Patents

Literature

92results about How to "No risk of injury" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

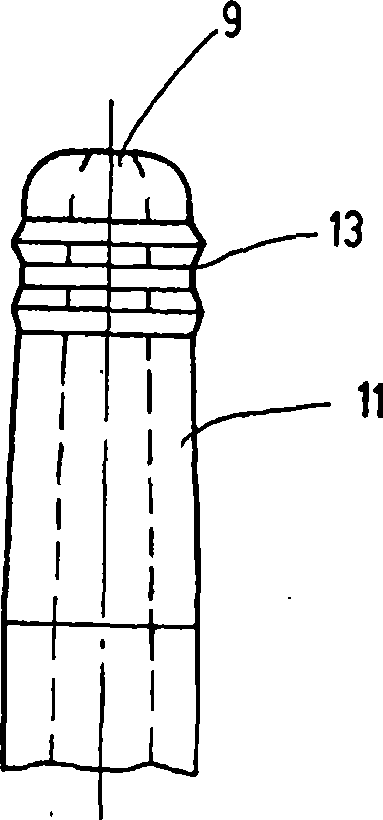

Special hanger with guide cover wheel hub and turning and hanging method

InactiveCN101966965ASmall form factorSimple structureWind energy generationLoad-engaging elementsEngineeringMechanical engineering

Owner:JIANGSU WENDE NEW ENERGY

Compound colloid for treating coal bed fire

InactiveCN1931397AImprove stabilityDisappear quicklyFire rescueFire extinguisherSuspending AgentsSlurry

The compound colloid for treating coal bed fire consists of water, aggregate and gel forming agent. The aggregate is fly ash, loess, sand soil or rock powder; and the gel forming agent is sodium polyacrylate. When the compound colloid is used, water and the aggregate are first mixed to form slurry, and sodium polyacrylate is then added. Into the compound colloid, aluminum sulfate and ammonium bicarbonate may be added to foam the gel and to decrease the slurry consumption, and some suspending agent may be added to avoid settling of the aggregate during pipelining. The fire extinguishing colloid for coal bed has low cost, simple operation and low consumption.

Owner:西安森兰科贸有限责任公司

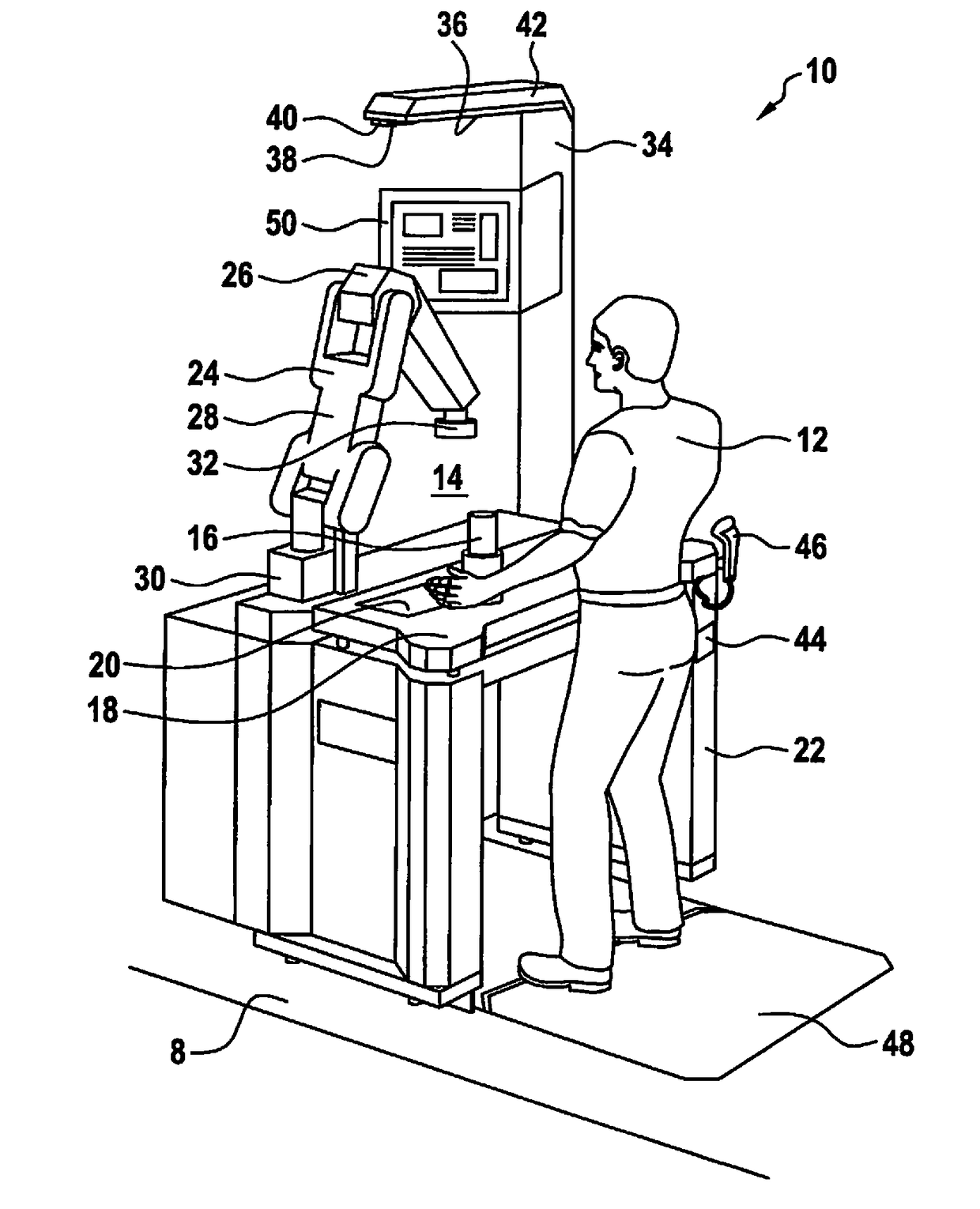

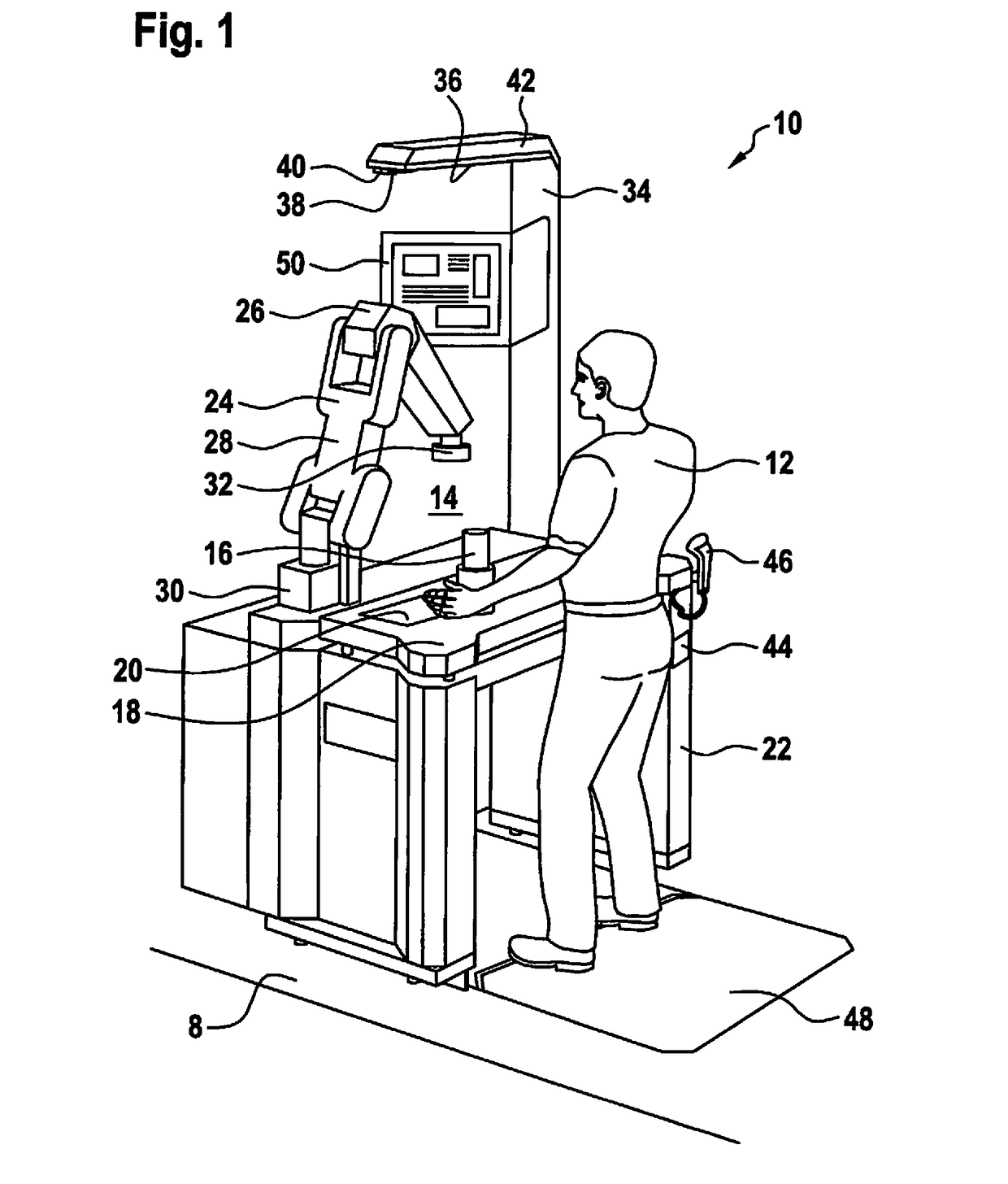

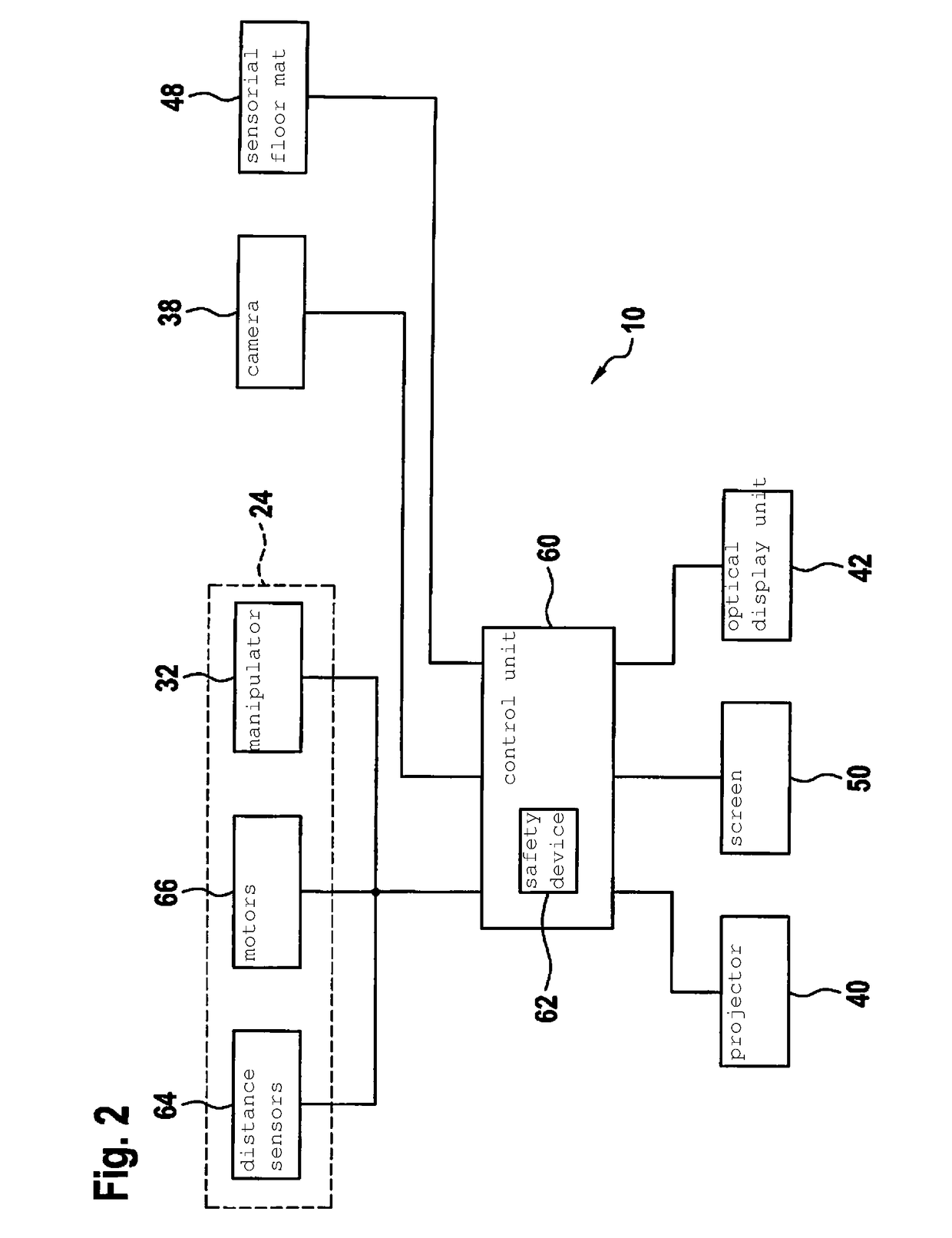

Manual work station and control unit for controlling the sequencing of a manual work station

InactiveUS20170305019A1No risk of injuryCooperation is safeProgramme controlProgramme-controlled manipulatorRobotic armControl cell

A manual work station, in particular a manual work station for manufacturing and / or a manual work station for packaging, comprising a work area accessible to a worker, the manual work station having at least one robotic arm, the manual work station having a safety device, which is designed in such a way that the robotic arm cooperates in a contact-free manner with the worker in the work area. The invention furthermore relates to a control unit for controlling the sequencing of a manual work station.

