Patents

Literature

1261results about How to "Easy to paint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

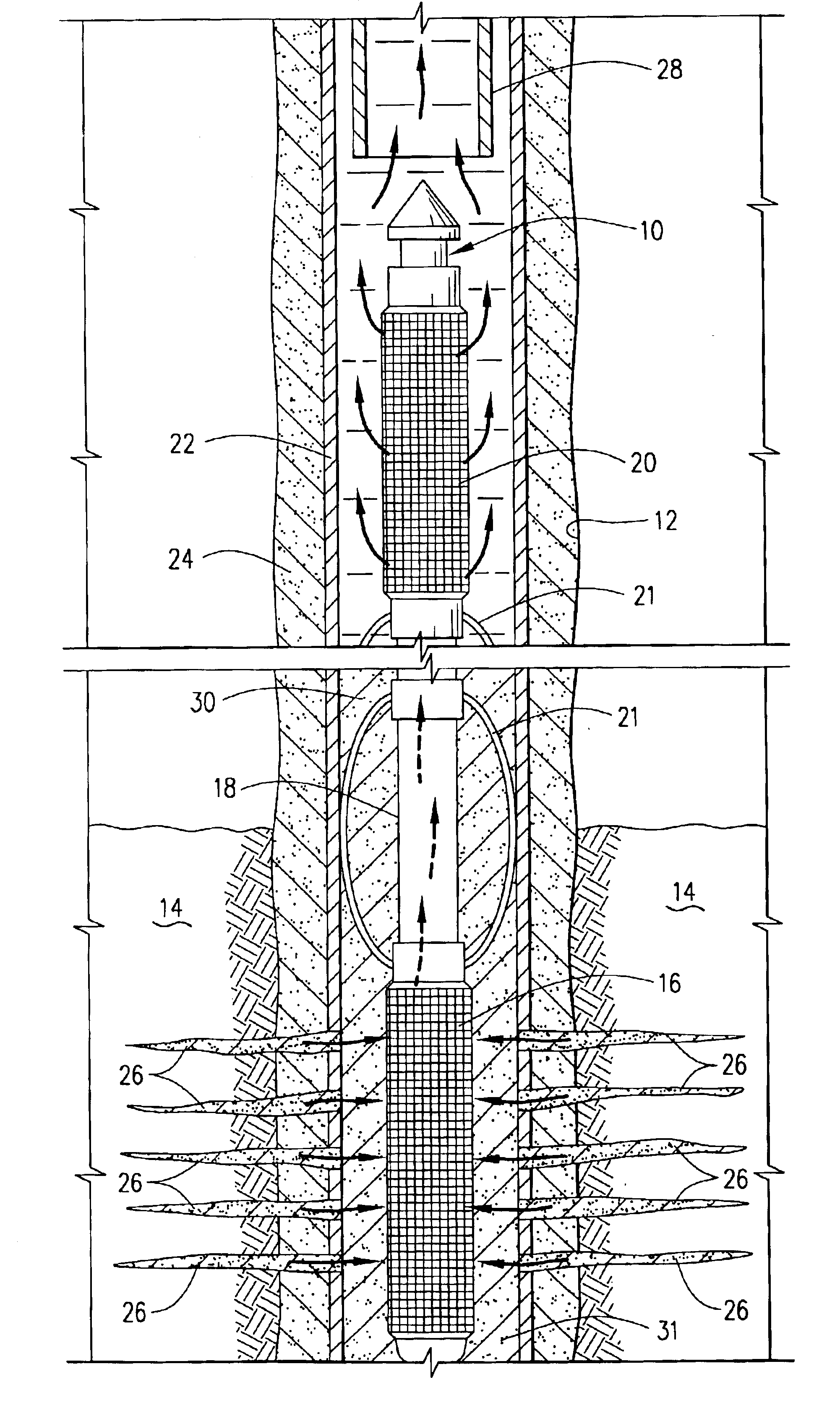

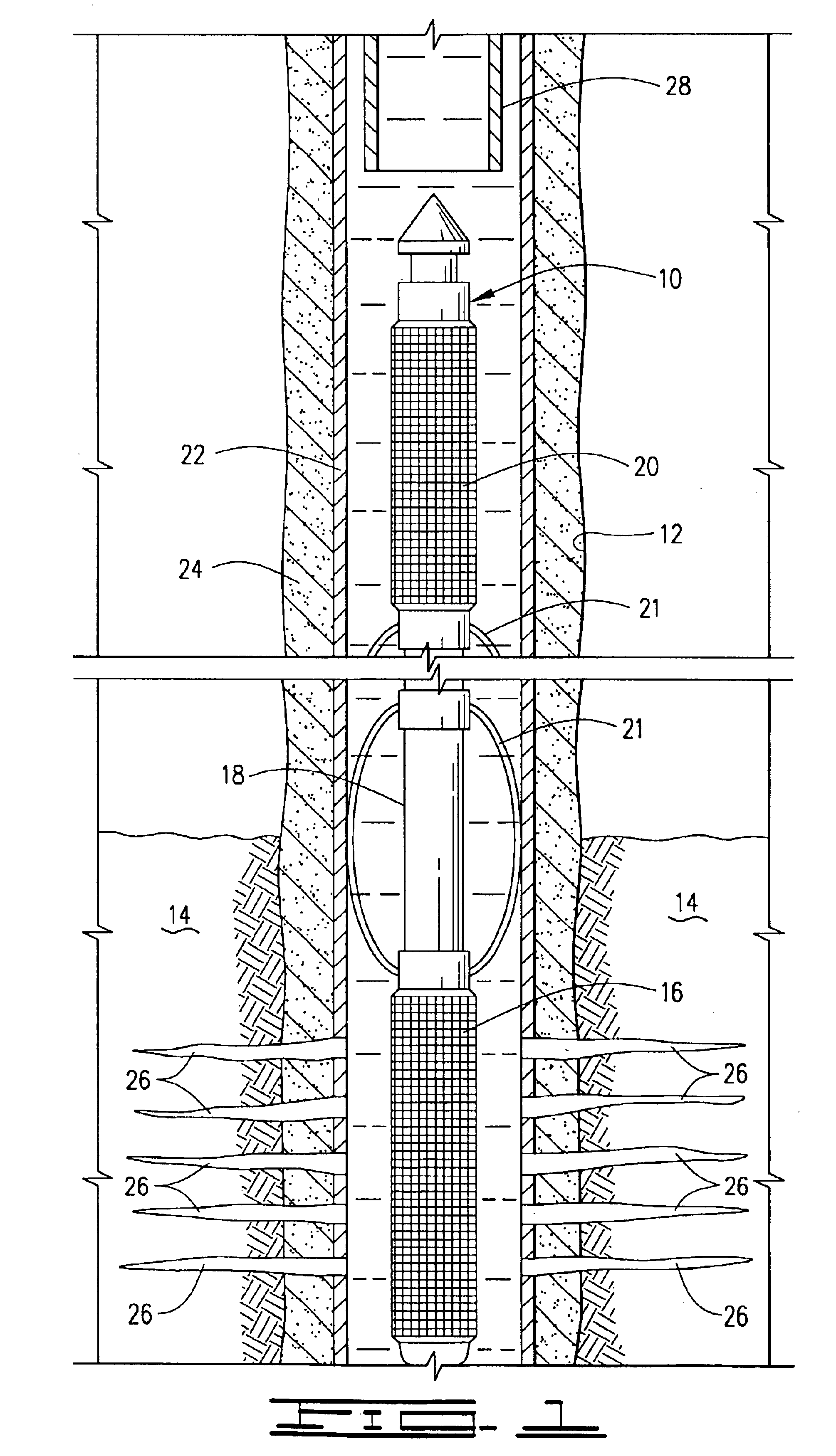

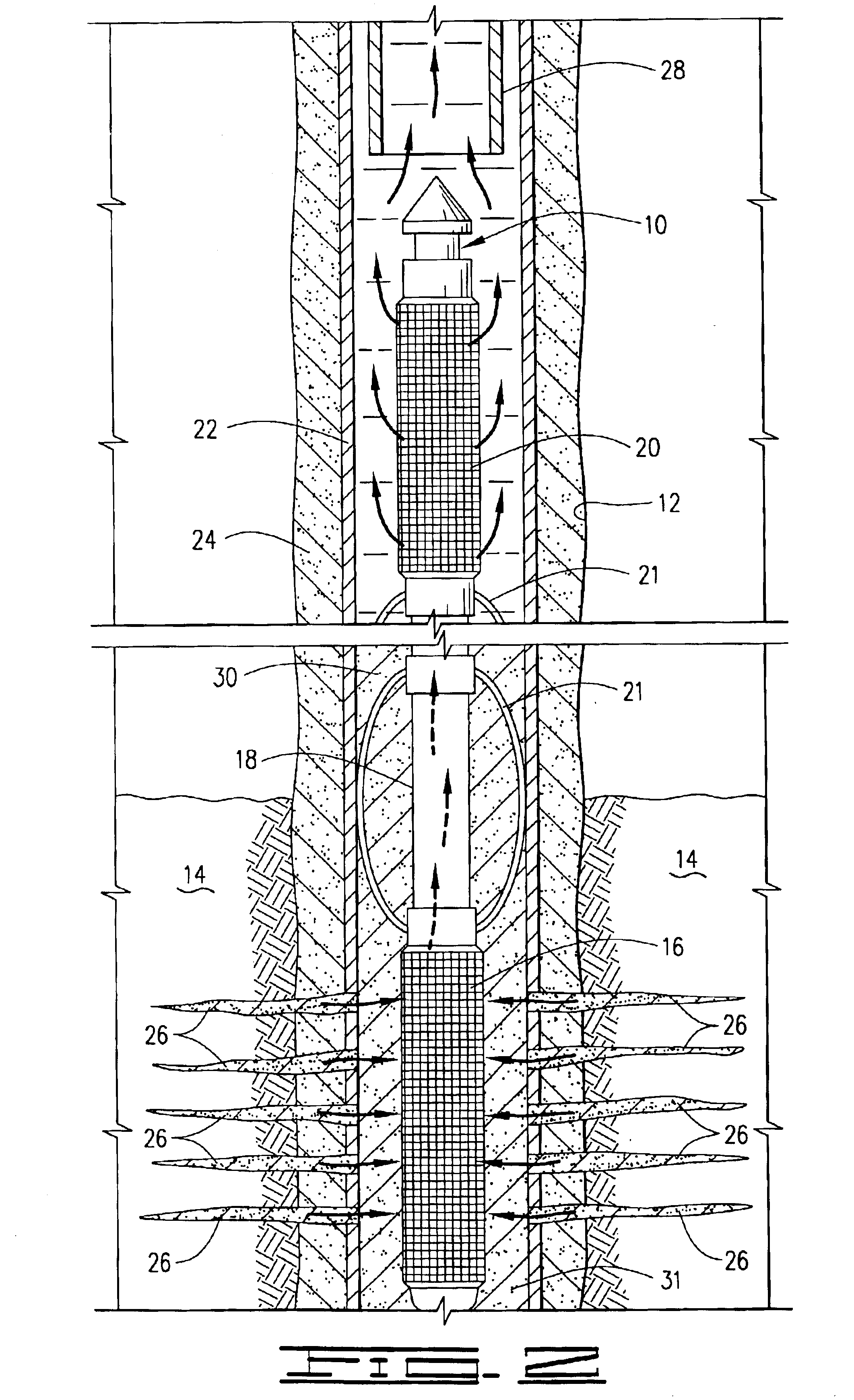

Methods of preventing gravel loss in through-tubing vent-screen well completions

Methods of forming through-tubing vent-screen tool completions in a well bore containing a producing zone are provided. The methods basically comprise placing the through-tubing vent-screen tool in the well bore adjacent to the producing zone, coating gravel to be placed in the well bore with a hardenable resin composition, combining the hardenable resin composition coated gravel with an aqueous carrier liquid, pumping the aqueous carrier liquid containing the coated gravel into the well bore between the producing zone and the tool to place hardenable resin composition gravel therein and allowing the hardenable resin composition to harden.

Owner:HALLIBURTON ENERGY SERVICES INC

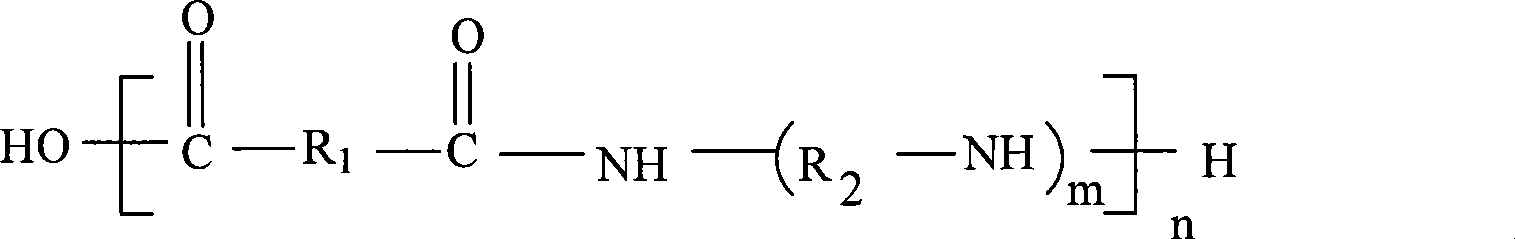

Biodegradable or compostable containers

The present invention provides an improved method and materials for forming biodegradable containers that can hold food products in dry, damp or wet conditions and provides the biodegradable containers prepared according to the disclosed process. The containers are produced through the use of a pre-gelled starch suspension that is unique in its ability to form hydrated gels and to maintain this gel structure in the presence of many other types of materials and at low temperatures.

Owner:NEW ICE LTD

Methods and compositons for forming subterranean fractures containing resilient proppant packs

InactiveUS20040040713A1Point becomes highEasy to paintFluid removalFlushingFracturing fluidHigh intensity

Improved methods of forming fractures containing resilient proppant particle packs which prevent the production of sand and fines with produced fluids and prevent proppant flow-back in a subterranean zone penetrated by a well bore are provided. As the fractures are formed, a liquid hardenable resin component is mixed with a liquid hardening agent component and a liquid rubber component to form a hardenable resin composition. The hardenable resin composition is coated onto dry proppant particles which are suspended in the fracturing fluid and placed in the fractures. The hardenable resin composition on the resin composition coated proppant particles is allowed to harden and consolidate the proppant particles into high strength resilient permeable packs.

Owner:HALLIBURTON ENERGY SERVICES INC

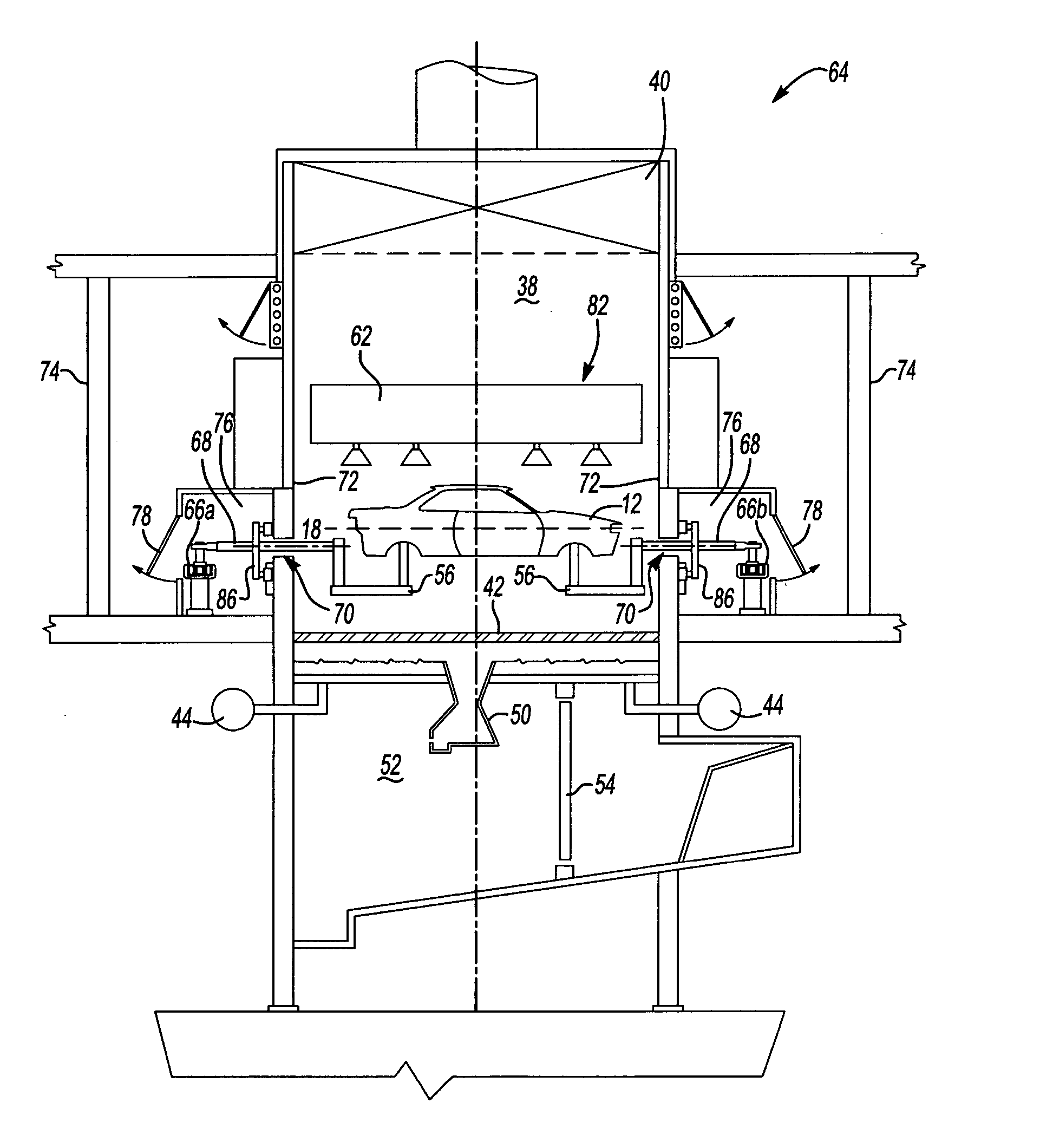

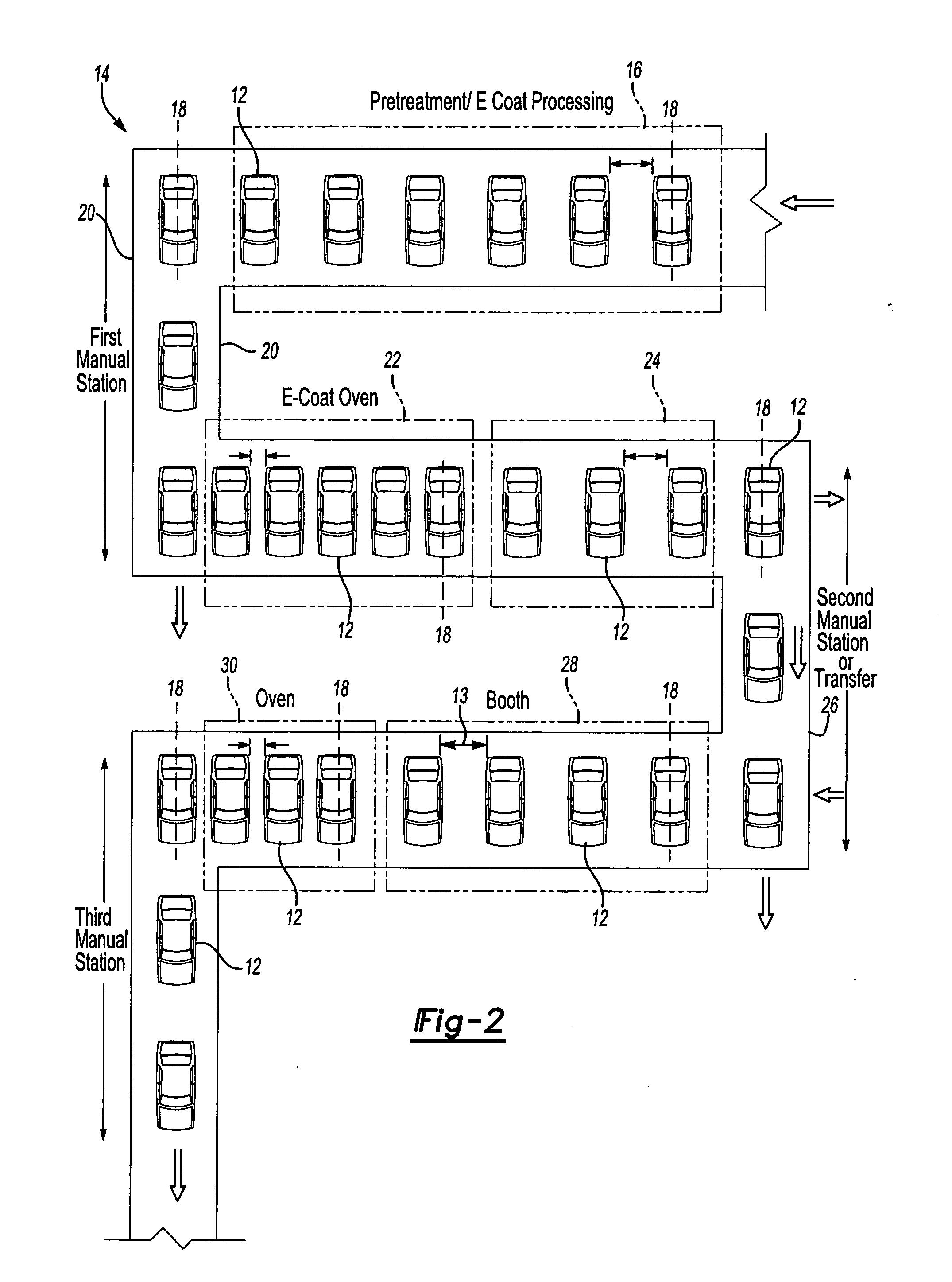

Production paint shop design

InactiveUS20060068094A1Improve paint qualityReduce flow rateConveyorsSpray nozzlesMotorized vehicleMechanical engineering

A paint application facility including a paint booth assembly for applying paint to automotive vehicles each defining a longitudinal axis includes a carrier adapted to serially move a plurality of automotive vehicles through the booth assembly in a direction generally perpendicular to the longitudinal axis of the vehicle.

Owner:FUJIFILM HEALTHCARE CORP +1

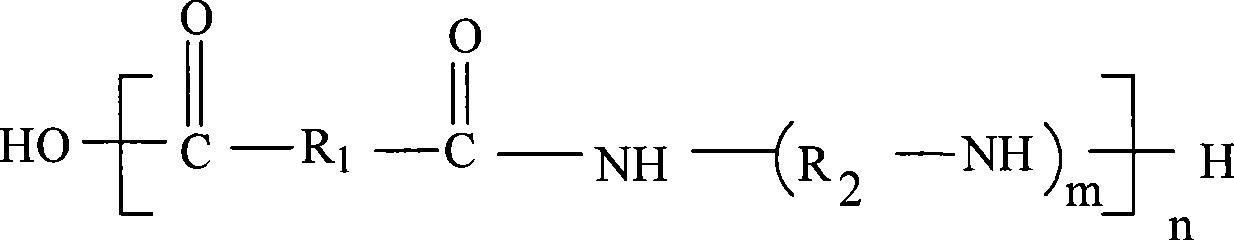

Novel non-formaldehyde wood adhesive and preparation thereof

ActiveCN101412898AImprove water resistanceLow priceProtein adhesivesGlue/gelatin preparationLignosulfonatesChemistry

The invention provides a novel aldehyde-free wood adhesive and a preparation method thereof. A mixture of plant protein and lignin sulphonate is used as a base material, and then high water resisting property is obtained through modifying the protein self. Dry strength of the real aldehyde-free wood adhesive is nearly that of urea-formaldehyde glue and phenol glue, the water resisting property of the aldehyde-free wood adhesive is far higher than that of the urea-formaldehyde glue and approximates to that of the phenol glue, the adhesive fully reaches the usage standard of class II glue, and the adhesive has the advantages of low cost, excellent performance and easy coating.

