Patents

Literature

203results about How to "Uniform coating thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Magnesium alloy non cyanogen plating copper chemical plating nickle and its plating process

InactiveCN1598059AImprove bindingUniform coating thicknessSuperimposed coating processCopper platingChemical plating

The invention discloses a method of plating Nickel with magnalium alloy without cyanogen and the plating technique. The direction for the plating solution is: 20 to 80g.dm-3 of copper charred phosphate; one or several of the 60 to 320g.dm-3 of sodium charred phosphate or Potassium charred phosphate or 60 to 250g.dm-3 of sodium citric acid, 5 to 20g.dm-3 of Potassium sodium tartaric acid, 60 to 250g.dm-3 of HEDP and 60 to 250g.dm-3 of amine ethylene; one or several of the 5 to 20g.dm-3 of hydrogen amine di-fluorin or 5 to20 g.dm-3 sodium fluoride or 5 to 20g.dm-3 of Potassium fluoride or 5 to 20g.dm-3 of lithium fluoride. The plating solution chooses the nickel sulfate or alkali type nickel carbonate or nickel acetic acid as the main salt and adds the reducing agent, combination agent and stabilization agent. The plating technique adopts the acid plating copper-plating three nickel-plating chromium. The invention has little pollution to the environment, high binding power and erosion-proof property.

Owner:GCI SCI & TECH +1

Plating solution of magnesium alloy nickle sulfate main salt and technology of chemical plating thereof

InactiveCN1598053ALow priceReduce manufacturing costLiquid/solution decomposition chemical coatingChemical platingThiourea

The invention discloses a plating solution of magnalium alloy Nickel sulfate and its chemical plating technique. The plating solution is made up of: (1) 5 to 40g.dm-3 of Nickel sulfate, (2) 10 to 50g.dm-3 of reducing agent of hypo-phosphite sodium; (3) one or several of the 2.5 to 30g.dm-3of the citric acid or tri-sodium citric acid, 2.5 to 30g.dm-3of the lactic acid, 2.5 to 30g.dm-3of the acetic acid, 2.5 to 30g.dm-3of the malic acid, 2.5 to 30g.dm-3 of the third acid and 2.5 to 30g.dm-3of the buta-acid; (4) one or several of the 5 to 30g.dm-3of Potassium fluoride, 5 to 30g.dm-3of sodium fluoride, 5 to 30g.dm-3of lithium fluoride and 5 to 30g.dm-3of NH4HF2; (5) 0.1 to 3g.dm-3of sulphur carbamide. The plating steps include: washing with ultrasonic->washing with alkali->washing with acid->activation->dipping it in the zinc solution->getting rid of the activation solution->secondary dipping it in the zinc solution->chemical plating->passivation and sealing the holes. The invention is featured by little pollution to the environment, low cost, uniform film and simpel technique.

Owner:HUNAN UNIV

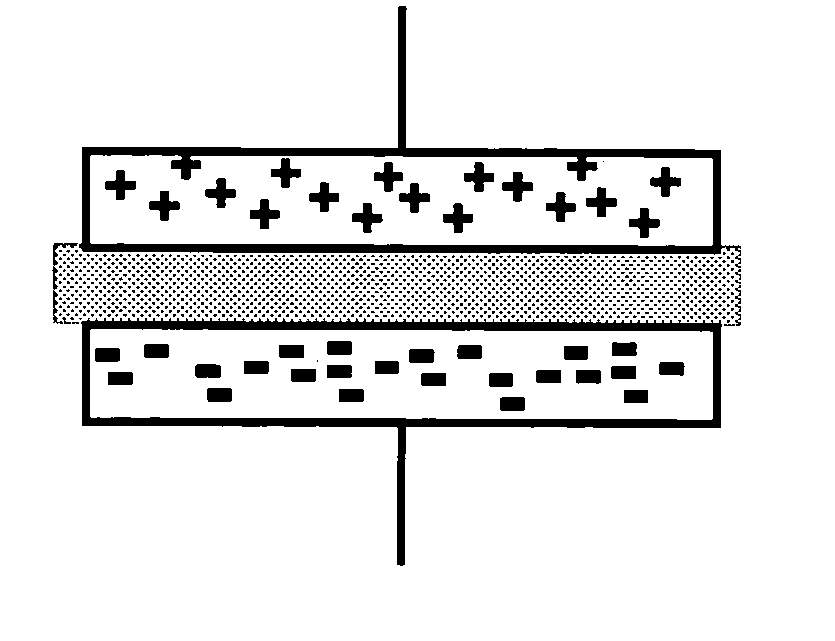

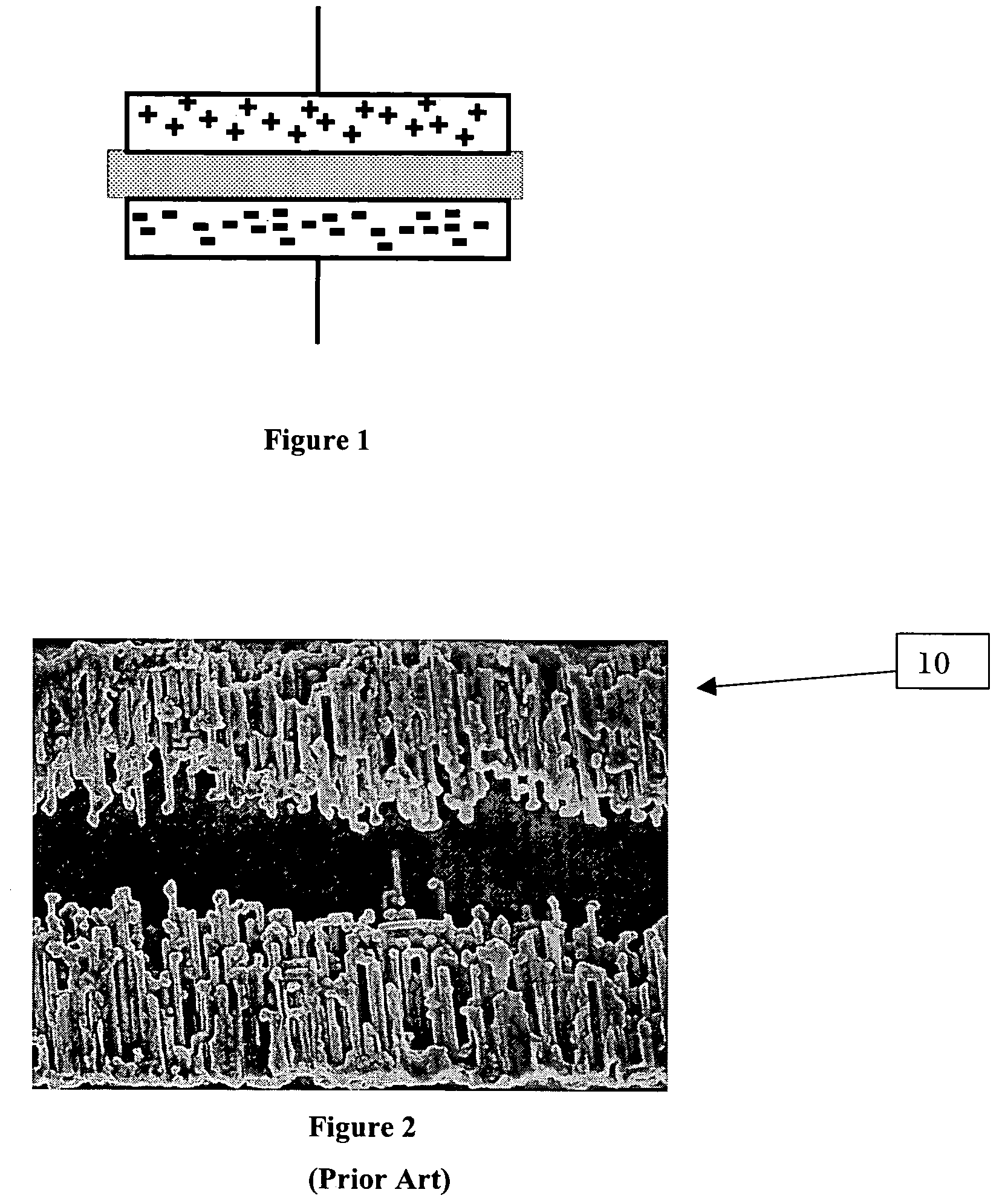

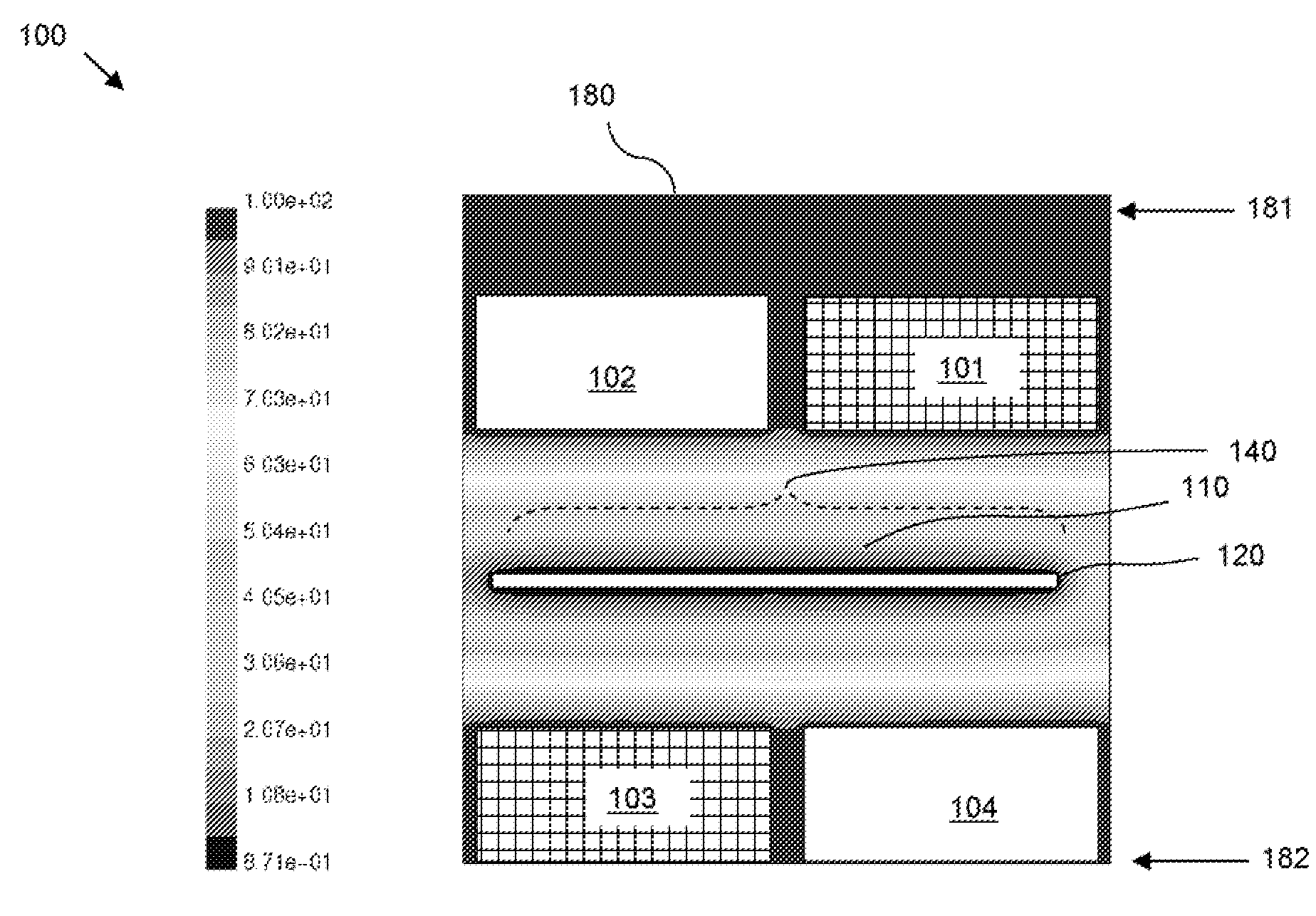

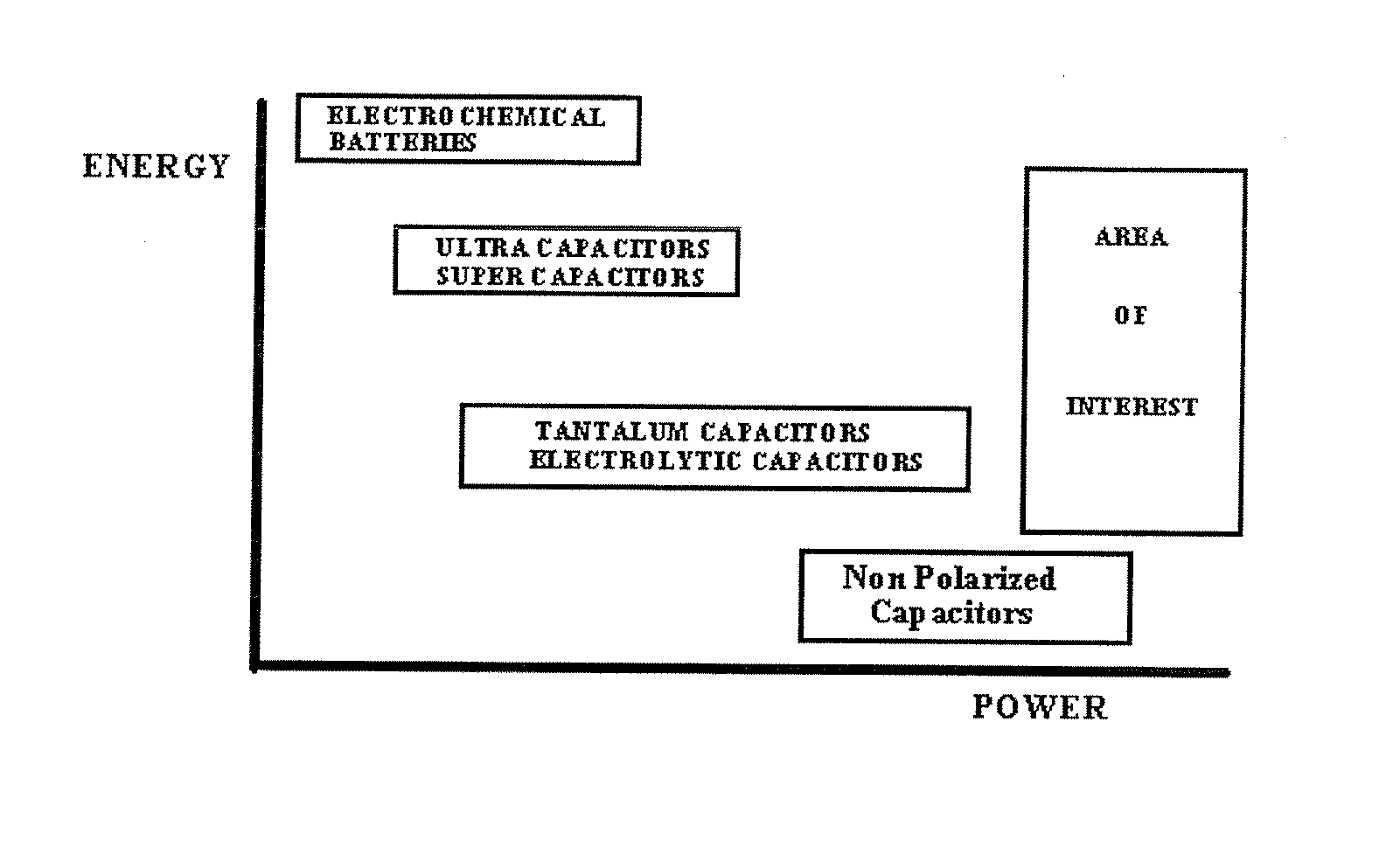

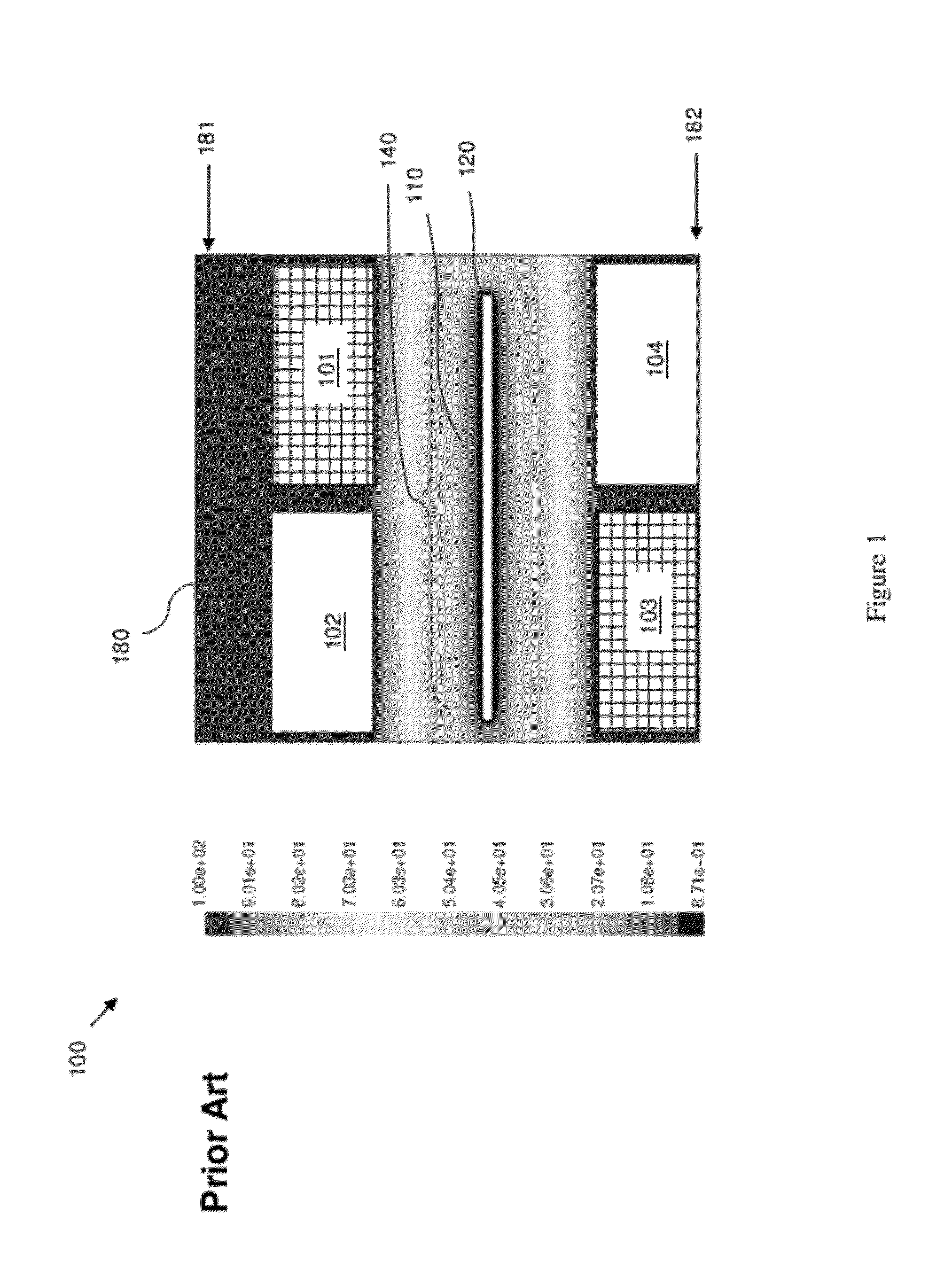

Electrical charges storage device having enhanced power characteristics

InactiveUS7289312B2Tighter the fit of the conformal coatingHigh bonding strengthElectrolytic capacitorsCell electrodesElectrical conductorElectrolysis

The present invention relates generally to an electrical charge storage device (ECSD) with enhanced power characteristics. More particularly, the present invention relates to enhancing the current density, voltage rating, power transfer characteristics, frequency response and charge storage density of various devices, such as capacitors, batteries, fuel cells and other electrical charge storage devices. For example, one aspect of the present invention is solid state and electrolytic capacitors where the conductor surface area is increased with smooth structures, thereby reducing the distance separating the conductors, and improving the effective dielectric characteristics by employing construction techniques on atomic, molecular, and macroscopic levels.

Owner:DUFF JR WILLIAM B

Burn and scald liquid, burn and scald ointment, and preparation method thereof

InactiveCN102302677ASave timeUniform coating thicknessHeavy metal active ingredientsHydroxy compound active ingredientsWestern medicineBurns/scalds

The present invention provides a burn and scald liquid and a burn and scald ointment. The burn and scald liquid provides good effects for treating first degree burn and scald, and second degree burn and scald. The burn and scald ointment provides significant effects for treating purulent infection, ulceration, healing requiring a long time, difficult growth of new muscle, burn and scald, especially the deep second degree burn and scald and three degree burn and scald. Compared to external application method in the western medicine, infrared therapeutic equipment, frequency spectrum therapeutic equipment, electronic therapeutic equipment, anion generator, and the like in the prior art, the burn and scald liquid and the burn and scald ointment provided by the present invention has characteristics of heat clearing and detoxification, inflammatory eliminating and analgesia, slough transforming and muscle growing, strong anti-infection property, rapid improvement of wound healing. With adopting the burn and scald liquid and the burn and scald ointment, the patients with slight and scald and without skin exfoliating can be healed in 3-7 days, the patients with deep second degree burn can be healed in 15-20 days, the patients with deep burn can be healed in about 2 months. In addition, after healing, the skin of the patient is smooth, the pores are revived, no scar is remained, and the significant healing effect is provided.

Owner:四川树德医药科技开发有限公司

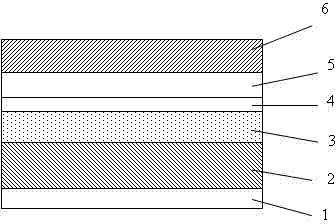

Anti-ultraviolet high-heat-insulation window film

ActiveCN102765224ASimple structureGood heat insulationSynthetic resin layered productsLight protection screensInsulation layerUltraviolet lights

An anti-ultraviolet high-heat-insulation window film is provided with a scratch resisting layer, a transparent thin film base material layer, a heat insulation layer, an ultraviolet blocking layer, a pressure-sensitive adhesive bonding layer and a release film layer, wherein the scratch resisting layer is arranged on one surface of the transparent thin film base material layer through ultraviolet light curing, the heat insulation layer is arranged on the other surface of the transparent thin film base material layer through ultraviolet light curing, the ultraviolet blocking layer is arranged on the outer surface of the heat insulation layer through heat curing, the pressure-sensitive adhesive bonding layer is arranged on the outer surface of the ultraviolet blocking layer through heat curing, and the release film layer is compounded on the outer surface of the pressure-sensitive adhesive bonding layer. The heat insulation layer is formed by coating, drying and curing coating liquid consisting of an ultraviolet light coating and a nanoscale metal oxide. The anti-ultraviolet high-heat-insulation window film is simple in preparation process, high in ultraviolet light blocking rate and capable of being applied to building windows or automobile windows.

Owner:乐凯胶片股份有限公司

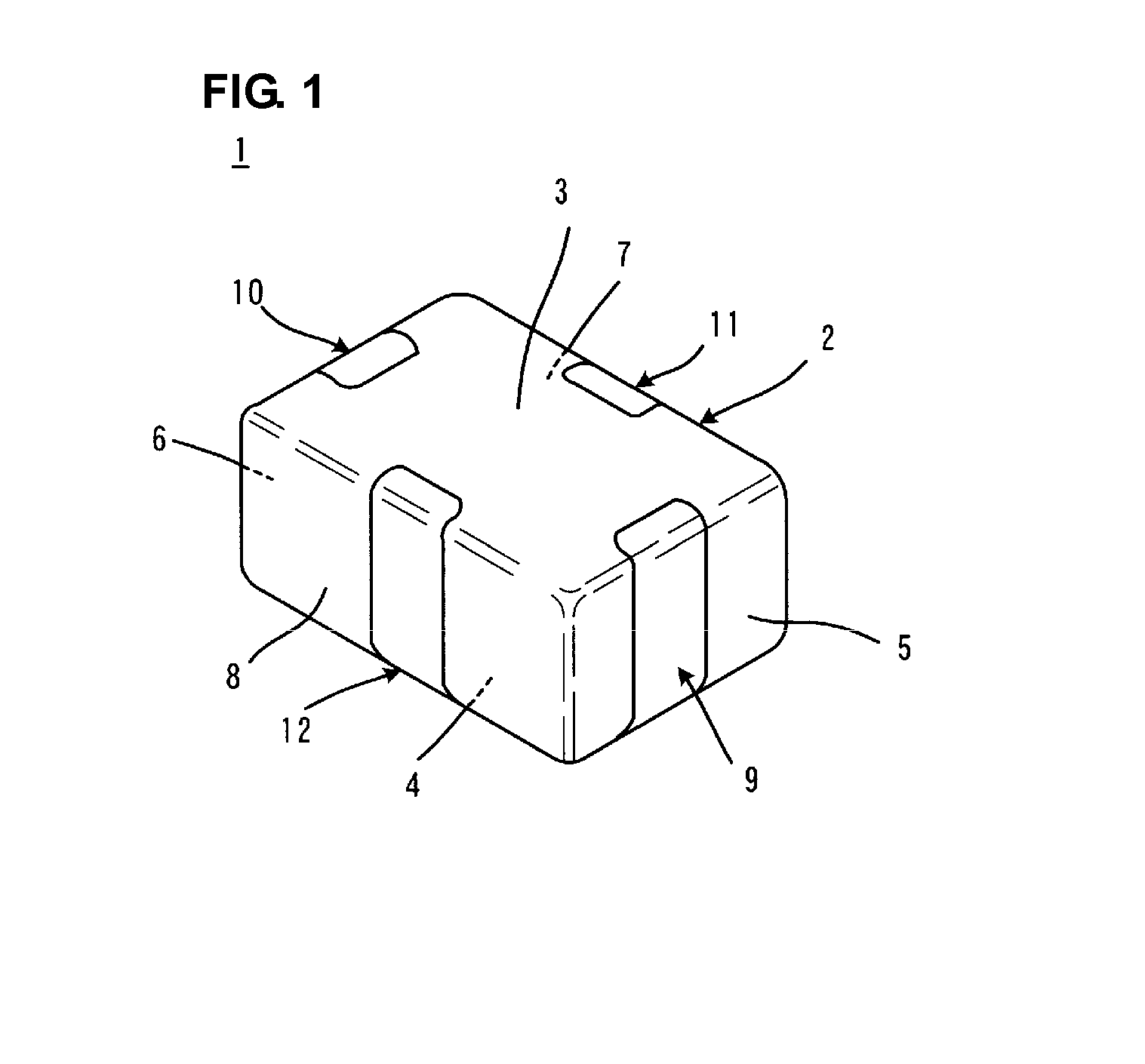

Monolithic electronic component

ActiveUS20080128860A1Uniform coating thicknessMoisture resistance of the monolithic electronic component can be ensuredSemiconductor/solid-state device detailsFixed capacitor dielectricEngineeringElectronic component

In a monolithic electronic component in which a resistive element is incorporated by forming a resistor film on a terminal electrode, a plating film can be formed on the terminal electrode having the resistor film via electroplating in an efficient manner and with a uniform film thickness. In order to form the terminal electrode, the resistor film is disposed directly on the surface of the component body, and a conductive resin film having a relatively low volume resistivity is disposed over the resistor film. The conductive resin film is preferably adapted to have a specific resistance of less than about 1×10−4 Ω·m, on which a plating film having a uniform film thickness can be formed efficiently via electroplating.

