Patents

Literature

965 results about "Potassium dichromate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

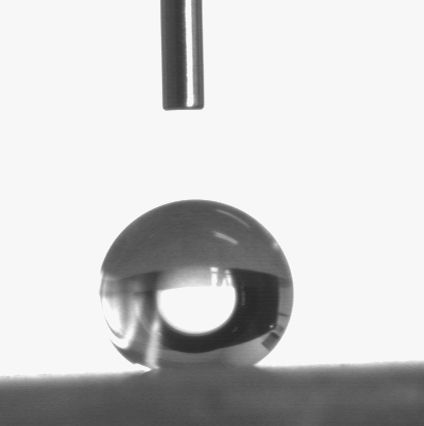

Potassium dichromate, K₂Cr₂O₇, is a common inorganic chemical reagent, most commonly used as an oxidizing agent in various laboratory and industrial applications. As with all hexavalent chromium compounds, it is acutely and chronically harmful to health. It is a crystalline ionic solid with a very bright, red-orange color. The salt is popular in the laboratory because it is not deliquescent, in contrast to the more industrially relevant salt sodium dichromate.

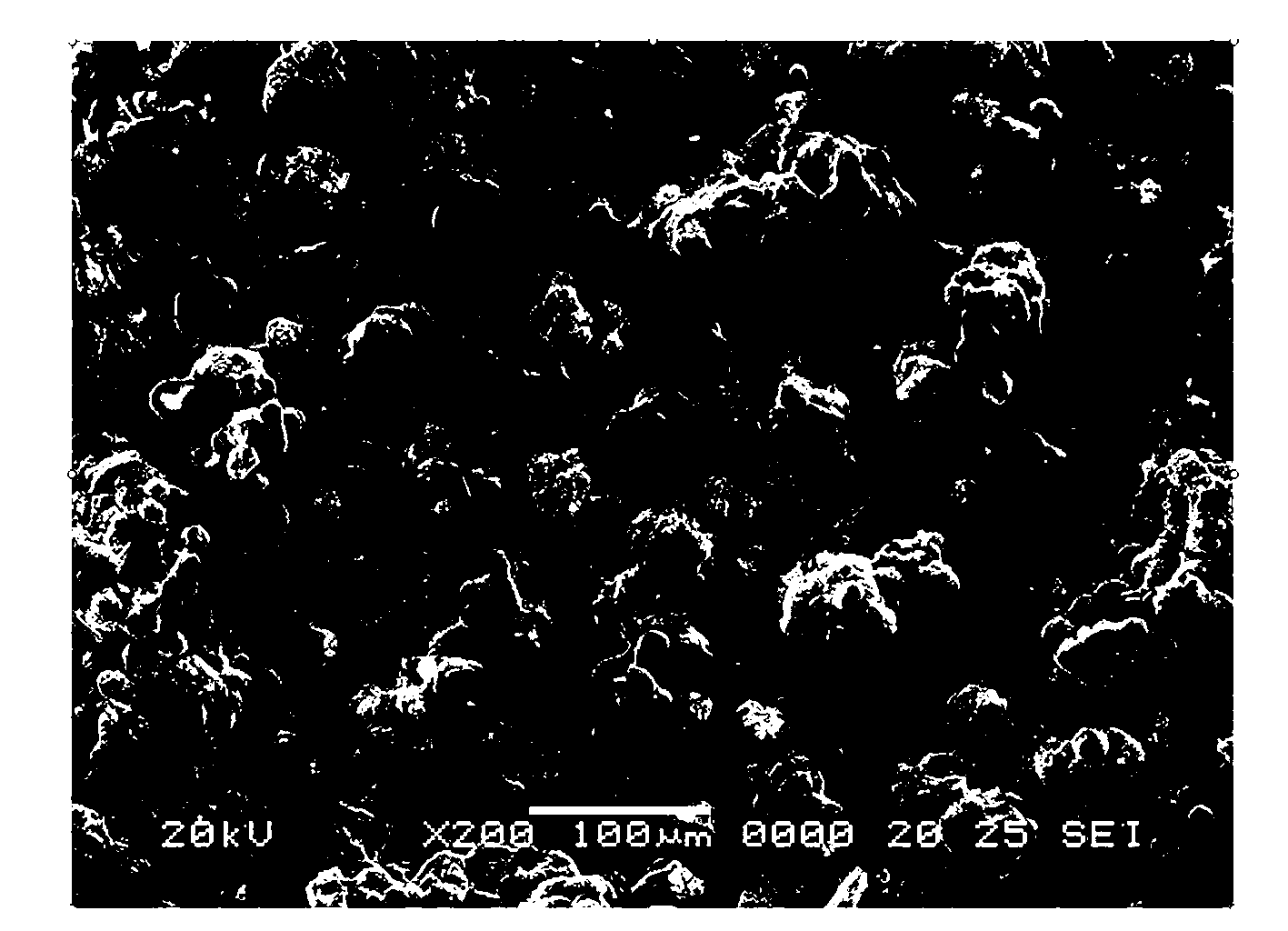

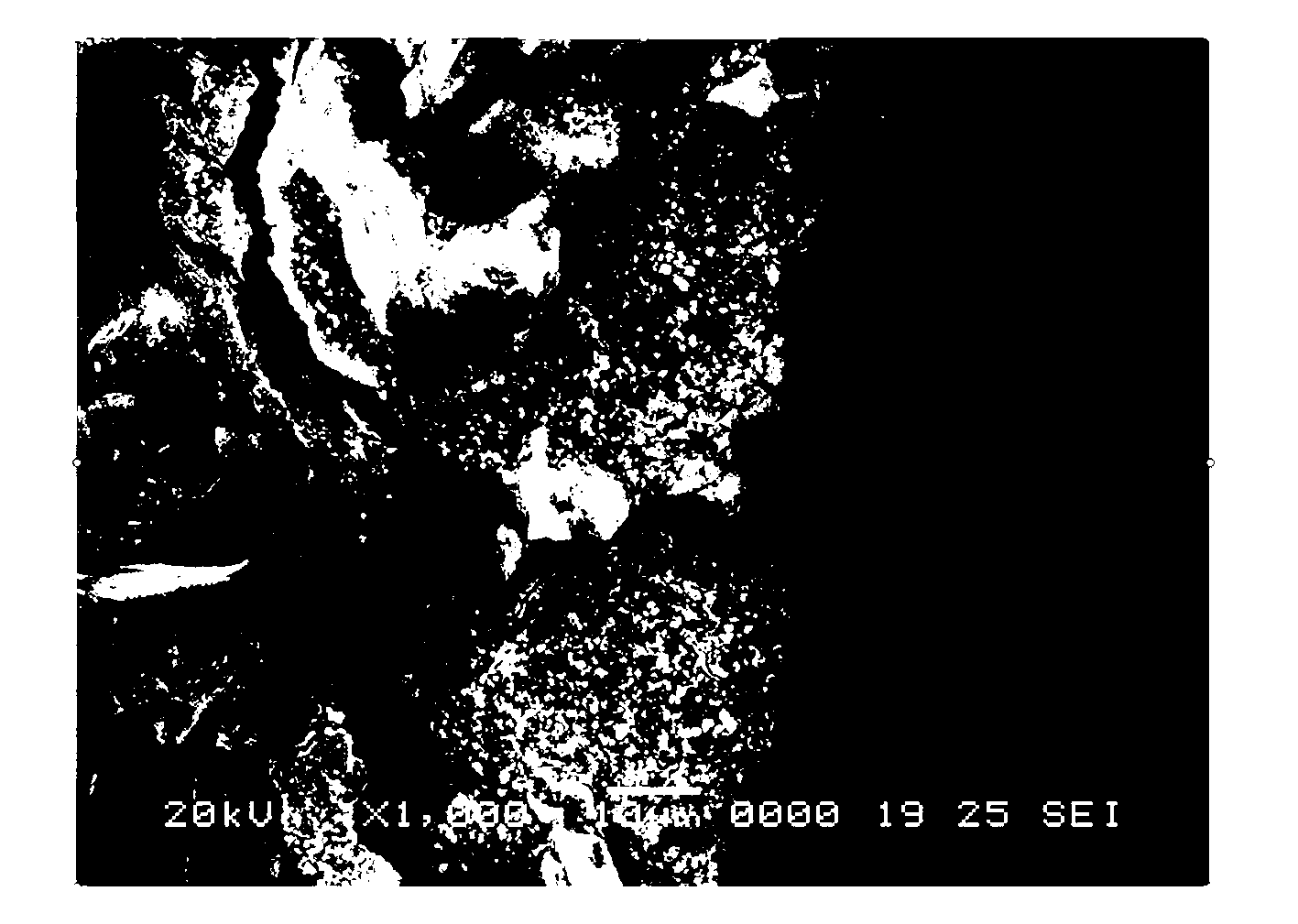

Method for rapidly preparing graphene in large quantities by utilizing graphite oxides

InactiveCN102502611ASimple processExcellent microwave absorbing mediumGrapheneNanotechnologyPotassium dichromatePotassium manganate

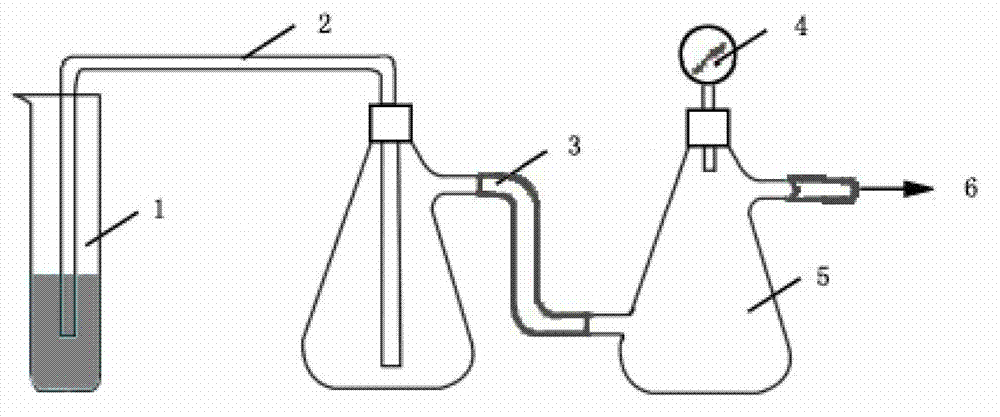

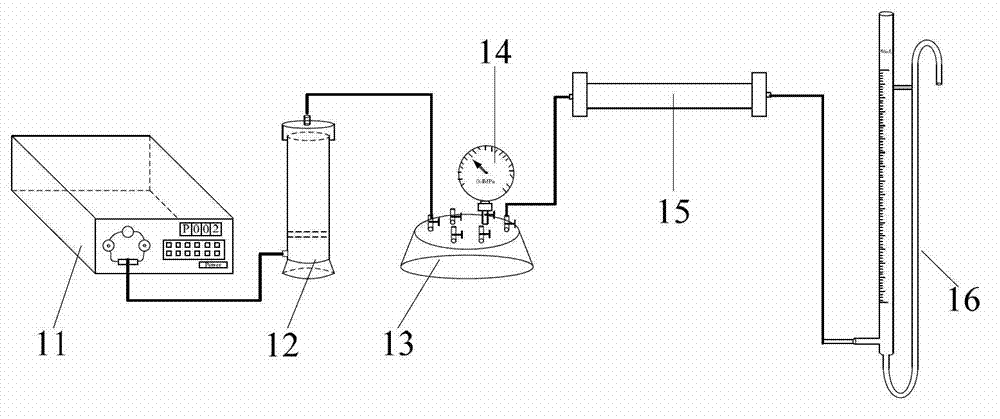

The invention aims at providing a preparation method for rapidly obtaining graphene in large quantities. On the basis of obtaining graphite oxides, the molecular thermodynamic movement of groups such as hydroxyl groups (-OH), carboxylic groups (-COOH) and the like which are generated on the surfaces of graphite oxide layers through oxidization can be induced and stimulated through microwave treatment so as to produce a momentary unsteady state, so that Van der Waals binding force between graphite layers is damaged, and graphene can be rapidly obtained in large quantities. The graphite oxides are obtained through the oxidization of metal salt such as potassium permanganate, potassium dichromate and the like as well as strong protonic acid such as concentrated sulphuric acid, concentrated nitric acid and the like, and then microwave irradiation is carried out under the conditions that the power ranges from 2 to 10 kW, the vacuum pressure ranges from 0.01 to 0.06 MPa and so on, so that microwave cleavage of the graphite oxides can be accomplished within 2 to 10 seconds, and graphene with less than ten layers can be obtained rapidly in large quantities. The preparation method can also control the layer number or the thickness of graphene products by controlling the concentration and the oxidation time of oxidizing mediums as well as the power, the degree of vacuum and the like of the microwave irradiation.

