Method for preparing novel aluminum-based composite lead dioxide-manganese dioxide anode for zinc electrodeposition

A lead dioxide and manganese dioxide technology, used in electrodes, electrolytic processes, electrolytic components, etc., can solve the problems of large internal stress, easy peeling of the deposited layer, poor electrical conductivity, etc., and achieve strong acid and alkali corrosion resistance. , The electrode price is low, the effect of superior acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

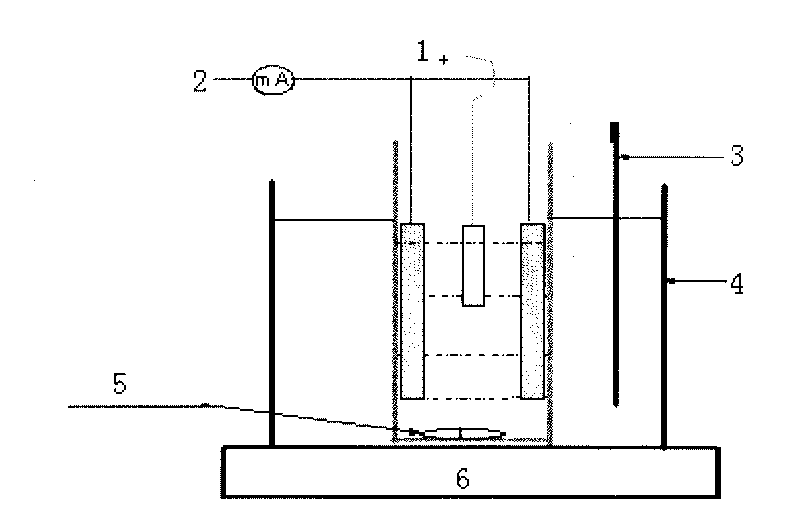

Method used

Image

Examples

Embodiment 1

[0036] The lead dioxide-manganese dioxide anode is compounded on the aluminum substrate, and the aluminum plate is processed into a small sample of 50mm×20mm×2mm. The process flow is: aluminum plate→quenching→degreasing→sandblasting→spraying conductive coating→electrodepositing α-PbO 2 -CeO 2 -TiO 2 →Electrodeposited β-PbO 2 -MnO 2 -WC-ZrO 2 , the alkaline composite plating α-PbO 2 -CeO 2 -TiO 2 Formula and process conditions: lead monoxide (PbO) 30g / L, sodium hydroxide (NaOH) 200g / L, particle size 30nm cerium dioxide (CeO 2 ) 10g / L, particle size 50nm titanium dioxide (TiO 2 )30g / L, temperature is 40℃, anode current density is 1~3A / dm 2 , and plated for 4 h under magnetic stirring. The thickness of this intermediate layer is approximately equal to 200 μm.

[0037] The acid composite plating β-PbO 2 -MnO 2 -WC-ZrO 2 Formula and process conditions: lead nitrate Pb(NO 3 ) 2 200g / L, nitric acid (HNO 3 )2~15g / L, sodium fluoride (NaF)3~10g / L, manganese nitrate Mn(N...

Embodiment 2

[0039] The lead dioxide-manganese dioxide anode is compounded on the aluminum substrate, and the aluminum plate is processed into a small sample of 50mm×20mm×2mm. The process flow is: aluminum plate→quenching→degreasing→sandblasting→spraying conductive coating→electrodepositing α-PbO 2 -CeO 2 -TiO 2 →Electrodeposited β-PbO 2 -MnO 2 -WC-ZrO 2 , the alkaline composite plating α-PbO 2 -CeO 2 -TiO 2 Formula and process conditions: lead monoxide (PbO) 30g / L, sodium hydroxide (NaOH) 200g / L, particle size 30nm cerium dioxide (CeO 2 ) 20g / L, particle size 50nm titanium dioxide (TiO 2 )20g / L, temperature is 40℃, anode current density is 1~3A / dm 2 , and plated for 2 h under magnetic stirring. The thickness of this intermediate layer is approximately equal to 100 μm.

[0040] The acid composite plating β-PbO 2 -MnO 2 -WC-ZrO 2 Formula and process conditions: lead nitrate Pb(NO 3 ) 2 250g / L, nitric acid (HNO 3 )2~15g / L, sodium fluoride (NaF)3~10g / L, manganese nitrate Mn(N...