Owner:MURATA MFG CO LTD

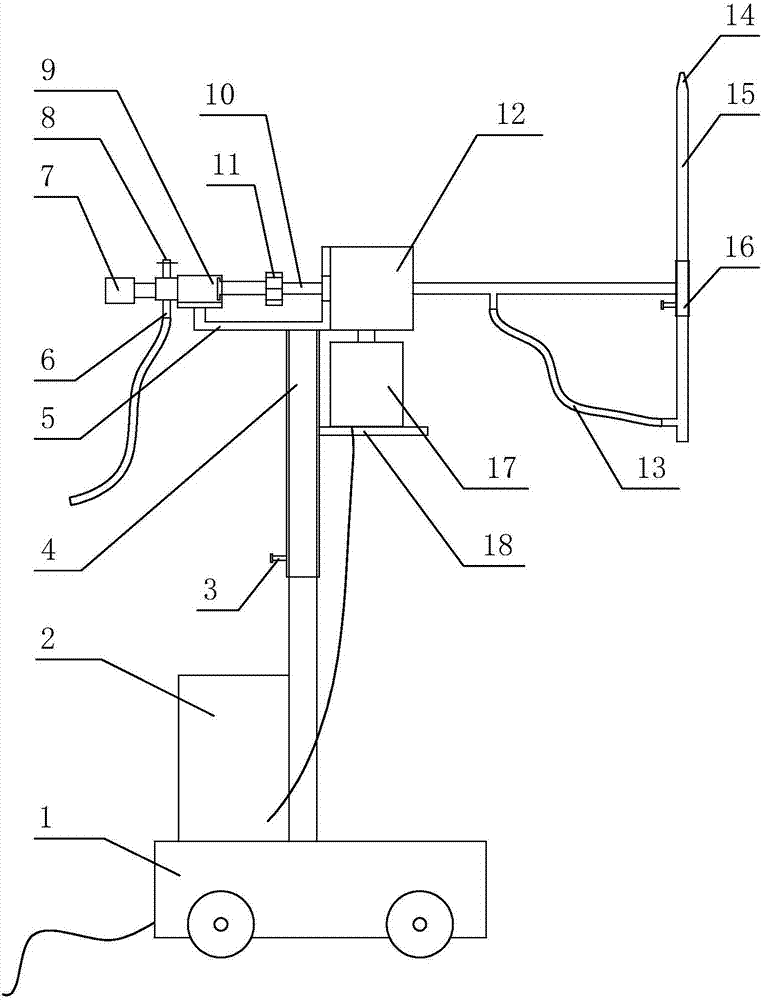

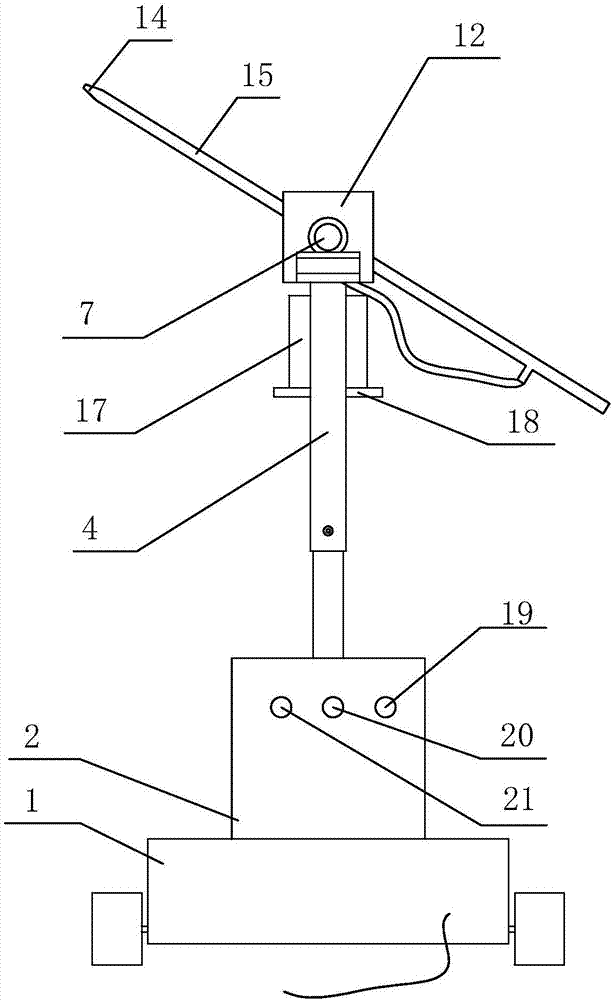

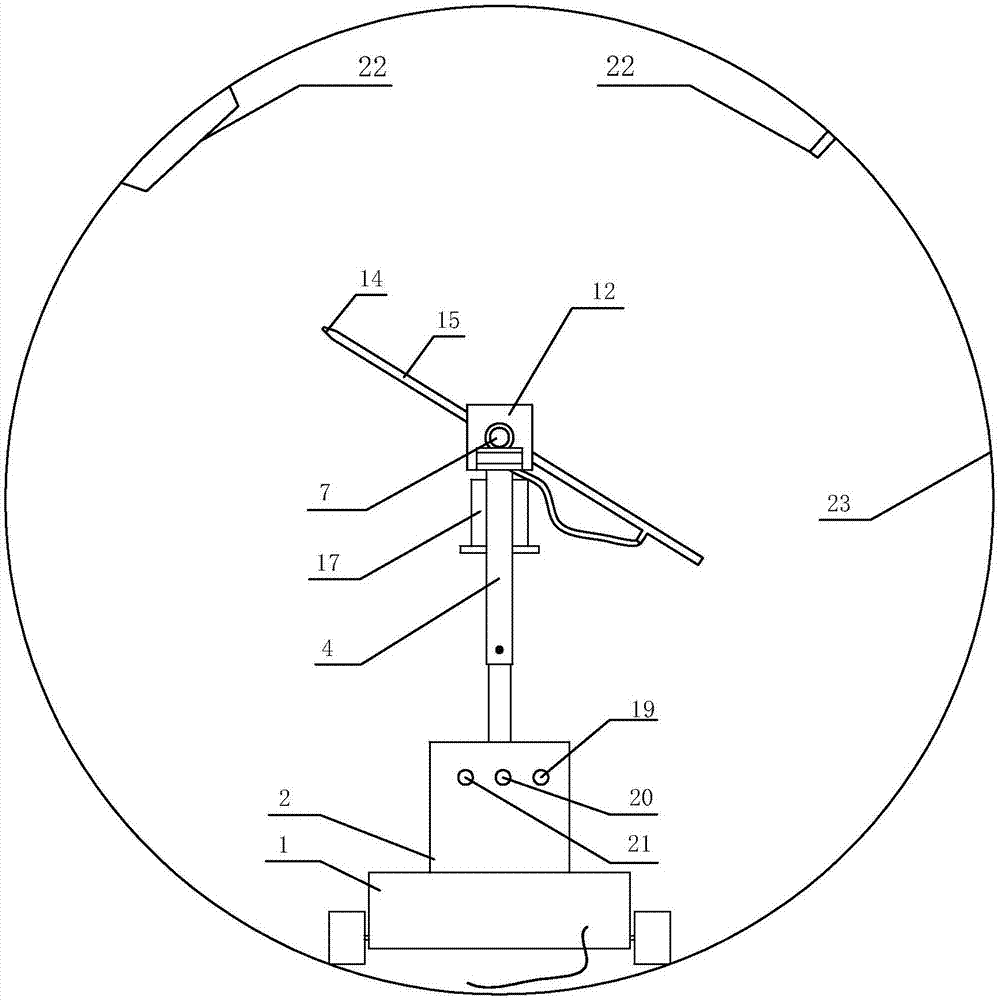

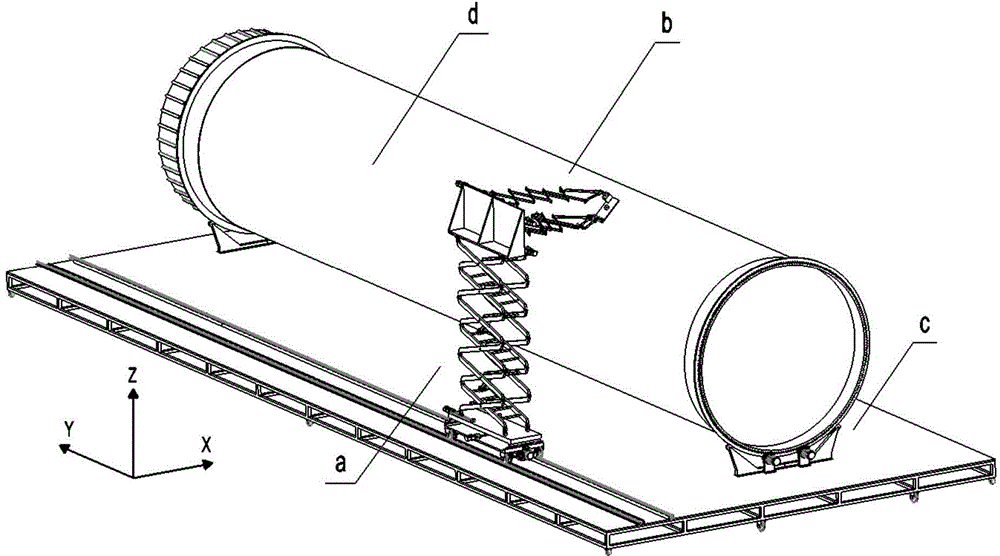

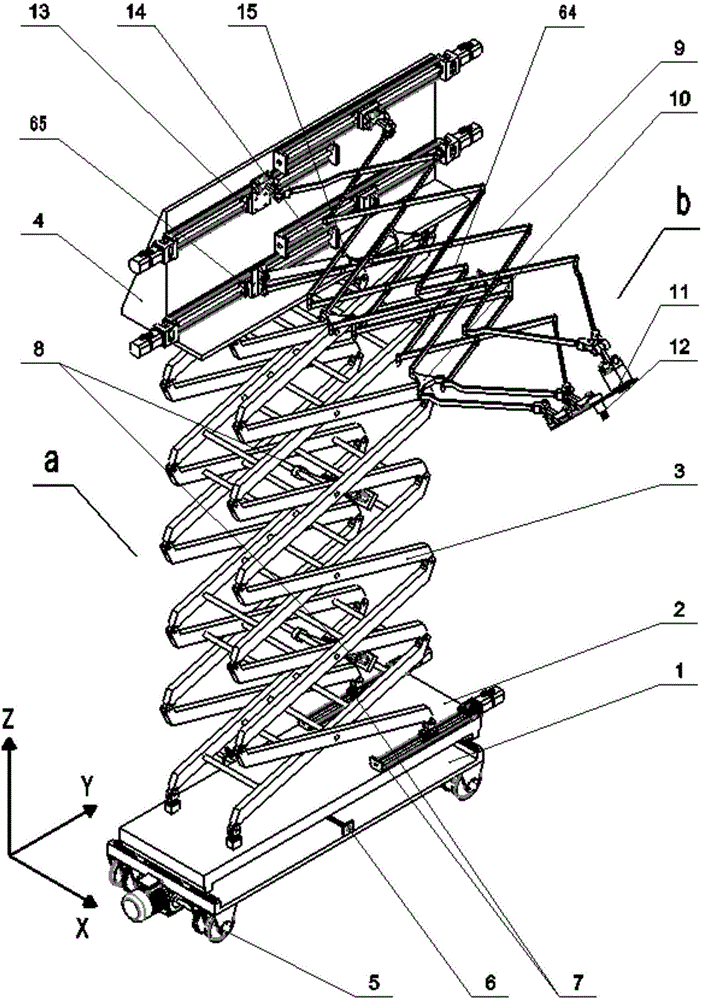

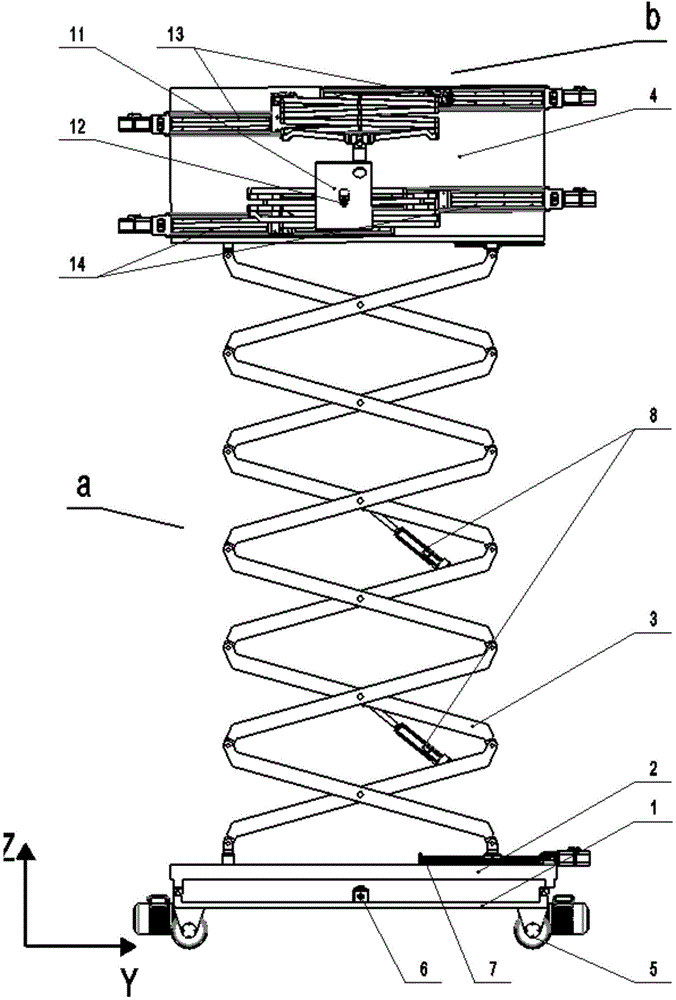

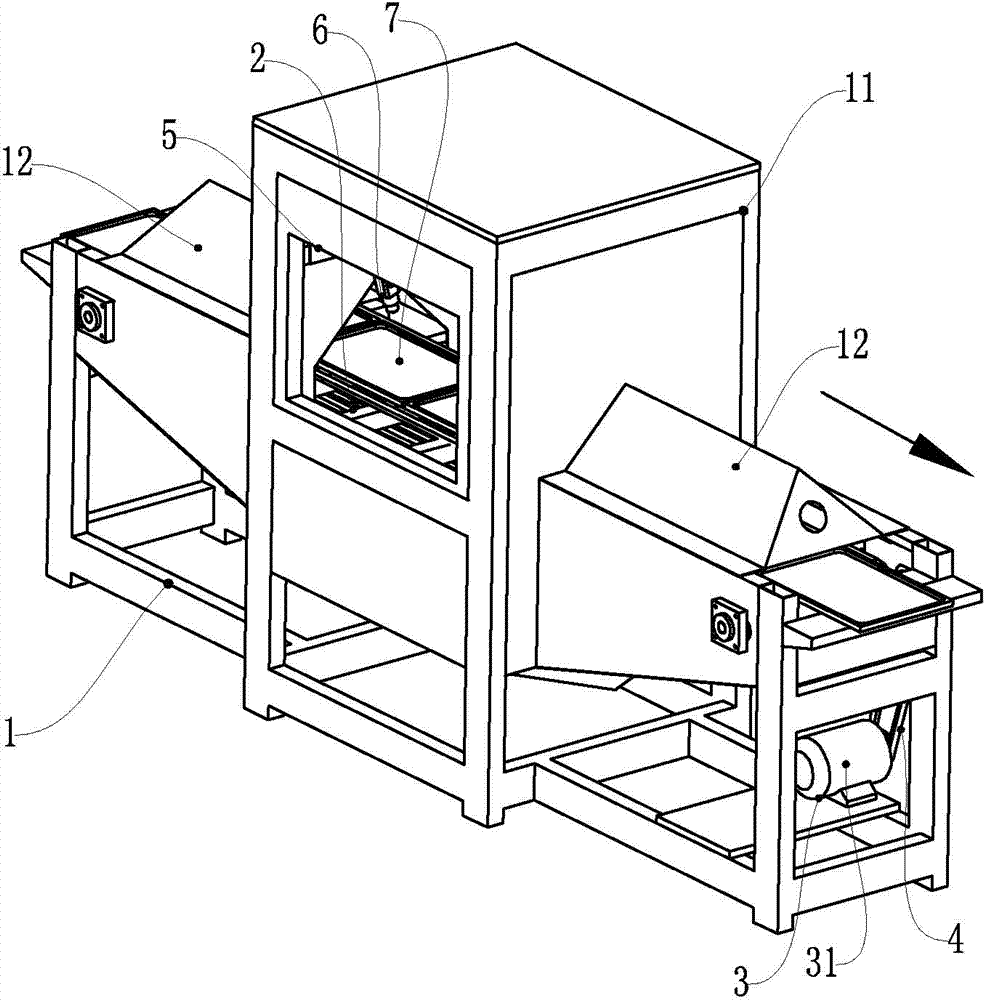

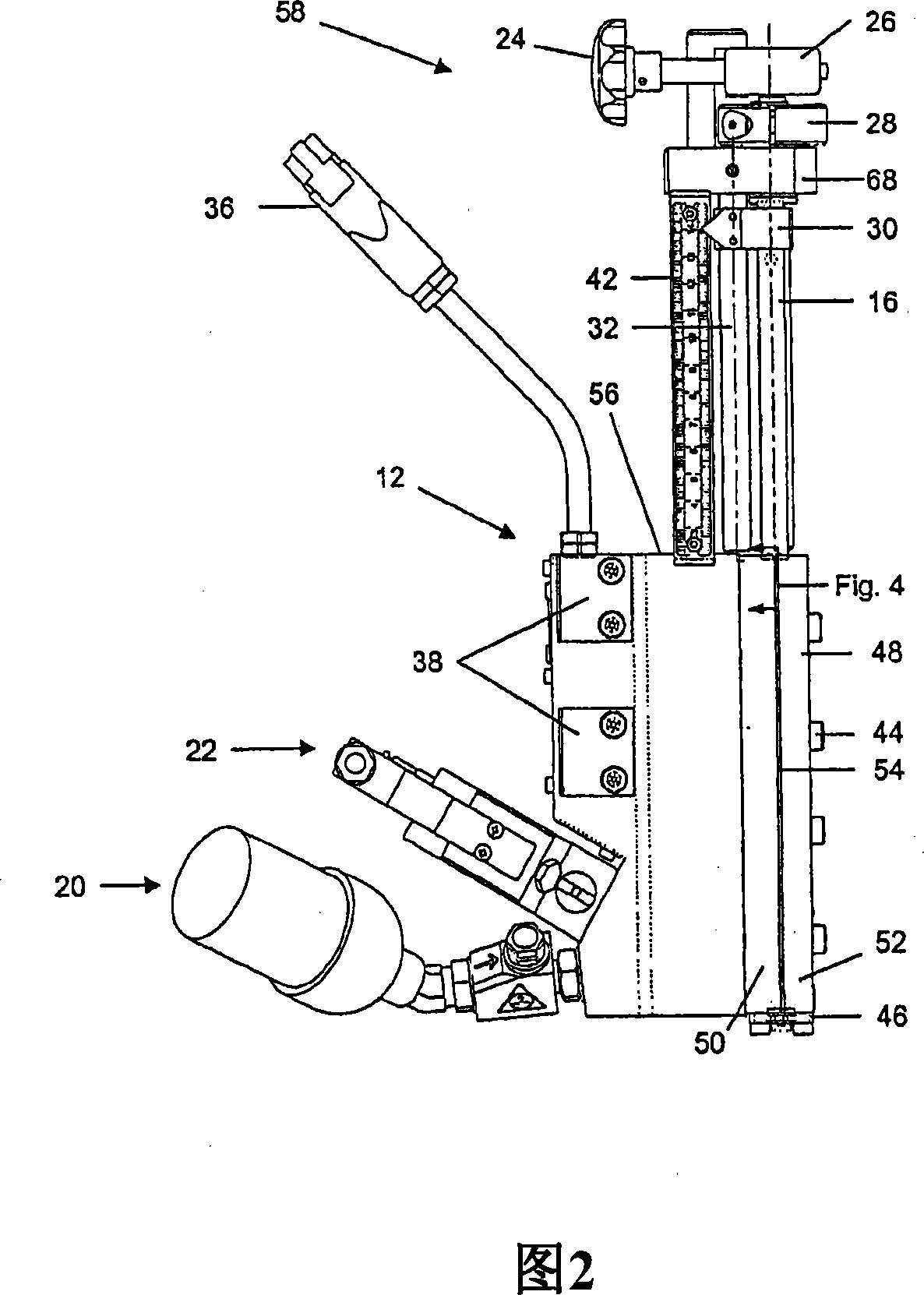

Automatic paint spraying device and automatic paint spraying method for inner wall of wind-powered electricity-generation tower pole

InactiveCN107051789AImprove efficiencyGood coating performanceLiquid surface applicatorsSpray nozzlesElectricityFixed frame

The invention relates to an automatic paint spraying device and automatic paint spraying method for an inner wall of a wind-powered electricity-generation tower pole. The automatic paint spraying device comprises a walking wagon, a supporting frame, a spray gun, a control cabinet, a fixing frame, a feed valve, a rotating valve, a hollow rotating shaft and a motor, wherein the motor is fixedly connected to the supporting frame and drives the hollow rotating shaft to rotate; the rotating valve is fixed to the supporting frame through the fixing frame; the feed valve is connected with the hollow rotating shaft through the rotating valve, and provides a material circulating channel, and the other end of the hollow rotating shaft is connected with the spray gun, and is used for enabling materials to be sprayed from a nozzle of the spray gun; the motor is in signal connection with the control cabinet; and the walking wagon is in signal connection with the control cabinet. The automatic paint spraying device disclosed by the invention is high in efficiency, good in paint spraying effect, uniform in paint spraying thickness, and suitable for paint spraying for the inner wall of a large-diameter steel pipe of which the diameter is 3-10 m; microcomputer control is adopted to realize automatic operation, and manual operation is not needed; the weariness of an operator is relieved, and the working efficiency is improved; the coating is level, smooth, and free from brush marks; and paint is saved.

Owner:广东粤水电装备集团有限公司

Composite-coating continuous casting crystallizer copper plate with long service life and manufacturing technology thereof

InactiveCN104759596AExtended service lifeImprove efficiencyMolten spray coatingSuperimposed coating processManufacturing technologyWear resistant

The invention provides a composite-coating continuous casting crystallizer copper plate with a long service life and a manufacturing technology thereof and belongs to the technical field of electroplating. The composite-coating continuous casting crystallizer copper plate with the long service life comprises a copper plate substrate and a coating on the surface of the copper plate substrate. The coating comprises an upper electroplating layer and a lower coating layer. The upper electroplated layer is a pure nickel layer or a low-cobalt nickel alloy layer resistant to high temperature and corrosion. The mass percent of cobalt in the low-cobalt nickel alloy layer is not higher than 3%. The lower coating layer is a wear-resistant coating layer or a ceramic coating layer. According to the composite-coating continuous casting crystallizer copper plate with the long service life and the manufacturing technology thereof, the electroplating technology and the supersonic thermal coating technology are combined, the upper portion and the lower portion of the crystallizer copper plate are different alloy coating layers, the different requirements for the upper portion and the lower portion of the crystallizer copper plate in continuous casting are effectively met, the upper electroplating layer is not prone to thermally cracking and falling at a high temperature, the lower coating layer has the excellent wear-resistant performance, in this way, the service life of the continuous casting crystallizer copper plate is greatly prolonged, and the product quality is greatly improved.

