Patents

Literature

536 results about "Projection line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

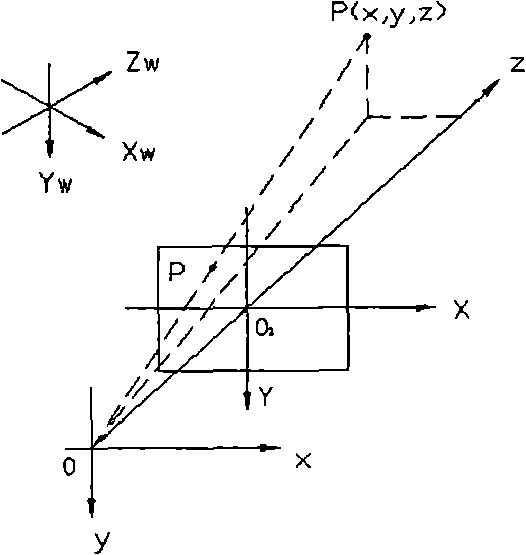

Projection of lines give an exact visual imagery of objects which can be expressed into mathematical terms. The projection can be used to estimate the area under or area covered and many other things that civil engineers or mechanical engineers might find useful during design of projects.

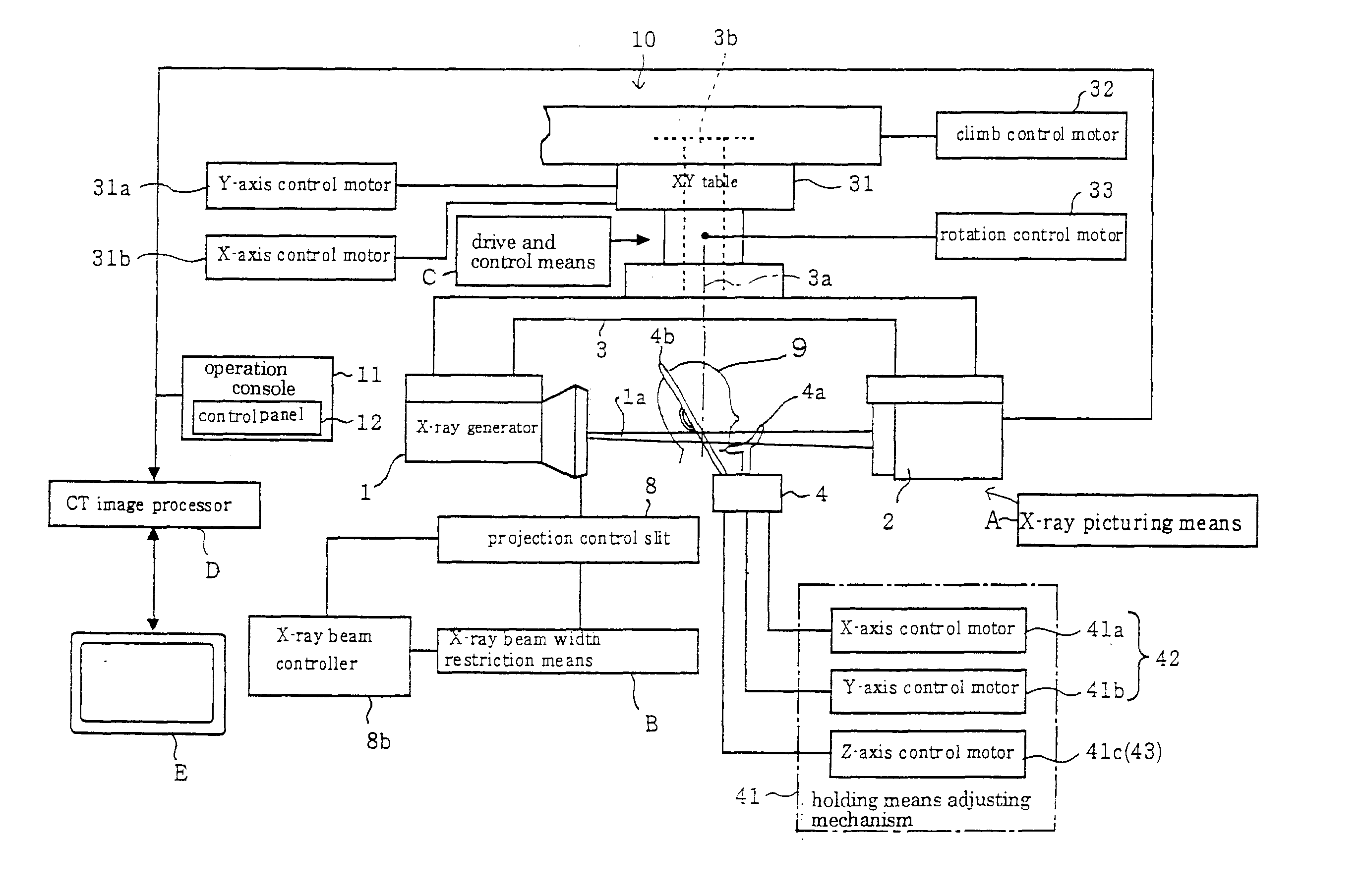

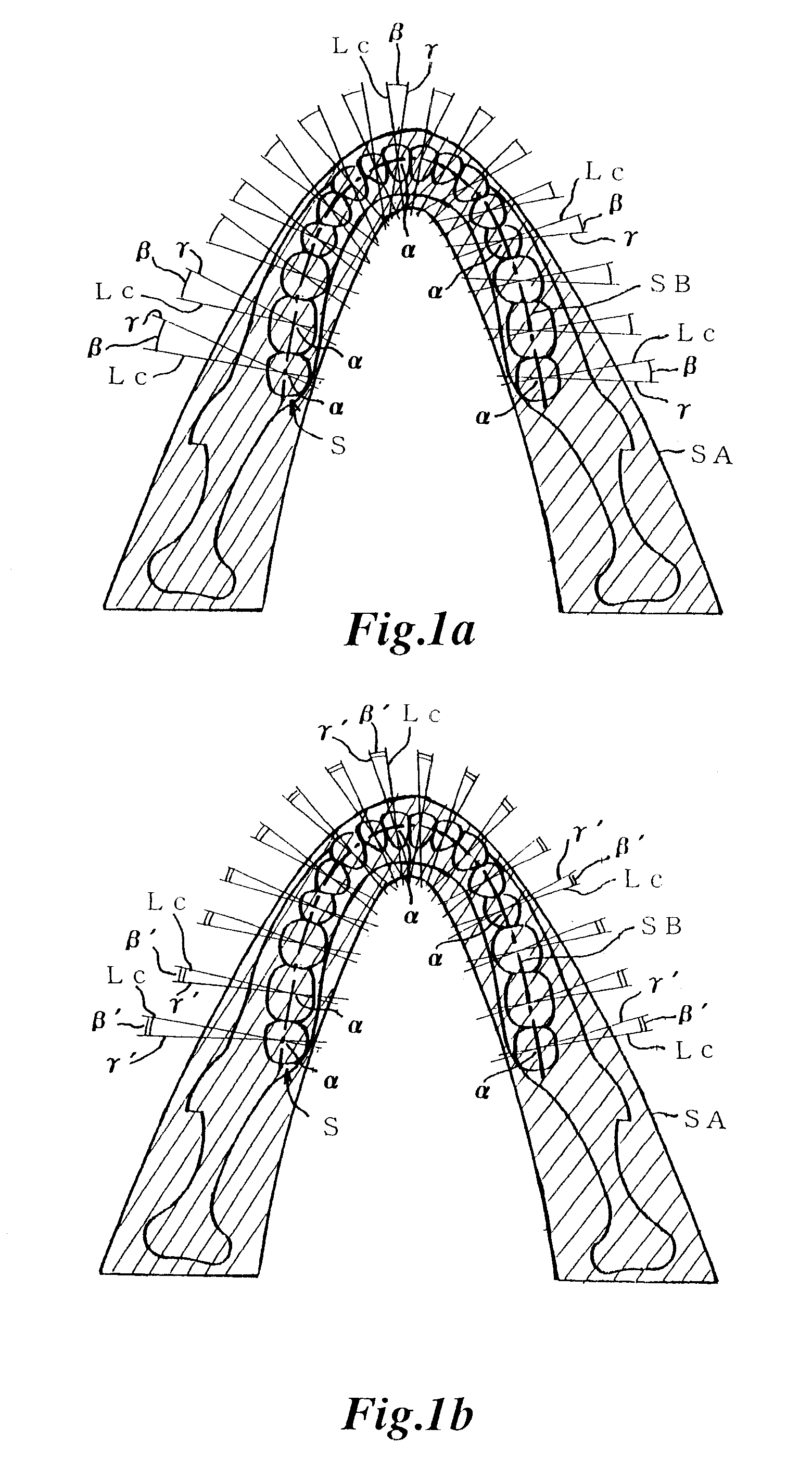

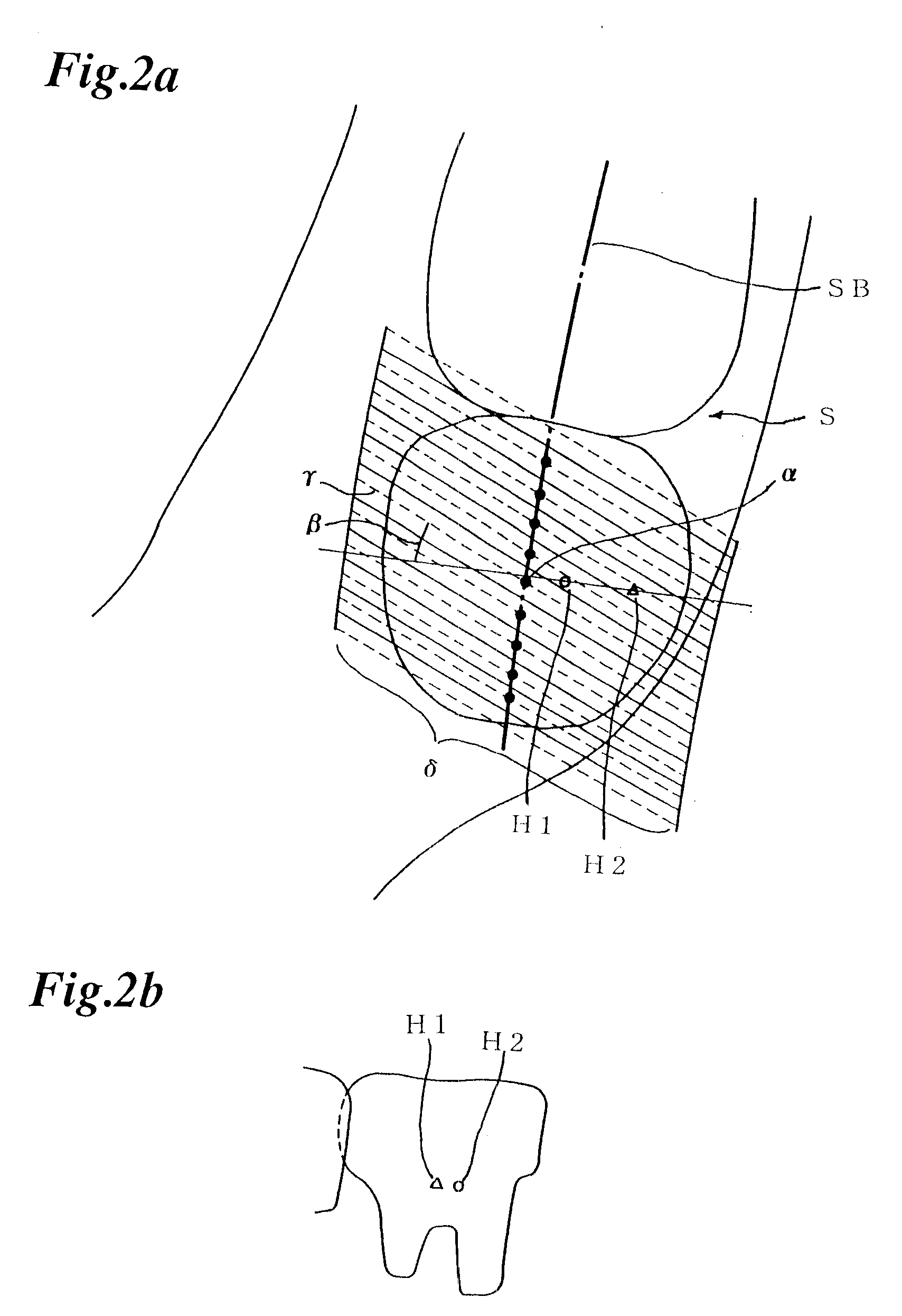

X-ray computed tomography method and apparatus

InactiveUS6493415B1Material analysis using wave/particle radiationRadiation/particle handlingSoft x rayX-ray

An X-ray computed tomography method and apparatus for obtaining a panoramic X-ray image seen from a direction of a projection line gamma (gamma') of a curved sectional area SA by expanding calculation results of three-dimensional distribution information of X-ray absorption coefficient on the projection line gamma (gamma') intersecting at a specified angle beta (beta') for any regions alpha of the panoramic sectional image layer SB on a two-dimensional plane based on the three dimensional distribution information of X-ray absorption coefficient of the curved sectional area SA obtained by a X-ray CT.

Owner:NIHON UNIVERSITY +1

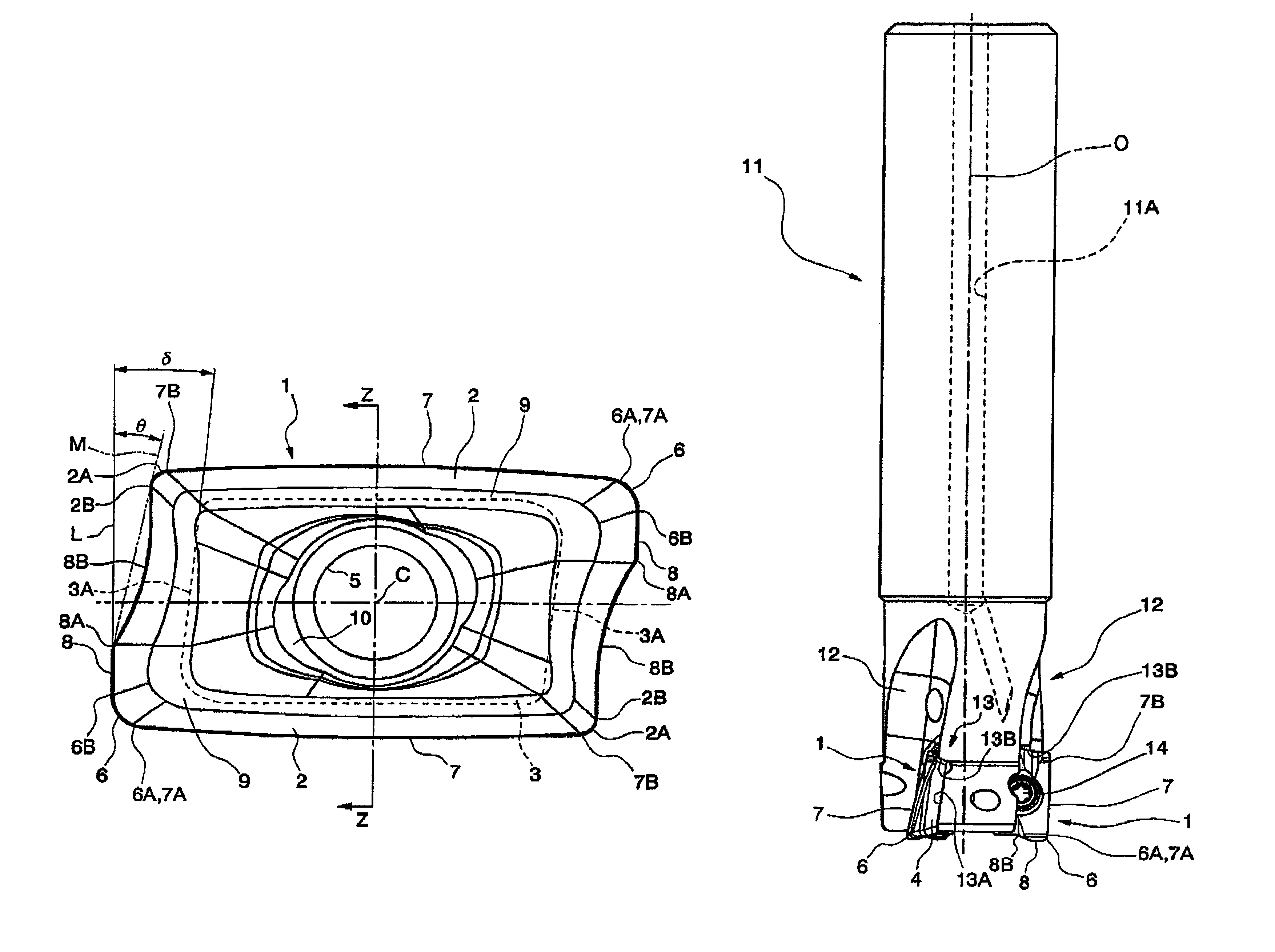

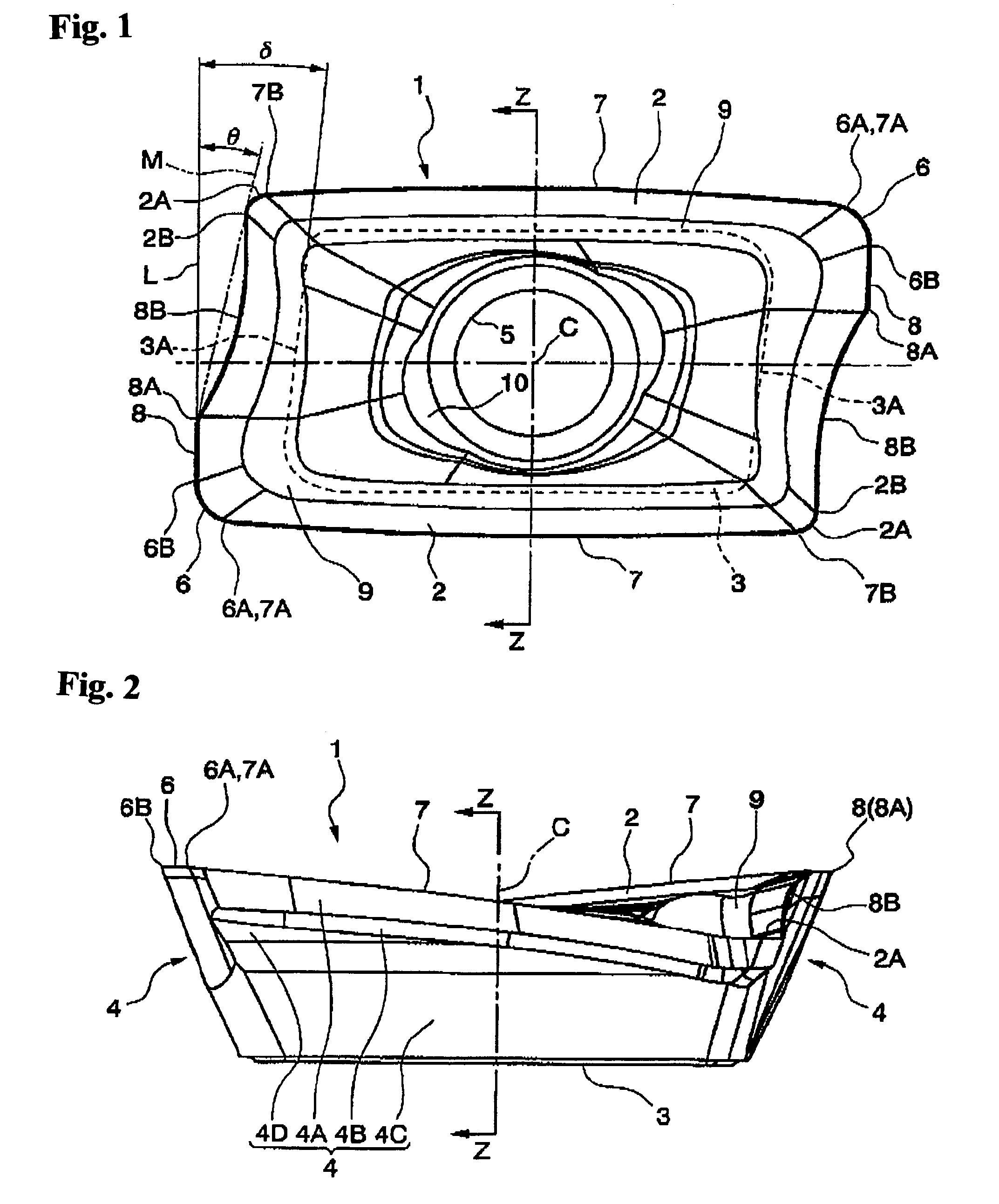

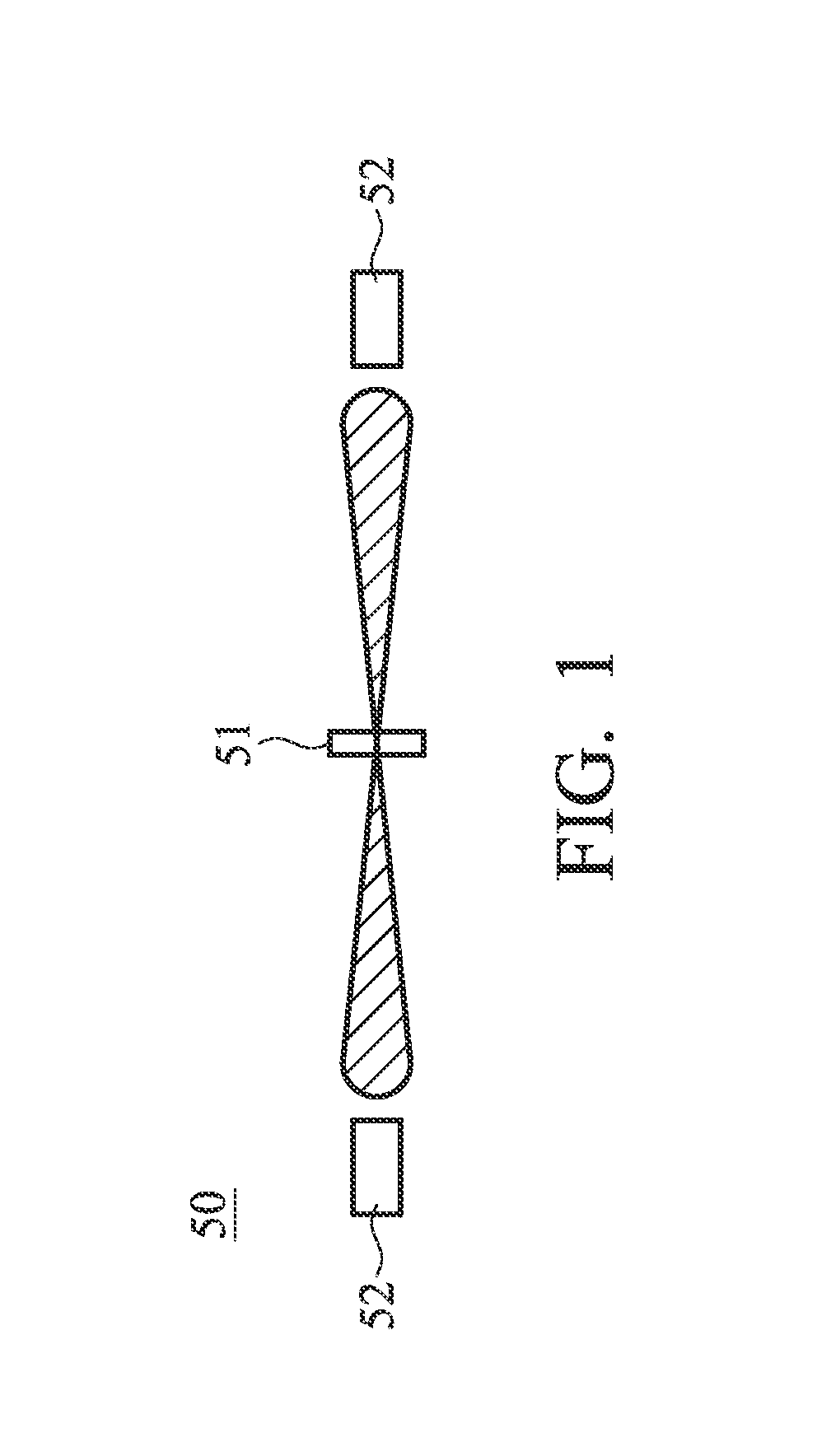

Throwaway insert and throwaway-type rotary cutting tool

ActiveUS7040844B1Improve accuracyImprove chip separationMilling cuttersAdverse effect compensationProjection lineCurve line

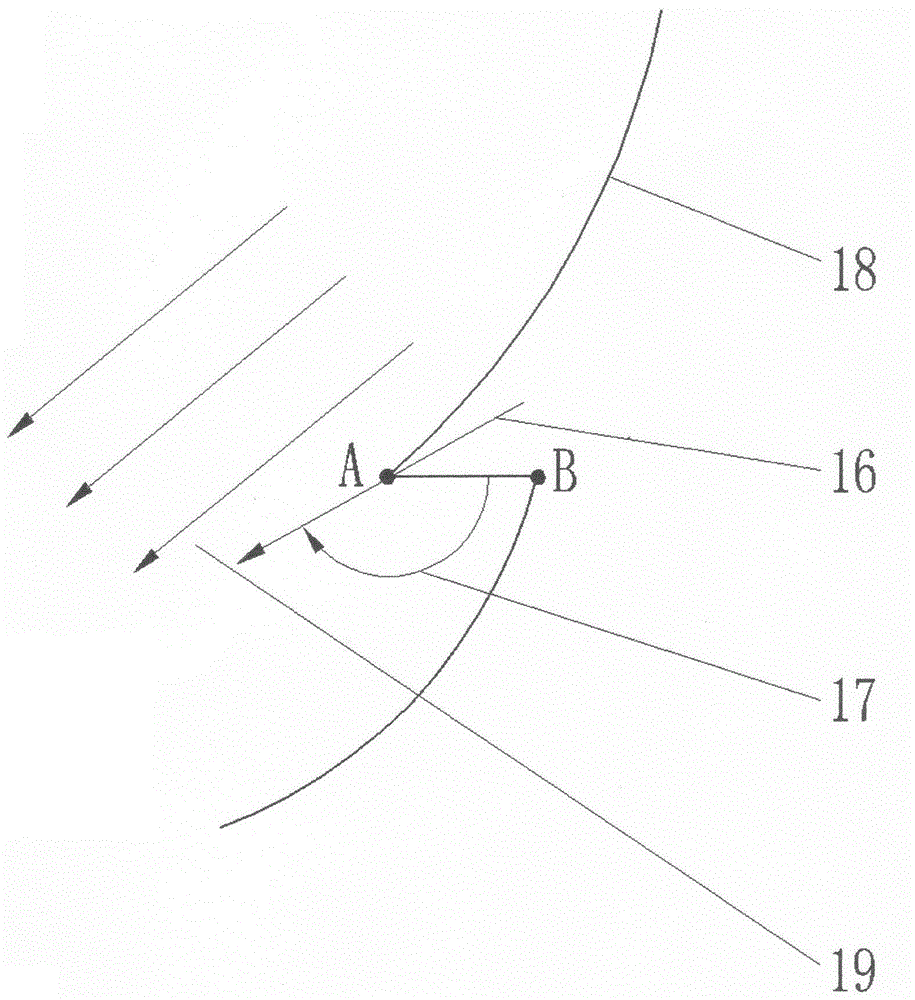

A tool main cutting edge extends rearward in a rotating direction as it approaches a rear end at the outer periphery. The main cutting edge is a convexly curved line protruding toward the outside of a rake face viewed from the top and another convexly curved line extending toward the seat face, convexly curving from one end of the main cutting edge to the other, viewed from the side. When mounted, an inclination angle defined by the rake face gradually decreases from one end toward the other, and a projection line of a rotation about a rotation axis of the tool forms a convex arc smoothly coming, at a middle portion of the main cutting edge, into contact with a cylindrical surface about the axis and gradually retreats inward from the cylindrical surface as it approaches both ends of the main cutting edge.

