Steel structure aqueous corrosion resisting paint without need of cleaning rust and preparation thereof

A technology for anti-corrosion and anti-corrosion coatings with rust, which is applied in the direction of anti-corrosion coatings, coatings, and devices for coating liquid on the surface. Improve the coating environment, shorten the drying time, and facilitate construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

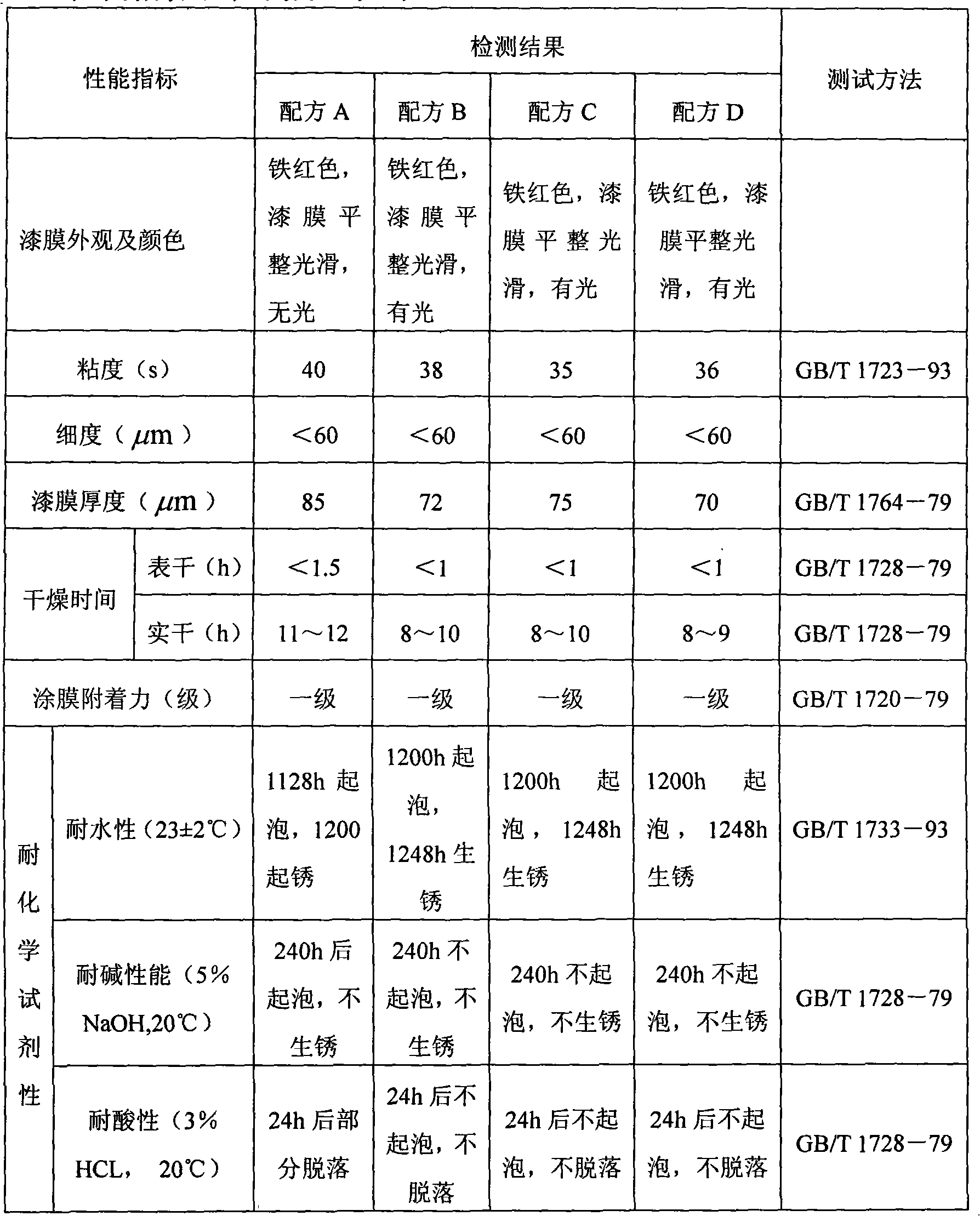

Examples

Embodiment 1

[0031]33.0% styrene-acrylic emulsion, 2.5% iron oxide, 9.0% talcum powder, 2.5% zinc phosphate, 2.0% zinc oxide, 1.0% aluminum hydroxide, 19.0% phosphoric acid, 5.5% tannic acid, 0.075% zinc dihydrogen phosphate, weight Sodium chromate 0.125%, film-forming aid 2.0%, dibutyl phthalate 1.45%, sodium hexametaphosphate 0.6%, defoamer 0.3%, water added to 100%.

[0032] The preparation process of this embodiment is:

[0033] (1) First mix phosphoric acid, aluminum hydroxide, zinc oxide, and tannic acid, and stir while heating until the solution is clear to obtain a conversion solution, and let it stand for a while.

[0034] (2) mixing and stirring iron oxide, talcum powder, zinc phosphate and water to prepare pigment and filler slurry;

[0035] (3) Mix the conversion liquid, pigment and filler slurry with film-forming substances, corrosion inhibitors, defoamers (2 / 3 of the dosage) and other additives, and stir for two hours at a speed of 3000r / min to obtain Slurry, then add film-...

Embodiment 2

[0037] 35.0% styrene-acrylic emulsion, 2.3% iron oxide, 8.0% talc, 2.5% zinc phosphate, 1.5% zinc oxide, 1.1% aluminum hydroxide, 19.0% phosphoric acid, 5.5% tannic acid, 0.075% zinc dihydrogen phosphate, weight Sodium chromate 0.125%, sodium hexametaphosphate 0.7%, film-forming aid 2.0%, dibutyl phthalate 1.4%, defoamer 0.35%, water added to 100%.

[0038] The preparation process of this embodiment is the same as that of Example 1.

Embodiment 3

[0040] Styrene-acrylic emulsion 38.0%, iron oxide 2.2%, talc powder 10.0%, zinc phosphate 3.0%, zinc oxide 1.8%, aluminum hydroxide 1.0%, phosphoric acid 18.5%, tannic acid 5.8%, zinc dihydrogen phosphate 0.1%, chromium 0.3% sodium hexametaphosphate, 0.6% sodium hexametaphosphate, 2.5% coalescent, 1.4% dibutyl phthalate, 0.36% defoamer, and water to 100%.

[0041] The preparation process of this embodiment is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com