Owner:宁波朝露新材料科技有限公司

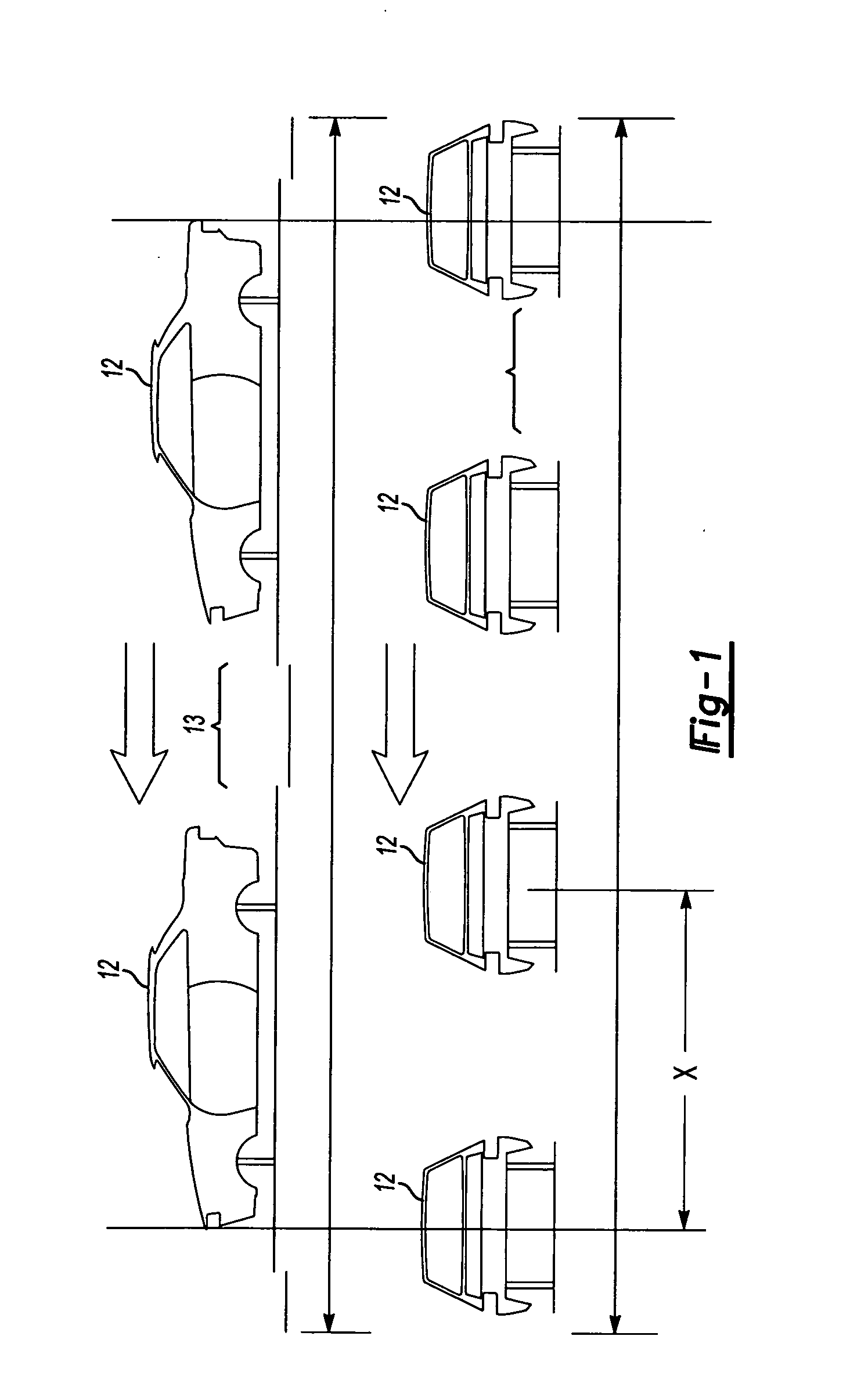

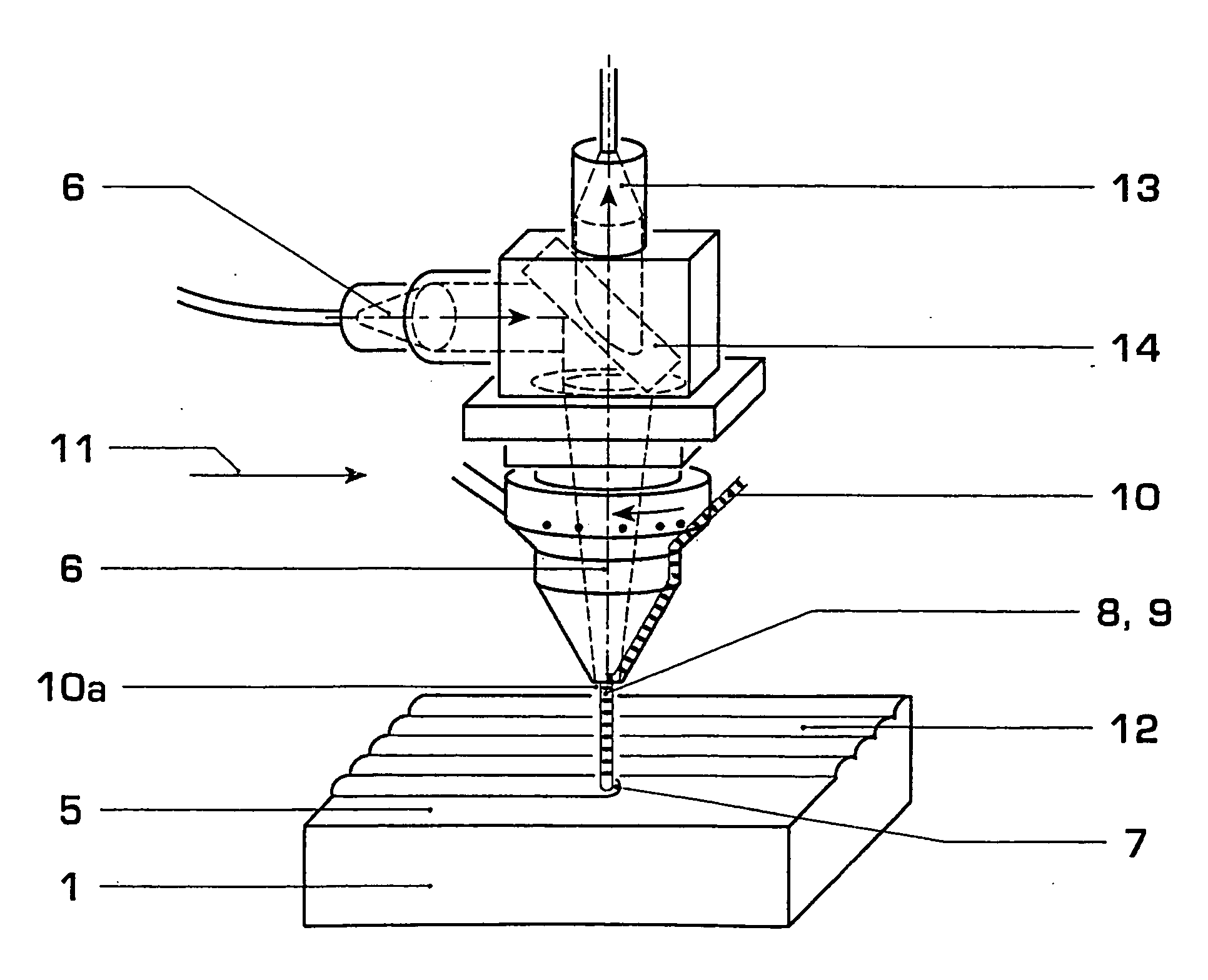

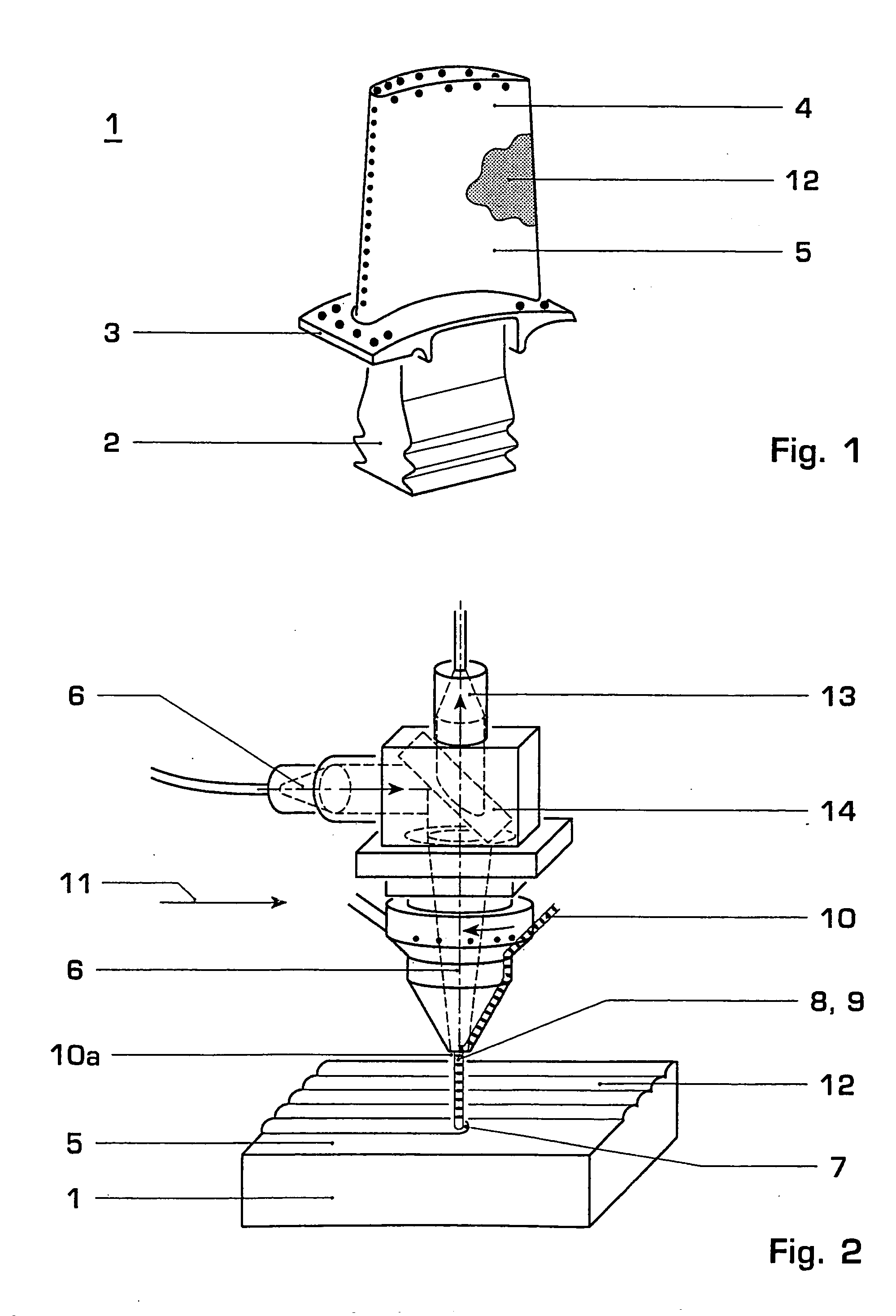

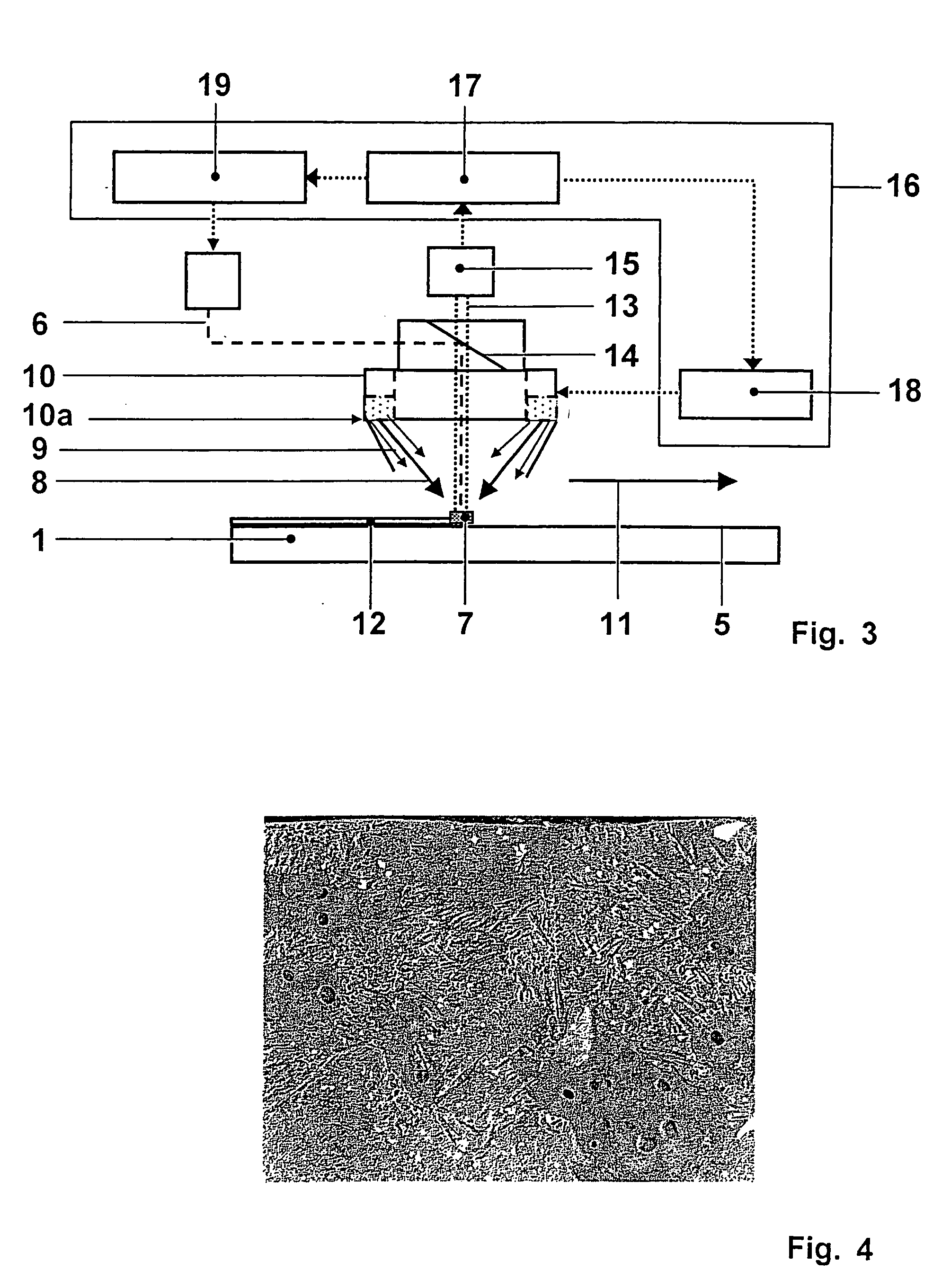

Method for controlling the microstructure of a laser metal formed hard layer

ActiveUS20060081571A1Function increaseShort timeTurbinesAdditive manufacturing apparatusControl systemMetal forming process

It is disclosed a method of applying a coating (12) with a controlled laser metal forming process. A light source with a specific power and a signal capturing apparatus is moved over an article (1) to form locally a melt pool (7) on the surface (5) of the article (1) to which a coating powder (8) is injected. An optical signal (13) is captured from the melt pool (7), and the monitored optical signal (13) is used for the determination of the temperature and temperature fluctuations of the melt pool (7). Furthermore, a control system (16) is used to adjust at least one process parameter such as the power of the light source to obtain desired melt pool properties. Subsequently the melt pool (7) solidifies. The high degree of control over the microstructure provides an efficient tool for generating laser metal formed hard coatings (12) with optimised wear properties.

Owner:ANSALDO ENERGIA IP UK LTD

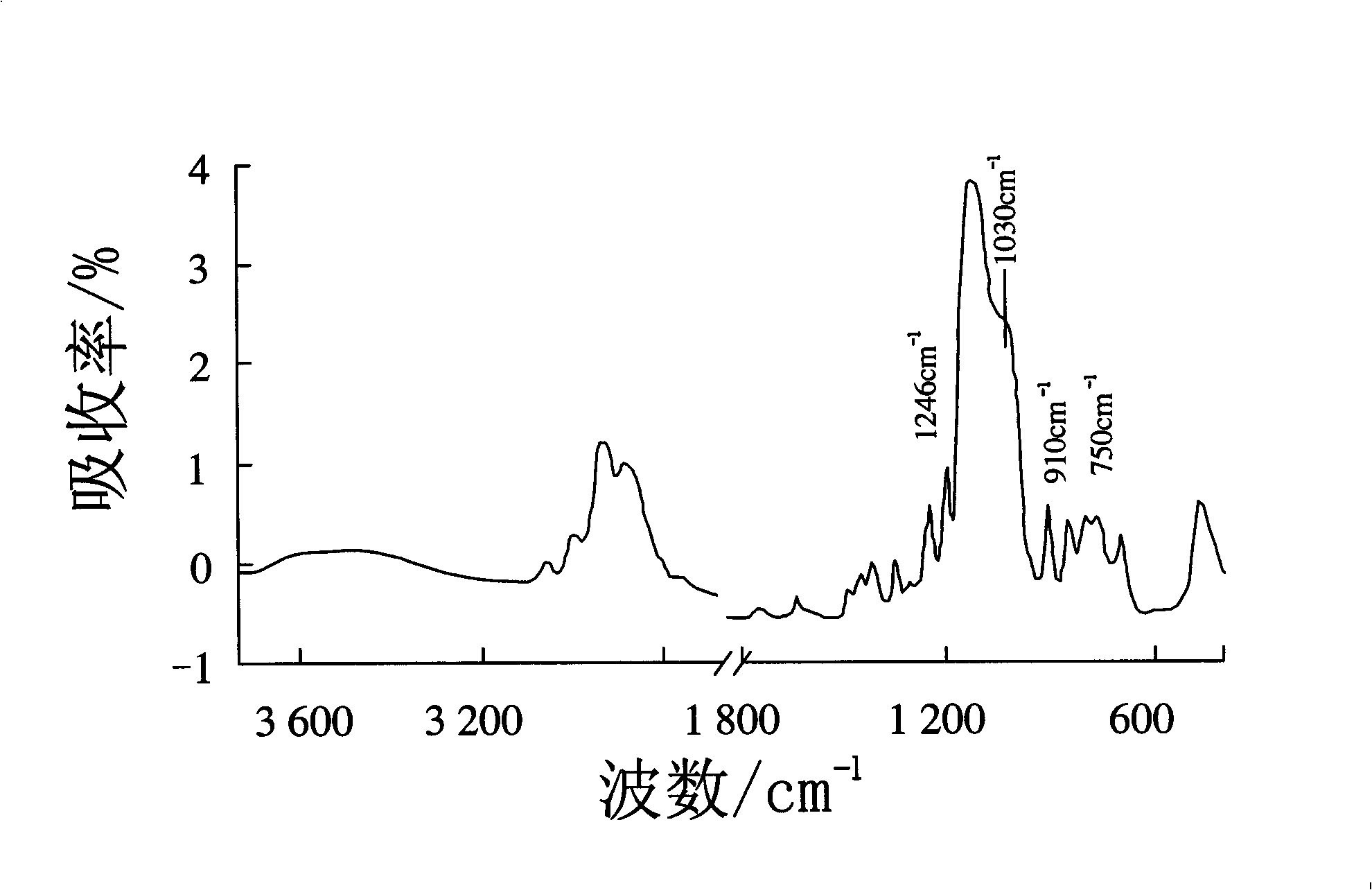

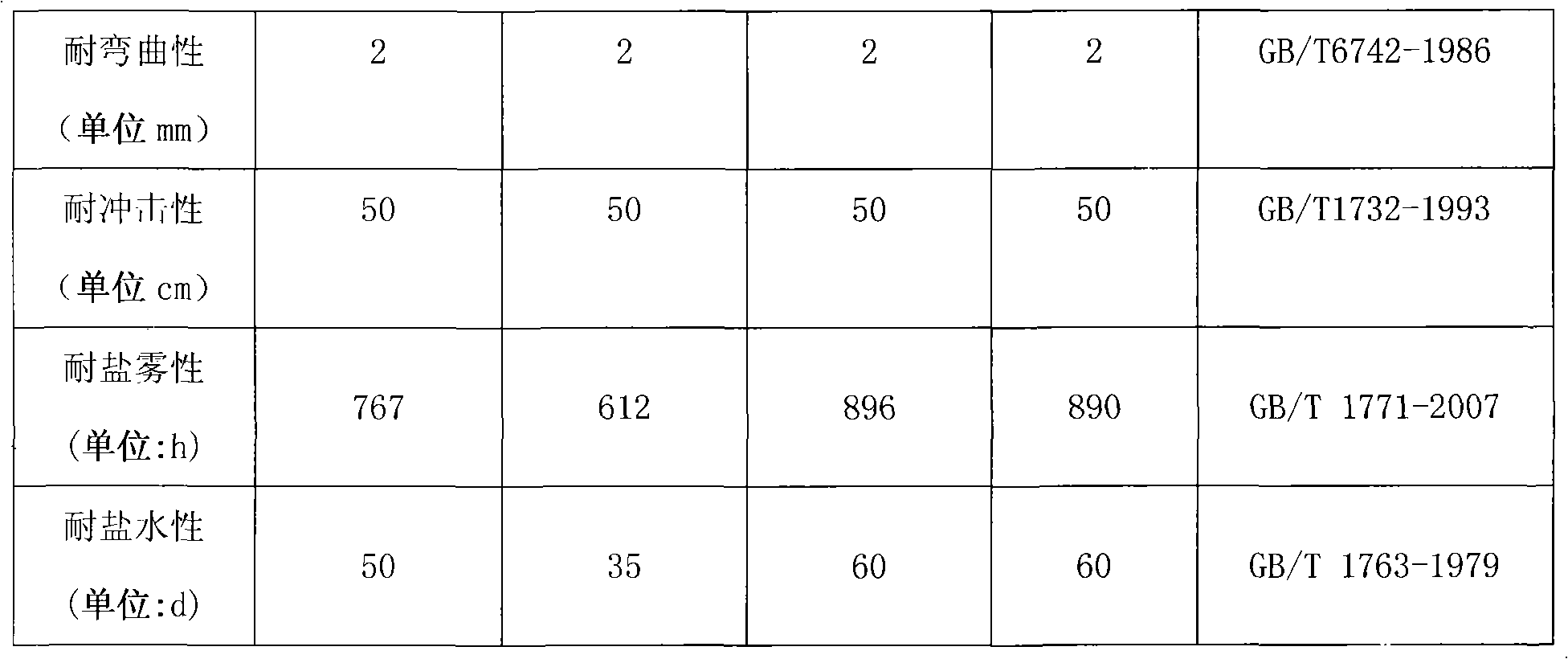

Aqueous organic-inorganic composite coating and preparation method thereof

The invention discloses an aqueous organic-inorganic composite coating, comprising the base materials of water-soluble film-forming material, pigment, filler, additive and water. The aqueous organic-inorganic composite coating is specifically composed of the following component, by weight: 15-25 parts of potassium silicate, 10-20 parts of styrene-acrylic emulsion, 0.2-0.5 part of stabilizer, 0.2-0.5 part of dispersing agent, 0.3-0.6 part of defoaming agent, 0.2-0.5 part of film-forming additive, 0.2-0.5 part of antifreeze, 0.1-0.3 part of thickening agent, 14-20 parts of titanium dioxide, 15-25 parts of heavy calcium, 5-10 parts of talcum powder and 20-25 parts of water. The invention has the following advantages: high film hardness, no cracking, excellent weather fastness, lasting replenished film, no addition of preservatives, excellent environmental protection performance, long recoating period of film and resource saving. In addition, the product has minimal construction resistance, and is easy for painting, promotion and application. The aqueous organic-inorganic composite coating has wide application range, and can be applied to coating of basement, underground parking, inner wall and outer wall.

