Patents

Literature

271results about How to "Save paint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Layered spraying track planning method used for spraying robot

InactiveCN102831306AEfficient sprayingImprove spraying efficiencySpecial data processing applicationsEconomic benefitsTrajectory optimization

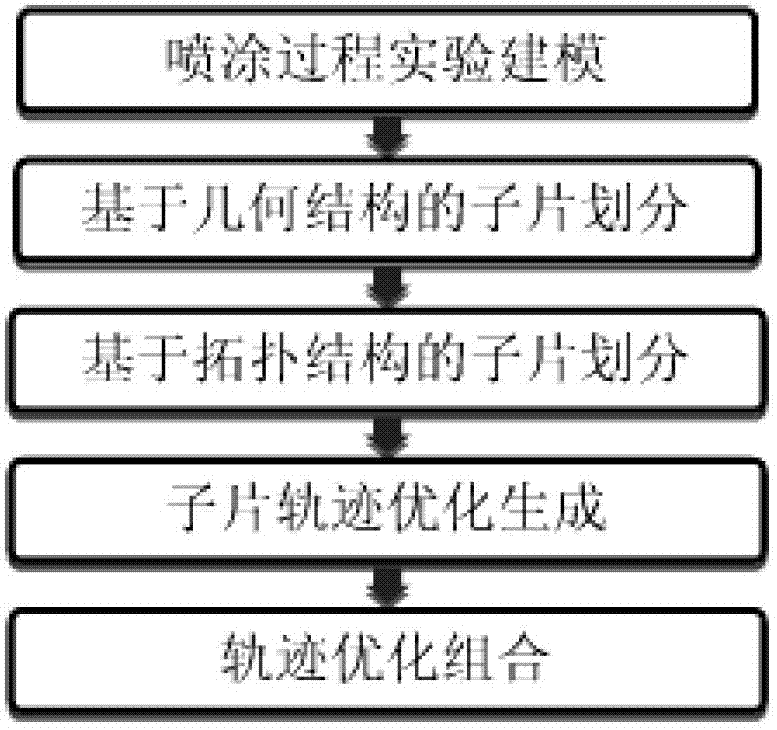

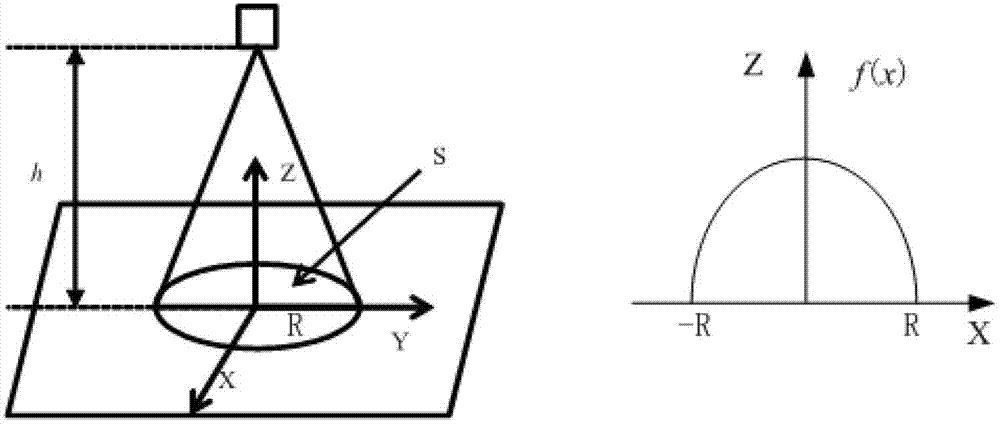

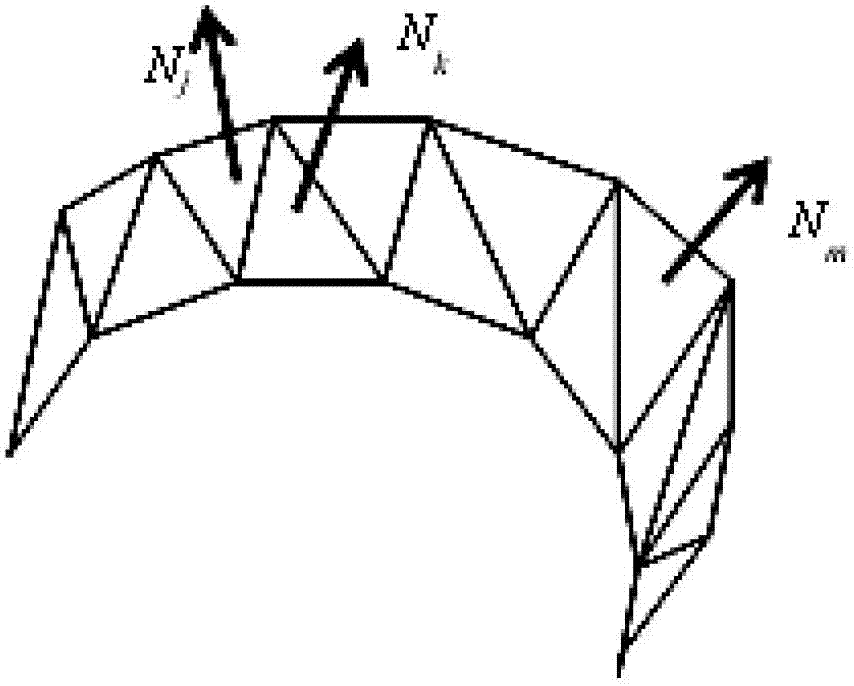

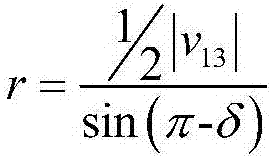

The invention discloses a layered spraying track planning method used for a spraying robot. The layered spraying track planning method comprises the steps of: firstly, designing an experiment method to build a model for the spraying process and fitting a coating distribution condition by introducing Gaussian and coating accumulative rate model; then adopting a layered track planning method and dividing a complex curve into a plurality of simple sub-curves by respectively applying a double deviation angle method and a projection method based on geometric and topological characteristics of a work-piece, establishing a corresponding spraying track optimization model and obtaining a travel parameter by adopting a numerical method so as to generate a spraying track in each sub-sheet; and finally, adopting an estimation of distribution algorithm to perform optimized combination on the track of each sub-sheet. The layered spraying track planning method used for the spraying robot, disclosed by the invention, has the advantages of improving the spraying production technology of the spraying robot, realizing track optimized generation of the spraying robot on each complex work-piece surface, improving distribution uniformity under the precondition of satisfying expected thickness of the coating, reducing paint waste, and thereby facilitating to improve production efficiency and economic benefits of the spraying manufacturing industry.

Owner:SOUTHEAST UNIV

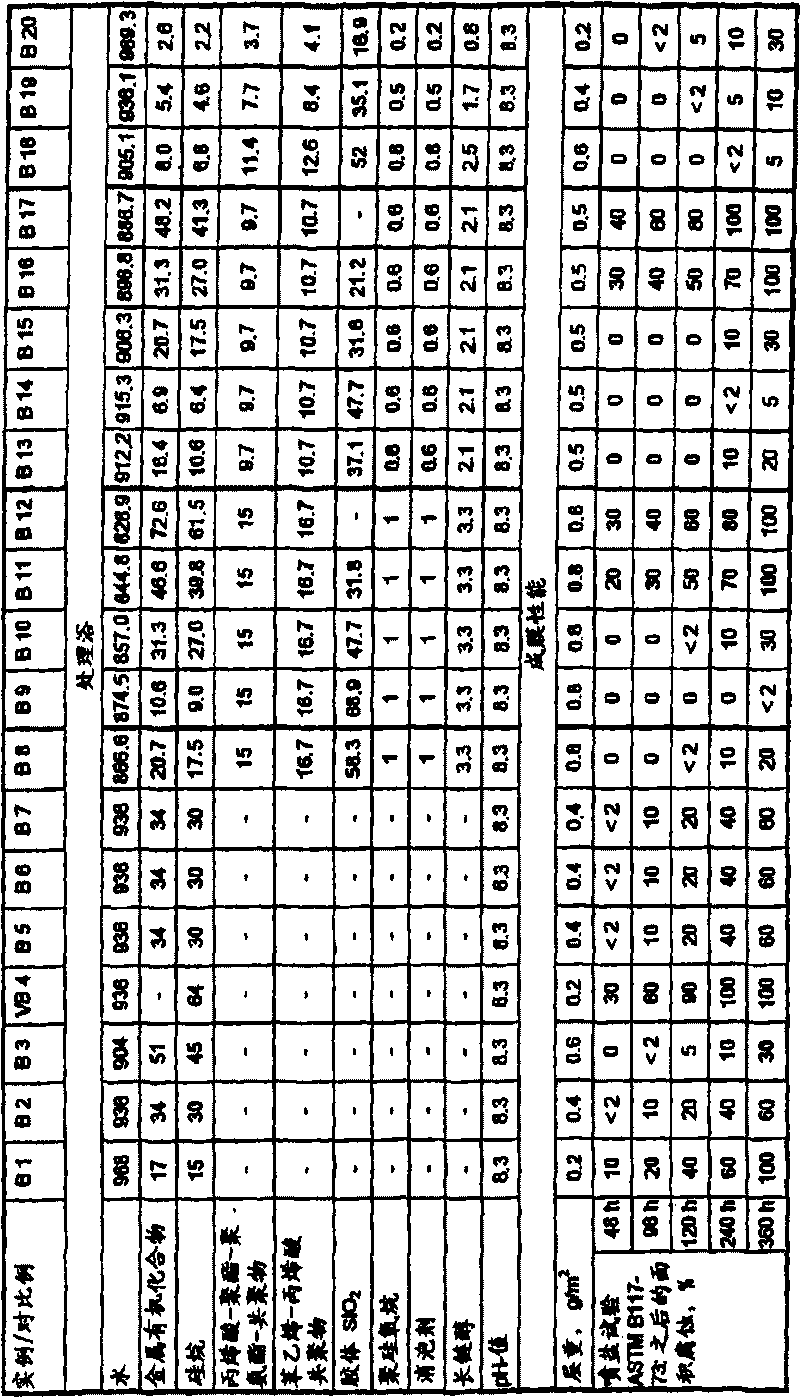

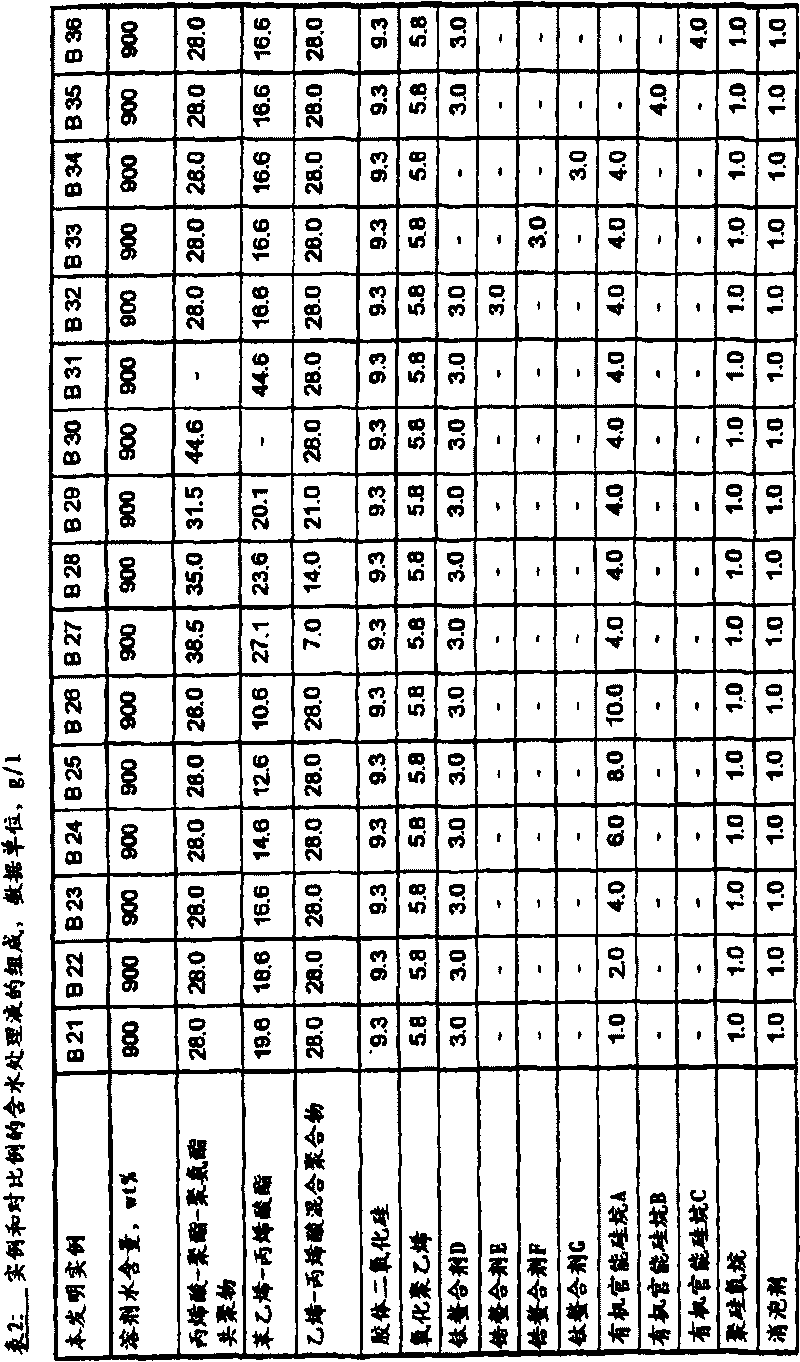

Method for coating metallic surfaces with a composition that is rich in polymers

InactiveCN101705484AImprove adhesionHigh strengthPretreated surfacesEfficient propulsion technologiesOrganic filmAlcohol

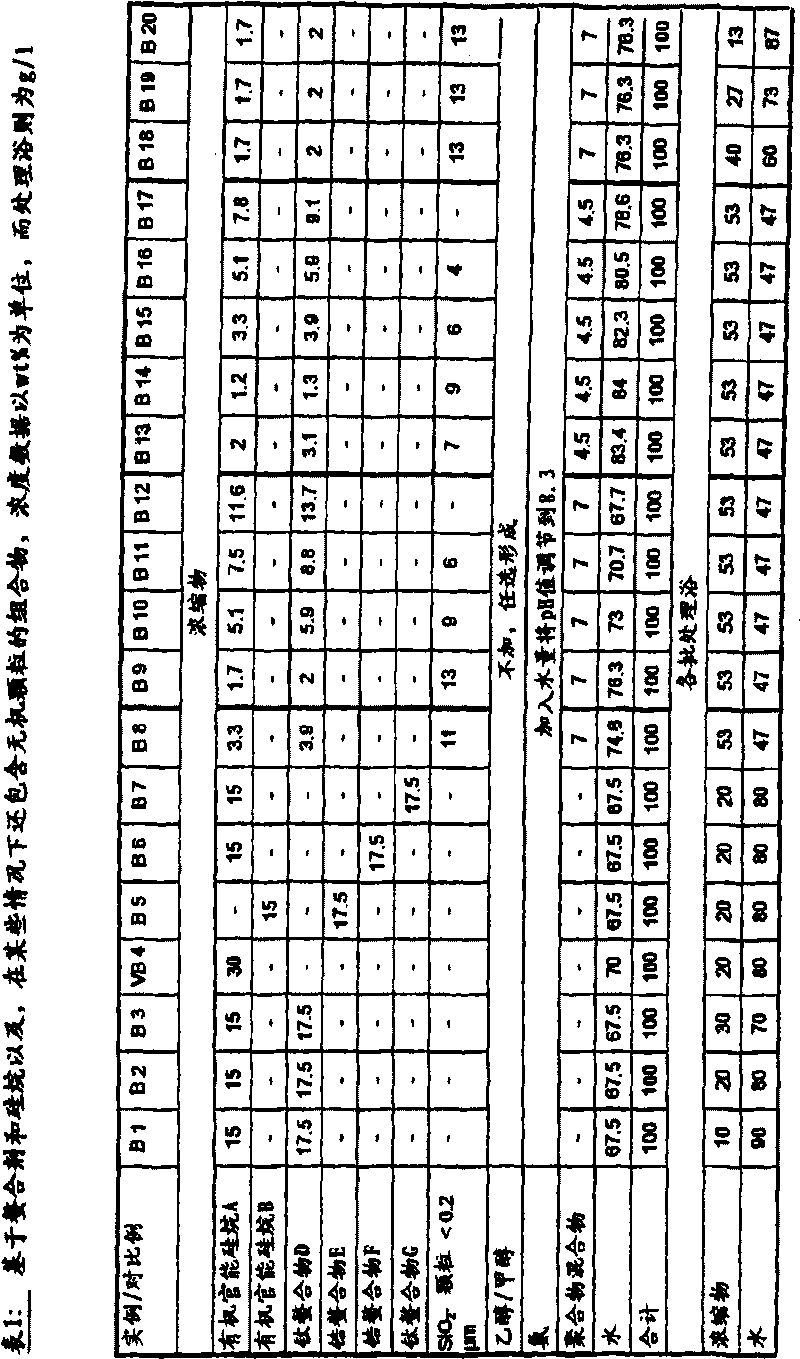

The invention relates to a method for coating a metallic surface with an aqueous composition for pretreating before applying another coating or for treating said metallic surface. In addition to water, the composition contains: a) at least one hydrolyzable or at least partially hydrolyzed silane; b) at least one metal chelate, if necessary, also; c) at least one organic film former; and d) at least one long-chain alcohol that serves as a film forming aid and / or. The unsoiled, scoured, cleaned and / or pretreated metallic surface is brought into contact with the aqueous composition and a film is formed on the metallic surface, is subsequently dried, compacted in part or completely by film formation and, if necessary, additionally hardened. The dried and, if necessary, additionally hardened film has a layer thickness ranging from 0.01 to 10 mum. The invention also relates to corresponding aqueous compositions.

Owner:CHEMETALLGMBH

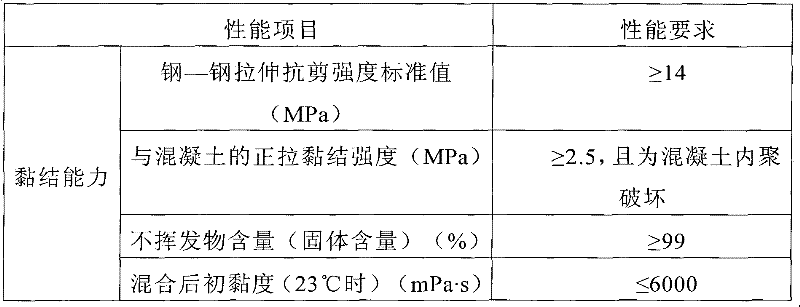

Concrete maintenance and reinforcement treatment method

InactiveCN102220813AGood sealingIncreasing the thicknessBuilding repairsBridge erection/assemblyFiberAdhesive

The invention relates to a concrete maintenance and reinforcement treatment method. The method comprises the following steps: (1) carrying out nondestructive treatment on the concrete base surface defects; (2) carrying out rust-proof treatment on reinforcing bars; (3) carrying out concrete alkalinity recovery treatment; (4) carrying out concrete crack repairing treatment; (5) daubing new and old concrete adhesives; (6) daubing inorganic polymer mortar and carrying out curing; (7) sticking carbon fiber cloth; (8) brushing an inorganic water and salt injury resistant concrete protective agent; and (9) brushing a surface self-cleaning material, thus completing construction. The method has the following beneficial effects: rust can be removed or prevented from the reinforcing bars to protect the reinforcing bars and prevent further corrosion; by adopting the carbon fiber cloth for reinforcement, the concrete structure has the characteristics of high strength, light weight, simpleness and convenience in construction and corrosion resistance; the bearing capability of the beam body is improved; the deflection of the structure is reduced; the construction efficiency is greatly improved by adopting the airless spraying and coating operations; the coating is saved by 30%; and by brushing the self-cleaning material, the structure has the self-cleaning capability, thus avoiding cleaning or reducing the cleaning frequency.

