Patents

Literature

122 results about "Aqueous corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Corrosion protective cleaning agent for tin-plated steel

InactiveUS6060122ASignificant positive effectGood effectOther chemical processesPretreated surfacesTitaniumNonionic surfactant

PCT No. PCT / EP96 / 01137 Sec. 371 Date Sep. 24, 1997 Sec. 102(e) Date Sep. 24, 1997 PCT Filed Mar. 15, 1996 PCT Pub. No. WO96 / 30558 PCT Pub. Date Oct. 3, 1996The invention concerns an aqueous corrosion-protective cleaning solution for tin-plated steel, in particular for tin-plated steel cans, the solution containing complex fluorides of the elements boron, titanium, zirconium, and hafnium; non-ionic surfactants; and corrosion inhibitors and having a pH within the range from 3 to 6. The invention also concerns an aqueous concentrate for preparing the solution by dilution with water and a method of cleaning tin-plated cans using the solution.

Owner:HENKEL KGAA

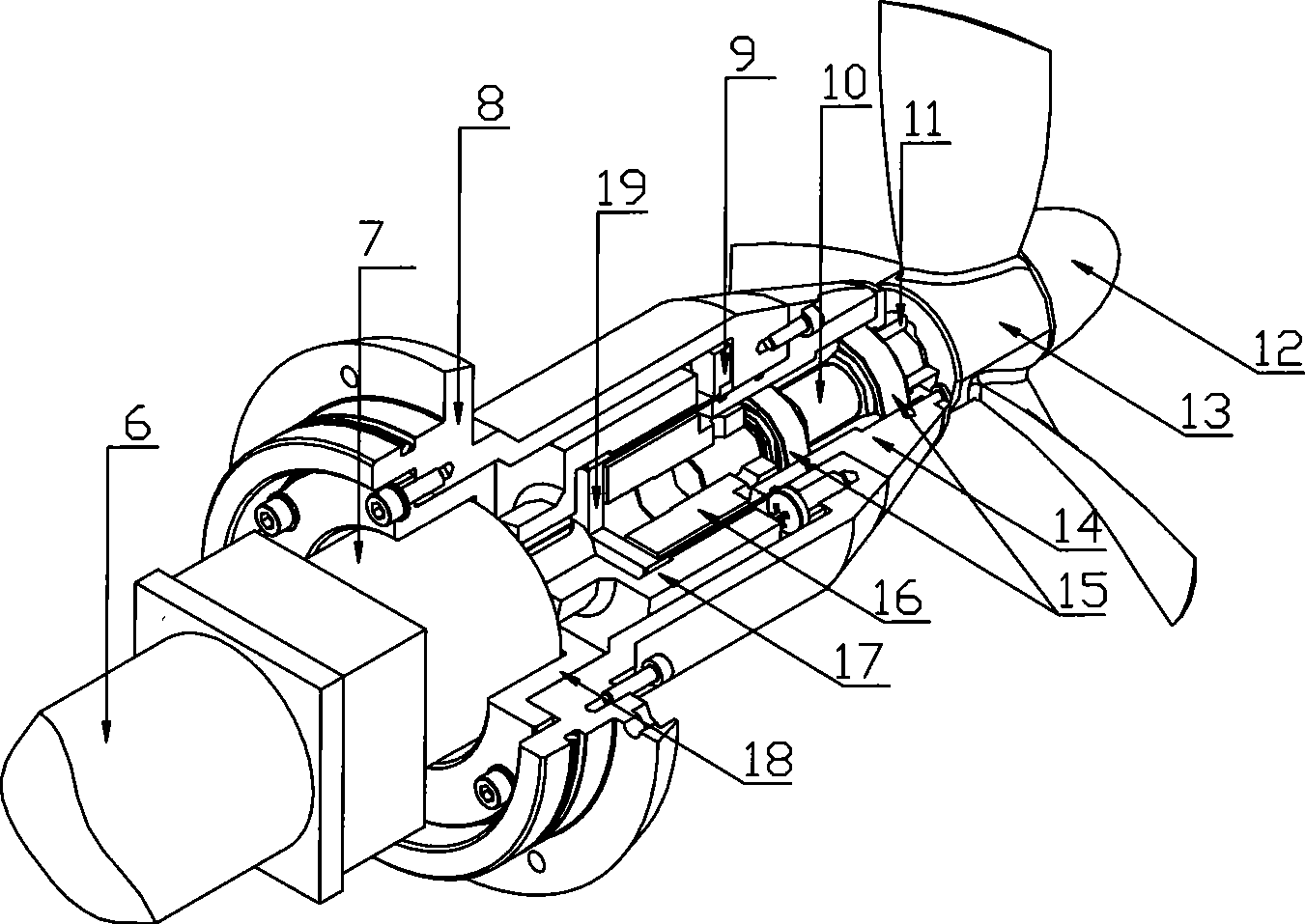

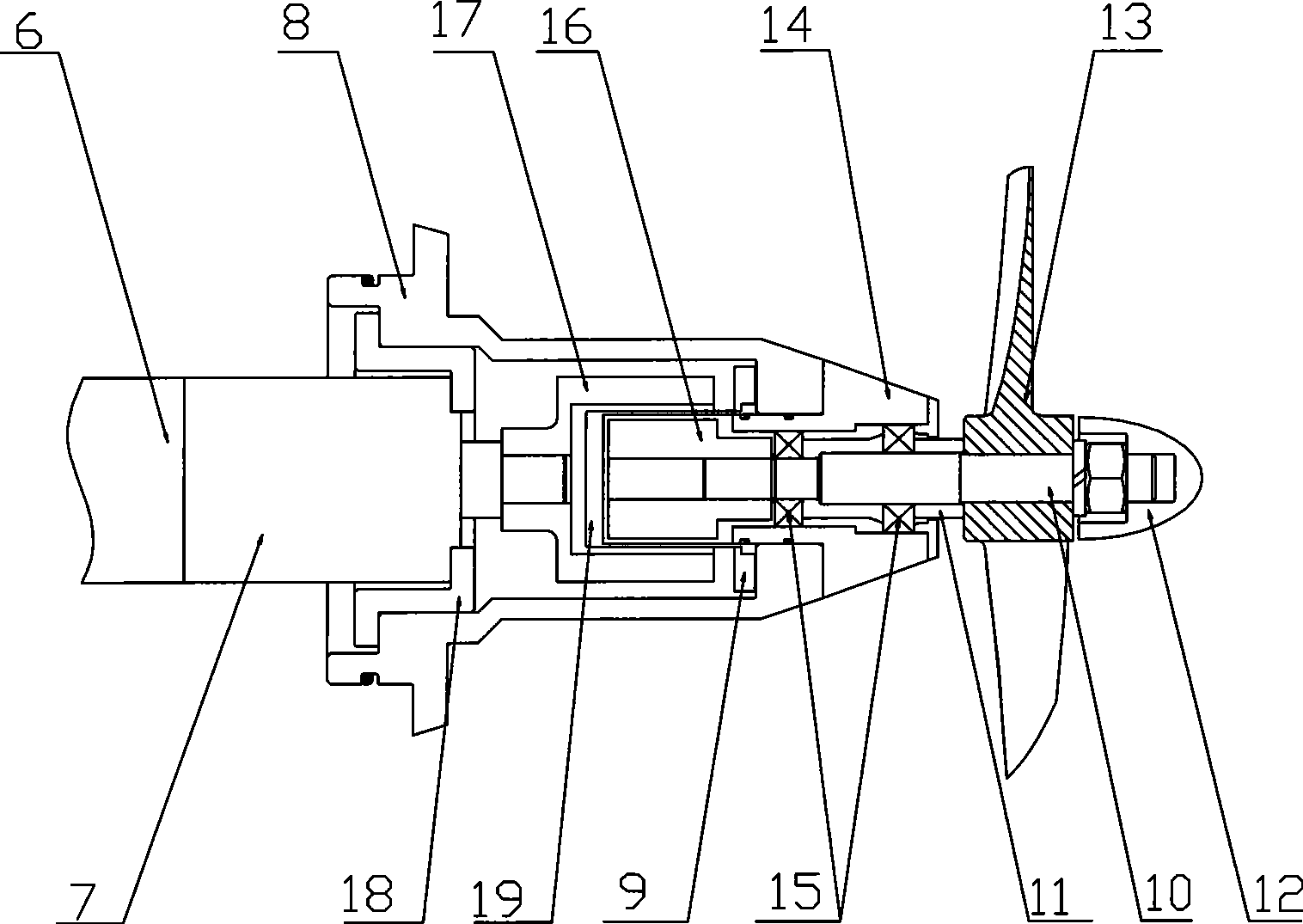

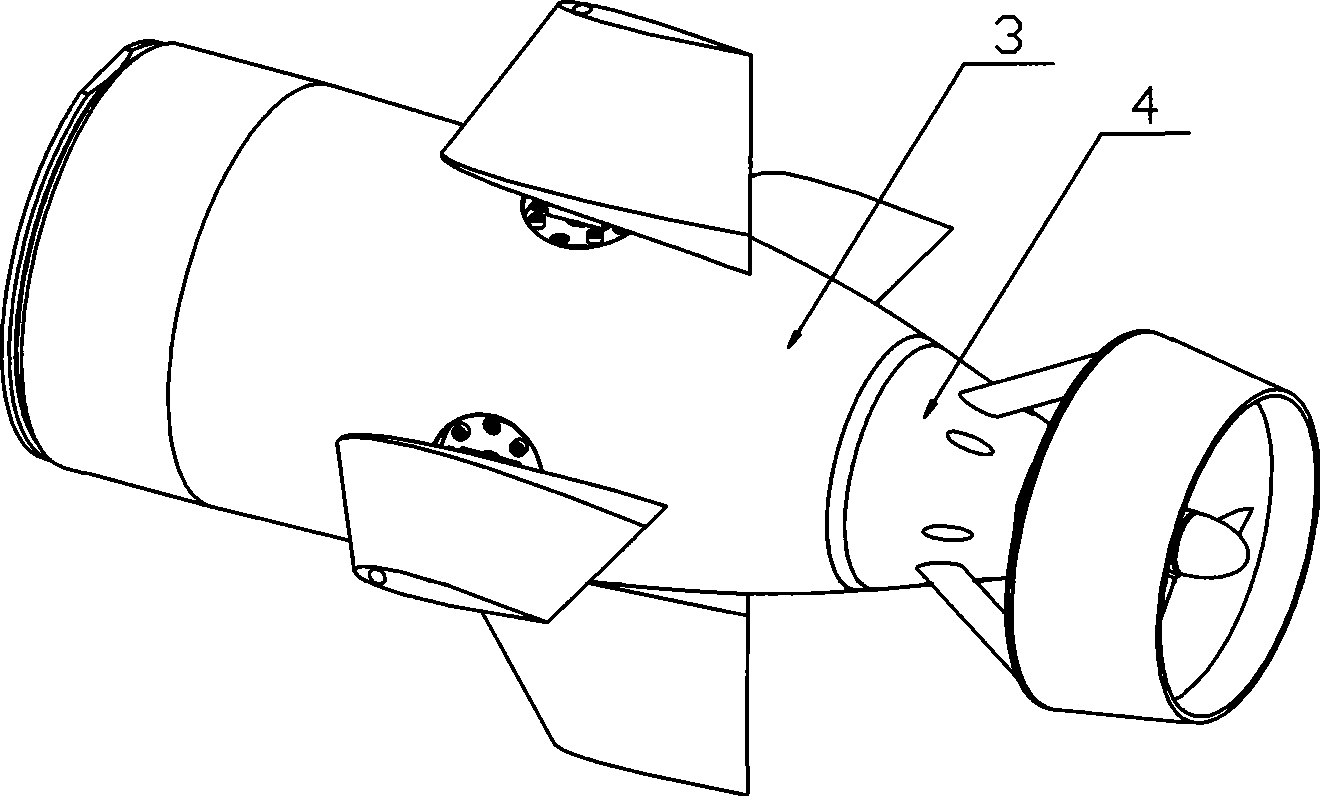

Underwater screw propulsion die and underwater navigation device containing the same

InactiveCN101508335AAchieve absolute sealingOvercoming frictional resistanceUnderwater vesselsUnderwater equipmentAqueous corrosionUnderwater navigation

The invention discloses an underwater screw propeller propelling module, which comprises a servo motor and a speed reducer connected with a tail cone, wherein the speed reducer is fixedly connected with the inside of the tail cone and is connected with a driven shaft passing through a bearing support through a shaft coupling, and the driven shaft is provided with a screw propeller; the shaft coupling is a magnetic shaft coupling consisting of an inner hub, an outer hub sleeved outside the inner hub, a stainless steel isolation cover arranged between the inner hub and the outer hub, and a clamp ring fixedly connected with the stainless steel isolation cover; and the outer hub is arranged on an output shaft of the speed reducer, the inner hub is arranged on the driven shaft, and the clamp ring is fixedly arranged in the tail cone. The invention also discloses an underwater vehicle comprising the underwater screw propeller propelling module. The underwater screw propeller propelling module adopts a magnetic coupling technique to realize power transmission, adopts the isolation cover to isolate water from a sealed cabin, adopts a corrosion resistant material and a ceramic bearing to solve the problem of aqueous corrosion resistance, adopts the modularization design to make the structure compact and easy to replace, dismount and mount, and achieves the absolute sealing between a pressure resistant cabin of the underwater vehicle and the external sea water.

Owner:TIANJIN UNIV

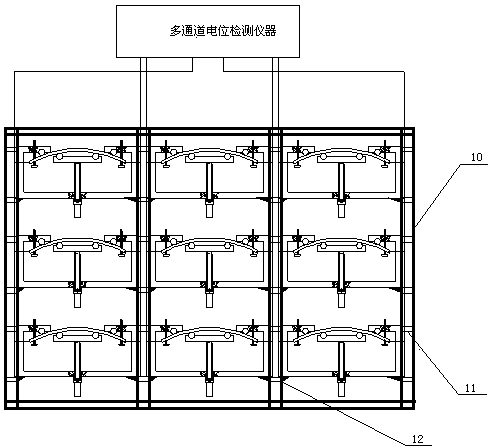

Method for testing seawater corrosion of low-alloy steel under stress state

InactiveCN103969176AAchieve stress corrosion performance evaluationTruly reflect the law of corrosionWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesAqueous corrosionMicrometer

The invention relates to a method for testing seawater corrosion of low-alloy steel under a stress state. The method comprises two steps: 1, loading a constant strain by adopting four-point bending, bending a sample by a spiral micrometer setting bolt, and measuring a flexibility; and 2, installing a plurality of constant-strain loading devices on a real sea sample charging frame with a slot, and installing a multichannel potential acquiring device, and performing potential monitoring in a natural seawater or deep sea environment. The method for testing the seawater corrosion of the low-alloy steel under the stress state, provided by the invention, is capable of realizing evaluation of stress corrosion performance of a stress member under a natural environment, and can be applied to research of a material stress corrosion mechanism in a laboratory. The invention provides a novel testing method for the research of the stress corrosion performance of a stress structure in a service working condition; by adopting test data obtained by the method, the corrosion rule of the material and the member under the working condition can be actually reflected, and a favorable corrosion research means is provided for the research of a use material in the working condition.