Owner:SOUTHEAST UNIV

Boiler coal combustion-improving desulfurizing and denitrifying agent composition and preparation method thereof

The invention provides a boiler coal combustion-improving desulfurizing and denitrifying agent composition. The composition comprises the following raw materials in parts by weight: 2-7 parts of sodium carbonate, 1-3 parts of alumina, 2-8 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 2-6 parts of ferric oxide, 3-10 parts of potassium permanganate, 3-10 parts of potassium chlorate, 10-35 parts of activated attapulgite clay, 15-30 parts of urea, 2-4 parts of ammonium formate, 2-4 parts of ammonium chloride, 6-23 parts of ammonium acetate, 3-9 parts of manganese oxide, 9-12 parts of copper chloride, 1-3 parts of copper oxide, 2-4 parts of zinc sulfate, 1-3 parts of zinc nitrate, 7-18 parts of potassium dichromate, 1.0-1.5 parts of titanium dioxide, 0.5-1.0 part of barium molybdate, 0.5-1.5 parts of cobalt sulfate, 0.5-1.5 parts of vanadium pentoxide, 0.3-0.7 part of cerium oxide, 0.1-0.2 part of sodium dodecyl benzene sulfonate and 0.1-0.2 part of alkyl glyceryl ether. The composition is convenient to use, has stable properties, plays roles of combustion improving, desulfurization and denitrification, has coal saving rate of 8-25% and can remove fixed sulfur by 50-70%.

Owner:兰州熙瑞化工科技有限公司

Carbon fiber reinforced composite material and preparation technology thereof

The invention provides a carbon fiber reinforced composite material and a preparation technology thereof. Carbon fiber braided fabric is pretreated in a composite pretreatment solution with the concentration of 50 to 60 percent, wherein the composite pretreatment solution comprises 5 to 20 percent of oxydol and one or more of the following components: 50 to 70 percent of nitric acid, 30 to 50 percent sodium nitrate, ferric chloride, potassium permanganate, and acidic potassium dichromate; the carbon fiber braided fabric is pre-tightened in a adjustable and controllable stretching mechanism byadopting a compression moulding forming method, and then is fixed on a mould through a positioning device and coated with thermosetting resin powder with a required thickness; according to the performance indexes of the carbon fiber reinforced composite material to be manufactured, the carbon fiber braided fabric and the thermosetting resin powder with the required thickness are laid in a matrix position in the mould lay by lay until to designed layer number and thickness are achieved; and then heating and compression molding are carried. Through the surface treatment to the carbon fiber withthe specially prepared composite solution, the compatibility of carbon fiber and thermoset material is greatly improved, and the adhesion property of the carbon fiber and matrix resin is improved. Through the adoption of compression moulding forming, the forming technology is simple, the production is flexible, the production cycle is short, the equipment investment is small, and the cost is low.

Owner:DANYANG DANJIN AVIATION MATERIAL TECH

Mixed casting molding sand and preparation method thereof

The invention discloses a mixed casting molding sand and a preparation method thereof. The preparation method mainly comprises: performing dry mixing of component raw materials including quartz sand, attapulgite, wax, asbestos, a furan resin, a phenolic resin, bentonite and potassium dichromate by certain weight parts; and adding water, mixing, placing sand, molding, casting, cooling and separating to obtain finished product. The preparation method of the invention is simple, the formula is reasonable, the cost is low, the production efficiency is high, the surface of an aluminum sand piece is made smooth by strictly controlling the particle size of quartz sand, and the breathability is high.

Owner:邹平县永通金属材料有限公司

Resin casting molding sand and preparation method thereof

ActiveCN102380575AEasy to prepareReasonable formulaFoundry mouldsFoundry coresDry mixingPotassium dichromate

The invention discloses resin casting molding sand and a preparation method thereof. The method mainly comprises: performing dry mixing of component raw materials including quartz sand, straw ash, tung oil, asbestos, a furan resin, a phenolic resin, kaoline and potassium dichromate by certain weight parts; and adding water, mixing, placing sand after mixing, molding, casting, cooling and separating to obtain a finished product. The preparation method is simple, the formula is reasonable, the cost is low, the production efficiency is high, the surface of the aluminum sand is made smooth by strictly controlling the particle size of the quartz sand, and the breathability is high.

Owner:托普工业(江苏)有限公司

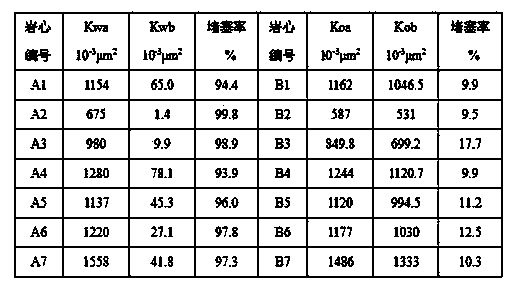

Plugging agent for deep profile control and water plugging and preparation method thereof

ActiveCN102816558AImprove stabilityGel forming time is controllableDrilling compositionHexamethylenetetramineSulfite salt

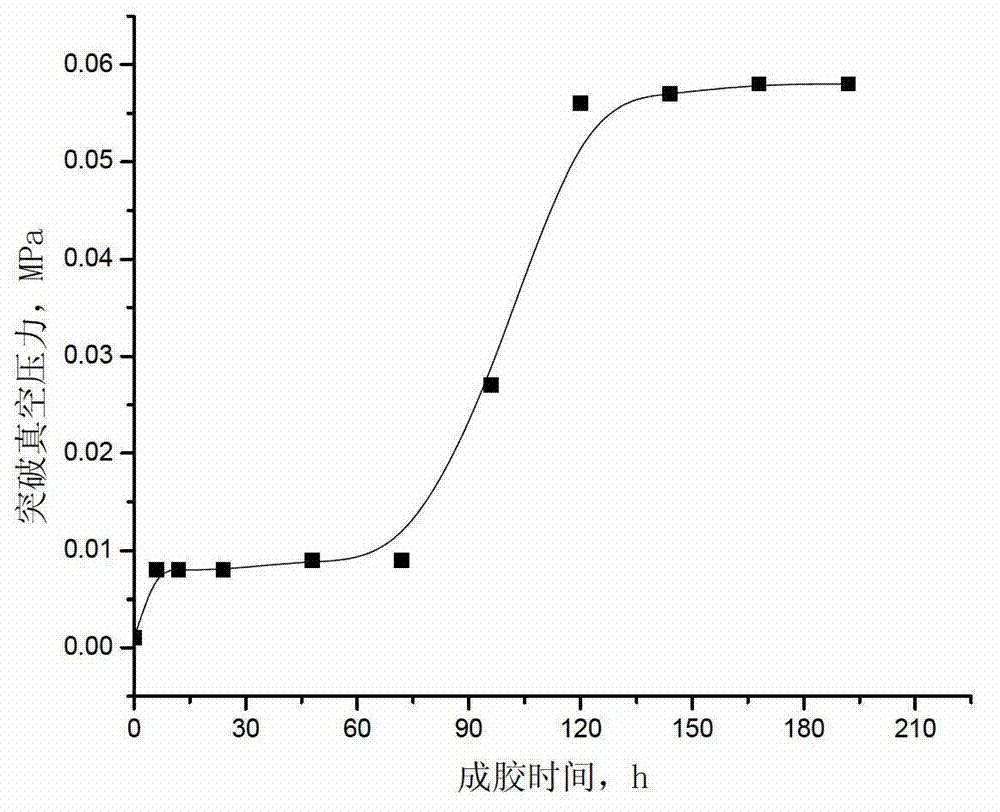

The invention relates to a plugging agent for deep profile control and water plugging and a preparation method thereof. The plugging agent comprises the following raw materials in percentage by weight: 0.10-0.30% of partially hydrolyzed polyacrylamide, 0.09-0.20% of potassium dichromate, 0.15-0.30% of sodium sulfite, 0.08-0.3% of hexamethylenetetramine, 0.06-0.24% of phenol, 0.04-0.14% of ammonium chloride and the balance of water. The invention also provides the preparation method of the plugging agent. The variation of the gelatinization strength of the plugging agent system along with time is in an obvious double-step trend. Thus, the plugging agent can be effectively prevented from leaking into a low-permeability layer in the injection process, and can effectively plug a high-permeability stratum when the plugging agent reaches the deep stratum.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

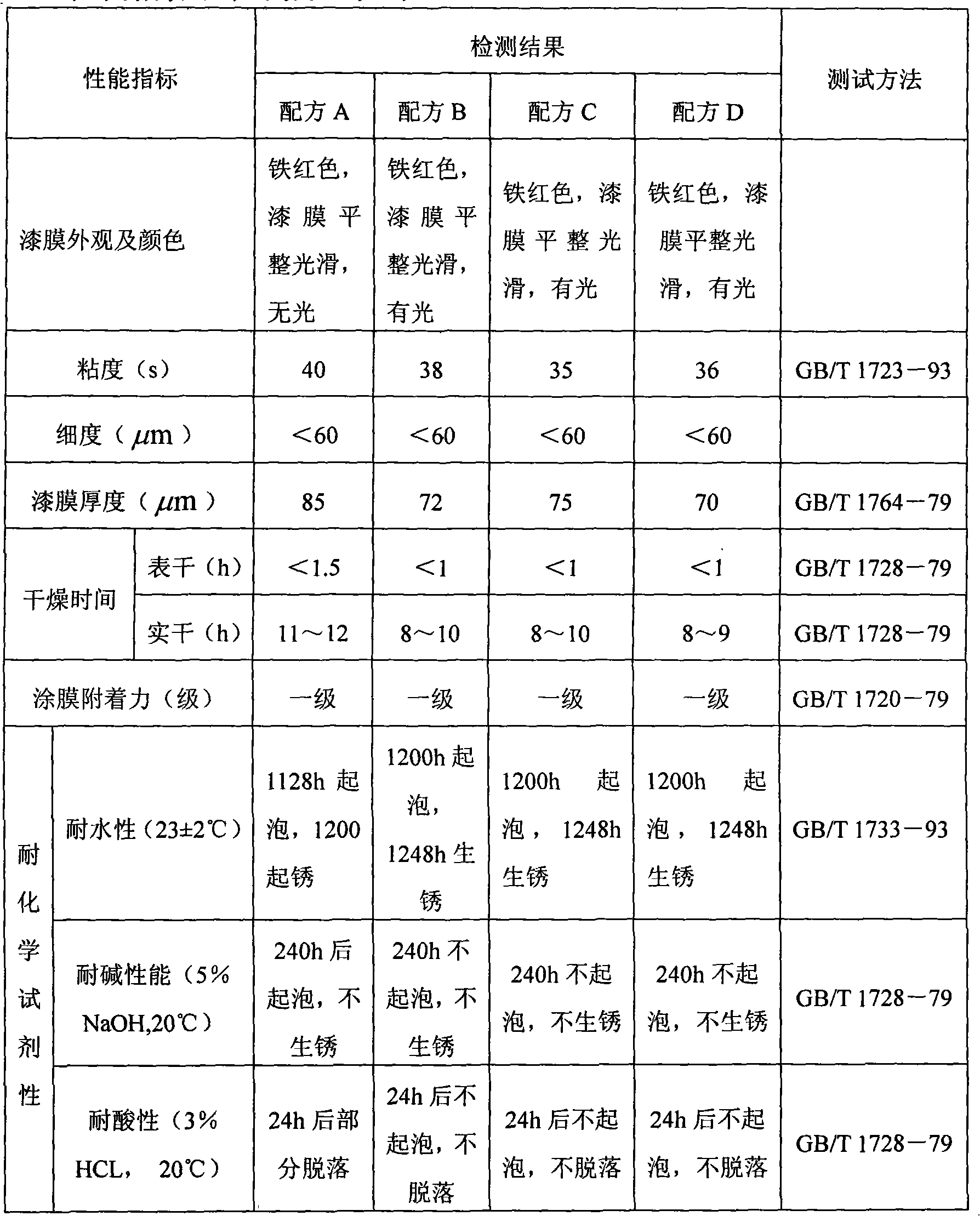

Steel structure aqueous corrosion resisting paint without need of cleaning rust and preparation thereof

InactiveCN101323726AGood acid and alkali resistanceImprove the painting environmentLiquid surface applicatorsAnti-corrosive paintsAqueous corrosionWater based

The invention relates to a water-base rusting anti-corrosion paint of a steel structure, and a manufacturing technology thereof. The water-base rusting paint comprises styrene-acrylic latex, ferric oxide, talcum powder, phosphoric acid, tannin, aluminum hydroxide, zinc oxide, zinc dihydric phosphate, potassium dichromate, a film-forming auxiliary agent, sodium hexametaphosphate, dibutyl phthalate, an antifoam agent and water which is added till 100 percent (mass). The preparation method of the paint of the invention is that a pigment filler is added into a ball mill to prepare pigment filler slurry according to a mixing ratio, the phosphoric acid, the tannin, the zinc oxide and the aluminum hydroxide are mixed and heated till the solution is clear so as to prepare transformation liquid, then the pigment filler slurry and the transformation liquid and other components are mixed and stirred, and finally a finished product is obtained after filtration. The paint of the invention is characterized by good performance and low cost, etc., can be used for hull painting with rust directly, and can be used not only as a base paint, but also as a surface paint.