Owner:广东嘉宝莉科技材料有限公司

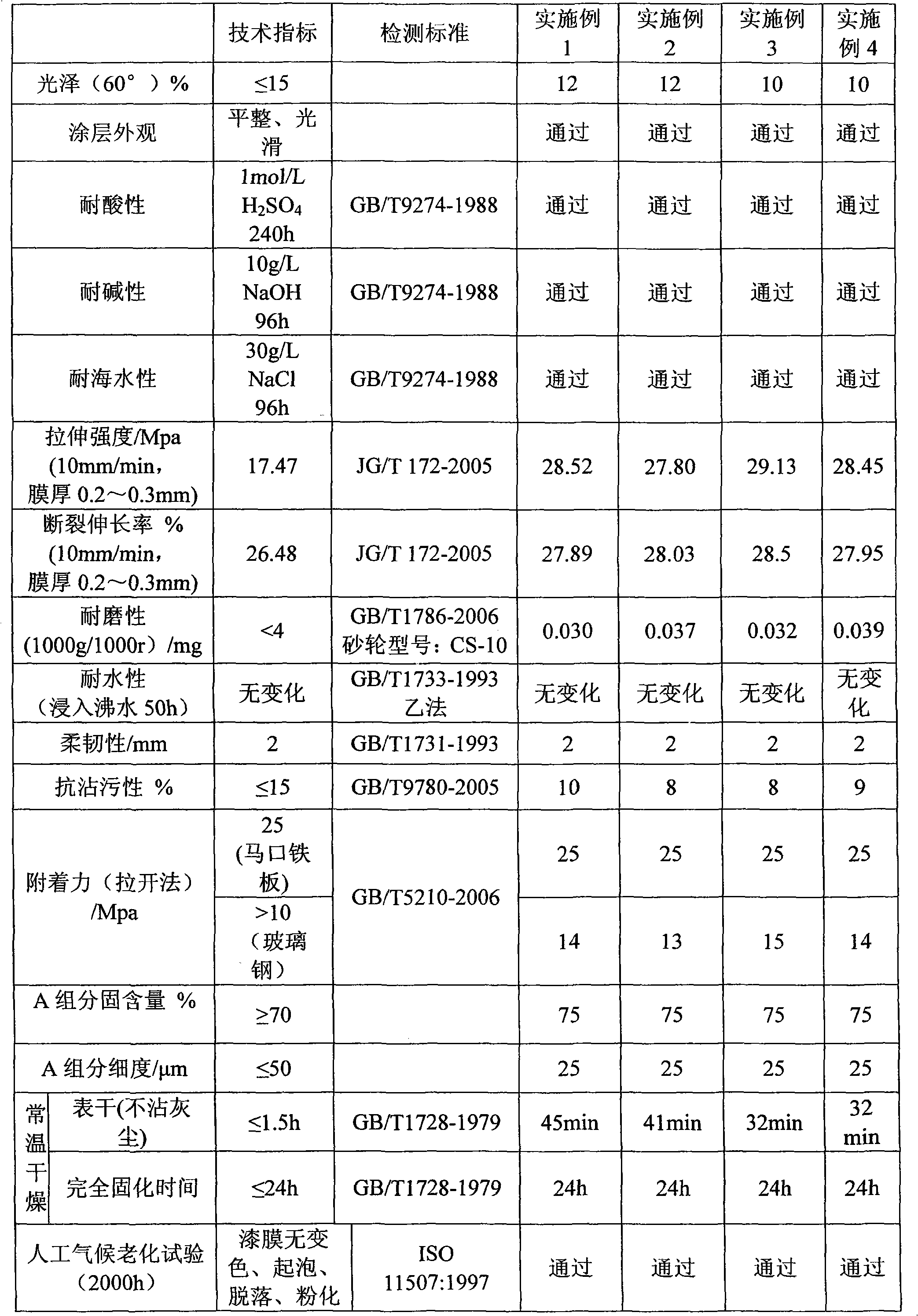

Protective coating for aerogenerator vanes and preparation method thereof

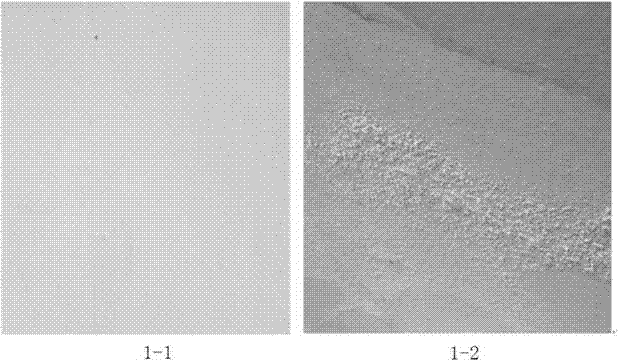

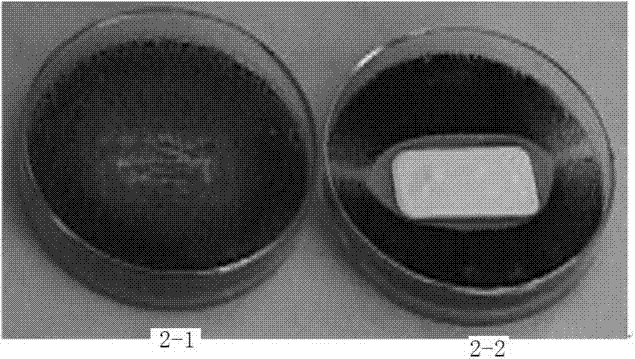

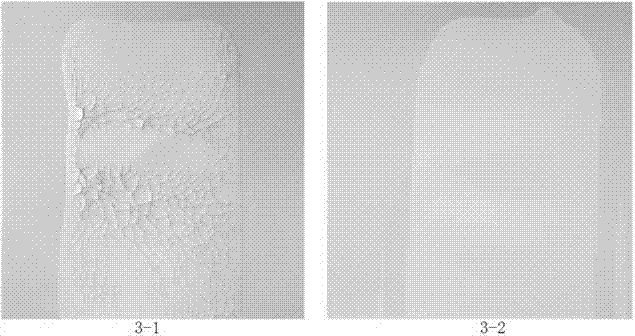

InactiveCN101613564AGood weather resistanceStrong UV resistanceMachines/enginesPolyurea/polyurethane coatingsOrganic solventPliability

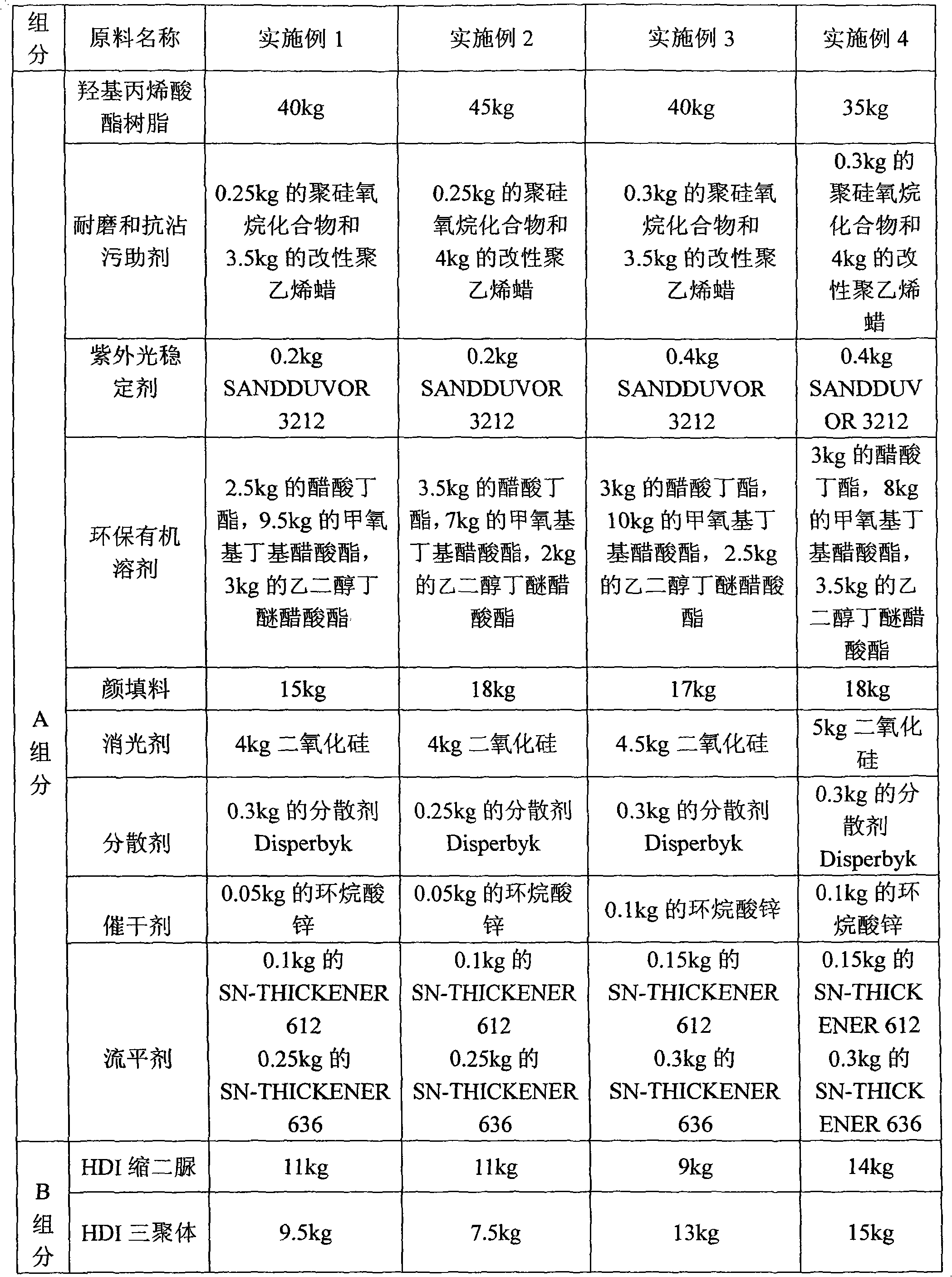

The invention relates to a protective coating for aerogenerator vanes and a preparation method thereof, wherein the protective coating has the advantages of excellent ultraviolet radiation resistance, abrasion resistance, stain resistance, corrosion resistance, adhesive force and flexibility. The preparation method uses hydroxyl acrylate resin as a base material of the surface protective coating for the aerogenerator vanes and uses the mixture of HDI biuret and HDI tripolymer as a curing agent. The coating consists of a component A and a component B, wherein the component A comprises the following materials in portion by weight: 10 to 55 portions of the hydroxyl acrylate resin, 1 to 5 portions of abrasion resistant and stain resistant auxiliary agent, 0.2 to 0.4 portion of ultraviolet stabilizer, 10 to 15 portions of environment-friendly organic solvent, 15 to 20 portions of pigments and fillers, 2 to 5 portions of delustering agent, 0.15 to 0.55 portion of dispersing agent, 0.01 to 0.3 portion of drying agent, and 0.25 to 0.55 portion of levelling agent; the component B comprises 1 to 15 portions of the HDI biuret and 1 to 15 portions of the HDI tripolymer; and the mass ratio of the component A to the component B is 2-6:1. When in use, the components A and B are mixed and stirred evenly in proportion, and then the mixture is adjusted to proper viscosity for construction by using a spraying method.

Owner:SOUTHEAST UNIV

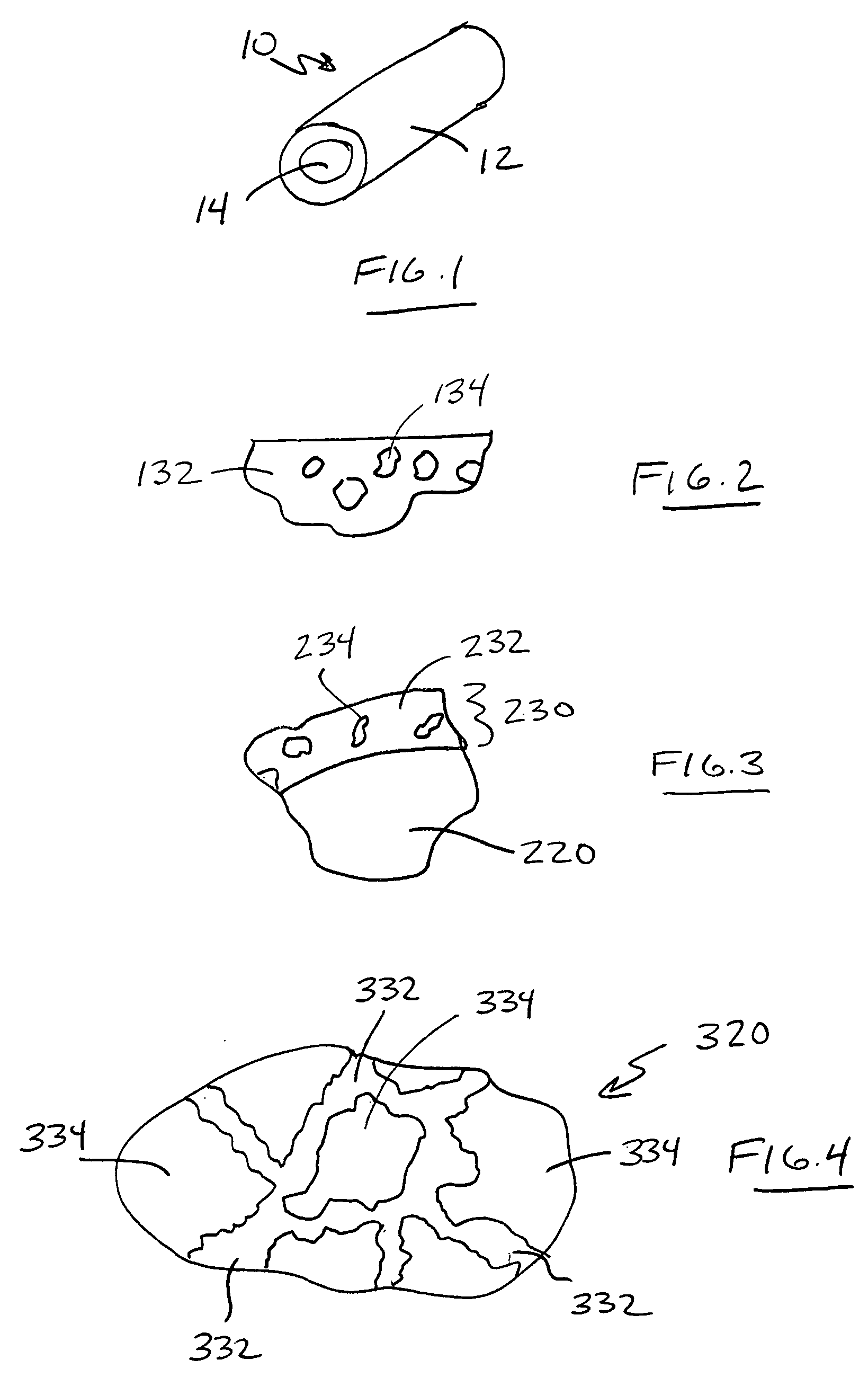

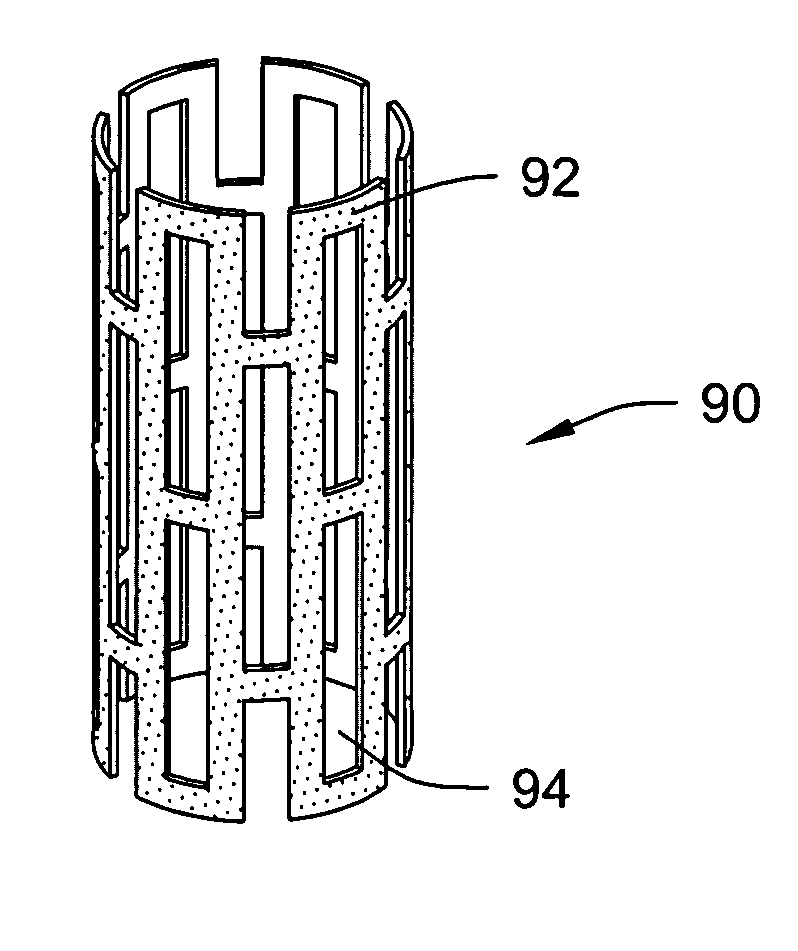

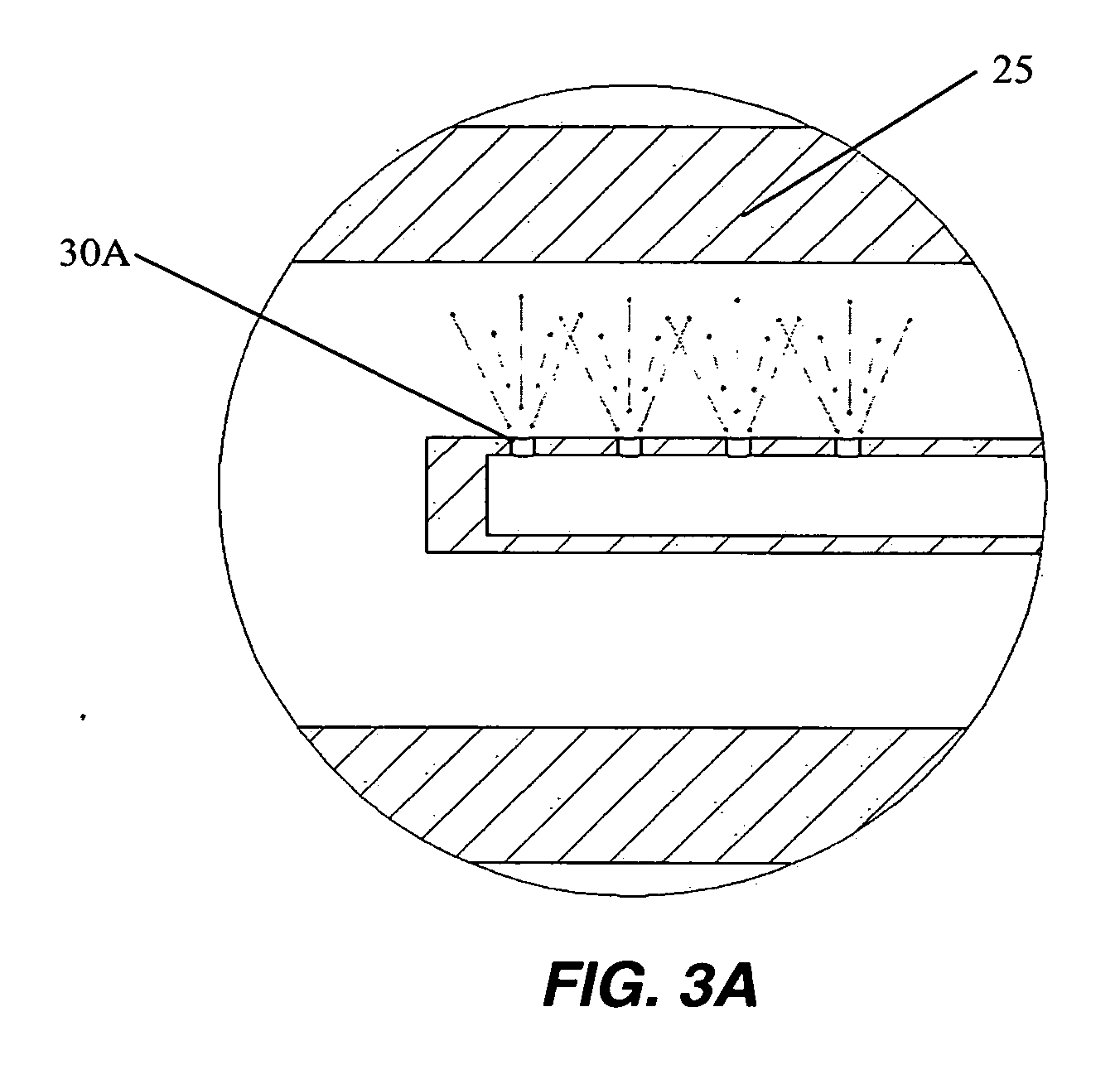

Kits, apparatus and methods for magnetically coating medical devices with living cells

ActiveUS20060286137A1Rapidly attractQuick attachStentsTransvascular endocardial electrodesHigh concentrationMagnetization

Medical devices with surfaces on which viable biologic cells are magnetically attracted and retained are disclosed along with methods of magnetic coating. The medical devices can be located in a carrier liquid containing high concentrations of magnetic cells before or after implantation. The carrier liquid with magnetic cells may be contact with the medical device in vitro or in vivo. In either case, the carrier liquid may have a concentration of magnetic cells that is high enough to facilitate coating of the medical device within an acceptable period of time, e.g., several hours or less. Magnetization of medical devices before, during, and / or after implantation and apparatus for performing the same are disclosed. Degaussing of magnetic medical devices is also disclosed.

Owner:MAYO FOUND FOR MEDICAL EDUCATION & RES

Super thin no-halogen less-smoke fire proof organic-inorganic composite paint and its prepn process

InactiveCN1974695AImprove heat resistanceImprove fire performanceFireproof paintsEpoxy resin coatingsHalogenFoaming agent

The present invention relates to one kind of super thin no-halogen less-smoke fireproof organic-inorganic composite paint and its preparation process. The composite paint is compounded with heat resistant organic and inorganic nanometer hybridized resin, organic resin, heat resistant pigment, heat resistant filler, carbon forming agent, foaming agent, catalyst, assistant, etc. In case of fire, the components of the paint synergy to swell, foam, isolate oxygen, delay heat transfer and inhibit fire spread. The fireproof paint may be used to form coating of controllable thickness in 0.2-2 mm, has fire resisting limit of 30-200 min, excellent heat resisting performance, excellent fire retarding performance, high fireproof performance, high anticorrosion performance and other advantages.

