Patents

Literature

422results about How to "Efficient spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

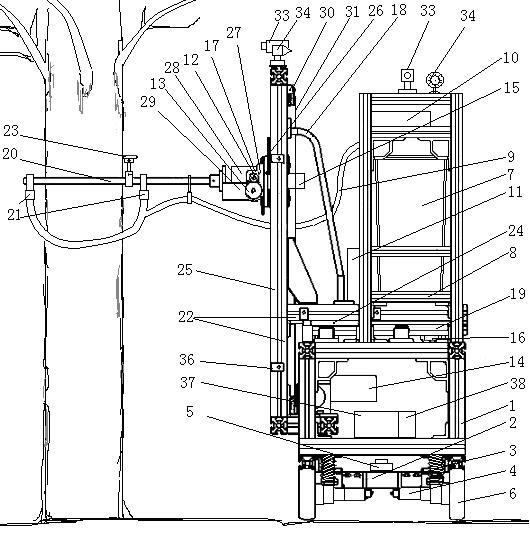

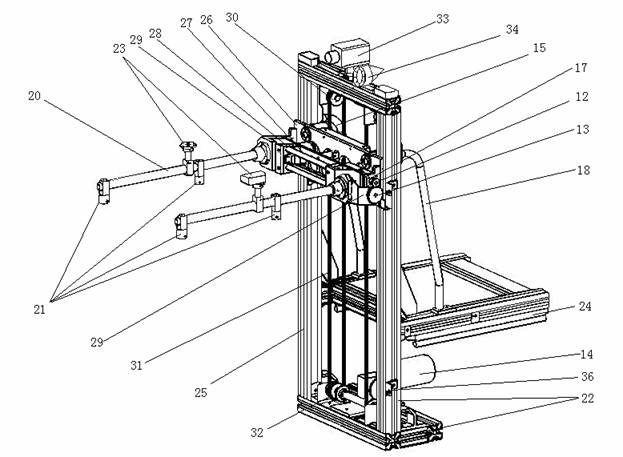

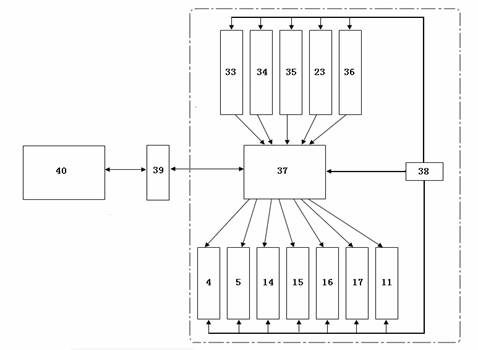

Intelligent tree trunk white paining robot

InactiveCN102151634AImprove work efficiencyQuality improvementLiquid spraying apparatusPlant protectionProgrammable logic controllerTree trunk

The invention discloses an intelligent tree trunk white painting robot and belongs to the related fields of urban and garden greening equipment. The intelligent tree trunk white painting robot comprises a machine frame system, a robot traveling system, a lime slurry supply system, an automatic white painting execution system and a real-time detection system. Adopting a spray painting mode for white painting of tree trunks, the robot can automatically walk along a side pavement and quickly and efficiently spray lime solution onto trees along the side pavement. In a real-time detection system, a digital compass, a laser sensor and a vision system are adopted to realize the semi-automatic searching of tree trunks and tree trunk automatic positioning, an ultrasonic transducer is adopted to realize automatic obstacle avoidance, and the whole-process real-time monitoring with a personal computer (PC) and a programmable logic controller (PLC) is realized. When the intelligent tree trunk white painting robot is used, coating is saved and the painting effect is optimized; and the robot automatically performs white painting of trees along the side pavement, the working efficiency is improved, labor force is saved, and the goals of intelligent control and green environmental sanitation are fulfilled.

Owner:SHANGHAI UNIV

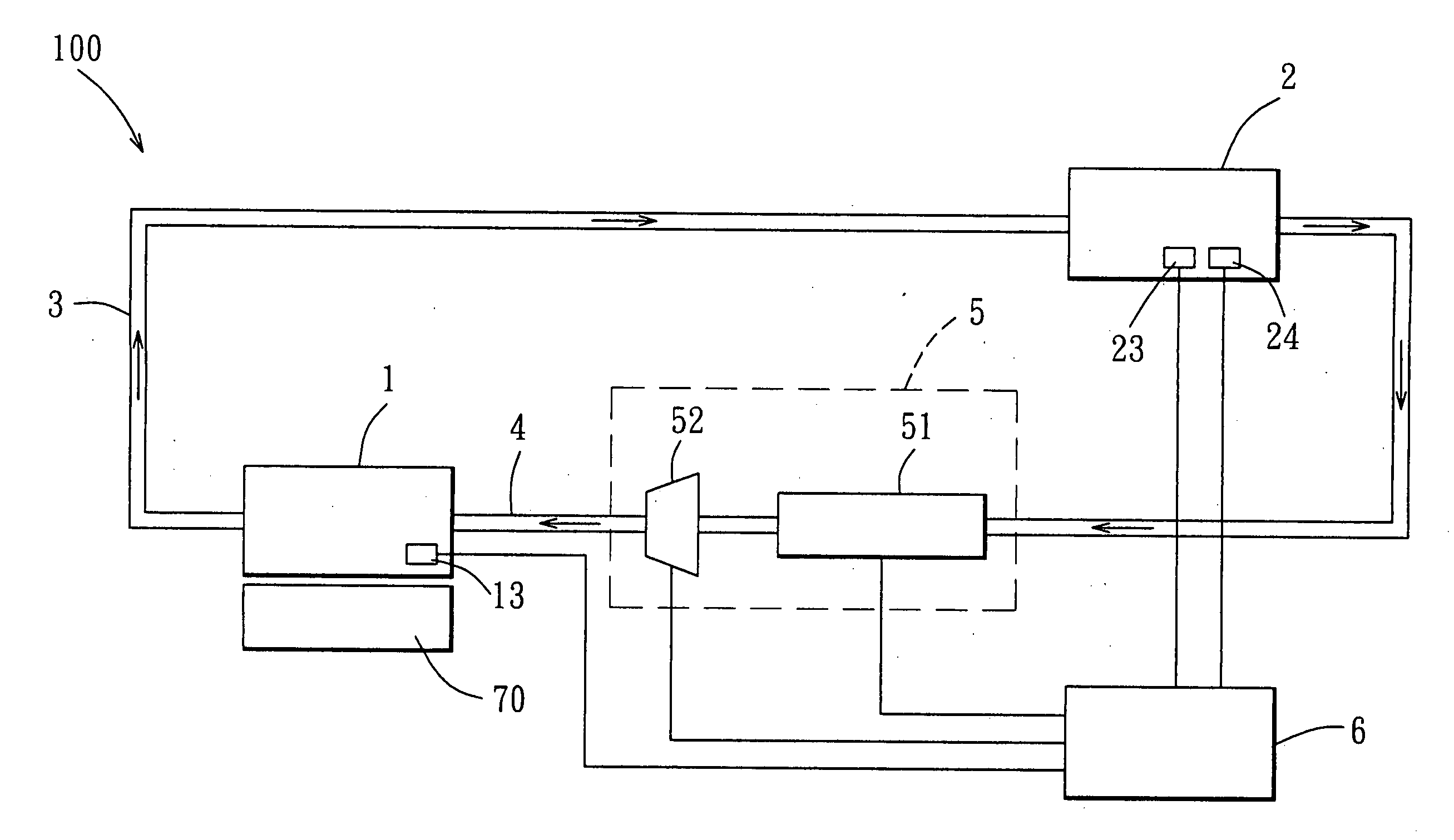

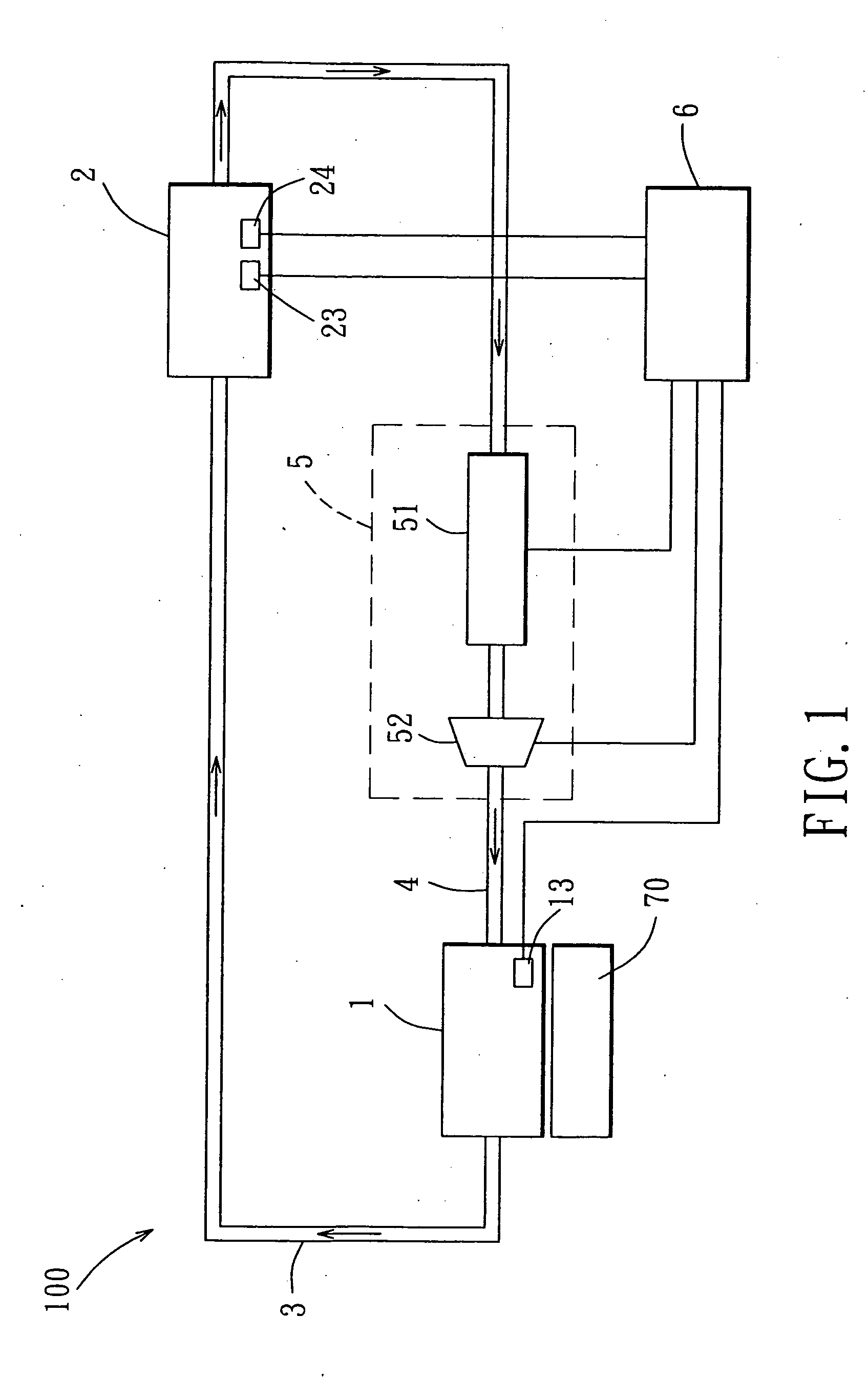

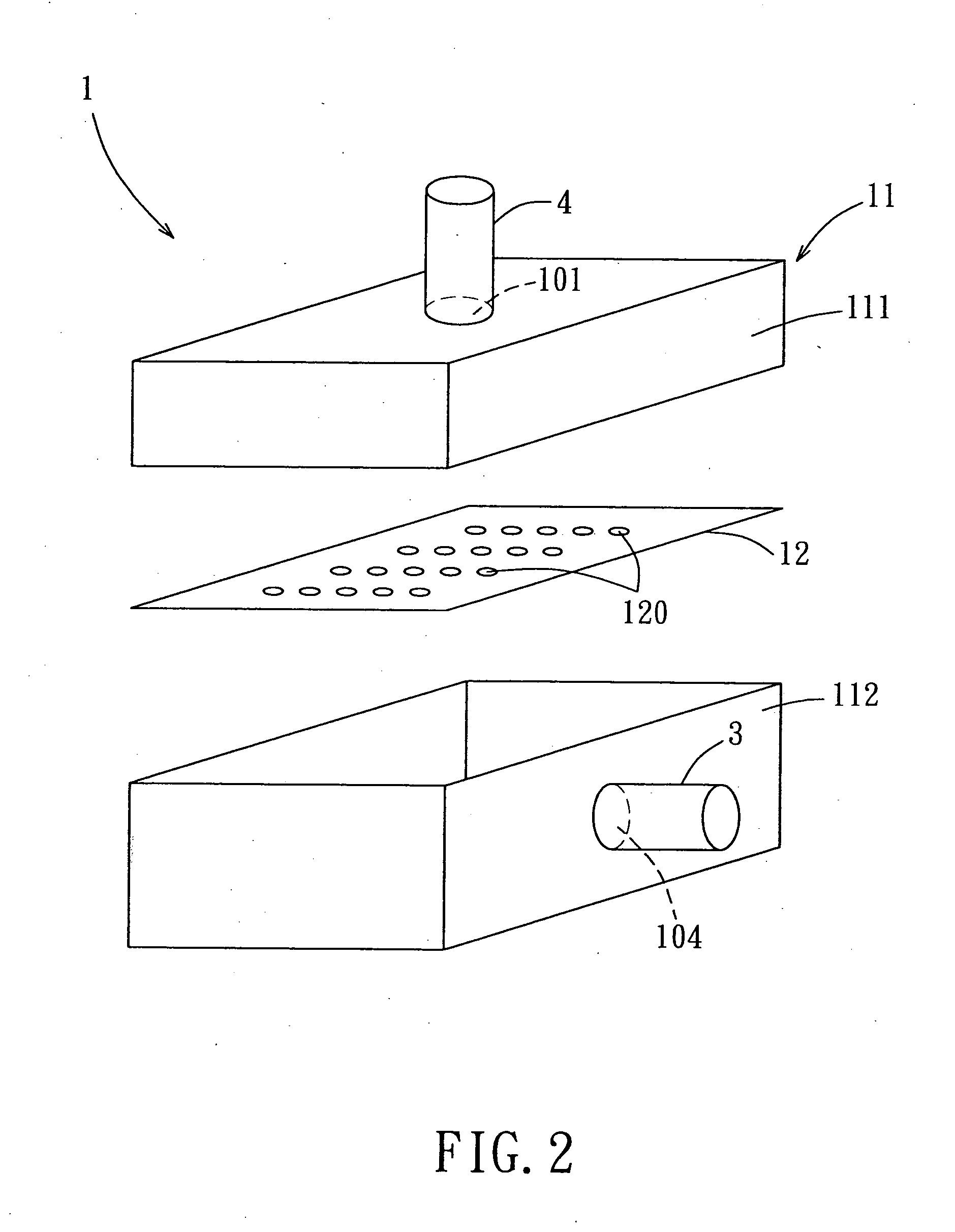

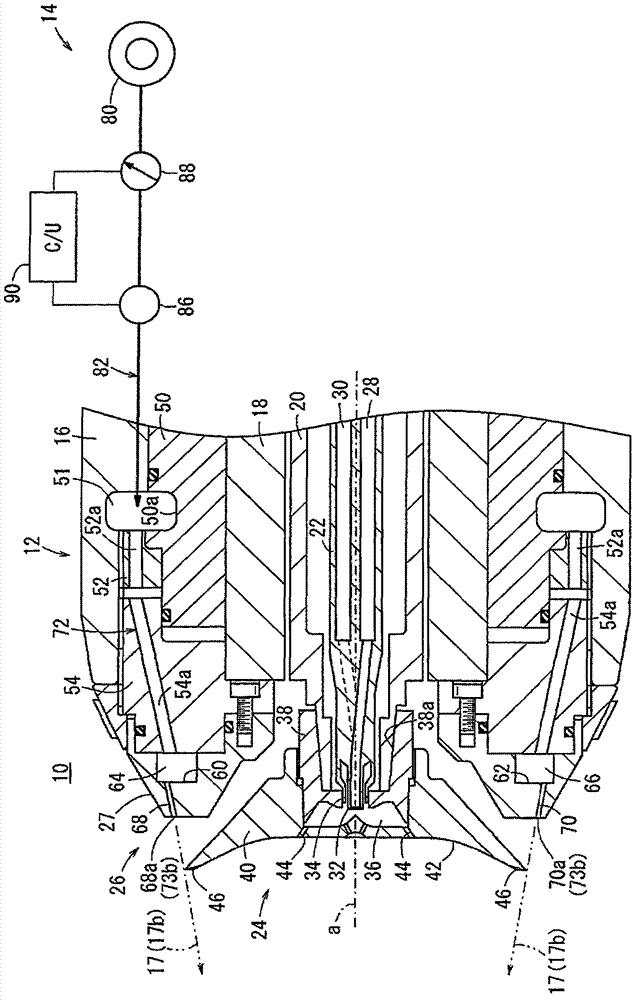

Heat dissipation system with a spray cooling device

InactiveUS20110277491A1Easy constructionSolve the low heat dissipation efficiencySemiconductor/solid-state device detailsSolid-state devicesVena contracta diameterMicrometer

A heat dissipation system includes a cooling device, a condenser, a vapor conveying duct and a cooling liquid conveying duct. The cooling device includes a housing, and an orifice plate dividing an inner space of the housing into a liquid supply chamber and an evaporation chamber proximate to the heat source, and formed with multiple micro orifices each having a diameter ranging from 5 to 1000 micrometers. The condenser includes a fluid inlet, a condensing chamber and a fluid outlet. The vapor conveying duct connects a vapor outlet of the housing and the fluid inlet of the condenser. The cooling liquid conveying duct connects a cooling liquid inlet of the housing and a fluid outlet of the condenser.

Owner:MICRO BASE TECH CORP

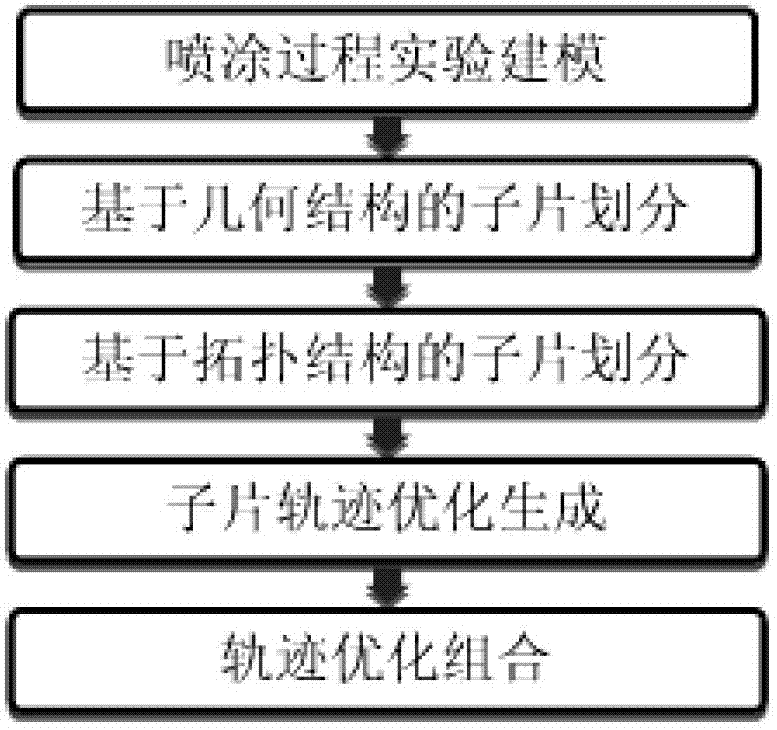

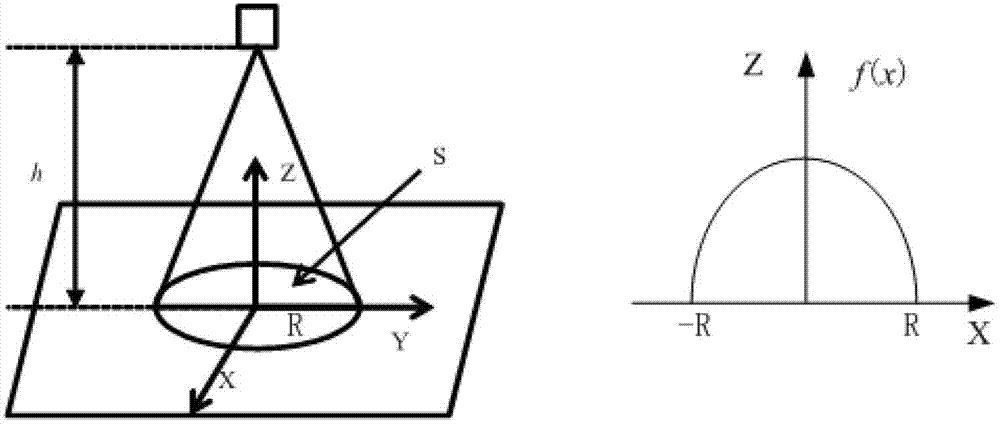

Layered spraying track planning method used for spraying robot

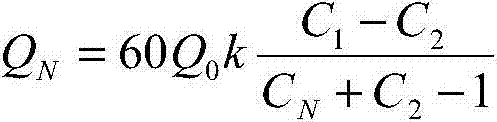

InactiveCN102831306AEfficient sprayingImprove spraying efficiencySpecial data processing applicationsEconomic benefitsTrajectory optimization

The invention discloses a layered spraying track planning method used for a spraying robot. The layered spraying track planning method comprises the steps of: firstly, designing an experiment method to build a model for the spraying process and fitting a coating distribution condition by introducing Gaussian and coating accumulative rate model; then adopting a layered track planning method and dividing a complex curve into a plurality of simple sub-curves by respectively applying a double deviation angle method and a projection method based on geometric and topological characteristics of a work-piece, establishing a corresponding spraying track optimization model and obtaining a travel parameter by adopting a numerical method so as to generate a spraying track in each sub-sheet; and finally, adopting an estimation of distribution algorithm to perform optimized combination on the track of each sub-sheet. The layered spraying track planning method used for the spraying robot, disclosed by the invention, has the advantages of improving the spraying production technology of the spraying robot, realizing track optimized generation of the spraying robot on each complex work-piece surface, improving distribution uniformity under the precondition of satisfying expected thickness of the coating, reducing paint waste, and thereby facilitating to improve production efficiency and economic benefits of the spraying manufacturing industry.

