Patents

Literature

270results about How to "Realize automatic spraying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

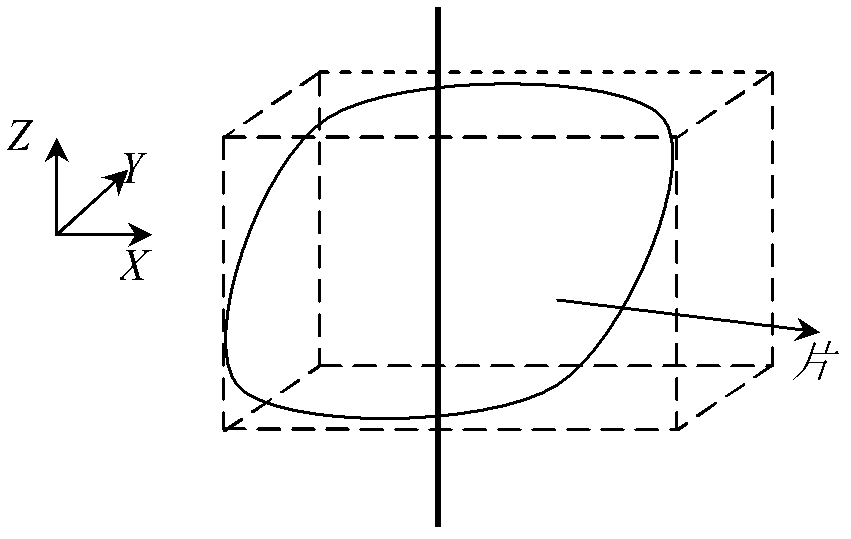

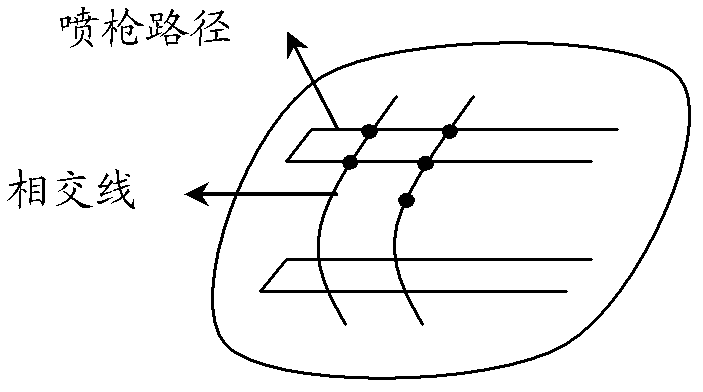

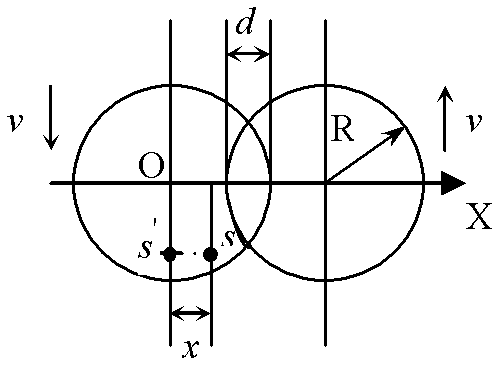

Optimization method for spray gun track of spraying robot on irregular polyhedron

ActiveCN102500498APracticalImprove work efficiency and product qualitySpraying apparatusSpecial data processing applicationsComputer Aided DesignParticle swarm algorithm

An optimization method for a spray gun track of a spraying robot on an irregular polyhedron includes the steps: triangularly dividing each face of the polyhedron according to CAD (computer-aided design) data of a polyhedral workpiece; computing the normal vector of each triangular face; generating a plurality of large pieces by means of connection according to a topological structure between each two adjacent triangular faces; and building a 'rectangular model' and generating the spraying path of each face of the polyhedron. The variance between the actual thickness of a coating and the ideal thickness of the coating serves as an objective function, and the optimal value of the width of an overlapped area is solved by a golden section method on each surface of the irregular polyhedron. In order to improve spraying efficiency, optimization and combination of the spray gun track on a curved surface are indicated by a non-directional connection diagram, and improved particle swarm algorithm is used for solving. Therefore, spraying quality is ensured, and spraying efficiency is also improved.

Owner:JIANGSU NEWBLUE INTELLIGENT EQUIP CO LTD

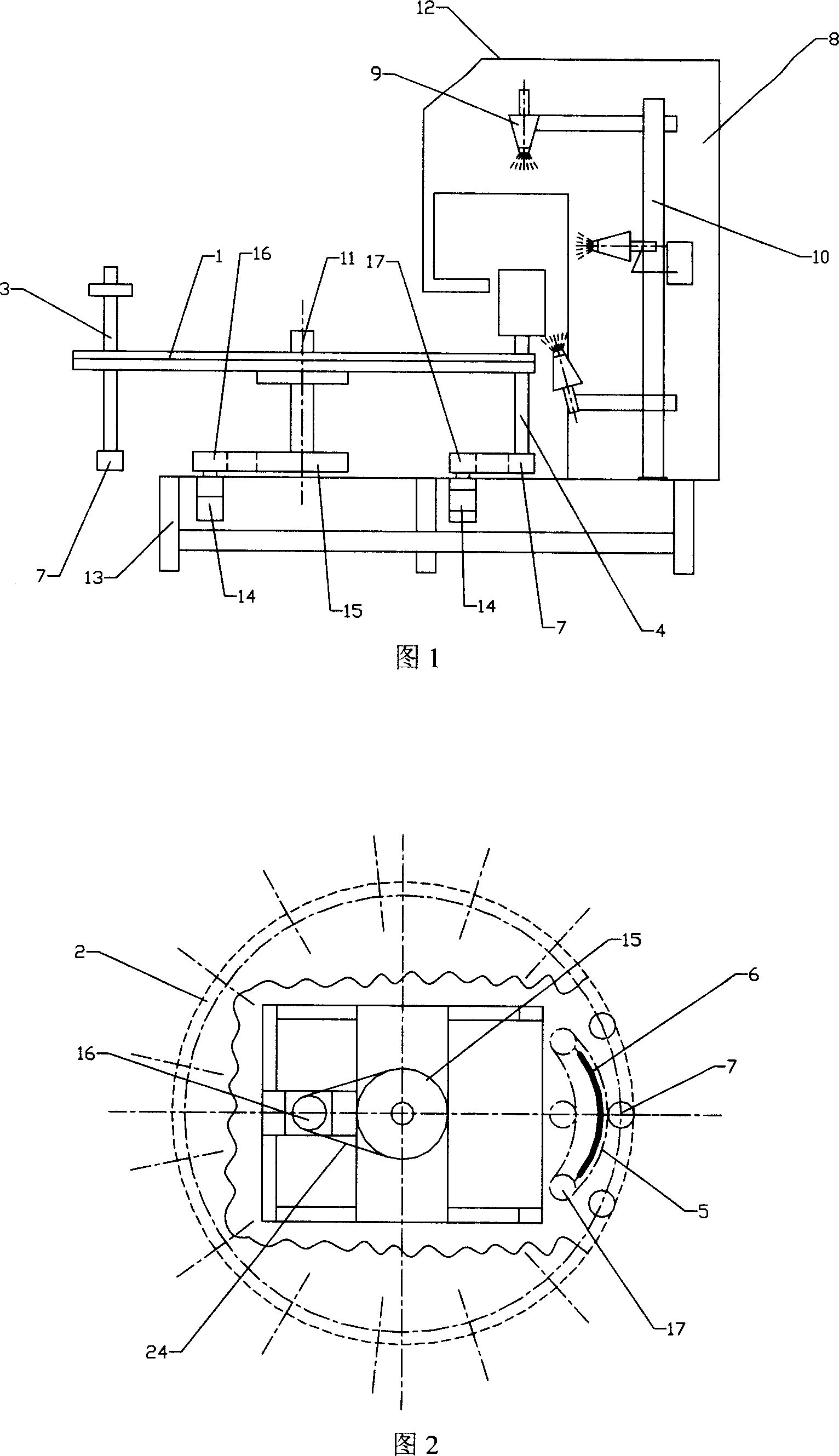

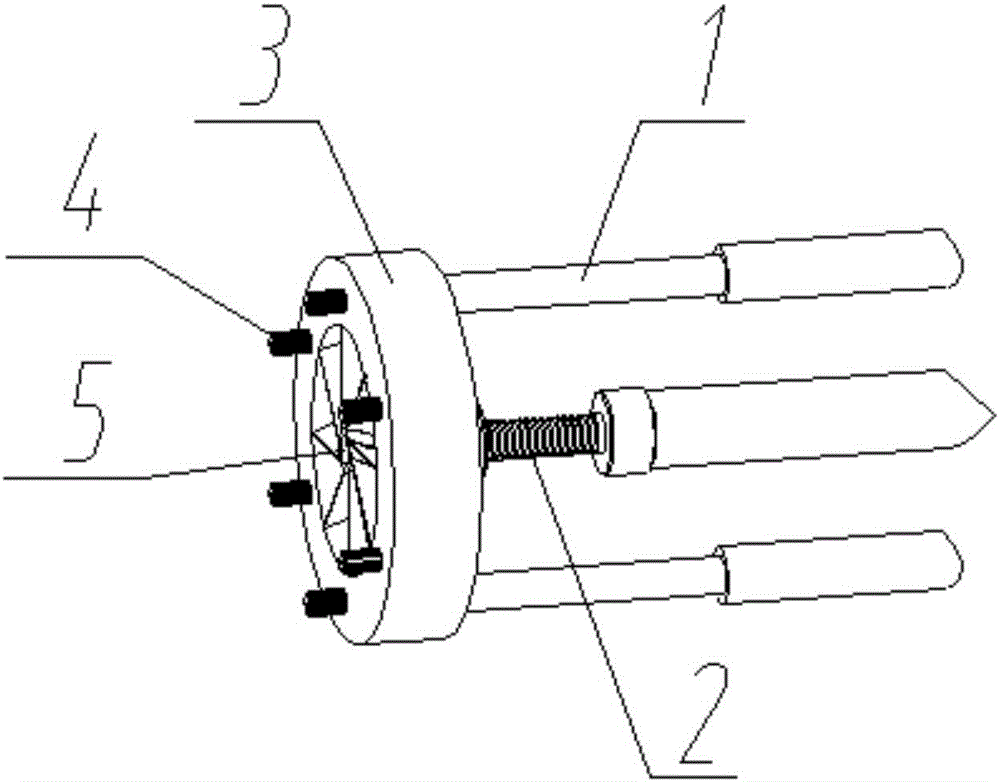

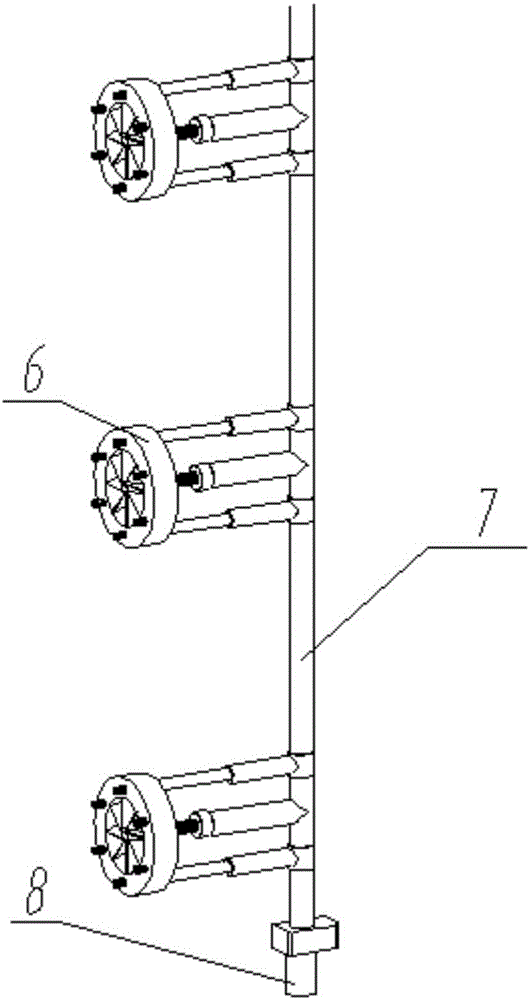

Spray technology of high voltage insulator surface coating and its spray device

ActiveCN100998974AAchieve uniformitySimple structureLiquid surface applicatorsSpraying apparatusEngineeringHigh pressure

A technology for spraying a dirt sparkle-resistant film layer on the surface of high-voltage insulator includes such steps as fixing several rotary supporters on the edge of a rotary disc, fixing an insulator to one rotary supporter, and driving said supporter to rotate by drive mechanism when the high-voltage insulator comes in a spraying room while spraying paint from high-pressure spray gun onto the surface of the insulator. Its apparatus is also disclosed.

Owner:FUZHOU UNIV +2

Automobile hub dust removal, spraying and drying device

InactiveCN104259038ASimple processSpray evenlyLiquid surface applicatorsCoatingsElectrostatic precipitatorEngineering

The invention provides an automobile hub dust removal, spraying and drying device which comprises a chain transmission mechanism, a spraying support, an electrostatic dust removal device, a spraying machine and a drying device. The chain transmission mechanism comprises a gear disc set, wherein the gear disc set is provided with four gear discs, chains are arranged on the gear discs, the spraying support is arranged on the chains, and the electrostatic dust removal device, the spraying machine and the drying device are sequentially arranged above the chain transmission mechanism. The automobile hub dust removal, spraying and drying device has the advantages that the device is simple in process and even in spraying, asymmetry and discordance situations in the spraying process are avoided, and the problem that a hub is simple in spraying color and luster can be solved; labors consumed in the automobile hub spraying process are decreased through the chain transmission mechanism and the spraying support, labor cost is reduced, and automatic spraying of the automobile hub is achieved; the electrostatic dust removal device and the drying device are added before and after spraying, so that the spraying quality of the automobile hub is further improved.

Owner:TIANJIN QINGLONG INTELLIGENT SCI & TECHCO

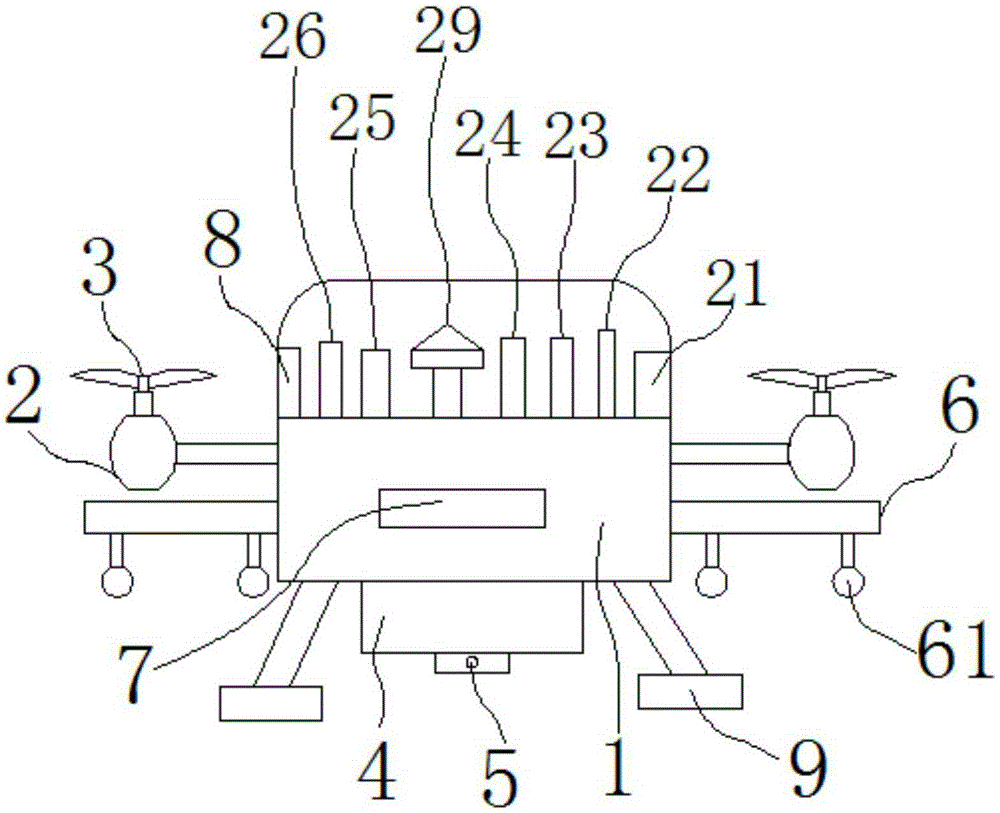

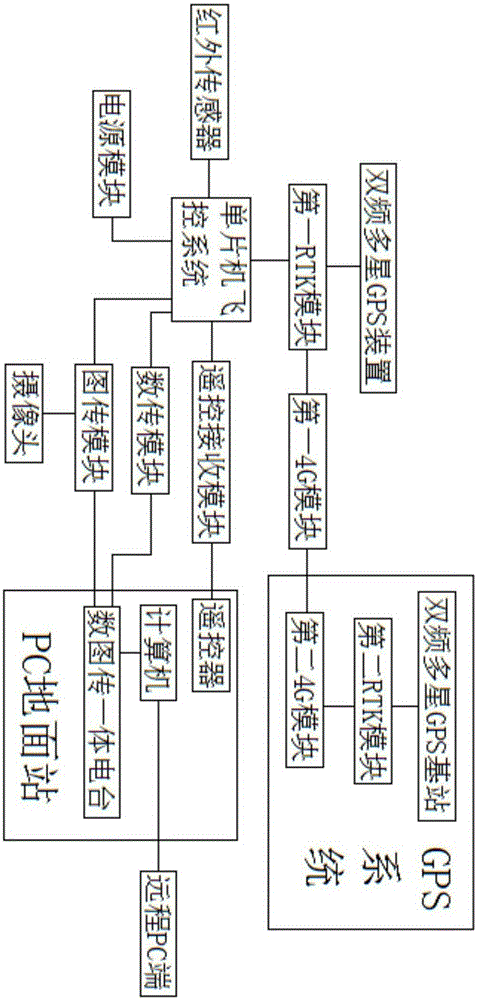

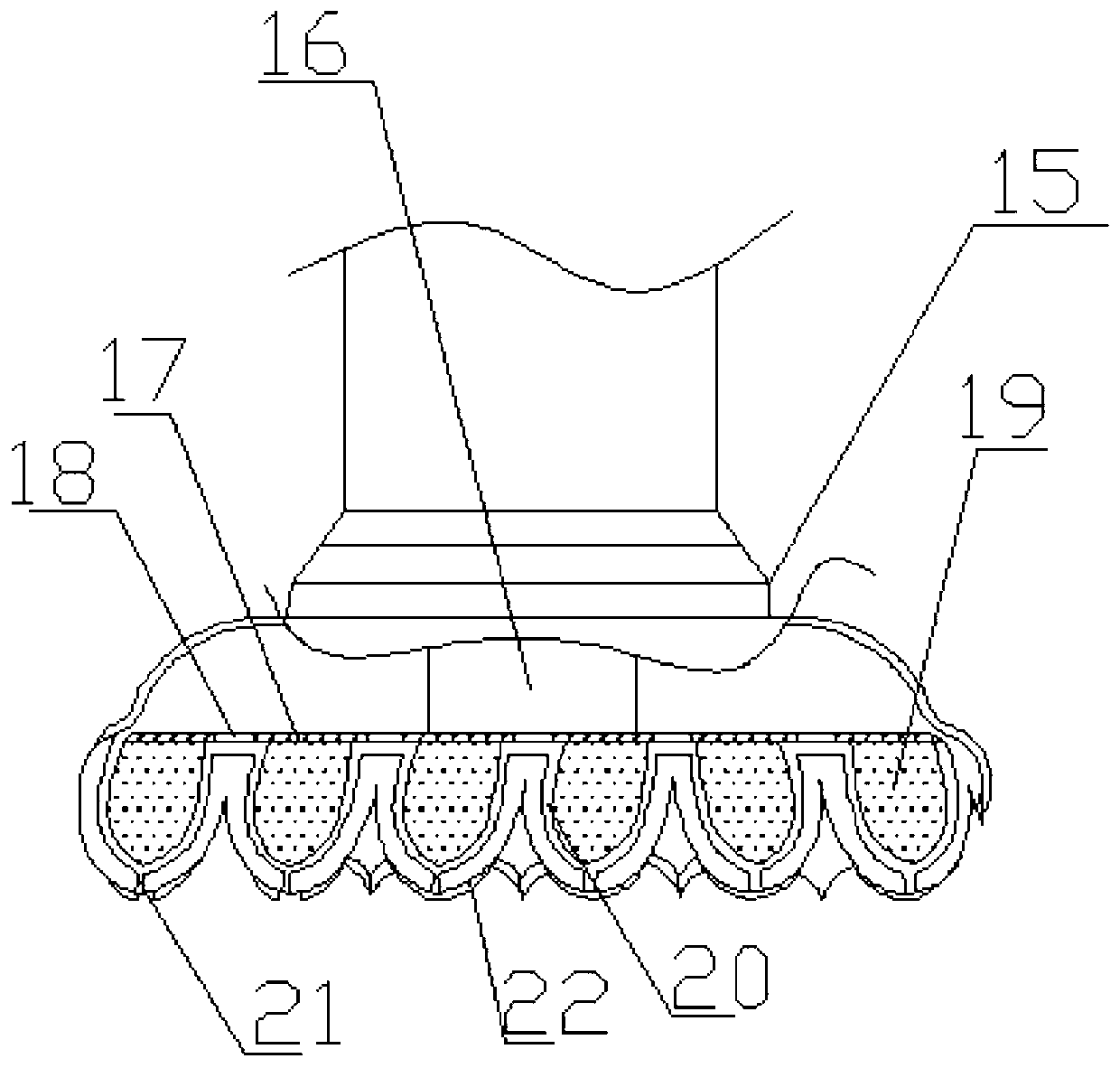

High precision plant protection robot unmanned plane

InactiveCN105182999APrecise travelRealize automatic sprayingAircraft componentsNavigation instrumentsMicrocontrollerEngineering

The invention discloses a high precision plant protection robot unmanned plane comprising an unmanned plane body and a ground station system; the unmanned plane body comprises a plane body, a motor, a rotor, a medicine box, a camera, and a spray pipe having nozzles; a one-chip microcomputer flight control system, a first 4G module, a first PTK module, a double-frequency multi-star GPS device, an image transmission module, a digit transmission module and a remote control reception module are arranged in the plane body; the one-chip microcomputer flight control system is respectively electrically connected with the first PTK module, the remote control reception module, the image transmission module, and the digit transmission module; the camera is electrically connected with the image transmission module; the first PTK module is respectively electrically connected with the double-frequency multi-star GPS device and the first 4G module; the ground station system comprises a GPS system and a PC ground station; the GPS system comprises a double-frequency multi-star GPS base station, a second PTK module, and a second 4G module; the PC ground station comprises a remote controller, a computer, and an image-digit integrated transmission radio connected with the computer; the beneficial effects are that the high precision plant protection robot unmanned plane can realize automation work, and is high in efficiency.