Owner:XIXIA LONGCHENG SPECIAL MATERIALS CO LTD

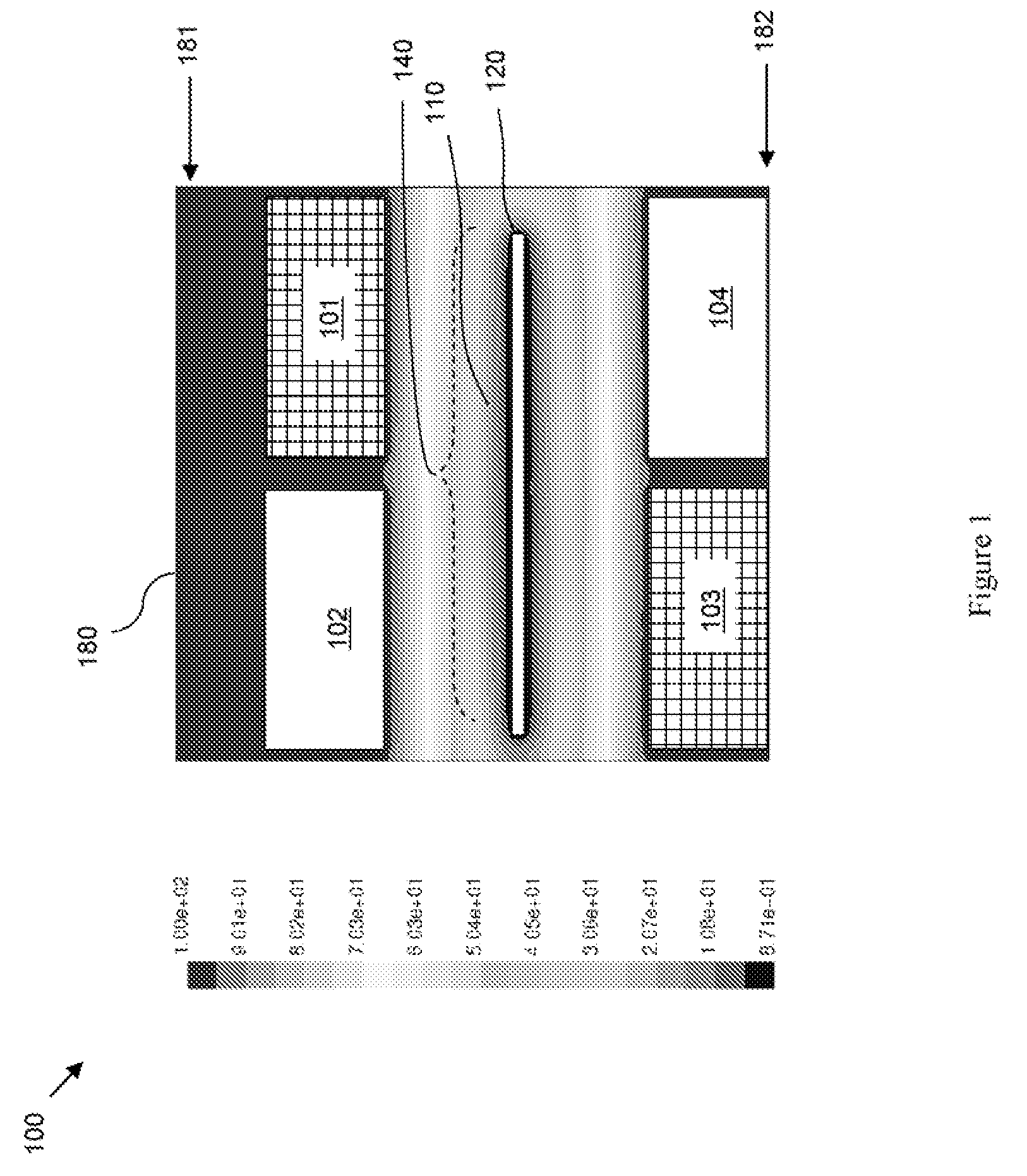

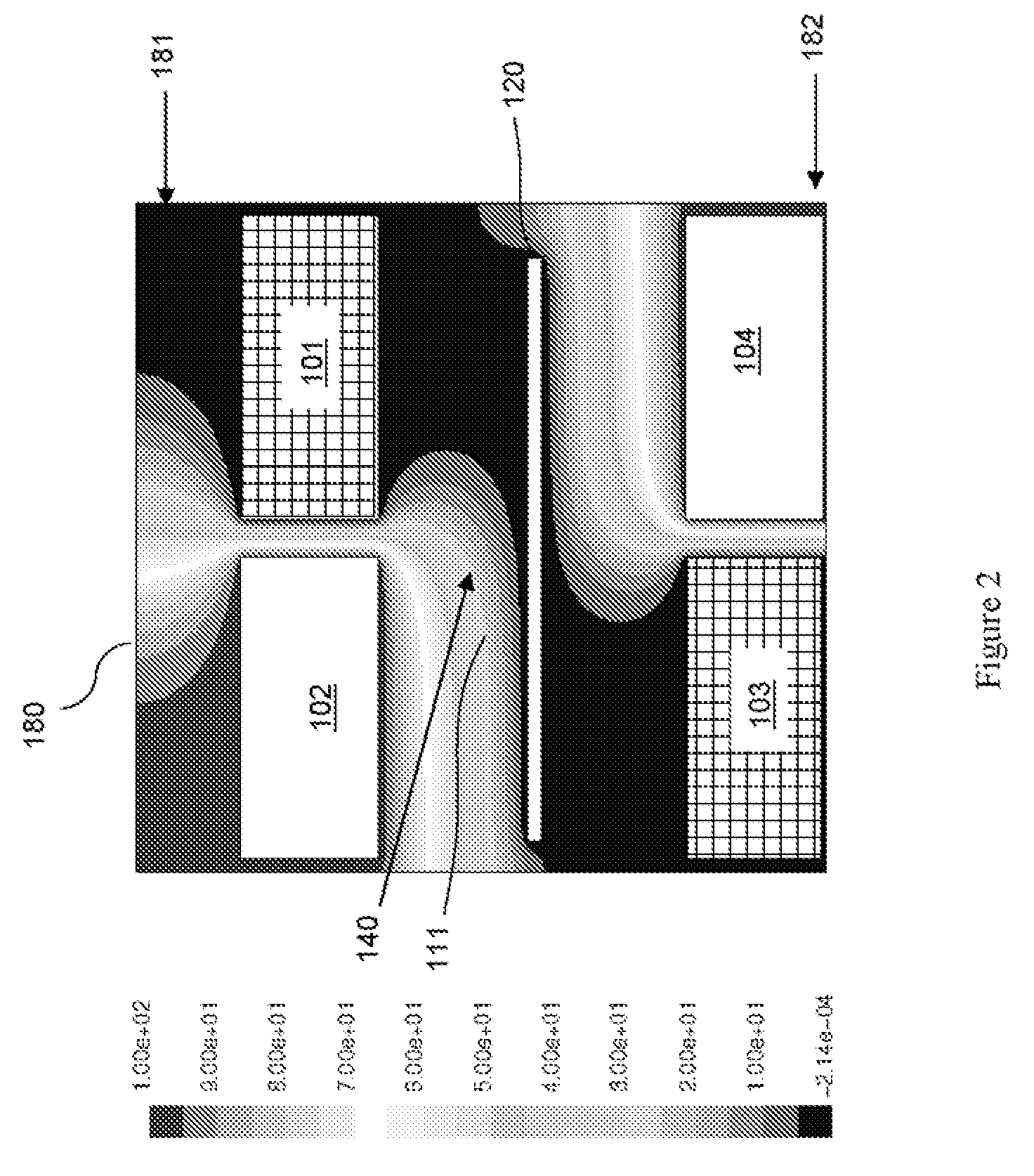

Multi-anode system for uniform plating of alloys

ActiveUS20080179192A1Uniform coating thicknessAvoid the needCellsCurrent conducting devicesElectricityPower flow

Disclosed are embodiments of an electroplating system and an associated electroplating method that allow for depositing of metal alloys with a uniform plate thickness and with the means to alter dynamically the alloy composition. Specifically, by using multiple anodes, each with different types of soluble metals, the system and method avoid the need for periodic plating bath replacement and also allow the ratio of metals within the deposited alloy to be selectively varied by applying different voltages to the different metals. The system and method further avoids the uneven current density and potential distribution and, thus, the non-uniform plating thicknesses exhibited by prior art methods by selectively varying the shape and placement of the anodes within the plating bath. Additionally, the system and method allows for fine tuning of the plating thickness by using electrically insulating selectively placed prescribed baffles.

Owner:MARVELL ASIA PTE LTD

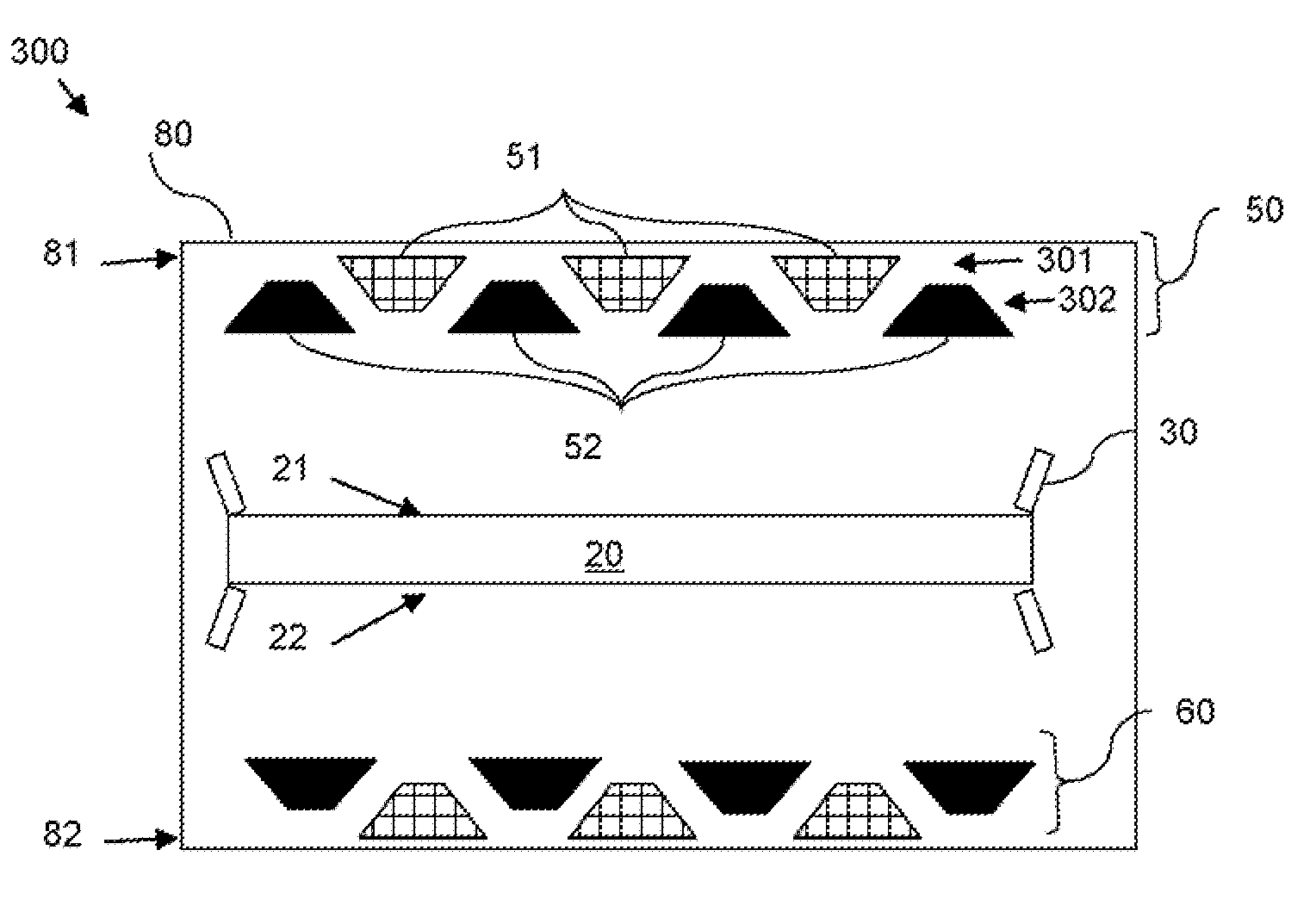

Electrical Charge Storage Device Having Enhanced Power Characteristics

InactiveUS20070285875A1Tighter the fit of the conformal coatingHigh bonding strengthElectrode carriers/collectorsSolid-state devicesElectricityElectrolysis

The present invention relates generally to an electrical charge storage device (ECSD) with enhanced power characteristics. More particularly, the present invention relates to enhancing the current density, voltage rating, power transfer characteristics, frequency response and charge storage density of various devices, such as capacitors, batteries, fuel cells and other electrical charge storage devices. For example, one aspect of the present invention is solid state and electrolytic capacitors where the conductor surface area is increased with smooth structures, thereby reducing the distance separating the conductors, and improving the effective dielectric characteristics by employing construction techniques on atomic, molecular, and macroscopic levels.

Owner:DUFF WILLIAM B JR

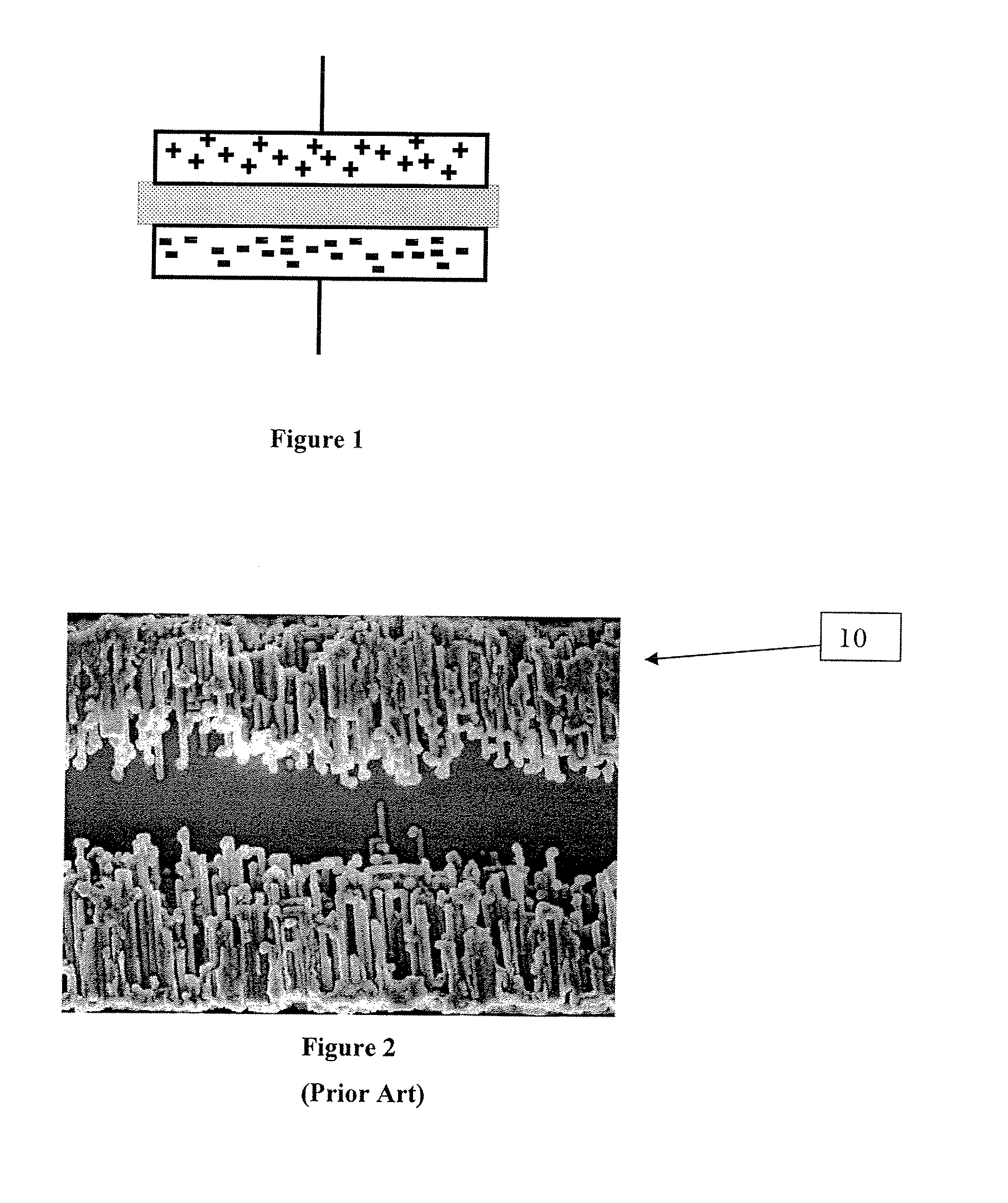

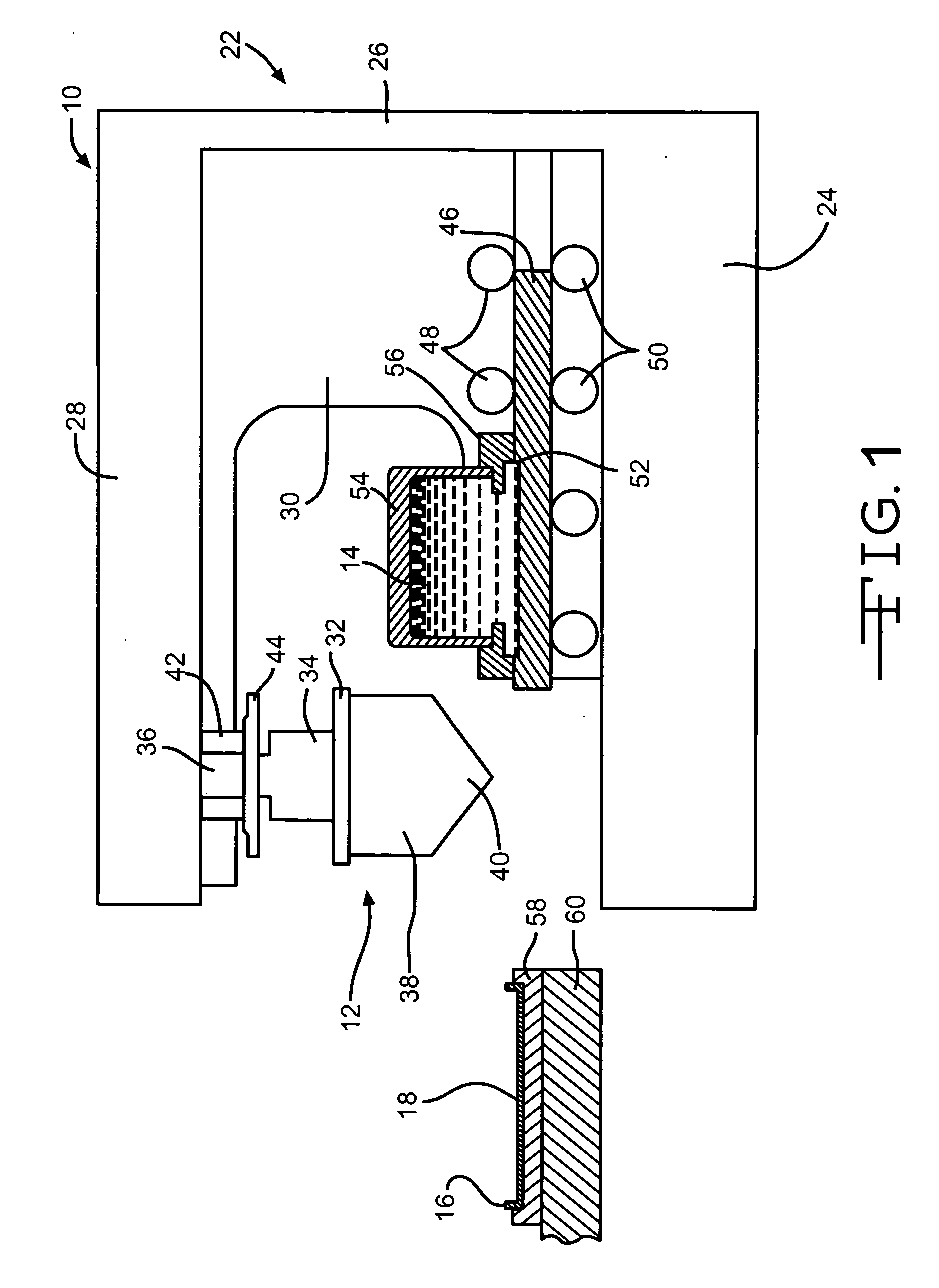

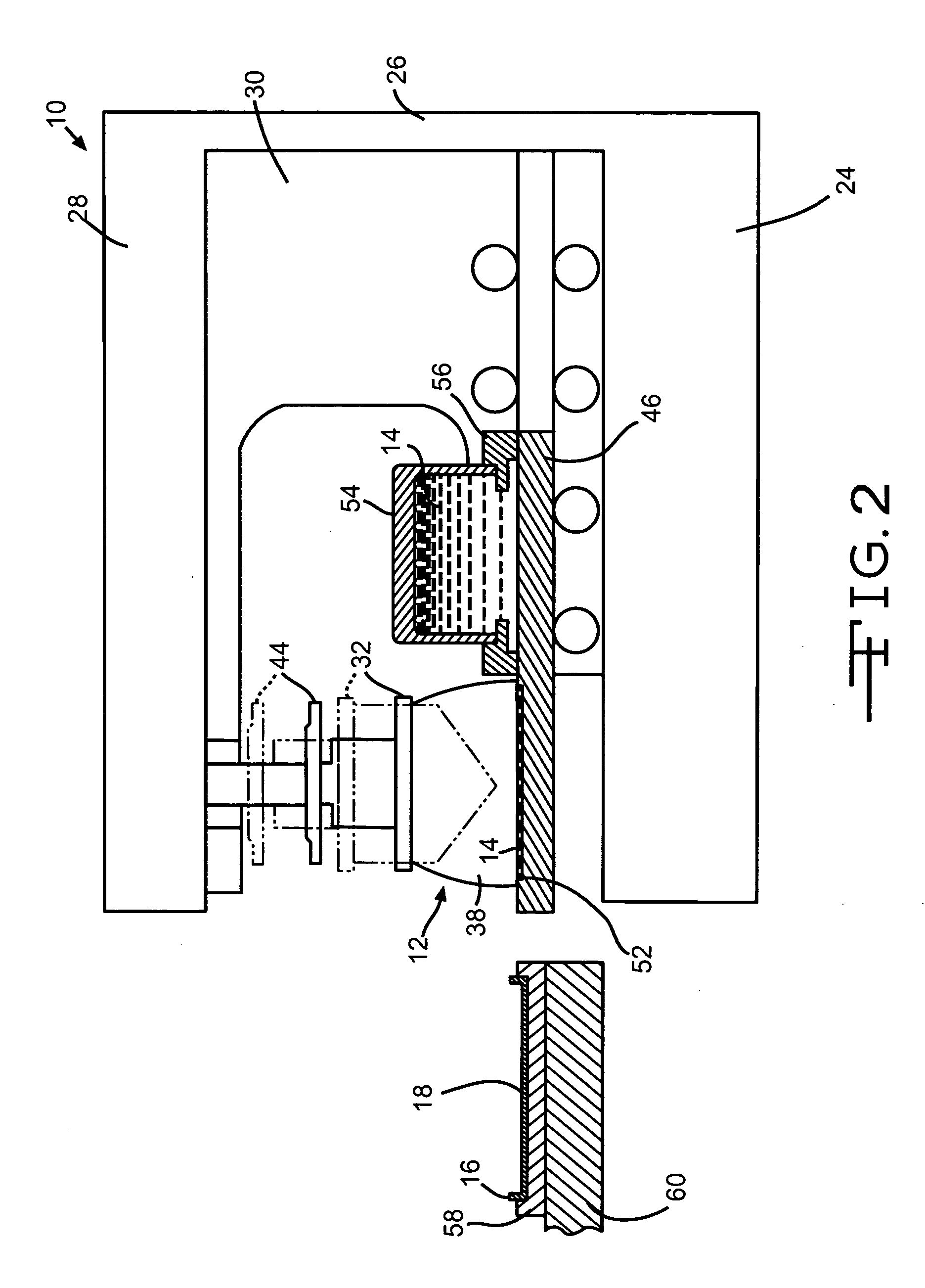

Use of pad printing in the manufacture of capacitors

ActiveUS20050041374A1Increase productionImprove adhesionRotary intaglio printing pressHybrid capacitor electrodesPad printingCarbide coating

Deposition of a metal-containing reagent solution or suspension onto a conductive substrate by various pad-printing techniques is described. This results in a pseudocapacitive oxide coating, nitride coating, carbon nitride coating, or carbide coating having an acceptable surface area for incorporation into an electrolytic capacitor, such a s one have a tantalum anode.

