Automatic spraying machine for internal and external walls of steel pipe

A technology of automatic spraying and internal spraying, which is used in coatings, devices for coating liquid on surfaces, etc., can solve the problems of reducing the service life of steel pipes, shortening the service life of steel pipes, and heavy workload, and achieve the effect of improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

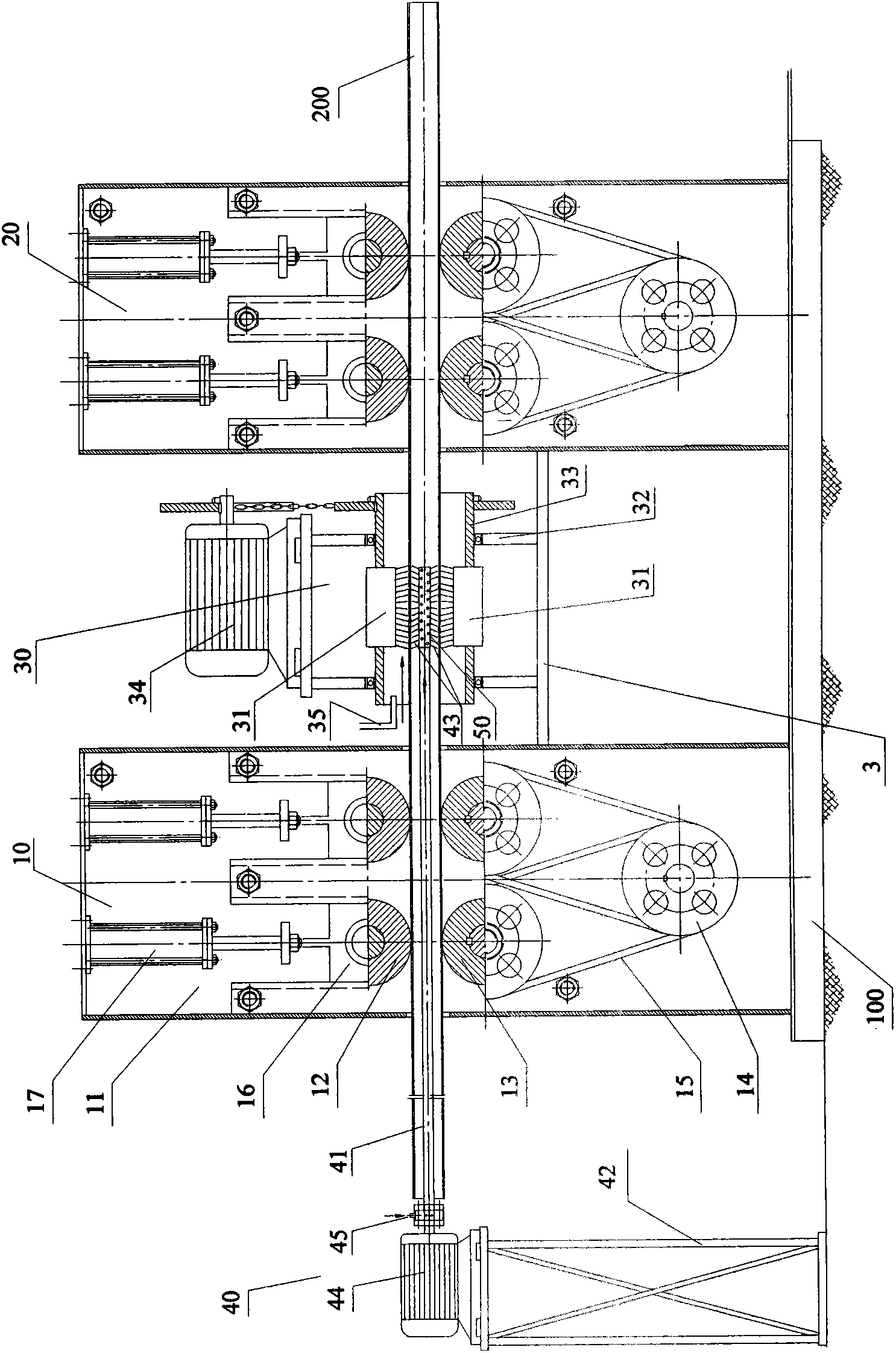

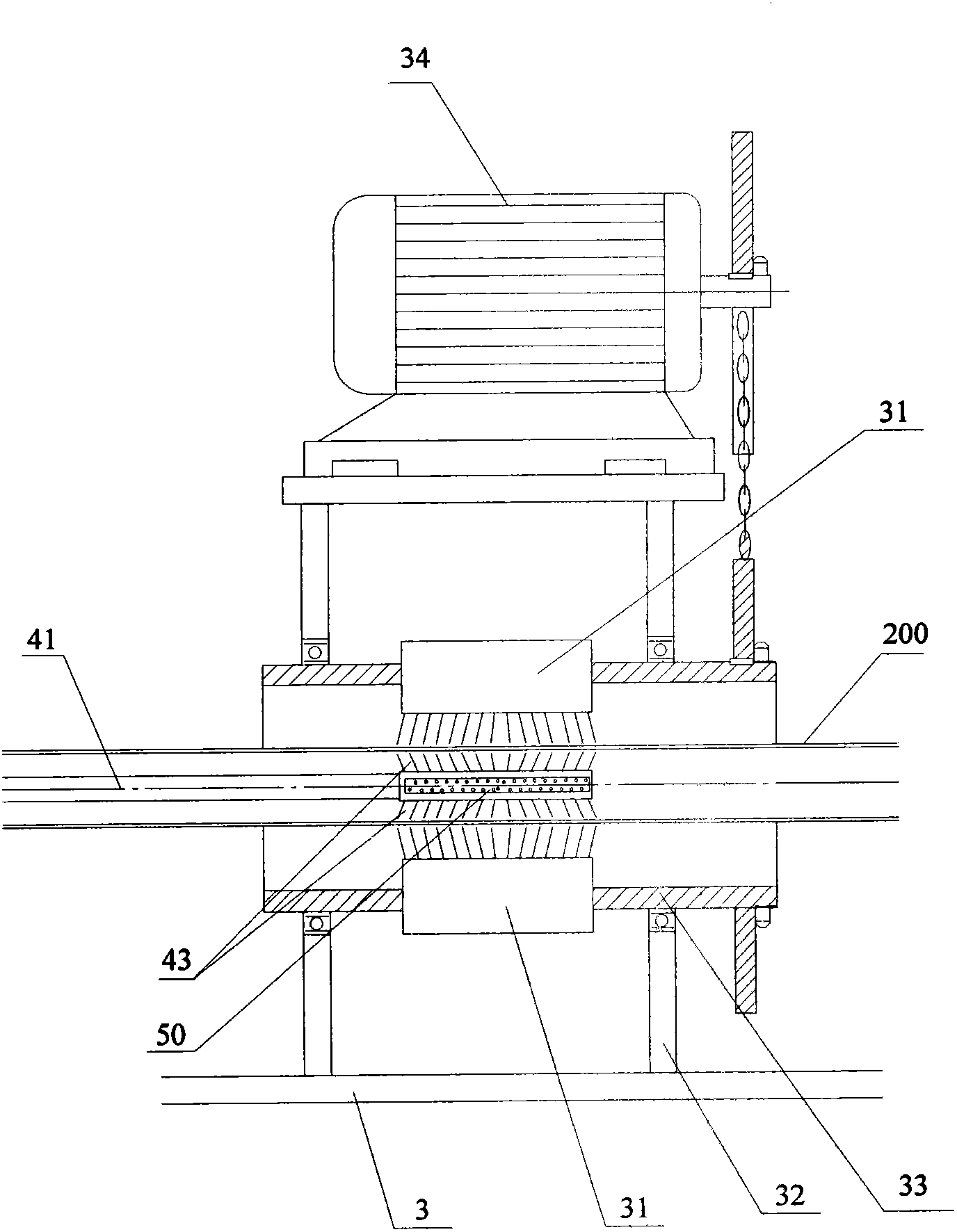