Owner:中国船舶重工集团公司第七二五研究所青岛分部

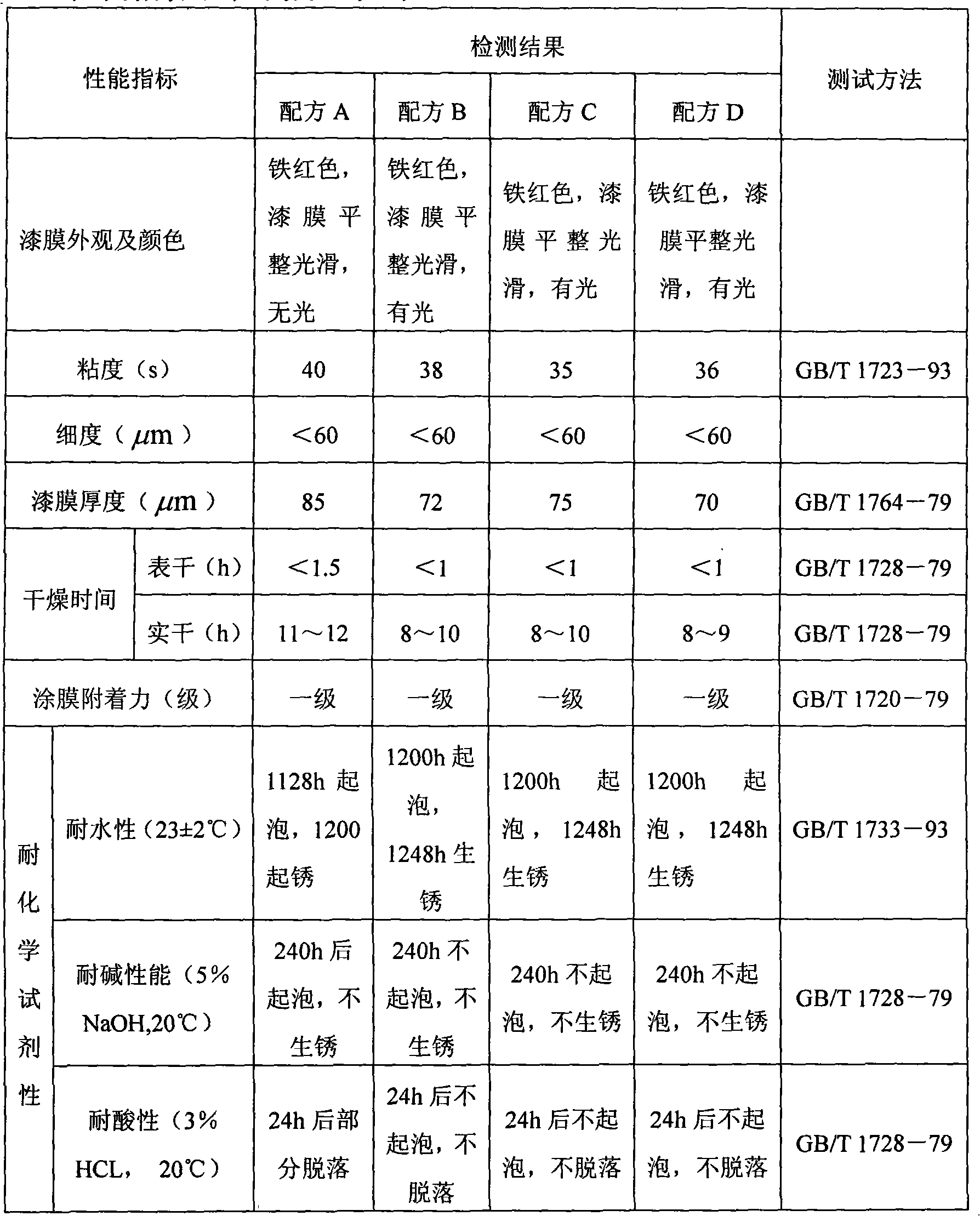

Steel structure aqueous corrosion resisting paint without need of cleaning rust and preparation thereof

InactiveCN101323726AGood acid and alkali resistanceImprove the painting environmentLiquid surface applicatorsAnti-corrosive paintsAqueous corrosionWater based

The invention relates to a water-base rusting anti-corrosion paint of a steel structure, and a manufacturing technology thereof. The water-base rusting paint comprises styrene-acrylic latex, ferric oxide, talcum powder, phosphoric acid, tannin, aluminum hydroxide, zinc oxide, zinc dihydric phosphate, potassium dichromate, a film-forming auxiliary agent, sodium hexametaphosphate, dibutyl phthalate, an antifoam agent and water which is added till 100 percent (mass). The preparation method of the paint of the invention is that a pigment filler is added into a ball mill to prepare pigment filler slurry according to a mixing ratio, the phosphoric acid, the tannin, the zinc oxide and the aluminum hydroxide are mixed and heated till the solution is clear so as to prepare transformation liquid, then the pigment filler slurry and the transformation liquid and other components are mixed and stirred, and finally a finished product is obtained after filtration. The paint of the invention is characterized by good performance and low cost, etc., can be used for hull painting with rust directly, and can be used not only as a base paint, but also as a surface paint.

Owner:HUNAN UNIV

Aqueous composition for corrosion resistant fastener coatings

InactiveUS20120237778A1Improve corrosion resistanceGood coating-substrate adhesionOther chemical processesAlkaline-earth metal silicatesAqueous corrosionPolyamide-imide

The present invention provides aqueous coating compositions for metal substrates, where the coating provides improved corrosion resistance compared to conventional aqueous corrosion resistant coatings. The coating comprises (a) one or more functionalized acrylic polymer; (b) one or more melamine resin; (c) one or more perfluorinated polymer; and (d) one or more dispersing polymer selected from the group consisting of polyimide (P1), polyamideimide (PAI), polyether sulfone (PES), polyphenylene sulfide (PPS), and a mixture thereof. The composition is particularly useful for fasteners, such as nuts and bolts, used in marine environments.

Owner:EI DU PONT DE NEMOURS & CO

Environmental protection and high efficiency corrosion inhibitor for inhibiting salt water corrosion on carbon steel, preparation method and use method thereof

ActiveCN103508570AEffective corrosion inhibitionAvoid corrosionScale removal and water softeningPhosphomolybdic acidBenzoic acid

The present invention provides an environmental protection and high efficiency corrosion inhibitor for inhibiting salt water corrosion on carbon steel, a preparation method and a use method thereof, and relates to the field of chemistry. The corrosion inhibitor has characteristics of high efficiency, low cost, low toxicity and environmental protection, and is prepared through carrying out mixing stirring dissolving on 5-50% of a benzotriazole substance, 1-10% of benzoic acid and a salt thereof, 1-10% of molybdate, tungstate, phosphomolybdic acid and a salt thereof, and phosphotungstic acid and a salt thereof, 2-20% of an alcohol amine substance, 1-10% of an acid phosphate, 1-10% of a gluconate, 1-10% of an alkaline regulator, 1-10% of an oxygen scavenging agent and the balance of water. According to the present invention, the potassium dichromate or the sodium nitrite with high toxicity, and the non-environmental protection high phosphorus and high zinc can be replaced, and corrosion of calcium chloride salt water on carbon steel and copper can be significantly inhibited when the concentration of the corrosion inhibitor is 0.3-0.5%.

Owner:CHAOYANG GUANGDA CHEM

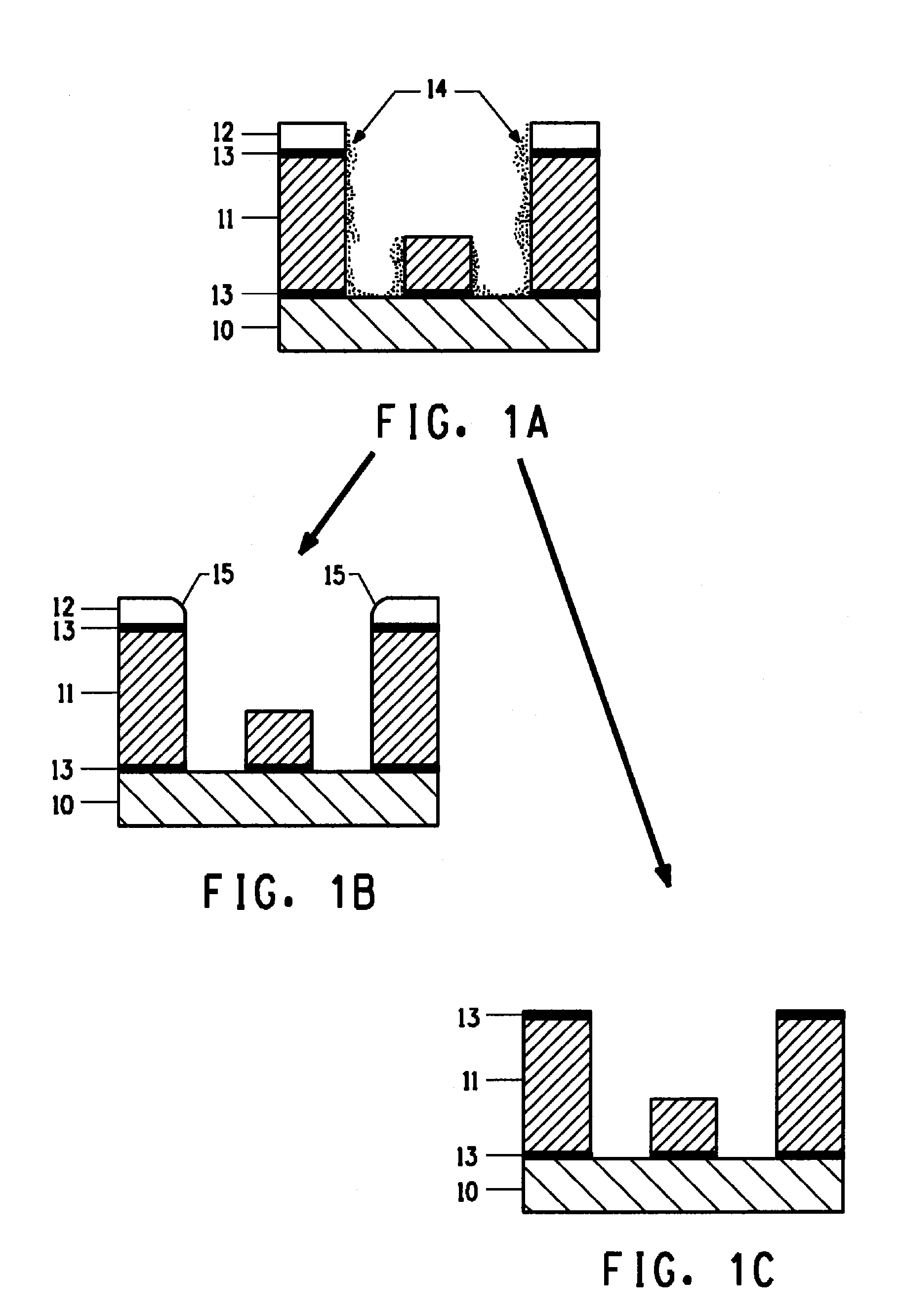

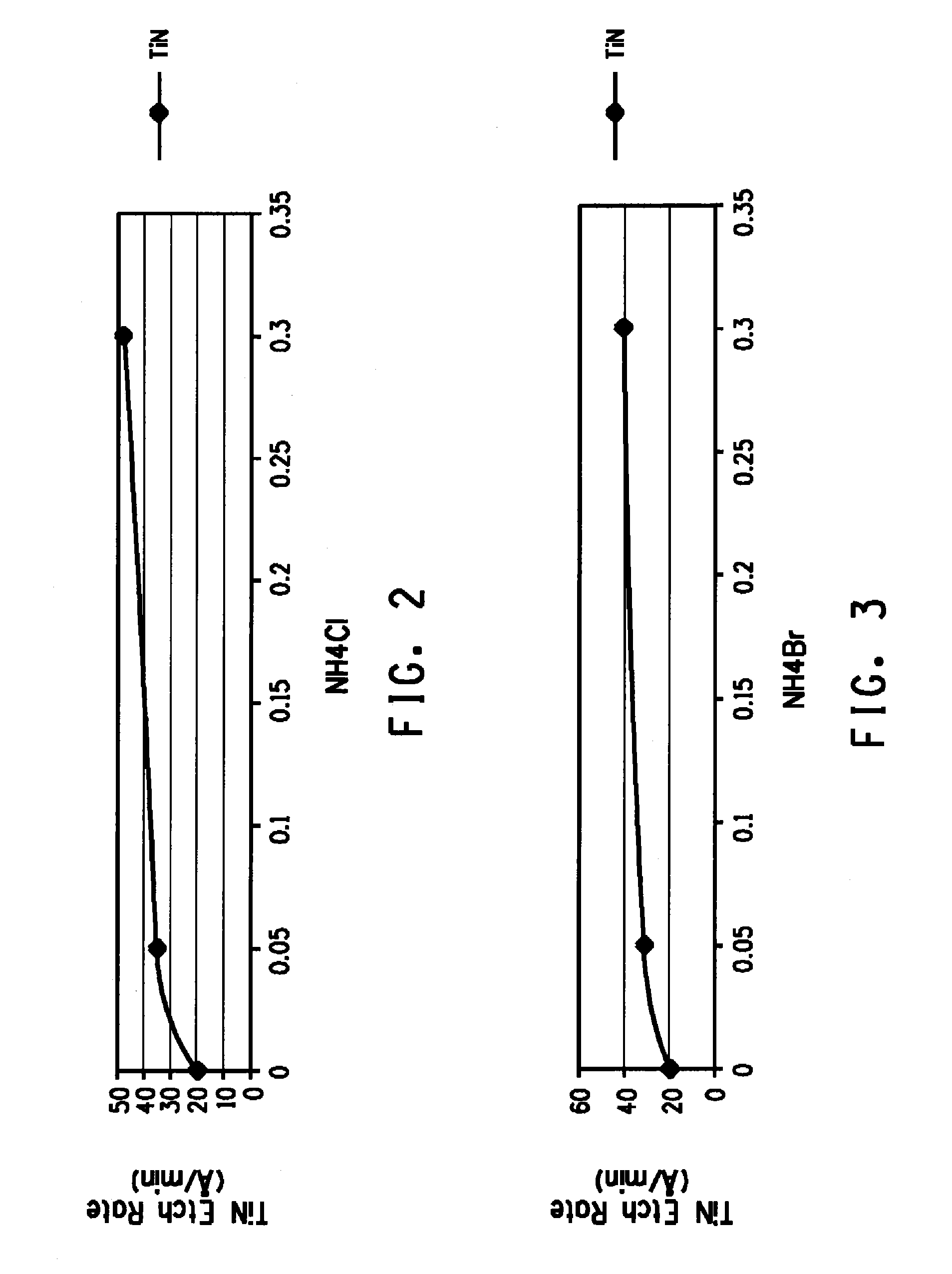

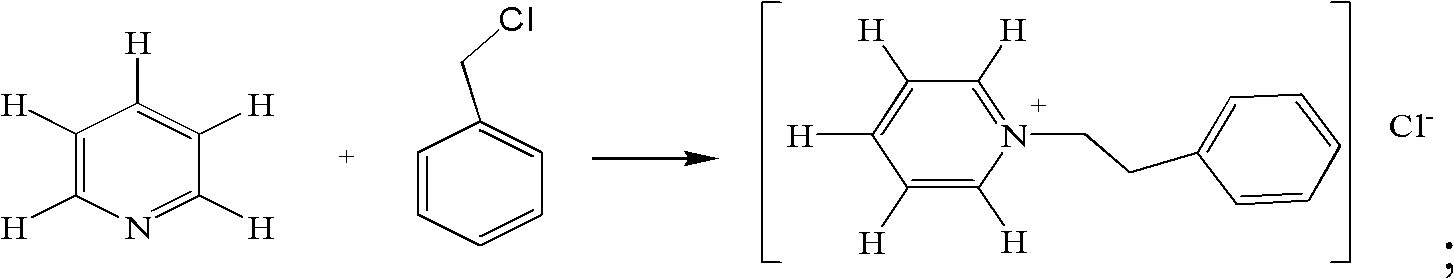

Method and composition for removing resist, etch residue, and copper oxide from substrates having copper, metal hardmask and low-k dielectric material

InactiveUS20130045908A1Increase etch rateReduced oxidizer decomposition rateNon-surface-active detergent compositionsDetergent mixture composition preparationResistCopper oxide

A semiconductor processing composition and method for removing photoresist, polymeric materials, etching residues and copper oxide from a substrate comprising copper, low-k dielectric material and TiN, TiNxOy or W wherein the composition includes water, a Cu corrosion inhibitor, at least one halide anion selected from Cl− or Br−, and, where the metal hard mask comprises TiN or TiNxOy, at least one hydroxide source.

Owner:EKC TECH

Physical and thermal protective coating

InactiveUS20050019552A1Reduce temperatureReduce heat absorptionBox making operationsPretreated surfacesCorrosion resistantMechanical force

The invention provides a strong, corrosion resistant protective coating comprising a homogeneous mixture of polyurea and microscopic granules capable of imparting the property of diffuse reflectivity and emissivity and its method of use as a means for reduction of thermal and radiant energy transmission and absorption as well as damage due to water, corrosion or mechanical forces when applied to the outer surface of an object or container.

Owner:WIERSMA JACK +1

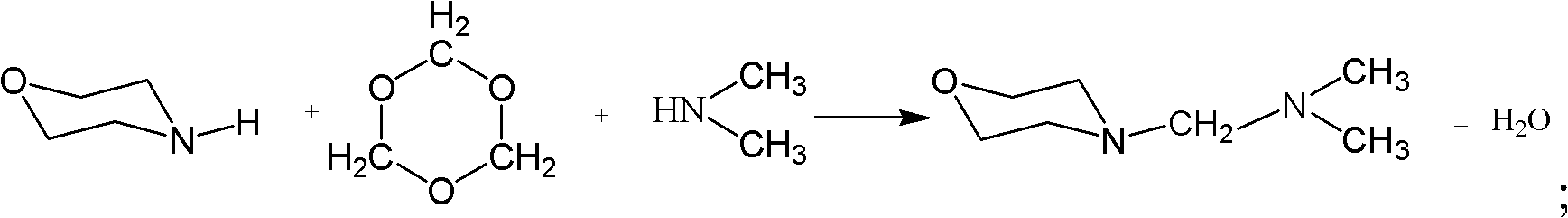

High-temperature O2/CO2 corrosion inhibitor for coiled tubing and preparation method of agent B of high-temperature O2/CO2 corrosion inhibitor

ActiveCN102627955AEnsure safe operationAvoid corrosionBorehole/well accessoriesSulfite saltMannich reaction

The invention discloses a high-temperature O2 / CO2 corrosion inhibitor for coiled tubing. The high-temperature O2 / CO2 corrosion inhibitor for the coiled tubing is used by matching an agent A mainly used for deoxidizing and an agent B mainly used for resisting corrosion of carbon dioxide, wherein the agent A is acetone oxime, D-ascorbic acid, sodium sulfite or ferrous sulphate; and the agent B is formed by mixing the components in percentage by weight: 20-30 percent of quaternary pyridine salt, 10-15 percent of mannich base chelate, 3-7 percent of surfactant and 48-67 percent of solvent. The quaternary pyridine salt is obtained by reacting pyridine with benzyl chloride; and the mannich base chelate is obtained by aldehyde ketone amine condensate generated by morpholine, trioxymethylene and dimethylamine through a mannich reaction with metal chloride. The corrosion inhibitor provided by the invention has use temperature up to 170DEG C, is suitable for a water-corrosive medium in which oxygen and carbon dioxde coexist and can be used for effectively inhibiting the corrosion of media such as the oxygen and the carbon dioxide and ensuring safe operation of the coiled tubing in the production process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

