Heat reflective insulating stoving varnish coating and preparation method thereof

A heat reflection and paint baking technology, applied in the field of baking paint coatings, can solve the problems of insufficient comprehensive performance aging resistance, insufficient weather resistance, chemical resistance, and the types of film-forming substances are not disclosed, so as to improve the light and heat reflection efficiency, Excellent outdoor weather resistance and aesthetics, excellent hiding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

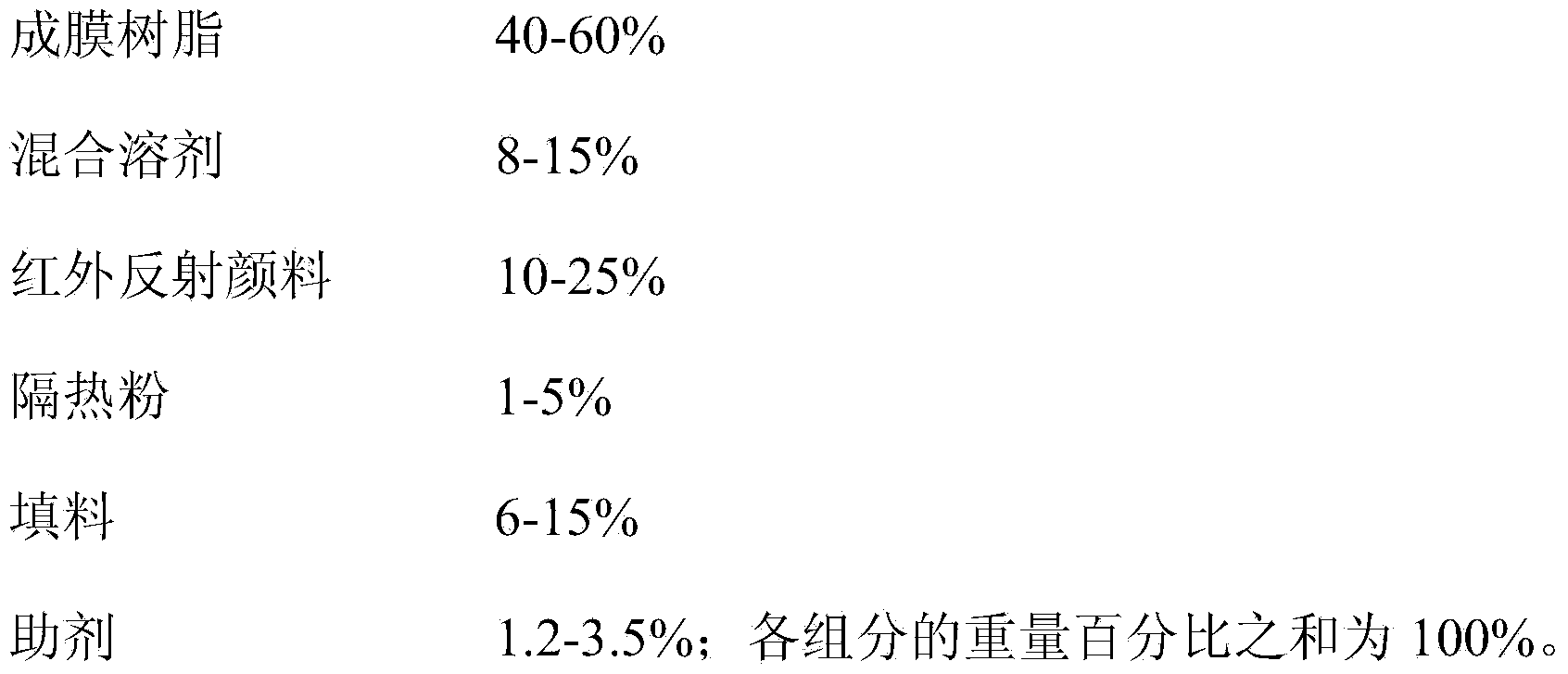

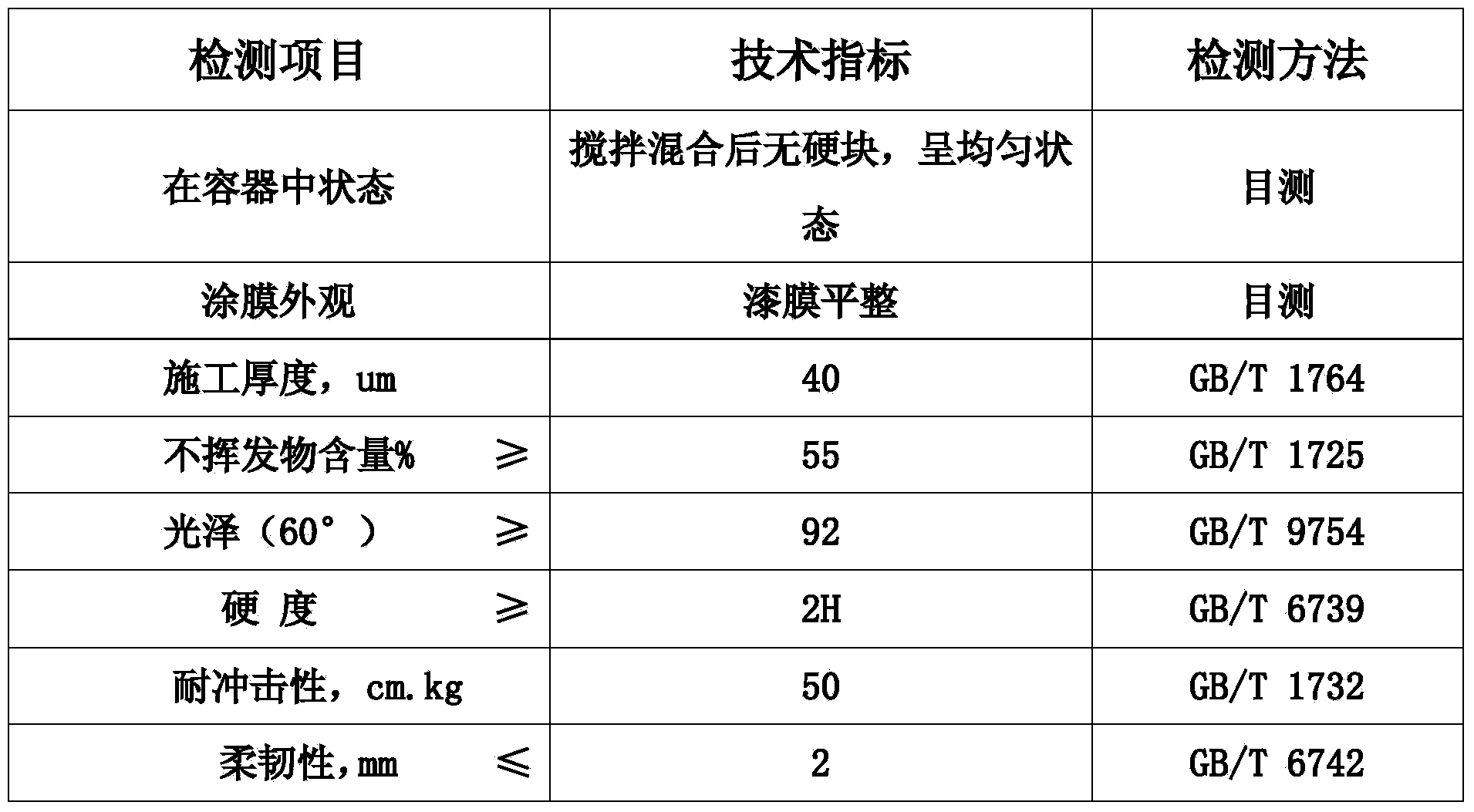

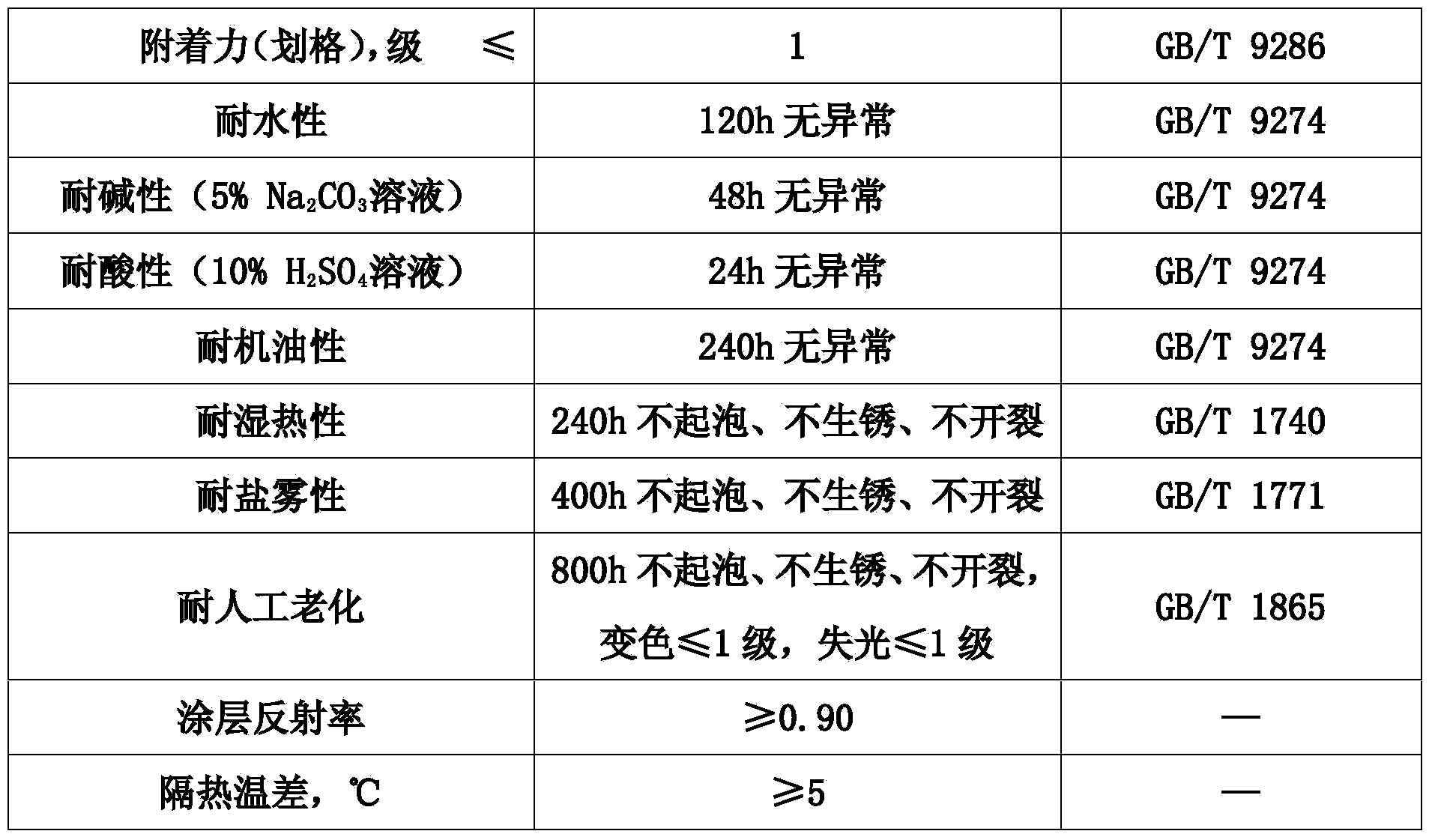

Method used

Image

Examples

Embodiment 1

[0042] The heat-reflecting and heat-insulating baking varnish coating comprises the following components in parts by weight: 28 parts by weight of thermosetting acrylic resin, 6.5 parts by weight of n-butanol and 6.5 parts by weight of ethylene glycol monobutyl ether, and 1.1 parts by weight of wetting and dispersing agent polyacrylate , 0.4 parts by weight of antifoaming agent polysiloxane, 25 parts by weight of rutile titanium dioxide, 13 parts by weight of filler alumina, 0.4 parts by weight of anti-settling agent polyethylene