Owner:广西万维空间科技集团有限公司

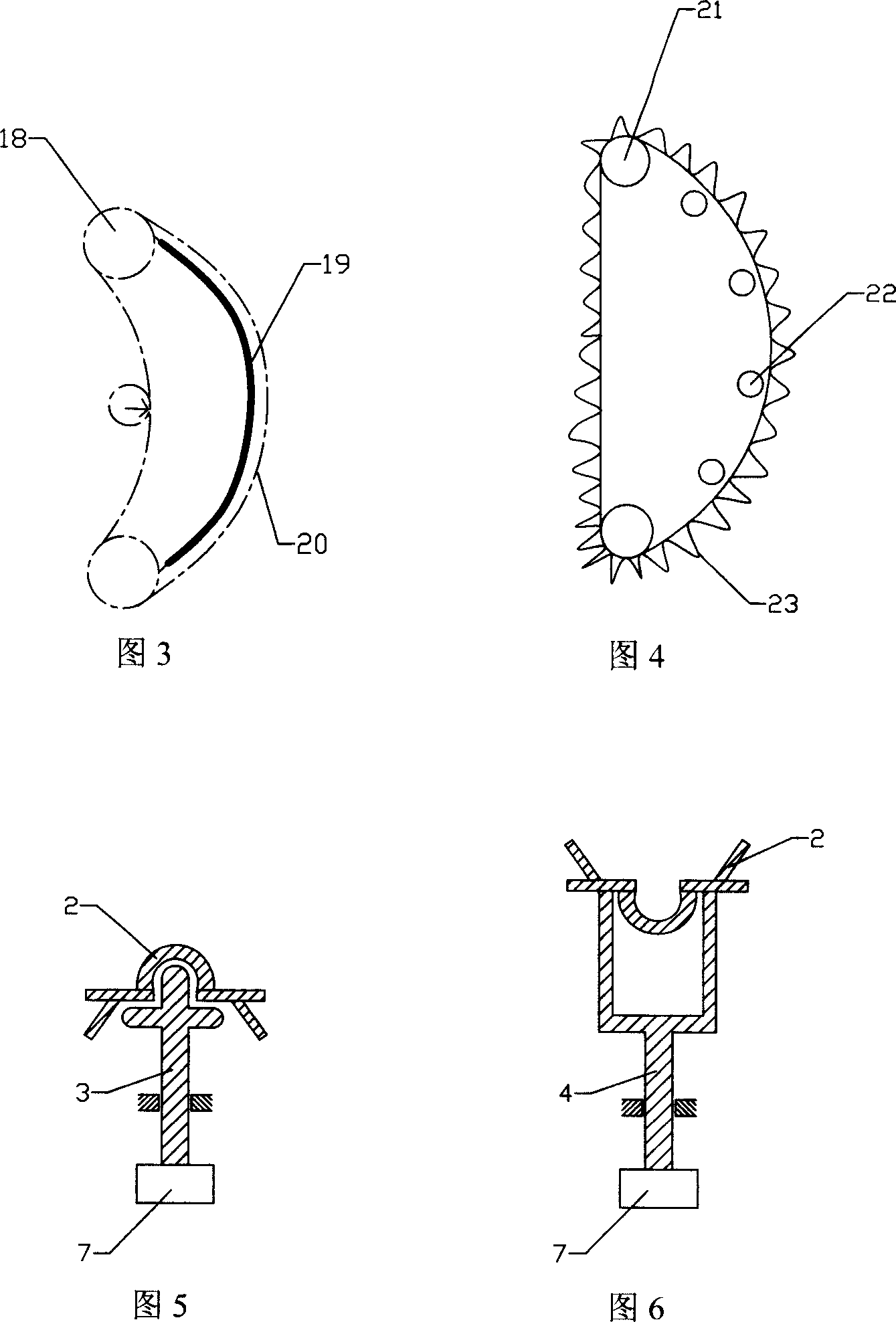

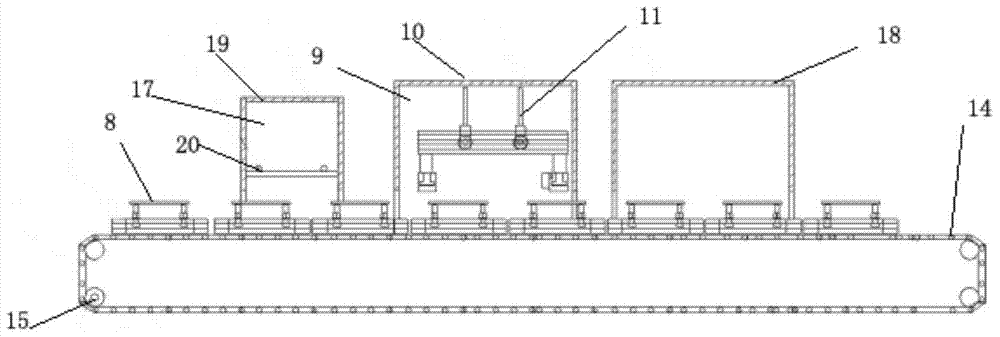

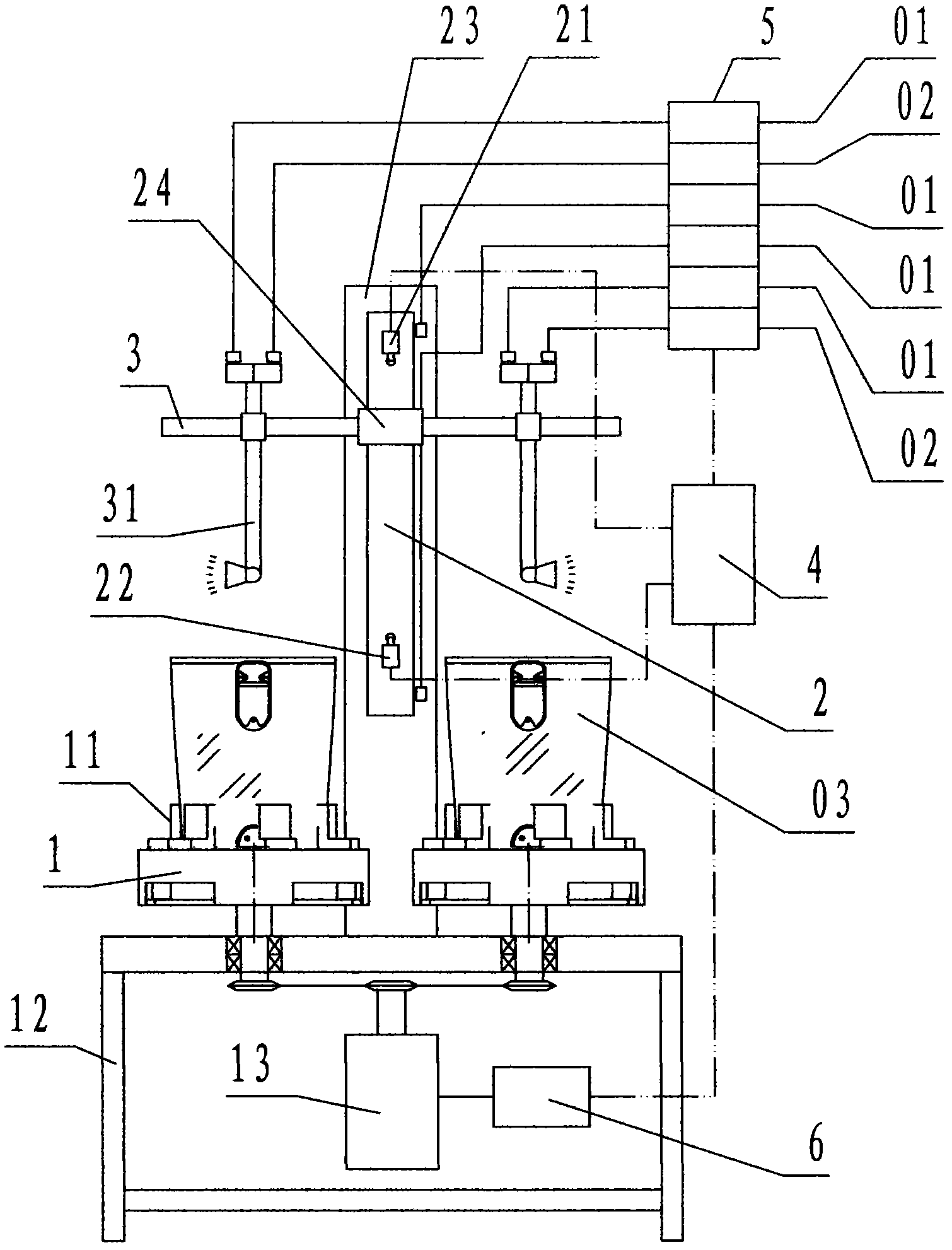

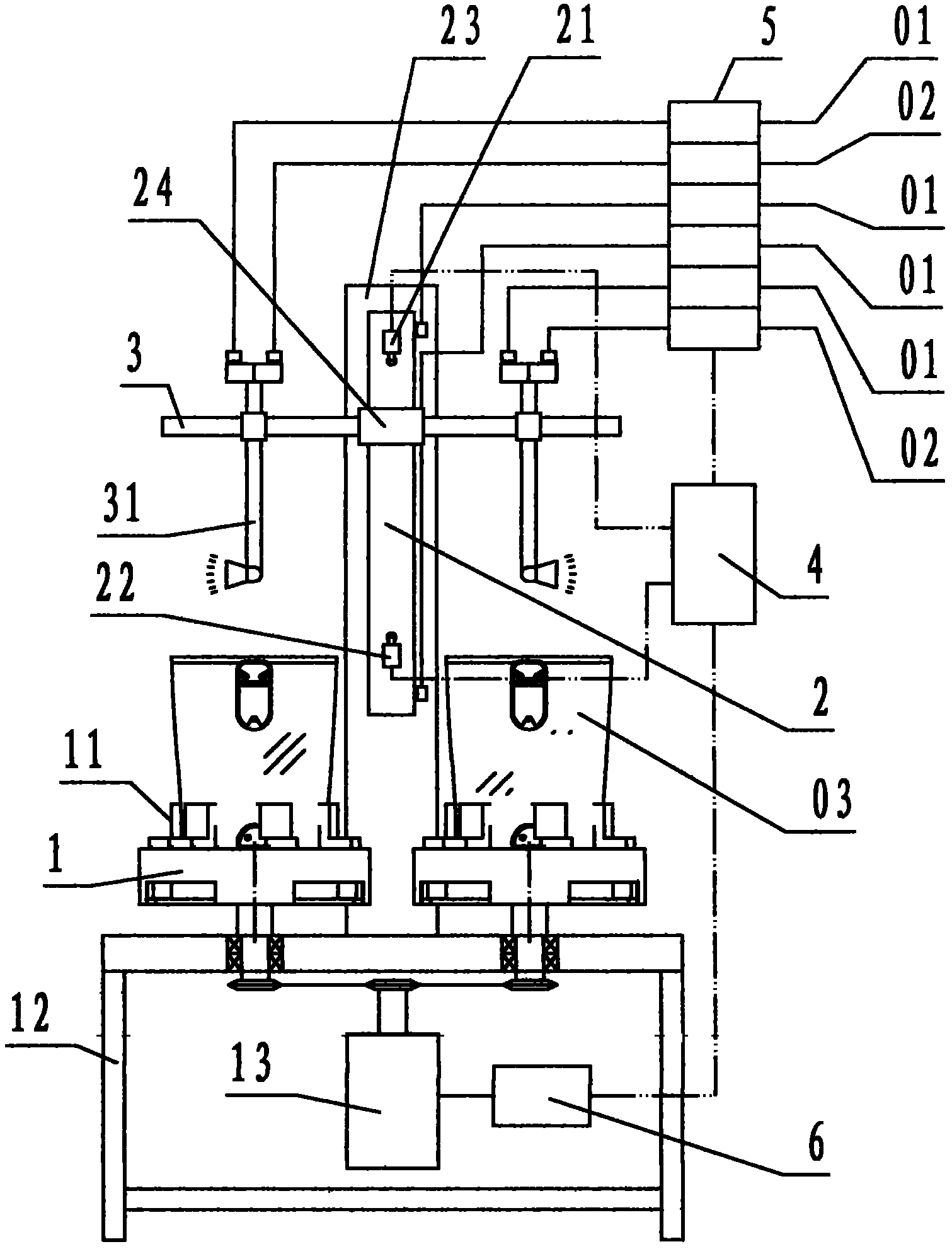

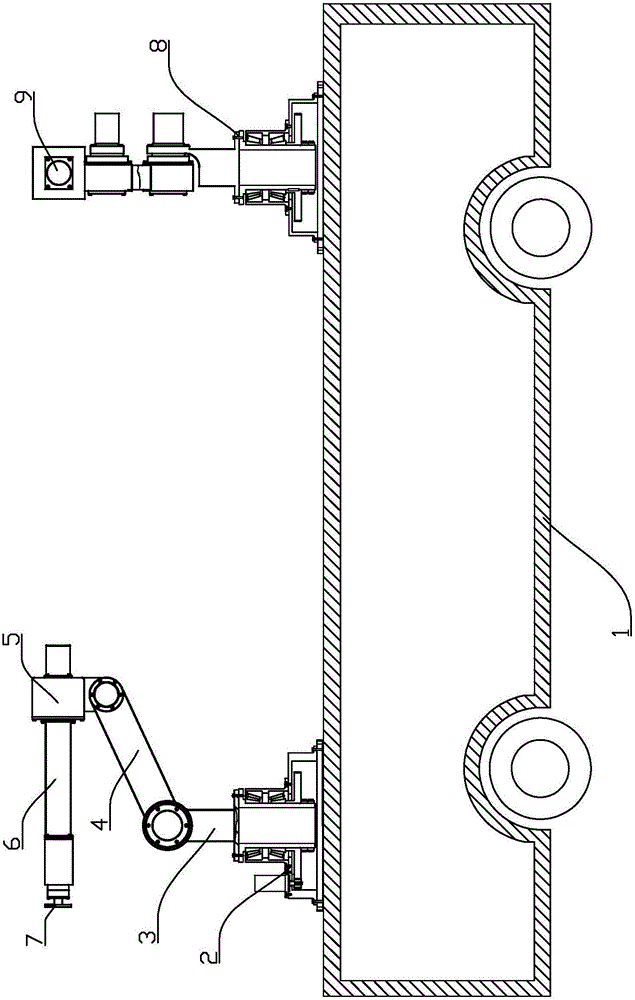

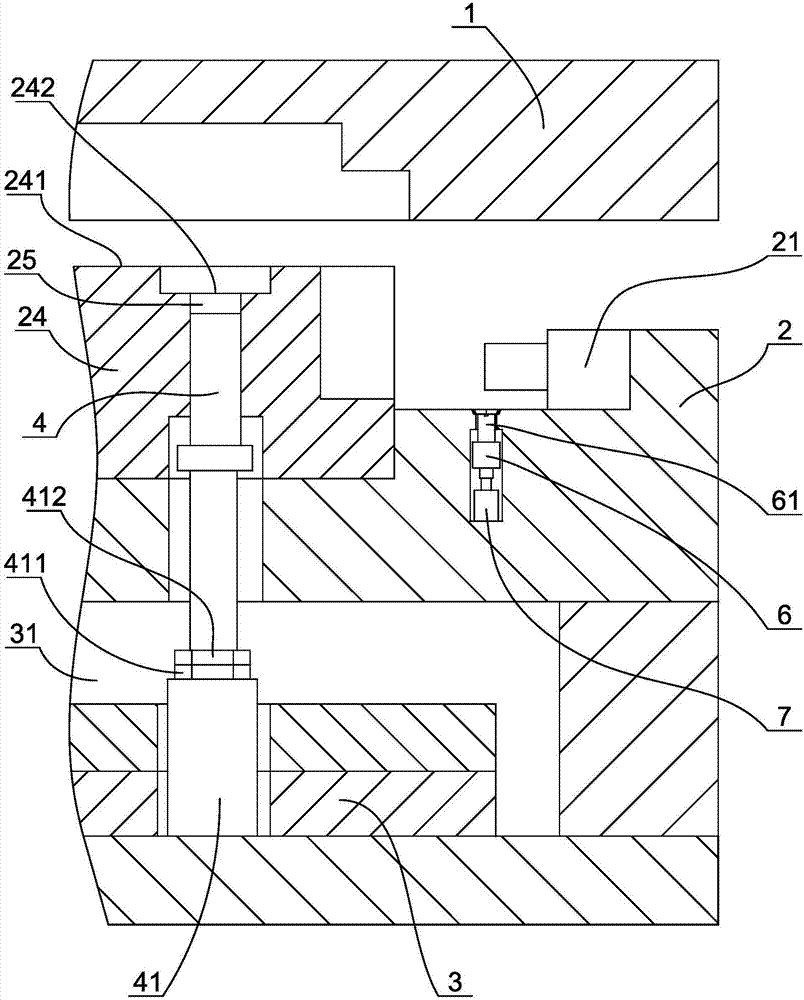

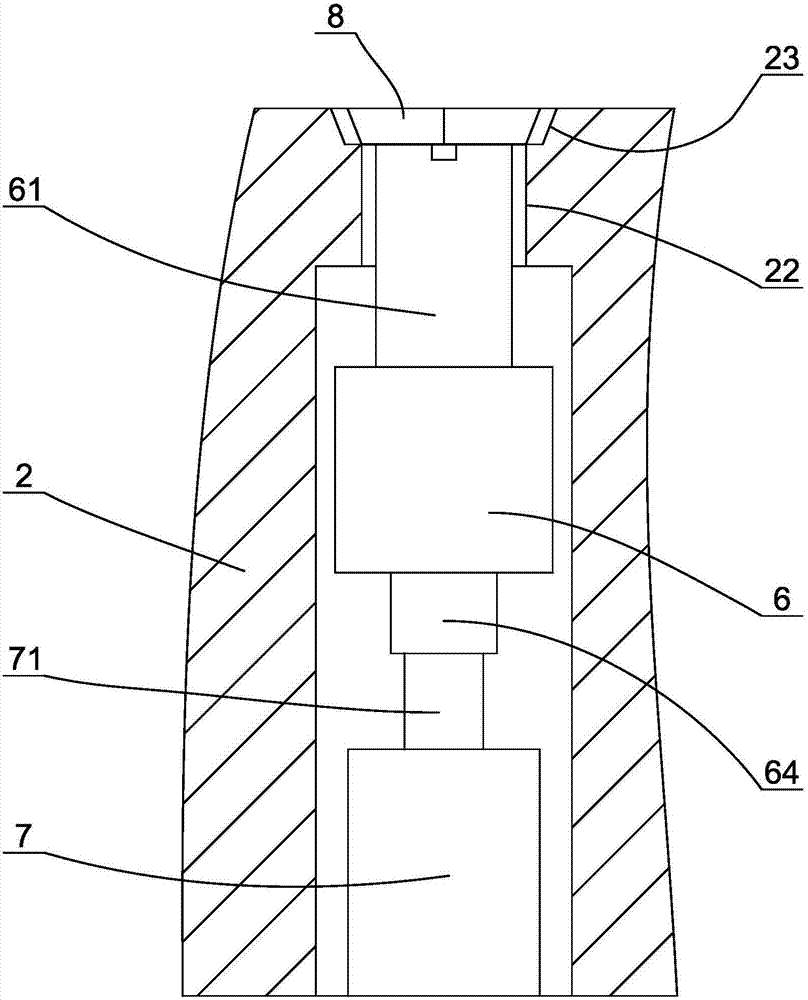

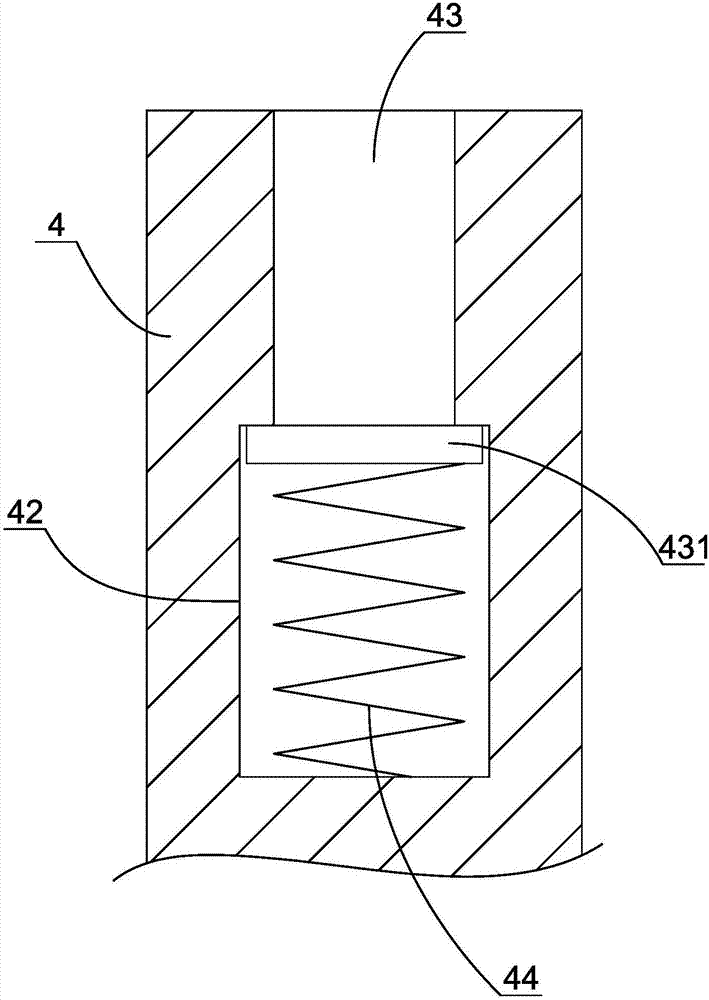

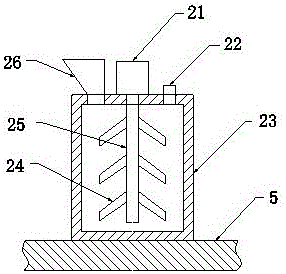

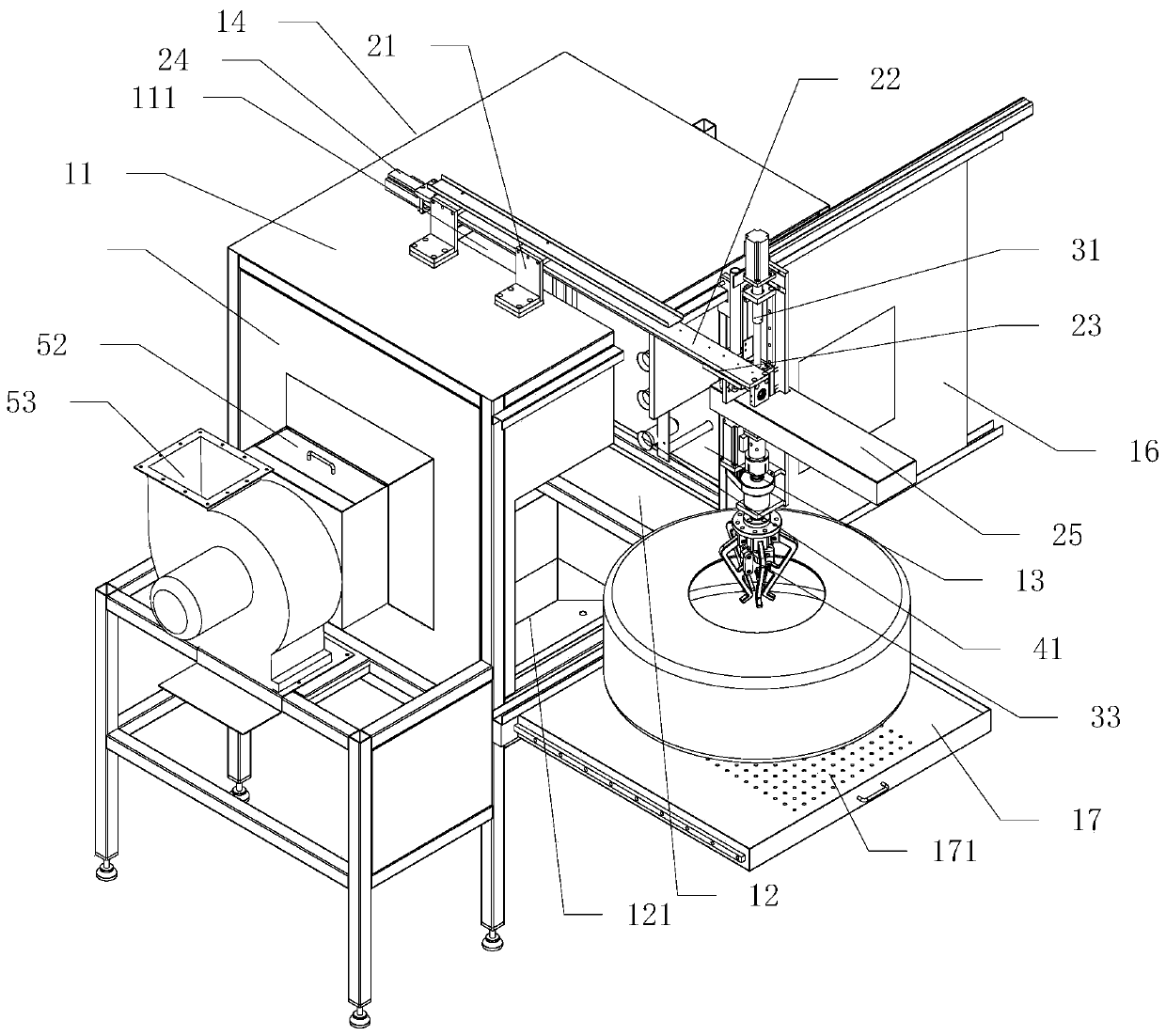

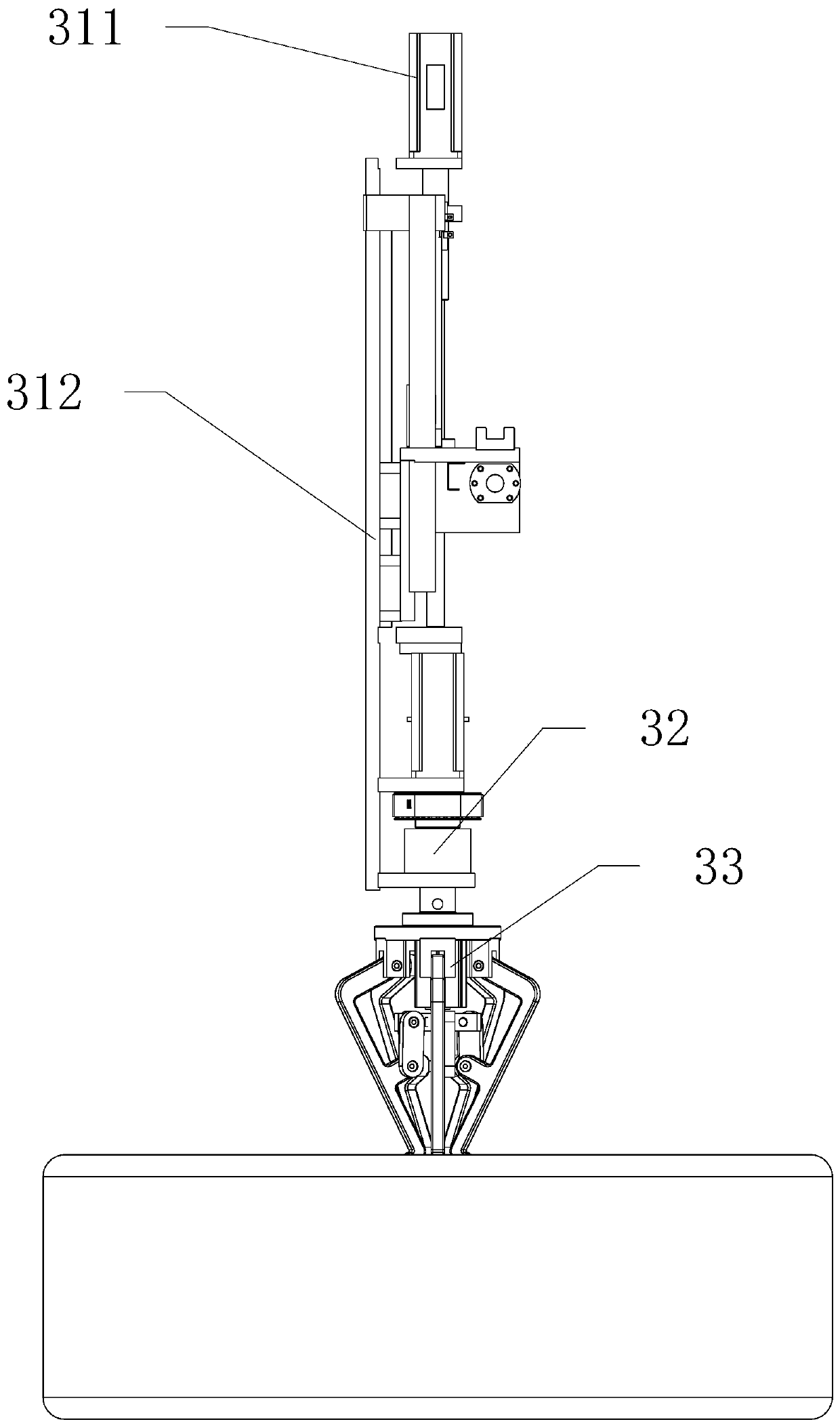

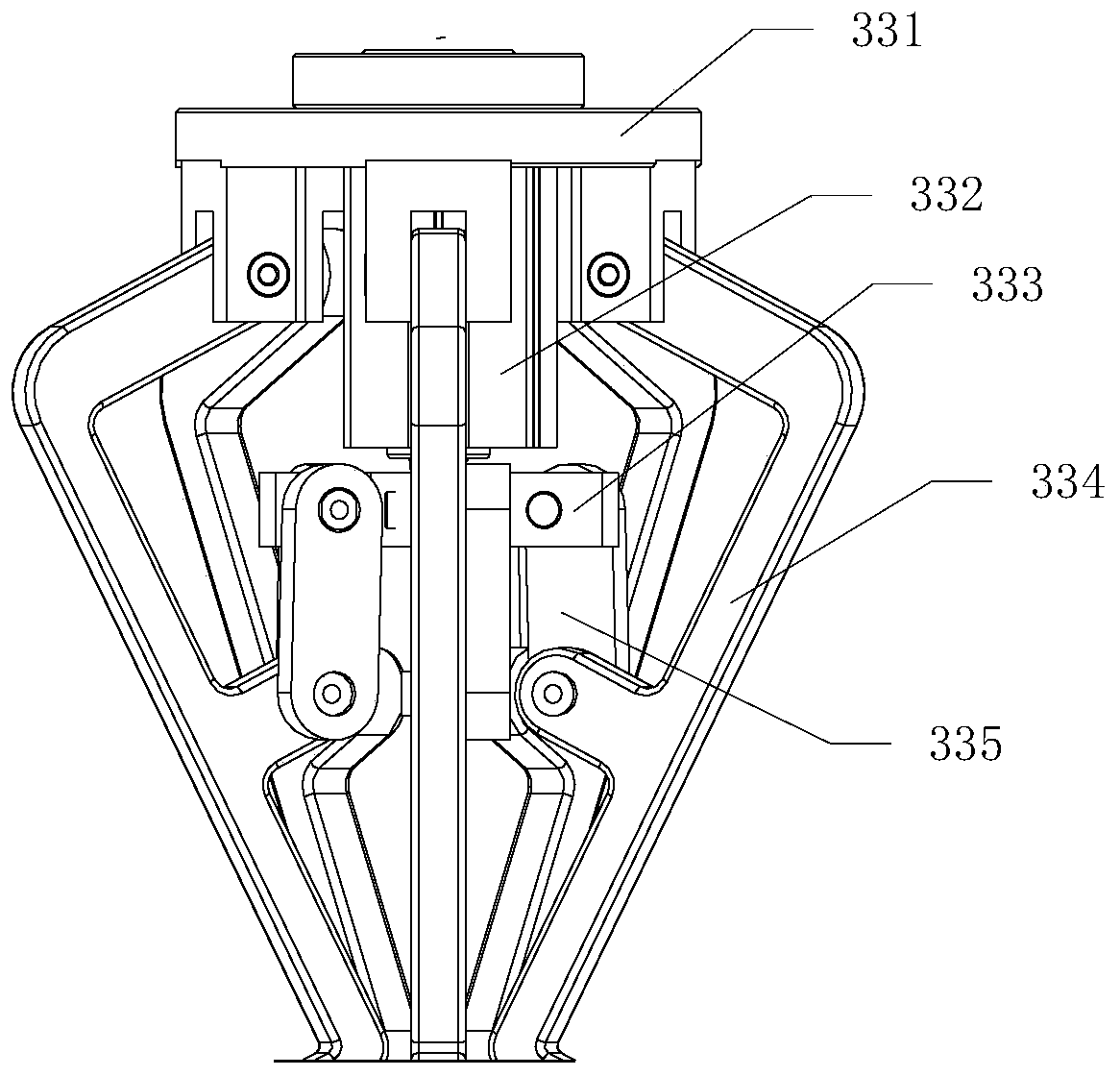

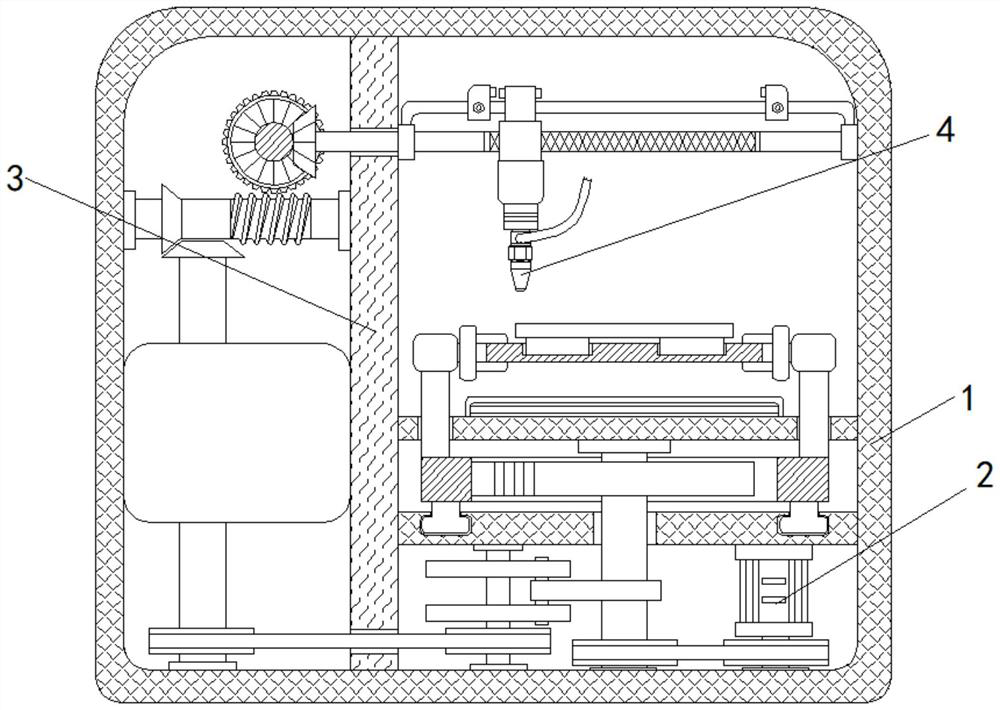

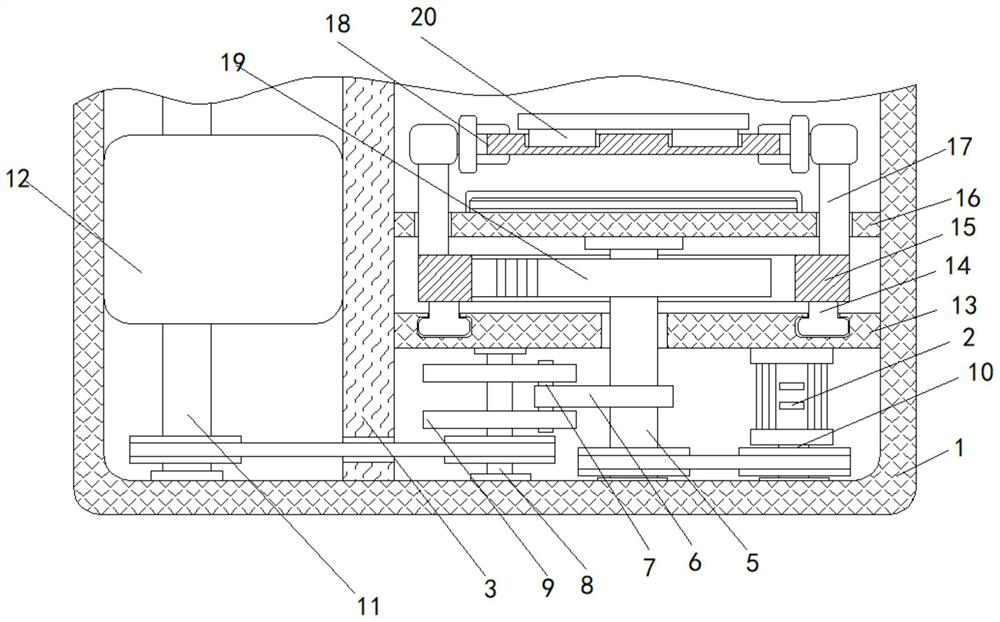

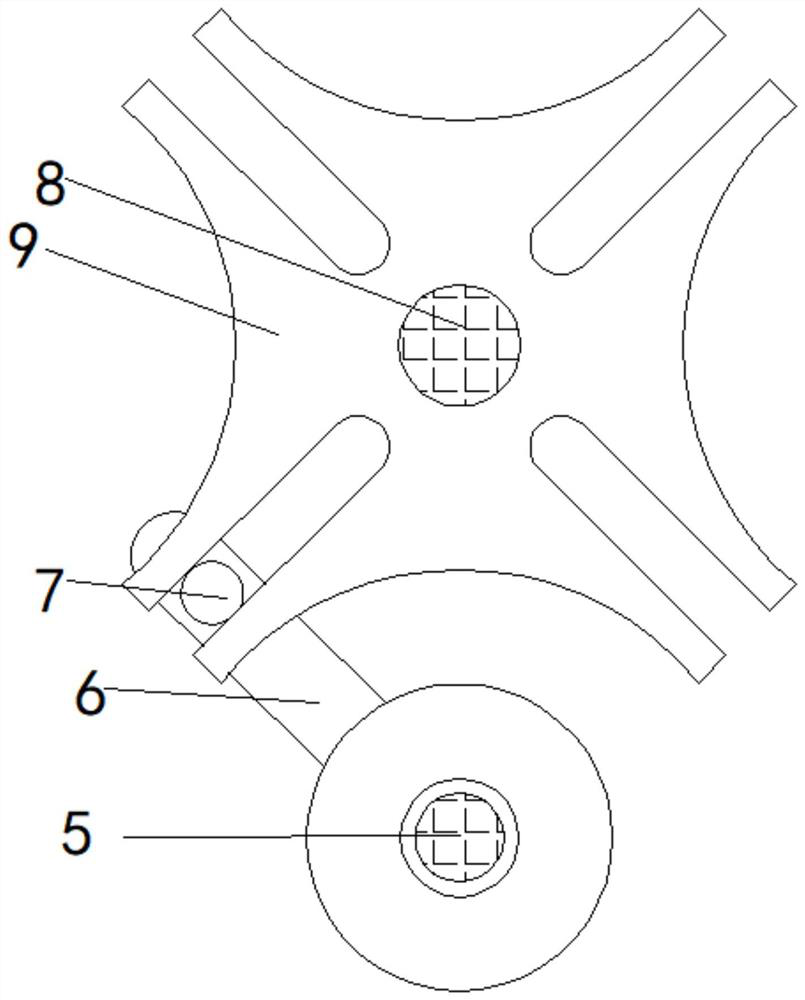

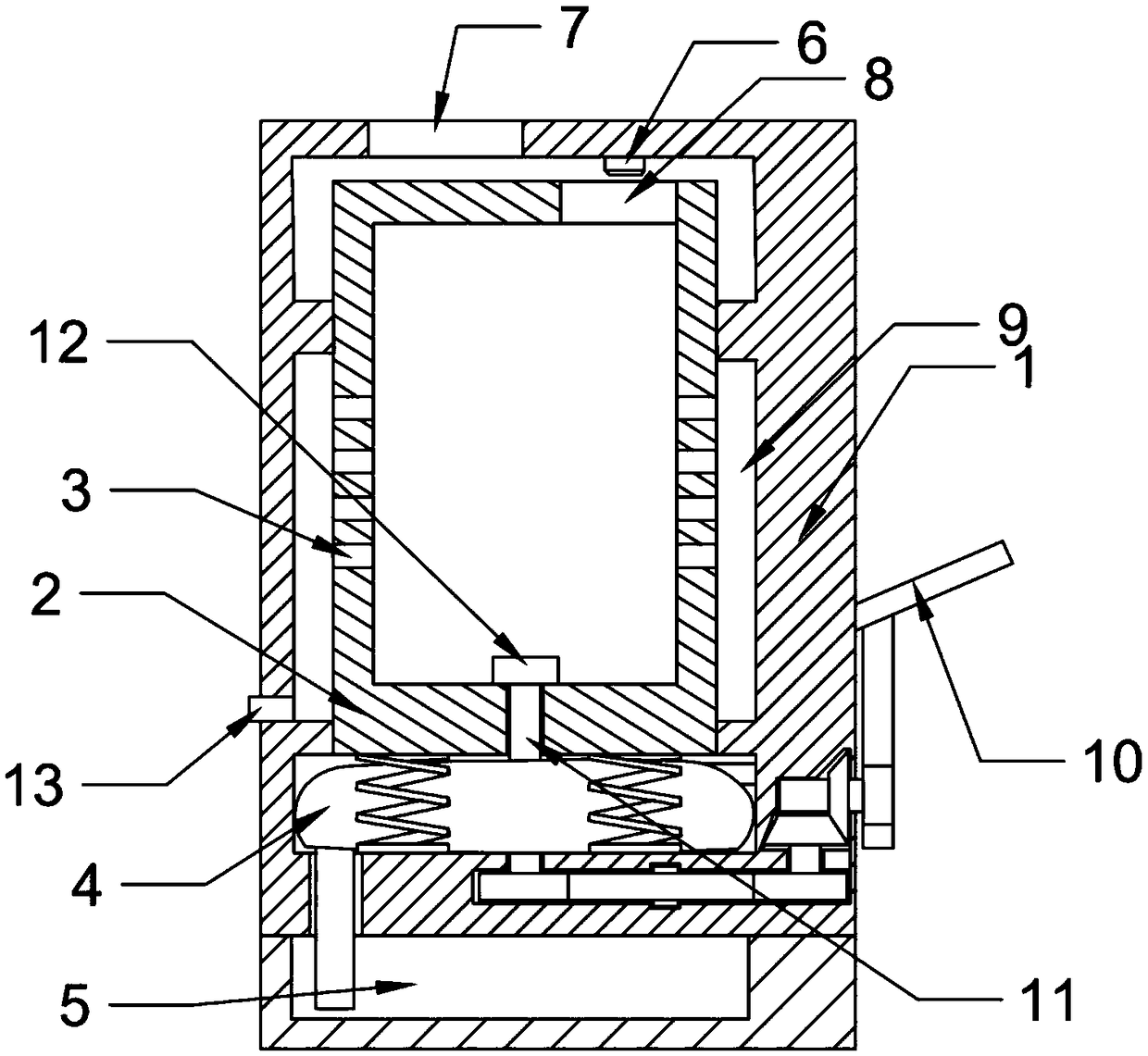

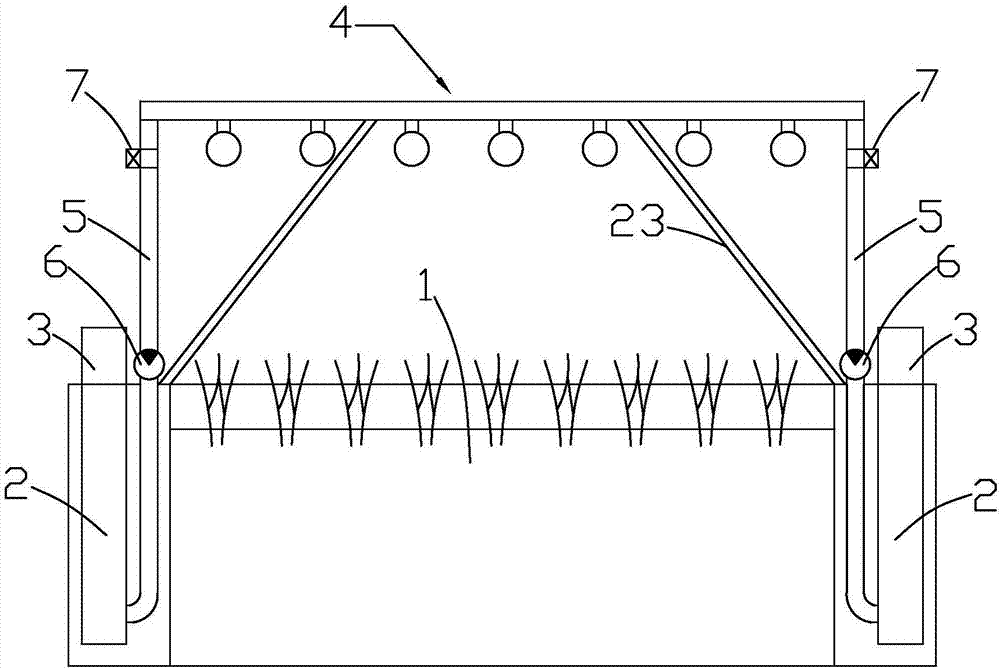

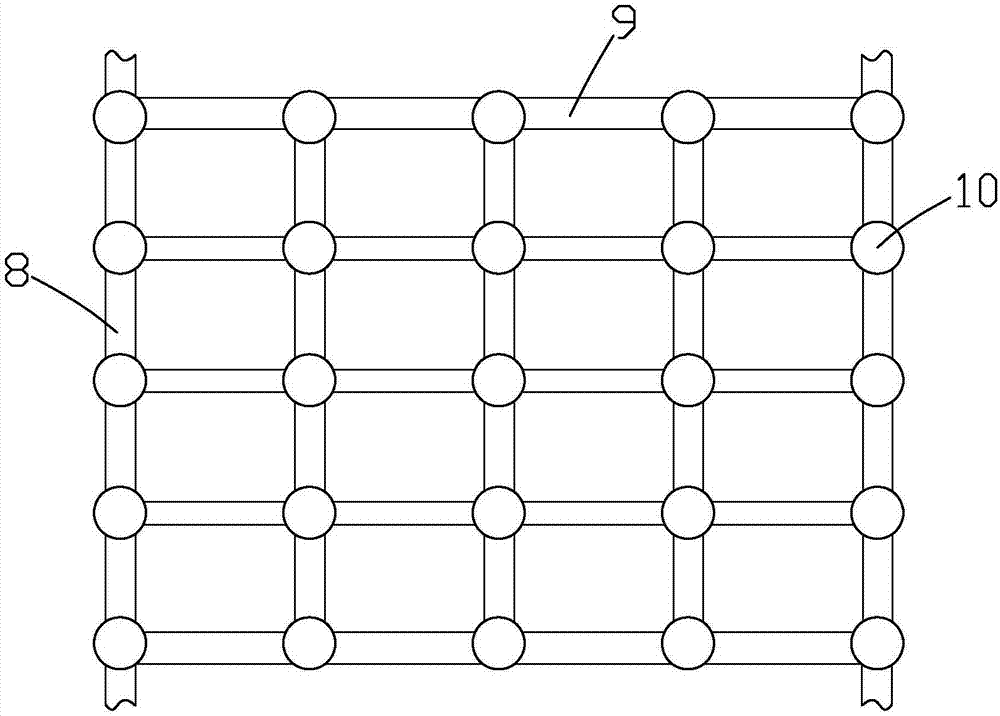

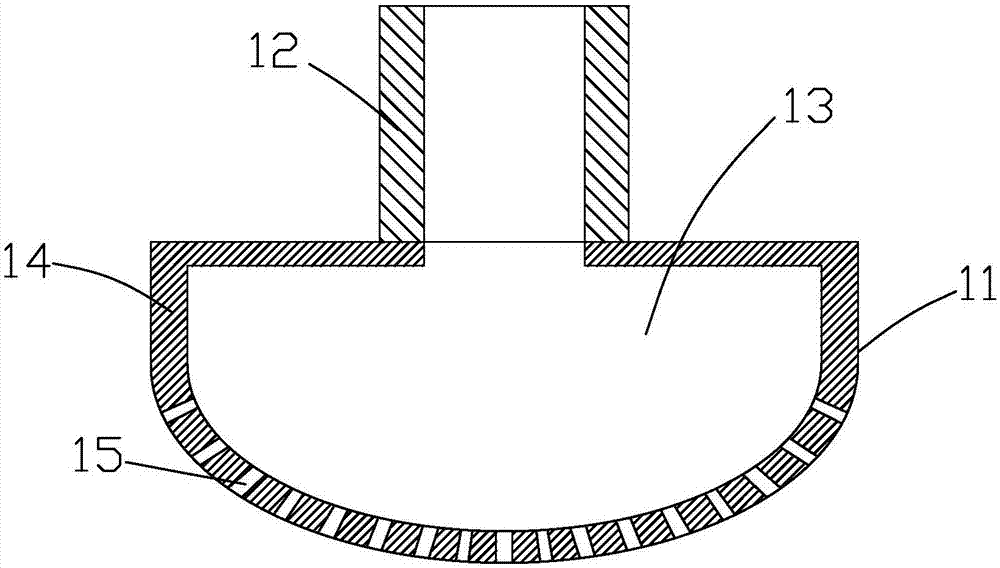

Automatic inner wall spraying device for round cup-shaped injection molding products

InactiveCN102626684AOvercome consistencyOvercome costsLiquid surface applicatorsSpraying apparatusFrequency conversionProgrammable logic controller

The invention discloses an automatic inner wall spraying device for round cup-shaped injection molding products. The automatic inner wall spraying device comprises a rotary workbench (1), a base (12), a motor (13), an air cylinder (2), a cantilever (3), a spray gun (31), a bracket (23), a PLC (Programmable Logic Controller) (4), an electromagnetic valve (5) and a frequency-conversion speed regulator (6). According to the invention, the device consisting of the rotary workbench, the motor, the air cylinder, the cantilever, the spray gun, the PLC, the electromagnetic valve and the frequency-conversion speed regulator is adopted; and when the automatic inner wall spraying device works, the round cup-shaped product is clamped on the rotary workbench and driven by the motor to rotate at a constant speed, the air cylinder drives the cantilever to carry the spray gun to be inserted into a cavity of the round cup-shaped product to spray up and down at a constant speed, and the PLC controls the spray gun to be started and stopped through the electromagnetic valve and controls the air cylinder to act up and down. Due to the technical scheme that the frequency-conversion speed regulator controls the rotating speed of the motor, the inner wall of the round cup-shaped injection molding product is sprayed to reach the purposes of keeping consistency of quality, reducing cost, improving efficiency and reducing waste.

Owner:NINGBO HUABAO PLASTICS & RUBBER MOLD

High-rise wall spraying robot

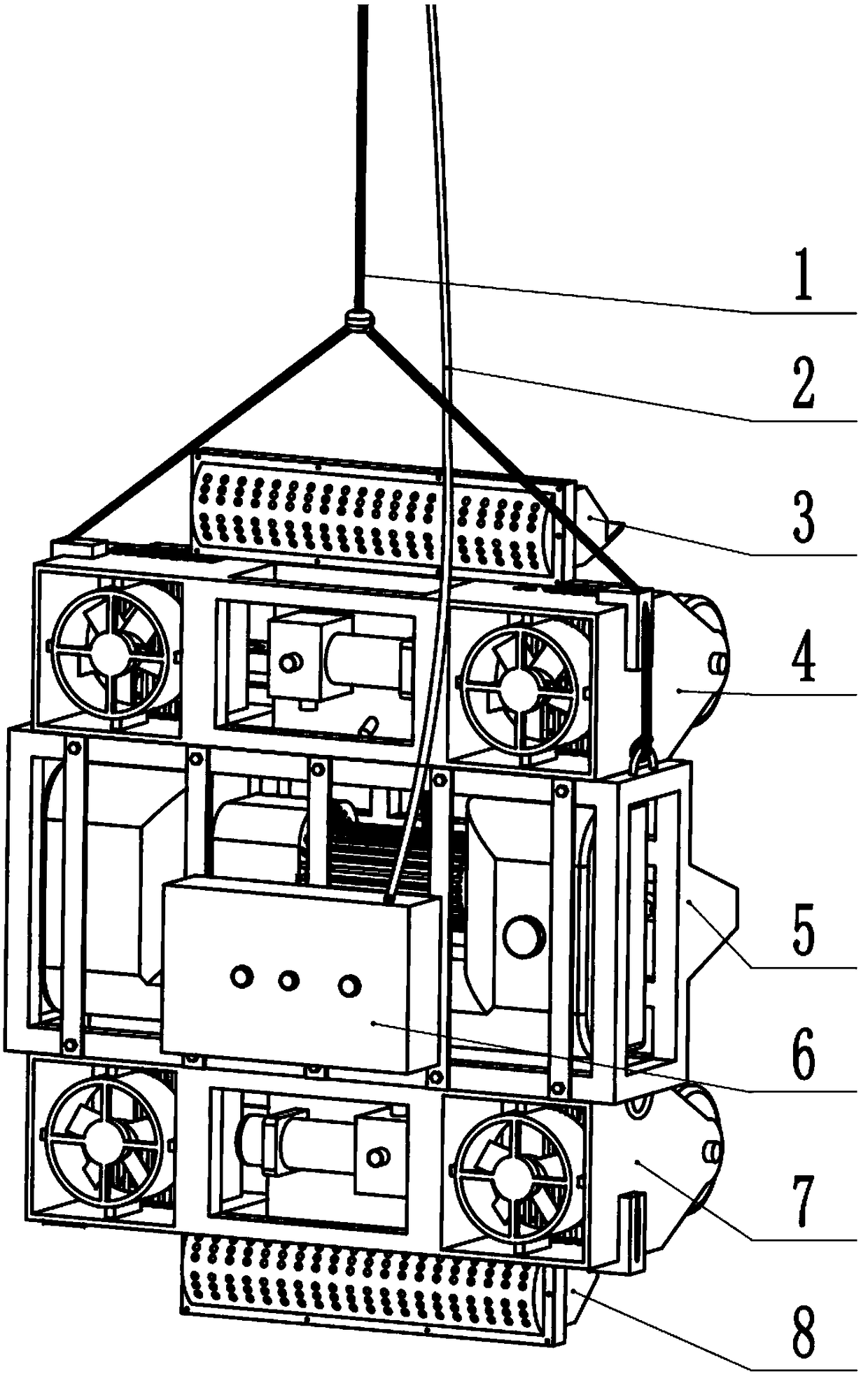

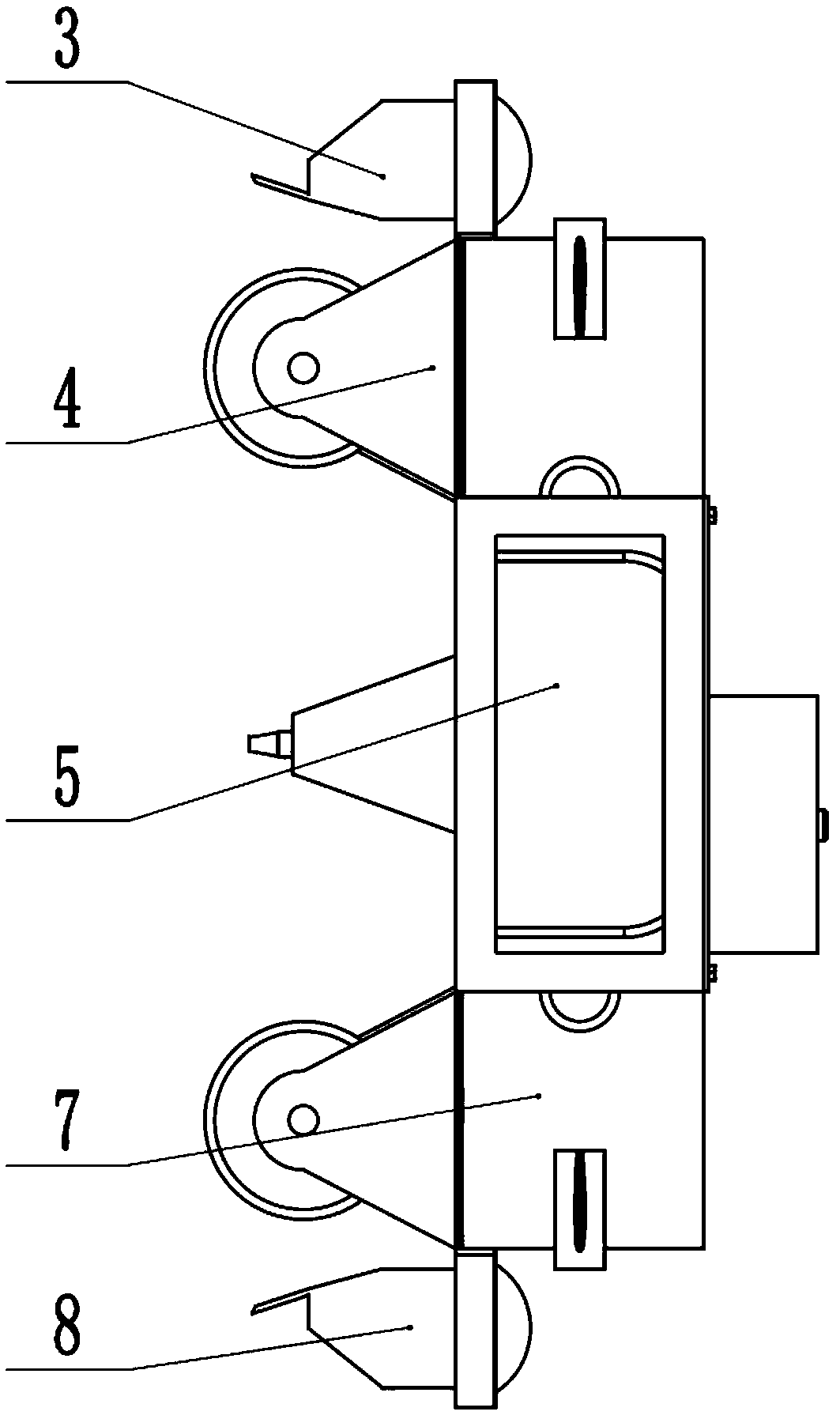

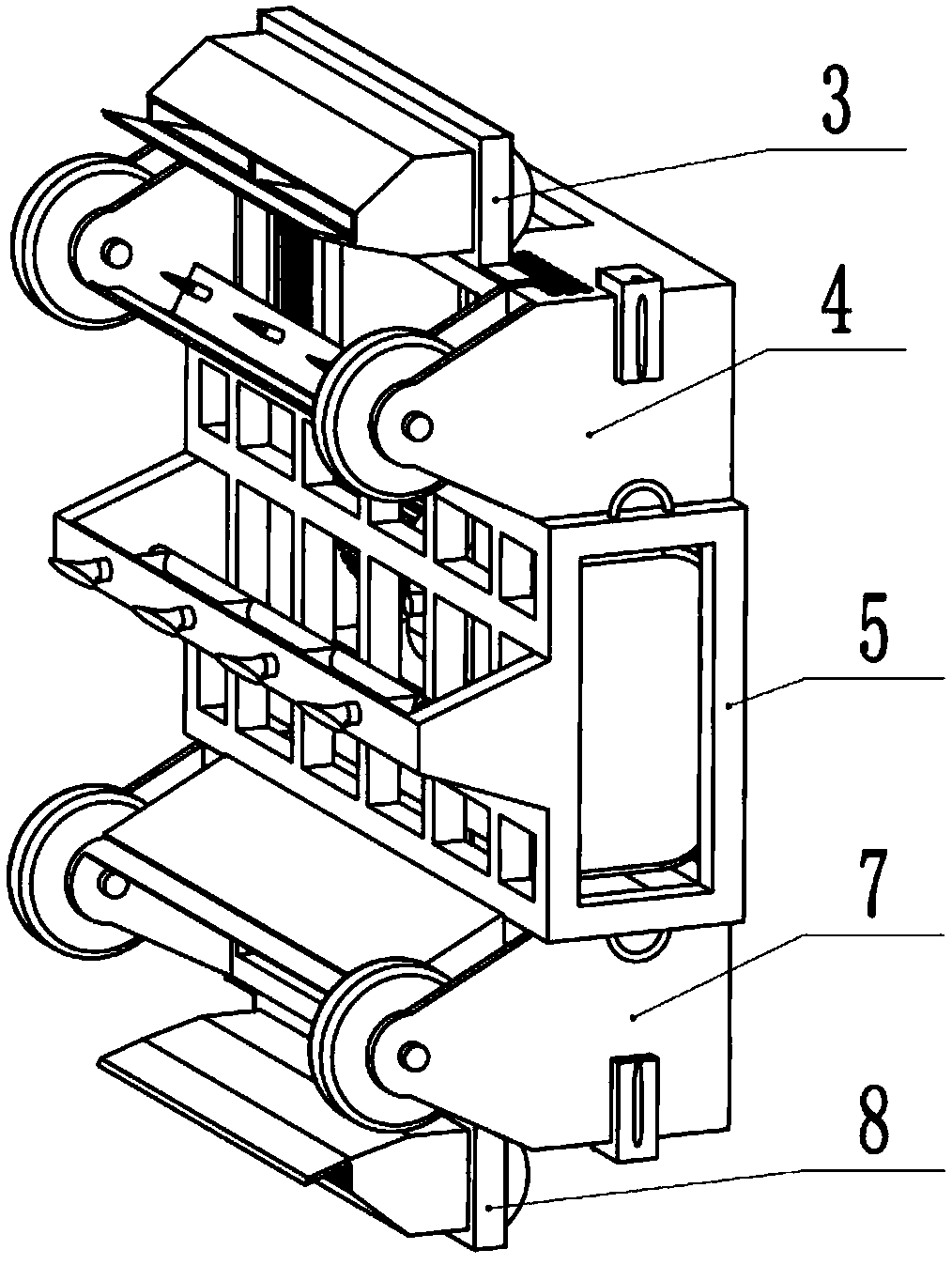

ActiveCN109162431AFully automatedGuaranteed uniformityBuilding constructionsRemote controlControl system

