Arc spraying device for shaft parts

A technology for arc spraying and shaft parts, which is applied in the direction of spraying devices and liquid spraying equipment, which can solve the problems of uneven spraying thickness, unstable spraying quality, and low production efficiency, and achieve good spraying quality, wide application range, and production high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

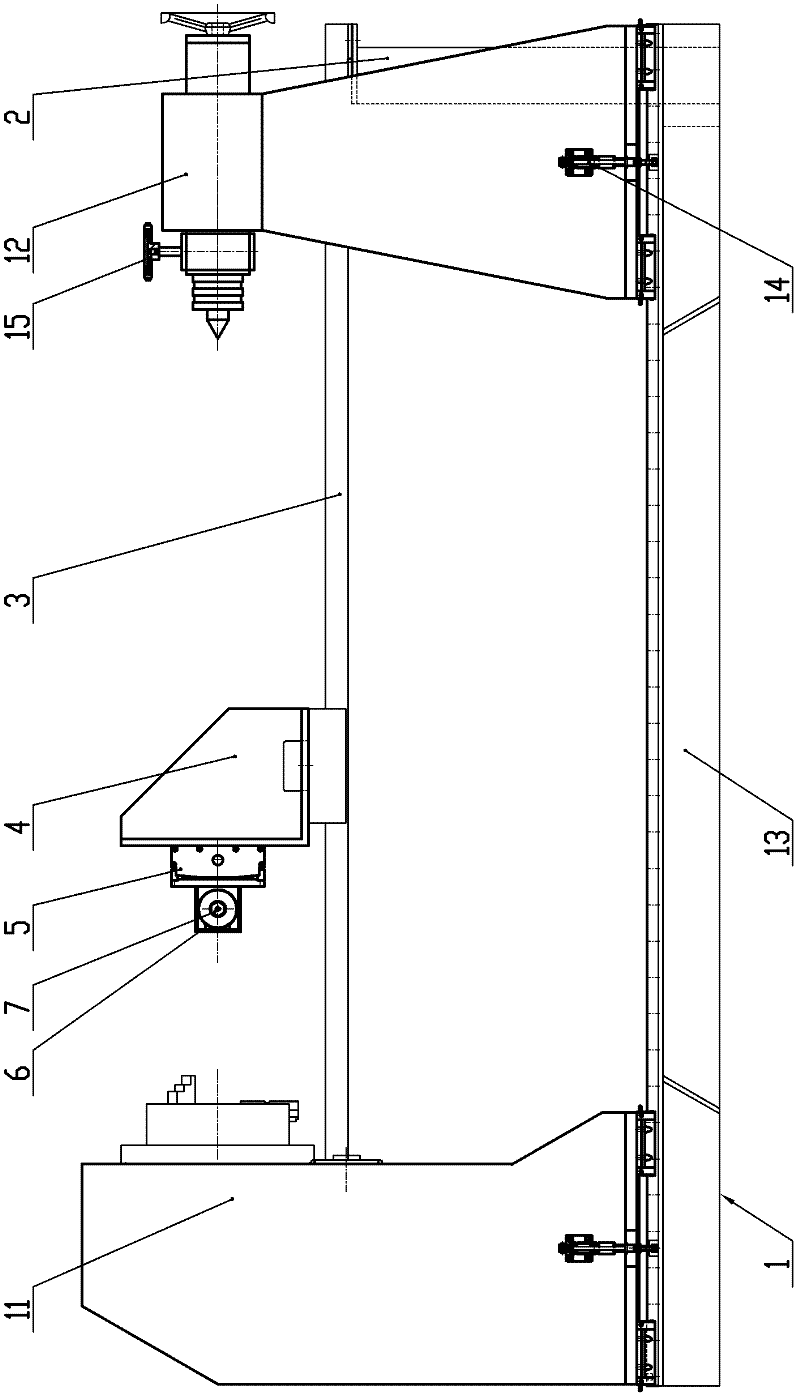

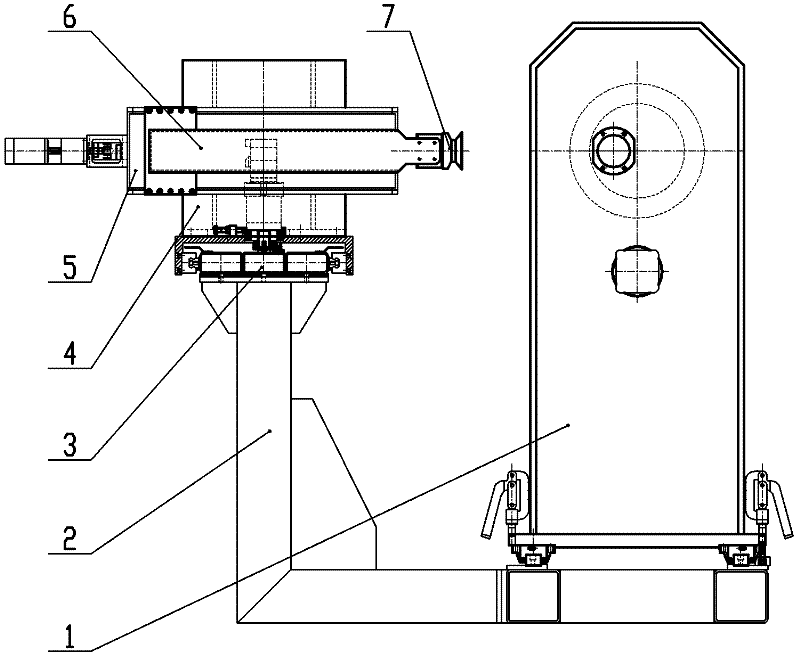

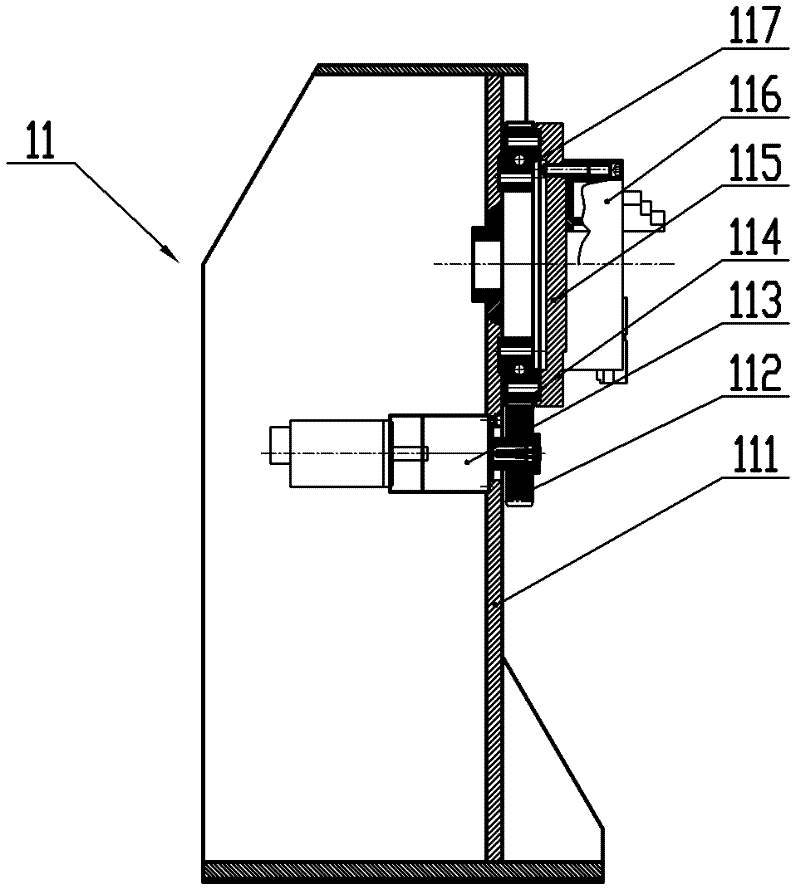

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Figure 1~Figure 7 Among them, it includes spraying machine tool 1, head frame 11, head frame seat 111, pinion gear 112, gear motor 113, large gear 114, connection plate 115, chuck 116, slewing bearing 117, tail stock 12, tail stock seat 121, slide Tube 122, sliding sleeve 123, top 124, keyway 125, feather key 126, lead screw 127, screw nut 128, handle 129, base 13, positioning device 14, locking device 15, locking handle 151, screw rod 152, locking Tight sleeve 153, lower locking sleeve 154, connecting frame 2, longitudinal moving mechanism 3, guide rail 31, first linear slide rail 32, first slide plate 33, dust cover 34, rack 35, gear 36, reducer seat 37 , the first reducer 38, the first motor 39, the transition frame 4, the spray gun telescopic mechanism 5, the second motor 51, the second reducer 52, the transition seat 53, the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com