Owner:HUNAN UNIV

Treatment method of black hard microarc oxidation ceramic membrane on surface of magnesium alloy

InactiveCN102021631AUniform colorImproved color stabilityAnodisationElectrolysisPlasma electrolytic oxidation

The invention belongs to the treatment technology of a black hard ceramic membrane on the surface of magnesium alloy, in particular relating to a treatment method of a black hard microarc oxidation ceramic membrane on the surface of magnesium alloy. The invention mainly solves the technical problems that the colour of a ceramic membrane treated by magnesium alloy microarc oxidation is white or grey white mostly and the deep colour and even black ceramic membranes can not be obtained in the prior art. The method provided by the invention comprises the steps that sodium phosphate, sodium fluoride, sodium hydroxide, sodium molybdate, potassium carbonate, sodium tungstate, copper sulphate and potassium dichromate are added into water and prepared into an alkaline electrolytic solution, and the solution is stirred for later use; and then magnesium alloy and a stainless steel plate are immersed into the alkaline electrolytic solution, the magnesium alloy is taken as an anode, the stainless steel plate is taken as a cathode, and microarc oxidation treatment is carried out until a compact black hard ceramic membrane grows in situ on the surface of the magnesium alloy.

Owner:杭州意来客电器设备有限公司

Preparation method for short carbon fiber/silicon carbide composites

The invention discloses a preparation method for short carbon fiber / silicon carbide composites by means of spark plasma sintering (SPS). The preparation method includes the steps: (1), pre-treating the short carbon fiber by placing the same in a heat-treatment furnace for heat preservation for 30 minutes under the temperature of 400 DEG C prior to soaking and coarsening the short carbon fibers in coarsening liquid composed of nitric acid, potassium dichromate, hydrogen peroxide and ammonium persulfate to be washed with deionized water and dried for standby; (2), placing the short carbon fiber, silicon carbide powder and sintering aids in a ball-milling pot to be ball-milled; (3), drying the materials in the step (2) through rotary evaporation prior to grinding the same to sieve the mixed powder; and (4), placing the mixed powder into a graphite mould and subjecting the mixed powder to the spark plasma sintering. The short carbon fiber / silicon carbide composites prepared by the method are good in performance, and volume content of the short carbon fibers can be controllable; and the short carbon fiber / silicon carbide composites have high specific modulus, high specific strength and excellent toughness, and can hopefully be applied to light weight armor field.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Method for measuring iron content in steel slag

The invention provides a method for measuring iron content in steel slag. The method includes grinding and screening a steel slag sample by multiple times; completely separating granular metal substances from slag in the steel slag sample; measuring the mass of the granular metal substances by a physical process; measuring iron content of the slag by a titanium trichloride and potassium dichromate volumetric process; and computing the full iron content of the steel slag sample via data of the iron content of the slag and the mass of the granular metal substances. The method has the advantages of convenience in operation, high accuracy of the measured iron content and good stability, repeatability and accuracy of a measuring result. Besides, as proved by tests, the method is reliable and practical, and the requirement on measuring iron content in steel slag in daily life can be met.

Owner:WUKUN STEEL

Manufacturing method and application of Cr(VI) anion imprinted material

InactiveCN104945580AAvoid embedding too deeplyAvoiding difficult elution problemsOther chemical processesCross-linkPolymer science

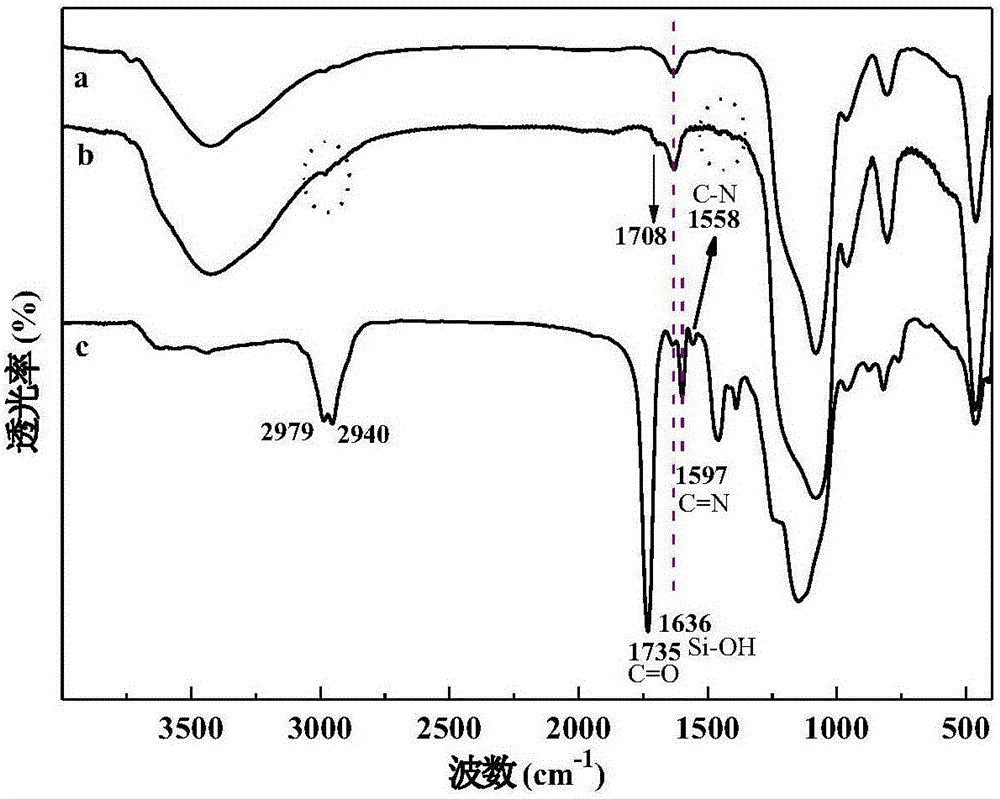

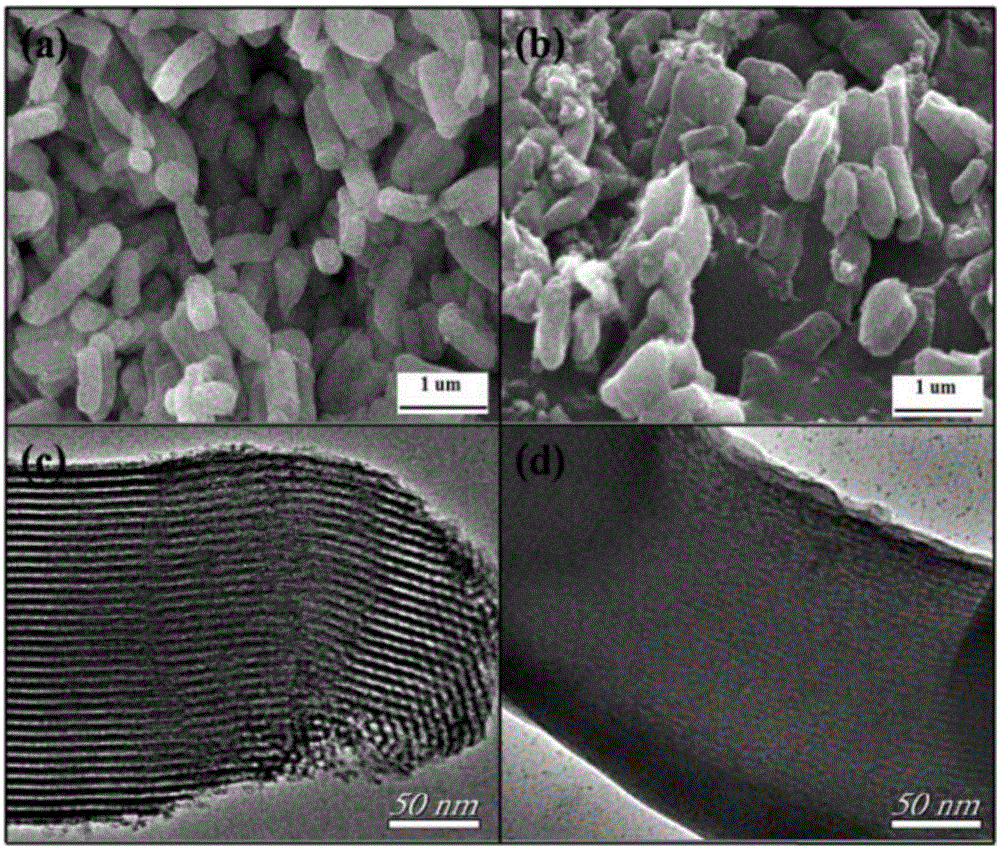

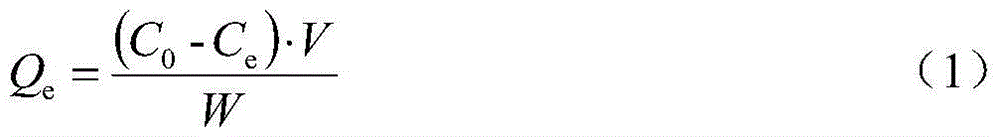

The invention provides a manufacturing method and application of a Cr(VI) anion imprinted material. The material can be used for selectively adsorbing Cr(VI) anions. The material is prepared with SBA-15 modified by methacryloxypropyltrimethoxysilane as a substrate, potassium dichromate as template molecules, methacrylic acid and 4-vinylpyridine as bi-functional monomers, ethylene glycol dimethacrylate as a cross-linking agent and azodiisobutyronitrile as an initiator. The material is used for selectively adsorbing the Cr(VI) anions and has a very good adsorption effect. An imprinted polymer is grafted on the surface of mesoporous silica (SBA-15), and the problem that template ions are embedded too deep and are difficult to elute is avoided. The prepared Cr(VI) anion imprinted polymer is applied to dynamic adsorption experiments, and excellent regenerability is also presented.