Owner:FUDAN UNIV

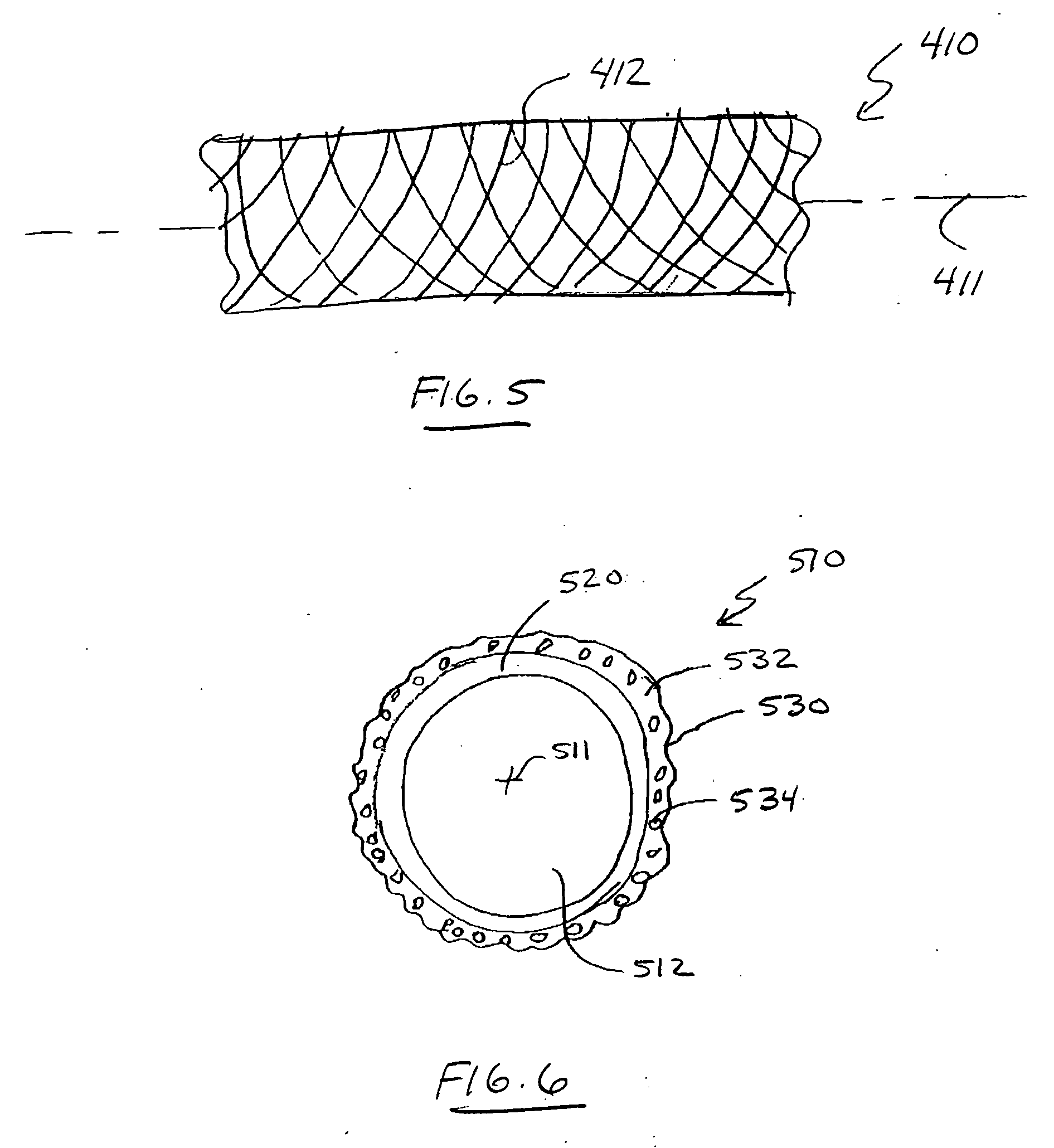

Selectively light curable support members for medical devices

Methods of forming support layers for use in catheters using having a support layer included, and stents incorporating coatings of photosensitive polymerizable resins and stents including fibers coated with photosensitive polymerizable resins. A fiber is coated with a PPC resin and incorporated into a support structure for a catheter. Portions of the PPC are polymerized by exposure to light of a desired wavelength, causing increased rigidity and strength to the polymerized portions. As the PPC is polymerized, the fibers coated by the PPC resins become stronger and change the flexibility of devices incorporating such fibers. Additional embodiments include stents incorporating PPC coatings and methods of using such stents, including polymerizing a PPC coating after inserting a self-expanding or balloon-expandable stent.

Owner:BOSTON SCI SCIMED INC

Jointing compound or plaster for construction elements, its method of preparation and method of producing a work

InactiveUS20030153651A1Efficient retentionImprove adhesionRoof covering using tiles/slatesCovering/liningsJoint compoundPolyvinyl alcohol

A jointing compound or plaster for construction elements, particularly paper-faced plasterboards. This plaster includes, in percentages by weight with respect to the total weight of plaster 50 to 85% of a mineral filler; 1 to 20% of an organic binder dispersible in an aqueous phase; 1 to 15% of a silicate-based agent other than the mineral filler; 0.2 to 5% of a hydrophobic agent which is a silicone derivative; 0.05 to 5% of polyvinyl alcohol; and water to make up to 100%. A method of producing a work such as a partition, a wall covering or a ceiling is also disclosed.

Owner:CONTINENTAL BUILDING PROD OPERATING COMPANY

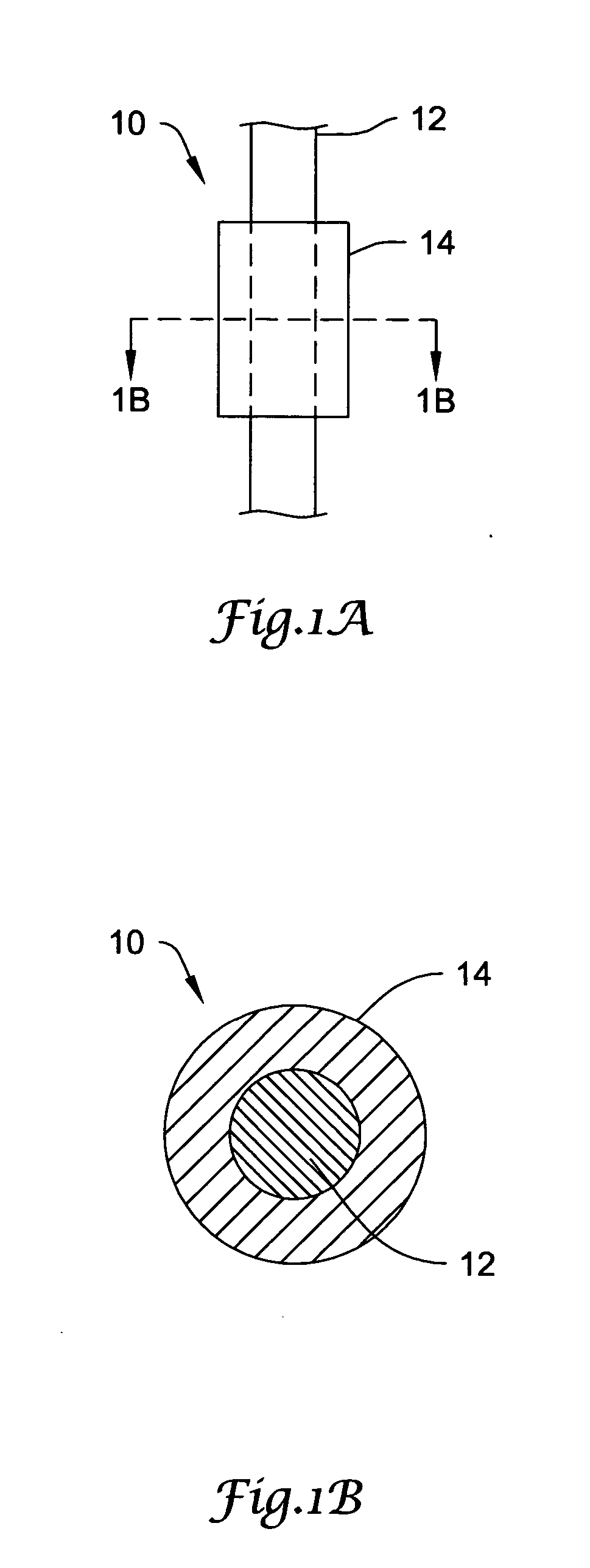

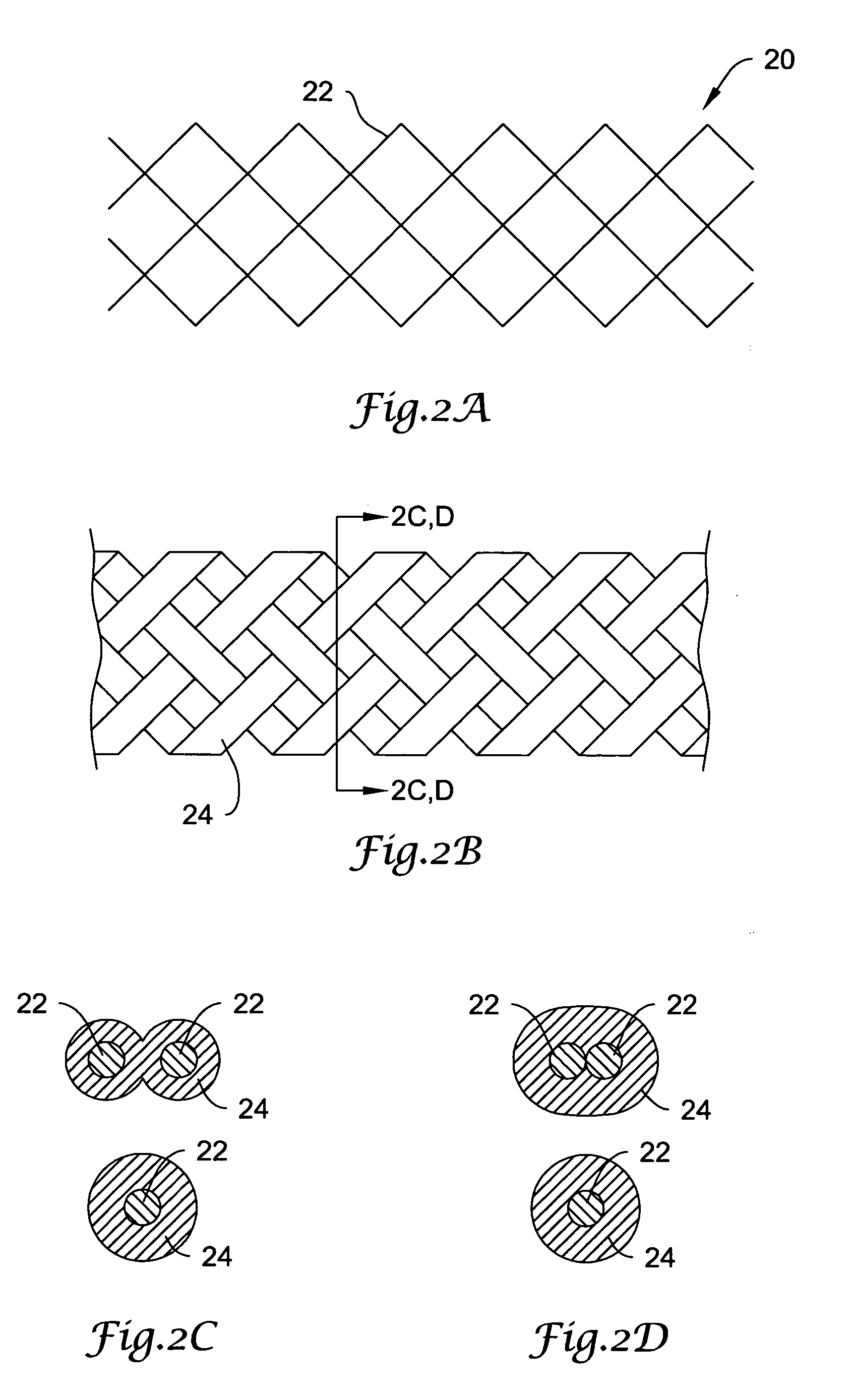

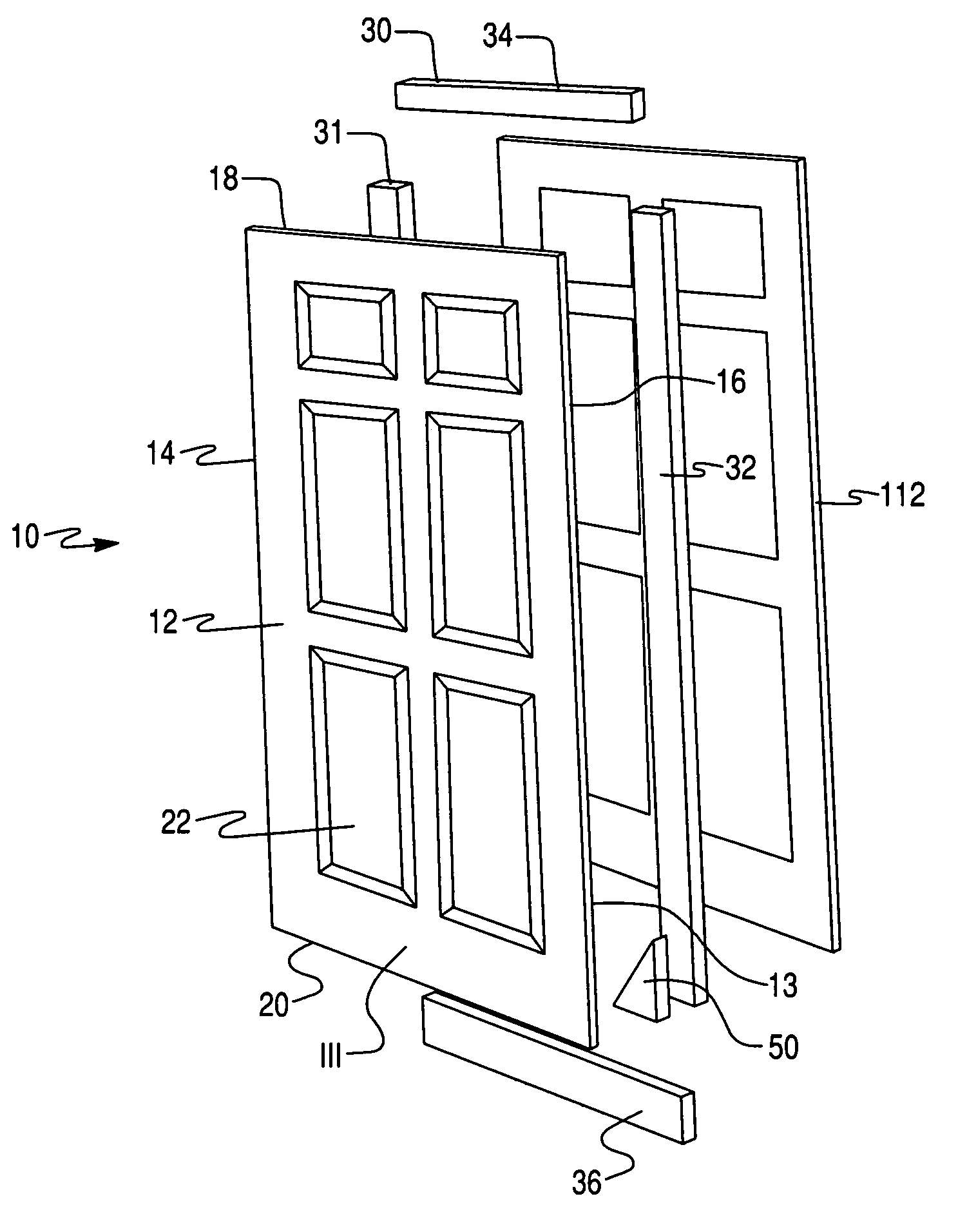

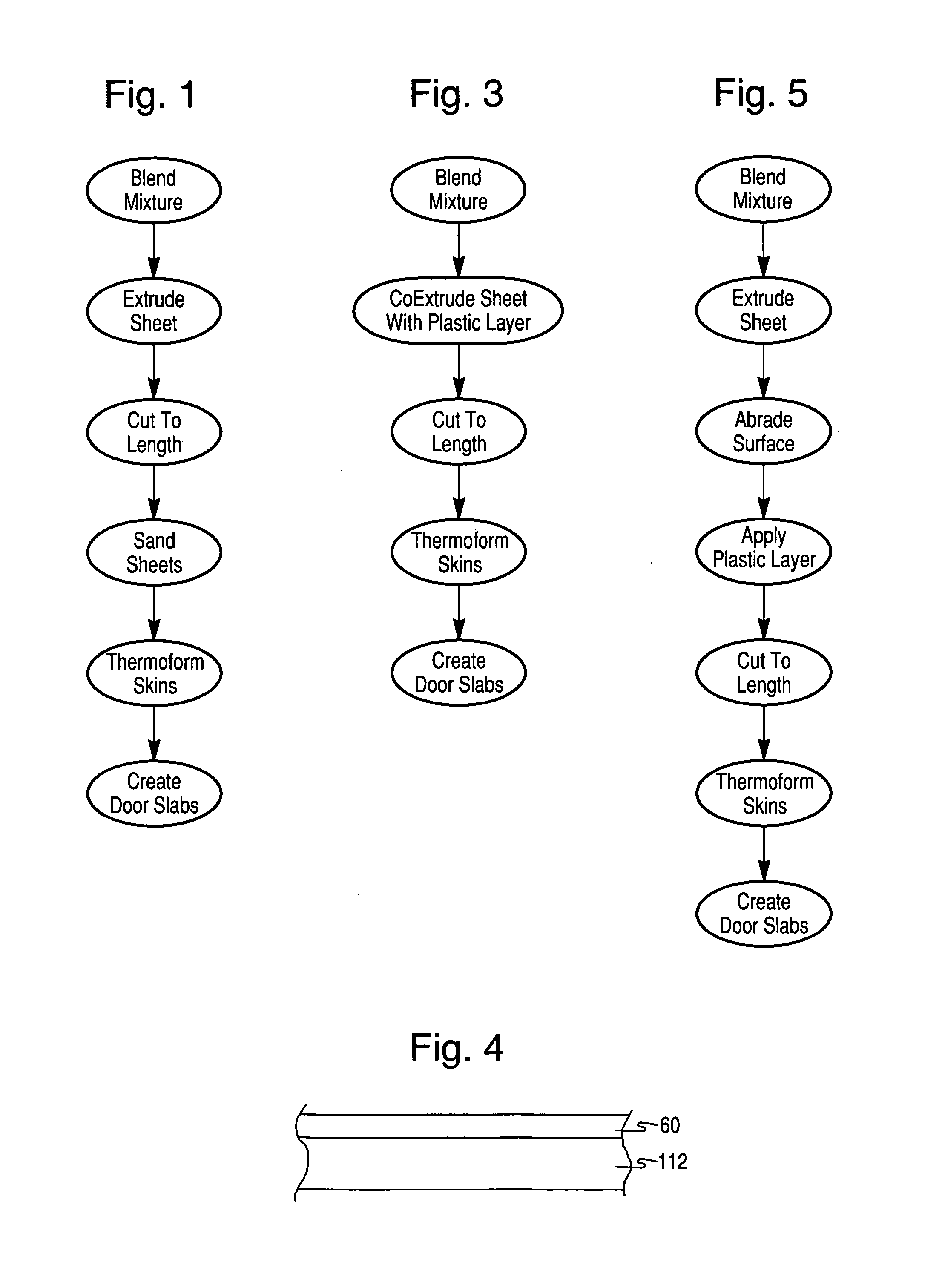

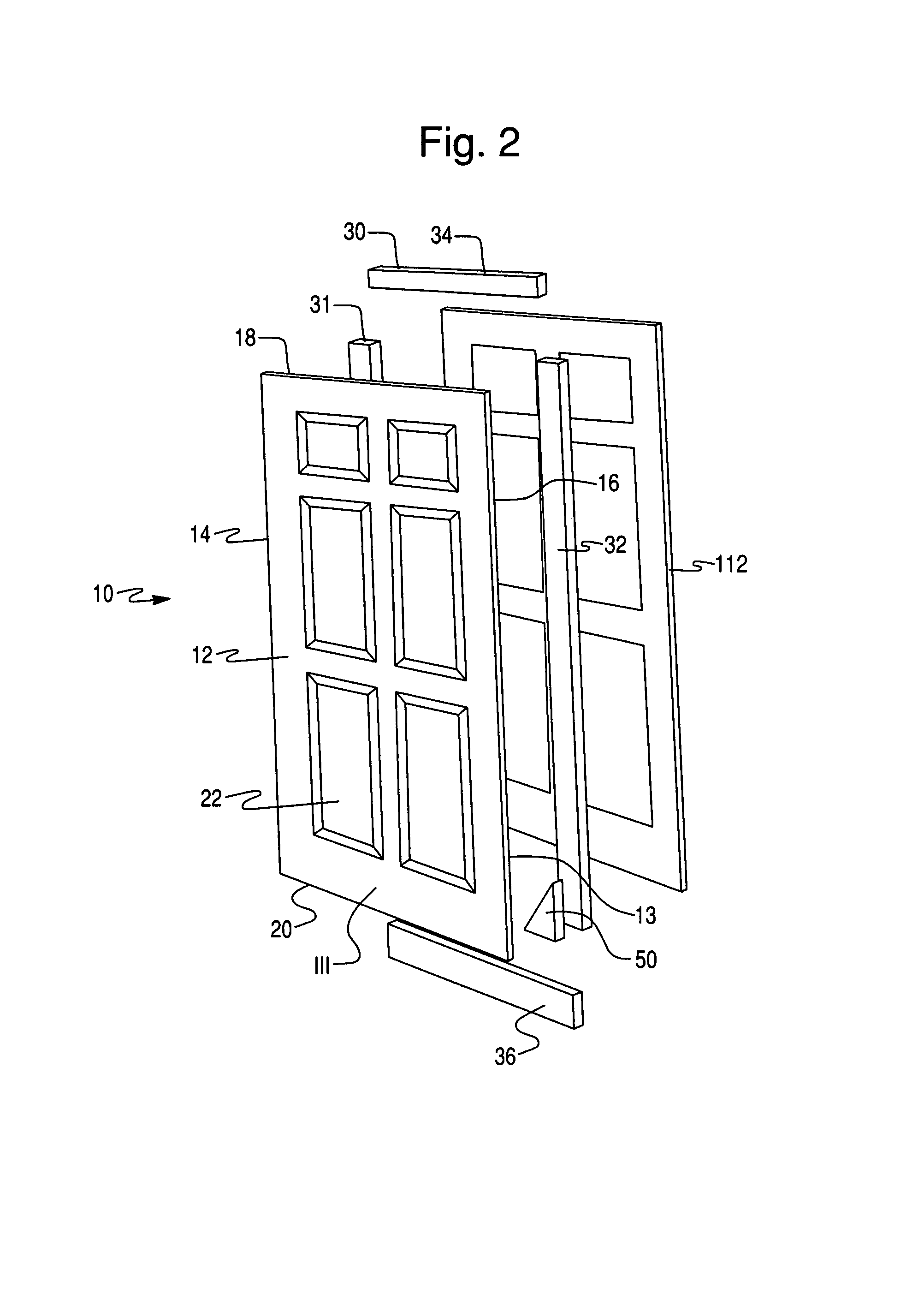

Composite door structure and method of forming a composite door structure

InactiveUS7178308B2Improve thermal performanceImprove impact resistanceAdhesivesDoor leavesThermoplastic polymerSurface plate

A method of forming a composite door is disclosed. The method comprises: mixing together a thermoplastic polymer with an organic fibrous material in a ratio such that the organic fibrous material constitutes 40 to 60 percent by weight of the mixture; extruding the mixture under heat and pressure to create a thin sheet form; cutting the sheet to a predetermined size; removing material from at least one surface of the sheet to create a homogeneous appearance devoid of obvious fibrous particles; thermoforming the sheet to impart to the at least one surface an exterior three dimensional door surface to create a thin door facing; and assembling two of the thermoformed thin door facings, a peripheral frame and a core material into a door.

