Patents

Literature

376results about How to "Reduce the number of employees" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

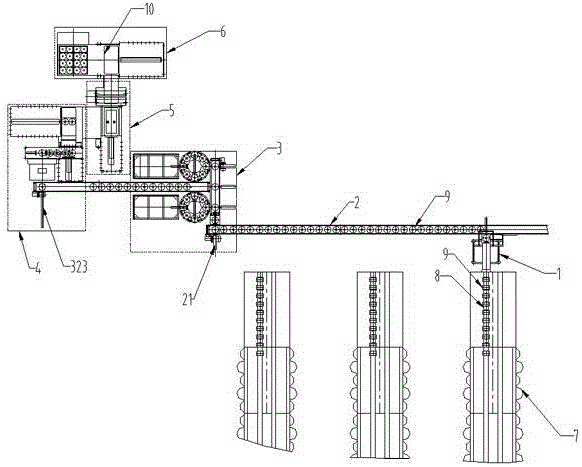

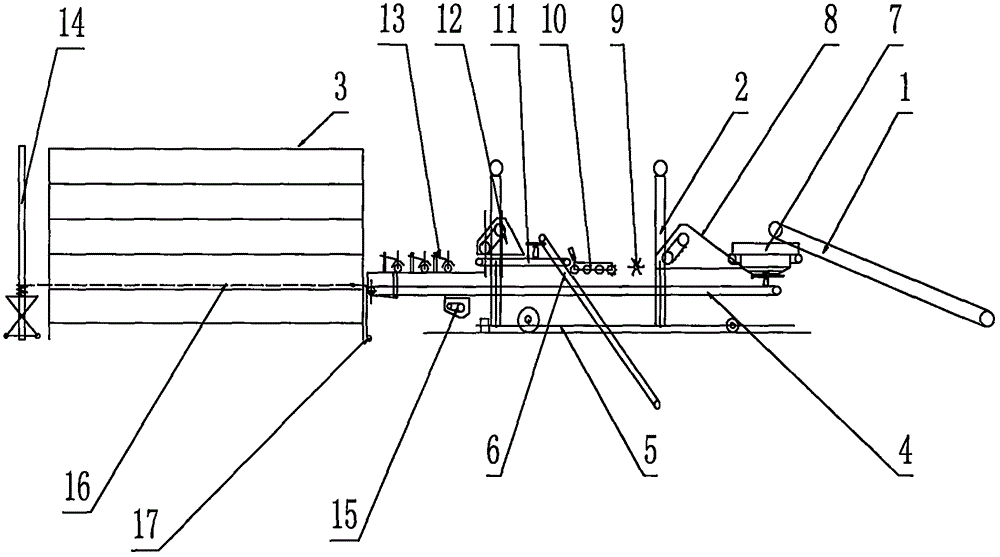

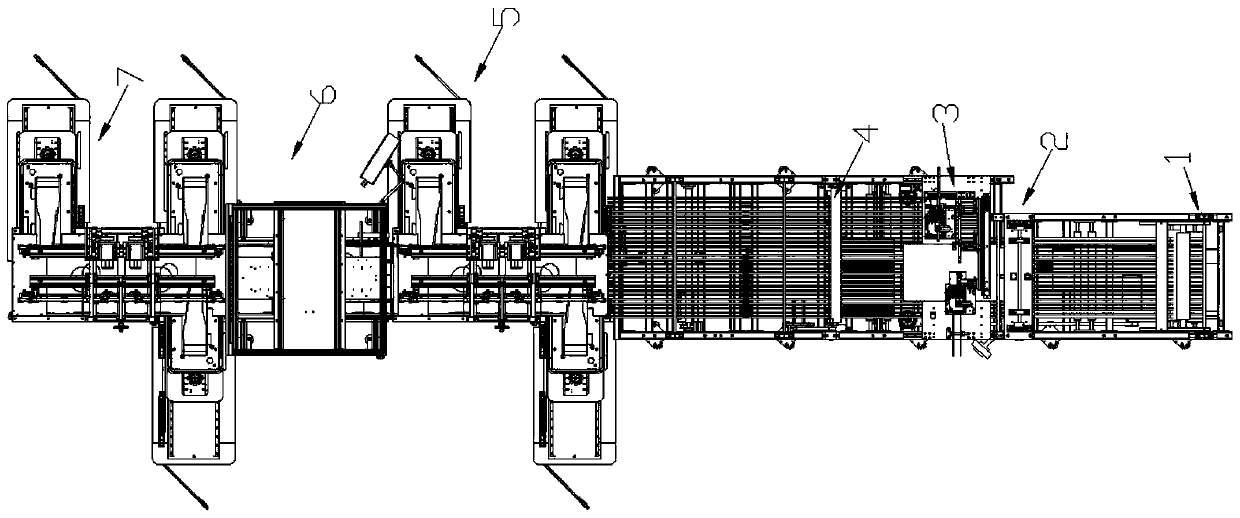

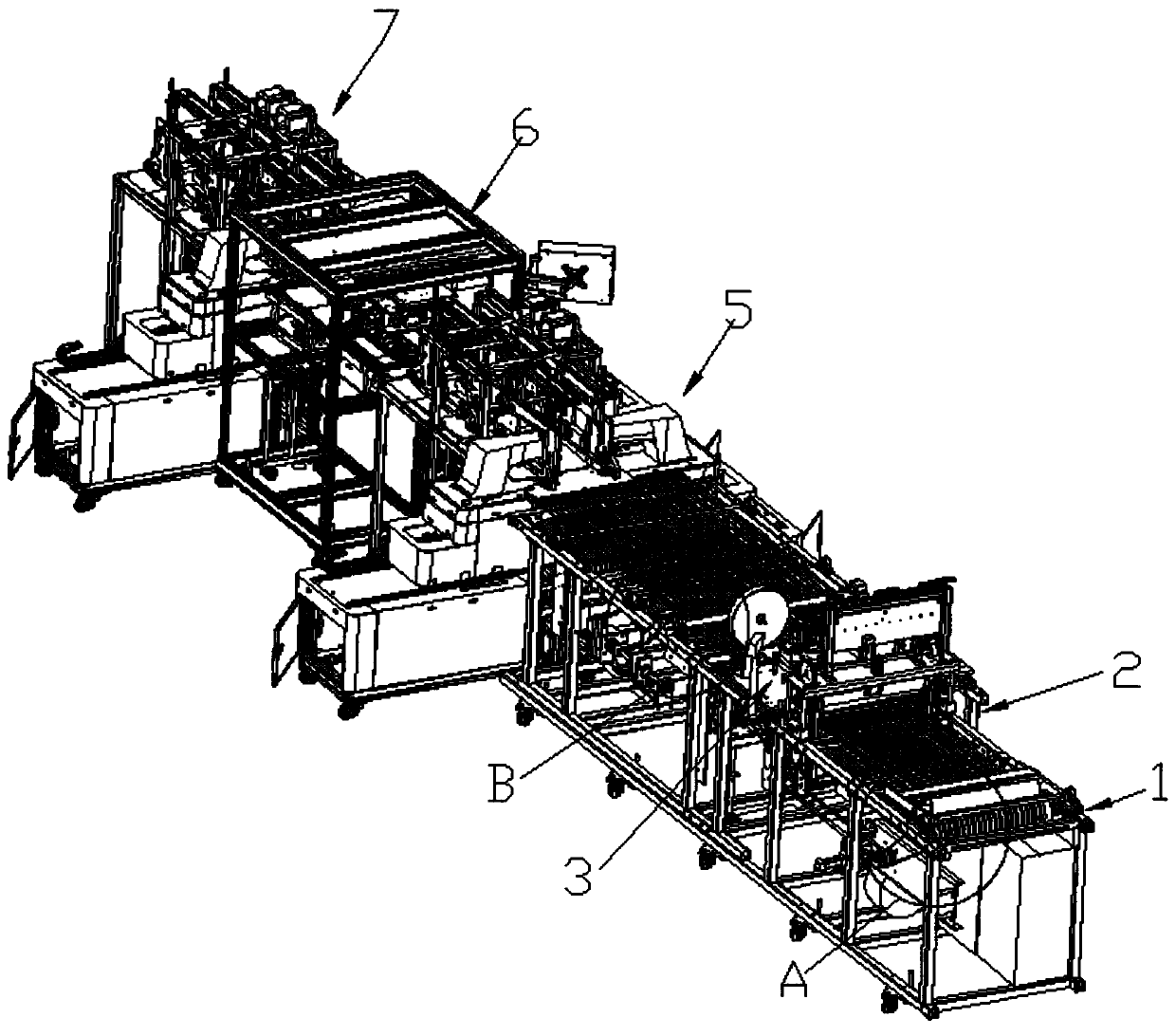

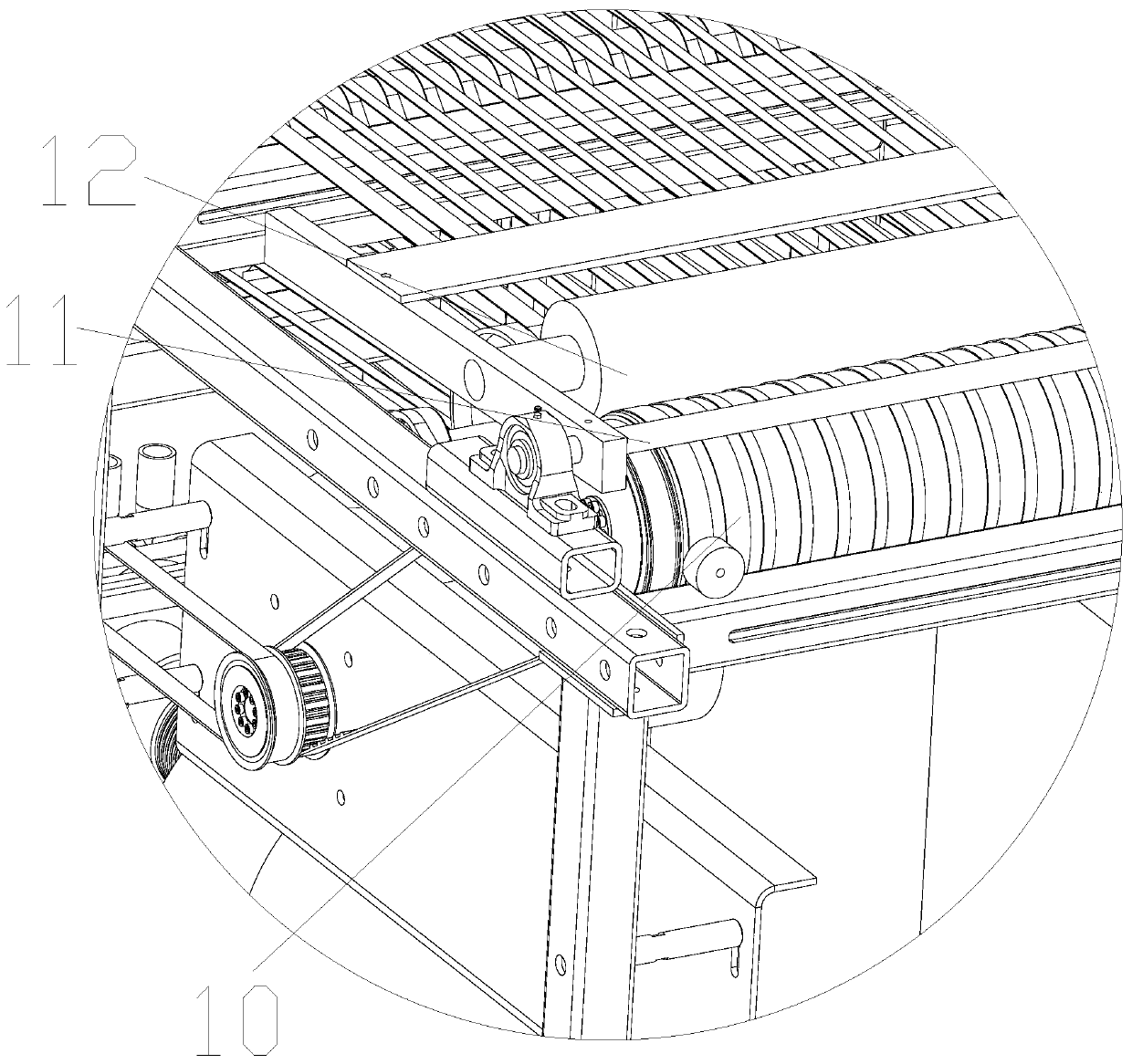

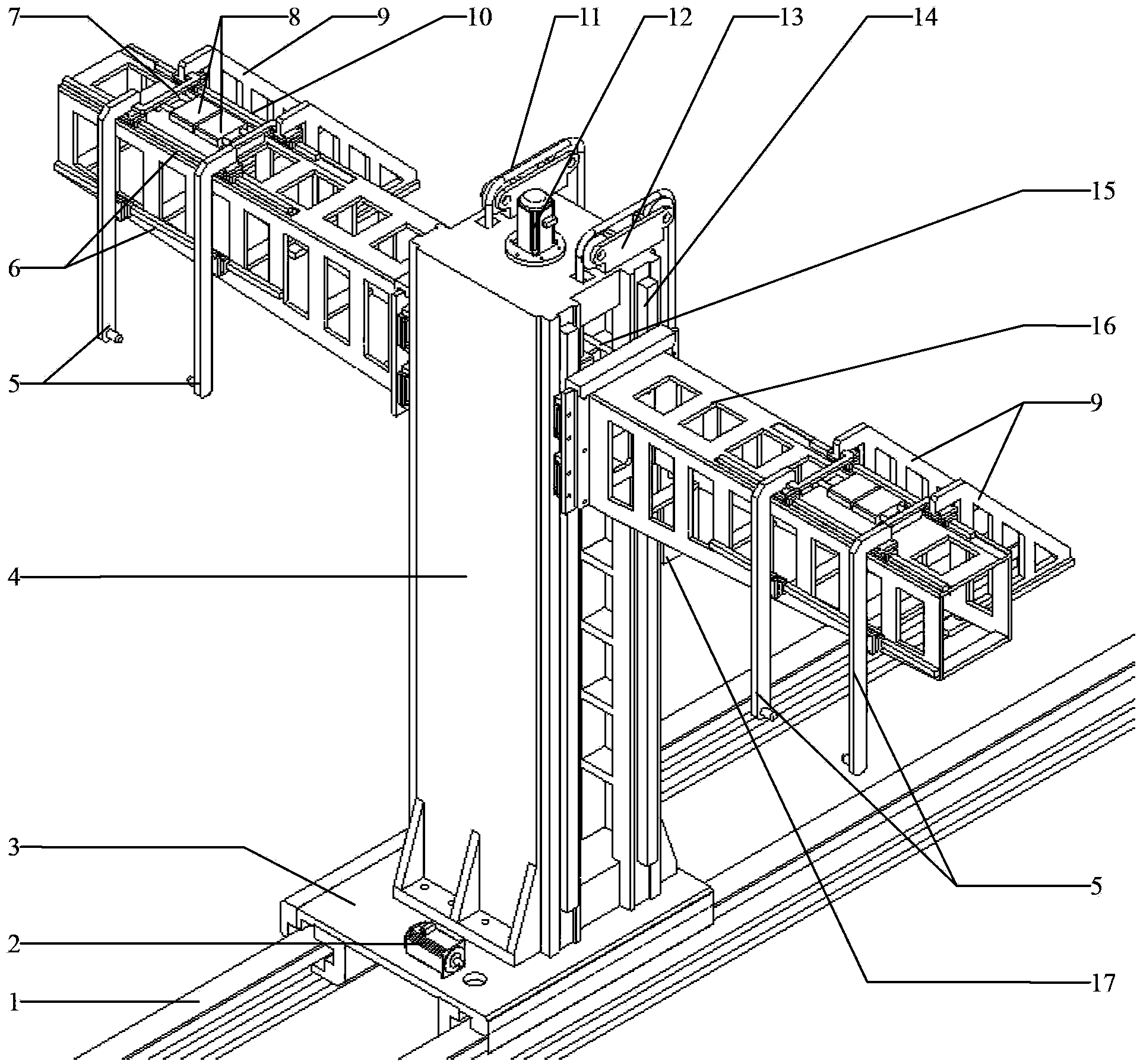

Goods sorting and split charging equipment and method thereof

InactiveCN101234677ASmall footprintReduce the number of employeesControl devices for conveyorsCo-operative working arrangementsElectronic control systemEngineering