Owner:MITSUBISHI MATERIALS CORP

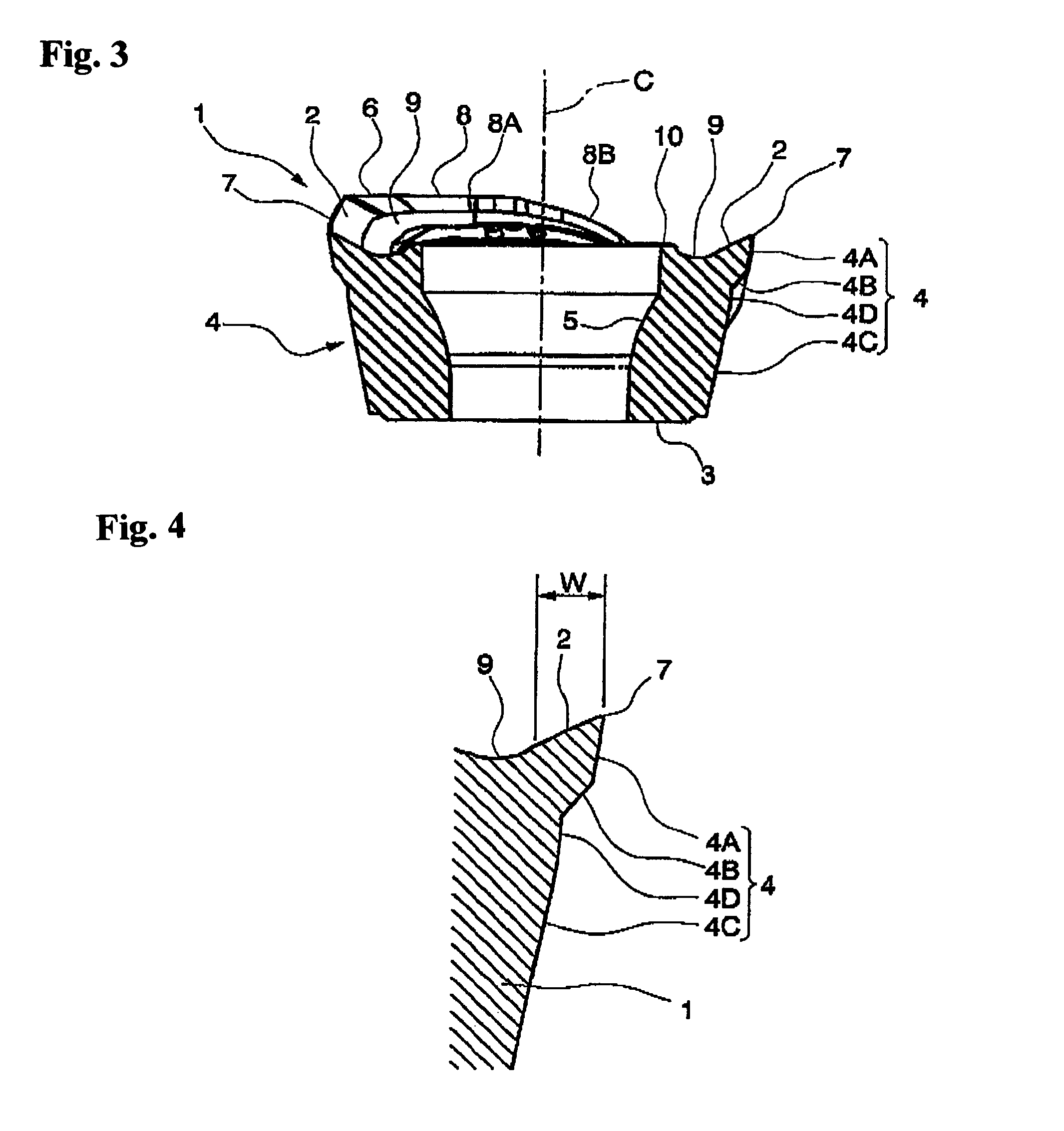

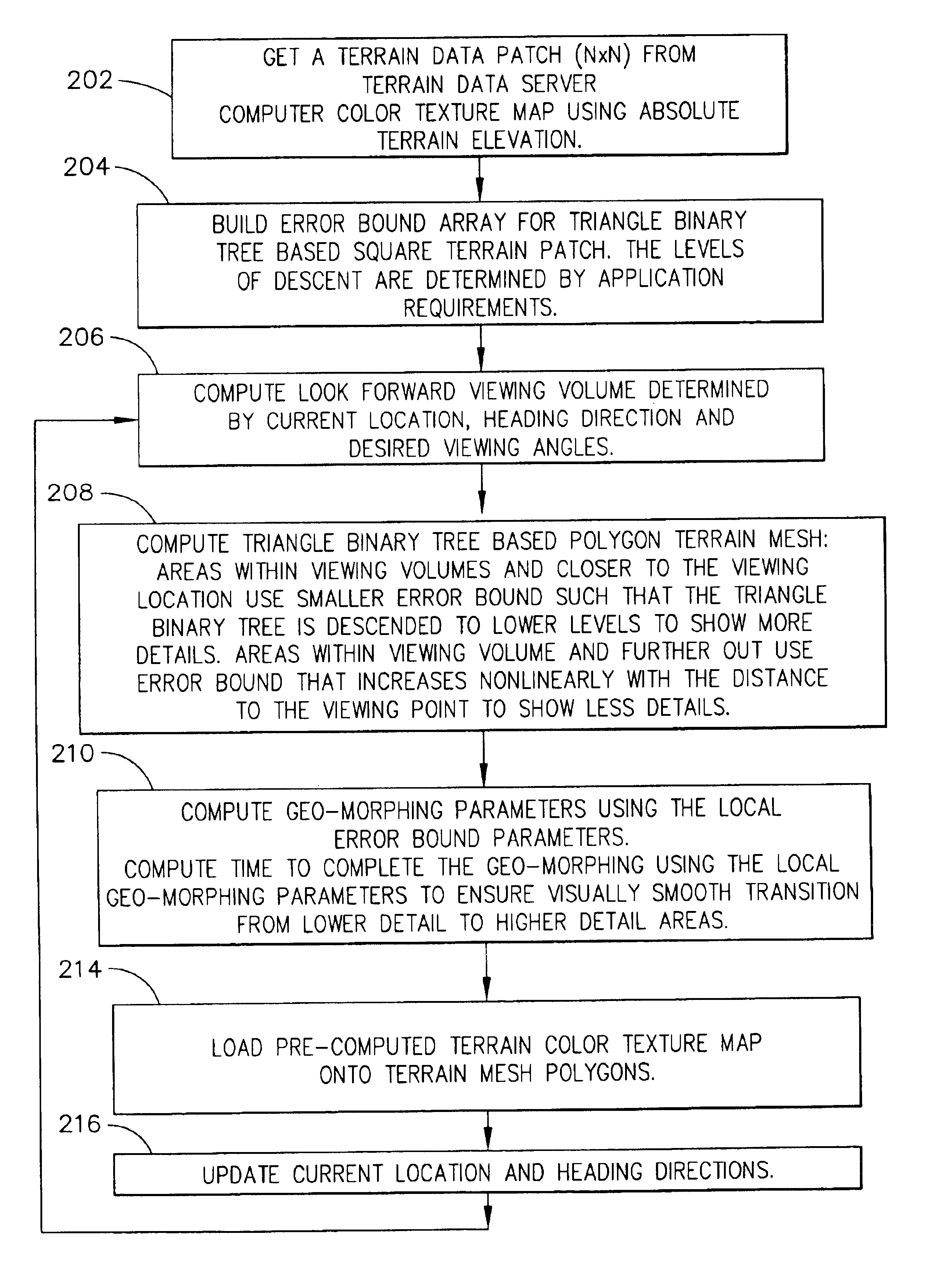

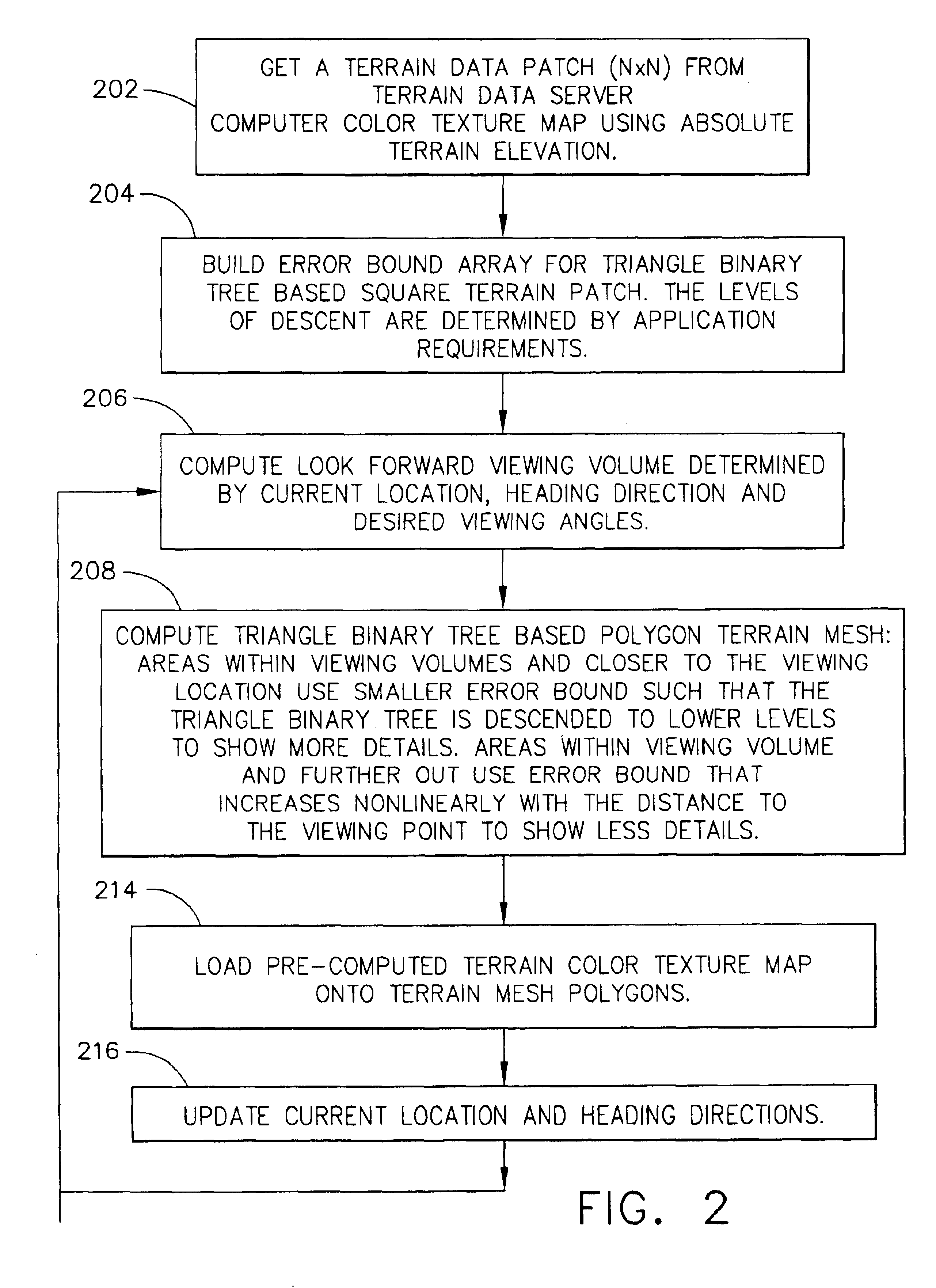

Method for producing 3D perspective view avionics terrain displays

InactiveUS6862501B2Reduce computationReduce data loadData processing applicationsAnalogue computers for trafficTerrainAviation

Methods for generating information for displaying terrain on an aircraft display system that significantly reduces the computation and data load for producing the terrain display. This is accomplished through the use of intelligent level of detail control that computes and displays terrain and dynamic on-terrain perspective projection lines and distance rings aligned with the aircraft heading for depth perception and relative altitude awareness. The terrain details are processed and displayed in a manner that shows all significant terrain features, e.g., peaks, towers, and the like, but through the use of nonlinear error bound geometric morphing, coupled with triangle binary tree based terrain mesh generation, the polygon count, and thus the computational load, are significantly reduced, while visual fidelity is maintained.

Owner:HONEYWELL INT INC

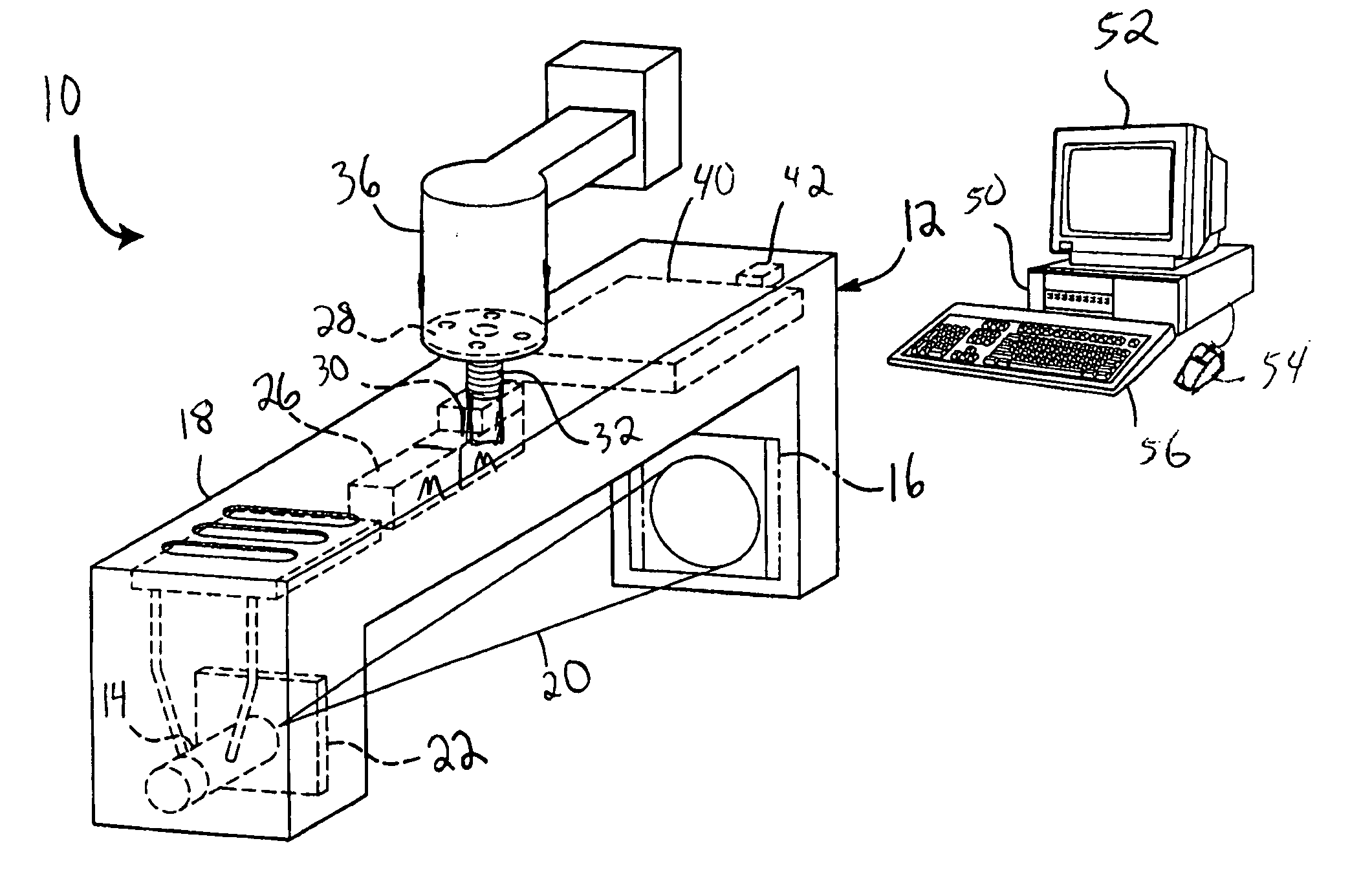

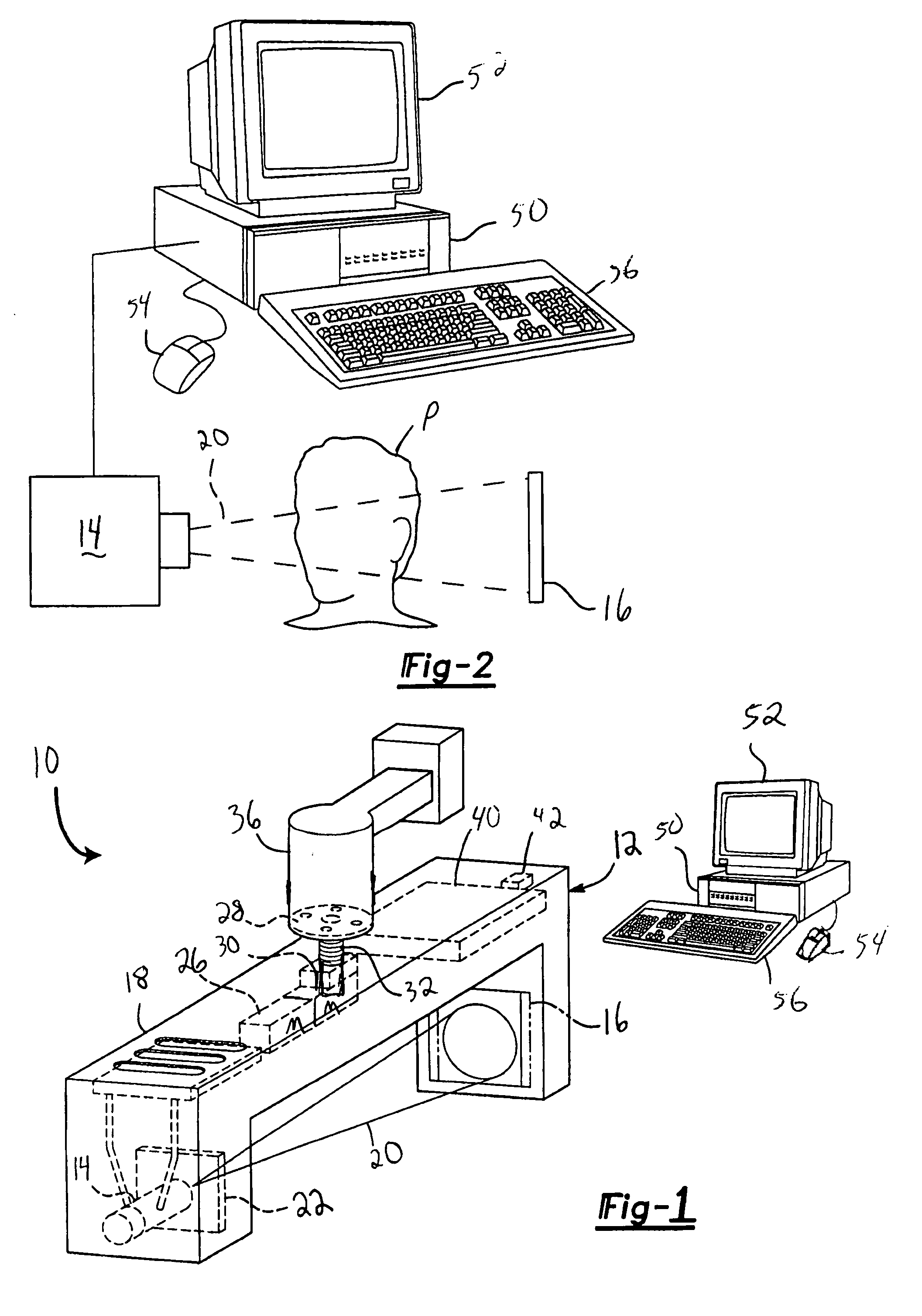

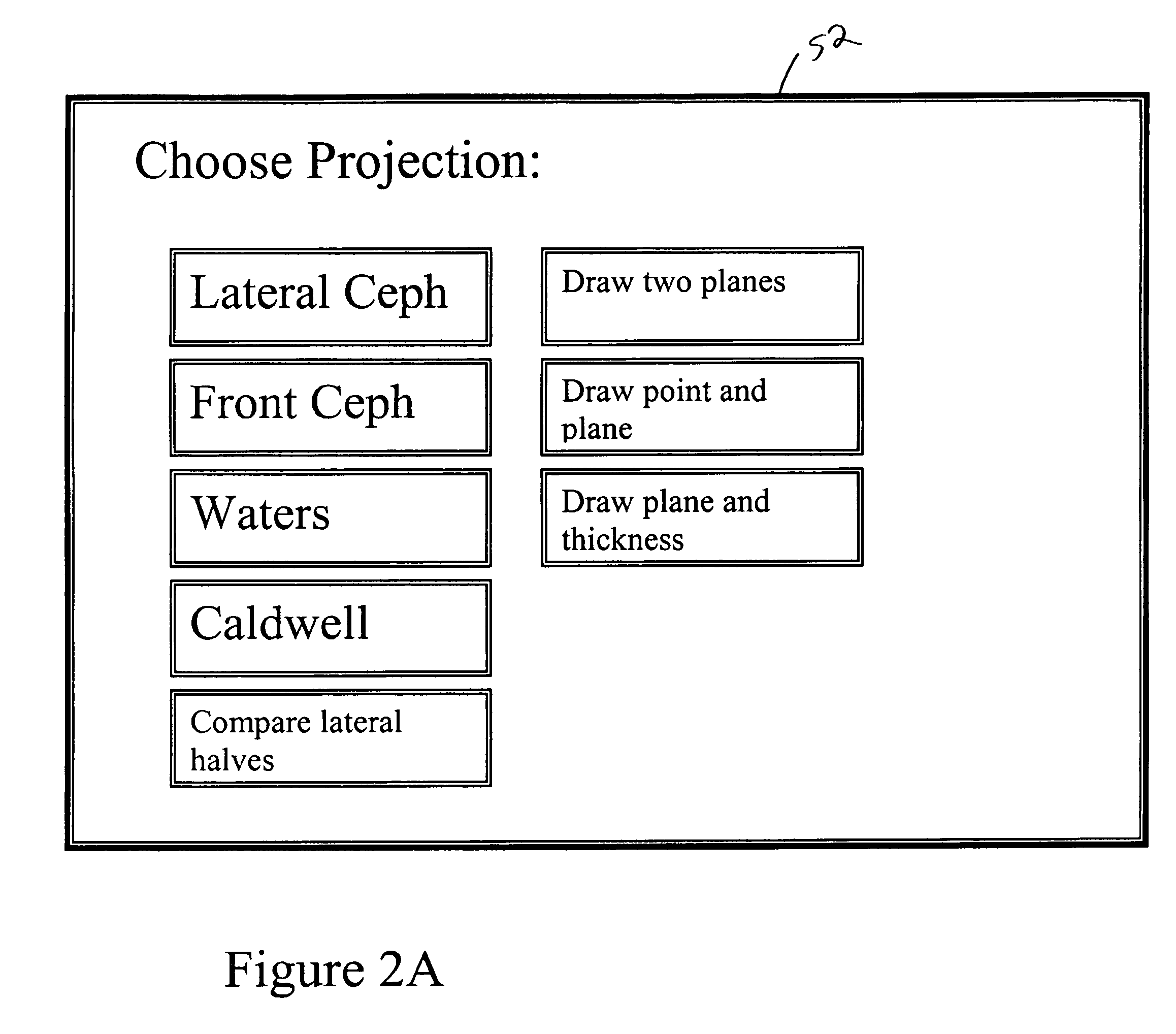

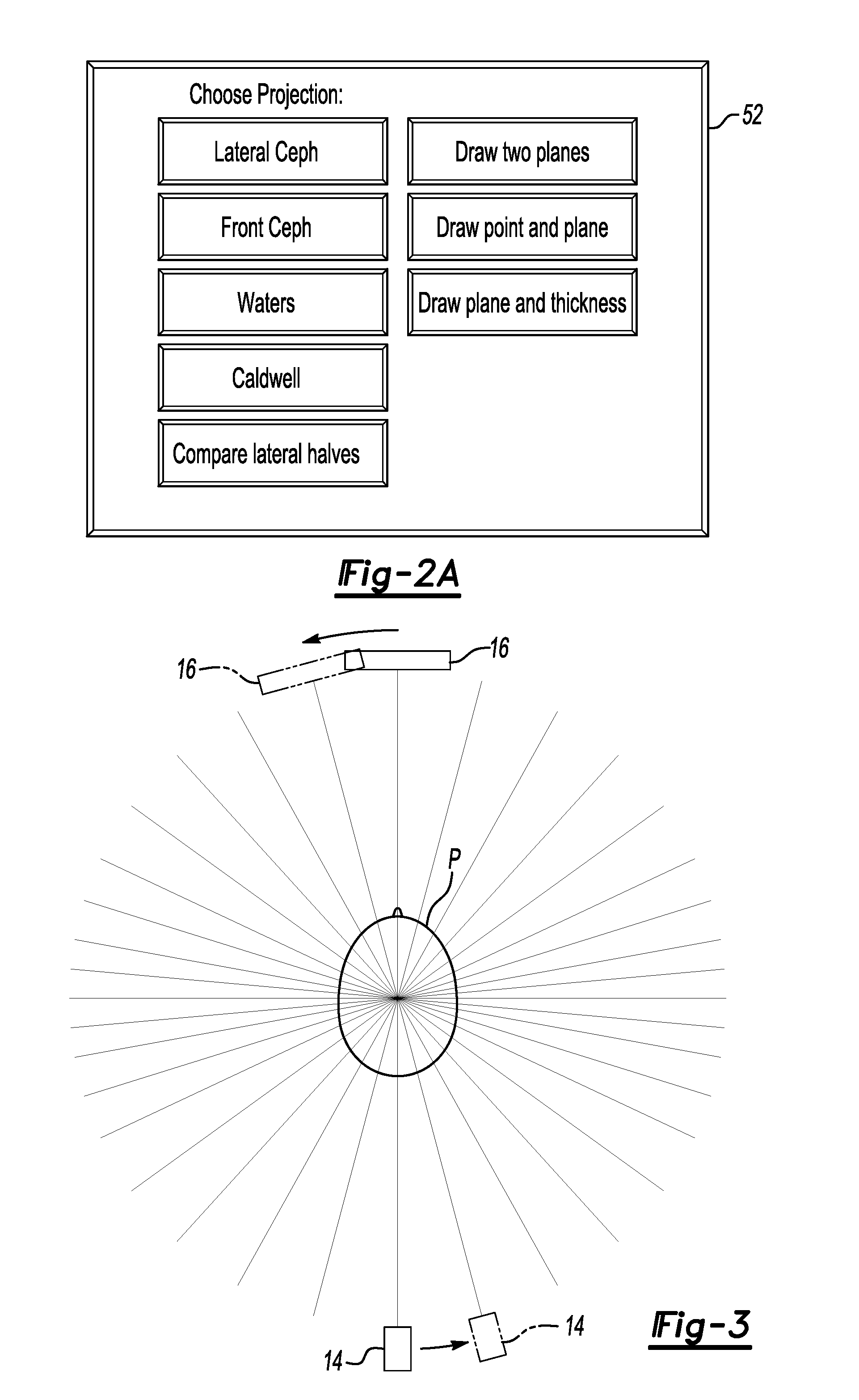

CT system with synthetic view generation

ActiveUS20060239400A1Reduce doseQuality improvementMaterial analysis using wave/particle radiationRadiation/particle handlingComputer graphics (images)Ct scanners

A CT scanner system provides projection-like images of a patient volume. After a CT scan is obtained and a three-dimensional model of the patient is created, any synthetic view can be generated by choosing any array of projection lines, e.g. between a point and a surface (a flat plane, curved plane, spherical, etc) or between two surfaces (parallel or not) and summing across the projection lines. The synthetic projections can mimic certain traditional views, such as a ceph scan, Water's view, Caldwell's projection, etc or can provide a new view that is impossible or impractical with traditional x-ray equipment, such as a perfect parallel projection, or a projection that does not pass all the way through the patient.

Owner:XORAN TECH

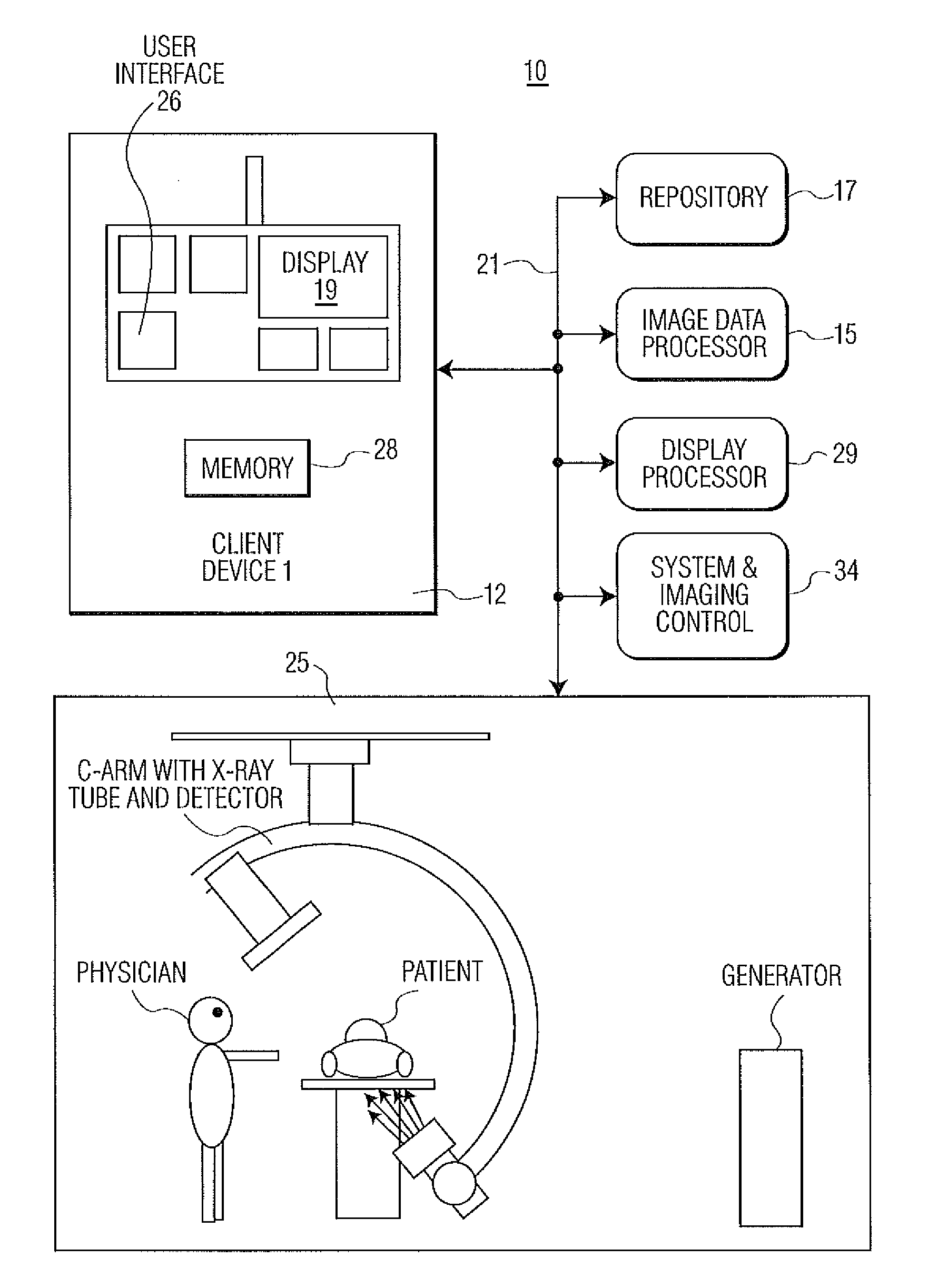

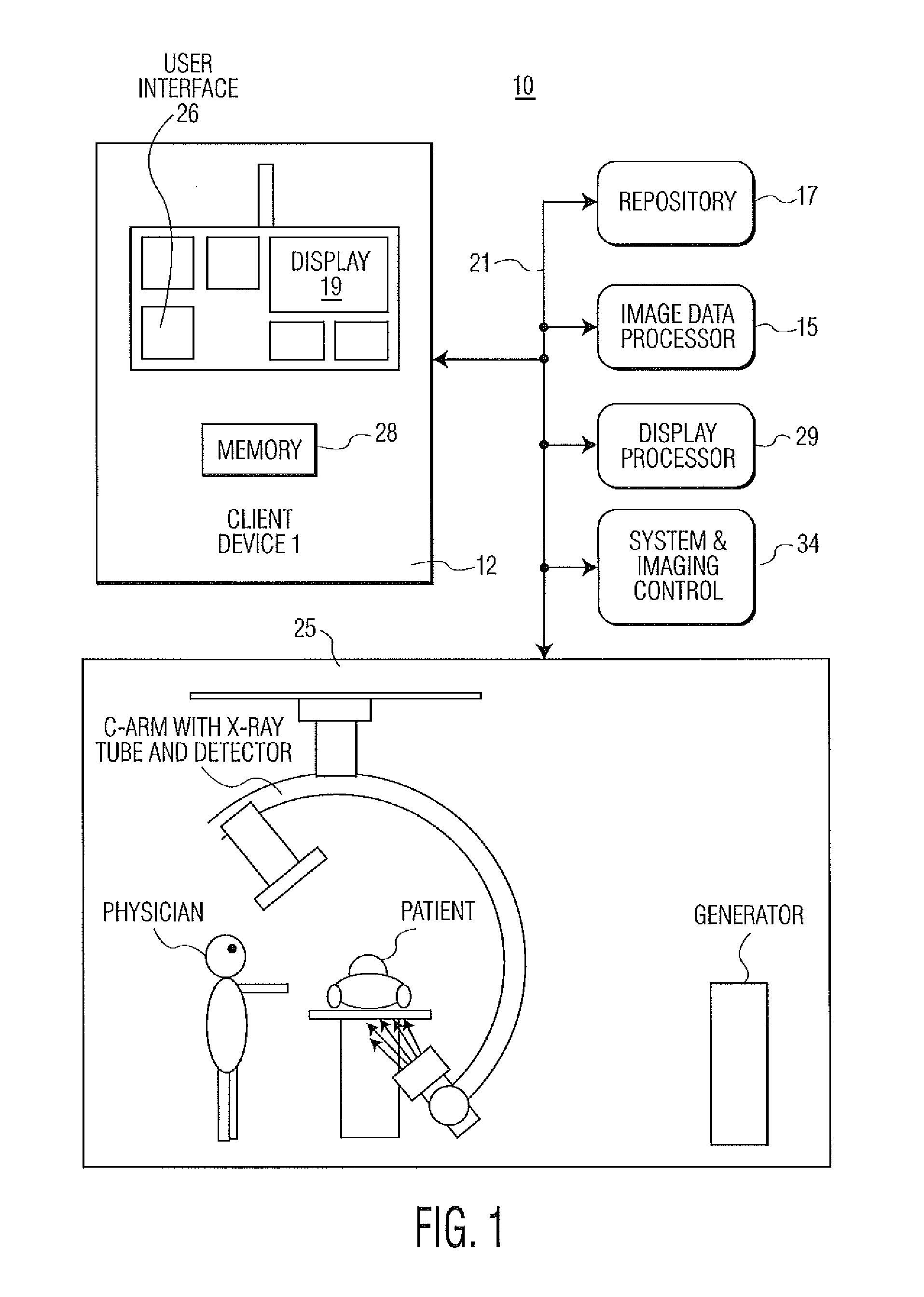

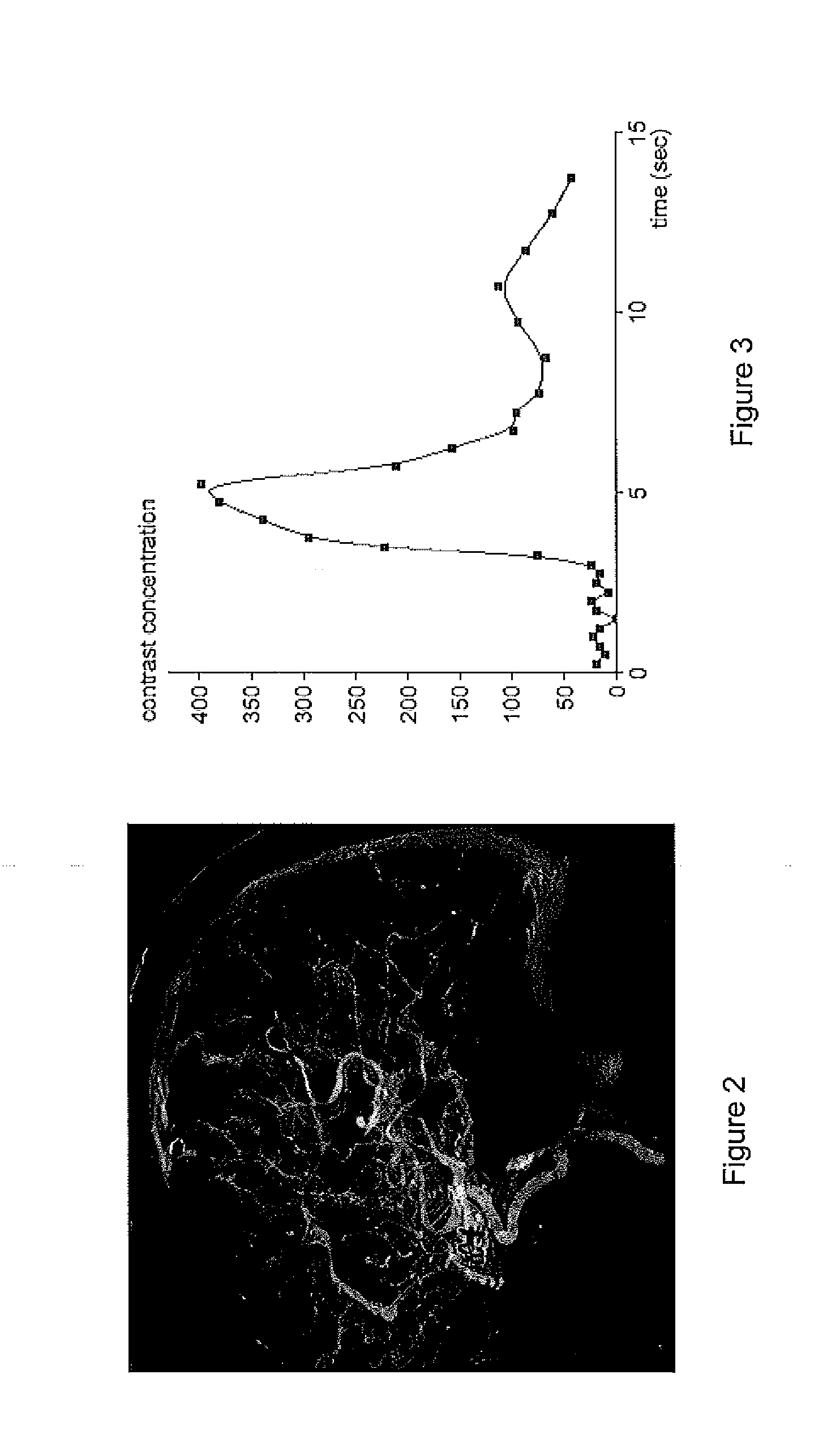

System for Providing Digital Subtraction Angiography (DSA) Medical Images

A method generates a two dimensional (2D) medical image through a three dimensional (3D) imaged volume of patient anatomy at a desired position, by storing 3D image data representing a 3D imaging volume including vessels in the presence of a contrast agent. The 3D image data comprises, data identifying multiple voxels representing multiple individual volume image element luminance values and luminance distribution data for individual voxels of a vessel in the 3D image data. For multiple individual voxels of a 2D image, the method determines composite luminance distribution data of an individual voxel in the 2D image by combining luminance distribution data of the 3D image data of multiple identified voxels substantially lying on a projection line from a source point to the individual voxel and generating data representing the 2D image using the determined composite luminance distribution data of the multiple individual voxels.