The invention discloses a high-rise wall spraying robot and relates to the technical field of high-rise wall surface spraying. The high-rise wall spraying robot comprises a hoist, an electric cable pay-off and take-up device, a roof moving crane, a panoramic camera, an anemometer, a remote control device, a steel wire rope and a cable line. The roof moving crane is parked on a side close to a wallto be painted. The high-rise wall spraying robot also includes a hot air drying device I, a dust cleaning device I, a spraying device, a control system device, a dust cleaning device II, and a hot air drying device II. The anemometer is also arranged on the mobile crane. The hoist is connected to the spraying device through the steel wire rope. The spraying device is provided with the control system device and the panoramic camera. An upper side of the spraying device is sequentially connected to the dust cleaning device I and the hot air drying device I, and a lower side of the spraying device is sequentially connected to the dust cleaning device II and the hot air drying device II. According to the invention, the automation of the wall surface spraying is realized, the spraying efficiency is improved, the uniformity of the spraying density is ensured, the labor cost is reduced, an artificial high-altitude operation is substituted, and the danger is reduced.

Owner:冠品机具(深圳)流体科技有限公司

Automatically sprayed ultraviolet curing paint and preparation method thereof

InactiveCN102372935AShorten the construction periodGood anti-corrosion effectAnti-corrosive paintsSolventPhotoinitiator

The invention relates to an ultraviolet curing paint, and concretely relates to an automatically sprayed ultraviolet curing paint and a preparation method thereof. A disadvantage of present ultraviolet curing paints is that: the curing process is completed in several seconds, and the large contraction makes the formation of the thick coating to be impossible, so the usage of the paints in the anticorrosion field is restricted. The ultraviolet curing paint comprises the following substances, by weight, 100 parts of an oligomer, 20-50 parts of a monomer, 10-30 parts of a coupling agent, 2-10 parts of an acid anhydride, 1-2 parts of a mixed assistant, 10-30 parts of nanometer silica, 3-10 parts of a photoinitiator, 80-200 parts of a solvent and 100-200 parts of a propellent. The ultraviolet curing paint of the invention, which allows a technical problem of ultraviolet curing paints for the equipment anticorrosion to be solved, has the advantages of good anticorrosion effect, convenient construction, no need of compressed air, realization of the automatic spray, simple preparation method, safety, no pollution, fast curing speed, high production efficiency, high film quality, and excellent coating performance.

