a turning mechanism

A technology of turning mechanism and rotating cylinder, applied in measuring devices, instruments, measuring instrument components, etc., can solve problems such as increased cost, unsafety, easy occurrence of accidents, etc., and achieves the improvement of work efficiency, detection automation, and accurate automation of turning devices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following descriptions are only preferred embodiments of the present invention.

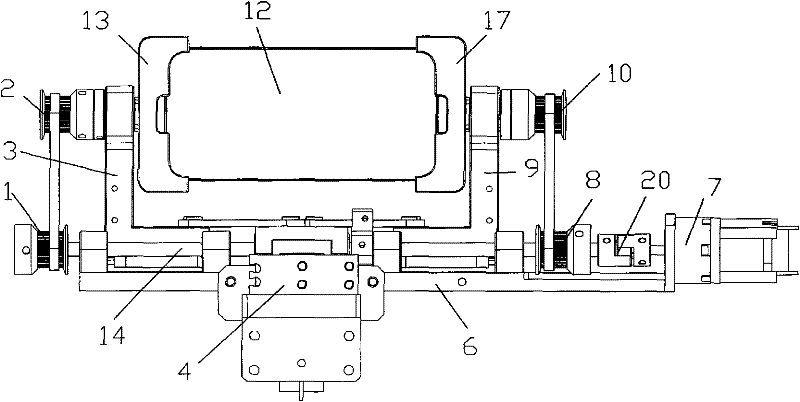

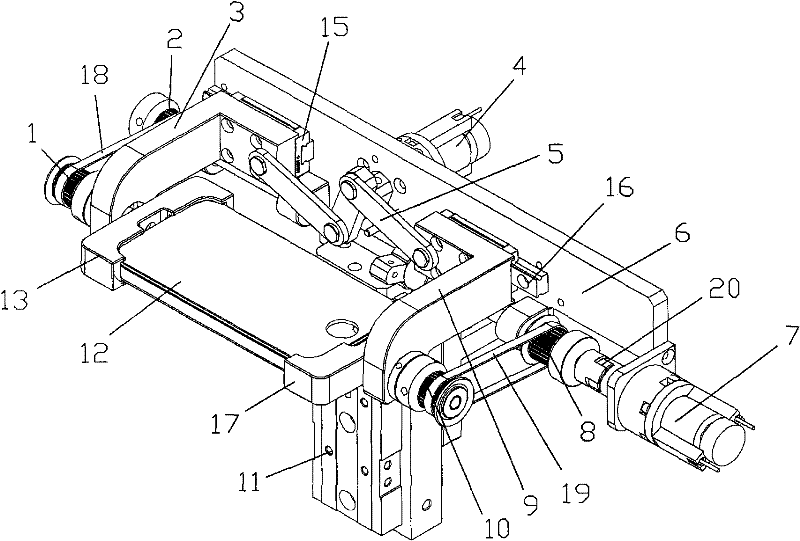

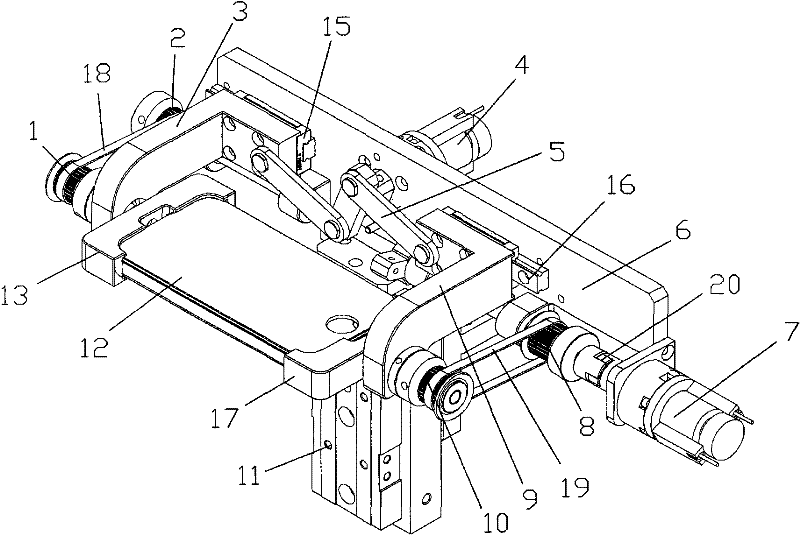

[0014] Examples, see attached figure 1 , 2 ; A turning mechanism, including a lifting cylinder 11 and a mounting plate 6, the lifting cylinder can drive the mounting plate 6 to rise and fall, provide space for turning over, and prevent it from colliding with other parts; the mounting plate 6 is screwed and fixed There are slide table cylinder 4, rotary cylinder 7 and left and right slide rails 15, 16, and a tie bar 5 is connected to the output shaft of slide table cylinder 4; tie bar 5 is composed of a vertical plate and two horizontal plates, which are hinged to each other connection; the stay bar 5 is hingedly connected with the left and right splints 3 and 9 installed on the left and right slide rails; the left and right splints can move on the left and right slide rails, and a transmission shaft 14 is fixed on the rotary cylinder 7, and the transmission There are left and right m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com