Owner:SIEMENS MEDICAL SOLUTIONS USA INC

Method of reconstructing an image function from radon data

InactiveUS20090297009A1Increase the scope of applicationImprove imaging resolutionReconstruction from projectionMaterial analysis using wave/particle radiationReconstruction algorithmImage fusion

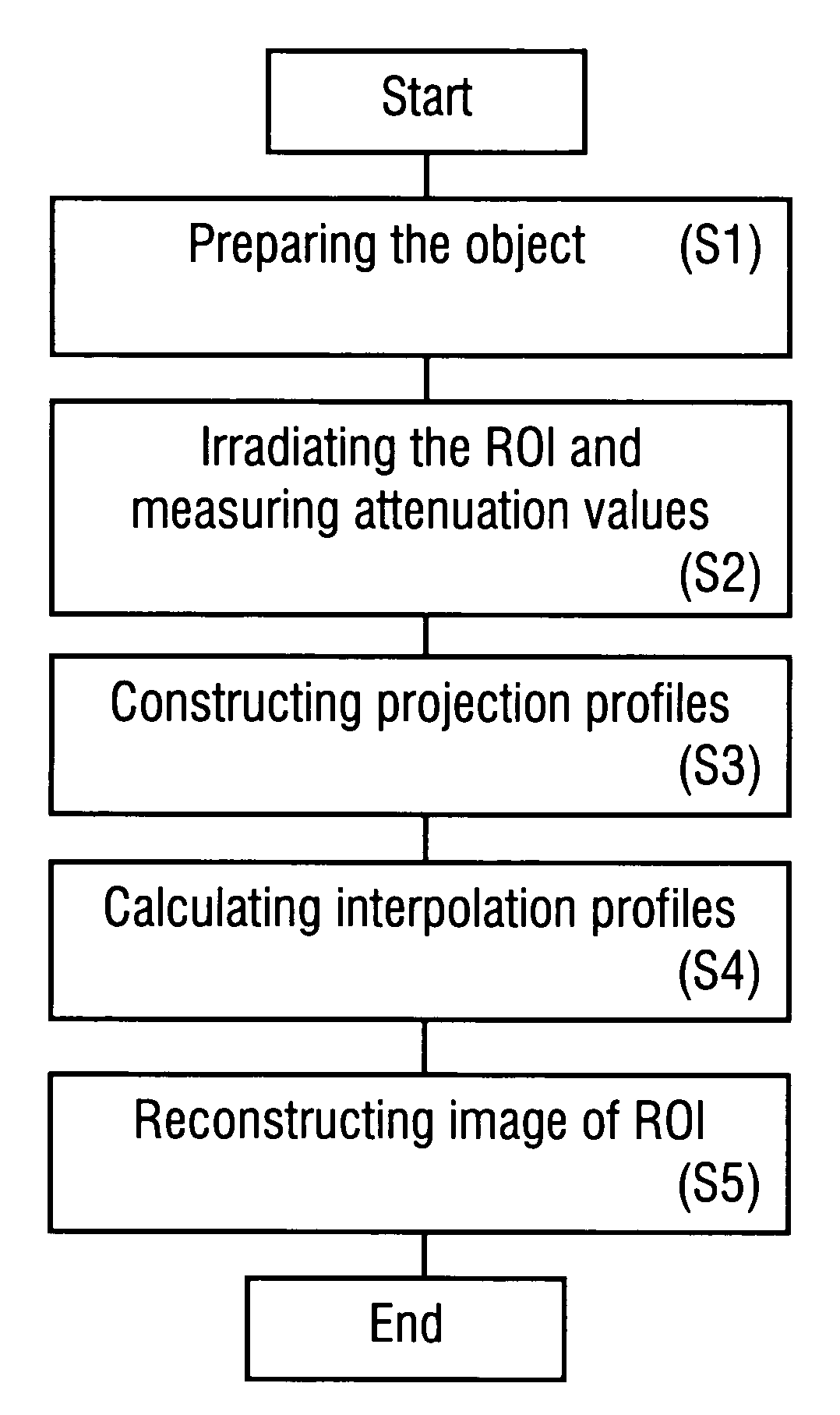

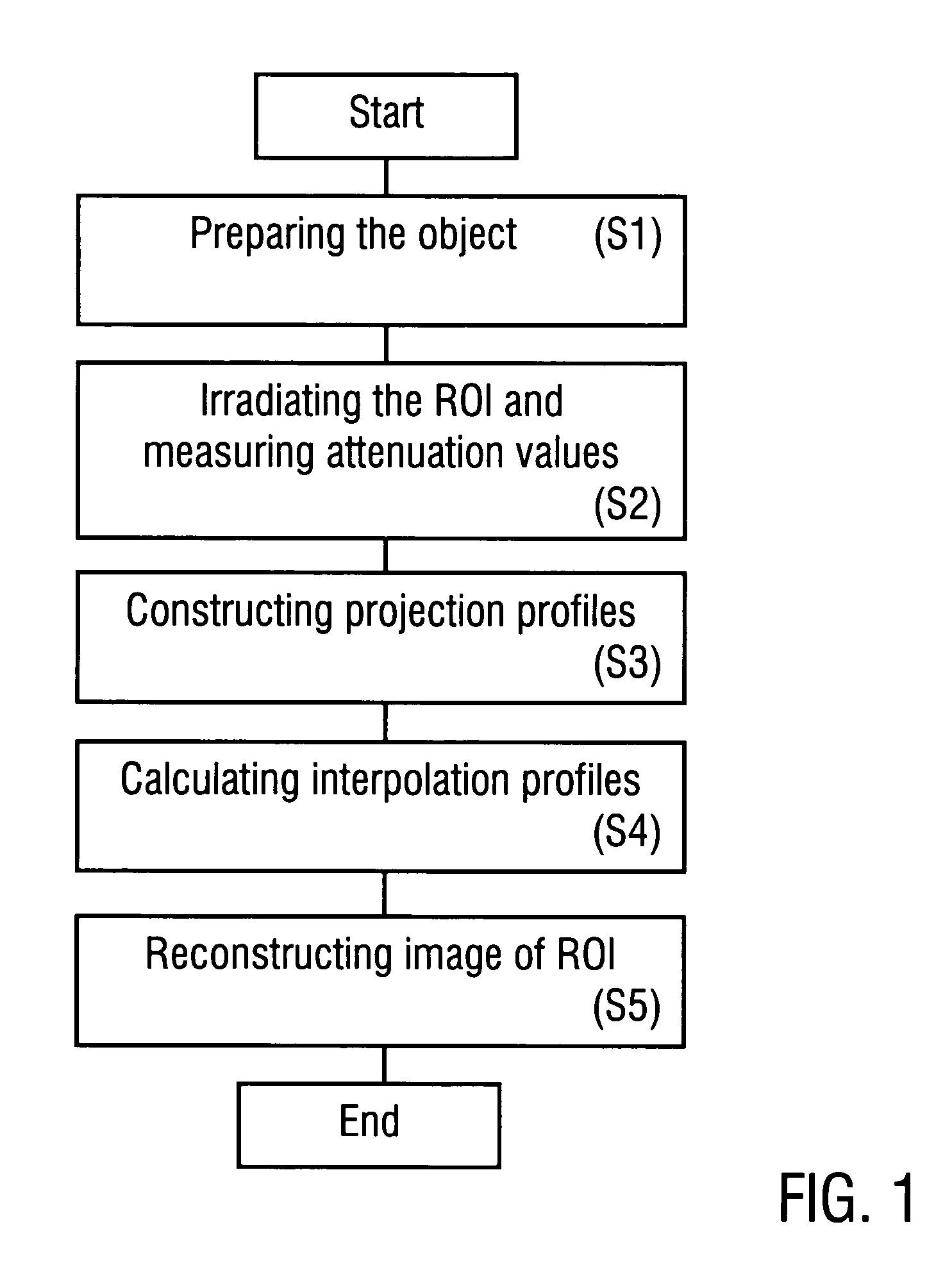

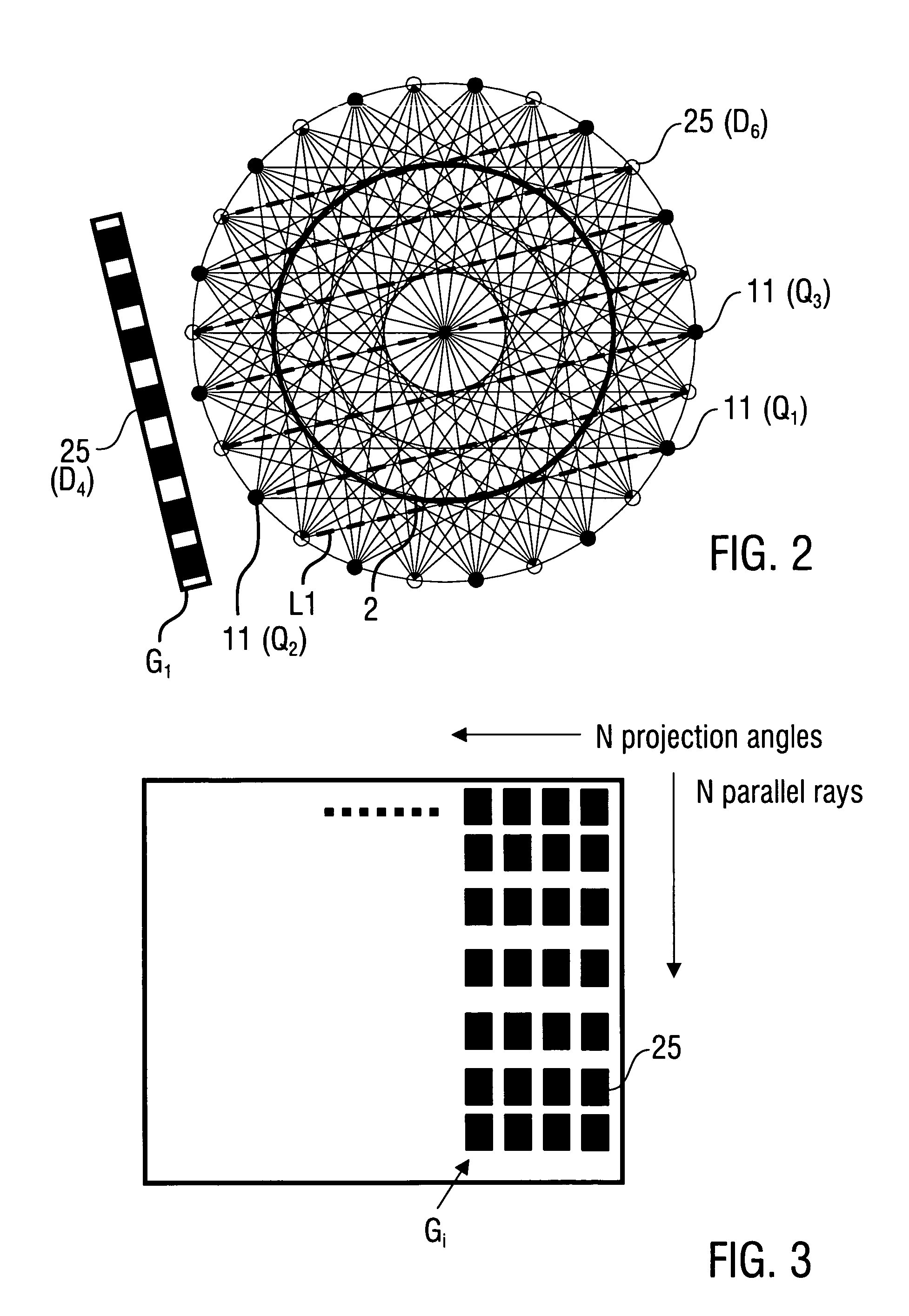

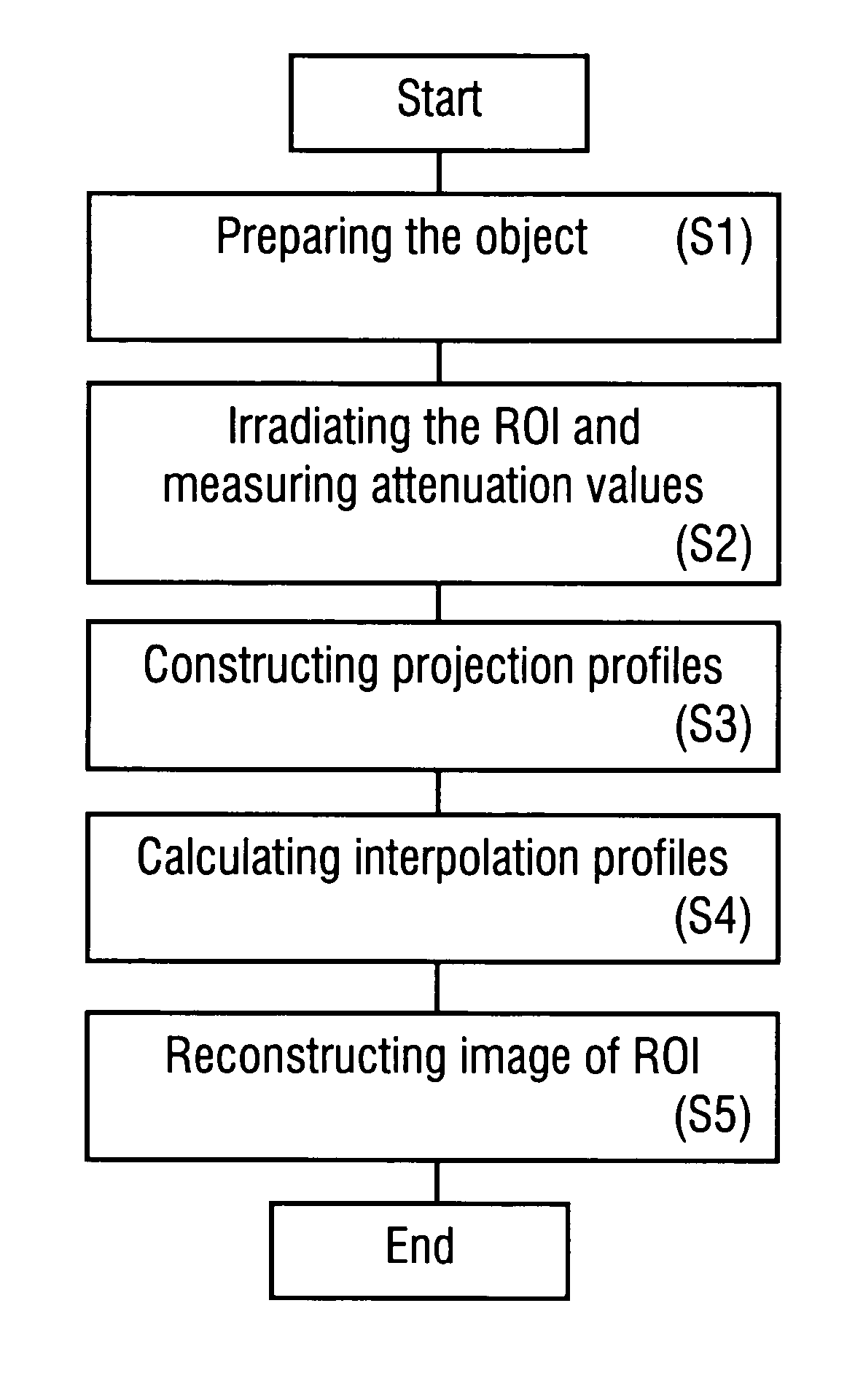

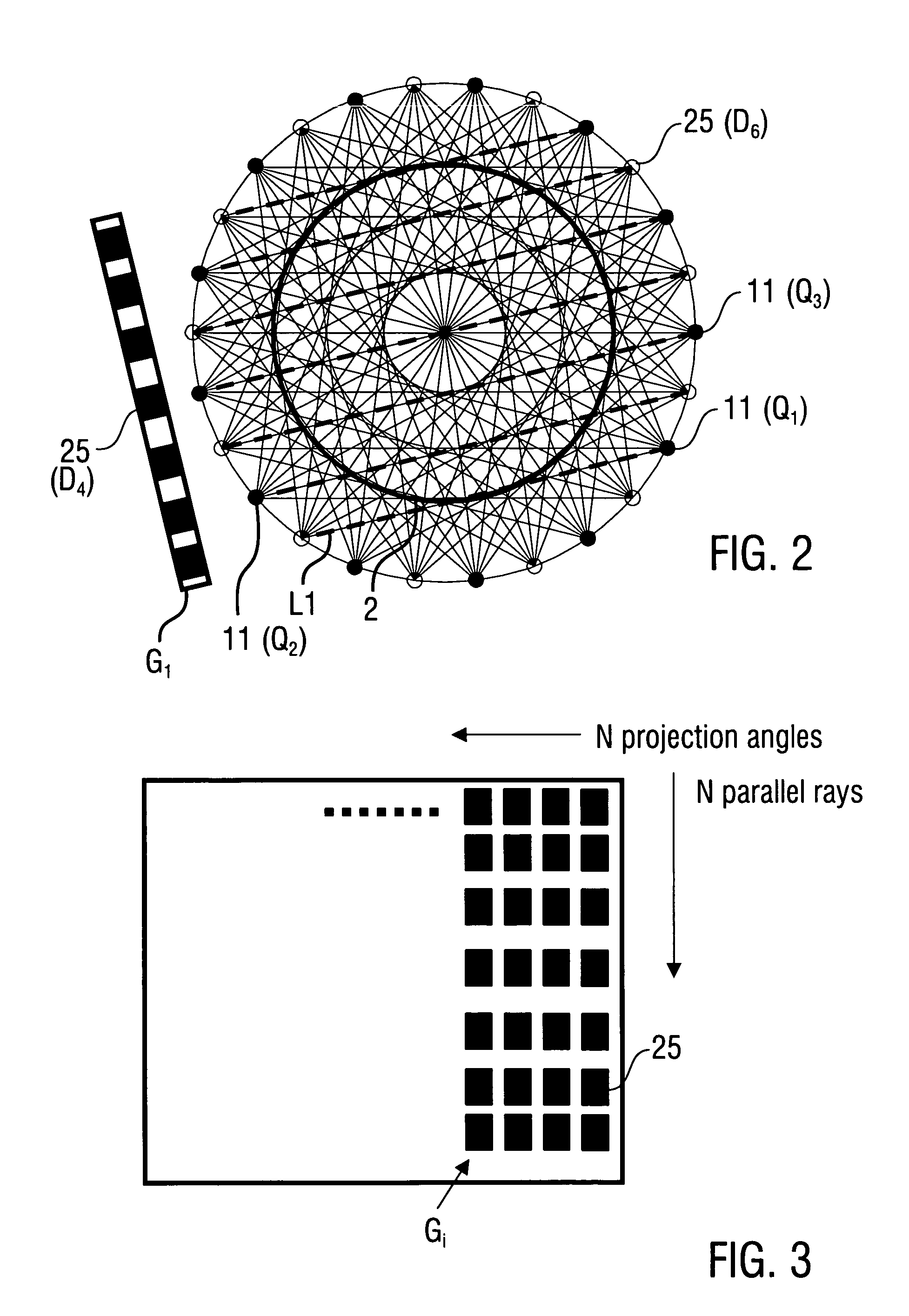

A method of reconstructing an image function on the basis of a plurality of projection profiles corresponding to a plurality of projection directions through a region of investigation, each projection profile including a series of value positions, wherein measured projection values corresponding to projection lines parallel to the respective projection direction are assigned to respective value positions and a plurality of remaining value positions are empty, comprises the steps of (a) assigning first interpolation values to the empty value positions for constructing a plurality of interpolation profiles on the basis of the projection profiles, wherein the first interpolation values are obtained from a first interpolation within a group of measured projection values having the same value position in different projection profiles, and (b) determining the image function by applying a predetermined reconstruction algorithm on the interpolation profiles.

Owner:UNIVERSITY OF OREGON +1

Method of reconstructing an image function from Radon data

InactiveUS8094910B2Improve imaging resolutionSimple methodReconstruction from projectionMaterial analysis using wave/particle radiationReconstruction algorithmImage fusion

A method of reconstructing an image function on the basis of a plurality of projection profiles corresponding to a plurality of projection directions through a region of investigation, each projection profile including a series of value positions, wherein measured projection values corresponding to projection lines parallel to the respective projection direction are assigned to respective value positions and a plurality of remaining value positions are empty, comprises the steps of (a) assigning first interpolation values to the empty value positions for constructing a plurality of interpolation profiles on the basis of the projection profiles, wherein the first interpolation values are obtained from a first interpolation within a group of measured projection values having the same value position in different projection profiles, and (b) determining the image function by applying a predetermined reconstruction algorithm on the interpolation profiles.

Owner:UNIVERSITY OF OREGON +1

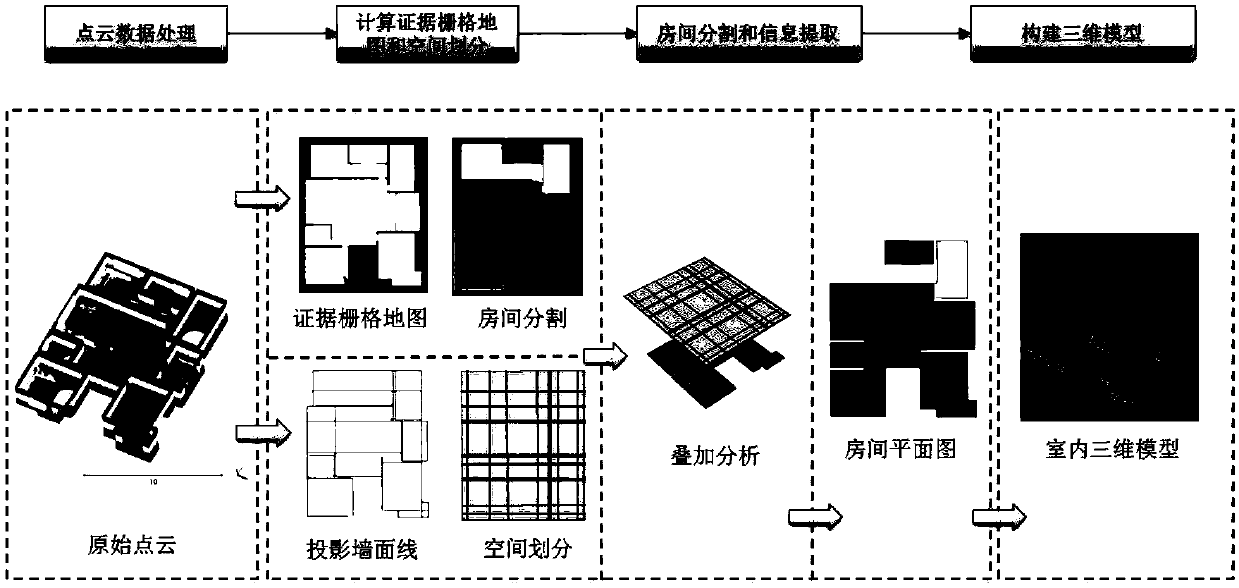

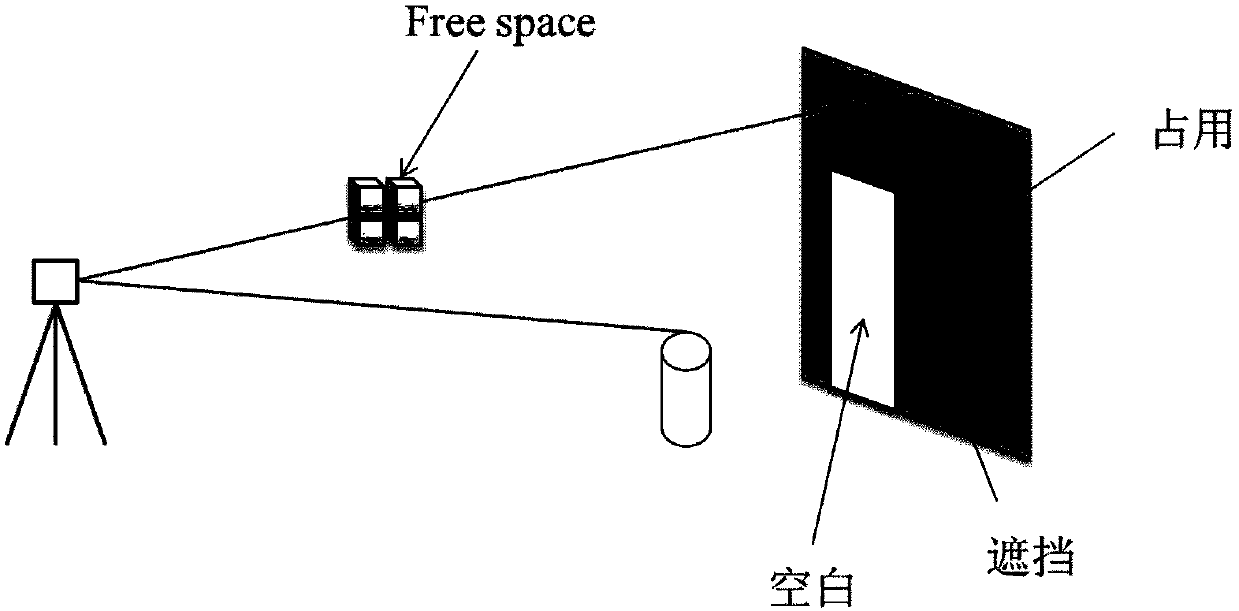

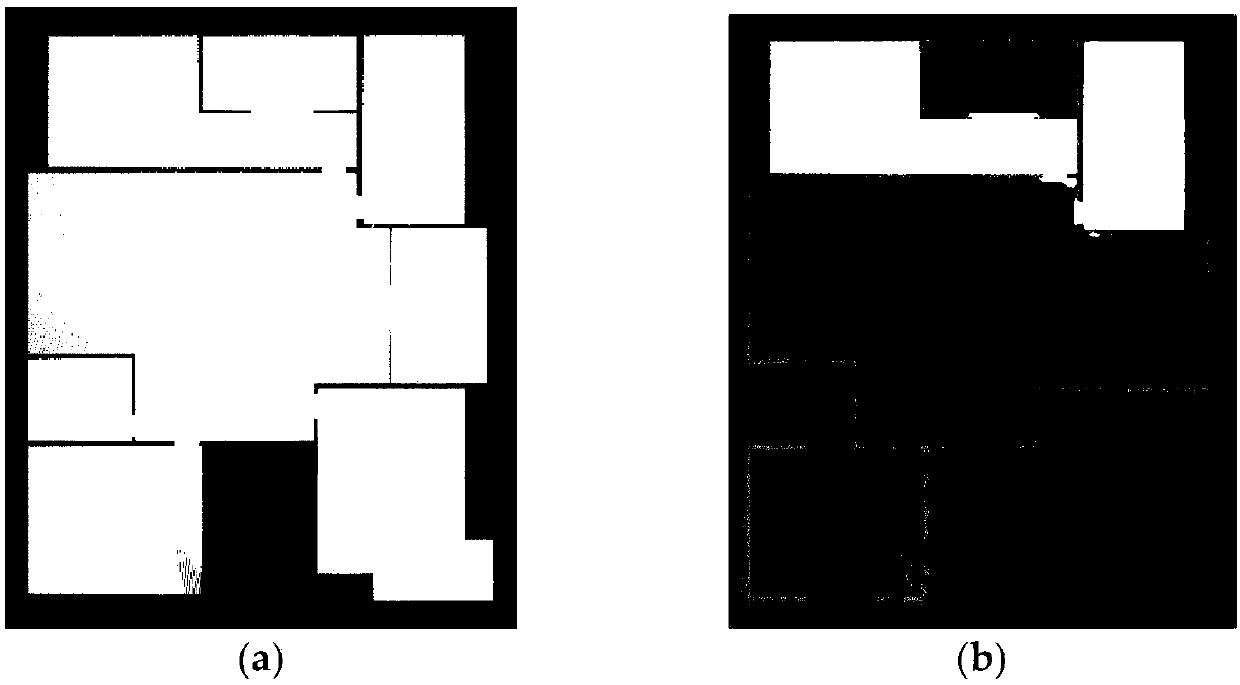

Mobile laser measurement point-based indoor structured three-dimensional reconstruction method

InactiveCN107862738AImprove build efficiencyImprove accuracy3D modellingTopological consistencyMeasurement point

The invention discloses a mobile laser measurement point-based indoor structured three-dimensional reconstruction method. The mobile laser measurement point-based indoor structured three-dimensional reconstruction method comprises performing room division on the basis of a laser scanning point cloud evidence raster map; performing space division on the basis of vector wall projection line segments; structuring a vector room plan and an indoor three-dimensional model on the basis of vector-raster overlaying. The mobile laser measurement point-based indoor structured three-dimensional reconstruction method makes full use of semantic information and structured elements of indoor space, converts an indoor three-dimensional reconstruction problem into room division and GIS-based (geographic information system-based) overlaid analysis problems, takes divided rooms as prior knowledge to solve the problem of shading and in complete data of laser measurement during a modeling process and can rapidly and effectively structure an indoor building three-dimensional model with topological consistency. Compared with other methods, the mobile laser measurement point-based indoor structured three-dimensional reconstruction method can better process point cloud data of indoor complicated environment and meet the demands on indoor structuralized three-dimensional reconstruction.

Owner:WUHAN UNIV

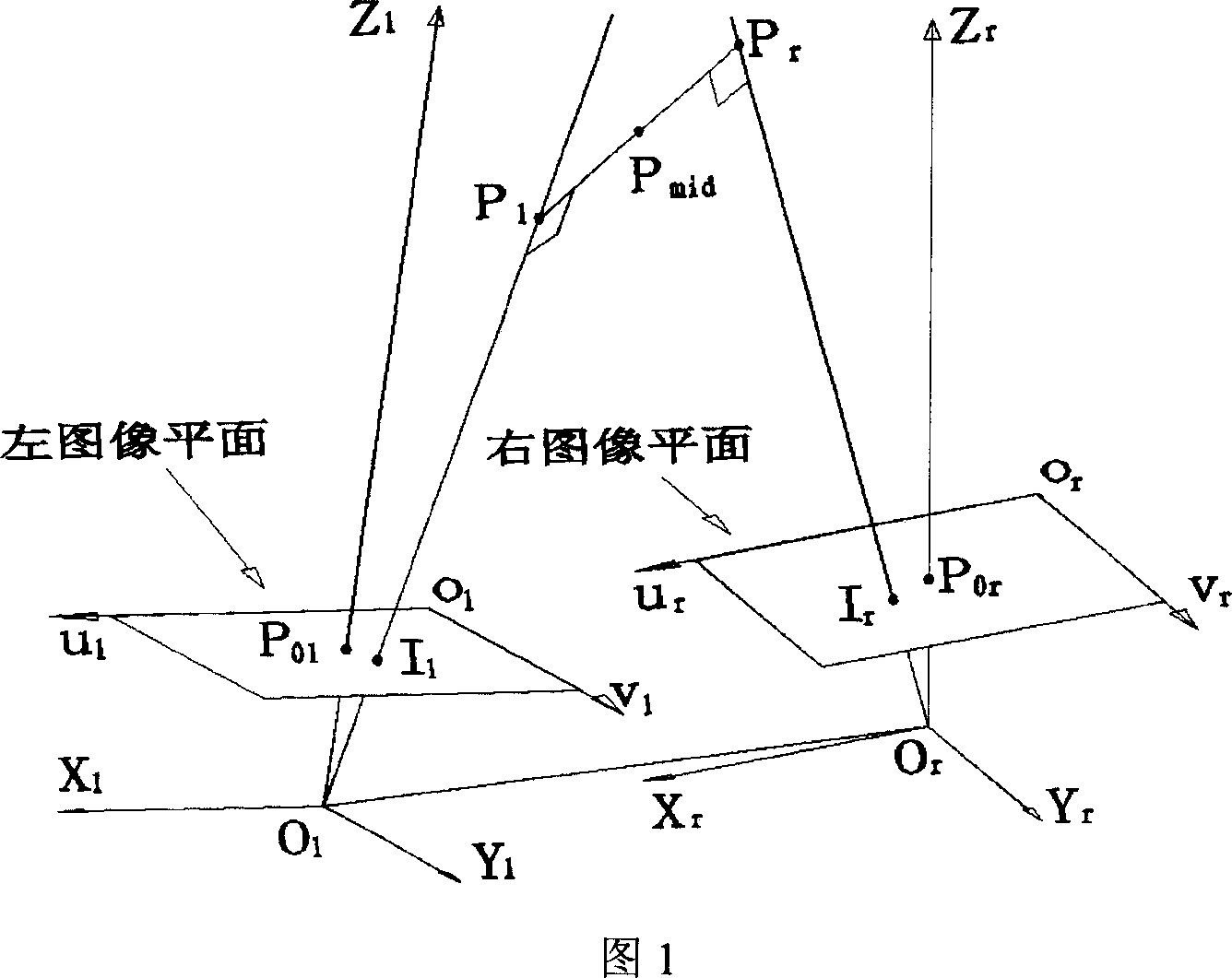

Scene depth restoring and three dimension re-setting method for stereo visual system

This invention relates to a method for recovering scene depth and re-building three-dimension of a stereoscopic vision system, which gets the inner parameters of right and left cameras, relative rotation matrix and shift vector by calibration, matching the corresponding points of the right and left images, evaluating the right and left normalization vectors of each pair of matched points from their image coordinates and relative inner parameters of the cameras, evaluating an equation of two projection lines from the center of the left camera to the left image point and from the center of the right camera to the right image point based on the coordinates and taking the depth value of the scene point in the coordinate systems of the two cameras as the parameter, evaluating the depth value and three-dimension coordinate of the common plumb end points of the two projection lines in the two camera coordinate systems by the normalized vector, the relative rotation matrix and the shift vector and evaluating the coordinate of the midpoint of the common plumb line from the coordinate of the two points of the line and takes the midpoint coordinate as the three-dimension one of the scene points to finish depth recovery and three-dimension restructuring.