Owner:JIANGSU UNIV

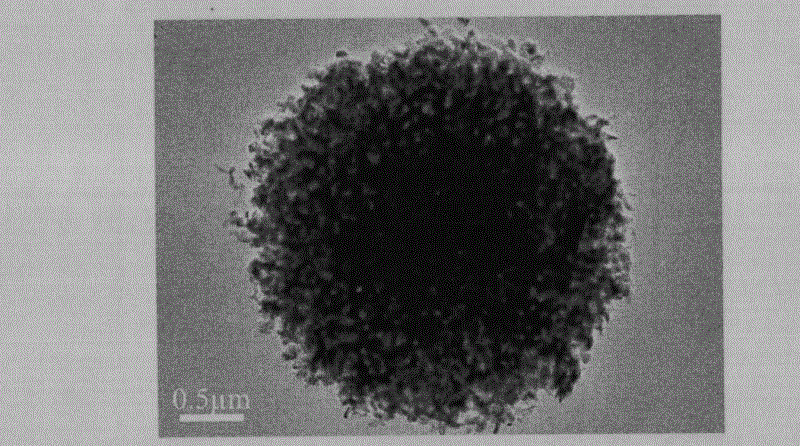

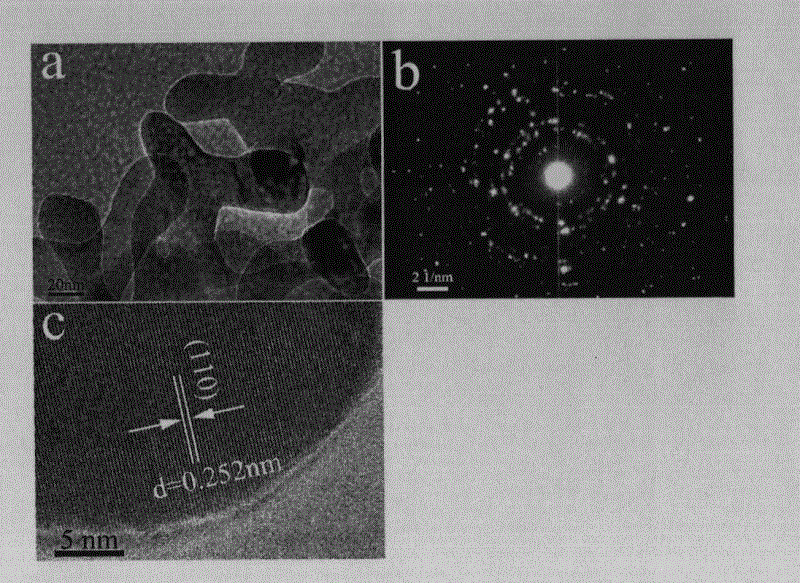

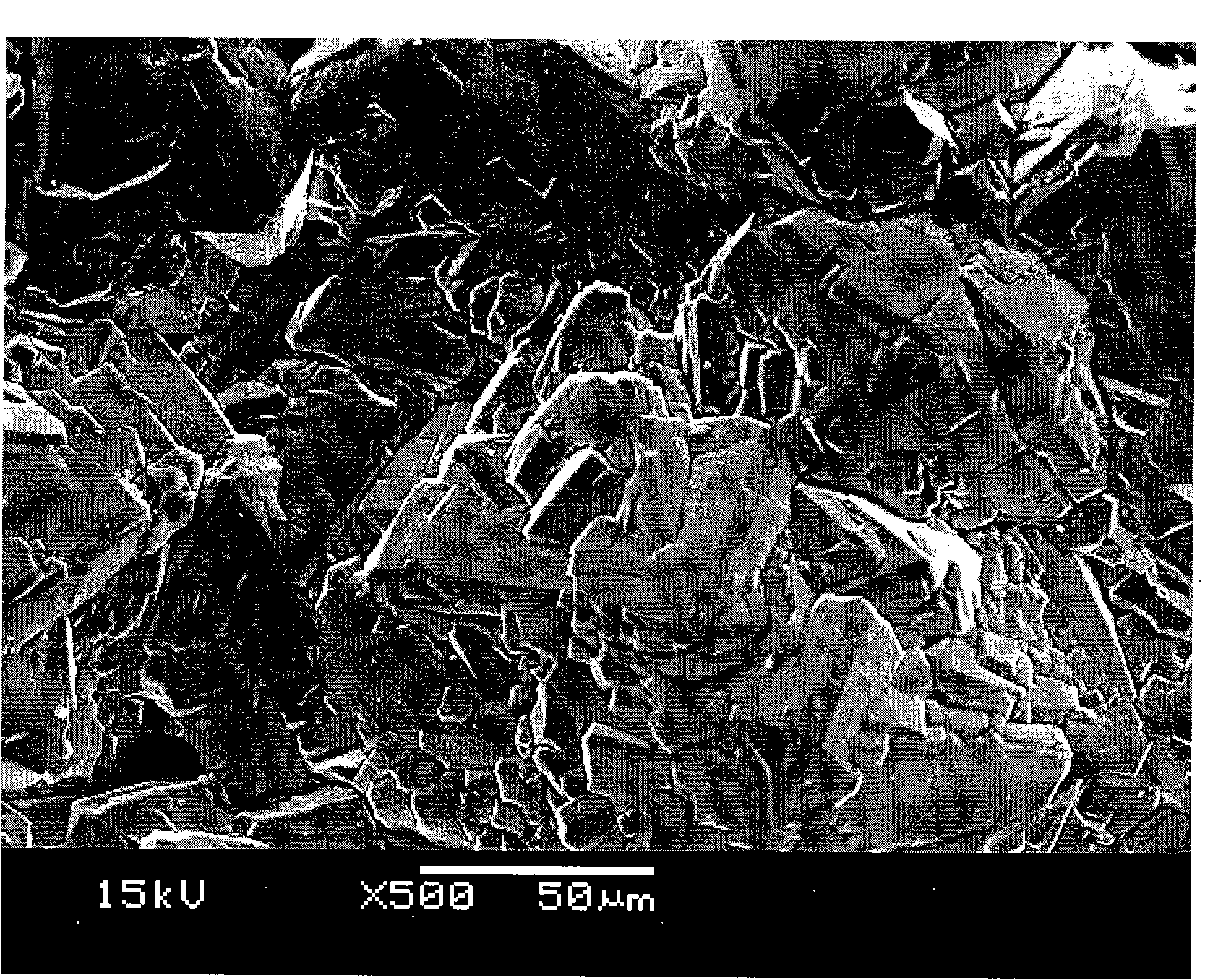

Fe2O3 micro-nano porous sphere, preparation method thereof and uses thereof

InactiveCN102616861ALarge specific surface areaImprove thermal stabilityWater/sewage treatment by irradiationOther chemical processesMicro nanoOrganic dye

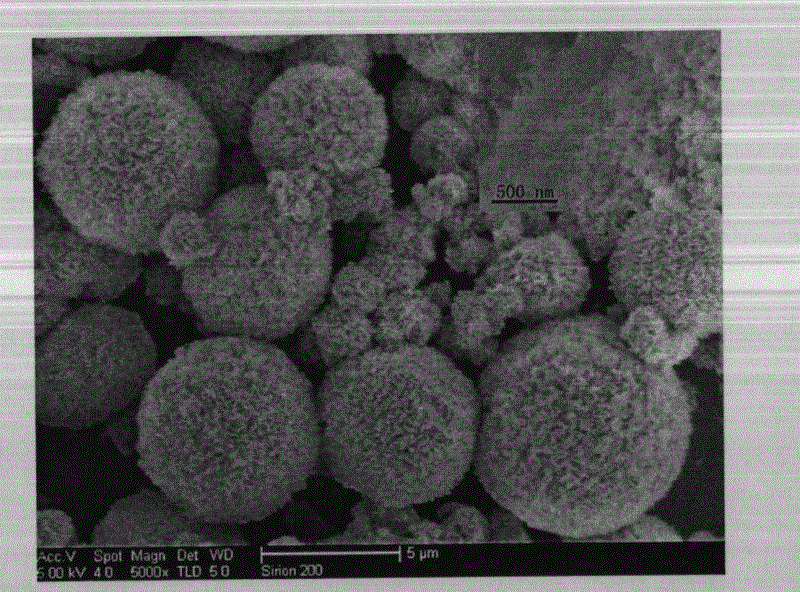

The invention discloses a Fe2O3 micro-nano porous sphere, a preparation method thereof and uses thereof. The porous sphere is formed by Fe2O3 nanoparticles having a nanometer mesoporous alpha-Fe2O3 phase structure therebetween, wherein the diameter of the sphere is 500-5000nm, the specific surface area of the sphere is 15-25m<2> / g, particle sizes of the particles are 20-60nm, and pore diameters of mesopores are 2-50nm. The method comprises the following steps: mixing ferric chloride hexahydrate, ascorbic acid, urea and water, and uniformly stirring them to obtain a mixed liquid; reacting the mixed liquid under conditions that the temperature is 140-180DEG C and the pressure is a self-generated pressure for at least 4h to obtain an intermediate product; separating, washing and drying the intermediate product to obtain porous iron carbonate; and annealing the porous iron carbonate at 450-550DEG C for at least 4h, and naturally cooling the porous iron carbonate to room temperature to prepare the Fe2O3 micro-nano porous sphere. The Fe2O3 micro-nano porous sphere can be placed in water polluted by organic dyes to photocatalytically degrade under visible light, or in water polluted by potassium dichromate to adsorb.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

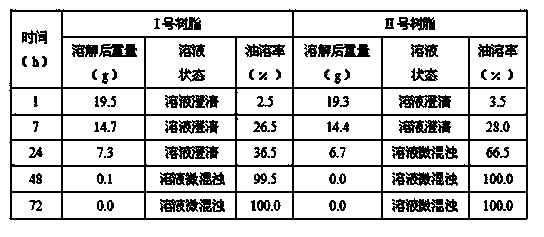

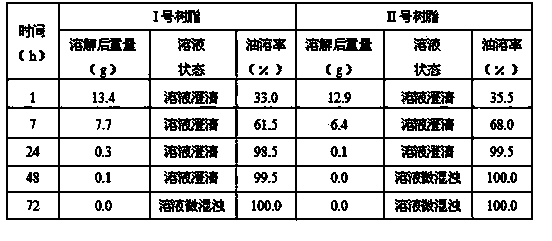

Oil well dual crosslinking selective plugging agent

InactiveCN104250546ATo achieve the effect of blocking waterPrevent another breakthroughDrilling compositionThioureaCross linker

The invention discloses an oil well dual crosslinking selective plugging agent, and solves the problems that the selectivity of selective plugging agents in the prior art is not high, and effective plugging of a water layer and complete unblocking of an oil layer cannot be achieved. The oil well dual crosslinking selective plugging agent comprises the following components by mass: 2% of dispersing agent calcium lignosulfonate, 0.6% of suspending agent polyacrylamide, 0.9% of a cross-linking agent, 8% of oil soluble resin, and balance of water; wherein the 0.9% of crosslinking agent comprises 0.4% of reductant thiourea and 0.5% of oxidizing agent potassium dichromate. Compared with general plugging agents, water phase plugging rate and oil phase recovery rate of the oil well dual crosslinking selective plugging agent are higher, and the selective water plugging performance of the oil well dual crosslinking selective plugging agent is more superior.

