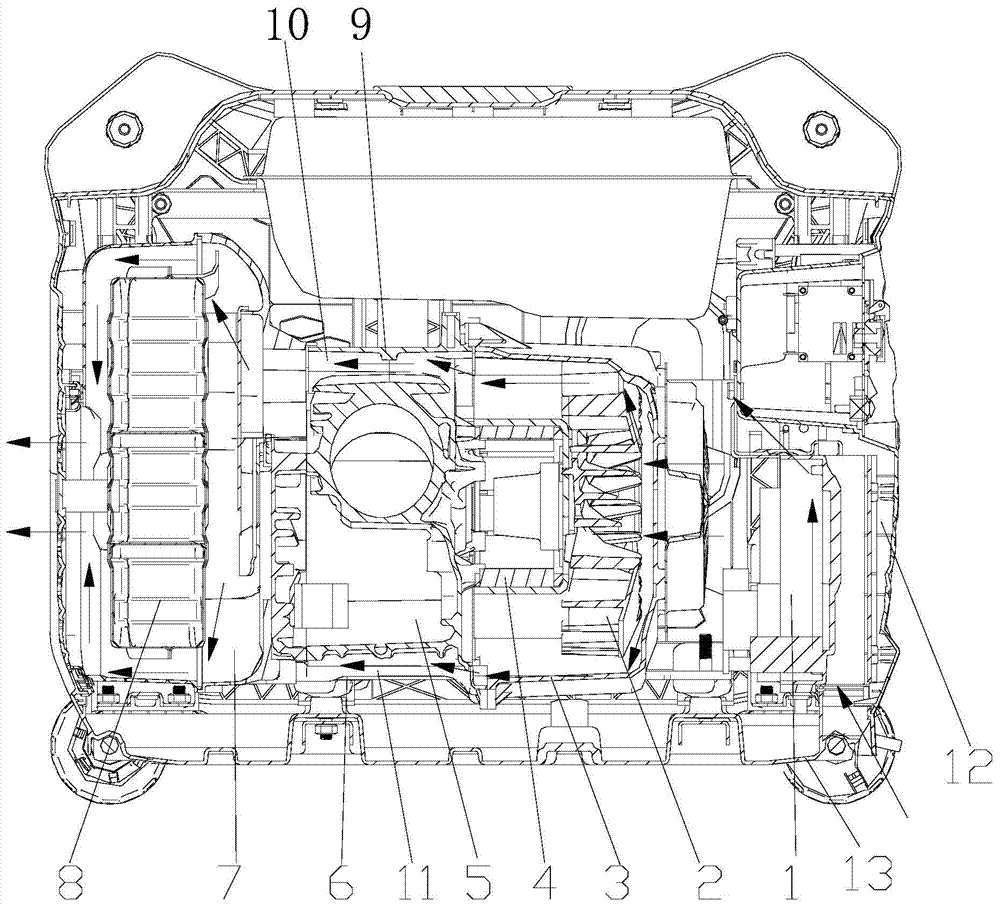

Auxiliary air-cooled generator

ActiveCN104481664BExtended service lifeReduce the temperatureMachines/enginesEngine cooling apparatusCooling effectEngineering

The invention discloses a power generator with an auxiliary air cooling effect. The power generator comprises auxiliary air channels. Air inlets of the auxiliary air channels are formed in covering parts, and the auxiliary air channels pass through gaps among an engine, a power generator body and the covering parts. The power generator has the advantages that the power generator is provided with auxiliary cooling air channel structures, the auxiliary cooling air channels can be used with main cooling air channels, preliminary cooling and heat-insulation effects can be realized, heat accumulation in a case can be initiatively eliminated, special heat-insulation processing on radiating positions can be omitted, accordingly, the integral structure of the power generator can be simplified, and the service cost can be saved; the structure of the power generator is further simplified, and accordingly merits of flexibility, mobility and the like of the small power generator can be exerted.

