U+I type ventilating system for top-coal caving face

A ventilation system and working face technology, which is applied in the ventilation of mines/tunnels, ground mining, mining equipment, etc., can solve the problem of poor reliability of gas discharge, reduction of wind flow capacity and radius of effective gas discharge, brackets and enclosures. Rock collapse and other problems, achieve reliable technical guarantee, eliminate spontaneous combustion of floating coal, and eliminate gas and coal dust explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

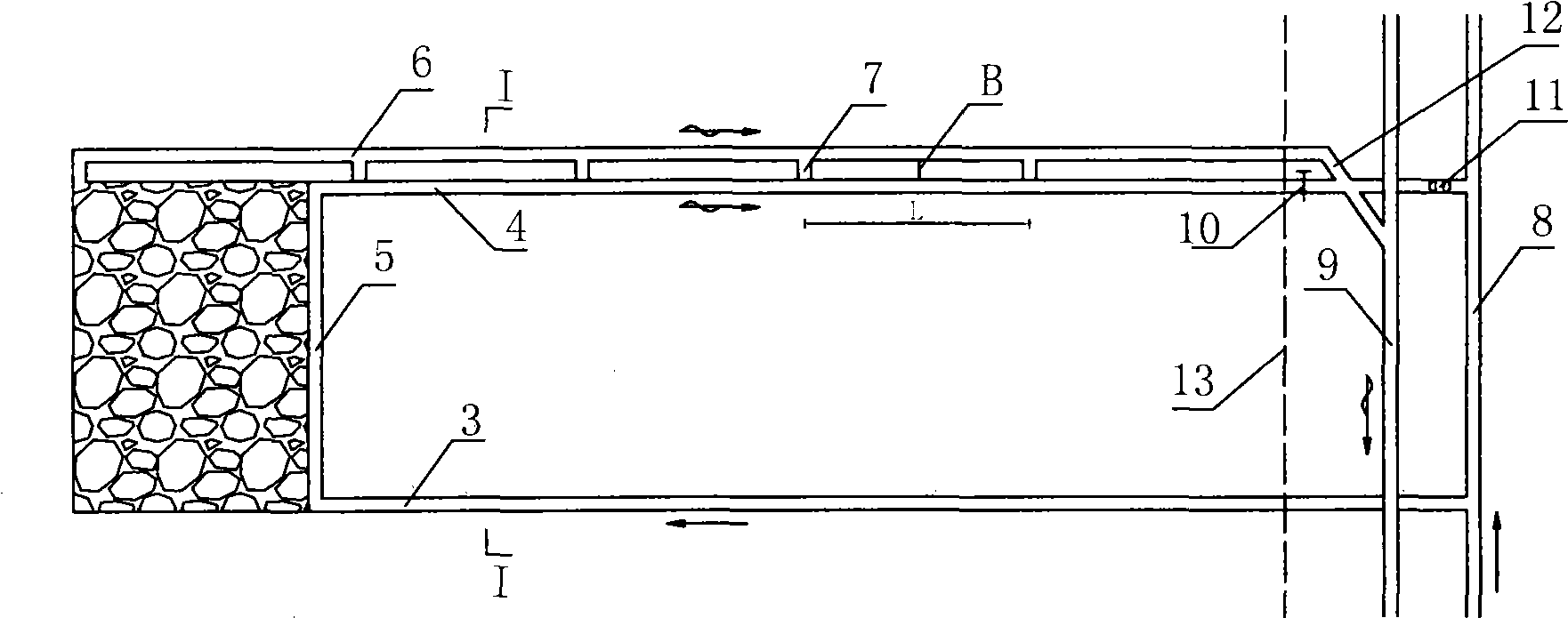

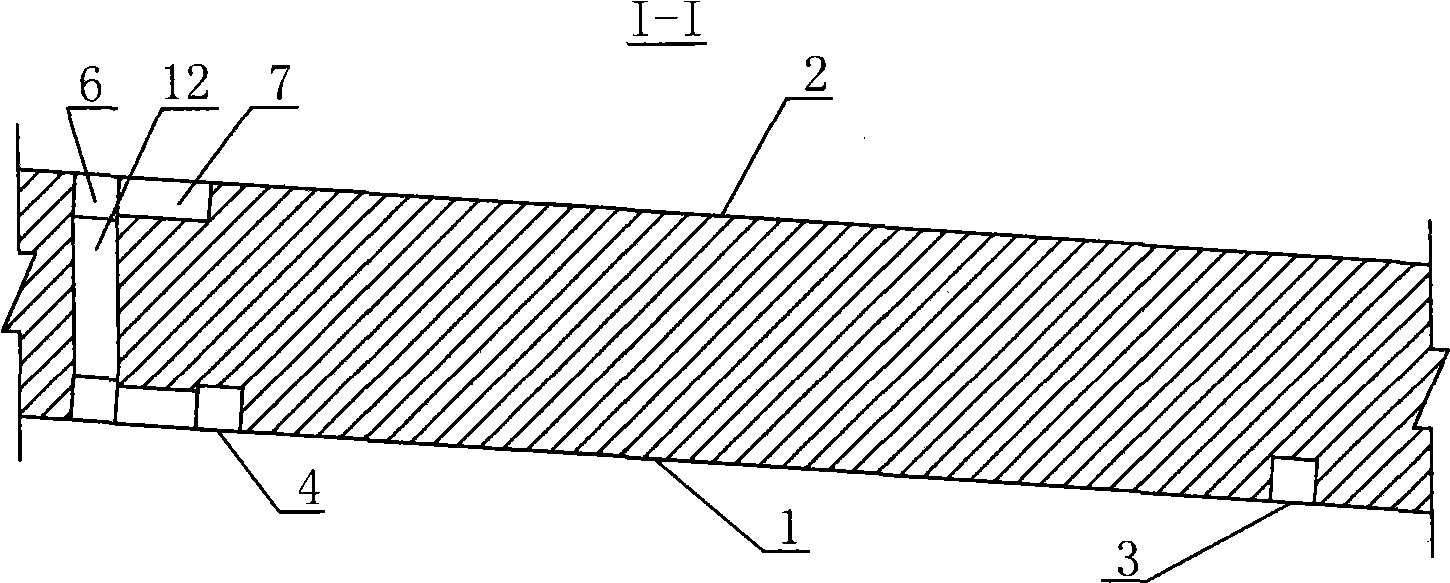

[0030] Such as figure 1 and figure 2 Shown, the schematic diagram of the U+I type ventilation system of the top-coal caving face of the present invention. The U+I ventilation system of the top-coal caving face includes the following parts:

[0031] 1. The air inlet trough and the return air trough of the top coal caving face are arranged along the coal seam floor, and are respectively connected with the air inlet and return air lanes of the mining area (or mine), and are connected with the inlet air trough on the bottom return air chute. The air door 11 is arranged near the connection of the wind lane, thereby forming the basic ventilation system for coal mining production at the bottom of the top coal caving face.

[0032] 2. In the return air trough on the bottom floor, a horizontal connection roadway is excavated to the outside of the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com