Owner:NORTHEAST GASOLINEEUM UNIV

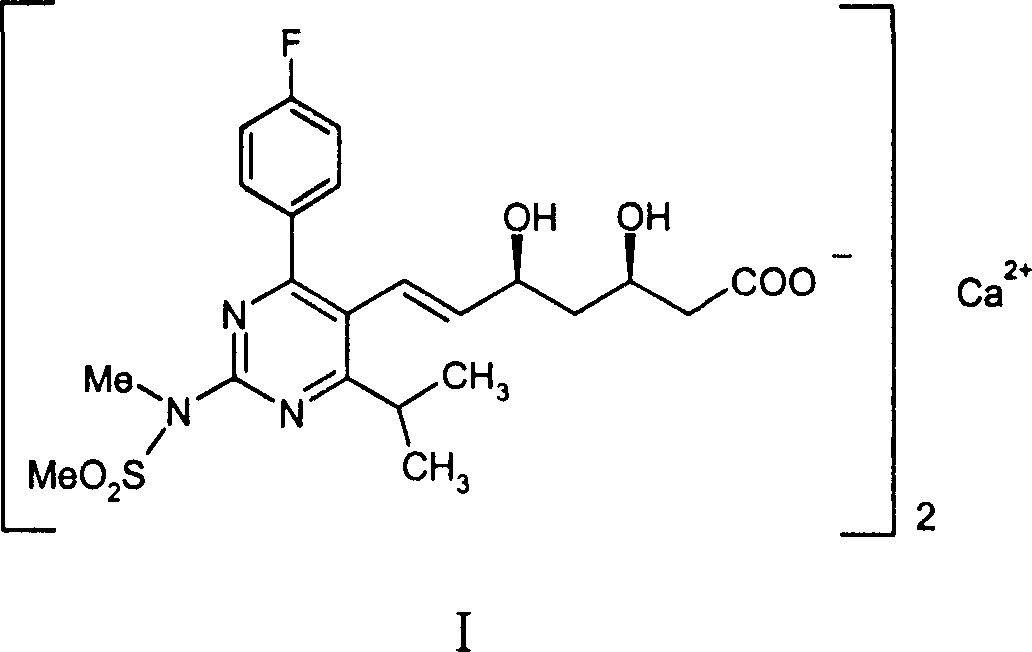

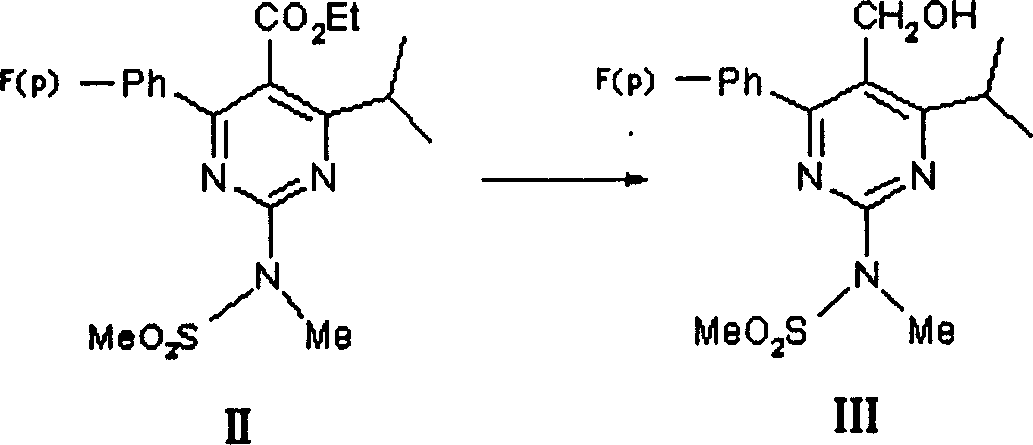

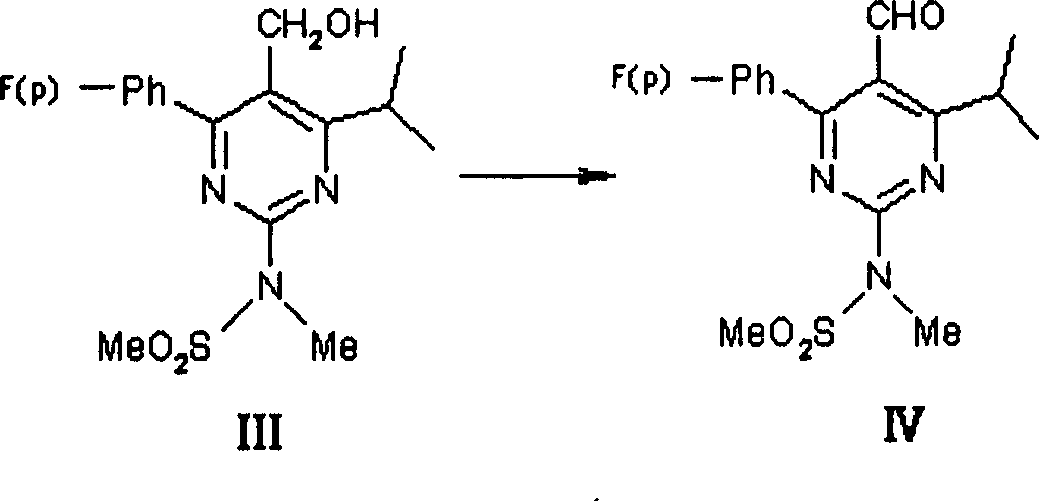

Method for preparing intermediate of synthesizing rosuvastatin calcium

ActiveCN1958593AReduce usageEliminate cryogenic operationGroup 4/14 element organic compoundsGroup 5/15 element organic compoundsRosuvastatin CalciumCarbonate

This invention discloses a method for preparing methyl (R)-7-[4-(4-fluorophenyl)-6-isopropyl-2-(N-methyl-N-mesylamino)pyrimidin-5-yl]-3-tert-butyldimethylsiloxyl-5-carbonyl-6(E)-hepetnate as the intermediate for synthesizing rosuvastatin calcium. The method comprises: reducing pyrimidine carbonate (II) by borohydride / chloride to obtain pyrimidine methanol (III), oxidizing by potassium dichromate to obtain pyrimidine formaldehyde, and condensing in the presence of chiral phosphonate to obtain methyl (R)-7-[4-(4-fluorophenyl)-6-isopropyl-2-(N-methyl-N-mesylamino)pyrimidin-5-yl]-3-tert-butyldimethylsiloxyl-5-carbonyl-6(E)-hepetnate (VI). The method has such advantages as abundant raw materials, low cost, mild reaction conditions, short time and high yield. The byproduct is water-soluble.

Owner:SHANGHAI INST OF PHARMA IND

Pickling and passivating treatment process for stainless steel pipes

InactiveCN102220591AImprove surface qualityImprove efficiencyMetallic material coating processesGramPotassium dichromate

The invention discloses a pickling and passivating treatment process for stainless steel pipes, which comprises the steps of pretreatment, liquid preparation and pickling and passivating treatment, wherein the pickling and passivating liquid consists of 20 to 22 percent of nitric acid (with specific gravity of 1.42), 30 to 50 grams per liter of potassium dichromate, 30 to 50 grams per liter of additive and the balance of water. In the pickling and passivating treatment process, pickling and passivating are accomplished in one step to form silvery white bright beautiful surfaces of the stainless steel pipes and form high-quality passivated films, so that the surface quality of the treated metal pipes is improved and the treated metal pipes have high corrosion resistance; the descaling speed and the descaling efficiency are high; the corrosion of the metal substrates is small and the corrosion inhibition rate is high; and acid mist in a cleaning operation process is avoided, and the long-existing NOx and HF serious pollution problem of stainless steel continuous pickling and passivating is solved.

Owner:扬州华宇管件有限公司

Gas phase oxidization-liquid phase oxidization-absorption three-section type dry-wet-process flue gas denitration process

InactiveCN104971594AEfficient removalReduce equipment costsDispersed particle separationAir quality improvementPotassium manganateSlurry

The invention discloses a gas phase oxidization-liquid phase oxidization-absorption three-section type dry-wet-process flue gas denitration process. According to the process, ozone is used as a gas-phase oxidant to oxidize one part of nitric oxide in flue gas into high-valence-state nitric oxide capable of being absorbed by slurry; any one or a mixture solution of more of hydrogen peroxide, sodium hypochlorite, sodium chlorite, sodium chlorate, sodium persulfate, potassium chlorate, potassium hypermanganate and potassium dichromate is sprayed to be used as a liquid-phase oxidant to oxidize the residual high-valence-state nitric oxide in the flue gas into the high-valence-state nitric oxide; and the flue gas enters an absorption tower and a magnesium hydroxide solution is sprayed to absorb the high-valence-state nitric oxide. Compared with the prior art, the process firstly adopts two times of oxidization of a gas phase and a liquid phase and a magnesium oxide wet process is used for absorbing so that a target of efficiently removing the nitric oxide is realized; and by virtue of the technical scheme, the use amount of the ozone is reduced, the equipment cost and operation cost are reduced and the denitration efficiency is improved and can reach more than or equal to 93%.