Owner:SHANGHAI TITANOS IND

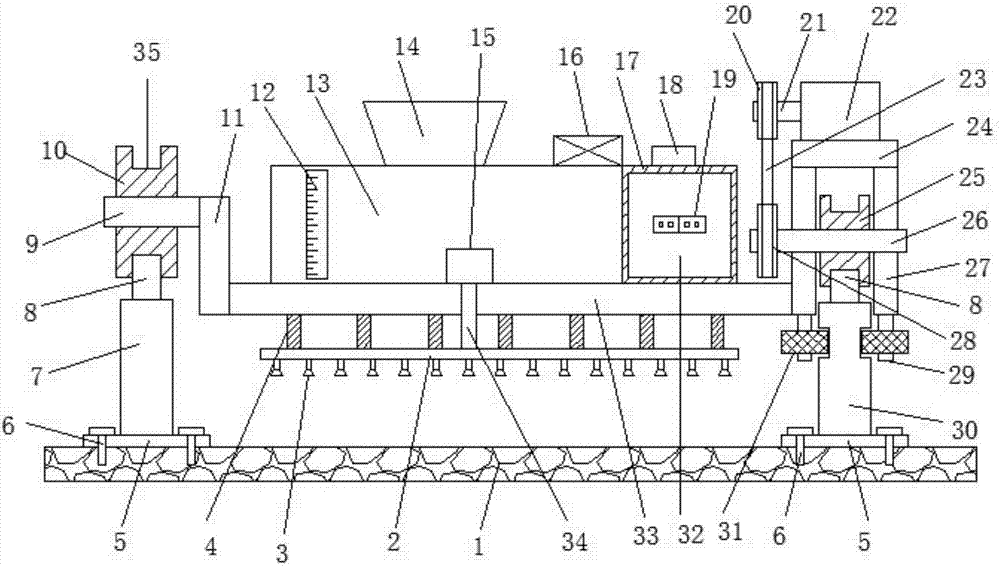

Concrete pavement automatic spraying and maintaining device for bridge construction

InactiveCN107419669AReasonable structureInnovative designBridge erection/assemblyRoads maintainenceWater storageDrive wheel

The invention discloses an automatic spray maintenance device for concrete pavement used in bridge construction, which comprises a pavement foundation and a mounting seat installed on the pavement foundation. The middle part of the guide wheel is connected with the traction shaft, the right end of the traction shaft is connected with the drawbar, the upper end of the right mounting seat is connected with the right guide rail, the upper end of the right guide rail is connected with the right guide wheel, the middle part of the right guide wheel is connected with the driven shaft, and the left end of the driven shaft is connected with the There is a driven wheel, the upper end of the driven wheel is connected to the driving wheel through a chain, the right end of the driving wheel is connected to the driving shaft, the right end of the driving shaft is connected to the traction motor, a connecting plate is installed between the traction rod and the left fixed frame, and a storage battery is installed on the upper end of the connecting plate. water tank. The present invention realizes the automatic spray maintenance of the bridge concrete pavement, increases the maintenance quality of the pavement, avoids manual sprinkler spraying at the same time, reduces the labor intensity of the staff, and realizes the automatic spraying of the pavement with low cost. .

Owner:李威

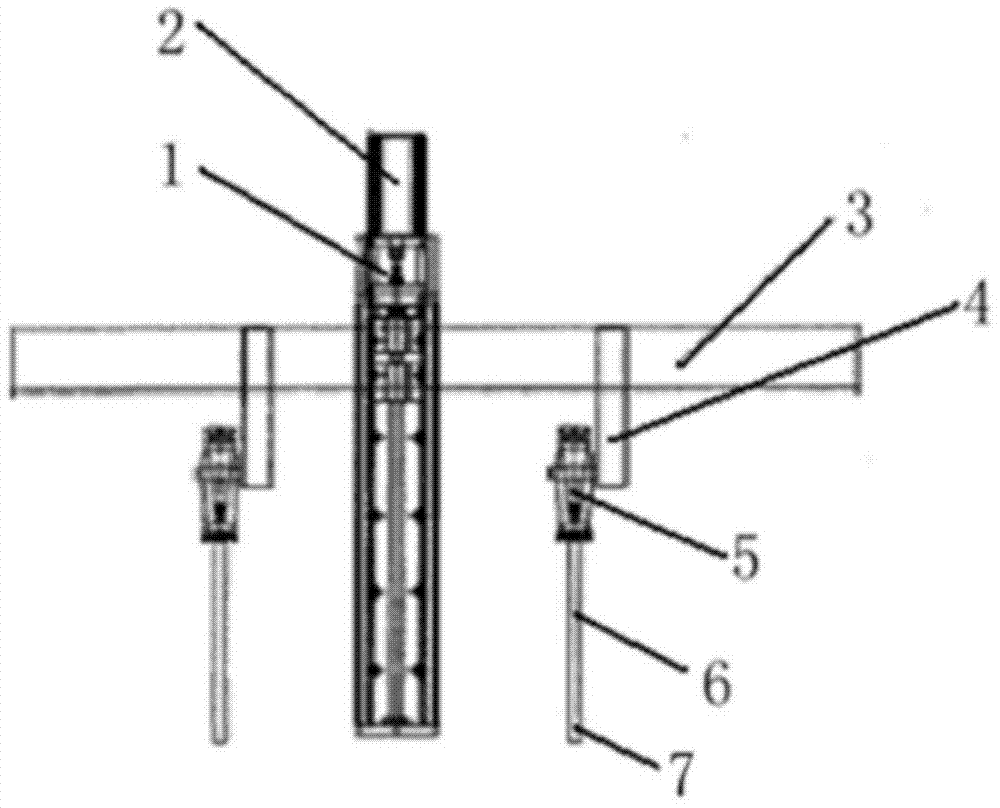

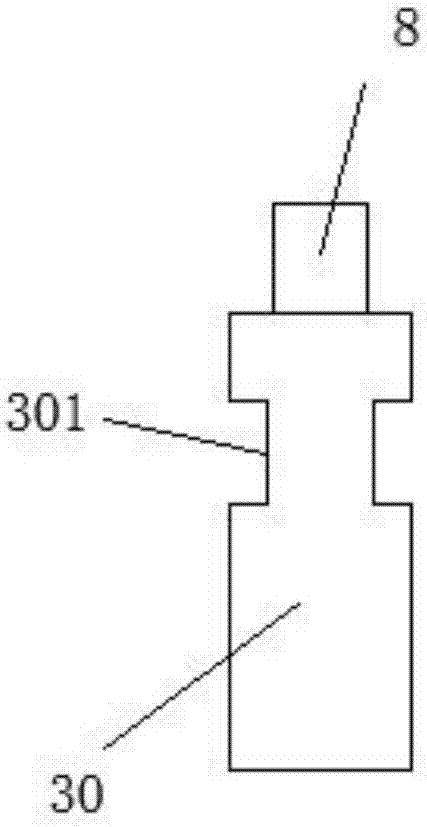

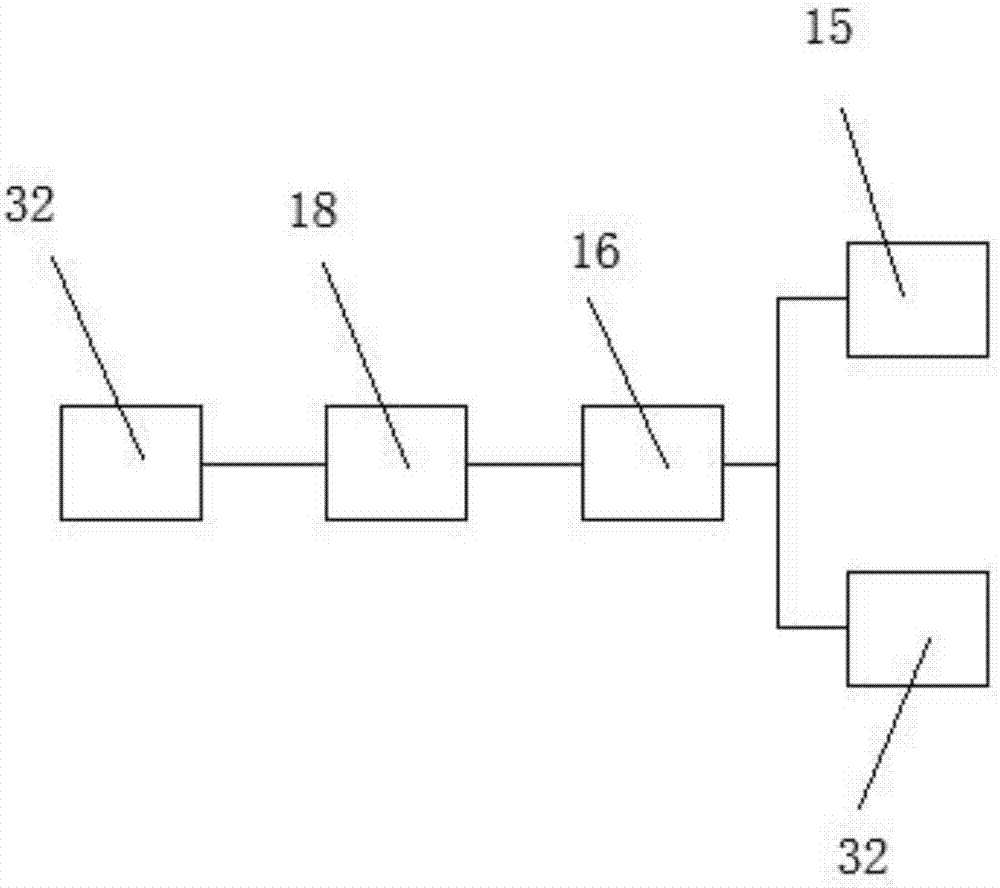

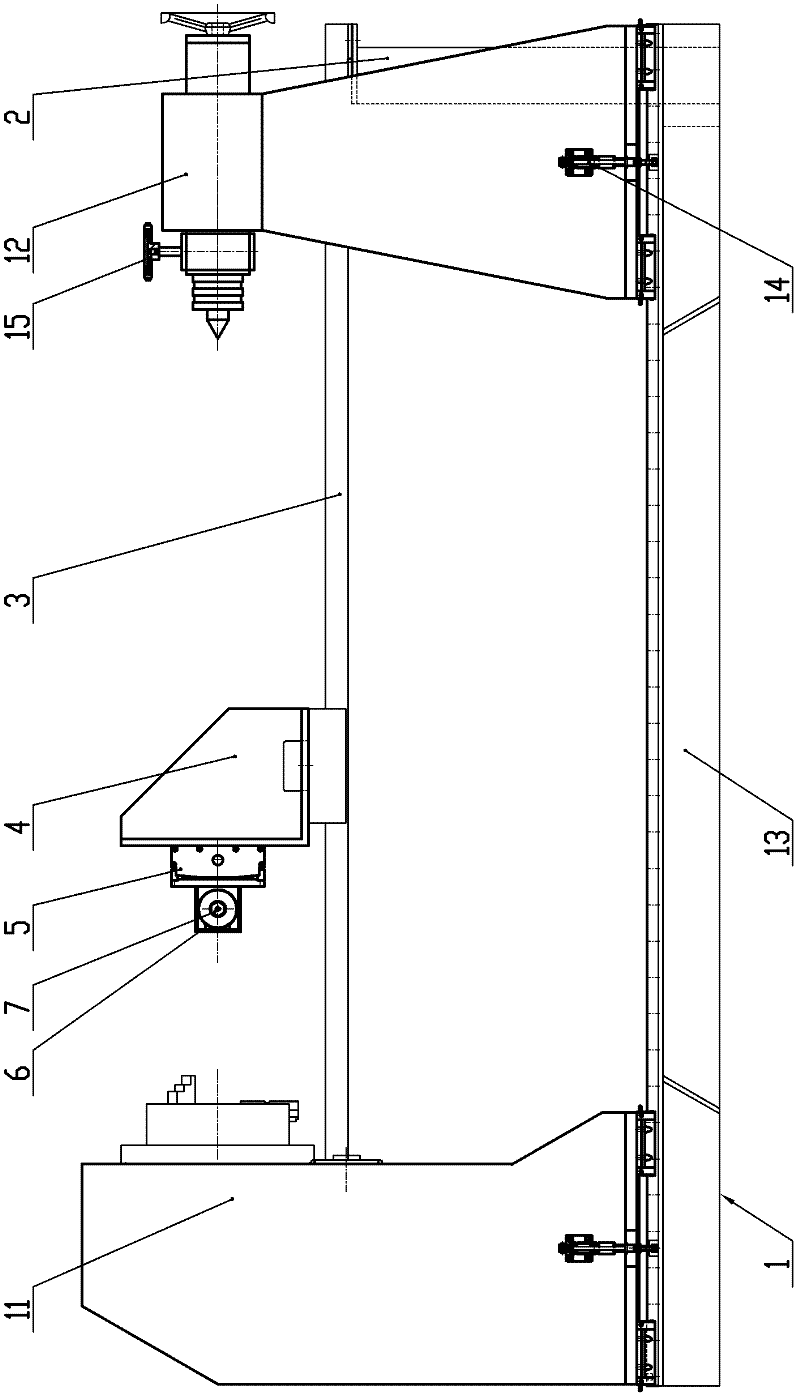

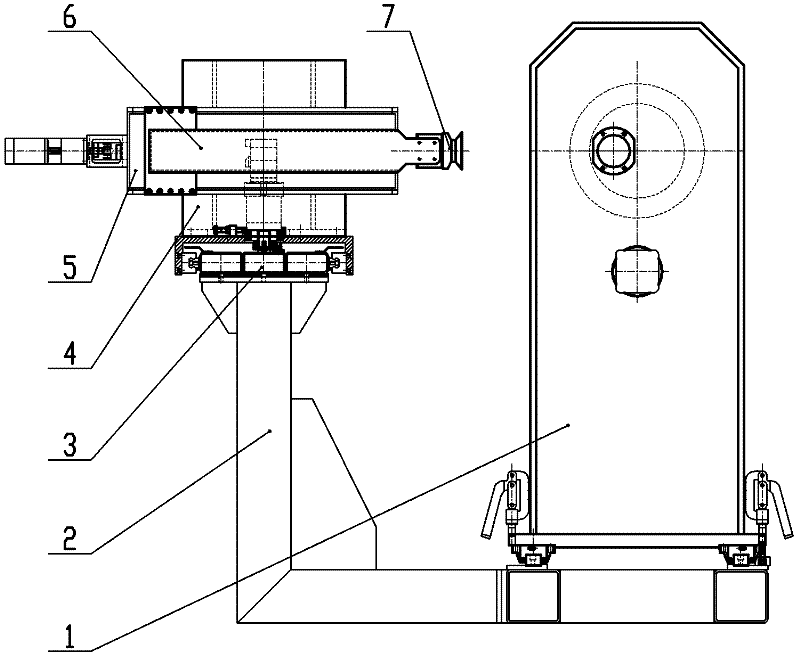

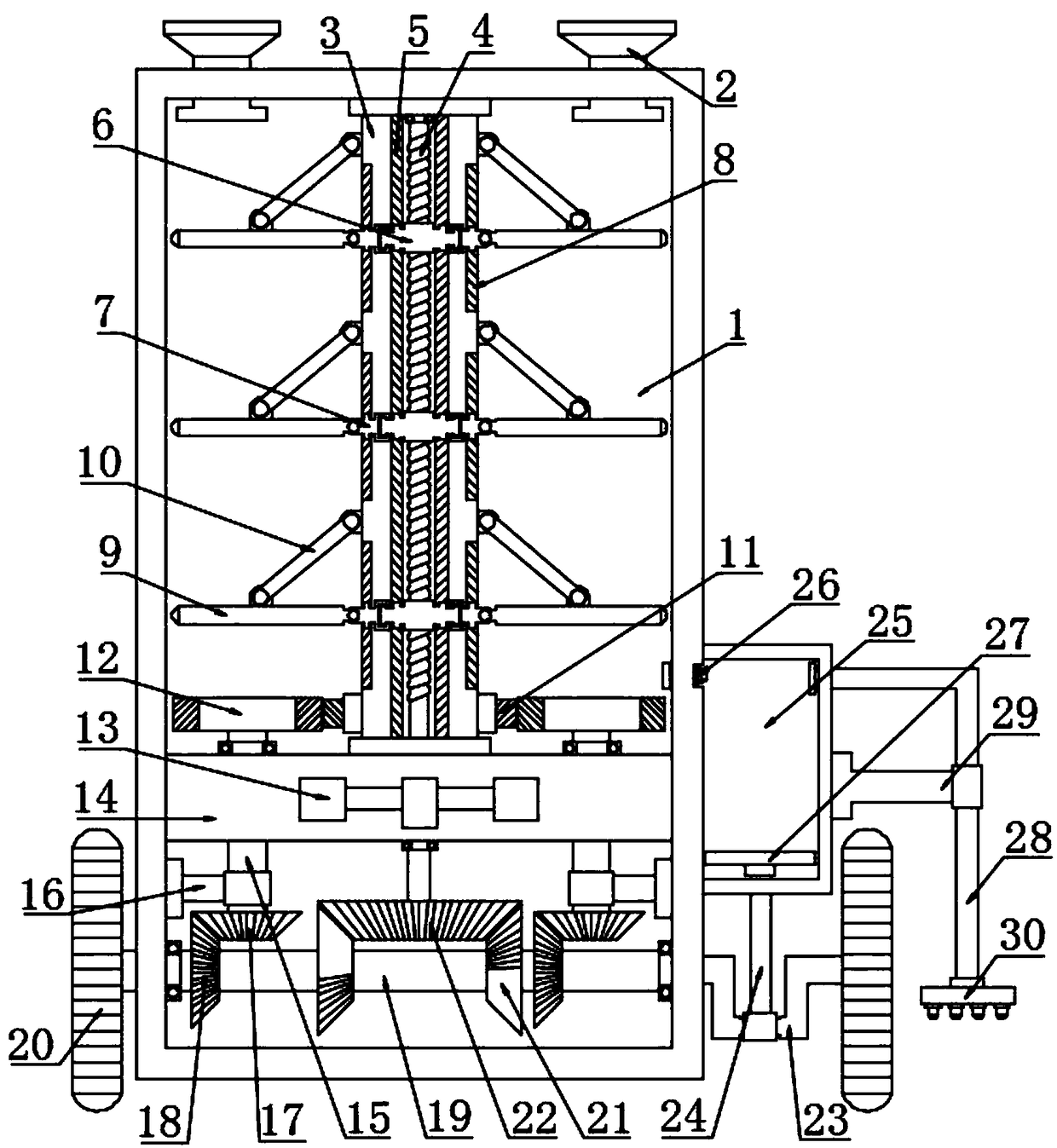

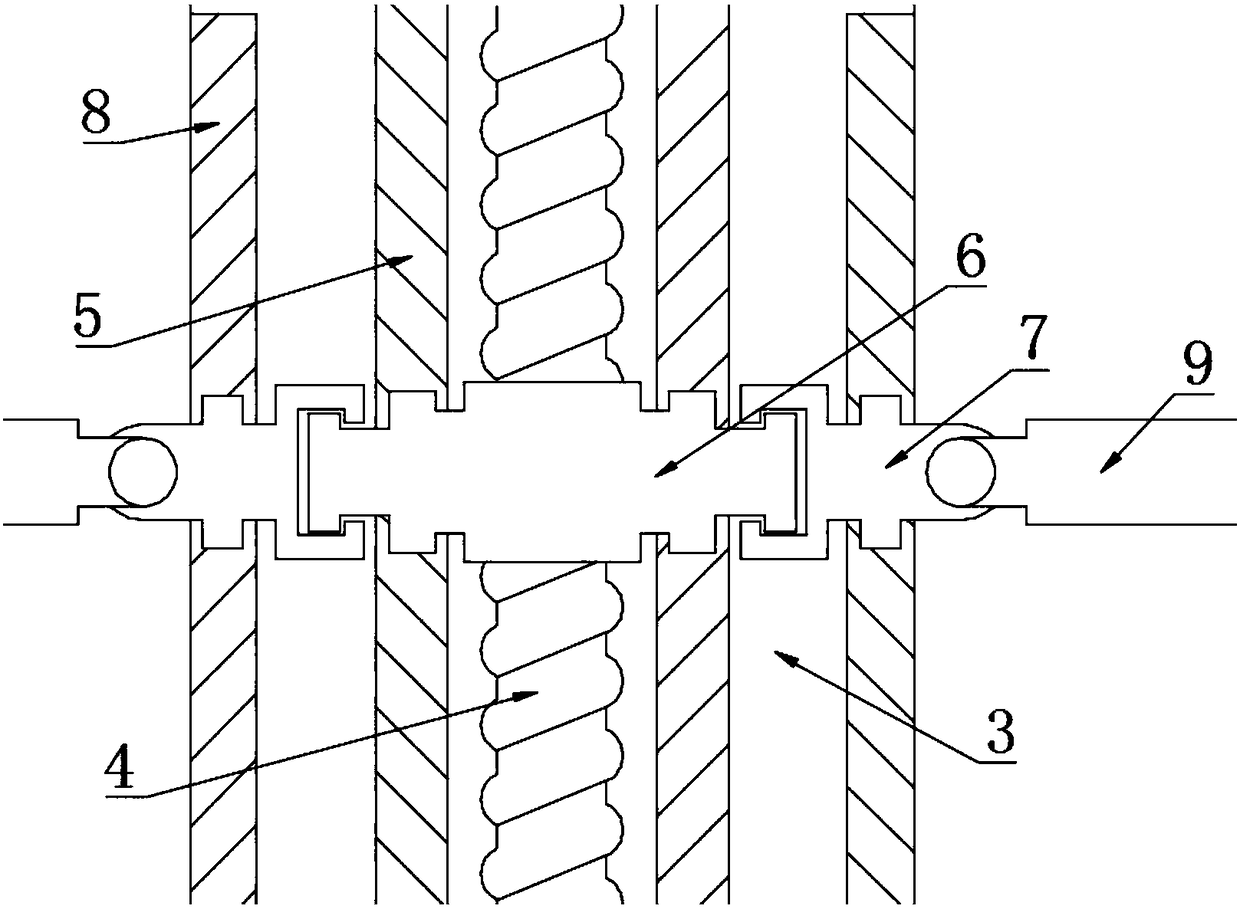

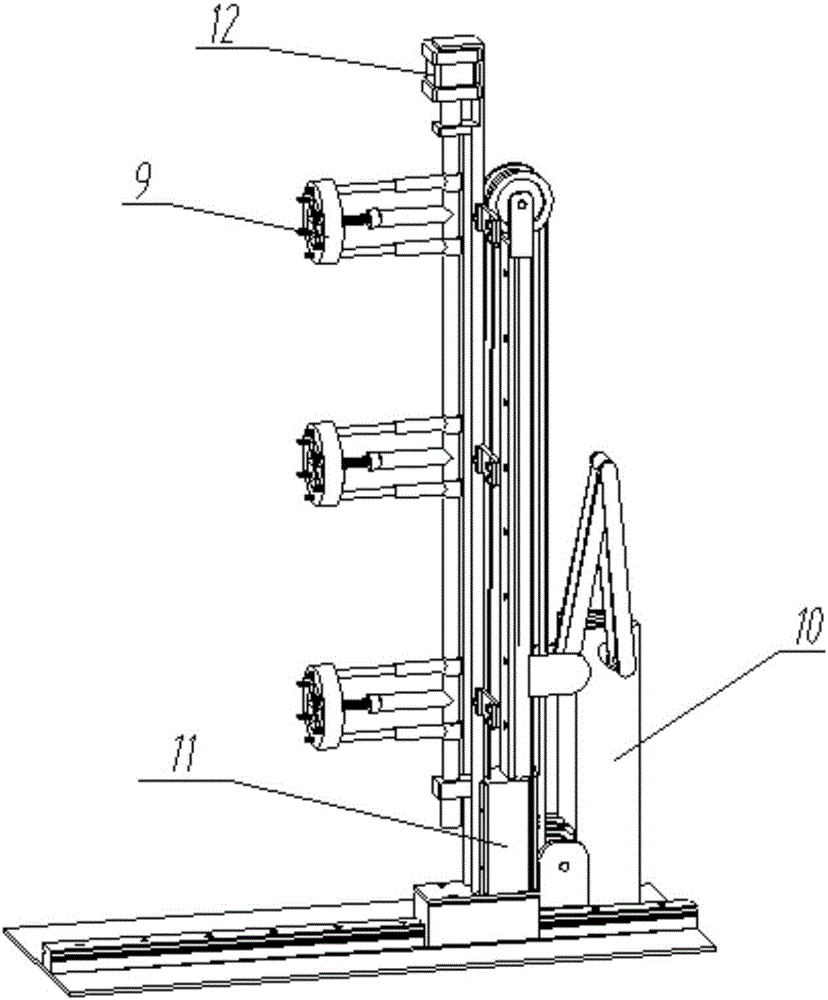

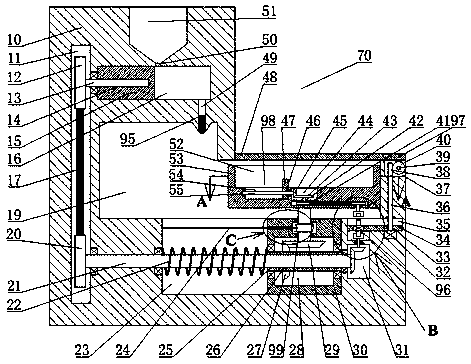

Arc spraying device for shaft parts

ActiveCN102266826ARealize automatic sprayingReduce labor intensityLiquid spraying plantsMachine toolArc spray

