Patents

Literature

46results about How to "The structure of the whole machine is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

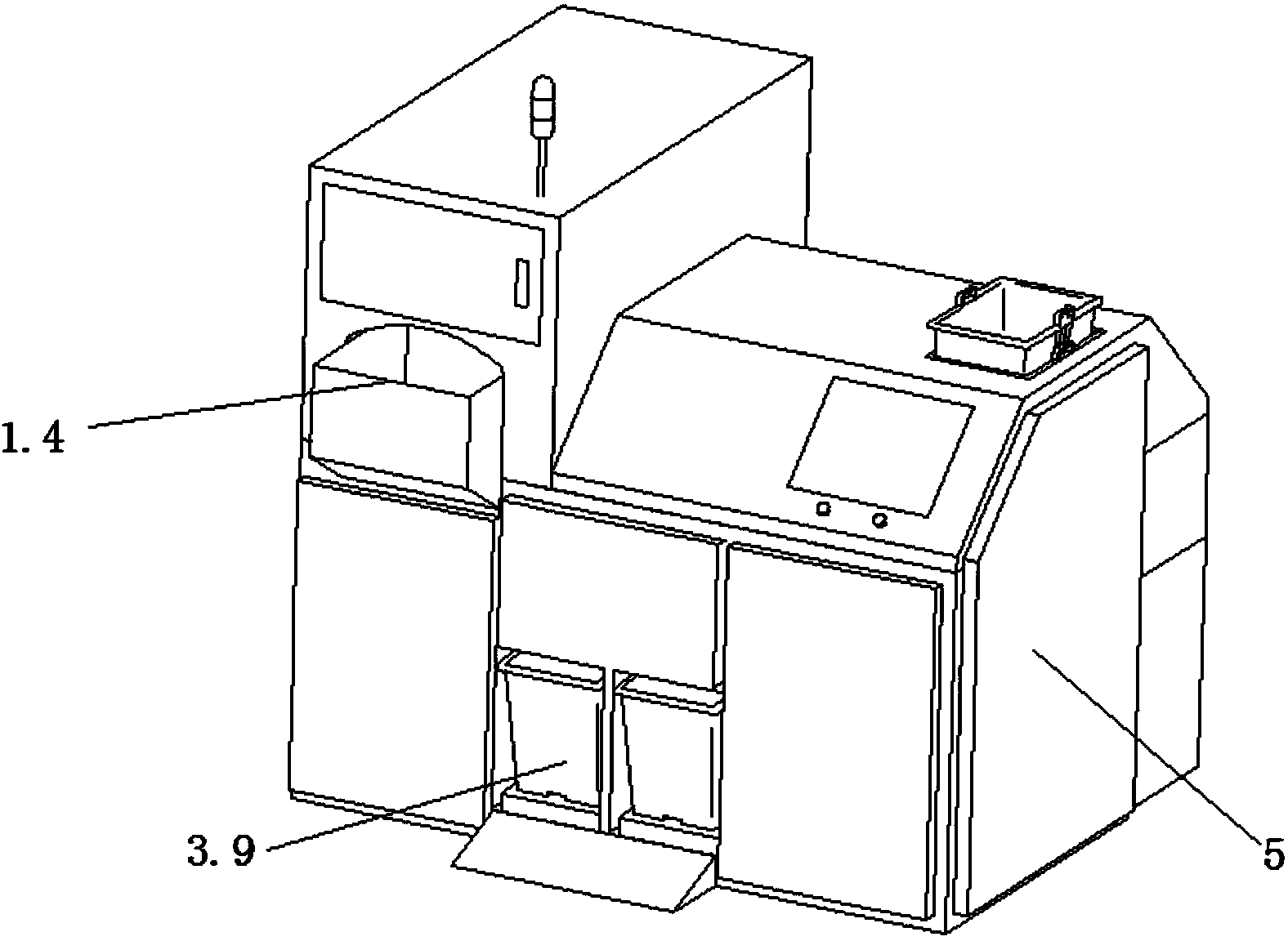

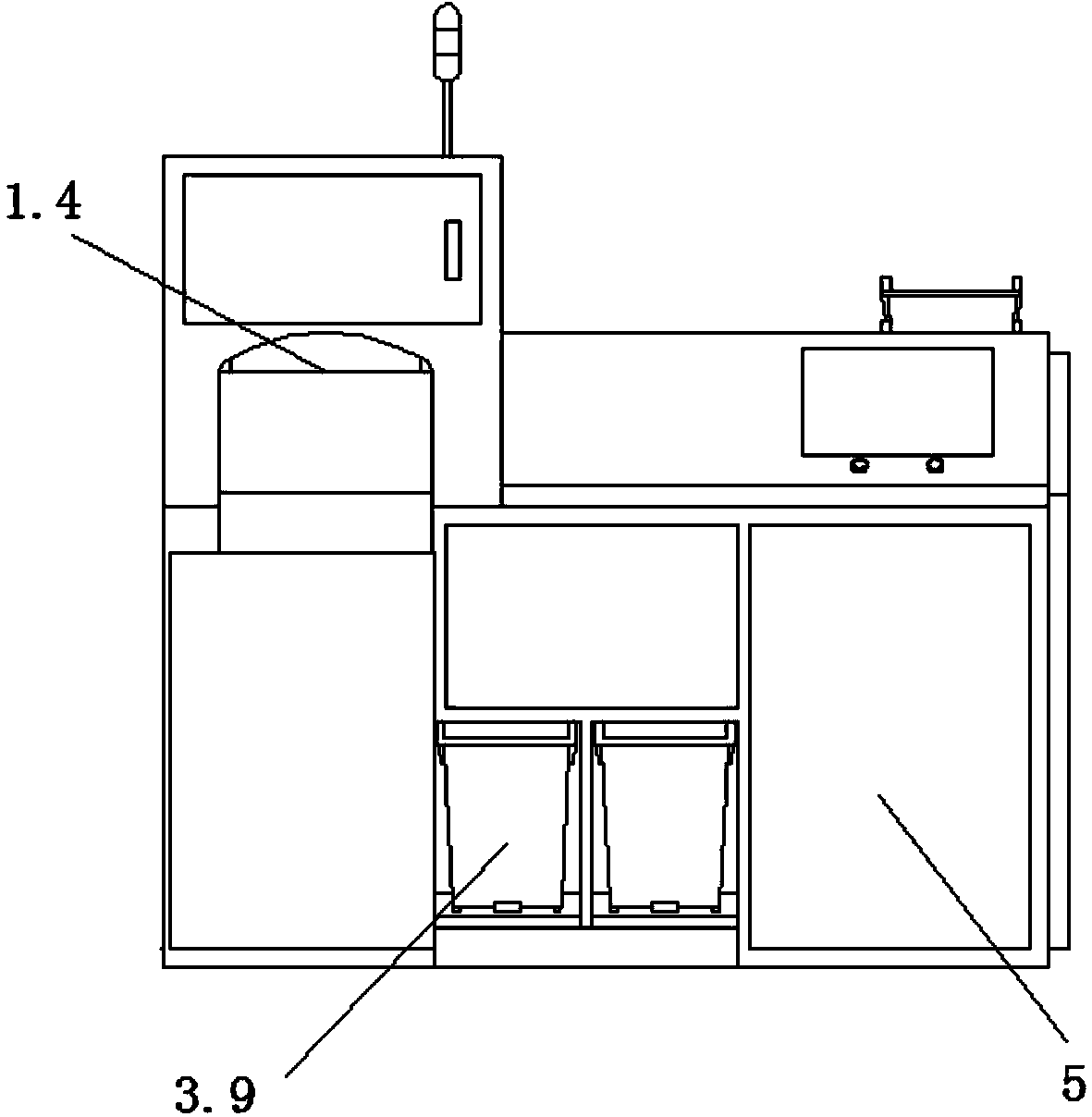

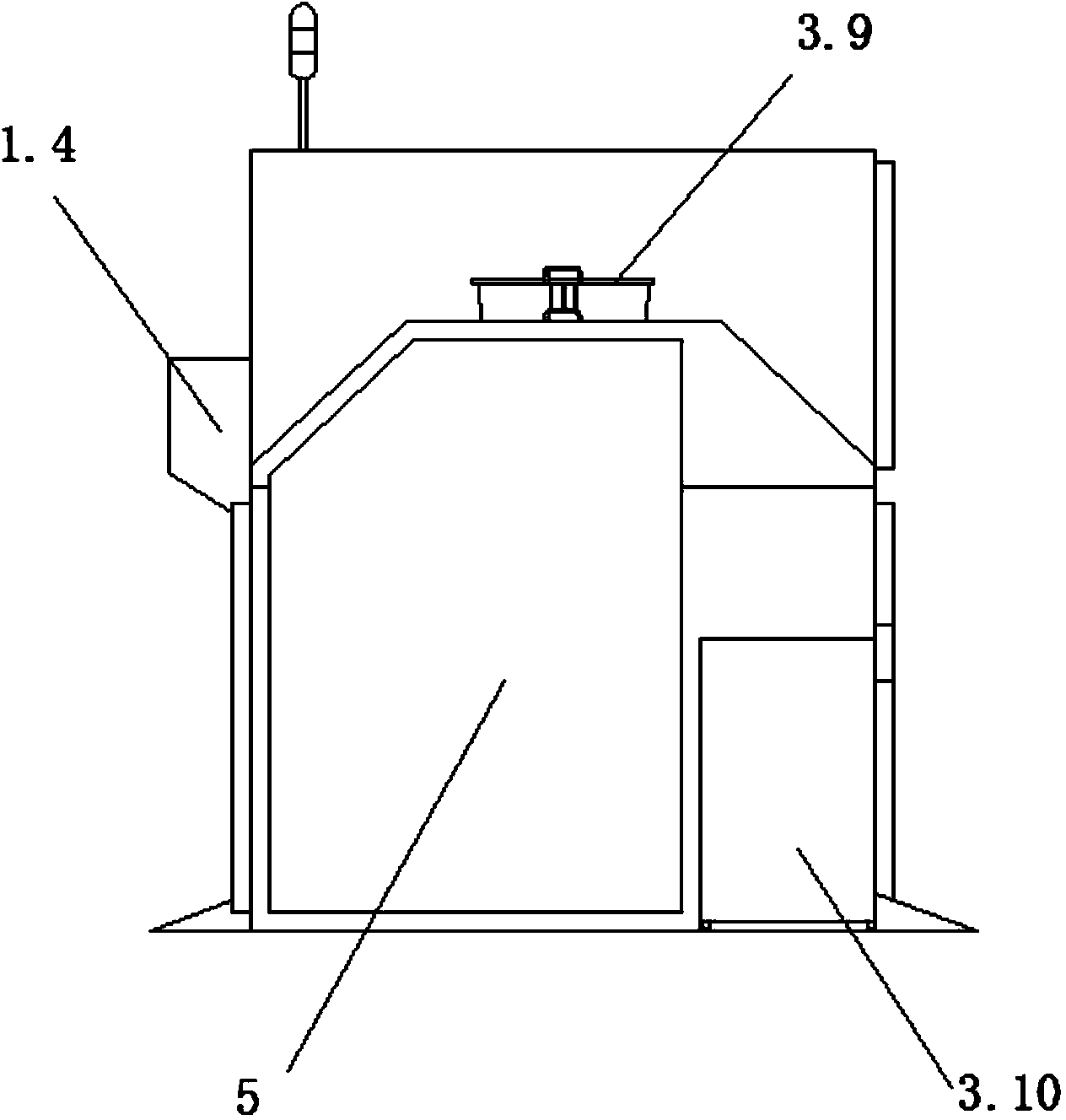

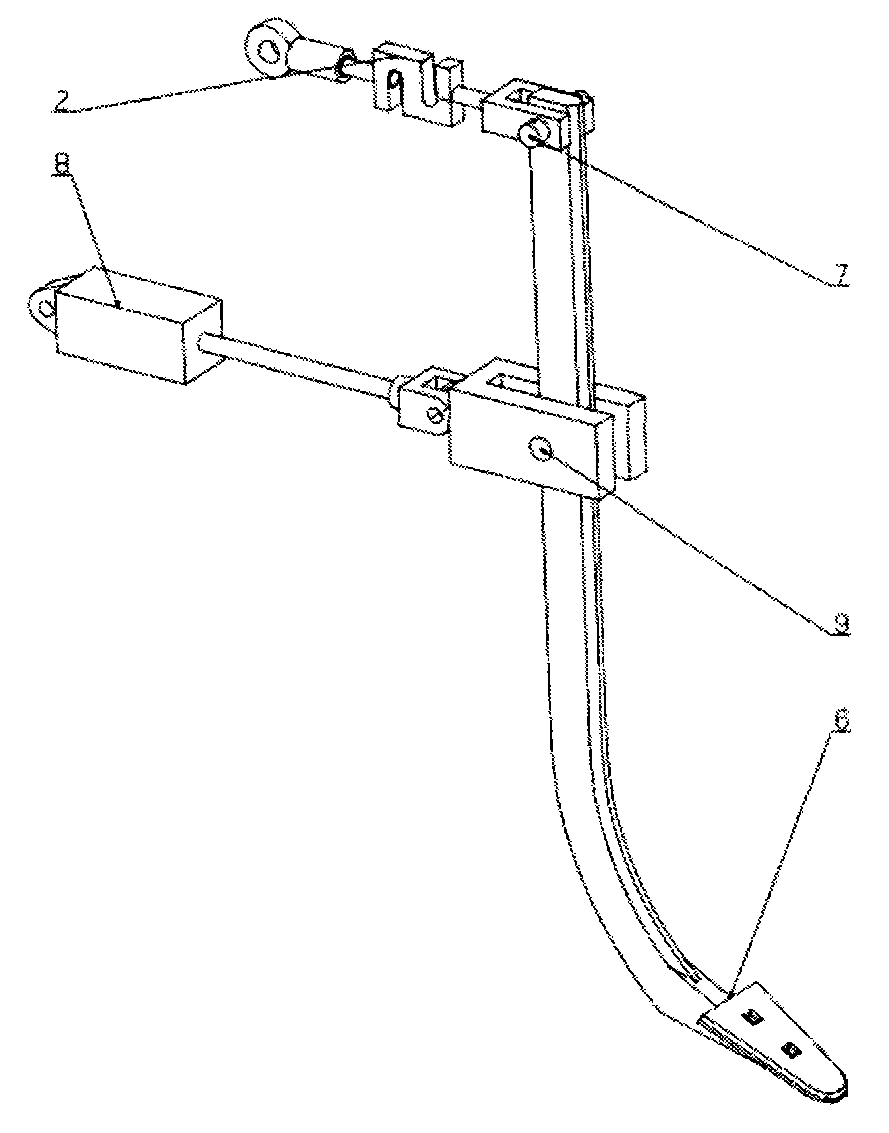

Pipe arrangement machine with function of distinguishing colors of bobbins

ActiveCN104030089AThe structure of the whole machine is simpleReduce manufacturing and tooling costsFilament handlingEngineeringBobbin

The invention provides a pipe arrangement machine with a function of distinguishing colors of bobbins. The pipe arrangement machine is characterized by comprising a pipe storage mechanism (1), a separate detection pipe turning mechanism (2), a rack (4) and a shell (5), wherein the pipe storage mechanism (1) comprises a lifter (1.1), a lifting block group (1.2) and a pipe receiving box (1.4); the separate detection pipe turning mechanism (2) comprises a sample pipe frame (2.1), a vision sensor (2.4), a pipe passing channel (2.5), a pipe conveying machine (2.6), a waste pipe channel (2.7), a pipe falling channel mechanism (2.8) and a separate detection pushing frame (2.9). The pipe arrangement machine further comprises an automatic basket replacement mechanism (3). According to the pipe arrangement machine with the function of distinguishing the colors of the bobbins, separate detection color comparison is directly perfomed; due to the arrangement of automatic basket replacement mechanism, manual operation is not needed; the pipe arrangement machine is simple in structure and low in processing and manufacturing cost.

Owner:BEIJING DAHENG IMAGE VISION

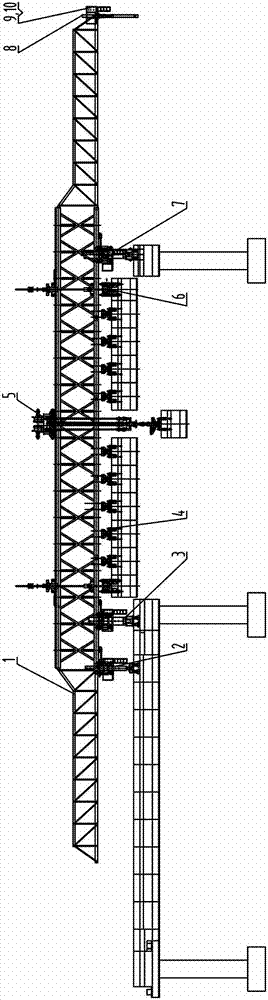

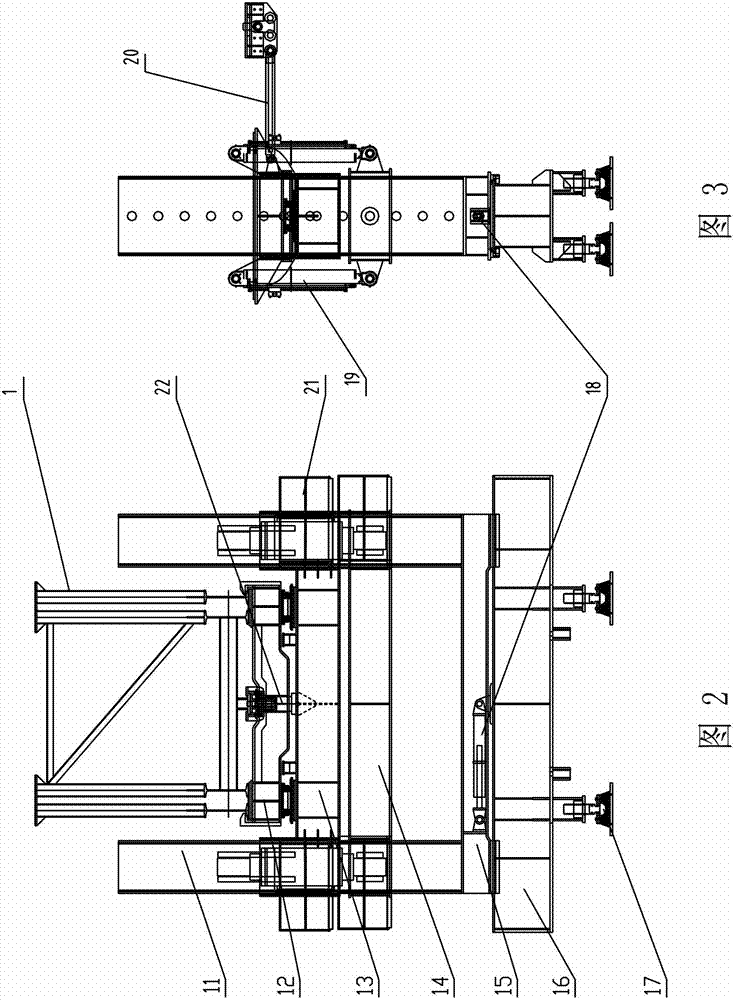

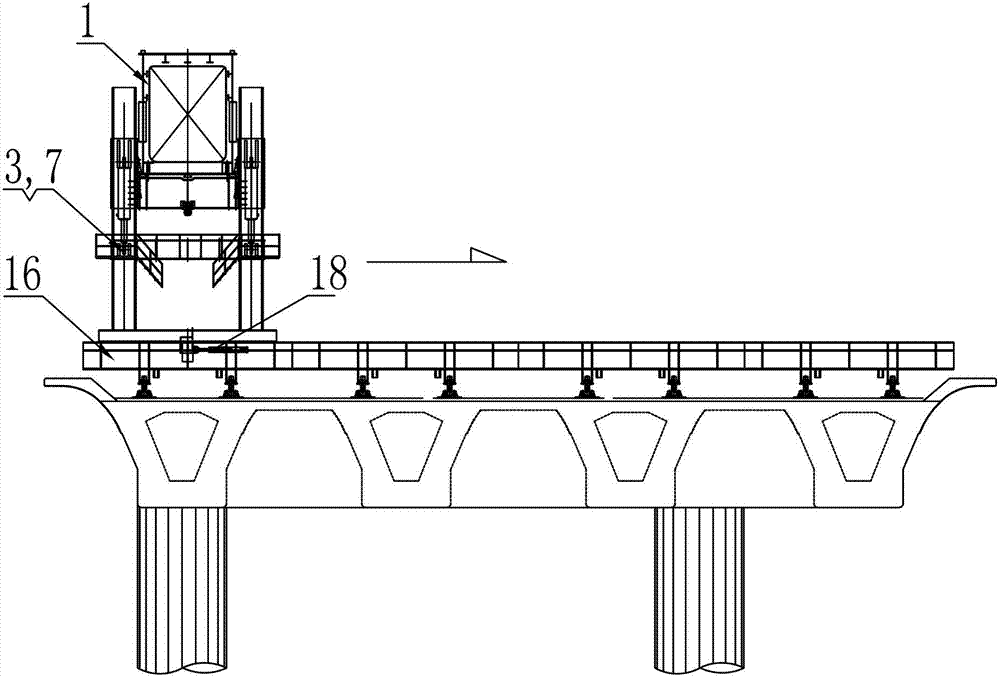

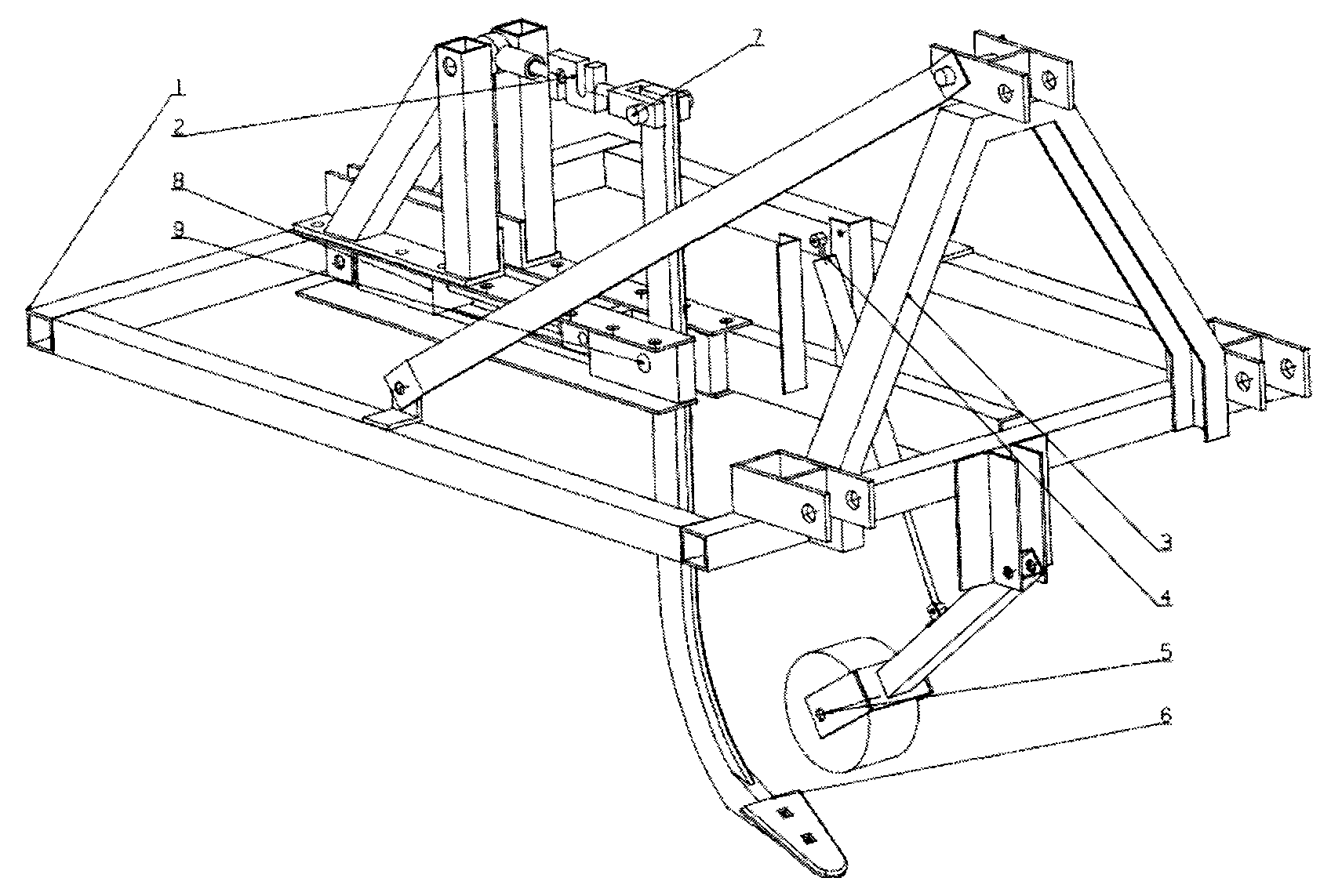

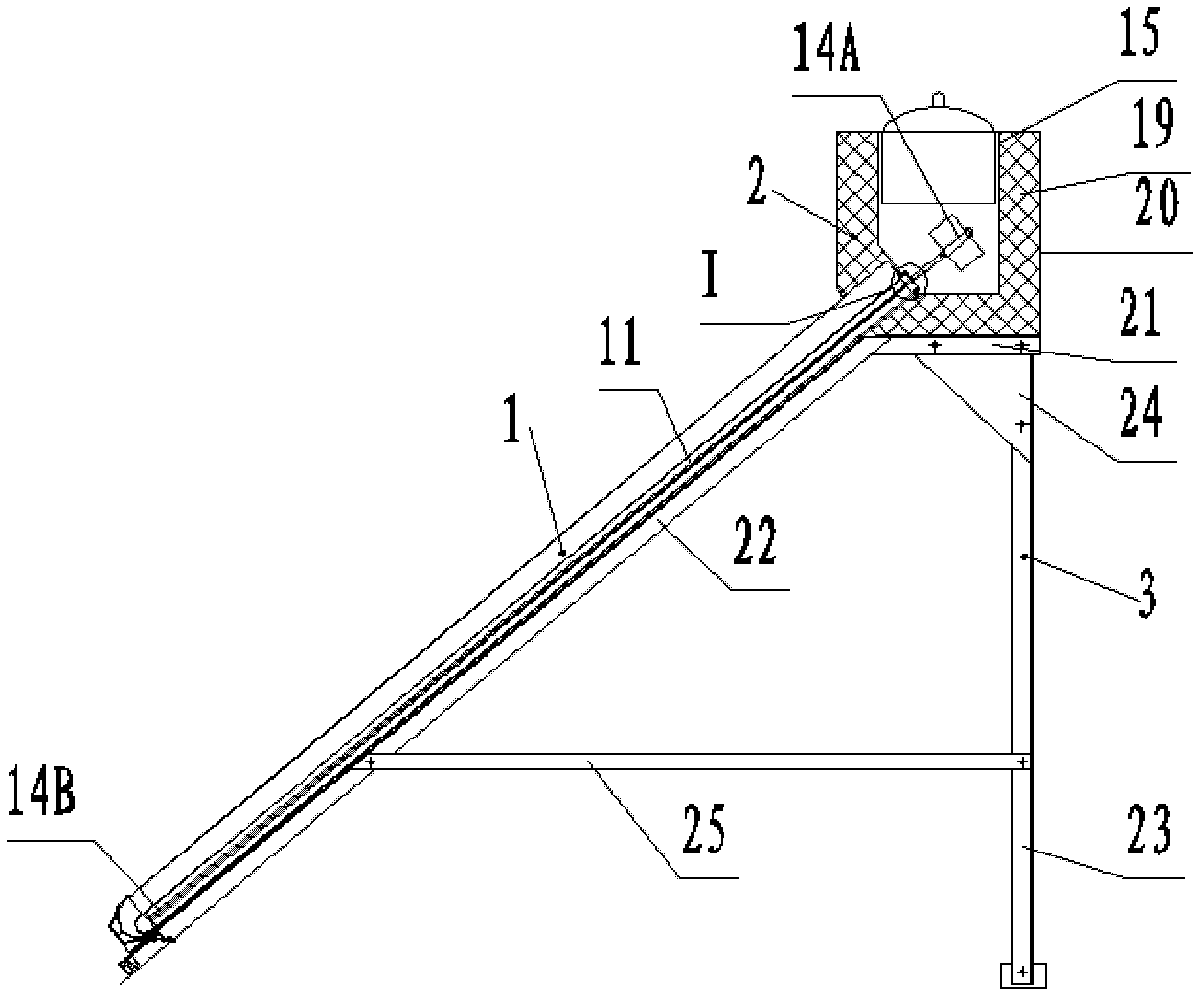

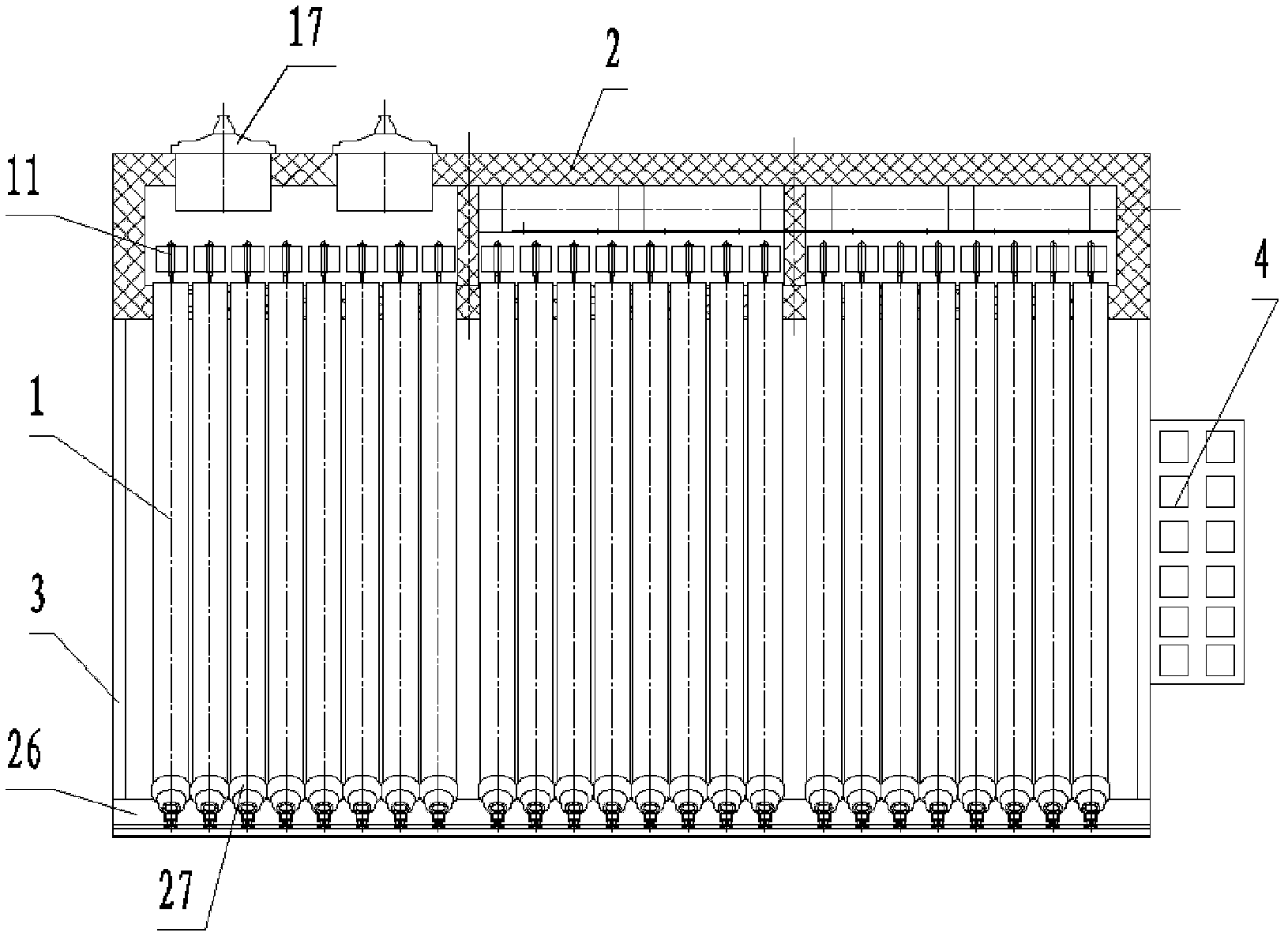

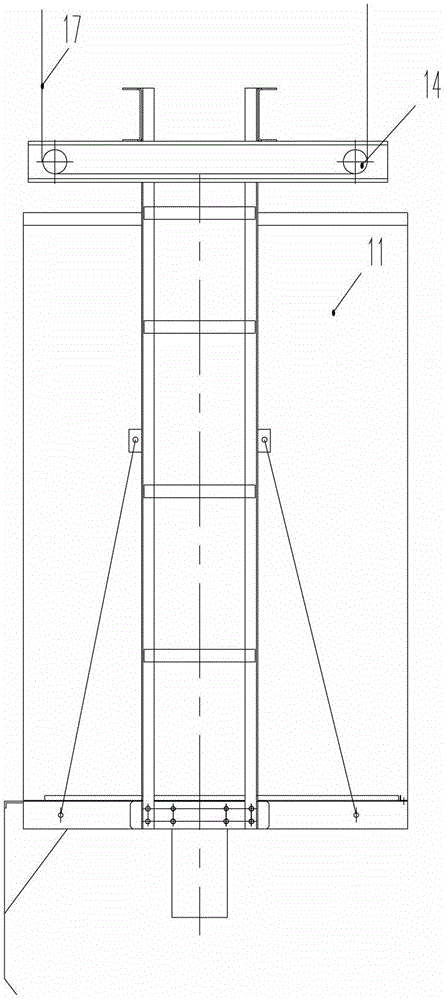

Section-assembling bridge girder erection machine suitable for erecting bridges with minimum curve radii