Owner:SHANGHAI FAHE BRIDGE & TUNNEL MAINTENANCE ENG TECH

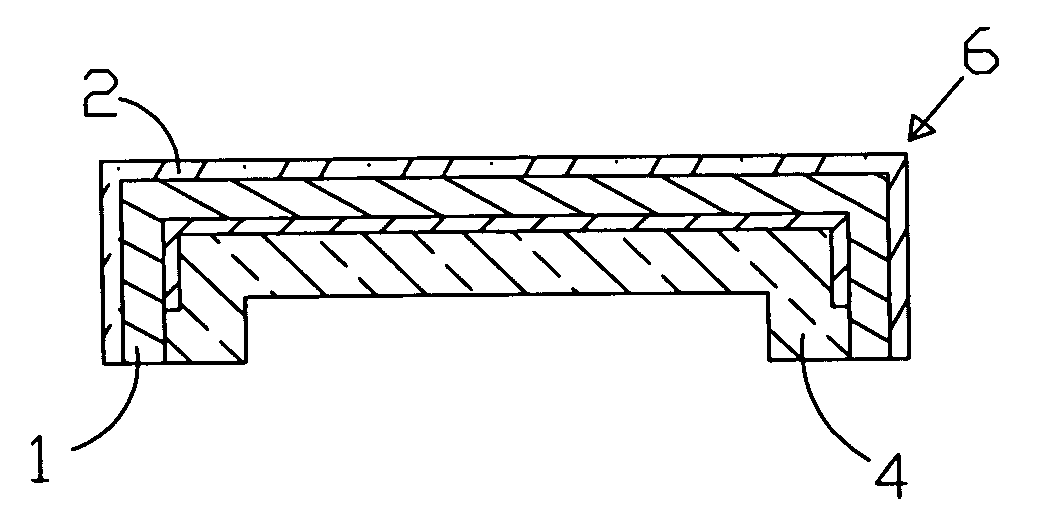

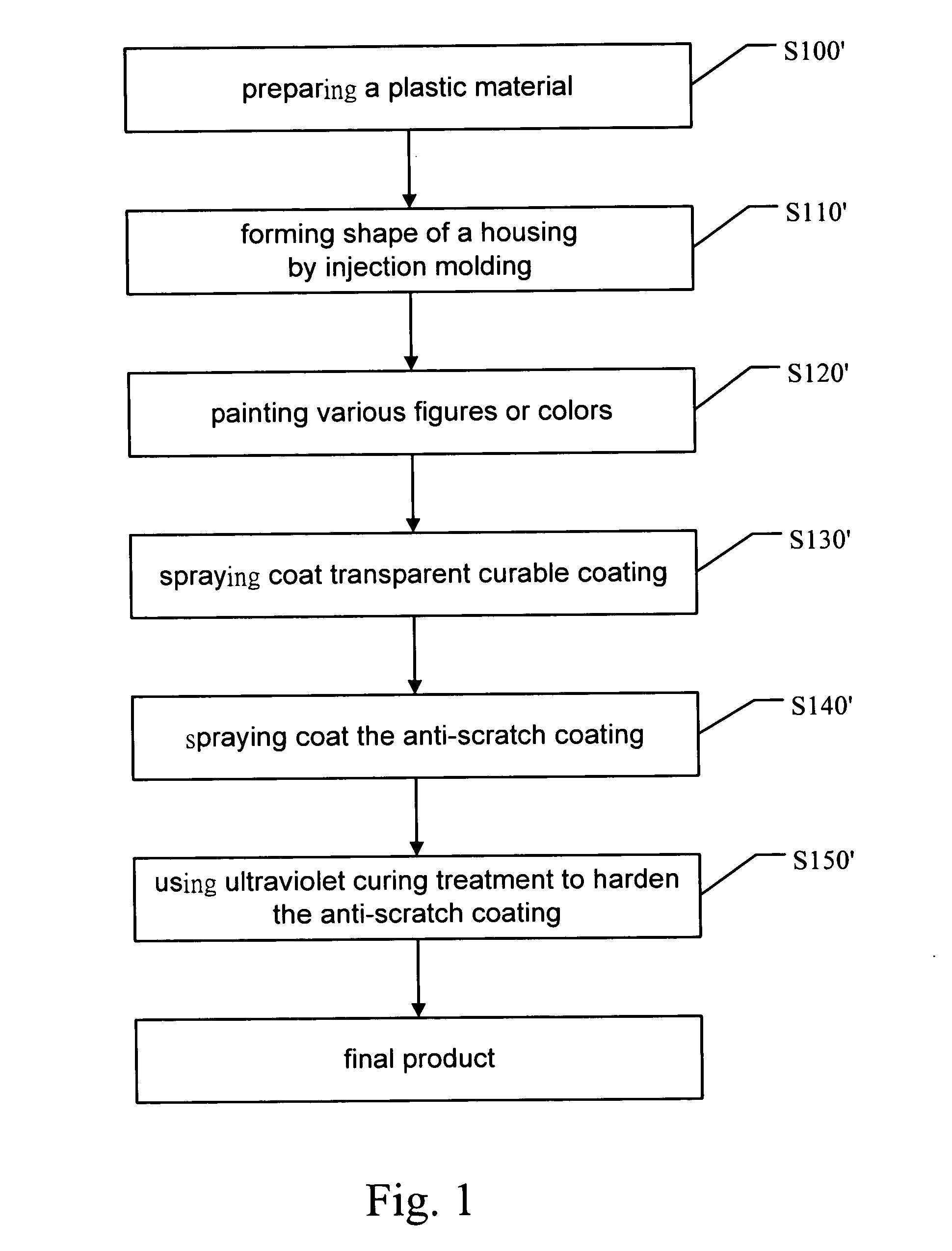

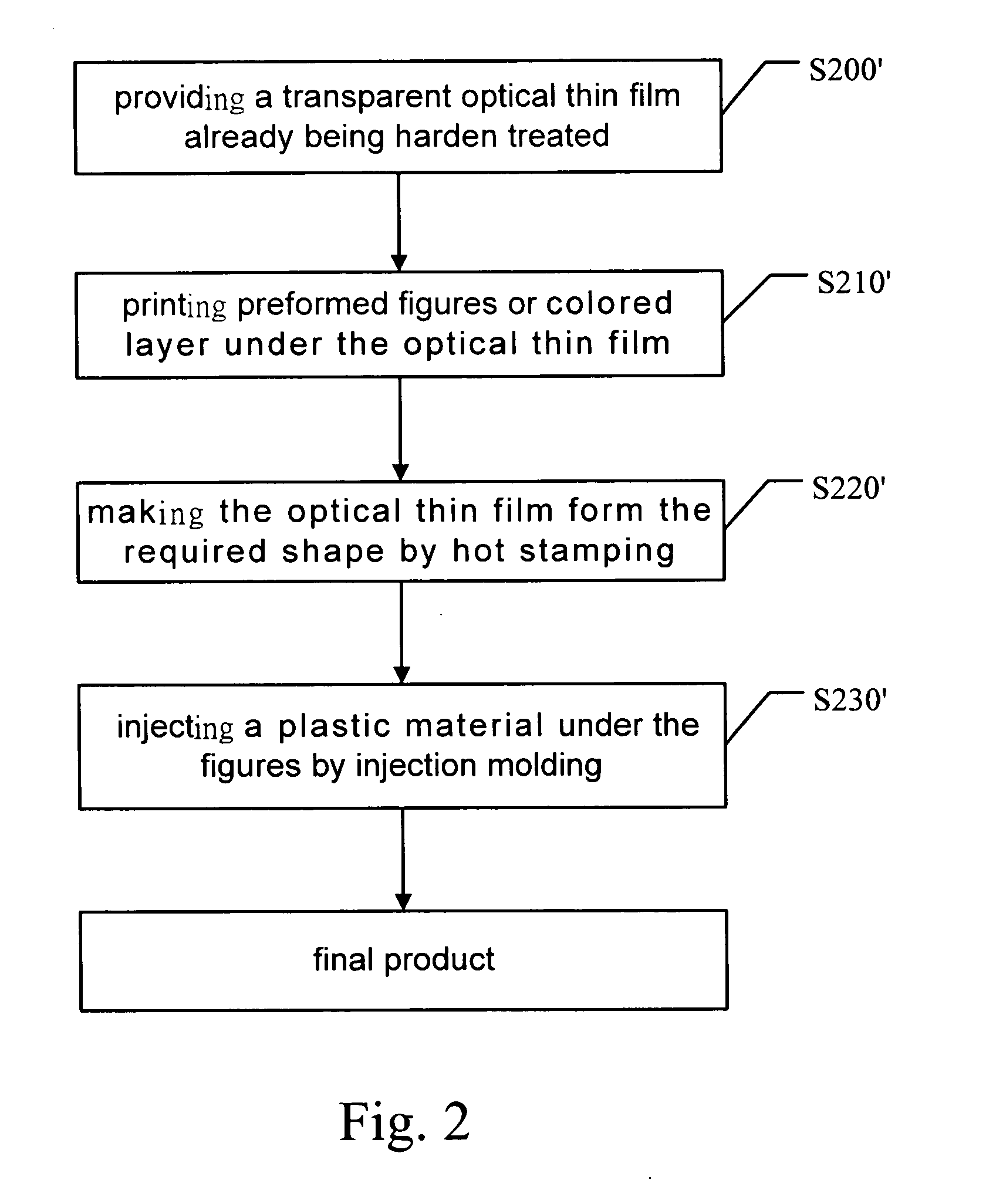

Optical thin film with high hardness made by insert mold technology and manufacturing processes thereof

ActiveUS20070160831A1Improve yield rateHigh hardnessOptical articlesRecord information storageOptoelectronicsHardness

An optical thin film with high hardness made by insert mold technology and manufacturing processes thereof are disclosed. The optical thin film is applied on surface of a plastic housing for increasing hardness of the plastic housing so as to prevent scratches. During manufacturing processes of insert mold for producing a hard coating film, the step of hardening treatment is moved to the last step so as to avoid cracks on the optical thin film generated during the procedures. Thus the yield rate is increased and the manufacturing cost is reduced.

Owner:ENTIRE TECH CO LTD

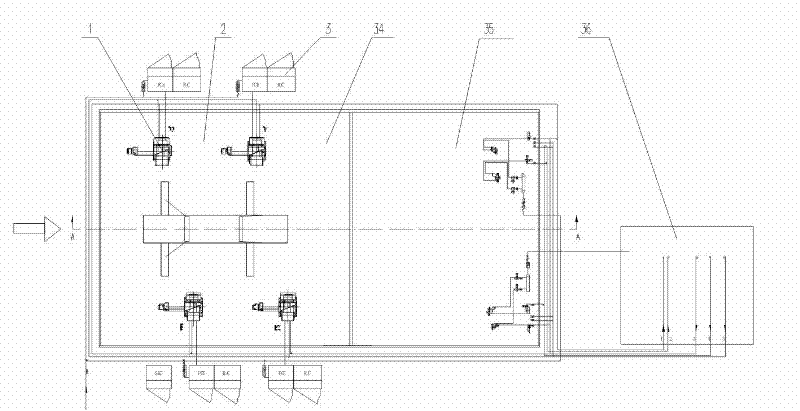

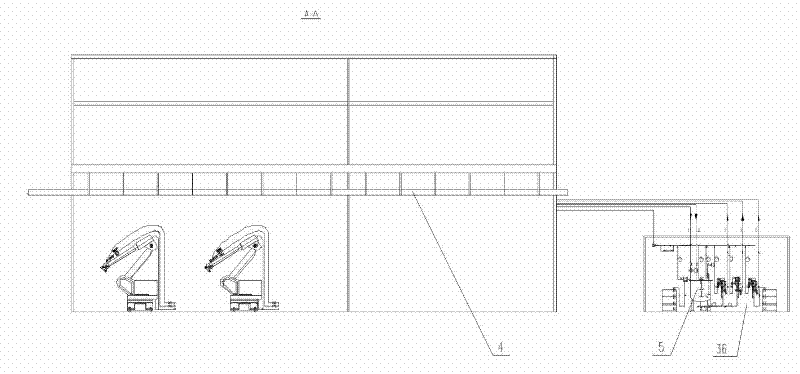

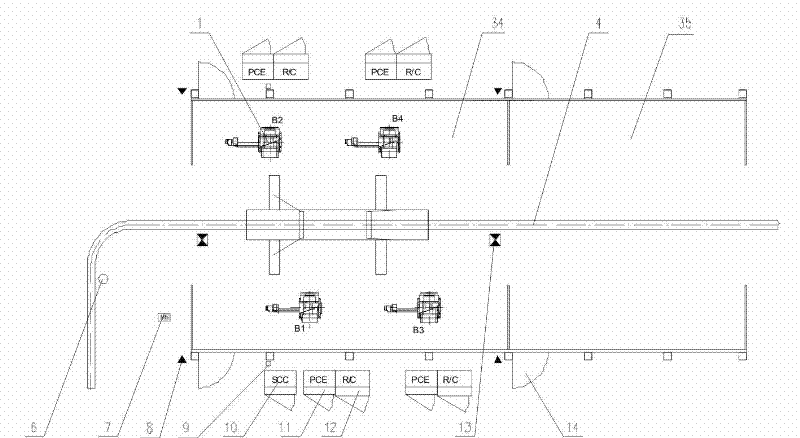

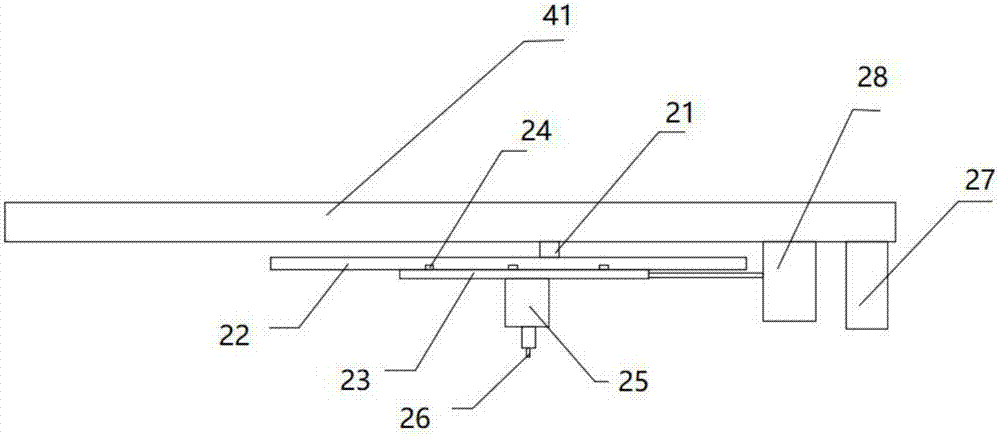

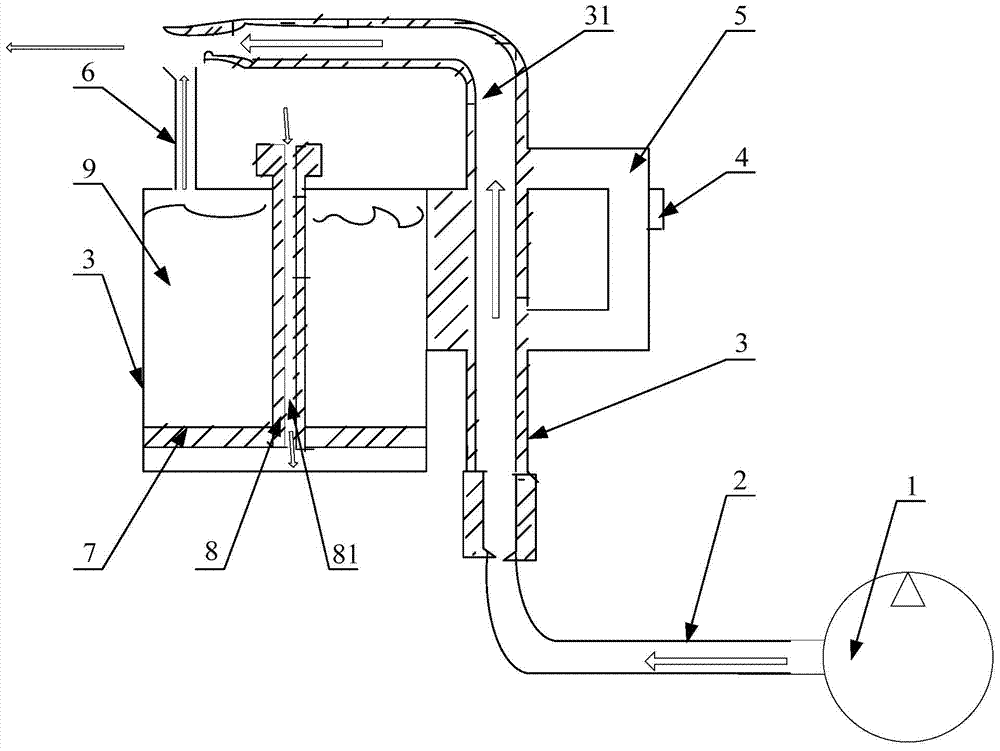

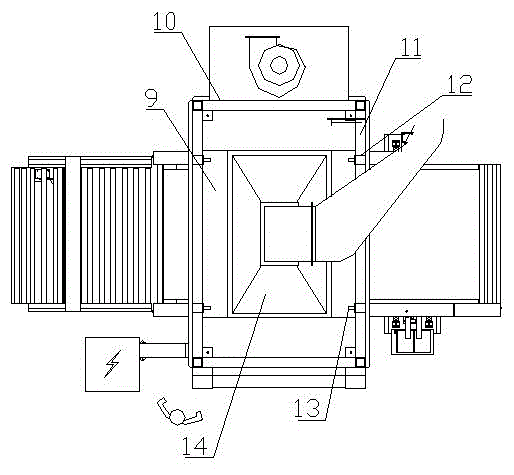

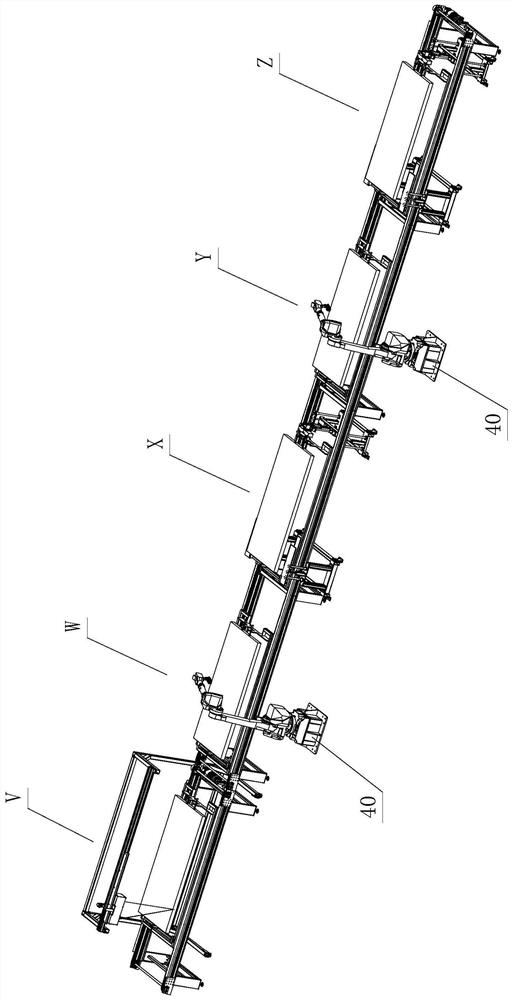

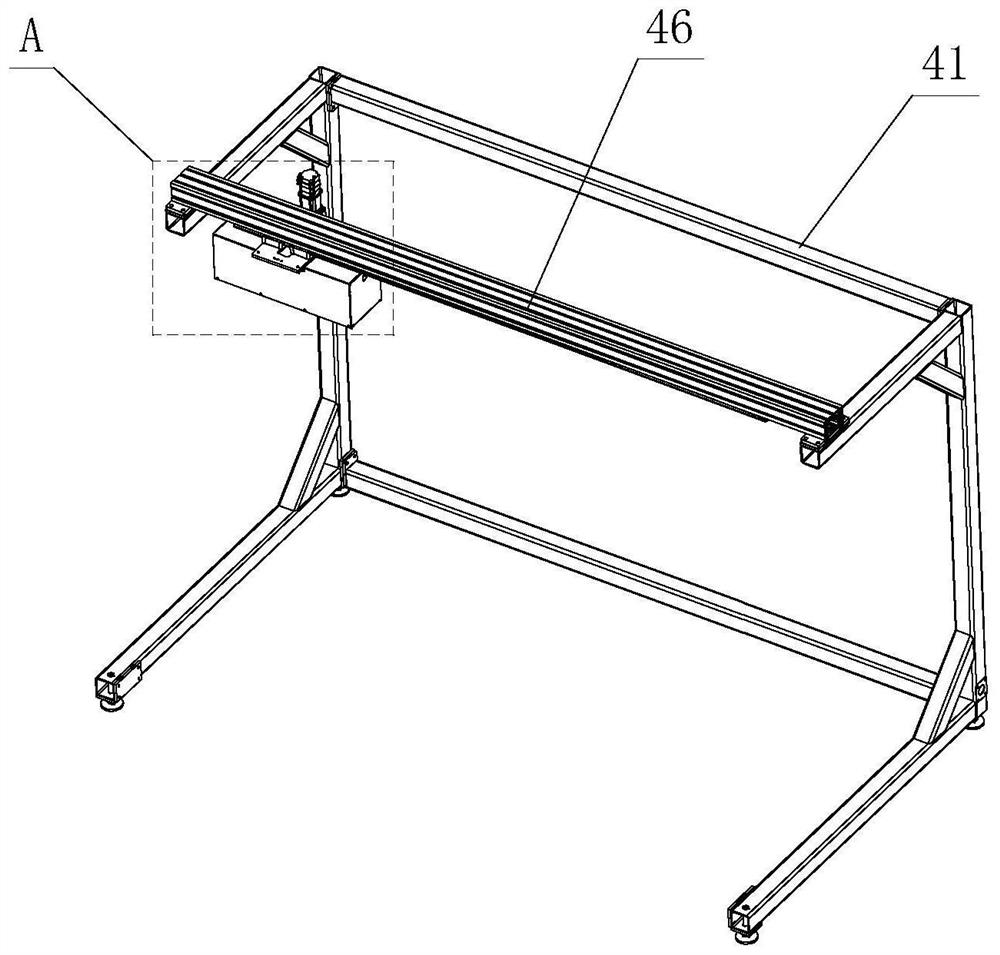

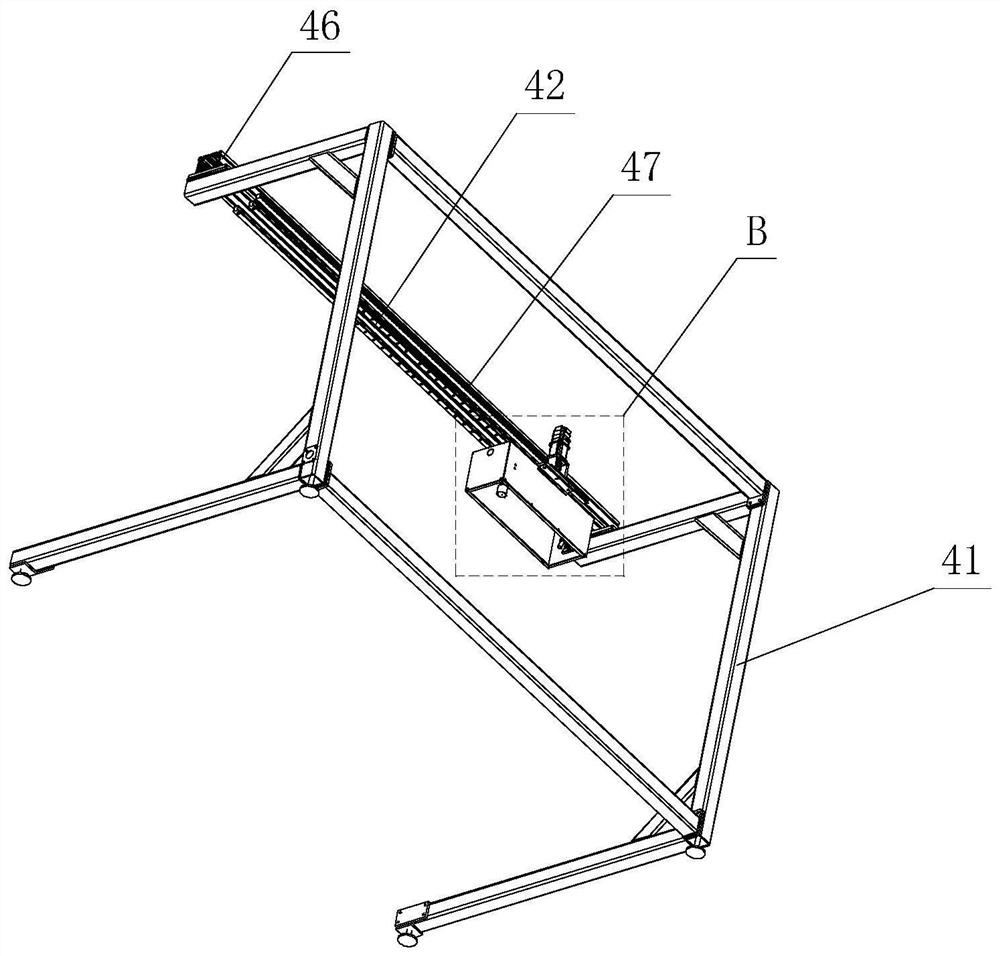

Flexible high-efficiency automatic spray-coating system and spray-coating process of big wheel tractor chassis

InactiveCN102371220AImprove the overall coating levelHigh strengthLiquid surface applicatorsSpraying apparatusControl systemWorking environment