Owner:ROBERT BOSCH GMBH

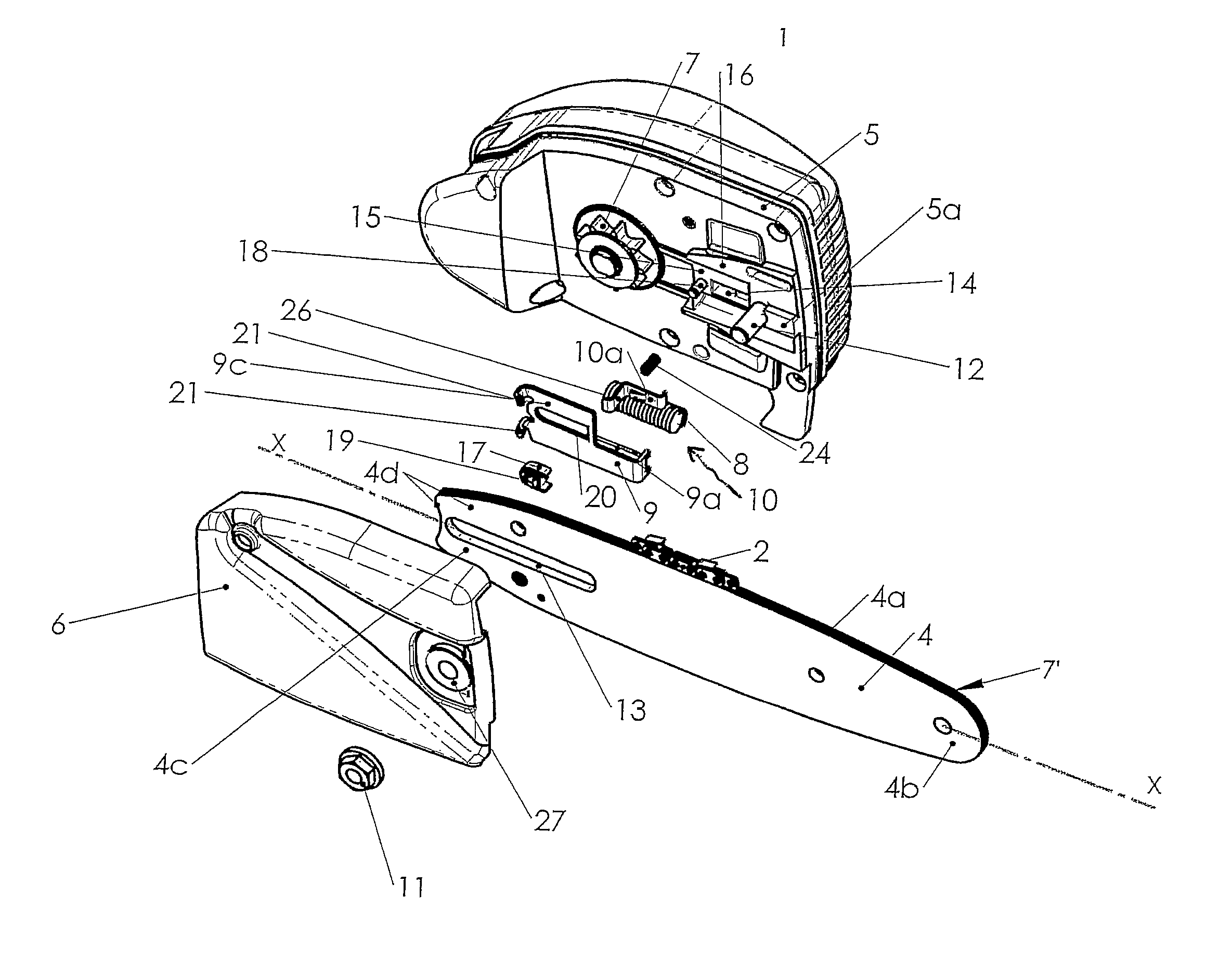

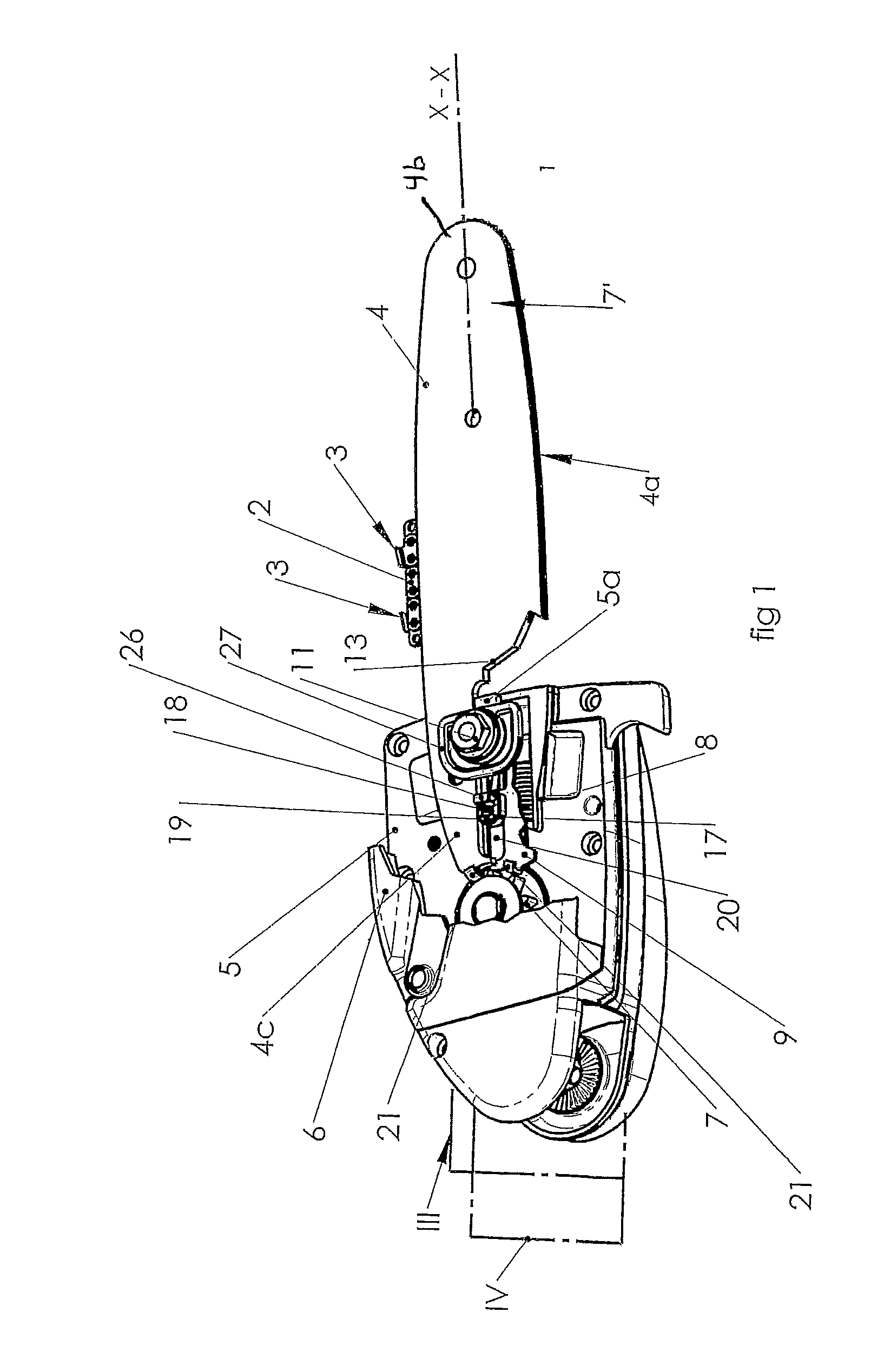

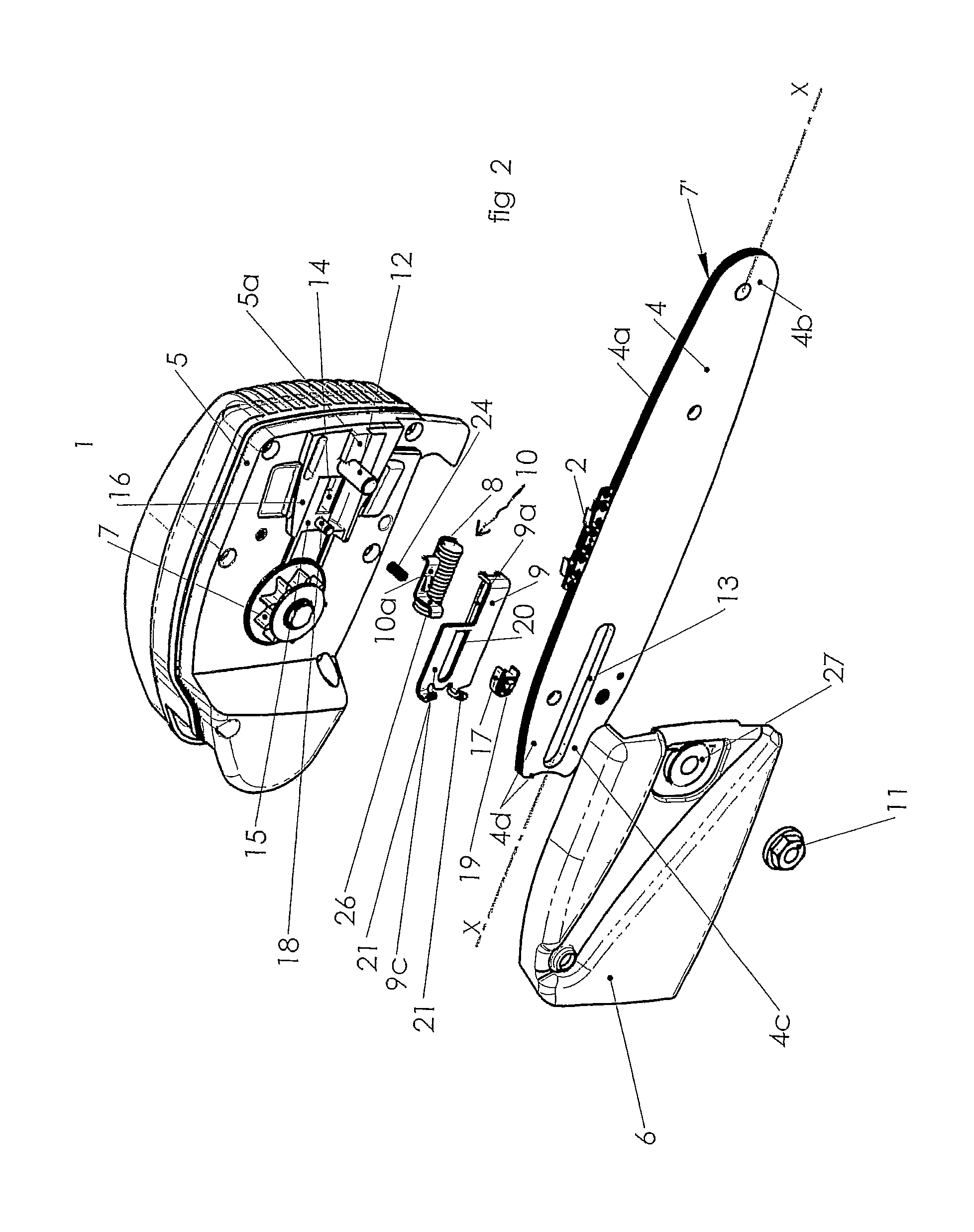

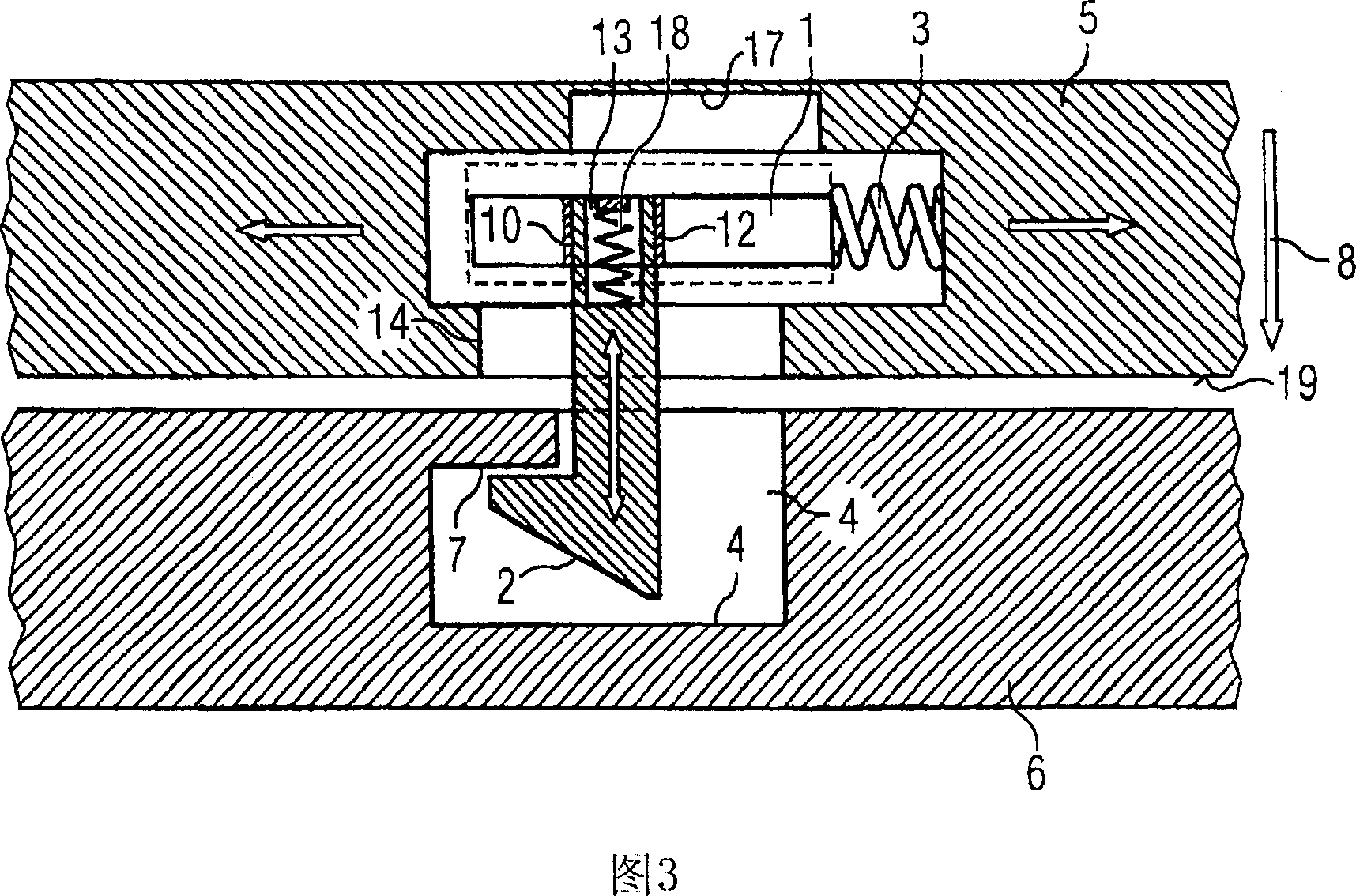

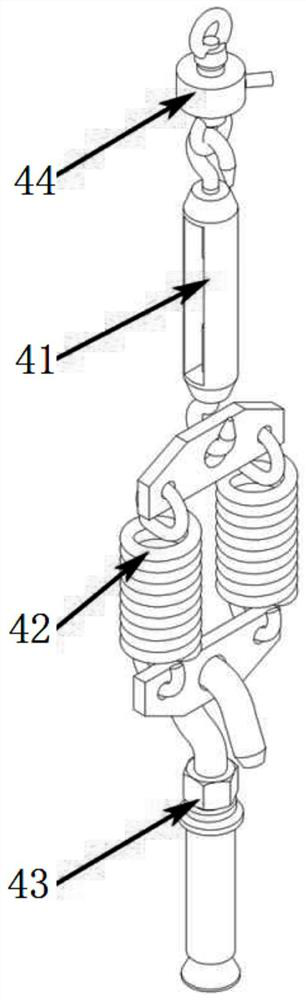

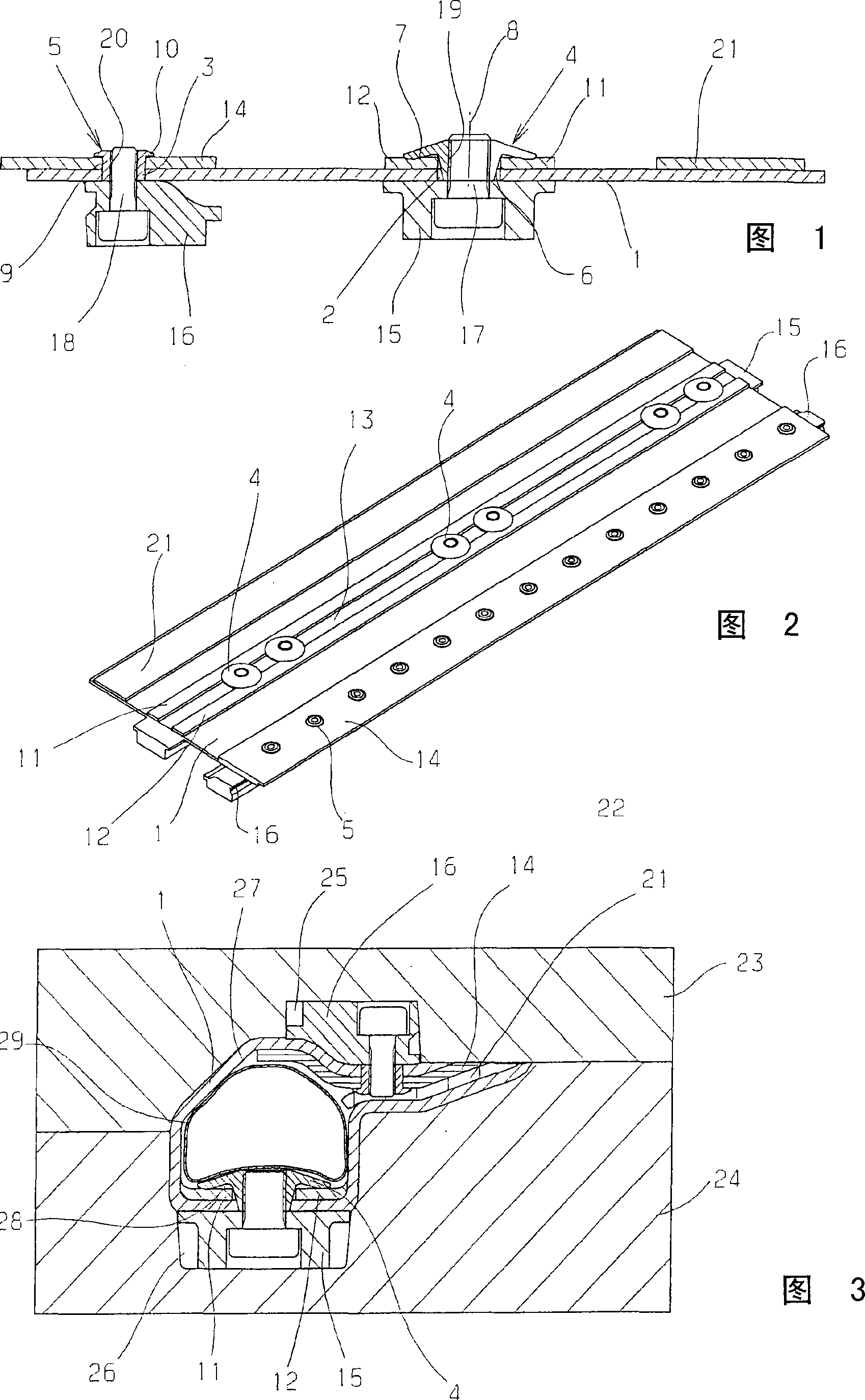

Chain saw with tension adjustment

ActiveUS8434236B2Realize automatic adjustmentEasy to operateMetal sawing devicesMetal sawing accessoriesElastic componentEngineering

A chain saw apparatus has a body, a guide bar extending from the body, a drive sprocket rotatably mounted to the body, a chain affixed to the drive sprocket and to the guide bar, an engagement device positioned on the body and cooperative with the guide bar so as to allow the guide bar to move toward and away from the body, and pushing device for automatically moving the guide bar away from the drive sprocket. The pushing device has a slide and an elastic component. The slide bears against a rear end of the guide bar. The elastic component urges between the body and the slide.

Owner:PELLENC SA

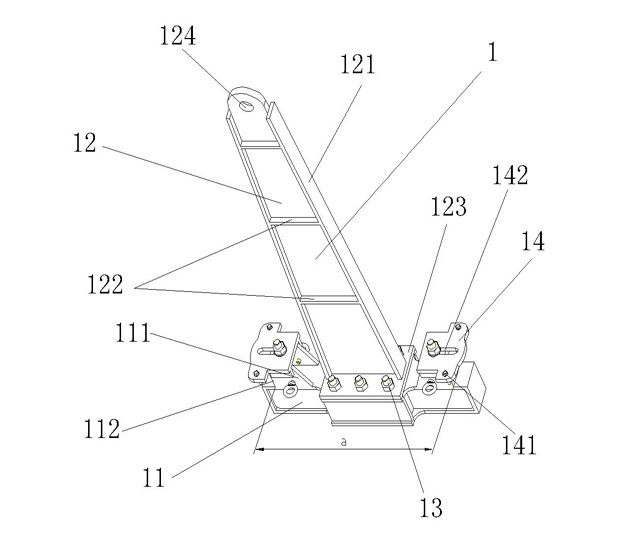

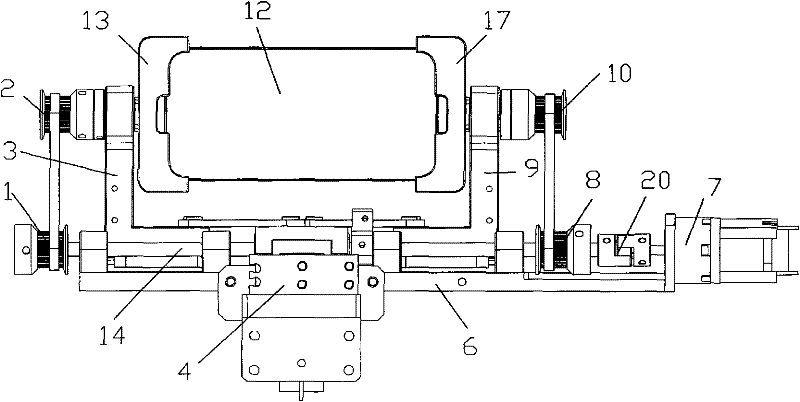

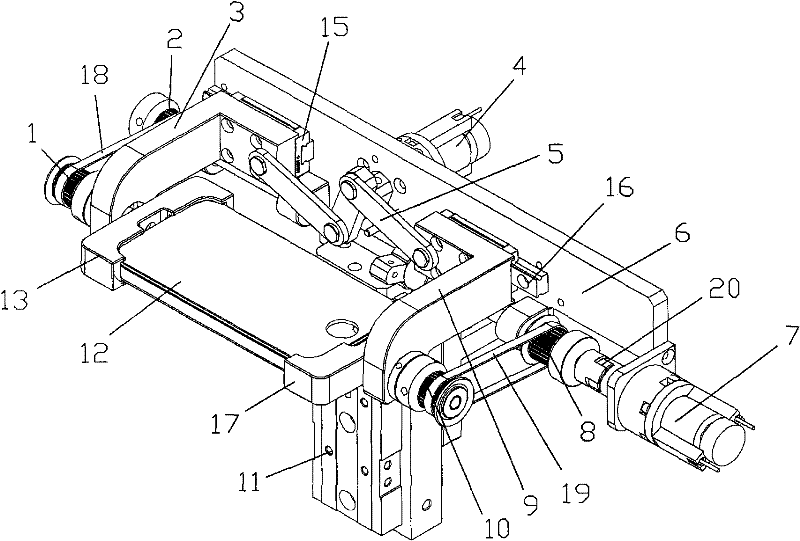

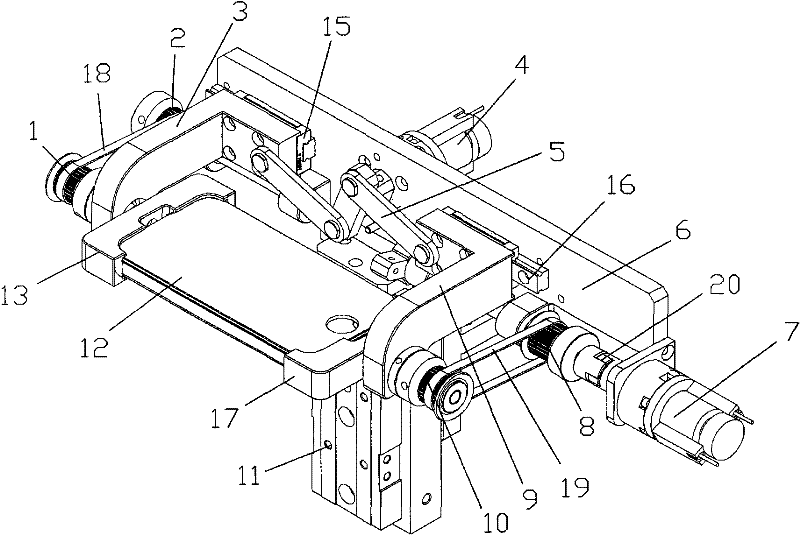

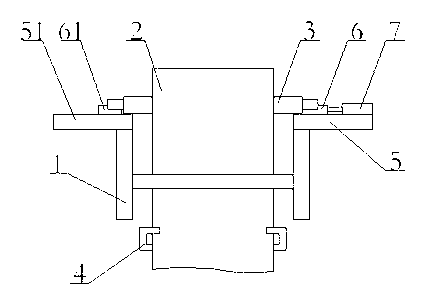

a turning mechanism

InactiveCN102269600ANo manual operation requiredImprove work efficiencyMeasurement apparatus componentsDrive shaftEngineering

The invention discloses an overturning mechanism, which comprises a lifting cylinder and a mounting plate. The mounting plate is screwed and fixed with a sliding table cylinder, a rotating cylinder and left and right slide rails, and a pull bar is connected to the output shaft of the sliding table cylinder; The stay bars are hingedly connected to the left and right splints installed on the left and right slide rails; a drive shaft is fixed on the rotary cylinder, and there are left and right moving gears on the drive shaft, and the left and right moving gears pass through the left and right belts and the left and right splints The left and right driven gears are connected; the left and right driven gears are fixed with left and right fixtures for clamping the workpiece. The invention provides a safe, fast and accurate automatic turning device, which does not require manual operation and greatly improves work efficiency.

Owner:BOZHON PRECISION IND TECH CO LTD

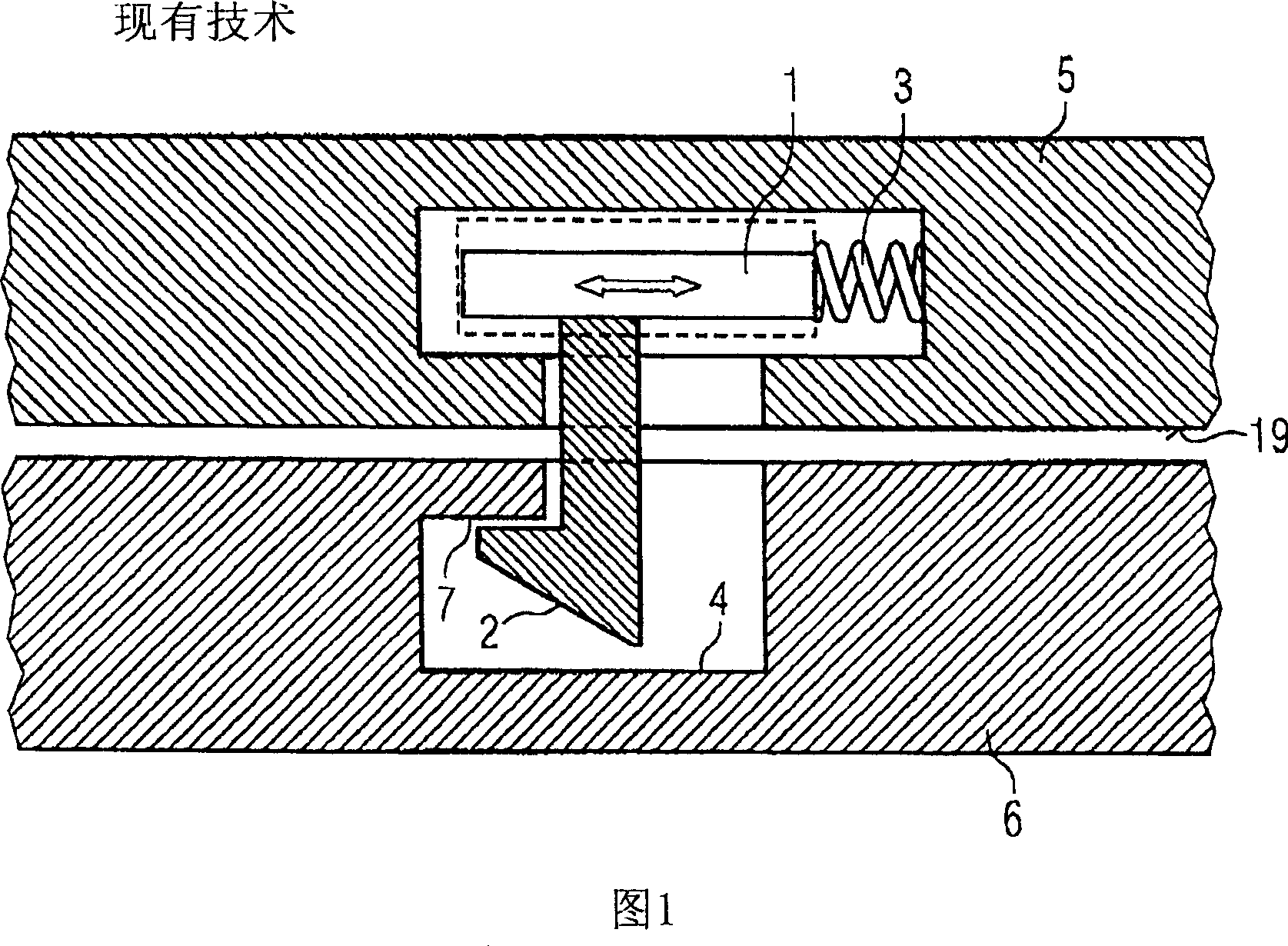

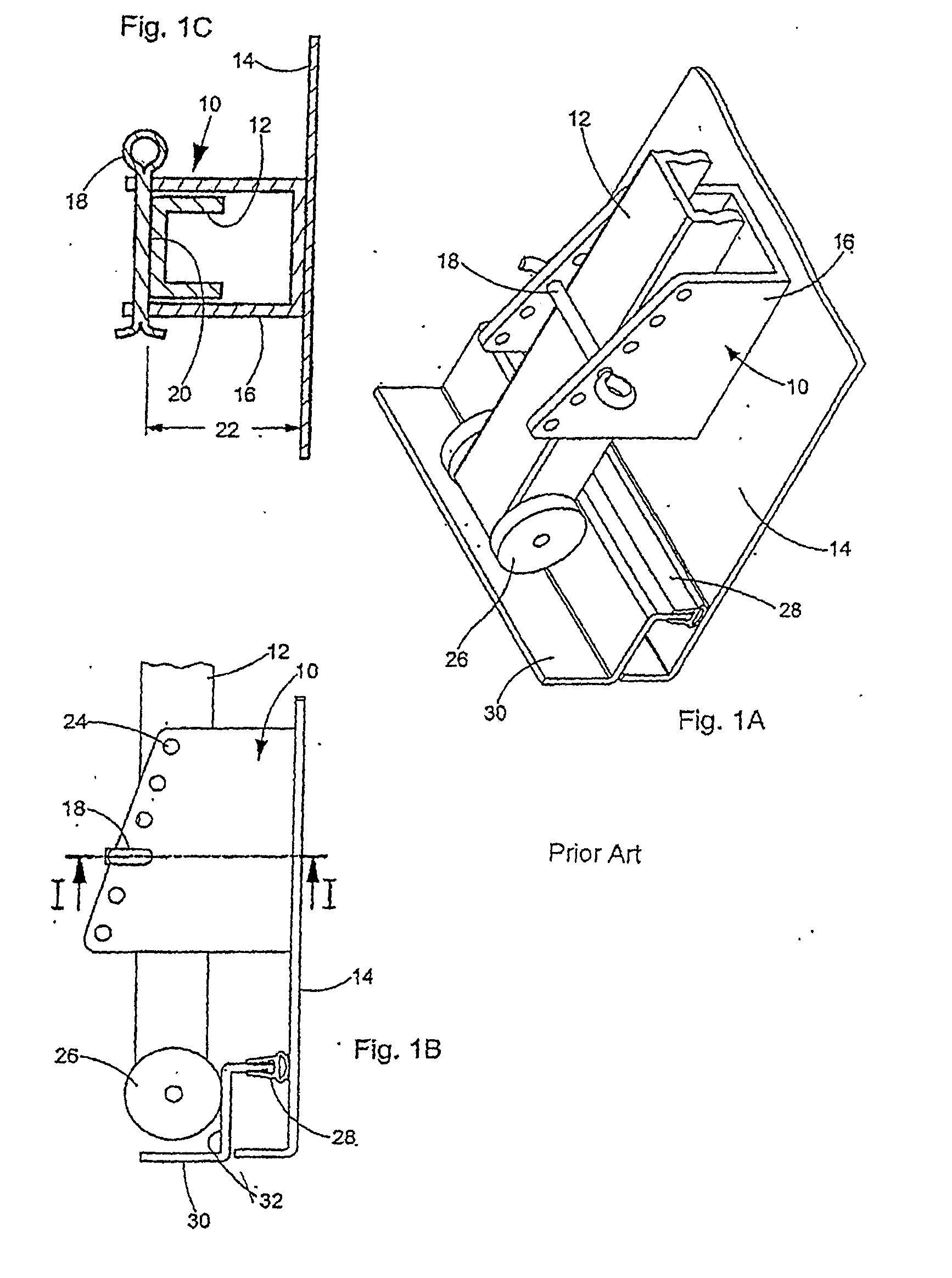

Locking device

InactiveCN1949130AReduce the risk of injuryImprove scalabilityBuilding locksWing fastenersEngineeringMechanical engineering

Owner:FUJITSU SIEMENS COMP GMBH

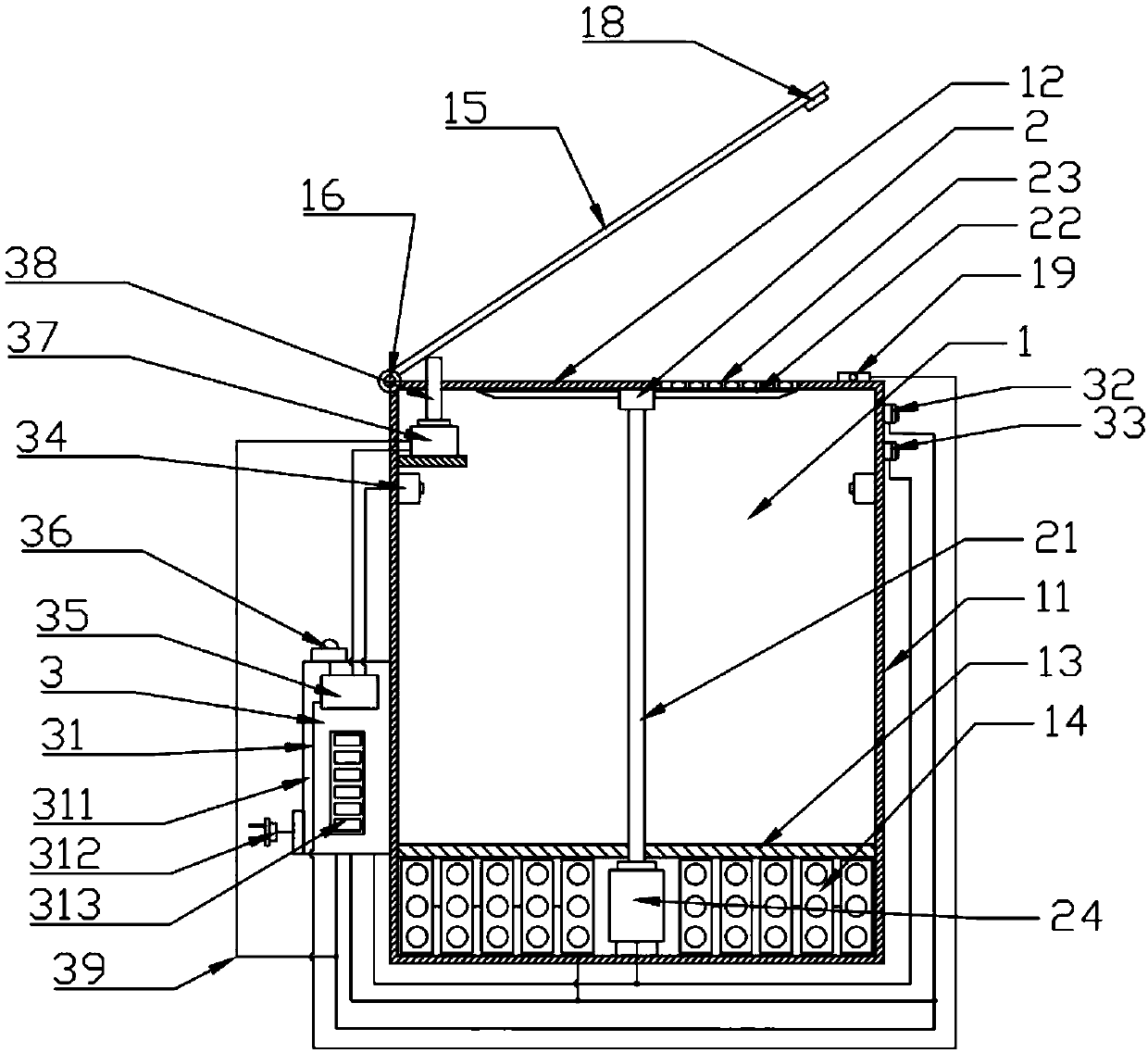

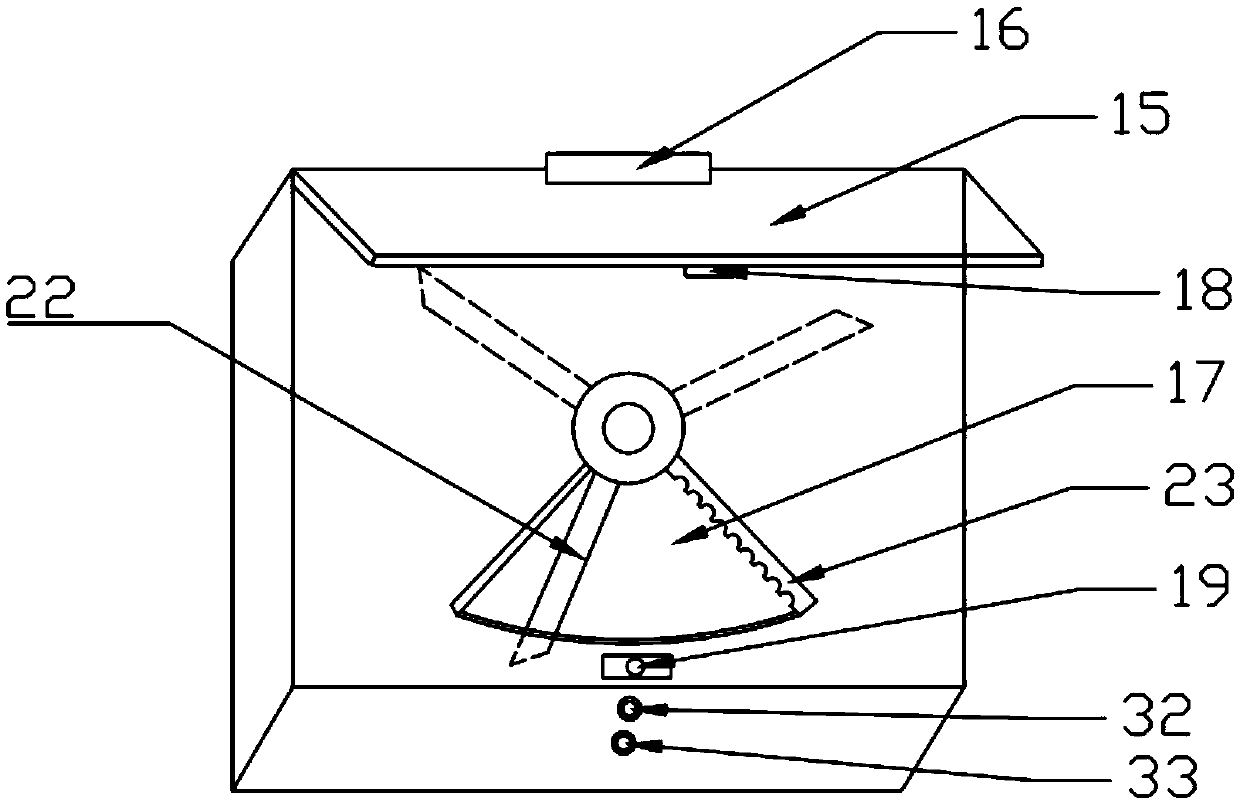

Magnetic fixed medical sharps box and using method thereof

InactiveCN109533730ASave spaceAvoid frequent replacementSurgical furnitureRefuse receptaclesMagnetic tension forceMotor drive

The invention discloses a magnetic fixed medical sharps box and a using method thereof. The magnetic fixed medical sharps box comprises a collection box, a shearing mechanism and a control system, wherein an electromagnet group is arranged at the inner bottom of the collection box; the shearing mechanism comprises a rotating shaft, a cutter blade, a cutter head and a rotor motor; the cutter bladeand the cutter head are arranged on an opening of the top of the collection box; the rotor motor and the cutter blade are arranged on the rotating shaft; a metal plate is arranged on a cover of the collection box; a top electromagnet is arranged at the corresponding position of the top of the box; when a start button on the control system is pressed down, the electromagnet group is charged, a stepper motor drives a push rod to open the cover of the collection box, sharps are put in the box, a cutting-off button on the control system is pressed down, the rotor motor drives the cutter blade to cut off a flexible pipe, and the sharps are tightly absorbed at the bottom of the box under the action of the magnetic force of the electromagnet group. When the collection box is almost full of the sharps, the box cover can also be automatically locked and is prevented from falling out. The magnetic fixed medical sharps box avoids the accidental injury caused by the direct contact between medicalpersonnel and discarded sharps, and is convenient and safe to operate.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