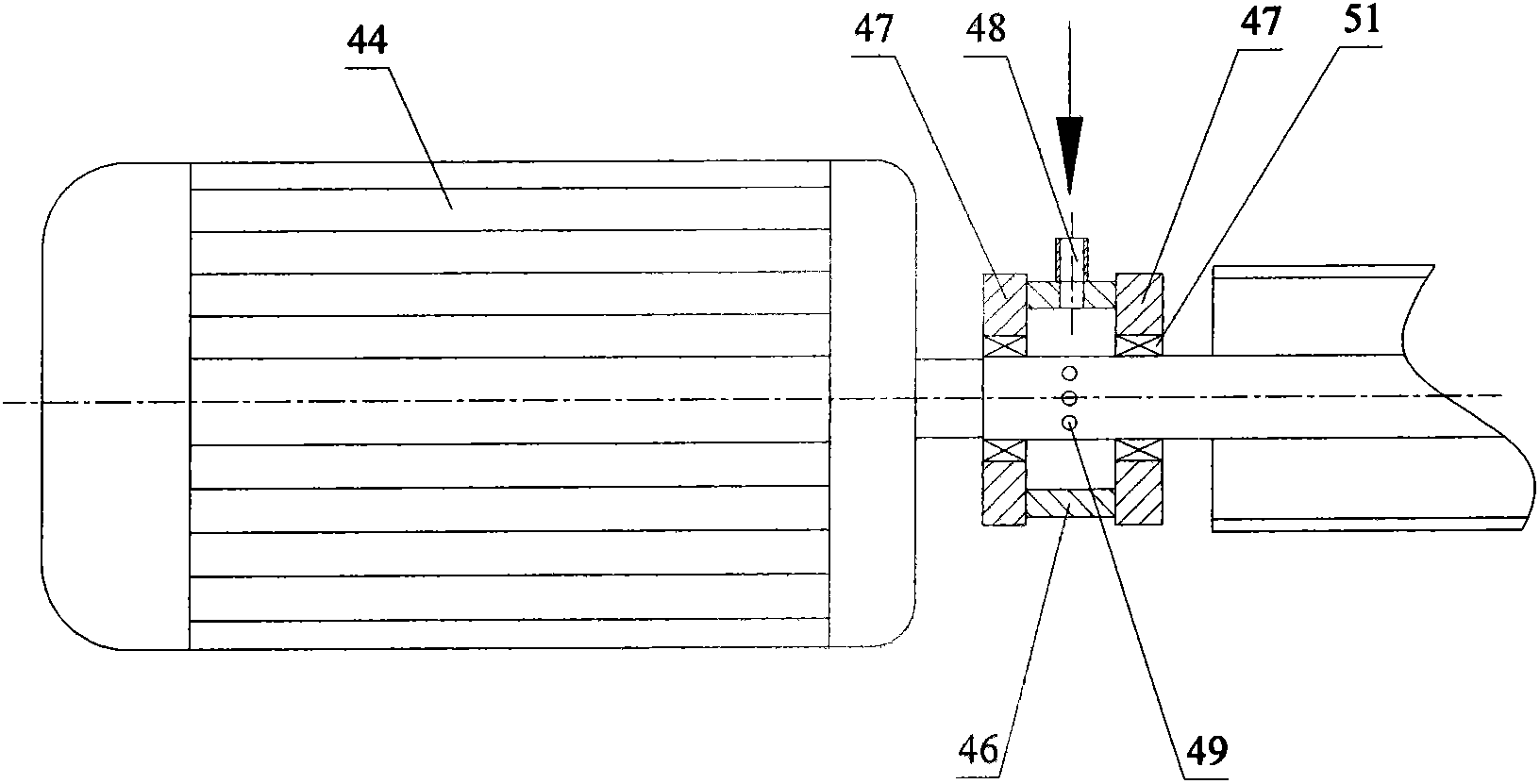

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 , figure 2 As shown, the automatic spraying machine for inner and outer walls of steel pipes provided by the present invention includes inner and outer wall paint spraying devices 40, 30 and left and right steel pipe driving devices 10, 20 fixedly arranged on the base 100 at left and right intervals, and left and right steel pipe driving devices The structures are the same, and are used to transport the steel pipe 200 to be sprayed and move left and right in the horizontal direction.

[0014] Taking the left steel pipe driving device 10 as an example, the left steel pipe driving device 10 includes a frame 11 fixed on the support 100 and several groups of upper and lower rollers 12, 13 that are relatively arranged on the frame 11 up and down, and the lower rollers 13 Driven by the motor 14 fixed on the frame 11 through the belt 15, the axle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com