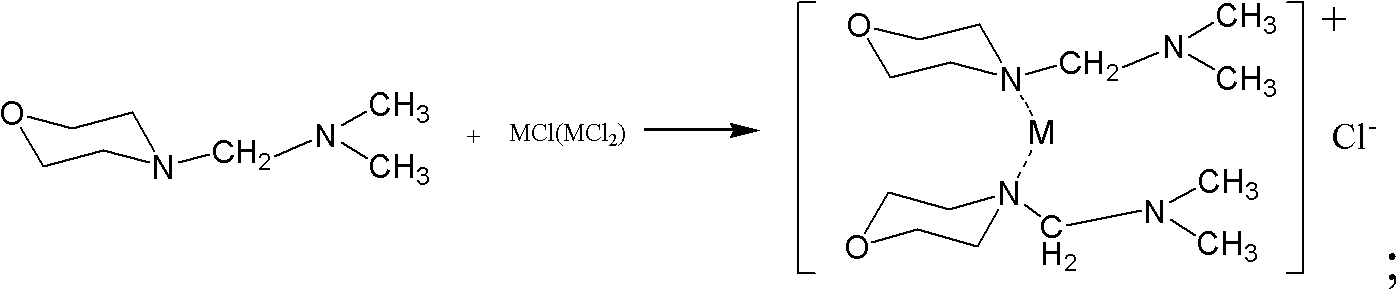

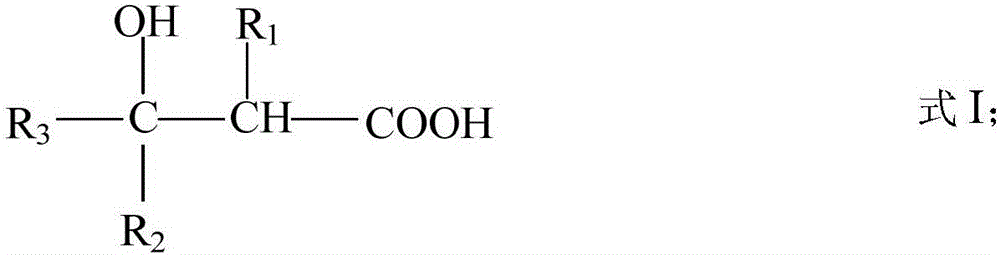

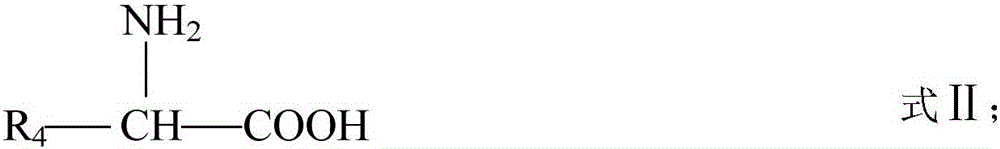

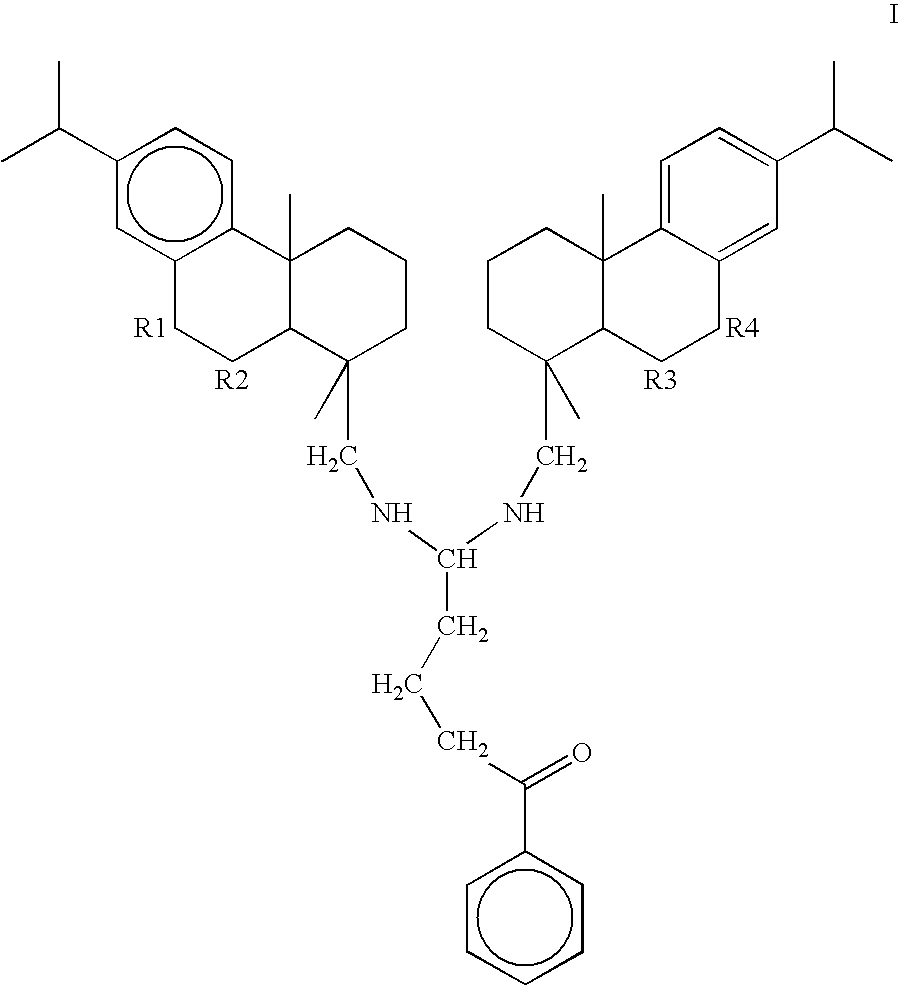

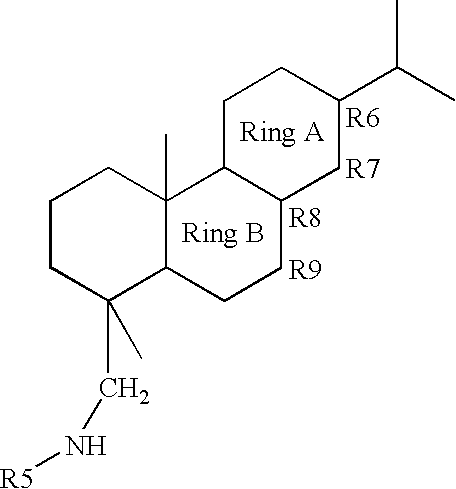

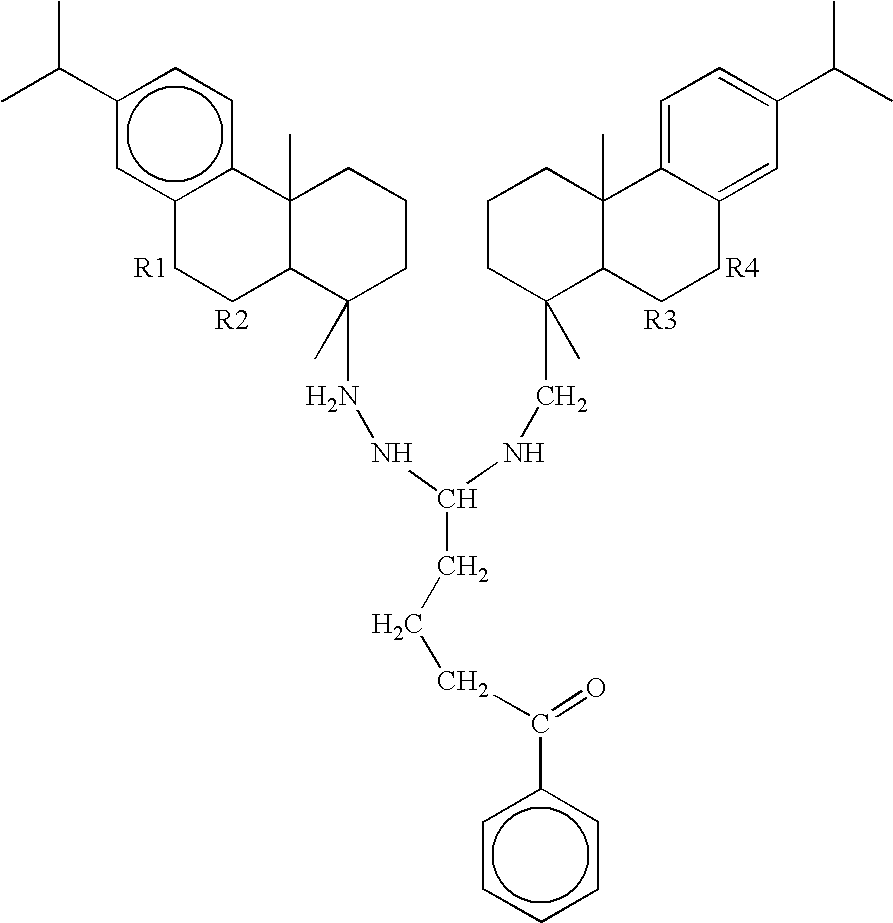

Corrosion inhibitors and corrosion inhibitor compositions, and preparation methods thereof, application of corrosion inhibitors and corrosion inhibitor compositions to inhibition of aqueous corrosion, and treating method for circulating water

InactiveCN107522300AGood corrosion inhibition effectEfficient use ofScale removal and water softeningAqueous corrosionMedicinal chemistry

The invention discloses corrosion inhibitors and corrosion inhibitor compositions, and preparation methods thereof, application of the corrosion inhibitors and the corrosion inhibitor compositions to inhibition of aqueous corrosion, and a treating method for circulating water. The corrosion inhibitors contain products of condensation reactions of compounds as shown in a formula I which is described in the specification and / or salts thereof with compounds as shown in a formula II which is described in the specification. In the formula I, R<1> is H or OH; R<2> is H or COOH; R<3> is COOH, CH<2>-COOH or C<3>H<7>O<3> as described in the specification. In the formula II, R4 is selected from a group consisting of H, C1-C4 alkyl groups, (CH<2>)<n>-COOH, (CH<2>)<4>-NH<2>, CH<2>-OH or other groups as described in the description, and n and m are independently selected from a group consisting of 1 and 2. The corrosion inhibitors have good slow release effect, are not prone to utilization by microbes and pose little influence to the content of microbes in water in the process of usage.

Owner:CHINA PETROLEUM & CHEM CORP +1

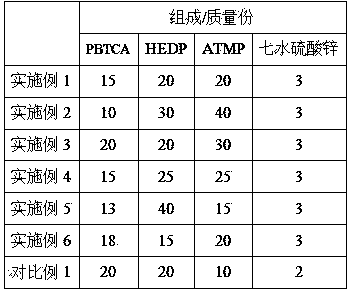

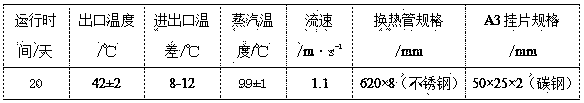

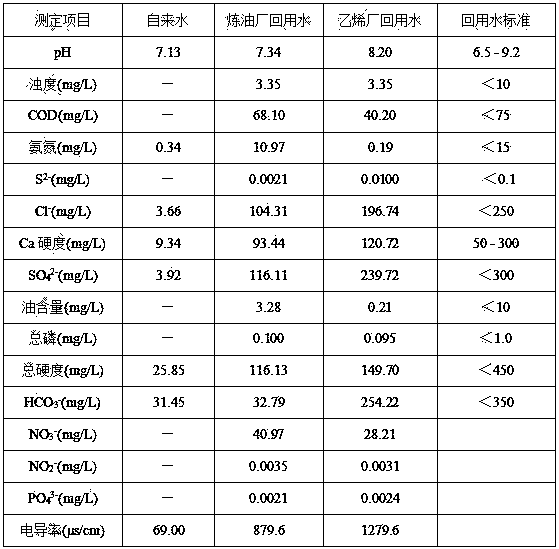

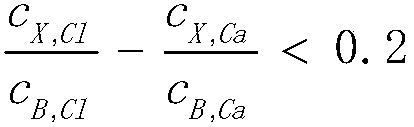

Composite slow-release scale inhibitor suitable for petrochemical wastewater reusing circulating water system

ActiveCN104230015AComply with corrosion rate less than 0.075 mm/a anti-corrosion requirementsAdd lessScale removal and water softeningAqueous corrosionPhosphate

The invention discloses a composite slow-release scale inhibitor suitable for a petrochemical wastewater reusing circulating water system. The composite slow-release scale inhibitor comprises 2-butane phosphate-1,2,4-tricarboxylic acid, hydroxy ethylidene diphosphonic acid, amino trimethylene phosphonic acid and zinc sulfate. After the composite slow-release scale inhibitor is adopted, by virtue of dynamic simulation experiment on oil refinery reuse water, the water quality inhibition rate is 86.18%; by virtue of the dynamic simulation experiment on ethylene plant reuse water, the water quality inhibition rate is 86.44%, and the scale inhibiting rate is 87.42%; the corrosion rate is reduced to 0.0168 mm / a and 0.0091 mm / a, which meets the anticorrosion requirement that the corrosion rate of China petrochemical circulating cooling water is less than 0.075 mm / a. Compared with the traditional polyphosphate carboxylate composite slow-release scale inhibitor, the composite slow-release scale inhibitor disclosed by the invention has the advantages of small addition amount and good corrosion inhibition effect and scale inhibition.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