Owner:LONCIN MOTOR

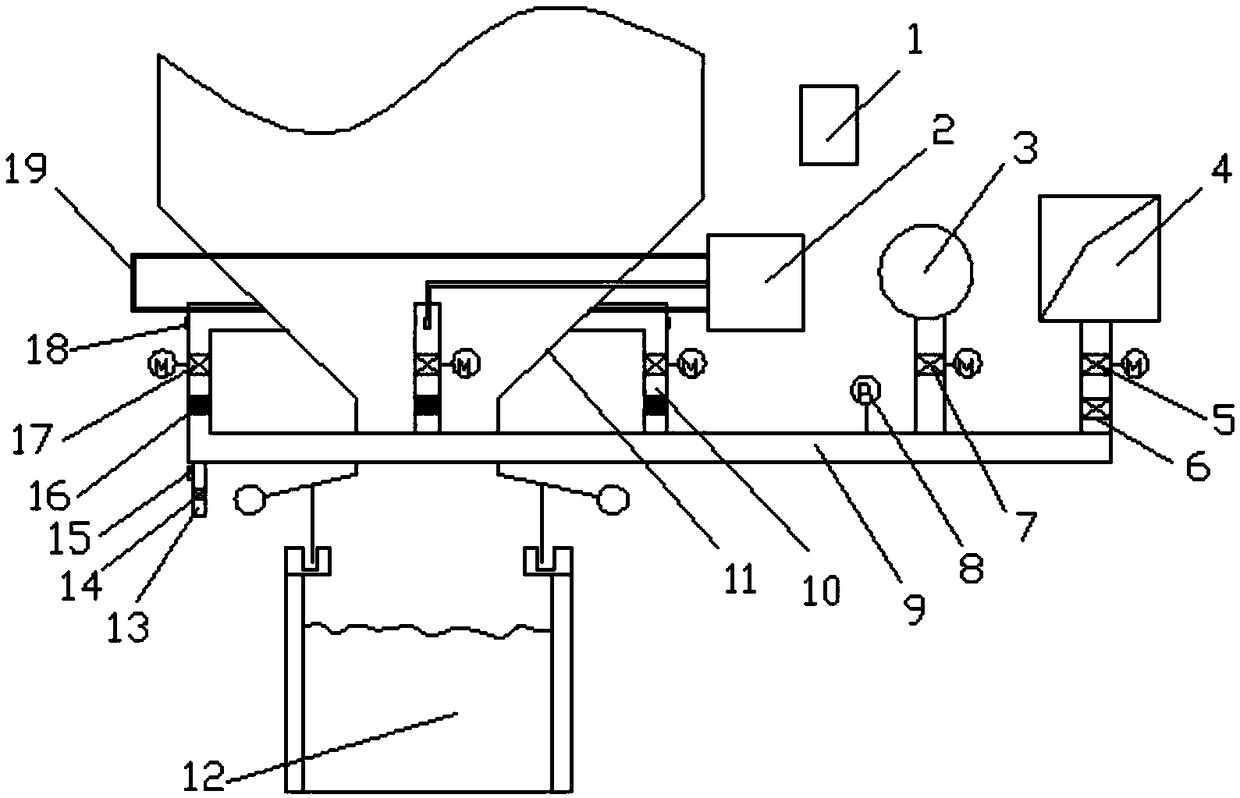

An intelligent system and method for preventing combustible gas deflagration at the furnace bottom

ActiveCN106907736BEliminate buildupPrevent deflagrationCombustion regulationControl systemCombustible gas

The invention discloses an intelligent system for preventing boiler bottom combustible gas from detonating and a method. The system comprises a hot air conveying and distributing subsystem, a boiler bottom atmosphere measuring subsystem and a control system; the hot air conveying and distributing subsystem conveys hot air taken from a primary hot air mother tube and a secondary hot air tank to spray ports in slopes of a dry bottom hopper at the boiler bottom; the boiler bottom atmosphere measuring subsystem is arranged at the boiler bottom and is used for sampling boiler ash and smoke and measuring the accumulation concentration of the boiler bottom combustible gas; the control system is used for controlling all hot air control baffles of the hot air conveying and distributing subsystem according to the combustible gas concentration measured by a measuring device and the boiler operation state and eliminating the accumulated combustible gas until the combustible gas concentration of each measuring point is lower than a set value, and the boiler bottom combustible gas is prevented from detonating. With the system and the method, accumulation of the boiler bottom combustible gas is eliminated in a fixed-point manner, the boiler bottom combustible gas is effectively prevented from detonating, and no negative effects are caused to the combustion condition in the boiler and the economic efficiency of boiler operation.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +2