Owner:无锡洲翔成套焊接设备有限公司

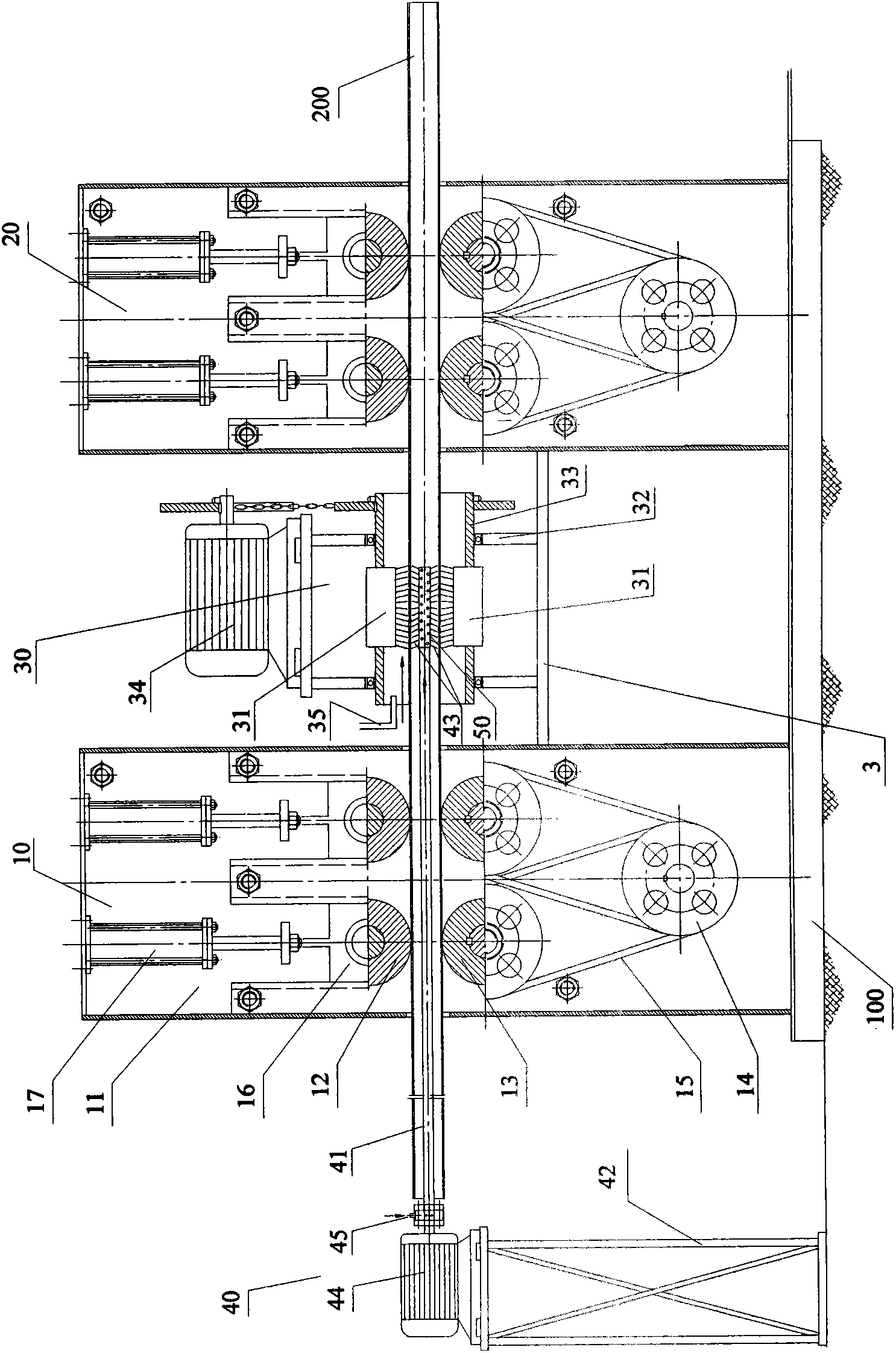

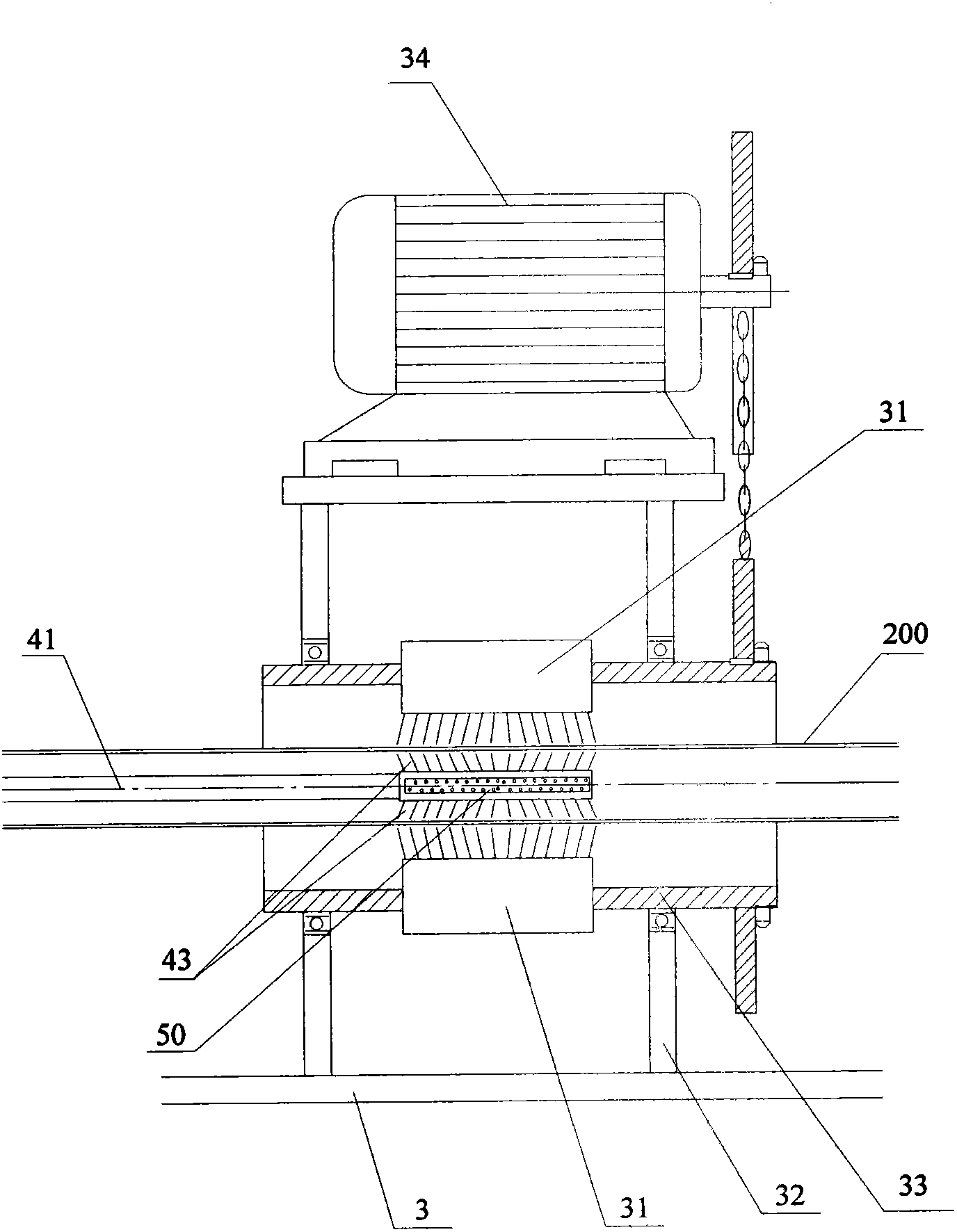

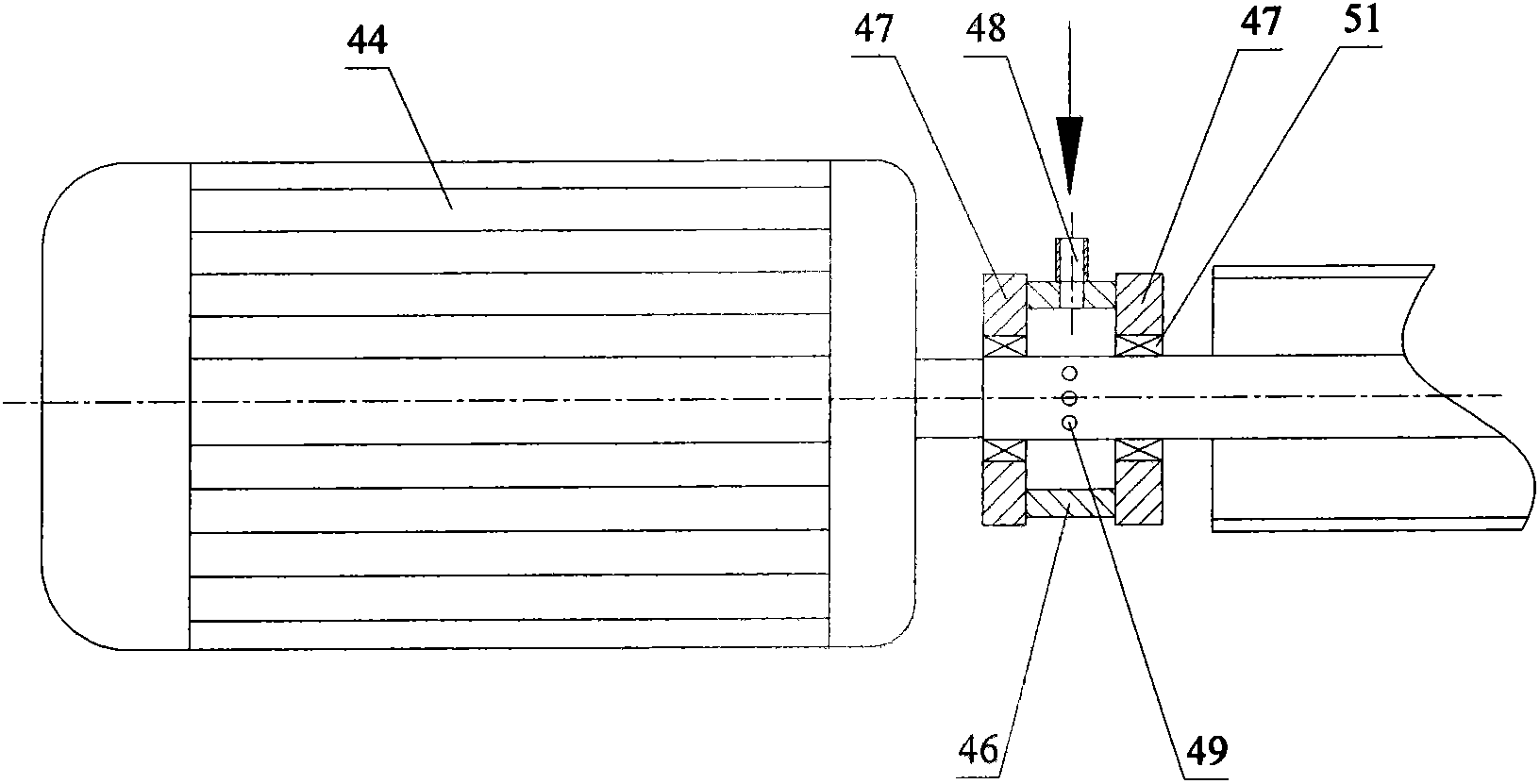

Automatic spraying machine for internal and external walls of steel pipe

InactiveCN102302998AImprove work efficiencyRealize automatic sprayingLiquid surface applicatorsCoatingsEngineering

The invention discloses an automatic spraying machine for internal and external walls of a steel pipe. The automatic spraying machine comprises an internal wall paint spraying device, an external wall paint spraying machine, a left steel pipe driving device and a right steel pipe driving device, wherein the left steel pipe driving device and the right steel pipe driving device are used for driving the steel pipe to do horizontal movement; the external wall paint spraying device comprises a supporting frame, a rolling drum and an external spraying electrical motor; the supporting frame is fixed between the left steel pipe driving device and the right driving device; the rolling drum is arranged on the supporting frame in a rotary manner; two external spraying rolling brushes are respectively fixed on the internal wall of the rolling drum; the external spraying electrical motor is fixed on the supporting frame and drives the rolling drum to rotate through a transmission mechanism; the internal wall paint spraying device comprises an internal spraying material-feeding pipe and an internal spraying electrical motor; the internal spraying material-feeding pipe is arranged along an axial direction of a spraying steel pipe; the internal spraying electrical motor is fixed on a base frame and the output shaft of the internal spraying electrical motor is fixed with the internal spraying material-feeding pipe; the other end of the internal spraying material-feeding pipe is provided with two internal spraying rolling brushes. According to the automatic spraying machine provided by the invention, the simultaneous automatic spraying to the internal and external walls of the steel pipe can be realized when the steel pipe is driven to do the horizontal movement by the left and right steel pipe driving devices; and the work efficiency is greatly increased.

Owner:张远见

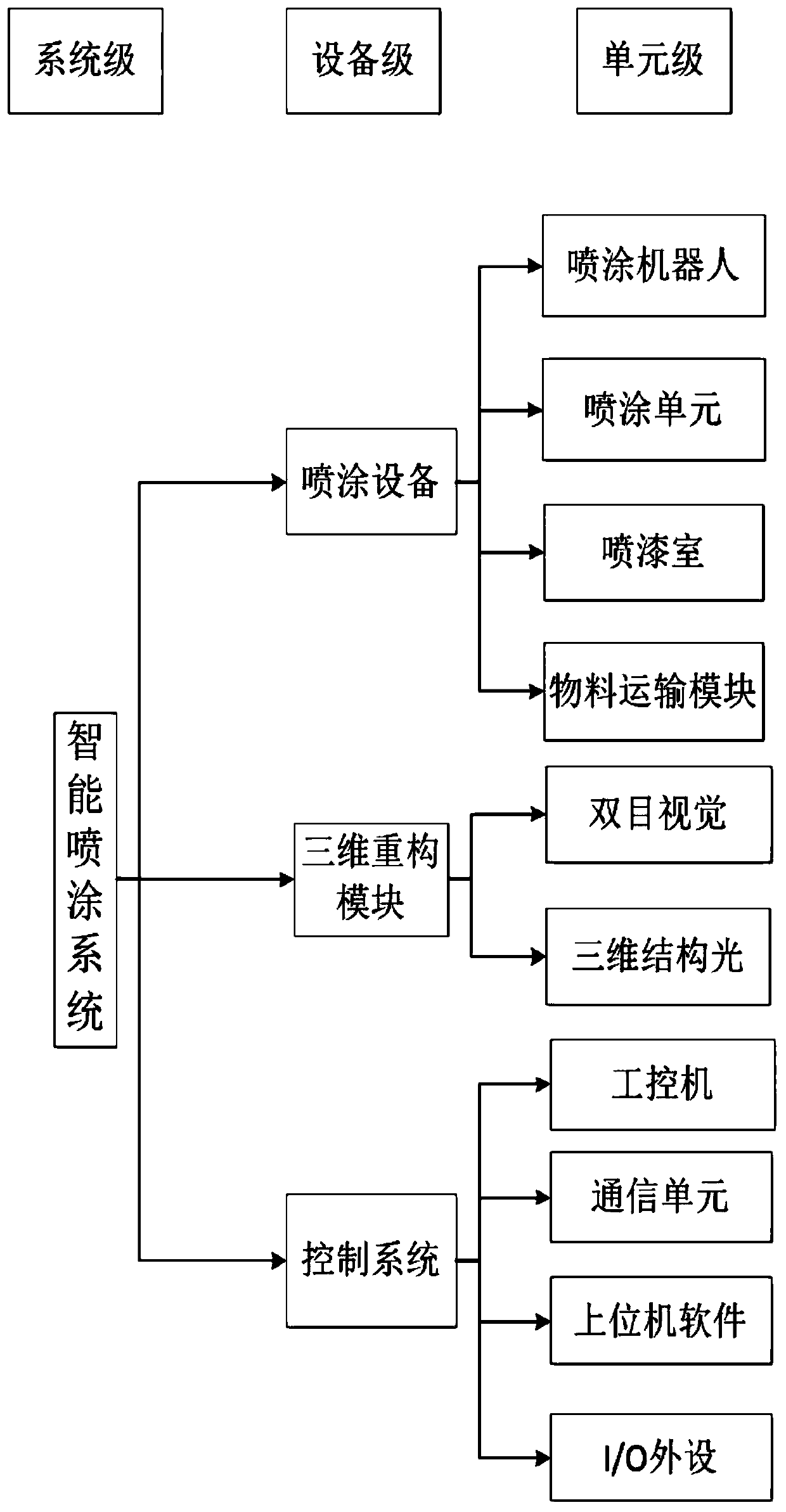

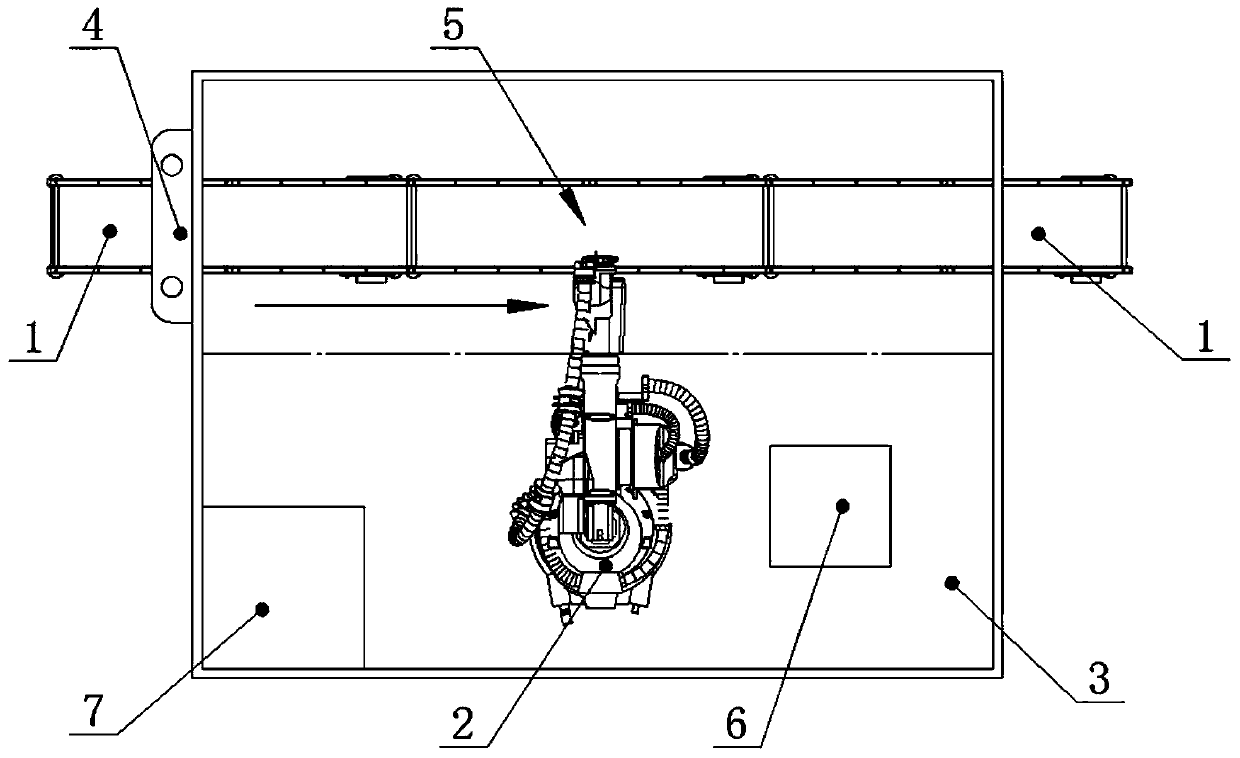

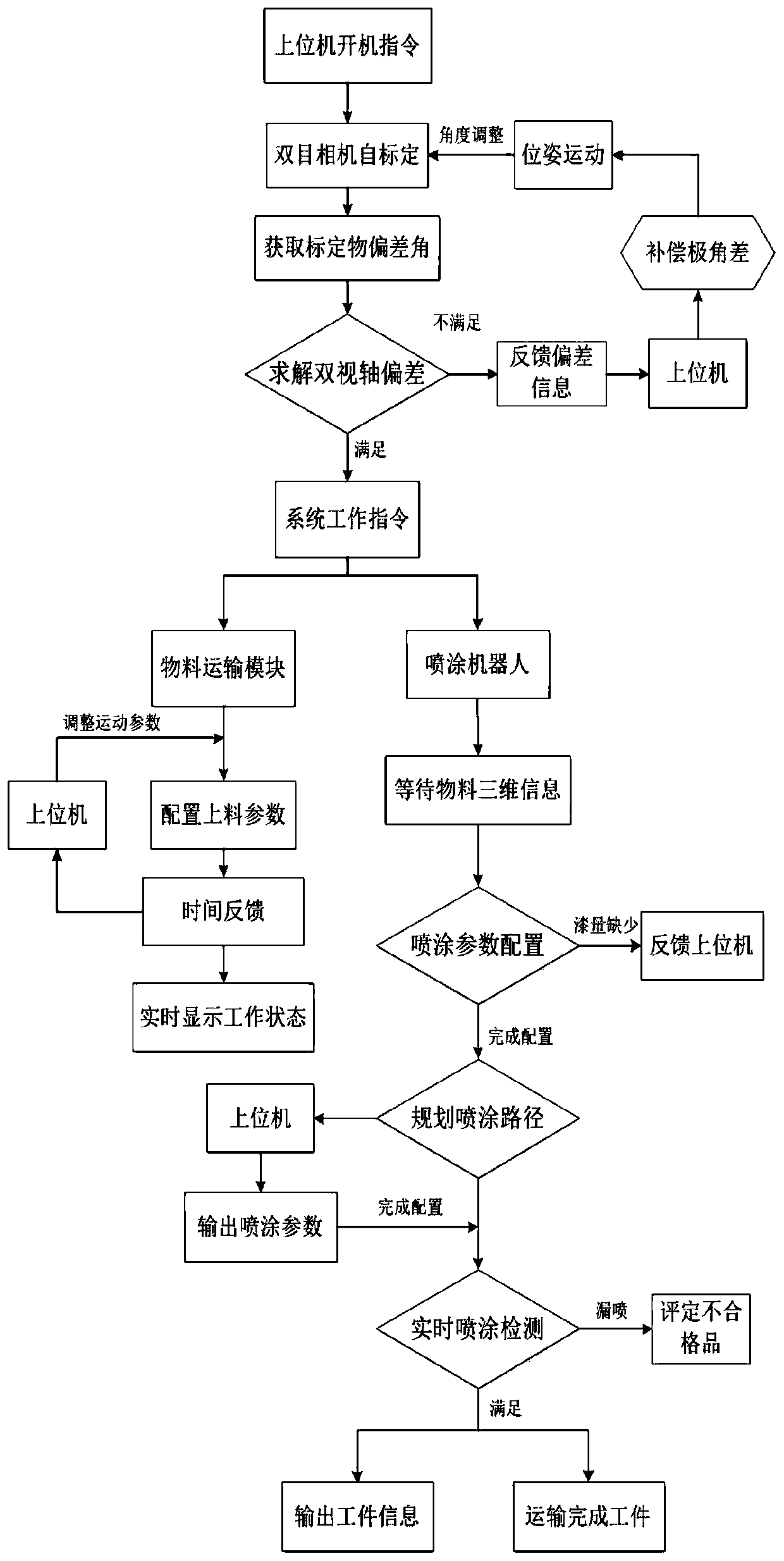

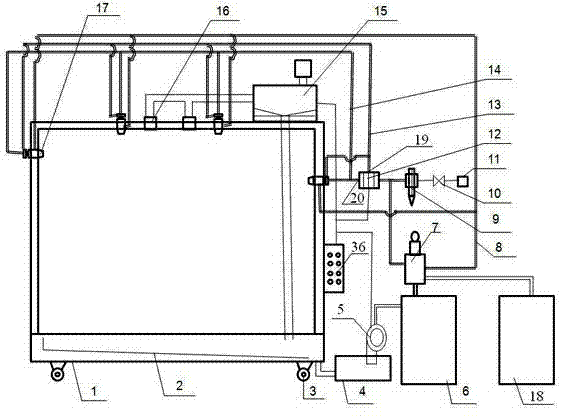

Automatic spraying system and method based on workpiece contour information three-dimensional reconstruction

InactiveCN109967292ARealize automatic spraying operationRealize online extractionSpraying apparatusProduction lineControl system

The invention discloses an automatic spraying system and method based on workpiece contour information three-dimensional reconstruction. The system involves a control system, a three-dimensional reconstruction module, a conveying system and automatic spraying equipment, the conveying system is connected with the control system and the automatic spraying equipment, the three-dimensional reconstruction module can model a contour of a workpiece to be sprayed and send the model to the control system for spraying path planning, paint spraying equipment comprises a paint spraying chamber, the paintspraying chamber is connected with the control system, and the workpiece to be sprayed can be automatically sprayed according to the spraying path through the the paint spraying chamber. According tothe system and method, the problems of single function and low spraying flexibility in an existing coating industry are solved, and the efficiency of spraying production line is improved.

Owner:CHINA UNITED NORTHWEST INST FOR ENG DESIGN & RES

Automatic oil spraying device and method

ActiveCN103657941ARealize automatic separationPrevent rustLiquid surface applicatorsLiquid spraying apparatusControl systemElectromagnetic valve

The invention discloses an automatic oil spraying device which comprises a closed oil spraying room, a fog spraying system, an oil recycling system and a control system. The fog spraying system comprises a main air source, a pressurizing mechanism, an oil drum, an electromagnetic valve and fog spraying valves, wherein the main air source is connected with the pressurizing mechanism, and the oil drum, the pressurizing mechanism and the fog spraying valves are sequentially connected through oil pipes. The electromagnetic valve comprises an air inlet, a first air outlet and a second air outlet, wherein the air inlet is connected with the main air source through a pipe, the first air outlet is connected with the fog spraying valves through a driving air source pipe, and the second air outlet is connected with the fog spraying valves through an atomization air source pipe. The driving air source pipe and the atomization air source pipe are provided with a first pressure adjustment mechanism and a second pressure adjustment mechanism respectively. The electromagnetic valve and the oil recycling system are respectively connected with the control system, and the oil recycling system is connected with the closed oil spraying room. The invention further discloses an automatic oil spraying method achieved through the automatic oil spraying device. By means of the automatic oil spraying device and the automatic oil spraying method, rapid and safe rust prevention processing on a large number of plates can be achieved, operation risks to persons are reduced, and waste oil can be recycled.

Owner:GUANGZHOU AUTOMIBILE GRP MOTOR

Municipal road traffic marking line spraying device

The invention discloses a municipal road traffic marking line spraying device. A movement idler wheel at the right end is fixedly connected with a crankshaft, the left end of the crankshaft is fixedlyconnected with a drive shaft, first bevel gears are fixedly connected with the two sides of the drive shaft, second bevel gears are fixedly connected with driven shafts, and the upper ends of the driven shafts are rotationally connected a transverse board through bearings and fixedly connected with gears; and gears are engaged with gear rings, the gear rings are fixedly connected with a main rotary shaft, the upper end of the main rotary shaft is rotationally connected with the top of a device body, the lower end of the main rotary shaft is rotationally connected with the transverse board, alead screw is sleeved with the inner portion of the main rotary shaft in a clearance mode, and the upper end of the lead screw is rotationally connected with the upper wall of the device body througha bearing. By the adoption of the device, stirring boards are driven by the drive shaft to rotate and swing up and down at the same time so as to stir paint contained in the upper portion of the device body, the crankshaft drives a piston board to repeatedly move up and down to achieve automatic spraying, the automation degree is high, the traffic marking line spraying efficiency is greatly improved, and labor is saved. The device is reasonable and applicable in structural design, high in work efficiency and capable of achieving an even stirring and mixing function in the paint working process.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD