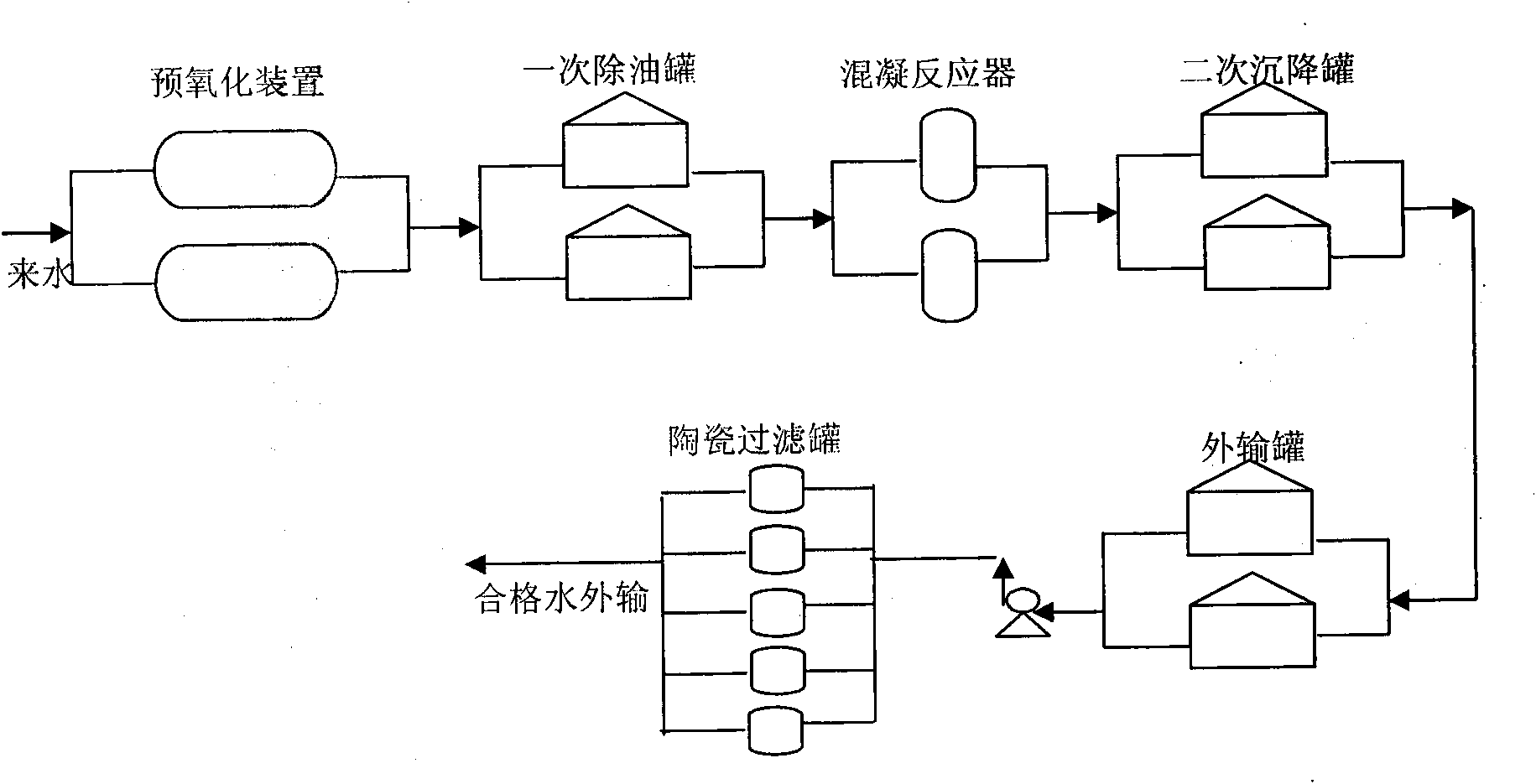

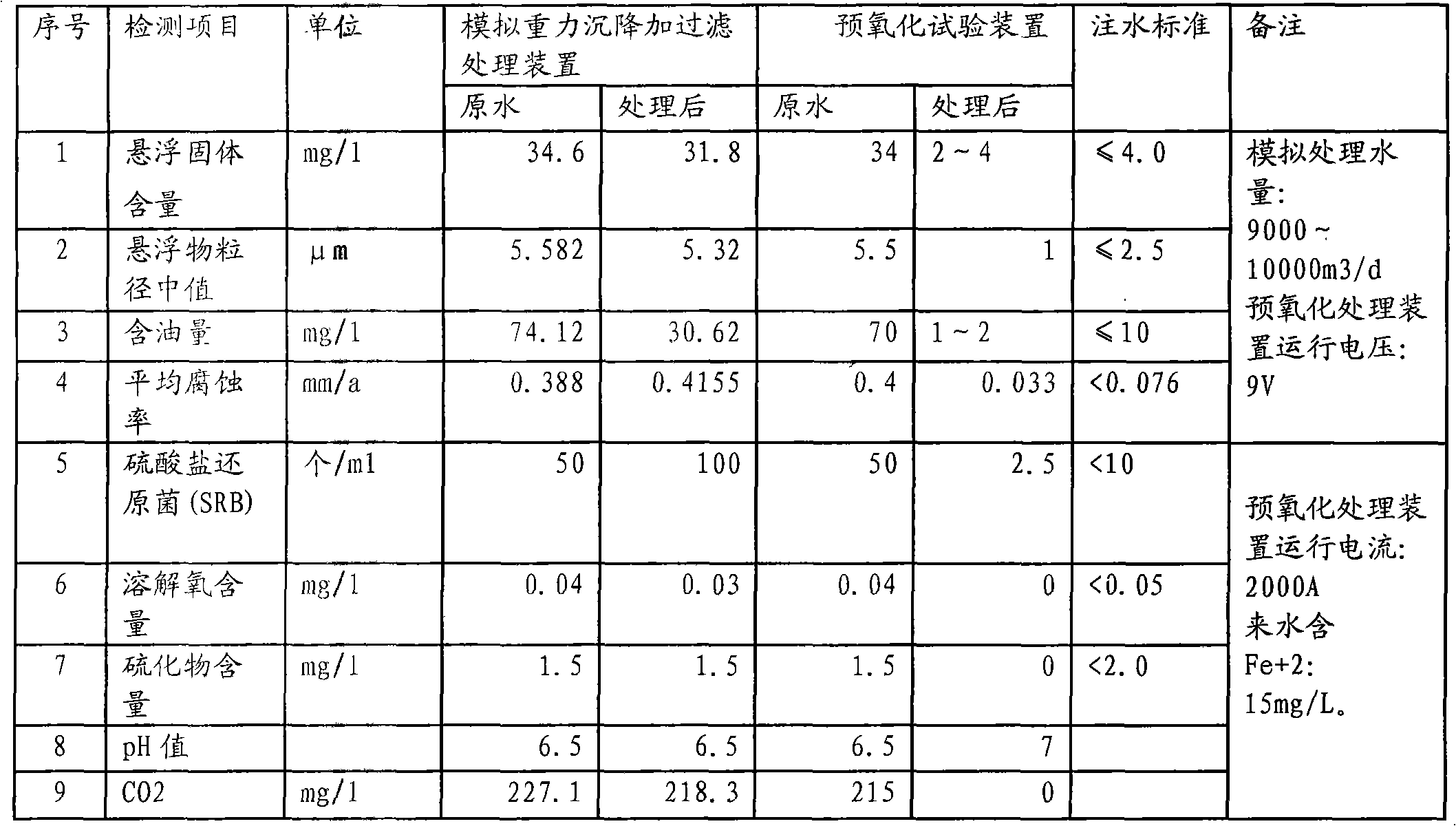

Method for treating oil field produced water and treatment flow thereof

InactiveCN101905936AControl and Improve Filtration EfficiencyControl adsorption capacityWaste water treatment from quariesMultistage water/sewage treatmentAqueous corrosionOil field

The invention discloses a method for treating oil field produced water in the petroleum industry and a treatment flow thereof for treating the oil field produced water and making the produced water meet the re-injection requirement. The treatment method comprises the following steps of: treating the oil field produced water by using a pre-oxidation treatment device, putting an agent between a primary oil removal tank and a secondary settlement tank, filtering the oil field produced water by using a micropore ceramic granular filter material and then delivering the filtered oil field produced water. The primary oil removal tank, the secondary settlement tank, a delivery tank and a delivery pump are adopted in the treatment flow and connected by adopting pipelines; the front end of the primary oil removal tank is connected with the pre-oxidation treatment device; a coagulation reactor is connected between the primary oil removal tank and the secondary settlement tank; and the tail end of the flow is connected with a ceramic filter tank. The treatment method can solve the problems of corrosion and scaling of the oil field produced water so that the water quality of the treated injection water comprehensively and stably reaches the standard. The treatment method generates a small amount of mud, and greatly reduces the subsequent treatment cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Corrosion inhibitor formulations with improved performance, lower toxicity and reduced manufacturing hazards

ActiveUS20070018135A1Improved corrosion inhibitorOther chemical processesSurface-active detergent compositionsAqueous corrosionCarboxylic acid

Aqueous corrosion inhibitor compositions, preferably storage-stable, useful in acidic cleaning solutions for cleaning the surfaces of metal, comprising reaction products of at least one rosin amine component, at least one non-flammable liquid ketone component, at least one carboxylic acid component, at least one paraformaldehyde component and water; aqueous acidic cleaners prepared therefrom; and methods of their use. The inventive corrosion inhibitor compositions are made by a simple process which reduces the presence of toxic and / or flammable raw materials, co-products, residual reactants and chloride ion while providing acid inhibition in aqueous acidic cleaners.

Owner:HENKEL KGAA

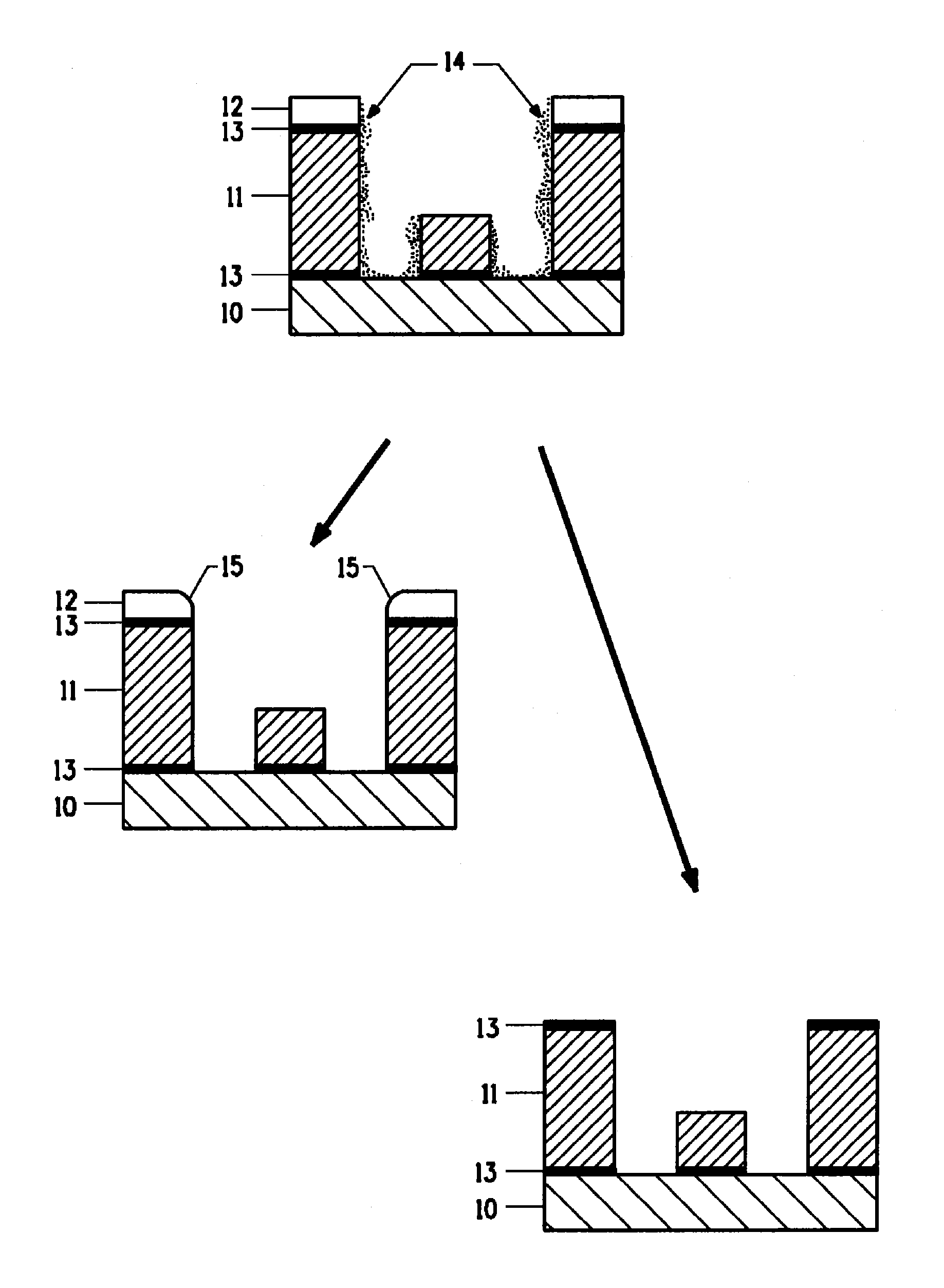

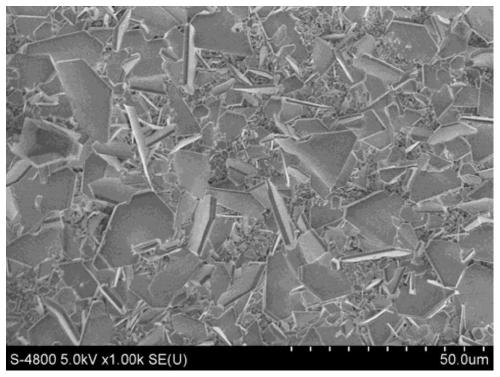

Preparation method of aqueous corrosion-resistant dendritic-crystal-free metal negative electrode

InactiveCN111312984ALess side effectsHigh affinityElectrochemical processing of electrodesSecondary cellsAqueous corrosionElectrolytic agent

The invention belongs to the technical field of energy storage and particularly relates to a preparation method of a corrosion-resistant dendritic-crystal-free metal negative electrode for water-basedelectrochemical energy storage. The method mainly comprises the following steps: polishing, grinding, cleaning and drying a metal sheet, and cutting the metal sheet into metal sheets with different sizes; carrying out surface modification on the metal sheets; and fully washing the modified metal sheets, removing impurities, and then performing evaporating and drying to obtain a surface-modified corrosion-resistant dendritic-crystal-free metal negative electrode. According to the invention, a layer of inactive metal is modified on a surface of relatively active metal; on one hand, an inactivemetal layer can reduce the side reaction between the active metal and an electrolyte; the active metal is endowed with corrosion resistance; on the other hand, the affinity to active metal atoms is higher, the deposition overpotential is reduced, the active metal is promoted to have more uniform deposition sites and ion flow in a deposition process, meanwhile, the surface of a rough modification layer has a relatively large specific surface area, the local current density is reduced, and then the dendritic-crystal-free metal negative electrode is obtained.

Owner:TIANJIN UNIV

Preparation method of anti-static corrosion and rust prevention coating

ActiveCN105348991AReduce penetrationImprove anti-corrosion performanceAnti-corrosive paintsEpoxy resin coatingsAqueous corrosionPolyethylene glycol

The invention discloses a preparation method of an anti-static corrosion and rust prevention coating and belongs to the field of coatings. According to the preparation method, a waterborne epoxy resin prepolymer is obtained by use of polyethyleneglycol and epoxy resin, and organic montmorillonite, a conductive material, a foam killer, a dispersant and other additives are added into the waterborne epoxy resin prepolymer to prepare the anti-static corrosion and rust prevention coating. Epoxy resin and a curing agent are cross-linked and cured to form a film with a three-dimensional network-like structure, so that permeability to water, corrosive media and the like can be reduced, and the anti-corrosion performance of the anti-static corrosion and rust prevention coating is improved; as a carbon black conductive packing is also added, the anti-static corrosion and rust prevention coating has superior anti-static property.

Owner:NANXIONG JIASHENG IND

Aqueous cold zinc spraying coating and preparation method thereof

ActiveCN105949981AStrong rust resistanceStrong adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsAqueous corrosionEpoxy

The invention discloses an aqueous cold zinc spraying coating and a preparation method thereof. The costing is made from the following materials of 10-12wt% of aqueous epoxy modified polyurethane resin, 0.1-0.2wt% of gas phase silicon dioxide, 80-86wt% of aqueous zinc powder, 1-3wt% of an aqueous corrosion inhibitor and 3-5wt% of water. The invention further discloses the preparation method of the coating. The preparation method comprises the following steps: adding the aqueous epoxy modified polyurethane resin, the aqueous corrosion inhibitor, the water and the gas phase silicon dioxide according to the proportion of a formula in a reaction kettle, performing uniform stirring, then slowly adding the aqueous zinc powder, continuing to perform stirring, and performing filtration so as to obtain the finished product. The coating has the characteristics that the coating has ultra-high corrosion prevention capacity, the coating is in single-package, and the content of zinc in dried films is as high as 92% or above; the preparation method of the coating is simple and controllable, and the energy consumption is low.

Owner:WUXI HUADONG ZINDN TECH

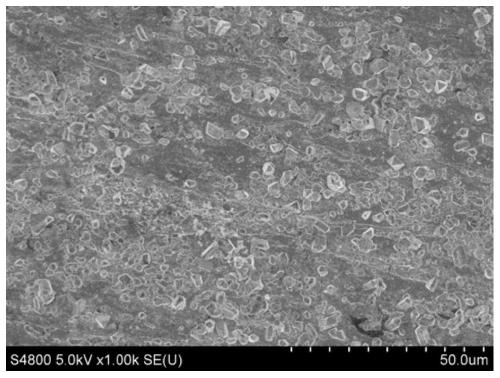

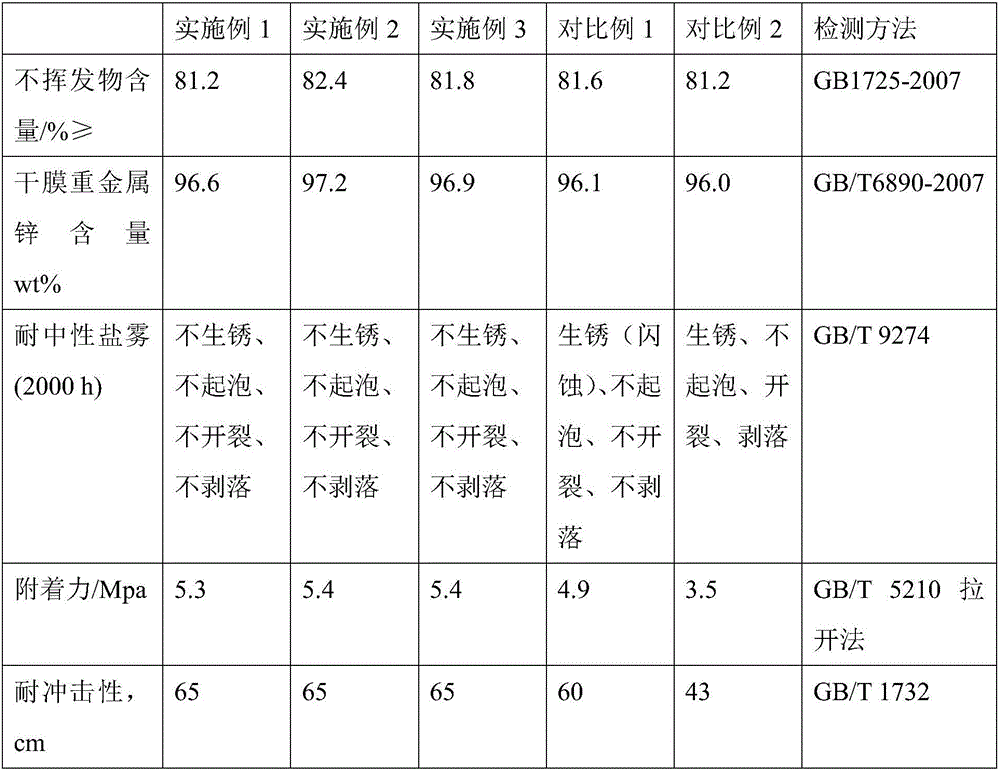

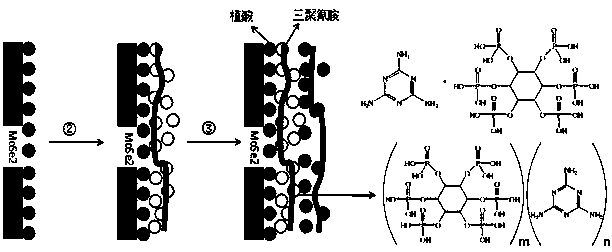

Method for preparing steel structure aqueous corrosion-resistant fireproof coating material

ActiveCN108314951AReduce electron cloud densityNot easily oxidizedFireproof paintsAnti-corrosive paintsAqueous corrosionEpoxy

The invention discloses a method for preparing a steel structure aqueous corrosion-resistant fireproof coating material and relates to a coating preparation method. The method comprises the followingsteps: establishing a melamine and phytic acid flame-retardant layer from molybdenum diselenide (MoSe2) nanosheets by using a layer-by-layer self-assembling method (LBL), and filling an aqueous epoxyresin with the functionalized molybdenum diselenide nanosheets, so as to obtain a steel structure aqueous corrosion-resistant fireproof coating. By adopting the method, the P-N system flame-retardantlayer is prepared, so that the flame retardancy of the aqueous epoxy resin can be improved; the phytic acid in the nano packing has great chelation potential energy, so that the coating can be connected in a relatively intense mode through the phytic acid, and the corrosion resistance and the durability of the coating can be improved; the problem that a nano particle is liable to aggregate becauseof the high surface energy can be also solved.