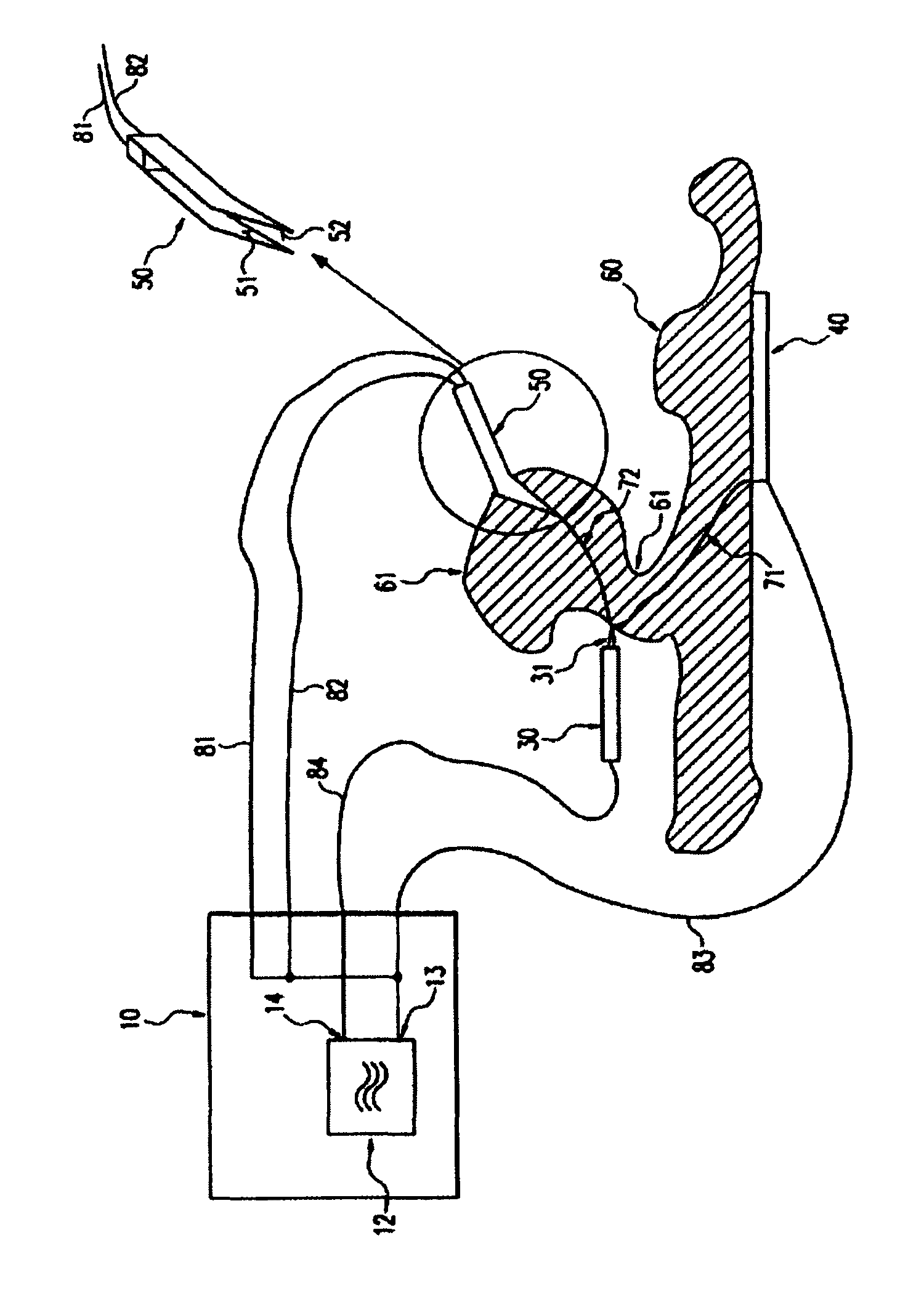

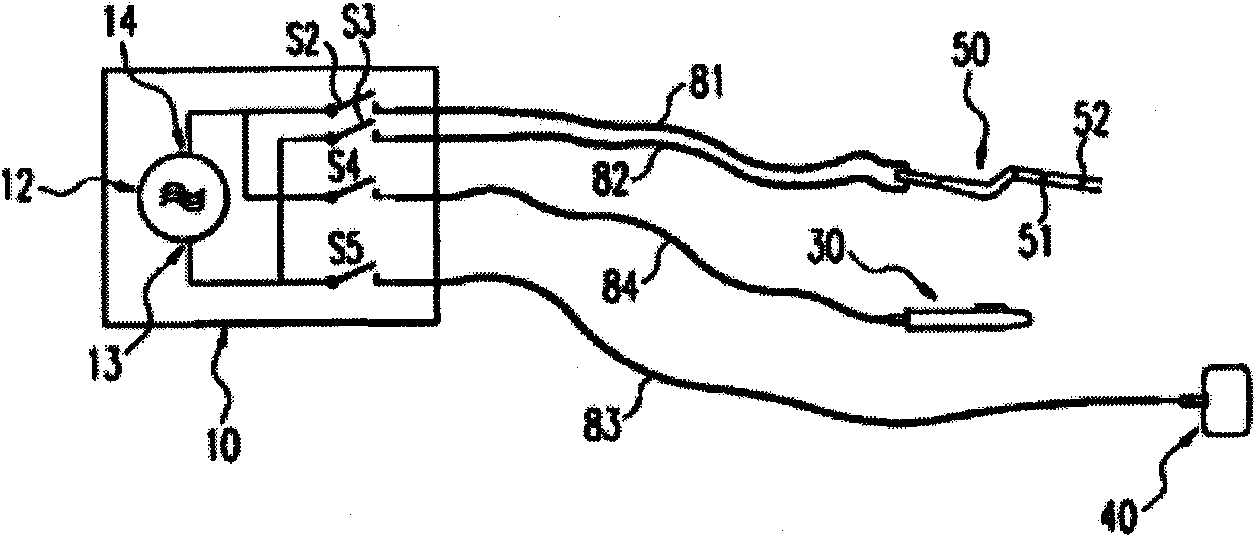

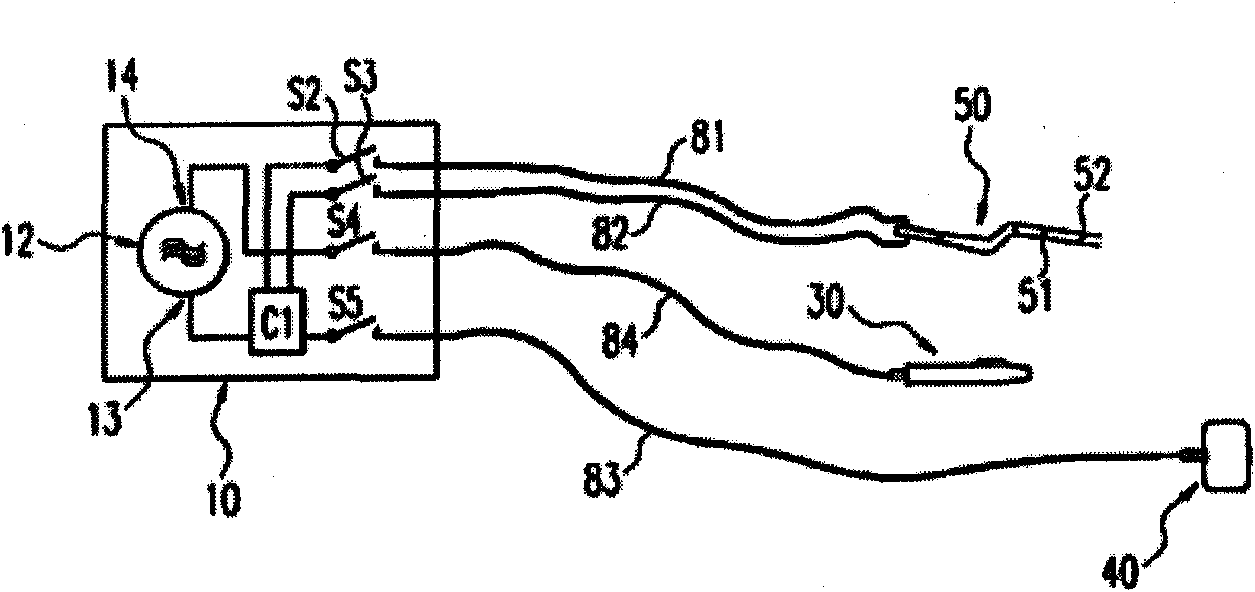

Electrosurgical hf generator

InactiveCN102159150ANo risk of injurySurgical instruments for heatingSurgical forcepsPower flowTissue heating

The invention relates to cutting or coagulating biological tissue using an electrosurgical HF generator (10) comprising a generator circuit (12) exciting an HF current between an active electrode (30) and at least one neutral electrode (40), wherein undesired tissue heating due to the HF current can be reduced if the electrosurgical HF generator (10) comprises at least one further auxiliary neutral electrode (50, 51, 52) connected in parallel to the neutral electrode (40).

Owner:ERBE ELEKTROMEDIZIN GMBH

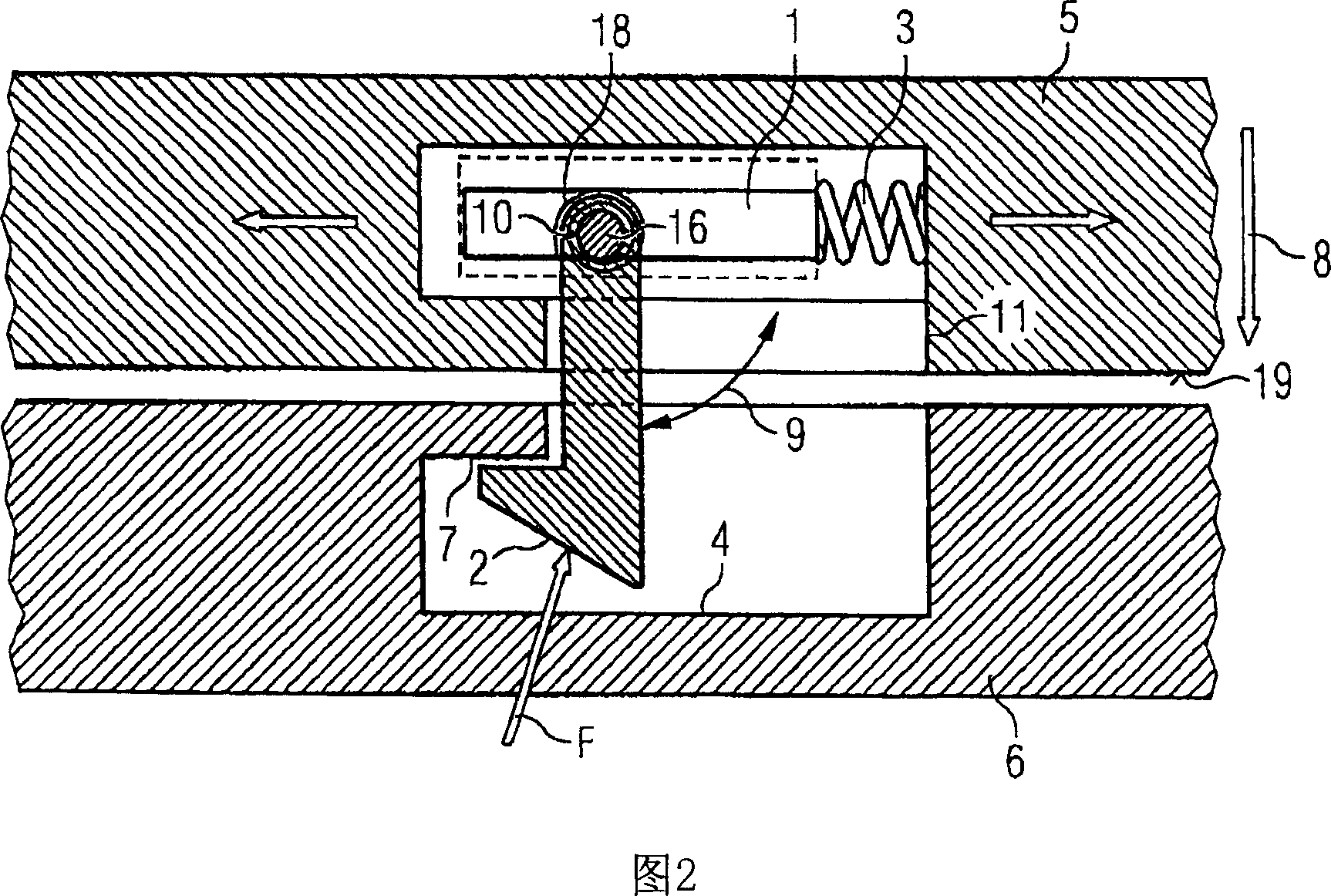

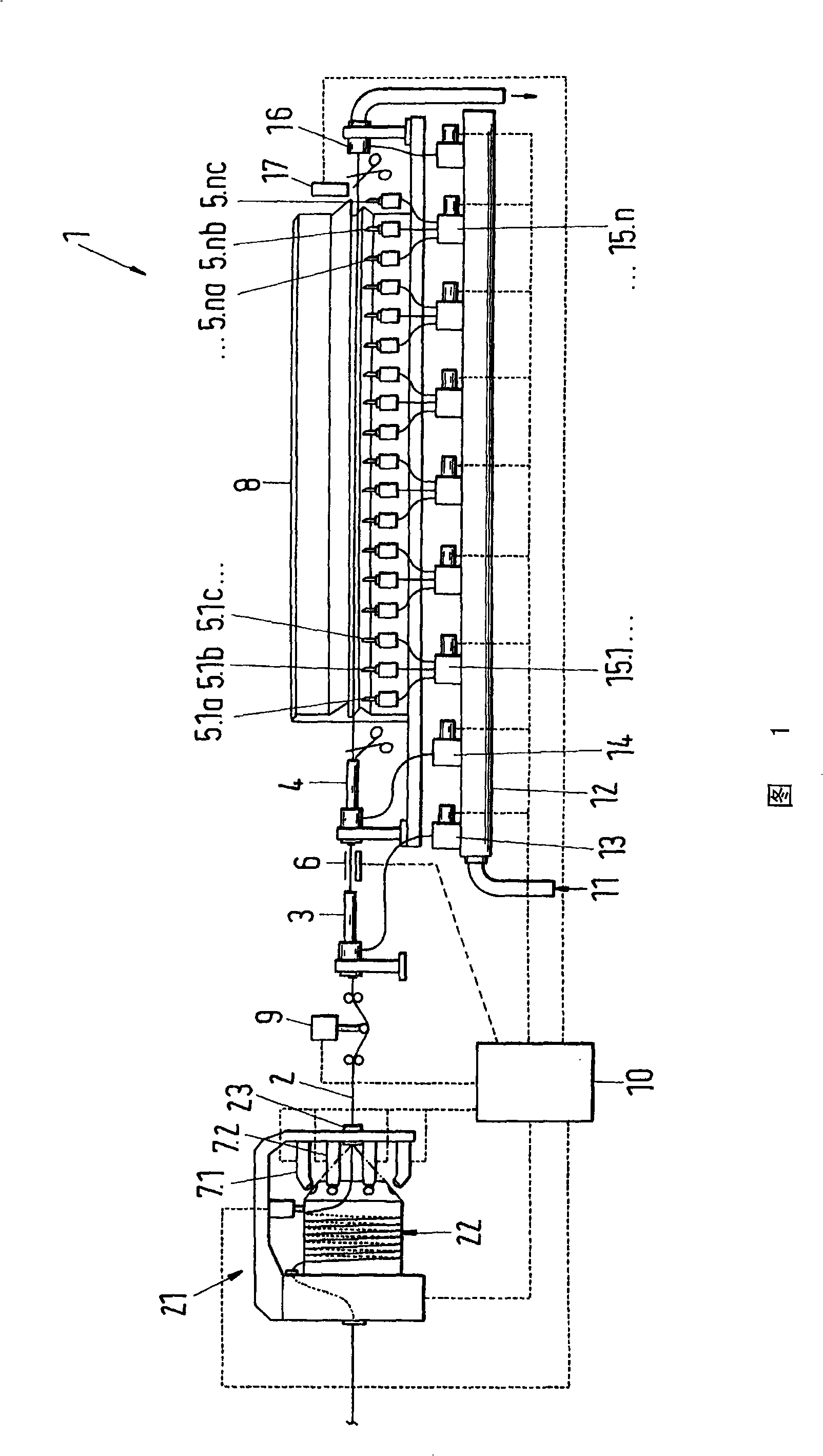

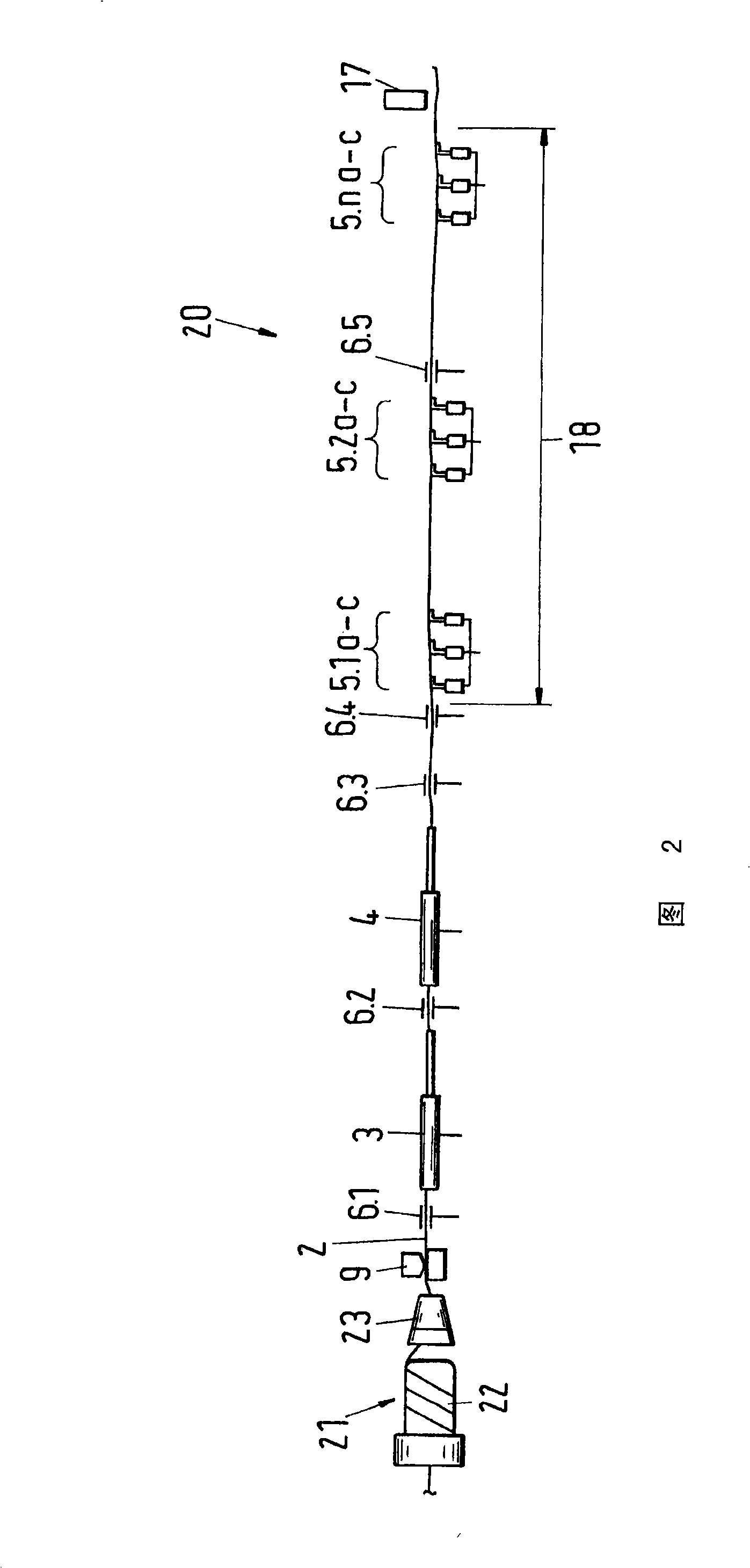

Method and device for inserting weft thread into a loom

A method for the insertion of a weft thread ( 2 ) into a shed of an air jet weaving machine ( 1 ) is presented in which the weft thread drawn from the thread store ( 21 ) is accelerated by means of an acceleration nozzle ( 3, 4 ) and supplied to the shed; the weft thread is transported further in the shed by means of a plurality of auxiliary nozzles ( 5.1 a-c to 5. n a-c); and measured values dependent on the speed of the weft thread and / or on the path traveled by the weft thread are measured in contact-free manner by means of one or more measurement pickups ( 7.1, 7.2, 17 ). In the method at least one of the measurement pickups is formed for multiple measurement within the weft insertion and is arranged at or after a first acceleration nozzle ( 3 ). Furthermore, measured values are measured in contact-free manner a plurality of times during the weft insertion by means of the at least one measurement pickup ( 6, 6.1 - 6.5 ) from which values for the speed and / or the path traveled by the weft thread are determined during the weft insertion; and the values determined during the weft insertion are used for the control of the weft insertion.

Owner:ITEMA (SWITZERLAND) LTD

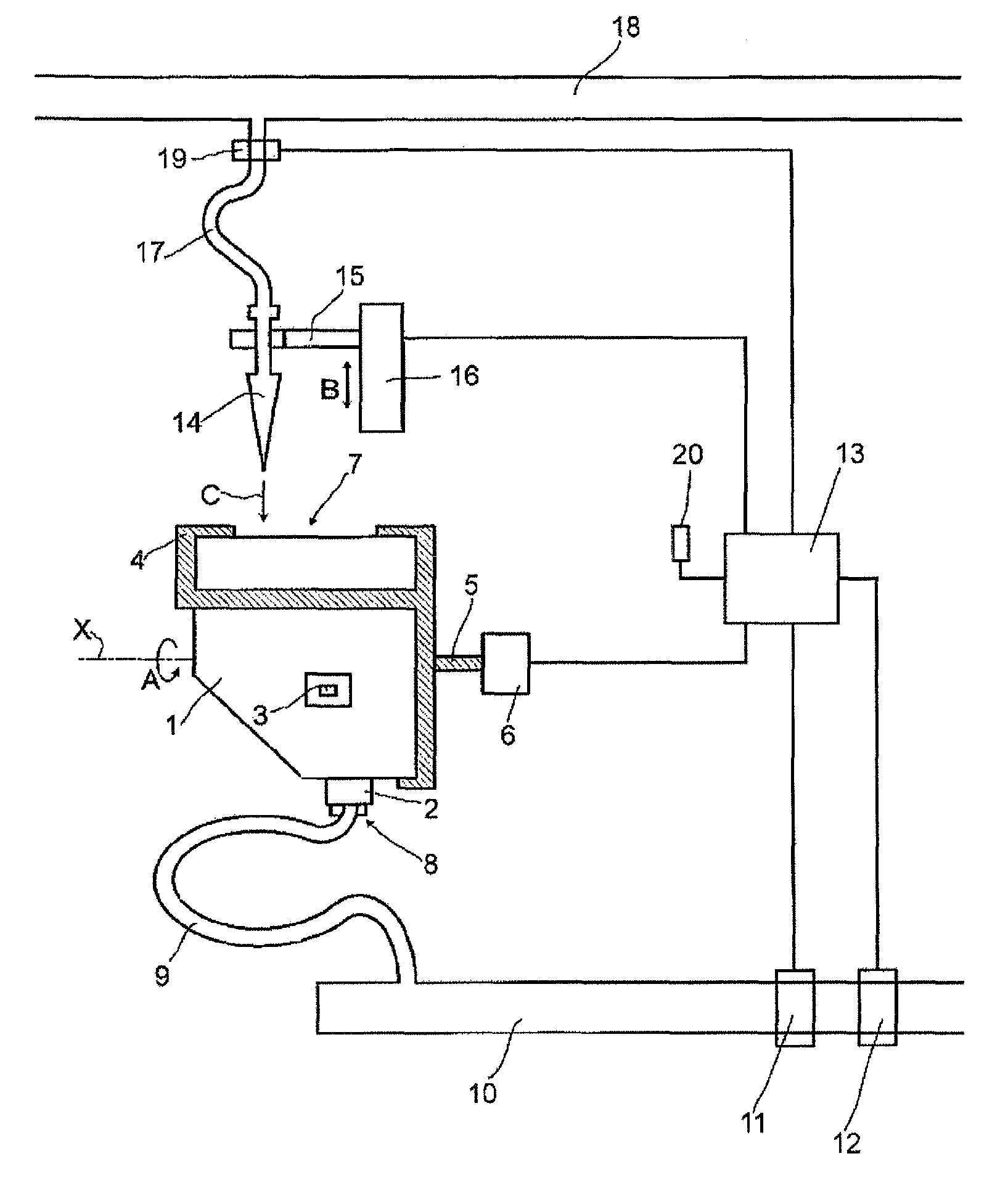

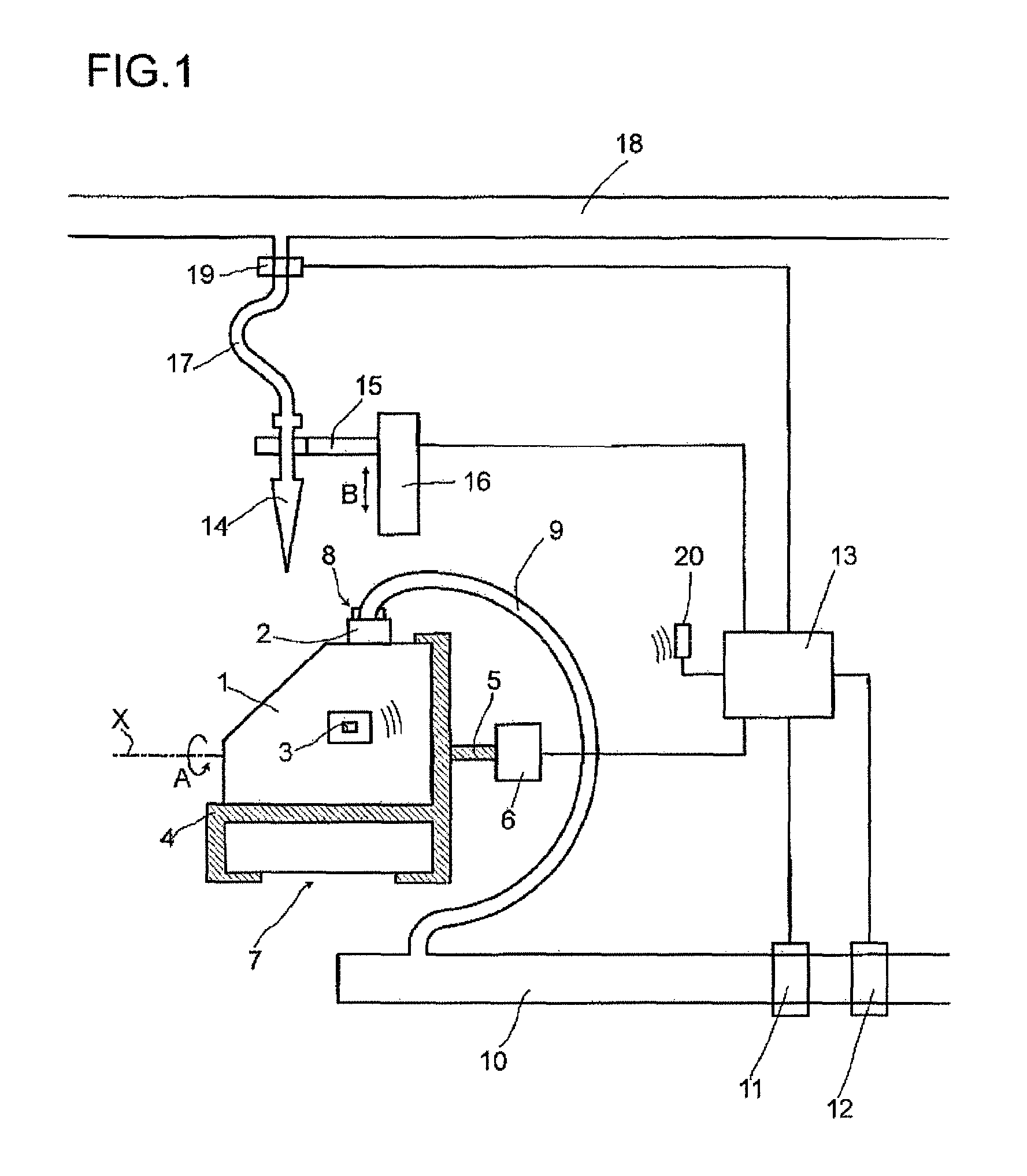

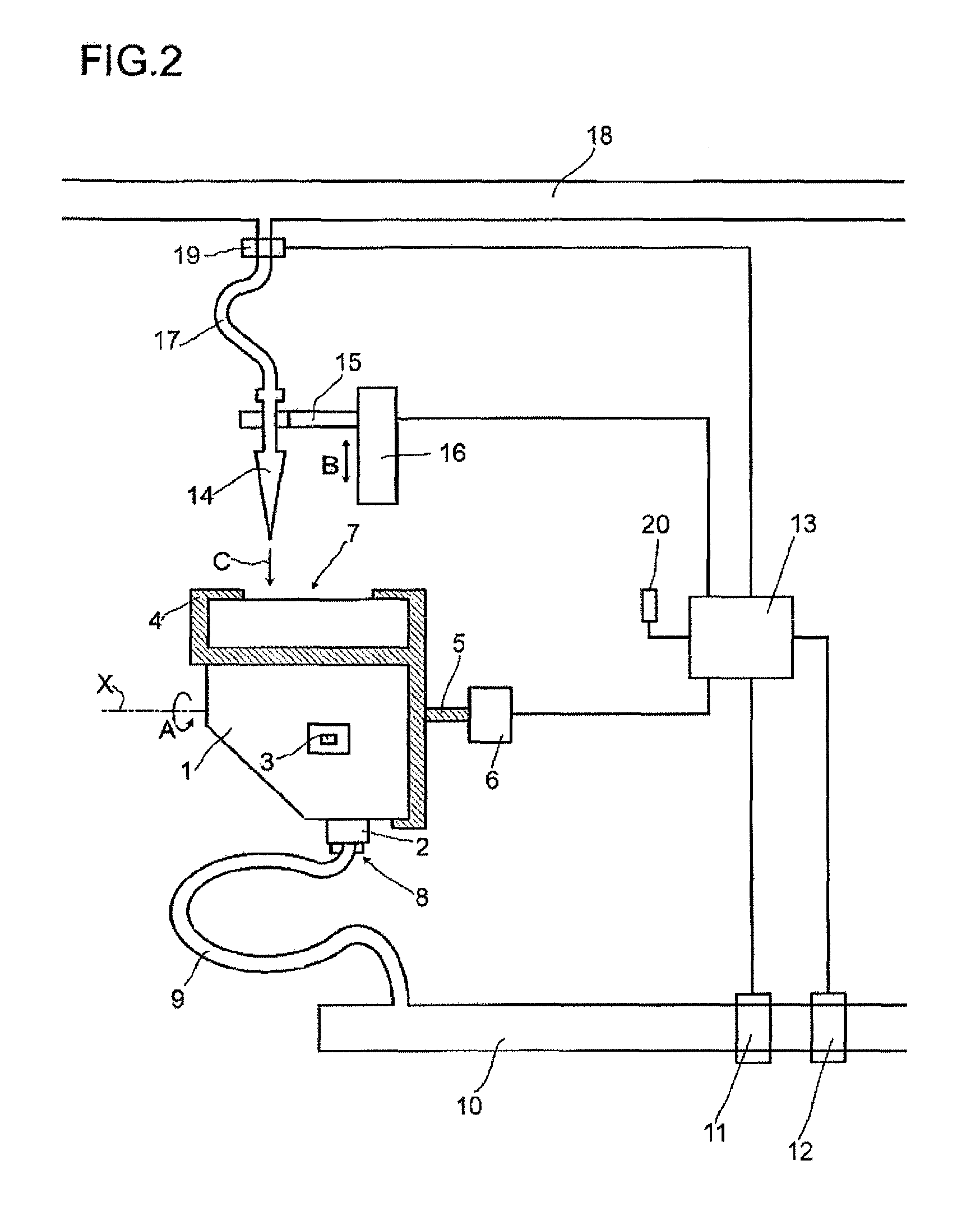

System for preparing and making available a flowable medium formed by mixing a dry substance with a fluid