Owner:SHANGHAI JIAO TONG UNIV

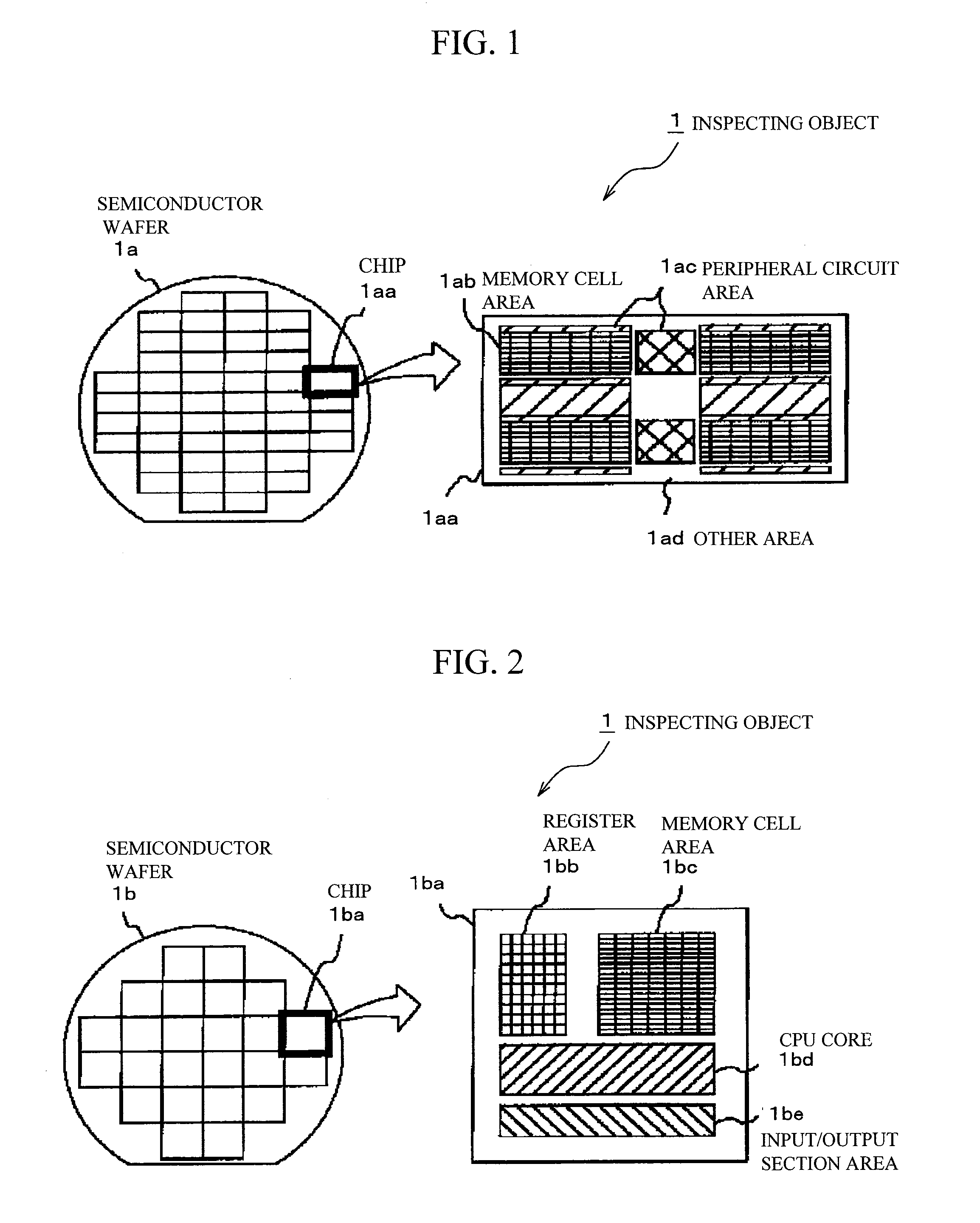

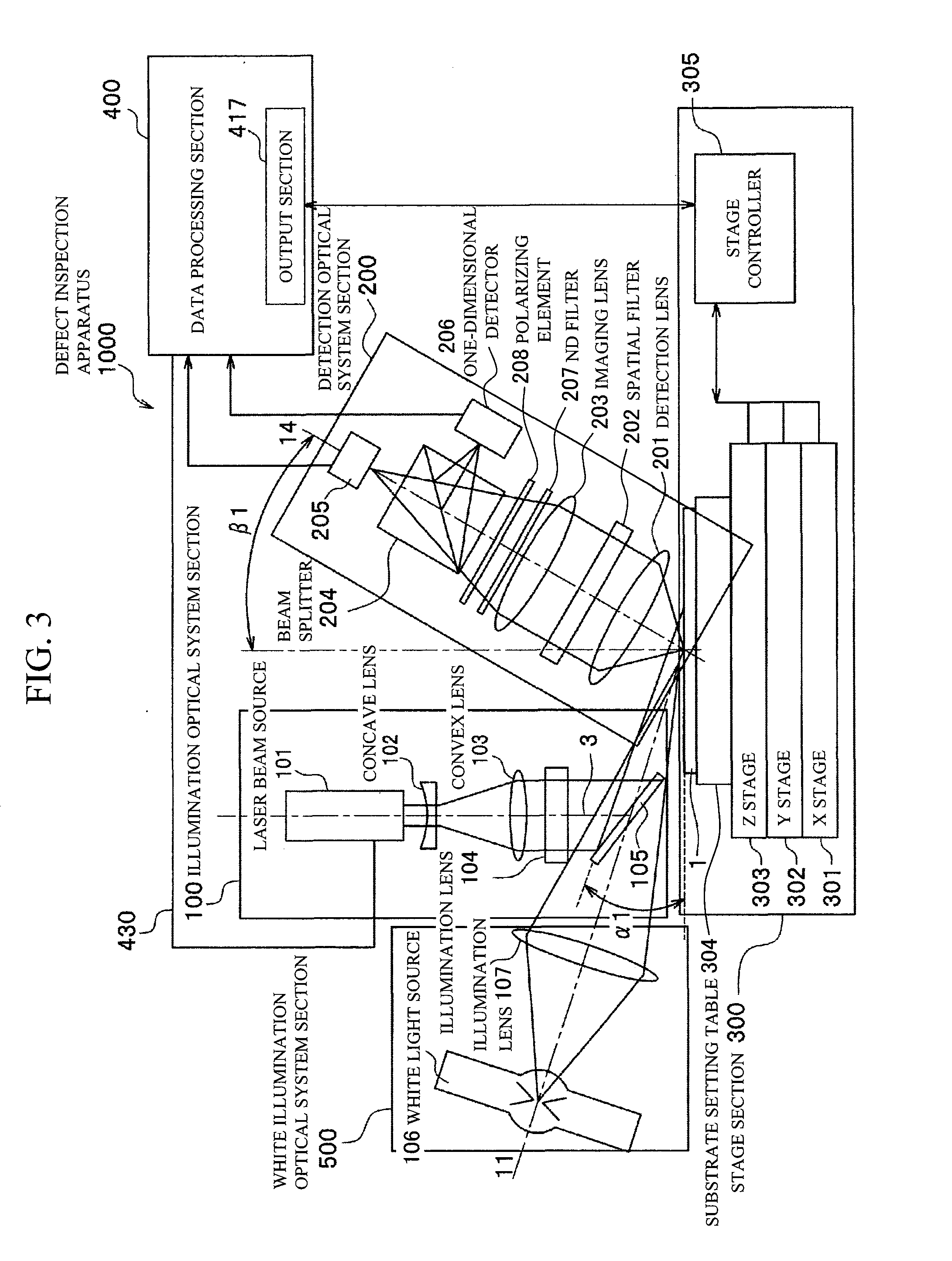

Defect Inspection Apparatus and Defect Inspection Method

InactiveUS20080059094A1Increase defect capture rate defectIncrease defect defect classification performanceImage enhancementImage analysisOptical axisLight beam

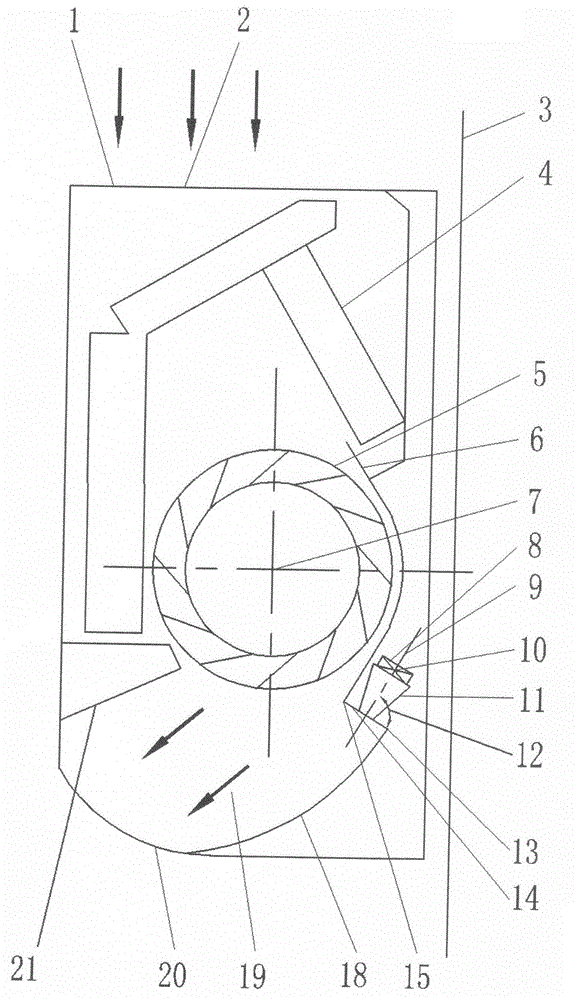

A defect inspection apparatus includes: stages each mounting an inspecting object on which a circuit pattern having a group of parallel lines is formed, and each running perpendicular or parallel to the group of lines; an illumination optical system which illuminating a surface of the inspecting object with a slit beam being slit light so that a longitudinal direction of the slit beam is substantially perpendicular to the running directions of the stages, and which has a first inclined angle formed by the direction of the group of lines and a projection line, of an optical axis of the slit beam, to the inspecting object; a spatial filter that shields or transmits reflected and scattered light of the inspecting object according to a difference in distribution of orientation; and a detection optical system that detects the reflected and scattered light transmitted through the spatial filter by image sensors. Moreover, the illumination optical system illuminates the inspecting object with another slit beam from a direction opposite to an incident direction of the slit beam on a plane.

Owner:HITACHI HIGH-TECH CORP

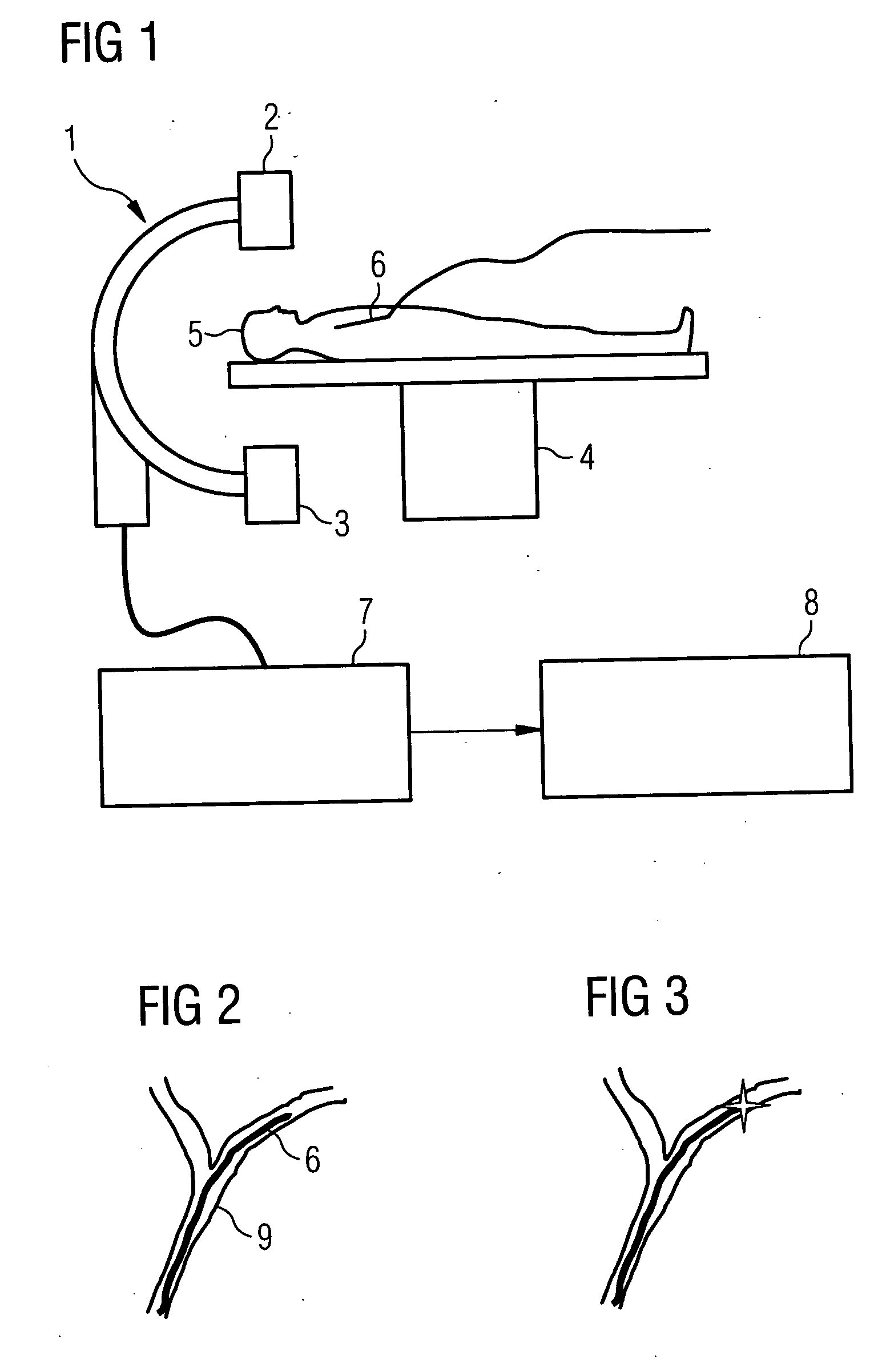

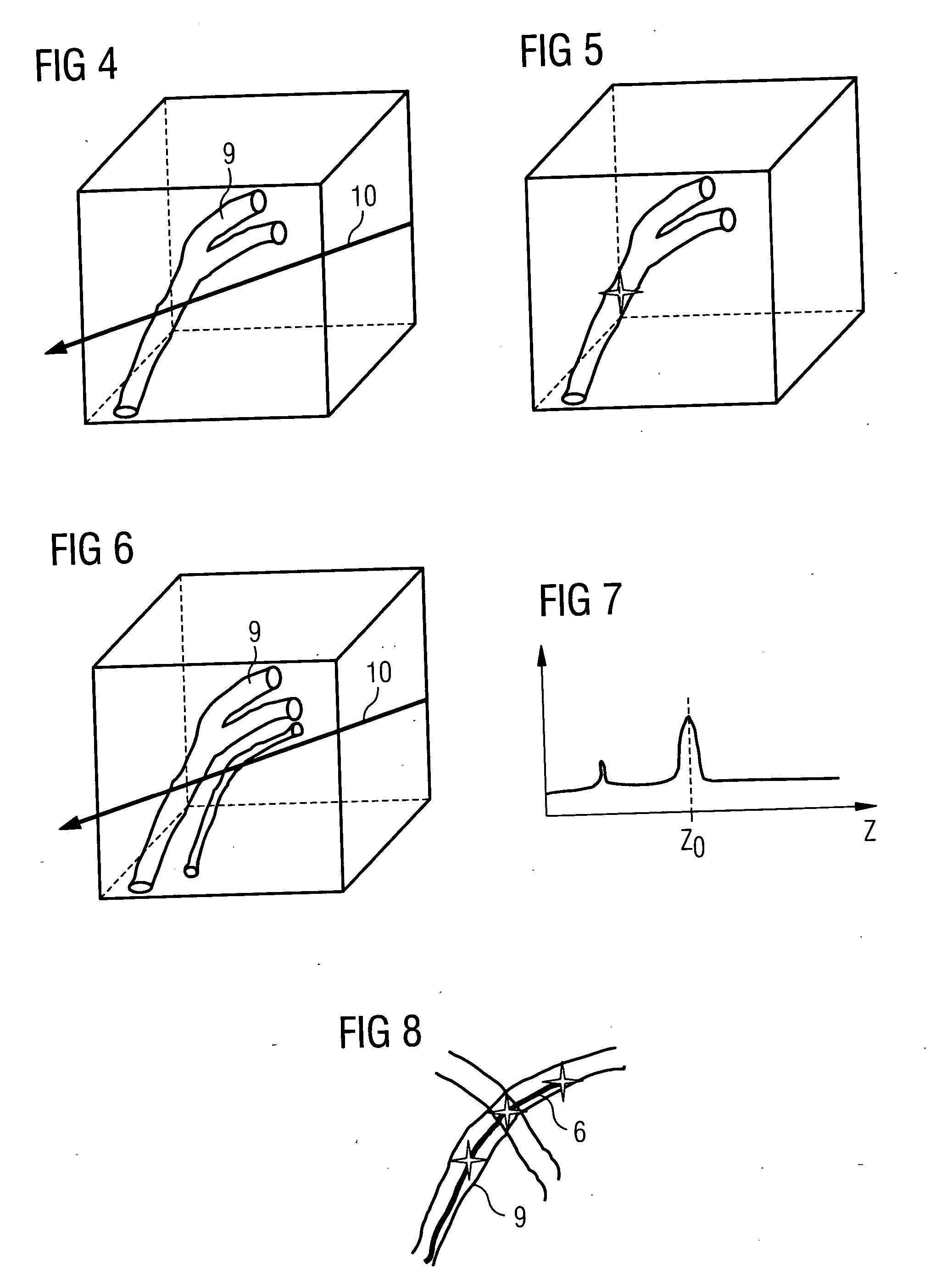

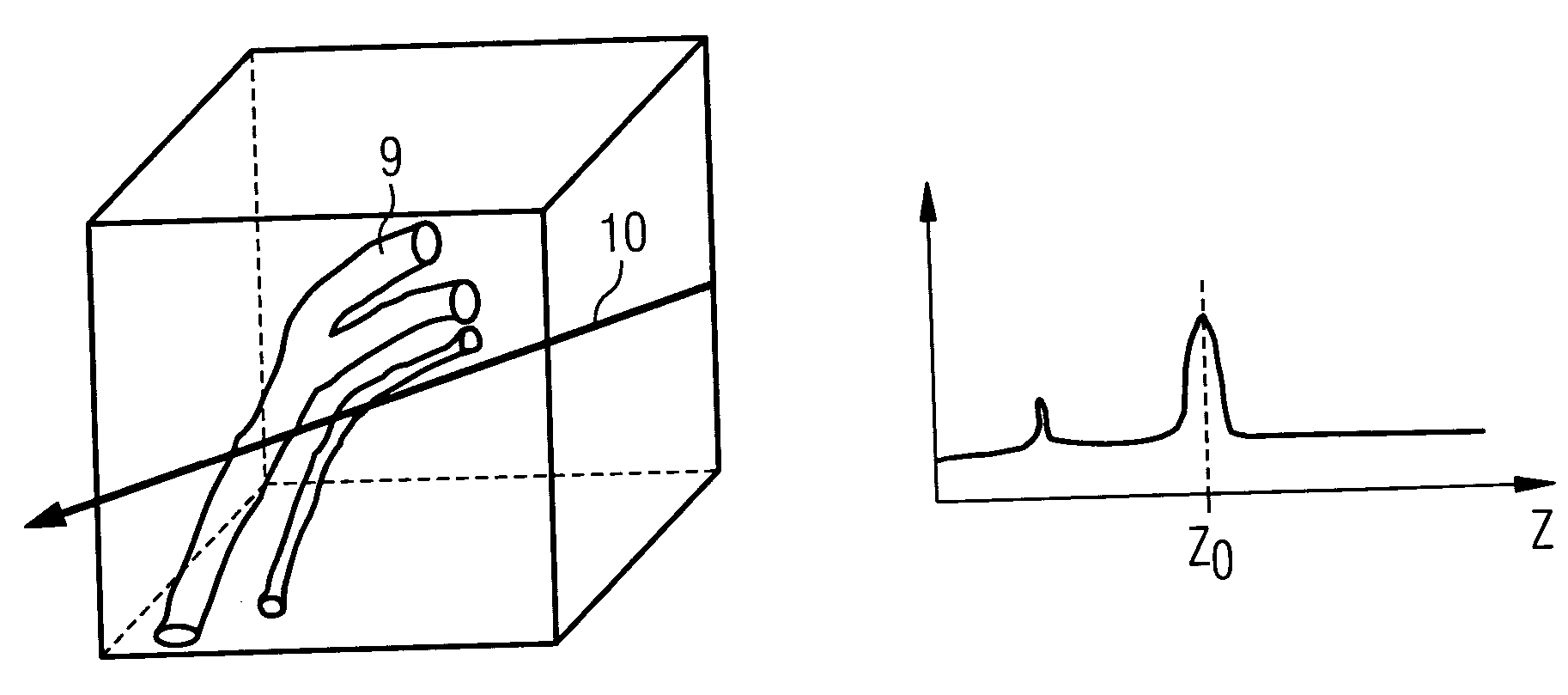

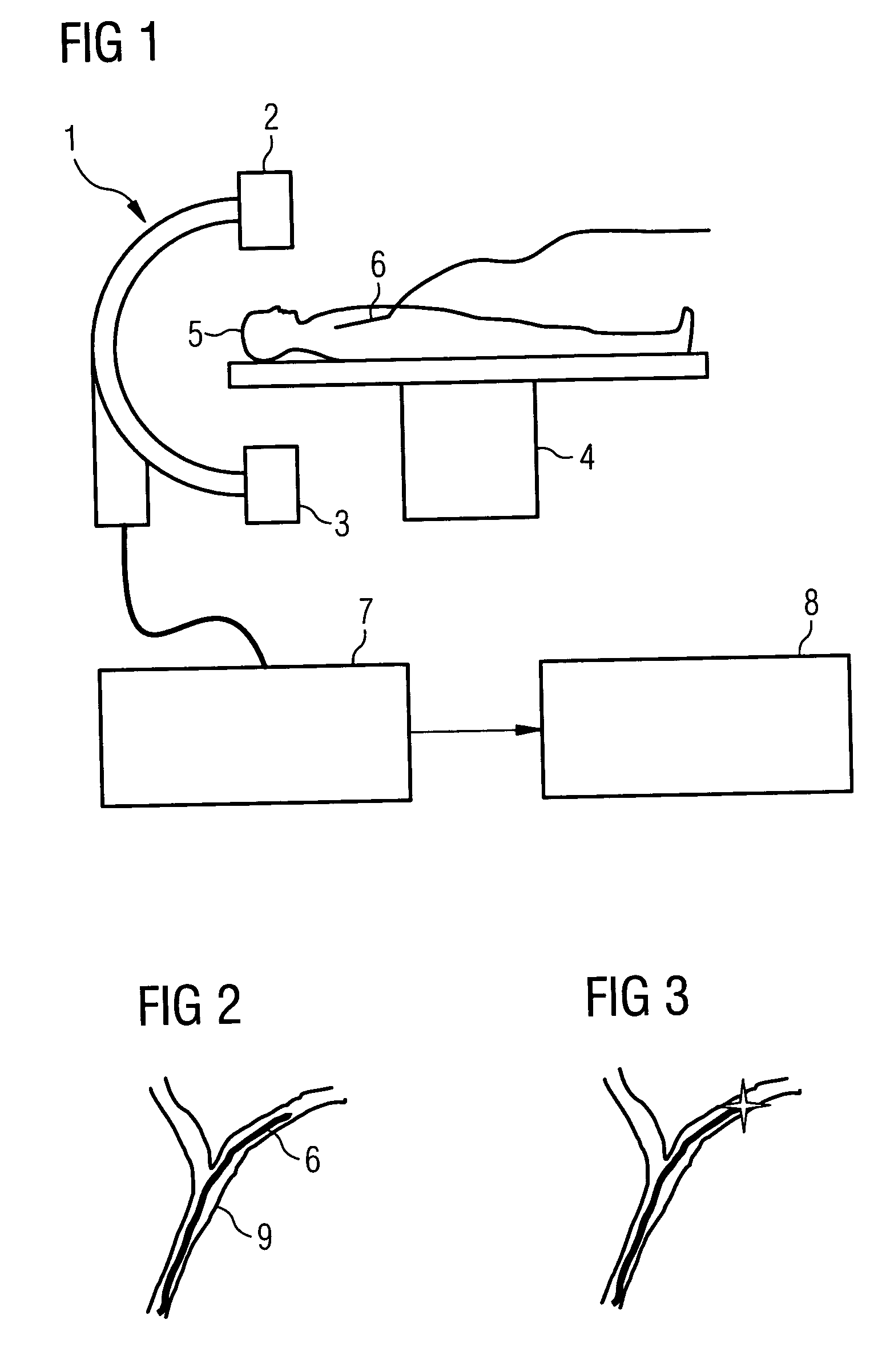

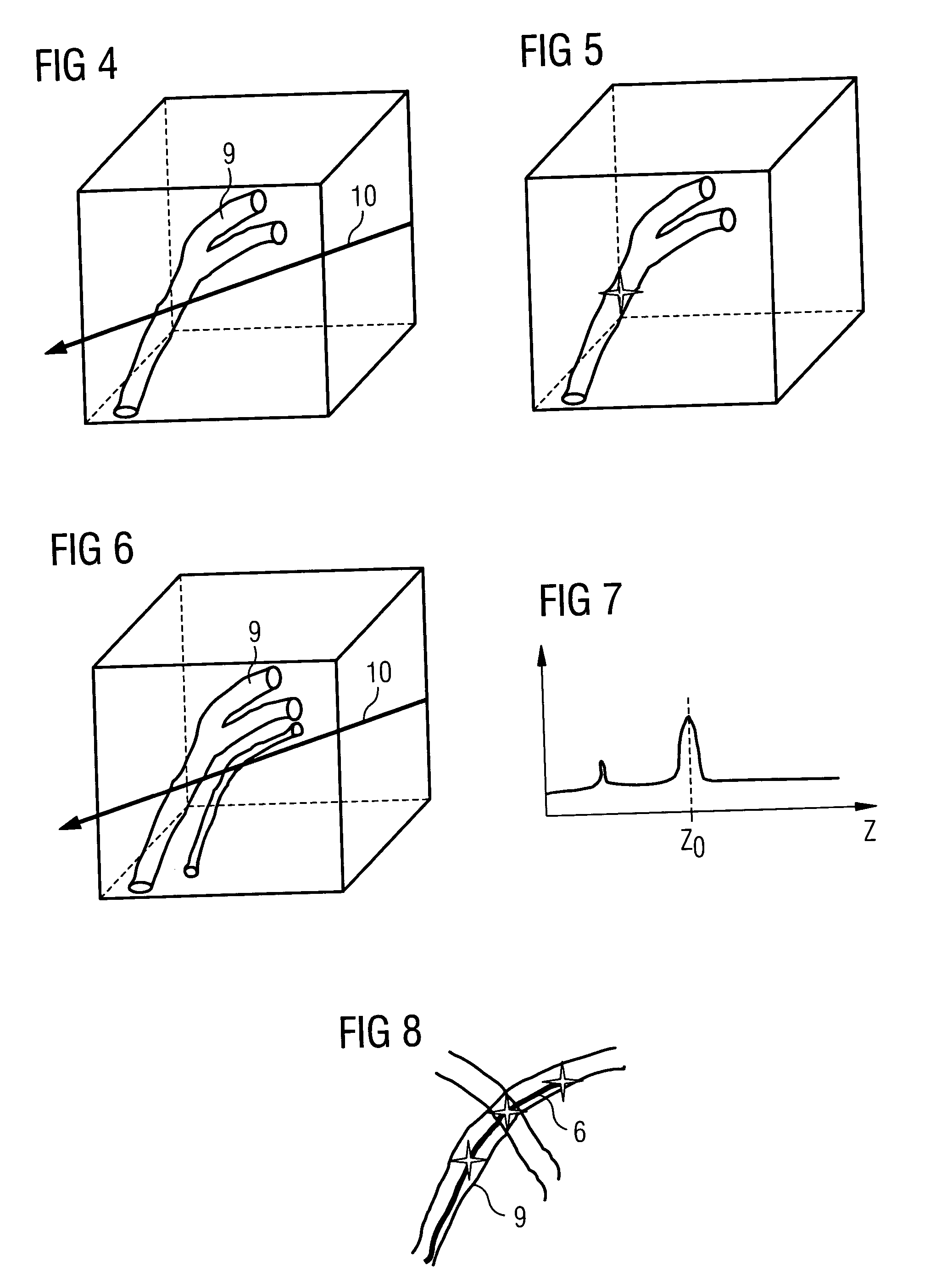

Method for determining the position of an instrument with an x-ray system

ActiveUS20060241413A1Less complicatedFlexible useSurgical navigation systemsCharacter and pattern recognition3d imageX-ray

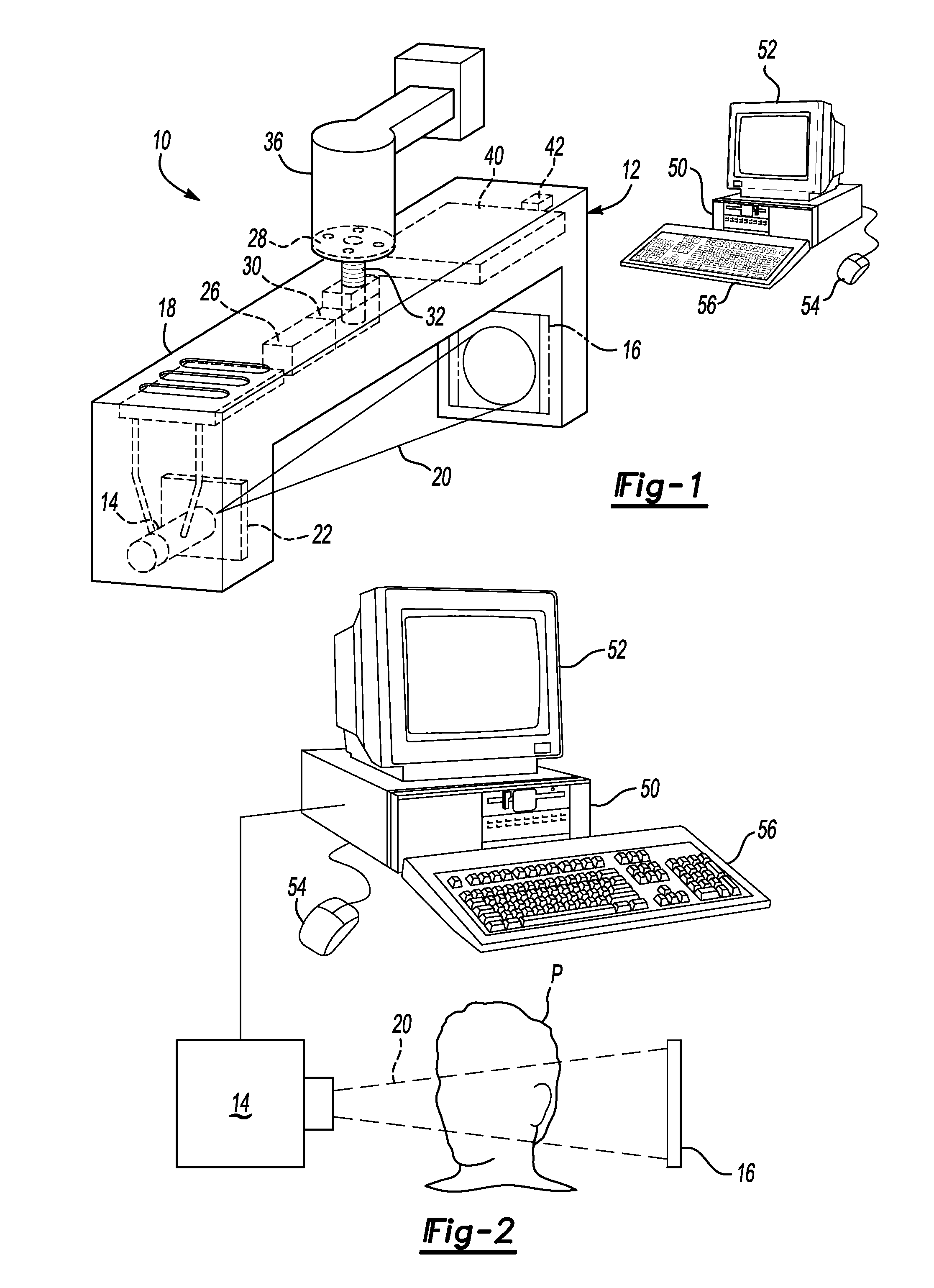

The present invention relates to a method for determining the position of an instrument in a structure of an object with an x-ray system, in which a 3D image data record is provided for at least one area of the object relevant for determining the position, the x-ray system is registered with the 3D image data record, after the introduction of the instrument into the structure at least one 2D x-ray image of the relevant area is recorded from at least one direction of projection with a known projection geometry with the x-ray system and a 2D position of a first location of the instrument is recorded in the 2D x-ray image. In the method a projection line in accordance with the known projection geometry is placed through the 3D image data record at the 2D position and a 3D position of the first location of the instrument in the 3D image data record is determined from an intersection of the projection line with the structure. The method enables the 3D position to be determined with a simple monoplanar x-ray system.