Owner:WILSON GREATBATCH LTD

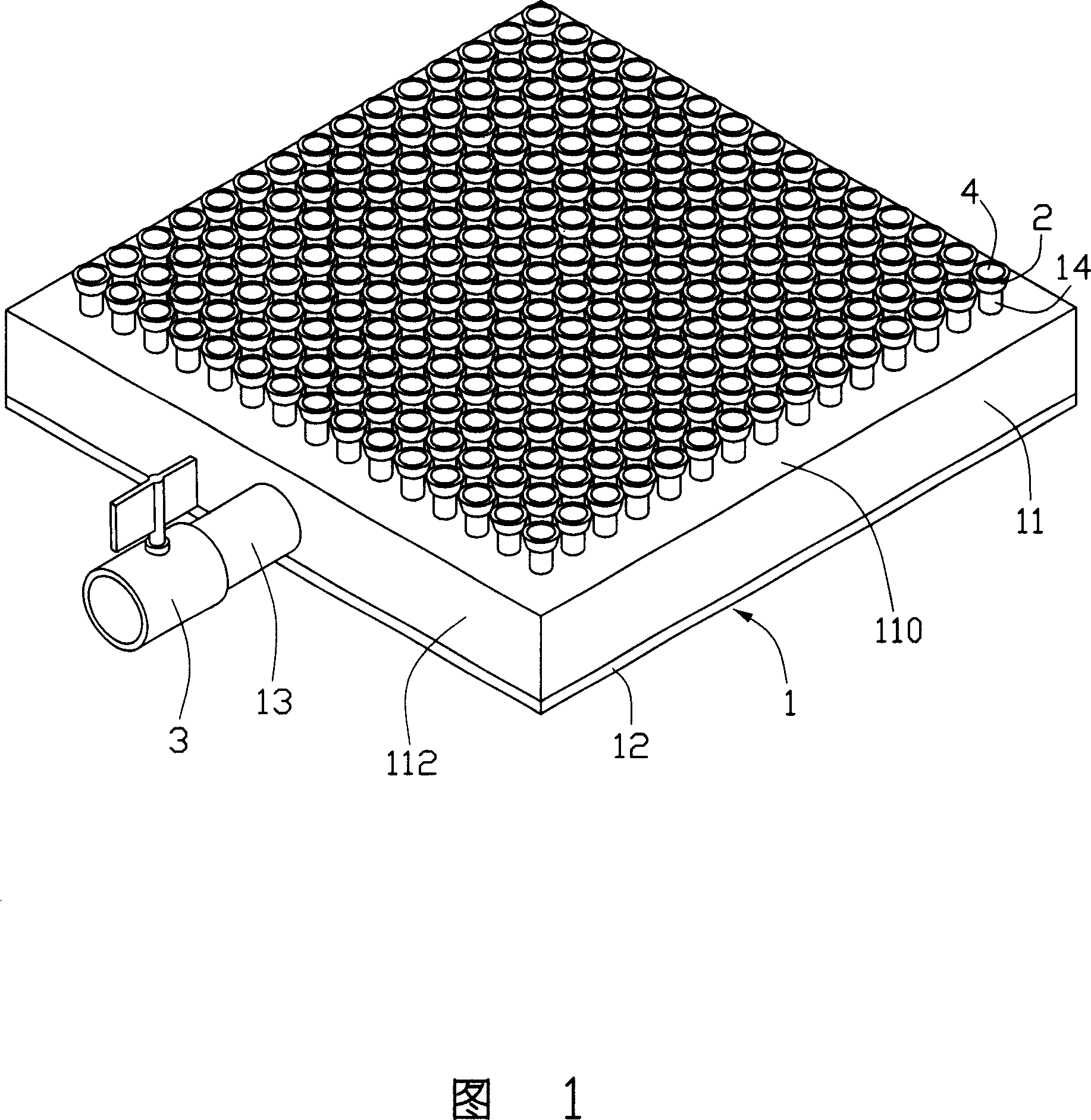

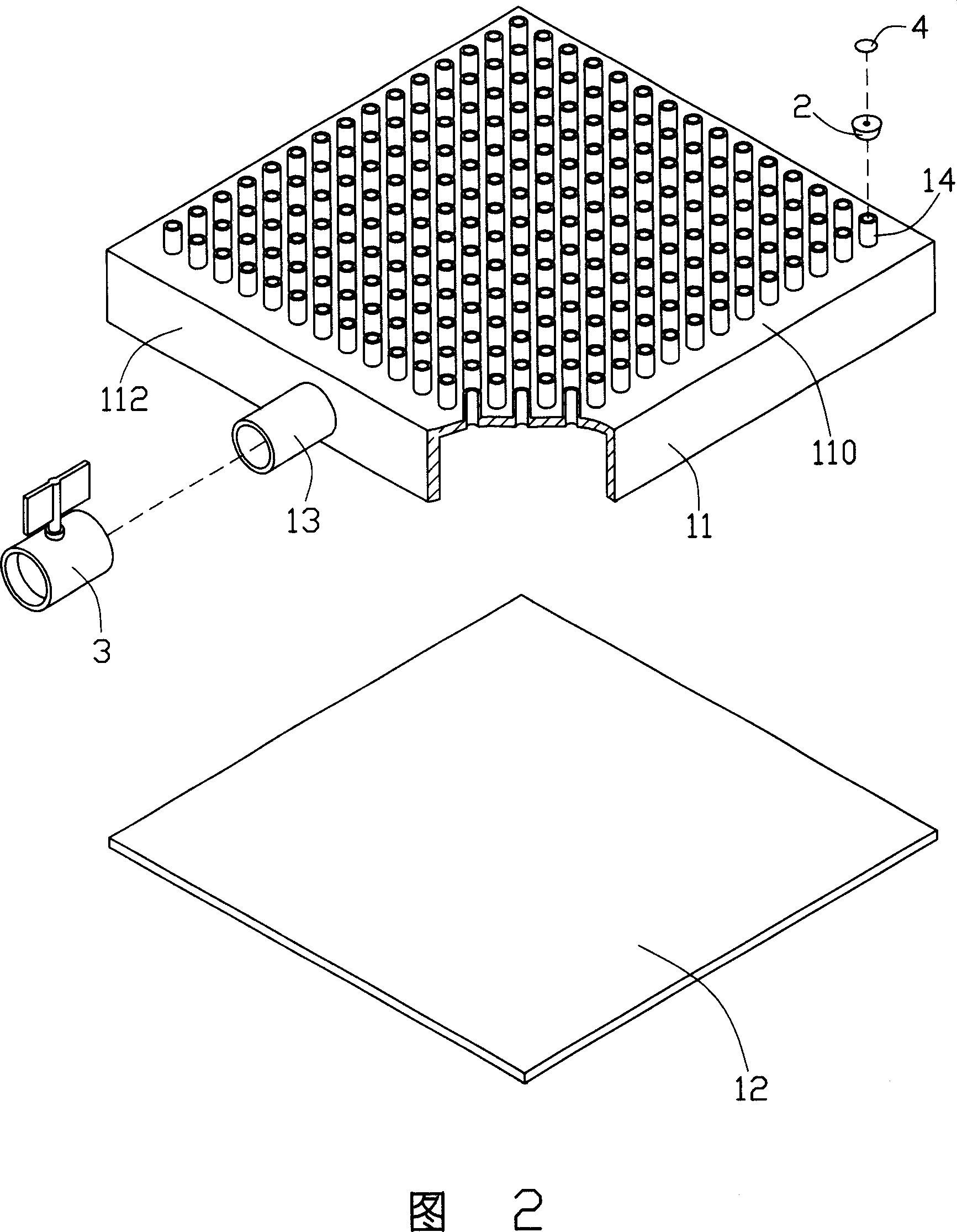

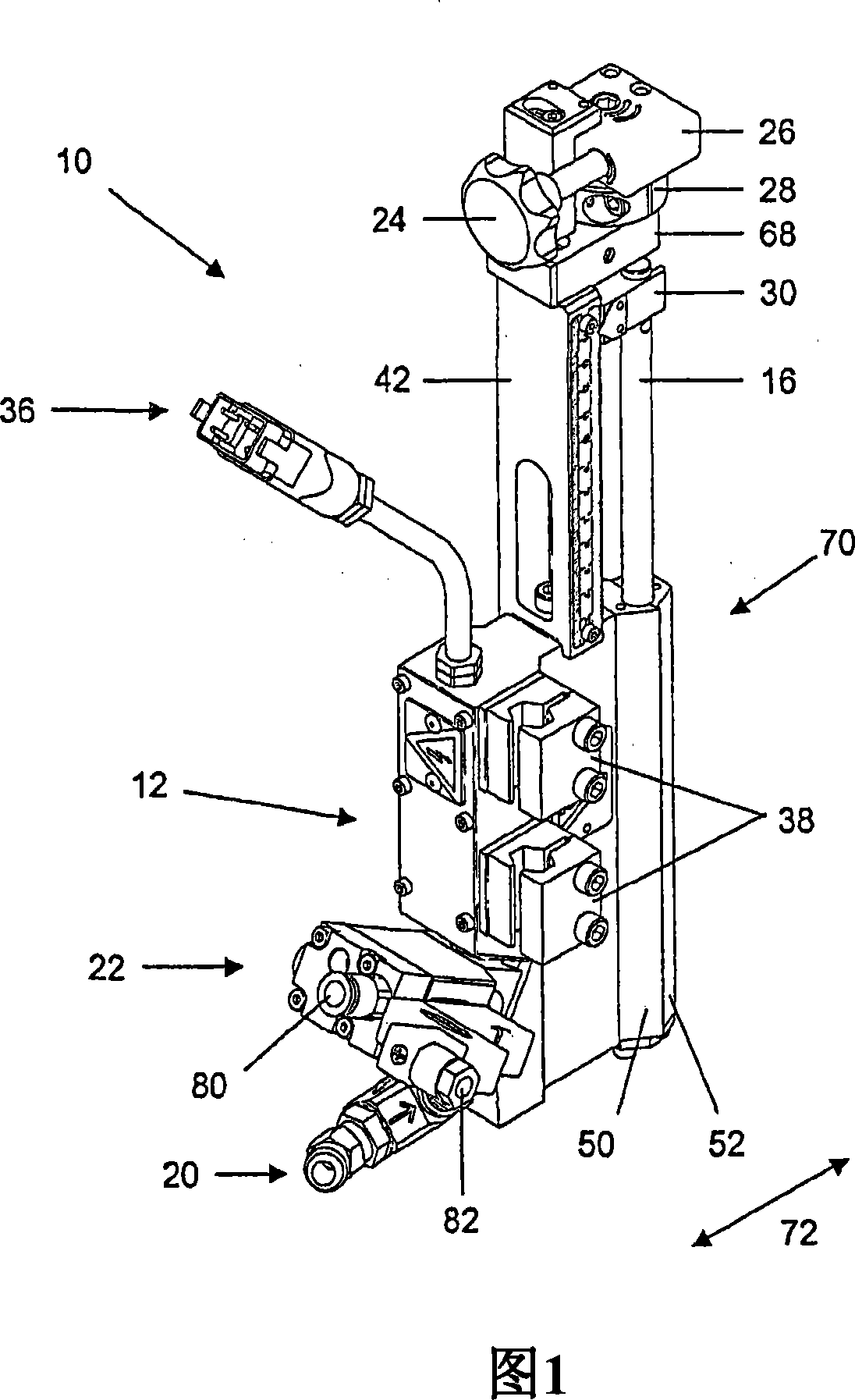

Automatic spraying robot device

ActiveCN104549849AReduce pollutionImprove flexibilitySpraying apparatusControl mannerEconomic benefits

The invention relates to an automatic spraying robot device in the field of automatic coating of an aircraft. The automatic spraying robot device comprises a movable spraying robot consisting of a three-vertical-coordinate-axis movable platform and a spraying execution mechanism, and a barrel supporting autorotation tool, wherein the three-vertical-coordinate-axis movable platform is connected with the spraying execution mechanism in a sliding manner and arranged on a slide rail at one side of a storage box, and the barrel supporting autorotation tool is connected with the storage box in a rotating manner. While the robot moves rapidly along a Y axis, a spray head can form any dihedral angle of 0 to 90 degrees with a YZ plane by adopting the Y axis as an intersection line, so that the spraying in the downward vertical direction, oblique upward direction and horizontal direction can be realized, and the automatic spraying robot device can be adaptive to storage boxes of different diameters and different work conditions, and the flexibility is very high, in addition, the automatic spraying robot can move to an arc end surface, an appropriate distance between the spray head and the arc end surface can be realized, and the vertical uniform automatic spraying can be realized in real time. The automatic spraying robot device is compact in layout, high in flexibility, simple in control way, high in spraying precision, uniform in coating thickness, small in environmental pollution, high in spraying efficiency and good in economic benefit.

Owner:SHANGHAI JIAO TONG UNIV

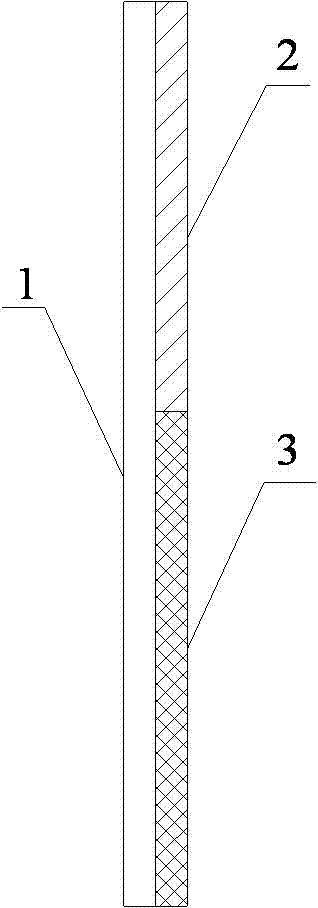

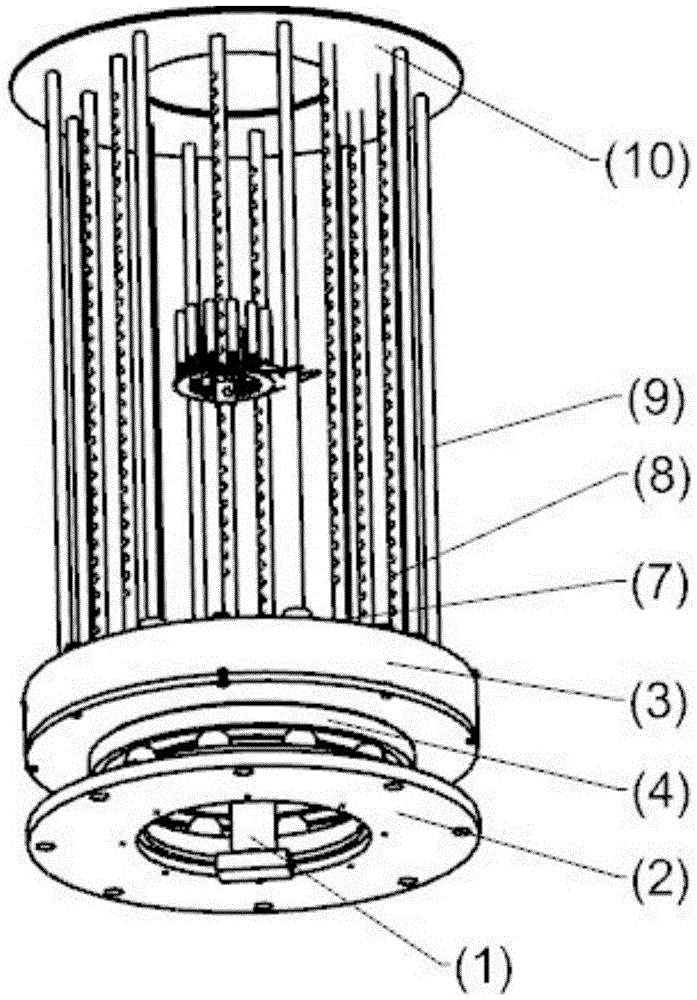

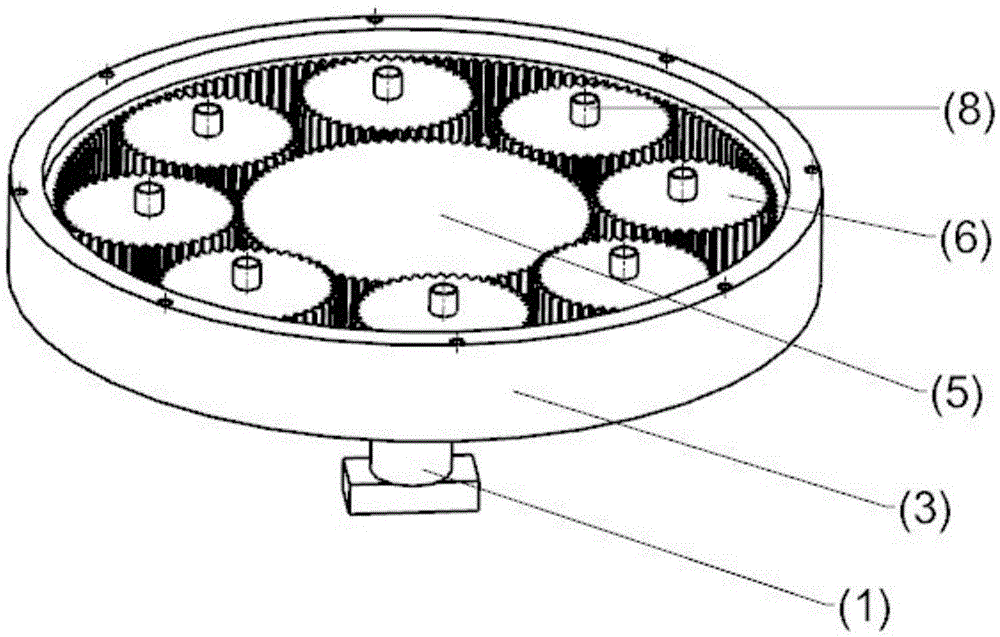

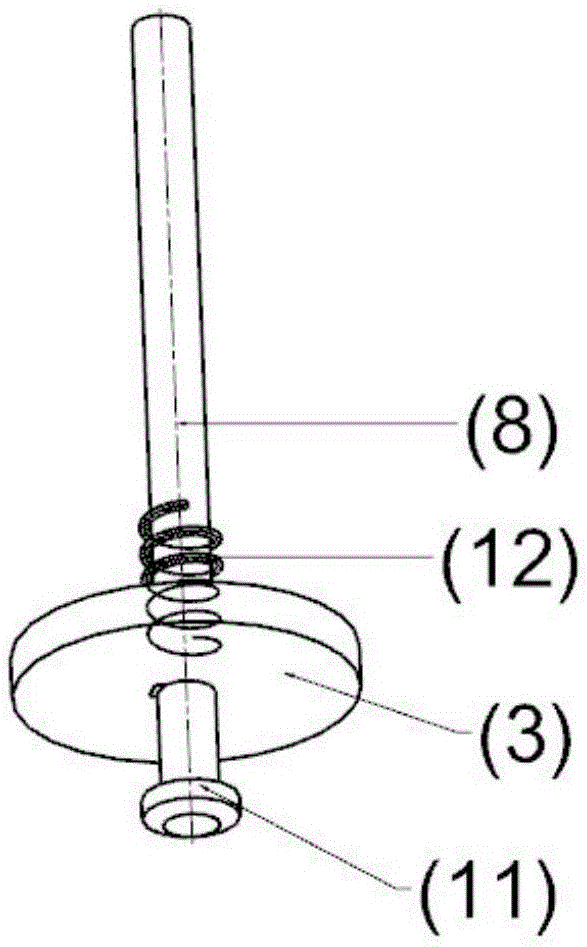

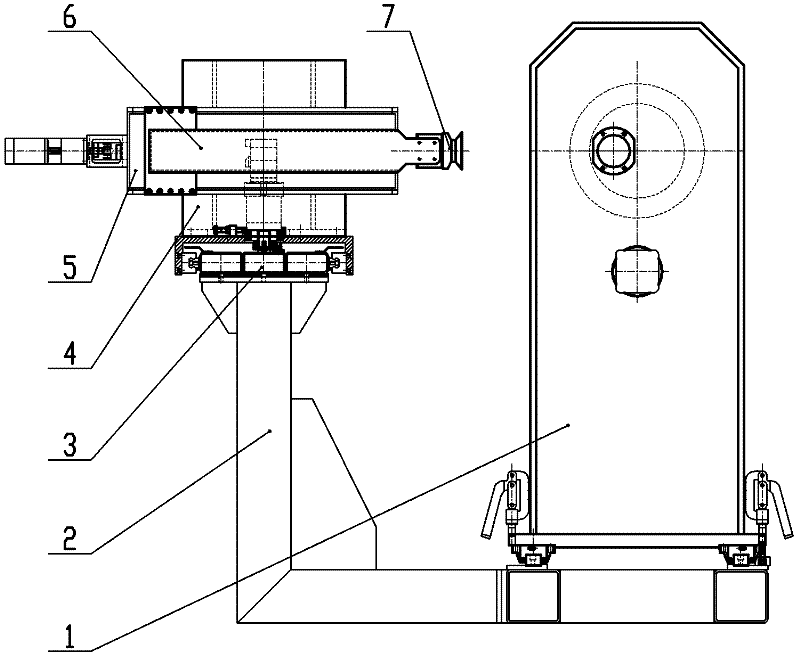

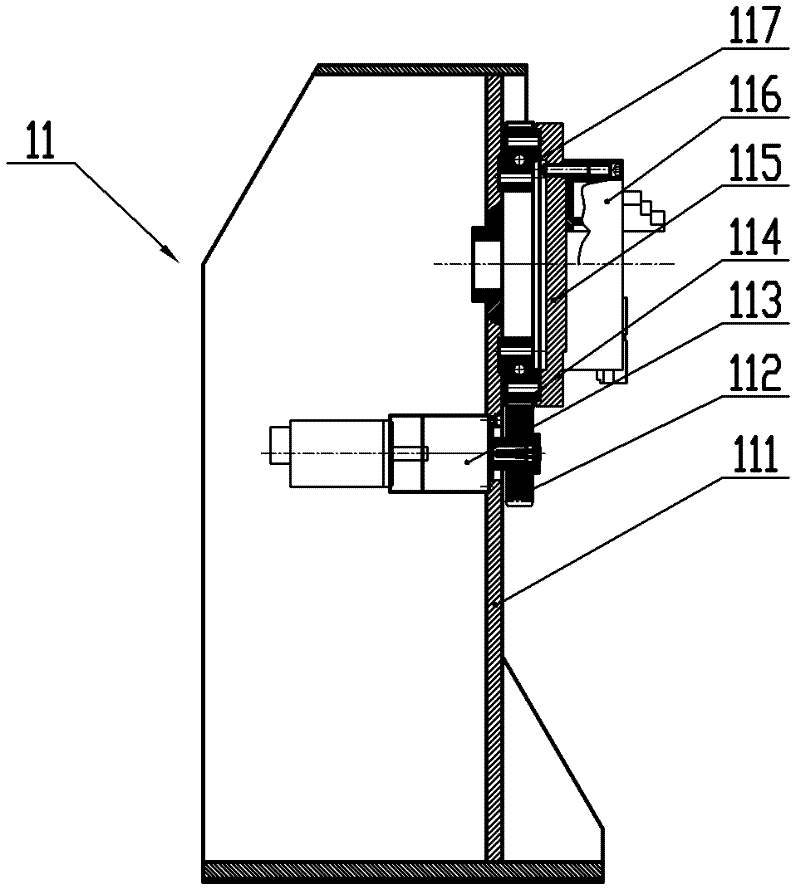

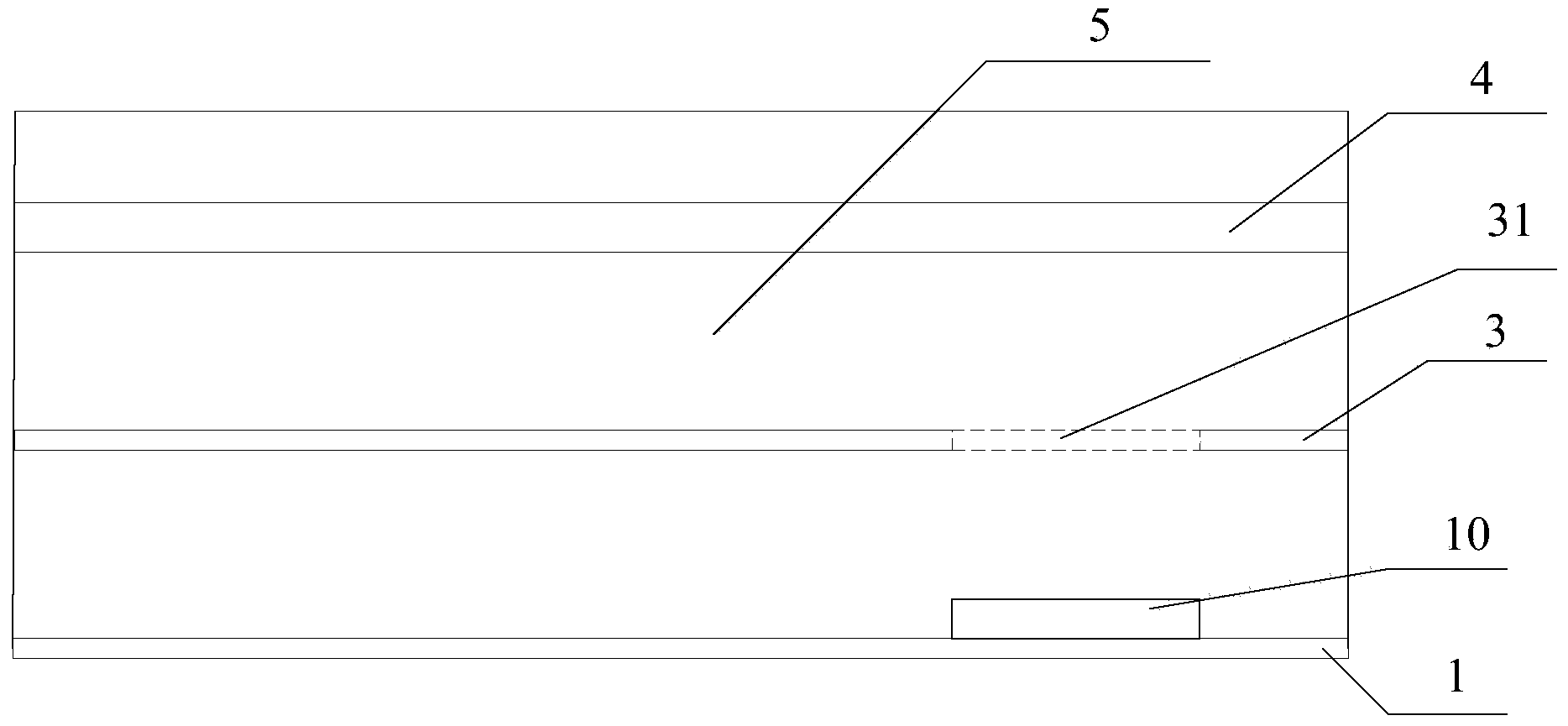

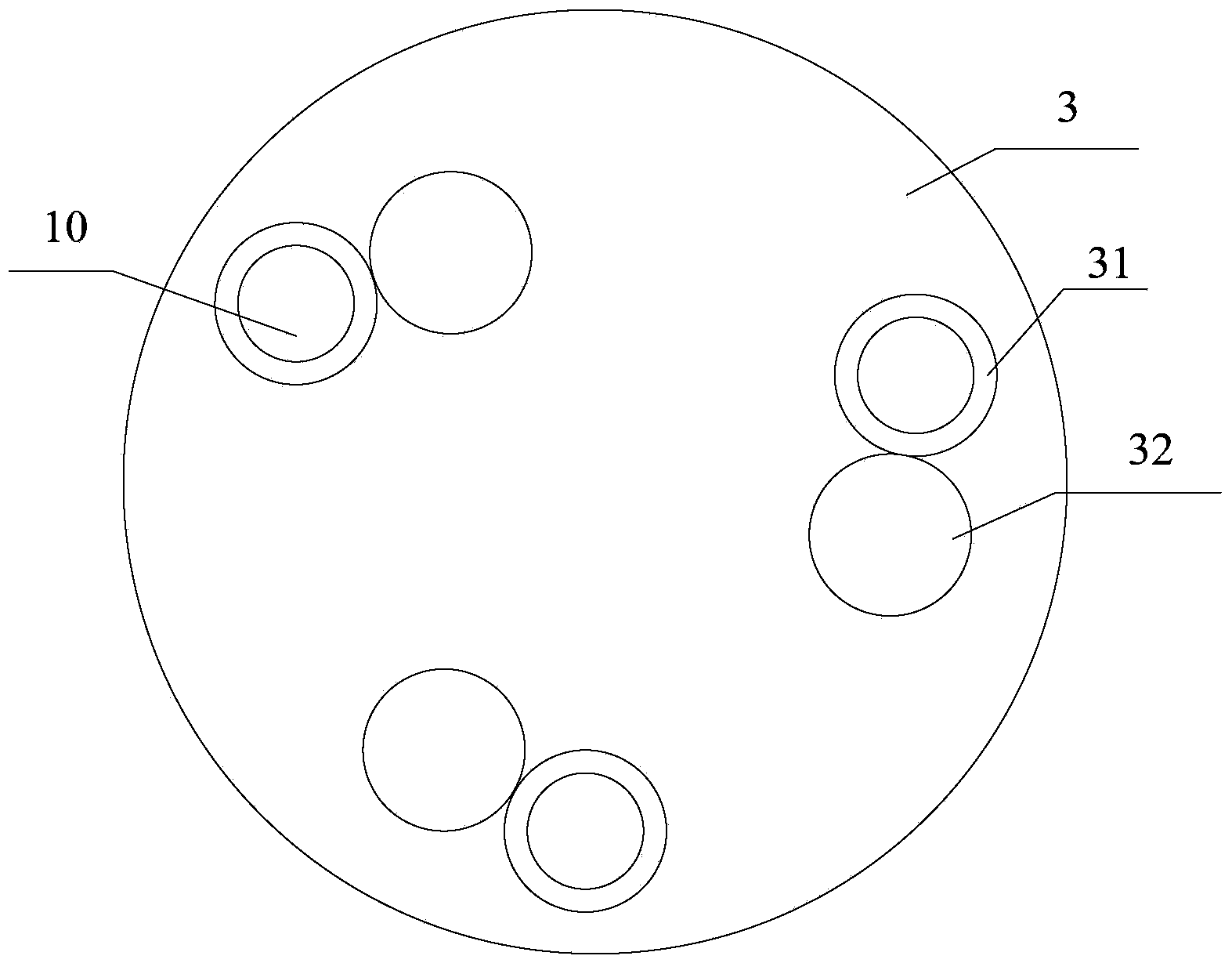

Flexible rotary workbench for preparing physical vapor deposition (PVD) coating on tool

InactiveCN105586577AUniform heightUniform coating thicknessVacuum evaporation coatingSputtering coatingInterference fitBall bearing

The invention relates to a flexible rotary workbench for preparing a physical vapor deposition (PVD) coating on a tool. The flexible rotary workbench comprises a driving rod (1), a lower rotary table (2), an upper rotary table (3), a thrust ball bearing (4) and clamping body fixing rods (8). The thrust ball bearing (4) is arranged between the upper rotary table (3) and the lower rotary table (2). A big gear (5) and pinions (6) are arranged in the upper rotary table (3). The pinions (6) are engaged with the big gear (5). The big gear (5) is in interference fit with the driving rod (1). The upper rotary table (3) is engaged with the pinions (6). A cover plate is arranged at the upper end of the upper rotary table (3). The clamping body fixing rods (8) penetrate through the cover plate (7) and are connected with the pinions (6). The clamping body fixing rods (8) are driven by the pinions (6) to revolve and rotate. Revolution and rotation of the tool to be coated can be achieved through the cooperation of the flexible rotary workbench and a clamping body matched with the workbench, so that the surface of the tool to be coated is evenly coated with required coating materials, and the coating thickness is uniform.