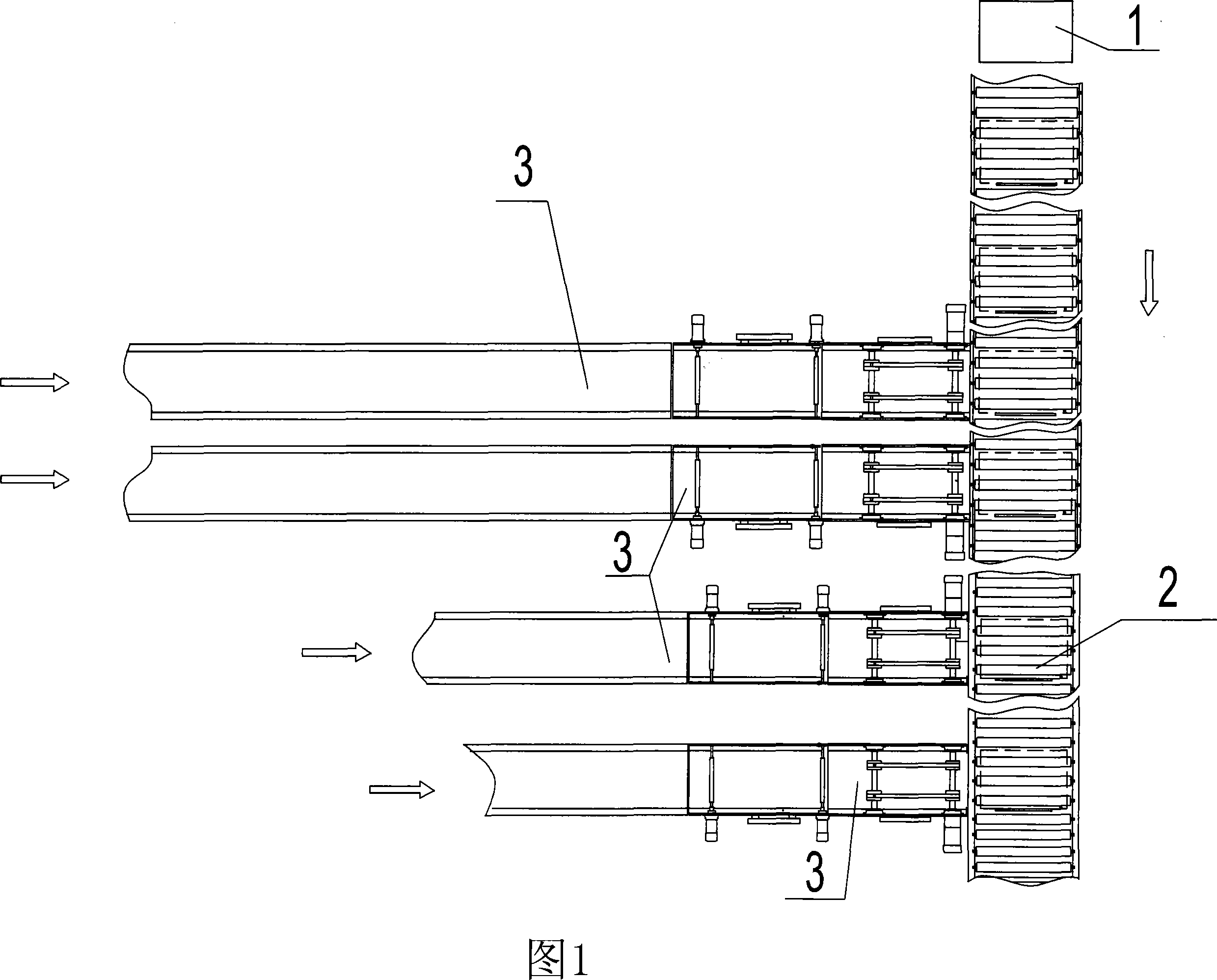

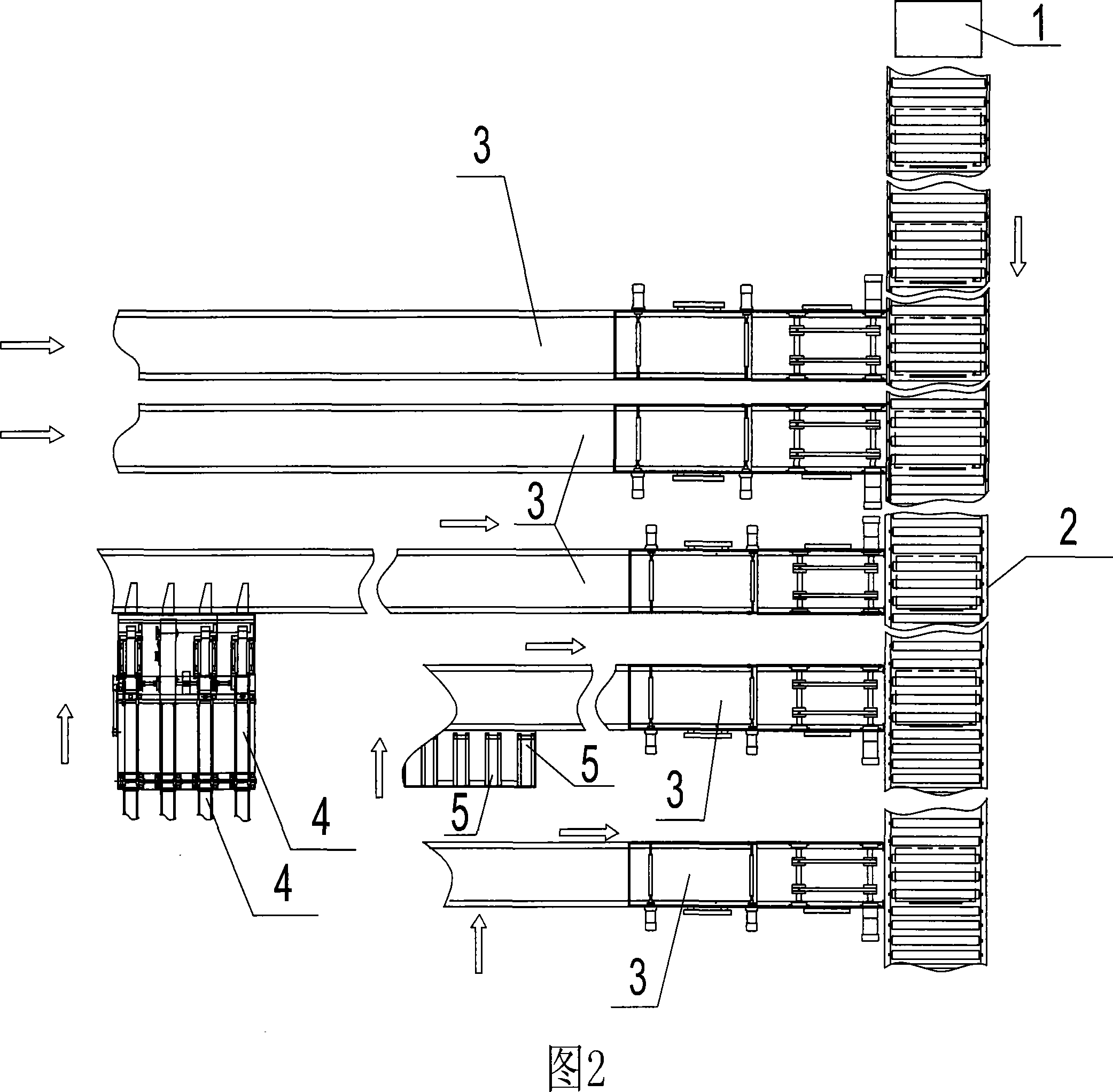

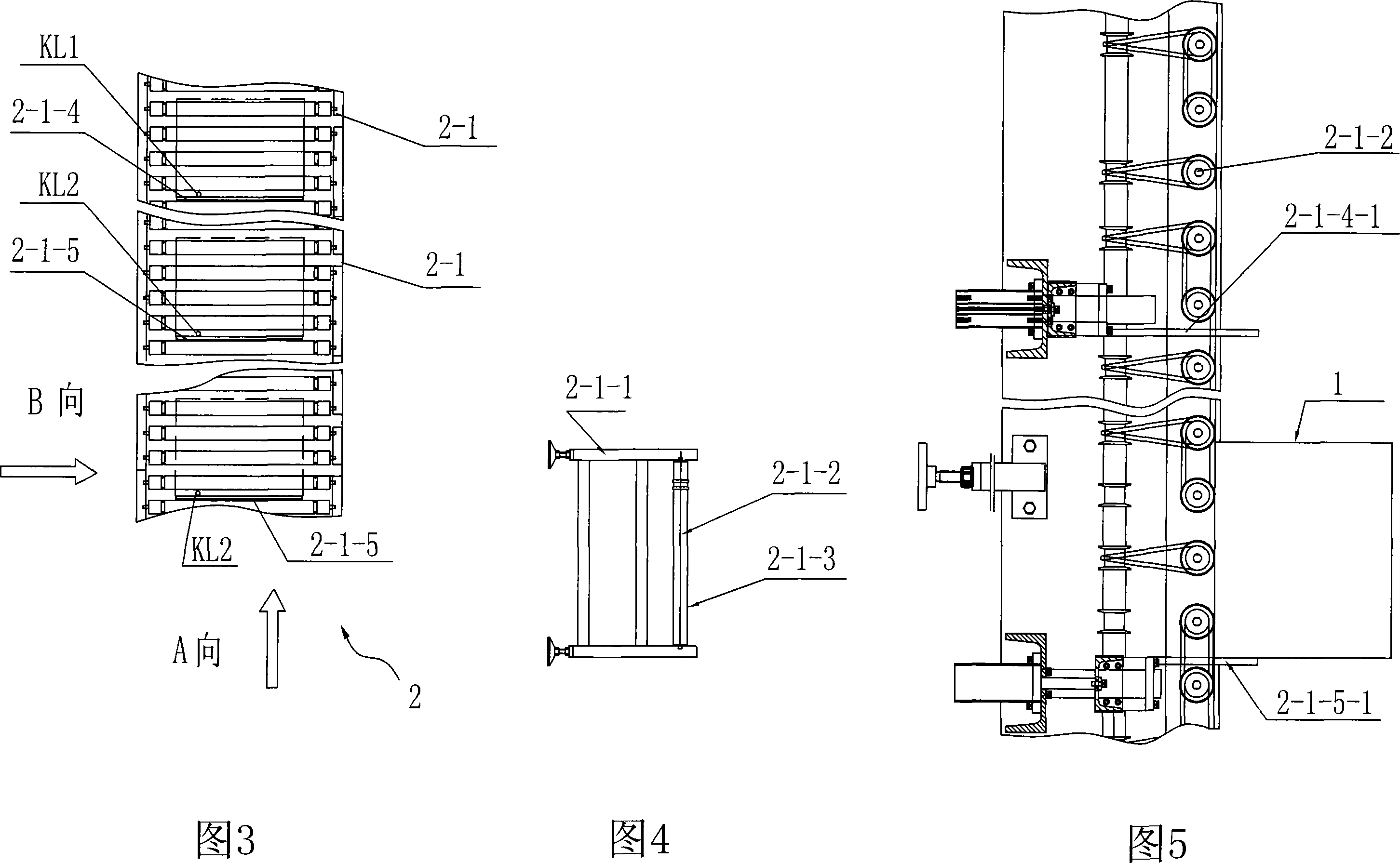

The invention discloses an equipment for sorting and packaging goods and a method thereof, wherein, the equipment comprises turning box baskets, a box basket transporting device, a goods-providing device, a radio frequency reader, a wireless radio frequency card, an electronic control system and a system of computer information management, wherein, each box basket box has the wireless radio frequency card; a side on a stopping position of a plurality of box baskets on the box basket transporting device is provided with the goods-providing device; the radio frequency reader is arranged near the stopping positions for the box backsets on the box basket transporting device. The method comprises the following steps: A. configuring devices for the whole line and determining the brands and specifications of goods to be delivered; B. setting the information of device configuration as well as the brands and specifications of the goods; C. setting the allocation proposal; D. preparing and implementing the allocation proposal; E. starting the whole line and pre-allocation; F. inputting empty box baskets; G. applying the box baskets for delivery and allocation; H. unloading the baskets. The equipment for sorting and packaging goods has the advantages of high speed, reliable work, low operation cost, compact structure, and small land occupancy, so the invention is applicable for various goods delivery centers with different delivery requirements and scopes.

Owner:姜广峻

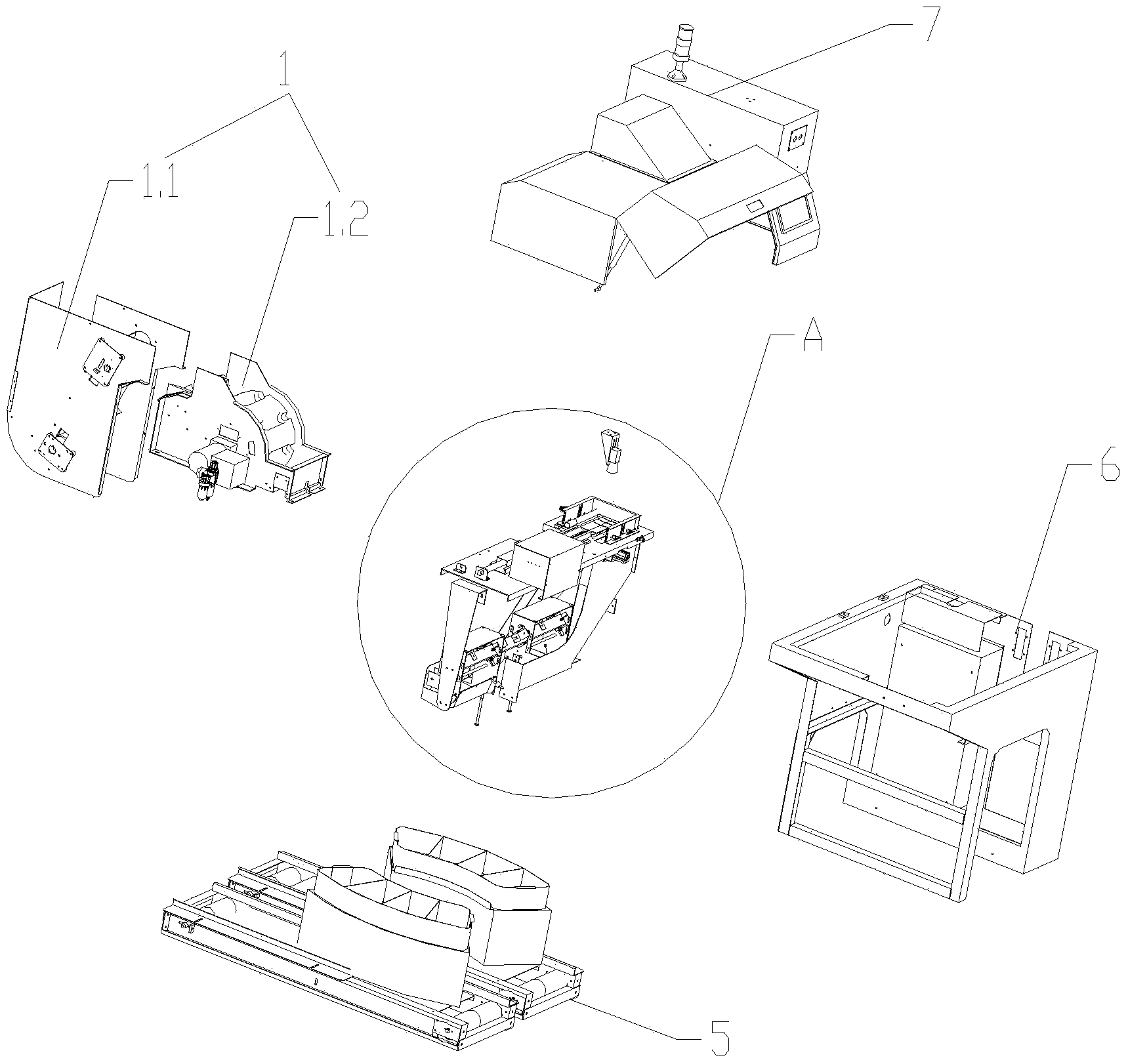

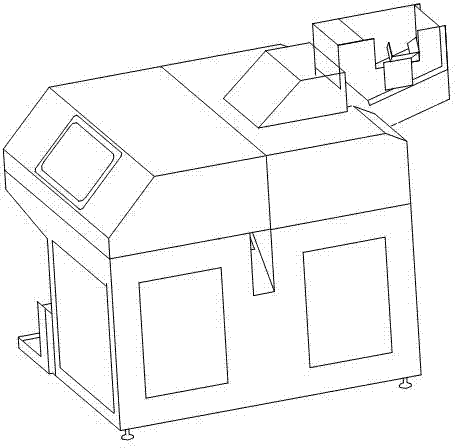

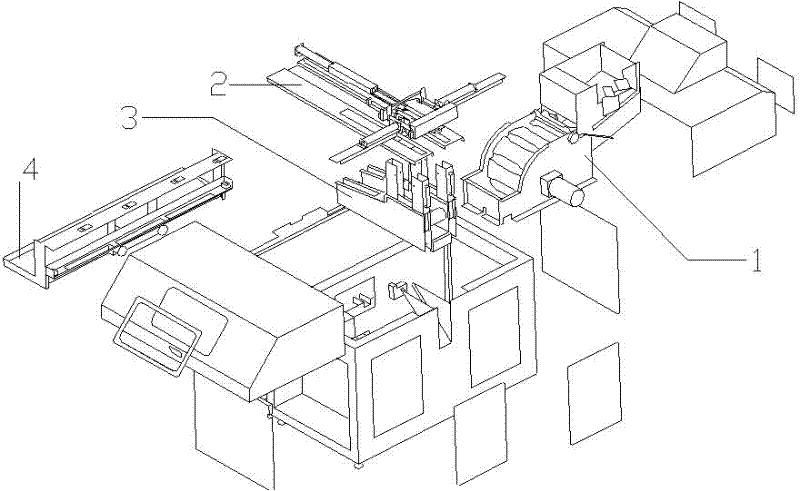

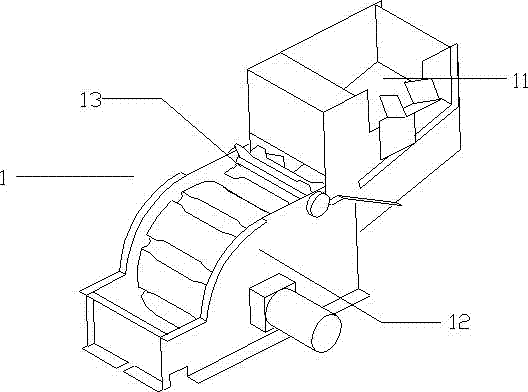

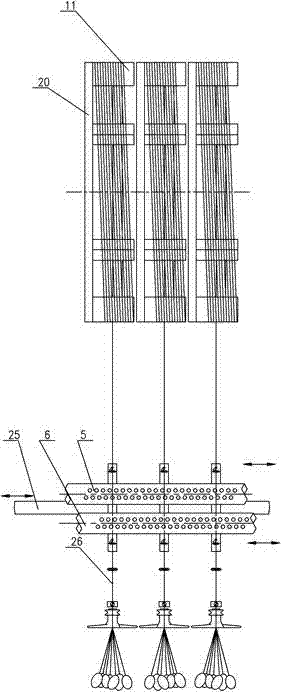

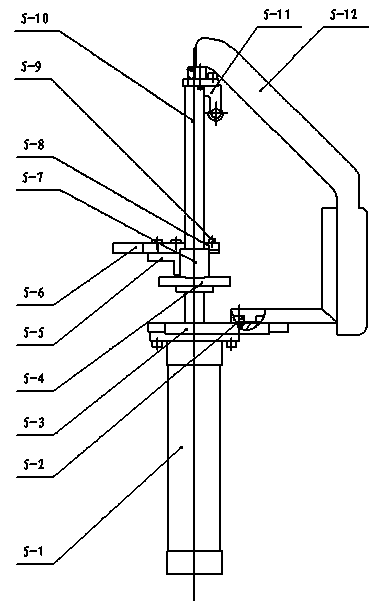

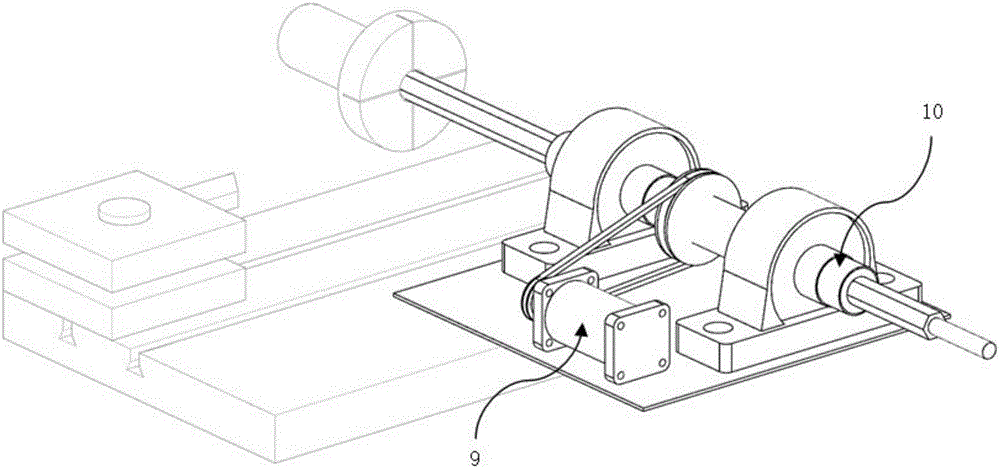

Bobbin burying machine

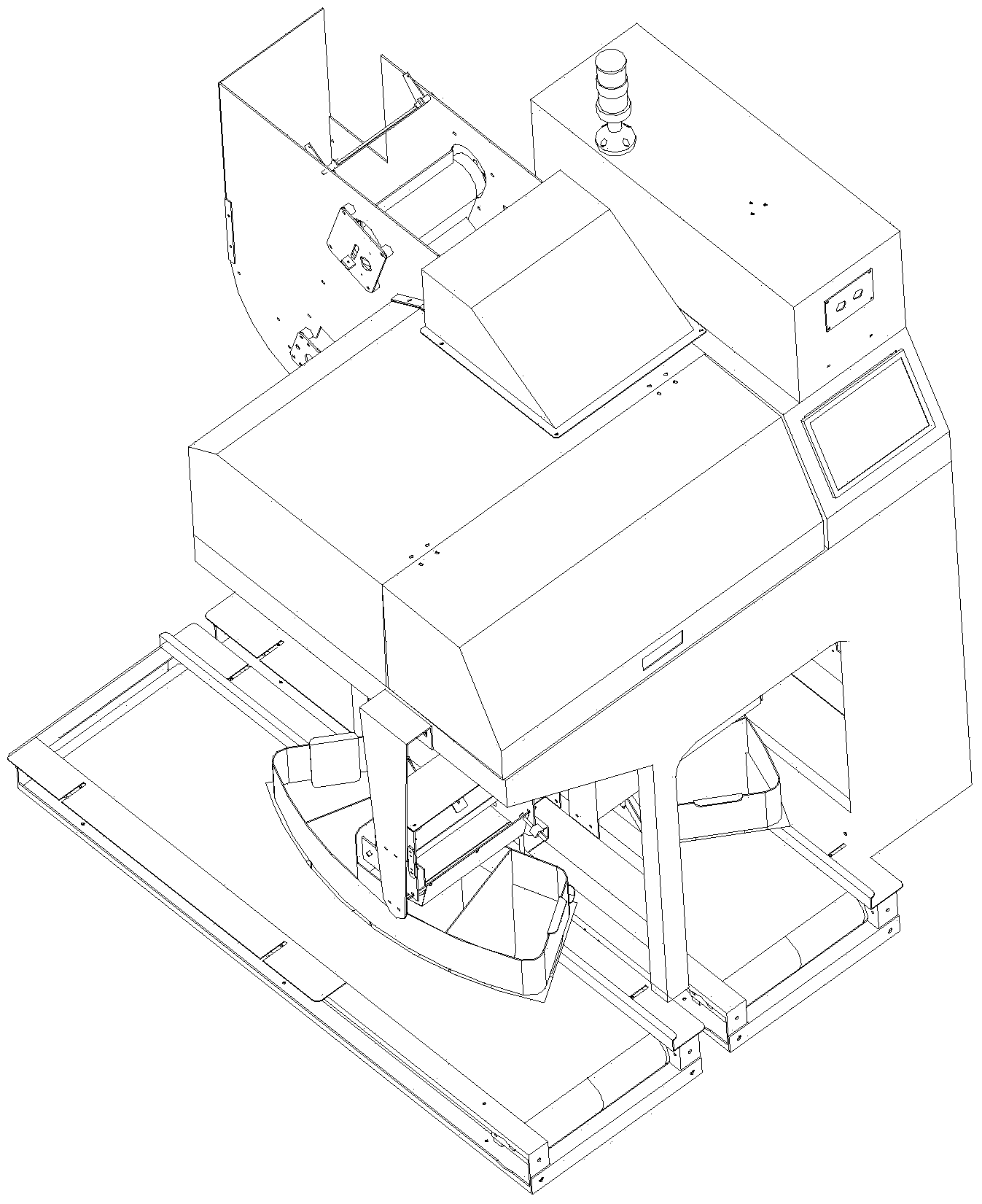

The invention relates to a bobbin burying machine. The bobbin burying machine is characterized by comprising a bobbin storage mechanism (1), a bobbin separating mechanism (2), a bobbin falling mechanism (3), a bobbin connecting buffer mechanism (4), a bobbin connecting mechanism (5), a rack (6) and an outer shell (7). The bobbin storage mechanism (1), the bobbin separating mechanism (2), the bobbin falling mechanism (3) and the bobbin connecting buffer mechanism (4) are arranged on the rack (6), the outer shell (7) covers the top of the rack (6), and the bobbin connecting mechanism (5) is arranged below the bobbin connecting buffer mechanism (4). According to the bobbin burying machine, whether bobbins contain yarn or not can be distinguished, the colors of empty bobbins are distinguished, the big ends and the small ends of the bobbins without the yarn are straightened out, automation is achieved in the whole process, the manual operation is not needed, the manual operation difficulty of workers is greatly relieved, the number of employees of enterprises can be effectively saved, the employment pressure of the enterprises can be effectively relieved, and the bobbin burying machine has the advantages of improving work efficiency, and being high in automation degree and capable of being applied to arc-shaped recycle cases.