Owner:SHANGHAI SANQING ENVIRONMENTAL PROTECTION TECH

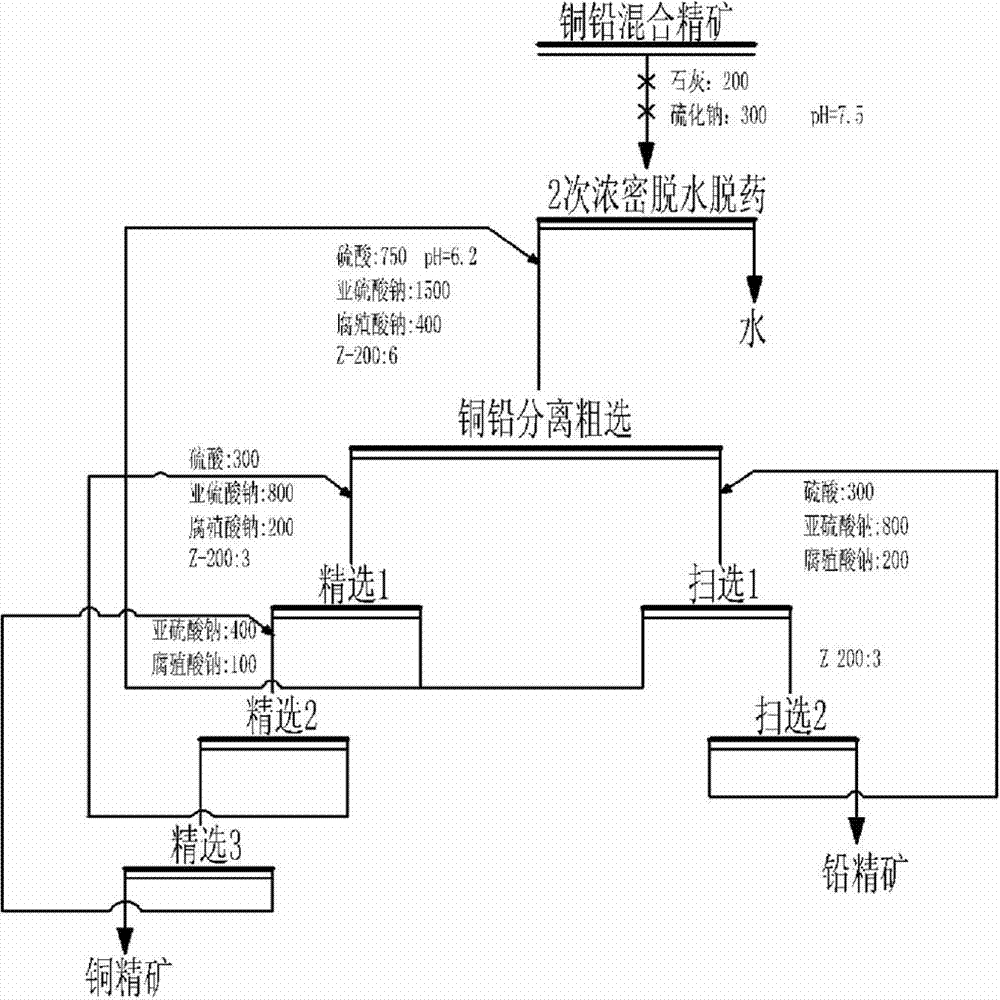

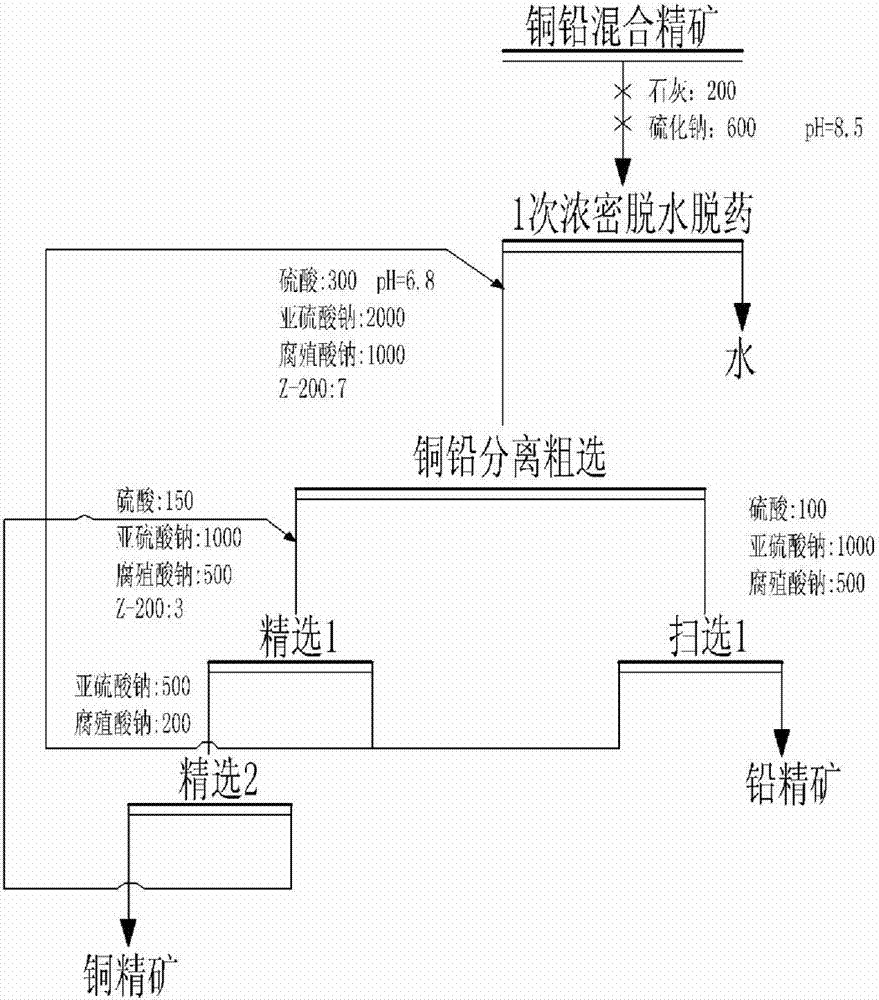

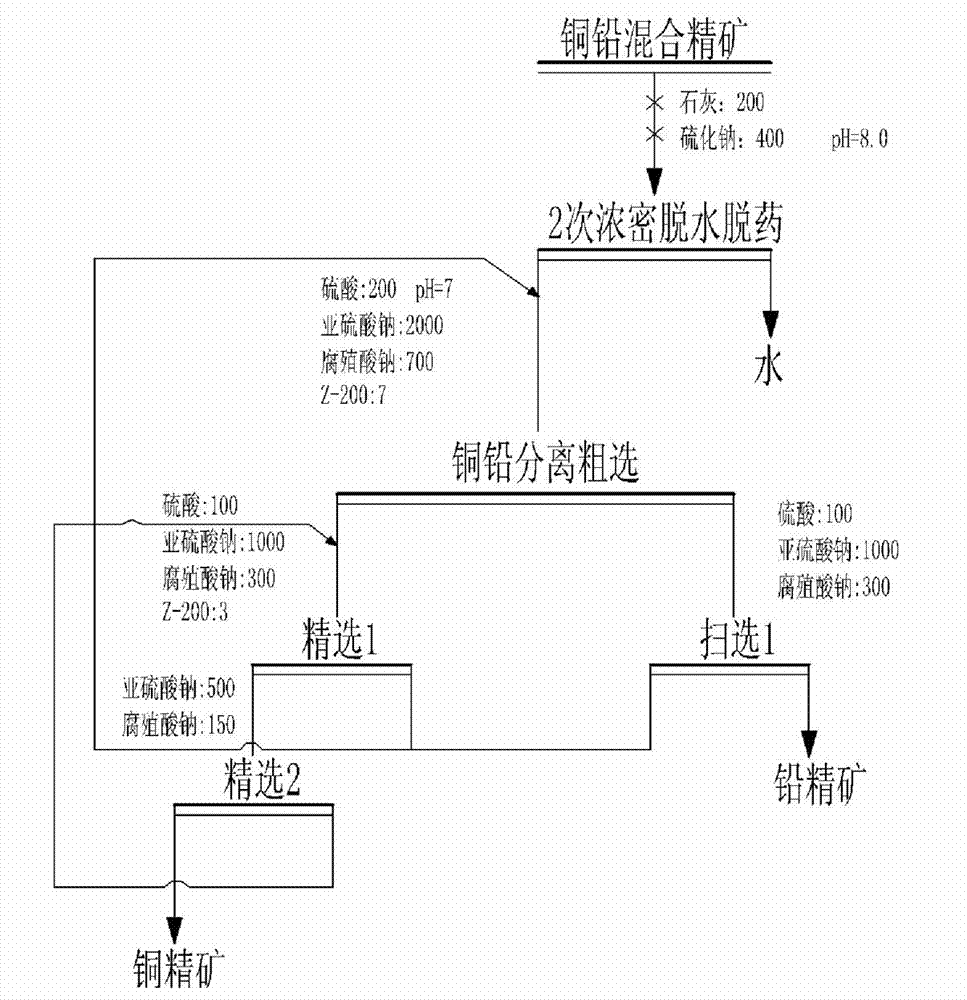

Flotation separation process for mixed copper and lead concentrate

The invention discloses a flotation separation process for mixed copper and lead concentrate. The flotation separation process comprises the following steps of adding lime and sodium sulphide to the mixed copper and lead concentrate after being separated from raw ore, and then, stirring for 2-4min until the lime and the sodium sulphide are stirred evenly; dehydrating and removing agents through a thickener, and then, adding a combined inhibitor and a collecting agent; performing rough concentration to obtain copper coarse ore and lead coarse ore; refining the copper coarse ore to obtain copper concentrate; scavenging the lead coarse ore to obtain lead concentrate, wherein the combined inhibitor is the combination of sulfuric acid, sodium sulfite and sodium humate. According to the flotation separation process disclosed by the invention, the grade and the recovery rate of the copper concentrate and the lead concentrate can be obviously increased, the copper and lead content is reduced, and the copper and lead separation effect is obvious; meanwhile, the mixed copper and lead concentrate has the characteristics of being stable in flow, high in adaptability, non-toxic and environmental friendly, can be used for replacing toxic agents, such as potassium dichromate, and is capable of overcoming the disadvantages that certain non-toxic agents are instable in flow, not obvious in effect, low in adaptability, and the like.

Owner:KUNMING METALLURGY INST

Environmental protection and high efficiency corrosion inhibitor for inhibiting salt water corrosion on carbon steel, preparation method and use method thereof

ActiveCN103508570AEffective corrosion inhibitionAvoid corrosionScale removal and water softeningPhosphomolybdic acidBenzoic acid

The present invention provides an environmental protection and high efficiency corrosion inhibitor for inhibiting salt water corrosion on carbon steel, a preparation method and a use method thereof, and relates to the field of chemistry. The corrosion inhibitor has characteristics of high efficiency, low cost, low toxicity and environmental protection, and is prepared through carrying out mixing stirring dissolving on 5-50% of a benzotriazole substance, 1-10% of benzoic acid and a salt thereof, 1-10% of molybdate, tungstate, phosphomolybdic acid and a salt thereof, and phosphotungstic acid and a salt thereof, 2-20% of an alcohol amine substance, 1-10% of an acid phosphate, 1-10% of a gluconate, 1-10% of an alkaline regulator, 1-10% of an oxygen scavenging agent and the balance of water. According to the present invention, the potassium dichromate or the sodium nitrite with high toxicity, and the non-environmental protection high phosphorus and high zinc can be replaced, and corrosion of calcium chloride salt water on carbon steel and copper can be significantly inhibited when the concentration of the corrosion inhibitor is 0.3-0.5%.

Owner:CHAOYANG GUANGDA CHEM

Tin disulfide/titanium dioxide compound photocatalyst and preparation method thereof

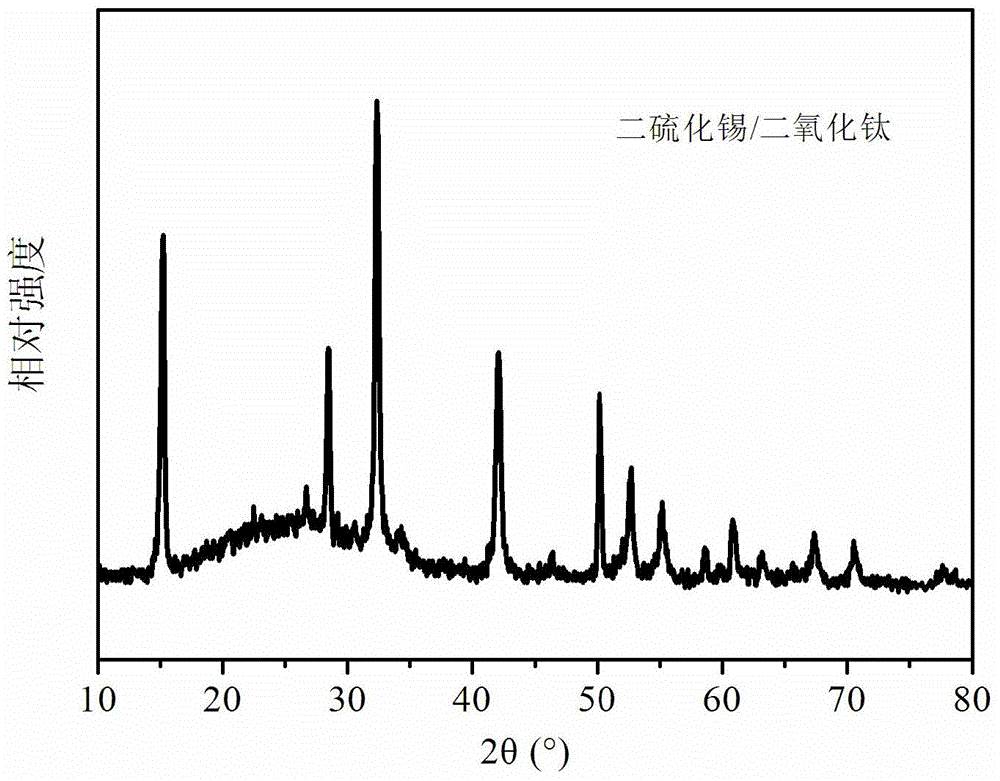

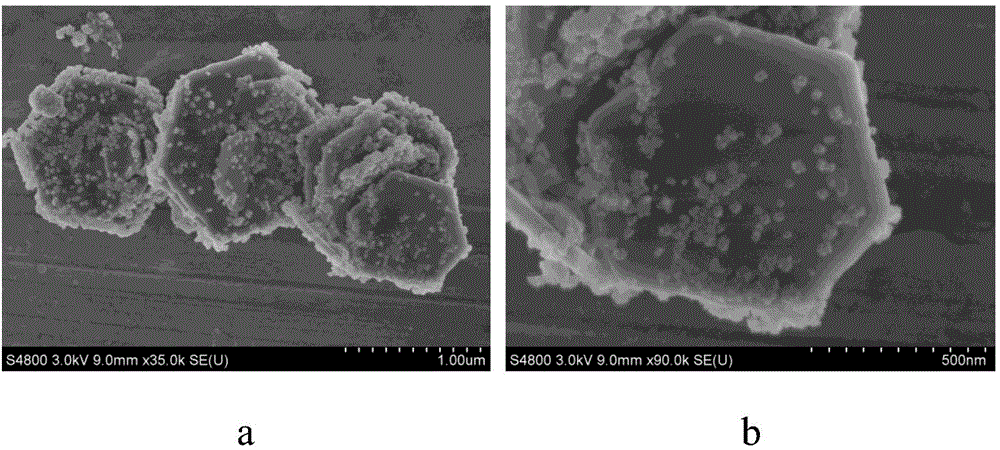

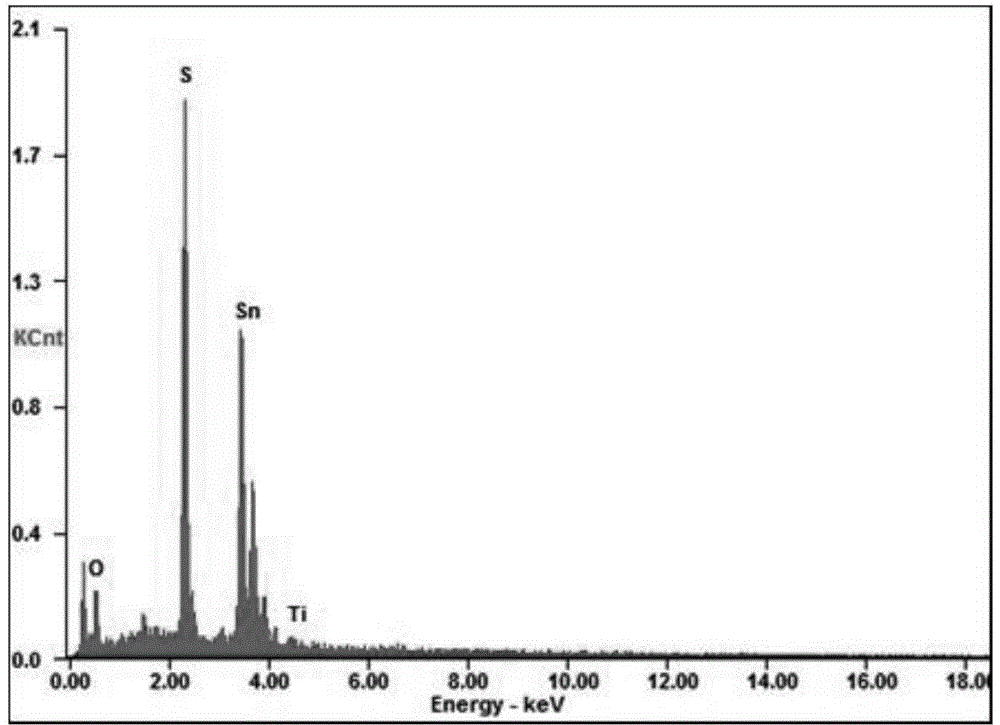

ActiveCN104888753AUniform sizeRegular shapeMaterial nanotechnologyWater/sewage treatment by irradiationThioureaPotassium dichromate

The invention discloses a tin disulfide / titanium dioxide compound photocatalyst which is prepared from a precursor solution through hydrothermal reaction, wherein the precursor solution is prepared from tin disulfide powder and butyl titanate in the mass ratio of 1:(20-100). The compound photocatalyst has controllable size, tin disulfide is of a hexagonal nanoscale flake shape, titanium dioxide nano-particles are uniformly loaded on tin disulfide, and the photocatalyst material has high photocatalytic reduction efficiency on potassium dichromate in a water body. The invention also discloses a preparation method of the compound photocatalyst. The preparation method comprises the following steps: a. preparing tin disulfide powder from tin chloride pentahydrate and thiourea; b. mixing the tin disulfide powder and butyl titanate to prepare the precursor solution; and c. hydrothermally heating the prepared precursor solution to prepare the compound photocatalyst. The preparation steps are simplified greatly, the control difficulty of technological parameters is lowered, and the large-scale preparation of the tin disulfide / titanium dioxide compound photocatalyst is realized.