Owner:SHANGHAI INST OF TECH

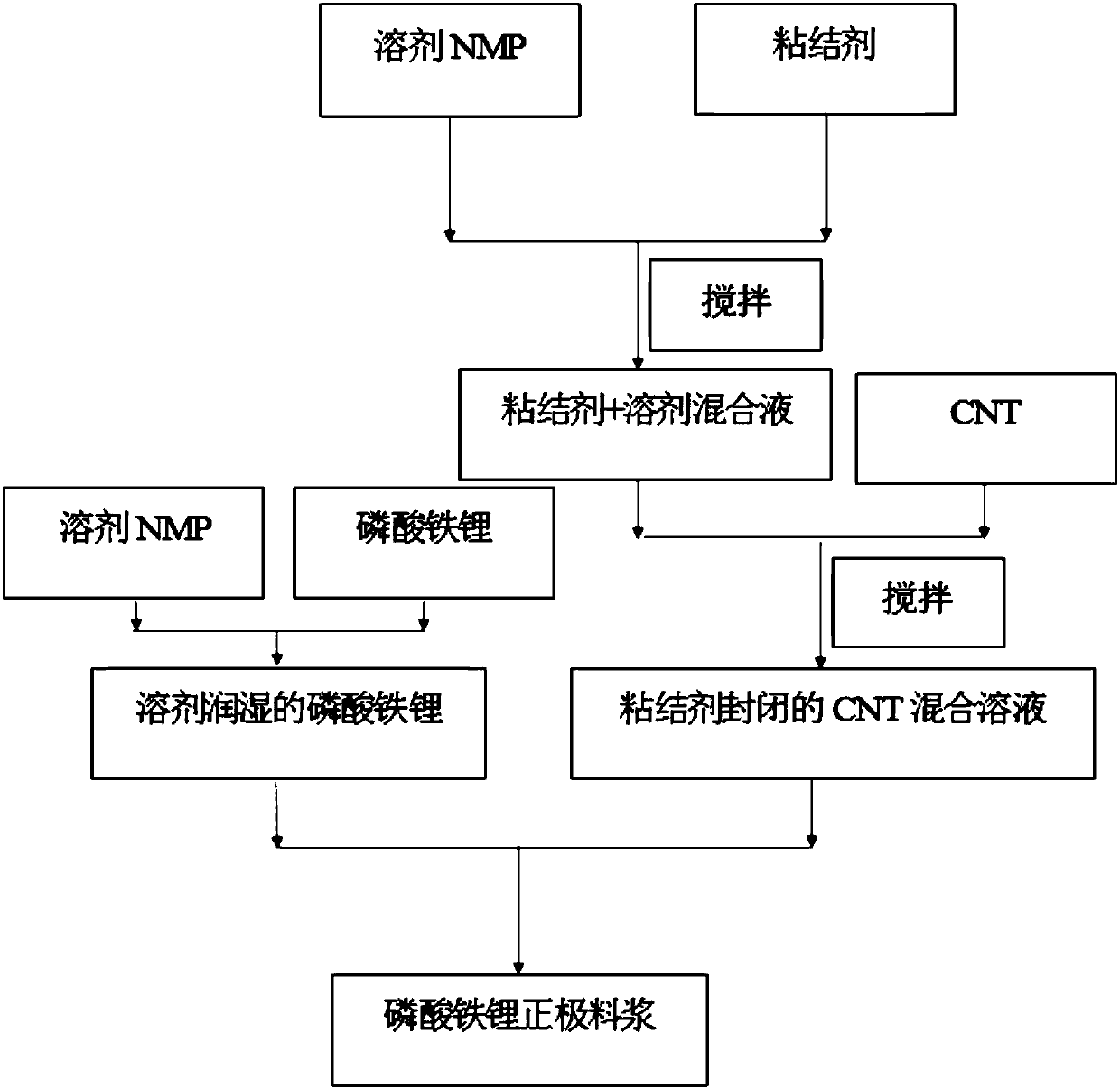

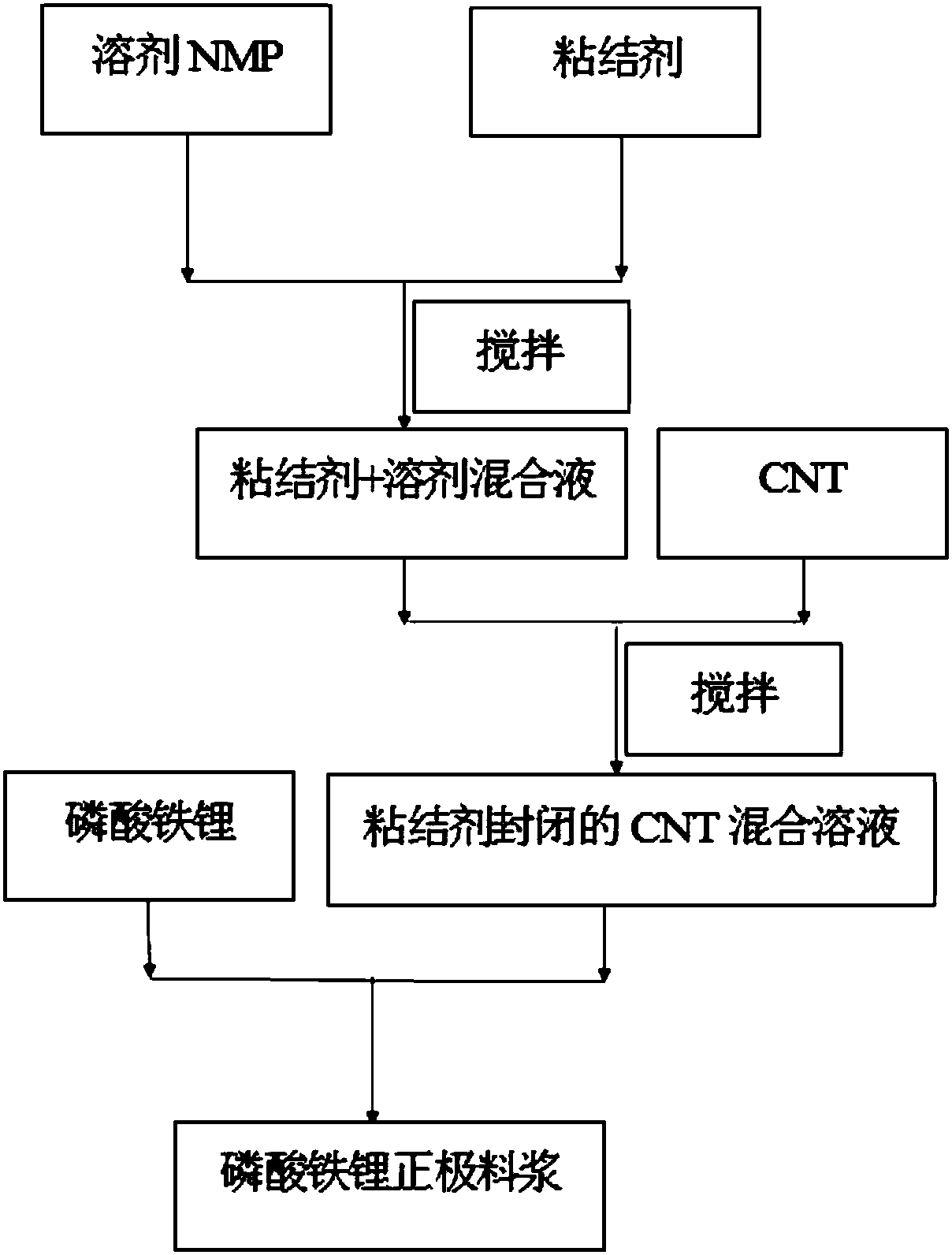

Preparation method of battery slurry with high solid content

ActiveCN107834019AHigh solid contentGood dispersionElectrode manufacturing processesSecondary cellsCarbon nanotubeSlurry

The invention belongs to the field of preparation of positive pole slurry of a lithium-ion battery, and particularly relates to a preparation method of battery slurry with high solid content. The preparation method comprises the following steps: 1) mixing a binder polyvinylidene difluoride resin with a solvent to prepare a meta-polyvinyl difluoride adhesive solution; 2) adding carbon-nanotube conductive slurry and a surface active agent into the meta-polyvinyl difluoride adhesive solution for mixing to obtain a carbon-nanotube mixed solution sealed by the binder; 3) adding a positive pole active substance into a solvent for soaking, thus obtaining soaking liquid of the positive pole active substance; 4) adding the carbon-nanotube mixed solution sealed by the binder into the fully-wetted positive pole active substance, and stirring for dispersion to obtain the positive pole slurry containing carbon nanotubes. The preparation method has the advantages that the dispersion uniformity of all the components in the positive pole slurry is good, and the dispersion uniformity of the carbon nanotubes is high; the surface active agent is added in the dispersion process, and the binder adoptedis a polymer, and in the process, the surface active agent and the polymer generate bidirectional action to disperse the carbon nanotubes in an auxiliary manner, so that the problem of agglomerationof the carbon nanotubes is avoided.

Owner:沈阳国科金能科技有限公司

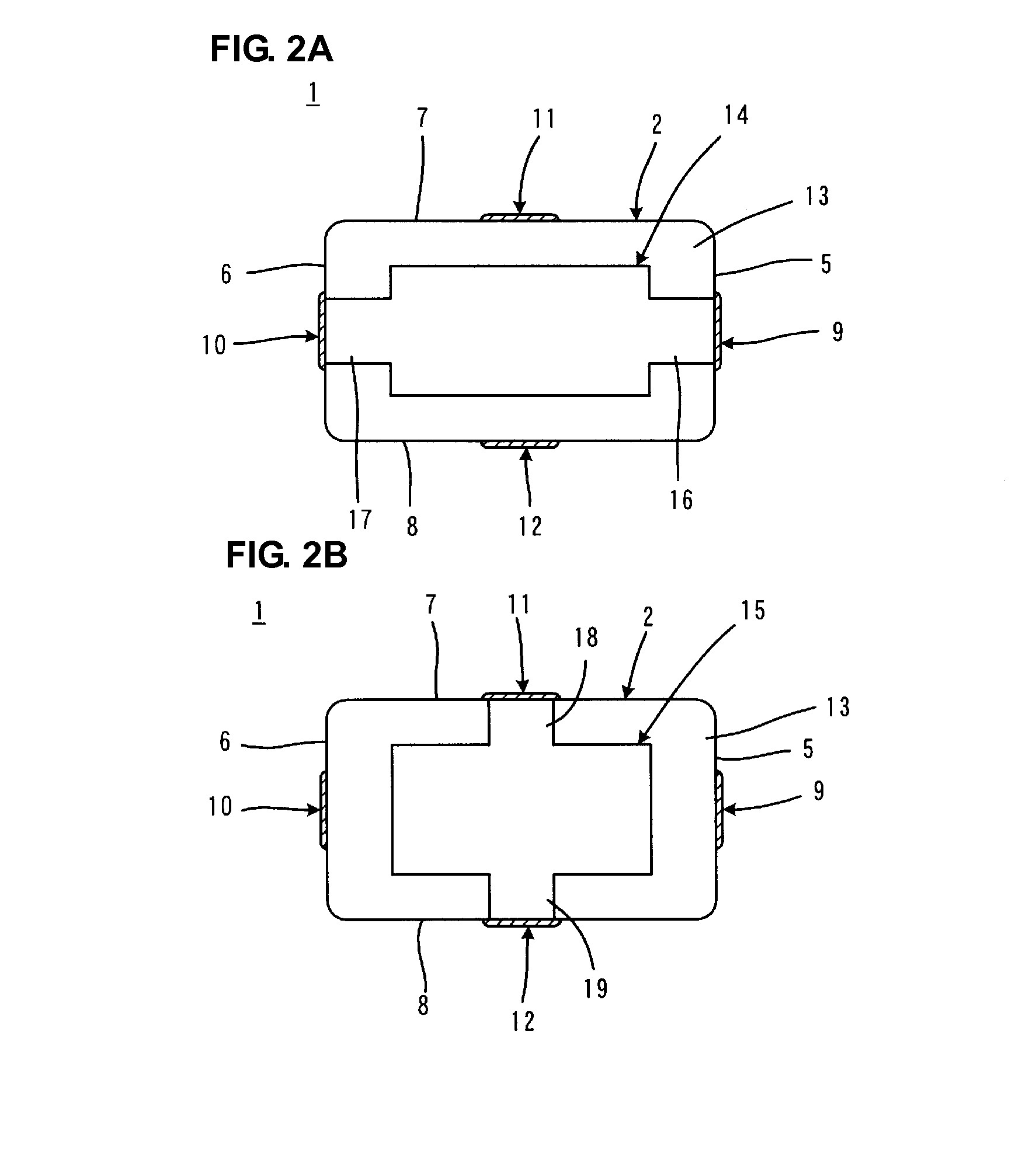

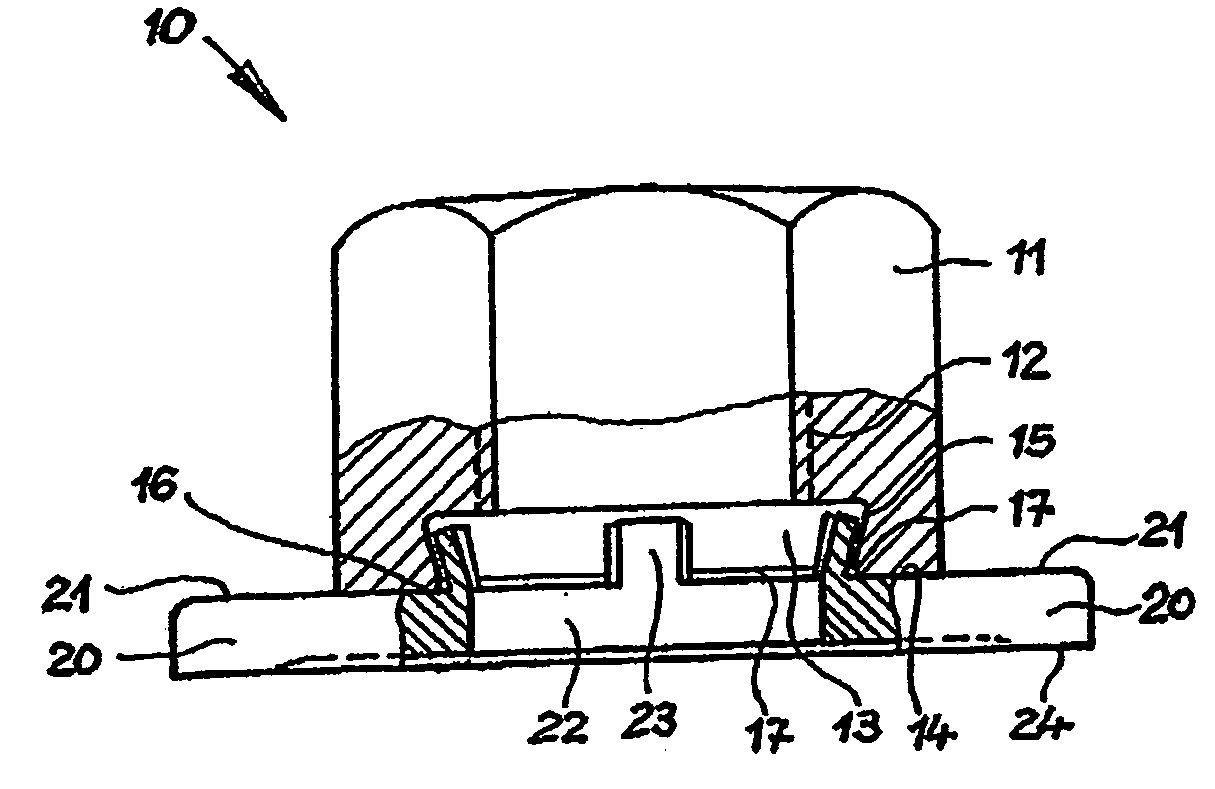

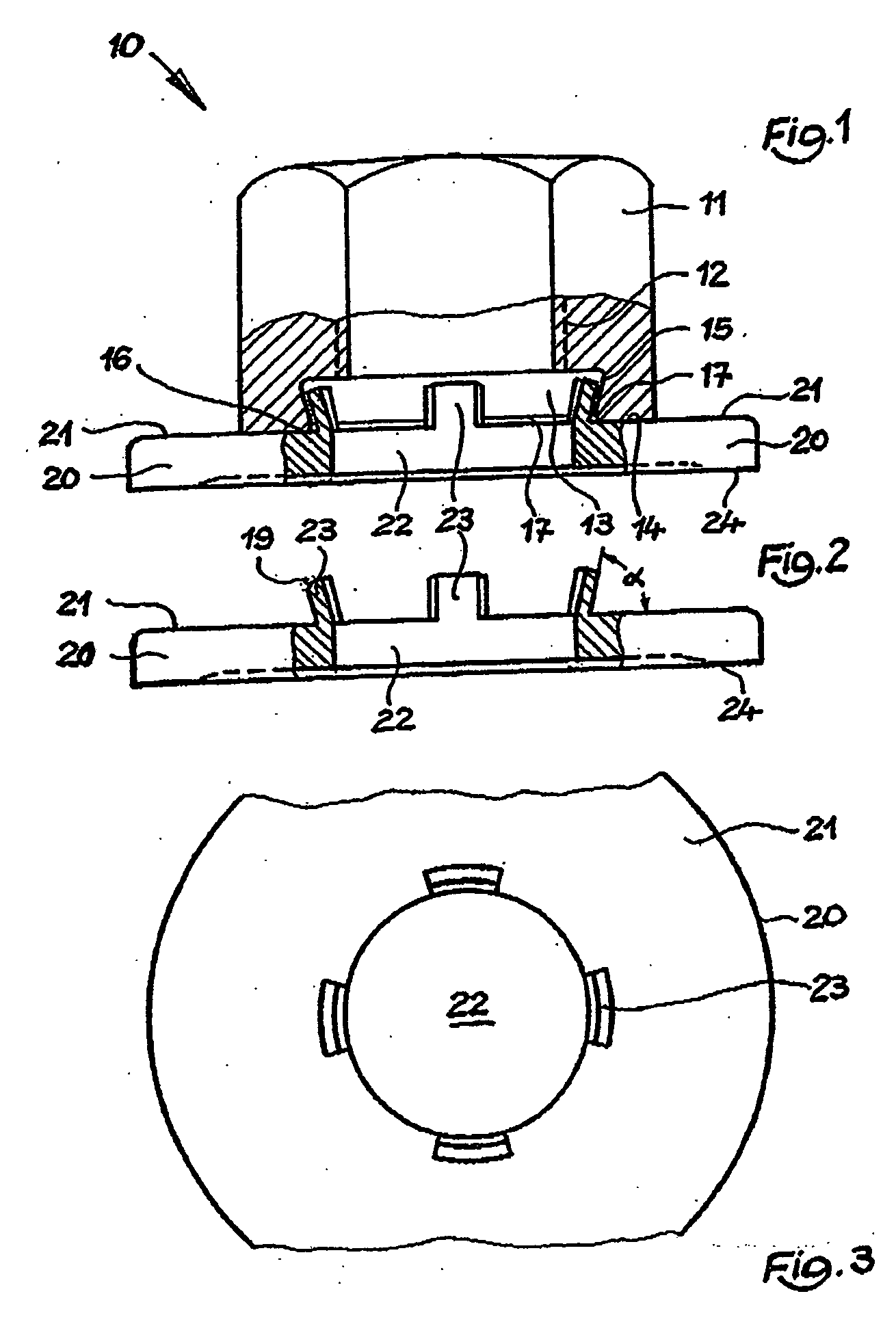

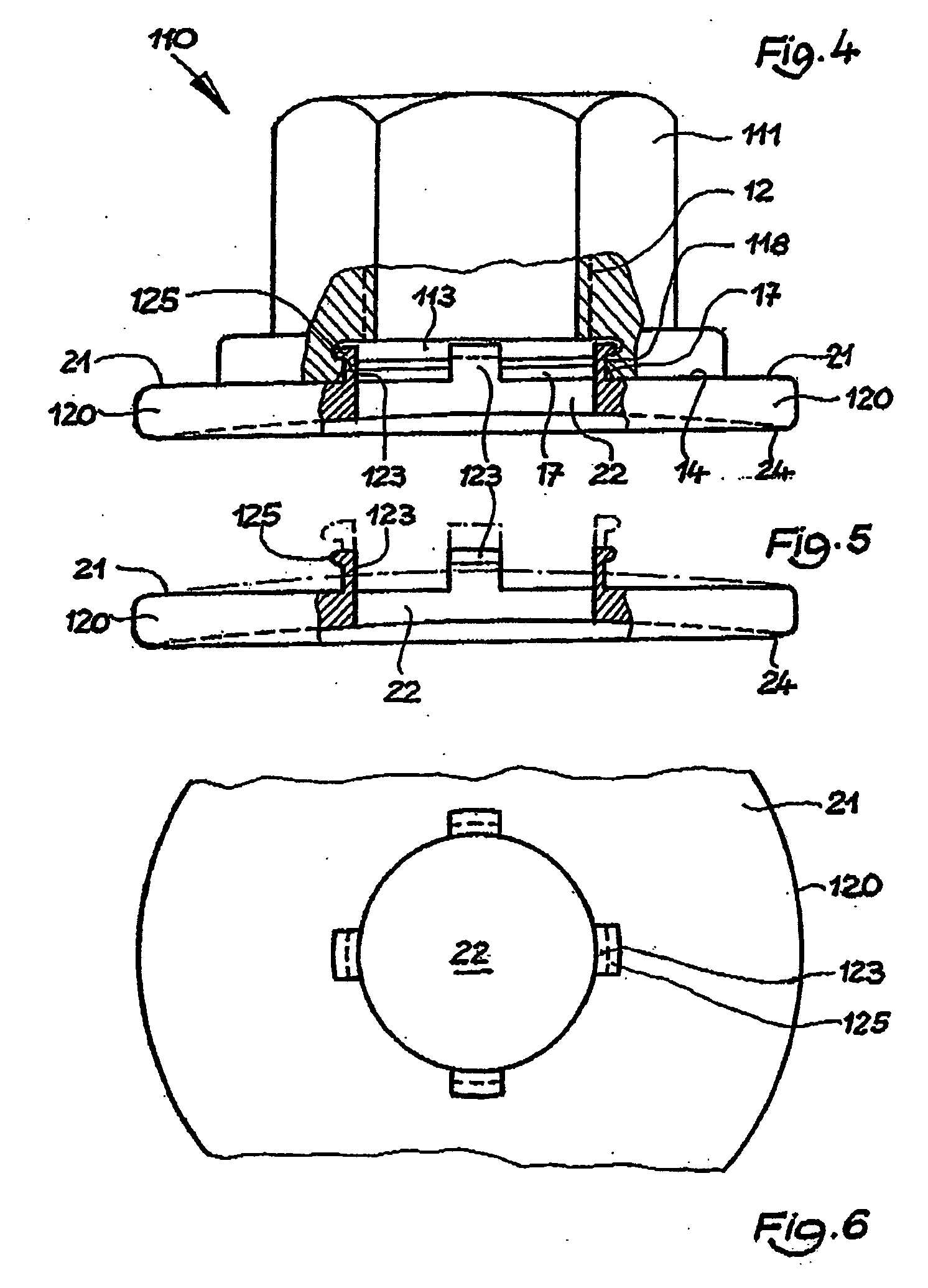

Fastening element, washer and fastening means therefrom

InactiveUS20050220567A1Reduce material consumptionLow production costPinsWashersSubject matterEngineering

The present invention relates to a fastening means (10; 110) consisting of a fastening element (11; 111) and a washer (20; 120), the washer (20; 120) being held on the fastening element (11; 111) in a rotatable and captive manner. Furthermore, the subject matter of the invention is such a fastening element (11; 111) which has at one end a bearing surface (14) for a washer (20; 120) held on the fastening element (11; 111) in a rotatable and captive manner and has an encircling undercut (13; 113) at the end facing its bearing surface (14). Finally, the subject matter of the invention is a washer (20; 120) having a contact surface (21) for the bearing surface (14) of a fastening element (11; 111), at least two axially extending retaining tabs (23; 123) being formed on the contact surface (21). The retaining tabs (23; 123) engage in the undercut (13; 113).