Owner:江阴市凯业纺织机械制造有限公司

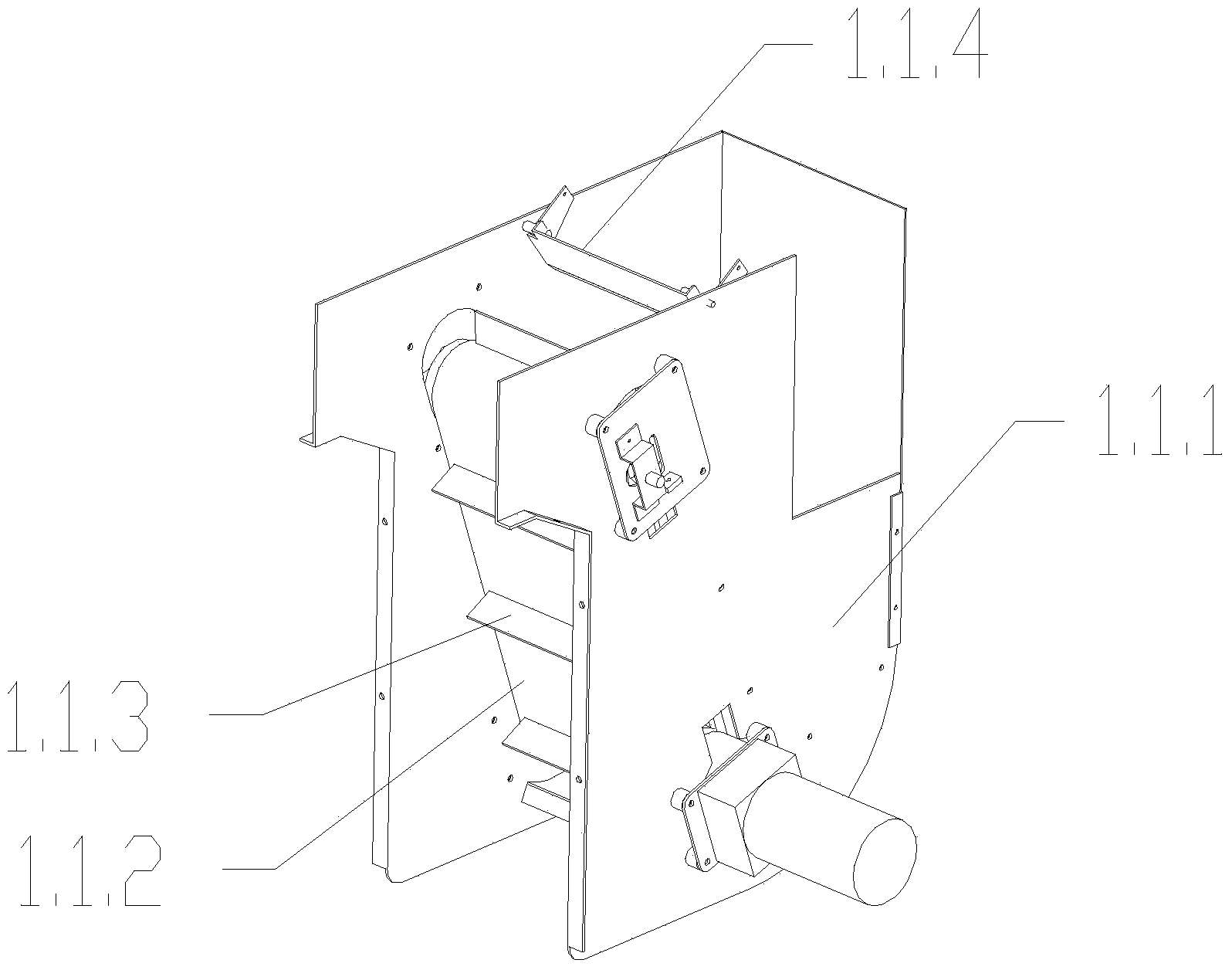

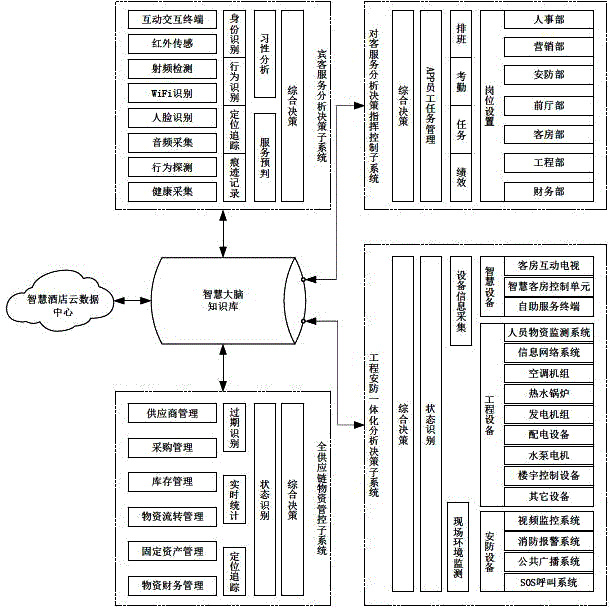

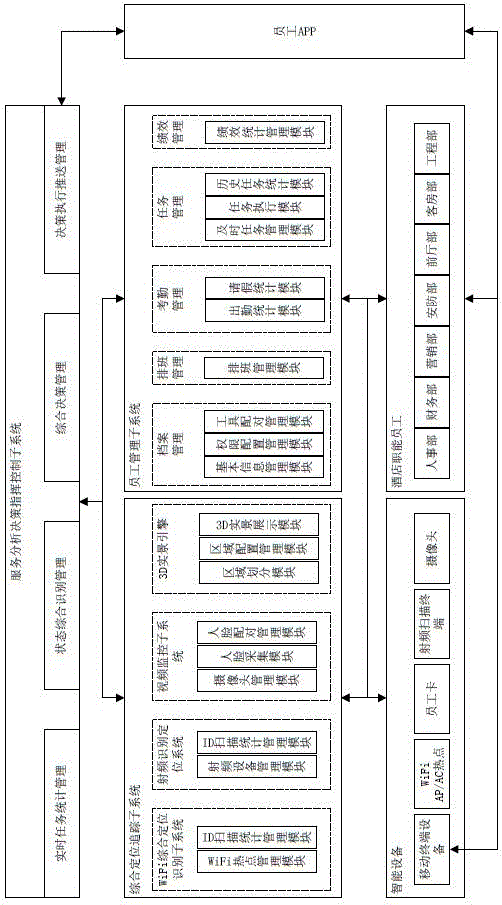

Intelligent hotel management system based on Internet of everything

InactiveCN106570641AImprove availabilityEfficient serviceResourcesTransmissionCommand and controlEcological data

The invention discloses an intelligent hotel management system based on the Internet of everything, which comprises an intelligent hotel cloud data center, an intelligent knowledge base and a plurality of intelligent hotel systems, and is characterized in that the intelligent hotel cloud data center is used for integrating hotel related data of all of the intelligent hotel systems and forming a database; the intelligent knowledge base is used for collecting data of the intelligent hotel systems in real time on the one hand, performing data interaction with the intelligent hotel cloud data center on the other hand, and performing analysis and decision-making on an intelligent hotel system according to field data of the intelligent hotel systems and the data integrated by the intelligent hotel cloud data center; and the intelligent hotel system comprises a guest service analysis and decision-making subsystem, a guest service analysis and decision-making command and control subsystem, a whole supply chain material management and control subsystem, an engineering security and protection integrated analysis and decision-making subsystem. The intelligent hotel management system explores values of data which includes facility and equipment operation data, guest behavior data and hotel business district ecological data; and real-time and accurate data enables hotel services and management decision-making to be more efficient and more scientific.

Owner:成都科曦科技有限公司

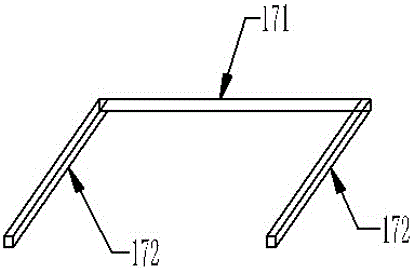

Tube managing machine

The invention relates to a tube managing machine which comprises a case. The tube managing machine is characterized in that the case is internally provided with a tube storing mechanism (1), a tube sorting mechanism (2) and a tube turning mechanism (3). The tube sorting mechanism (2) is connected with a PLC (Programmable Logic Controller) through multiple photoelectric sensors and color sensors to control a main driving cylinder (23), a downward turning cylinder (28) and branch cylinders (29) for distinguishing the existence of yarns and colors of various yarns; a small head of a bobbin is enabled to point downwards through the tube turning mechanism (3) and is transmitted into a cart through a conveying belt (34). The tube managing machine disclosed by the invention can be used for identifying bobbins with or without yarns, and distinguishing the colors of the bobbins, straightening out big and small heads of the bobbins without yarns, and realizes automation of the whole process without manual operation, thus manual operating intensity of workers is greatly reduced and employment number of enterprises and ease employment pressure of enterprises can be effectively decreased.

Owner:江阴市凯业纺织机械制造有限公司

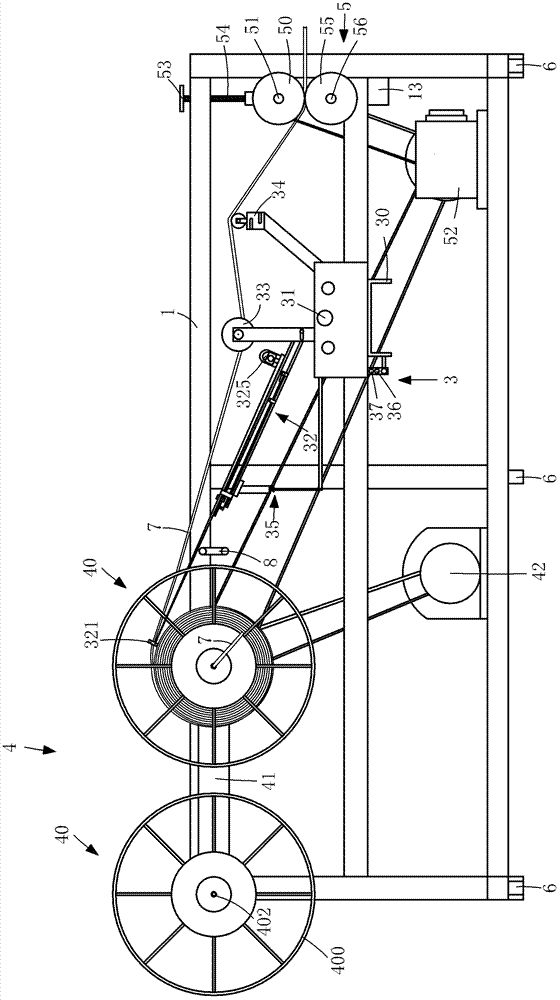

Spindle automatic package system and spindle separation counter weight method

ActiveCN105059615AAutomate the packaging processRealize automated productionPackaging automatic controlEngineeringAutomatic testing

The invention discloses a spindle automatic package system comprising a doffing dolly, a spindle conveyer belt, a quota weight sorting mechanism, an automatic sleeving bagging mechanism, an automatic packing belt mechanism and an automatic bag loading mechanism; the doffing dolly is arranged between a spinning machine and the spindle conveyer belt; a discharge end of the spindle conveyer belt is provided with a charging cylinder. The spindle automatic package system is suitable for automatic weighing, counterweight, sleeving, bagging, packing belt, and bag loading steps of the spindle weaved and formed by the spinning machine like a ring spinning, an air spinning, an air-jet spinning, a vortex spinning, a siro spinning and a compact spinning; the method only needs to do artificial intervention in the automatic sleeving bagging mechanism so as to complete a spindle bag seal step, so full automation production of the spindle package can be basically realized, thus greatly reducing workshop labor number, and saving labor cost.

Owner:LUZHOU SHUIYUAN HYDRAULIC MACHINE +1

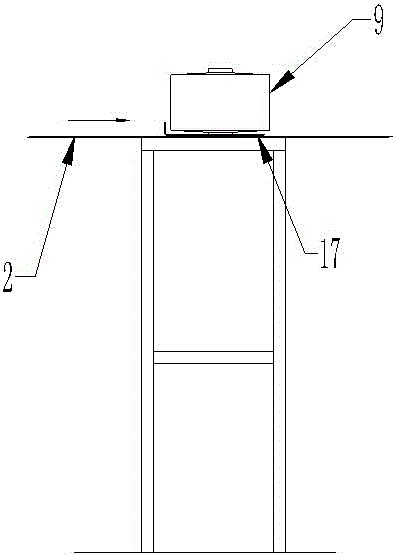

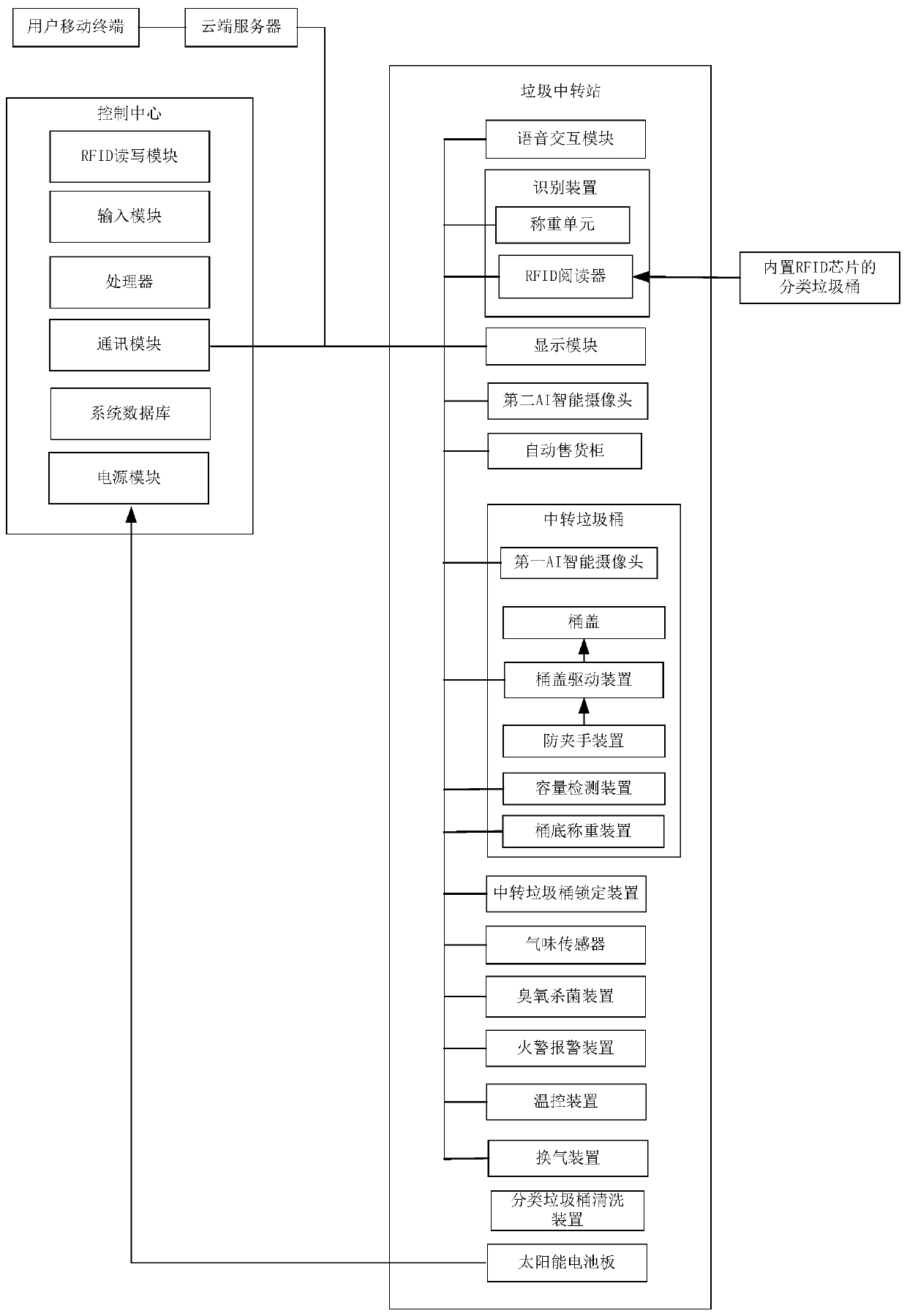

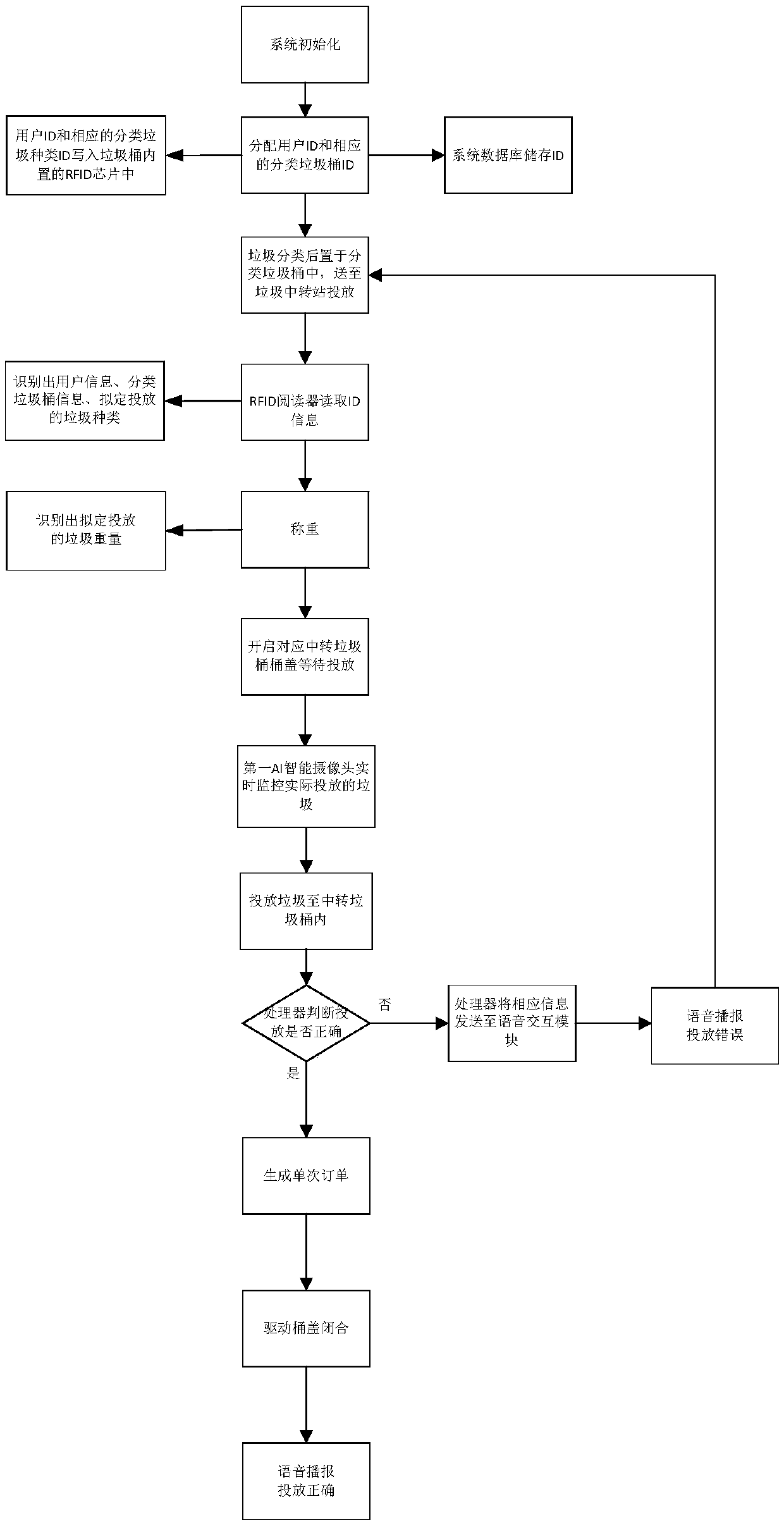

Garbage classification recovery system

InactiveCN110436075AImprove accuracyReduce usageData processing applicationsParticular environment based servicesIdentification deviceEmbedded system

The invention discloses a garbage classification recovery system. The system comprises a classified garbage bin used for classifying garbage by a user and a garbage transfer station used for classifying and throwing garbage by the user; an RFID chip is arranged in the classified garbage bin; the garbage transfer station is provided with a recognition device, a transfer garbage can with a cover, avoice interaction module and a control center; the identification device comprises a weighing unit and an RFID reader; a can cover of the transfer garbage can is opened and closed by a driving device;an inner first AI intelligent camera is arranged on the can cover; and the control center comprises a communication module, an input module, a processor, a system database, a power module and an RFIDread-write module. According to the garbage classification recovery system, the technologies of internet of things communication, RFID and the like are adopted to realize intelligent identification of classified garbage throwing and whole process monitoring, unattended operation is realized, the user can use the system for 24 hours, the garbage is strictly classified and controlled from the source, the use of a garbage bag is avoided, and the accuracy of garbage classification and the user experience are remarkably improved.

Owner:浙江钧工智能科技有限公司

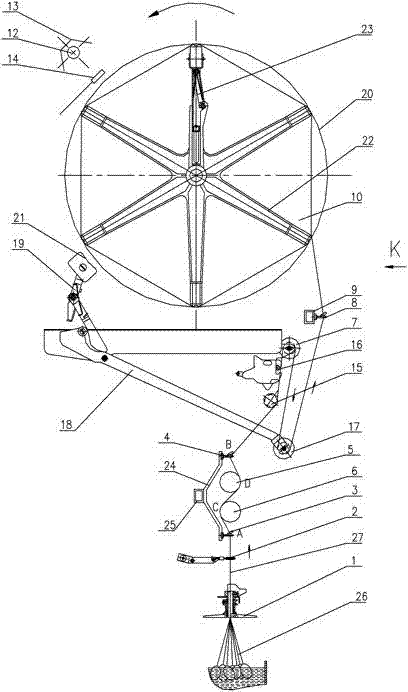

Silk reeling method and exclusive device for reeling raw silk

The invention relates to a silk reeling method and device, particularly to a silk reeling method and an exclusive device for reeling raw silk, which aim to solve the technical problems in the prior art that the energy consumption is large, the technological process is long, and more workers are needed all caused by silk reeling, rereeling and repeated drying; more time and labors are consumed because the bore diameter of a filament guide button is small; during the silk reeling process, the manual manner is adopted to form a silk sheath structure, and the hygrometric state raw silk is gathered by the function of the silk sheath in the method of gathering hygrometric state raw silk, the operation is complicated and the labor productivity is low. According to the invention, bave is processed by a hygrometric state raw silk gathering device after passing through an end feeding wing and a leading-in type filament guide button so as to enable the hygrometric state raw silk to be closely gathered, and moisture in a silk strip to be emitted by extrusion, tiny fouls on the bave surface are eliminated through kneading in a rotary manner, then, the bave is directly wound on a large shade and forms large flourishing yarn sheets through infra-red heating and drying, and the yarn sheets become reeled raw silk after silk falling arrangement.

Owner:ZHEJIANG SCI-TECH UNIV

Plastic flexible pipe winder

InactiveCN102701002AAvoid deformationEvenly arrangedFilament handlingProduction lineEconomic benefits

The invention discloses a plastic flexible pipe winder and relates to the technical field of winding equipment. The plastic flexible pipe winder orderly comprises a feeding device, a strand oscillator and a winding device, wherein the feeding device, the strand oscillator and the winding device are connected with an electric control device; the plastic flexible pipe winder also comprises an inflating device for inflating a plastic flexible pipe; the inflating device comprises an air inlet pipe connected with an opening of the plastic flexible pipe; the air inlet pipe corresponds to the position of the winding device, and an air stopping device for preventing the air in the plastic flexible pipe from returning to a production procedure section is arranged at upstream of the air inlet pipe. The plastic flexible pipe winder can be joined with a production line of the plastic flexible pipe and can automatically finish winding work of the plastic flexible pipe under the condition of ensuring that the plastic flexible pipe is not stacked and deformed, so the operation is stable and reliable, the automatic degree is high, the production efficiency is improved, the labor intensity of a worker is reduced, the production cost is reduced, and the economic benefit of an plastic flexible pipe enterprise is increased.