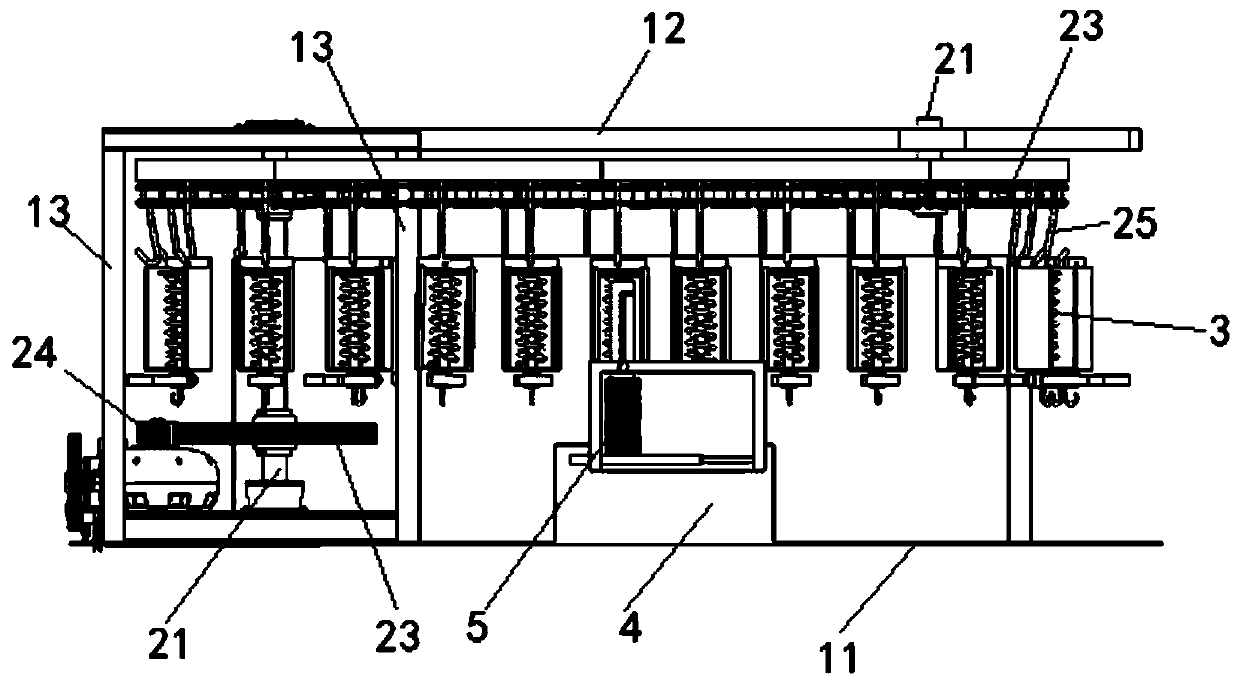

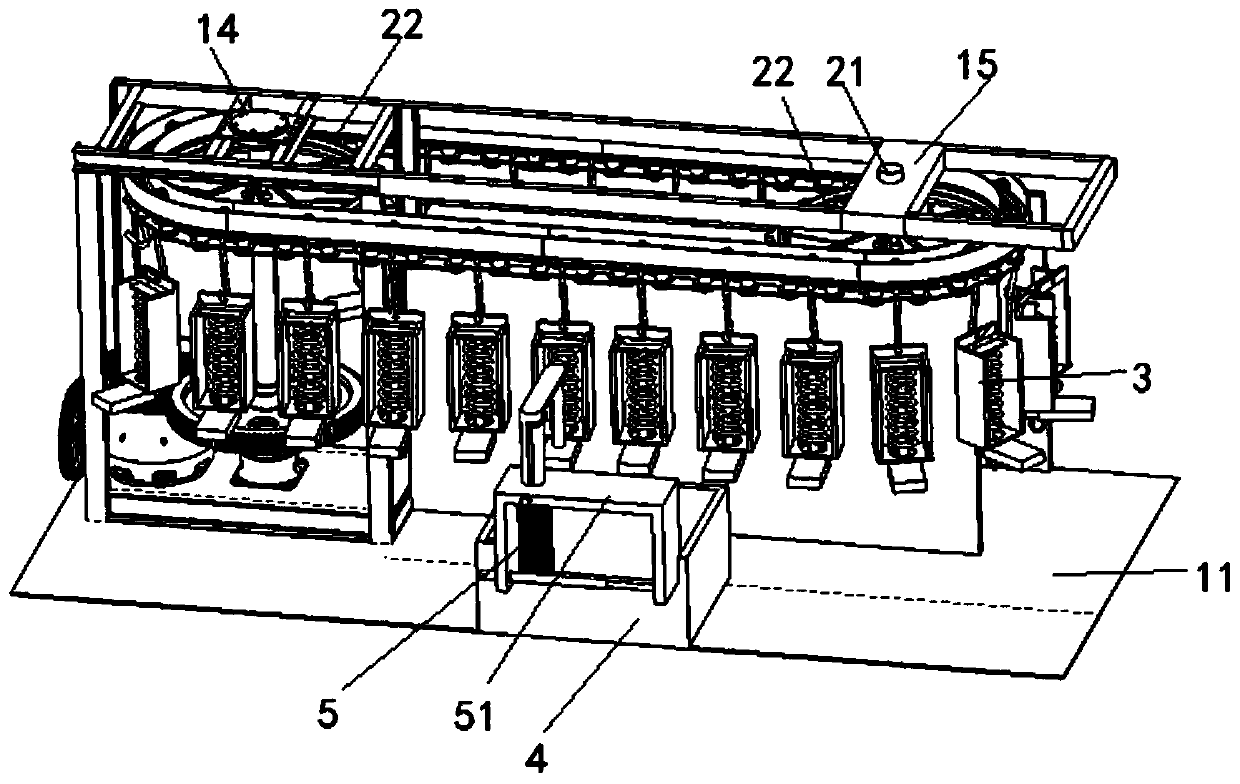

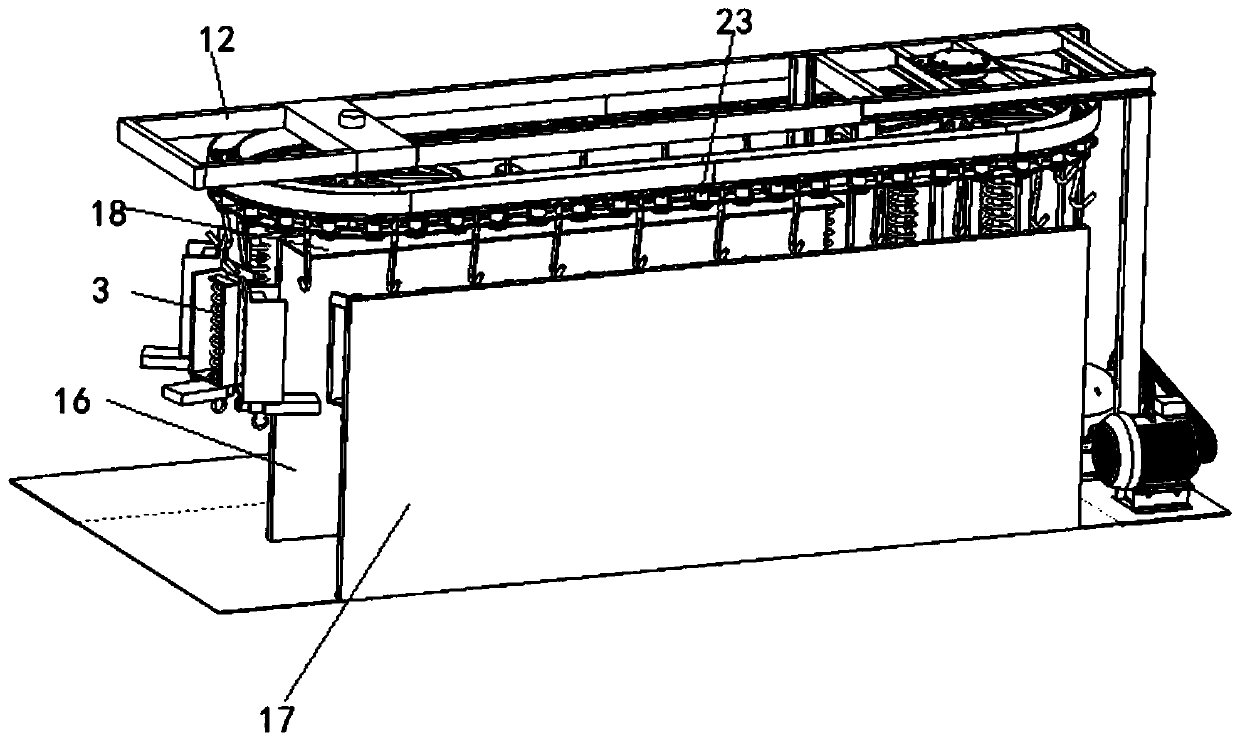

The invention discloses a flexible high-efficiency automatic spray-coating system of a big wheel tractor chassis. The system comprises a spray-coating robot system, a mixed gas spray-coating system, a top-supply and bottom-water-absorption rotary paint spraying room, a wide push rod underslung power and free chain and a control system. During spray-coating operation, the top-supply and bottom-water-absorption rotary paint spraying room can ensure an appropriate working environment of a spray-coating robot; the wide push rod underslung power and free chain is used for conveying parts of the big wheel tractor chassis to the spray-coating robot and tracking and interlocking the big wheel tractor chassis; and an automatic mixed gas spray gun at the front end of an arm of the spray-coating robot moves according to the demonstrating track and optimized process parameters and works together with the robot to complete the spray-coating work. The flexible high-efficient automatic spray-coating system of the big wheel tractor chassis has the advantages of intelligence, high efficiency, low pollution and high coating utilization rate, can ensure the consistency of the spray-coating operation and can flexibly change the spray-coating track according to different workpieces.

Owner:FIRST TRACTOR

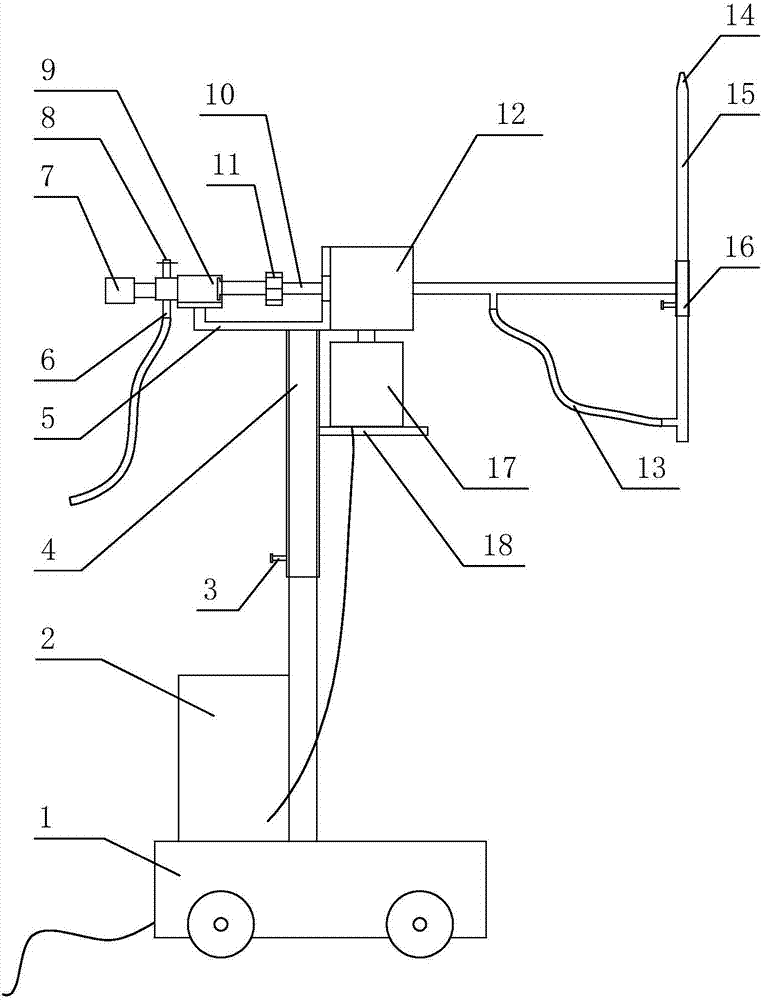

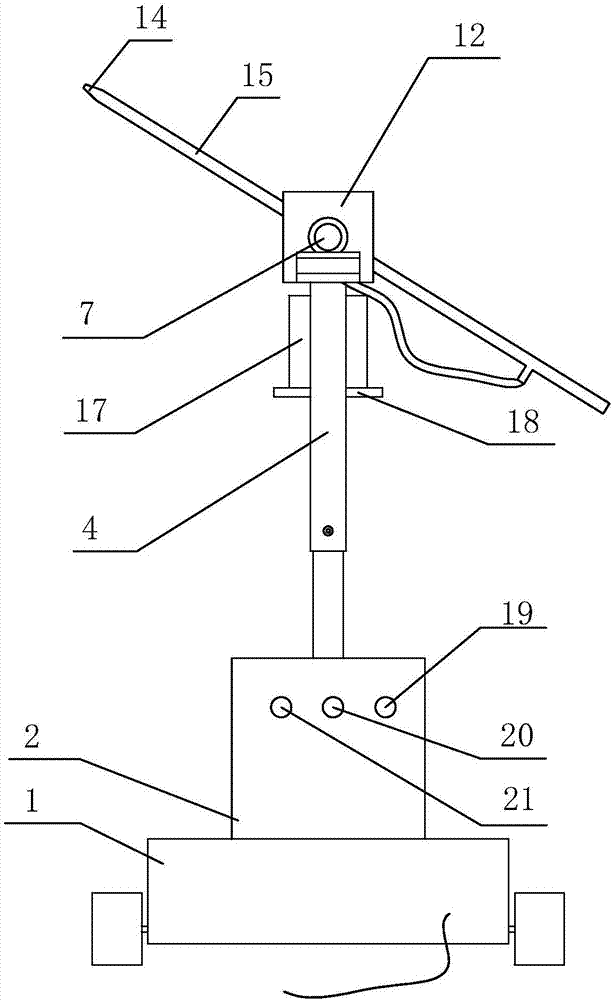

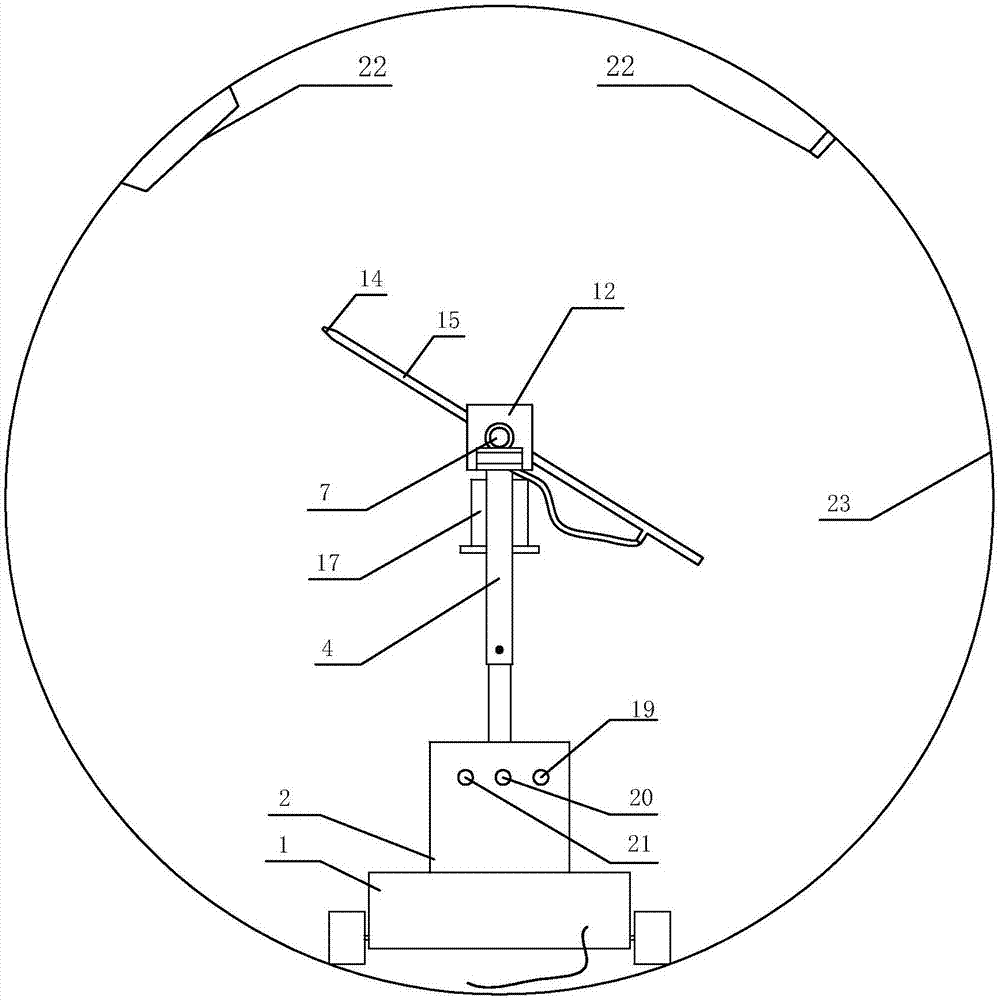

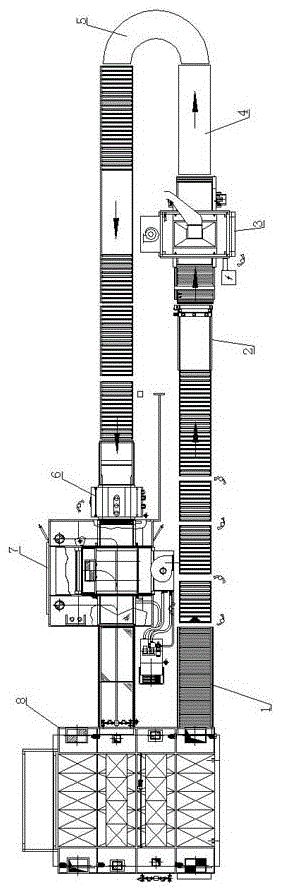

Automatic paint spraying device and automatic paint spraying method for inner wall of wind-powered electricity-generation tower pole

InactiveCN107051789AImprove efficiencyGood coating performanceLiquid surface applicatorsSpray nozzlesElectricityFixed frame

The invention relates to an automatic paint spraying device and automatic paint spraying method for an inner wall of a wind-powered electricity-generation tower pole. The automatic paint spraying device comprises a walking wagon, a supporting frame, a spray gun, a control cabinet, a fixing frame, a feed valve, a rotating valve, a hollow rotating shaft and a motor, wherein the motor is fixedly connected to the supporting frame and drives the hollow rotating shaft to rotate; the rotating valve is fixed to the supporting frame through the fixing frame; the feed valve is connected with the hollow rotating shaft through the rotating valve, and provides a material circulating channel, and the other end of the hollow rotating shaft is connected with the spray gun, and is used for enabling materials to be sprayed from a nozzle of the spray gun; the motor is in signal connection with the control cabinet; and the walking wagon is in signal connection with the control cabinet. The automatic paint spraying device disclosed by the invention is high in efficiency, good in paint spraying effect, uniform in paint spraying thickness, and suitable for paint spraying for the inner wall of a large-diameter steel pipe of which the diameter is 3-10 m; microcomputer control is adopted to realize automatic operation, and manual operation is not needed; the weariness of an operator is relieved, and the working efficiency is improved; the coating is level, smooth, and free from brush marks; and paint is saved.

Owner:广东粤水电装备集团有限公司

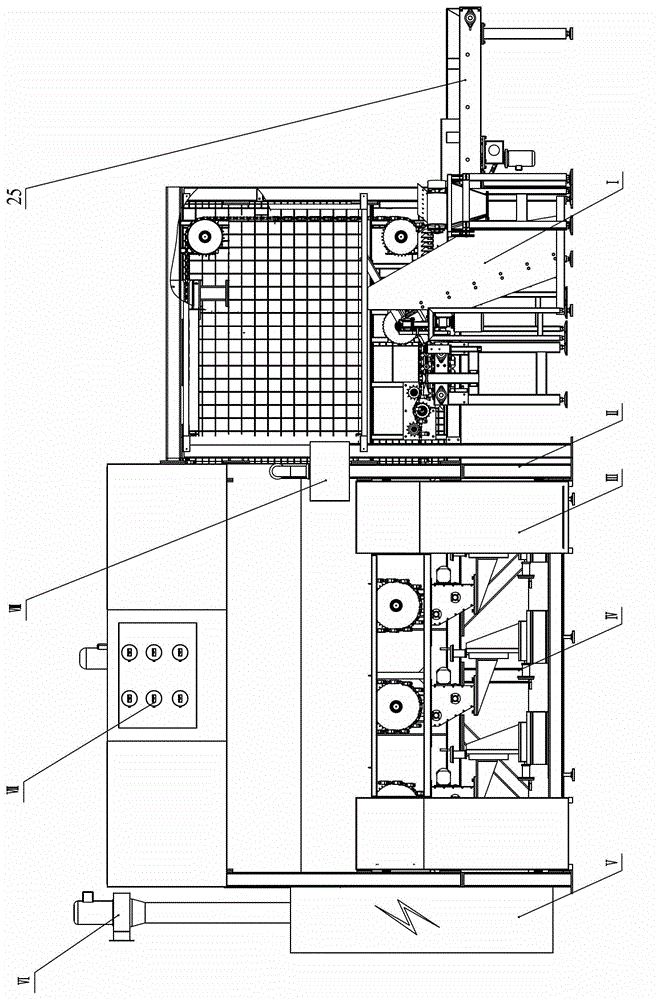

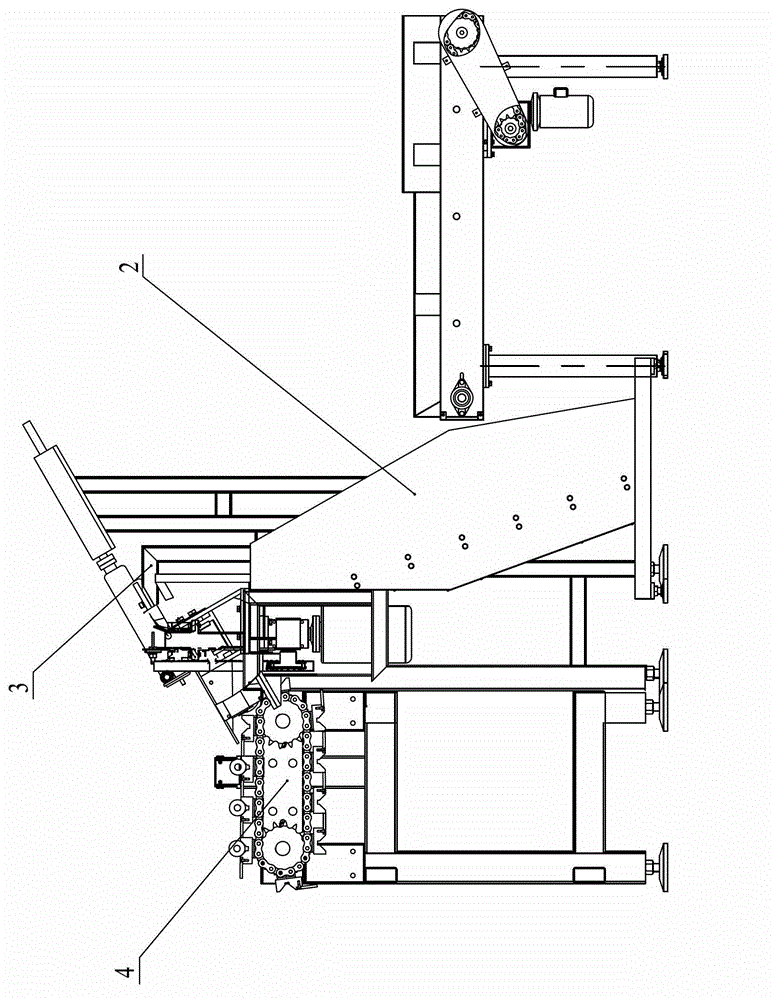

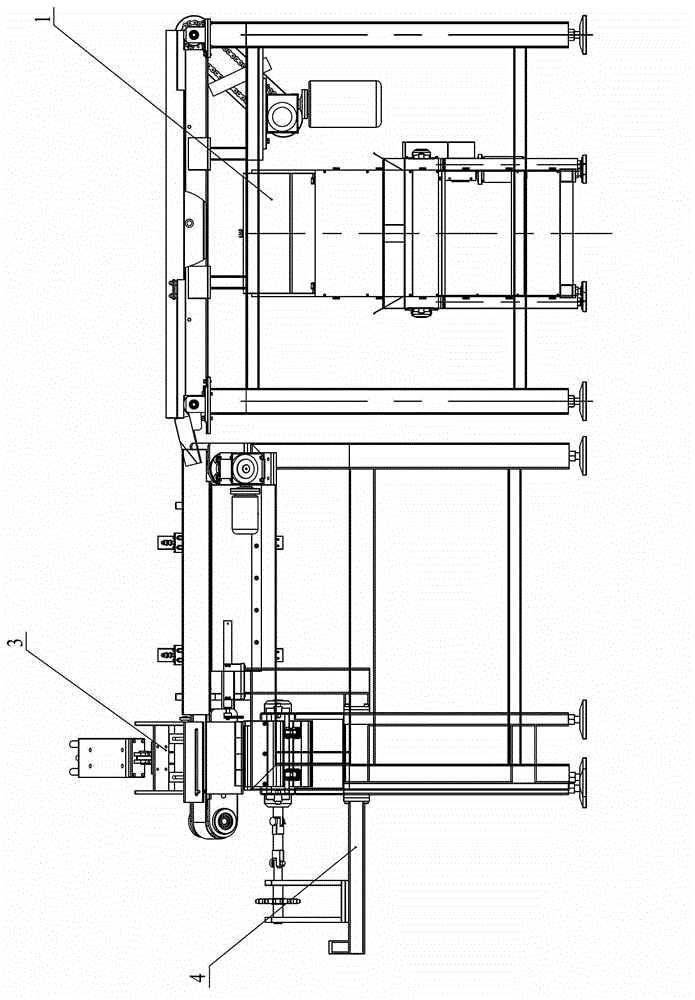

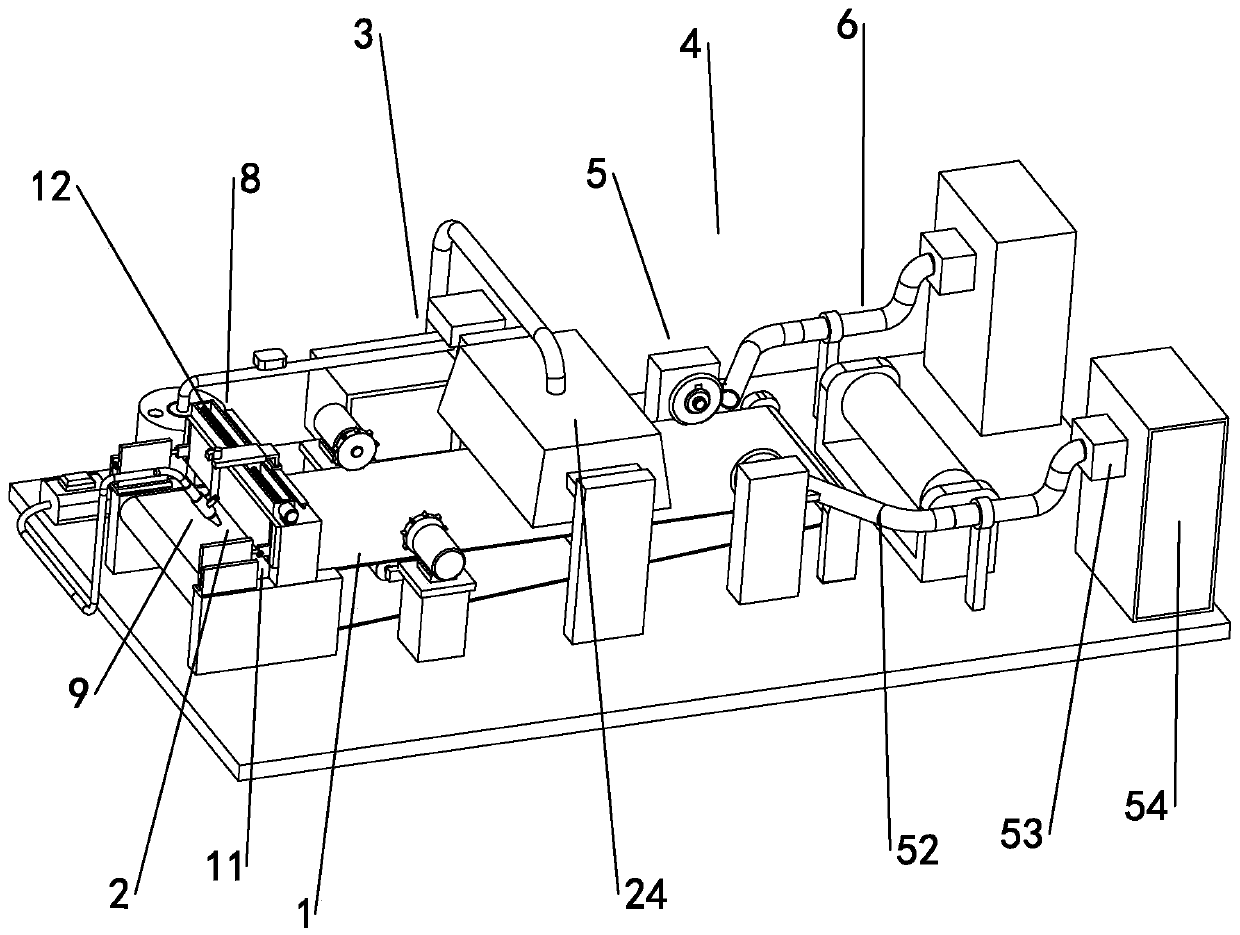

Roller coating machine

ActiveCN102974498ASolve Adhesion ProblemsSolve for uniformityPretreated surfacesCoatingsMachineIndustrial engineering