ActiveCN103031811APrecise constructionThe structure of the whole machine is simpleBridge erection/assemblyTerrainModularity

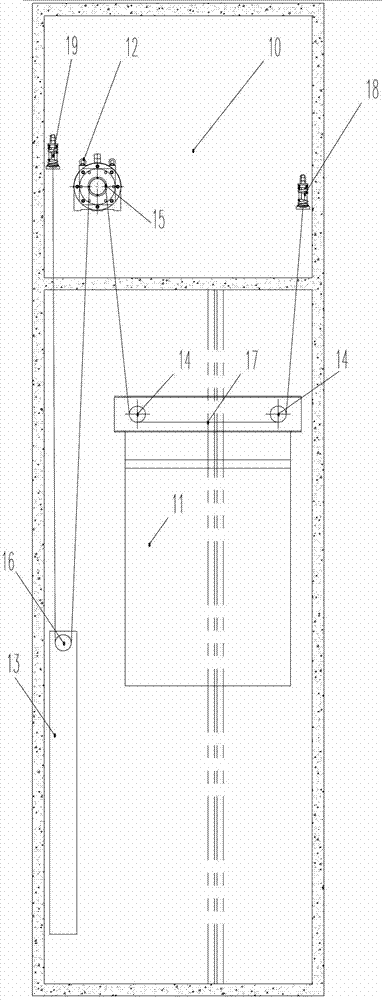

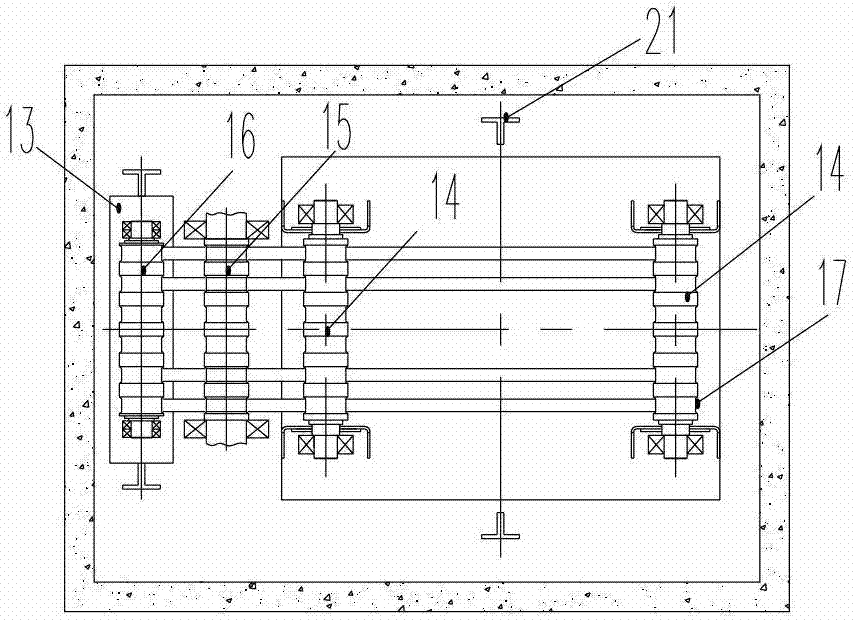

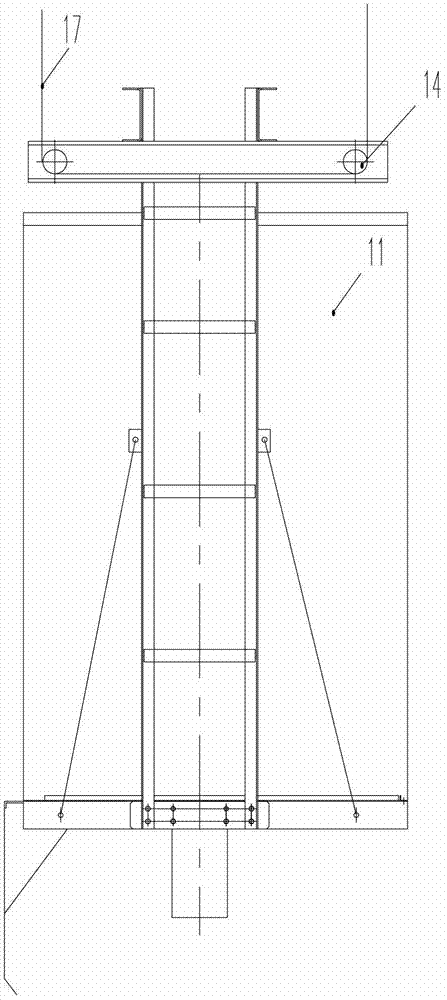

The invention relates to a section-assembling bridge girder erection machine suitable for erecting bridges with minimum curve radii. A girder assembly (1) is of a single-truss structure; No.1 middle support legs and No.2 middle support legs have the same structure, each middle support leg comprises a middle support leg-traversing mechanism, both ends of a middle support leg-traversing oil cylinder are respectively connected with a middle support leg-connecting crossbeam and a lower middle support leg crossbeam through pins, and the lower middle support leg crossbeam is of a horizontally assembled modularized structure; a rotary pin is welded on the top of the middle of a lower middle support leg turnplate crossbeam, and an upper middle support leg turnplate crossbeam is rotatably sleeved on the rotary pin. The section-assembling bridge girder erection machine can be hydraulically pushed to stably and accurately traverse, and can realize rapid, convenient and accurate construction in the process of erecting a bridge with a minimum curve radius and accurately align curved girder sections. The section-assembling bridge girder erection machine can swing girders, can pass through an opening along a curve during the construction of a bridge with a curve radius of 190 meters, and is suitable for construction in mountainous areas with complex terrains; for municipal construction in the downtown of a developed city, the site needed by the usage of the machine is small, and the affection of the machine on existing structures is little.

Owner:CHINA RAILWAY 11TH BUREAU GRP +2

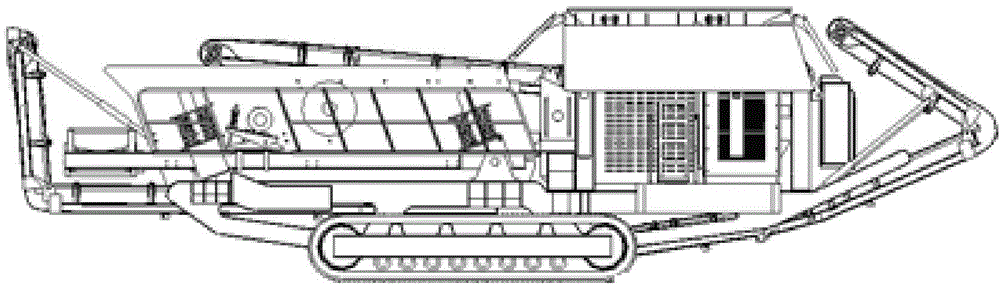

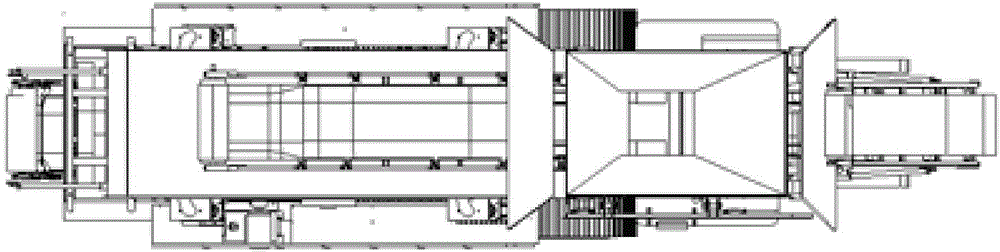

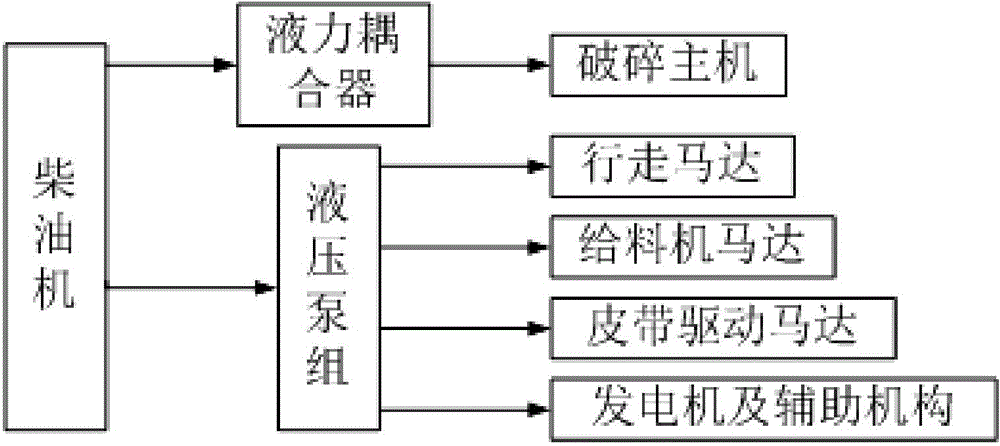

Electrically-driven movable crushing station

The invention discloses an electrically-driven movable crushing station. The electrically-driven movable crushing station comprises a control device and a crushing execution mechanism, wherein the control device is electrically connected with an external power grid and the crushing execution mechanism; in the crushing process, the crushing execution mechanism is electrified by the external power grid and is controlled to work by virtue of the control device. The electrically-driven movable crushing station is electrified by the power grid, so that the working energy consumption and the operation cost of the movable crushing station are lowered, the noise pollution and the environmental pollution are reduced, the whole structure of the movable crushing station is simplified, and the production cost is lowered; a running system can be subjected to stepless speed regulation, is electrified by virtue of a storage battery and can be recycled, so that hostile work environments can be adapted, and faults are convenient to check and maintain.

Owner:XUZHOU XCMG MINING MACHINERY CO LTD

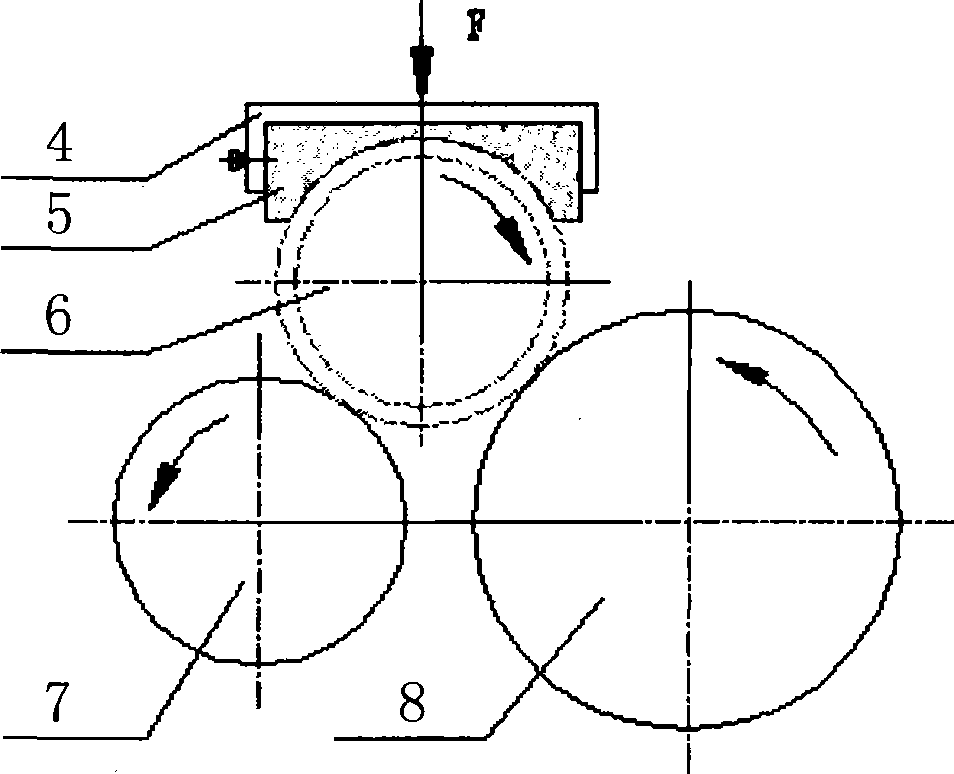

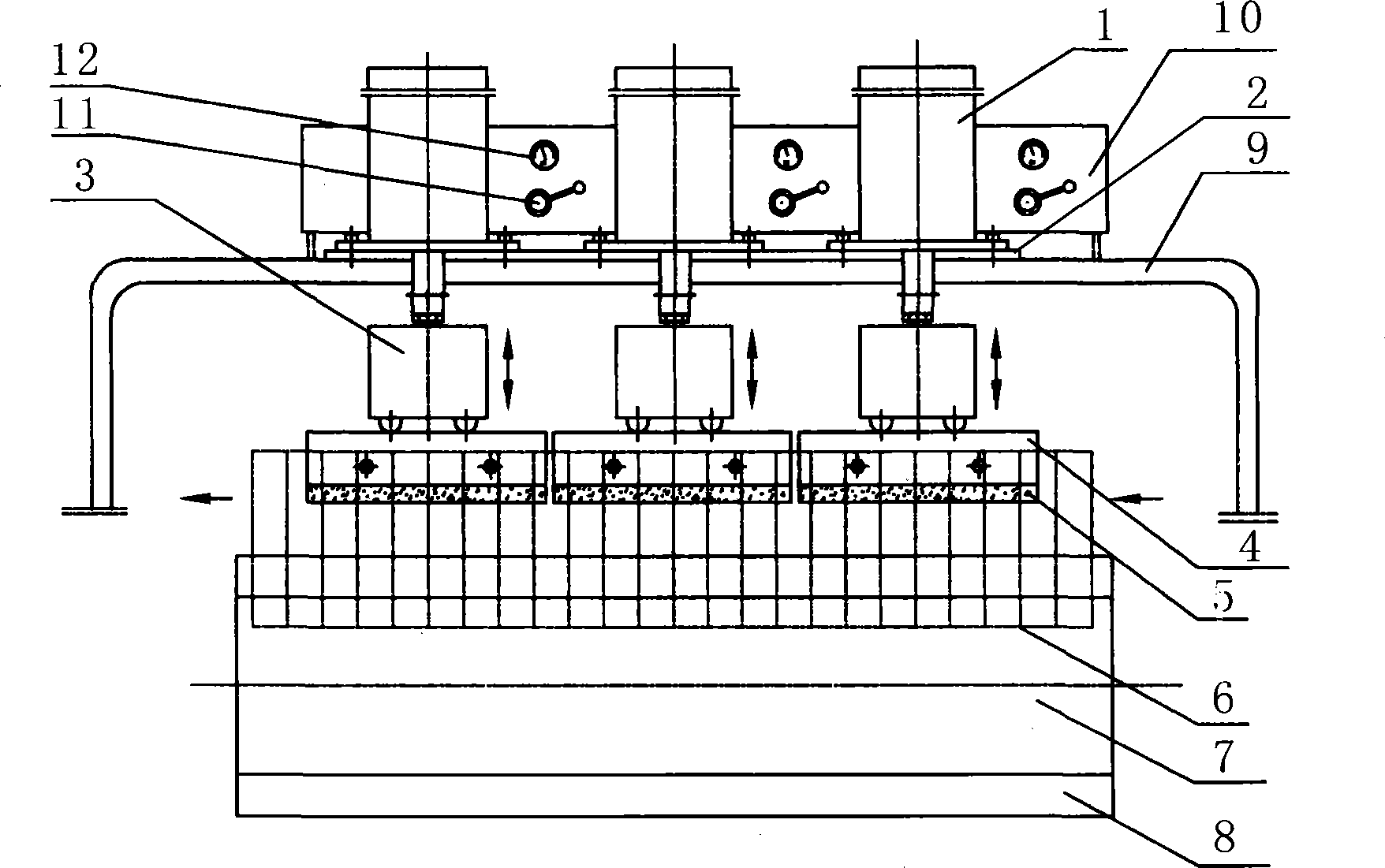

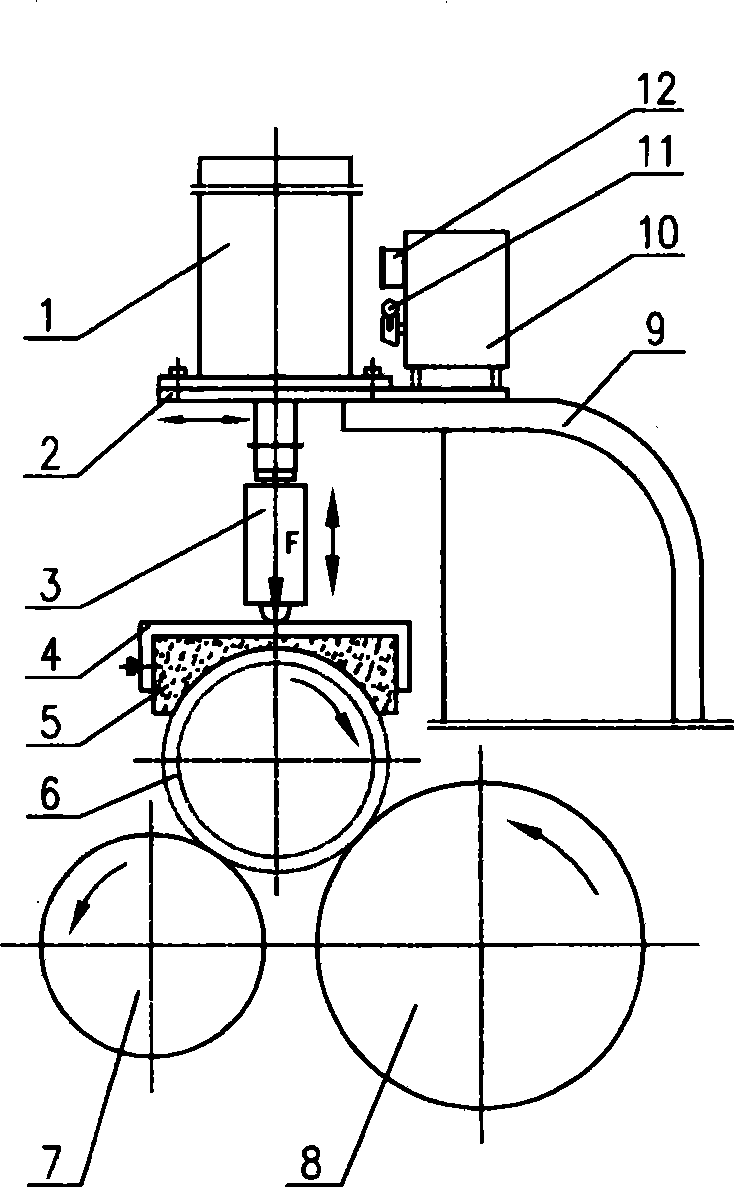

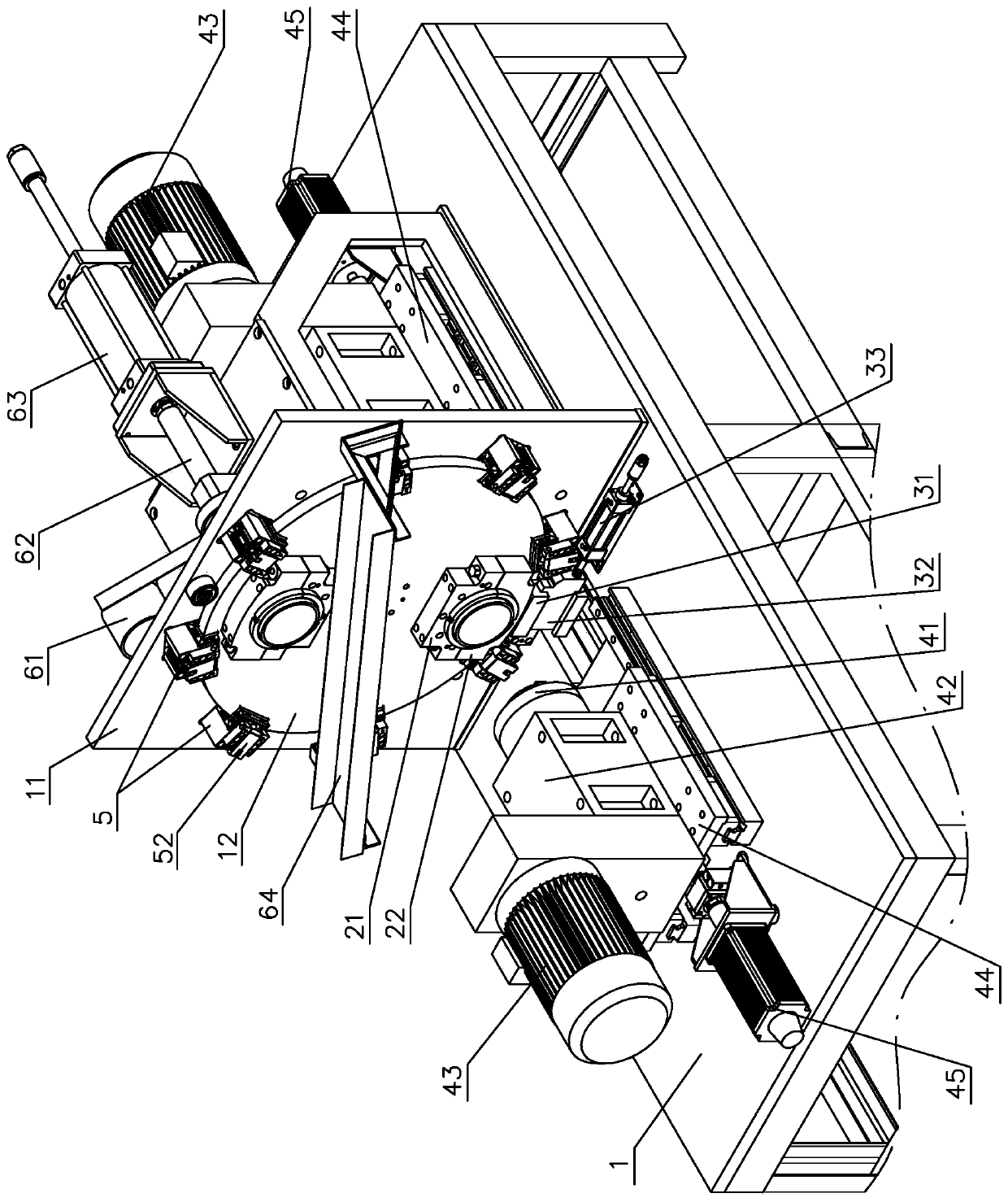

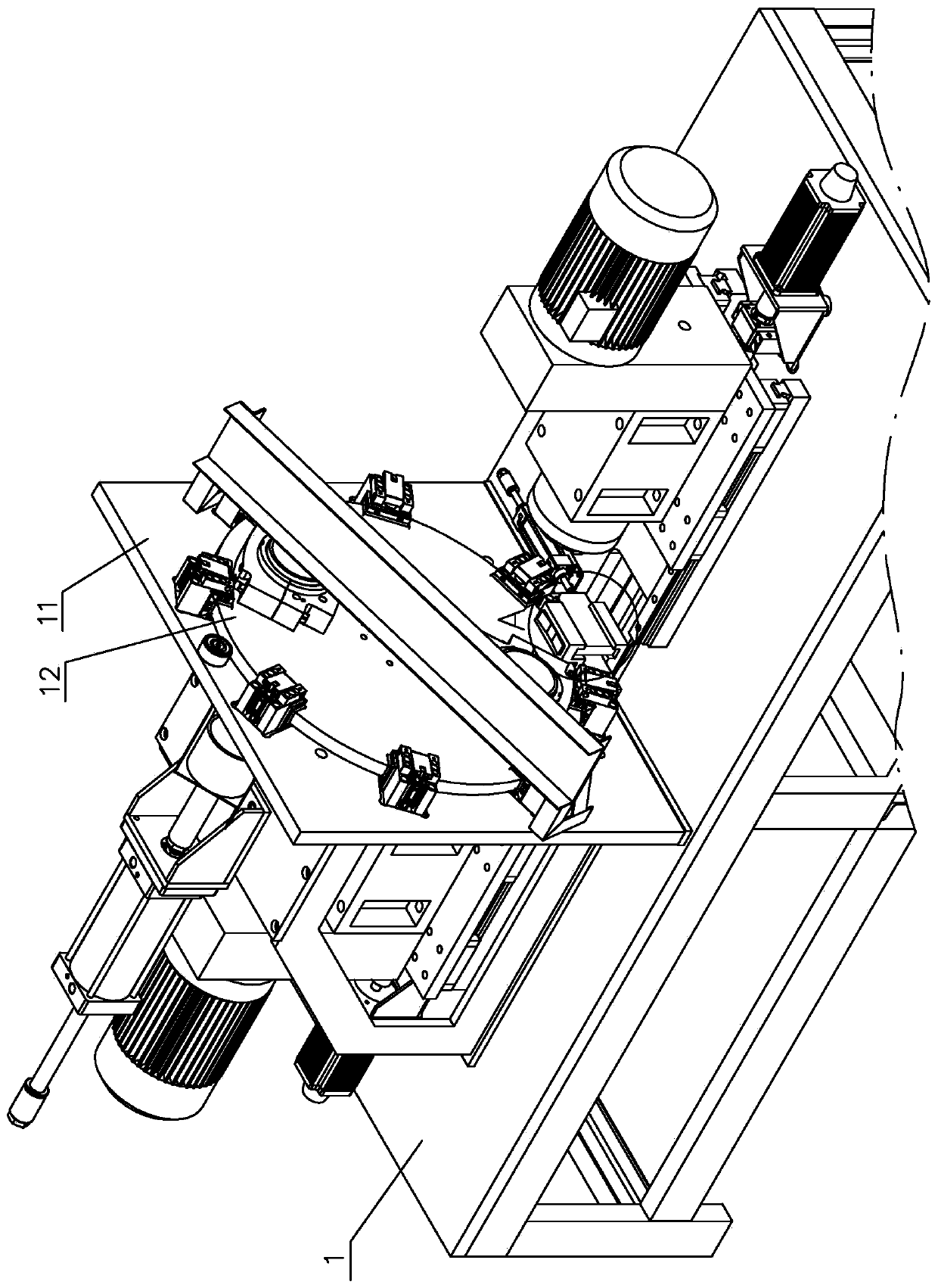

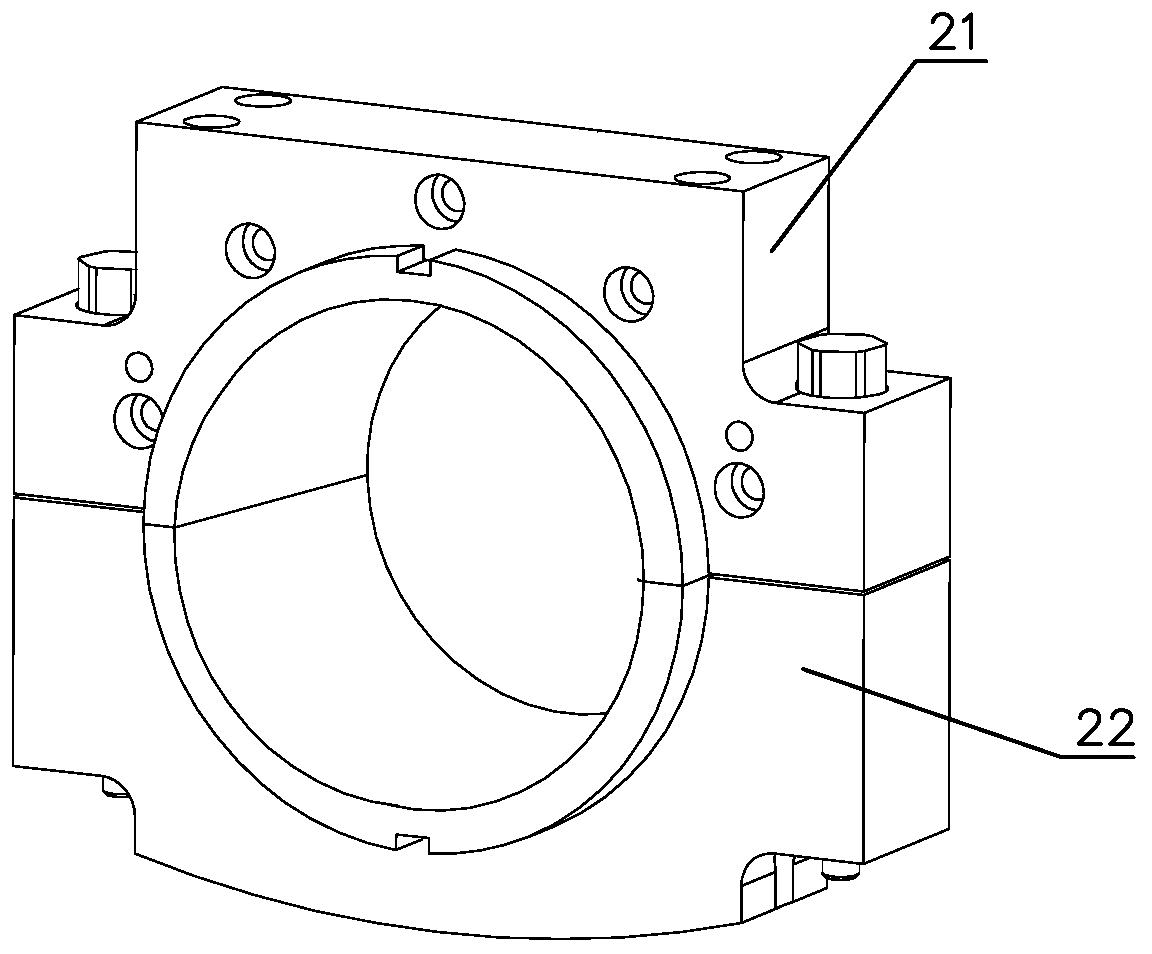

External diameter grinding machine pressurized by cylinder

InactiveCN101396798AThe structure of the whole machine is simpleReduce processing costsRevolution surface grinding machinesEngineeringMechanical engineering