Owner:董长国

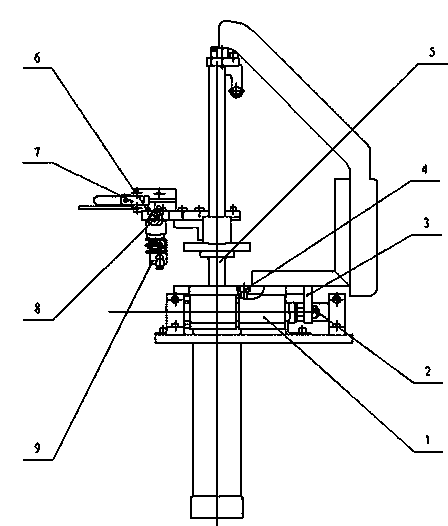

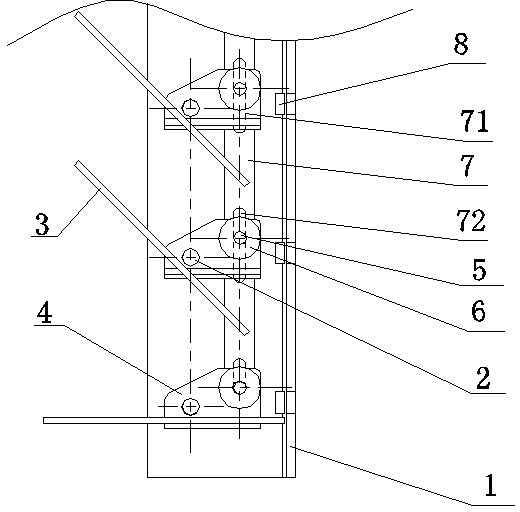

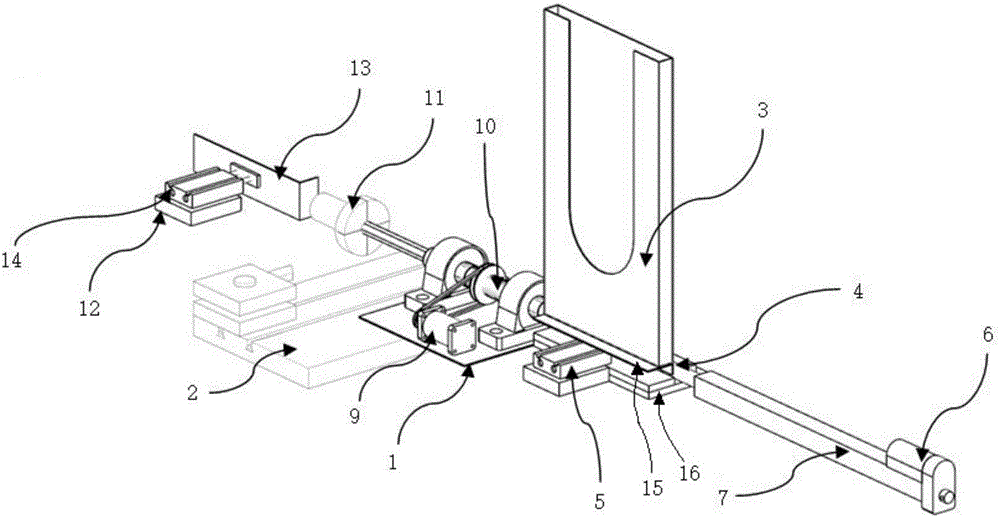

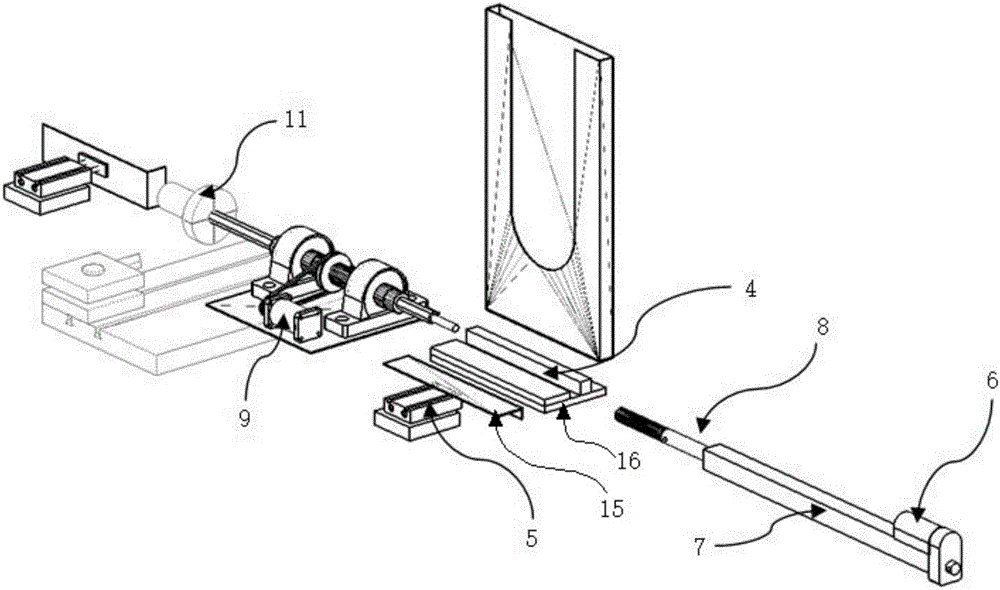

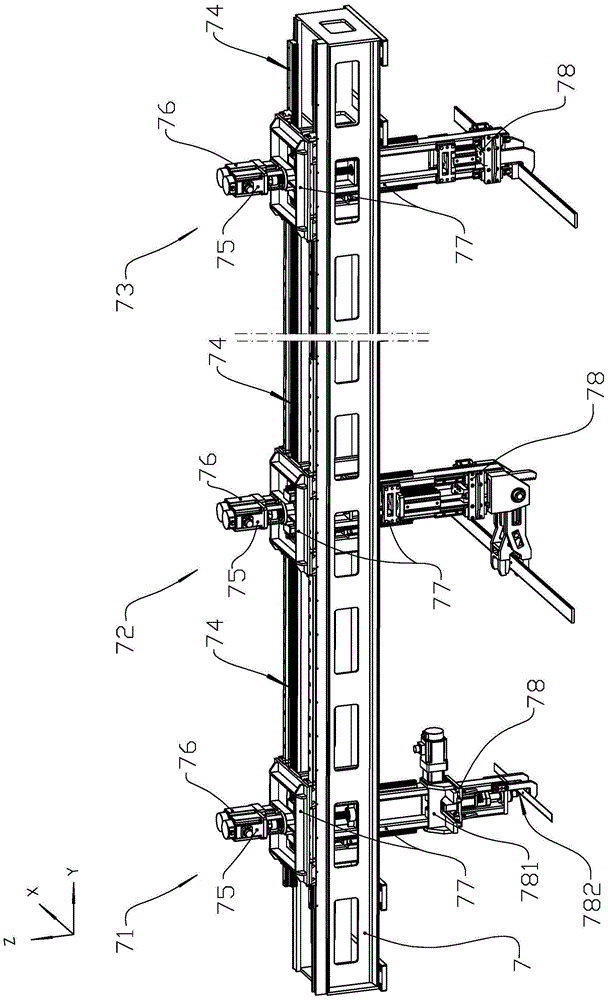

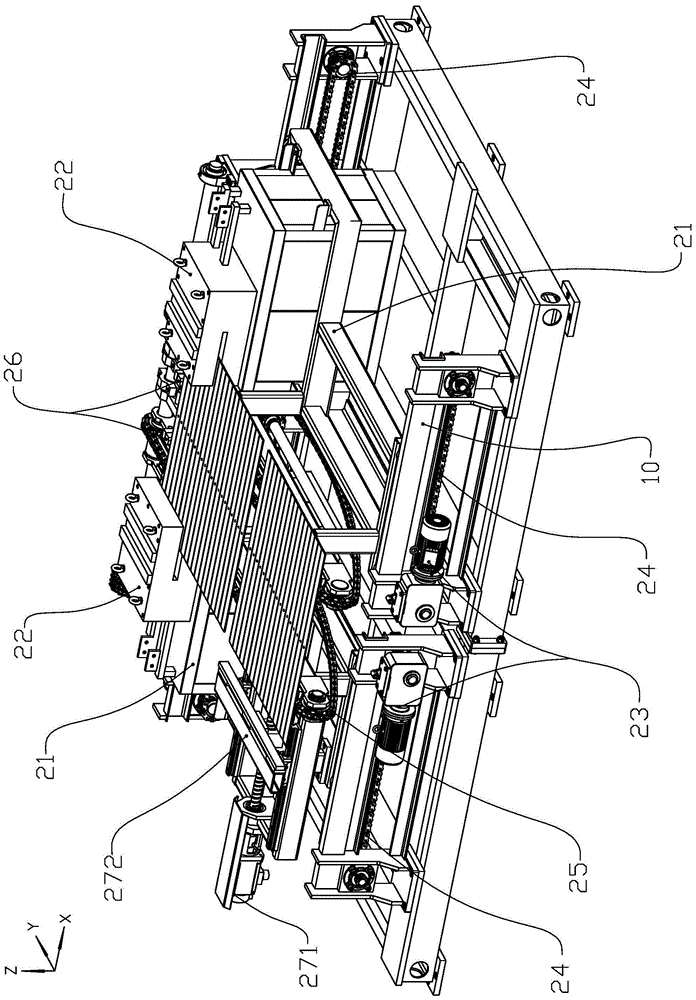

Automatic cop drawing device and method of ring spinning frame

The invention discloses an automatic cop drawing device and method of a ring spinning frame, relates to an automatic doffing cop drawing device of a ring spinning frame, in particular to an automatic cop drawing device and method of a ring spinning frame for separating and collecting the cop and a spindle. The automatic cop drawing device comprises a pneumatic manipulator (7), a horizontal moving assembly (1), a lifting assembly (5), a yarn cutting part (9) and a bobbin collecting device; up-down one dimension motion of a lifting cylinder and the clamping and releasing of the pneumatic manipulator are realized by the steps of initializing, horizontal moving to a rear position, vertically moving to a lower position, cop clamping, drawing the bobbin to an upper position, overturning, yarn cutting, bobbin collecting and the like, so the cop is drawn and descended, harm to the yarns in the bobbin drawing process is avoided, no radial force is generated to an ingot, and the automatic cop drawing device has the beneficial effects of reducing labor intensity of a worker and worker number and improving operation efficiency and doffing quality.

Owner:RIZHAO YUXIN MOTIVE POWER

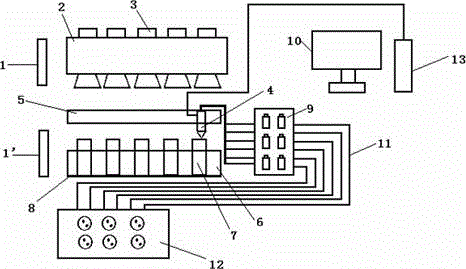

Laboratory COD automatic analysis robot

InactiveCN104914209AReduce the number of employeesImprove accuracyChemical analysis using titrationAutoanalysisPotassium dichromate

The invention discloses a laboratory COD automatic analysis robot. The laboratory COD automatic analysis robot comprises a plurality of digestion pipes which are arranged on a digestion pipe disc and are used for storing a water sample to be detected, an automatic liquid feeding system, a digestion heating system, a cooling system, a titration finishing point judging system and a controller for controlling each system to finish experiment operation steps, wherein the input end of the controller is connected with instruction input equipment; the output end of the controller is connected with the automatic liquid feeding system, the digestion heating system, the cooling system and the titration finishing point judging system respectively; and the output end of the titration finishing point judging system is further connected with display equipment. The laboratory COD automatic analysis robot integrates automatic sample feeding, batch determination and automatic analysis functions; and a potassium dichromate titration method is adopted so that the COD of a water sample can be rapidly determined, and a plurality of samples can be tested simultaneously so that the laboratory COD automatic analysis robot is convenient and rapid and has high accuracy.

Owner:WUXI DIANCHUANG TECH

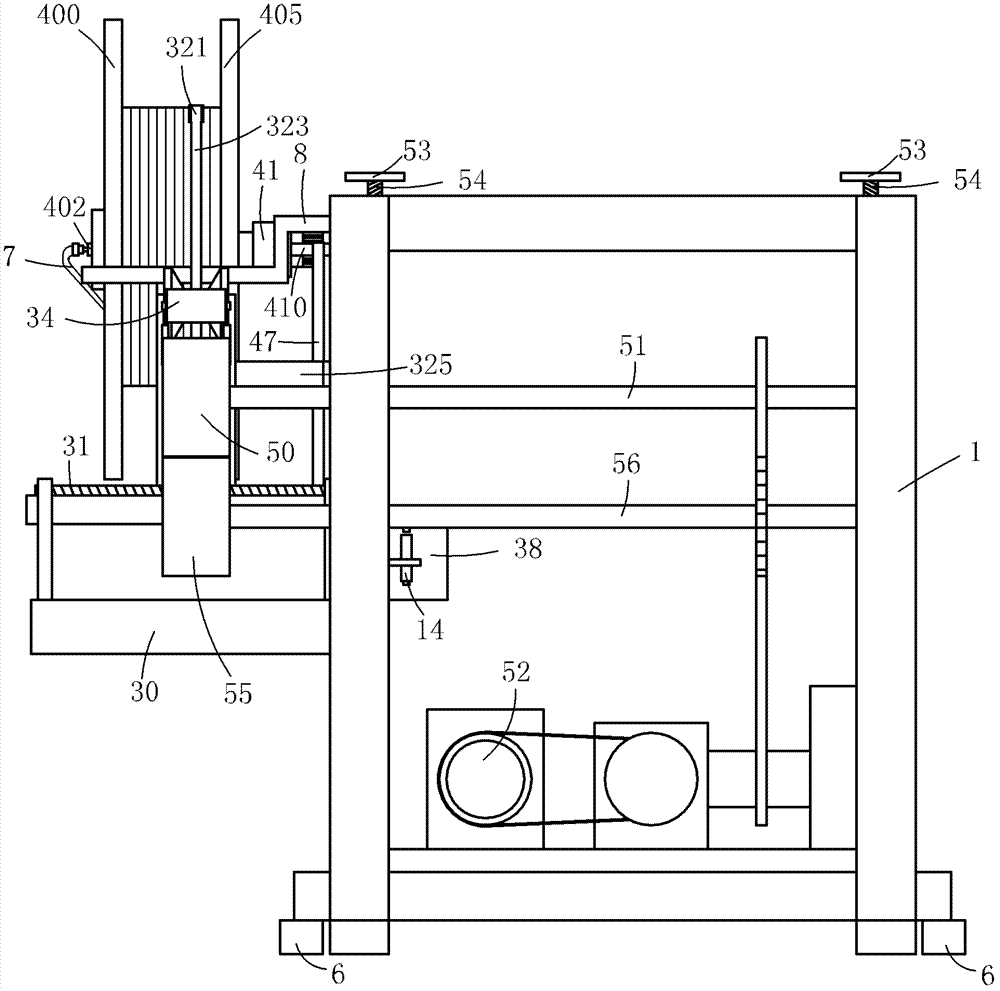

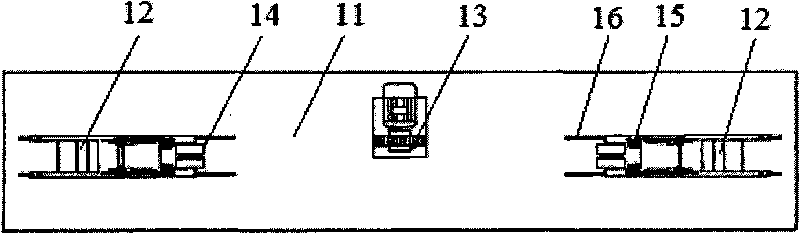

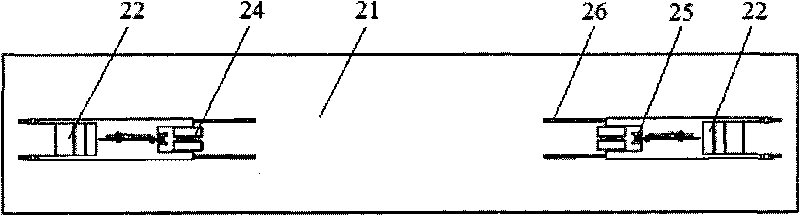

Manufacturing method of reinforcement cage of pouring pile with large diameter

ActiveCN101761071AImprove manufacturing precisionReduce the number of employeesBulkheads/pilesLow speedGear wheel

The invention discloses a manufacturing method of a reinforcement cage of a pouring pile with the large diameter, relating to the technical field of construction project. The invention aims at reducing the labor intensity while improving manufacturing accuracy and work efficiency. The method is characterized in that a manufacturing device consisting of a plurality of rolling bearing frame assemblies and transmission bearing frame assemblies is arranged according to a projection line of a central axis line of the reinforcement cage; openable ring mould assemblies are arranged on each transmission bearing frame assembly; inner walls of the ring mould assemblies are provided with a plurality of main reinforcement positioning grooves; main reinforcements of the reinforcement cage is lifted into the ring mould assemblies, the ring mould assemblies are driven through a low-speed drive gear to rotate so that each main reinforcement enters the main reinforcement positioning grooves and is fixedly welded with rectilinear hoops; and the ring mould assemblies are rotated and winded and reinforcing steel bars are rounded by using spot welding so as to realize mechanization manufacture of the reinforcement cage of the pouring pile with the large diameter. The method provided by the invention can realize high manufacturing accuracy and cage-making work efficiency of the reinforcement cage, can greatly reduce the labor intensity and reduce the worker amount of unit cage manufacture amount and is beneficial to quickening the project progress.

Owner:SHANGHAI GUANGLIAN ENVIRONMENTAL & GEOTECHNICAL ENG CO LTD

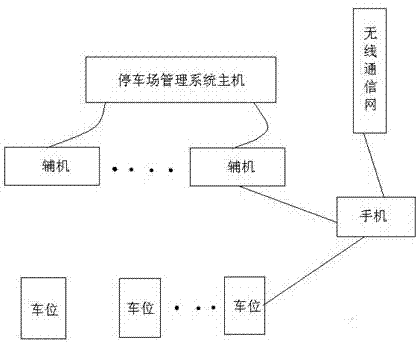

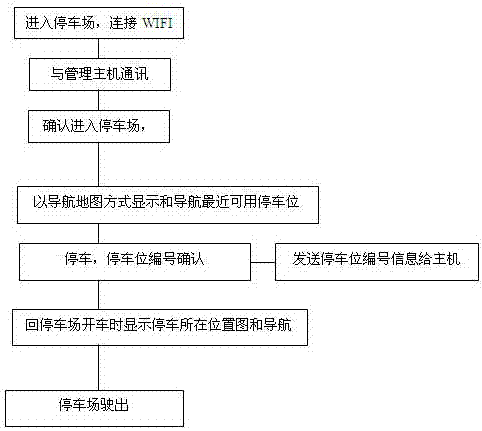

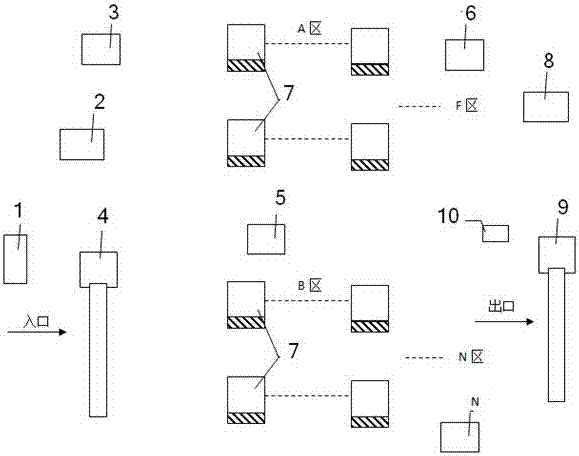

Smart phone-based parking lot parking and car searching method and system device

InactiveCN107393333AImprove management levelImprove the image of the industryIndication of parksing free spacesParking areaParking space

The invention relates to a smart phone-based parking lot parking and car searching method and system device. According to the smart phone-based parking lot parking and car searching method and system device, a smart phone plays a leading role to guide and manage unoccupied parking space searching and car searching in a parking lot; various kinds of parking space information of the underground parking lot is compiled into a networked or APP-style parking management system through software; the parking management system is uploaded to a wireless communication network; when a vehicle is to enter the parking lot and park there, the owner of the vehicle can use the smart phone to download the parking management system of the parking lot at first, parks his or her vehicle under the guidance of the parking management system, confirms the parking location directly through the smart phone and uploads the confirmed parking location information to the parking management system; after finishing his or her business, the owner of the vehicle uses the smart phone to confirm the location of the vehicle through the parking lot management system and quickly finds the location of the vehicle under the guidance of the parking management system of the smart phone.