Owner:SOUTHEAST UNIV

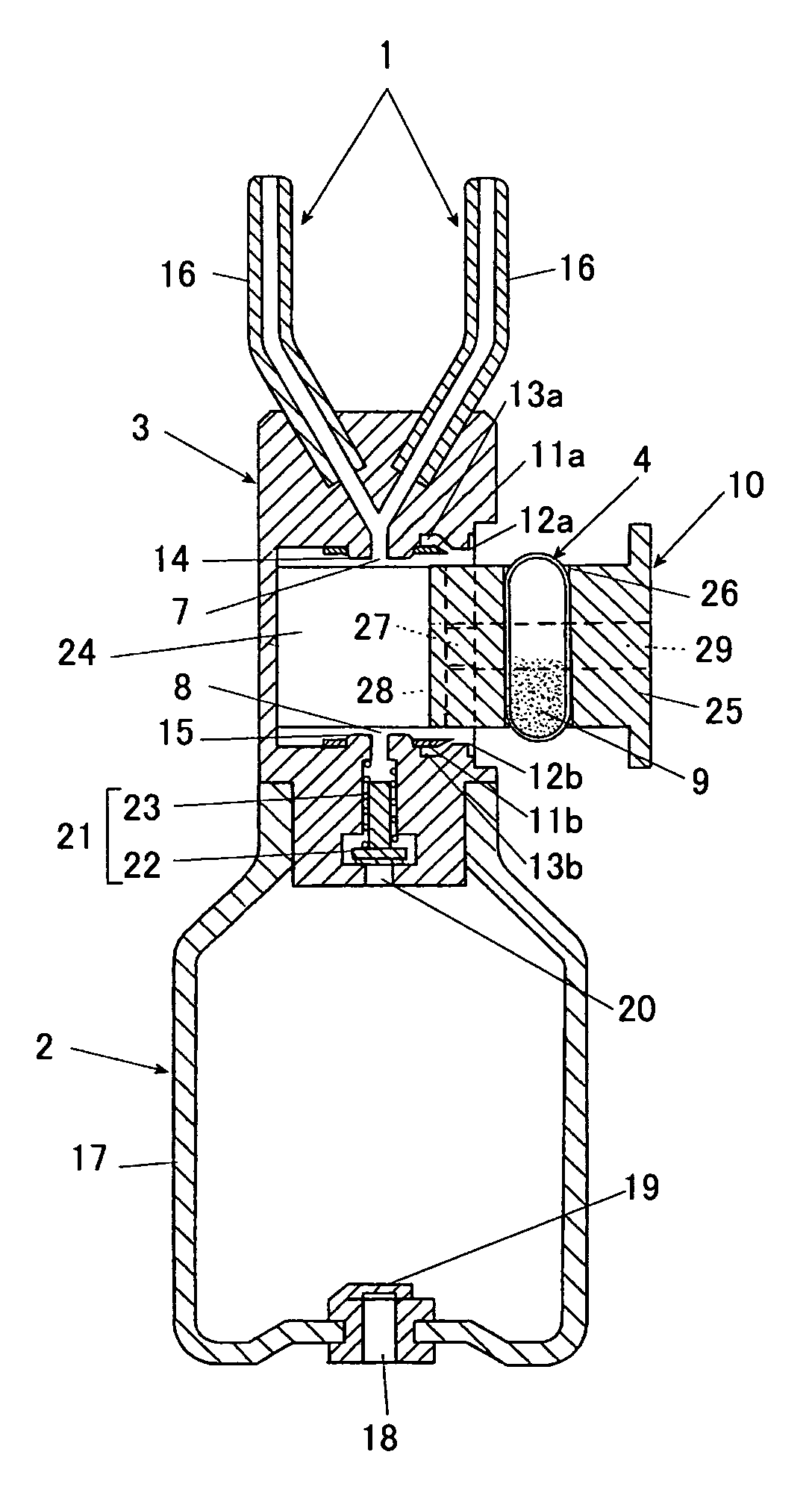

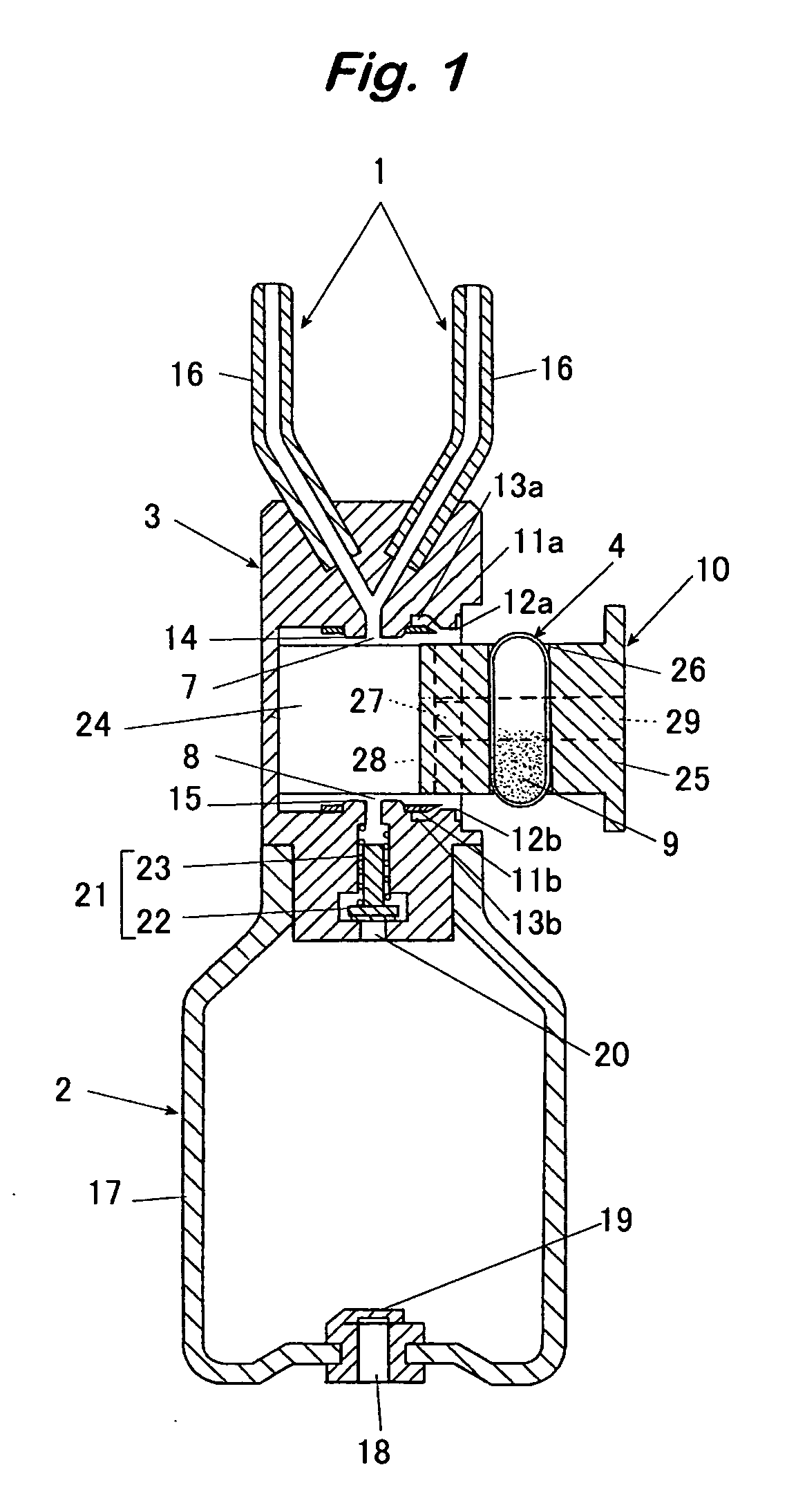

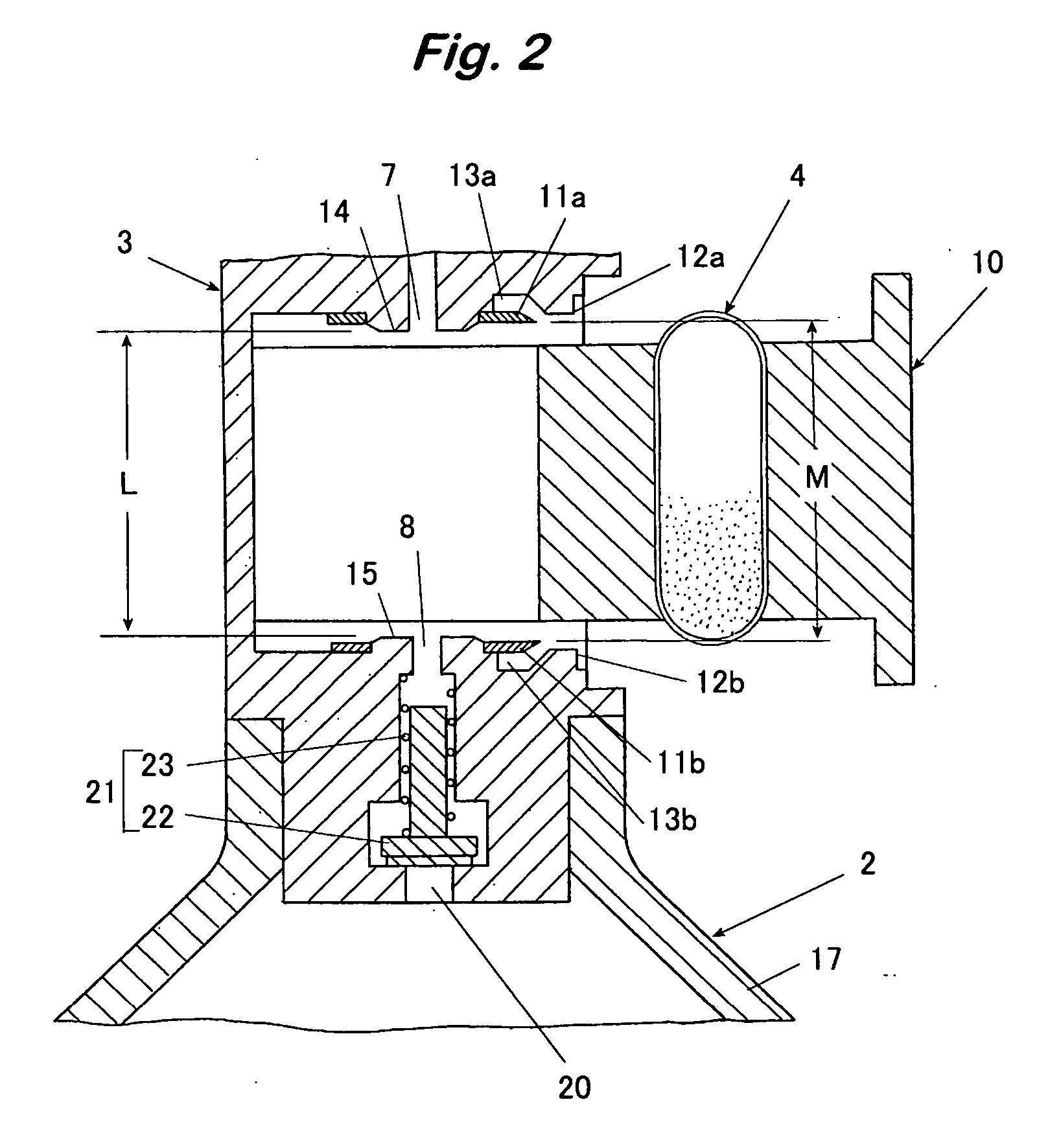

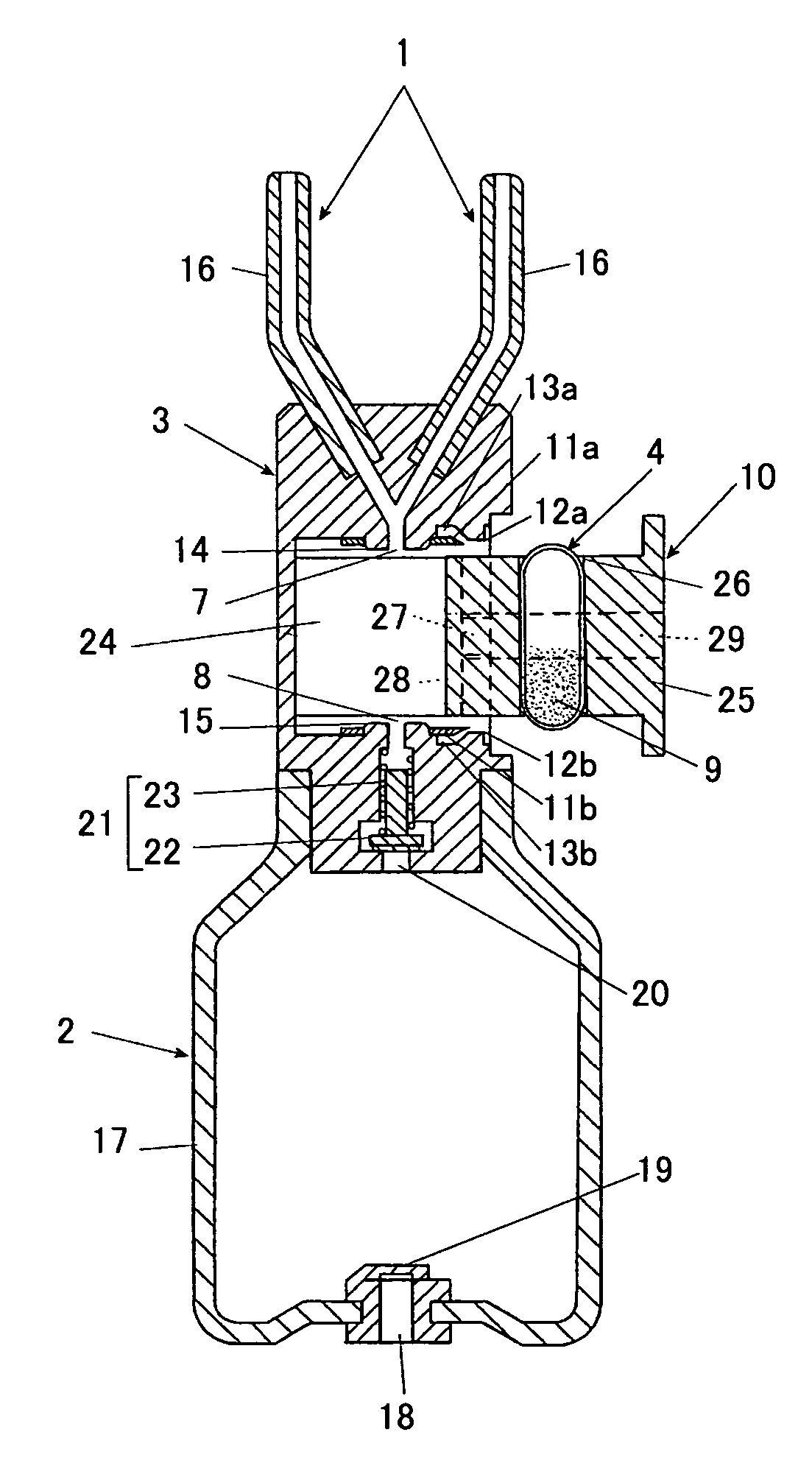

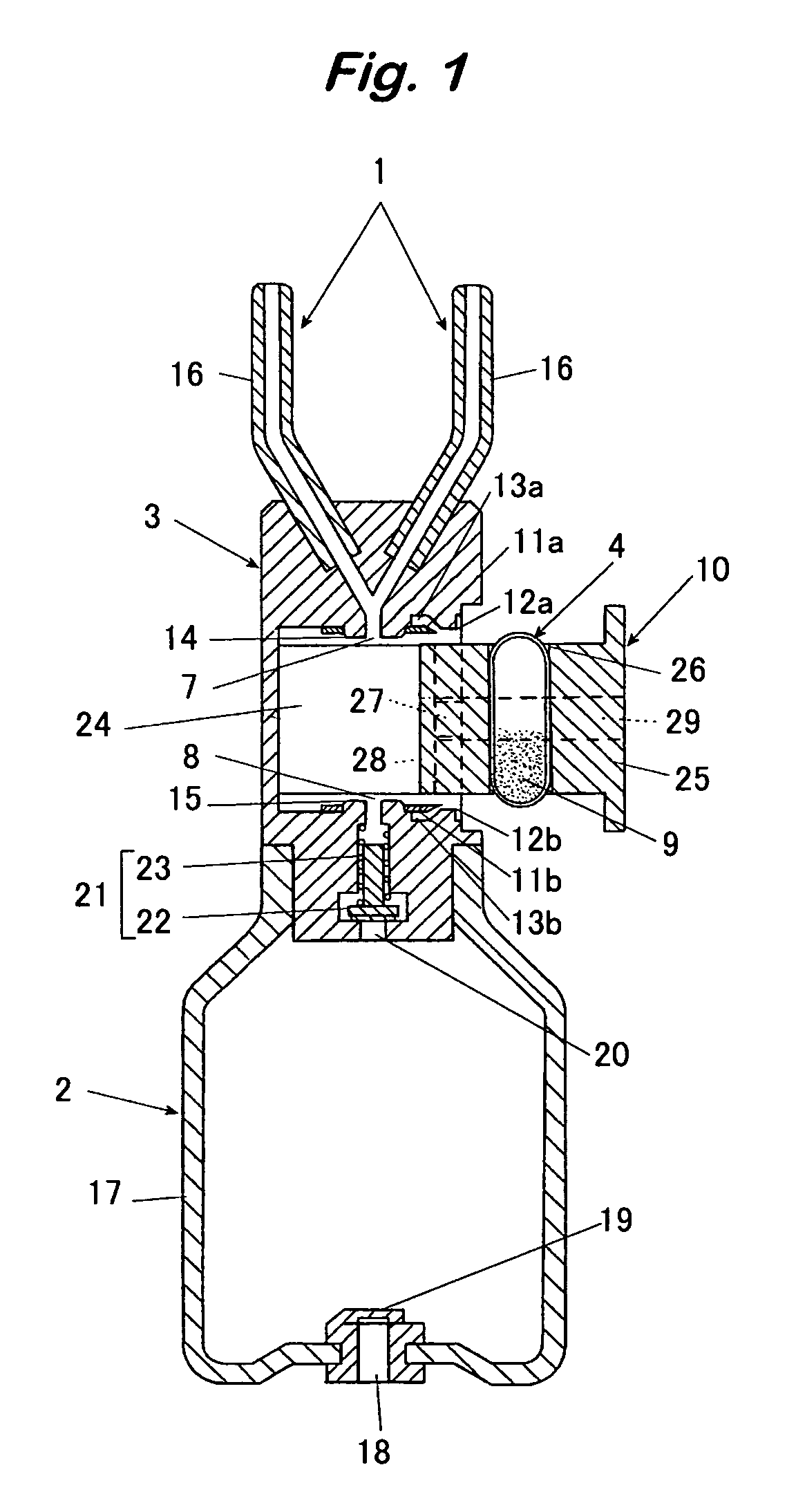

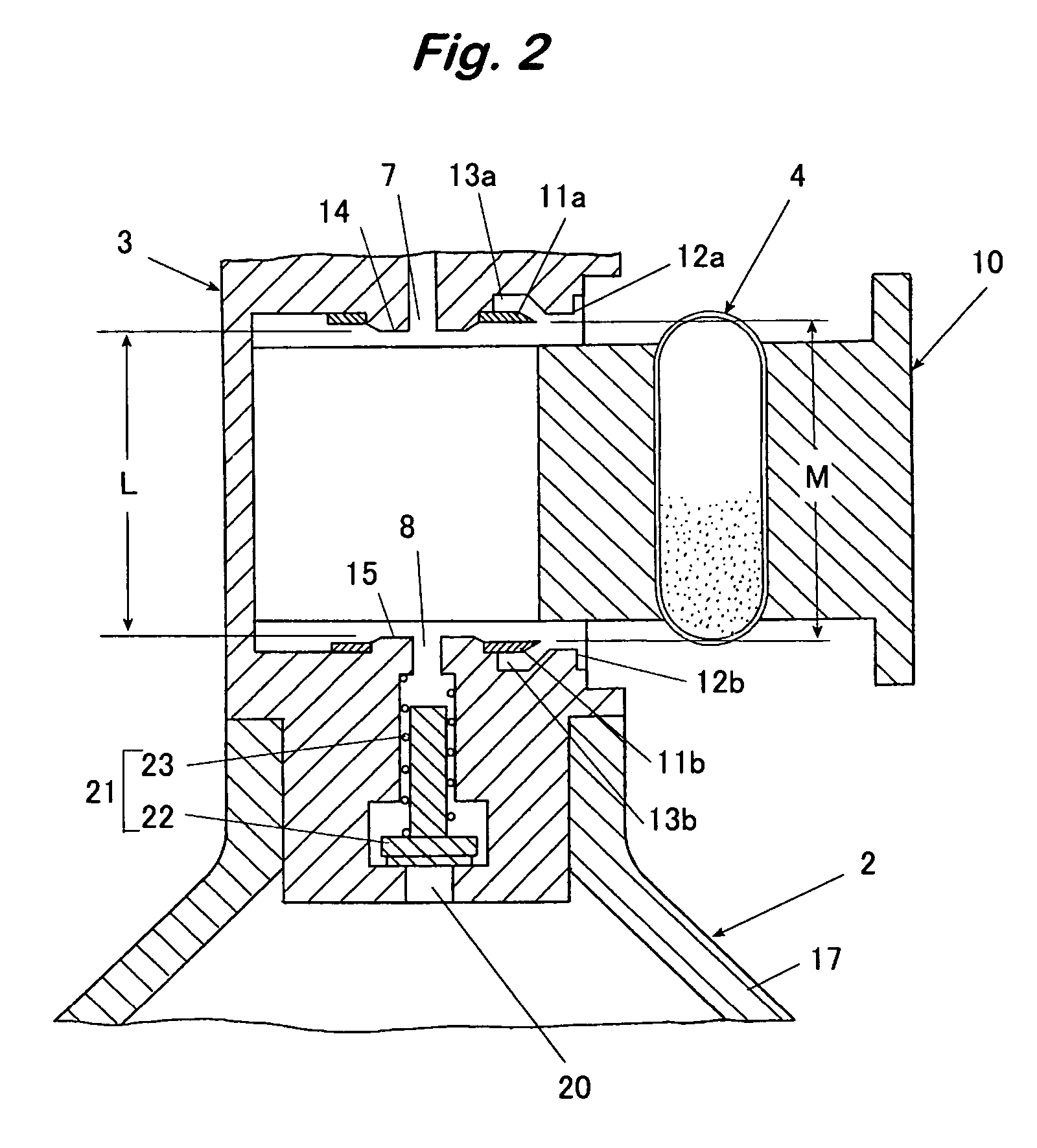

Device to deliver a powdery medicine into nasal cavity

InactiveUS20070060868A1Improve accuracyEfficient sprayingRespiratorsAmpoule syringesNasal Cavity EpitheliumDistances Between Ports

A device that delivers a powdery medicine for a nasal cavity includes positioning guides that cause a capsule to slide as far as a predetermined position and are provided on the side of cutters to make holes on both ends of the capsule provided between the connection port on the side of a nozzle that sprays the powdery medicine into the nasal cavity. The device further includes a connection port on the side of a pump that supplies spray air to the nozzle in order to make the size of the holes made on both ends of the capsule constant, wherein a distance between the connection ports is made shorter than a distance between blade tips of the cutters (length of the capsule after cutting off the both ends by the cutters), to prevent scattering of the powdery medicine in the capsule from both ends of the capsule provided between the connection ports, so that both ends of the capsule loaded between the connection ports are pressed by peripheral edges of the connection ports.

Owner:SHIN NIPPON BIOMEDICAL LAB

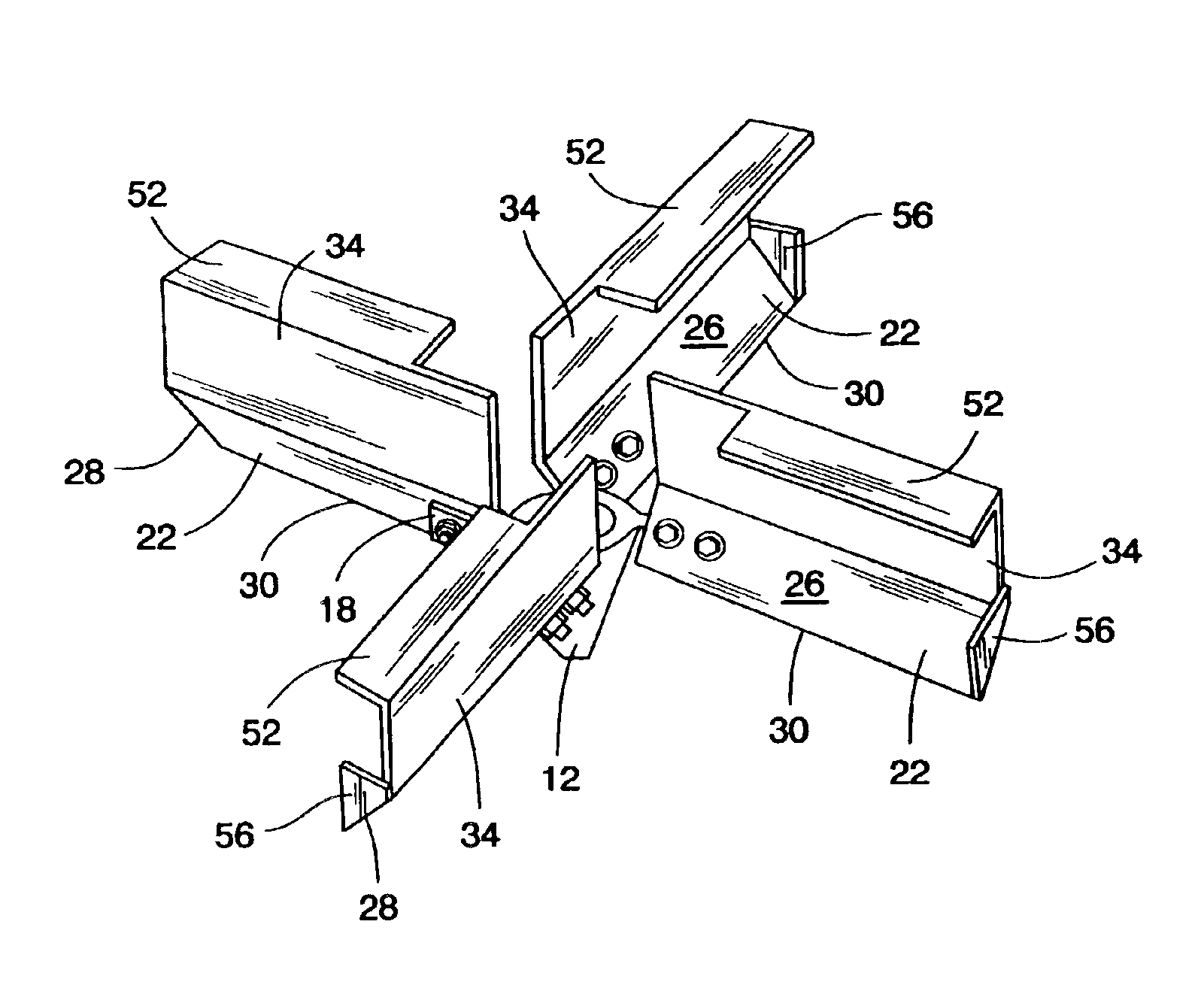

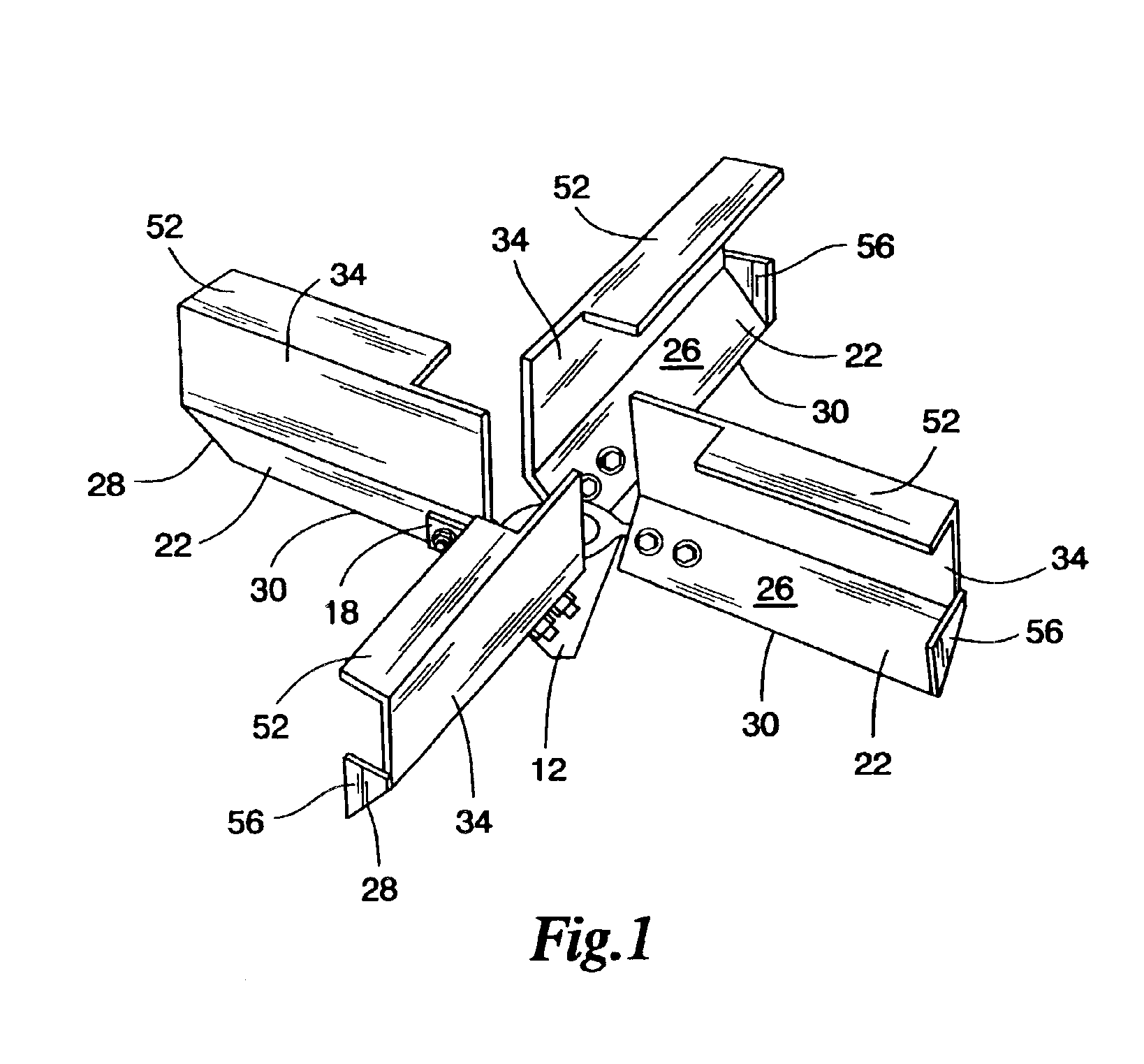

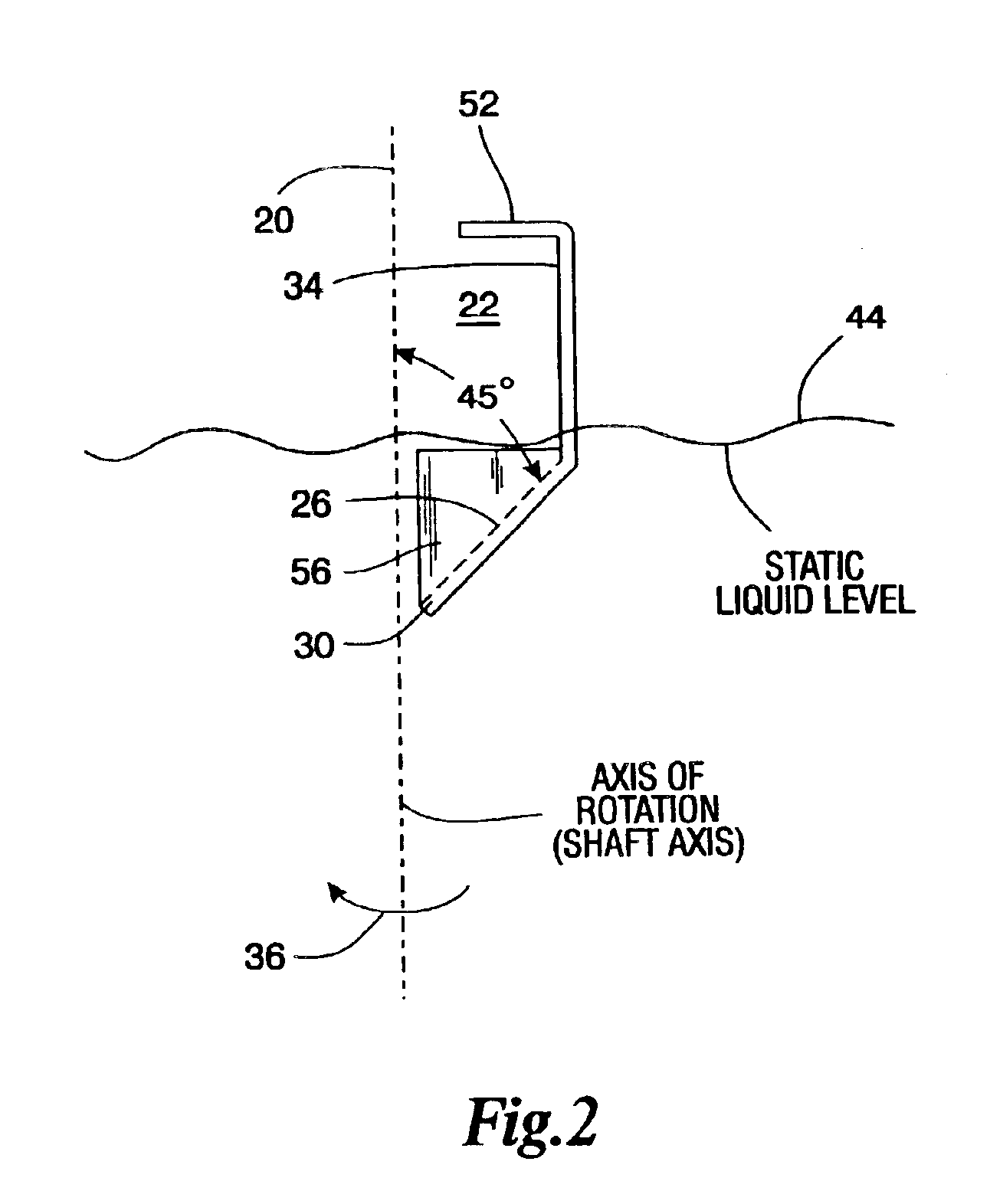

Surface aeration impellers

InactiveUS6877959B2Efficient sprayingImproves gas entrainmentPropellersFlow mixersImpellerEngineering

The invention is an improved surface aeration impeller for use in a liquid filled tank which particularly increases the surface turbulence and the entrainment of gas into the liquid surface. The impeller is an axial flow impeller and may be either a pitched blade turbine (PBT) or have airfoil shaped blades. In either case, the impeller has a portion which extends radially along an edge thereof which projects above the surface of the liquid being mixed in a vertical direction. The blades of the impeller are modified to include a top horizontal plate to lower the spray height of the liquid and an optional endcap, both of which can enhance and increase the standard aeration efficiency. Preferably, the impeller is rotated in an up-pumping direction and propels the liquid being aerated in a radially upward and outward direction. A sufficient upward surge of liquid is produced so that the liquid is observed to splash back onto the surface a plurality of times in the course of operation of the impeller. Such multiple splashing action enhances the contact between the air and the liquid itself to improve the oxygen transfer efficiency of the aeration impeller.