Owner:CCB RE HLDG

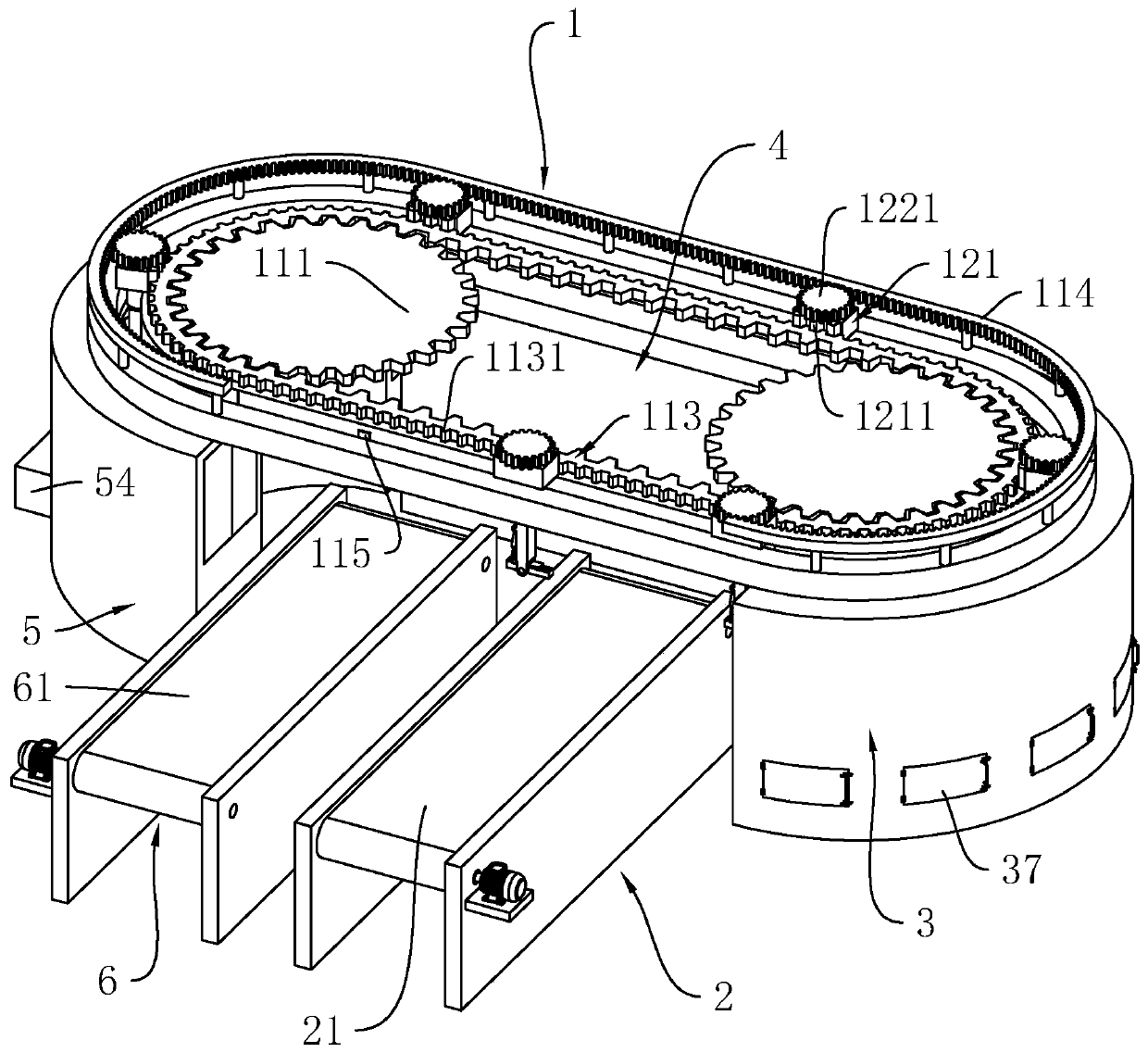

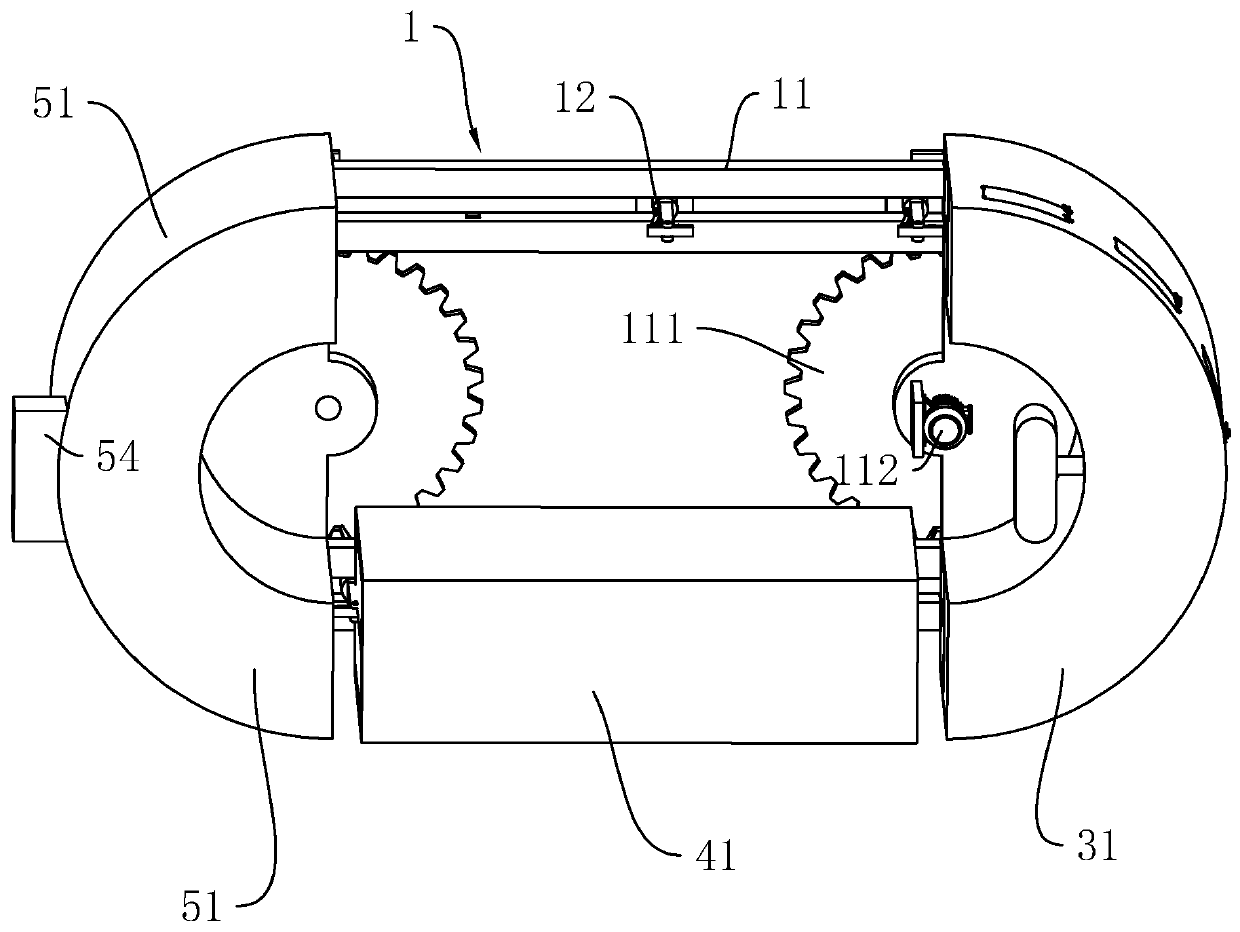

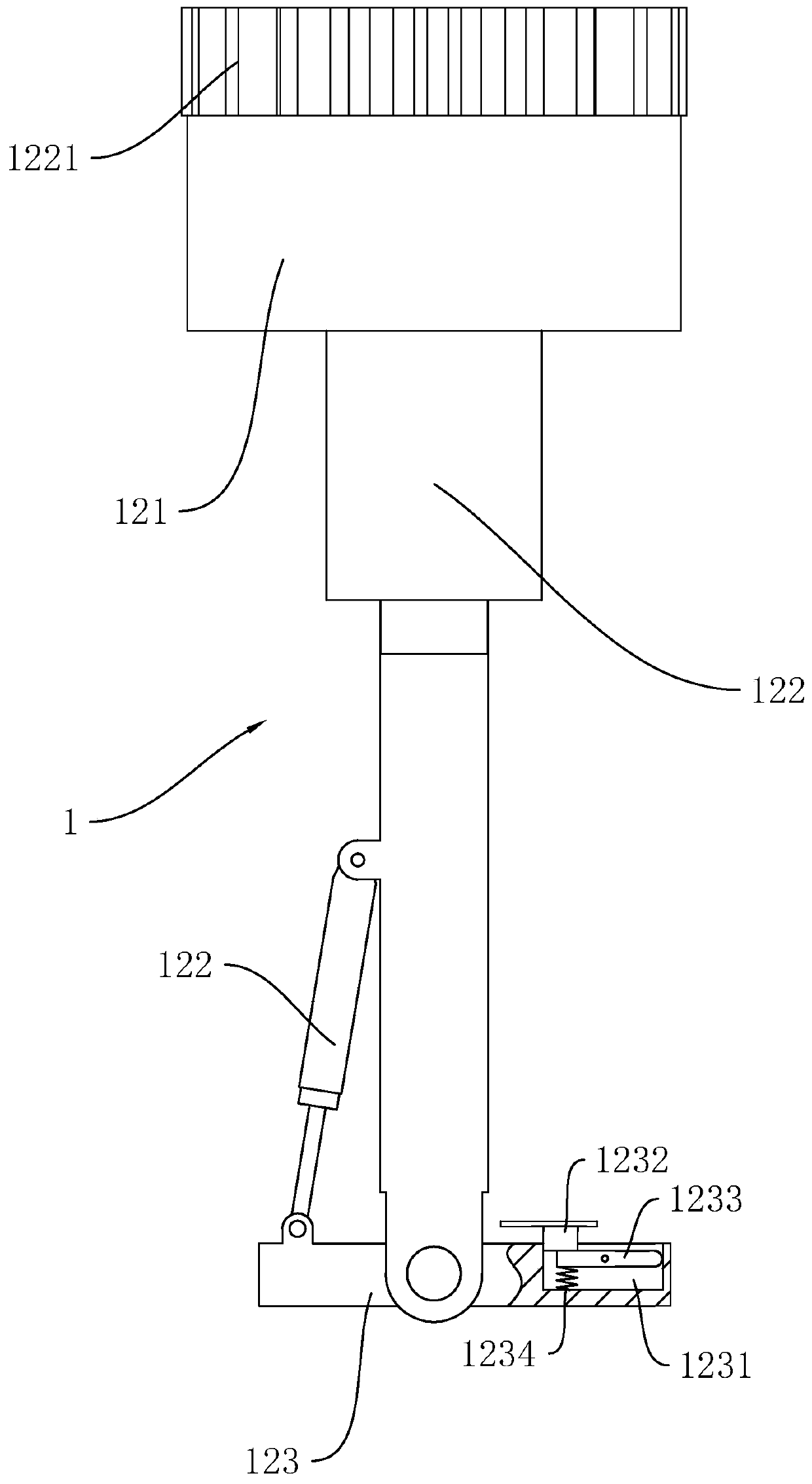

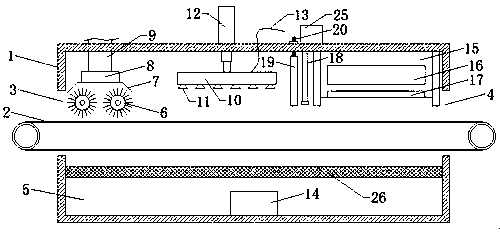

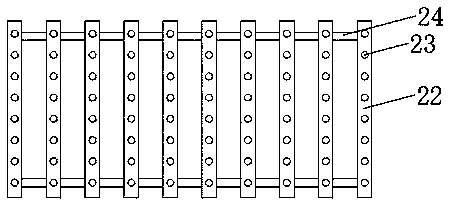

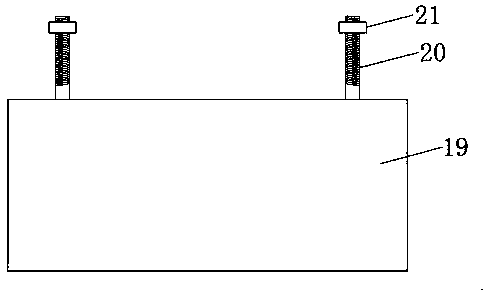

Workpiece lifting spraying production line

The invention relates to a workpiece lifting spraying production line which comprises a lifting conveying device, a feeding station, a spray cleaning station, a spraying station, a drying station anda discharging station. The lifting conveying device comprises a conveying rail in the shape of a kidney-shaped ring, and multiple lifting frames arranged on the lower side of the conveying rail. The spray cleaning station comprises a spray cleaning box, and a first through groove for the lower ends of the lifting frames to be inserted into the spray cleaning box conveniently is formed in the upperside of the spray cleaning box. Multiple gas spraying guns capable of spraying gases to workpieces are arranged at the positions, corresponding to the lifting frame conveying track, of the two sidesof the spray cleaning box. A blanking groove is fixedly connected to the position, corresponding to the lower side of the lifting frame, of the spray cleaning box along the movement track of the lifting frame, and a cloth bag dust collecting bag with an opening formed in the upper end is arranged on the lower side of the blanking groove. A draught fan is fixedly connected to the position, corresponding to the lower side of the cloth bag dust collecting bag, of the spray cleaning box. First flexible dust blocking curtains are further fixedly connected to the two ends of the spray cleaning box.The workpiece lifting spraying production line has the beneficial effects that the workpieces can be automatically cleaned, the labor intensity is lowered, and the work efficiency is improved.

Owner:青岛欧轩机械有限公司

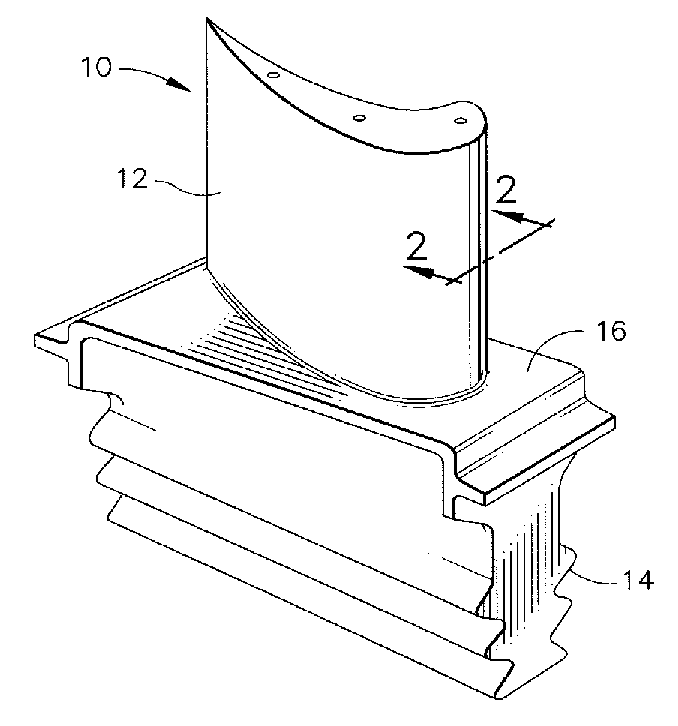

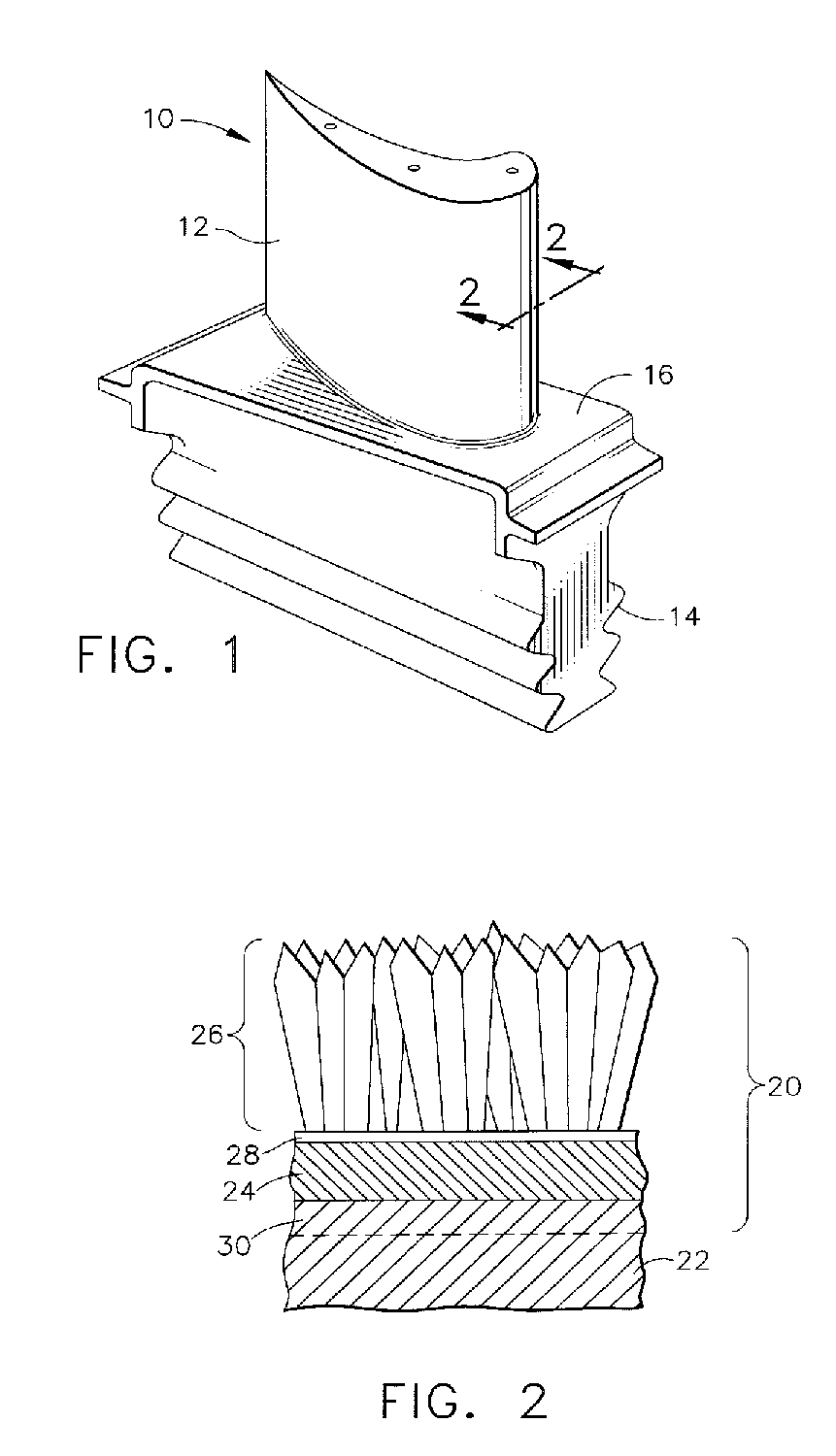

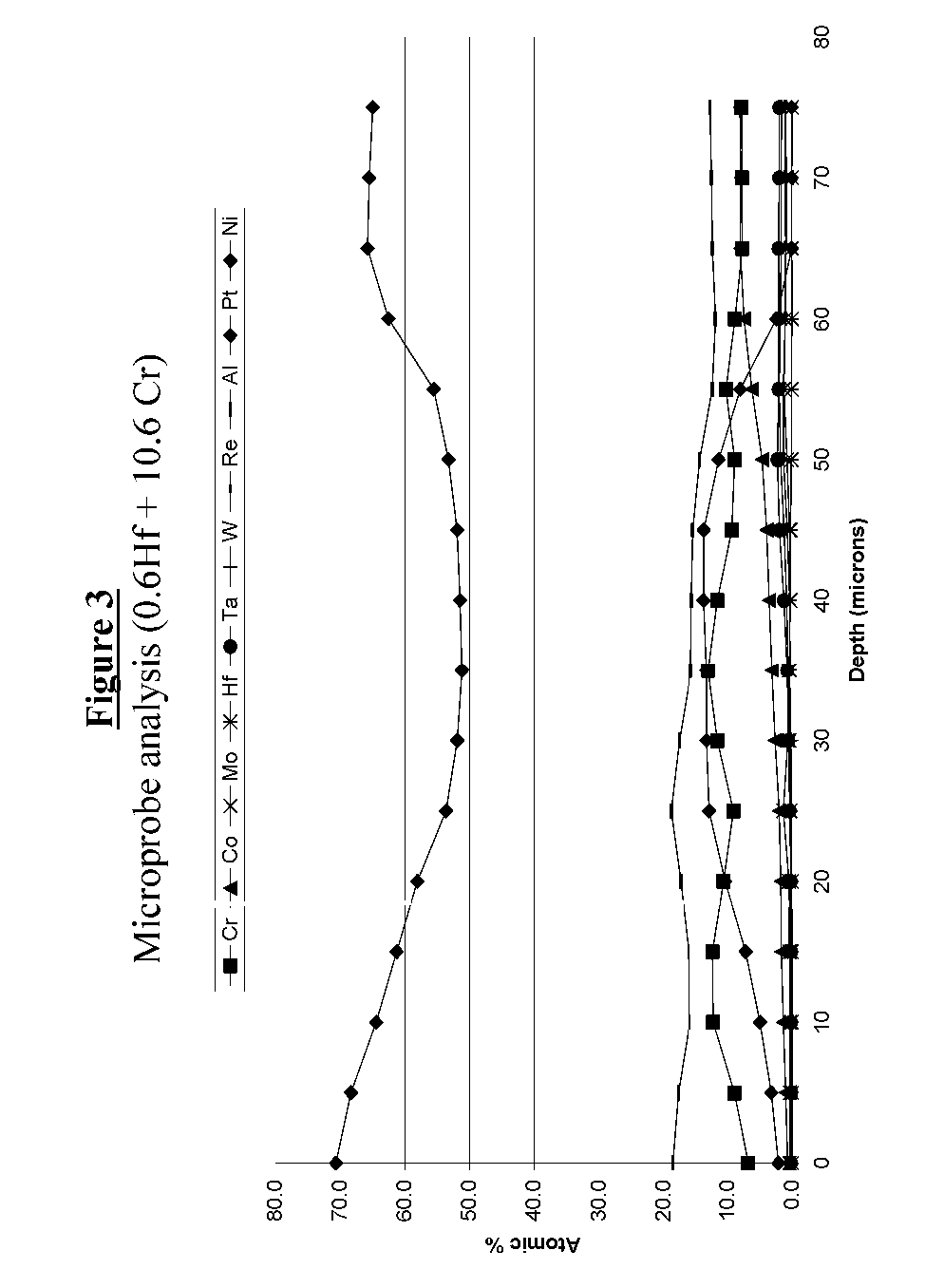

Gamma prime phase-containing nickel aluminide coating

ActiveUS20070071996A1Desirable environmental and mechanical propertyOxidation resistance can be improvedPropellersReaction enginesCeriumHafnium

An intermetallic composition suitable for use as an environmentally-protective coating on surfaces of components used in hostile thermal environments, including the turbine, combustor and augmentor sections of a gas turbine engine. The coating contains the gamma-prime (Ni3Al) nickel aluminide intermetallic phase and either the beta (NiAl) nickel aluminide intermetallic phase or the gamma solid solution phase. The coating has an average aluminum content of 14 to 30 atomic percent and an average platinum-group metal content of at least 1 to less than 10 atomic percent, the balance of the coating being nickel, one or more of chromium, silicon, tantalum, and cobalt, optionally one or more of hafnium, yttrium, zirconium, lanthanum, and cerium, and incidental impurities.