Owner:METALLWARENFAB HERMANN WINKER

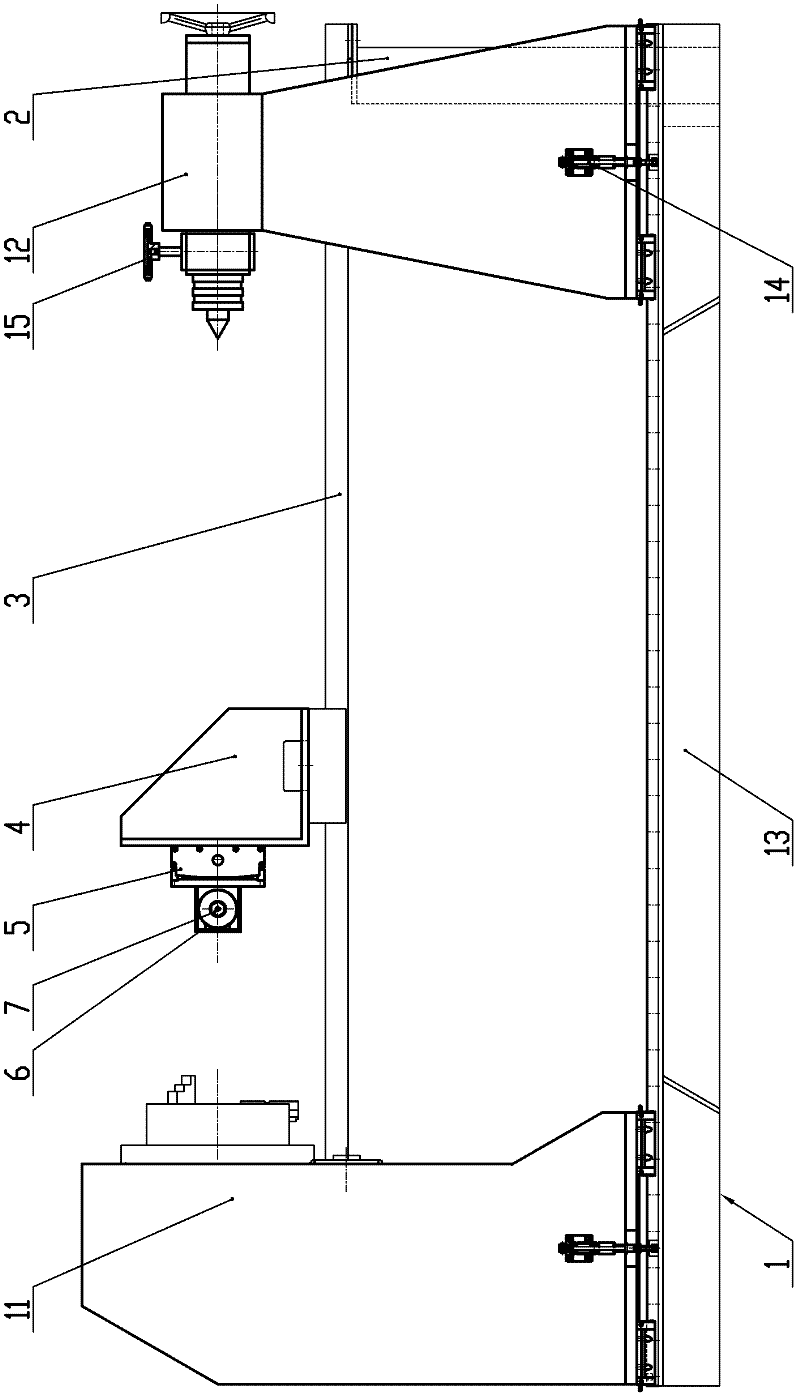

Arc spraying device for shaft parts

ActiveCN102266826ARealize automatic sprayingReduce labor intensityLiquid spraying plantsMachine toolArc spray

Owner:无锡洲翔成套焊接设备有限公司

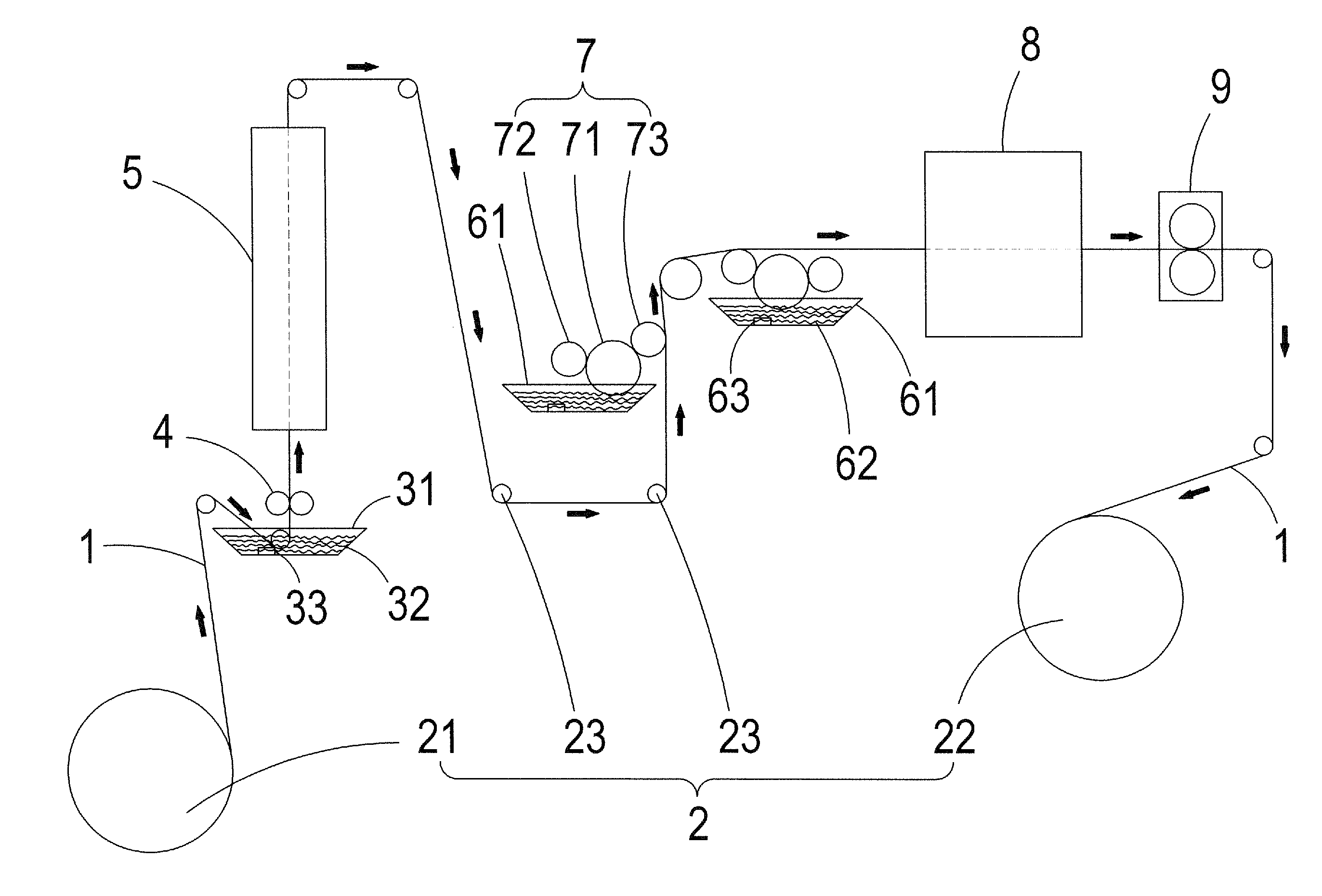

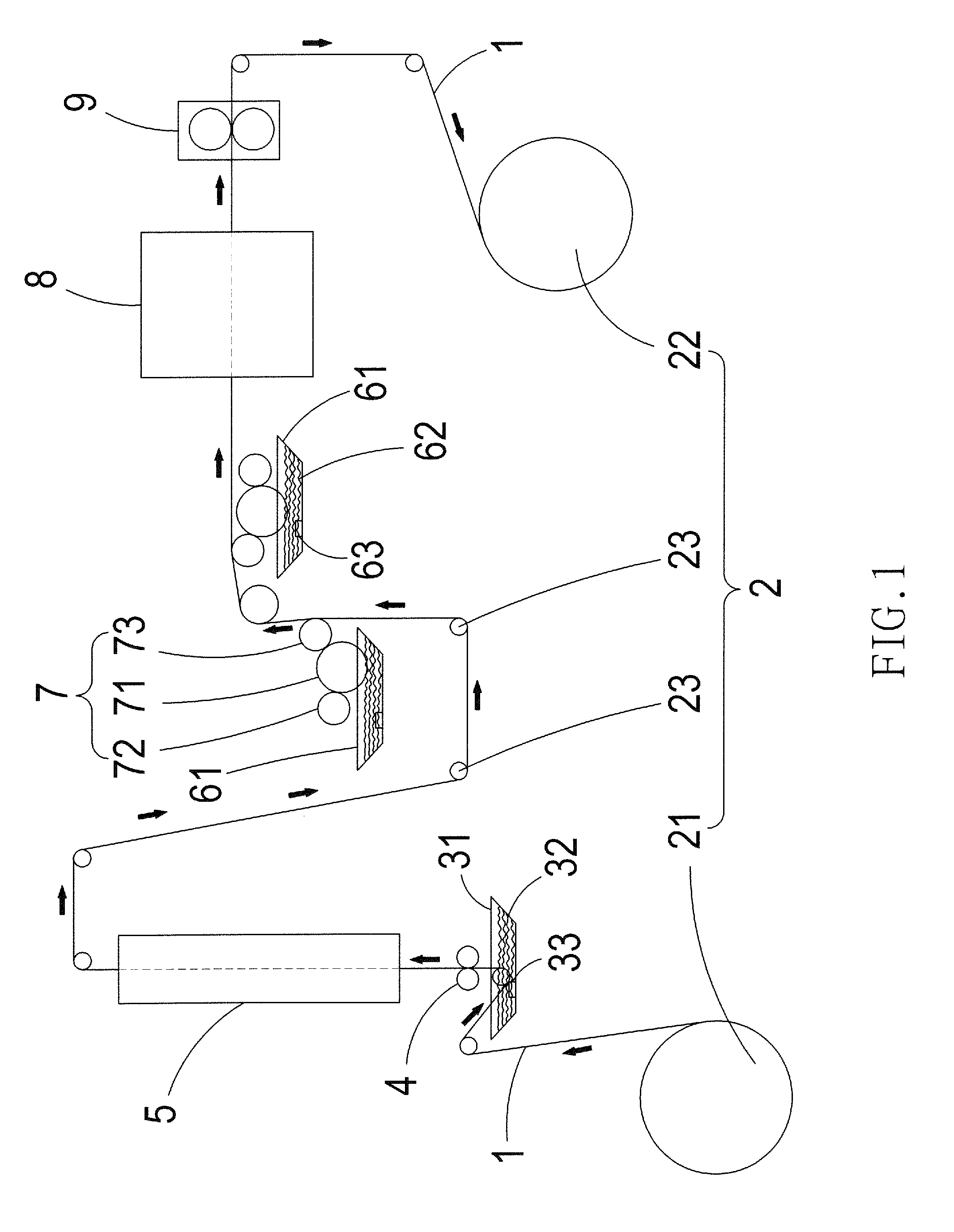

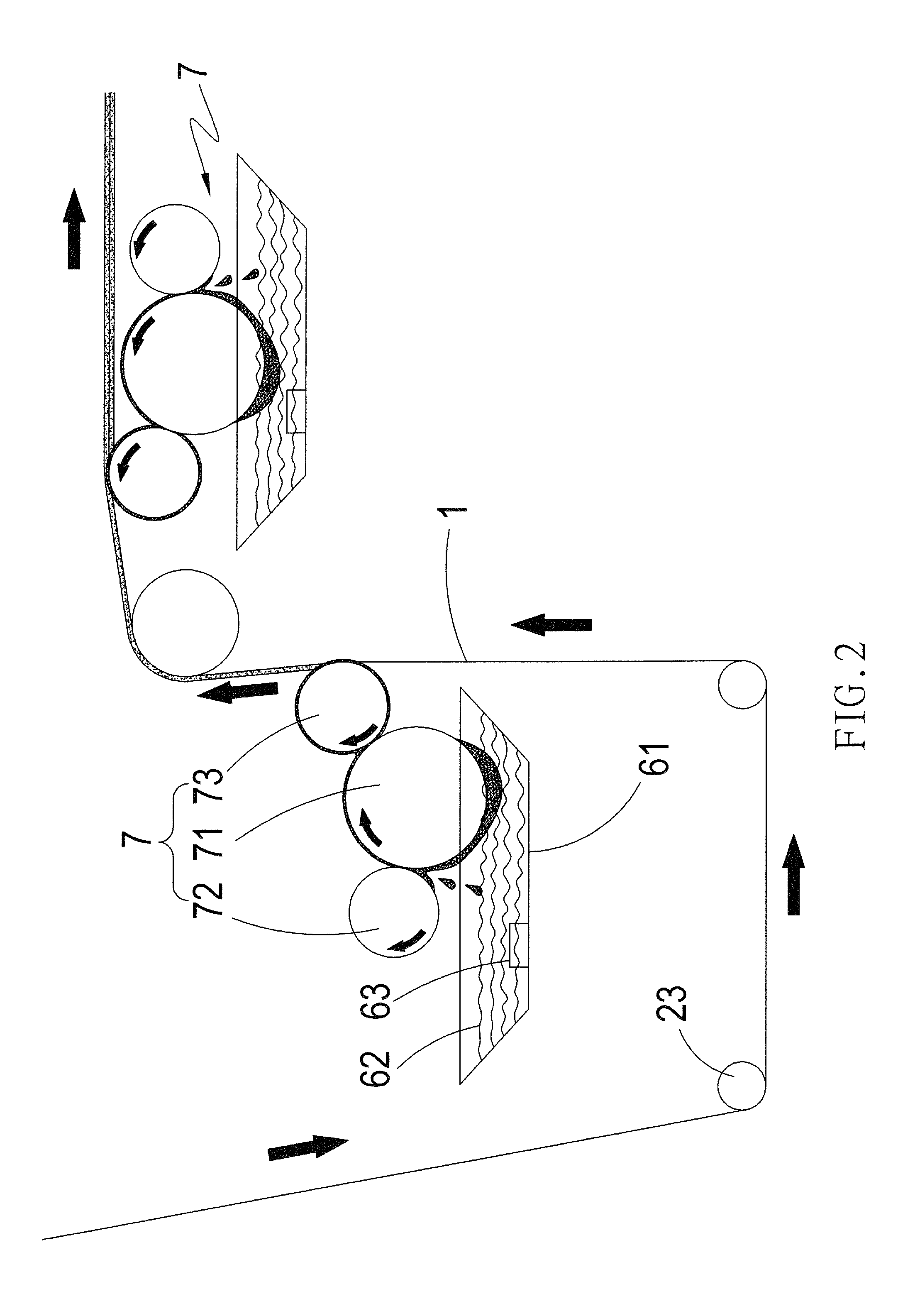

Surface treatment process and coating mechanism of rolled tape

InactiveUS20150174601A1Uniform coating thicknessEnsure uniform thicknessFibre treatmentPretreated surfacesMechanical engineeringSURFACTANT BLEND

The present invention relates to a surface treatment process and a coating mechanism of a rolled tape, in which a feeding module conveys a rolled tape so that the rolled tape is conveyed by the feeding module to first contact a surfactant received in a surfactant tank and then moved to a drying device to have the surfactant dried, and then moved to one side of a coating assembly to contact therewith, where the coating assembly receives a covering material contained in a receiving tank to attach thereto and control the thickness thereof for subsequently applying and coating the covering material to the rolled tape. The rolled tape, after being coated, is moved towards a baking device to have the covering material dried and is then collected by the feeding module.

Owner:TOP LONG INDAL

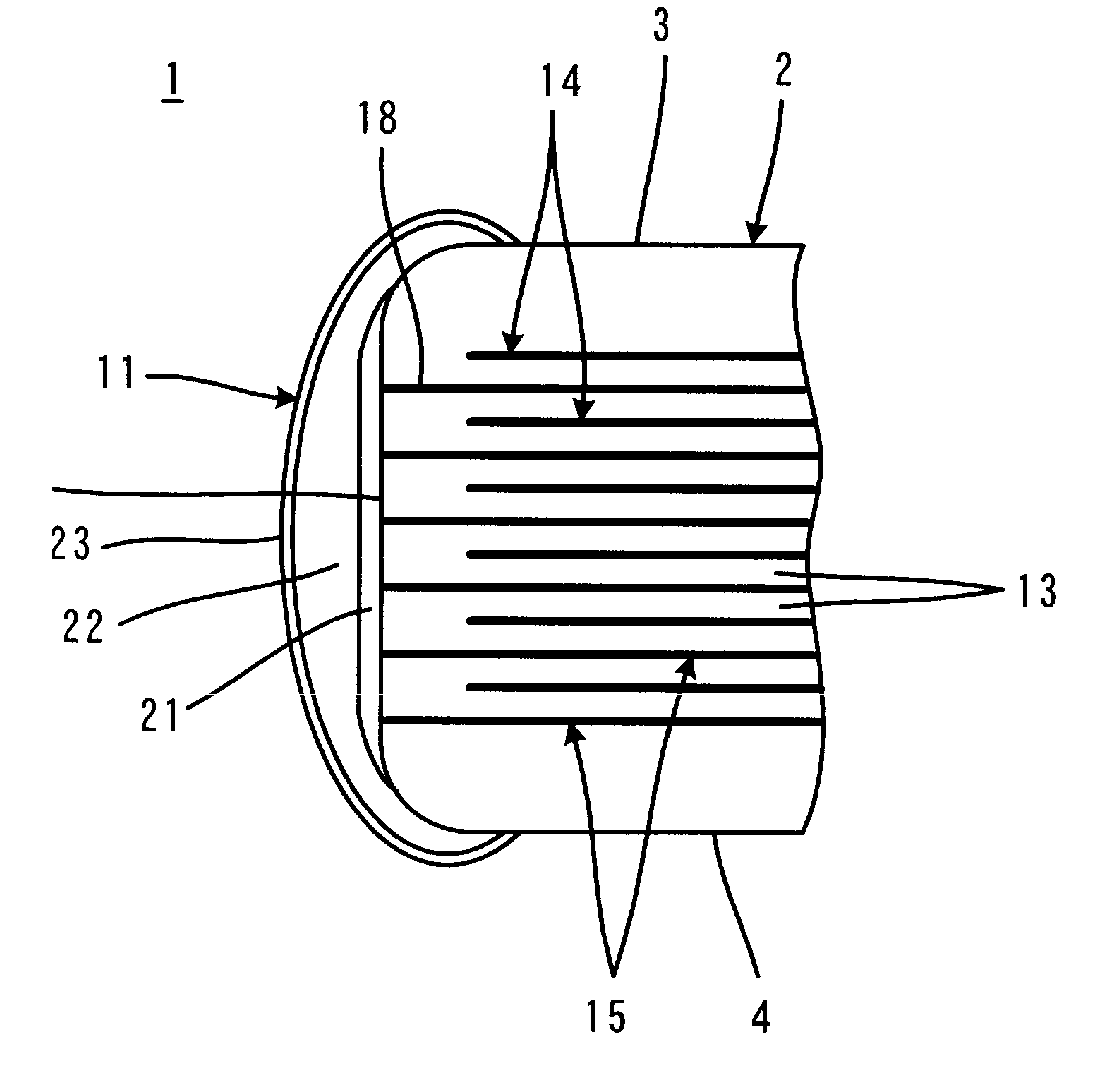

Vacuum evaporation device

ActiveCN103540898AUniform coating thicknessAdjustable sizeVacuum evaporation coatingSputtering coatingEvaporation chamberVacuum evaporation

The invention provides a vacuum evaporation device, which belongs to the field of vacuum evaporation and can be used for effectively solving a problem that thickness of a coating film formed by the existing vacuum evaporation device is not uniform. The vacuum evaporation device comprises an evaporation chamber, an evaporation source device arranged in the evaporation chamber, and a baffle plate assembly arranged between the evaporation source device and a to-be-evaporated base plate, wherein the evaporation source device is arranged on the center area of the evaporation chamber; the baffle plate assembly is provided with a baffle plate assembly opening which is corresponding to the position of the evaporation source device and used for passing through evaporated substances. The evaporation source device is arranged on the center area of the bottom plate of the evaporation chamber, and the thickness of the coating film on the base plate is more uniform.