Embodiment 3

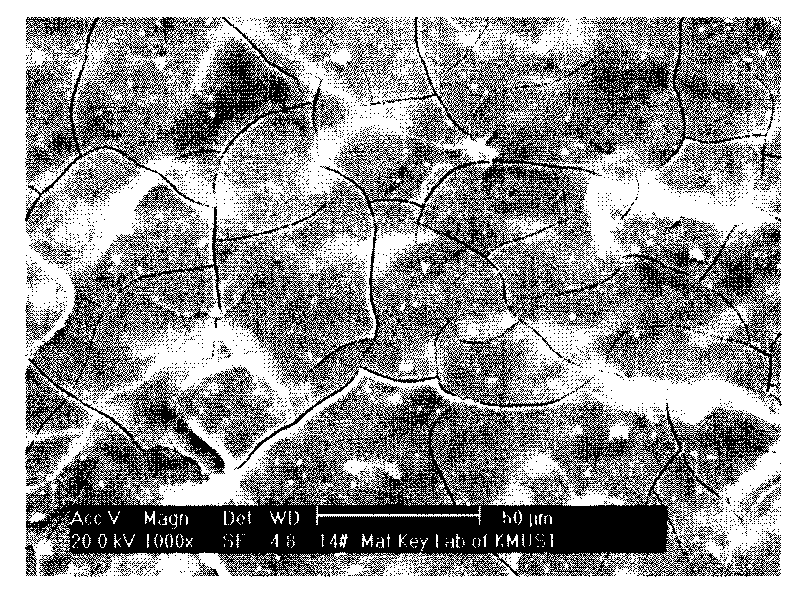

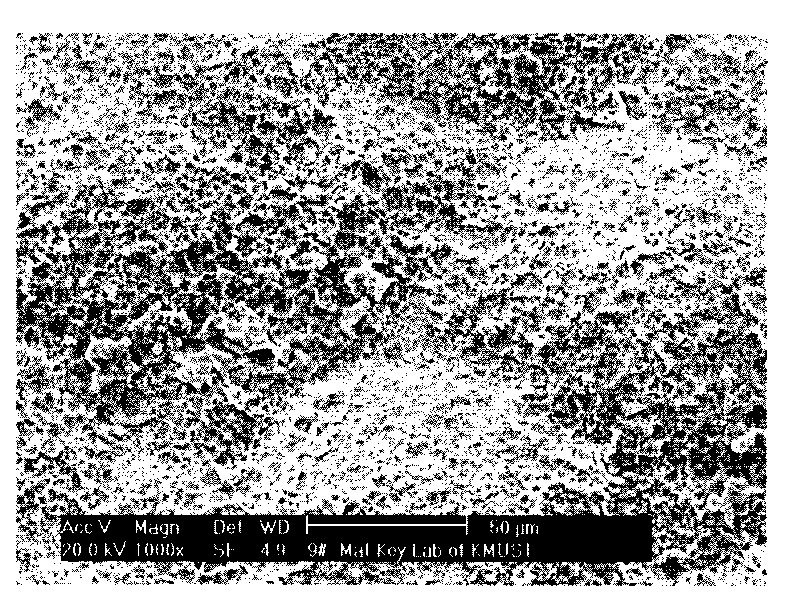

[0042] The preparation method and process parameters are as described in Example 1. The acid composite plating β-PbO 2 -MnO 2 -WC-ZrO 2 Formula and process conditions: lead nitrate Pb(NO 3 ) 2 280g / L, nitric acid (HNO 3 )2~15g / L, sodium fluoride (NaF)3~10g / L, manganese nitrate Mn(NO 3 ) 2 80g / L, particle size 50nm zirconia (ZrO 2 ) 40g / L, 0.02~1 anode tungsten carbide (WC) 10g / L, use pure lead plate as cathode, temperature is 50~60℃, current density is 3~4A / dm 2 , and plated for 3 h under magnetic stirring. Thus, about 250 μm thick β-PbO 2 (61wt%)-MnO 2 (32wt%)-WC(5.9wt%)-ZrO 2 (1.1wt%) coating, the surface morphology of its coating is as attached Figure 4 . The coating is used as an anode in the electrolytic zinc plating solution system, the cell voltage is 2.7-2.8V; the current density at 40°C is 2A / cm 2 150g / L H 2 SO 4 Electrolysis is carried out in the solution, and the time elapsed when the voltage of the electrolytic cell rises (about 10V) is the expecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com