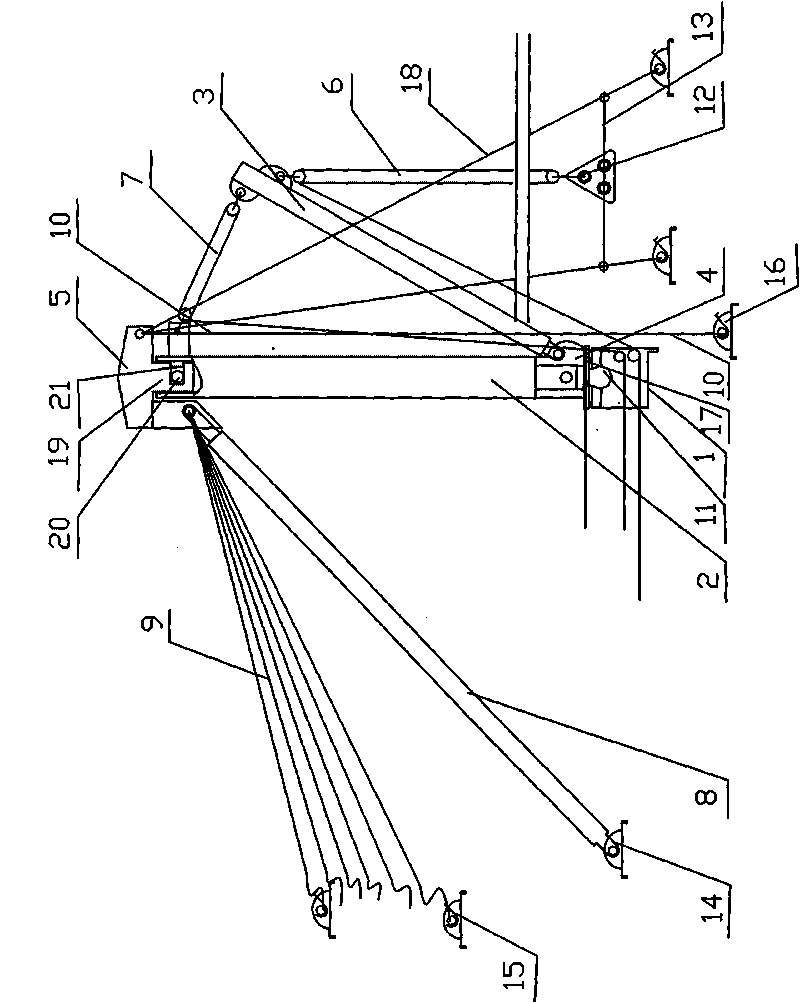

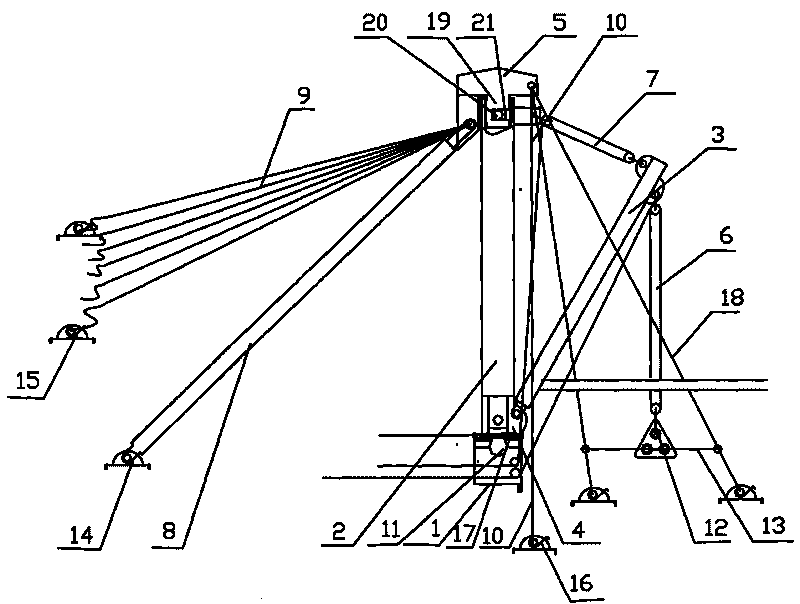

Method and device for lifting weight on top floor of super high-rise building

A lifting device and super high-rise technology, applied in the direction of cranes, etc., can solve the problems of long assembly process time, ultra-high bearing capacity limitation, and rising crane manufacturing and installation costs, etc., to achieve convenient equipment entry and exit, large hoisting and lifting capacity , the effect of large space movement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The height of a certain project is 204m, the minimum unit weight of the hoisted object is 8 tons, and the lifting height difference is 214m. A 30t class super high-rise building top floor heavy object hoisting device is used, and 3 stabilizers are used. Stress cables apply 7 tons of prestress at the same time; make the angle between the stabilizer bar on the horizontal plane projection: 2*40°, and the angle between the stabilizer bar and the stabilizer bar on the horizontal plane projection line: 45°; use the cable There are 6 winds, so that the angle between the projection of the cable wind on the horizontal plane is: 5*20°, and the angle between the projection line of the cable wind and the cable wind on the horizontal plane is: 30°; start the peripheral hoisting equipment to make the hoist The hook on the block block, the hoisting balance beam to the lifting point, and the hoisted weight is tied and hung on the hoisting balance beam; then, the weight is lifted to an e...

Embodiment 2

[0038] The building height of a certain project is 125m, the minimum unit weight of the hoisted object is 15 tons, and the lifting height difference is 135m. A 30t class super high-rise building top floor heavy object lifting device is used, and 2 stabilizers are used. Stress cables apply 10 tons of prestress at the same time; make the angle between the stabilizing bar on the horizontal plane projection: 90°, and the angle between the stabilizing bar and the stabilizing bar on the horizontal plane projection line: 60°; use cable wind 6 root, so that the angle between the projection of the cable wind on the horizontal plane is: 5*22°, and the angle between the projection line of the cable wind and the cable wind on the horizontal plane is: 40°; start the peripheral hoisting equipment to lift the block The hooks and the hoisting balance beam on the upper floor are lowered to the lifting point, and the heavy objects to be hoisted are tied and hung on the hoisting balance beams; th...

Embodiment 3

[0040] The building height of a certain project is 70m, the minimum unit weight of the hoisted object is 14 tons, and the lifting height difference is 80m. A 20t class super high-rise building top floor heavy object lifting device is used, and 2 stabilizers are used. Stress cables apply 7 tons of prestress at the same time; make the angle between the stabilizer bar on the horizontal plane projection: 90°, and the angle between the stabilizer bar and the stabilizer bar on the horizontal plane projection line: 30°; use cable wind 6 root, so that the angle between the projection of the cable wind on the horizontal plane is: 5*24°, and the angle between the projection line of the cable wind and the cable wind on the horizontal plane is: 13°; start the peripheral hoisting equipment to lift the block The hook and the hoisting balance beam on the hoist are lowered to the lifting point along the guide cable, and the heavy objects to be hoisted are tied and hung on the hoisting balance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com