Owner:MIXING & MASS TRANSFER TECH

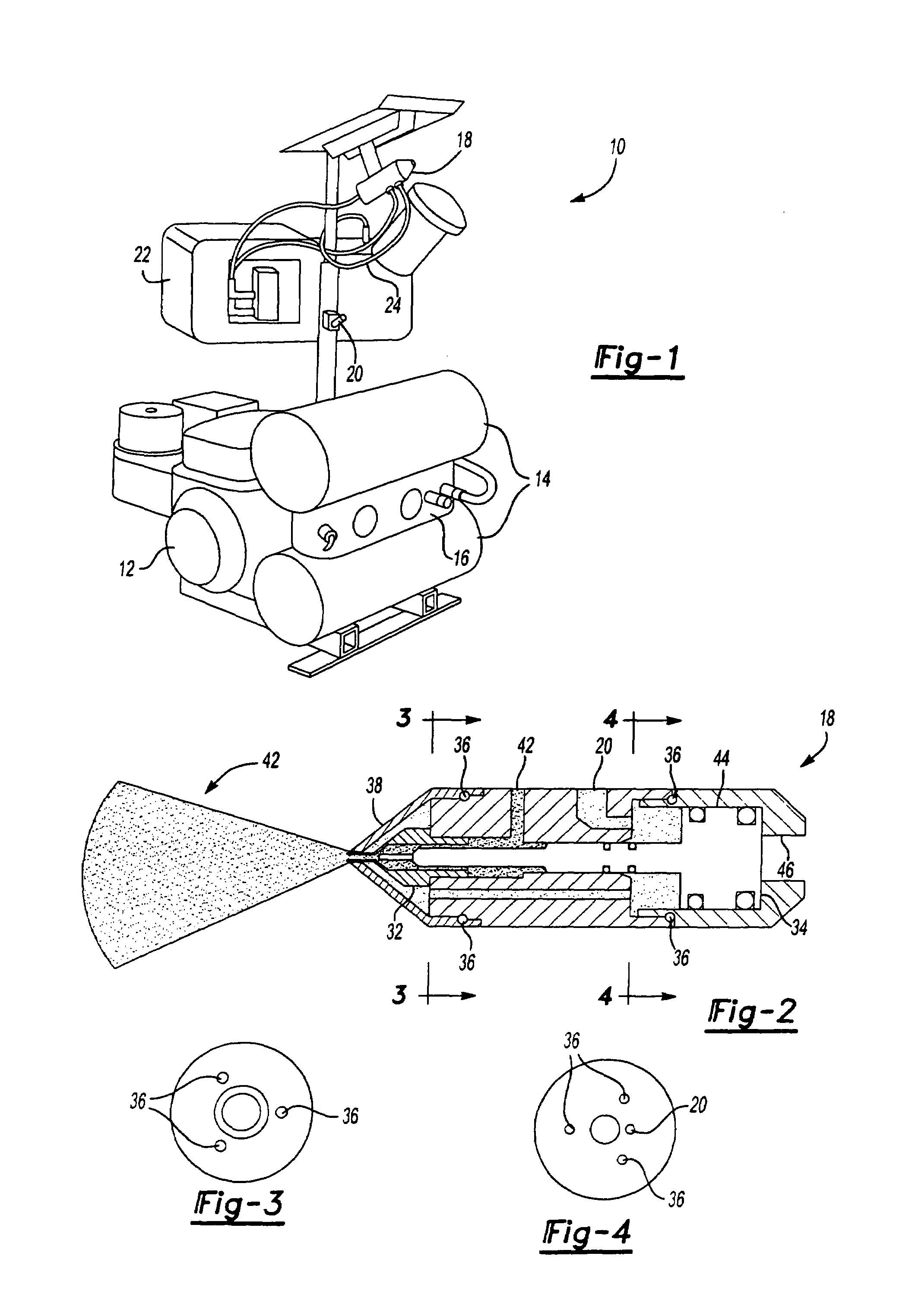

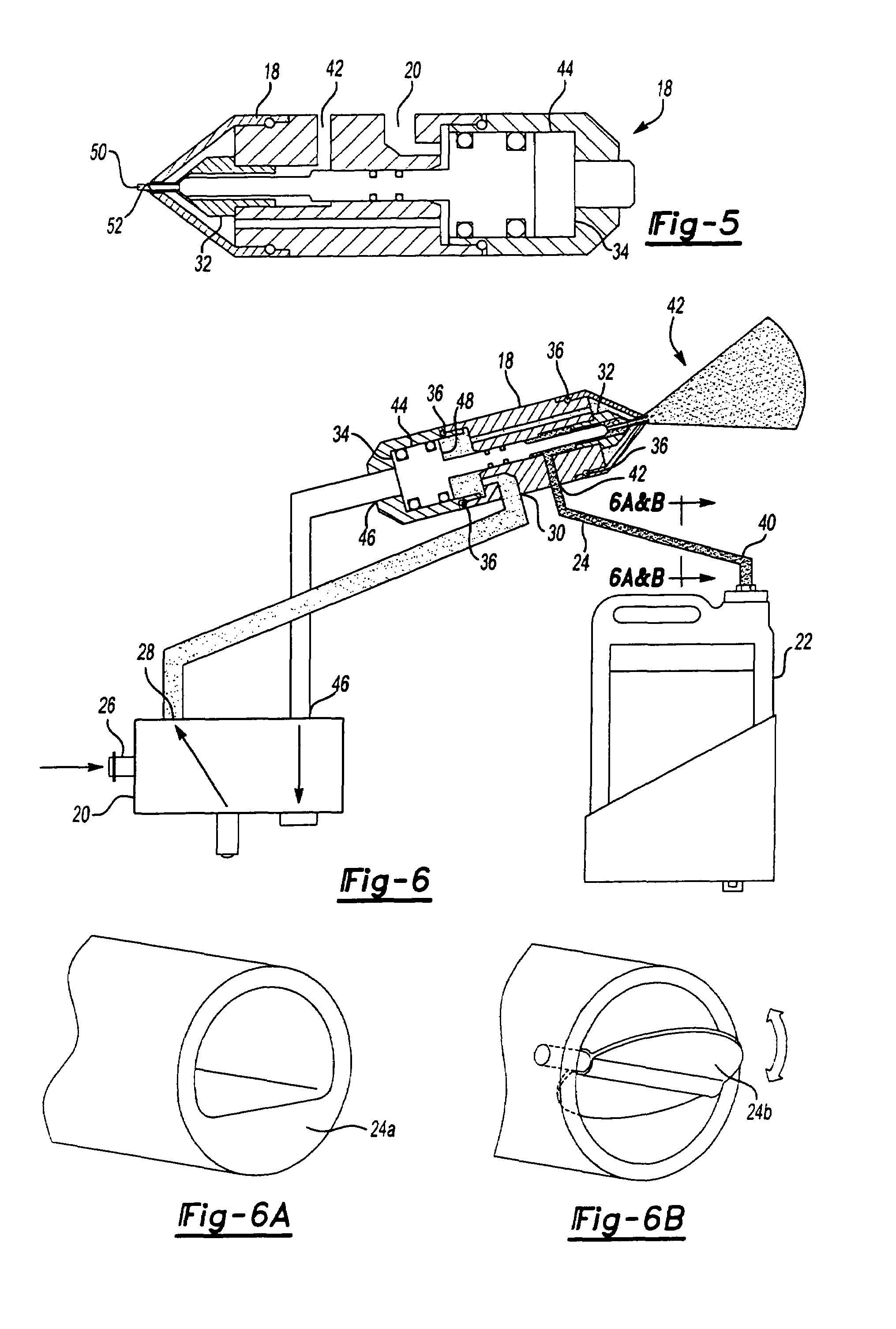

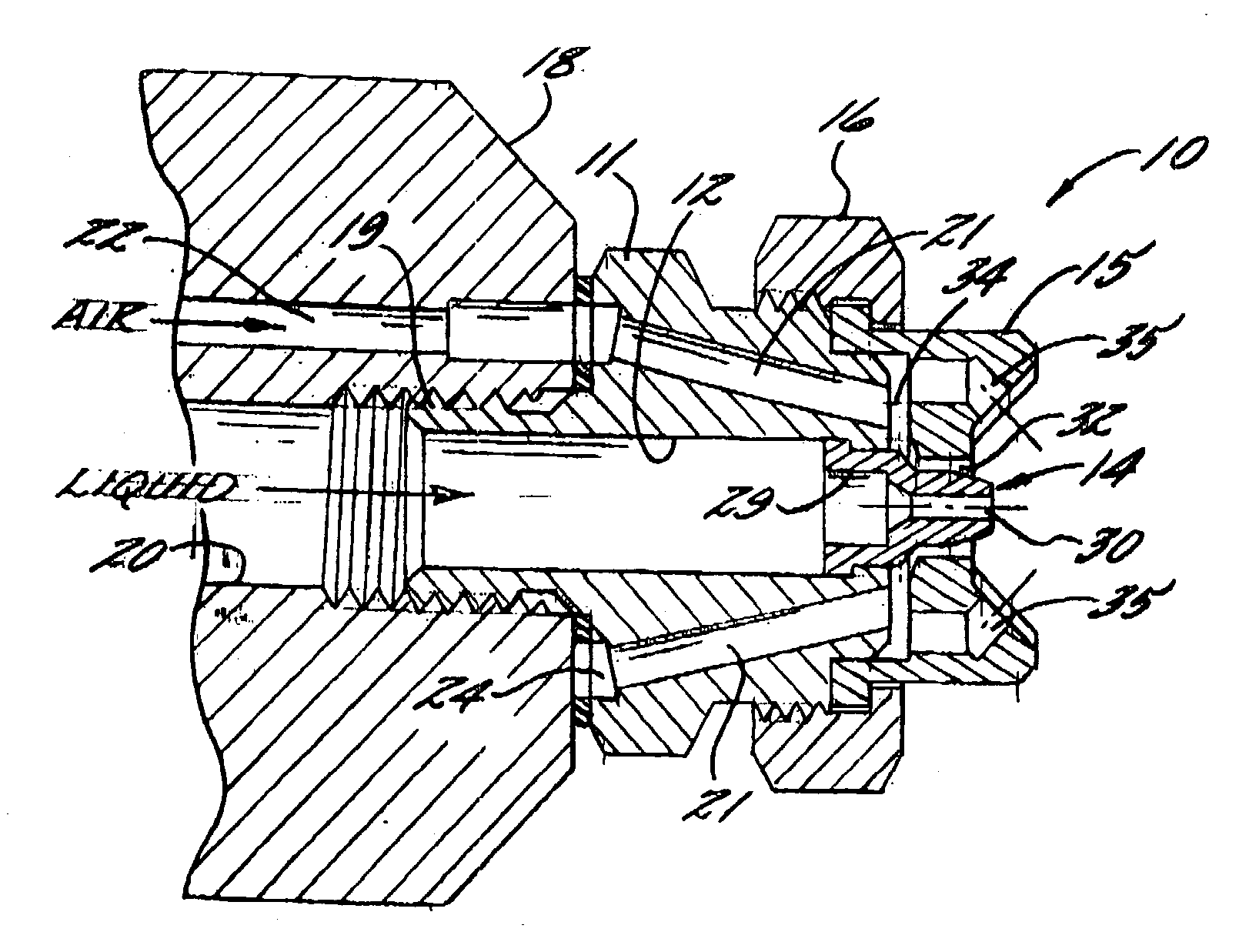

Spraying device system and method of dispersing and disseminating materials

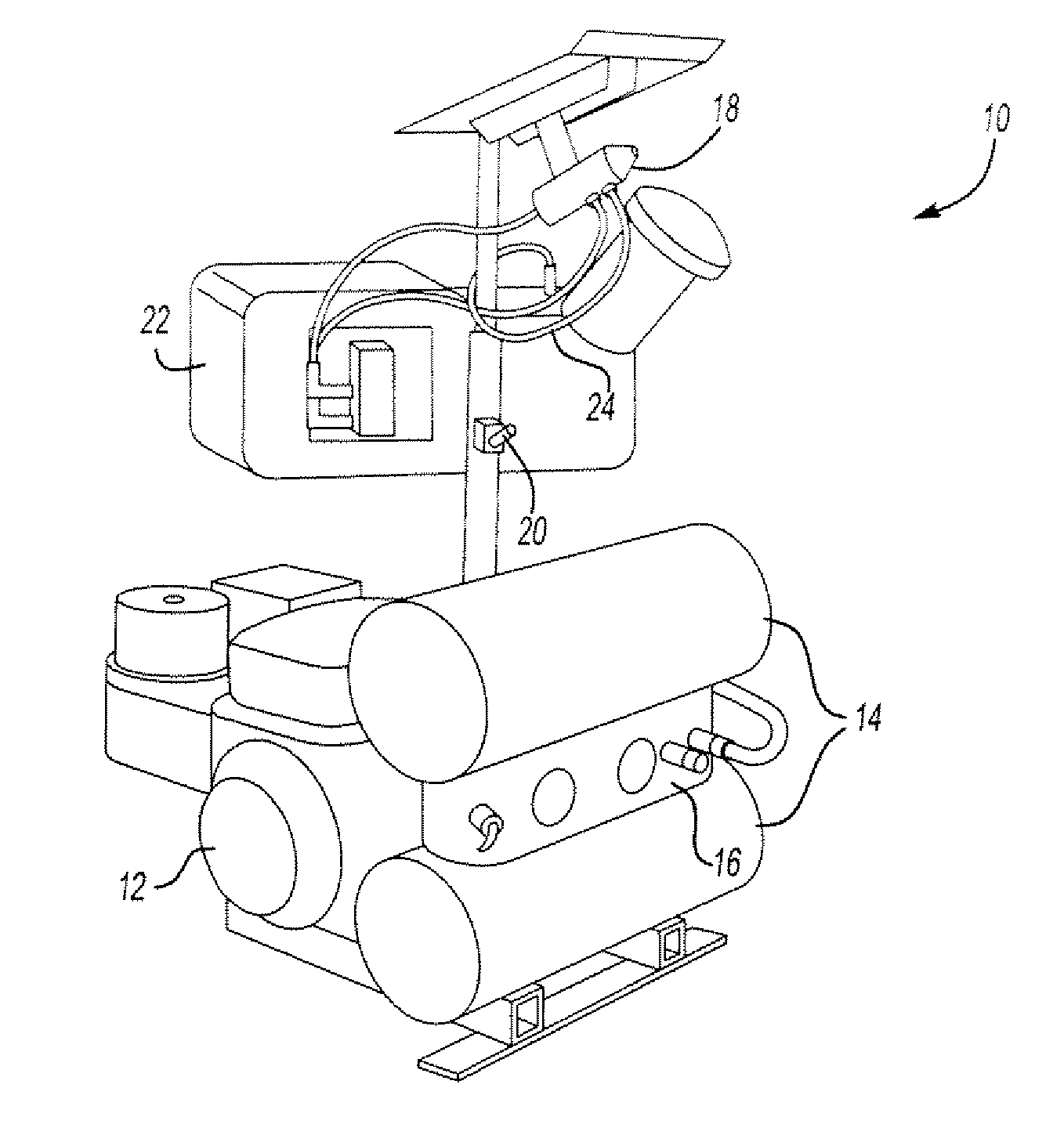

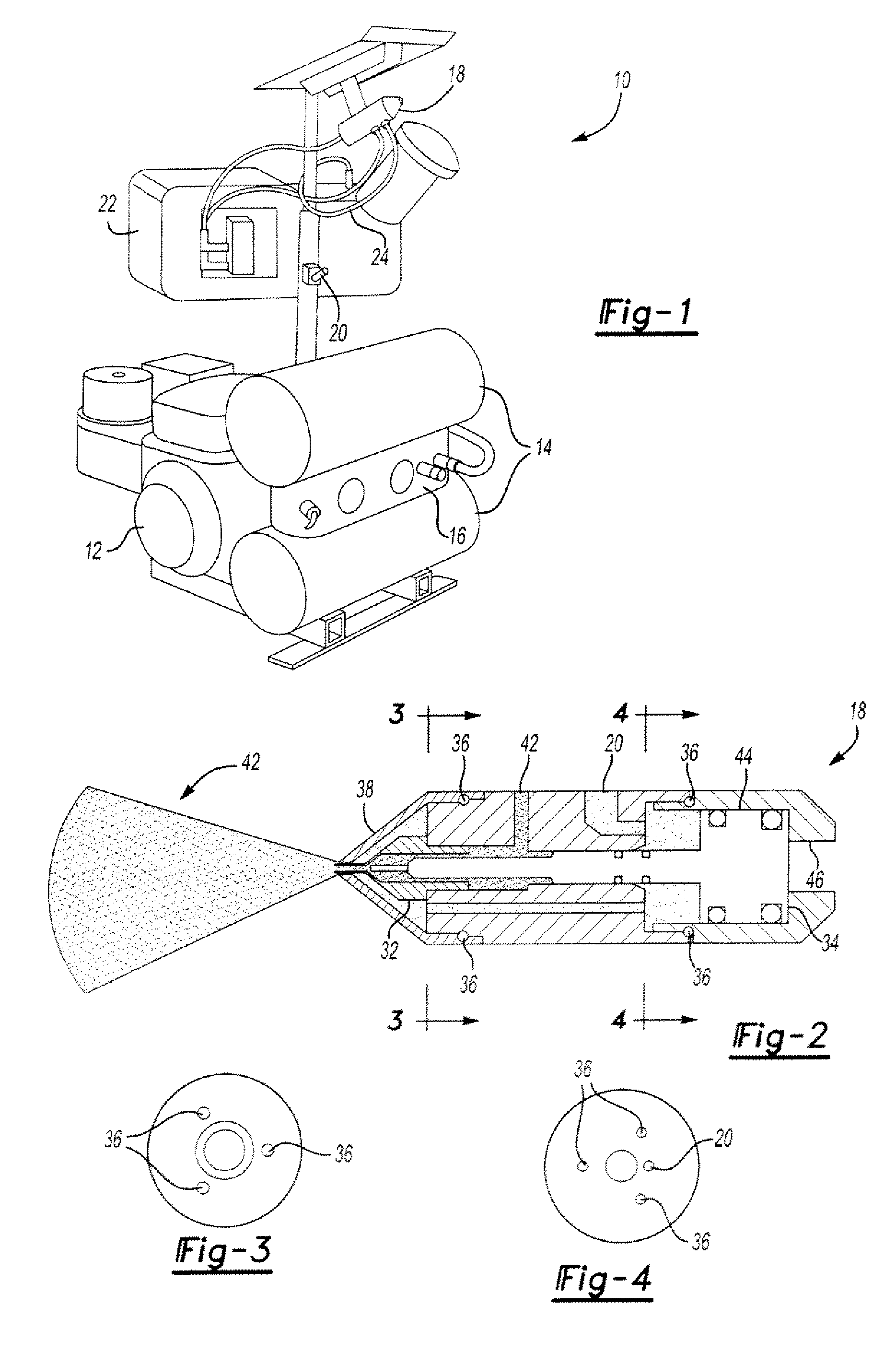

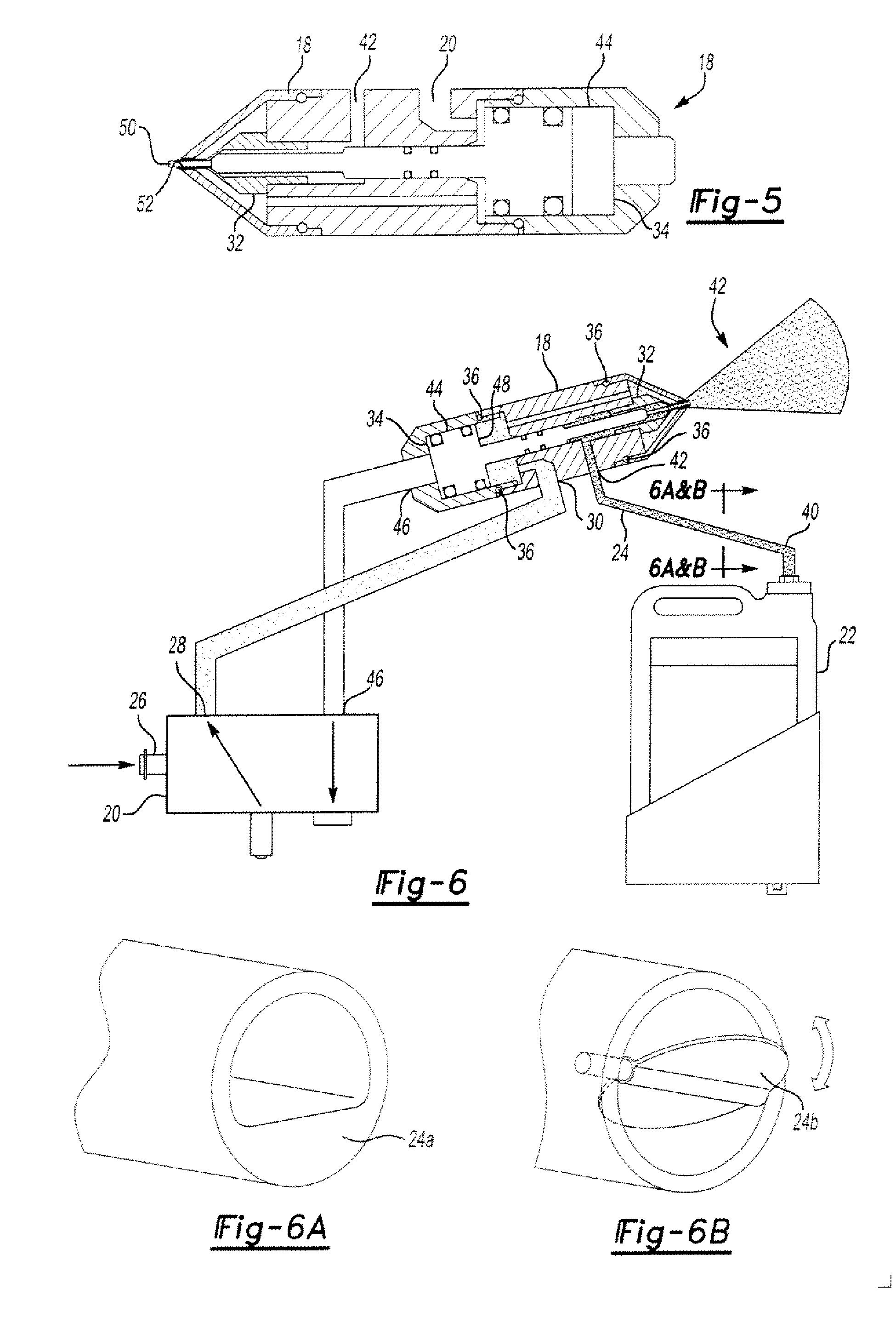

InactiveUS7073734B2Efficient sprayingFacilitate mosquito and insect controlSpray nozzlesFire rescueAirflowEngineering

The invention includes a spraying device (10) for producing a precise degree of liquid droplet generation on a repeatable basis by combining a specified rate of regulated flow of liquid material with a regulated flow of high-pressure air. The spraying device (10) includes an electric or engine driven direct drive compressor (12). Coupled to the compressor (12) is an air storage tank (14) providing air pulsation reduction to the regulated air and serves as a reservoir for excess airflow generation. A Venturi nozzle (18) is connected to the compressor (12). A liquid supply tube (24) uses a fixed or variable restriction to regulate the liquid flow to the nozzle (18). The vacuum in the liquid supply line (24) draws this liquid flow and mixes the liquid externally with the regulated air in exacting proportions forming specified liquid droplet sizes. The device (10) uses air and liquid regulation combined with a Venturi nozzle (18) and is able to generate extremely consistent liquid droplet sizes.

Owner:RD

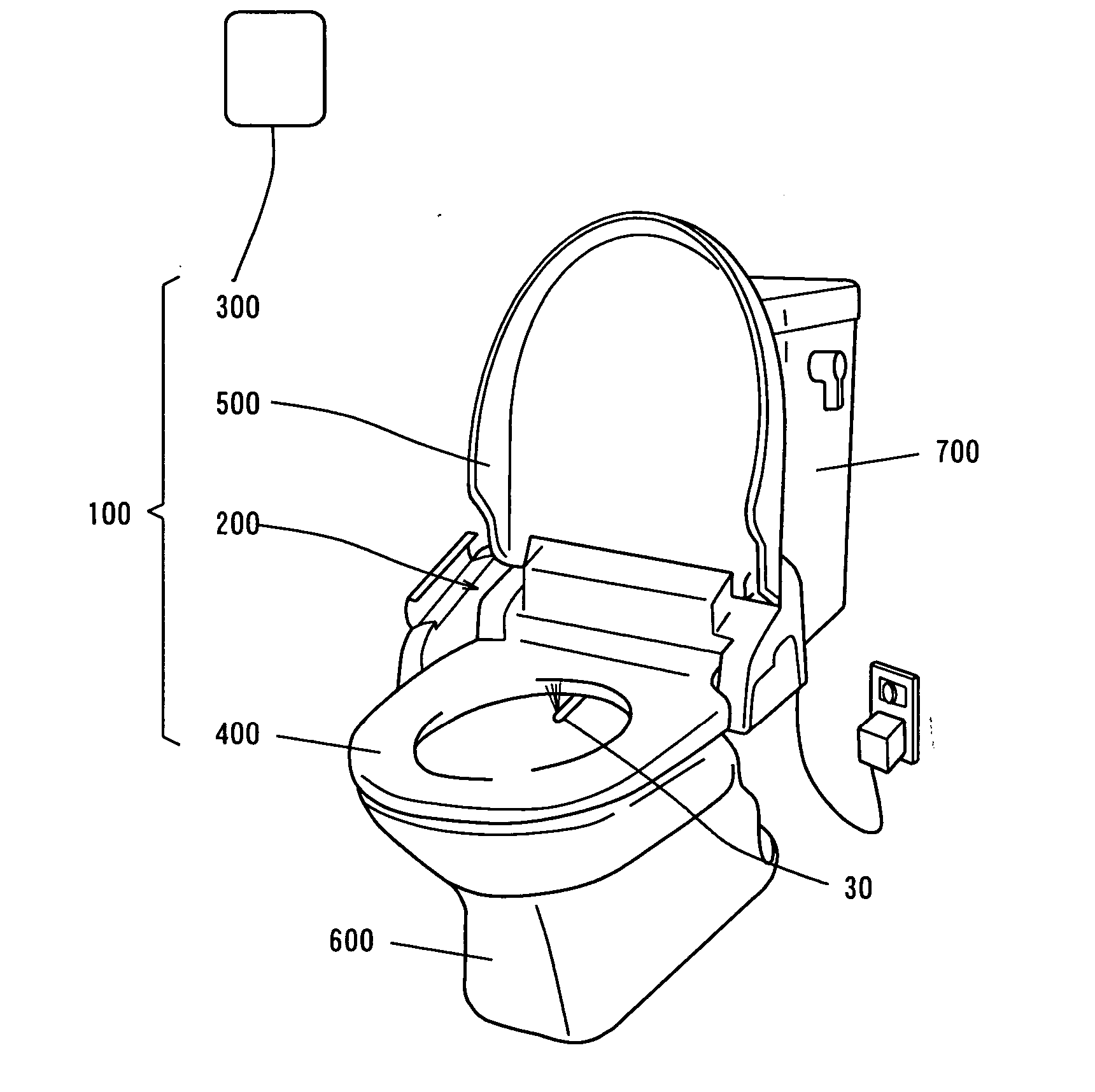

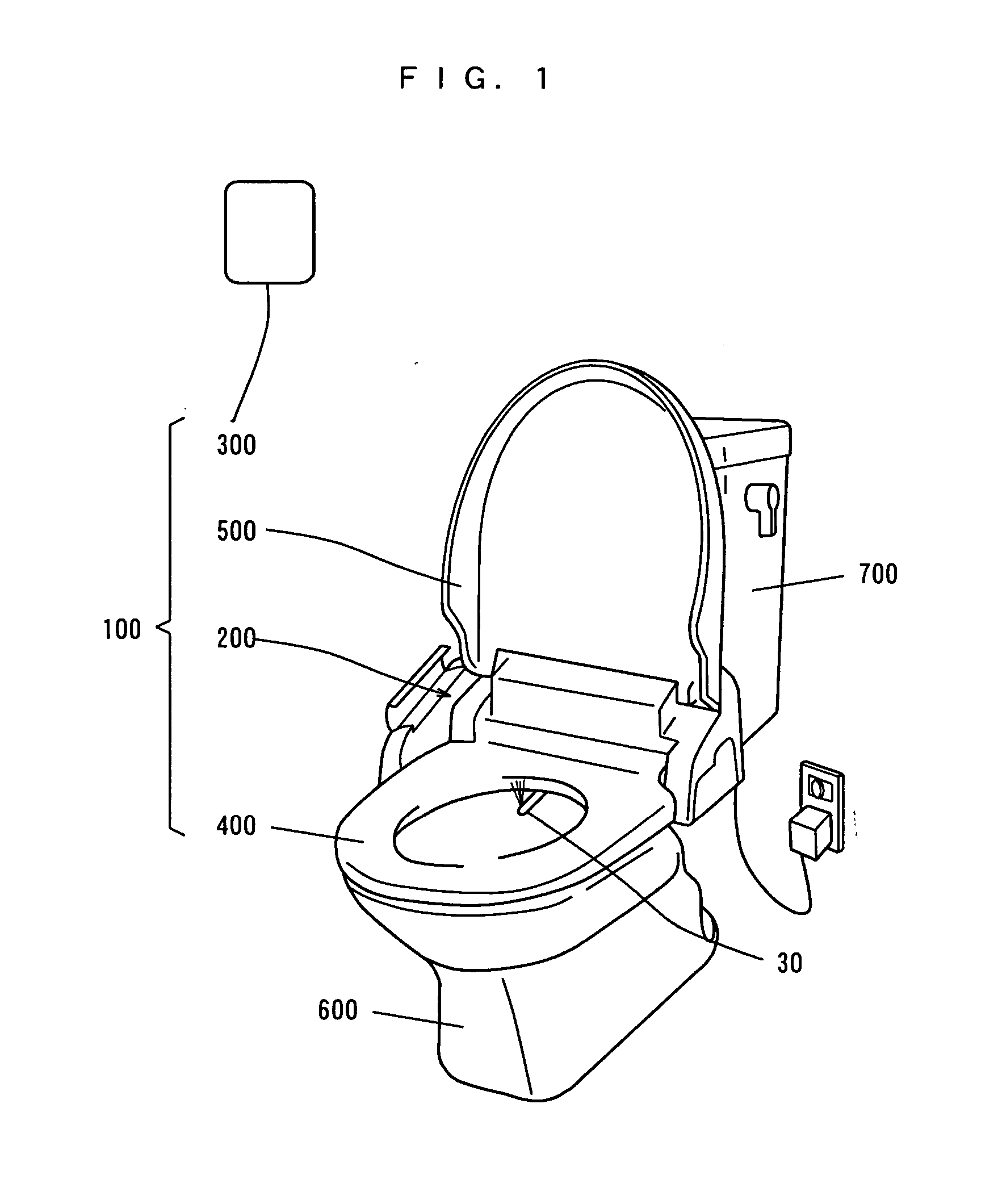

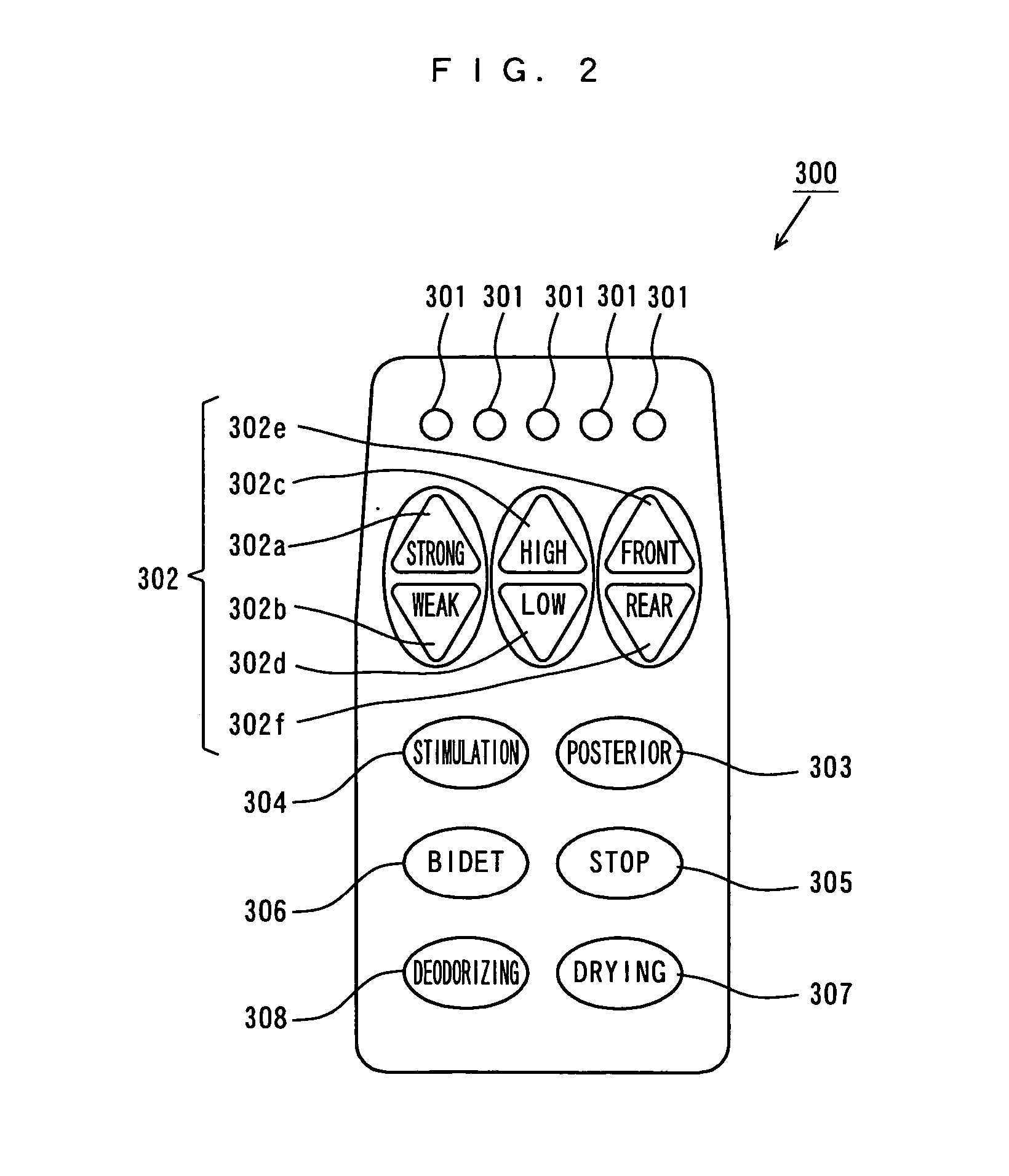

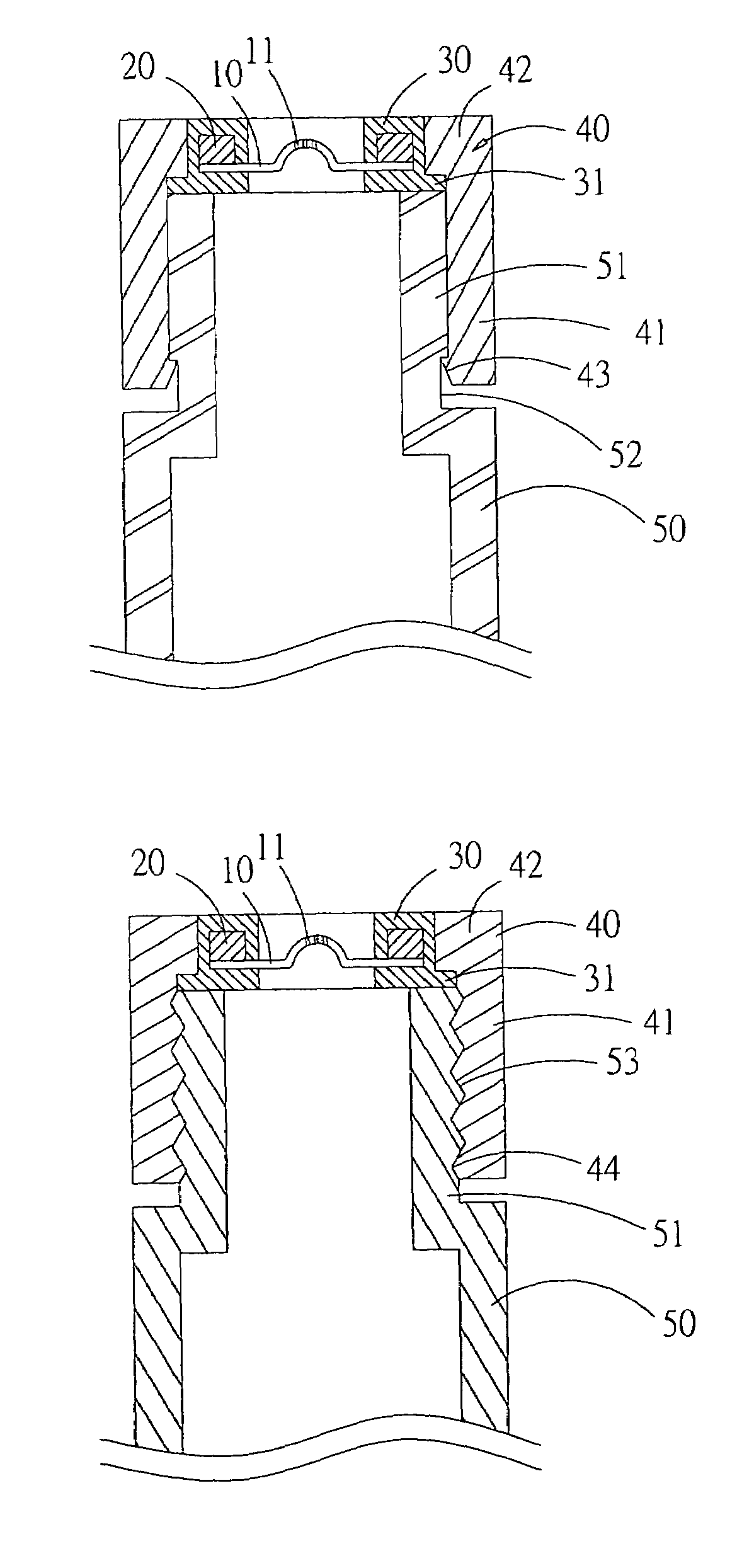

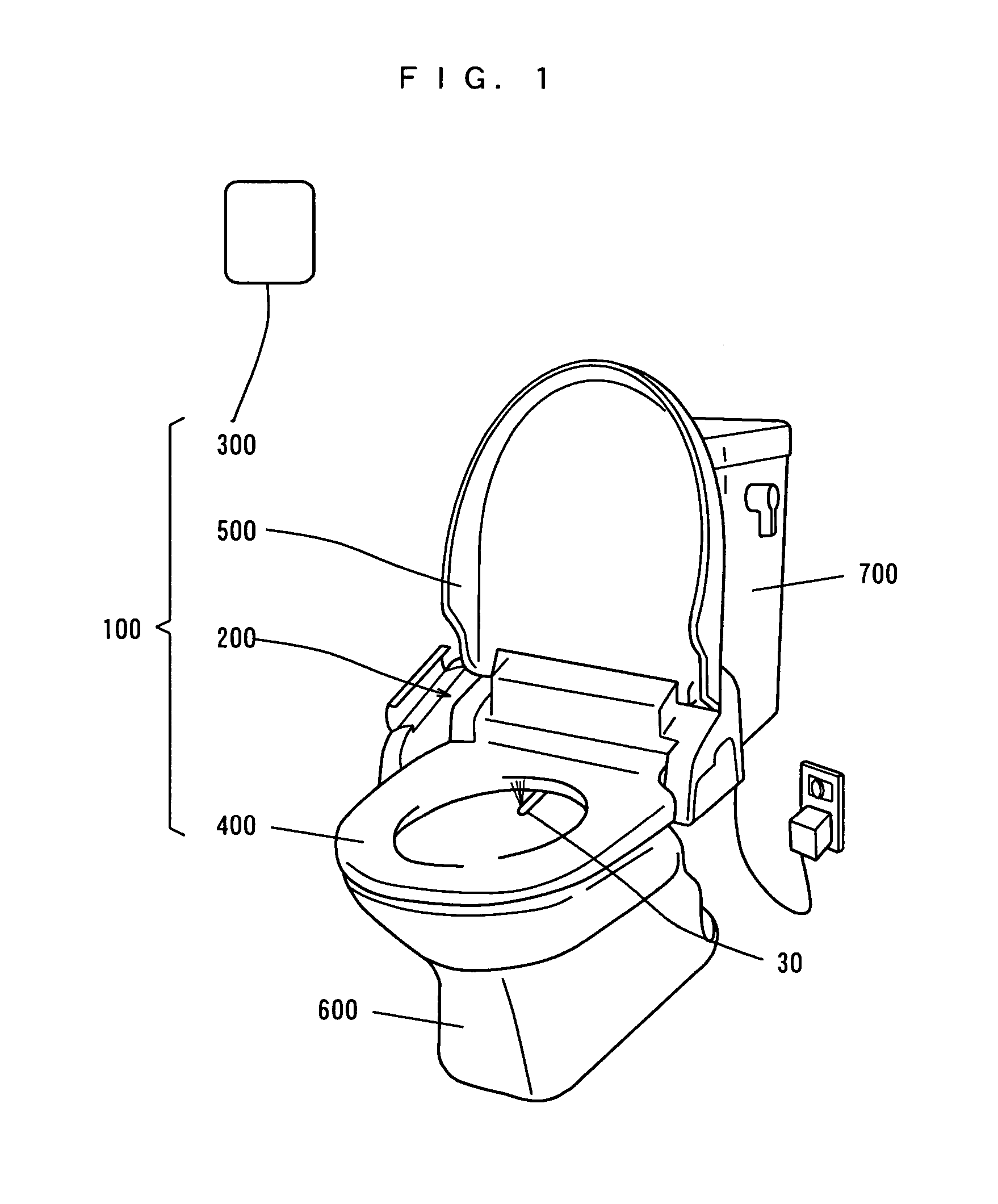

Nozzle device and hygienic washing device

Since the inner diameter of a flow-contracting portion continuously decreases toward a cylindrical swirl chamber, the velocity of flow of washing water flowing in the flow-contracting portion continuously rises. Since the inner diameter of the flow-contracting portion continuously decreases toward a spray hole, the velocity of flow of the washing water flowing in the flow-contracting portion continuously rises. Washing water supplied to one of flow paths in a two-flow path pipe is supplied to a flow path merger through a one-flow path pipe. The washing water supplied to the other flow path in the two-flow path pipe is supplied to the flow path merger after passing through a space between the one-flow path pipe and a nozzle cover. Washing water sprayed from a nozzle cleaning hole flows out of an opening at a front end of a nozzle cleaning cylinder along an outer peripheral surface of a piston while being spirally swirled in a space between an inner wall of the nozzle cleaning cylinder and the outer peripheral surface of the piston. A position fixing member having a curved shape along an inner surface at a front end of the nozzle cover is formed at a front end of the flow path merger. While a posterior nozzle moves from a forward position to a backward position, dispersed spiral flow and linear flow are alternately sprayed.