Owner:株洲新科力科技有限公司

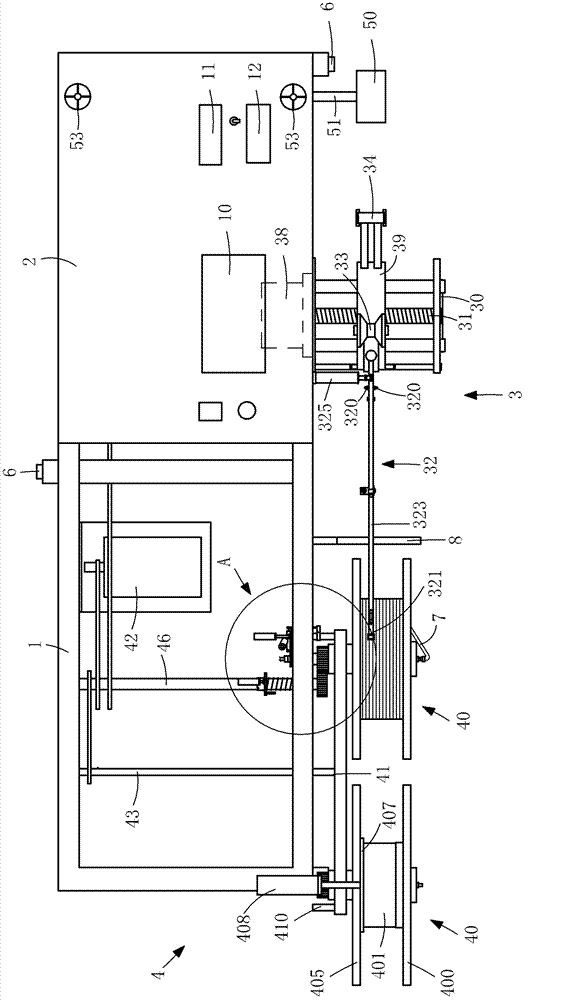

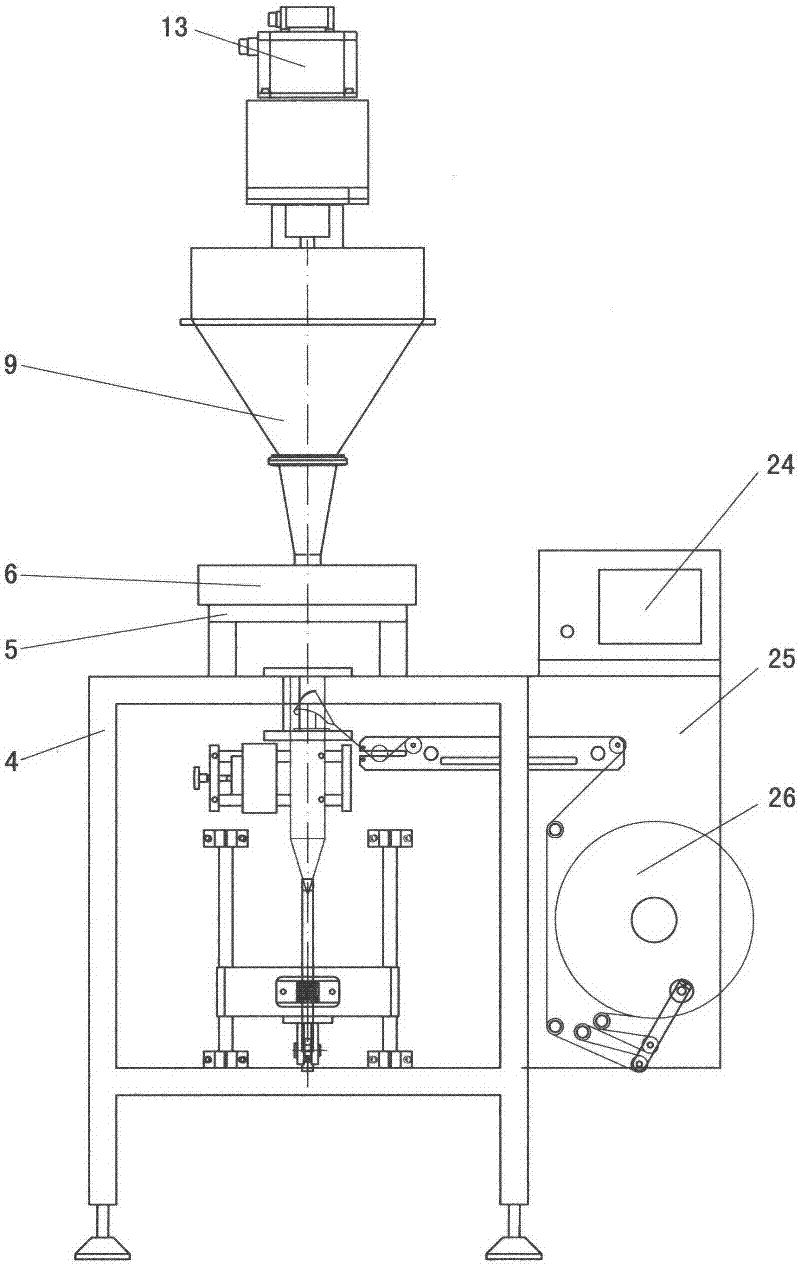

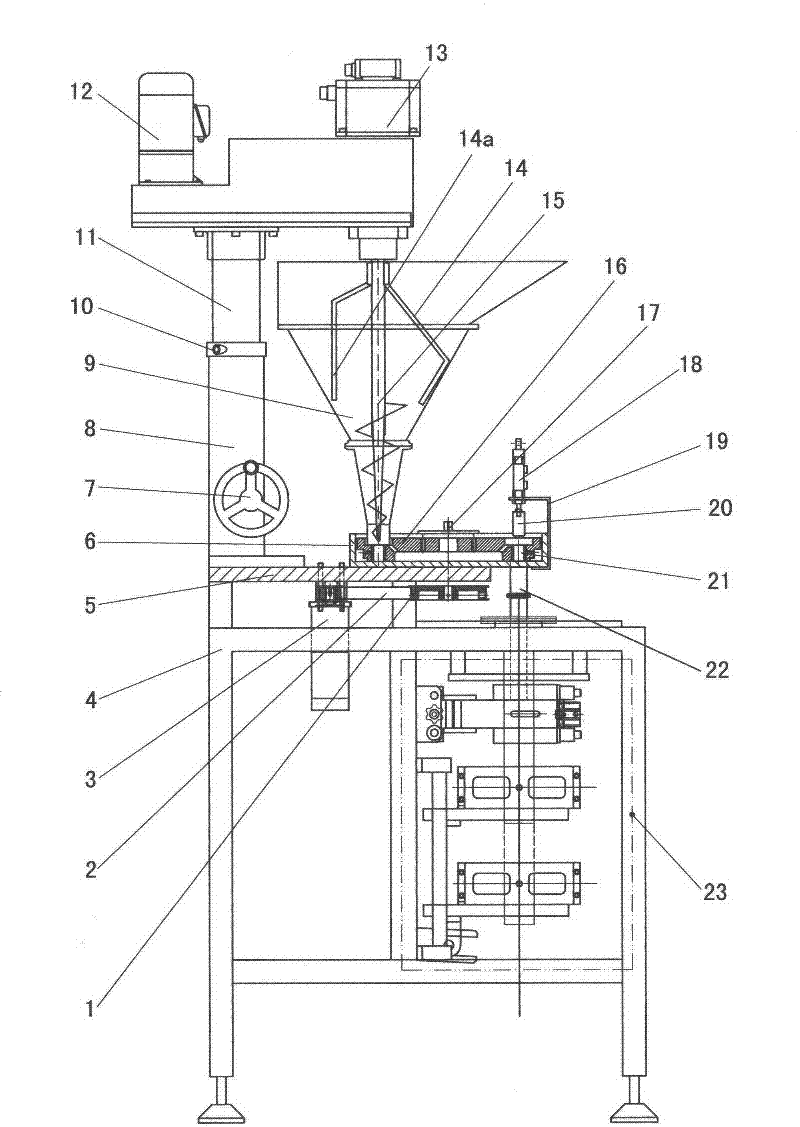

Automatic packaging machine

ActiveCN102501993AFully automatedReduce the number of employeesLiquid materialAutomatic controlViscous material

The invention relates to the technical field of material packaging, in particular to an automatic packaging machine. Aiming to solve the problem that viscous materials with specified values cannot be automatically measured in the prior art, the invention provides the following technical scheme: the automatic packaging machine comprises a rack (4), conveying equipment, packaging equipment (23) and an automatic control circuit and is characterized in that a measuring device comprises a turntable mechanism and a knockout mechanism; the turntable mechanism comprises a turntable (16) and a rotating submechanism for driving and controlling the turntable (16) to rotate; the turntable (16) is internally provided with more than one measuring cup (21); a feeding device conveys materials into the measuring cup (21), and the materials in the measuring cup (21) are separated by the knockout mechanism and conveyed to the packaging equipment (23) for packaging after the turntable (16) rotates for a specified angle. The automatic packaging machine provided by the invention can be used for automatically measuring the viscous materials with the specified values and the like.

Owner:SHANGHAI JINWE PACKAGING MACHINE

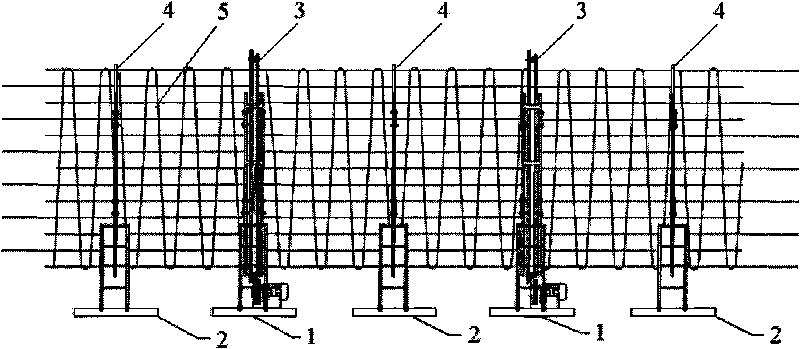

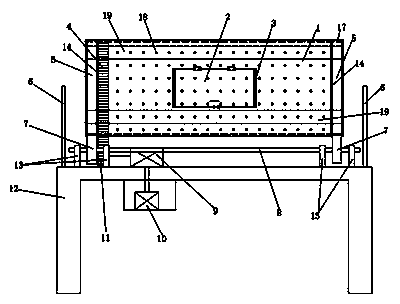

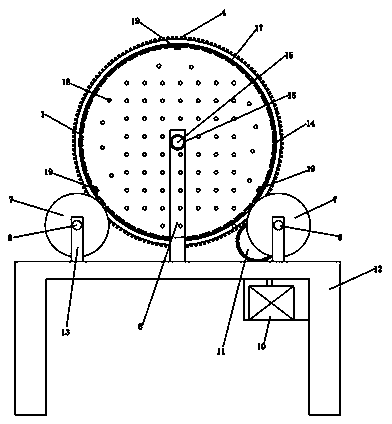

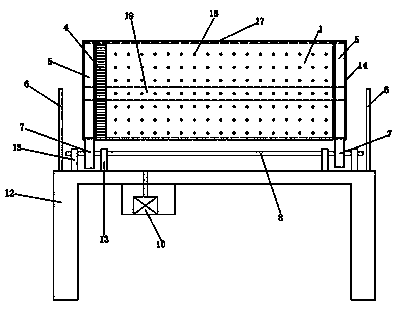

Washing device of labor protection safety net

InactiveCN103658095AReduce the number of employeesReduce water consumptionCleaning using liquidsSafety netGear wheel

The invention relates to a washing device of a labor protection safety net. The washing device comprises a speed reducer and a motor, fixed frames are fixedly arranged on the rack, pulleys are arranged at the two ends of a transverse rod, and the transverse rod is fixedly connected to the fixed frames. Pulley rails and ribbed bars are arranged on a roller, and the pulleys are matched with the pulley rails. A large gear ring is arranged on the roller, a small gear ring is connected with the speed reducer, the speed reducer is connected with the motor, and the small gear ring is matched with the large gear ring. A feed port is formed in the roller, a feed port cover and the roller are hinged together through a hinge, and water drainage clearances are reserved around the feed port cover and a feed port. Water inlets are formed in the two ends of the roller. A rubber blanket is arranged on the surface of the inner wall of the roller and is fixedly connected to the roller through screws. At least three rubber strips are evenly distributed on the inner side of the rubber blanket. After the washing device for the safety net is used, the number of deployed workers can be reduced, labor intensity can be lowered, and washing quality is greatly improved.

Owner:哈尔滨安赛福经贸有限公司

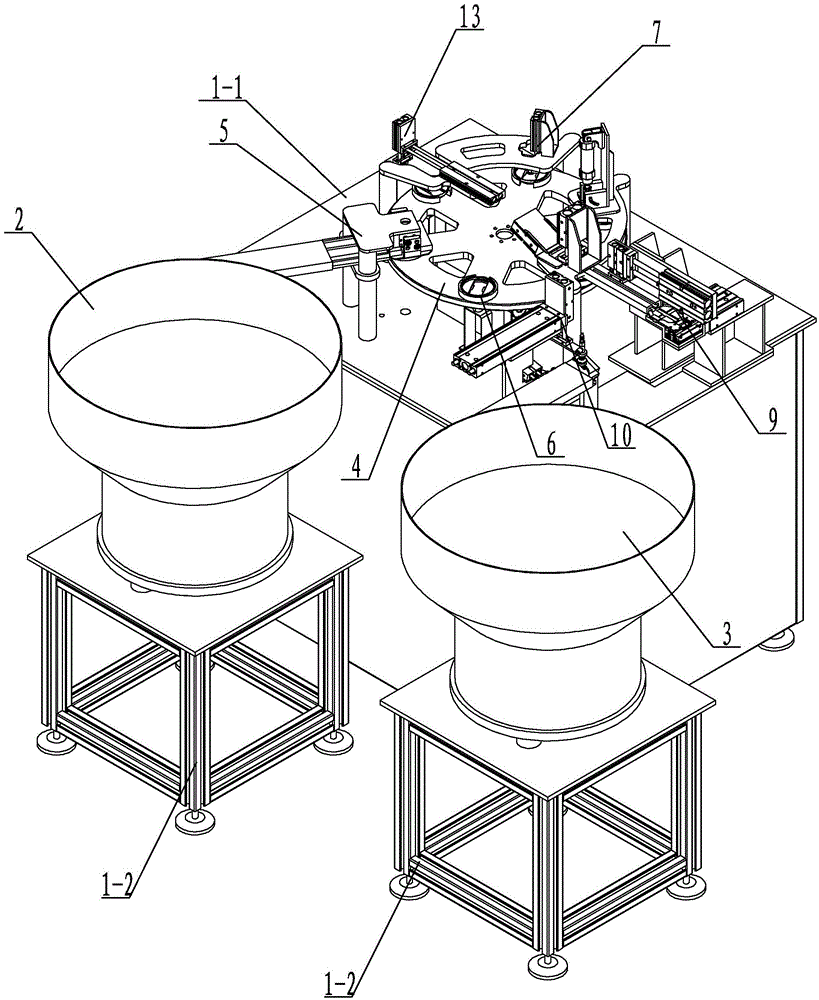

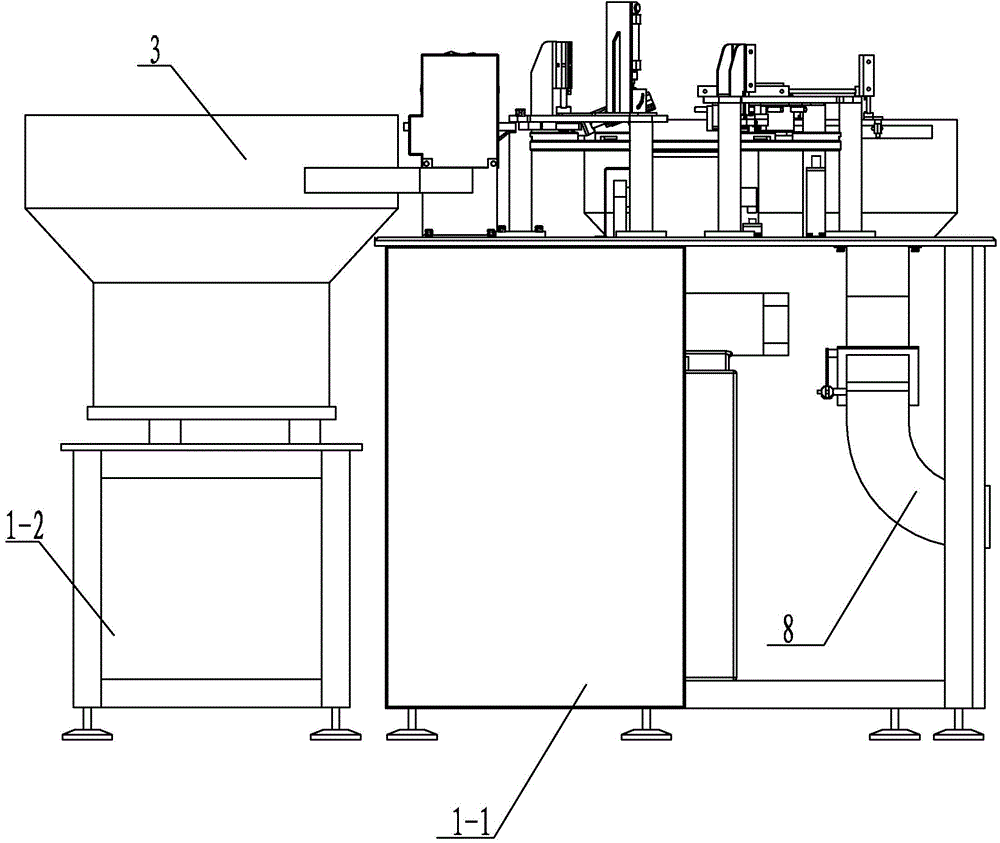

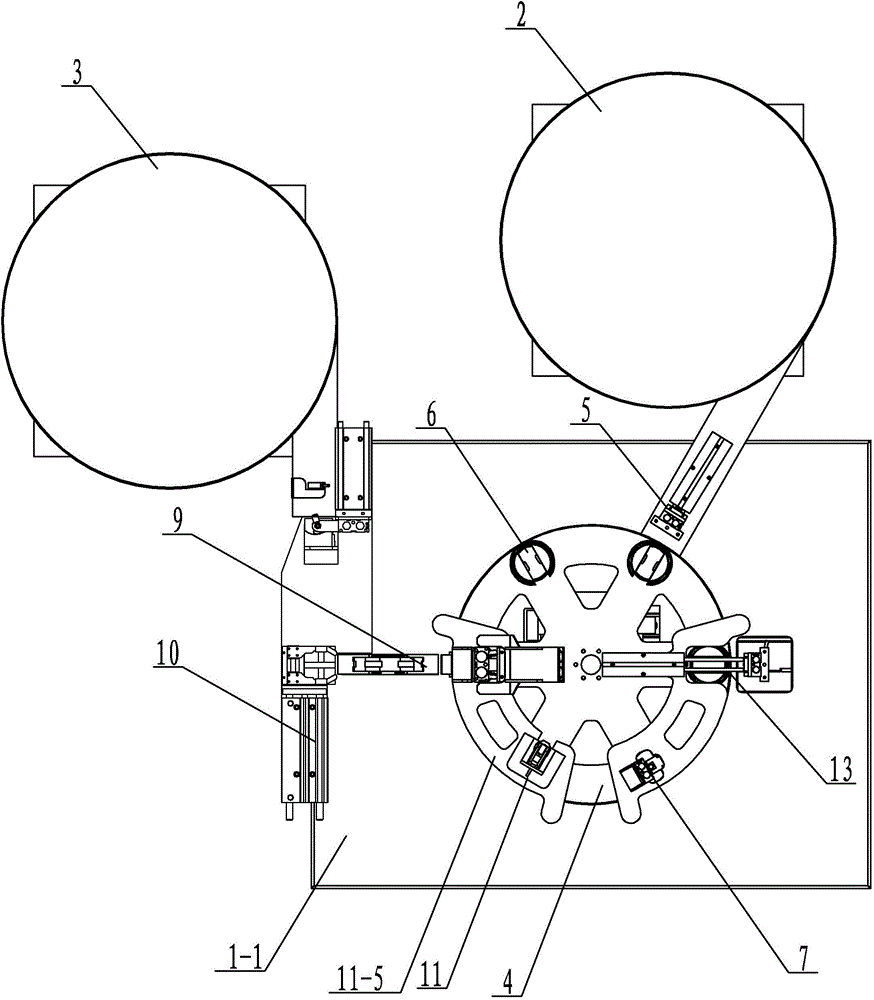

Automatic assembling machine for folding spoon or fork and box cover in can/barrel food

ActiveCN104526323AReduce the number of employeesMonitor running statusMetal working apparatusUltimate tensile strengthMechanical engineering

The invention discloses an automatic assembling machine for a folding spoon or a folding fork and a box cover in can / barrel food, and relates to automatic assembling machines. The automatic assembling machine aims to solve the problems that a box cover and a folding spoon or a folding fork in existing can / barrel food are generally assembled in a manual mode, hence, the assembling efficiency is low and the labor intensity of workers is high. According to the automatic assembling machine, a cover feeding material tray and a spoon feeding material tray are mounted on an auxiliary rack body, a rotary indexing mechanism is mounted on a main rack body, the cover feeding material tray and the rotary indexing mechanism are connected through a cover feeding station assembly, a cover existence detecting station assembly is mounted below the rotary indexing mechanism on the right side of the cover feeding station assembly in an anticlockwise mode, a spoon existence detecting station assembly and a discharging station assembly are mounted on a rotary indexing mechanism station in an anticlockwise mode, a folding and initial pressing station assembly and a re-pressing station assembly are mounted between the cover existence detecting station assembly and the spoon existence detecting station assembly, and the spoon feeding material tray is connected with the folding and initial pressing station assembly through a spoon feeding mechanism. The automatic assembling machine is used for automatically assembling the folding spoon or the folding fork and the box cover.

Owner:HARBIN ZHANDA ROBOT AUTOMATION CO LTD

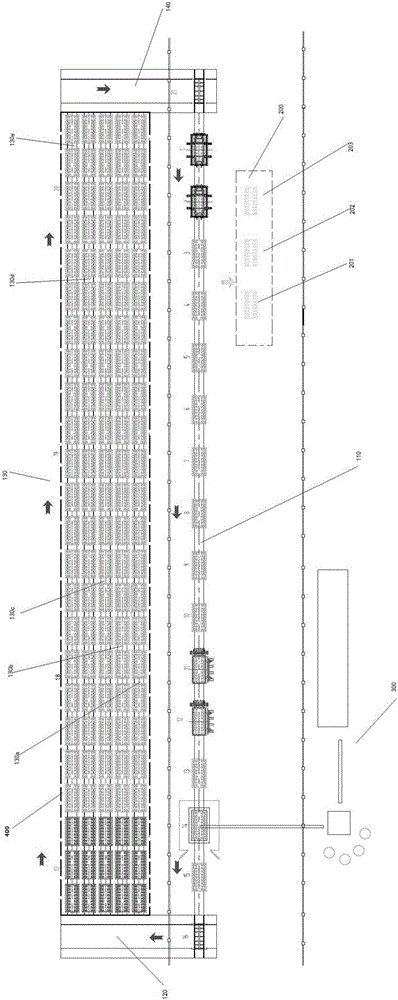

Assembly-line automatic manufacturing technology for pre-stressed concrete track board unit by pre-tensioning method

ActiveCN106466882AImprove turnover rateReduce areaDischarging arrangementBallastwayManufacturing technologyAutomatic control

The invention provides an assembly-line automatic manufacturing technology for a pre-stressed concrete track board unit by a pre-tensioning method. Traction equipment drives a model to flow on a track according to a time beat, wherein the time beat is working time of each station; the model bears tensioning stress, and all the stations are lined up on an assembly line and work together at the same time; and the quality and the working progress of each station are controlled by a sensor, and each station is commanded by a central control system, so that the operation of the whole system is controlled. Compared with a matrix production method, the assembly-line automatic manufacturing technology has the advantages that temporary components such as a tensile pedestal are eliminated, the model turnover rate is increased by 50 percent, the area of a factory is reduced by 30 percent or above, and the number of workers is reduced by 50 percent or above. The production process fulfills the aims of full-automatic control, informationalized transmission of key data, remote monitoring, and relocation and quick installation of all sets of equipment according to engineering requirements.