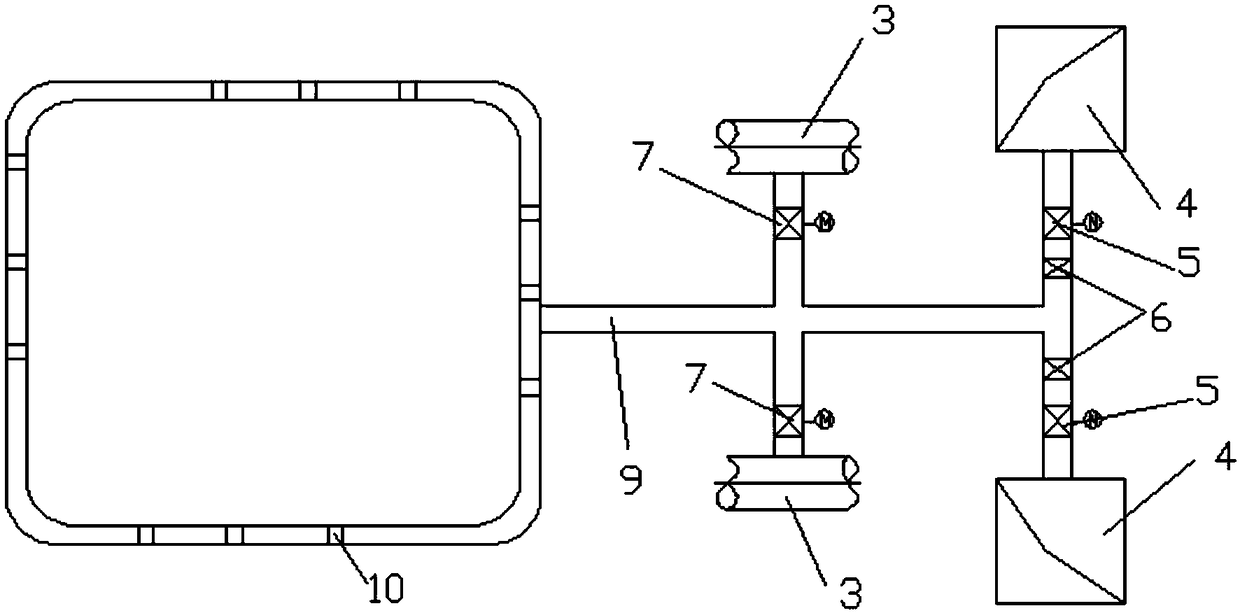

Climate hall for vehicle testing

PendingCN113710860AReduce personal injuryReduce risk of damageVehicle testingTents/canopiesEngineeringMechanical engineering

