Drilling machine and drilling method

A technology for drilling rigs and drilling tools, which is applied to earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of high equipment cost, large environmental pollution, low excavation efficiency, etc., and achieves convenient operation, reduced environmental pollution, and high drilling efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

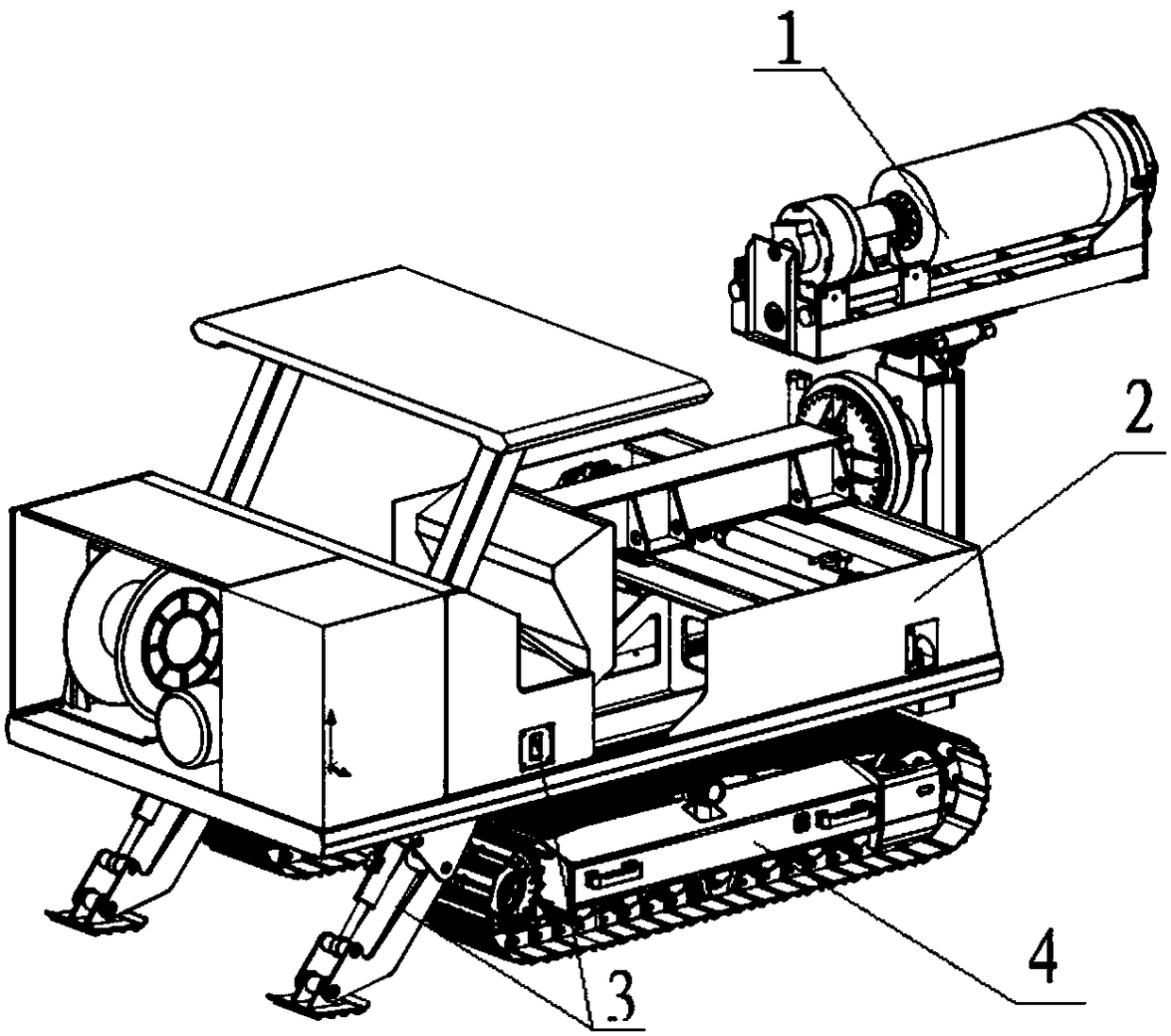

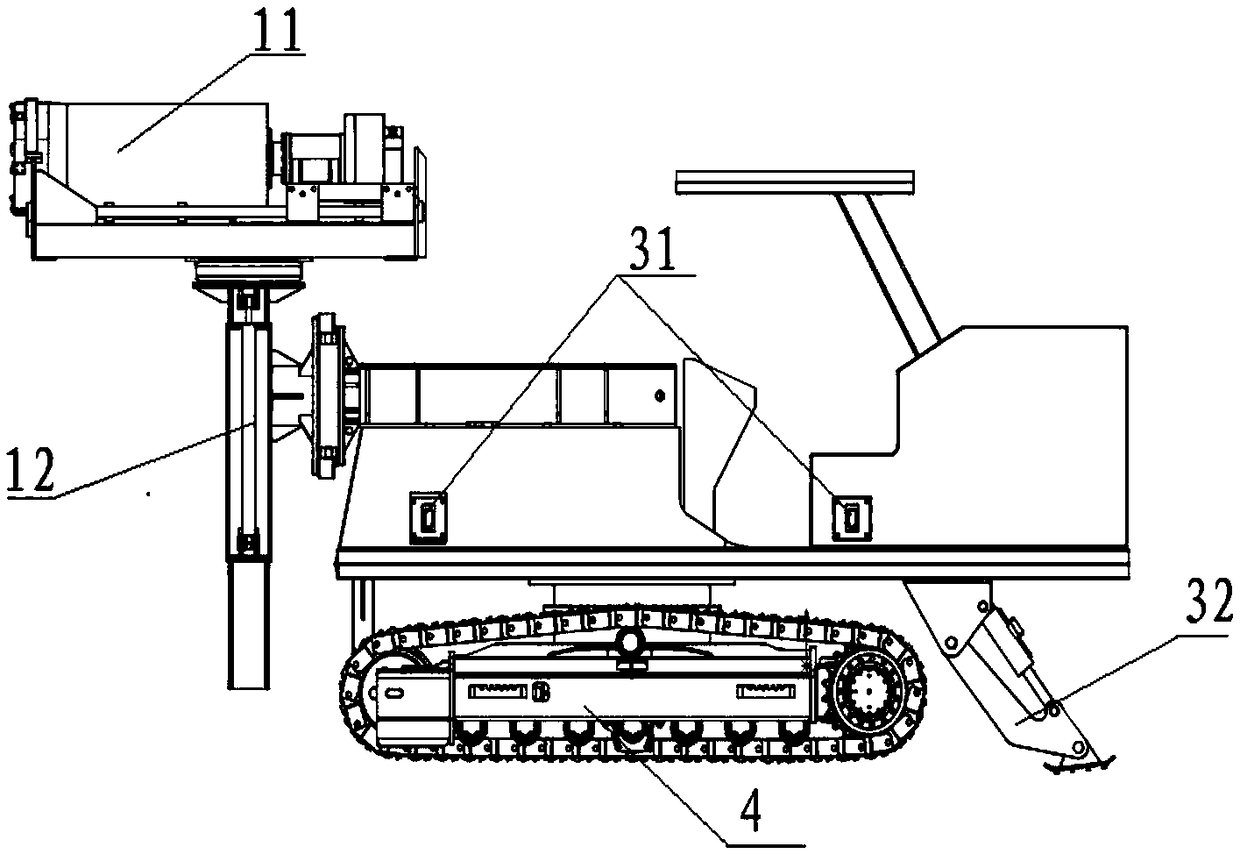

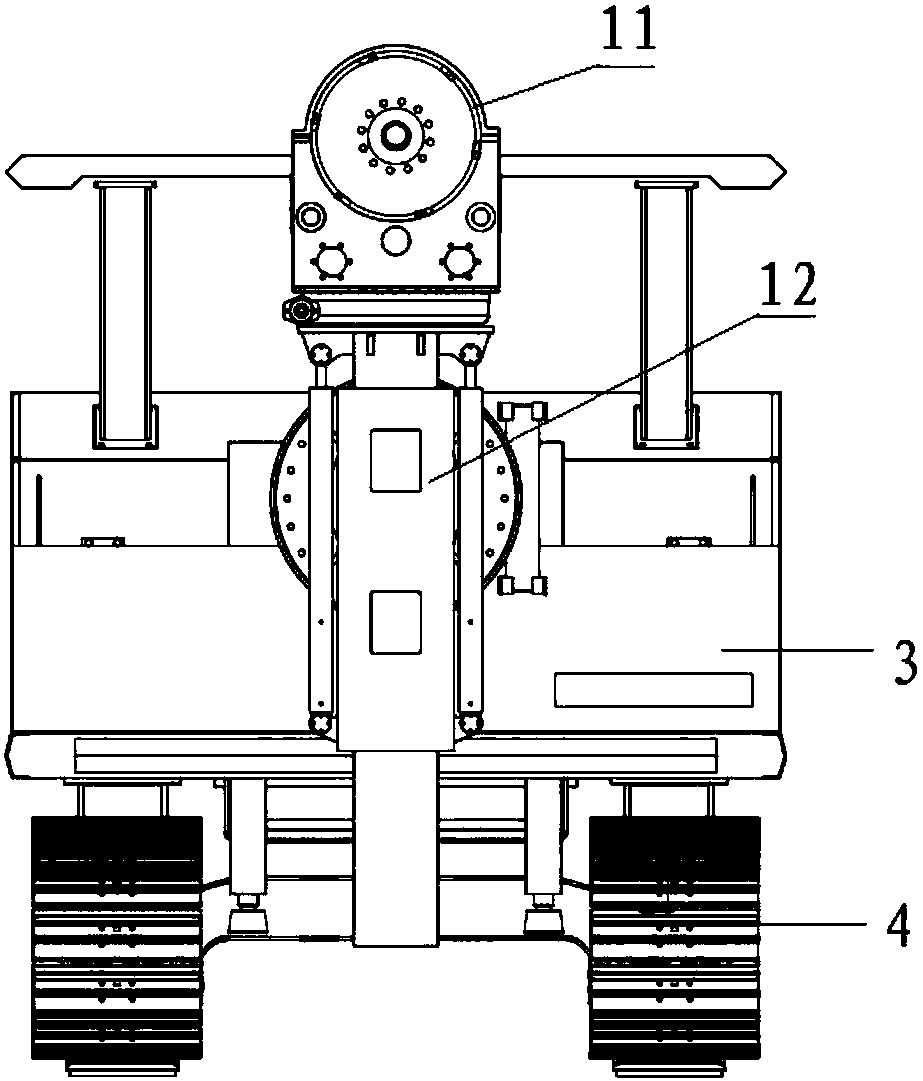

[0040] Please see attached figure 1 -3, this embodiment provides a drilling rig, which includes a drilling part 1, a vehicle body 2 and a balance support part 3;

[0041] The drilling portion 1 includes a drilling tool 11 and a drilling tool adjusting portion 12 , the drilling tool adjusting portion 12 is arranged at the front end of the vehicle body 2 , and the drilling tool 11 is arranged at the drilling tool adjusting portion 12 . , used to drill annular grooves in the area to be drilled;

[0042] The balance support parts 3 are provided on both sides and the bottom of the vehicle body 2 , and are pressed against the wall or the ground to maintain the balance of the vehicle body 2 when the drilling tool 11 is drilling.

[0043] This embodiment provides a drilling rig. The drilling tool is set at the front end of the vehicle body through the drilling tool adjusting part, and the front, rear, left, and right of the vehicle body are positioned and supported through the balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com