Owner:SHANDONG LINQU SLEEPER

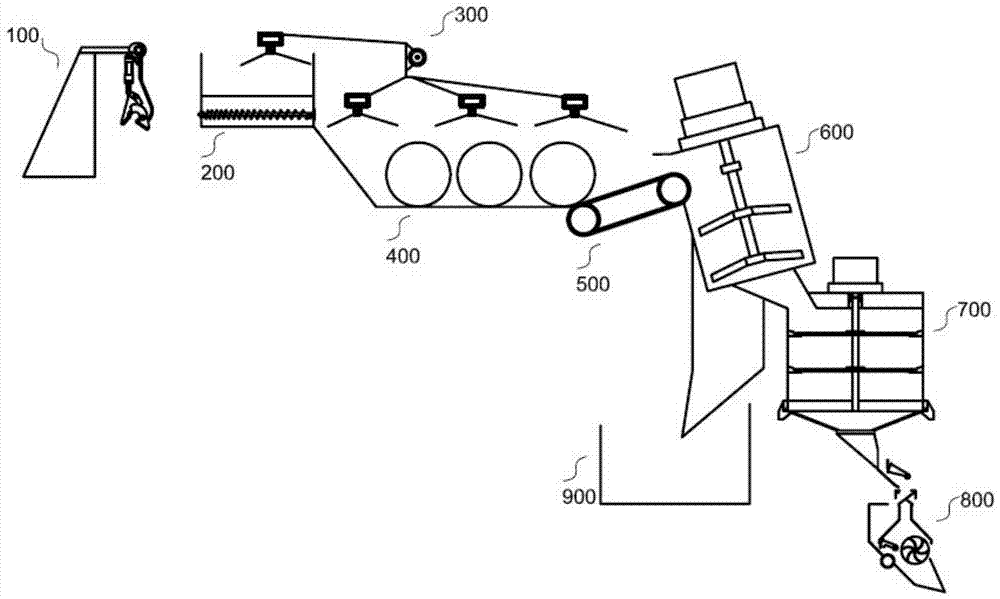

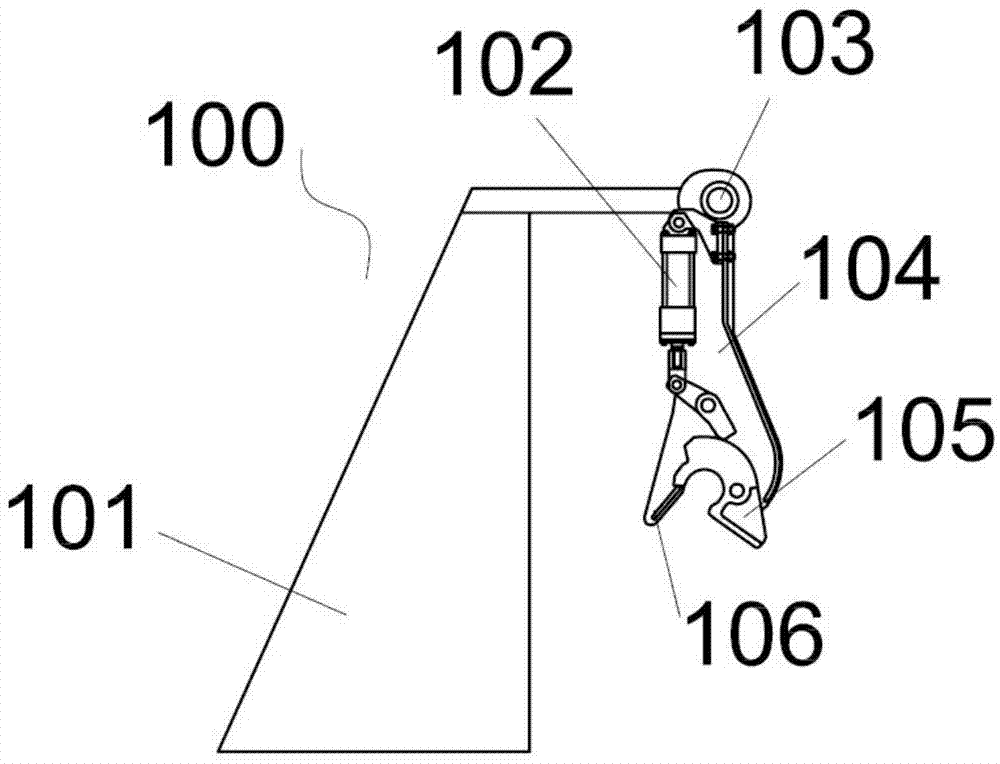

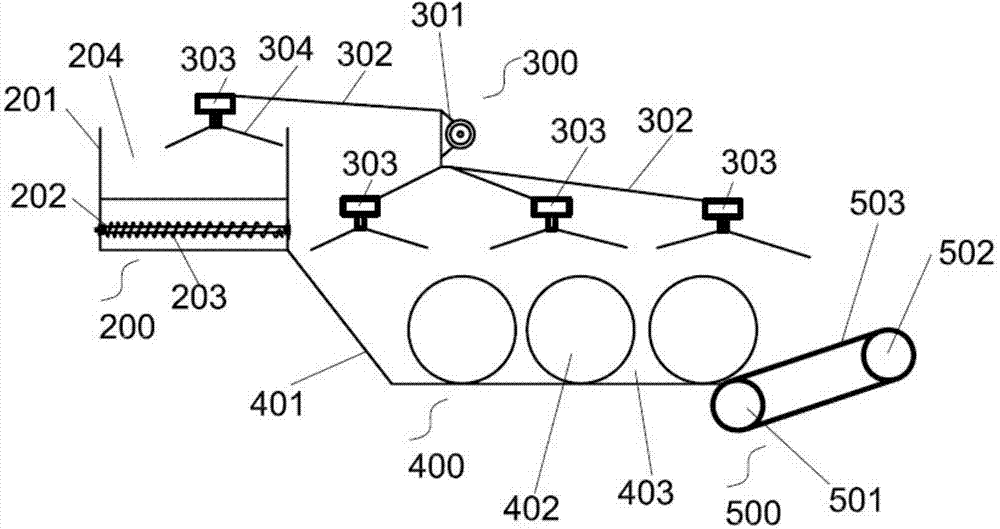

Waste plastic recycling system

The invention discloses a waste plastic recycling system. The waste plastic recycling system comprises a feeding unit, a rough washing unit, a fine washing unit, a dehydrating unit, a crushing unit, and a drying unit, wherein the dehydrating unit comprises a dehydrating barrel, a dehydrating shaft and a plurality of dehydrating wheels; the dehydrating shaft is rotationally arranged on the dehydrating barrel, and the dehydrating wheels are fixedly arranged on the dehydrating shaft; the crushing unit comprises a crushing barrel, a crushing rotating shaft, a plurality of stationary knives and a plurality of rotating knives; the drying unit comprises a flow control device and a drying device, wherein the drying device comprises a drying oven and a fan. The waste plastic recycling system is high in automation degree, low in manufacture cost and simple in structure and can be maintained conveniently, the production takts of all units are consistent, energy is saved, the production yield in unit time is high, the human invention is reduced and the labor investment is saved.

Owner:ZHEJIANG EXPO NEW MATERIALS CO LTD

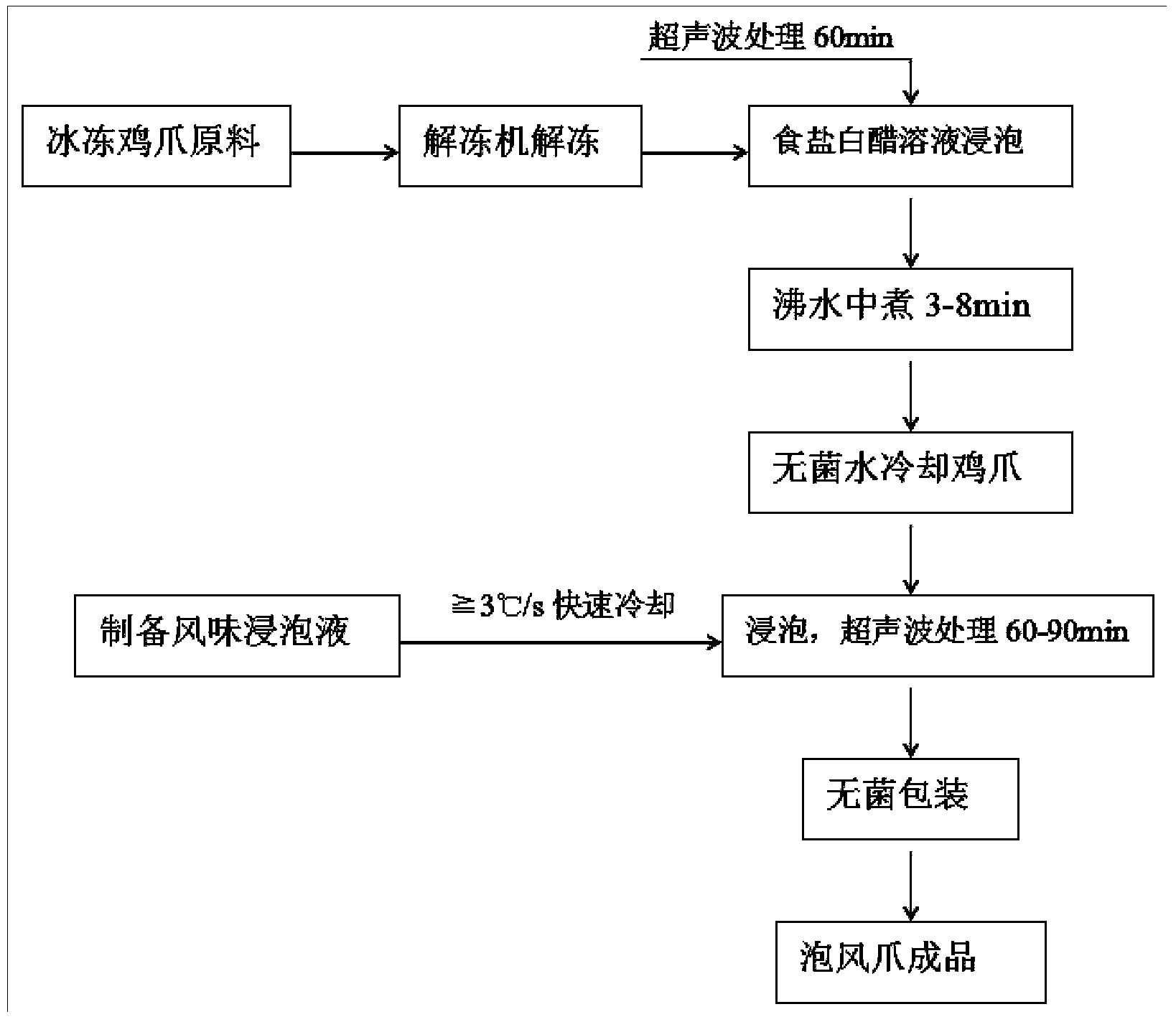

Rapid production method of pickled chicken claws

ActiveCN103907950AShorten the soaking timeImprove securityNatural extract food ingredientsFood ultrasonic treatmentChicken-clawsPreservative

The invention discloses a method for rapidly producing pickled chicken claws. The method comprises the following steps: 1, clearing and unfreezing chicken claws; 2, soaking the chicken claws with a liquid having 1-2% of salt and 5-10% of white vinegar and treating by ultrasonic wave; 3, boiling the treated chicken claws together with the liquid having 1-2% of salt and 3-4% of white vinegar for 3-8min; 4, cooling the boiled chicken claws by aseptic cold water added with 2-3% of white vinegar; 5, preparing a flavored soak liquid; 6, adding the cooled chicken claws in the flavored soak liquid and treating by the ultrasonic wave for 60-90min; and 7, vacuum-packing the pickled chicken claws to obtain finished products. The method for rapidly producing pickled chicken claws is characterized in that the soak liquid used by the pickled chicken claws is subjected to a fast cooling technology such that the soak liquid can achieve commercial sterilization, ultrasonic treatment is used in the soaking process for shortening soaking time, an irradiation technology is not used and only biological preservatives or extracts of fruits and vegetables are used as preservatives, and the shelf life is more than one year by computing according to current standards.

Owner:CHONGQING TECH & BUSINESS UNIV

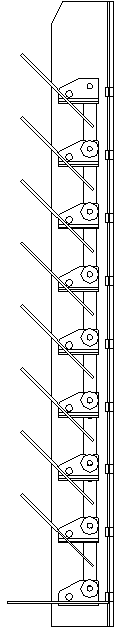

Material rack provided with automatic overturning structure

The invention provides a material rack provided with an automatic overturning structure, relates to a production tool and particularly relates to the technical field of a structure of the material rack. A material rack linking mechanism comprises a plurality of small rotary rods which are vertically arrayed along the height direction of a frame body stand column; each small rotary rod is respectively and rotatably supported on the frame body stand column; each small rotary rod is respectively and fixedly connected with a rotary plate and a bent piece; each bent piece is respectively and rotatably provided with a large rotary rod in a penetrating manner; each large rotary rod is externally and respectively coaxially connected with a large idler wheel; a connection plate provided with upper and lower long through holes is arranged between the adjacent large rotary rods; the adjacent large rotary rods respectively penetrate through the upper and lower long through holes; and an anti-inversion limiting block is arranged on the frame body stand column. When a car roof and a semi-finished part of a floor are placed, the rotary plate is automatically leveled and a specially-assigned person does not need to be dispatched to overturn the rotary plates; and the material rack provided with the automatic overturning structure has the advantages that the use is convenient, the worker quantity is reduced, the labor intensity is reduced, the production efficiency is improved and the service life of the material rack is prolonged.

Owner:仪征赛克工装装备有限公司

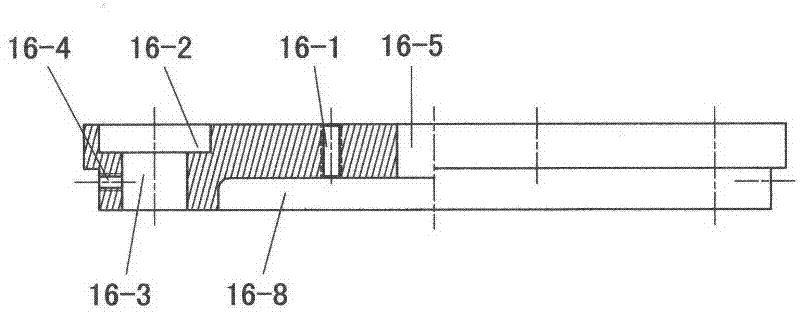

Automatic ridged-bar feeding and discharging system applicable to numerically controlled lathe and application thereof

InactiveCN106624966ARealize automatic loading and unloading operationsReduce labor intensityMetal working apparatusSystems designPush out

The invention relates to an automatic ridged-bar feeding and discharging system applicable to a numerically controlled lathe and application thereof. The automatic ridged-bar feeding and discharging system applicable to the numerically controlled lathe comprises a storage mechanism, a feeding mechanism, a guide-in mechanism, a discharging mechanism and a controller. The storage mechanism is used for storing ridged bar workpieces. The feeding mechanism is located below the storage mechanism and used for receiving workpieces in the storage mechanism. The guide-in mechanism pushes workpieces in the feeding mechanism into the numerically controlled lathe so that feeding of workpieces can be completed. The discharging mechanism pushes out machined workpieces, so that a discharging process is completed. The controller is electrically connected with the storage mechanism, the feeding mechanism, the guide-in mechanism and the discharging mechanism, so that automatic operation of the whole feeding and discharging system is achieved. The automatic feeding and discharging system designed for ridged bar workpieces can be perfectly matched with the numerically controlled lathe, automatic operation of feeding and discharging of ridged bar workpieces is achieved, production efficiency is improved, product cost is reduced, and the system has the advantages of being simple and practical in structure, reliable in performance, high in efficiency and the like.

Owner:LIAOCHENG UNIV

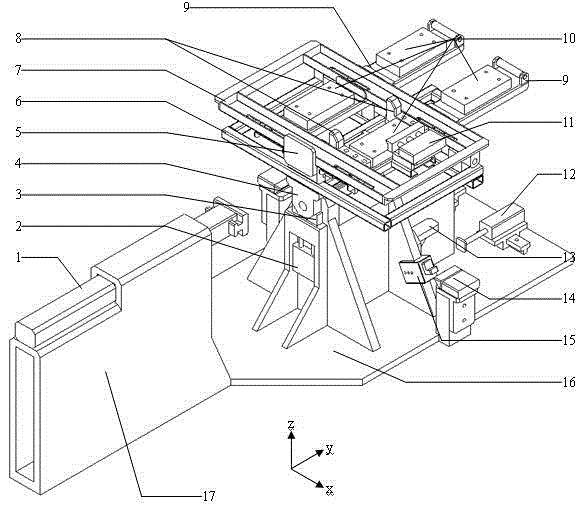

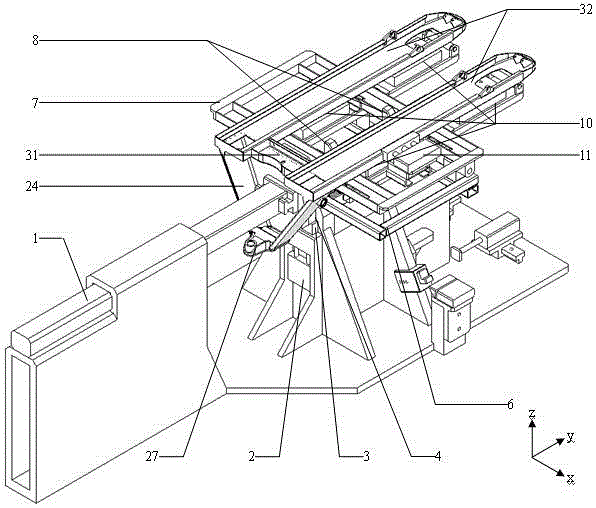

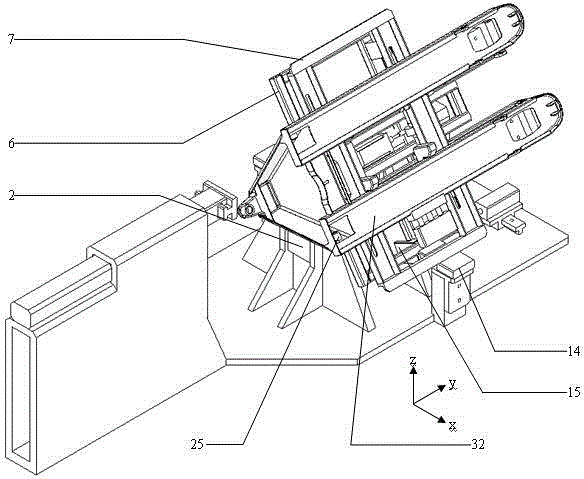

Automatic repair welding flexible positioner of manual-operation pallet truck

InactiveCN102744548AImprove quality and efficiencyIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesWorking environmentTruck

The invention discloses an automatic repair welding flexible positioner of a manual-operation pallet truck. An auxiliary foundation base is fixedly connected to one side of a foundation base, a y axis clamping cylinder is installed on the auxiliary foundation base, a lower rotation frame is rotatably connected onto the foundation base, one side of an upper rotation frame is rotatably connected with one side of the lower rotation frame away from the auxiliary foundation base, a worm wheel of a worm and gear pair is fixedly sleeved on an x axis rotation shaft, two electromagnetic chuck bases are symmetrically installed on the upper rotation frame, two electromagnetic chucks are fixedly installed on each electromagnetic chuck base, the electromagnetic chucks attract forks of the manual-operation pallet truck through electromagnetic force, two lower rotation frame limit devices are symmetrically installed on two sides of the foundation base, and two upper rotation frame limit devices are symmetrically installed on one side of the foundation base. The automatic repair welding flexible positioner of the manual-operation pallet truck is compact in structure, improves welding quality and production efficiency of the manual-operation pallet truck, reduces labor intensity of workers, improves working environment of the workers, and meets automatic repair welding processing requirements of the manual-operation pallet truck.

Owner:ZHEJIANG UNIV

Application method of edible fungus factory planting device

InactiveCN106212052AQuality improvementIncrease productionHorticultureAgricultural engineeringFarmyard manure

The invention provides an application method of an edible fungus factory planting device. During production, a travelling mechanism drives a planting production intelligent device, so that the rear end of a feeding conveyor belt of the planting production intelligent device and a first fungus bed layer of an edible fungus bed brake correspondingly; edible fungus base material is stacked at one side of a loading conveyor belt, and farmyard manure for later use is stacked at one side of a fertilizer distributing conveyor belt; by virtue of the loading conveyor belt of the edible fungus factory planting device, a material distributor swings and a flatting scraping plate rotates to feed the edible fungus base material onto the upper surface of the feeding conveyor belt; meanwhile, plow harrow teeth carry out levelling on the upper surface of the edible fungus material, refining levelling and compaction moulding are carried out on the upper surface of the edible fungus base material, and the farmyard manure is covered; then the edible fungus base material enters the edible fungus bed, a gantry lifting frame enables the feeding conveyor belt to correspond to the plane of each fungus bed layer of the edible fungus bed until planting is completed on all the fungus bed layers of the edible fungus bed, the travelling mechanism is started to drive the edible fungus factory planting device to carry out edible fungus base material planting on another edible fungus bed.