InactiveCN101394824AOperational securityNo risk of injuryFlow mixersPharmaceutical containersEngineeringFluid system

Owner:贝恩德·汉森

Coiled membrane deviation correcting device

InactiveCN103303723AImprove coiling qualitySatisfy the use of coilingWebs handlingEngineeringMechanical engineering

The invention relates to a coiled membrane deviation correcting device which comprises a coiling roller mounted on a rack and used for coiling a coiled membrane, wherein a width position detection head is arranged on the rack corresponding to the side of the coiled membrane in an adjustable fixing state; an adjusting cylinder and two sliding adjusting bases are all mounted on the rack; two ends of the coiling roller are respectively connected with the two sliding adjusting bases; any one end or two ends of the coiling roller are connected with the adjusting cylinder to be in the state that the coiling roller is driven by the adjusting cylinder to slide in the axial direction; and the width position detecting head is connected with the adjusting cylinder. A deviation signal is detected by employing the width position detecting head, the coiling roller is driven by the sliding adjusting base to move in the axial direction so as to realize the deviation correction operation of the membrane, the coiled membrane deviation correcting device is simple in structure, stable in membrane conveying, free of hidden damage danger and capable of effectively correcting the deviation correction problem in the membrane conveying process and improving the coiling quality.

Owner:泰兴联创绝缘材料有限公司

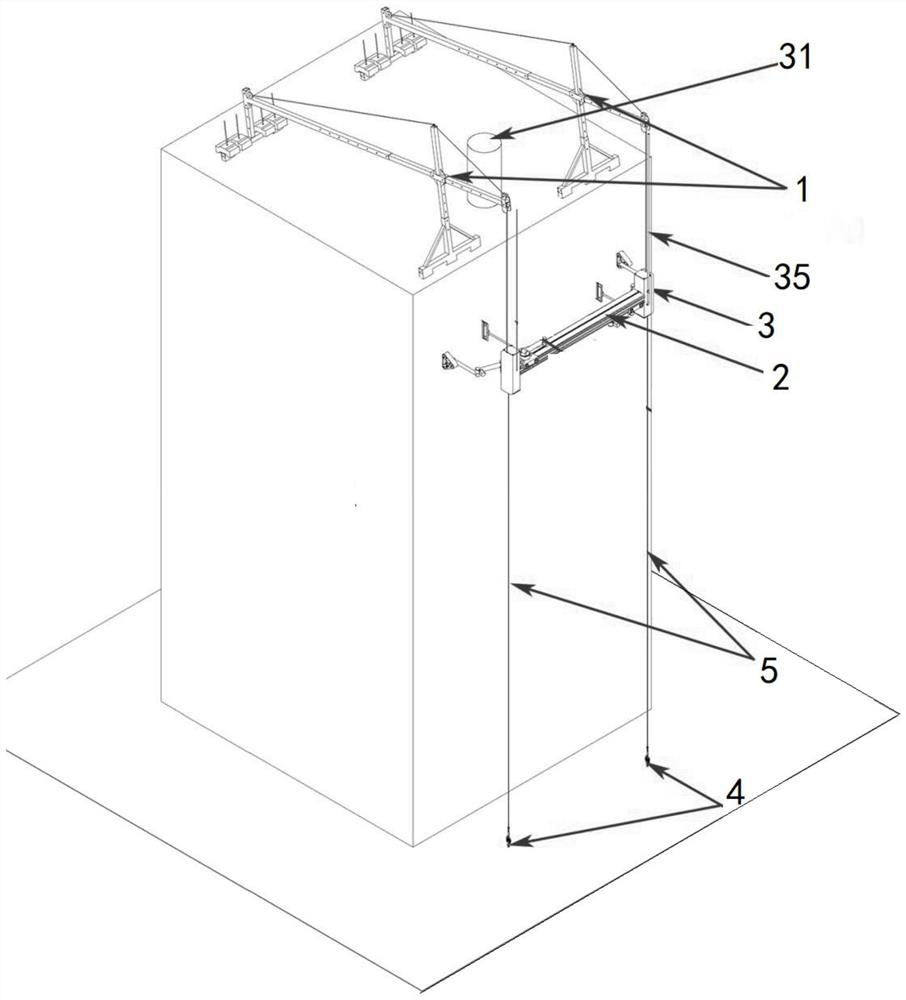

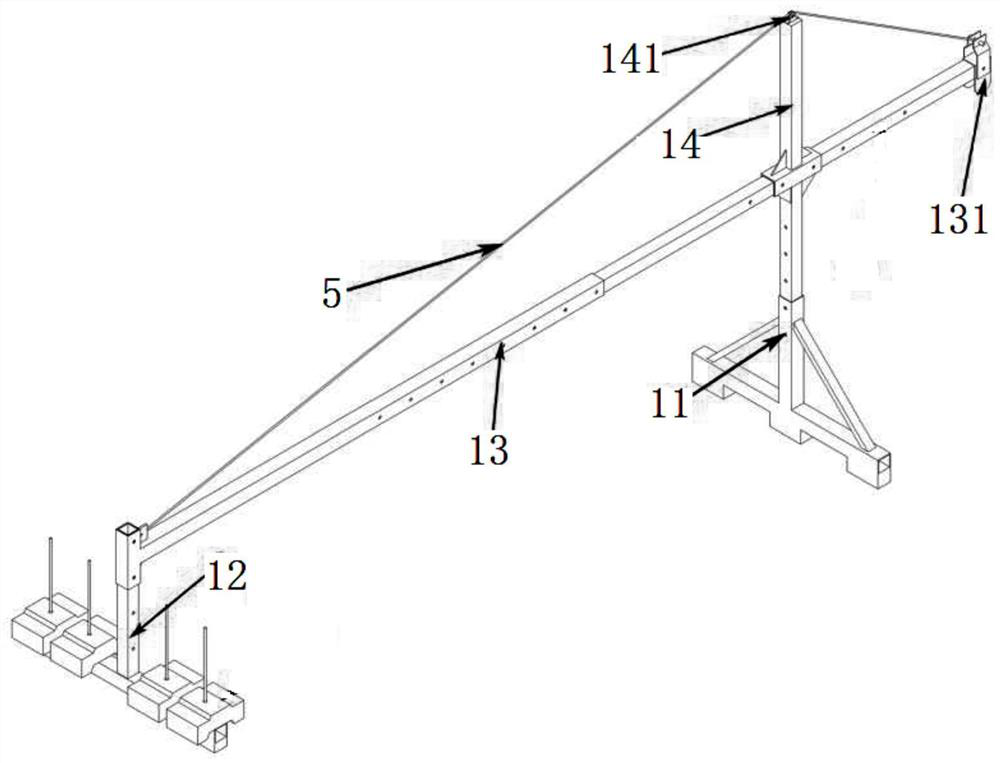

High-rise spraying robot

PendingCN112832490ARealize automatic sprayingNo risk of injuryBuilding constructionsAutomatic controlControl system

The embodiment of the invention discloses a high-rise spraying robot. The high-rise spraying robot comprises a hanging basket support, a driving device, a spraying device, a tensioning device and a control system. The hanging basket support is arranged on a roof, and a rope which is arranged on the outer side of an outer wall from the roof is fixed to the hanging basket support. The driving device comprises a cross beam, a rope climbing device and a moving platform; the spraying device comprises a material pump, a spraying head and a scraping plate, a spraying gap exists between the spraying head and the outer wall, the spraying head is installed on the moving platform through a first mechanical arm, and the scraping plate is arranged above the spraying head and installed on the first mechanical arm, so that the scraping plate makes contact with the outer wall; and the tensioning device is fixed to the ground and connected with the bottom end of the rope. On the basis of automatic control of the control system, the first mechanical arm drives the spraying head to move and spray under the action of the moving platform, putty is scraped to be flat through the scraping plate, so that automatic spraying of the outer wall of the high-rise building is achieved, workers do not need to work high above the ground, and no danger is ensured.

Owner:邯郸市永年区华翼机械科技有限公司

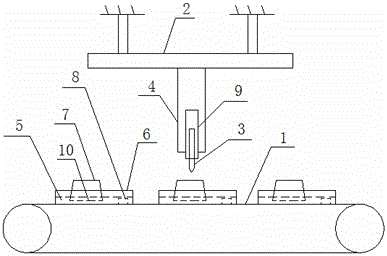

Duck web deboning and cutting device

ActiveCN106387006ASimple and reasonable structureIncrease productivityPoultry processingBones partsEngineering

The invention discloses a duck web deboning and cutting device. The device comprises a conveying belt, a hanging bracket and a cutter, wherein the hanging bracket is arranged above the conveying belt; a tool rest is mounted on the hanging bracket; the cutter is mounted on the tool rest; multiple duck web storage boxes are fixedly mounted on the conveying belt; web supporting bosses and clamps are sequentially fixed in the duck web storage boxes; the clamps are fixedly mounted at bottoms of the duck web storage boxes; the web supporting bosses are higher than the side walls of the duck web storage boxes; the distance between a tool nose of the cutter and each web supporting boss is 50-150 mm. The duck web deboning and cutting device is simple and reasonable in structure, duck web centers are placed on the web supporting bosses, the web supporting bosses are glidingly adjusted and fixed on the corresponding duck web storage boxes, leg bone parts of the duck webs are fixed in the corresponding clamps, the conveying belt drives the duck web storage boxes and the web supporting bosses to move, the duck webs move along with movement of the duck web storage boxes and the web supporting bosses, the tool nose of the cutter cuts off three toe backs of each duck web, manual cutting is replaced with mechanical cutting, so that time and labor are saved, the production efficiency is high, the operation is simple and safe, and the risk of injury is avoided.

Owner:蚌埠禹辰科技有限公司

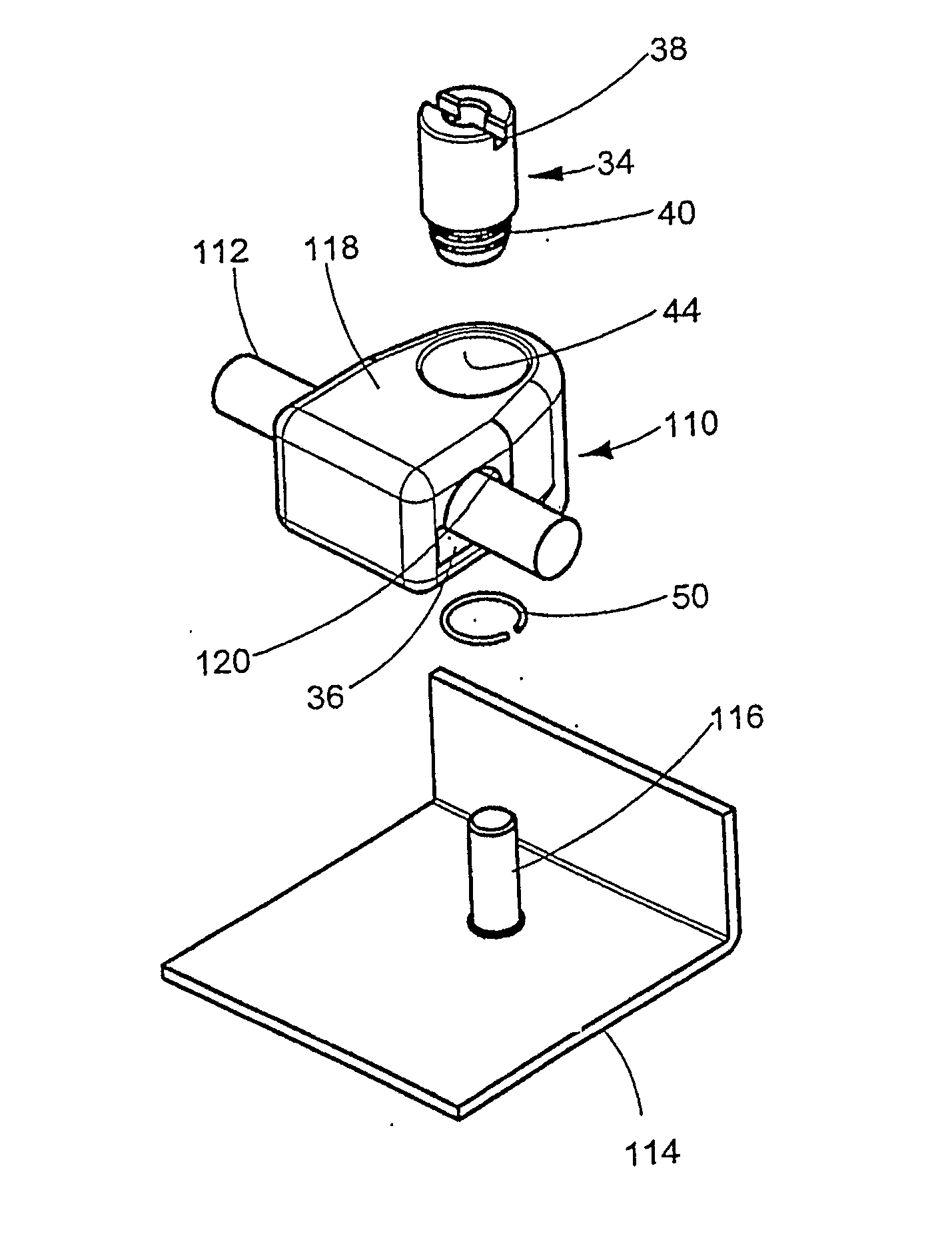

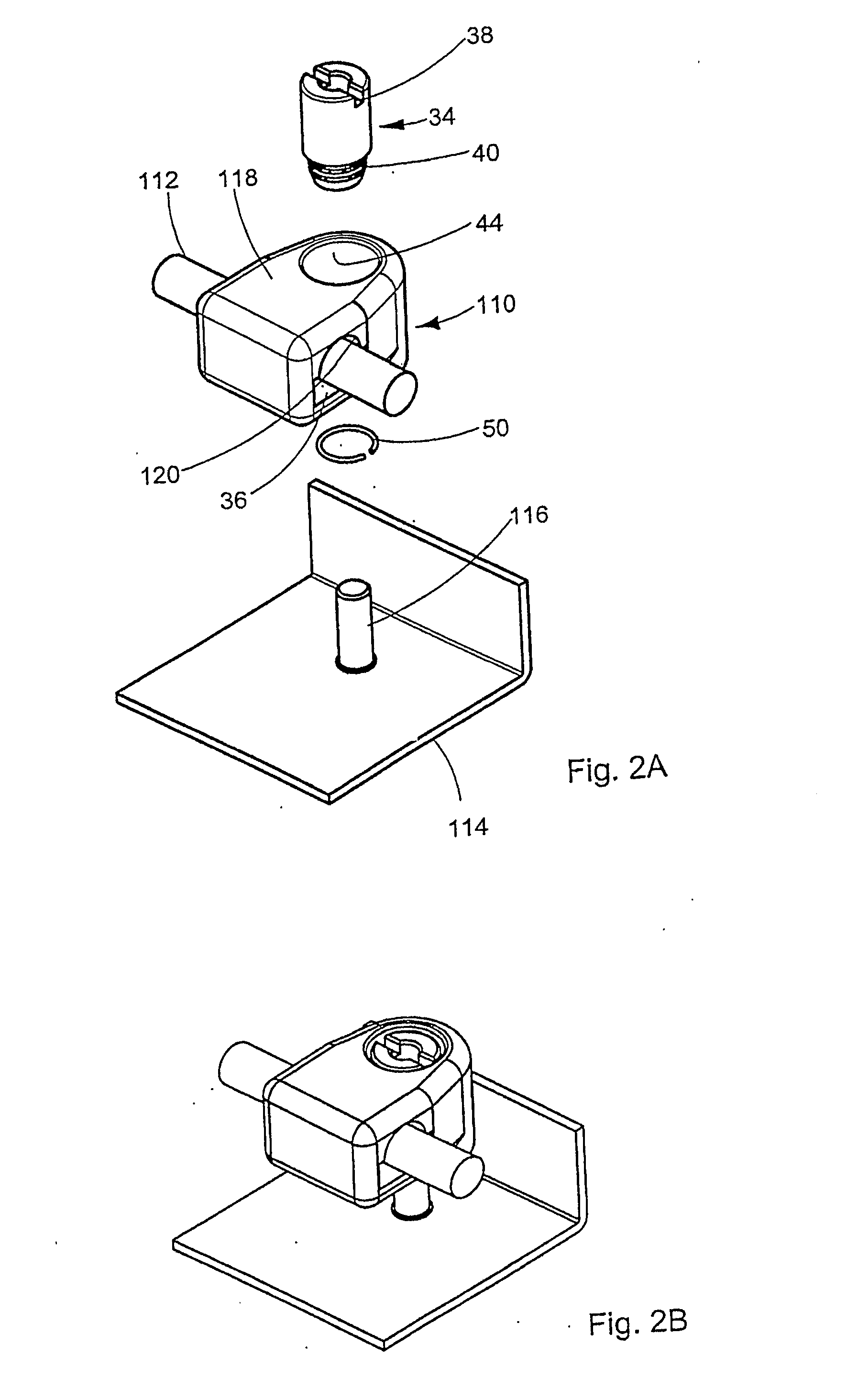

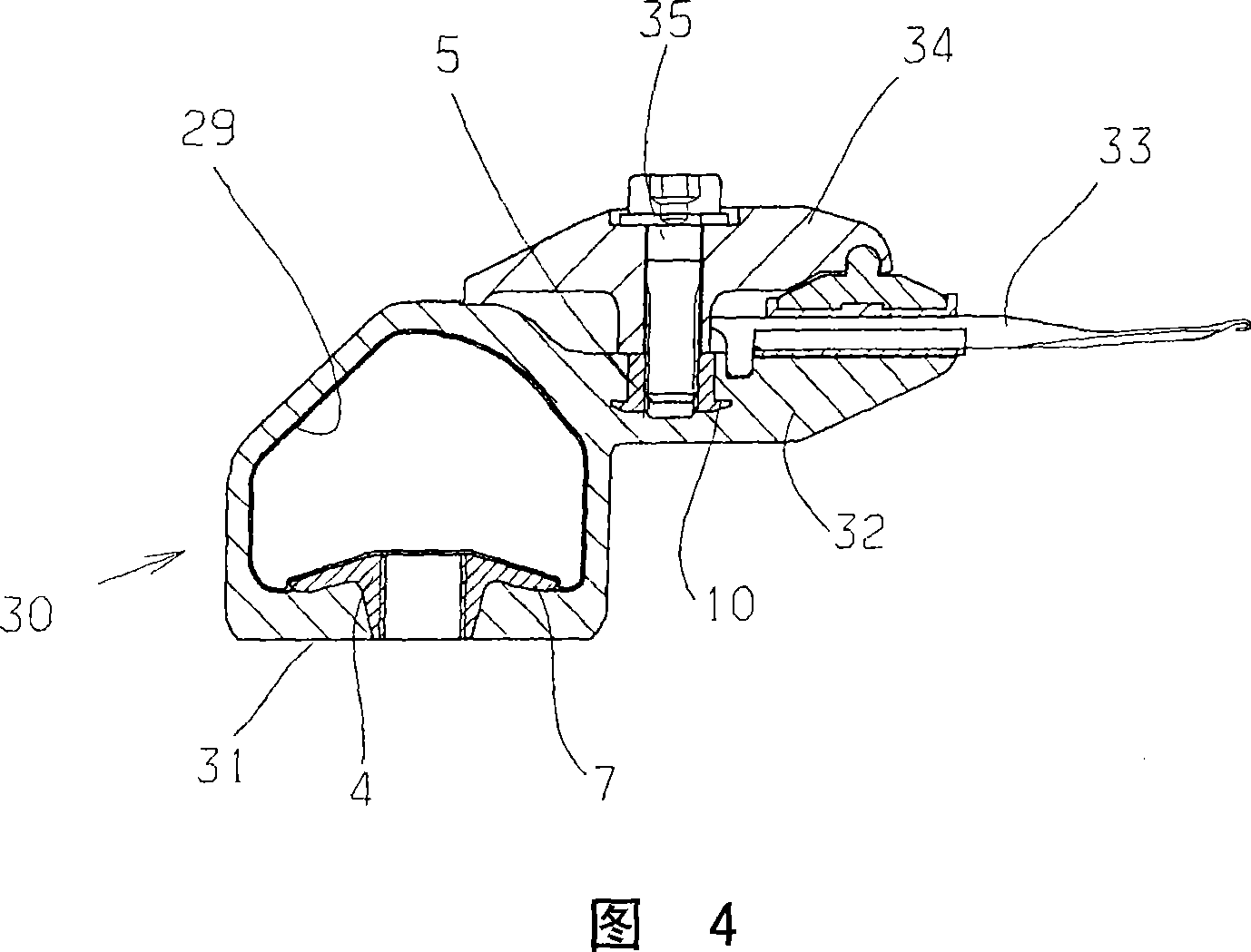

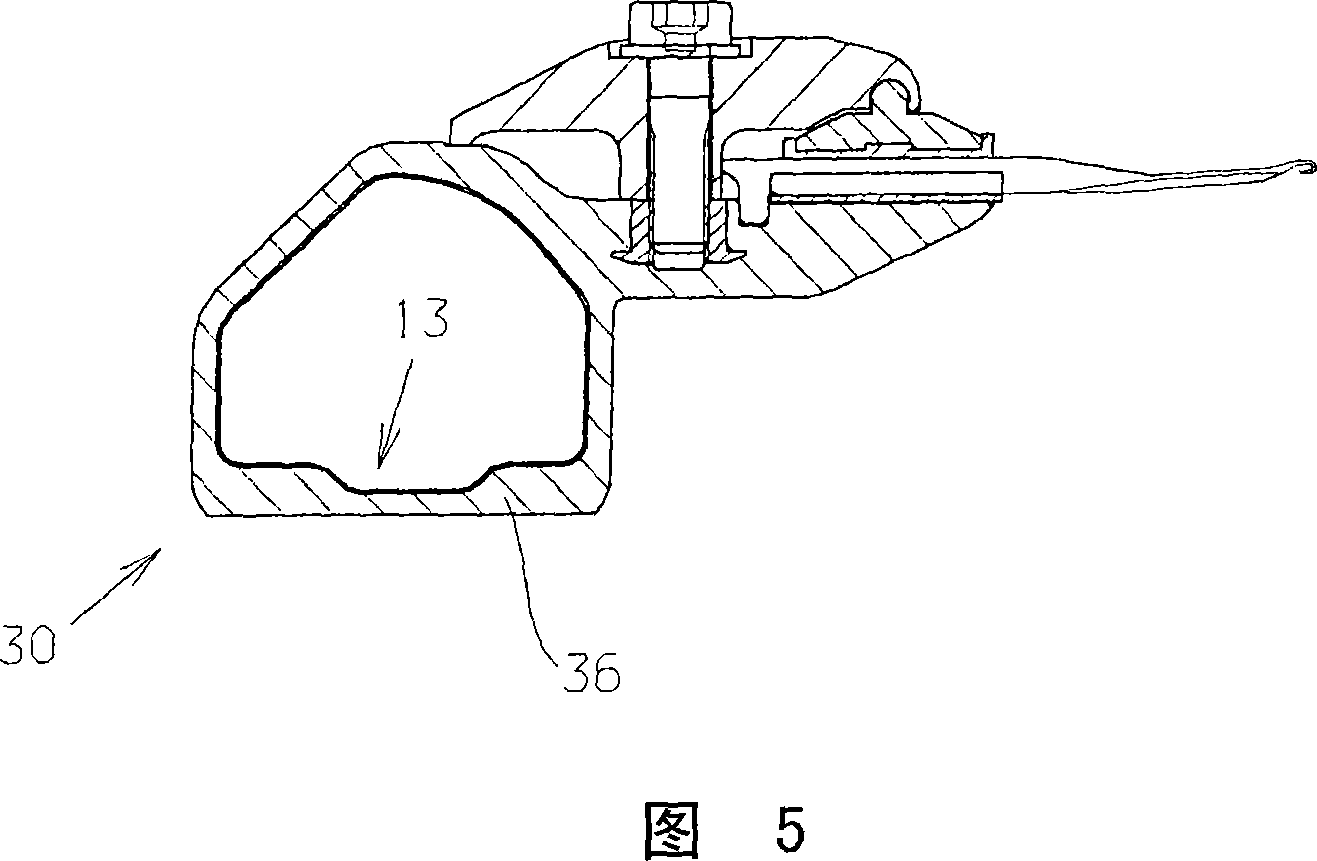

Adjustable Bar Guide

ActiveUS20100201136A1Improve the level ofNovel configurationBuilding locksWing fastenersEngineeringScrew thread

A bar guide for guiding locking bars on sheet metal cabinet doors, or the like, comprises a carrier which can be secured, e.g., spot welded, to the inside surface of the door leaf and a guide element which can be mounted on the carrier and which has a guide surface whose distance from the inside surface of the door leaf is adjustable. According to the invention, the carrier which is spot welded to the door leaf is a pin with a circumferential thread, and an adjusting screw or adjusting nut can be screwed, or is screwed, on this pin. The guide element is a housing which encloses the adjusting screw and which has a guide channel forming the guide surface for the locking bar.