Owner:PANASONIC CORP

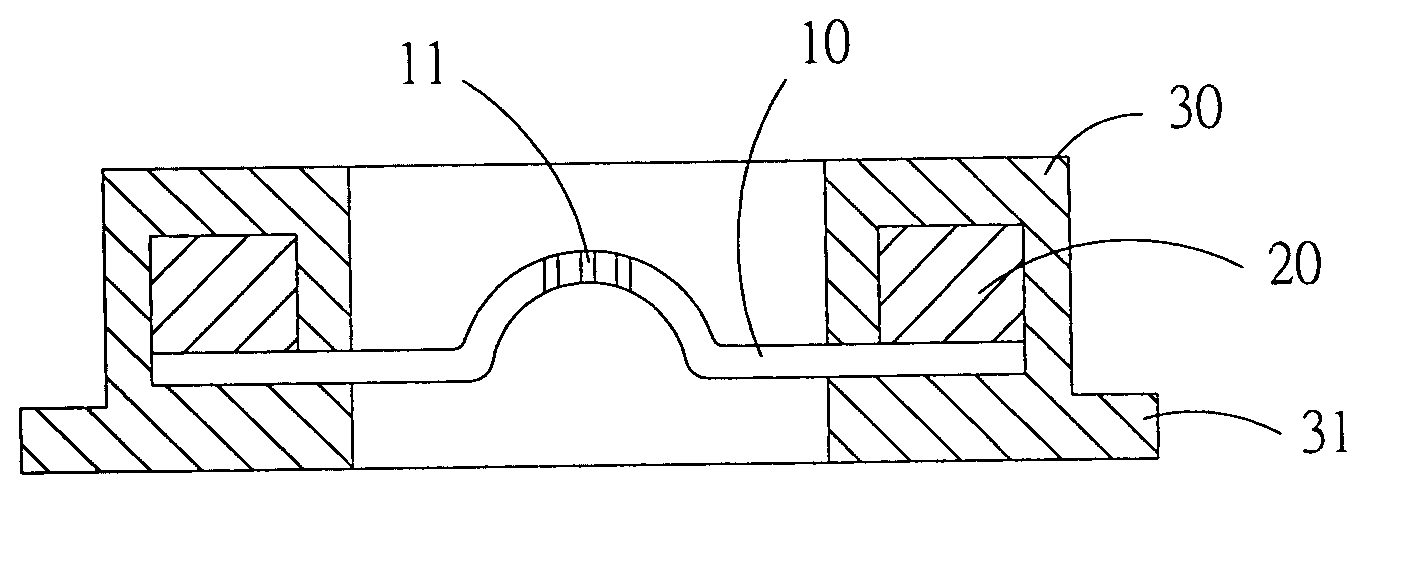

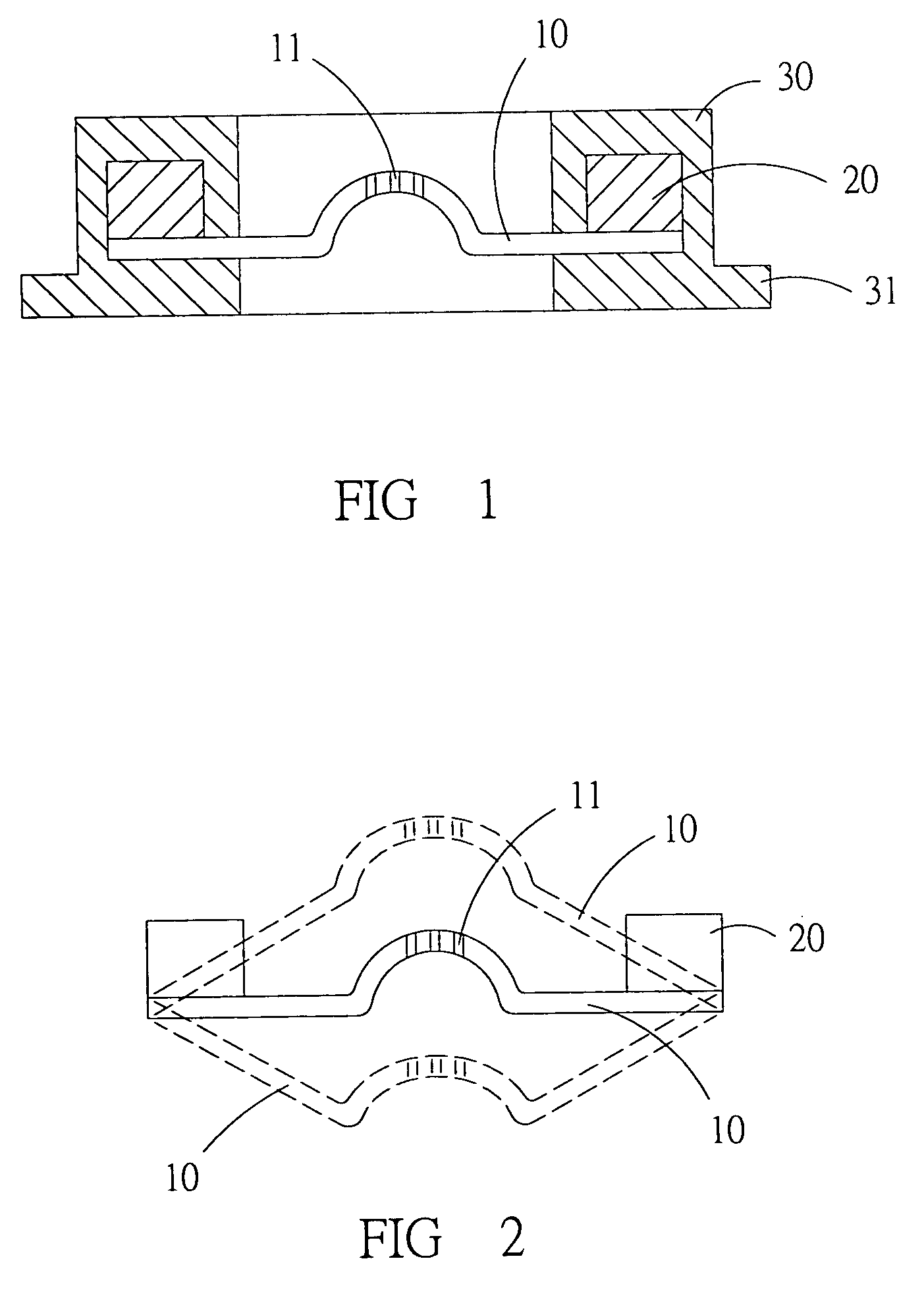

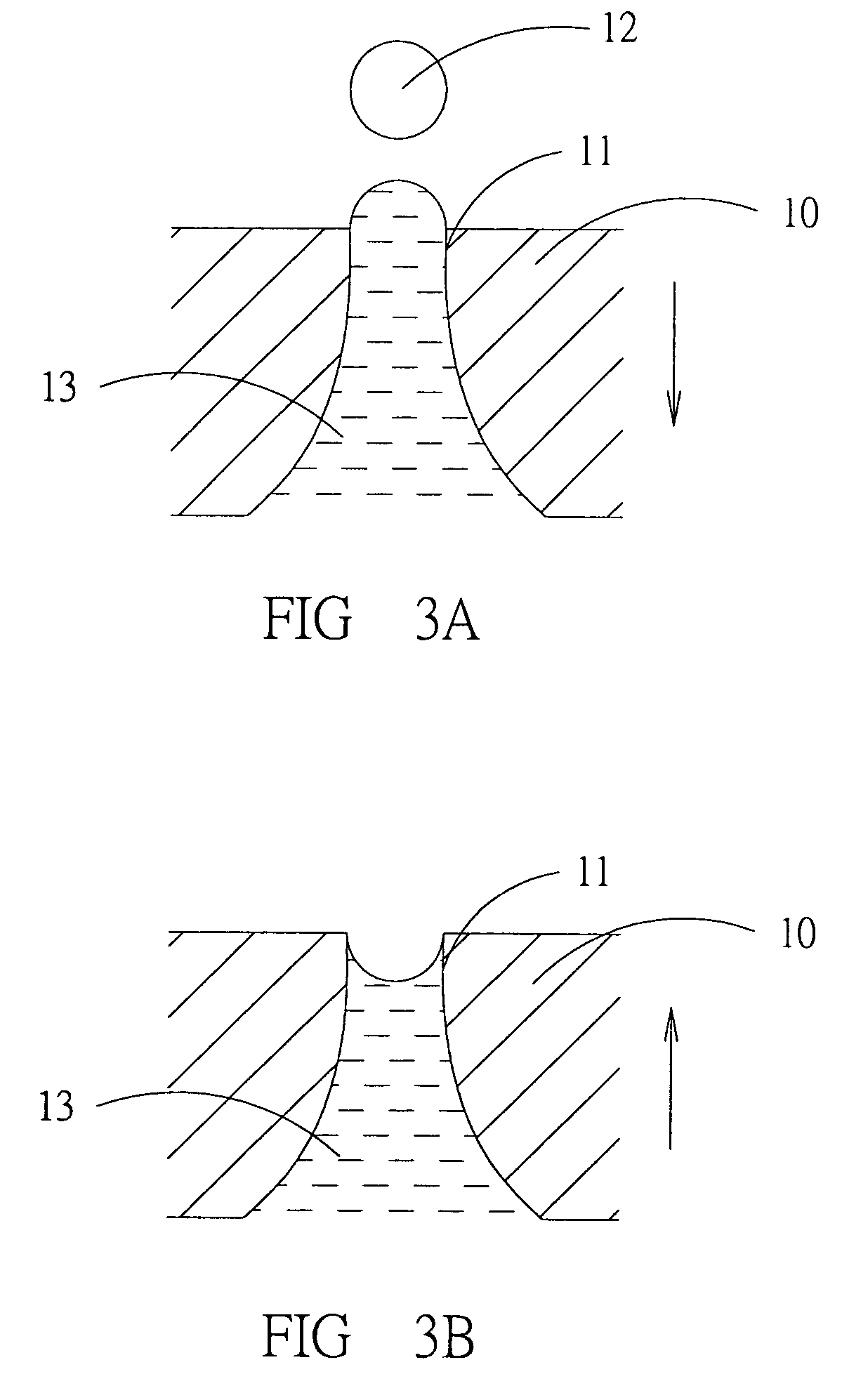

Spraying device

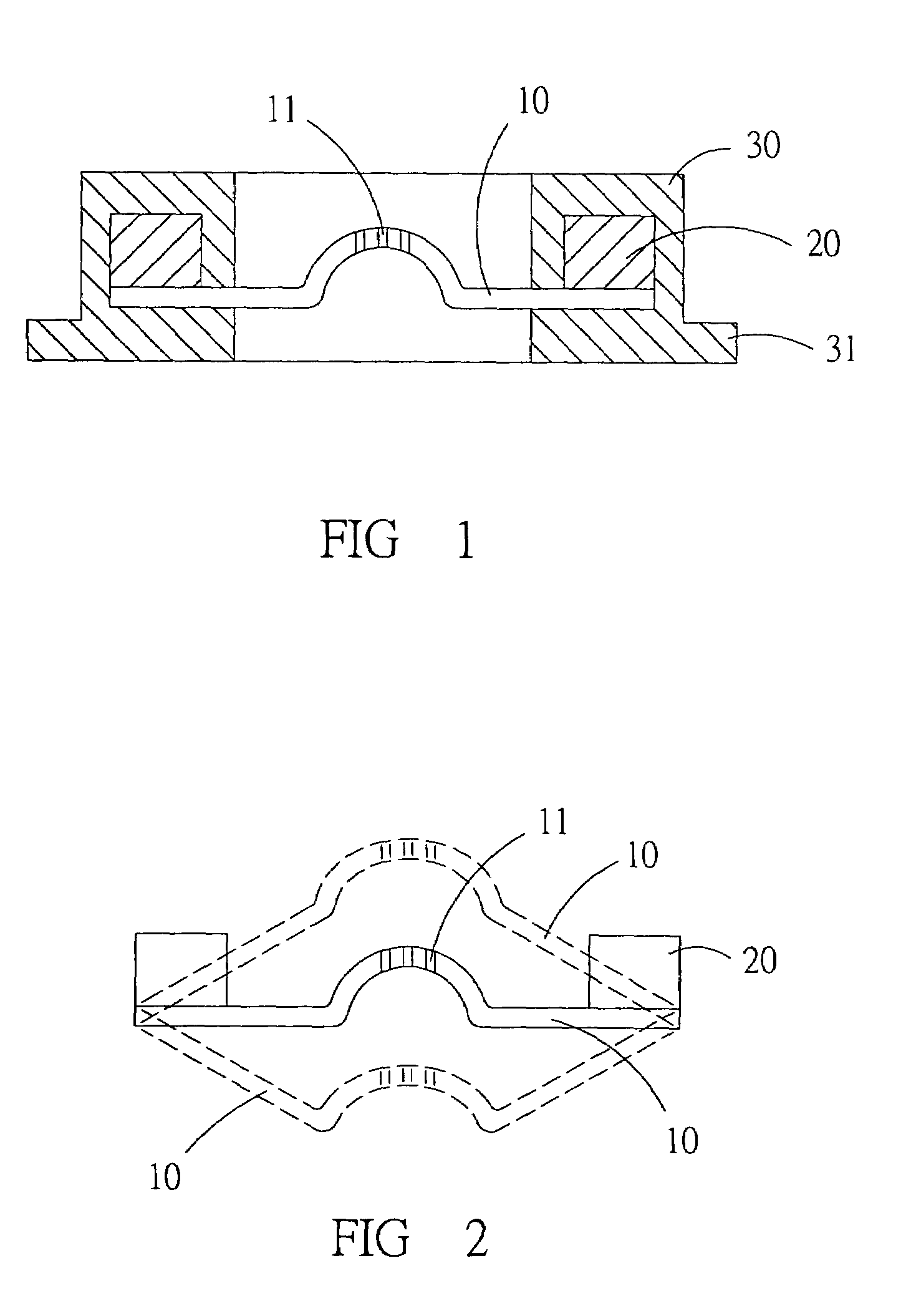

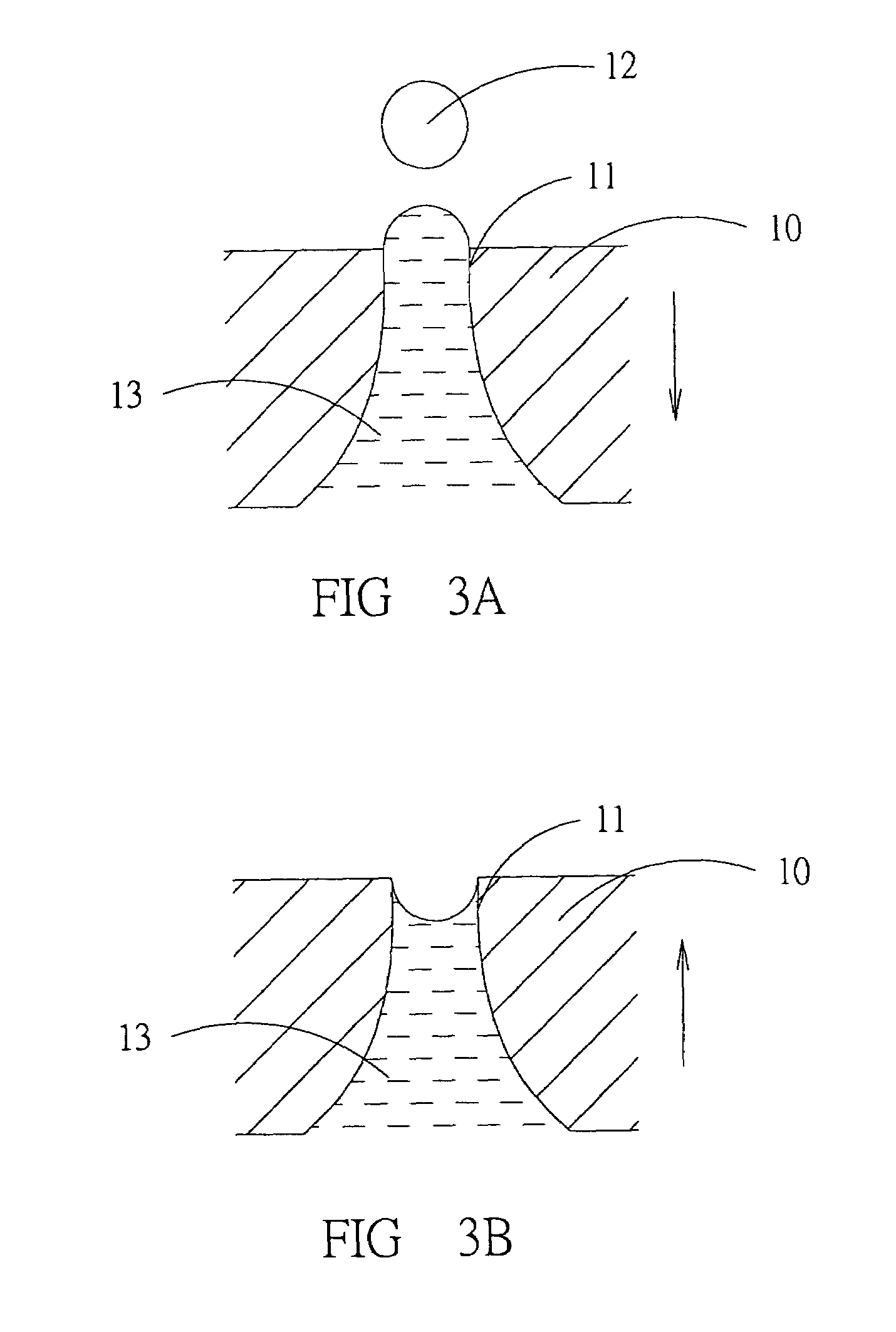

ActiveUS7168633B2Efficient sprayingReduce energy consumptionPiezoelectric/electrostriction/magnetostriction machinesMovable spraying apparatusSoft materialsEngineering

A spraying device comprises a spraying plate, having a plurality of tiny holes, a vibrating element, set on a periphery of the spraying plate, and driving a vibrating movement thereof, a wrapping layer, made of soft material and tightly surrounding the vibrating element, sealing the vibrating element from the liquid, and a fastening cap, allowing for quick mounting and dismounting of the spraying device; wherein the vibrating movement of the spraying plate causes liquid adjacent to a lower side of the spraying plate to be periodically compressed and thereby to be pressed through the holes of the spraying plate, and wherein the wrapping layer prevents external interference with the vibrating movement, at the same time minimizing transmission losses of vibrational energy, enhancing effectivity of spraying.

Owner:IND TECH RES INST

Device to deliver a powdery medicine into nasal cavity

InactiveUS7722566B2Improve accuracyEfficient sprayingRespiratorsAmpoule syringesNasal cavityBiomedical engineering

A device that delivers a powdery medicine for a nasal cavity includes positioning guides that cause a capsule to slide as far as a predetermined position and are provided on the side of cutters to make holes on both ends of the capsule provided between the connection port on the side of a nozzle that sprays the powdery medicine into the nasal cavity. The device further includes a connection port on the side of a pump that supplies spray air to the nozzle in order to make the size of the holes made on both ends of the capsule constant, wherein a distance between the connection ports is made shorter than a distance between blade tips of the cutters.

Owner:SHIN NIPPON BIOMEDICAL LAB

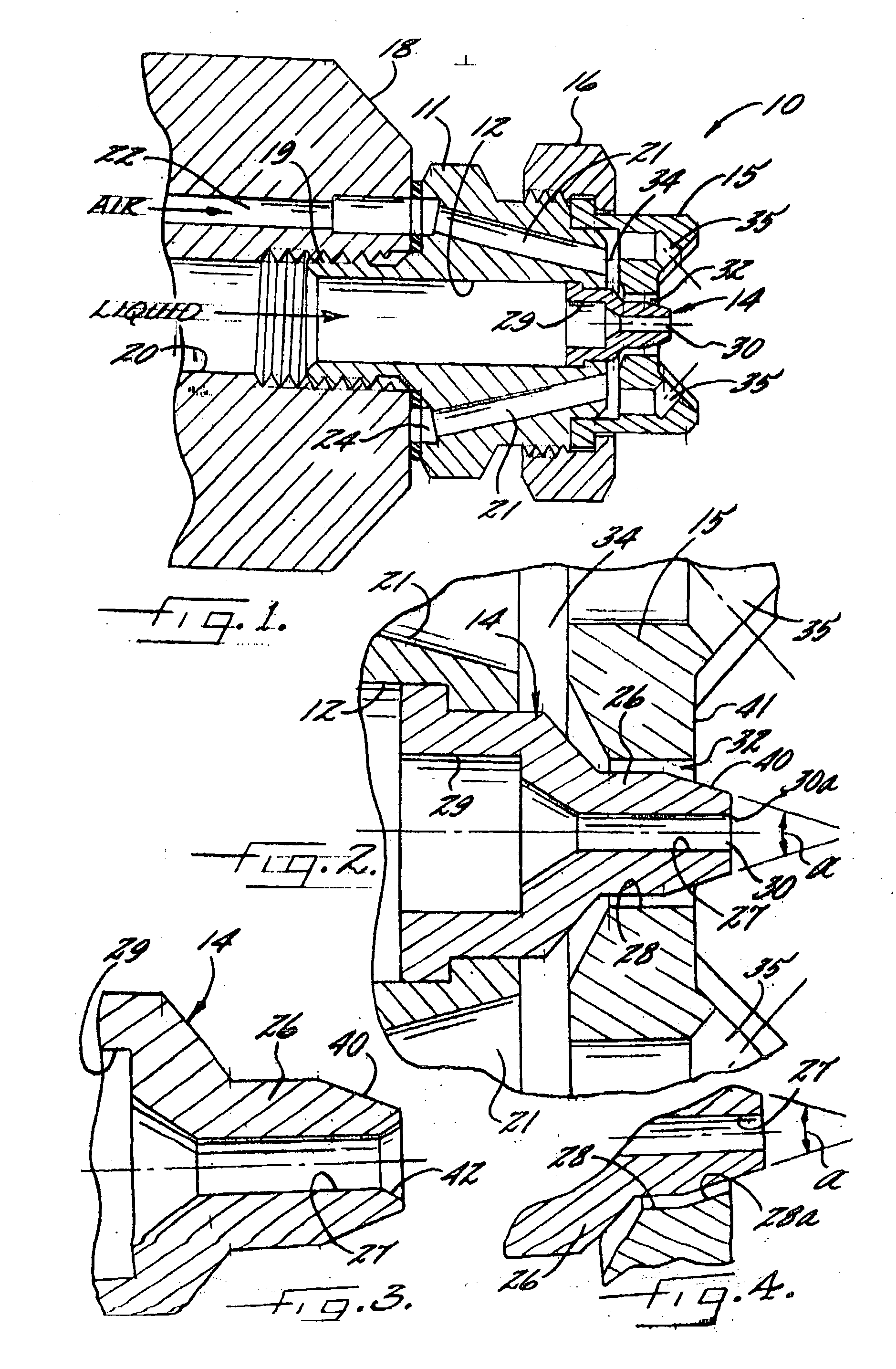

Air assisted spray nozzle assembly for spraying viscous liquids

InactiveUS20040159720A1Efficient sprayingReduces and eliminates undesirable buildSpray nozzlesFire rescueViscous liquidAir entrainment

An external mix air atomizing spray nozzle assembly having a nozzle body formed with liquid and air passages, a spray tip at a downstream end of the nozzle body having a nose portion that defines a liquid discharge orifice, and an air cap mounted in surrounding relation to the spray tip nose portion. The air cap defines an annular pressurized air orifice about the spray tip nose portion and a plurality of angled air passages disposed radially outwardly thereof. Pursuant to the invention, the spray tip nose portion has a frustoconical end tapering inwardly in a downstream direction which enhances air entrainment and minimizes liquid turbulence in a zone immediately in front of the air cap and around the spray tip nose portion to prevent undesirable build up of spray material on the exposed end surfaces of the spray tip nose portion and air cap.