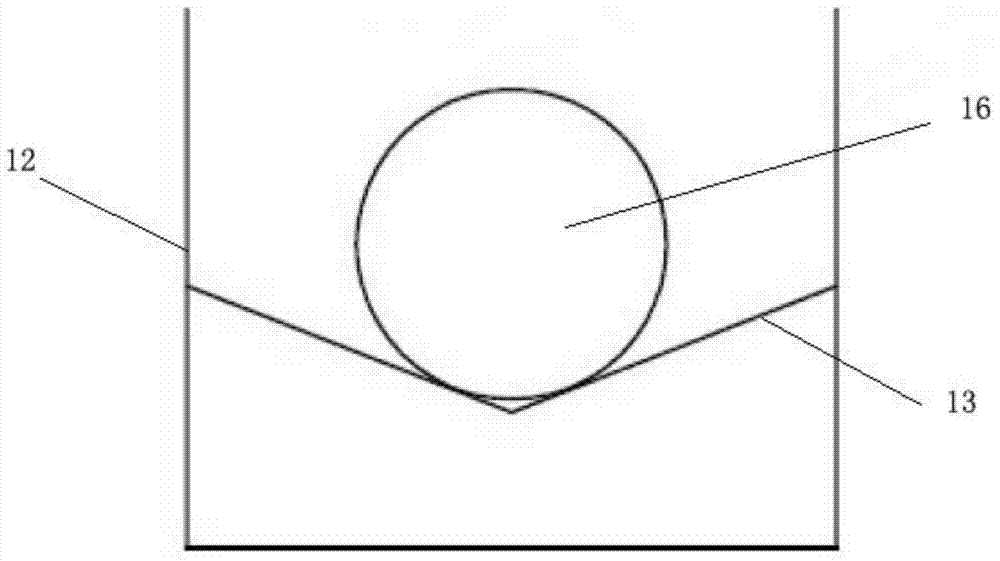

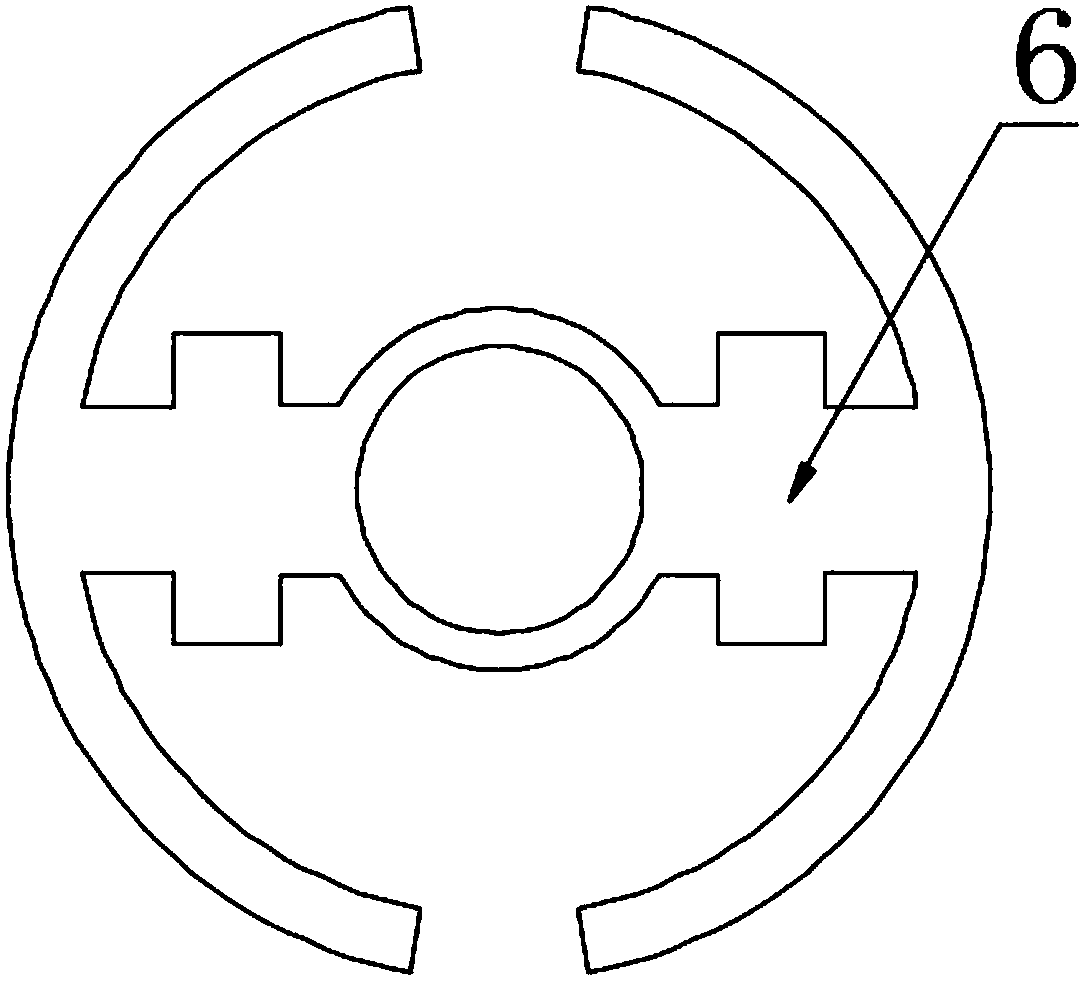

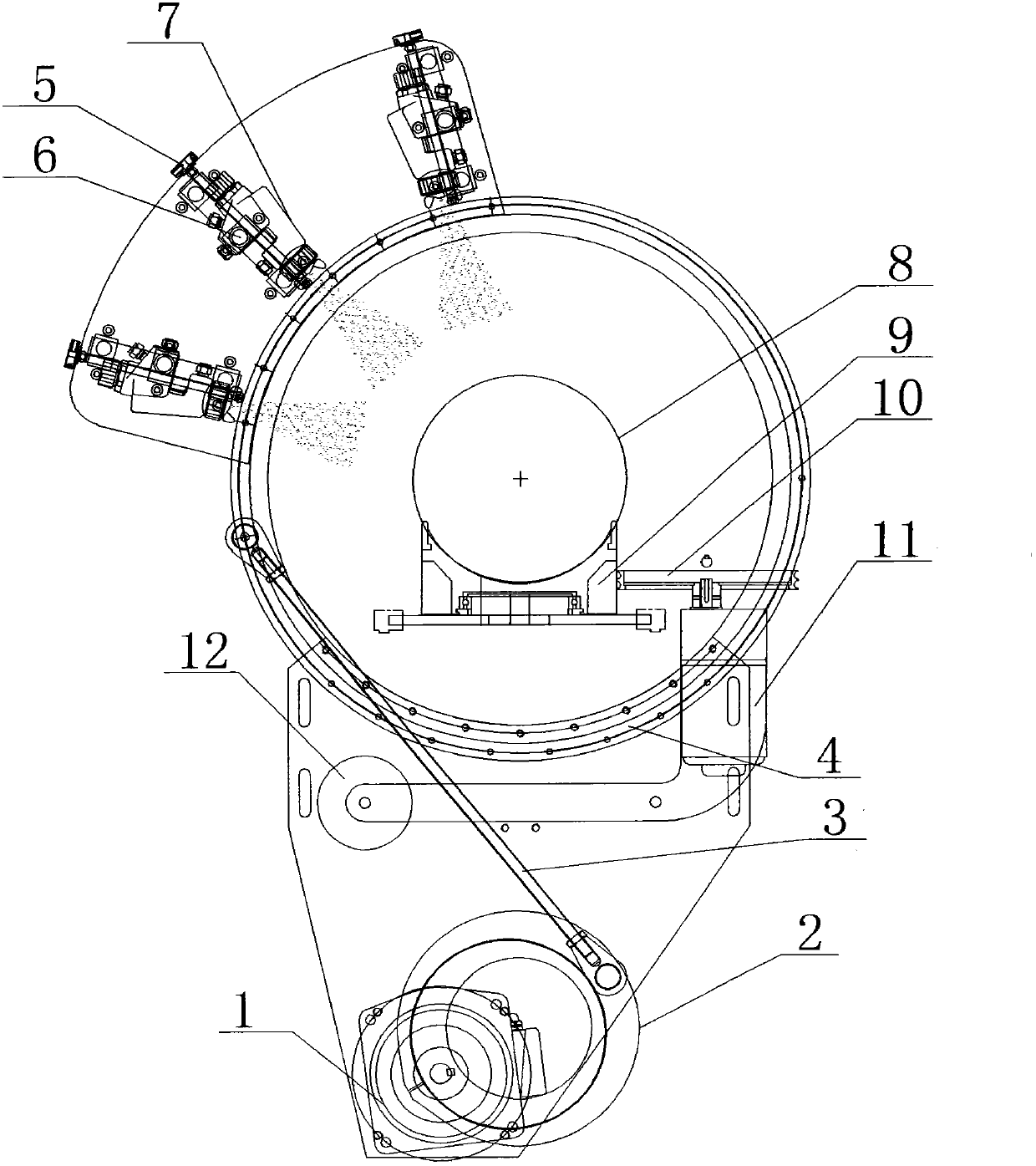

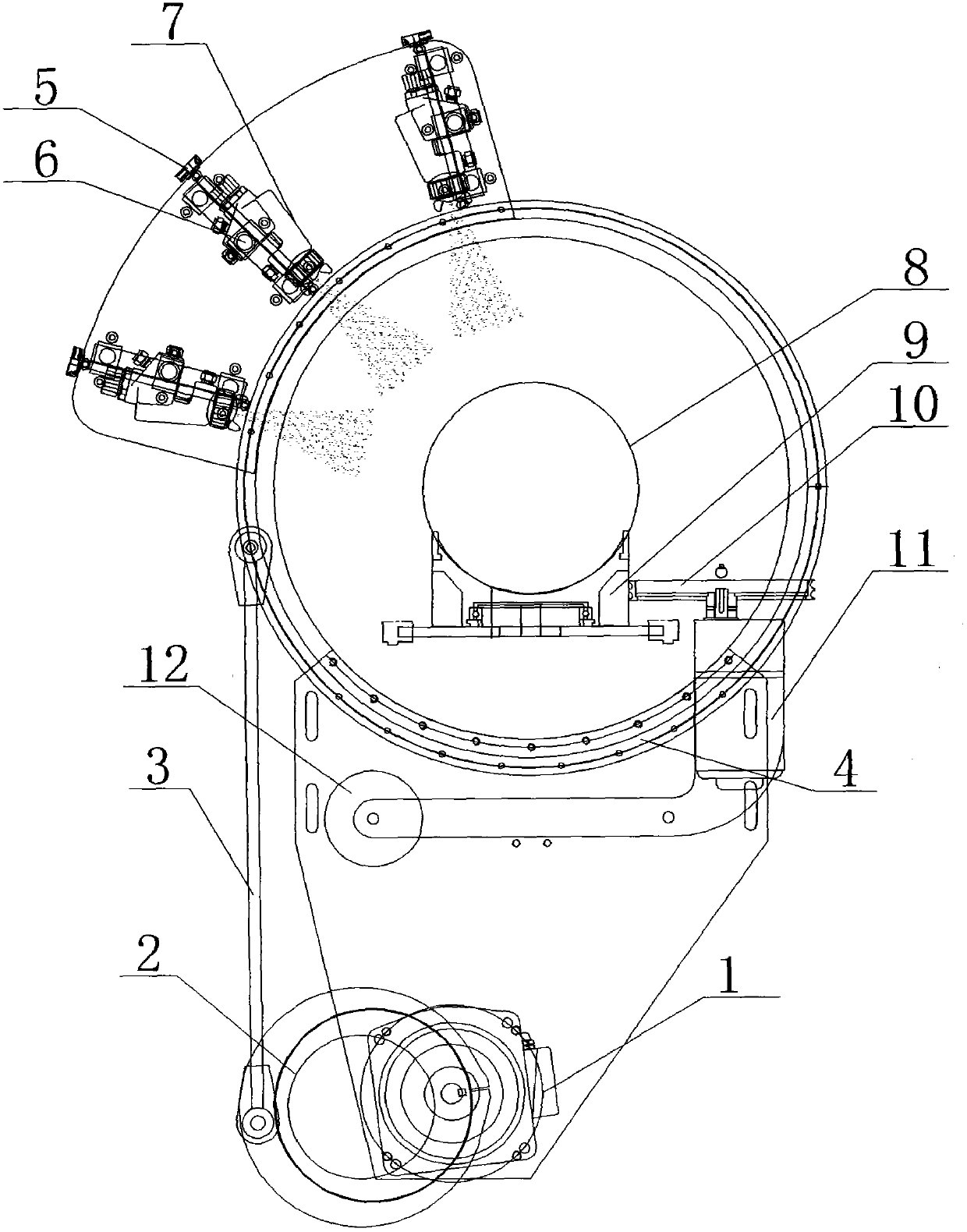

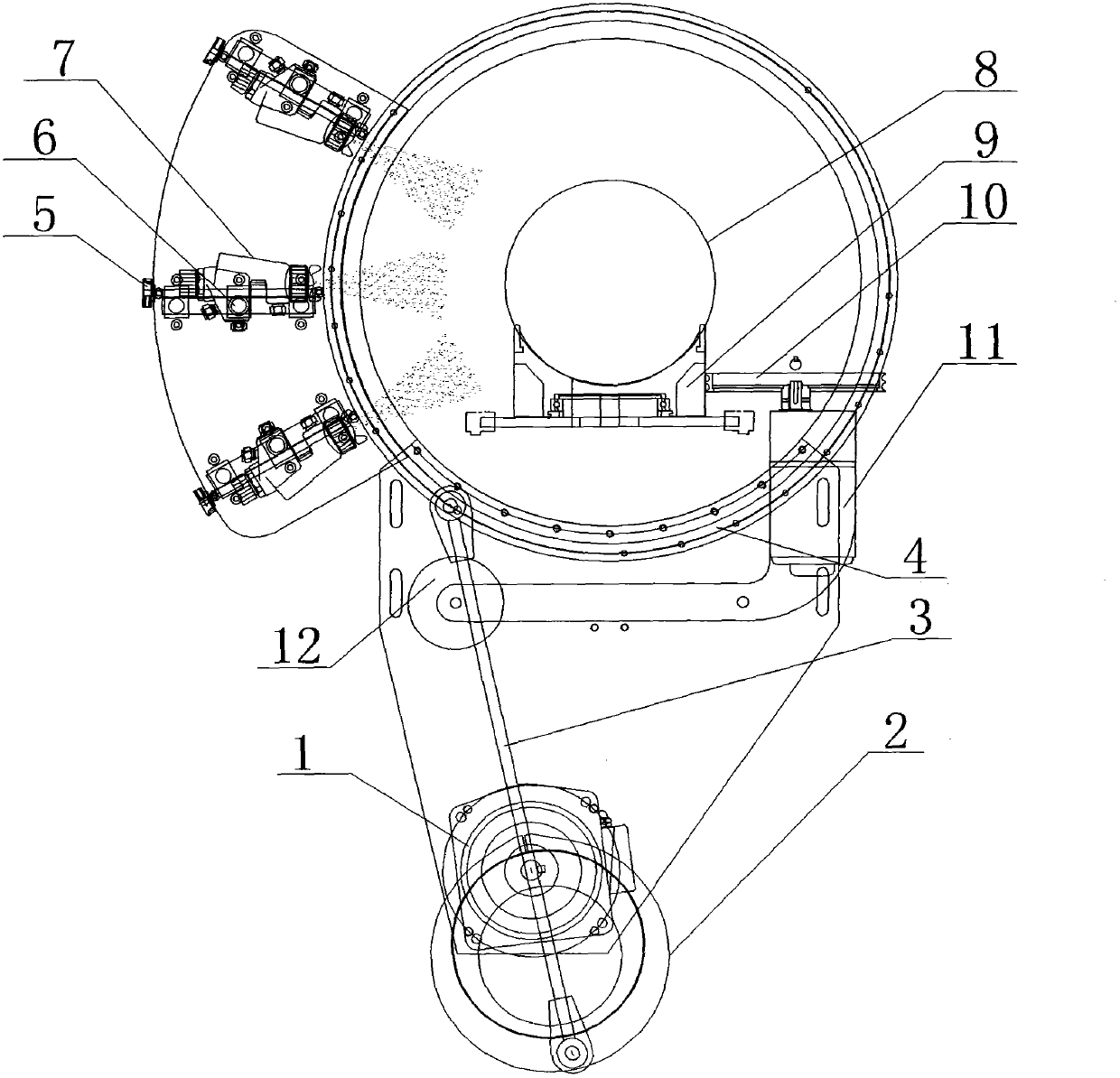

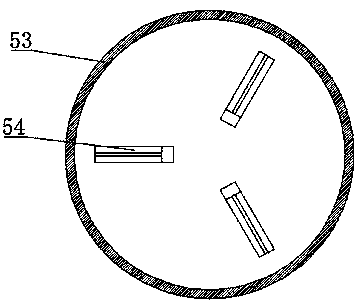

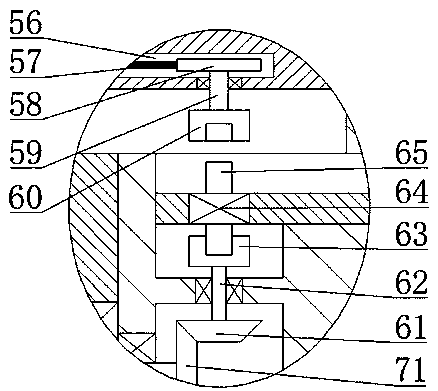

Automatic spherical surface coating machine

InactiveCN103272732ARealize automatic sprayingSimple structureSpraying apparatusCircular discSpherical form

The invention relates to an automatic spherical surface coating machine which is characterized in that three adjusting devices are arranged on a round disc bearing. Installation rods are arranged on the adjusting devices. Coating guns are arranged on the installation rods. Distances between the coating guns to the surface of a spherical workpiece and angles of the coating guns can be adjusted through the adjusting devices. A decentralizer is arranged below the round disc bearing which is connected with the decentralizer through a connecting rod. The decentralizer is arranged on a revolving shaft of a swing motor. The adjusting devices on the round disc bearing can swing up and down under the drive of the swing motor. An amplitude of swing of the adjusting devices can be adjusted through the decentralizer. An initial coating position can be adjusted through the connecting rod. The spherical workpiece is absorbed onto a self-absorbing clamp which can rotate around the principal axis of the clamp. A friction wheel is arranged on the outer side of the self-absorbing clamp. The self-absorbing clamp is jointed with the friction wheel which is installed on a rotation motor fixed on a tightening device. The automatic spherical surface coating machine is simple in structure, easy to operate and maintain, high in efficiency and constant in quality and general staff can operate the machine after being trained.

Owner:佘建锋

Drainage pipeline spraying-repairing construction process

InactiveCN105926752ARealize automatic sprayingExtended service lifeSewer pipelinesSpray nozzleEngineering

The invention discloses a drainage pipeline spraying-repairing construction process. The construction process comprises the following steps: opening an operation well lid and upstream and downstream well lids for realizing ventilation; plugging water in an upstream box culvert; dredging the inside of a repaired pipeline; washing the inner wall of the repaired pipeline, drying the washed inner wall of the repaired pipeline, placing a spraying device capable of moving along the repaired pipeline at the starting point of the repaired pipeline, connecting a spraying material mixing device and a spraying device by adopting a special long conduit, enabling the spraying device to move along the repaired pipeline, and along with the walking of the spraying device, enabling a rotating spray nozzle to carry out the spraying operation on the inside of the repaired pipeline after the rotating spray nozzle rotates along the rotation center. The process is simple, the operation is convenient, the service efficiency is high, and the service life of the drainage pipeline can be prolonged after the drainage pipeline is repaired. In addition, the operation of an operator inside the pipeline is avoided, therefore, the personal safety of the operator is protected, and the work efficiency is improved.

Owner:GUANGZHOU MUNICIPAL ENG GROUP

Aluminum alloy die casting mold

ActiveCN107570681AAvoid shrinkage dimples and shrinkage holesQuality improvementMetallurgyAluminium alloy

The invention discloses an aluminum alloy die casting mold. The aluminum alloy die casting mold comprises an upper mold, a lower mold and an ejector plate; the lower mold is provided with a transversecore pulling slide block; a mold core outer molding surface of the lower mold consists of a first molding surface and a second molding surface; the wall thickness of a die-cast piece corresponding tothe second molding surface is larger than the wall thickness of a die-cast piece corresponding to the first molding surface; a mold core is provided with a feeding hole in the second molding surface;a pressing rod associated with a driving oil cylinder is arranged in the feeding hole; the driving oil cylinder enables the pressing rod to axially move from a molding position to a feeding position;the lower mold is provided with a spraying hole corresponding to the transverse core pulling slide block; a plunger spraying device is arranged in the spraying hole; a sealing plate associated with the plunger spraying device is arranged in an opening of the spraying hole; and the sealing plate has a molding state for shielding the plunger spraying device, and a spraying state for exposing the spraying hole outside. The aluminum alloy die casting mold can effectively improve the problems of shrinkage recesses and shrinkage holes, can realize automatic spraying of a die casting release agent,and facilitates demolding of the transverse core pulling slide block.

Owner:宁波环亚机械制造有限公司

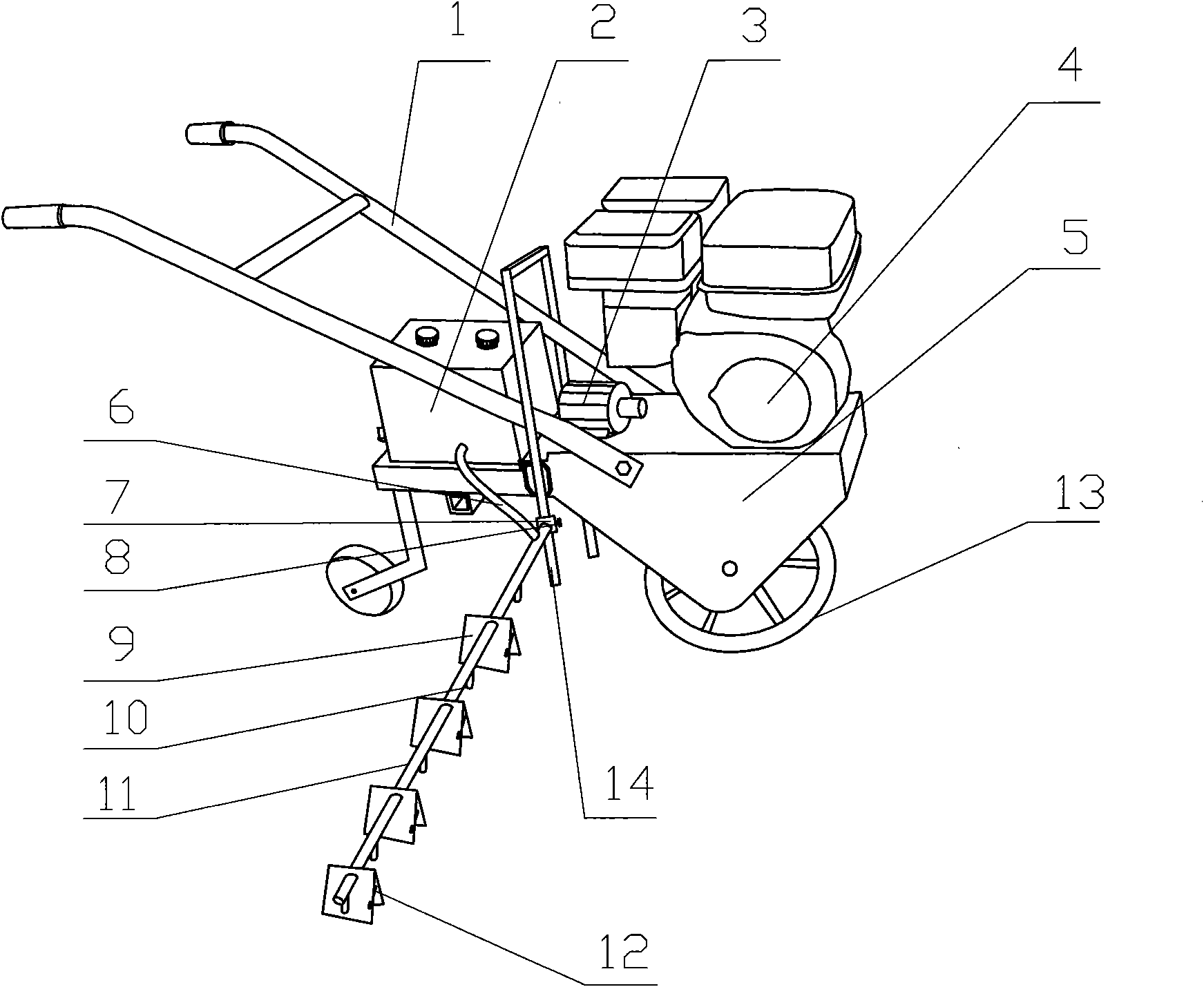

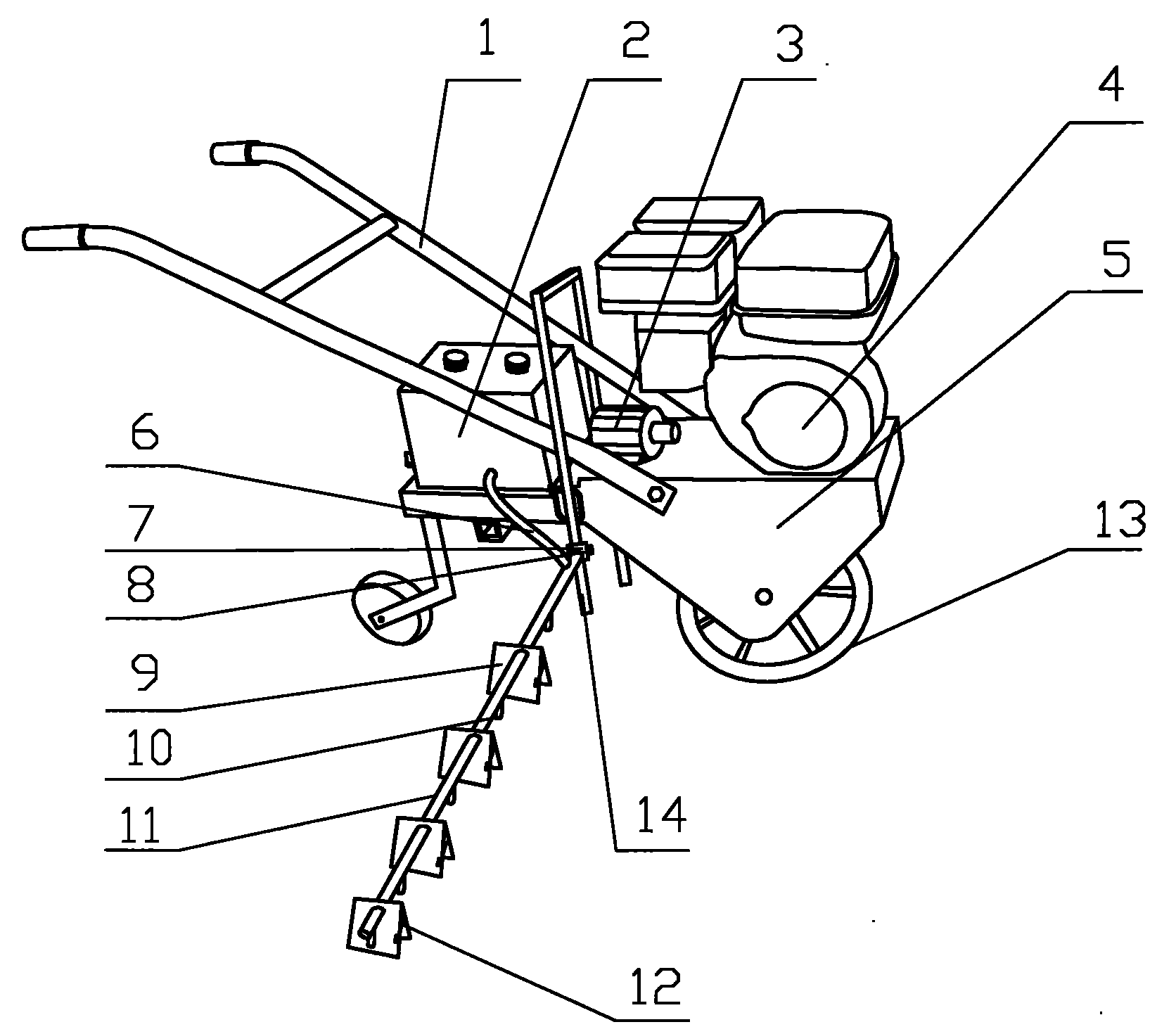

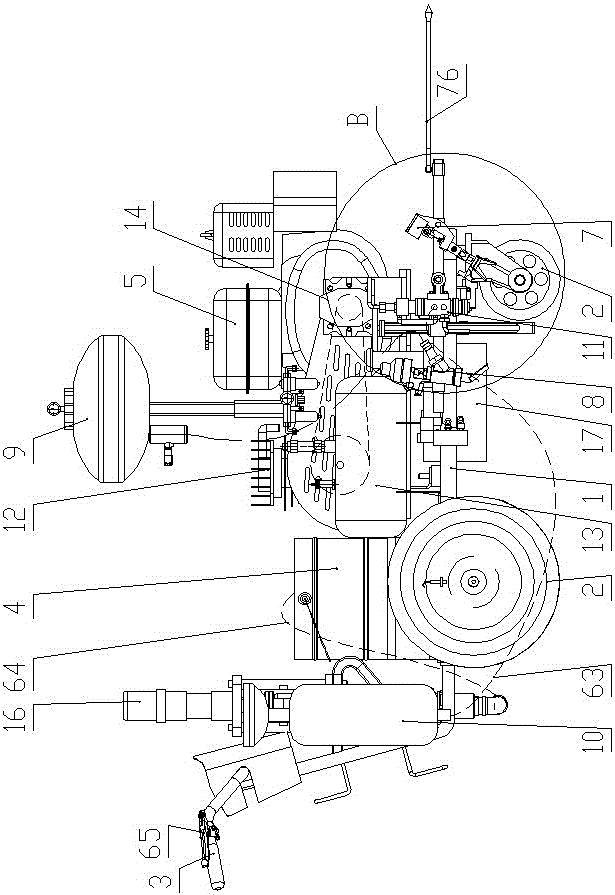

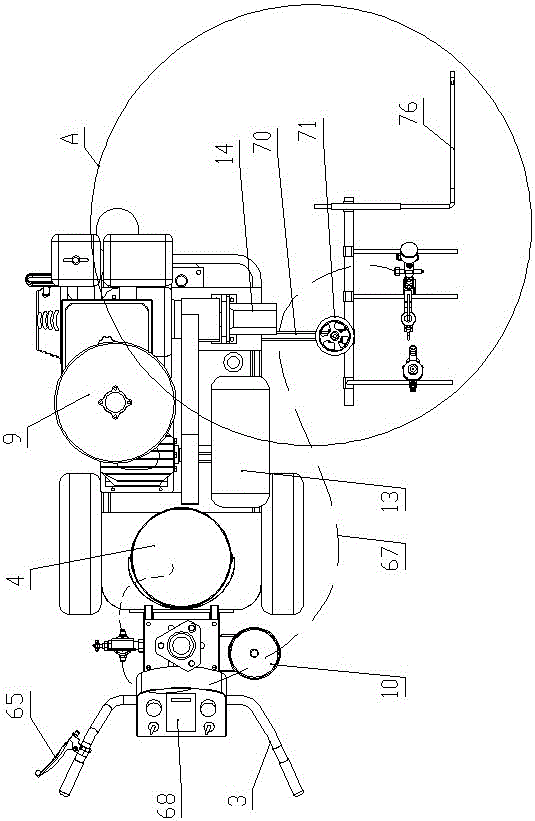

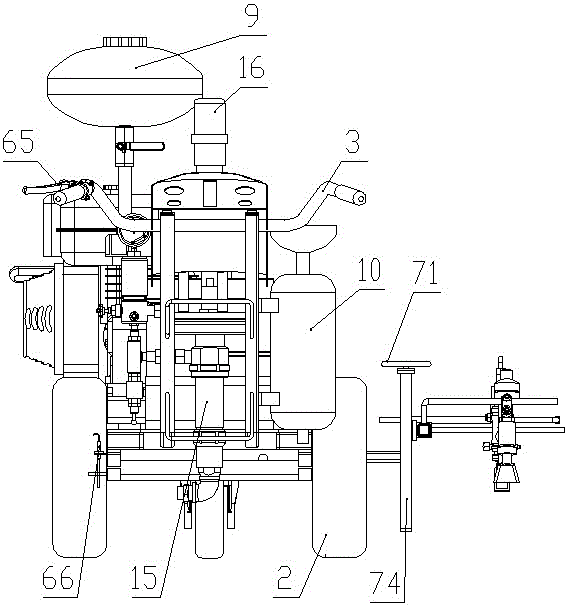

Farmland spraying machine

InactiveCN101984801ARealize automatic sprayingLiquid spraying apparatusInsect catchers and killersDrive wheelAgricultural engineering

The invention discloses a farmland spraying machine. Driving wheels in roll connection are arranged below a vehicle body, the upper part of the vehicle body is provided with a power plant, and the driving wheels are driven by the power plant via a transmission mechanism; the vehicle body behind the power plant is provided with a spraying machine, two sides of the middle of the vehicle body are respectively provided with a vertical rail rod which is sheathed with a horizontal spraying cross rod, the spraying cross rod is connected with the spraying machine by a pesticide tube, a plurality of spraying nozzles are connected below the spraying cross rod, and the spaces between the nozzles are adaptive to the line spacing of sprayed plants. In the invention, plants in multiple ridges can be simultaneously operated, spraying height can be regulated according to plants, pesticide is prevented from dispersing to cause pollution and harm to human and environment, pesticide is saved and labor efficiency is improved greatly.