wax, 12 parts by weight of high imino type methyl etherified amino resin, 6 parts by weight of saturated polyester resin, 0.4 part by weight of silicone leveling agent, 0.3 part by weight of antioxidant 1010, and 0.4 part by weight of cooling agent.

[0043] Its production method comprises the following steps:

[0044] Put thermosetting acrylic resin, half of the mixed solvent, anti-settling agent, wetting and dispersing agent, defoamer, rutile titani...

Embodiment 2

[0048] The heat-reflecting and heat-insulating baking varnish coating comprises the following components in parts by weight: 40.5 parts by weight of thermosetting acrylic resin, 3 parts by weight of n-butanol, 3 parts by weight of ethylene glycol monobutyl ether, 3 parts by weight of butyl acetate, and 3 parts by weight of xylene 0.9 parts by weight of wetting and dispersing agent sodium polyacrylate, 0.4 parts by weight of defoamer polysiloxane, 10 parts by weight of red powder, 3 parts by weight of heat insulating powder titanium oxide, 13 parts by weight of barium sulfate filler, 0.2 parts by weight of wax slurry 15 parts by weight of high imino type methyl etherified amino resin, 4.5 parts by weight of saturated polyester resin, 0.3 parts by weight of fluorine-modified acrylic leveling agent, 0.2 parts by weight of anti-ultraviolet additive UV-360, 1 weight part of cooling agent share.

[0049] The preparation method and construction method are basically the same as in Exa...

Embodiment 3

[0051] The heat-reflecting and heat-insulating baking varnish coating comprises the following components in parts by weight: 31 parts by weight of thermosetting acrylic resin, 4 parts by weight of n-butanol, 4 parts by weight of ethylene glycol monobutyl ether, 4 parts by weight of butyl acetate, and 4 parts by weight of xylene 1 part by weight of wetting and dispersing agent nonylphenol polyoxyethylene ether, 0.4 part by weight of defoamer polysiloxane, 21 parts by weight of medium yellow powder, 2 parts by weight of heat insulating powder magnesium oxide, 9 parts by weight of filler calcium carbonate, 0.4 parts by weight of anti-settling agent polyethylene wax, 15 parts by weight of high imino type methyl etherified amino resin, 7 parts by weight of saturated polyester resin, 0.5 parts by weight of organic silicon leveling agent, 0.3 parts by weight of anti-ultraviolet auxiliary agent, cooling 0.4 parts by weight.

[0052] The preparation method and construction method are b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com