The invention relates to a roller coating machine. Workpieces needing to be coated are pushed into a material turnover frame of a material turnover mechanism; the material turnover mechanism rotates the material turnover frame; the workpieces are turned and are poured into a material blocking hopper; the workpieces are conveyed to a material storage hopper of a discharge mechanism by a discharge conveying machine; the workpieces are lifted by the discharge mechanism, then are arranged in order and roll into a vibration transmission rack according to a certain rule; the workpieces are conveyed to a synchronous material-pushing mechanism; the workpieces arranged tidily are pushed to a V-shaped groove of a synchronous material-loading mechanism by the synchronous material-pushing mechanism; the workpieces are subjected to position adjustment by the synchronous material-loading mechanism and then are pushed to a material hanging mechanism on a workpiece transmission rack; the material hanging mechanism drives the workpieces and feeds them into an automatic glue-rolling device; a glue liquid is uniformly roll-coated on the surfaces of the workpieces by the automatic glue-rolling device; the workpieces coated with the glue liquid are fed to an unloading mechanism by the workpiece transmission rack; and the workpieces coated with the glue liquid are fed to a material receiving hopper by the unloading mechanism, then are fed into a workpiece delivery wagon and then are output. The roller coating machine adopts a roll-coating technology to realize workpiece surface treatment, is efficient, saves energy, is environmentally friendly and is suitable for large-scale glue-rolling of tubular workpieces.

Owner:WUXI HUANENG SURFACE TREATMENT

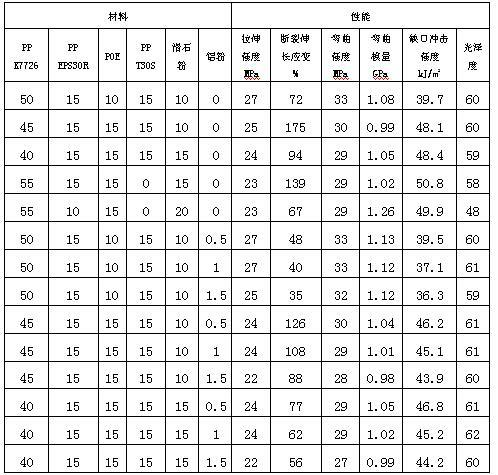

Formula of non-painted automobile bumper with metal luster and production process thereof

The invention provides a formula of a non-painted automobile bumper with metal luster and a production process thereof. The automobile bumper is prepared from the following components in part by weight: 60 to 90 parts of PP, 8 to 12 parts of POE, 0.5 to 1.5 parts of aluminum powder and 8 to 12 parts of talcpowder. The automobile bumper produced by adopting the technique of blending the aluminum powder, PP and POE, the paint-spraying process is saved, the metal luster is obtained, the environment is protected, the paint-spraying process step in the production process is eliminated, the product produced by the formula and the method has the effect of the metal flashing paint sprayed on the surface, and the metal luster is high in durability and is not lost due to environmental factors as well as surface abrasion; and in addition, because the surface of the automobile bumper is not painted, the automobile bumper is recovered more conveniently.

Owner:JIANGLIN GUIZHOU HI TECH DEV CO LTD

Protection method for rust removal, paint removal and anticorrosion of metal surface

InactiveCN102218386ASolve the work of rust removal and rust preventionReduce labor intensityPretreated surfacesCoatingsBenzeneKetone

The invention relates to a protection method for rust removal, paint removal and anticorrosion of a metal surface. The method comprises three steps of (1) metal surface lossless rust removal technology, (2) conversion of rust iron on a metal surface and antirust processing, (3) painting of anticorrosion paint on the metal surface. Compared with prior art, the protection processing on the metal surface of the invention employs a high-pressure water-sand blending technology to remove rust, so that rust removal efficiency is higher and the method is safe and environment-friendly. Free rust on the metal surface can be conversed into antirust priming paint when a rust removal transforming agent is being painted, so as to complete metal rust removal and rust prevention by one step, and solve problems, that harm antirust quality, such as local corrosion and free rust at one time. The rust transforming agent employed in the technology belongs to an aqueous system, is without harmful solvents of benzene, ketone, etc., or heavy metal compositions and is nontoxic and environmental-friendly, so that base materials with rust can be used in construction to save costs and raise efficiency. Anticorrosion coating on the metal surface employs a high-pressure air-free coating spraying, so that construction quality is more reliable and the efficiency is higher.

Owner:SHANGHAI FAHE BRIDGE & TUNNEL MAINTENANCE ENG TECH

Spraying-free nano nylon 6 composite material

The invention discloses a spraying-free nano nylon 6 composite material. The spraying-free nano nylon 6 composite material is prepared from the following raw materials in parts by mass: 70 to 94 partsof a nano nylon 6 composite material, 4 to 10 parts of metal master batch, 1 to 10 parts of an antistatic agent and 1 to 10 parts of an antibacterial agent; the nano nylon 6 composite material is prepared from the following raw materials in parts by mass: 81 to 87 parts of caprolactam and 3 to 6 parts of montmorillonite. The composite material disclosed by the invention does not need to be sprayed, so that coating is saved and the working mount in a production process is reduced; the spraying-free nano nylon 6 composite material has an environment protection effect and also has the advantagesof good color and luster, high strength, strong wear resistance, antistatic performance, antibacterial performance and the like.

Owner:GUANGDONG XINHUI MEIDA NYLON

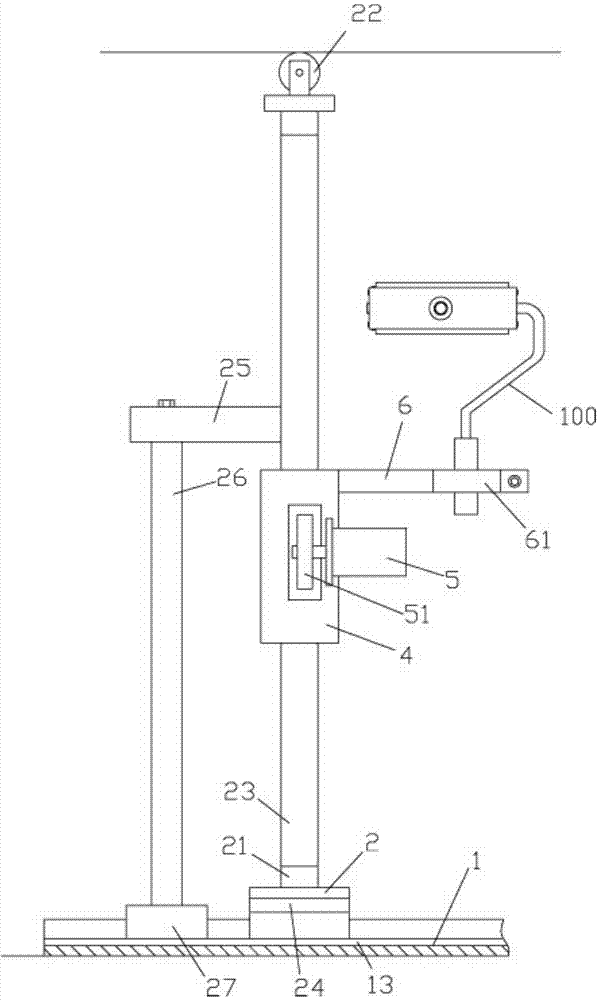

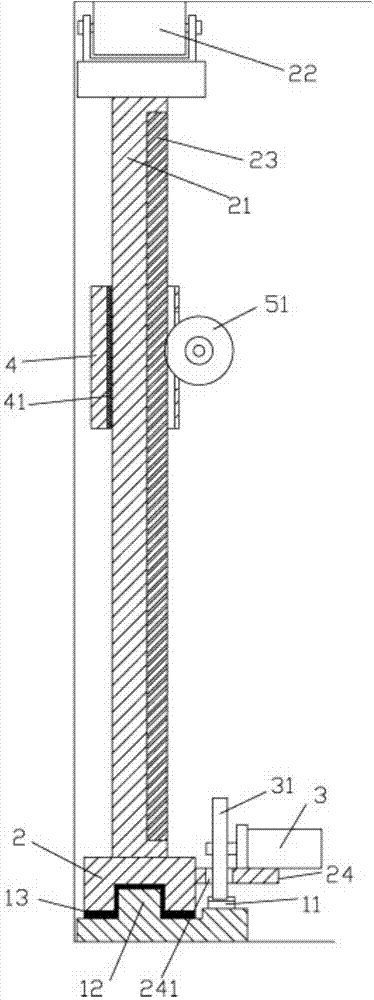

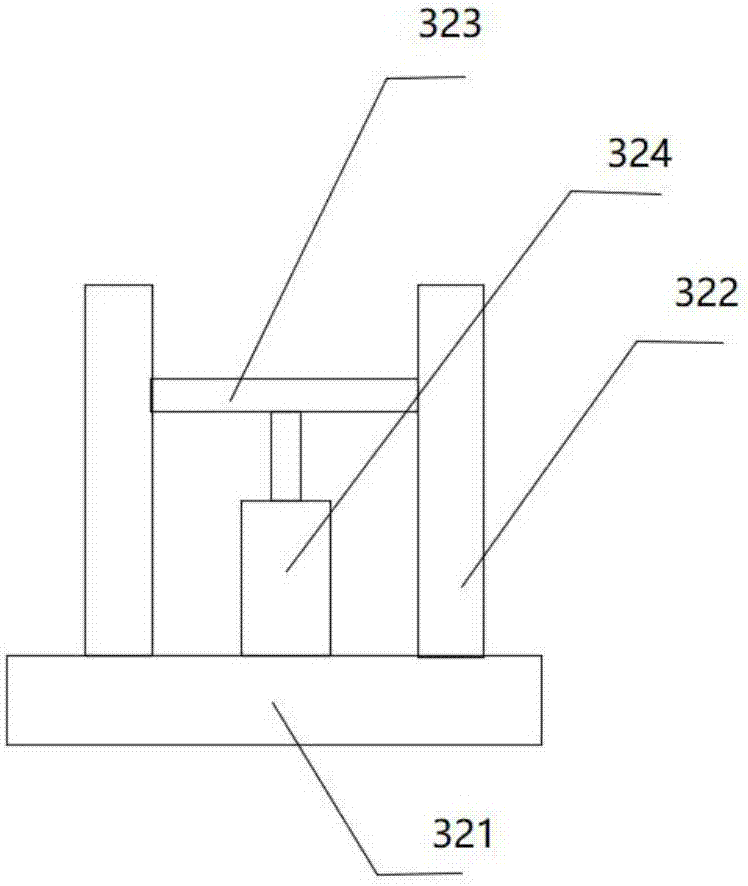

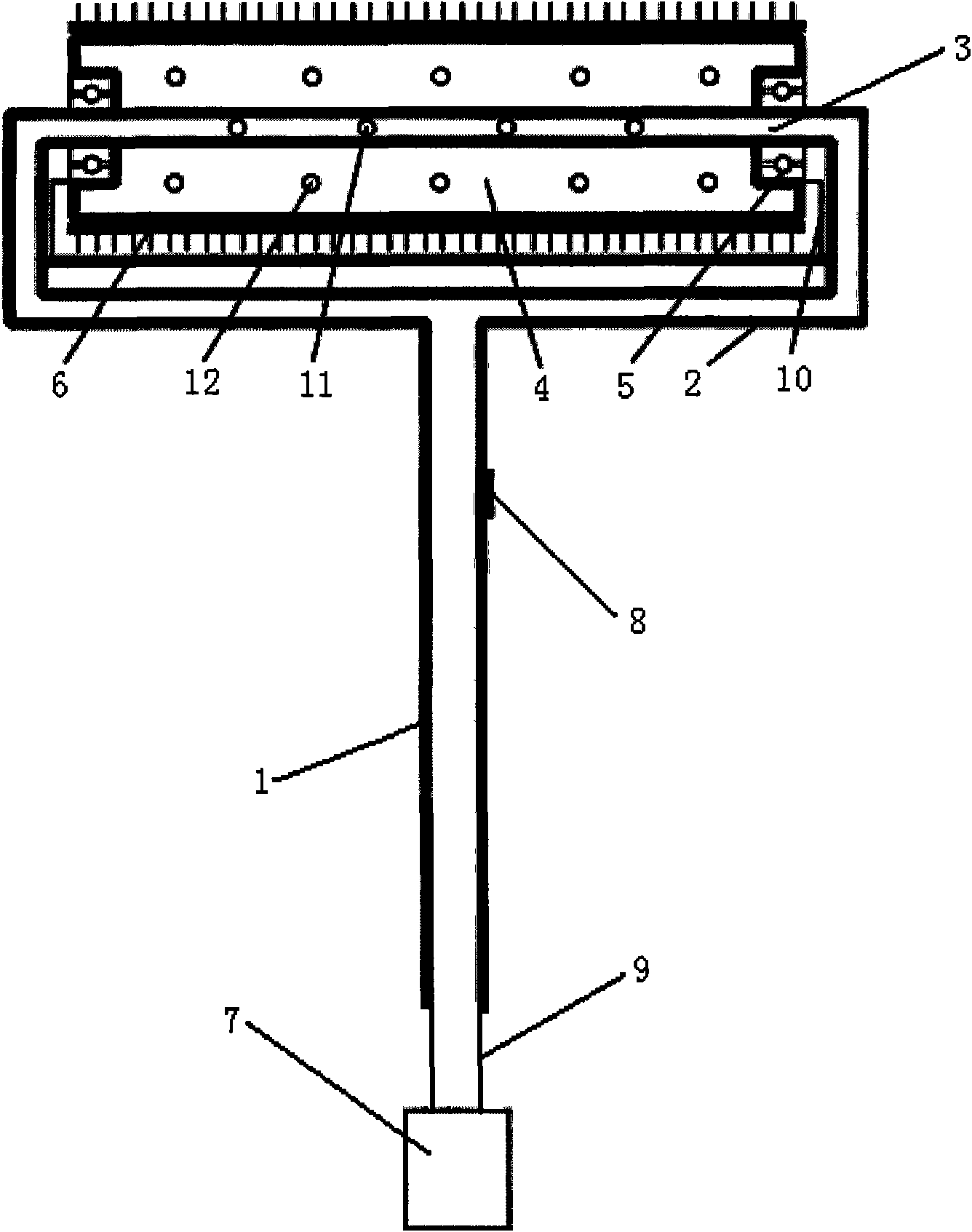

Automatic rolling brush device

InactiveCN104328896AGood effectReduce the amount of manual laborBuilding constructionsElectric machineryBrush device

The invention discloses an automatic rolling brush device, which comprises a lower rail, wherein a lower part slide block is arranged on the lower rail, an operation rack parallel to the lower rail is fixedly arranged on the lower rail, a transverse servo motor is fixedly arranged on the lower part slide block, a transverse operation gear is fixedly arranged on an output shaft of the transverse servo motor, the transverse operation gear is engaged with the operation rack, the top surface of the lower part sliding block is fixedly provided with a vertical transverse rod, the top of the vertical transverse rod is hinged to a support rolling wheel, the support rolling wheel is pressed and leaned on the top surface of a roof, a vertical rack is fixedly arranged in the vertical transverse rod, a sliding sleeve is inserted in the vertical transverse rod in a sleeving way, a vertical servo motor is fixedly arranged on the sliding sleeve, a vertical gear is fixedly arranged on an output shaft of the vertical servo motor, the vertical gear is engaged with the vertical rack, a clamping frame is fixedly arranged on the sliding sleeve, and a rolling brush is fixedly arranged in the clamping frame. The automatic rolling brush device has the advantages that the leftward rightward and upward moving can be automatically carried out, the automatic wall painting can be carried out when a rolling tube brush is arranged on the automatic rolling brush device, the effect is good, and the manual work quantity is reduced.

Owner:ZHEJIANG TONGTAI CONSTR GRP

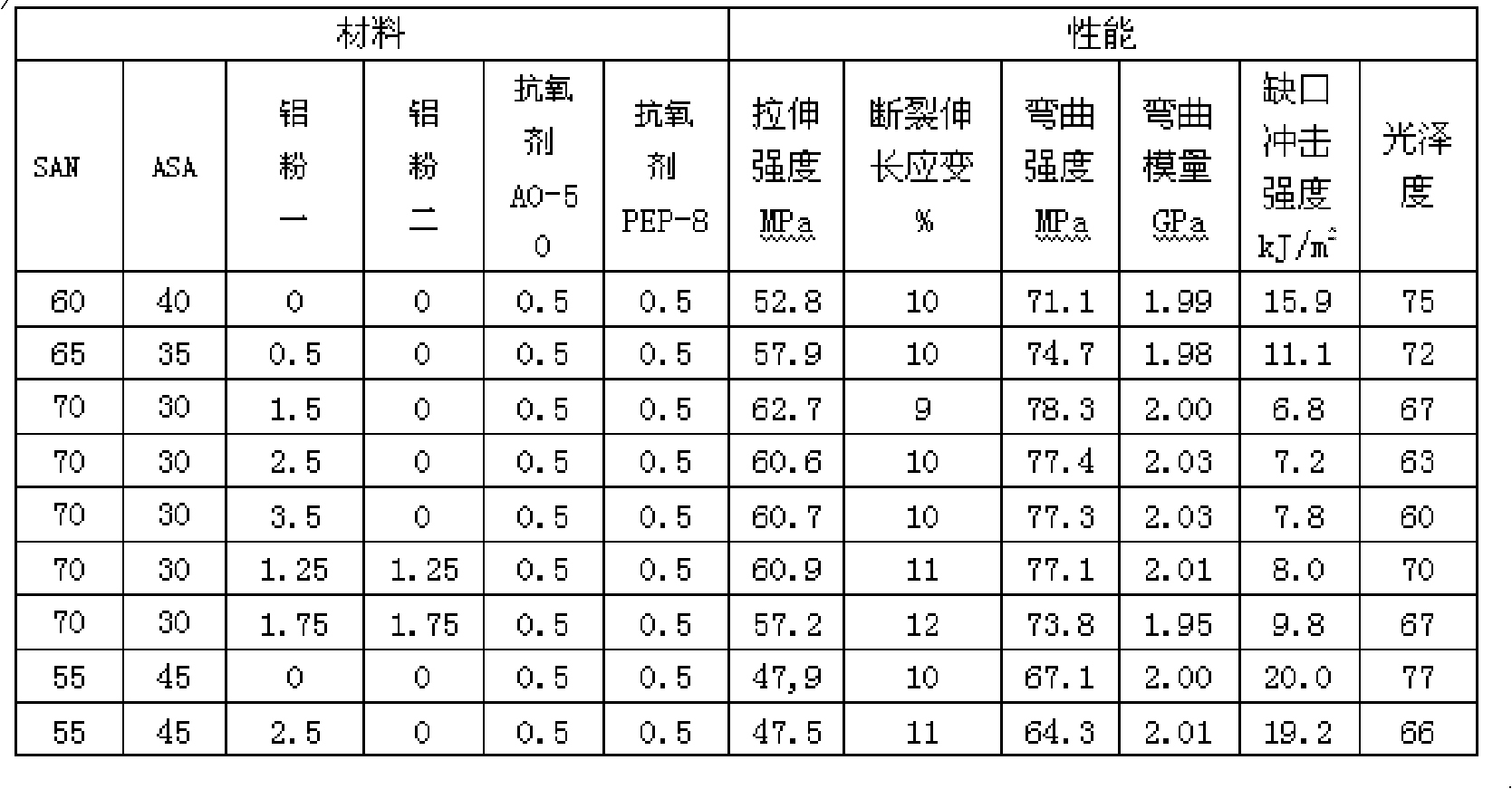

Formula of plastic material with metallic luster and preparation method thereof

The invention discloses a formula of a plastic material with metallic luster and a preparation method thereof. The formula comprises 55 to 70 parts of SAN resin, 30 to 45 parts of ASA resin, 0.5 to 3.5 parts of aluminium powders and 1 part of antioxidant. A product prepared by the method has good metallic luster, high durability, and particularly high lightfast aging performance; the metallic luster cannot fall off or fade; even if the surface of the product is scraped and abraded, the inside of the product still has the metallic luster, and a surface treatment process of spraying metallic flashing paint or metallic surface plating layer on the surface is not needed; therefore, the plastic material is suitable to serve as an automotive workpiece and can also replace the metallic workpiece. The method is simple and easy to implement, can substantially reduce production cost, and has good use effect.