Owner:星湖控股公司

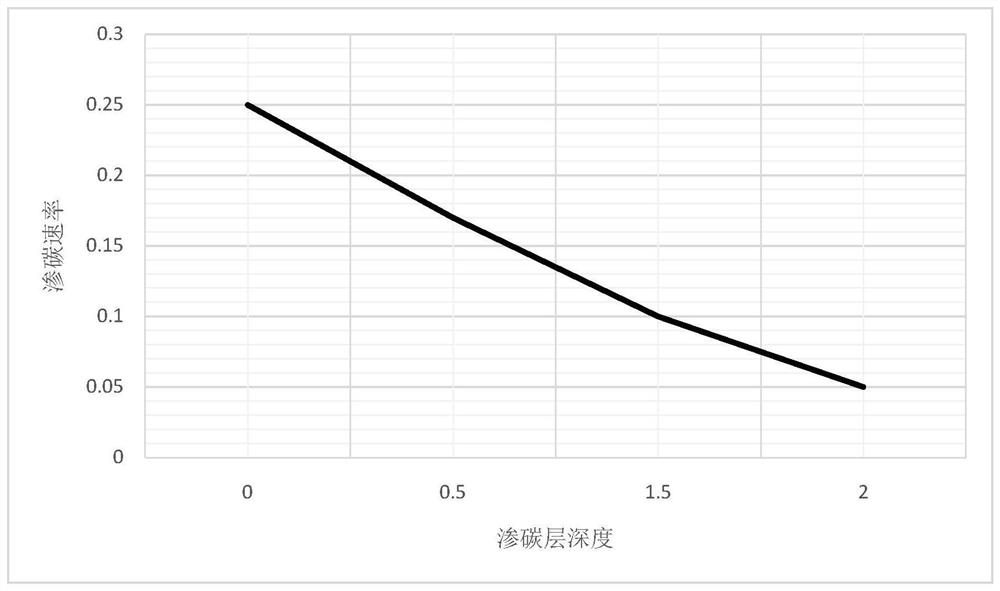

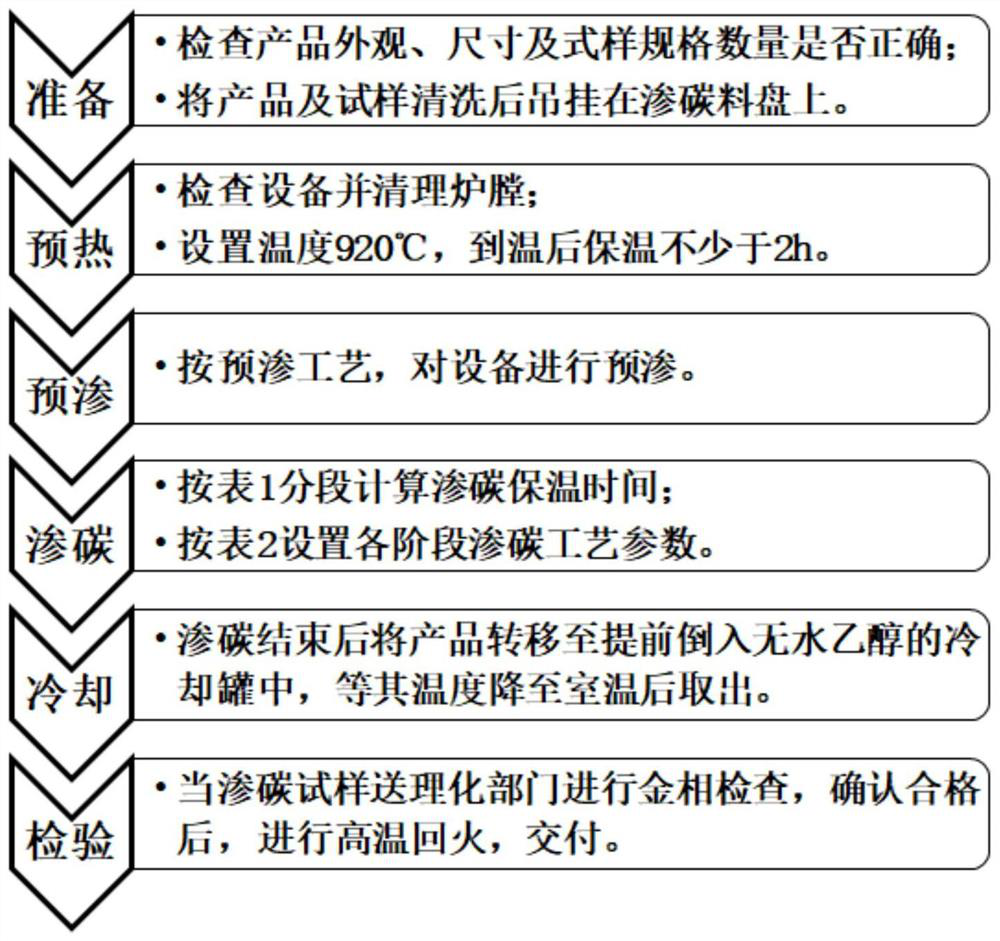

Carburizing method suitable for instillation type gas carburizing furnace

PendingCN114214589AKeep it brightPrevent oxidationSolid state diffusion coatingMetallic materialsHeat conservation

The invention discloses a carburizing method suitable for an instillation type gas carburizing furnace, and belongs to the technical field of metal material heat treatment. According to the stage type carburizing method, the carburizing layer depth is divided, the heat preservation time is calculated section by section, and the total carburizing heat preservation time is obtained through accumulation, so that the carburizing depth accuracy can be achieved, and the carburizing layer depth uniformity is ensured; and meanwhile, carbon black accumulation and decarburization phenomena on the surface of the carburized product are avoided.