Owner:DIRAK DIETER RAMSAUER KONSTRUKTIONSELEMENTE GMBH & CO KG

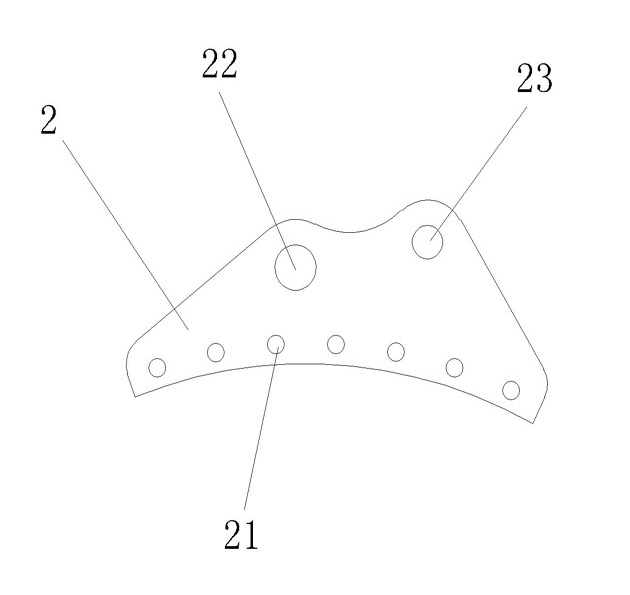

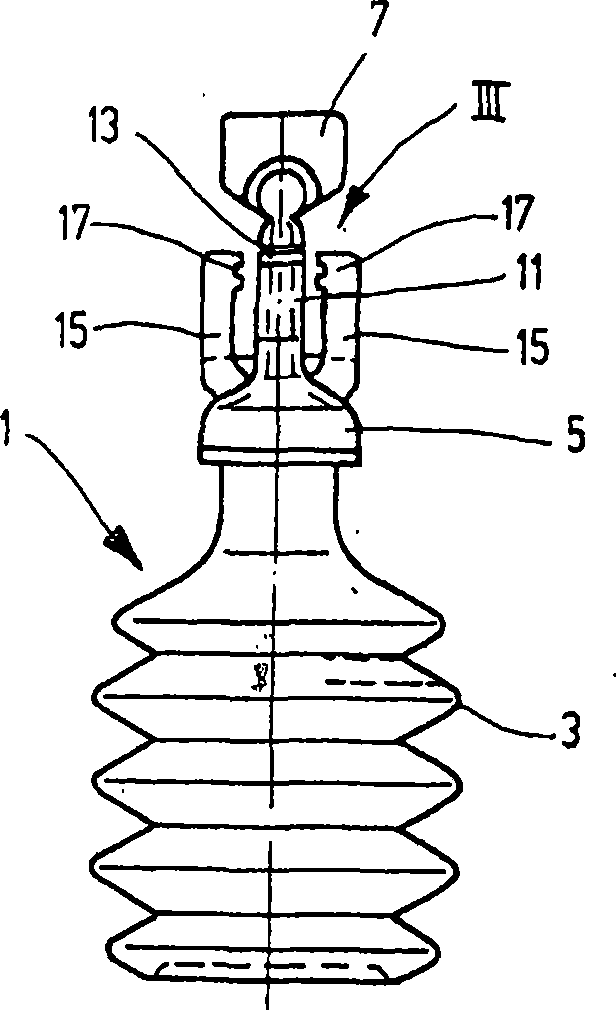

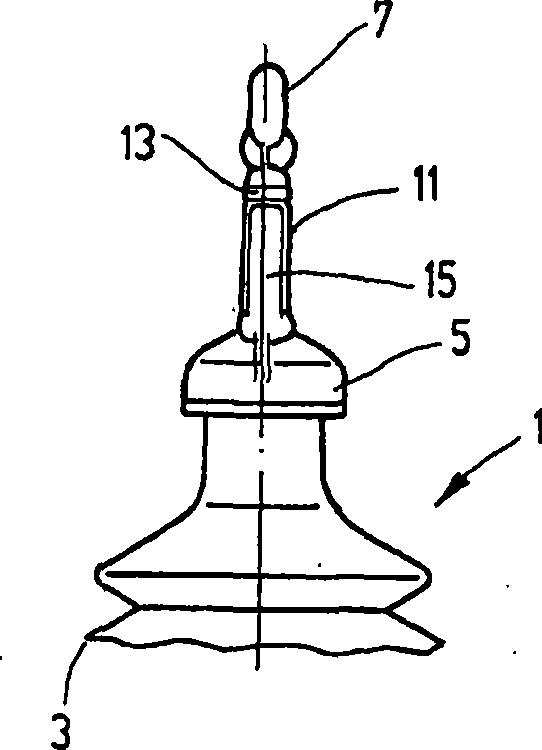

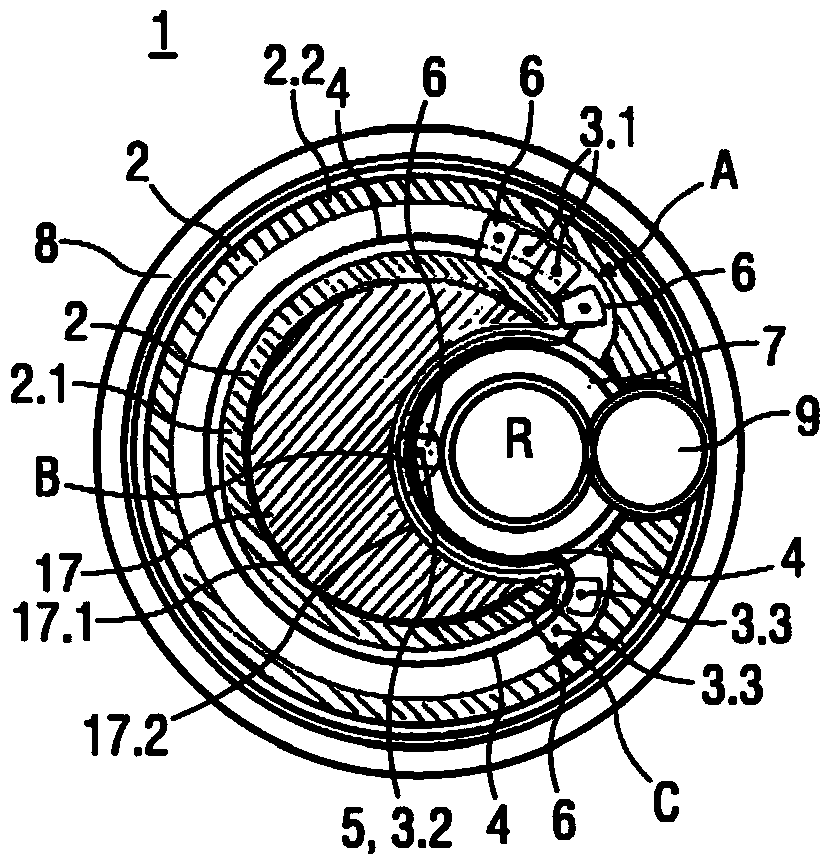

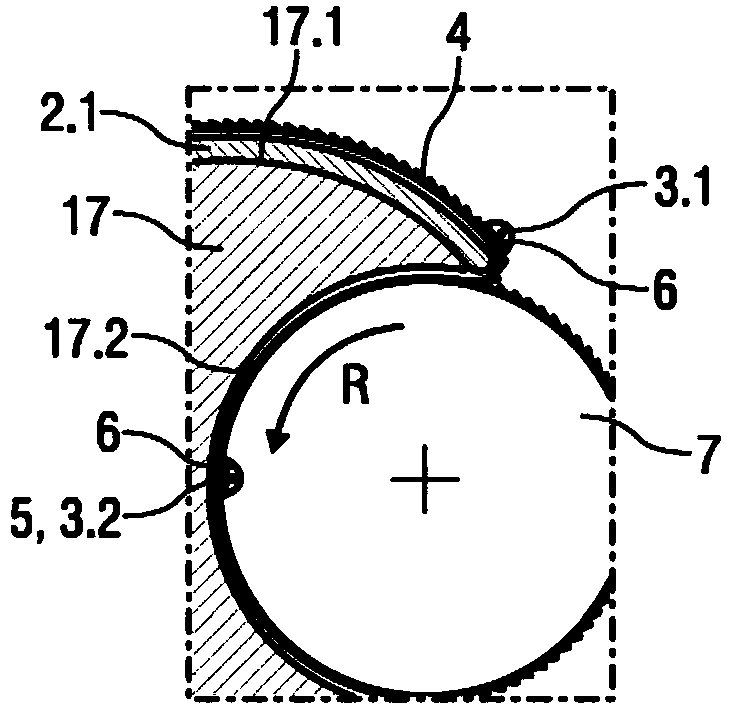

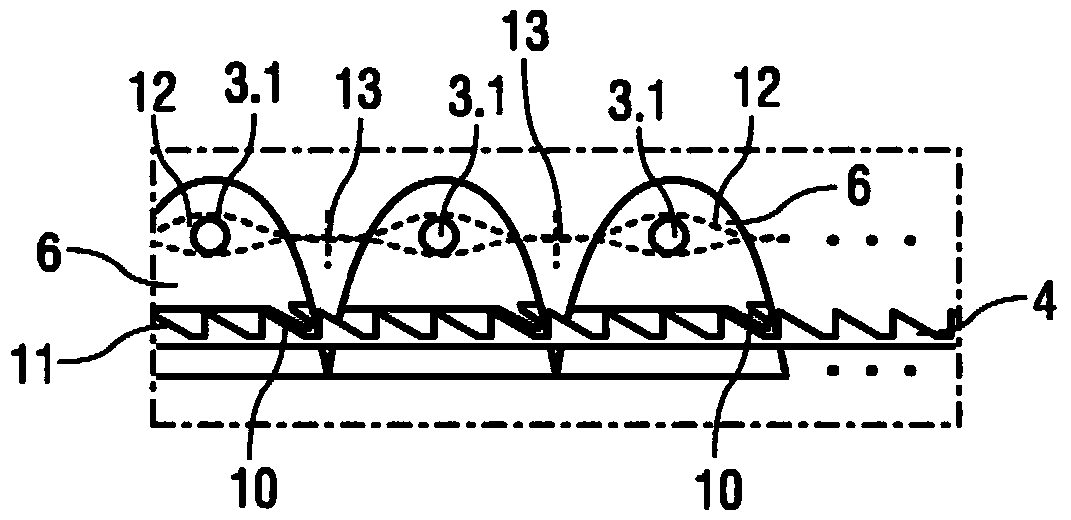

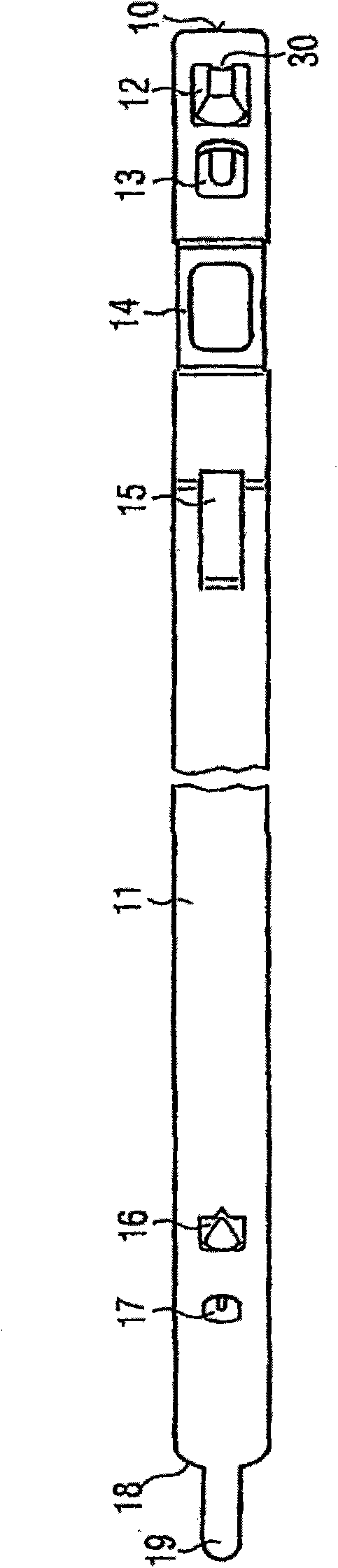

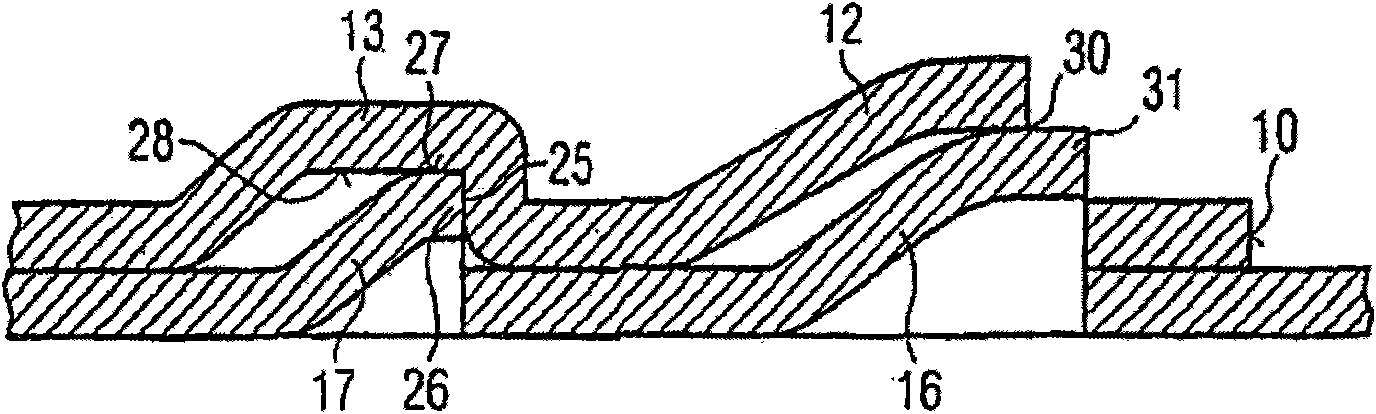

Needle storage magazine

InactiveCN104114207ASafe and convenient transportationImprove securityInfusion needlesCarriageSyringe needle

The invention relates to a needle storage magazine (1) for storing a number of injection needles (3.1, 3.2, 3.3) and attaching and / or detaching them to or from an injection device (14), the needle storage magazine (1) comprising a crescent shaped track having a convex part and a concave part, wherein the track is adapted to hold a set of needles (3.1, 3.2, 3.3) in respective needle supports (6) within the track, wherein the convex part is adapted to hold unused needles (3.1) and used needles (3.3), wherein a centre position (B) is defined within the concave part for a needle (3.2) in use or to be used, wherein a sliding carriage (17) is arranged for attaching the injection device (14) to the needle storage magazine (1) such that the centre position (B) is essentially concentric to a longitudinal axis (5) of the injection device (14), wherein a separation wheel (7) is rotatably arranged, the separation wheel (7) having at least one notch (15) for entraining the needle support (6) of one unused needle (3.1) at a time from the convex part into the centre position (B) or the needle support (6) of the needle (3.2) in use out of the centre position (B) onto the convex part.

Owner:SANOFI AVENTIS DEUT GMBH

Vermiculite mesh gel foam mud fire prevention and extinguishing agent

The invention discloses a vermiculite mesh gel foam mud fire prevention and extinguishing agent. The key point of the technical scheme adopted by the invention lies in that the vermiculite mesh gel foam mud fire prevention and extinguishing agent is composed of a vermiculite composite flame retardant foaming agent, attapulgite pottery clay powder with an air purifying function, inorganic fiber spray coating cotton, expanded vermiculite powder, coal gangue powder, sodium alginate and water. The ingredients of the vermiculite mesh gel foam mud fire prevention and extinguishing agent are input into a rake type mixing machine to undergo high-speed stirring, thus obtaining the vermiculite mesh gel foam mud fire prevention and extinguishing agent. The mesh gel foam mud is sprayed to a burning coal layer by an inorganic fiber spray coating machine, thus facilitating generating an integral mesh gel foam mud film in a fire prevention and extinguishing process. The film can always cover and adhere to an ore bed surface to rapidly isolate the burning coal layer from air, prevent coal mine from keeping burning and avoid reburning of the coal layer, thus reaching the purposes of flame retardance and fire prevention and extinguishing. The vermiculite mesh gel foam mud fire prevention and extinguishing agent is suitable for fire prevention and extinguishing of coal mines, mine operation areas and forests.

Owner:嘉善创越知识产权服务有限公司

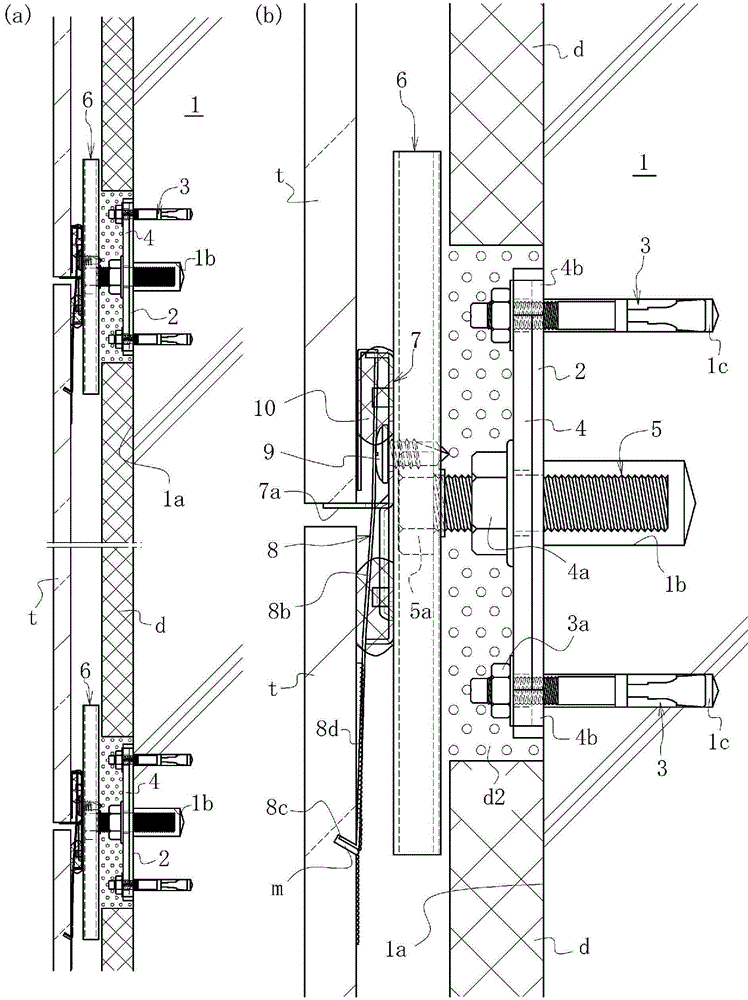

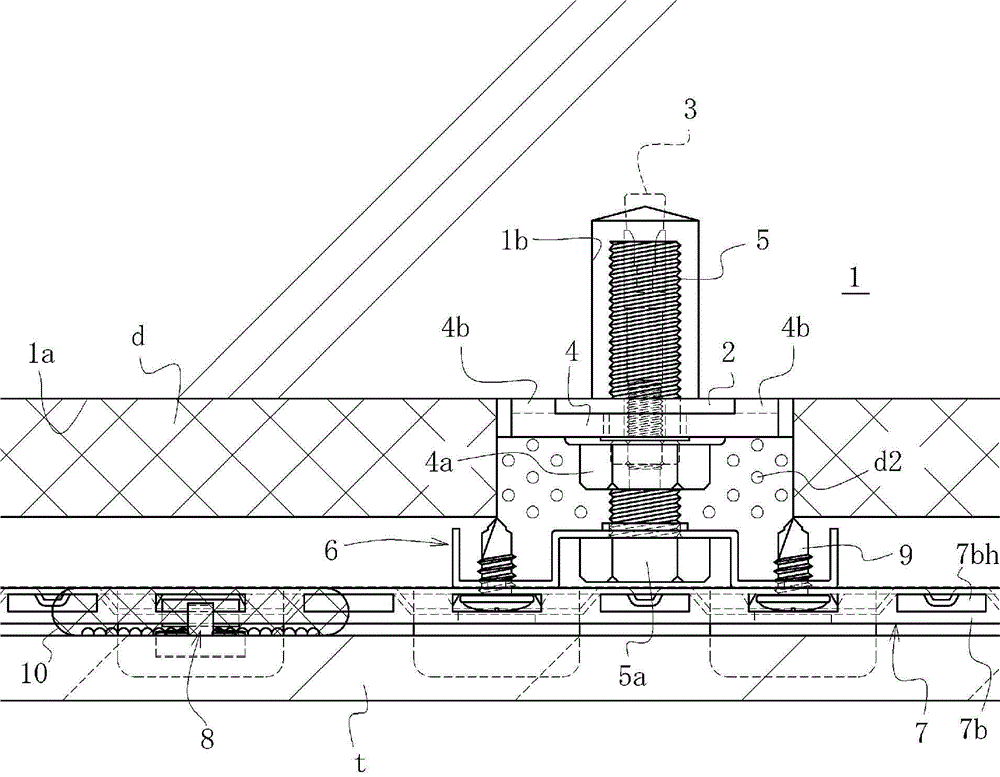

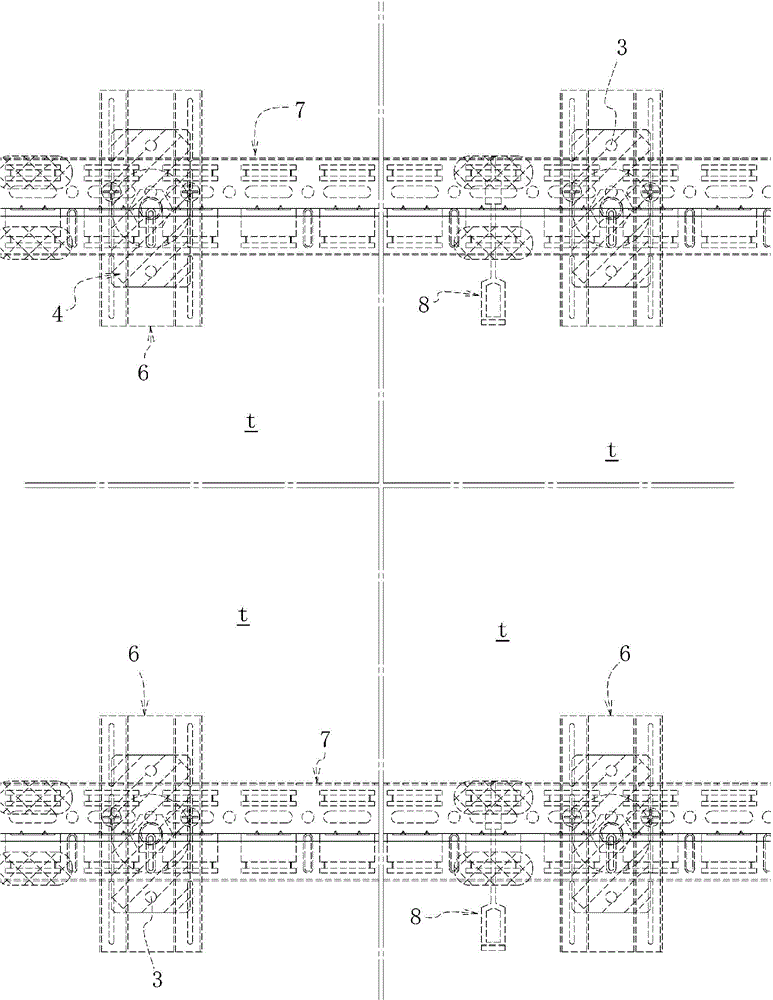

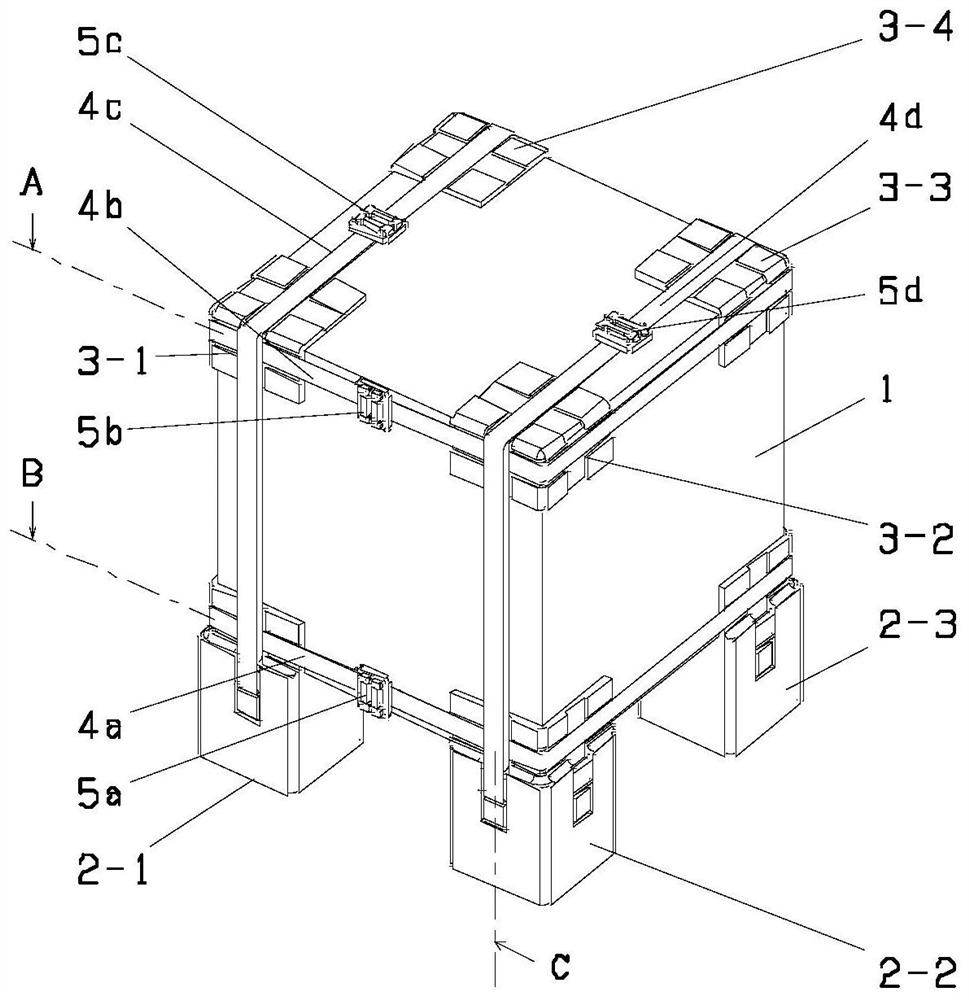

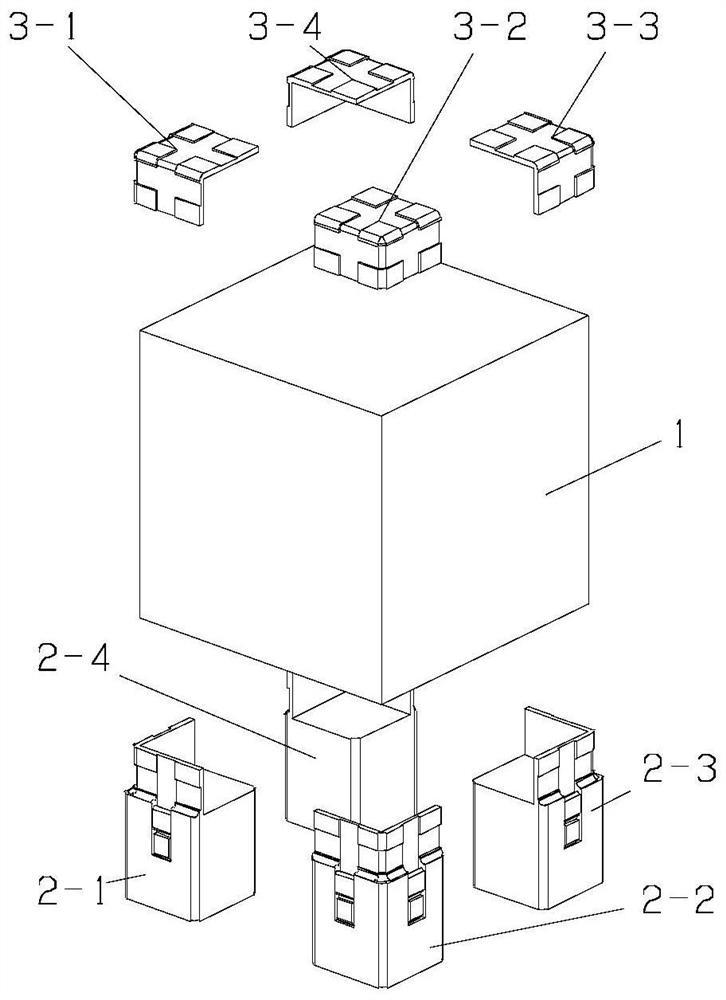

Exterior material mounting bracket for externally insulated building

ActiveCN105408560AAdjust unevennessNo risk of injuryCovering/liningsHeat proofingThermal bridgeArchitectural engineering

In order to attach exterior material to a building frame surface reliably while regulating unevenness so that the exterior material does not fall off even during a fire or the like while maintaining a narrow gap between the building frame surface of a RC constructed, externally insulated building and the exterior material mounted to the building frame surface and preventing occurrences of thermal bridges to the extent possible, an exterior material mounting bracket for externally insulated building comprises: a mounting plate member (4) that directly anchors an insulating member (2) to a wall face (1a) of a building frame (1) for a RC constructed building via an anchor bolt (3) and for which leg portions (4b) project in the four corners on the back side; an adjustment support bolt (5) that screws into a screw support portion (4a) of the mounting plate member (4) by passing through the front and back thereof and the end of which is then inserted, so as to freely advance or retreat, into an insertion space (1b) that is formed on the building frame (1) wall face (1a) that faces the back face of the mounting plate member (4); and a support member for the exterior material that is configured on the distal end of the adjustment support bolt (5).