Owner:辽宁麦琪新材料集团有限公司

Silicon carbide coating and preparation method thereof

InactiveCN104212309AGood wear resistance and self-cleaningResistance to oxidation and corrosionAntifouling/underwater paintsPaints with biocidesSolventAqueous corrosion

The invention discloses a silicon carbide coating which is characterized by being prepared from the following components in parts by weight: 10-30 parts of silicon carbide powder, 2-5 parts of a solvent, 12-18 parts of epoxy resin, 3-5 parts of epoxy acrylate, 10-12 parts of glycidol, 8-10 parts of a titanium dioxide pigment, 8-10 parts of phenyl propyl lactate, 10-12 parts of tourmaline and 7-14 parts of an auxiliary, wherein the auxiliary is prepared from the following components in parts by weight: 10-15 parts of a dispersant, 20-35 parts of a curing agent, 5-10 parts of a thickener, 0.5-0.8 part of a wetting agent, 5-10 parts of a coalescing agent, 1-5 parts of a pH adjustor, 5-10 parts of a silane coupling agent and 2-6 parts of a flatting agent. The silicon carbide coating disclosed by the invention can resist long-term immersion of strong solvents and mixed solvents, oxidation corrosion of concentrated sulfuric acid and concentrated hydrochloric acid, corrosion of high-temperature chlorine and high-temperature seawater corrosion, and can maintain relatively good water and corrosion protection at a high temperature of 1000 DEG C and has wear resistance and self-cleaning property. The invention further provides a preparation method of the silicon carbide coating.

Owner:JIANGSU MARINE VICTORY COATING

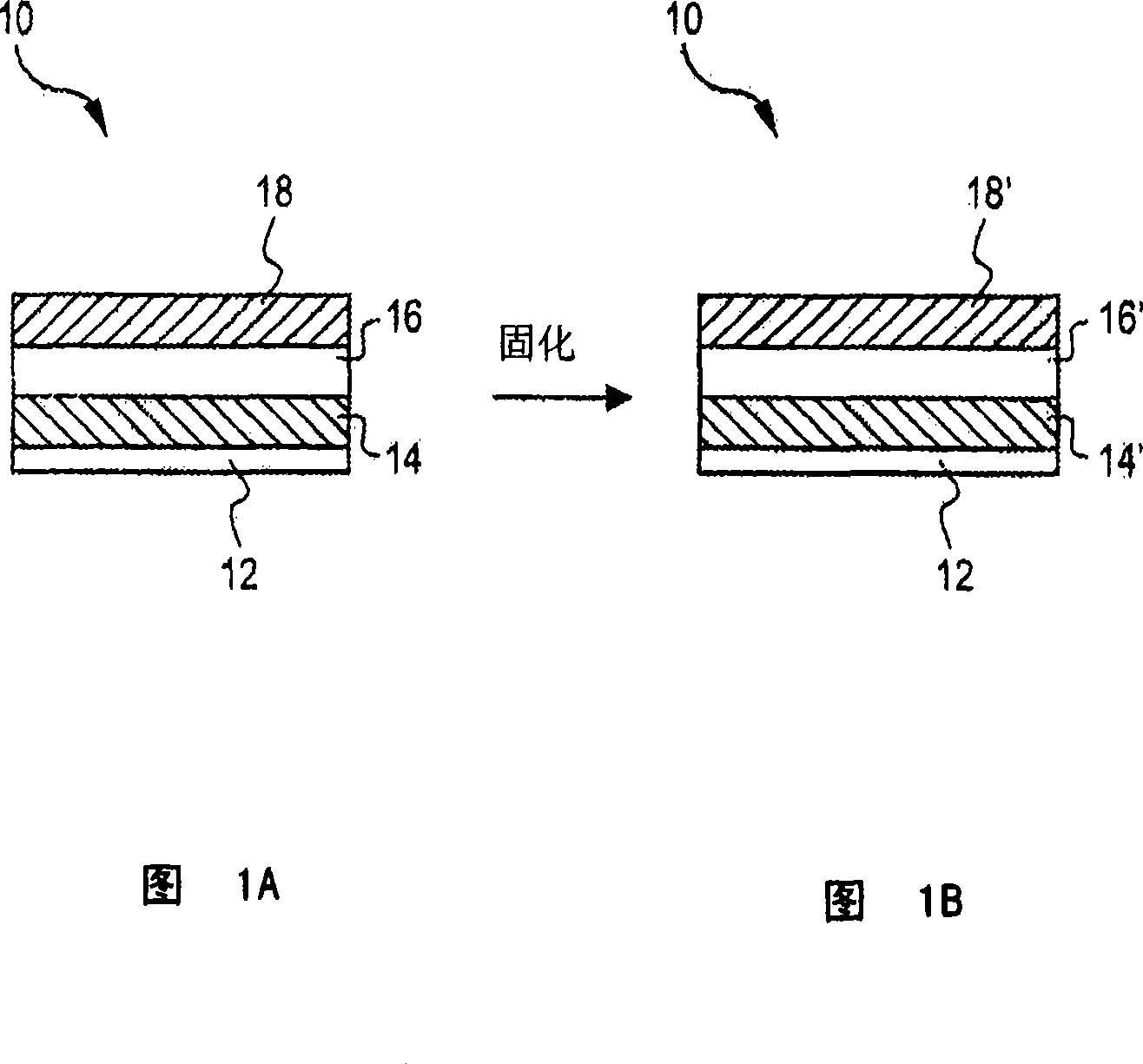

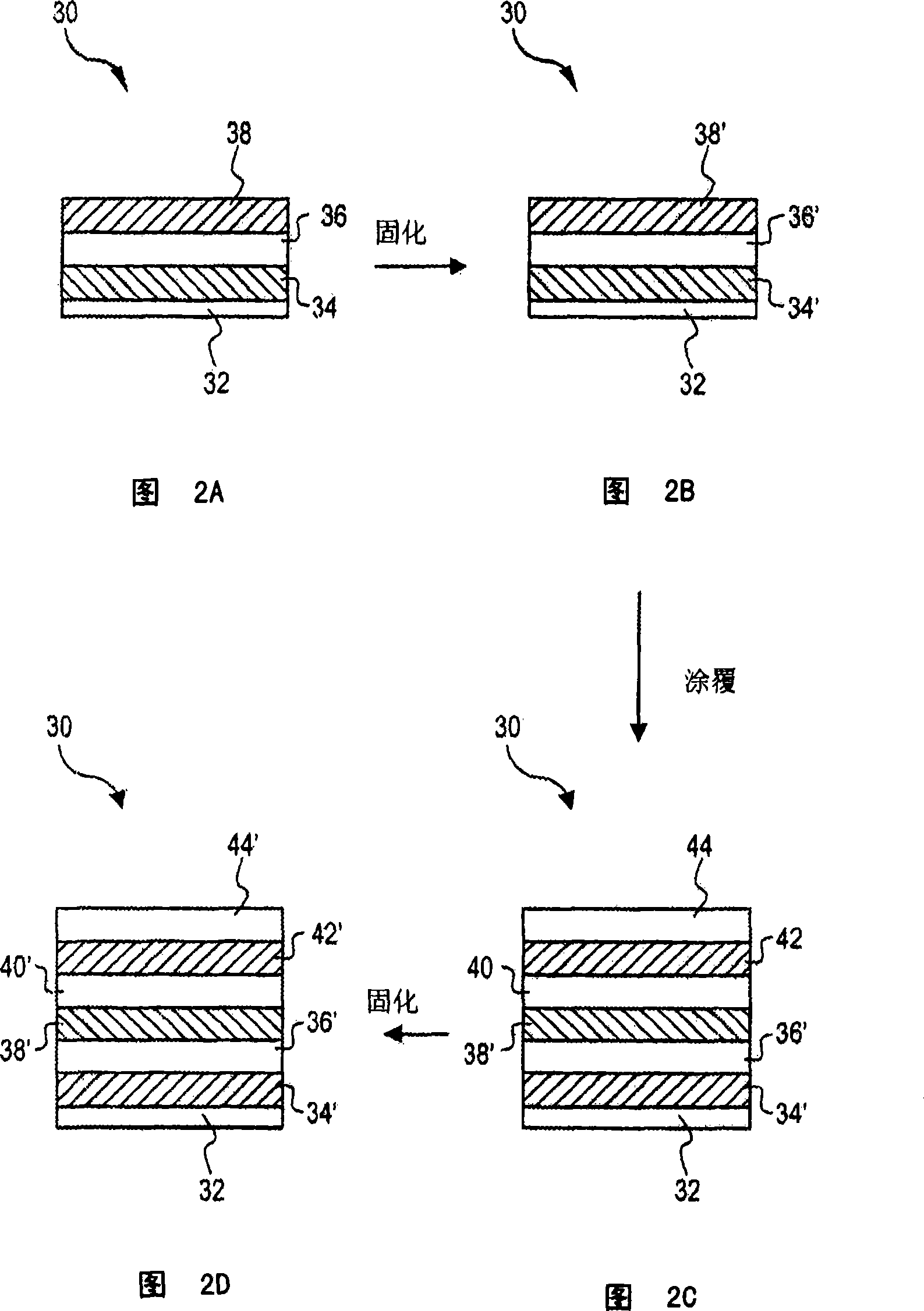

Methods of forming composite powder coatings and articles thereof

A method of forming a composite powder coating comprises depositing multiple layers of a powder coating composition onto a substrate, wherein adjacent layers are formed of a different powder coating composition; and curing the multiple layers of the powder coating composition in a single thermal curing step. The layers can be used to protect power generation equipment from aqueous corrosion, particle erosion, slurry erosion, fretting, and fouling.

Owner:GENERAL ELECTRIC CO

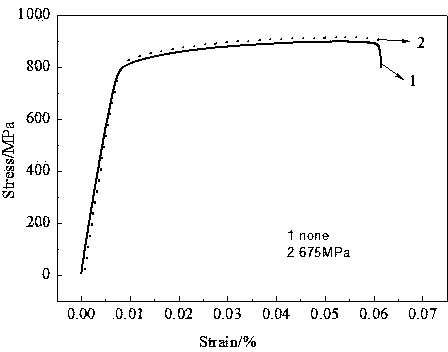

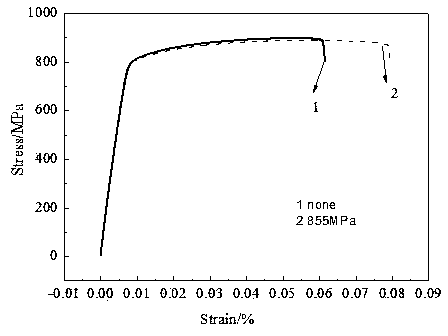

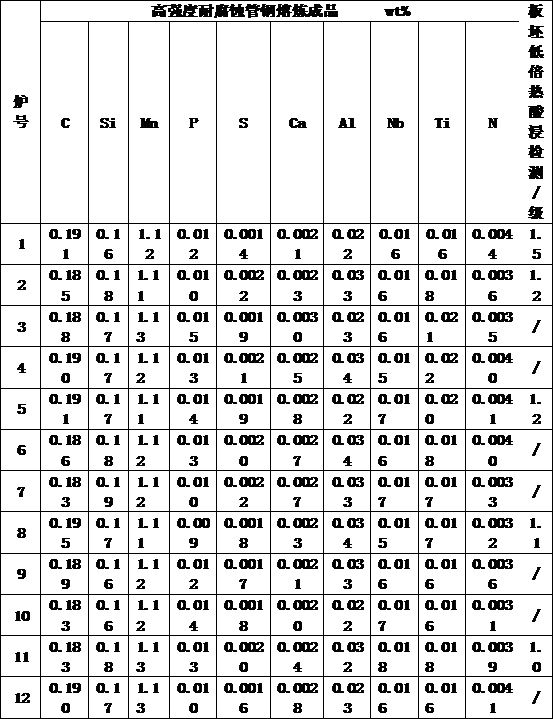

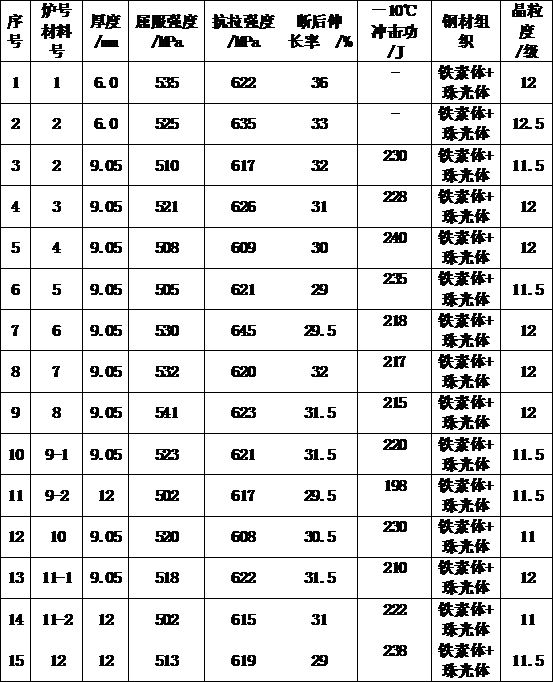

Production method of hot-rolled plate coil used for high-strength corrosion-resistant pipe steel

ActiveCN113512684ATensile stabilitySmall fluctuationProcess efficiency improvementAqueous corrosionProduct inspection

The invention discloses a production method of a hot-rolled plate coil used for high-strength corrosion-resistant pipe steel. The hot-rolled plate coil used for the high-strength corrosion-resistant pipe steel comprises the following components: 0.18 to 0.21 wt% of C, 0.10 to 0.20 wt% of Si, 1.15 to 1.25 wt% of Mn, less than or equal to 0.015 wt% of P, less than or equal to 0.0025 wt% of S, 0.015 to 0.20 wt% of Nb, 0.015 to 0.25 wt% of Ti, 0.015 to 0.035 wt% of Al, less than or equal to 0.0045 wt% of N and the balance impurities. The material production technology comprises the steps of molten iron desulphurization pretreatment, top-bottom combined blowing converter blowing, LF refining, RH vacuum treatment, slab continuous casting, slab cleaning, slab entering a furnace and reheating, controlled rolling and cooling, coiling, steel coil finished product inspection and performance detection. The method is developed aiming at various problems of high-strength steel used for petroleum casing pipes in the current market, the high-strength corrosion-resistant pipe steel is steel used for oil casing pipes, gas casing pipes and geothermal water pipes, and the steel is resistant to corrosion of H2S, CO2, Cl<-> and the like, resistant to water corrosion and good in comprehensive performance.