Owner:澄城县海泰电子材料有限责任公司

Method for rapidly determining total iron in sulfur acid residue

InactiveCN101609078AAchieve complete decompositionReduce labor intensityAnalysis using chemical indicatorsChemical analysis using titrationTest sampleHigh energy

The invention provides a method for rapidly determining total iron in sulfur acid residue, which is as follows: reagent is used for analyzing in public and in a blank way volume difference of potassium dichromate standard titrimetric solution which is consumed by front and back titration, wherein the volume difference is blank valve (V0=V1-V2); milliliter quantity obtained by V1-V0 is used for calculating mass friction of total iron in sulfur acid residue test sample. The method overcomes shortcomings that the existing analytic method has poor accuracy, and a method of recycling and resolving sulfur acid residue test sample by alkali fusion or acid soluble is fussy, and has high energy consumption and the like. The method determining total iron in sulfur acid residue has the advantages of economy, environmental protection, simplicity, rapidness and accuracy.

Owner:WUHAN IRON & STEEL (GROUP) CORP

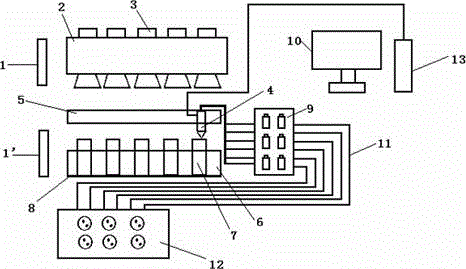

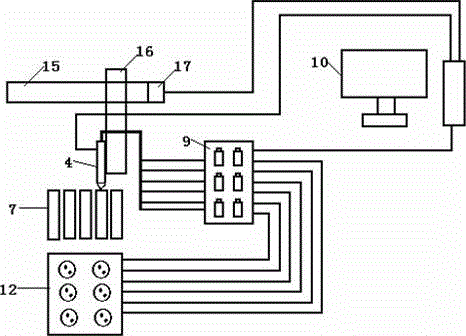

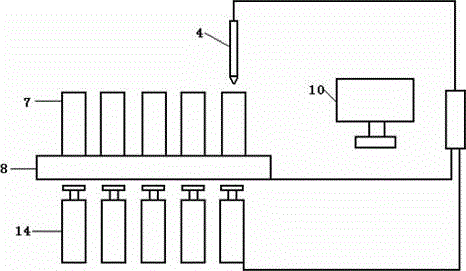

Laboratory COD automatic analysis robot

InactiveCN104914209AReduce the number of employeesImprove accuracyChemical analysis using titrationAutoanalysisPotassium dichromate

The invention discloses a laboratory COD automatic analysis robot. The laboratory COD automatic analysis robot comprises a plurality of digestion pipes which are arranged on a digestion pipe disc and are used for storing a water sample to be detected, an automatic liquid feeding system, a digestion heating system, a cooling system, a titration finishing point judging system and a controller for controlling each system to finish experiment operation steps, wherein the input end of the controller is connected with instruction input equipment; the output end of the controller is connected with the automatic liquid feeding system, the digestion heating system, the cooling system and the titration finishing point judging system respectively; and the output end of the titration finishing point judging system is further connected with display equipment. The laboratory COD automatic analysis robot integrates automatic sample feeding, batch determination and automatic analysis functions; and a potassium dichromate titration method is adopted so that the COD of a water sample can be rapidly determined, and a plurality of samples can be tested simultaneously so that the laboratory COD automatic analysis robot is convenient and rapid and has high accuracy.

Owner:WUXI DIANCHUANG TECH

Blast black powder for fireworks

InactiveCN101270014ANo pollution in the processGood detonation effectInorganic oxygen-halogen salt explosive compositionsMetallic materialsFireworks

The present invention discloses explosive black powder that is used for fireworks. The black powder contains the following components with the following weight portions: 40 to 75 portions of potassium perchlorate, 0 to 35 portions of potassium nitrate, 1 to 5 portions of potassium dichromate, 5 to 15 portions of sulfur, 5 to 25 portions of charcoal, 0.5 to 2 portions of carbon black, and 5 to 20 portions of potassium terephthalic acid or potassium acid phthalate. The explosive black powder is made of the components according to the ratio. No metal material or toxic substances are used. The explosive black powder has the advantages of low mechanical sensitivity, excellent stability, large explosive scale, excellent explosive sound, black medicine, easily prepared raw materials and relatively low cost. Thus the explosive black powder is the ideal explosive black powder.

Owner:湖南省浏阳金生花炮有限公司

Fire coal combustion improver

InactiveCN102191110AImprove operational safetyExtended service lifeSolid fuelsChromium trioxideDolomite

The invention relates to an improvement of a fire coal combustion improver. The improved fire coal combustion improver is characterized by being prepared by compounding and mixing the following components: 20 to 30 weight percent of dolomite powder, 5 to 15 weight percent of dicyclopentadieny iron, 3 to 10 weight percent of chromium trioxide, 3 to 10 weight percent of manganese dioxide, 3 to 15 weight percent of magnesium nitrate, 3 to 15 weight percent of sodium dichromate and / or potassium dichromate, 3 to 18 weight percent of zinc oxide, 15 to 30 weight percent of active clay. The fire coal combustion improver has a plurality of functions of combustion acceleration, sulfur solidification, smoke abatement and the like; the thermal efficiency of a boiler can be improved by 3 to 8 percent; the coal-saving efficiency is up to 5 to 15 percent; the Ringelmann smoke blackness is less than 1; the total removal rate of SO2, NOx and the like is 25 to 60 percent, and the combustion improver has remarkable coal-saving and environmental-protection effect. Since the combustion effect is improved, the inferior coal (such as coal gangue), which is difficult to combust normally, is combusted and comes into play. After the long use, the boiler is not corroded, the scaling of the calcium sulfate in the boiler can be reduced, the operation safety of the boiler can be improved and the service life of the boiler can be prolonged.