The invention provides an external diameter grinder which is pressurized by a cylinder; the large guide roller seat (9) of the grinder is provided with a pressurization device which consists of a cylinder (1), a supporting plate (2), a flexible compressing device (3), a pneumatic element box (10), a pressure gauge (11) and a manual valve (12); three cylinders are fixed on the supporting plate which can move forwards and backwards; the supporting plate, the pneumatic element box, the pressure gauge and the manual valve are arranged on the large guide roller seat and control the cylinders by connection pipelines; the piston rod extending end of the cylinder is connected with the flexible compressing device, thus driving the flexible compressing device to move upwards and downwards; during the grinding process, after the distance of a large guide roller (8) and a small guide roller (7) is adjusted, bearing rings (6) are sequentially piled one by one; three oilstones (5) and a splint (4) are arranged on the bearing rings; according to the size of the external diameter and the requirement of coarse grinding and fine grinding, the pressure and the up-down stroke of the cylinder are adjusted; the pressure is middle so as to lead two fulcrums of the three flexible compressing devices to be supported at the middle positions of respective splint symmetrically, thus carrying out the grinding of the external diameter.

Owner:LUOYANG BEARING SCI & TECH CO LTD

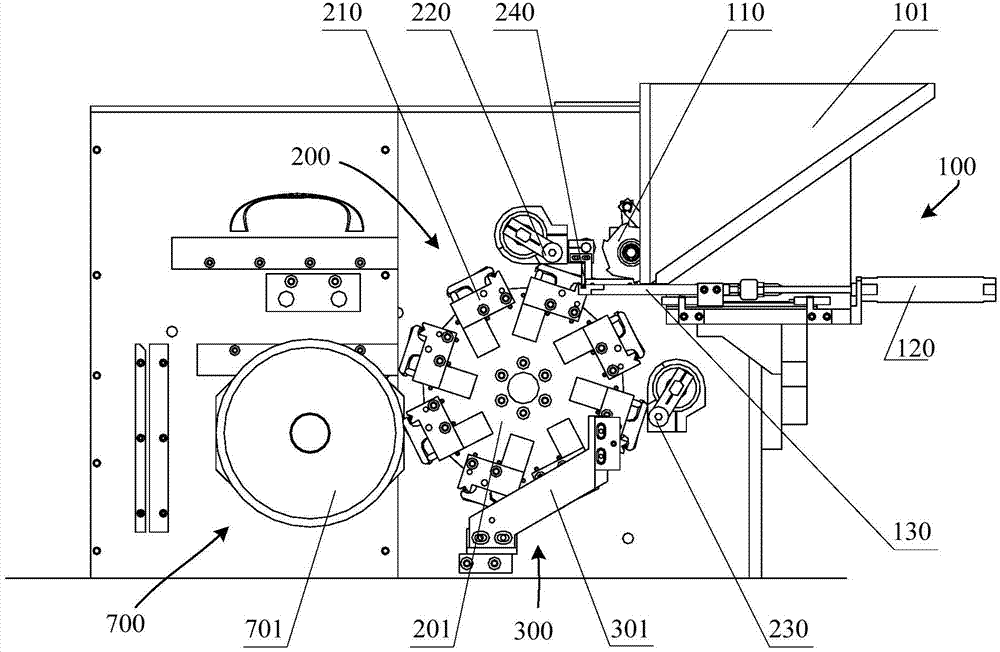

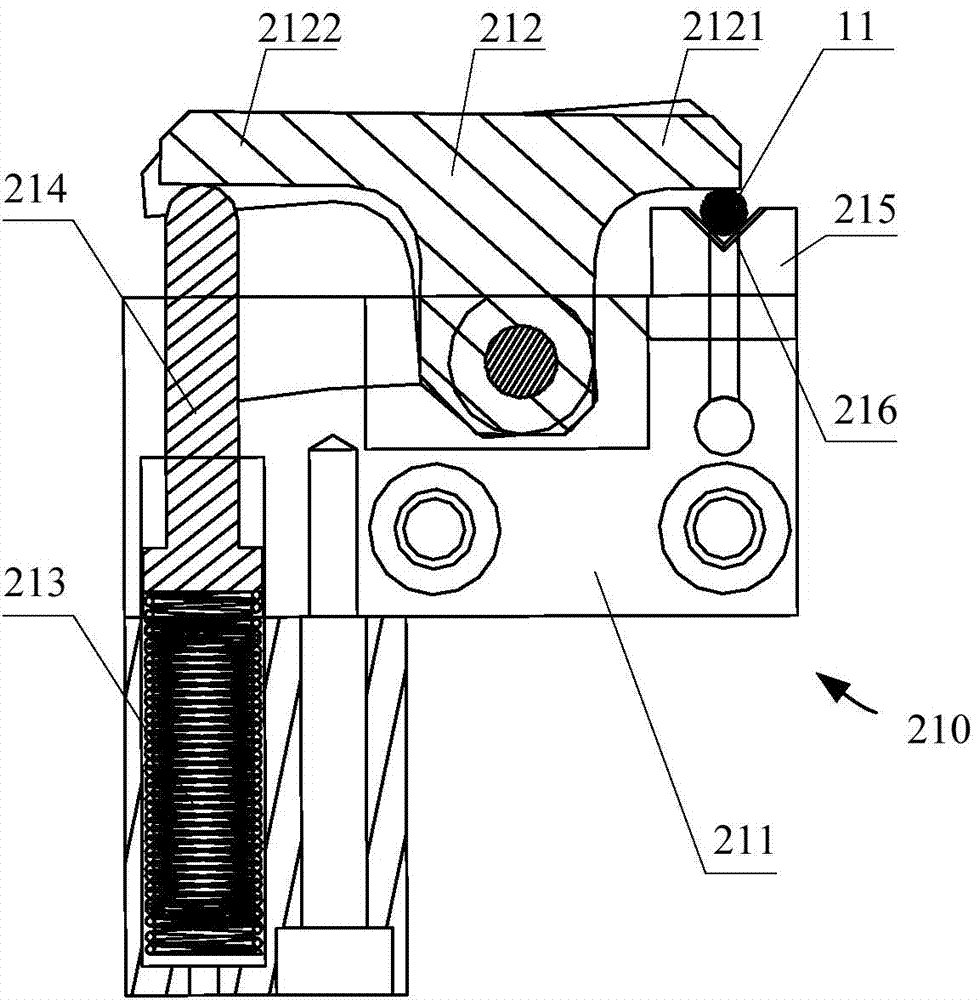

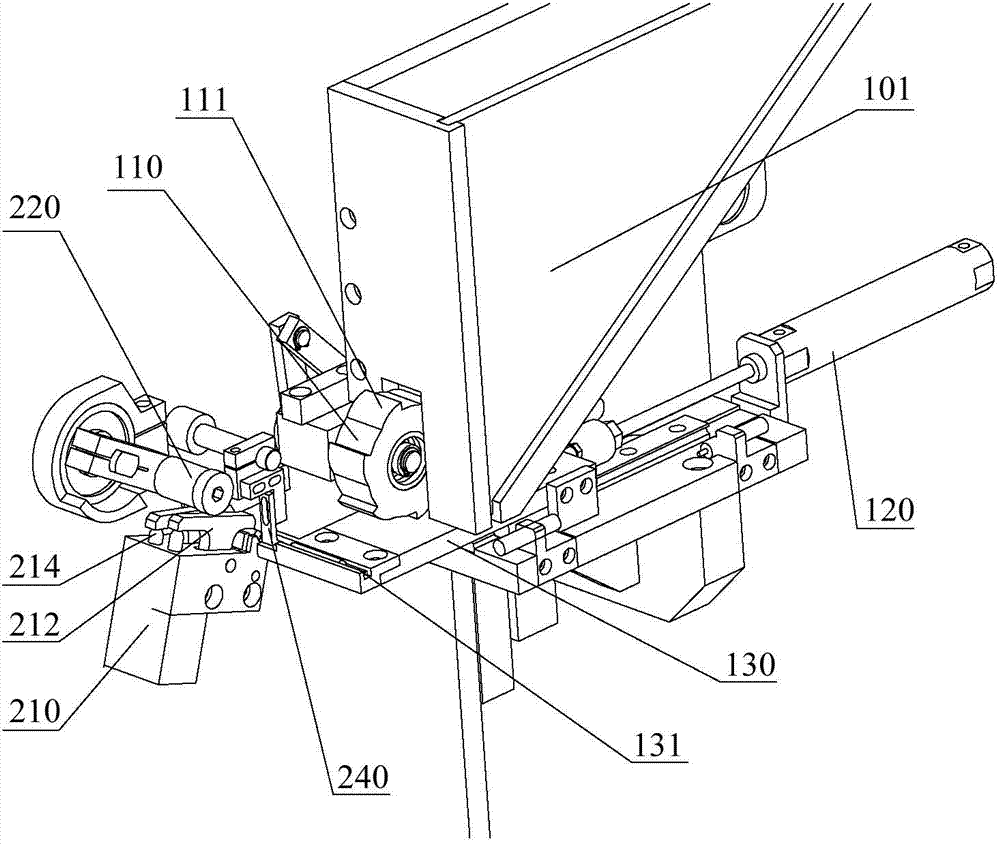

Dividing cutting machine and station transformation device

ActiveCN103481172ASimplify the station changeover processSimple machine structureGrinding machinesGrinding work supportsEngineeringButt joint

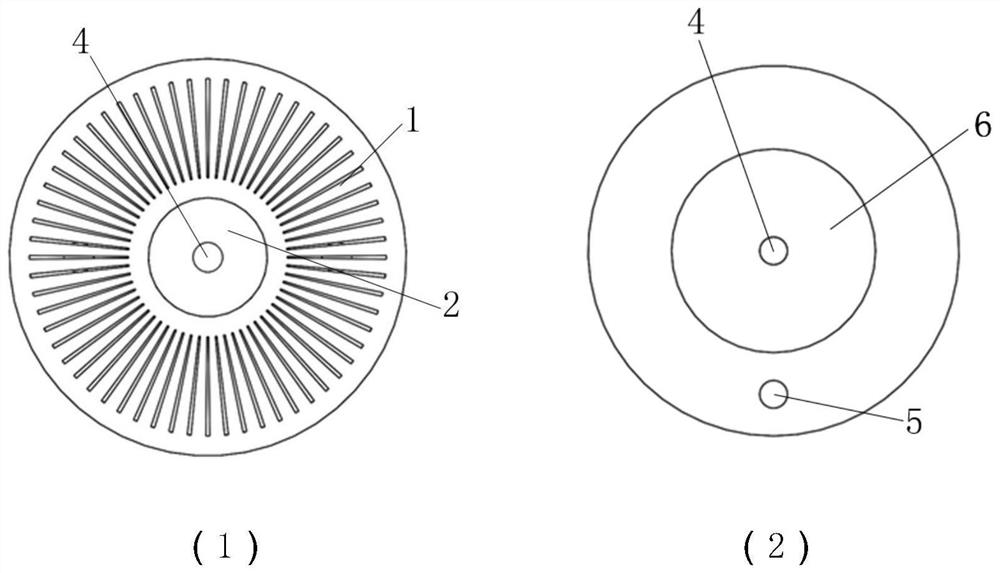

The invention discloses a dividing cutting machine and a station transformation device. The cutting machine comprises a feeding device, the station transformation device, a cutting device and a discharging device. The station transformation device comprises a dividing plate, at least one clamping mechanism arranged at the edge of the dividing plate and a driving device for driving the dividing plate. The feeding device, the cutting device and the discharging device are arranged at the edge of the dividing plate respectively. The station transformation device is in butt joint with the feeding device, the cutting device and the discharging device respectively through the clamping mechanisms. The station transformation process of the cutting machine is simplified, therefore, a machine structure of the cutting machine is simplified, and cost of the cutting machine is reduced. A plurality of clamping mechanisms can be arranged on the dividing plate, therefore, continuousness of stations can be kept, and production efficiency is improved.

Owner:SHENZHEN JINZHOU PRECISION TECH

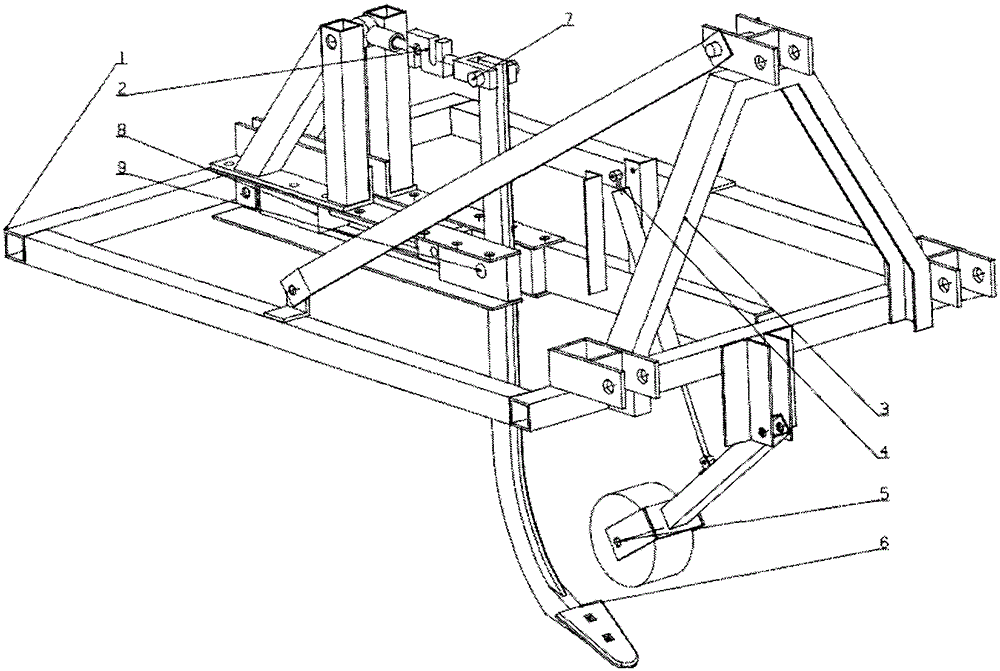

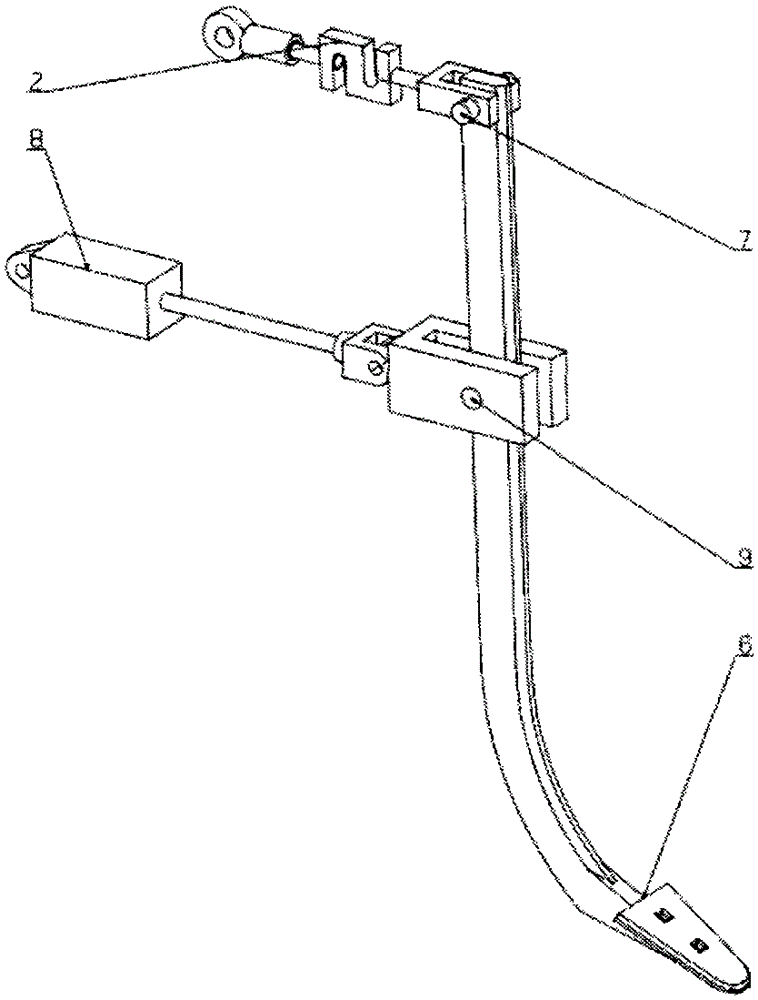

Subsoiler capable of measuring mechanical resistance of soil continuously

InactiveCN103918365AThe structure of the whole machine is simpleEasy to install and replaceSoil-working equipmentsApparatus for force/torque/work measurementEngineeringMechanical resistance

The invention discloses a subsoiler capable of measuring the mechanical resistance of soil continuously, and aims to measure the mechanical resistance of the soil. A displacement sensor is used for measuring the tillage depth of the subsoiler and installed between a machine frame and a profiling wheel. A scraper knife of the subsoiler is hinged to a sliding block, and a hydraulic cylinder is connected with the sliding block. Under the condition that the tillage resistance is not large and the scraper knife can not be damaged, the hydraulic cylinder prevents the scraper knife from moving backwards. In the tillage process, if the scraper knife meets foreign bodies, the value of the resistance on the scraper knife exceeds the set pressure value of the hydraulic cylinder, the hydraulic cylinder contracts, and the scraper knife moves backwards and avoids the foreign bodies. The scraper knife is connected with a force sensor used for measuring the resistance of tillage.

Owner:XINJIANG AGRI UNIV

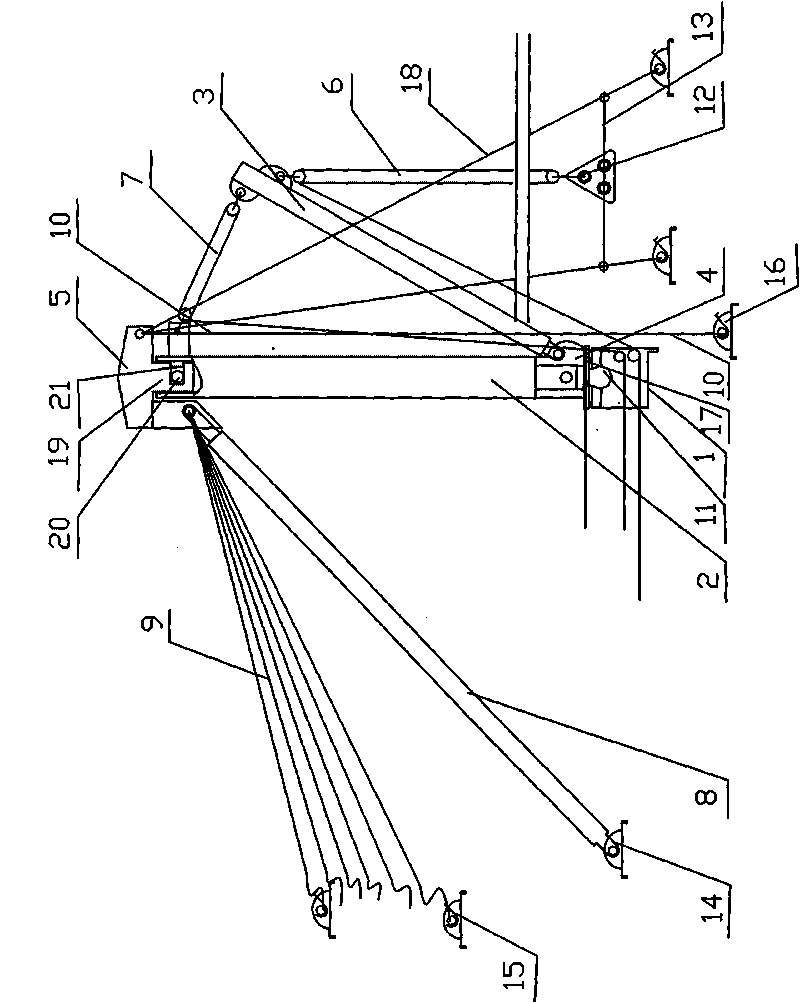

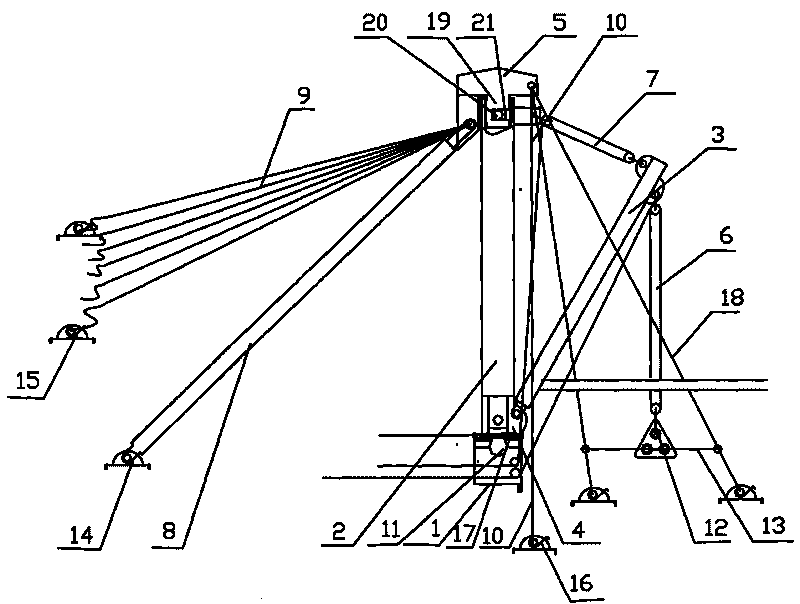

Method and device for lifting weight on top floor of super high-rise building

ActiveCN101700855AThe structure of the whole machine is simpleReduce volumeCranesHeavy loadLifting weight

The invention relates to a method and a device for lifting weights on the top floor of a super high-rise building, wherein the device comprises a stand, a fixed mast, a movable mast, a ball joint, a guy cable combined disk, a hoisting block, an amplitude-change block, a stabilizing bar, a guy cable and a prestressed drag line; the stabilizing bar, the stand, the guy cable combined disk and the fixed mast are utilized to form a stable support structure, and meanwhile, prestressing force applies to the guy cable and the prestressed drag line; when weights are lifted, the stabilizing bar is in a state with small stress or no stress and generates sufficient stability and safeguard; and a guideline resists transverse wind loads. The invention has a simple process method, and the device has reasonable structure, simple and convenient operation, small overall weight, flexible movement, convenient assembly, disassembly, entrance and exit, safe operation, low cost and short construction period, and can realize the integral lifting of overweight objects on the top floor of the super high-rise building, overcome the difficulty of the integral lifting of the overweight objects on the top floor of the super high-rise building which can not be finished by traditional construction elevators, tower cranes and traveling cranes, solve the difficult problem puzzling the technical field of construction and installation for a long time, and realize standardized and mass large-scale production.