Owner:XINJIANG BAYI IRON & STEEL

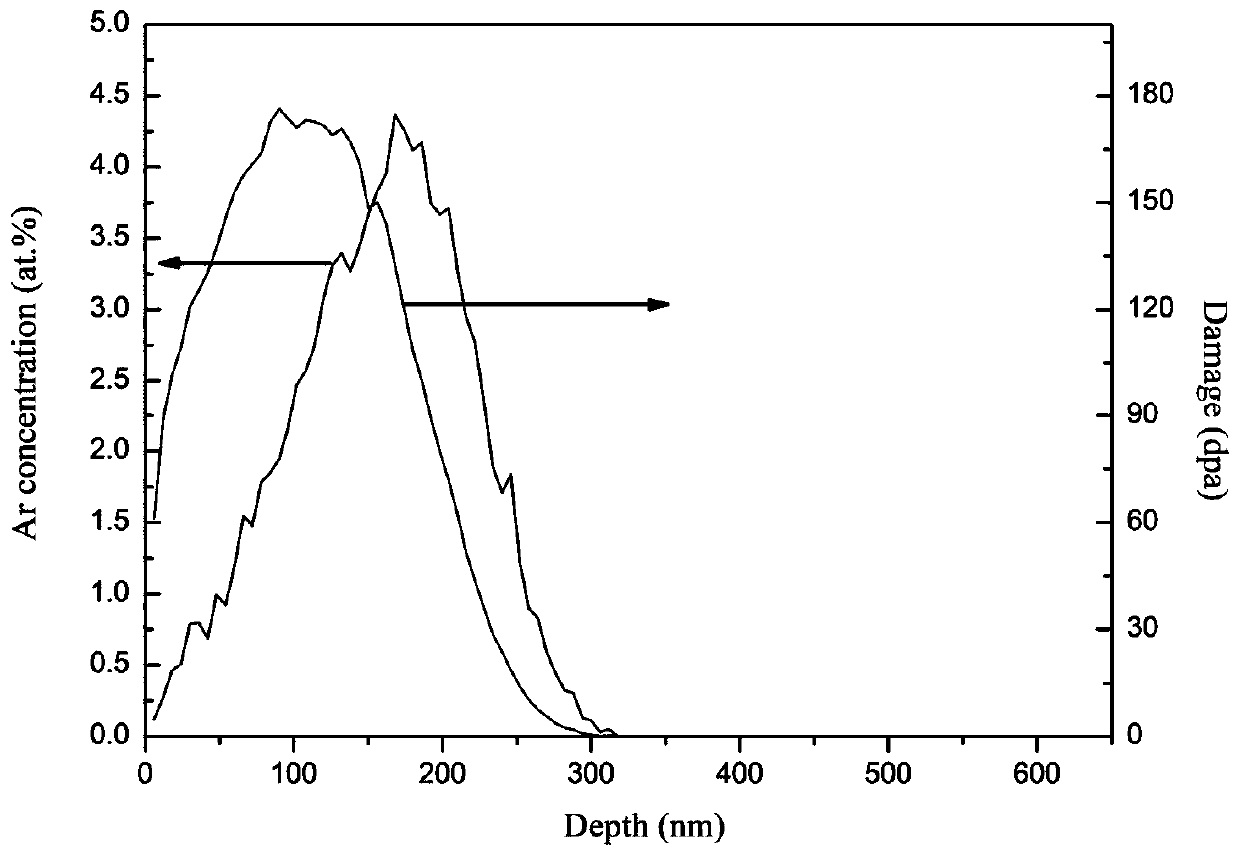

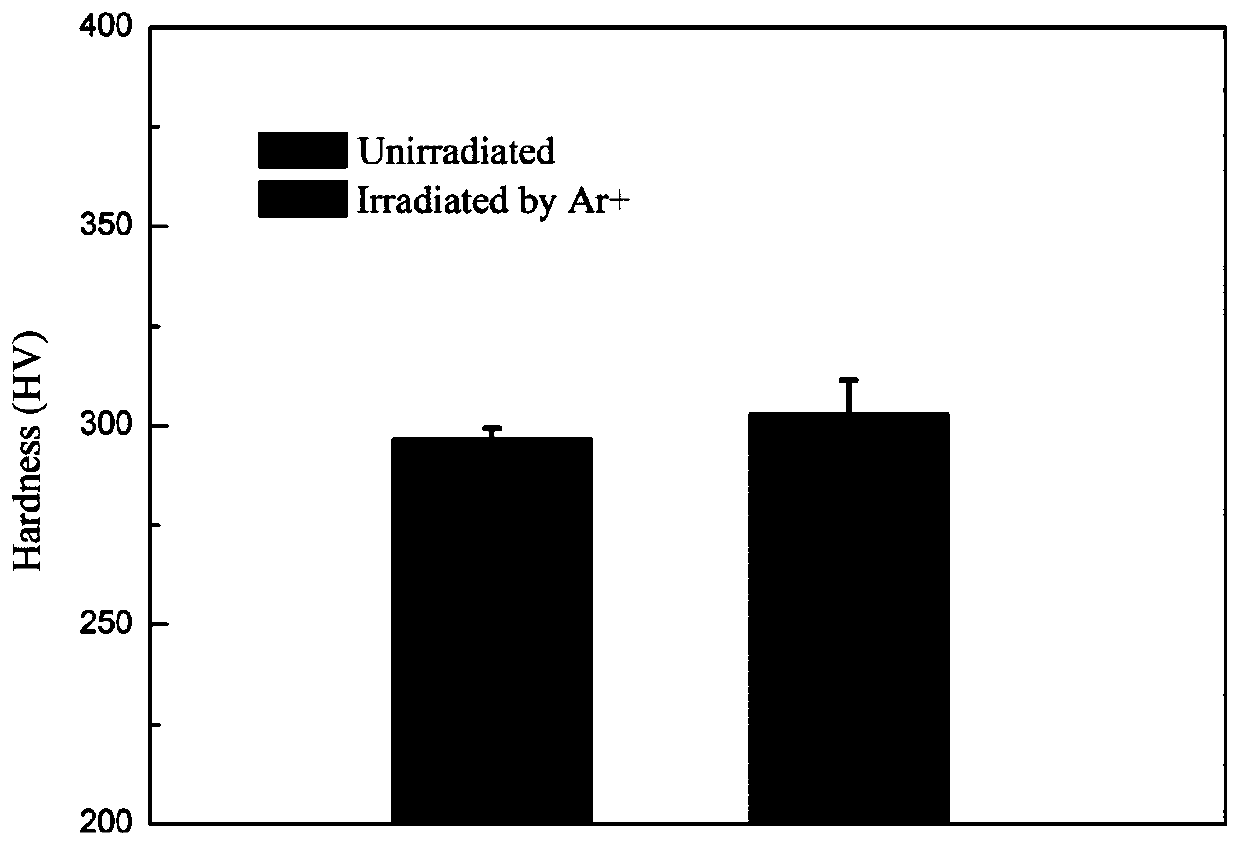

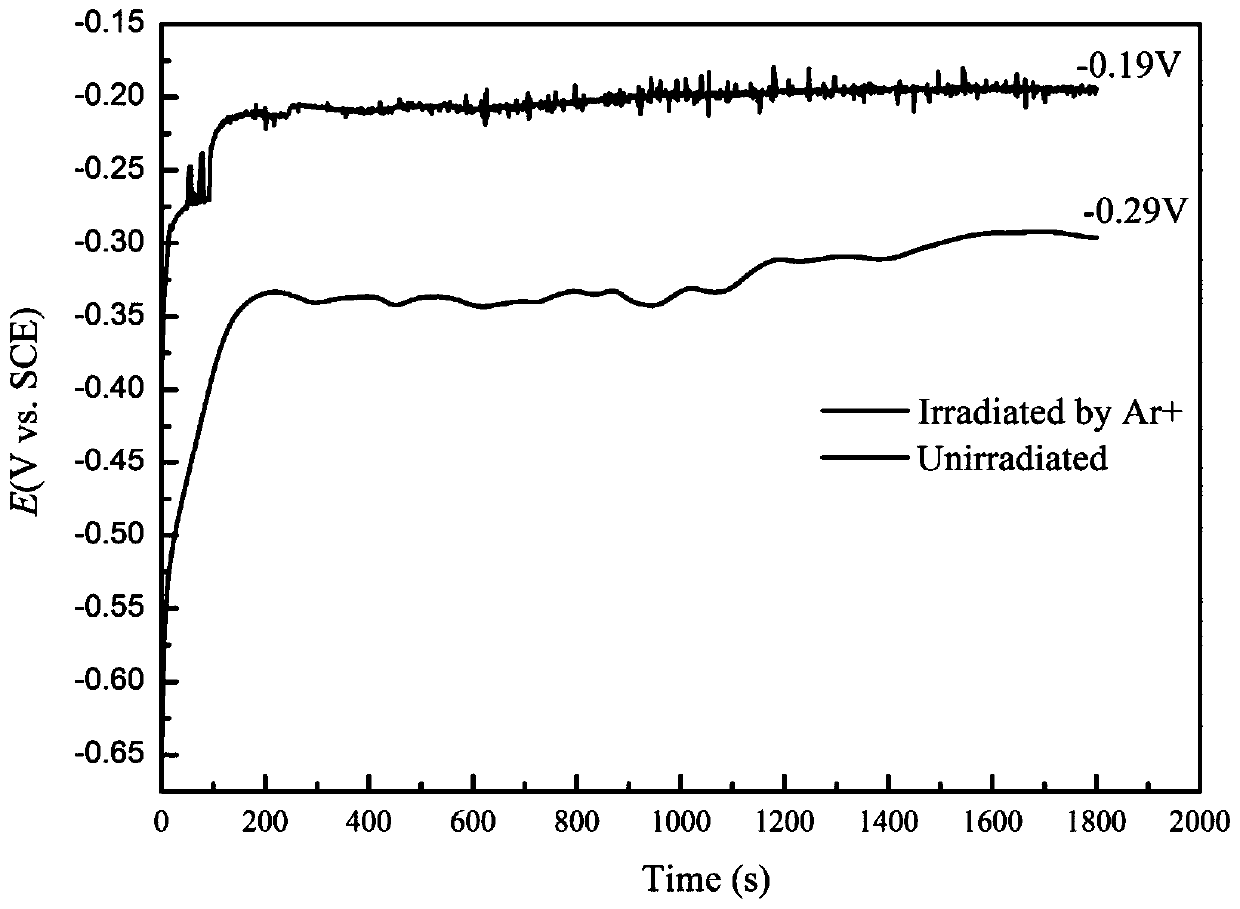

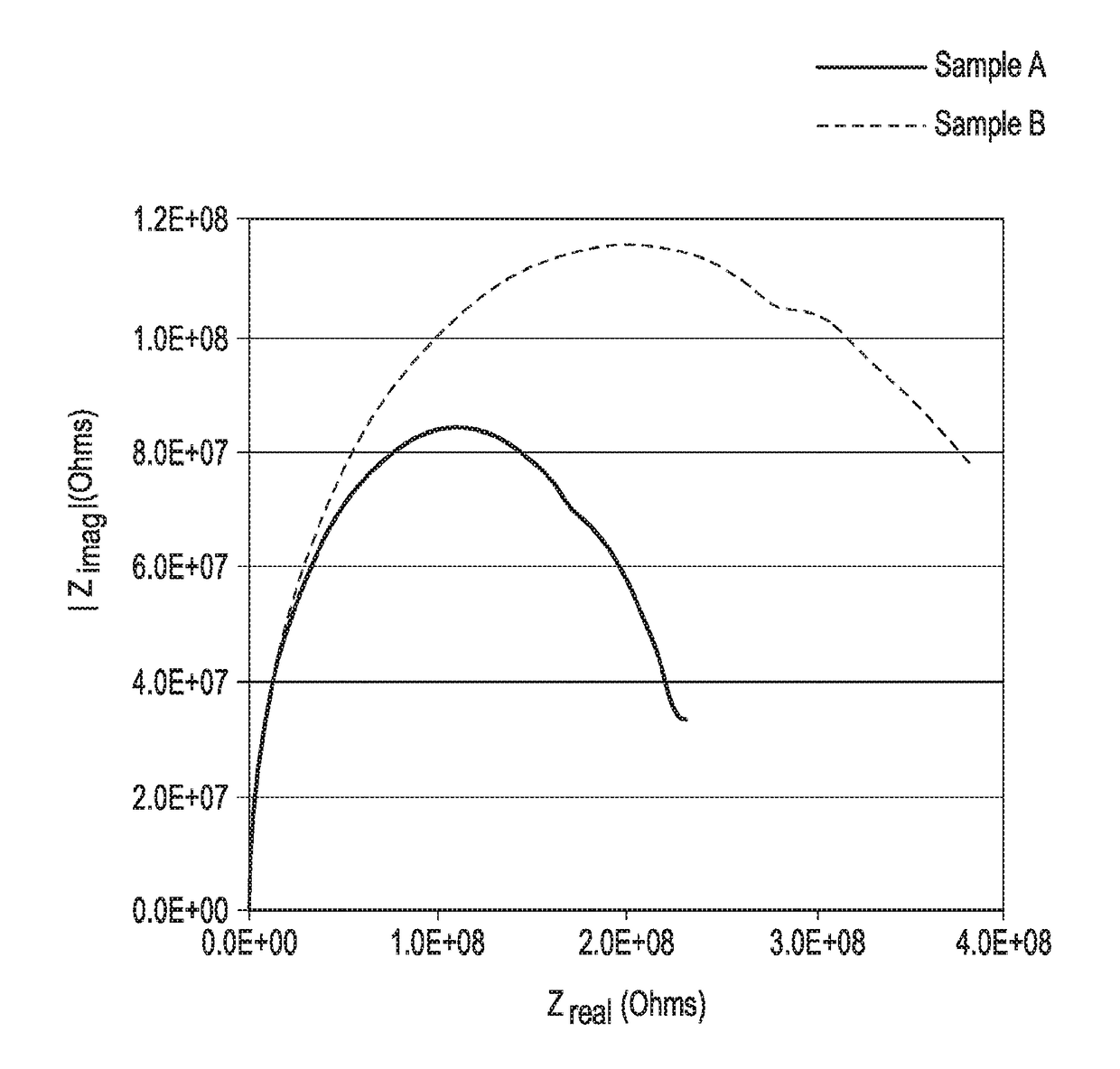

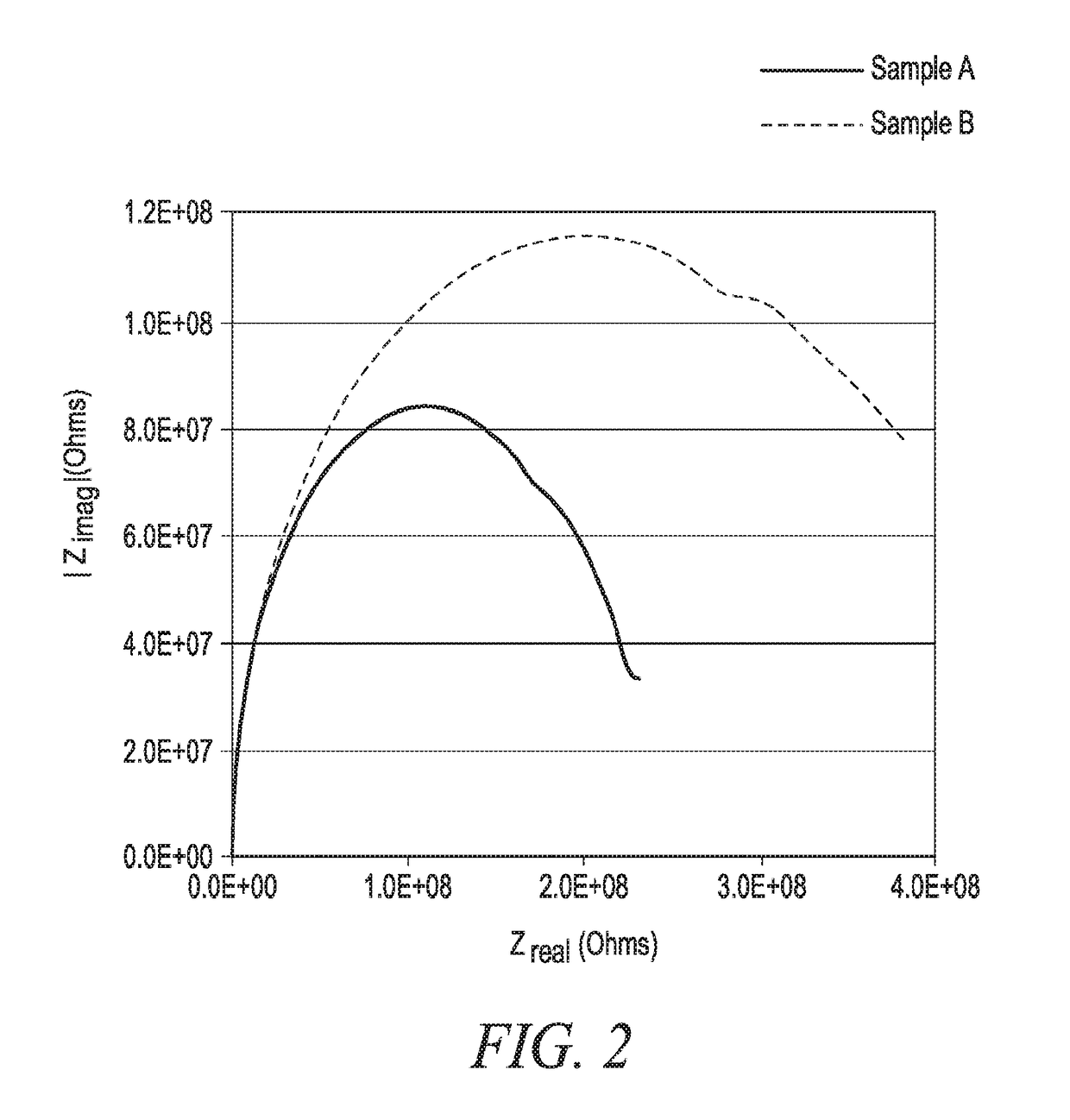

Surface treatment method for water-corrosion-resistant refractory metal molybdenum

ActiveCN111421144AImprove water corrosion resistanceEvaluation of water corrosion resistanceAqueous corrosionNeutron irradiation

The invention discloses a surface treatment method for water-corrosion-resistant refractory metal molybdenum. The method includes the steps that molybdenum powder is prepared, press forming is carriedout, sintering is carried out, heat machining and heat treatment are carried out, an experimental sample is prepared, and ion irradiation is carried out. The vacuum degree in a sample irradiation cavity is kept, Ar ions are adopted for irradiating the surface of the sample at a set temperature, the dosage is selected at 3-4*1016 ion / cm<2>, the acceleration voltage is selected at 350-400 KeV, theaverage atom displacement energy is selected at 25-35 eV, and a molybdenum block obtained after surface treatment is obtained. The corrosion resistance of the sample obtained before and after irradiation is evaluated through electrochemical open circuit potential, a polarization curve, impedance and other tests. The refractory metal molybdenum treated with the method has good corrosion resistance,and the burn-out life of the molybdenum in a water medium is greatly prolonged. By researching and analyzing the influences of the neutron irradiation effect on corrosion, scientific data are provided for application of the molybdenum and alloys thereof in the nuclear power field.

Owner:XI AN JIAOTONG UNIV

Aqueous corrosion resistant coatings with surface-hydrophobic inorganic particles

InactiveUS20180002532A1Avoid corrosionPigmenting treatmentSilicon organic compoundsAqueous corrosionInorganic particle

Aqueous coating compositions providing enhanced anticorrosive and water-resistant properties. The anticorrosive coating comprises water borne resin, surface-hydrophobic inorganic pigments, and / or surface-hydrophobic inorganic extenders.

