Automatic paint spraying device and automatic paint spraying method for inner wall of wind-powered electricity-generation tower pole

A technology for automatic painting and wind power towers, which is applied in the direction of spraying devices, spraying devices, liquid spraying devices, etc. It can solve the problems of uneven local thickness of manual painting, great impact on the occupational health of operators, and large diameters of offshore wind power towers, etc. problems, achieve the effect of reducing operator fatigue, good coating effect and uniform coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

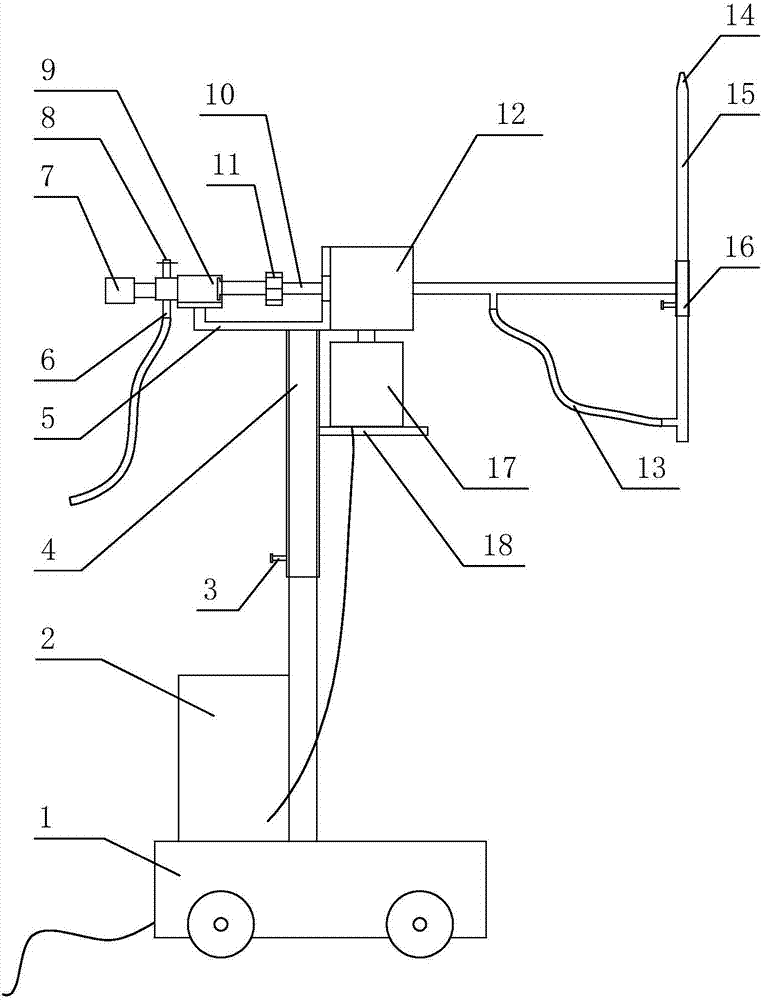

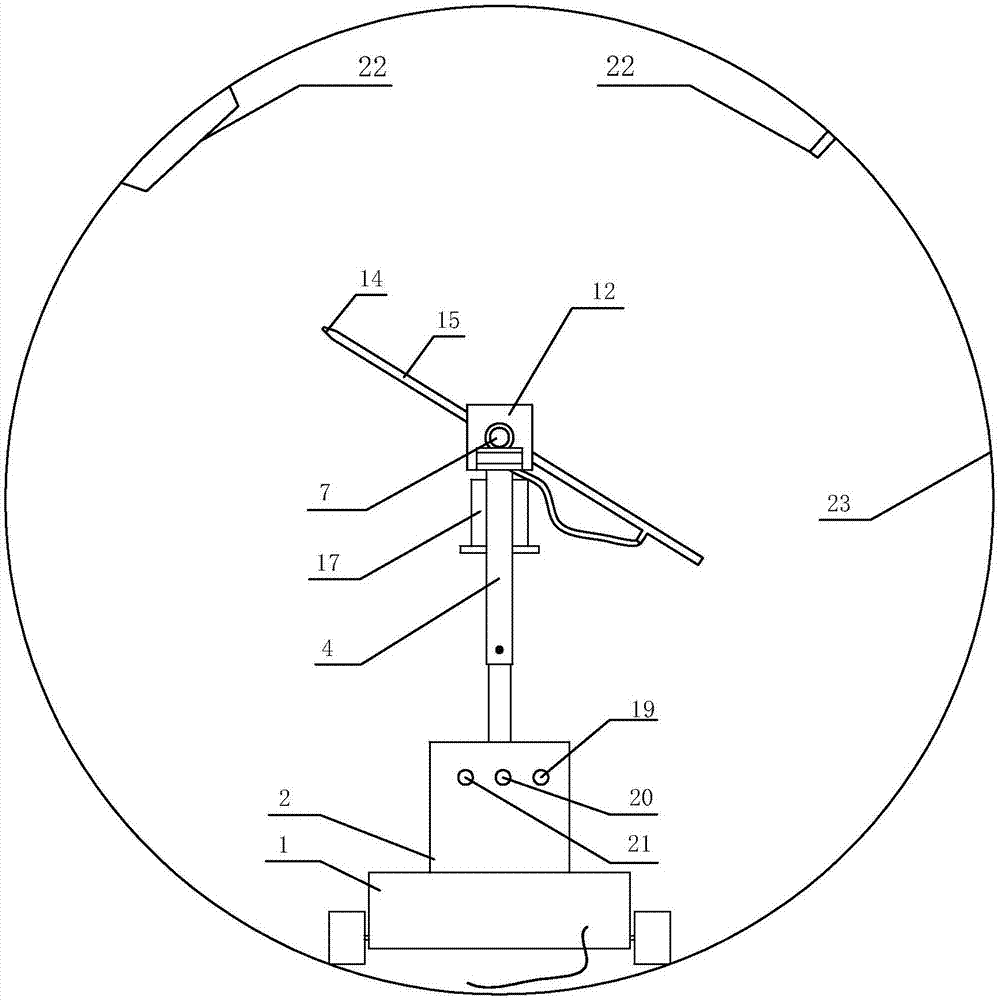

[0031] refer to figure 1 , an automatic painting device for the inner wall of a wind power tower, including a walking trolley 1, a support frame 4 fixed on the walking trolley 1, and a spray gun 15 connected to the support frame 4, and also includes: a control cabinet 2, a fixing frame 5, Feed valve 8, rotary valve 9, hollow shaft 10, motor 17; the motor 17 is fixedly connected to the support frame 4 and drives the hollow shaft 10 to rotate, and the rotary valve 9 is fixed by the fixed frame 5 On the support frame 4, the feed valve 8 is connected to the hollow rotating shaft 10 through the rotary valve 9 and provides a material circulation channel, and the other end of the hollow