Integrated hot end structure of pulse tube refrigerator and implementation method

An integrated technology of pulse tube refrigerator, applied in the field of integrated hot end structure of pulse tube refrigerator, can solve the problems of gas flow loss and large weight, complex structure of the whole machine, and numerous pipelines of pulse tube refrigerator, etc. Achieve the effects of improving the integration of the whole machine, simplifying the structure of the whole machine, and reducing the weight of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

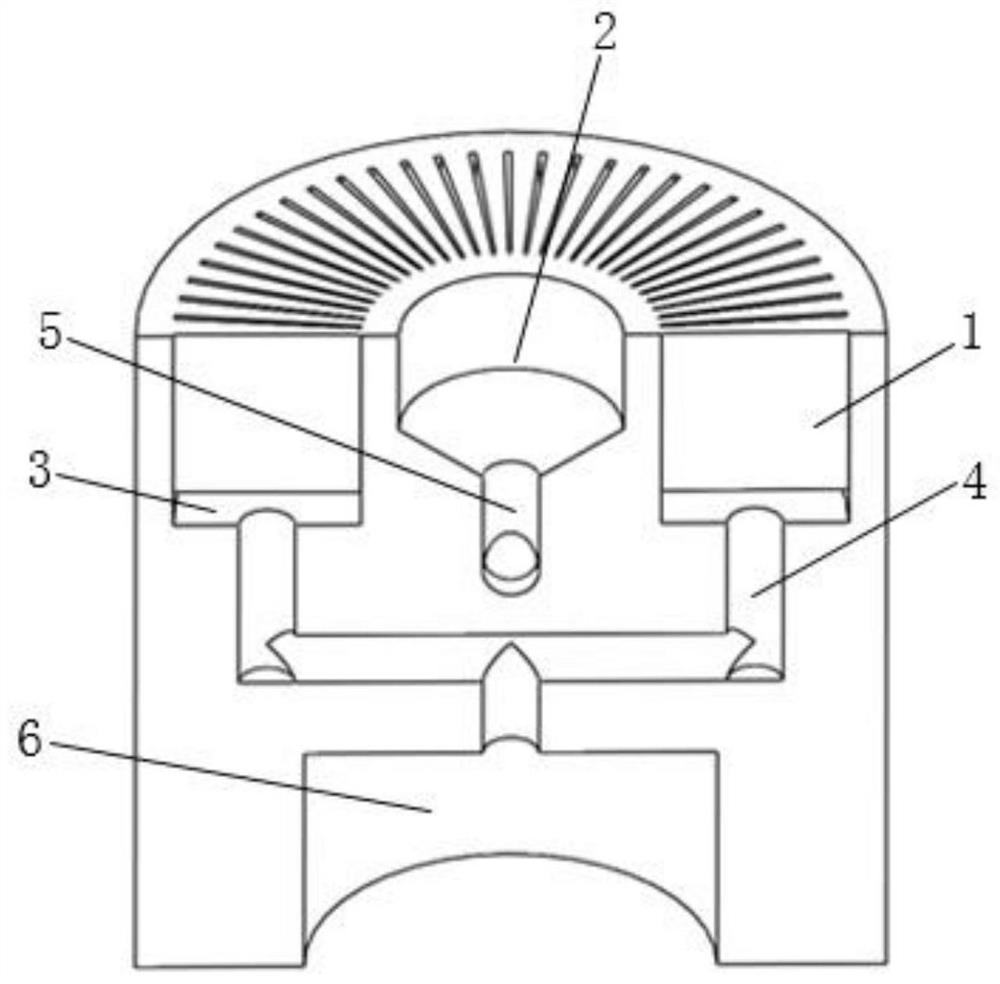

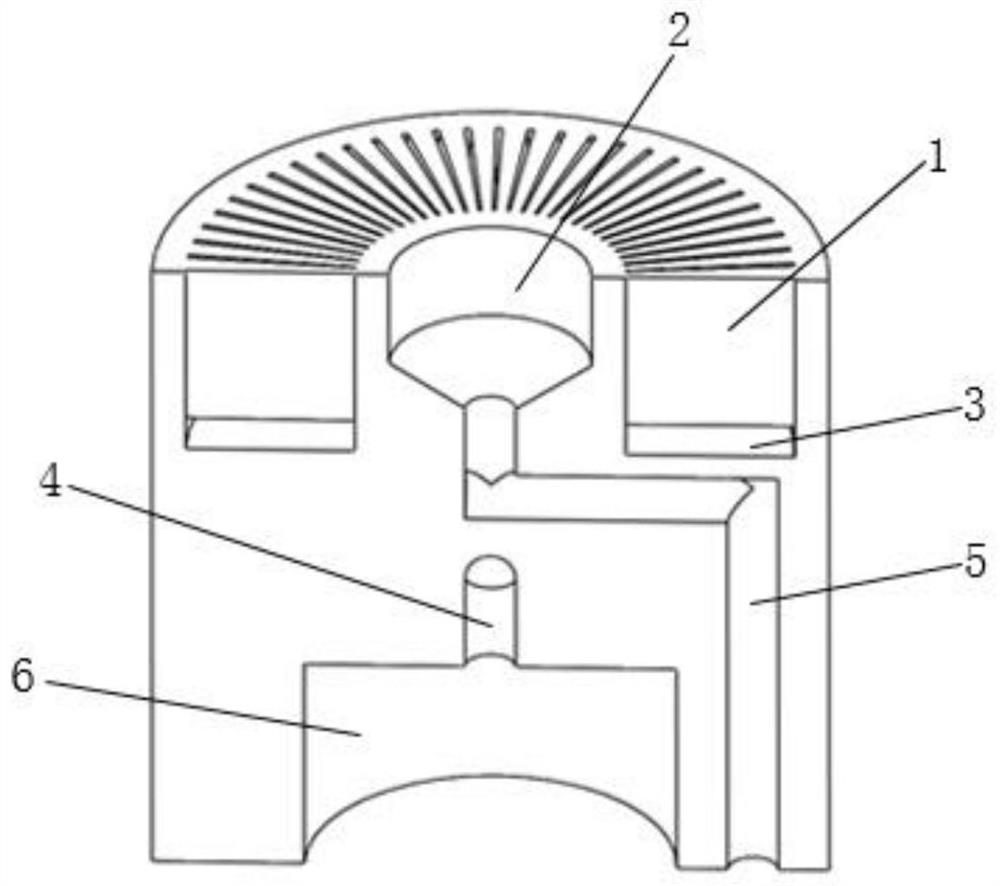

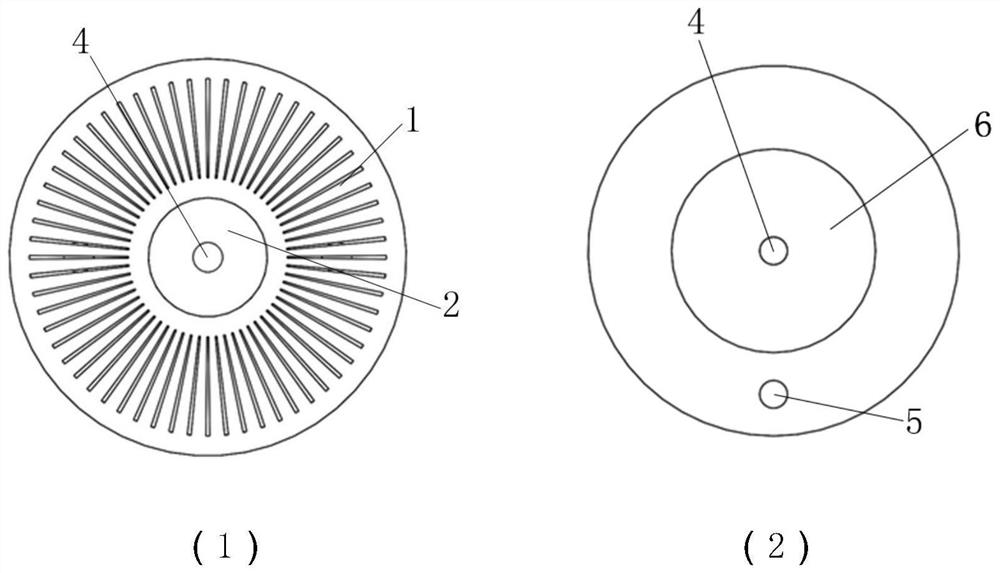

[0020] like figure 1 and figure 2 As shown, the embodiment of the present invention provides an integrated hot end structure of a pulse tube refrigerator, which includes: an annular slit body 1, a pulse tube hot end hole 2, a rectification cavity 3, a compressed gas flow channel 4, and a phase-modulating gas Runner 5 and compression chamber 6. The body of the heat exchanger is cylindrical, and from top to bottom are the annular slit body 1, the hot end hole 2 of the pulse tube, the rectification cavity 3, the compressed gas flow channel 4, the phase-modified gas flow channel 5, and the compression cavity 6. The annular slit extends radially away from the axis of the heat exchanger body and runs through the annular slit body 1. The hot end hole 2 of the pulse tube is coaxially distributed with the annular slit. The top view is as follows: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com