Owner:唐福强

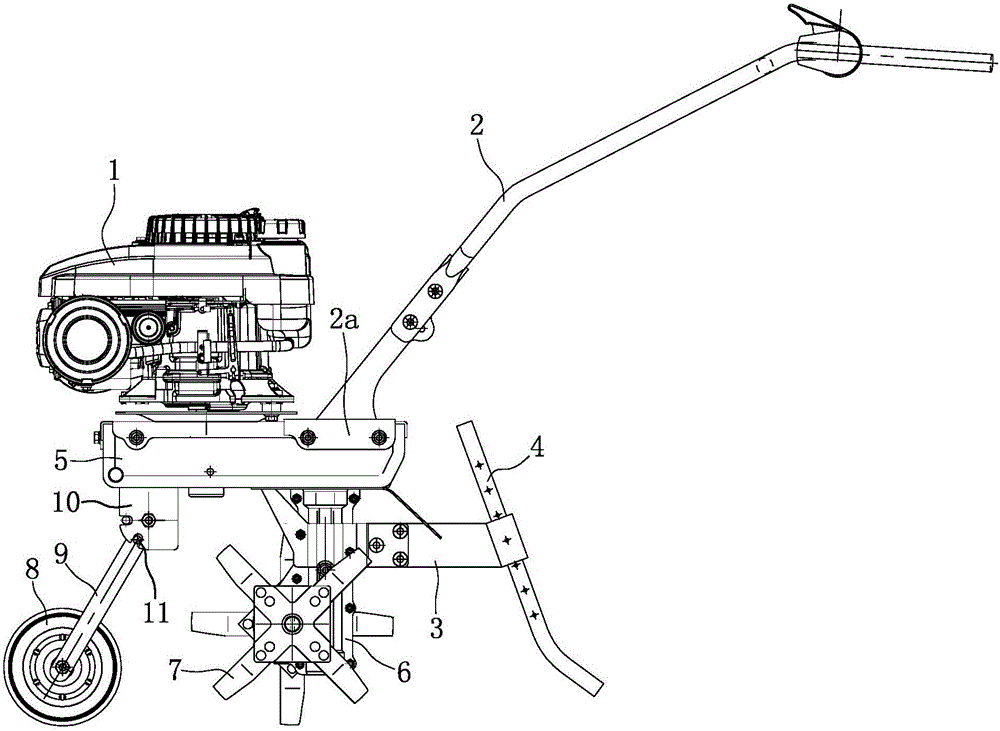

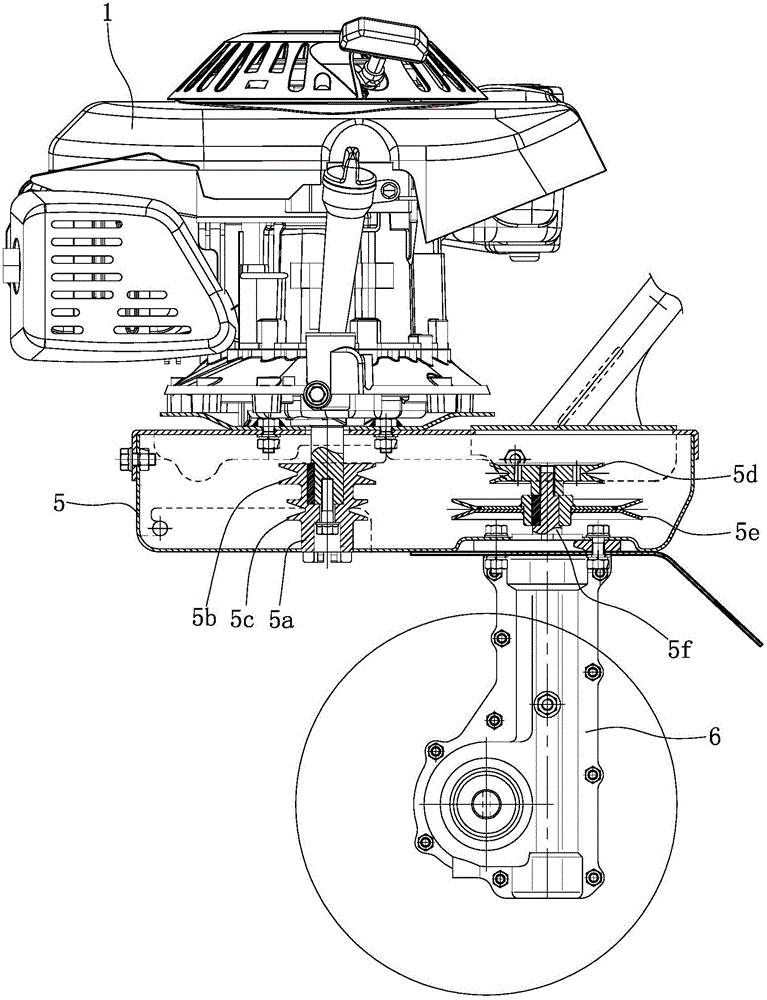

Two-gear micro ploughing machine

InactiveCN105052260AThe structure of the whole machine is simpleReduce volumeTilling equipmentsEngineeringLow speed

The invention discloses a two-gear micro ploughing machine. An engine (1) is mounted at the front end of the top of a main transmission case (5), a handhold assembly (2) is mounted at the rear end of the top of the main transmission case (5), an output shaft of the engine (1) extends into the main transmission case (5) and is connected with a driving wheel shaft (5a), the lower end of a driven wheel shaft (5f) is connected with the input end of a worm transmission case (6), and a ploughing knife (7) or a travelling wheel is mounted on an output shaft of the worm transmission case (6); a positioning frame (10) is arranged in front of the worm transmission case (6) and consists of a top plate and side plates symmetrically arranged left and right, the upper end of a sloped tube (9) is positioned between the two side plates of the positioning frame (10), and a front wheel (8) is mounted under the sloped tube (9). The micro ploughing machine disclosed by the invention is simple and compact in structure, small in size and low in cost; the front wheel has two states of folding and unfolding, so that the requirements for different using states of the micro ploughing machine can be met. The micro ploughing machine has two gears of high speed and low speed, and is smooth and reliable in transmission, and the applicable range is wide.

Owner:CHONGQING JIAMU MACHINERY

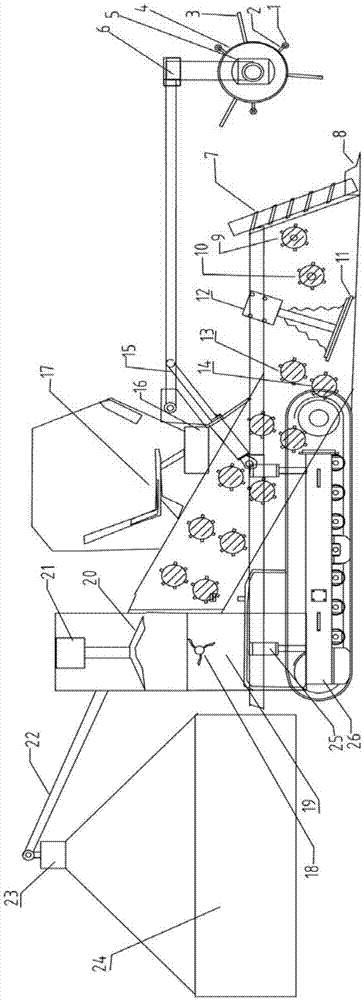

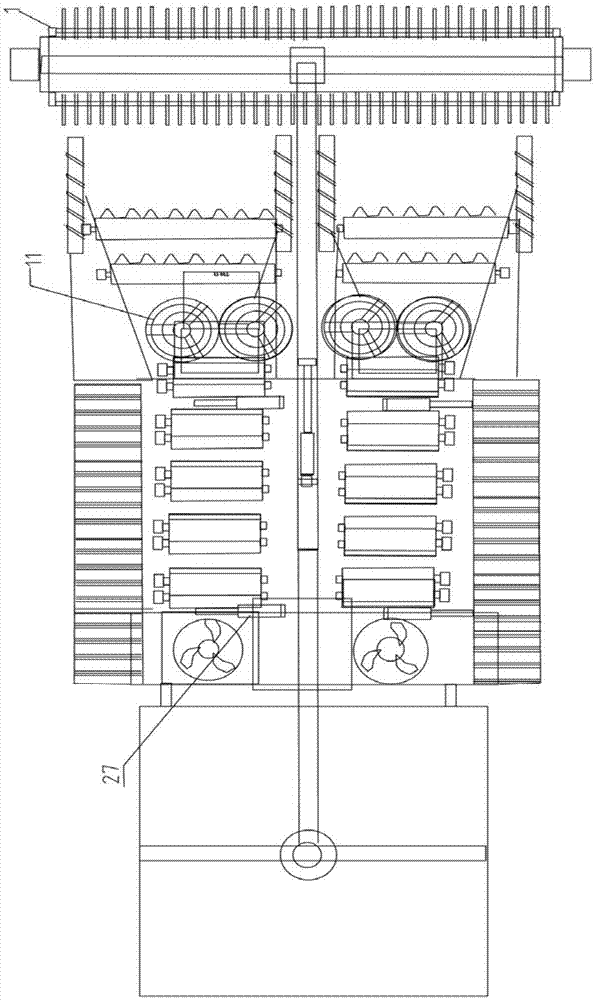

Efficient whole-rod type sugarcane combine-harvester

InactiveCN105432232AReduce the rate of broken headsIncrease productionHarvestersEngineeringMotor drive

The invention discloses an efficient whole-rod type sugarcane combine-harvester. The combine-harvester comprises a tail removal device located on a harvester frame, two or more straightening devices with the outer roller space adjustable, two or more root cutting devices with the space adjustable, a conveying device, a loading and unloading device, a traveling mechanism with the space between a left wheel and a right wheel adjustable and a harvester frame structure with the ground clearance adjustable; the tail removal device comprises a leaf smashing roller and a leaf smashing motor driving the leaf smashing roller to rotate, leaf smashing strips and tail tip clamping rods are arranged at the peripheral circle of the leaf smashing roller alternately, and the tail tip clamping rods are used for beating away tail tips of sugarcane; each straightening device comprises a ground attachment awl and a straightening roller arranged above the corresponding ground attachment awl, each ground attachment awl scoops up the sugarcane on the ground and delivers the sugarcane to the corresponding straightening roller, and each straightening roller aligns the sugarcane and lifts the sugarcane to the operation scope of the corresponding root cutting device. The efficient whole-rod type sugarcane combine-harvester has the advantages of being simple in procedure, extremely high in efficiency, reasonable in structure and reliable in work, and the same machine can be used for multiple purposes.

Owner:韦瑞峯

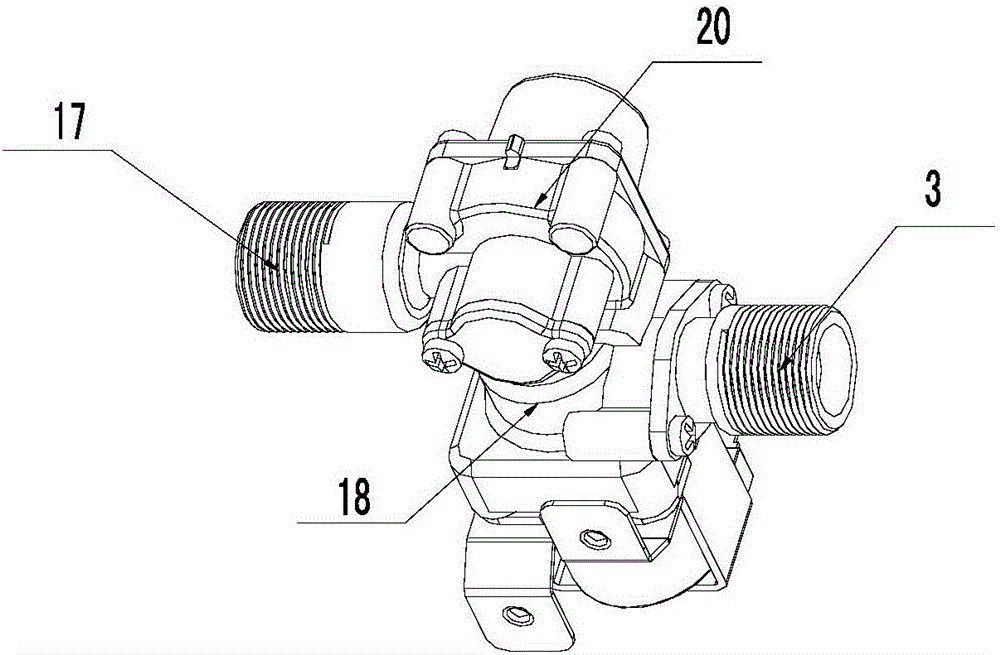

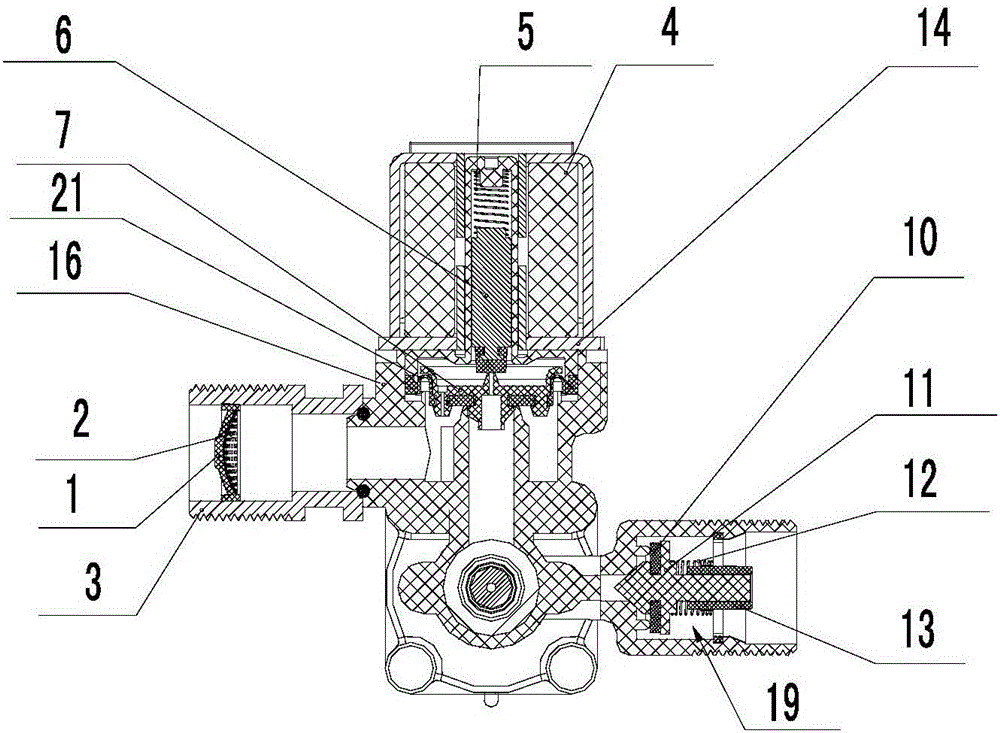

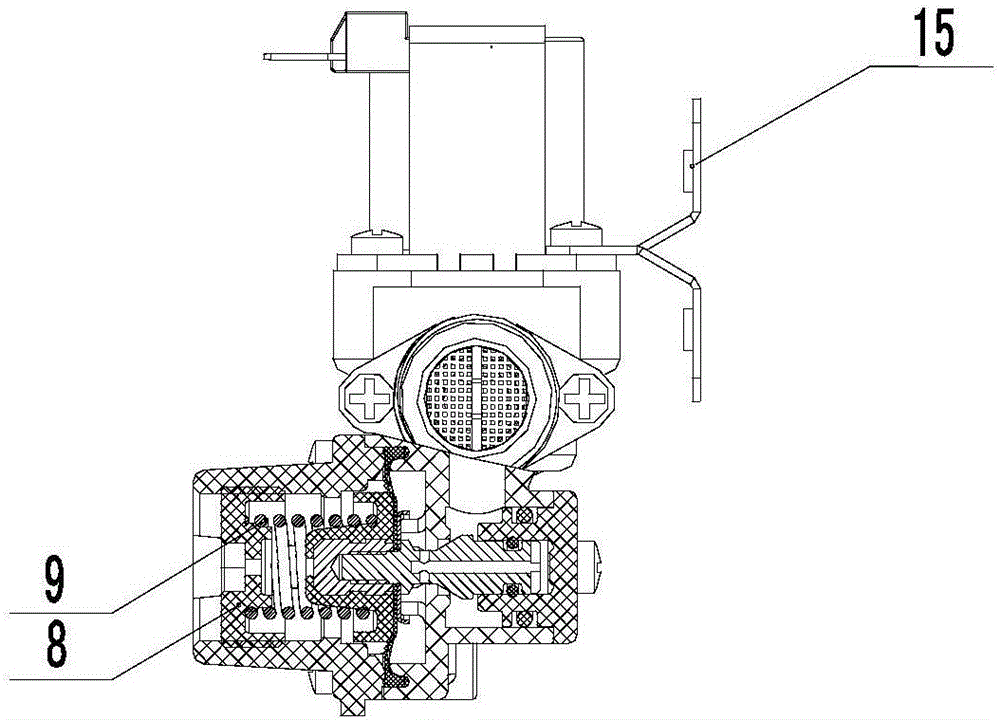

Integrated electromagnetic valve structure and pipeline water dispenser

ActiveCN106195409AEasy to installReduce usageOperating means/releasing devices for valvesCheck valvesInlet channelWater leakage

Owner:GREE ELECTRIC APPLIANCES INC

Efficient and energy-saving magnet-collecting direction-control linear motor for compression refrigeration

InactiveCN106505820AThe structure of the whole machine is simpleUse energy efficientPiston pumpsDynamo-electric machinesElectricityElectric machine

The invention discloses an efficient and energy-saving magnet-collecting direction-control linear motor for compression refrigeration. The linear motor comprises an annular permanent magnet stator or a mover and an iron core coil mover or a stator; the linear motor is characterized in that N poles or S poles of permanent magnets for forming an annular magnetic field all face to interior of a ring to form inner ring homo-polar property so as to generate a strong annular inversion magnetic field with opposite ring opening magnetic field directions; the S poles or N poles of the permanent magnets for forming the annular magnetic field all face to exterior of the ring to form outer ring homo-polar property; and an iron core coil with certain length is placed in the inversion magnetic field ring. The efficient and energy-saving magnet-collecting direction-control linear motor has the advantages of simple structure, low production cost, energy-saving, electricity-saving, and high working efficiency; when a motor apparatus and a compression apparatus are directly combined into one body, a complex crank connecting rod structure can be omitted, intermediate consumption of electric energy can be reduced, and the operating efficiency of a mechanical system can be greatly improved by prolonging a piston travel of the inversion magnetic field, thereby enabling the piston pushing force to be higher.

Owner:李扬远

Subsoiler with continuous measurement of soil mechanical resistance

InactiveCN103918365BEasy to installEasy to replaceSoil-working equipmentsApparatus for force/torque/work measurementHydraulic cylinderMechanical resistance

Owner:XINJIANG AGRI UNIV

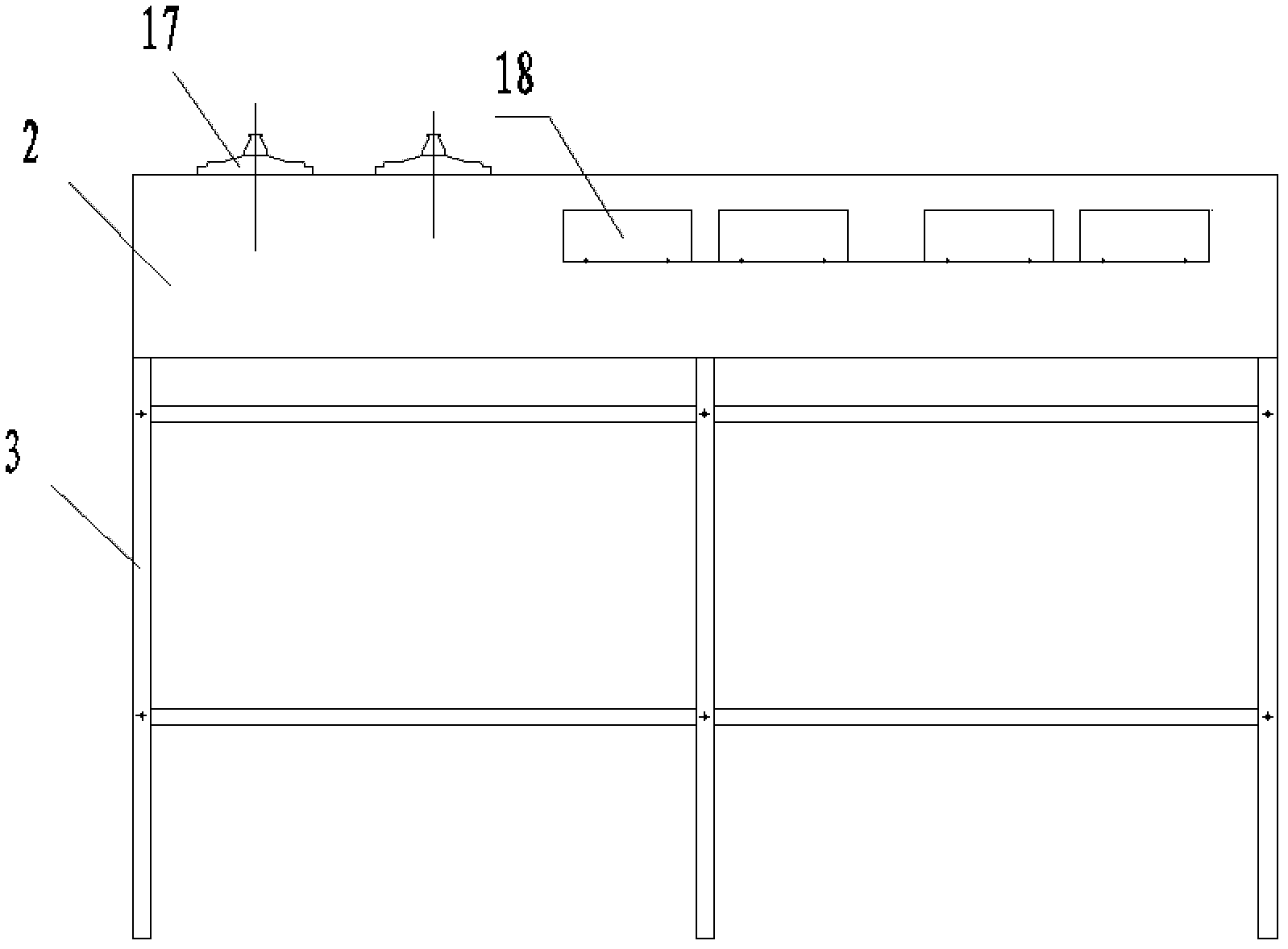

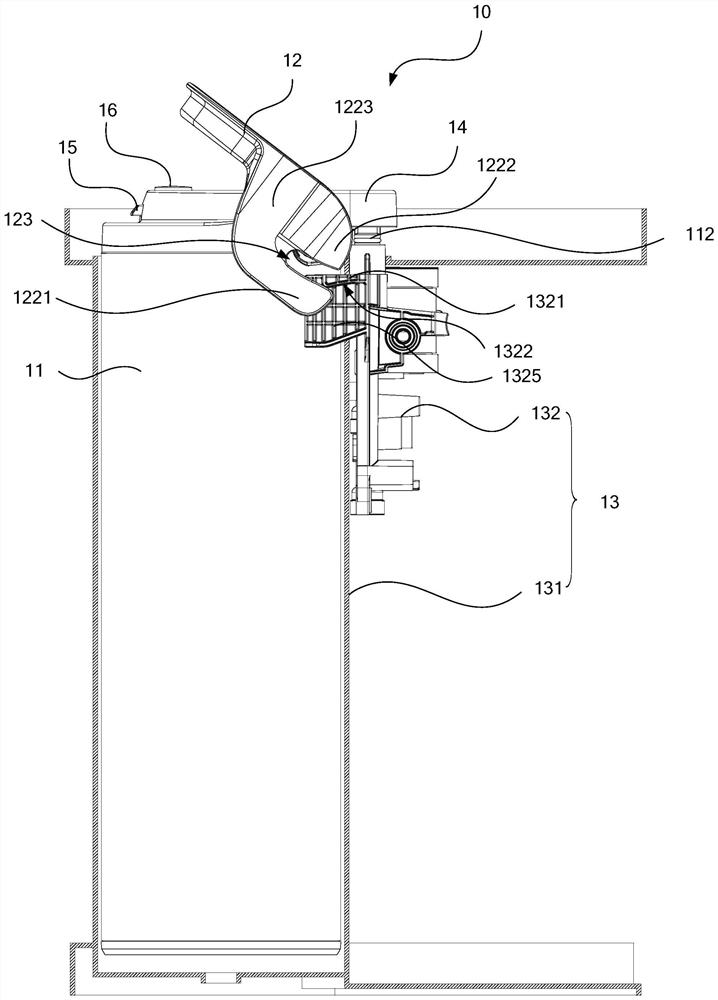

Solar stove

InactiveCN102589164AThe structure of the whole machine is simpleEasy to useSolar heating energySolar heat devicesHeat transfer efficiencyEngineering

The invention discloses a solar stove, which belongs to the field of application of solar energy and comprises a support, a heat collecting element and a cooking box. The support is used for mounting the heat collecting element and the cooking box, the heat collecting element is used for collecting heat and transmitting the heat to the cooking box, the cooking box is used for mounting cooking utensils, the heat collecting element consists of a full-glass vacuum heat collecting tube and a heat tube, the full-glass vacuum heat collecting tube is used for condensing light and collecting the heat, the heat tube comprises an evaporation end and a condensation end, the evaporation end of the heat tube is inserted into the full-glass vacuum heat collecting tube, the condensation end of the heat tube is inserted into the cooking box, and the heat collected by the full-glass vacuum heat collecting tube is transmitted into the cooking box by the heat tube via heat-conducting media. The solar stove in an embodiment of the invention has the advantages that the structure of an integral machine is simplified, manual adjustment for sunlight focusing is omitted, the solar stove is simple and convenient in utilization and operation, total cost is lowered, simultaneously, shortcomings of snow accumulation, scale depositing and increase of wind resistance of an external CPC (composite parabolic condenser) reflector are overcome, and heat transmission, heat exchange and heat transfer efficiency are high.