Owner:HIRO

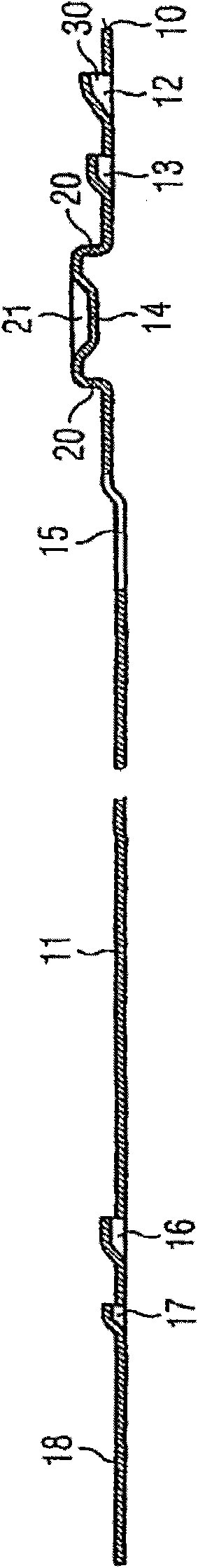

Hose clamps

ActiveCN102066821AHigh strengthNo risk of injuryFriction grip releasable fasteningsHose connectionsEngineeringUltimate tensile strength

The invention relates to a hose clamp, whereby the connection of the two ends of the band 10, 18 is made by a guide hook 16 disposed on the inner band region and engaging in a guide receptacle 12 on the outer end of the band, and a retaining hook 17 also provided on the inner band region and engaging in a retaining receptacle 13 on the outer band region. The mounting receptacle 13 is formed as an embossment formed from the band material and attached to the band material on all sides, the inner surface thereof transitioning perpendicular to the band surface into a support region 25 adjacent to the outer end of the band 10. The retaining hook 17 has a dog facing away from the inner end of the band 18, a cutting edge of said dog engaging in the support region 25 of the retaining receptacle 13 when the hose clamp is tightened. Because it is configured as one piece with the band material, the retaining receptacle 13 has much greater strength than conventional penetrations or cutouts in the band.

Owner:OETIKER SCHWEIZ AG

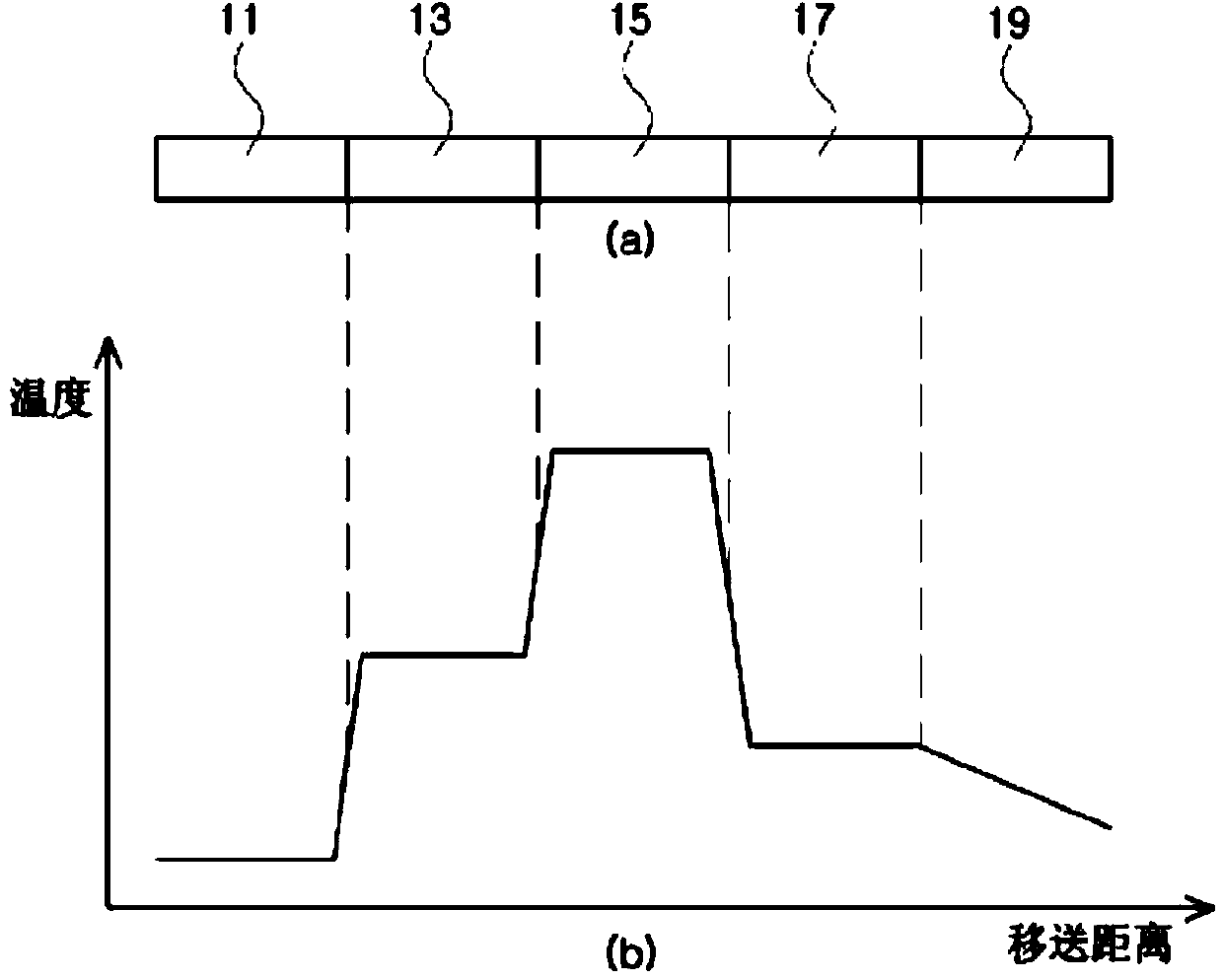

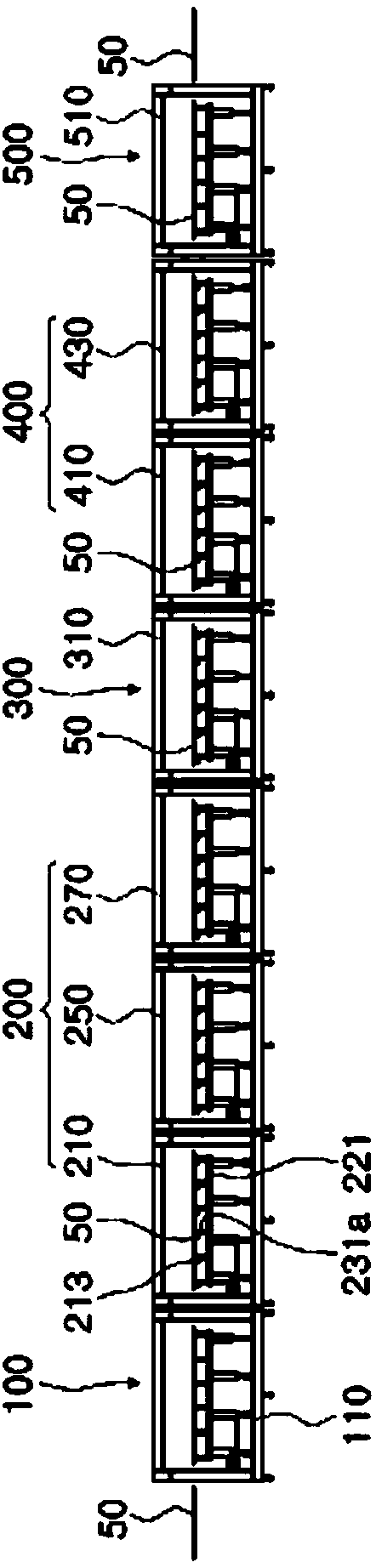

In-line heat treatment device

InactiveCN103503123ANo risk of injuryImprove productivitySemiconductor/solid-state device manufacturingProduction rateThermal shock

Disclosed is an in-line heat treatment device. The in-line heat treatment device according to the present invention has a plurality of heaters which are respectively installed in a plurality of furnaces, wherein each of the plurality of the heaters is controlled independently. Thus, since the temperature of each furnace and the temperature difference between mutually neighboring furnaces linearly change by forming a slow grade along the transferring direction of a substrate, there are no concerns regarding damage which may be caused by thermal shocks or thermal stress. Furthermore, the in-line heat treatment device according to the present invention enables the substrate to be lifted up when being transferred such that there is no friction between the substrate and components for transferring the substrate. Thus, since the generation of particles caused by the friction is prevented, there is no damage to the substrate due to the particles. In addition, the in-line treatment device according to the present invention prevents the components for transferring the substrate from being worn out by friction, thereby precisely transferring the substrate. Therefore, there are no errors during a heat treatment process for the substrate. Consequently, according to the present invention, productivity and reliability of the heat treatment process for the substrate are improved.

Owner:TERASEMICON CO LTD

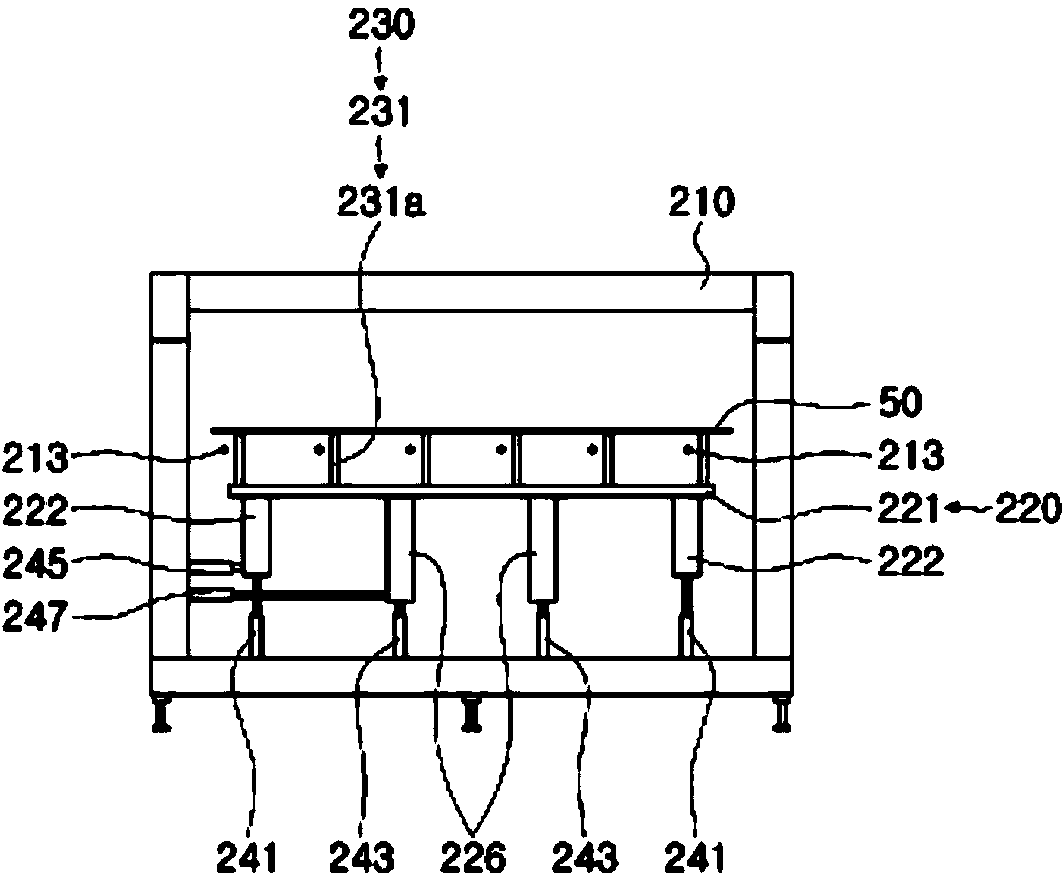

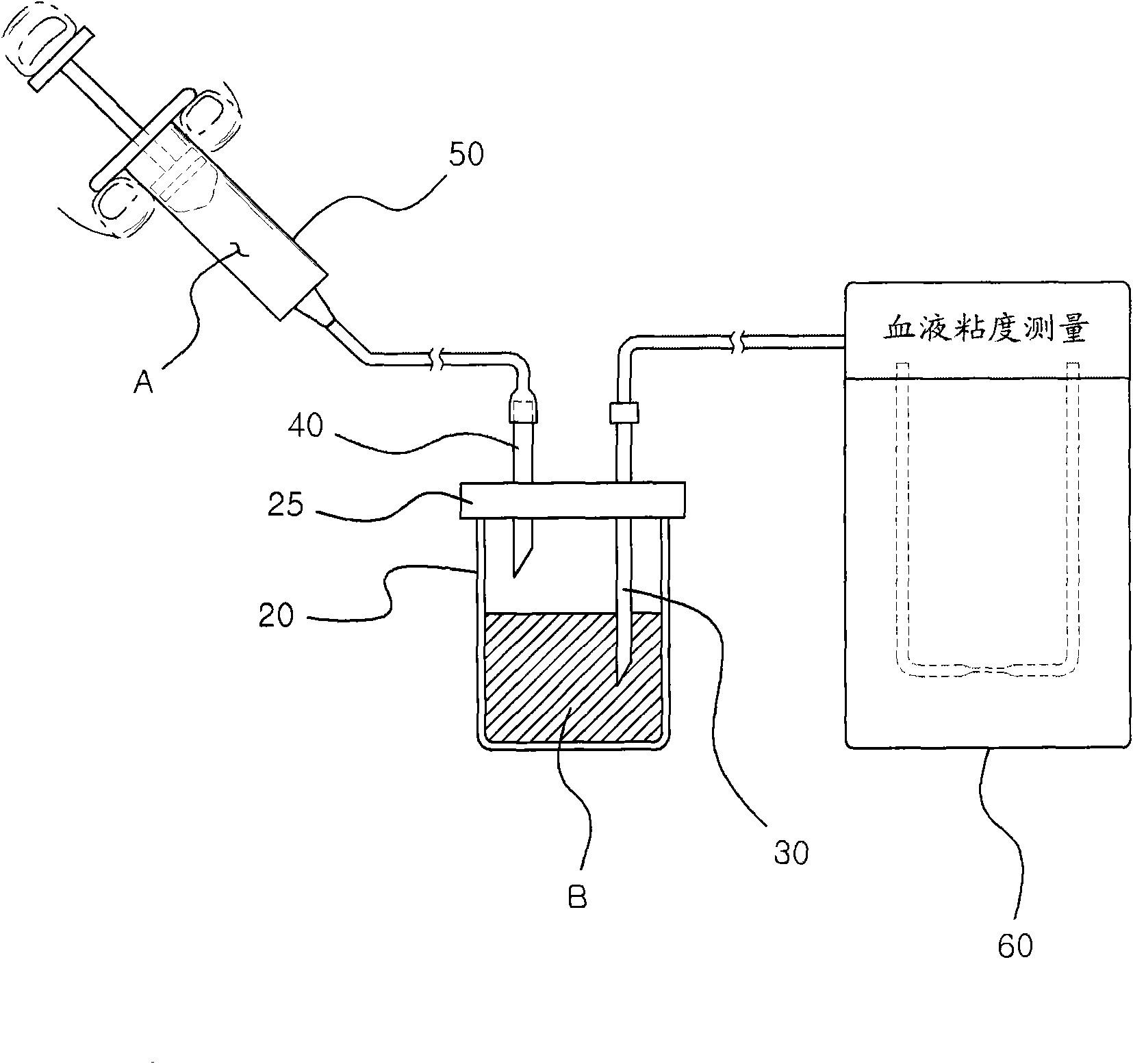

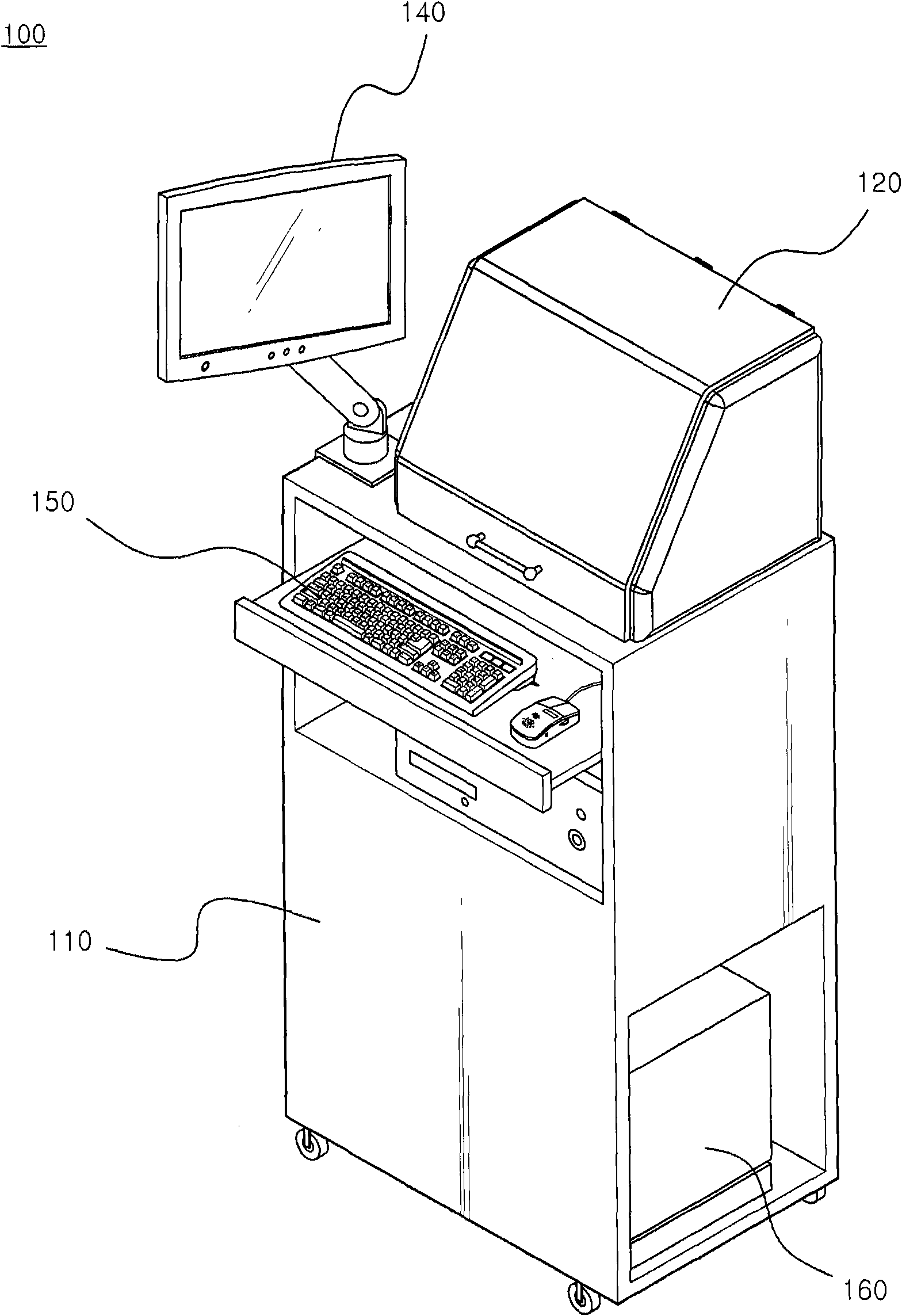

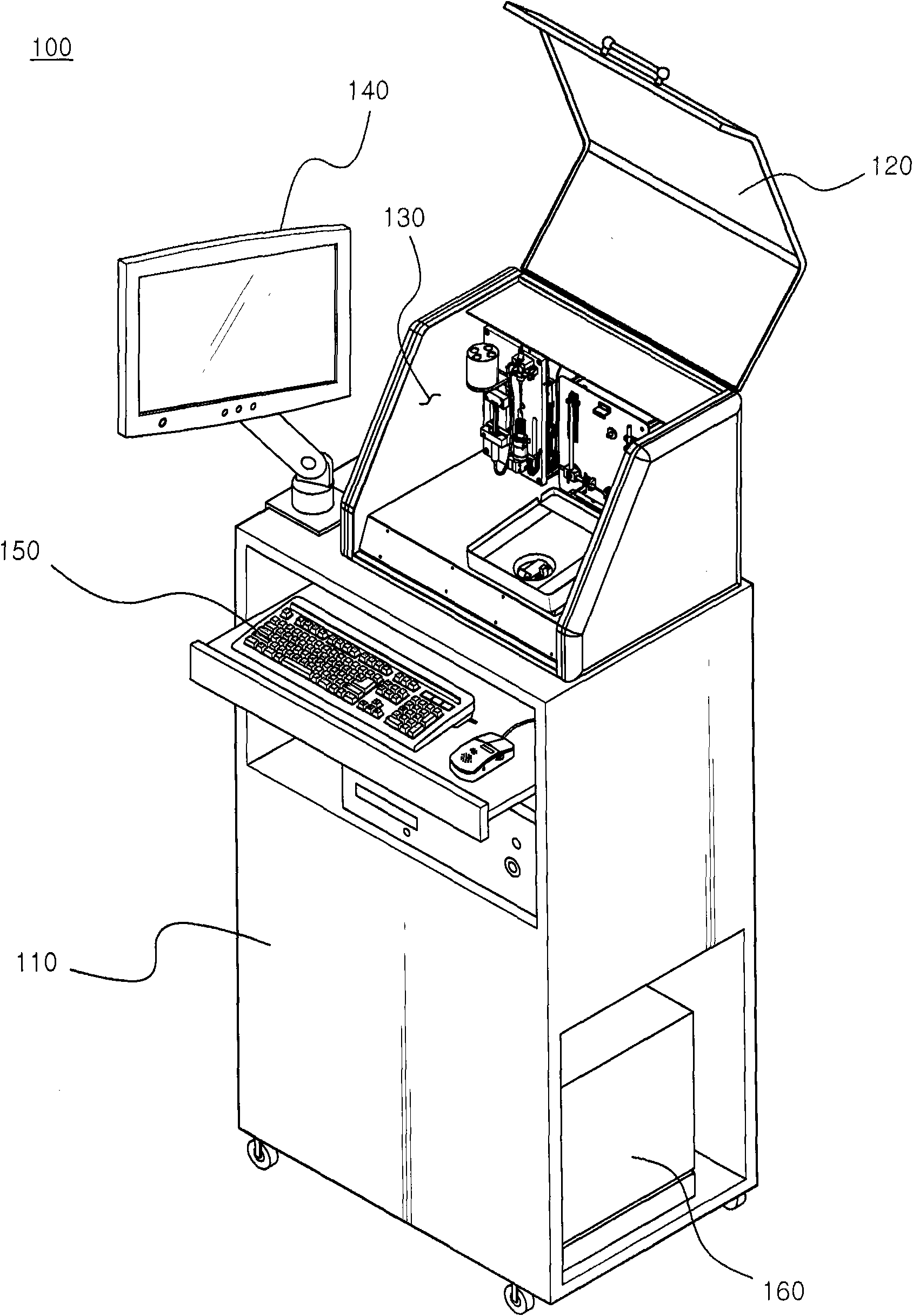

Device for automatically measuring viscosity of liquid

InactiveCN102062717ANo risk of injuryReduce errorsBiological testingDirect flow property measurementBiomedical engineeringViscosity measurement

A device for automatically taking out a sample liquid contained in a reservoir and measuring the viscosity of the liquid is described herein. The device includes a base body and a transferring part provided on the stage of the base body for taking the sample liquid out of the reservoir and supplying the sample liquid to a viscosity measuring part. The viscosity measuring part is provided on the stage for measuring the viscosity of the sample liquid supplied from the transferring part. The device also includes a control part for controlling operations of the transferring part and the viscosity measuring part. Additionally, the device includes a display part for displaying the results measured by the viscosity measuring part.

Owner:BIO VISCO

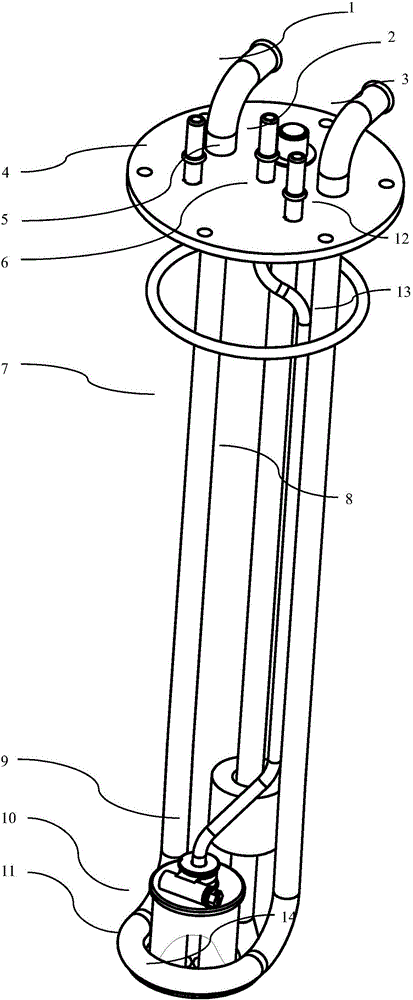

Urea liquid supply module used for high-pressure vehicles and integrating liquid level sensor

The invention discloses a urea liquid supply module used for high-pressure vehicles and integrating a liquid level sensor, belongs to the field of after treatment of automobile exhaust and aims to solve the problems that existing urea supply modules are unreasonable in structure and can harm disassembling persons easily during disassemble under air pressure and external filter pipelines are complex. The urea liquid supply module for the vehicles integrates a urea heat exchange water pipe, a gas inlet port, an exhaust port, a liquid supply pipe and a filter, integrates a urea liquid level and a urea temperature sensing signal and can resist the pressure of compressed gas of the whole vehicle chassis. The high-accuracy replaceable urea liquid filter is integrated and installed at a liquid inlet end of a urea liquid supply pipe. A damping hole is formed in an inlet of the liquid supply pipe to prevent high-speed jet of urea, and the safety is very high.