Owner:BOE TECH GRP CO LTD

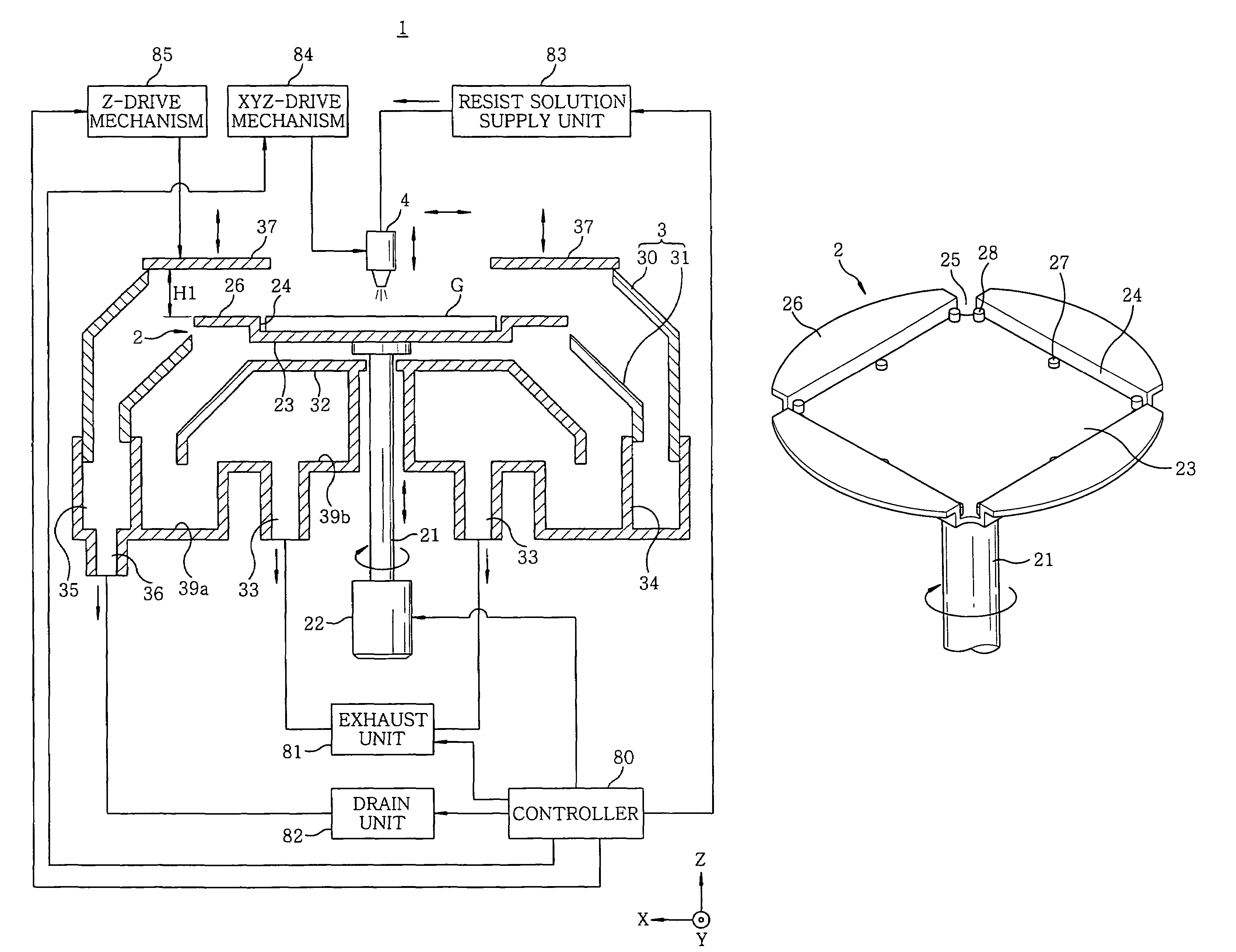

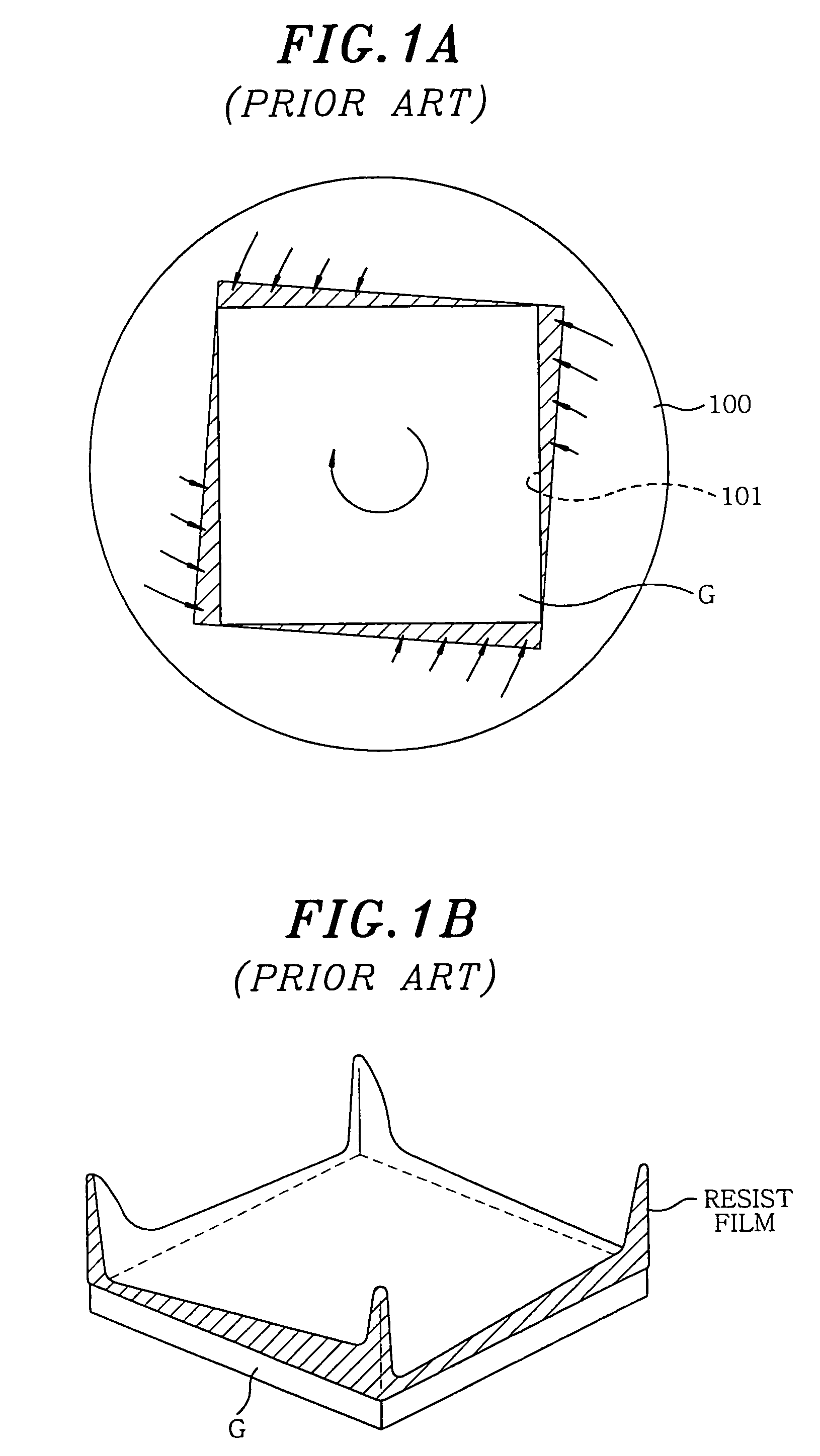

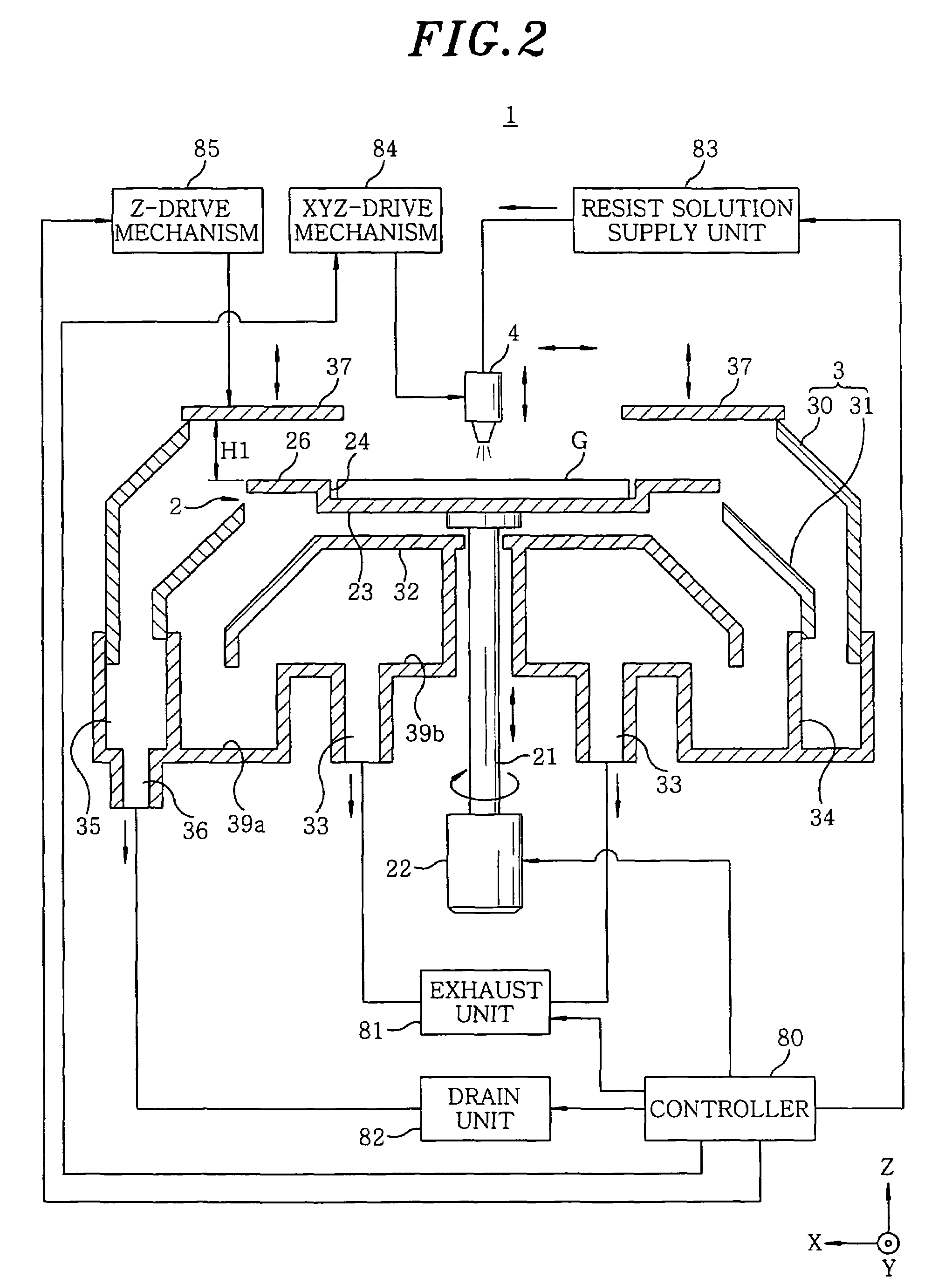

Liquid processing apparatus and liquid processing method

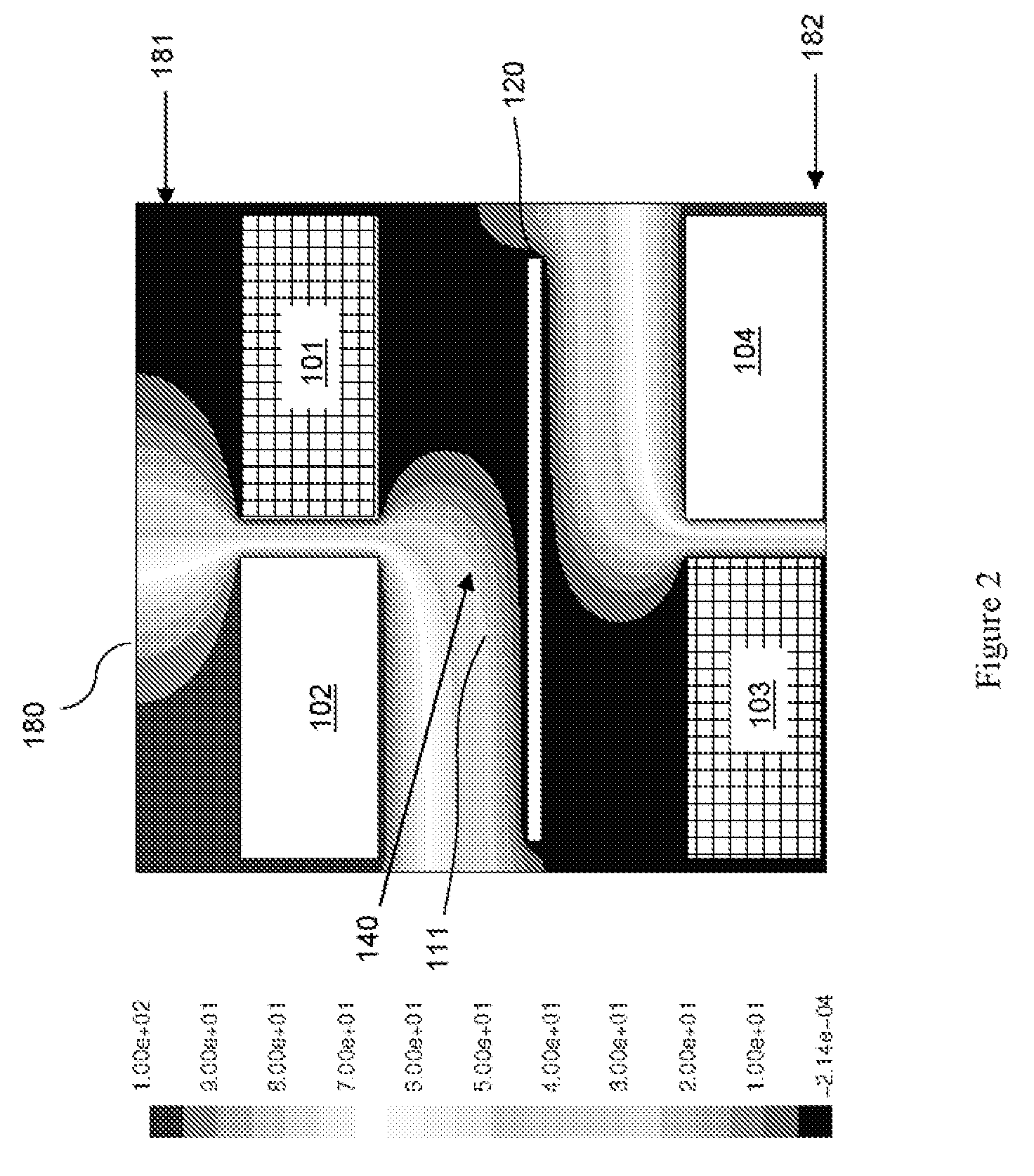

ActiveUS7566365B2Uniform coating thicknessLoading and unloadingSpraying apparatusSemiconductor/solid-state device manufacturingEngineeringSpin coating

In a liquid processing apparatus for forming a coating film on a polygonal substrate by spin coating in an ambient with a descending clean air flow, a spin chuck includes a support plate for substantially horizontally supporting the substrate thereon. Air flow control members are provided on the spin chuck such that the air flow control member being disposed adjacent to a periphery of the polygonal substrate supported on the spin chuck, wherein the air flow control member is not provided near corner portions of the substrate supported on the spin chuck. The liquid processing apparatus may includes an air flow regulation ring which is provided with an air inlet having an opening surrounding an outer periphery of the air flow control member, wherein the air inlet communicates with the exhaust unit.

Owner:TOKYO ELECTRON LTD

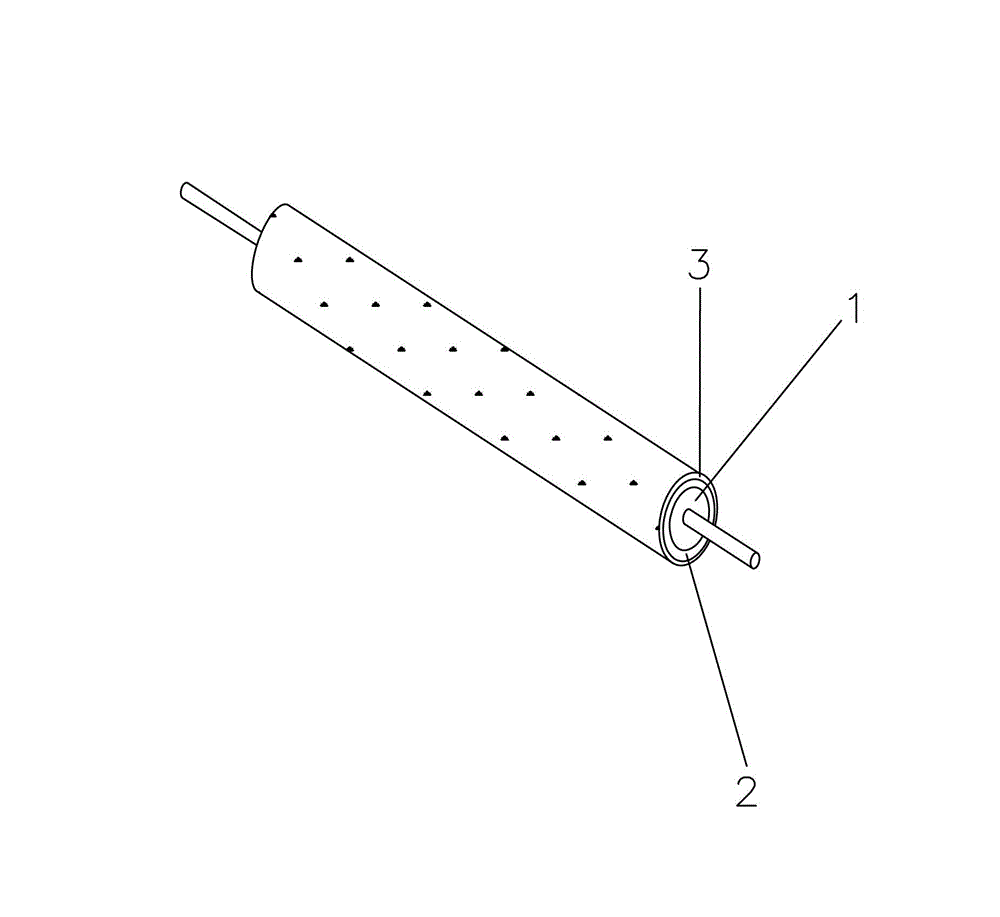

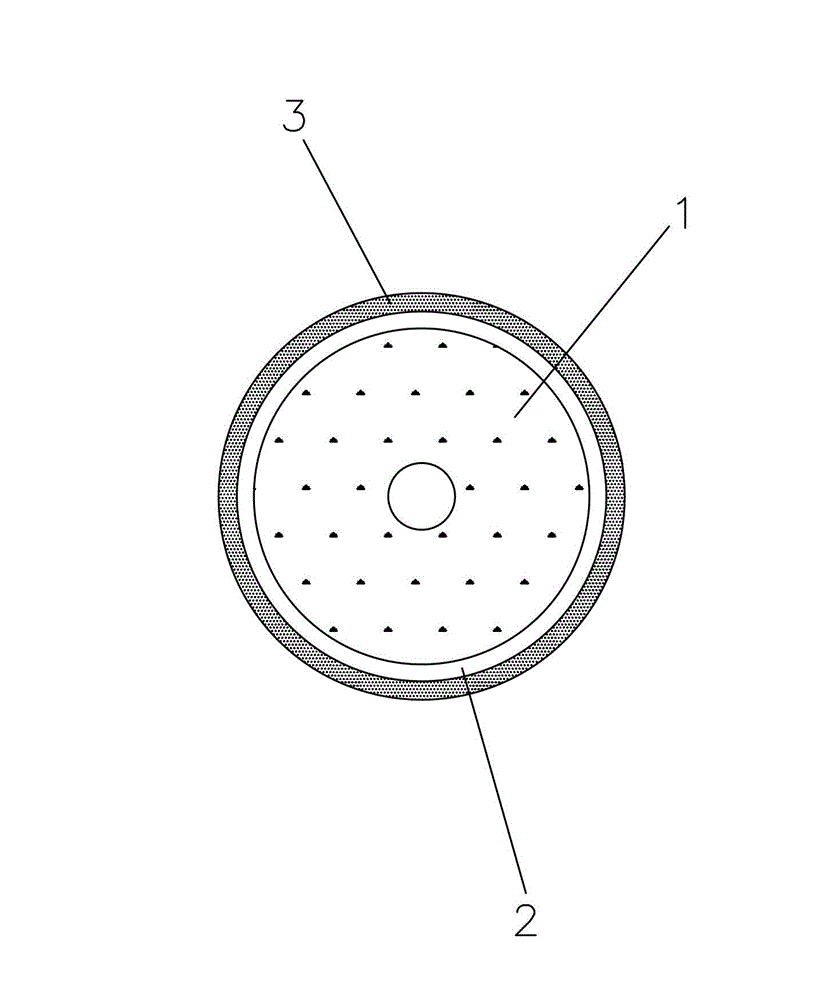

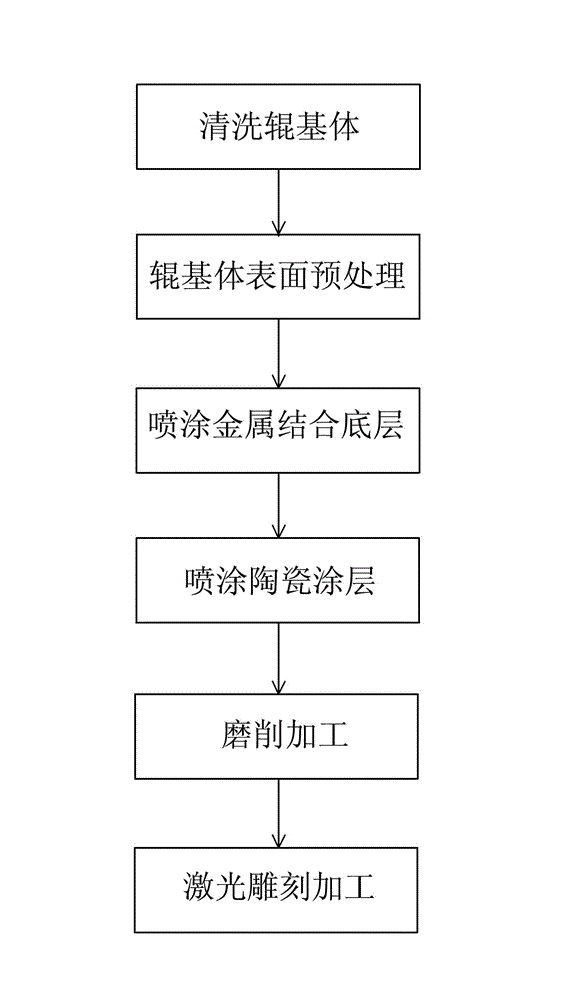

Laser engraved ceramic coating anilox roller and production method thereof

InactiveCN104002552AImprove printing accuracyHigh densityCeramic layered productsPrinting press partsCeramic coatingSpray coating

The invention discloses a laser engraved ceramic coating anilox roller and a production method thereof. The laser engraved ceramic coating anilox roller comprises a roller body, a transition layer and a working layer; the transition layer is a metal combined bottom layer, and the working layer is a ceramic coating layer; the transition layer is fixed onto the roller surface of the roller body, and the ceramic coating layer is fixed to the transition layer. The production method includes the steps of roller body cleaning, roller body surface pretreatment, metal combined bottom layer spray coating, ceramic working layer spray coating, spray coated ceramic working layer abrasive machining and ceramic working layer laser engraving machining. The laser engraved ceramic coating anilox roller has the advantages of long service life and high printing accuracy. The production method is fewer in process steps and not demanding in production conditions, can ensure the technical effect of the ceramic anilox roller, and is applicable to industrial batch production.

Owner:SUZHOU ZHISHUN SURFACE TECH

High-temperature automotive intermediate paint suitable for electrostatic spraying of automatic robots and preparation method thereof

The invention relates to a high-temperature automotive intermediate paint suitable for the electrostatic spraying of automatic robots and a preparation method thereof. The high-temperature automotive intermediate paint comprises the following components in part by weight: 35-65 parts of a resin, 20-40 parts of pigments and fillers, 0.5-5 parts of auxiliaries, and 10-30 parts of a solvent. When an automatic electrostatic robot sprays the intermediate paint, the coating process is implemented sequentially through the steps of spraying the intermediate paint, air-drying the intermediate paint, spraying a metallic colored paint, air-drying the metallic colored paint, spraying an overcoat varnish, and drying the overcoat varnish, so that compared with traditional coating processes, intermediate coating is implemented without drying firstly, therefore, the process is relatively simple and easy to operate, and to a certain extent, the energy consumption is saved by one time, the production efficiency is increased by over two times, and the labor cost is reduced.

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

Multi-anode system for uniform plating of alloys

ActiveUS8177945B2Uniform coating thicknessAvoid the needCellsCurrent conducting devicesElectricityPower flow

Disclosed are embodiments of an electroplating system and an associated electroplating method that allow for depositing of metal alloys with a uniform plate thickness and with the means to alter dynamically the alloy composition. Specifically, by using multiple anodes, each with different types of soluble metals, the system and method avoid the need for periodic plating bath replacement and also allow the ratio of metals within the deposited alloy to be selectively varied by applying different voltages to the different metals. The system and method further avoids the uneven current density and potential distribution and, thus, the non-uniform plating thicknesses exhibited by prior art methods by selectively varying the shape and placement of the anodes within the plating bath. Additionally, the system and method allows for fine tuning of the plating thickness by using electrically insulating selectively placed prescribed baffles.

Owner:MARVELL ASIA PTE LTD

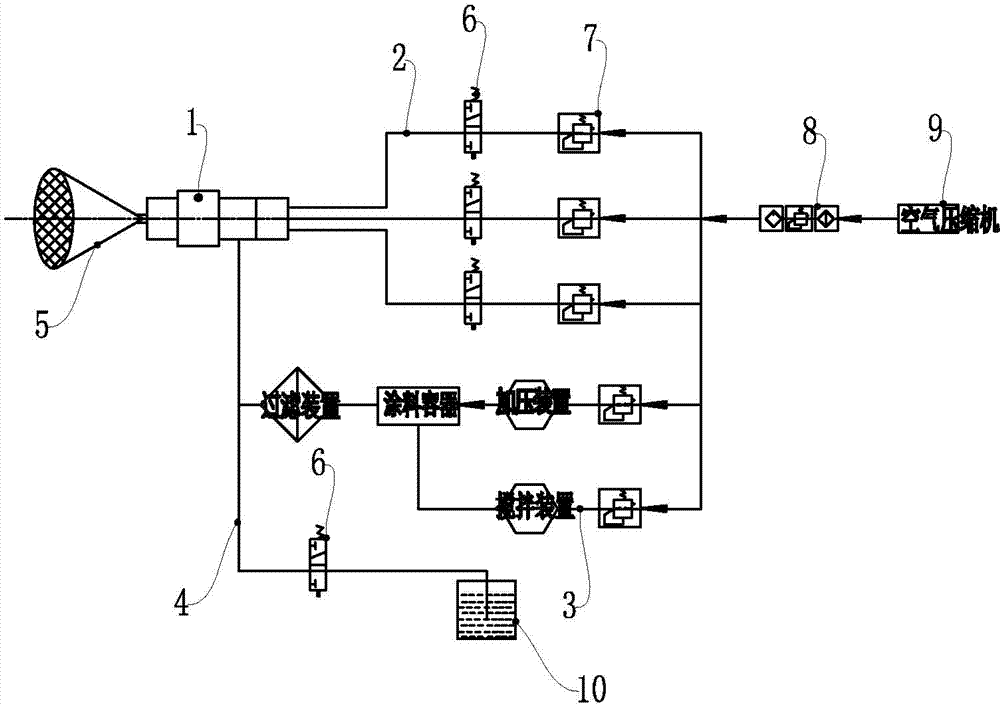

Boat spray painting machine system

InactiveCN103769325AImprove work efficiencyUniform coating thicknessLiquid surface applicatorsLiquid spraying apparatusWork statusProcess engineering

An automatic boat spray painting line comprises a coating spray gun, a compressed air loop, a coating loop and a washing loop, wherein the output end of the compressed air loop is communicated with a power input hole of the coating spray gun, the output end of the coating loop and the output end of the washing loop share a section of pipeline and are communicated with a coating input hole of the coating spray gun, and the input end of the compressed air loop and the input end of the coating loop are communicated with the output end of an air compressor. According to the automatic boat spray painting line, compressed air is taken as power for spray painting, opening and closing operation can be performed on spray guns with different serial numbers to change the spraying swath of the spray guns, it is ensured that high-viscosity coatings in a coating container are always in a stirred state and not solidified to block an inner hole of the spray gun, working states of all the executive components are automatically executed by a control system on the basis of operation content and operation requirements according to design instructions, working efficiency is high, and the spray painting thickness is even.

Owner:河源富马硬质合金股份有限公司

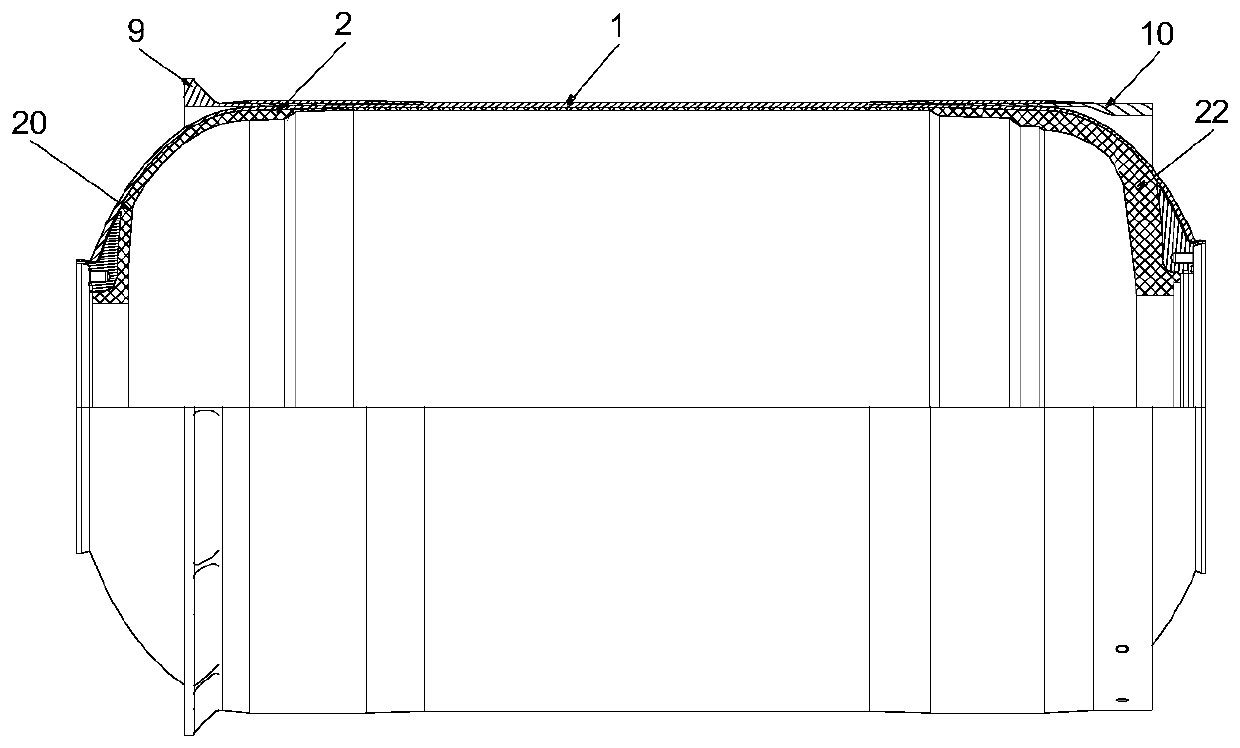

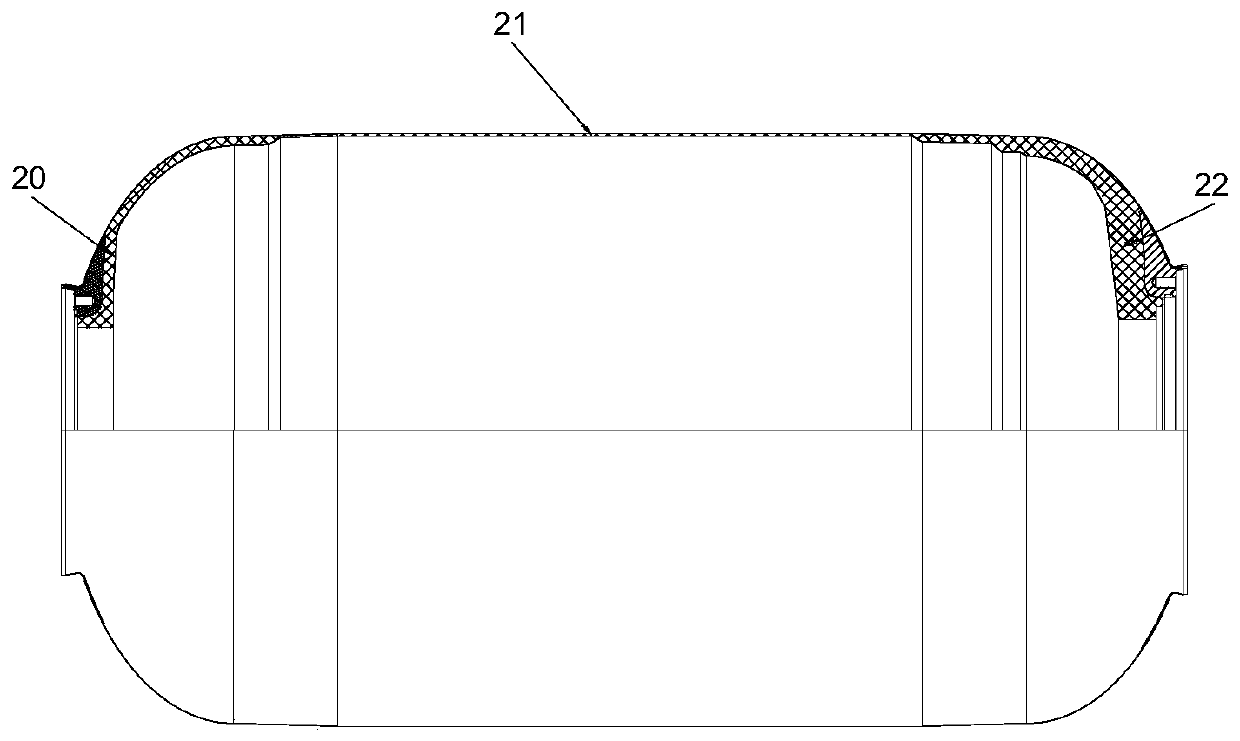

Charge combustion chamber shell and forming method thereof

ActiveCN109989852AThe preparation process is simple and reliableImprove adhesionRocket engine plantsFiberInsulation layer

The invention discloses a forming method of a charge combustion chamber shell. The charge combustion chamber shell comprises an outer shell and a heat insulation layer, the heat insulation layer is arranged on the inner surface of the outer shell, and the heat insulation layer comprises a front seal head heat insulation structure, a column section heat insulation structure and a rear seal head heat insulation structure which are sequentially distributed and connected in the length direction of the outer shell. The forming method of the charge combustion chamber shell characteristically involves the following steps of providing a winding core model, a seal head mold and heat insulation slurry; spraying the heat insulation slurry in the seal head mold, and preparing the front seal head heatinsulation structure and the rear seal head heat insulation structure by adopting a press moulding manner; assembling the front seal head heat insulation structure and the rear seal head heat insulation structure on the winding core model; spraying the heat insulation slurry on the outer surface of the winding core model to form the column section heat insulation structure; winding fibers on the outer surface of the heat insulation layer to form the outer shell; and curing to form the charge combustion chamber shell.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

Barrier mechanism

InactiveCN1955336AIncrease elasticityUniform coating thicknessVacuum evaporation coatingSputtering coatingEngineeringCoating

A mechanism of bearing the weight, of which characteristics is including: A medium altitude box and many soil receiver suction end, this medium altitude box has a medium altitude chamber, and this medium altitude box is designed with many suction mouth and a suction gas mouth that communicate with this medium altitude chamber, correspondingly this soil receiver suction end and this suction mouth match tightly. The mentioned mechanism of bearing the weight can adsorb lens on the soil receiver suction end by negative pressure, make transport of lens be more convenient, and plating film thickness that is obtained in the process of plating film is more uniform.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Surface chromium electroplating technique of magnesium alloy die casting

InactiveCN103898585AImprove bindingImprove corrosion resistanceLiquid/solution decomposition chemical coatingAcid washingChromium coating

The invention discloses a surface chromium electroplating technique of a magnesium alloy die casting, which comprises the following steps: alkali washing, acid washing, activating, zinc immersion and cyanideless chromium electroplating, chemical nickel plating and chromium electroplating. By selecting the plating solutions in various steps and regulating the content, the plating solution has stable performance, and favorable technical effects can be obtained for each treatment, thereby laying favorable base for subsequent techniques. The finally prepared chromium coating has high chromium coating; and the metallic coating has uniform coating thickness and high corrosion resistance. The whole plating process does not use any cyanide, and the fluoride consumption is lower than that in the prior art, so the plating technique is green and environment-friendly.