Owner:洛阳泽智传动机械有限公司

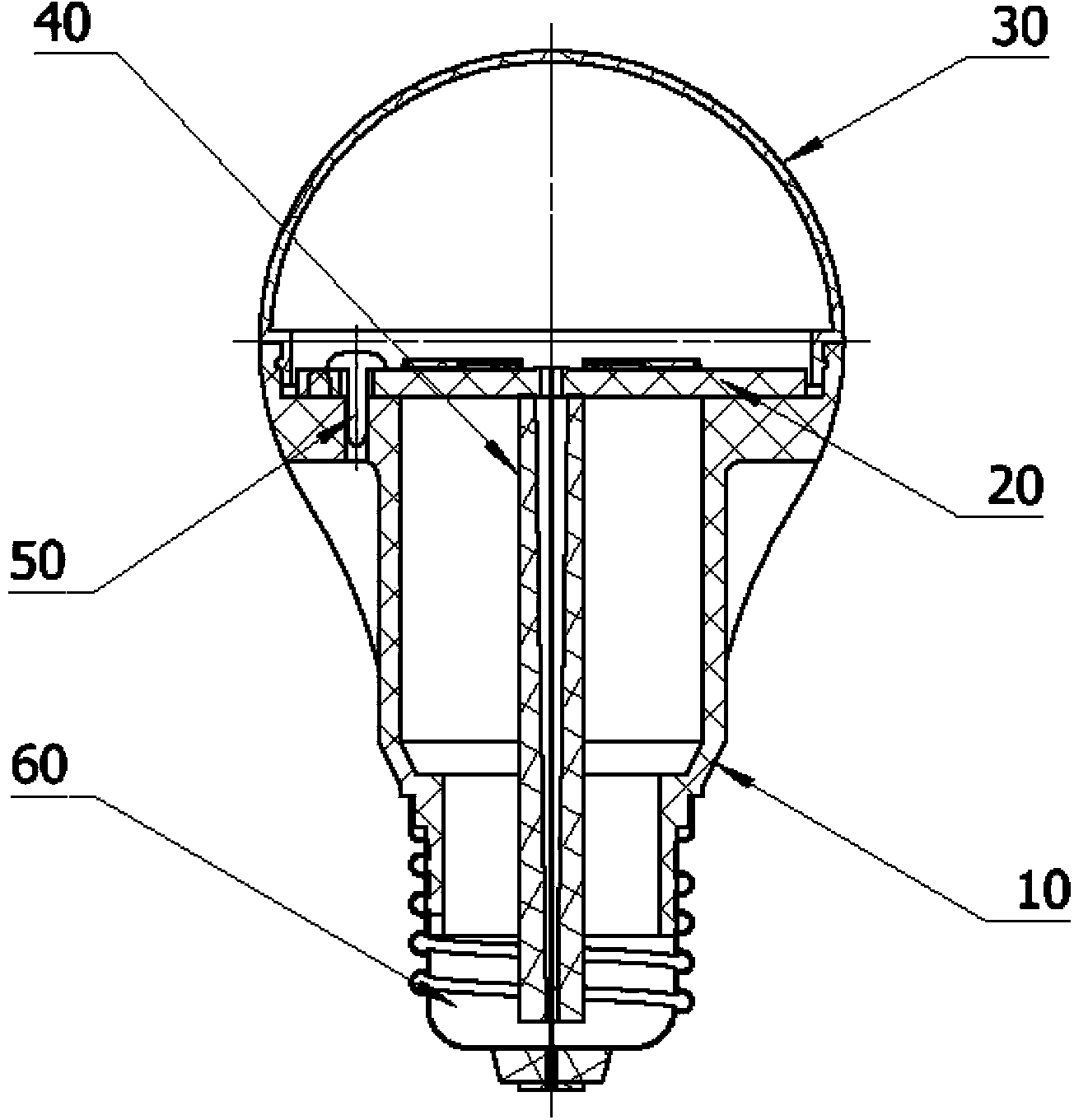

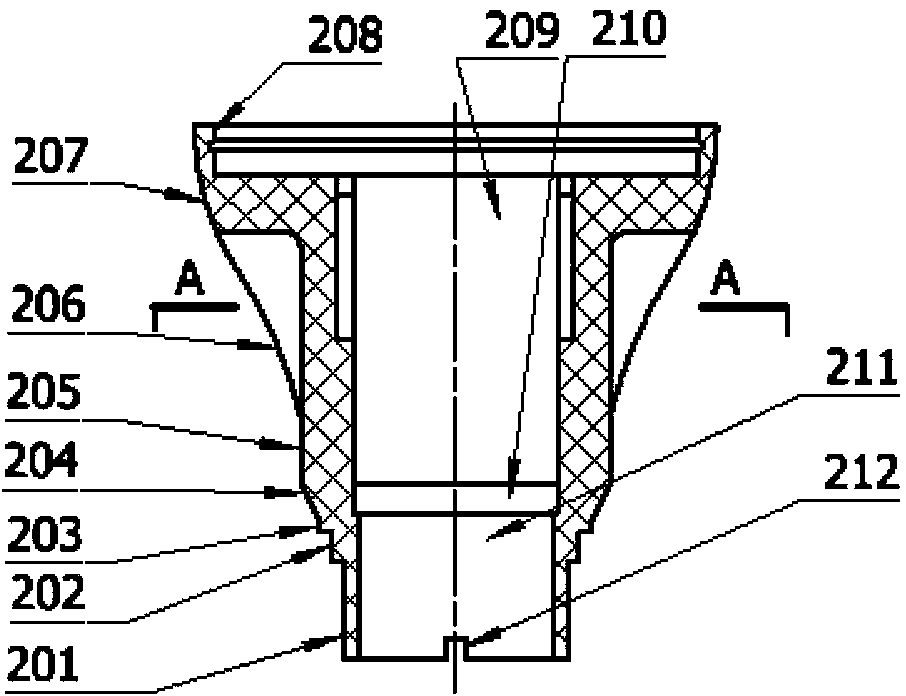

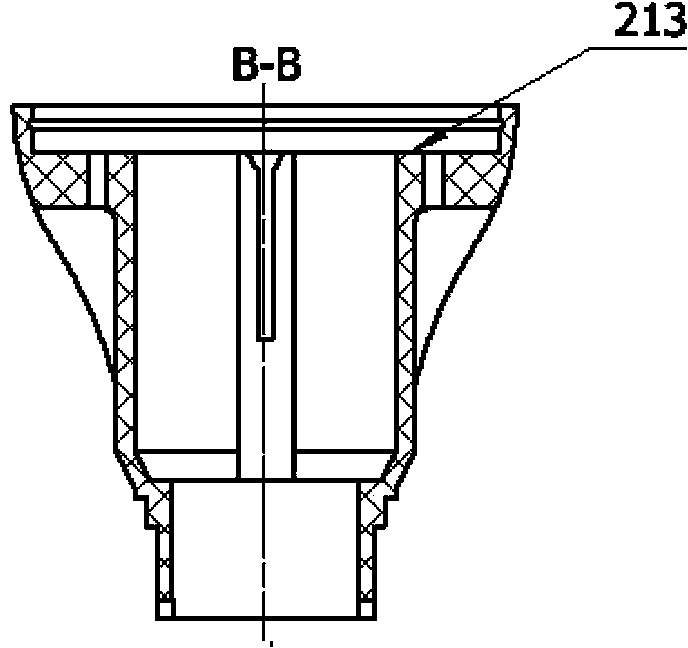

LED bulb lamp easy for automatic assembly

InactiveCN103486472AInsulation sleeve is omittedReduce the number of partsPoint-like light sourceLighting heating/cooling arrangementsFastenerLight source

The invention discloses an LED bulb lamp easy for automatic assembly. The LED bulb lamp comprises a lampshade, a lamp body, fasteners, a light source and power source combination, a wire board and a lamp cap, and is characterized in that the lampshade is clamped into an annular groove formed at the upper end of the lamp body, an annular platform formed by concaving is arranged at the upper end of the lamp body, the light source and power source combination is mounted on the annular platform, the annular platform and the light source and power source combination are fastened through the fasteners, two symmetrical rectangular grooves are formed inside the lamp body, the wire board is inserted into the rectangular grooves, and the lamp cap is mounted on a round stepped tube arranged at the lower end of the lamp body. Being structurally designed in an optimized, standardized and serialized manner, the LED bulb lamp is interchangeable, simple in structure, easy for automatic production, good in radiating effect, high in production efficiency and low in cost.

Owner:SOUTHEAST UNIV

Abdominal cushion machine

PendingCN109763272ASimple structureEasy to operateWorkpiece carriersWork-feeding meansEngineeringSpot welding

The invention relates to an abdominal cushion machine. The machine comprises a feeding assembly, a fixed length cutting mechanism, an ultrasonic spot welding labeling mechanism, a folding assembly, afirst sewing assembly, a rotating table and a second sewing assembly which are sequentially distributed, wherein the feeding assembly is used for conveying a fabric forwards; the fixed length cuttingmechanism is used for cutting the fabric after the fabric is fixed in length; the ultrasonic spot welding labeling mechanism is used for sewing cotton labels and glue labels together to the fabric; the folding assembly is used for folding and turning the fabric; the first sewing assembly is used for sewing two side edges of the fabric and the middle of the two side edges; the rotating table is used for rotating the fabric by 90 degrees; the second sewing assembly is used for sewing the other two side edges of the fabric and the middle of the other two side edges. The abdominal cushion machineautomatically finishes fixed-length cutting of the fabric, the cotton labels and the glue labels are sewn on the fabric, first sewing, rotation and second sewing are performed, accordingly, productionof an abdominal cushion is completed automatically, a small number of workers are needed in the whole process, production cost is high, production efficiency is high, competitiveness of enterprises is improved, and development requirements of the market are met.

Owner:SUZHOU TRANSPARENT TECH CO LTD

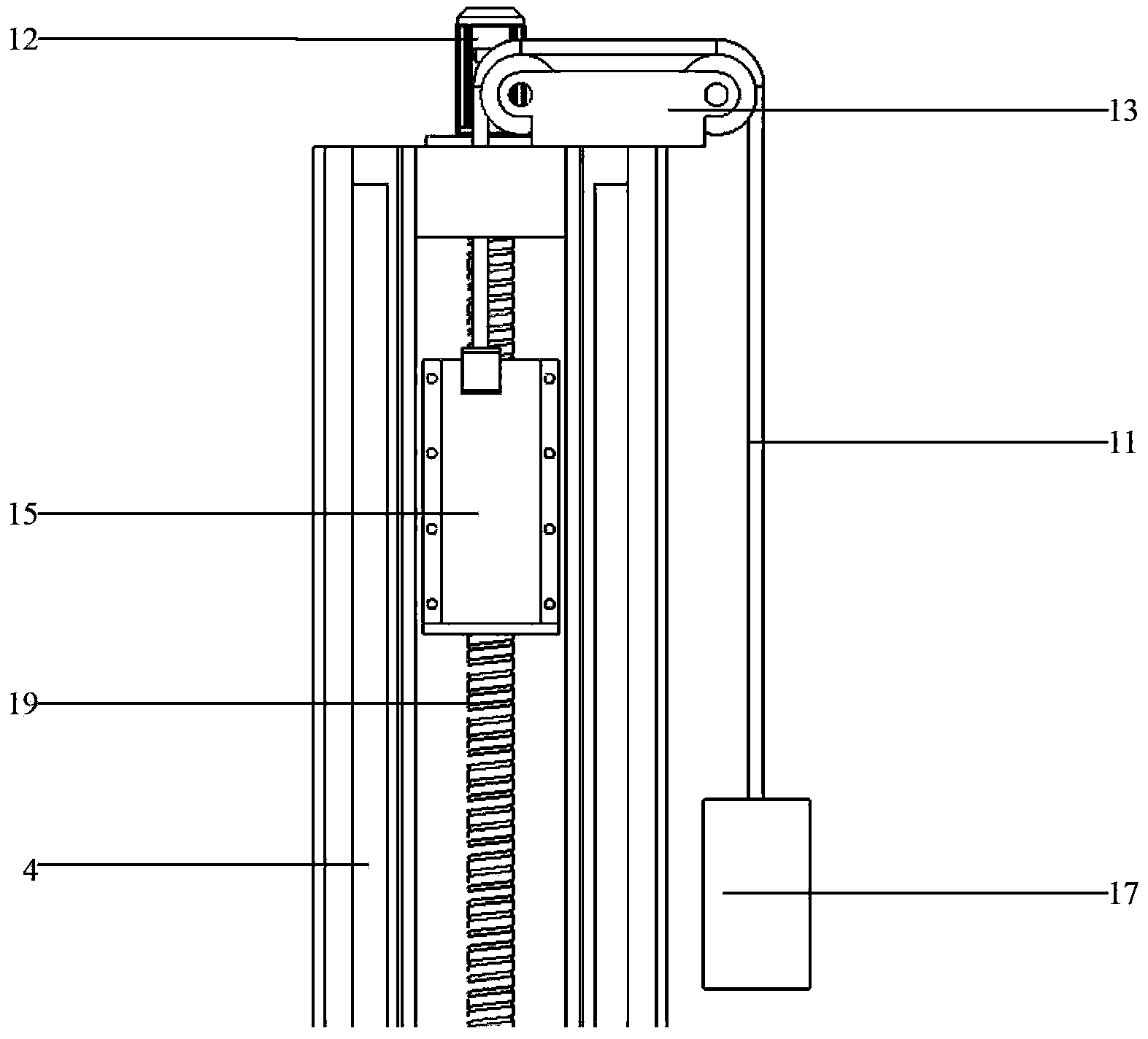

Flexible automatic feeding and blanking mechanism of manual pallet truck

The invention discloses a flexible automatic feeding and blanking mechanism of a manual pallet truck, which is a full-automatic mechanical device used for feeding and blanking of the manual pallet truck. The flexible automatic feeding and blanking mechanism comprises a pillar which can move along a sliding rail, wherein a ball screw mechanism is arranged at the center of the pillar in the vertical direction, a suspension arm seat is connected with a movable nut in the ball screw mechanism, two sides of the suspension arm seat are symmetrically provided with suspension arms which stretch outwards, the suspension arms move in sliding fit with the pillar simultaneously when vertically moving along with the suspension arm seat, two connecting rods which can move in different directions along the stretching direction are arranged on each suspension arm, the arrangement direction of the two connecting rods is parallel to the movement direction of the sliding rail, and at least one end of each connecting rod is connected with a part taking manipulator which is a hanging claw or an electromagnetic suction arm. The flexible automatic feeding and blanking mechanism has the characteristic of flexibility, is compact in structure, and can be used for meeting needs of feeding and blanking of the manual pallet trucks of various specifications, so that the welding quality and production efficiency of the manual pallet trucks are effectively improved, the labor intensity of workers is alleviated, and a labor environment of the workers is improved.

Owner:SUZHOU ZIJINGANG INTELLIGENT MFG EQUIP

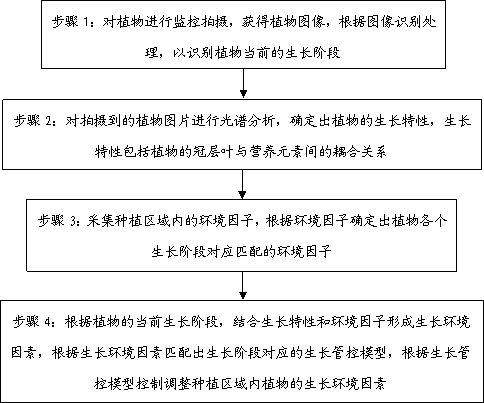

Plant growth precision control method based on production base

InactiveCN112197819AEasy to monitorImprove operation and maintenance levelFlowers cultivationCharacter and pattern recognitionGrowth plantSpectral analysis

The invention relates to a plant growth precision control method based on a production base. The plant growth precision control method comprises the steps of: 1, carrying out monitoring and photographing on a plant, acquiring plant images, and recognizing a current growth stage of the plant according to image recognition processing; 2, performing spectral analysis on the shot plant pictures, determining growth characteristics of the plant, wherein the growth characteristics comprise a coupling relation between canopy leaves of the plant and nutrient elements; 3, collecting environmental factors in a planting region, and determining the environmental factors correspondingly matched with each growth stage of the plant according to the environmental factors; and 4, forming growth environmentfactors according to the current growth stage of the plant in combination with the growth characteristics and the environment factors, matching a growth management and control model corresponding to the growth stage according to the growth environment factors, and controlling and adjusting the growth environment factors of the plant according to the growth control model. According to the plant growth precision control method, the plant production operation and maintenance level is improved, the personnel labor is reduced, the labor cost is reduced, and factory planting of plants is realized.

Owner:GLORYVIEW TECH INC

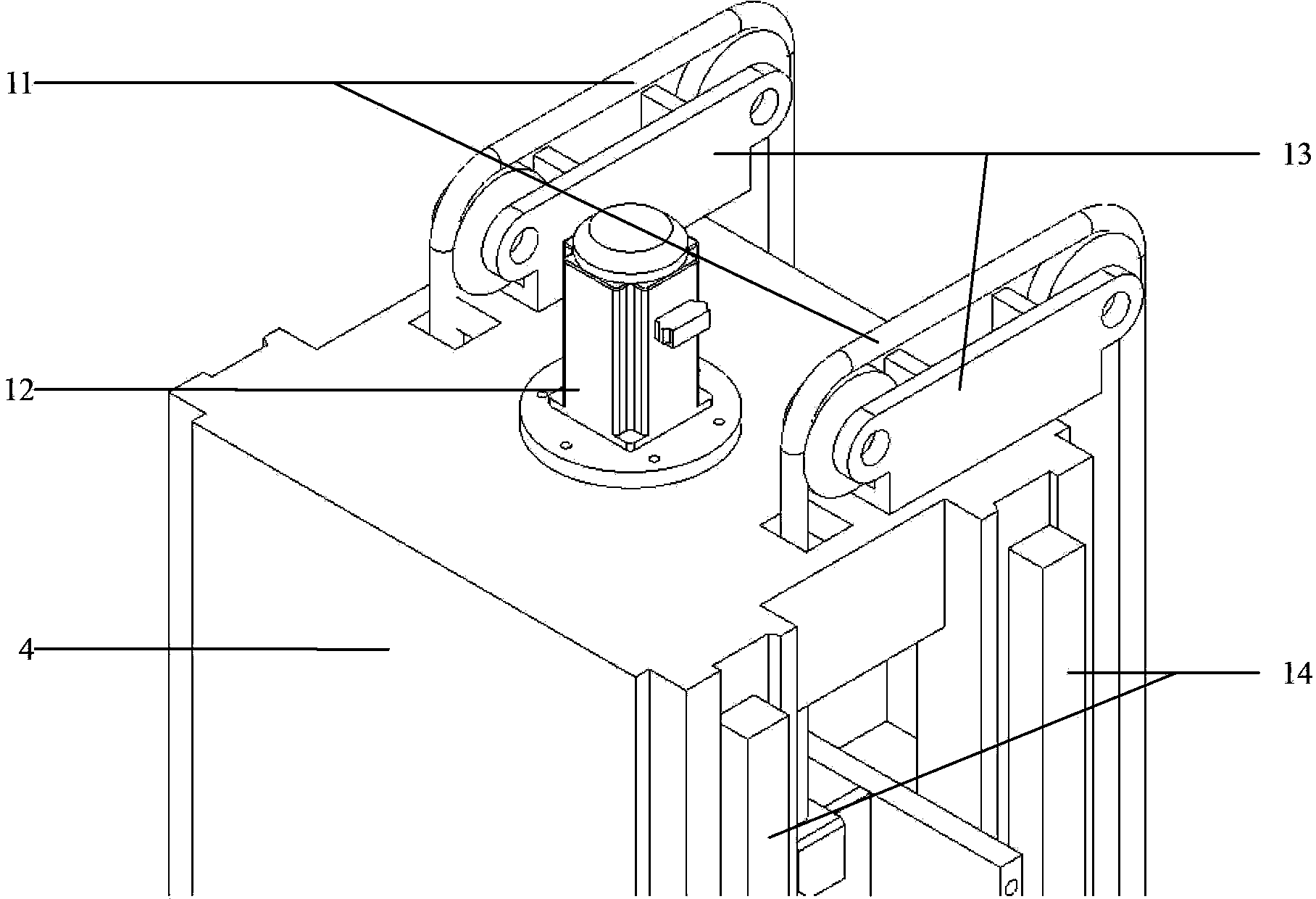

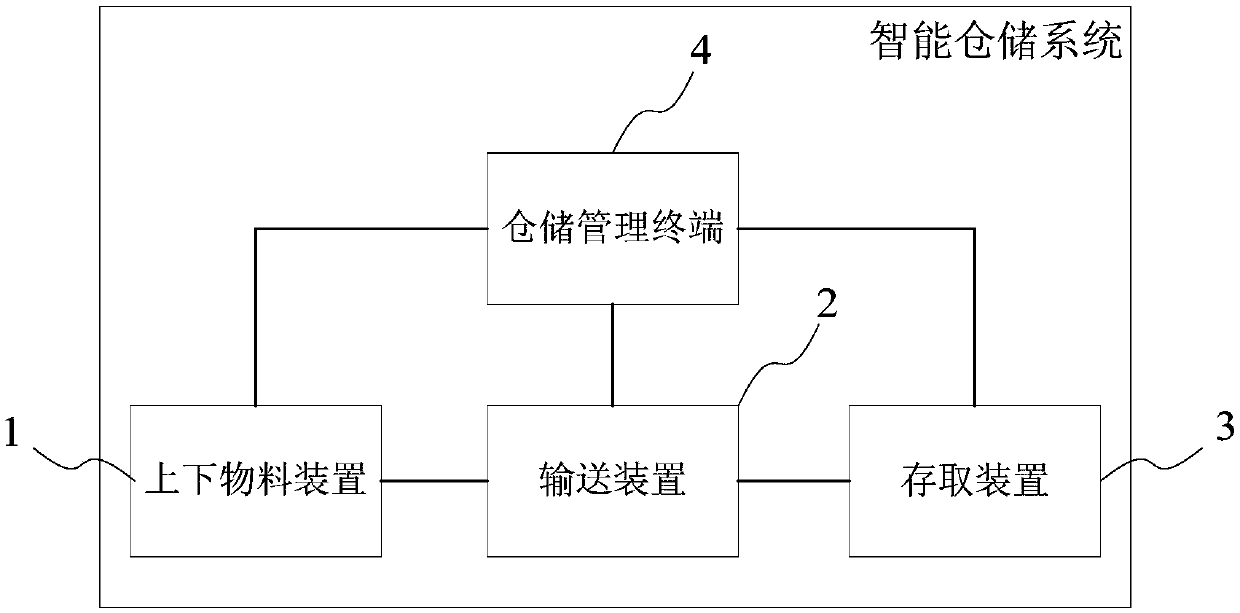

Intelligent warehousing system

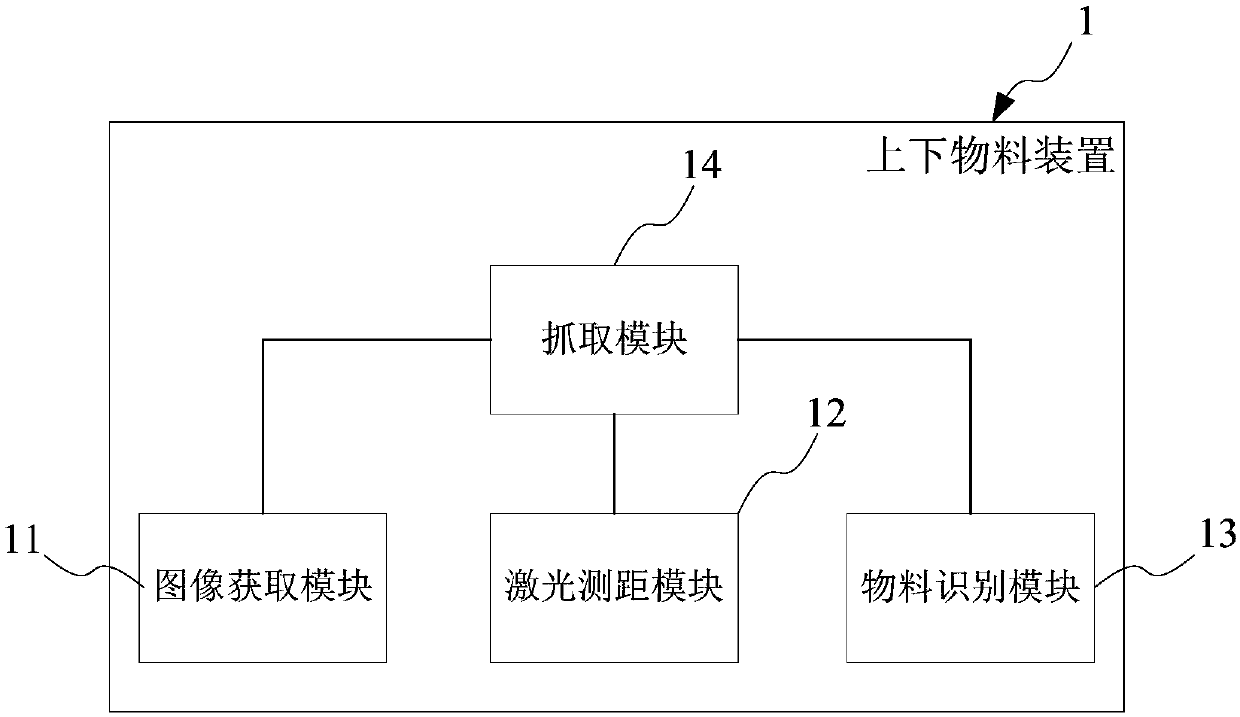

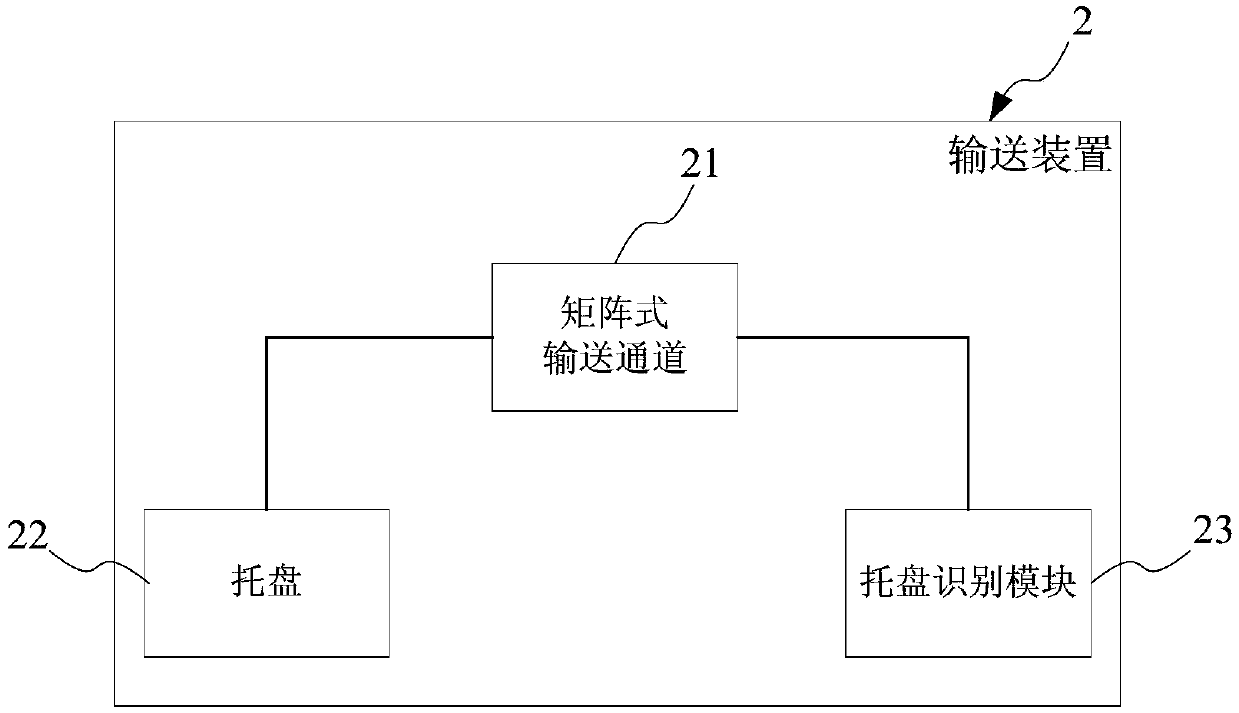

InactiveCN109649913AFully automatedFast and reliable responseConveyorsLogisticsEngineeringComputer terminal