Owner:THE CHEMOURS CO FC LLC

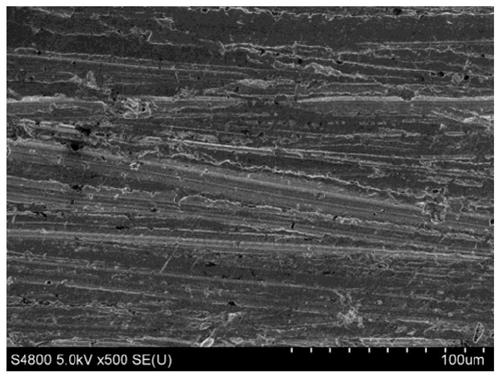

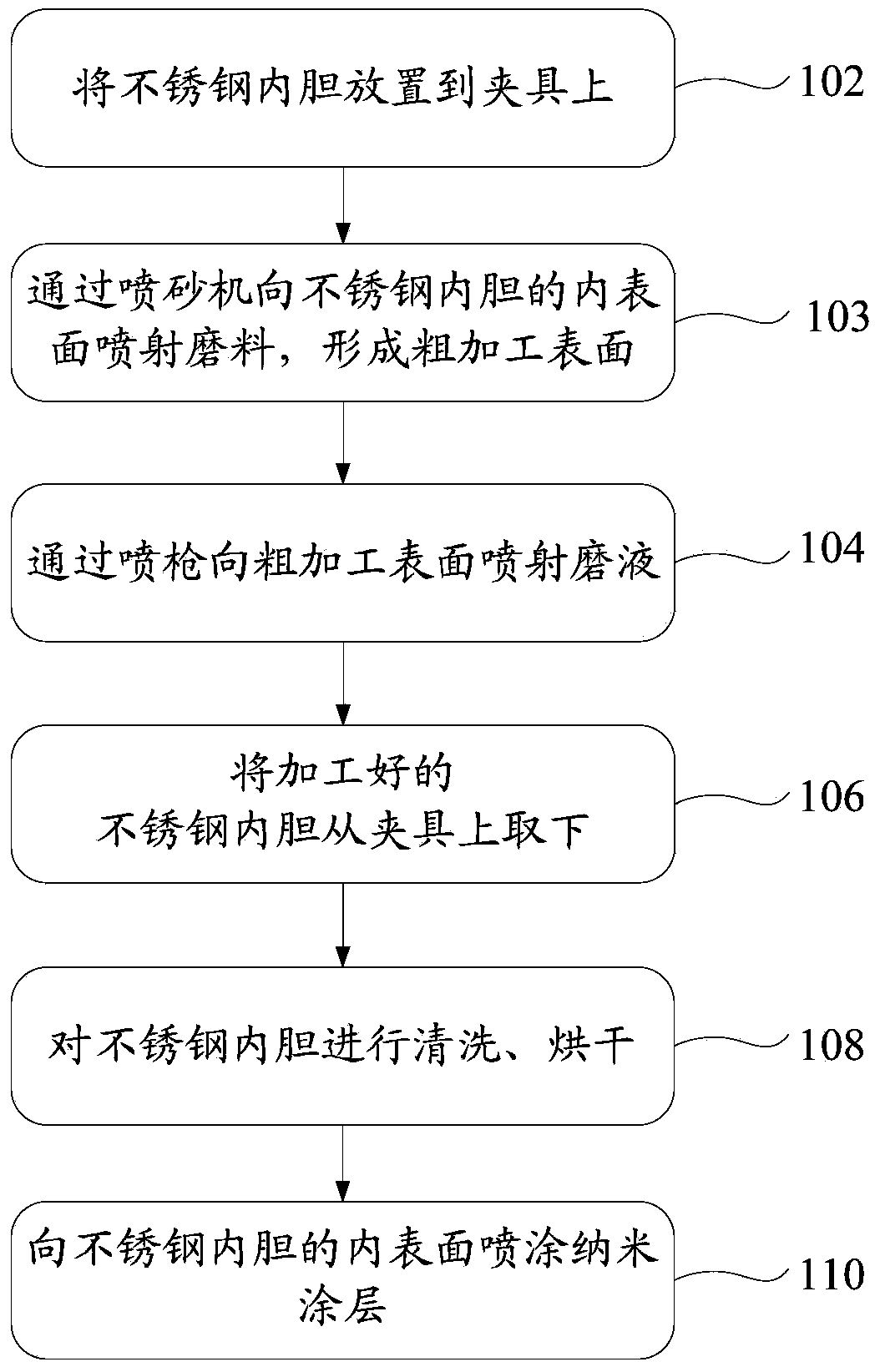

Cuisine appliance stainless steel inner container and polishing technology thereof, and electric heating canteen

The invention provides a cuisine appliance stainless steel inner container and a polishing technology thereof, and an electric heating canteen. A rough layer is arranged on the inner surface of the stainless steel inner container; the rough layer is provided with a convex structure and a concave structure; the thickness of the rough layer is 0.1-0.5 mm; the roughness of the rough layer is 0.1-0.3 mm; the mirror reflection rate of the stainless steel inner container is 5-20%; the thickness of the rough layer of the inner surface of the stainless steel inner container provided by the invention is 0.1-0.5 mm; the roughness of the rough layer is 0.1-0.3 mm; the mirror reflection rate of the stainless steel inner container is 5-20%; therefore, a 'bright mist' effect is shown on the inner surface of the stainless steel inner container; the hand feeling is very smooth and fine; water residue on the inner surface of the stainless steel inner container is avoided, so that the stainless steel inner container is effectively prevented from water corrosion and rusting; the inner surface of the stainless steel inner container is also prevented from being slightly scratched.

Owner:GUANGDONG MIDEA CONSUMER ELECTRICS MFG CO LTD +1

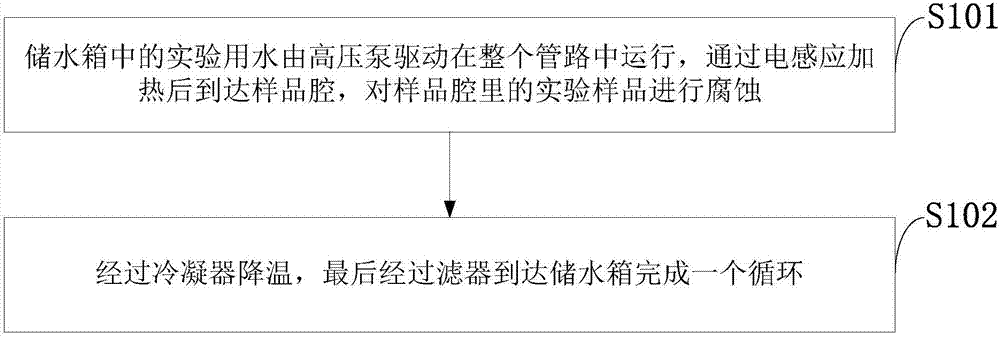

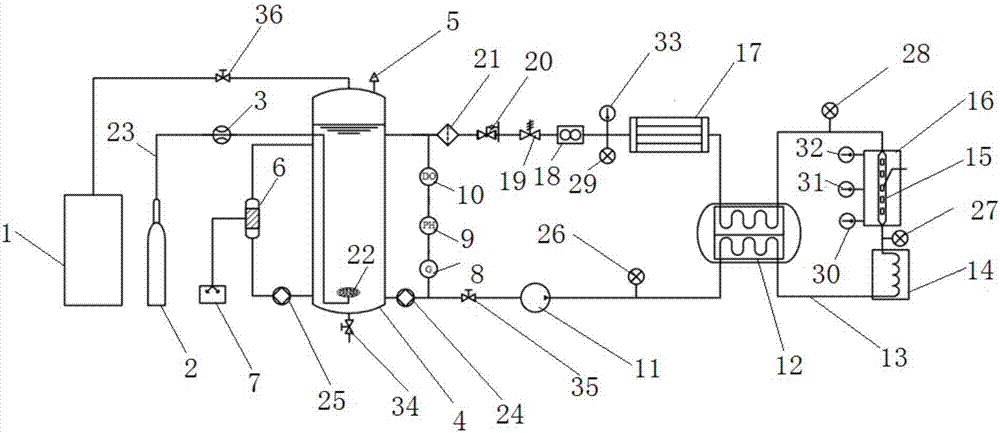

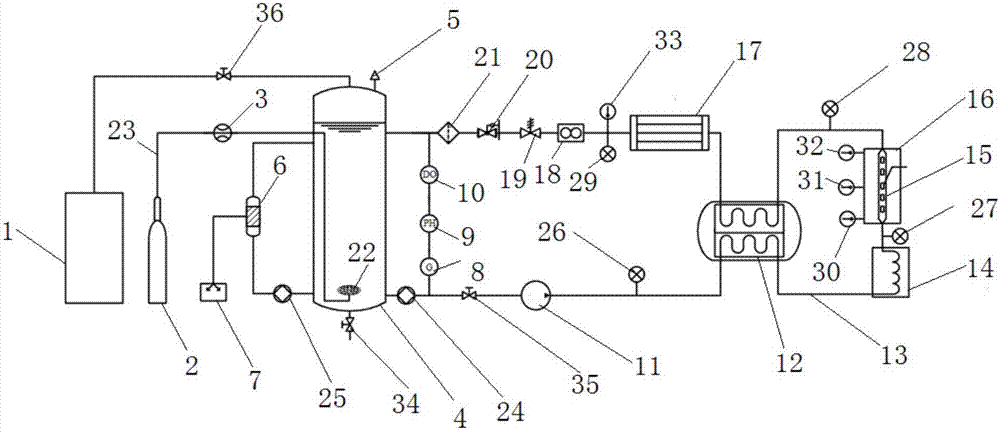

Application method of oxygen content-controlled high-flow velocity multi-state aqueous corrosion experiment apparatus

InactiveCN107884331AReduce cavity sizeStudy and Evaluate CorrosionWeather/light/corrosion resistanceWater useAqueous corrosion

The invention belongs to the technical field of a corrosion experiment apparatus, and discloses an application of an oxygen content-controlled high-flow velocity multi-state aqueous corrosion experiment apparatus. According to the invention, water used for experiment in a water storage tank is driven by a high-pressure pump and is operated in a whole pipeline, after electric induction heating, water is introduced into a sample chamber, and an experiment sample in the sample chamber can be corroded; after cooling by a condenser, and the material is introduced into the water storage tank througha filter for a circulation. The oxygen content-controlled high-flow velocity multi-state aqueous corrosion experiment apparatus can simulate different media environments under a plurality of experiment parameters, and provides different temperatures (less than 700 DEG C), pressure (less than 30 MPa), flow velocity (less than 3m / s), supercritical water (less than 10m / s), and superheated water vapour (less than 40 m / s); can simulate service environment of a light-water reactor nuclear power station, service environment of a supercritical water reactor and supercritical thermal power, and superheated steam environment in thermal power, and reduces N2 consumption; and can heat rapidly flowed medium.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

Oxygen content-controlled high-flow velocity multi-state aqueous corrosion experiment apparatus

InactiveCN107884332AHigh trafficSmall sizeWeather/light/corrosion resistanceAqueous corrosionNuclear power

The invention belongs to the technical field of a corrosion experiment apparatus, and discloses an oxygen content-controlled high-flow velocity multi-state aqueous corrosion experiment apparatus. Theoxygen content-controlled high-flow velocity multi-state aqueous corrosion experiment apparatus comprises a water supply system, an oxygen-controlled system, a hydrochemical survey system, a loop pipeline, a heating insulation system, a heat exchange system, a sample chamber, a back-pressure valve, a filter, and a control cabinet; and an experiment sample is placed in a sample chamber. The oxygencontent-controlled high-flow velocity multi-state aqueous corrosion experiment apparatus can simulate different media environments under a plurality of experiment parameters, and provides different temperatures (less than 700 DEG C), pressure (less than 30 MPa), flow velocity (less than 3m / s), supercritical water (less than 10m / s), and superheated water vapour (less than 40 m / s); can simulate service environment of a light-water reactor nuclear power station, service environment of a supercritical water reactor and supercritical thermal power, and superheated steam environment in thermal power, and reduces N2 consumption; and can heat rapidly flowed medium.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