Owner:肖山模

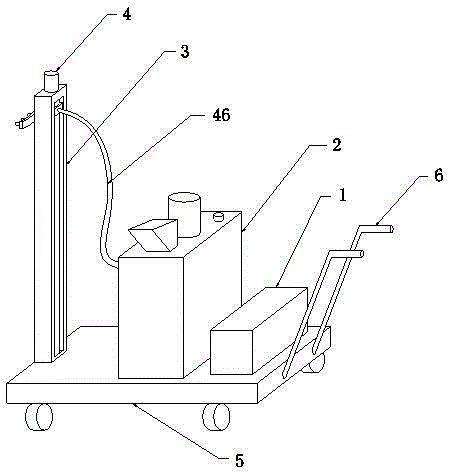

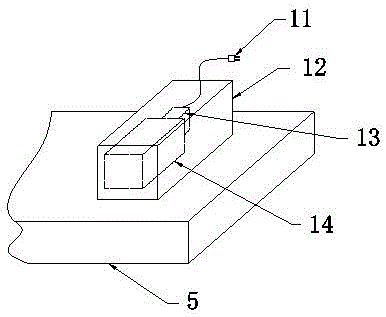

Efficient fruit tree whitewashing device

InactiveCN106423666AAvoid uneven mixingRealize automatic stirring functionSpraying apparatusFruit treeAgricultural engineering

The invention provides an efficient fruit tree whitewashing device. The efficient fruit tree whitewashing device comprises a base, a supporting frame, a material storage box, a hoisting stepping motor, a screw rod, a nut seat, a spraying nozzle frame, atomization spraying nozzles, a material conveying pipe, a plug, a charger and a storage battery, wherein the hoisting stepping motor is mounted on an upper end face of the supporting frame; the screw rod is assembled in the supporting frame; the upper end of the screw rod is connected with the hoisting stepping motor; the lower end of the screw rod is connected with the bottom of the supporting frame through a bearing; the nut seat is mounted on the screw rod; the spraying nozzle frame is fixedly arranged on a front end face of the nut seat; four groups of the atomization spraying nozzles are distributed on the front end face of the spraying nozzle frame at equal intervals; the left end of the material conveying pipe is connected with the nut seat and the right end of the material conveying pipe is connected with the material storage box; the plug is connected with the charger through a lead wire; and the charger is connected with the storage battery through a lead wire. The efficient fruit tree whitewashing device is novel in structure, reasonable in process, high in spraying and brushing efficiency, high in automation degree, wide in applicable range and high in reliability.

Owner:钟山县公安镇力发水果种植专业合作社

Hydraulic control pressure difference spray marking device of plunger pump type normal temperature marking machine

ActiveCN105672108AImprove construction efficiencyHigh failure rateRoads maintainenceWorking lifeControl system

The invention provides a hydraulic control pressure difference spray marking device of a plunger pump type normal temperature marking machine, which comprises a hydraulic control pressure difference system; a glass bead spray gun, a curing agent spray gun and a high pressure spray gun are arranged on the plunger pump type normal temperature marking machine; the hydraulic control pressure difference system is connected with the high pressure spray gun; the high pressure spray gun is arranged on a stand of the plunger pump type normal temperature marking machine through mounting a gun rack; the hydraulic control pressure difference system comprises a hydraulic pump, a high pressure plunger pump, an automatic reciprocating cylinder, a hydraulic oil tank and an energy accumulator which are arranged on the stand of the plunger pump type normal temperature marking machine; an engine is connected with the hydraulic pump in a transmission mode; an inlet of the hydraulic pump is connected with the hydraulic oil tank through an oil pipe; an outlet of the hydraulic pump is connected with the automatic reciprocating cylinder through the oil pipe; the automatic reciprocating cylinder and the high pressure plunger pump are vertically arranged; and the automatic reciprocating cylinder is positioned right above the high pressure plunger pump. The device provided by the invention is simple in structure, long in working life, low in equipment failure rate, high in construction efficiency and convenient to operate and turn, and the control system can not be easily affected by equipment vibration and outside signals.

Owner:天途路业集团有限公司

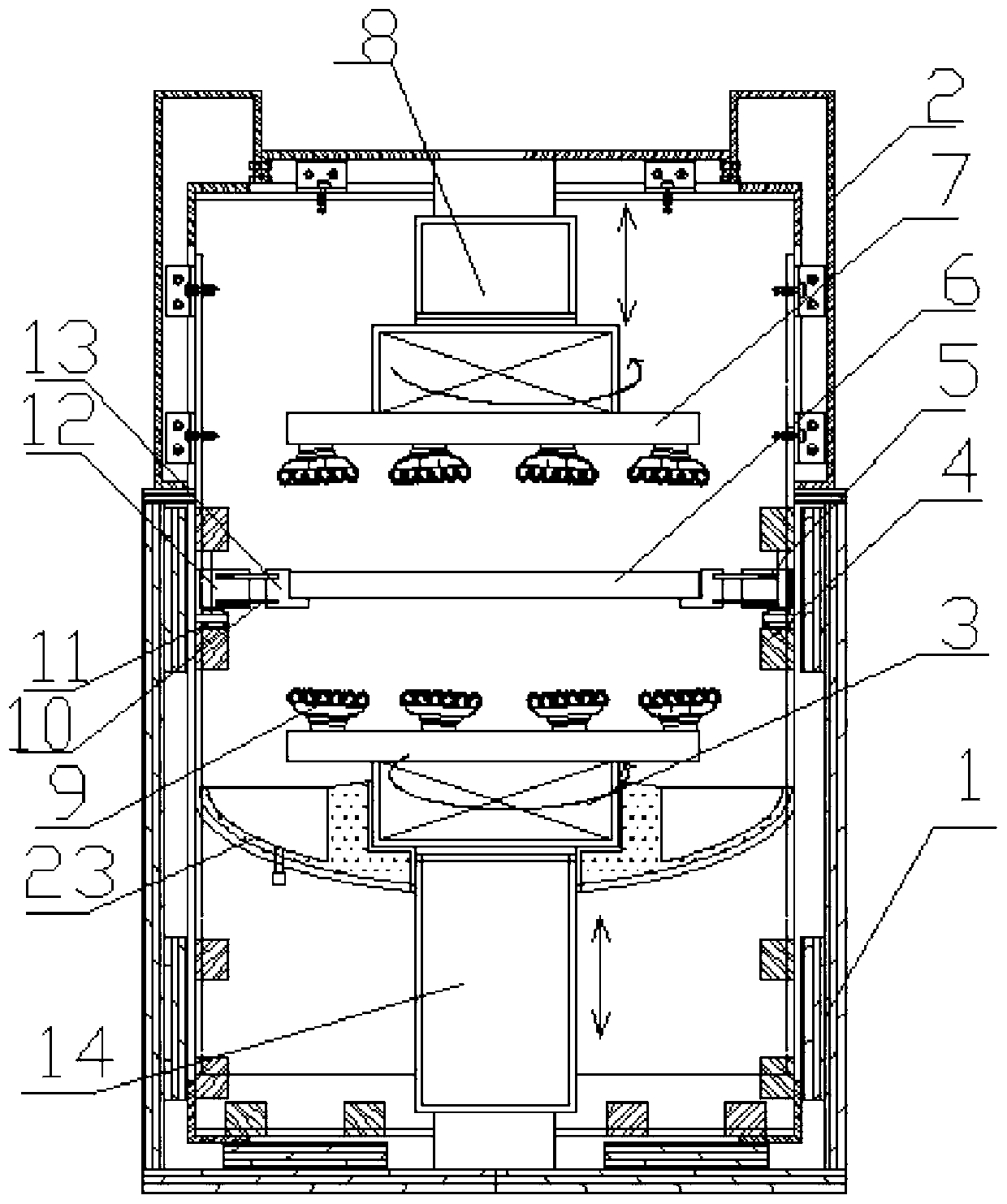

Tire bladder spray machine

PendingCN110000042AGood for recyclingRealize automatic sprayingSpray boothsSpray nozzleMechanical engineering

The invention belongs to the technical field of equipment for tire production, and particularly relates to a tire bladder spray machine. The tire bladder spray machine comprises a spraying room, a horizontal mechanism arranged above the spraying room, a supporting hook mechanism arranged on the horizontal mechanism, a spray nozzle system arranged on one side of the spraying room and a filtering and exhausting system arranged on the other side of the spraying room. According to the technical scheme, the automatic spraying of the tire bladder is realized through the arrangement of the spraying room, the horizontal mechanism, the supporting hook mechanism, the spray nozzle system and the filtering and exhausting system, the supporting hook mechanism is used in hoisting a tire bladder, the surface of the tire bladder is prevented from contacting as contacting can cause damage, the spraying process is controlled in the relatively closed spraying room, the external environment cannot be influenced, and recycling of spraying oil is facilitated; and problems of the safety, the environmental protection and energy saving in the tire bladder spraying process are completely solved.

Owner:SUZHOU UNIV OF SCI & TECH

Spraying equipment for building decoration

ActiveCN110449293AImprove adhesionRealize the clamping effectSpraying apparatusEngineeringMechanical engineering

The invention discloses spraying equipment for building decoration. An included angle of larger than 0 degree and smaller than 10 degrees is formed between a disc body center axis of a spraying head disc module and a vertical center axis; when decoration parts are sprayed, the spraying head disc module can be rotated at a high speed, so that spraying mediums sprayed by the spraying head are actedon the decoration parts in a direction non-perpendicular to the surfaces of the decoration parts, and are acted on spraying surfaces in an inclined mode, the adhesive force of the spraying mediums attached on the surfaces of the decoration parts is improved, and the spraying effect is improved; the decoration parts can be clamped and positioned on a decoration part positioning and moving mechanism, so that the clamping and the positioning of the decoration parts with different sizes can be realized, and the decoration parts can move in the horizontal direction to achieve automatic spraying; the spraying mediums can be recycled; the synchronous double-surface spraying can be realized to achieve high spraying efficiency; and the uniformity of the spraying mediums can be improved through an oscillation module in the spraying disc body to prevent the problem of nonuniform spraying caused by blockage of the spraying mediums.