Owner:CHINA FIRST AUTOMOBILE

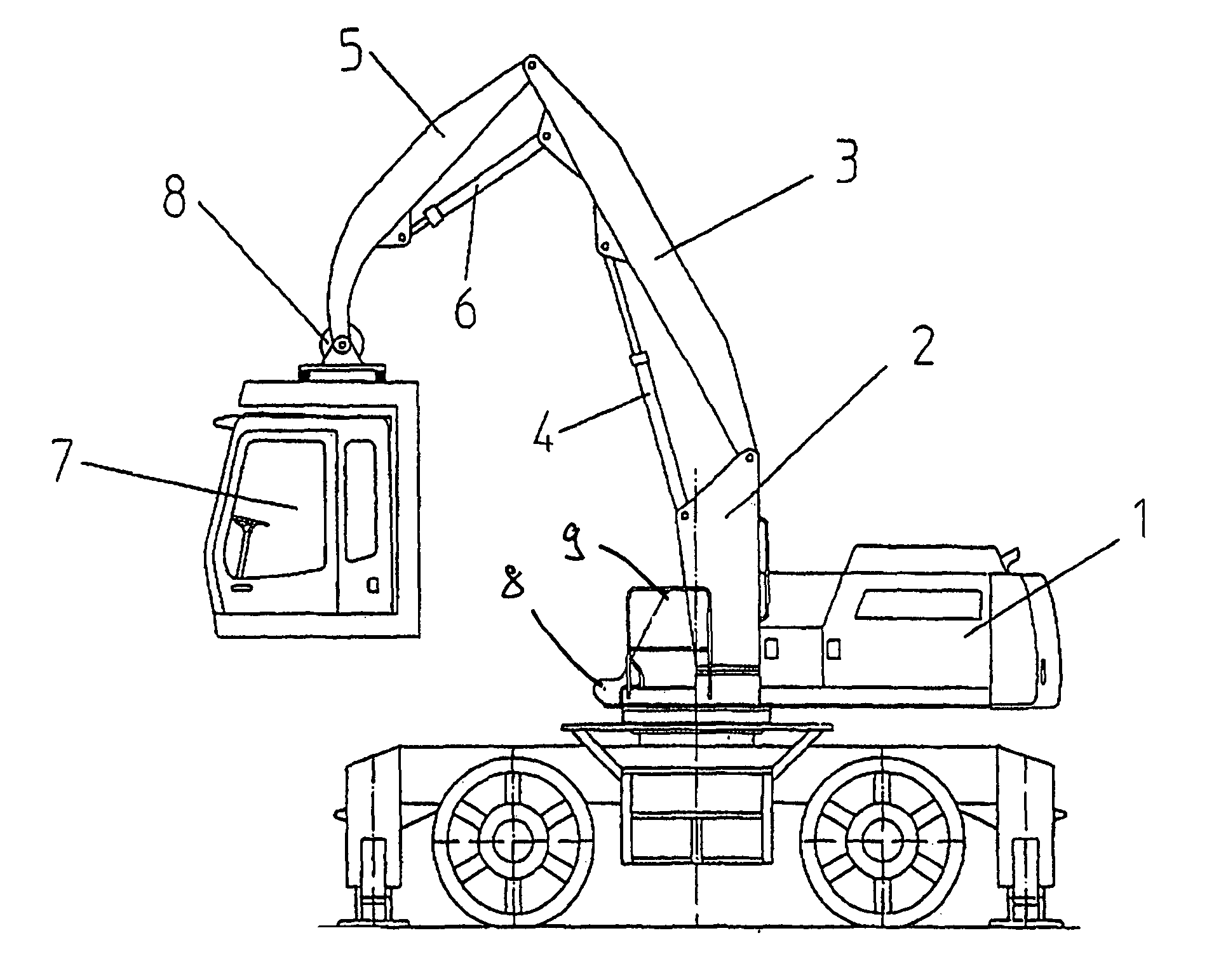

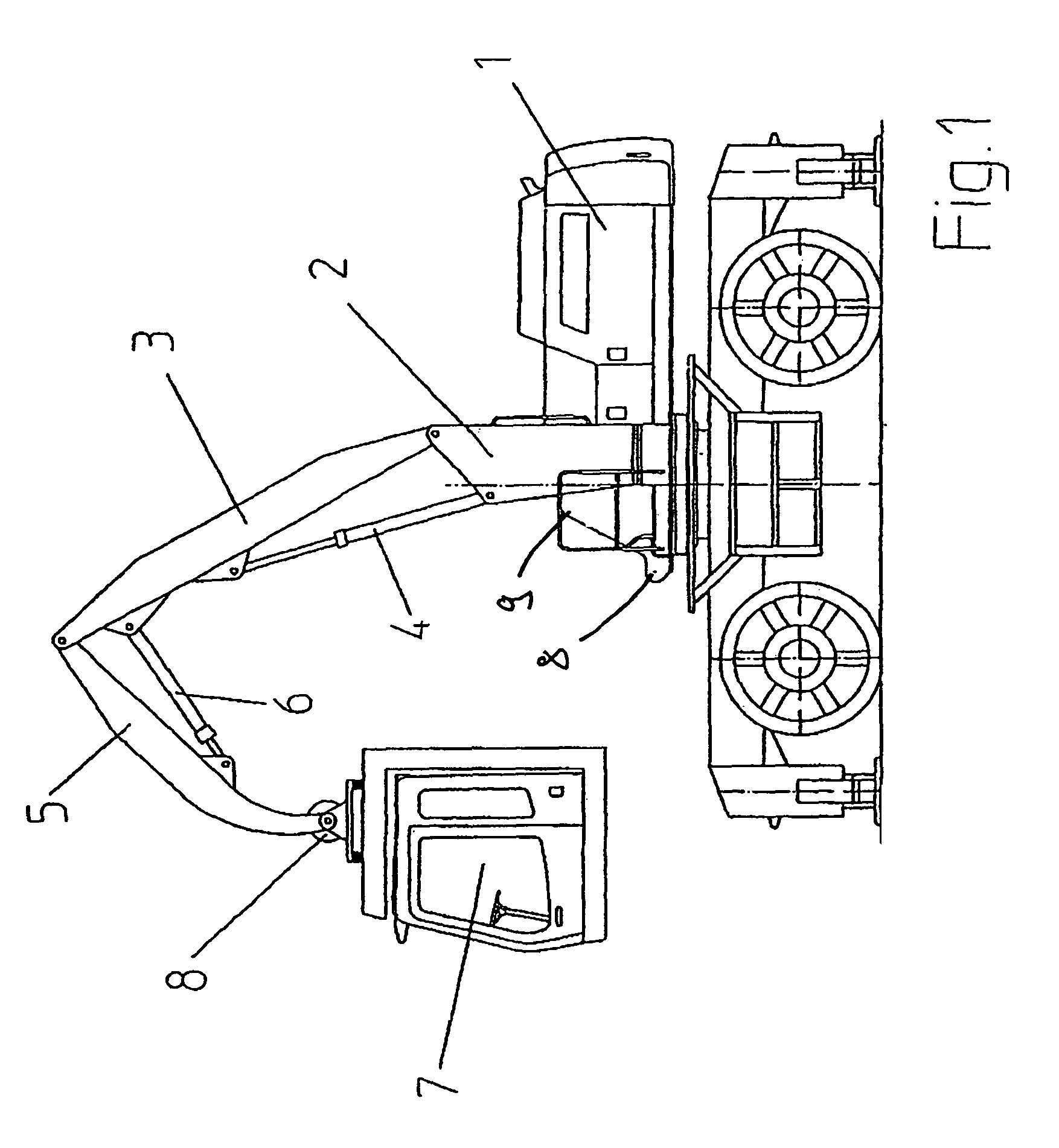

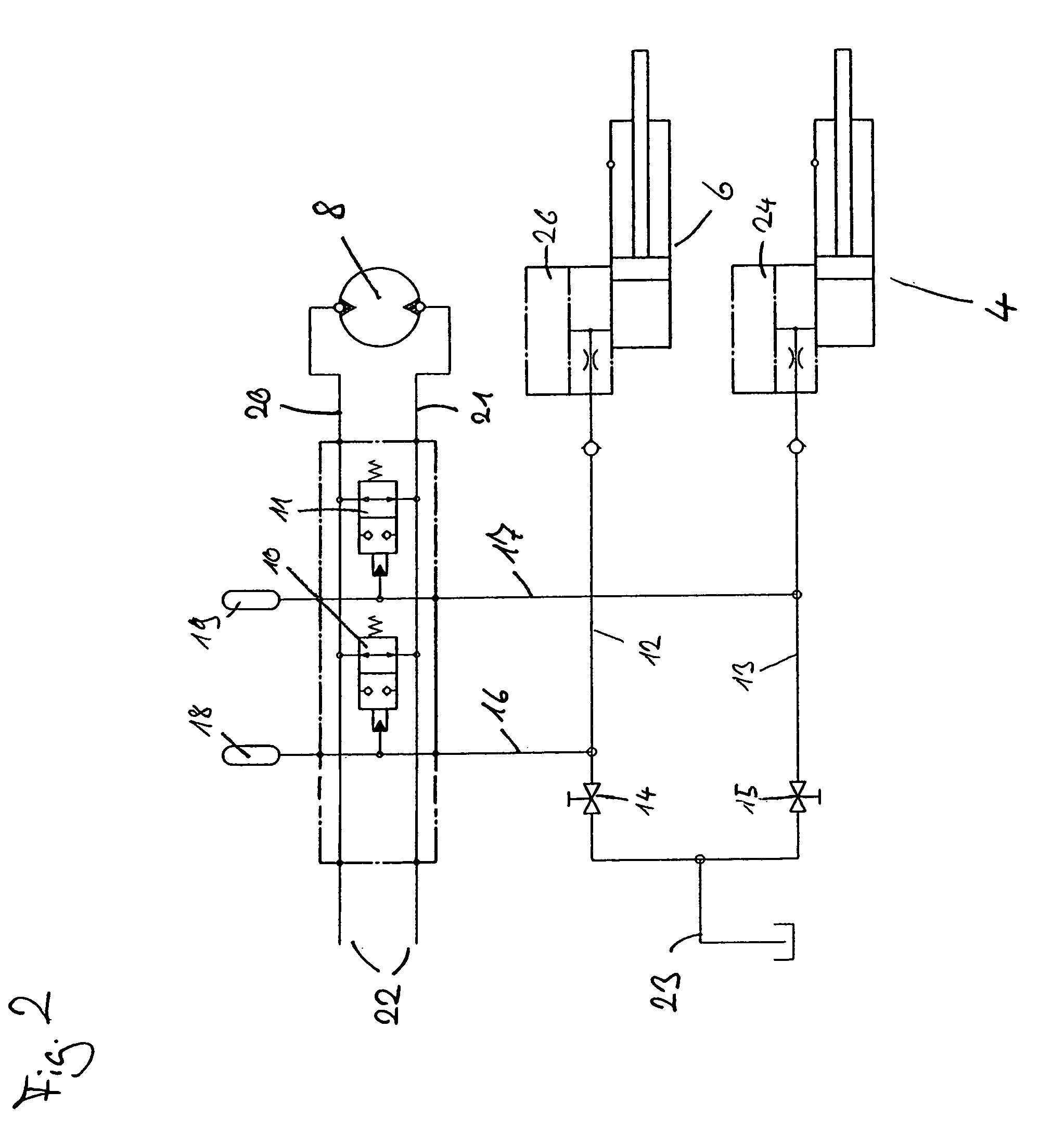

Working machine and emergency lowering system

ActiveUS8061764B2Safer emergency loweringNo risk of injuryVehicle seatsSoil-shifting machines/dredgersHorizontal axisEngineering

The present invention relates to a working machine, in particular a traveling material-handling machine, in particular a hydraulic excavator, comprising a basic machine, a cabin and a cabin arm pivotally mounted on the basic machine, by means of which the position of the cabin with respect to the basic machine can be varied, wherein the cabin arm can be swivelled with respect to the basic machine about a horizontal axis by means of at least one hydraulic actuator, and wherein the cabin is pivotally mounted on the cabin arm via a hydraulic inclination adjustment device. In accordance with the invention, the cabin includes an emergency lowering system, in which an inclination emergency valve is provided for the inclination adjustment device of the cabin, which in a case of emergency lowering provides for alignment of the cabin into a normal position.

