Metal finishing agent using silane coupling agent as main component for metal surface pretreatment

A technology of metal surface treatment and silane coupling agent, applied in the field of metal surface treatment agent, can solve the problems of unreported, difficult to play a role or effect, etc., and achieve the effect of wide source of raw materials, low price and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

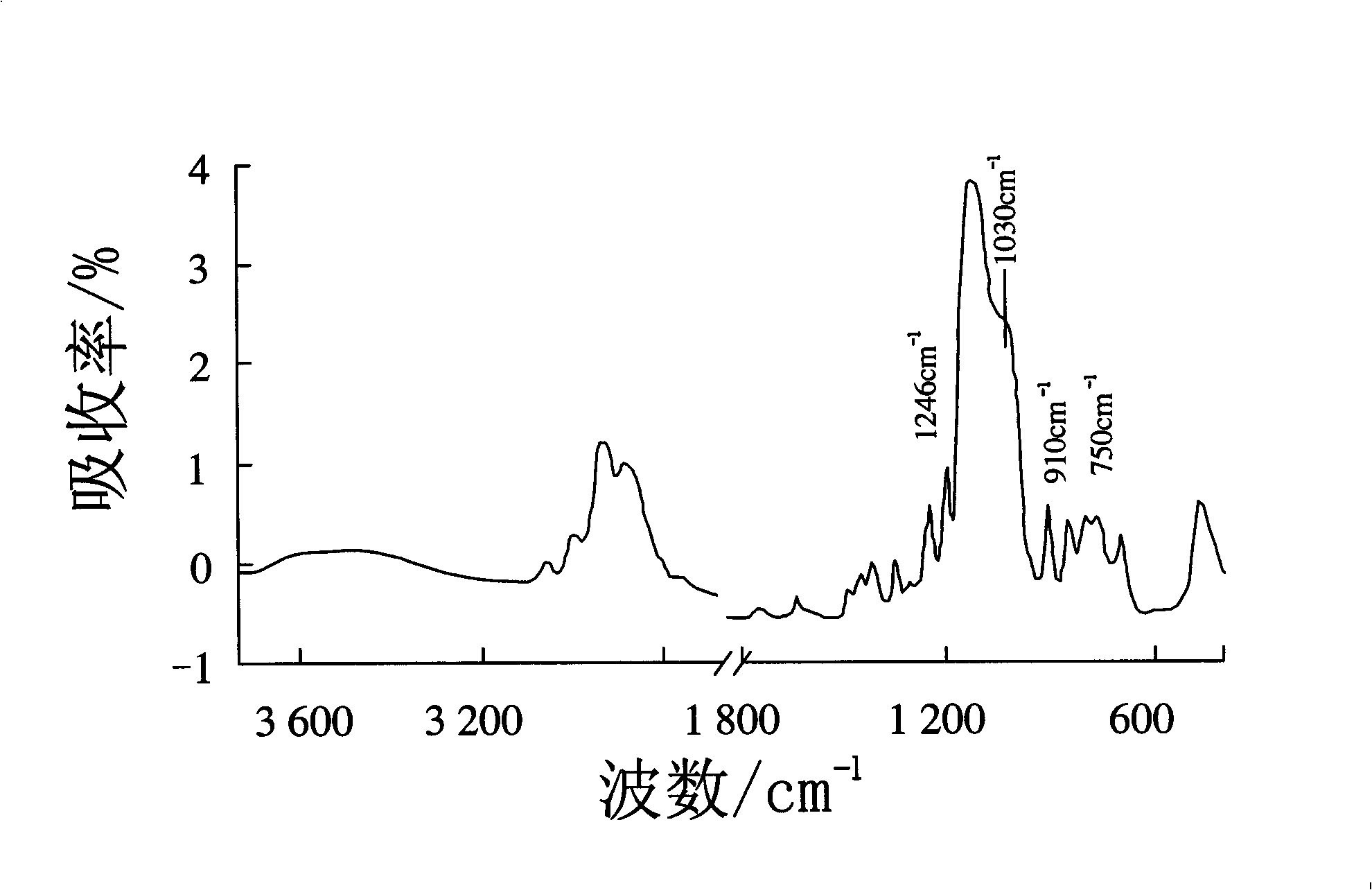

Image

Examples

Embodiment 1

[0041] The metal surface treatment agent mainly composed of silane coupling agent used for metal surface pretreatment is composed of the following raw materials:

[0042] 1,2-diethoxysilicate ethane (BTSE) 20 grams

[0043] γ-Aminopropylsilane (γ-APS) 50g

[0044] Water-dispersible silica 298g

[0047] Acetic acid 0.5 g

[0048] Water 928 grams.

[0049] The preparation method of the metal surface treatment agent mainly composed of a silane coupling agent for metal surface pretreatment comprises the following steps:

[0050] (1) Weigh 20 g of 1,2-diethoxysilyl ethane (BTSE) and add it to 630 g of water, stir it fully and add 50 g of γ-aminopropylsilane (γ-APS) to it after it is completely dissolved. After fully stirring, semi-finished products are obtained;

[0051] (2) Weigh 1g of water-dispersible silicon dioxide and add it to 298g of water, stir fully until it is completely dissolved, then add 1g of zirco...

Embodiment 2

[0054] The metal surface treatment agent mainly composed of silane coupling agent used for metal surface pretreatment is composed of the following raw materials:

[0055] 1,2-diethoxysilyl ethane (BTSE) 25 grams

[0056] γ-Aminopropylsilane (γ-APS) 45g

[0057] Water-dispersible silica 290g

[0059] Titanium fluoride 1 g

[0060] Acetic acid 0.5 g

[0061] Water 928 grams.

[0062] The preparation method comprises the following steps:

[0063] (1) Weigh 25 g of 1,2-diethoxysilyl ethane (BTSE) and add it to 630 g of water, stir it fully and then add 45 g of γ-aminopropylsilane (γ-APS) to it after it is completely dissolved. After fully stirring, semi-finished products are obtained;

[0064] (2) Weigh 5g of water-dispersible silicon dioxide and add it to 290g of water, stir fully until it is completely dissolved, then add 5g of zirconium fluoride and 1g of titanium fluoride to it and then fully stir to prepare a semi-finished product for us...

Embodiment 3

[0067] The metal surface treatment agent mainly composed of silane coupling agent used for metal surface pretreatment is composed of the following raw materials:

[0068] 1,2-diethoxysilicate ethane (BTSE) 20 grams

[0069] γ-Aminopropylsilane (γ-APS) 50g

[0070] Water-dispersible silica 298g

[0071] Zirconium fluoride 3 g

[0072] Acetic acid 0.5 g

[0073] Water 928 grams.

[0074] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com