Owner:国家复合改性聚合物材料工程技术研究中心

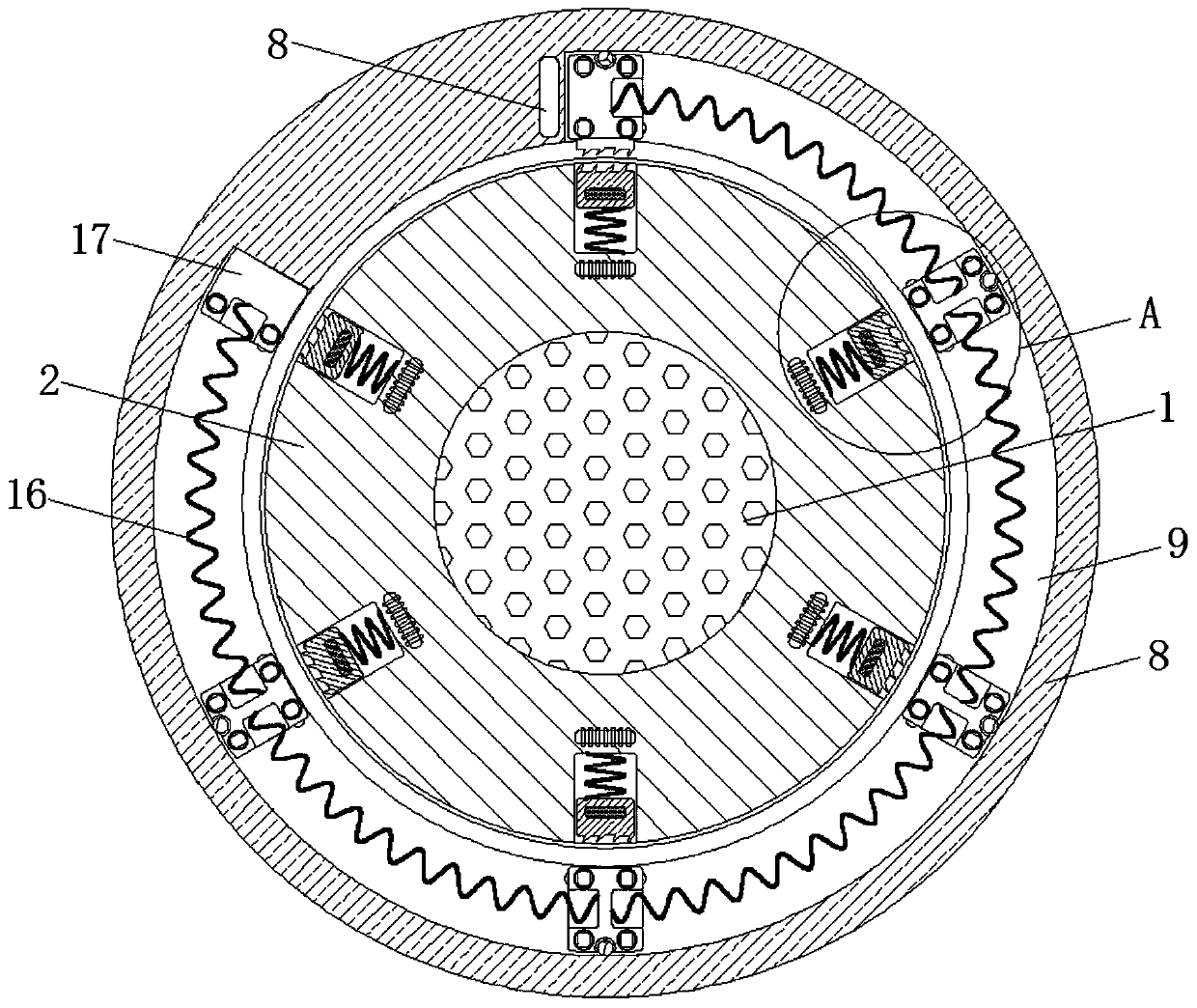

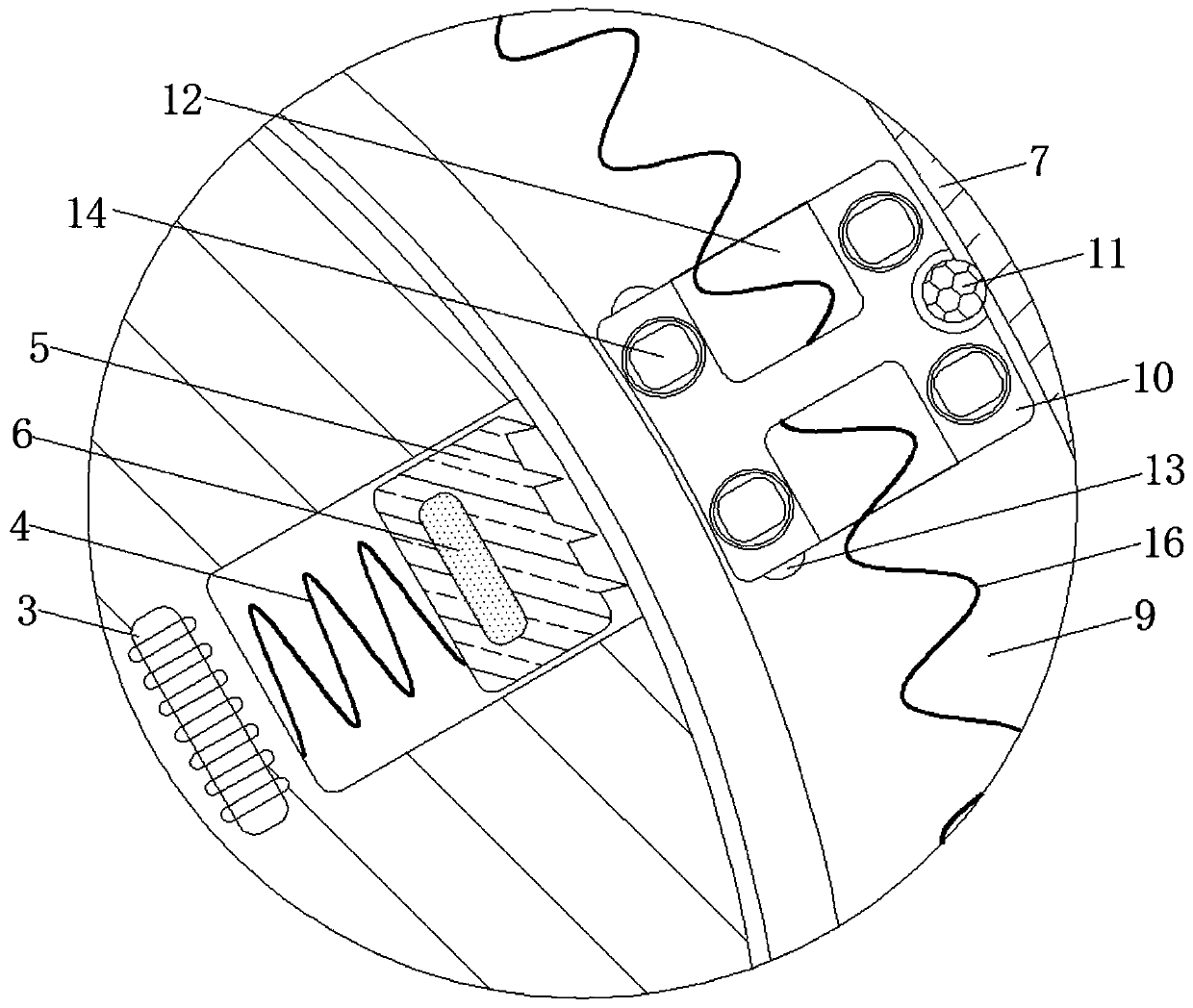

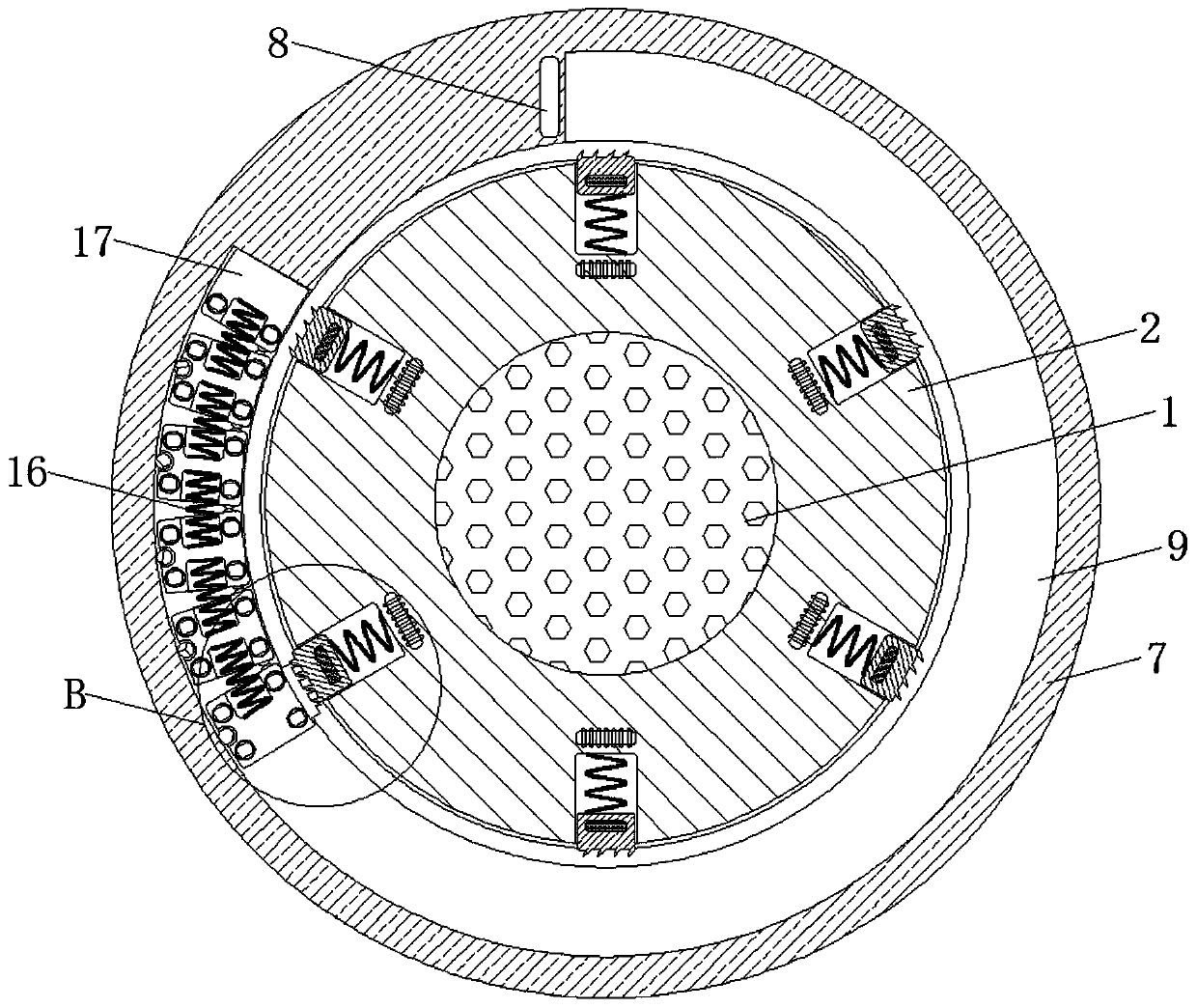

Centrifugal force change-based device for preventing stirring device from stalling

InactiveCN111495264APrevent splashSave paintTransportation and packagingMixer accessoriesElectrical resistance and conductanceEngineering

A centrifugal force change-based device for preventing a stirring device from stalling relates to the technical field of furniture, and comprises a rotating shaft, a turntable is fixedly connected tothe outer side of the rotating shaft, uniformly distributed electromagnets I are fixedly connected to the inner wall of the turntable, and uniformly distributed springs I are fixedly connected to theouter side of the turntable. According to the centrifugal force change-based device for preventing the stirring device from stalling, a clamping block is matched with a movable resistor for use, whenthe rotating shaft rotates and stalls, the clamping block can move outwards under the action of release force, and is clamped to the limiting block to increase the resistance, if stall is too large, the clamping block can drive the movable resistor at the top to gradually rotate rightwards, the larger the stall is, the more the finally electrically connected resistors are, the lower the circuit voltage is, and the lower the rotating speed is, and when the stall reaches the maximum value, all the movable resistors are electrically connected and finally electrically connected with the power-offblock, so that the whole circuit of the stirring device is disconnected, splashing of a coating is effectively avoided, and the coating is effectively saved.

Owner:山东鑫联胜运输有限公司

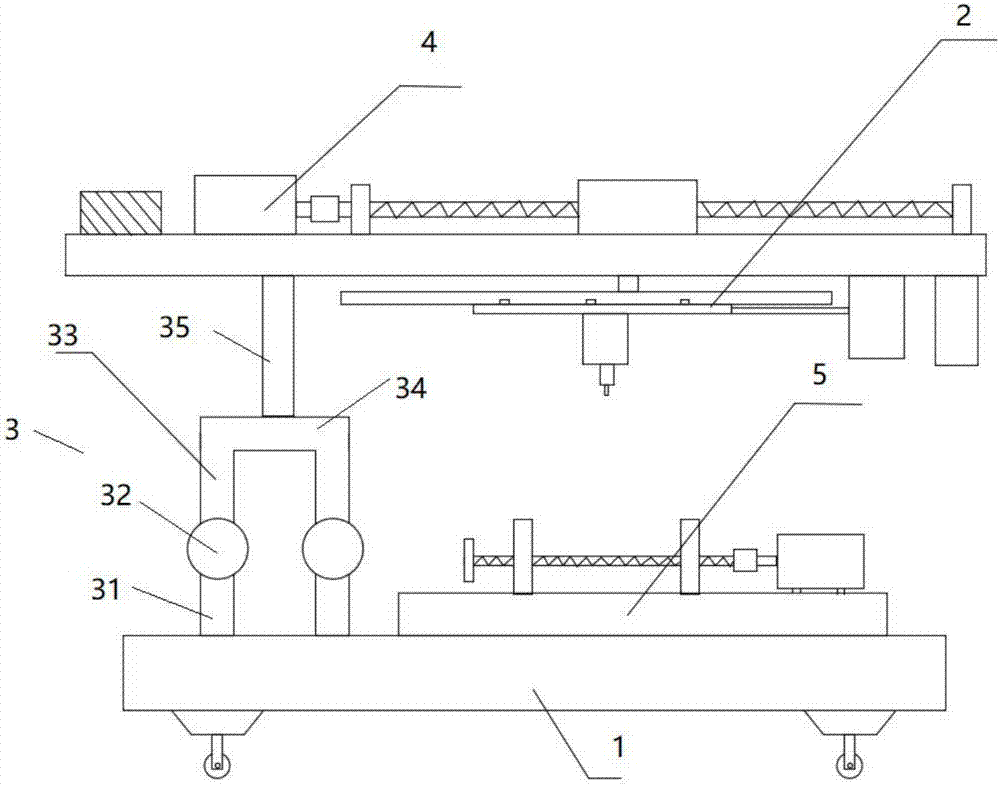

Lifting type coating device

The invention provides a lifting type coating device. The lifting type coating device comprises a main base and a turnover assembly arranged on the right side of the upper surface of the main base. A lifting type supporting assembly is further fixed to the left side of the upper surface of the main base. A horizontal displacement assembly is fixed to the top of the lifting type supporting assembly. A coating assembly is further connected to the lower end of the horizontal displacement assembly. The turnover assembly is located on the left side of the lifting type supporting assembly. According to the lifting type coating device, a to-be-treated part is fixed to the turnover assembly, the coating assembly is firstly used for single face spraying, and coating adjustability is high; after single face spraying is carried out, the to-be-treated part is controlled by a servo motor to rotate, and therefore spraying of the second face is carried out; and the production efficiency can be improved easily, and the spraying effect is good.

Owner:嘉善蓝欣涂料有限公司

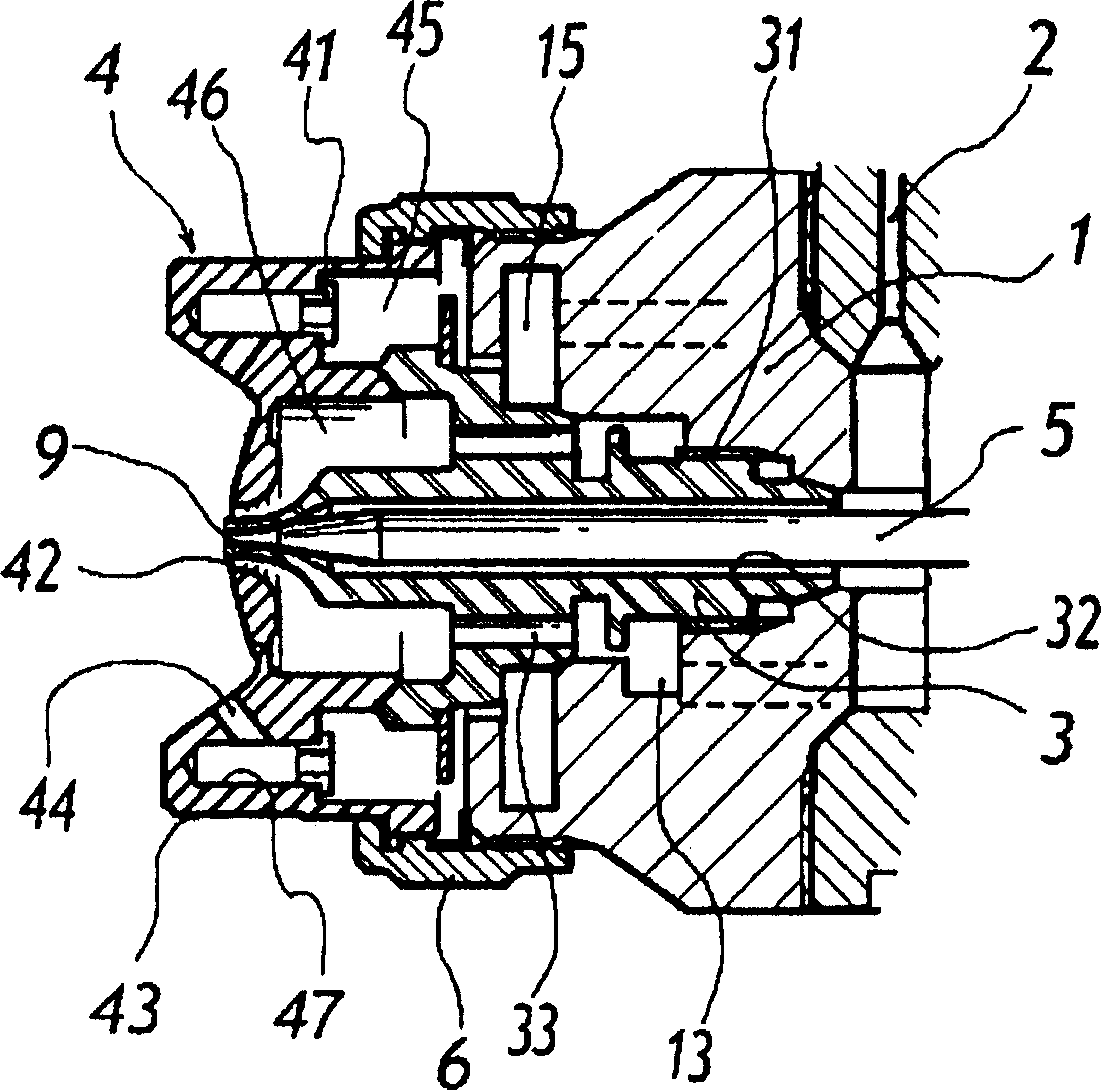

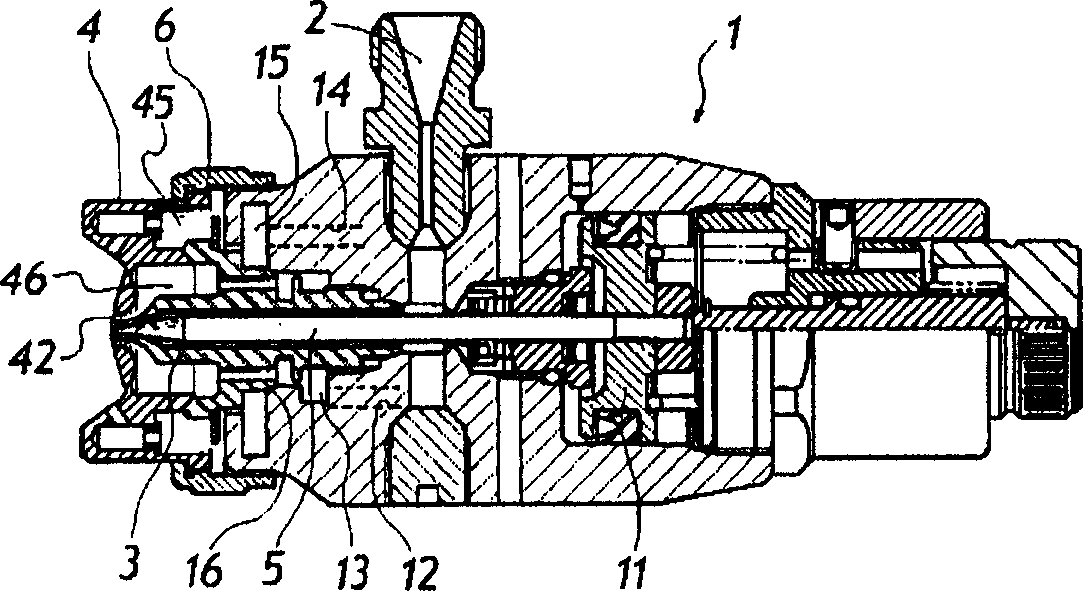

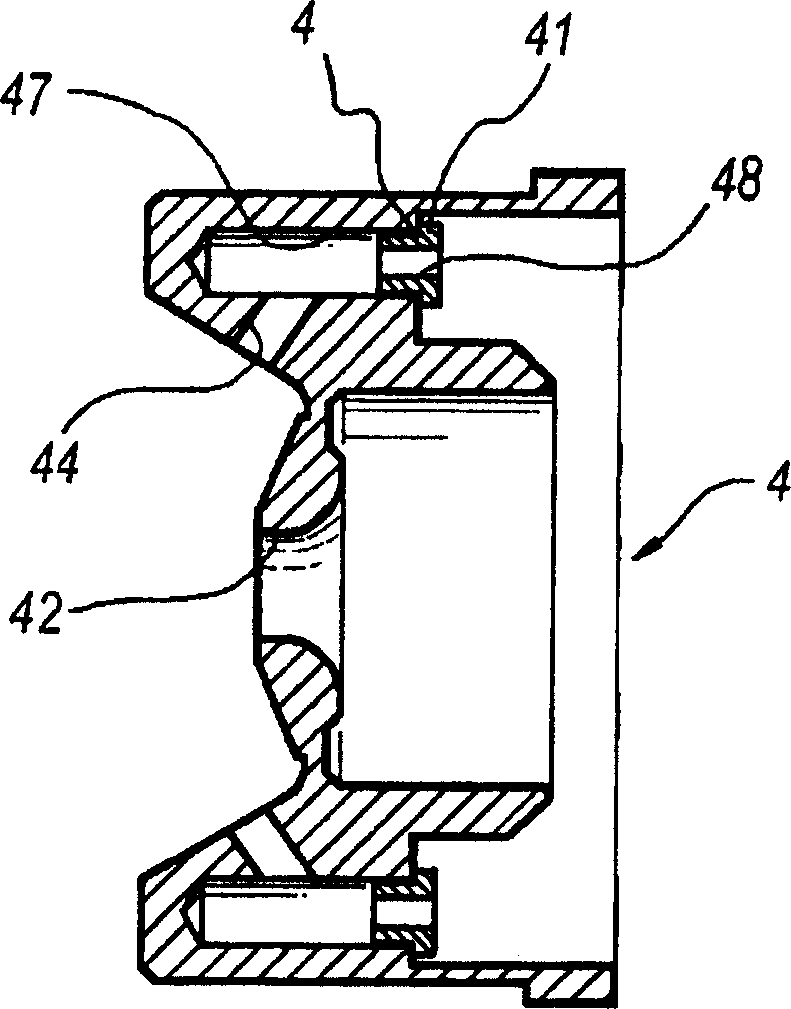

Air atomization air cover for spray gun

ActiveCN1899704AIncrease air velocityReduce speed lossSpray nozzlesLiquid spraying apparatusCoatingCompressed air

The invention provides an atomization apparatus capable of lessening the unevenness of the entire patterned region at the time of spraying and accordingly making the coating thickness distribution uniform in the coated face and easily forming a smooth coating free from disorder of the coating face in an air atomizing spray gun. The air cap is to be used in an air spray gun for atomization with compressed air and has a center air port composing a circular air port in the outer peripheral part of a center coating material jetting port, a pair of corner parts formed symmetrically in the outside of the center air port, and side air ports for forming spraying patterns by jetting air through the corner parts. In the air cap, the surface area of inlet parts of vertical holes formed in the respective corner parts and communicating with the side air ports is made smaller than the surface area of the side air ports. To make the inlet surface area narrower than the vertical hole surface area by narrowing the flow channel surface area, a bush is fitted or caulking is carried out in the circumference of the vertical hole inlets.