Owner:大连长丰实业总公司

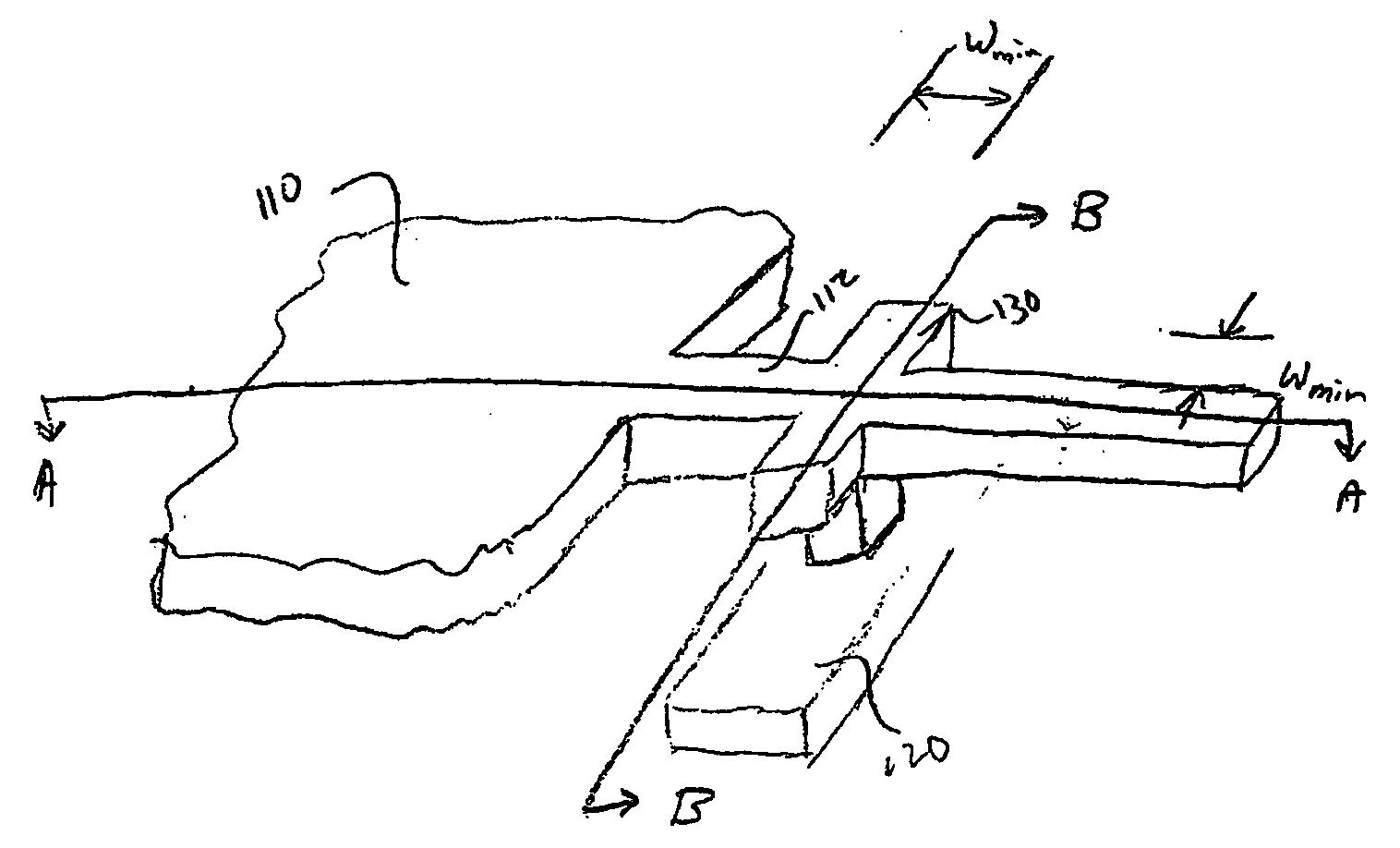

Interconnect structure to reduce stress induced voiding effect

InactiveUS20060099794A1Reducing metal void formationReduce formationSemiconductor/solid-state device detailsSolid-state devicesStress inducedContact pad

An interconnect structure that may reduce or eliminate stress induced voids is provided. In an embodiment, a via is formed below a conductive line to provide an electrical connection to an underlying conductive region. The conductive line includes a widened region above the via. The widened region serves to reduce or eliminate stress induced voids between the via and the underlying conductive region. In another embodiment, one or more redundant lines are formed extending from a conductive region, such as a contact pad, such that the redundant line does not electrically couple the conductive region to an underlying conductive region. In a preferred embodiment, the redundant lines extend from a conductive region on a side adjacent to a side having a conductive line coupled to a via.

Owner:TAIWAN SEMICON MFG CO LTD

Lubricant for preventing and removing carbon deposits in internal combustion engines

ActiveUS11078436B2Prevent and remove carbon buildupPrevent buildupBase-materialsAniline pointPolyolefin

A lubricant formulation which is effective to remove or prevent carbon deposits in internal combustion engines has a solvency as defined by aniline point from about 20 to about 115, a volatility (as measured by NOACK) of less than 15%, an oxidative stability (as measured by PDSC) of above 40 minutes and a base oil viscosity of above 2 and below 10 cSt. The lubricant formulation can be formed from a blend of Group III, IV and V lubricants, in particularly polyalphaolefins, alkylated naphthalenes and polar Group V base stocks such as polyol esters. The carbon deposits can be removed from the engine piston by simply running the engine with the lubricant for one required cycle, or can be used continuously in the engine to prevent buildup.

Owner:VGP IPCO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com