rotating shaft 10 is connected to the spray gun 15 and allows the material It is sprayed from the nozzle 14 of the spray gun 15; the motor 17 is connected to the control cabinet 2 by signal; the walking trolley 1 is connected to the control cabinet 2 by signal. A mixer is connected to the rotary valv...

Embodiment 2

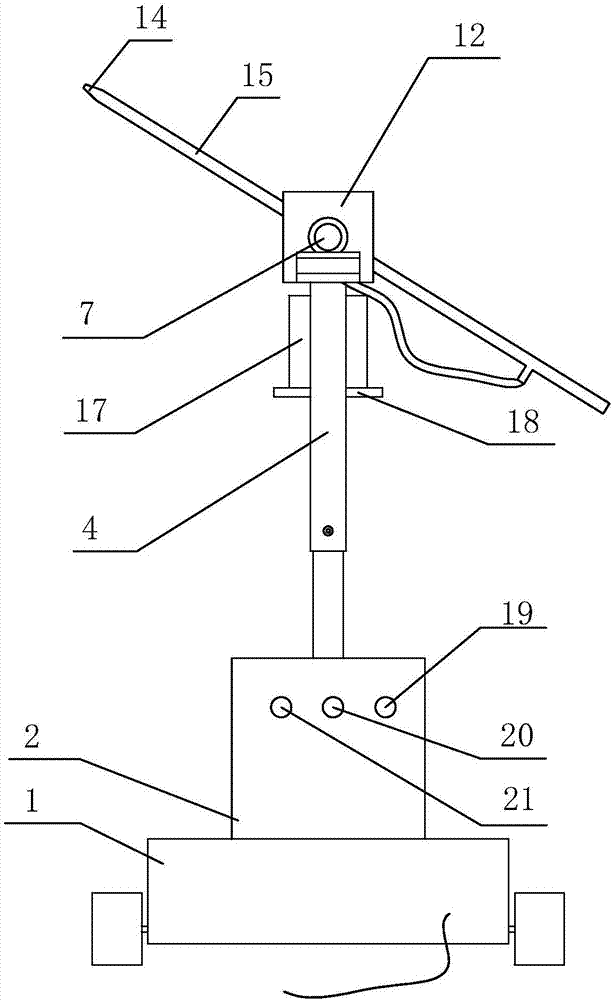

[0044] refer to Figure 4 The difference from Embodiment 1 is that the spray gun 15 is a telescopic rod structure, and the length of the spray gun 15 itself can be adjusted in this structure, so as to adjust the relative distance of the nozzle 14 relative to the hollow shaft 10 . In this way, the adjustment sleeve 16 is not required, and the connecting hose 13 may not be provided, and the material coming out from the hollow rotating shaft 10 directly enters the spray gun 15 . The function of this structure is the same as that of the embodiment 1, which is to adjust the relative position of the nozzle 14 relative to the hollow shaft 10 . All the other structures and effects are the same as in Example 1.

[0045] A kind of automatic painting method using the automatic painting device for the inner wall of any wind power tower tube of the present invention, specifically:

[0046] Step 1. Connect the intake valve 6 to the pipeline of the high-pressure airless sprayer, connect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com