Owner:ANEST IWATA CORP

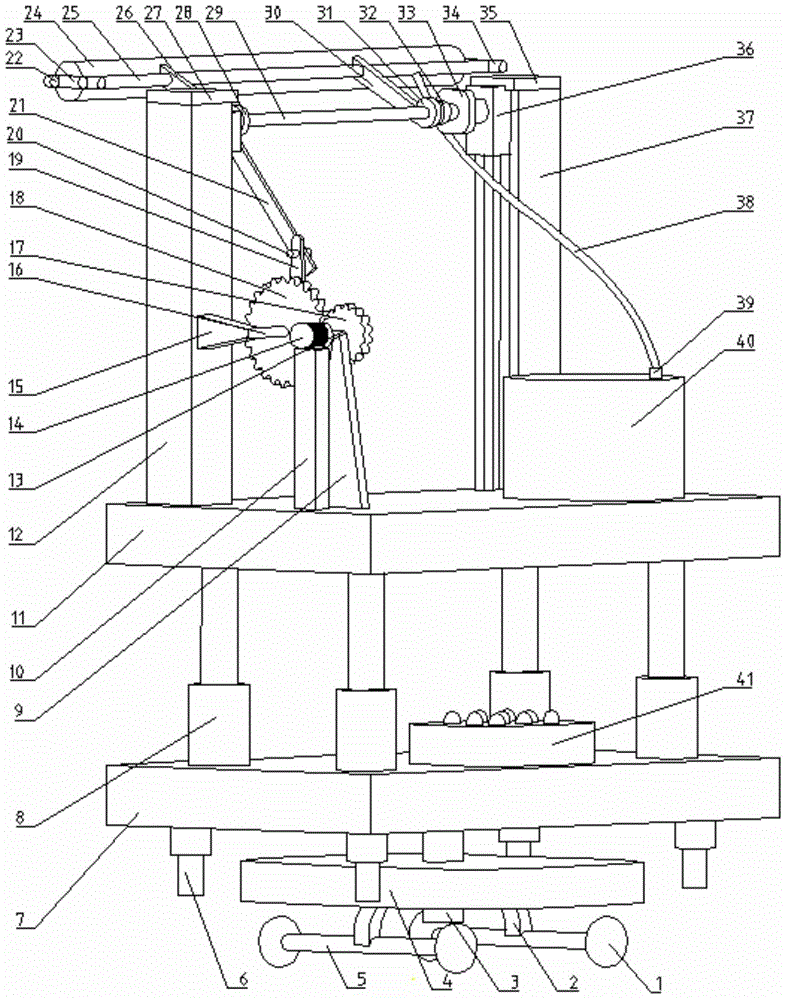

Intelligent lifting wall painting machine which is driven by crank and slider, fixed at step length and adjustable in work range

InactiveCN104533063AFastIncrease the speed of painting wallsBuilding constructionsHydraulic cylinderSlurry

The invention discloses an intelligent lifting wall painting machine which is driven by a crank and a slider, fixed at step length and adjustable in work range. The intelligent lifting wall painting machine comprises a slurry spraying barrel and a roller brush, wherein the slurry spraying barrel is connected with a paint bucket, a vertical pillar is arranged on a second base, a driving fixed gear and a driven fixed gear which are mutually meshed are arranged on the lower portion of the vertical pillar, the driving fixed gear is driven by a motor, a shaft provided with the driven fixed gear is fixedly connected with the crank hinged to a connecting rod, the connecting rod is hinged to the slider, the slider is provided with a second rotary shaft, the second rotary shaft is fixedly connected with a rotary disc, the slurry spraying barrel is fixedly connected with the rotary disc, the two ends of the slurry spraying barrel are each provided with a connecting rod, and a roller brush shaft is arranged between the two connecting rods and provided with the roller brush; a first base and the second base are connected through a second hydraulic cylinder, a first hydraulic cylinder is installed at the bottom of the first base, the second rotary shaft is fixed in the middle of the first base and connected with a rotary plate, and a wheel is installed at the bottom of the rotary plate. The height of the roller brush can be automatically adjusted, the wall painting speed is improved, and it is guaranteed that wall surfaces at all the heights can be painted.

Owner:GUANGXI UNIV

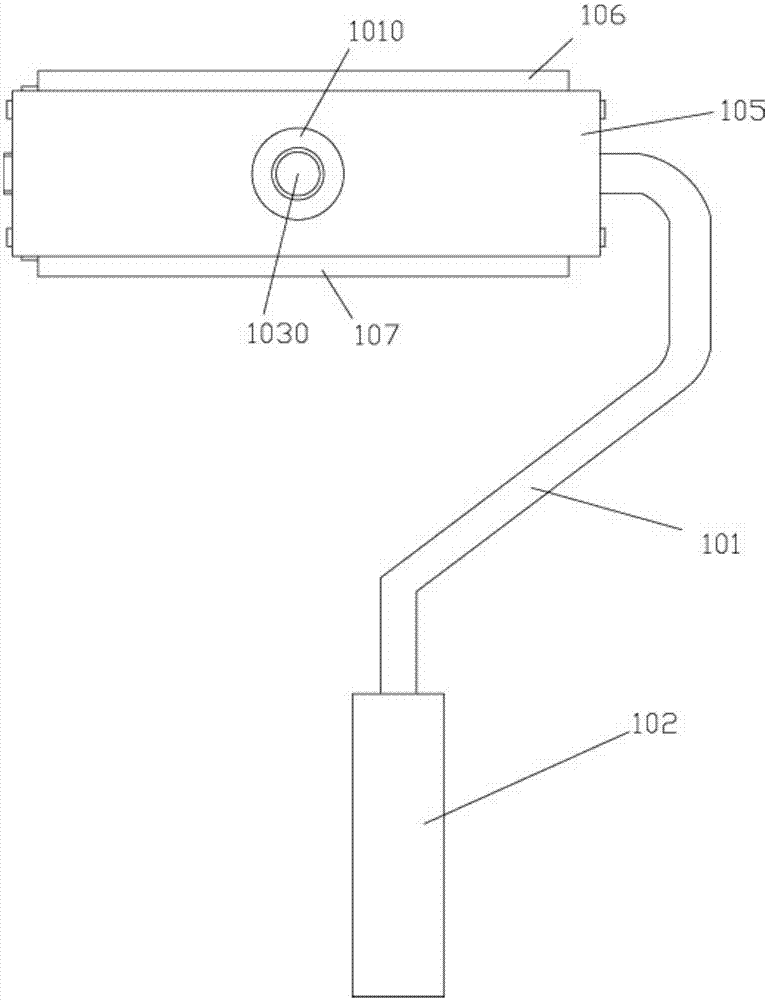

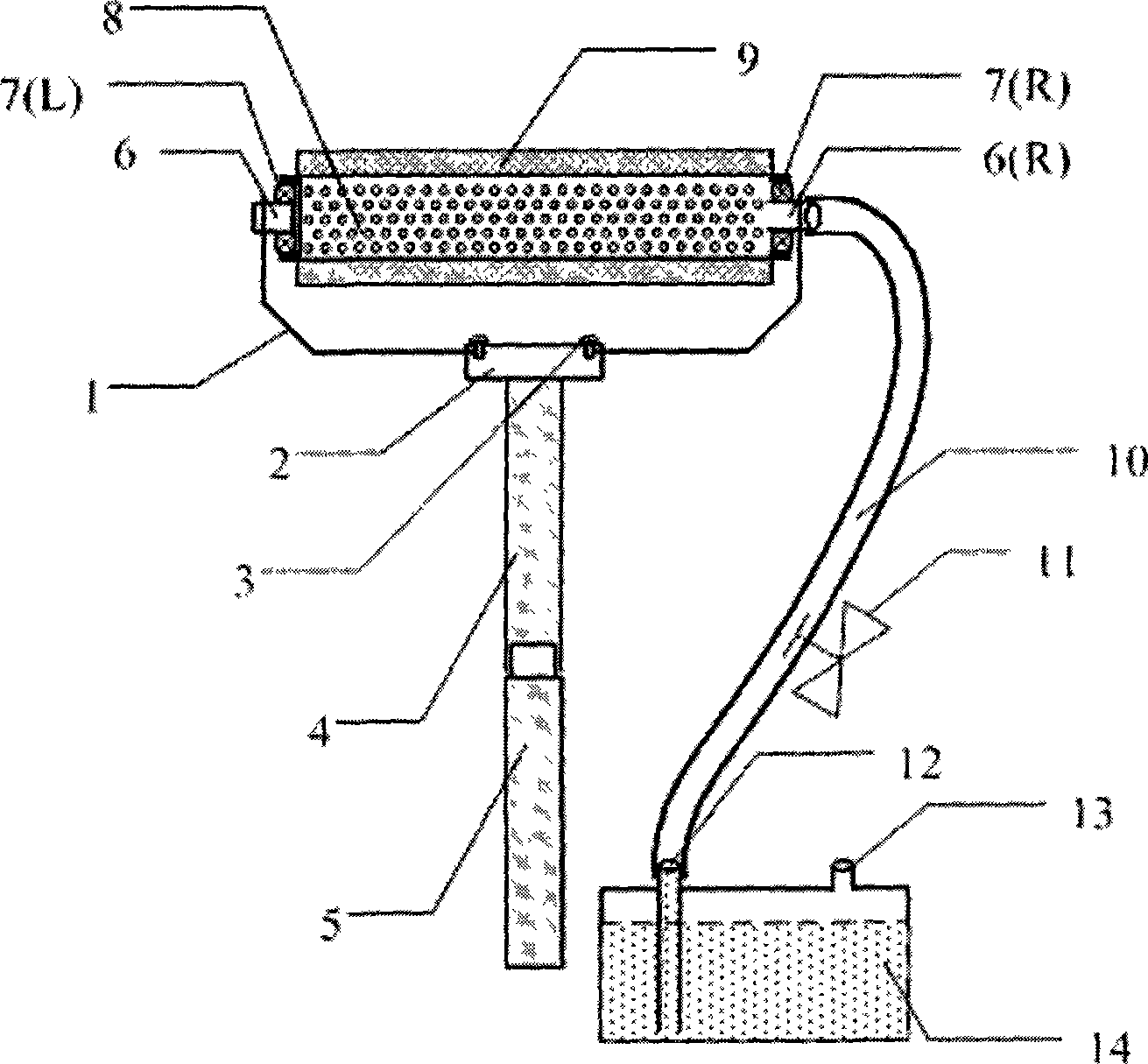

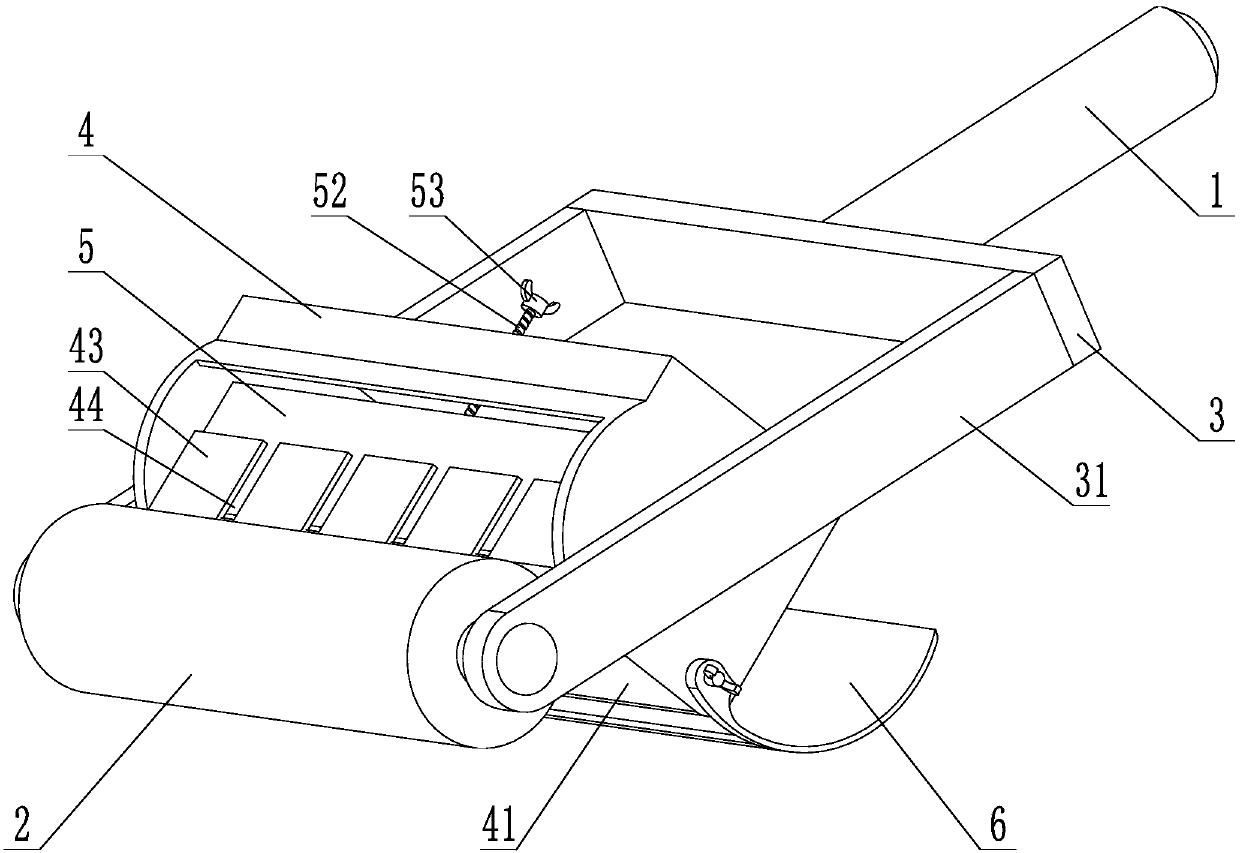

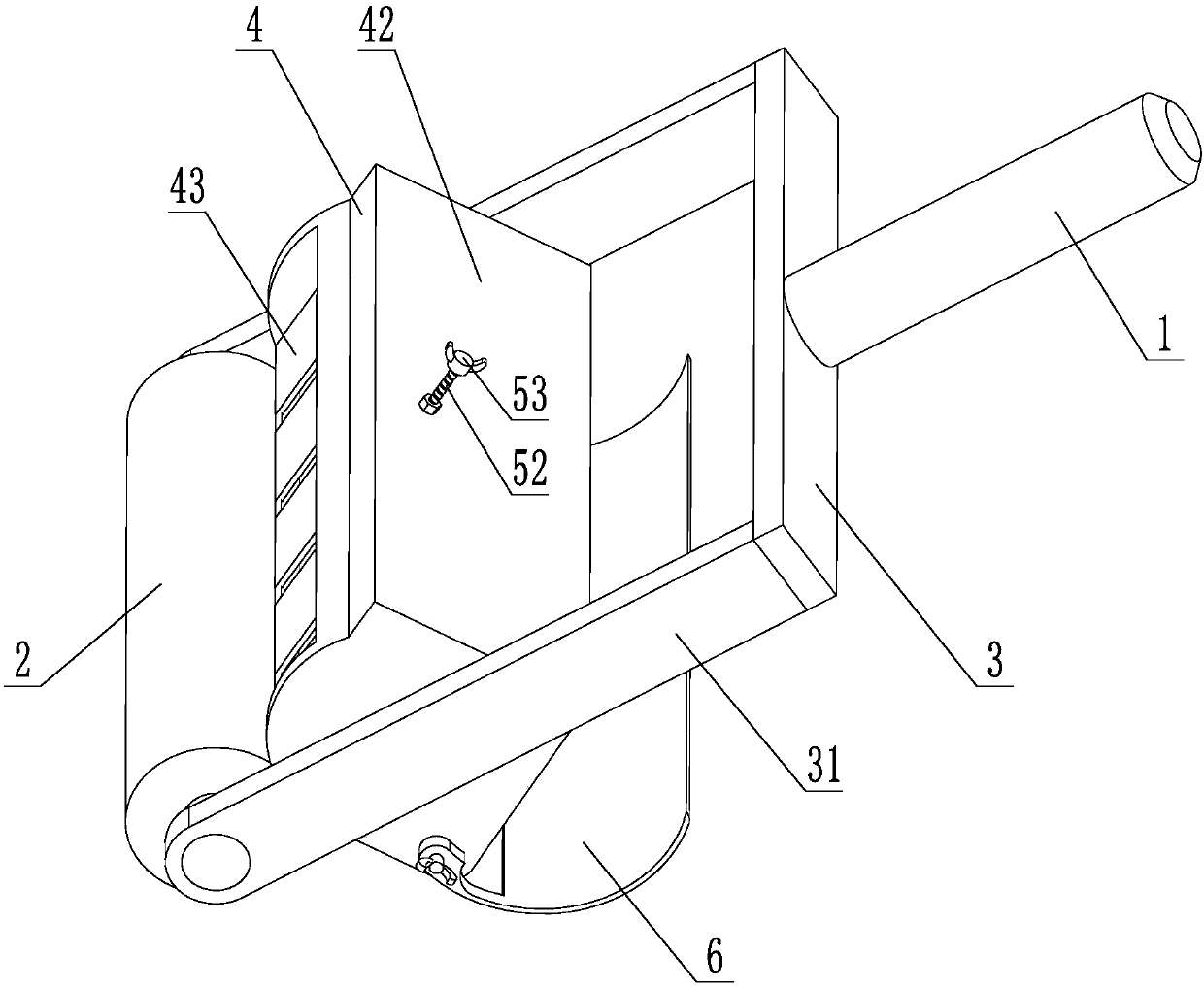

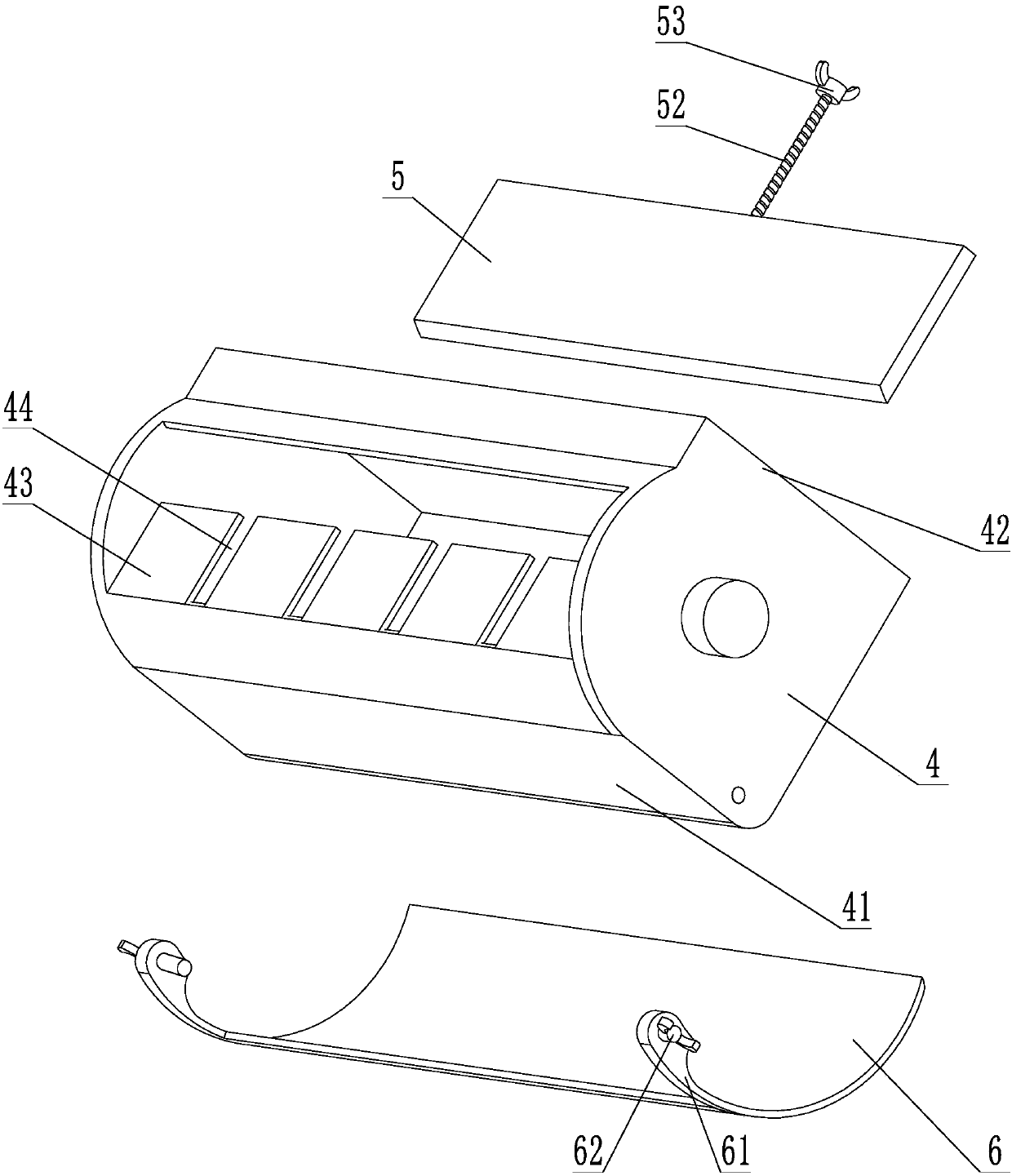

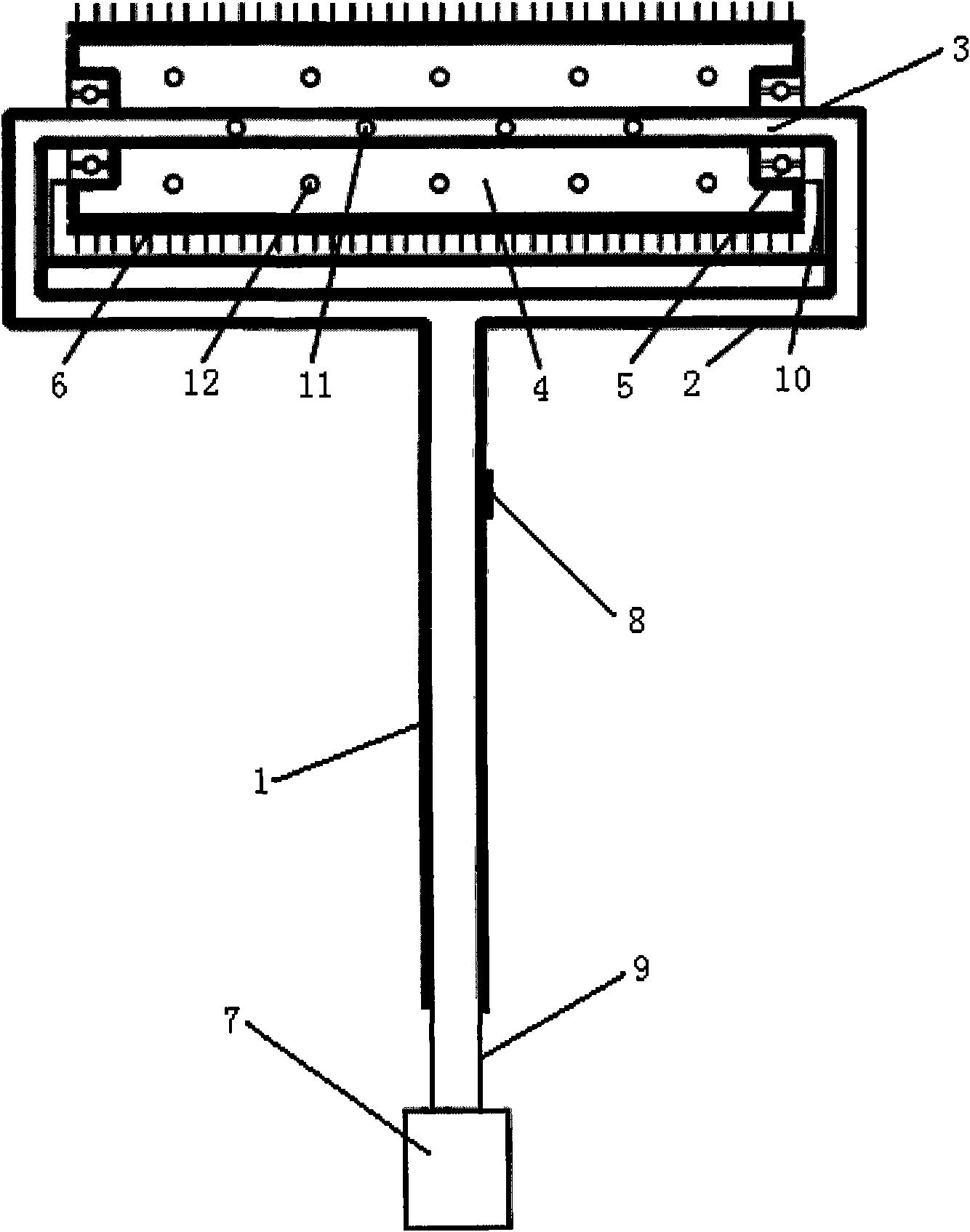

Pneumatic material feeding roller brush

InactiveCN101382010AUniform outputQuality improvementBuilding constructionsEngineeringAtmospheric pressure

The invention belongs to a roll painting device, and in particular relates to a pneumatic loading roller brush. The aim of the invention is to provide a highly-efficient roll painting device integrating the functions of automatic loading and roll painting. The pneumatic loading roller brush comprises a bearing frame, a cylindrical roller, a roller enwrapping layer and a handle, wherein round through holes are distributed all over the cylindrical roller, a common bearing is embedded on the left end of the cylindrical roller, a sealed bearing is embedded on the right end of the cylindrical roller, inner rings of the common bearing and the sealed bearing are in small interference connection with a hollow shaft which is fixedly connected with the bearing frame, the outer port of the right end of the hollow shaft is sleeved with a material-injecting hose one end of which is sleeved on a discharge port of a pneumatic material storage bucket, and the material-injecting hose is provided with a flow regulating valve for controlling the flow rate of the paint. The roll painting device has the advantage of integrating the functions of automatic loading and roll painting, not only can improve the working efficiency, relieve the labor intensity, save paint and reduce environmental pollution, but also can keep the even material-discharging quantity by keeping the roller brush constant due to the stability of the liquid pressure in the cylindrical roller, thereby improving the roll painting quality.