Owner:SPRAYING SYST

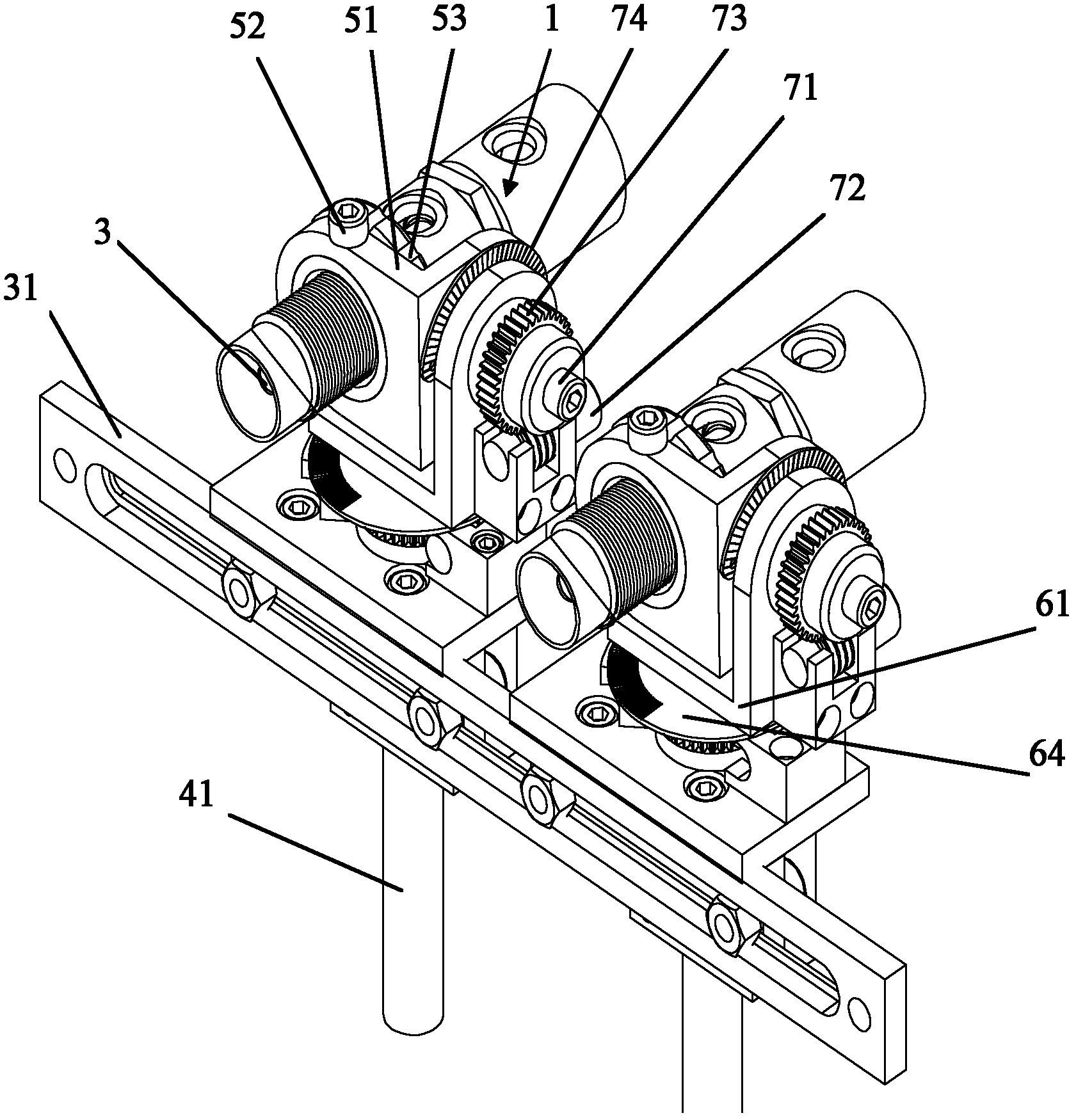

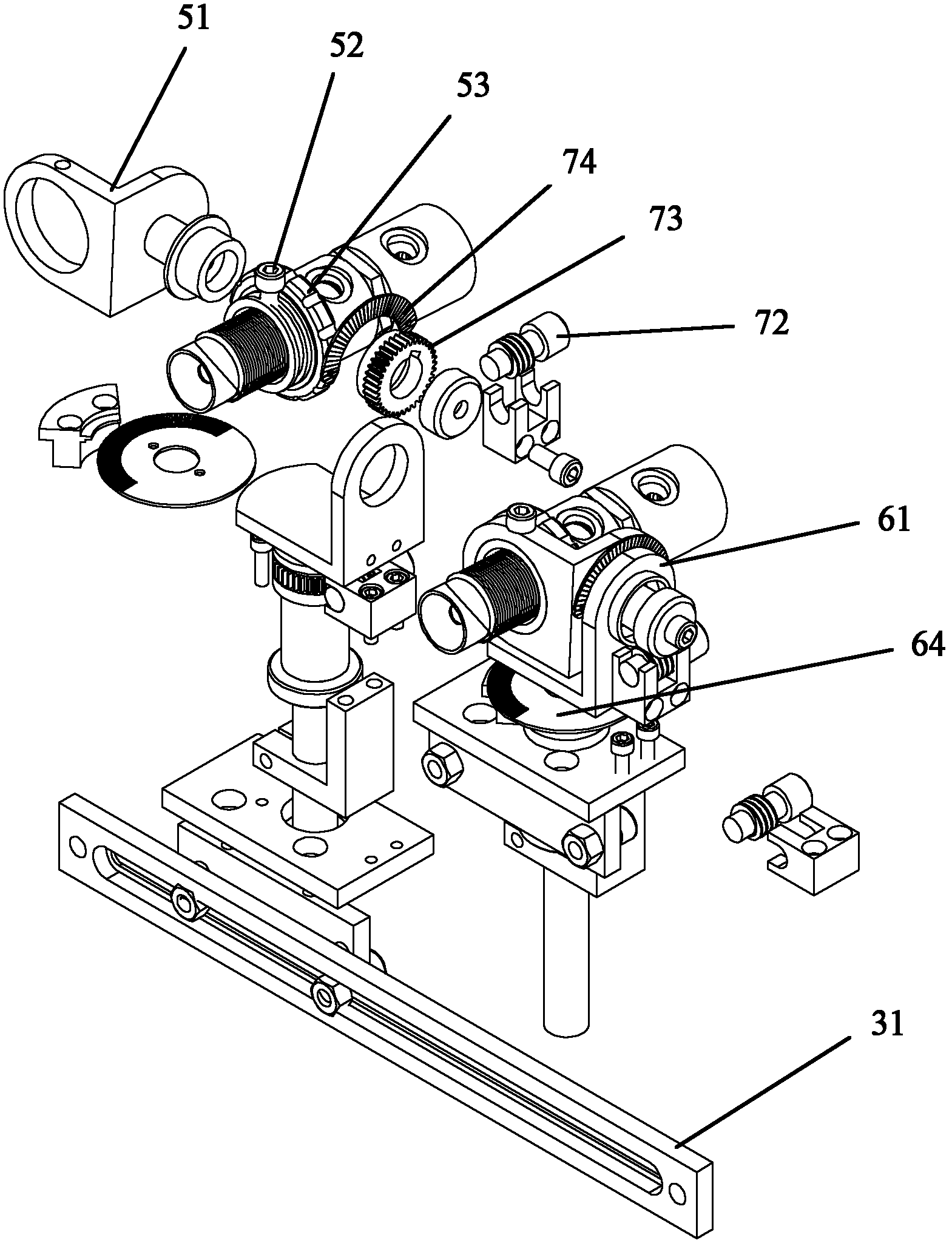

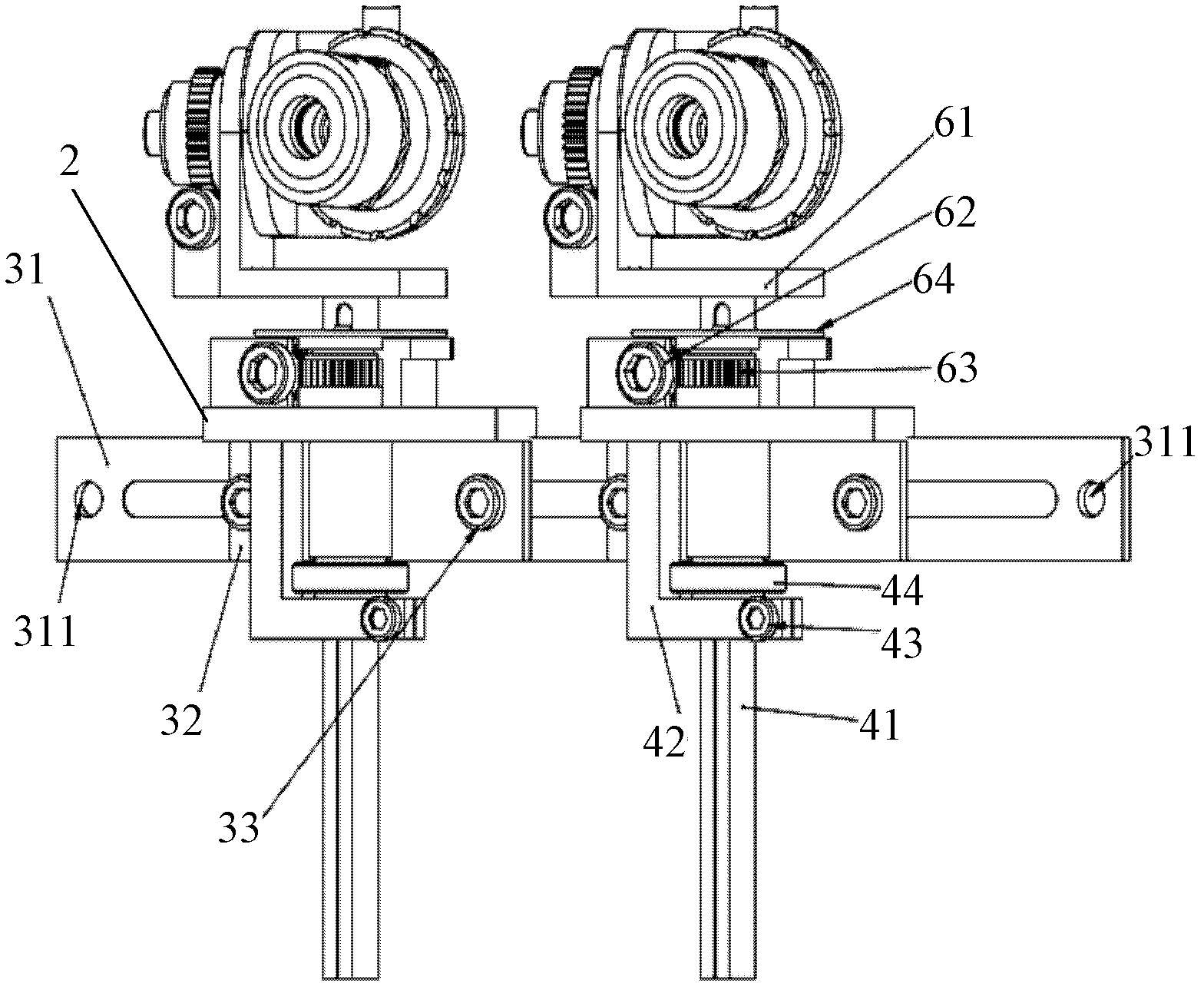

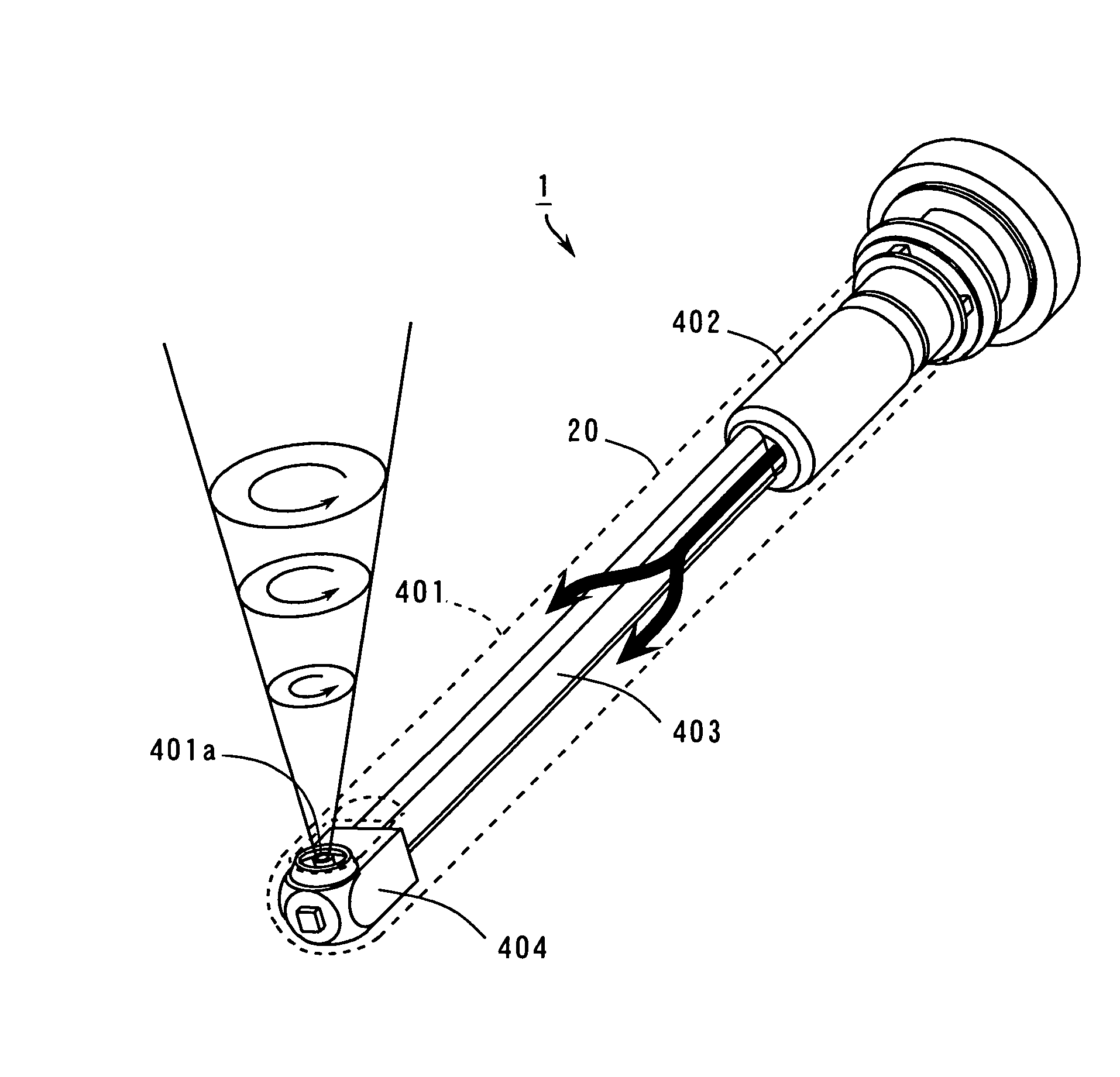

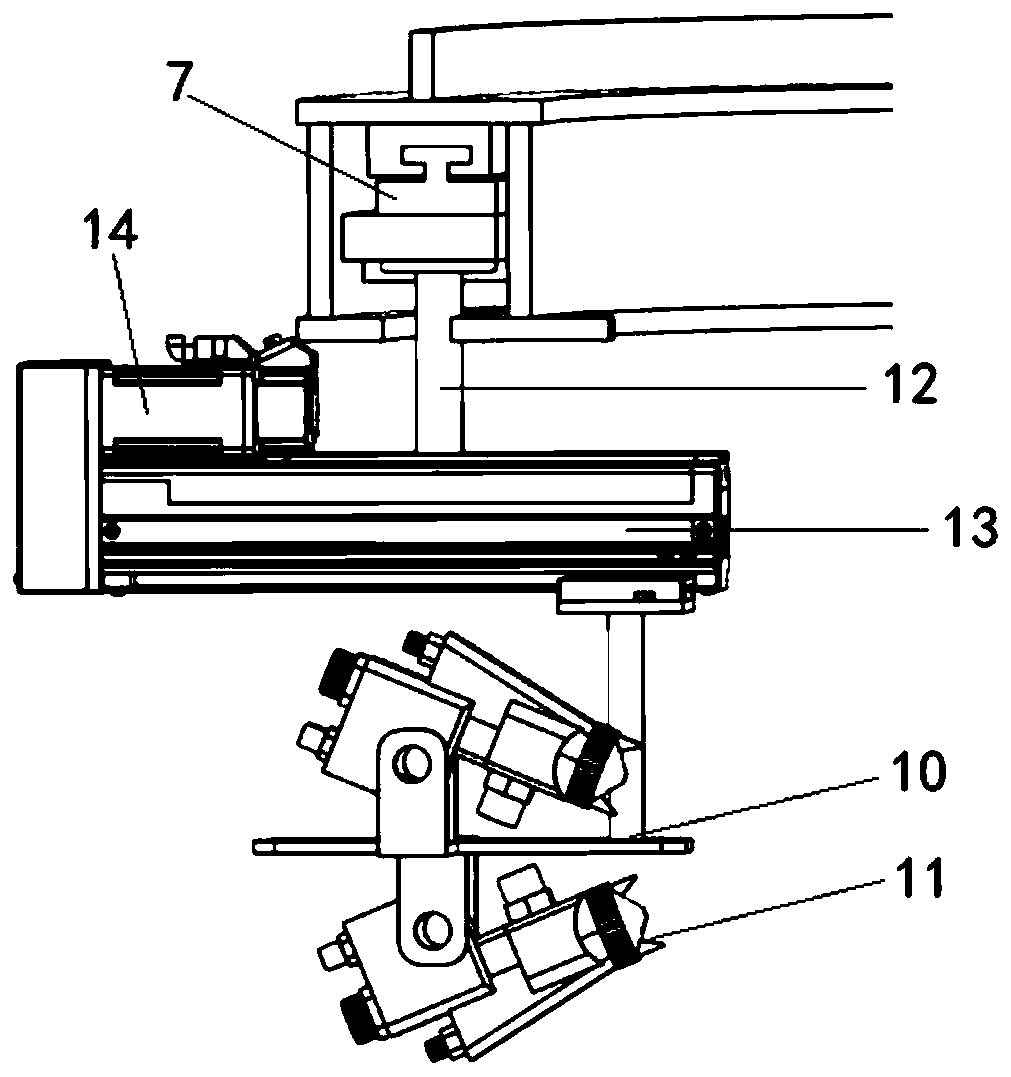

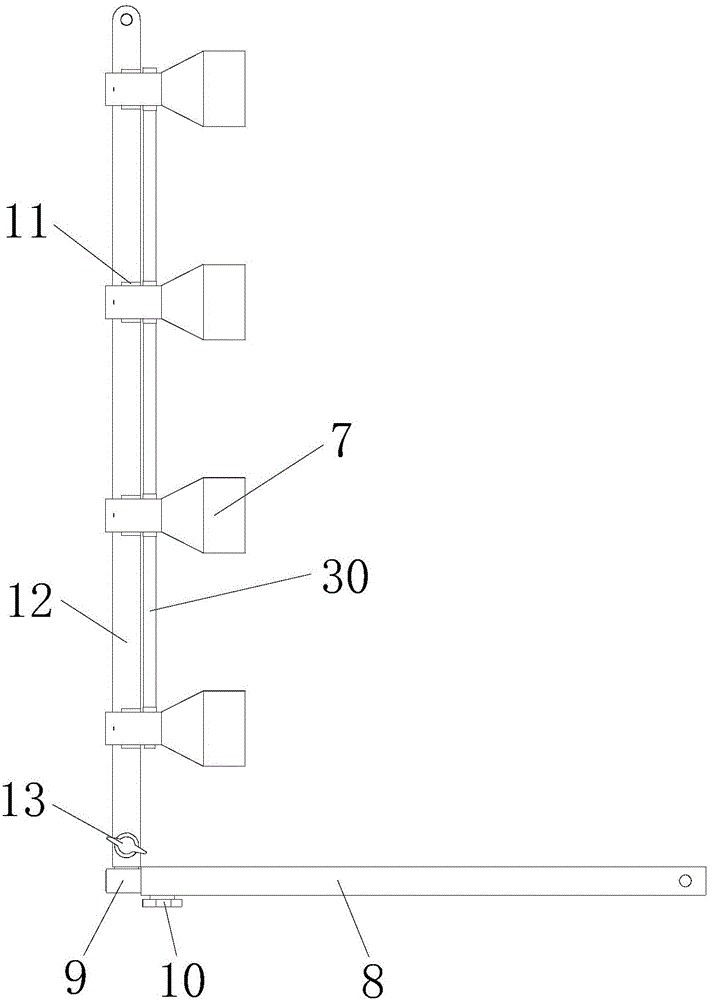

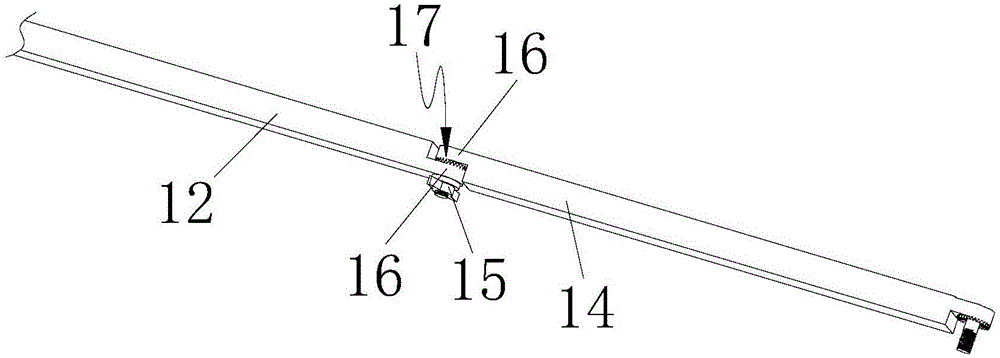

Nozzle three-dimensional positioning and angle adjusting device

ActiveCN102632007AStable sprayingEfficient sprayingTobacco preparationSpraying apparatusPulp and paper industryDepth direction

The invention discloses a nozzle three-dimensional positioning and angle adjusting device comprising a nozzle body, a substrate, a horizontal direction conditioning mechanism, a vertical direction conditioning mechanism, a depth direction conditioning mechanism, a horizontal plane angle conditioning mechanism and a pitch conditioning mechanism. The horizontal direction conditioning mechanism is arranged at one side of the substrate; the vertical direction conditioning mechanism is arranged at the lower part of the substrate; the horizontal plane angle conditioning mechanism is arranged at the upper part of the substrate; and the nozzle body, the depth direction conditioning mechanism and the pitch conditioning mechanism are connected together and are arranged at the upper part of the horizontal plane angle conditioning mechanism. The nozzle three-dimensional positioning and angle adjusting device provided by the invention can adjust a position of the nozzle body in a full-direction manner, so that the injection angle of the nozzle is multi-dimensionally and accurately controlled. Therefore, the nozzle is more stable and more efficient to spray, so that the uniformity for adding sugar liquid and perfume liquid into a material can be ensured.

Owner:SHANGHAI TOBACCO GRP CO LTD

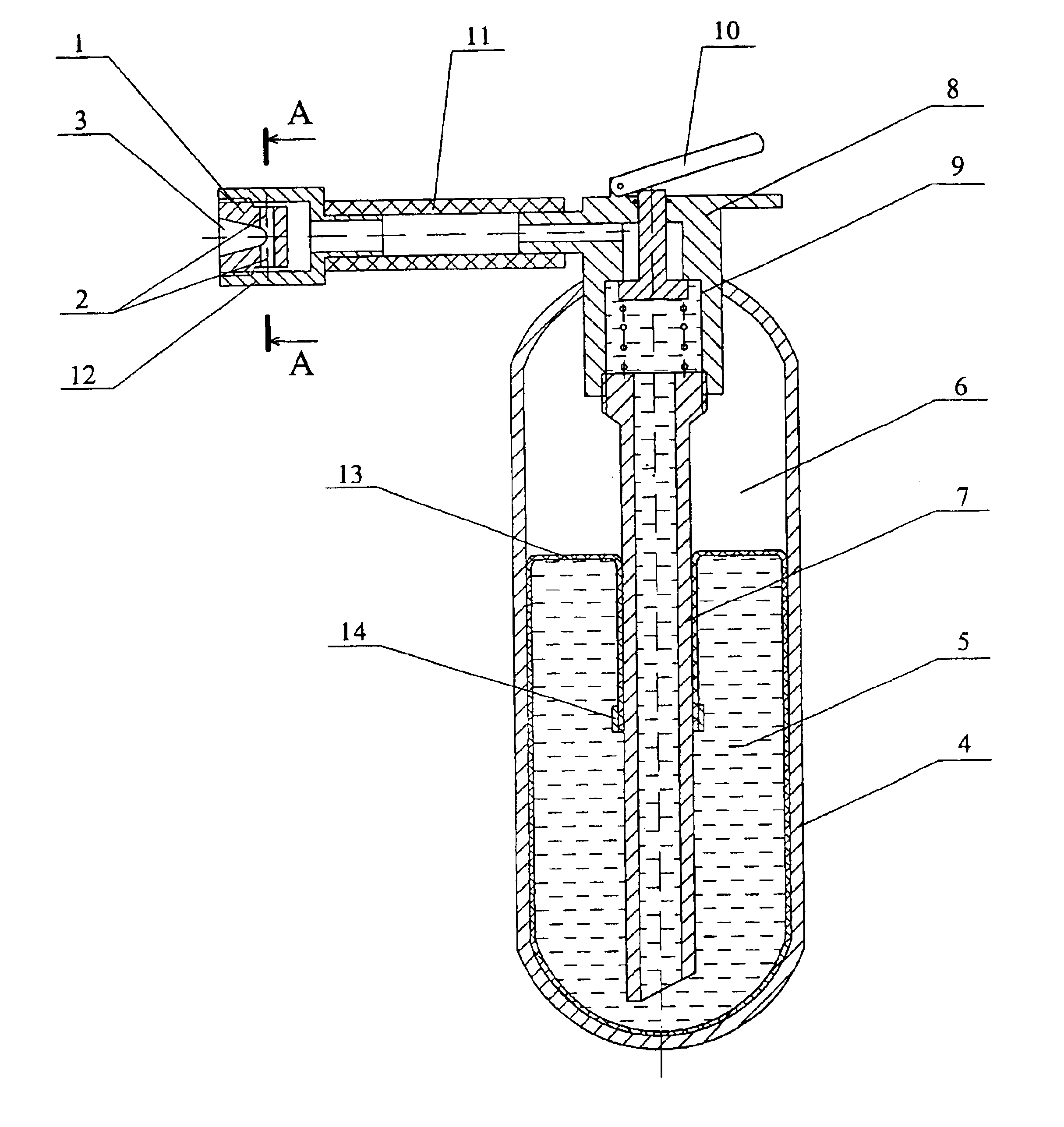

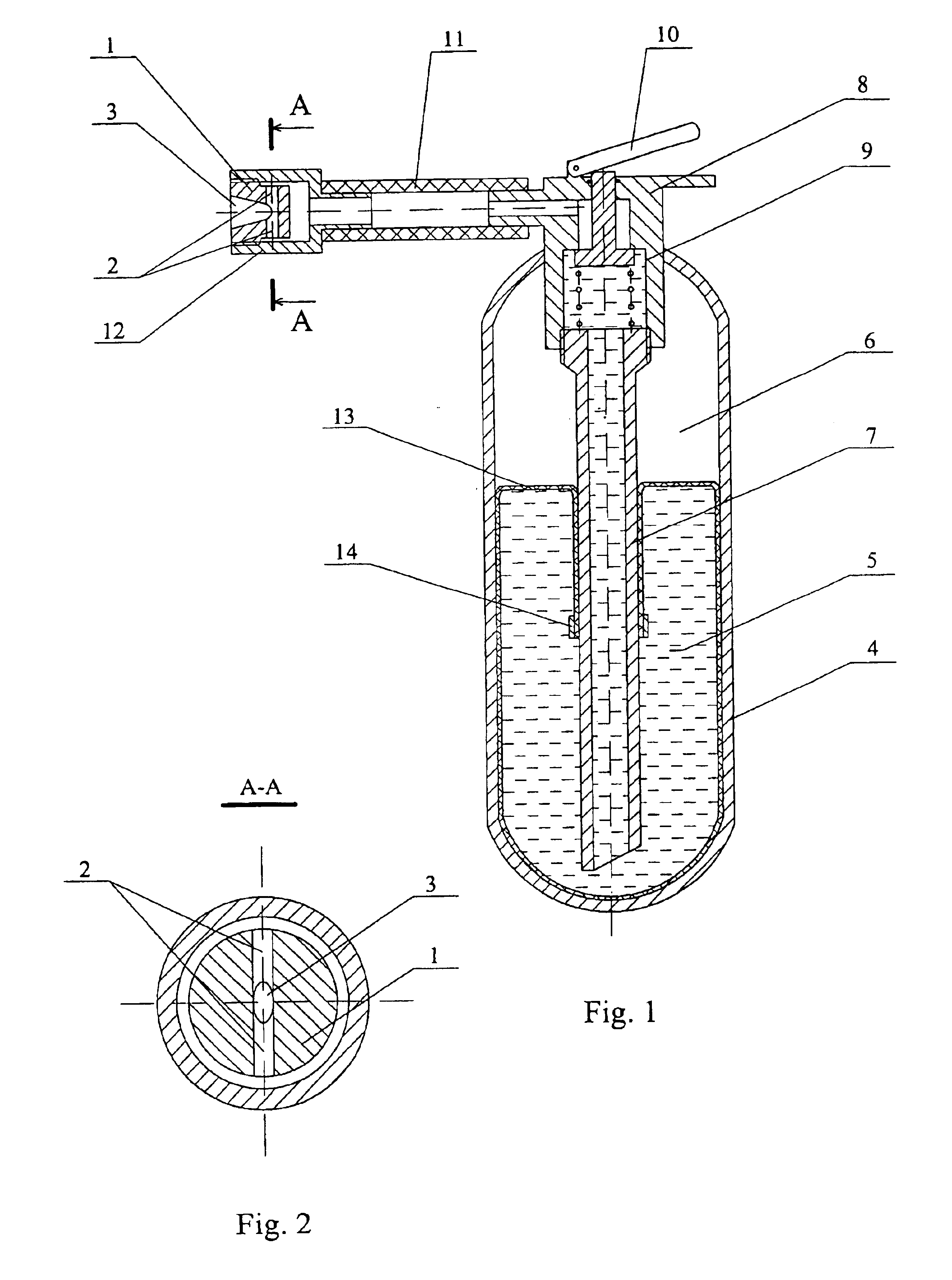

Fluid spray nozzle and fire extinguisher

InactiveUS6886640B1Improve efficiencyEfficient sprayingSpray nozzlesFire rescueSpray nozzleEngineering

The invention is aimed at generating a finely dispersed gas-and-drop flow with its cross-section in the shape of an ellipse and uniform intensity distribution. A fluid spray nozzle is built in the form of a body (1) with two coaxial channels (2) of the same cross-section designed for head liquid supply and a nozzle having a shape of a conical diffuser (3). The diffuser (3) is oriented transverse to the channels, the area of its inlet orifice not exceeding the total cross-section area of the channels. The fire extinguisher fitted with a fluid spray nozzle comprises a liquid vessel (4) for fire extinguishing, a liquid expulsion system, a pipeline (11), connecting a liquid cavity (5) of the vessel (4) to a spray nozzle and at least one valve or a regulator (8) to control the liquid supply to the spray nozzle.

Owner:OBSCHESTVO S OGRANICHENNOI OTVETABTVENNOSTJU UNIPAT

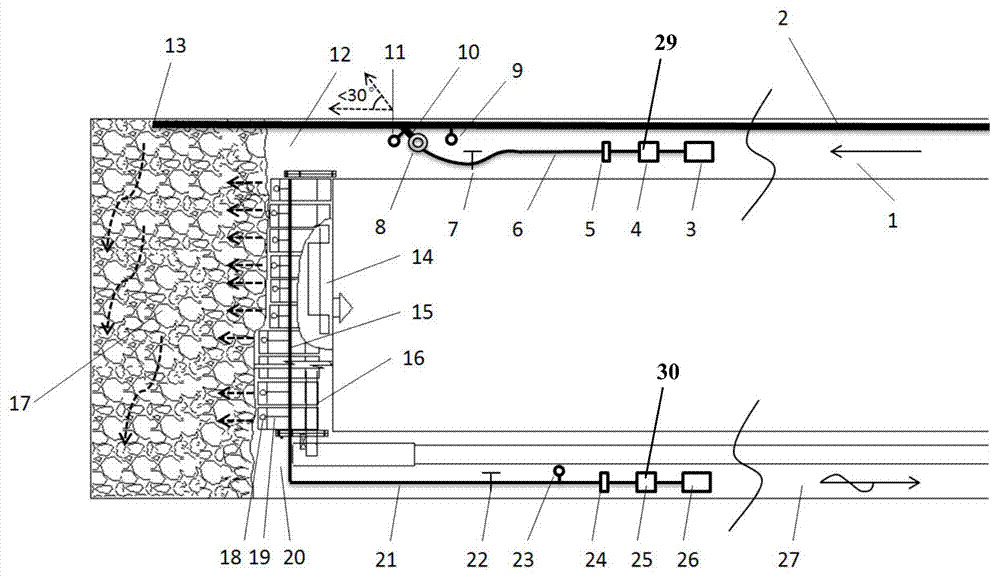

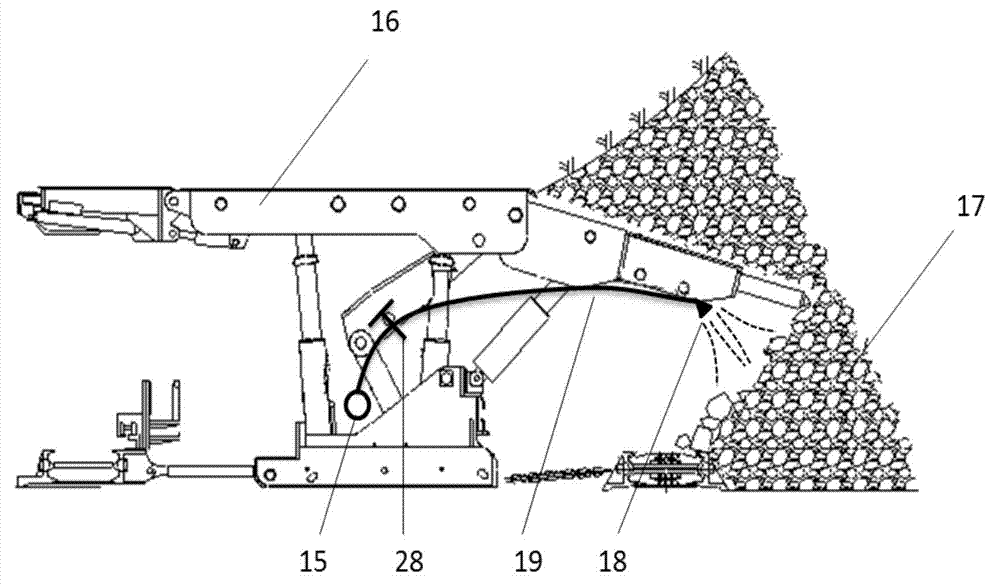

Gob retardant efficient spraying system and spraying method

InactiveCN104329109AImprove the spraying processRealize secondary sprayingDust removalFire preventionNatural disasterNitrogen

The invention discloses a gob retardant efficient spraying system and a gob retardant efficient spraying method, and belongs to the technical field of prevention and control of natural disasters under a coal mine. The system comprises a retarding pump station and a nitrogen conveying pipeline, wherein a liquid storage tank is connected with the input ends of retarding pumps; the output end of the first retarding pump is connected with the input end of an atomizer through a first filter; the output end of the atomizer is connected with the first port of a tee joint; the second port of the tee joint is connected with the nitrogen conveying pipeline; a first pressure gauge is arranged on the third port of the tee joint; the output end of a second retarding pump is connected with a spray head arranged on the back part of a hydraulic bracket respectively after passing through a second filter; a first high-pressure ball valve is arranged on a pipeline between the first filter and the atomizer; a second pressure gauge and a second high-pressure ball valve are arranged on a pipeline between the second filter and the spray head; a third pressure gauge is arranged on the nitrogen conveying pipeline. In the spraying method, by taking high-pressure nitrogen gas as a carrier, an atomized retardant is delivered to the back part of a working surface bracket and is then automatically sprayed from a plurality of points .

Owner:LIAONING TECHNICAL UNIVERSITY

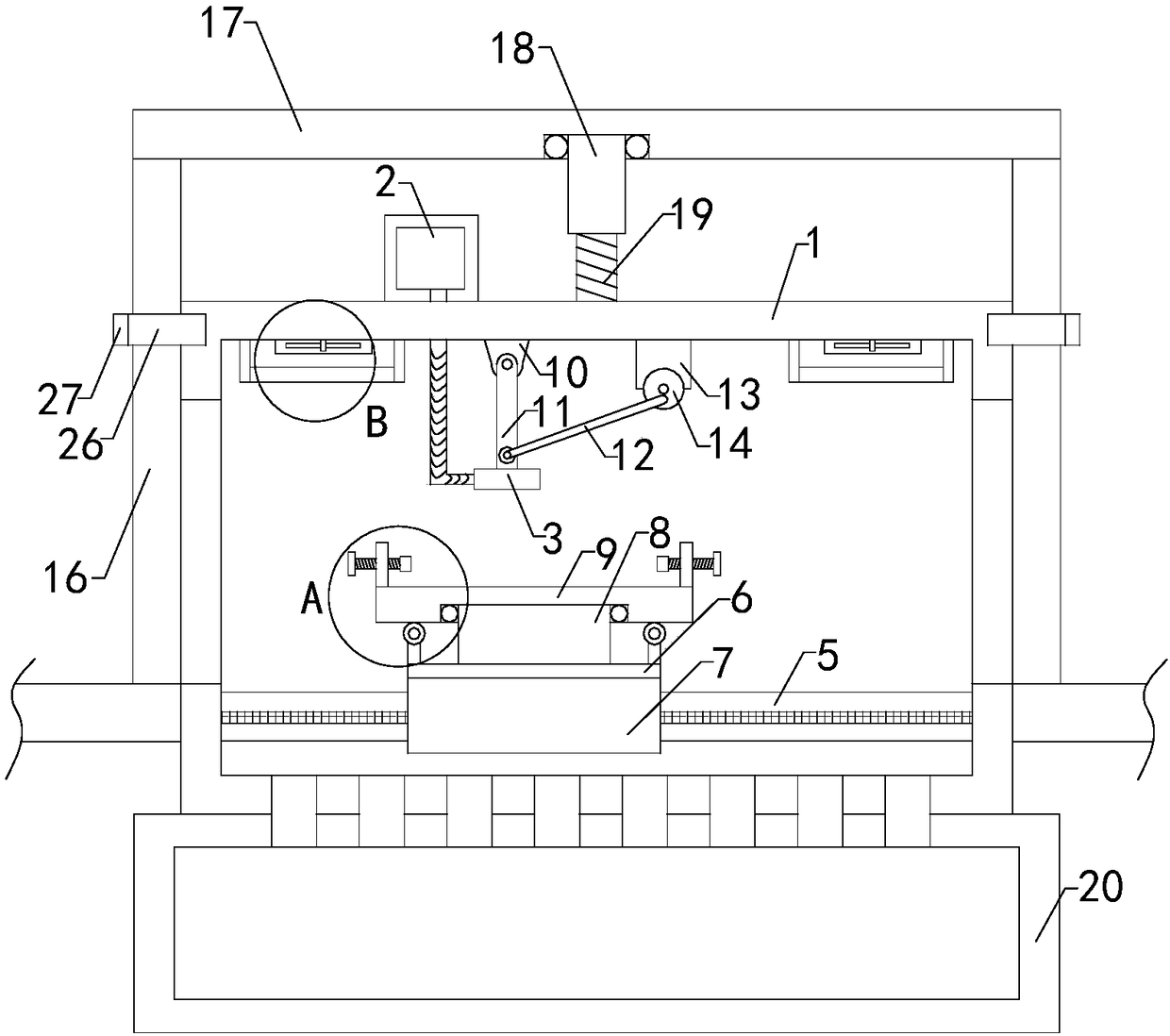

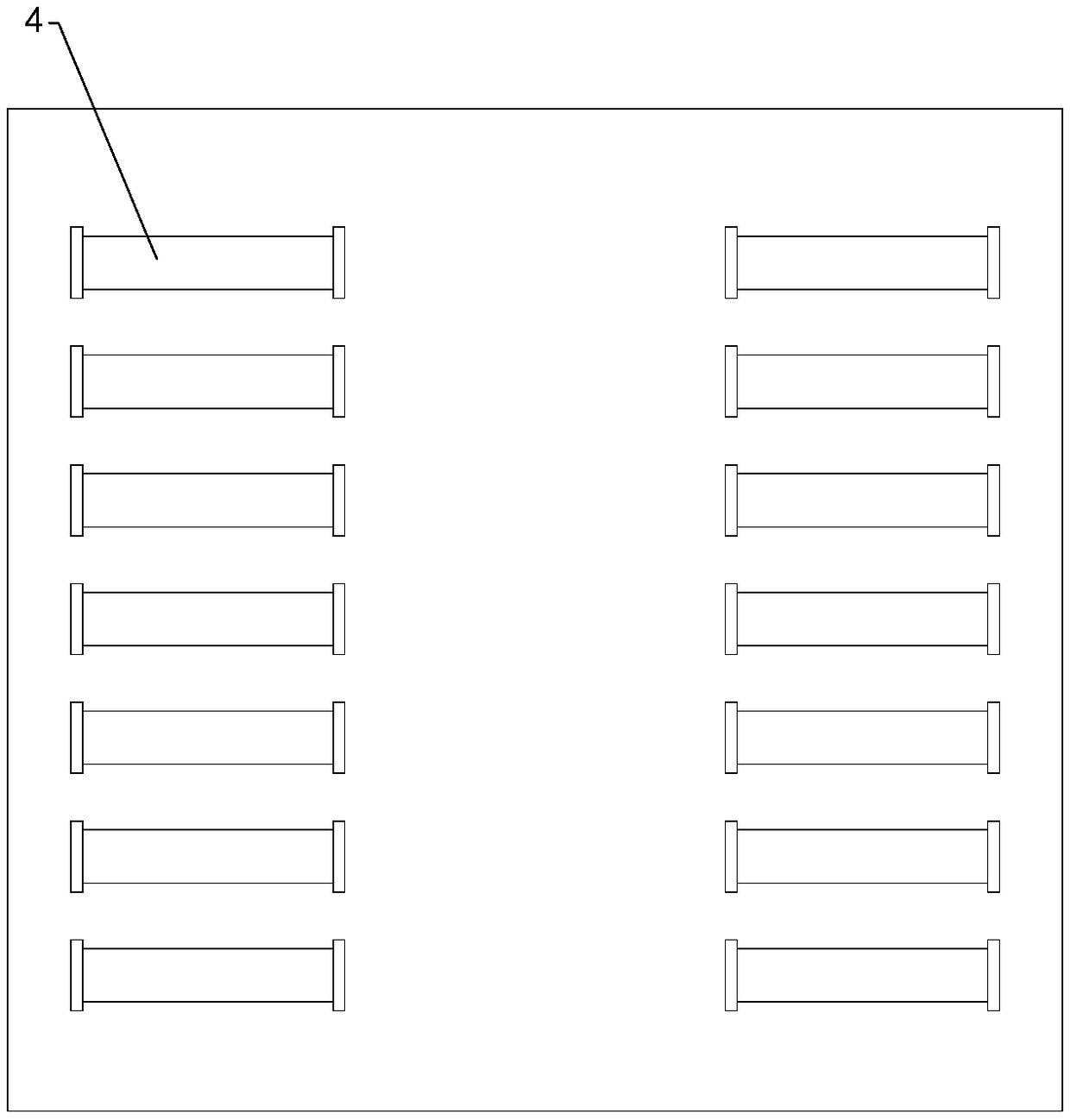

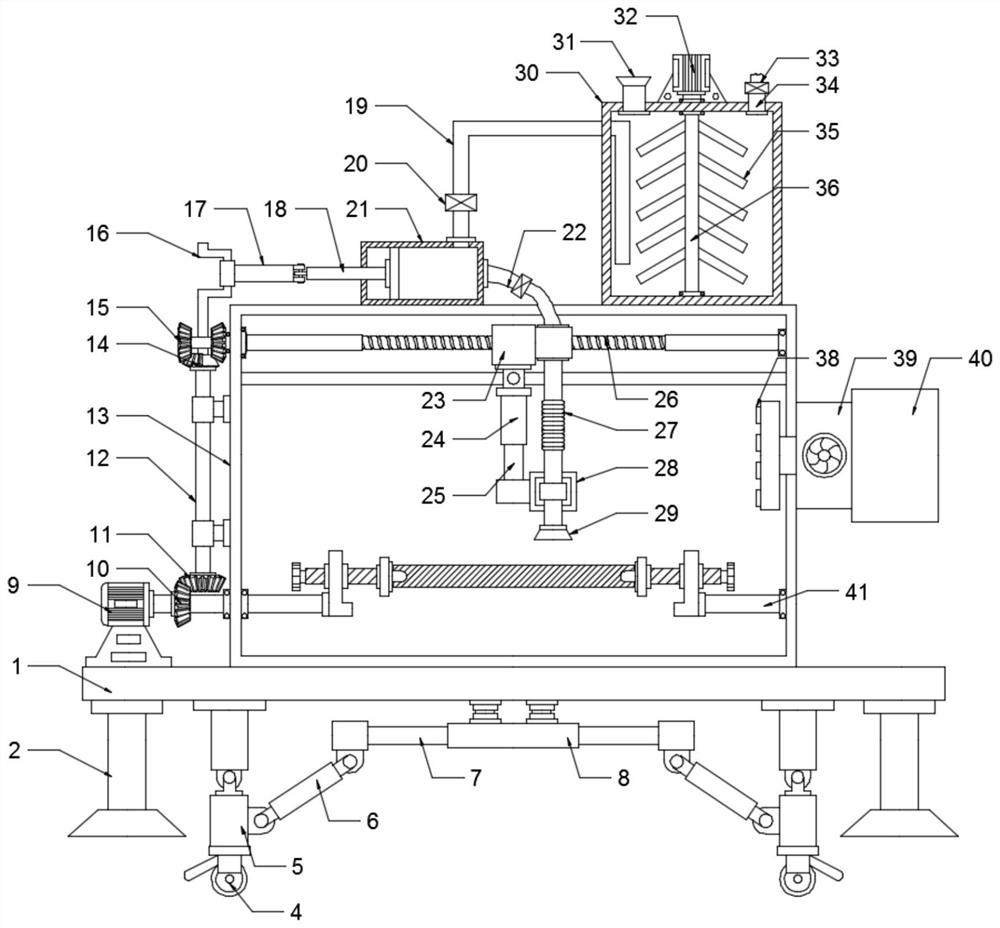

Spraying and baking room for large workpieces

The invention relates to the technical field of spraying machine accessory devices, in particular to a spraying and baking room for large workpieces. Due to the spraying and baking room for the largeworkpieces, the workpieces can conveniently move in a work cavity, and spraying on the workpieces by a spraying head is made comprehensive; meanwhile, the spraying and baking room for the large workpieces can perform comprehensive baking on the workpieces, and the using limitation is lowered; and the spraying range of the pressure spraying head can be adjusted, so that the pressure spraying head can perform efficient spraying on the workpieces, and practicability is improved. A room body, a paint material box, the pressure spraying head, a plurality of sets of left heating lamp pipes and a plurality of sets of right heating lamp pipes are included; a front slide rail, a rear slide rail, a movable plate, a front sliding plate, a rear sliding plate, a rotating shaft and a containing plate are included; an upper twisting ring, a first rotating rod, a second rotating rod and an eccentric motor are further included; the top end of the upper twisting ring is connected with the inner wall ofthe top end of the work cavity, and the top end of the first rotating end is rotationally connected with the bottom end of the upper twisting ring due to first rotating; and the bottom end of the first rotating rod is connected with the top end of the pressure spraying head, and the front output end of the eccentric motor is provided with an eccentric shaft.