The invention provides an intelligent warehousing system. The intelligent warehousing system comprises a charging and discharging device used for automatically identifying three-dimensional positioning information of materials, moving the materials into or out of a conveying device according to the three-dimensional positioning information, obtaining material identification information and transmitting the material identification information to a warehouse management terminal, the conveying device used for conveying the materials in the conveying area so as to provide the materials moved in through the charging and discharging device for a storage device or provide the materials moved in through the storage device for the charging and discharging device, the storage device used for storingthe materials conveyed by the conveying device at a preset position of a storage area or taking out the materials from the preset position and moving the materials into the conveying device, and thestorage management terminal used for controlling operation of the charging and discharging device, the conveying device and the storage device and updating storage information of the materials based on the material identification information. Through the intelligent storage system, the storage space and human resources can be fully utilized, and the efficiency is high.

Owner:欧米瑞(广东)智能制造有限公司

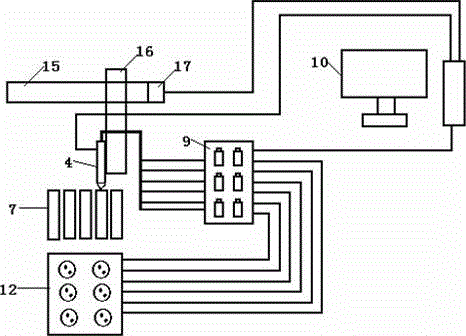

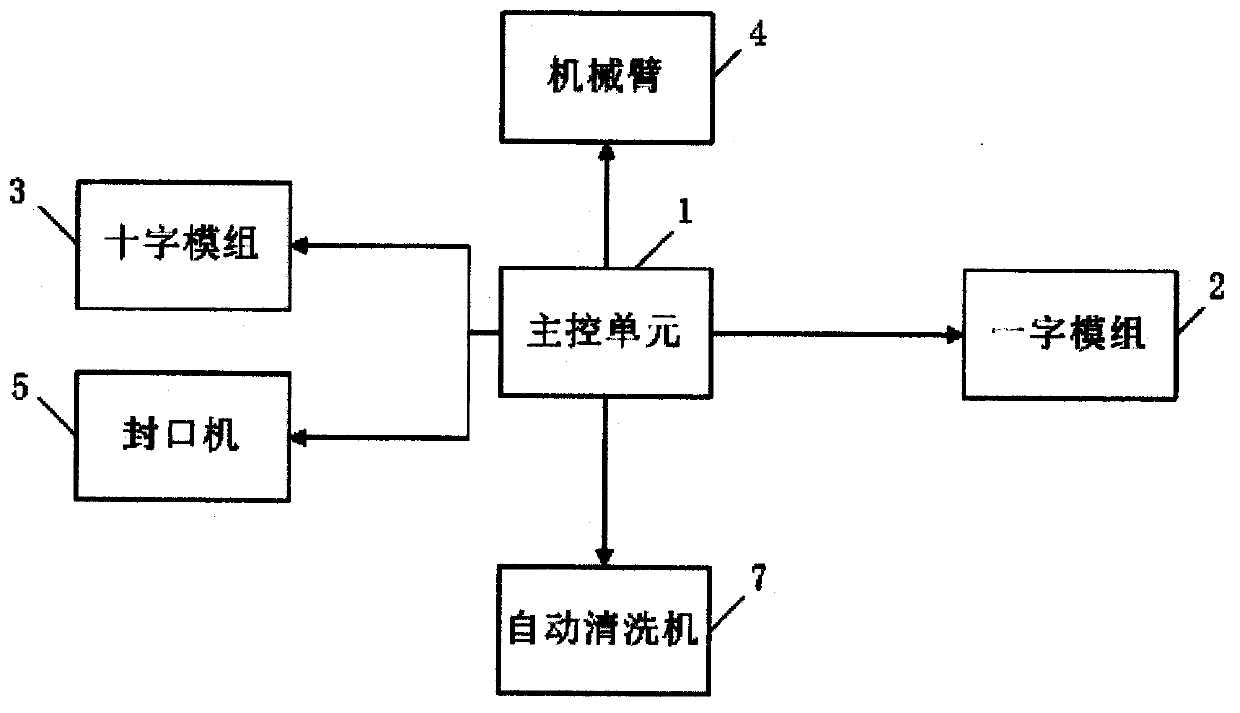

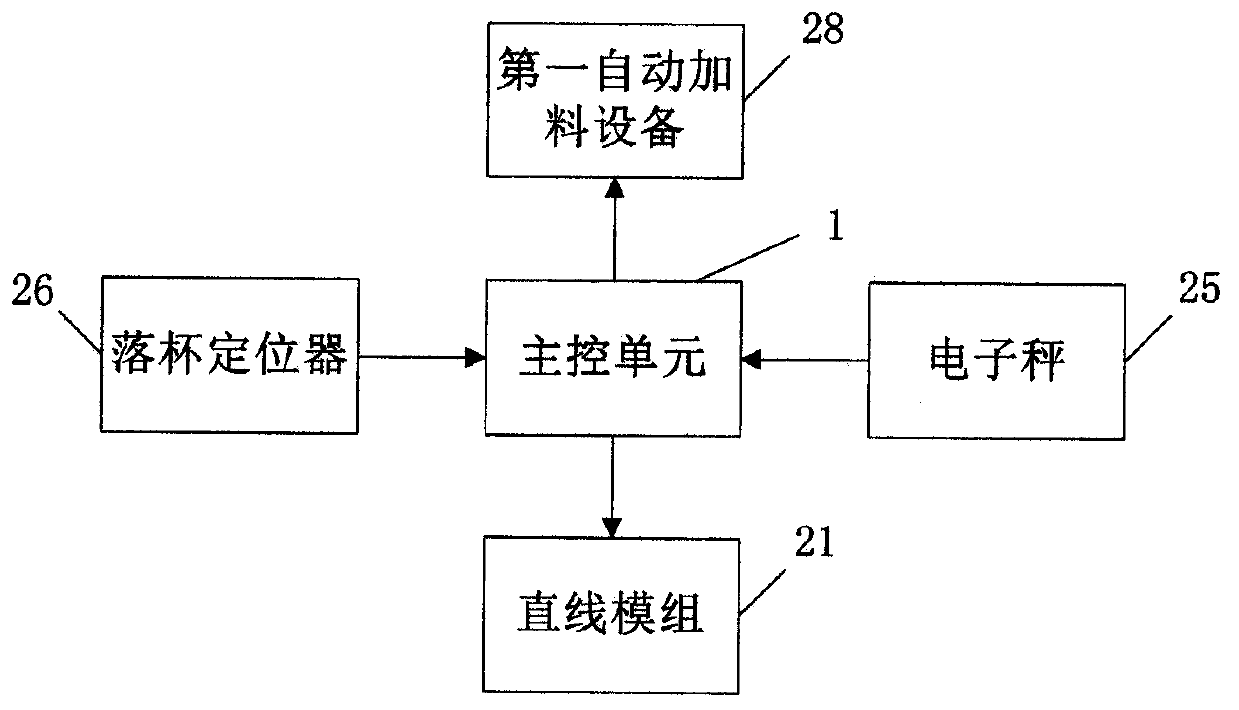

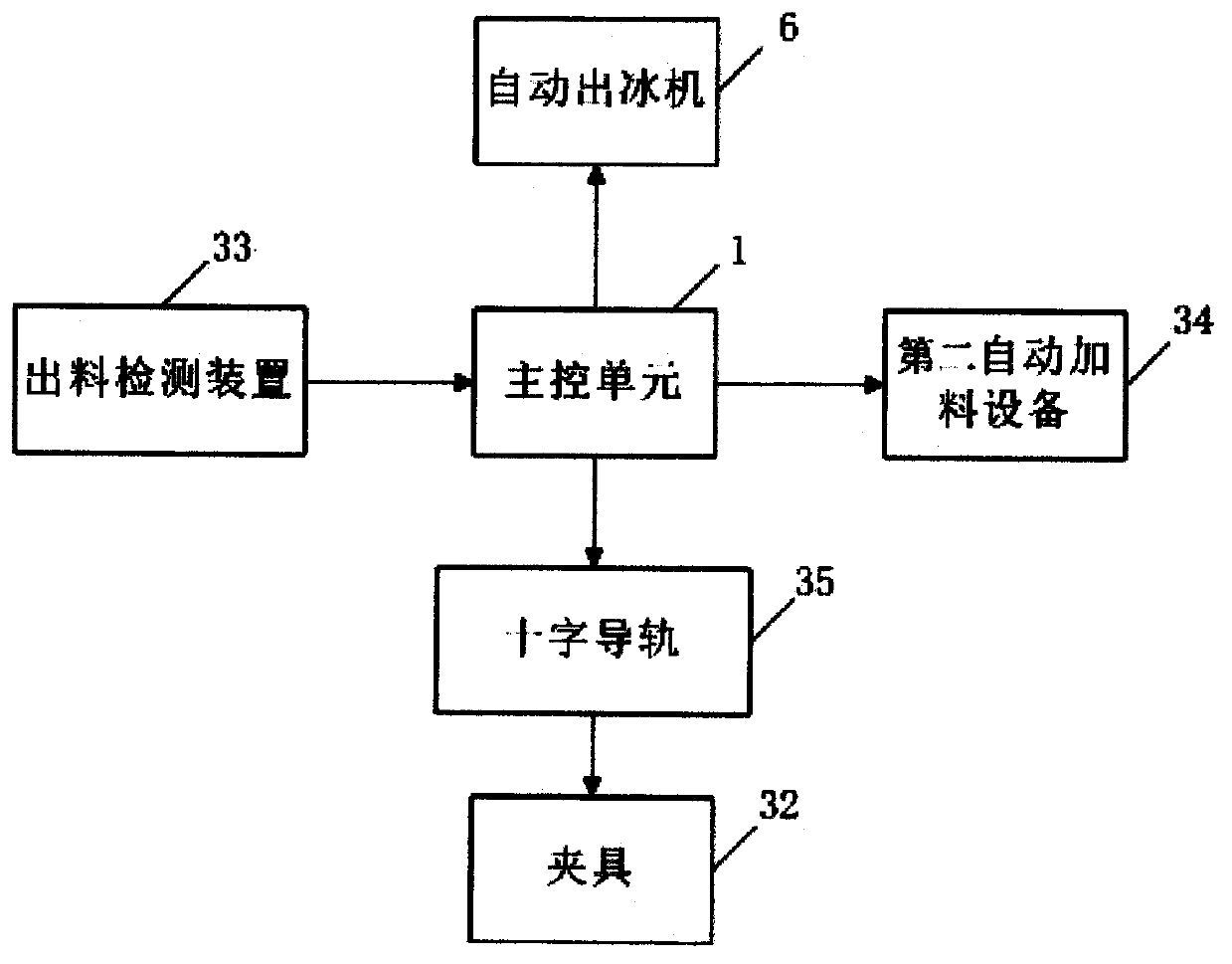

Fill-automatic milk tea production device and method

PendingCN110179337ACompact structureEasy to monitor injection volumeBeverage vesselsPackagingDissolutionEngineering

The invention provides a full-automatic milk tea production device and a method. The full-automatic milk tea production device comprises a main control unit, a straight-line-shaped module, a cross module, a mechanical arm and a sealing machine, wherein the straight-line-shaped module, the cross module, the mechanical arm and the sealing machine are controlled by the main control unit; the straight-line-shaped module is used for obtaining a finished product cup and quantificationally adding materials to the finished product cup; the cross module is used for obtaining a shaker and adding materials to the shaker; the mechanical arm is used for adding the mixture in the shaker to the finished product cup; and the sealing machine is used for sealing the finished product cup carrying the milk tea. The full-automatic milk tea production device is compact in structure, is convenient for monitoring the injection amount of materials in various milk tea production processes, solves the inconvenience of manually taking raw materials by spoons, increases a stirring function, and accelerates the dissolution and mixing of raw materials; the function of making multiple cups of milk tea one by oneis realized, the work efficiency is improved, and the number of employees is reduced.

Owner:刘伟利

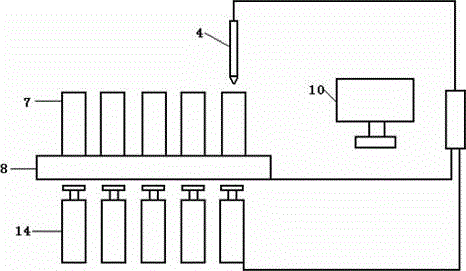

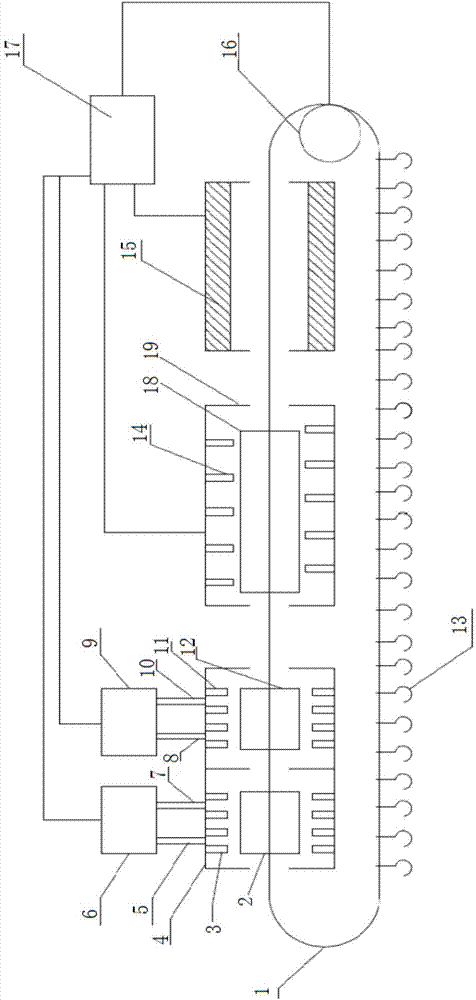

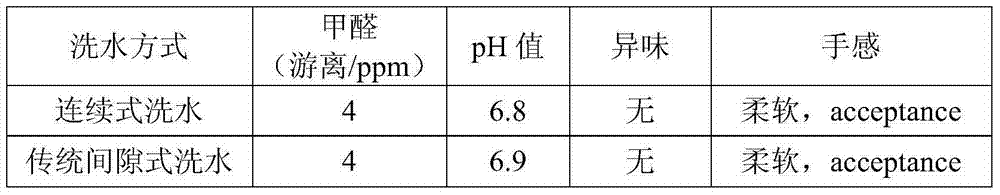

Method and equipment for water washing of clothes

ActiveCN104775247AReduce labor intensityReduce the number of employeesTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringPollution

The invention provides a method and equipment for water washing of clothes. The method comprises the following steps of pre-spraying, spraying material treatment, water removal, and suspension and drying, so as to complete the water washing process; in the pre-spraying process, a washing liquid is uniformly sprayed to the clothes by a spraying method; in the spraying material treatment process, a spraying material treatment liquid is uniformly applied to the clothes by the spraying method; preferably, in the pre-spraying and material spraying treatment process, the clothes are suspended. The invention also provides the water washing equipment using the method. By adopting the technical scheme, the method has the beneficial effects that the water washing procedures of the clothes are continuously performed, the residual liquid in the water washing procedure is recycled, the labor is saved, the water usage amount is reduced, the pollution is reduced, and the production efficiency is improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

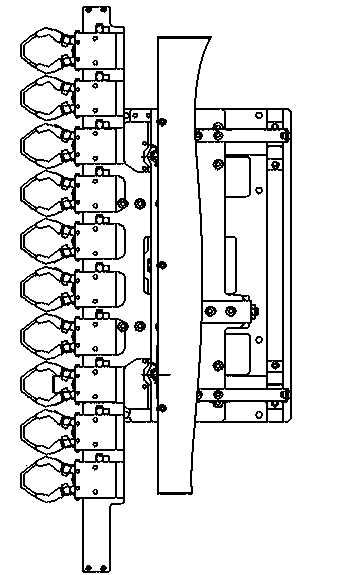

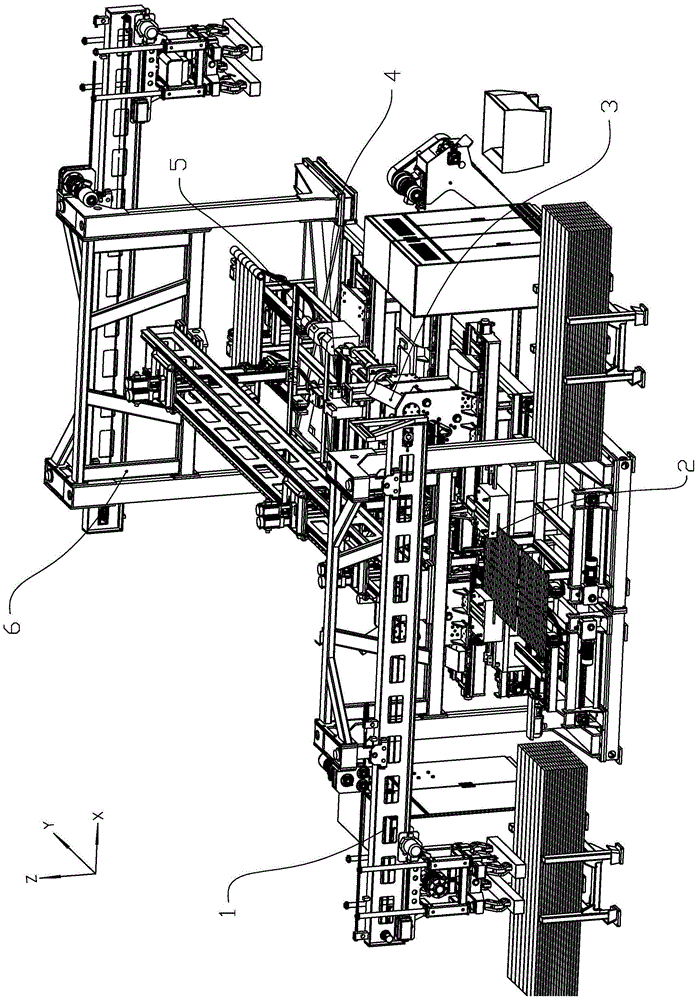

Plate spring double-headed synchronous eye coiling production line and head cutting, eye coiling and shaping units thereof

ActiveCN104923657AReduce operating intensityReduce the number of employeesMetal-working feeding devicesPositioning devicesProduction lineEngineering

The invention discloses a plate spring double-headed synchronous eye coiling production line and head cutting, eye coiling and shaping units thereof. The production line is sequentially provided with a feeding unit, a heating unit, the head cutting unit, the eye coiling unit, the shaping unit and a product integrated packaging unit from front to back. A mechanical arm guiding track bracket which extends front and back is arranged between the feeding unit and the product integrated packaging unit, and the mechanical arm guiding track bracket is provided with a mechanical arm so that a plate spring can be transferred between all the units. The number of electromagnetic heating furnaces, the number of head cutting machines, the number of eye coiling machines and the number of shapers are all two, and the electromagnetic heating furnaces, the head cutting machines, the eye coiling machines and the shapers are all symmetrically arranged relative to the left-right center base line of the production line. The plate spring can be positioned when the two ends of the plate spring are heated, the transferring time difference to the head cutting process is shortened, the thermoplasticity of the plate spring in the head cutting process is guaranteed, the two ends can be cut synchronously in the head cutting process, and thus efficiency is high. In the eye coiling process, the feed machining method of the eye coiling machines is adopted, double-headed synchronous eye coiling is realized, eye machining efficiency is greatly improved, and the quality of obtained coiled eyes is obviously improved as well. Double-headed synchronous shaping is conducted, and hence the depth of parallelism of the coiled eyes of the plate spring can be better improved.

Owner:山东森德数控机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com