Owner:樊民革

Inner wall environmental protection water-proof putty

the invention discloses an environmental-protective water-proof putty of internal wall, which consists of base material and powder material, wherein the weight rate of base material and powder material is 1: 5-8; the base material contains 40-50% modified polyvinyl alcohol, 40-50% fiber solution and 5-10% water; the powder material concludes 15-30% white cement and 50-70% compound filler. the invention improves constructing efficiency, which saves paint and increases hiding power, fullness and leveling property.

Owner:ZHEJIANG ZHONGCHENG CONSTR GRP

Rolling painting brush

InactiveCN107605129AImprove the efficiency of wall paintingExtended use timeBuilding constructionsAcute angleMechanical engineering

The invention relates to a rolling painting brush. The rolling painting brush comprises a brush handle, a brush roller and a U-shaped connecting frame connected with the brush handle and the brush roller. The material bin used for storing paint is connected between two side rods of the connecting frame. An included angle formed between the opening direction of the material bin and the extending direction of the side rods towards the brush roller is an acute angle. An opening of the nearest side plate, close to the brush roller, of the material bin abuts against the brush roller. Baffles are arranged in the opening of the nearest side plate at intervals. Blanking openings are formed between the baffles. The baffles face the direction of the far side plate which is opposite to the near sideplate. The far side plate is connected with a gate which can movably regulate the size of the blanking openings through a connecting assembly. The gate is attached to the inner side surfaces of the baffles. By means of the rolling painting brush, feeding can be continuously conducted on the rolling painting brush in the process of wall paint brushing, again and again material dipping is not needed, a larger area can be brushed by once paint feeding, and the efficiency of wall brushing is greatly improved.

Owner:北京城建长城建设集团有限公司

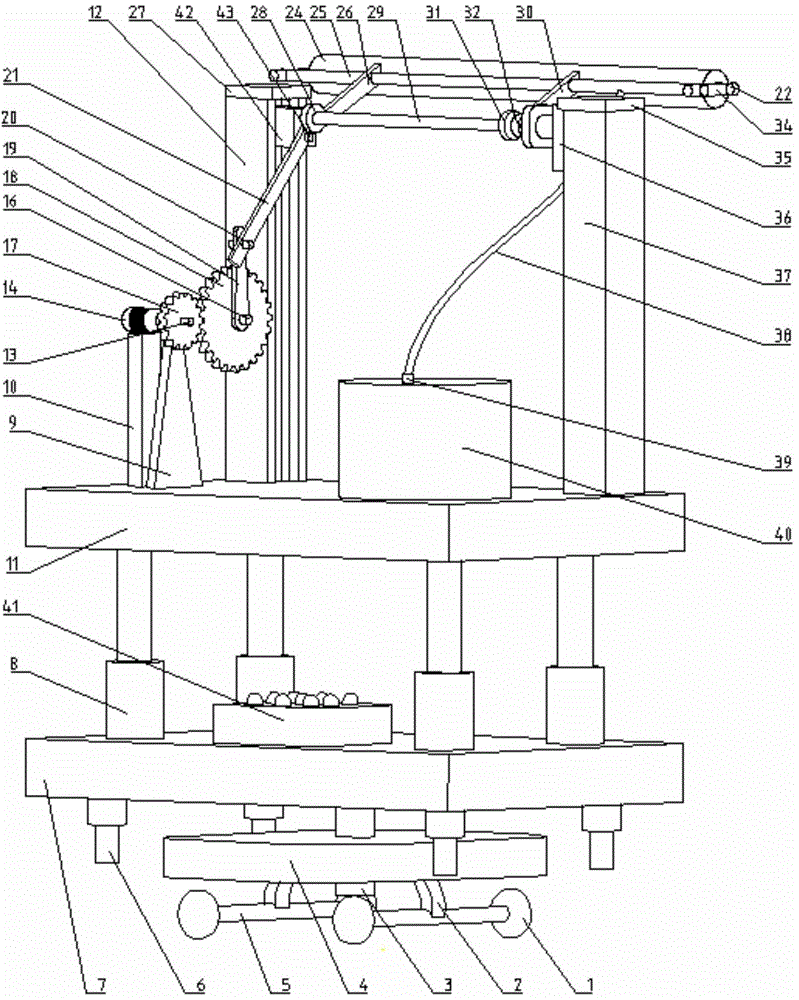

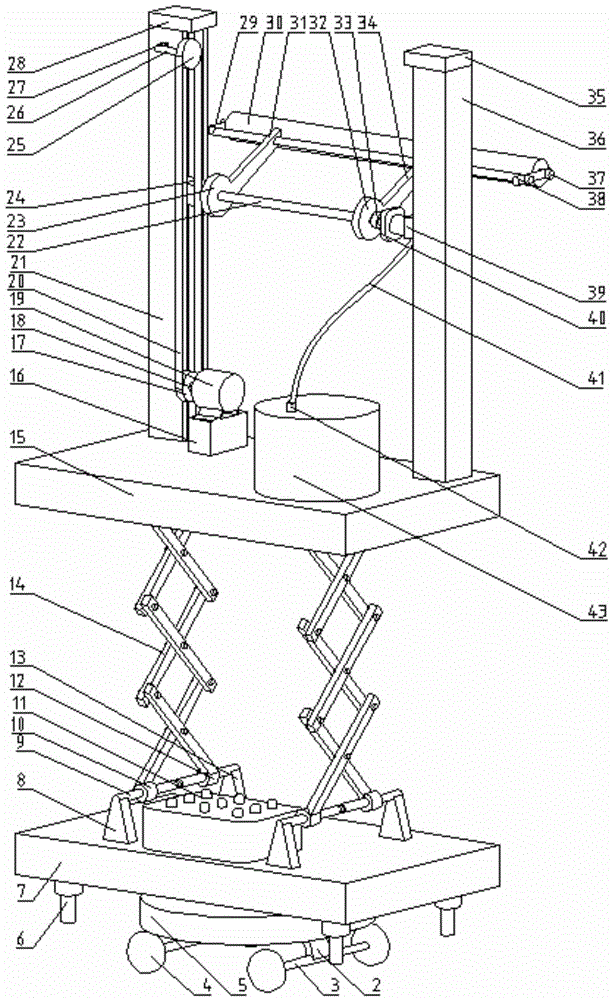

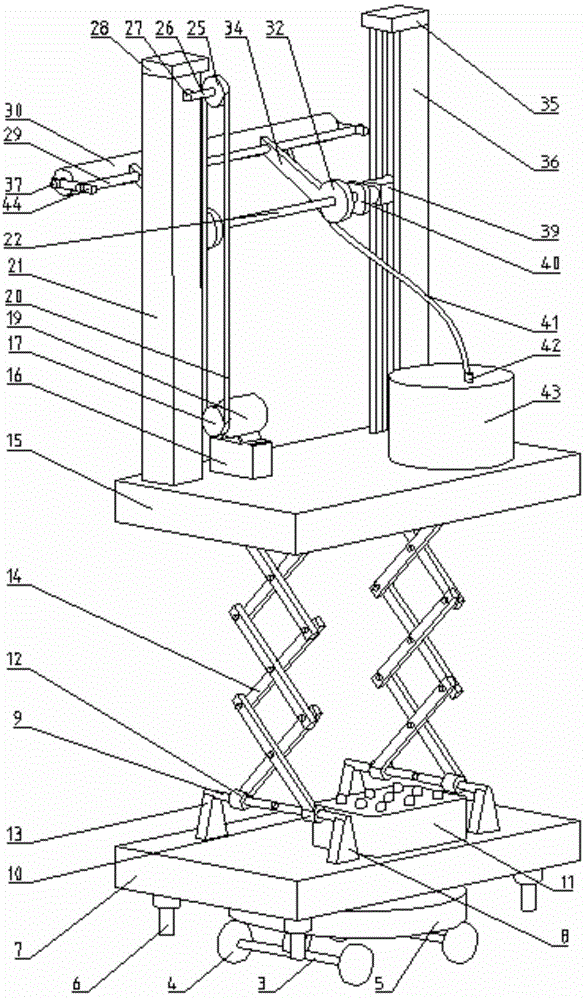

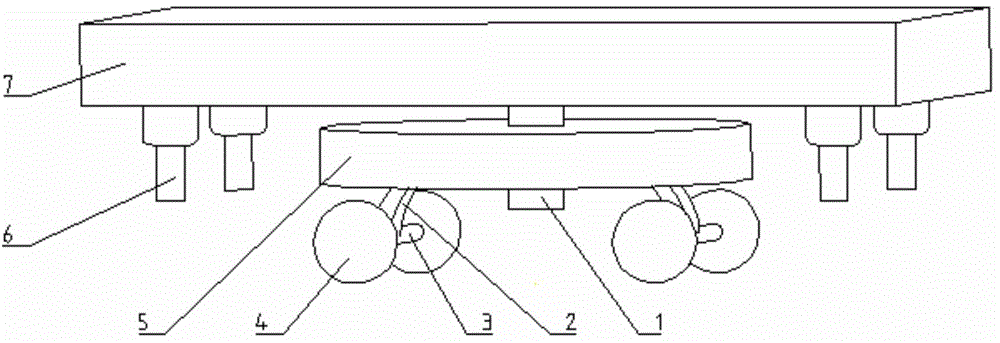

Intelligent shear type lifting wall painting machine fixed in step length and adjustable in working range

The invention discloses an intelligent shear type lifting wall painting machine fixed in step length and adjustable in working range. The intelligent shear type lifting wall painting machine comprises a first base, a second base, a concrete spraying barrel and a rolling brush, wherein the concrete spraying barrel is connected with a coating bucket, a column is fixed on the second base, and a driving chain wheel is arranged at the lower portion of the column and driven by a motor. A driven chain wheel is installed at the upper portion of the column, the driving chain wheel and the driven chain wheel are connected through a chain, a slide block is fixed to the chain, a second rotary shaft is installed on the slide block, a turntable is fixed to the second shaft, the concrete spraying barrel is fixedly connected with the turntable, connecting rods are fixed to two ends of the concrete spraying barrel respectively, a rolling brush shaft is fixed between the two connecting rods, and the rolling brush is installed on the rolling brush shaft. The first base is installed under the second base and is connected with the second base through a shear type lifting mechanism. The first base 7 can achieve longitudinal and transverse walking. The height of the rolling brush can be automatically adjusted, the wall brushing speed is improved, and the wall face at all heights can be brushed.

Owner:GUANGXI UNIV

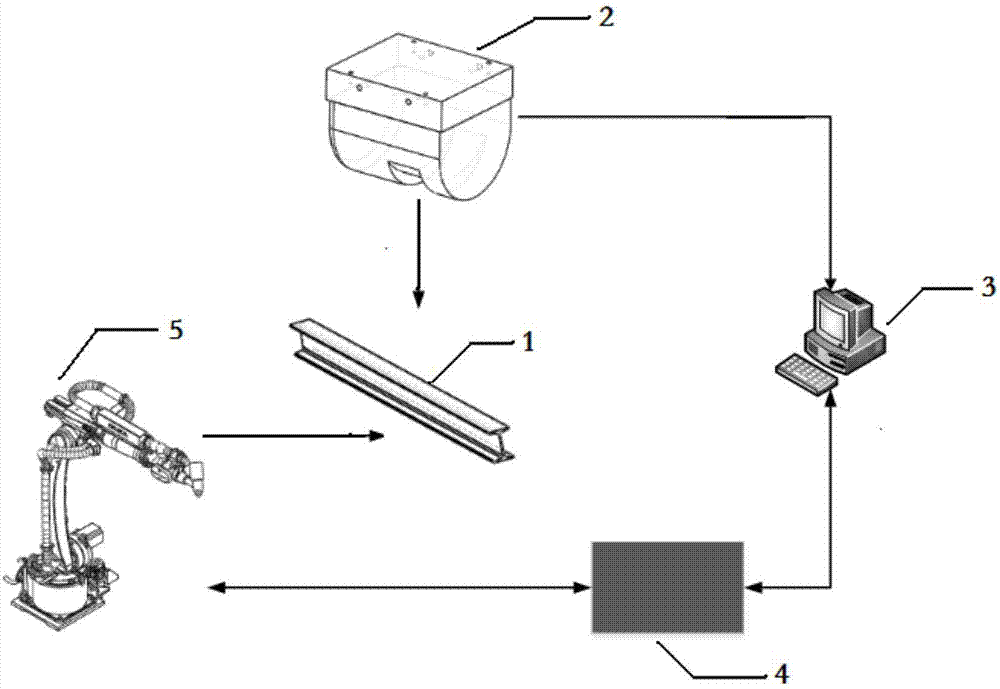

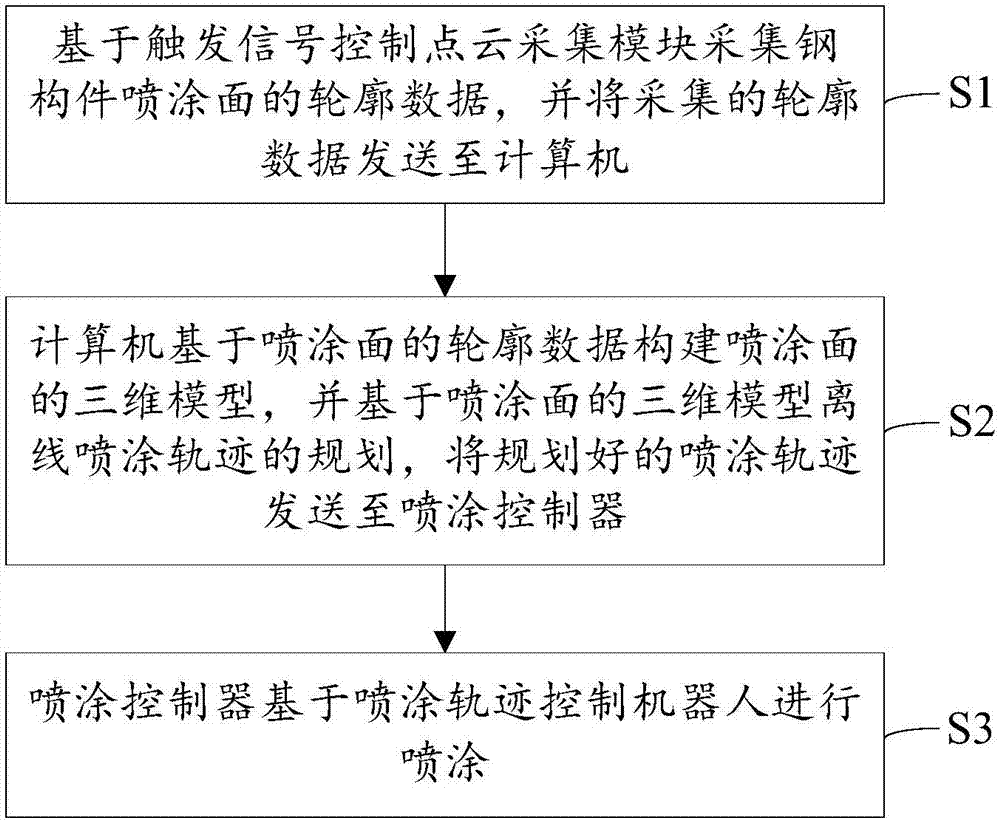

Steel component spraying system based on three-dimensional vision technology

ActiveCN107983570ARealize identificationAchieve acquisitionSpraying apparatus3D modellingPoint cloudRadar

The invention belongs to the technical field of robot spraying, and provides a steel component spraying system based on three-dimensional vision. The system comprises a point cloud collection module,a computer and a spraying controller. The point cloud collection module collects outline data of a steel component spraying face and sends the collected outline data to the computer. The computer constructs a three-dimensional model of the steel component spraying face on the basis of the outline data, plans the spraying track offline on the basis of the three-dimensional model of the spraying face and sends the generated spraying track to the spraying controller. The spraying controller controls a spraying robot to conduct spraying according to the planned spraying track. By means of the steel component spraying system based on the three-dimensional vision technology and provided in the embodiment, recognition of different types of steel components and related spraying position information obtaining can be rapidly and accurately obtained; in addition, a laser radar sensor is wide in measurement range, the three-dimensional information of an object can be accurately obtained, stabilityis quite high, robustness is good, and influences from the outside environment are not likely to happen.

Owner:WUHU HIT ROBOT TECH RES INST

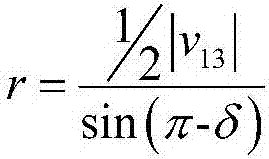

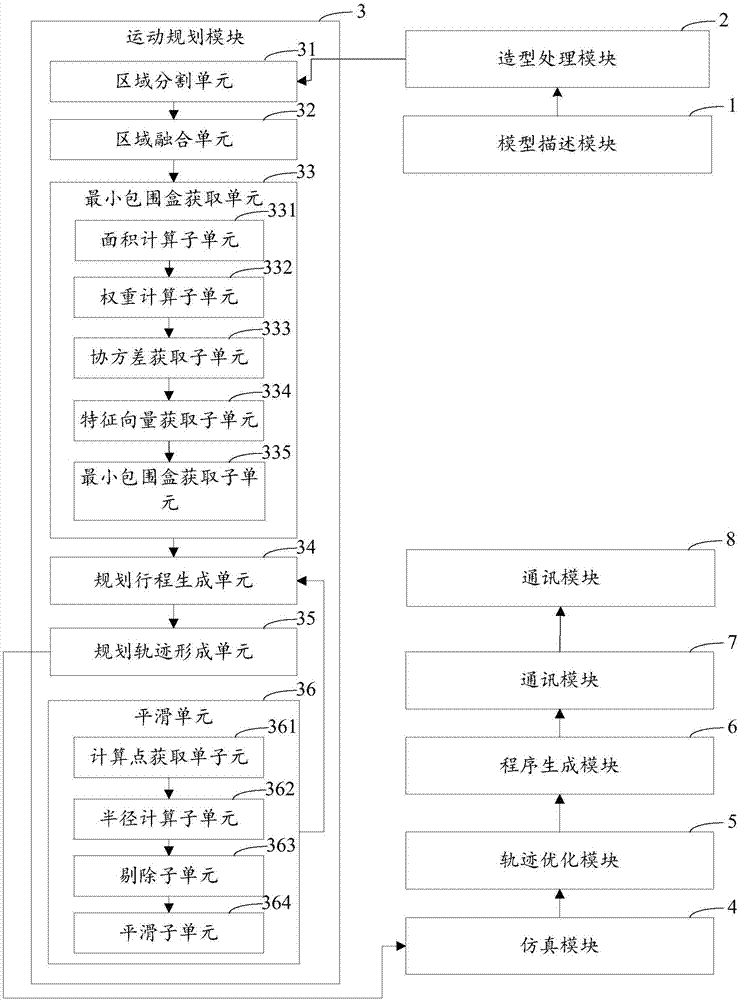

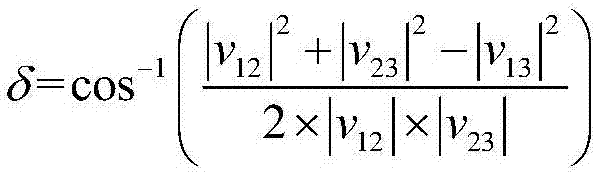

Complicated workpiece track planning and simulating system on basis of ROS (robot operating system) platforms

The invention is applicable to the field of robot track planning technologies, and provides a complicated workpiece track planning and simulating system on the basis of ROS (robot operating system) platforms. The complicated workpiece track planning and simulating system comprises a model description module, a shape processing module, a movement planning module, a simulating module, a track optimizing module, a program generating module and a communication module. Imported three-dimensional workpiece models and three-dimensional robot models can be transformed into URDF data formats by the model description module; workpieces can be divided into triangular patches on the basis of grid algorithms by the shape processing module, and triangular patch information can be extracted by the shapeprocessing module; robot movement tracks can be planned on the basis of the triangular patch information of selected regions by the movement planning module; movement of three-dimensional robots and end actuators on the basis of planned tracks can be graphically displayed by the simulating module, and operation data of the end actuators can be given by the simulating module; the planned tracks canbe optimized via man-machine interactive interfaces on the basis of simulation results by the track optimizing module; optimized robot movement tracks can be transformed into program language by theprogram generating module; the program language generated by the program generating module can be transmitted to robot controllers by the communication module. The complicated workpiece track planningand simulating system has the advantage that tracks of the complicated workpieces can be planned by the complicated workpiece track planning and simulating system.