Owner:HIMIN SOLAR

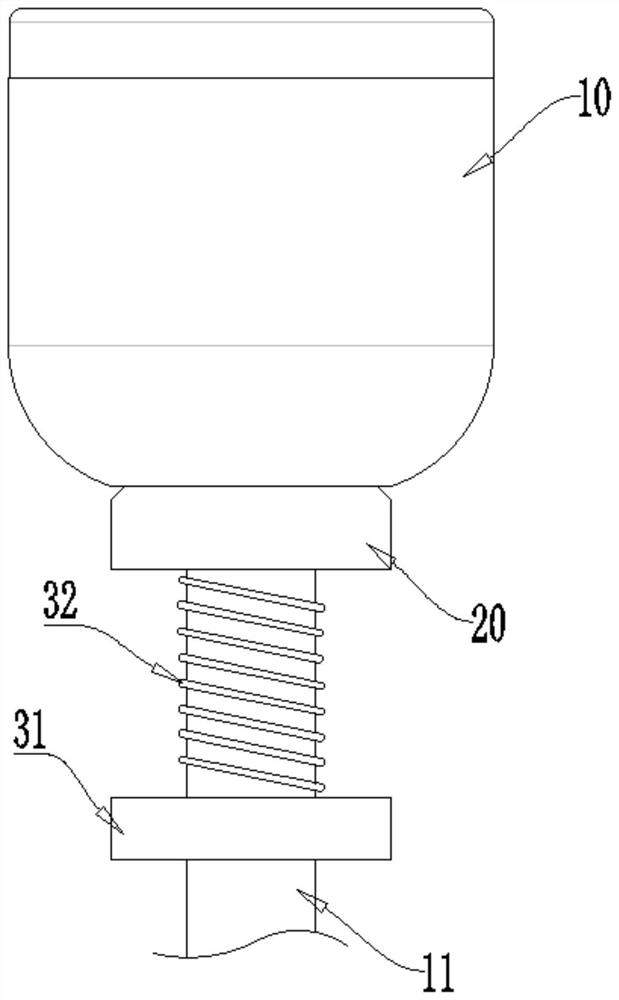

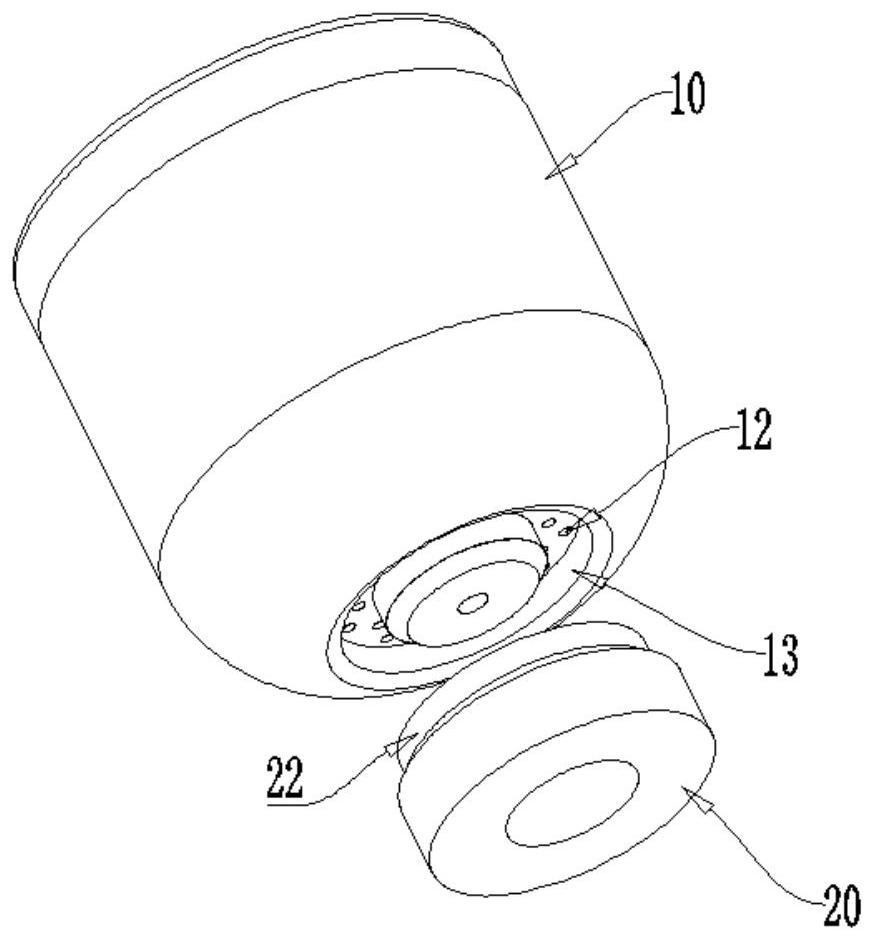

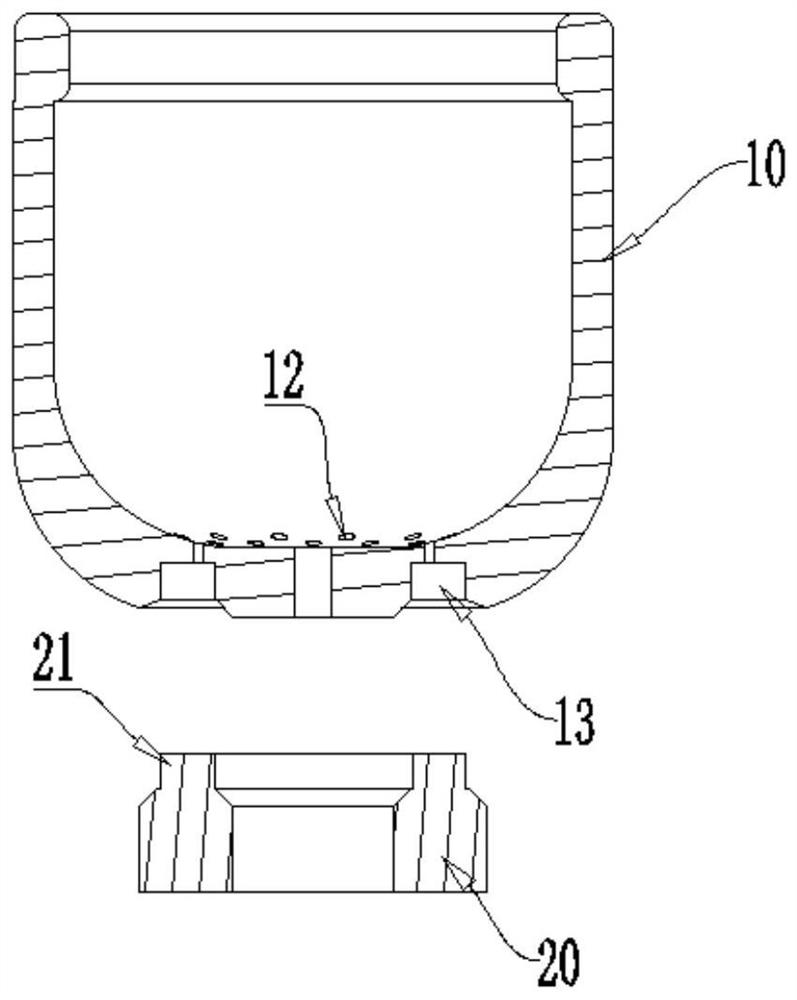

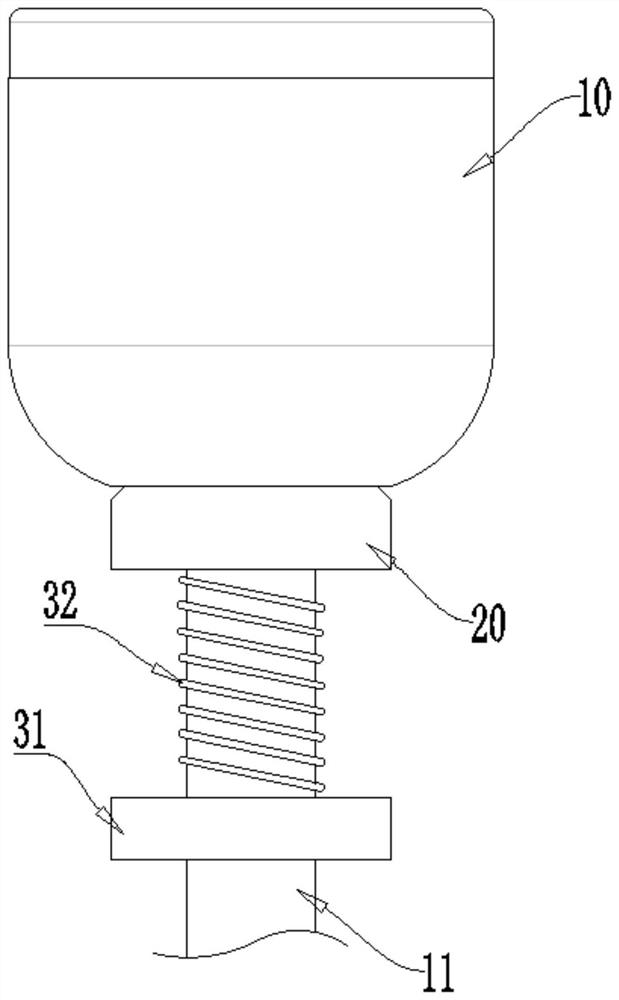

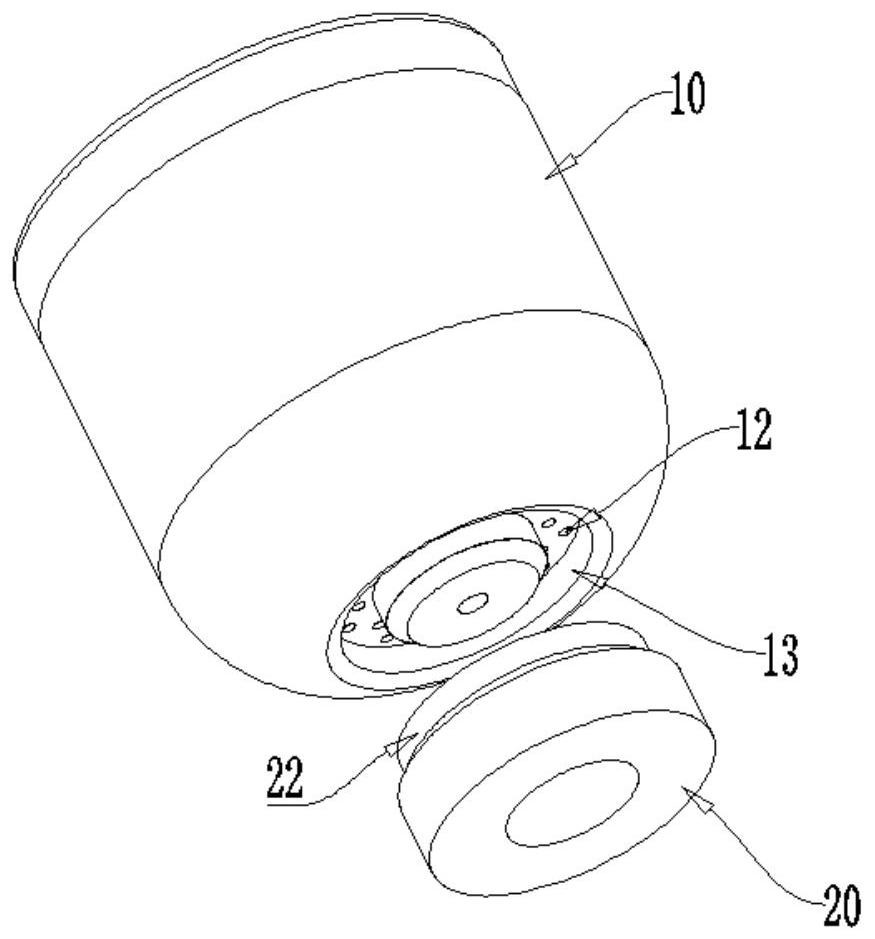

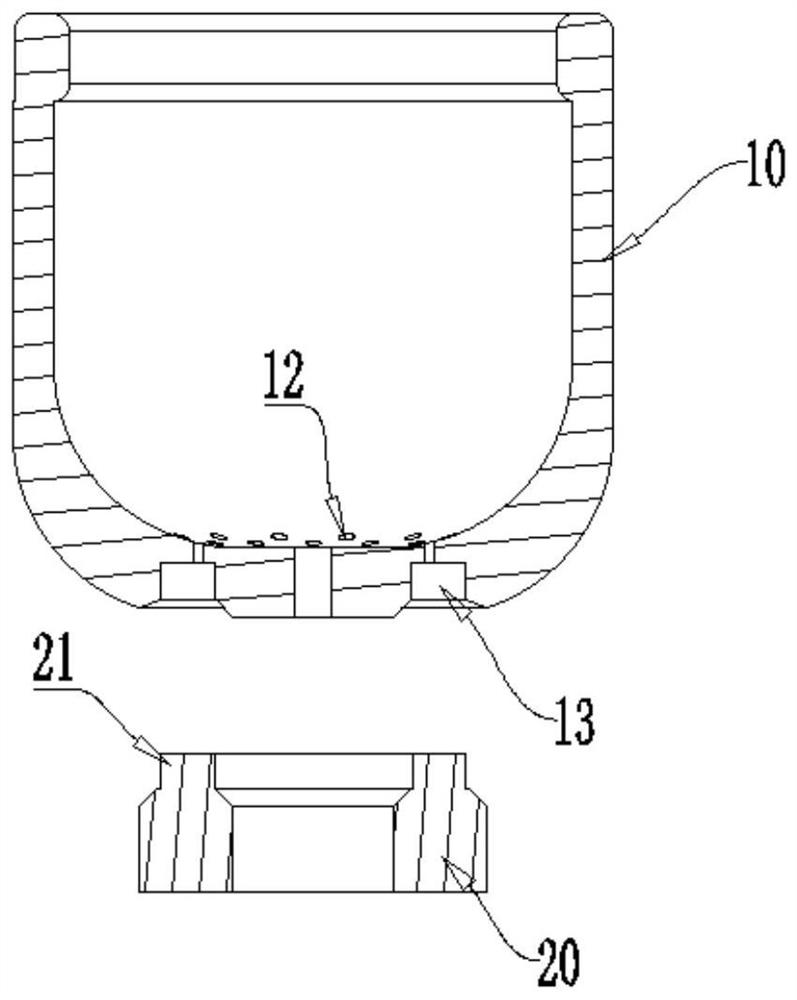

Water purifier

PendingCN112843856ASimple structureLow costTreatment involving filtrationWater/sewage treatment apparatusManufacturing cost reductionStructural engineering

The invention relates to a water purifier. The water purifier comprises a complete machine shell assembly, a filter element assembly and a handle, the complete machine shell assembly is provided with an installation cavity and a limiting part, the filter element assembly is detachably installed in the installation cavity, the handle is rotationally connected with the filter element assembly, and the handle is provided with a locking part and a dismounting part. When the handle rotates forwards relative to the filter element assembly, the locking part abuts against the limiting part so that the filter element assembly can be tightly pressed in the mounting cavity, and when the handle rotates reversely relative to the filter element assembly, the dismounting part abuts against the limiting part so that the filter element assembly can be loosened from the mounting cavity. The operation requirements of the two processes of locking and disassembling can be met at the same time by means of the single handle, the whole structure of the water purifier is simplified, and therefore the manufacturing cost and the failure rate are reduced.

Owner:GREE ELECTRIC APPLIANCES INC

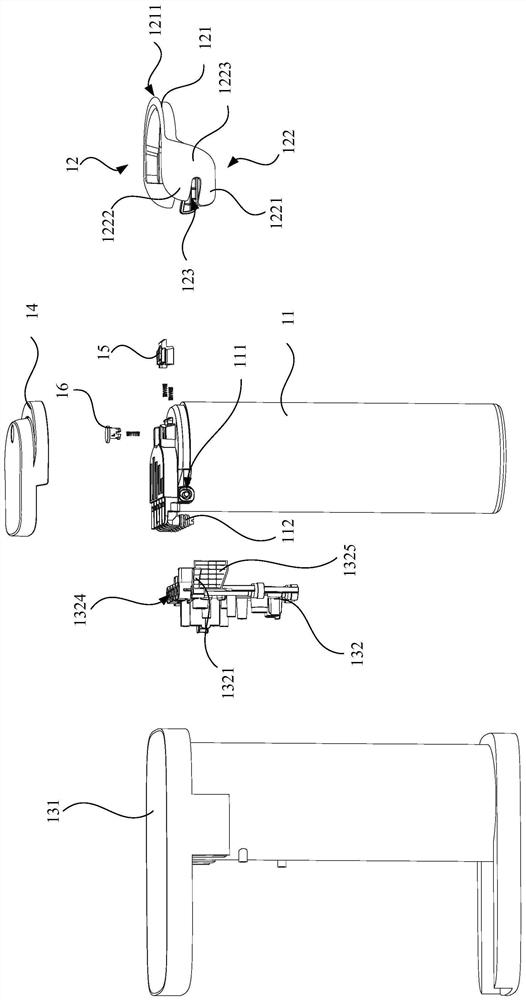

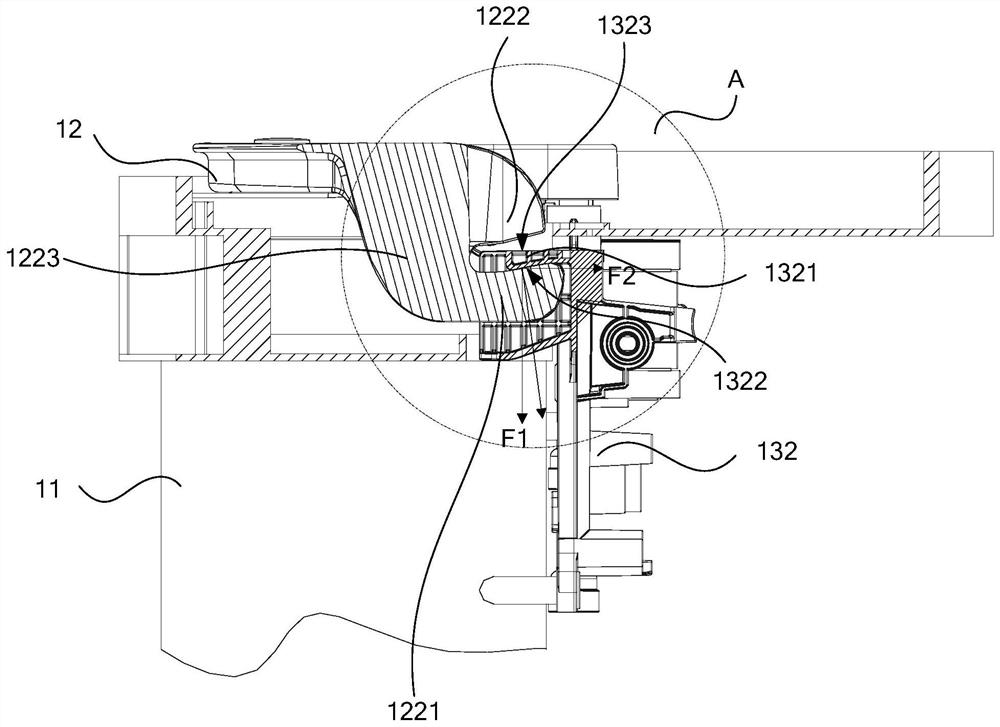

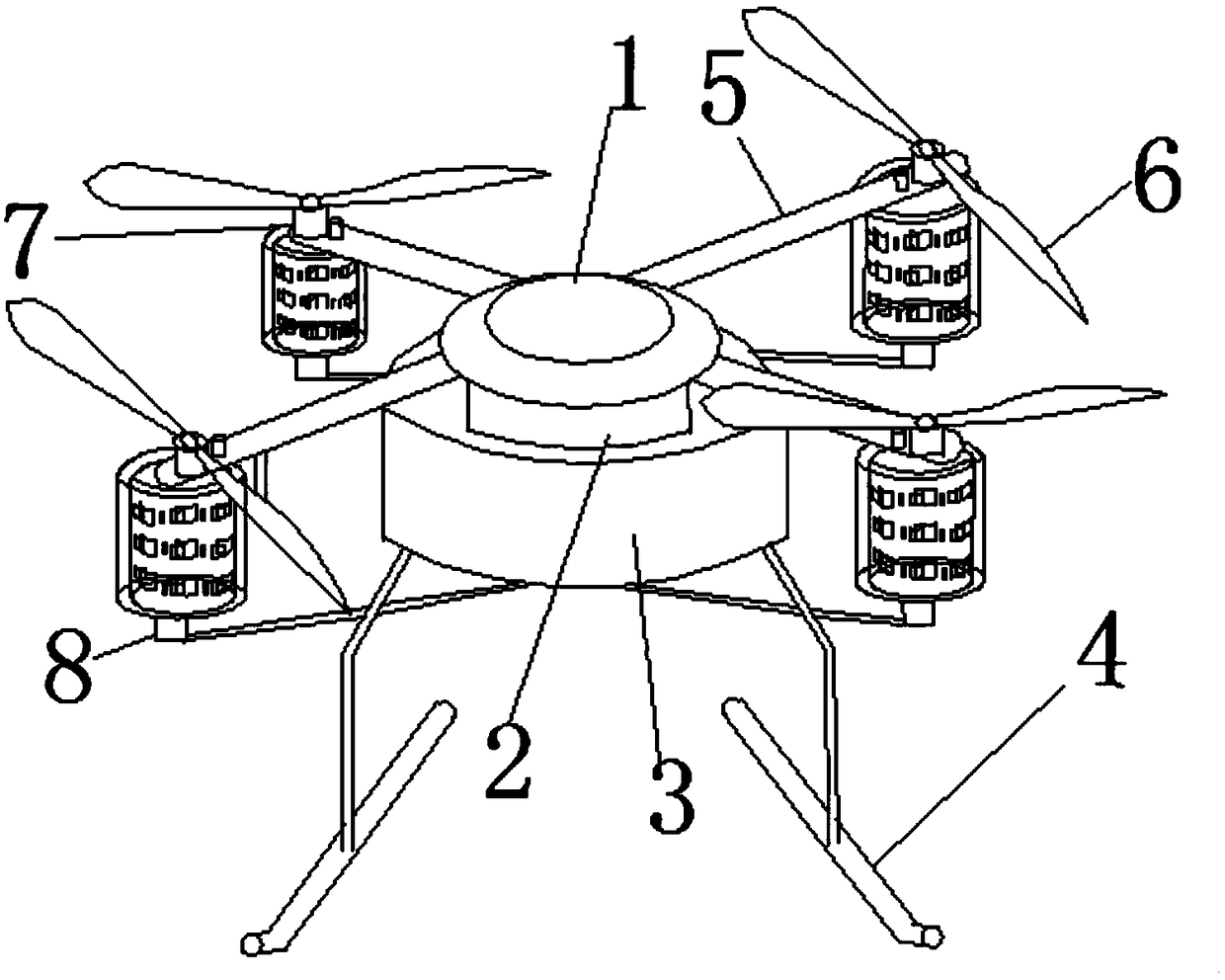

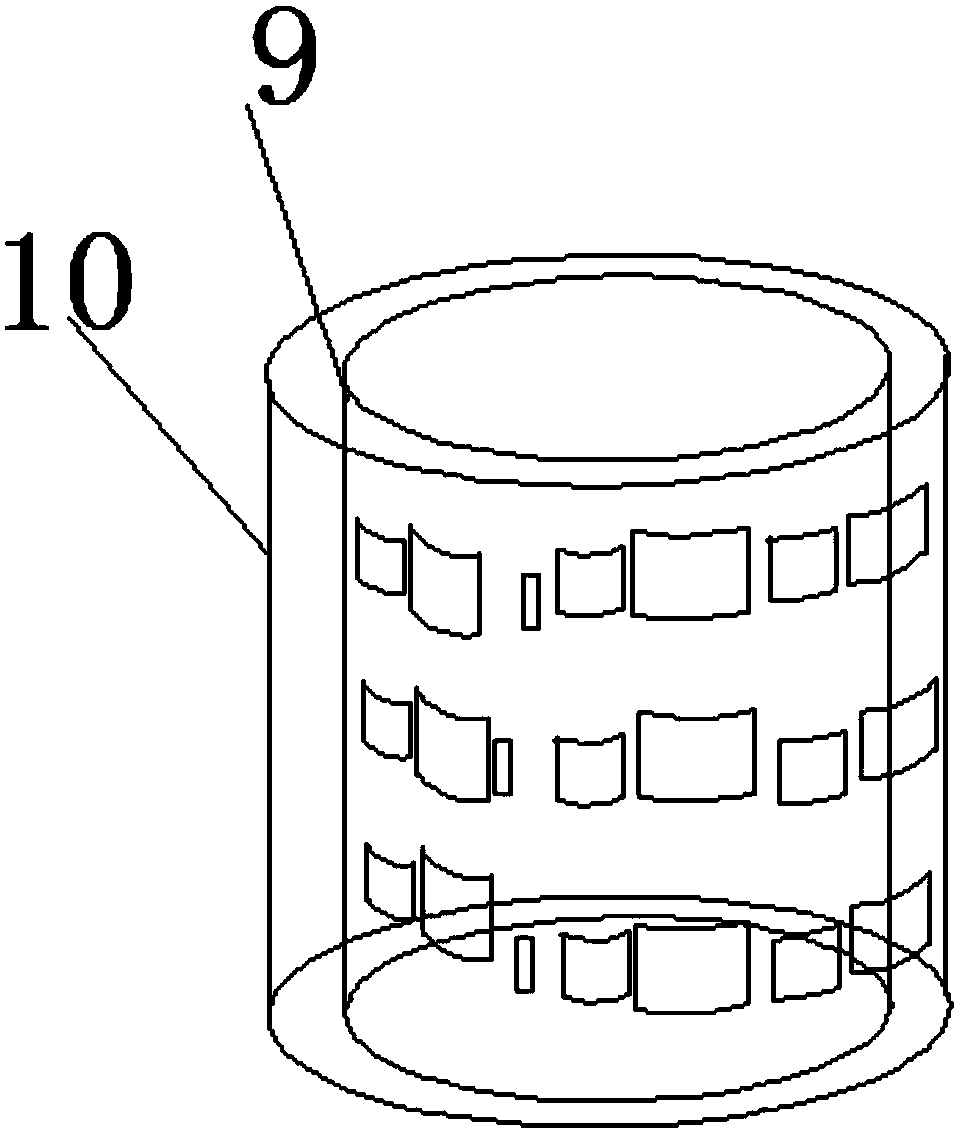

Atomizing spraying device of unmanned aerial vehicle

InactiveCN108910045AThe structure of the whole machine is simpleReduce the amount of sprayingAircraft componentsLaunching weaponsPropellerDrive motor

The invention discloses an atomizing spraying device of an unmanned aerial vehicle. The atomizing spraying device comprises a fuselage, a connecting block, a pesticide box, rotor wings, propellers, alifting unit, a double-spindle motor, a drive motor, an atomizing spraying device body, a motor control system and a pesticide delivery pipe. By means of sleeving of inner and outer barrels and setting corresponding holes in the inner and outer barrels to rotate relatively, liquid is atomized and sprayed, the process of atomizing and spraying is completed simultaneously with one device, the structure of the whole device is simplified, less dosage of spraying in the area that does not require heavy spraying is achieved, and waste of the liquid is prevented.

Owner:李春威

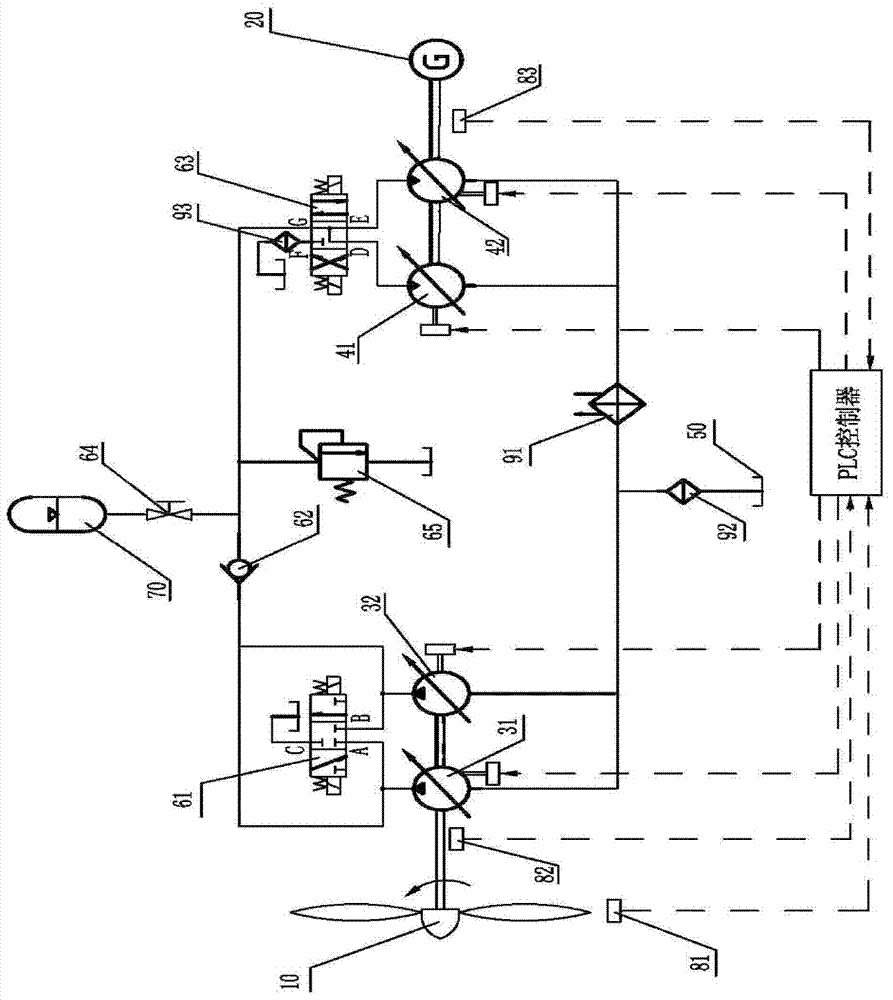

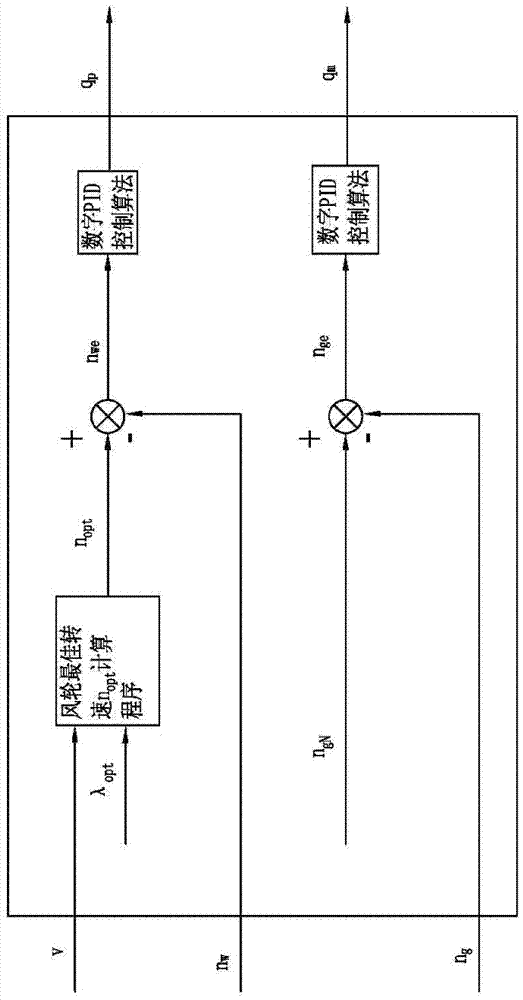

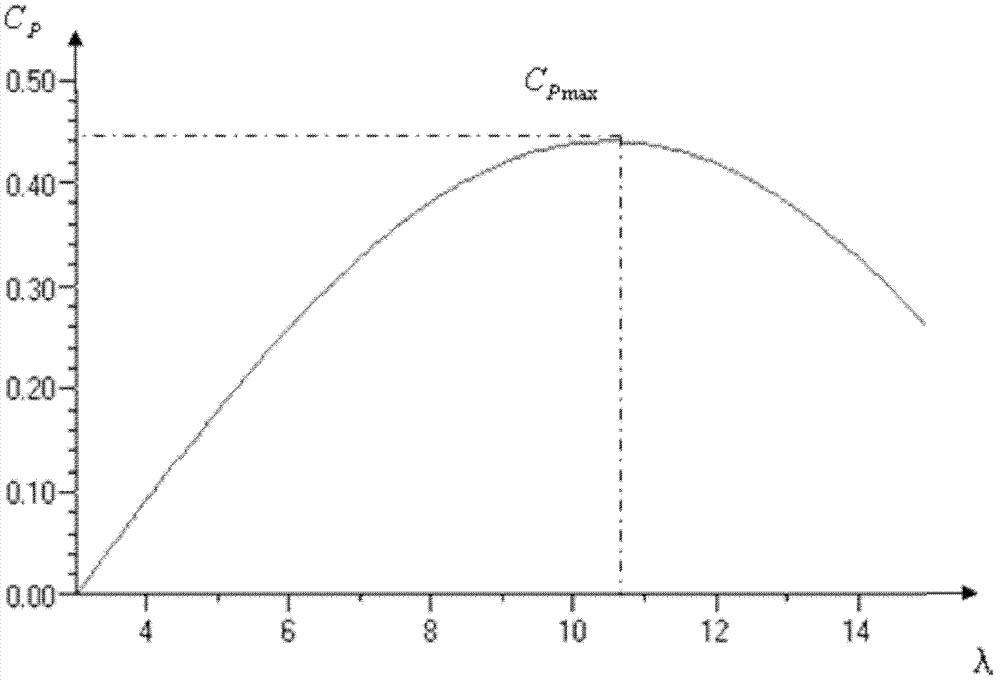

Variable speed constant frequency method for wind power generation and device thereof

ActiveCN102403944BEnables maximum power captureConsistent frequencyWind motor controlMachines/enginesHydraulic motorConstant frequency

The invention belongs to the field of wind power generation, particularly to a variable speed constant frequency method for wind power generation and a device thereof; the variable speed constant frequency method obtains signals of wind speed, rotating speed of a wind wheel and the rotating speed of a generator by monitoring, and inputs the signals to a PLC (Programmable Logic Controller) controller; the PLC controller calculates according to certain control algorithm and outputs displacement control signal to regulate the displacement of variable hydraulic pumps and variable hydraulic motors, thereby regulating the rotating speed of the wind wheel to follow the wind speed to operate at variable speed, and regulating the generator to operate at constant frequency; the variable speed constant frequency device comprises a wind wheel, two variable hydraulic pumps, two variable hydraulic motors and a generator; a three-position three-way electromagnetic directional valve is used for controlling the type and the number of the variable hydraulic pumps in real work; and a three-position four-way electromagnetic directional valve is used for controlling the type and the number of the variable hydraulic motors in real work. The method and device provided by the invention realize variable speed constant frequency power generation of a wind power generation device by regulating the displacement of the variable hydraulic pumps and the variable hydraulic motors, thus improving energy capture efficiency and achieving stable energy output of the generator.