Owner:GENERAL ELECTRIC CO

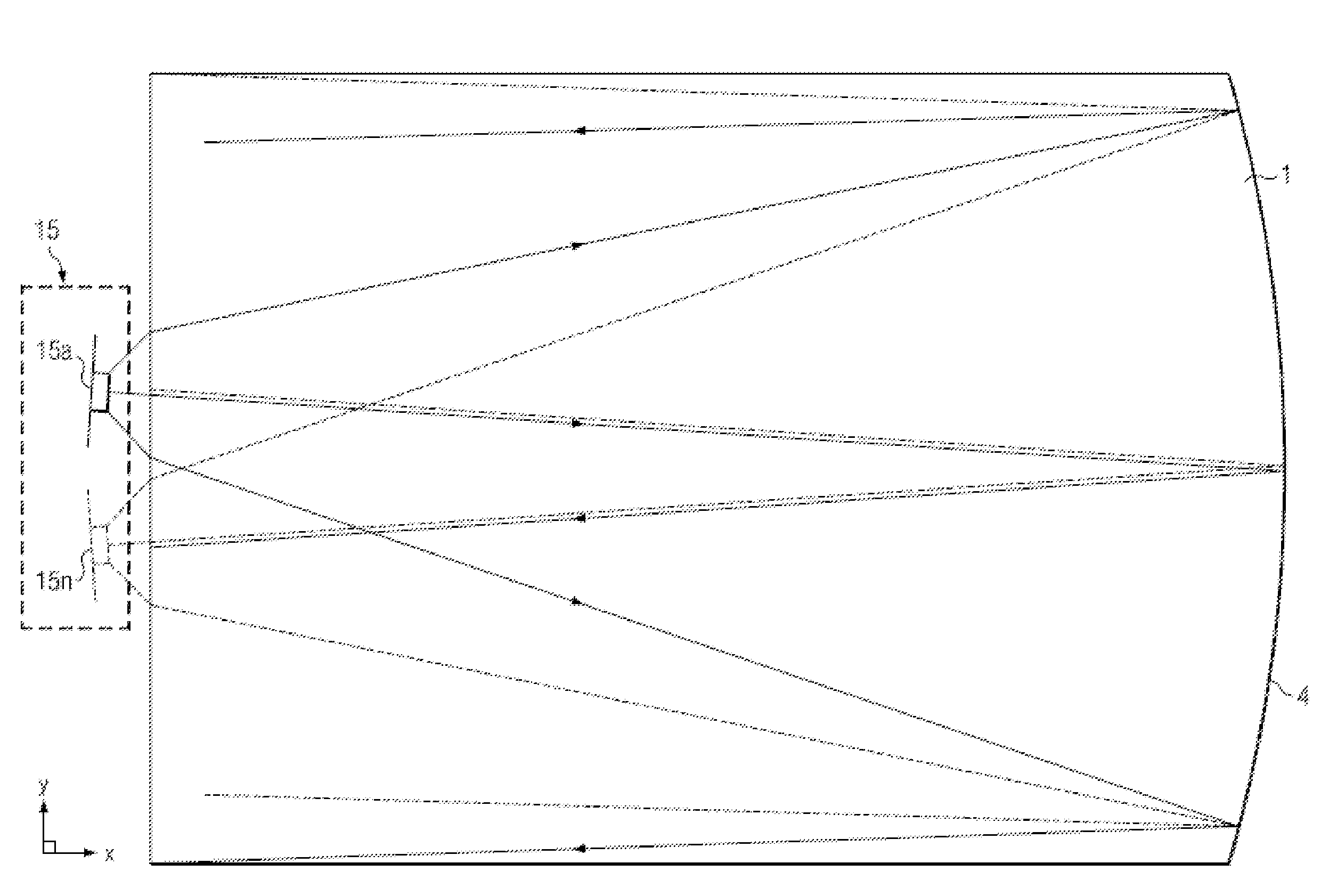

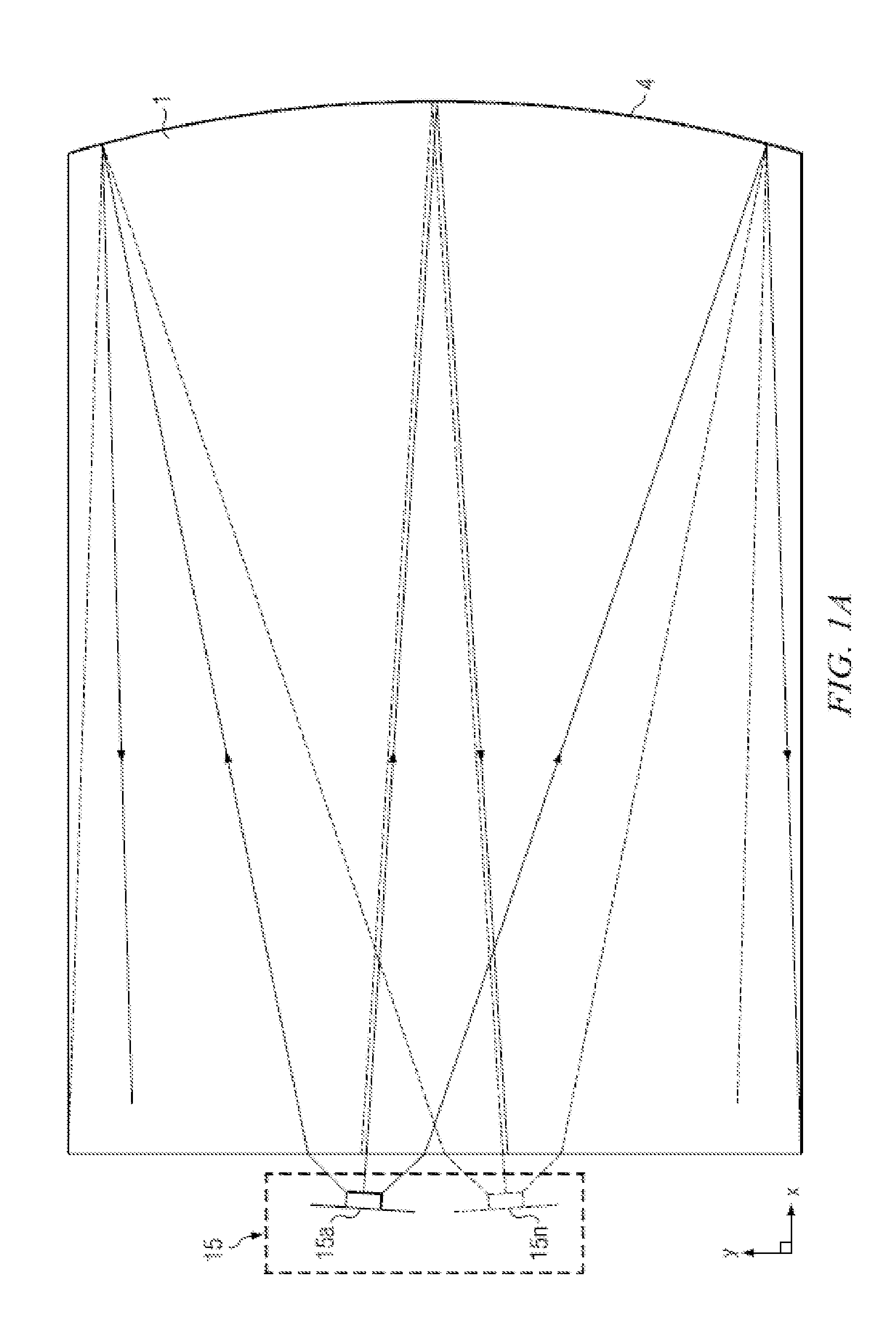

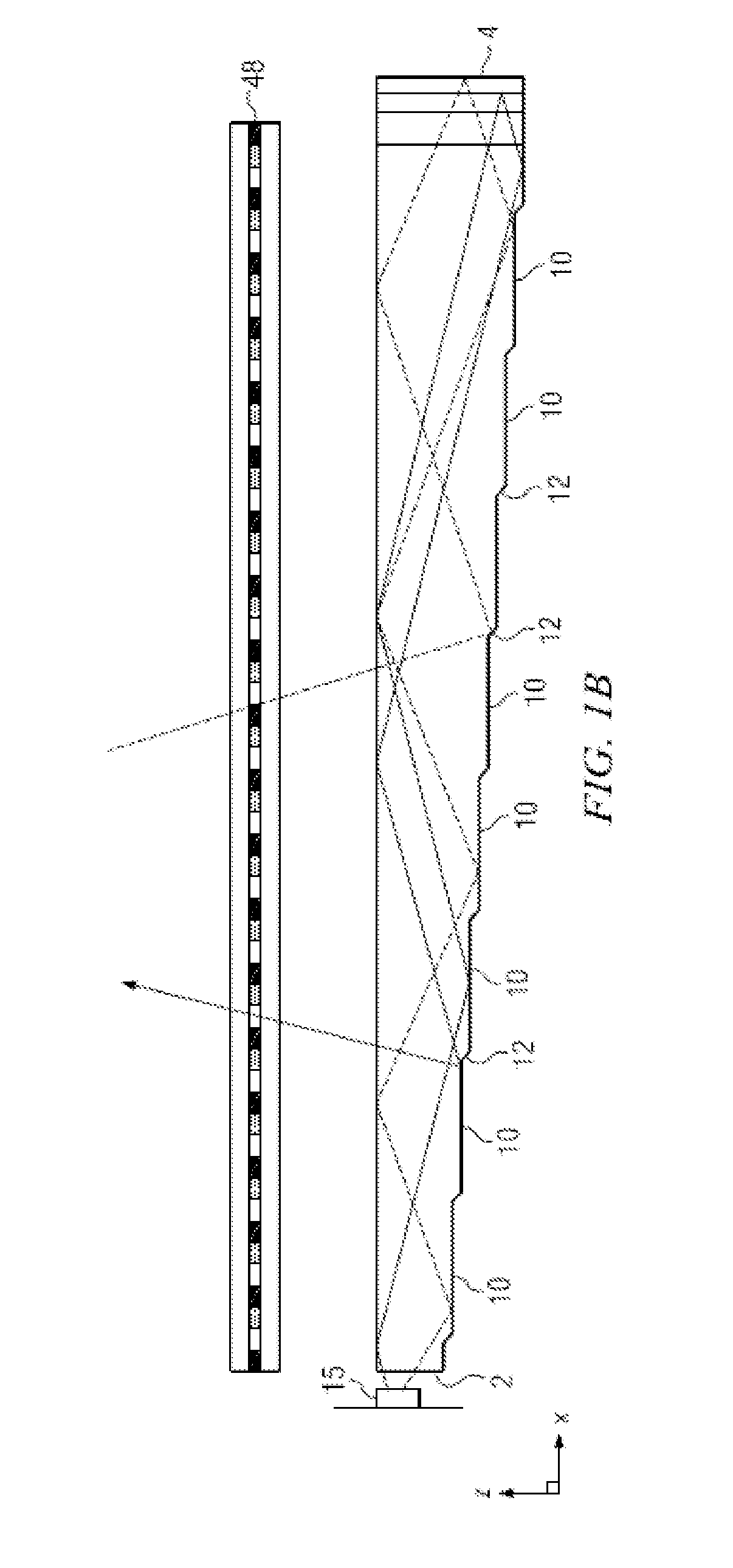

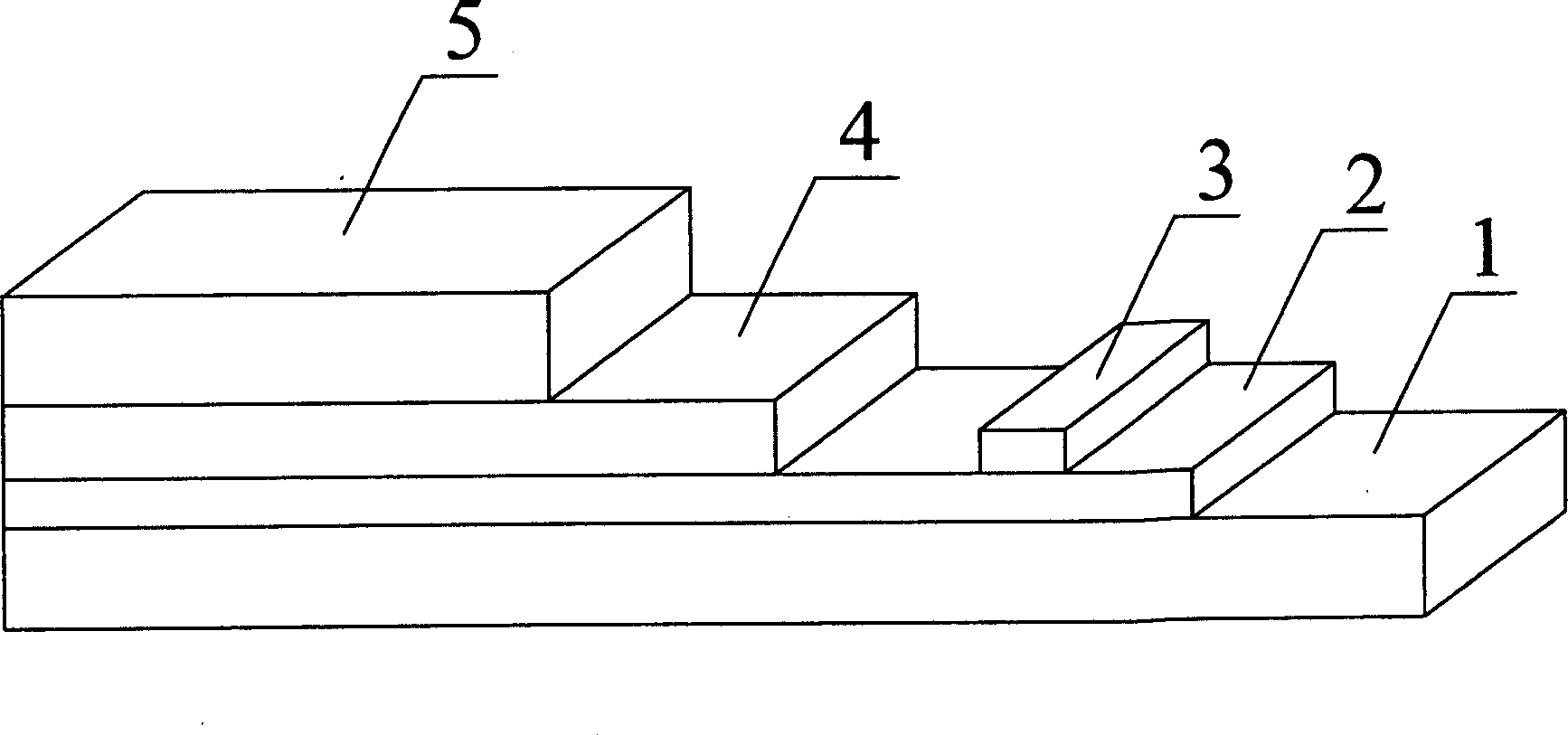

Method of manufacturing directional backlight apparatus and directional structured optical film

InactiveUS20140041205A1Low scatteringHigh efficiencyMechanical apparatusWave amplification devicesEngineeringOptical film

Disclosed is a manufacturing method for a stepped imaging directional backlight apparatus which may include a structured optical film and a tapered body. The structured optical film may include multiple optical functions and may be assembled by folding onto the tapered body, reducing cost and complexity of manufacture.

Owner:REALD SPARK LLC

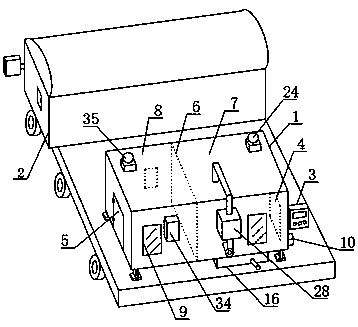

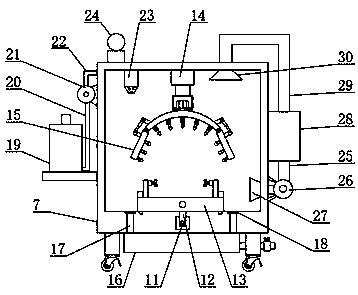

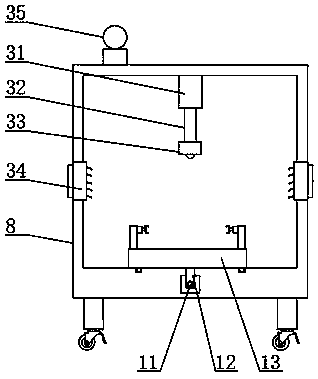

Mobile environment-friendly paint spraying booth

InactiveCN109604101AEasy to paintImprove painting efficiencyPretreated surfacesCoatingsHydraulic cylinderInternal cavity

The invention discloses a mobile environment-friendly paint spraying booth in the technical field of paint spraying. The paint spraying booth comprises a paint spraying booth body and a transport vehicle; an inner cavity of the paint spraying booth body is divided by a dividing plate into a paint spraying chamber located on the right side and a drying chamber located on the left side; a driving mechanism is mounted in the center of the inner wall of the top of the paint spraying chamber; a dust sensor is mounted on the back side of the inner wall of the top of the paint spraying chamber; the top end of a filtering box is connected with the bottom end of an air inlet pipe; the top end of the air inlet pipe extends to the top of an inner cavity of the paint spraying chamber; an air inlet cover is mounted at the top end of the air inlet pipe; and the bottom of a hydraulic cylinder I is connected with a detecting mechanism through a telescopic rod I. According to the paint spraying booth,an upper paint spraying pipe cooperates with side paint spraying devices on two sides, clamped workpieces are rotated by 180 degrees by two rotation motors, and two-side paint spraying is performed onthe workpieces, so that the paint spraying efficiency for the workpieces is improved effectively; and the workpieces after paint spraying are dried by the aid of a fan with heat produced by a heatingresistance wire II during working, so that environmental pollution caused by waste gas and waste liquids which are produced during paint spraying is avoided.

Owner:袁大力

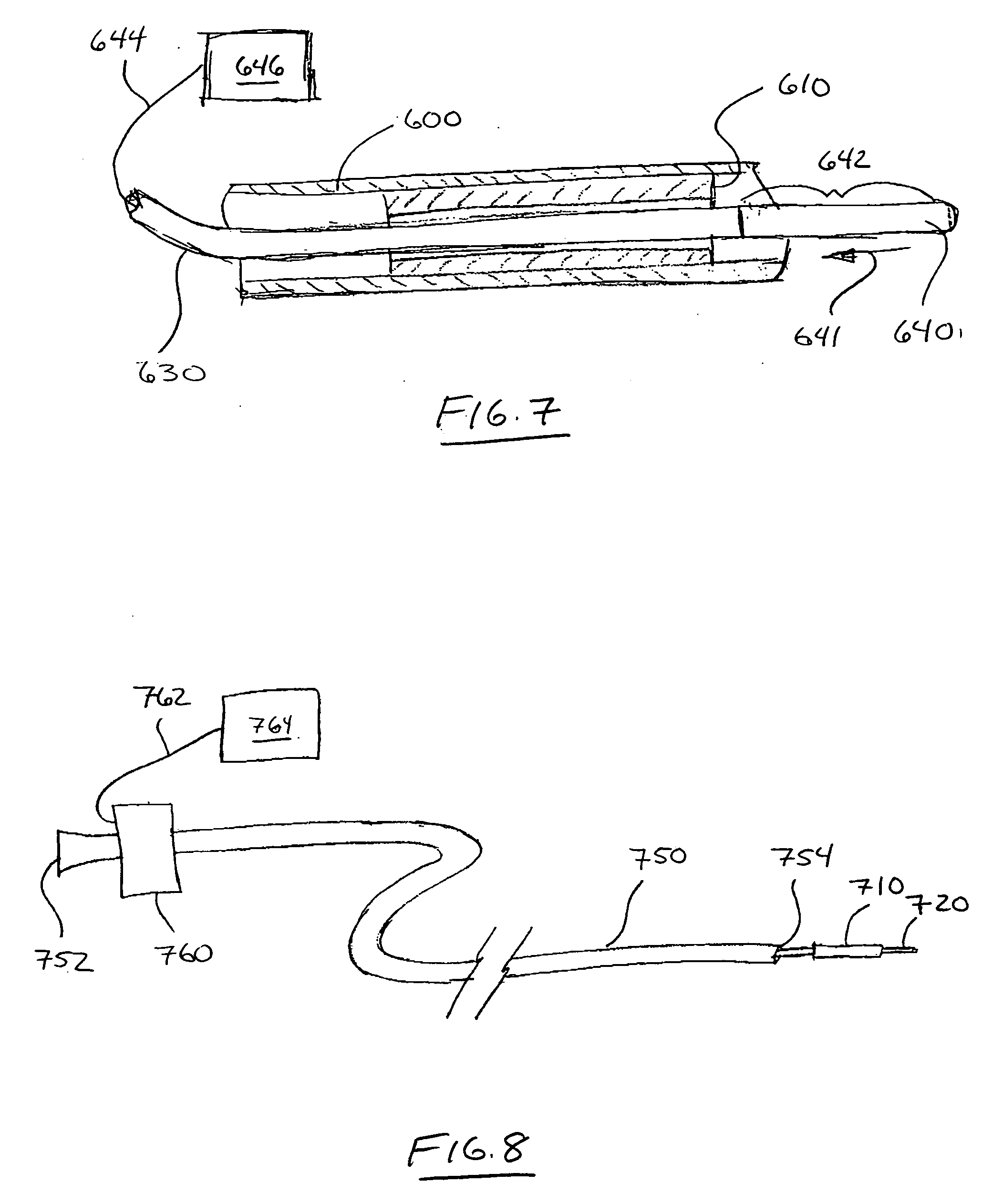

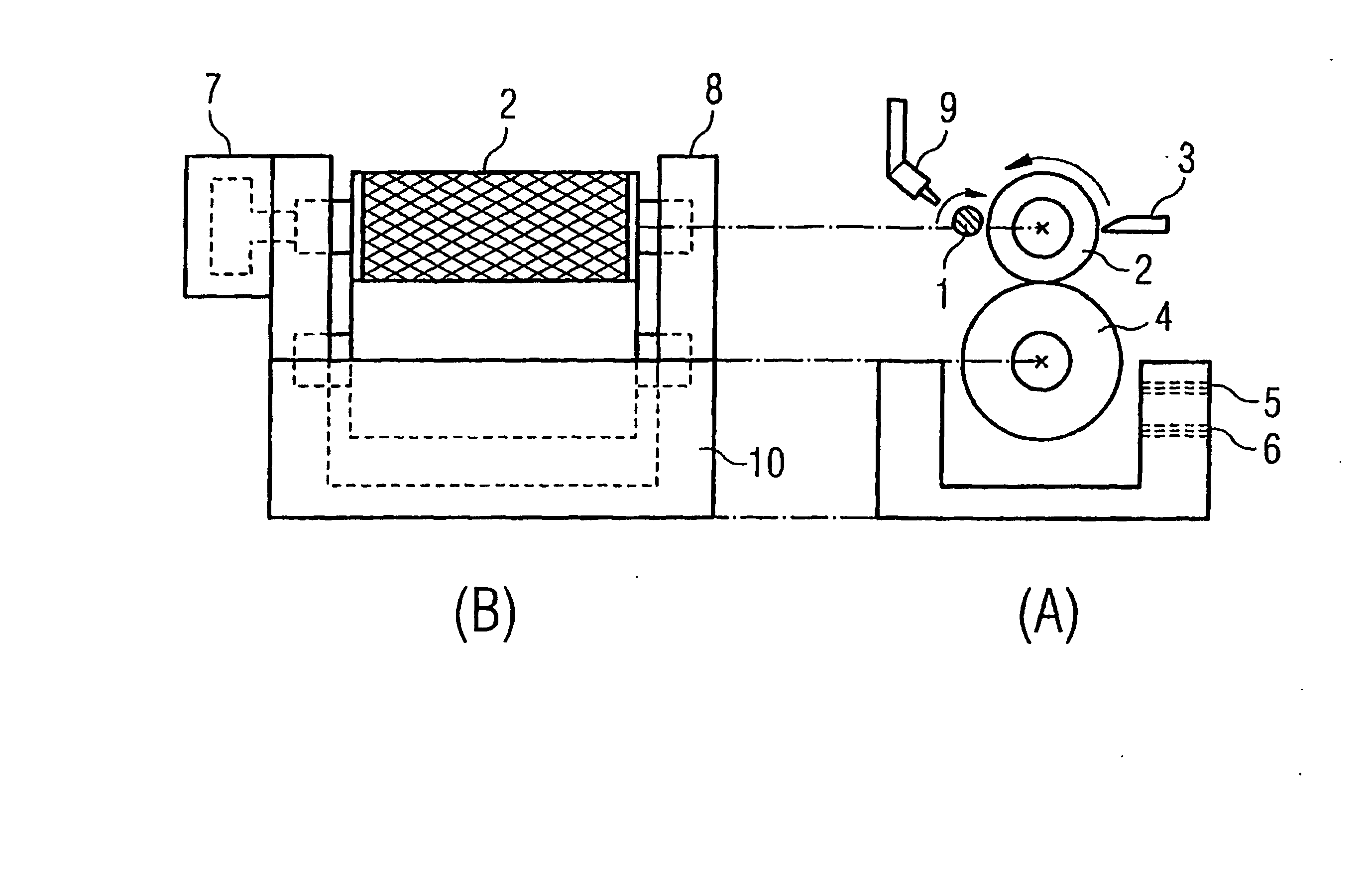

Method and apparatus for coating of implants

The present invention relates to a method and a device for applying a defined amount of a coating material onto the surface of an implant by means of a printing process, in particular using a printing roller. The invention also relates to the use of a printing process, in particular a printing roller, for applying a defined amount of a coating material onto the surface of the implant to be coated and to correspondingly produce coated implants.