Owner:SHANGHAI TECHN INST OF ELECTRONICS & INFORMATION

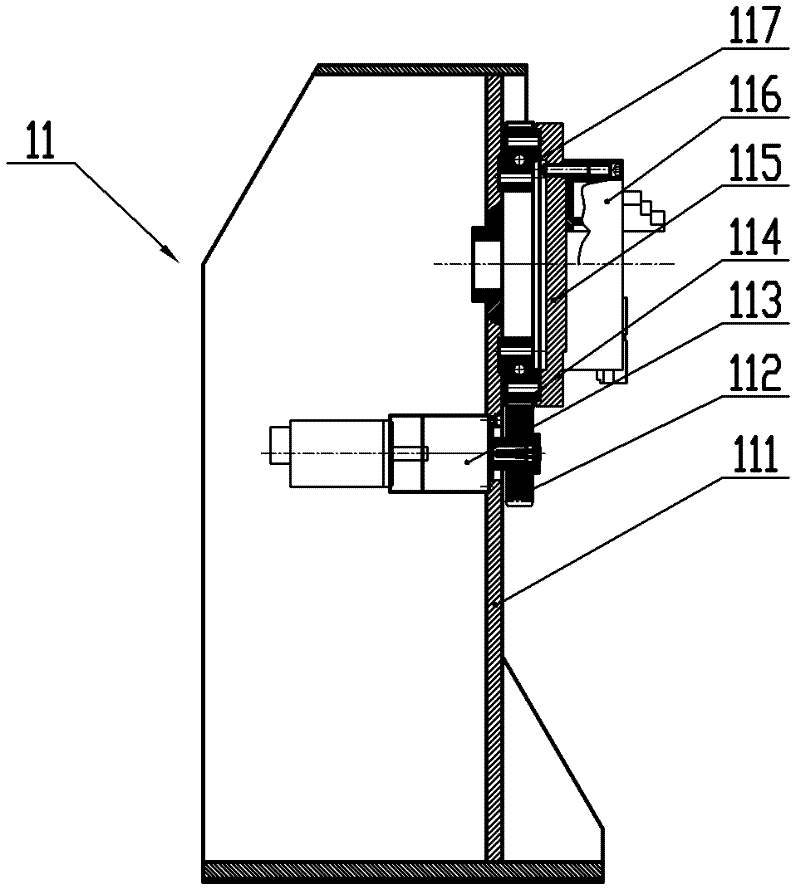

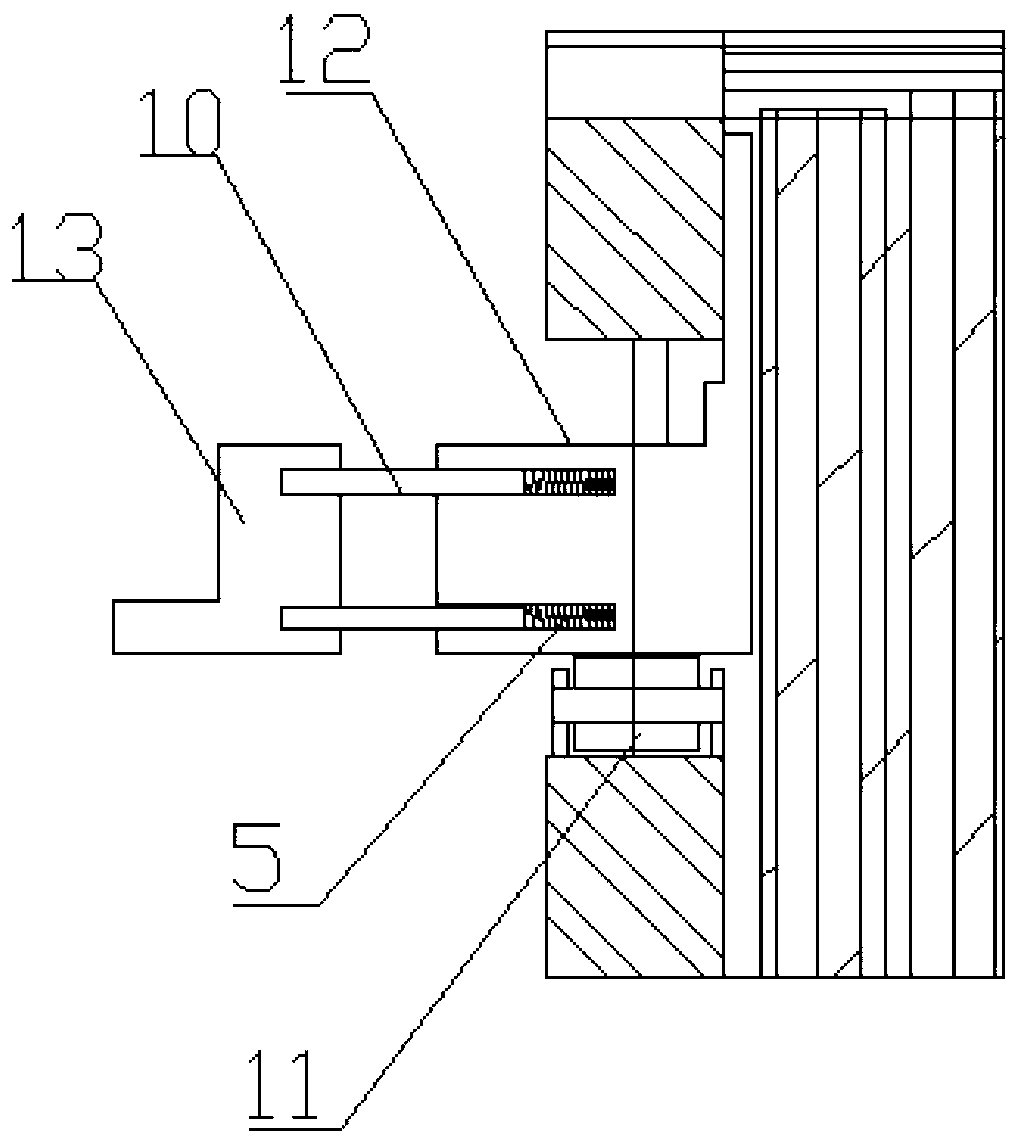

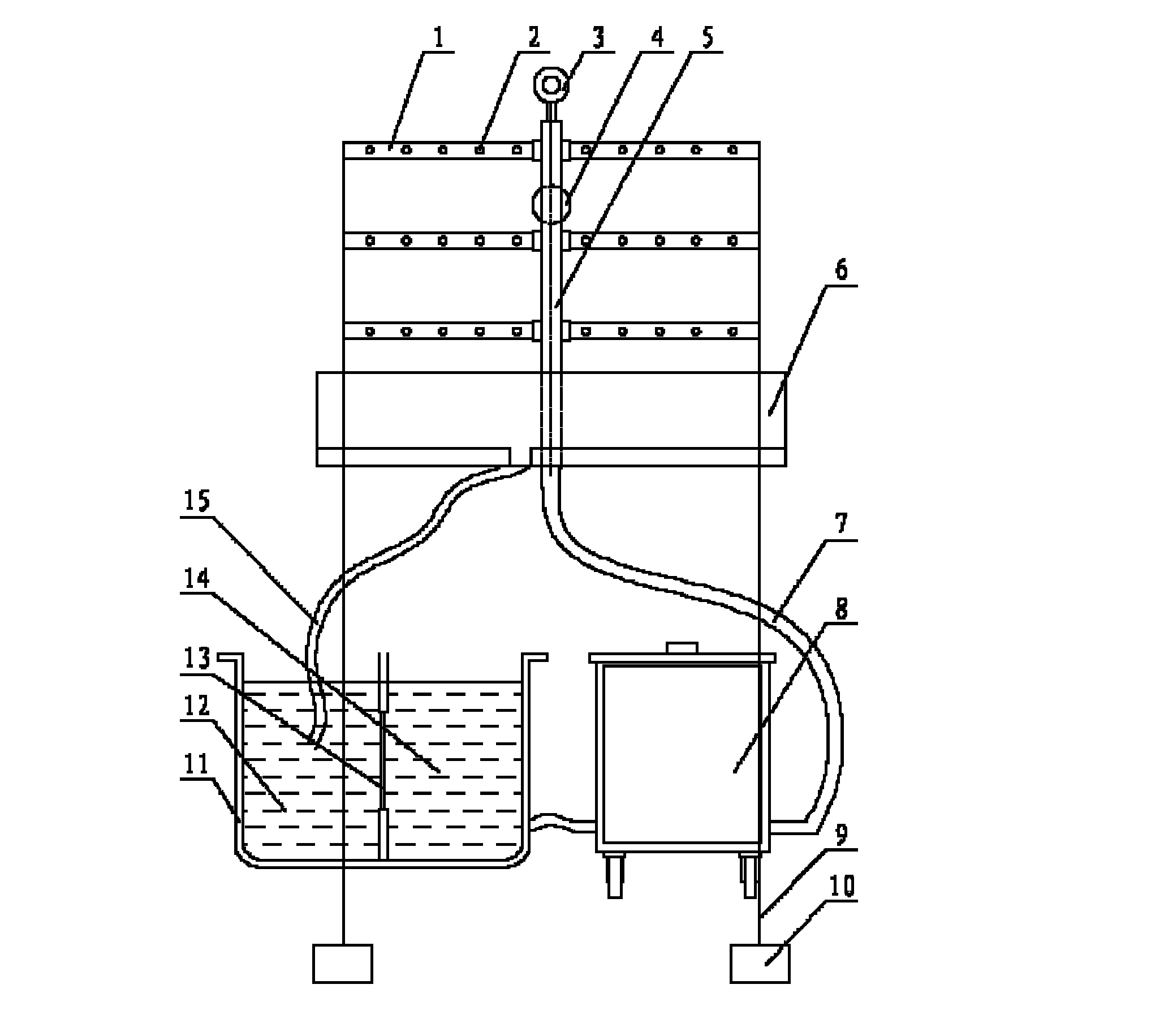

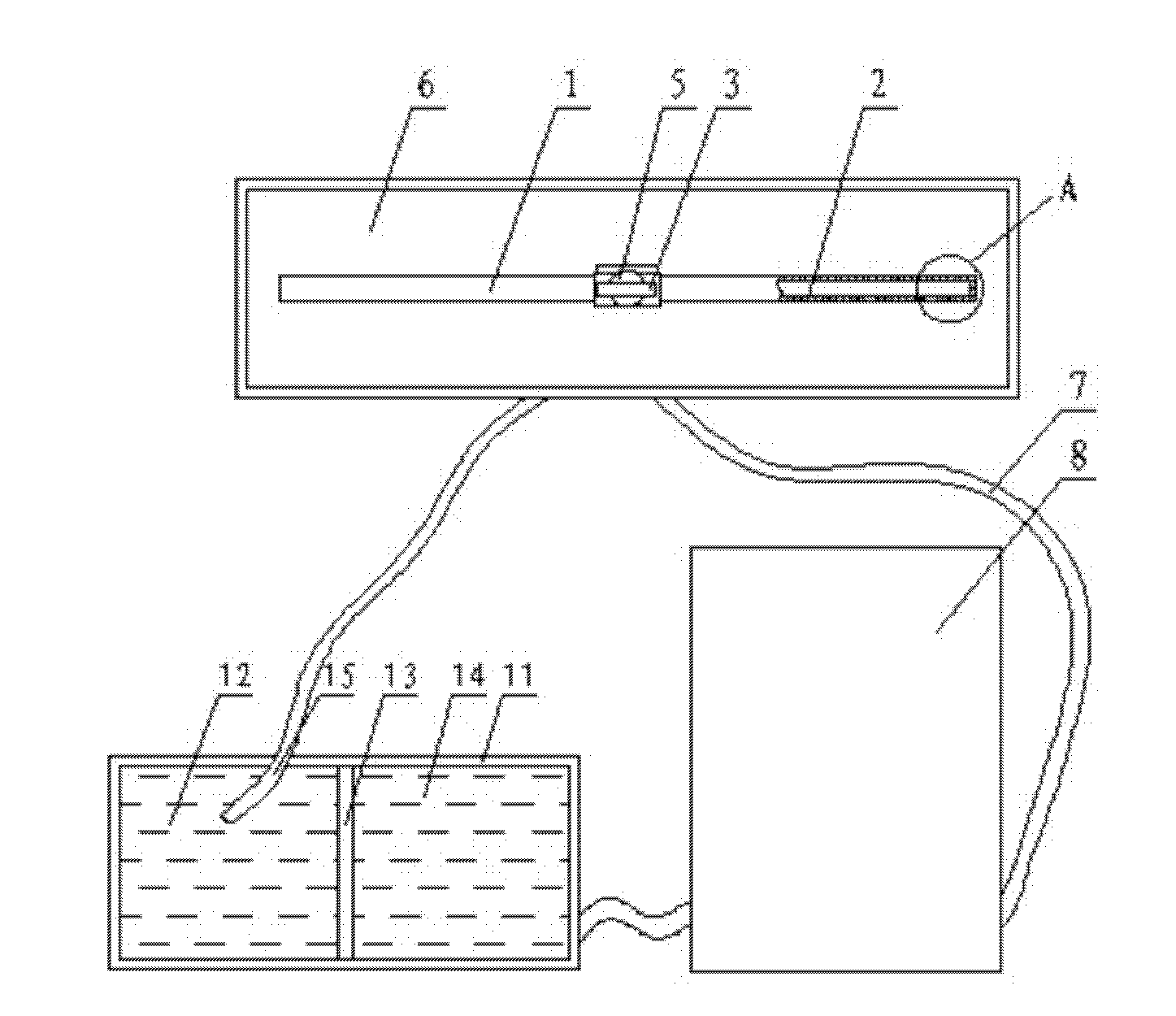

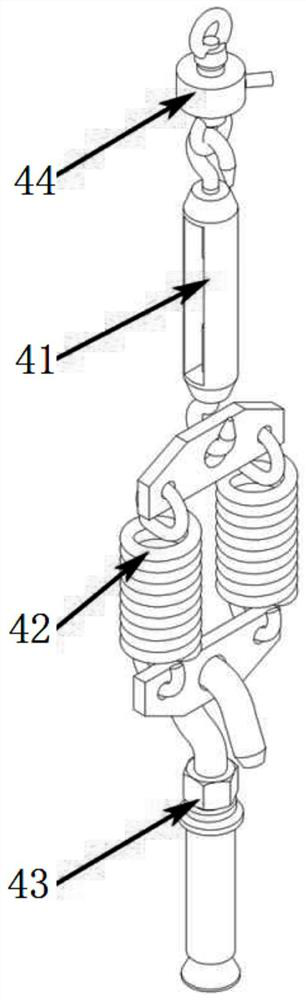

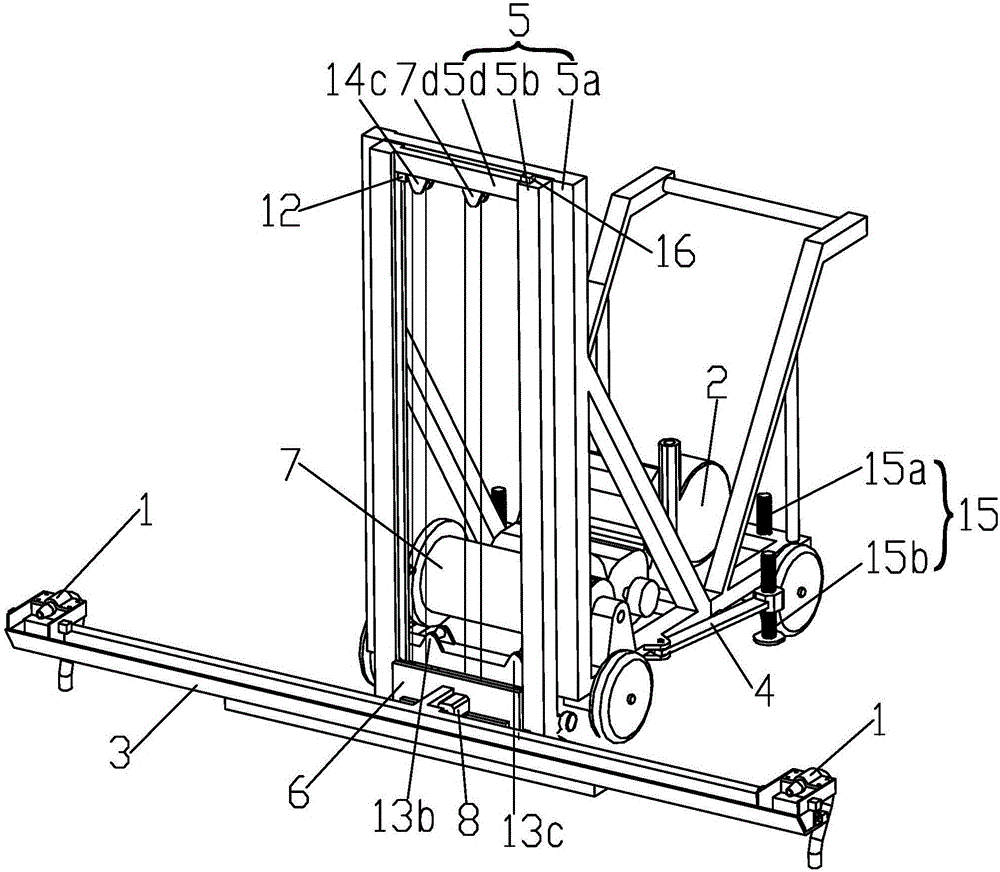

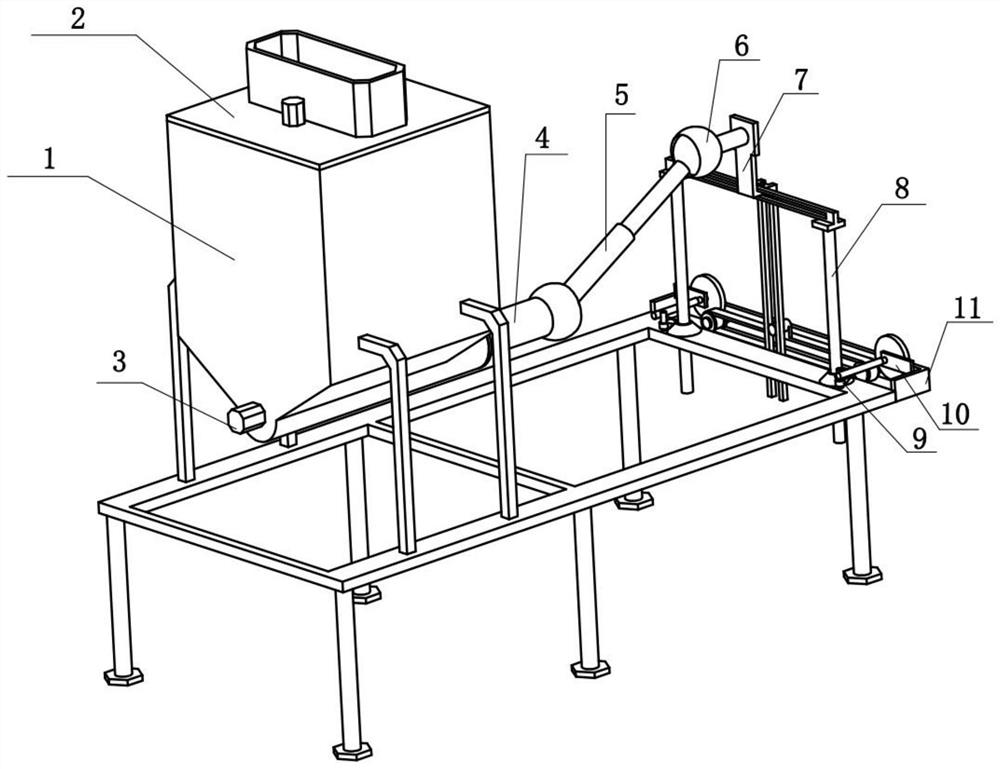

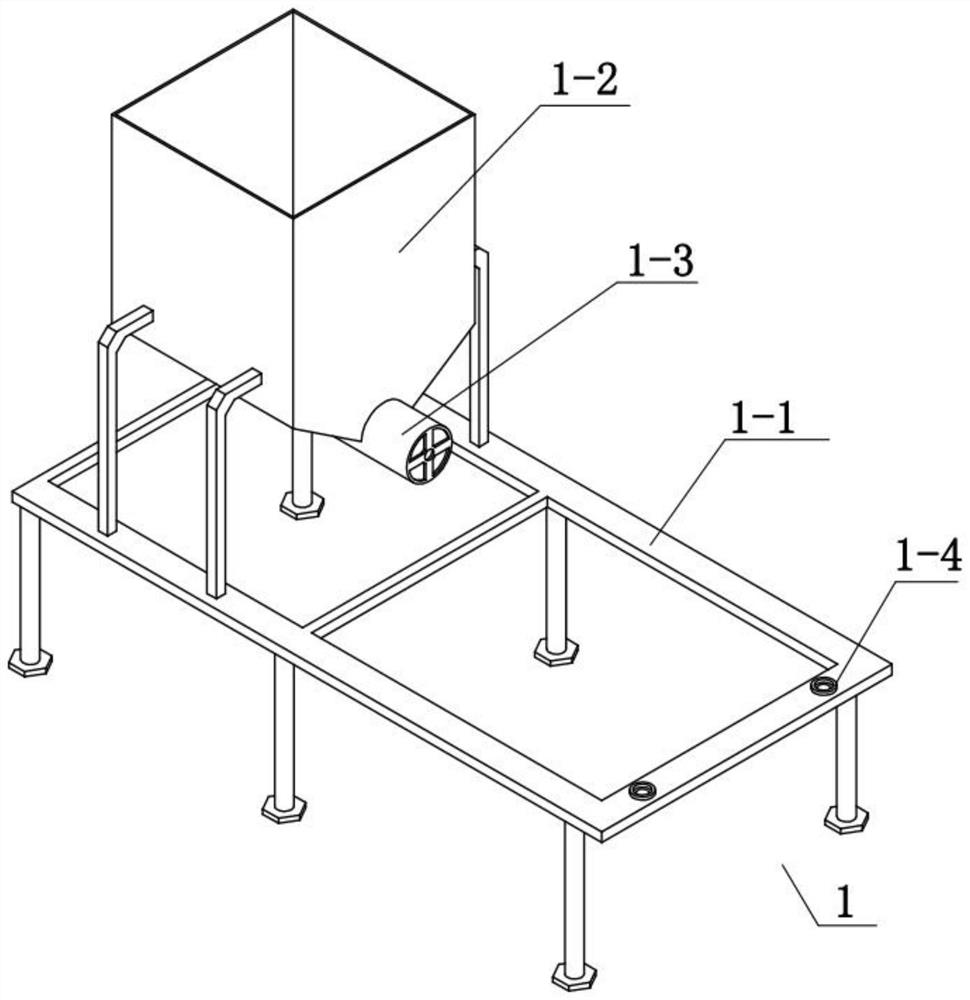

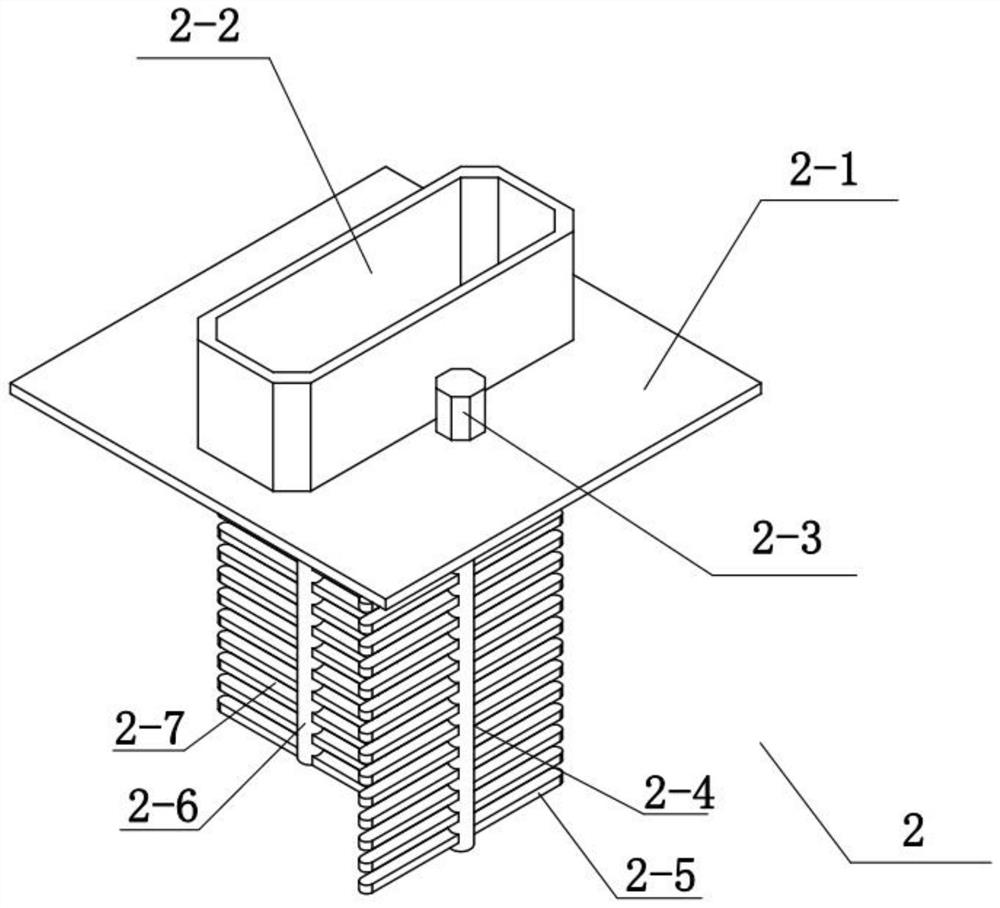

Water pouring test equipment for door and window of outer eave of building

InactiveCN102589814ARealize automatic sprayingGuaranteed accuracyFluid-tightness measurement using fluid/vacuumEavesWater resources

The invention relates to water pouring test equipment for a door and a window of an outer eave of a building. The water pouring test equipment comprises a motor, a water pump and a water spray device, wherein the motor is connected with the water pump, a water outlet of the water pump is connected with the water spray device, and a hanging ring hung on a lifting device is arranged at the upper end of the water spray device. The water pouring test equipment for the door and the window of the outer eave of the building is reasonable in design, scientific in structure, convenient in movement and strong in practicability, saves effort, quickens the test speed, guarantees the accuracy of the test result and improves the recovery rate of water resources.

Owner:天津东正测控技术发展有限公司 +2

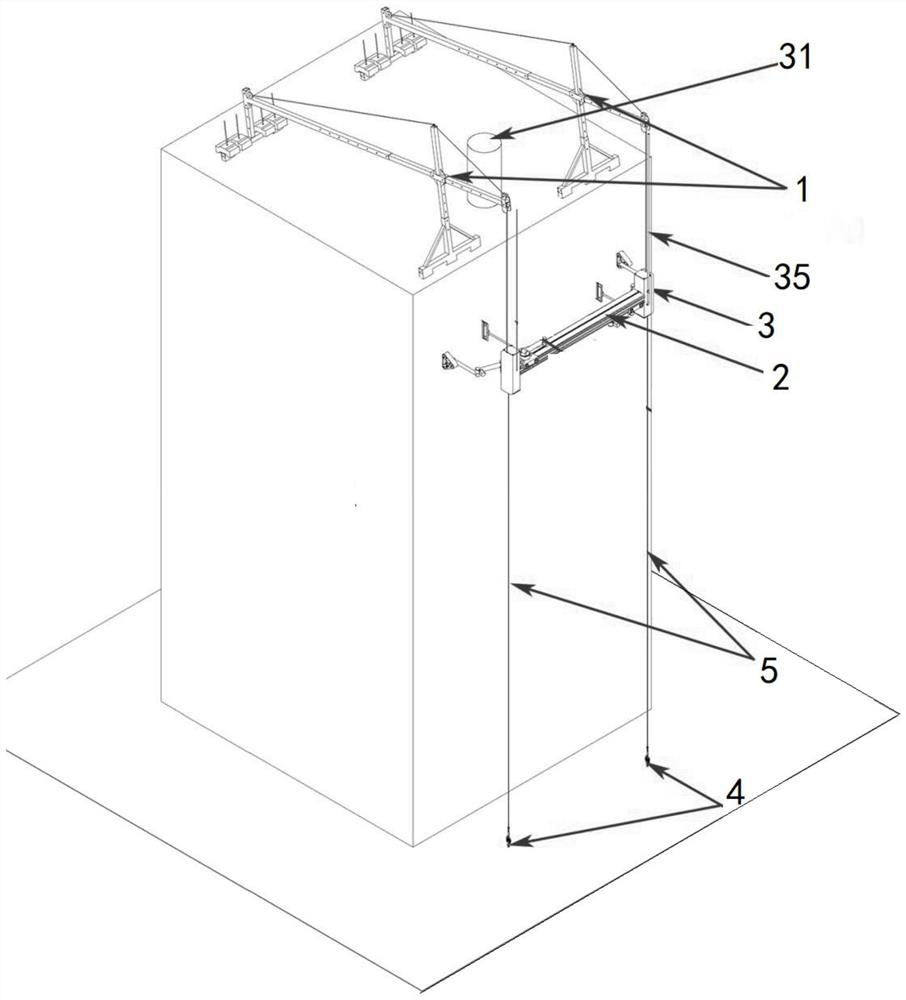

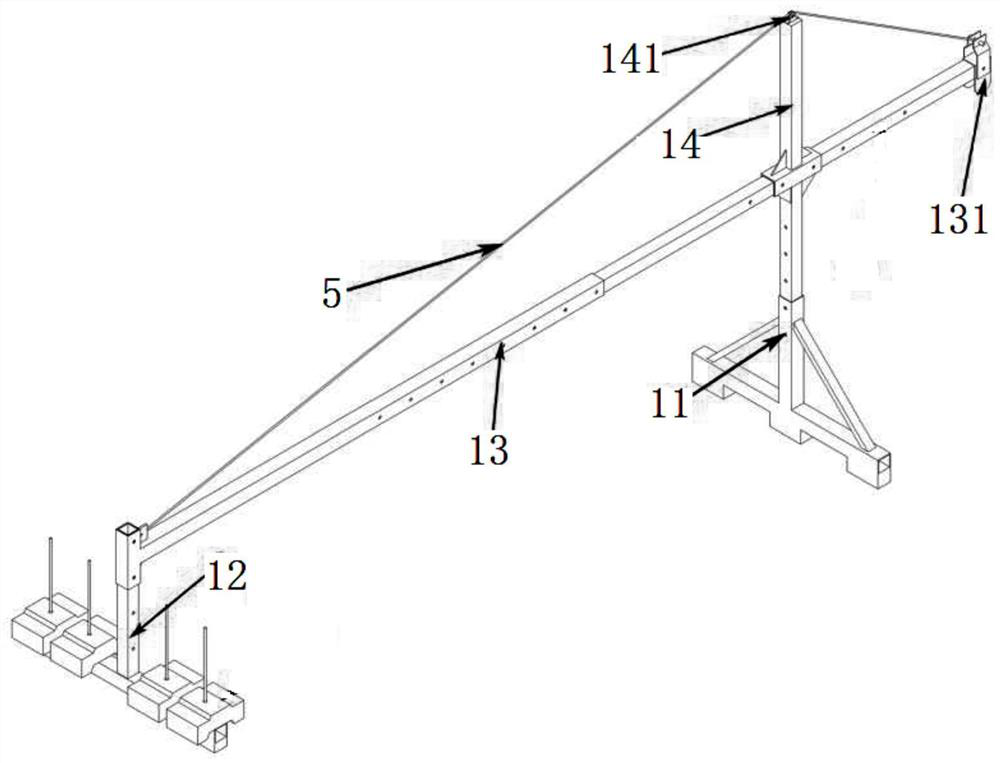

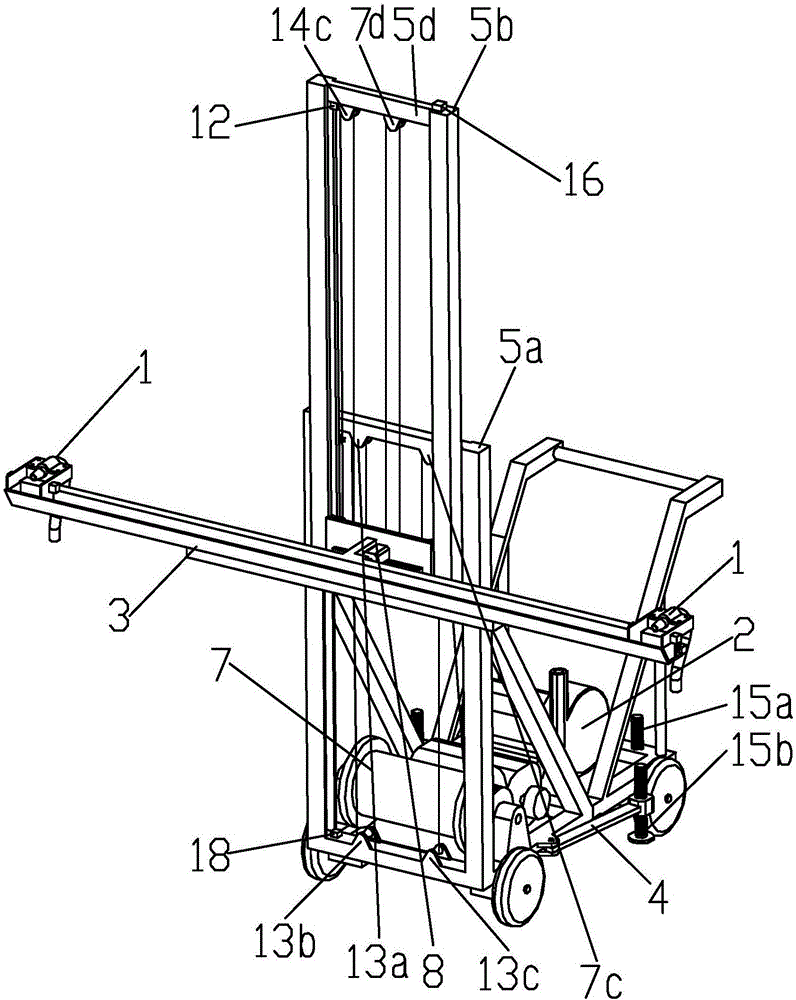

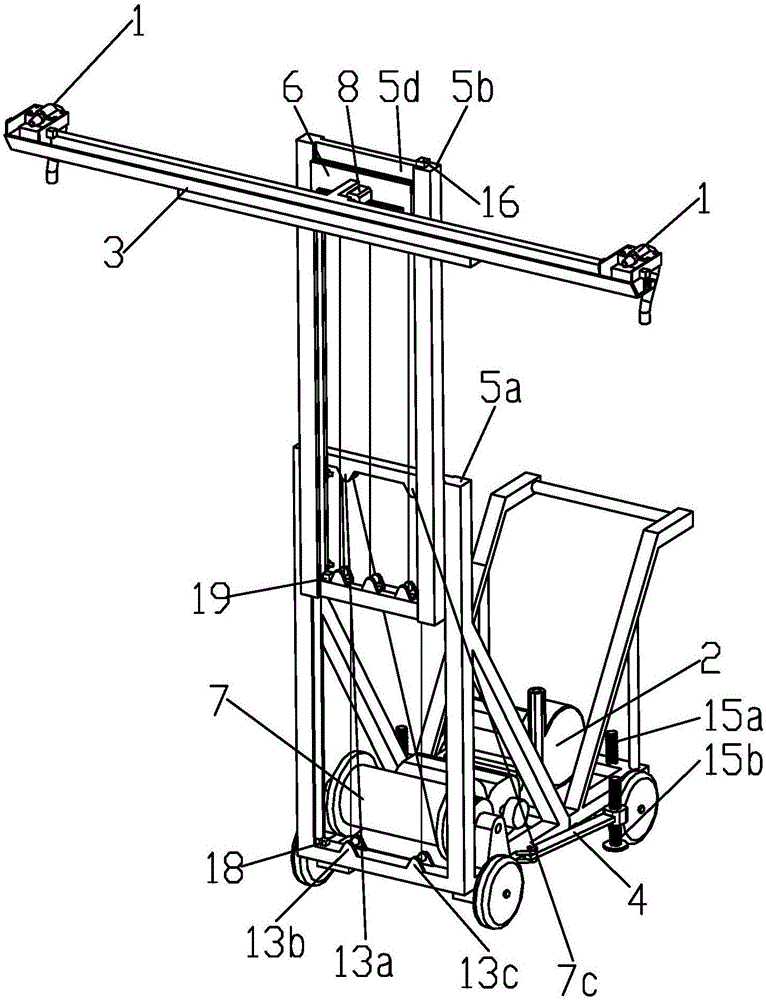

High-rise spraying robot

PendingCN112832490ARealize automatic sprayingNo risk of injuryBuilding constructionsAutomatic controlControl system

The embodiment of the invention discloses a high-rise spraying robot. The high-rise spraying robot comprises a hanging basket support, a driving device, a spraying device, a tensioning device and a control system. The hanging basket support is arranged on a roof, and a rope which is arranged on the outer side of an outer wall from the roof is fixed to the hanging basket support. The driving device comprises a cross beam, a rope climbing device and a moving platform; the spraying device comprises a material pump, a spraying head and a scraping plate, a spraying gap exists between the spraying head and the outer wall, the spraying head is installed on the moving platform through a first mechanical arm, and the scraping plate is arranged above the spraying head and installed on the first mechanical arm, so that the scraping plate makes contact with the outer wall; and the tensioning device is fixed to the ground and connected with the bottom end of the rope. On the basis of automatic control of the control system, the first mechanical arm drives the spraying head to move and spray under the action of the moving platform, putty is scraped to be flat through the scraping plate, so that automatic spraying of the outer wall of the high-rise building is achieved, workers do not need to work high above the ground, and no danger is ensured.

Owner:邯郸市永年区华翼机械科技有限公司

Water-based paint uniform spraying device and method for color steel plate spraying

PendingCN112705433ASpray evenlyRealize the function of intermittent movementLiquid surface applicatorsSpraying apparatusElectric machineStructural engineering

The invention discloses a water-based paint uniform spraying device and method for color steel plate spraying, and relates to the technical field of color steel plate production. The water-based paint uniform spraying device comprises a shell, wherein a motor is installed on the inner wall of the bottom end of the shell through a pipeline, the output end of the motor is fixedly sleeved with an output shaft, and the outer wall of the output shaft is in transmission connection with a rotating shaft through a belt; the outer wall of top of the rotating shaft is fixedly sleeved with an incomplete gear, and the outer side of the incomplete gear is engaged with annular racks. According to the water-based paint uniform spraying device and method, a threaded rod drives a mounting block to move rightwards, the mounting block drives a spray head to move rightwards through an electric push rod, automatic spraying work is conducted on the X axis of a color steel plate, and the whole color steel plate surface can be sprayed, so that the function of intermittently moving the color steel plate while spraying is achieved; and a nozzle moving device does not need to be additionally arranged, so that energy conservation and environmental protection are achieved.

Owner:深圳市深赛尔股份有限公司

Building surface spraying robot

The invention discloses a building surface spray painting robot. The building surface spray painting robot comprises a spraying gun, a slurry spraying machine, a large scraper blade, a traveling trolley and a control system, wherein the spraying gun is connected with the slurry spraying machine through a hose; a supporting arm is arranged at the front end of the traveling trolley; the large scraper blade is vertically and slidably mounted on the supporting arm through a guiding and sliding assembly; the traveling trolley is provided with a lifting mechanism which is used for driving the large scraper blade to slide vertically; the spraying gun is transversely and slidably mounted on the large scraper blade; a spraying head of the spraying gun and the large scraper blade are arranged in the same direction; the large scraper blade or the guiding and sliding assembly is provided with a driving mechanism which drives the spraying gun to slide transversely; the slurry spraying machine is mounted on the traveling trolley; and the slurry spraying machine, the lifting mechanism and the driving mechanism are respectively connected with the control system electrically. The spraying gun is transversely and slidably mounted on the large scraper blade, the large scraper blade is slidably mounted on the supporting arm through the guiding and sliding assembly, so that automatic slurry spraying and automatic floating are realized, automation of plastering of the surface of a wall of a building is realized, and labor intensity of workers is greatly reduced.

Owner:武汉科技大学资产经营有限公司

Spraying device, spraying mechanism and intelligent micro-spray pesticide applying system

ActiveCN106259266ASmall diameterReduce the impactInsect catchers and killersEngineeringHigh pressure

The invention relates to a spraying device, a spraying mechanism and an intelligent micro-spray pesticide applying system. The spraying device comprises two linear pushing rods, a high-pressure hose, a pressure communication tank and multiple atomizers, wherein the two linear pushing rods are both fixedly connected with the pressure communication tank, the high-pressure hose is communicated with the pressure communication tank, a fan is arranged in the middle of the pressure communication tank, and the fan blows wind towards the end, away from the linear pushing rods, of the pressure communication tank; the atomizers are placed at the end, away from the linear pushing rods, of the pressure communication tank and communicated with the pressure communication tank, and the atomizers form a circle to surround the edge of the pressure communication tank. Compared with the prior art, the spraying device has the advantages that micro-spray pesticide applying quality and efficiency can be improved, control precision is high, the influence of pesticides on the environment can be reduced, the device is flexible and can be adapted to various geomorphological conditions to conduct mechanical and automatic pesticide application, and labor intensity can be relieved.

Owner:SOUTHWEST UNIVERSITY

Mortar spraying device with gradually-changed spraying direction

ActiveCN111927054APrevent precipitation or condensationWell mixedDischarging apparatusBuilding constructionsStructural engineeringMechanical engineering

The invention relates to the technical field of mortar spraying equipment, in particular to a mortar spraying device with a gradually-changed spraying direction. The mortar spraying device has the advantage that the spraying direction of mortar is always perpendicular to a wall surface. The mortar spraying device comprises a supporting frame assembly, a stirring assembly, a feeding assembly, a first connecting pipe, a second connecting pipe, a spraying pipe, a limiting assembly, a lifting assembly, intermittent transmission assemblies, transmission assemblies and a transverse moving assembly.The transverse moving assembly drives the limiting assembly to slide from one side to the other side, the limiting assembly drives the spraying pipe to slide, and spraying in the front-back directionis achieved; the transverse moving assembly drives the lifting assembly through intermittent meshing of the two transmission assemblies and the two intermittent transmission assemblies, the spraying pipe automatically ascends or descends after running from one end of the front-rear side to the other end, and then automatic spraying of the spraying pipe to the wall surface is achieved; and the limiting assembly always keeps the spraying direction of the spraying pipe perpendicular to the wall surface, so that the mortar is uniformly sprayed on the wall surface, and subsequent finishing is not needed.

Owner:祎禾科技有限公司

Coating device for coating special for aluminum alloy hub

The invention relates to the field of spraying equipment, in particular to a coating device for a coating special for an aluminum alloy hub. The coating device comprises a machine body, a spraying cavity in the machine body and an operating cavity arranged in the right side end wall of the machine body, wherein the bottom of the operating cavity communicates with the spraying cavity, a sliding cavity with an upward opening is formed in the bottom wall of the spraying cavity, a sliding frame is arranged in the sliding cavity in a left-and-right manner, the sliding frame drives the sliding frame to move left and right through a winding device arranged in the sliding frame. According to the coating device special for the aluminum alloy hub, the automatic spraying of the hub can be realized, the spraying space is sealed during spraying at the same time, so that it is guaranteed that air is prevented from being polluted by spraying substances, and the health of workers is harmed, the equipment adopts annular progressive spraying at the same time, so that the spraying is more uniform, the flatness of a paint surface is higher, and production and popularization are facilitated.

Owner:威海佳美化工有限公司

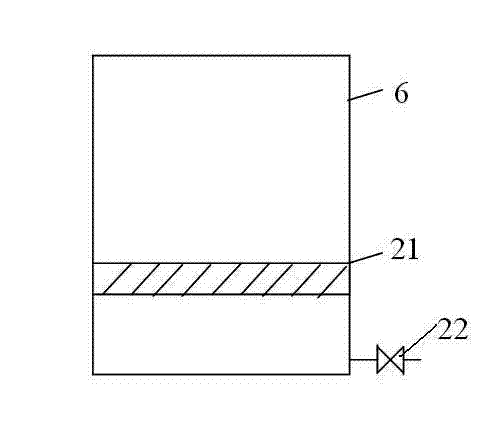

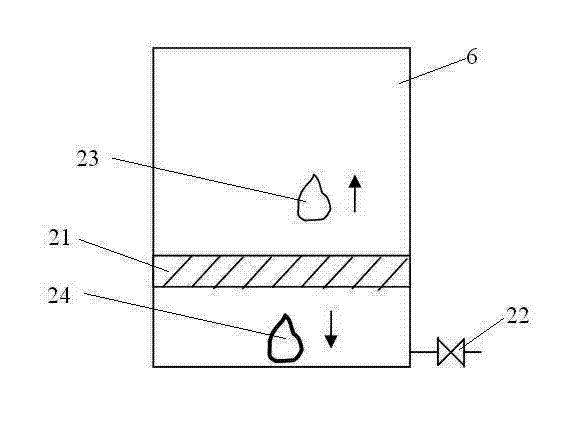

Self-adaptive deodorization intelligent garbage can

ActiveCN109319347AAvoid odorAchieve moisture separationRefuse receptaclesRefuse cleaningSelf adaptiveEngineering

The invention relates to the technical field of garbage cans, in particular to a self-adaptive deodorization intelligent garbage can. The self-adaptive deodorization intelligent garbage can comprisesan inner barrel, an outer barrel and a rotary shaft, wherein the inner barrel is connected in the outer barrel in a sleeving mode; the rotary shaft is rotatably connected with the bottom of the outerbarrel; a water passing hole is formed in the side wall of the inner barrel; a liquid collecting cavity is formed between the side wall of the inner barrel and the side wall of the outer barrel; a power acquisition device is arranged on the outer barrel; the power acquisition device comprises a pedal and a transmission mechanism; the transmission mechanism is in transmission connection with the rotary shaft; a first top plate is arranged on the top of the outer barrel; a first adding hole is formed in the first top plate; a second top plate is arranged on the top of the inner barrel; a secondadding hole is formed in the second top plate; a baffle plate is arranged on the rotary shaft; a spiral spline is arranged between the baffle plate and the bottom of the outer barrel; and the bottom of the inner barrel is connected with the rotary shaft through the spiral spline. The self-adaptive deodorization intelligent garbage can provided by the invention can separate water in garbage, and solves the problem that garbage is liable to go mouldy and smelly after being placed for a long time.

Owner:广东数智化信息服务有限公司

Automatic drug spraying device for Zizania aquatic planting and method

InactiveCN107211988AExpand the spraying rangeQuality improvementInsect catchers and killersMedicineDrug Storage

The invention discloses an automatic drug spraying device for Zizania aquatic planting and a method. The automatic drug spraying device for Zizania aquatic planting comprises an automatic drug spraying mechanism, a drug storage pond and a drug feeding device; the an automatic drug spraying mechanism is fixedly connected to the upper part of a Zizania aquatic field through a supporting bracket; the drug spraying mechanism comprises a vertical guide pipe and a horizontal guide pipe which are vertically connected to each other; the intersection of the vertical guide pipe and the horizontal guide pipe is equipped with a nozzle; the vertical guide pipe at the end part is connected with the drug storage pond through the conveying pipe, both sides of the Zizania aquatic field are symmetrically provided with the drug storage pond; the drug feeding device is fixedly connected to the top face of the drug storage pond. The method includes steps of measurement and laying-out, construction of the drug storage pond, installation of the drug feeding device, installation of the automatic drug spraying mechanism, test running of the automatic drug spraying device and equipment cleaning and maintenance. The using method is simple in step and strong in practicability; the labor intensity of manual operation is reduced; the automatic drug spraying is realized; besides, the disinsection efficiency is improved.

Owner:梁燕君

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com