Owner:ZHEJIANG UNIV

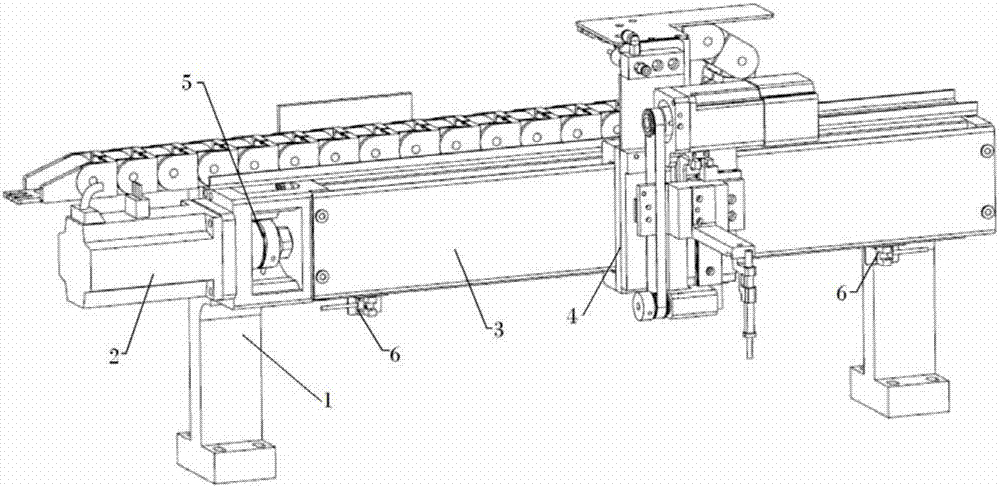

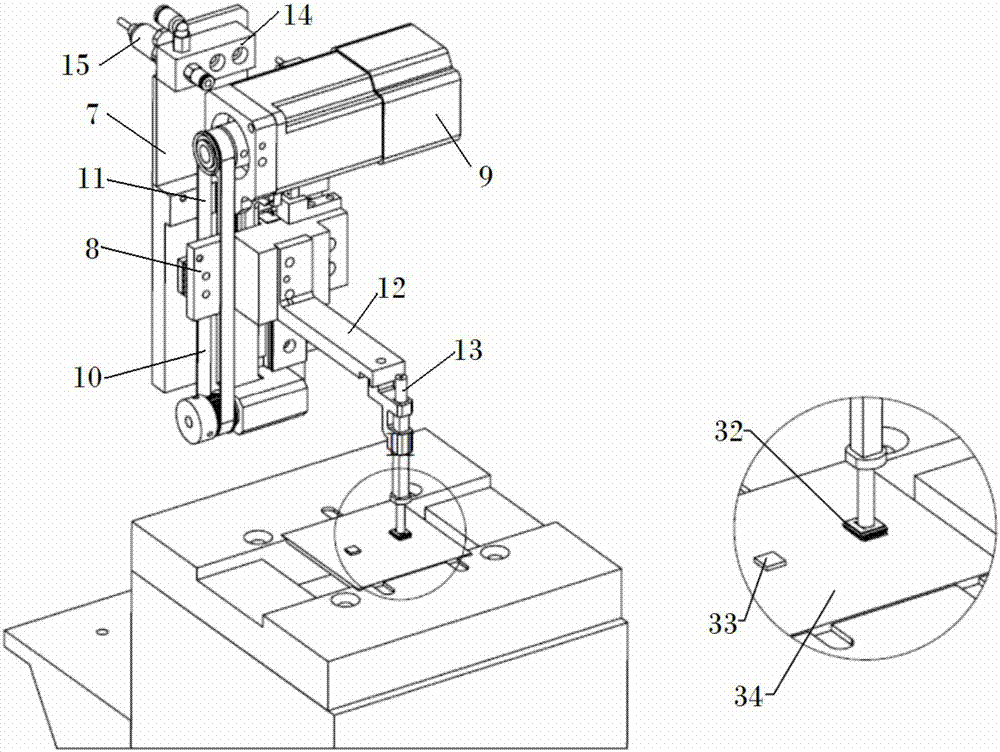

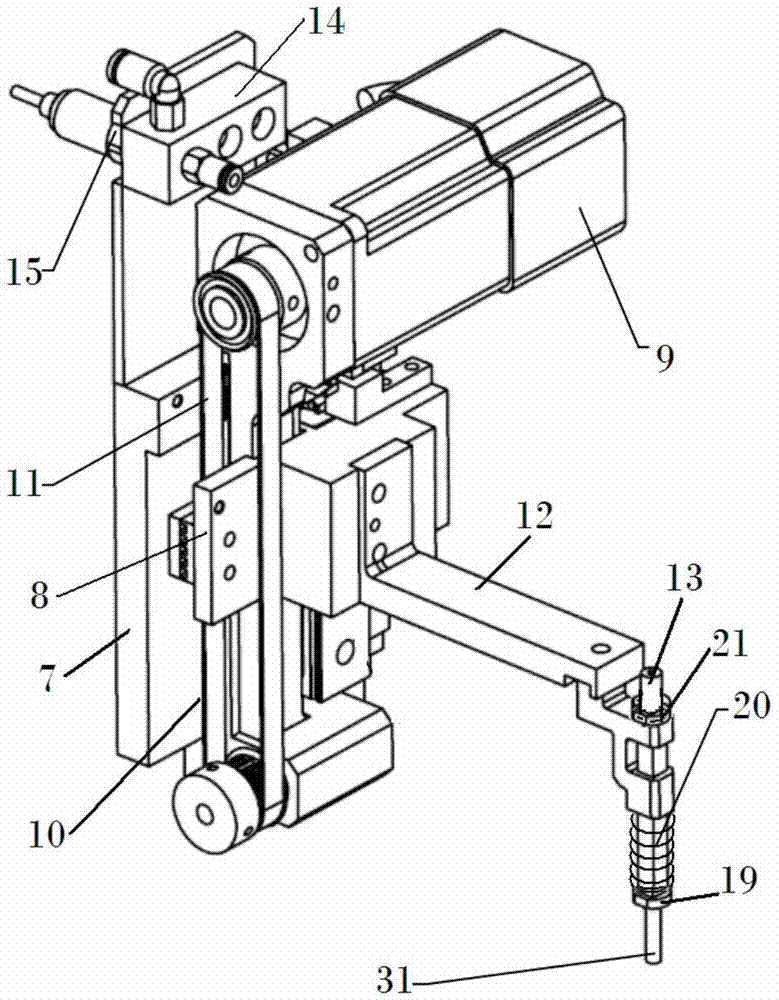

QFP chip appearance sampling inspection system based on PC controlling

InactiveCN107068582AReduce in quantityThe structure of the whole machine is simpleSemiconductor/solid-state device testing/measurementEngineeringElectromagnetic valve

The invention discloses a QFP chip appearance sampling inspection system based on PC controlling. The QFP chip appearance sampling inspection system comprises a PC, an attracting-and-releasing device, a material feeding device and a visual detection device. The attracting-and-releasing device comprises an X-direction moving assembly, a Z-direction moving assembly and a device attracting-and-releasing assembly. The Z-direction moving assembly comprises a synchronous wheel-synchronous notched belt transmission mechanism which is connected with an output shaft of a Z-axis motor. The device attracting-and-releasing assembly comprises a photoelectric sensor which is arranged on a backboard, and an attracting rod which can perform Z-direction movement. The attracting rod is connected with a pipeline. The pipeline is provided with a vacuum sensor, a vacuum electromagnetic valve and a compressed air electromagnetic valve. The material feeding device comprises a base board, a Y-direction movement unit and a tray fixing base board, wherein the base board, the Y-direction movement unit and the tray fixing base board are arranged from bottom to top. The driver, the photoelectric sensor, the vacuum sensor, the vacuum electromagnetic valve and the compressed air electromagnetic valve of an X-axis motor and a Z-axis motor are connected with a PC; and a visual detecting device transmits a detected signal to the PC. In performing a sampling inspection operation on a small number of QFP finished products, the QFP chip appearance sampling inspection system can realize a quick and accurate result at a low cost.

Owner:TIANJIN UNIV

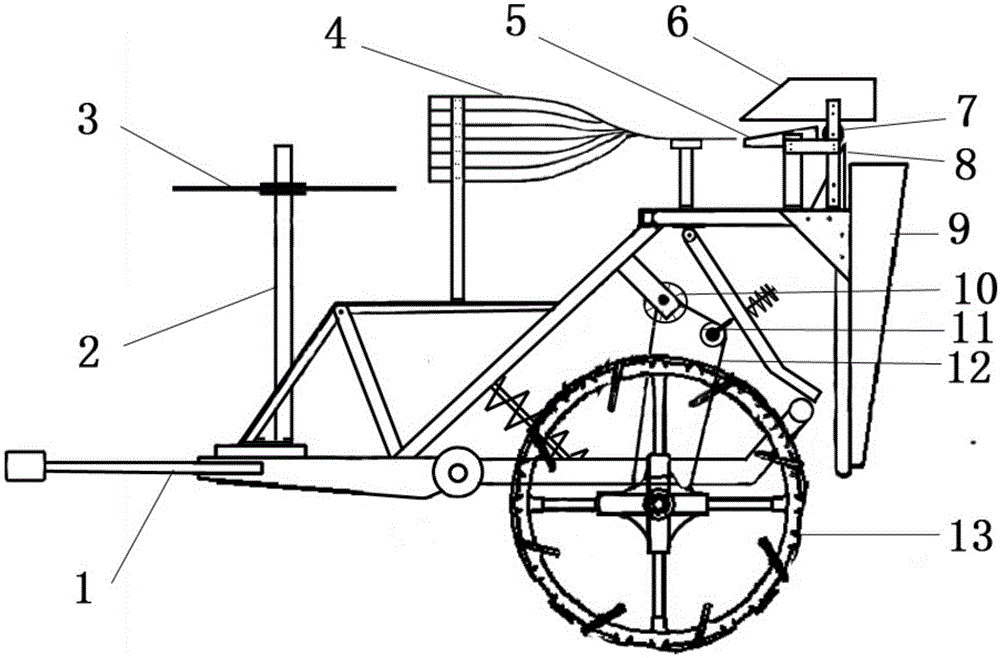

Pot seedling transplanter for paddy rice on-film pot seedling culture

InactiveCN105009757AImprove job qualityThe structure of the whole machine is simpleTransplantingBiologyOryza sativa

The invention discloses a pot seedling transplanter for paddy rice on-film pot seedling culture. The pot seedling transplanter comprises a rack, a seedling rack, a seedling base, a turning seedling guide rail, an ejection baffle, a limiting seedling distribution baffle, a round turning roll, a separating baffle, a seedling guide device, a film recovery roll, a driving belt, a tensioning device and a land wheel, wherein the land wheel transfers power to the film recovery roll by virtue of the belt; the film recovery roll is positioned below a space between the seedling base and the round turning roll; the seedling base is arranged on the seedling rack; the turning seedling guide rail is positioned between the seedling base and the round turning roll; the ejection baffle is positioned in front of the round turning roll; the limiting seedling distribution baffle is positioned above the round turning roll; the separating baffle is positioned behind the round turning roll. The simple and practical pot seedling transplanter provided by the invention is simple and reasonable in machine structure and low in manufacturing cost.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Elevator traction system

ActiveCN103171953AGood strength and stiffnessImprove securityBuilding liftsLoad carryingTraction system

The invention discloses an elevator traction system. The elevator traction system comprises guiding pulleys which are arranged on an elevator lift car frame, an elevator main engine and a counterpoise, and composite steel belts which successively pass through the guiding pulleys, wherein the guiding pulleys are in an integrated structure of a pulley and a bearing main shaft, a guiding groove which is formed in a bearing main shaft is formed in the bearing main shaft, and the guiding groove is a groove with a flat base. On one hand, the elevator traction system solves the problems that the composite steel belts are in line deflection and load carrying capacity is uneven, on the other hand, the elevator traction system further solves the problems of inability to slip caused by an oversize friction coefficient by adopting the composite steel belts with a concave shape and a protruding shape and a rope sheave, so that the elevator traction system is authentically suitable for long term operation of the elevator. The elevator traction system has the advantages of being good in rigidity and intensity by adopting a wheel axle integrated structure, high in safety coefficient, compact in structure, capable of ensuring that an elevator device and an elevator complete machine structure are simplified, thereby reducing occupied space of the elevator device to an elevator well, and effectively saving well space.

Owner:GUANGZHOU GUANGRI ELEVATOR IND

Net supporting and stripping device of needling machine

PendingCN113529285AThe structure of the whole machine is simpleReduce the weight of the whole machineNeedling machinesMachinePower output

The invention relates to a net supporting and stripping device of a needling machine. The net supporting and stripping device comprises a machine frame, a net supporting plate, a net supporting plate lifting mechanism, a net stripping plate and a net stripping plate lifting mechanism, the net supporting plate lifting mechanism and the net stripping plate lifting mechanism are both arranged on the machine frame, the net stripping plate is arranged right above or below the net supporting plate, the net stripping plate is arranged at the power output end of the net stripping plate lifting mechanism. The net supporting and stripping device of the needling machine is characterized in that the net supporting plate comprises a first U-shaped plate, the first U-shaped plate comprises a first transverse plate and two first vertical plates, a plurality of first pricking needle through holes are formed in the first transverse plate, the two first vertical plates are correspondingly connected with the left edge and the right edge of the first transverse plate, and the two first vertical plates are installed at the power output end of the net supporting plate lifting mechanism. According to the net supporting and stripping device of the needling machine, the whole machine structure of the needling machine can be simplified, the whole machine weight of the needling machine is reduced, and the occupied installation space can be reduced.

Owner:广东三辉无纺机械有限公司 +1

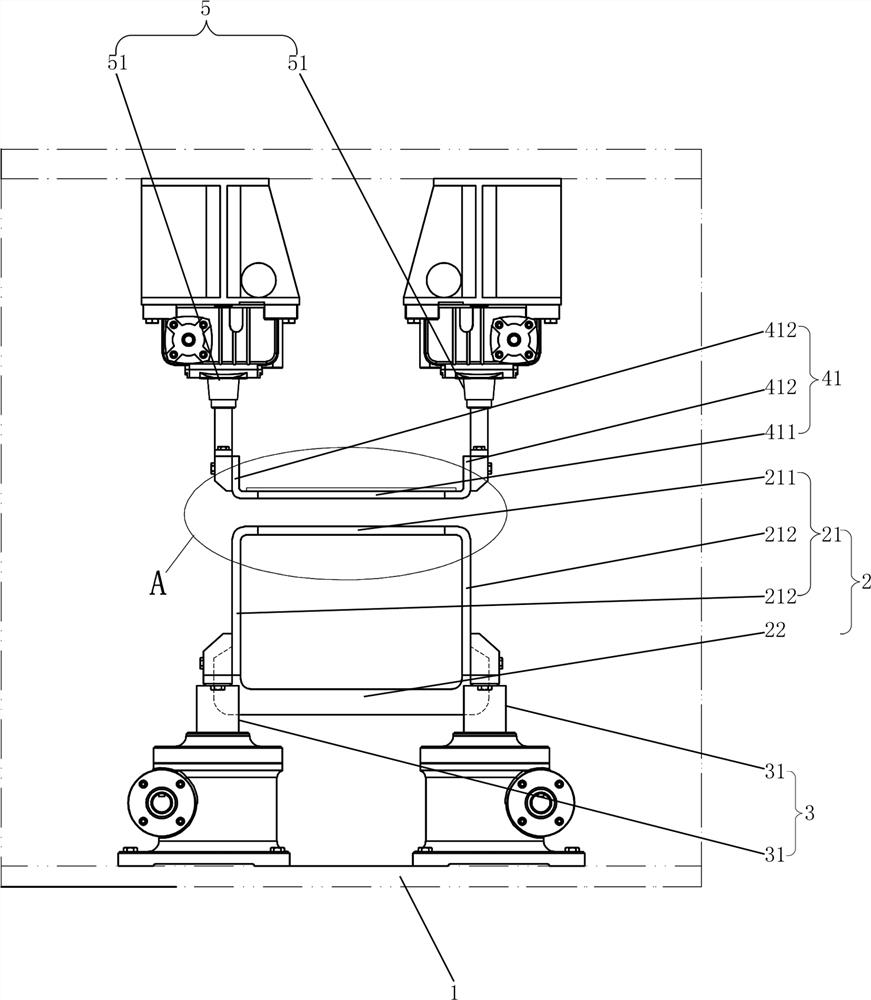

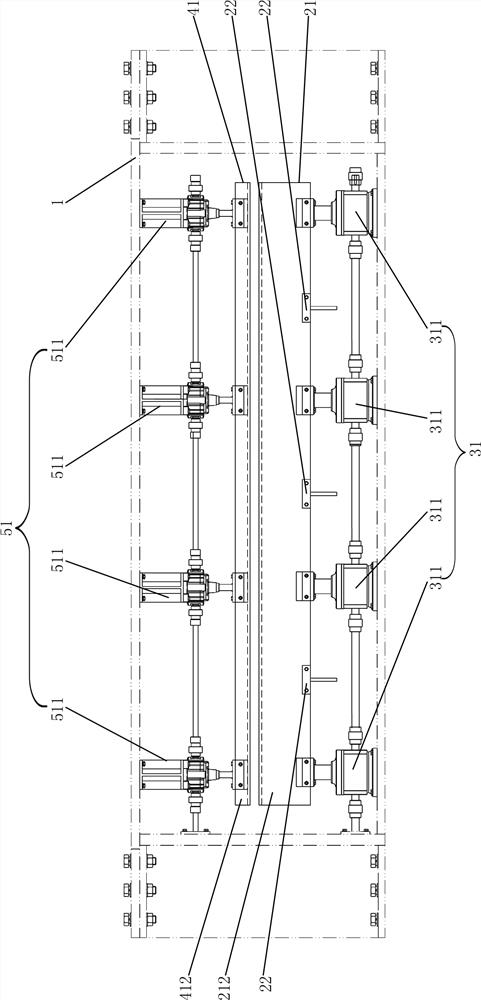

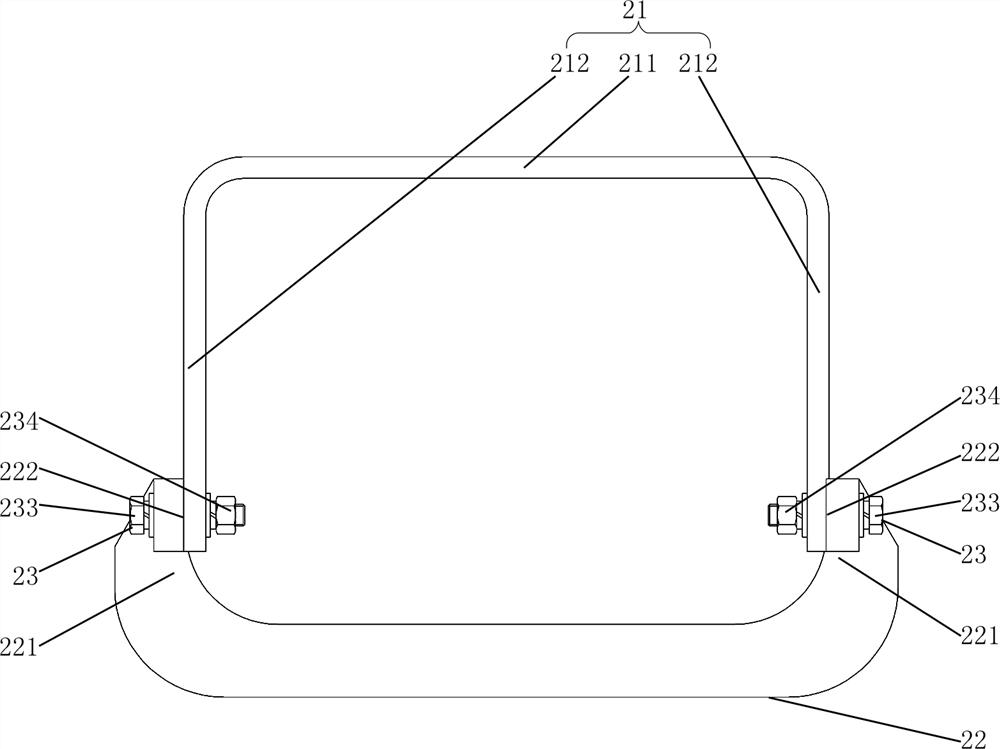

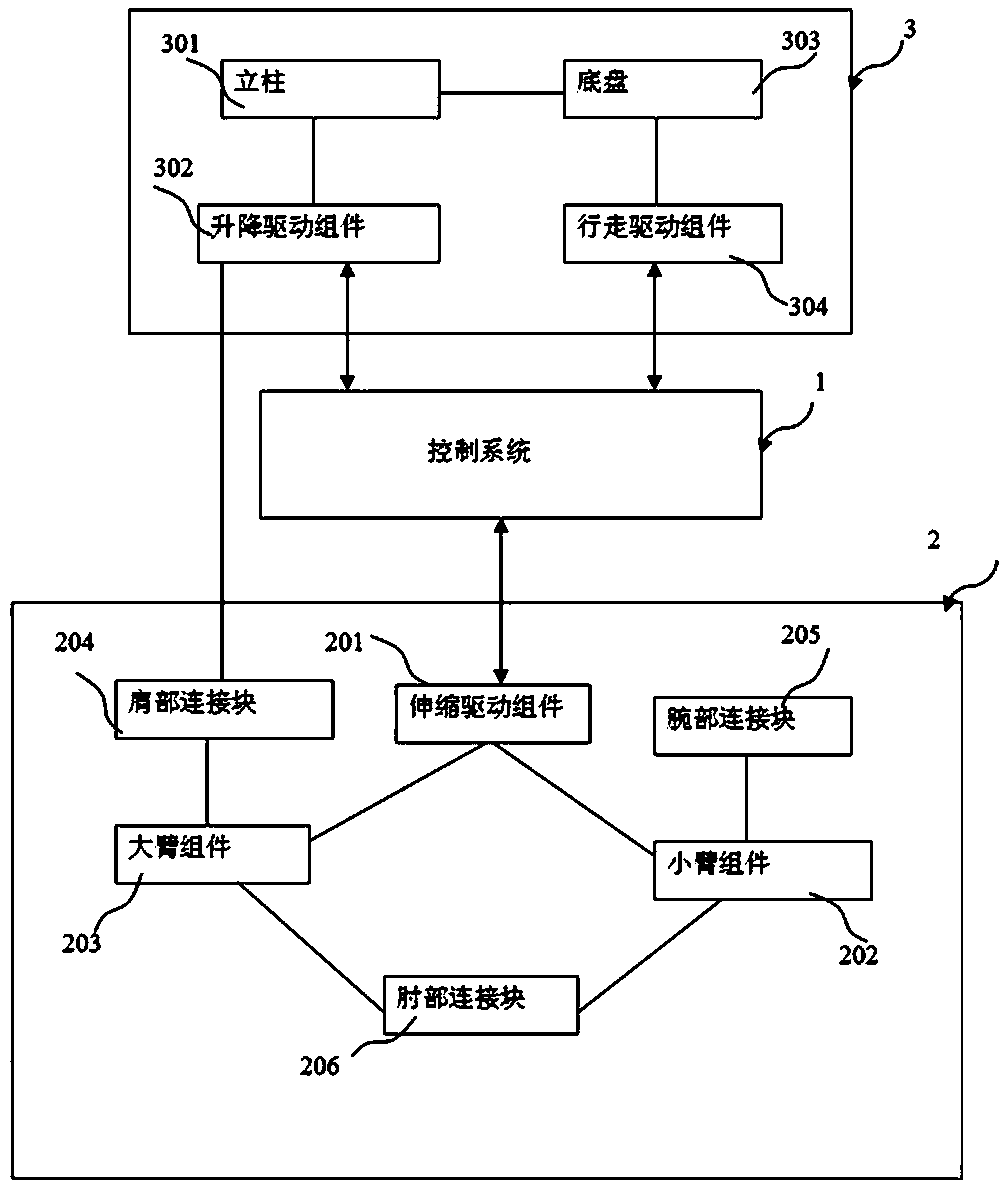

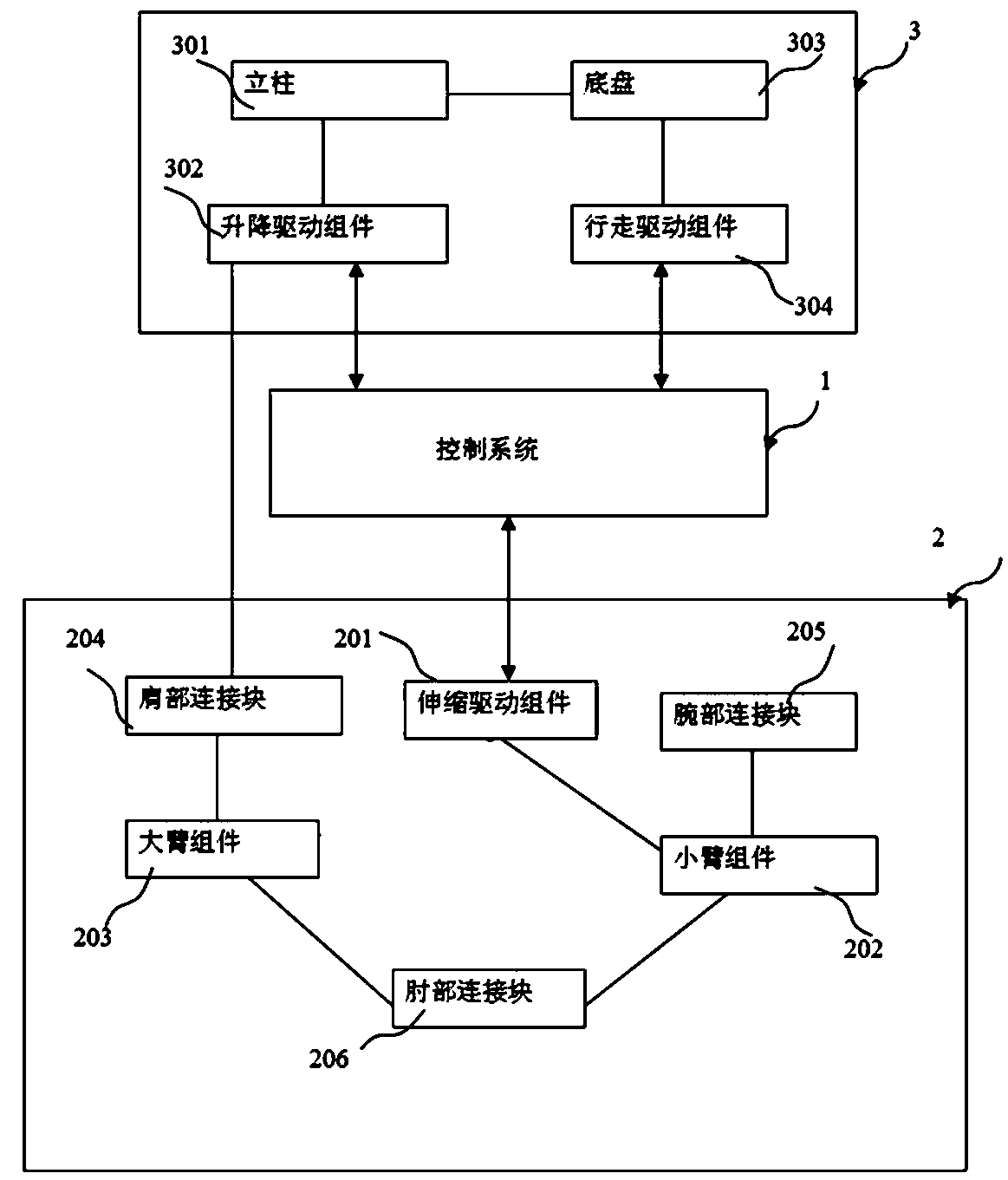

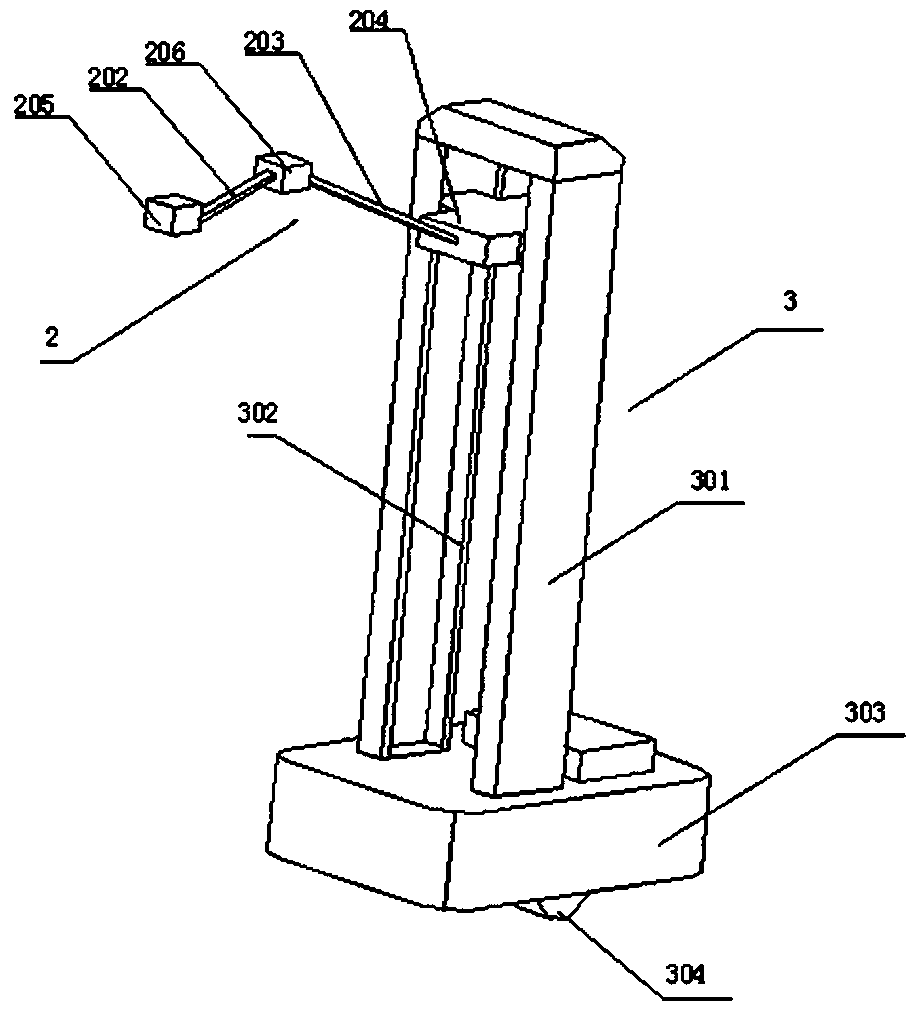

Movable robot

ActiveCN110497374AFlexible application scenariosThe structure of the whole machine is simpleArmsHome positionJoints types

The invention discloses a movable robot. The movable robot is composed of a movable lifting column, a mechanism type stretchable arm and a control system, the movable robot can walk freely on the ground, and a carrying path is planned according to an initial position and an end point position of a target object. Compared with a fixed stacking robot, the movable robot can realize multi-position stacking and carrying of the target object, and the application scene is more flexible. A rotary table structure of the fixed type stacking robot is replaced with the in-situ rotation of the movable lifting column, the mechanism type stretchable arm is adopted to replace a joint type swinging arm and a rail type movable arm, so that the structure of the whole machine is simpler, the power mass ratiois higher, the power consumption of the whole machine and the weight of the whole machine are greatly reduced.