Owner:CINVENTION AG

Metal finishing agent using silane coupling agent as main component for metal surface pretreatment

The invention relates to a metal surface treatment agent for metal surface pretreatment, in which silane coupling agent is the main composition. The treatment agent comprises the following raw materials: 1, 2- diethoxy estersil ethane (BTSE), gamma- aminopropyl silane (gamma-APS), water dispersible silicon dioxide, fluorine compound, acetic acid and water. On the basis of silane coupling agent film forming mechanism, by selecting and remixing the main composites silane: coupling agent (SA), surface conditioner and auxiliary film forming agent, a metal surface parkerizing substitute with silicon coupling agent as the main film forming agent is researched. The invention has the characteristics of innocuity, harmlessness, non-pollution, low-temperatrue fast processing, operation simplicity, wide material resource, low price, production clearness, etc.

Owner:合肥华清金属表面处理有限责任公司

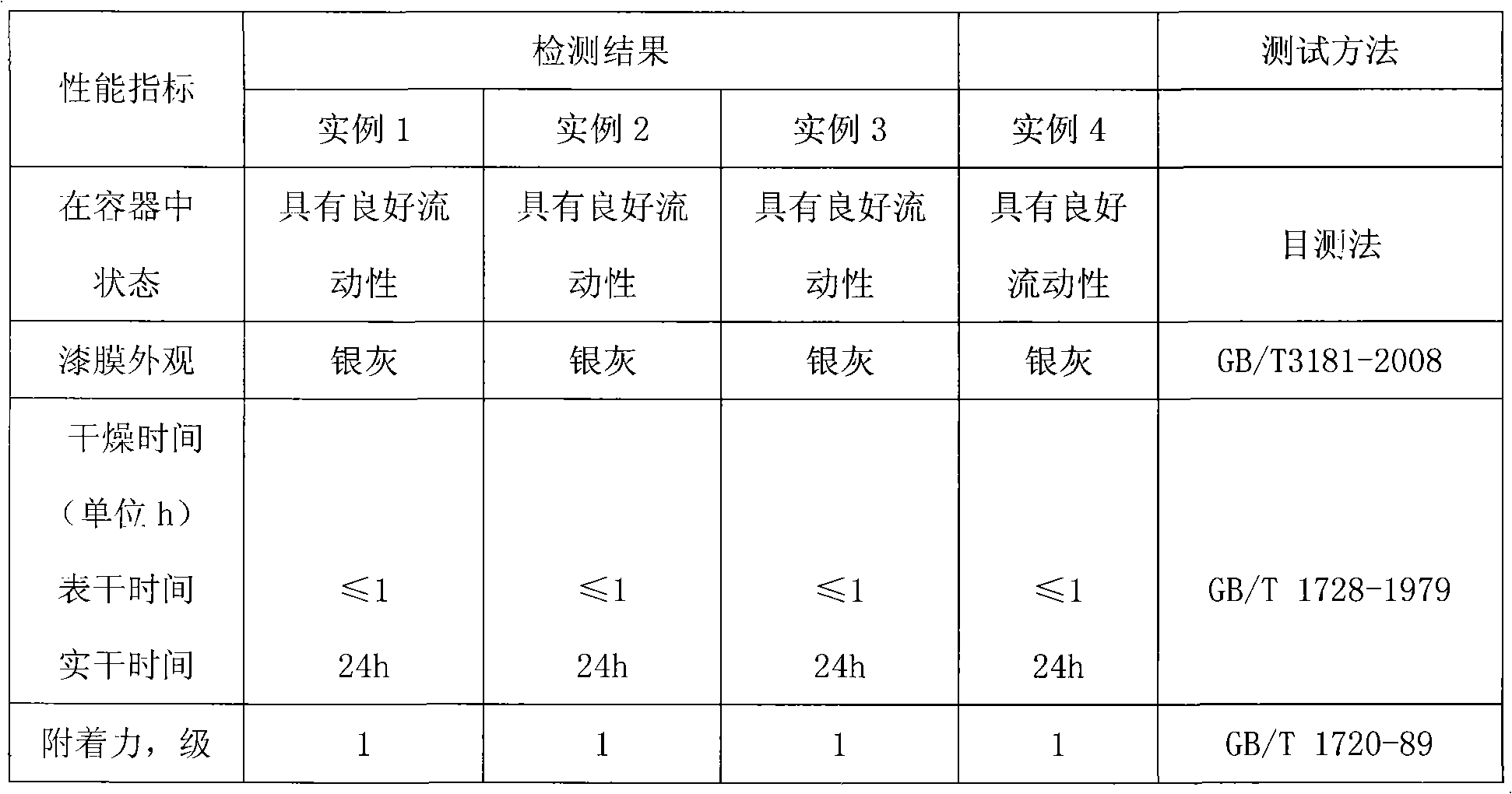

Low-surface treatment rusty rust inhibiting primer for hot galvanized steel

ActiveCN101928507AReduce dosageGood flexibilityAnti-corrosive paintsEpoxy resin coatingsSolventPigment

The invention relates to a low-surface treatment rusty rust inhibiting primer for hot galvanized steel. The low-surface treatment rusty rust inhibiting primer is characterized by comprising a component A and a component B based on 100 parts of the low-surface treatment rusty rust inhibiting primer, wherein the component A is prepared by blending, stirring and grinding 15 to 40 parts of film-forming resin solution, 10 to 30 parts of pigment, 4 to 12 parts of rust corrosion transforming agent and 0.5 to 1 part of anti-settling agent; the component B comprises 20 to 30 parts of mixed curing agent and 15 to 35 parts of mixed solvent; and the mass ratio of the component A to the component B is 5+ / -0.5:1. The components of the primer reduce the using amount of dimethylbenzene and have very good bonding force with the surface of the hot galvanized steel, wherein the adhesive force is 1 grade. The coating has high flexibility and corrosion resistance and can be used for rusty coating on the surface of the rusty hot galvanized steel.

Owner:CHINA ELECTRIC POWER RES INST +1

Conductive epoxy resin lawn pigment and coating process thereof

InactiveCN1854217AImprove conductivityUnlimited adjustable colorsEpoxy resin coatingsElectrical resistance and conductanceEpoxy

An electrostatic-conducted epoxy-resin terrace coating and its coating process are disclosed. The coating consists of finish and primer, finish uses conductive short-staple slurry with excellent conductive and dispersing performances, and surface and volume resistances reach to 5*10(4)-1*10(6)omega, furthermore, finish utilizes composite accessory system with disperser, leveling agent, antifoaming agent and rheological agent; primer uses conductive graphite powder, and surface and volume resistances reach to 10(3)-10(4)omega. The process is carried out by pasting conductive copper foil at an interval 1m*2m, building an electrostatic dissipative leakage layer, connecting a grounding device by1000m2 with grounding resistance<4omega and composing complete electrostatic leakage system. It's simple, convenient and has excellent and long-acting electrostatic-conducting effect.

Owner:上海秀珀化工有限公司

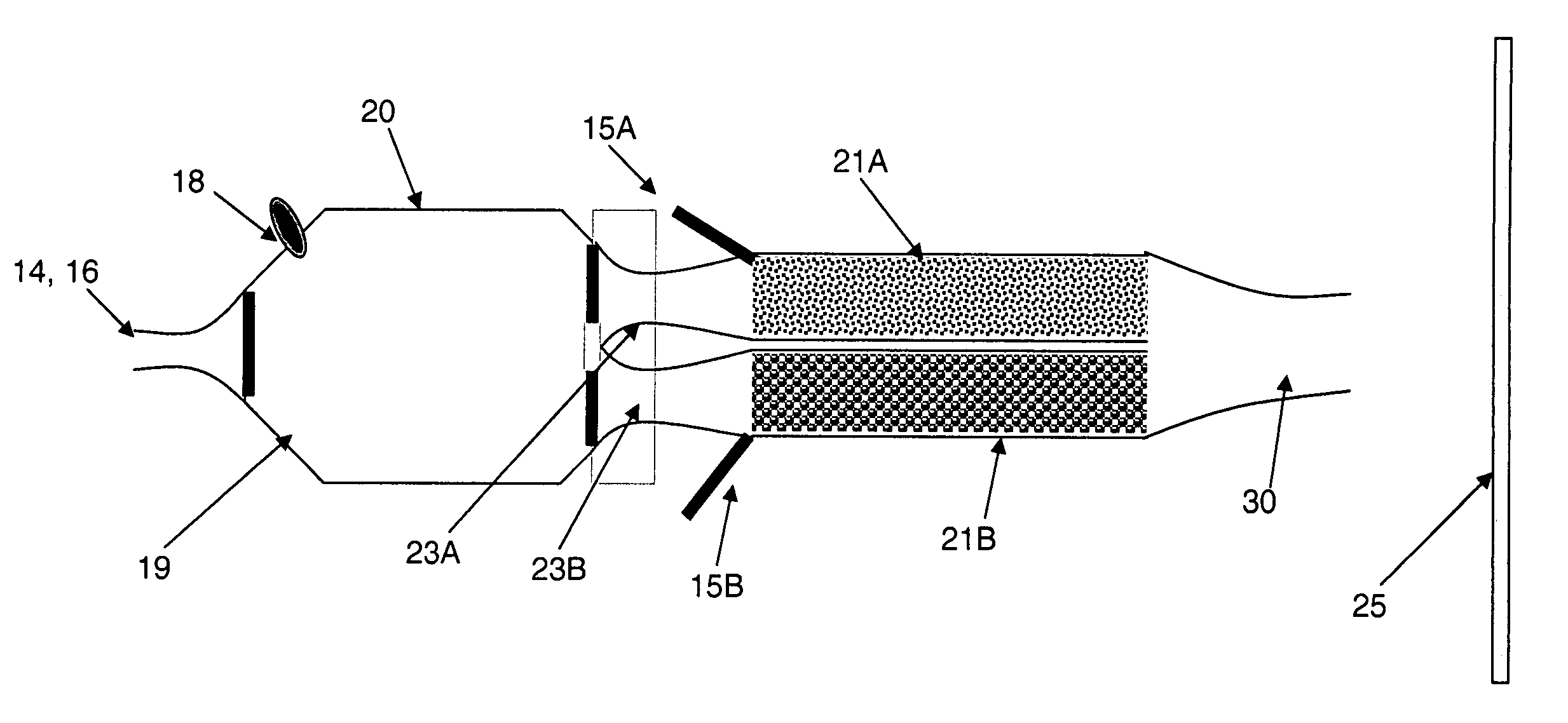

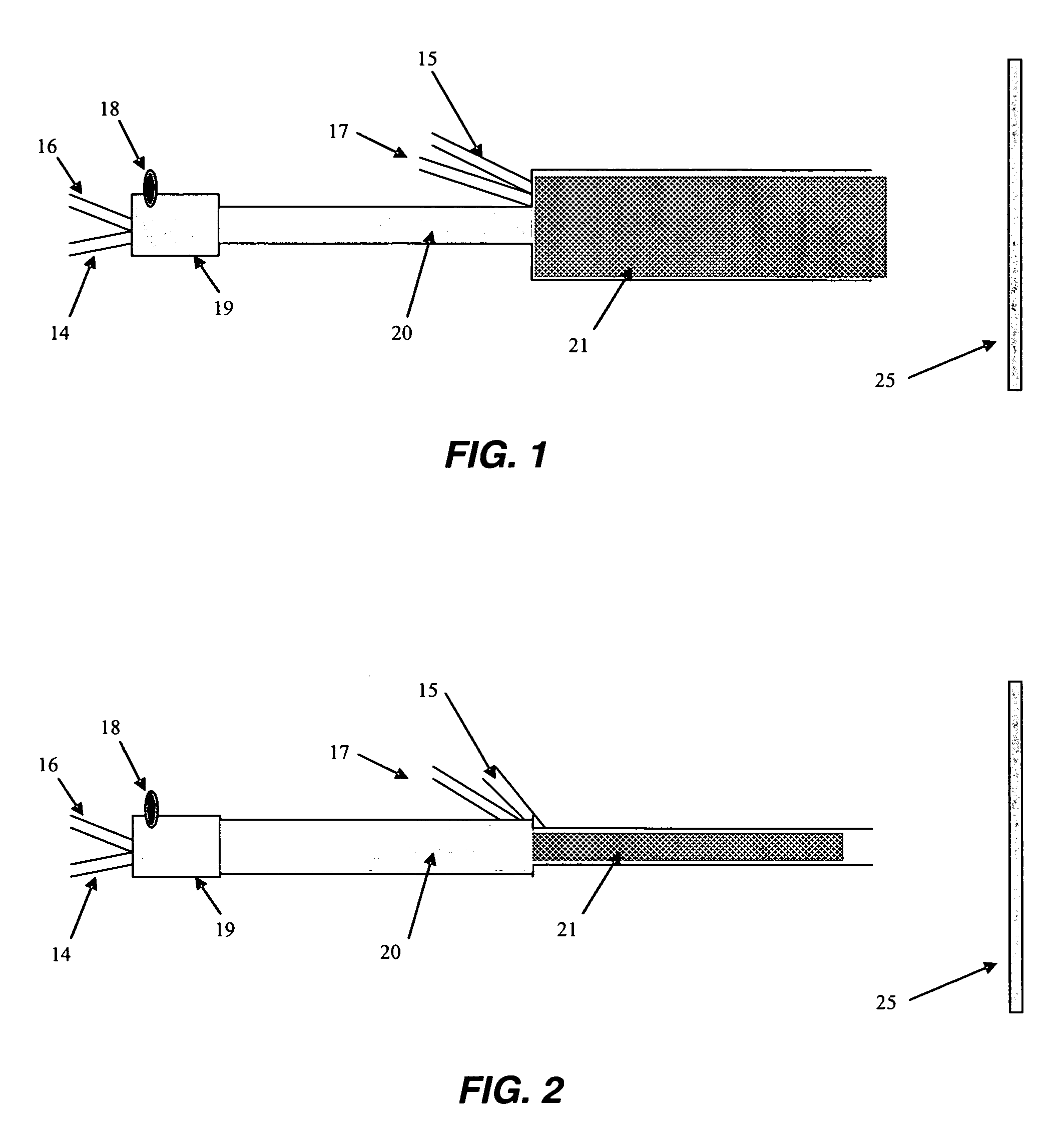

Multi-sectioned pulsed detonation coating apparatus and method of using same

InactiveUS20060251821A1Quality improvementHigh-quality coatingLiquid surface applicatorsMolten spray coatingDetonationSubstrate surface

A pulsed detonation gun, according to one embodiment, has a first section into which a detonable mixture is injected and a second section into which a coating precursor is injected. A detonable or reactive mixture is formed and ignited in the first section, and the detonation or reaction products expand through the first section and into the second section into contact with the coating precursor. Detonation products containing the coating precursor are discharged through an outlet and contacted with a substrate to produce a coating. The device is particularly useful for coating the inside surfaces of small-diameter tubes and a variety of other difficult-to-reach substrate surfaces.

Owner:SCI APPL INT CORP

Fire resistant coating for composite steel structure and preparation method thereof

InactiveCN102344726ALow smoke productionDelayed transmissionFireproof paintsEpoxy resin coatingsFoaming agentPermanganic acid

The invention discloses a fire resistant coating for a composite steel structure and a preparation method thereof. The fire resistant coating comprises the following ingredients: organic-inorganic nano hybridized resin, organic resin, ceramic filling material, foaming agent, carbon forming agent, catalyst and ferric permanganate. The fire resistant coating has the advantages of simple and convenient painting, excellent fireproof performance, little smoke generation, large foaming intensity and the like. Generally, the coating is used for brushing 3-5 times, the thickness is controlled to be 0.3-1.8 mm, and the duration of fire resistance can reach to 30-240 min.

Owner:江苏海云花新材料有限公司

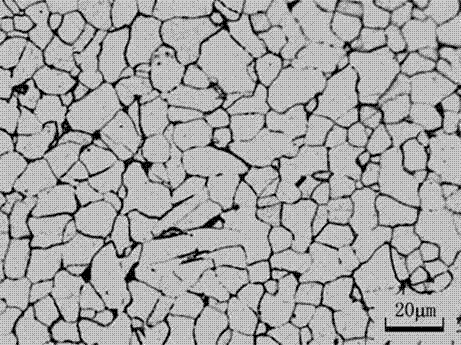

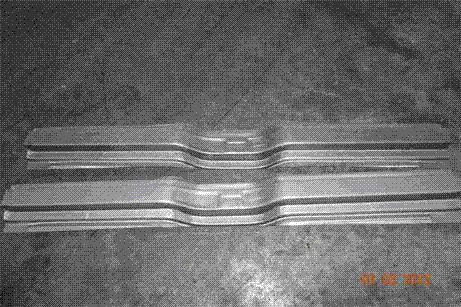

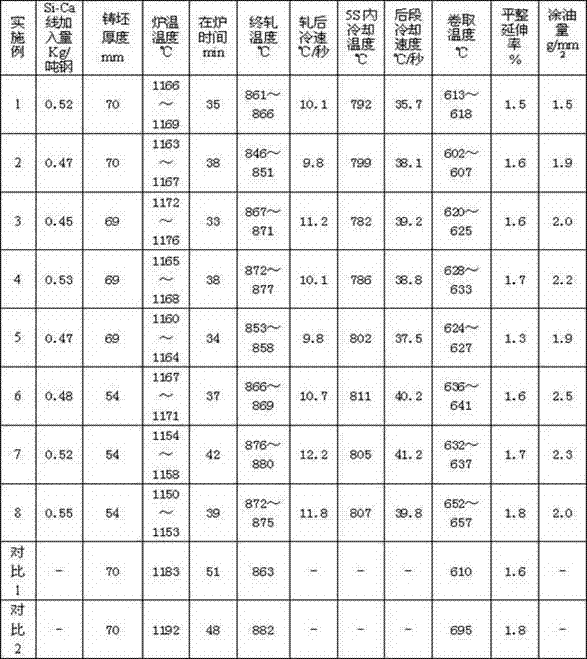

Thin hot-rolled pickled steel with good formability and production method thereof

ActiveCN102787270AReduce the difficulty of productionImprove surface qualityMetal rolling arrangementsChemical compositionHigh pressure water

The invention relates to a thin hot-rolled pickled steel with good formability, which comprises the following chemical components by weight percent (wt%): 0.04-0.07% of C, 0.10-0.30% of Si, 0.41-0.60% of Mn, 0.025% of P or less, 0.012% of S and 0.010-0.030% of Als. The preparation method of the thin hot-rolled pickled steel with good formability comprises the following steps: desulphurizing molten iron, smelting by a converter, alloying, treating by a ladle furnace, casting and rolling continuously, dephosphorizing high-pressure water, controlling rolling, cooling by laminar flow, curling, pickling by acid levelling and finishing adopting static oil removal. The produced hot-rolled pickled steel which has the tensile strength of 370MPa or higher and the thickness of 1.8 mm or lower, is low production difficulty and good in surface quality and is convenient to weld, oil and paint. In addition, the thin hot-rolled pickled steel has the advantages of good punch formability, high forming size accuracy, short production cycle, high yield and low cost.

Owner:武汉钢铁有限公司

Biodegradable or compostable containers

InactiveUS20050120915A1Improve bindingEffectively biodegradableWrappersBio-packagingImproved methodFood products

The present invention provides an improved method and materials for forming biodegradable containers that can hold food products in dry, damp or wet conditions and provides the biodegradable containers prepared according to the disclosed process. The containers are produced through the use of a pre-gelled starch suspension that is unique in its ability to form hydrated gels and to maintain this gel structure in the presence of many other types of materials and at low temperatures.

Owner:NEW ICE LTD

Paint-spraying device with desusting and drying integrated structure

InactiveCN109261416AGuaranteed long-term useSolving Recycling ProblemsPretreated surfacesLiquid spraying apparatusSprayerEngineering

The invention relates to the field of paint spraying, and particularly discloses a paint-spraying device with a desusting and drying integrated structure. The paint-spraying device comprises a shell,a conveying belt, a feeding inlet, a discharging outlet and a paint collection tank, wherein a dust suction hood, an installation support and a drying cavity are arranged / formed above the conveying belt from left to right in sequence; a plurality of brush rollers are arranged below the dust suction hood, the dust suction hood is communicated with a dust suction blower, and the installation supportis fixedly connected with an electrical telescoping rod which stretches and retracts in the vertical direction; a vertical hot air suction pipe is arranged on the outer portion on the left side of the drying cavity, and a wind deflector with adjustable height is arranged on the left side of the hot air suction pipe. By means of the drying cavity, the paint on the surface of wood can be quickly dried, meanwhile, hot air overflows outwards can be recycled, the hot air is prevented from flowing to the position of a paint sprayer, the paint is prevented from being dried in the sprayer, it is ensured that the paint sprayer is used for a long time, and the service life is prolonged.