Owner:SIEMENS HEALTHCARE GMBH

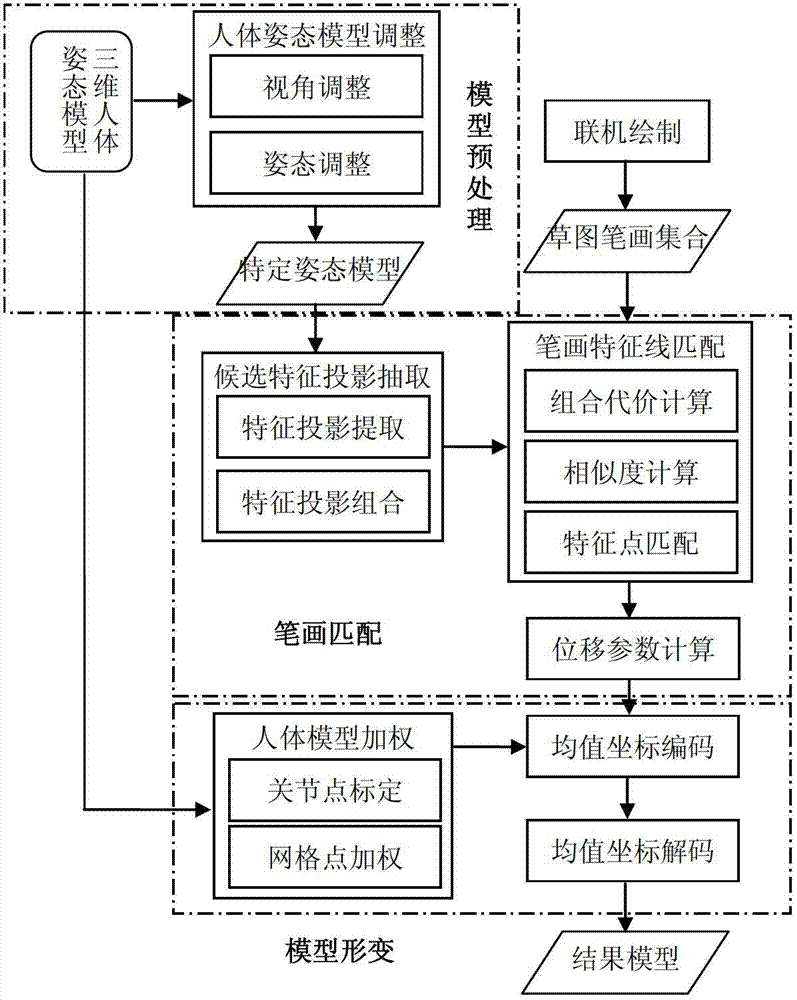

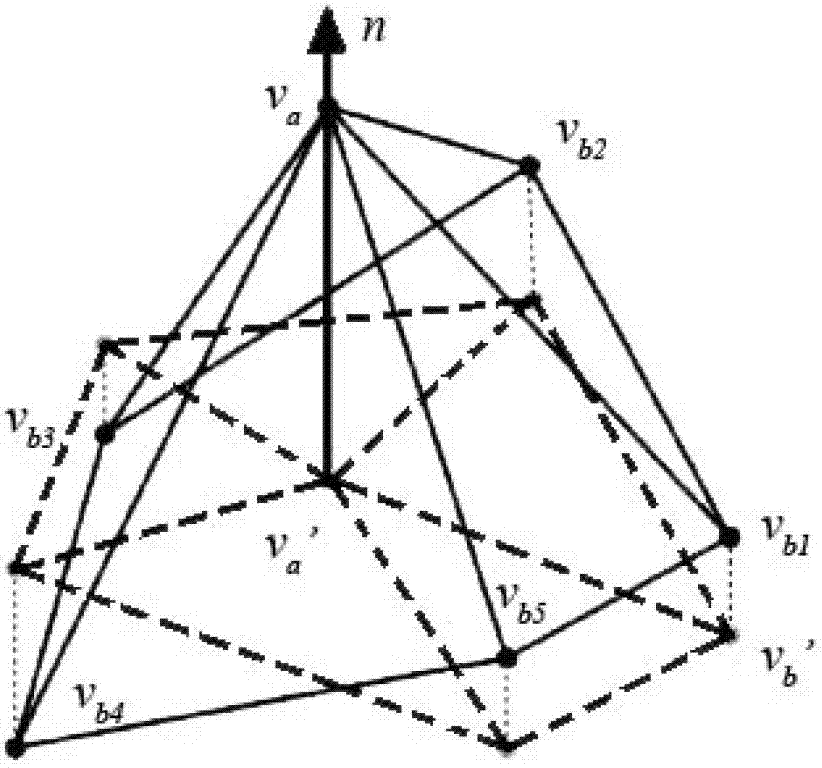

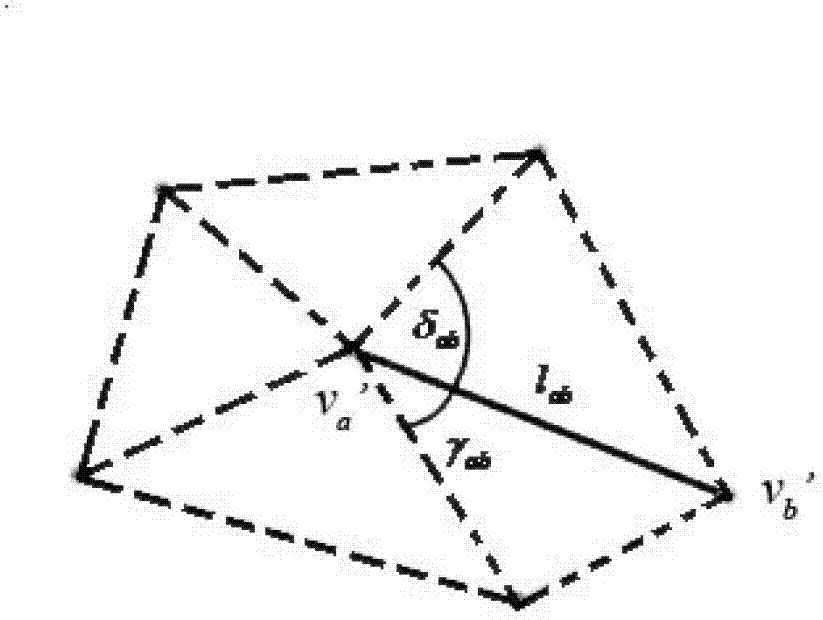

Three-dimensional human body multi-gesture modeling method by adopting free-hand sketches

InactiveCN102831638AMaintain joint propertiesEasy to editImage analysis3D modellingHuman bodySuggestibility

The invention provides a three-dimensional human body multi-gesture modeling method by adopting free-hand sketches. The method comprises the following steps of: displaying and drawing a human body feature draft, adjusting an observation viewing angle and a human body gesture as being accorded with the human body draft under a given three-dimensional human body gesture model, and weighting the human body model according to a position relationship between human body gesture model grid points and human body joint points; projecting the human body gesture model and extracting feature projection line sets including contour lines, suggestibility contour lines, valley lines, regression lines and the like under the observation viewing angle and the human body gesture; matching human body draft drawing lines with the feature projection line sets; constructing a Hidden Markov Model according to a geometric relationship between the draft drawing lines and the feature projection line sets; corresponding draft drawing points to the three-dimensional model grid points and calculating displacement parameters of corresponding points; and carrying out deformation on a human body grid model through a mean value coordinate encoding deformation algorithm under the constraint of corresponding three-dimensional model grid point displacement parameters so as to obtain final three-dimensional human body grid models.

Owner:NANJING UNIV

Method for determining the position of an instrument with an x-ray system

ActiveUS7590442B2Less complicatedFlexible useSurgical navigation systemsCharacter and pattern recognitionSoft x ray3d image

The present invention relates to a method for determining the position of an instrument in a structure of an object with an x-ray system, in which a 3D image data record is provided for at least one area of the object relevant for determining the position, the x-ray system is registered with the 3D image data record, after the introduction of the instrument into the structure at least one 2D x-ray image of the relevant area is recorded from at least one direction of projection with a known projection geometry with the x-ray system and a 2D position of a first location of the instrument is recorded in the 2D x-ray image. In the method a projection line in accordance with the known projection geometry is placed through the 3D image data record at the 2D position and a 3D position of the first location of the instrument in the 3D image data record is determined from an intersection of the projection line with the structure. The method enables the 3D position to be determined with a simple monoplanar x-ray system.

Owner:SIEMENS HEALTHCARE GMBH

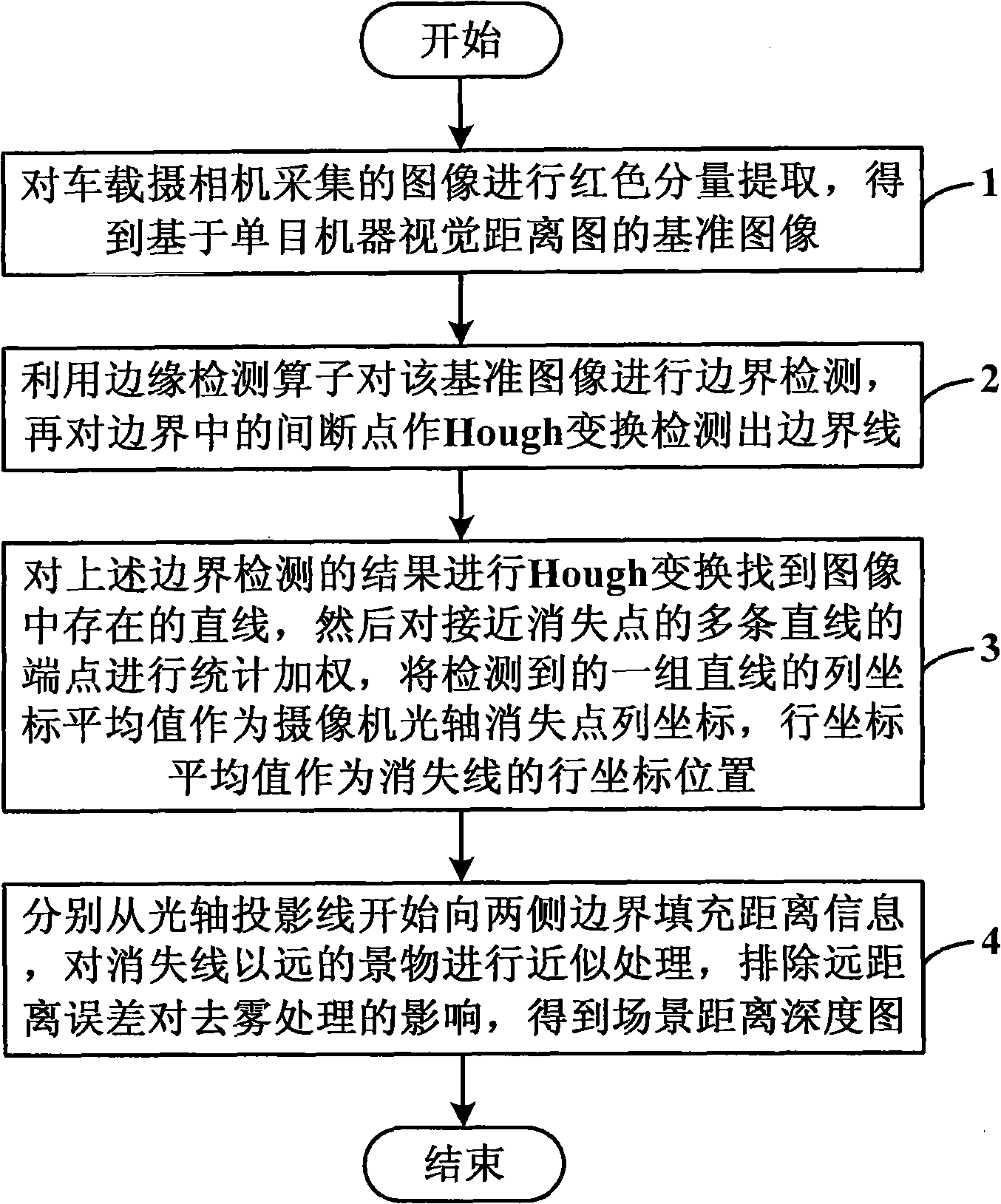

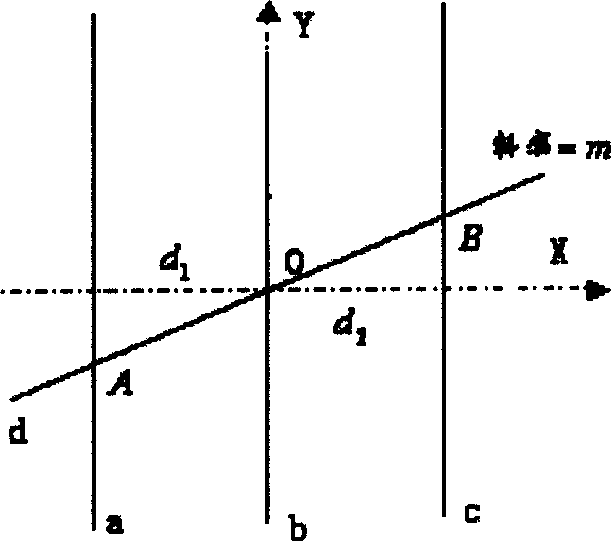

Method for creating distance map based on monocular camera machine vision

ActiveCN101789123ASolve the problem of difficult to create, expensive distance measurement equipmentImage enhancementImage analysisBoundary detectionVisual perception

The invention discloses a method for creasing a distance map based on monocular camera machine vision, which comprises the following steps: carrying out red component extraction on an image collected by a car camera for obtaining a baseline image; utilizing an edge detection operator for carrying out boundary detection on the baseline image, and further carrying out Hough transform on discontinuity points in the boundary for detecting a boundary line; carrying out the Hough transform on the boundary detection result for finding out straight lines in the image, then carrying out statistical weighting on end points of a plurality of straight lines approaching a vanishing point, taking the average value of detected column coordinates of a group of the straight lines as the column coordinate of the vanishing point of an optical axis of the camera, and taking the average value of row coordinates as the row coordinate position of a vanishing line; and respectively filling distance information from a projection line of the optical axis to the boundaries on the two sides, carrying out approximate treatment on scenes being far away from the vanishing line, eliminating the impacts of long-distance errors on defogging treatment and obtaining the distance-depth map of the scenes. The utilization of the method can solve the problems of difficult creation of the distance map and expensive distance measuring equipment during model defogging.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

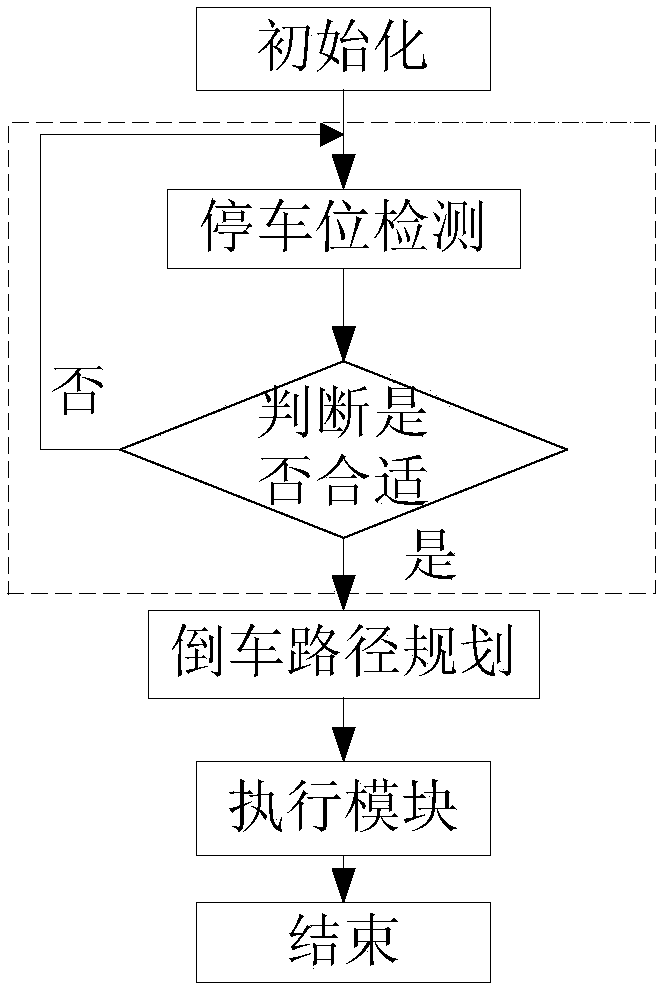

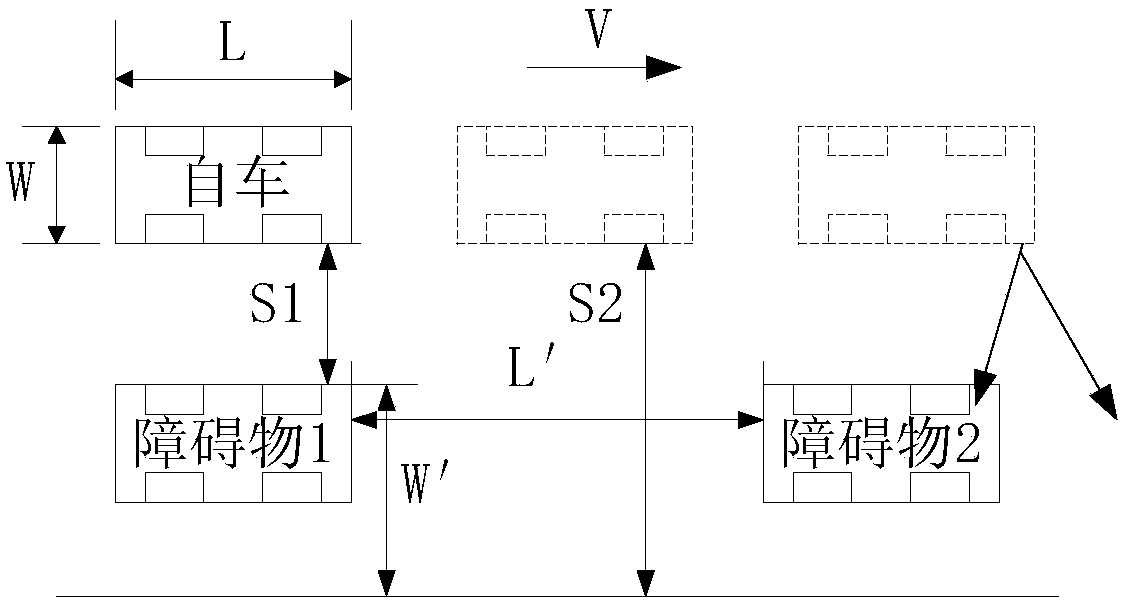

Parking space detection method based on ultrasonic radar, and terminal

An embodiment of the invention discloses a parking space detection method based on an ultrasonic radar, and is applied to parking space detection. The method includes by a terminal, acquiring echo signals received by the ultrasonic radar at a plurality of moments, wherein the echo signals are signals of the configured terminal, which are reflected by obstacles during the movement of vehicles relative to the obstacles; by the terminal, constructing a coordinate system of a parking space; by the terminal, dividing the parking space into a plurality of spatial units in the coordinate system; by the terminal, determining projection lines of possible distribution areas of the obstacles in the coordinate system according to the echo signals; by the terminal, counting the number of the projectionlines included in the first spatial unit, wherein the first spatial unit is any one of the spatial units; when the number of the projection lines included in the first spatial unit is greater than apreset threshold, by the terminal, determining that the first spatial unit is a spatial unit that includes the outlines of the obstacles; by the terminal, determining the parking space size accordingto the first spatial unit.

Owner:HUAWEI TECH CO LTD

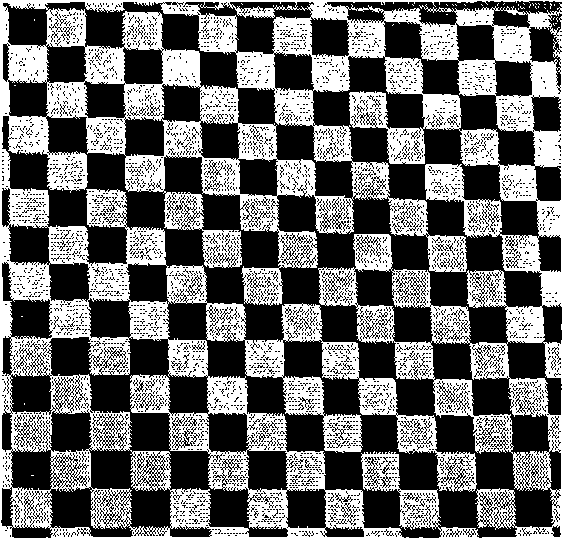

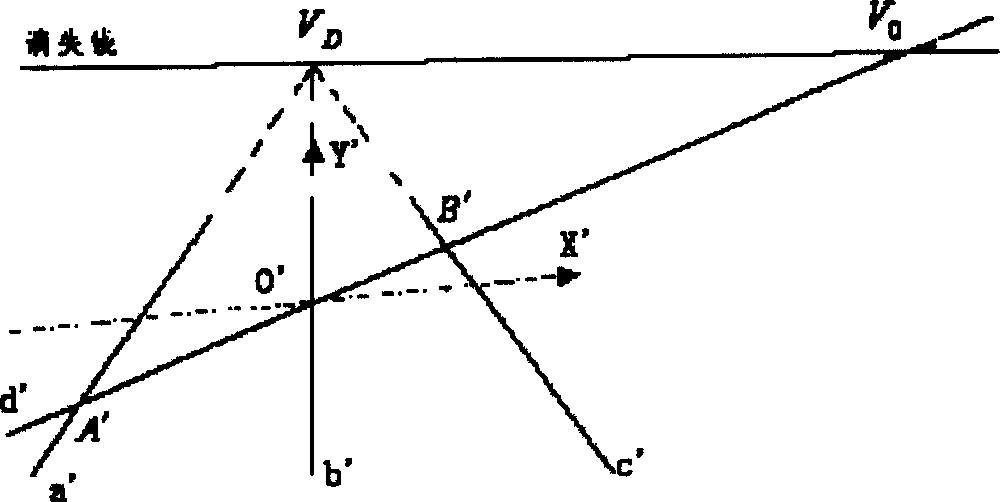

Calibrating method of pick-up device under condition of traffic monitering

InactiveCN1564581ASimple methodEasy to implementTelevision system detailsColor television detailsComputation complexityComputer graphics (images)

The method includes following steps: the three parallel edges whose interval are known and a straight line, intersecting with parallel line, whose slop is known are selected from traffic scene to be as the calibration target; each projection straight line corresponding to them in the image is found and the intersection coordinates of each projection line is figured out; according to the data, the focal length, direction and location parameters about the video cameral is figured out. The invention can use the traffic scene such as zebra crossing and traffic lane including the two side of road, and combine the distribution information about a lot of special straight line in road surface to determine relevant parameter of the video camera.

Owner:SHANGHAI JIAO TONG UNIV

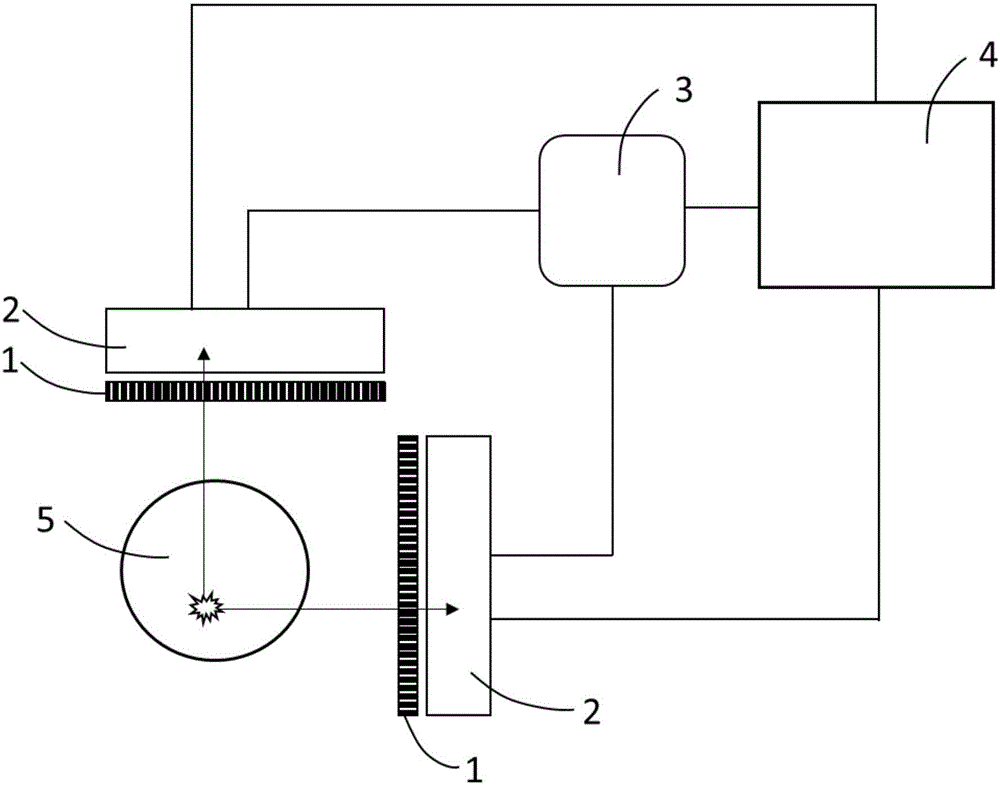

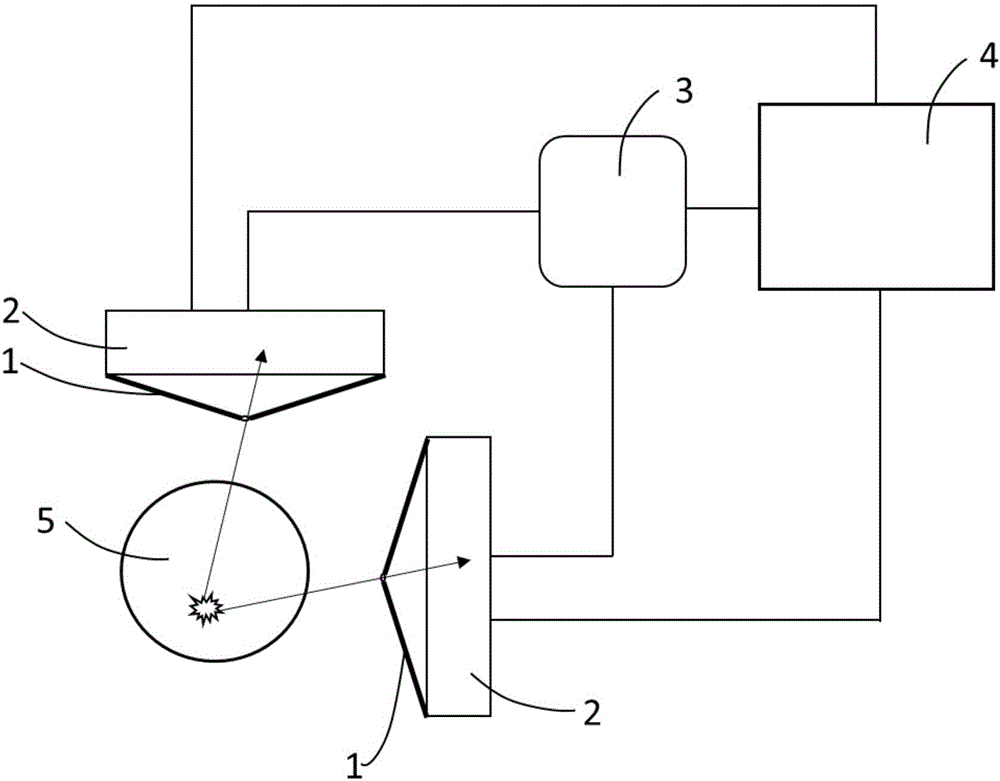

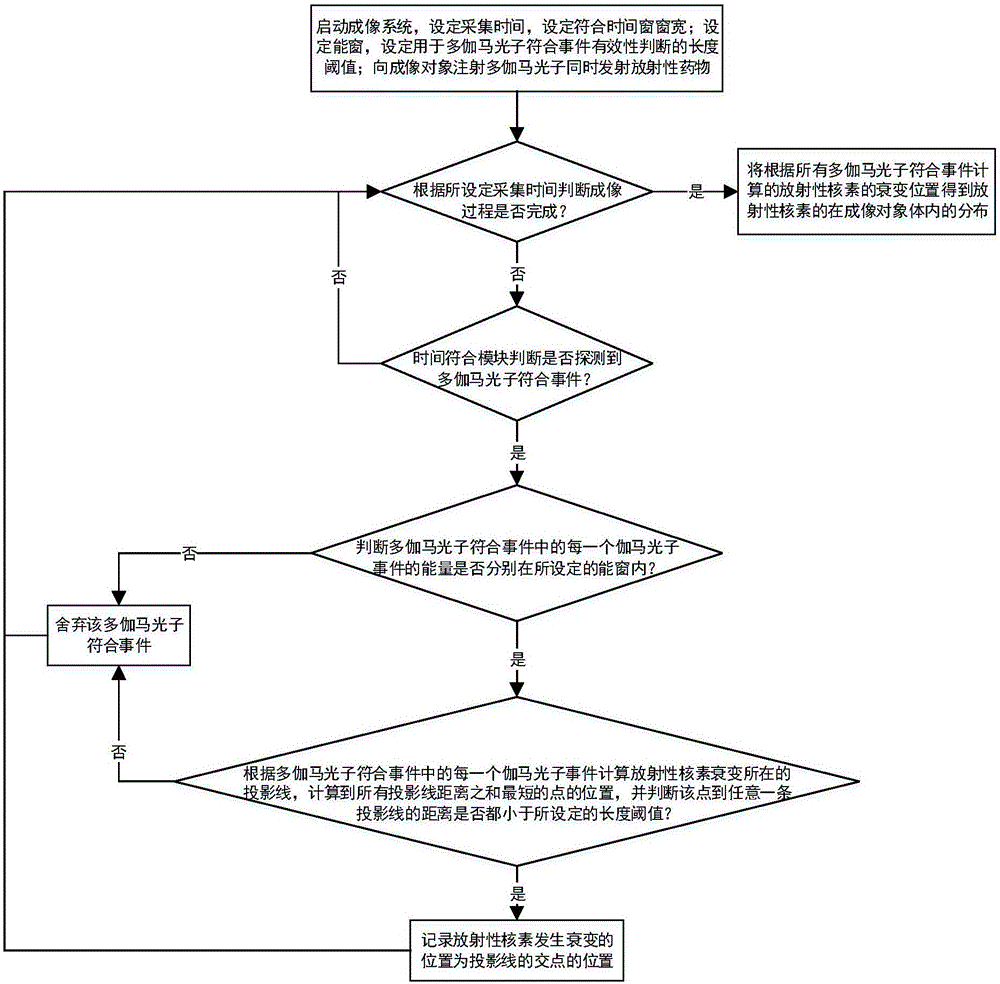

Multi-gamma-photo simultaneous medicine emission time coincidence nuclear medical imaging system and method

ActiveCN106108934AGet the distributionImprove signal-to-noise ratioRadiation diagnostic device controlComputerised tomographsReconstruction algorithmNuclear medicine imaging

The invention discloses a multi-gamma-photo simultaneous medicine emission time coincidence nuclear medical imaging system and method, and belongs to the field of nuclear medical images. The system comprises multiple detector probes arranged in non-parallel mode, a time coincidence module and a computer platform. Each detector probe is composed of a collimator and a gamma photo detector with a time measuring function. Multiple gamma photos radiated by detection radionuclides within a short time form multiple gamma-photo coincidence events. The point with the smallest sum, of distances of projection lines determined by the multiple gamma-photo coincidence events, calculated by the method is the disintegration position of radionuclides, and the distribution of radionuclides in living bodies can be obtained by accumulating a certain number of mult-gamma-photo coincidence events. By means of the imaging system and method, reconstruction algorithm is simplified, the signal to noise ratio of reconstructed images is improved, the requirement for the gamma photo total count is lowered, and the irradiation risk to patients is lowered.