Owner:HANGZHOU TIANMING TECH CO LTD

Chamfering machine

PendingCN110405262AReliable clampingEasy loading and unloadingMilling equipment detailsMetal working apparatusEngineeringMechanical engineering

The invention relates to a chamfering machine. The chamfering machine comprising a machine table, a clamp, a chamfering mechanism and a propelling mechanism, the propelling mechanism comprises an upper sliding block and a lower sliding block, wherein the upper sliding block and the lower sliding block are arranged on the machine table, the upper sliding block can move up and down relative to the machine table, the upper sliding block is located above the lower sliding block and is pressed on the lower sliding block, and the lower sliding block can move back and forth relative to the machine table; the clamp comprises an upper clamp, a lower clamp and a reset spring, the upper clamp is arranged on the machine table, the lower clamp is movably arranged on the upper clamp, the upper sliding block is located below of the lower clamp, the upper sliding block moves forwards or backwards to push the upper sliding block to move upwards, and the upper sliding block moves upwards to push the lower clamp to move towards the upper clamp; the upper clamp and the lower clamp together clamp a workpiece, when the lower sliding block retracts, the upper sliding block moves downwards, and the resetspring enables the upper clamp and the lower clamp to return to a non-clamping state. According to the chamfering machine, the workpiece is clamped by adopting a simple mechanical structure, the non-clamping state is automatically restored after the clamp thrust is released, the structure of the whole machine is very simple, the operation is convenient, the cost is low and the production efficiency is high.

Owner:浙江飞宇自动化科技股份有限公司

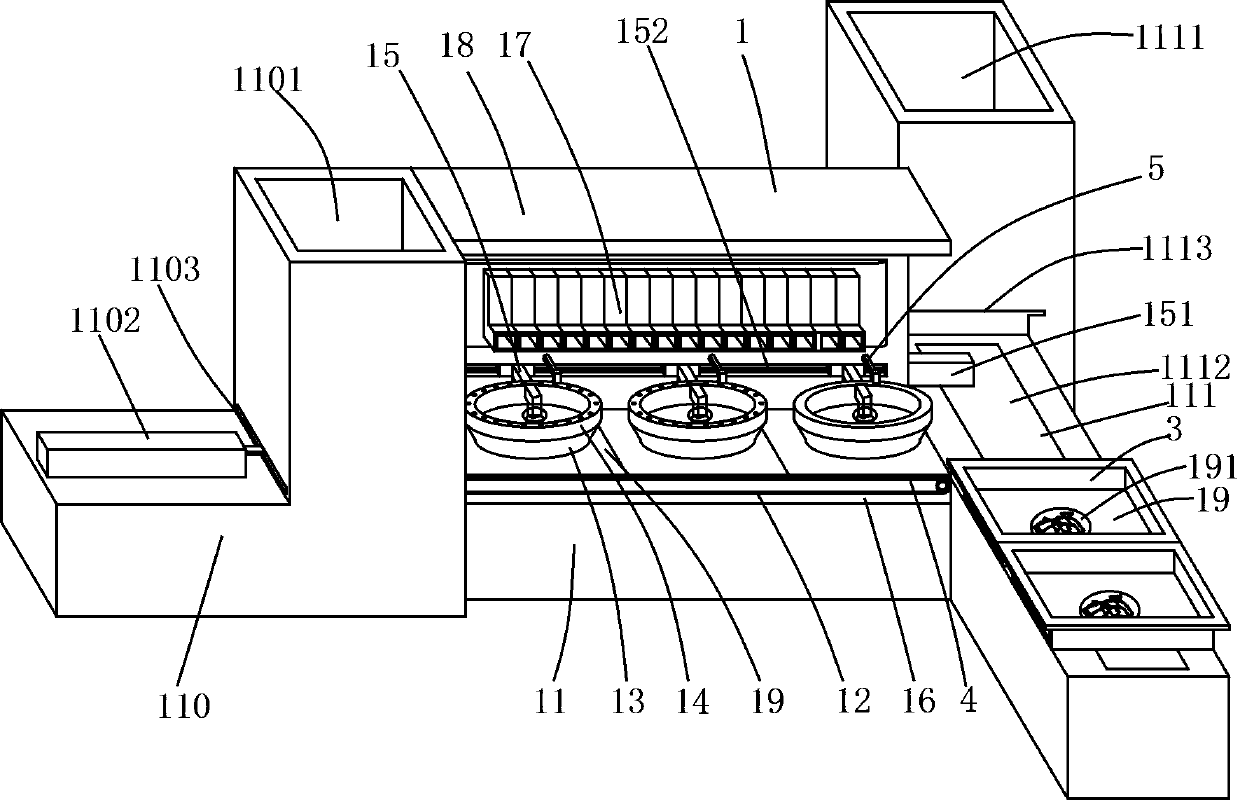

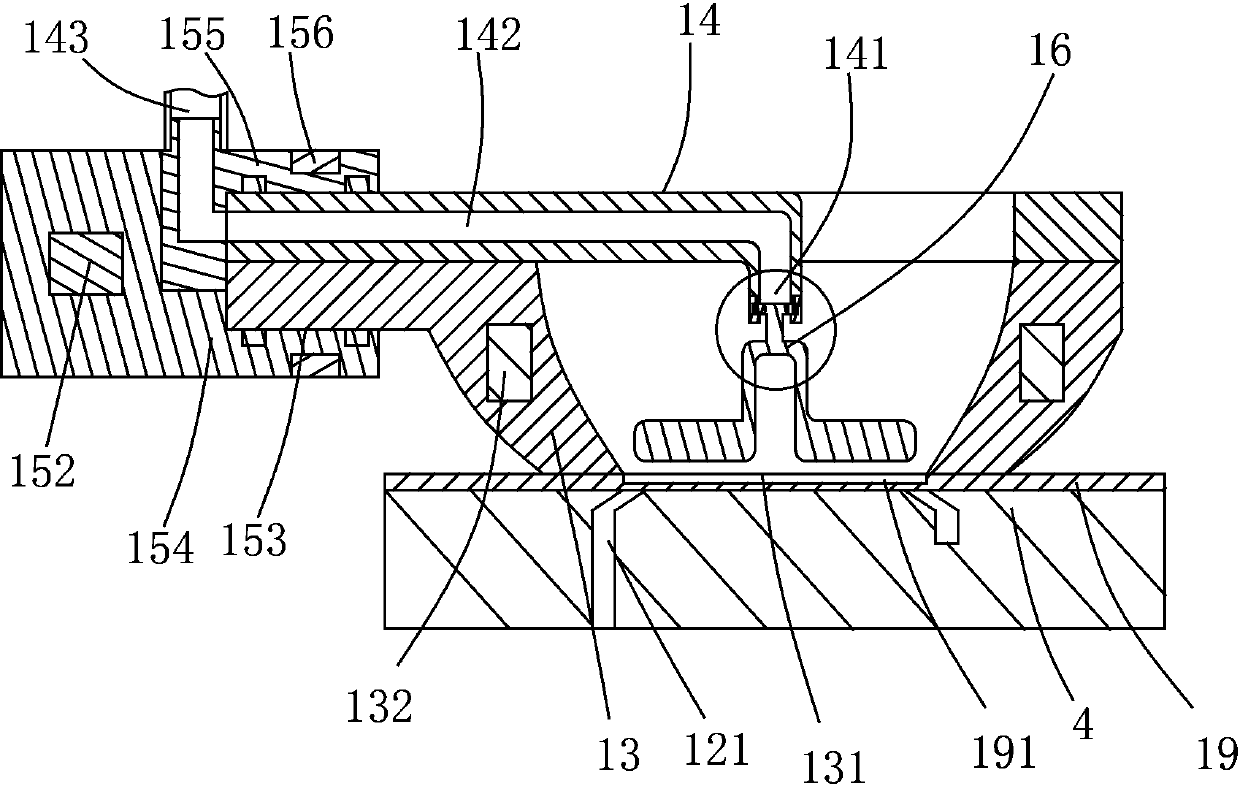

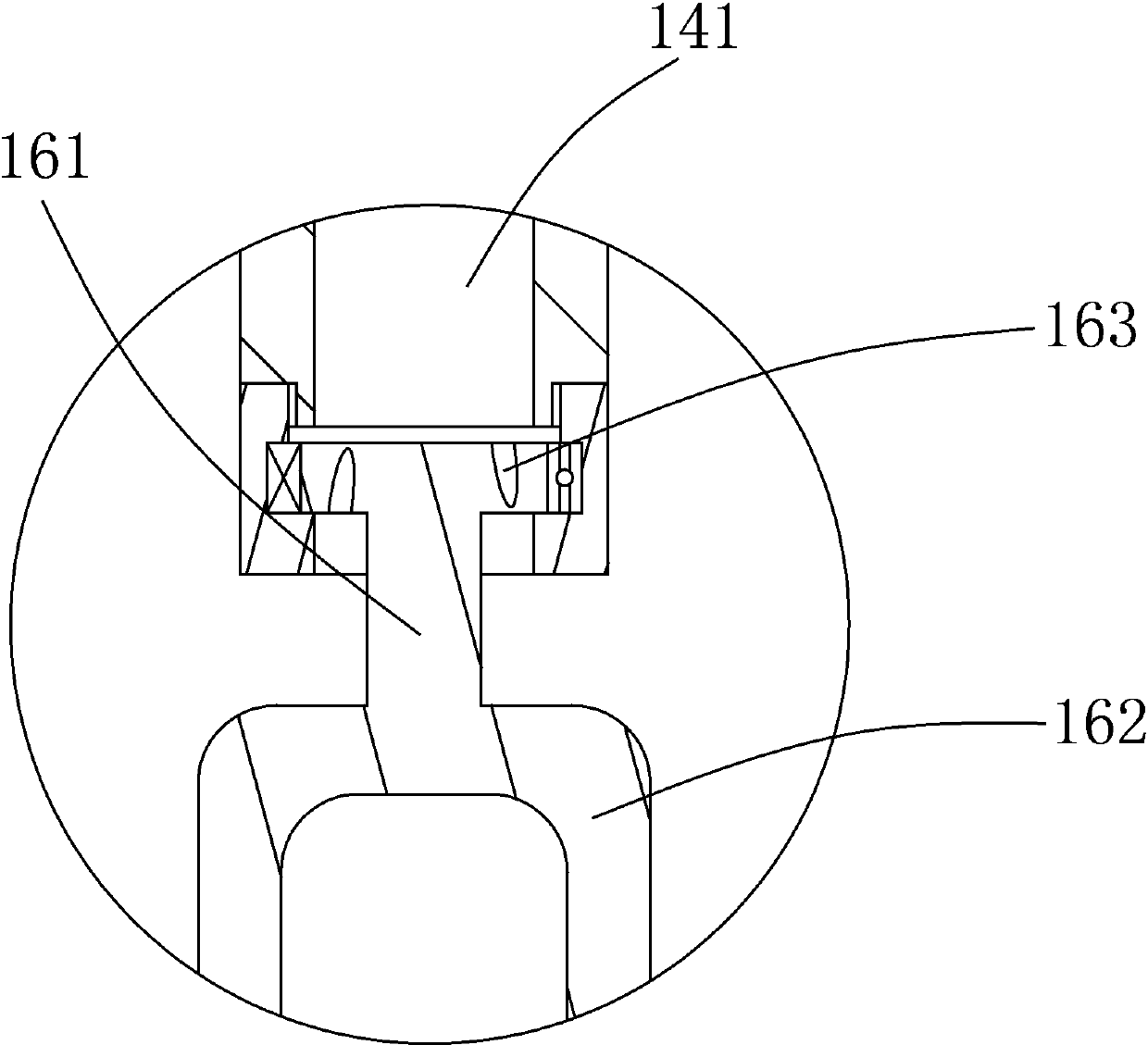

Automatic cooking and meal delivering robot

InactiveCN107822484AThe structure of the whole machine is simpleEasy to manageMultiple-unit cooking vesselsCookerMeal

The invention discloses an automatic cooking and meal delivering robot, which includes an automatic cooking robot and an automatic meal delivering robot; the automatic cooking robot comprises a cooking bench, a plurality of induction cookers, a plurality of pots, a plurality of oil fume suction devices, a turning pot device, a stir-fry device, a charging passage, a storage box, a cooking plate, acooking plate automatic discharging mechanism, a cooked dish conveying device and a first control device; the automatic meal delivering robot comprises a cart body, a dish storage box body, a liftingmechanism, a heat-insulating device, a dish serving mechanism, an obstacle avoiding sensor, a positioning sensor, a mobile power supply and a second control device; and the first control device and the second control device are in wireless connection. The automatic cooking and meal delivering robot can be used for frying and delivering dishes in accordance with preset program operations as vegetables are cleaned and chopped and seasonings are added into corresponding storage passages, so that the consistency of the dishes is guaranteed.

Owner:马建山

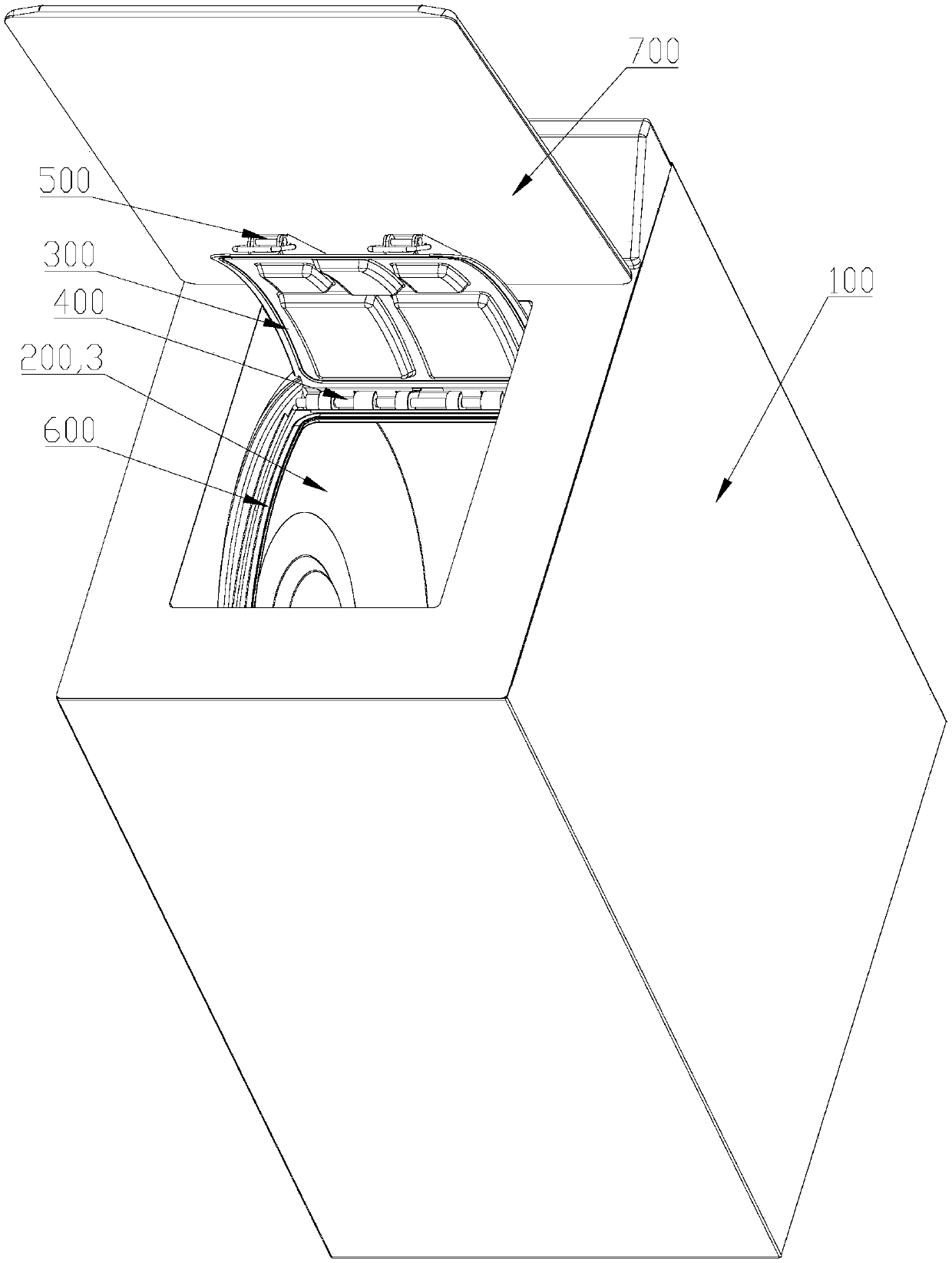

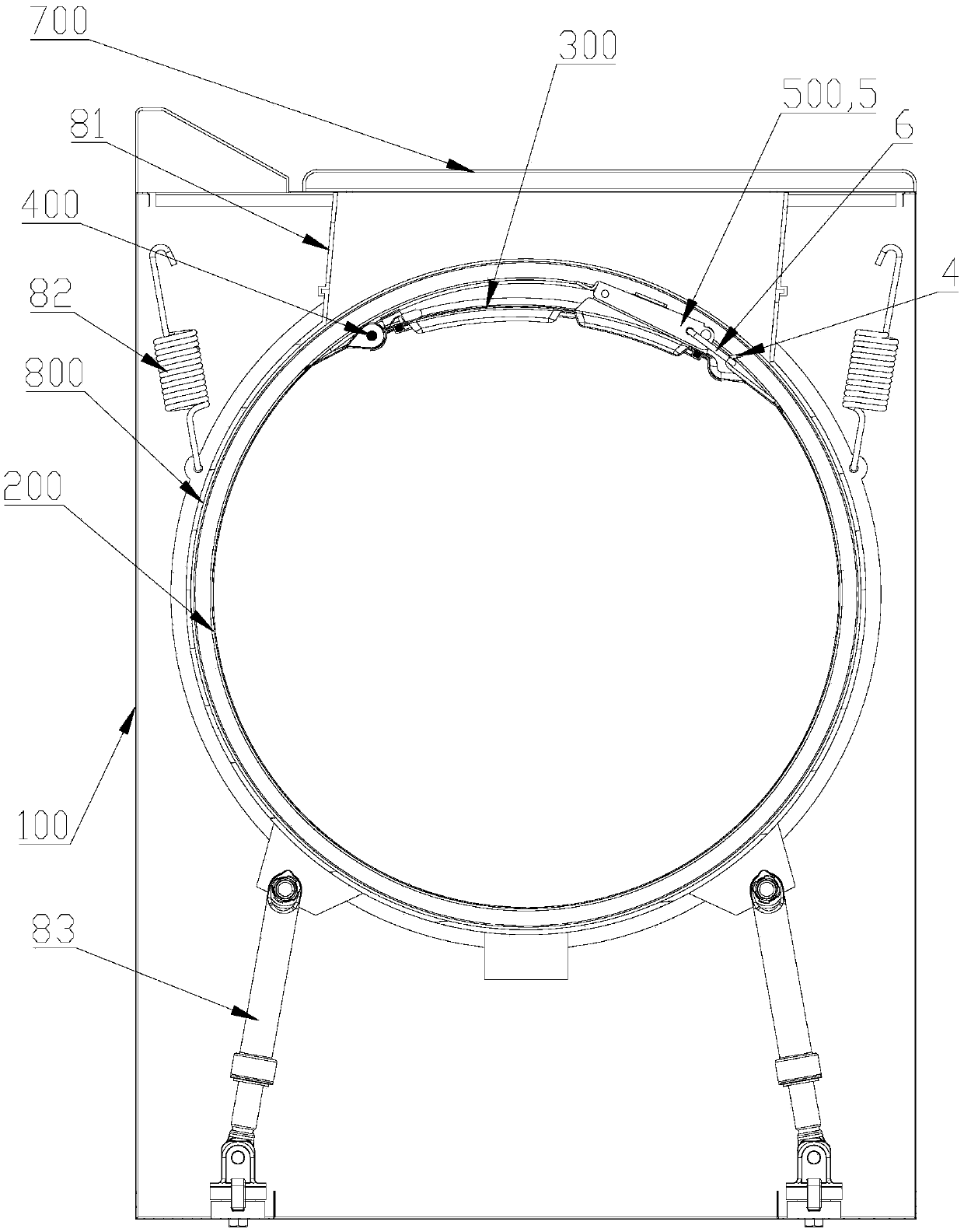

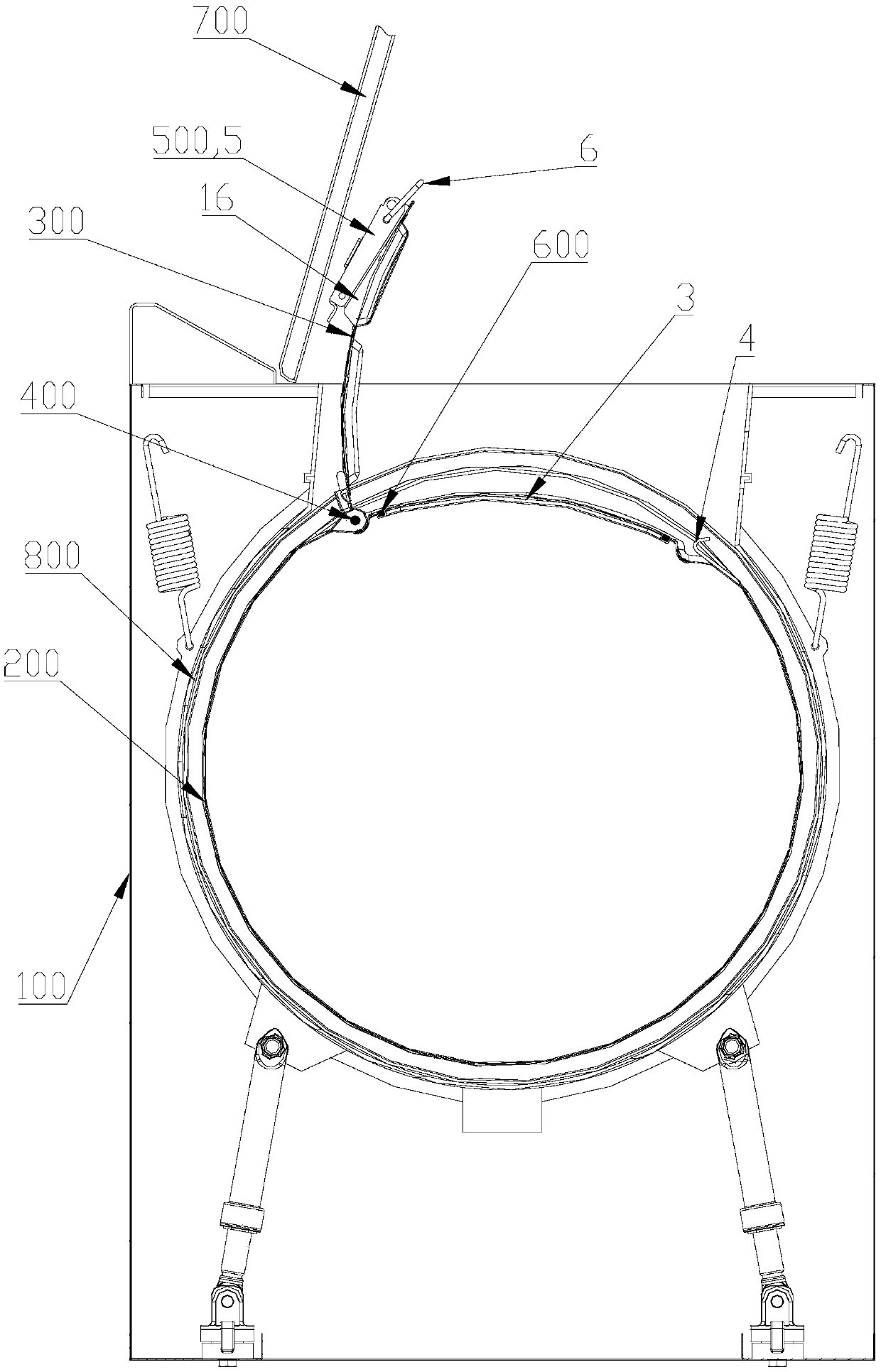

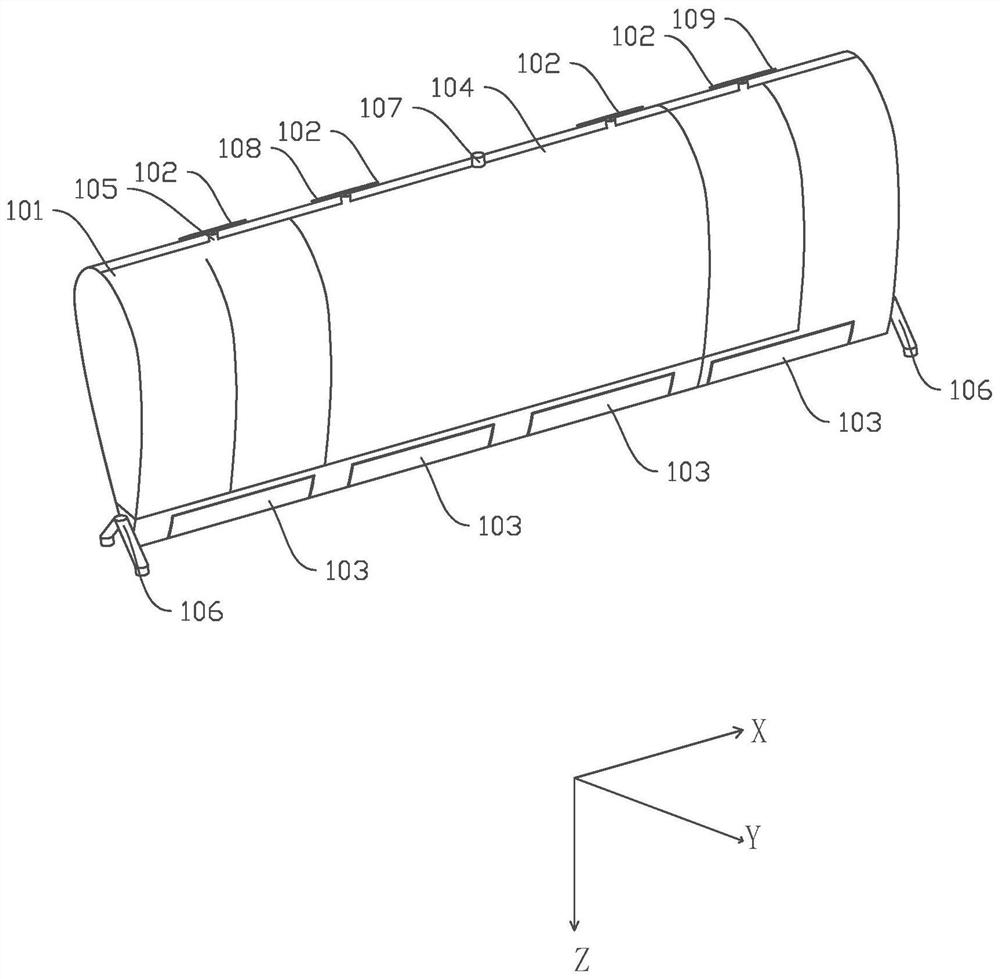

Washing machine

ActiveCN110552175AAvoid eccentric rotation situationsOptimize the structure of the whole machineOther washing machinesTextiles and paperMechanical engineering

The invention discloses a washing machine which comprises a roller installed in the shell. A clothes deposit hole is formed in the side wall of the roller and provided with a door body capable of being opened and closed. Through the arrangement, the aims of forming the clothes deposit hole in the side wall of the roller of the washing machine and correspondingly sealing and closing the clothes deposit hole of the roller by the door body or opening the door body to take or place clothes are realized; meanwhile, the aims of forming the clothes deposit hole in the side wall of the roller and allowing a user to open the door body from the upper side of the washing machine and taking and placing the clothes in the roller are realized. More specially, the clothes deposit hole of the roller is sealed by the door body, the roller can be set into a sealed container, the two ends of the roller can be each supported by a rotating shaft in the washing process of the roller, and the eccentric rotation of the roller is avoided.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +2