Owner:JIANGSU ZIQIANG COATING MACHINERY

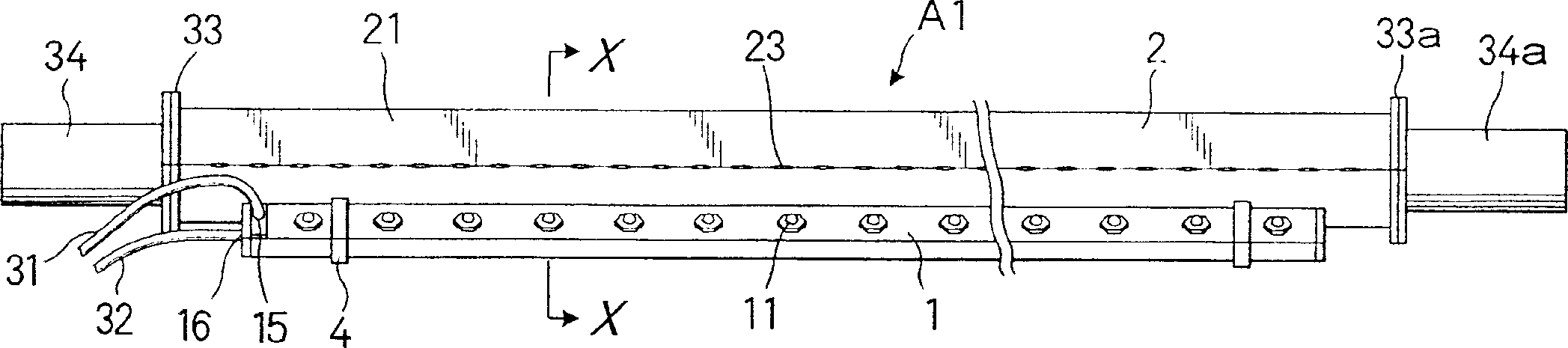

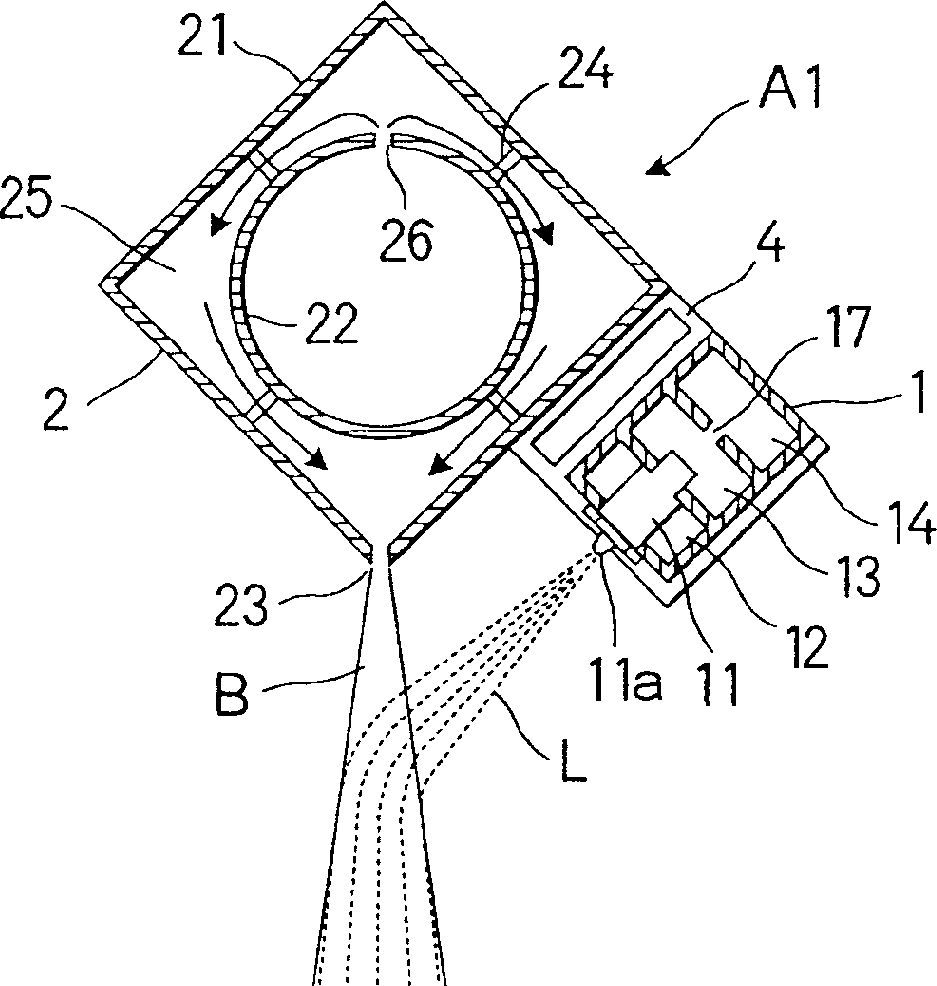

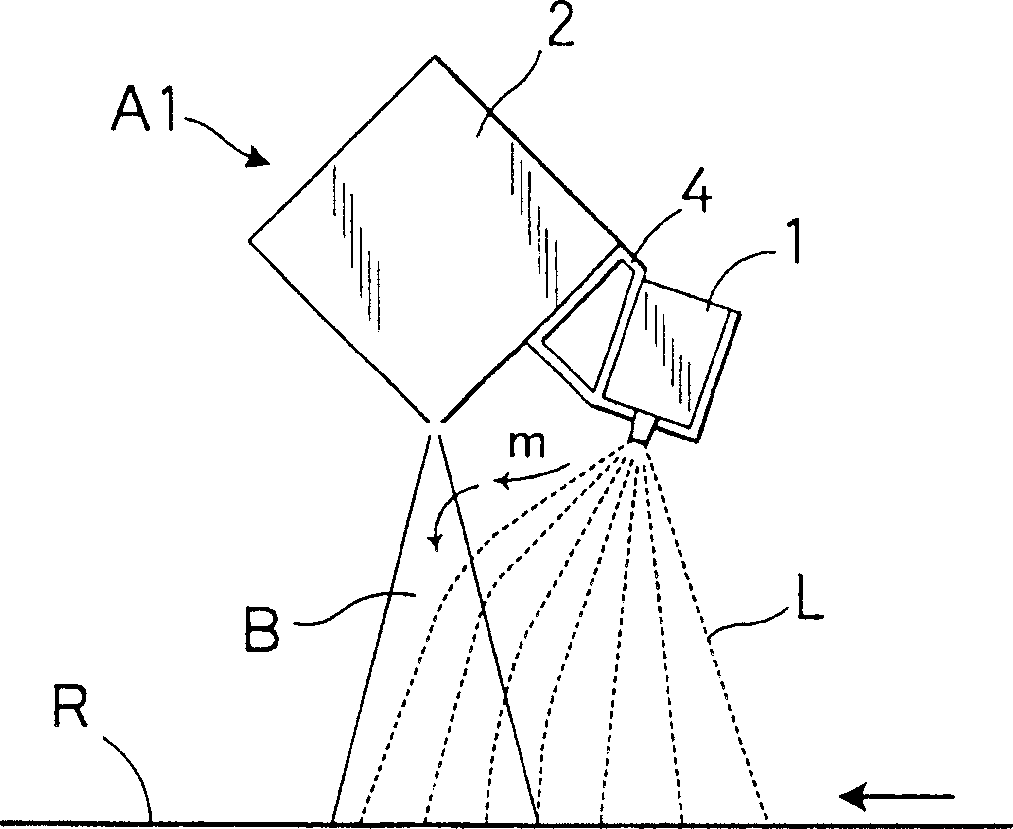

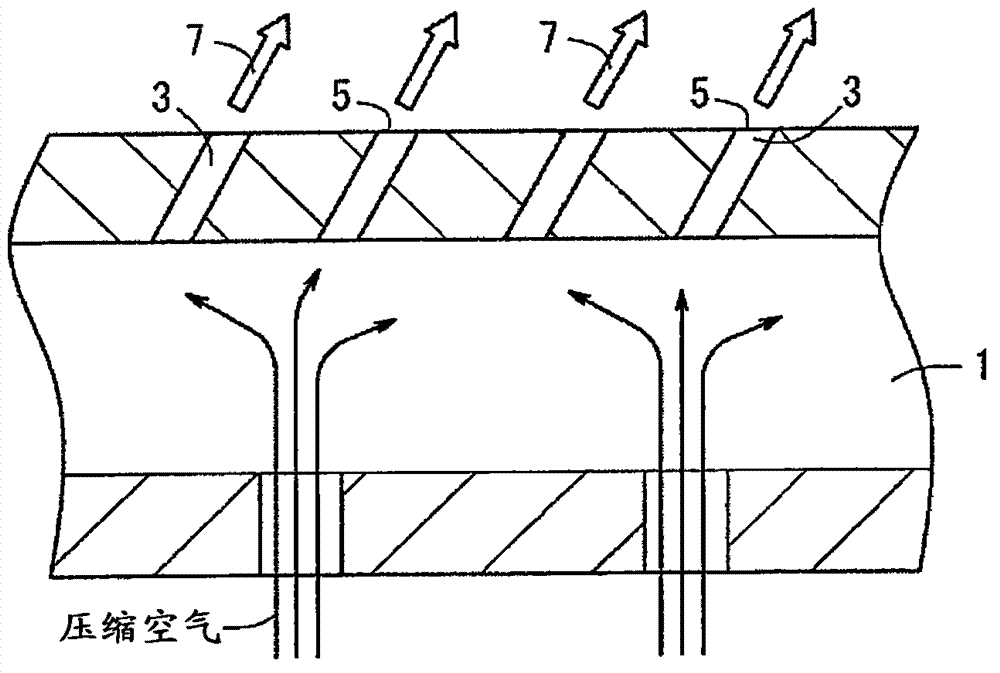

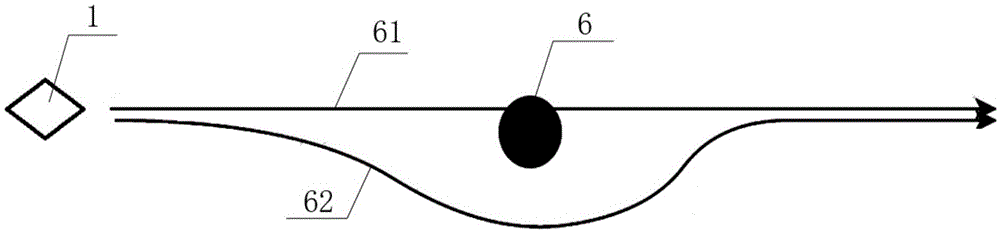

Liquid spray unit, method for spraying liquid using it, and chemical

InactiveCN1668382ASpeed up sprayingApply stabilityWater-repelling agents additionReinforcing agents additionInterior spaceSpray nozzle

A liquid spray unit which can impart liquid (treating liquid, medicine, or the like) surely to a traveling body even in a high speed paper making machine. The liquid spray unit for spraying liquid to a traveling body comprises a spray tube provided with a nozzle for spraying liquid, and an air box provided with an opening for jetting an air flow, wherein the spray tube and the air box are arranged such that the air flow is jetted from the air jet opening toward the liquid sprayed from the spray nozzle and the sprayed liquid can be blown to the traveling body after being accelerated by the air flow. The liquid can be sprayed more effectively to the traveling body by making compact the unit depending on the quantity of liquid being imparted or the inner space of a paper making machine, or the like, or by employing a unit of a type of reciprocating a single nozzle.

Owner:明答克株式会社

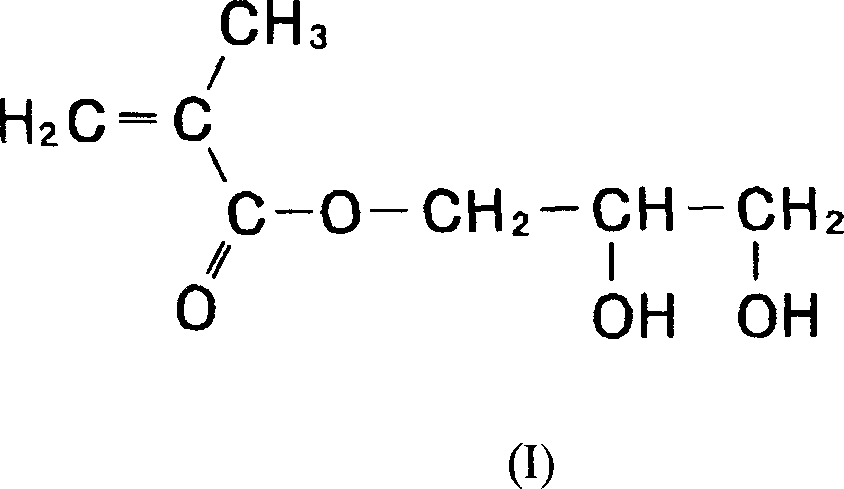

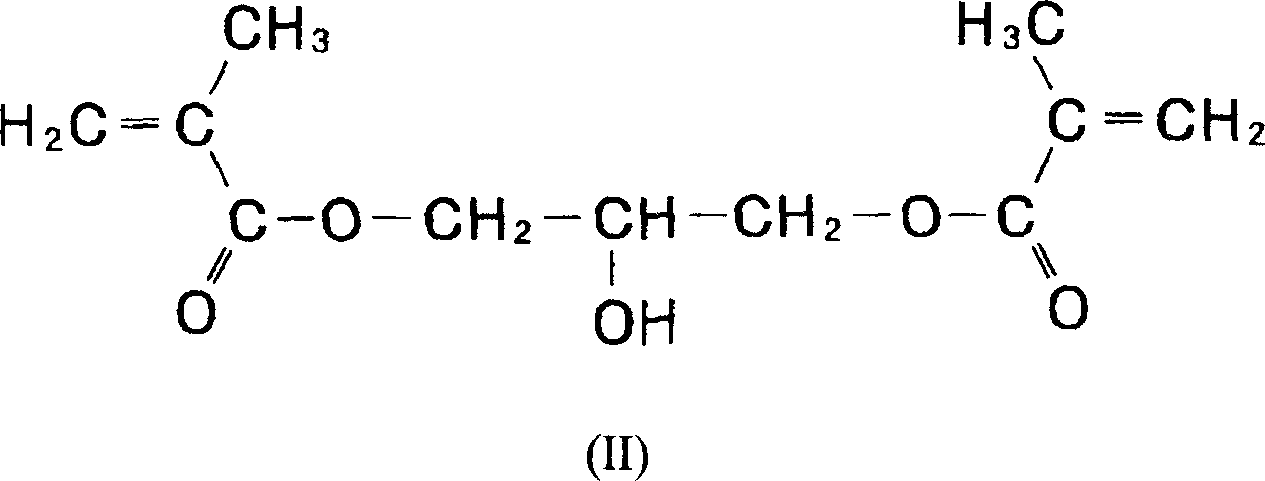

Printing ink using ultraviolet cured resin composition as active ingradient

The present invention relates to one kind of printing ink, and the printing ink has ultraviolet cured resin composition as the effective component. The ultraviolet cured resin composition contains glyceryl monomethacrylate and / or glyceryl dimethacrylate as light reactive diluent, and may be used in printing, spraying or adhering polypropylene, polyethylene and other polyolefin, ethylene-vinyl alcohol copolymer and other un-adhesive plastic material. In addition, it may be used in printing, spraying or adhering polycarbonate, polyester, paper, metal and other adhesive material.

Owner:SEIKO ADVANCE

Spraying device

ActiveUS20060226253A1Efficient sprayingReduce energy consumptionPiezoelectric/electrostriction/magnetostriction machinesMovable spraying apparatusEngineeringSoft materials

A spraying device comprises a spraying plate, having a plurality of tiny holes, a vibrating element, set on a periphery of the spraying plate, and driving a vibrating movement thereof, a wrapping layer, made of soft material and tightly surrounding the vibrating element, sealing the vibrating element from the liquid, and a fastening cap, allowing for quick mounting and dismounting of the spraying device; wherein the vibrating movement of the spraying plate causes liquid adjacent to a lower side of the spraying plate to be periodically compressed and thereby to be pressed through the holes of the spraying plate, and wherein the wrapping layer prevents external interference with the vibrating movement, at the same time minimizing transmission losses of vibrational energy, enhancing effectivity of spraying.

Owner:IND TECH RES INST

Air conditioner

ActiveCN104501387ACost-effectiveEasy to makeCondensate preventionLighting and heating apparatusEngineeringWater tanks

The invention provides an air conditioner. The air conditioner comprises a condenser, a water beating device and a guiding device, wherein a water receiving tank is arranged below the condenser; the water receiving tank is used for storing condensed water formed by the air conditioner; the water beating device is positioned in the water receiving tank below the condenser; the water beating deviceis used for enabling the condensed water in the water receiving tank to splash; the guiding device is connected with the upper end of the condenser and is used for guiding the splashed condensed waterto the upper part of the condenser. By the adoption of the technical scheme, the condensed water in the water tank is enabled to splash by the water beating device, and the condensed water splashed to the guiding device flows through the surface of the condenser in a reasonable path to cool the condenser on the premise the wind resistance of the condenser is not influenced, so that the working efficiency of the condenser is improved, the noise generated when water drops collide with the peripheral area of the condenser is effectively avoided, a water bridge formed when larger water drops aresplashed to fins of the condenser is avoided, and thus the resistance of air flowing through the condenser is increased.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

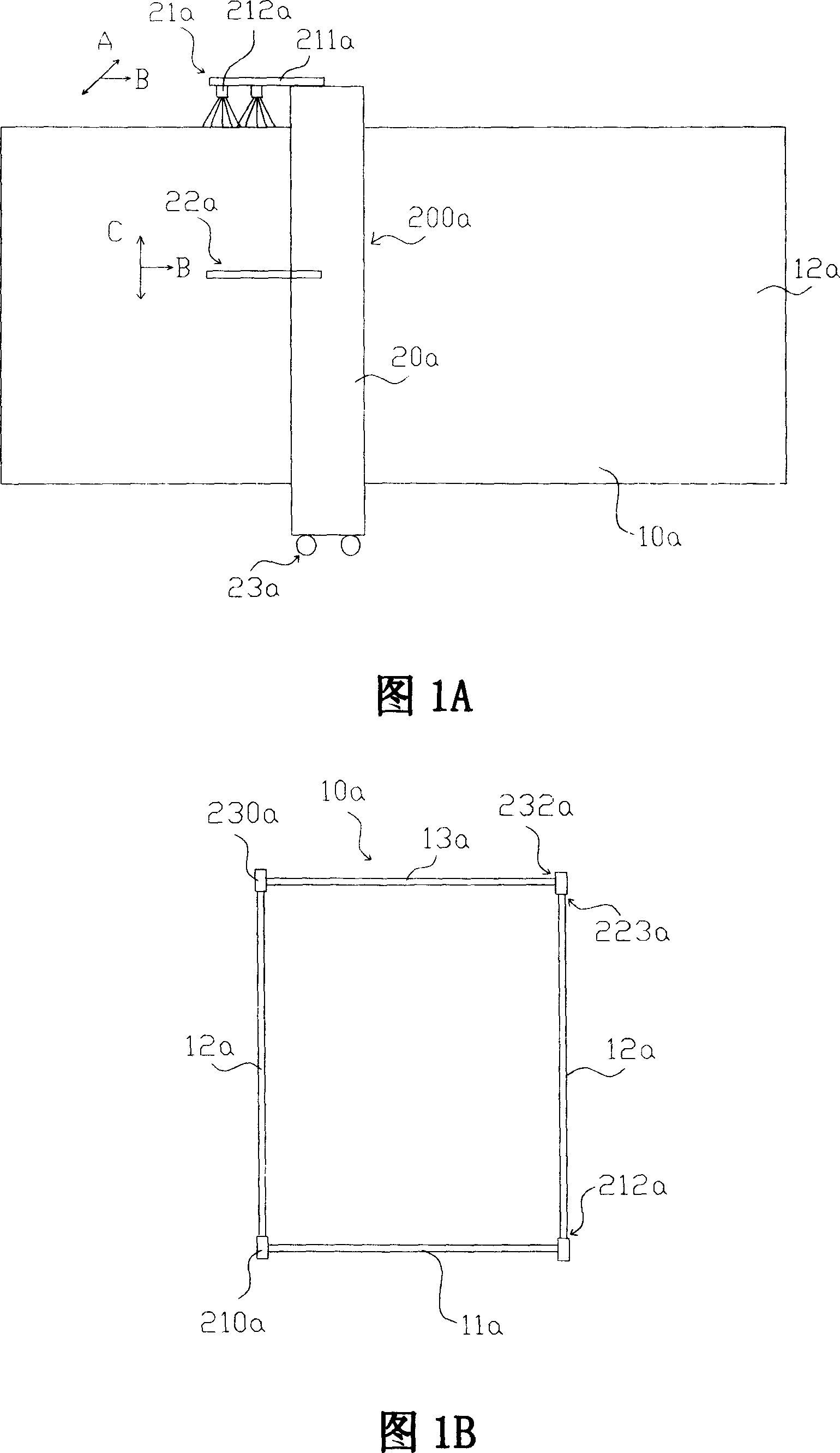

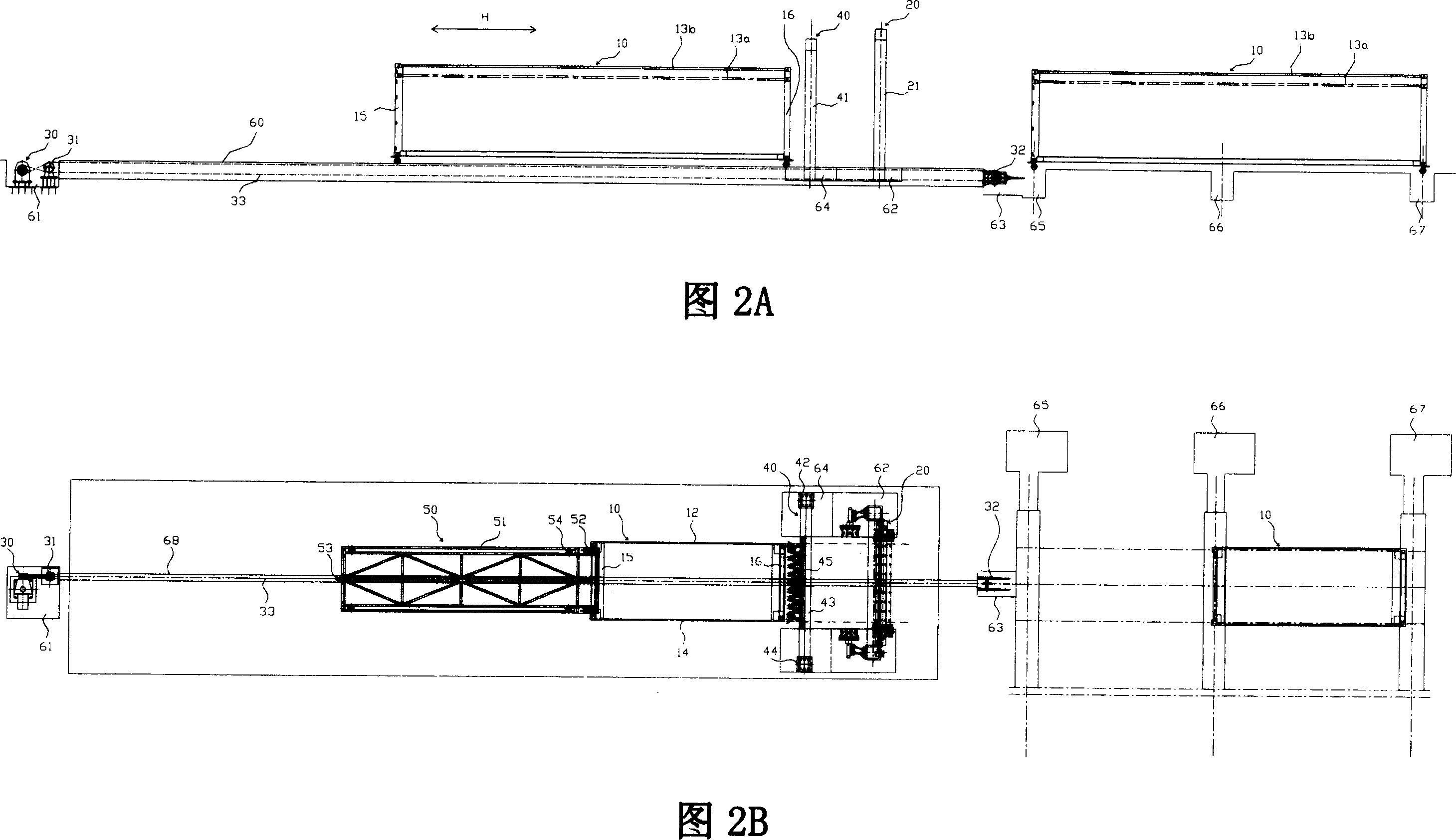

Container outside paint spraying system

ActiveCN101104163AAvoid wastingKeep healthyLiquid surface applicatorsSpraying apparatusEngineeringSpray painting

The invention relates to a box-outside paint spray system of a container, which is used to spray-paint the outside of the box body of the container, the box-outside paint spray system includes at least: one box-outside gantry frame, which is arranged across the outside of the box body of the container, a plurality of spray guns communicated with the spray painting source are distributed on the box-outside gantry frame, the plurality of spray guns are disposed as shapes corresponding to the container on the box-outside gantry frame; and one driving mechanism, which is connected with the box-outside gantry frame and the box body of the container, and is used to drive the box-outside gantry frame and the box body of the container to move relatively to the box body of the container and the box-outside gantry frame. The invention can avoid the waste of paint, and is more environment-friendly.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +1

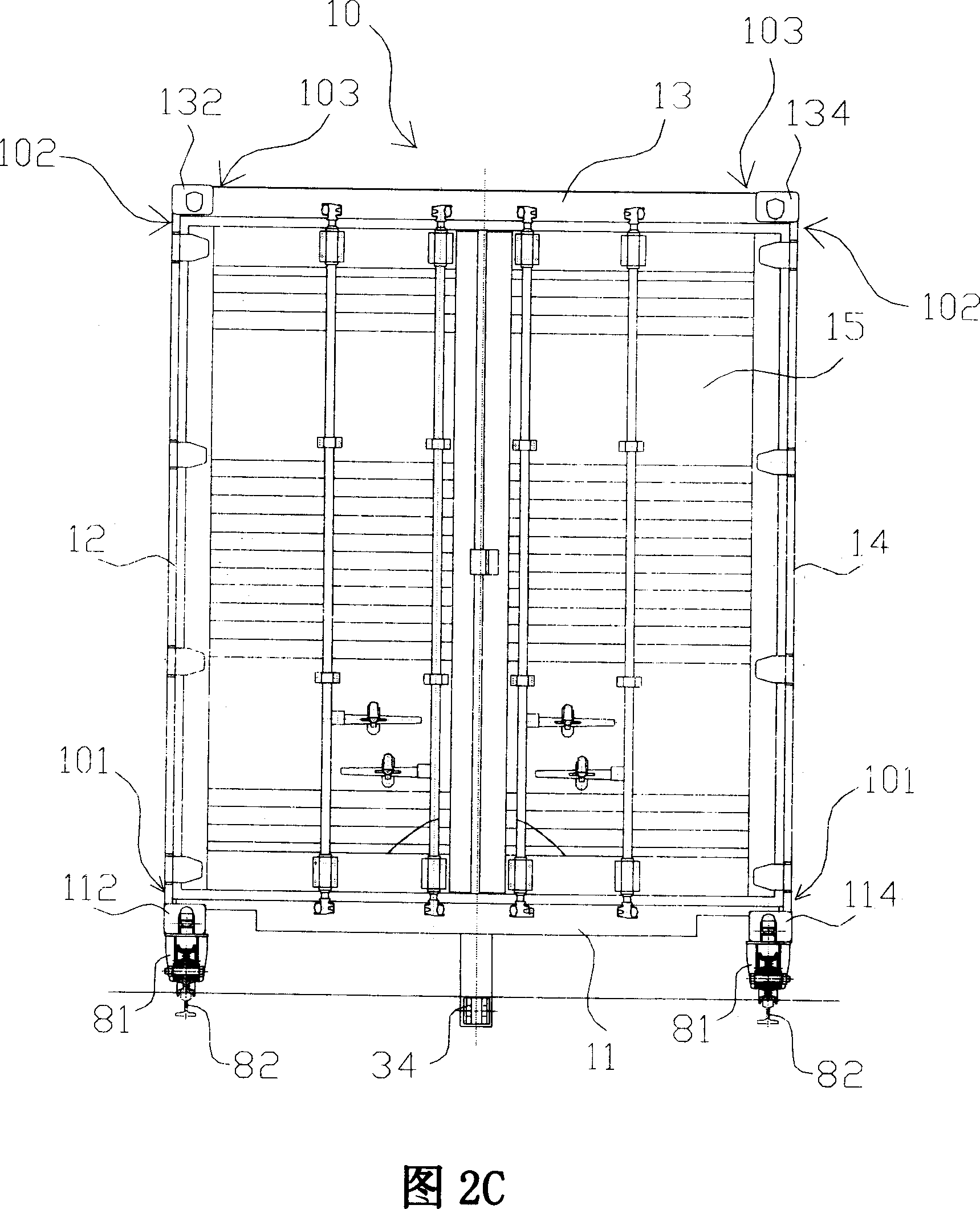

Controllable spraying device

InactiveCN101972721AEven and efficient sprayingFulfil requirementsMovable spraying apparatusMicrocontrollerEnvironmental resistance

The invention discloses a controllable spraying device which comprises a water tank, a direct current water pump, a connecting water pipe, a rotating water pipe, a needle cylinder type piston, a spray head, a rotating drive device, a drive circuit and a controller. The voltage of the direct current water pump is controlled by using a preset spraying distance to ensure that water sprayed out of the spray head only covers the preset range. By depending on the control of a singlechip, the regularization of a water spraying track is intelligently completed, the function of whole water spraying is automatically completed, thus the effects of fully efficiently utilizing water resources and saving water as well as protecting the environment are achieved. The invention can meet the requirement for spraying water drops on various fields of gardens, greenbelts, vegetables and fruits, agriculture and the like. If the spraying liquids are changed into pesticides, paints, anticorrosive paints and the like, the controllable spraying device can carry out the spraying. Irrigation requirements on different use areas can be met through the combination of a plurality of spray heads. Various shapes such as square, triangle, regular hexagon and the like can be obtained through spraying.

Owner:WUHAN UNIV

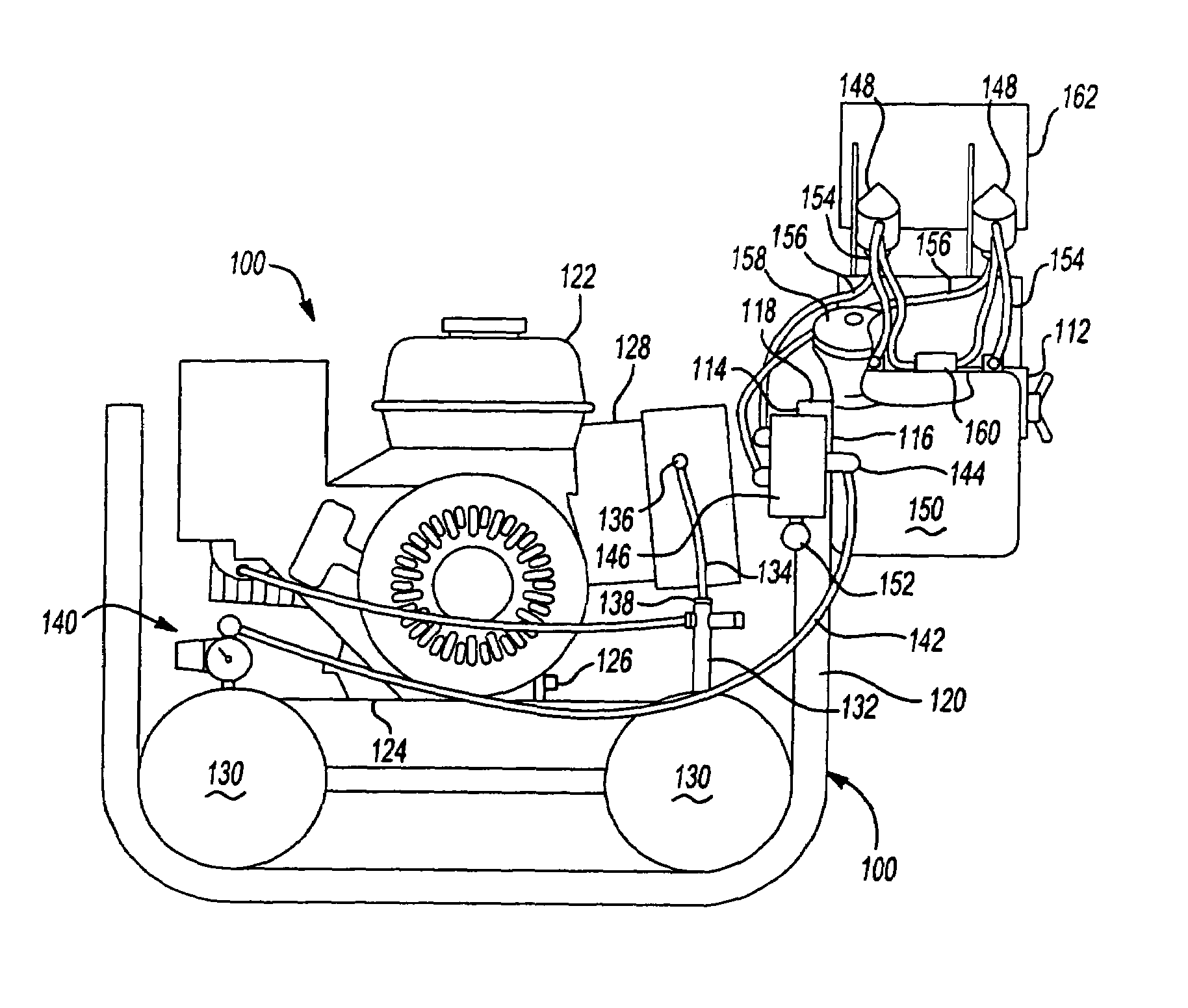

Spraying device and system and method of dispersing and disseminating materials

InactiveUS20070040046A1Efficient sprayingLower levelSpray nozzlesFire rescueEngineeringHigh pressure

The invention includes a spraying device (10) for producing a precise degree of liquid droplet generation on a repeatable basis by combining a specified rate of regulated flow of liquid material with a regulated flow of high-pressure air. The spraying device (10) includes an electric or engine driven direct drive compressor (12.) Coupled to the compressor (12) is an air storage tank (14) providing air pulsation reduction to the regulated air and serves as a reservoir for excess airflow generation. A Venturi nozzle (18) is connected to the compressor (12.) A liquid supply tube (24) uses a fixed or variable restriction to regulate the liquid flow to the nozzle (18.) The vacuum in the liquid supply line (24) draws this liquid flow and mixes the liquid externally with the regulated air in exacting proportions forming specified liquid droplet sizes. The device (10) uses air and liquid regulation combined with a Venturi nozzle (18) and is able to generate extremely consistent liquid droplet sizes.