Owner:TSINGHUA UNIV

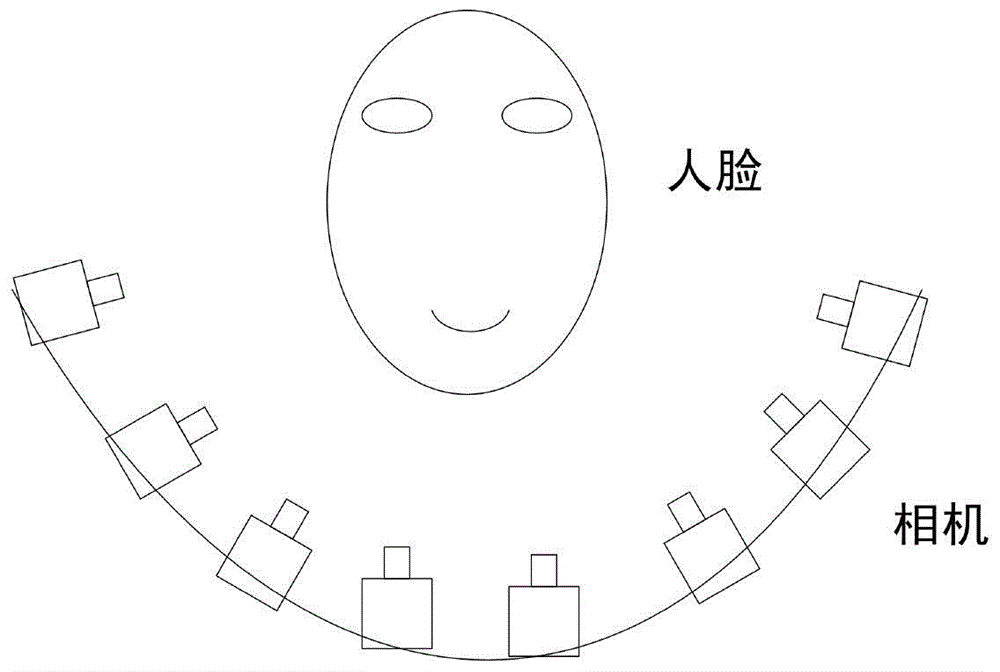

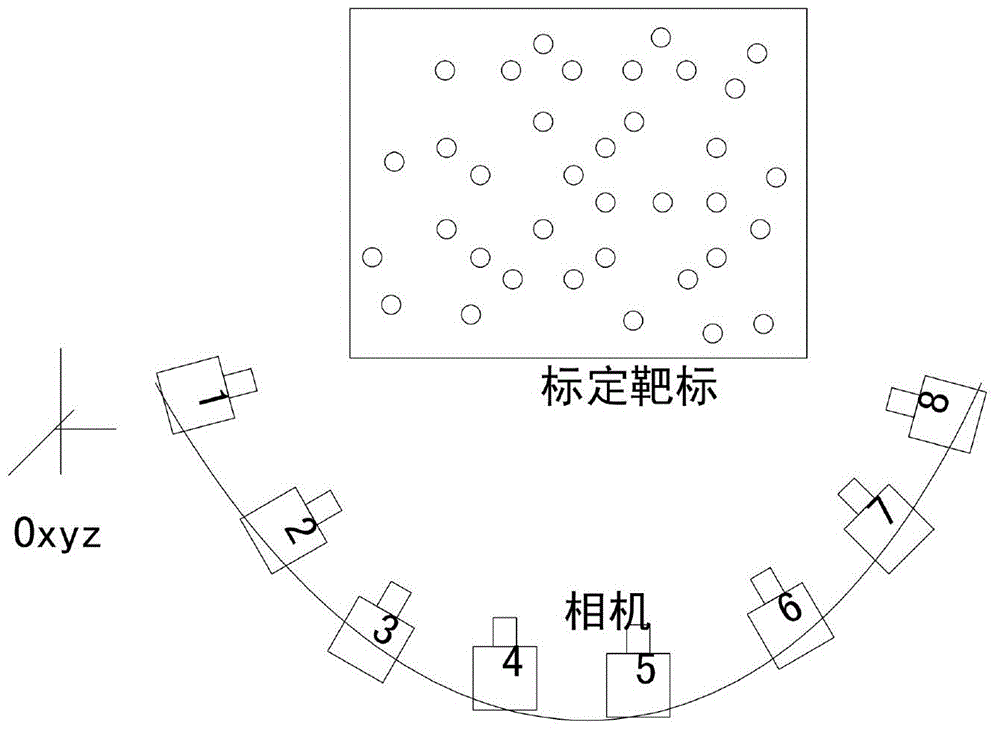

Method for reconstructing real-time three-dimensional face data with multiple images

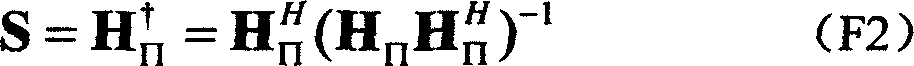

InactiveCN104794728AWill not missRich in detailsImage enhancementImage analysisHat matrixObject point

The invention discloses a method for reconstructing real-time three-dimensional face data with multiple images. The method includes the following steps: constructing shooting systems of eight cameras; performing multi-camera calibration; performing image matching, to be more specific, calculating global matching points of an ith group of images, and calculating accurate matching points of the ith group of images; calculating three-dimensional face coordinates via the matching points and a projection matrix of the cameras, to be more specific, imaging an object point on the third image of the ith group, and taking an intersection of three projection lines as the object point so as to complete reconstructing of the real-time three-dimensional face data. The face data obtained in the method are global, dense and real-time and can be used directly, and the method can be widely applied to the fields such as the animation industry, computer 3D (three-dimensional) games, human-computer interaction, identity recognition, medical virtual surgery, videophones, face recognition, face expression, age simulation, film and TV advertising production and computer cognition.

Owner:成都元天益三维科技有限公司

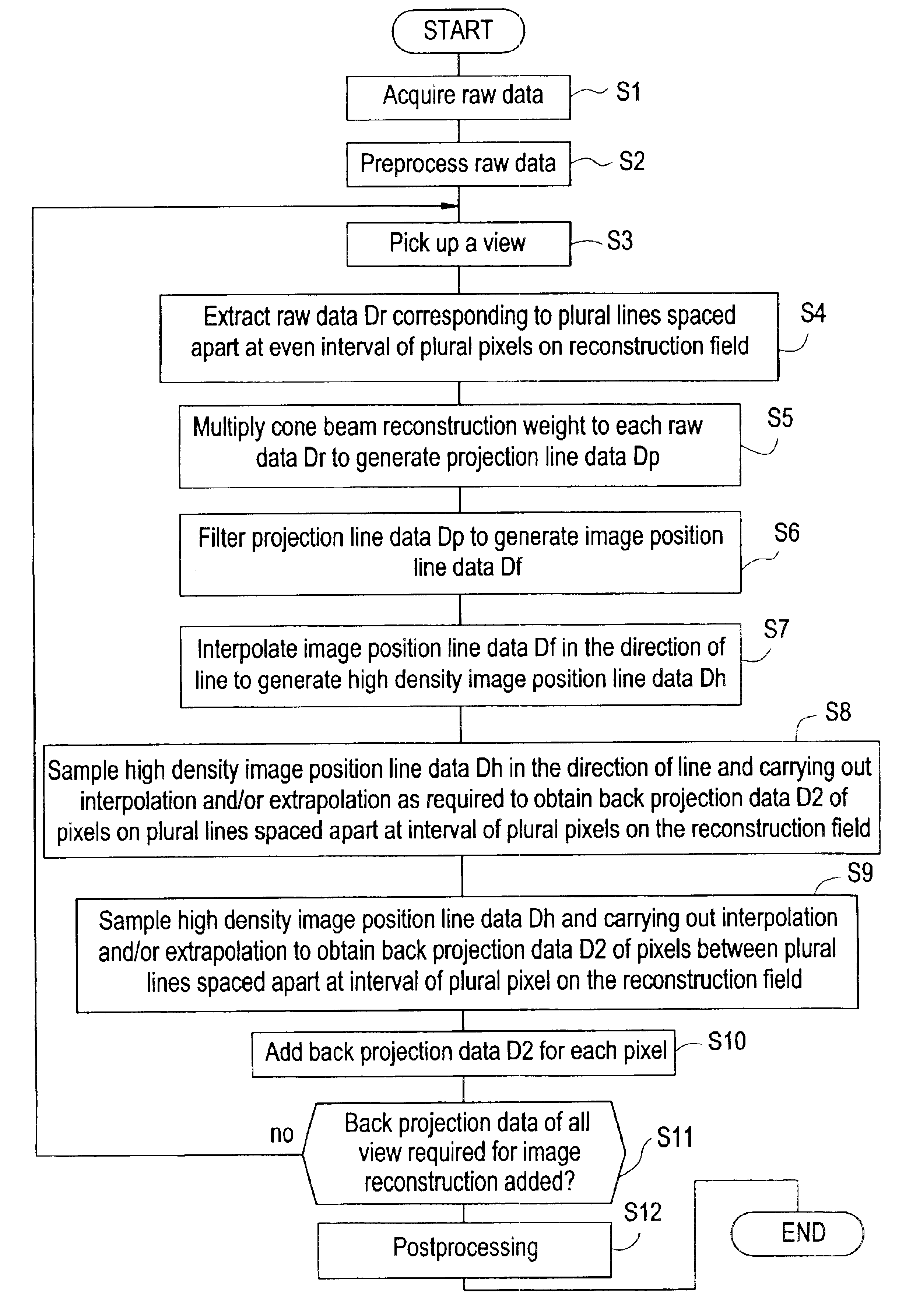

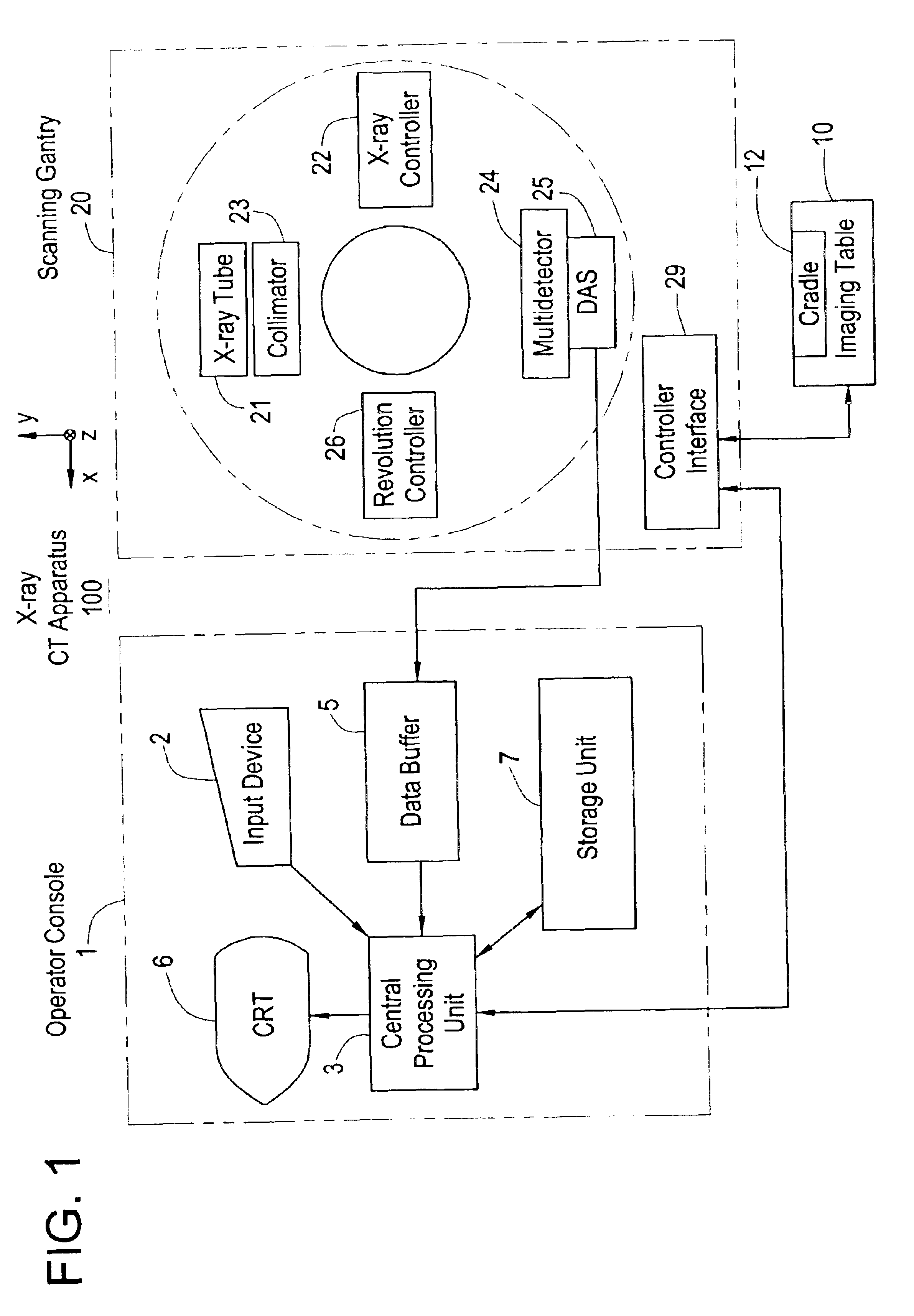

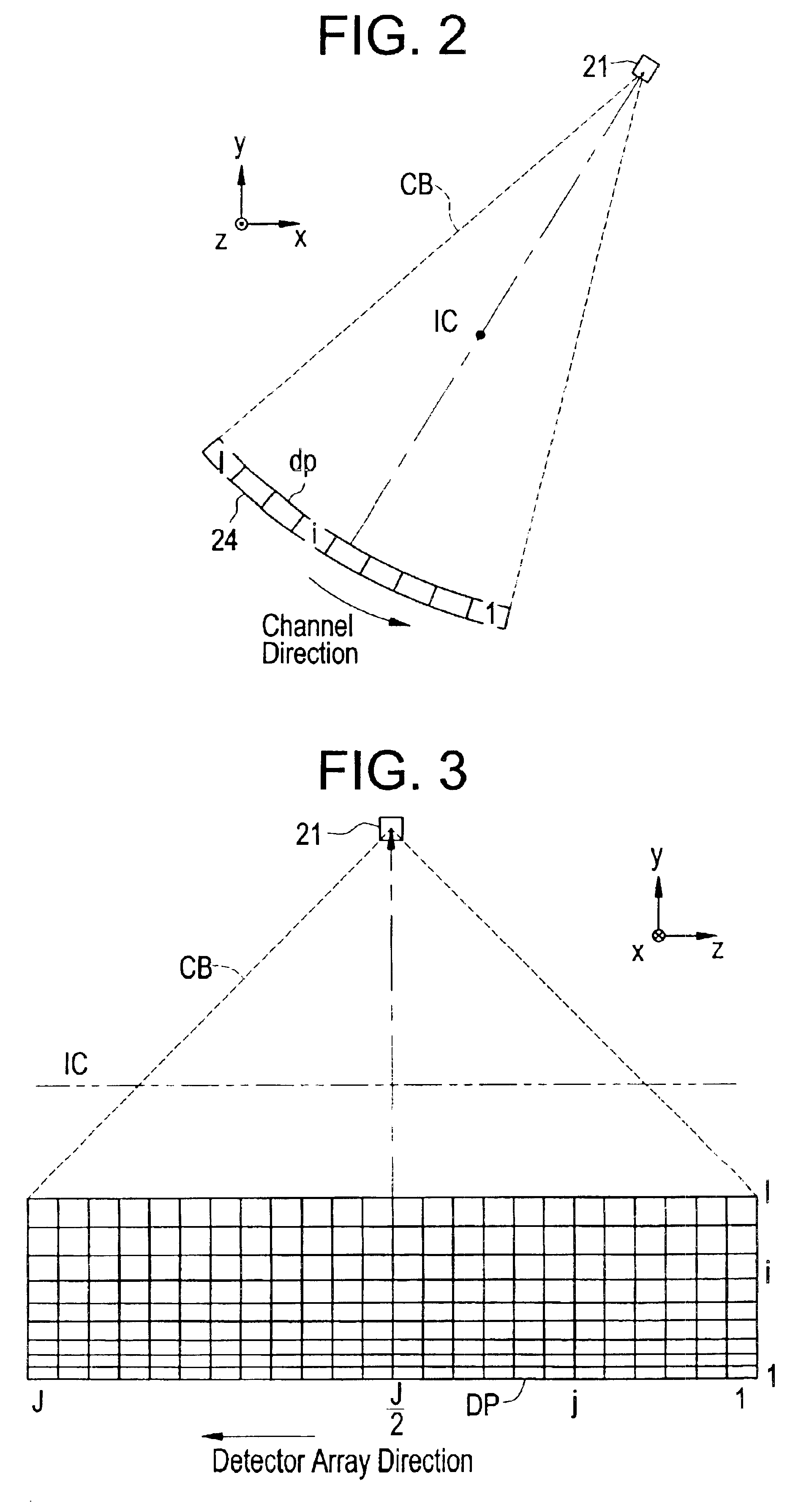

Three dimensional back projection method and an X-ray CT apparatus

InactiveUS6865247B2Reduce the amount of calculationReduce the amount requiredReconstruction from projectionMaterial analysis using wave/particle radiationImaging qualityBack projection

In order to reduce the amount of computation in the cone beam reconstruction, the invention provides, from within raw data acquired using a multidetector, extracting raw data Dr corresponding to plural lines on reconstruction field (S4), generating projection line data (S5) by multiplying raw data with cone beam reconstruction weight, filtering projection line data to generate image positional line data Df (S6), determining back projection pixel data (S7, S8, S9) of each pixel on the reconstruction field based on the image positional line data, adding, for each pixel, back projection pixel data of all views used for the image reconstruction to determine back projection data (S10, S11). The number of lines may be variable in compliance with a desired image quality.

Owner:GE MEDICAL SYST GLOBAL TECH CO LLC

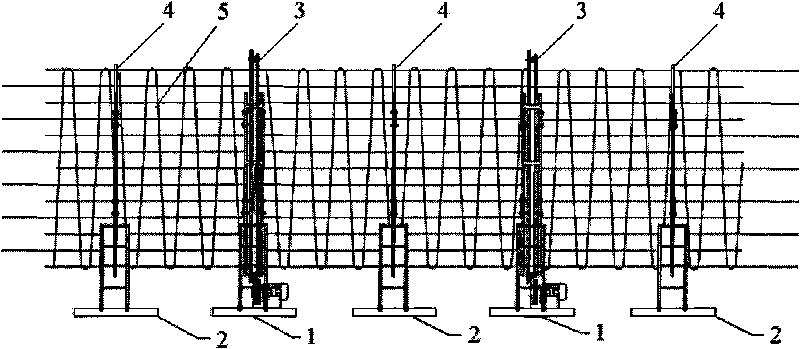

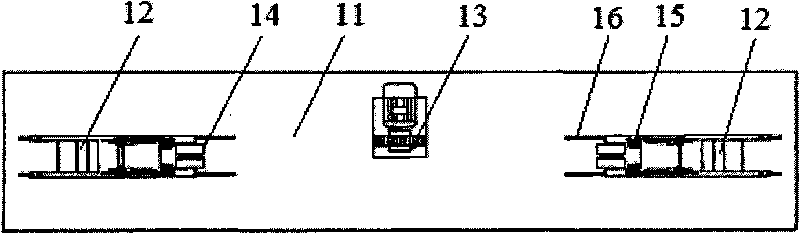

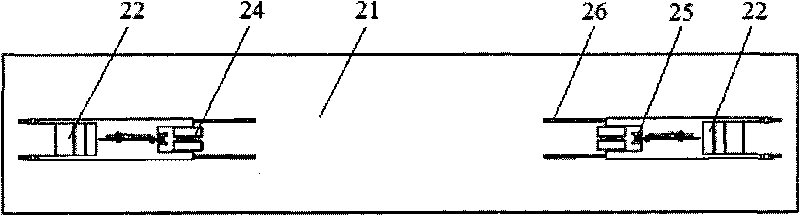

Manufacturing method of reinforcement cage of pouring pile with large diameter

ActiveCN101761071AImprove manufacturing precisionReduce the number of employeesBulkheads/pilesLow speedGear wheel

The invention discloses a manufacturing method of a reinforcement cage of a pouring pile with the large diameter, relating to the technical field of construction project. The invention aims at reducing the labor intensity while improving manufacturing accuracy and work efficiency. The method is characterized in that a manufacturing device consisting of a plurality of rolling bearing frame assemblies and transmission bearing frame assemblies is arranged according to a projection line of a central axis line of the reinforcement cage; openable ring mould assemblies are arranged on each transmission bearing frame assembly; inner walls of the ring mould assemblies are provided with a plurality of main reinforcement positioning grooves; main reinforcements of the reinforcement cage is lifted into the ring mould assemblies, the ring mould assemblies are driven through a low-speed drive gear to rotate so that each main reinforcement enters the main reinforcement positioning grooves and is fixedly welded with rectilinear hoops; and the ring mould assemblies are rotated and winded and reinforcing steel bars are rounded by using spot welding so as to realize mechanization manufacture of the reinforcement cage of the pouring pile with the large diameter. The method provided by the invention can realize high manufacturing accuracy and cage-making work efficiency of the reinforcement cage, can greatly reduce the labor intensity and reduce the worker amount of unit cage manufacture amount and is beneficial to quickening the project progress.

Owner:SHANGHAI GUANGLIAN ENVIRONMENTAL & GEOTECHNICAL ENG CO LTD

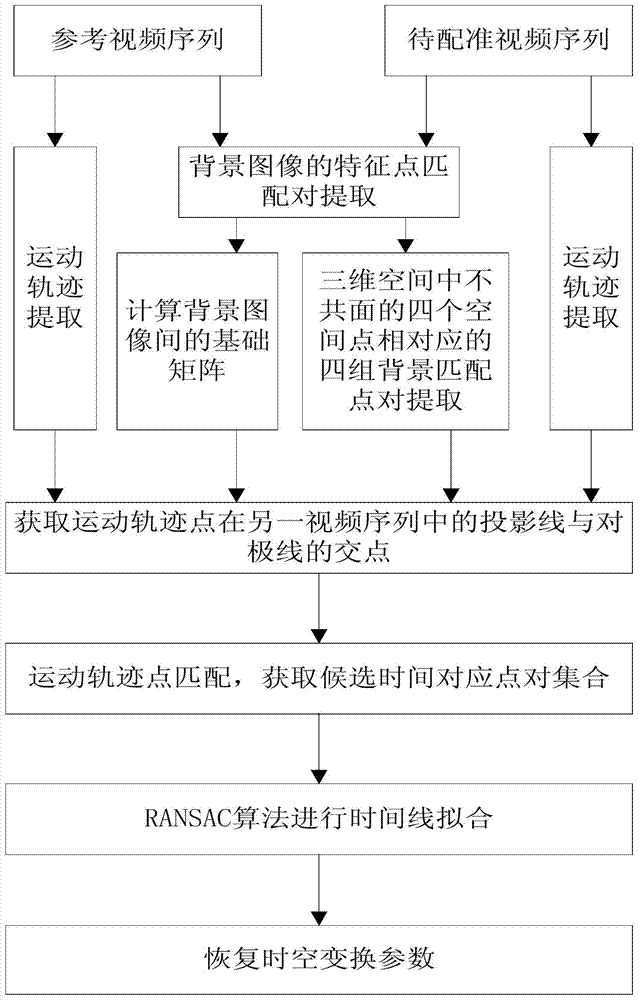

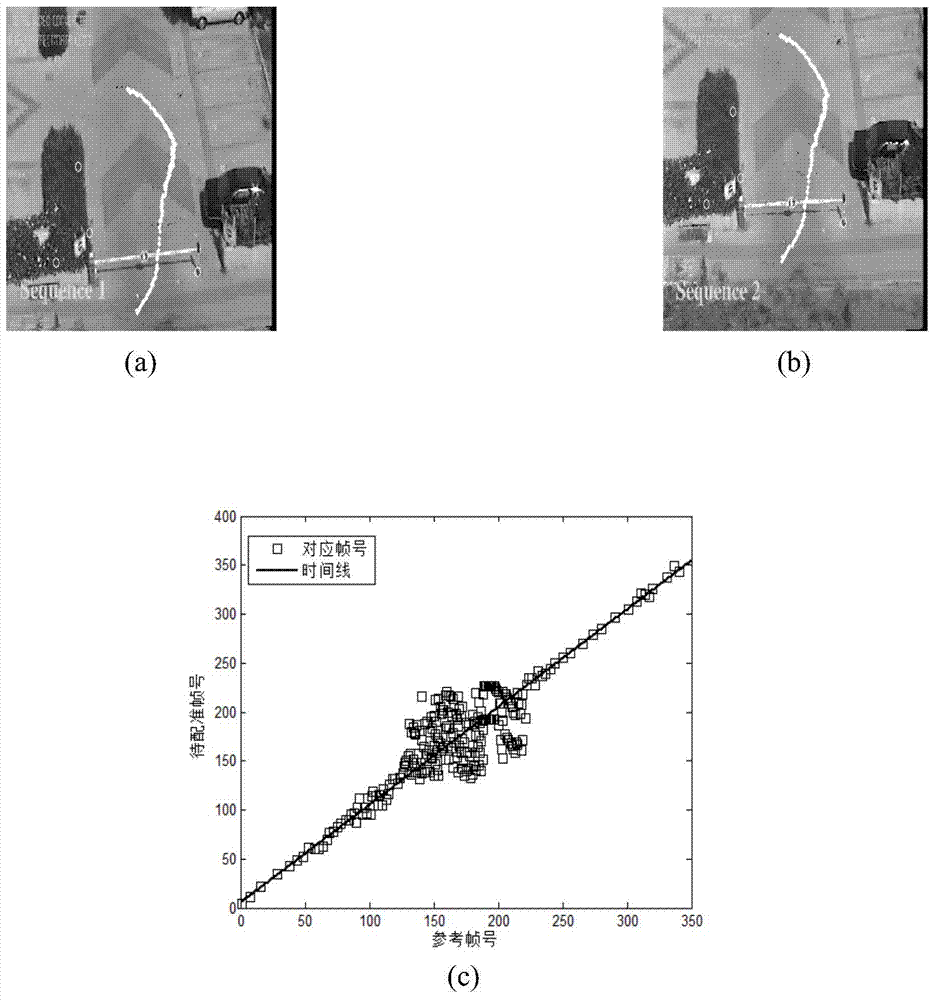

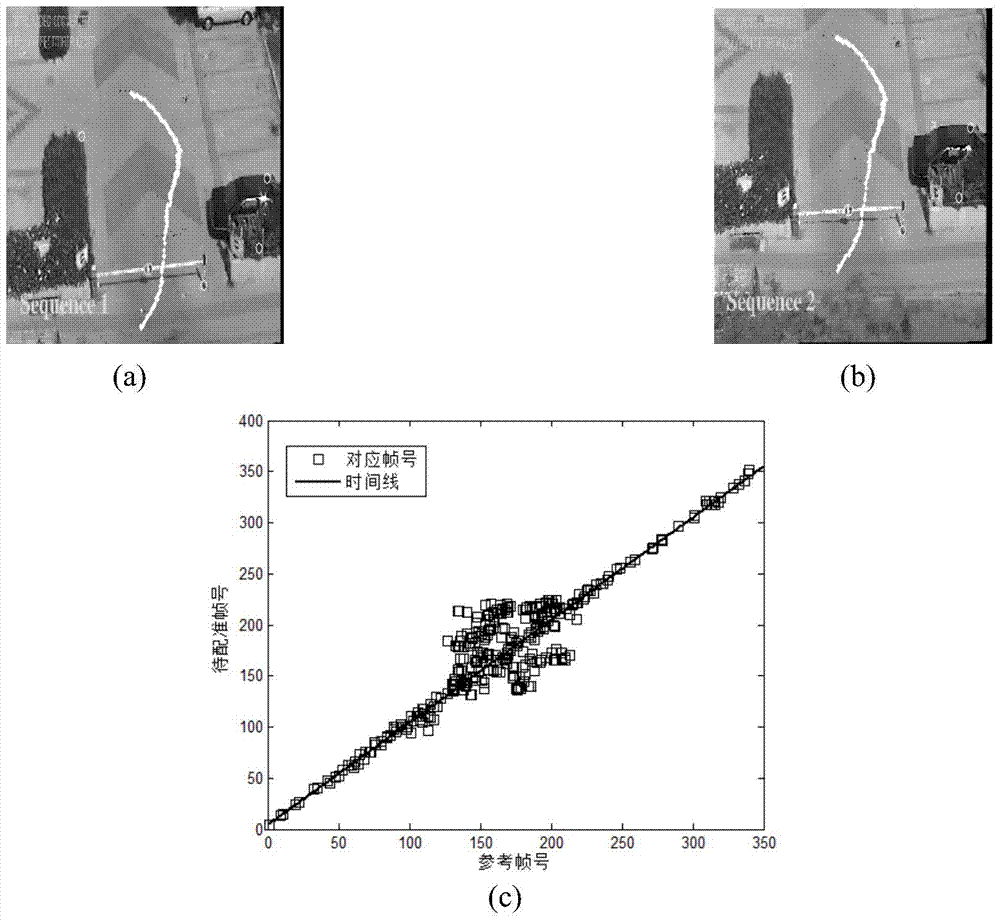

Video sequence registering method based on combination of motion information and background information

ActiveCN104268866AExact searchImprove the defects of mismatched pairsImage analysisCharacter and pattern recognitionTime transformationThree-dimensional space

The invention discloses a video sequence registering method based on combination of motion information and background information. The method mainly solves the problem that in the prior art, video sequences in different view points cannot be accurately registered. The method includes the steps that (1) separation of background images and motion targets is carried out on two input video sequences; (2) feature point matching pairs of the background images are obtained, and basis matrixes between the background images are calculated; (3) four sets of matching point pairs corresponding to four spatial points not on the same plane in a three-dimensional space are selected from the background images; (4) intersection points of projection lines, in another video sequence, of points in motion tracks and bipolar lines are obtained; (5) motion track points are matched and a point pair set corresponding to candidate time is obtained; (6) a time line is fitted and time transformation parameters are recovered. The time relation between video sequences can be accurately recovered, registering accuracy is improved and the method can be used for registering video sequences with static backgrounds.