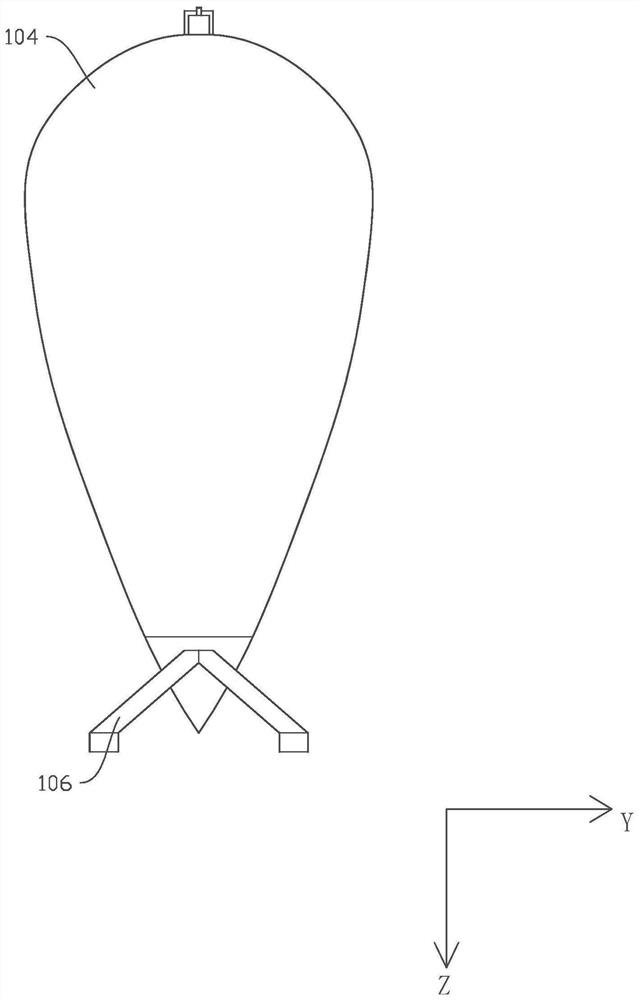

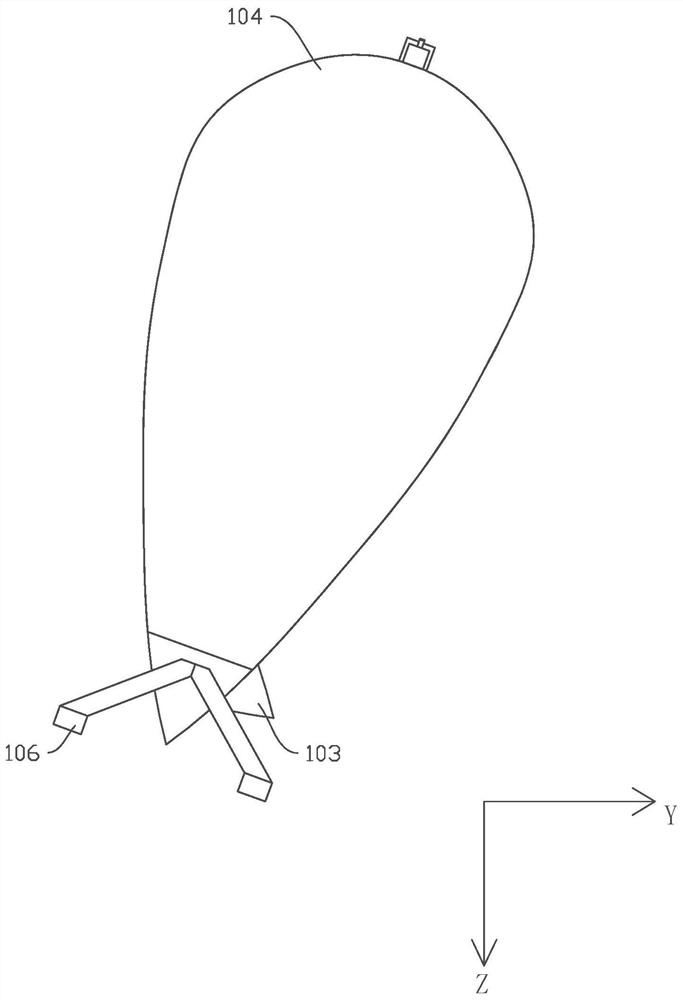

Vertical take-off and landing aircraft and flight method

PendingCN112046740AThe structure of the whole machine is simpleSimple structureAircraft controlVertical landing/take-off aircraftsFlight vehicleTakeoff

The invention relates to the technical field of vertical take-off and landing aircrafts, and discloses a vertical take-off and landing aircraft and a flight method. The vertical take-off and landing aircraft comprises a fuselage, a propeller and an elevator. The propeller is located at the top of the fuselage and used for driving the vertical take-off and landing aircraft to vertically take off. The elevator is located on the aircraft body, can swing relative to the aircraft body and is used for driving the hovering vertical take-off and landing aircraft to conduct steering or overturning motion. In the take-off process of the vertical take-off and landing aircraft, the vertical take-off and landing aircraft can vertically take off through the propeller, and when the vertical take-off andlanding aircraft takes off to a certain height, the vertical take-off and landing aircraft can horizontally move or turn or turn over by changing the angle of the elevator and the rotating speed of the propeller on the vertical take-off and landing aircraft. Therefore, the vertical take-off and landing aircraft can perform normal flight motion through a relatively simple structure. The flight method comprises a takeoff step, a cruise step and a landing step.

Owner:TAIZHOU RES INST OF SOUTHERN UNIV OF SCI & TECH

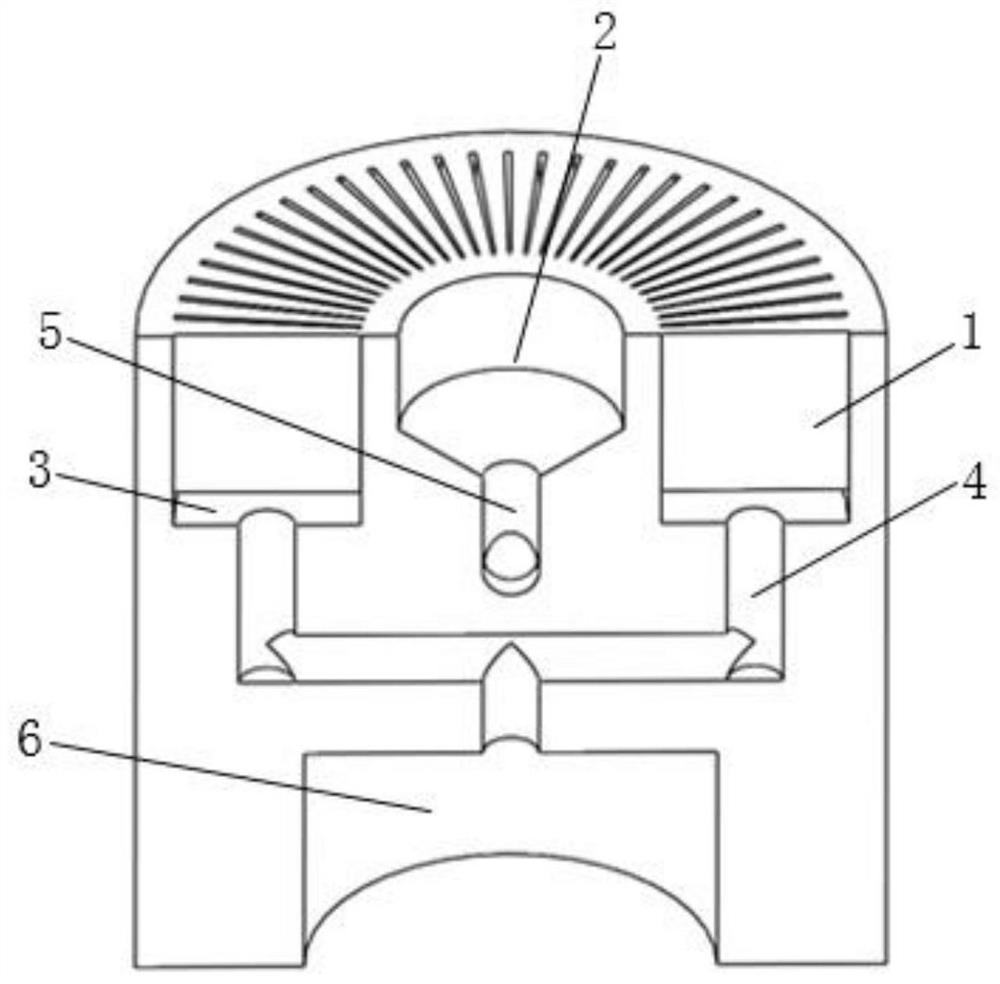

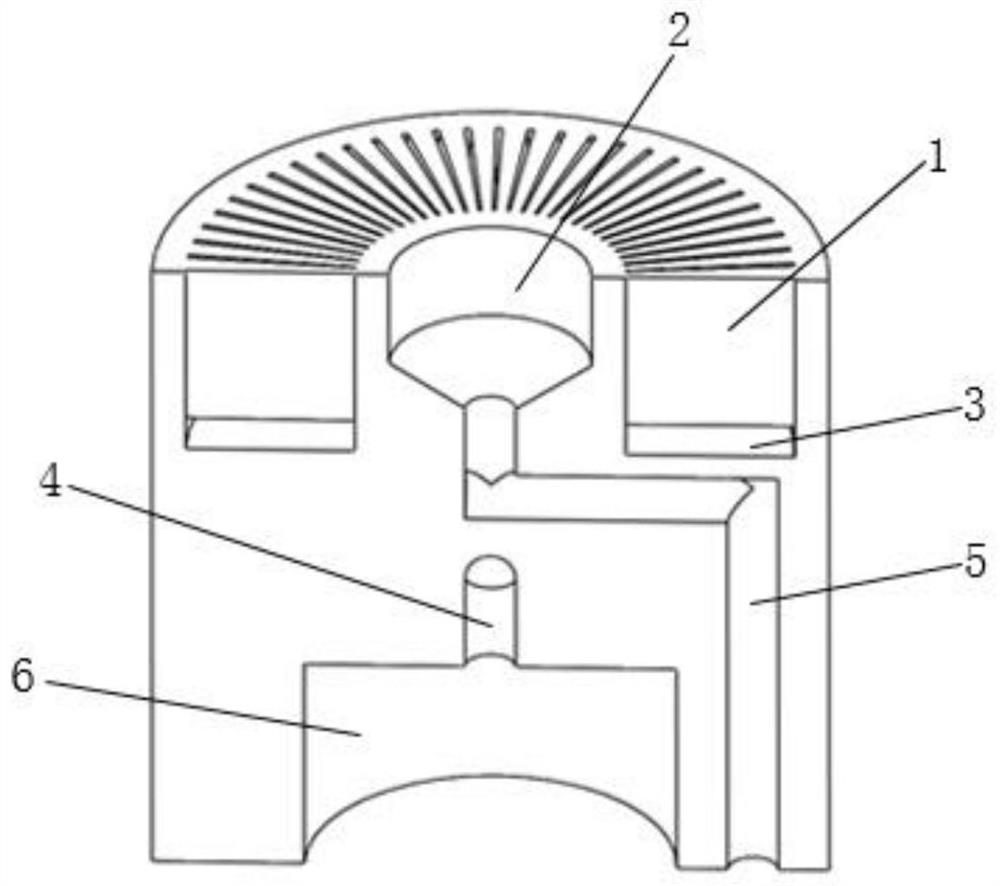

Integrated hot end structure of pulse tube refrigerator and implementation method

PendingCN113091343AHighly integratedThe structure of the whole machine is simpleCompression machinesEvaporators/condensersPulse tube refrigeratorEngineering

The invention discloses an integrated hot end structure of a pulse tube refrigerator and an implementation method. The integrated hot end structure comprises an annular slit body, a pulse tube hot end hole, a rectifying cavity, a compressed gas flow channel, a phase modulation gas flow channel and a compression cavity. A heat exchanger body is a cylinder, an annular slit extends outwards in the radial direction away from the axis of the heat exchanger body in a radial shape and penetrates through the annular slit body, and the rectifying cavity is an annular hollow flow channel and communicates with the annular slit body; and the compressed gas flow channel and the phase modulation gas flow channel are distributed in the circumferential direction, the pulse tube hot end hole communicates with the phase modulation gas flow channel, and the compression cavity is a cylindrical cavity body and communicates with the rectifying cavity through the compressed gas flow channel. The invention further discloses the implementation method of the integrated hot end structure. According to the integrated hot end structure of the pulse tube refrigerator, the whole structure of the pulse tube refrigerator can be simplified, the weight of the whole refrigerator can be reduced, the flow loss of a pipeline can be reduced, the flocculation flow disturbance of gas in the heat exchanger can be effectively inhibited, the efficiency of the heat exchanger can be improved, and high-efficiency refrigeration can be realized.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Drilling machine and drilling method

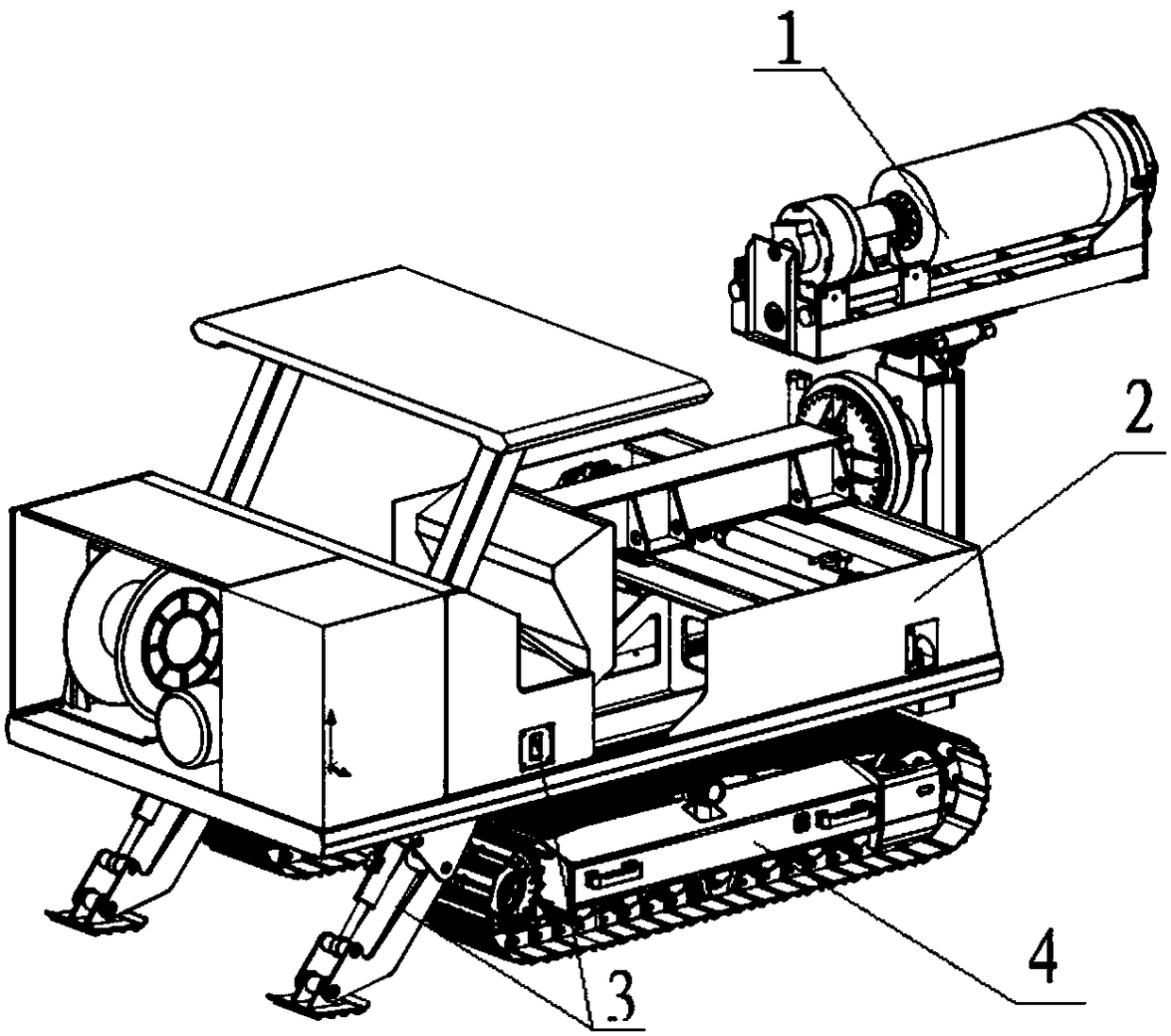

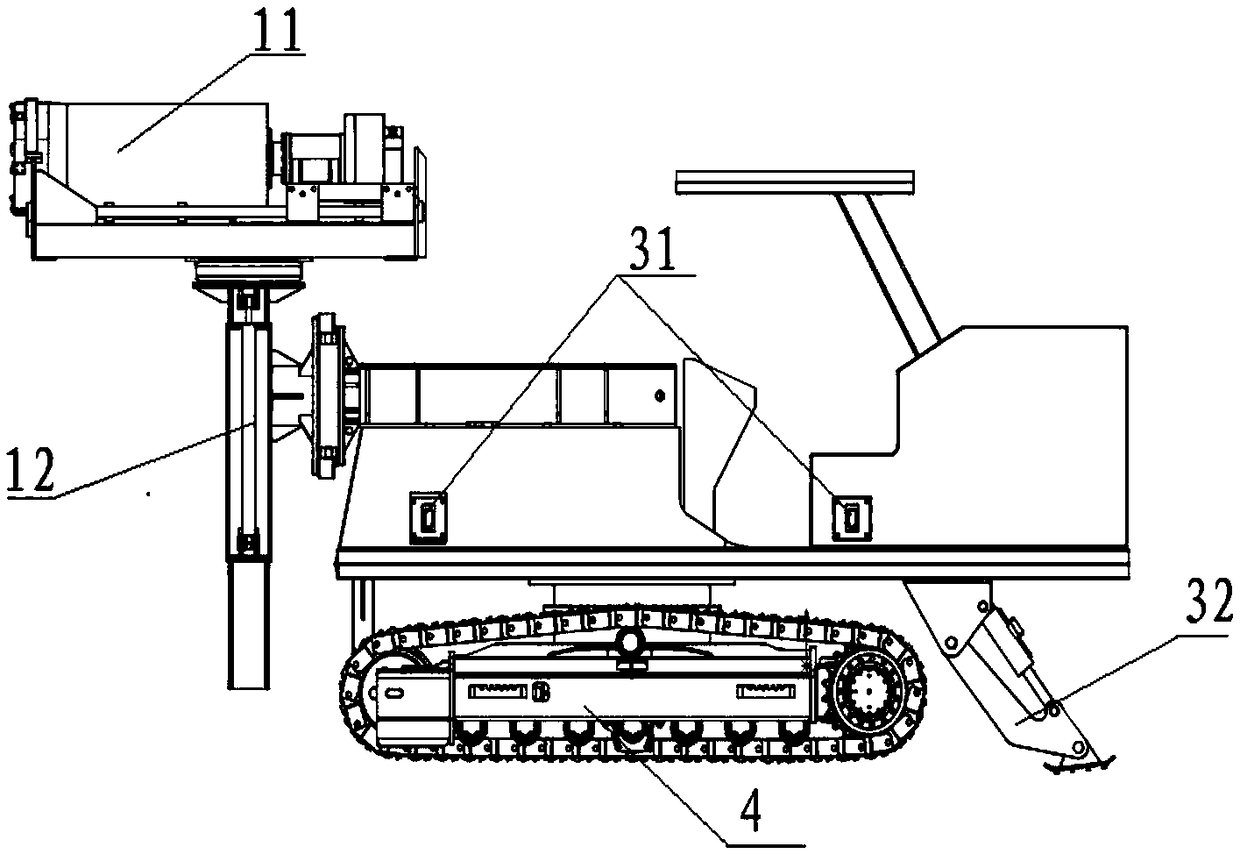

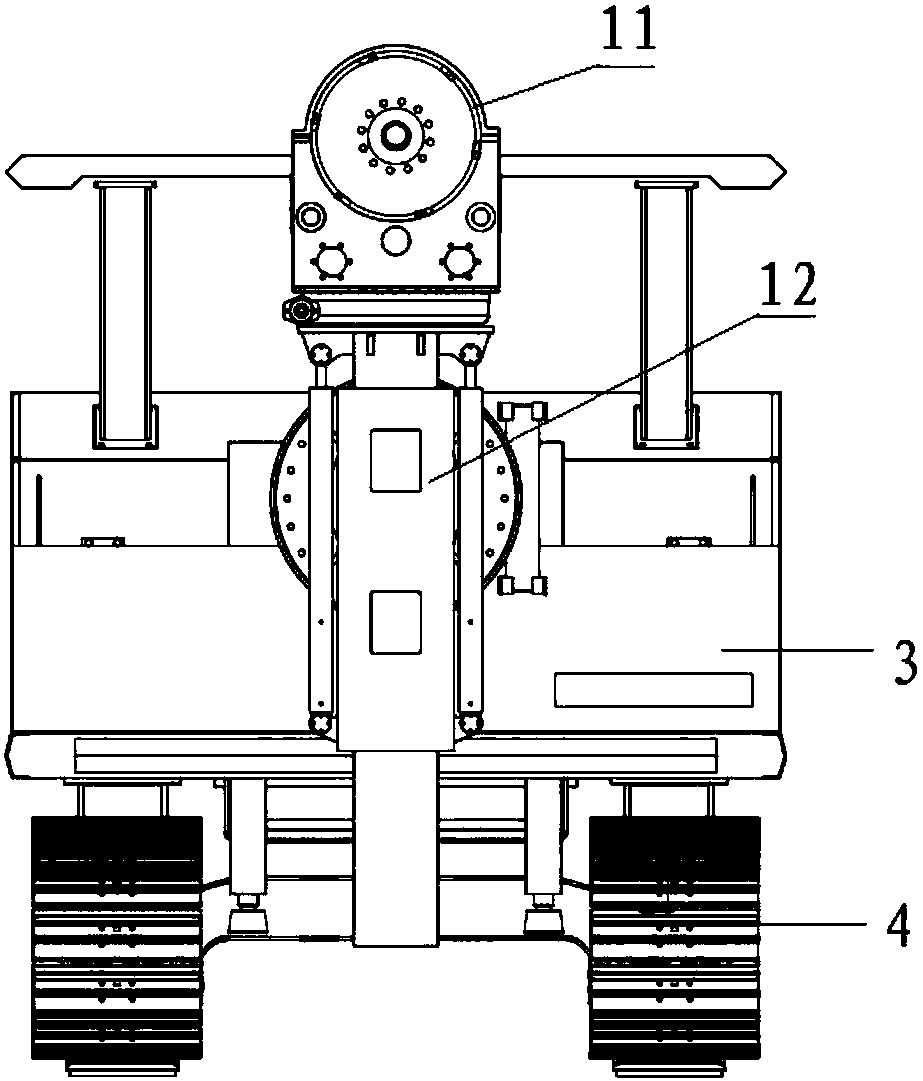

InactiveCN108131152AThe structure of the whole machine is simpleEasy to operateTunnelsDrilling machinesPetroleum engineering

The invention relates to the technical field of engineering machinery, and provides a drilling machine and a drilling method. The drilling machine comprises a drilling part, a carriage body and balance supporting parts; the drilling part comprises a drilling tool and a drilling tool adjusting part, the drilling tool adjusting part is arranged at the front end of the carriage body, and the drillingtool is arranged on the drilling tool adjusting part and used for drilling annular grooves in an area to be drilled; the balance supporting parts are arranged at the two sides and the bottom of the carriage body and used for maintaining the balance of the carriage body in the drilling process of the drilling tool. The drilling machine is simple in structure and greatly reduces equipment cost; besides, the drilling machine is convenient to operate and high in drilling efficiency and reduces environmental pollution.

Owner:江苏中贵重工有限公司

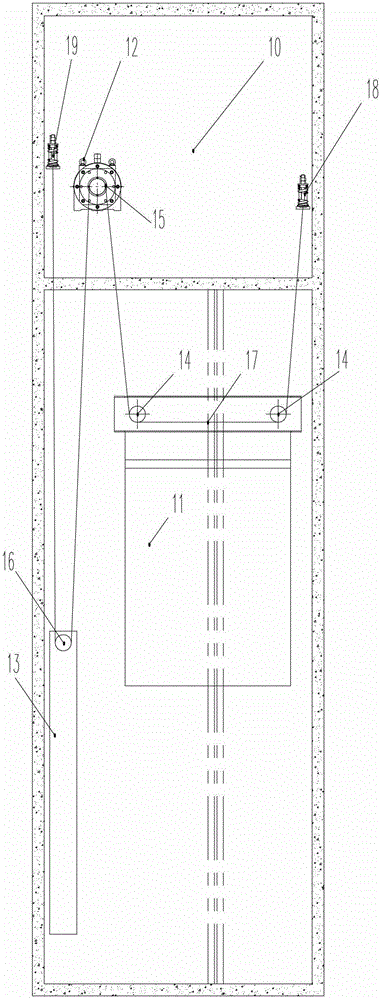

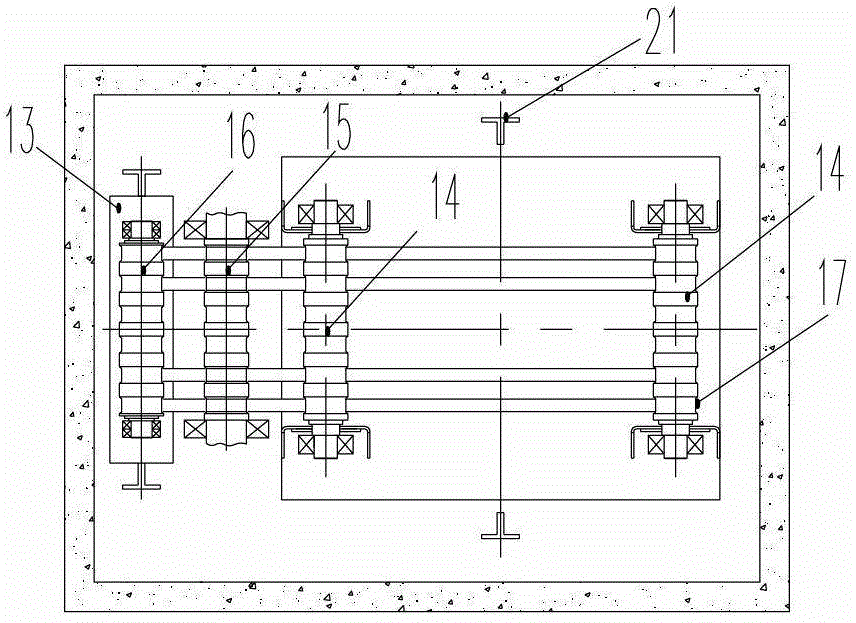

Drainage structure of single-barrel washing machine and single-barrel washing machine comprising drainage structure

ActiveCN113389019AEasy to controlThe structure of the whole machine is simpleOther washing machinesTextiles and paperLaundry washing machineMechanical engineering

The invention provides a drainage structure of a single-barrel washing machine and the single-barrel washing machine comprising the drainage structure. The drainage structure of the single-barrel washing machine is used for controlling opening and closing of a drainage opening of a washing barrel of the single-barrel washing machine; the washing barrel is of a single-barrel structure; the drainage opening is distributed in an annular area at the bottom of the washing barrel; the circle center of the annular area is located on the rotating axis of the washing barrel; the drainage structure comprises a plugging block and a driving mechanism; the blocking block is movably arranged in the axial direction of the washing barrel and is provided with a first working position for blocking the drainage opening and a second working position for opening the drainage opening; and the driving mechanism is used for driving the blocking block to move to the first working position or the second working position. According to the drainage structure of a single-barrel washing machine and the single-barrel washing machine comprising the drainage structure provided by the invention, the drainage structure of the single-barrel washing machine can be simplified, and implementation is convenient.

Owner:GREE ELECTRIC APPLIANCES INC

Drainage structure of single-tub washing machine and single-tub washing machine including same

ActiveCN113389019BEasy to controlThe structure of the whole machine is simpleOther washing machinesTextiles and paperLaundry washing machineProcess engineering

The invention provides a single-tub washing machine drainage structure and a single-tub washing machine comprising the same. The single-tub washing machine drainage structure is used to control the opening and closing of the washing tub drain of the single-tub washing machine. The washing tub has a single-tub structure, and the drainage outlets are distributed in the circular area at the bottom of the washing tub , the center of the ring-shaped area is located on the rotation axis of the washing tub, and the drainage structure includes: a blocking block, which is movably arranged along the axial direction of the washing tub and has a blocking The first working position of the drain opening and the second working position of opening the drain opening, the driving mechanism is used to drive the blocking block to move to the first working position or the second working position. The invention can simplify the drainage structure of the single barrel washing machine and is convenient for implementation.

Owner:GREE ELECTRIC APPLIANCES INC

elevator traction system

ActiveCN103171953BSolve deviationSolve the force problemBuilding liftsTraction systemAgricultural engineering

The invention discloses an elevator traction system. The elevator traction system comprises guiding pulleys which are arranged on an elevator lift car frame, an elevator main engine and a counterpoise, and composite steel belts which successively pass through the guiding pulleys, wherein the guiding pulleys are in an integrated structure of a pulley and a bearing main shaft, a guiding groove which is formed in a bearing main shaft is formed in the bearing main shaft, and the guiding groove is a groove with a flat base. On one hand, the elevator traction system solves the problems that the composite steel belts are in line deflection and load carrying capacity is uneven, on the other hand, the elevator traction system further solves the problems of inability to slip caused by an oversize friction coefficient by adopting the composite steel belts with a concave shape and a protruding shape and a rope sheave, so that the elevator traction system is authentically suitable for long term operation of the elevator. The elevator traction system has the advantages of being good in rigidity and intensity by adopting a wheel axle integrated structure, high in safety coefficient, compact in structure, capable of ensuring that an elevator device and an elevator complete machine structure are simplified, thereby reducing occupied space of the elevator device to an elevator well, and effectively saving well space.

Owner:GUANGZHOU GUANGRI ELEVATOR IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com