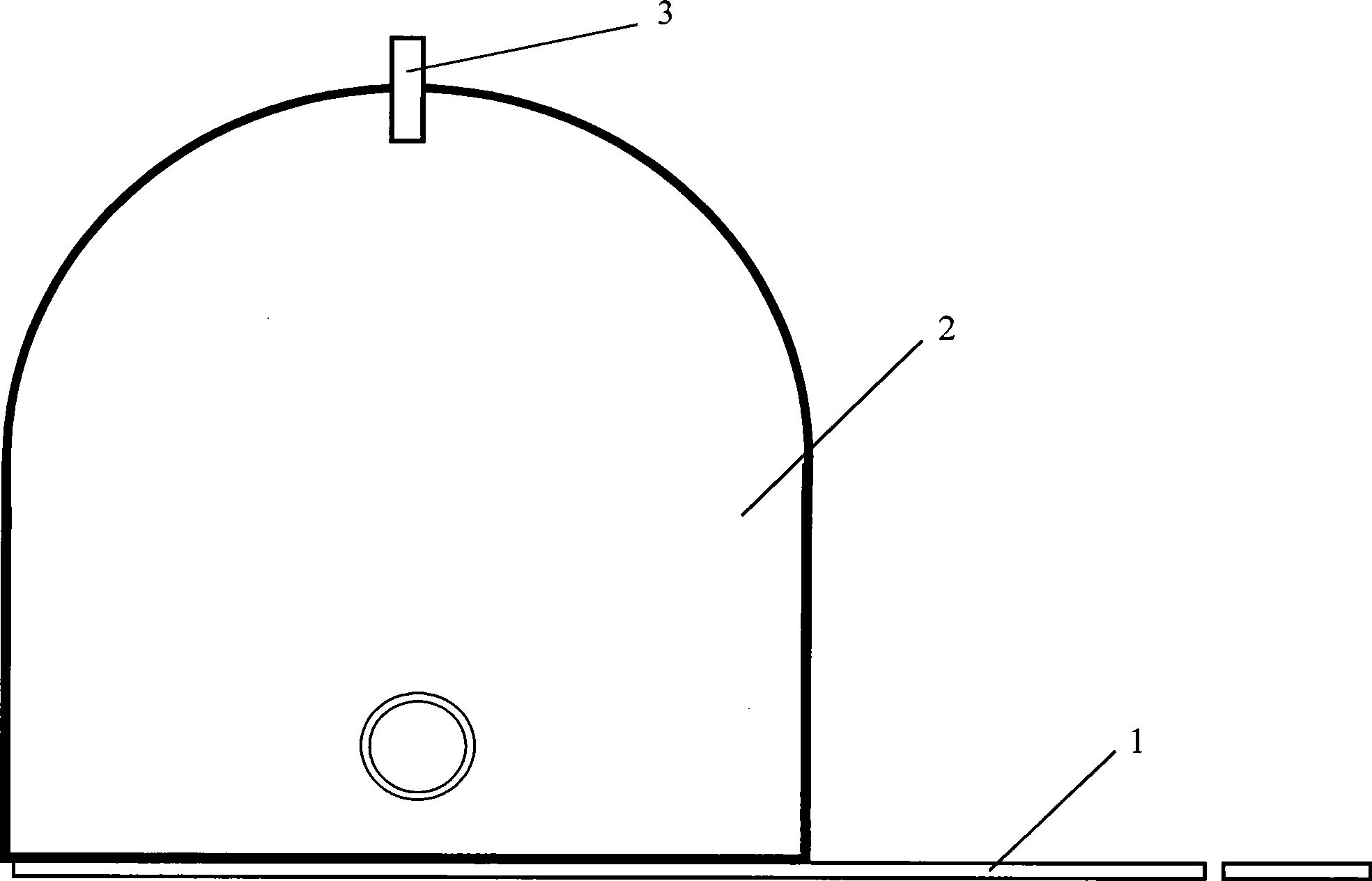

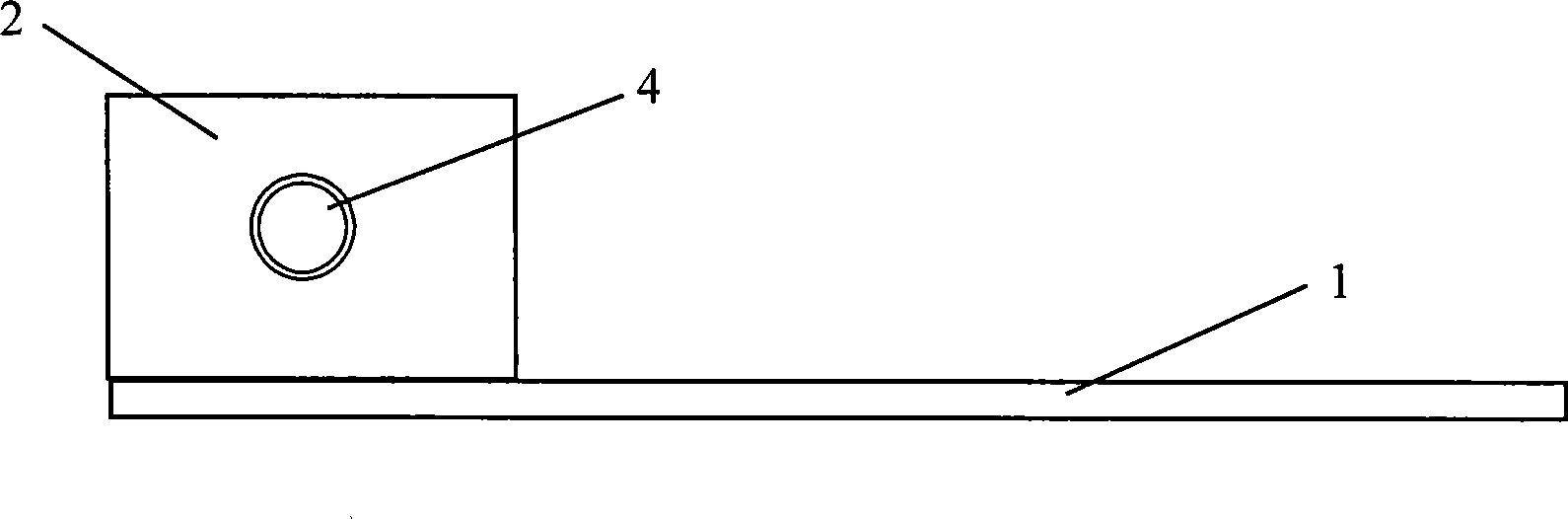

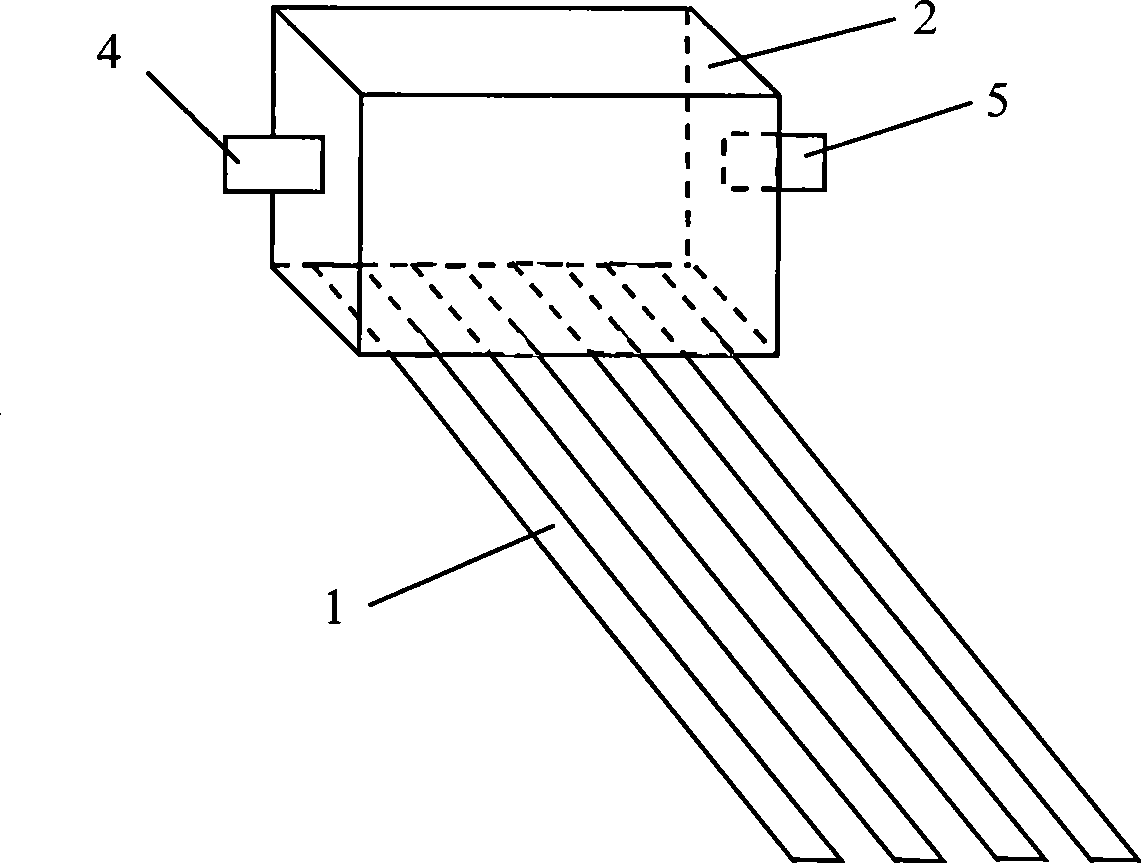

Improved plate type solar heat collection method, its heat collector and water heating system

InactiveCN101504198ASolve problems such as sealingExtend your lifeSolar heating energySolar heat devicesHeat conductingCollector device

The invention relates to an improved flat solar heat collecting method, a collector and a hot-water system. The improved flat solar heat collecting method comprises the following steps: solar energy heat collection is carried out by a flat heat pipe and a hot water collecting tank, the flat heat pipe is a flat plate which is made of metal material, formed by extrusion or punching and has two and more through hole arrays which are arranged side by side; through holes are filled with a liquid working substance, and two ends of the flat heat pipe are encapsulated; a condensation section of the flat heat pipe is contacted with the outer wall surface of a heat-conducting liner of the hot water collecting tank; and the condensation and heat release of the flat heat pipe are transferred to water in the hot water collecting tank through heat conduction to make hot water. The method solves the problems of corrosion of the flat heat pipe by the water in the hot water collecting tank, surface scaling of the flat heat pipe and the airtightness between the flat heat pipe and the hot water collecting tank, and the like.

Owner:GUANGWEI HETONG ENERGY TECH BEIJING CO LTD

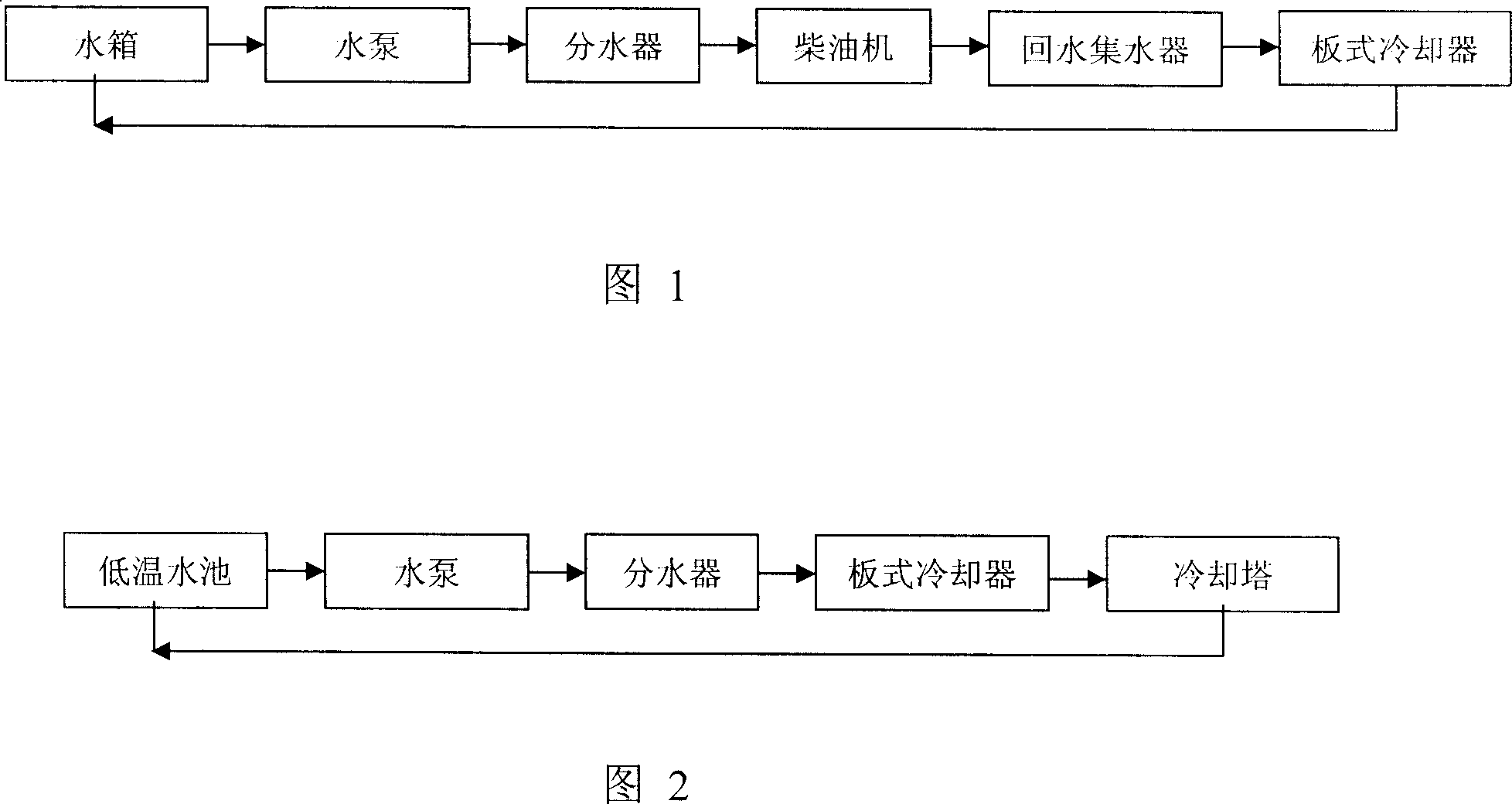

Diesel engine test-drive platform circulated water treatment method

The invention relates to the bench test circulating cooling system for diesel engine. It is an enclosed system with separated high and low temperature water system, the former composed of water tank, water pump, water separator, diesel engine, return water collector, plate cooler, and the latter composed of low temperature water pool, water pump, water separator, cooling tower, to form the high and low temperature circulation water system. It avoids the pollution of rain and microbiology of the water circulation system.The coolant corrosion inhibitor is made of water treatment agent: water=1:100(l). The PH value of the coolant is kept between 8.3-10, better solved rust and deposition issue of the components, ensured reliability of the diesel engine.

Owner:CSSC MARINE POWER

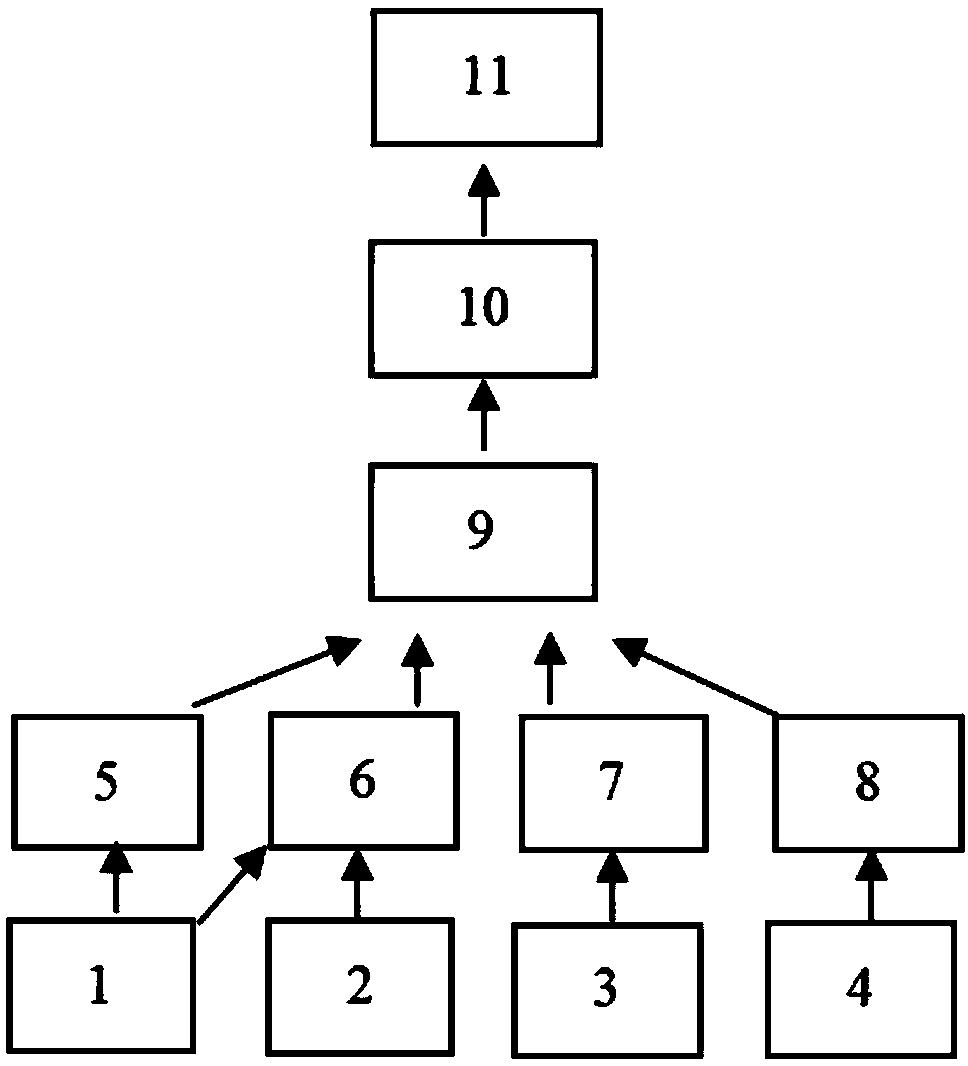

Diagnosis and analysis system and method for corrosion state of circulating cooling water

InactiveCN107621526AEnsure safetyGuarantee economic operationTesting waterAnalysis dataWater quality

The invention relates to a diagnosis and analysis system and method for the corrosion state of the circulating cooling water. The system comprises four kinds of acquisition modules of water quality, condenser tube attachments, pharmaceutical treatment formula information and equipment material and structural data, the above modules are respectively connected with a water quality analysis module, an attachment analysis module, a pharmaceutical treatment formula and equipment material analysis module and a structural analysis module and are then connected with a decision layer module through a data layer module and a feature layer data processing module. The method includes: acquiring water quality information, equipment material information, structural information, condenser attachment information and pharmaceutical treatment formula information; respectively analyzing and processing data acquired by the acquisition modules; excluding pathological data; extracting characteristic quantity of the analyzed data; conducting comprehensive analysis and diagnosis of an expert system. Corrosion and scaling conditions are integrated, scaling analysis and solution are given, feedwater qualityof boilers is guaranteed, and long-term, efficient and economical operation of the circulating cooling water system is ensured.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +2

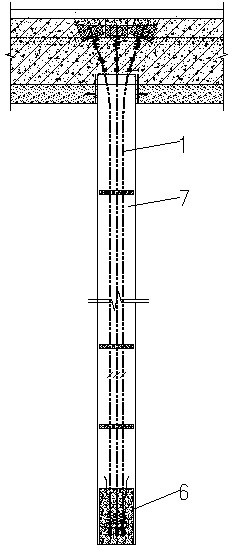

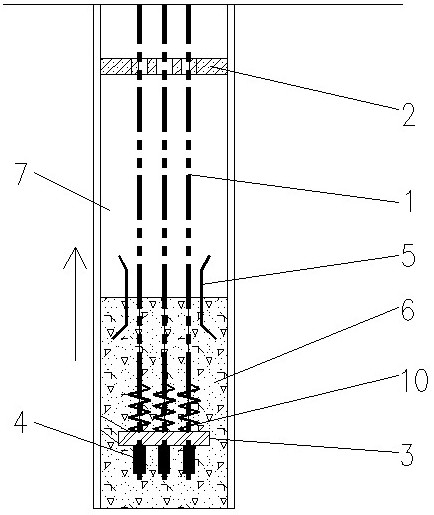

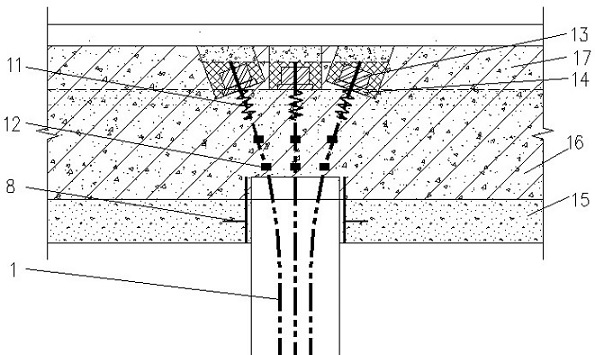

Prestressed anti-corrosion anti-floating anchor rod and construction method

The invention discloses a prestressed anti-corrosion anti-floating anchor rod and a construction method. The construction method comprises the steps that a plurality of retard-bonded prestressed steelstrands, the lower ends of the retard-bonded prestressed steel strands, a first water stop plate and a lower bearing plate are integrally formed through pre-grouting pouring to form a first column body, a part of the first water stop plate is exposed out of the first column body, the outer side of the exposed part of the first water stop plate is continuously poured to form a second column body to form a prefabricated anchor rod, the second column body warps the exposed part of the first water stop plate, the upper part of the retard-bonded prestressed steel strand is sleeved with a second water stop plate, a post-pouring column body is formed between the interior of the second water stop plate and the retard-bonded prestressed steel strands through supplementary pouring, and the post-cast column body is connected with the second column body. In this way, according to the prestressed anti-corrosion anti-floating anchor rod and the construction method thereof, the retard-bonded prestressed steel strands are adopted, the whole anchor rod is prevented from being corroded by water through the novel waterproof structure and the construction method, and the problem that the anti-floating anchor rod loses efficacy is avoided.

Owner:CHINA ACAD OF BUILDING RES +1

Nitrogen gas cabinet

InactiveCN103697319ANot easy to corrodeGood moisture absorption and moisture resistanceVariable capacity gas holdersAnti-corrosive paintsAqueous corrosionNitrogen gas

The invention discloses a nitrogen gas cabinet. An upper coating and a lower coating are coated on a cabinet body of the nitrogen gas cabinet; the lower layer is a corrosion-resistant bottom coating of 0.35 mm in thickness while the upper layer is a moisture-absorbing surface coating of 0.47 mm in thickness; the corrosion-resistant bottom coating is formed by drying aqueous corrosion-resistant bottom coating paint; the moisture-absorbing surface coating is formed by drying aqueous moisture-absorbing surface paint; the aqueous moisture-absorbing surface paint includes the following components. The nitrogen gas cabinet when being used for a long time is corroded hardly and good moisture-absorbing as well as moisture-proof performances of the inner part of the cabinet body are achieved.

Owner:常熟市加腾电子设备厂(普通合伙)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com