Owner:DORENDORF BRUCE +1

Nozzle device and hygienic washing device

In a nozzle device a spray hole for spraying washing water and a pipe forming a first flow path that introduces the washing water to the spray hole is provided. Further, the spray hole is provided in a cover that surrounds the pipe. The cover is integrally formed of a cylindrical metal whose front end is closed. A space between an outer surface of the pipe and an inner peripheral surface of the cover member forming a second flow path that introduces the washing water to the spray hole. Further, the second flow path surrounds surface of the pipe in a circumferential direction of the cover member.

Owner:PANASONIC CORP

Coating method and coating apparatus

ActiveCN102950091AEfficient sprayingLiquid surface applicatorsMovable spraying apparatusEngineeringWind speed

A coating apparatus has a rotary atomizing head that discharges paint to a work, and an air injecting unit that injects annular shaping air towards an outer peripheral edge portion of the rotary atomizing head. The air injecting unit has first air injecting ports and second air injecting ports. First air of relatively high wind speed is injected from the first air injecting ports and second air of relatively low wind speed is injected from the second air injecting ports.

Owner:HONDA MOTOR CO LTD

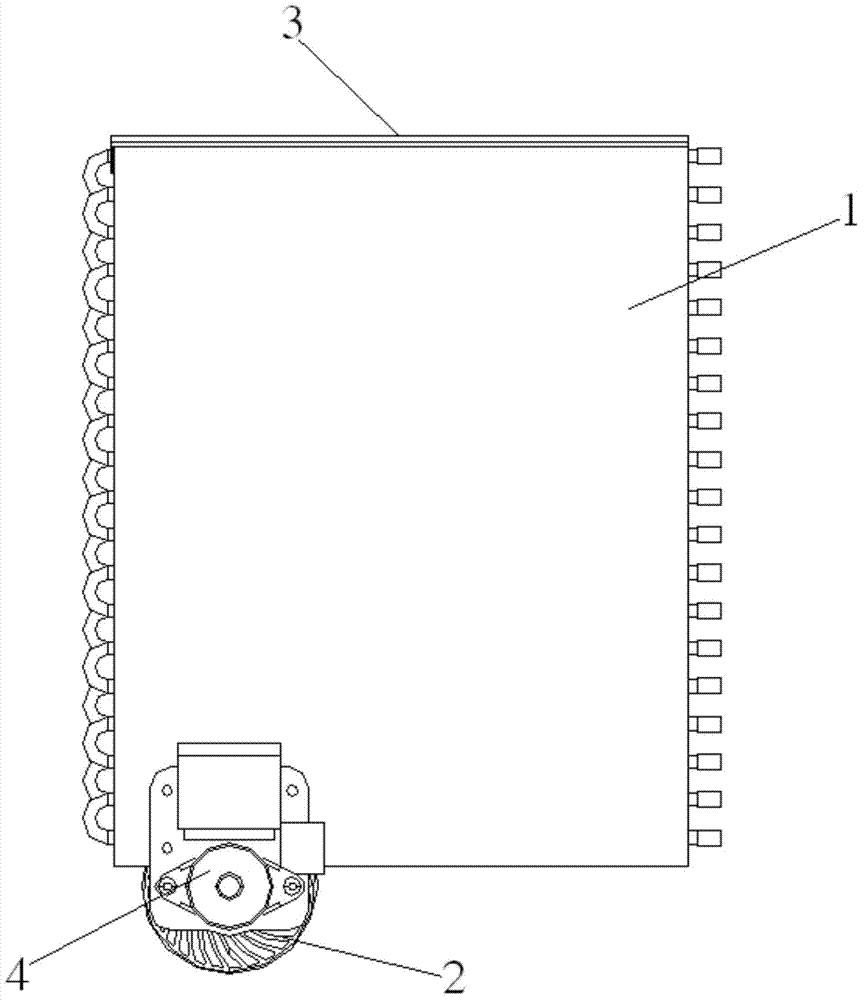

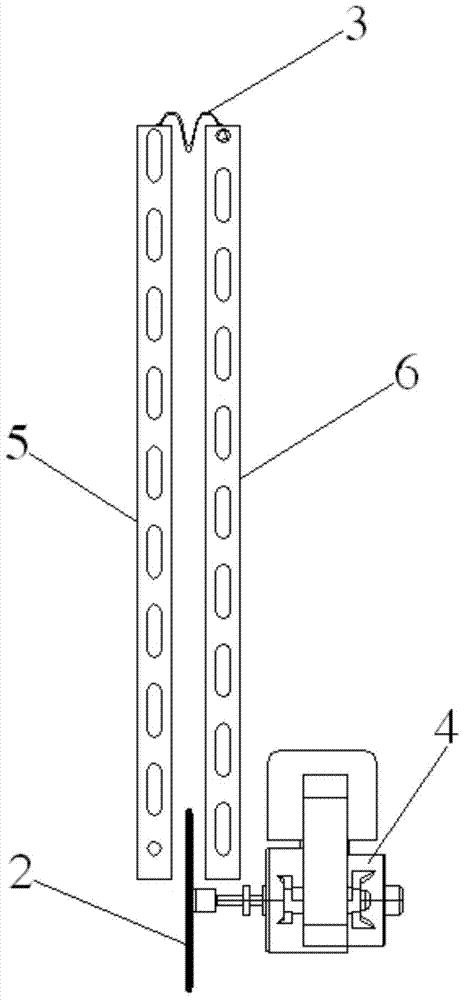

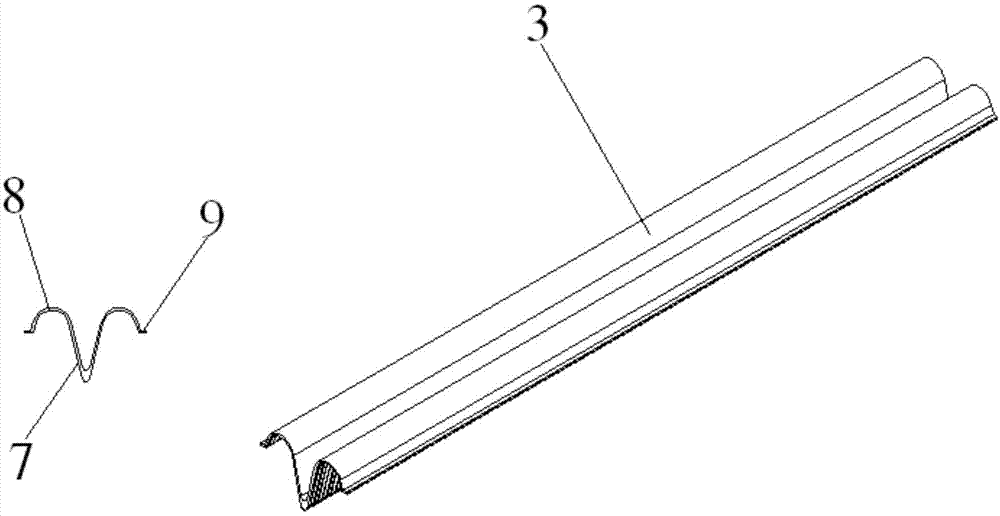

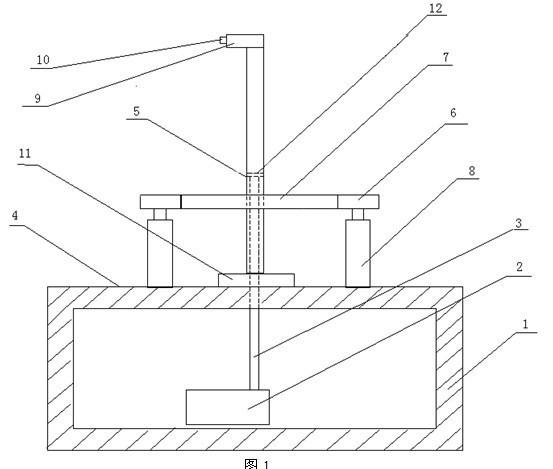

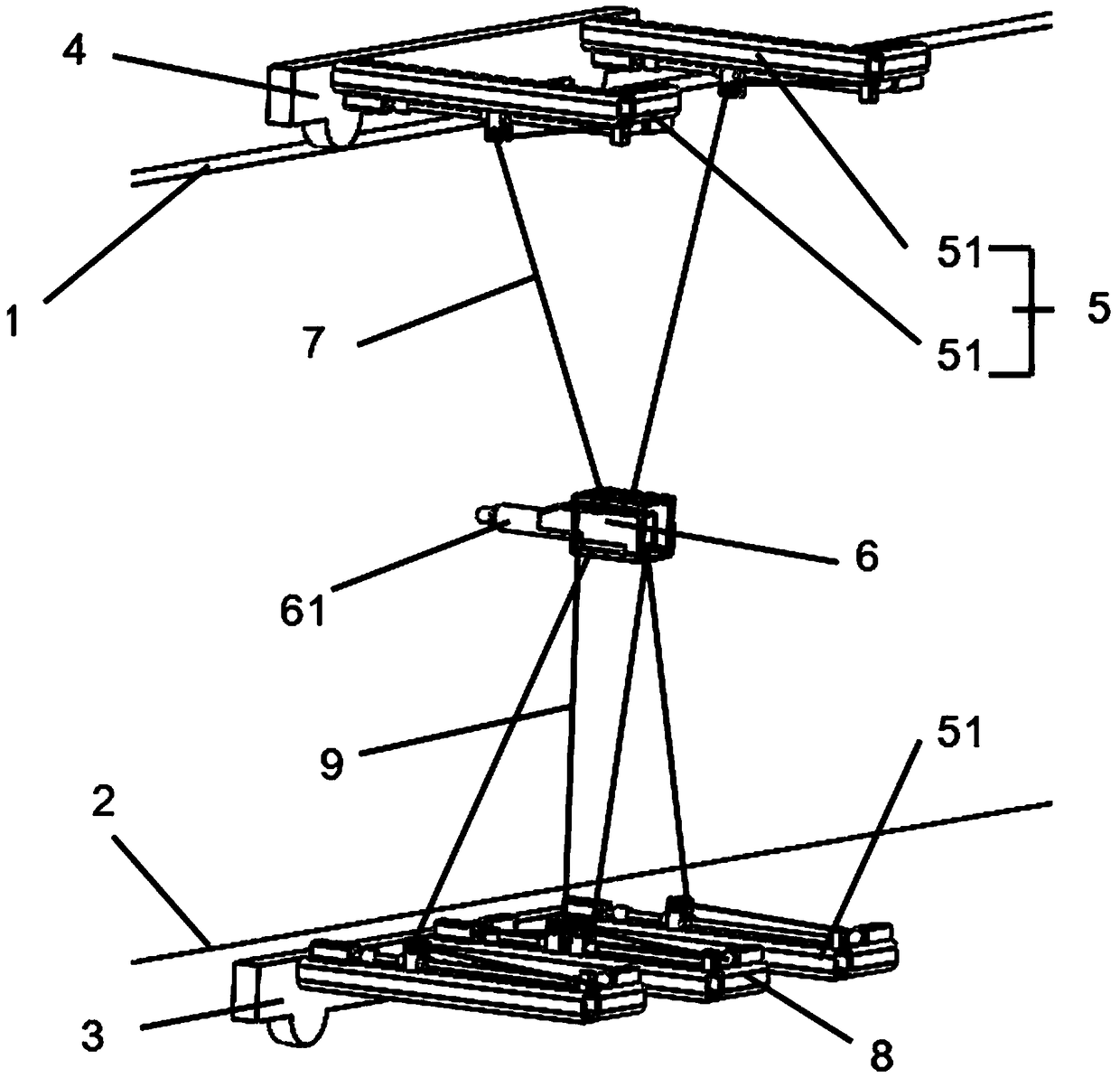

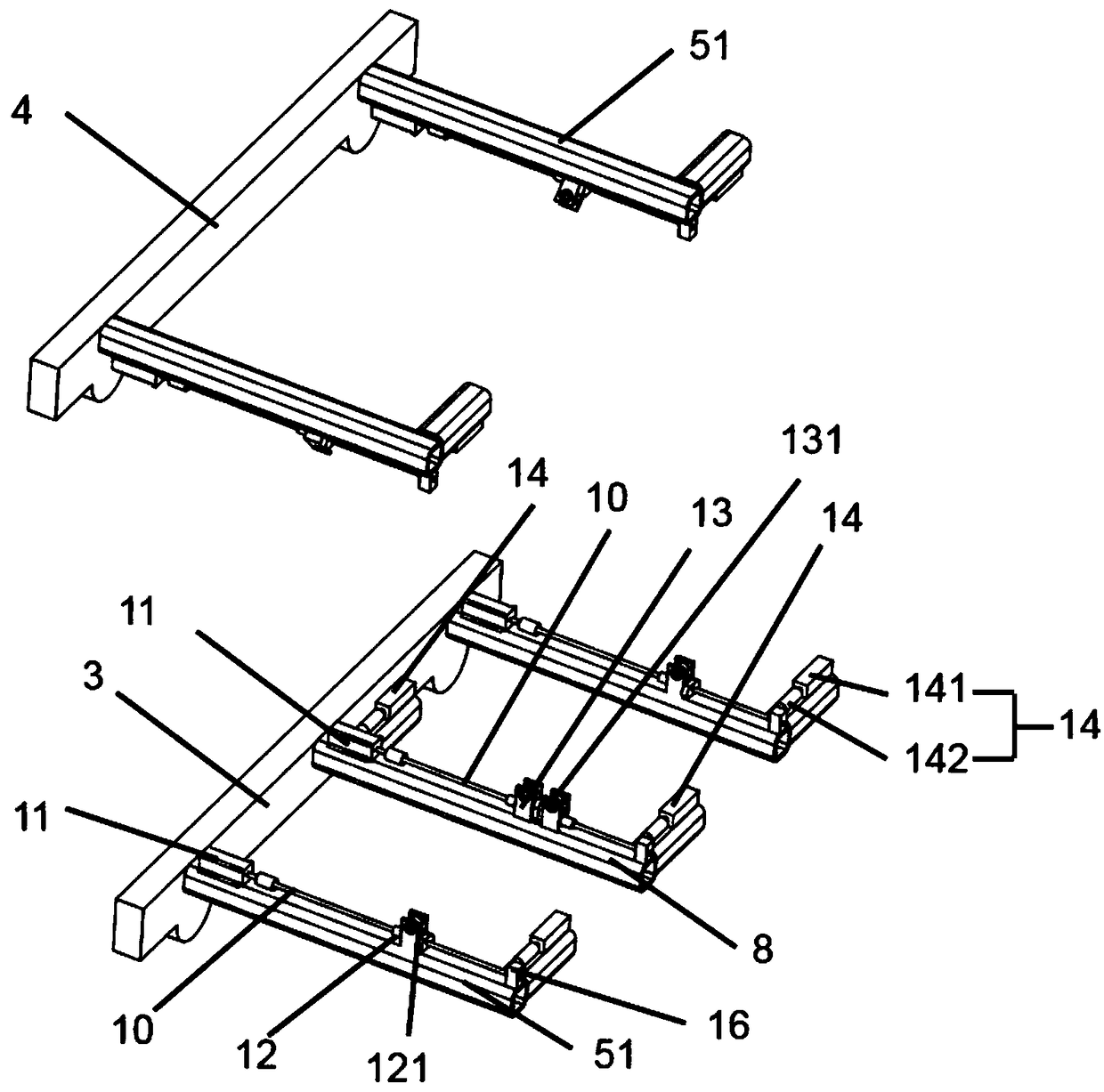

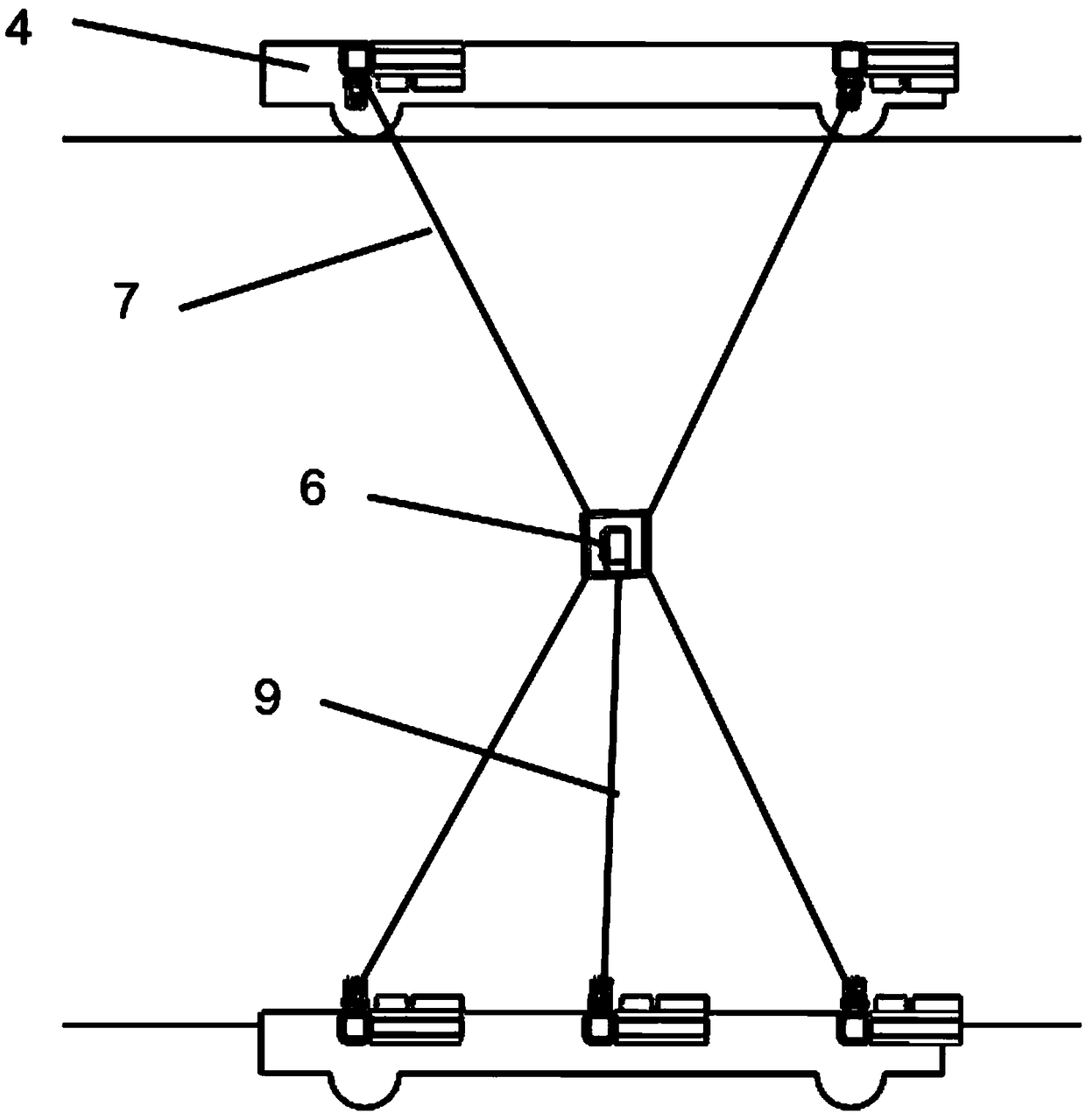

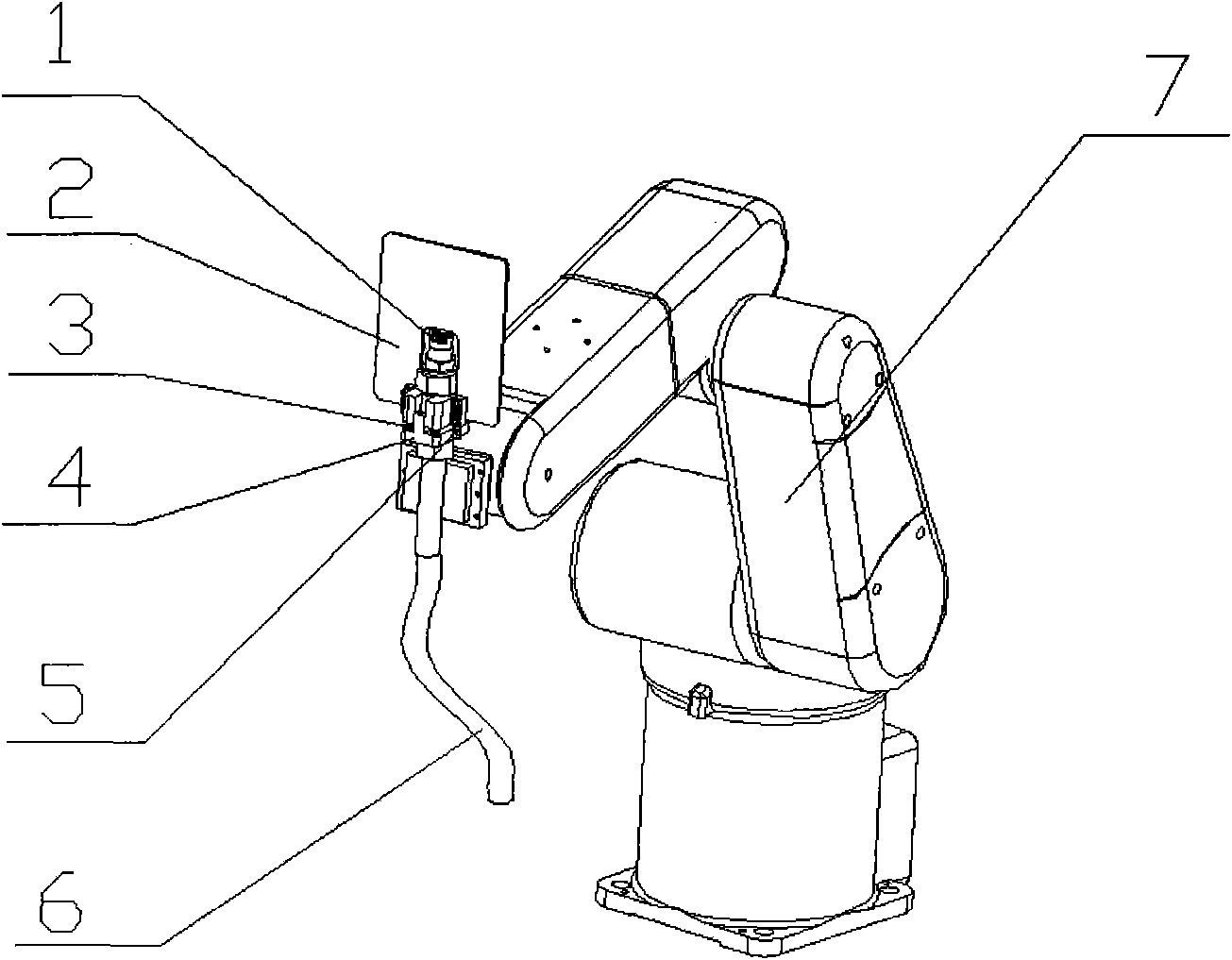

Ship body outer surface rope traction parallel spraying robot

PendingCN108942897AEfficient sprayingProgramme-controlled manipulatorSpraying apparatusMarine engineeringWire rope

The invention discloses a ship body outer surface rope traction parallel spraying robot. The ship body outer surface rope traction parallel spraying robot comprises an upper guide rail and a lower guide rail oppositely arranged on the side surfaces of a ship body; a lower base is slidingly arranged on the lower guide rail; an upper base is slidingly arranged on the upper guide rail; the lower baseand the upper base are provided with support frame sets perpendicular to the extension direction of the lower guide rail; the support frame sets comprise two support rods arranged in parallel; the support rods are provided with slide ways and slide blocks slidingly arranged on the slide ways; rollers are arranged on the slide blocks; ropes sleeve the rollers; one ends of the ropes are fixedly connected with execution pieces, and the other ends are connected with length adjusting devices; the execution pieces are connected with two support frame sets through the ropes on the slide blocks; theexecution pieces comprise nozzles for spraying paint; adjusting devices for controlling the slide blocks are arranged on the support rods; steel wire ropes are used as transmission elements; motions and forces of drivers are transferred to spraying guns; and through control of quick moving capacity of the spraying guns in spraying surfaces, the efficient spraying of large-area walls on two sides of the ship body is realized.

Owner:HANGZHOU GUOCHEN ROBOT TECH CO LTD

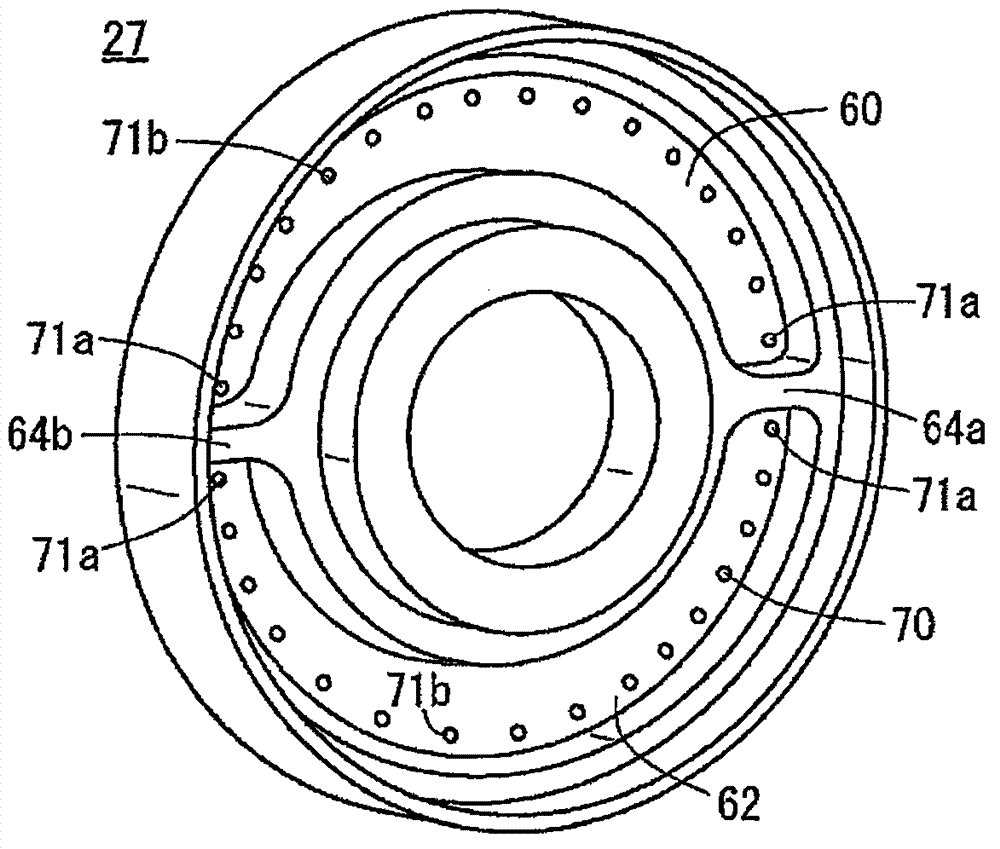

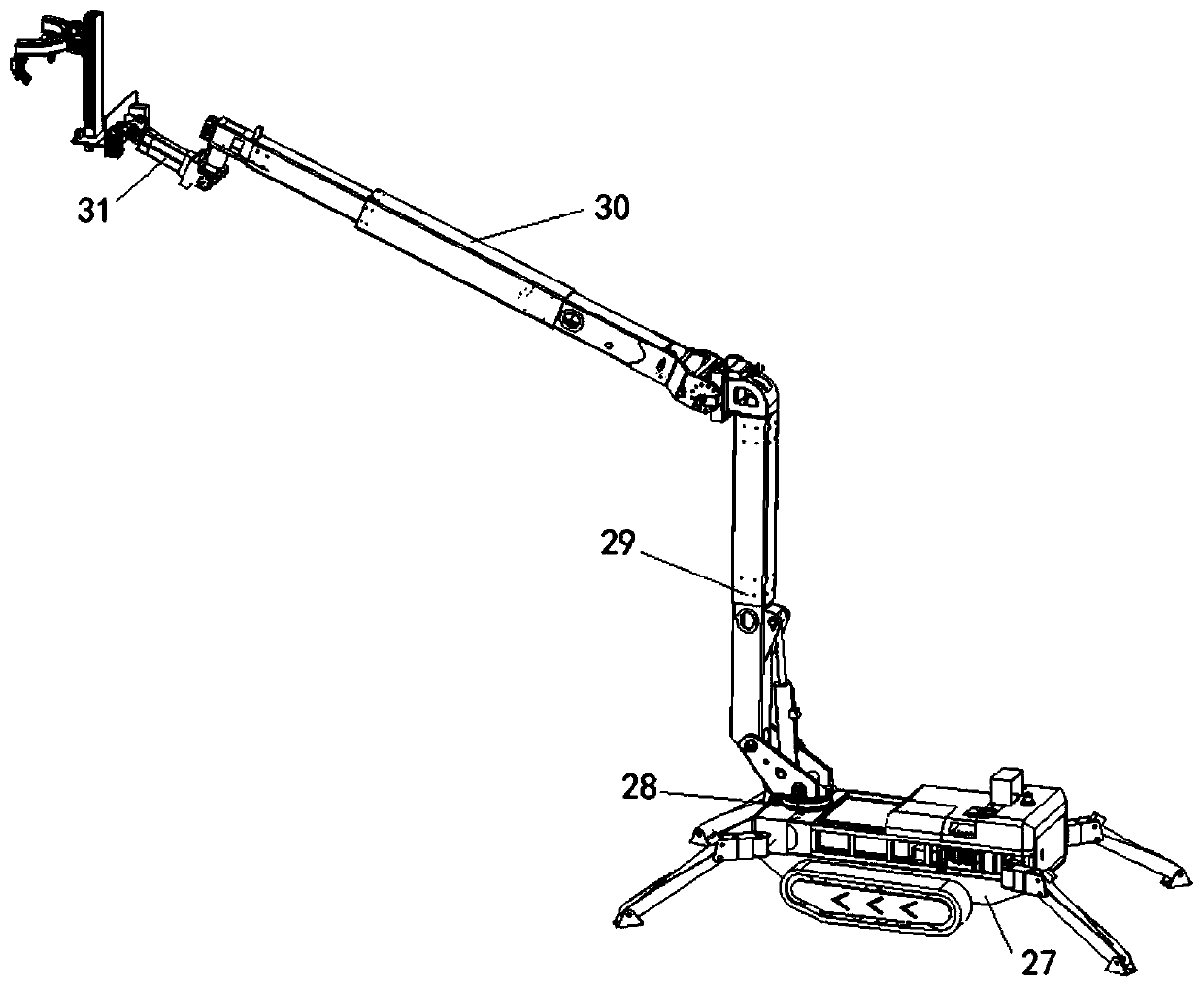

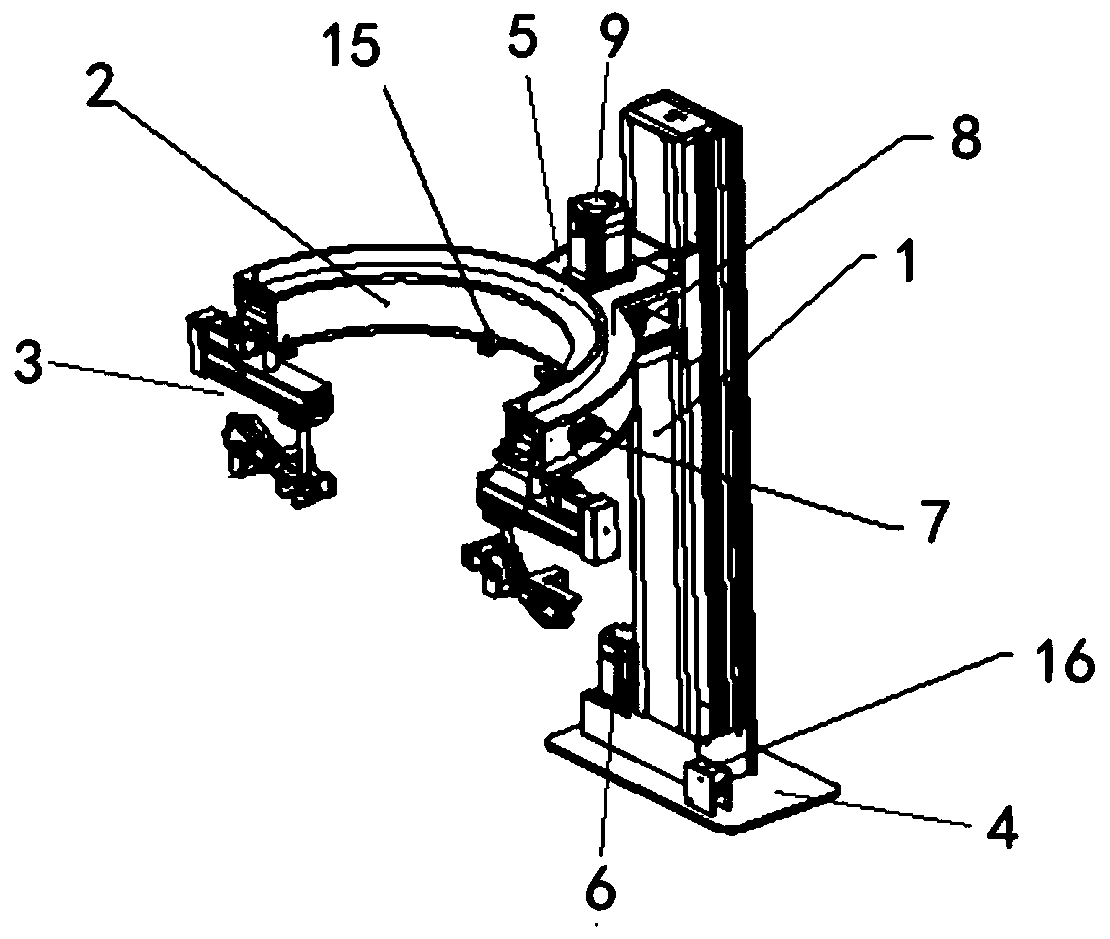

Robot system for spraying anti-pollution flashover coatings on substation insulators and spraying method

ActiveCN110899027AAll-round three-dimensional spraying realizationSolve the dead angle of sprayingSpraying apparatusControl engineeringStructural engineering

The invention discloses a robot system for spraying anti-pollution flashover coatings on substation insulators and a spraying method. The robot system is characterized by comprising a robot body and aspraying tool, wherein the robot body comprises a lifting mechanism, and the spraying tool is arranged at the front end of the lifting mechanism; the spraying tool comprises a supporting mechanism, asurrounding mechanism and at least one spraying mechanism; the surrounding mechanism is connected with the supporting mechanism and can carry out vertical lifting movement relative to the supportingmechanism; the surrounding mechanism comprises an annular inner chamber and an annular component which can move along the annular inner chamber, and an annular opening is formed in the lower part of the annular inner chamber; and at least one spraying mechanism is arranged under the supporting mechanism, is connected with the annular component and can move along with the annular component along the annular opening. The robot system can realize uniform spraying for the insulators.