Owner:WUHU HIT ROBOT TECH RES INST

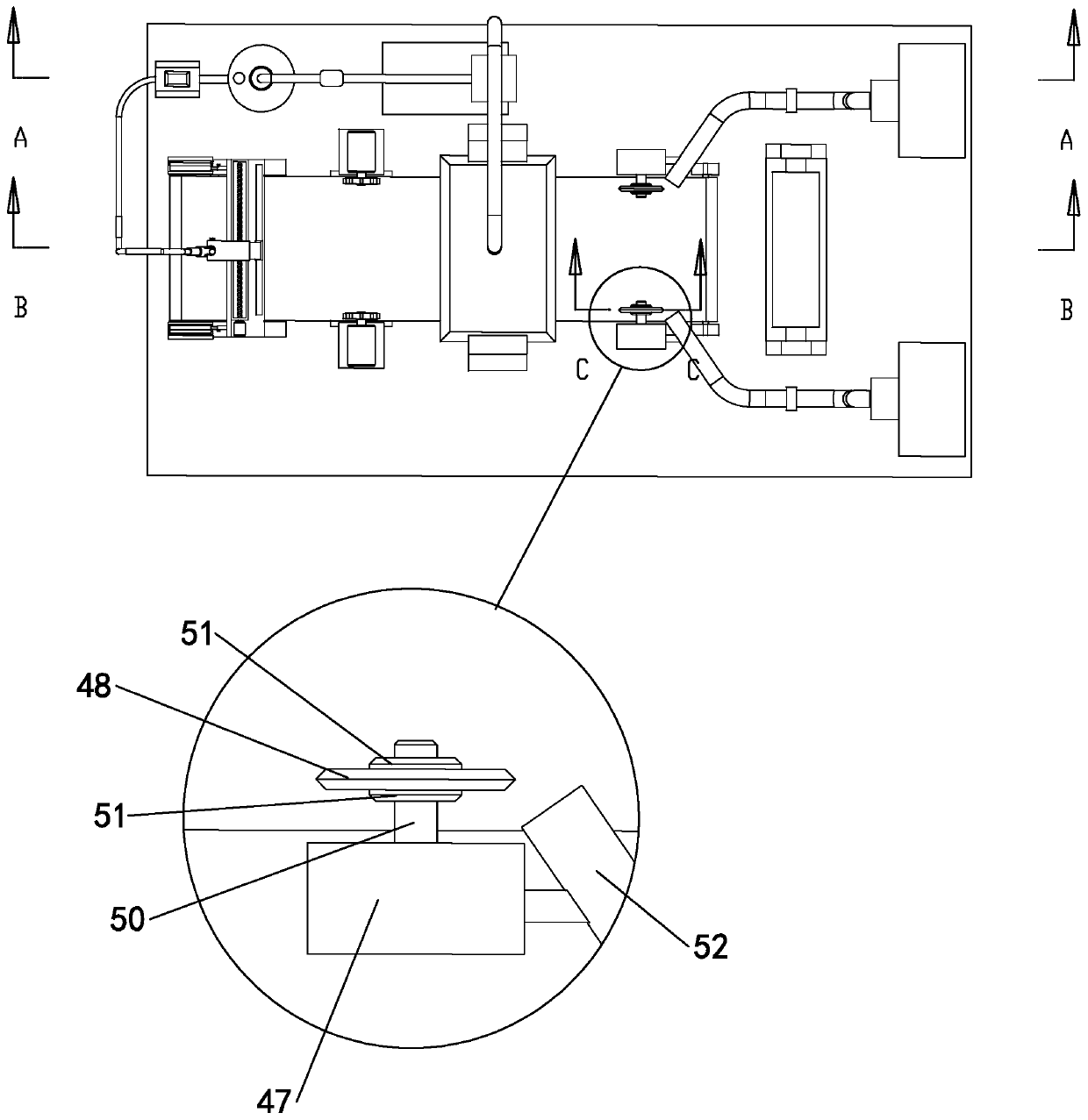

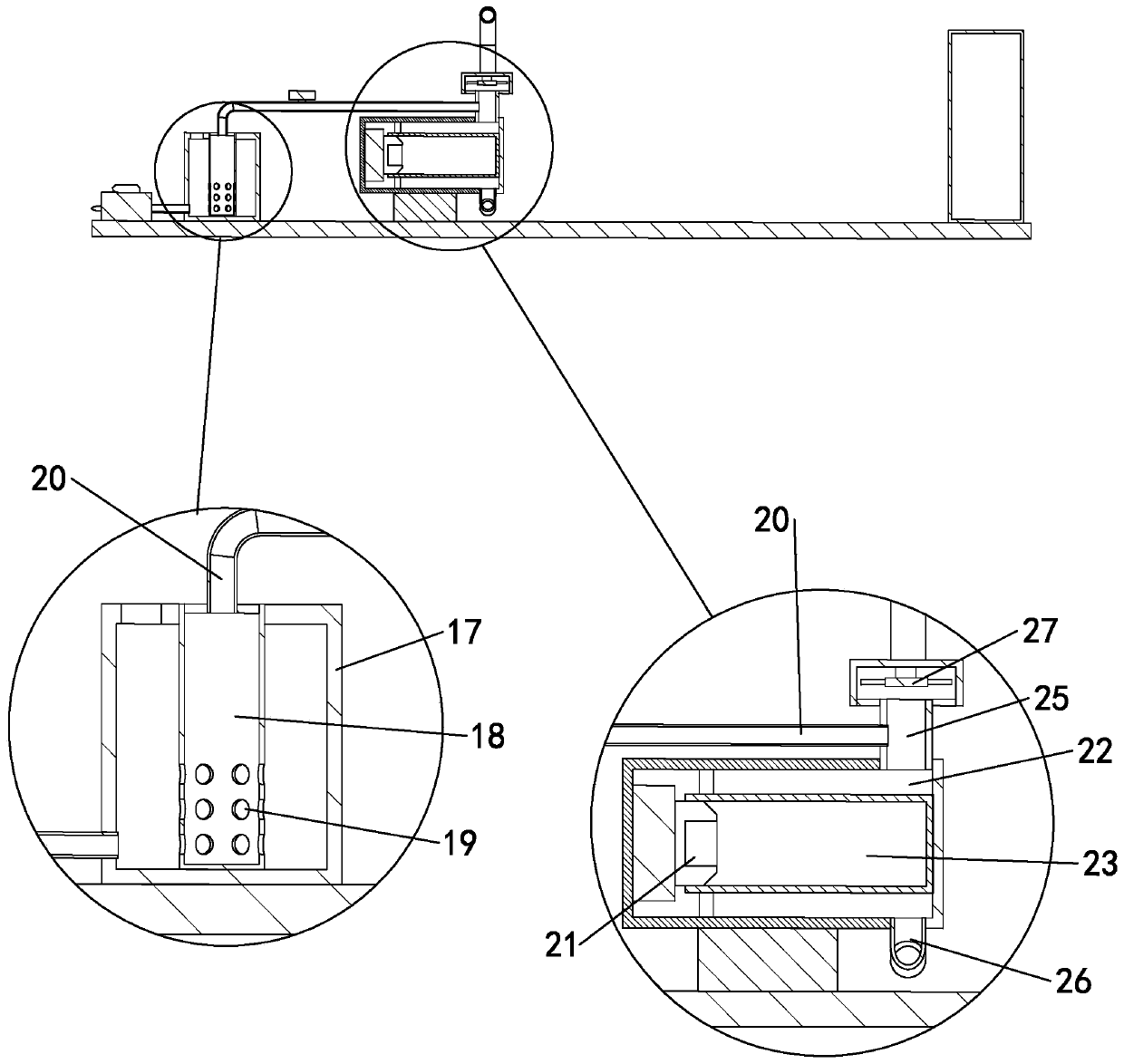

Integrated paint dip-coating and drying device

The invention discloses an integrated paint dip-coating and drying device. The device comprises a support frame and a chain transmission mechanism arranged at the top of the support frame, wherein a plurality of elastic suspension mechanisms are hung and fixed on the chain transmission mechanism; objects to be dip-coated are hung at the bottoms of the elastic suspension mechanisms; meanwhile, a paint containing box containing paint is arranged at the bottom of the support frame and positioned under the elastic suspension mechanisms; and a rotary lifting and positioning mechanism is installed on one side of the top of the paint containing box. According to the integrated paint dip-coating and drying device, a plurality of workpieces can be dip-coated, and after dip-coating, the redundant paint on the surfaces of the workpieces can fall into the paint containing box through the vibration actions of the elastic suspension mechanisms, so that not only is the paint saved, but also the paintis effectively prevented from dropping on a bearing frame in the continuous transmission process of the objects to pollute the bearing frame, and the efficiency of the hot air drying of the objects is effectively improved after the redundant paint is vibrated out.

Owner:安徽钜将家具制造有限公司

Paint coating device

ActiveCN103657921AReduce spillageImprove spraying efficiencyLiquid spraying apparatusSiphonSpray nozzle

The invention provides a paint coating device. The paint coating device comprises a paint tank, a piston, a piston handle, a spraying nozzle and a high-pressure fluid pump, wherein a cavity of the paint tank is filled with paint, a paint outlet is formed in the top end of the paint tank, the piston is arranged inside the paint tank in a vertical sliding mode, the piston handle extends into the paint tank from a top plate of the paint tank, the bottom end of the piston handle is fixedly connected with the piston, the piston handle is provided with a ventilation hole communicated between the outside and a lower cavity, the spraying nozzle is arranged at one side of the paint tank and provided with a fluid passage, an outlet of the fluid passage is located above the paint outlet, the high-pressure fluid pump is used for guiding high-pressure fluid into the fluid passage, and an outlet of the high-pressure fluid pump is communicated with an inlet of the fluid passage. Pressure difference is generated between the cavity, filled with the paint, of the paint tank and the outside, the paint inside the paint tank is automatically pressed into the paint outlet based on the siphon principle, and then automatic coating is achieved. The paint coating device can be applied to coating of paint with different viscosities, and therefore the paint coating device can replace manual coating, is used for coating anti-corrosion paint or fire retardant or the like with high viscosity, and improves coating efficiency.

Owner:STATE GRID CORP OF CHINA +1

Roller brush utilizing water pump as power

The invention provides a roller brush utilizing a water pump as power, which comprises a handheld rod, a connecting bar, a cross bar, a roller, a bearing, a boa ring, a water pump, a water pump switch, a hose and a baffle, wherein the handheld rod is connected with the connecting bar; the connecting bar is connected with the cross bar; the roller is connected with the cross bar via the bearing; the roller is provided with the boa ring; the baffle is arranged between the connecting bar and the cross bar; the hose is arranged in the handheld rod, one end of the hose is connected with the connecting bar and the other end is connected with the water pump; the hose, the connecting bar, the cross bar and the roller are communicated mutually; the cross bar is provided with a cross bar hole; and the roller is provided with roller holes. The roller brush utilizing the water pump as power in the invention can be used conveniently and is clean, can paint coating evenly, has high painting efficiency and saves the painting.

Owner:XIANGMING MIDDLE SCHOOL SHANGHAI

Special integrated production device for furniture parts

ActiveCN105057150AReduce transfer stepsSuitable for mechanized productionLiquid surface applicatorsCoatingsEngineeringMechanical engineering

A special integrated production device for furniture parts comprises a machine frame and a feeding rack arranged on the machine frame. One end of the feeding rack is a feeding end, the other end of the feeding rack is a discharging end, and a first automatic dust removal device, a embellishing device, a drying device, a paint spraying device and an airing bin are arranged on the feeding rack sequentially from the feeding end to the discharging end at intervals. The embellishing device and the paint spraying device each comprises a paint spraying chamber with a paint spraying platform and two groups of spraying guns arranged in the paint spraying chamber, wherein each group comprises two spraying guns, a conveying belt is laid horizontally on the paint spraying platform, a transverse sliding rail is arranged above a feeding end and a discharging end of the conveying belt, and a movable seat is installed on the transverse sliding rail. The two spraying guns in each group are installed on the same movable seat and are arranged in the mode of inclining downwards towards the two outer sides of the corresponding paint spraying platform. The transverse sliding rails and the movable seats are arranged, uniform paint spraying on the furniture parts is realized through transverse and reciprocating swinging of the spraying guns. The special integrated production device is suitable for embellishing and paint spraying of various furniture parts, and improves the production and quality.

Owner:LIANYUNGANG MOBO HOUSEHOLD

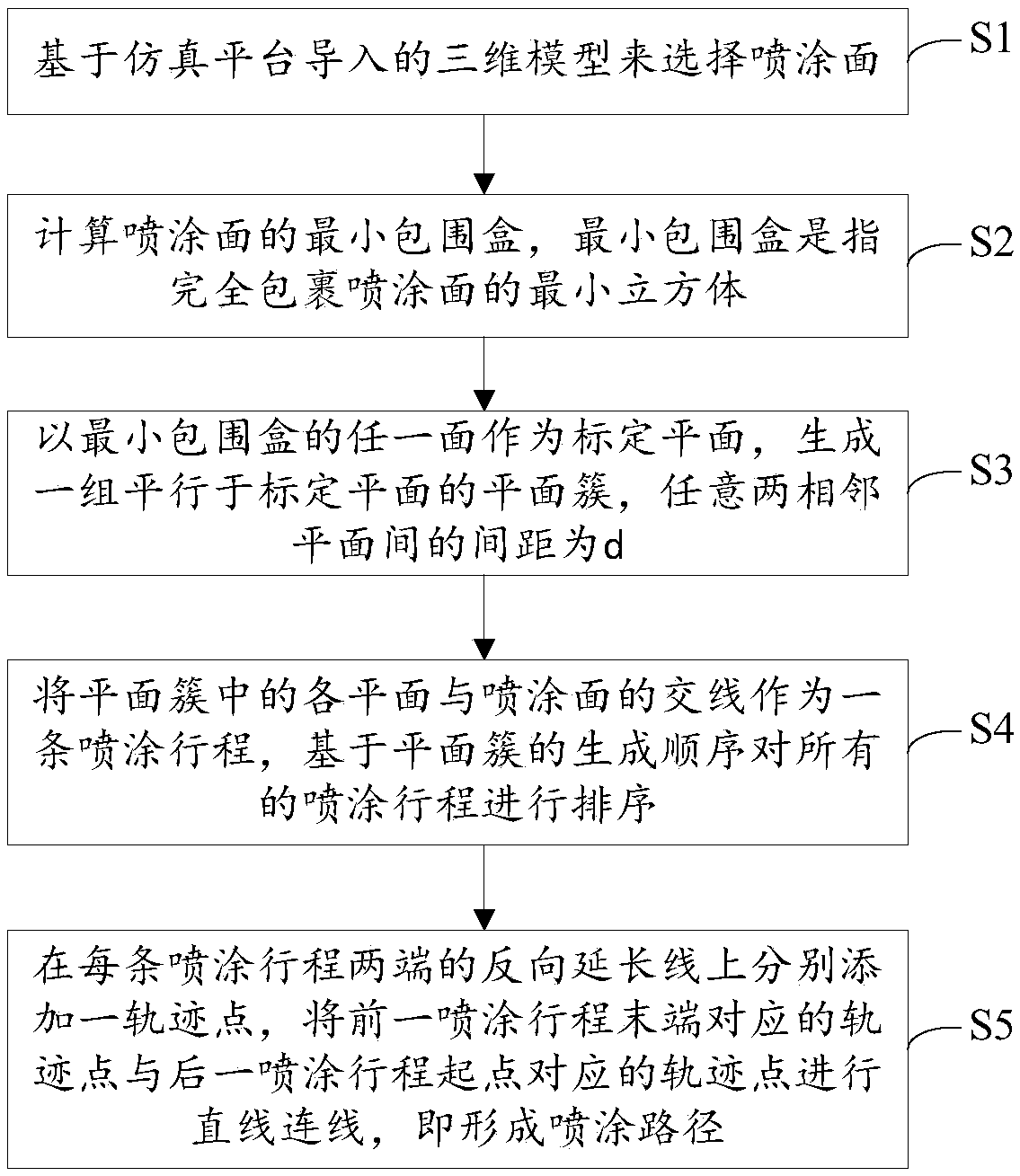

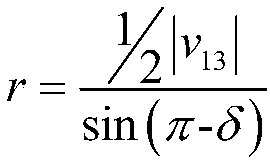

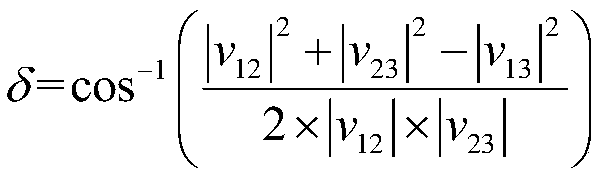

Three-dimensional model-based robot spraying path generation method

ActiveCN108227620ANo need to take timeReduce manual involvementNumerical controlSimulationPath generation

The invention is applied to the technical field of robot spraying, and provides a three-dimensional model-based robot spraying path generation method. The method comprises the following steps: S1. Selecting a spraying surface based on a three-dimensional model conducted by a simulation platform; calculating the minimal bounding case of the spraying surface; by taking any one surface of the minimalbounding case as a calibration plane, generating a group of plane clusters parallel to the calibration plane, wherein the distance between any two adjacent planes; by taking an intersection line of each plane in the plane clusters and the spraying surface as a spraying stroke, sequencing all the spraying strokes based on the generation sequence of the plane clusters; respectively adding a path point on counter extension lines from two ends of each spraying stroke, and performing line connection of the path point corresponding to the tail end of the front spraying stroke with the path point corresponding to the beginning end of the next spraying stroke, thus forming a spraying path. By using the method, the spraying path of the robot can be automatically generated only by needing manual setting of part parameters.

Owner:WUHU HIT ROBOT TECH RES INST

Intelligent door leaf spraying line with robot

PendingCN113145342AGood modelingIncrease productivitySpraying apparatusEngineeringMechanical engineering

The invention discloses an intelligent door leaf spraying line with a robot. The intelligent door leaf spraying line comprises a door leaf clamp used for clamping and supporting a door leaf and a chain conveying device used for conveying the door leaf clamp, and a door leaf scanning area, a door leaf front face spraying area, a door leaf front face supplementary coating area, a door leaf back face spraying area and a door leaf back face supplementary coating area are sequentially arranged in the conveying direction of the chain conveying device. A three-dimensional scanning device is arranged on the door leaf scanning area, and the three-dimensional size and / or shape of a door leaf are scanned through the three-dimensional scanning device; spraying robots are arranged on the outer side of the door leaf front face spraying area and the outer side of the door leaf back face spraying area respectively, and the front face and the back face of the door leaf are sprayed through the spraying robots respectively; and the door leaf front face supplementary coating area and the door leaf back face supplementary coating area conduct manual detection and manual supplementary coating on the front face spraying condition and the back face spraying condition of the door leaf respectively. The intelligent door leaf spraying line has the characteristics of simple and reasonable structure, clear production and processing process planning, high automation degree, high production efficiency, low cost, safe and reliable spraying process and the like, and is strong in practicability.

Owner:广东博硕涂装技术有限公司

Production and processing device for composite coating

PendingCN111359821AProduce pollutionPrevent fallingSevering textilesPretreated surfacesGas burnerEngineering

The invention discloses a production and processing device for composite coating. The production and processing device comprises a cloth conveying mechanism, a paint coating mechanism, a coating drying mechanism and a leftover shearing mechanism, wherein the paint coating mechanism is arranged on the front side of the upper end of the cloth conveying mechanism, the leftover shearing mechanism is arranged on two sides of the cloth conveying mechanism and located on the rear side of the coating drying mechanism, the paint coating mechanism comprises a paint scraper, a spray gun moving mechanismand a paint spray gun assembly, the coating drying mechanism comprises a gas burner, a hot air chamber, a burning chamber and a drying cover, a cold air pipeline and a hot air outlet are arranged on the hot air chamber, an air intake fan is arranged on the cold air pipeline, a hot air channel is connected to the hot air outlet, the end, away from the hot air outlet, of the hot air channel is connected to the upper end of the drying cover, the drying cover is located right above the cloth conveying mechanism, and the far end, away from an air outlet hollow pipe, of an air delivery pipe is connected to the side wall of the cold air pipeline.

Owner:桐乡市迪诺纺织股份有限公司

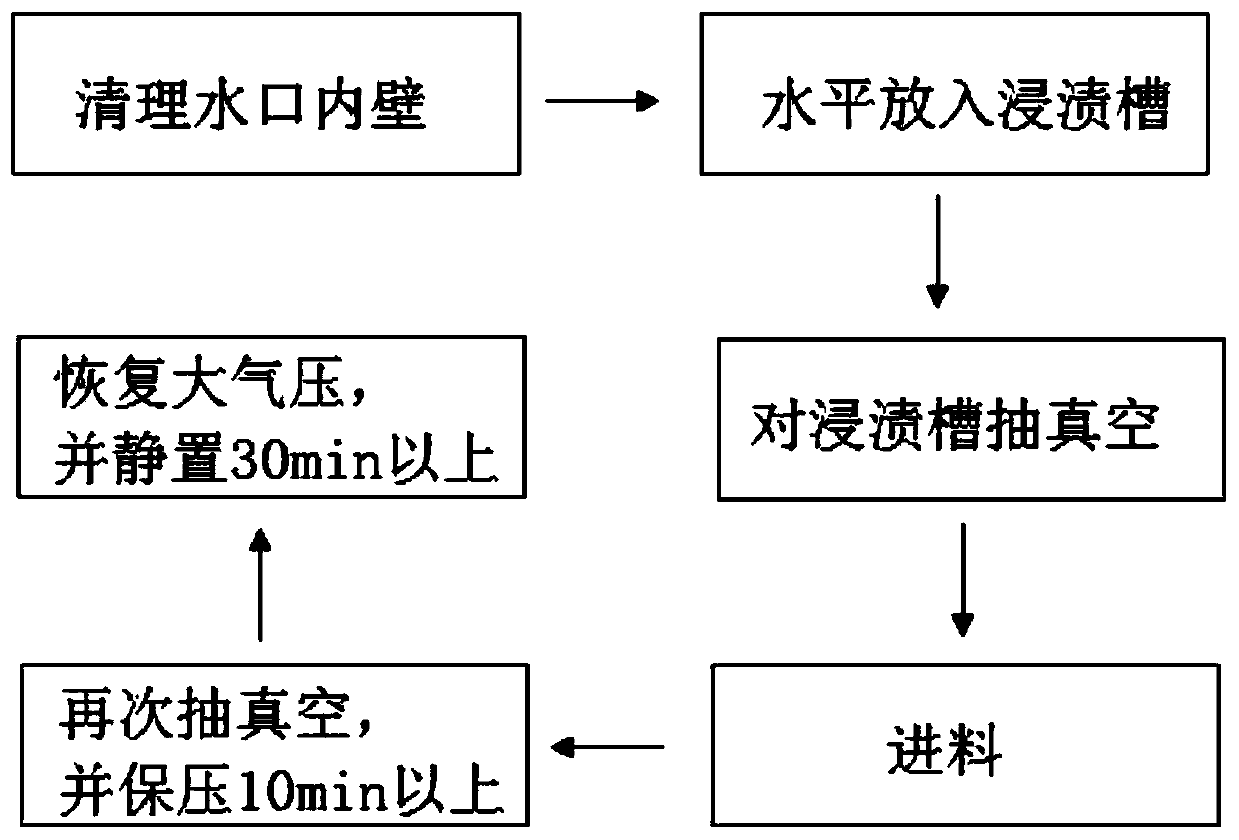

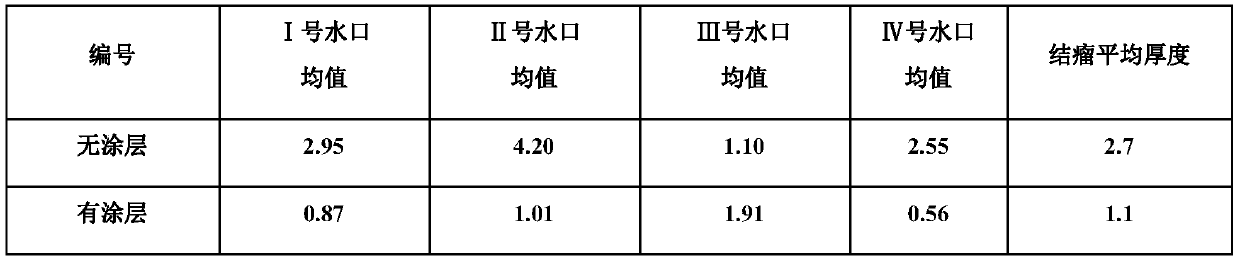

Coating material for preventing submersed nozzle from nodulation and preparation method thereof

ActiveCN110922214AGood adhesion performanceGood oxidation resistanceMelt-holding vesselsPhosphoric acidOxide

The invention discloses a coating material for preventing a submersed nozzle from nodulation and a preparation method thereof, and belongs to the technical field of coating materials of submersed nozzles. The coating material comprises the following components in parts by weight: 20-56 parts of mullite fine powder, 15-23 parts of corundum fine powder, 4-8 parts of Guangxi white mud, 7-18 parts ofactivated aluminum oxide micro powder, 5-8 parts of aluminum dihydrogen phosphate, 8-12 parts of a fluxing agent, 2-11 parts of an antioxidant and 0.3-2.0 parts of a dispersing agent. The invention aims to solve the problems that in the prior art, a submersed nozzle is easy to bake and oxidize, and nodules are generated to block the submersed nozzle. According to the coating material for preventing the submersed nozzle from nodulation and the preparation method thereof, the purposes of preventing the submersed nozzle from being baked and oxidized and preventing air from entering molten steel through the nozzle in the using process can be achieved, and the submersed nozzle is prevented from blocking caused by nodulation.

Owner:MAANSHAN IRON AND STEEL COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com