Owner:湖南匡沐环保科技有限公司

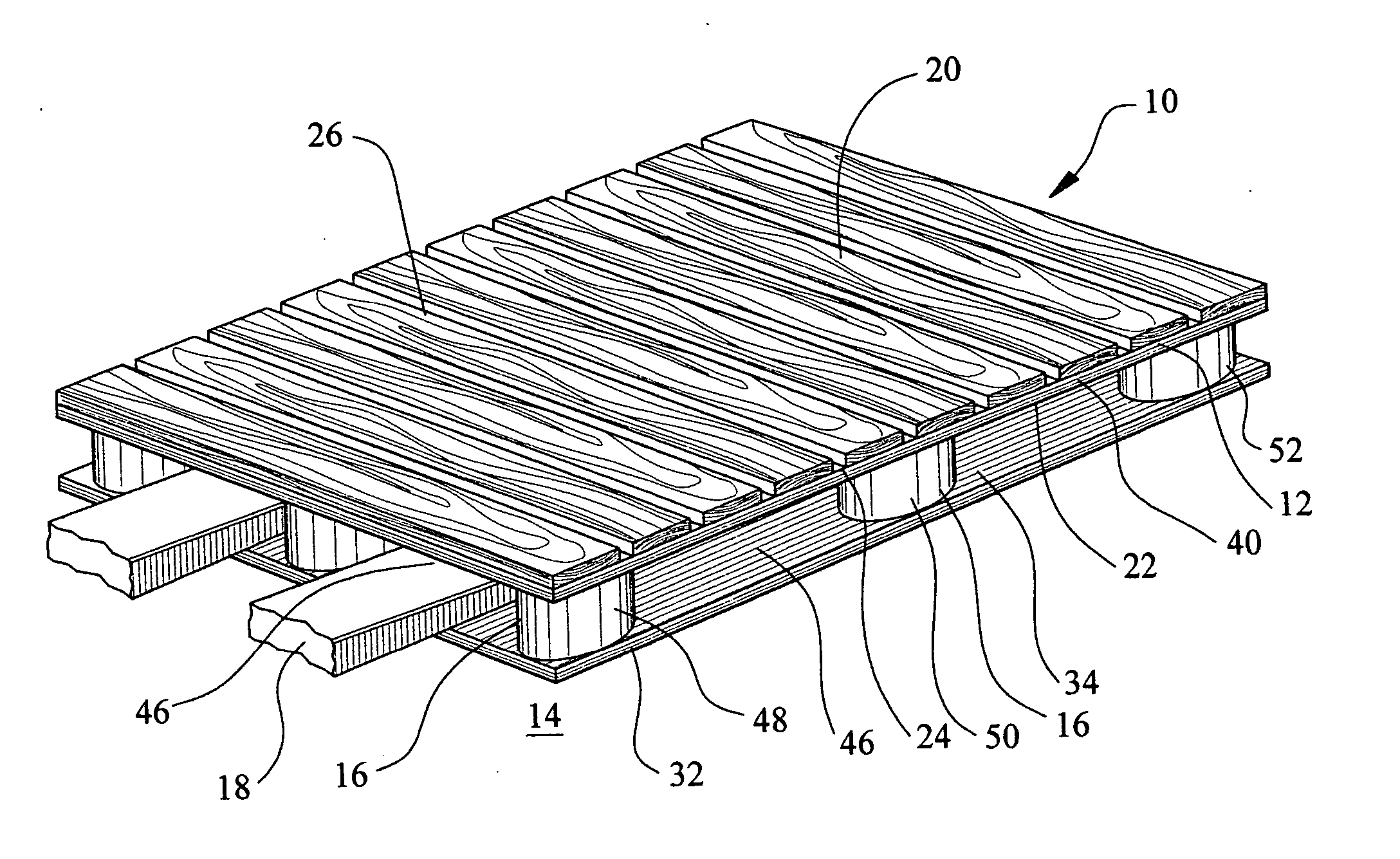

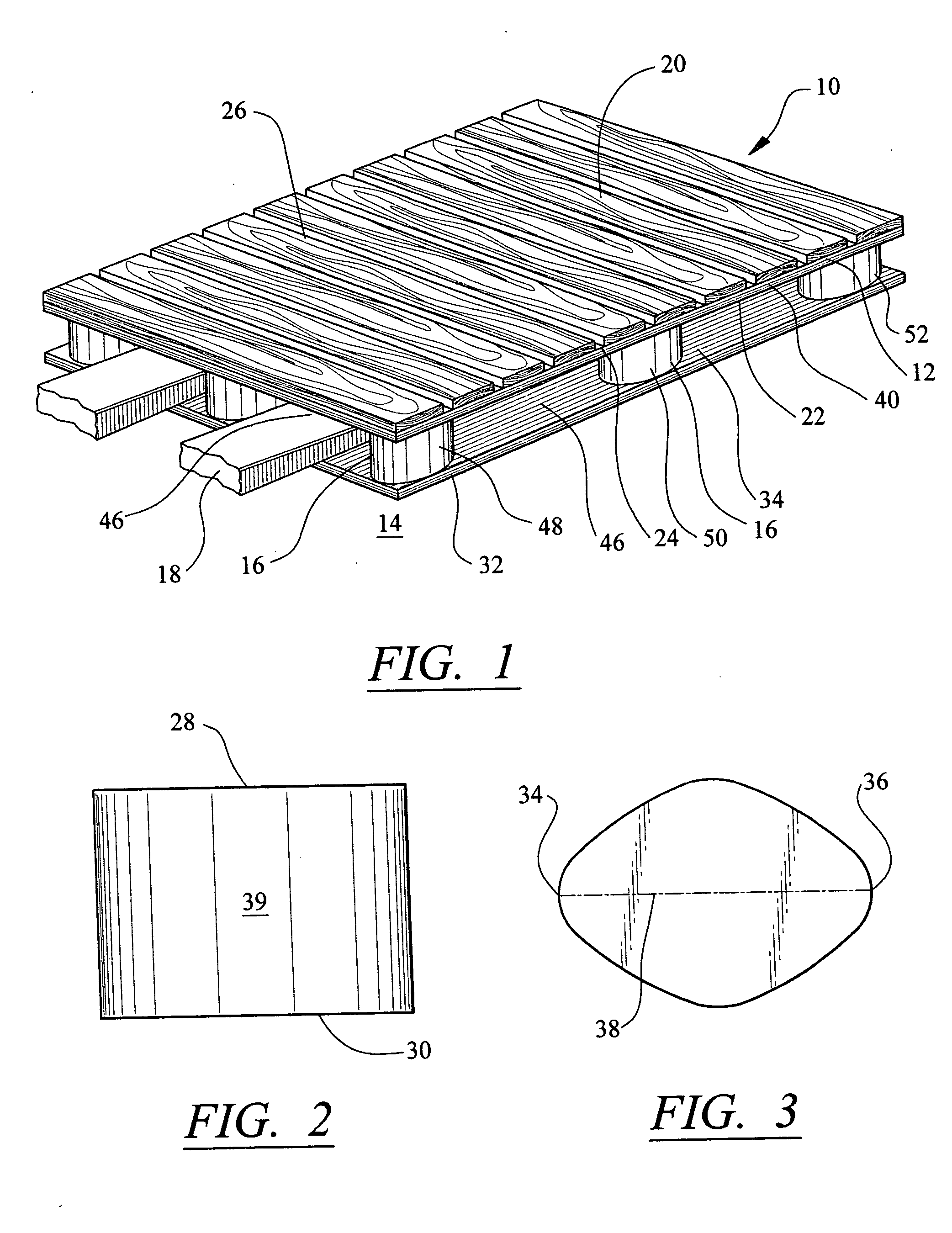

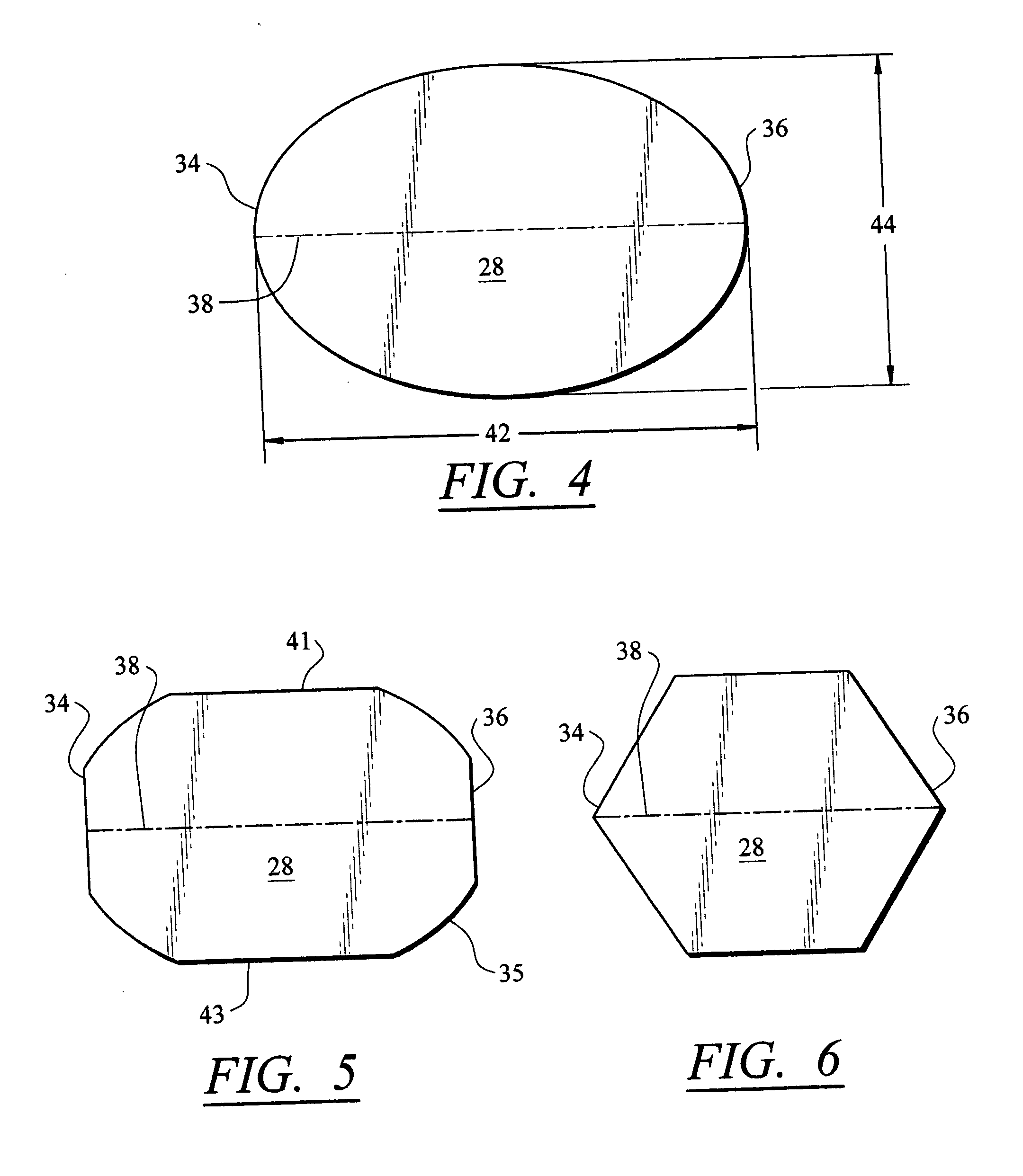

Pallet

A pallet having a top support member for supporting cargo and support elements for supporting the top support member above a surface and for creating one or more cavities for receiving a lifting member for moving the pallet. The support elements may have an oval cross-section for guiding the lifting members into the cavity. The support elements may be formed from a composite material for increased strength and durability.

Owner:CHEP TECH PTY LTD

Steel structure aqueous corrosion resisting paint without need of cleaning rust and preparation thereof

InactiveCN101323726AGood acid and alkali resistanceImprove the painting environmentLiquid surface applicatorsAnti-corrosive paintsAqueous corrosionWater based

The invention relates to a water-base rusting anti-corrosion paint of a steel structure, and a manufacturing technology thereof. The water-base rusting paint comprises styrene-acrylic latex, ferric oxide, talcum powder, phosphoric acid, tannin, aluminum hydroxide, zinc oxide, zinc dihydric phosphate, potassium dichromate, a film-forming auxiliary agent, sodium hexametaphosphate, dibutyl phthalate, an antifoam agent and water which is added till 100 percent (mass). The preparation method of the paint of the invention is that a pigment filler is added into a ball mill to prepare pigment filler slurry according to a mixing ratio, the phosphoric acid, the tannin, the zinc oxide and the aluminum hydroxide are mixed and heated till the solution is clear so as to prepare transformation liquid, then the pigment filler slurry and the transformation liquid and other components are mixed and stirred, and finally a finished product is obtained after filtration. The paint of the invention is characterized by good performance and low cost, etc., can be used for hull painting with rust directly, and can be used not only as a base paint, but also as a surface paint.

Owner:HUNAN UNIV

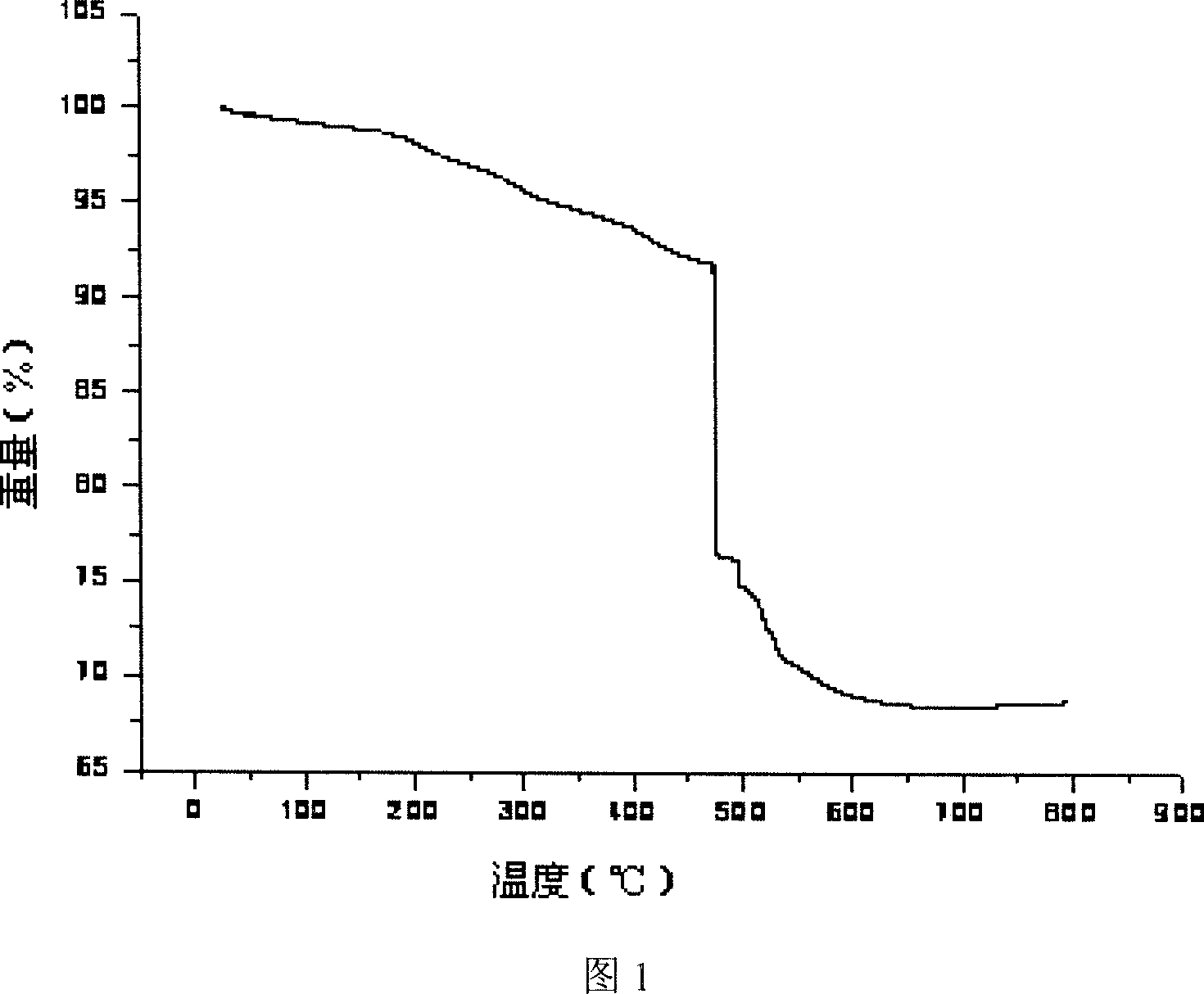

Flame-retardant anti-corrosive fiber bamboo base material and preparation technology thereof

ActiveCN102794801AIncrease profitCarbonization pyrolysis effect is remarkableWood compressionLayered productsFiberCarbonization

The invention discloses a flame-retardant anti-corrosive fiber bamboo base material and a preparation technology thereof. The method comprises the following steps of: 1) cutting raw bamboo into bamboo filament; 2) flame-retardant treatment: soaking the bamboo filament prepared in the step 1) in a flame retardant aqueous solution; 3) drying: after the flame-retardant treatment, drying the bamboo filament at 55-65 DEG C until the absolute water content does not exceed 12%; 4) carbonization pyrolysis: feeding the dried bamboo filament into a carbonization pyrolysis kiln, and performing high-temperature treatment according to the pyrolysis gradient; and 5) sequentially performing gumming, post-gumming drying, pressing, curing, maintaining and splitting to obtain the bamboo base material. The bamboo base material has strong stability, the product surface does not crack, the corrosion resistance is enhanced, good flame retardance is realized, and the bamboo base material can be used in various weathers and environments.

Owner:WUXI BODA BAMBOO & WOOD INDAL

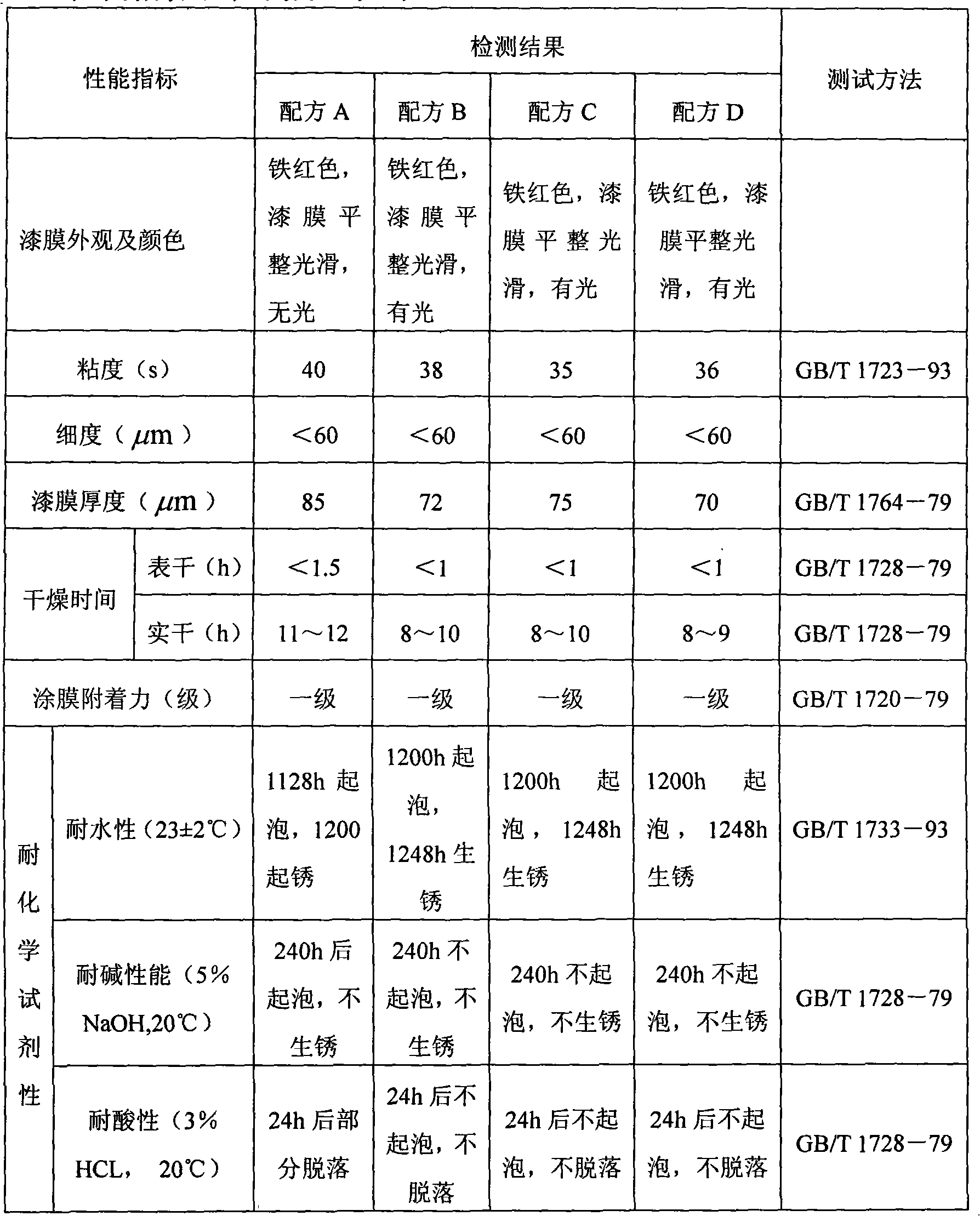

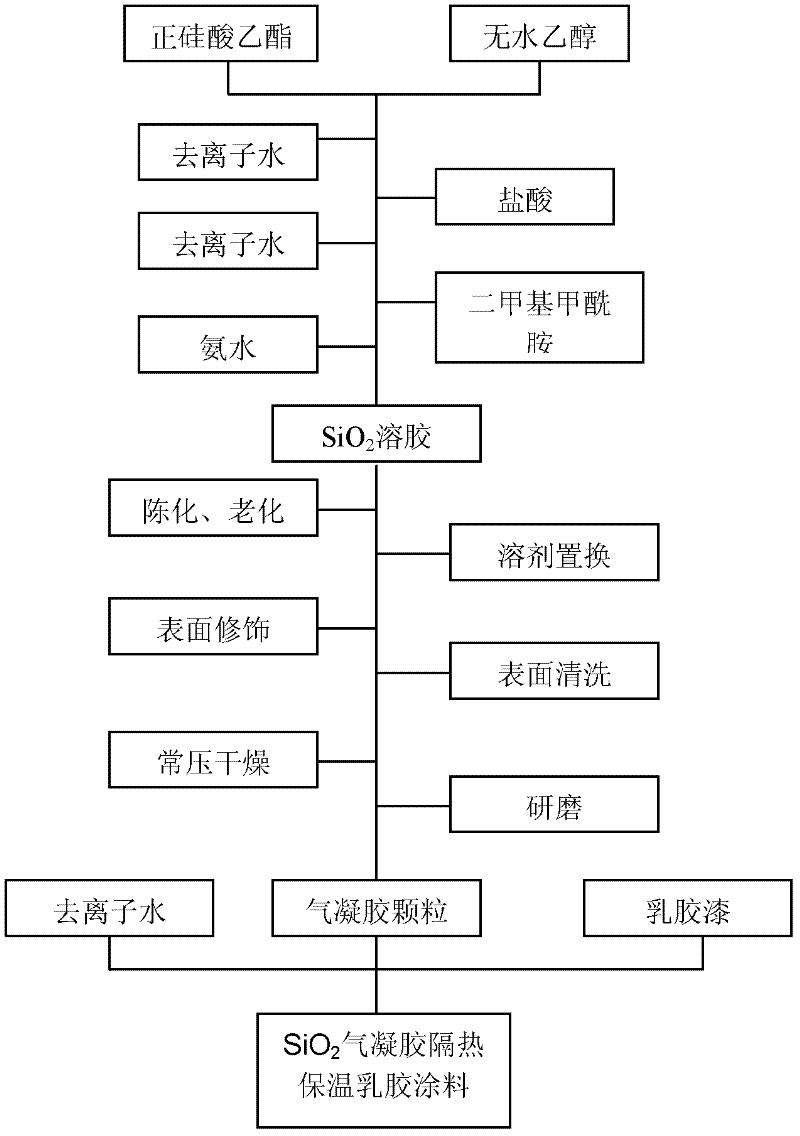

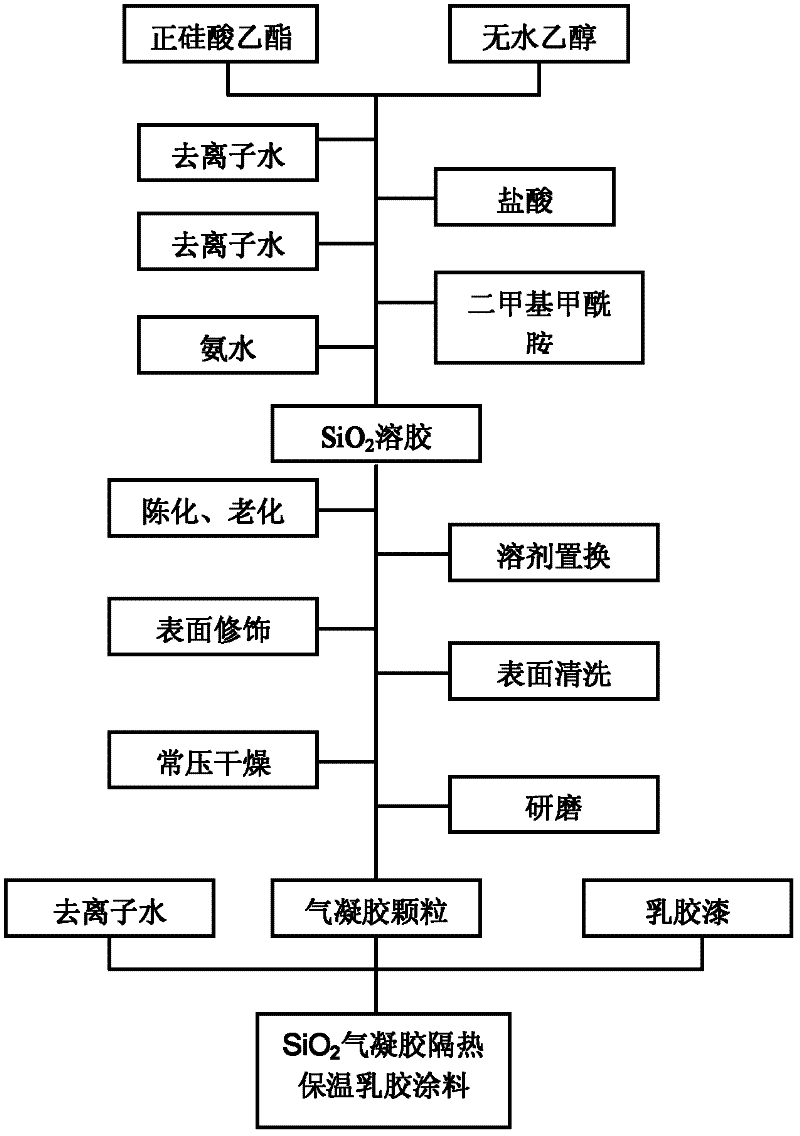

SiO2 aerogel thermal insulation latex paint and preparation method thereof

ActiveCN102604468AImprove performanceGood heat insulationEmulsion paintsPigment treatment with organosilicon compoundsThermal insulationEmulsion

The invention discloses a SiO2 aerogel thermal insulation latex paint and a preparation method of the SiO2 aerogel thermal insulation latex paint. The paint is formed by proportionally stirring SiO2 aerogel particles, emulsion paint and water. The SiO2 aerogel thermal insulation latex paint has the characteristics of good thermal insulation, flame resistance, high temperature resistance, incombustibility, high safety, high toughness, high compactness and the like, and is good thermal insulation paint.

Owner:广州泰祥混凝土外加剂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com