Owner:YIXING KEQI CHEM

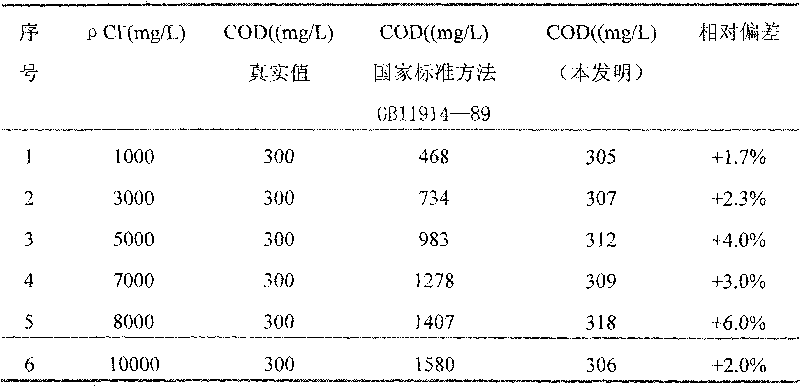

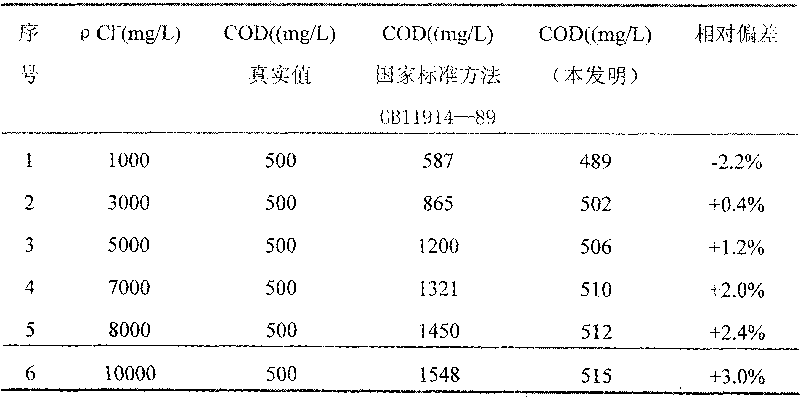

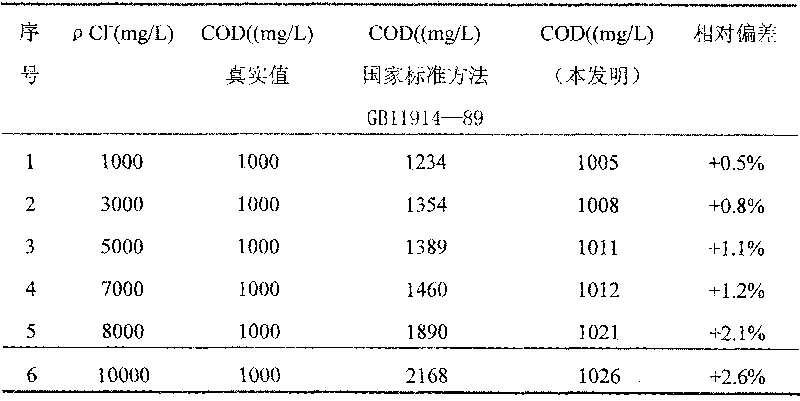

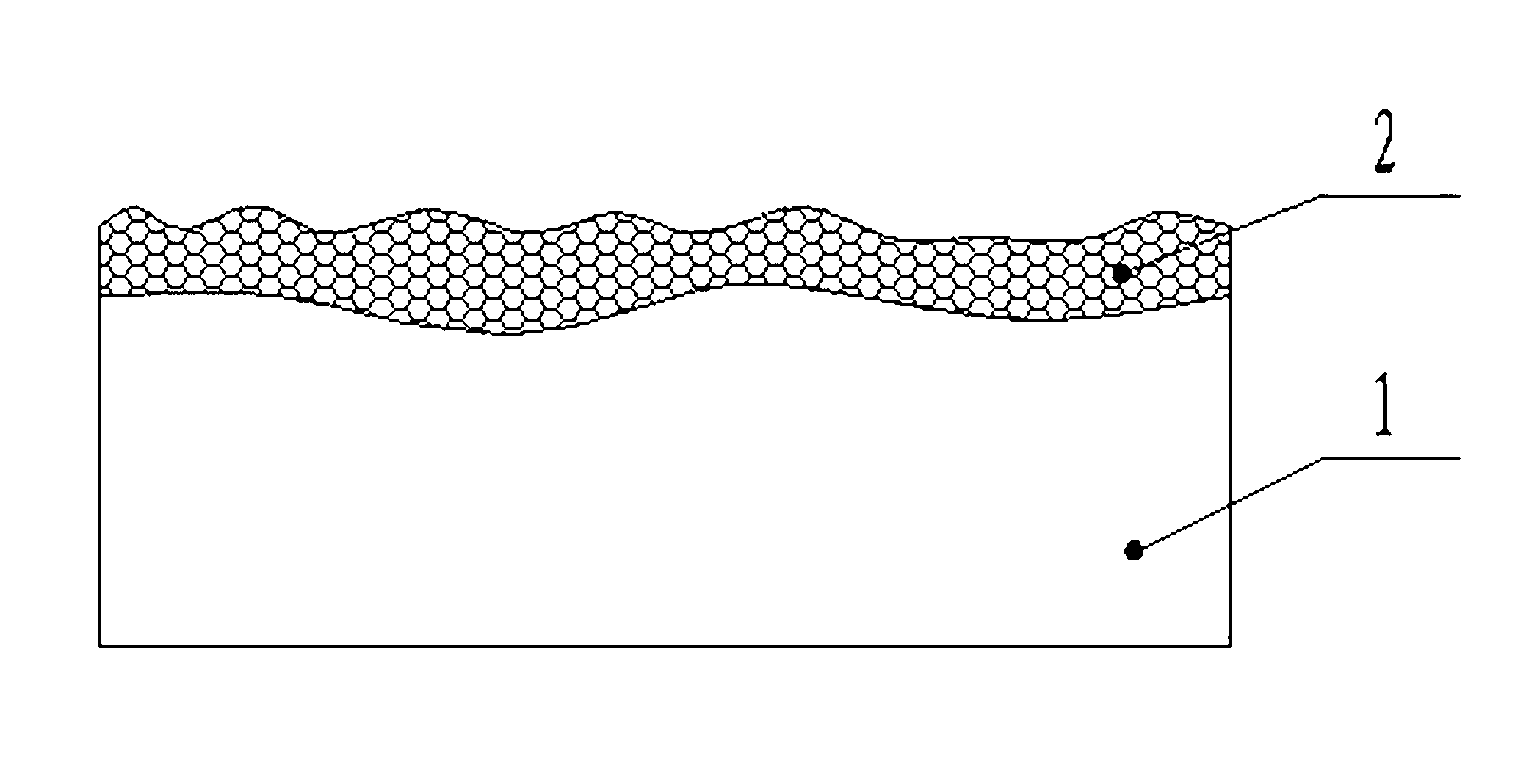

Reagent and method for determining chemical oxygen demand of high-chloride wastewater

InactiveCN101713739AShort measurement timeShort analysis timeMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsDigestionChromium

The invention discloses a reagent and a method for determining the chemical oxygen demand of high-chloride wastewater. The reagent consists of a reagent A and a reagent B, wherein the reagent A comprises 20 to 40 mass percent of potassium dichromate, 20 to 50 mass percent of aluminum potassium sulfate, and 10 to 60 mass percent of ammonium molybdate; and the reagent B comprises 20 to 40 mass percent of silver sulfate, 10 to 20 mass percent of bismuth nitrate, 10 to 20 mass percent of chromium potassium sulfate, and 20 to 60 mass percent of mercury sulfate. The method comprises the steps of: during the determination, sequentially adding the reagent A and the reagent B into a water sample, placing the obtained solution into a digestion device for digestion, cooling the obtained product, and then performing colorimetric determination. The reagent and the method are suitable for wastewater with the chloride ion concentration of between 1,000 and 10,000mg / L; and the reagent has the characteristics of accurate formula proportion, accurate and reliable determined data, short determination time, simple determination steps, convenient operation and the like; and the method can perform batch determination.

Owner:JIANGSU POLYTECHNIC UNIVERSITY +1

Cavity corrosion proof zinc-rich paint and preparing method thereof

InactiveCN101100569AAnti-corrosive paintsPolyurea/polyurethane coatingsCarbon nanotubeSODIUM SILICATE SOLN

A zinc-enriched coating against cavity corrosion and its production are disclosed. The coating consists of carbon nanometer tube: 0.3-4 wt%, nanometer zinc powder 3-8 wt%, and organic resin additive 12-30 wt%. The process is carried out by reflux decontaminating for carbon nanometer tube by mixed acid, soaking in diluted lithium aqueous glass, centrifugal treating, collecting or mixing carbon nanometer tube with silicon acid, ball grinding, adding carbon nanometer tube into lithium silicate-sodium silicate solution, adding into organic resin, heavy potassium chromate solution, FC80, methyl-methoxide, multifunctional accessories and de-foaming agent while agitating to obtain coating component A, mixing ordinary zinc powder with nanometer zinc powder proportionally to obtain coating component B, and mixing component A with component B proportionally to obtain final product.

Owner:HUAZHONG NORMAL UNIV

Aluminum alloy with army-green micro-arc oxidation ceramic membrane on surface and preparation method of aluminum alloy

InactiveCN103014804AReduce pollutionImprove wear resistanceAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses an aluminum alloy with an army-green micro-arc oxidation ceramic membrane on the surface, and a preparation method of the aluminum alloy. The aluminum alloy and the preparation method mainly solve the technical problem that most of the ceramic membranes treated by a light metal micro-arc oxidation technology existing in the prior art are off-white, white, black and the like. An electrolytic solution of the aluminum alloy comprises the following solutes: sodium phosphate, sodium silicate, sodium hexametaphosphate, sodium hydroxide, ethylene diamine tetraacetic acid, potassium dichromate, sodium carbonate, lauryl sodium sulfate and hydrogen peroxide; deionized water is adopted as a solvent; and the solutes and the solvent are blended into an alkaline electrolytic solution, stirred, placed for 1-2 hours, and then subjected to micro-arc oxidation treatment, therefore, the army-green ceramic membrane is obtained. The aluminum alloy has the benefits that the aluminum alloy is simple in preparation method, low in cost and small in environmental pollution. The prepared army-green ceramic membrane has the advantages that the army-green ceramic membrane is high in wear resistance, good in corrosion resistance, uniform in color and luster, good in stability, and compact, and does not fade easily. The army-green ceramic membrane is particularly suitable for disguise requirements of army products.

Owner:GUILIN UNIV OF ELECTRONIC TECH

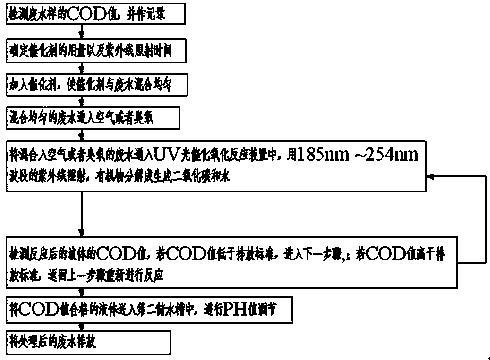

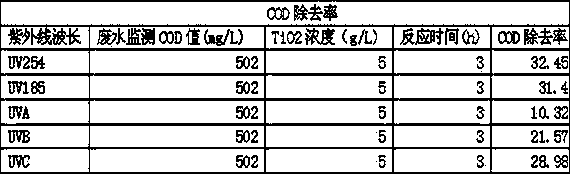

Wastewater treatment and recycling technology based on UV photocatalytic oxidation

InactiveCN104341022AStrong oxidation abilityImplement batch processingWater/sewage treatment by irradiationWater/sewage treatment apparatusEnvironmental resistanceHigh concentration

The invention discloses a wastewater treatment and recycling technology based UV photocatalytic oxidation. The method comprises the following steps: a, detecting the COD value of waste water with a potassium dichromate method; b, determining the amount of catalyst and UV irradiation time according to the COD value of wastewater; c, adding the catalyst, evenly mixing the catalyst with wastewater; d, introducing air or ozone; e, introducing into a UV photocatalytic oxidation reaction device, and irradiating by ultraviolet; f, detecting the COD value of the liquid; if the COD value is lower than the emission standard, entering to the step g, and if the COD value is higher than the emission standard, returning to the step for re-reaction; and g, adjusting the pH value within 6 to 9; and h. discharging the treated wastewater. The technology provided by the invention makes pollutants completely harmless, and realizes more significant decomposition effect and the bulk chemical wastewater treatment of high concentration COD. The technology has the advantages of wide application range, no secondary pollution, green, environment-friendliness, and low cost of processing equipment.

Owner:上海银木电器制造有限公司

Polishing solution for ultra-precise low-damage polish of large size diamond wafer and preparation thereof

InactiveCN101302403AImprove surface accuracyQuality improvementPolishing machinesAqueous dispersionsChromium trioxideSuperhard material

The invention belongs to the superhard material polishing technical field and discloses polishing solution used for ultraprecise and low-damage polishing of a large-scale diamond wafer and a method for preparing the same. The method is characterized in that: oxidants with strong oxidbillity including chromium trioxide, ammonium persulphate, potassium permanganate, potassium dichromate, oxydol, potassium ferrate, potassium perchlorate and so on are adopted as main compositions; a proper amount of abrasive material is added for preparing the polishing solution; and micro-removal of surface material of the diamond wafer can be realized by means of chemical and mechanical composite action at normal temperature or low temperature. Moreover, the polishing effect of the polishing solution can be improved by addition of proper amount of catalyst, stabilizer, dispersant and so on as well. The polishing solution and the method have the advantages that: the polishing solution prepared has the advantages of high polishing efficiency, good polishing quality, good stability and so on; and the ultraprecise and low-damage polishing of the large-scale diamond wafer can be realized at the normal temperature or the low temperature.

Owner:DALIAN UNIV OF TECH

Multifunctional expandable fiber anti-cracking waterproof agent and preparation method

The invention discloses a multifunctional expandable fiber anti-cracking waterproof agent. The multifunctional expandable fiber anti-cracking waterproof agent comprises the following components in parts by weight: 8-27.3 parts of calcium sulphoaluminate, 4-9 parts of calcium oxide, 5-9 parts of magnesium oxide, 14.7-23.5 parts of fly ash, 4-9 parts of an iron powder expanding agent, 1.5-7.8 partsof a modified sepiolite fabric, 1-4.5 parts of modified polypropylene fibers, 1.5-4 parts of sodium methyl silicate, 0.5-1.5 parts of sodium fluosilicate and 1-4 parts of a polycarboxylic acid effective water reducing agent, wherein the modified sepiolite fabric is modified through diluted hydrochloric acid and a silane coupling agent, the modified polypropylene fibers are modified through potassium dichromate, concentrated sulfuric acid and a silane coupling agent, thus, mutually cross-linked net-shaped structures are formed in concrete, compared with an existing anti-cracking waterproof agent which takes common sepiolite, sepiolite fibers and polypropylene fibers as raw materials, the anti-cracking waterproof agent is better in anti-cracking property and expanding property, shorter in time of coagulation and higher in concrete performance. The invention further provides a preparation method of the anti-cracking waterproof agent, and the raw materials are blended by a two-step method.

Owner:TIANJIN JINSHENGYUAN SPECIAL BUILDING MATERIALS

Anodic oxidation method for preparing aluminum-based super-hydrophobic film

InactiveCN102304741ASimple operation processGood reproducibilityAnodisationOXALIC ACID DIHYDRATEElectrolytic agent

The invention belongs to the field of preparation technology of super-hydrophobic surface and provides an anodic oxidation method for preparing an aluminum-based porous super-hydrophobic surface. The method comprises the following steps: performing mechanical polishing on an aluminum alloy board, removing surface defects and oxidation films, washing with ethanol and deionized water, and drying; preparing electrolyte consisting of 1.803 mol / L of sulfuric acid, 0.068 mol / L of potassium dichromate, 0.079 mol / L of oxalic acid, 2.57 mol / L of sodium chloride and 1.37 mol / L of glycerin; then electrifying by taking the aluminum board as an anode and graphite as a cathode for reaction, wherein the current density is controlled to 1.2 A / dm<2> and the reaction time is 30-40 min; washing the reacted aluminum board with distilled water, and drying or naturally airing; placing the aluminum board in 1 wt% stearic acid ethanol solution to soak for 20-30 min and then taking out the aluminum board; washing the aluminum board with a proper amount of alcohol; taking out the aluminum board and cleaning with clean water; and drying at the room temperature in the atmospheric environment for 24-28 hours under the relative humidity of 60-75% to prepare the porous aluminum alloy super-hydrophobic surface.

Owner:HUNAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com