Owner:STATE GRID INTELLIGENCE TECH CO LTD

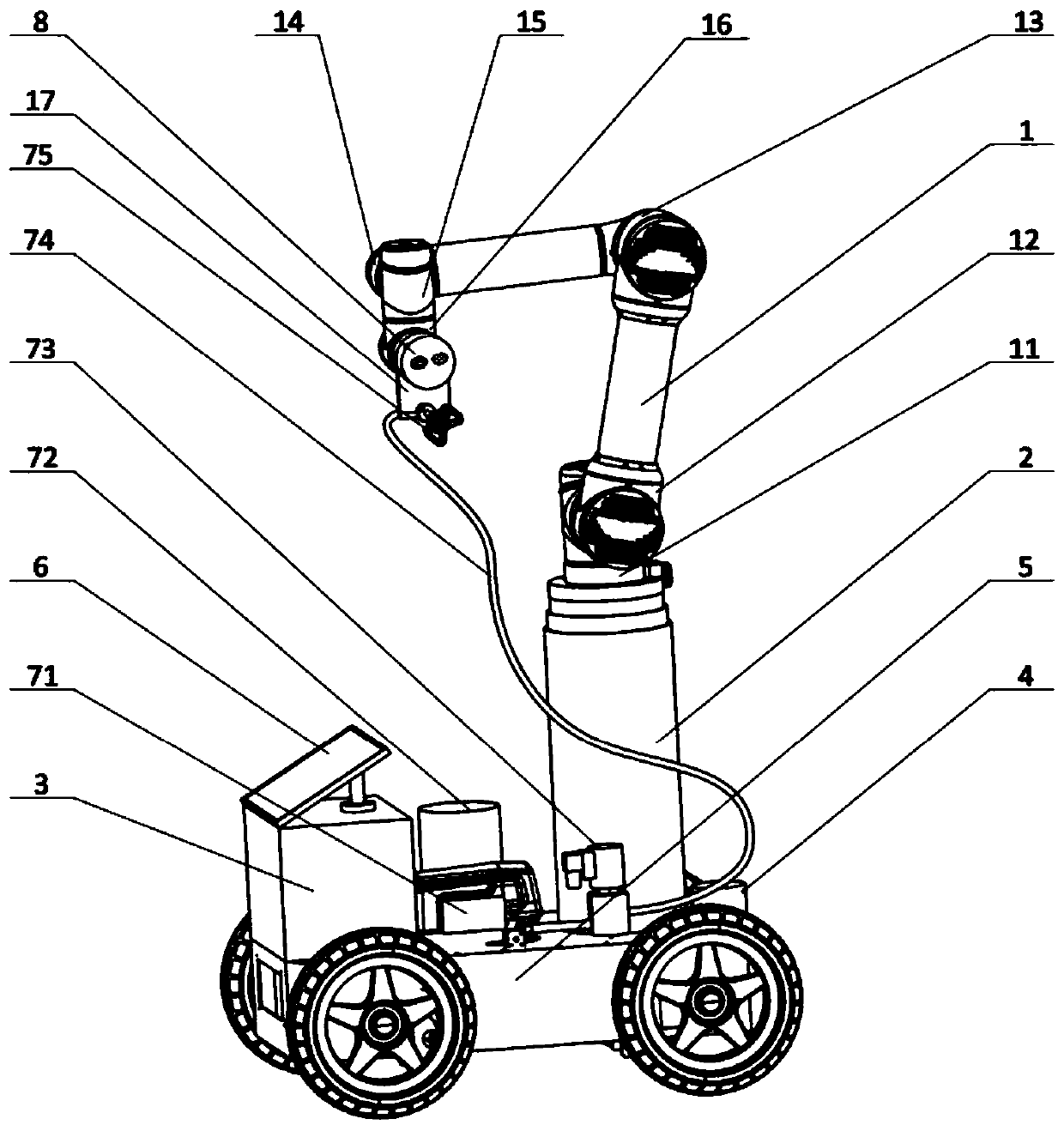

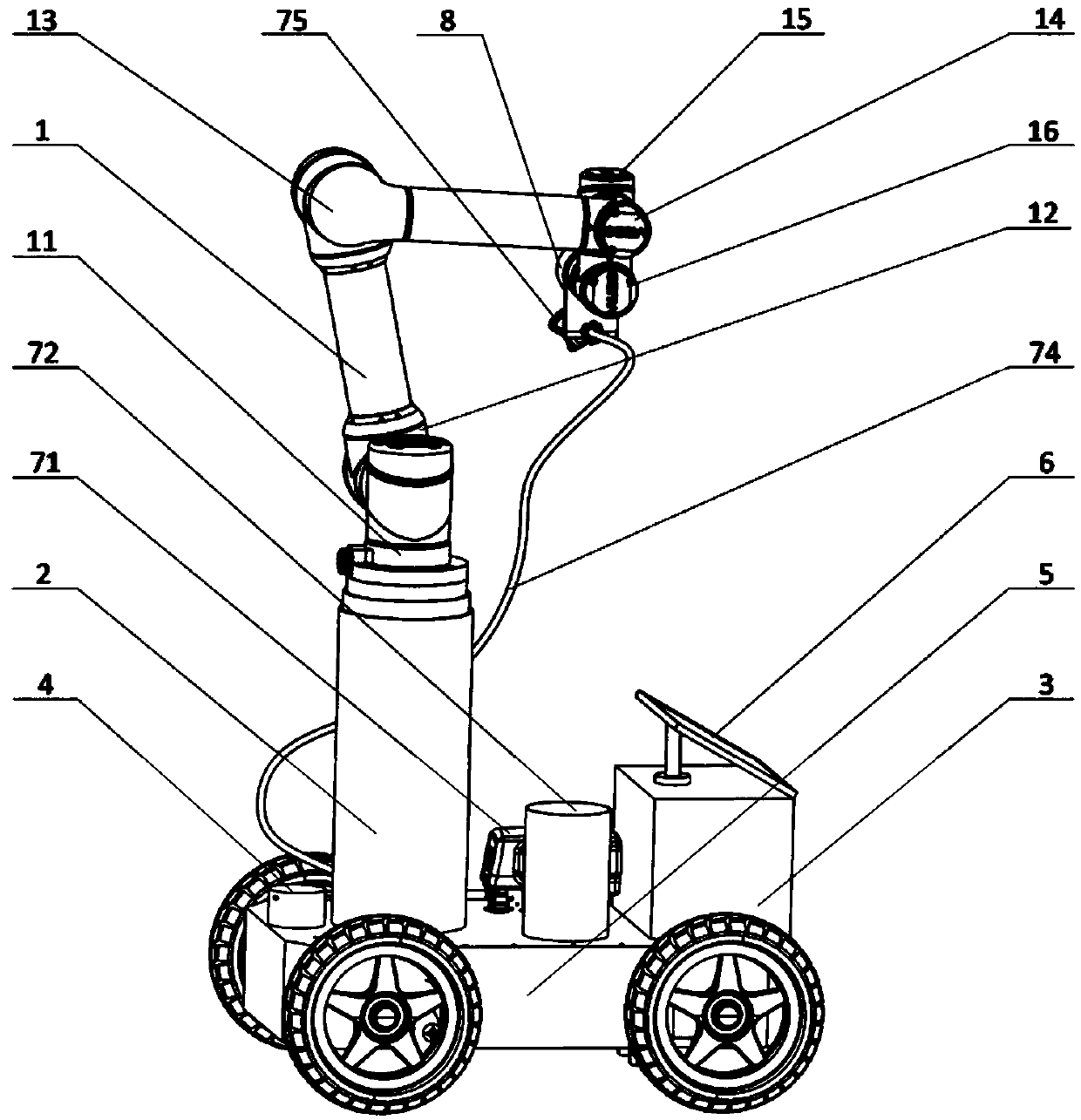

Mobile spraying robot for indoor wall bodies

The invention discloses a mobile spraying robot for indoor wall bodies. The mobile spraying robot comprises a carrying platform capable of moving horizontally, wherein the carrying platform is connected with a mechanical arm by virtue of a lifting apparatus; a spray head is arranged at the tail end of the mechanical arm; the mechanical arm drives the spray head to move in a space range to realizethe posture change; the carrying platform is provided with an air compressor, a first laser radar, a paint storage tank and a console with a display screen; the mechanical arm is provided with a second laser radar; the high-pressure gas provide by that air compressor is delivered to the spray head by virtue of a high-pressure spraying pipe, the laser radar is used for indoor map establishment, navigation and three-dimensional reconstruction of wall body characteristics, the console carries out the centralized management and control to adjust the action positions of the carrying platform and the mechanical arm, and the spray head is opened after being arranged in place to perform a spraying function, so that the high-pressure gas pressurizes and atomizes the paint; the display screen is used for displaying a working state of the robot and simulation displaying a spraying track. By adopting the mobile spraying robot for the indoor wall bodies, different spraying tasks can be carried outaccording to the wall bodies, and high efficiency, high quality and automatic spraying can be achieved.

Owner:王金虎 +3

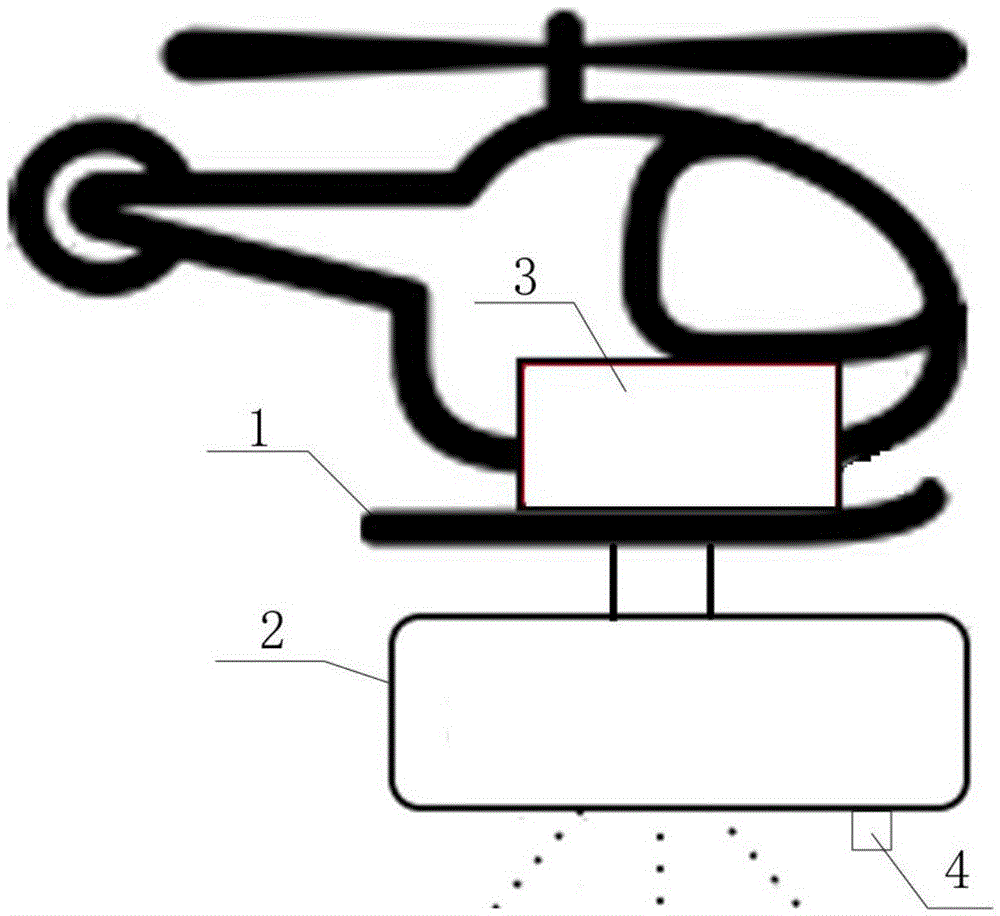

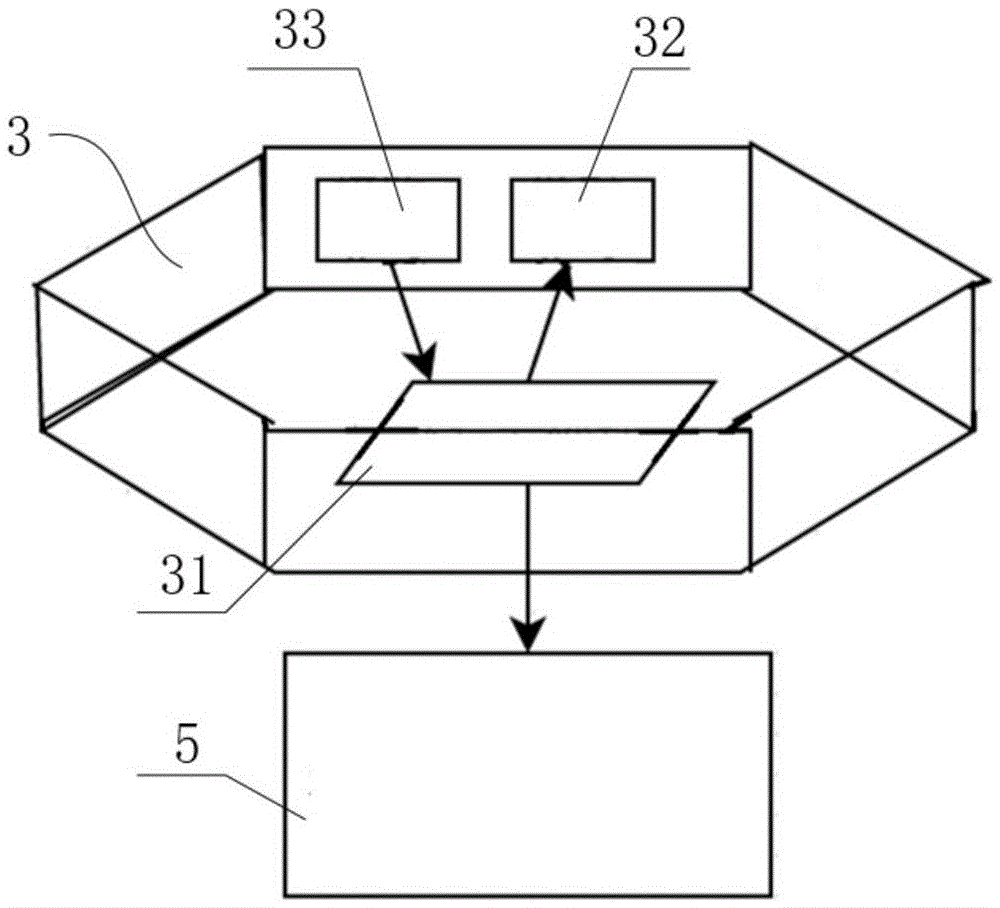

Control system and control method for unmanned plane

InactiveCN105425814AImprove flight safetySpray evenlyPosition/course control in three dimensionsFlight heightControl system

The invention discloses a control system and control method for an unmanned plane. The control system comprises a flight controller, a microwave sensor, and a microwave altimeter. The flight controller is used for controlling a flight state of a plane body. The microwave sensor that is installed at the plane body and is connected with the flight controller is used for detecting an obstacle around the plane body and transmitting the position information of the obstacle to the flight controller. And the microwave altimeter that is installed at the unmanned plane body and is connected with the flight controller is used for detecting the height of the unmanned plane body and transmitting the height information to the flight controller. According to the invention, with the system and method, the flight safety of the unmanned plane is improved and damages caused by collision of the plane body and the obstacle can be prevented. Besides, the flight height of the unmanned plane can be adjusted timely with spraying of pesticide, so that the pesticide spraying becomes uniform and effective.

Owner:木牛(青岛)科技有限公司

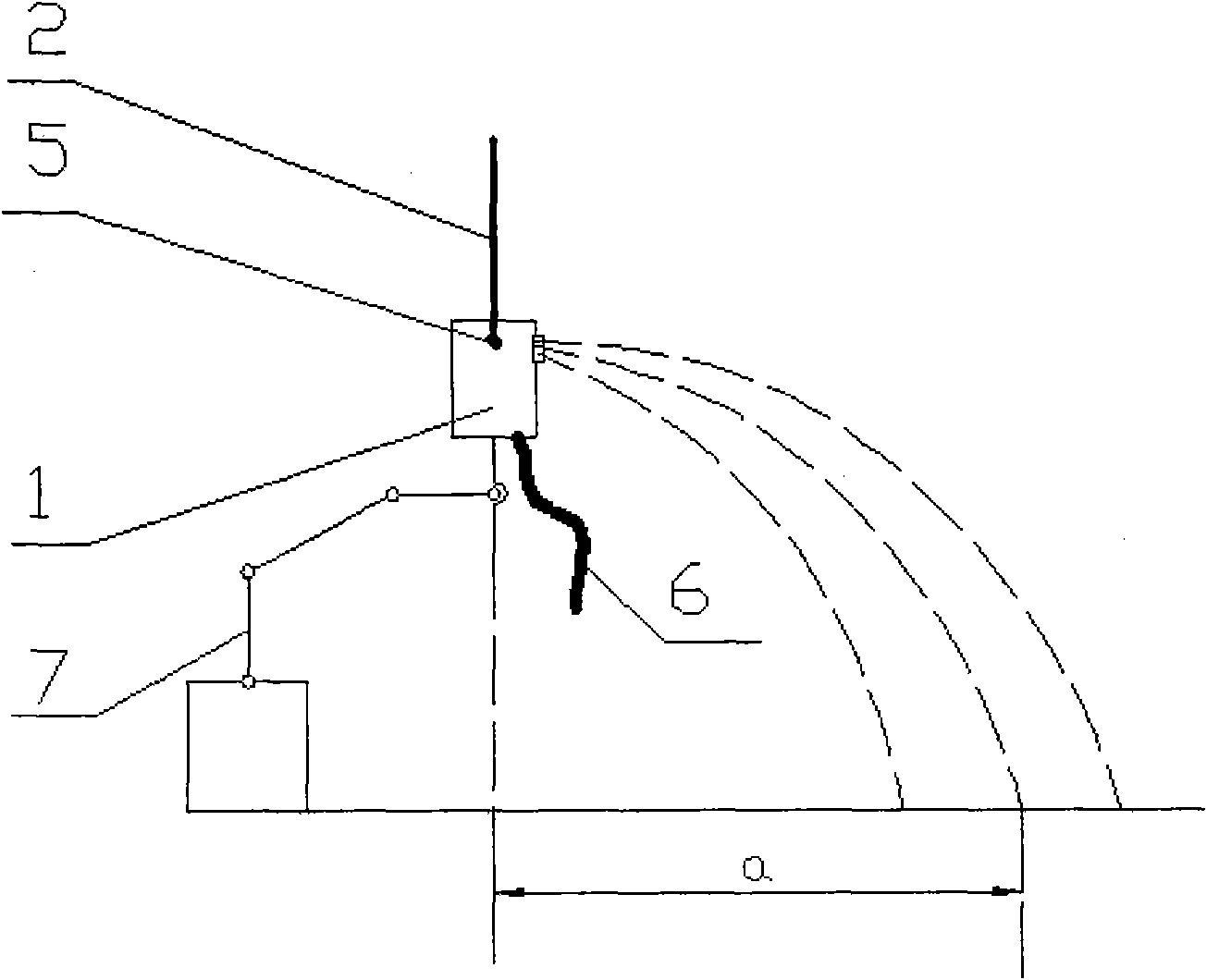

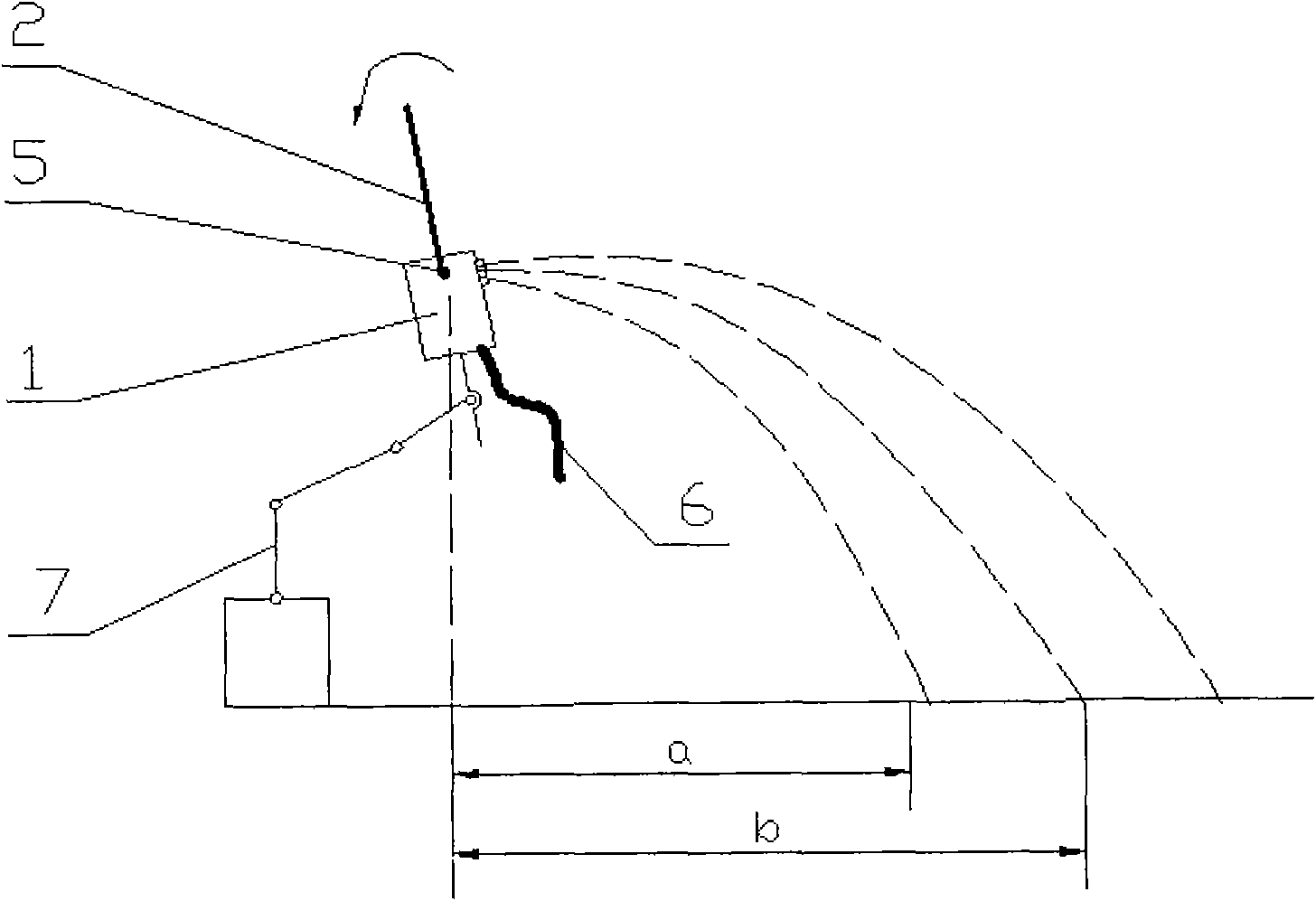

Wind-resisting water-saving sprinkler head robot for sprinkling irrigation

InactiveCN102039244ASimple structureHigh degree of intelligenceMovable spraying apparatusWater savingEcological environment

The invention discloses a wind-resisting water-saving sprinkler head robot for sprinkling irrigation, belonging to the technical field of sprinkling irrigation device. The robot comprises: a sprinkler head body (1), a sprinkler head seat (4), a flexible water inlet pipe (6), a movable connecting device (3) connected with the sprinkler head body and the sprinkler head seat. And the robot is also characterized by further comprising a wind sensing plate (2), a sensor (5), and a swing amplitude controlling manipulator device (7); the wind sensing plate (2) is fixedly connected with the sprinkler head body (1); the sensor (5) is provided under the wind sensing plate (2); the swing amplitude controlling manipulator device (7) is fixedly connected with the sprinkler head body (1). The robot provided by the invention has a capability of implementing feedback type wind-resisting water-saving sprinkling irrigation, and allows the sprinkled water flow to be oriented accurately thus to realize wind-resisting water-saving sprinkling in agricultural production and gardening activities and save water resource consumed during sprinkling irrigation; and the robot provided by the invention can be applicable to wind-resisting sprinkling irrigation of plants to protect urban greening and ecological environment.

Owner:GUANGZHOU UNIVERSITY

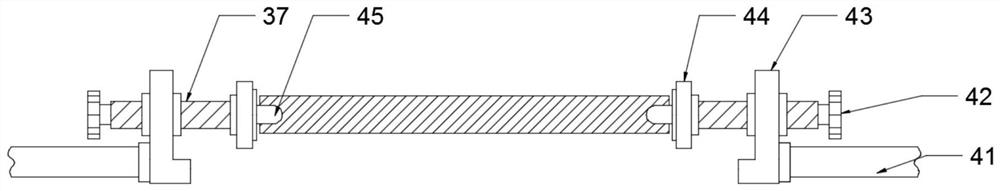

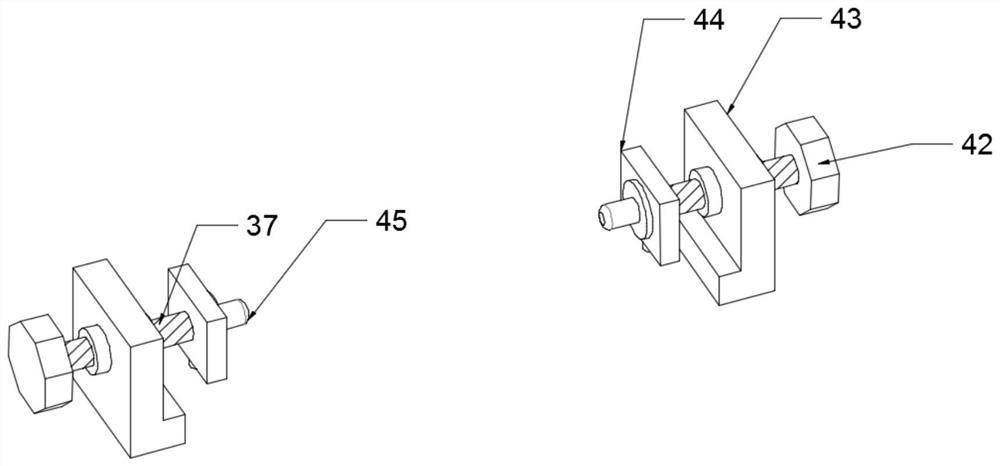

Steel pipe spraying device for construction engineering construction

InactiveCN111822177ASpraying is fully effectiveEfficient sprayingLiquid spraying apparatusElectric machineryDrive motor

The invention discloses a steel pipe spraying device for construction engineering construction, and relates to the technical field of construction engineering equipment. The steel pipe spraying devicecomprises a supporting base and a spraying box. A driving motor I is arranged on the left side of the spraying box. Supports are symmetrically arranged on the left side and the right side in the spraying box and are connected with rotating shafts. Fastening lead screws are arranged within the supports and are connected with clamping plates. Positioning columns are arranged on the surfaces of theclamping plates. The driving motor I is connected with a bevel gear I. A rotating column is arranged on the left side of the spraying box. Two ends of the rotating column are connected with a bevel gear II and an incomplete bevel gear. A screw is arranged above the spraying box. A spraying liquid box is arranged on the right side of the upper surface of the top wall of the spraying box, and is connected with a piston cylinder through a liquid conveying pipe. The rotating shafts drive the supports and a steel pipe to rotate to enable the surface of the steel pipe to be sufficiently and effectively sprayed. The liquid conveying pipe pumps spraying liquid in the spraying liquid box out and conveys the spraying liquid to a spraying pipe and a nozzle, a nut drives the nozzle at the bottom to move left and right in the horizontal direction to realize repeated spraying of the steel pipe.

Owner:杨庆美

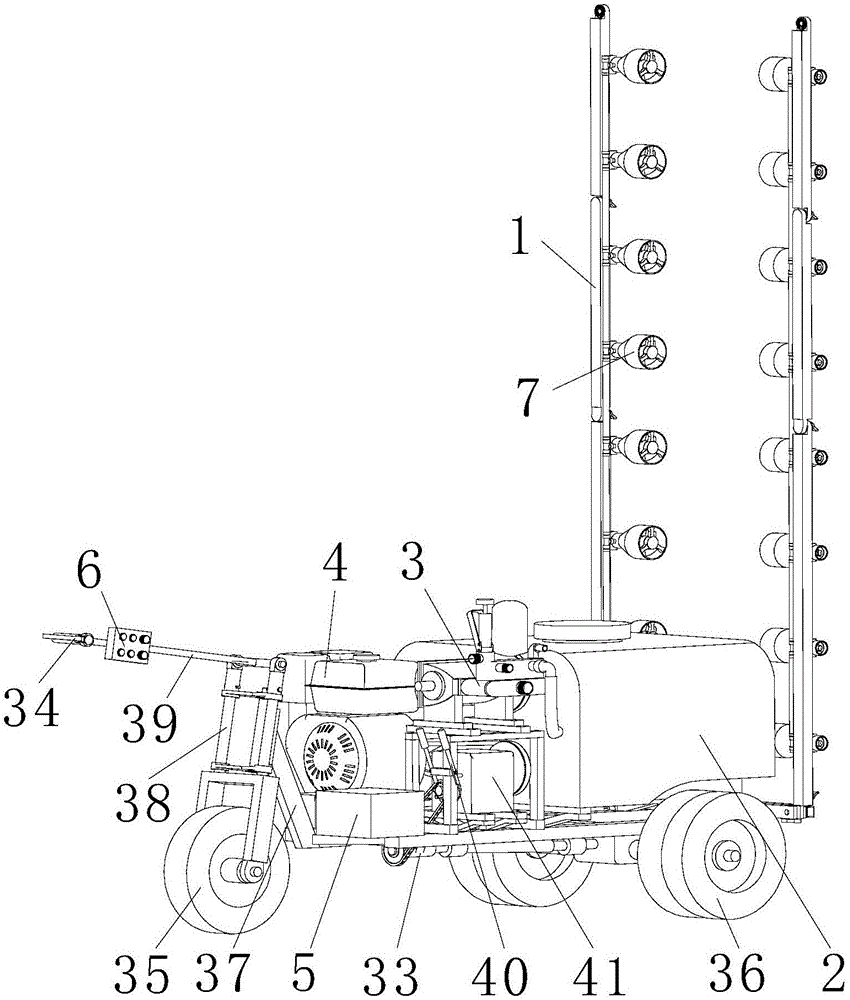

Dispersed wind source directional air-blast electrostatic spraying machine

ActiveCN106172354AReduce energy lossSimple body structureInsect catchers and killersEnergy consumptionNozzle

The invention discloses a dispersed wind source directional air-blast electrostatic spraying machine. The machine comprises a traveling cart, an adjustable boom frame, a pesticide box, a liquid pump, a power system and multiple air-blast electrostatic nozzle components, wherein the adjustable boom frame, the pesticide box, the liquid pump and the power system are arranged on the traveling cart, the multiple air-blast electrostatic nozzle components are fixed to the adjustable boom frame, and each air-blast electrostatic nozzle component comprises an air feeding component and an electrostatic nozzle component which are connected; the input end of the liquid pump is connected with the pesticide box, the output end of the liquid pump is connected with the electrostatic nozzle components through liquid delivery hoses, and the power system is used for providing power for the liquid pump. By the adoption of the machine, dispersed wind source type air feeding is achieved, air generated by a wind source directly acts on an air outlet, energy consumption of an existing air-blast spraying machine adopting centralized air feeding design in an air feeding pipeline is reduced, the machine body structure of the spraying machine can be effectively simplified, and the machine body weight of the spraying machine can be reduced.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com