Owner:无锡市锡山区鹅湖镇荡口青荡金属制品厂

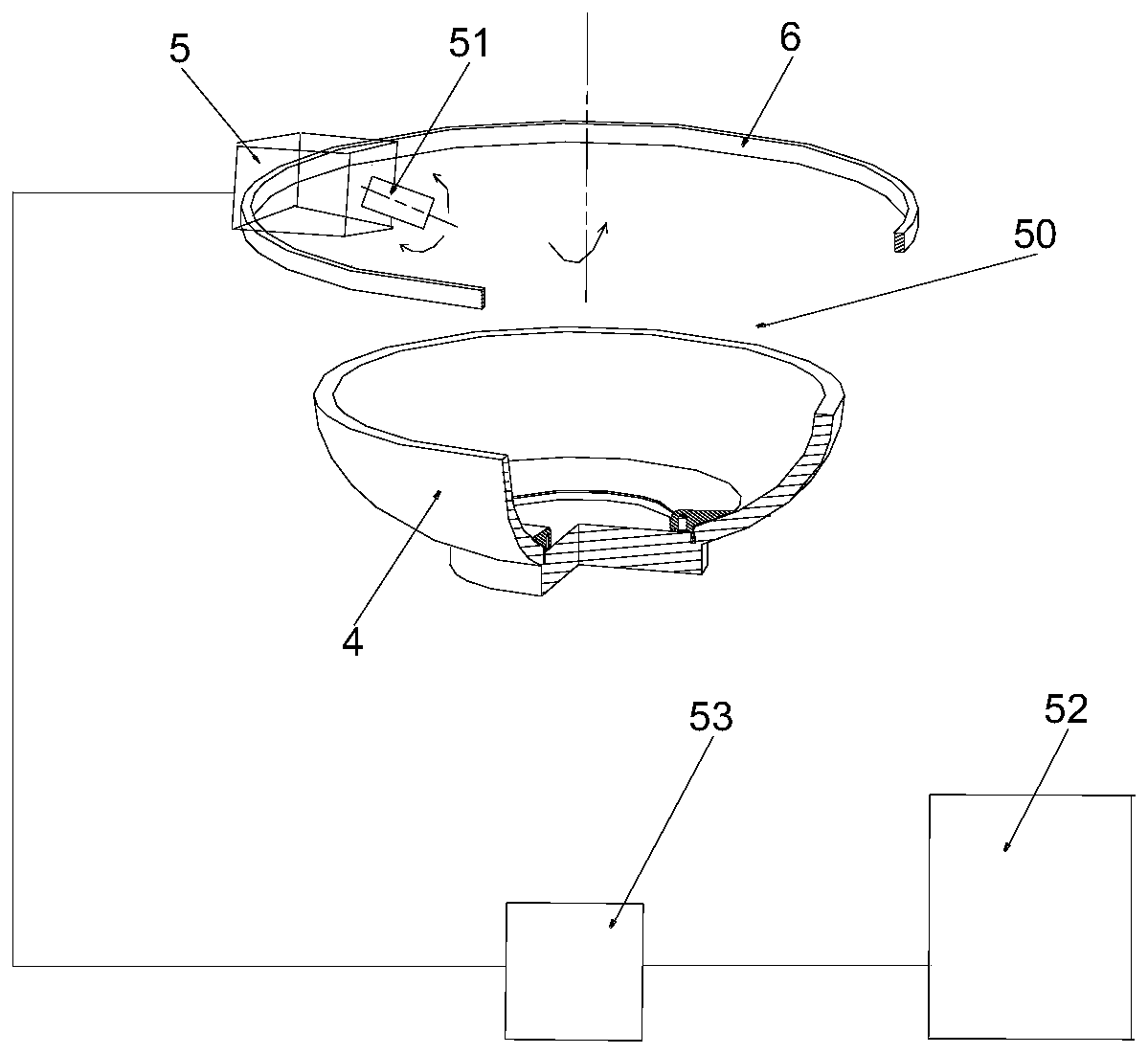

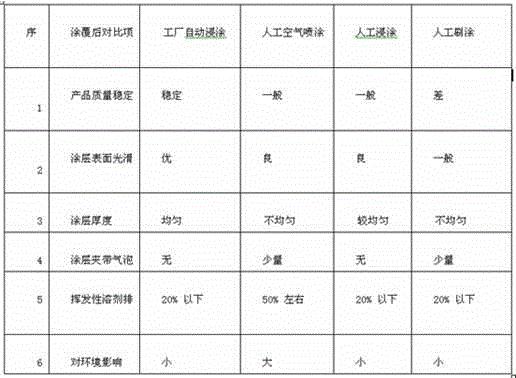

Anti-flashover RTV (Room Temperature Vulcanization) coating material coating method for umbrella-shaped and bell-shaped insulators

The invention belongs to the field of insulator coating and particularly relates to an anti-flashover RTV (Room Temperature Vulcanization) coating material coating method for umbrella-shaped and bell-shaped insulators. The coating method comprises the step of preparing the umbrella-shaped or bell-shaped insulators, coating equipment, a coating material, a related vessel and tooling appliances and is characterized by comprising the following steps of pretreating the umbrella-shaped or bell-shaped insulators, detecting, loading, rotatably dipping the umbrella-shaped or bell-shaped insulators into the coating material, coating, then, unloading, detecting appearance, storing for curing, re-detecting, packaging and storing or transporting. The coating method provided by the invention has the advantages that the operation is simple, the cost is low, the pollution is low, the production is safe, the process from dip-coating to initial curing can be automatically controlled, the quality of products is easy to control, the productivity is high, the coating is uniform, and the appearance is smooth, is free from bubbles, dropping and accumulation and is consistent in thickness.

Owner:眉山拓利科技有限公司

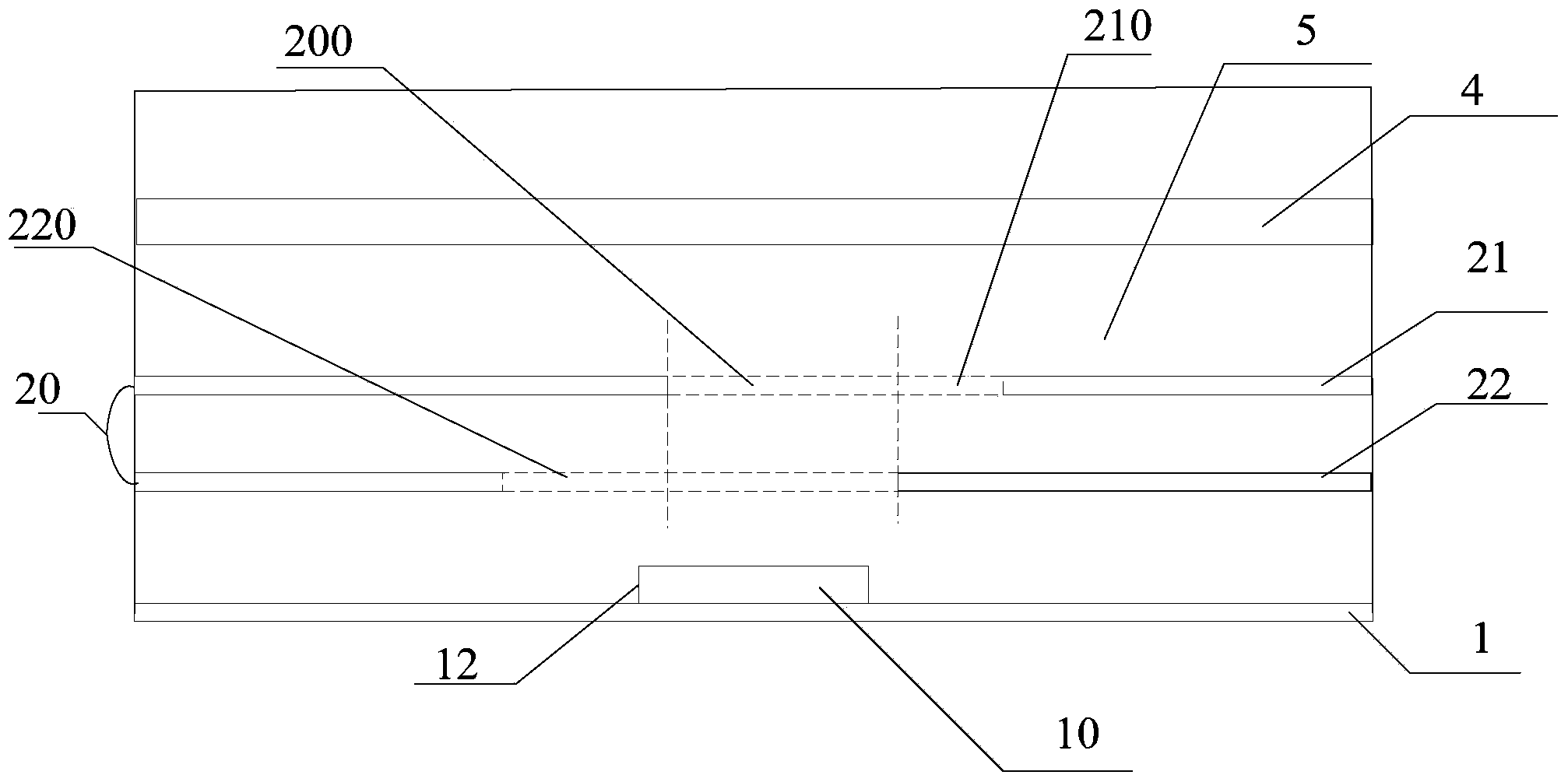

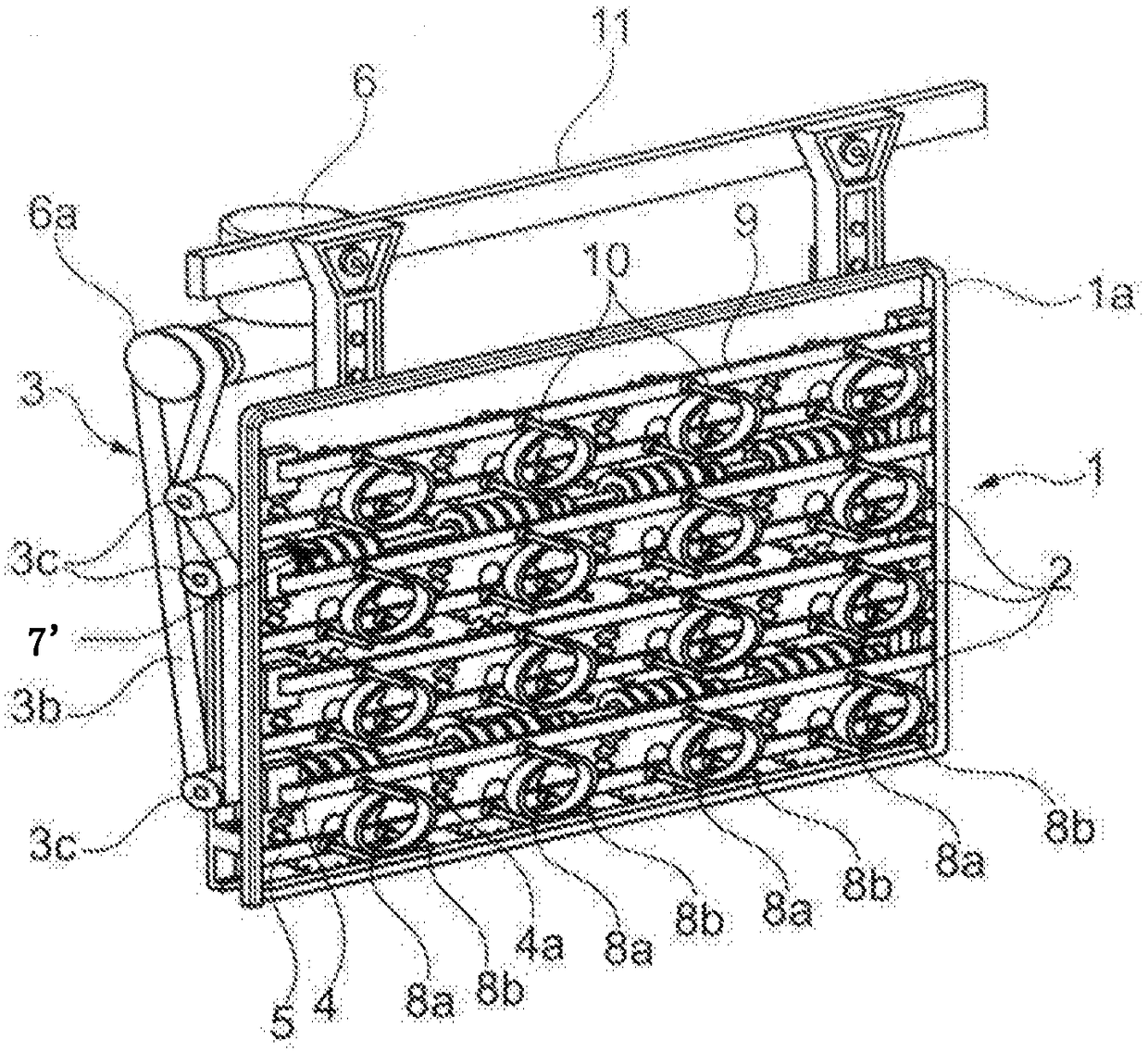

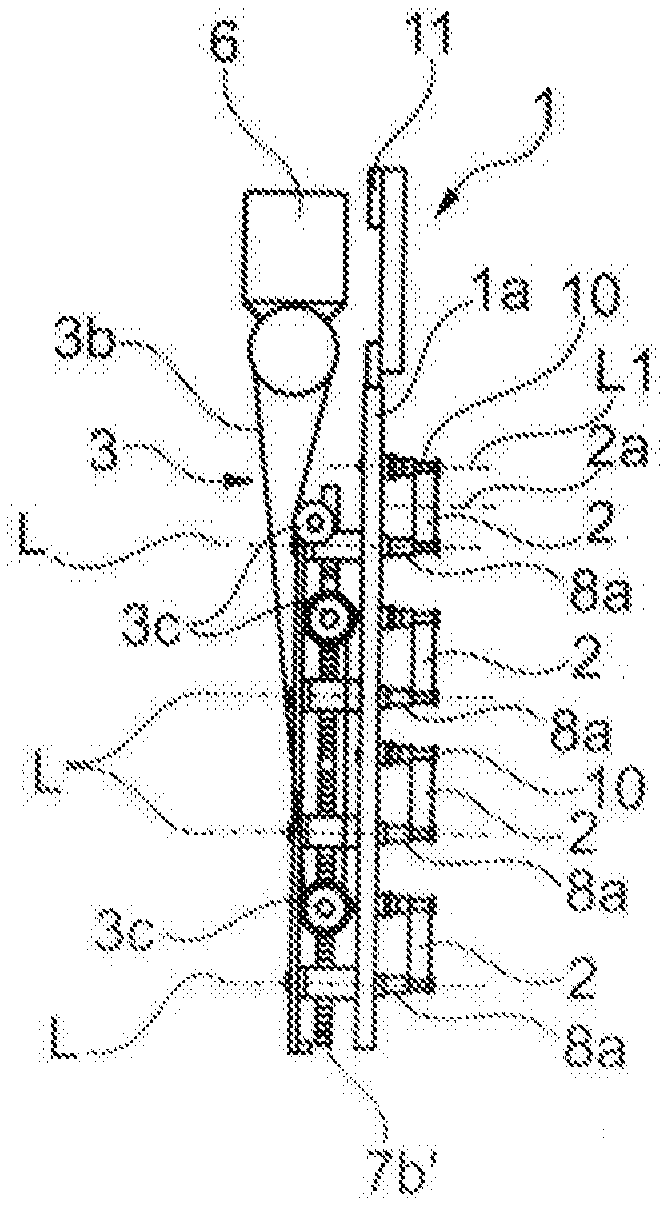

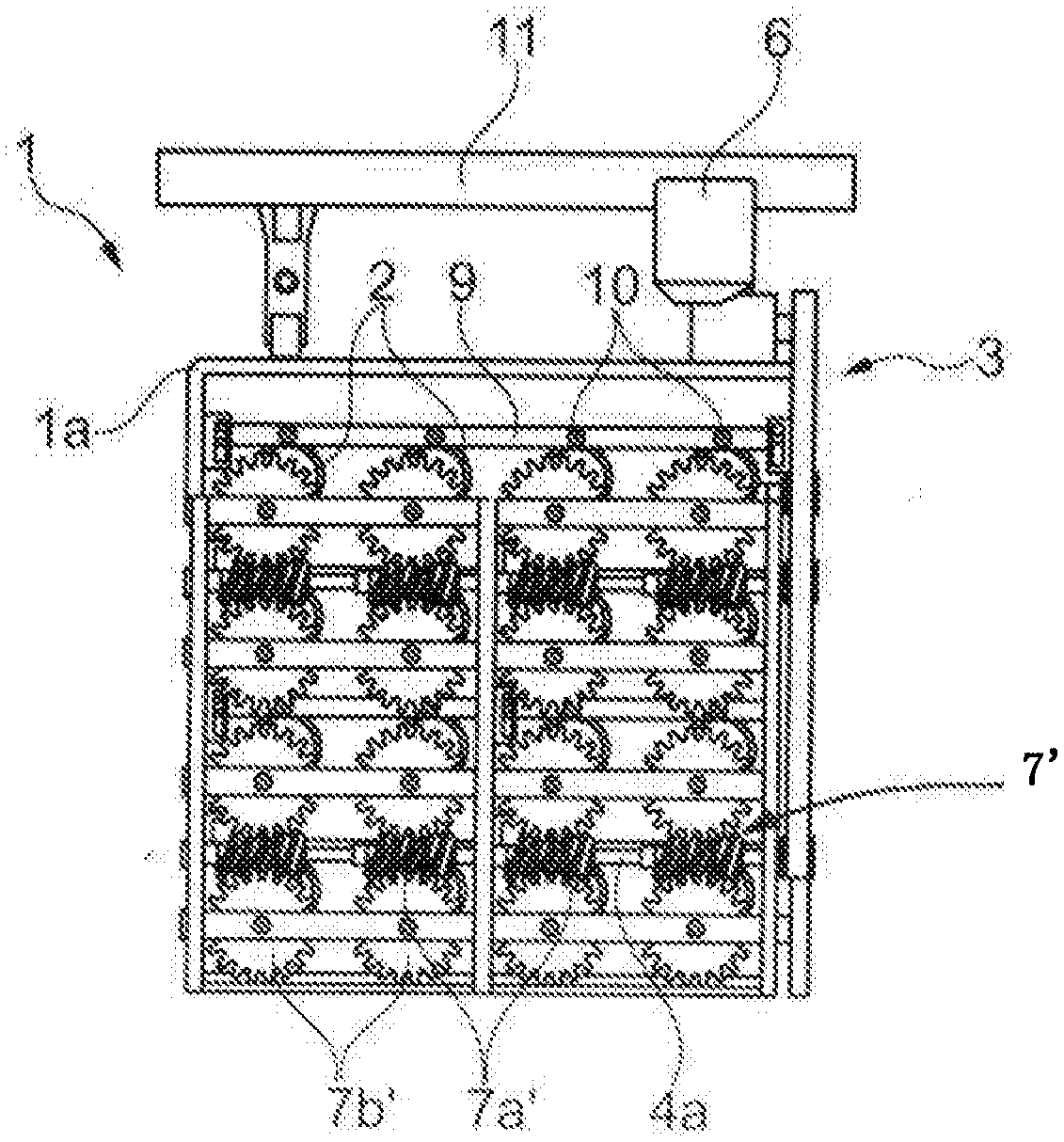

Frame for receiving annular components and method

ActiveCN108291322APermanent rotary driveIncrease exerciseContacting devicesReflex reflectorsDrive motorEngineering

The invention relates to a frame for receiving annular components, in particular bearing rings or cages of rolling bearings or plain bearings, and for chemically or galvanically coating the componentsin an electrolyte bath. The frame comprises: a support frame which has at least one first drive unit, at least one second drive unit, and at least one horizontally arranged first transverse bracing,at least one drive motor for driving the at least one first drive unit, wherein the at least one first drive unit is drivingly connected to the at least one second drive unit; and at least two horizontally arranged drive pins, which can be rotated about their longitudinal axes and which are arranged on the at least one first transverse bracing, for receiving the annular components. The at least two drive pins are connected to the at least one second drive unit (4) so as to be driven by the at least second drive unit. The invention further relates to a method for chemically or galvanically coating annular components.

Owner:SCHAEFFLER TECH AG & CO KG

Hot-dipped galvanized alloy coating with high corrosion resistance for steel member and preparation process thereof

ActiveCN103173707ASimple processUniform coating thicknessHot-dipping/immersion processesHot-dip galvanizationCorrosion resistant

The invention provides a hot-dipped galvanized alloy coating with high corrosion resistance for a steel member. The improvement is that, when the alloy coating is prepared, an adopted alloy ingot comprises the following components in percentage by weight: 0.01-2% of Al, 0.01-2% of Mg, 0.05-3% of Re, 0.002-1% of Cu and the balance of Zn. The alloy coating has the characteristics of high corrosion resistance, low zinc consumption, better economy and the like, which are suitable for the steel members of power transmission lines, and the alloy coating can effectively prolong the corrosion-resistant service life of the steel member of the power transmission line and prolong the corrosion-resistant service life by above 2 times in comparison with industrial hot-dipping of pure zinc while ensuring that the thickness of the coating is not increased.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +1

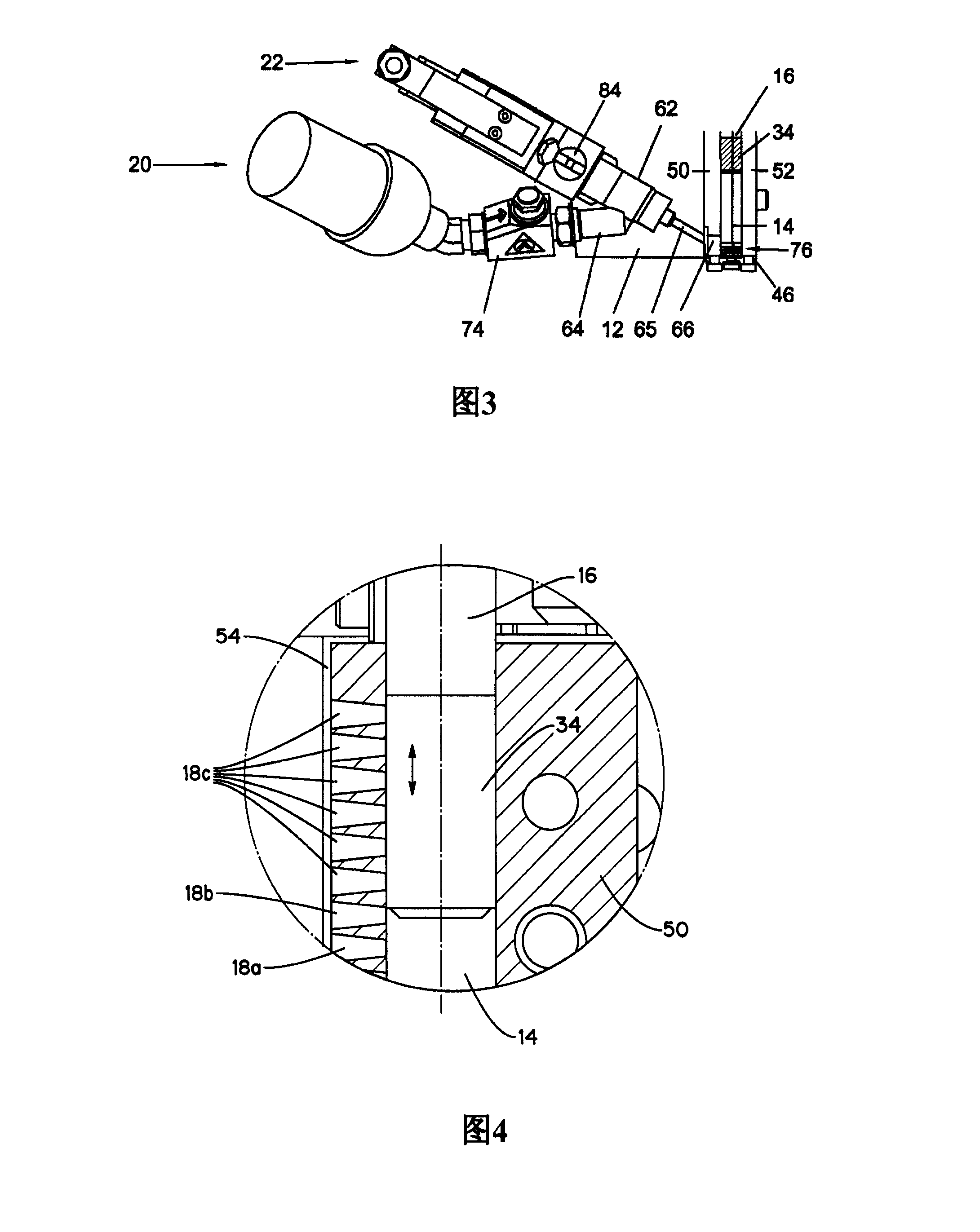

Device for coating liquid, which is such as adhesive agent, especially hot melt adhesive

InactiveCN101244415AReduce adverse effectsAvoid or reduce flow variablesLiquid surface applicatorsCoatingsEngineeringHot-melt adhesive

A device is used for coating the liquid to the base, wherein the liquid is such as adhesive, especially the hot-melt adhesive. The base can move relative to the device, having a basal body (12) and a transfer valve (22) for selectively interrupting or releasing the liquid, wherein the basal body (12) can be connected with the liquid source and matched with a groove nozzle opening (54) communicated with a distributing channel (14) and a piston (16) moving in the distributing channel (14). By means of the piston (16), the distributing channel (14) can be changed and the length of the liquid canbe loaded, characterized in that, the nozzle opening (54) is communicated with the distributing channel (14) by means of a plurality of distant excurrent passages (18).

Owner:NORDSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com