Owner:XIDIAN UNIV

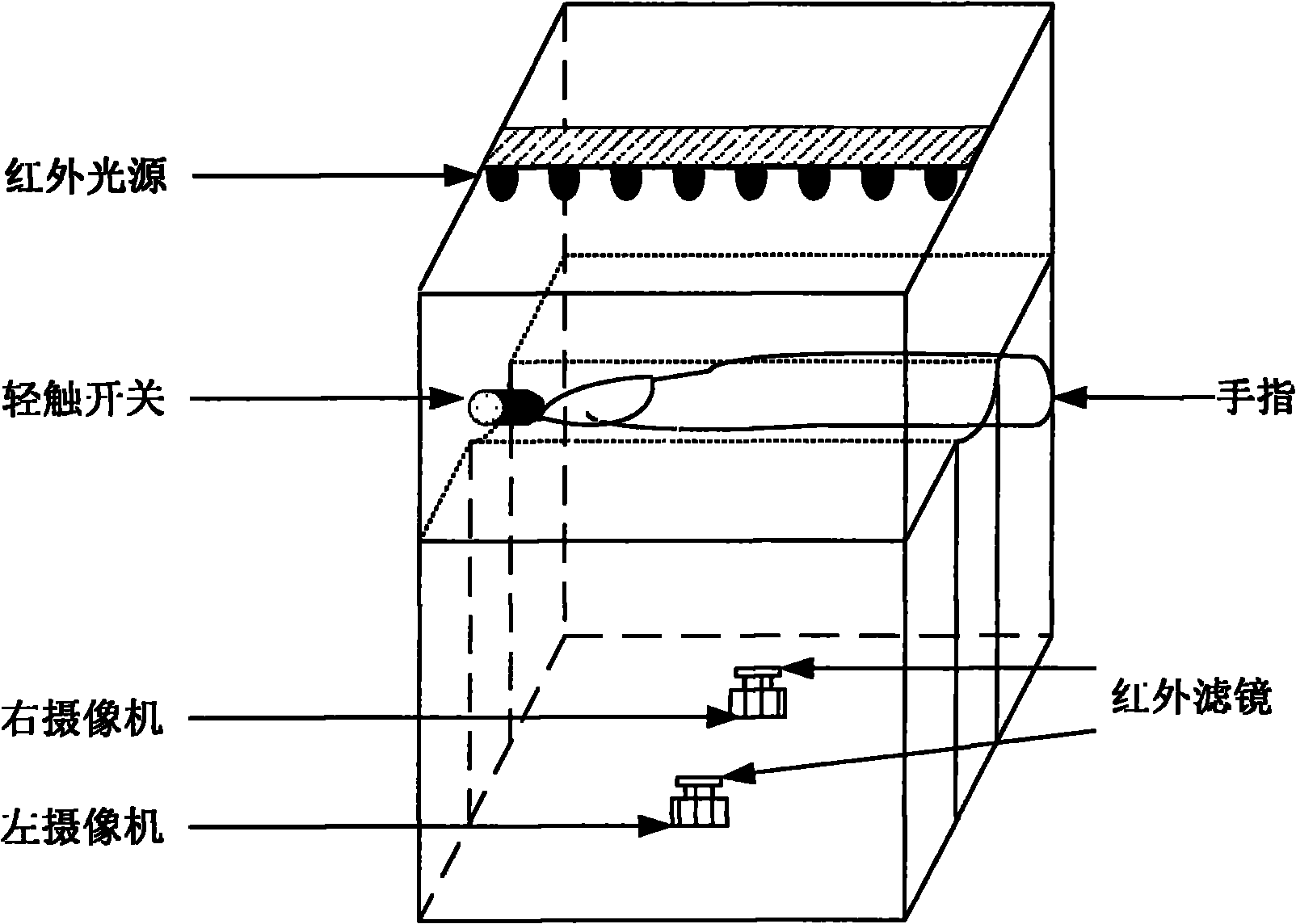

Binocular vision-based finger vein three-dimensional identification method and device

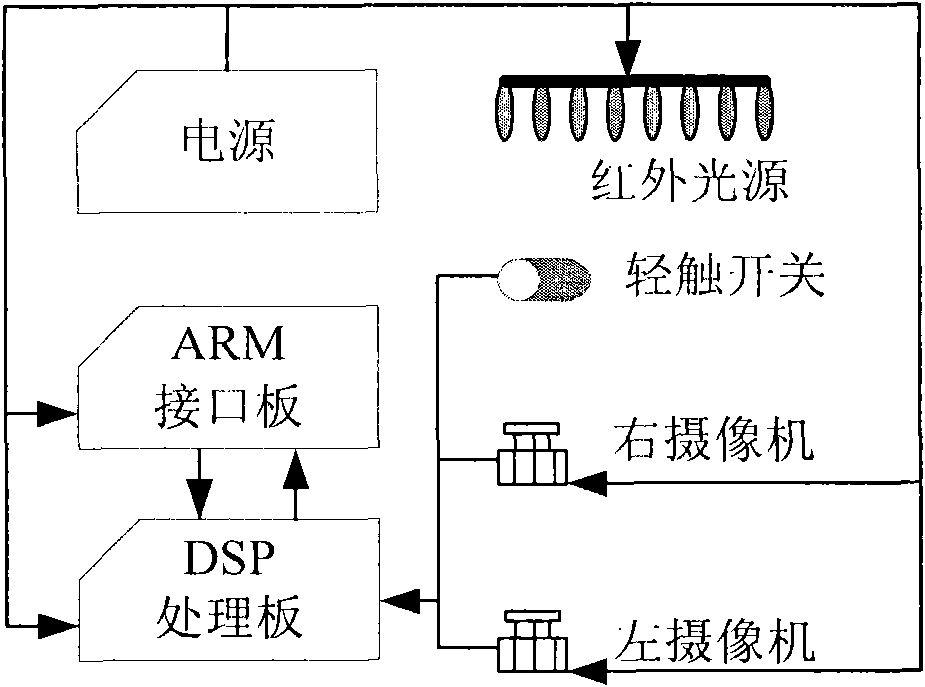

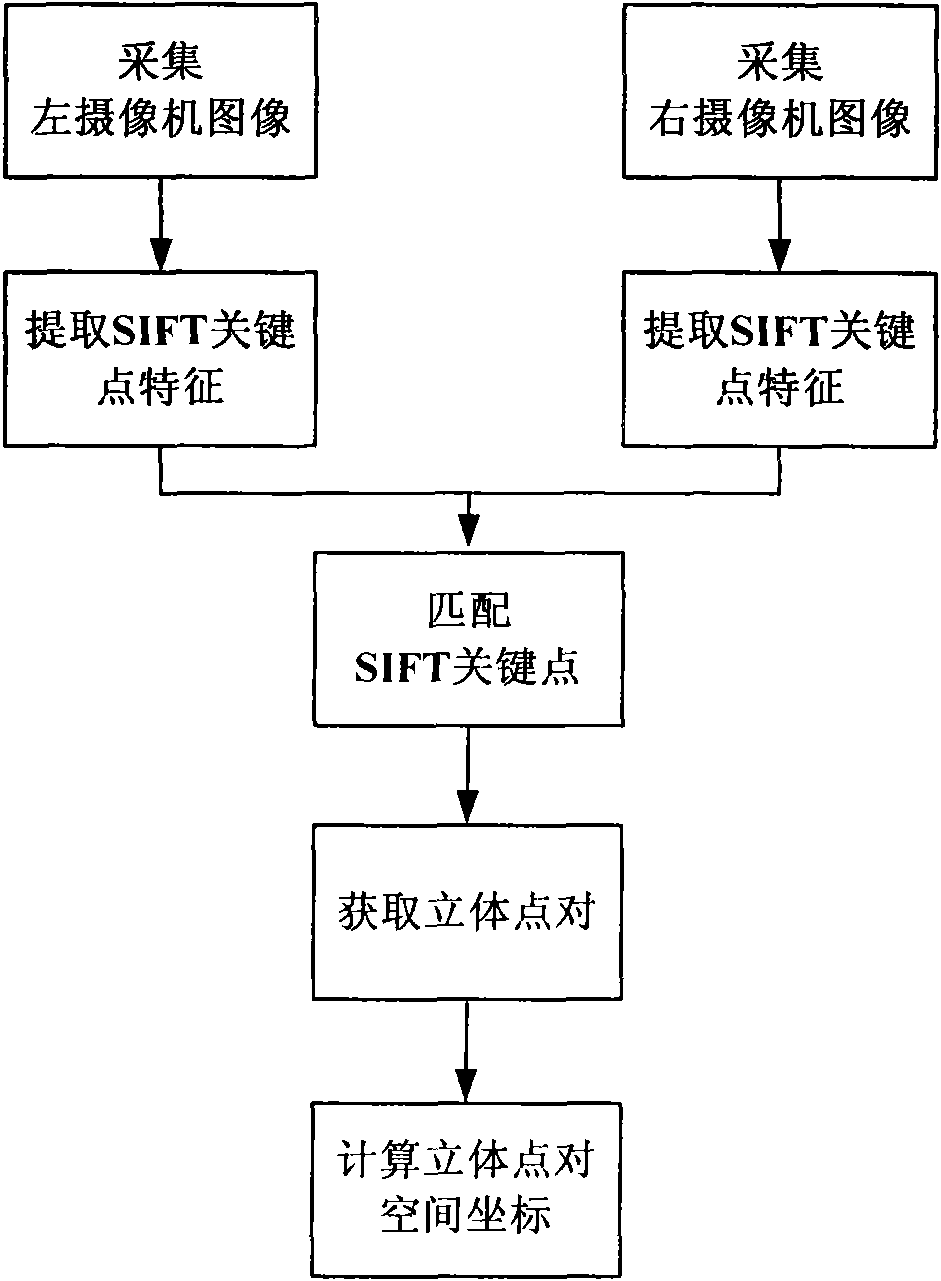

ActiveCN101980243AEasy to identifyImprove securityCharacter and pattern recognitionDigital signal processingLight touch

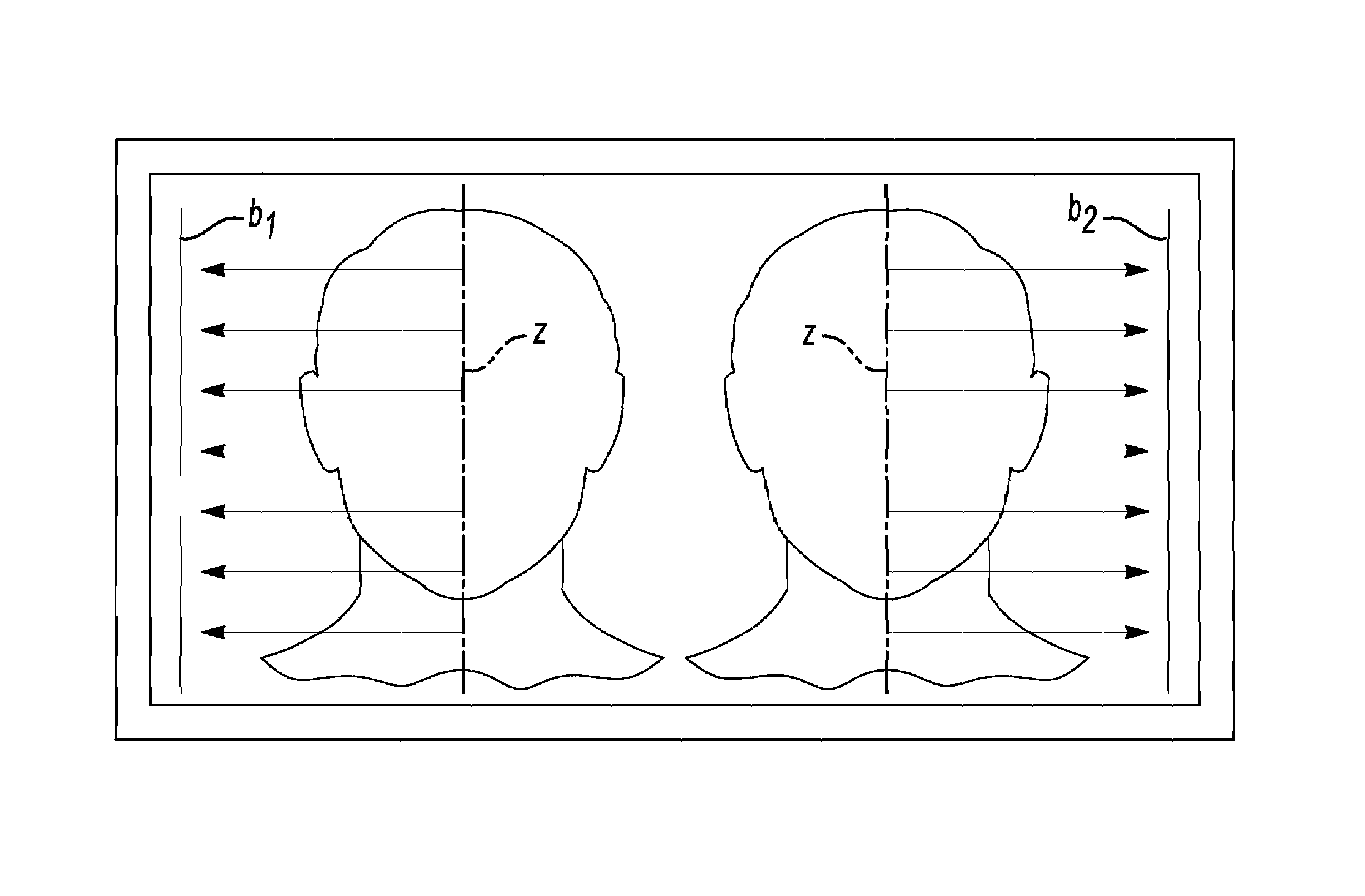

The invention discloses a binocular vision-based finger vein three-dimensional identification method and a binocular vision-based finger vein three-dimensional identification device. The device mainly comprises an infrared light source, a light touch switch, a left camera, a right camera, infrared filters, a power supply, an advanced RISC machines (ARM) interface board and a digital signal processing (DSP) plate, wherein the infrared light source, a finger and the left camera and the right camera are positioned on three horizontal planes; the left camera and the right camera are positioned on the two sides of a finger projection line respectively; and the connecting line of the left camera and the right camera is vertical to the finger projection line. The method comprises the following steps of: if that the light touch switch is pressed is detected, operating the left camera and the right camera to acquire the binocular image of the finger, and extracting and matching the three-dimensional characteristics of finger veins based on the binocular vision principle and a scale invariant feature transform (SIFT) operator so as to realize the function of registering or identifying the finger. The method and the device effectively improve the identification rate and security level of finger vein identification equipment.

Owner:NAT UNIV OF DEFENSE TECH

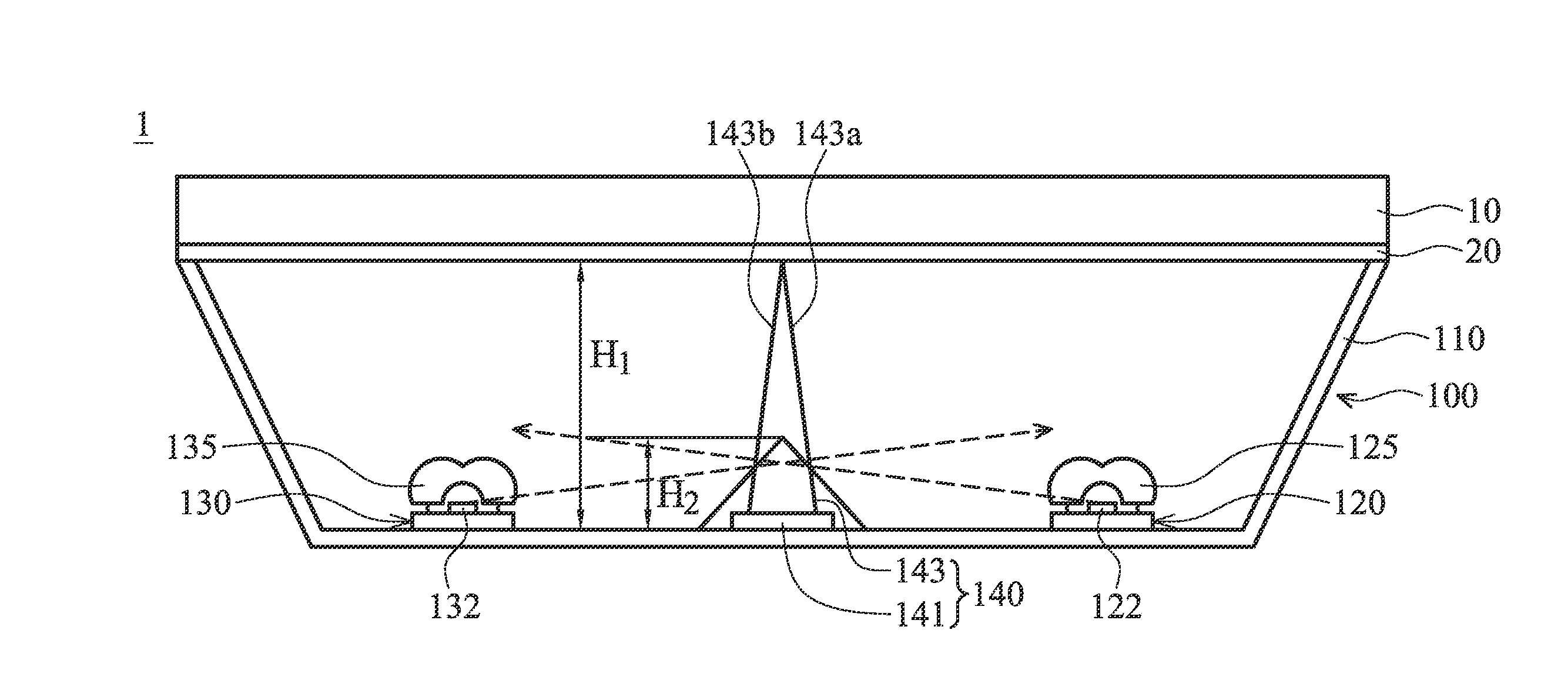

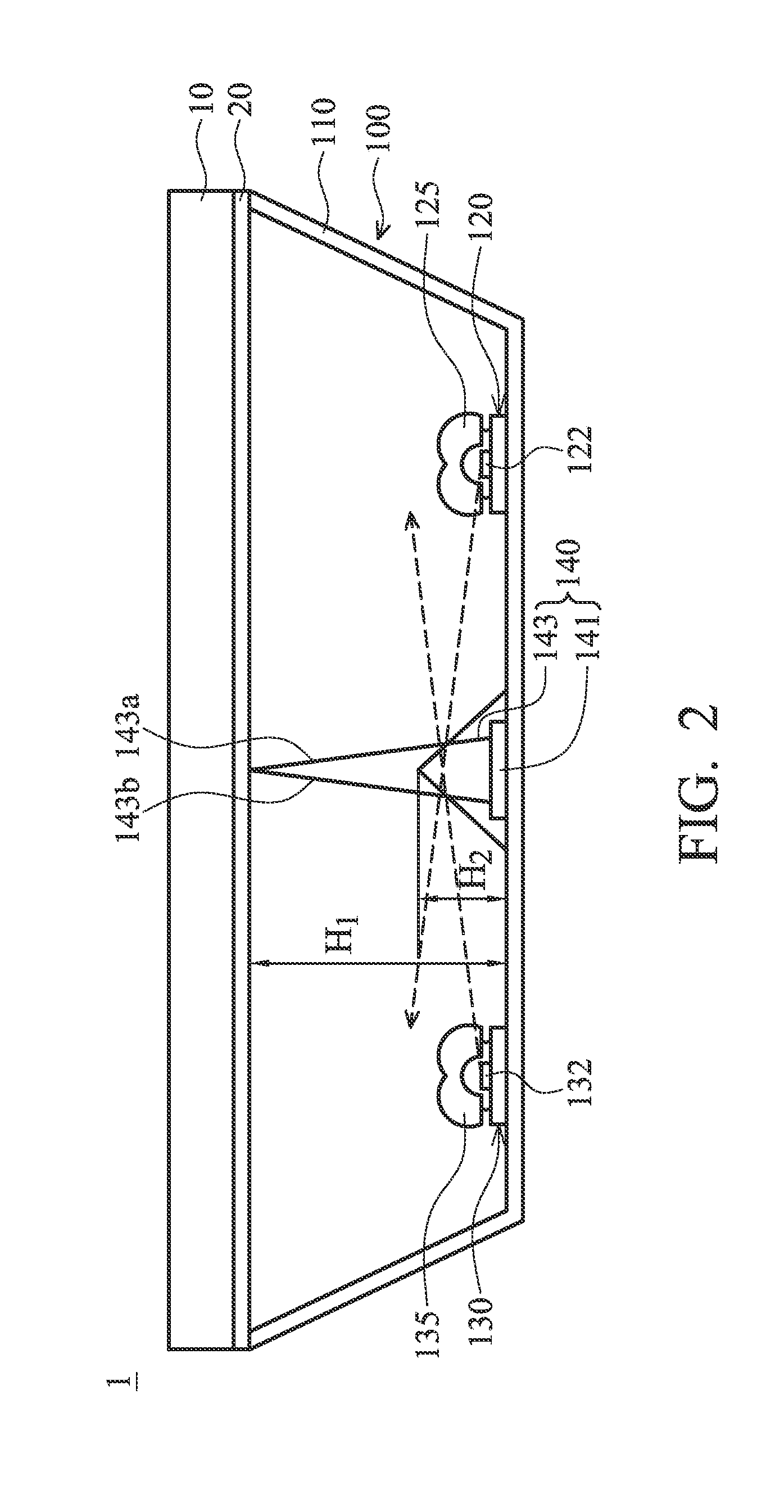

Backlight module and display device including the same

InactiveUS20130194529A1Uneven brightnessRemove shadowsIlluminated signsNon-linear opticsDisplay deviceOptoelectronics

A backlight module is provided, which includes a base, a light source, and at least one polygonal support member. The base has a lower surface, and the light source is disposed on the base. A transverse section of the polygonal support member includes a first side, and an angle formed by a projection line of a connecting line between the midpoint of the first side and the light source on the lower surface and a projection line of the first side on the lower surface is between 80 degrees and 100 degrees.

Owner:INNOCOM TECH SHENZHEN +1

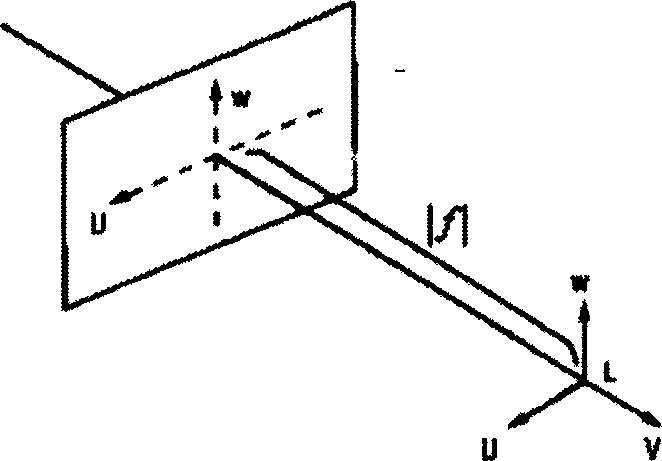

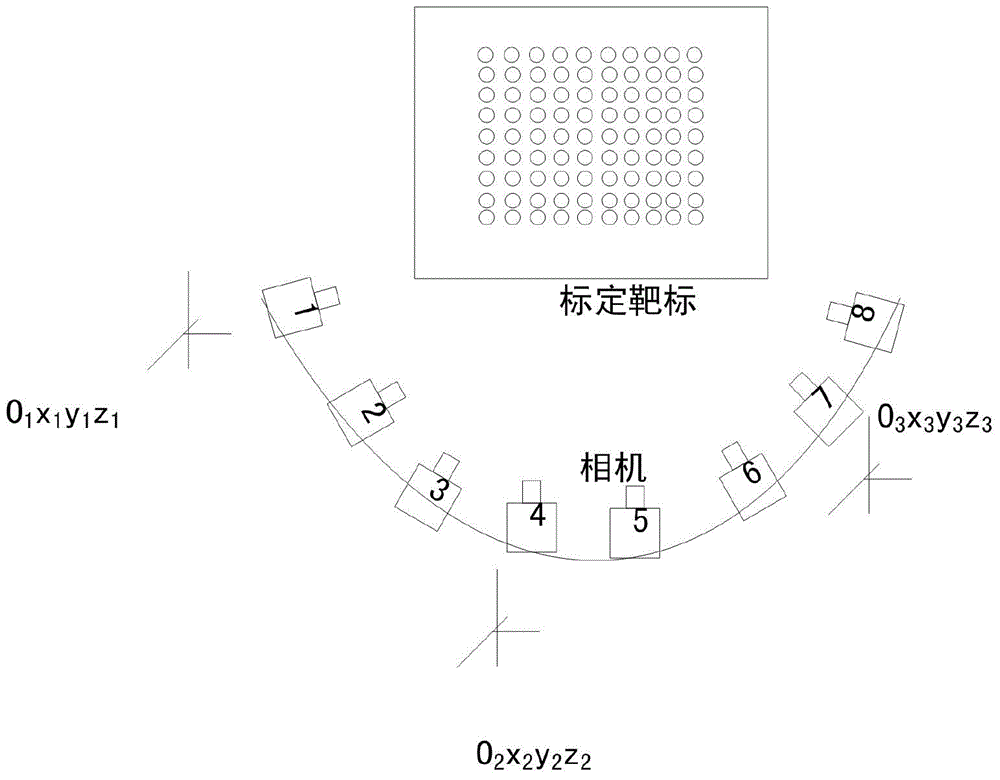

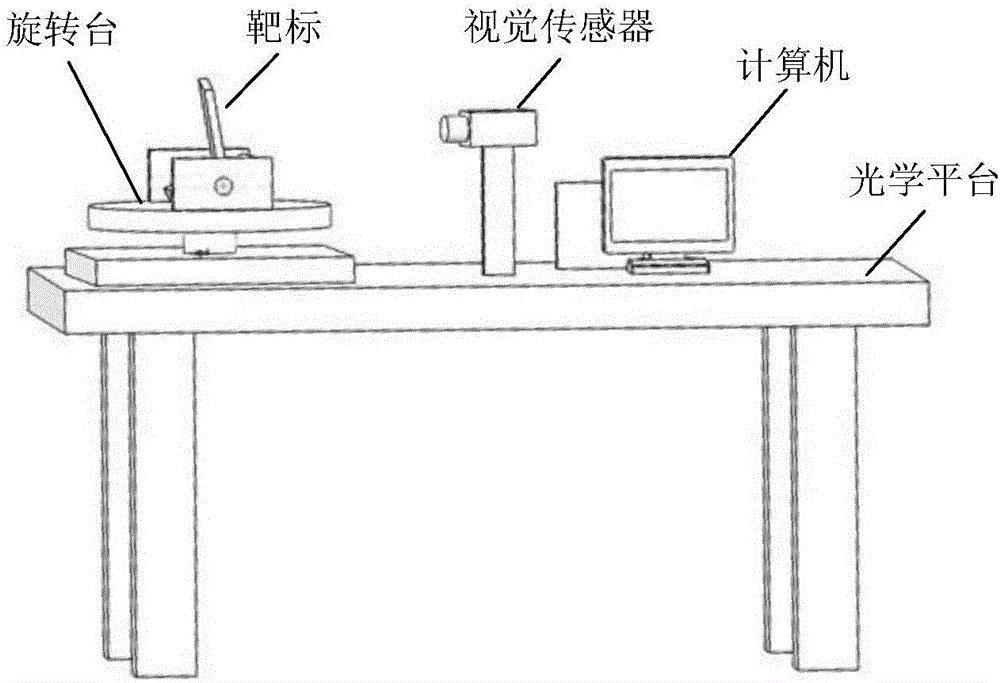

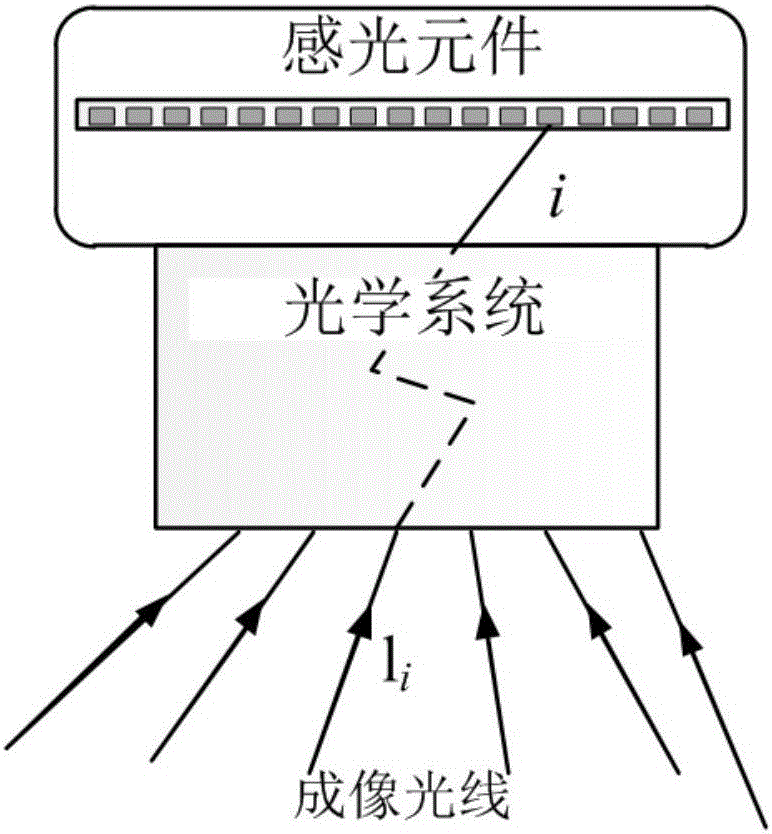

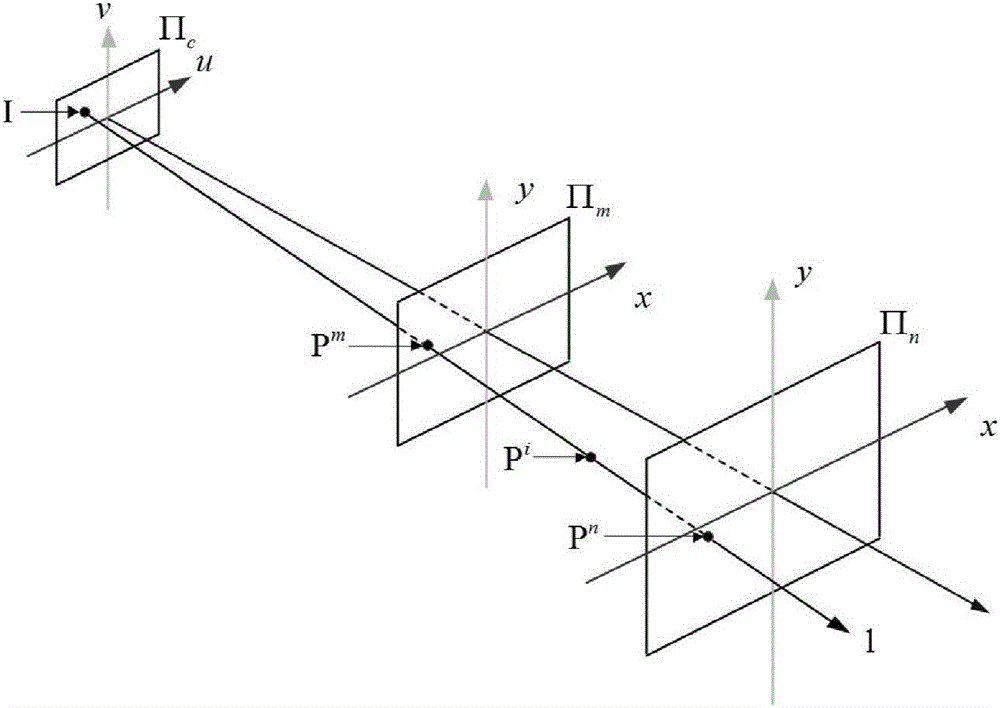

Method for geometrically constraining pose based on perspective projection line

InactiveCN105913417AImprove the accuracy of pose calculationImage enhancementImage analysisEuclidean vectorProjection line

The invention relates to a monocular vision pose resolving method, which solves the non-coplanar P4P problem, solves the problems that the current P4P algorithm measurement range is small and the measurement accuracy is low, and realizes the large-range high-accuracy measurement of the target pose. The method for geometrically constraining the pose comprises steps of raising a perspective projection line according to a general camera imaging system, establishing and solving an optimal target function of the coordinates of four non-coplanar characteristic points under a camera coordinator system by combining the geometrical constraints between the four non-coplanar characteristic points, solving a rotation matrix and a displacement vector of a target according to the characteristic point coordinator obtained through solution so as to obtain the position and pose parameters of the target. The invention is mainly used for the monocular visual sense pose resolving occasion.