Owner:LEIBHERR HYDRAULIKBAGGER GMBH

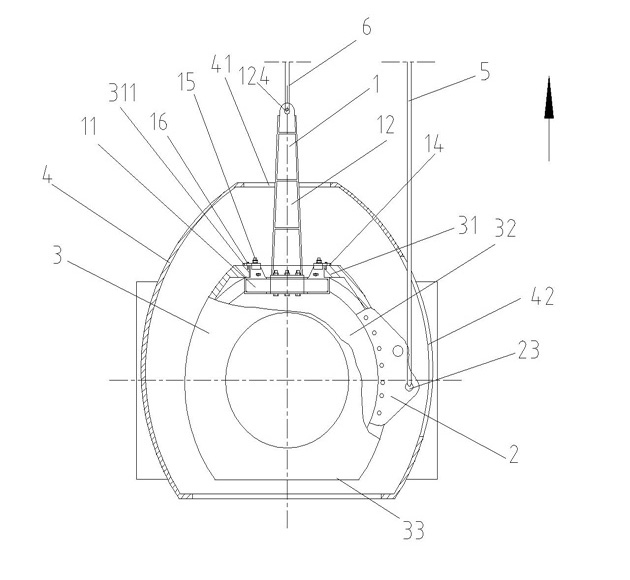

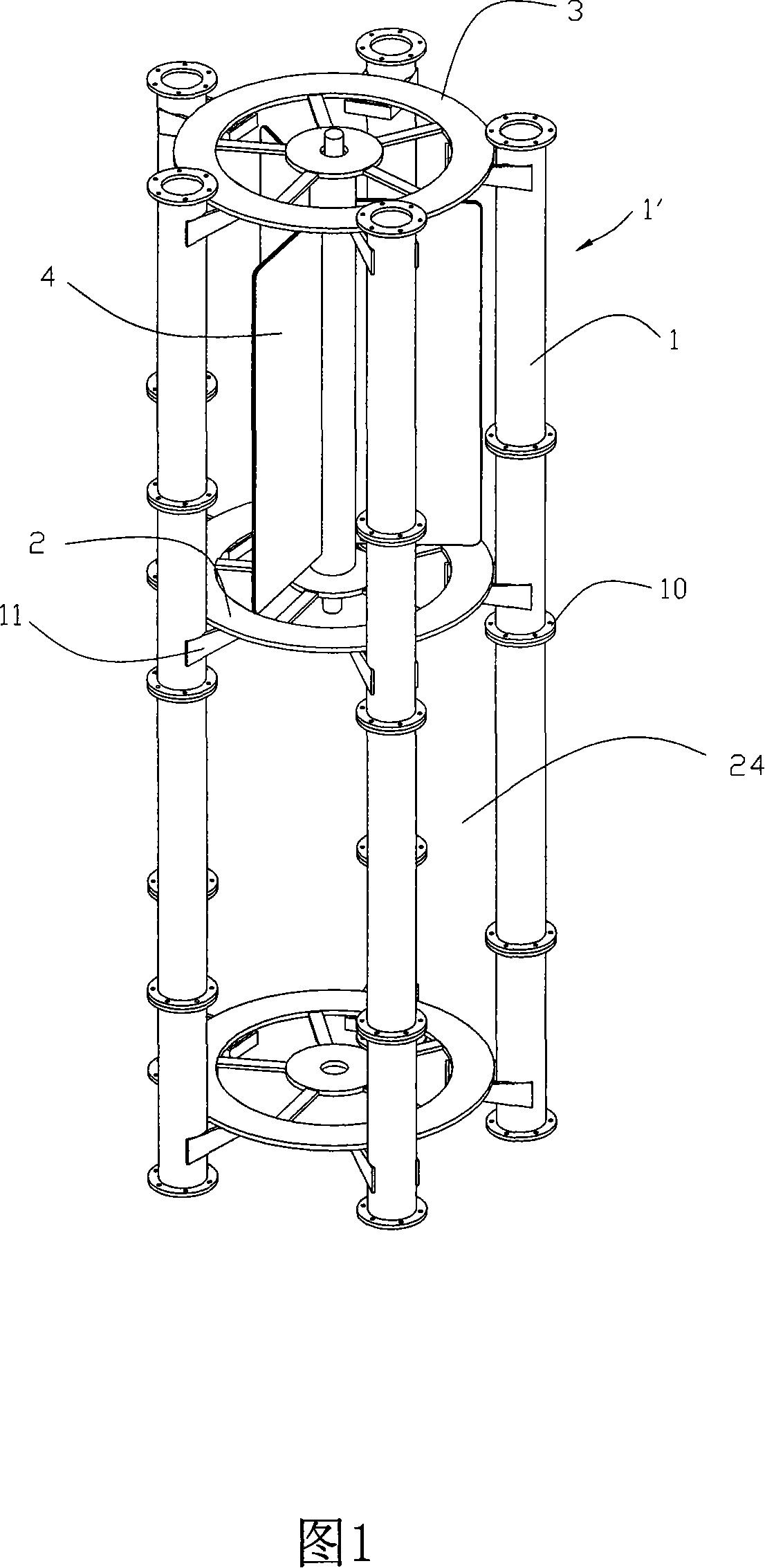

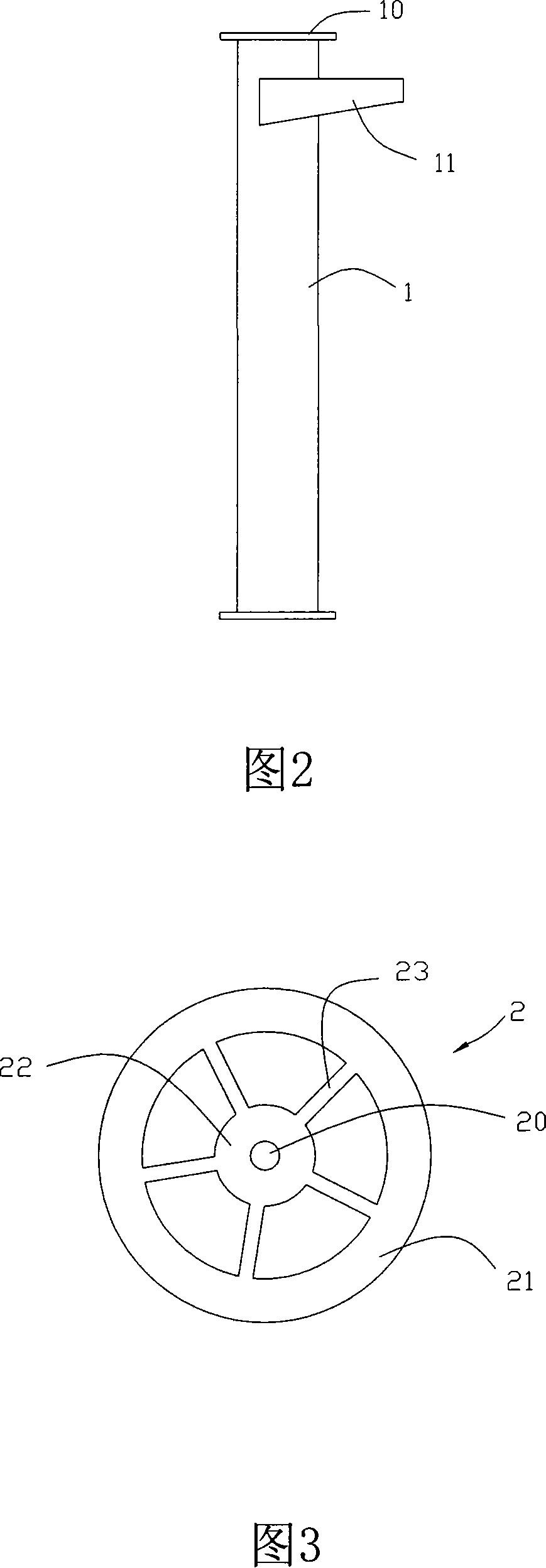

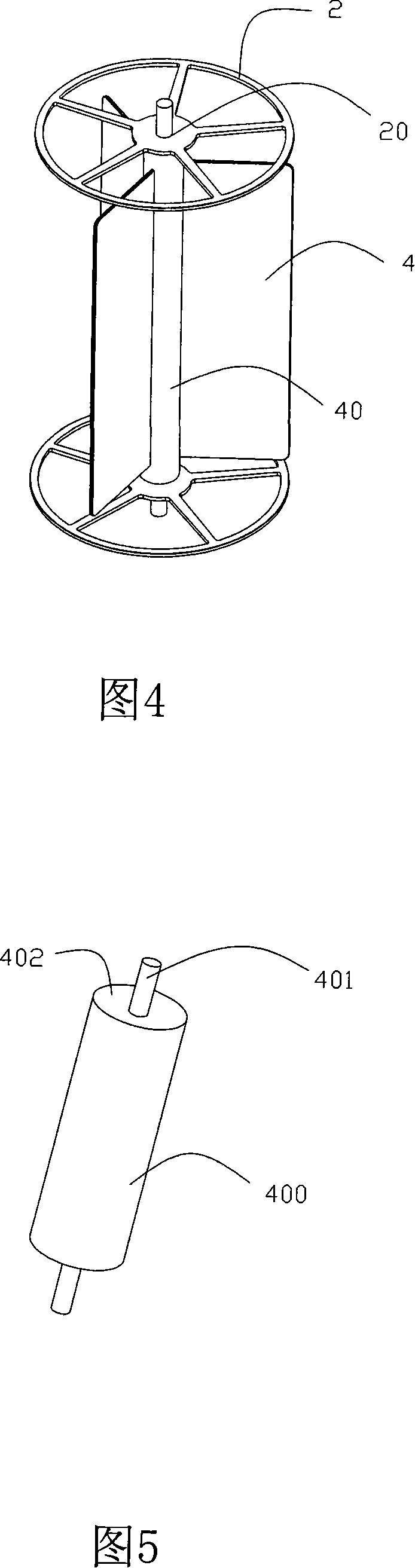

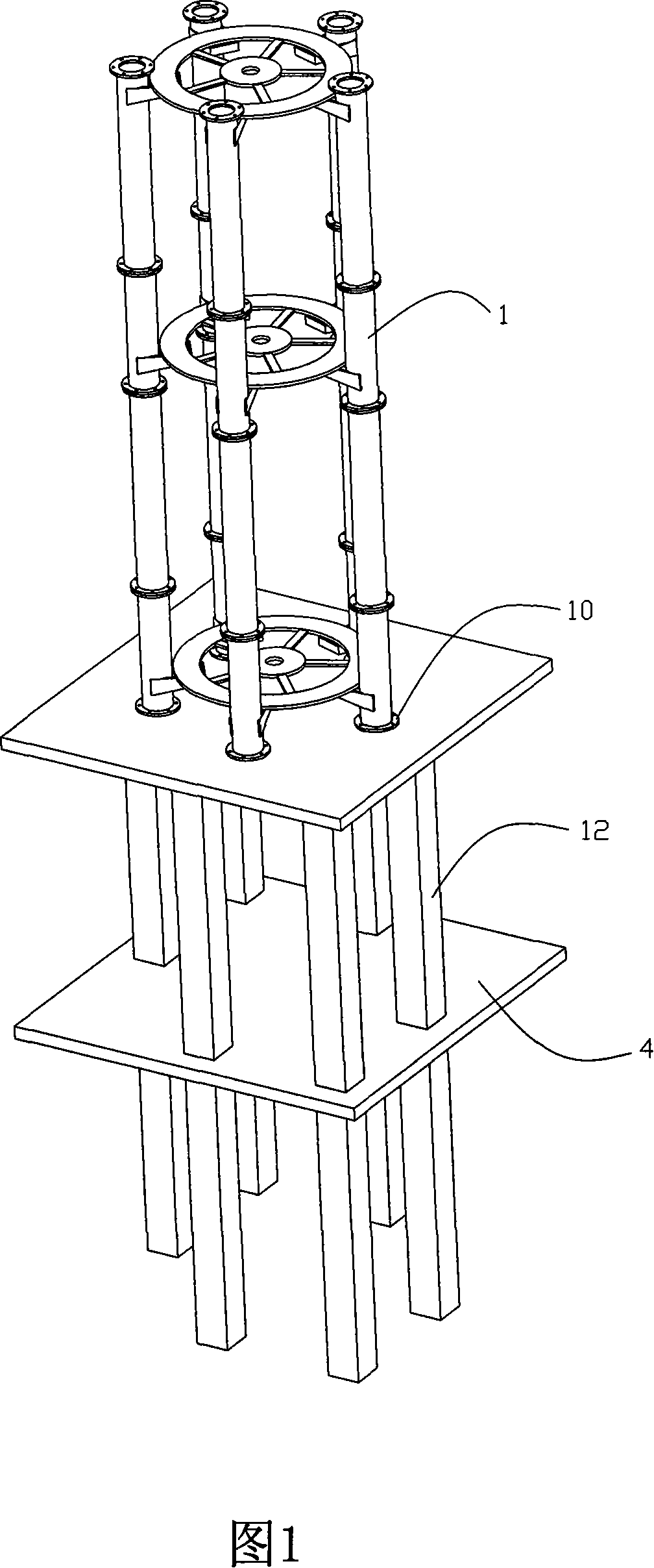

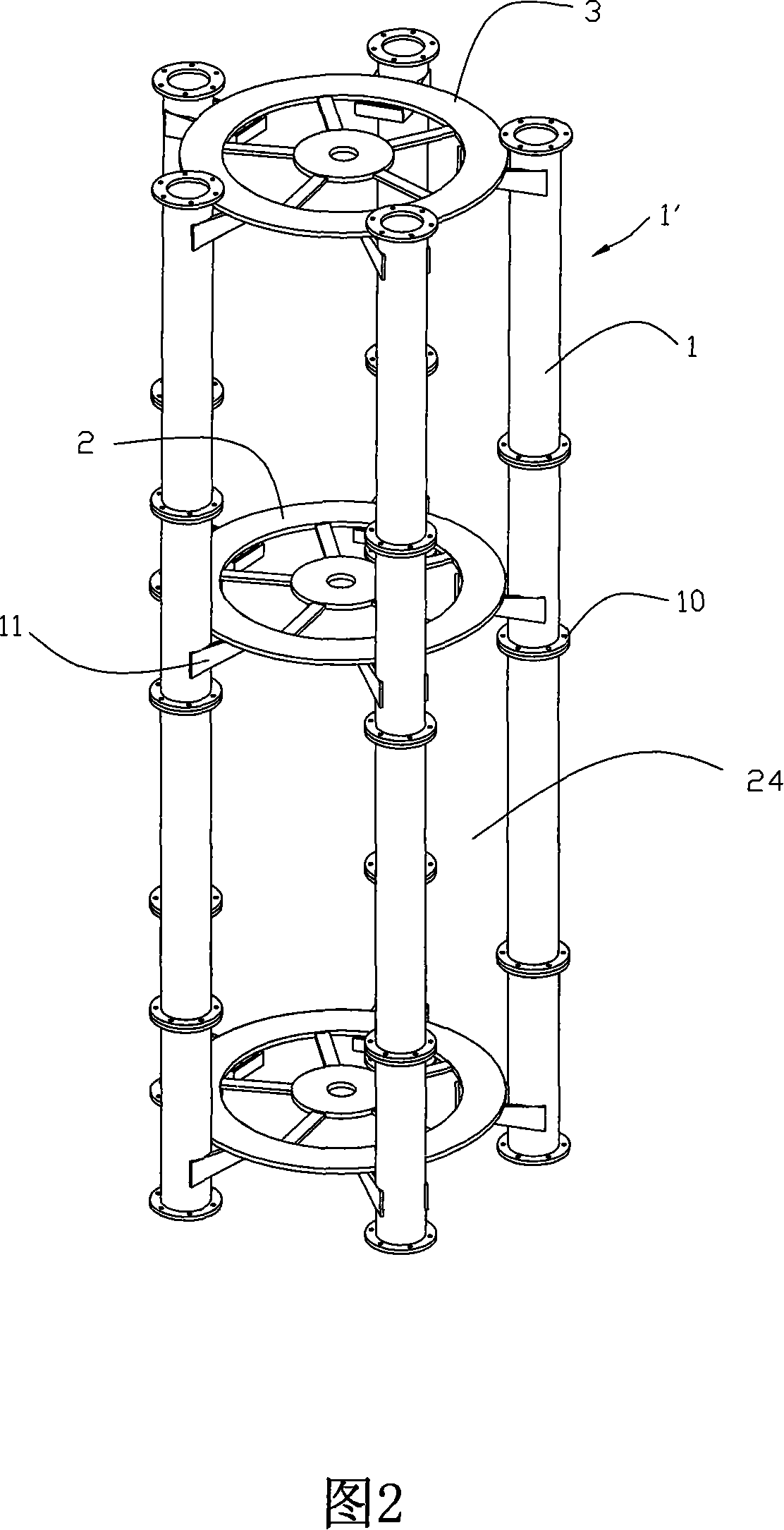

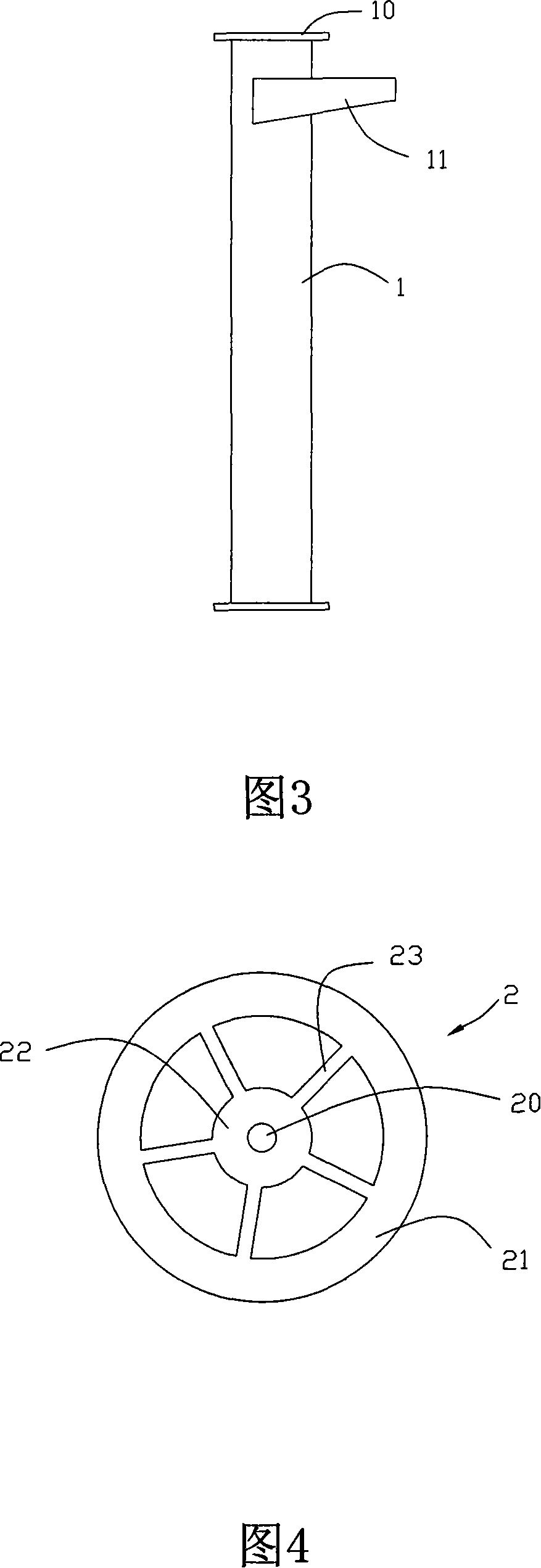

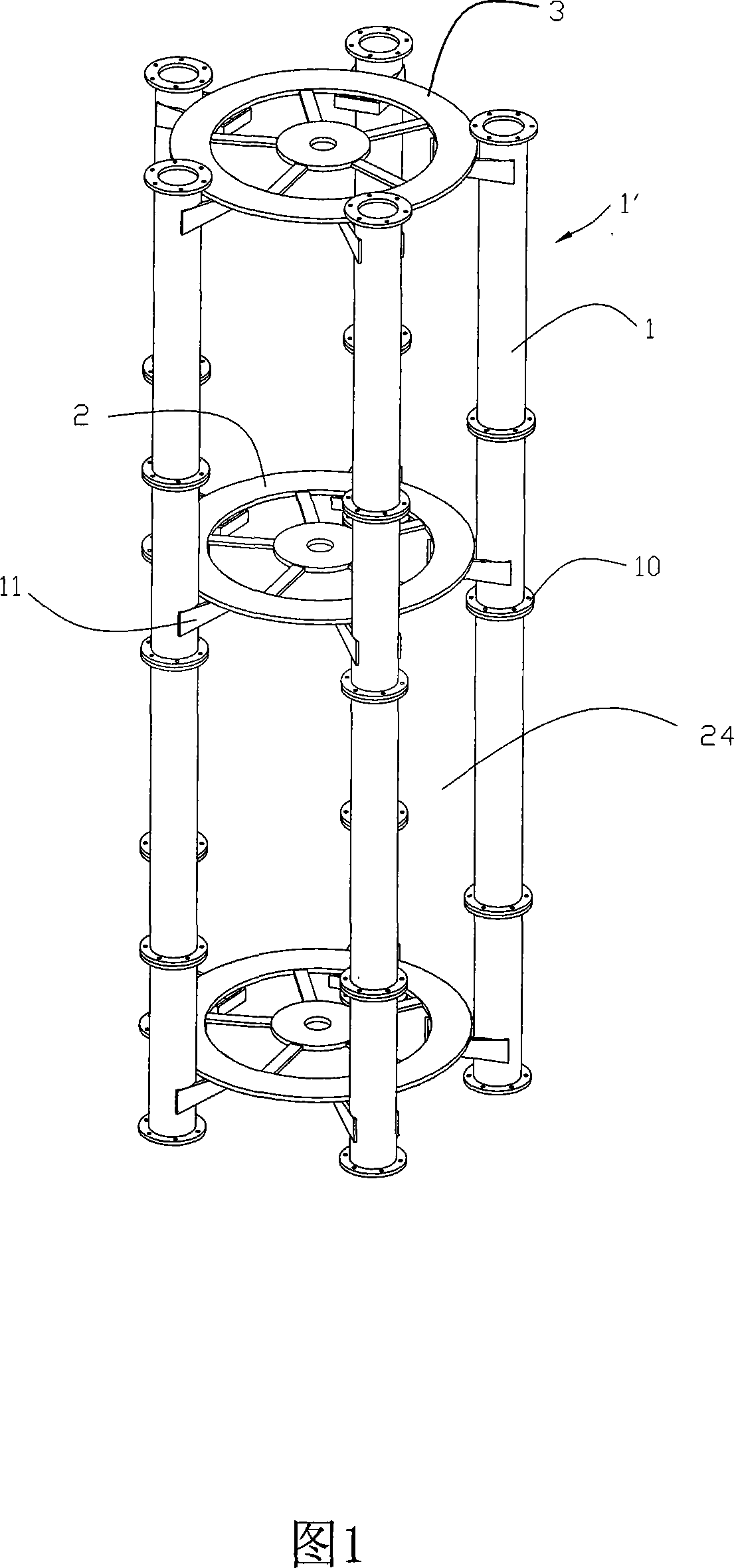

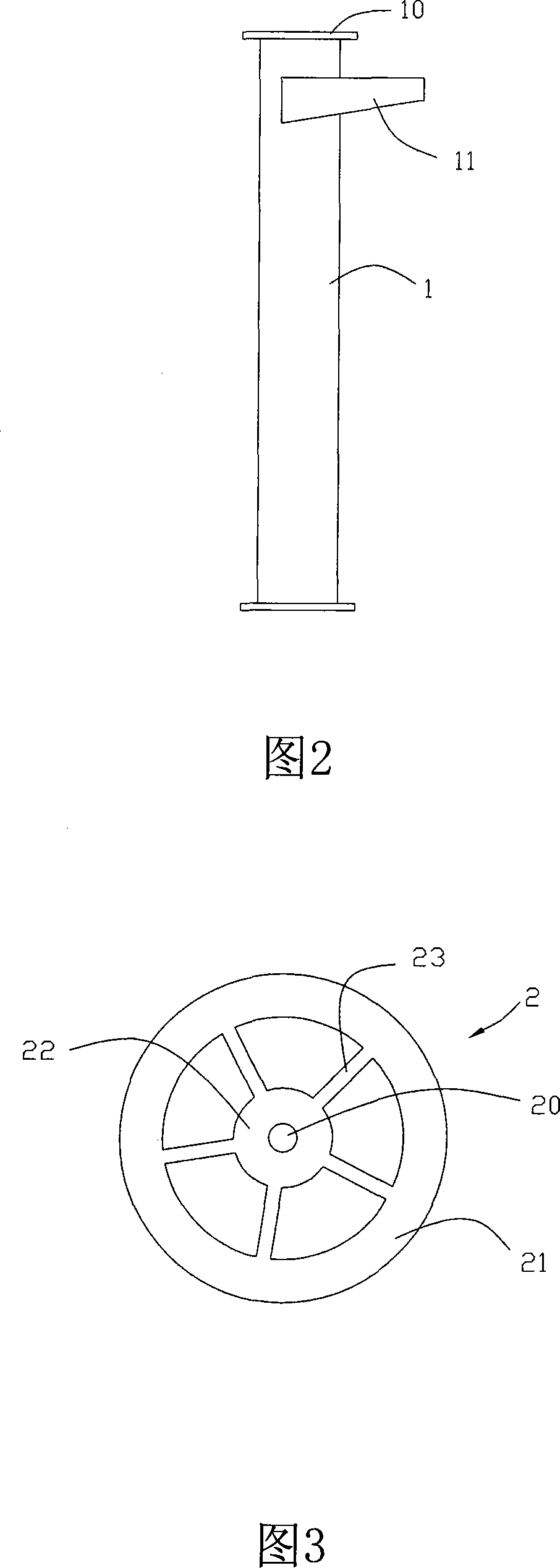

Vertical wind power generator

InactiveCN101105171AEasy to installWon't cause damage easilyWind motor controlWind motor supports/mountsWind drivenEngineering

A tower structure for vertical wind-driven generator is composed of three or more sets of support bars, wherein each set of support bar is vertically upward and in the same circle, and the center of the circle is the center of the tower structure; a frames and a wind wheel arranged on the frame is provided on the tower structure; the wind wheel comprises a rotation shaft and three or more leaf blades arranged on the rotation shaft, the rotation shaft is perpendicular with ground level and is the center of the circle; the leaf blade comprises a supporting rack and at least two movable plates arranged on the supporting rack, the movable plates are connected together in series via a tension bar, the up and down movement of the tension bar switches the movable plates between opening state and closing state, and the tension bar is arranged supporting rack and perpendicular to the wind wheel. The generator may not easily cause the damage of the rotation shaft, so as to prolong the service life thereof. The tower can be firmly arranged on the ground, so that the tower will not be inclined and fallen down to hurt of staff and damage of equipments. The invention also has the advantages of long service life and convenient repairing and maintenance.

Owner:GUANGZHOU YATU NEW ENERGY TECH

Method for manufacturing plastic coiling tool bar and plastic coiling tool bar

ActiveCN101046031AReduced carrying capacityPrecise positioningWeft knittingWarp knittingWork in processEngineering

Owner:KARL MAYER STOLL R&D GMBH

Device and method for draining and rinsing containers filled with fluid

ActiveUS9427784B2Easy to useAvoid contactSolid waste disposalHollow article cleaningLine tubingCoupling

The invention relates to a device for draining and rinsing containers filled with fluid, comprising an accommodating unit for accommodating the container and comprising a removal unit, which has a removal line, a coupling connected to the removal line for connecting the a removal opening of the container, and a pumping apparatus by means of which the fluid in the container can be pumped out of the container, and comprising a rinsing unit, which has a rinsing pin, a rinsing line connected to the rinsing pin, and a control apparatus, wherein the rinsing pin can be moved by means of the control apparatus in such a way that the rinsing pin automatically pierces a wall of the container and rinses out the container after the container has been drained.

Owner:BASF AG

Perpendicular wind-driven generator

InactiveCN101139973AEasy to installNo risk of injuryWind motor supports/mountsMachines/enginesWind drivenWind force

A vertical wind power generator: A rotary shaft of the generator air vanes is perpendicular to the ground; the generator is characterized in that the tower structure is composed of three or more groups of bracing rods; each group of the bracing rods are arranged vertically upward and in the same periphery; the peripheral center is the center of the tower structure; wherein, each group of the bracing rods comprise two or more than two bracing rods that are laminated in sequence. Each bracing rod is connected with a connection structure. The lower part of the tower structure is a fixed building; due to the fixed building in the lower part, it is not necessary to occupy too many lands. Therefore, it is possible to save materials in building construction. Moreover, the invention has advantages of long service life and convenient maintenance and services during operation.

Owner:GUANGZHOU YATU NEW ENERGY TECH

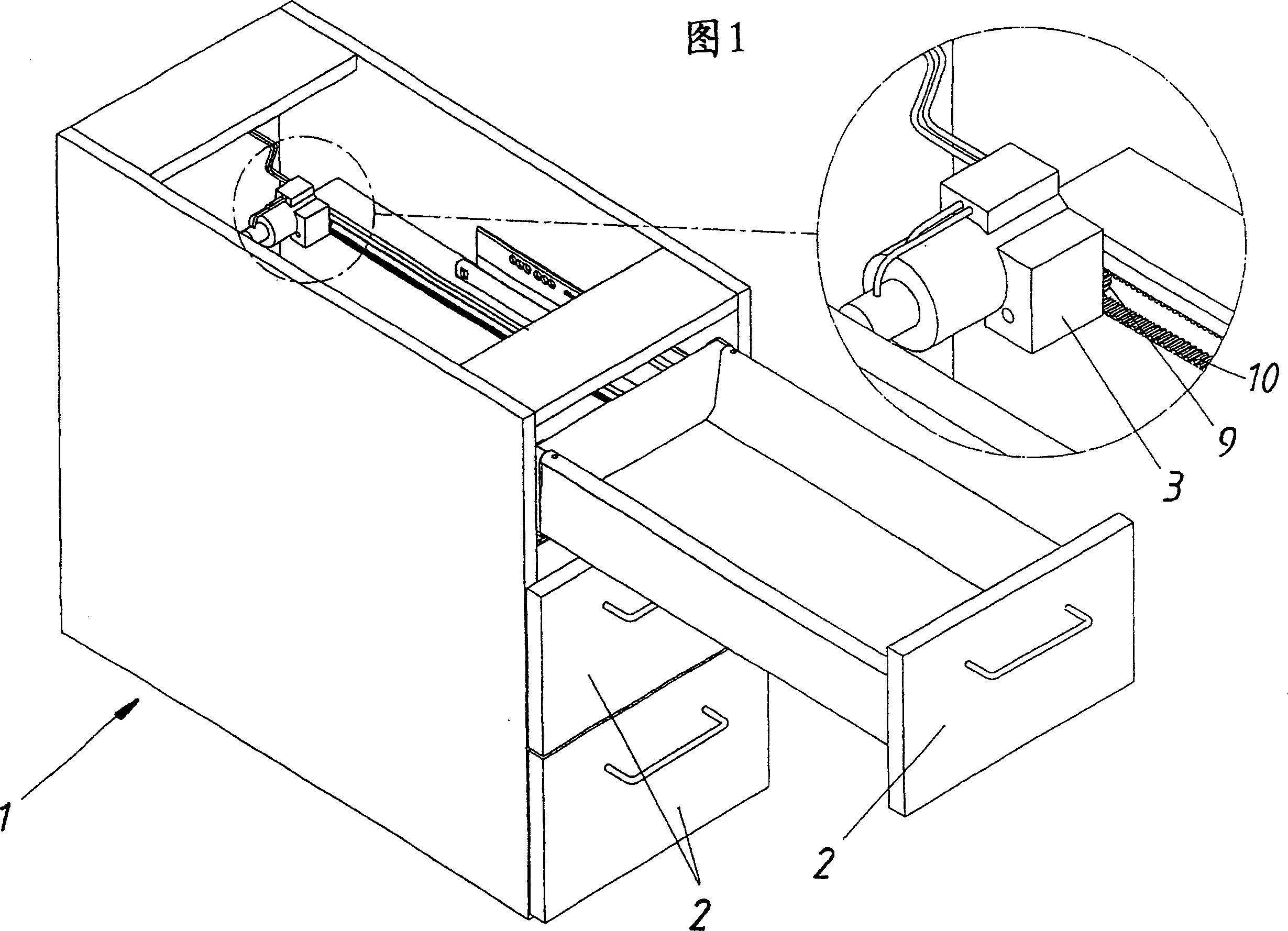

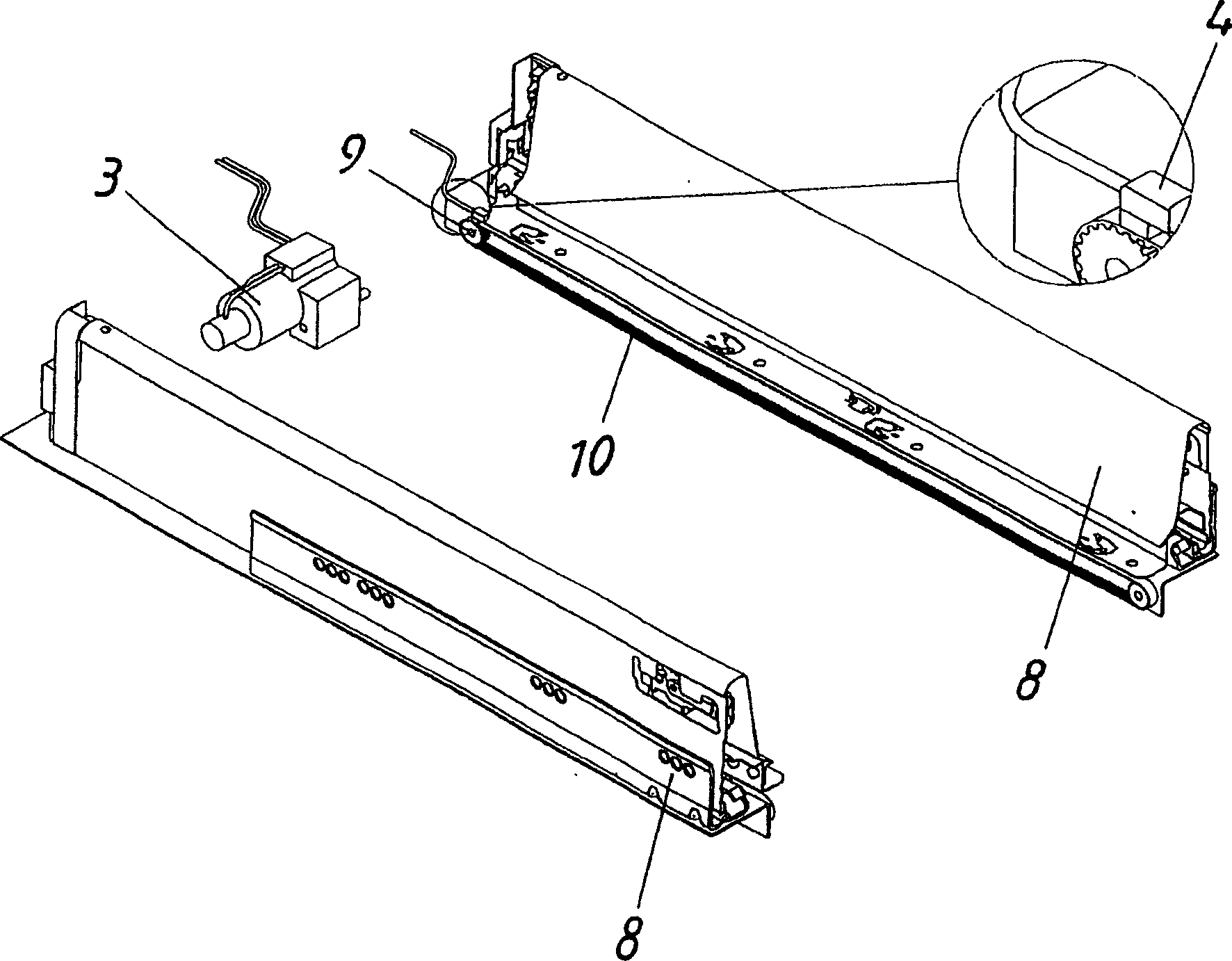

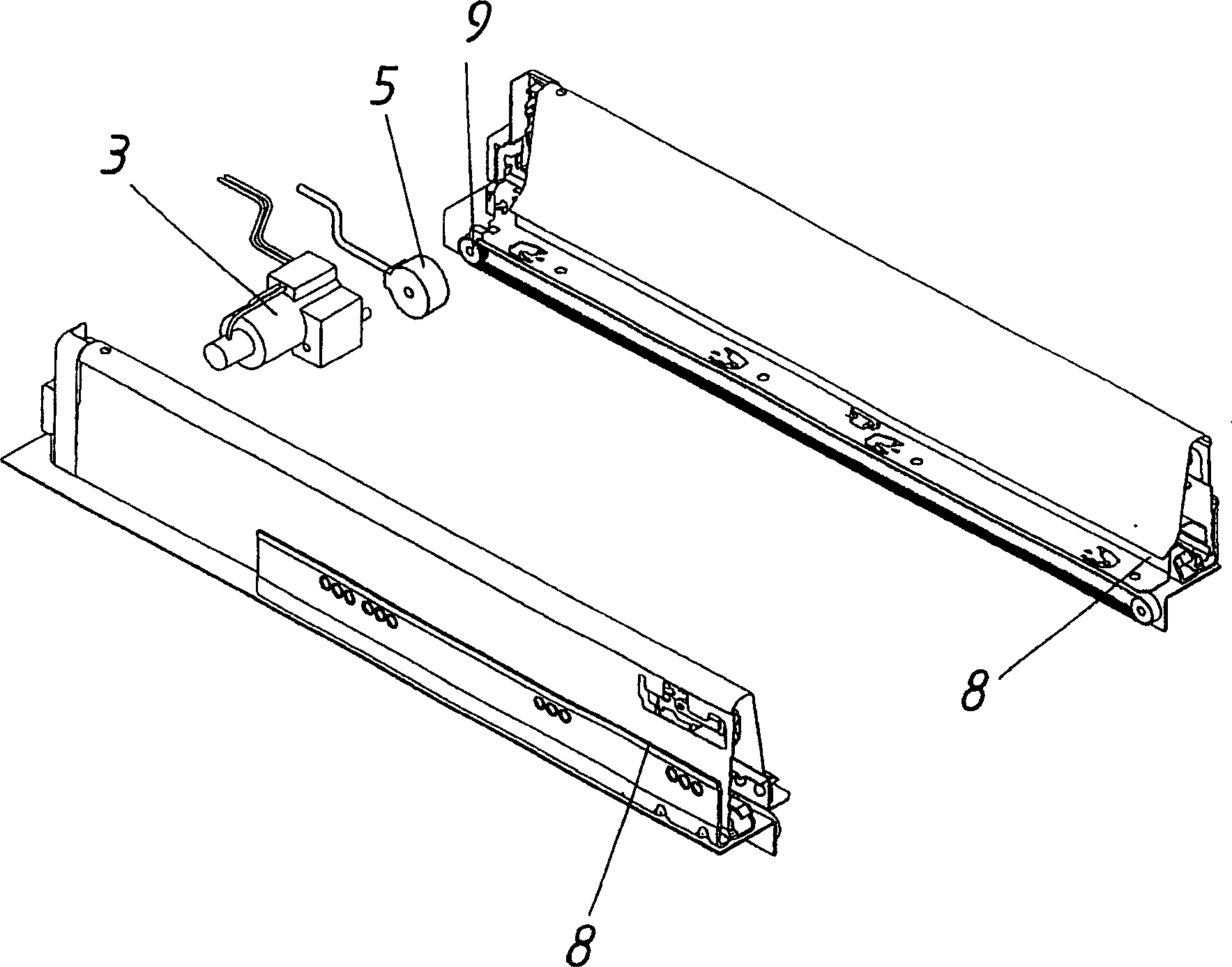

Method for driving a movable part of a piece of furniture

ActiveCN1787764AAvoid damageSimple operabilityPower-operated mechanismDrawersStructural engineeringElectric drive

Owner:JULIUS BLUM GMBH

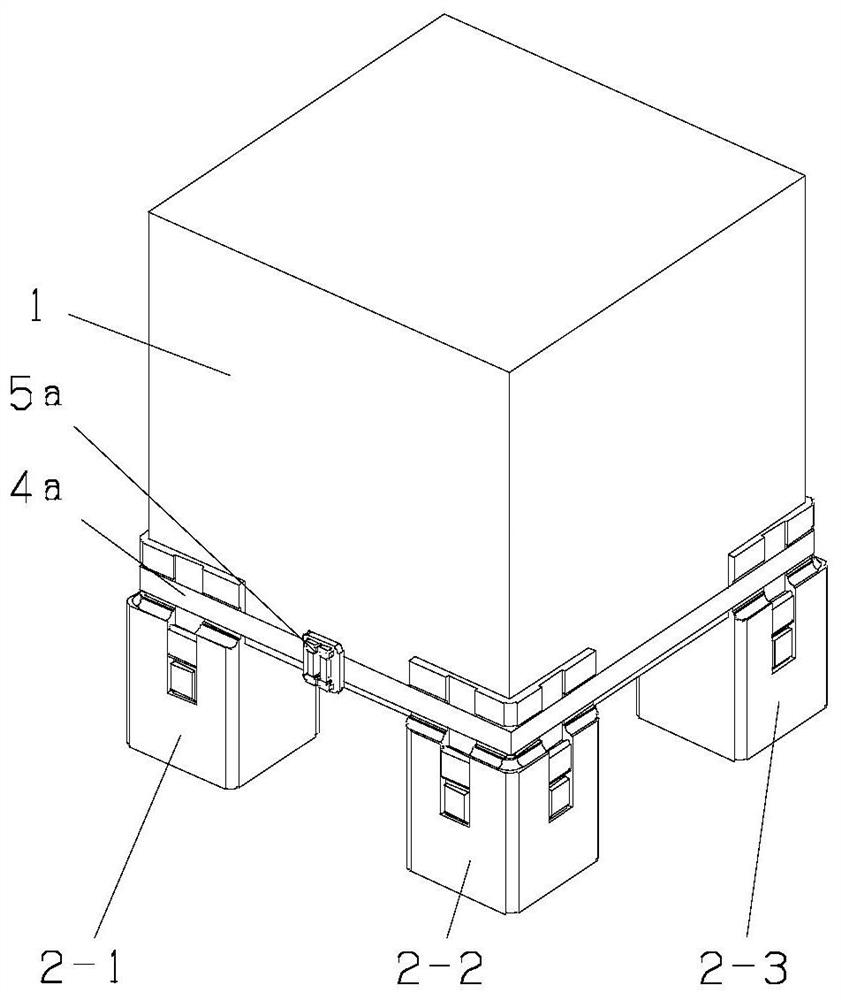

Heavy object baling method

InactiveCN111824592AShorten the preparation cycleReduce weightClosuresAgricultural engineeringMechanical engineering

According to a heavy object baling method, wooden frame baling serves as a mainstream; if a professional practitioner is entrusted to carry out baling operation, several days need to be spent until completion, and due to the fact that fumigation treatment needs to be carried out, the number of days is also accumulated, and the shipment day is delayed. Besides, due to the fact that the material ofthe wooden frame bale has weight, transportation cost is increased, bale breaking operation is changed into manual labor, and therefore the risk of injury is high. And in addition, the unpacked wood becomes industrial waste, so that the treatment cost is generated. Components are placed at the four corners of the bottom side or the four corners of the bottom side and the four corners of the top side of an object to be baled, or a pedestal is arranged at the bottom side of the object to be baled, so that the components are placed at the pedestal and the four corners of the top side, and balingwork is completed through binding belts. Due to the fact that the baling operation can be completed in a short time on the site of one side of the baler, fumigation treatment is not needed, and the baler is made of resin, the baler is light in weight, unbaling operation is easy, and waste can be reduced due to the fact that the baler can be reused.

Owner:株式会社饭田模具

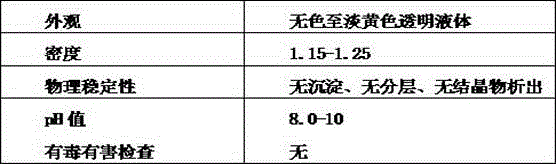

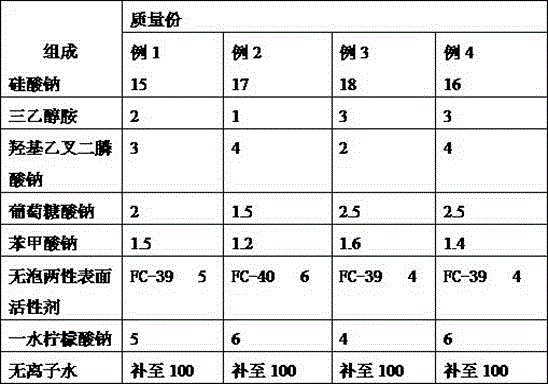

Whitening agent for aluminum cell phone battery cover and preparation method of whitening agent

ActiveCN106757094AOvercome the complex process shortcomings of separate cleaning treatmentImprove bindingWhitening AgentsCitric Acid Monohydrate

The invention provides a whitening agent for an aluminum cell phone battery cover and a preparation method of the whitening agent. The preparation method comprises the following steps that firstly, under the normal temperature, the solid raw materials of sodium silicate, sodium gluconate, sodium citrate monohydrate, sodium benzoate and 1-hydroxyethanediphosphonic acid sodium salt are sequentially stirred and dissolved in deionized water, then liquid raw materials of triethanolamine and a bubble-free ampholytic surfactant are added and stirred uniformly, and transparent liquid is obtained; the die-cast aluminum cell phone battery cover can be cleaned through the transparent liquid, and the good cleaning effect is achieved; and the raw materials used in the product formula are all environmental-friendly raw materials, no environment controlled matter components exist, and the product is gentle in performance, environmentally-friendly, free of toxin, simple in manufacturing process, low in cost, free of flavor and good in effect, and discharge is free of pollution to the environment.

Owner:江西瑞思博新材料有限公司

Vertical wind power generator

InactiveCN101100976AEasy to installNo risk of injuryWind motor supports/mountsWind motor combinationsRotational axisTower

This invention is vertical wind-mill generator. The rotating shaft of power generator wind wheel is vertical to the ground. The wind-mill generator has an engine base. Its tower support is composed of three or more than three groups of supporting bars, which are upwards and at the same circle. The center of the said circle is the center of the said tower support. The same height at inner circle side of each supporting bar is arranged with gravity bearing support, which can bear the said engine base. This invention has large working space. Power generator and wind wheel are assembled firmly in the working space of tower support. The tower support can be set firmly on the ground and can be repaired and maintained conveniently.

Owner:GUANGZHOU YATU NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com