Owner:TIANJIN UNIV

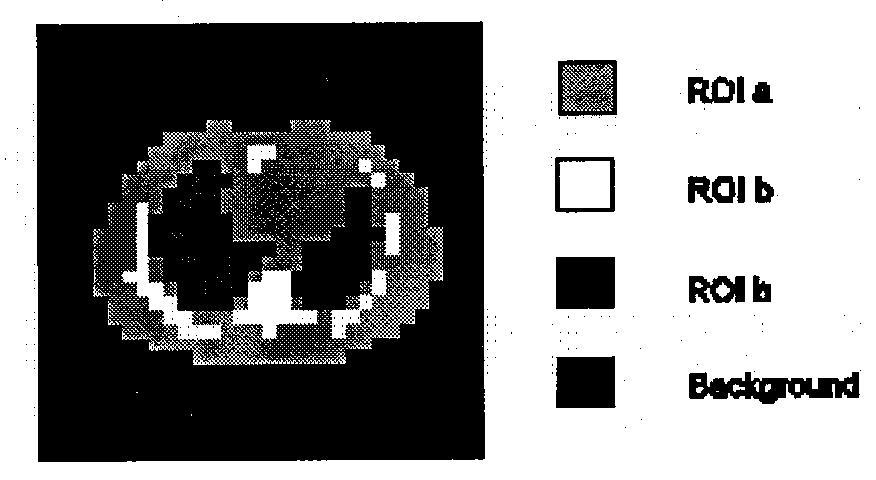

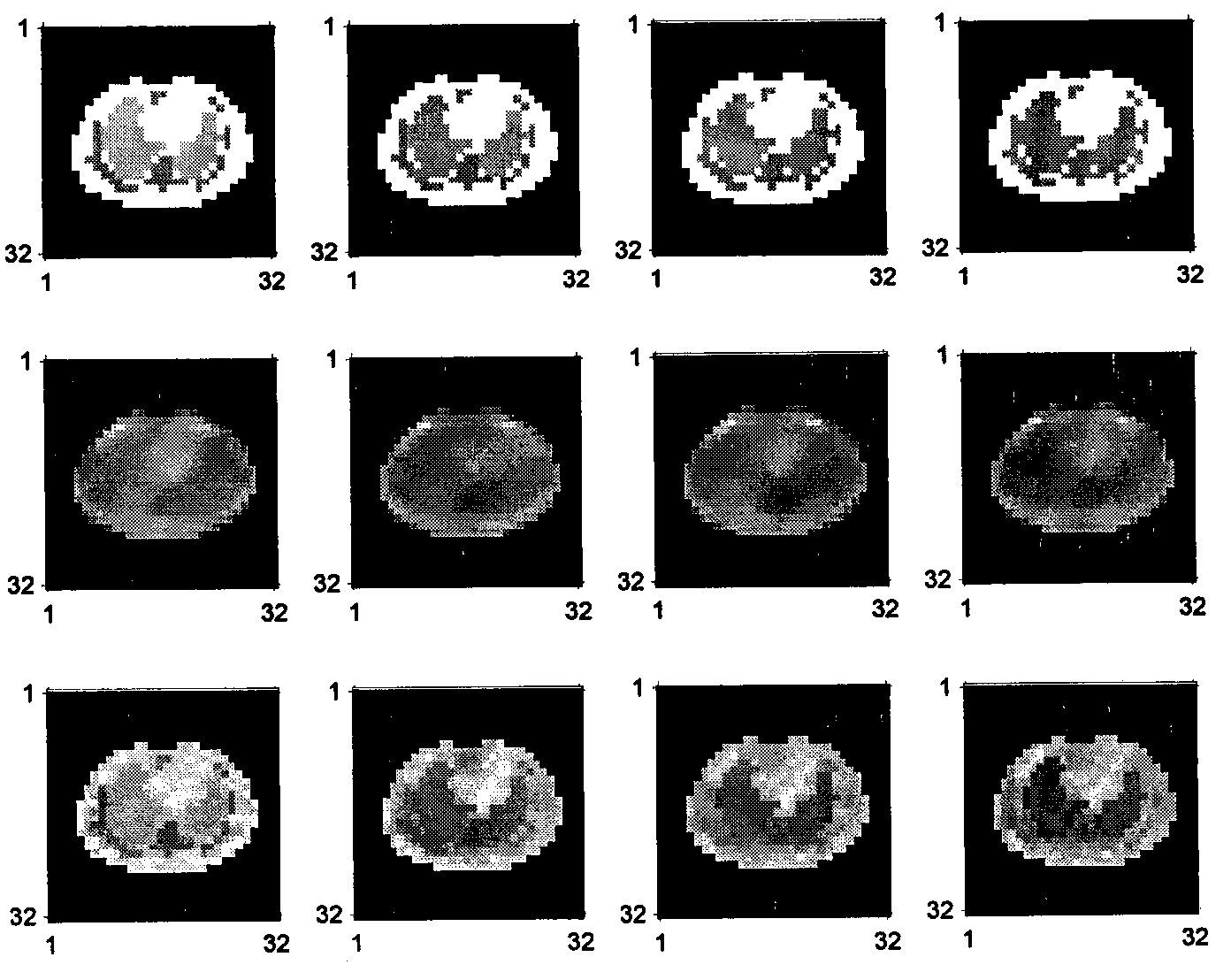

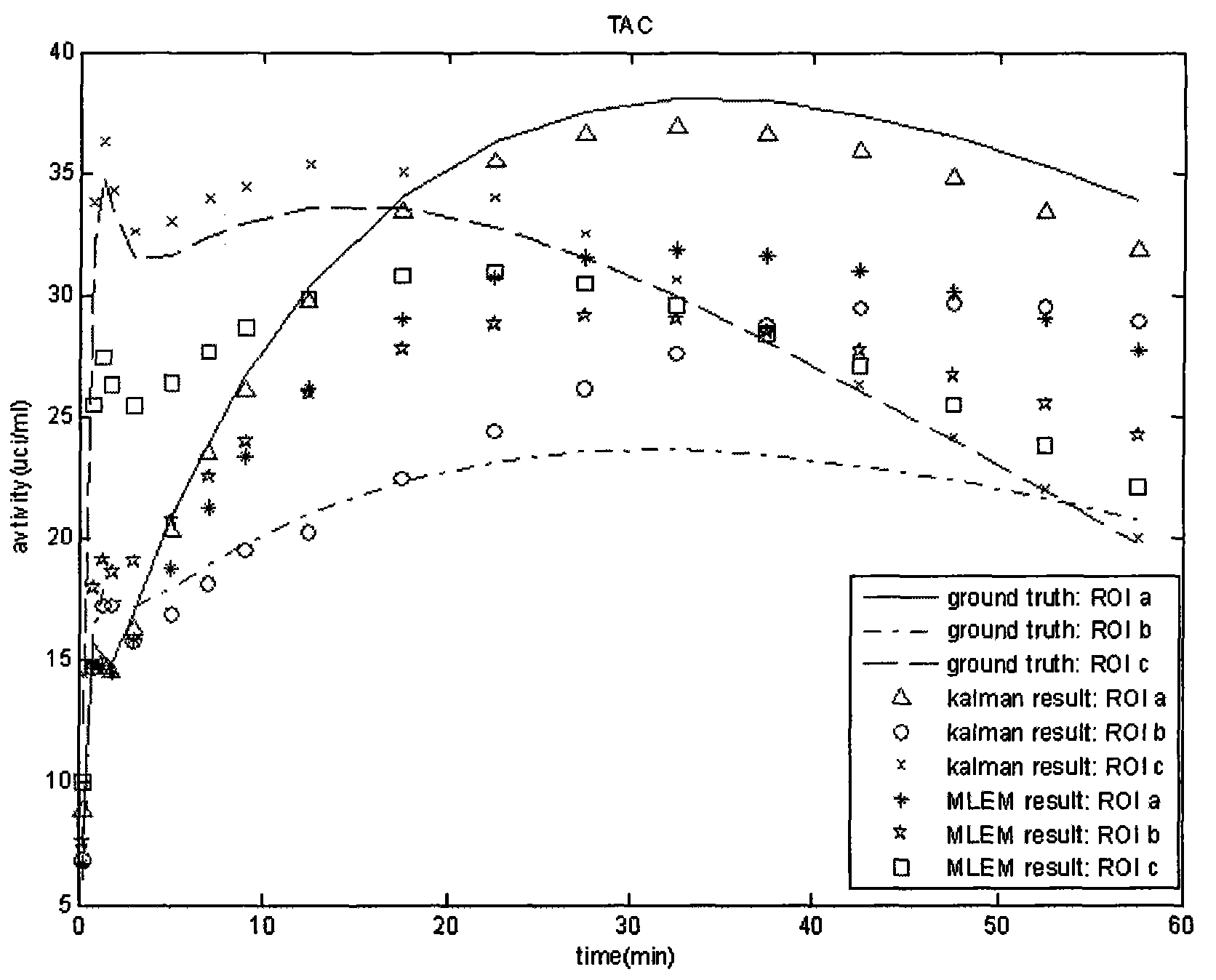

PET concentration reestablishing method based on Kalman filtration in limited sampling angle

ActiveCN101627919AImprove adaptabilityThe result is obviousComputerised tomographsTomographyFractographyFiltration

The invention discloses a PET concentration reestablishing method based on Kalman filtration in a limited sampling angle, comprising the following steps: obtaining incomplete sine figure data of an original projection line by a PET positive electron emission faultage scanner; establishing a state space system by combining a house model theory; and finally solving by a Kalman filtering method based on the state space theory to obtain radioactivity distribution, namely realizing image reestablishment. Because of the transcendental guide of a house model and the high adaptability of the Kalman filtering method on the incomplete data, the quality of a reestablished PET image is not influenced by data loss. Compared with an MLEM experiment of the prior reestablishing method, both the qualitative analyzing result and the quantitative analyzing result indicate that the method has certain superiority.

Owner:ZHEJIANG UNIV

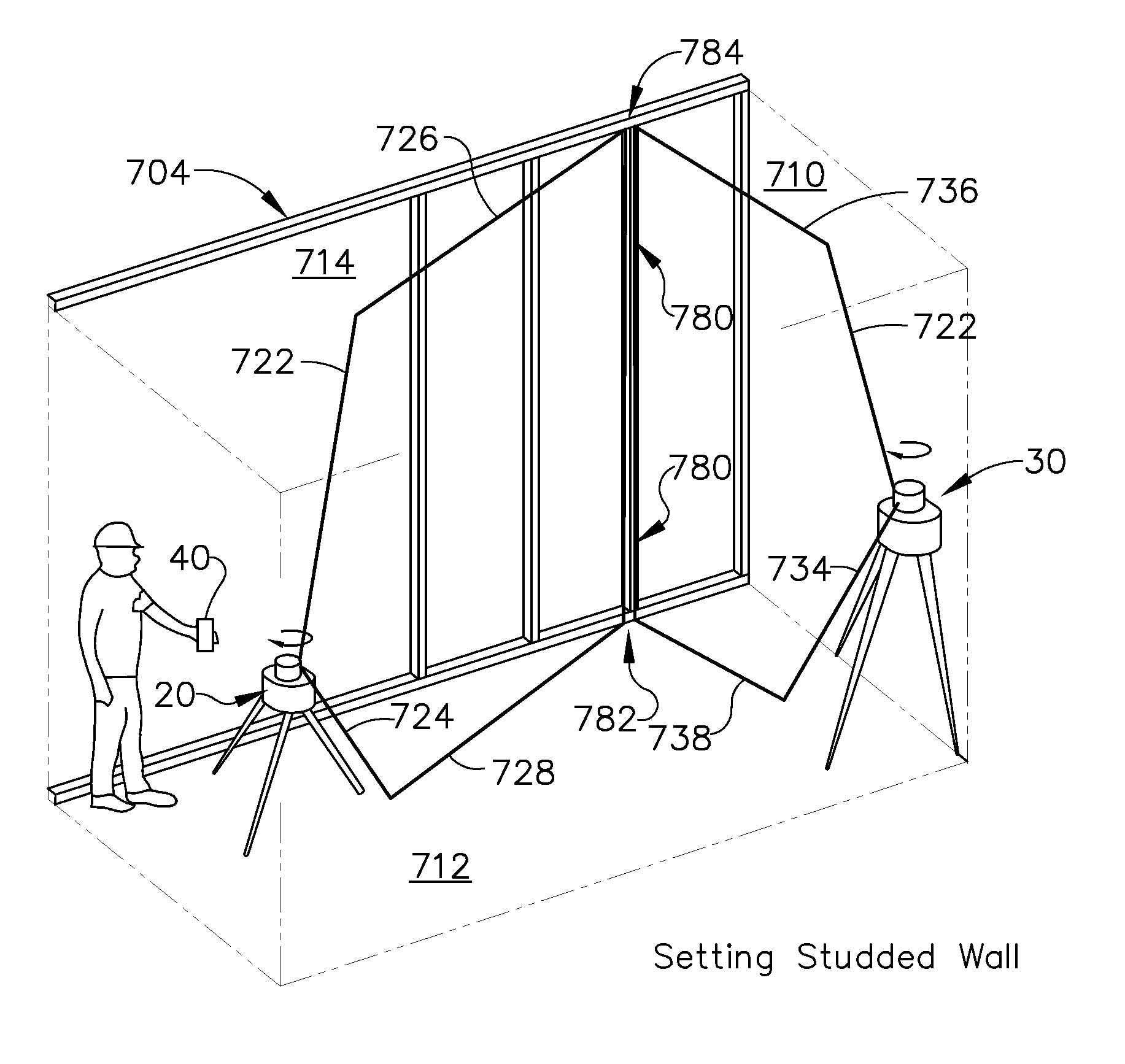

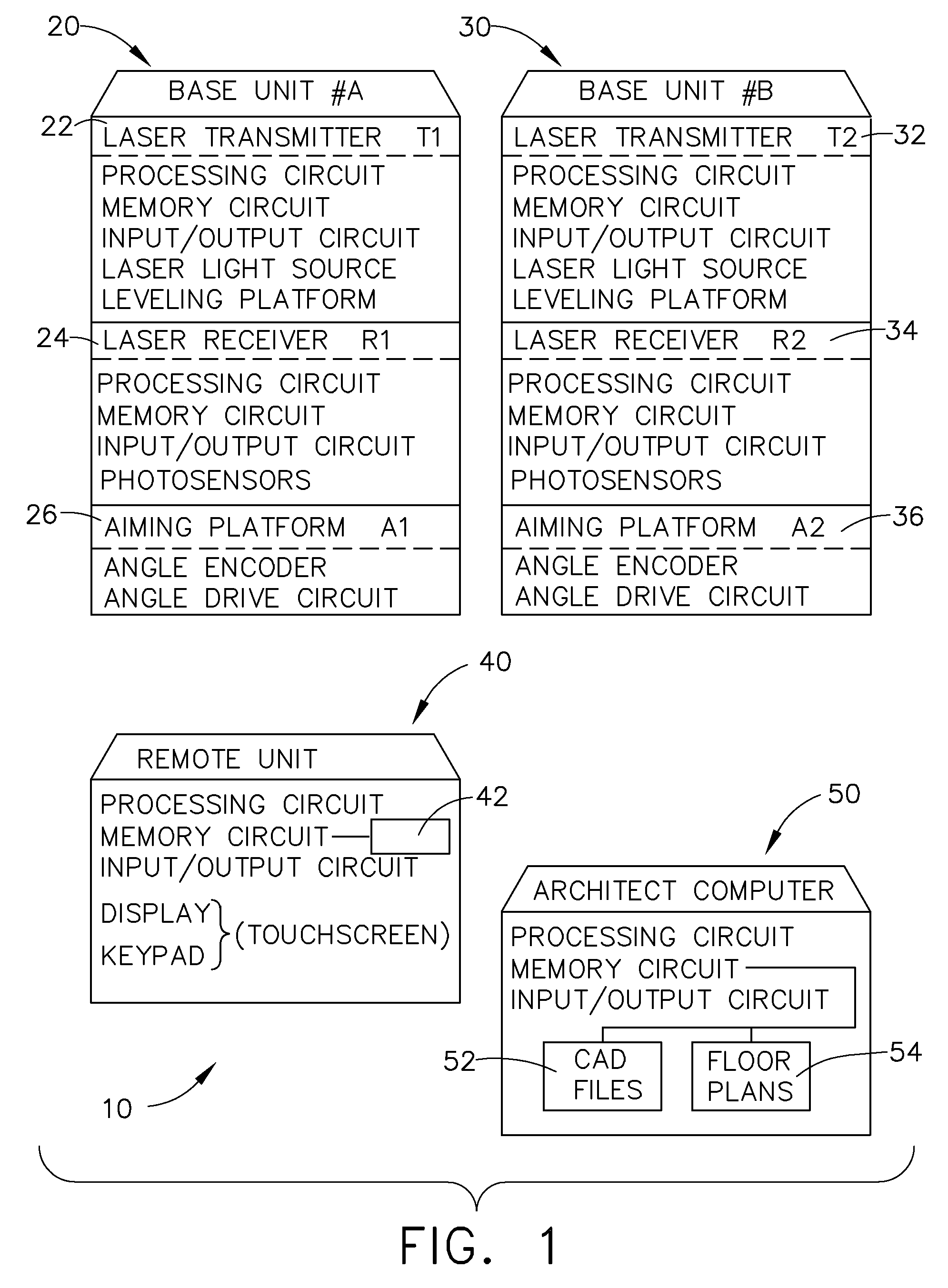

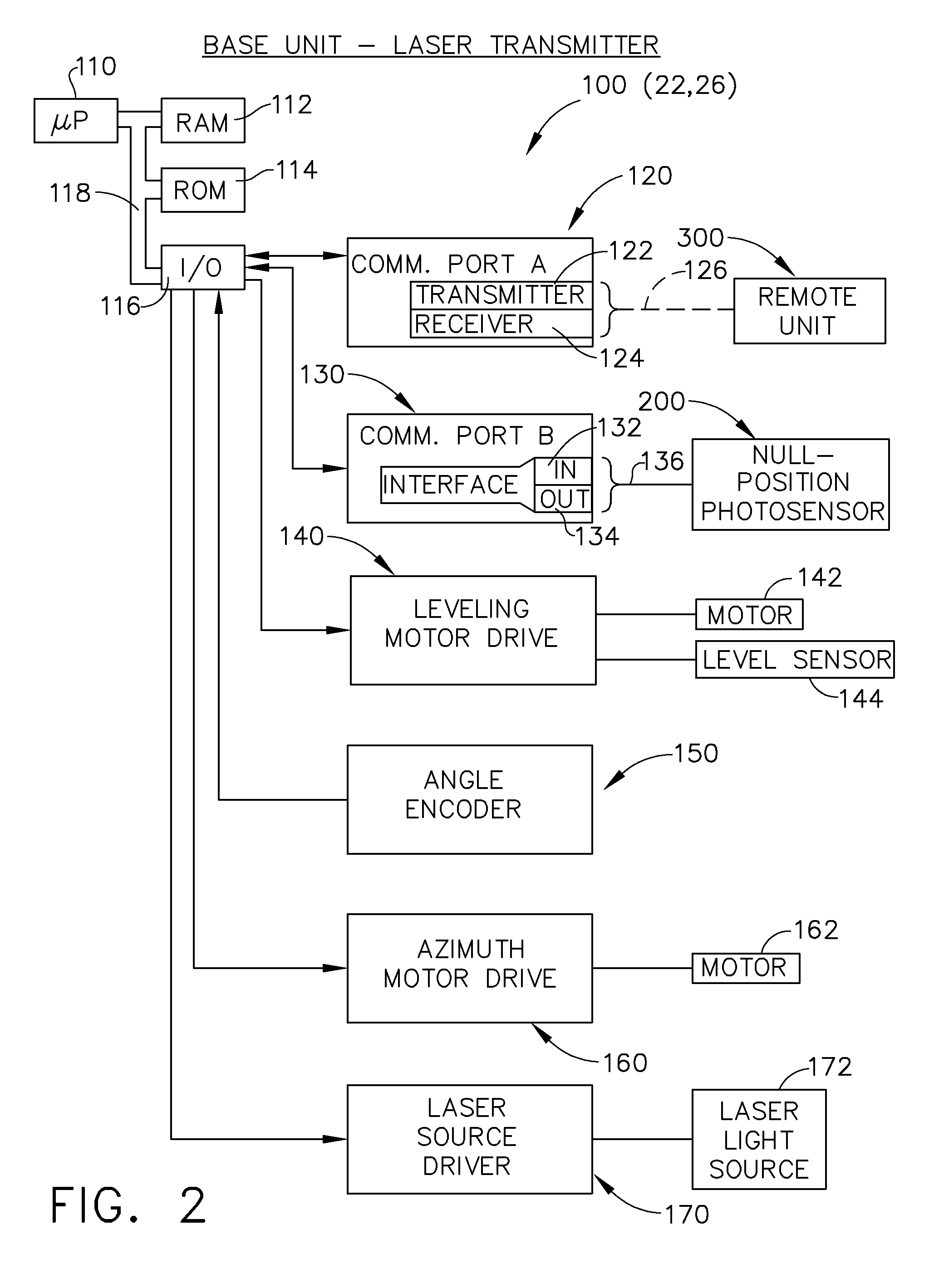

Two dimension layout and point transfer system

A two-dimension layout system identifies points and their coordinates, and transfers identified points on a solid surface to other surfaces in a vertical direction. Two leveling laser light transmitters are used with a remote unit to control certain functions. The laser transmitters rotate about the azimuth, and emit vertical (plumb) laser planes. After being set up using benchmark points, the projected lines of the laser planes will intersect on the floor of a jobsite at any point of interest in a virtual floor plan, under control of a user with the remote unit. The laser light planes also project lines that will intersect along the ceiling at a point that is truly plumb above the crossing point on the floor. The laser planes also provide an “implied” plumb line that is projected in space, which is visible along a solid vertical surface between the intersecting floor and ceiling points.

Owner:SPECTRA PRECISION (USA) LLC

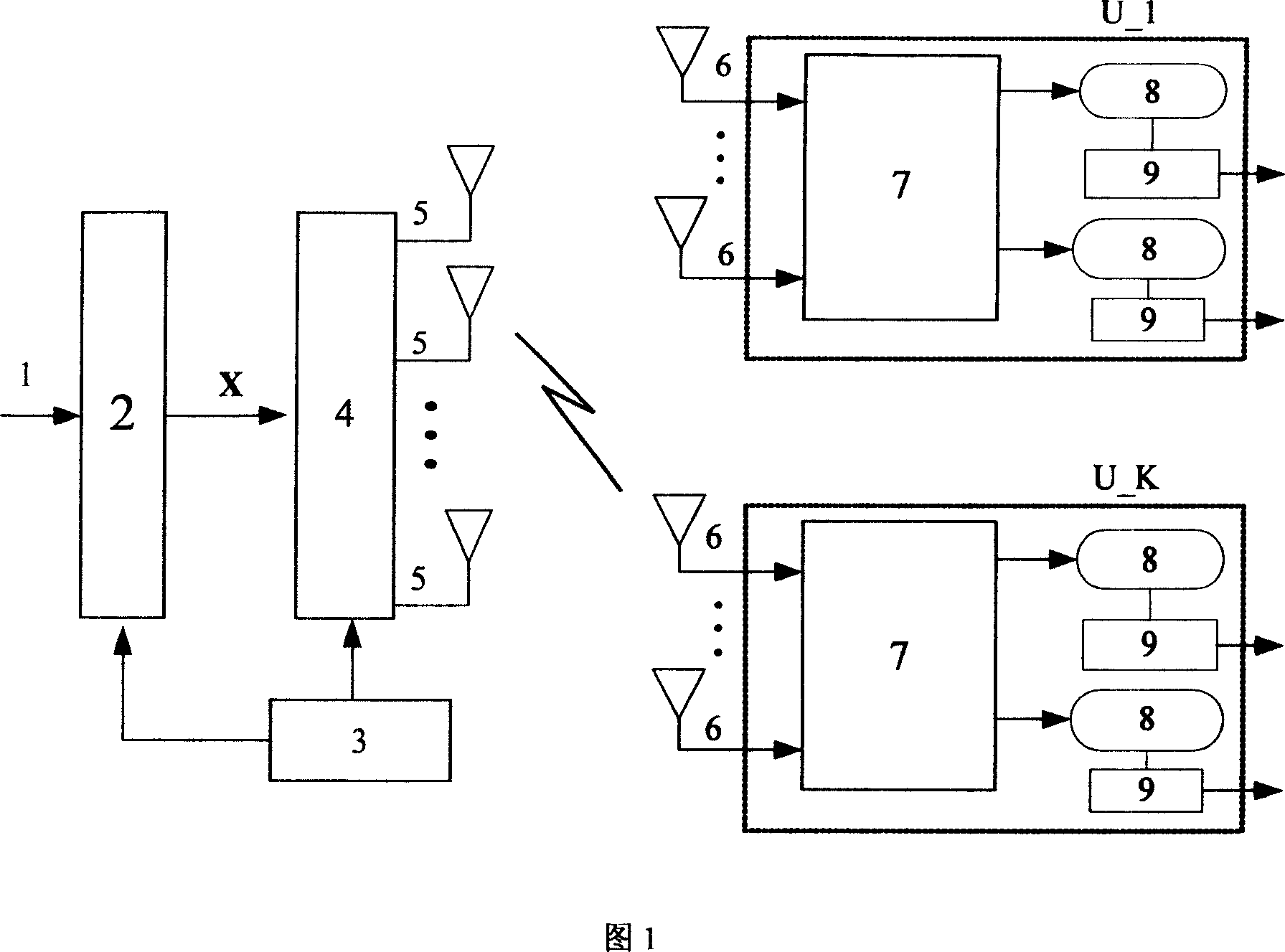

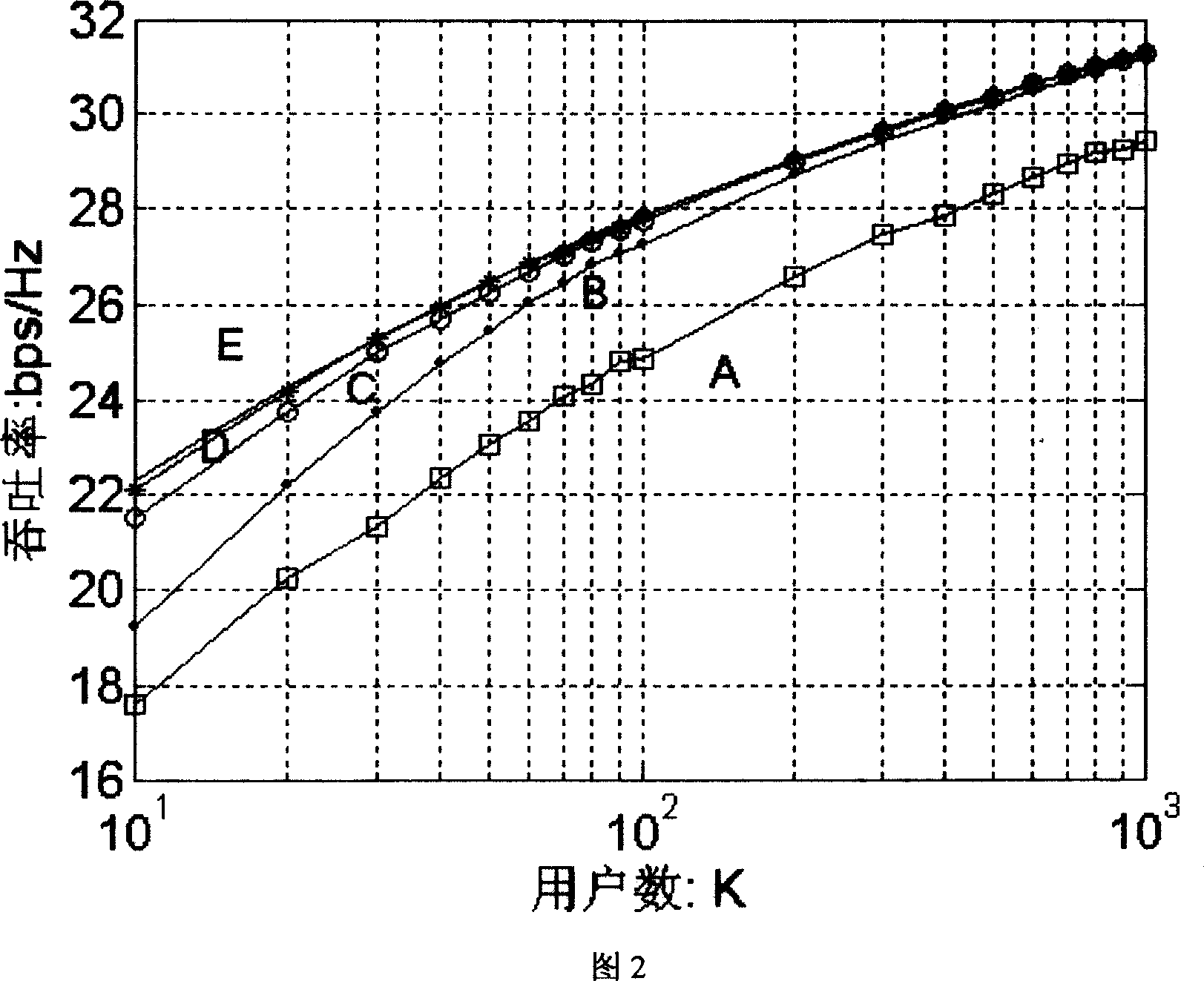

Downlink multi-user method combined with receiving antenna selection and close-to zero beam forming

InactiveCN101047414ALow costReduce the numberSpatial transmit diversityChannel state informationMultiplexing

A downlink multi-user multiplexing method integrating with receiving antenna selection and zero-approach bean formation (ZABF) includes setting number of radio frequency component at user end to be less than number of receiving antenna, operating greedy selection algorithm on user channel matrix by user end, selecting line with matrix second-order norm (MSON) from said matrix, projecting the rest lines and selecting projection line with MSON, repeating selection steps till number of radio component selected by user is equal to number of antenna subset, activating channel state information of all users to receive selection of antenna subset and ZABF.

Owner:UNIV OF SCI & TECH OF CHINA

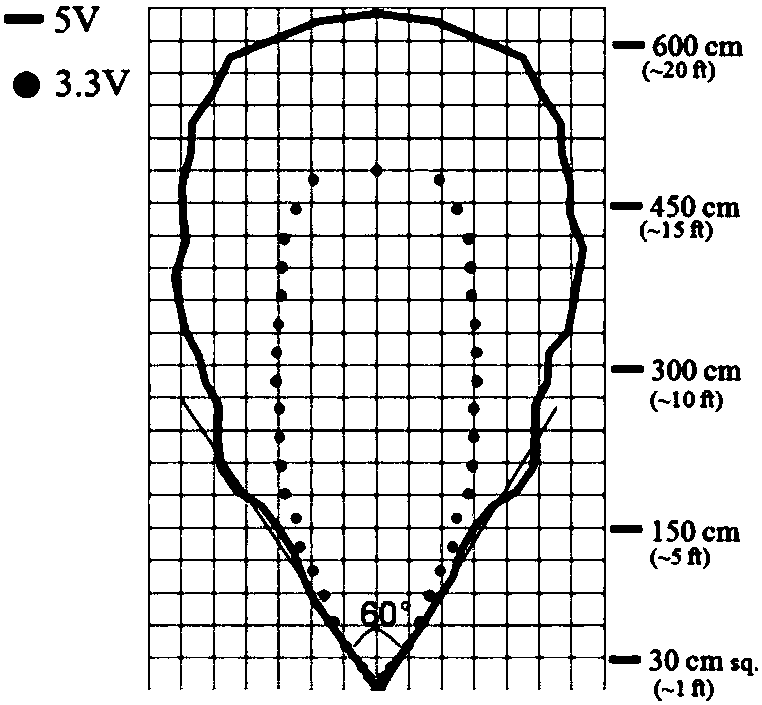

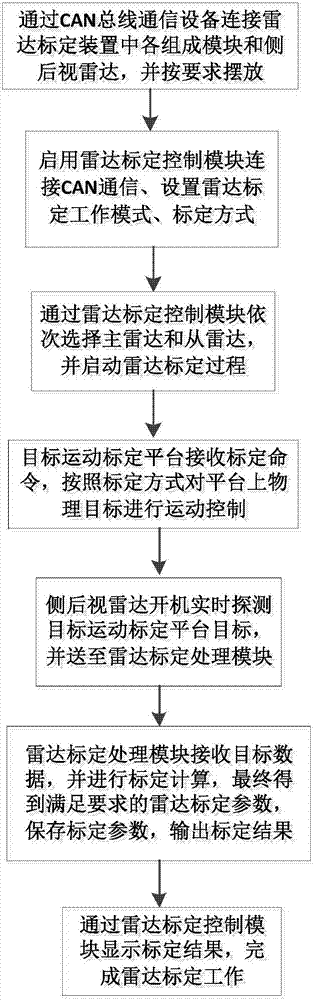

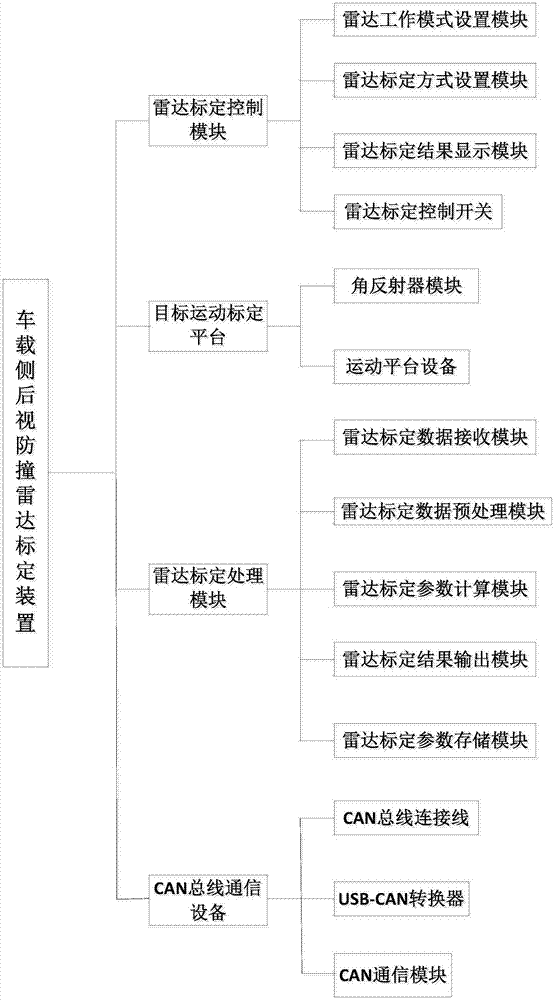

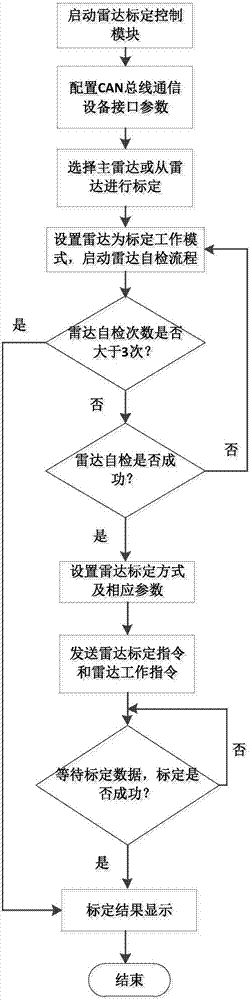

Vehicle-mounted side rearview anti-collision radar calibration device and calibration method thereof

ActiveCN106980111AMeet the needs of useSolve assembly problemsWave based measurement systemsProduction lineIn vehicle

The invention relates to a vehicle-mounted side rearview anti-collision radar calibration device, which comprises a radar calibration control module, a target motion calibration platform, a radar calibration processing module and CAN bus communication equipment, and is characterized in that the radar calibration control module sets a radar operating mode, controls the whole process of radar calibration and displays radar calibration parameters and a calibration result after calibration is completed; the target motion calibration platform provides a necessary detection target for radar calibration, receives a calibration control instruction and performs target motions according to the instruction; the radar calibration processing module accumulatively calculates a target integrated data sequence by using a calibration processing algorithm, and calculates a radar calibration result according to the target integrated data sequence after calibration is completed; and the CAN bus communication equipment is used for being responsible for connection and data communication of the composition modules in the radar calibration device. The vehicle-mounted side rearview anti-collision radar calibration device effectively solves a problem of radar calibration after radar installation of mass-produced vehicle models on a projection line of a complete vehicle manufacturer, meets use requirements of users for radar, and provides a unified calibration platform for wide applications of vehicle-mounted side rearview anti-collision radar products in the field of automotive electronics.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Mixed air outflow air conditioning indoor unit

InactiveCN105674399APromote circulationImprove physical comfortLighting and heating apparatusAir conditioning systemsImpellerAir volume

The invention discloses a hybrid air conditioner indoor unit, which comprises an indoor unit casing, a cross-flow impeller air outlet duct, and a cross-flow impeller air outlet duct wall, and is characterized in that: the cross-flow impeller air outlet duct wall is set There is an air inlet, the air inlet is perpendicular to the axis line of the cross-flow impeller of the indoor unit, and the projection line on the projection plane where the air outlet of the indoor unit is located on the lower left side, the point where it intersects with the wall of the air outlet duct is the upper tangent point of the outlet air The clockwise included angle of the positive direction section of the tangent line of the channel wall is greater than or equal to 12° to less than or equal to 198°, and an induction fan is installed on the outside of the air outlet wall of the cross-flow impeller, and the air outlet of the induction fan is connected to the induction air duct. The air outlet communicates with the air induction opening provided on the wall of the air outlet duct of the cross-flow impeller. The invention has the advantages of large air volume and speed, long shooting range, and the heat exchange air and indoor air form cool but not cold mixed air.

Owner:孙海潮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com